Page 1

A-dec 311, 411, and 511 Dental Chairs Service Guide

Contents

Overview ......................................................................................................... 3

Copyright and Regulatory Information ................................................................. 3

Trademarks and Additional Intellectual Property Rights ....................................... 3

Product Service ........................................................................................................ 3

Regulatory Information ............................................................................................3

Product Models and Versions Covered in This Document .................................... 3

Customer Service Information............................................................................... 4

A-dec Headquarters ................................................................................................. 4

A-dec Australia ......................................................................................................... 4

A-dec China .............................................................................................................. 4

A-dec United Kingdom ............................................................................................. 4

Other Sources of Information ................................................................................ 4

A-dec 311, 411, and 511 Dental Chairs Service Reference ................................. 4

Other A-dec Service Documents ............................................................................. 4

Electronic Documentation ...................................................................................... 4

A-dec Dental Chairs ................................................................................................ 5

Chair Comparison Chart ......................................................................................... 6

Flow Diagrams ............................................................................................... 8

311 (A) Chair Flow Diagram (Before March 2013) .............................................. 8

311 (A) [Effective March 2013]/311 (B)/411 Chair Flow Diagram ................... 9

511 Chair Flow Diagram ...................................................................................... 10

Circuit Board Components ......................................................................... 12

311 (A and B)/411 Chair Circuit Board .............................................................. 12

311 (A and B)/411 Chair Circuit Board LED Identication .................................13

311 (A and B)/411 Chair Circuit Board Identication .........................................13

511 Chair Circuit Board ....................................................................................... 14

511 Chair Circuit Board LED Identication ..........................................................15

511 Chair Circuit Board Identication ..................................................................15

311 (A) Chair Service, Adjustments, and Maintenance ...........................16

Chair Covers [311 (A)] ..........................................................................................16

Integrated Floor Box Cover Removal ....................................................................16

Contoured Floor Box Cover Set Removal ............................................................. 17

Lift Arm Covers Removal ....................................................................................... 17

Upholstery [311 (A)] .............................................................................................18

Back Upholstery Removal/Attachment ................................................................18

Headrest Upholstery Removal/Attachment .........................................................18

Seat Upholstery Removal/Attachment .................................................................18

Factory Default Routine [311 (A and B) and 411] .............................................19

Chair Drive System [311 (A)]................................................................................20

Chair Manifold Adjustment System [311 (A)] ......................................................20

Hydraulic Fluid Replenishment [311 (A)] ............................................................. 21

Capacitor Replacement [311 (A and B)/411] ....................................................22

Chair Input Voltages ..............................................................................................22

Motor Driven Electro-Mechanical Actuator [311 (A and B)/411] ....................23

Position Sensor [311 (A and B)/411] .................................................................23

Factory Default Routine ........................................................................................23

Limp Along Feature................................................................................................23

Solenoid [311 (A)] ................................................................................................. 24

Solenoid Testing ....................................................................................................24

Magnetic Pull Test for Coil Resistance ................................................................. 24

Volt/Ohm Meter Test for Coil Resistance ............................................................. 24

Solenoid Assembly Replacement [311 (A)] .........................................................25

Headrest Adjustments [311 (A)] ..........................................................................26

Patient-Adjustable Neck Support Removal/Attachment ....................................26

Reposition Neck Support ......................................................................................26

Dual-Articulating Headrest [311 (A and B)/411] .............................................. 26

Headrest Adjustment ............................................................................................26

Glide Bar Tension Adjustment ..............................................................................26

Two-Position Armrest Adjustments [311 (A)] ..................................................... 27

Armrests Repositioning ......................................................................................... 27

Armrests Locking ................................................................................................... 27

86.0380.00 Rev B Contents 1

Page 2

A-dec 311, 411, and 511 Dental Chairs Service Guide Contents 2

311 (B) and 411 Chairs Service, Adjustments, and Maintenance ........ 28

Chair Covers ......................................................................................................... 28

Upholstery [311 (B) and 411] .............................................................................. 29

Back Upholstery Removal/Attachment ................................................................29

Headrest Upholstery Removal/Attachment .........................................................29

Seat Upholstery Removal/Attachment .................................................................29

Chair Drive System [311 (B) and 411] ................................................................30

Hydraulic System [311 (B) and 411] .................................................................... 31

Hydraulic Fluid Reservoir Replenishment [311 (B) and 411] ............................. 31

Factory Default Routine [311 (A and B) and 411] .............................................32

Capacitor Replacement [311 (B)/411] ..............................................................33

Chair Input Voltages ..............................................................................................33

Motor Driven Electro-Mechanical Actuator [311 (B) and 411] .........................34

Position Sensor [311 (A and B)/411] .................................................................35

Factory Default Routine ........................................................................................35

Limp Along Feature................................................................................................35

Solenoid [311 (B) and 411] .................................................................................36

Solenoid Testing ....................................................................................................36

Magnetic Pull Test for Coil Resistance .................................................................36

Volt/Ohm Meter Test for Coil Resistance .............................................................36

Solenoid Assembly Replacement [311 (B) and 411] .......................................... 37

Chair Stop Plate [311 (B) and 411] .....................................................................38

Stop Switch ............................................................................................................38

Chair Bump-Up Feature [311 (B) and 411] ..........................................................38

Dual-Articulating Headrest [311 (A)/311 (B)/411] ........................................... 39

Headrest Adjustment ............................................................................................39

Glide Bar Tension Adjustment ..............................................................................39

Armrest Adjustments [311 (B) and 411] ............................................................40

Two-Position Armrests Adjustment .......................................................................40

Arm Rest Rotation Tension Adjustment ................................................................40

Swivel Brake Adjustment [311 (B) and 411] ...................................................... 41

Swivel Brake........................................................................................................... 41

Swivel Brake Tension Adjustment ........................................................................ 41

Factory Default Routine (511) .............................................................................44

Chair Drive System (511) ..................................................................................... 45

Hydraulic Cylinders ............................................................................................... 45

Motor Driven Hydraulic Pump ..............................................................................45

Hydraulic System (511) .........................................................................................46

Hydraulic Fluid Reservoir Replenishment (511) ..................................................46

Capacitor (511) ..................................................................................................... 47

Solenoid (511) ......................................................................................................48

Solenoid Testing ...................................................................................................48

Magnetic Pull Test for Coil Resistance .................................................................48

Volt/Ohm Meter Test for Coil Resistance .............................................................48

Solenoid Assembly Replacement (511) ...............................................................49

Position Sensors (511) .........................................................................................50

Chair Stop Plate (511) .......................................................................................... 51

Stop Switch ............................................................................................................ 51

Chair Bump-Up Feature (511) ............................................................................... 51

Headrest Adjustment (511) ................................................................................. 52

Swivel Brake Adjustment (511) ...........................................................................53

Swivel Brake Operation .........................................................................................53

Swivel Brake Tension Adjustment ........................................................................53

Chair Programming .................................................................................... 54

Overview ................................................................................................................ 54

Chair Positioning ..................................................................................................55

Chair Direction Buttons .........................................................................................55

Programmable Chair Buttons/Factory Presets ....................................................55

Customize the X-Ray/Rinse Button ......................................................................55

Troubleshooting .......................................................................................... 56

Overview ................................................................................................................ 56

A-dec 311 (A and B) and 411 Dental Chairs Troubleshooting ..........................56

A-dec 511 Dental Chairs Troubleshooting .......................................................... 59

Chair Circuit Board Diagnostics .......................................................................... 63

511 Chair Service, Adjustments, and Maintenance ............................... 42

Chair Covers (511) ................................................................................................ 42

Upholstery (511) ................................................................................................... 43

Back Upholstery Removal/Attachment ................................................................43

Headrest Upholstery Removal/Attachment .........................................................43

Seat Upholstery Removal/Attachment .................................................................43

Page 3

Overview

Copyright and Regulatory Information

Copyright

© 2015 A-dec Inc. All rights reserved.

A-dec Inc. makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. A-dec Inc. shall not be held liable

for any errors contained herein or any consequential or other damages

concerning the furnishing, performance or use of this material. The

information in this document is subject to change without notice. If you

find any problems in the documentation, please report them to us in

writing. A-dec Inc. does not warrant that this document is error-free.

No part of this document may be copied, reproduced, altered, or

transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or by any information storage and

retrieval system, without prior written permission from A-dec Inc.

Trademarks and Additional Intellectual Property Rights

A-dec, the A-dec logo, A-dec 500, A-dec 300, Cascade, Cascade Master

Series, Century Plus, Continental, Decade, ICX, ICV, Performer,

Preference, Preference Collection, Preference ICC, and Radius are

trademarks of A-dec Inc. and are registered in the United States and

other countries. A-dec 400, A-dec 200, Inspire, Preference Slimline, and

reliablecreativesolutions are also trademarks of A-dec Inc. None of

the trademarks or trade names in this document may be reproduced,

copied, or manipulated in any manner without the express, written

approval of the trademark owner.

Product Service

For product service information, please contact your local authorized

A-dec dealer. To find your local dealer, visit www.a-dec.com.

Regulatory Information

Warranty information is provided in the Regulatory Information,

Specifications, and Warranty document (p/n 86.0221.00), which is

available in the Document Library at www.a-dec.com. This document

includes:

• Serial number identification

• Software revisions

• Deluxe touchpad help messages

• Intended application and use statements

• Identification of symbols

• Environmental specifications

• Classification of equipment

• Electrical rating and electromagnetic information

• Chair load capacity

Product Models and Versions Covered in This Document

A-dec uses product versions to indicate significant changes to a product

model. Modifications identified by a change to the product version

include, but are not limited to, significant changes to features and

options, and product compatibility.

Certain touchpad symbols are proprietary to A-dec Inc. Any use of

these symbols, in whole or in part, without the express written consent

of A-dec Inc., is strictly prohibited.

86.0380.00 Rev B Overview 3

Models Versions Description

311 A, B Dental Chairs

411 A Dental Chairs

511 A Dental Chairs

Page 4

A-dec 311, 411, and 511 Dental Chairs Service Guide Overview 4

Customer Service Information

For questions not addressed in this document, contact A-dec Customer

Service using contact information for your region.

A-dec Headquarters

2601 Crestview Drive

Newberg, Oregon 97132

United States

Tel: 1.800.547.1883 within USA/CAN

Tel: +1.503.538.7478 outside USA/CAN

Fax: 1.503.538.0276

www.a-dec.com

A-dec Australia

Unit 8

5-9 Ricketty Street

Mascot, NSW 2020

Australia

Tel: 1.800.225.010 within AUS

Tel: +61.(0).2.8332.4000 outside AUS

A-dec China

A-dec (Hangzhou) Dental Equipment Co., Ltd.

528 Shunfeng Road

Qianjiang Economic Development Zone

Hangzhou 311106

Zheijiang, China

Tel: +1.503.538.7478

A-dec United Kingdom

EU Authorized Representative

Austin House, 11 Liberty Way

Nuneaton, Warwickshire CV11 6RZ

England

Tel: 0800.ADEC.UK (2332.85) within UK

Tel: +44.(0).24.7635.0901 outside UK

Tel: +44 (0) 24 7635 0901 outside UK

www.a-dec.co.uk

Web Contact

Partner Resources websites: www.a-dec.biz.

Other Sources of Information

A-dec 311, 411, and 511 Dental Chairs Service Reference

The A-dec 311, 411, and 511 Dental Chairs Service Guide is a companion

to the A-dec 311, 411, and 511 Dental Chairs Service Reference (p/n

86.0381.00). The service reference contains illustrated parts breakdown

content. Circuit board components and flow diagrams are in both

documents.

Other A-dec Service Documents

The A-dec 300, 400, and 500 Delivery Systems Service Guide (p/n

86.0382.00) contains service, maintenance, and troubleshooting

content. The A-dec 300, 400, and 500 Delivery Systems Service Reference

(p/n 86.0383.00) contains illustrated parts breakdown content. Circuit

board components and flow diagrams are in both documents. These

documents include cuspidors, floor boxes, and support centers.

The A-dec Dental Lights and Monitor Mounts Service Guide (p/n

86.0326.00) contains service, maintenance, and troubleshooting content

for A-dec dental lights and monitor mounts. The A-dec Dental Lights and

Monitor Mounts Service Reference (p/n 86.0328.00) contains illustrated

parts breakdown content. Circuit board components and flow diagrams

are in both documents.

Genuine A-dec Parts Catalog

The Genuine A-dec Service Parts Catalog, p/n 85.5000.00, provides part

number and ordering information for A-dec serviceable parts. This

catalog details service parts for current products and products which

are no longer manufactured but are still supported. Refer to this catalog

for additional details on parts found in the service guide.

Electronic Documentation

The latest versions of A-dec documents are available as electronic

documents on the A-dec website (www.a-dec.com). On the website,

select Document Library in the upper-right corner of the page. Check

this location for the most current technical information about A-dec

products.

