Page 1

Owner’s Guide

CASCADE

®

1040 Chair

85.2605.00

Page 2

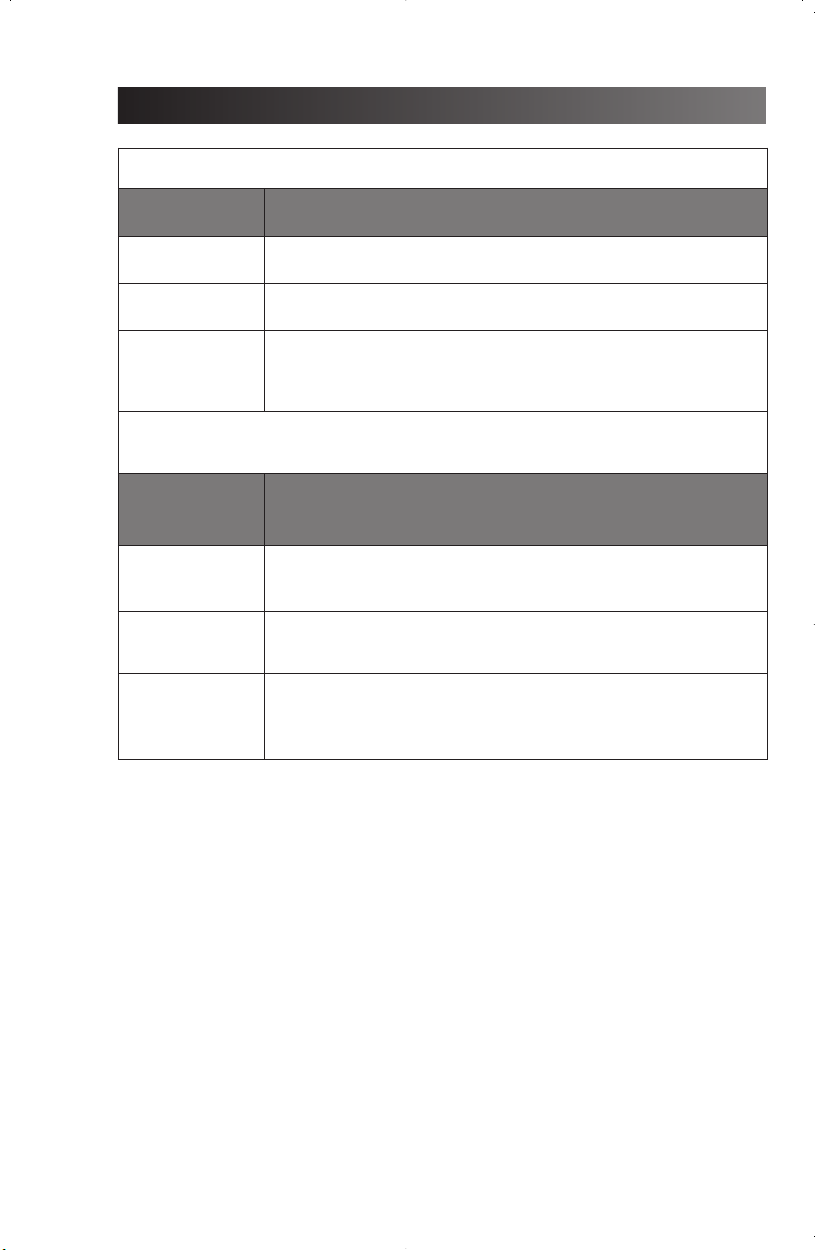

Cascade Chair Serial Number Location:

• On the upper structure, under the upholstery

For service information contact your local authorized A-dec dealer.

Check with local codes and A.D.A. (Americans with Disabilities Act)

Requirements for Installation of this product.

