Page 1

ATM Multimode Fiber

Transceivers

for SONET OC-3/SDH STM-1 in

Low Cost 1x9 Package Style

Technical Data

Features

• Full Compliance with ATM

Forum UNI SONET OC-3

Multimode Fiber Physical

Layer Specification

• Multisourced 1 x 9 Package

Style with Choice of Duplex

SC or Duplex ST* Receptacle

• Wave Solder and Aqueous

Wash Process Compatibility

• Manufactured in an ISO 9002

Certified Facility

Applications

• Multimode Fiber ATM

Backbone Links

• Multimode Fiber ATM

Wiring Closet to Desktop

Links

• Very Low Cost Multimode

Fiber 800 nm ATM Wiring

Closet to Desktop Links

• ATM 155 Mbps/194 MBd

Encoded Links (available

upon special request)

Description

The HFBR-5200 family of transceivers from Agilent Technologies

provide the system designer with

products to implement a range of

solutions for multimode fiber

SONET OC-3 (SDH STM-1)

physical layers for ATM and other

services.

These transceivers are all

supplied in the new industry

standard 1x9 SIP package style

with either a duplex SC or a

duplex ST* connector interface.

ATM 2000 m Backbone Links

The HFBR-5205/-5205T are

1300 nm products with optical

performance compliant with the

SONET STS-3c (OC-3) Physical

Layer Interface Specification. This

physical layer is defined in the

ATM Forum User-Network Interface (UNI) Specification Version

3.0. This document references the

ANSI T1E1.2 specification for the

details of the interface for 2000

meter multimode fiber backbone

links.

Selected versions of these

transceivers may be used to

implement the ATM Forum UNI

Physical Layer Interface at the

155 Mbps/194 MBd rate.

The ATM 100 Mbps/125 MBd

Physical Layer interface is best

implemented with the HFBR-5100

family of FDDI Transceivers

which are specified for use in this

4B/5B encoded physical layer per

the FDDI PMD standard.

HFBR-5203/-5203T

800 nm 300 m

HFBR-5204/-5204T

1300 nm 500 m

HFBR-5205/-5205T

1300 nm 2 km

ATM 500 m Backbone and

Desktop Links

The HFBR-5204/-5204T are 1300

nm products which are similar to

the HFBR-5205/5205T except

that they are intended to provide

a lower cost SONET OC-3 link to

distances up to 500 meters in

62.5/125 µm multimode fiber

optic cables.

Very Low Cost ATM 300 m

Desktop Links

The HFBR-5203/-5203T are very

low cost 800 nm alternatives to

the HFBR-5204/-5204T for

SONET OC-3 links to distances up

to 300 meters in 62.5/125 µm

multimode fiber optic cables.

Transmitter Sections

The transmitter sections of the

HFBR-5204 and HFBR-5205

series utilize 1300 nm InGaAsP

LEDs and the HFBR-5203 series

*ST is a registered trademark of AT&T Lightguide Cable Connectors.

Page 2

2

uses a low cost 800 nm AlGaAs

LED. These LEDs are packaged in

the optical subassembly portion

of the transmitter section. They

are driven by a custom silicon IC

which converts differential PECL

logic signals, ECL referenced

(shifted) to a +5 Volt supply, into

an analog LED drive current.

Receiver Sections

The receiver sections of the

HFBR-5204 and HFBR-5205

series utilize InGaAs PIN photodiodes coupled to a custom

silicon transimpedance preamplifier IC. The HFBR-5203 series

uses the same preamplifier IC in

conjunction with an inexpensive

silicon PIN photodiode. These are

packaged in the optical subassembly portion of the receiver.

These PIN/preamplifier combinations are coupled to a custom

quantizer IC which provides the

final pulse shaping for the logic

output and the Signal Detect

function. The data output is

differential. The signal detect

output is single-ended. Both data

and signal detect outputs are

PECL compatible, ECL referenced

(shifted) to a +5 volt power

supply.

design complies with the

maximum height allowed for the

duplex SC connector over the

entire length of the package.

The optical subassemblies utilize

a high volume assembly process

together with low cost lens

elements which result in a cost

effective building block.

The electrical subassembly consists of a high volume multilayer

printed circuit board on which the

IC chips and various surfacemounted passive circuit elements

are attached.

The package includes internal

shields for the electrical and

optical subassemblies to insure

low EMI emissions and high

immunity to external EMI fields.

The outer housing including the

duplex SC connector or the

duplex ST ports is molded of filled

non-conductive plastic to provide

mechanical strength and electrical

isolation. The solder posts of the

Agilent design are isolated from

the circuit design of the

transceiver and do not require

connection to a ground plane on

the circuit board.

The transceiver is attached to a

printed circuit board with the nine

signal pins and the two solder

posts which exit the bottom of the

housing. The two solder posts

provide the primary mechanical

strength to withstand the loads

imposed on the transceiver by

mating with the duplex or simplex

SC or ST connectored fiber

cables.

Note: The “T” in the product

numbers indicates a transceiver

with a duplex ST connector

receptacle. Product numbers

without a “T” indicate transceivers

with a duplex SC connector

receptacle.

Application Information

The Applications Engineering

group in the Agilent Optical

Communication Division is

available to assist you with the

technical understanding and

design trade-offs associated with

these transceivers. You can contact them through your Agilent

sales representative.

