Page 1

Owner's Guide

®

®

CASCADE

2615 Cart

and 3175

Wall Mount

85.0664.00

Page 2

Warranty Information

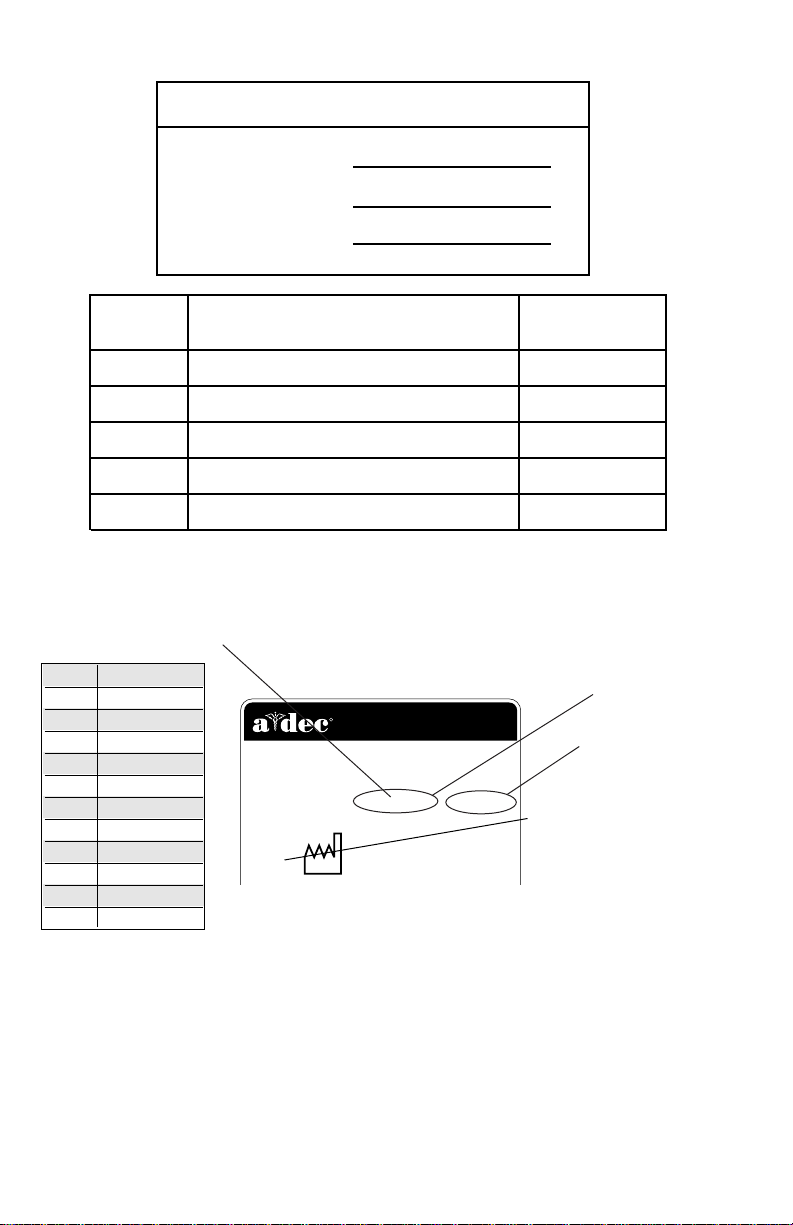

Serial Number

Model Number

Date Purchased

Date of

Service

Model/Description of Service

Technician's

Initials

R

NEWBERG, OREGON 97132 USA

2601 CRESTVIEW DRIVE

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV116RZ

Tele: (44) 1203-350901

SN: J828287 REF: 2122

1993

ALPHABETICAL

EQUIVALENT TO THE

NUMERAL OF THE MONTH

MANUFACTURED

A January

B February

C March

D April

E May

F June

G July

H August

I September

J October

K November

L December

SERIAL

NUMBER

MODEL

NUMBER

YEAR

MANUFACTURED

SERIAL NUMBER

IDENTIFICATION

Serial Number Location:

• Located on the underside of the assistant’s work surface.

