Page 1

Owner's Guide

AUTOCLAVABLE

SYRINGE

85.0680.00

®

Page 2

Warranty Information

N/A

N/A

For service information contact your local authorized A-dec dealer.

Check with local codes and A.D.A. (Americans with Disabilities Act)

Requirements for Installation of this product.

Serial Number

Model Number

Date Purchased

Date of

Service

Model/Description of Service

Technician's

Initials

Page 3

Warranty

Printed in U.S.A. • Copyright © 1999 • All Rights Reserved

A-dec warrants its products and A-dec/W&H Synea

handpieces against defects in material or workmanship

for one year from time of delivery. All other handpiece

instrumentation has a warranty period of six months.

A-dec’s sole obligation under the warranty is to provide

parts for the repair, or at its option, to provide the

replacement product (excluding labor). The buyer shall

have no other remedy. (All special, incidental, and

coincidental damages are excluded.) Written notice of

breach of warranty must be given to A-dec within the

warranty period. The warranty does not cover damage

resulting from improper installation or maintenance,

accident or misuse.The warranty does not cover damage resulting from the use of cleaning, disinfecting or

sterilization chemicals and processes. The warranty also

does not cover light bulbs. Failure to follow instructions

provided in A-dec’s Operation and Maintenance

Instructions (Owner’s Guide) may void the warranty.

NO OTHER WARRANTIES AS TO

MERCHANTABILITY OR OTHERWISE ARE MADE.

All product names used in this document are trademarks or

registered trademarks of their respective holders.

®

Page 4

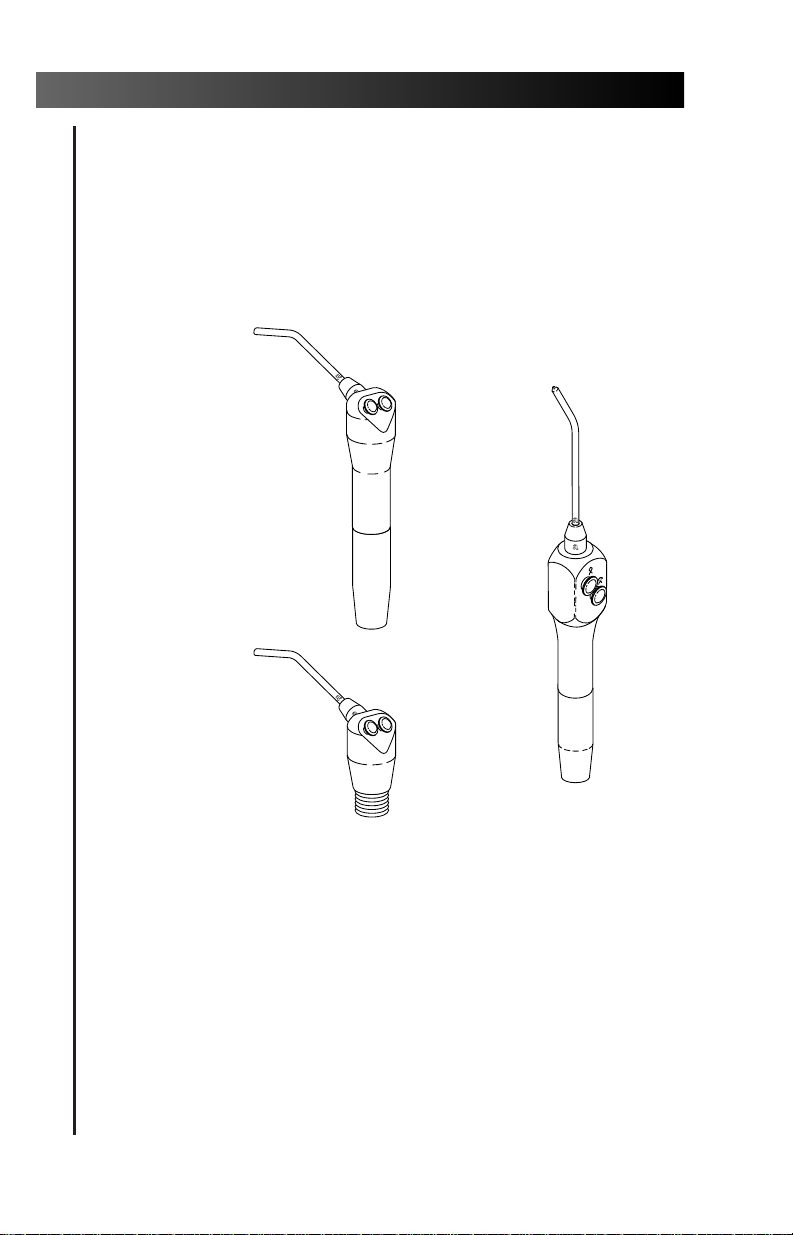

Autoclavable Syringe

Autoclavable

Syringe

Autoclavable

Continental

Autoclavable

Easy-Clean

Syringe Head

Page 5

Serial number location, service information, and

warranty information are located on the inside

front cover and front page.

