Page 1

A-dec DV Dry Vacuum Service Guide

A-dec DV Dry Vacuum

Service Guide

Contents

Overview .......................................................... 2

Copyright and Regulatory Information ....................................... 2

Requirements ..................................................... 3

Description of Operation ......................................................3

Vacuum Models ..................................................................3

Site Specications and Sizing Information ..................................4

HVAC Requirements .............................................................5

Operate ............................................................ 6

Turn On/Turn Off Power ........................................................6

Master Power Switch ............................................................. 6

LED Push-Button Controls ....................................................... 6

Optional Smart Shield Touchscreen Controls ................................ 6

Vacuum Gauge and Operation................................................. 7

Vacuum Gauge .....................................................................7

Vacuum Startup and Normal Operation ........................................7

Separator Tank Drain and Washdown Cycles ..................................7

Smart Shield Touchscreen Controls ..........................................8

Vacuum Startup and Shutdown ................................................. 8

Vacuum System Status Icons .................................................... 9

Mechanical Room Controls....................................................11

Mechanical Room 24 V Competitive Cross Reference ........................ 13

Flow Diagram ..................................................... 14

Components ...................................................... 15

Wiring Diagram ................................................... 17

Fuse Identication ............................................................ 18

Maintain/Troubleshoot .......................................... 19

Regular Maintenance Tasks .................................................. 19

Annual Check Valve Change ..................................................21

Troubleshooting Tasks ........................................................ 22

Status Lights ................................................................... 23

Circuit Board Electrical Test Locations .................................... 24

Initial Startup Checklist ...................................................... 25

86.0897.00 Rev A

1

Page 2

A-dec DV Dry Vacuum Service Guide Overview

Overview

Copyright and Regulatory Information

Copyright

© 2021 A-dec Inc. All rights reserved.

A-dec, Inc. makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. A-dec, Inc. shall not be held liable for any

errors contained herein or any consequential or other damages concerning

the furnishing, performance or use of this material. The information in this

document is subject to change without notice. If you find any problems in

the documentation, please report them to us in writing. A-dec, Inc. does not

warrant that this document is error-free.

No part of this document may be copied, reproduced, altered, or transmitted

in any form or by any means, electronic or mechanical, including

photocopying, recording, or by any information storage and retrieval system,

without prior written permission from A-dec, Inc.

Trademarks and Additional Intellectual Property Rights

A-dec, the A-dec logo, A-dec Inspire, Cascade, Century Plus, Continental,

Decade, ICX, ICV, Performer, Preference, Preference Collection,

Preference ICC, Radius, and reliablecreativesolutions are trademarks

of A-dec, Inc. and are registered in the United States and other countries.

A-dec 500, A-dec 400, A-dec 300, A-dec 200, and EasyFlex are also trademarks

of A-dec, Inc. None of the trademarks or trade names in this document may

be reproduced, copied, or manipulated in any manner without the express,

written approval of the trademark owner.

Regulatory Information and Warranty

For required regulatory information and the A-dec warranty, see

the Regulatory Information, Specifications, and Warranty document

(p/n 86.0221.00) available in the Resource Center at www.a-dec.com.

Product Service

Product service is available through your local authorized A-dec dealer.

For service information, or to locate an authorized dealer, contact A-dec at

1.800.547.1883 in the USA or visit www.a-dec.com.

Product Models and Versions Covered in This Document

Models Versions

DV5/DV7

DV10/DV12

n/a Dry Vacuum

Description

Certain touchpad symbols and icons are proprietary to A-dec, Inc. Any use

of these symbols or icons, in whole or in part, without the express written

consent of A-dec, Inc., is strictly prohibited.

86.0897.00 Rev A

2

Page 3

A-dec DV Dry Vacuum Service Guide Requirements

Requirements

Description of Operation

• The dry vacuum system has a variable speed vacuum pump that reduces electrical consumption. The integrated separator tank and firmware allow for fully

automated operation.

• The vacuum creation and operation is free from water and oil.

• The vacuum motor is controlled by a vacuum sensor connected to the separator tank. The speed of the motor will increase or decrease to maintain the pre-set

vacuum level.

• The vacuum system has an automated tank washdown maintenance cycle that starts within 1 minute of the system being turned off. The washdown solenoid

opens to allow fresh water to spray into the tank, rinsing the tank free from debris. This cycle runs for approximately 1 minute.

• The integrated separation tank has been designed to collect the fluids evacuated during a normal operating day. If an excessive amount of fluids is collected,

the float switch in the separator will stop the vacuum in order for the tank to automatically drain. This process takes about 10 seconds. The vacuum will

automatically restart after the drain cycle.

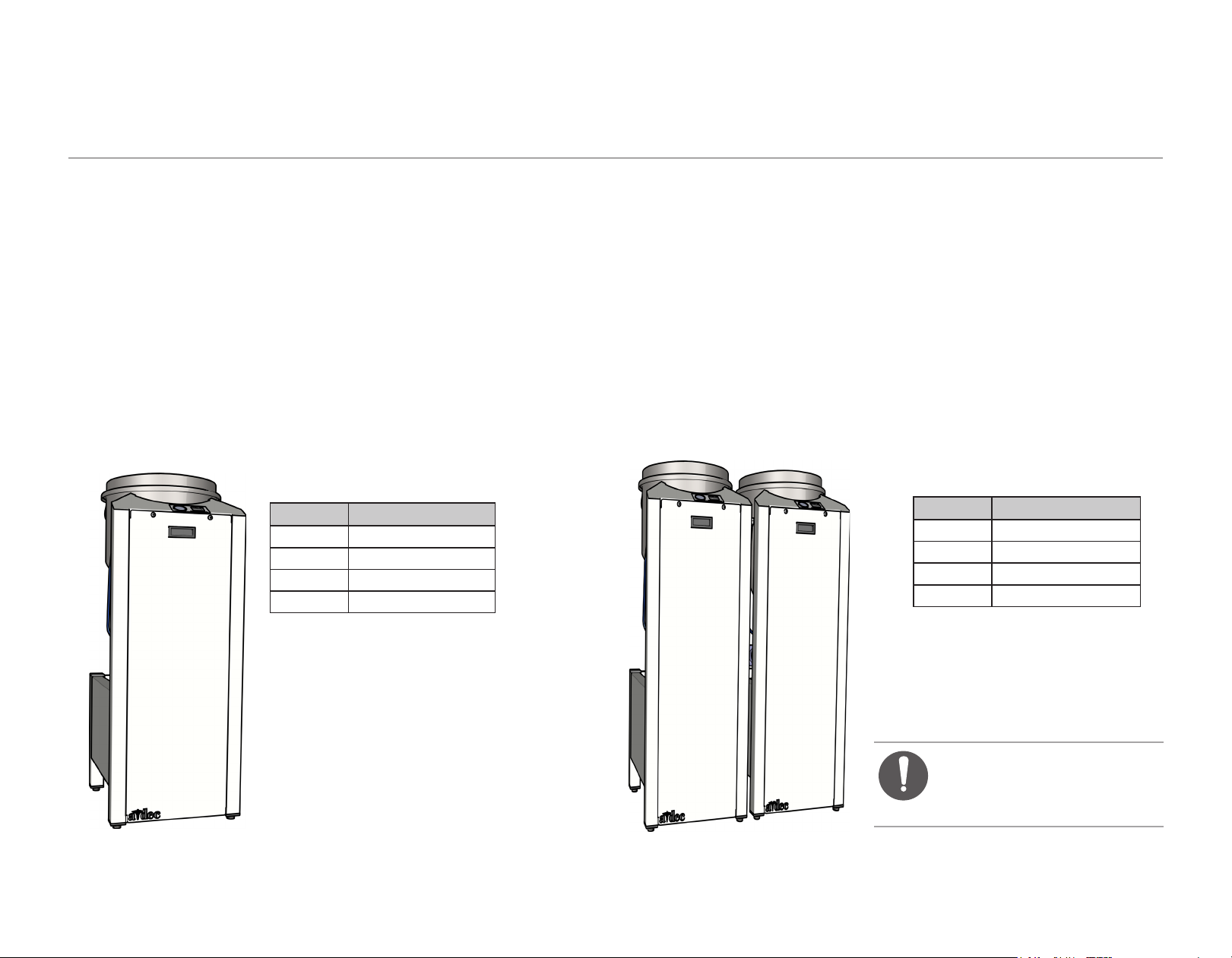

Vacuum Models

86.0897.00 Rev A

Single Vacuum Models

Model Number of Users

DV5 1 - 5

DV7 5 -7

DV10 7 - 10

DV12 10 - 12

Tandem Vacuum Models

Model Number of Users

DV5t 7 - 10

DV7t 10 - 14

DV10t 14 - 20

DV12t 20 - 24

NOTE Three or more vacuums

can be combined. Contact

A-dec Customer Service for

information.