SERIAL

NUMBER

MODEL

NUMBER

YEAR MANUFACTURED

ALPHABETICAL EQUIVALENT

TO THE NUMERAL OF THE

MONTH MANUFACTURED

A January

B February

C March

D April

E May

F June

G July

H August

I September

J October

K November

L December

Serial Number Identification

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV116RZ

1999

2601 CRESTVIEW DRIVE

NEWBERG, OREGON 97132 USA

Tele: (44) 24 7635 0901

SN: J828287

MADE

IN USA

REF: 2122

Page 3

Printed in U.S.A. • Copyright © 2006 • All Rights Reserved

Warranty

All product names used in this document are trademarks or

registered trademarks of their respective holders.

A-dec warrants all products in this catalog against defects

in material or workmanship for one year from time of

delivery. A-dec’s sole obligation under the warranty is to

provide parts for the repair, or at its option, to provide the

replacement product (excluding labor). The buyer shall

have no other remedy. All special, incidental, and

coincidental damages are excluded.

Written notice of breach of warranty must be given to

A-dec within the warranty period. The warranty does not

cover damage resulting from improper installation or

maintenance, accident or misuse. The warranty does not

cover damage resulting from the use of cleaning,

disinfecting or sterilization chemicals and processes. The

warranty also does not cover light bulbs. Failure to follow

instructions provided in the A-dec owner’s guide

(operation and maintenance instructions) may void

the warranty.

A-dec warrants A-dec dental chair cylinders, both lift and

tilt, for ten years from the date of purchase of the chair or

the cylinder. This warranty is retroactive to A-dec chair

cylinders already in the field. The warranty covers chair

cylinders A-dec finds to have manufacturing related

irregularities. Stool cylinders are covered under A-dec‘s

one-year warranty.

No other warranties as to merchantability

or otherwise are made.

Page 4

Cascade 1040 Chair

Cascade 1040 Chair

Page 5

1

Cascade 1040 Chair

Serial number location, service information, and

warranty information are located on the inside

front cover and front page.

About Your Cascade Chair ............................. 2

Chair LED.......................................................... 2

Chair Stop Plate .............................................. 2

8-Function Footswitch .................................... 3

Touch Pad ....................................................... 3

Programming the Chair .....................................5

Swivel Brake ................................................... 8

Double-Articulating Headrest ........................ 9

Headrest Positioning for Wheelchair ..... 10

Headrest Drift Adjustment ..................... 11

Upholstery Replacement .............................. 12

Back Upholstery ..................................... 12

Double-Articulating

Headrest Upholstery ......................... 13

Seat Upholstery ...................................... 14

Armrest Upholstery ................................ 15

Care Instructions .......................................... 16

Adjustments and Specifications ................... 17

Maintenance ................................................ 17

Safety Considerations for

Accessory Equipment ............................... 18

Transporting the Dental Unit ......................... 18

Identification of Symbols ............................. 19

Classification of Equipment (EN 60601-1) .... 19

CONTENTS

Page 6

Your Cascade chair is an electronically controlled,

hydraulically powered dental chair (see Figure 1).

Chair functions are controlled by the 8-function

footswitch or touch pad (see Figure 2 or 2a on

page 3).

The chair LED indicates the status of the chair:

ON: Normal operation.

SLOW BLINK: The cuspidor or stop plate limit

switches have been activated. Remove any obstructing

object.

The chair stop plate (see Figure 1) stops the chair

immediately when any part of it is pressed. Should

anything inadvertently become lodged under the chair,

press Base UP on the footswitch or touch pad to raise

the chair so the object can be removed. As long as

pressure is applied to the stop plate, the chair base will

not go down any further.

2

Cascade 1040 Chair

Figure 1. Lift, Tilt, and Stop Plate

CHAIR

STOP

PLATE

BASE LIFT

CHAIR BACK /

TOEBOARD TILT

Chair LED

Chair Stop Plate

About Your Cascade Chair

LED

Page 7

The 8-function footswitch (see Figure 2) or the chair

touch pad (see Figure 2a) gives you both manual and

programmed control of chair positioning. The arrows

on the footswitch and touch pad manually control chair

back/toeboard tilt and chair lift. The numbered buttons

are for Entry/ Exit and programmed chair positions.

