Page 1

Owner's Guide

DECADE

®

2561/2562

CART

85.2614.00

®

Page 2

Warranty Information

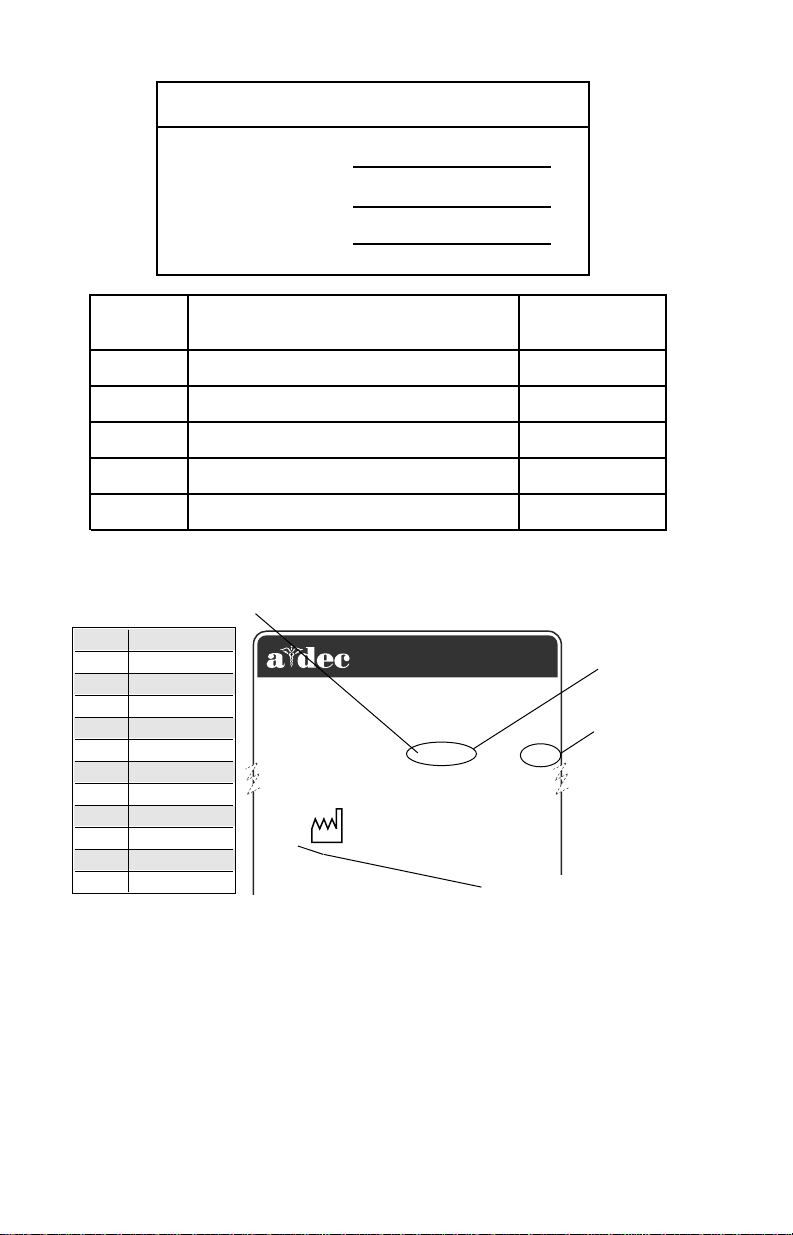

Serial Number Location:

• Located on the underside of the cart housing.

For Replacement Parts or Service Information

contact your local authorized A-dec dealer.

SERIAL NUMBER IDENTIFICATION

SERIAL

NUMBER

MODEL

NUMBER

YEAR MANUFACTURED

ALPHABETICAL EQUIVALENT

TO THE NUMERAL OF THE

MONTH MANUFACTURED

A January

B February

C March

D April

E May

F June

G July

H August

I September

J October

K November

L December

Serial Number

Model Number

Date Purchased

Date of

Service

Model/Description of Service

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV116RZ

1999

2601 CRESTVIEW DRIVE

NEWBERG, OREGON 97132 USA

Tele: (44) 24 7635 0901

SN: J828287

MADE

IN USA

Technician's

Initials

REF: 2122

Page 3

Printed in U.S.A .• Copyright © 1999 • All Rights Reserved

Warranty

A-dec warrants its products and A-dec/W&H Synea

handpieces against defects in material or workmanship

for one year from time of delivery. All other handpiece

instrumentation has a warranty period of six months.

A-dec’s sole obligation under the warranty is to provide

parts for the repair, or at its option, to provide the

replacement product (excluding labor). The buyer shall

have no other remedy. (All special, incidental, and

coincidental damages are excluded.) Written notice of

breach of warranty must be given to A-dec within the

warranty period. The warranty does not cover damage

resulting from improper installation or maintenance,

accident or misuse.The warranty does not cover damage resulting from the use of cleaning, disinfecting or

sterilization chemicals and processes. The warranty also

does not cover light bulbs. Failure to follow instructions

provided in A-dec’s Operation and Maintenance

Instructions (Owner’s Guide) may void the warranty.

NO OTHER WARRANTIES AS TO

MERCHANTABILITY OR OTHERWISE ARE MADE.

All product names used in this document are trademarks or

registered trademarks of their respective holders.

