Page 1

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 111

A-dec Service Guide, Vol. II Cuspidor

The support center and cuspidor are installed on the lower support arm. The support

side mounted water bottle, and the cuspidor circuit board are located inside the

support center.

This section provides information related to servicing, maintenance, and adjustments.

Detail on how to service the cuspidor and troubleshoot specific problems is presented.

For information on service parts, see the Genuine A-dec Service Parts Catalog or contact

A-dec customer service.

Page 2

Page 112 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Support Center Components A-dec Service Guide, Vol. II

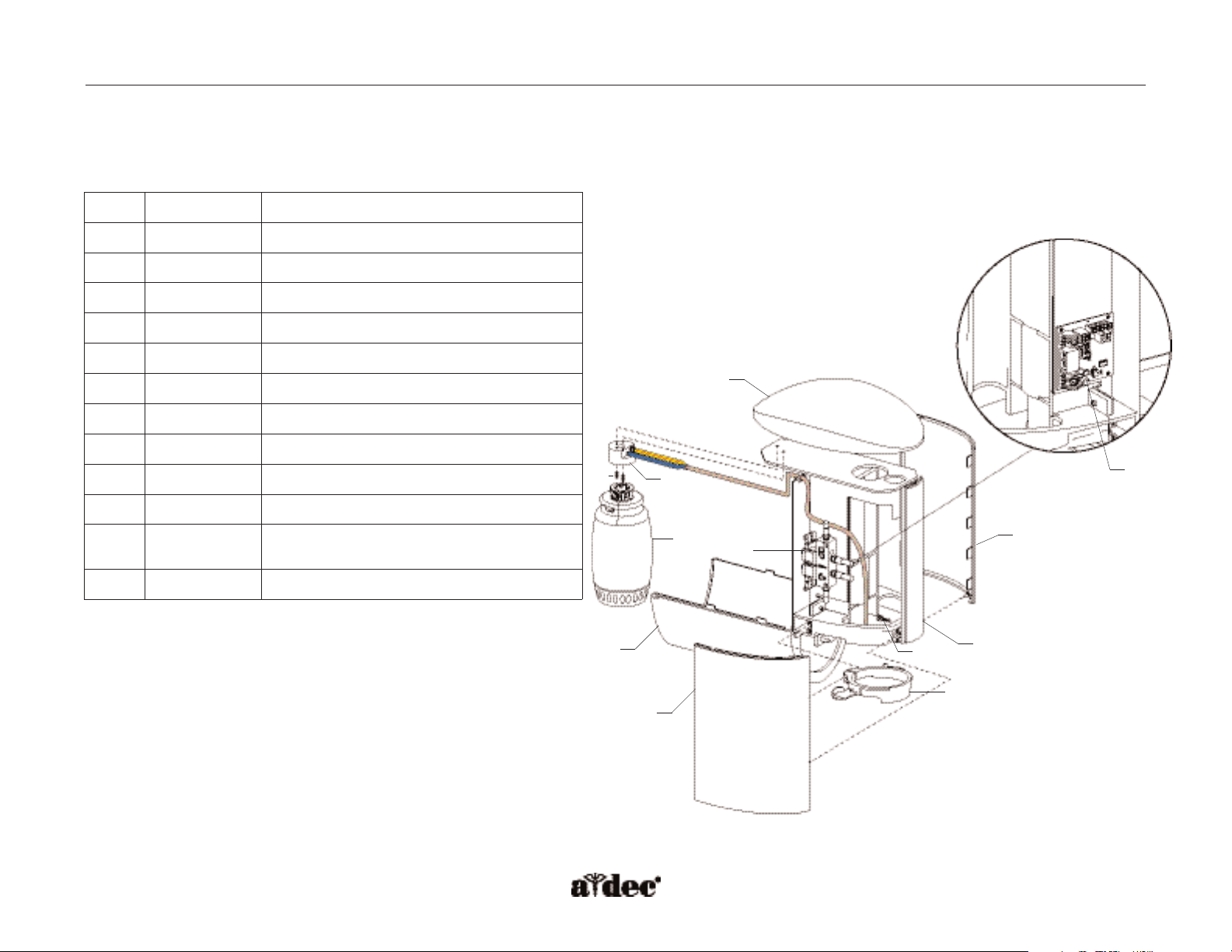

How to Identify Support Center Components

The support center houses the cuspidor fill/rinse manifold, cuspidor circuit board, and support side water bottle.

Item #

Part Number

Description

1

77.0034.00

Cover, top

2

77.0036.00

Cover, right

3

77.0037.00

Cover, nose

4

77.0035.00

Cover, left

5

14.0456.00

Cover, water bottle

6

38.1803.00

Cuspidor manifold

7

001.089.00

Screw

8

90.1079.00

Cuspidor circuit board kit

9

77.0232.00

Rotational stop

10

14.0469.00 Bottle receptacle assembly

11

002.112.00 Screw

NOTE: Torque 13-17 inch lb

12

14.0468.00 Self-contained water bottle assembly

1

2

4

3

5

6

7

8

9

10

11

12

Figure 80. Identification of the support center components.

Page 3

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 113

A-dec Service Guide, Vol. II Support Center Covers

Support Center Top Housing Cover Replacement

If replacement of the support center top housing cover is necessary, remove the support center top housing cover using these steps.

Cuspidor Removal

1. Remove side covers and water bottle cover.

2. Remove the two screws from under cuspidor support.

3. Disconnect the cup fill and bowl rinse tubings from the cuspidor fill/rinse manifold.

4. Disconnect the three wire connections from cuspidor circuit board

5. Remove the cuspidor by lifting it up and laying it on its side.

Top Housing Cover Removal

1. Remove the three screws from the top of cuspidor arm and lift off.

2. Remove the screw in the center of swivel and lift off the lower arm.

3. Remove the four screws holding the top cover on the housing, and lift off the top cover.

Top Housing Cover Replacement

Align two screws through lower arm and carefully thread into air trap bracket. Check seam alignment for bowl and arm, and tighten.

