A-dec Dental Chair Service manual

85.0812.00, 2003 CH-1

Chairs Overview

A-dec model 1040, 1021 and 8000 chairs are electronically controlled, hydraulically powered

dental chairs. Buttons on both the touchpad and 8-button footswitch and actuators on the

8-function footswitch are used to position and program auto-positioning functions into the chair.

The hydraulic system is controlled by the electronic control module using relays and solenoidactuated valves.

This section provides information related to locating serial/model numbers, servicing,

maintenance, and adjustment of chairs. Detail on how to service chairs and troubleshoot specific

problems related to them is presented.

Locating

Serial/Model

Number

85.0812.00, 2003 CH-2

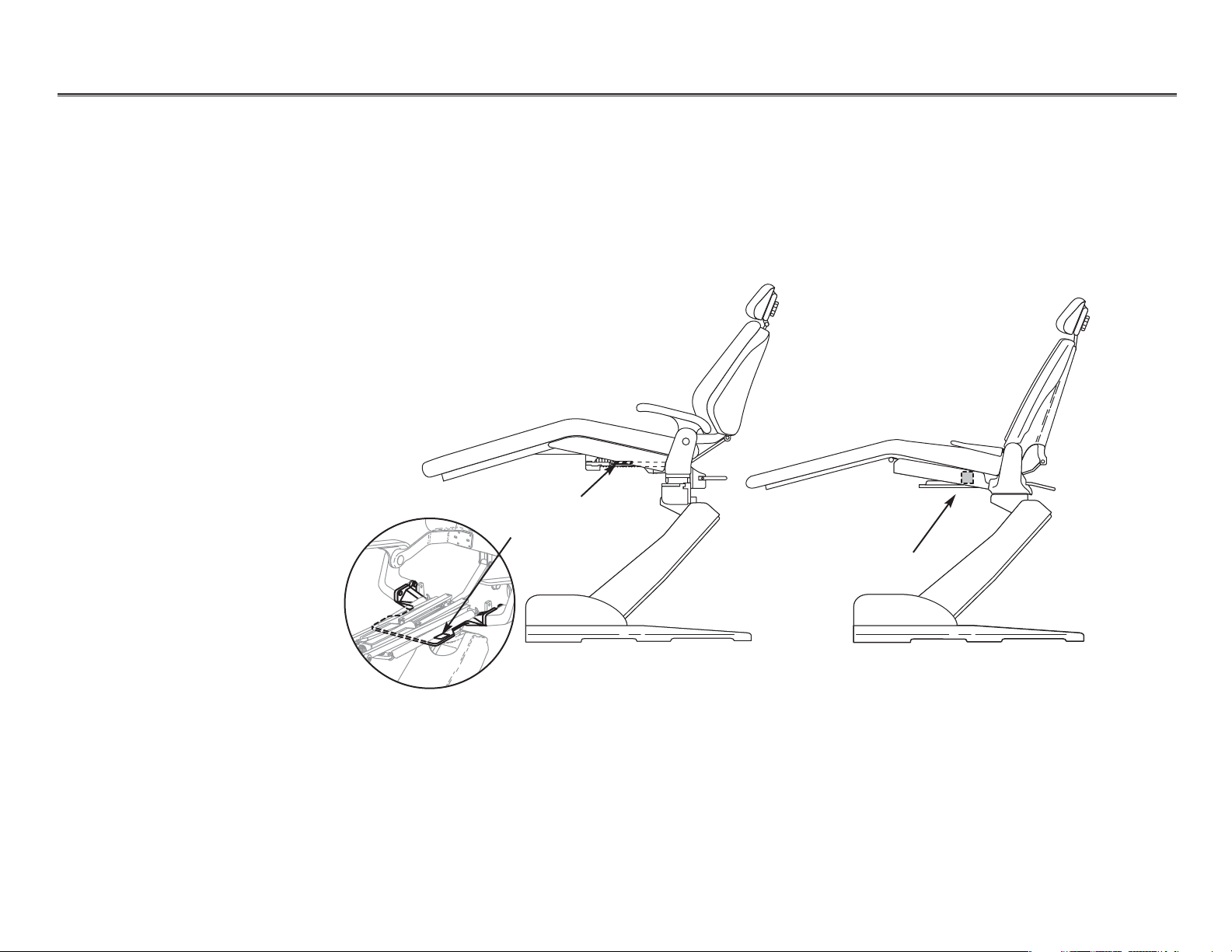

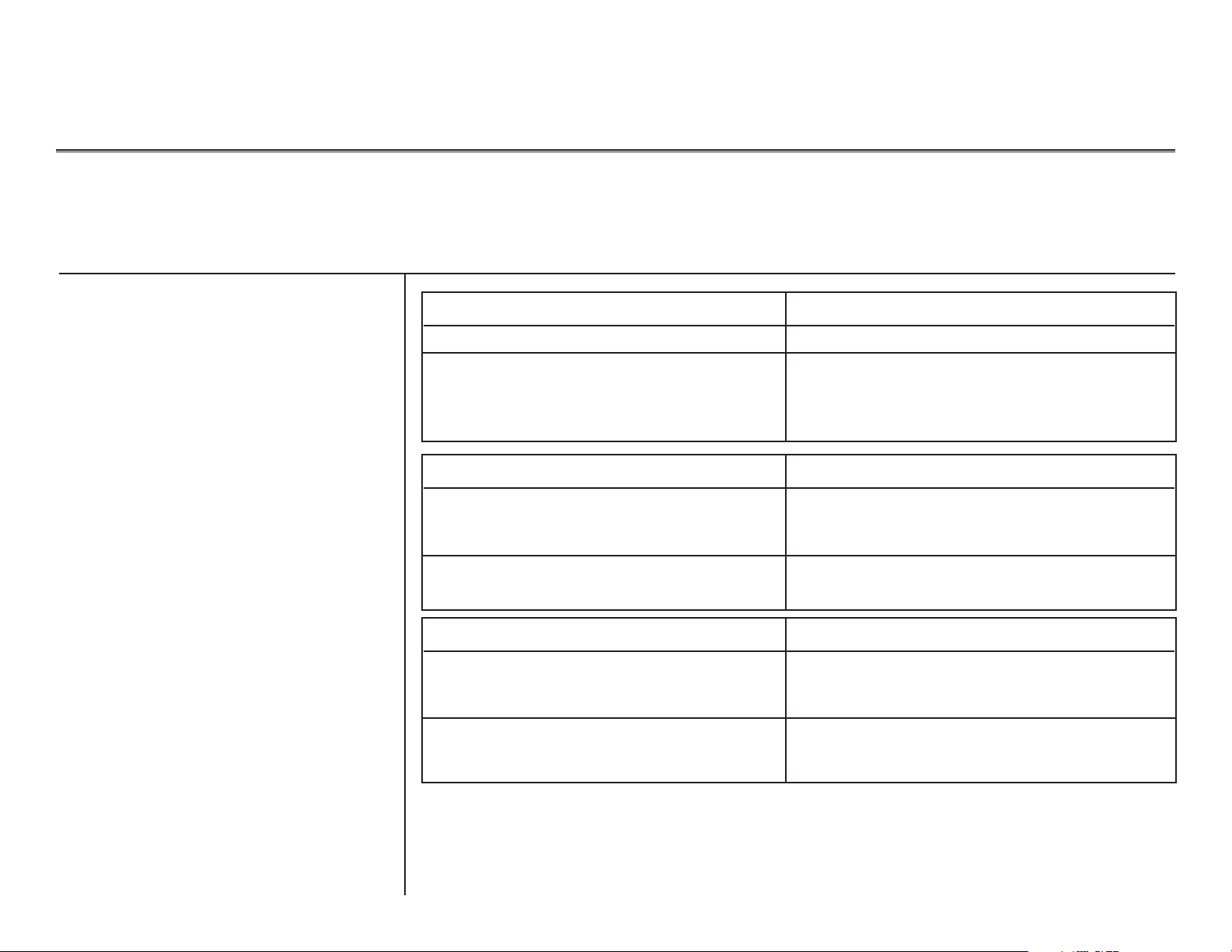

Chairs Serial/Model Number Locations

Cascade 1040 ChairDecade 1021/1011 Chair

Serial number

label location

Serial number

label location

The serial/model number tags identify the chair model and manufacture date. The label can be

found either on the top surface of a chair’s upper structure (raise the toeboard) or on the righthand side of the upper structure. If you have difficulty locating the serial/model number label,

the following example may be helpful.