3

Page 4

A-dec DV Dry Vacuum Service Guide Requirements

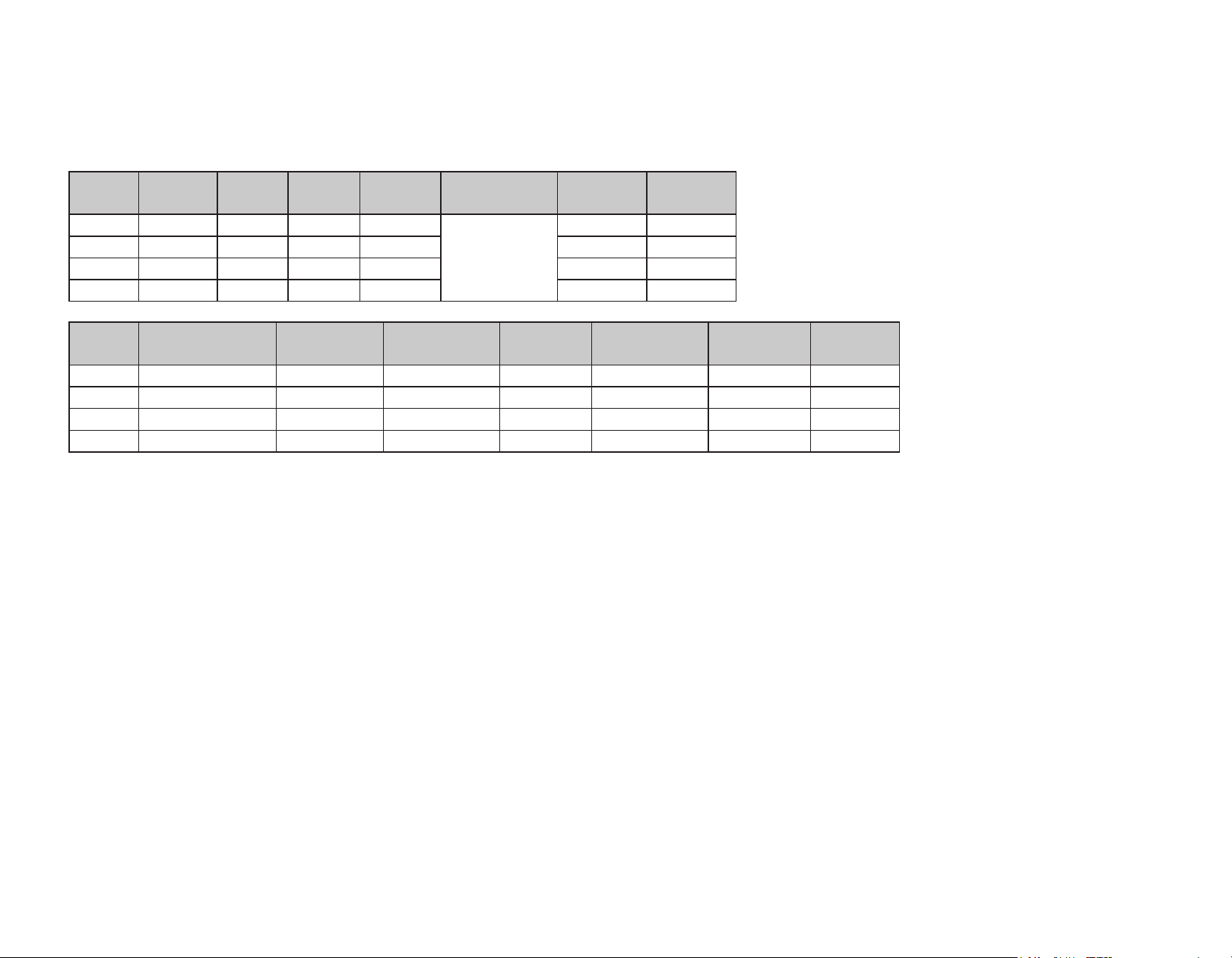

Site Specifications and Sizing Information

Model Max

Users

DV5 5 35 10 2.3

DV7 7 57 10 3.0 20.6 30

DV10 10 74 10 3.4 22.0 30

DV12 12 92 10 4.1 24.0 30

Model Dims - WxDxH

Installed

DV5 18 x 19.5 x 48.5" 152 lbs 24 x 31 x 55" 183 62.8 57. 4 5,700

DV7 18 x 19.5 x 48.5" 152 lbs 24 x 31 x 55" 183 70.0 57. 4 6,800

DV10 18 x 19.5 x 48.5" 191 lbs 24 x 31 x 55" 214 63.2 58.3 8,700

DV12 18 x 19.5 x 48.5" 191 lbs 24 x 31 x 55" 214 70.5 58.3 10,436

CFM

@8"Hg

Set

"Hg

Weight

Installed

Total HP Voltage

Range

200-240 VAC

Dims - WxDxH

Packaged

Weight

Packaged

Amps

Max

14.1 20

Breaker

Size

Sound db(A)

Max

Sound db(A)