Page 5

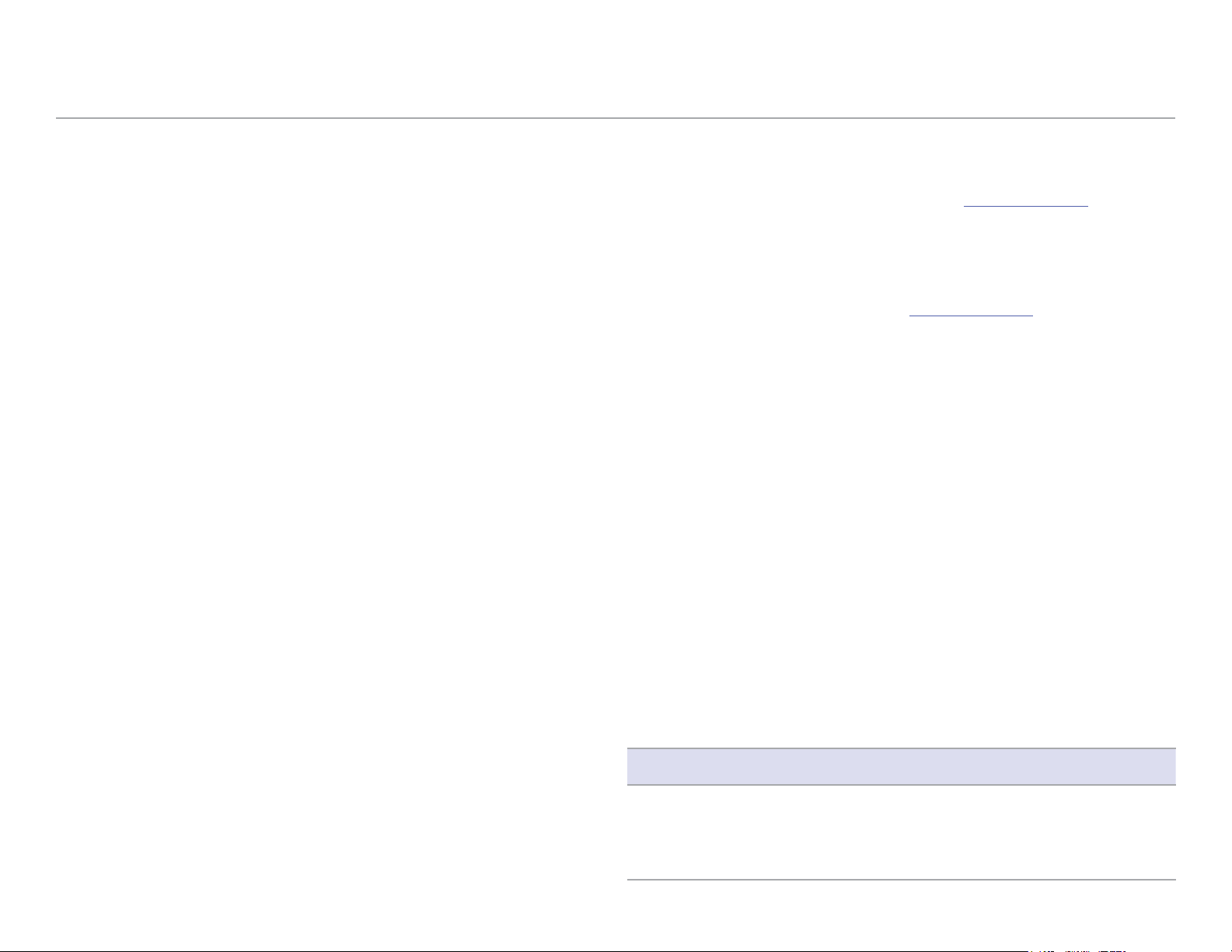

A-dec Dental Chairs

A-dec 311 (Version A) Dental Chair

An optional contoured floor box is also available.

A-dec 311 (Version B) Dental Chair

A-dec 411 Dental Chair

A-dec 511 Dental Chair

86.0380.00 Rev B Overview 5

Page 6

A-dec 311, 411, and 511 Dental Chairs Service Guide Overview 6

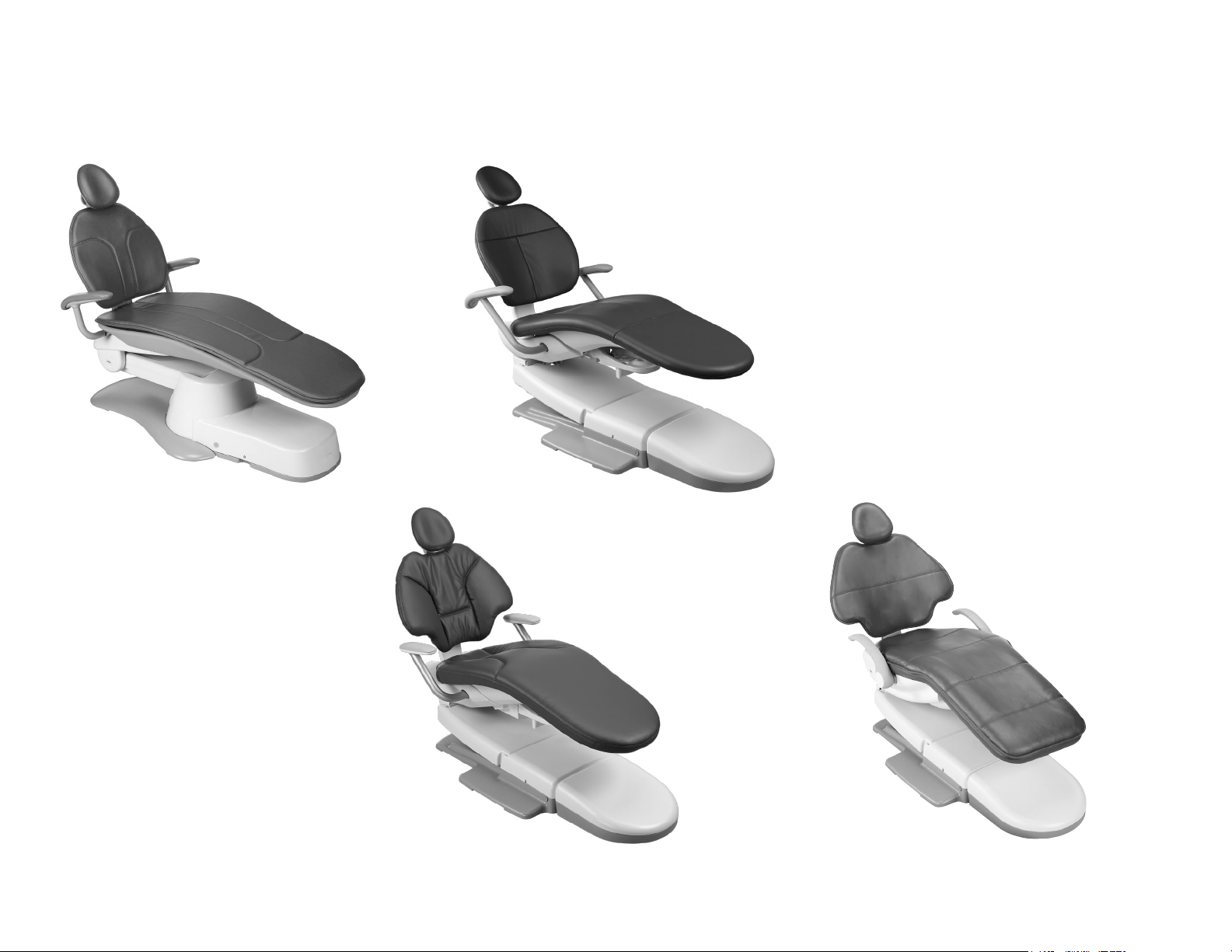

Chair Comparison Chart

A-dec 311 (Version A) Chair A-dec 411/311 (Version B) Chair A-dec 511 Chair

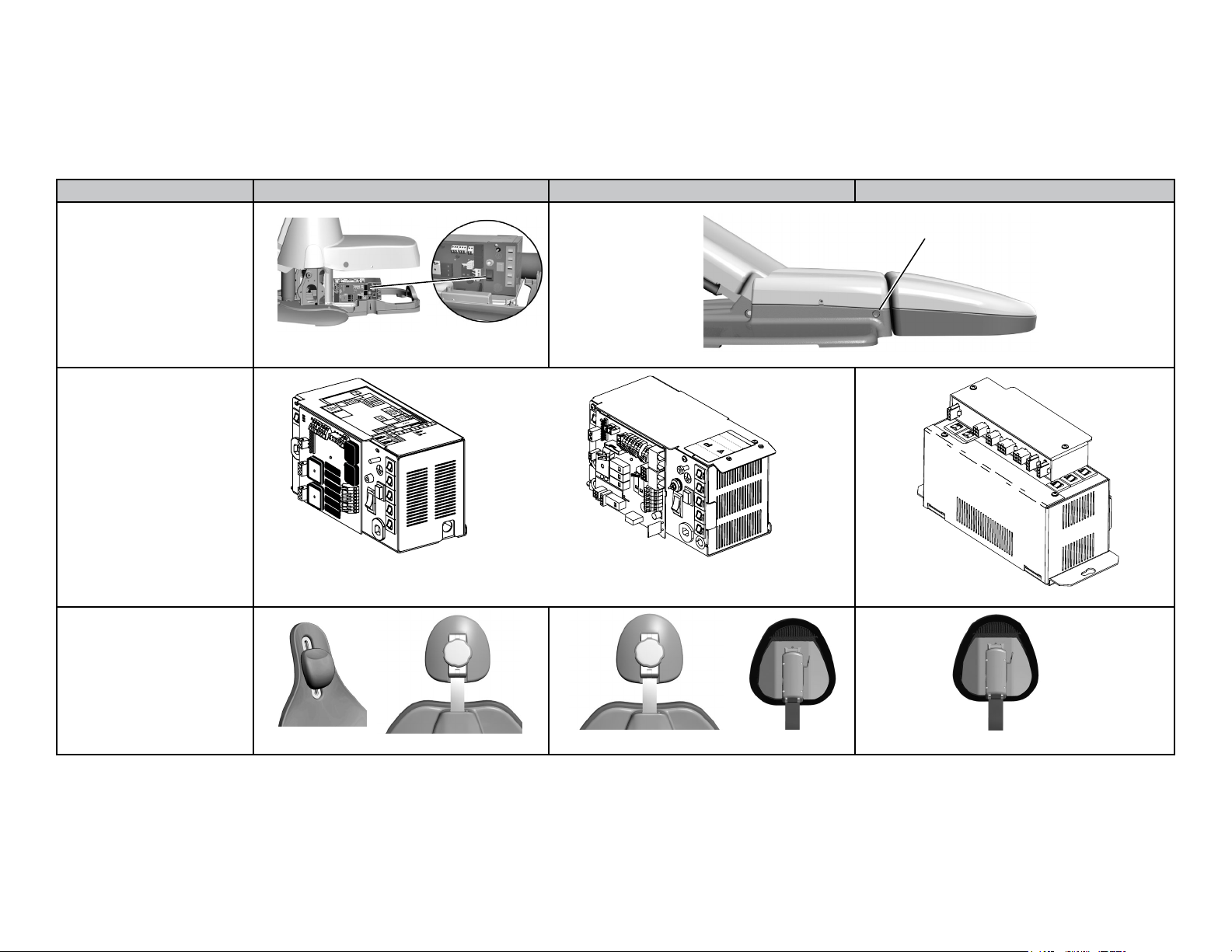

On/Off Button Location

Power On/Off

Power Supplies

Dual Articulating Headrests/

Neck Support

311 Power Supply

(Before March 2013)

Neck Support

Locking Knob

311 (A and B) /411 Power Supply

(Effective March 2013)

Locking Knob

Lever Release

Lever Release

Page 7

A-dec 311 (Version A) Chair A-dec 411/311 (Version B) Chair A-dec 511 Chair

Stop Switch Location (not applicable)

Stop Switch

Chair Drive System Hydraulic Base

Electrical Back

Armrests Two-Position Armrest Multi-Position Armrest

Hydraulic Base

Hydraulic Back

86.0380.00 Rev B Overview 7

Page 8

A-dec 311, 411, and 511 Dental Chairs Service Guide Flow Diagrams 8

Flow Diagrams

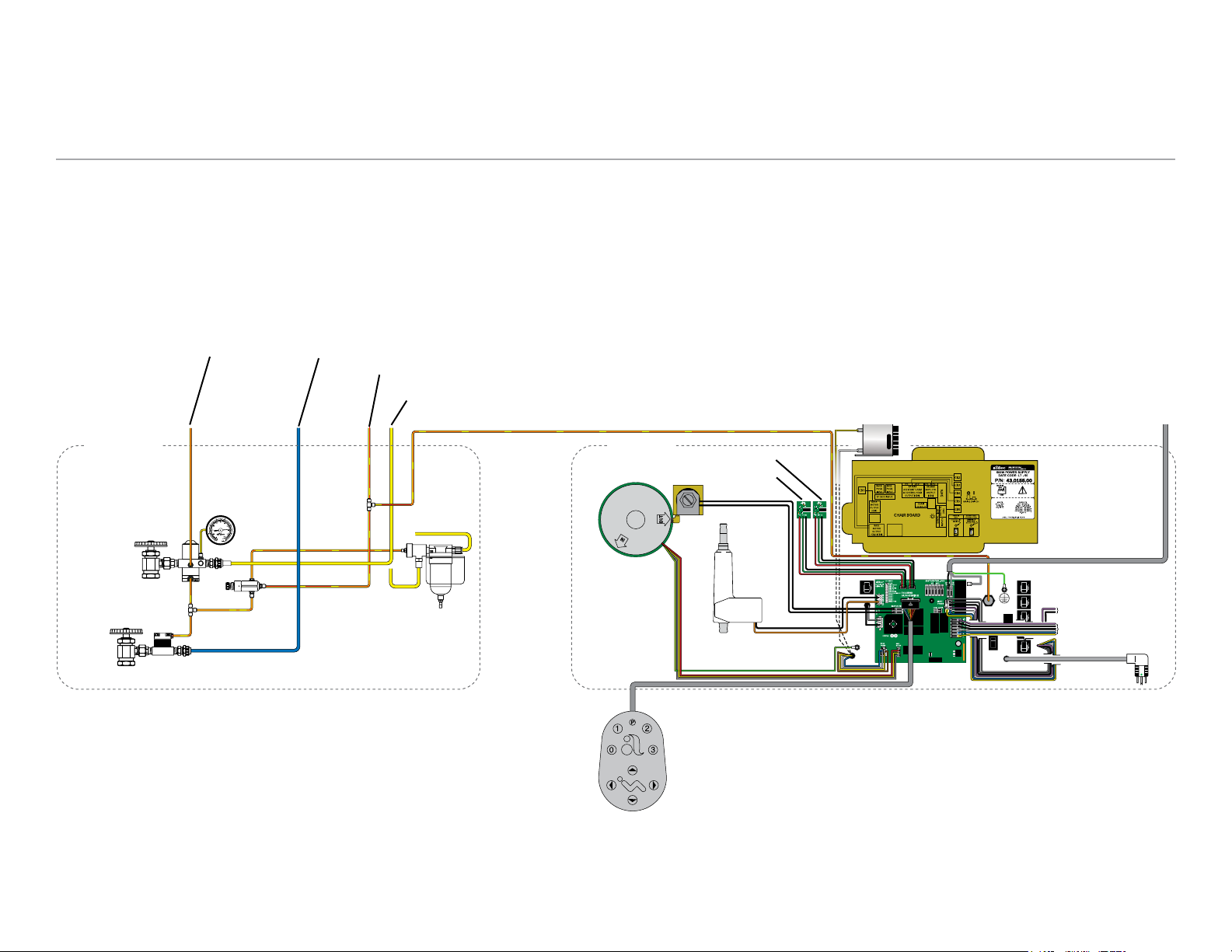

311 (A) Chair Flow Diagram (Before March 2013)