85.0812.00, 2003 CH-3

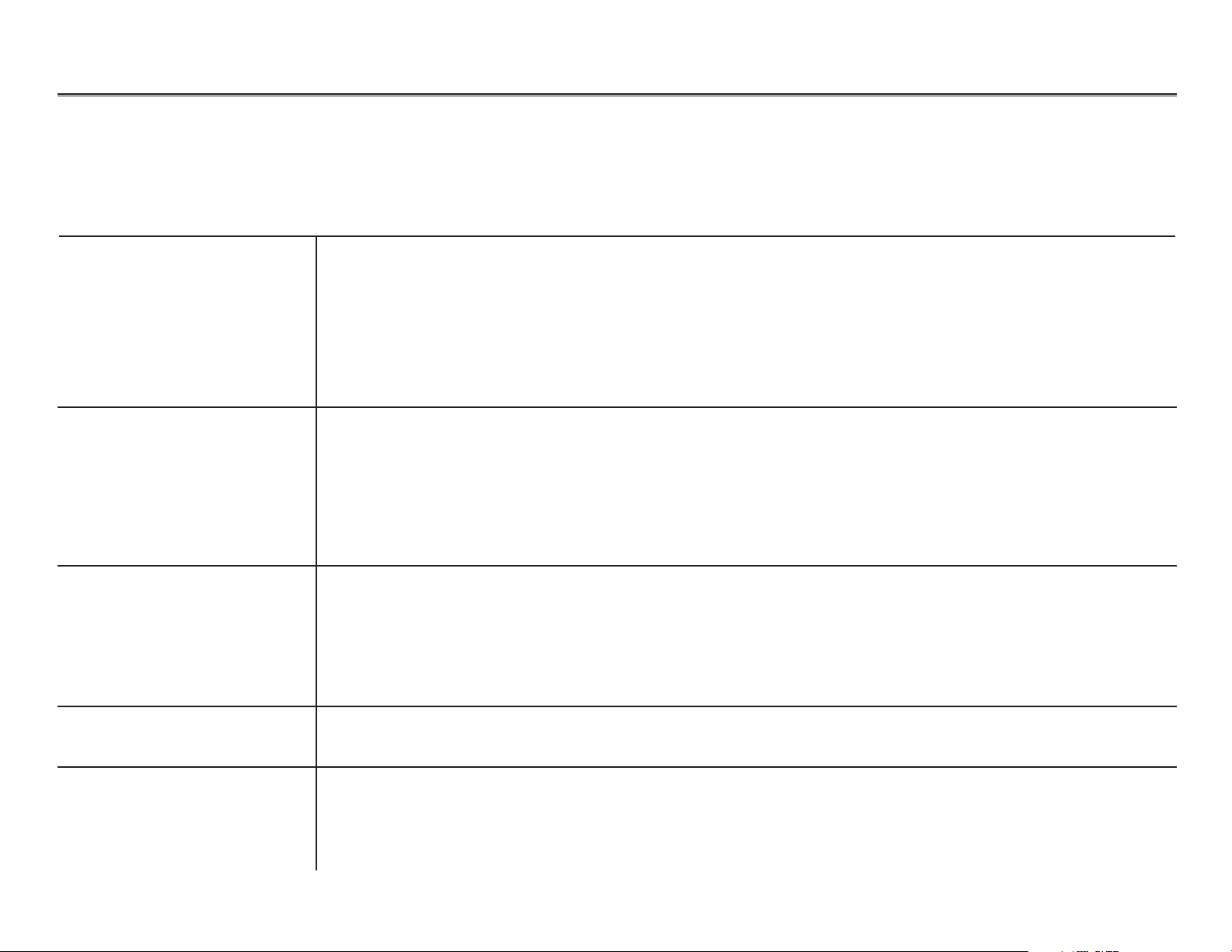

Chairs Manufacture Date

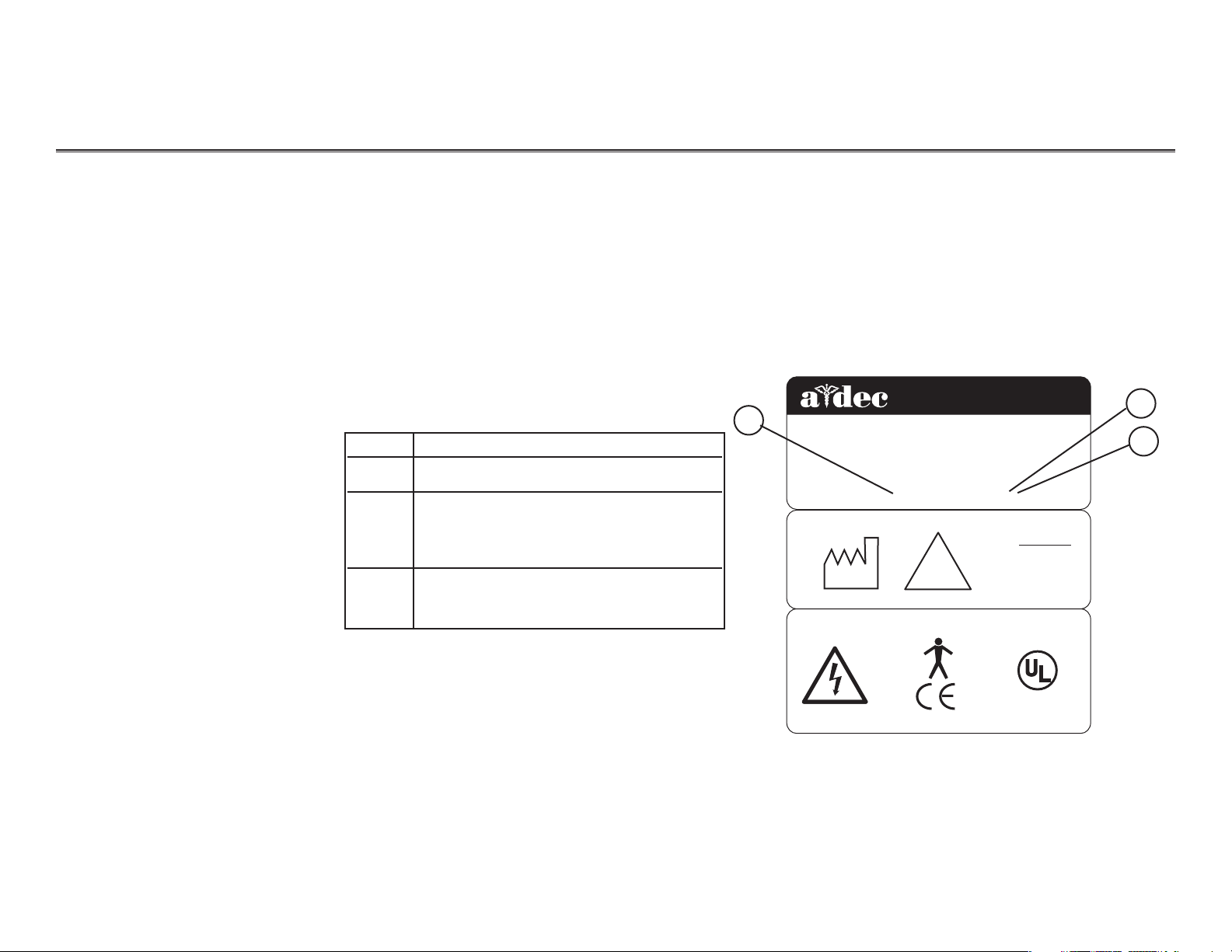

Serial/Model Number Label

Reading the

Manufacture Date

1

Item # Description

1Model number

2 The first letter of the serial number

indicates the month the product was

manufactured; e.g., A is January.

3First digit indicates the year

of manufacture.

2

1

Different models of the chair can be identified by referring to the “REF” number. Each chair is further

identified by its month and year of manufacture.

This example shows how to identify the model and month and year of manufacture of the chair.

2601 CRESTVIEW DRIVE

®

NEWBERG, OREGON 97132 USA

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV 116RZ

DENTAL

CHAIR

Tele: (44) 1203-350901

REF: 1040

S/N: J167856

2001

MADE IN

USA

!

DENTAL CHAIR

INPUTS

-

120 V

10 AMPS MAX

50-60 Hz

CAUTION!

