Page 1

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 39

A-dec Service Guide, Vol. II Doctor’s Side

The doctor’s side of the A-dec 500 system includes both the Traditional (model 532)

and Continental

®

(model 533) delivery systems, the front-mount monitor (model 531),

and self-contained water system.

The delivery system supplies and regulates the air and water used to operate dental

handpieces, syringes, and accessories. The A-dec 532 and 533 delivery systems have

been designed to mount only to the A-dec 511 chair and communicate with the entire

A-dec 500 product line through the Data Communications System (DCS).

This section of the A-dec Service Guide,Vol.II contains the electrical and plumbing flow

diagrams for the delivery systems, along with illustrations of exploded parts,

troubleshooting and adjustments for all of the doctor’s side modules.

For information on service parts, see the Genuine A-dec Service Parts Catalog, or contact

A-dec customer service.

Page 2

Page 40 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Components A-dec Service Guide, Vol. II

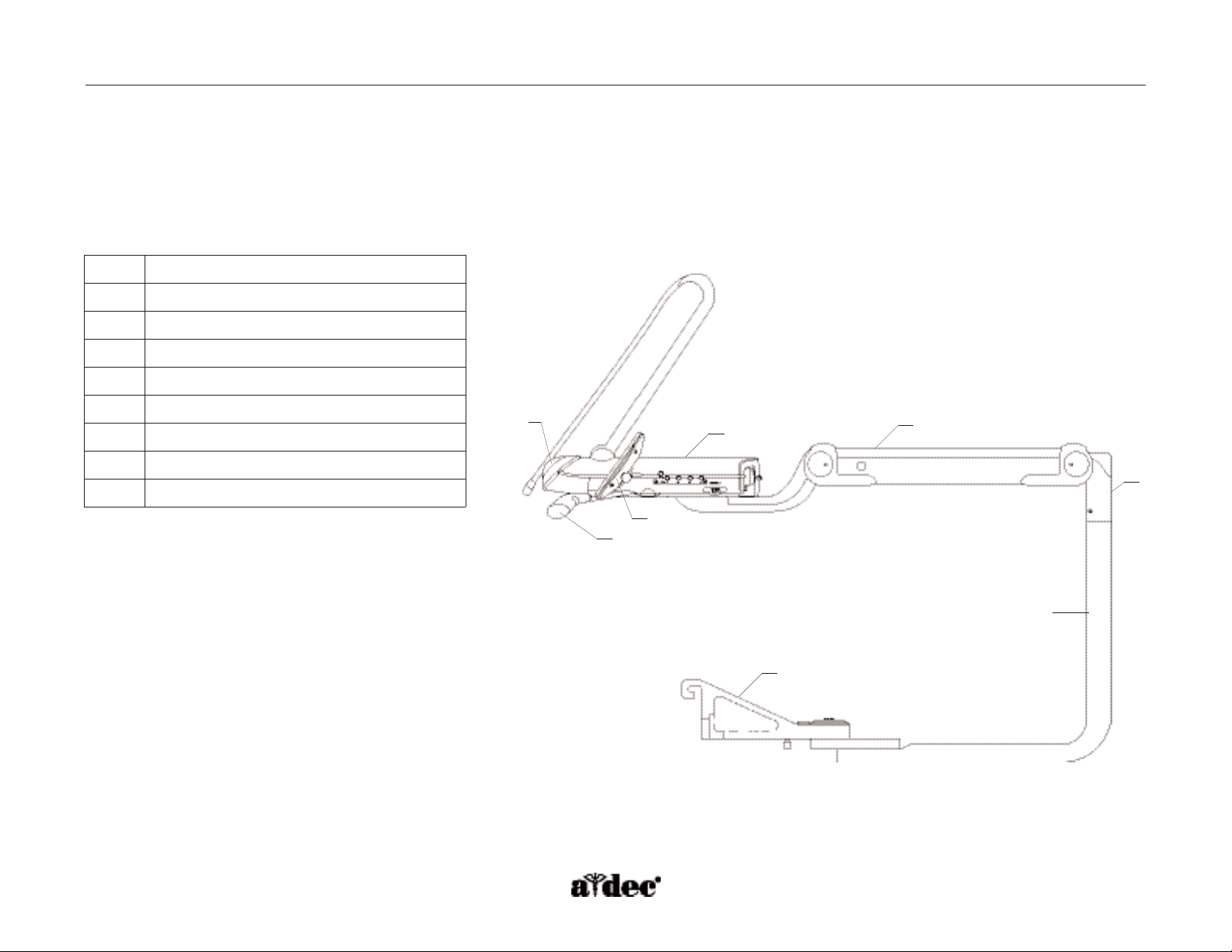

A-dec 500 Delivery System Components

The A-dec 500 delivery systems and front-mount monitor both mount to the A-dec 511 chair.This mounting structure provides left/right

capabilities for both the delivery system and the monitor.

Item # Description

1

Delivery system cover

2

Delivery system front cover

3

Touchpad

4

Brake handle

5

Flexarm

6

Front-mount arm

7

Flexarm hub

8

Front-mount casting

Figure 25. Delivery system and front-mount arm components.