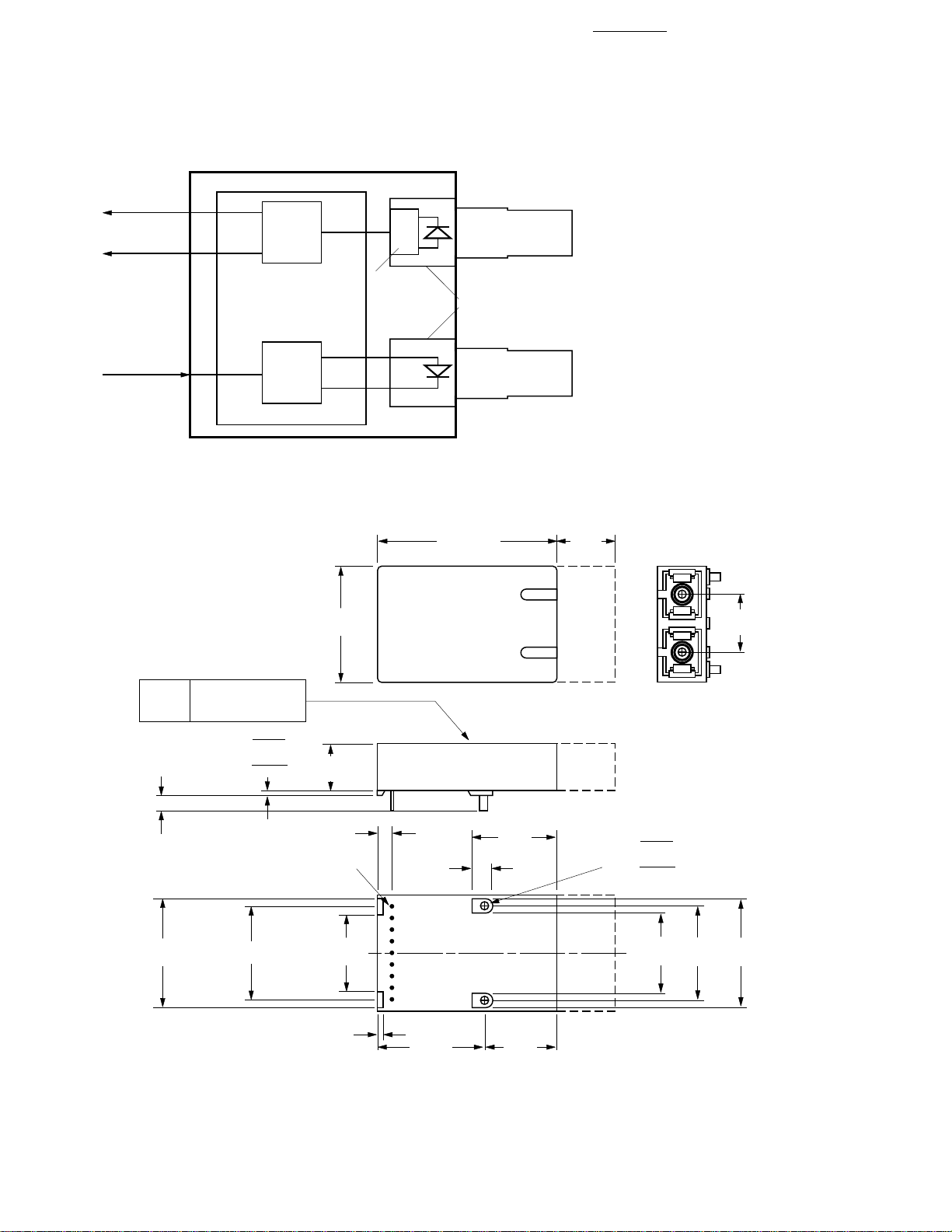

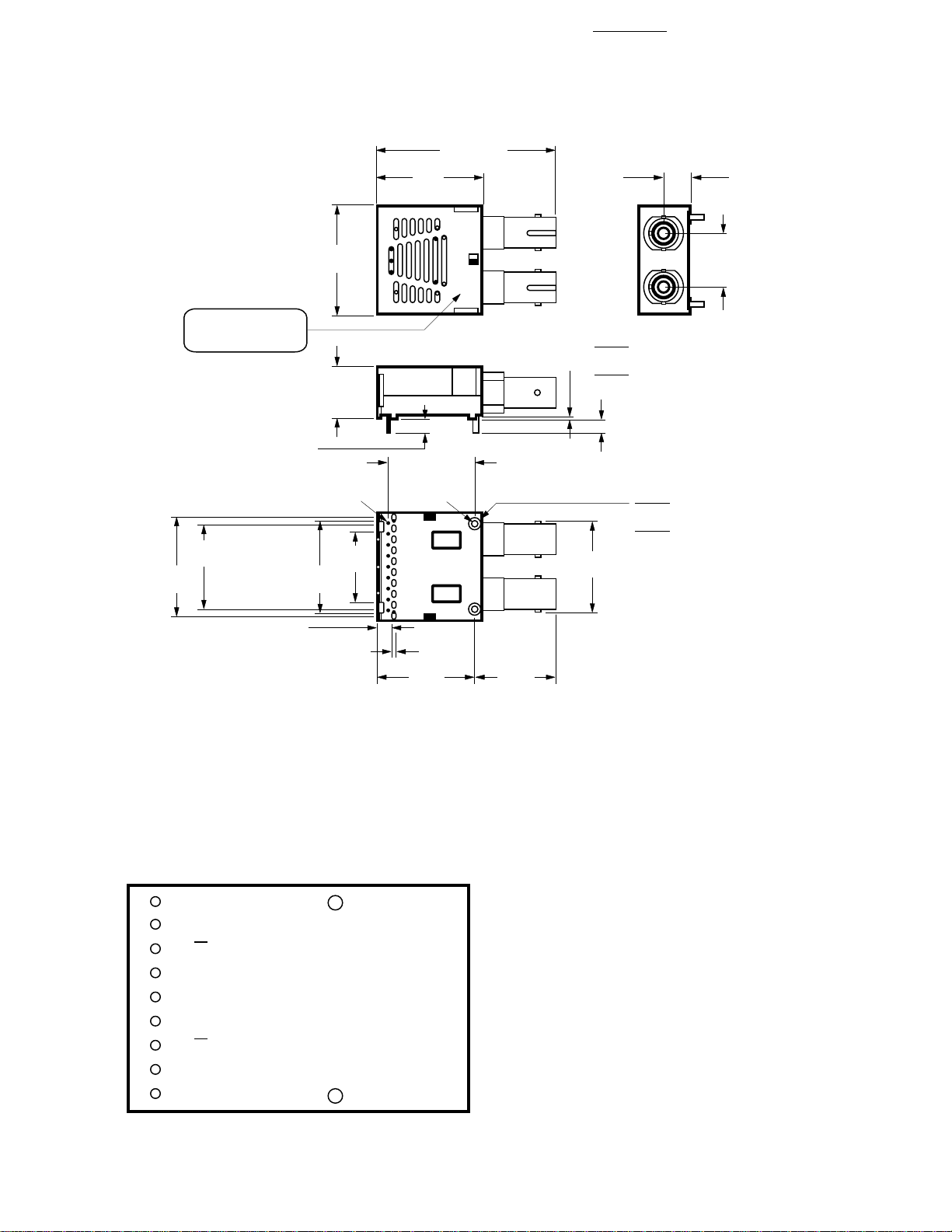

Package

The overall package concept for

the Agilent transceivers consists

of three basic elements; the two

optical subassemblies, an

electrical subassembly, and the

housing as illustrated in the block

diagrams in Figure 1 and

Figure 1a.

The package outline drawing and

pin out are shown in Figures 2,

2a, and 3. The details of this

package outline and pin out are

compliant with the multisource

definition of the 1x9 SIP. The low

profile of the Agilent transceiver

ELECTRICAL SUBASSEMBLY

DIFFERENTIAL

DATA OUT

SINGLE-ENDED

SIGNAL

DETECT OUT

DIFFERENTIAL

DATA IN

Figure 1. Block Diagram.

QUANTIZER IC

DRIVER IC

DUPLEX SC

RECEPTACLE

PIN PHOTODIODE

PREAMP IC

OPTICAL

SUBASSEMBLIES

LED

TOP VIEW

Page 3

3

ELECTRICAL SUBASSEMBLY

DIFFERENTIAL

DATA OUT

SINGLE-ENDED

SIGNAL

DETECT OUT

QUANTIZER IC

DIFFERENTIAL

DATA IN

DRIVER IC

Figure 1a. ST Block Diagram.

TOP VIEW

25.40

(1.000)

PREAMP IC

MAX.

DUPLEX ST

RECEPTACLE

PIN PHOTODIODE

OPTICAL

SUBASSEMBLIES

LED

39.12

MAX.

(1.540)

12.70

(0.500)

AREA

RESERVED

FOR

PROCESS

PLUG

12.70

(0.500)

HFBR-5XXX

DATE CODE (YYWW)

A

SINGAPORE

+ 0.08

0.75

3.30 ± 0.38

(0.130 ± 0.015)

23.55

(0.927)

(0.800)

NOTE 1: THE SOLDER POSTS AND ELECTRICAL PINS ARE PHOSPHOR BRONZE WITH TIN LEAD OVER NICKEL PLATING.