U

®

LISTE

15VJ

S

D

C

LABEL P/N: 051.515.02 REV L

85.0812.00, 2003 CH-4

Chairs Hydraulics

Working with

Hydraulics

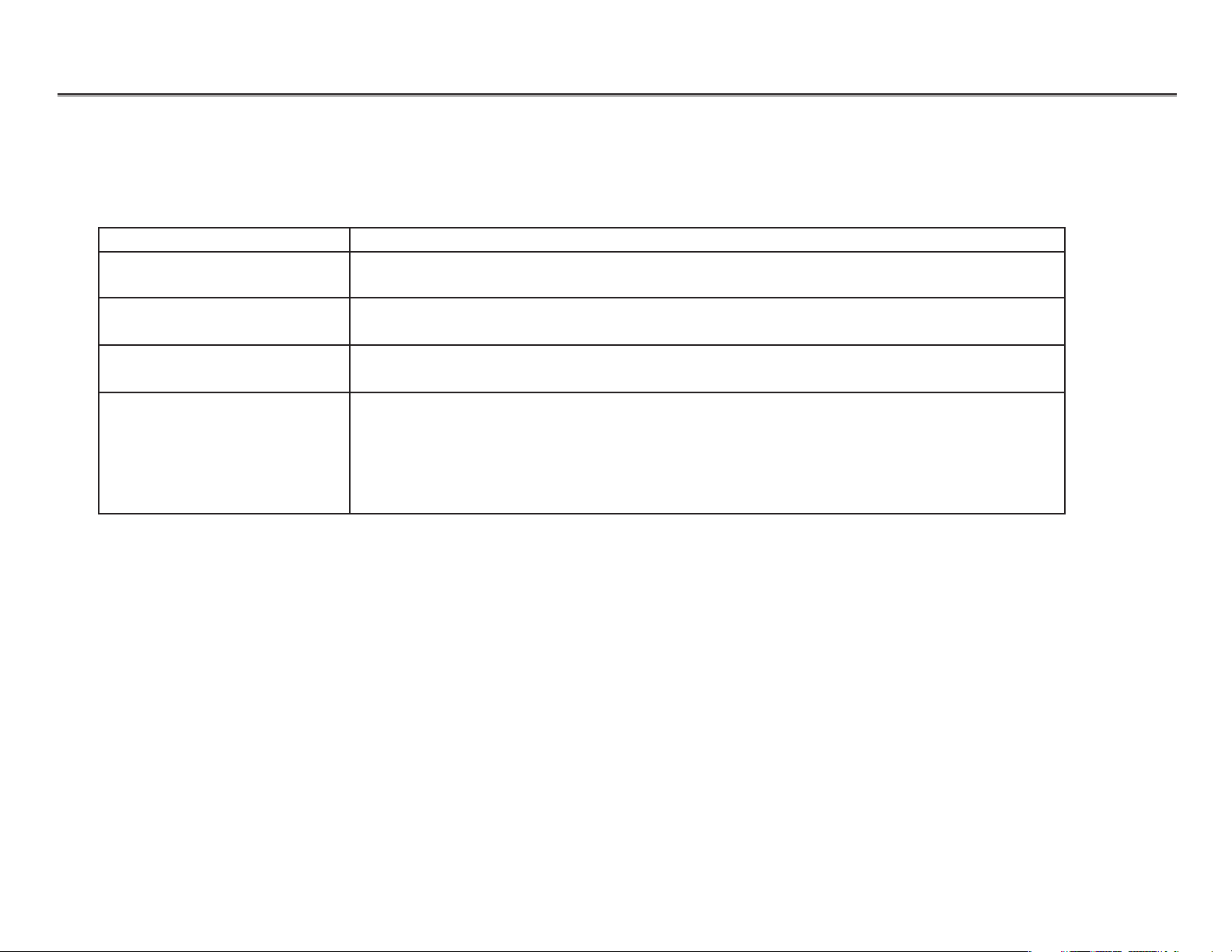

Part Description

Hydraulic fluid reservoir The fluid level in the reservoir can be seen through the sides of the reservoir and is serviced via a

top fill cap.

Hydraulic cylinders The hydraulic cylinders control the base lift and back functions. Springs and gravity retract the

rod during base and back down functions.

Motor-driven hydraulic pump The hydraulic pump and the starter capacitor supply hydraulic fluid from the reservoir, under

pressure, to the chair lift and tilt hydraulic cylinders for back up and base up functions.

Solenoid/manifold assembly This assembly gates hydraulic fluid to and from the two cylinders. Depending on the chair

function called for, the controller selects which solenoid-actuated manifold valves are opened or

closed. The solenoid/manifold assembly also includes four adjustable needle valves used to

restrict or divert the flow of hydraulic fluid to and from the lift and tilt cylinders. These valves

provide the rate of travel adjustment for chair base and back movement.

The hydraulic system consists of the following:

85.0812.00, 2003 CH-5

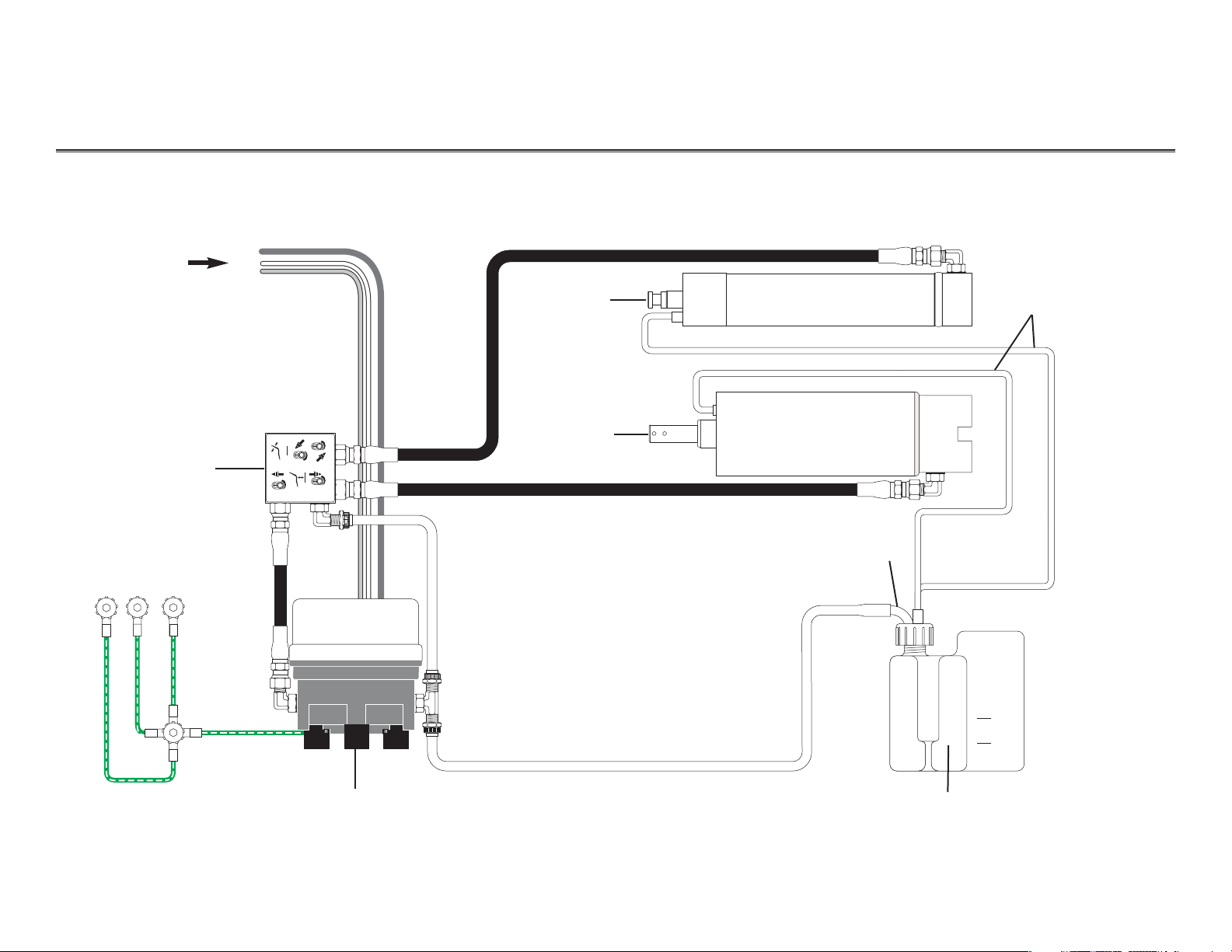

Chairs Hydraulic System Flow Diagram

From

motor/pump

start capacitor

{

Solenoid

manifold

assembly

Tilt cylinder

Lift cylinder

Vent tubes

Pickup tube

Hydraulic fluid reservoir (check fluid level with base and

back full up)

NOTE: Use only A-dec fluid P/N 61.0197.00.

Hydraulic

pump

motor

MAX

MIN

85.0812.00, 2003 CH-6

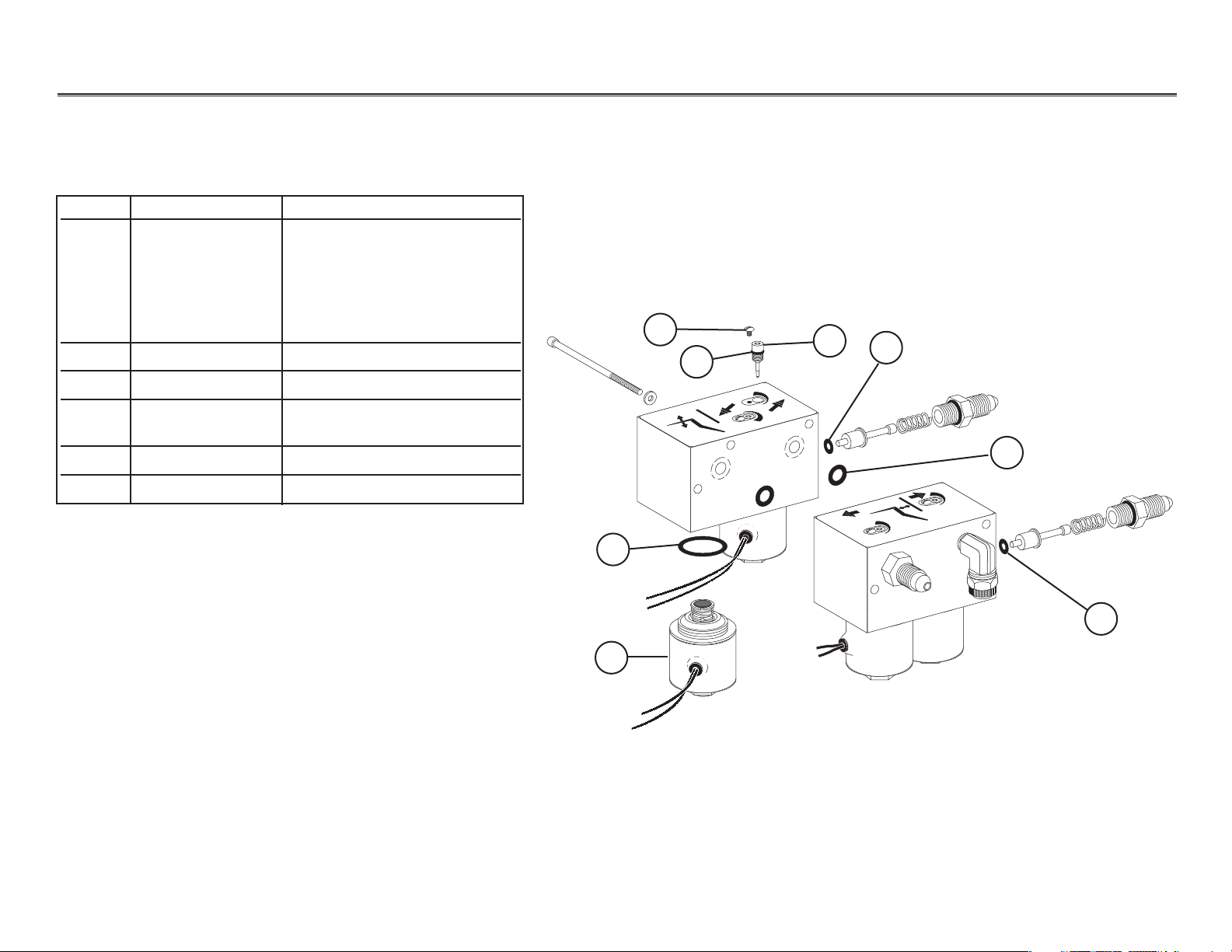

Chairs Hydraulic Manifold

Hydraulic Manifold

Item # Part Number Description

1 61.1335.00 Solenoid, (8-watt, 100V,

Yellow wires)