Page 4

Page 114 85.0816.00 Rev A 2004-11 (PCA 04002.12)

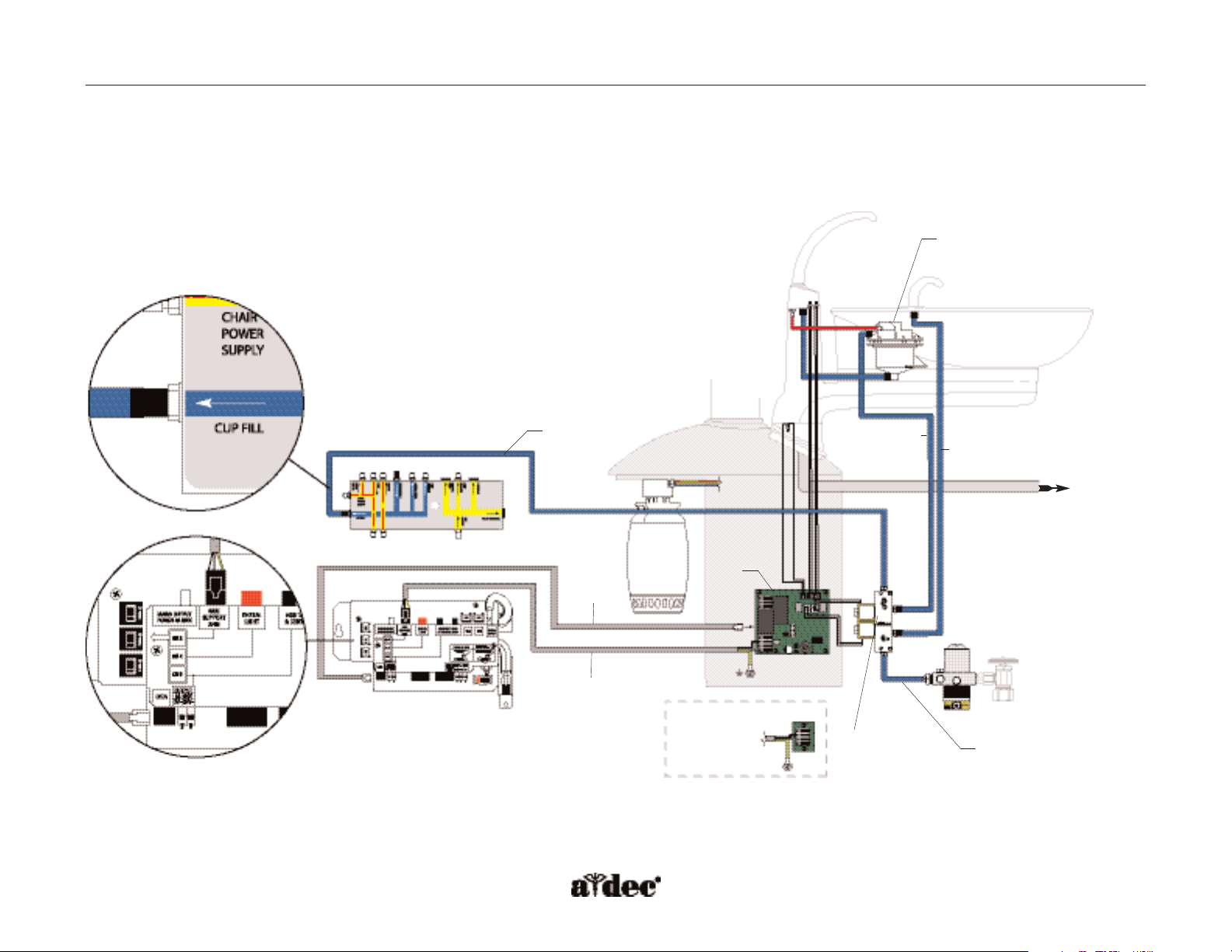

Cuspidor and Support Center Flow Diagram

This flow diagram describes the plumbing and electrical connections of the cuspidor and support center.

Flow Diagram A-dec Service Guide, Vol. II

Cuspidor

Support

center

Without

a cuspidor

Chair air/water manifold

Chair 300-watt

power supply

Water regulator for cuspidor only

(floor box)

Bowl rinse,

city water

Cup fill, self

contained

water

Cuspidor

circuit

board

Data line

Po wer cable

To gravity

drain (floor box)

