Page 1

Owner's Guide

ASSISTANT’S

INSTRUMENTATION

85.2610.00

®

Page 2

Warranty Information

N/A

N/A

For service information contact your local authorized A-dec dealer.

Check with local codes and A.D.A. (Americans with Disabilities Act)

requirements for installation of this product.

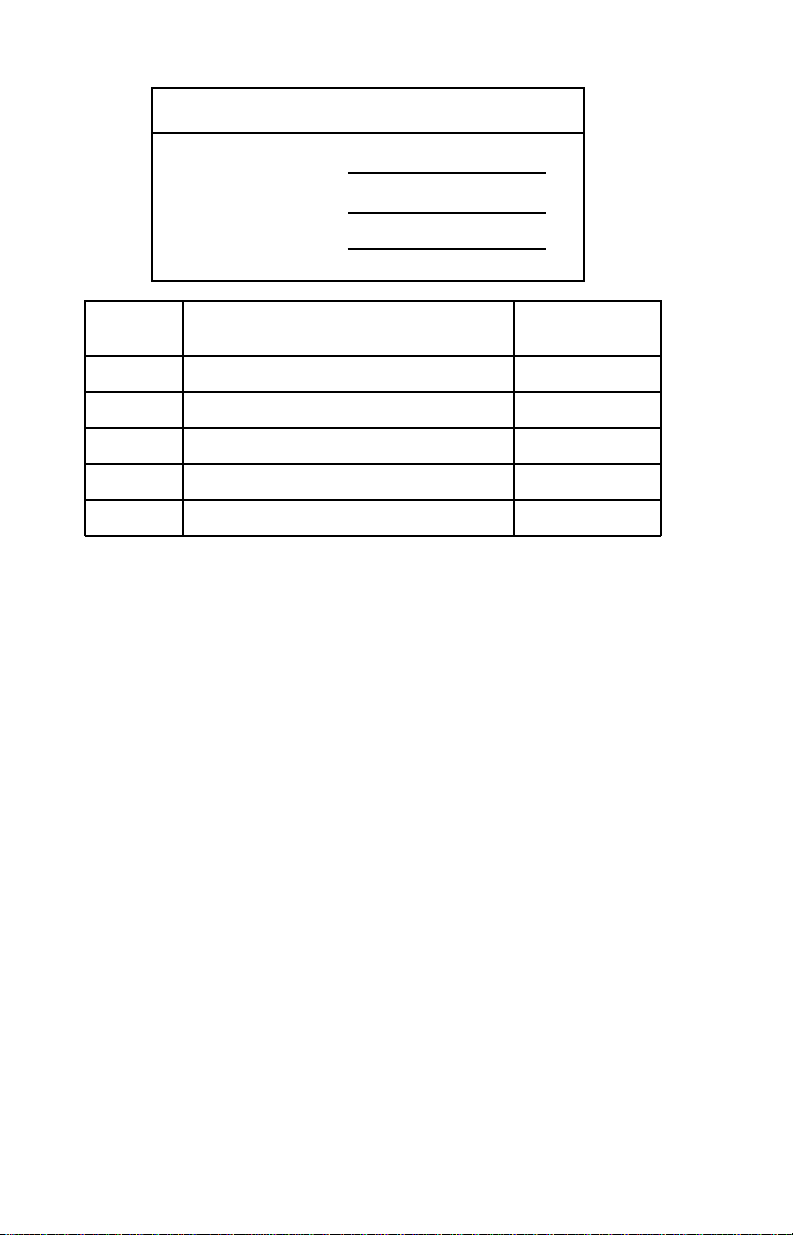

Serial Number

Model Number

Date Purchased

Date of

Service

Model/Description of Service

Technician's

Initials

Page 3

Printed in U.S.A. • Copyright © 1999 • All Rights Reserved

Warranty

A-dec warrants its products and A-dec/W&H Synea

handpieces against defects in material or workmanship

for one year from time of delivery. All other handpiece

instrumentation has a warranty period of six months.

A-dec’s sole obligation under the warranty is to provide

parts for the repair, or at its option, to provide the

replacement product (excluding labor). The buyer shall

have no other remedy. (All special, incidental, and

coincidental damages are excluded.) Written notice of

breach of warranty must be given to A-dec within the

warranty period. The warranty does not cover damage

resulting from improper installation or maintenance,

accident or misuse.The warranty does not cover damage resulting from the use of cleaning, disinfecting or

sterilization chemicals and processes. The warranty also

does not cover light bulbs. Failure to follow instructions

provided in A-dec’s Operation and Maintenance

Instructions (Owner’s Guide) may void the warranty.