61.1336.00 Solenoid, (8-watt, 120 V,

Black wires)

61.1337.00 Solenoid, (8-watt, 240 V,

Red wires)

2 035.041.02 O-ring, special pkg 10

3 030.004.02 O-ring, AS568-004 pkg 10

4 030.010.00 O-ring, AS568-010

(only on dual-block manifolds)

5 61.0460.00 Flow adjust screw with o-ring

6 001.002.00 Screw, truss-head slot

1

2

3

4

5

6

3

3

Before January 1999

85.0812.00, 2003 CH-7

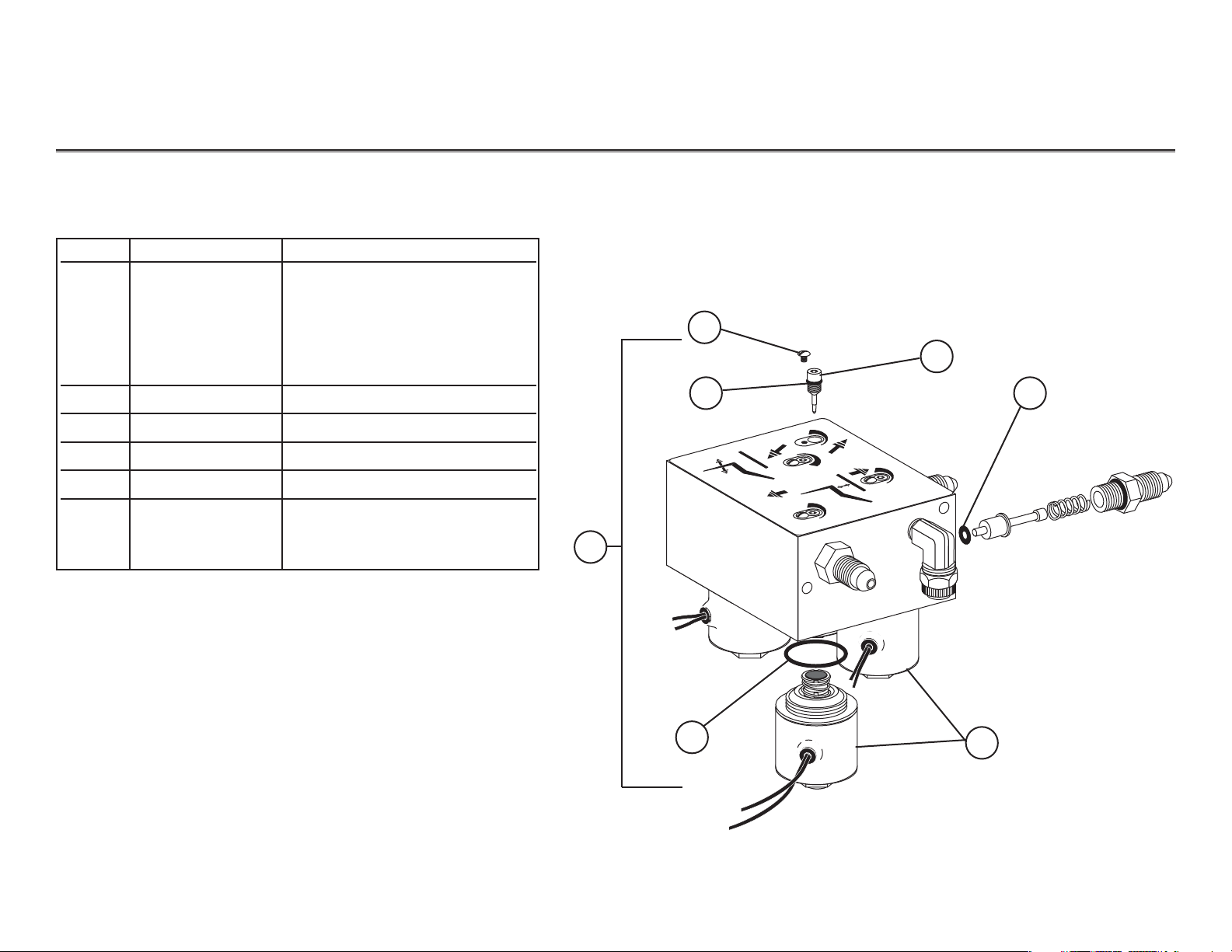

Chairs Hydraulic Manifold

Hydraulic Manifold

Item # Part Number Description

1 61.1335.01 Solenoid, (8-watt, 100V,

Yellow wires)

61.1336.01 Solenoid, (8-watt, 120V,

Black wires)

61.1337.01 Solenoid, (8-watt, 240V,

Red wires)