Air trap valve assembly

Cuspidor

fill/rinse

manifold

Cup fill

City water

Page 5

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 115

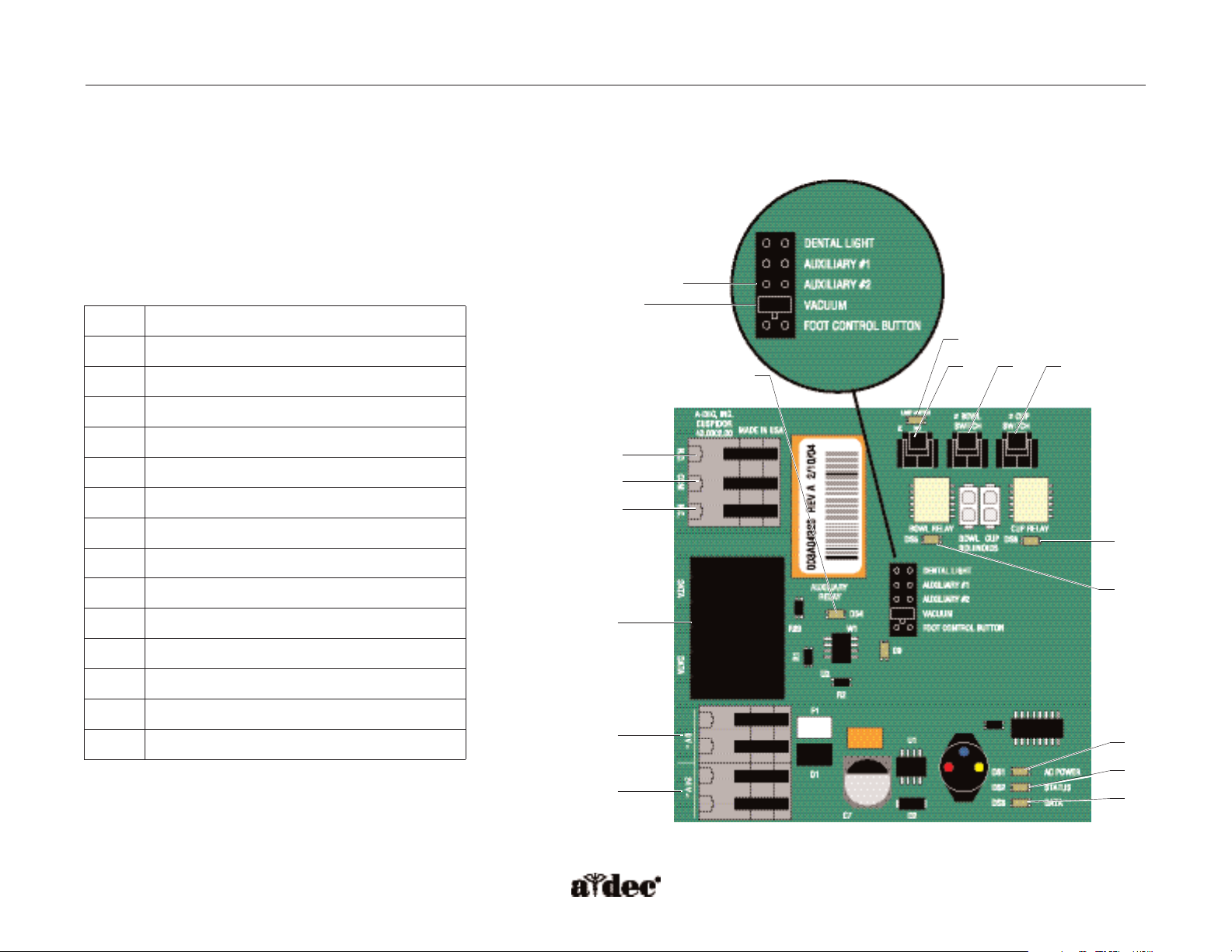

A-dec Service Guide, Vol. II Cuspidor Circuit Board

How to Identify Cuspidor Circuit Board Components

(P/N 90.1079.00)

The cuspidor circuit board controls the bowl rinse and cup fill solenoids.

The LEDs on the circuit board indicate the status of the cuspidor and can

be used for troubleshooting. The circuit board is also equipped with a

built-in A-dec relay.The built-in relay functions exactly like the A-dec

relay module.

Relay outputs

Item # Description

1

P5 - DCS terminals

2

J1 - Ø VAC terminal strip

3

J2 - 24 VAC terminal strip

4

P4 - Cuspidor limit switch connector

5

P2 - Bowl rinse switch connector

6

P3 - Cup fill switch connector

7

P1 - A-dec relay selection header

8

DS5 - Bowl rinse relay LED

9

DS6 - Cup fill relay LED

10

DS4 - Auxiliary relay LED

11

DS1 - AC power LED

12

DS2 - Status LED

13

DS3 - Data LED

14

DS7 - Limit switch LED

Figure 81. Cuspidor circuit board components.

N.O.

COM

N.C.

