Page 1

PRODUCTDOCUMENTATION

PROTECT PV.630

Solarinverter

EN

Page 2

Page 3

Operating instructions

Installation and Start-up

Maintenance and Servicing

Single-line Diagram

Outline Drawing

Connection Diagram

Technical Data Sheet

Page 4

Page 5

Operating instructions

Protect PV.630

AEG Power Solutions GmbH, Warstein-Belecke

Department: PS AED

Revision: 00

Revision date: 23.01.2013 / Schenuit

Released: 23.01.2013 / Wäsche

Document no. 8000047961 BAL, en

Page 6

Protect PV.630 Operating Instructions

AEG Power Solutions GmbH

Emil-Siepmann-Strasse 32

59581 Warstein

Germany

+49 2902 763 100

Fax: +49 2902 763 645

e-mail: service.aegpss@aegps.com

Internet: http://www.aegps.com

2 of 72 8000047961 BAL

Page 7

Protect PV.630 Operating Instructions

Table of Contents

1 Information on How to Use these Instructions ............... 6

1.1 General Information ............................................................. 6

1.2 Target Groups ..................................................................... 7

1.3 Explanations of Target Groups ............................................ 7

1.3.1 Obligations of the Equipment Operator ............................... 7

1.3.2 Skilled Personnel Skills and Trainings ................................ 8

1.4 Storing Instructions .............................................................. 9

2 Explanation of Symbols and Safety Instructions ......... 10

2.1 Explanation of Symbols ..................................................... 10

2.2 Safety Instructions ............................................................. 11

2.2.1 Signal Words Used ............................................................ 11

2.2.2 Hazard Symbols Used ....................................................... 11

2.2.3 Signs Containing Orders for Personal Protective

2.2.4 Abbreviations ..................................................................... 13

2.3 Emergency Procedure (e.g. in the Event of a Fire) ........... 13

2.4 Safety Awareness ............................................................. 13

2.5 Particular Dangers associated with Photovoltaic Systems 14

2.6 Safety Signs and Warning Notices on the Equipment ....... 15

2.7 Safety and Protection Devices for the Equipment ............. 15

2.7.1 Protective Covers .............................................................. 15

2.7.2

2.7.3 Guard ................................................................................ 16

2.8 Residual Hazards .............................................................. 16

2.8.1 Electrical Hazards ............................................................. 17

2.8.2 Risks Due to Moving Parts ................................................ 18

2.8.3 Fire-Related Risks ............................................................. 18

2.8.4 Risks due to Loss of Control ............................................. 19

2.8.5 Risks from Maintenance and Repair Work ........................ 19

Equipment ......................................................................... 12

Lockable Equipment Doors ............................................... 16

3 Product Details ................................................................ 20

3.1 Product Description ........................................................... 20

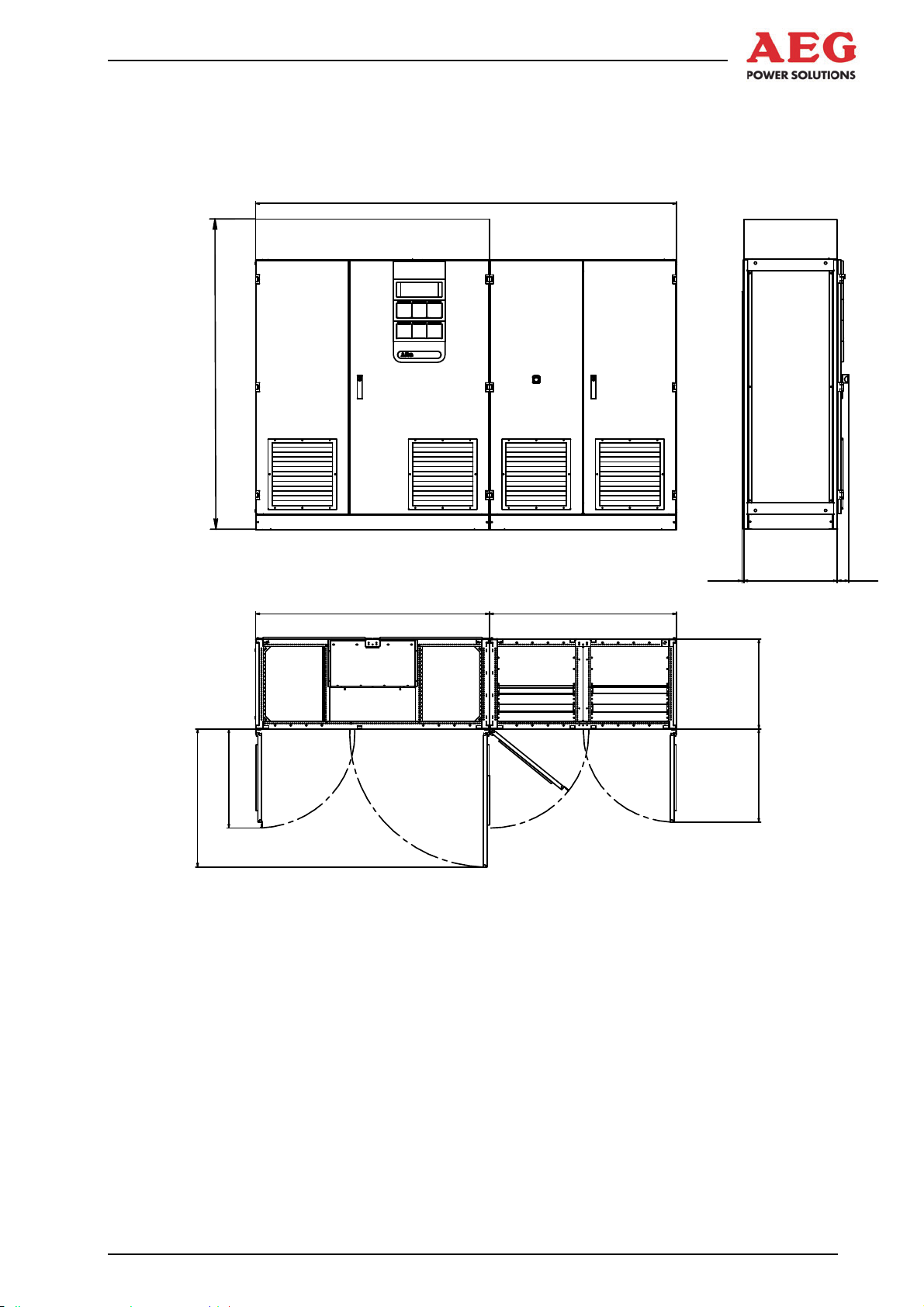

3.2 Dimensions and Views ...................................................... 21

3.3 Appropriate Use ................................................................ 21

3.4 Inappropriate Use .............................................................. 22

3.5 Standards, Directives and CE Mark .................................. 22

3.6 Nameplate ......................................................................... 22

3.7 Technology ........................................................................ 23

3.8 Operating Elements ........................................................... 24

4 System Description ......................................................... 25

4.1 Operating Modes ............................................................... 25

4.1.1 Individual Operation .......................................................... 25

4.1.2

8000047961 BAL 3 of 72

Partner Operation .............................................................. 25

Page 8

Protect PV.630 Operating Instructions

5 System Function ............................................................. 26

5.1 Description of Sequence Control ....................................... 26

5.1.1 The “OFF” Status .............................................................. 26

5.1.2 The “Waiting for Feed Conditions” Status ......................... 26

5.1.3 The “Operation” Status ...................................................... 27

5.1.4 The “Waiting” Status .......................................................... 27

5.1.5 The “Fault” Status .............................................................. 28

5.1.6 The “Night” Status ............................................................. 28

5.1.7 Sequence Control During the Course of the Day .............. 28

5.1.8 Sequence Control Parameters .......................................... 30

5.2 Description of Fan Control ................................................. 31

5.2.1 General .............................................................................. 31

5.2.2 Fan Control, Cabinet Fan .................................................. 31

5.2.3 Cabinet Fan Control Parameters ....................................... 32

5.2.4 Fan Control, Inverter Stack Fan ........................................ 32

5.2.5 Parameters of Inverter Stack Fan Control ......................... 33

5.3 Insulation Monitoring and Earthing of PV Cells ................. 33

5.3.1 General .............................................................................. 33

5.3.2 Operation With Monocrystalline or Polycrystalline Solar

Cells .................................................................................. 34

5.3.3 Operation with Thin-Film Solar Cells ................................. 34

5.3.4 Insulation Monitoring in Partner Operation ........................ 35

5.3.5 Insulation Monitoring Parameters ...................................... 35

5.4 MPP Tracker ..................................................................... 36

5.5 Partner Operation .............................................................. 36

5.5.1 Linked Operation ............................................................... 36

5.5.2 Single Operation ................................................................ 37

5.5.3 Linked Operation in the Event of a Fault ........................... 38

5.5.4 Partner Operation During the Course of the Day .............. 38

5.5.5 Partner Operation Parameters .......................................... 39

5.6 “Extended” operating mode ............................................... 39

5.6.1 Parameters of the “Extended” operating mode ................. 40

6 Monitoring Systems, Messages and Faults .................. 40

6.1 General .............................................................................. 40

6.2 Table of Faults ................................................................... 42

4 of 72 8000047961 BAL

Page 9

Protect PV.630 Operating Instructions

7 Interfaces ......................................................................... 46

7.1 Communication Interface .................................................. 46

7.1.1 General .............................................................................. 46

7.1.2 Technical Data .................................................................. 47

7.1.3 Structure of the MultiCom CCC Interface ......................... 48

7.1.4 Configuration ..................................................................... 52

7.1.4.1Configuration Preparations ................................................ 52

7.1.4.2Configuring the Modbus Protocol ...................................... 54

7.1.4.3Configuring Modbus Data Transmission ........................... 55

7.2 COM Server ...................................................................... 56

7.2.1 General .............................................................................. 56

7.2.2 Network Connection .......................................................... 56

7.2.3 Structure of the COM Server ............................................. 56

7.2.4 Installation of the COM Server .......................................... 57

7.2.5 Network Integration Configuration ..................................... 58

7.2.6 Configuration of the Virtual COM Port ............................... 58

7.3 Remote Signalling ............................................................. 59

8 Graphical Display and Operation Unit ........................... 61

8.1 General .............................................................................. 61

8.1.1 Signalling ........................................................................... 62

8.1.2

Keyboard Operation .......................................................... 62

8.2 Start-up .............................................................................. 63

8.3 Menu Structure .................................................................. 64

8.3.1 Menu Tree ......................................................................... 64

8.3.2 Main Menu ......................................................................... 64

8.3.3 Operating Display .............................................................. 65

8.3.4 Status/Measured Values ................................................... 70

8.3.5 Blocking ............................................................................. 71

8.3.6 Fault History ......................................................................... 72

8.3.7 Settings ............................................................................. 72

8.3.8 Information ........................................................................ 72

8.3.9 Service .............................................................................. 72

8.3.10 Help ................................................................................... 72

8000047961 BAL 5 of 72

Page 10

Protect PV.630 Operating Instructions

1 Information on How to Use these Instructions

This chapter contains general information about these instructions

and the people they are intended for.