®

Page 4

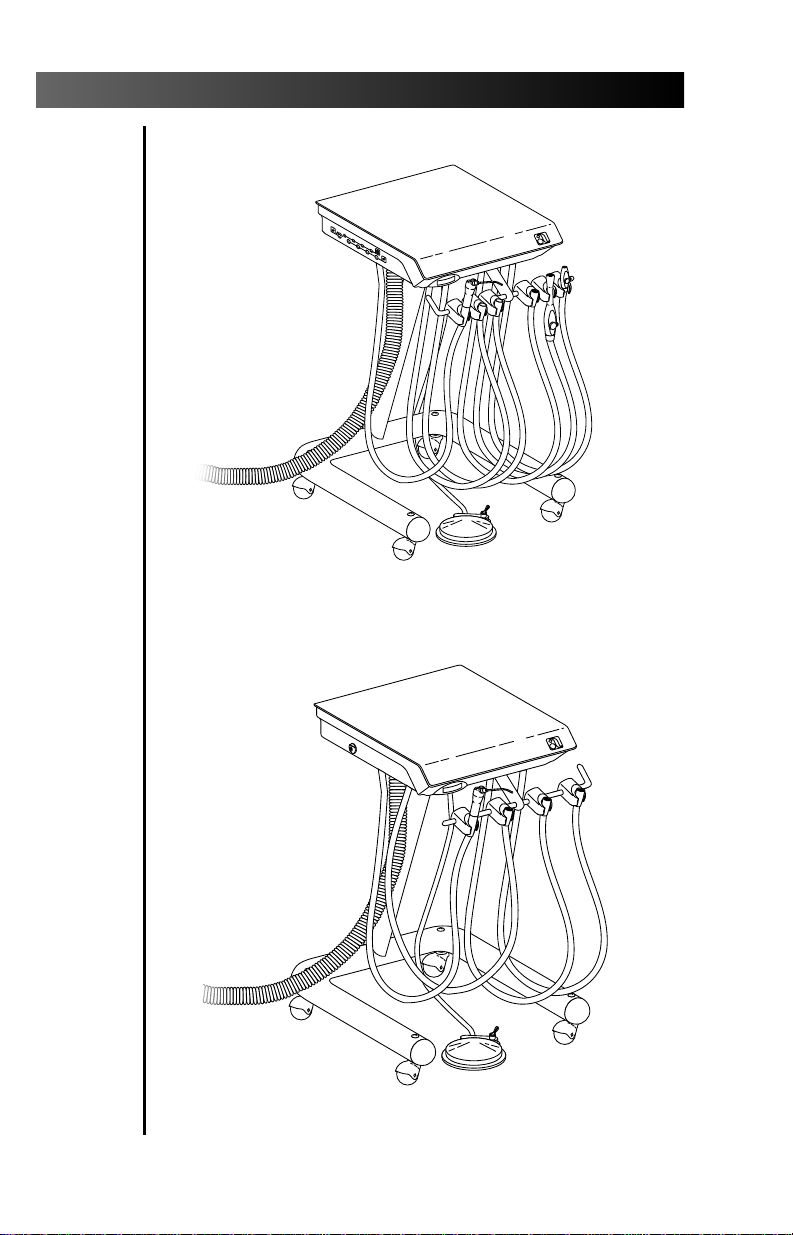

Decade 2561/2562 Cart

Decade 2561 Duo Cart

Decade 2562 Doctor’s Cart

1

2

3

4

50

50

Page 5

1

Decade 2561/2562 Cart

Serial Number Location, Service Information,

and Warranty Information are located on the

inside front cover and front page.

About Your Decade Cart .................................. 2

Handpiece Controls ......................................... 3

Drive Air Pressure Gauge............................ 4

Foot Control ................................................ 5

Drive Air Pressure Adjustment ................... 6

Coolant Air Flow Adjustments ................... 7

Coolant Water Flow Adjustments .............. 8

Handpiece Tubing Flush System ............... 9

Handpiece Positioning ............................. 10

Handpiece Dry Block Conversion ........... 11

Oil Collector .............................................. 12

Care Instructions ........................................... 12

Autoclavable Syringe ..................................... 13

Adjusting Syringe Flow ............................ 13

Vacuum Instruments (Model 2561 Only) ..... 14

Autoclavable HVE and Saliva Ejector ...... 15

Solids Collector ......................................... 15

Utility Controls ............................................... 16

System Air and Water

Pressure Adjustments ........................... 17

Filter Maintenance ................................... 19

Air and Water Filter Elements .............. 19

Maintenance................................................... 21

Adjustments and Specifications ..................... 22

Identification of Symbols................................ 23

Classification of Equipment (EN 60601-1)..... 23

CONTENTS

Page 6

Your Decade 2561 or 2562 Cart is built around

A-dec's Century Plus® handpiece control system.

This system provides automatic control of each

handpiece. Until you lift a handpiece from its

holder, it is inactive and cannot operate. As soon

as you lift a handpiece it automatically becomes

active, allowing it to run when you press the foot

control disc.

With the exception of the drive air pressure gauge,

all controls and indicators are located on the sides

and bottom panel of the unit.