2 030.015.02 O-ring, pkg 10

3 030.004.02 O-ring, AS568-004 pkg 10

4 61.0460.00 Flow adjust screw with o-ring

5 002.118.01 Screw, button-head, socket

6 61.1332.00 Manifold assy, hyd, 100V

61.1333.00 Manifold assy, hyd, 120V

61.1334.00 Manifold assy, hyd, 240V

3

4

5

2

6

1

3

After January 1999

85.0812.00, 2003 CH-8

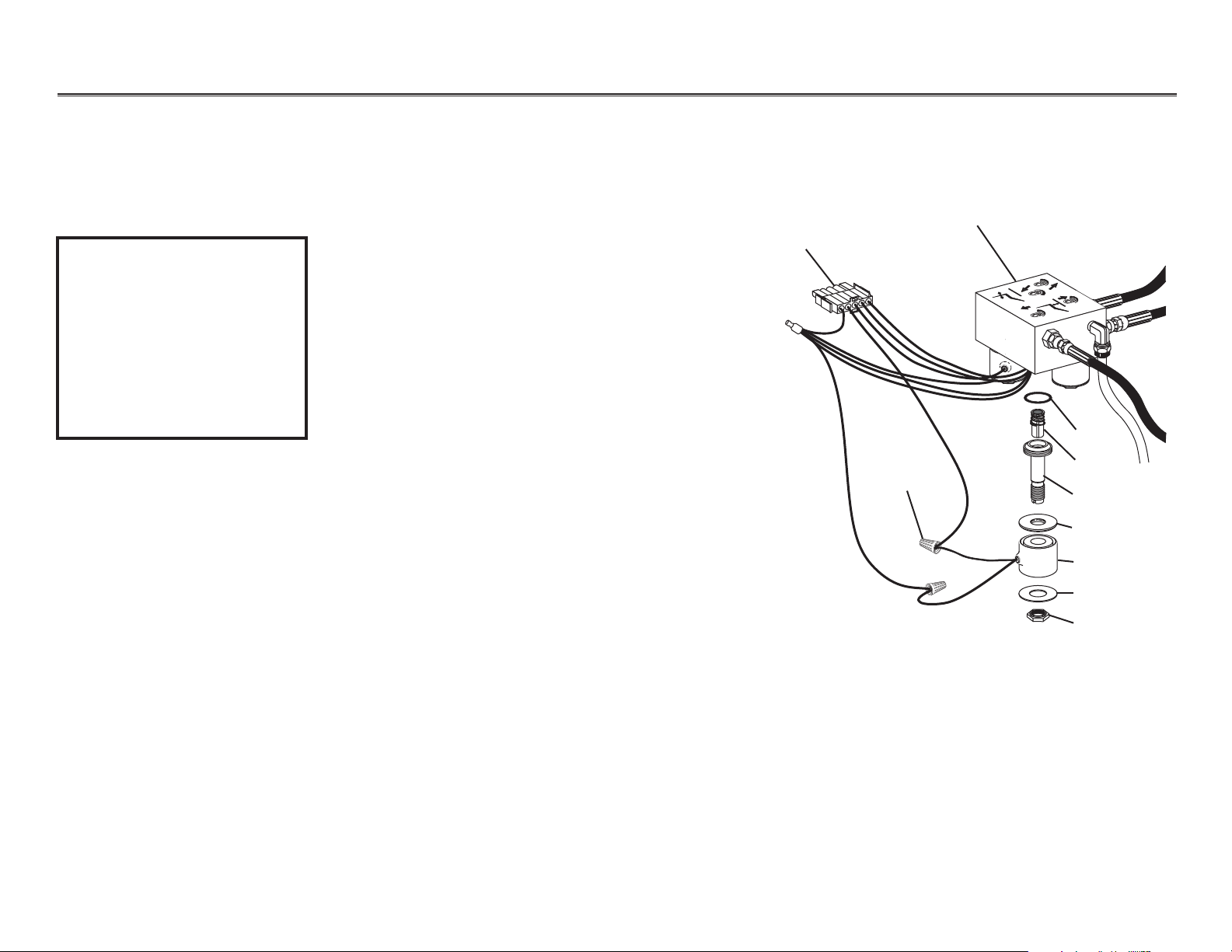

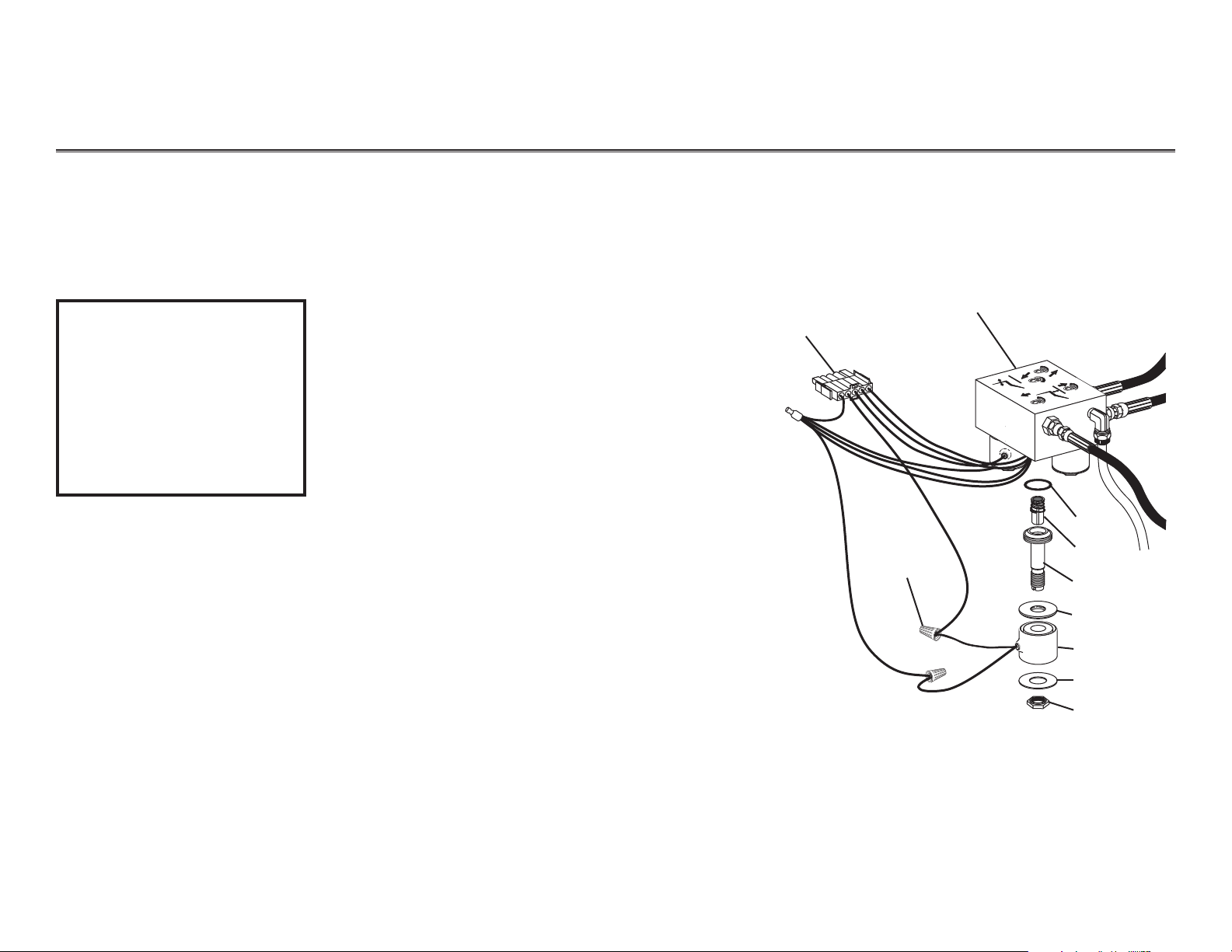

Chair Hydraulic Manifold

The following steps will guide you through the

removal of a solenoid.

Task Description

1 Lower the chair base and back to the

full down position to depressurize the

hydraulic system. Remove the motor

pump cover, then unplug the chair.

2 If necessary, remove the two mounting

screws that secure the manifold to the

hydraulic tray. Rotate the manifold so

the solenoids are accessible.

3Using a flat blade screwdriver and a 9/16"

wrench, remove the defective solenoid.

4 Cut the defective solenoid wires 3" (74mm)

from the coil and discard.

5Remove the old o-ring from the solenoid

cavity and completely dry the cavity.

Replace the o-ring (refer to Solenoid

installation instructions for correct o-ring).

Hydraulic manifold

O-ring

Poppet sleeve

Washer

ID washer

Retaining nut

Poppet

Coil

Wire nut

J10

Removing a

Solenoid

WARNING

The solenoid coils are

powered by line voltage

(100, 120, or 240V AC).

Failure to unplug the

chair may result in

serious injury from

electrical shock.

Removing a Solenoid

85.0812.00, 2003 CH-9

Chair Hydraulic Manifold

The following steps will guide you through

replacing a solenoid.

Task Description

1 Install the new solenoid stem and poppet into

the manifold and tighten to 35-40 in lb

(.11085-.2284 Nm). Position the remaining

solenoid parts on the stem and secure by

tightening the retaining nut to 25-30 in lb

(.14275-.1713 Nm).

2 Cut the solenoid wires 3" (75 mm) from the coil.

Install the stripped wires from the solenoid and

the connector housing into a wire nut. Repeat

for the remaining wire.

3Using the mounting screws, secure the

manifold to the hydraulic tray.

4. Plug in the chair. Test the chair functions to

ensure proper operations and that no fluid

leakage occurs. Reinstall the motor pump cover.

Hydraulic manifold

O-ring

Poppet sleeve

Washer

ID washer

Retaining nut

Poppet

Coil

Wire nut

J10

Replacing a

Solenoid

WARNING

The solenoid coils are

powered by line voltage

(100, 120, or 240V AC).

Failure to unplug the

chair may result in

serious injury from

electrical shock.

Replacing a Solenoid

85.0812.00, 2003 CH-10

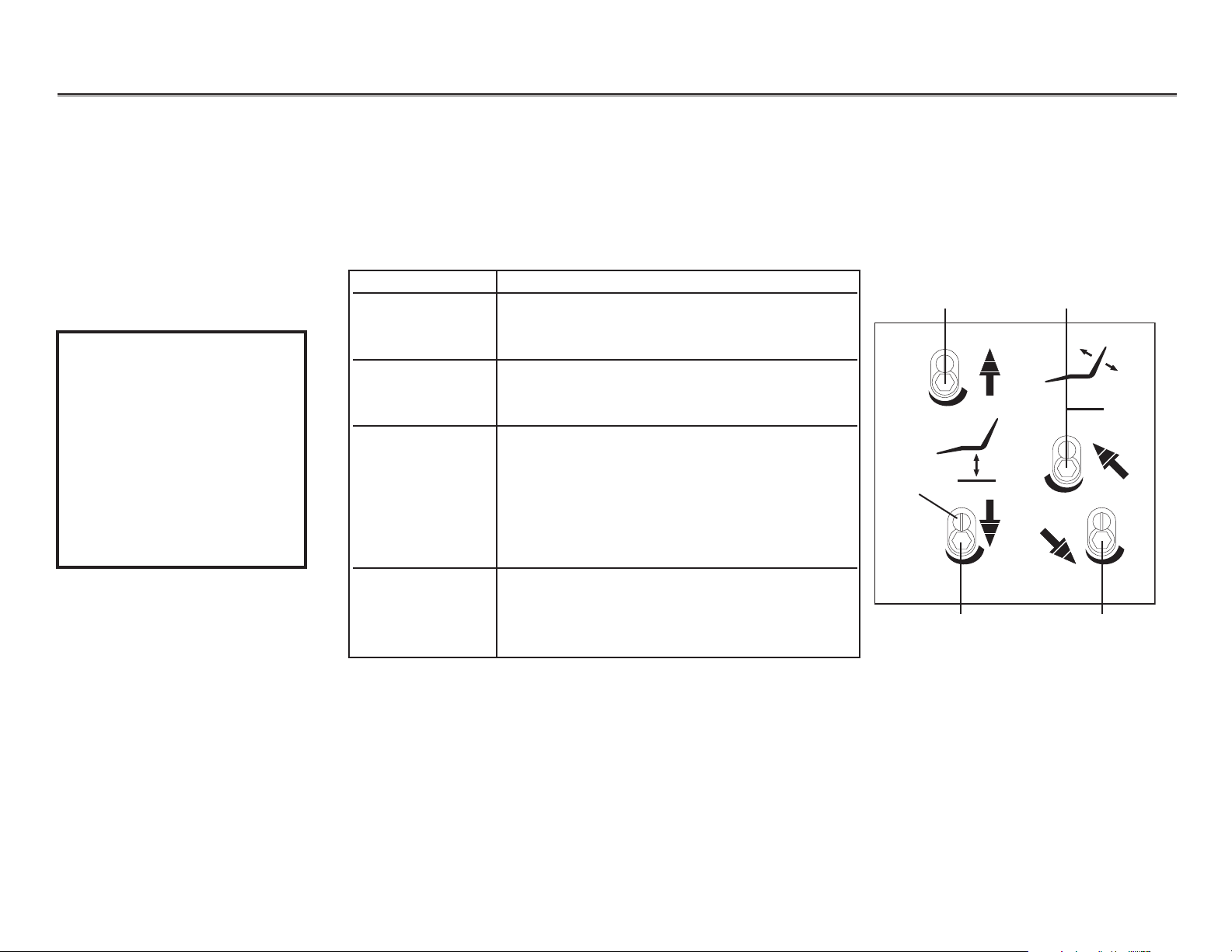

Chairs Hydraulic Manifold

Base down

control valve

Base up

control valve

Back down

control valve

Back up

control valve

CAUTION

Do not completely close

a speed control valve.