The Protect PV.630 with two control cabinets (+DCD/ACD, +INV)

is referred to as 'equipment' in the rest of the instructions. The precise name (PV.630) cannot be avoided in some situations. In such

cases the equipment is referred to as the PV.630 equipment or the

individual control cabinets are mentioned.

1.1 General Information

Validity

These instructions correspond to the technical specifications of the

equipment at the time of publication. The contents of these instructions do not constitute a subject matter of the contract, but are for

information purposes only.

AEG Power Solutions GmbH reserves the right to make modifications to the content and technical data in these instructions without

prior notice. AEG Power Solutions GmbH cannot be held liable for

any inaccuracies or inapplicable information in these instructions,

which came about as a result of changes to the content or technology applied after this equipment was supplied, as there is no

obligation to continuously update the data and maintain its validity.

Warranty

Our goods and services are subject to the general conditions of

supply for products in the electrical industry, and our general sales

conditions. We reserve the right to alter any specifications given in

these instructions, especially with regard to technical data, operation, dimensions and weights. AEG Power Solutions GmbH will rescind all obligations such as warranty agreements, service contracts, etc. entered into by AEG Power Solutions GmbH or its representatives without prior notice in the event of maintenance and

repair work being carried out with anything other than original AEG

Power Solutions GmbH spare parts or spare parts purchased from

AEG Power Solutions GmbH.

Complaints

In the event of complaints, please contact us within eight days of

receipt of goods and provide the following details:

Type designation

Serial number

Nature of complaint

Period of use

Ambient conditions

Any claims submitted after this point cannot be considered.

6 of 72 8000047961 BAL

Page 11

Protect PV.630 Operating Instructions

Handling

These instructions are structured so that all work necessary for

operation can be performed by appropriately qualified skilled personnel.

Illustrations are provided to clarify and facilitate certain steps.

If danger to personnel and equipment cannot be ruled out in the

case of certain work, it is highlighted accordingly by pictograms

explained in Chapter 2, Safety Regulations.

1.2 Target Groups

This document explains which groups these instructions are intended for and the obligations of these groups. Definitions of staff

requirements are also provided.

Every care has been taken in drafting these instructions. Should

you notice any errors, please contact the manufacturer immediately.

So that the instructions remain up to date, please remember to insert any supplements received from AEG Power Solutions GmbH.

1.3 Explanations of Target Groups

These instructions are intended for various target groups:

The equipment operator or the person appointed by him (the

party responsible for the equipment)

The skilled personnel responsible for using the equipment

1.3.1 Obligations of the Equipment Operator

The equipment operator or the person appointed by him/her (the

party responsible for the equipment) is responsible for the safety of

personnel and for the safety, function and availability of the equipment. These factors depend on compliance with the safety instructions. Compliance with the safety instructions is required at all

times.

To ensure the safety of personnel, the equipment operator

must:

Select skilled personnel on the basis of skills and training (

Chapter 1.3.2)

Make skilled personnel aware of the need for compliance with

regulations ( Chapter 1.3.2)

Provide skilled personnel with personal protective equipment,

user information and instructions

Provide skilled personnel with regular briefings about all safety

measures and keep a record of such briefings

Inform skilled personnel of where fire extinguishers are located

and how to use them

To ensure the safety of the equipment, the equipment operator must:

8000047961 BAL 7 of 72

Page 12

Protect PV.630 Operating Instructions

Only operate the equipment in perfect working order and in ac-

cordance with good electrical engineering practice

Arrange a fault detection check immediately if the equipment

starts to behave differently

Keep all safety signs and warning notices on the equipment in a

complete and clearly legible condition

Install fire extinguishers in the immediate vicinity of the equip-

ment

1.3.2 Skilled Personnel Skills and Trainings

Only trained and qualified skilled personnel may perform the work

described, using tools, equipment and test equipment intended for

the purpose and in perfect working order.

All work is coordinated and monitored by the person responsible

for work. The person responsible for work is directly responsible

for the execution of the work. Before work commences, the person

responsible for work must inform the person responsible for the

equipment and agree on a work schedule with him. The persons

responsible for the work and equipment must be trained and qualified skilled personnel and may be one and the same person.

“Trained skilled personnel” means electricians who as a result of

their specialist training:

Have knowledge and experience of the relevant standards,

regulations, requirements and accident prevention regulations

Have been instructed in the mode of operation and operating

conditions of the equipment

Have the ability to assess the effect of any intended work on

the safe operation of this particular equipment

Can assess the work and recognise and avoid potential risks

Compliance with the safety instructions described is essential for

the protection of skilled personnel and the equipment. Skilled personnel must be aware of and follow these safety instructions.

8 of 72 8000047961 BAL

Page 13

Protect PV.630 Operating Instructions

Obligations of skilled personnel

Observe the following safety instructions.

Work on and in electrical equipment is governed by strict rules

in order to avoid electrical accidents. The rules are summarised

in the five rules of safety. You must observe these rules:

1. Disconnect safely.

2. Secure the unit against being switched back on.

3. Verify that all poles are de-energised.

4. Earth and short-circuit the equipment.

5. Provide protection in the form of covers or barriers for any

neighbouring live parts.

Once work is complete, reverse the five safety rules starting at

number 5 and working back to number 1.

Read these instructions. Memorise the safety instructions.

( Chapter 2)

Ensure compliance with the following regulations:

Accident prevention regulations of the respective country of

destination and the generally valid safety regulations according

to IEC 364.

BGV A1 (Prevention principles)

BGV A3 (Electrical systems and equipment)

BGV A8 (Safety and health protection warnings in the work-

place)

Report damage to the equipment and electrical installations to

the equipment operator.

Only use spare parts approved by the manufacturer for mainte-

nance

and repair work.

Use personal protective equipment (PPE) as intended.

Check that PPE is in perfect working order and report any de-

fects you notice to the equipment operator.

Wear a hair net if you have long hair. Do not wear loose cloth-

ing or jewellery.

Reinstate protection devices (including covers) on completion

of all work on or with the equipment.

Keep the instructions in the pull-out document pocket.

1.4 Storing Instructions

Store these instructions in an appropriate place. A pull-out document pocket is located on the inside of the door. These instructions

must be stored together with the equipment.

Should the equipment change hands, include these instructions

when handing it over to the new operator.

8000047961 BAL 9 of 72

Page 14

Protect PV.630 Operating Instructions

2 Explanation of Symbols and Safety Instructions

All of the symbols and abbreviations used in the text are described

below.

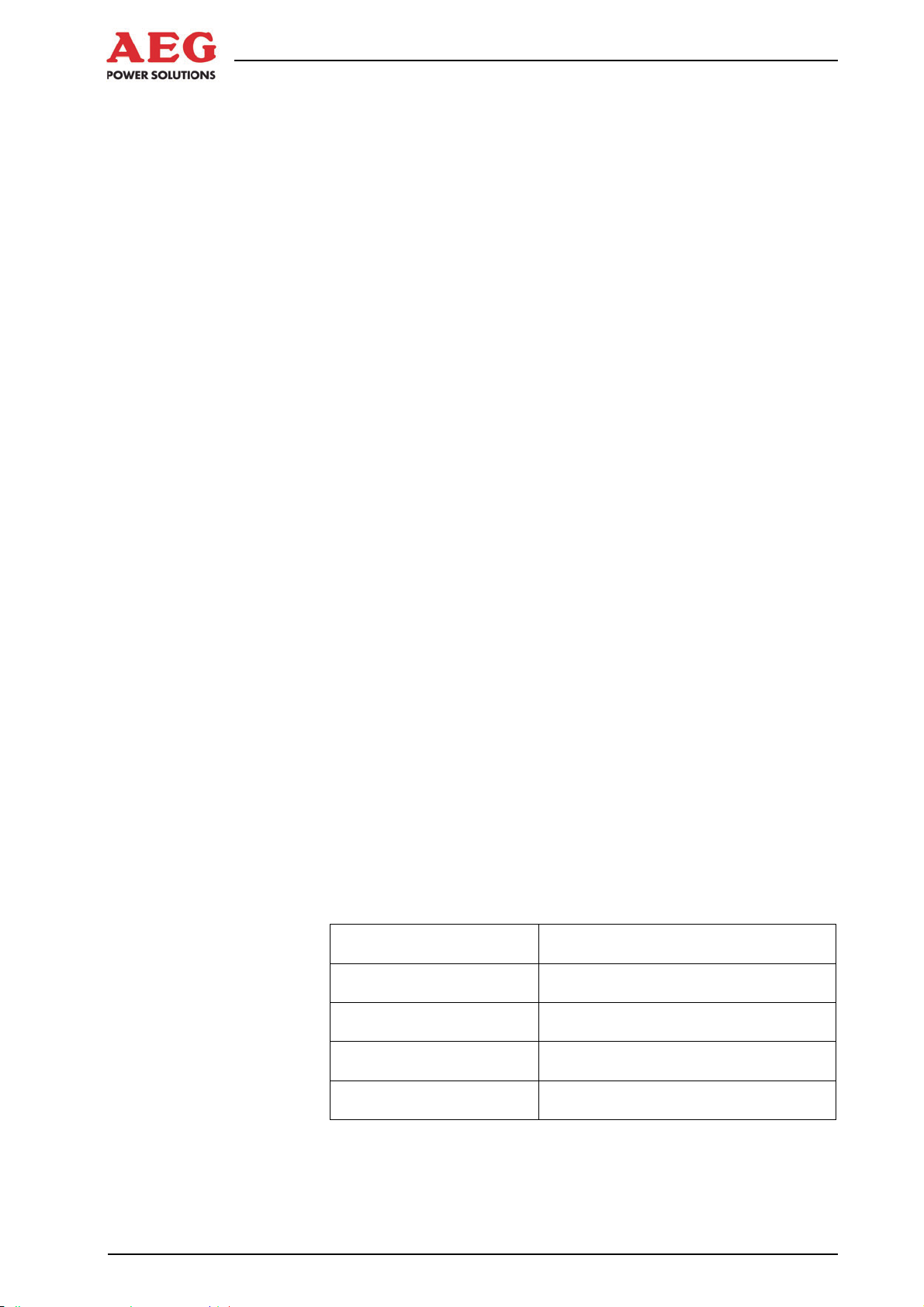

2.1 Explanation of Symbols

This section describes the symbols used in these instructions.

Symbol Meaning

Hazard symbols are triangular and feature a

yellow background, black border and corresponding symbol.

Signs containing orders are round and have a

blue background with a white symbol.

Information is indicated by the letter i. These

i

Table 1 Instruction and warning symbols in these operating

instructions

Other symbols and their meanings

Typograph-

ical element Meaning

This symbol is used for action instructions.

1.

2.

3.

sections contain important information about the

phases of the equipment's service life.

Instructions relating to the environment are

identified by a wheelie bin. Instructions relating

to the environment make reference to mandatory requirements set out by regional or national

authorities which are of particular relevance

when disposing of materials used during operation, for example.

Numbers are used for action instructions that

need to be followed in a specific order.