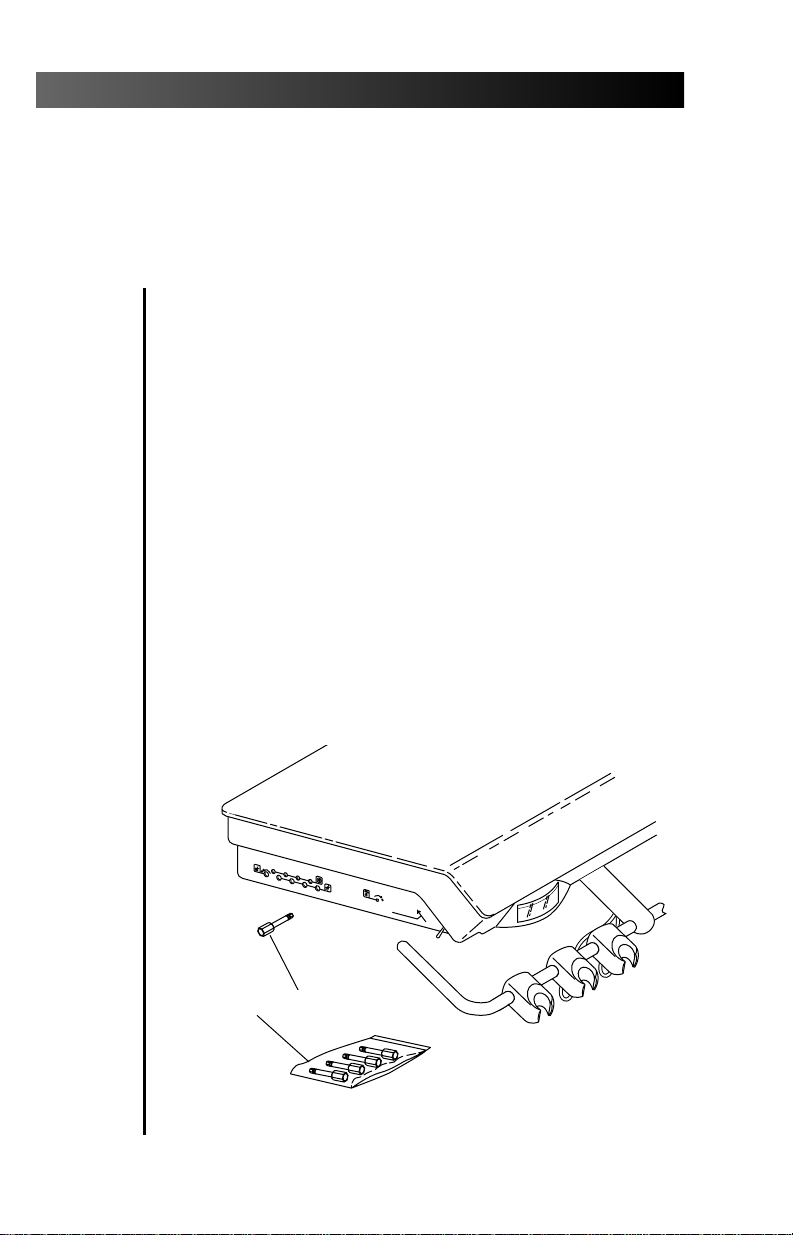

Autoclavable adjustment keys (see Figure 1) are

provided for making adjustments to the recessed

controls. If the adjustment keys are ever lost or

misplaced, you can use a 1⁄8" hex key. You may

also order additional keys from your authorized

A-dec dealer.

2

Decade 2561/2562 Cart

OPERATION

About Your Decade Cart

Figure 1. Autoclavable Adjustment Keys

ADJUSTMENT KEY(S)