For service information contact your local authorized A-dec dealer.

Check with local codes and A.D.A. (Americans with Disabilities

Act) Requirements for Installation of this product.

Page 3

A-dec warrants its products against defects in material or

®

workmanship for one year from time of delivery (except

for handpieces which have a warranty period of six

months). A-dec’s sole obligation under the warranty is to

provide parts for the repair, or at its option, to provide the

replacement product (excluding labor). The buyer shall

have no other remedy. (All special, incidental, and

coincidental damages are excluded.) Written notice of

breach of warranty must be given to A-dec within the

warranty period. The warranty does not cover damage

resulting from improper installation or maintenance,

accident or misuse. The warranty does not cover damage

resulting from the use of cleaning, disinfecting or

sterilization chemicals and processes. The warranty also

does not cover light bulbs. Failure to follow instructions

provided in A-dec’s Operation and Maintenance

Instructions (Owner’s Guide) may void the warranty.

NO OTHER WARRANTIES AS TO

MERCHANTABILITY OR OTHERWISE ARE MADE

Warranty

All product names used in this document are trademarks or

registered trademarks of their respective holders.

Printed in USA • Copyright © 1999 • All Rights Reserved

Page 4

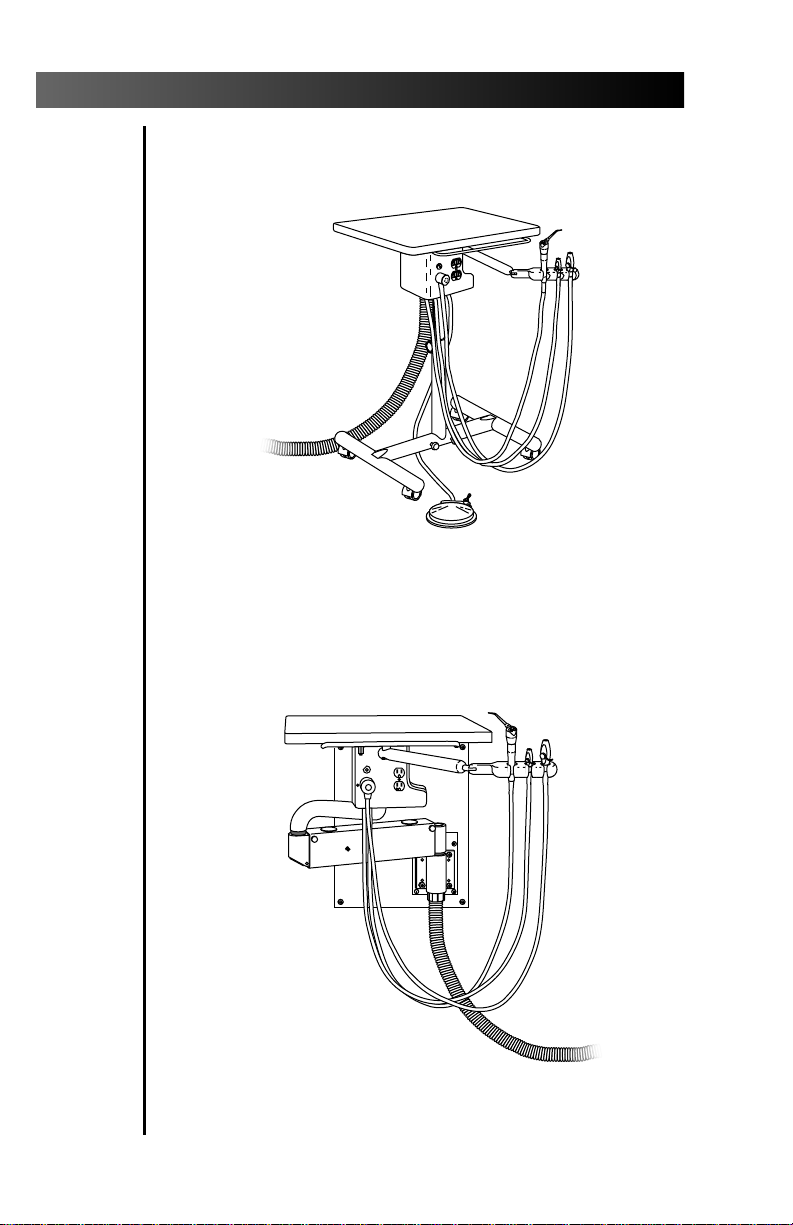

Cascade 2615 Cart / Cascade 3175 Wall Mount

Cascade 2615 Assistant’s Cart

Cascade 3175 Assistant’s Wall Mount

Page 5

Cascade 2615 Cart / Cascade 3175 Wall Mount

Serial Number Location, Service Information,

and Warranty Information are located on the

inside front cover and front page.