This symbol is used for bulleted lists.

Table 2 – Other symbols

10 of 72 8000047961 BAL

References to figures, chapters or tables are

shown using the symbol on the left.

Page 15

Protect PV.630 Operating Instructions

2.2 Safety Instructions

All safety instructions have the following structure:

SIGNAL WORD

Type and source of hazard

Figure 1 Warning associated with operator action

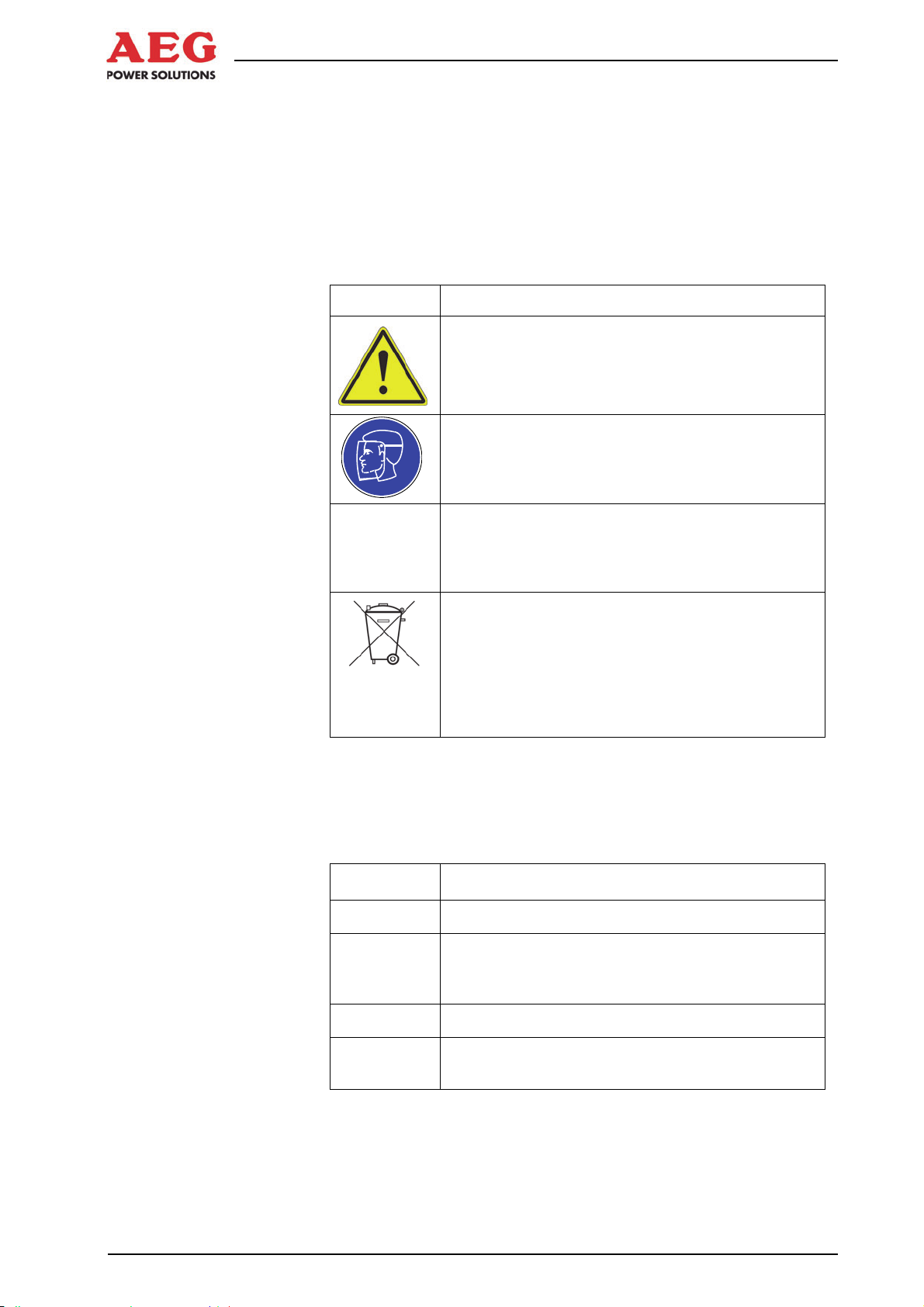

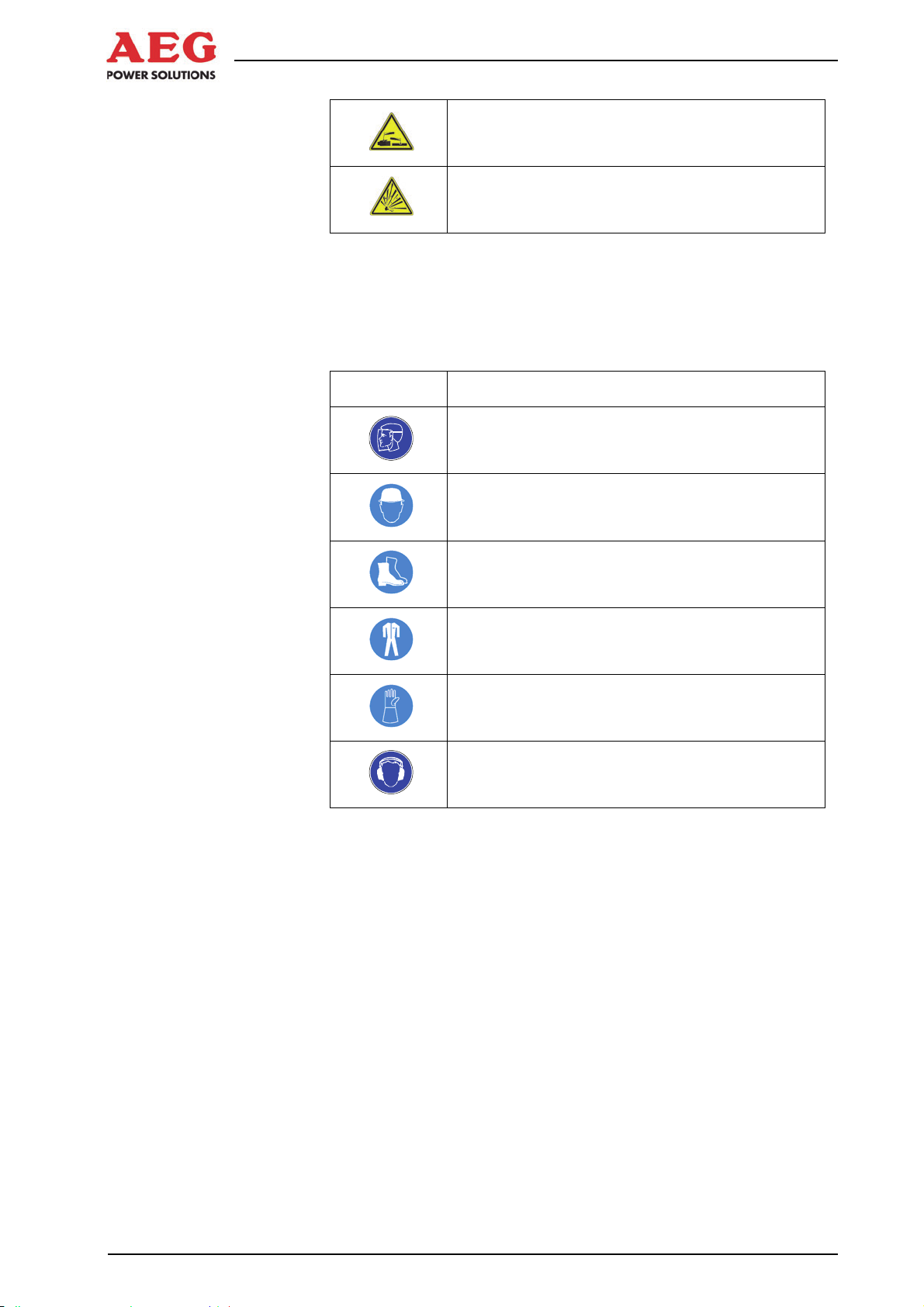

2.2.1 Signal Words Used

Signal words at the start of safety instructions indicate the type and

severity of the consequences if the measures for avoiding the hazard are not taken.

Warning colour Consequences

Symbol

DANGER

WARNING

CAUTION

Consequence(s) of noncompliance

Measure(s) to avoid hazard.

Warns of a situation posing an immediate

hazard which will lead to death or serious

injury.

Warns of a situation posing a possible hazard which may lead to death or serious injury.

Warns of a situation posing a possible hazard which may lead to minor injury.

ATTENTION

2.2.2 Hazard Symbols Used

The following hazard symbols are used to illustrate hazards in the

safety instructions.

Symbol Meaning for skilled personnel

Warns of possible damage to property and

the environment which could interrupt operation.

General hazard source

Electrical hazard

Risk of falling loads

Risk posed by flammable material

8000047961 BAL 11 of 72

Page 16

Protect PV.630 Operating Instructions

Risk posed by corrosive vapours and liquids

Risk posed by explosive material

Table 3 – Hazard symbols

2.2.3 Signs Containing Orders for Personal Protective Equipment

The following signs relate to the use of personal protective equipment. You are required to comply with them.

Symbol Meaning for skilled personnel

Wear a face shield.

Wear an electrician's safety helmet.

Wear insulating safety boots.

Wear insulating overalls.

Wear insulating gloves with long sleeves.

Wear hearing protection when operating the

equipment.

Table 4 Signs containing orders for PPE

Check that personal protective equipment is in perfect working order and report any defects you notice to the equipment operator.

12 of 72 8000047961 BAL

Page 17

2.2.4 Abbreviations

Protect PV.630 Operating Instructions

The following abbreviations are used in these operating instructions:

DOU Display and operation unit

AC

Alternating current

BGV Regulation set out by Employer's Liability Insurance

Association (Germany)

CAN Controller Area Network

CNF Manufacturing order number

DC

Direct current

DCD/ACD DC/AC control cabinet

DCS Distributed control system

DIN German Standards Institute

EPO Emergency power off (system off)

GCB Generator connection box

Grid Power utility mains (power utility company's mains)

IEC International Electrotechnical Commission

IGBT Insulated gate bipolar transistor

INV Inverter cabinet

PE conductor Protective earth conductor, earthing

PV Photovoltaics

VDE Verband der Elektrotechnik Elektronik Informations-

technik e. V. (German Association for Electrical,

Electronic & Information Technologies)

INV Inverter

2.3 Emergency Procedure (e.g. in the Event of a Fire)

Never put your own life at risk. Your own safety is paramount.

Call the fire brigade.

Call the emergency doctor, if necessary.

Shut down the equipment using the system stop switch (ensur-

ing your own safety).

2.4 Safety Awareness

The qualified skilled personnel defined in Chapter 1.3.2 are responsible for safety. The member of personnel who is responsible

for the equipment must ensure that only suitably qualified persons

are allowed access to the equipment or permitted within its vicinity.

The following points must be observed:

All such working procedures which are detrimental to the safe-

ty of persons and the operation of the equipment in any way

are prohibited.