3

Cascade 1040 Chair

8-Function Footswitch

Touch Pad

Figure 2. 8-Function Footswitch

BASE UP

BACK DOWN

BASE DOWN

BACK UP

PROGRAM BUTTON

PROGRAMMABLE

POSITION (1)

PROGRAMMABLE

POSITION (2)

PROGRAMMABLE

ENTRY/EXIT (0)

CUSPIDOR/RETURN (3)

Figure 2a. Chair Touch Pad

BASE UP

BACK DOWN

BASE DOWN

BACK UP

PROGRAM BUTTON

PROGRAMMABLE

POSITION (1)

PROGRAMMABLE

POSITION (2)

PROGRAMMABLE

ENTRY/EXIT (0)

CUSPIDOR/RETURN (3)

1

0

21

0

2

3

3

Page 8

Manual Controls

The Base Up/Down (lift) function controls chair lift,

or vertical movement. To raise the chair, push the up

arrow on the footswitch or touch pad. To lower the

chair, push the down button on the footswitch or touch

pad. Push the button until the chair reaches the desired

height, then release it.

The Back Up/Down (tilt) function controls the chair

back/toeboard tilt. To raise the chair back, push the right

arrow on the footswitch or touch pad. To lower the chair

back, push the left arrow on the footswitch or touch

pad. Push the button until the chair back reaches the

desired position, then release it.

Program Button

The Program Button (located on the top middle of the

footswitch, or in between the arrows on the touch pad)

is used to save the settings for Entry/ Exit (0),

programmable positions (1 and 2), and

Cuspidor/Return (3).

4

Cascade 1040 Chair

Page 9

Programmable Positions 1 and 2

To send the chair to a programmed operating position,

push either 1 or 2 (or press 1 or 2 on the touch pad).

Positions 1 and 2 are programmed at the factory to

move the chair to the same position.

To change a programmable position, locate the

program button on the footswitch or touch pad

(see Figures 2 or 2a on page 4).

1. Using the manual arrows on the footswitch or

touch pad, set the chair to the operating position that

you prefer.

2. Press and release the program button. An

audible tone will be emitted. Then, within four

seconds, push the button for 1or 2 to store that

position. You will hear an audible tone confirming that

the programmable function has been reprogrammed.

3. Check the programmed position by manually

moving the chair to another position. Then push either

1 or 2 programmed in Step 2. The chair should move

automatically to the position set in Step 1.

5

Cascade 1040 Chair

Programming the Chair

NOTE

When 1 or 2 are pressed on the footswitch or

touch pad, the chair base and back go to the

preset position.

To stop the chair at any point, press any

button on the footswitch (or press any

button on the touch pad).

Page 10

Optional Program Functions

Position 3 is factory set in the Cuspidor/Return

mode. In this mode, the chair back will rise to a

pre-programmed upright position providing the patient

access to the cuspidor. Pressing position 3 a second time

lowers the chair back to its previous operating position.

Position 3 may also be used as a third Pre-Position or

as a last recall.

Contact an authorized A-dec Dealer to have Position 3

reconfigured to a third Pre-Position or as a last position

recall.

6

Cascade 1040 Chair

Page 11

Entry/ Exit (0)

To send the chair to a preset entry/exit position, push

the position 0 button (see Figure 2 or 2a on page 3).

If you want to change the preset entry/exit position,

first locate the program button on the footswitch or

touch pad (see Figure 2 or 2a on page 3).

1. Using the manual arrows, set the chair to the

desired patient entry/exit position.

2. Press and release the program button. An

audible tone will be emitted. Then, within four

seconds, press the Entry/Exit (0) button on the

footswitch or touch pad. You will hear an audible tone

confirming that the chair has been reprogrammed. This

stores your preferred patient entry/exit position.

