Page 1

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 17

A-dec Service Guide, Vol. II A-dec 511 Chair

The A-dec 511 chair is designed to provide a range of movements to position the

patient for dental treatment.The dental chair consists of a stable base, an ergonomically

synchronized seat and back support, adjustable head support, and collapsible arm

support.The chair movement is controlled through the use of a footswitch and/or

touchpad(s). Entry, treatment, and exit positioning of the chair is delivered through the

use of a hydraulic system and four programmable positions.The deluxe touchpad

option provides two operators with four more potentially programmable positions for a

total of eight.

This section provides information related to servicing, maintenance, and adjustments.

Detail on how to service the chair and troubleshoot specific problems is presented.

For information on service parts, see the Genuine A-dec Service Parts Catalog or contact

A-dec customer service.

Page 2

Page 18 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Features A-dec Service Guide, Vol. II

Chair Specifications

Chair Capacity:

Patient Load: 300 lb (135 kg) maximum

Accessory Load: 250 lb (113 kg) maximum

Specifications are subject to change without notice.

NOTE: Ensure the chair is bolted to the floor after installation.

Power On/Off Button

The power On/Off button is located on the base of the chair, and is the main disconnect that completely shuts down the dental unit. When the

button is pressed in, power is on. When the button is out, power is off.

Limp-Along Feature

If there is an electronic feature problem or malfunction, the limp-along feature allows the operator to move the chair in the up direction, for one

second intervals by pushing the manual control buttons on the touchpad or footswitch.This feature is enabled when there is a problem with the

automatic position sensing system and allows the operator to position the chair.