1

2

3

10

14

4

5 6

9

8

11

12

13

7

Relay jumper

Page 6

Page 116 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

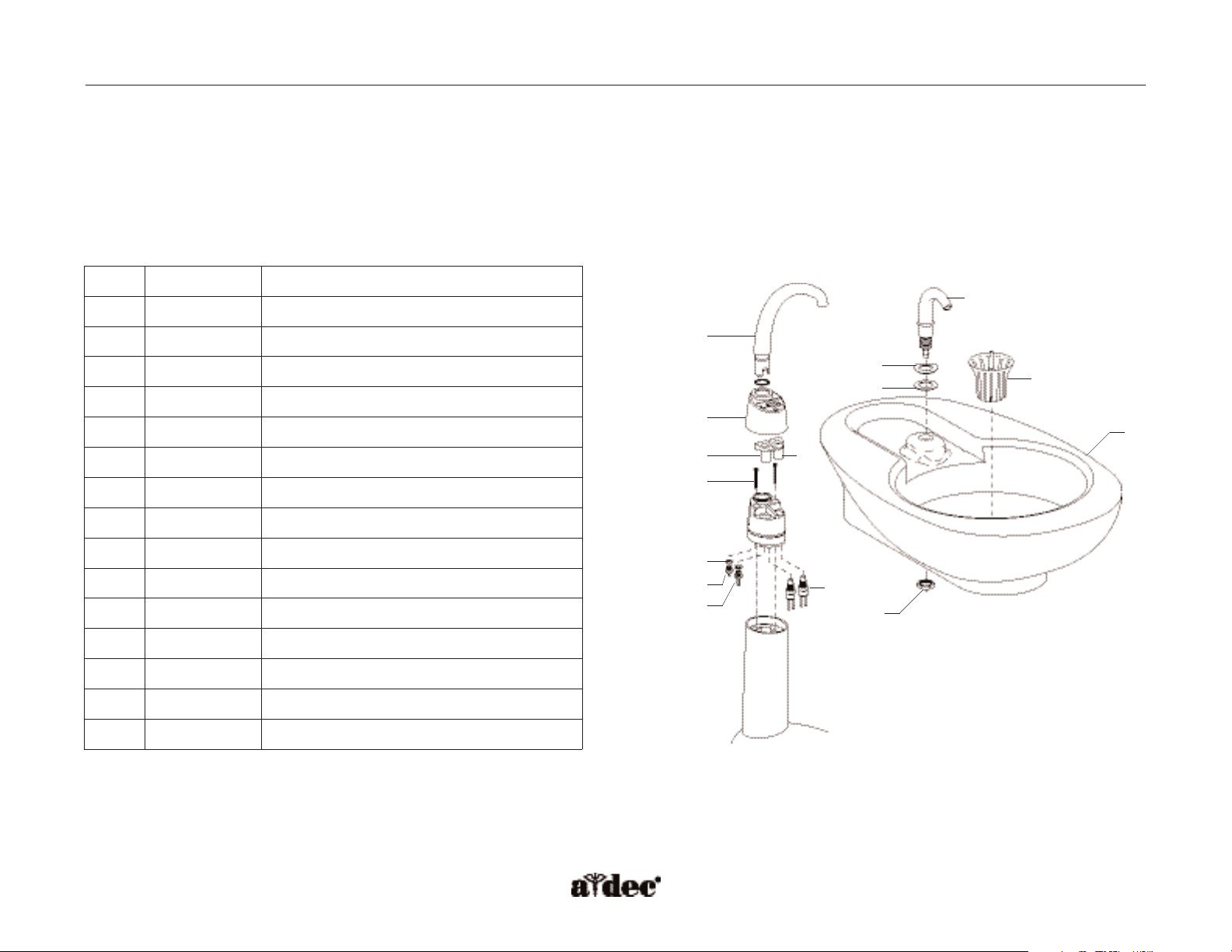

How to Identify Cuspidor Components

Upper Assembly

The cuspidor is preset with an automatic timed cup fill and bowl rinse. Both the cup fill and the bowl rinse functions can be reprogrammed.

Item #

Part Number

Description

1

77.0043.01

Cup fill spout

2

77.0042.01

Bowl rinse spout

3

77.0044.00

Spout gasket

4

77.0099.00

Bowl rinse button

5

77.0100.00

Cup fill button

6

005.088.00

Screw

7

77.0038.00

Cuspidor bowl

8

75.0035.01

Bowl screen, pkg 5

9

004.005.02

Washer, pkg 10

10

023.811.00 Barb

11

023.805.01 Barb, pkg 10

12

43.0010.00 Bowl rinse and cup fill switch assemblies

13

006.009.00 Nut

14

004.132.00 Washer

15

004.035.00 Washer

1

3

4

6

9

10

11

12

5

2

14

15

8

7

13

Figure 82. Identification of the upper cuspidor components.