The motor/pump could

overheat and become

damaged from pumping

against a closed valve.

Do not remove retaining

screw from the control

valves.

Retaining

screw

The hydraulic manifold incorporates four speed control valves, which restrict or divert the flow of

hydraulic fluid to and from the lift and tilt cylinders.

NOTE: The speed control valves are hex drive.

To adjust... Do this...

Base up speed Turn base up control valve:

clockwise to decrease speed, or

counterclockwise to increase speed.

Base down speed Turn base down control valve:

clockwise to decrease speed, or

counterclockwise to increase speed

Back up speed Turn back up control valve

counterclockwise to decrease speed, or

clockwise to increase speed.

NOTE: This is opposite of the other

three control valves. Turning the back

up valve counterclockwise too far may

prevent the back from moving up.

Back down speed Turn the back down control valve:

clockwise to decrease speed, or

counterclockwise to increase speed.

Adjusting the Hydraulic Manifold

Adjusting the

Hydraulic Manifold

85.0812.00, 2003 CH-11

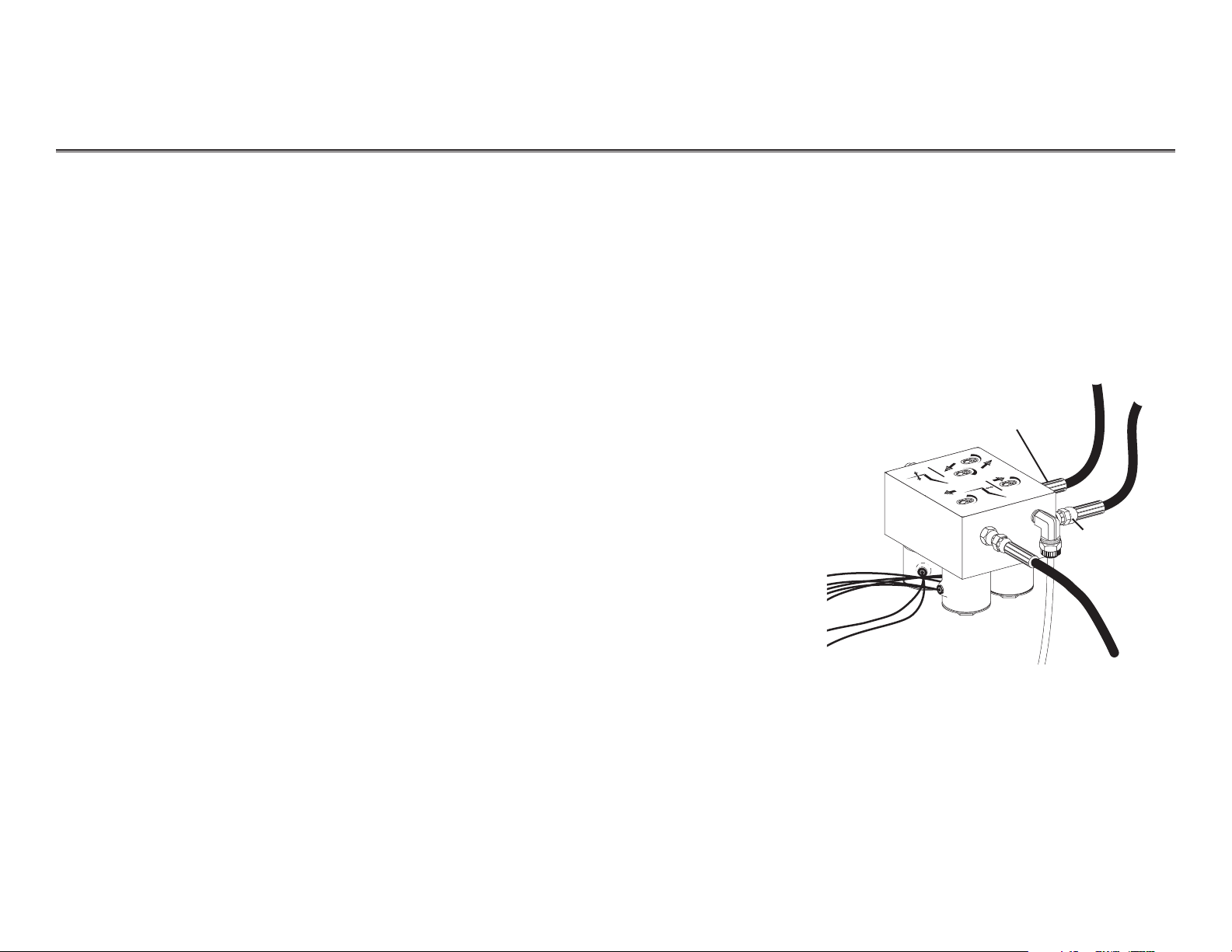

Chairs Hydraulic Manifold

Task Description

1 Remove the motor/pump cover from the chair.

2 Fit a 5/8" wrench to the high pressure outlet port

(either lift or tilt, whichever is in hydrostatic lock) of

the hydraulic manifold. Hold the port still and use a

9/16" wrench to loosen the hose fitting.

3 Place a shop rag around the fitting to absorb

the fluid.

4 Carefully loosen the fitting counterclockwise until oil

begins to leak from the fitting. Retighten the fitting.

Operate the down function. A second release of

hydraulic fluid may be required.

5 Adjust the limit switch that caused the hydrostatic

lock (refer to Adjusting the Base Up Limit Switch). In

some cases, it may be necessary to remove and

replace the limit switch. Adjust the new limit switch

as needed. Also ensure that the large gear/actuator

is securely installed and not slipping.

6Cycle the chair a couple of times to verify it is no

longer in hydrostatic lock.

Tilt cylinder

high pressure

fitting

Lift cylinder

high pressure

fitting

Correcting

Hydrostatic

Lock

Hydraulic lock occurs based on the following conditions:

•chair base or back is stuck in full up position

• limit switch not activated, or

• down solenoid poppet is unable to open based on excess hydraulic pressure.