Utilities

To Control Head

Master Toggle

To Water Manifold/

Cuspidor

From Control Head

To Control Head and

Foot Control

(Optional

Moisture

Separator)

To Drain

Chair

Hydraulic

Pump

Base Position Sensor

Back Position Sensor

Solenoid

Linear

Actuator

Power Supply

Capacitor

To Support Center

Power Supply (Top

View)

From 371 Dental

Light or 571-300

Dental Light

Footswitch

Page 9

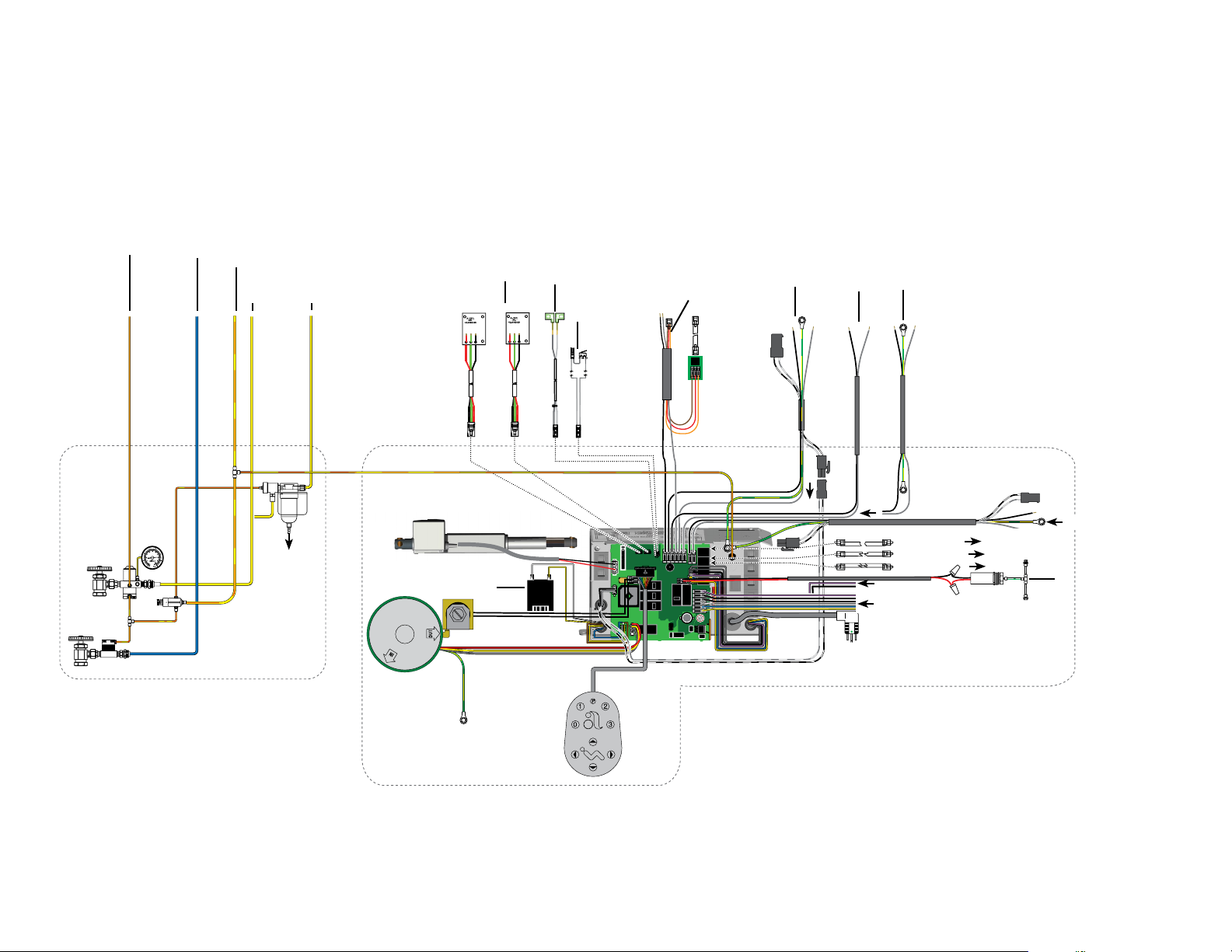

311 (A) [Effective March 2013]/311 (B)/411 Chair Flow Diagram

To Control Head

Master Toggle

To Water Manifold/

Cuspidor

From Control Head

To Control Head and

Foot Control

To Drain

(Optional Moisture

Separator)

Utilities

From Control Head (optional

moisture separator)

Back Tilt Motor

Power Supply

Capacitor

Solenoid

Hydraulic

Pump

Position Sensors

(Back) (Base)

Back Limit Switch (411 Only)

From LED Light

Base Limit Switch (311 (B) and 411 Only)

43.0363.00

Power Supply (Front View)

From Radius Delivery

From 551 Assistant’s Arm

To Chair Power Supply

371 Light

571-300 Light

Chair

From 461 Post Box

300 Delivery

551 Assistant’s

461 Post Box

To Chair Power Supply

361, 362, 363 Post Box

Chair Lockout Kit

Footswitch

86.0380.00 Rev B Flow Diagrams 9

Page 10

A-dec 311, 411, and 511 Dental Chairs Service Guide Flow Diagrams 10

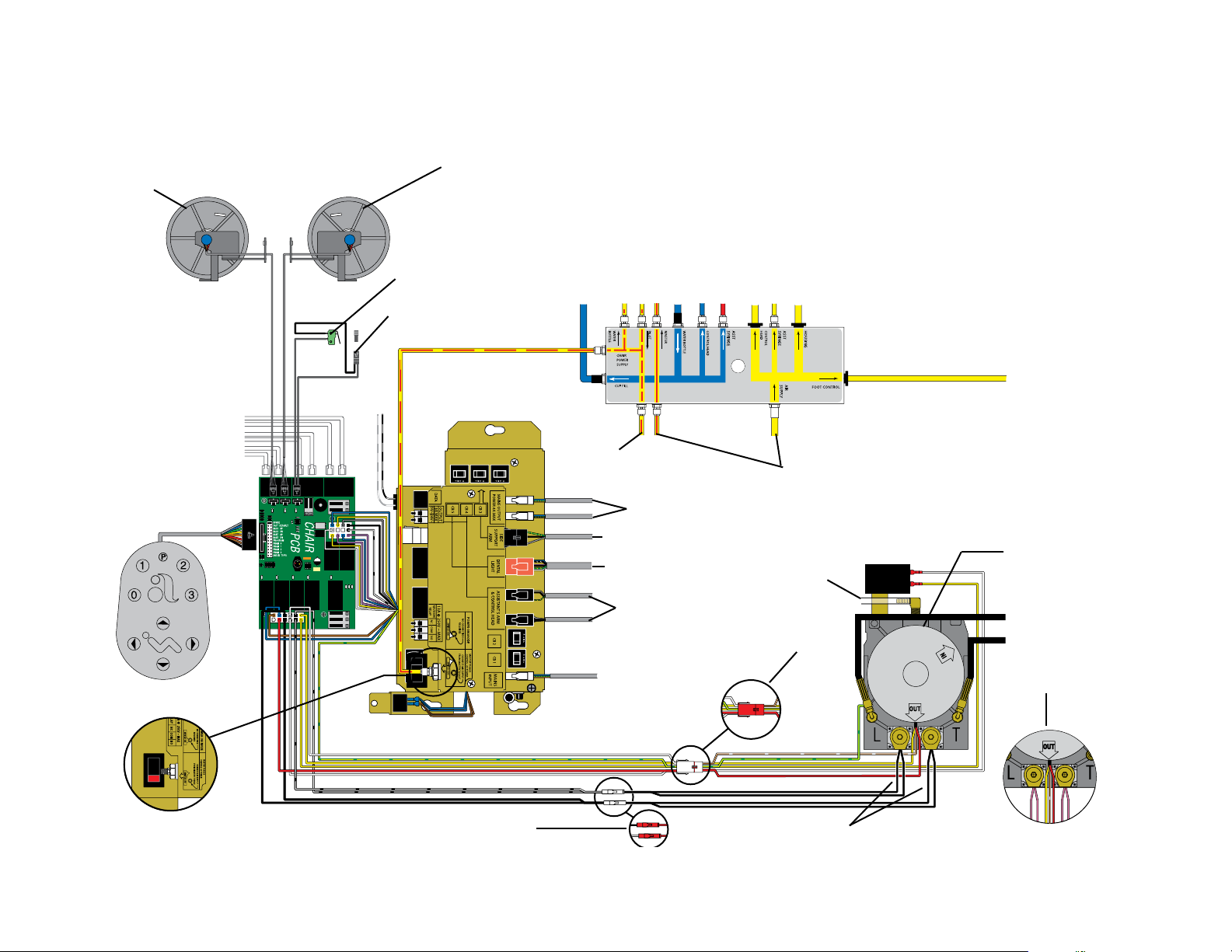

511 Chair Flow Diagram

Base Position

Sensor

Base Stop Switch

Lower Support Arm and

Link Limit Switch

Back Position

Sensor

To Water Bottle

To Cuspidor Cupfill

From Master Toggle

From Water bottle

To Master Toggle

To Control Block

To Flush Valve and Doctor's Syringe

To Assistant’s Syringe

To Assistant’s Syringe

To Amalgam Separator

To Data as Required

Footswitch

(Switch without Tubing)