Page 3

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 19

A-dec Service Guide, Vol. II Chair Covers

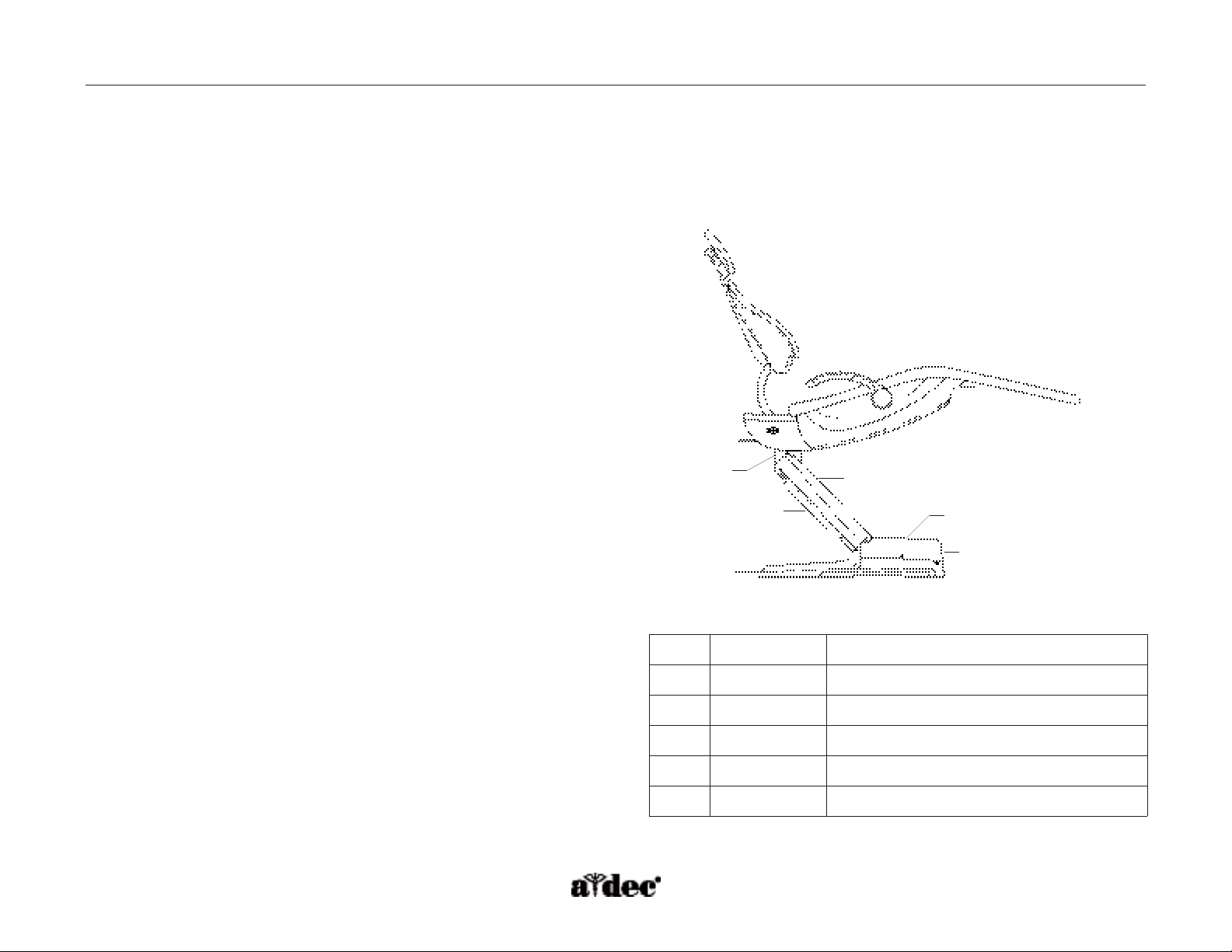

How to Remove/Install Chair Covers

The A-dec 511 chair motor pump, lift arm, and stop plate covers should be removed in the following order.

Motor Pump Cover

Remove -Remove screw from each side and lift up.

Install - Replace cover,and attach with two screws.

Lift Arm Cover

Remove -Pull one side of the cover until it releases from the lift arm.

Install - Align one side of the cover with the lift arm and snap into place.

Ensure both sides are firmly attached.

Stop Plate

Remove -Pull one side of the cover until it releases from the lift arm.

Install - Slide one side of the cover over the post on the lift arm and attach.

Swivel Cover

Remove -Pull one side of the cover and pull off.

Install - Align the cover with the holes on one side and snap cover into

place by applying pressure to the center of the cover.

Item #

Part Number

Description

1

62.0080.00

Motor pump cover

2

62.0081.00

Lift arm cover

3

62.0084.00

Stop plate cover

4

62.0122.00

Swivel cover

5

62.0101.00

Motor pump cover plug

4

3

2

5

1

Figure 13. A-dec 511 chair covers.

Page 4

Page 20 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Flow Diagram A-dec Service Guide, Vol. II

