Page 1

OPERATING MANUAL

AGILENT 603xA FAMILY

AUTORANGING SYSTEM DC

POWER SUPPLIES

AGILENT Part No. 5959-3342

Microfiche Part No. 5959-3343 Edition 1 Printed: September 1990

Edition 2 Printed: January 1992

Updated: February 2000

Page 2

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the

factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States

National Bureau of Standards, to the extent allowed by the Bureau’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a

period of three years from date of delivery. Agilent software and firmware products, which are designated by

Agilent for use with a hardware product and when properly installed on that hardware product, are warra nted not

to fail to execute their programming instructions due to defects in material and workmanship for a period of 90

days from date of delivery. During the warranty period Agilent Technologies will, at its option, either repair or

replace products which prove to be defective. Agilent does not warrant that the operation for the software

firmware, or hardware shall be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility

designated by Agilent. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products

returned to Agilent for warranty service. Except for products returned to Customer from another country, Agilent

shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent’s product price, only if Customer

pays Agilent international prices (defined as destination local currency price, or U.S. or Geneva Export price).

If Agilent is unable, within a reasonable time to repair or replace any product to condition as warranted, the

Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the

Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of

the environmental specifications for the product, or improper site preparation and maintenance. NO OTHER

WARRANTY IS EXPRESSED OR IMPLIED. AGILENT SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER’S SOLE AND EXCLUSIVE REMEDIES. AGILENT

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contacts,

product maintenance agreements and customer assistance agreements are also available. Contact your nearest

Agilent Technologies Sales and Service office for further information on Agilent’s full line of Support Programs.

Copyright 2000 Agilent Technologies Update___February, 2000

2

Page 3

Safety Summary

The following general safety precautions must be observed during all phases of operation of this instrument. Failure to

comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the instrument. Agilent Technologies assumes no liability for the customer’s failure to

comply with these requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The protective features of this

product may be impaired if it is used in a manner not specified in the operating instructions.

Any LEDs used in this product are Class 1 LEDs as per IEC 825-1.

This ISM device complies with Canadian ICES-001. Cet appareil ISM est conforme à la norme NMB-001 du Canada.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category II, pollution degree 2 environment. It is designed to

operate at a maximum relative humidity of 95% and at altitudes of up to 2000 meters. Refer to the specifications tables for

the ac mains voltage requirements and ambient operating temperature range.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage, the correct fuse is installed, and all safety precautions are

taken. Note the instrument’s external markings described unde r "Safety Symbols".

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical ground. The instrument

must be connected to the ac p ower supply mains through a three-conductor power cable, with the third wire firmly

connected to an electrical ground (safety ground) at the power outlet. For instruments designed to be hard-wired to the ac

power lines (supply mains), connect the protective earth terminal to a protective conductor before any other connection is

made. Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will cause

a potential shock hazard that could result in personal injury. If the instrument is to be energized via an external

autotransformer for voltage reduction, be certain that the autotransformer common terminal is connected to the neutral

(earthed pole) of the ac power lines (supply mains).

ATTENTION: Un circuit de terre continu est essentiel en vue du fonctionnement sécuritaire de l’appareil. Ne

jamais mettre l’appareil en marche lorsque le conducteur de mise … la terre est d‚branch‚.

FUSES

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do

not use repaired fuses or short-circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made

by qualified service personnel. Do not replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power, discharge

circuits and remove external voltage sources before touching components.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is

present.

DO NOT EXCEED INPUT RATINGS

This instrument may be equipped with a line filter to reduce electromagnetic interference and must be connected to a

properly grounded receptacle to minimize electric shock hazard. Operation at line voltages or frequencies in excess of

those stated on the data plate may cause leakage currents in excess of 5.0 mA peak.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized

modifications to the instrument. Return the instrument to an Agilent Technologies Sales and Service Office for service and

repair to ensure that safety features are maintained.

Instruments that appear damaged or defective should be made inoperative and secured against unintended operation until

they can be repaired by qualified service personnel.

3

Page 4

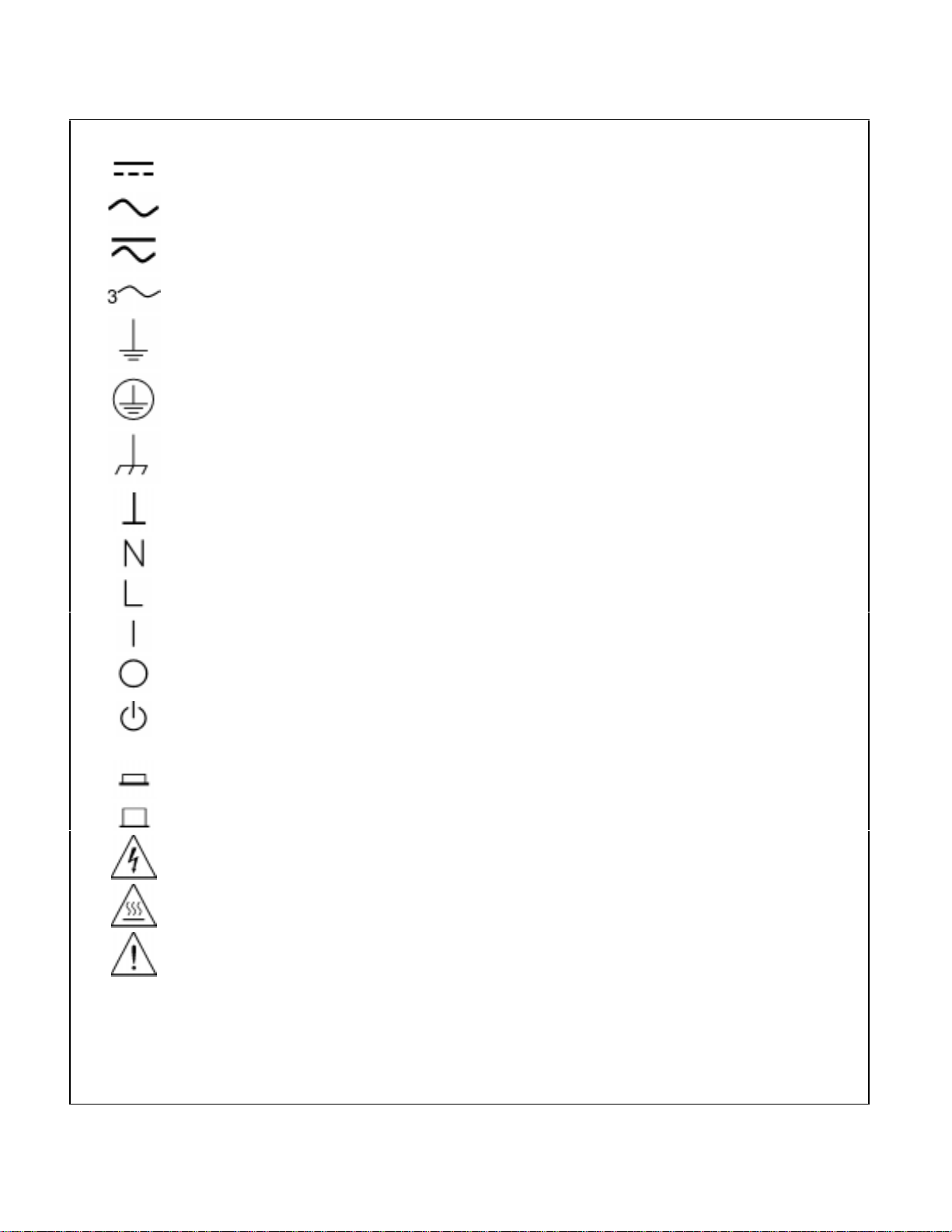

SAFETY SYMBOLS

Direct current

Alternating current

Both direct and alternating current

Three-phase alternating current

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to be operated with

one terminal at earth potential.

Terminal for Neutral conductor on permanently installed equipment

Terminal for Line conductor on permanently installed equipment

On (supply)

Off (supply)

Standby (supply). Units with this symbol are not completely disconnected from ac mains when this

switch is off. To completely disconnect the unit from ac mains, either disconnect the power cord or have

a qualified electrician install an external switch.

In position of a bi-stable push control

Out position of a bi-stable push control

Caution, risk of electric shock

Caution, hot surface

Caution (refer to accompanying documents)

WARNING The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING

sign until the indicated conditions are fully understood and met.

Caution The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if

not correctly performed or adhered to, could result in damage to or destruction of part or all of the

product. Do not proceed beyond a CAUTION sign until the indicated conditions are fully understood and

met.

4

Page 5

Declaration Page

DECLARATION OF CONFORMITY

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name: Agilent Technologies

Manufacturer’s Address: 150 Green Pond Road

Rockaway, New Jersey 07866

U.S.A.

declares that the Product

Product Name: a) Single Output System Power Supply

b) Autoranging Power Supply

Model Number: a) Agilent 6030A, 6031A, 6032A, 6035A, 6033A, 6038A

b) Agilent 6010A, 6011A, 6012B, 6015A, 6023A, 6028A

conforms to the following Product Specifications:

Safety: IEC 348 1978 / HD 401S1: 1981

EMC: CISPR 11:1990 / EN 55011:1991 - Group 1 Class B

Supplementary Information:

The product herewith complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE-marking accordingly.

Note 1: The product family was introduced prior to 12/93.

New Jersey January 1997

Location Date Bruce Krueger / Quality Manager

European Contact: Your local Agilent Technologies Sales and Service Office or Agilent Technologies GmbH,

Department TRE, Herrenberger Strasse 130, D-71034 Boeblingen (FAX:+49-7031-14-3143)

1

IEC 801-2:1991 / EN 50082-1:1992 - 4 kV CD, 8 kV AD

IEC 801-3:1984 / EN 50082-1:1992 - 3 V / m

IEC 801-4:1988 / EN 50082-1:1992 - 0.5 kV Signal Lines

1 kV Power Lines

5

Page 6

Acoustic Noise Statement

Herstellerbescheinigung

Diese Information steht im Zusammenhang mit den Anfor derungen der

Maschinenlärminformationsverordnung vom 18 Januar 1991.

* Schalldruckpegel Lp < 70 dB(A) * Am Arbeitsplatz * Normaler Betrieb * Nach DIN 45635

T. 19 (Typprüfung)

Manufacturer’s Declaration

This statement is provided to comply with the requirements of the German Sound Emission

Directive, from 18 January 1991. This product has a sound pressure emission (at the operator

position) < 70 dB.

* Sound Pressure Lp < 70 dB(A) * At Operator Position * Normal Operation * According to

ISO 7779 (Type Test).