Average

BTU/Hr

Max

86.0897.00 Rev A

4

Page 5

A-dec DV Dry Vacuum Service Guide Requirements

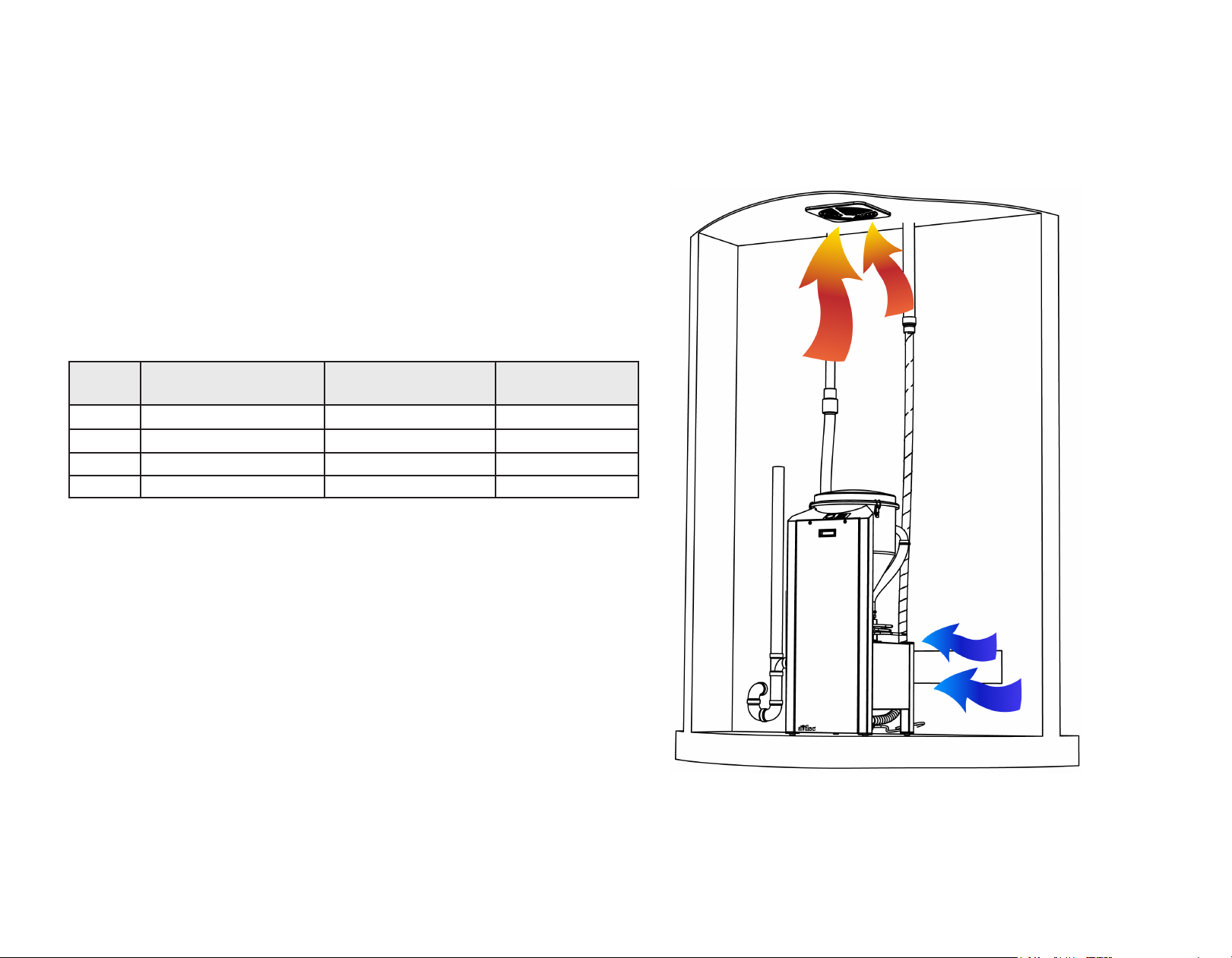

HVAC Requirements

Adequate cooling air is required. All vacuum models are installed and

operated in a thermostatically or otherwise stable ambient temperature

environment. Forced air and HVAC input are recommended for use in

addition to an exhaust fan if normal ambient temperatures vary from

specified operating temperature range.

The operating temperature range of the vacuum is 40º F to 104º F or 4.4 to

40º C.

Vacuum life is directly affected by the operating temperature.

Model

DV5 5,700 1,425 200

DV7 6,800 1,700 230

DV10 8,700 2,175 350

DV12 10,346 2,175 400

* Based on 80º F/27º C cooling air available and 100º F/38º C maximum mechanical room

temperature. This does not account for overall mechanical room size and additional heat

sources. Consult an HVAC specialist for proper temperature range.

Maximum Heat

Rejection (BTU/Hr)

Average Heat

Rejection (BTU/Hr)

CFM Cooling Fan *

86.0897.00 Rev A

5

Page 6

A-dec DV Dry Vacuum Service Guide Operate

Operate

Turn On/Turn Off Power

NOTE If you turn off the vacuum unit for long periods of non-use,

like an extended office shutdown, ensure that the power remains

connected. The vacuum will automatically turn on, momentarily,

every 12 hours to prevent components from seizing. This also helps

extend the life of the motor.

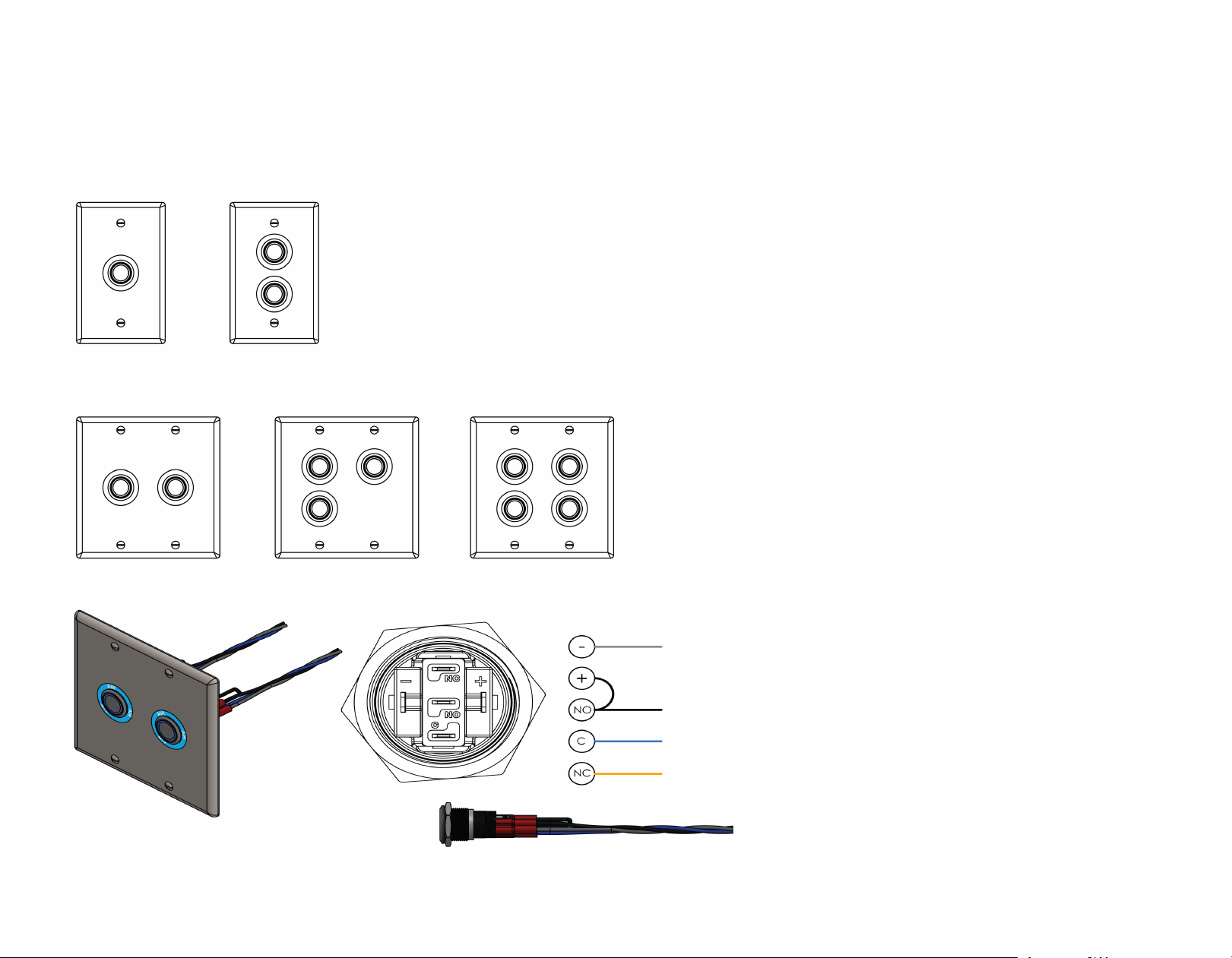

Master

Power

LED Push-Button Control

(single-button)

Switch

LED Push-Button Control

(four-button)