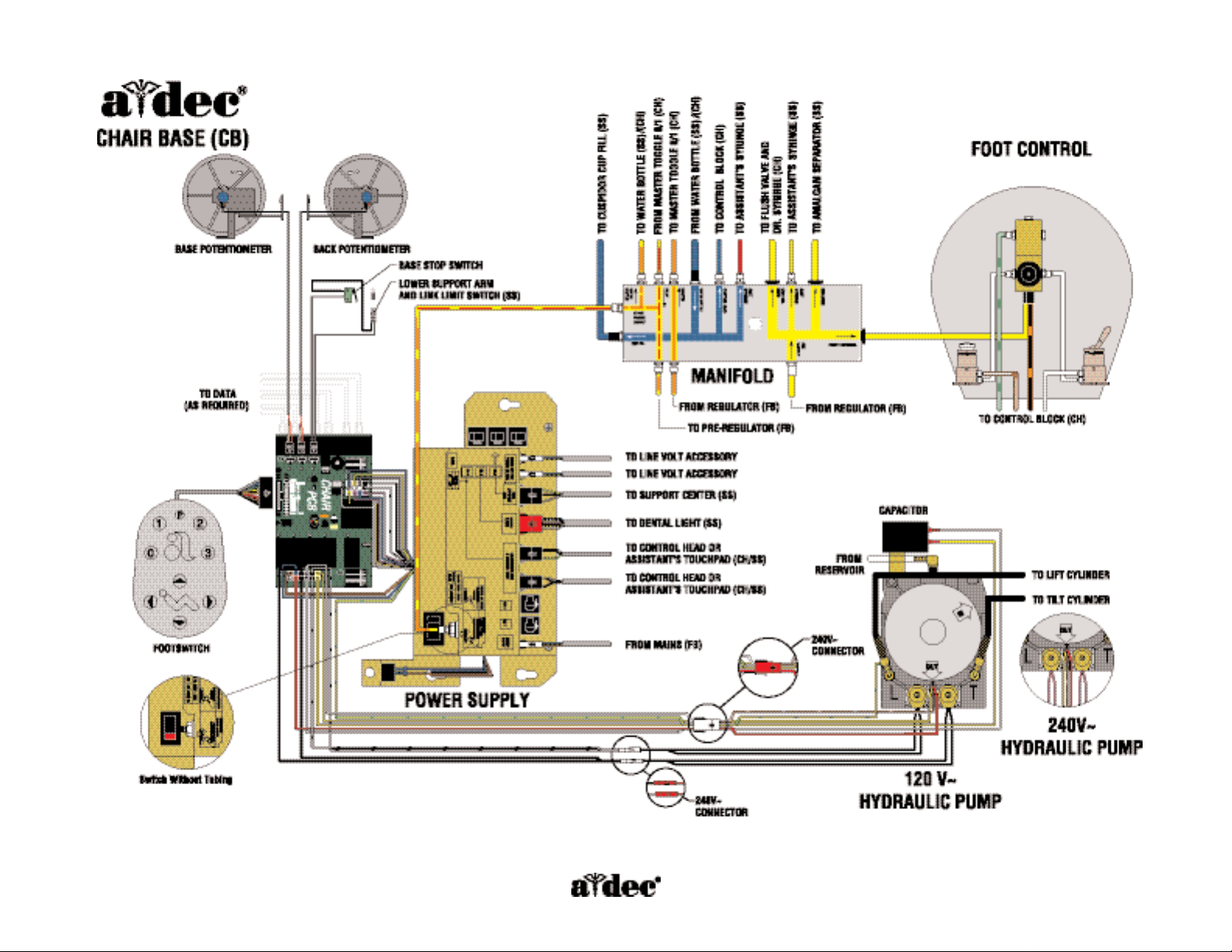

Chair Flow Diagram

This flow diagram details both electrical and plumbing information for servicing and troubleshooting the A-dec 511 chair. It is located on the

motor pump cover.This diagram includes the air electric switch,motor pump connections, and potentiometers.

Page 5

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 21

Air electric switch connects the

power supply to pilot air.

Chair Flow Diagram

Page 6

Page 22 85.0816.00 Rev A 2004-11 (PCA 04002.12)