To Delivery

System

Power Supply

240 V Connector

To Pre-Regulator

To Line volt Accessory

To Support Center

To Dental Light

To Control Head

or Assistant’s

Touchpad

From Mains

Manifolds

From Regulator

From

Reservoir

240 V Connector

Capacitor

To Foot Control

120 V - Hydraulic Pump

To Lift Cylinder

To Tilt Cylinder

240 V - Hydraulic Pump

(Pink Wires)Black and White Wires

Page 11

86.0380.00 Rev B Flow Diagrams 11

Page 12

A-dec 311, 411, and 511 Dental Chairs Service Guide Circuit Board Components 12

BACK

BASE

43.0363.00

16

5

25

26

27

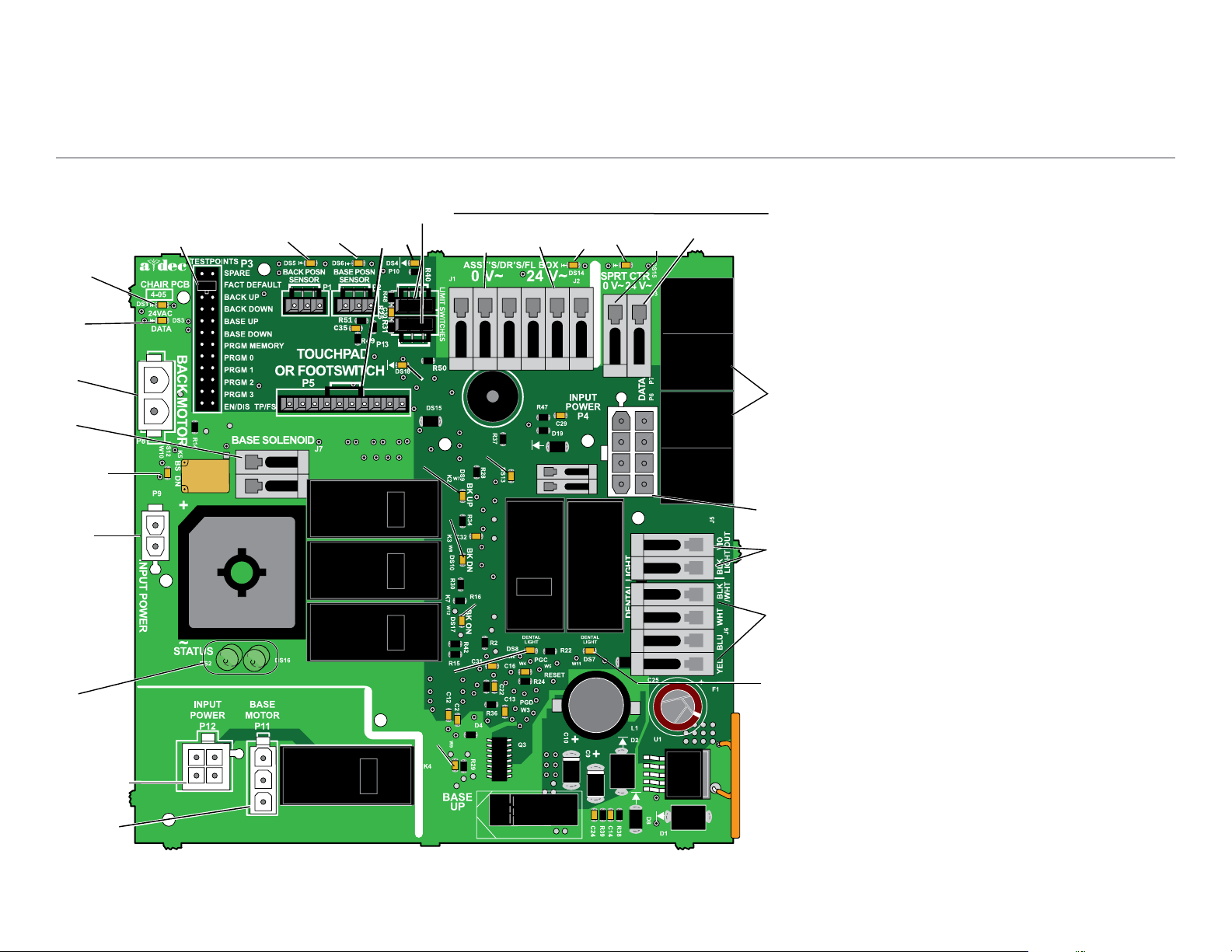

Circuit Board Components

311 (A and B)/411 Chair Circuit Board

20

30

21

31 32

4

1

3

11

18

33

24

34

8

12

9

15

13

14

P13 and DS4:

• 311 (A): Effective July 2013: Jumpers are required on P10 and

P13 for the 311 (A) chair.

• 311 (B): Jumpers are required on P13 only.

• 411: No jumpers required. 411 has a base and a back limit switch.

19

17

28

29

7

2

10

23

22

6

Page 13

311 (A and B)/411 Chair Circuit Board LED Identification

311 (A and B)/411 Chair Circuit Board Identification

LED Status Description

DS1, DS14, and

DS15 - AC power

LED

DS2 and DS16Status LED

DS3 - Data LED Off No DCS communication, not connected to

DS13 - Chair lockout Off Open, (normal)

DS5, DS6 - Chair

position sensors

DS9, DS10, DS11,

DS12, DS17- Chair

relay LEDs

DS7, DS8 - Dental

light relay LEDs

Off No 24 VAC power, tripped circuit breaker,

power supply turned off

Green, steady

Off System is not functioning, no power, or

Blue, steady

Blue, single blink

Blue, double blink

Green, steady

Green, blinking

Red, on

Off Position Sensor: not connected or bad

Yellow, steady

Yellow, fast blink

Yellow, slow blink

Off Relay is off

On Relay is on

Off Relay is off

On Relay is on

24 VAC present

circuit board has failed

Normal operation

Duty cycle limit of chair back has been

exceeded

Jumper is in factory mode

the DCS, or DCS has failed

Detects active DCS

Valid DCS Message

Closed, (activated)

connection; moving in wrong direction;

limited range of motion

Normal operation

Upper end of travel

Lower end of travel

CAUTION: Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from the

circuit board. Circuit boards should be installed only by an

electrician or qualified service person.

Item Description Item Description

1 DS1 - AC power LED (CB1) 18 P5 - touchpad or footswitch connector

2 DS2, DS16 - status LEDs 19 P6/P7 - data ports

3 DS3 - data LED 20 P8 - back motor connector

4 DS5 - back position sensor, LED/

P1 Connector

5 DS6 - base position sensor LED/

P2 connector

6 DS7 - dental light LED/Relay K6 23 P12 - input power connector

7 DS8 - dental light LED/Relay K1 24 J1 - 0 VAC terminal strip (output) for

8 DS9 - back up LED/Relay K2 25 J2 - 24 VAC terminal strip (output) for

9 DS10 - back down LED/relay K3 26 J3 - 0 VAC terminal strip (output) for

10 DS11 - base up LED/relay K4 27 J3 - 24 VAC terminal strip (output) for

11 DS12 - base down LED/relay K5 28 J5 - dental light output terminal strip

12 DS13 - chair lockout LED/terminal

strip J4

13 DS14 - AC power LED (CB4) 30 J7 - base solenoid terminal strip

14 DS15 - AC power LED (CB5) 31 P10 - Jumper - 311 (A) chair only

15 DS17 - back on LED/Relay K7 32 P13 - Jumper - 311 (A and B) chairs

16 P3 - testpoints header 33 DS4 - Base stop switch

17 P4 - input power connector 34 DS 18 - Back stop switch

21 P9 - input power connector

22 P11 - base motor connector

Assistant’s, doctor’s, oor box

assistant’s, doctor’s and oor box

support center

support center

29 J6 - dental light input terminal strip

86.0380.00 Rev B Circuit Board Components 13

Page 14

A-dec 311, 411, and 511 Dental Chairs Service Guide Circuit Board Components 14

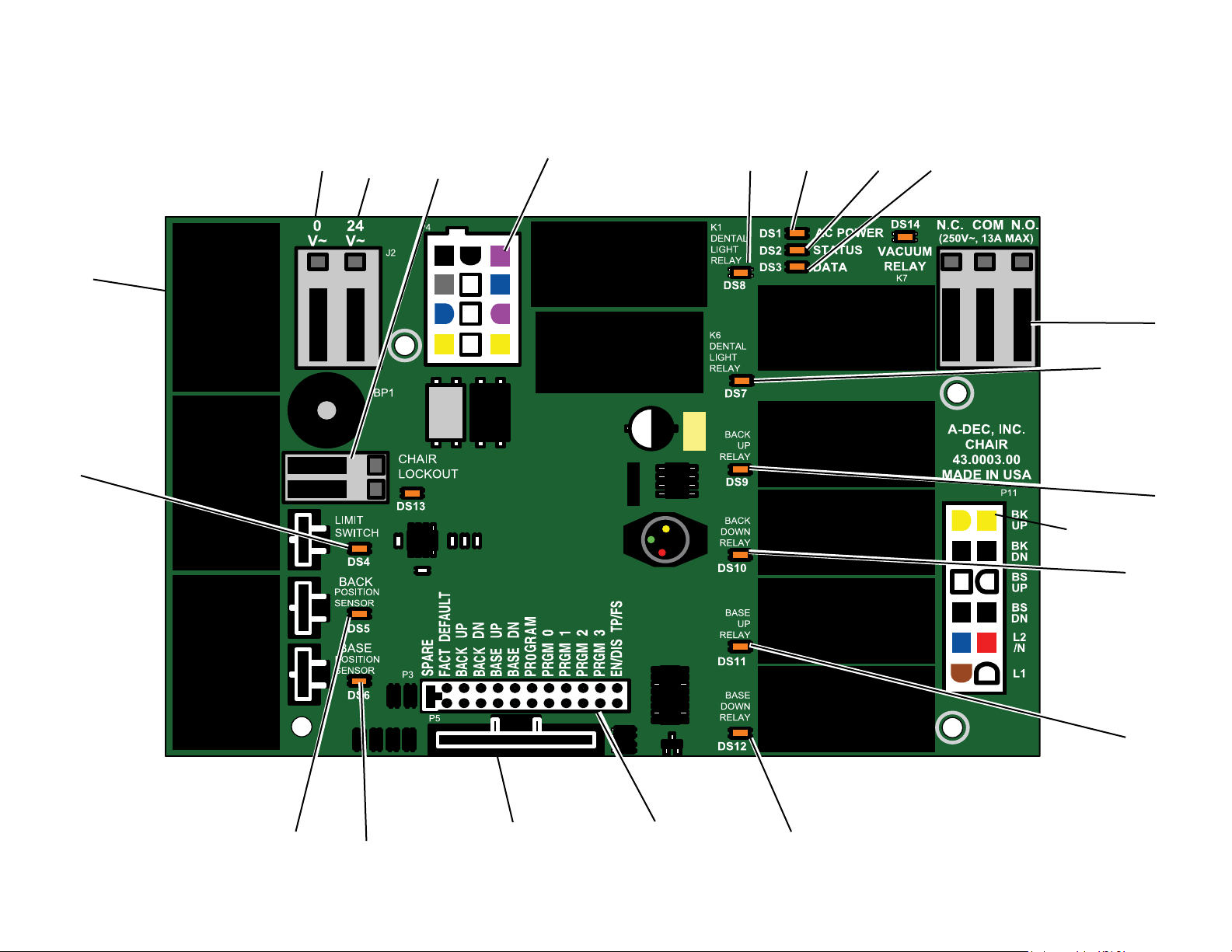

511 Chair Circuit Board

15

1

2

16

14

17

20

11

12

13

18

21

10

19

9

8

3

4

5

6

7

Page 15

511 Chair Circuit Board LED Identification

511 Chair Circuit Board Identification

LED Status Description

DS1 - AC power

LED

DS2 - Status LED Off System is not functioning, no power or circuit

DS3 - Data LED Off No DCS communication, not connected to the

DS4 - Chair limit

switch

DS13 - Chair

lockout

DS5 + DS6 Chair position

sensors

DS9, DS10,

DS11, DS12 Chair relay LEDs

DS7, DS8 Dental light relay

LEDs

DS14 - Vacuum

relay LED

Off No 24 VAC power, tripped circuit breaker, power

supply turned off, no line voltage

Green, steady

Green, steady

Green, steady

Green, blinking

Off Closed, (normal)

Red

Off Open, (normal)

Red

Off Position Sensor: Not connected or bad connection;

Yellow, steady

Yellow, fast blink

Yellow, slow blink

Off Relay is off

On Relay is on

Off Relay is off

On Relay is on

Off Relay is off

On Relay is on

24 VAC at the terminal strip

board has failed

Normal operation

DCS, or DCS has failed

Detects active DCS

Valid DCS message

Open, (activated)

Closed, (activated)

moving in wrong direction; limited range of motion;

or cable is not on the pully

Normal operation

Upper end of travel

Lower end of travel

Item Description Item Description

1 P7, P8, P9 - data ports 11 DS1 - AC power LED

2 DS4 - stop switch LED (limit

switch)/P10 connector

3 DS5 - back position sensor LED/

P1 connector

4 DS6 - base position sensor LED/

P2 connector

5 P5 - footswitch connector 15 J2 - 0 VAC terminal strip (output)

6 P3 - testpoints header 16 J2 - 24 VAC terminal strip (output)

7 DS12 - base down LED/relay K5 17 P4 - Input power/dental light

8 DS11 - base up LED/relay K4 18 J3 - vacuum relay K7 output terminal

9 DS10 - back down LED/relay K3 19 P11 - pump motor/solenoid

10 DS9 - back up LED/relay K2 20 DS8 - dental light LED relay/K1

12 DS2 - status LED

13 DS3 - data LED

14 DS13 - chair lockout LED/terminal

strip J1

connector

strip

connector

21 DS7 - dental light LED relay/K6

CAUTION: Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from the

circuit board. Circuit boards should be installed only by an

electrician or qualified service person.