DIMENSIONS ARE IN MILLIMETERS (INCHES).

(0.030

20.32

[8x(2.54/.100)]

- 0.05

+ 0.003

- 0.002

)

0.46

(0.018)

NOTE 1

10.35

(0.407)

2.92

(0.115)

(9x)ø

16.70

(0.657)

0.87

(0.034)

MAX.

23.24

(0.915)

18.52

(0.729)

4.14

(0.163)

15.88

(0.625)

1.27

(0.050

+ 0.25

- 0.05

+ 0.010

- 0.002

NOTE 1

17.32

(0.682)

)

20.32

(0.800)

23.32

(0.918)

Figure 2. Package Outline Drawing.

Page 4

24.8

(0.976)

42

(1.654)

4

MAX.

5.99

(0.236)

HFBR-5103T

DATE CODE (YYWW)

SINGAPORE

20.32

[(8x (2.54/0.100)]

(0.800)

22.86

(0.900)

3.2

(0.126)

3.6

(0.142)

25.4

(1.000)

12.0

(0.471)

φ

(0.022)

NOTE 1

21.4

(0.843)

MAX.

MAX.

0.46

17.4

(0.685)

1.3

(0.051)

20.32

φ

(0.102)

23.38

(0.921)

± 0.38

(± 0.015)

2.6

18.62

(0.733)

+ 0.08

0.5

- 0.05

(0.020)

+ 0.003

(

- 0.002

3.3 ± 0.38

(0.130) (± 0.015)

20.32

(0.800)

(

+ 0.25

- 0.05

+ 0.010

(

- 0.002

12.7

(0.500)

(

NOTE 1: PHOSPHOR BRONZE IS THE BASE MATERIAL FOR THE POSTS & PINS

WITH TIN LEAD OVER NICKEL PLATING.

DIMENSIONS IN MILLIMETERS (INCHES).

Figure 2a. ST Package Outline Drawing.

1 = V

2 = RD

3 = RD

4 = SD

5 = V

6 = V

7 = TD

8 = TD

9 = V

EE

CC

CC

EE

TOP VIEW

N/C

N/C

Figure 3. Pin Out Diagram.

Page 5

5

The following information is

provided to answer some of the

most common questions about

the use of these parts.

Agilent LED technology has

produced 800 nm LED and 1300

nm LED devices with lower aging

characteristics than normally

associated with these technolo-

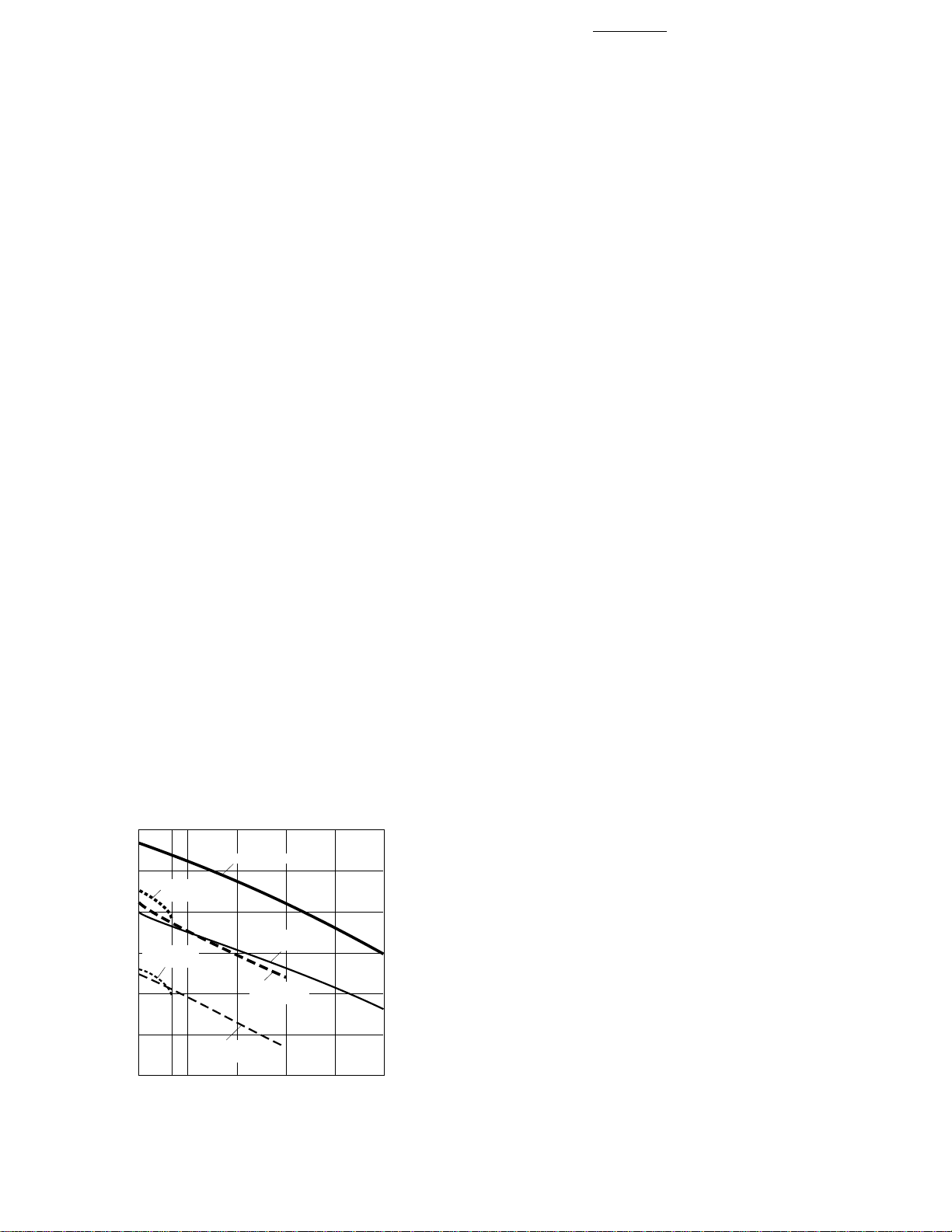

Transceiver Optical Power

Budget versus Link Length

Optical Power Budget (OPB) is

the available optical power for a

fiber optic link to accommodate

fiber cable losses plus losses due

to in-line connectors, splices,

optical switches, and to provide

margin for link aging and

unplanned losses due to cable

gies in the industry. The industry

convention is 3 dB aging for 800

nm and 1.5 dB aging for 1300 nm

LEDs. The 1300 nm HP LEDs are

specified to experience less than

1 dB of aging over normal

commercial equipment mission

life periods. Contact your Agilent

sales representative for additional

details.

plant reconfiguration or repair.