6

Page 7

Table Of Contents

1. General Information

Introduction .................................................................................................................................................. 11

Description .................................................................................................................................................... 11

Safety Considerations ...................................................................................................................................12

Options..........................................................................................................................................................12

Accessories ................................................................................................................................................... 12

Instrument & Manual Identification..............................................................................................................13

GP-IB Cables & Interconnections.................................................................................................................14

GP-IB Compatibility.....................................................................................................................................14

Ordering Additional Manuals........................................................................................................................14

Related Documents.......................................................................................................................................15

Specifications ...............................................................................................................................................15

2. Installation

Introduction .................................................................................................................................................. 21

Initial Inspection............................................................................................................................................21

Mechanical Check.......................................................................................................................................21

Electrical Check..........................................................................................................................................21

Preparation for Use .......................................................................................................................................21

Location & Cooling.....................................................................................................................................21

Outline Diagram..........................................................................................................................................21

Bench Operation..........................................................................................................................................22

Rack Mounting............................................................................................................................................22

Input Power Requirements ..........................................................................................................................22

Power Connection.......................................................................................................................................22

Line Voltage Option Conversion...................................................................................................................24

AC Line Impedance Check ...........................................................................................................................27

Repacking for Shipment................................................................................................................................27

Rear Panel Screw Sizes and Part Numbers ...................................................................................................27

3. Operating Instructions

Introduction .................................................................................................................................................. 29

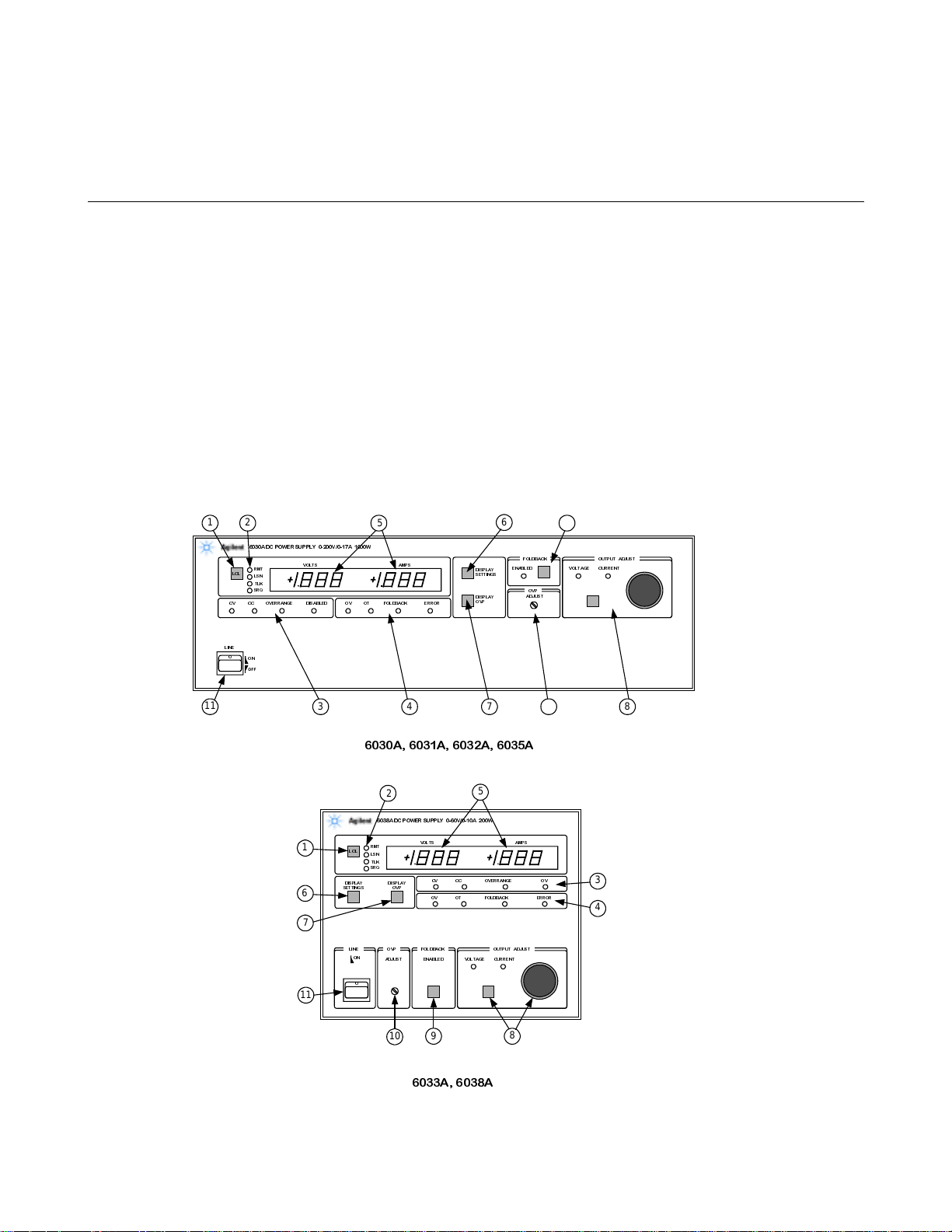

Controls & Indicators....................................................................................................................................30

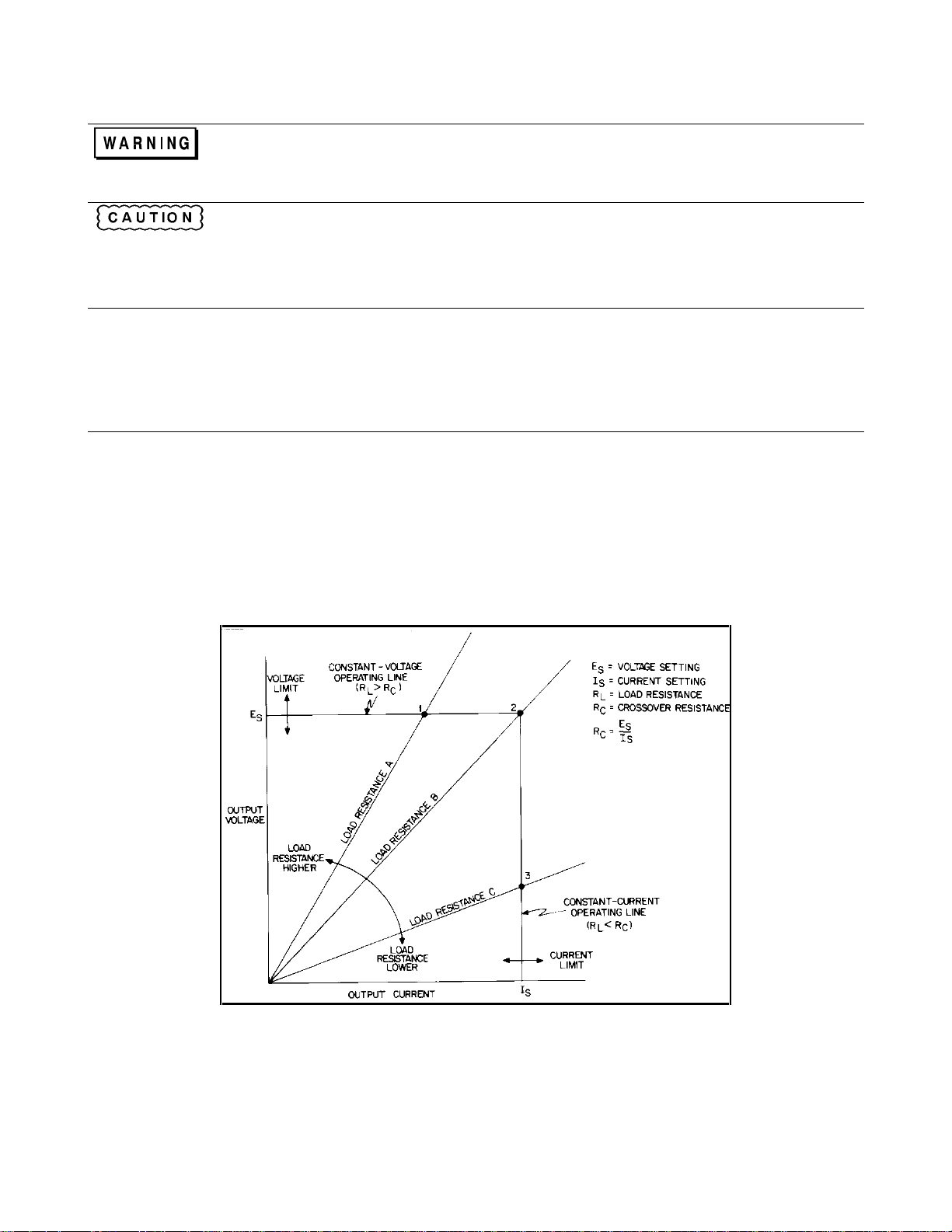

Output Range ................................................................................................................................................30

Turn-On Checkout Procedure.......................................................................................................................33

Initial Setup & Interconnections....................................................................................................................35

Connecting the Load...................................................................................................................................35

Overvoltage Protection................................................................................................................................38

Adjustment ...............................................................................................................................................38

Reset .........................................................................................................................................................38

Foldback Protection ....................................................................................................................................39

Remote Voltage Sensing.............................................................................................................................39

Mode Switches............................................................................................................................................40

GP-IB Connection.......................................................................................................................................41

Monitor Signals...........................................................................................................................................42

Protective Circuits .......................................................................................................................................42

Overrange .................................................................................................................................................42

Disabled ...................................................................................................................................................42

Overvoltage ..............................................................................................................................................42

Overtemperature .......................................................................................................................................42

AC Line Voltage.......................................................................................................................................42

Foldback....................................................................................................................................................43

7

Page 8

Table Of Contents (continued)

Error.......................................................................................................................................................... 43

Local Operation.............................................................................................................................................43

Constant Voltage Operation........................................................................................................................43

Constant Current Operation.........................................................................................................................44

Return to Local............................................................................................................................................44

GP-IB Operation...........................................................................................................................................44

Interface Functions......................................................................................................................................44

Multiline Message Control........................................................................................................................45

Service Request (SR1) ..............................................................................................................................45

Serial Poll..................................................................................................................................................45

Parallel Poll...............................................................................................................................................45

Remote/Local ...........................................................................................................................................46

Device Clear..............................................................................................................................................46

Device Trigger ..........................................................................................................................................46

GP-IB Address Selection ..............................................................................................................................46

Power-On Service Request............................................................................................................................47

INH-FLT/RLY LNK Operation....................................................................................................................47

Initial Conditions...........................................................................................................................................47

Programming Syntax.....................................................................................................................................48

Numbers Sent to Supply..............................................................................................................................48

Numbers Returned to Controller .................................................................................................................49

Separators for Data Sent to Power Supply..................................................................................................49

Terminators for Data Sent to Power Supply................................................................................................54

Termination for Data to Controller .............................................................................................................55

Voltage Setting............................................................................................................................................55

Current Setting............................................................................................................................................56

OVP Measurement......................................................................................................................................56

Soft Limits...................................................................................................................................................57

Delay...........................................................................................................................................................57

Output On/Off.............................................................................................................................................58