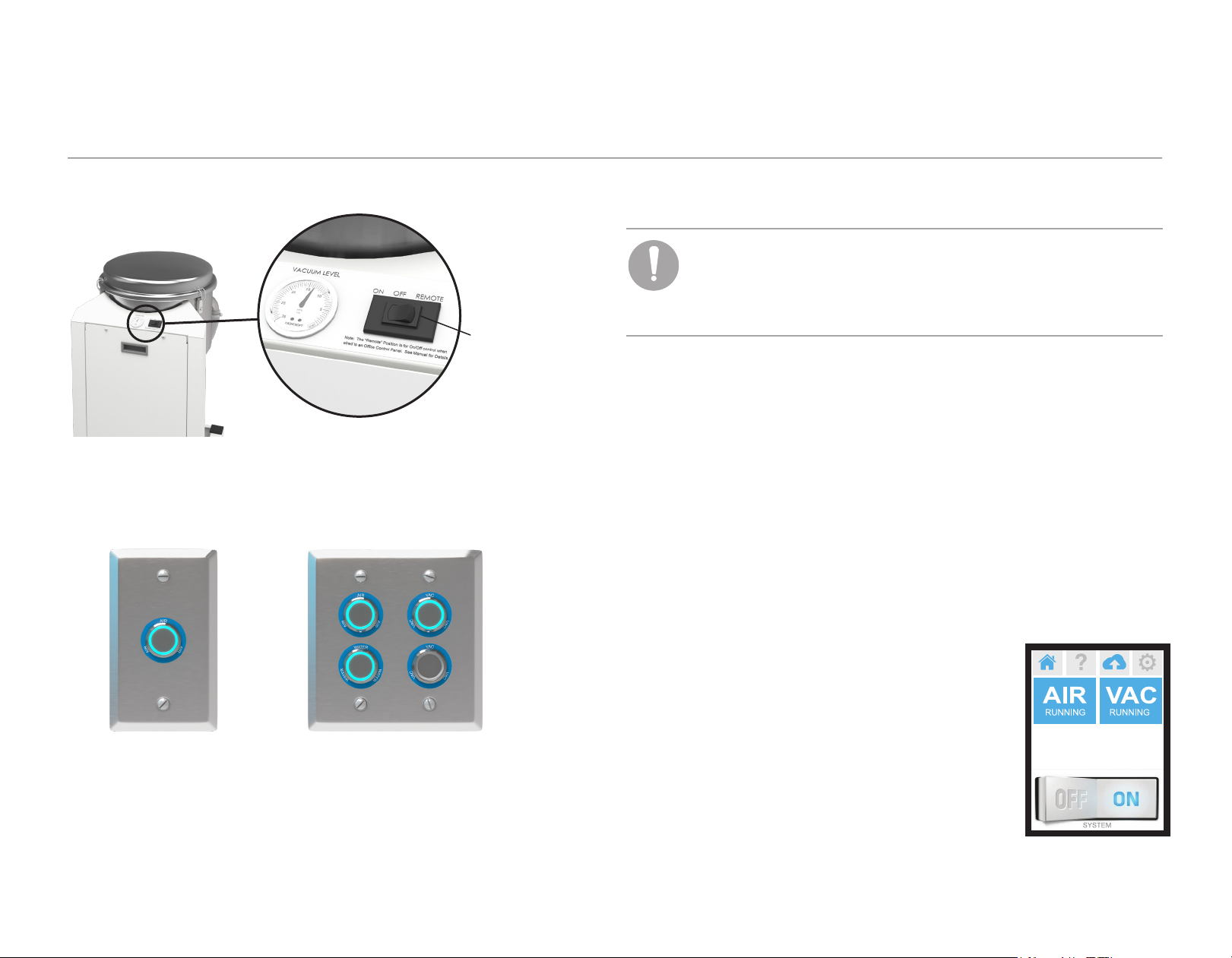

Master Power Switch

The master power switch turns the vacuum on or off. It also overrides the

other remote power functions. If your vacuum is connected to remote LED

push-button controls or a Smart Shield touchscreen, this switch should be in

the REMOTE position.

LED Push-Button Controls

If you have LED push-button controls, press the button once to turn the

vacuum unit on or off. Blue LED lighting indicates that the vacuum is on. If

the LED does not illuminate, check and verify that the master power switch on

the vacuum is in the REMOTE position.

86.0897.00 Rev A

Optional Smart Shield Touchscreen Controls

For congurations with the Smart Shield

touchscreen, use the power switch icon at the

bottom of the screen or tap the VAC icon to turn

the vacuum unit on or off. If the Smart Shield does

not operate, check and verify that the master power

switch on the vacuum is in the REMOTE position.

For more information on the touchscreen, see

“Smart Shield Touchscreen Controls” on page 8.

4

6

Page 7

A-dec DV Dry Vacuum Service Guide Operate

Vacuum Gauge and Operation

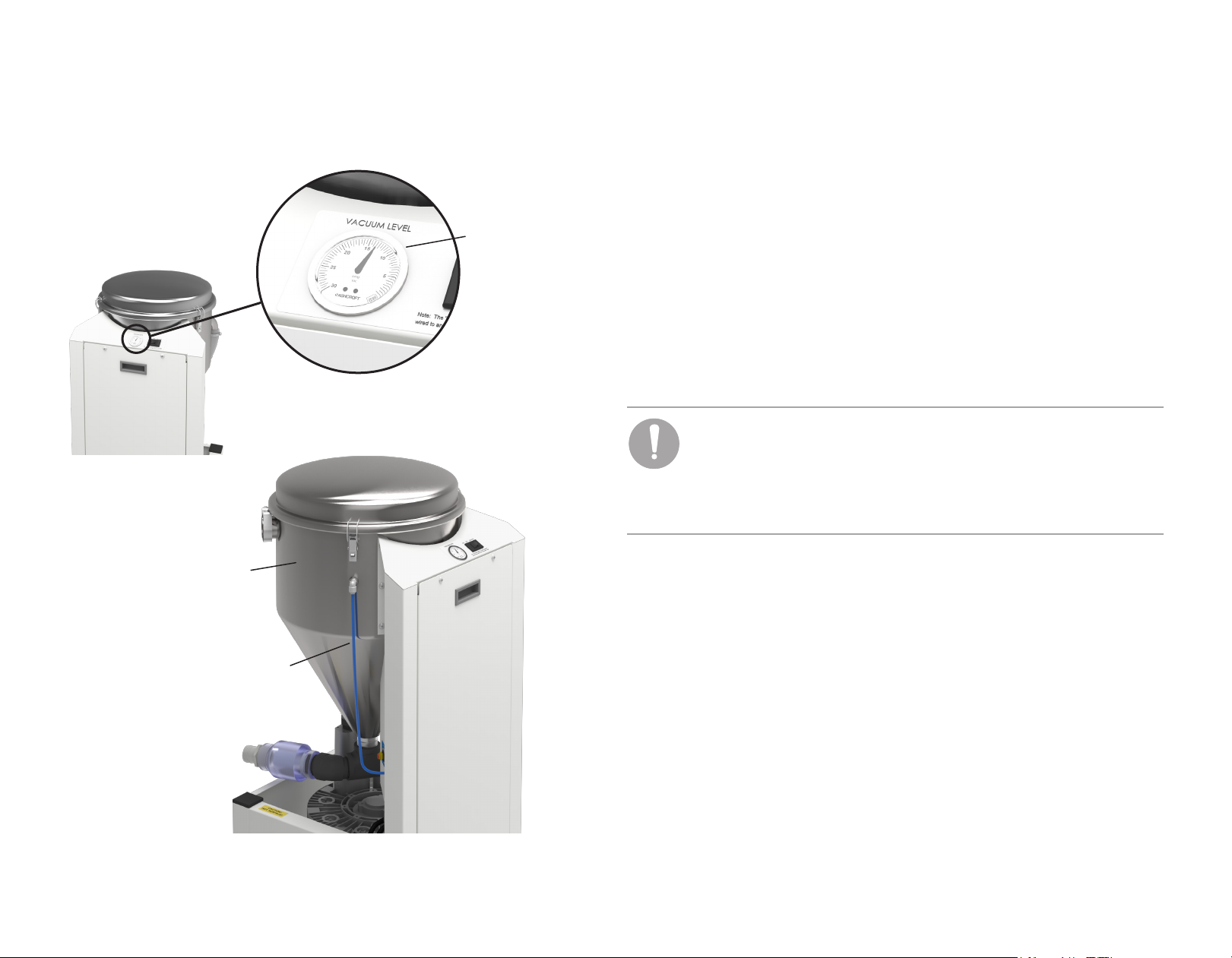

Vacuum Gauge

The vacuum gauge is located next to the master power switch on the top panel

Vacuum

Gauge

of the vacuum. This gauge provides a real-time level of the negative pressure

inside the separator tank. The DV dry vacuum is factory preset to maintain

10 inHg (34 kPa) during normal operation.

Vacuum Startup and Normal Operation

At initial startup, the vacuum motor runs until the system reaches the factory

preset of 10 inHg (34 kPa). As vacuum instruments are opened and closed, the

motor rpm will increase or decrease (depending on demand) to maintain that

level.

NOTE You may hear the vacuum motor frequently speeding up

or slowing down as it compensates for various levels of demand.