1

6

3

2

7

5

4

8

Page 3

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 41

A-dec Service Guide, Vol. II Delivery System Components

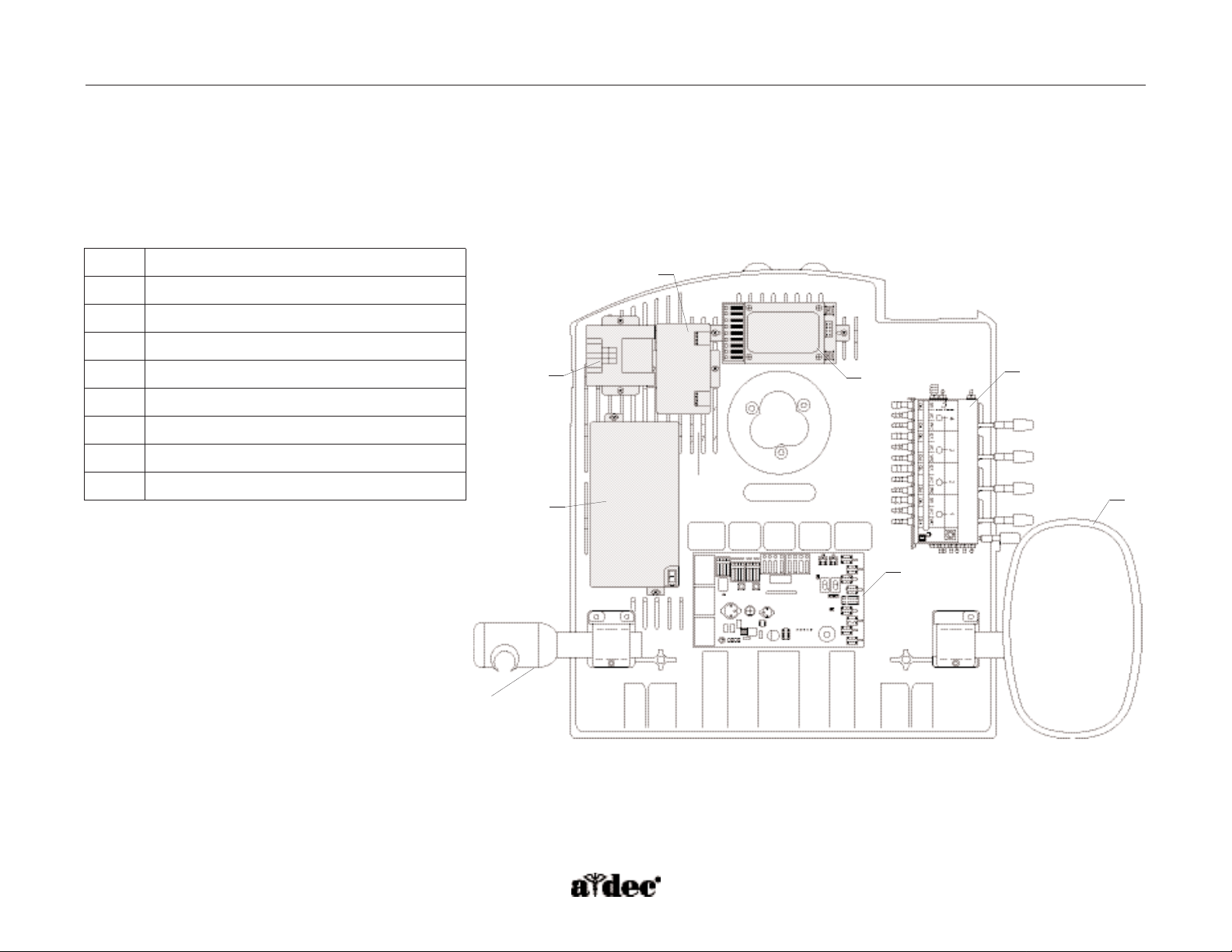

Internal Control Components

The A-dec 532 and 533 delivery systems feature a structural platform in the base of the control head.This metal mounting grid allows easy

attachment of component parts and extra control modules required by accessories.

Figure 26. Identification of the internal control components mounted on the structural platform.

Item # Description

1

Scaler control module

2

Electric micromotor control module

3

Curing light control module

4

Camera control module

5

Control block

6

Delivery system circuit board

7

Touchpad

8

Accessory holder

7

6

5

4

3

1

2

8

Page 4

Page 42 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Page 5

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 43

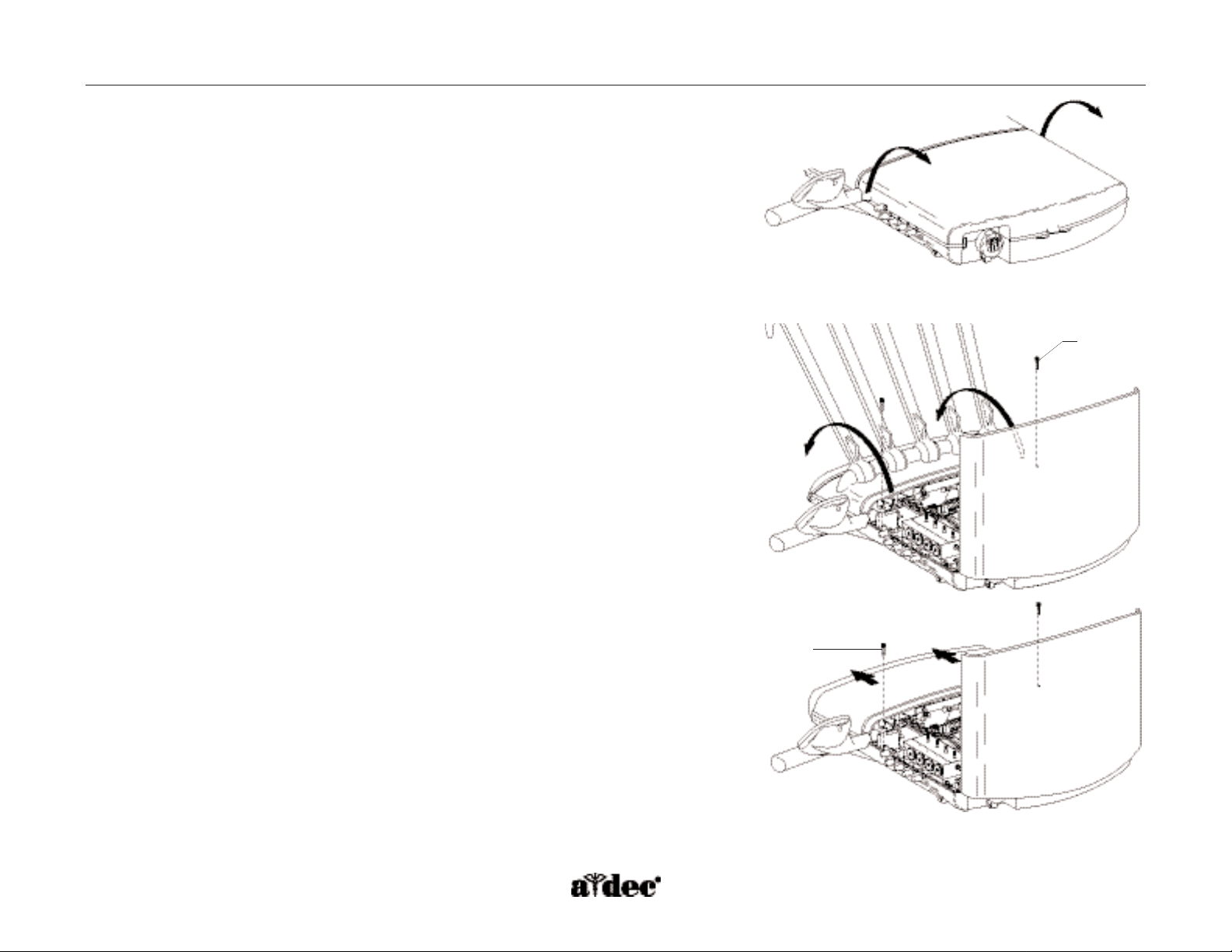

A-dec Service Guide, Vol. II Delivery System Covers

How to Remove the Delivery System Covers

The delivery system covers are designed for easy access to control components.

Delivery System Cover

Lift up on the center tab on the back of the delivery system cover and then, lift up the tabs

on both sides of the delivery system cover and open the cover. Pinch the hinge brackets at

the cover base to remove the cover.

Delivery System Front Cover — Continental

Move the whips forward, and remove the two screws holding the delivery system front cover

in place. Open the front cover carefully, until the lanyard is taut.

CAUTION: Remove handpieces from the delivery system before opening the delivery

system front cover.

Delivery System Front Cover — Traditional

Remove the two screws holding the delivery system front cover in place. Slide the front

cover forward and lift up.

Figure 27. Open the delivery system cover.

A

A

Figure 28. Open the delivery system front covers.

(A) screw

Page 6

Page 44 85.0816.00 Rev A 2004-11 (PCA 04002.12)