1

2

3

4

1

MASTER

0

Page 7

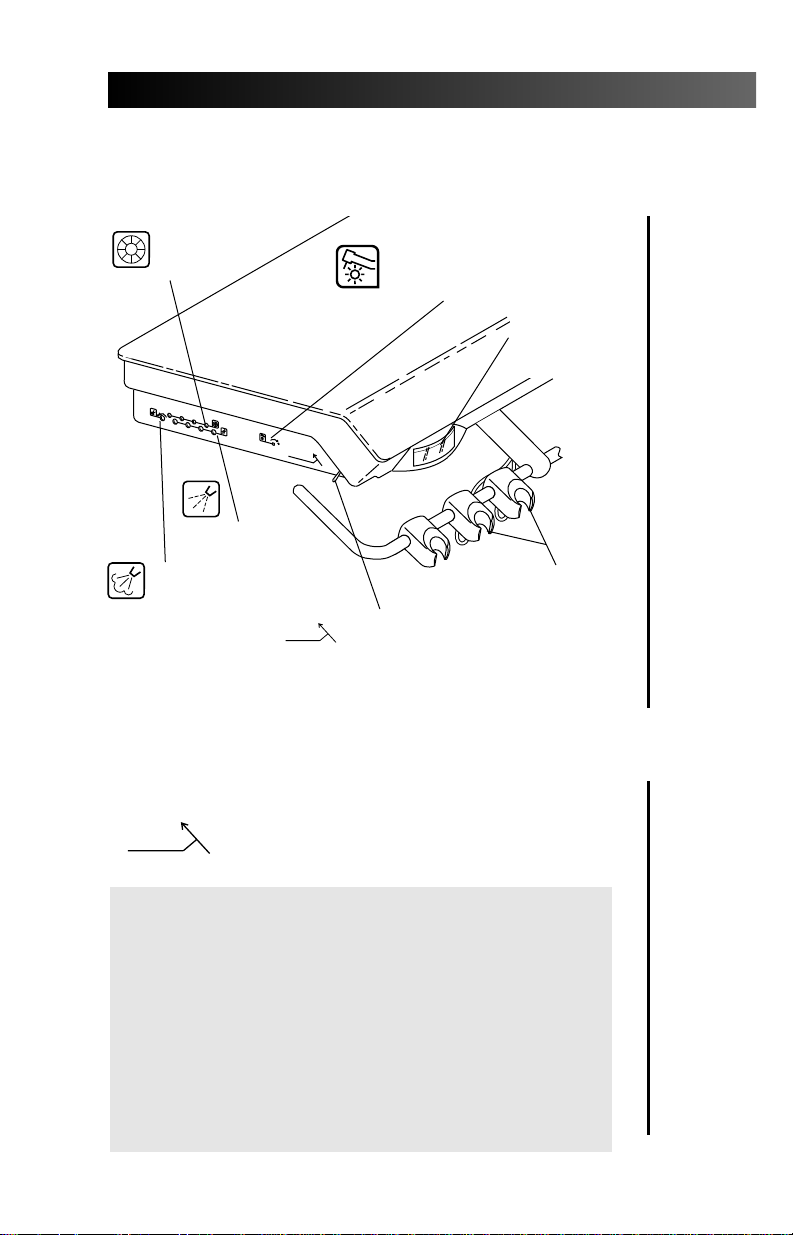

Master ON/OFF Toggle. Turns on

and off the air, water, and electrical

power to the system.

3

Decade 2561/2562 Cart

Handpiece Controls

Figure 2. Handpiece Controls

WATER COOLANT

FLOW CONTROLS

AIR COOLANT

FLOW CONTROL

DRIVE AIR

PRESSURE

GAUGE

DRIVE AIR

PRESSURE

CONTROLS

AUTOMATIC

HANDPIECE

HOLDERS

FOCUS HANDPIECE

LIGHT INTENSITY

CONTROL (option)

MASTER ON/OFF

TOGGLE

CAUTION

The MASTER ON/OFF TOGGLE should be in the

OFF (0) position whenever the unit is not in use.

This will prevent the possibility of water damage

should a leak occur while the unit is unattended.

Making sure the unit is off will also prevent the

possibility of self-activation and the resulting

burn-out of your electrical accessories.

Master On/Off Toggle

1

2

3

4

MASTER

MASTER

1

0

I

O

I

MASTER

O

Page 8

The drive air pressure gauge (see Figure 3) indicates,

in psi and kg/cm2, the drive air pressure to the

active handpiece (refer to page 6).

The water outlet with flow control (see Figure 4)

provides water for hydrocolloid tubing. The outlet

accepts A-dec’s quick disconnect (QD) flow-control.

Flow is controlled by a knob on the QD itself. To

increase flow, turn the knob counterclockwise; to

decrease flow turn the knob clockwise.

4

Decade 2561/2562 Cart

Figure 3. Drive Air Pressure Gauge

DRIVE AIR

PRESSURE

GAUGE

Drive Air Pressure Gauge

Water Outlet with Flow Control

Figure 4. Water Outlet With Flow Control

WATER OUTLET

QUICK DISCONNECT (QD)

KNOB

FLOW-CONTROL

QUICK DISCONNECT (QD)

1

2

3

4

MASTER

1

0

Page 9

The foot control modulates drive air to the active

handpiece and provides an air signal that activates

the coolant air and coolant water flow. The foot

control is operated by light foot pressure applied to

any part of the foot control disc.

The foot control is equipped with a wet/dry toggle

and can be equipped with an optional chip blower

button (see Figure 5).

Wet/Dry Toggle. Allows you to shut off the

coolant water to the handpiece without moving

your hands from the oral cavity. Using your foot,

move the toggle away from the blue dot to turn

the coolant water OFF. Move the toggle toward the

blue dot to turn the coolant water ON.

Chip Blower Button. Sends a jet of air through

the handpiece when it is not running.

5

Decade 2561/2562 Cart

Foot Control

Figure 5. Foot Control

CHIP BLOWER

BUTTON

(Optional)

FOOT CONTROL DISC

WET/DRY TOGGLE

BLUE DOT

Page 10

The drive air pressure controls

(see Figure 6)

are u

sed to adjust the drive air pressure to

each handpiece.

Adjust the drive air pressure to meet the handpiece

manufacturer’s dynamic drive air pressure specification. Refer to the documentation that came with your

handpiece for the dynamic drive air pressure specification.

You will need a 3⁄32" hex key to complete this adjustment.

1. Install a bur in the handpiece.

2. Locate the drive air gauge on the front of the

control head (see Figure 3 on page 4).

3. Move the wet/dry toggle on the foot control

(see Figure 4 on page 5) to the OFF position,

away from the blue dot.

4. Turn the drive air control clockwise until the

valve seats.

5. Fully depress the foot control disc.

6. While running the handpiece, watch the

drive air gauge and adjust the handpiece

dynamic drive air pressure to meet

manufacturer’s specifications.

• Turn the drive air control counterclockwise to

increase drive air pressure flow.

• Turn the control clockwise to decrease flow.