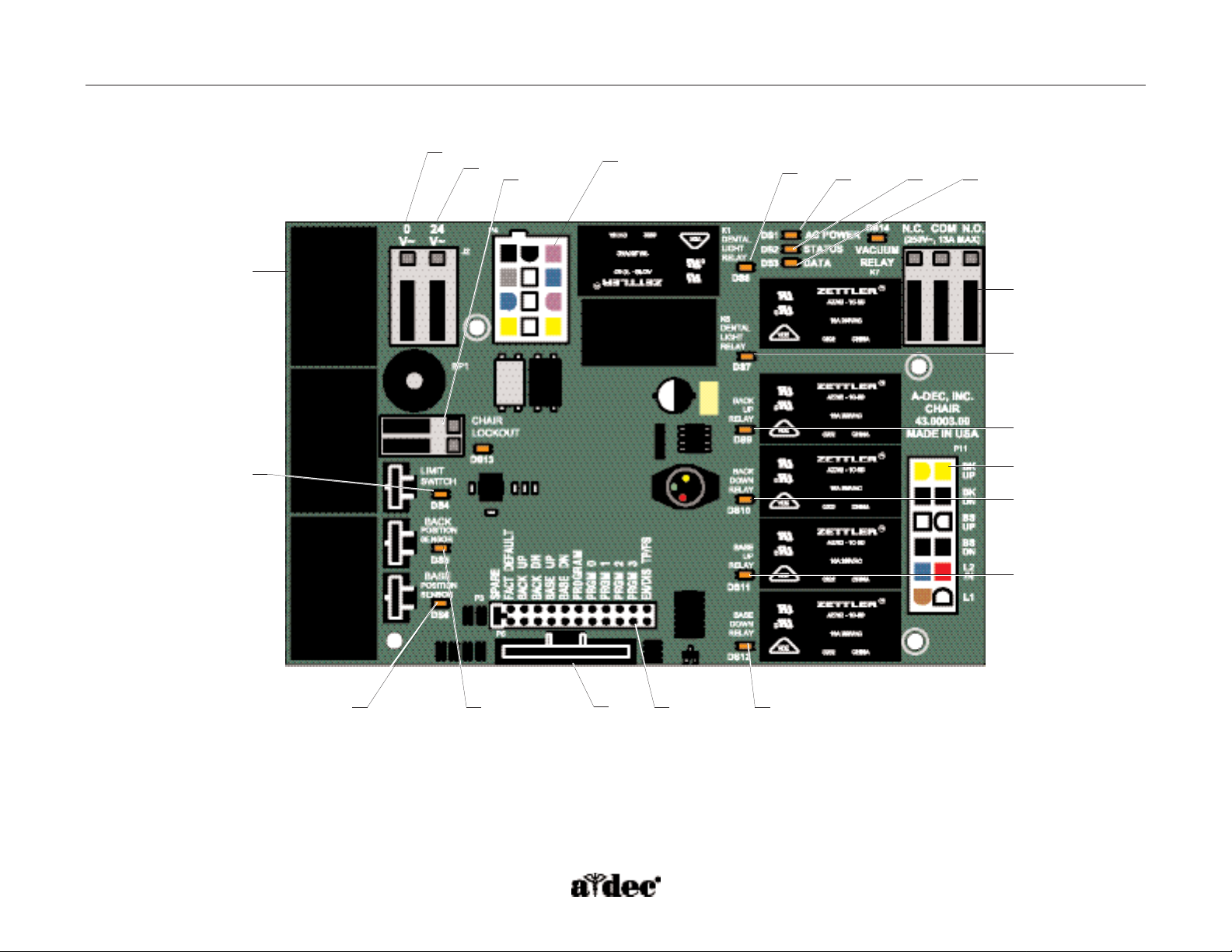

Chair Circuit Board A-dec Service Guide, Vol. II

How to Identify the Chair Circuit Board Components

(P/N 90.1072.00)

The chair circuit board contains the relays necessary for controlling the chair’s motor

pump and solenoids.The chair circuit board is equipped with test points that allow

manual chair operation without a footswitch or a touchpad.

The chair circuit board is located on the power supply.To access the circuit board,

remove the pump cover. Use the LEDs located on the circuit board to determine if the

chair is functioning correctly.

Item # Description

1

P7, P8, P9 - Data line ports

2

DS4 - Stop switch LED (limit switch) and

P10 connector

3

DS5 - Back potentiometer LED and P1 connector

4

DS6 - Base potentiometer LED and P2 connector

5

P5 - Footswitch connector

6

P3 - Test points

7

DS12 - Base down LED and relay

8

DS11 - Base up LED and relay

9

DS10 - Back down LED and relay

10

DS9 - Back up LED and relay

11

DS1 - AC power LED

12

DS2 - Status LED

13

DS3 - Data LED

14

DS13 - Chair lockout LED and terminal strip J1

15

J2 - Ø VAC terminal strip (output)

16

J2 - 24 VAC terminal strip (output)

17

P4 - Input power and dental light connector

18

J3 - Vacuum relay output terminal strip

19

P11 - Pump motor and solenoid connector

20

DS8 - Dental light relay

21

DS7 - Dental light relay

Page 7

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 23

A-dec Service Guide, Vol. II Chair Circuit Board

Figure 14. A-dec 511 chair circuit board components.

1

11

12

13

14

4

3

5

6

7

8

9

10

21

18

16

15

17

20

2

19

Page 8

Page 24 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Circuit Board A-dec Service Guide, Vol. II

Factory Default Routine

When a new circuit board is installed in the chair, the circuit board needs to run the factory default routine to learn the range of motion of the

chair.The routine sets the base and back upper limits, calculates new presets based on actual range of motion of the chair, and verifies that the

potentiometers work.

To start the factory default routine, place the “spare” jumper in the factory default position on the P3 test points of the chair circuit board.

When running the factory default routine the chair:

• Moves base down

• Moves base up

• Moves back down

• Moves back up

• Moves base and back to Position 0, and

• Beeps three times.

NOTE: The jumper must remain in the factory default position to complete the factory default routine.

The status LEDs on the standard and deluxe touchpads and the chair circuit board double blink

while the factory default routine is running and after the routine is complete.