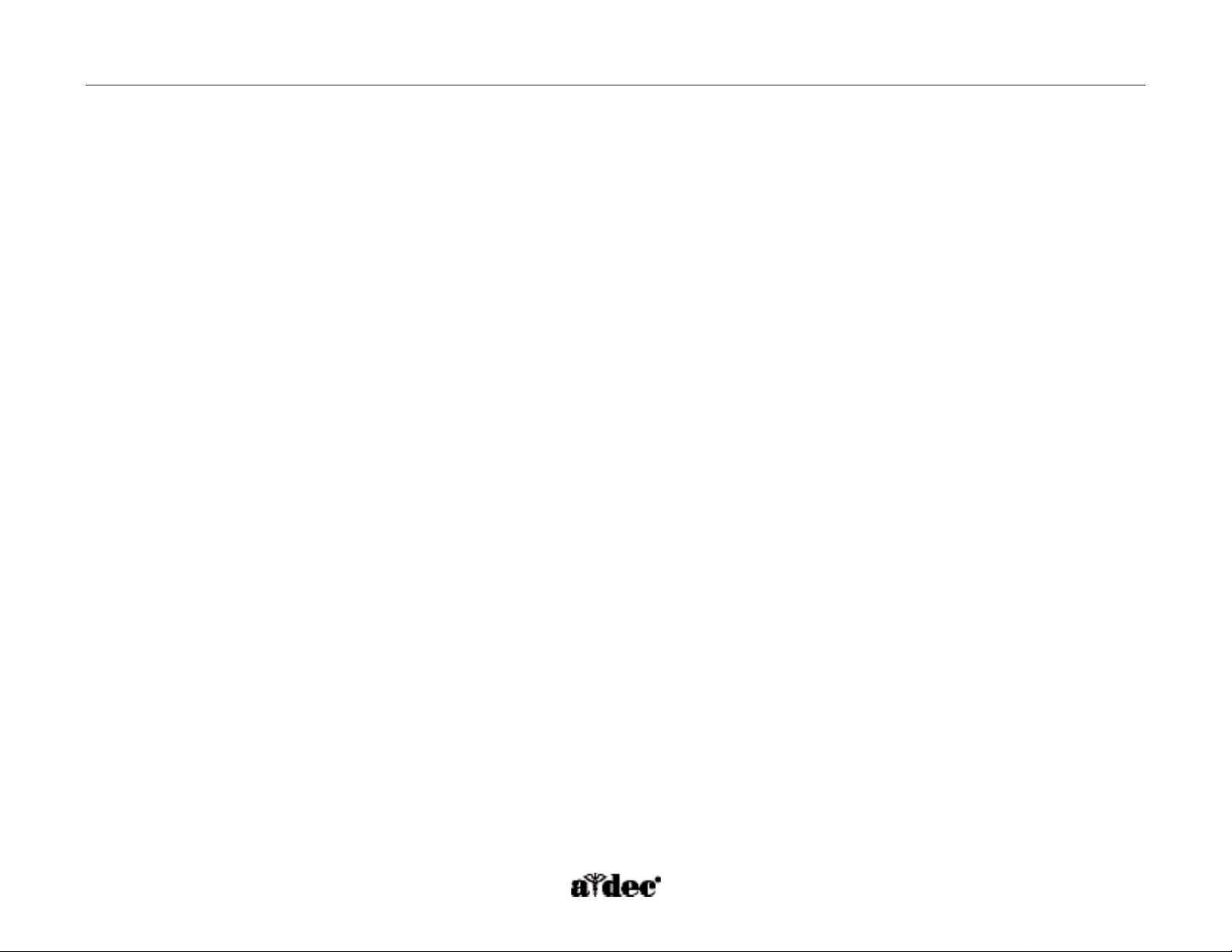

Flow Diagram A-dec Service Guide, Vol. II

Delivery System Flow Diagram

This flow diagram details both electrical and plumbing information for servicing and troubleshooting A-dec 532 and 533 delivery systems. It is

located on the inside cover of the delivery system.This diagram includes the plumbing and wiring for the standard touchpad, deluxe touchpad,

camera, and electric micromotor.

Page 7

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 45

Page 8

Page 46 85.0816.00 Rev A 2004-11 (PCA 04002.12)

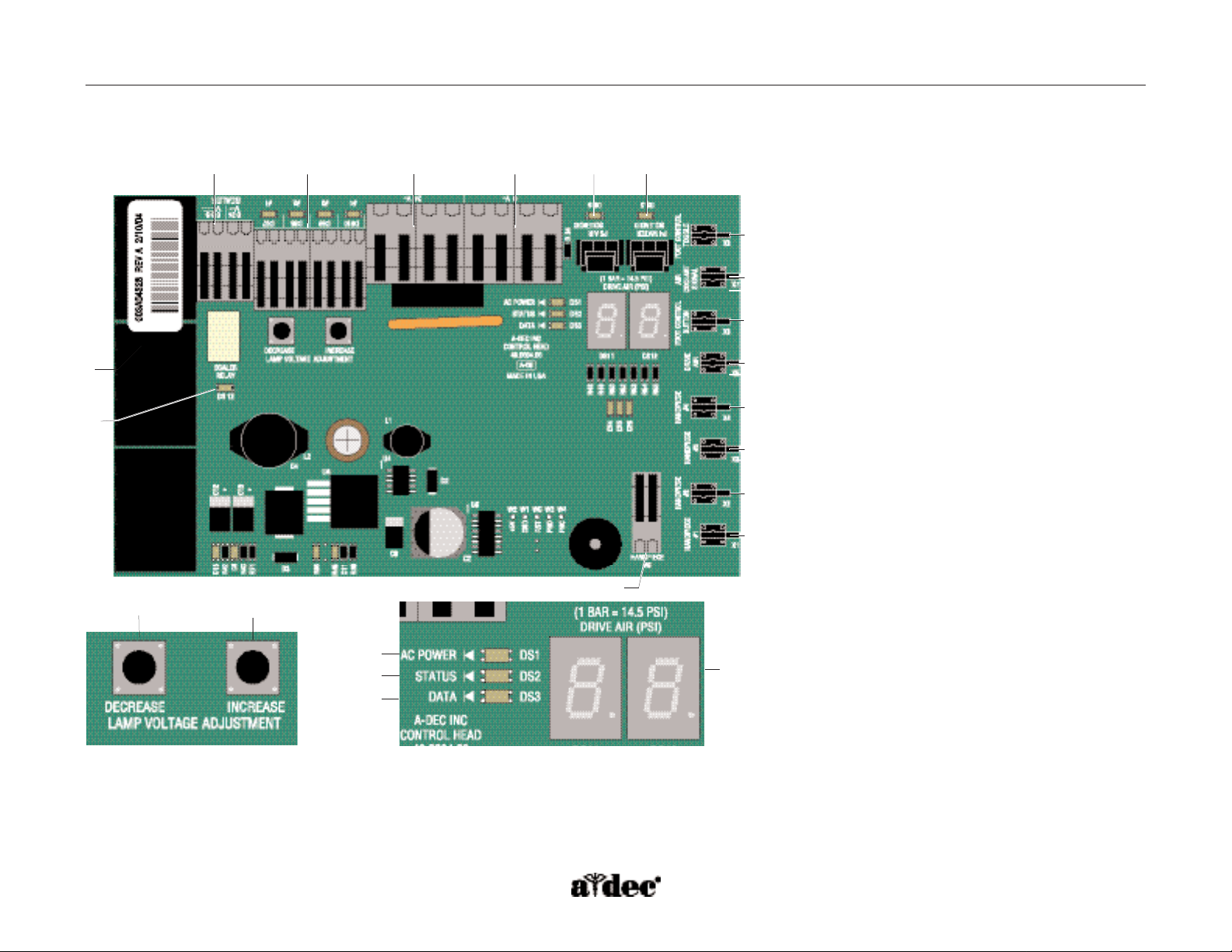

How to Identify Delivery System Circuit Board Components

(P/N 90.1076.00)

The delivery system circuit board has a wide range of functionality with a built-in

intraoral light source, drive air pressure digital readout, and status LEDs.Transducers

translate air signals to electronic signals, communicating with the touchpad and other

components when a handpiece is ready for use.

Item # Description

1

P1, P2, P3 - Data line ports (DCS)

2

J6 - Scaler power terminal strip

3

J4, J5 - Intraoral light source strip and LEDs DS7,

DS8, DS9, DS10

4

J2 - 24 VAC terminal strip

5

J2 - Ø VAC terminal strip

6

DS6 - Air coolant solenoid LED and connector

7

DS5 - Water coolant solenoid LED and connector

8

X8 - Water coolant signal transducer

(foot control toggle)

9

X7 - Air coolant signal transducer

10

X6 - Accessory button (foot control)

signal transducer

11

X5 - Drive air signal transducer

12

X4 - Handpiece 4, holdback transducer

13

X3 - Handpiece 3, holdback transducer

14

X2 - Handpiece 2, holdback transducer

15

X1 - Handpiece 1, holdback transducer

16

J3 - Handpiece 5, terminal strip

17

DS11, DS12 - Drive air LED display

18

DS1 - AC Power LED

19

DS2 - Status LED

20

DS3 - Data LED

21

S2 - Increase intraoral light source voltage adjustment

22

S1 - Decrease intraoral light source voltage adjustment

23

DS13 - Scaler relay LED

Delivery System Circuit Board A-dec Service Guide, Vol. II

Page 9

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 47

Figure 29. Components of the delivery system circuit board.