About Your Autoclavable Syringe............................ 2

Installation ......................................................... 2

Button Functions ................................................ 3

Syringe Tip Retainer Assembly

(Non-locking) ................................................. 3

Optional Configurations ................................... 4

A-dec Syringe Tips..................................................... 5

Installing an A-dec Syringe Tip ......................... 6

Removing an A-dec Syringe Tip ........................ 7

Syringe Air and Water Flow Control ........................ 8

Doctor’s Syringe.................................................. 8

Assistant’s Syringe............................................ 10

Disconnecting the Syringe Head ............................ 11

Locking Syringe Tip Retainer Assembly................. 12

Installing an A-dec Syringe Tip ....................... 12

Restricting Tip Rotation.................................... 14

Removing an A-dec Syringe Tip ...................... 15

Heated Syringe Tubing with

In-line Low Voltage Water Heater............... 16

Quick Disconnect Syringe Terminal ...................... 17

Syringe and Tip Asepsis .......................................... 18

Pre-Cleaning...................................................... 18

Sterilization....................................................... 19

General Information............................................... 20

Using A-dec Silicone Lubricant ......................... 20

Using A-dec Replacement Parts....................... 20

Maintaining Syringe Tip

Retainer Assemblies ..................................... 21

Troubleshooting...................................................... 21

Adjustments and Specifications ............................. 25

Maintenance........................................................... 25

Identification of Symbols........................................ 26

Classification of Equipment (EN 60601-1)............. 26

1

Autoclavable Syringe

CONTENTS

Page 6

Your Autoclavable Continental or

Autoclavable Easy-Clean Syringe is a threeway air and water syringe featuring a patented

quick disconnect autoclavable tip system.

1. Turn off the unit’s master switch.

2. Purge the water and air lines by holding the

syringe over a sink or basin and pressing the

water and air buttons.

3. Disconnect the old syringe by turning the tubing

connector nut counterclockwise.

4. Separate the syringe and tubing.

5. Connect the A-dec syringe to the tubing and

turn the nut clockwise until it is finger tight.

6. Depress separately the air and water buttons to

verify air and water flow.

7. Depress both the air and water buttons

simultaneously to verify desired spray pattern.

If a change of flow is desired, see Syringe Air

and Water Flow Control on page 8.

2

Autoclavable Syringe

OPERATION

About Your New Autoclavable Syringe

Installation

Page 7

All three syringes feature two buttons that provide

three-way, modulated control of syringe water, air,

and spray functions.

The button functions are indicated with

internationally recognized icons for air and water

(see Figure 1).

All three syringe heads are factory equipped

with a non-locking syringe tip retainer assembly.

This style of syringe tip retainer (identified by a

smooth exterior surface, see Figure 2) allows the

syringe tip to be easily removed and installed.

The non-locking syringe tip retainer assembly is

not appropriate for use as cheek retractor

because it allows the syringe tip to rotate.

3

Autoclavable Syringe

Button Functions

Water Air

Figure 1. Water and Air Icons

Syringe Tip Retainer Assembly (Non-Locking)

Figure 2. Syringe Tip Retainer Assembly

(Non-Locking)

SMOOTH

EXTERIOR

SURFACE

Page 8

Locking Syringe Tip Retainer Assembly

The syringe tip may be locked in place, allowing

it to be used for cheek retraction, when the locking

syringe tip retainer assembly option has been

ordered. Refer to page 12 for further information.

Heated Syringe Water

Warm water may be delivered through the

syringe, eliminating the discomfort that can be

caused by spraying cold water on sensitive tissues,

when either the circulating warm water or heated

syringe tubing option has been ordered. Refer to

pages 15 through 17 for further information.