7. Repeat steps 1 through 6 for EACH handpiece.

6

Decade 2561/2562 Cart

Drive Air Pressure Controls

Figure 6. Drive Air Pressure Adjustment

DRIVE AIR

PRESSURE

GAUGE

DRIVE AIR

ADJUST

3/32" HEX KEY

1

2

3

4

1

MASTER

0

Page 11

The coolant air flow control

(see Figure 7) is used to adjust the

coolant air flow to all handpieces.

You will need an adjustment key (see Figure 1

on page 2) or a 1⁄8" hex key to complete this adjustment.

1. Install a bur in the handpiece.

2. Locate the coolant air control (see Figure 7).

3. Move the wet/dry toggle on the foot control

(see Figure 5 on page 5) to the OFF position,

away from the blue dot.

4. Insert an adjustment key, or a 1⁄8" hex key,

into the coolant air flow control.

5. Fully depress the foot control disc to activate

the handpiece.

6. Adjust the coolant air flow to fit your needs. A

strong flow of air is recommended.

• Turn the control clockwise to decrease the flow.

• Turn counterclockwise to increase the flow.

7. The coolant air has been set for ALL handpieces.

7

Decade 2561/2562 Cart

Coolant Air Flow Control

Figure 7 Coolant Air Adjustment

AIR

COOLANT

ADJUSTMENT

KEY

1

2

3

4

MASTER

1

0

Page 12

The coolant water flow controls are used

to adjust the flow of coolant water to

each handpiece

(see Figure 8)

.

You will need an adjustment key (see Figure 1 on page 2)

or a 1⁄8" hex key to complete this adjustment.

1. Install a bur in the handpiece.

2. Locate the coolant water flow controls

(see Figure 8).

3. Move the wet/dry toggle on the foot control

(see Figure 5 on page 5) to the ON position,

toward the blue dot.

4. Insert an adjustment key, or a 1⁄8" hex key,

into the coolant water flow control for the

handpiece being adjusted.

5. Fully depress the foot control disc to activate

the handpiece.

6. Adjust the coolant water flow to fit your needs.

• Turn the control clockwise to decrease the flow.

• Turn counterclockwise to increase the flow.

7. Adjust the coolant water for EACH handpiece.

8

Decade 2561/2562 Cart

Coolant Water Flow Controls

Figure 8. Coolant Water Adjustment

ADJUSTMENT

KEY

WATER

COOLANT

1

2

3

4

MASTER

1

0

Page 13

The handpiece tubing flush system

flushes more water through the tubings

in less time than is normally possible

when operating the foot control only. The

handpieces should not be connected

when flushing the tubings.

How Often Should the Handpiece Tubings be Flushed?

After Each Patient:

Flush the tubings for about 20-30 seconds.

At the Beginning of Each Day:

Flush the tubings for 2-3 minutes.

Flushing the Handpiece Tubings

Gather up all the handpiece tubings that use

coolant water and hold them over a sink, cuspidor

bowl or basin. Be sure you hold the tubings so that

the water will be directed away from you and into

the receptacle (see Figure 9).

Locate the handpiece tubing flush toggle (see

Figure 9). Move the toggle toward the front of the

cart and hold for the appropriate time required,

either for flushing between patients or flushing at

the beginning of each day. Release the toggle and

replace the tubings in their holders.