The equipment may only be operated when in perfect working

order.

Never remove or render inoperable any safety devices.

8000047961 BAL 13 of 72

Page 18

Protect PV.630 Operating Instructions

All necessary operational measures must be initiated prior to

deactivating any safety device in order to perform maintenance, repair or any other work on the unit.

Safety awareness also entails informing colleagues of any unsuitable behaviour and reporting any faults detected to the appropriate

authority or person.

The member of personnel responsible for the equipment must

ensure that:

The safety instructions and operating instructions are readily

available and are complied with

The operating conditions and technical data are observed

Safety devices are used

The prescribed maintenance work is performed

Maintenance personnel are informed without delay or the

equipment is shut down immediately in the event of abnormal

voltages or noise, high temperatures, vibrations or any similar

phenomena, so that the cause of this can be determined

2.5 Particular Dangers associated with Photovoltaic Systems

Here you will find information about the additional dangers associated with photovoltaic systems.

An active power source is connected. Depending on the operating

status, the PV cells and the equipment may be live.

Crystalline silicon cells

Crystalline PV cells (silicon cells) usually have an IT system

configuration, i.e. a non-earthed system that will be inadvertently

earthed in the event of an earth fault.

A generator with a complex branched structure can only be shut

down with a great deal of difficulty (in the event of a short circuit,

for example).

DANGER

Contact with voltage! Extremely high DC voltages of

up to 1000 VDC are present.

Risk to life due to electric shock.

Do not touch live parts.

Wear personal protective equipment ( Chapter

2.2.3).

Thin-film cells

To prevent corrosion, thin-film cells must be earthed.

Lightning protection

The desired level of protection can only be achieved if a lightning

protection zone concept has been implemented for the building

where the unit is to be installed, in accordance with DIN VDE

0185-4.

14 of 72 8000047961 BAL

Page 19

Protect PV.630 Operating Instructions

System stop switch

The system stop switch is on the door of the equipment's DC/AC

control cabinet.

The system stop switch is not intended for switching off the equipment. It may only be used in an emergency.

The DOU is used, amongst other things, to switch the equipment

on and off.

The system stop switch causes the

- PV inputs

- mains input and

- mains 2 input

to be separated. This interrupts the energy supply.

It does not mean that the unit has been de-energised!

2.6 Safety Signs and Warning Notices on the Equipment

Safety signs and warning notices are located in the vicinity of danger spots. They provide information about electrical hazards and

residual hazards associated with working on and with the equipment.

Safety signs and warning notices must always be in perfect condition and clearly legible. You must comply with safety signs and

warning notices whenever you are working on or with the equipment.

2.7 Safety and Protection Devices for the Equipment

This section describes all safety and protection devices. Safety

and protection devices protect personnel against hazards which

cannot be countered by safe design.

Safety and protection devices must always be in perfect working

order.

2.7.1 Protective Covers

The equipment is designed so that the live components in the operating area are secured with protective covers wherever possible.

The protective covers provide protection against accidental contact

with live parts.

Such protection may only be removed for start-up and for maintenance or repair work.

The covers must be replaced immediately on completion of such

work and checked to ensure that they are in perfect working order.

8000047961 BAL 15 of 72

Page 20

Protect PV.630 Operating Instructions

2.7.2 Lockable Equipment Doors

The equipment doors are fitted with a control cabinet lock. This

prevents unauthorised personnel from accessing the equipment.

The equipment door must be kept closed at all times.

It may be opened for maintenance and repair work.

The space requirement for the opened equipment doors

i

The equipment door must be closed again once maintenance and

repair work is complete.

2.7.3 Guard

The guard forms the equipment's housing. It protects against unintended contact with live parts and electromagnetic rays.

It may be removed for maintenance and repair work.

must be taken into account

i

The guard must be put back in place once maintenance and repair

work is complete.

2.8 Residual Hazards

This section describes residual hazards. Despite the measures

taken to ensure safety and protection, the equipment poses residual hazards which cannot be countered by design.

Observe warnings at all times while you are working.

The area around the equipment must be made secure

when the guard is removed.

16 of 72 8000047961 BAL

Page 21

Protect PV.630 Operating Instructions

2.8.1 Electrical Hazards

DANGER

Contact with voltage!

Risk to life due to electric shock.

Use dry insulating material to remove the victim from

the live parts.

Seek medical assistance and inform the control room.

Disconnect the equipment safely.

DANGER

Electric shock after activating “System stop”!

Parts of the equipment remain live after “System stop”

has been activated (e.g. external voltage present at remote signal terminals).

Risk to life due to electric shock.

Disconnect the equipment safely.

DANGER

Electric shock caused by inverter.

Parts of the equipment remain live after the inverter has

been shut down.

Risk to life due to electric shock.

Disconnect the equipment safely.

DANGER

Electric shock caused by back feeding.

The input terminals of the equipment may remain live

after the incoming power supply has been interrupted.

Risk to life due to electric shock.

Disconnect the equipment safely.

Install back feeding protection (a disconnector) in the

load circuit.

DANGER

Electric shock caused by leakage currents.

The capacitors generate high leakage currents in the

equipment. Conductive parts may be live in the event of

connection errors.

Risk to life due to electric shock.

Establish a PE conductor connection prior to start-up.

8000047961 BAL 17 of 72

Page 22

Protect PV.630 Operating Instructions

i

2.8.2 Risks Due to Moving Parts

Using residual-current-operated safety devices (FI) alone

is not permitted.

WARNING

Water in electrical equipment!

Risk to life due to electric shock.

Do not use water to clean the cabinets.

Do not place any vessels containing fluids on electrical

equipment.

2.8.3 Fire-Related Risks

Installation of fireproof enclosures (EN 60950-1)

A built-in floor plate ensures that, in the event of a fire, no molten

or burning material can fall out of the equipment.

We recommend having a separate supply/exhaust air connection

for the PV.630 in order to prevent smoke spreading in the event of

a fire.

CAUTION

Risk of injury due to rotating fans!

The fans of the INV control cabinet are freely accessible.

Never reach into rotating fans.

When setting up any system, ensure that the fans

cannot be touched.

WARNING

Spread of smoke in electrical operating areas.

If smoke is detected or a fire breaks out, immediately

disconnect the equipment from the power supply and

inform the maintenance personnel.

18 of 72 8000047961 BAL

Page 23

Protect PV.630 Operating Instructions

2.8.4 Risks due to Loss of Control

ATTENTION

Failure of remote signalling.

If remote signalling fails or the signal lines are interrupted,

the control room can no longer control the equipment.

In such an event, faults can only be identified locally at the

unit itself.

Failure of external emergency switching device

Disconnect the equipment safely.

ATTENTION

Failure of the display and operation unit.

If the display and operation unit fails, the skilled personnel

will no longer be able to control the equipment.

In such an event, faults will no longer be displayed.

Inform the control room.

2.8.5 Risks from Maintenance and Repair Work

Only trained and qualified skilled personnel (as de-

i

scribed above) may work on or around the equipment

while strictly observing the safety regulations.

DANGER

Risk to life due to electric shock.

Potentially fatal voltages are present in the equipment.

Disconnect safely.

Secure the unit against being switched back on.

Verify that all poles are de-energised.

Earth and short-circuit the equipment.

Provide protection in the form of covers or barriers for

any neighbouring live parts.

ATTENTION

Damage to property.

Only use original spare parts.

Do not intervene in the equipment without authorisa-

tion to do so.

Observe the safety regulations.

8000047961 BAL 19 of 72

Page 24

Protect PV.630 Operating Instructions

3 Product Details

The equipment has been designed for solar power plants and provides professional solutions for the use of installations covering

large roofs or in open spaces.

3.1 Product Description

The equipment is a solar inverter (INV) that feeds the electrical

energy produced by the PV cells into a medium-voltage mains

(e.g. 10 kV; 20 kV; 33 kV).

The required mains transformer is not supplied with the unit and

can be ordered as an extra if necessary. It is possible to combine

two Protect PV.630 units to create a 1.26 kW system. A joint isolating transformer can be used, with an electrically isolated lowvoltage connection for each Protect PV.630. 1.26 MW systems can

be made to support “partner operation” to increase their efficiency.

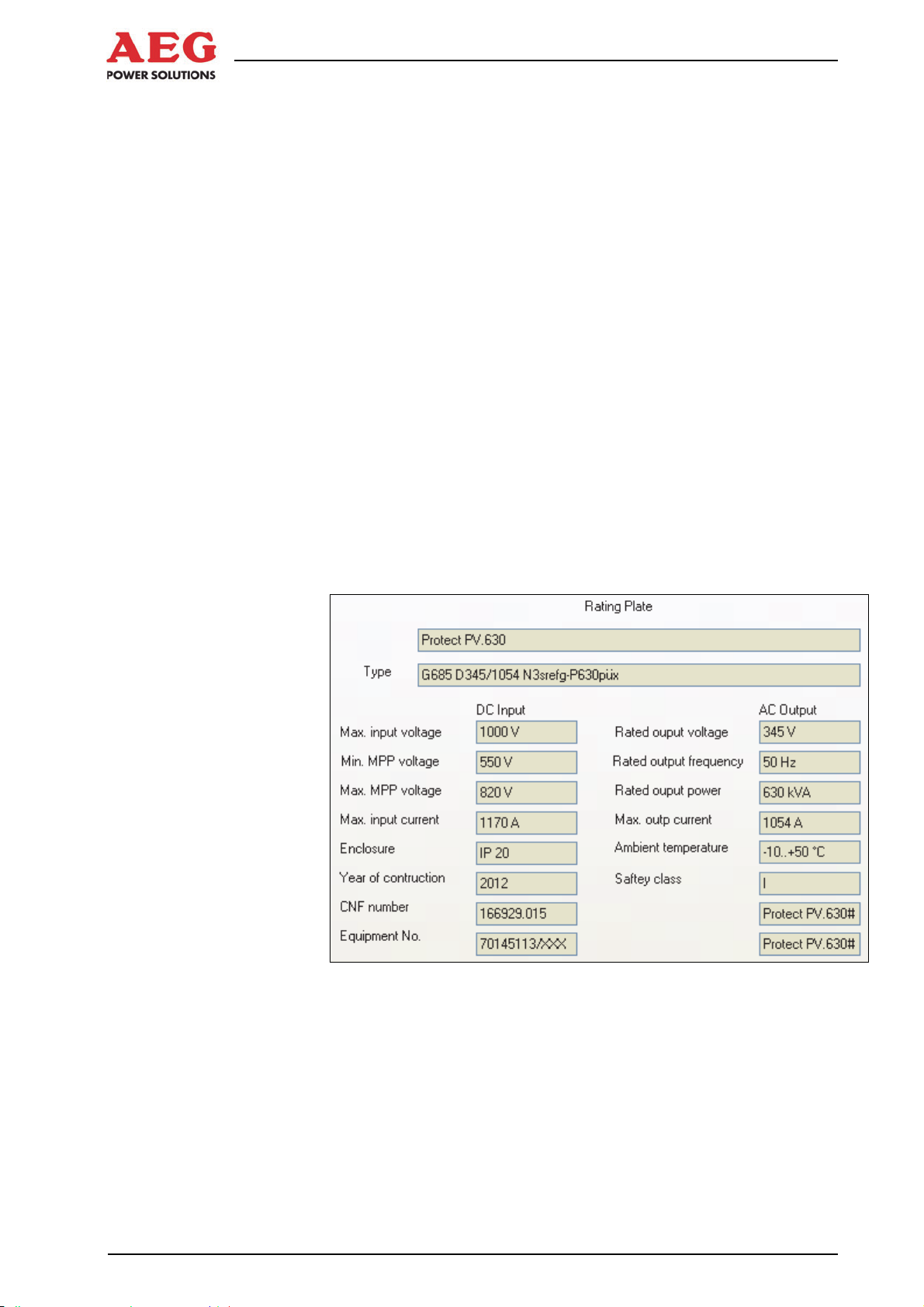

The rating plate, featuring all the relevant data, is located on the

inside of the door.