86.0380.00 Rev B Circuit Board Components 15

Page 16

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 16

311 (A) Chair Service, Adjustments, and Maintenance

Chair Covers [311 (A)]

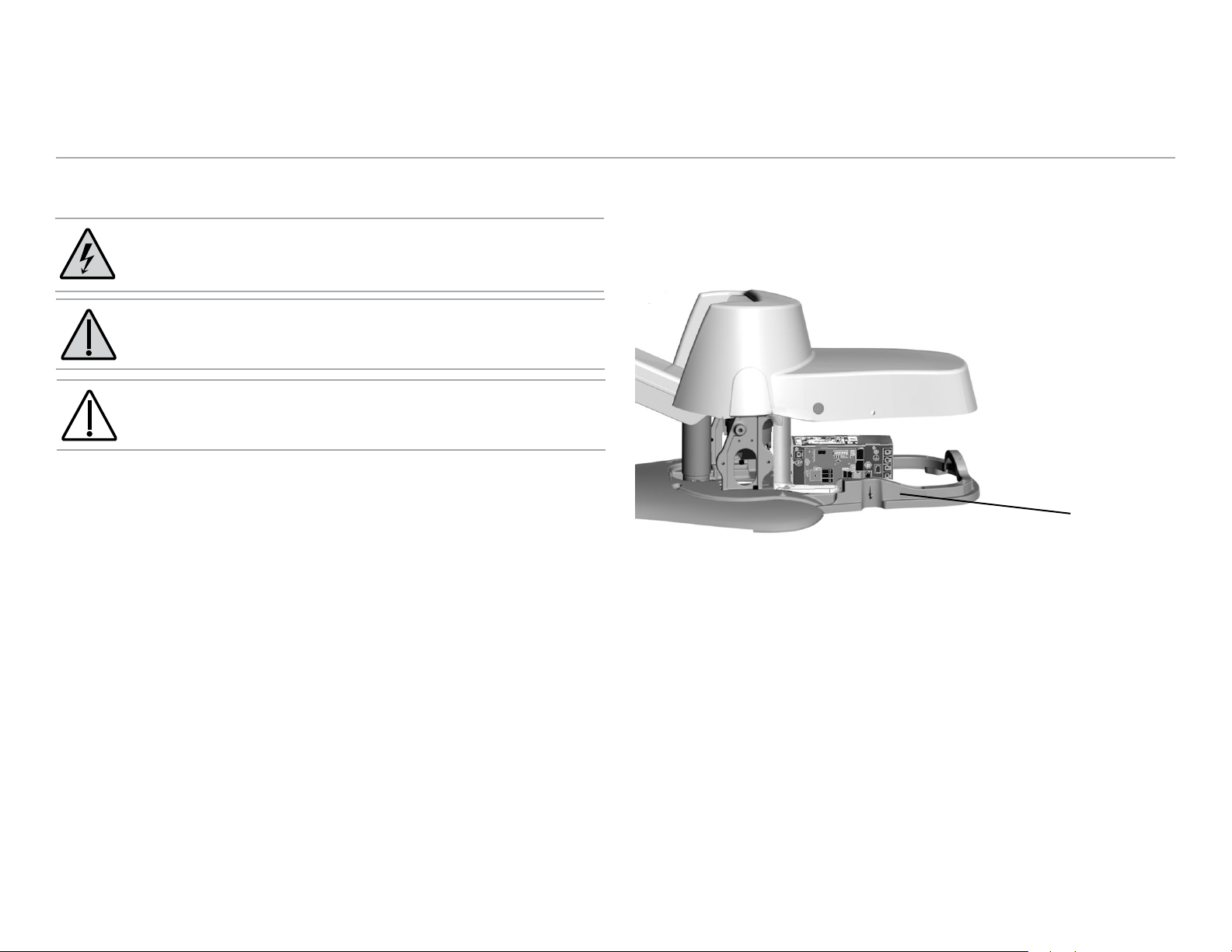

DANGER Failure to turn off the power before you begin this

procedure can lead to electrical shock.

WARNING Failure to turn off the power before you begin this

procedure can lead to product damage and result in serious

injury or death.

CAUTION When removing or replacing covers, take care not

to damage any wiring or tubing. Verify that the covers are

secure after replacing them.

Integrated Floor Box Cover Removal

To access the on/off button and power supply on chairs with an

integrated floor box cover, pull the utility cover out at the cover posts

and lift the cover off .

Cover

Post

Page 17

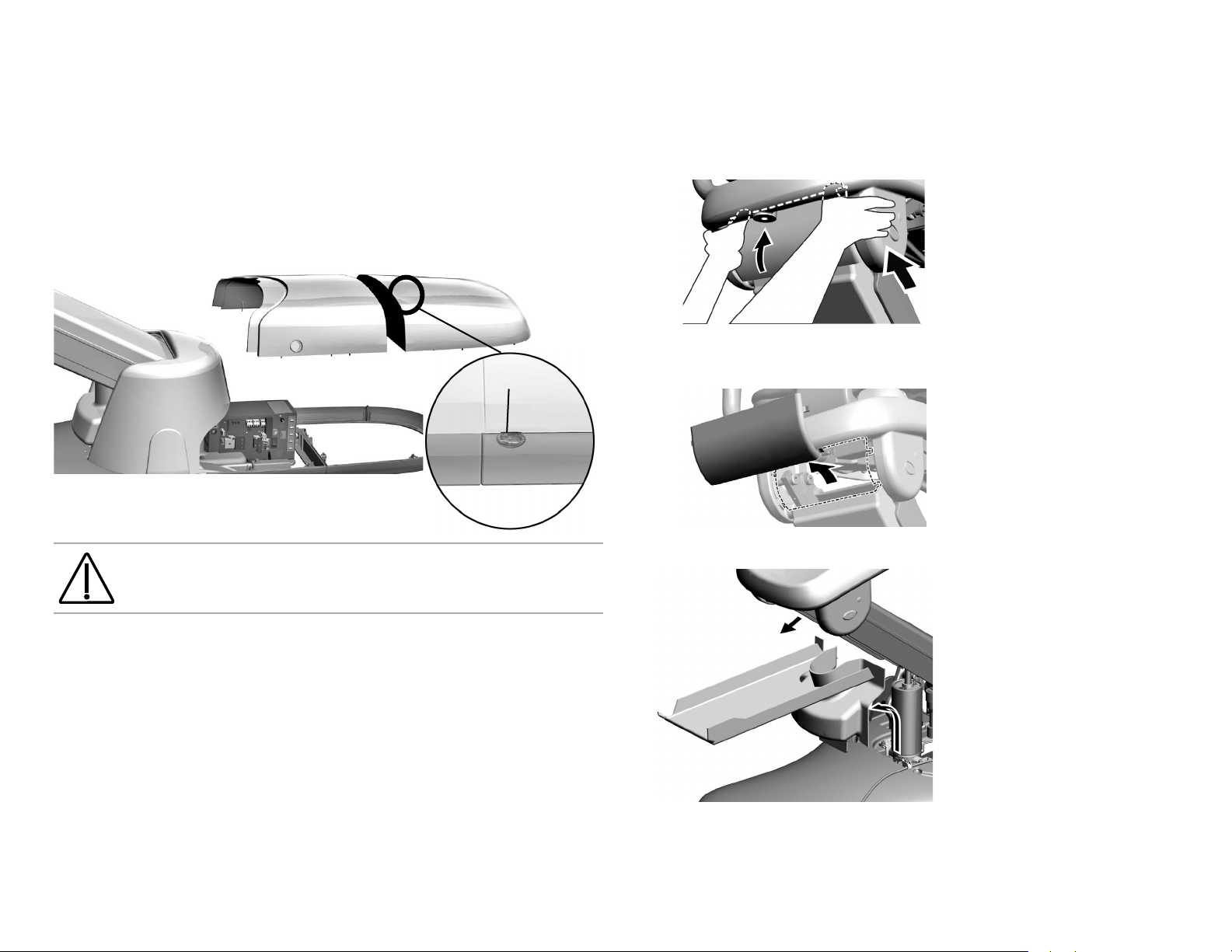

Contoured Floor Box Cover Set Removal

To access the on/off button and power supply on chairs with a

contoured floor box cover set, first remove the front floor box cover.

Grasp the cover on both sides and pull up. If needed, use a large coin in

the integrated coin slot to gently separate the contoured floor box cover

from the frame. Then remove the power supply cover.

2. With your thumbs on the top of the upper lift arm cover, grasp

from the bottom and pull up and push in to disengage tabs from

slots.

3. Lift out the upper lift arm cover.

Coin Slot

CAUTION Take care not to damage the cover when using the

coin slot.

Lift Arm Covers Removal

If the utility cover is installed, remove it before beginning this

procedure.

1. Raise the chair base all the way up.

4. Remove the lift arm and lower lift arm cover.

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 17

Page 18

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 18

Upholstery [311 (A)]

Back Upholstery Removal/Attachment

To remove the upholstery, firmly grasp the bottom edge of the armature

and lift up, then lift the upholstery away from the chair back support.

To reattach, place the key holes in the armature over the large fastener

heads, then push down until the upholstery inserts into position.

Remove

Headrest

Lift up, then

pull out

Fastener

Heads

Fastener

Heads

Headrest Upholstery Removal/Attachment

To remove the headrest upholstery, position the headrest to access the

two screws on the back, loosen the screws and remove the upholstery.

To reattach, position the headrest to access the screws, place the

upholstery on the headrest, insert and tighten the screws.

Lift up, then

pull out

Seat Upholstery Removal/Attachment

To remove the seat upholstery, pull the pins out on both sides of the

seat armature, then lift the seat and move it away.

CAUTION When replacing the upholstery, ensure the pins are

completely in place. The pin ring should be flush with the

seat armature.

Armature

Pin Ring

Mounting

Screws

Page 19

BACK

BASE

43.0363.00

Factory Default Routine [311 (A and B) and 411]

CAUTION The position sensors can be inadvertently installed

upside down. Improper installation will limit the chair’s

functionality.

After installing a new chair, circuit board, or position sensor, run the

factory default routine. The routine:

• Sets the chair base and back upper limits

• Calculates new preset positions based on actual range of motion

of the chair

• Verifies that the position sensors work correctly

To start the factory default routine, place the spare jumper in the factory

default position on the P3 test points of the chair circuit board.

CAUTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from

the circuit board. Circuit boards should be installed only by

an electrician or qualified service person.

Jumper in

Factory

Default

Position

When running the factory default routine, the chair:

1. Moves base down.

2. Moves base up.

3. Moves back down.

4. Moves back up.

5. Moves base and back to mid position.

6. Moves back and base down.

7. Moves base and back to mid position.

8. Moves base and back to Entry/Exit.

9. Three beeps confirm the routine completed successfully.

Once the routine completes, place the jumper into the Spare position

on P3.

NOTE The jumper must remain in the factory default

position to complete the factory default routine. The status

LEDs on the standard and deluxe touchpads and the chair

circuit board double blink while the factory default routine

is running and after the routine is complete. When the

routine is complete, three beeps sound. If the routine stops

prematurely, one beep sounds.

NOTE One beep indicates the routine failed to complete. See

page 56 for troubleshooting.

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 19

Page 20

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 20

Chair Drive System [311 (A)]

The hydraulic chair system controls the base movement of the chair. An

electro-mechanical tilt actuator controls the back movement.

The chair seat has a vertical range of 13.75" (349 mm) to 29.5" (749 mm)

above the floor.

Chair Manifold Adjustment System [311 (A)]

Use a 3/32" hex key, to move the base down adjustment screw to

change the base down [chair] speed. Turning the screw clockwise

(tightening) decreases the base down speed. Turning the screw counterclockwise increases the base down speed.

Base Down

Hydraulic Motor

Pump Assembly

Adjustment Screw

Chair Manifold

Assembly

NOTE Do not over tighten the adjustment screw. If the screw

is too tight, the chair may not move.

Page 21

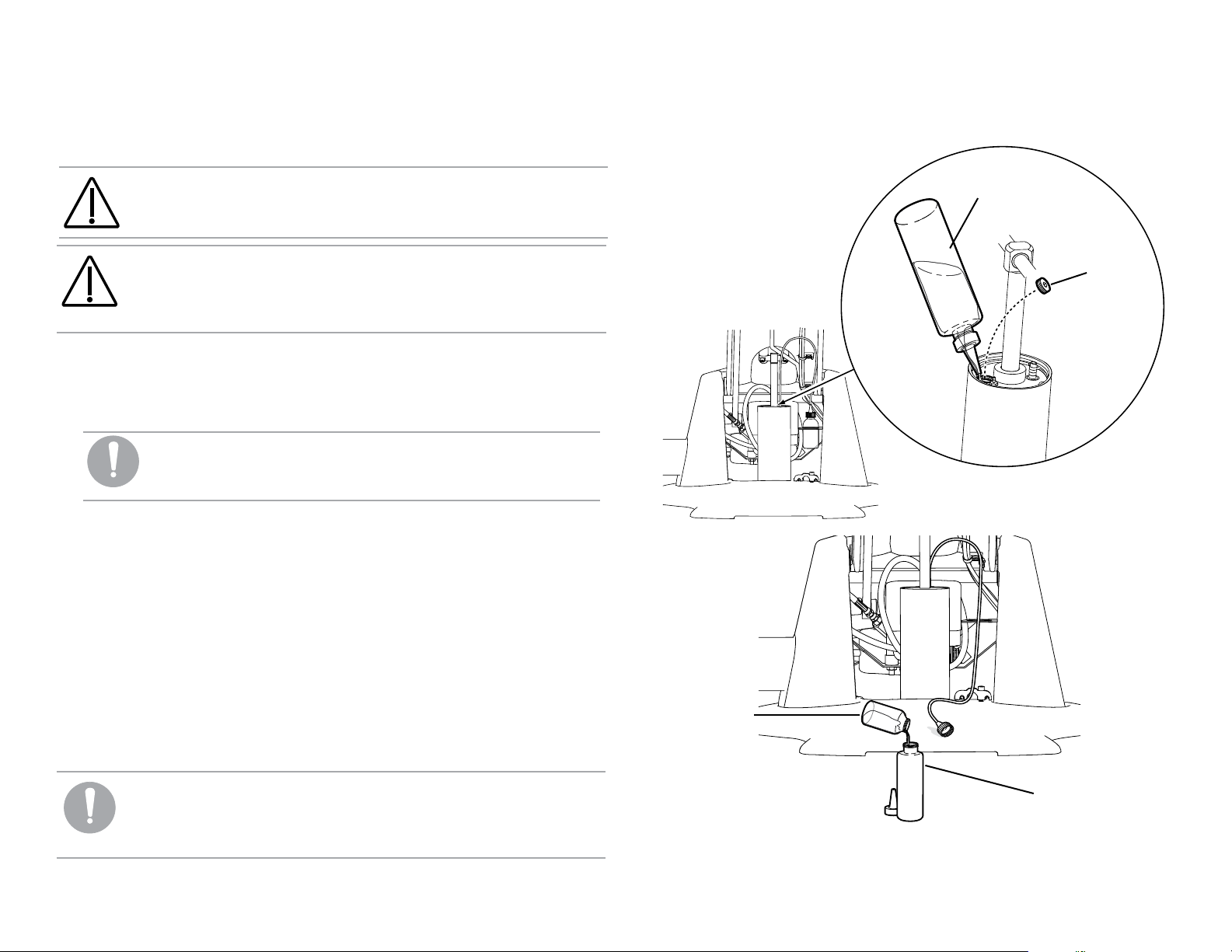

Hydraulic Fluid Replenishment [311 (A)]

Follow the steps below to add hydraulic fluid.