3. Check the Entry/ Exit (0) function by manually

moving the chair to another position. Push the Entry/

Exit (0) button. The chair should move automatically to

the position you set in Step 1.

7

Cascade 1040 Chair

NOTE

When pushed, Entry/ Exit (0) will cause the

chair base and back to go to the preset

entry/exit position.

To stop the chair at any point, push any

button on the footswitch or touch pad.

Page 12

When engaged, the chair swivel brake restricts

rotation of the chair. With the brake released, you can

rotate the chair to any position within approximately

30° either side of center. To unlock the swivel brake,

push the brake lever to the right. To lock the swivel

brake, push the brake lever to the left.

If the chair swivels left or right with the brake

engaged, or if it is difficult to move with the brake

disengaged, the swivel brake tension must be adjusted.

Using a 3⁄16-inch hex key, adjust the swivel brake

tension. Turn the adjusting screw clockwise to increase

brake friction. Turn the screw counterclockwise to

decrease brake friction.

8

Cascade 1040 Chair

Swivel Brake

Figure 4. Swivel Brake Adjustment

ADJUSTING SCREW

LOCKED UNLOCKED

Page 13

The locking knob allows you to easily adjust the

headrest for a full range of positions.

To position the headrest, release the locking knob by

turning the knob out (counterclockwise), then adjust

the headrest as necessary to fit the head and neck. Lock

the headrest in the desired position by turning the knob

in (clockwise).

To move the headrest higher or lower, simply pull up

or push down on the headrest until it is at the desired

height.

9

Cascade 1040 Chair

Figure 5. Double-Articulating Headrest

LOCKING

KNOB

Double-Articulating Headrest

Page 14

The headrest can be used to accommodate wheelchair

patients. Slide the headrest up until it is free from the

chair, turn it 180°, then slide it back into the backrest

and push it all the way down. Run the chair to its full

Back Up position. Adjust headrest height by moving the

chair up or down (using the Base Up function on the

footswitch or touch pad), then position the headrest as

desired.

10

Cascade 1040 Chair

Figure 6. Headrest Positioning for

Wheelchair Usage

Headrest Positioning for Wheelchair

Page 15

If the headrest drifts downward, or if it is difficult to

move up or down, the glide bar tension must be

adjusted. Remove the headrest glide bar to access the

adjusting screw.

Using a Phillips screwdriver, adjust the glide bar

tension. Turn the adjusting screw clockwise three to four

revolutions to increase friction and hold the headrest

more securely. Turn the screw counterclockwise three to

four revolutions to decrease friction and allow the

headrest to move up and down more freely. Reinstall

the headrest and recheck glide bar tension.

11

Cascade 1040 Chair

Figure 7. Headrest Drift Adjustment

HEADREST

GLIDE BAR

Headrest Drift Adjustment

Page 16

A-dec’s unique formed upholstery makes replacing

upholstery quick and easy.

The upholstery on your Cascade 1040 Chair is

installed in four sections: back, headrest, seat, and

armrests. Each section is easily removed and replaced.

To remove back upholstery firmly grasp the bottom

edge of the cushion and lift upward, approximately

1-inch, to release the four large, flat-headed fasteners

from the cushion key-slots.

To install back upholstery place the large fastener

heads in the cushion keyhole pockets then push in and

down in one motion.

12

Cascade 1040 Chair

Figure 8. Replacing the Back Upholstery

KEY SLOT

IN BACK

UPHOLSTERY

LARGE HEAD

FASTENER

Upholstery Replacement

Back Upholstery

Page 17

Use the following procedure to replace the headrest

upholstery.

1. Loosen the headrest knob and rotate the headrest

to a full upright position.

2. Remove the top Phillips mounting screw from the

headrest back-plate, located just above the knob

assembly.