Page 7

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 117

A-dec Service Guide, Vol. II Illustrated Parts

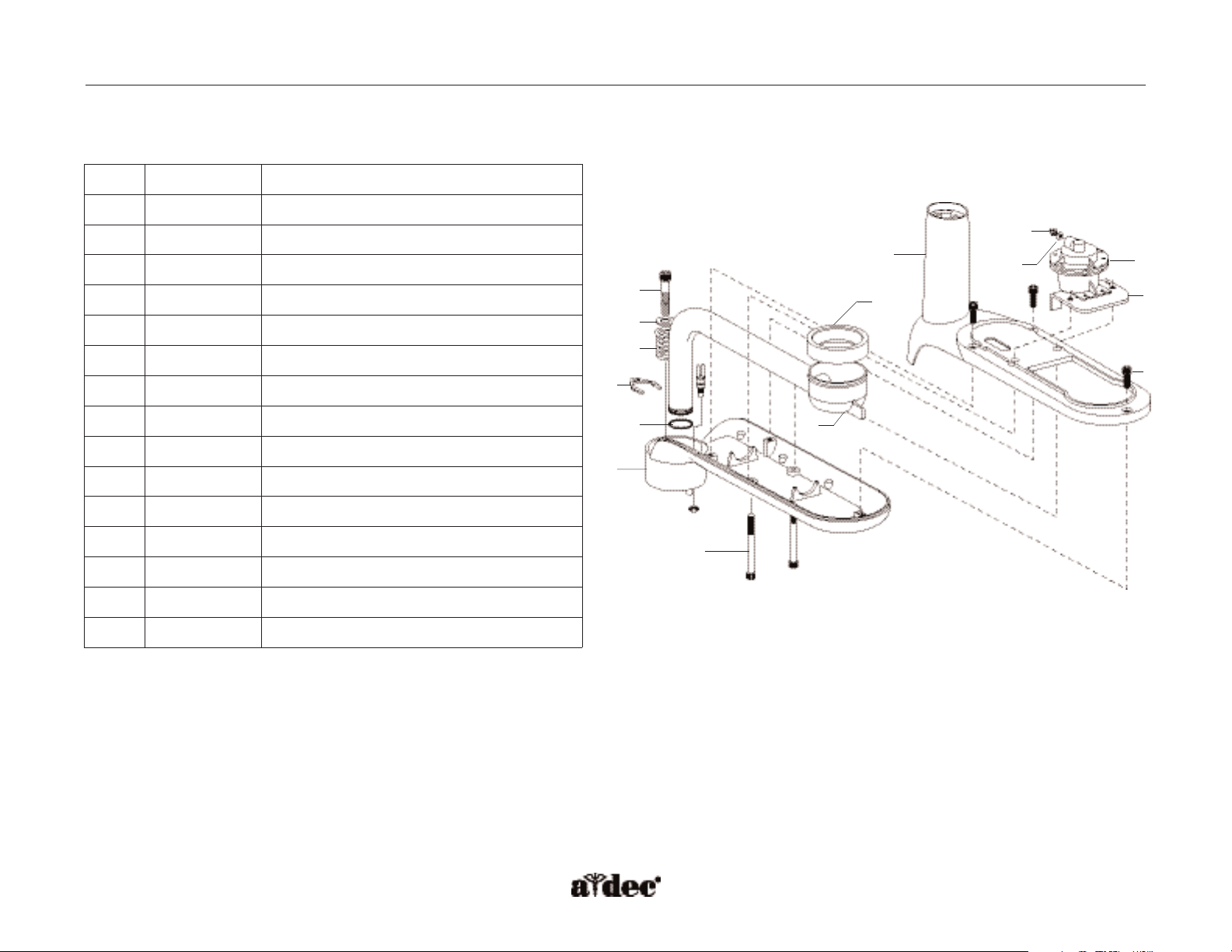

Lower Assembly

Item #

Part Number

Description

1

13.0403.00

Air trap valve assy

2

77.0236.00

Bracket, hold down

3

001.088.00

Screw

4

77.0108.00

Top housing

5

12.0991.00

Drain seal

6

002.082.03

Screw

7

004.141.00

Washer

8

013.061.01

Spring

9

77.0040.00

Cuspidor drain

10

022.090.00 Durr connector clip

11

035.053.01 O-ring, pkg 10

12

77.0109.00 Bottom housing

13

005.106.00 Screw

14

023.811.00 Restrictor barb

15

004.005.02 Washer, pkg 10

1

2

3

14

15

4

5

9

6

7

8

10

11

12

13

Figure 83. Identification of the lower cuspidor components.

Page 8

Page 118 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Illustrated Parts A-dec Service Guide, Vol. II

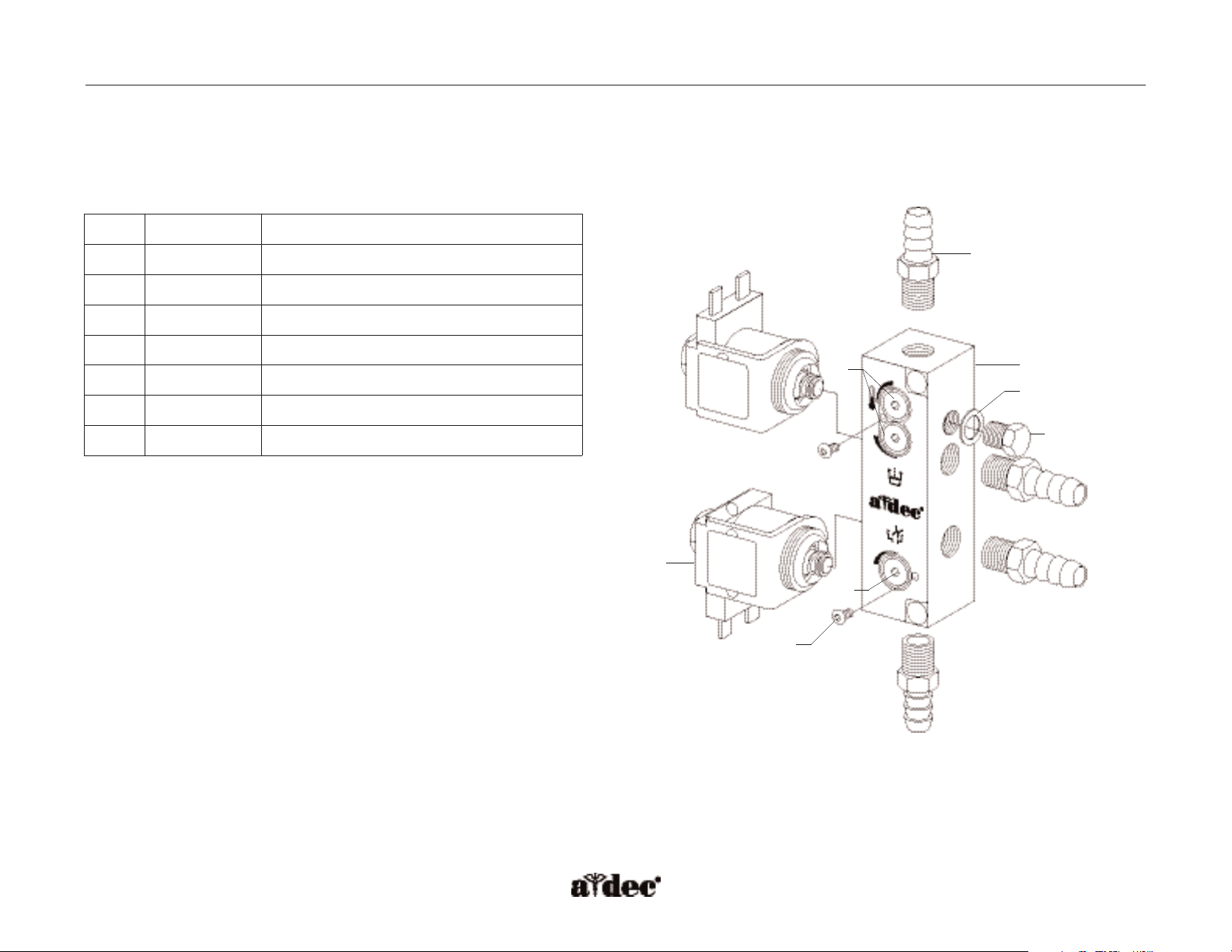

Cuspidor Fill/Rinse Manifold

(P/N 38.1803.00)

The cuspidor fill/rinse manifold assembly is mounted inside the support center.

Item #

Part Number

Description

1

041.660.00

Solenoid, 24 VAC

2

023.804.00

Barb, 5/16"

3

38.1794.00

Block, fill/rinse/mix

4

75.0222.00

Stem, flow adjustment

5

002.105.00

Screw, button head socket

6

004.005.02

Washer, pkg 10

7

021.016.04

Plug, hex head, pkg 10

2

3

6

7

5

4

1

4

Figure 84. Identification of the fill/rinse components.

Page 9

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 119

A-dec Service Guide, Vol. II Cuspidor Adjustments

How to Adjust the Cuspidor Timing

Cup Fill and Bowl Rinse Functions

Cup fill and bowl rinse timing can be reprogrammed using a touchpad or the footswitch program button and the appropriate button on the

cuspidor tower.

The cup fill function allows water to flow from the cuspidor cup fill spout into a cup. Quickly press the Cup Fill button to activate a timed

operation. A long press activates a manual operation.