CAUTION Use only A-dec hydraulic fluid, p/n 61.0197.00.

Hydraulic Fluid

Bottle

CAUTION If the hydraulic cylinder needs to be replaced, or

if there has been a significant loss of hydraulic fluid, contact

A-dec Customer Service. The steps to replace the hydraulic

cylinder are complicated and specific.

1. Raise the chair to its highest level.

2. Use a 3/16" hex key to remove the fill plug from the top of the

hydraulic cylinder.

NOTE It may be difficult to measure exactly to the thread

level. You may want an absorbent towel available to

soak up some of the fluid if it seems too full.

3. Fill the hydraulic fluid to the plug thread level.

4. Replace the fill plug.

5. Lower the chair fully. The overflow bottle will capture any excess

fluid.

6. Raise the chair.

7. Remove the overflow bottle from the bracket.

8. Empty the overflow bottle.

9. Return the overflow bottle to the bracket.

Plug

Overflow Bottle

10. Run the factory default routine. (See page 19.)

NOTE Allow the chair to settle before operating. This allows

the air bubbles to separate from the oil. If you use the chair

Hydraulic Fluid

Bottle

and it makes noises, repeat steps 1 through 10 above.

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 21

Page 22

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 22

Capacitor Replacement [311 (A and B)/411]

The hydraulic system used for the chair’s base movement is operated

using a motor capacitor, located in the power supply of the chair. There

are three specific capacitors for different line voltage ranges. The chair

motor capacitor can be replaced within the power supply.

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

Chair Input Voltages

Mains Chair Input Voltage A-dec Capacitor Part Number

100 VAC 90.1198.00

110 - 120 VAC 90.1199.00

220 - 240 VAC 90.1200.00

Before March 2013

Capacitor

Effective March 2013

Capacitor

Page 23

Motor Driven Electro-Mechanical Actuator [311 (A and B)/411]

The back-up and back-down movements are controlled with an electromechanical tilt actuator, which is located under the seat of the chair.

Back Position Sensor

Actuator

Base Position Sensor

A diagnostic LED is provided on the chair board for each position

sensor. Refer to Chair Circuit Board LED Identification, see page 12

for information. An additional LED, indicating power, is present on

each position sensor circuit board.

LED

Red

Green

Black

Black

Factory Default Routine

If a position sensor or chair board is replaced, run the factory default.

For instructions on running the factory default, see page 19.

Position Sensor [311 (A and B)/411]

The position sensor circuit boards provide positioning data to the chair

board. There is a position sensor for the back and a position sensor for

the base.

CAUTION The position sensors can be inadvertently installed

upside down. Improper installation will limit the chair’s

functionality.

Limp Along Feature

There are two position sensors, one for the base of the chair and one for

the back of the chair. If there is a problem or malfunction with a position

sensor, the limp along feature allows the operator to move the chair in

the up direction for one to three second intervals by pushing the manual

control buttons on the touchpad or footswitch. Refer to Chair Circuit

Board LED Identification on page 12 for further information. When in

limp along mode, presets will not function.

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 23

Page 24

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 24

Solenoid [311 (A)]

p/n: 62.0317.00 21.6 VDC

Solenoid Testing

A solenoid is energized during base down function. To determine if

a solenoid has failed, check for coil resistance using magnetic pull or

volt/ohm meter test.

Magnetic Pull Test for Coil Resistance

1. Hold a paper clip loosely in your hand.

2. Activate the solenoid by pressing base down on the footswitch or

touchpad.

3. If there is a pull on the paper clip, the solenoid is being energized.

Volt/Ohm Meter Test for Coil Resistance

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

1. Disconnect the solenoid power at the chair board’s base solenoid

terminal strip (J7).

2. Place one Ohm meter probe on each of the solenoid wires.

Solenoid=38Ohms(Ω)±4Ohms(Ω)

J7

Solenoid

Paper Clip

Page 25

Solenoid Assembly Replacement [311 (A)]

CAUTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from

the circuit board. Circuit boards should be installed only by

an electrician or qualified service person.

WARNING Lower the chair base to the mechanical limit

before removing the solenoid.

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

5. Wipe up any fluid and replace existing O-rings on the solenoid base.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

Remove the Solenoid Assembly:

When replacing a solenoid wipe up any fluid and replace existing

O-rings on the solenoid base.

1. Remove the utility cover(s).

2. To minimize pressure in the hydraulic system, lower the chair base

to the mechanical limit

3. Disconnect the solenoid from the chair circuit board terminal

strip J7.

4. Loosen the nut on the solenoid and use a screw driver to remove

the solenoid assembly.

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 25

Install the New Solenoid Assembly:

1. Install the new solenoid.

2. Reconnect the solenoid to the chair circuit board, terminal strip J7. It

does not matter which solenoid wire goes into which terminal. The

solenoid will work either way.

3. Turn on the power.

4. Move the chair up and down to ensure there are no leaks.

5. Reinstall the utility cover.

Page 26

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (A) Chair Service, Adjustments, and Maintenance 26

Headrest Adjustments [311 (A)]

The chair features one of two choices of backrest: a thin-line back

with patient-adjustable neck support or a thin-line back with dualarticulating headrest.

Patient-Adjustable Neck Support Removal/Attachment

Neck support cushions manufactured prior to October 2013 can be

repositioned in the track. To reposition, place your thumb against the

neck support armature and pull the cushion out from the track. Flip the

cushion around and insert it back into the track. The cushion includes a

graphic on the back that depicts proper orientation for shorter or taller

patients.

Reposition Neck Support

Neck Support Track

Before October 2013

Dual-Articulating Headrest [311 (A and B)/411]

Headrest Adjustment

The dual-articulating headrest offers a “glide” feature, as well as

manual articulation. The locking knob allows you to adjust the headrest

for a full range of positions.

Release the headrest by turning the locking knob to the left, then adjust

the headrest for a proper fit. Lock the headrest in the desired position

by turning the knob to the right. For minor height adjustment, slide

the headrest cushion up and down. For additional height adjustment,

reposition the glide bar.

Glide Bar Tension Adjustment

A dual-articulating headrest may be difficult to move or may drift

downward because of the amount of tension on its glide bar. To adjust

the tension, use a 1/8" hex key and turn the tension adjustment screw to

the right to increase friction or to the left to decrease friction.

Headrest

Note: This neckrest can

rotate/mount two ways.

Neck Support Track

Note: This neckrest can

only mount one way.

Effective October 2013

Locking

Knob

Glide Bar

1/8” Hex Key

Note: the lever headrest is

an option for the 411 chair..

Page 27

Two-Position Armrest Adjustments [311 (A)]

Armrests Repositioning

Pull or push the armrests to reposition them in the forward or backward

position. The armrests can also be locked into the upright position.

Armrests Locking

The armrests can be unlocked from the upright position. Using a 3/16''

hex key, remove the rotational stop screw from the back of the armrest

and install it in the front of the armrest.

Effective October 2012

Effective October 2012

Stop Screw in Front for

Positional Armrest

Stop Screw in Back

for Locked Armrest

Before October 2012

Before October 2012

86.0380.00 Rev B 311 (A) Chair Service, Adjustments, and Maintenance 27

Page 28

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 28

311 (B) and 411 Chairs Service, Adjustments, and Maintenance

Chair Covers

Remove the chair motor pump, lift arm and stop

plate covers in the following order:

CAUTION When removing or

replacing covers, take care not to

damage any wiring or tubing. Verify

that the covers are secure after

replacing them.

1. Motor Pump Cover: Remove the screw from

each side of the cover and lift up.

2. Lift Arm Cover: Position the chair so it is

raised half way up. Pull one side of the cover

until it releases from the lift arm. To replace,

align one side of the cover with the lift arm

and insert it into place. Ensure both sides are

firmly attached.

3. Stop Plate: Pull one side of the cover until it

releases from the lift arm. To replace, slide

one side of the cover over the post on the lift

arm and attach.

Side Cover [311 (B) and 411 only]

Rear Cover

Assembly

Lift Arm Cover

Rear Cover

or

Swivel Cover

Stop Plate Cover

Side Cover [311 (B) and 411 only]

Motor Pump Cover

A-dec 311 B Shown

Page 29

Upholstery [311 (B) and 411]

Back Upholstery Removal/Attachment

NOTE The 311 (B) and 411 upholstery backs are not

interchangeable.

To remove the back, firmly grasp the bottom edge of the cushion and lift

up, then lift the upholstery out and away from the chair back support.

To reattach the back upholstery, place the key holes on the cushion over

the large fastener heads, then push down until it inserts into position.

Headrest Upholstery Removal/Attachment

Seat Upholstery Removal/Attachment

To remove the seat upholstery, move the armrests forward and pull out

the side covers. Remove the pins that are under the chair frame, then

lift upholstery off of the frame. To reattach, move the armrests forward,

line up the holes in the seat upholstery with the holes in the chair frame.

Push the pins through the seat upholstery and chair frame until the

rings touch the seat, then reinstall the covers.

Locking knob and lever release headrests are used with the

A-dec 311 (B) and 411. The headrest upholstery installs the same way for

both styles. The locking knob headrest is shown.

To remove the headrest upholstery, position the headrest to access the

two screws on the back, loosen the screws, and remove the upholstery.

To reattach, position the headrest to access the screws, place the

upholstery on the headrest, then insert and tighten the screws.

Screws

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 29

A-dec 411 Shown

Page 30

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 30

Chair Drive System [311 (B) and 411]

The hydraulic chair system controls the base movement of the chair. An

electro-mechanical tilt actuator controls the back movements.

The chair seat has a vertical range of 13.75" (349 mm) to 31.5" (800 mm)

above the floor.

311 (B) and 411 (effective January 2015) include an adjustable BASE

DOWN speed adjustment: To adjust the BASE DOWN: Use a 3/32" hex

key to adjust the speed.

To slow the base down, turn the set screw clockwise.

To speed up the base down, turn the screw counterclockwise.

Page 31

Hydraulic System [311 (B) and 411]

The hydraulic system deactivates automatically at the upper and

lower extremes of travel. The system is leak-free during transportation,

storage, and operation. The hydraulic system consists of hydraulic fluid

reservoir, hydraulic cylinders, and motor-driven hydraulic pump with

solenoids.

CAUTION Use only A-dec hydraulic fluid, p/n 61.0197.00.

Hydraulic Fluid Reservoir Replenishment [311 (B) and 411]

The hydraulic fluid reservoir is located in the lift arm of the chair under

the stop plate cover. You can see through the translucent material to

determine the fluid level in the reservoir.

Add hydraulic fluid to the reservoir:

1. Raise the chair to the full base up position.

2. Fill the reservoir with hydraulic fluid to the top of the fluid level

indicator.

CAUTION Do not overfill.