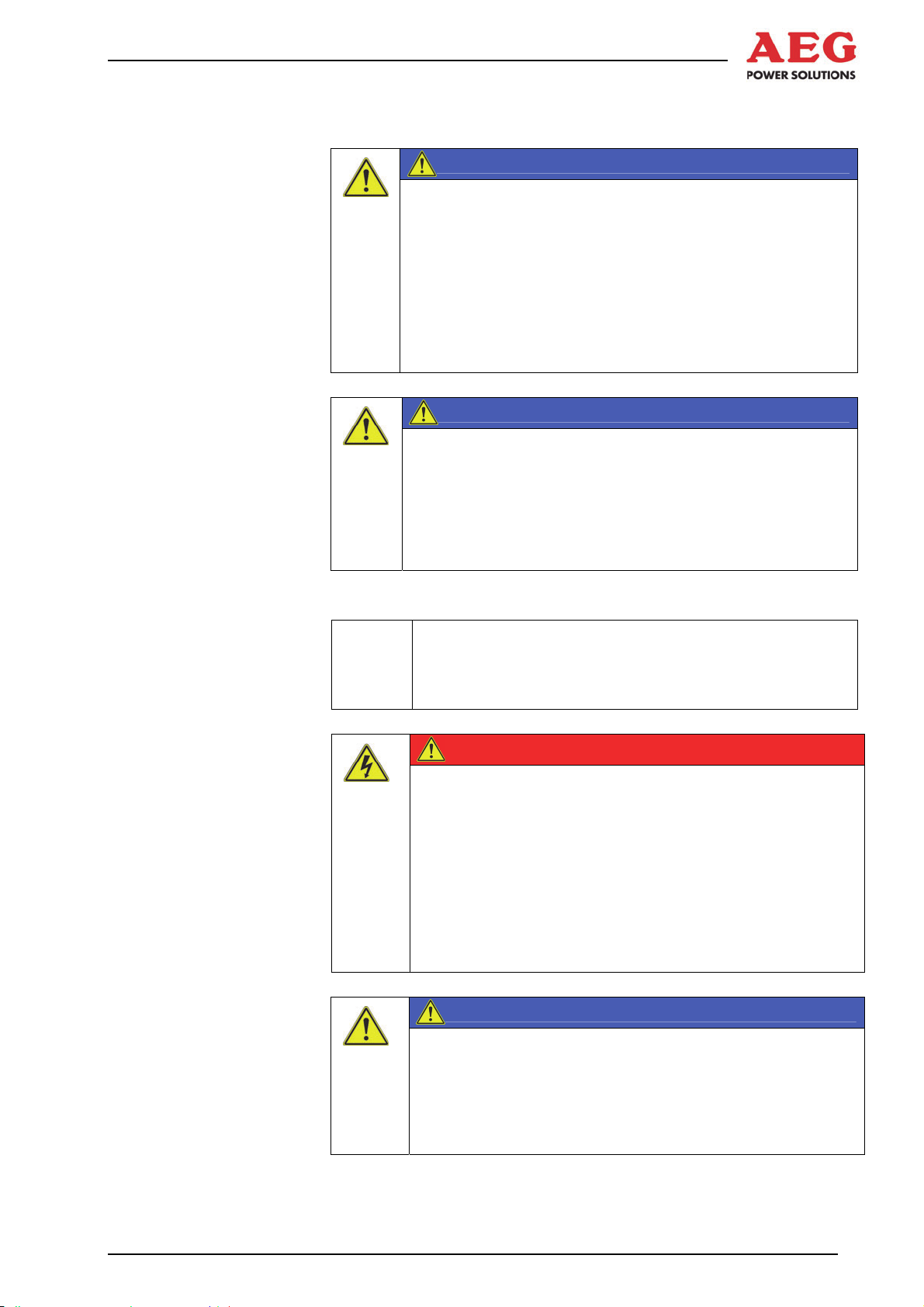

A B

Figure 2 PV.630 equipment

Item Designation

3

1

2

1 Display and operation unit (DOU)

2 System stop

3 Fan assembly (fan cover optional)

A INV control cabinet +INV

B DC/AC control cabinet +DCD/ACD

Important information about equipment documentation

i

20 of 72 8000047961 BAL

Further descriptions and unit diagrams are included in the

document folder.

Page 25

Protect PV.630 Operating Instructions

3.2 Dimensions and Views

0

7

0

2

2700

660

925

Figure 3 Dimensions and views

3.3 Appropriate Use

Only operate the equipment with the maximum permissible connection values stated in the technical data sheet. Any other use or

modification constitutes inappropriate use.

Unauthorised repairs, manipulations or changes made to the

equipment and its safety devices without the manufacturer's approval are not permitted. The manufacturer cannot be held liable

for damage resulting from such repairs, manipulations or changes.

Safety

The equipment will operate reliably and safely subject to compliance with the instructions, the operating and equipment specifications and regulations set out by the Employer's Liability Insurance

Association.

1500 1200

60011,5

600

625

75

8000047961 BAL 21 of 72

Page 26

Protect PV.630 Operating Instructions

3.4 Inappropriate Use

No liability is accepted if the equipment is used for applications not

intended by the manufacturer (= inappropriate use). Inappropriate

use can cause serious or fatal personal injury. The responsibility

for any measures necessary for the prevention of personal injury

or damage to property is borne by the equipment operator or user.

3.5 Standards, Directives and CE Mark

The equipment complies with currently applicable DIN and VDE

regulations. The requirements of BGVA3 are met on the basis of

compliance with EN 50274/VDE 0660-51.

The requirements of VDE 0100, Part 410, IEC 60364-4-41, “Functional extra-low voltage with safe isolation” and IEC 62109, “Safety

of power converters for use in photovoltaic power systems” have

been complied with where applicable.

The CE mark on the unit confirms compliance with the EC framework directives for 2006/95/EC (Low Voltage) and for 2004/108/EC

(Electromagnetic Compatibility), provided that the actions outlined

in the instructions are observed.

3.6 Nameplate

The following information appears on the nameplate:

Figure 4 Rating plate (example)

22 of 72 8000047961 BAL

Page 27

3.7 Technology

Protect PV.630 Operating Instructions

Due to the utilisation of high-performance electronic components,

the equipment boasts a very high degree of operational reliability,

is extremely efficient and is characterised by its versatility in communicating with other systems by means of interfaces.

The entire control electronics system for the equipment is based

on the use of microcomputer assemblies. The fact that the various

assemblies are logically integrated and linked into the overall system means that unit properties can be defined by making unitspecific parameter settings in the software.

Information is exchanged between the individual modules using

the CAN bus (Controller Area Network). This CAN bus features

high interference immunity and is used in a wide variety of industrial applications.