This is normal. However, if the motor does not slow down after

all vacuum instruments are closed, or if your system is unable to

consistently maintain 10 inHg (34 kPa), see “Troubleshooting Tasks”

on page 22 or contact A-dec Customer Service.

86.0897.00 Rev A

Separator

Tank

Washdown

Waterline

Separator Tank Drain and Washdown Cycles

The vacuum removes liquid from the air and collects it in the separator tank.

When more than 10 gallons (38 L) are collected, a float switch in the tank stops

the vacuum and drains the tank. Once the water level drops and the float

switch turns off, the vacuum will turn back on in about 10 seconds.

To manually initiate the drain and washdown cycles, you must turn off the

vacuum. Combined, both cycles take less than 2 minutes. A-dec recommends

that you turn off the vacuum to activate this process at least once a day. For

more information, see “Regular Maintenance Tasks” on page 19.

7

Page 8

A-dec DV Dry Vacuum Service Guide Operate

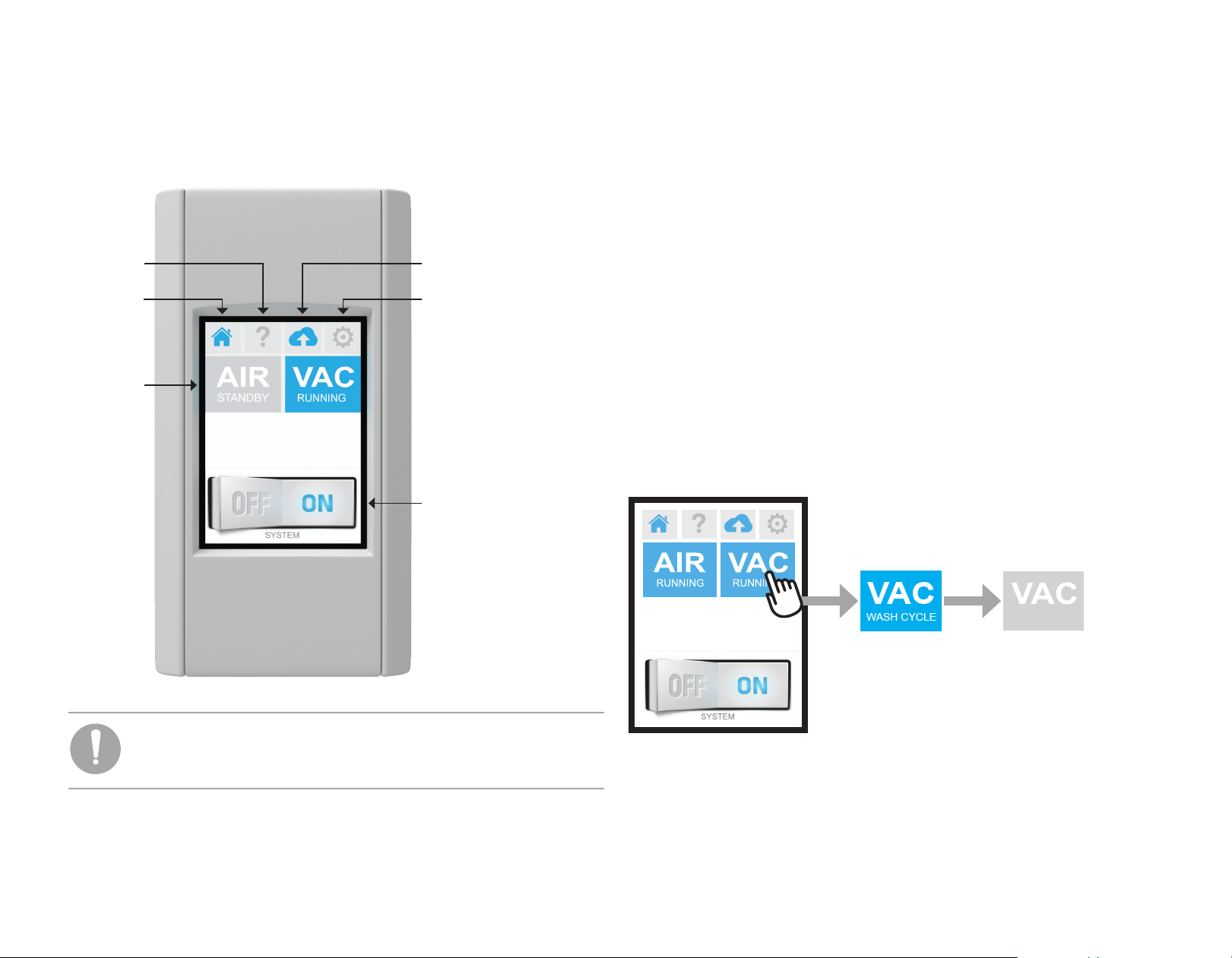

Smart Shield Touchscreen Controls

The optional Smart Shield touchscreen provides power control and system

status of your mechanical room equipment.

Service

Contact

Information

Home

System

Status

Icons

Remote Monitoring

Status

Software Version

and Reset

Power Switch

Tap the on/off switch icon at the bottom of the screen to turn on or turn off

all connected equipment at the same time. Tap the blue system status icons to

turn on or turn off individual equipment. These status icons also dynamically

change according to the operational state of the equipment.

Vacuum Startup and Shutdown

When you turn on the vacuum system, Smart Shield displays the

VAC RUNNING icon. When you tap the VAC RUNNING icon, the VAC OFF

icon appears, indicating the start of the separator tank drain cycle. Once the

drain cycle is complete, the VAC WASH CYCLE icon appears, indicating the

start of the washdown cycle. After that cycle is complete, the VAC OFF icon

reappears.

Vacuum Shutdown

(Tap to Initiate)

4

OFF

NOTE If the Smart Shield does not operate, check and verify that

the master power switch on the vacuum is in the REMOTE position.

For more information, see “Troubleshooting Tasks” on page 22.