Correcting Hydrostatic Lock

85.0812.00, 2003 CH-12

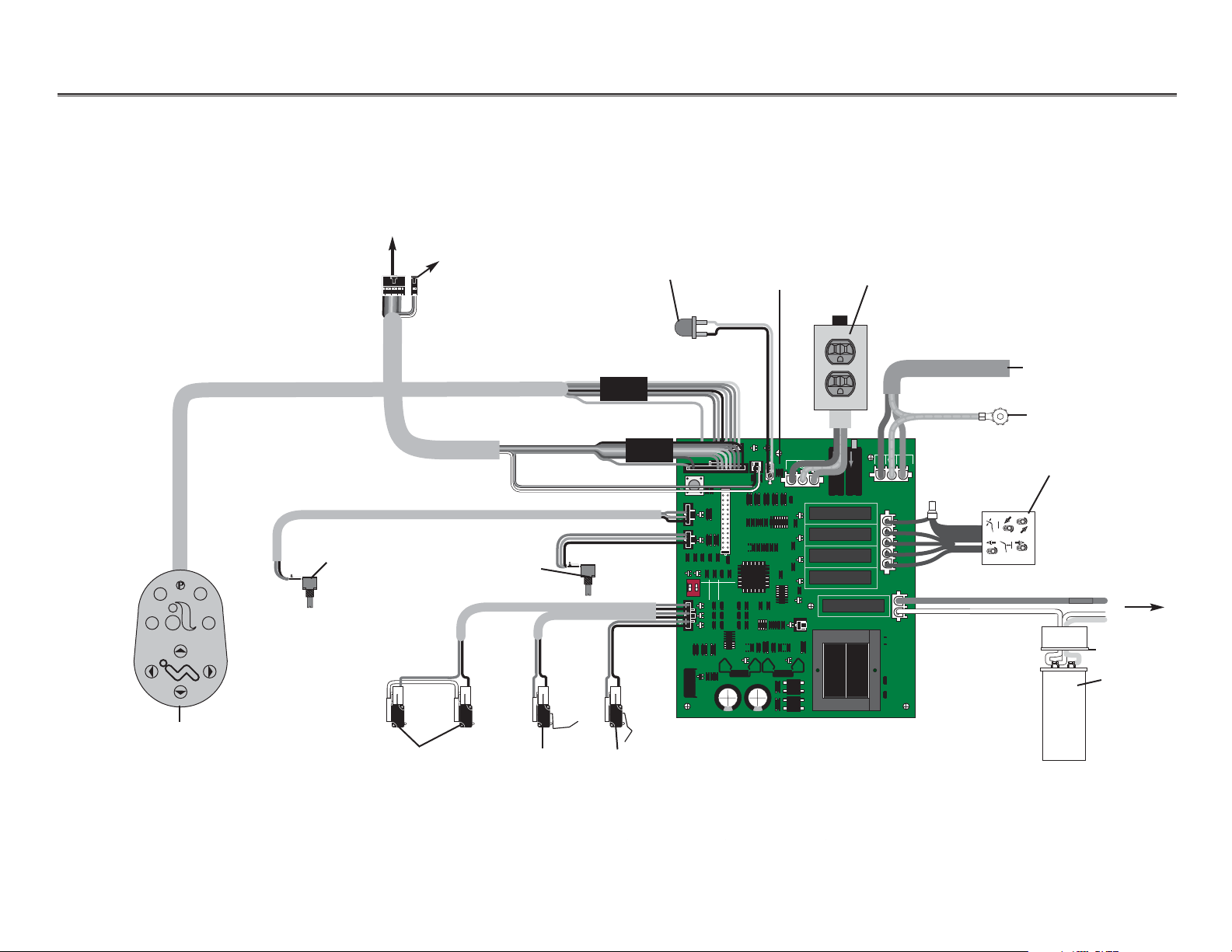

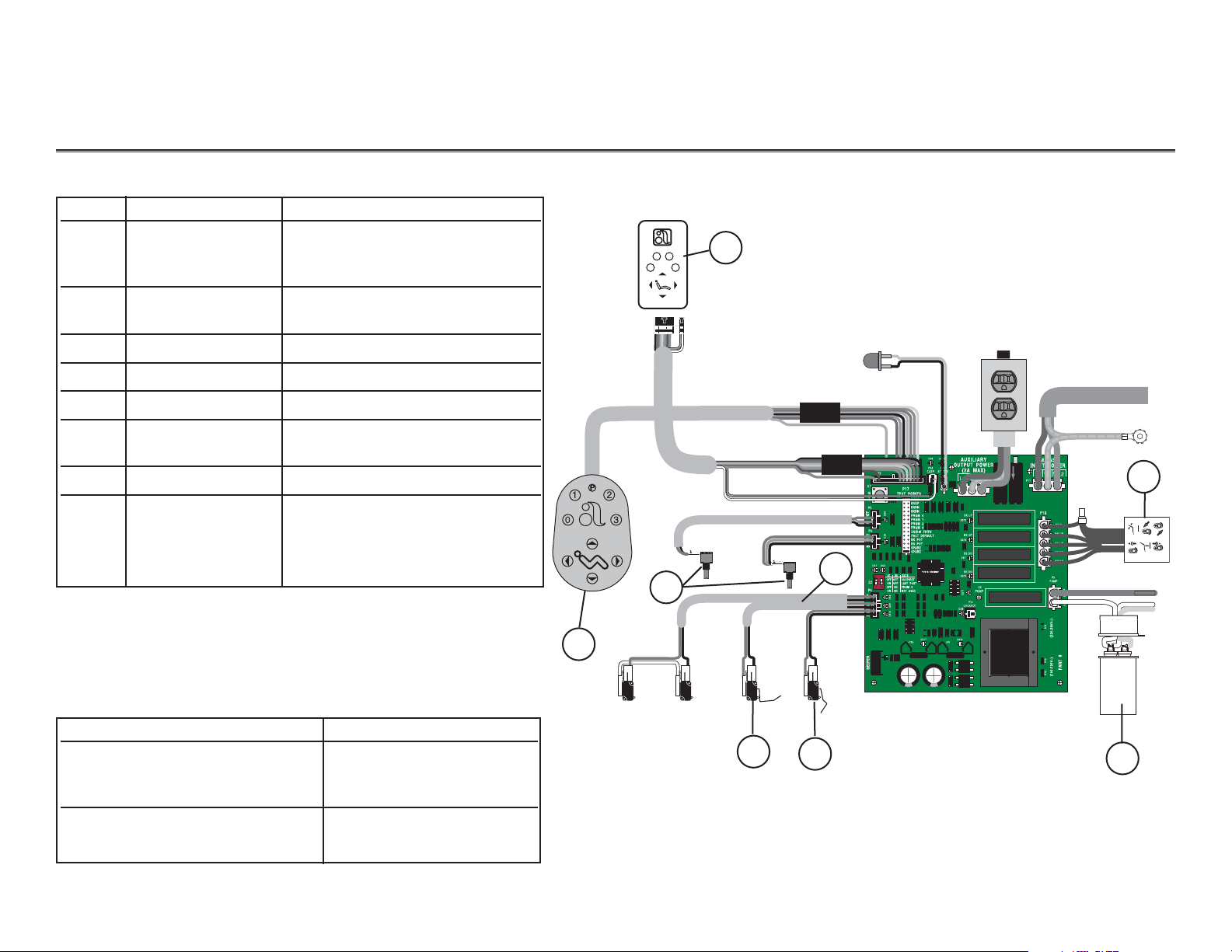

Chairs Electrical System Wiring Diagram

Optional duplex

100V and 120V only

Ground

Footswitch

LED light

Back positioning

potentiometer

Base positioning

potentiometer

Main power from

electrical outlet

Hydraulic manifold

To post box, or

Radius lift arm connector

Stop plate

limit switches

Base up limit

switch

Back up limit

switch

Capacitor

To hydraulic

motor/pump

}

To cuspidor

stop switch

NOTE: If there is no cuspidor, remove

jumper from cable and place

on board

Place jumper

here if there is

no cuspidor

DS8

P

17

BKUP

BSU

P

BSDN

BK

DN

PRGM

0

PRGM

1

PRGM

2

PRGM

3

EN/DIS TP/F

FACT DEFAU

BK POT

BS PO

T

SPAR

E

SPAR

E

"STATIC SENSITIVE

CUSP/RET

AST POS

T

L

PRGM

3

NOT USE

D

+12V +5V

P14

CUSP STATUS

S

LT

DS15

P16

"

AUXILIARY

OUTPUT POWE

(2A MAX

L1 N/L2

BK UP

DS12

BS UP

DS14

BS DN

DS7

BK DN

DS13

K5

PUMP

DS11

P13

LOCKOUT

DS4

DS16DS17

CB2

CB1

R

)

P12

MAINS

INPUT POWER

L1

P11

P10

R74 R72 R73

N/L2

N/L2

BK UP

BS UP

BS DN

BK DN

P9

PUMP

PUMP

N/L2

)

~

V

240

220

(

#

)

~

T

V

R

A

120

-

P

100

(

P1

P2

S1

TEST POINTS

PRGM

P5

T

DS3DS5

O

P

BK

P4

T

O

SP

2

1

0

3

B

DS1

DS2

#1 #2SETS

ON

O

FF

O

FF

S2

O

N

O

FF

12

O

FF

O

N

P6

O

N

O

N

SP

DS6DS9DS10

BK

S

B

R

E

P

EE

B

85.0812.00, 2003 CH-13

Chairs Electrical Systems Service Parts

Item # Part Number Description

1 61.1332.00 100V, Yellow wires

61.1333.00 120V, Black wires

61.1334.00 240V, Red wires

2 90.1031.00 Capacitor with boot (100-120V)

90.1034.00 Capacitor with boot (240V)

3 041.372.00 Positioning potentiometer

4 61.2065.00 Back up limit switch

5 044.184.01 Base up limit switch

6 61.2099.00 Cable assy, tilt switch

(1040) only

7 61.3043.00 8-button footswitch

8 39.1045.00 Chair touchpad

39.1385.00 Performer touchpad

39.1090.00 Cascade Master with cuspidor

39.1090.00 Cascade Master w/o cuspidor

To Replace Circuit Board P/N Order this kit

61.2510.00 90.1029.00 (100-120V)

61.1214.01

61.1373.01

61.2512.00 90.1029.01(220-240V)