Quick Disconnect Syringe Terminal

The syringe head may be removed from the

syringe tubing without shutting the delivery

system unit off when the quick disconnect syringe

terminal option has been ordered. Refer to page 17

for further information.

4

Autoclavable Syringe

Optional Configurations

Page 9

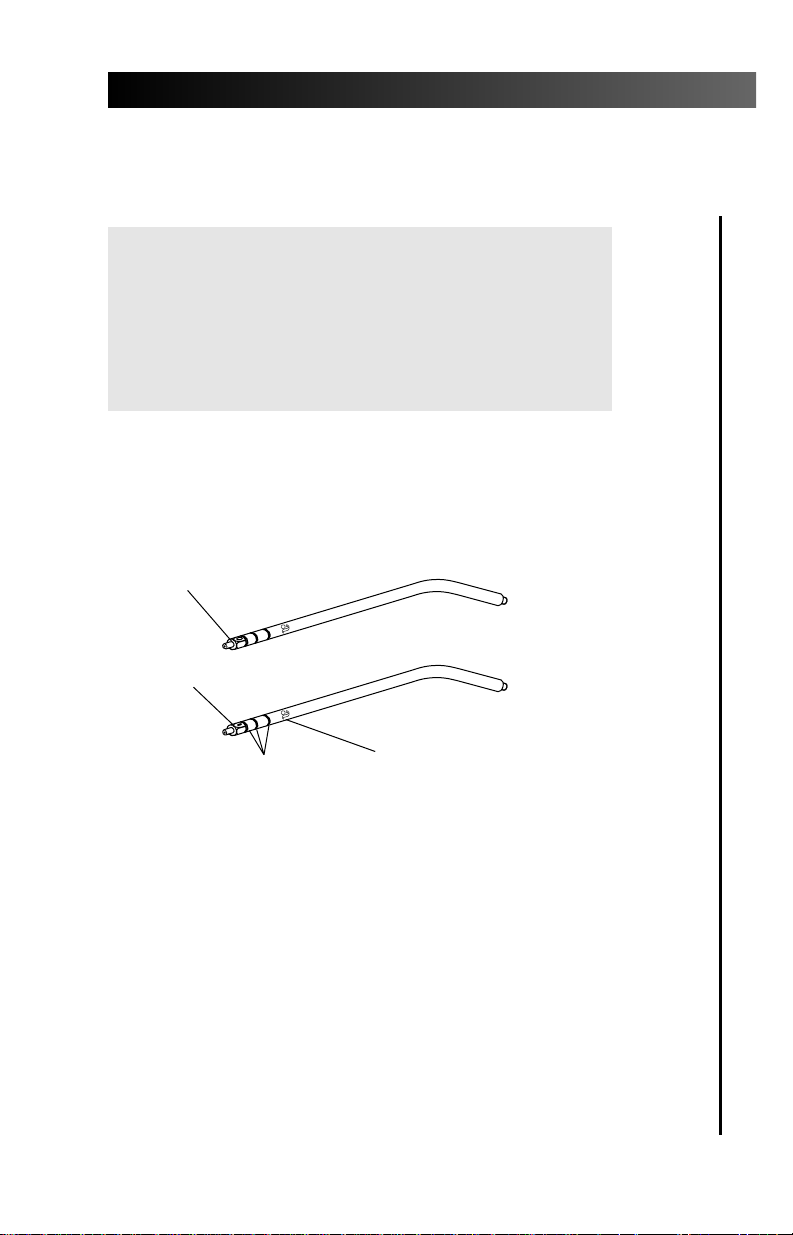

Your syringe is packaged with two specially

designed A-dec syringe tips. These tips have three

grooves and a distinguishing “O” or “I” and an

A-dec “a” marking (see Figure 3).

5

Autoclavable Syringe

A-dec Syringe Tips

Figure 3. Specially Designed A-dec Syringe Tip

THREE GROOVES

DISTINGUISHING “O” MARK

DISTINGUISHING “I” MARK

DISTINGUISHING A-DEC

“a” MARK

Warning

USE ONLY A-DEC SYRINGE TIPS.

A-dec syringe tips have been engineered and manufactured for use with A-dec syringes. Using syringe

tips manufactured by a company other than

A-dec can result in syringe tip ejection.

Page 10

To ensure that the syringe will perform properly, it

is important that you install the tip correctly.