CONTENTS

About Your Assistant’s Unit ............................. 2

Assistant’s Instrumentation ............................. 3

Autoclavable HVE &

Autoclavable Saliva Ejector ................. 3

Solids Collector ........................................... 4

Autoclavable Syringe ................................ 4

Tray Holder (Optional) ........................................ 5

Left/Right Conversion ................................ 5

System Air and Water

Pressure Adjustments ................................. 6

Care Instructions............................................... 6

Wall Mount Adjustments ................................. 6

Leveling ...................................................... 6

Arm Spring Tension ................................... 8

Arm Brake Adjustment............................... 9

Cart Adjustments............................................ 11

Work Surface Height ................................ 11

Wall Mount & Cart Adjustments ................... 12

Left/Right Conversion .............................. 12

Work Surface Leveling ............................. 12

Maintenance................................................... 14

Adjustments and Specifications ..................... 14

Identification of Symbols................................ 16

Classification of Equipment (EN 60601-1)..... 17

1

Page 6

Cascade 2615 Cart / Cascade 3175 Wall Mount

OPERATION

About Your Assistant’s Unit

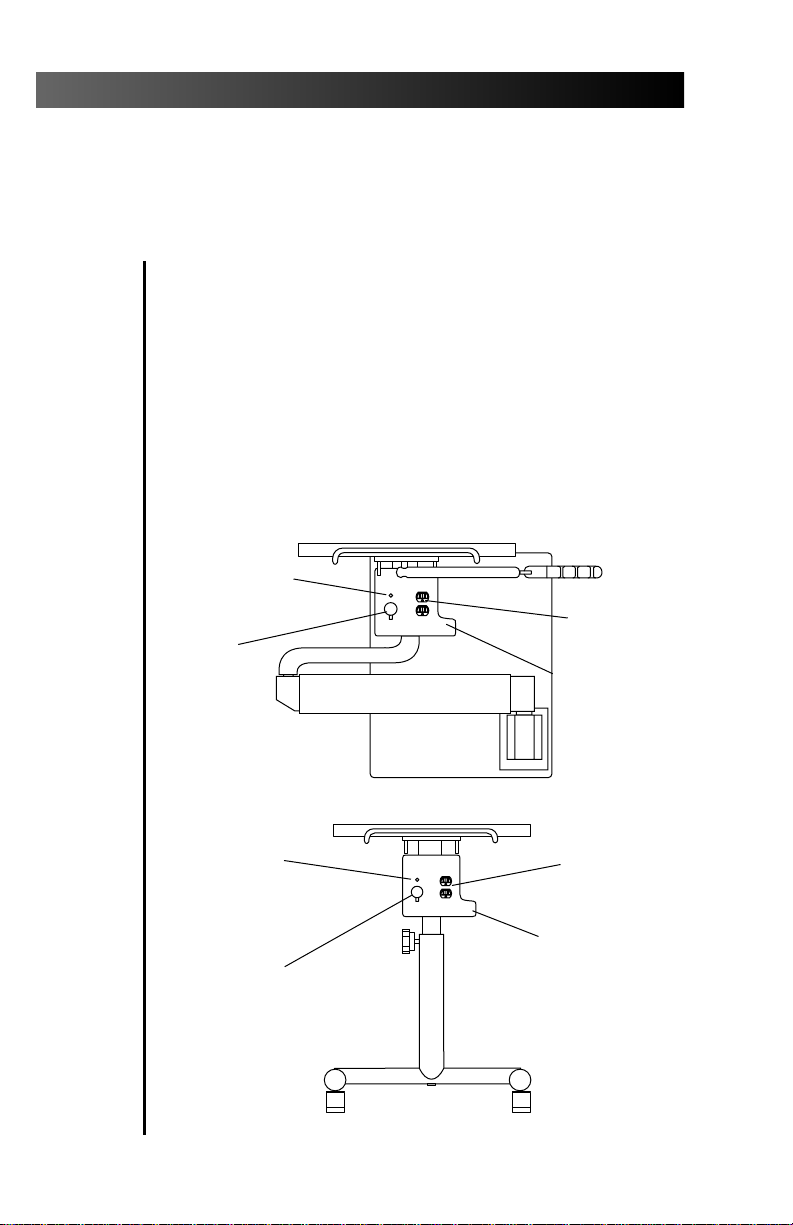

Your Cascade 2615 Assistant’s Cart or Cascade

3175 Assistant’s Wall Mount is equipped with the

following instrumentation: autoclavable syringe,

autoclavable saliva ejector, and autoclavable HVE

(two HVEs optional). The unit’s post box contains a

solids collector, a water quick disconnect (QD), and

a power supply duplex (see Figure 1). An optional

tray holder is easily fitted for right-hand or lefthand usage (refer to page 5).

WATER QUICK

DISCONNECT (QD)

SOLIDS

COLLECTOR

POWER

SUPPLY

DUPLEX

POST BOX

WATER QUICK

DISCONNECT (QD)