The cup fill will only run a maximum of two minutes in the manual operation mode.

The bowl rinse function provides rinse water for the cuspidor bowl. A quick press of the bowl rinse button activates a timed operation. A long

press activates the manual operation. If the button is pressed twice in less than two seconds, the continuous operation will be activated. To stop

the continuous bowl rinse operation, press the bowl rinse button once.There is no maximum time limit for this function.

Figure 85. Cuspidor buttons for cup fill

and bowl rinse. (A) cup fill; (B) bowl rinse

A

B

Page 10

Page 120 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Cuspidor Troubleshooting A-dec Service Guide, Vol. II

How to Troubleshoot the Cuspidor

Tips and troubleshooting information are listed in the tables to assist in diagnosing cuspidor problems.

These tables are not intended to cover every situation, but do include the most common problems that

may be encountered.

LED Status Function

DS1 - AC Power LED Off No 24 VAC power, tripped circuit breaker, power supply turned Off, no

line voltage

Green, steady 24 VAC at terminal strip

DS2 - Status LED Off System is not functioning, no power or circuit board has failed

Green, steady Normal condition

DS3 - Data LED Off No DCS communication, not connected to the data communication system, the

DCS has failed

Green, steady Active DCS detected

Green, blinking Valid DCS message

DS4 - Auxiliary relay LED Off Auxiliary relay is off

Yellow Auxiliary relay is on

DS5, DS6 - Bowl rinse/cup fill relays Off Relay is off

Yellow Relay is on

DS7 - Cuspidor limit switch LED Off Limit switch is not activated (closed)

Red Limit switch is activated (open)

Page 11

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 121

A-dec Service Guide, Vol. II Cuspidor Troubleshooting

Problem Possible Cause Action

Water drips from the cup fill spout The cup fill solenoid has failed or the solenoid

seat in the manifold has been damaged

Using the master On/Off toggle, turn the unit OFF. Use a syringe to bleed the

dental unit water pressure. Remove the cup fill solenoid. If the manifold seat

is good, replace the cup fill solenoid. If the manifold seat is damaged, replace

the manifold.

Water drips from the bowl rinse spout The bowl rinse solenoid has failed or the

solenoid seat in the manifold has been damaged

Close the manual city water shutoff. Use the master On/Off toggle to turn

the unit OFF and remove the bowl rinse solenoid. If the manifold seat is good,

replace the bowl rinse solenoid. If the manifold seat is damaged, replace

the manifold.

Cup fill and bowl rinse functions

are switched at the touchpad and

tower buttons

The cuspidor water solenoid connectors are

reversed on the cuspidor circuit board

Switch solenoid connections at P6 and P7.

Cup fill and bowl rinse functions are

switched at the tower buttons only

(touchpads operate normally)

The cuspidor tower switch connectors are

swapped on the cuspidor circuit board

Switch tower switch connections at P2 and P3.

Water runs constantly from either the cup

fill or bowl rinse spout and the red LED

(DS7) is illuminated on the cuspidor

circuit board

The cuspidor stop switch connector is

swapped with one of the cuspidor tower

switch connectors

The red LED (DS7) on the cuspidor circuit board is illuminated. Disconnect

all three switch connectors from the cuspidor circuit board. One at a time,

connect each of the switch connectors to the cuspidor circuit board until the red

LED goes out. Then connect one of the remaining switch connectors to

connector P3 on the cuspidor circuit board, and the other switch connector to

P2.Verify that a cup fill cycle runs when requested from the cuspidor tower cup

fill button. If the bowl rinse runs, swap the two switch connections to the

cuspidor circuit board.

Cup fill and bowl rinse functions are

switched at the touchpad only (tower

buttons operate normally)

The cuspidor water solenoid connectors and the

cuspidor tower switch connectors are swapped.

Switch the solenoid connections at P6 and P7. Switch the tower switch

connections at P2 and P3.

Page 12

Page 122 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Cuspidor Troubleshooting A-dec Service Guide, Vol. II

Problem Possible Cause Action

Cup fill spout sputters air/water The self-contained water bottle is empty or

near empty

Refill the bottle.

The bowl rinse function works, but the

cup fill spout sputters excessively, and

does not work from the cuspidor cup fill

button or the touchpad

The cuspidor air trap valve is faulty Remove and replace the air trap valve.

Cuspidor works but the red LED

(DS7) on the cuspidor circuit board

is illuminated

The cuspidor stop switch is activated or the

wiring is faulty

Remove any obstacles from under the cuspidor bowl. Disconnect the cuspidor

stop switch from P4 on the cuspidor circuit board; install the jumper from P1

on the cuspidor circuit board. If the red LED on the cuspidor circuit board goes

out, the cuspidor stop switch or wiring is faulty and must be replaced.

Bowl rinse button on the cuspidor tower

does not work, but the function does

work from the touchpad

Cuspidor tower bowl rinse button assembly is

faulty or is disconnected from the cuspidor

circuit board P2 connector

Visually inspect the cuspidor circuit board. Ensure that the cuspidor tower

switches are connected.

• P2 - Bowl rinse switch

• P3 - Cup fill switch

If the switches are connected, check the continuity of the bowl rinse switch

with an Ohm meter. With the bowl rinse switch held down (closed),it should

measure less than ten Ohms. If it measures “open”across the closed switch,

remove and replace the bowl rinse switch assembly (P/N 43.0010.00).

NOTE: Switching switch assemblies at P2 and P3 allows verification that the

switch assembly is defective.

Cup fill button on the cuspidor tower

does not work but the function does

work from the touchpad

Cuspidor tower cup fill button assembly is faulty

or is disconnected from the cuspidor circuit

board P3 connector

Visually inspect the cuspidor circuit board, ensure that the cuspidor tower

switches are connected:

• P2 - Bowl Rinse Switch

• P3 - Cup Fill Switch

If the switches are connected, check the continuity of the cup fill switch with an

Ohm meter. With the cup fill switch held down (closed), it should measure less

than ten Ohms. If it measures “open”across the closed switch, remove and

replace the cup fill switch assembly (P/N 43.0010.00).