Push the syringe tip into the syringe tip retainer

assembly. As you push the tip in you will feel two

“clicks” as O-rings inside the syringe tip retainer

assembly slide into the grooves. If you do not feel

two “clicks” when installing the syringe tip, do not use

the syringe. The O-rings inside the syringe tip

retainer assembly are damaged and may allow

the syringe tip to be ejected. The syringe tip

retainer assembly must be repaired prior to using

the syringe.

When properly installed none of the grooves on

the A-dec syringe tip are visible (see Figure 4).

After installing a tip, point the syringe at the

floor and press the air button several times to be

sure the tip is properly installed.

An improperly installed A-dec syringe tip allows

water to enter the air tubing in the syringe tip.

6

Autoclavable Syringe

Installing an A-dec Syringe Tip

Figure 4. Installing the A-dec syringe tip

NO GROOVES

ARE SHOWING.

THIS TIP IS

PROPERLY

INSTALLED.

A GROOVE IS

SHOWING. THIS TIP

IS IMPROPERLY

INSTALLED.

CORRECT INCORRECT

Page 11

To remove the A-dec syringe tip, pull it straight out

of the syringe tip retainer assembly (see Figure 5).

7

Autoclavable Syringe

Removing an A-dec Syringe Tip

Figure 5. Removing an A-dec syringe tip

Page 12

Cascade®Delivery Systems.

Syringe air and water flow is controlled by flow

control valves inside the handpiece control unit

(see Figure 6). To adjust the flow, turn the hex body of

the flow control valve clockwise to reduce flow or

counterclockwise to increase flow. Press both syringe

buttons to test the spray.

8

Autoclavable Syringe

Syringe Air and Water Flow Control

Doctor’s Syringe

Figure 6. Flow Control Valves

AIR FLOW CONTROL VALVE

WATER FLOW CONTROL VALVE

Caution

Flow adjustment valves and screws are not

intended to completely stop the air and water.

Forcing the screws to turn beyond their limit will

damage the flow adjustment valves.

A

L

W

L

D

A

D

W

Page 13

Excellence®, Decade®, Mini-Trol®, and

Auto-Trol

®

Delivery Systems.

Syringe air and water flow is controlled by flow

adjusting screws in the faceplate or side of the

handpiece control unit (see Figure 7). To adjust

the flow (with a 3/32-inch hex key), turn the

adjustment screw clockwise to reduce flow or

counterclockwise to increase flow. Press both

syringe buttons to test the spray.

Solo and Older A-dec Delivery Systems

Syringe air and water flow is controlled by pinch

valves (see Figure 8) inside the chair back or inside the

handpiece control unit. To adjust the flow, turn the

adjustment screw clockwise to reduce flow or counterclockwise to increase flow. Press both syringe buttons

to test the spray.

9

Autoclavable Syringe

Figure 8. Pinch Valves

Figure 7. Flow Adjusting Screws

DECREASE

AIR ADJUSTMENT

SCREW

WATER ADJUSTMENT

SCREW

INCREASE

WATER

TUBING

ADJUSTMENT

SCREWS

AIR

TUBING

(ribbed)

Page 14

Syringe air and water flow is controlled either by

pinch valves (see Figure 9) or a syringe block (see

Figure 10). These controls are located inside the

post box, floor box, chair back, or inside a cabinet

(depending upon the application). To adjust the

flow through a pinch valve, turn the adjustment

screw clockwise to reduce flow or counterclockwise

to increase flow. To adjust the flow through a

syringe block use a 3/32-inch hex key to turn the

adjustment screw clockwise to reduce flow or

counterclockwise to increase flow. Press both

syringe buttons to test the spray.

10

Autoclavable Syringe

Assistant’s Syringe

Figure 10. Syringe Block

ADJUSTMENT

SCREWS

AIR TUBING

(ribbed)

WATER TUBING OMITTED FOR CLARITY

Caution

Flow adjustment valves and screws are not

intended to completely stop the air and water.

Forcing the screws to turn beyond their limit will

damage the flow adjustment valves.

Figure 9. Pinch Valves

WATER

TUBING

ADJUSTMENT

SCREWS

AIR

TUBING

(ribbed)

Page 15

To disconnect your syringe head from the syringe

tubing, move the master on/off toggle to the OFF

position. Use the syringe to bleed the system of air

and water pressure.

Turn the syringe handle counterclockwise until

the syringe separates from the handle then pull

the syringe head away from the terminal.

When the syringe head is disconnected, a little

water, which is left inside of the syringe head and

tubing, will drip out.