Fluid Level

Indicator

3. Move the chair down and up after fluid has been added.

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 31

Page 32

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 32

BACK

BASE

43.0363.00

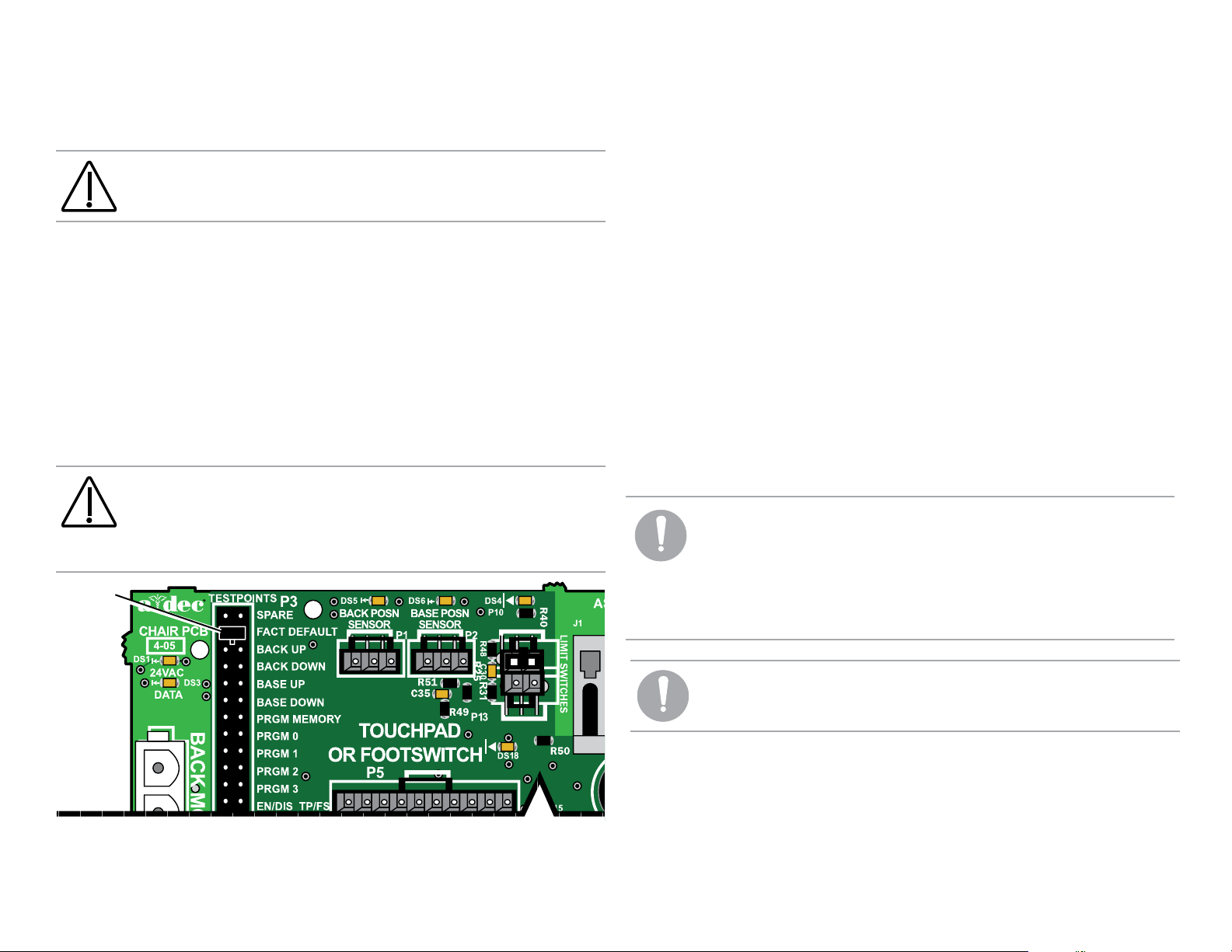

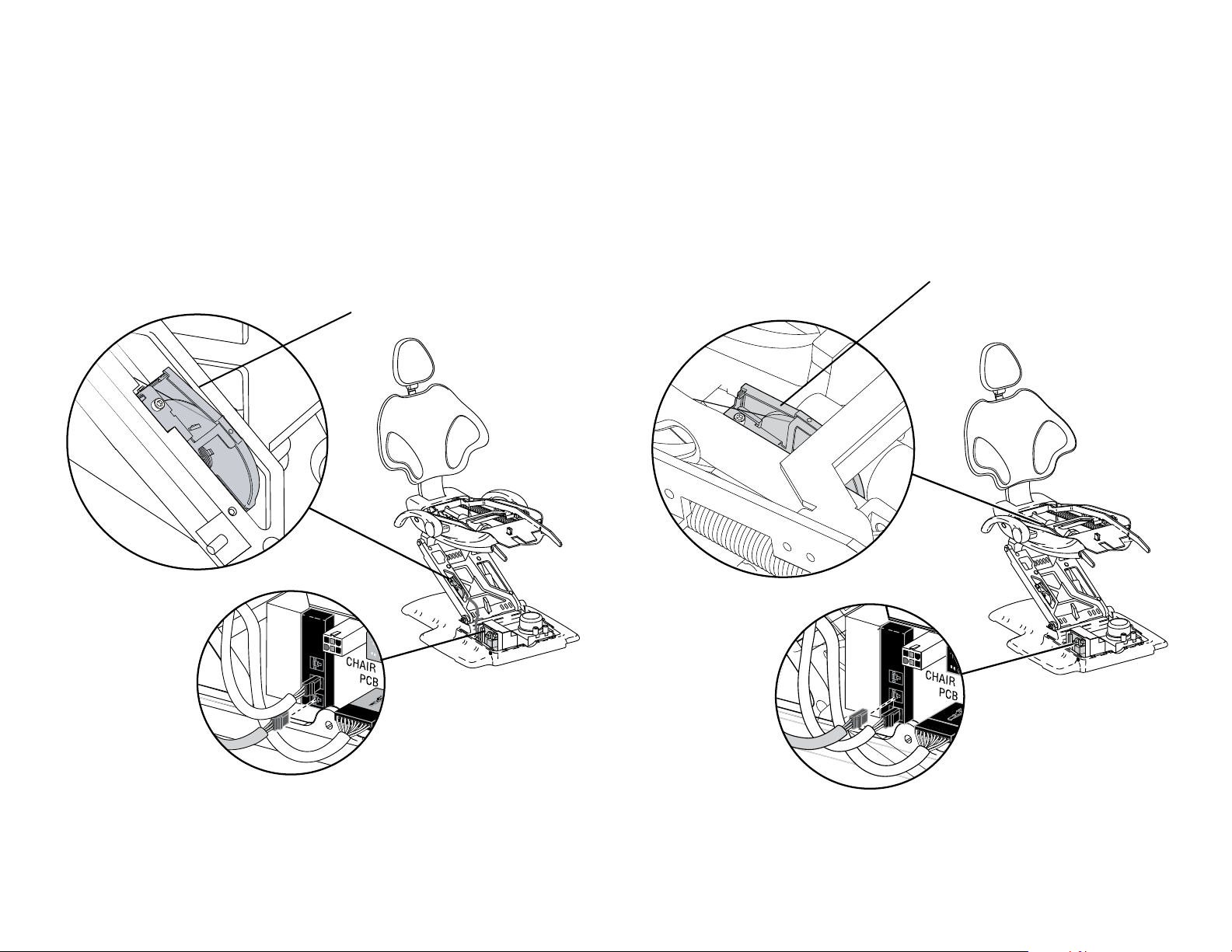

Factory Default Routine [311 (A and B) and 411]

CAUTION The position sensors can be inadvertently installed

upside down. Improper installation will limit the chair’s

functionality.

After installing a new chair, circuit board, or position sensor, run the

factory default routine. The routine:

• Sets the chair base and back upper limits

• Calculates new preset positions based on actual range of motion

of the chair

• Verifies that the position sensors work correctly

To start the factory default routine, place the spare jumper in the factory

default position on the P3 test points of the chair circuit board.

CAUTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from

the circuit board. Circuit boards should be installed only by

an electrician or qualified service person.

Jumper in

Factory

Default

Position

When running the factory default routine, the chair:

1. Moves base down.

2. Moves base up.

3. Moves back down.

4. Moves back up.

5. Moves base and back to mid position.

6. Moves back and base down.

7. Moves base and back to mid position.

8. Moves base and back to Entry/Exit.

9. Three beeps confirm the routine completed successfully.

Once the routine completes, place the jumper into the Spare position

on P3.

NOTE The jumper must remain in the factory default

position to complete the factory default routine. The status

LEDs on the standard and deluxe touchpads and the chair

circuit board double blink while the factory default routine

is running and after the routine is complete. When the

routine is complete, three beeps sound. If the routine stops

prematurely, one beep sounds.

NOTE One beep indicates the routine failed to complete. See

page 56 for troubleshooting.

Page 33

Capacitor Replacement [311 (B)/411]

The hydraulic system used for the chair’s base movement is operated

using a motor capacitor, located in the power supply of the chair. There

are three specific capacitors for different line voltage ranges. The chair

motor capacitor can be replaced within the power supply.

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

Chair Input Voltages

Mains Chair Input Voltage A-dec Capacitor Part Number

100 VAC 90.1198.00

110 - 120 VAC 90.1199.00

220 - 240 VAC 90.1200.00

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 33

Capacitor

Page 34

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 34

Motor Driven Electro-Mechanical Actuator [311 (B) and 411]

The back-up and back-down movements are controlled with an electro-mechanical tilt actuator, which is located under the seat of the chair.

Reference the chart below to identify the location of actuators and switches.

Tilt Actuator

Tilt Actuator Switch (411 only)

Back Position Sensor

A-dec 411 shown

Stop Switch

Base Position Sensor

Page 35

Position Sensor [311 (A and B)/411]

The position sensor circuit boards provide positioning data to the chair

board. There is a position sensor for the back and a position sensor for

the base.

CAUTION The position sensors can be inadvertently installed

upside down. Improper installation will limit the chair’s

functionality.

A diagnostic LED is provided on the chair board for each position

sensor. Refer to Chair Circuit Board LED Identification, see page 12

for information. An additional LED, indicating power, is present on

each position sensor circuit board.

LED

Factory Default Routine

If a position sensor or chair board are replaced, run the factory default.

For instructions on running the factory default, see page 32.

Limp Along Feature

There are two position sensors, one for the base of the chair and one for

the back of the chair. If there is a problem or malfunction with a position

sensor, the limp along feature allows the operator to move the chair in

the up direction for one to three second intervals by pushing the manual

control buttons on the touchpad or footswitch. Refer to Chair Circuit

Board LED Identification, page 12 for further information. When in

limp along mode, presets will not function.

Red

Green

Black

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 35

Black

Page 36

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 36

Solenoid [311 (B) and 411]

p/n: 62.0317.00 21.6 VDC

Solenoid Testing

A solenoid is energized during base down function. To determine if

a solenoid has failed, check for coil resistance using magnetic pull or

volt/ohm meter test.

Magnetic Pull Test for Coil Resistance

1. Hold a paper clip loosely in your hand.

2. Activate the solenoid by pressing base down on the footswitch or

touchpad.

3. If there is a pull on the paper clip, the solenoid is being energized.

Paper

Clip

Volt/Ohm Meter Test for Coil Resistance

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

1. Disconnect the solenoid power at the chair board’s base solenoid

terminal strip (J7).

2. Place one Ohm meter probe on each of the solenoid wires.

Solenoid=38Ohms(Ω)±4Ohms(Ω)

J7

Solenoid

Page 37

Solenoid Assembly Replacement [311 (B) and 411]

4. Loosen the nut on the solenoid and use a screw driver to remove

the failed solenoid assembly.

CAUTION The circuit board is static sensitive. ESD

precautions are required. The circuit board should be

installed by an electrician or qualified service personnel.

WARNING Lower the chair base to the mechanical limit

before removing the solenoid.

Remove the Solenoid Assembly:

When replacing a solenoid wipe up any fluid and replace existing

O-rings on the solenoid base.

1. Remove the utility cover(s).

2. To minimize pressure in the hydraulic system, lower the chair base

to the mechanical limit.

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result

in electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result

in product damage, serious injury, and/or death.

3. Disconnect the solenoid from the chair circuit board, terminal

strip J7.

NOTE Cover the solenoid with a rag. Fluid is still under

pressure when removing the solenoid.

5. Wipe up any fluid and replace existing O-rings on the solenoid base.

Install the New Solenoid Assembly:

1. Install the new solenoid.

2. Reconnect the solenoid to the chair circuit board, terminal strip J7. It

does not matter which solenoid wire goes into which terminal. The

solenoid will work either way.

3. Turn on the power.

4. Move the chair up and down to ensure there are no leaks.

5. Reinstall the utility cover.

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 37

Page 38

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 38

BACK

BASE

Chair Stop Plate [311 (B) and 411]

Stop Switch

If an object presses against the chair stop plate as the chair is lowered,

a stop switch will interrupt and reverse the chair motion. If the

object becomes lodged, press the base up button on the footswitch or

touchpad. Remove the object and resume normal chair operation.

WARNING Be sure to turn off power to the chair and

disconnect it from its power source before replacing the stop

switch.

CAUTION Use cable ties to secure wires to the lift arm to

prevent kinking and pinching.

Chair Bump-Up Feature [311 (B) and 411]

The chair stop plate triggers the chair to move upwards if it was moving

down when the stop plate switch was activated.

Chair Stop Plate

Stop Switch

Assembly

A-dec 411 Shown

Page 39

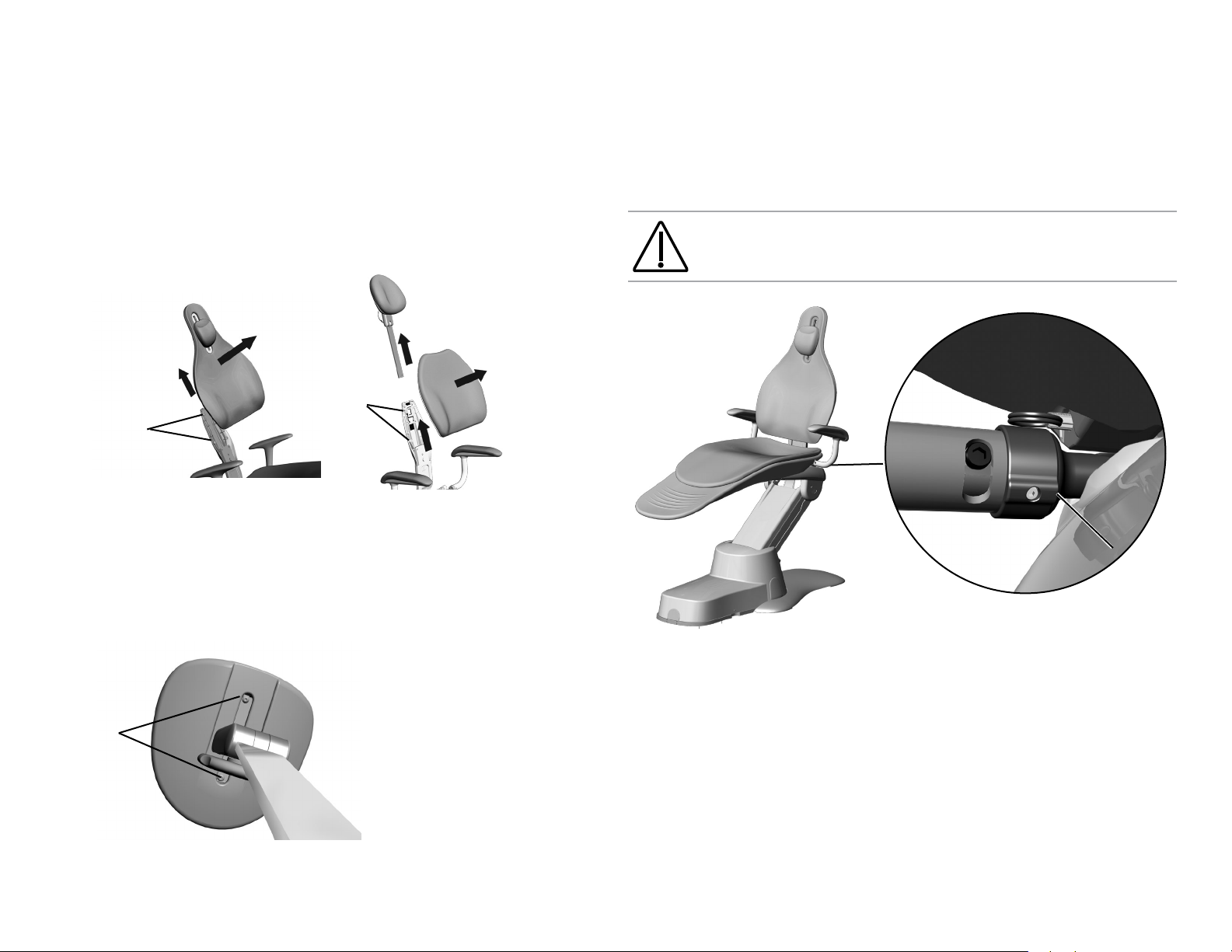

Dual-Articulating Headrest [311 (A)/311 (B)/411]

Headrest Adjustment

The dual-articulating headrest offers a “glide” feature, as well as

manual articulation. The locking knob allows you to adjust the headrest

for a full range of positions.