Foldback Protection ....................................................................................................................................58

Reset............................................................................................................................................................59

Hold & Trigger............................................................................................................................................59

Store & Recall.............................................................................................................................................60

Status Register.............................................................................................................................................60

Accumulated Status Register.......................................................................................................................61

Mask & Fault Registers...............................................................................................................................61

Service Request (SRQ)................................................................................................................................62

Clear ...........................................................................................................................................................63

Error ........................................................................................................................................................... 63

Test..............................................................................................................................................................63

Model Identification....................................................................................................................................65

Analog Programming ....................................................................................................................................65

CV Output, Resistance Control...................................................................................................................66

CV Output, Voltage Control.......................................................................................................................66

CC Output, Resistance Control ...................................................................................................................67

CC Output, Voltage Control........................................................................................................................67

Multiple-Supply Operation............................................................................................................................67

Auto-Parallel Operation..............................................................................................................................68

Setting Voltage & Current.........................................................................................................................69

Overvoltage Protection..............................................................................................................................69

8

Page 9

Table Of Contents (continued)

Remote Sensing.........................................................................................................................................69

Series Operation............................................................................................................................................69

FLT & Remote INH Connections ...............................................................................................................70

A 100 VAC Input Power Option 100

General Information......................................................................................................................................75

Description .................................................................................................................................................75

Scope of Appendix A..................................................................................................................................75

Using Appendix A.......................................................................................................................................75

Manual Changes..........................................................................................................................................75

Section I Manual Changes...........................................................................................................................75

Section II Manual Changes.........................................................................................................................76

Section III Manual Changes........................................................................................................................76

B Blank Front Panel Option 001

Introduction ................................................................................................................................................... 79

Description....................................................................................................................................................79

Turn-On Checkout Procedure.......................................................................................................................79

Overvoltage Protection Setting .....................................................................................................................81

C Standard Commands for Programmable Instruments

About this Appendix.....................................................................................................................................83

Reader Path...................................................................................................................................................83

References .................................................................................................................................................... 83

Introduction ................................................................................................................................................... 84

Language Switching......................................................................................................................................84

Stand-Alone Connections..............................................................................................................................84

Linked Connections ......................................................................................................................................85

Installation...................................................................................................................................................85

Setting the Address......................................................................................................................................86

Primary Address........................................................................................................................................86

Secondary Address....................................................................................................................................86

Addressing Over the Bus.............................................................................................................................86

Language Dictionary ....................................................................................................................................87

Keywords....................................................................................................................................................87

Parameters...................................................................................................................................................87

Order of Presentation..................................................................................................................................87

COMMON Commands ...............................................................................................................................87

Subsystem Commands.................................................................................................................................87

Status Reporting..........................................................................................................................................104

Questionable Status Group........................................................................................................................104

Register Functions...................................................................................................................................104

Register Programming.............................................................................................................................105

Status Programming Examples................................................................................................................105

Operation Status Group...............................................................................................................................105

Register Functions.....................................................................................................................................105

Register Programming...............................................................................................................................105

Status Programming Example ...................................................................................................................107

Standard Event Status Group....................................................................................................................107

9

Page 10

Table Of Contents (continued)

Register Functions...................................................................................................................................107

Status Programming Examples................................................................................................................108

Status Byte Register ..................................................................................................................................108

The RQS Bit............................................................................................................................................108

The MSS Bit............................................................................................................................................108

Clearing the Status Byte Register............................................................................................................108

Service Request Enable Register.................................................................................................................108

Register Functions.....................................................................................................................................108

Register Programming...............................................................................................................................109

Status Programming Examples..................................................................................................................109

Output Queue..............................................................................................................................................109

SCPI Error Messages..................................................................................................................................109

System Errors............................................................................................................................................109

Device-Dependent Errors..........................................................................................................................110

Hardware Errors During Selftest.............................................................................................................110

Hardware Errors During Operation.........................................................................................................110

SCPI Command Summary...........................................................................................................................111

ARP/SCPI Commands ................................................................................................................................112

D Programming the Agilent 603xA Power Supplies Using BASIC

Introduction ................................................................................................................................................. 115

I/O Path Names...........................................................................................................................................115

Initialization................................................................................................................................................115

Voltage and Current Programming..............................................................................................................115

Voltage and Current Readback....................................................................................................................116

Output Inhibit/Enable..................................................................................................................................118

Power Supply Status.................................................................................................................................... 118

Present Status............................................................................................................................................118

Accumulated Status...................................................................................................................................119

Fault and Mask Registers..........................................................................................................................120

Serial Poll..................................................................................................................................................121

Service Request.........................................................................................................................................122

Delay Time................................................................................................................................................123

Programming Error Detection ..................................................................................................................123

Protection Features......................................................................................................................................125

Overvoltage...............................................................................................................................................125

Foldback ...................................................................................................................................................125

Soft Programming Limits.......................................................................................................................... 125

Fault Indicator and Inhibit.........................................................................................................................125

Advanced Topics ........................................................................................................................................126

Hold Mode................................................................................................................................................126

Machine States..........................................................................................................................................126

Index ....................................................................................................................................................................129

Agilent Sales and Support Office ........................................................................................................................133

10

Page 11

1

General Information

Introduction

This manual contains specifications, installation instructions, and operating instructions for System Power Supply Models:

Agilent 6030A, 6031A, 6032A, 6033A, 6035A, and 6038A. Refer to "Related Documents" for other information

concerning these products.

Description

This system power supply is an autoranging GP-IB power supply. It uses power MOSFETs in a 20 kHz switching converter

to provide an autoranging output characteristic with laboratory performance. Output voltage and current are continuously

indicated on individual meters. LED indicators show the complete operating state of the unit. Front-panel controls allow the

user to set output voltage, current and overvoltage protection trip levels. Overvoltage p rotection (OVP) protects the load by

quickly and automatically interrupting energy transfer if a preset trip voltage is exceeded. Foldback protection can be

selected to disable the power supply output if the unit switches from Constant Voltage (CV) to Constant Current (CC) mode

or vice-versa.

The power supply can be both a listener and talker on the GP-IB, and can be programmed directly in volts and amps. Power

supply status can be read over the GP-IB, and the power supply can be instructed to request service for any of ten

conditions. Upon command, the power supply will measure its output voltage, output current, or OVP trip voltage and put

the value on the GP-IB. New output values can be put on hold and triggered later, allowing the controller to synchronize

multiple power supplies at one time.

The following parameters and features can be controlled via the GP-IB:

•

Output voltage setting (12 bits)

•

Output current setting (12 bits)

•

Trigger (update output)

•

Output disable/enable

•

OVP reset

•

"Soft" voltage and current limits

•

Status reporting

•

Service request capability

•

Foldback protection

•

Output voltage measurement (12 bits)

•

Output current measurement (12 bits)

•

OVP setting measurement

•

Machine state initialization

• 16 machine state presets

• Self test

Output connections are made to rear-panel screw-on terminals. Either the positive or negative output terminal may be

grounded or the output may be floated up to + 550 Vdc (including output voltage) from chassis ground. Output voltage can

be locally or remotely sensed.

The power supply is fan cooled and is packaged in an Agilent Technologies System ll-compatible modular enclosure which

is sturdy, attractive and provides easy access for servicing.

General Information

11

Page 12

A fault indicator (FLT) and remote inhibit (INH) circuit provides additional shutdown protection, should either the GP-IB

and/or controller fail.

The FLT circuit provides the user with a means of knowing the status of any unmasked fault register bit independently of

the SRQ function available through the GP-IB. You don’t have to rely on the controller to inform you of a fault within the

power supply.

The INH circuit (which is also independent of the GP-IB) controls the RI bit in the fault registers, and provides a way to

disable the supply remotely (i.e. a "panic button’’). This gives you a means to bypass the controller and/or GP-IB to disable

the supply.

Safety Considerations

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The instrument and this manual

should be reviewed for safety markings and instructions before operation. Refer to the Safety Summary page at the

beginning of this manual for a summary of general safety information. Safety information for specific procedures is located

at appropriate places in this manual.

Options

Options are standard factory modifications or accessories that are delivered with the supply. The following options are

available. Note lower output power and voltage specifications for Option 100, which is described in Appendix A.

Option Description

001 Blank Front Panel for line Options 120, 220, and 240 Vdc

100 Input power: 100 Vac + 6%, -10%;

48-63 Hz single phase.

120 Input power: 120 Vac +6%, -13%.

48-63 Hz single phase.

220 Input Power: 220 Vac +6%, -13%;

48-63 Hz, single phase.

240 Input power: 240 Vac +6%, -13%;

48-63 Hz, single phase.

800 Rack mount kit for two units side by side

(Agilent 6033A and Agilent 6038A only)

908 Rack mounting kit

909 Flanges with Handles

0L2

0B3 Service Manual

One additional Operating Manual

Accessories

The System-II cabinet accessories listed below may be ordered with the power supply or separately from your local Agilent

Technologies Sales and Support Office (see list of addresses at rear of this manual).

For 6030A, Agilent 603lA, Agilent 6032A, Agilent 6035A only

Agilent Part No

5062-3989 Front handle kit for 5-1/4 inch high cabinets

1460-1345 Tilt stand (1) snaps into standard foot on; must be used in pairs

5062-3977 Rack flange kit for 5-1/4 inch high cabinet (will be shipped with supply if ordered as

Option 908)

5062-3983 Rack mount flange kit with handles

General Information

12

Description

Page 13

1494-0060 Rack slide kit, non tilting

5060-2865 Service kit, includes extenders for control and power mesh boards, three cables to

allow GP-IB and PSI boards to lie on table outside unit, and control board test

connector.

5060-2866 FET service kit. Includes FETs and all components that should be replaced with FETs.

59510A Relay Accessory

59511A Relay Accessory (Polarity Reversing)

5062-3960 Rack mounting adapter kit for side mounting one 7-inch high cabinet, includes one

rack flange and one half-module width extension adapter. (Will be shipped with

instrument if ordered as Option 908). This rack mounting adapter kit is not compatible

with front handle kit Agilent P/N 5061-3990).

5062-3961 Rack mounting adapter kit for center mounting one 7-inch high cabinet, includes one

rack flange and one quarter-module width extension adapter (two kits required), there

will be surplus of hardware.

5062-3978 Rack flange kit for 7-inch high cabinet. Must be used with another half-module width

unit of equal depth with lock link kit 5061-9694. (Will be shipped if instrument is

ordered as Option 800).

5061-9694 Lock link kit for joining units of equal depth, contains hardware for three side-by-side

joints (four units) and two over-under joints (three units). Locking cabinets together

horizontally in a configuration wider than one full module is not recommended. 5062-

3978 and 5061-9694 will be shipped if Option 800 is ordered.

5062-3990 Front handle kit for 7-inch high cabinets. Corresponding flange kit is 5061-2072. This

front handle kit is not compatible with rack mounting adapter kit (Agilent PIN 5062-

3960) or Option 908.