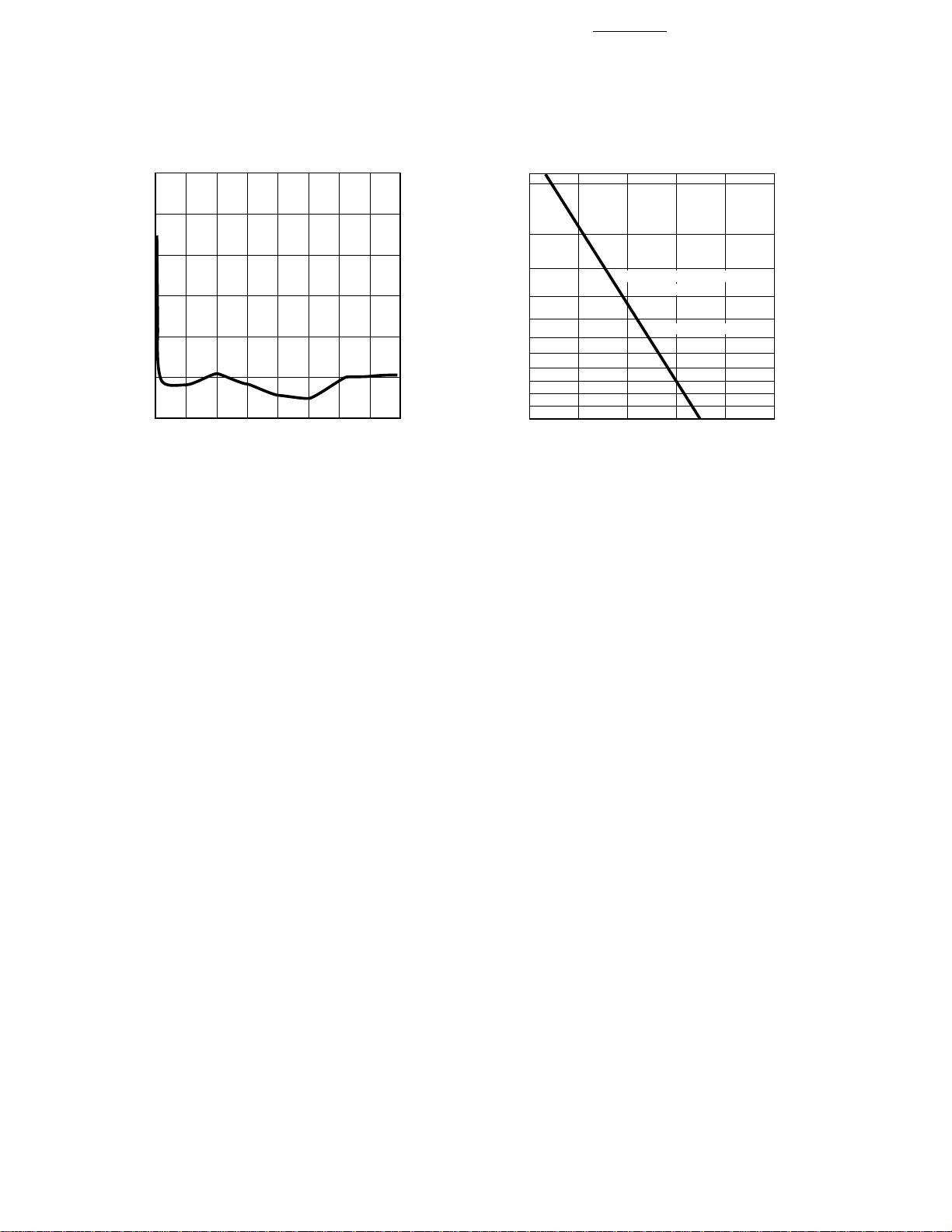

Figure 4 was generated for the

Figure 4 illustrates the predicted

OPB associated with the three

transceivers series specified in

this data sheet at the Beginning of

Life (BOL). These curves represent the attenuation and chromatic

plus modal dispersion losses

associated with the 62.5/125 µm

and 50/125 µm fiber cables only.

The area under the curves

represents the remaining OPB at

any link length, which is available

for overcoming non-fiber cable

losses.

1300 nm transceivers with an

Agilent fiber optic link model

containing the current industry

conventions for fiber cable

specifications and the draft ANSI

T1E1.2. These optical parameters

are reflected in the guaranteed

performance of the transceiver

specifications in this data sheet.

This same model has been used

extensively in the ANSI and IEEE

committees, including the ANSI

T1E1.2 committee, to establish

the optical performance

requirements for various fiber

12

10

8

HFBR-5203,

6

50/125 µm

4

2

OPTICAL POWER BUDGET (dB)

0

Figure 4. Optical Power Budget vs. Fiber Optic Cable Length.

HFBR-5205, 62.5/125 µm

HFBR-5203,

62.5/125 µm

HFBR-5205,

50/125 µm

HFBR-5204,

62.5/125 µm

HFBR-5204,

50/125 µm

0.5 1.5 2.0 2.5

1.00.3

FIBER OPTIC CABLE LENGTH (km)

optic interface standards. The

cable parameters used come from

the ISO/IEC JTC1/SC 25/WG3

Generic Cabling for Customer

Premises per DIS 11801 document and the EIA/TIA-568-A

Commercial Building

Telecommunications Cabling

Standard per SP-2840.

The HFBR-5203 series 800 nm

transceiver curve in Figure 4 was

generated based on extensive

empirical test data of the 800 nm

transceiver performance. The

curve includes the effect of typical

fiber attenuation, plus receiver

sensitivity loss due to chromatic

and metal dispersion losses

through the fiber.

Transceiver Signaling

Operating Rate Range and BER

Performance

For purposes of definition, the

symbol (Baud) rate, also called

signaling rate, is the reciprocal of

the symbol time. Data rate (bits/

sec) is the symbol rate divided by

the encoding factor used to

encode the data (symbols/bit).

When used in 155 Mbps SONET

OC-3 applications the performance of the 1300 nm transceivers,

HFBR-5204/5205 is guaranteed

to the full conditions listed in

individual product specification

tables.

The transceivers may be used for

other applications at signaling

rates different than 155 Mbps

with some variation in the link

optical power budget. Figure 5

gives an indication of the typical

performance of these products at

different rates.

These transceivers can also be

used for applications which

require different Bit Error Rate

(BER) performance. Figure 6

Page 6

6

2.5

2.0

1.5

1.0

0.5

AT CONSTANT BER (dB)

0

0.5

25 75 100 125

0 200

TRANSCEIVER RELATIVE OPTICAL POWER BUDGET

CONDITIONS:

1. PRBS 2

2. DATA SAMPLED AT CENTER OF DATA SYMBOL.

3. BER = 10

4. TA = 25° C

5. V

6. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

Figure 5. Transceiver Relative Optical Power Budget

at Constant BER vs. Signaling Rate.

50 150

SIGNAL RATE (MBd)

7

-1

-6

= 5 Vdc

CC

175

-2

1 x 10

-3

1 x 10

-4

1 x 10

-5

1 x 10

-6

1 x 10

-7

1 x 10

BIT ERROR RATE

-8

1 x 10

-9

1 x 10

-10

1 x 10

-11

1 x 10

-12

1 x 10

-6 4

-4 2-2

RELATIVE INPUT OPTICAL POWER – dB

CONDITIONS:

1. 155 MBd

2. PRBS 2

3. CENTER OF SYMBOL SAMPLING.

4. T

= 25° C

A

5. V

= 5 Vdc

CC

6. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

Figure 6. Bit Error Rate vs. Relative Receiver Input

Optical Power.