SOLIDS COLLECTOR

Figure 1. Cart & Wall Mount Post Box

POWER

SUPPLY

DUPLEX

POST BOX

2

Page 7

Cascade 2615 Cart / Cascade 3175 Wall Mount

Assistant’s Instrumentation

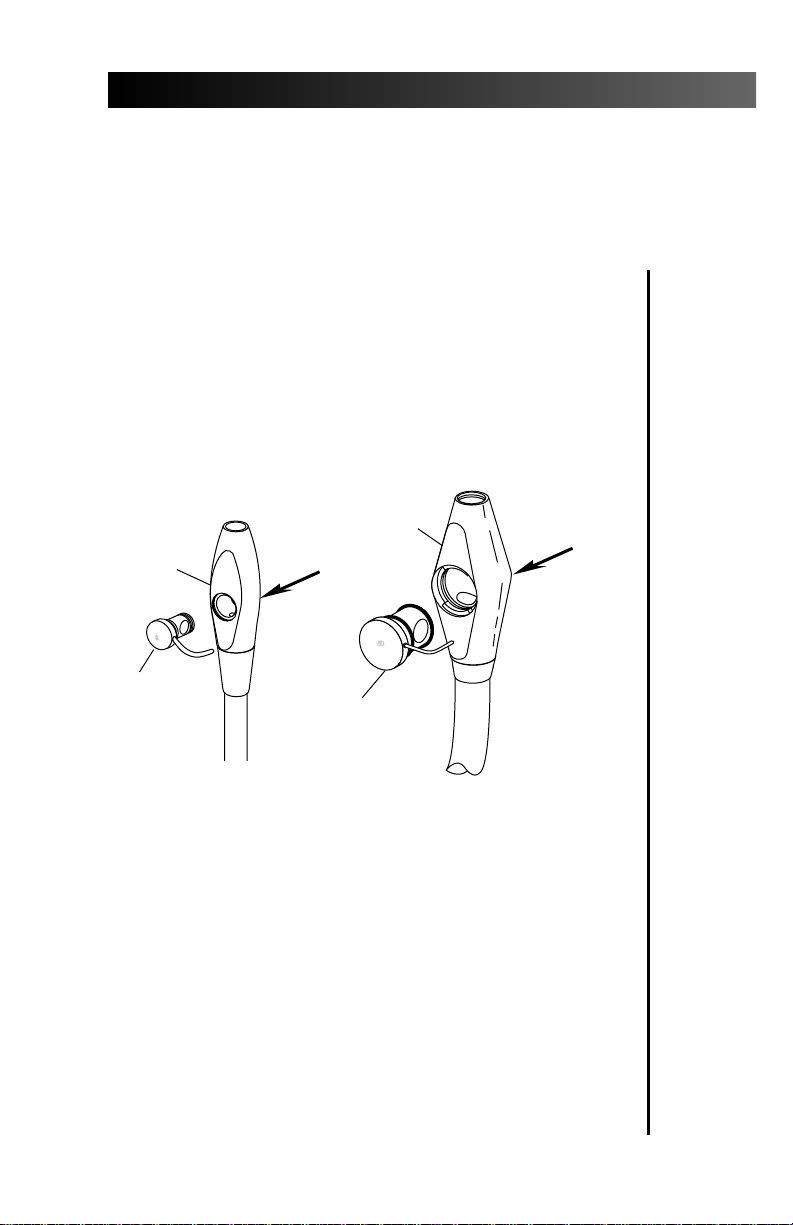

Autoclavable HVE & Autoclavable Saliva Ejector

To operate the autoclavable HVE and saliva

ejector, simply turn the control valve.

The autoclavable HVE and saliva ejector can be

easily converted for right- or left-hand operation.

To convert, press the control valve out of the valve

body (see Figure 3). Rotate the control valve 180°,

then press it back into the valve body.

VALVE

BODY

VALVE

BODY

CONTROL

VALVE

AUTOCLAVABLE

SALIVA EJECTOR

CONTROL

VALVE

AUTOCLAVABLE HVE

Figure 2. Right- to Left-Hand Conversion

Refer to your Assistant’s Instrumentation

Owner's Guide (A-dec Publication No. 85.2610.00)

for complete instructions on cleaning your HVE

and saliva ejector.

3

Page 8

Cascade 2615 Cart / Cascade 3175 Wall Mount

Solids Collector

The solids collector (see Figure 3) prevents solids

from entering the central vacuum system.

HVE TUBING

ASSEMBLY

Figure 3. Solids Collector

SOLIDS

COLLECTOR

SCREEN

Refer to your Assistant’s Instrumentation

Owner’s Guide (A-dec Publication No. 85.2610.00) for

complete solids collector maintenance instructions.

Autoclavable Syringe

CAP

To operate the syringe (see Figure 4):

• Move the on/off toggle to the ON position.

• Air — Press the right button down.

• Water – Press the left button down.

• Spray – Press both buttons down.

AIR

WATER

SPRAY

Figure 4. Autoclavable Syringe

Refer to your Autoclavable Syringe Owner’s Guide

(A-dec Publication No. 85.0680.00) for complete

syringe operation and maintenance instructions.

4

Page 9

Cascade 2615 Cart / Cascade 3175 Wall Mount

Tray Holder (Optional)

Left/Right Conversion

The optional tray holder can be easily mounted

on either side of the unit’s work surface (see Figure 5).

LEFT-HAND

MOUNTING

LOCATION

TRAY HOLDER

(Shown mounted

for right-hand use.)

WORK SURFACE

(top view)

Figure 5. Tray Holder Left/Right Conversion

1. Remove the plug from the work surface corner

opposite the current tray holder location.

2. Remove the tray holder from the unit’s work

surface and set aside.

3. Remove the brass tray holder bushing from

the work surface by removing the 9⁄16" hex

nut (located on the underside of the unit’s

work surface) that secures the bushing to the

work surface.