NOTE: Switching switch assemblies at P2 and P3 allows verification that the

switch assembly is defective.

Page 13

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 123

A-dec Service Guide, Vol. II Cuspidor Troubleshooting

Problem Possible Cause Action

Inadequate or excessive cup fill

water flow

The cup fill water flow needs adjustment Open the cup fill flow controls for full water flow. Turn the flow controls to

adjust the water flow.

The self-contained water system 40 psi regulator

has failed

The 40 psi regulator can be tested as follows:

1. Turn the dental unit OFF using the master On/Off toggle.

2. Remove the water bottle from the dental unit and set it aside.

3. Remove the air bleed setscrew from the water bottle cap assembly and set

it aside.

4. Install an 1/8" barb with washer in the port where the air bleed setscrew

was removed.

5. Connect an air pressure gauge to the 1/8" barb using the 1/8" tubing.

6. Turn the dental unit ON. The air pressure reading on the gauge should be

35 – 40 psi.

7. Turn the dental unit OFF using the master On/Off toggle.

8. Remove the air pressure gauge from the 1/8" barb and washer from the air

bleed setscrew port.

9. Reinstall the air bleed setscrew and replace the water bottle (continued on

next page).

Figure 86. Line up the indicator dots on

the flow controls to adjust.

Page 14

Page 124 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Cuspidor Troubleshooting A-dec Service Guide, Vol. II

Problem Possible Cause Action

Inadequate or excessive cup fill

water flow (continued)

The self-contained water system 40 psi regulator

has failed

If a reading of 35 – 40 psi could not be obtained at the air bleed setscrew port,

the 40 psi regulator is faulty and must be replaced as follows:

1. Turn the dental unit OFF using the master On/Off toggle on the

delivery system.

2. Remove the water bottle cap assembly from the post or side support.

3. Remove and replace the 40 psi regulator.

4. Reinstall the water bottle cap assembly and water bottle.

5. Turn the dental unit ON and test the cup fill function for adequate

water pressure.

The self-contained water system air bleed set

screw is partially clogged with debris

1. Use the master On/Off toggle, to turn the dental unit OFF, and remove the

water bottle.

2. Remove the air bleed setscrew from the water bottle cap assembly and

clean it of debris, or replace it.

3. Reinstall the setscrew in the water bottle cap assembly and replace the

water bottle.

4. Turn the dental unit ON and test the cup fill function.

Inadequate bowl rinse water flow The bowl rinse water flow needs to be adjusted,

the water filter element is partially plugged, or

there is a kinked hose

Adjust the bowl rinse flow clockwise to increase water flow, or counterclockwise to

decrease flow, (one full turn from minimum to maximum).

To check for plugged water regulator filter element.

1. Close the city water manual shut-off valve in the floor box and bleed the

cuspidor bowl rinse water pressure, using the bowl rinse function.

2. Turn the dental unit OFF using the master On/Off toggle on the delivery

system and remove the water regulator filter element cap. Remove and

discard the filter element.

3. Install a new filter element on the water regulator and reinstall the filter cap.

4. Open the city water manual shut-off valve. Turn the dental unit ON using

the master On/Off toggle, and test the bowl rinse function for adequate

water flow.

Check for a restriction downstream from the filter. Locate and eliminate any kinks

in the blue 5/16" bowl rinse water tube.

Page 15

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 125

A-dec Service Guide, Vol. II Cuspidor Troubleshooting

Problem Possible Cause Action

Bowl rinse function does not work from

the cuspidor tower and/or the touchpad

bowl rinse button. The cup fill function

does work

The bowl rinse relay on the cuspidor circuit

board has failed

At the cuspidor circuit board, swap the water solenoid connectors at P6 and P7.

Press the cup fill button on any touchpad or the cup fill switch on the cuspidor

tower, if the bowl rinse runs, remove and replace the cuspidor circuit board.

The cuspidor data line is damaged Ensure that the cuspidor tower switches are connected:

• P2 – Bowl rinse switch

• P3 – Cup fill switch

Disconnect the data line from the cuspidor and press the bowl rinse switch on

the cuspidor tower. If the bowl rinse runs; remove and replace the cuspidor

data line.

The bowl rinse solenoid has failed Remove and replace the bowl rinse water solenoid.

Cup fill function does not work from the

cuspidor tower and/or from any touchpad

cup fill button. The bowl rinse function

does work

The cup fill relay on the cuspidor circuit board

has failed

Swap the water solenoid connectors at P6 and P7, at the cuspidor circuit board.

Press Bowl Rinse on any touchpad or the bowl rinse switch on the cuspidor

tower. If the cup fill runs, remove and replace the cuspidor circuit board.

The cuspidor data line is damaged Ensure that the cuspidor tower switches are connected correctly:

• P2 – Bowl rinse switch

• P3 – Cup fill switch

Disconnect the data line from the cuspidor and press the cup fill switch on the

cuspidor tower. If the cup fill runs; remove and replace the cuspidor data line.

The cup fill water solenoid has failed Remove and replace the cup fill water solenoid.

Page 16

Page 126 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Support Side Water Bottle A-dec Service Guide, Vol. II

How to Identify Support Side Water Bottle Components

The self-contained water bottle mounts inside the support center module. To access the water

bottle, swing open the end cover of the support center. The support side water bottle uses the

same cap housing assembly to mount the water bottle as the front mount self-contained water

bottle, but without the outer housing.

CAUTION: Use caution when using the self-contained water system with any dental units

equipped with components that might fail when the water supply is interrupted.

Some types of scalers and water heaters are examples of components that can

be permanently damaged if operated without a continuous water source.

A-dec does not recommend using saline solutions, mouth rinses, or any

chemical solutions, not specified by A-dec, in the A-dec self-contained water

system. These may damage the water system components and cause the

failure of the dental unit.