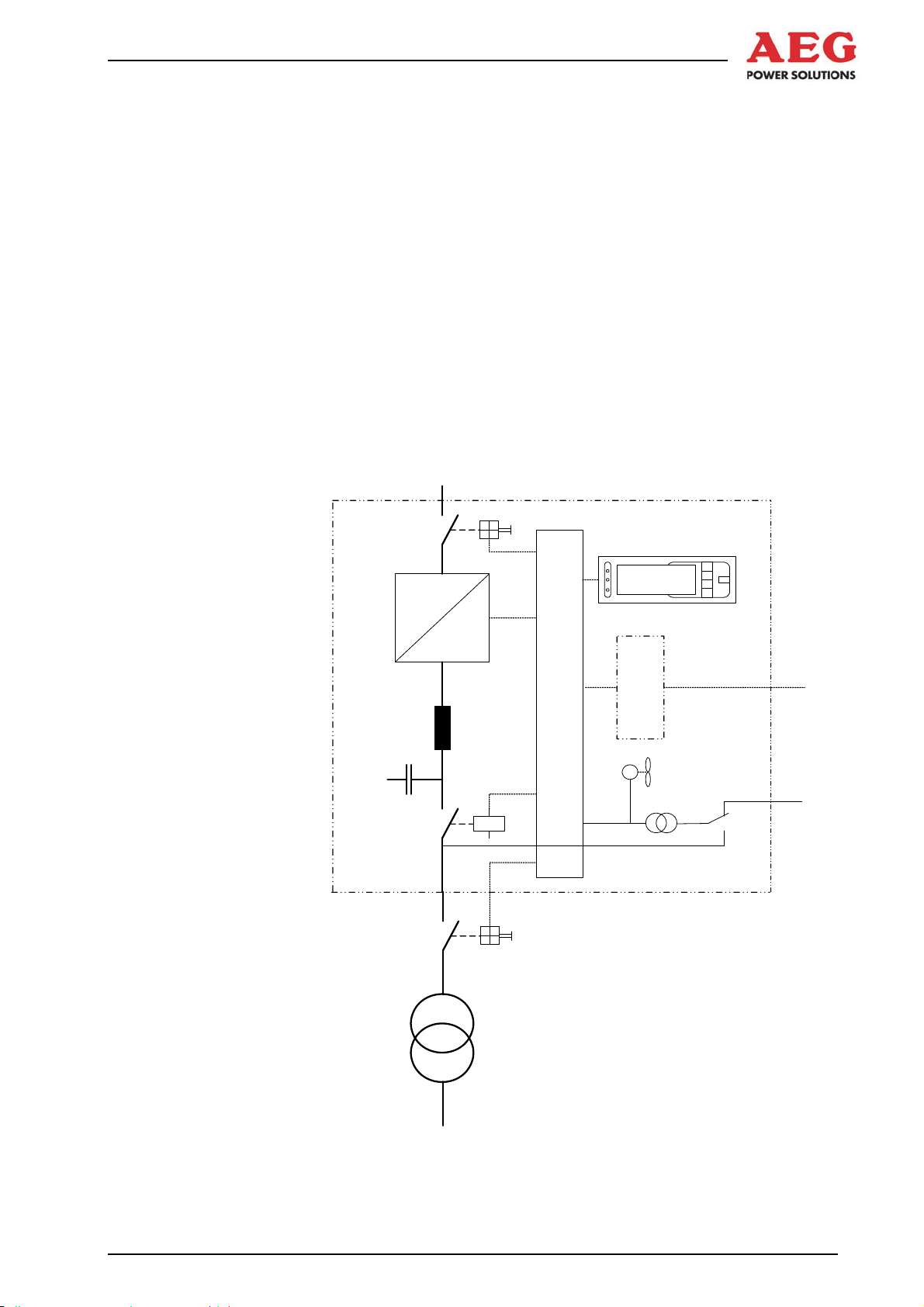

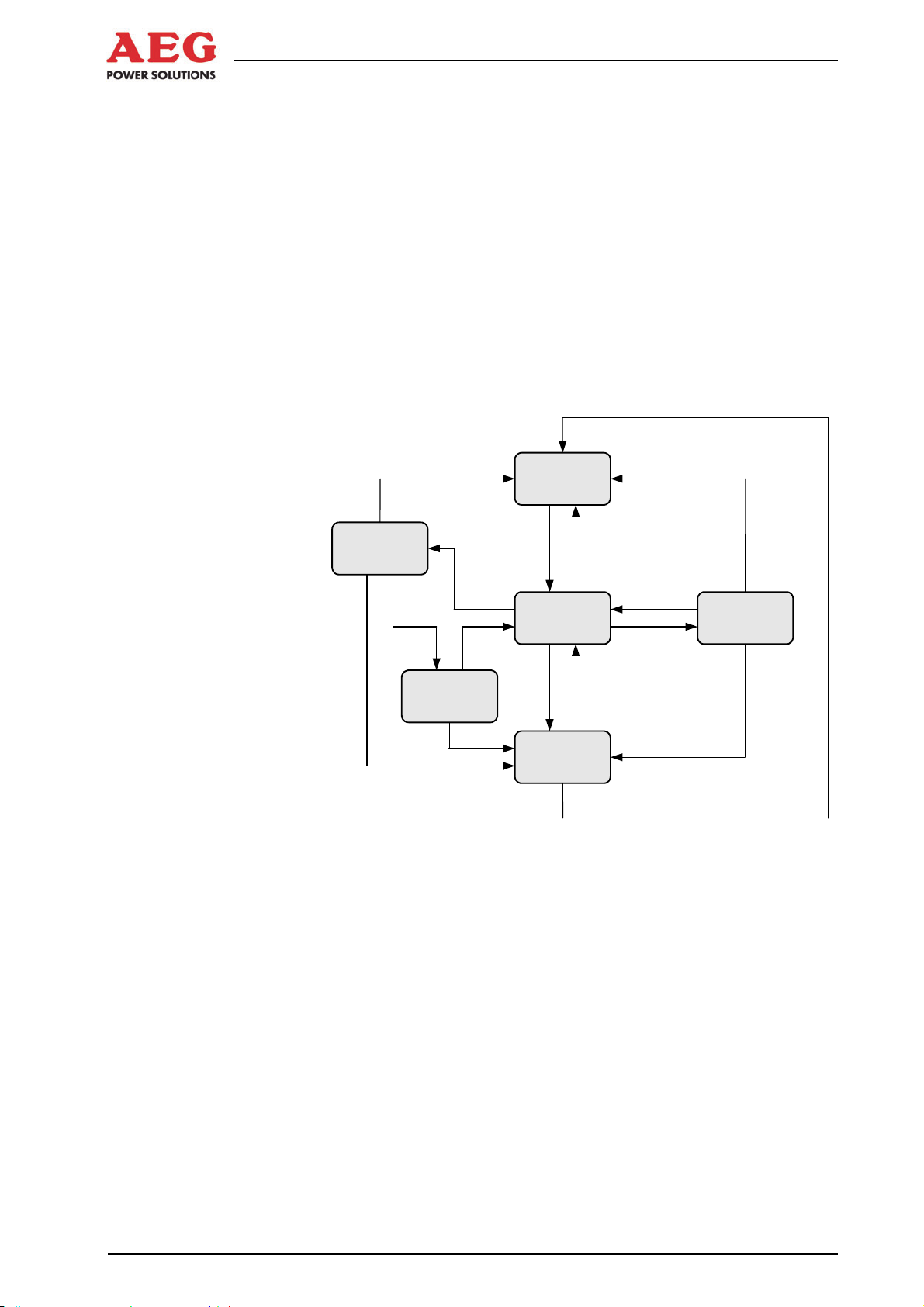

The figure below illustrates the principle of the equipment.

DC

(PV-modules)

Protect PV.500

Q4

=

K7

Q26

Display

~

~

~

Communication

M

Control unit

Control unit

supply

AC mains 2

Medium-voltage mains

Figure 5 Functional principle of the equipment for connection to a low-

voltage mains

8000047961 BAL 23 of 72

Page 28

Protect PV.630 Operating Instructions

The main assemblies of the inverter are:

DC load interrupter switch Q4

Inverter stack, display and control unit with communication

components

AC filter

Inverter output contactor K7

Mains transformer (external)

Mains disconnector Q26 (external)

The PV cells supply the inverter stack with DC voltage via DC load

interrupter switch Q4. The inverter stack converts this DC voltage

into a 3-phase AC voltage. A sinusoidal current is fed into the

mains via the AC filter, inverter output contactor K7 and the mains

transformer.

DANGER

Risk to life due to electric shock.

Mains disconnector Q26 (external) and the isolator in the generator connection box (GCB) are there to isolate the inverter in the

event of unit faults or when maintenance needs to be performed

on the unit.

The control unit is supplied with power from the AC mains or, optionally, from a second AC mains.

3.8 Operating Elements

For details of how the internal operating elements are arranged,

please refer to the documents included in the unit.

Potentially fatal voltages are present at the terminals on

the equipment.

Do not touch live parts.

24 of 72 8000047961 BAL

Page 29

Protect PV.630 Operating Instructions

4 System Description

This chapter describes the operating modes and functions of the

equipment.

4.1 Operating Modes

Two different operating modes may be used:

Individual operation

Partner operation

4.1.1 Individual Operation

In individual operation, the inverter works independently and is not

connected to any other inverters. The DC infeed from the PV cells

and the link to the AC mains are only connected to this inverter.

Switching operations, control commands and modifications to setting parameters are only performed by the unit concerned.

4.1.2 Partner Operation

In partner operation, two inverters are connected via a CAN bus.

The DC voltage infeeds of both units can be linked using a coupling breaker. Levels of efficiency can be increased in this operating mode by running one inverter on two connected PV cells at

less than full power. It is the inverter itself that connects and disconnects the DC voltage; it is also responsible for switching the

units on and off.

This operating mode is described in detail in Chapter 5.5.

8000047961 BAL 25 of 72

Page 30

Protect PV.630 Operating Instructions

5 System Function

5.1 Description of Sequence Control

As soon as the equipment's control module is supplied with voltage, sequence control starts.

Initially, load interrupter switch Q4 remains open. Once the initialisation phase is complete and if no deactivating faults are pending,

load interrupter switch Q4 is closed. During subsequent operation,

the switch is only opened by deactivating faults ( Chapter 6).

Inverter output contactor K7 remains open initially. The contactor is

switched by the sequence control.

The figure below provides a graphical illustration of the sequence

control statuses.

5.1.1 The “OFF” Status

OFF command OFF command

Feed-in

conditions met

Delay

complete

ON command

Waiting for feed

Fault

Operation

Fault

Operating

conditions

no longer

met

Waiting

Fault

Figure 6 Sequence control

OFF

conditions

Fault

OFF command

OFF command

Daytime detection

Night-time detection

Fault

acknowledgement

Fault

Night

The equipment has been switched off logically via the DOU or the

master control unit.

The equipment is running without faults, the monitoring systems

are not activated.

In this status, no power is fed into the mains.

Possible change of status:

The status can be switched from “OFF” to “Waiting for feed conditions” by switching the equipment on via the DOU and the master

control unit.

5.1.2 The “Waiting for Feed Conditions” Status

The values of the DC voltage on the PV cells, the mains voltage

and the mains frequency are monitored by the equipment.

26 of 72 8000047961 BAL

Page 31

Protect PV.630 Operating Instructions

The set monitoring values are regularly checked.

In this status, no power is fed into the mains.

Possible change of status:

If the DC voltage rises above a certain value for a certain time and

the mains voltage and mains frequency are within a certain range,

the unit switches to the “Operation” status. A start-up attempt is

made, which involves switching on the inverter stack. If the DC

voltage collapses too dramatically during this start-up attempt, the

inverter stack is switched off again and there is a delay before attempting to start up again. The equipment will not switch to the

“Operation” status until any dip in the DC voltage that occurs during a start-up attempt is within acceptable limits.

If the DC voltage falls below a certain value for a certain time, the

equipment switches to the “Night” status.

If a deactivating or self-acknowledging fault is triggered, the

equipment switches to the “Fault” status.

The status can be switched from “Waiting for feed conditions” to

“OFF” using the “Off” control command.

5.1.3 The “Operation” Status

The equipment has met all conditions for operation and no deactivating or self-acknowledging faults are present.

The set monitoring values are regularly checked.

In this status, power is fed into the mains and inverter output con-

tactor K7 is closed.

Possible change of status:

If the generated power falls below a certain value for a certain

time, the operating conditions are no longer met. The equipment

then switches to the “Waiting” status.

If a deactivating or self-acknowledging fault is triggered, the

equipment switches to the “Fault” status.

The status can be switched from “Operation” to “OFF” using the

“Off” control command.

5.1.4 The “Waiting” Status

If the power fed in falls below a certain value when the equipment

is in “Operation”, it switches to the “Waiting” status. Although the

incoming power is low, the DC voltage of the PV cell could still be

high enough and even stable enough to meet the feed conditions

in the “Waiting for feed conditions” status. So that the inverter does

not switch back on again immediately, thereby subjecting inverter

output contactor K7 to unnecessary strain due to frequent switching, after the “Operation” status the unit initially switches to the

“Waiting” status. It remains in this status for a certain time, only

switching to the “Waiting for feed conditions” status once this time

has elapsed.

The set monitoring values are regularly checked.

Possible change of status:

Once the delay has elapsed, the unit switches to the “Waiting for

feed conditions” status.

8000047961 BAL 27 of 72

Page 32

Protect PV.630 Operating Instructions

If a deactivating or self-acknowledging fault is triggered, the

equipment switches to the “Fault” status.

The status can be switched from “Operation” to “OFF” using the

“Off” control command.

5.1.5 The “Fault” Status

If a deactivating or self-acknowledging fault is triggered ( Chapter 6), the equipment switches to the “Fault” status.

The set monitoring values are regularly checked.

In this status, no power is fed into the mains.

Possible change of status:

If a self-acknowledging fault has been triggered and this fault does

indeed acknowledge itself, the unit switches to the “Waiting for

feed conditions” status.

If a deactivating fault has been triggered, the “Acknowledge fault”

control command can be used to switch back to the “Waiting” status.

The status can be switched from “Fault” to “OFF” using the “Off”

control command. In the “OFF” status, the unit is always free of

faults.

5.1.6 The “Night” Status

If the DC voltage falls below a certain value for a certain time, the

equipment switches to the “Night” status.

The set monitoring values are regularly checked.