9

Decade 2561/2562 Cart

Handpiece Tubing Flush

Figure 9. Locate the Flush Toggle

Page 14

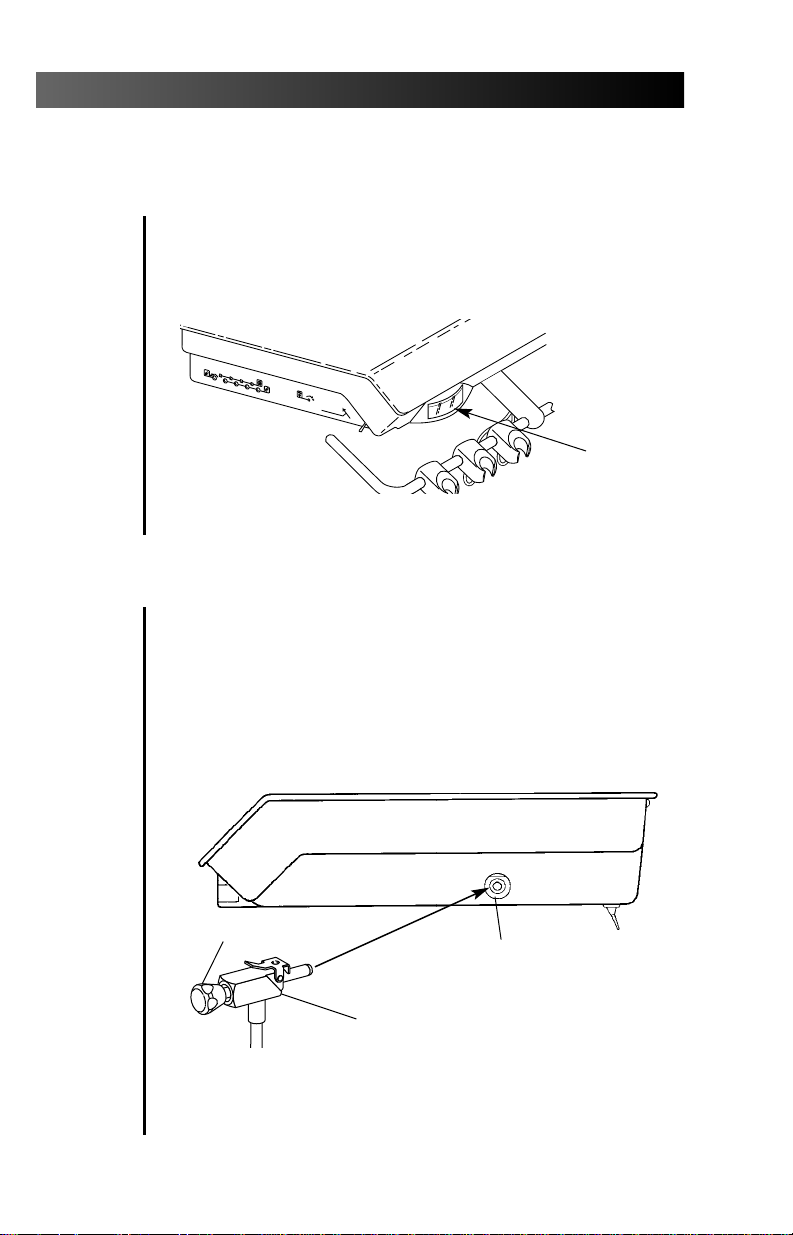

The holder tension was set at the factory. However; if

a holder is difficult to reposition or repositions too

easily, the holder tension can be adjusted.

To adjust the holder tension:

• Loosening or tightening the tension adjustment

screw shown in Figures 10.

To reposition a holder:

• Rotate the holder to the desired angle.

10

Decade 2561/2562 Cart

Handpiece Holder Tension Adjustment & Positioning

Figure 10. Individual Handpiece Holder

Page 15

Your Cascade handpiece control system has one to

four handpiece control blocks with coolant water to

the handpiece. In some cases a control block without

coolant water, a dry block, is required. If you require

a dry block (offering no water to the handpiece) on

your handpiece control system, a dry block conversion kit has been included with your system.

Installing the Dry Block Conversion Kit

1. Move the master on/off toggle to the OFF position. Bleed the system water by operating the

syringe and flushing the handpiece tubings.

2. Locate the handpiece control block position

that will be the dry block. Access the control

blocks underneath the control head.

3. Use a 3/32" hex key to remove the large red

cartridge from the control block. Install the large

black cartridge from the dry block conversion kit

into the control block (see Figure 11).

4. Use a 3/32" hex key to remove the small blue

cartridge from the same control block. Install

the small black cartridge from the dry block

conversion kit into the control block (see

Figure 11).

5. Turn your handpiece control system on, then

check the function of the dry block handpiece

conversion. A small amount of residual water

may be discharged from the handpiece tubing

but should dry after a few seconds.

11

Decade 2561/2562 Cart

Handpiece Dry Block Conversion

Figure 11. Handpiece Dry Block Conversion

REMOVE THE RED

CARTRIDGE AND

REPLACE WITH

THE LARGE BLACK

CARTRIDGE

REMOVE THE BLUE CARTRIDGE

AND REPLACE WITH THE

SMALL BLACK CARTRIDGE

DO NOT REMOVE

THE YELLOW CARTRIDGE

Page 16

The oil collector on your unit needs to be changed

once a week for normal usage. Change more often

for heavier use.

1. Remove the oil collector jar from the unit and

discard the old gauze (see Figure 12).

2. Fold in quarters a new two inch square gauze

pad and place against the spring inside the jar.

3. Screw the oil collector jar onto the unit. Do not

overtighten.

For recommended asepsis instructions, refer

to your Equipment Asepsis Owner’s Guide

(A-dec Publication No. 85.0696.00) .

For recommended self-contained water system

care, refer to A-dec Self-contained Water System

Owner’s Guide (A-dec Publication No. 85.0675.00).

12

Decade 2561/2562 Cart

Oil Collector

Care Instructions

Figure 12. Oil Collector

CART HOUSING

Page 17

To operate the syringe (see Figure 13):

• Move the on/off toggle to the ON position.

• Air – Press the right button down.

• Water – Press the left button down.

• Spray – Press both buttons down.

Syringe Flow Controls. Located underneath the

cart top. Flow is controlled by adjustable air and

water flow restrictors (tubing pinch valves) on the

syringe tubing under the cart top (see Figure 14).

Refer to your Autoclavable Syringe Owner’s Guide

(A-dec Publication No. 85.0680.00) for complete

syringe operation and maintenance instructions.

13

Decade 2561/2562 Cart

Syringe

Figure 13. Autoclavable Syringe

AIR

WATER

SPRAY

Figure 14. Adjusting Syringe Flow

Page 18

To operate the autoclavable HVE and saliva

ejector, simply turn the control valve.

The autoclavable HVE and saliva ejector can be

easily converted for right- or left-hand operation.

To convert, press the control valve out of the valve

body (see Figure 15). Rotate the control valve 180°,

then press it back into the valve body.

Refer to your Assistant’s Instrumentation

Owner's Guide (A-dec Publication No. 85.2610.00)

for complete instructions on cleaning your HVE

and saliva ejector.