3. Rotate the headrest back 45° to expose the two

Phillips mounting screws on the lower headrest

back-plate (see Figure 9). Remove the two screws

and the headrest cushion.

4. To attach the replacement upholstery, reverse this

procedure.

13

Cascade 1040 Chair

Figure 9. Replacing the Headrest Upholstery

HEADREST

BACK-PLATE

MOUNTING

SCREWS

(one hidden)

TOP

MOUNTING

SCREW

(hidden)

Double-Articulating Headrest Upholstery

Page 18

Use the following procedure to replace the

seat upholstery.

1. Lower the chair back, lift the toeboard, and hold it

by the frame.

2. Detach and remove the clear vinyl toeboard cover.

3. Using a 3/16-inch hex key, loosen the four screws

that secure the seat/toeboard upholstery assembly

to the seat frame.

4. Lower the toeboard and lift off the seat/toeboard

upholstery assembly.

5. Place the new seat/toeboard upholstery assembly

on the seat frame.

6. Lift the toeboard and tighten the four screws, then

lower the toeboard.

7. Attach the new clear vinyl toeboard cover.

14

Cascade 1040 Chair

Figure 10. Replacing the Seat Upholstery

SEAT FRAME

SCREWS

3/16" HEX KEY

SEAT

UPHOLSTERY

Seat Upholstery

Page 19

Use the following procedure to replace the armrest

upholstery assembly.

1. Lift the armrest away from the seat pocket. Use a

Phillips screwdriver and remove the retaining screw

from the underside of the armrest.

2. Push the armrest upholstery assembly toward the

toe end of the chair, approximately 1⁄2-inch, then

lift the armrest upholstery away from the arm.

3. Place the new armrest on the arm and slide it

toward the chair back. Replace the retaining screw

on underside.

15

Cascade 1040 Chair

Figure 11. Replacing the Armrest Upholstery

RETAINING

SCREW

ARMREST

UPHOLSTERY

ASSEMBLY

Armrest Upholstery

Page 20

For recommended asepsis instructions, refer to

the Asepsis section of the Owner’s Guide

(A-dec Publication No. 85.0696.00).

16

Cascade 1040 Chair

Care Instructions

Page 21

Programming the Chair.................................... page 5

Swivel Brake ...................................................... page 8

Double-Articulating Headrest .......................... page 9

Headrest Drift Adjustment............................. page 11

Chair Capacity:

Patient Load: 300 lbs. (135 kg) maximum.

Accessory Load: 150 lbs. (67.5 kg) maximum.

Maximum Load from Accessories:

Chair Adapter: 200 lbs. (90 kg) weight combined

with a moment of 250 ft. lbs. (339 N·m)

Radius Front Mount: 180 lbs. (81 kg)

weight combined with a moment of

525 ft. lbs. (711.8 N·m)

Radius Rear Mount: 70 lbs. (31.5 kg)

weight combined with a moment of

160 ft. lbs. (216.9 N·m)

Upholstery Replacement ................................ page 12

Back Upholstery ......................................... page 12

Double-Articulating

Headrest Upholstery .............................. page 13

Seat Upholstery.......................................... page 14

Armrest Upholstery.................................... page 15

Care Instructions ............................................. page 16

Equipment Asepsis Owner’s Guide................85.0696.00

Maintenance Parts Owner’s Guide ................85.2634.00

Specifications are subject to change without notice.

17

Cascade 1040 Chair

Adjustments and Specifications

Maintenance

Page 22

The use of accessory equipment not complying with

the equivalent safety requirements of this equipment

may lead to a reduced level of safety of the resulting

system.

Consideration relating to the use of accessory

equipment shall include:

Evidence that Safety Certification of the accessory

equipment has been performed in accordance to the

appropriate IEC 601 and IEC 601-1 Harmonized

National Standards.

When transporting the dental unit the chair base

should be fully down, and the chair back should be fully

up. The chair body should be secured to the chair

baseplate. Do not lift the chair by the chair body.