4. Lift the brass bushing from its seat and move it

to the opposite side of the unit work surface.

5. Install the 9⁄16" hex nut to the new position

and tighten the hex nut.

6. Install the tray holder into the brass bushing.

7. Place the plug into the open tray holder hole.

5

Page 10

Cascade 2615 Cart / Cascade 3175 Wall Mount

System Air and Water Pressure

For system air and water pressure adjustments,

refer to your Floor Boxes Owner’s Guide(A-dec

Publication No. 85.2611.00).

Care Instructions

For recommended asepsis instructions, refer

to your Equipment Asepsis Owner’s Guide

(A-dec Publication No. 85.0696.00) .

For recommended self-contained water system

care, refer to A-dec Self-contained Water System

Owner’s Guide (A-dec Publication No. 85.0675.00).

Wall Mount Adjustments

Leveling

6

Your wall-mounted unit is leveled during

installation and should not require adjustment.

However, if the unit needs to be leveled, the

following procedures will help you.

Leveling Front-To-Back:

Two leveling setscrews are supplied with the unit.

These will be either in the top or bottom leveling

screw holes (see Figure 6).

If the unit tilts forward from the wall (see Figure 6A),

1. Place a leveling device on the work surface.

2. Loosen the bottom two mounting screws.

3. Install the leveling setscrews in the bottom two

holes, then tighten them until the unit is level.

4. Retighten the mounting screws.

Page 11

Cascade 2615 Cart / Cascade 3175 Wall Mount

If the unit tilts toward the wall (see Figure 6B):

1. Place a leveling device on the work surface.

2. Loosen the top two mounting screws.

3. Place the leveling setscrews in the top two

holes, then tighten until the unit is level.

4. Retighten the mounting screws.

FRONT TO BACK

LEVELING

A

BACKBOARD

Figures 6A & 6B

LEVELING SETSCREW

POSITIONS (For Front-

to-Back Leveling)

LEVELING CAM

(Use 3/4" openend wrench.)

B

SIDE-TO-SIDE LEVELING

MOUNTING

SCREWS

(mounting panel)

Figure 6. Leveling the Wall Mount

Leveling Side-To-Side:

1. Loosen the four hex screws in the mounting

panel, about 1/4 of a turn.

2. Place a leveling device on the work surface.

3. Using a 3⁄4" open-end wrench, gently turn the

leveling cam (see Figure 6) until the unit is level.

4. Retighten the mounting screws.

7

Page 12

Cascade 2615 Cart / Cascade 3175 Wall Mount

Arm Spring Tension

When you move the unit, it should stay where

you place it. If the unit tends to drift up or down,

the tension of the arm’s internal spring needs to

be adjusted.

NOTE

The spring tension should be adjusted with a

“normal” load on the work surface. The brake

on/off toggle should be in the OFF position.

1. Locate the adjustment screw under the arm

(see Figure 7).

1/4" HEX KEY

Figure 7. Arm Spring Tension Adjustment

2. Use a 1⁄4" hex key to make the adjustment.

• If the unit drifts down, turn the screw

clockwise to increase spring tension.

• If the unit drifts up, turn the screw

counterclockwise to decrease spring tension.

8

Page 13

Cascade 2615 Cart / Cascade 3175 Wall Mount

Arm Brake Adjustment

NOTE

Adjust arm spring tension prior to arm brake

adjustment (refer to page 8). Retest the brake

after spring adjustment.

The air-actuated arm brake on your wallmounted unit has been set at the factory and

should not need further adjustment. If the

brake does not hold, first check to be sure that

the brake on/off toggle is in the ON position,

and that there is air (at least 60 psi) to the unit.

Refer to your Floor Box Owner’s Guide

(A-dec Publication No. 85.2611.00) for complete

air pressure adjustment procedures.

If the brake will not hold, the brake may be

too loose. A brake which is too tight will cause

a screeching or scraping noise as you move the

unit up or down when the brake is not on.