14

Decade 2561/2562 Cart

Vacuum Instruments (model 2561 only)

Autoclavable HVE & Autoclavable Saliva Ejector

Figure 15. Right- to Left-Hand Conversion

AUTOCLAVABLE HVE

AUTOCLAVABLE

SALIVA EJECTOR

CONTROL

VALVE

VALVE

BODY

VALVE

BODY

CONTROL

VALVE

Page 19

The solids collector, located inside the cart (see

Figure 16), collects solids and prevents them from

entering the central vacuum system. To remove

the canister lid, turn off the vacuum, then twist

the lid counterclockwise and lift it off.

At least once per week, remove and clean the solids

collector screen (see Figure 17). This is necessary to

ensure proper suction from the central vacuum.

Refer to your Assistant’s Instrumentation

Owner’s Guide (A-dec Publication No. 85.2610.00) for

complete solids collector maintenance instructions.

15

Decade 2561/2562 Cart

Solids Collector

Figure 16. Solids Collector

SOLIDS

COLLECTOR

CANISTER

(2561 ONLY)

LID

SCREEN

CANISTER

Figure 17. Cleaning the Solids Collector

4

4

3

3

50

50

60

60

5

5

40

40

2

2

70

70

30

30

80

80

20

20

6

1

6

1

90

90

10

10

100

100

0

0

psi

psi

7

7

0

0

2

2

kg/cm

kg/cm

Page 20

System utility controls (see Figure 18) are located

under the cart top.

Pre-Regulator controls the air and water pressures

in the unit. The procedure for adjusting system

pressure is given on page 17.

Air and Water Filters prevent solids from

entering the unit. The procedures for checking

and replacing the filters are given on pages

19 and 20.

16

Decade 2561/2562 Cart

Utility Controls

AIR PRESSURE

GAUGE

(70 – 80 psi)

WATER PRESSURE

GAUGE

(30 – 40 psi)

AIR FILTER

WATER FILTER

HANDPIECE

PRESSURE

GAUGE

AIR PREREGULATOR

WATER PREREGULATOR

SOLIDS

COLLECTOR

(2561 Only)

UTILITY

MODULE

HANDPIECE

CONTROL

BLOCKS

Figure 18. In-Cart Utilities

3

40

2

30

20

1

10

0

0

4

4

3

50

50

60

60

5

5

40

2

70

70

30

80

80

20

6

6

1

90

90

10

100

100

0

psi

psi

7

7

0

2

kg/cm

2

kg/cm

Page 21

The air and water manual shutoff valves, as well

as any vacuum or drain outlets, are located in the

floor box mounted over the office plumbing on the

floor or wall.

Before making any adjustments to components in

the cart top, verify that the manual shutoff valves

in the floor box are all the way open (turned fully

counterclockwise) and that the compressor is on

and functioning properly.

The air compressor should maintain 80 – 120 psi

(552 – 690 kPa) in the tank. If it doesn’t, refer to

the instructions for the compressor.

1. Be sure that the manual shutoff valves are

fully open (counterclockwise).

2. Move the master on/off toggle to the ON position.

3. Check the pressure gauges inside the cart

housing (see Figure 18 on page 16).

• Air pressure should be 70–80 psi (483–552 kPa).

• Water pressure should be 35–40 psi (241–276 kPa).

4. While watching the gauges, operate the syringe.

If the system air pressure drops by more than

15 psi (103 kPa), or water pressure by more

than 10 psi (69 kPa), check for clogged filters.

17

Decade 2561/2562 Cart

System Air and Water Pressure Adjustments

Page 22

5. If adjustment of either the air or water pressure

is required, turn the appropriate pre-regulator

knob (see Figure 19).

• Clockwise to increase pressure.

• Counterclockwise to decrease.

6. Test the unit by operating the syringe and

handpieces for several seconds. Make sure air

and water pressure are maintained.

18

Decade 2561/2562 Cart

System Air and Water Pressure Adjustments (continued)

NOTE

When decreasing system air or water pressure,

you will not see the air or water pressure

gauge in the utility center change until you

relieve pressure from the system. Activate the

syringe for a few seconds, then check the

gauge. Repeat this process each time you

make an adjustment to decrease pressure.

AIR PRESSURE GAUGE

(70–80 psi [483–552 kPa])

AIR PRE-REGULATOR

WATER PRE-REGULATOR

WATER PRESSURE GAUGE

(30–40 psi [241–276 kPa])

Figure 19. Air and Water Pressure Adjustment

2

20

1

10

0

AW

4

3

50

60

40

30

0

4

3

50

5

70

80

6

90

100

psi

7

2

kg/cm

60

40

2

30

20

1

10

100

0

psi

0

kg/cm

5

70

80

6

90

7

2

Page 23

Air and water pass through separate filters in

the utility module before entering the regulator.

A filter must be replaced when it becomes sufficiently clogged, restricting flow to the regulator.

To determine the location of your system utility

module, (see Figure 18 on page 16).

To check the air filter, move the master on/off

toggle to the ON position and lift the cart top.

While watching the air pressure gauge in the

cart top, press the syringe air button. If the air

pressure indicated by the gauge drops by more

than 15 psi (103 KPA), the filter element is

clogged and must be replaced.

To check the water filter, move the master on/off

toggle to the ON position and lift the cart top.