Page 9

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 25

A-dec Service Guide, Vol. II Chair Circuit Board

LED Identification

LED Status Description

DS1 - AC power LED Off

Green, steady

No 24 VAC power, tripped circuit breaker, power supply turned off,

no line voltage

24 VAC at the terminal strip

DS2 - Status LED Off

Green, steady

System is not functioning, no power or circuit board has failed

Normal operation

DS3 - Data LED Off

Green, steady

Green, blinking

No DCS communication, not connected to the DCS, or DCS has failed

Detects active DCS

Valid DCS message

DS4 - Chair limit switch Off

Red

Closed, (normal)

Open, (activate)

DS13 - Chair lockout Off

Red

Open, (normal)

Closed, (activate)

DS5 + DS6 - Chair potentiometers Off Potentiometer:

• Not connected or bad connection

• Moving in wrong direction

• Limited range of motion, or

• Cable is not on wheel.

Yellow, steady Normal operation

Yellow, fast blink Upper end of travel

DS9, DS10, DS11, DS12 - Chair

relay LEDs

Off

On

Relay is off

Relay is on

DS7, DS8 - Dental light relay LEDs Off

On

Relay is off

Relay is on

DS14 - Vacuum relay LED Off

On

Relay is off

Relay is on

Page 10

Page 26 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Power Supply A-dec Service Guide, Vol. II

Chair Power Supply

The 300-watt power supply comes standard with the A-dec 511 chair. It is located in the motor pump area of the chair.The total available

auxiliary load is a maximum of 4 Amps.

Circuit Breaker Function

CB 1

Mains

CB 2

Mains

CB 3

Support side arm (side support arm)

CB 4

Dental light

CB 5

Assistant’s arm, control head (delivery

system), and chair circuit board

Figure 15. Chair power supply circuit breaker identification

CB 4

CB 3

CB 1

CB 2

CB 5

Page 11

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 27

A-dec Service Guide, Vol. II Hydraulic System

How the Hydraulic System Operates

The hydraulic system deactivates automatically at the upper and lower extremes of travel.The system is leak-free during transportation, storage,

and operation.The hydraulic system consists of:

• Hydraulic fluid reservoir

• Hydraulic cylinders

• Motor-driven hydraulic pump with solenoids

Hydraulic Fluid Reservoir

The hydraulic fluid reservoir is located in the lift arm of the chair under the stop plate cover.

The fluid level in the reservoir can be seen through the sides of the reservoir and is serviced

via a top fill cap.The hydraulic system holds 40 ounces (2.5 pints [1.18 l]) of hydraulic fluid.

• Place the chair in the full base and back up position, when filling the reservoir.

• The reservoir should be filled to the green Max line. Do not over fill. Cycle the chair

after the reservoir is filled.

Figure 16. Identifying the hydraulic fluid

reservoir fluid levels.

Page 12

Page 28 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Hydraulic System A-dec Service Guide, Vol. II

Hydraulic Cylinders

The hydraulic cylinders operate during the Base Up and Back Up functions. Springs and gravity retract the piston during base and

Back Down functions.

The chair seat travels vertically from a low point of 13.5" (343 mm) to a high point of 31.5" (800 mm) above the floor.

Motor-driven Hydraulic Pump

The hydraulic pump takes hydraulic fluid from the reservoir and pressurizes it to extend the chair lift and tilt hydraulic cylinders for back and

base up functions.The bi-directional pump rotates one direction for Base Up and one direction for Back Up.The solenoids mounted to the

pump assembly gate hydraulic fluid from the two cylinders. Depending on the chair function, the controller selects which solenoid-actuated

manifold valves are opened or closed.The 100-120 VAC pump and 220-240 VAC pump are equipped with an automatic reset 110°C (230°F)

thermostat.There are no serviceable parts on the hydraulic pump other than the solenoids.

NOTE: The speed of the chair is not adjustable.

Figure 17. Hydraulic cylinder operation.

Page 13

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 29

A-dec Service Guide, Vol. II Hydraulic System

Capacitor

100 VAC (P/N 041.642.00)

110 - 120 VAC (P/N 041.643.00)

220 - 240 VAC (P/N 041.644.00)

The capacitor is energized during chair Base Up or Back Up functions.