5061-2072 Flange kit to be used with front handle kit 5062-3990.

5062-3984 Rack mounting flange kit with handles for 7-inch high cabinet. Must be used with

another half-module width unit of equal depth with lock link kit 5061-9694.

5062-4003 Bail handle kit for carrying 7-inch high, half-module width cabinet.

1460-1345 Tilt stand (1) snaps into standard foot on instrument, must be used in pairs.

5062-3998 Support shelf bit for mounting on or more 7-inch high cabinets of any depth to 20

inches.

5062-4027 Front filler panel, half-module width, for 7-inch high cabinet on support shelf.

1494-0065 Slide kit for 5061-0098 support shelf.

06033-60005 Service kit, includes extenders for control and power mesh boards, three cables to

allow GP-IB and PSI boards to lie on table outside unit, and control board test

connector.

5060-0138 GP-IB connector non-metric to metric conversion kit.

5060-2860 FET service kit, includes FETs and all components that should be replaced with FETs.

59510A Relay Accessory

59511A Relay Accessory (Polarity Reversing)

Instrument and Manual Identification

Agilent Technologies power supplies are identified by a unique two-part serial number, such as 3023A-06181. The first part

is the prefix, which denotes the date of the last significant design change and the country of manufacture. Adding 1960 to

the first two digits gives the year of the change (30 = 1990, 31 = 1991, etc.) and the second two digits identify the week of

that year. The letter indicates the country of manufacture (A = U.S.A.). The second part of the serial number consists of a 5digit number sequentially assigned to each power supply.

General Information

13

Page 14

The serial number prefixes listed on the front of this manual indicate the versions of the supplies that were available when

the manual was issued. If the serial prefix of your supply is not listed in this manual, the manual may include a yellow

"Manual Change’’ sheet. That sheet updates this manual by defining any differences b etween the version of your supply and

the versions included here, and may also include information for correcting any manual errors. Note that because not all

changes to the product require changes to the manual, there may be no update information required for your version of the

supply.

GP-IB Interconnection Cables and Connectors

Cables for interconnecting GP-IB devices are available in four different lengths. The connector block at both ends of each

GP-IB cable has a plug on one side and a matching receptacle on the other, so that several cables may be connected in

parallel, thus simplifying system interconnection. Lock screws provide secure mounting of each connector block to a GP-IB

instrument, or to another cable connector block.

Model

Agilent 10833A GP-IB Cable, 1 m (3.3 ft.)

Agilent 10833B GP-IB Cable, 2 m (6.6 ft.)

Agilent 10833C GP-IB Cable, 4 m (13.2 ft.)

Agilent 10833D GP-IB Cable, 0.5 m (1.6 ft.)

Agilent 10834A GP-IB Connector Extender

Agilent 5080-2148 Serial Link Cable, 2 m (6.6 ft)

The Agilent 10834A extender was designed to help in cases where rear panel space results in difficult cabling situations.

The extender provides clearance by extending the first connector block 2.3 cm away from the rear panel of the instrument.

Serial link cables may be used to connect power supplies together when programming with SCPI. With serial link cables,

you can connect up to 15 additional power supplies per GP-IB address. See Appendix C for more information

GP-IB Compatibility

The system power supplies implement the following GP-IB interface functions:

SH1(Source Handshake) RL1(Remote Local)

AH1(Acceptor Handshake) PP1(Parallel Poll)

T6(Talker) DC1(Device Clear)

L4(Listener) DT1(Device Trigger)

SR1(Service Request)

Ordering Additional Manuals

One Operating manual is shipped with each power supply. Additional manuals may be purchased directly from your local

Agilent Technologies Sales office. Specify the model number, serial number prefix, and the manual part number provided

on the title page. (When ordered at the same time as the power supply, additional manuals may be purchased by adding

Option 910 to the order. Each Option 910 includes one Operating and one Service Manual).

General Information

14

Page 15

Related Documents

The following documents may be useful for your GP-IB systems. The Agilent documents can be ordered from your local

Agilent Sales Office.

Agilent 6033A/38A Service Manual, Agilent part number 5959-3346.

Agilent 6030A/31A/32A/35A Service Manual, Agilent part number 5959-3344.

Tutorial Description of the Agilent T echnologies Interface Bus, Agilent Part Number 5952-0156, November 1987

ANSI/IEEE Std 488.1-1987, IEEE Standard Digital Interface for Programmable Instrumentation, available from:

IEEE

345 East 47th Street

New York NY 10017 USA

Specifications

Specifications for the power supply fall into two major categories: performance specifications and supplemental

characteristics. Performance specifications (see Table 1-1) describe the supply’s warranted performance. The power supply

Service Manual has procedures for verifying the performance specifications.

Supplemental characteristics (see Table 1-2) give typical but nonwarranted performance parameters. Supplemental

characteristics are useful in accessing applications for the power supply.

General Information

15

Page 16

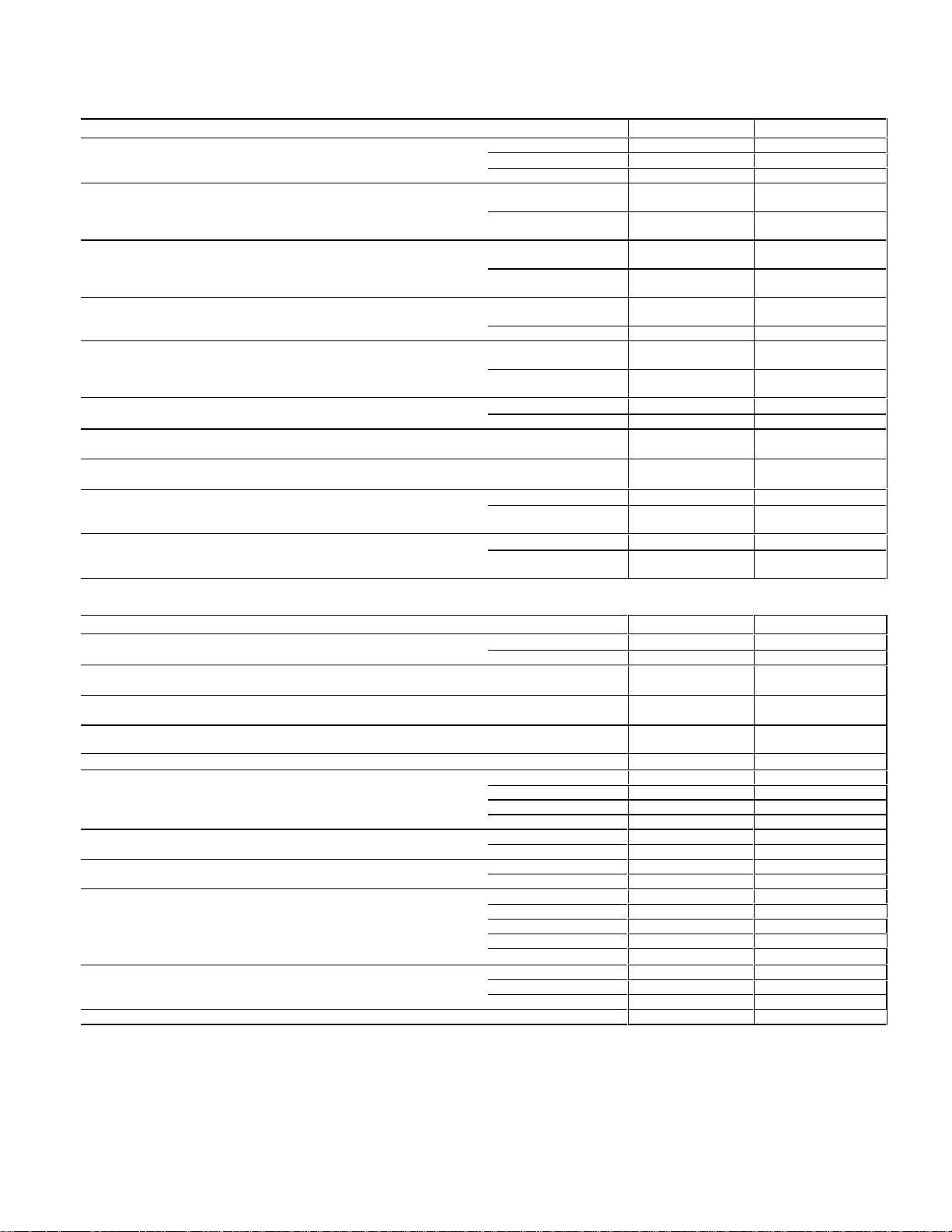

Table 1-1. Performance Specifications

Agilent Technologies Model 6033A 6038A

DC Output: Voltage, current and power spans indicate range Volts 0-20 V 0-60 V

over output may be varied using front panel c ont rols .

Maximum Power 200-240 W 200-240 W

Load Effect (Load Regulation) Voltage load effect is given for a load

current change equal to the current rating of the supply. Current load

effect is given for a load v olt age c hange equal t o t he voltage rating of the

supply.

Source Effect (Line Regulation): Given for a change within the rated line

voltage for any output within the rated output voltage, c urrent and

power of the supply Current 0.01% + 6 mA 0.01% + 2 mA

Amps 0-30 A 0-10 A

Voltage 0.01% + 2 mV 0.01% + 3 mV

Current 0.01% + 9 mA 0.01% + 5 mA

Voltage 0.01% + 1 mV 0.01% + 2 mV

PARD (Ripple and Noise): Measured at any line v olt age and under any

load condition within rating (rms 10 Hz to 10 Mhz/p-p 10 Hz to

20 MHz) Current 30 mA/

Load Effect Transient Recovery: Maximum time required for output

voltage to recover with the specified band around the nom inal out put

voltage following a 10% step change in output current while operating in

the constant voltage mode

Programming: (25 ± 5°C) Given for control of the

output over the GP-IB or with front panel controls Current Ac c urac y 0.15% +20 mA 0.085% + 10 mA

Remote Voltmeter: (25 ± 5°C) Refers to data read back to the controller

over the GP-IB

Remote Ammeter: (25 ± 5°C) Refers to data read back to the controller

over the GP-IB.

Front Panel Voltmeter: (25 ± 5°C)

Front Panel Ammeter: (25 ± 5°C)

Voltage Accuracy 0.035% + 9 mV 0.035% + 40 mV

Voltage 3 mV/30 mV 3 mV/30 mV

1

Time 1 ms 1 ms

Level 50 mV 75 mV

Accuracy 0.07% + 6 mV 0.07% + 50 mV

Accuracy 0.3% + 25 mA 0.2% + 11 mA

Range 2 V, 20 V, 200 V 2 V, 20 V, 200 V

Accuracy 0.07% +6 mV, 11

mV, 56 mV

Range 20 A, 200 A 20 A

Accuracy 0.3% + (20 mA, 65

mA)

1

5 mA/

0.07% + 50 mV, 55

mV, 100 mV)

0.2% + 11 mA

Table 1-2. Supplemental Characteristics

Agilent Technologies Model 6033A 6038A

Programming: (25 ± 5°C) Given for control of the

output over the GP-IB or with front panel controls Current Resolution 7.5 mA 2.5 mA

Remote Voltmeter: (25 ± 5°C) Refers to data read back to the controller

over the GP-IB

Remote Ammeter: (25 ± 5°C) Refers to data read back to the controller

over the GP-IB.