NO OTHER WARRANTIES AS TO

MERCHANTABILITY OR OTHERWISE ARE MADE.

All product names used in this document are trademarks or

registered trademarks of their respective holders.

®

Page 4

Assistant’s Instrumentation

Assistant’s Instrumentation

Page 5

Service information and warranty information

are located on the inside front cover and

front page.

About Your Assistant’s Instrumentation ......... 2

Controls ............................................................ 3

Instruments ...................................................... 4

Autoclavable HVE and

Saliva Ejector............................................... 4

Right- to Left-Hand Conversion

of the Autoclavable HVE

and Saliva Ejector ......................................... 4

Autoclavable HVE and

Saliva Ejector Asepsis ................................. 5

Autoclavable Syringe ................................. 6

Solids Collector ................................................. 7

Solids Collector Asepsis .............................. 8

Adjustments ................................................... 10

Instrument Holder Positioning ................ 10

Leveling Adjustment ................................ 11

Touch Pad ........................................................ 12

Maintenance................................................... 13

Adjustments and Specifications ..................... 13

Identification of Symbols................................ 14

Classification of Equipment ........................... 14

1

CONTENTS

Assistant’s Instrumentation

Page 6

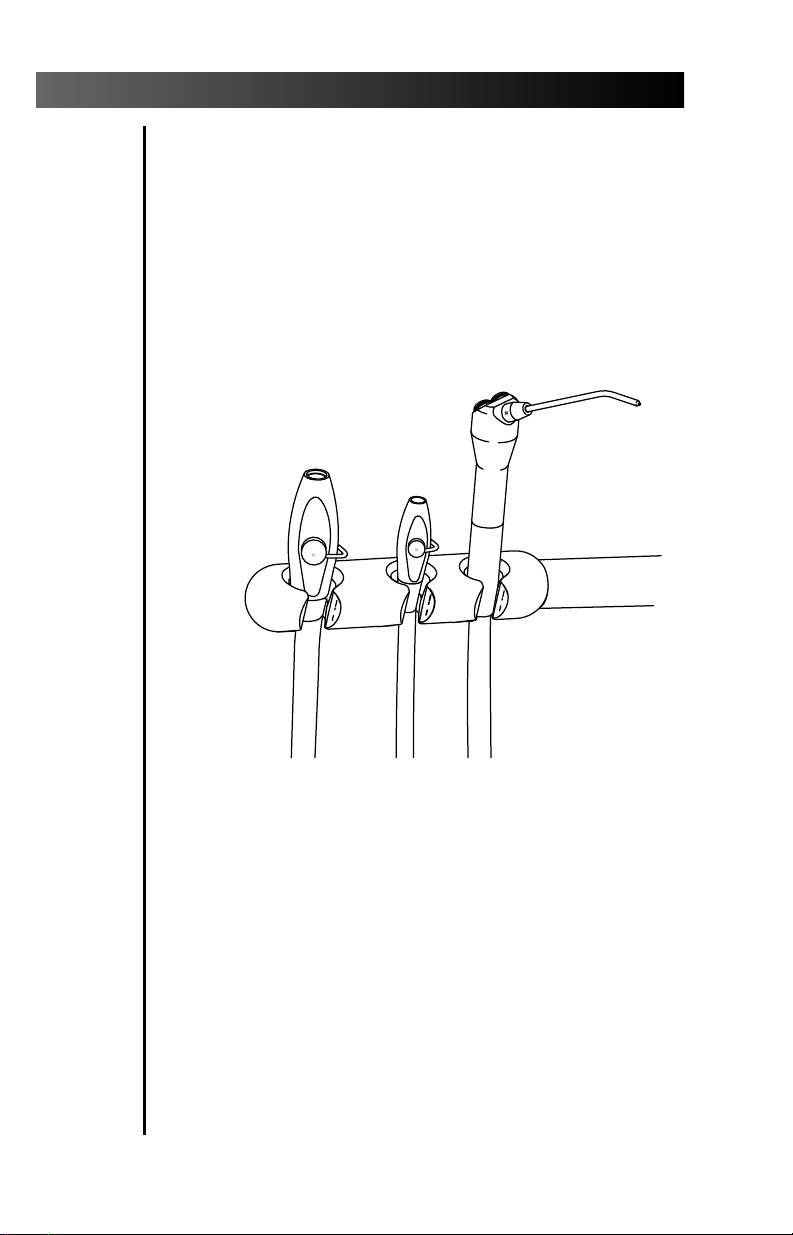

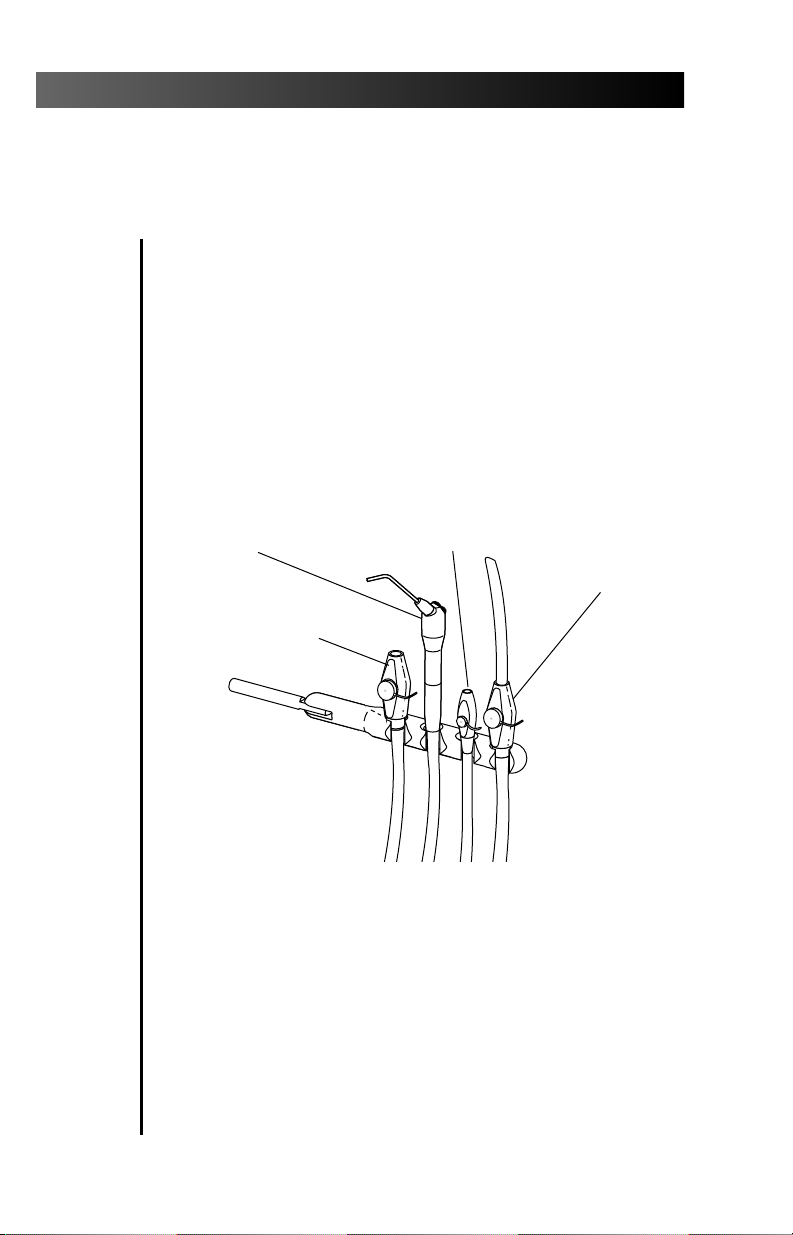

Assistant’s instrumentation typically includes

A-dec’s Autoclavable Syringe, Autoclavable HVE,

and Autoclavable Saliva Ejector as standard

equipment. On some units and carts, optional

instruments may include an additional HVE. The

Solids Collector (see Figures 3 and 4 on page 7) is also

a part of the Assistant’s Instrumentation, but its

location varies depending on your system.