Figure 18. A-dec 511 chair capacitor located on the motor pump assembly. (A) capacitor

A

Page 14

Page 30 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Hydraulic System A-dec Service Guide, Vol. II

Solenoids

100 - 120 VAC (P/N 90.1070.00)

220 - 240 VAC (P/N 90.1071.00)

The two chair solenoids, one for each cylinder, control the down functions of the chair.The solenoid (A) controls the base down function and the

solenoid (B) controls the back down function.The base and back down solenoids are interchangeable, and available in two voltage ranges.

How to Test Solenoids

To check for a failed solenoid, test the solenoids using a volt/ohm meter or

magnetic pull test.

• Magnetic pull - Hold a paper clip loosely in your hand and activate the

solenoid by pressing Base Down or Back Down on the footswitch or

touchpad. If there is a pull, the solenoid is being activated.

• Coil resistance - Disconnect the solenoid power at the 2-position

connector. Place on Ohm meter probe on each of the solenoid

connector terminals.

100 - 120 VAC = 177 Ohms ± 18 Ohms

220 - 240 VAC = 845 Ohms ± 85 Ohms

NOTE: If the solenoid is hot, then the resistance will read higher.

ELECTRICAL WARNING: The solenoid coils are powered by line voltage

(100, 120, or 240 VAC). Failure to unplug the

chair may result in serious injury from

electrical shock.

WARNING: The base or back system must be depressurized prior to

removing the solenoid.To depressurize base or back system,

remove the failed solenoid coil and replace with the operating

solenoid coil. Lower the chair base and back.

NOTE: When replacing a solenoid, wipe up any oil, and replace existing

O-rings on the solenoid base.

Figure 19. A-dec 511 chair solenoids located in the motor pump

assembly. (A) base down solenoid; (B) back down solenoid

B

A

Page 15

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 31

A-dec Service Guide, Vol. II Potentiometers

How the Potentiometer Operates

The potentiometer and cable assembly is a simple, accurate unit, which eliminates position float.“Float”is seen as a slight change or variation in

the pre-programmed positions.The same potentiometer assembly is used for both lift and tilt requirements. If a potentiometer should fail, the

limp-along feature allows the operator to position the chair for one second intervals by pushing the manual control buttons on the

touchpad or footswitch.

Figure 20. Location of the chair Base Up and Back Up potentiometers. (A) Base Up potentiometer; (B) Back Up potentiometer

A

B

Page 16

Page 32 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Stop Plate A-dec Service Guide, Vol. II

How the Chair Stop Plate Operates

(P/N 90.1095.00)

The chair stop switch stops chair movement when the stop plate is pressed. Should anything inadvertently become lodged under the chair, press

Base Up on the touchpad or footswitch to raise the chair so the object can be removed. As long as pressure is applied to the stop plate, the chair

will not move down.

The stop plate has only one switch.The switch and all other parts snap into place for easy removal or replacement. No tools are required.

Be sure to power off the chair and disconnect it from its power source before replacing the stop

switch. Cable tie the wires to the lift arm to prevent kinking and pinching.

Chair Bump-Up Feature

The chair stop plate and the assistant’s arm, trigger the chair to move

upwards if it was moving down when the stop plate switch was activated.

Figure 21. A-dec 511 chair stop plate. (A) stop switch

A

Page 17

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 33

A-dec Service Guide, Vol. II Chair Adjustments

How to Adjust the Chair

Swivel Brake

The chair can rotate to any position within 30° either side of center.The chair

swivel brake restricts rotation of the chair to keep the chair from moving.To

engage the brake, push the brake lever firmly to the left.To release the swivel

brake, push the brake lever to the right.

Tension Adjustment

If the chair swivels left or right with the brake engaged, or if it is difficult to

move with the brake disengaged, adjust the swivel brake tension.To adjust the

tension, use a hex key and turn the tension adjustment screw clockwise to

increase brake friction or counterclockwise to decrease brake friction.

If proper adjustment cannot be obtained through rotation of the hex key,

replace the brass brake pad by removing the brake handle and using a hex key

to disengage the pad. Remove the old pad and replace with new one. Replace

the brake handle and handle retainer.

NOTE: The shipping pin can be reinstalled in the chair if swivel feature

is not desired.

Figure 22. Chair swivel.

Figure 23. Swivel brake tension adjustment. (A) tension

adjustment screw

Engaged Released

A

Page 18

Page 34 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Adjustments A-dec Service Guide, Vol. II

Headrest

The headrest adjustment lever allows the headrest to be adjusted using one hand.When the lever is released, the headrest holds its position.