Front Panel Voltmeter: (25 ± 5°C)

Front Panel Ammeter: (25 ± 5°C)

Maximum AC Input Current: +6% -13% (48-63) Hz

Temperature Coefficient: Output change per degree Celsius change

in ambient following 30 minute warm-up. Current 100 ppm + 2 mA 90 ppm + 0.3 mA

Drift (Stability): Change in output (dc to 20 Hz) over 8-hour internal

under constant line, load, and ambient following 30-minute warm-up Current 0.03% + 10 mA 0.03% + 3 mA

Programming Response Time: The maximum time required

to change from zero volts to full scale voltage or from full Up Full Load 100 ms 150 ms

scale voltage to 2 volts ( 5 volts for Agilent 6035A) and settle No Load 100 ms 120 ms

within the specified band. Full load is defined as the Down Full Load 200 ms 150 ms

resistance equal to Vp1/Ip1. Light load is as s pec if ied Light Load

Overvoltage Protection: Trip voltage adjustable via front

panel control using the Display OVP function Resolution 100 mV 100 mV

Typical input power at rated output power: (see point P2 on Figure 1-1)

Voltage Resolution 5 mV 15 mV

Resolution 5 mV 15 mV

Resolution 7.5 mA 2.5 mA

Resolution 5 mV, 10 mV, 100mV15 mV, 15 mV, 100

mV

Resolution 10 mA, 100 mA 10 mA

100 Vac (Opt.100) 6.0 A 6.0 A

120 Vac (Std.) 6.5 A 6.5 A

220 Vac (Opt.220) 3.8 A 3.8 A

240 Vac (Opt.240) 3.6 A 3.6 A

Voltage 50 ppm + 0.6 mV 50 ppm + 3 mV

Voltage 0.02 % + 1 mV 0.02% + 2 mV

Settling Band 5 mV 15 m V

500 ms (50 Ω) 750 ms (400 Ω)

Range 0-23 V 0-63 V

Accuracy 0.3% + 200 mV 0.25% + 300 mV

340 W 325 W

General Information

16

Page 17

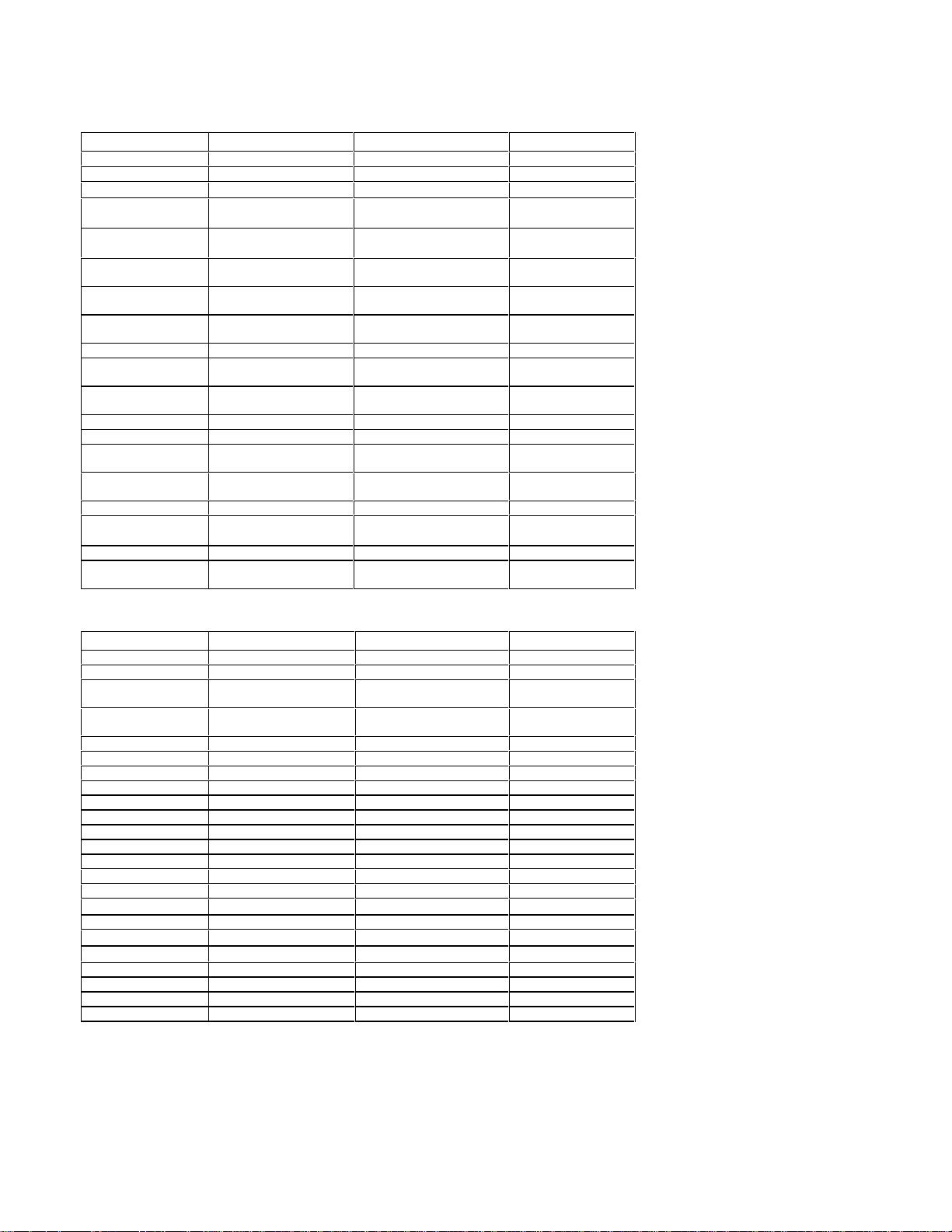

6030A 6031A 6032A 6035A NOTES.

0-200 V 0-20 V 0-60 V 0-500 V

0-17 A 0-120 A 0-50 A 0-5 A

1000-1200 W 840-1072 W 1000-1200 W 1000-1050 W

0.0l% + 5 mV 0.0l% + 3 mV 0.0l% + 5 mV 0.0l% + 40 mV

0.0l% + l0 mA 0.0l% + l5 mA 0.0l% + l0 mA 0.03%+34 mA f or 15 m inut es , t he inc reas e

0.0l% + 5 mV 0.0l% + 2 mV 0.0l% + 3 mV 0.0l% + l3 mV 3 After a five-minute wait.

0.0l% + 5 mA 0.0l% + 25 mA 0.0l% + l0 mA 0.03%+l7 mA

22 mV/50 mV

l5 mA/

2

1

8 mV/50 mV 5 mV + 0.005% Vout/40mV50 mV/160 mV

l20 mA/

1

25 mA/

1

50 mA

1

2 ms 2 ms 2 ms 5 ms

l50 mV l00 mV l00 mV 200 mV

0.035% + l45 mV 0.035% + l5 mV 0.035% + 40 mV 0.25%+400 mV

0.2% + 25 mA 0.25% + 250 mA3 0.2% + 85 mA 0.3%+85 mA

0.08% + 80 mV 0.08% + 7 mV 0.08% + 20 mV 0.5%+200 mV

0.36% + l5 mA 0.4% + 100 mA

3

0.36% + 35 mA 0.5%+50 mA

20V, 200V, 2000V 2V,20V,200V 20V,200V 200V, 2000V

0.08%+(65mV,110m

V,560mV)

0.08%+(7mV,12mV,57

mV)

0.08% + (20 mV, 70 mV)

0.5%±(300mV,

1.0V)

2 A, 20 A 20 A, 200 A 20 A, 200 A 10 A

0.36% + (l5 mA,

0.7% + 300 mA 0.36% + (40 mA, 90 mA) 0.5%+60 mA

20 mA)

1. Not specified

2. Initially, for each degree

below 20°C the ripple

increases 2.4 mV/°C.

After loadis applied

becomes 1.4 mV/°C.

6030A 6031A 6032A 6035A

50 mV 5 mV l5 mV l25 mV

4.25 mA 30 mA l2.5 mA 1.25 mA

50 mV 5 mV l5 mV l25 mV

4.25 mA 30 mA l2.5 mA l.25 mA

50 mV, 100 mV, 1 V 5 mV, l0 mV, l00 mV l0 mV, l00 mV l00 mV, l V

5 mA, l0 mA l0 mA, l00 mA l0 mA, l00 mA 20 m A

24A 24A 24A 24A

24 A 24 A 24 A 24A

l5 A l5 A l5 A l5 A

l4 A l4 A l4 A l4 A

50 ppm + 12mV 70 ppm + 2 mV 50 ppm + 4 mV l00 ppm+30 mV

l00 ppm 3 mA l80 ppm + l5 mA l00 ppm + 8 m A l00 ppm+7 mA

0.03% + l5 mV 0.03% + 3 mV 0.03% + 5 mV 0.03%+40 mV

0.03% + 5 mA 0.l% + 25 mA 0.03% + l0 mA 0.03%+l7 mA

300 mV 30 mV 90 mV 750 mV

300 ms (40 Ω)

300 ms 300 ms 300 ms 250 ms

600 ms (40 Ω)

3.5 sec (∞ Ω) l.5 sec (50 Ω) 3.0 sec (100 Ω) 7.0 sec (∞ Ω)

0-2l4 V 02-22 V 0-64 V 0-535 V

600 mV l00 mV 200 mV 1 V

0.3% + l.25 V 0.3% + 350 mV 0.3%+350 mA l.0%+3. l3 V

l435 W l375W l450 W l256 W

300 ms 300 ms

500 ms 2.0 sec

350 ms (250Ω)

600 ms (250Ω)

General Information

17

Page 18

Table 1-2. Supplemental Characteristics (continued)

DC Floating Voltage

: Either output terminal may be floated up to the following voltage (including the output voltage) from

earth ground:

±

240 Vdc on Models 6031A, 6032A, 6033A, and 6038A

±

550 Vdc on Models 6030A and 6035A

Exceeding these voltage can result in damage to the equipment.

Remote Sensing: The power supply maintains specifications at the load with up to 0.5 volt drop per load lead. Operation

with up to 2 volts per load lead is possible with some degradation of the load effect specification.

Absolu te maximum ratings

•

between FLT Terminals 1 and 2 is 17.5 Volts dc. (external resistor required to limit current to 1.25 mA max)

•

between INH Terminals 3 and 4 is 5.5 Volts dc.