1

17

18

19

20

22

21

A-dec Service Guide, Vol. II Delivery System Circuit Board

23

2

3 4 5 6

7

8

9

10

11

12

13

14

15

16

Page 10

Page 48 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Page 11

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 49

A-dec Service Guide, Vol. II Illustrated Parts

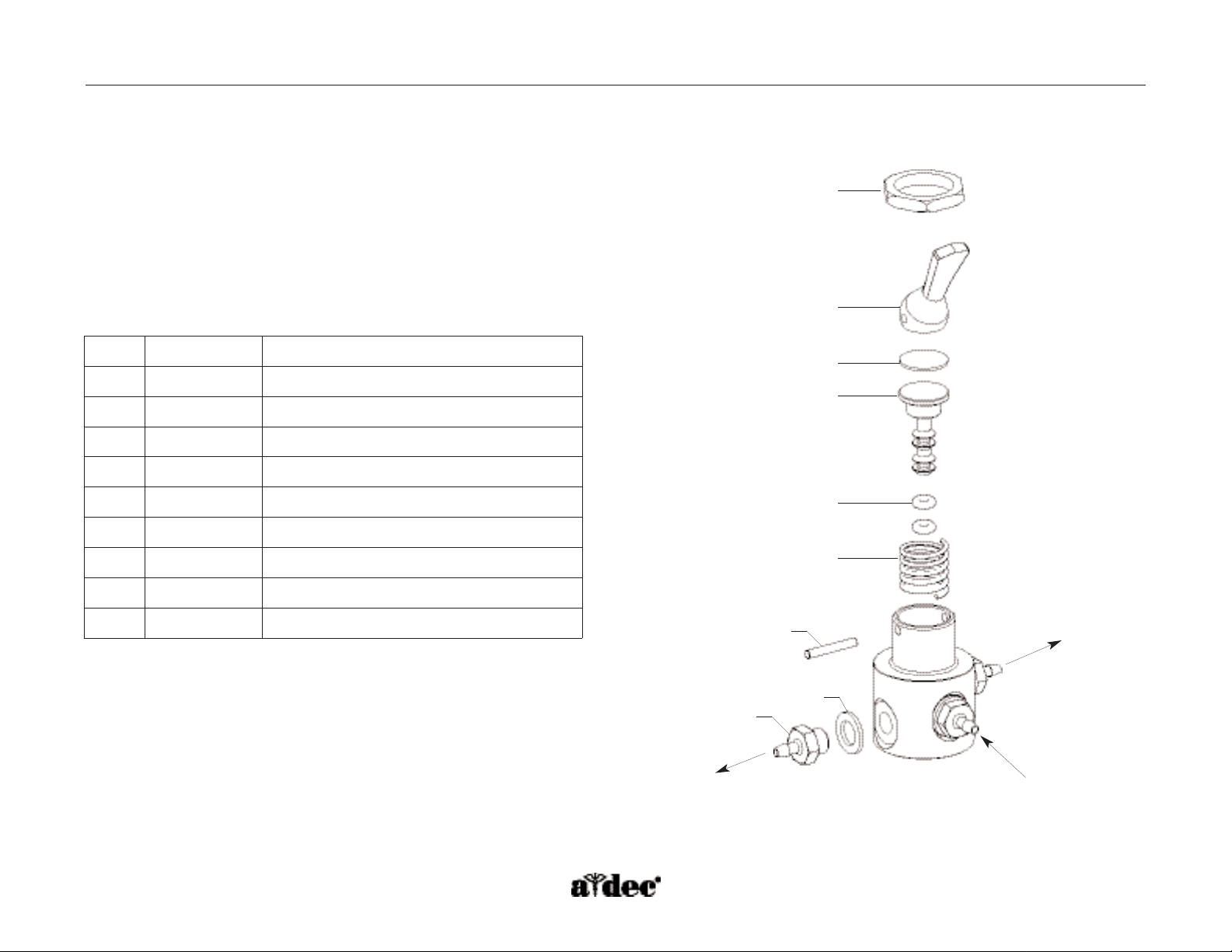

Handpiece Flush Toggle

(P/N 33.0168.00)

The flush toggle is located on the back of the delivery system. It uses holdback air to

operate the handpiece flush function. When the momentary valve is on, the

holdback air is exhausted and air signal is sent toward the water cartridge.

If the handpiece is in the holder (holdback active), the flush will not be activated.

If the handpiece is out of the holder (holdback exhausted), the flush will operate.

Item #

Part Number

Description

1

006.009.00

Hex nut 15/32-32" x 9/16 x 3/32"

2

33.0036.02

Momentary toggle lever

3

030.003.02

O-ring, .056 ID x .060 W, pkg 10

4

013.076.00

Spring, compression, .360 OD x .35 FL

5

011.038.01

Straight pin, .062 Dia x .430 Lg, SS, pkg 5

6

023.004.03

Barb, 1/8" x 10-32, pkg 10

7

004.005.02

Flat nylon washer, .187 ID,pkg 10

8

33.01470.00* Stem

9

80.5025.00* Spacer

1

2

9

8

3

4

5

6

7

Figure 30. Identification of the handpiece flush

toggle components.

* Item not for sale.