11

Autoclavable Syringe

Disconnecting the Syringe Head

Page 16

The syringe heads may be optionally equipped

with a locking syringe tip retainer assembly . This

style of syringe tip retainer assembly (identified by a

hex shaped exterior, see Figure 11) functions like the

standard syringe tip retainer assembly (smooth

shaped exterior) but allows the retaining nut to be

tightened, preventing the tip from easily

rotating.

The tip can then be used for cheek retraction.

Your syringe is packaged with two specially

designed A-dec syringe tips. These tips have three

grooves and a distinguishing “O” or “I” and an

A-dec “a”marking (see Figure 3 on Page 5).

12

Autoclavable Syringe

OPTIONAL CONFIGURATIONS

Locking Syringe Tip Retainer Assembly

Installing an A-dec Syringe Tip

Warning

USE ONLY A-DEC SYRINGE TIPS.

A-dec syringe tips have been engineered and manufactured for use with A-dec syringes. Using syringe

tips manufactured by a company other than A-dec

can result in syringe tip ejection.

Figure 11. Locking Syringe Tip Retainer Nut

HEX-SHAPED

EXTERIOR

SURFACE

Page 17

To ensure that the syringe will perform properly,

it is important that you install an A-dec syringe

tip correctly.

Push the syringe tip into the syringe tip retainer

assembly. As you push the tip in, you will feel two

“clicks” as O-rings inside the syringe tip retainer

assembly slide into the grooves. When properly

installed, none of the grooves on the A-dec syringe

tip are visible (see Figure 12).

After installing a tip, point the syringe at the

floor and press the air button several times to be

sure the tip is properly installed.

An improperly installed A-dec syringe tip allows

water to enter the air tubing in the syringe tip.

13

Autoclavable Syringe

Caution

Be sure the hex portion of the syringe tip retainer

assembly is loose before installing an A-dec

syringe tip.

If you attempt to force the tip into the syringe tip

retainer assembly, you will damage the internal

collet of the retainer and make it difficult or

impossible to properly install a tip, remove a tip,

or use your syringe.

Figure 12. Installing an A-dec syringe tip

NO GROOVES

ARE SHOWING.

THIS TIP IS

PROPERLY

INSTALLED.

A GROOVE IS

SHOWING. THIS TIP

IS IMPROPERLY

INSTALLED.

CORRECT INCORRECT

Page 18

Your syringe tip rotates to spray in different

directions. However, if you use your syringe tip for

cheek retraction and you have the hex-shaped

syringe tip retainer nut, you may prefer to adjust

the tip so that it does not rotate easily.

To adjust the installed syringe tip so that it does

not rotate easily, simply tighten the hex portion of

the syringe tip retainer assembly (see Figure 13).

Tighten only until you cannot easily rotate the tip.

14

Autoclavable Syringe

Restricting Tip Rotation

Caution

Tighten the syringe tip retainer assembly nut by

hand or with the plastic wrench provided.

Overtightening the nut will make it more

difficult to remove the syringe tip later—use

only as much force as needed to keep the

syringe tip from rotating easily.

Never tighten the syringe tip retainer assembly nut

when a syringe tip is improperly installed. The

internal collet will be crushed making removal of

the tip difficult and proper installation of a new

tip impossible.

Figure 13. Eliminating Tip Rotation

BE SURE THE TIP IS

PROPERLY INSTALLED.

ROTATE THE NUT

COUNTERCLOCKWISE

TO ADJUST THE TIP SO

THAT IT DOES NOT

ROTATE FREELY.

SEE CAUTION ABOVE.

Page 19

To remove the A-dec syringe tip, turn the tip

retainer nut counterclockwise until it turns easily,

no more than a 1/4 turn. Then pull the A-dec tip

straight out of the syringe tip retainer (see Figure 14).

15

Autoclavable Syringe

Removing an A-dec Syringe Tip

Figure 14. Removing the A-dec Tip

RETAINER

NUT

Page 20

Water temperature at the syringe is controlled by

the use of an in-line water heater (see Figure 15)

and resistance wiring in the syringe tubing.

To determine if you have this type of warm water

syringe, look for the in-line water heater (see Figure 15

on page 15) in the control head or in the post box.

Additionally, the syringe tubing will be warm to

the touch after the unit has been turned on for a

few minutes.