86.0897.00 Rev A

8

Page 9

A-dec DV Dry Vacuum Service Guide Operate

MANUAL

MANUAL

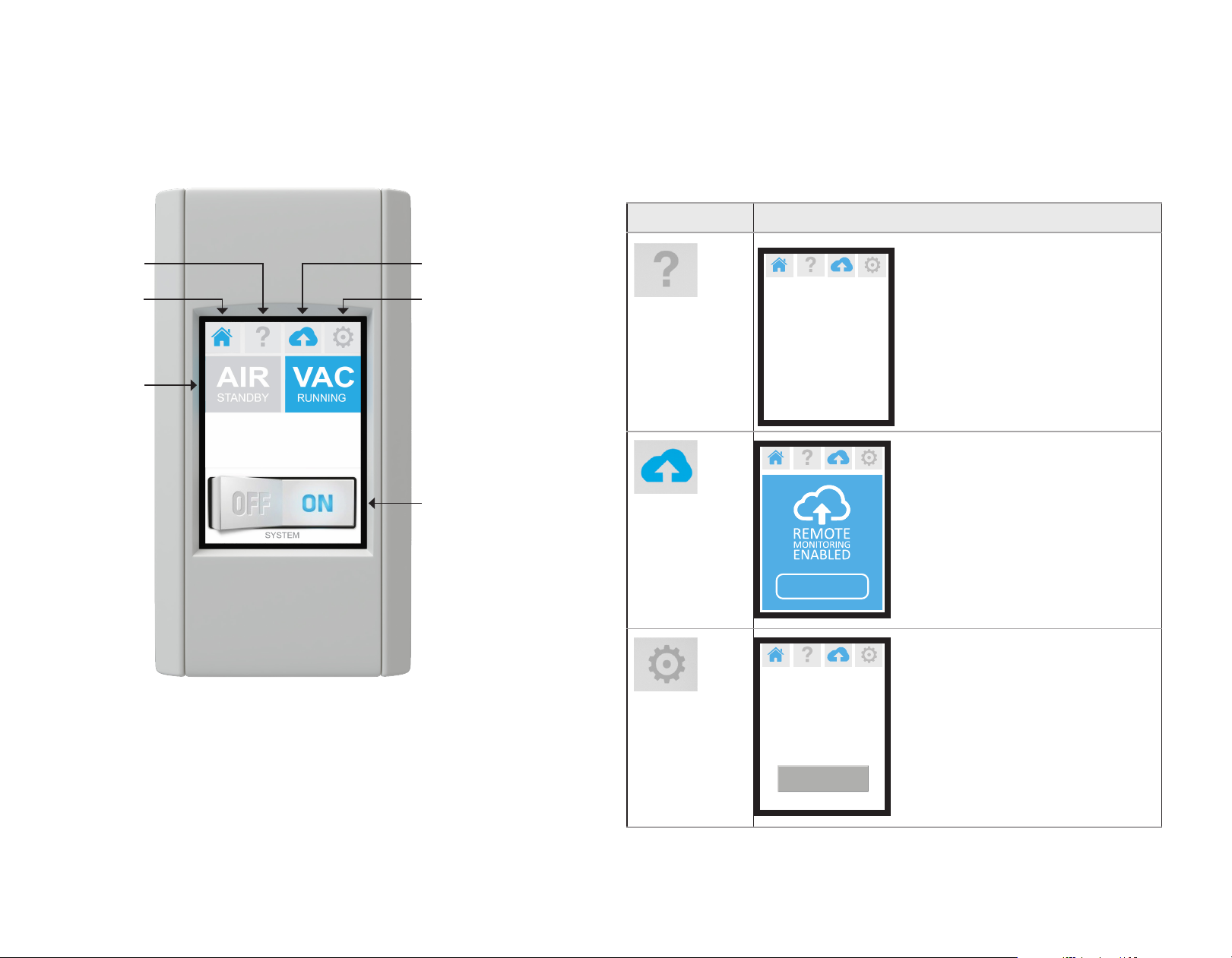

Smart Shield Touchscreen Controls (continued)

Vacuum System Status Icons

Service

Contact

Information

Home

System

Status Icons

(Tap to turn

equipment

on or off

individually.)

Remote Monitoring

Status

Software Version

and Reset

Power Switch

(Tap to turn all

attached equipment

on or off at the

same time.)

Icon State/Status

Displays during initial system startup and normal

operation mode.

“Manual” appears on status icons when the master

power switch on the vacuum is in the ON or OFF

position. To control power through the Smart Shield

touchscreen, ensure that the master power switch on

the vacuum is in the REMOTE position.

Displays when the vacuum is turned off from the Smart

Shield touchscreen controls.

OFF

Displays after the vacuum is turned off and the drain

cycle is complete.

Displays when the annual maintenance interval is

reached. This caution/reminder is reset whenever

power to the system is disconnected.

Displays when there is a fault in the system. Contact

A-dec Customer Service.

NOTE If additional warning icons appear on your screen and are

not shown here, contact customer service for more information.

86.0897.00 Rev A

9

Page 10

A-dec DV Dry Vacuum Service Guide Operate

Smart Shield Touchscreen Controls (continued)

Additional Smart Shield Functions

Service

Contact

Information

Home

System

Status

Icons

Remote Monitoring

Status

Software Version

and Reset

Power Switch

Icon State/Status

Q uestions?

1-800-547-1883

PRESS HERE TO

REQUEST SERVICE

Software V ersion

20180309

Displays contact information that will

route you to A-dec, Inc.

Displays your status as enabled if you

are registered with the remote

monitoring service. For questions,

contact A-dec Customer Service.

Displays software version. The reset

button turns off the screen, reboots the

software, and reloads the equipment

status. You can use RESET during

specic faults with the equipment. For

more information, see “Troubleshooting

Tasks” on page 22 .

86.0897.00 Rev A

RESET

10

Page 11

A-dec DV Dry Vacuum Service Guide Operate

Mechanical Room Controls

48 V Power Supply

with 8' Cord

86.0897.00 Rev A

Internet/LAN

Compressor,

Vacuum,

Smart Shield Touchscreen

Water Valve, or

NOTE The firmware in the smart hub was updated in March 2020

to include a dedicated port for the touchscreen.

Smart Hub Extender

11

Page 12

A-dec DV Dry Vacuum Service Guide Operate

Mechanical Room Controls (continued)

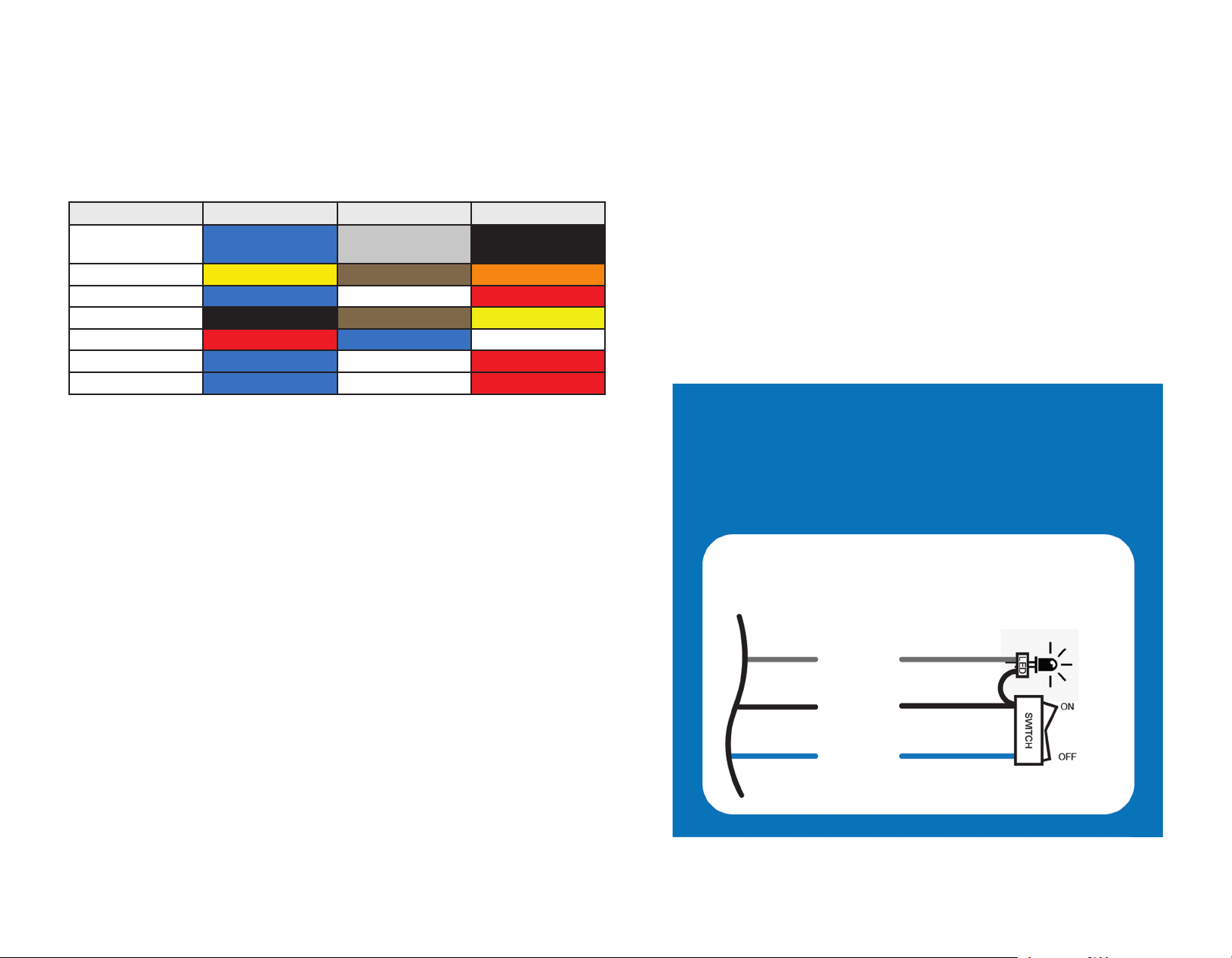

LED Push-Button Controls

86.0897.00 Rev A

Gray

Black - Run Signal

Blue - 24 V Power

Orange - Stop/Close (optional)