Page 12

Page 50 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

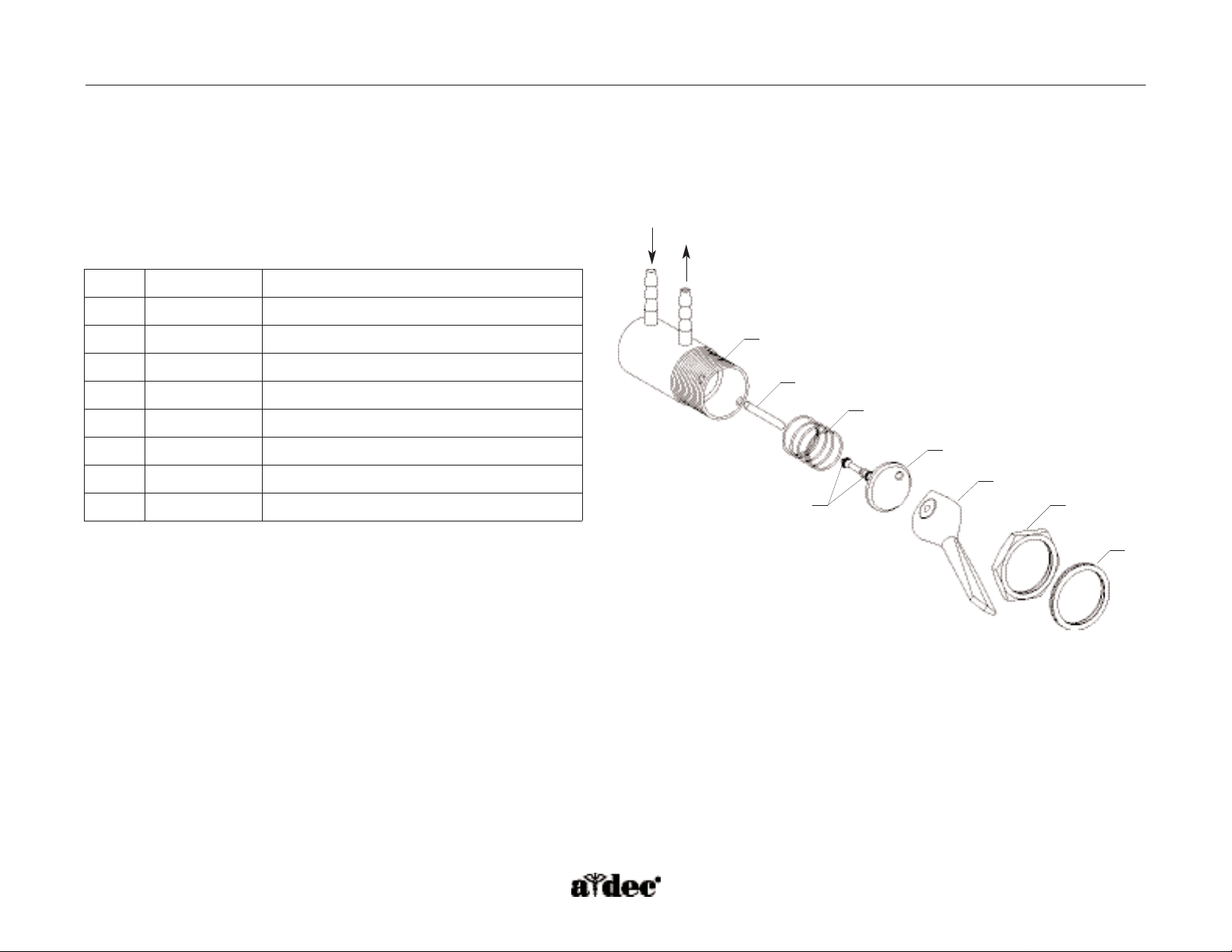

Master On/Off Toggle

(P/N 33.0048.04)

The master On/Off toggle is located on the side of the delivery system.The toggle operates with unregulated air and supplies air to the chair

air/water manifold and the control block, for holdback air.

Item #

Part Number

Description

1

33.0050.00

Round toggle valve body

2

011.038.01

Straight pin, .062 Dia x .430, pkg 5

3

22.0040.00

Compression spring, .300 OD x .40

4

030.001.02

O-ring, pkg 10

5

29.0840.00

Valve stem with O-rings, 3-way

6

22.0462.02

Plastic toggle valve lever,Surf 4

7

006.009.00

Hex nut, 15/32-32" x 9/16 x 3/32"

8

006.069.00

Knurl nut, 15/32-32"

1

2

3

4

5

6

7

8

Figure 31. Identification of the master On/Off toggle components.

Page 13

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 51

A-dec Service Guide, Vol. II Illustrated Parts

Whip Assembly

(P/N 77.0291.01)

The whip return tension can be adjusted by placing the bail in two

different locations.

The whip cover is removable for easy handpiece tubing replacement.To reinstall

the whip cover,fully extend the whip and attach the back starting at the ball end

and work toward the handpiece end.

Item #

Part Number

Description

1

013.123.00

Spring, extension, .460 OD x 2.473

2

77.0155.00 Bail

3

001.033.00

Socket head screw 6-32" x 3/8" stainless steel

4

77.0063.00

Whip cover,Surf 4

Figure 32. Whip assembly with the adjustable bail position for

(A) greater tension or (B) lesser tension.

1

2

3

4

A

B

Page 14

Page 52 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

Item #

Part Number

Description

1

23.0872.01

Syringe tip, pkg 5

2

035.048.01

O-ring, pkg 10

3

034.003.01 O-ring, pkg 10

4

23.1112.00

Retainer nut

5

23.1193.01

Screw, pkg 5

6

013.064.01

Spring, pkg 10

7

23.1232.01

Button valve, pkg 2

8

030.002.02

O-ring, pkg 10

9

23.1110.00

Terminal

10

23.1015.00 Handle

11

024.155.02 Tubing assembly, D-Surf, 7'

Autoclavable Syringe

The Continental and Traditional autoclavable syringes have serviceable air and water

button valves.The tip retaining nuts have replaceable O-rings.

WARNING: Turn OFF and bleed the system of air and water before servicing the

syringe.The use of disposable syringe tips in A-dec syringe

tip nuts is not recommended.

1

4

2

3

5

6

7

8

9

10

11

Continental

Traditional

Figure 33. Identification of the autoclavable syringe components.

Page 15

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 53

A-dec Service Guide, Vol. II Illustrated Parts

Brake Handle

The brake handle activates a replaceable microvalve, releasing pressure on the brake inside the flexarm.

Item # Part Number Description

1

77.0163.00 Brake button, Surf 6

2

013.121.00 Spring, torsion, stainless steel, .210 L, .030 W Dia

3

013.120.00 Spring, compression, .240 OD x .560

1

2

3

Figure 34. Identifying the brake handle components.

Page 16

Page 54 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

Accessory Holder

(P/N 99.0681.00 Standard or P/N 99.0684.00 Auto-electric)

The accessory holder is either an active or non-active position on the delivery system. It can be mounted on either side of the delivery system,

opposite the touchpad.

Auto-electric holders have a power source at the terminal for handpiece position 5 on the delivery system circuit board.

Item #

Part Number

Description

1

99.0683.00

Auxiliary holder hub, Surf 4

2

99.0686.00

Rotation stopper

3

007.023.00

Setscrew, 1/4-20 x 3/4, soc cup pt

4

99.0653.01

Syringe/saliva ejector holder,Surf 4

5

99.0648.00*

End cap for holder assembly

1

2

3

4

5

Figure 35. Identifying accessory holder components.

* Item not for sale.

Page 17

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 55

A-dec 500 Foot Control

The A-dec 500 foot control is a

foot-operated regulator. Handpieces

are operated by applying pressure on

the foot control. As pressure is applied

to the foot control, the black piston

exhaust vent seals against the poppet,

then pushes the poppet away from

the inlet seat. When the poppet is

unseated, regulated air flows through

the valve and out to the delivery

system as drive air. Regulated air is

also sent through the relay block and

to the delivery system as air coolant

signal. When pressure is released from

the foot control, the poppet reseals on

the inlet and pressure is exhausted

from the outlet side of the valve and

up through the piston.

To cuspidor cup fill

To water bottle

From master On/Off toggle

To master On/Off toggle

From water bottle

To control block

To assistant’s syringe

To flush valve and doctor’s syringe

To assistant’s syringe

To amalgam separator

Foot control P/N 38.1805.00

To delivery system

Accessory button

P/N 38.0612.00

Water coolant toggle

P/N 38.0604.00

Foot control valve

service kit

P/N 90.0593.00

Chair air/water manifold

From air filter regulator (80 psi)

From air filter regulator

(unregulated air)

A-dec Service Guide, Vol. II Flow Diagram

To air pre-regulator

To 300-watt

power supply

A/E switch

Page 18

Page 56 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

Item #

Part Number

Description

1

22.0110.00

Cover

2

38.0076.00

Foam liner

3

38.0237.00

Black retaining ring,, 5" OD

4

38.1802.00

2-Hole housing, Surf 6, 5/16"

5

40.0689.00

Yellow plastic indicator

6

40.0691.00

Blue plastic indicator

7

38.0610.00

Accessory button, Surf 6

8

38.0604.00

Wet/dry toggle valve, Surf 6

9

003.031.00

Phillips head screw, #4 x 1/2", zinc

10

003.022.00 Phillips head screw, #6 x 1/2", zinc

11

003.078.00 Socket head screw, 4-40 1/4" zinc

12

38.0059.02 Base, Surf 6

1

2

3

5

6

4

7

8

9

10

11

12

Foot Control

(P/N 38.1805.00)

Figure 36. Identifying the foot control components.

Page 19

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 57

A-dec Service Guide, Vol. II Illustrated Parts

Item #

Part Number

Description

1

38.0070.00

Actuator button

2

38.0075.03

Toggle lever, Surf 6

3

38.0066.00

Cap

4

22.0040.00

Spring, helical compression

5

010.056.00

Retainer spring

6

011.016.00

Pin

7

38.0072.03

Holder, Surf 6

8

007.002.00

Setscrew, cup point, 6-32 x 3/16

9

33.0134.00

Two-way micro valve

10

33.0138.00 Three-way micro valve

2

3

4

5

7

8

10

1

9

5

4

6

8

7

Foot Control Accessory Button

(P/N 38.0610.00)

Wet/Dry Toggle

(P/N 38.0604.00)

Foot control accessory button Wet/dry toggle

Figure 37. Foot control accessory button and wet/dry toggle

component identification.