To adjust the brake:

1. Move the brake on/off toggle to the OFF position.

2. Remove the plug from the access hole on the

left side of the arm (see Figure 8).

ACCESS

HOLE

PLUG

Figure 8. Arm Brake

(Continued on page 10.)

9

Page 14

Cascade 2615 Cart / Cascade 3175 Wall Mount

Arm Brake Adjustment (continued)

3. Push down on the arm until the inner hole

lines up with the outer hole, then insert a

5/32" hex key.

ACCESS

HOLE

5/32"

HEX KEY

7/16" OPEN-END (or

crescent) WRENCH

Figure 9. Arm Brake Adjustment

10

NOTE

Adjust the nut in small increments and retest

the brake. Overtightening or overloosening

the adjustment nut may damage the brake.

4. Locate the adjustment nut under the arm

(see Figure 9).

• To tighten the brake, use a 7/16" open-end wrench

to hold the adjustment nut while you turn the

hex key clockwise

• To loosen the brake, use a 7/16" open-end wrench

to hold the adjustment nut while you turn the

hex key counterclockwise.

Page 15

Cascade 2615 Cart / Cascade 3175 Wall Mount

Cart Adjustments

Work Surface Height

WARNING

The cart is very heavy. Cart height adjustment requires two people to safely complete.

Firmly tighten the knob after adjusting the

cart height, serious bodily injury may result

if the knob is not secure.

1. Securely hold the cart top so it will not drop,

loosen the knob.

Figure 10. Cart Height Adjustment

2. Lift or lower the cart top until the work surface

is at the desired height.

3. Firmly tighten the knob. If the top lowers, the

knob was not tightened enough.

11

Page 16

Cascade 2615 Cart / Cascade 3175 Wall Mount

Wall Mount & Cart Adjustments

Left/Right Conversion

Your assistant’s cart or wall mount can be easily

converted for opposite-hand delivery.

Simply rotate the assistant’s arm to the opposite

side of the work surface (see Figure 11).

Figure 11. Left/Right Conversion

Work Surface Leveling

To level your assistant’s unit work surface:

1. Place a leveling device on the work surface.

2.Check for level front-to-back and side-to-side.

3.Locate the four mounting screws found in the

leveling plate on the underside of the work

surface (see Figure 12). Using a 3⁄16" hex key,

loosen but do not remove these screws.

12

Page 17

Cascade 2615 Cart / Cascade 3175 Wall Mount

MOUNTING

SCREWS

LEVELING

LEVELING

SETSCREWS

PLATE

MOUNTING

SCREWS

WORK SURFACE HANDLE

LEVELING

SETSCREWS

Figure 12. Leveling the Work Surface

(Viewed from the bottom of the work surface and

shown without assistant’s arm or post box.)

4. Locate the four leveling setscrews

(there is one in each corner of the leveling

plate underneath the unit work surface).

Front-to Back Leveling:

Face the work surface handle.

If the work surface tilts toward you, use a 3⁄16" hex

key and tighten the two leveling setscrews closest

to you until the work surface is level.

If the work surface tilts away from you, tighten the

two leveling setscrews furthest away until the

work surface is level.

Side-to-Side Leveling:

Face the work surface handle.

If the work surface tilts to the left, tighten the two

leveling setscrews on the left side of the leveling

plate until the work surface is level.

If the work surface tilts to the right, tighten the two

leveling setscrews on the right side of the leveling

plate until the work surface is level.

5. When you have completed these steps tighten

the four mounting screws, then check the work

surface again for level.