The water temperature is not adjustable. The

water should feel lukewarm on the back of your

hand. If the water temperature is too warm or

cold, contact your factory authorized A-dec dealer.

16

Autoclavable Syringe

Heated Syringe Tubing with

In-line Low Voltage Water Heater

Figure 15. In-line Low Voltage Water Heater

Made in USA

85-0966-00

INLINE WATER HEATER

Part # 40-1060-00

24 VAC 4 AMPS

5/93

Page 21

Your A-dec syringe tubing may be optionally

equipped with a quick disconnect syringe

terminal (see Figure 16). This terminal allows you

to remove the syringe head without shutting the

delivery system off.

To remove the syringe head, turn the syringe

handle counterclockwise until the syringe separates

from the handle then pull the syringe head away

from the terminal.

17

Autoclavable Syringe

Quick Disconnect Syringe Terminal

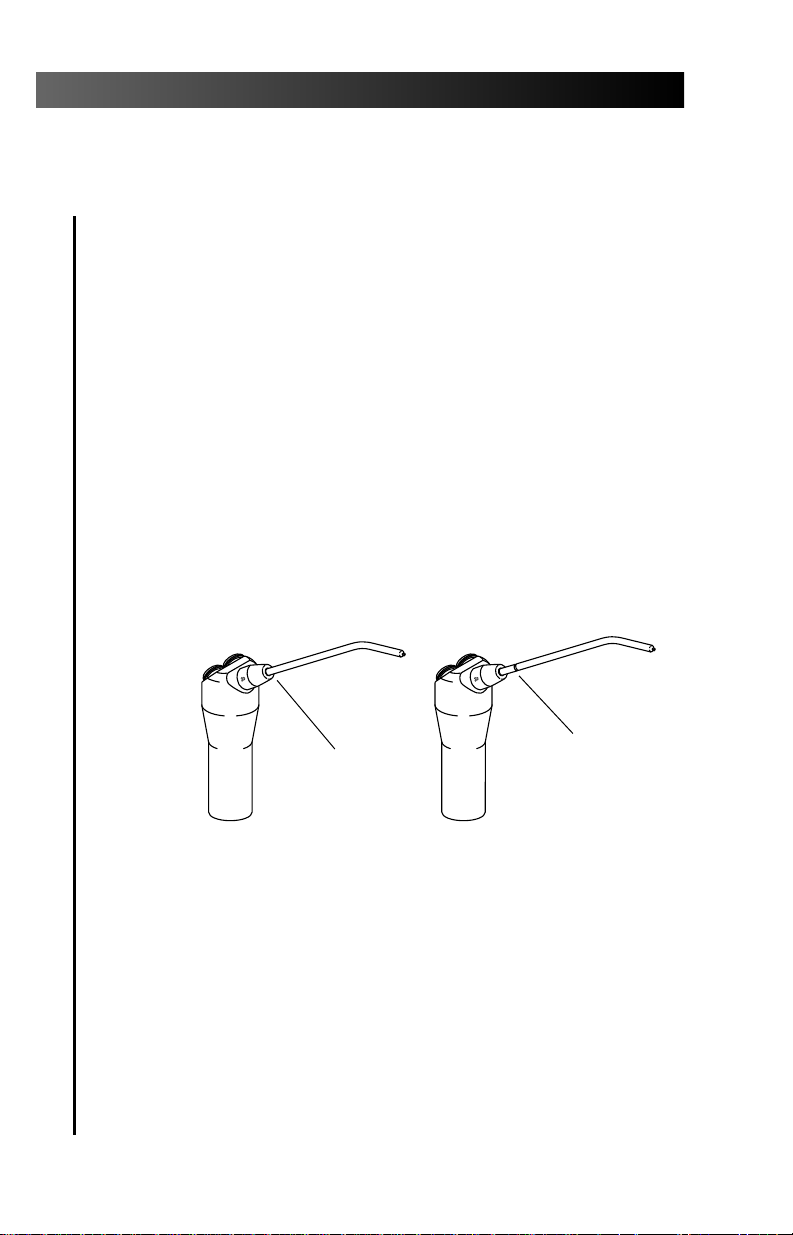

Figure 16. Quick Disconnect Syringe Terminal

STANDARD

QUICK

DISCONNECT

TERMINAL

CIRCULATING

SYRINGE

QUICK

DISCONNECT

TERMINAL

Page 22

All syringe tips are considered critical items and

must be heat sterilized between patients. The

syringe and syringe tips have been designed to be

heat sterilized.