Drift Adjustment

If the headrest drifts downward, or if it is difficult to move up or down, the glide bar tension needs to be adjusted. To adjust the tension, use a

hex key and turn the tension adjustment screw clockwise to increase friction or counterclockwise to decrease friction.

Figure 24. Headrest adjustments. (A) headrest adjustment lever;

(B) glide bar; (C) glide bar tension adjustment

B

A

C

Page 19

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 35

A-dec Service Guide, Vol. II Chair Troubleshooting

How to Troubleshoot the Chair

Tips and troubleshooting information are listed in the table to assist in diagnosing chair problems.

These tables are not intended to cover every situation, but do include the most common problems that

may be encountered.

Problem Possible Cause Action

No power to chair or unit, office still

has power

The chair is unplugged Plug chair in to power source.

The power button is in Off position Press in power button.

No pilot air to power supply Verify master On/Off toggle is in the On position. Verify pilot air is connected to

the power supply and air manual shutoff valve is fully open.

Power supply circuit breaker is tripped or power

supply has failed

Check circuit breaker and reset. If the circuit breaker trips again, disconnect all

power cables from the power supply then reconnect one at a time observing

which one causes the circuit breaker to trip – that will identify the problem circuit.

Circuit board has failed Check chair circuit board power LED.If not illuminated, check connections and

replace circuit board, if needed.

No base and back up function, the motor

relay clicks and LED illuminates

Capacitor is disconnected or has failed Verify the base up or back up relay clicks and the LED (DS10 or DS12) on the

chair circuit board is illuminated. Check capacitor connections. Replace the

capacitor with one of correct voltage.

No base or back down, relay clicks and

LED illuminates

Solenoid has failed • Check for magnetic pull while operating base or back down function.

• Check for correct resistance value at solenoid connector:

100 - 120 VAC 177 Ohms ± 18 Ohms

220 - 240 VAC 845 Ohms ± 85 Ohms

• Replace solenoid.

WARNING: Depressurize system before replacing the failed solenoid.To

operate chair to full Base Down and Back Down, switch the

good solenoid coil for the failed one and operate the function

until full down position is reached.

Back down is pressed, base moves or

base down is pressed, back moves

The base and back solenoid connectors

are switched

Connect the solenoids correctly.

Base or back moves up for only one

second, no automatic buttons work

(limp-along feature)

DS5 - (back) not illuminated

DS6 - (base) not illuminated

The potentiometer for that movement has failed,

is disconnected, or is not turning

Check sensor electrical connections, wiring and the pull cable. Replace as an

assembly if damaged.

Page 20

Page 36 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Troubleshooting A-dec Service Guide, Vol. II

Problem Possible Cause Action

Base Down and programmed positions

do not work, but the chair back functions,

A-dec status icon is flashing, DS4 red

LED on the chair circuit board

is illuminated

Stop switch for chair, or support side arm is

activated or has failed

Check for obstruction under chair, or support side arm and remove.

• Disconnect the chair stop switch connector at the chair circuit board

and insert the jumper. If the red LED (DS4) goes out and the chair

works, then the chair circuit board is functioning normally.

• Remove the spare jumper from the chair circuit board, and reconnect

the chair stop switch connector. Disconnect the support side stop

switch wiring from the chair stop switch connector and insert the

jumper. If the red LED (DS4) goes out and the chair works, replace the

side support stop switch. If the red LED (DS4) stays on, then replace

and/or repair the chair stop switch assembly.

No chair movement from a touchpad,

status icon is illuminated

Touchpad DCS is interrupted Verify the chair operates with the footswitch or the test points on the chair

circuit board.Then check the data line connection, and if needed, replace the

data line connected to the touchpad.Verify the data light illuminates.

No chair movement from the touchpad,

status icon is not illuminated

Faulty touchpad Verify AC power to chair and that chair can be operated from the footswitch or

other touchpad.Verify 24 VAC to touchpad circuit board. If 24 VACs present,

replace the touchpad.

Faulty touchpad power cable Verify the AC power LED (DS1) is illuminated on the delivery system circuit

board or chair circuit board.Verify the touchpad functions normally by using an

external touchpad power cable. Replace the touchpad power cable, if needed.