•

between Terminals 1 or 2 to 4 or chassis to ground is 42 Volts dc.

Fault (FLT) levels (Terminals 1 and 2) (All models)

•

Ioh (Low Level Output Current) is + 1.2 mA maximum

•

Vol (Low Level Output Voltage) is 0.5 Volts Maximum

Inhibit (INH) Levels (Terminals 3 and 4) (All models)

•

Vih (High Level Input Voltage) is 2 Volts

•

Vil (Low Level Input Voltage) 0.5 Volts Maximum

•

tw (Pulse Width) (minimum) = 50 ms (2 ms typ)

•

td (Delay Time) = 2 ms typ

•

Iil (Low Level Input Current) = -1.25 mA maximum

Multiple Operations: Up to two similar units may be connected in series or auto-parallel, to provide increased output

capabilities. Mixing supplies with dissimilar output capabilities is not recommended because under certain conditions, the

lower output supply may be stressed beyond its maximum voltage and or current capabilities by the higher output supply.

Temperature Rating (°C):

•

Operating is 0-50 (Agilent 6030/6031/6032/6035); 0-55 (Agilent 6033/6038)

•

Storage is - 40 + 75 (all models)

Weight kg. (Ibs)

Model Agilent 6030A Agilent 6031A Agilent6032A Agilent 6033A Agilent 6035A Agilent 6038A

Net 16.3 (36) 17.2 (38) 16.3 (36) 9.6 (21) 16.3 (36) 9.6 (21)

Shipping 21.7 (48) 22.7 (50) 21.8 (48) 11.4 (25) 21.7 (48) 11.4 (25)

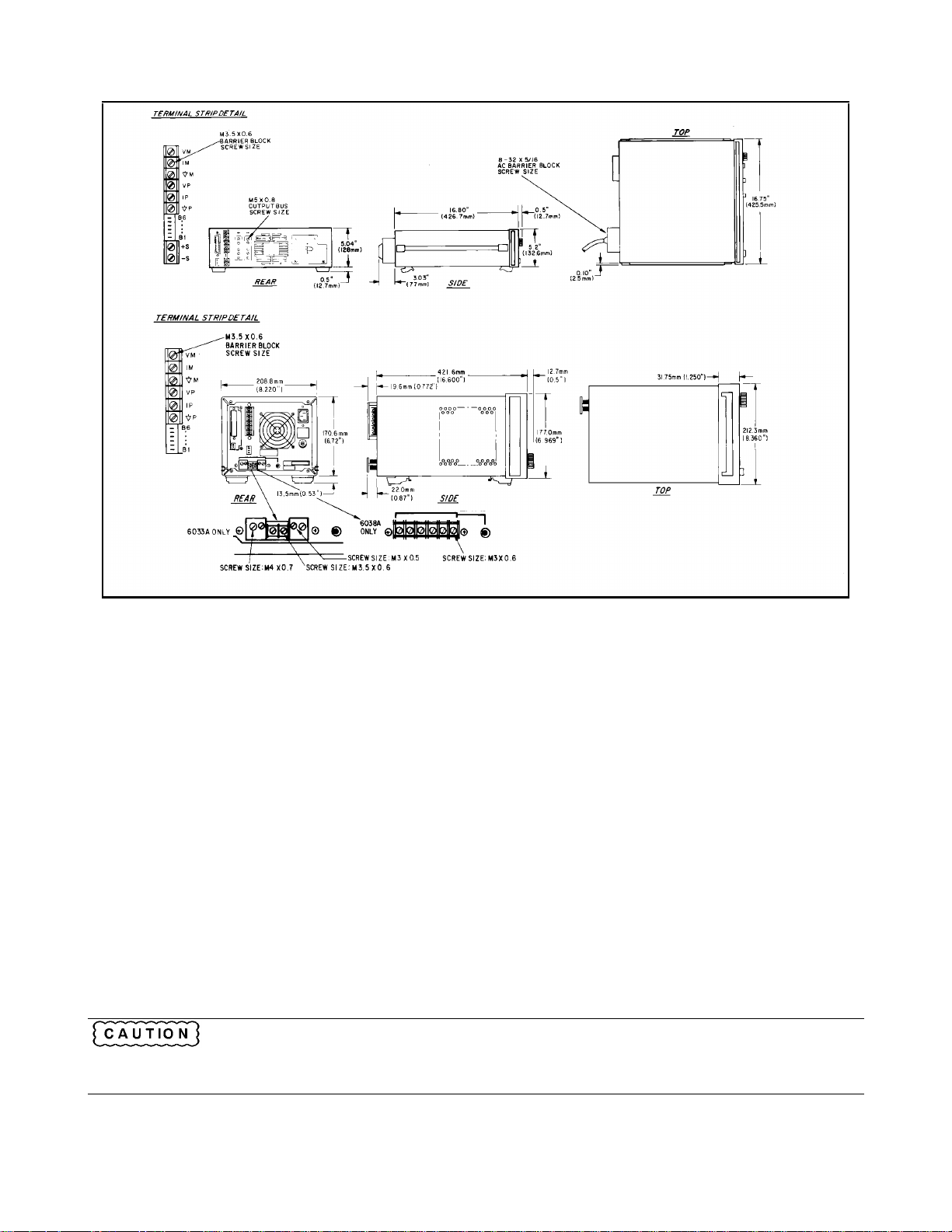

Dimensions: See Figure 2-1.

Certification:

The unit is designed to comply with these requirements:

• ICE 348-Safety Requirements for Electronic Measuring Apparatus.

• CSA Electrical Bulletin 556B-Electronic Instruments and Scientific Apparatus for Special Use and Applications.

• VDE 0871.6.78 Level B-RFI Suppression of Radio Frequency Equipment for Industrial, Scientific, and Medical (ISM)

and similar purposes.

• VDE 0411-Electronic Measuring Instruments and Automatic Controls.

• UL 1244-Electrical and Electronic Measuring & Testing Equipment.

• ANSI C39.5 Part 0 Draft 8-Electrical Testing, Measurement, and Control Equipment.

General Information

18

Page 19

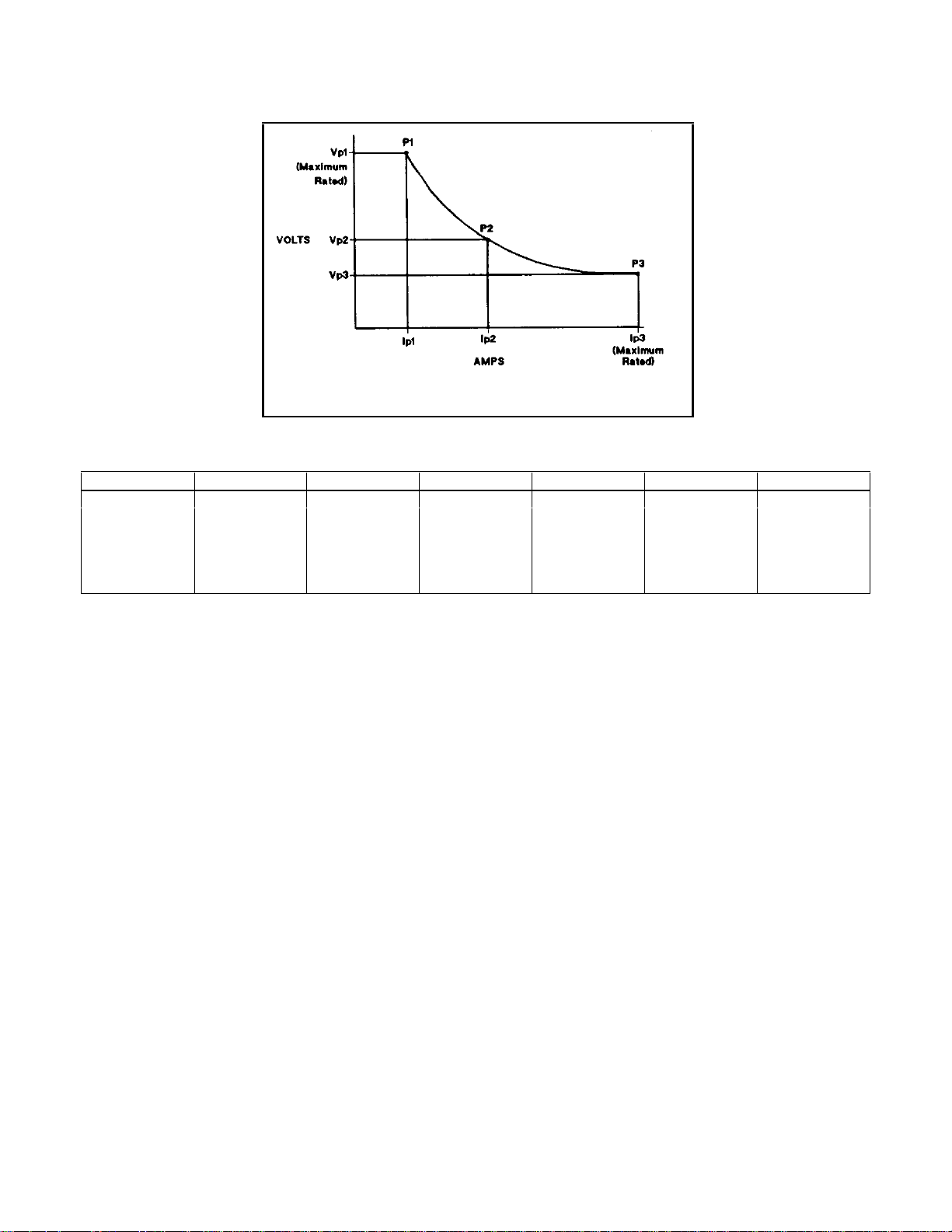

Figure 1-1. Output Characteristic Curve

Agilent Model 6030A 6031A 6032A 6033a 6035A 6038A

Vp1 200 V 20 V 60 V 20 V 500 V 60 V

Ip1 5 A 50 A 17.5 A 10 A 2 A 3.3 A

Vp2 120 V 14 V 40 V 14 V 350 V 40 V

Ip2 10 A 76 A 30 A 17.2 A 3 A 6 A

Vp3 60 V 7 V 20 V 6.7 V 200 V 20 V

Ip3 17 A 120 A 50 A 30 A 5 A 10 A

General Information

19

Page 20

General Information

20

Page 21

2

Installation

Introduction

This section contains instructions for checking and repacking the supply, bench or rack mounting, connecting the sup ply to

ac input power, and converting the supply from one line voltage to another if required. Instructions for connecting load and

GP-IB cables, and for setting the GP-IB address are given in Section III.

Note Agilent 603xA power supplies generate magnetic fields which may affect the operation of other

instruments. If your instrument is susceptible to operating magnetic fields, do not locate it in the

immediate vicinity of the Agilent 603xA power supply. Typically, at three inches from the supply, the

electromagnetic field is less than 5 gauss.