HFBR-5203/5204/5205

SERIES

CENTER OF SYMBOL

7

-1

0

illustrates the typical trade-off

between link BER and the

receivers input optical power

level.

Transceiver Jitter

Performance

The Agilent 1300 nm transceivers

are designed to operate per the

system jitter allocations stated in

Table B1 of Annex B of the draft

ANSI T1E1.2 Revision 3 standard.

The Agilent 1300 nm transmitters

will tolerate the worst case input

electrical jitter allowed in Annex

B without violating the worst case

output optical jitter requirements.

The Agilent 1300 nm receivers

will tolerate the worst case input

optical jitter allowed in Annex B

without violating the worst case

output electrical jitter allowed.

The jitter specifications stated in

the following 1300 nm transceiver

specification tables are derived

from the values in Table B1 of

Annex B. They represent the

worst case jitter contribution that

the transceivers are allowed to

make to the overall system jitter

without violating the Annex B

allocation example. In practice,

the typical contribution of the

Agilent transceivers is well below

these maximum allowed amounts.

Recommended Handling

Precautions

Agilent recommends that normal

static precautions be taken in the

handling and assembly of these

transceivers to prevent damage

which may be induced by

electrostatic discharge (ESD).

The HFBR-5200 series of

transceivers meet MIL-STD-883C

Method 3015.4 Class 2 products.

Care should be used to avoid

shorting the receiver data or

signal detect outputs directly to

ground without proper current

limiting impedance.

Solder and Wash Process

Compatibility

The transceivers are delivered

with protective process plugs

inserted into the duplex SC or

duplex ST connector receptacle.

This process plug protects the

optical subassemblies during

wave solder and aqueous wash

processing and acts as a dust

cover during shipping.

These transceivers are compatible

with either industry standard

wave or hand solder processes.

Shipping Container

The transceiver is packaged in a

shipping container designed to

Page 7

NO INTERNAL CONNECTION NO INTERNAL CONNECTION

HFBR-520X

TOP VIEW

Rx Rx Tx Tx

RD RD SD V

V

EE

123456789

CCVCC

C1 C2

TD TD V

EE

7

V

CC

TERMINATION

AT PHY

DEVICE

INPUTS

R6 R8

NOTES:

THE SPLIT-LOAD TERMINATIONS FOR ECL SIGNALS NEED TO BE LOCATED AT THE INPUT

OF DEVICES RECEIVING THOSE ECL SIGNALS. RECOMMEND 4-LAYER PRINTED CIRCUIT

BOARD WITH 50 OHM MICROSTRIP SIGNAL PATHS BE USED.

R1 = R4 = R6 = R8 = R10 = 130 OHMS.

R2 = R3 = R5 = R7 = R9 = 82 OHMS.

C1 = C2 = C3 = C5 = C6 = 0.1 µF.

C4 = 10 µF.

L1 = L2 = 1 µH COIL OR FERRITE INDUCTOR.

Figure 7. Recommended Decoupling and Termination Circuits.

V

CC

R5 R7

C6

RD RD SD V

protect it from mechanical and

ESD damage during shipment or

storage.

L1 L2

C3 C4

VCC FILTER

AT V

PINS

CC

TRANSCEIVER

R9

R10

CC

with these parts. It is further

recommended that a contiguous

ground plane be provided in the

R2 R3

R1 R4

C5

TERMINATION

AT TRANSCEIVER

INPUTS

TD TD

circuit board directly under the

Board Layout - Decoupling

Circuit and Ground Planes

It is important to take care in the

layout of your circuit board to

achieve optimum performance

from these transceivers. Figure 7

transceiver to provide a low

inductance ground for signal

return current. This recommendation is in keeping with good

high frequency board layout

practices.

provides a good example of a

schematic for a power supply

decoupling circuit that works well

Board Layout - Hole Pattern

The Agilent transceiver complies

with the circuit board “Common

Transceiver Footprint” hole

pattern defined in the original

multisource announcement which

defined the 1x9 package style.

This drawing is reproduced in

Figure 8 with the addition of ANSI

Y14.5M compliant dimensioning

to be used as a guide in the

mechanical layout of your circuit

board.

Page 8

20.32

.800

20.32

.800

(2X)

(9X)

1.9 ± 0.1

ø

.075 ± .004

Ø0.000

0.8 ± 0.1

ø

.032 ± .004

Ø0.000

8

–A–

MA

MA

2.54

(8X)

.100

Figure 8. Recommended Board Layout Hole Pattern.

Board Layout - Art Work

The Applications Engineering

group is developing Gerber file

duplex SC and duplex ST

transceiver packages in relation

to the chassis panel.

art work for a multilayer printed

circuit board layout incorporating

the recommendations above.

Contact your local Agilent sales

representative for details.

Regulatory Compliance

These transceiver products are

intended to enable commercial

system designers to develop

equipment that complies with the

Board Layout - Mechanical

For applications interested in

providing a choice of either a

duplex SC or a duplex ST connector interface, while utilizing

the same pinout on the printed

circuit board, the ST port needs

various international regulations

governing certification of Information Technology Equipment.

See the Regulatory Compliance

Table for details. Additional

information is available from your

Agilent sales representative.

to protrude from the chassis

panel a minimum of 9.53 nm for

sufficient clearance to install the

ST connector.

Electrostatic Discharge (ESD)

There are two design cases in

which immunity to ESD damage

is important.

Please refer to Figure 8a for a

mechanical layout detailing the

recommended location of the

TOP VIEW

The first case is during handling

of the transceiver prior to

mounting it on the circuit board.

It is important to use normal ESD

handling precautions for ESD

sensitive devices. These precautions include using grounded

wrist straps, work benches, and

floor mats in ESD controlled

areas.

The second case to consider is

static discharges to the exterior of

the equipment chassis containing

the transceiver parts. To the

extent that the duplex SC

connector is exposed to the

outside of the equipment chassis

it may be subject to whatever ESD

system level test criteria that the

equipment is intended to meet.

Page 9

9

0.51

0.75

12.0

11.1

9.53

(NOTE 1)

12.09

6.79

42.0

39.12

24.8

Electromagnetic Interference

(EMI)

Most equipment designs utilizing

these high speed transceivers

from Agilent will be required to

meet the requirements of FCC in

the United States, CENELEC

EN55022 (CISPR 22) in Europe

and VCCI in Japan.

25.4

These products are suitable for

use in designs ranging from a

desktop computer with a single

transceiver to a concentrator or

switch product with large number

of transceivers.

In all well-designed chassis, the

two 0.5" holes required for ST

connectors to protrude through,

will provide 4.6 dB more

shielding than one 1.2" duplex SC

rectangular cutout. Thus, in a

25.4

well-designed chassis, the duplex

ST 1x9 transceiver emissions will

be identical to the duplex SC 1x9

transceiver emissions.

NOTE 1: MINIMUM DISTANCE FROM FRONT

OF CONNECTOR TO THE PANEL FACE.

Figure 8a. Recommended Common Mechanical Layout for ST and ST 1x9

Connectored Transceivers.

Immunity

Equipment utilizing these transceivers will be subject to radiofrequency electromagnetic fields

in some environments. These

transceivers have a high immunity

to such fields.