The delivery system should be over the seat

upholstery and the light should be centered above

the chair.

The delivery system and light should be secured to

prevent movement. The entire Dental Unit should be

secured to the transporting vehicle.

18

Cascade 1040 Chair

Safety Considerations for

Accessory Equipment

Transporting the Dental Unit

Page 23

19

Cascade 1040 Chair

Identification of Symbols

Symbol Description

Recognized by Underwriters Laboratories Inc. with respect to electric

shock, fire and mechanical hazards only in accordance with UL 60601-1

(2601-1) and under mutual recognition agreement with CAN/CSA

C22.2, No. 601.1.

Classified by Underwriters Laboratories Inc. with respect to electric

shock, fire and mechanical hazards only in accordance with UL 60601-1

(2601-1) and under mutual recognition agreement with CAN/CSA

C22.2, No. 601.1.

UL listed to UL 61010A-1, BS EN 61010-2-010 and Canadian (CAN/CSA

C22.2, No. 1010.1-92) safety standards.

Conforms to European Directives (refer to Declaration of Conformity)

Protective earth (ground).

Functional earth (ground).

Attention, consult accompanying documents. No user serviceable parts.

Attention, line voltage. Only licensed electrician should remove cover.

Type B Applied Part.

Class II equipment.

Caution: Metal surfaces can be hot during and following the dry cycle.

Page 24

20

Cascade 1040 Chair

Classification of Equipment (EN-60601-1)

Type/Mode Classification

Type of shock

protection

CLASS I EQUIPMENT: Dental chairs, dental lights, and

power supplies

CLASS II EQUIPMENT: Chair, wall, and cart mounted

delivery systems

Degree of shock

protection

TYPE B APPLIED PART: Delivery systems only

Degree of

protection

against water

ingress

ORDINARY EQUIPMENT: All products

Mode of

operation

CONTINUOUS OPERATION: All models except Dental Chairs

CONTINUOUS OPERATION WITH INTERMITTENT LOADING:

Dental chairs -

5% duty cycle

Flammable

Gasses

Not suitable for use in the presence of a flammable anesthetic

mixture with air, oxygen, or nitrous oxide, where such gasses may

accumulate in concentration (closed space).

Page 25

Electrical Rating

Type Specification

Volts 100/110-120/220-240 VAC

Frequency 50-60 Hz

Current As configured and specified in equipment manual (products

labeled 15A or greater require dedicated circuit, identified in

distribution panel)

Environmental Specifications

Temperature

/Humidity

Specification

Storage/

Transportation

Temperature: -40°C to 70°C (-40°F to 158°F)

Relative Humidity: 95% maximum

Operating Temperature: 10°C to 40°C (50°F to 104°F)

Relative Humidity: 95% maximum

Indoor Use Altitude up to 2,000m (6, 563 ft.), installation category II, pollu-

tion degree 2. (UL 61010A-1 and CAN/CSA C22.2, No. 1010.1-92

only)

Cascade 1040 Chair

Page 26

85.2605.00

2006-03 Rev H

(05188)

Printed in USA.

©A-dec Inc. 2006

All Rights Reserved

USA and Canada

2601 Crestview Drive

Newberg, Oregon 97132 USA

Phone: 1.800.547.1883

1.503.538.7478

Fax: 1.503.538.0276

www.a-dec.com

International

Phone: 1.503.538.9471

Fax: 1.503.538.5911

Distribution Centers

A-dec Australia

41-43 Bowden Street

Alexandria, NSW 2015, Australia

Phone: 61 (0)2 9699 4600

www.adec.com.au

A-dec United Kingdom

Austin House

11 Liberty Way

Nuneaton, Warwickshire

England CV11 6RZ

Phone: 0800 ADECUK (233285) Within UK

44 24 7635 0901 Outside UK

www.a-dec.co.uk

Loading...

Loading...