Page 20

Page 58 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Item #

Part Number

Description

1

023.805.01

Barb, 1/4" x 10-32, .760 OD x .47, pkg 10

2

004.005.02

Flat nylon washer, .187 ID,pkg 10

3

023.004.03

Barb, 1/8" x 10-32, pkg 10

4

013.011.00

Spring, helical compression

5

38.0054.02

Diaphragm, 3/4"square x .013 thick, pkg 10

6

22.0778.00

Valve stem with O-rings

7

38.0056.00

Signal relay body valve

8

002.102.00

Socket head screw 4-40 x 7/8", zinc

9

021.016.04

Hex plug, 10-32, pkg 10

10

10.0440.00 Spring, compression .93 OD x 250

11

030.001.02 O-ring, .029 ID x .040 wide, pkg 10

12

030.012.02 O-ring, .364 ID x .070 wide, pkg 10

13

22.0060.00 Poppet

14

22.0050.00 Cap

15

22.0580.00 Spring, compression, .312 OD x .25

16

38.0760.00* Piston

5

1

12

2

3

4

Illustrated Parts A-dec Service Guide, Vol. II

6

11

10

7

9

8

15

14

13

Foot Control Valve

Figure 38. Identifying the foot control valve components.

* Item not for sale.

16

Page 21

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 59

A-dec Service Guide, Vol. II Tray Holders

Tray Holders

Continental Tray Holder

(P/N 77.0294.01)

Continental tray holders can be mounted on the left or right side above the delivery system.

Item #

Part Number

Description

1

002.023.01 Hex head screw, 3/8-16" x 1-1/4"

2

004.019.00 Spring washer, .384 ID stainless steel

3

004.172.00 Thrust washer, .375 ID

4

016.102.00 Thrust bearing, .375 ID

5

77.0198.00 Screw cover,Surf 4

6

004.242.00 Flat polyethylene washer, .387 ID

7

005.012.03 Button head socket screw, 10-32 x 3/8",

stainless steel

8

77.0190.00 Bracket, Surf 4

9

75.0017.00 Melamine tray holder,Surf 4

10

77.0189.00 Arm, Surf 4

11

005.026.00 Button head hex screw with

patch lock, 1/4-20 x 3/4

12

77.0194.00 Top base, Surf 4

13

77.0196.00 Bottom base, tray holder, Surf 4

14

77.0332.00 Base level, Surf 4

15

77.0192.00 Elbow cover, Surf 4

16

002.024.00 Socket head screw, 4-40 x 3/4

9

8

7

6

5

4

3

2

1

10

11

15

16

12

6

14

13

Figure 39. Identifying Continental tray holder components.

Page 22

Page 60 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Traditional Tray Holder

(P/N 77.0294.00)

The traditional tray holder can be mounted on the left or right side below the

delivery system.

Tray Holders A-dec Service Guide, Vol. II

1

2

3

4

5

6

7

8

9

10

Item #

Part Number

Description

1

002.023.01 Hex head screw, 3/8-16" x 1-1/4"

2

004.019.00 Spring washer, .384 ID stainless steel

3

004.172.00 Thrust washer, .375 ID

4

016.102.00 Thrust bearing, .375 ID

5

77.0198.00 Screw cover,Surf 4

6

004.242.00 Flat polyethylene washer, .387 ID

7

005.012.03 Button head socket screw, 10-32 x 3/8",

stainless steel

8

77.0190.00 Bracket, Surf 4

9

75.0017.00 Melamine tray holder,Surf 4

10

77.0189.00 Arm, Surf 4

11

005.026.00 Button head hex screw with

patch lock, 1/4-20 x 3/4

12

77.0194.00 Top base, Surf 4

13

77.0196.00 Bottom base, tray holder, Surf 4

14

77.0332.00 Base level, Surf 4

15

77.0192.00 Elbow cover, Surf 4

16

002.024.00 Socket head screw, 4-40 x 3/4

17

77.0197.00 Arm extender, Surf 4

18

005.157.00 Hex head screw

15

11

12

13

14

16

17

18

Figure 40. Identifying Traditional tray holder components.

Page 23

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 61

A-dec Service Guide, Vol. II Monitor Mount

A-dec 531 Monitor Mount

The A-dec 531 monitor mount is intended for use only with the A-dec 511 chair. It mounts on the front-mount arm and casting. Level the

monitor mount with the leveling cam and the leveling bolts.The screws to attach the monitor to the mount come off the back of the monitor.

Item #

Part Number

Description

1 77.0103.00

Lower bearing, Surf 4

2 77.0102.00

Upper bearing, Surf 4

3 001.088.00

Socket head screw, 10-32 x 5/8"

stainless steel

4

—

Clutch assembly

5 004.141.00

Flat washer,.261 ID

6 006.052.00

Locking nut, 1/4-20"x 7/16" x 5/16"

7 002.119.00

Socket head screw, 1/4-20" x 2-3/4"

stainless steel

8 002.094.02

Button head screw, 10-32 x 1/4"

stainless steel

9 77.0213.00

Small cover,Surf 4

10 77.0026.00 Monitor mount cover

11 77.0112.00 Mounting bracket

12 002.130.00 Socket head screw, 10-32 x 3/8"

13

—

Handle bracket kit

14

002.130.00 Screws

1

2

7

8

9

3

4

5

6

14

11

12

13

10

Figure 41. Identifying A-dec 531 monitor mount components.

Page 24

Page 62 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Self-Contained Water System A-dec Service Guide, Vol. II

The Self-Contained Water System

(P/N 14.0468.00)

The A-dec self-contained water system is a closed system, which

isolates treatment water from the municipal water supply. The

A-dec 500 water bottle is designed to prevent cross-contamination

during refilling.The pickup tube is located inside the bottle assembly and

is not exposed to outside contaminates.

Air pressure forces water from the water bottle into the pick-up tube.

Water is distributed through the chair air/water manifold to the delivery

system syringe and handpieces, assistant’s syringe, and cuspidor cup fill.

WARNING: Use only A-dec water bottles. Do not use other brands, or

damaged bottles.They can pose a serious safety hazard if

broken while pressurized.The A-dec plastic water bottles

cannot withstand heat sterilization. Attempting to do so

will damage the bottle and the sterilizer.

Item #

Part Number

Description

1

035.048.01

O-ring, .114 ID x .070W, pkg 10

2

010.002.00

Retaining ring, ext, .187 ID

3

031.130.01

O-ring, 1.612 ID x .103 W, pkg 10

4

14.0467.00*

Pick-up tube, 7.8"

5

14.0458.00

Clamp, Surf 4

6

005.110.00

Button head socket screw, 10-32 x 1/2"

7

14.0466.00

Water bottle base

1

2

3

4

5

6

7

Figure 42. Self-contained water bottle components.

* Item not for sale.

Page 25

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 63

A-dec Service Guide, Vol. II Illustrated Parts

Water Bottle Housing and Receptacle

(P/N 90.1101.00)

The water bottle housing and receptacle assembly will mount on the front-mount arm and uses a 2 liter A-dec 500 water bottle.The same

receptacle can be disassembled from the housing and mounted inside the support center.

Item #

Part Number

Description

1

14.0455.02

Housing, Surf 4

2

034.213.00

O-ring, .921 ID x .139 W

3

002.112.00

Socket head screw, 10-32 x 7/8"

4

023.809.00

Restrictor setscrew, 10-32

1

2

4

3

Figure 43. Self-contained water bottle components.