For additional information regarding EMI, susceptibility, ESD and

conducted noise testing procedures and results on the 1x9

transceiver family, please refer to

Applications Note 1075, Testing

and Measuring Electromagnetic Compatibility

Performance of the HFBR510X/-520X Fiber Optic

Transceivers.

Page 10

10

200

180

1.0

160

1.5

140

2.0

t

– TRANSMITTER

2.5

120

SPECTRAL WIDTH (FWHM) –nm

∆λ – TRANSMITTER OUTPUT OPTICAL

3.0

100

1260

1280 1300 1320

λC – TRANSMITTER OUTPUT OPTICAL

CENTER WAVELENGTH –nm

HFBR-5205 TRANSMITTER TEST RESULTS

OF λ

, ∆λ AND t

C

COMPLY WITH THE ALLOWED SPECTRAL WIDTH

AS A FUNCTION OF CENTER WAVELENGTH FOR

VARIOUS RISE AND FALL TIMES.

r/f

OUTPUT OPTICAL

RISE/FALL TIMES – ns

ARE CORRELATED AND

r/f

3.0

13601340

Figure 9. Transmitter Output Optical Spectral Width

(FWHM) vs. Transmitter Output Optical Center

Wavelength and Rise/Fall Times.

5

4

3

2

1

RELATIVE INPUT OPTICAL POWER (dB)

0

-3 -1 0 1

CONDITIONS:

1.T

A

2. V

3. INPUT OPTICAL RISE/FALL TIMES = 1.0/2.1 ns.

4. INPUT OPTICAL POWER IS NORMALIZED TO

CENTER OF DATA SYMBOL.

5. NOTE 16 AND 17 APPLY.

HFBR-5203/-5204/-5205

SERIES

-2 2

EYE SAMPLING TIME POSITION (ns)

= 25° C

= 5 Vdc

CC

3

Figure 10. Relative Input Optical Power vs. Eye Sampling

Time Position.

Regulatory Compliance Table

Feature Test Method Performance

Electrostatic Discharge MIL-STD-883C Meets Class 2 (2000 to 3999 Volts)

(ESD) to the Electrical Method 3015.4 Withstand up to 2200 V applied between electrical

Pins pins.

Electrostatic Discharge Variation of Typically withstand at least 25 kV without damage

(ESD) to the Duplex SC IEC 801-2 when the Duplex SC Connector Receptacle

Receptacle is contacted by a Human Body Model probe.

Electromagnetic FCC Class B Transceivers typically provide a 13 dB margin

Interference (EMI) CENELEC EN55022 (with duplex SC receptacle) or a 9 dB margin

Class B (CISPR 22B) (with duplex ST receptacles) to the noted

VCCI Class 2 standard limits when tested at a certified test

range with the transceiver mounted to a circuit

card without a chassis enclosure.

Immunity Variation of IEC 801-3 Typically show no measurable effect from a

10 V/m field swept from 10 to 450 MHz applied

to the transceiver when mounted to a circuit card

without a chassis enclosure.

Page 11

11

Transceiver Reliability

and Performance

Qualification Data

The 1 x 9 transceivers have

passed Agilent reliability and

performance qualification testing

and are undergoing ongoing

quality monitoring. Details are

available from your Agilent sales

representative.

These transceivers are

manufactured at the Agilent

Singapore location which is an

ISO 9002 certified facility.

Ordering Information

The HFBR-5204/-5204T and

HFBR-5205/-5205T 1300 nm

products and the HFBR-5203/

-5203T 800 transceivers are

available for production orders

through the Agilent Component

Field Sales Offices and Authorized

Distributors world wide.

Applications Support

Materials

Contact your local Agilent

Component Field Sales Office for

information on how to obtain PCB

Layouts, Test Boards and demo

boards for the 1x9 transceivers.

Evaluation Kits

Agilent has available three

evaluation kits for the 1x9

transceivers. The purpose of these

kits is to provide the necessary

materials to evaluate the performance of the HFBR-520X family in

a pre-existing 1x13 or 2x11

pinout system design configuration or when connectored to

various test equipment.

1. HFBR-0305 – ATM Evaluation

Kit:

This kit consists of one HFBR5205, one 1 x 13 to 1 x 9 pin

out adapter card, and one three

meter duplex SC to duplex ST

connectored 62.5/125 µm fiber

optic cable.

2. HFBR-0303 – FDDI Evaluation

Kit:

This kit consists of one HFBR5103, one 2 x 11 to 1 x 9 pin out

adapter card, one 1 x 13 to 1 x 9

pin out adapter card, and one

three meter duplex SC to MIC/

Receptacle connectored 62.5/

125 µm fiber optic cable.

3. HFBR-0319 – Evaluation Test

Fixture Board:

This test fixture converts +5 V

ECL 1x9 transceivers to –5 V

ECL BNC Coax Connections so

that direct connections to

industry standard fiber optic test

equipment can be accomplished.

Accessory Duplex SC

Connectored Cable Assemblies

Agilent recommends for optimal

coupling the use of flexible-body

duplex SC connectored cable.

Page 12

HFBR-5203, -5204, and -5205 Series

Absolute Maximum Ratings

Parameter Symbol Min. Typ. Max. Unit Reference

Storage Temperature T

Lead Soldering Temperature T

Lead Soldering Time t

Supply Voltage V

Data Input Voltage V

Differential Input Voltage V

Output Current I

S

SOLD

SOLD

CC

I

D

O

HFBR-5203, -5204, and -5205 Series

Recommended Operating Conditions

12

-40 100 °C

260 °C

10 sec.

-0.5 7.0 V

-0.5 V

CC

1.4 V Note 1

50 mA

V

Parameter Symbol Min. Typ. Max. Unit Reference

Ambient Operating Temperature T

Supply Voltage V

Data Input Voltage - Low V

Data Input Voltage - High V

IL

IH

Data and Signal Detect Output Load R

A

CC

- V

- V

070°C

4.75 5.25 V

-1.810 -1.475 V

CC

-1.165 -0.880 V

CC

L

50 Ω Note 2

Page 13

13

Agilent offers two such

compatible Duplex SC connectored jumper cable assemblies to

assist you in the evaluation of

these transceiver products. These

2. HFBR-BKD010

A duplex cable 10 meters long

assembled with 62.5/125 µm fiber

and Duplex SC connector plugs

on both ends.

cables may be purchased from

Agilent with the following part

numbers.

Accessory Duplex ST

Connectored Cable Assemblies

Agilent recommends the use of

1. HFBR-BKD001

A duplex cable 1 meter long

assembled with 62.5/125 µm fiber

Duplex Push-Pull ST connectored

cable for optimal repeatibility of

the optical power coupling.

and Duplex SC connector plugs

on both ends.