12

Page 13

A-dec DV Dry Vacuum Service Guide Operate

Mechanical Room Controls (continued)

Mechanical Room 24 V Competitive Cross Reference

Mtg/Wire A B (Light) C

A-dec Blue

+ 24 VDC

AirTechniques Yellow Brown Orange

Midmark Blue White Red

Dental EZ Black Brown Yellow

Matrix Red Blue White

Apollo Blue White Red

Tech West Blue White Red

Gray

-Lamp

Black

Run Signal

Remote Panel 24 VAC Wiring

Do Not Tie Together

86.0897.00 Rev A

Remote Panel 24 VAC Wiring

-Light

Run

+24 ~

80 mA

Max

13

Page 14

A-dec DV Dry Vacuum Service Guide Flow Diagram

Flow Diagram

Roof Exhaust

Vent

Exhaust Hose

Separator Tank Filter

Airflow Coming from Operatories

PVC

86.0897.00 Rev A

Clear Inspection

Hose

Intake Hose

Washdown Water Line Inlet

Check Valve

Drain Hose

Drain

Flow Arrow Color Indicator

Moisture

Cool Air

Warm Air

Hot Air

14

Page 15

A-dec DV Dry Vacuum Service Guide Components

Components

Vacuum Gauge

Separator Access

Latch

Separator

Tank

Drain Check Valve

(Clear for Inspection)

On/Off/Remote

Switch

Access Door

(Service Personnel)

Separator Tank

Clear Inspection

Hose

Suction Inlet

Drain

Washdown

Waterline Inlet

86.0897.00 Rev A

Adjustable Feet

(4)

Exhaust Air

Connection

Drip Leg Hose

Connection

15

Page 16

A-dec DV Dry Vacuum Service Guide Components

Components (continued)

Front Components

Float

Switch

Circuit

VFD

Water

Washdown

Solenoid

Board

86.0897.00 Rev A

Voltage

Line Filter

Impeller

Housing

Exhaust

Elbow

Vacuum

Motor

16

Page 17

A-dec DV Dry Vacuum Service Guide Wiring Diagram

Wiring Diagram

VFD

Display

Comm

Wire

19" Gray

18GA

21" Black

18GA

COMM/Control Board

19" Brown 16GA

ON 19" Blue 18GA

19" Gray 18GA

Remote 19" Black 18GA

Float Switch

(normally open)

Rocker

Switch

24VDC

Solenoid

Valve

Remote Panel

24 VDC Wiring by Others

Light

Run

+24~

LED

Remote

Off

On

80A

MAX

On

Off

Motor

86.0897.00 Rev A

To VFD

14" Red 12GA

14" White 12GA

36"L

Incoming Power

EMC

Filter

78"L

ATTENTION Circuit boards are sensitive to

static electricity. Electrostatic Discharge (ESD)

precautions are required when touching a circuit

board or making connections to or from the circuit

board. Circuit boards should be installed only by

an electrician or qualified service person.

17

Page 18

A-dec DV Dry Vacuum Service Guide Wiring Diagram

Fuse Identification

Fuse IDPurpose Part

Description Fuse ID

Number

F1 Low volt switch

F2

F3 VFD (Variable Frequency

F4

F5 Washdown solenoid and

F6 Low volt switch E0141 FUSE GLASS

F7 CPU board (5V)

transformer (24 Vac) and

CPU board

Drive)

CPU board power feed

(2V)

E0140 FUSE GLASS 2A

250 VAC 5 x 20 mm

E0139 FUSE CERAMIC

20A 250 VAC 5 x

20 mm

E0140 FUSE GLASS 2A

250 VAC 5 x 20 mm

500mA 250VAC

5X20 mm

NOTE To verify the fuse is good, the fuse must be removed from

the board to test for continuity.

COMM/Control Board

F2AL250V

T20AH250V

F7

F2AL250V

F500mAL250V

F5

F6

86.0897.00 Rev A

F1

F2

F3

F4

18

Page 19

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Maintain/Troubleshoot

Regular Maintenance Tasks

WARNING Before performing any maintenance function, turn

off the vacuum unit and disconnect main power to the vacuum.

Failure to do so may result in injury or equipment damage.

Do not open the service panel or service the vacuum for issues

other than those described in this section, or you may risk injury or

equipment damage. All other service requires a qualified service

technician from your authorized A-dec dealer.

Separator

Tank

Washdown

Waterline

CAUTION Do not clean the vacuum lines with oxidizing or acidic

cleaners with a pH less than 6 or greater than 8 (including bleach,

chlorine, iodine and peroxide). These may lead to the dissolution

of solid mercury which can corrode and damage components in

your system. Use a non‑foaming vacuum‑line cleaner and always

follow the manufacturer’s instructions. For recommendations on

vacuum-line cleaners, contact your authorized A-dec dealer.

To keep your vacuum system running smoothly, be sure to schedule a service

checkup with your authorized A-dec dealer every year. And although the DV

dry vacuum requires very little maintenance, see the table below for important

recommended maintenance tasks.

Frequency Item Task/Procedure

Once or

Twice Daily

Vacuum-line

cleaning.

Separator tank

drain and rinse.

Follow your normal vacuum-line cleaning

protocols to help prevent debris from settling in

the vacuum plumbing.

Turn off the vacuum at the end of the day (from

the master power switch or remote on/off

controls) to initiate the separator tank drain and

rinse cycles. For busier days and larger clinics,

turn off the vacuum once at lunchtime and once

at the end of the day. This will also help you

avoid an unplanned shutoff/drain cycle during a

procedure.

86.0897.00 Rev A

19

Page 20

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Regular Maintenance Tasks (continued)