61.1217.01

1

2

3

4

5

6

7

8

21

0

3

CH-14

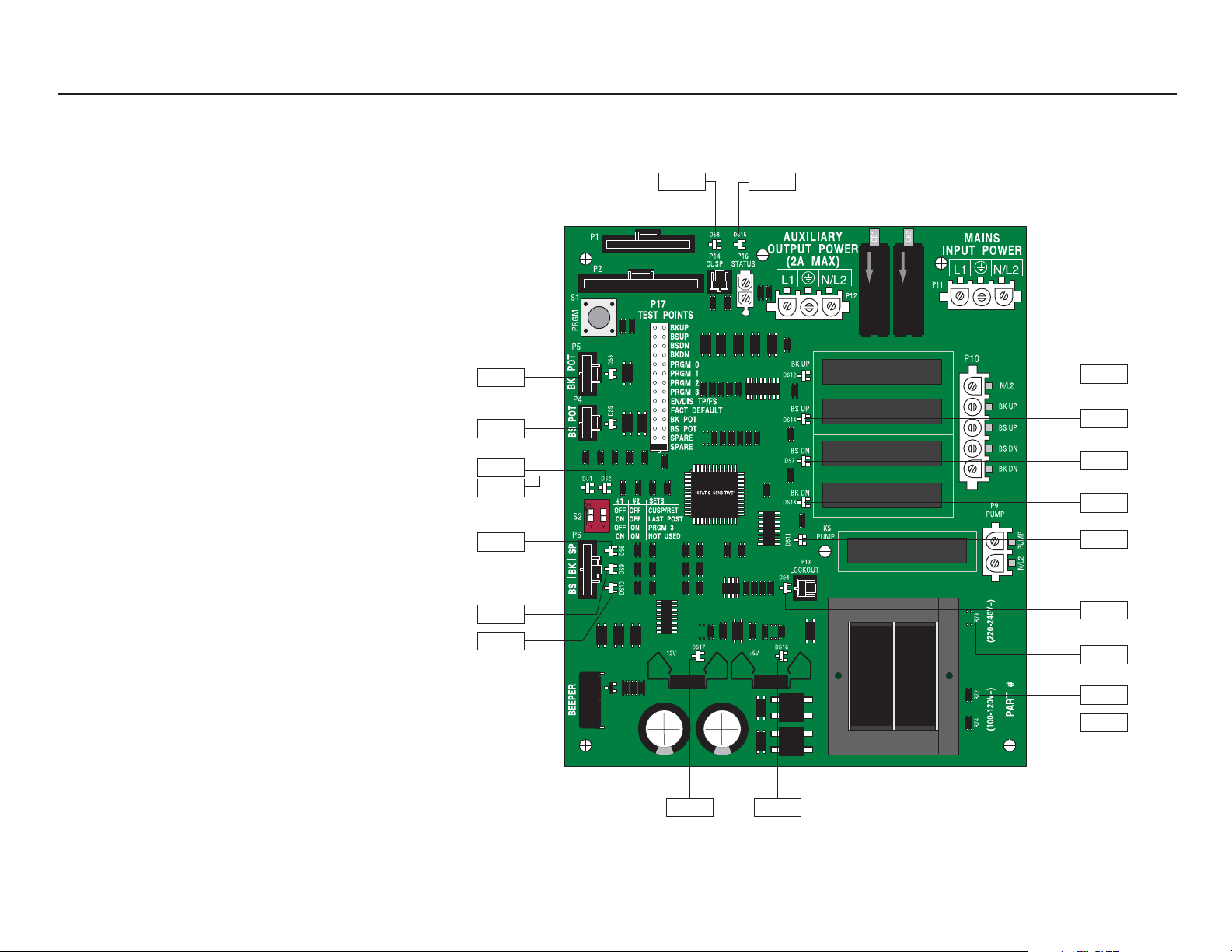

Chairs Diagnostic LEDs for the Circuit Board

LEDs

NOTE: Refer to Testing Factory Defaults

for more details.

DS1

DS2

DS3

DS7

DS8

DS9

DS10

DS11

DS12

DS13

DS4

DS5

DS6

DS14

DS15

DS16

DS17

R73

R72

R74

85.0812.00, 2003

85.0812.00, 2003 CH-15

Chairs Diagnostic LEDs for the Circuit Board

LED Description Information Communicated

DS1 S2 (red DIP switch) is ON Switch is ON

DS2

DS3 Back Potentiometer LED ON Back potentiometer is functioning normally when the chair back is moving

DS4 Handpiece Lockout LED ON Lockout enabled

DS5 Base Potentiometer LED ON Base potentiometer is functioning normally when the chair base is moving

DS6 Chair Stop Plate Limit Switch LED ON Chair stop plate limit switch activated

DS7 Base Down LED Relay is ON when LED is ON and the function is moving

DS11 Pump LED

DS12 Back Up LED

DS13 Back Down LED

DS14 Base Up LED

DS8 Cuspidor Limit Switch LED ON Cuspidor limit switch activated, or jumper is missing

DS9 Back Up Limit Switch LED ON Back Up limit switch activated

DS10 Base Up Limit Switch LED ON Base Up limit switch activated

DS15 Status LED ON ON: Normal operation

OFF: Microcontroller is not functioning. Verify voltage regulator LEDs

(DS16 and DS17) are ON. Is the chair plugged in? Circuit breaker tripped?

Slow Blink: Check cuspidor (DS8) and stop plate (DS6) limit switch LEDs

Fast Blink: Check handpiece lockout (DS4) LED

Double Blink: A SPARE jumper is in the FACT DEFAULT position

DS16 5V Regulator LED OFF 1. Power to circuit board is OFF, or

2. There is a short in the cable to the base or back potentiometer. Disconnect all cables

except the power cable. Plug the cables in one at a time (the LED will turn ON when the

problem is fixed).

DS17 12V Regulator LED OFF 1. Power to circuit board is OFF, or

2. There is a short in the cable to the status light or limit switch (the LED will turn ON when

the problem is fixed).

85.0812.00, 2003 CH-16

Chairs Chair Printed Circuit Board (PCB)

Testing and

Programming

the Circuit Board

WARNING

The chair will begin to

move automatically

during this test; to avoid

injury or equipment

damage, remove all

possible obstructions and

maintain a safe distance

from the chair. To

interrupt the chair cycle,

press any button on the

touchpad or footswitch,

or activate the chair

stop plate.

Follow these steps to test and program the chair circuit board.

Task Description

1 Insert the SPARE jumper into the FACT DEFAULT location (on P17).

Result: The chair will cycle the base and back movements and automatically

reprogram the memory positions to the factory settings

(position 0 to entry/exit; 1 and 2 to the same pre-programmed positions;

and 3 to cuspidor/return).

If the circuit board beeps three times, continue with step two.

If the circuit board beeps just once, the chair cycle has been interrupted. Diagnose

and correct any errors, then press either circuit breaker for five seconds to restart

the cycle (refer to Testing Factory Defaults).

2Move the jumper from the FACT DEFAULT location (on P17) back to the

SPARE location.

NOTE: The jumper must be in the SPARE position for normal chair functions and

safe operation.

3Press “1” on the touchpad or footswitch, or the green position on the

8-function footswitch.

Result: The chair will move to the operating position.

4Press “0” on the touchpad or footswitch, or the red button on the 8-function

footswitch.

Result: The chair will move to the entry/exit position.

NOTE: The chair programmable position buttons can be reprogrammed to the

desired positions as specified by the dental team.

85.0812.00, 2003 CH-17

Chairs Tests

Problem Action

Factory Default test will not start

(LEDs DS15, DS16 and DS17

are Off)

Factory Default test will not start

(LED DS15 is Off; DS16 and DS17

are ON)

Factory Default test will not start

(LED DS15 is blinking; DS16 and

DS17 are ON)

If . . .

Then . . .

Transformer thermal limiter is open

Circuit breaker is tripped

Wait for transformer to cool off.

Reset circuit breaker (short circuit fault currents

may damage the circuit breaker and prevent it

from resetting).

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

Testing Factory Defaults

The table lists conditions and corrective actions for testing the factory defaults for LEDs.

85.0812.00, 2003 CH-18

Chairs Tests

Problem Action

Factory Default test halts during

the BASE UP test and the PCB

board beeps one time

Factory Default test halts during

the BACK DOWN test and PCB

board beeps one time

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Base Up limit switch is activated

Motor thermal limiter is open, motor is hot

Motor capacitor is defective

Base Up solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and

R74 (220-240VAC=R73).

Verify switch operation.

Wait for motor to cool off.

Test capacitor and replace, if needed.

Test solenoid and replace, if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED comes ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Stop plate is jammed

Back Down solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Remove and reinstall the stop plate.

Test solenoid and replace if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

85.0812.00, 2003

CH-19

Chairs Tests

Problem Action

Factory Default test halts during

the BACK UP test

Factory Default test halts during

the BASE DOWN test

Chair moves by itself when power

is turned ON

If . . .

Then . . .

Back up limit switch is activated

Back Up solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace, if needed.

Refer to the Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Base Down solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

The jumper is in FACT DEFAULT position

Short circuit in touchpad or footswitch

Short circuit on circuit board

Verify that the jumper is in the

SPARE position.

Unplug the touchpad and footswitch; reset the

circuit breaker. If the problem isn’t repeated, the

touchpad or footswitch may have shorted.

Replace the circuit board.

Chairs Chair Printed Circuit Board (PCB)

Raise the chair with the

stop plate limit switch

Enable and disable touchpad

and footswitch buttons

Handpiece lockout

Diagnostic LEDs

Test Points Header

Plug the chair into an electrical outlet.

Tap the chair stop plate three times within five seconds and hold on the third tap.

Result: The chair base will continue to rise as long as the stop plate is held in. This function is

automatically disabled after five minutes but is re-enabled upon each power up. To reset the

five-minute timer, depress either circuit breaker until the LEDs turn OFF, then release the

circuit breaker.

Place the SPARE jumper in the EN/DIS TP/FS position of the Test Points header P17.

Push the buttons to be Enabled or Disabled (PRGM, PRGM 0, PRGM 1, PRGM 2, PRGM 3).

Result: One beep indicates the button is disabled. Three beeps indicate the button in enabled.

Place the SPARE jumper back into the SPARE position of the Test Points header P17.

Plumb a normally open air-electric switch ( kit P/N 61.1384.00) to the air-coolant tubing (green with

long white dashes).

Insert the two position connector from the air-electric switch into P13 Lockout (next to the transformer)

See Diagnostic LEDs for the Circuit Board.

Use a SPARE jumper to test the chair manual functions (BKUP, BSUP, BSDN, BKDN).

BK POT and BS POT points allow test meter check of potentiometer voltages and

measurement of the analog DC voltage from pin 2 of the potentiometer.

Feature Programming

The chart provides information on new features and associated programming on the PCB.

CH-2085.0812.00, 2003

Identifying

New Features

Loading...

Loading...