Headrest

Locking

Knob

Release the headrest by turning the locking knob to the left, then adjust

the headrest for a proper fit. Lock the headrest in the desired position

by turning the knob to the right. For minor height adjustment, slide

the headrest cushion up and down. For additional height adjustment,

reposition the glide bar.

Glide Bar Tension Adjustment

A dual-articulating headrest may be difficult to move or may drift

downward because of the amount of tension on its glide bar. To adjust

the tension, use a 1/8" hex key and turn the tension adjustment screw to

the right to increase friction or to the left to decrease friction.

Glide Bar

1/8” Hex Key

Headrest

Lever (411 only)

Glide Bar

1/8” Hex Key

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 39

Page 40

A-dec 311, 411, and 511 Dental Chairs Service Guide 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 40

Armrest Adjustments [311 (B) and 411]

Two-Position Armrests Adjustment

Push or pull the armrests to reposition them in the forward or back

position

Arm Rest Rotation Tension Adjustment

If the armrests become loose or are difficult to move, you can adjust the

rotation tension. To adjust each armrest:

1. Remove the chair side cover by pulling on the left and lower right

sides of the cover. Pull the cover out of the way to access the adjustment screw.

2. Use a 5/32" hex key and turn clockwise to tighten or counterclockwise to loosen the armrest tension. Only a small adjustment is

needed to significantly increase or decrease tension.

5/32"

Hex Key

2

1

1

2

A-dec 411 Shown

Page 41

Swivel Brake Adjustment [311 (B) and 411]

Swivel Brake Tension Adjustment

Swivel Brake

The chair can rotate to any position within 30° either side of center. The

chair swivel brake locks the chair in the selected position. To engage the

brake, push the brake lever firmly to the left. To release the swivel brake,

push the brake lever to the right.

NOTE The 311 (Version B) Dental Chair may not have the

swivel break feature.

If the chair swivels left or right with the brake engaged, or is difficult

to move with the brake disengaged, adjust the swivel brake tension.

Properly tensioned, the brake handle should be in the middle when it is

fully engaged. To make the adjustment:

1. Move the brake handle to the right.

2. If the chair includes a back mount module, swivel the chair to

access the adjustment screw.

3. Use a 7/64" hex key with a long shaft to turn the tension adjustment screw clockwise to increase brake friction or counterclockwise

to decrease brake friction. Only a small adjustment is needed to

significantly increase or decrease tension.

NOTE To disable the swivel feature, reinstall the shipping

pin.

Hex Key

A-dec 411 Shown

86.0380.00 Rev B 311 (B) and 411 Chairs Service, Adjustments, and Maintenance 41

Page 42

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 42

511 Chair Service, Adjustments, and Maintenance

Chair Covers (511)

Remove the chair motor pump, lift arm and stop plate

covers in the following order:

CAUTION When removing or replacing

covers, take care not to damage any wiring

or tubing. Verify that the covers are secure

after replacing them.

1. Motor Pump Cover: Remove the screws from each

side and lift up.

2. Lift Arm Cover: Position the chair so that it is

raised half way up. Pull one side of the cover

until it releases from the lift arm. To replace, align

one side of the cover with the lift arm and insert it

into place. Ensure both sides are firmly attached.

3. Stop Plate: Pull one side of the cover until it

releases from the lift arm. To replace, slide one

side of the cover over the post on the lift arm and

attach.

Rear Cover Assembly

Left Side Cover

Lift Arm Cover

Right Side Cover

Stop Plate Cover

Motor Pump Cover

Page 43

Upholstery (511)

Back Upholstery Removal/Attachment

To remove the back, firmly grasp the bottom edge of the cushion and lift

up, then lift the upholstery out and away from the chair back support.

To reattach the back upholstery, place the key holes on the cushion over

the large fastener heads, then push down until it inserts into position.

Headrest Upholstery Removal/Attachment

To remove the headrest upholstery, position the headrest to access the

two screws on the back, loosen the screws, and remove the upholstery.

To reattach the headrest upholstery, position the headrest to access the

screws, place the upholstery on the headrest, then insert and tighten the

screws.

CAUTION Do not remove the positioning mechanism screws

or plate. The brake assembly will fall out.

Upholstery Screws

Seat Upholstery Removal/Attachment

To remove the seat, first remove the plastic clip under the seat frame,

then lift the toe of the seat to unhook it from the chair carriage, and

move it away. To reattach, place the two seat upholstery hooks under

the chair carriage, then push the toeboard back and down until the lock

is through the seat frame. Insert the clip into the lock.

86.0380.00 Rev B 511 Chair Service, Adjustments, and Maintenance 43

Page 44

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 44

Factory Default Routine (511)

After installing a new chair, circuit board, or position sensor, run the

factory default routine. The routine:

• Sets the chair base and back upper limits

• Calculates new preset positions based on actual range of motion

of the chair

• Verifies that the position sensor work correctly

To start the factory default routine, place the spare jumper in the factory

default position on the P3 test points of the chair circuit board.

CAUTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from

the circuit board. Circuit boards should be installed only by

an electrician or qualified service person.

NOTE The jumper must remain in the factory default

position to complete the factory default routine. The status

LEDs on the standard and deluxe touchpads and the chair

circuit board double blink while the factory default routine

is running and after the routine is complete. When the

routine is complete, three beeps sound. If the routine stops

prematurely, one beep sounds.

When running the factory default routine the chair:

1. Moves base down

2. Moves base up

3. Moves back down

4. Moves back up

5. Moves base and back to Position 0

6. Beeps three times

NOTE One beep indicates the routine failed to complete. See

page 56 for troubleshooting.

Jumper in Factory

Default Position

Page 45

Chair Drive System (511)

Hydraulic Cylinders

The hydraulic cylinders operate during the base up and back up

functions. Springs and gravity retract the piston during base down and

back down functions.

The chair seat has a vertical range of 13.5" (343 mm) to 31.5" (800 mm)

above the floor.

Motor Driven Hydraulic Pump

During base and back up functions, the hydraulic pump transfers

hydraulic fluid from the reservoir to the base and back hydraulic

cylinders. Solenoids, mounted to the pump assembly, control the flow

of hydraulic fluid back to the reservoir during base and back down

functions.

NOTE You cannot adjust the speed of the chair.

86.0380.00 Rev B 511 Chair Service, Adjustments, and Maintenance 45

Page 46

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 46

Hydraulic System (511)

The hydraulic system deactivates automatically at the upper and

lower extremes of travel. The system is leak-free during transportation,

storage, and operation. The hydraulic system consists of hydraulic fluid

reservoir, hydraulic cylinders, and motor-driven hydraulic pump with

solenoids.

CAUTION Use only A-dec hydraulic fluid, p/n 61.0197.00.

Hydraulic Fluid Reservoir Replenishment (511)

The hydraulic fluid reservoir is located in the lift arm of the chair under

the stop plate cover. You can see the fluid level in the reservoir through

the sides of the reservoir. Add hydraulic fluid to the reservoir:

1. Raise the chair to the full base up and back up position.

2. Fill the reservoir with hydraulic fluid to the top of the fluid level

indicator.

CAUTION Do not overfill.

3. Move the chair down and up after fluid has been added.

Fluid Level

Indicator

Page 47

Capacitor (511)

p/n: 041.642.00, 100 VAC, 041.643.00, 110 - 120 VAC, 041.644.00, 220 - 240 VAC

The capacitor is energized during chair base up or back up functions.

Capacitor

86.0380.00 Rev B 511 Chair Service, Adjustments, and Maintenance 47

Page 48

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 48

Solenoid (511)

p/n: 90.1070.00, 110 - 120 VAC, 90.1071.00, 220 - 240 VAC

Solenoid Testing

A solenoid is energized during base down and back down functions.

To determine if a solenoid has failed, check for coil resistance using

magnetic pull or volt/ohm meter test.

Magnetic Pull Test for Coil Resistance

1. Hold a paper clip loosely in your hand.

2. Activate the solenoid by pressing base down or back down on the

footswitch or touchpad.

3. If there is a pull on the paper clip, the solenoid is being energized.

Volt/Ohm Meter Test for Coil Resistance

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

electrical shock.

WARNING Turn off the power to the system before you

continue with this procedure. Failure to do so can result in

product damage, serious injury, and/or death.

1. Disconnect the solenoid power at the 2-position connector.

2. Place on Ohm meter probe on each solenoid connector terminals.

• 100-120VAC=177Ohms±18Ohms

• 220-240VAC=845Ohms±85Ohms

Page 49

Solenoid Assembly Replacement (511)

CAUTION Circuit boards are sensitive to static electricity.

Electrostatic Discharge (ESD) precautions are required when

touching a circuit board or making connections to or from

the circuit board. Circuit boards should be installed only by

an electrician or qualified service person.

WARNING Lower the chair base to the mechanical limit

before removing the solenoid.

Remove the Solenoid Assembly:

When replacing a solenoid wipe up any fluid and replace existing

O-rings on the solenoid base.

1. Remove the utility cover(s).

2. To minimize pressure in the hydraulic system, lower the chair base

and back to the mechanical stops.

Four Screws

DANGER Turn off the power to the system before you

continue with this procedure. Failure to do so can result

Solenoid

Connector

in electrical shock.

WARNING Turn off the power to the system before you

Install the New Solenoid Assembly:

continue with this procedure. Failure to do so can result

in product damage, serious injury, and/or death.

1. Insert the new solenoid and fasten it with the four screws.

2. Reconnect the solenoid connector.

3. Disconnect the solenoid connector.

4. Use a 9/64" hex key to remove the four screws that fasten the

solenoid assembly.

5. Wipe up any fluid and replace three O-rings on the solenoid base.

86.0380.00 Rev B 511 Chair Service, Adjustments, and Maintenance 49

3. Turn on the power.

4. Run the chair through its full range of motion to check for leaks.

5. Reinstall the utility cover.

Page 50

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 50

Position Sensors (511)

The position sensor and cable assembly eliminates position float (a slight change or variation in the pre-programmed positions). The chair uses the

same position sensor assembly for both lift and tilt requirements. If a position sensor fails, the limp-along feature allows the operator to position the

chair for one second intervals by pushing the manual control buttons on the touchpad or footswitch.

Back Position Sensor

Base Position Sensor

Page 51

Chair Stop Plate (511)

Stop Switch

If an object presses against the chair stop plate as the chair is lowered,

a stop switch will interrupt and reverse the chair motion. If the object

becomes lodged, press base up on the footswitch or touchpad. Remove

the object and resume normal chair operation.

WARNING Be sure to turn off power to chair and disconnect

it from its power source before replacing the stop switch.

CAUTION Use cable ties to secure the wires to the lift arm to

prevent kinking and pinching.

Chair Bump-Up Feature (511)

The chair stop plate and the assistant’s arm trigger the chair to move

upwards if it was moving down when the stop plate switch was

activated.

Stop Switch

Assembly

Chair Stop Plate

86.0380.00 Rev B 511 Chair Service, Adjustments, and Maintenance 51

Page 52

A-dec 311, 411, and 511 Dental Chairs Service Guide 511 Chair Service, Adjustments, and Maintenance 52

Headrest Adjustment (511)

The headrest adjustment lever allows you to use one hand to adjust the

headrest. When the lever is released, the headrest holds its position.

If the headrest drifts downward, or if it is difficult to move up or down,

adjust the glide bar tension. To adjust the tension, use a 1/8" hex key

and turn the tension adjustment screw clockwise to increase friction or

counterclockwise to decrease friction.

Glide

Bar

Headrest

Adjustment Lever

1/8” Hex Key

Glide Bar Tension Adjustment

Page 53

Swivel Brake Adjustment (511)

Swivel Brake Tension Adjustment

Swivel Brake Operation

The chair can rotate to any position within 30° either side of center. The

chair swivel brake keeps the chair from moving. To engage the brake,

push the brake lever firmly to the left. To release the swivel brake, push

the brake lever to the right.

NOTE To disable the swivel feature, reinstall the shipping

pin.

If the chair swivels left or right with the brake engaged, or is difficult

to move with the brake disengaged, adjust the swivel brake tension.

Properly tensioned, the brake handle should be in the middle when it is

fully engaged. To make the adjustment: