Page 1

Service Guide

A-dec® Service Guide Volume II

Featuring A-dec 500® and Clinical Products

Page 2

A-DEC® SERVICE GUIDE VOLUME II

A-

DEC 500

®

AND CLINICAL PRODUCTS

Page 3

Copyright

Trademarks

©2007 A-dec™ Inc. All Rights Reserved.

2601 Crestview Drive, Newberg, OR 97132, USA

Printed in USA.

A-dec Inc. makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. A-dec, Inc. shall not be held liable

for any errors contained herein or any consequential or other damages

concerning the furnishing, performance or use of this material. The

information in this document is subject to change without notice. If you

find any problems in the documentation, please report them to us in

writing. A-dec Inc. does not warrant that this document is error-free.

No part of this document may be copied, reproduced, altered, or

transmitted in any form or by any means, electronic or mechanical,

including photocopying, recording, or by any information storage and

retrieval system, without prior written permission from A-dec Inc.

Publication Number: 85.0816.00

Revision Date: Rev B 2007-04

A-dec, the A-dec logo, A-dec 500, Cascade, Cascade Master Series,

Century Plus, Continental, Decade, ICX, Performer, Preference,

Preference Collection, Preference ICC, and Radius are registered

trademarks in the U.S. Patent and Trademarks office.

Preference Slimline and ICV are also trademarks of A-dec Inc.

Comments and Feedback

Thank you for taking the time to use the A-dec Service Guide, Vol. II.

We would appreciate any feedback or comments you have about this

document. Please mail, email, or phone us with your comments.

You can reach us at:

A-dec Inc.

Technical Communications Department

2601 Crestview Drive

Newberg, OR 97132

Reach us by phone at: 1.800.547.1883

email: techcomm@a-dec.com

website: www.a-dec.com

Page 4

CONTENTS

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

Inside This Guide ......................................................2

Document Conventions ...........................................2

Getting Support........................................................3

Customer Service ..................................................3

Other Sources of Information.......................................4

Genuine A-dec Parts Catalog.....................................4

A-dec Dental Furniture Technical Packet ......................4

A-dec Illustrated Parts Breakdown..............................4

Electronic Documentation........................................4

OrderNet............................................................4

Serial and Model Numbers...........................................5

A-dec 500 .............. ..... ..... .... ..... ..... ..... ..... ..... ......5

Reading Serial Number Labels ...................................6

Service Tools ...........................................................7

Recommended Tools...............................................7

CHAPTER 2: DENTAL CHAIR

Product Overview ...................................................10

A-dec 511 Chair .................................................. 10

A-dec 511 Chair Specifications................................. 11

Flow Diagram .........................................................14

Chair Flow Diagram .............................................14

Service/Usage Information ........................................16

Chair Covers ......................................................16

Factory Default Routine.........................................17

Chair Circuit Board Components...............................18

The Hydraulic System ........................................... 21

Potentiometer ...................................................25

Chair Stop Plate .................................................26

Adjustments ..........................................................27

Swivel Brake .....................................................27

Tension Adjustment.............................................. 27

Headrest .......................................................... 28

85.0816.00 Rev B 2007-04 i

Page 5

A-dec Service Guide, Vol. II

Illustrated Parts Breakdown ...................................... 29

Part Identification ...............................................29

Baseplate and Motor Pump Assembly .........................30

Hydraulic Hose and Solenoid Assembly........................32

Lift Cylinder and Link Arm .....................................34

Lower Assembly ..................................................36

Upper Structure/Swivel Assembly ................... ..... .....38

Back and Tilt Cylinder Assembly ...............................40

Upper (Springs and Cam Assembly)............................42

Upper (Seat Assembly) .... ..... .... ..... ..... ..... ..... ..... .....44

Headrest Assembly ...............................................46

CHAPTER 3: PROGRAMMING

Status Icon............................................................ 50

Chair Positions....................................................... 51

Position Buttons...................................................52

Cuspidor Functions ................................................. 54

Cup Fill.............................................................54

Bowl Rinse .........................................................54

Customize Cup Fill and Bowl Rinse ............................54

Dental Light .......................................................... 55

Dental Light Auto Feature.......................................55

Electric Handpiece Settings (Deluxe Touchpad Only)........ 56

Standard Mode ....................................................56

Endodontics Mode ................................................58

Other System Choices .............................................. 60

Intraoral Light Source............................................60

Touchpad Circuit Board Components ........................... 62

Standard Touchpad ...............................................62

Deluxe Touchpad..................................................64

CHAPTER 4: DELIVERY SYSTEMS

Product Overview ................................................... 68

CHAIR-MOUNTED DELIVERY SYSTEMS................ 69

Product Overview (532/533)...................................... 70

A-dec 500 Delivery System Components...................... 70

Covers.............................................................. 72

Whip Assembly ................................................... 73

Continental Tray Holder (533 only) ........................... 74

Flow Diagram (532/533) ........................................... 76

Adjustments (532/533)............................................. 78

Front Mount....................................................... 78

Front-to-Back Leveling.......................................... 80

Side-to-Side Leveling............................................ 80

Illustrated Parts Breakdown .......................................81

Part Identification ............................. ..... ..... ..... ... 81

Traditional Chair Mounted Delivery System (Model 532)... 82

Continental Chair Mounted Delivery System (Model 533).. 84

Delivery System — Upper Exploded (532 and 533) ......... 86

Delivery System — Lower Exploded (532 and 533) ......... 88

Traditional Holder Assembly (532) ............................ 90

Continental Whip Assembly (533) ............................. 92

Continental Tray Holder......................................... 94

SIDE-MOUNTED DELIVERY SYSTEMS.................. 97

Product Overview (542)............................................ 98

Components....................................................... 98

Flow Diagrams (542) .............................................. 100

Leveling/Adjustments (542)..................................... 102

Flexarm Counterbalance.......................................102

ii 85.0816.00 Rev B 2007-04

Page 6

TABLE OF CONTENTS

Illustrated Parts Breakdown (542) ..............................103

Part Identification.............................................. 103

Side Delivery System........................................... 104

Side Delivery System Upper Structure....................... 106

Side Delivery System Covers and Brake..................... 108

Control Head .................................................... 110

Traditional Holder Assembly .................................. 112

CHAIR/SIDE SYSTEMS COMMON FEATURES........ 115

Product Overview

(Chair/Side Delivery Common Features) ......................116

Internal Control Components................................. 116

Adjustments.........................................................118

Covers ............................................................ 118

Rotational Tension Adjustment............................... 119

12 O’CLOCK DELIVERY SYSTEMS 121

Product Overview (12 O’Clock) .................................122

A-dec 541 12 O’Clock Duo

Delivery System ................................... 122

A-dec 541 Internal Components.............................. 123

Flex-Holder...................................................... 124

Wiring Service/Usage Information ........................... 125

Control Center Covers (541) .................................. 125

Doctor’s Holder ................................................. 126

Flow Diagrams ......................................................128

Plumbing......................................................... 129

Adjustments/Maintenance ....................................... 130

Level the Arm Assembly and Worksurface ..................130

Worksurface Height.............................................132

Instrumentation Arm Positioning .............................133

Illustrated Parts Breakdown

(541 and 545) ...................................................... 135

Part Identification ............................. ..... ..... ..... ..135

Duo Delivery System (Model 541).............................136

Worksurface Module............................................138

Mounting Platform Installation................................140

Control Center...................................................142

Doctor’s Arm Assembly.........................................144

Doctor’s Turret, 2" Holder Assembly .........................146

Vacuum and Upper Structure Assembly......................148

Assistant’s Holder—Electric ...................................150

Assistant’s Holder—Standard ..................................152

A-DEC 500 DELIVERY SYSTEMS

COMMON FEATURES................................... 153

Product Overview

(All Delivery) ....................................................... 154

A-dec Tubing.....................................................154

Data Communication System..................................159

Circuit Board Components.....................................160

Brake Handle ....................................................162

Accessory Holder................................................162

Master On/Off Toggle...........................................163

Flush Toggle......................................................164

Traditional Tray Holder.........................................165

Foot Control .....................................................166

Self-Contained Water Bottle ..................................167

Standard Syringe ................................................168

85.0816.00 Rev B 2007-04 iii

Page 7

A-dec Service Guide, Vol. II

Autoclavable HVE Standard and 11/15 mm.................218

Warm Water Syringe............................................ 169

Tooth Dryer ...................................................... 171

Autoclavable HVE with Large Bore 15mm (541 and 545

) 219

Autoclavable Saliva Ejector ...................................220

Adjustments (Common Features) ...............................172

Control Block.................................................... 172

Tray Holder ...................................................... 175

Intraoral Light Source Voltage................................ 176

Flow Diagrams ......................................................177

Foot Control..................................................... 177

Service/Usage Information .......................................178

Remove the Control Block..................................... 178

Illustrated Parts Breakdown (Cross System) ..................179

Part Identification.............................................. 179

Control Block Assembly........................................ 180

Water Coolant Relay Assembly ............................... 182

Dual Solenoid Manifold Assembly (D

lx Touchpad Only)... 184

Master On/Off Toggle .......................................... 186

Flush Toggle ..................................................... 188

A-dec Foot Control ............................................. 190

Foot Control Accessory Button and Wet/Dry Toggle Valve192

Foot Control Signal Relay Main Body Valve ................. 194

Oil Collector................ ..... ................................ 196

Brake Handle Assembly........................................ 198

Traditional Tray Holder ........................................ 200

Holder (532,533 and 542) .....................................202

Holder (541 and 545)........................................... 206

Self-Contained Water Bottle.................................. 208

Self-Contained Water Bottle Housing (Cabinet-Mounted) 210

Self-Contained Water Bottle Housing (Chair-Mounted)... 212

Traditional and Continental Syringes ........................ 214

Warm Water Traditional and Continental Syringes ........ 216

ASSISTANT’S INSTRUMENTATION ................... 223

Product Overview (551).......................................... 224

Components......................................................224

Holders ...........................................................226

Assistant’s Touchpad............................................228

Solids Collector..................................................230

Tip-Up Feature ..................................................231

Flow Diagrams (551) .............................................. 232

Standard Holder.................................................232

Electric Holder ..................................................233

Adjustments (551)................................................. 234

Left or Right Conversion .......................................234

Product Overview (545).......................................... 235

Components......................................................235

Holders ...........................................................236

Solids Collector..................................................238

Flow Diagram (545) ............................................... 239

Plumbing Diagram...............................................239

Plumbing Diagram...............................................240

Leveling (545)...................................................... 241

Arm Assembly....................................................241

Worksurface......................................................243

Adjustments (545)................................................. 244

Worksurface Height.............................................244

Instrumentation Arm Positioning .............................245

iv 85.0816.00 Rev B 2007-04

Page 8

CHAPTER 5: CUSPIDOR AND SUPPORT CENTER

CUSPIDOR............................................... 248

Product Overview ..................................................248

Flow Diagram .......................................................250

Cuspidor and Support Center ................................ 250

Service/Usage Information .......................................252

Cuspidor Circuit Board Components......................... 252

Adjustments/Maintenance .......................................254

Cup Fill Functions .............................................. 254

Bowl Rinse Functions........................................... 254

Cup Fill and Bowl Rinse Timing............................... 255

TABLE OF CONTENTS

Illustrated Parts Breakdown .................................... 273

Part Identification Symbols........................ ..... .......273

Floor Box ........................................................274

Air and Water Filter Regulators ..............................276

Air and Water Filter Regulators

Body Assembly .....................................277

Moisture Separator..............................................278

CHAPTER 7: SUPPORT SIDE FEATURES

Product Overview ................................................. 280

Components......................................................280

Limit Switch Operation.........................................281

Flow Diagram ....................................................... 282

Support Side Limit Switch Electrical Diagram ..............282

Illustrated Parts Breakdown......................................257

Part Identification.............................................. 257

Cuspidor Upper Assembly ..................................... 259

Cuspidor Lower Assembly ..................................... 262

Cuspidor Fill/Rinse Manifold.................................. 264

AMALGAM SEPARATOR HOUSING ................... 265

Components .........................................................265

Adjustments/Maintenance ....................................... 283

Leveling ..........................................................283

Illustrated Parts Breakdown ..................................... 287

Part Identification ............................. ..... ..... ..... ..287

Support Link .....................................................288

Limit Switch Components......................................289

Lower Support Arm .............................................290

CHAPTER 8: MONITOR MOUNTS

CHAPTER 6: FLOOR BOX

Product Overview ..................................................270

Air and Water Manual Shutoff Valves........................ 270

Gauge and Pre-Regulator...................................... 270

Service/Maintenance .............................................271

Filter Element .................................................. 271

85.0816.00 Rev B 2007-04 v

Product Overview ................................................. 292

Monitor Mount Specifications .................................292

Components......................................................293

Page 9

A-dec Service Guide, Vol. II

Adjustments ........................................................300

Friction Adjustment............................................ 300

Tray Holder Tension Adjustment

(Support Side Monitor Mount, 561).............301

Panning Friction Adjustment

(500 Track Mount Monitor)....................... 302

Illustrated Parts Breakdown......................................303

Part Identification.............................................. 303

Front Mount Monitor Mount (531)............................ 304

Support Side Monitor Mount (561) ........................... 307

Support Side Monitor (561) Tray Holder..................... 310

A-dec 500 Track Monitor Mount ................. ..... ..... ... 312

A-dec 500 Track Monitor Mount Components............... 315

A-dec 500 Track Monitor Mount Trolley Assembly

(Before February 2007)........................... 318

A-dec 500 Track Monitor Mount Trolley Assembly

(After February 2007) ............................ 320

CHAPTER 9: DENTAL LIGHTS

Product Overview ..................................................324

Dental Light Specifications ................................... 324

On/Off Functions .............................................. 325

Intensity Switches ............................................. 325

Service/Usage Information .......................................326

Identifying Switch Connections .............................. 326

Circuit Breakers ................................................ 330

Power Cable .................................................... 331

Transformers ............... ........................ ............. 332

Circuit Board Components .................................... 334

Adjustments/Maintenance .......................................339

Focus ............................................................. 339

Light Head Rotation ............................................340

Flexarm...........................................................343

Light Shield Cleaning...........................................344

Lamp Replacement .............................................345

Illustrated Parts Breakdown .................................... 347

Part Identification Symbols........................ ..... .......347

Light Head .......................................................348

571 Dental Light ................................................350

6300 Track Dental Light .......................................352

Trolley Assembly ...............................................354

6300 Ceiling Mount Dental Light (Upper)...................356

6300 Ceiling Mount Dental Light (Lower)....................358

6300 Preference Mount Dental Light.........................360

6300 Wall Mount Dental Light.................................363

CHAPTER 10: CLINICAL PRODUCTS

EA-50LT AND EA-51LT ELECTRIC MICROMOTOR . 368

Flow Diagram ....................................................... 368

Maintenance ........................................................ 370

EA-50LT and EA-51LT O-ring Replacement ..................370

EA-50LT and EA-51LT Bushing Replacement.................371

EA-50LT Bulb Replacement ...................................372

EA-51LT Bulb Replacement ...................................373

A-DEC INTRAORAL CAMERA

(OCTOBER 2003- JANUARY 2007) ................. 374

Flow Diagram ....................................................... 374

vi 85.0816.00 Rev B 2007-04

Page 10

TABLE OF CONTENTS

SOPRO INTRAORAL CAMERA (717 & 595)......... 376

Flow Diagram .......................................................376

SP NEWTRON SCALER ................................ 378

Flow Diagram .......................................................378

SP Newtron Scaler with Deluxe Touchpad .................. 378

SP Newtron Scaler with Standard or No Touchpad ........ 380

MINILED CURING LIGHT .............................. 382

Flow Diagram .......................................................382

CHAPTER 11: ICV

Product Overview ..................................................386

Vacuum Requirements ......................................... 387

ICV Tubing and Cables ......................................... 388

ICV Display Panel .............................................. 389

Flow Chart ...................................................... 390

Flow Diagram .......................................................391

Service/Usage Information ......................................392

ICV Control Circuit Board ..................................... 392

ICV Display Circuit Board ..................................... 393

Adjustments/Maintenance .......................................394

Cycle Time Test................................................. 394

Cycle Time Adjustment........................................ 394

Illustrated Parts Breakdown .................................... 395

Part Identification Symbols ............................ ..... ..395

ICV Components ................................................396

ICV Display Panel ...............................................398

ICV Dual Panel ..................................................400

CHAPTER 12: TROUBLESHOOTING

Introduction ........................................................ 404

Dental Chair ........................................................ 405

Delivery Systems .................................................. 413

Data Communication System .................................... 424

Cuspidor ............................................................. 428

Floor Box ............................................................ 435

Dental Light......................................................... 436

Clinical Products................................................... 438

Warm Water Syringes ..........................................438

Tooth Dryer ......................................................440

A-dec Intraoral Camera ........................................441

Sopro Intraoral Cameras (717 and 595)......................442

SP Newtron.......................................................444

MiniLED ...........................................................446

EA-50/51LT Electric Micromotor..............................447

ICV .................................................................... 448

85.0816.00 Rev B 2007-04 vii

Page 11

A-dec Service Guide, Vol. II

viii 85.0816.00 Rev B 2007-04

Page 12

A-dec Service Guide, Vol. II

INTRODUCTION

1

Welcome to the A-dec 500 Service Guide. This guide provides a complete

review of:

• A-dec 511 chair

• A-dec 500 delivery systems

• Programming

•Cuspidor

• Floor box

• Support side features

• Monitor mounts

• Dental lights

• Clinical products

This guide is intended for newly trained and seasoned service

technicians responsible for installing and maintaining A-dec products.

The technician should understand the operation of dental equipment,

how to use flow diagrams and how to perform basic maintenance on

dental or medical equipment.

85.0816.00 Rev B 2007-04 1

Page 13

A-dec Service Guide, Vol. II INTRODUCTION Document Conventions

I NSIDE THIS GUIDE

Inside this guide you will find the tools, maintenance, adjustments and

troubleshooting information for servicing A-dec 500 products.

This guide contains:

• Adjustments and maintenance information

• Flow diagrams for routing tubing and wiring

• Step-by-step instructions for troubleshooting

• Part number information on serviceable/saleable parts, and nonsaleable parts

• Exploded illustrated parts breakdown of assemblies, showing

sequence of assembly

Document Conventions

A number of items and instructions appear throughout this document.

The information contained within these pages uses special formatting,

note styles and symbols to help identify important instructions or

component status.

Formatting Conventions

The formatting conventions are designed to make information quick

and easy to find and understand.

• Italic type indicates document names and to indicate emphasis.

• Bold type indicates new terms or glossary terms, and is used for

section headings

.

WARNING Warnings indicate potential loss of life or limb.

CAUTION Cautions indicate potential equipment damage.

NOTE Notes indicate additional information.

Part Identification Symbols

The conventions for the serviceable components tables are designed to

identify all parts and kits, including ones that are not for sale. Symbols

with reference notes are used.

Symbol Definition

† Indicates that the individual part is not available for

sale (these parts are typically part of a kit and/or

larger assembly that is for sale)

No symbol Part is fo r sale

2 85.0816.00 Rev B 2007-04

Page 14

A-dec Service Guide, Vol. II INTRODUCTION Customer Service

G ETTING SUPPORT

Customer Service

For questions not addressed in this document, contact A-dec Customer Service using contact information for your region.

U.S. and Canada

A-dec Inc.

2601 Crestview Drive

Newberg, OR 97132 USA

Tel: 1.800.547.1883 within US and Canada

Tel: 1.503.538.7478 outside US and Canada

www.a-dec.com

www.a-dec.biz

International

(For United Kingdom and Australia see those regions)

A-dec International Inc.

2601 Crestview Drive

Newberg, OR 97132 USA

Tel: 1.503.538.7478

www.a-dec.com

www.a-dec.biz

United Kingdom

A-dec United Kingdom

Austin House, 11 Liberty Way

Nuneaton, Warwickshire CV11 6RZ

England

Tel: 0800 ADECUK (233285) within UK

Tel: 44 24 7635 0901 outside UK

www.a-dec.co.uk

Australia

A-dec Australia

Unit 8, 5-9 Ricketty St.

Mascot, NSW 2020

Australia

Tel: (02) 8332 4000

1.800.225.010

www.a-dec.com.au

Web Contact

OrderNet/Partner Resources websites: www.a-dec.biz

85.0816.00 Rev B 2007-04 3

Page 15

A-dec Service Guide, Vol. II INTRODUCTION Genuine A-dec Parts Catalog

O THER SOURCES OF INFORMATION

There are a number of other related documents in the A-dec

documentation set. These documents cover a wide range of reference

information.

Genuine A-dec Parts Catalog

The Genuine A-dec Parts Catalog, P/N 85.5000.00, provides part number

and ordering information for A-dec serviceable parts. This catalog

details service parts for current products and products which are no

longer manufactured, but still in use. Refer to this catalog for

additional details on parts found in the service guide addendum.

A-dec Dental Furniture Technical Packet

The A-dec Dental Furniture Technical Packet, P/N 86.0142.00, contains

information specifically related to dental furniture. The content is

intended to assist you in specifying plumbing, utilities, framing and

construction requirements for installation of dental furniture.

A-dec Illustrated Parts Breakdown

The A-dec Illustrated Parts Breakdown (IPB), P/N 85.0851.00, contains

illustrated, exploded views of assemblies with part numbers and

descriptions for associated parts for products produced before

A-dec 500.

Electronic Documentation

Electronic versions (PDF files) of our documentation (installation

instructions, service guides, technical information) can be viewed or

downloaded from the Partner Resources section of the A-dec website

(www.a-dec.biz). Check this location for current detail on products and

technical information.

OrderNet

OrderNet is a simple, convenient online ordering system that is

available 24 hours. Use OrderNet to place quick orders for service parts

or use to configure product and prepare proposals. Order

acknowledgments are emailed as soon as you place your order.

4 85.0816.00 Rev B 2007-04

Page 16

A-dec Service Guide, Vol. II INTRODUCTION A-dec 500

S ERIAL AND MODEL NUMBERS

Product serial and model number information can be found on the

serial/model number labels. When you contact customer service, the

serial number helps identify the product and when it was

manufactured.

A-dec 500

A-dec 500 serial and model number information can be found on

serial/model number labels.

Item Description

1 Light, underside of the flexarm

2 Delivery system, underside of the delivery system

3 Chair, chair upper structure frame, under the toeboard

4 Cuspidor, inside support center

5 Assistant’s instrumentation, underside of the assistant’s arm

6 Power supply, inside motor pump area

Track light - on back of circuit breaker cover; wall-mounted - on top of

circuit breaker cover or at the very base of the post on the transformer

side; Preference-mounted - on the transformer cover underneath the

x-ray cap or at the end of the post by the transformer; ceiling-mounted on top of circuit breaker cover.

Figure 1 Serial/Model Number Locations on A-dec 500

1

3

4

6

5

2

85.0816.00 Rev B 2007-04 5

Page 17

A-dec Service Guide, Vol. II INTRODUCTION Reading Serial Number Labels

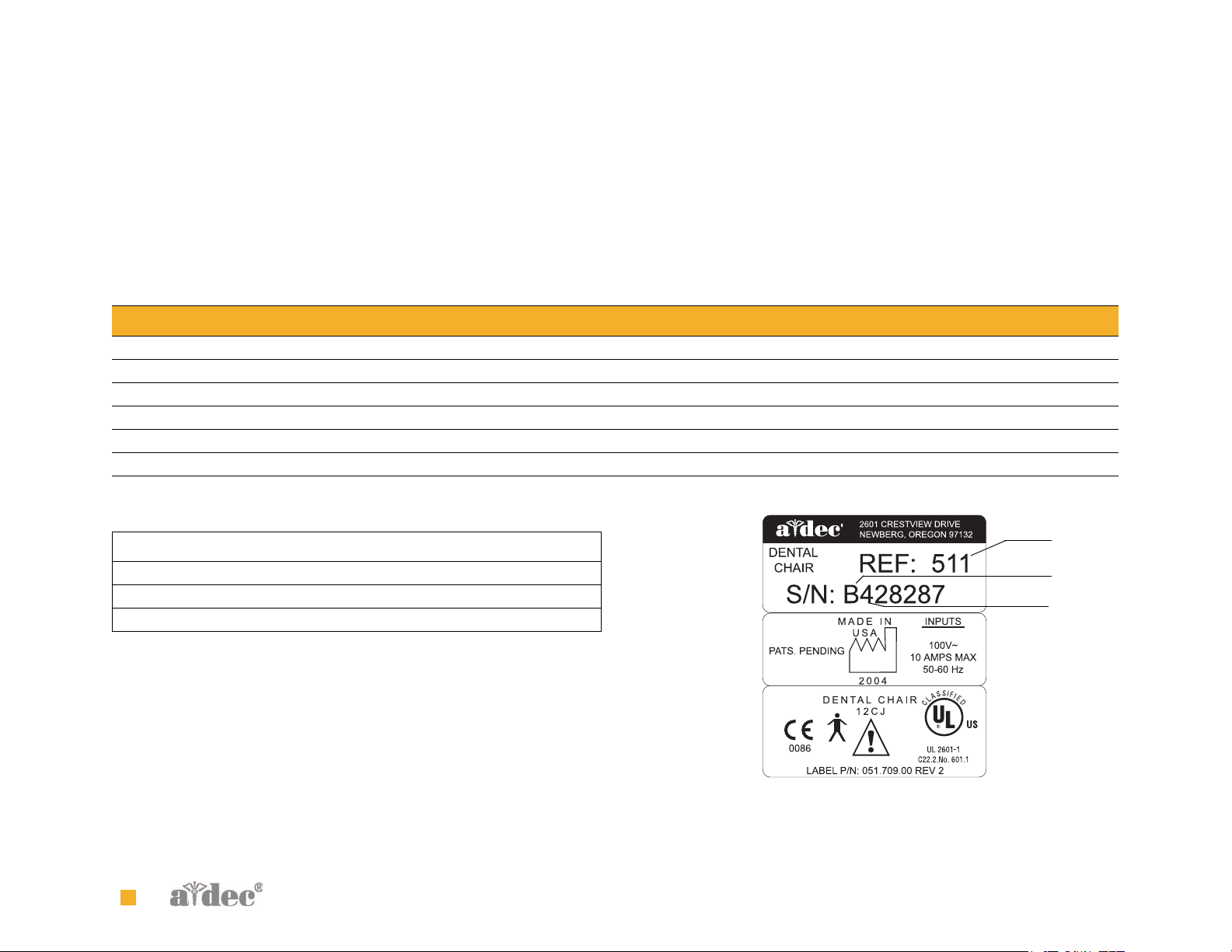

Reading Serial Number Labels

Use the tables shown and Figure 4 to reference how to identify serial/

model number information. The REF: number is the model number.

The S/N: is the serial number.

Tab l e 1 Month Identification Table

Letter Month Letter Month

A January G July

B February H August

C March I September

DApril J October

E May K November

F June L December

Item Description

1 Model number of the product

2 Month code (see Table 1)

3 Year the product was manufactured

The first letter of the serial number is the month the product was

manufactured (see Table 1). The first digit following the letter is the

year the product was manufactured.

Figure 2 Serial Number Label (511 chair)

1

2

3

6 85.0816.00 Rev B 2007-04

Page 18

A-dec Service Guide, Vol. II INTRODUCTION Recommended Tools

S ERVICE TOOLS

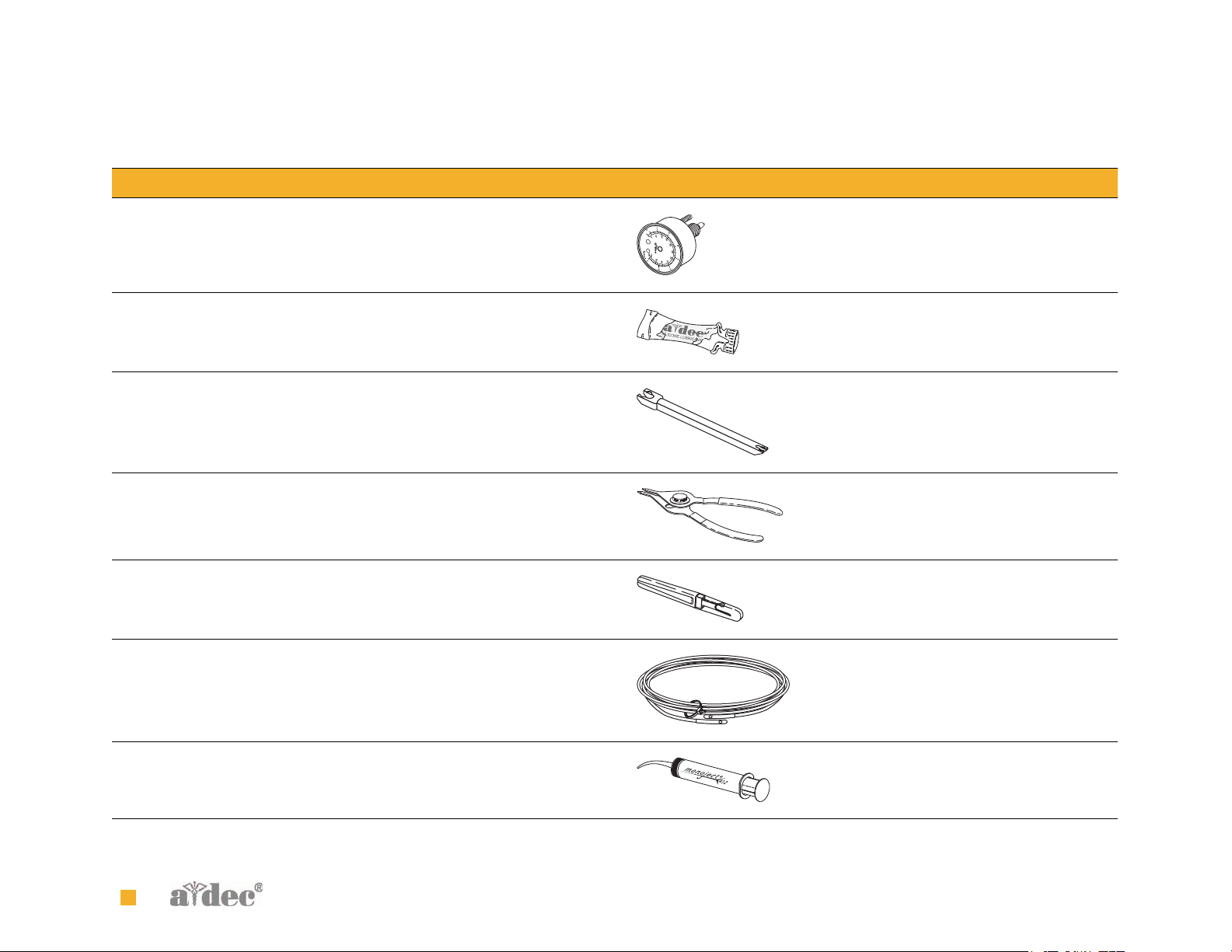

Recommended Tools

Table 2 lists the types of tools available from A-dec for servicing A-dec equipment and their recommended use:

Tab l e 2 Recommended Tools

Tool Tas k Part Illustration Part Number

Drive air pressure gauge Adjusting handpiece drive air

pressure, 0-60 psi (4.13 bar). This

gauge does not fit the Borden 3-hole

coupler

50.0271.00

Hemostat Troubleshooting or repairing a unit to

stop air or water flow through tubing

Hex hey set Servicing or installing A-dec

equipment (plastic case included)

®

Loctite

O-ring tools Replacing O-rings during quick field

85.0816.00 Rev B 2007-04 7

Installing threaded fasteners to

prevent loosening

repairs (fits the four smallest O-ring

sizes)

009.008.00

009.018.00

060.001.00 (Red 271)

060.002.00 (Blue 242)

009.013.00

Page 19

A-dec Service Guide, Vol. II INTRODUCTION Recommended Tools

Tool Tas k Part Illustration Part Number

Panel mount gauge Checking air/water pressure

Can also be used as an inline pressure

gauge for testing purposes

026.118.00

Silicone lubricant Lubrication of internal moving parts

such as O-rings, oral evacuator valves,

and bushings

Sleeve tool Aid in securing 1/4" tubing sleeves

and 1/8" uni-clamps

Snap ring tool Installation and removal of internal

and external snap rings (fits all snap

rings used in A-dec equipment)

Tubing stripper Separation of the extruded air and

water lines in vinyl tubing

Umbilical stringer Route additional tubing or wiring

through existing umbilical assemblies

(12’ [3.66 mm] stringer with

threading holes on both ends)

Valve test syringe Quick tests of pilot operated valves;

used to apply a static pressure of 5-75

psi (.34-5.17 bar)

98.0090.01

98.0072.00

009.007.00

009.035.00

009.015.00

98.0050.01

8 85.0816.00 Rev B 2007-04

Page 20

A-dec Service Guide, Vol. II

DENTAL CHAIR

This section provides information related to servicing, maintenance,

and adjustments. Detail on how to service the chair and troubleshoot

specific problems is presented. For information on service parts, see the

Genuine A-dec Service Parts Catalog or contact A-dec customer service.

C HAIR CONTENTS

2

Product Overview, page 10

Flow Diagram, page 14

Service/Usage Information, page 16

Adjustments, page 27

Illustrated Parts Breakdown, page 29

85.0816.00 Rev B 2007-04 9

Page 21

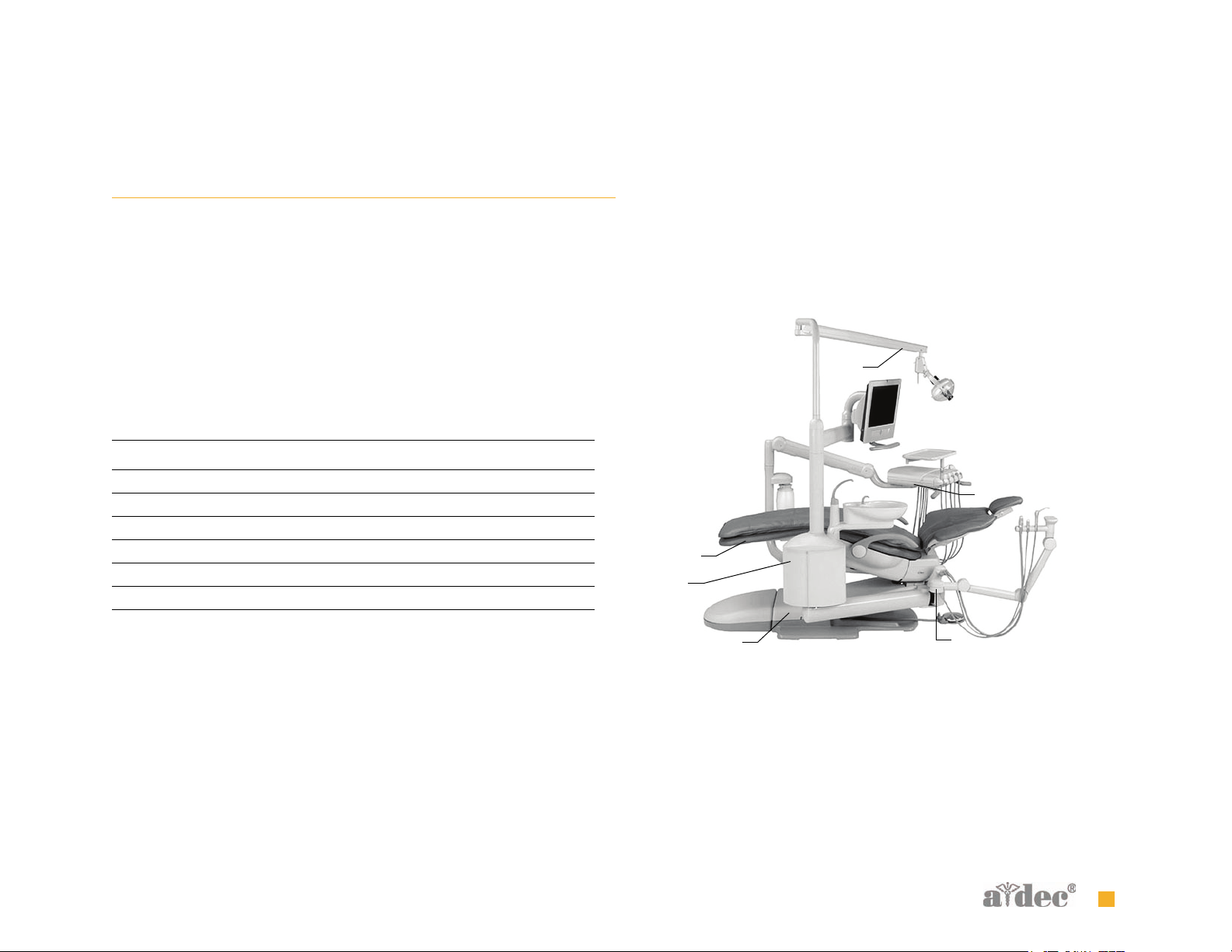

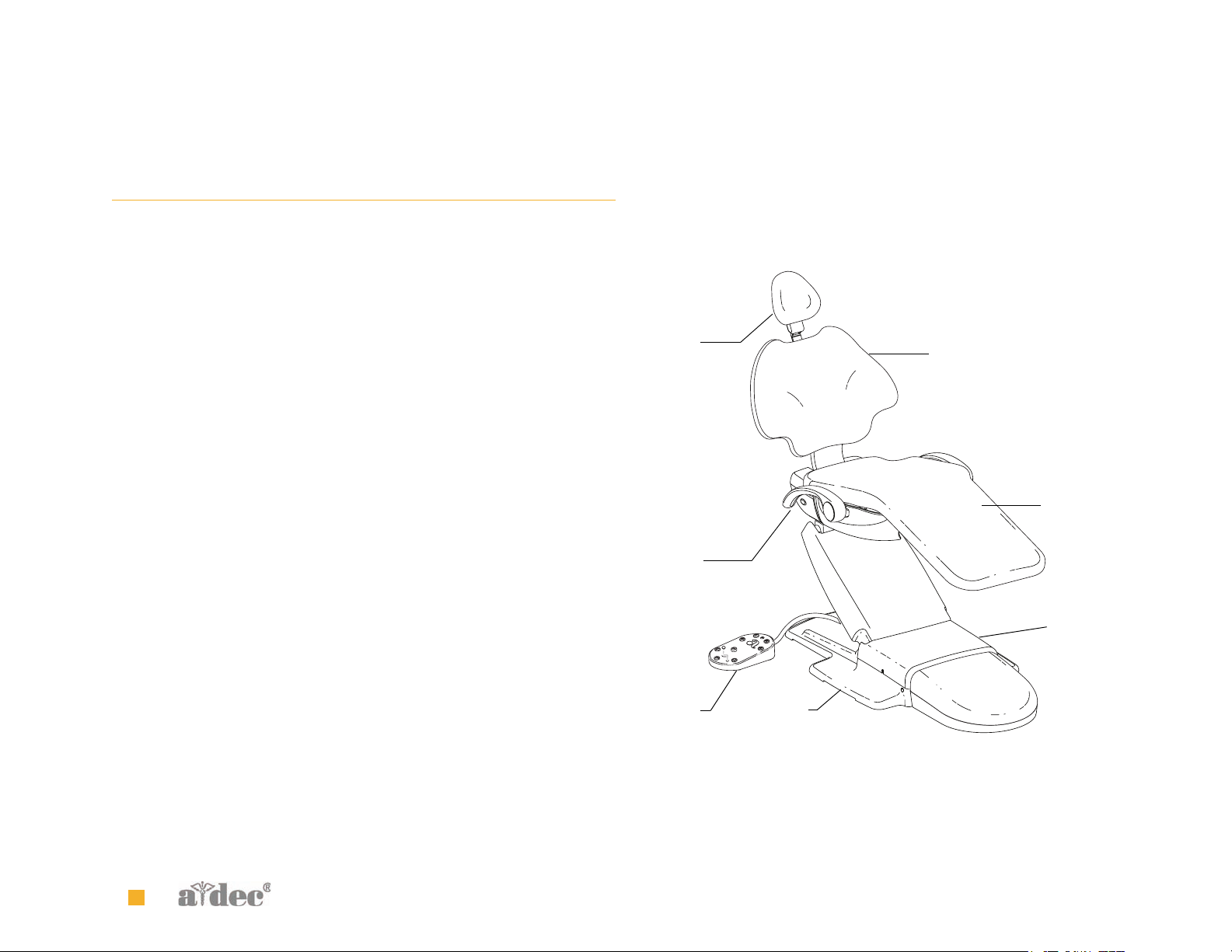

P RODUCT OVERVIEW

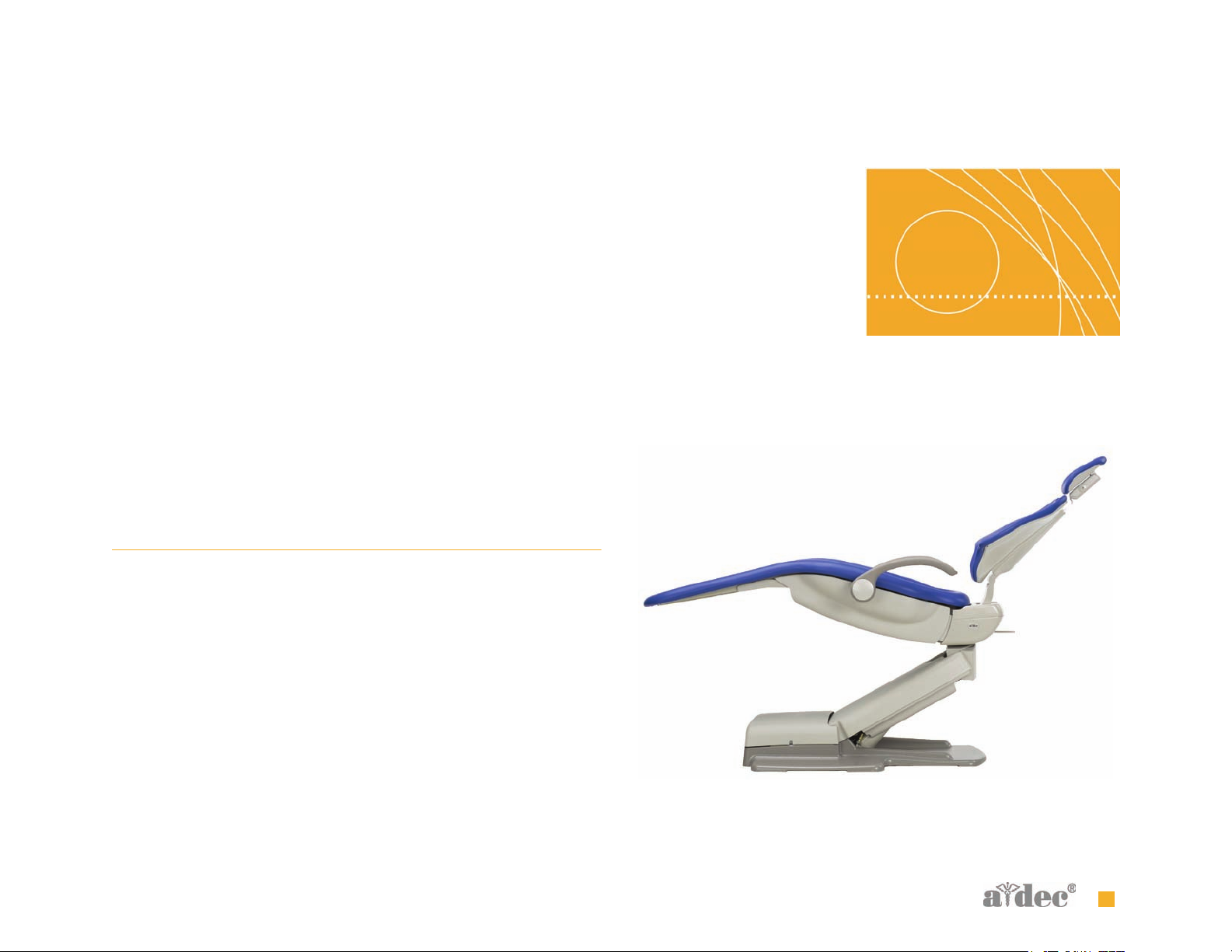

Product Overview A-dec 511 Chair

A-dec 511 Chair

The A-dec 511 chair provides a range of movements to position the

patient for dental treatment. The dental chair consists of a stable base,

an ergonomically synchronized seat and back support, adjustable head

support, and collapsible arm support. A footswitch and/or

touchpad(s) control the chair movement. A hydraulic system and four

programmable positions deliver entry, treatment, and exit positioning.

The deluxe touchpad option provides two operators with four more

programmable positions for a total of eight.

Figure 1 A-dec 511 Chair Features

A

B

E

F

G

C

(A) Headrest; (B) Armrest; (C) Foot Switch; (D) Baseplate; (E) Back; (F) Seat;

(G) Hydraulic Motor Pump Assembly

10 85.0816.00 Rev B 2007-04

D

Page 22

Product Overview A-dec 511 Chair Specifications

A-dec 511 Chair Specifications

Load Capacity

Patient Load: 300 lb. (135 kg) maximum

Accessory Load: 250 lb. (113 kg) maximum

Specifications are subject to change without notice.

NOTE Ensure the chair is bolted to the floor after installation.

Power On/Off Button

The power On/Off button is located on the base of the chair, and is the

main disconnect that completely shuts down the electrical systems.

When the button is pressed in, power is on. When the button is out,

power is off.

Figure 2 On/Off Button

A

(A) On/Off Button

Limp-Along Feature

If there is a problem or malfunction, the limp-along feature allows the

operator to move the chair in the up direction for one second intervals

by pushing the manual control buttons on the touchpad or footswitch.

85.0816.00 Rev B 2007-04 11

Page 23

Product Overview A-dec 511 Chair Specifications

Chair Power Supply

The 300-watt power supply comes standard with the A-dec 511 chair. It

is located in the motor pump area of the chair. The total available

auxiliary load is a maximum of 4 Amps.

NOTE The electric switch connects the power supply to

pilot air.

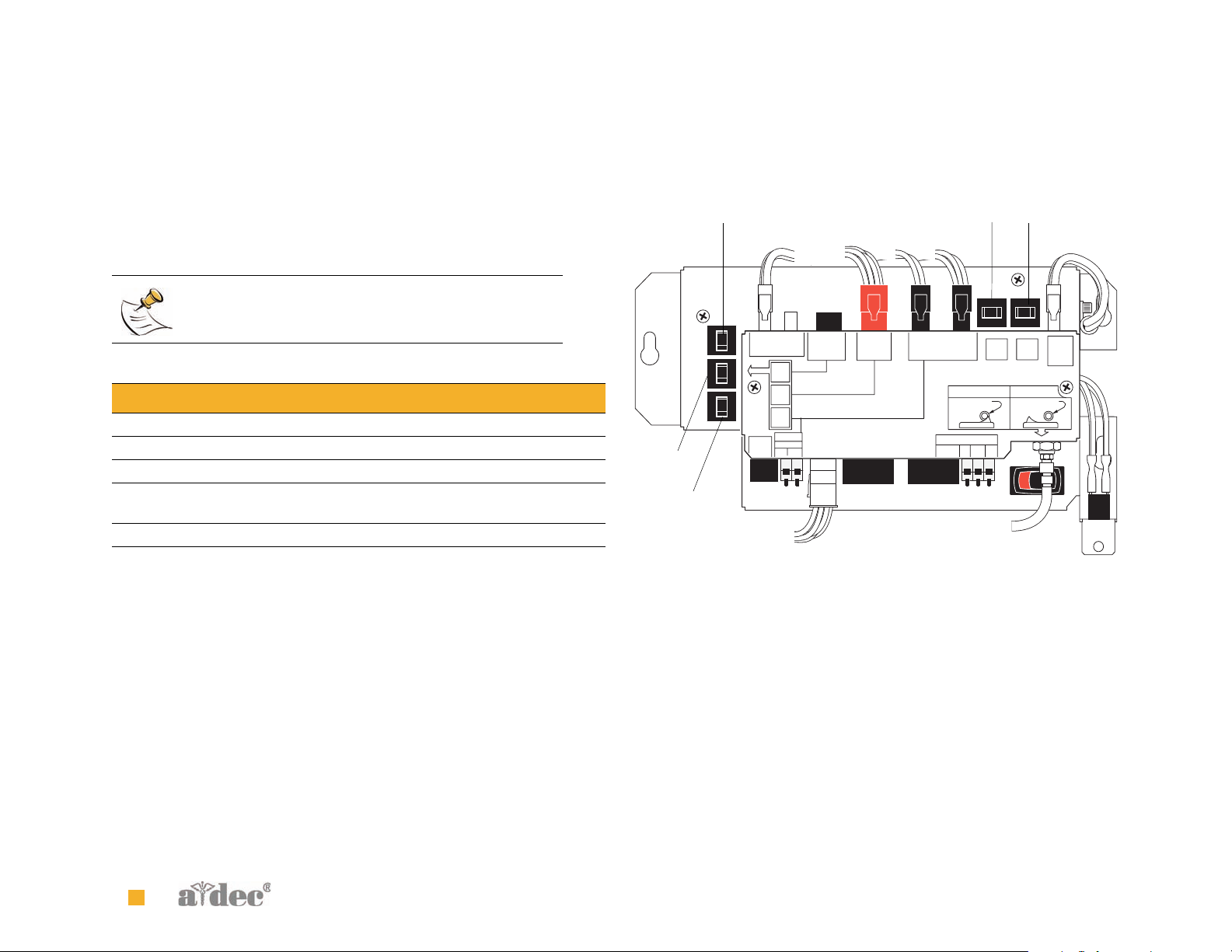

Tab l e 3 Power Supply Circuit Breaker Function

Circuit Breaker Function

CB 1 Mains

CB 2 Mains

CB 3 Support side arm (side support arm)

CB 4 Assistant’s arm, control head (delivery system) and

chair circuit board.

CB 5 Dental light

Figure 3 Chair Power Supply Circuit Breaker Identification

CB 2

POWER ON MODE

NO CONNECTION

REQUIRED

SWITCH ON

13A @ 250V ~ MAX

VACUUM

NC NOCOM

RELAY

AMP

10

CB 4

CB 3

10

A

M

P

10

A

M

P

10

A

M

P

MAINS OUTPUT

POWER 4A MAX

CB 3

CB 4

CB 5

OUTPUT

8A MAX

DATA

OV~ 24V~

SIDE

SUPPORT

ARM

DENTAL

LIGHT

ASSITANT'S ARM

& CONTROL HEAD

CB 5

CB 1

AMP

10

CB 1CB 2

MASTER TOGGLE

CONTROL OF POWER

CONNECT AIR SUPPLY

FROM MASTER TOGGLE

SWITCH ON

MAINS

INPUT

12 85.0816.00 Rev B 2007-04

Page 24

Product Overview A-dec 511 Chair Specifications

85.0816.00 Rev B 2007-04 13

Page 25

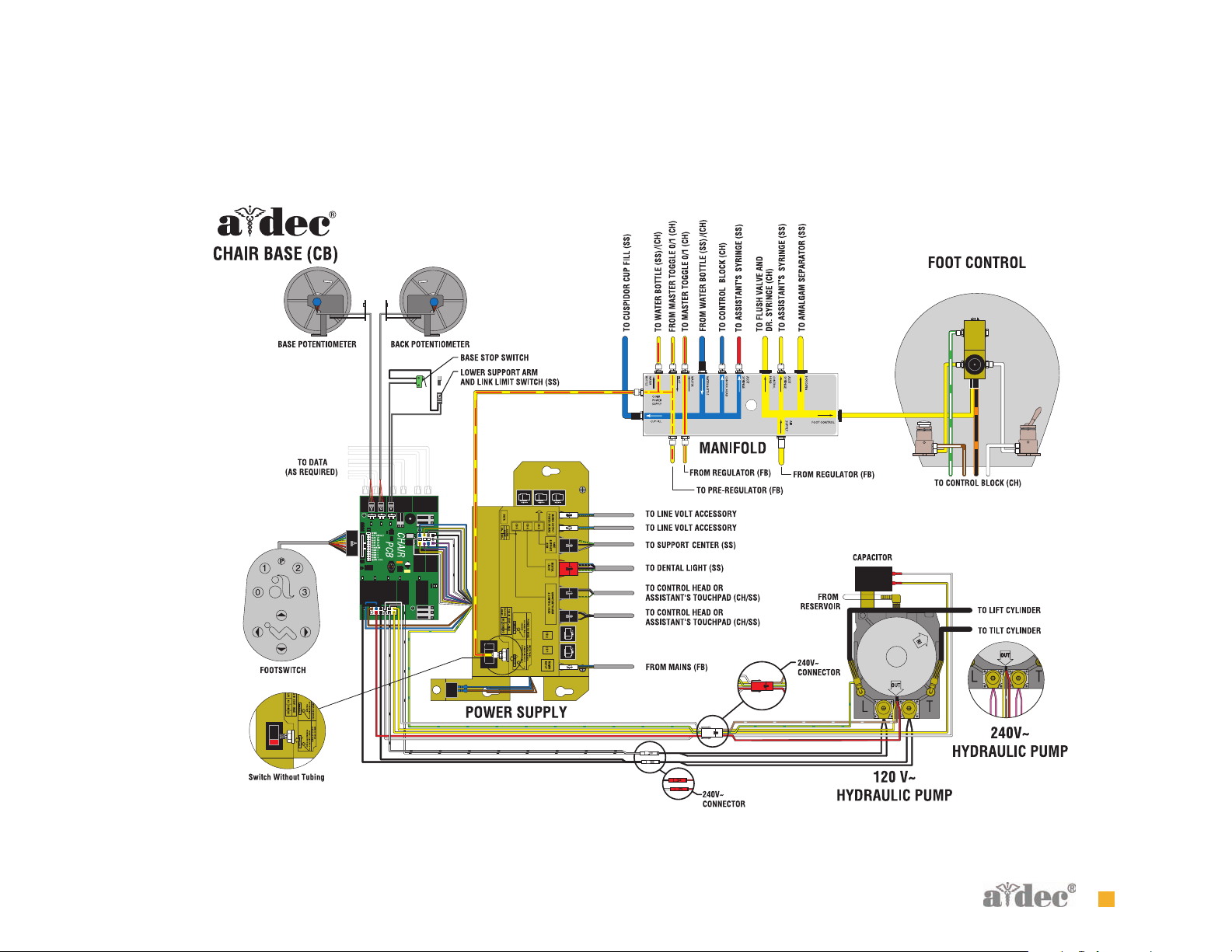

Flow Diagram Chair Flow Diagram

F LOW DIAGRAM

Chair Flow Diagram

This flow diagram details both electrical and plumbing information for servicing and troubleshooting the A-dec 511 chair. The flow diagram is

located on the inside of the motor pump cover. This diagram includes the air electric switch, motor pump connections, and potentiometers.

14 85.0816.00 Rev B 2007-04

Page 26

Figure 4 Chair Flow Diagram

Flow Diagram Chair Flow Diagram

85.0816.00 Rev B 2007-04 15

Page 27

S ERVICE/USAGE INFORMATION

Service/Usage Information Chair Covers

Chair Covers

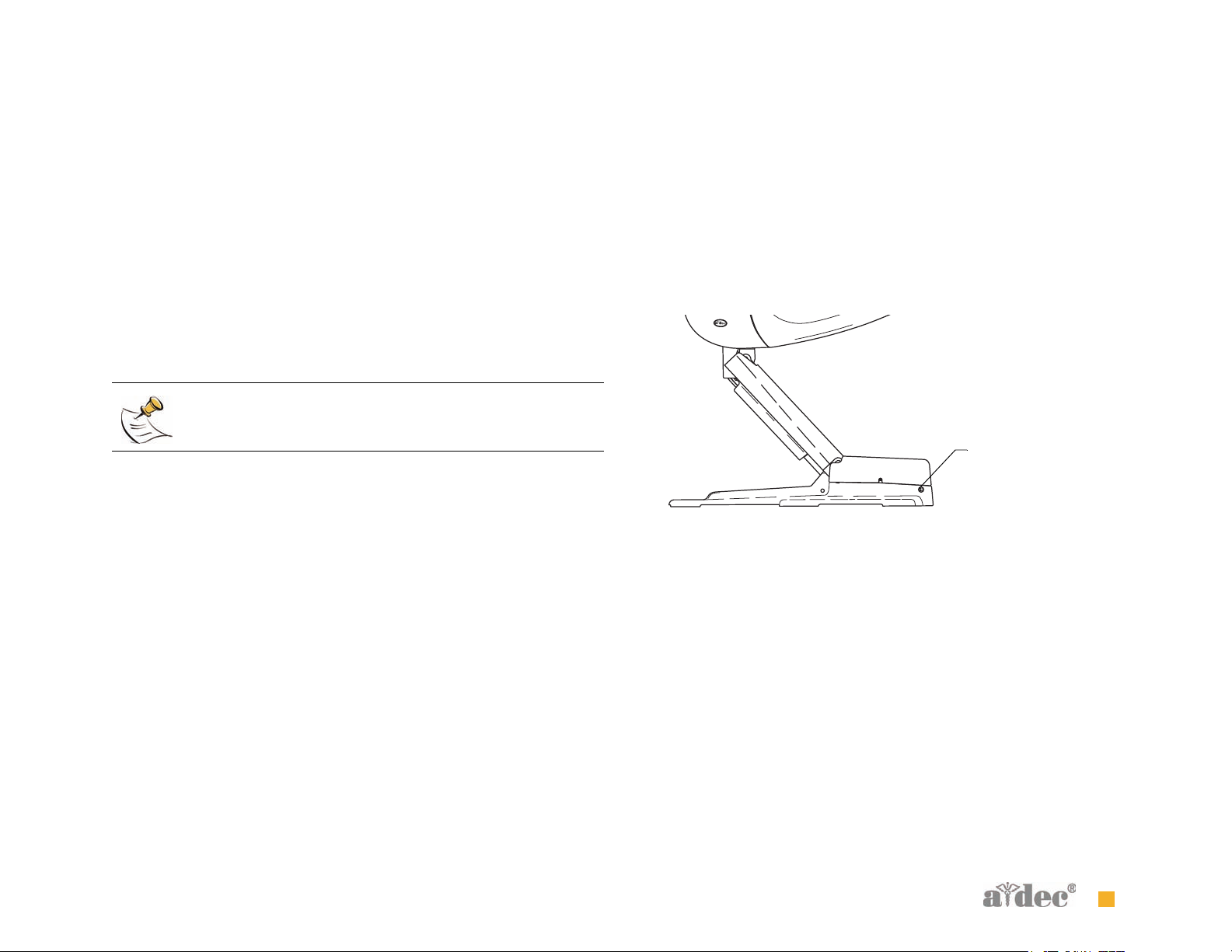

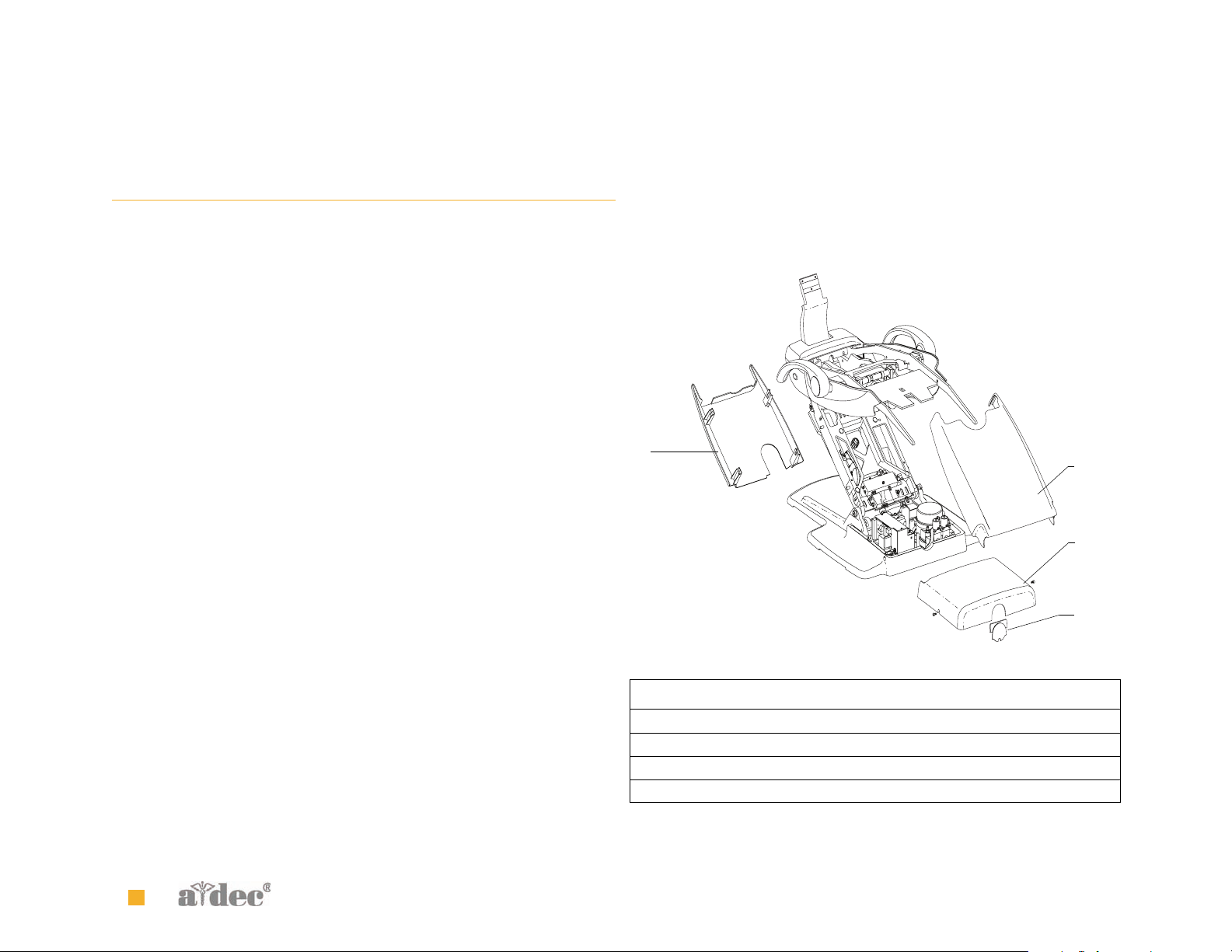

The A-dec 511 chair motor pump, lift arm and stop plate covers are

removed in the following order:

1. Motor Pump Cover

• To remove: Remove screw from each side and lift up.

• To replace: Replace cover, and attach with two screws.

2. Lift Arm Cover

• To remove: Pull one side of the cover until it releases from the

lift arm.

• To replace: Align one side of the cover with the lift arm and snap

into place. Ensure both sides are firmly attached.

3. Stop Plate

• To remove: Pull one side of the cover until it releases from the

lift arm.

• To replace: Slide one side of the cover over the post on the lift arm

and attach.

Figure 5 A-dec 511 Chair Covers

3

Item Part Number Description

1 62.0080.00 Motor pump cover

2 62.0081.00 Lift arm cover

3 62.0084.00 Stop plate cover

4 62.0101.00 Motor pump cover plug

2

1

4

16 85.0816.00 Rev B 2007-04

Page 28

Service/Usage Information Factory Default Routine

Factory Default Routine

When a new circuit board is installed in the chair, the circuit board

needs to run the factory default routine to learn the range of motion of

the chair.

The routine:

• sets the base and back upper limits

• calculates new presets based on actual range of motion of the chair

• verifies that the potentiometers work

To start the factory default routine, place the “spare” jumper in the

factory default position on the P3 test points of the chair circuit board.

When running the factory default routine the chair:

1. Moves base down

2. Moves base up

3. Moves back down

4. Moves back up

5. Moves base and back to Position 0

6. Beeps three times

NOTE The jumper must remain in the factory default position

to complete the factory default routine. The status LEDs on the

standard and deluxe touchpads and the chair circuit board

double blink while the factory default routine is running and

after the routine is complete.

85.0816.00 Rev B 2007-04 17

Page 29

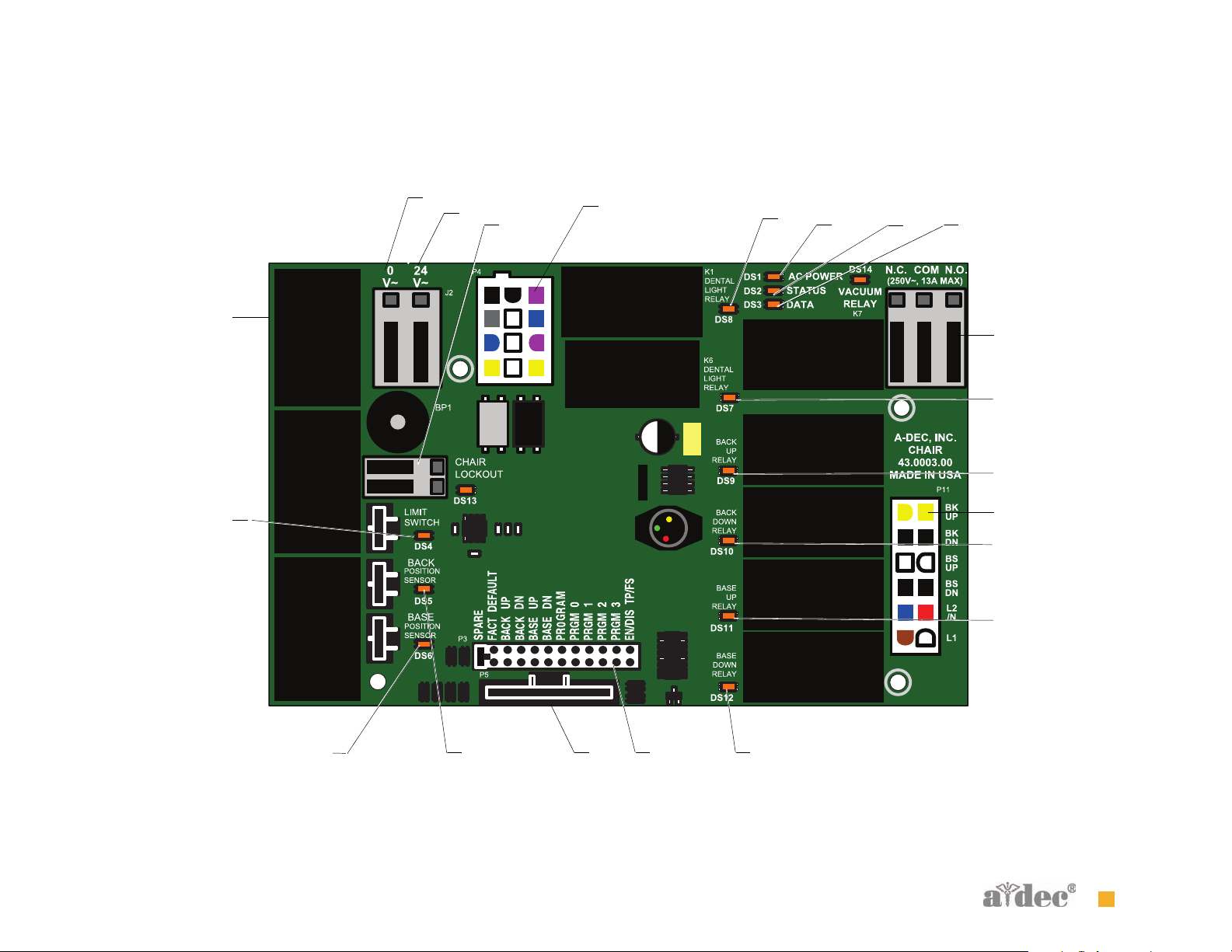

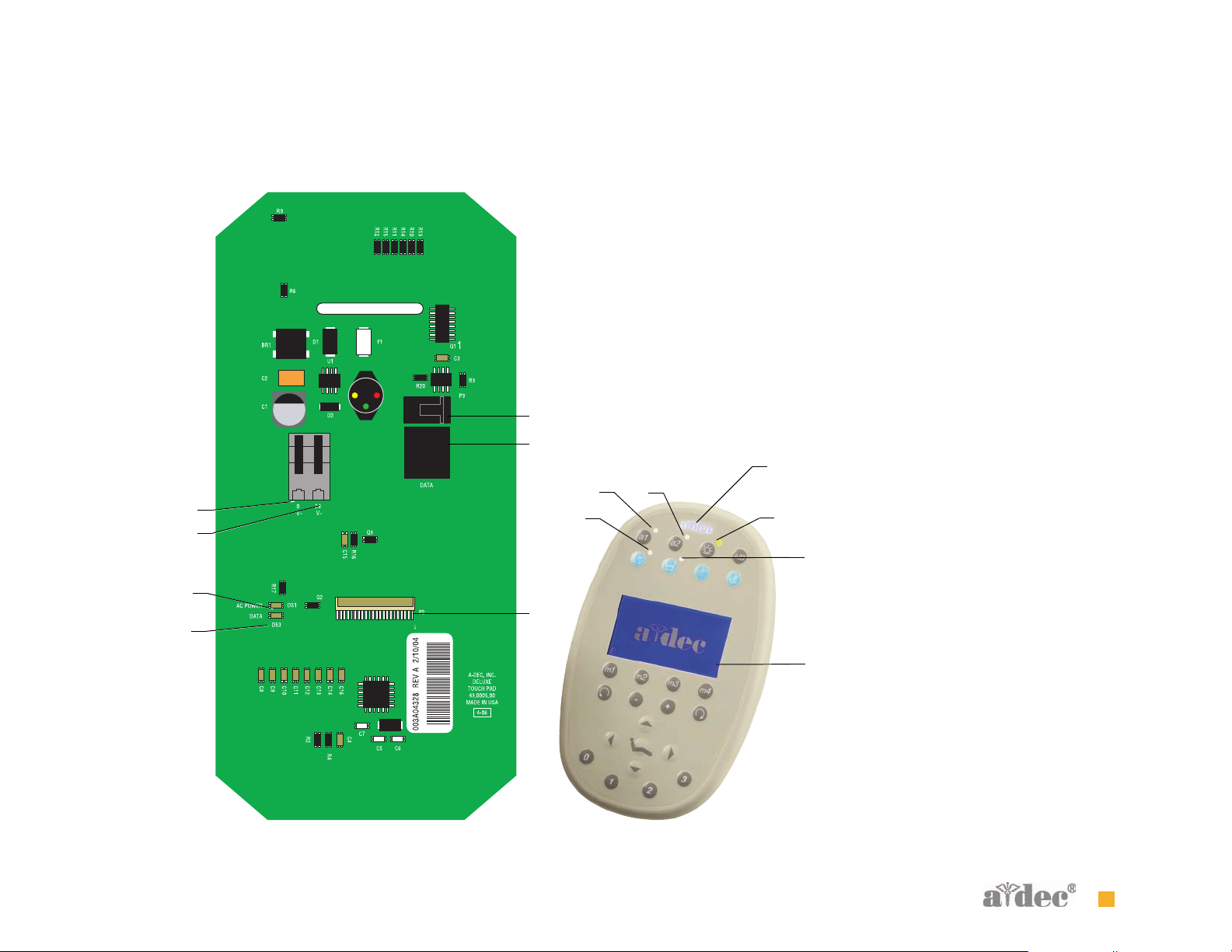

Chair Circuit Board Components

Service/Usage Information Chair Circuit Board Components

Part No: 90.1072.00

Item Description

1 P7, P8, P9 - Data line ports

2 DS4 - Stop switch LED (limit switch) and P10 connector

3 DS5 - Back potentiometer LED and P1 connector

4DS6 - Base potentiometer LED and P2 connector

5 P5 - Footswitch connector

6P3 - Test points

7 DS12 - Base down LED and relay K5

8 DS11 - Base up LED and relay K4

9DS10 - Back down LED and relay K3

10 DS9 - Back up LED and relay K2

11 DS1 - AC power LED

12 DS2 - Status LED

13 DS3 - Data LED

14 DS13 - Chair lockout LED and terminal strip J1

15 J2 - Ø VAC terminal strip (output)

16 J2 - 24VAC terminal strip (output)

17 P4 - Input power and dental light connector

18 J3 - Vacuum relay K7 and output terminal strip

19 P11 - Pump motor and solenoid connector

20 DS8 - Dental light LED and relay K1

21 DS7 - Dental light LED and relay K6

18 85.0816.00 Rev B 2007-04

Page 30

Figure 6 A-dec 511 Chair Circuit Board Components

15

1

16

14

17

Service/Usage Information Chair Circuit Board Components

20

11

12

13

18

21

10

2

19

9

8

4

85.0816.00 Rev B 2007-04 19

3 5 6 7

Page 31

LED Identification

Figure 4 describes the LEDs on the chair circuit board.

Tab l e 4 LED Identification

LED Status Description

Service/Usage Information Chair Circuit Board Components

DS1 - AC power

LED

DS2 - Status LED Off System is not functioning, no power or circuit board has failed

DS3 - Data LED Off No DCS communication, not connected to the DCS, or DCS has failed

DS4 - Chair limit

switch

DS13 - Chair

lockout

DS5 + DS6 - Chair

potentiometers

DS9, DS10, DS11,

DS12 - Chair relay

LEDs

DS7, DS8 - Dental

light relay LEDs

DS14 - Vacuum

relay LED

Off No 24 VAC power, tripped circuit breaker, power supply turned off, no line voltage

Green, steady 24VAC at the terminal strip

Green, steady Normal operation

Green, steady Detects active DCS

Green, blinking Valid DCS Message

Off Closed, (normal)

Red Open, (activated)

Off Open, (normal)

Red Closed, (activated)

Off Potentiometer:

• Not connected or bad connection

• Moving in wrong direction

• Limited range of motion, or

• Cable is not on wheel

Yellow, steady Normal operation

Yellow, fast blink Upper end of travel

Off Relay is off

On Relay is on

Off Relay is off

On Relay is on

Off Relay is off

On Relay is on

20 85.0816.00 Rev B 2007-04

Page 32

Service/Usage Information The Hydraulic System

The Hydraulic System

The hydraulic system deactivates automatically at the upper and lower

extremes of travel. The system is leak-free during transportation,

storage, and operation. The hydraulic system consists of:

• Hydraulic fluid reservoir

•Hydraulic cylinders

• Motor-driven hydraulic pump with solenoids

Hydraulic Fluid Reservoir

The hydraulic fluid reservoir is located in the lift arm of the chair under

the stop plate cover. You can see the fluid level in the reservoir through

the sides of the reservoir. A top fill cap allows you to add fluid. The

hydraulic system holds 40 ounces (2.5 pints [1.18 l]) of hydraulic fluid.

To fill the reservoir:

1. Place the chair in the full base and back up position.

2. Fill to the green Max line (see Figure 7).

CAUTION Do not over fill.

Figure 7 Hydraulic Fluid Reservoir

A

B

3. Cycle the chair after the reservoir is filled.

(A) Max Level; (B) Min Level

85.0816.00 Rev B 2007-04 21

Page 33

Service/Usage Information The Hydraulic System

Hydraulic Cylinders

The hydraulic cylinders operate during the Base Up and Back Up

functions. Springs and gravity retract the piston during Base Down

and Back Down functions.

The chair seat travels vertically from a low point of 13.5" (343 mm) to a

high point of 31.5" (800 mm) above the floor (see Figure 8).

Motor-driven Hydraulic Pump

The hydraulic pump takes hydraulic fluid from the reservoir and

pressurizes it to extend the chair lift and tilt hydraulic cylinders for

back and base up functions. The bi-directional pump rotates one

direction for Base Up and the opposite direction for Back Up. The

solenoids mounted to the pump assembly gate hydraulic fluid from the

two cylinders. Depending on the chair Down function, the controller

selects which solenoid-actuated manifold valves are open or closed.

The 100-120 VAC pump and 220-240 VAC pump are equipped with an

automatic reset 110°C (230°F) thermal limiter. There are no serviceable

parts on the hydraulic pump other than the solenoids.

NOTE You can not adjust the speed of the chair.

Figure 8 Hydraulic Cylinder Operation

13.5"

343mm

31.5"

800mm

22 85.0816.00 Rev B 2007-04

Page 34

Capacitor

Part No: 041.642.00, 100 VAC

Part No: 041.643.00, 110 - 120 VAC

Part No: 041.644.00, 220 - 240 VAC

The capacitor is energized during chair Base Up or Back Up functions.

Figure 9 A-dec 511 Chair Capacitor

Service/Usage Information The Hydraulic System

A

(A) Capacitor

85.0816.00 Rev B 2007-04 23

Page 35

Service/Usage Information The Hydraulic System

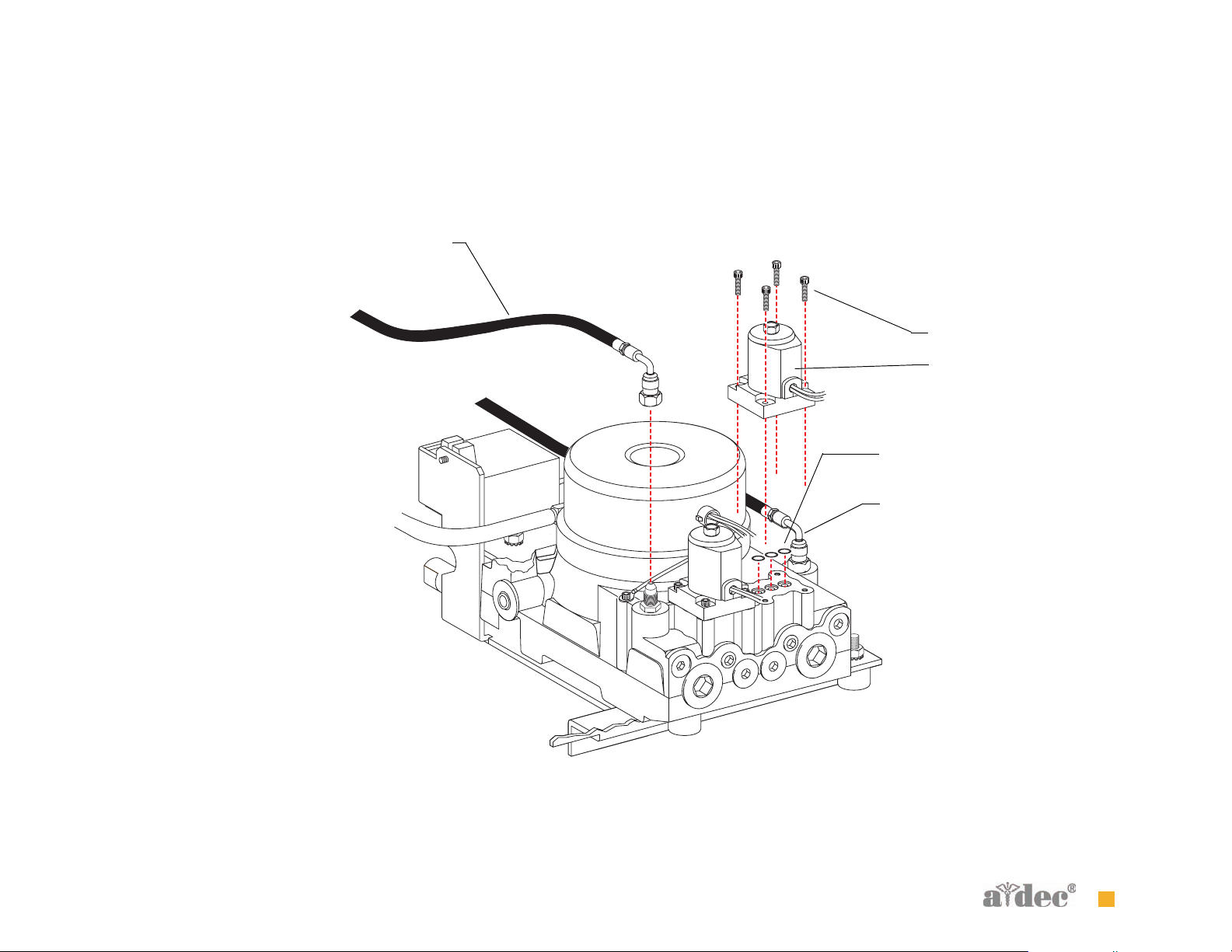

Solenoids

Part No: 90.1070.00, 110 - 120 VAC

Part No: 90.1071.00, 220 - 240 VAC

How to Test Solenoids

A solenoid is entergized during Base Down and Back Down functions.

To check for a failed solenoid, test the solenoids using a volt/ohm

meter or magnetic pull test:

Magnetic pull

1. Hold a paper clip loosely in your hand.

2. Activate the solenoid by pressing Base Down or Back Down on the

footswitch or touchpad.

3. If there is a pull on the paper clip, the solenoid is being entergized.

Coil resistance

1. Disconnect the solenoid power at the 2-position connector.

2. Place on Ohm meter probe on each of the solenoid connector

terminals.

100 - 120 VAC = 177 Ohms ± 18 Ohms

220 - 240 VAC = 845 Ohms ± 85 Ohms

WARNING You must depressurize the base or back system

prior to removing the solenoid.

1. Depressurize base or back system,

2. Remove the failed solenoid coil

3. Replace with the operating solenoid coil.

4. Lower the chair base and back.

Figure 10 A-dec 511 Chair Solenoids

B

C

A

NOTE If the solenoid is hot, then the resistance reads higher.

NOTE When replacing a solenoid, wipe up any oil, and

replace existing O-rings on the solenoid base.

ELECTRICAL WARNING The solenoid coils are powered by line

voltage (100, 120, or 240 VAC). Failure to unplug the chair may

result in serious injury from electrical shock.

(A) Base Down Solenoid; (B) Back Down Solenoid; (C) Motor Pump Assembly

24 85.0816.00 Rev B 2007-04

Page 36

Service/Usage Information Potentiometer

v

U

R

U

R

AZ762 - 1C-5D

C

VDE

Potentiometer

The potentiometer and cable assembly is a simple, accurate unit, which eliminates position float. “Float” is a slight change or variation in the

pre-programmed positions. The chair uses the same potentiometer assembly for both lift and tilt requirements. If a potentiometer should fail, the

limp-along feature allows the operator to position the chair for one second intervals by pushing the manual control buttons on the

touchpad or footswitch.

Figure 11 Location of the Chair Base Up and Back Up Potentiometers

A

B

D

v

AZ762 - 1C-5

U

R

U

R

E

C

VD

(A) Base Up Potentiometer; (B) Back Up Potentiometer

85.0816.00 Rev B 2007-04 25

Page 37

Service/Usage Information Chair Stop Plate

Chair Stop Plate

The chair stop switch stops chair movement when you press the stop

plate. Should anything inadvertently become lodged under the chair,

press Base Up on the touchpad or footswitch to raise the chair so you

can remove the object. As long as you apply pressure to the stop plate,

the chair does not move down.

The stop plate has only one switch. The switch and all other parts snap

into place for easy removal or replacement. No tools are required.

WARNING Be sure to power off the chair and disconnect

it from its power source before replacing the stop switch.

CAUTION Cable tie the wires to the lift arm to prevent

kinking and pinching.

Chair Bump-Up Feature

The chair stop plate and the assistant’s arm trigger the chair to move

upwards if it was moving down when the stop plate switch

was activated.

Figure 12 A-dec 511 Chair Stop Plate

A

(A) Stop Switch Assembly

26 85.0816.00 Rev B 2007-04

Page 38

A DJUSTMENTS

Adjustments Swivel Brake

Swivel Brake

The chair can rotate to any position within 30° either side of center. The

chair swivel brake keeps the chair from moving. To engage the brake,

push the brake lever firmly to the left. To release the swivel brake, push

the brake lever to the right.

Tension Adjustment

If the chair swivels left or right with the brake engaged or if it is

difficult to move with the brake disengaged, adjust the swivel brake

tension. To adjust the tension, use a 5/32 hex key and turn the tension

adjustment screw;

• Clockwise to increase brake friction

• Counterclockwise to decrease brake friction.

If you cannot obtain proper adjustment through rotation of the hex

key, replace the brass brake pad by removing the brake handle and

using a hex key to disengage the pad. Remove the old pad and replace

with new one. Replace the brake handle and handle retainer.

NOTE To disable the swivel feature, reinstall the shipping pin.

Figure 13 Chair Swivel

30°

30°

Figure 14 Swivel BrakeTension Adjustment

A

Engaged

(A) Tension Adjustment Screw

85.0816.00 Rev B 2007-04 27

Released

Page 39

Adjustments Headrest

Headrest

The headrest adjustment lever allows you to use one hand to adjust the

headrest. When the lever is released, the headrest holds its position.

Drift Adjustment

If the headrest drifts downward, or if it is difficult to move up or down,

adjust the glide bar tension. To adjust the tension, use a 1/8 hex key

and turn the tension adjustment screw clockwise to increase friction or

counterclockwise to decrease friction.

Figure 15 Headrest Adjustments

C

A

B

(A) Headrest Adjustment Lever; (B) Glide Bar;

(C) Glide Bar Tension Adjustment

28 85.0816.00 Rev B 2007-04

Page 40

I LLUSTRATED PARTS BREAKDOWN

Illustrated Parts Breakdown Part Identification

This section contains illustrated parts breakdowns specific to the

A-dec 511 Chair.

Part Identification

The conventions for the serviceable components tables are designed to

identify all parts and kits, including ones that are not for sale. Symbols

with reference notes are used.

Symbol Definition

†

No symbol Part is for sale

Indicates that the individual part is not available for

sale (these parts are typically part of a kit and/or

larger assembly that is for sale)

C HAIR IPB CONTENTS

Baseplate and Motor Pump Assembly, page 30

Hydraulic Hose and Solenoid Assembly, page 32

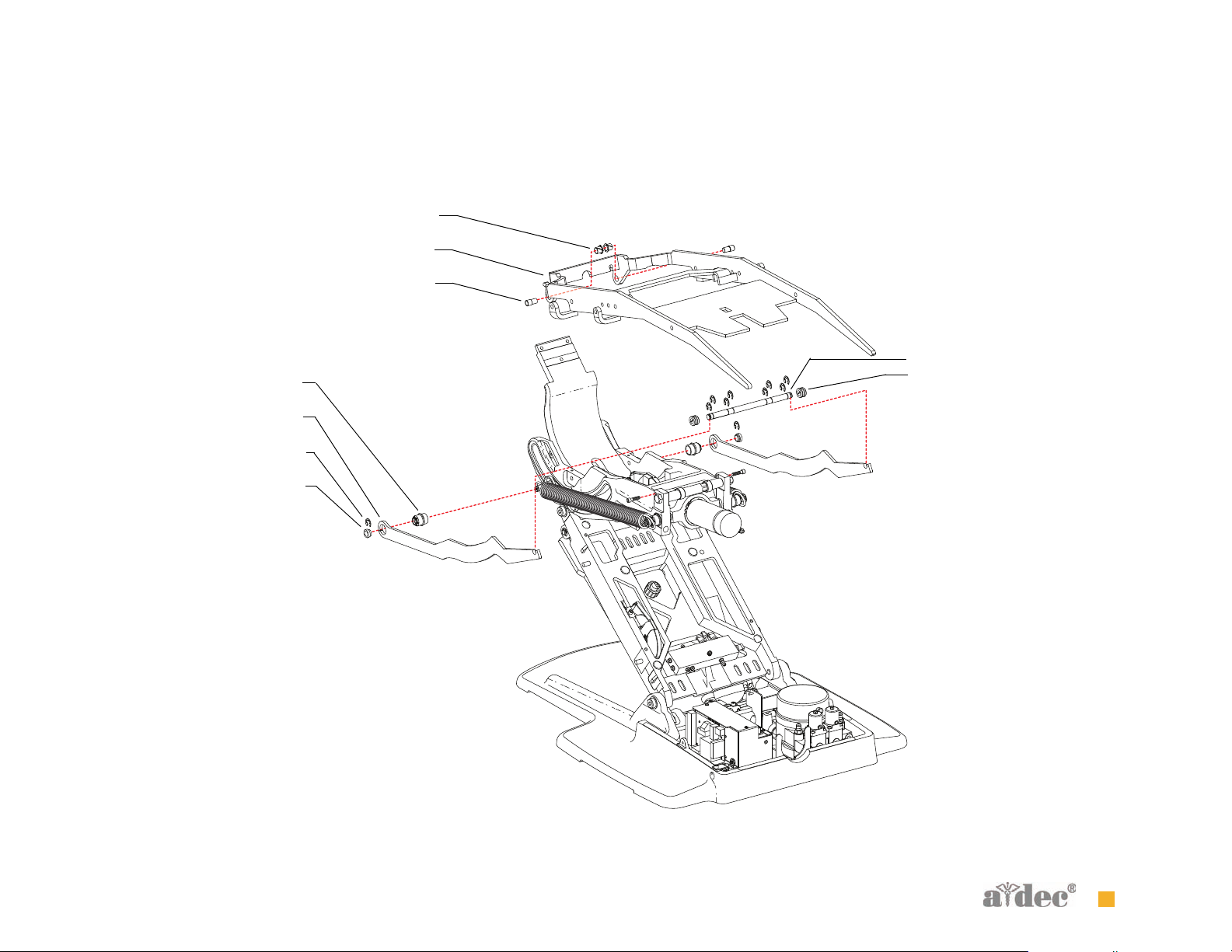

Lift Cylinder and Link Arm, page 34

Lower Assembly, page 36

Upper Structure/Swivel Assembly, page 38

Back and Tilt Cylinder Assembly, page 40

Upper (Springs and Cam Assembly ), page 42

Upper (Seat Assembly), page 44

Headrest Assembly, page 46

85.0816.00 Rev B 2007-04 29

Page 41

Illustrated Parts Breakdown Baseplate and Motor Pump Assembly

Baseplate and Motor Pump Assembly

Item Part Number Description

1 002.010.00 Screw, socket head, patch, 1/4-20 x 3/8" stainless steel

2 90.1073.00 Power supply, 100V

90.1074.00 Power supply, 120V

90.1075.00 Power supply, 240V

3 90.1082.00 Stand-off, package of 5

4 90.1072.00 Chair PCB (includes item #3 stand-offs)

5 62.0029.00† Baseplate

6 005.008.01 Screw, 1/4-20 x 1/2"

7 001.229.00 Screw, truss head, Phillips, 6-32 x 1/2", stainless steel

8 041.642.00 Capacitor, 100V

041.643.00 Capacitor, 110-120V

041.644.00 Capacitor, 220-240V

9 006.141.00 Nut, hex, KEPs 1/4-20

10 037.040.00 Isolator

11 90.1094.00 Hydraulic motor pump assembly, 100V

90.1094.01 Hydraulic motor pump assembly, 120V

90.1094.02 Hydraulic motor pump assembly, 240V

12 025.112.00 Clamp, half type

13 002.120.00 Screw, socket head, patch, 1/4-20 x 1" stainless steel

14 62.0131.00 Strain relief

15 Spring - Part of Main On/Off Switch Kit, P/N 90.1068.00

16 Button - Part of Main On/Off Switch Kit, P/N 90.1068.00

30 85.0816.00 Rev B 2007-04

Page 42

Figure 16 Baseplate and Motor Pump Assembly

Illustrated Parts Breakdown Baseplate and Motor Pump Assembly

1

2

3

4

5

13

14

1

12

6

7

8

9

10

11

15

16

85.0816.00 Rev B 2007-04 31

Page 43

Illustrated Parts Breakdown Hydraulic Hose and Solenoid Assembly

Hydraulic Hose and Solenoid Assembly

Item Part Number Description

1 62.0046.00 Hydraulic hose, lift

2 001.250.00 Screw, socket head cap, 8-32 x 5/8", black

3 90.1070.00 Solenoid, 110-120V, kit

90.1071.00 Solenoid, 220-240V, kit

4

5 62.0047.00 Hydraulic hose, tilt

035.055.00

†

O-ring, 5.8mm ID x 1.9 W, Buna

32 85.0816.00 Rev B 2007-04

Page 44

Figure 17 Solenoid Assembly

Illustrated Parts Breakdown Hydraulic Hose and Solenoid Assembly

1

2

3

4

5

85.0816.00 Rev B 2007-04 33

Page 45

Illustrated Parts Breakdown Lift Cylinder and Link Arm

Lift Cylinder and Link Arm

Item Part Number Description

1 90.1083.00 Lift cylinder assembly

2 002.120.00 Screw, socket head patch, 1/4-20 x 1" stainless steel

3 62.0135.00 Pin

4 010.031.01 Retaining e-ring, external 1/2" ID, stainless steel

5 62.0078.01 Link arm

6 62.0134.00 Pin, link arm

7 90.1095.00 Kit, Stop switch replacement

34 85.0816.00 Rev B 2007-04

Page 46

Figure 18 Lift Cylinder and Link Arm

Illustrated Parts Breakdown Lift Cylinder and Link Arm

1

2

3

4

5

6

7

85.0816.00 Rev B 2007-04 35

Page 47

Illustrated Parts Breakdown Lower Assembly

Lower Assembly

Item Part Number Description

1

2

3

4 004.148.00 Washer, flat nylatron

5 001.165.00 Screw, socket shoulder, 1/2-13 x 5/8 x 7/8

6 010.031.01 Retaining e-ring, external 1/2" ID stainless steel

7 62.0077.00 Pin, linkarm

8 002.010.00 Screw, socket head patch, 1/4-20 x 3/8" stainless steel

9 90.1069.00 Potentiometer

10 005.008.01 Screw, 1/4-20 x 1/2"

11 38.1804.00 Manifold assembly

62.0091.00

62.0089.00

011.124.00

90.1083.00 Kit, Lift cylinder (includes 1, 2 and 3)

†

†

†

Swivel mount

Liftarm

Pin, clevis

36 85.0816.00 Rev B 2007-04

Page 48

Figure 19 Lower Assembly

Illustrated Parts Breakdown Lower Assembly

4

5

1

2

3

6

7

8

9

10

11

85.0816.00 Rev B 2007-04 37

Page 49

Illustrated Parts Breakdown Upper Structure/Swivel Assembly

Upper Structure/Swivel Assembly

Item Part Number Description

1

2 62.0237.00 Wear ring, 2-3/4 OD x 5/8"

3 016.133.00 Thrust bearing

4 61.2051.00 Locknut, spanner

5 62.0218.00 Brake handle assembly

6 005.008.01 Screw, 1/4-20 x 1/2" socket head

7 004.170.00 Washer, flat, nylon

8 62.0042.00 Adjuster, brake

9 62.0043.00 Plunger, brake

10 011.097.00 Ship pin

62.0050.00

†

Upper structure

38 85.0816.00 Rev B 2007-04

Page 50

Figure 20 Upper Structure/Swivel Assembly

Illustrated Parts Breakdown Upper Structure/Swivel Assembly

4

3

5

6

7

1

2

3

8

9

10

85.0816.00 Rev B 2007-04 39

Page 51

Illustrated Parts Breakdown Back and Tilt Cylinder Assembly

Back and Tilt Cylinder Assembly

Item Part Number Description

1 010.031.01 Retaining e-ring, 1/2" ID stainless steel

2 62.0201.00 Bolt, spring support

3 62.0202.00 Bolt, slider, shoulder

4 016.145.00 Bearing, flanged, .75 ID x .8125 OD

5 62.0200.00 Tvunnion

6 90.1085.00 Tilt cylinder assembly

7 62.0199.00 Trolley, chair back

8 002.010.00 Screw, socket head patch, 1/4-20 x 3/8" stainless steel

9 90.1069.00 Potentiometer

10 62.0061.00 Back track slider

11 62.0189.00 Spacer

12 005.036.00 Screw, 3/8-16 x 1-3/4, 2N, patch

13 005.138.01 Screw, button head socket, 10-32 x 5/16 patch

14 99.0719.00 Bracket

15 001.244.00 Screw, JCB, socket, 1/4-20 x 15mm, stainless steel

16 001.245.00 Screw, socket head, cap, 1/4-20 x 3/4"

17 62.0103.00 Wear pad, upper headrest brake

18 62.0102.00 Wear pad, lower headrest brake

19 006.148.00 Coupling

20 007.158.00 Setscrew, cone point, 1/4-20 x 1" stainless steel

21 90.1099.00 Support, back

40 85.0816.00 Rev B 2007-04

Page 52

Figure 21 Back and Tilt Cylinder Assembly

7

Illustrated Parts Breakdown Back and Tilt Cylinder Assembly

1

2

3

4

5

6

11

12

8

9

10

15

16

13

14

17

18

19

20

21

85.0816.00 Rev B 2007-04 41

Page 53

Illustrated Parts Breakdown Upper (Springs and Cam Assembly )

Upper (Springs and Cam Assembly )

Item Part Number Description

1 62.0070.00 Guide, lateral

2 001.245.00 Screw, socket head, cap, 1/4-20 x 3/4"

3 62.0067.00 Roller, cam

4 013.114.00 Spring

5 010.031.01 Retaining e-ring, external 1/2" ID, stainless steel

6 62.0185.00 Spring, support

7 77.0206.00 Cam

8 001.163.00 Screw, hex head

42 85.0816.00 Rev B 2007-04

Page 54

Figure 22 Upper (Springs and Cam Assembly)

1

2

3

4

5

6

Illustrated Parts Breakdown Upper (Springs and Cam Assembly )

7

8

85.0816.00 Rev B 2007-04 43

Page 55

Illustrated Parts Breakdown Upper (Seat Assembly)

Upper (Seat Assembly)

Item Part Number Description

1 016.065.00 Bearing, flanged, .500 ID x .562 OD

2 90.1103.00 Seat frame (includes items 1 and 3)

3 62.0196.00 Stud, mounting, shoulder, 7/16-4

4 62.0067.00 Roller, cam

5 62.0062.00 Cam seat lift

6 010.031.01 Retaining e-ring, external, 1/2" ID, stainless steel

7 62.0185.00 Spring support

8 62.0069.00 Bar

44 85.0816.00 Rev B 2007-04

Page 56

Figure 23 Upper (Seat Assembly)

4

5

6

7

Illustrated Parts Breakdown Upper (Seat Assembly)

1

2

3

8

7

85.0816.00 Rev B 2007-04 45

Page 57

Illustrated Parts Breakdown Headrest Assembly

Headrest Assembly

Item Part Number Description

1 035.048.01 O-ring, E, .115 ID x .07 W, package of 10

2 90.1092.00 Cover, headrest cushion

3 001.042.01 Screw, socket head, 6-32 x 1/2", stainless steel, patch

4 62.0021.00 Bearing, slider, headrest cushion

5 90.1091.00 Headrest assembly (includes items 3, 4, 6, 7 and 8)

6 62.0094.00 Bearing, slider, brake, headrest

7 013.005.00 Spring

8 62.0141.00 Cap, headrest

9 001.021.00 Screw, socket head, 4-40 x 1/2", stainless steel

46 85.0816.00 Rev B 2007-04

Page 58

Figure 24 Headrest Assembly

Illustrated Parts Breakdown Headrest Assembly

6

7

1

2

3

4

5

8

9

85.0816.00 Rev B 2007-04 47

Page 59

Illustrated Parts Breakdown Headrest Assembly

48 85.0816.00 Rev B 2007-04

Page 60

A-dec Service Guide, Vol. II

3

PROGRAMMING

The A-dec 500 touchpad centralizes treatment room controls into one

touch surface. Some touchpad buttons have indicators to alert you if

the operation is functioning. A-dec touchpads control multiple chair

and delivery system functions:

• Standard Touchpad—chair, light, cuspidor controls and auxiliary

equipment

• Deluxe Touchpad—chair, light, cuspidor, air/water coolant, electric

handpiece, scaler, multiple users and auxiliary equipment

This section provides programming information for all of the A-dec

500 modules as well as information related to servicing, maintenance,

and adjustments. For information on service parts, see the Genuine

A-dec Service Parts Catalog or contact A-dec customer service.

P ROGRAMMING CONTENTS

Status Icon, page 50

Chair Positions, page 51

Cuspidor Functions, page 54

Dental Light, page 55

Electric Handpiece Settings (Deluxe Touchpad Only), page 56

Other System Choices, page 60

Touchpad Circuit Board Components, page 62

85.0816.00 Rev B 2007-04 49

Page 61

A-dec Service Guide, Vol. II Status Icon

S TATUS ICON

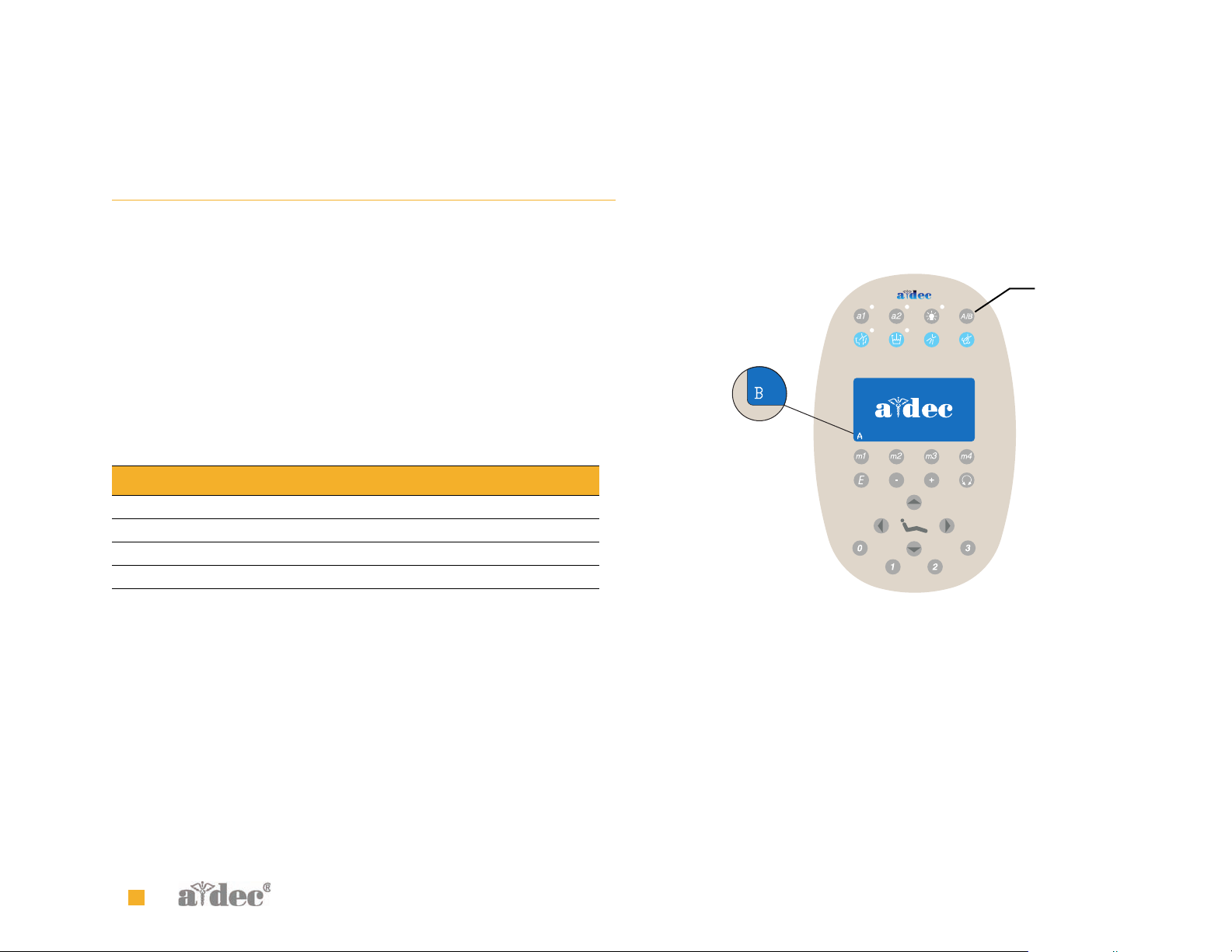

The A-dec logo on the Deluxe touchpad indicates the system status:

• Solid blue—normal operation and power is on.

• Blinking— chair stop plate or cuspidor limit switch is active.

The icon returns to solid blue once you remove any obstructions.

• Double blink pattern—jumper is on the factory default position on

the chair circuit board. The icon returns to solid blue once you

remove the jumper.

Figure 25 Deluxe Touchpad

A

(A) Status Icon

50 85.0816.00 Rev B 2007-04

Page 62

A-dec Service Guide, Vol. II Chair Posi tions

C HAIR POSITIONS

The chair direction arrows on the touchpad allow you to manually move the chair base up/down and back up/down. Table 5 lists and describes

the direction arrows:

Tab l e 5 Chair Direction

Icon Action

Back down

Base down

Back up

Base up

85.0816.00 Rev B 2007-04 51

Page 63

A-dec Service Guide, Vol. II Chair Positions Position Buttons

Position Buttons

Chair position buttons are factory preset to automatically move the

chair (see Figure 26).

Figure 26 Chair Position Touchpad Buttons

C

A

A

B

B

Table 6 lists and describes the factory presets:

Tab l e 6 Chair Position Factory Presets

Button Description

Entry/exit Position. Automatically positions chair and

turns off dental light.

Position 1. Automatically positions the chair base and

back and turns on the dental light.

Position 2. Automatically positions the chair base and

back and turns on the dental light.

Position 3 (x-ray/rinse). Automatically positions the

chair back to either x-ray or the previous position.

Toggles between the two positions and turns on/off the

dental light as appropriate.

(A) Chair Direction Arrow; (B) Chair Position Button; (C) Program Button

52 85.0816.00 Rev B 2007-04

Page 64

A-dec Service Guide, Vol. II Chair Positions Position Buttons

Customize Chair Positions 0-2

To customize the chair positions:

1. Use the manual controls to adjust the chair position as desired.

2. Press and release the Program button. One beep indicates

programming mode.

3. Press the chair position button, within four seconds, you wish to

reset (for example, Position 1). Three beeps indicate the new setting

is programmed in memory.

Customize Chair Position 3

Position 3 functions either as a toggle between x-ray/rinse position and

last position or as a programmable position. To customize:

1. Press and hold the program button and the Position 3 button

simultaneously for three seconds. Three beeps confirm the

x-ray/rinse position is now inactive, and the chair is available for

programming.

2. Press the manual chair controls (arrow icons) to position the chair

to the desired operating position.

3. Press and release the program button. One beep confirms

programming mode.

4. Within 3 seconds, press the Position 3 button. Three beeps indicate

the new setting is programmed in memory.

NOTE If Position 3 is changed to a programmable

position, it operates the same as Positions 1 and 2.

To reactivate the x-ray/rinse function:

Press and hold the program button and the Position 3 button

simultaneously for three seconds. Three beeps confirm the x-ray/rinse

position is now active.

85.0816.00 Rev B 2007-04 53

Page 65

A-dec Service Guide, Vol. II Cuspidor Functions Cup Fill

C USPIDOR FUNCTIONS

Cup Fill

The cup fill function controls water flow from the cuspidor into a cup

(see Figure 27).

Figure 27 Cup Fill Button

• Press the cup fill button for a timed operation. The factory preset is a

2.5 second fill.

• Press and hold the cup fill button for manual operation.

Bowl Rinse

Bowl rinse provides rinse water for the cuspidor bowl (see Figure 28).

Figure 28 Bowl Rinse Button

• Press the bowl rinse button for a timed operation. The factory preset

is a 30 second rinse.

• Press and hold the bowl rinse button for manual operation.

Customize Cup Fill and Bowl Rinse

To program the cup fill and bowl rinse timing:

1. Press and release the Program button. One beep indicates

programming mode.

2. Within 3 seconds, press and hold the cup fill or bowl rinse button

for the desired time.

3. Release the button. Three beeps confirm the setting.

NOTE If you have a Standard touchpad and wish to use

the Auxiliary (A1/A2) buttons, automated cup fill and

bowl rinse features are not available.

NOTE If you press the bowl rinse button twice in less

than two seconds, it switches to continuous operation

mode. Press the button once to end the continuous bowl

rinse mode.

54 85.0816.00 Rev B 2007-04

Page 66

A-dec Service Guide, Vol. II Dental Light Dental Light Auto Feature

D ENTAL LIGHT

The dental light button on the touchpad functions as a three-way

switch. You can turn the dental light on or off from either the touchpad

or the dental light (see Figure 29).

Figure 29 Dental Light Button

Press the dental light button to turn on the dental light. Press the

button again to toggle between two intensity settings. The dental light

toggles between composite-medium intensity or composite-high

intensity settings. When the dental light is in composite mode, the

indicator light next to the button blinks (see Figure 30). Hold the button

1 second to turn the dental light off.

Figure 30 Dental Light Composite Mode

A

Dental Light Auto Feature

The dental light has an auto on/off feature. When you use a

programmed chair position (1 or 2), the dental light turns on when the

chair reaches operating position. Press Position 0 (entry/exit) or

Position 3 (x-ray/rinse) and the dental light automatically turns off.

NOTE If Position 3 has been changed to a

programmable position, it operates the same as Positions

1 and 2.

To activate/deactivate:

• Press and hold the program and light button simultaneously for

three seconds. One beep confirms the factory preset is off.

• Press and hold the program and light button simultaneously for

three seconds. Three beeps confirming the factory preset is on.

(A) Dental Light Composite Mode Blinking Indicator

85.0816.00 Rev B 2007-04 55

Page 67

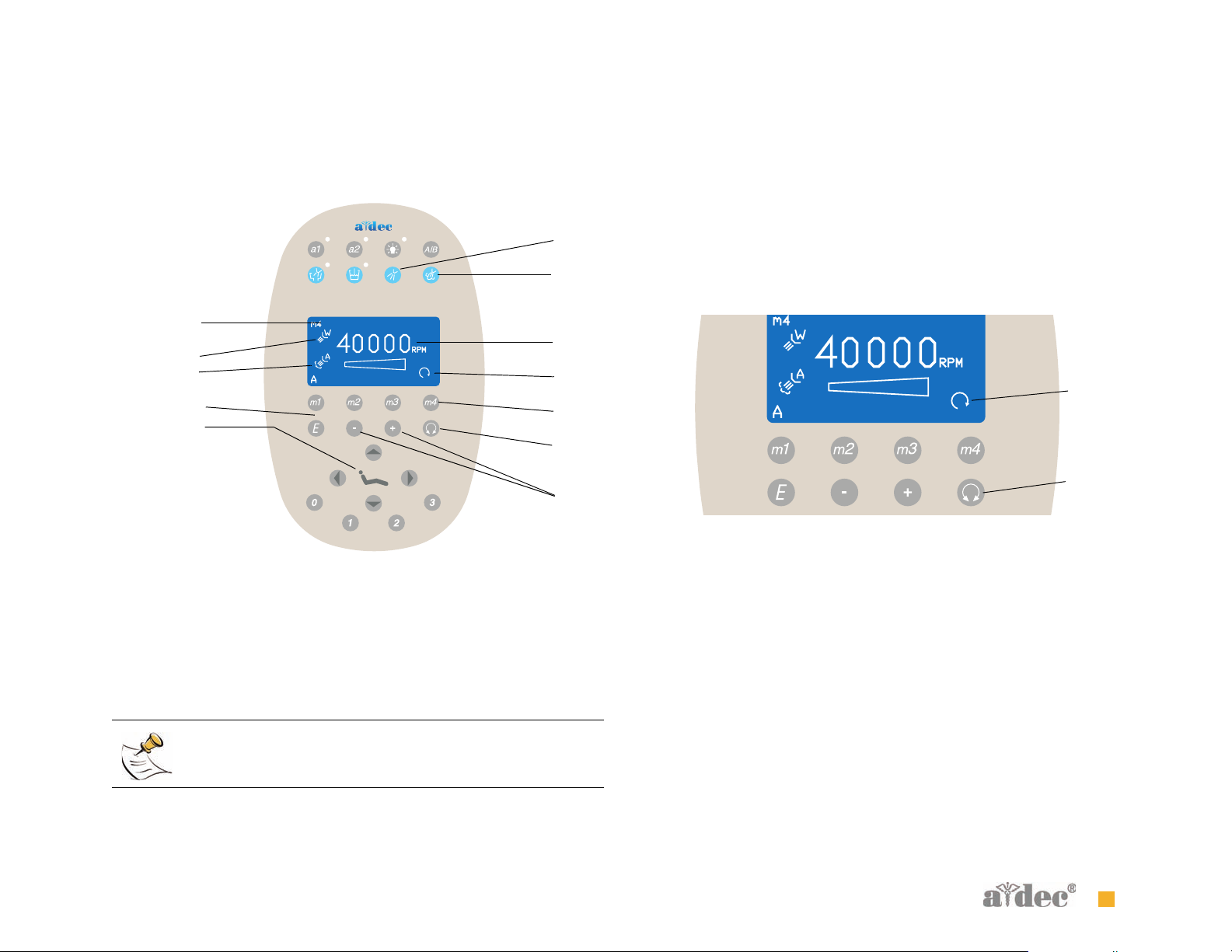

A-dec Service Guide, Vol. II Electric Handpiece Settings (Deluxe Touchpad Only) Standard Mode

E LECTRIC HANDPIECE SETTINGS (DELUXE TOUCHPAD ONLY)

Standard Mode

Activate the electric motor by withdrawing the handpiece from the

holder. The settings that appear are the ones last used for that

handpiece position.

The electric handpiece allows you to choose a precise pre-set speed or

to “feather” up to that speed. Figure 7 lists the factory presets for

electric handpieces:

Tab l e 7 Electric Motor, Air and Water Coolant Presets (Standard Mode)

Memory Button Preset Speed Air Coolant Water Coolant

M1 2,000 RPM On On

M2 10,000 RPM On On

M3 20,000 RPM On On

M4 40,000 RPM On On

Program the A-dec Touchpad in Standard Mode

The A-dec Deluxe touchpad allows you to program four memory

buttons with your specific RPM setting. The total range is 300-40,000

RPM. Each button can retain one setting per handpiece per operator

A/B, so that a total of 16 customized settings per handpiece is possible

(8 in standard mode plus 8 in endodontic mode). To specify a setting

for an operator, toggle the A/B operator button before changing a

setting. The display screen indicates the operator status (see Figure 31).

Figure 31 Operator Status

A

(A) A/B Operator Toggle Button

To change your handpiece setting:

1. Press the minus (-) and plus (+) buttons to adjust the RPM. The

RPM values appear in the display screen (see Figure 32).

2. If desired, use the toggle buttons on the touchpad to change air and

water settings.

3. To place the setting into memory (optional), press the Program

button, then press the memory button you want to set. Three beeps

confirm the setting.

56 85.0816.00 Rev B 2007-04

Page 68

A-dec Service Guide, Vol. II Electric Handpiece Settings (Deluxe Touchpad Only) Standard Mode

Figure 32 Program Handpiece Standard Mode Settings

B

C

A

K

L

F

H

(A) Memory Setting Indicator; (B) Water Coolant Button; (C) Air Coolant

Button; (D)) Speed Limit Setting; (E) Forward/Reverse Indicator;

(F) Memory Button; (G) Forward/Reverse Toggle Button; (H) Program Button;

(J) Use - and + Buttons to Adjust Speed; (K) Water Coolant Indicator;

(L) Air Coolant Indicator

D

E

F

G

J

Forward/Reverse Button

The forward/reverse toggle button changes the handpiece direction.

The system defaults to the forward position when you return the

handpiece to the holder or turn off the system (see Figure 33). In

reverse mode, the screen indicator flashes continuously.

Figure 33 Forward/Reverse Button

A

B

(A) Forward/Reverse Indicator; (B) Forward/Reverse Toggle Button

NOTE You can also use the foot control as a forward/

reverse toggle. When the motor has stopped, tap the

accessory (chip/air) button to change the direction.

85.0816.00 Rev B 2007-04 57

Page 69

A-dec Service Guide, Vol. II Electric Handpiece Settings (Deluxe Touchpad Only) Endodontics Mode

Endodontics Mode

In addition to handpiece speed adjustments, the endodontics mode

allows you to change a number of settings based on the specific file and

desired handpiece behavior. Icons in the touchpad window reflect the

settings (see Figure 34).

NOTE For more information regarding speed limit

and torque limit for a specific file, consult the

file manufacturer.

Figure 34 Endodontics Mode Touchpad Screen

A

B

C

L

D

N

E

F

G

H

J

K

M

O

Program the A-dec Touchpad in Endodontics Mode

To change a setting:

1. Withdraw the handpiece from the holder.

2. If the touchpad window is not in endodontics mode, press the

endodontics mode toggle button (see Figure 34). The endodontics

screen appears.

3. Use the + or - button to activate the endodontics change mode. A

white reverse video box appears.

4. Use the chair positioning buttons to move from setting to setting in

the touchpad window.

5. Use the + and - buttons to change the setting as desired.

6. To place the speed limit, torque limit and ratio into memory

(optional), press the Program button, then the memory button you

want to set. Three beeps confirm the setting.

P

(A) Memory Setting Indicator; (B) Water Coolant Indicator; (C) Air Coolant

Indicator; (D) Operator Status Indicator; (E) Memory Button; (F) Endodontics

Mode Toggle Button; (G) File Speed Setting; (H) Warning Beep Indicator;

(J) Handpiece Light Indicator; (K) File Torque Unit Indicator; (L) File Torque

Limit; (M) Forward/Reverse Indicator; (N) Handpiece Ratio Setting;

(O) Torque Mode Indicator; (P) Forward/Reverse Toggle Button

58 85.0816.00 Rev B 2007-04

Page 70

A-dec Service Guide, Vol. II Electric Handpiece Settings (Deluxe Touchpad Only) Endodontics Mode

Figure 8 lists and defines the touchpad window icons for Endodontics mode:

Tab l e 8 Endodontics Mode Settings

Icon Setting Description

Speed Setpoint for file speed limit. For more information,

consult your file manufacturer.