How the Self-Contained Water Bottle Works

The A-dec self-contained water bottle uses air pressure to force water from the bottle into the

water pick-up tube and out to the chair air/water manifold. There it connects to various water

outputs such as the handpiece control block, syringe, and the cuspidor cup fill.

Figure 87. Swing open the end cover to

access the water bottle.

Figure 88. How the water bottle works.

Page 17

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 127

A-dec Service Guide, Vol. II Support Side Water Bottle Components

Support Side Water Bottle

The one-piece design of the A-dec water bottle reduces contamination when maintaining the system by not touching the pick-up tube during

refilling and maintenance.

WARNING: Use only A-dec water bottles. Do not use other brands, or damaged bottles.

They can pose a serious safety hazard if broken while pressurized.The A-dec plastic

water bottles cannot withstand heat sterilization. Attempting to do so will damage

the bottle and the sterilizer.

Item #

Part Number

Description

1

035.048.01

O-ring, pkg 10

2

14.0457.00

Connector

3

14.0453.00

Funnel

4

010.002.00

Retaining ring

5

031.130.01

O-ring, pkg 10

6

14.0458.00

Clamp

7

005.110.00

Screw

8

14.0466.00

Water bottle

1

2

3

4

5

8

6

7

Figure 89. Identification of the water bottle components.

Page 18

Page 128 85.0816.00 Rev A 2004-11 (PCA 04002.12)

How to Identify Amalgam Separator Housing Components

The A-dec 500 amalgam separator housing is attached to the support center. Use the support center nose cover on the amalgam separator

housing after installation.

Several brands of amalgam separators can be mounted inside the A-dec 500 amalgam separator housing. Follow the manufacturers instructions

for the specific separator being installed.

Item #

Part Number

Description

1

77.0011.00

Cover, top

2

77.0009.00

Cover, side (both sides)

3

77.0037.00 Cover, nose

2

1

3

Figure 90. Identification of the amalgam separator housing components.

Amalgam Separator Housing A-dec Service Guide, Vol. II

Page 19

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 129

A-dec Service Guide, Vol. II Amalgam Separator Housing

Item #

Part Number

Description

1

002.073.00

Sockethead screw 10-32 x 3/4

2

001.089.00

Sockethead screw 1/4-20 x 5/8

1

2

Figure 91. Identification of the amalgam separator housing mounting hardware.

Page 20

Page 130 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Support Side Monitor Mount A-dec Service Guide, Vol. II

How to Identify Support Side Monitor Mount Components

Minimum Monitor Specifications:

Digital Monitor Requirements

• Medical-grade monitor

• 15" diagonal active display

• 1024 x 768 resolution

• Digital inputs

• VESA mounting compliant

•SVGA

Analog Monitor Requirements

• Color palette adjustments

• 13" HDTV flat panel for analog integration

• NTSC or PAL format

•Video inputs

• Composite video display capability

•RCA connection port

Item #

Part Number

Description

1

28.1501.00

Cap

2

001.088.00

Screw, adjustment

3

77.0213.00

Small cover, Surf 4

4

77.0026.00

Monitor mount cover

5

77.0102.00

Bearing, upper

6

77.0103.00

Bearing, lower

7

77.0201.00

Rotation stop

8

77.0112.00

Pivot assembly

9

77.0113.00*

VESA adapter

10

77.0199.00 Monitor post

11

*

Rigid arm

12

77.0114.01 Support arm

13

002.130.00 Button head screw

14

002.094.00 Screw

15

006.022.00 Nut

16

77.0115.00* Monitor bracket

17

77.0116.00* Monitor handle

* Item not for sale.

Page 21

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 131

A-dec Service Guide, Vol. II Support Side Monitor Mount

1

5

6

7

10

11

12

2

4

9

8

Power

supply

Monitor

Figure 92. Identification of the support side monitor mount components.

14

15

13

3

17

16

Page 22

Page 132 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Support Side Monitor Mount A-dec Service Guide, Vol. II

Support Side Monitor Tray Holder

Item #

Part Number

Description

1

005.157.00

Screw

2

004.019.00

Washer

3

004.172.00

Washer

4

016.102.00

Thrust bearing

5

77.0365.00

Hub

6

004.242.00

Washer

7

77.0197.00

Extender

8

004.021.00

Washer

9

77.0189.00

Arm

10

77.0190.00 Bracket

11

77.0198.00 Cover

12

002.112.00 Screw

13

005.012.03 Screw

14

77.0071.00 Tray holder, large

15

75.0017.00 Standard tray holder

Page 23

85.0816.00 Rev A 2004-11 (PCA 04002.12) Page 133

A-dec Service Guide, Vol. II Support Side Monitor Mount

1

2

3

4

3

5

12

7

8

6

9

14

10

13

11

3

4

2

6

Figure 93. Identification of monitor tray holder components.

Page 24

Page 134 85.0816.00 Rev A 2004-11 (PCA 04002.12)

Support Side Monitor and Tray Holder Adjustments A-dec Service Guide, Vol. II

How to Adjust Support Side Mounted Monitor and Tray Holder

Monitor Mount Tilt/Friction Adjustments

There are two adjustments that can be made to the monitor: tilt and drift friction.

Tilt Friction

The tilt friction can be adjusted by tightening or loosening the tilt friction adjustment screw

located on the top of the monitor mount.

Drift Friction

The drift friction can be adjusted by tightening or loosening the drift adjustment screw located

on the top of the monitor mount.

Tray Holder Tension Adjustment

The tension adjustment screw for the tray holder is located in the hub of the tray holder arm.

1. Locate the small hole in the tray holder hub.

2. Insert a 5/32" hex key through the hole.

3. Rotate the tray support arm to adjust the tension, (clockwise

to increase tension — counterclockwise to decrease tension).

Figure 94. Monitor tilt and

friction adjustments.

Figure 95. Monitor tray adjustment.

Loading...

Loading...