13

Page 18

Cascade 2615 Cart / Cascade 3175 Wall Mount

Maintenance

Solids Collector.........................................page 4

Also refer to the following documentation for

more maintenance information:

Assistant’s Instrumentation

Assistant’s Instrumentation

Owner’s Guide ..............................85.2610.00

Autoclavable Syringe

Owner’s Guide ..............................85.0680.00

Care Instructions

Equipment Asepsis

Owner’s Guide ..............................85.0696.00

Self-contained Water

Owner’s Guide ..............................85.0675.00

Power Supplies

Floor Boxes

Owner’s Guide ..............................85.2611.00

Adjustments and Specifications

Wall Mount Adjustments:

Leveling..............................................page 6

Arm Spring Tension ...........................page 8

Arm Brake Adjustment......................page 9

Cart Adjustments:

Work Surface Height ..........................page 11

Wall Mount & Cart Adjustments:

Tray Holder (optional)

Left/Right Conversion..................page 5

Left/Right Conversion........................page 12

Work Surface Leveling .......................page 12

14

Page 19

Cascade 2615 Cart / Cascade 3175 Wall Mount

Adjustments and Specifications

Service Requirements for Unit Operation:

Minimum Air:

2.50 cfm (70.80 l/min) at 80 psi (551 kPa)

Minimum Water:

1.50 gpm (5.68 l/min) at 40 psi (276 kPa)

Minimum Vacuum:

12 cfm (339.84 l/min)

at 8 inches of mercury (27 kPa)

Cart Specifications:

25 lb (11.34 kg) vertical load is the maximum

safe load capability of the work surface.

5 lb (2.27 kg) vertical load is the maximum

safe load capability of the optional tray holder.

Wall Mount Specifications:

40 lb (18.14 kg) vertical load on work surface

will be supported by the arm brake.

100 lb (45.36 kg) maximum unit weight.

200 ft-lb (270 N·m) maximum moment

created at the wall by the freestanding unit.

5 lb (2.27 kg) vertical load is the maximum

safe load capability of the optional tray holder.

(continued)

Any optional non-A-dec attachments and/or

accessories must comply with EN 60601-1 and

EN 60601-1-2.

Also refer to the following documentation for

more adjustment and specification information:

System Air and Water Pressure Adjustments

Floor Box

Owner’s Guide ..............................85.2611.00

Specifications are subject to change without notice.

15

Page 20

Cascade 2615 Cart / Cascade 3175 Wall Mount

LISTED

®

!

Identification of Symbols

Recognized by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Recognized with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

UL listed to US (UL 544) and Canadian (CAN/CSA C22.2, No.

125) safety standards.

Classified by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Classified with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

Conforms to European Directives

Protective earth (ground).

Functional earth (ground).

Attention, consult accompanying documents.

TYPE B APPLIED PART.

CLASS II EQUIPMENT.

(refer to Declaration Statement)

16

Page 21

Cascade 2615 Cart / Cascade 3175 Wall Mount

Classification of Equipment (EN 60601-1)

Type of shock protection:

CLASS I EQUIPMENT

(Dental Chairs, Dental Lights, & Power Supplies)

CLASS II EQUIPMENT

(Chair, Wall, & Cart Mounted Delivery Systems)

Degree of shock protection:

TYPE B APPLIED PART (All products)

Degree of protection against water ingress:

ORDINARY EQUIPMENT (All products)

Mode of operation

CONTINUOUS OPERATION

(All models except Dental Chairs)

Mode of operation

CONTINUOUS OPERATION

WITH INTERMITTENT LOADING (Dental Chairs)

17

Page 22

2601 Crestview Drive

®

Newberg, Oregon 97132 U.S.A.

Telephone 1-800-547-1883

(503) 538-7478

Fax (503) 538-0276

Designated Representative’s Address:

A-dec Dental U.K., Ltd.

Austin House

11 Liberty Way

Attleborough Fields

Nuneaton, Warwickshire

England. CV11 6RZ

Telephone: 0800 233285 (within UK)

00 44 24 7635 0901 (outside UK)

Fax: 00 44 24 7634 5106

Designated Representative’s Address:

A-dec Australia

41-43 Bowden Street

Alexandria, N.S.W. 2015, Australia

Telephone: (61) 1.800.225010

85.0664.00

1999-06

Rev K (01076)

Made with 50% waste paper

Printed in USA.

Copyright © 1999,

All Rights Reserved.

Loading...

Loading...