2

Assistant’s Instrumentation

About Your Assistant’s Instrumentation

Figure 1. Assistant’s Instrumentation

(Shown with optional four position unitized holder

and additional Autoclavable HVE)

ADDITIONAL

AUTOCLAVABLE

QD HVE (optional)

AUTOCLAVABLE

SYRINGE

AUTOCLAVABLE

SALIVA EJECTOR

AUTOCLAVABLE

QD HVE

275¡F

136¡C

Page 7

The location of the master on/off toggle for

assistant’s instrumentation will vary but the

function is the same. Moving the toggle to the

ON position provides air and water to the system.

Move the toggle to the OFF position while the

unit is unattended to prevent water damage in

case of a leak.

Where assistant’s instrumentation is installed as

part of a delivery system (such as a chair mount

system, duo cart, duo Preference unit, or duo wall

mount unit), the master on/off toggle is located

on the control head. Other types of assistant’s

instrumentation may have the master on/off

toggle located on the post box .

When the instrumentation is installed on an

assistant’s cart or assistant’s wall mount unit, the

master on/off toggle is located on the side of the

cart or wall mount unit.

The master on/off toggle for chair-mounted

assistant’s instrumentation is located on the side

of the floor box .

3

Assistant’s Instrumentation

Controls

Page 8

Assistant’s instrumentation includes an A-dec

Autoclavable HVE and an Autoclavable Saliva

Ejector. It may also include a second HVE as an

option. The autoclavable HVE and Saliva Ejector

are equipped with a quick disconnect to remove

the valve body from the tubing for cleaning and

autoclaving.

The HVE and Saliva Ejector can be easily converted

for opposite-hand operation (see Figure 2).

To convert the HVE or Saliva Ejector for oppositehand use, press the control valve out of the HVE

body (see Figure 2). Rotate the control valve 180°,

then press it back into place.

4

Assistant’s Instrumentation

Instruments

Autoclavable HVE and Saliva Ejector

Right- to Left-Hand Conversion of the Autoclavable HVE

and Saliva Ejector

Figure 2.

CONTROL

VALVE

VALVE

BODY

TO REMOVE THE

CONTROL VALVE,

PRESS ON SMALL

DIAMETER SIDE

HVE

SALIVA

EJECTOR

Page 9

1. Remove the tip from the valve body. (For

recommended HVE tip asepsis, see Sterilizing the

HVE Tip on page 6).

2. Although it is not necessary to do so, you may

want to turn off the central vacuum before

disconnecting the HVE or Saliva Ejector.

3. To remove the HVE or saliva ejector body, simply

separate the body from the tubing by pulling it

apart at the tailpiece (see Figure 2).

4. Remove the control valve by pressing it out of

the HVE or saliva ejector valve body.

5. Clean and rinse the valve body and control

valve using a mild detergent, water, the

brushes that have been provided, and allow

to dry completely.

6. Heat sterilize the valve body and control valve

using any of the following methods:

steam autoclave, dry heat, or chemical vapor.

7. Apply a light coat of A-dec Silicone Lubricant

(Part No. 98.0090.01, package of six) on the

O-ring seals of the control valve.

8. Reinstall the control valve in the valve body.

(see Figure 2).

9. Reinstall the body on the tubing tailpiece.

10. Operate the HVE and the saliva ejector valves

several times to verify that it rotates smoothly.

5

Assistant’s Instrumentation

Autoclavable HVE and Saliva Ejector Asepsis

Caution

Use only silicone lubricant when lubricating

instrumentation O-rings. Petroleum products will

cause permanent damage to the O-rings.

Page 10

Sterilizing the HVE Tip

It is recommended that the A-dec stainless steel

tips used on the A-dec HVE be heat sterilized

between patients by any of the following methods:

steam autoclave, dry heat, or chemical vapor.

1. Remove the HVE tip from the HVE valve body.

2. Clean and rinse the HVE tips using a mild detergent

and water, then allow the tips to completely dry.

3. Sterilize the HVE tips using one of the methods

listed above.

If you are using disposable HVE tips, be sure to

replace them with new tips between patients.

For information on the operation, care, and

maintenance of A-dec’s Autoclavable Syringe, refer to

your Autoclavable Syringe Owner’s Guide(A-dec

Publication No. 85.0680.00).

6

Assistant’s Instrumentation

Autoclavable Syringe

Note

The standard A-dec HVE is designed with a

cannula connection opening of 0.435 ± 0.006 inch

(11.05 ± 0.15 mm). Please select tips compatible

with this if not using A-dec tips.

Note

The A-dec 15 mm HVE has a cannula connection

opening of .592 inch (14.8 mm) + 1 1/2˚ per side per

DIN-13-938 section 3.1. Please select tips compatible

with this.

Note

The A-dec Saliva Ejector is designed with a cannula

connection opening of 0.265 ± 0.006 inch (6.73 ±

0.15 mm). Please select tips compatible with this.

Page 11

The solids collector prevents solids from entering

the central vacuum system (see Figures 3 and 4).

7

Assistant’s Instrumentation

Solids Collector

Figure 3. Cascade and Radius Solids Collector

Figure 4. Decade Cart Solids Collector

DECADE

CART SOLIDS

COLLECTOR

CANISTER

ASSEMBLY

SOLIDS

COLLECTOR

4

4

3

3

50

50

60

60

5

5

40

40

2

2

70

70

30

30

80

80

20

20

6

6

1

1

90

90

10

10

100

100

0

0

psi

psi

7

7

0

0

2

2

kg/cm

kg/cm

AW

Page 12

At least once per week, remove and clean (with a

mild detergent and water) or discard and replace the

solids collector screen for the Cascade products (see

Figure 5) or for the Decade products (see Figure 6). This

is necessary to ensure proper suction from the central

vacuum, and to maintain proper treatment room

asepsis.

Solids Collector for Cascade

Turn OFF vacuum or, if vacuum is ON, open the

HVE control valve to facilitate removal of the solids

collector cap.

Remove the solids collector screen and cap from the

connector. Pull out on the cap: the screen is

attached to the cap.

Remove the screen from the cap. Place your thumb

on the large hole and forefinger on the key directly

opposite the large hole (see Figure 5). Squeeze, then

slide the cap out of the screen. Clean the screen. If

you have a disposable HVE screen, discard following

the manufacturer’s instructions.

8

Assistant’s Instrumentation

Solids Collector Asepsis

Caution

Do not empty the screen into your cuspidor.

Doing so could plug the drain.

Page 13

Reinstall the solids collector. Insert the cap back

into the screen until the two circular buttons on

the cap snap into place. Make sure they are

properly aligned with the tongue on the cap

directly opposite to the large hole in the screen

(see Figure 5). Slide the screen and cap into the

vacuum connector, making sure the key faces up

and the hole faces down.

Solids Collector for Decade

Turn OFF the vacuum in order to remove the solids

collector cap. However, if vacuum is ON, open the

HVE to facilitate removal of the solids collector cap

(see Figure 6). Clean the screen. DO NOT lubricate

the O-rings on the vacuum canister cap.

9

Assistant’s Instrumentation

Figure 5. Solids Collector for Cascade

HVE

HANDPIECE

TUBING

SOLIDS

COLLECTOR

CAP

SOLIDS

COLLECTOR

SCREEN

VACUUM

CONNECTOR

KEY

(align for

reinstallation)

LARGE HOLE

(underneath, align

for reinstallation)

Figure 6. Solids Collector for Decade

CAP

SCREEN

CANISTER

Page 14

The multi-position style instrument holder is

designed to pivot or twist to provide flexibility in

positioning the instruments to suit your style of

practice. Pivot and twist tension are set at the

factory and should not need to be adjusted. If the

pivot or twist movement is too tight or too loose,

you may want to adjust the friction.

Pivot Friction

To adjust the pivot friction, locate the adjustment

setscrew (see Figure 7). Use a 5/32-inch hex key and

turn the key clockwise to increase friction which

will make the holder pivot less freely. Turn the key

counterclockwise to decrease friction and allow the

holder to pivot more freely.

Twist Friction

To adjust the twist friction, locate the adjustment

setscrew (see Figure 7). Use a 3/32-inch hex key and

turn the key clockwise to increase friction which

will make the holder twist less freely. Turn the key

counterclockwise to decrease friction and allow the

holder to twist more freely.

10

Assistant’s Instrumentation

Adjustments

Instrument Holder Positioning

Figure 7. Pivot and Twist Adjustments

TWIST ADJUSTMENT

SCREW (Underneath)

PIVOT ADJUSTMENT

SCREW (Underneath)

Page 15

If you have a telescoping assistant’s instrumentation

arm, it has been leveled at the factory and should not

require further adjustment. However, if the arm needs

to be leveled, locate the adjustment setscrew

underneath the telescoping arm (see Figure 8).

To tilt the arm up, use a 1/8-inch hex key and

turn the key clockwise.

To tilt the arm down, use a 1/8-inch hex key and

turn the key counterclockwise.

11

Assistant’s Instrumentation

Leveling Adjustment

Figure 8. Leveling Adjustment

LEVELING

ADJUSTMENT

SETSCREW

(underneath)

PIVOT ARM

TELESCOPING

ARM

Page 16

For chair touch pad instructions, refer to the

Cascade 1040 Chair Owner's Guide, A-dec

Publication No. 85.2605.00 or Decade 1011/1021

Chair Owner's Guide, A-dec Publication No.

85.2635.00 depending on your model of chair.

For Master touch pad instruction, refer to your

Master Series Touch Pad Owner’s Guide, A-dec

Publication No, 85.2627.00.

12

Assistant’s Instrumentation

Touch Pad Programming (optional)

Page 17

Autoclavable HVE and

Saliva Ejector .................................................. page 5

Sterilizing the HVE tip ...................................... page 6

Autoclavable Syringe

Owner’s Guide ..................................... 85.0680.00

Solids Collector Asepsis .................................... page 8

Floor Boxes

Owner’s Guide ..................................... 85.2611.00

Maintenance Parts

Owner’s Guide ..................................... 85.2634.00

Instrument Holder Positioning ....................... page 10

Pivot Friction ................................................... page 10

Twist Friction .................................................. page 10

Leveling Adjustment ...................................... page 11

Touch Pad Programming

Cascade 1040 Chair

Owner’s Guide ........................................85.2605.00

Decade 1011/1021 Chair

Owner’s Guide ........................................85.2635.00

Master Touch Pad

Owner’s Guide ........................................85.2627.00

Minimum air, water, and vacuum service

requirements for proper unit operation:

Air: 2.50 cfm (70.80 l/min) at 80 psi (551 kPa).

Water: 1.50 gpm (5.68 l/min) at 40 psi (276 kPa).

Vacuum: 12 cfm (339.84 l/min) at 8 inches (27 kPa)

of mercury.

Weight of optional touch pad: .50 lbs. (.23 kg).

Specifications are subject to change without notice.

13

Assistant’s Instrumentation

Maintenance

Adjustments and Specifications

Page 18

14

Assistant’s Instrumentation

Recognized by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Recognized with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

UL listed to US (UL 544) and Canadian (CAN/CSA C22.2, No.

125) safety standards.

Classified by Underwriters Laboratories Inc. ® with respect to

electric shock, fire and mechanical hazards only in accordance

with UL 2601-1. Classified with respect to electric shock, fire,

mechanical and other specified hazards only in accordance with

CAN/CSA C22.2, No. 601.1.

Conforms to European Directives

(refer to Declaration Statement)

Protective earth (ground).

Functional earth (ground).

Attention, consult accompanying documents.

TYPE B APPLIED PART.

CLASS II EQUIPMENT.

Type of shock protection:

CLASS I EQUIPMENT

(Dental Chairs, Dental Lights, & Power Supplies)

CLASS II EQUIPMENT

(Chair, Wall, & Cart Mounted Delivery Systems)

Degree of shock protection:

TYPE B APPLIED PART (All products)

Degree of protection against water ingress:

ORDINARY EQUIPMENT (All products)

Mode of operation

CONTINUOUS OPERATION

(All models except Dental Chairs)

Mode of operation

CONTINUOUS OPERATION

WITH INTERMITTENT LOADING (Dental Chairs)

Identification of Symbols

Classification of Equipment (EN 60601-1)

®

LISTED

!

Page 19

Page 20

Printed in USA.

Copyright © 1999,

All Rights Reserved.

Made with 50% waste paper

85.2610.00

1999-11 Rev L

(01649)

2601 Crestview Drive

Newberg, Oregon 97132 U.S.A.

Telephone 1-800-547-1883

(503) 538-7478

Fax (503) 538-0276

®

Designated Representative’s Address:

A-dec Dental U.K., Ltd.

Austin House

11 Liberty Way

Attleborough Fields,

Nuneaton, Warwickshire,

England CV11 6RZ

Telephone: 00 44 24 7635 0901

Fax: 00 44 24 7634 5106

Designated Representative’s Address:

A-dec Australia

41-43 Bowden Street

Alexandria, N.S.W. 2015, Australia

Telephone: (61) 1.800.225010

Loading...

Loading...