While watching the water pressure gauge in the

cart top, press the syringe water button. If the

water pressure indicated by the gauge drops by

more than 10 psi (69 KPA), the filter element is

clogged and must be replaced.

19

Decade 2561/2562 Cart

Filter Maintenance

Air and Water Filter Elements

Page 24

To inspect or replace a filter element, move the

master on/off toggle to the OFF position, then

close the manual shutoff valves in the floor box.

Bleed the system of air and water pressure by

operating the syringe buttons until air and water

no longer flow. Using a standard (flat-blade)

screwdriver, remove the filter housing from the

utility module (see Figure 20) and remove the filter.

If the filter is visibly clogged or discolored, you will

need to replace it. Order A-dec Part No. 24.0234.00.

When installing a new filter, notice that one end

of the filter has a beveled edge. Install the filter

with the beveled edge facing the utility module

(see Figure 20). The system will not work properly

if the filter is installed incorrectly.

20

Decade 2561/2562 Cart

FILTER HOUSING

BEVELED EDGE

WATER SIDE

(Black Regulator)

UTILITY MODULE

AIR SIDE

(White Regulator)

FILTER ELEMENT

(Part No. 24.0234.00;

Pkg of 6: 24.0234.01)

O-RING

(Part No. 030.019.00)

Figure 20. Filter Replacement

Air and Water Filter Elements (continued)

Page 25

Handpiece Controls

Handpiece Flush..........................................page 9

Oil Collector ................................................page 12

Utility Controls

System Air and Water

Pressure Adjustments ..............................page 17

Filter Maintenance

Air and Water Filter Elements ....................page 19

Also refer to the following A-dec documentation

for more maintenance information:

Assistant’s Instrumentation

Assistant’s Instrumentation

Owner’s Guide......................................85.2610.00

Autoclavable Syringe

Owner’s Guide......................................85.0680.00

Care Instructions

Equipment Asepsis

Owner’s Guide......................................85.0696.00

Self-contained Water

Owner’s Guide......................................85.0675.00

Power Supplies

Floor Boxes

Owner’s Guide......................................85.2611.00

21

Decade 2561/2562 Cart

Maintenance

Page 26

Handpiece Controls

Drive Air Pressure ......................................page 6

(Refer also to your handpiece documentation for

the manufacturer’s maximum dynamic drive air

pressure specification.)

Coolant Air Flow .......................................page 7

Coolant Water Flow ..................................page 8

Handpiece Holder .....................................page 10

Service Requirements for Unit Operation:

Minimum Air:

2.50 cfm (70.80 l/min) at 80 psi (551 kPa)

Minimum Water:

1.50 gpm (5.68 l/min) at 40 psi (276 kPa)

Minimum Vacuum:

12 cfm (339.84 l/min)

at 8 inches of mercury (27 kPa)

Cart Weight Specifications:

25 lb (11.34 kg) vertical load is the maximum

safe load capability of the work surface.

Weights of optional attachments:

Tooth Dryer: 1 lb (.45 kg)

Intra-Oral Light Sources: 1 lb (.45 kg)

Any optional non-A-dec attachments and/or

accessories must comply with EN 60601-1 and

EN 60601-1-2.

Specifications are subject to change without notice.

22

Decade 2561/2562 Cart

Adjustments and Specifications

Page 27

Type of Shock Protection:

CLASS I EQUIPMENT

(Dental Chairs, Dental Lights, & Power Supplies)

CLASS II EQUIPMENT

(Chair, Wall, & Cart Mounted Delivery Systems)

Degree of Shock Protection:

TYPE B APPLIED PART (All products)

(Degree of protection against water ingress:

ORDINARY EQUIPMENT (All products)

Mode of Operation

CONTINUOUS OPERATION

(All models except Dental Chairs)

Mode of Operation

CONTINUOUS OPERATION WITH

INTERMITTENT LOADING (Dental Chairs)

23

Decade 2561/2562 Cart

Identification of Symbols

Recognized by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Recognized with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

UL listed to US (UL 544) and Canadian (CAN/CSA C22.2, No.

125) safety standards.

Classified by Underwriters Laboratories Inc. ® with respect to elec-

tric shock, fire and mechanical hazards only in accordance with

UL 2601-1. Classified with respect to electric shock, fire, mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

Conforms to European Directives

(refer to Declaration Statement)

Protective earth (ground).

Functional earth (ground).

Attention, consult accompanying documents.

TYPE B APPLIED PART.

CLASS II EQUIPMENT.

®

Classification of Equipment (EN 60601-1)

LISTED

!

Page 28

85.2614.00

1999-11

Rev E (01649)

Printed in USA.

Copyright © 1999,

All Rights Reserved.

Made with 50% waste paper

2601 Crestview Drive

Newberg, Oregon 97132 U.S.A.

Telephone 1-800-547-1883

(503) 538-7478

Fax (503) 538-0276

®

Designated Representative’s Address:

A-dec Dental U.K., Ltd.

Austin House

11 Liberty Way

Attleborough Fields,

Nuneaton, Warwickshire,

England CV11 6RZ

Telephone: 00 44 24 7635 0901

Fax: 00 44 24 7634 5106

Designated Representative’s Address:

A-dec Australia

41-43 Bowden Street

Alexandria, N.S.W. 2015, Australia

Telephone: (61) 1.800.225010

Loading...

Loading...