HFBR-5203, -5204 and -5205 Series

Transmitter Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Supply Current I

Power Dissipation P

Data Input Current - Low I

Data Input Current - High I

CC

DISS

IL

IH

145 185 mA Note 3

0.76 0.97 W

-350 0 µA

14 350 µA

HFBR-5203, -5204 and -5205 Series

Receiver Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Supply Current I

Power Dissipation P

Data Output Voltage - Low VOL - V

Data Output Voltage - High VOH - V

Data Output Rise Time t

Data Output Fall Time t

Signal Detect Output Voltage - Low VOL - V

Signal Detect Output Voltage - High VOH - V

Signal Detect Output Rise Time t

Signal Detect Output Fall Time t

CC

DISS

82 145 mA Note 4

0.3 0.5 W Note 5

-1.840 -1.620 V Note 6

CC

-1.045 -0.880 V Note 6

CC

r

f

CC

CC

r

f

0.35 2.2 ns Note 7

0.35 2.2 ns Note 7

-1.840 -1.620 V Note 6

-1.045 -0.880 V Note 6

0.35 2.2 ns Note 7

0.35 2.2 ns Note 7

Page 14

Agilent offers two such

compatible duplex Push-Pull ST

connectored jumper cable

assemblies to assist you in your

evaluation of these products.

These cables may be purchased

from Agilent with the following

part numbers.

1. HFBR-XXX001

A duplex cable 1 meter long

assembled with 62.5/125 µm fiber

and Duplex Push-Pull ST

connector plugs on both ends.

2. HFBR-XXX010

A duplex cable 10 meters long

assembled with 62.5/125 µm fiber

and Duplex Push-Pull ST

connector plugs on both ends.

14

Page 15

15

HFBR-5203/-5203T

Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Output Optical Power BOL P

O

62.5/125 µm, NA = 0.275 Fiber EOL -20

Output Optical Power BOL P

O

50/125 µm, NA = 0.20 Fiber EOL -23.8

Optical Extinction Ratio 0.01 % Note 10

Output Optical Power at PO (“0”) -45 dBm avg. Note 11

Logic “0” State

Center Wavelength λ

C

Spectral Width - FWHM ∆λ 100 nm Note 12

- nm RMS 43 nm RMS

Optical Rise Time t

Optical Fall Time t

r

f

Systematic Jitter Contributed SJ 1.7 ns p-p Note 14

by the Transmitter

Random Jitter Contributed RJ 0.52 ns p-p Note 15

by the Transmitter

-17 -12 dBm avg. Note 9

-20.8 -12 dBm avg. Note 9

-40 dB

800 900 nm

4.5 ns Note 13

4.5 ns Note 13

HFBR-5203/-5203T

Receiver Optical and Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Input Optical Power P

Minimum at Window Edge

Output Optical Power P

Minimum at Eye Center

Input Optical Power Maximum P

Operating Wavelength λ 800 900 nm

Systematic Jitter Contributed SJ 0.9 ns p-p Note 18

by the Receiver

Random Jitter Contributed RJ 1.16 ns p-p Note 19

by the Receiver

Signal Detect - Asserted P

Signal Detect - Deasserted P

Signal Detect - Hysteresis PA - P

Signal Detect Assert Time 0 100 µs Note 22

(off to on)

Signal Detect Deassert Time 0 350 µs Note 23

(on to off)

(W) -26 dBm avg. Note 16

IN Min.

(C) -27 dBm avg. Note 17

IN Min.

IN Max.

A

D

D

-12 dBm avg. Note 16

PD + 1.5 dB -28 dBm avg. Note 20

-45 PA-1.5 dBm avg. Note 21

1.5 dB

Page 16

16

HFBR-5204/-5204T

Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Output Optical Power BOL P

O

62.5/125 µm, NA = 0.275 Fiber EOL -22

Output Optical Power BOL P

O

50/125 µm, NA = 0.20 Fiber EOL -25.5

Optical Extinction Ratio 0.03 % Note 10

Output Optical Power at PO (“0”) -45 dBm avg. Note 11

Logic “0” State

Center Wavelength λ

C

Spectral Width - FWHM ∆λ 250 nm Note 12

- nm RMS 107 nm RMS

Optical Rise Time t

Optical Fall Time t

r

f

Systematic Jitter Contributed SJ 0.04 1.2 ns p-p Note 14

by the Transmitter

Random Jitter Contributed RJ 0 0.52 ns p-p Note 15

by the Transmitter

-21 -14 dBm avg. Note 8

-24.5 -14 dBm avg. Note 8

-35 dB

1270 1310 1380 nm

4 ns Note 13

4 ns Note 13

HFBR-5204/-5204T

Receiver Optical and Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Input Optical Power P

Minimum at Window Edge Figure 10

Input Optical Power P

Minimum at Eye Center Figure 10

Input Optical Power Maximum P

Systematic Jitter Contributed SJ 0.2 1.2 ns p-p Note 18

by the Receiver

Random Jitter Contributed RJ 1 1.91 ns p-p Note 19

by the Receiver

Operating Wavelength λ 1270 1380 nm

Signal Detect - Asserted P

Signal Detect - Deasserted P

Signal Detect - Hysteresis PA - P

Signal Detect Assert Time 0 55 100 µs Note 22

(off to on)

Signal Detect Deassert Time 0 110 350 µs Note 23

(on to off)

(W) -29 dBm avg. Note 16

IN Min.

(C) -30 dBm avg. Note 17

IN Min.

IN Max.

A

D

D

-14 dBm avg. Note 16

PD + 1.5 dB -31 dBm avg. Note 20

-45 dBm avg. Note 21

1.5 dB

Page 17

17

HFBR-5205/-5205T

Transmitter Optical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Output Optical Power BOL P

O

62.5/125 µm, NA = 0.275 Fiber EOL -20

Output Optical Power BOL P

O

50/125 µm, NA = 0.20 Fiber EOL -23.5

Optical Extinction Ratio 0.001 0.03 % Note 10

Output Optical Power at PO ("0") -45 dBm avg. Note 11

Logic "0" State

Center Wavelength λ

C

Spectral Width - FWHM ∆λ 137 nm Note 24

- nm RMS 58 nm RMS Figure 9

Optical Rise Time t

Optical Fall Time t

r

f

Systematic Jitter Contributed SJ 0.04 1.2 ns p-p Note 14

by the Transmitter

Random Jitter Contributed RJ 0 0.52 ns p-p Note 15

by the Transmitter

-19 -14 dBm avg. Note 9

-22.5 -14 dBm avg. Note 9

-50 -35 dB

1270 1310 1380 nm Note 24

Figure 9

0.6 1.0 3.0 ns Note 12, 24

Figure 9

0.6 2.1 3.0 ns Note 12, 24

Figure 9

Page 18

18

HFBR-5205/-5205T

Receiver Optical and Electrical Characteristics

(TA = 0°C to 70°C, VCC = 4.75 V to 5.25 V)

Parameter Symbol Min. Typ. Max. Unit Reference

Input Optical Power P

Minimum at Window Edge Figure 10

Input Optical Power P

Minimum at Eye Center Figure 10

Input Optical Power Maximum P

Operating Wavelength λ 1260 1360 nm

Systematic Jitter Contributed SJ 0.2 1.2 ns p-p Note 18

by the Receiver

Random Jitter Contributed RJ 1 1.91 ns p-p Note 19

by the Receiver

Signal Detect - Asserted P

Signal Detect - Deasserted P

Signal Detect - Hysteresis PA - P

Signal Detect Assert Time 0 55 100 µs Note 22

(off to on)

Signal Detect Deassert Time 0 110 350 µs Note 23

(on to off)

(W) -30 dBm avg. Note 16

IN Min.