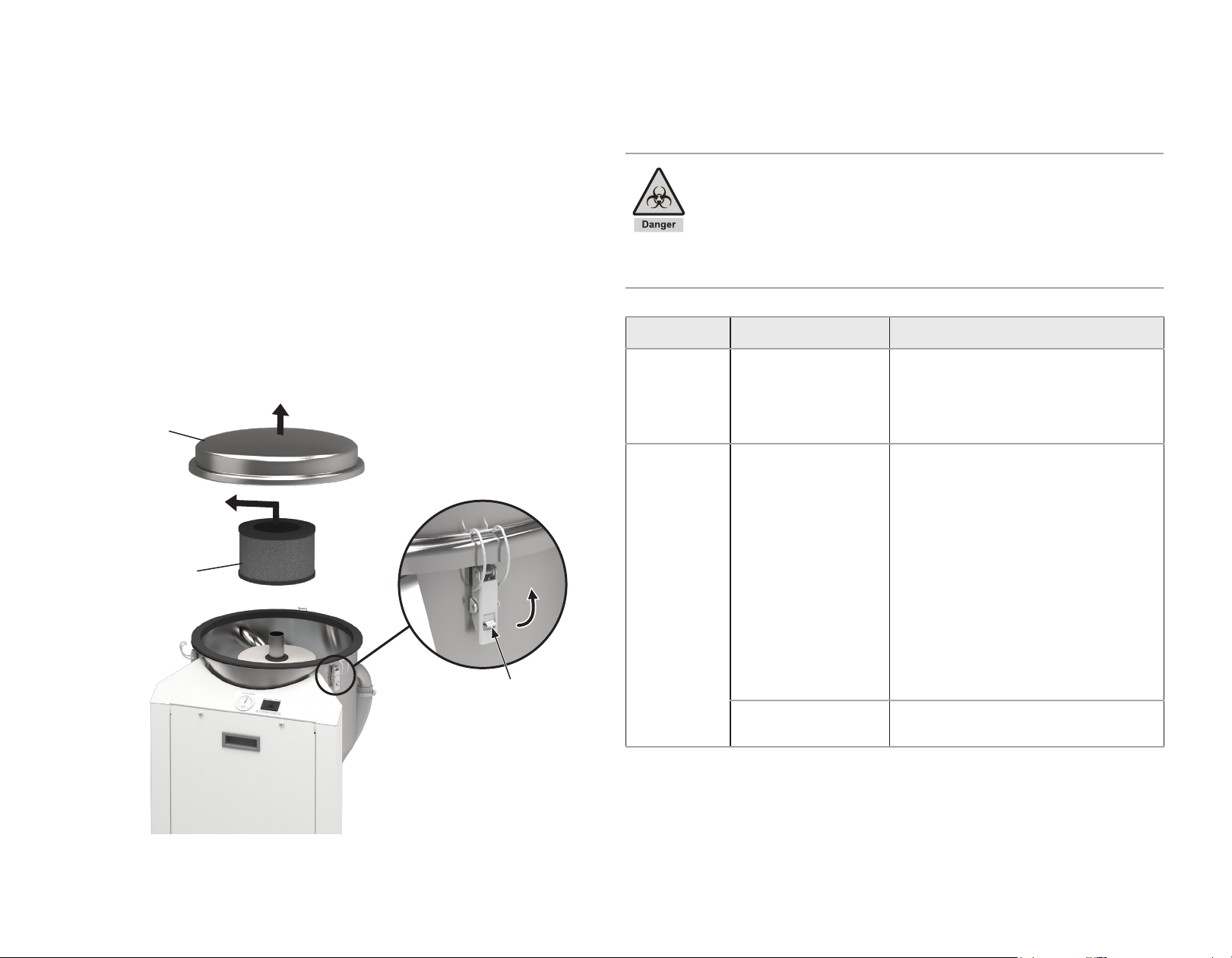

WARNING Infectious biohazardous waste may be present. To

prevent cross contamination, follow all infection control and

personal protective equipment (PPE) protocols.

In addition to biohazardous waste, the separator tank filter may

contain amalgam particles. Follow your local regulations when you

dispose of the old filter.

Frequency Maintenance Items Task/Procedure

Tank Lid

Tank Filter

3

2

Safety Clamp

Latch

1111

Press here

and lift.

Weekly/

Monthly

Yearly Tank lter Replace the separator tank lter* once a year.

Exterior case and

tubing connections.

Vacuum Drain Check

Valve.

Use a dry, lint-free cloth to dust off and

clean the exterior. Turn on the system,

listen, and inspect the tubing. If you

discover any leaks or debris, contact your

authorized A-dec dealer for assistance.

Turn off power to the vacuum and wait a few

minutes before following these steps (to

ensure the drain and rinse cycle have

nished):

1. Release the three clamps securing the

separator tank lid to the tank.

2. Remove the lid and ensure that the

tank is empty.

3. Remove the tank filter and replace with

a new one.

*For the separator tank lter replacement kit,

order p/n A0049.

Change the drain check valve.

See page 21

86.0897.00 Rev A

20

Page 21

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Annual Check Valve Change

CAUTION Never remove the check valve without first inspecting

the inside of the tank to ensure that there are no residual liquids

still trapped inside of the tank.

1. Turn off the vacuum and make sure power has been disconnected.

2. Ensure the tank has been drained of uids.

3. Remove the check valve.

4. Install the new check valve and ensure that the valve ow direction and

mounted positions are correct.

NOTE Ensure the check valves are installed correctly according to

the markings on the manifold that indicate which side should be up,

and an arrow indicating the airflow goes from the manifold to the

vacuum

Flow Points

Towards Drain

86.0897.00 Rev A

21

Page 22

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Troubleshooting Tasks

The following table is intended to help you identify common issues with your vacuum that may or may not require attention.

Condition Potential Cause Procedure/Remedy

Vacuum motor runs

continuously with little

to no suction.

Vacuum motor won’t run

while the master power

switch is on.

LED push-button or

Smart Shield controls

do not function.

Leak in the vacuum system.

Pinched or kinked vacuum tubing. Check to see if the dental equipment tubing is pinched or kinked. If the tubing is damaged, contact

Stuck separator tank drain check valve (open). Turn off the vacuum to initiate a drain and rinse cycle. If this does not remedy the condition, contact

Stuck separator tank oat switch. Turn off the vacuum to initiate a drain and rinse cycle. If this does not remedy the condition, contact

Vacuum is in power safe mode.

(Note: power safe mode occurs when the vacuum

loses power and cannot restart within 15 seconds.)

Master power switch on the vacuum is not in

the REMOTE position.

Close all vacuum instruments and listen for leaks throughout the system. Check

the vacuum runs continuously and cannot reach or consistently maintain 10 inHg (34 kPa) (or your

adjusted preset level), contact A-dec Customer Service.

Note: Check this when all instruments are closed and the system is at a rest.

A-dec Customer Service.

A-dec Customer Service.

A-dec Customer Service.

To resume normal operation:

1. Turn off the vacuum master power switch.

2. Disconnect the power to the vacuum for 3 minutes.

3. Reconnect the power.

4. Turn on the vacuum master power switch or put it in the REMOTE position. Resume

normal use.

If this does not remedy the condition, contact A-dec Customer Service.

Ensure that the master power switch on the vacuum is in the REMOTE position. If it is, and you have

push-button controls, contact A-dec Customer Service. If the master power switch is in the REMOTE

position and you have the Smart Shield touchscreen, see the remedy below.

the vacuum gauge. If

86.0897.00 Rev A

Communication disruption/fault between system and

Smart Shield touchscreen.

Tap on at the top of the touchscreen, then tap RESET. If this does not resolve the condition,

unplug the Smart Hub router power cord, wait 10 seconds, then plug it back in (note: this will reset

the annual maintenance reminder to 12 months). If this does not resolve the condition, contact

A-dec Customer Service.

22

Page 23

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Status Lights

Status Lights on the

Internal Circuit Board

Mean This...

The vacuum has been turned on at the local switch, and is running.

The Remote switch to the vacuum, either the Smart Shield touchscreen or the LED Push-Buttons, has been enabled

from the local switch.

The On signal is not detected from the Remote switch, so the vacuum is not running.

The Remote switch to the vacuum, either the Smart Shield touchscreen or the LED Push-Buttons, has been enabled

from the local switch.

The On signal is detected from the Remote switch, so the vacuum is running.

86.0897.00 Rev A

The Float switch is on, which stops the vacuum because water has lled up the vacuum’s tank.

The vacuum starts 10 seconds after the water level has dropped enough to turn the Float switch off, then this light

turns off.

23

Page 24

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Circuit Board Electrical Test Locations

86.0897.00 Rev A

ATTENTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from the

circuit board. Circuit boards should be installed only by an

electrician or qualified service person.

24

Page 25

A-dec DV Dry Vacuum Service Guide Maintain/Troubleshoot

Initial Startup Checklist

WARNING This system can start automatically without warning.

• Inspect unit for any visible signs of damage that may have occurred in shipment or during installation.

• Verify the electrical connection attachments, and that incoming line voltage is between 200 and 240 VAC.

• Activate main disconnect switch or circuit breaker.

• Turn on the vacuum, and ensure unit starts. If it does not start, refer to “Status Lights” on page 23.

• Check the gauge on the front of the vacuum for proper vacuum level. See the Set "HG column in the table “Site Specifications and Sizing Information” on

page 4.

• Check that all of the HVEs and SEs have proper suction.

• Check for leaks in all connections and the piping system.

Turn off the vacuum.

• Optional - Verify washdown operation begins 45-60 seconds after turning off the vacuum. Listen for the solenoid to open the water line and look at the drain

check valve to confirm that the water is draining.

• Verify the Drain hose flows cleanly and has no low spots to trap debris.

• If remote buttons or a touchscreen are in use:

• Switch the rocker to the remote position.

• Verify the system turns on /off with remote switches or trouchscreen.

• If the system uses remote monitoring, call A-dec Customer Service to confirm it is reporting.

86.0897.00 Rev A

25

Page 26

A-dec Headquarters

2601 Crestview Drive

Newberg, Oregon 97132

United States

Tel: 1.800.547.1883 within USA/CAN

Tel: +1.503.538.7478 outside USA/CAN

Fax: 1.503.538.0276

www.a-dec.com

A-dec St. Louis

1601 Manufacturers Drive

Fenton, MO 63026 USA

86.0897.00 Rev A

Date of Issue 2021-02-02

Copyright 2021 A-dec, Inc.

All rights reserved.

Loading...

Loading...