In this status, no power is fed into the mains.

Possible change of status:

If, the following morning, the DC voltage rises above a certain value for a certain time, the equipment switches to the “Waiting for

feed conditions” status.

If a deactivating or self-acknowledging fault is triggered, the

equipment switches to the “Fault” status.

The status can be switched from “Operation” to “OFF” using the

“Off” control command.

5.1.7 Sequence Control During the Course of the Day

Early morning:

The equipment is in the “Night” status. The sun's rays increase the

DC voltage generated by the PV cells. If this voltage stays above a

certain value for a certain time, the unit switches to the “Waiting for

feed conditions” status.

The DC voltage continues to be monitored in this status. In order

for a start-up attempt to be made, it must remain above a certain

value for a certain time. The mains voltage and mains frequency

are also checked. These values must be within certain limits.

28 of 72 8000047961 BAL

Page 33

Protect PV.630 Operating Instructions

If the DC voltage continues to increase due to the sun's rays getting stronger and the mains voltage and mains frequency are within acceptable limits, a start-up attempt is made. During a start-up

attempt, the inverter stack is switched on, thereby drawing power

from the DC voltage that is present. Inverter output contactor K7 is

open during a start-up attempt. If the load on the DC voltage causes it to collapse too dramatically during this start-up attempt, the

inverter stack is switched off again and there is a delay until the

next start-up attempt is made. If the DC voltage does not dip too

significantly, inverter output contactor K7 closes and power is fed

into the mains. The inverter is now in the “Operation” status.

Day:

During the course of the day, the inverter will remain in the “Operation” status if the sun's rays are strong enough and no faults occur.

Power is fed into the mains and inverter output contactor K7 is

closed.

Evening:

As the sun goes down, the power fed into the mains decreases. If

this power falls below a certain value for a certain time, the operating conditions are no longer met. The inverter stack is switched off,

inverter output contactor K7 opens and the unit switches to the

“Waiting” status.

Once the “Waiting” status delay has elapsed, the unit switches

back to “Waiting for feed conditions”. Although the sun's rays are

not as strong, the DC voltage might still be high enough for a successful start-up attempt with the inverter stack and inverter output

contactor K7 being switched on again. However, because the

sun's rays are not as strong, it is unlikely that the operating conditions will still be met in the “Operation” status. As a result, the

equipment will switch back to the “Waiting” status once a delay has

elapsed.

When the unit switches back to this status, the delay is extended

until the unit switches back to the “Waiting for feed conditions” status.

The cyclic changes of status “Operation” -> “Waiting” -> “Waiting

for feed conditions” -> “Operation” can take place several times

depending on insolation, the time of year, location and other conditions (e.g. snow on the PV cells). So that inverter output contactor

K7 is not overloaded by this cycle of changes, the “Waiting” status

delay is extended every time the unit switches to this status.

This has very little effect on the energy fed in, because the low

levels of insolation mean that hardly any energy is being generated.

Later in the evening:

Levels of insolation continue to fall. As a result, the DC voltage

drops again. If the DC voltage drops below a certain value for a

certain time, no more start-up attempts are made. If the DC voltage continues to drop, the unit switches to the “Night” status.

Night:

The equipment shuts down all possible loads so that as little energy as possible is being consumed. The equipment remains in the

“Night” status until the following morning.

8000047961 BAL 29 of 72

Page 34

Protect PV.630 Operating Instructions

5.1.8 Sequence Control Parameters

Switch-on conditions

Underfrequency, overfrequency, undervoltage, overvoltage:

The equipment will only switch from the “Waiting for feed conditions” status to the “Operation” status if the feed conditions are

met. These conditions include the mains voltage and the mains

frequency. These values must be within certain limits described by

the switch-on conditions.

Voltage limit value for night detection,

delay time for night detection:

If the DC voltage falls below the voltage limit value for longer than

the delay time, the unit switches to the “Night” status.

Voltage limit value for day detection,

delay time for day detection:

If the DC voltage rises above the voltage limit value for longer than

the delay time, the equipment switches to the “Waiting for feed

conditions” status.

Inverter stack switch-on time:

The time for which the inverter stack is switched on during a startup attempt

Permissible voltage dip after switching on the stack:

Prior to the start-up attempt, a limit value is calculated from the

present DC voltage and the permissible voltage dip.

If the start-up attempt causes the DC voltage to fall below this calculated limit value, this start-up attempt will fail.

Delay until the next start-up attempt following failure on account of excess voltage dip:

After the failure of a start-up attempt, this delay must elapse before

the next start-up attempt is made.

Power limit value for shutdown,

delay time for shutdown:

If the power fed into the mains remains below the limit value for

longer than the delay time, the unit switches to the “Waiting” status.

Standard delay for a renewed start-up attempt following shutdown,

offset delay added to the standard delay after shutdown,

maximum number of times the offset delay can be added to

the standard delay:

Variable delay in the “Waiting” status Chapter 5.1.4.

Minimum DC voltage,

fill factor (PV system parameter):

If the DC voltage rises above a value resulting from the minimum

DC voltage divided by the fill factor, a start-up attempt is made.

30 of 72 8000047961 BAL

Page 35

Protect PV.630 Operating Instructions

5.2 Description of Fan Control

5.2.1 General

The equipment features temperature-dependent fan control. The

fans are either switched off, run on a fast or slow fan stage (cabinet fan only) or are gradually speeded up or slowed down (stack

fan only).

Fan control:

Extends the operating time of the fans

Minimises the noise generated by the fans

Improves the efficiency of the equipment by reducing its power

consumption

5.2.2 Fan Control, Cabinet Fan

As soon as the equipment's control module is supplied with voltage, fan control always starts with the fast fan stage. The control

can be restarted to check whether the fans are working correctly.

For example, after maintenance work, it is not necessary to wait

for the fans to reach the temperature criterion to switch on the fast

fan stage.

The fast fan stage is always active for at least a certain time. The

unit exhaust air temperatures are checked after this time. If the

highest temperature from the two sensors is below a certain value,

the fan control switches to the slow fan stage.

The unit exhaust air temperatures are also checked in the slow fan

stage. If the highest temperature from the two sensors is below a

certain value, the fans are switched off. If the highest temperature

rises again during operation with the lower fan stage, fan control

switches to the fast fan stage.

If, when the fans are switched off, the highest temperature from

the two sensors rises above a certain value, fan control switches to

the fast fan stage.

Initialisation

Fast fan stage,

minimum time!

Unit exhaust air

temperature > limit

value

Unit exhaust

air temperature

> limit value

Figure 7 Fan control

Slow fan stage

Fan switched off

Unit exhaust air

temperature < limit

value

Unit exhaust air

temperature < limit

value

8000047961 BAL 31 of 72

Page 36

Protect PV.630 Operating Instructions

5.2.3 Cabinet Fan Control Parameters

Unit exhaust air temperature limit value for switching on the

fan:

If the highest exhaust air temperature rises above this limit value,

the fans which were switched off are switched to the fast fan stage.

Unit exhaust air temperature limit value for switching off the

fan:

If the highest exhaust air temperature falls below this limit value,

the fans which were running in the slow fan stage are switched off.

Unit exhaust air temperature limit value for switching to the

fast fan stage:

If the highest exhaust air temperature rises above this limit value,

the fans which were running in the slow fan stage are switched to

the fast fan stage.

Unit exhaust air temperature limit value for switching to the

slow fan stage,

minimum time in the fast fan stage:

If the highest exhaust air temperature falls below this limit value,

the fans which were running in the fast fan stage are switched to

the slow fan stage if the minimum time in the fast fan stage has

elapsed.

5.2.4 Fan Control, Inverter Stack Fan

As soon as the equipment's control module is supplied with voltage, fan control always starts with the maximum fan speed. This

means that the control can be restarted to check whether the fan is

working correctly. For example, after maintenance work, it is not

necessary to wait for the fan to reach the temperature criterion to

switch on the maximum fan speed.

The maximum fan speed is always active for at least a certain

time. The IGBT temperatures are checked after this time. The fan

speed is then determined using the highest of these temperatures.

If the highest temperature from the two sensors is below a certain

value, the fan is switched off completely.

If, when the fans are switched off, the highest temperature from

the two sensors rises above a certain value, the fan is again operated at the maximum speed for a certain time.

32 of 72 8000047961 BAL

Page 37

Protect PV.630 Operating Instructions

Initialisation

Maximum speed,

minimum time!

Minimum time elapsed

IGBT temperature

> limit value

Figure 8 Fan control

Variable speed

depending on IGBT

temperature

Fan switched off

5.2.5 Parameters of Inverter Stack Fan Control

IGBT temperature limit value for switching off the fan:

If the highest IGBT temperature falls below this limit value, the fan

is switched off.

IGBT temperature limits and fan speeds, x-y coordinates for

determining variable speed:

The variable fan speed is determined by a linear x-y characteristic

on the basis of these values.

IGBT temperature limit:

If the IGBT temperature rises above the lower limit value, the fan

that was previously switched off is run at maximum speed for the

minimum time.

Minimum time, maximum speed:

If the minimum time has elapsed, the fan is controlled variably using the measured IGBT temperature.

IGBT temperature

< limit value

5.3 Insulation Monitoring and Earthing of PV Cells

5.3.1 General

Insulation measurements and tests are carried out with an integrated isometer. This device detects and checks the insulation resistance.

The insulation resistance detected is compared with two limit values stored in the isometer. If the insulation resistance is below one

of the limit values, the unit generates a signal. If the limit value is

below the other limit value, the device generates a second signal.

The limit values can be modified on the isometer.

The two signals are sent to the equipment control. Signalling faults

are generated from the two isometer signals ( Chapter 6).

8000047961 BAL 33 of 72

Page 38

Protect PV.630 Operating Instructions

Sequence control behaviour differs depending on which solar cells

are connected. The solar cells do not need to be earthed for operation with monocrystalline or polycrystalline solar cells. In this

case, insulation measurement is always active.

For operation with thin-film solar cells, the solar cells must be

earthed. In this case, insulation measurement is not active during

earthing.

Insulation measurement sequence control features a “Maintenance

mode”. This mode can only be activated for thin-film solar cells.

Activating this mode disconnects earthing. This can be useful

when mowing areas where solar panels are installed, for example.

5.3.2 Operation With Monocrystalline or Polycrystalline Solar Cells

General:

This type of solar cell does not require active earthing.

Sequence control:

Insulation monitoring is always active.

Maintenance mode:

No action in the event of a “Maintenance mode” command.

Starting the insulation test manually:

No action, since the insulation test is always active.

5.3.3 Operation with Thin-Film Solar Cells

General:

This type of solar cell requires active earthing.

Active earthing is switched on during the day and switches off at

night. An insulation test is carried out at night.

When active earthing is switched on, the digital signals from the

isometer are ignored.

Once active earthing is switched off, a certain time is allowed to

elapse before the digital signals from the isometer are evaluated.

Sequence control:

When the equipment sequence control switches to the “Night” status (see Chapter 5.1.6), active earthing is switched off once a certain time has elapsed.