Initial Inspection

Before shipment, this supply was inspected and found to be free of mechanical and electrical defects. As soon as the supply

is unpacked, inspect for any damage that may have occurred in transit. Save all packing materials until the inspection is

completed. If damage is found, file claim with carrier immediately. The Agilent Technologies Sales and Support office

should be notified as soon as possible.

Mechanical Check

This check should confirm that there are no broken knobs or connectors, that the cabinet and panel surfaces are free of dents

and scratches, and that the meter face and rear-panel plastic covers are not scratched or cracked.

Electrical Check

Section III contains an abbreviated check which can be used quickly to place the supply into operation. Refer to the inside

front cover of the manual for Certification and Warranty statements.

Preparation For Use

In order to be put into service, the power supply must be connected to an appropriate ac input power source. Also, the line

voltage for which the supply is set must be checked. Additional steps may include line voltage conversion and rack

mounting. Do not apply power to the supply before reading Input Power Requirements paragraph on the following page.

Location and Cooling

The supply is fan cooled and must be installed with sufficient space in the rear and on sides for air flow. It should be used in

an area where the ambient temperature does not exceed + 50 °C.

Outline Diagram

Figure 2-1 illustrates the outline shape and dimensions of the cabinet.

Installation

21

Page 22

Figure 2-1. Outline Diagram

Bench Operation

The supply cabinet has plastic feet, which are shaped to ensure self aligning when stacked with other Agilent Technologies

System II cabinets.

Rack Mounting

The supply can be mounted in a standard 19-inch rack enclosure. Rack mounting accessories for this unit are listed in the

ACCESSORIES paragraph in Section I. Complete installation instructions are included with each rack mounting kit.

Support rails are also required for rack mounting. These are usually supplied with the system cabinet.

Input Power Requirements

This supply may be operated from a nominal 120 V, 220 V or 240 V single-phase ac power source (48-63 Hz). The input

voltage range and input current required for each of the nominal inputs are listed in Table 1-1. A label on the rear panel

indicates the nominal line voltage for which the supply was set at the factory. If necessary, the user can convert the

instrument from one line voltage option to another by following the instructions in the Line Voltage Option Conversion

section of this chapter.

Power Connection

Connection of this supply to an ac power source should be done only by an electrician or other

qualified personnel. Before connecting the supply to the ac power source, check the label on the rear

panel to ensure that the supply is set for the ac voltage to be used. If necessary, convert the supply

from one line voltage to another by following the instructions under “Line Voltage Conversion.”

Installation

22

Page 23

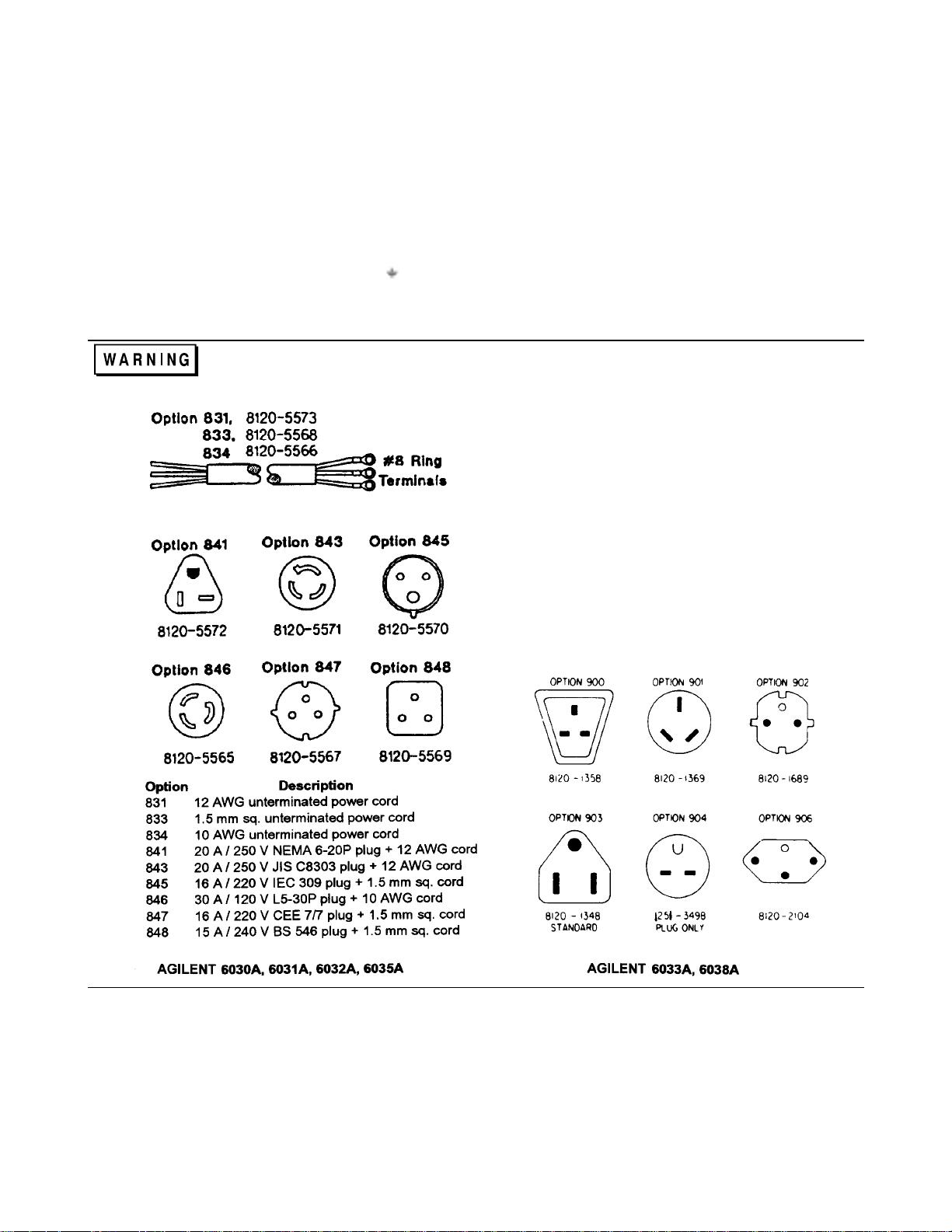

Agilent Models 6033A, 6031A, 6032A, 6036A. Figure 2-2 illustrates the standard configuration of power-cord plugs used by

Agilent Technologies. To connect input power, to the instrument proceed as follows:

a. Remove the AC filter assembly cover by unscrewing the four locating screws.

b. Insert the power cord through the strain relief cla mp located on the cover.

c. Connect the wires to the terminal block in accordance with the prevailing color codes.

Green or green/yellow to the terminal labeled "

White or blue wire to the terminal labeled "N’’

Black or brown wire to the terminal labeled ’’L"

For proper protection by the instrument circuit breaker, the wire connected to the "L’’ terminal on the

instrument must be connected to the "L’’ side of the line (hot); the wire connected to the ’’N" terminal

must be connected to the "N" side of the line (neutral or common).

’’

Figure 2-2. Power-Cord Plug Configurations

To protect operating personnel, the wire connected to the terminal must be connected to earth ground. In no event shall this

instrument be operated without adequate ground connection.

Installation

23

Page 24

d. Replace the cover, tighten all four screws and tighten the strain relief clamp. (All four screws must be tightened for unit

to meet RFI specifications.)

e. Connect the other end of the power cord to an appropriate power source.

Note Connections to the ac power line must be made in accordance with applicable electrical codes. The

international color code for identifying mains supply conductors is green/yellow, blue, and brown for

earth, neutral, and line respectively. Corresponding USA/Canadian codes are green, white, and black.

Before applying power to the instrument, check to see that the rear-panel circuit breaker CB1 is on

(breaker may trip because of rough handling during transit). If the breaker trips while power is on, or

if the breaker is found to be tripped at any time for unknown reasons, refer to troubleshooting

procedures in the Service Manual.

Agilent Models 6033A, 6038A. The power supply is shipped from the factory with a power-cord plug appropriate for the

user’s location. Figure 2-2 illustrates the standard configuration of power-cord plugs used by Agilent Technologies. With

each drawing is the Agilent Part Number for a replacement power cord equipped with a plug of that configuration. If a

different power cord is required, contact the nearest Agilent Technologies Sales and Service office.

To protect operating personnel, the National Electrical Manufacturers Association (NEMA) recommends that the instrument

panel and cabinet be grounded. This supp ly is equippe d with a three-conductor power cable; the third conductor is the

ground conductor. When the cable is p lugged into an appropriate receptacle the supp ly is grounded. In no event shall this

supply be operated without an adequate cabinet ground connection.

The offset pin on the standard power cable three-prong connector is the ground connection. If a two-contact receptacle is

encountered, it must be replaced with a properly grounded three-contact receptacle in accordance with the National

Electrical Code, local codes and ordinances. The work should be done by a qualified electrician.

Note Generally, it is good practice to keep the ac input lines separated from signal lines.

Line Voltage Option Conversion

Conversion to or from 100 V operation requires recalibration and replacement of internal components

in addition to the line voltage components, and is to be done only at the factory. Failure to reconfigure

and recalibrate the power supply may result in damage to the unit.

Agilent Models 6030A, 6031A, 6032A, 6035A. Line voltage conversion is accomplished by adjusting three components:

a two-section line select switch, and a line-voltage jumper. To convert the supply from one line voltage option to another,

proceed as follows:

Some components and circuits are at ac line voltage even with the LINE switch off. To avoid electric

shock hazard, disconnect line cord and load, and wait two minutes before removing cover.

a. Remove the outside cover by removing the four screws that hold the carrying straps, spread the bottom of the cover

slightly and carefully slide the cover to the rear of the supply until it is clear. Next remove the top inside cover by

removing the nine screws, four on top, three on right side, and two on left side, which connect the top inside cover to

the supply chassis.

Installation

24

Page 25

b. Use a small-blade screwdriver to set the two switch sections of S2 to match the pattern silk-screened on main board for

nominal line voltage to be used. For example, to set switches for 120 V operation, move forward switch section so that

its white slot is toward front of supply and move rearward switch section so that its white slot is toward rear of the

instrument.

c. Set switch S1 to match the rearward section of S2, i.e., toward the rear for 100/120 V operation, toward the front for

220/240 V operation.

d. One end of W1 is soldered to the main board; the other end has a female quick-connect terminal that fits onto one of

two terminals soldered to the main board. For 100 V or 120 V operation, W1 must be connected to terminal J9; for 220

V or 240 V operation, W1 must be connected to terminal J10. Be certain that jumper is firmly mated with connector on

main board. Do not grip jumper insulation with pliers; either grip jumper wire by hand or grip jumper terminal with

pliers.

e. Replace the inside top cover and the outside top cover. Mark the unit clearly with a tag or label indicating correct line

voltage to be used.

f. Change line label.