1. Remove the syringe head and tip from the

syringe terminal.

2. If the threads on the syringe head appear dirty,

gently brush the threads free of debris using a

nylon or brass bristle brush.

3. Remove the syringe tip for sterilization.

18

Autoclavable Syringe

Syringe and Tip Asepsis

ASEPSIS

Pre-Cleaning

Warning

When cleaning syringe tips, do not use cleaning

solutions which contain ammonia or amines.

These chemicals are harmful to the brass

syringe tips and can cause possible damage and

tip ejection.

Note

To ease the removal and assembly of the

syringe head and the syringe nut, periodically

check the threads on the syringe head for

accumulated debris.

Page 23

4. Immerse the tip in an appropriate holding

solution until ready for ultrasonic cleaning.

5. Clean the syringe tips ultrasonically. Follow

the instructions provided by the manufacturer

of your ultrasonic cleaning equipment.

6. Purge all cleaning agents from the syringe

and syringe tips by vertically holding under

running water.

1. Rinse the syringe and syringe tips in clear water.

2. Use a dispensing bottle to flush isopropyl alcohol

or Harvey’s Vapo-Steril

®

through the tips.

3. Sterilize the syringe tips and/or syringe:

Sterilize SYRINGE TIPS using the methods of

steam autoclave, dry heat, or chemical vapor

(275°F [135°C] maximum temperature).

Sterilize the SYRINGE using the methods of

steam autoclave or chemical vapor

(275°F [135°C] maximum temperature).

19

Autoclavable Syringe

Sterilization

Caution

Sterilizing equipment at higher temperatures

will reduce the seal life of the O-rings.

Page 24

Your syringe is designed to be easily serviced in the

operatory. The syringe parts subject to wear under

normal use are provided in a syringe repair kit which

can be ordered from your authorized A-dec dealer.

Proper care and maintenance of your A-dec Syringe

is critical in ensuring the safety of your patients

and the reliability of this precision instrument.

Use only A-dec Silicone Lubricant when

performing maintenance on your A-dec syringe.

The O-rings used in the syringe head and

syringe tip retainer assembly are a compound

(Ethylene Propylene) which best resists the

autoclave process.

The use of petroleum based lubricants (jellies,

creams, or lotions) will cause the O-rings in the

syringe to swell and/or deteriorate, resulting in

syringe malfunction or failure.

Use only A-dec replacement parts when

performing maintenance on your A-dec syringe.

A-dec replacement parts have been precisely

designed for your A-dec syringe and ensure that

the syringe will function properly.

20

Autoclavable Syringe

MAINTENANCE

General Information

Using A-dec Silicone Lubricant

Using A-dec Replacement Parts

Page 25

As a means of preventive maintenance, A-dec

recommends replacing the two internal O-rings

and the small O-rings in the syringe tip retainer

assembly at least once a year (see Figure 17). Please

lubricate the O-rings with A-dec silicone lubricant

at the time of replacement.

The syringe is leaking from a button.

Replace the valve assembly.

The syringe is leaking from the end of the tip

while the syringe is not in use.

The valve assembly is damaged and must

be replaced.

21

Autoclavable Syringe

Troubleshooting

Maintaining Syringe Tip Retainer Assemblies

INTERNAL

O-RINGS

SMALL O-RING

BRASS

ADAPTER

BRASS

ADAPTER

SMALL O-RING

INTERNAL

O-RINGS

Figure 17. Syringe Nut Retainer Assemblies

NON-LOCKING

RETAINER ASSEMBLY

LOCKING

RETAINER ASSEMBLY

Page 26

There is a spray of water from the tip when the air

button is pressed.

1. Is the A-dec syringe tip properly installed?

YES: Install a different syringe tip and test the

syringe. If this solves the problem, discard

the damaged syringe tip. If there is still a

momentary spray of water from the tip

when the air button is pressed, replace the

small O-ring in the brass adapter section

of the syringe nut retainer assembly (see

Figure 17 on page 21) or replace the

syringe nut retainer assembly.

NO: Ensure that the syringe tip is properly

installed, then retest the syringe.

There is leakage from the syringe handle.

1. Is the syringe tightly connected to the

syringe tubing?

YES: The O-rings on the terminal connector tubes

(inside the syringe handle) are damaged

and must be replaced (see Figure 18).

NO: Ensure that the syringe and the syringe

tubing connector are tightly screwed

together and retest the syringe.