Page 26

Page 64 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

A-dec 500 Control block

How to Dismount the Control Block

1. Loosen the hex screw holding the master toggle mounting bracket to the delivery system platform.

2. Slide the bracket toward the back of the delivery system.

3. Lift the control block from the back, unhooking the front of the block.

Item #

Part Number

Description

1

38.1785.01

Drive air stem with O-ring

2

38.1777.00

Control block

3

38.0526.00

Air coolant stem with O-ring

4

38.1783.00

Dry cartridge assembly

5

38.0516.00

Water flow adjustment stem with O-ring

6

38.1780.00

Water cartridge assembly

7

023.004.03

Barb, 1/8 x 10-32, pkg 10

8

004.005.02

Washer, flat nylon, .187 ID, pkg 10

9

001.240.00

Screw, socket head, 6-32 x 3/4

10

38.1778.00 Control block cap

11

38.1787.00 Control block diaphragm

12

023.805.01 Barb, 5/16 x 10-32, pkg 10

13

38.1800.00 Barb retainer

Figure 44. Components of the A-dec 500 control block.

3

2

1

12

13

11

10

9

8

7

6

5

4

Page 27

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 65

A-dec Service Guide, Vol. II Delivery System Adjustments

A

Figure 45. Location of the air and water coolant

adjustments. (A) drive air adjustment stem;

(B) water coolant adjustment stem; (C) air coolant

adjustment stem

How to Adjust Handpiece Controls

The adjustment controls for air coolant and water coolant flow are located on the side of the

delivery system.The drive air adjustment stem is located on top of the control block for each

handpiece position.

B

C

Page 28

Page 66 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Adjustments A-dec Service Guide, Vol. II

Drive Air

1. Use a handpiece pressure gauge to adjust the drive air for each

handpiece tubing.

2. Install a bur into the handpiece and activate the position.

3. Fully depress the foot control.

4. Adjust the drive air flow (controls are on the top of the

control block).

Air turbine handpieces should be set to 40 psi. EA-50LT electric micromotors

(controller) should be set at a minimum of 60 psi.

NOTE: There is a digital gauge inside the delivery system that reads drive

air pressure only at the control block. For accurate handpiece

pressure settings use a pressure gauge at the end of the

handpiece tubing.

Water Coolant

1. Flip the wet/dry toggle on the foot control to the ON position.

2. Install a bur into the handpiece and activate the position.

3. Fully depress the foot control.

4. Turn the water coolant adjustment key to adjust the flow to fit the operator’s needs.

5. Repeat steps two through four for each wet handpiece.

Figure 46. Rotate the adjustment stem

counterclockwise to increase flow and clockwise

to decrease flow.

Page 29

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 67

Air Coolant

Adjusting the air coolant for one handpiece sets it for all of the positions.

1. Flip the wet/dry toggle on the foot control to the ON position.

2. Install a bur into a handpiece and activate the position.

3. Fully depress the foot control.

4. Adjust the handpiece air coolant adjustment key to create a cooling mist at the bur.

A-dec Service Guide, Vol. II Delivery System Adjustments

Page 30

Page 68 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Adjustments A-dec Service Guide, Vol. II

Intraoral Light Source Voltage

The intraoral light source voltage adjustment on the A-dec 500 delivery system is located on the delivery system circuit board.

The voltage is preset to 3.2 volts at the lamp terminals when the lamp is On.

1. Determine the handpiece wire length and recommended bulb voltage.

2. Use a voltmeter to measure the voltage at the delivery system circuit board

IOLS terminal.

Length and Voltage Table

Wire length in

A-dec tubing

Voltage at terminal strip

A-dec/W&H, Bien Air, or other bulbs rated at 3.5V

(in) (cm) VDC +/- .02

48 122 3.51

54 137 3.54

60 152 3.56

66 168 3.59

72 183 3.62

78 198 3.65

84 213 3.67

90 229 3.69

96 244 3.71

102 259 3.74

108 274 3.76

114 290 3.79

120 305 3.82

126 320 3.85

132 335 3.57

138 351 3.90

144 366 3.93

150 381 3.96

156 396 3.99

Figure 47. Use the buttons labeled Decrease and Increase to adjust the

voltage for the intraoral bulb in the handpiece.

Page 31

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 69

A-dec Service Guide, Vol. II Delivery System Adjustments

How to Level and Make Adjustments

Front Mount

Level

Position all front-mount modules, (e.g., delivery system, flexarm, tray holder

assemblies) to align with the centerline of the chair.

1. Use the bubble level to determine when the correct front mount

adjustments have been made.

2. Loosen the stabilizing screws and flanged nuts.

3. Adjust the leveling cam for side-to-side leveling.

4. Use one of the leveling bolts to adjust the front-to-back leveling.

Assure both bolts are touching the casting when the delivery system is

level front-to-back.

5. Tighten the leveling cam securely.

6. Tighten the stabilizing screws until the screws make contact with

the casting when all of the front mount leveling adjustments have

been made. Do not overtighten.

NOTE: You may need to lower the back to improve access.

7. Securely tighten the flanged nuts.

Tension Adjustment

If the front-mount arm drifts, adjust the front-mount tension.To adjust the

front mount tension, tighten or loosen the rotation bolt connecting the

front-mount arm to the front-mount casting.Turning the rotation bolt

clockwise increases the tension on the arm and counterclockwise decreases

the tension.

Figure 48. Leveling and adjusting the front mount arm.

Item # Description

1

Leveling cam

2

Stabilizing screw, 1/4-20" x 2-1/4"

3

Flanged nuts

4

Leveling bolts

5

Bubble level

6

Rotation bolt

1

2

3

4

5

6

Page 32

Page 70 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Adjustments A-dec Service Guide, Vol. II

Delivery System

Front-to-Back Leveling

1. Remove the flexarm front knuckle covers.

2. Position the delivery system in line with the flexarm.

3. Tighten or loosen the adjustment screw on the underside of the

front knuckle until the delivery system is level front-to-back.

4. Replace the covers.

Side-to-Side Leveling

Alternately tighten and loosen the two leveling screws on the

underside of the delivery system until it is level side-to-side.

Tighten both screws when level.

Figure 49. Level the delivery system in two locations.

Page 33

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 71

A-dec Service Guide, Vol. II Delivery System Adjustments

Rotational Tension Adjustment

Tighten or loosen the friction adjustment screw located in the center of the delivery system structural platform to adjust the rotational tension.

Figure 50. Adjust the delivery system rotation tension.

Page 34

Page 72 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Adjustments A-dec Service Guide, Vol. II

Tray Holder

Level

The tray holder assembly can be mounted on either side of the delivery system.To level

the tray holder front-to-back or side-to-side:

1. Position the tray holder directly in front of the delivery system.

2. Loosen one of the tray adjustment screws under the delivery system.

3. Tighten the opposite screw until the satisfactory position is reached.

4. Tighten both screws.

Tension Adjustment

To tighten the rotational tension of the tray holder, turn the hex bolt under the tray

clockwise.To loosen the rotational tension, turn it counterclockwise.To adjust the

rotational tension of the tray arm, tighten or loosen the hex bolt at the delivery system

end of the arm.

Figure 51. Level the tray holder front-to-back and

side-to-side. (A) adjust for tray rotation; (B) adjust for

arm rotation

A

B

Front-to-back

Side-to-side

Page 35

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 73

How to Adjust the Front Monitor Mount

There are two main adjustments that can be made to the monitor: the tilt and drift friction. If you have a support side monitor, refer to Support

Side Monitor Adjustments.

Tilt Friction

The tilt friction can be adjusted by tightening or loosening the tilt friction adjustment screw located on the top of the monitor mount.

Drift Friction

The drift friction can be adjusted by tightening or loosening the drift adjustment screw located on the top of the monitor mount.