Base or back will not move to full up

position, LED for that function is flashing

Potentiometer connections are switched Connect potentiometers to correct chair circuit board locations.

P1 — Back potentiometer

P2 — Base potentiometer

Unable to change chair

programmed positions

Potentiometer connections are switched Connect potentiometers to correct board locations.

P1 — Back potentiometer

P2 — Base potentiometer

The potentiometer for that movement has failed,

is disconnected, or is not turning

Check sensor electrical connections, wiring, and the pull cable. Replace as an

assembly if damaged.

Page 21

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 37

ELECTRICAL WARNING: The solenoid coils are powered by line voltage (100,100 - 120, or 220 - 240 VAC). Failure to unplug the chair may

result in serious injury from electrical shock.

WARNING: The hydraulic system must be depressurized before removing the solenoid.To depressurize the hydraulic system, remove the

failed solenoid coil and replace with the operating solenoid coil. Lower the chair base and back.

NOTE: When replacing a solenoid, wipe up any oil, and replace existing O-rings on the solenoid base.

Problem Possible Cause Action

The three tap feature used at installation

no longer works

The three tap feature is disabled The three tap feature is disabled when a powered touchpad has been connect-

ed to the DCS, a footswitch is installed or the test points have been used to

move the chair.

To re-enable the three tap feature:

• Disconnect the DCS touchpad connections

• Disconnect the footswitch

• Cycle power to the chair

No or limited chair functions

from footswitch

Footswitch connector/wiring is damaged Check that chair operates from a touchpad or the test points (P3). Replace the

footswitch connector and/or wiring assembly.

Footswitch membrane is damaged Check footswitch connectors and membrane, replace as necessary.

The chair makes a noise when Base Up

or Back Up is pressed

Chair is low on hydraulic fluid Remove motor pump,lift arm, and stop plate covers. Check fluid level with

chair base and back up by viewing the reservoir from the back of the chair.Add

fluid to maximum level.

Hydraulic hose from reservoir to pump

is pinched

Inspect all hydraulic hoses, ensure they are not being pinched in any position. If

the supply tube between the pump and the reservoir is kinked, order and install

kit P/N 90.1100.00.

Motor pump has as obstruction or is damaged If chair continues to growl, lower base and add up to 4 oz (.12 l) more fluid. If

noise continues, replace motor assembly.

A button on a touchpad does not work,

but function works from other location(s)

Faulty touchpad Verify the touchpad circuit board is snapped into the plastic cover.

Verify the function does work from other locations (footswitch, chair test points,

light switches, cuspidor buttons), then replace the touchpad.

The automatic positions do not work, the

A-dec logo is flashing, double blinks

The jumper is in the factory default position on

the chair circuit board test points (P3)

Move the jumper from the factory default position to the “spare”position on the

test points.

The chair will not move up from the full

base down with the foot control under

the stop plate

The automatic chair lockout feature has been

activated by an air signal from the

foot control

Remove the motor pump cover and disconnect the delivery system data line.

Turn the chair power OFF and then ON again. The chair circuit board test

points or footswitch can now be used to raise the chair and remove the foot

control from under the lift arm.

A-dec Service Guide, Vol. II Chair Troubleshooting

Page 22

Page 38 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Chair Troubleshooting A-dec Service Guide, Vol. II

Problem Possible Cause Action

Chair brake does not hold Brake needs adjusting or the pad needs replacing Adjust or replace brake components as necessary.

Chair glide bar slides down or is difficult

to lift up

Glide bar needs adjusting or the wear pads

needs replacing

Adjust or replace glide bar components as necessary.

Headrest will not lock or is difficult

to unlock

Headrest needs adjustment or needs replacing Operating lever may be too tight, adjust for slight play in movement.

If the headrest still does not work correctly, replace it as an assembly. No field

service to locking components.

Armrest(s) will not lock in up position or

are difficult to operate

Armrests may have an obstruction or

be damaged

Check for obstruction or damage. Replace as an assembly.

Circuit breaker 1 or 2 opens Electrical short in a module Remove all connections from the power supply.

Reset the circuit breaker.

Reconnect modules one at a time until the circuit breaker trips.

Review troubleshooting for that module.

Circuit breaker will not reset Faulty circuit breaker Replace the power supply.

Loading...

Loading...