22

Autoclavable Syringe

Figure 18. Syringe Terminal Assemblies

O-RINGS

O-RINGS

Page 27

Air is leaking around the syringe tip at the top of

the syringe tip retainer assembly.

1. Is the A-dec syringe tip damaged?

YES: Install a different syringe tip and test the

syringe. If this solves the problem, discard

the damaged syringe tip.

NO: The two syringe tip retainer assembly

internal O-rings are damaged (see Figure

17 on page 21). Replace the O-rings or the

syringe tip retainer assembly.

Water is leaking around the base of the syringe

tip retainer assembly.

1. Is the syringe tip retainer assembly tightly

installed in the syringe head?

YES: The small O-ring in the brass adapter

section of the syringe tip retainer

assembly has failed (see Figure 17 on

page 21). Replace the O-ring or replace

the syringe tip retainer assembly.

NO: Tighten the syringe tip retainer assembly

and retest the syringe.

The syringe tip is difficult to install.

1. Has a petroleum based lubricant been used

to lubricate the syringe tip retainer assembly

internal O-rings (see Figure 17 on page 21)?

YES: The two syringe tip retainer assembly

internal O-rings are damaged. Replace

the O-rings or the syringe tip retainer

assembly.

NO: The syringe tip retainer assembly has

been damaged and must be replaced.

Do not use the syringe until the syringe

tip retainer assembly has been replaced.

23

Autoclavable Syringe

Page 28

The syringe tip is too easily removed from the

syringe nut retainer assembly.

1. Are you using an A-dec syringe tip? Ensure

that syringe tip being used is an A-dec syringe

tip (see Figure 3 on page 5).

YES: The two syringe tip retainer assembly

internal O-rings have been damaged or

worn (see Figure 17 on page 21). Replace

the O-rings or the syringe tip retainer

assembly.

NO: Properly install an A-dec syringe tip and

retest the syringe.

24

Autoclavable Syringe

Page 29

Installing an A-dec Syringe Tip .......................page 6 and 12

Syringe Air and Water

Flow Control .............................................................page 8

Restricting Tip Rotation .............................................page 14

Heated Syringe Tubing with

Inline Low Voltage Water Heater ..........................page 16

Syringe Tip Asepsis ....................................................page 18

Sterilization ................................................................page 19

Troubleshooting...........................................................page 21

Specifications are subject to change without notice.

25

Autoclavable Syringe

Adjustments and Specifications

Maintenance

Page 30

26

Autoclavable Syringe

Recognized by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Recognized with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

UL listed to US (UL 544) and Canadian (CAN/CSA C22.2, No.

125) safety standards.

Classified by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Classified with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

Conforms to European Directives

(refer to Declaration Statement)

Protective earth (ground).

Functional earth (ground).

Attention, consult accompanying documents.

TYPE B APPLIED PART.

CLASS II EQUIPMENT.

Type of shock protection:

CLASS I EQUIPMENT

(Dental Chairs, Dental Lights, & Power Supplies)

CLASS II EQUIPMENT

(Chair, Wall, & Cart Mounted Delivery Systems)

Degree of shock protection:

TYPE B APPLIED PART (All products)

Degree of protection against water ingress:

ORDINARY EQUIPMENT (All products)

Mode of operation

CONTINUOUS OPERATION

(All models except Dental Chairs)

Mode of operation

CONTINUOUS OPERATION

WITH INTERMITTENT LOADING (Dental Chairs)

Identification of Symbols

Classification of Equipment (EN 60601-1)

®

LISTED

!

Page 31

Page 32

85.0680.00

1999-11 Rev T

(01649)

Printed in USA.

Copyright © 1999,

All Rights Reserved.

Made with 50% waste paper

2601 Crestview Drive

Newberg, Oregon 97132 U.S.A.

Telephone 1-800-547-1883

(503) 538-7478

Fax (503) 538-0276

®

Designated Representative’s Address:

A-dec Dental U.K., Ltd.

Austin House

11 Liberty Way

Attleborough Fields,

Nuneaton, Warwickshire,

England CV11 6RZ

Telephone: 00 44 24 7635 0901

Fax: 00 44 24 7634 5106

Designated Representative’s Address:

A-dec Australia

41-43 Bowden Street

Alexandria, N.S.W. 2015, Australia

Telephone: (61) 1.800.225010

Loading...

Loading...