The insulation test starts with a delay. Once a certain test time has

elapsed, the insulation test finishes and active earthing is switched

on again. If the sequence control switches to “Operation” status

before the test time has elapsed, the timer control is ignored, the

insulation test is terminated and active earthing is switched back

on.

34 of 72 8000047961 BAL

Page 39

Protect PV.630 Operating Instructions

Maintenance mode:

Maintenance mode can be triggered either via a command or by

means of remote signalling. Active earthing switches off immediately when maintenance mode is activated. However, the digital

signals from the isometer continue to be ignored. Active earthing is

switched on again the next time a switch is made to “Operation”

status. However, the unit remains in maintenance mode for at least

a certain time; i.e. even if the unit is switched over to the “Operation” status, maintenance mode is not terminated until this time has

elapsed.

Starting the insulation test manually:

The insulation test can be started manually for maintenance work.

Active earthing is switched off when the insulation test is started

and the test actually commences once a delay has elapsed. When

the test time has elapsed, the insulation test ends and active earthing is switched on again.

The insulation test can only be started manually if an insulation

test is not already running at the time.

5.3.4 Insulation Monitoring in Partner Operation

In partner operation (see Chapter 5.5), both inverters are fitted with

the isometer.

Insulation measurement in single operation

In single operation, the two inverters behave like two individual

units. Insulation measurement is active in both inverters.

Insulation measurement in linked operation

In linked operation, the inverters are connected on the DC voltage

side. If both inverter isometers were to be active in this operating

mode, this would distort the measurement of the insulation resistance. Therefore, in linked operation, the isometer of the inverter which is not active is switched off and its sensors are disconnected from the DC voltage. Now only one isometer is active and

the measurement of the insulation resistance is correct.

5.3.5 Insulation Monitoring Parameters

All parameters are only relevant for operation with thin-film solar

cells.

Insulation test time:

The analogue and digital signals from the isometer are evaluated

during this time.

Delay for insulation test following shutdown of K21 (earthing

of PV cells):

Once the earthing has been disconnected, this time must elapse

before insulation measurement can start.

Delay for shutdown of K21 in night operation:

Once sequence control has switched to the “Night” status, this time

must elapse before earthing is removed with contactor K21.

Minimum time in maintenance mode:

If maintenance mode has been activated, the earthing is disconnected and remains so for at least this time.

8000047961 BAL 35 of 72

Page 40

5.4 MPP Tracker

Protect PV.630 Operating Instructions

In the “Operation” status (see Chapter 5.1.3), the inverter detects

the maximum power point (MPP) of the PV cells.

The MPP tracker detects the point at which the solar cells give off

maximum power.

This enables the system to achieve optimum efficiency.

Figure 9 MPP performance curve

5.5 Partner Operation

In “partner operation”, the efficiency of a system with two inverters

can be increased by connecting the two PV cells at less than full

power.

If insolation levels fall, the PV cells are connected and only one inverter is in operation.

If insolation levels rise, the connection is terminated. Now both inverters are in operation. Each inverter is supplied with power by its

associated PV panel.

5.5.1 Linked Operation

One inverter is switched on and is feeding power into the mains.

The other inverter is logically switched off. The tie switch is closed.

The inverter which is active in linked operation changes daily.

This operating mode is active when insolation levels are low.

36 of 72 8000047961 BAL

Page 41

Protect PV.630 Operating Instructions

Figure 10 Linked operation in partner operating mode

Change of status to separate operation:

If capacity utilisation in the inverter which is switched on rises

above a certain value, once a delay has elapsed, the two inverters

are switched to separate operation.

First, the inverter which is switched on is switched off. Then, the tie

switch is opened. Once the tie switch is open, both inverters are

switched on.

Change of status to linked operation in the event of a fault:

In the event of a deactivating or self-acknowledging fault in the inverter which is switched on, the system switches to linked operation.

The inverter which is switched off is switched on. The faulty inverter is shut down due to the fault.

5.5.2 Single Operation

Both inverters are switched on and are feeding power into the

mains. The tie switch is open.

This operating mode is active when insolation levels are high.

Figure 11 Single operation in partner operating mode

Change of status to linked operation:

If the capacity utilisation of the two inverters falls below a certain

value, the system switches to linked operation once a set delay

has elapsed.

The MPP tracker is switched off in both inverters and an attempt is

made to regulate the two inverters to a uniform DC voltage. When

the DC voltages are approximately identical, the tie switch is

closed and one inverter is switched off. If the DC voltages cannot

be regulated to the same value in a certain time, the two MPP

trackers switch back on. Once a delay has elapsed, the MPP

trackers are switched back off again and the next attempt to match

the DC voltage is started.

Change of status to linked operation in the event of a fault:

In the event of a deactivating or self-acknowledging fault in one inverter, the two inverters are switched to linked operation. First, the

inverter which is not affected by the fault is also switched off.

8000047961 BAL 37 of 72

Page 42

Protect PV.630 Operating Instructions

If the faulty inverter has a self-acknowledging fault, the DC voltages of both inverters are compared. When the DC voltages are approximately identical, the tie switch is closed and the inverter which

is not affected by the fault is then switched back on. If the DC voltages are still not the same once a set time has elapsed, the inverter which is not affected by the fault is switched back on. After a delay, a new attempt is made to exit single operation and switch to

linked operation in the event of a fault.

If the faulty inverter has been permanently deactivated by a deactivating fault, the DC voltages cannot be compared because the

faulty inverter is disconnected from the DC voltage via switch Q4.

In such a case, there is no possibility of equalising currents being

generated when the tie switch is closed. The tie switch is therefore

closed and the inverter which does not have a fault is switched

back on again.

5.5.3 Linked Operation in the Event of a Fault

One inverter is switched on and is feeding power into the mains.

The other inverter has been shut down due to a fault. The tie

switch is closed.

This operating mode is active when one inverter is affected by a

fault.

Figure 12 Linked operation in the event of a fault in partner operating mode

Change of status to linked operation:

The system switches to linked operation when the fault message is

acknowledged in the inverter affected by the fault. The inverter affected by the fault is switched off logically once the fault has been

acknowledged.

5.5.4 Partner Operation During the Course of the Day

Early morning:

The tie switch is closed from the previous day. Overnight, a decision has been made as to which inverter will be switched on logically in linked operation on this day and which will be switched off

logically. If the sequence control (see Chapter 4.1) of both inverters now switches from the “Night” status to the “Waiting” status,

one inverter is switched off logically. The other inverter is switched

on logically and feeds power into the mains if the sun's rays are

strong enough.

“Linked operation” is active.

38 of 72 8000047961 BAL

Page 43

Protect PV.630 Operating Instructions

Later that morning:

Insolation increases. As a result, the inverter feeding power into

the mains works at increased capacity. If capacity utilisation rises

above a certain value, the system switches to single operation.

The tie switch opens and the inverter which is switched off logically

is switched on.

“Single operation” is active.

Evening:

Levels of insolation fall during the course of the day. The capacity

utilisation at which the two inverters are working drops as a result.

If the capacity utilisation of the two inverters falls below a certain

value, the system switches to linked operation. The tie switch is

closed and one inverter is switched off logically.

“Linked operation” is active.

Later in the evening:

Levels of insolation fall further. Capacity utilisation drops as a result. If capacity utilisation falls below a certain value, sequence

control on both inverters switches to the “Night” status. Power

stops being fed into the mains.

“Linked operation” is active.

Night:

Overnight, a decision is made as to which inverter is to be active in

linked operation the next day. So that both inverters are operated

for approximately the same amount of time, the inverters are operated alternately.

5.5.5 Partner Operation Parameters

Load threshold for terminating the INV connection:

If capacity utilisation in linked operation rises above the parameter

value, the system switches to single operation.

Load threshold for connecting the INV:

If capacity utilisation in single operation falls below the parameter

value, the system switches to linked operation.

Maximum DC voltage difference for connecting the INV:

When the system switches from single operation to linked operation, the MPP trackers in both inverters are switched off and an attempt is made to match the DC voltages. The system only switches to linked operation if the difference is less than the parameter

value.

5.6 “Extended” operating mode

The “Extended” operating mode is an optional operating mode. Its

parameters are set in the factory. The technical data sheet indicates whether the function is active or not. If the operating mode is

active, the inverter can feed a higher power under certain conditions. The transformer must be designed for this increased feed-in

capacity.

8000047961 BAL 39 of 72

Page 44

Protect PV.630 Operating Instructions

The inverter is designed for a rated output power (sustained power) of 630 kW, see the technical data sheet. However, at low supply air temperatures, the inverter is capable of feeding in a higher

power. When the function is activated, the maximum feed-in capacity at low supply air temperatures is increased according to a

characteristic curve. If the temperature rises, the maximum feed-in

capacity drops. If the temperature rises above a certain value, the

device can only continue outputting the rated output power. The

relationship between the possible feed-in capacity and the temperature is shown in Figure 13a.

Figure 13 a Extended operating mode

5.6.1 Parameters of the “Extended” operating mode

Temperature value at which the rated output power can be

fed:

If the supply air temperature rises above this value, it is only possible to continue feeding the rated output power.

Temperature value at which the maximum excess power can

be fed:

If the supply air temperature drops below this value, it is possible

to output the maximum excess power.

Power rating for normal feed-in capacity:

If the supply air temperature rises above the value, it is possible to

feed this power as the maximum. This value corresponds to the

rated output power.

Power rating for increased feed-in capacity:

If the supply air temperature drops below a value, it is possible to

feed this power as the maximum.

6 Monitoring Systems, Messages and Faults

6.1 General

All monitoring systems only generate fault messages when the inverter is switched on; when it is switched off, the inverter is always

reported as being free of faults.

40 of 72 8000047961 BAL

Page 45

Protect PV.630 Operating Instructions

A distinction is made between deactivating, self-acknowledging

and signalling faults.

Deactivating faults switch the equipment off permanently once

they have occurred a number of times. K7 and Q4 are opened.

When a fault first occurs, it is acknowledged after a certain time

has elapsed and the inverter makes a start-up attempt. This startup attempt is only made if the DC voltage did not drop too dramatically during the fault. If the cause of the fault is still present after

the start-up attempt, the inverter is switched off again.

A maximum of 3 start-up attempts are made.

Each time the inverter is switched off, K7 and Q4 are opened.

After a successful start-up attempt and once a certain operating

time has elapsed, the counter for start-up attempts is reset again.

If the third start-up attempt is also unsuccessful, the inverter is

switched off permanently. The fault is then no longer selfacknowledging. It can be acknowledged by switching the equipment off and on or by manually acknowledging the fault. However,

if the cause of the fault is still present following manual acknowledgement, another deactivating fault will be generated.

Self-acknowledging faults switch the equipment off. K7 is

opened, Q4 remains closed.

The equipment starts up again when the cause of the fault is no

longer present. The fault can also be acknowledged manually or

by switching the equipment off and on. However, if the cause of

the fault is still present following manual acknowledgement, another self-acknowledging fault will be generated.

Signalling faults do not have any effect on the equipment's sequence control. K7 and Q4 remain closed.

A signalling fault acknowledges itself automatically when the cause