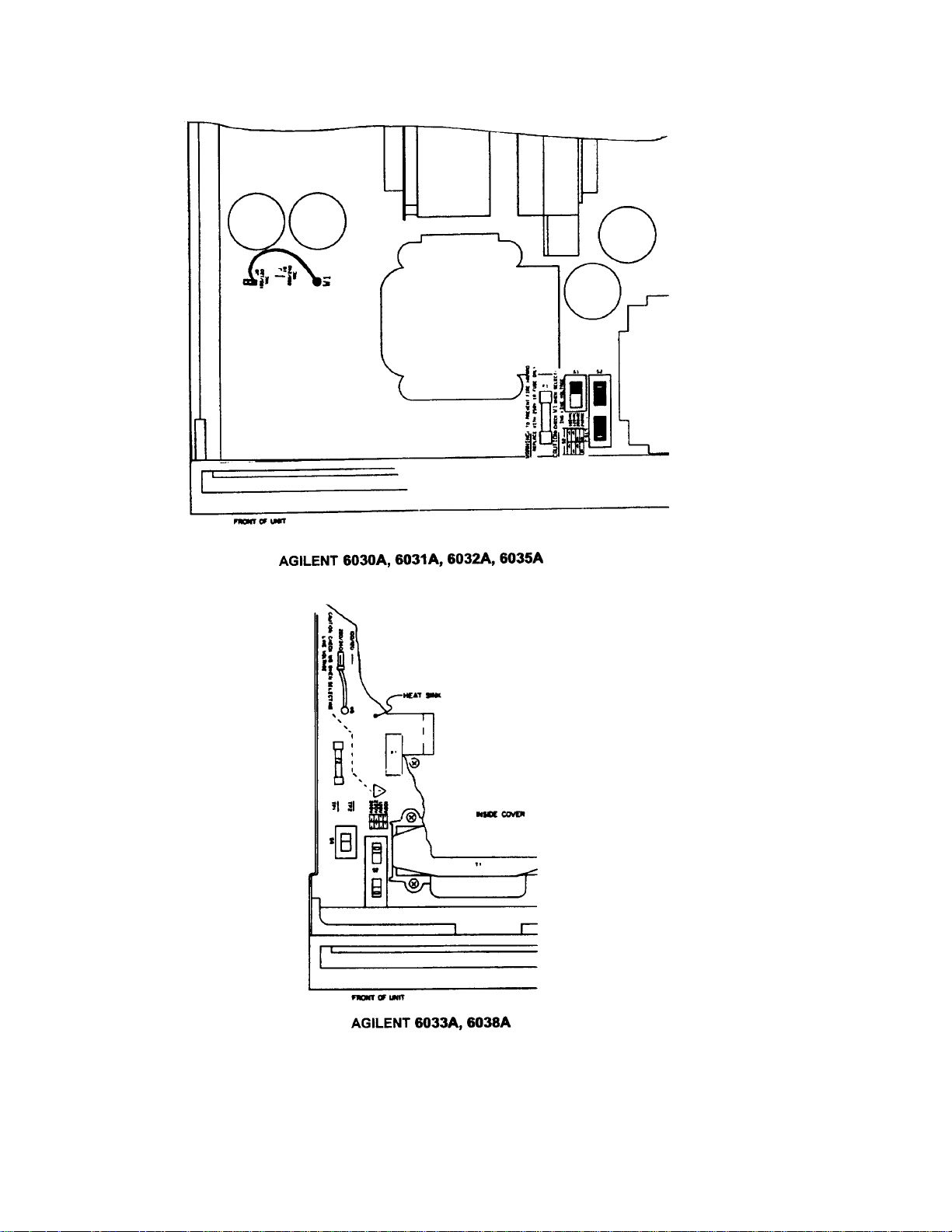

Agilent Models 6033A, Agilent 6038A. Line voltage conversion is accomplished via three components; a two-section line

select switch, line voltage jumper, and a rear panel fuse.

To convert the supply from one voltage to another, proceed as follows:

a. Remove the outside cover by removing the rear screw that holds the carrying strap, then carefully slide the cover to the

rear of the supply until it is clear.

b. The line voltage select switch (S2) is located in the front left corner of the supply (see Figure 2-3). Use a small-blade

screwdriver to set the two switch sections to match the pattern silk-screened on p.c. main board as shown in Figure 2-3.

For example, to set switches for 120 V operation (as illustrated), move forward switch section so that its white slot is

toward front of supply and move rearward switch section so its white slot is toward rear of supply.

c. One end of W5 is soldered to motherboard; the other end has a female right-angle quick-connect terminal that fits onto

one of two terminals soldered to motherboard. For 100 V or 120 V operation, W5 must be connected to terminal closer

to center of supply; for 220 V or 240 V operation, W5 must be connected to terminal closer to side of supply. Be

certain that jumper is firmly mated with terminal on motherboard. Do not grip jumper insulation with pliers; either grip

jumper wire by hand or grip jumper terminal with pliers.

d. Check rating of fuse installed in rear-panel fuseholder. It should be 8 A for 100 or 120 Vac line voltages, or 4 A for

220 or 240 Vac line voltages. If necessary, replace the fuse with one of correct value. Do not use time-delay fuses.

8 AM fuse, Agilent part number 2110-0383

4 AM fuse, Agilent part number 2110-0055

e. Replace covers and mark the supply clearly with a tag or label indicated correct line voltage and fuse to be used.

Installation

25

Page 26

Installation

26

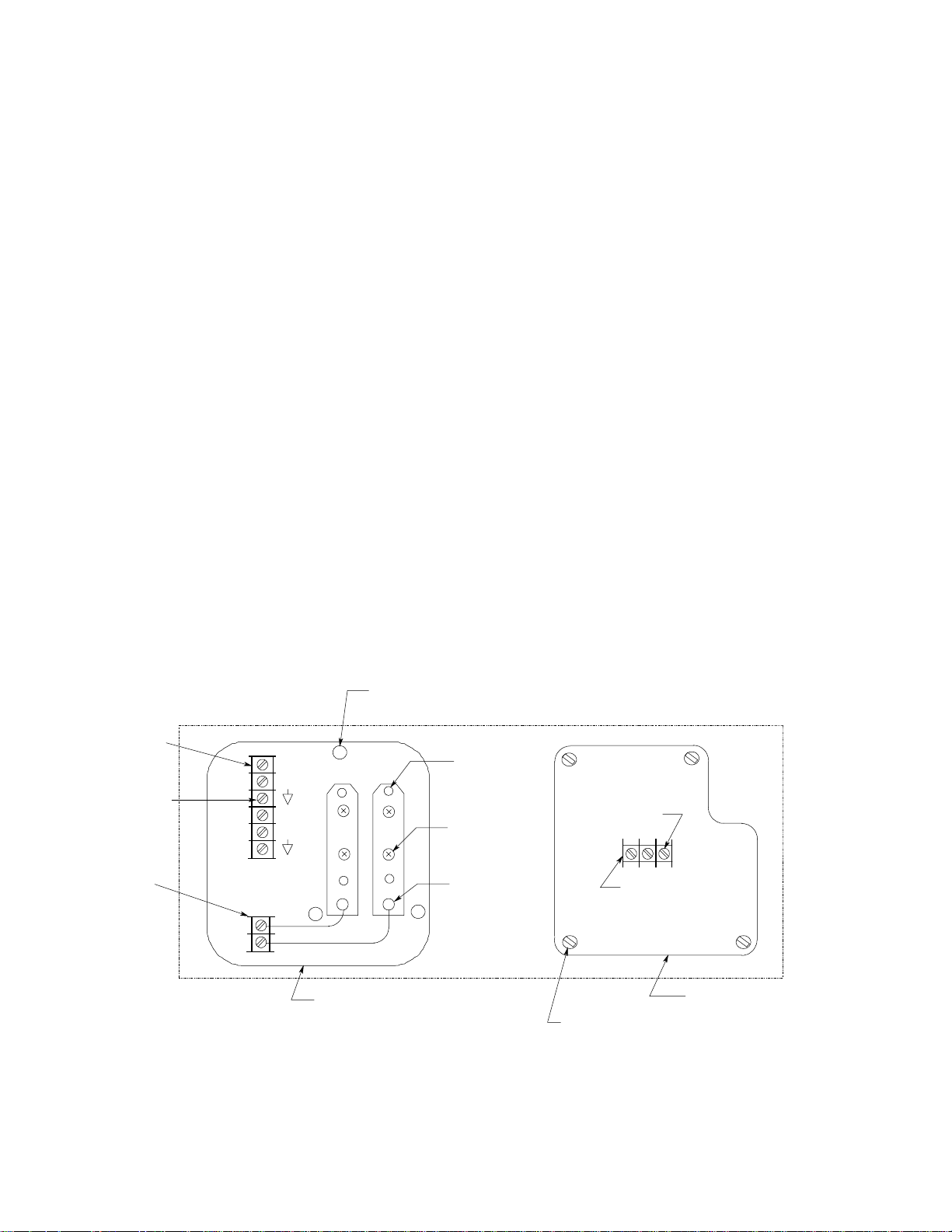

Figure 2-3. Line Voltage Conversion Components

Page 27

AC Line Impedance Check

The power supply is designed for proper operation with line impedance typically found in ac power lines. However, if the

supply is connected to an ac power line having high impedance combined with line voltage near the minimum specified

value, (e.g., 104 Vac for nominal 120 Vac), the unit will go out of regulation if it is asked to provide full rated output power.

Such a situation might occur if the supply is connected to ac power an extended distance from the main ac distribution

terminals and/or if the ac power wires from the main ac distribution terminals are of relatively small gauge.

Measurement of ac line voltage at the supply input terminals typically is not a reliable indication of the actual ac line voltage

because of the peak clipping effect of the power supply and the averaging effect of the voltmeter. Symptoms of excessive

line impedance may include erratic or no output from the supply and/or inability of the supply to provide full output power.

If there is reason to suspect the ac power lines to the supply may have high impedance, perform the following check:

This check should be performed only by service-trained personnel who are aware of the hazards

involved (for example, fire and electrical shock). Turn power supply off before making or breaking

connections to power supply. Hazardous voltages are present within the unit even when power switch

is turned off.

a. Connect a variable load to the supply. Using the OUTPUT ADJUST controls and DISPLAY SETTINGS, set voltage

and current (see Section III for detailed description) to maximum rating.

b. Set the load to the maximum rated output current for the power supply (see Table 1-1). The power supply output

voltage should be greater than:

65 V for Agilent 6030A 6 V for Agilent 6033A

8 V for Agilent 6031A 220 V for Agilent 6035A

22 V for Agilent 6032A 20 V for Agilent 6038A

c. If the supply voltage is less than specified, perform the power limit calibration given in the Service Manual. If the

power limit is calibrated correctly, but the unit still does not provide the required output, then the power supply is not