(C) -31 dBm avg. Note 17

IN Min.

IN Max.

A

D

D

-14 dBm avg. Note 16

PD + 1.5 dB -31 dBm avg. Note 20

-45 dBm avg. Note 21

1.5 dB

Notes:

1. This is the maximum voltage that

can be applied across the Differential

Transmitter Data Inputs to prevent

damage to the input ESD protection

circuit.

2. The outputs are terminated with

50 Ω connected to VCC -2 V.

3. The power supply current needed to

operate the transmitter is provided

to differential ECL circuitry. This

circuitry maintains a nearly constant current flow from the power

supply. Constant current operation

helps to prevent unwanted electrical

noise from being generated and

conducted or emitted to neighboring

circuitry.

4. This value is measured with the

outputs terminated into 50 Ω

connected to VCC -2 V and an Input

Optical Power level of -14 dBm

average.

5. The power dissipation value is the

power dissipated in the receiver

itself. Power dissipation is calculated as the sum of the products of

supply voltage and currents, minus

the sum of the products of the output

voltages and currents.

6. This value is measured with respect

to VCC with the output terminated

into 50 Ω connected to VCC -2 V.

7. The output rise and fall times are

measured between 20% and 80%

levels with the output connected to

VCC -2 V through 50 Ω.

8. These optical power values are

measured with the following

conditions:

• The Beginning of Life (BOL) to

the End of Life (EOL) optical

power degradation is typically

1.5 dB per the industry convention for long wavelength LEDs.

The actual degradation observed

in Agilent’s 1300 nm LED products

is <1 dB, as specified in this

datasheet.

• Over the specified operating voltage

and temperature ranges.

• With 25 MBd (12.5 MHz square-

wave) input signal.

• At the end of one meter of noted

optical fiber with cladding modes

removed.

The average power value can be

converted to a peak power value by

adding 3 dB. Higher output optical

power transmitters are available on

special request.

9. The same comments of note 9 apply

except that industry convention for

short wavelength LED (800 nm)

aging is 3 dB. This value for Output

Optical Power will provide a

minimum 6 dB optical power budget

at the EOL, which will provide at

least 150 meter link lengths with

margin left over for overcoming

normal passive losses, such as inline connectors, in the cable plant.

The actual degradation observed in

normal commercial environments

will be considerably less than this

amount with Agilent’s 800 nm LED

products. Please consult with your

local Agilent sales representative for

further details.

10. The Extinction Ratio is a measure of

the modulation depth of the optical

signal. The data “0” output optical

power is compared to the data “1”

peak output optical power and

Page 19

19

expressed as a percentage. With the

transmitter driven by a 25 MBd

(12.5 MHz square-wave) input

signal, the average optical power is

measured. The data “1” peak power

is then calculated by adding 3dB to

the measured average optical power.

The data “0” output optical power is

found by measuring the optical

power when the transmitter is

driven by a logic “0” input. The

extinction ratio is the ratio of the

optical power at the “0” level

compared to the optical power at the

“1” level expressed as a percentage

or in decibels.

11. The transmitter will provide this low

level of Output Optical Power when

driven by a logic “0” input. This can

be useful in link troubleshooting.

12. The relationship between Full Width

Half Maximum and RMS values for

Spectral Width is derived from the

assumption of a Gaussian shaped

spectrum which results in a 2.35 X

RMS = FWHM relationship.

13. The optical rise and fall times are

measured from 10% to 90% when

the transmitter is driven by a 25

MBd (12.5 MHz square-wave) input

signal. The ANSI T1E1.2 committee

has designated the possibility of

defining an eye pattern mask for the

transmitter optical output as an

item for further study. Agilent will

incorporate this requirement into

the specifications for these products

if it is defined. The HFBR-5204 and

HFBR-5205 products typically

comply with the template requirements of CCITT (now ITU-T) G.957

Section 3.2.5, Figure 2 for the STM1 rate, excluding the optical receiver

filter normally associated with

single mode fiber measurements

which is the likely source for the

ANSI T1E1.2 committee to follow in

this matter.

14. Systematic Jitter contributed by the

transmitter is defined as the combination of Duty Cycle Distortion

and Data Dependent Jitter.

Systematic Jitter is measured at

50% threshold using a 155.52 MBd

(77.5 MHz square-wave), 27 - 1

psuedorandom data pattern input

signal.

15. Random Jitter contributed by the

transmitter is specified with a

155.52 MBd (77.5 MHz squarewave) input signal.

16. This specification is intended to

indicate the performance of the

receiver section of the transceiver

when Input Optical Power signal

characteristics are present per the

following definitions. The Input

Optical Power dynamic range from

the minimum level (with a window

time-width) to the maximum level is

the range over which the receiver is

guaranteed to provide output data

with a Bit Error Ratio (BER) better

than or equal to 1 x 10

• At the Beginning of Life (BOL)

• Over the specified operating

temperature and voltage ranges

• Input is a 155.52 MBd, 223 - 1

PRBS data pattern with 72 “1”s

and 72 “0”s inserted per the

CCITT (now ITU-T) recommendation G.958 Appendix I.

• Receiver data window time-width

is 1.23 ns or greater for the clock

recovery circuit to operate in. The

actual test data window timewidth is set to simulate the effect

of worst case optical input jitter

based on the transmitter jitter

values from the specification

tables. The test window timewidths are as follows: HFBR-5203

is 4.4ns, HFBR-5205 and HFBR5204 are 3.32 ns.

-10

.

• Transmitter operating with a

155.52 MBd, 77.5 MHz squarewave, input signal to simulate

any cross-talk present between

the transmitter and receiver

sections of the transceiver.

17. All conditions of Note 16 apply except

that the measurement is made at

the center of the symbol with no

window time-width.

18. Systematic Jitter contributed by the

receiver is defined as the combination of Duty Cycle Distortion and

Data Dependent Jitter. Systematic

Jitter is measured at 50% threshold

using a 155.52 MBd (77.5 MHz

square-wave), 27 - 1 psuedorandom

data pattern input signal.

19. Random Jitter contributed by the

receiver is specified with a 155.52

MBd (77.5 MHz square-wave) input

signal.

20. This value is measured during the

transition from low to high levels of

input optical power.

21. This value is measured during the

transition from high to low levels of

input optical power.

22. The Signal Detect output shall be

asserted within 100 µs after a step

increase of the Input Optical Power.

23. Signal detect output shall be deasserted within 350 µs after a step

decrease in the Input Optical Power.

24. The HFBR-5205 transceiver

complies with the requirements for

the tradeoffs between center wavelength, spectral width, and rise/fall

times shown in Figure 9. This figure

is derived from the FDDI PMD

standard (ISO/IEC 9314-3 : 1990

and ANSI X3.166 - 1990) per the

description in ANSI T1E1.2 Revision

3. The interpretation of this figure is

that values of Center Wavelength

and Spectral Width must lie along

the appropriate Optical Rise/Fall

Time curve.

Page 20

www.semiconductor.agilent.com

Data subject to change.

Copyright © 1999 Agilent Technologies, Inc.

Obsoletes 5963-5774E (2/95)

5965-9729E (11/99)

Loading...

Loading...