Figure 52. Monitor adjustments. (A) tilt friction adjustment screw;

(B) drift friction adjustment screw

A-dec Service Guide, Vol. II Front Monitor Mount Adjustments

A

B

Minimum Monitor Specifications:

Digital Monitor Requirements

• Medical-grade monitor

• 15" diagonal active display

• 1024 x 768 resolution

• Digital inputs

• VESA mounting compliant

•SVGA

Analog Monitor Requirements

• Color palette adjustments

• 13" HDTV flat panel for analog integration

• NTSC or PAL format

• Video inputs

• Composite video display capability

• RCA connection port

Page 36

Page 74 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Problem Possible Cause Action

No water coolant to all the handpieces Water bottle is empty Press the water button on the doctor’s syringe, to verify water is available at the

control block. Fill the water bottle with treatment water.

The wet/dry toggle on the foot control is in the

dry position

Pick up a wet handpiece, and move the wet/dry toggle to the wet position.If a

deluxe touchpad is installed, verify the water coolant icon appears on the

screen. Press the foot control to test the unit.

Water coolant flow controls require adjustment See Delivery System Adjustments - Water Coolant.

No water coolant signal from the foot control

wet/dry toggle

Disconnect the water coolant signal tubing from the foot control at the inline

connector in the chair lift arm. With the wet/dry toggle in the wet position

(toward blue dot), step on the foot control. There should be 80 psi (5.52 bar) of

air at the tubing end. If you have no air, repair or replace the wet/dry toggle.

Check the water coolant air tubing for kinks or obstructions.

Verify the water coolant icon appears on the deluxe touchpad when the

handpiece position is activated.

Water coolant relay is not activated Check the LED (DS5) for water coolant signal is activated on the delivery

system circuit board. If so, manually open the water solenoid.

No water to all handpieces and

the syringe

Water bottle is empty Refill bottle with treatment water.

Self-contained water system regulator has failed Replace the water bottle receptacle.

Restrictor setscrew is plugged Remove the restrictor setscrew and use air to blow out debris inside the water

bottle receptacle assembly.Reinstall the restrictor setscrew.

How to Troubleshoot

the A-dec 532/533

Delivery System

Tips and troubleshooting information are listed in the tables to assist in diagnosing delivery system

problems.These tables are not intended to cover every situation, but do include the most common

problems that may be encountered.

Delivery System Troubleshooting A-dec Service Guide, Vol. II

Page 37

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 75

A-dec Service Guide, Vol. II Delivery System Troubleshooting

Problem Possible Cause Action

No water coolant to one handpiece Water coolant adjustment stem is closed or

requires adjustment

See Delivery System Adjustments - Water Coolant.

Deluxe touchpad water coolant icon is not on

when handpiece position is activated

Activate handpiece and press water coolant icon on the touchpad or move

the foot control wet/dry toggle.The water coolant icon should appear on

the display.

Handpiece tubing or terminal plugged Remove handpiece and coupler from tubing. Operate foot control with water

toggle on. Check to see if water is in the green handpiece tubing at the

control block.

Water coolant cartridge has failed Exchange the failed cartridge with known good cartridge and test the

handpiece position.

Too much water coolant flow and unable

to decrease it

Not enough holdback air from the flush toggle Verify 80 psi (5.52 bar) air at flush toggle inlet

Verify 80 psi (5.52 bar) air at flush toggle outlet

Verify 80 psi (5.52 bar) at control block inlet

Plumb unregulated air to the flush toggle inlet and plug the regulated

air tubing.

Control block diaphragm has failed Replace the control block diaphragm.

Sputtering water from syringe

and handpieces

Faulty or dirty O-ring on barb of pickup tube Replace O-ring on pickup tube barb of the water bottle.

Intermittent water coolant to handpieces Faulty control block diaphragm Replace the diaphragm.

Page 38

Page 76 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Problem Possible Cause Action

Water leaks from vent hole in control

block when a wet handpiece is in use

Faulty water coolant cartridge Replace water coolant cartridge.

A wet handpiece drips water while in

its holder

Faulty water cartridge Replace the water cartridge.

Faulty control block diaphragm Replace diaphragm.

Water leaks from the handpiece

control block

The water coolant stem is leaking water Replace the stem or the O-rings on the stem.

Water continues to flow after foot control

is released

Pinched water coolant signal tubing Remove handpiece and coupler.Locate the clear tubing from the foot control

and check for water coolant signal.

The foot control main valve is sticking Install a foot control field service kit in the foot control.

Plugged handpiece or coupler Remove handpiece and coupler and retest water coolant flow.

Water coolant flow set too high Adjust water coolant flow to a minimum setting.

Flush system holdback has failed Check for 80 psi (5.52 bar) air pressure into the flush toggle.As a test,

temporarily connect unregulated air to the flush toggle inlet and test the unit.

If the flush holdback does not function, remove and replace the control

block diaphragm.

Any handpiece drips when holder is

activated, but foot control is

not activated

No holdback from flush valve Replace O-rings on flush valve stem.

Water continues to flow after foot

control is released only in air/water

combined mode

Faulty relay stem in foot control Replace the stem, or the O-rings on the stem.

Can not flush one or more

handpiece tubings

A dry cartridge is in place for this handpiece Change the dry cartridge to a water cartridge.

Handpiece or coupler plugged Remove handpiece and coupler and test flush.

Inadequate signal air pressure from the flush

toggle to the water coolant cartridge

Check for 80 psi (5.52 bar) air pressure from the flush toggle when it is

held open.

Delivery System Troubleshooting A-dec Service Guide, Vol. II

Page 39

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 7785.0816.00 Rev A 2004-11 (PCA 04002.12) Page 77

A-dec Service Guide, Vol. II Delivery System Troubleshooting

Problem Possible Cause Action

Unable to configure DCS to recognize

new handpiece (deluxe touchpad only)

Handpiece not recognized by DCS Configure handpiece position on touchpad.

Handpiece type is not listed as a choice Assign the handpiece as “other.”

Holder valve is inactive (locked open) Activate the holder valve by unhooking the valve arm.

Holder valve does not exhaust holdback air

when the handpiece is picked up

Replace failed holder valve.

No power to micromotor handpiece controller Assure the micromotor controller has 24 VAC .

No data line or a faulty data line to

micromotor handpiece controller

Replace data line.

Unable to combine air and water coolant

functions (deluxe touchpad only)

Deluxe touchpad has not been programmed for

combined air/water coolant function

Press and hold Program and either the air or water coolant button for three

seconds.Three beeps signal the functions are now combined.

One of the solenoids has failed or is

disconnected from the delivery system

circuit board

Verify the coolant LEDs (DS5 and DS6) are illuminating on the delivery system

circuit board. If not, assure the solenoid is attached to the delivery system

circuit board. If attached, replace the solenoid and verify coolant operation.

Figure 53. Active and non-active handpiece

positions. (A) actuator

Active

Non-active

A

Page 40

Page 78 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Delivery System Troubleshooting A-dec Service Guide, Vol. II

Problem Possible Cause Action

A button on the touchpad does not work Faulty data line from touchpad Replace data line.

Faulty touchpad Verify the touchpad circuit board is snapped into the plastic cover.

Replace touchpad.

Faulty data line from delivery system to

chair circuit board

Replace delivery system data line.

Deluxe touchpad screen is blank, or the

status icon does not light when the

master toggle is on.

No power to touchpad Verify that DS1 is illuminated on the delivery system circuit board. If DS1 is not

illuminated, check for 24 VDC across J1 and J2 on the circuit board. Check for

an open circuit breaker on the 511 chair power supply.

Low air pressure to syringe or handpieces Plugged filter on air filter regulator in floor box Replace the filter.

Handpiece holder valve leaking air Faulty holder valve Replace holder valve.

Handpiece holder valve not exhausting Holder valve is locked open (inactive) Activate the holder by unhooking the the valve arm.

Faulty holder valve Replace the holder valve.

Loading...

Loading...