Adam Equipment PMB53, PMB202 User Manual

Adam Equipment

PMB Moisture Analyser

Software Version 1.44

Adam Equipment strives to be more environmentally focused and uses recycled materials and environmentally friendly packaging where possible. As part of this initiative we have developed a short form manual that uses less paper and ink to describe the main functions of your new Adam moisture analyzer. A more detailed manual for this product, as well as manuals for all our current products, are available at www.adamequipment.com. Thank you for your support of Adam Equipment and we hope that you enjoy your new moisture analyzer.

1

©Adam Equipment 2017

SAFETY

This Moisture Analyzer complies with the European Council Directives and international standards for electromagnetic compatibility, and safety requirements.

Improper use or handling can result in damage or injury.

To prevent damage to the equipment, read these operating instructions thoroughly. Keep these instructions in a safe place.

The Moisture Analyzer is used for determination of the moisture in samples. Do not use it for any other purpose. Improper use is dangerous and can cause injury or damage to others and property.

The Moisture Analyzer must be operated as described in this manual. The environment must be controlled so that hazardous materials or conditions are not present.

The Moisture Analyzer must be operated only by trained personnel who are familiar with the properties of the samples used and with the operation of the instrument. Do not leave the analyzer unattended when running a test.

Make sure before getting started that the voltage printed on the rear panel is identical to your local voltage.

Your Moisture Analyzer is supplied with a 3-pin power cable with a grounding conductor. Use cables that meet the safety standards for your location and include the earth ground conductor. The power connection uses a standard IEC C13 socket on the cable with a plug suitable for the location. Do not use adaptors if the plug does not match your power supply.

The fuse should only be replaced with a time lag type fuse with high breaking capacity, 5Amp current rating.

DO NOT disconnect the earth ground connection.

The mains cable should not touch the enclosure where it can be heated during the test.

Remove the power cable if the Moisture Analyzer is serviced.

Protect the Moisture Analyzer from external liquids. Clean any spills immediately.

If there are any visible damage to the Moisture Analyzer or the power cable, Stop using the instrument immediately. Unplug the power and isolate the analyzer. Do not use until the faults have been repaired.

All repairs must be done by a trained technician. There are no user serviceable parts in the enclosure.

Contact Adam Equipment or your dealer for assistance or questions.

HOT SURFACES

During test the cover of the heating chamber can become very hot, especially near the top vent. Keep all material away from the vent area. Do not touch hot surfaces.

Leave 20 cm (about 8 inches) around the moisture analyzer and 1 m (3 ft.) above.

Samples will be hot after a test. Do not use bare fingers to pick up any samples pans or touch the materials. The internal surfaces of the weighing chamber may be hot for some time after a test.

MATERIALS

The PMB moisture analyzer is not suitable for all materials. During the drying process samples will be heated to high temperatures. Materials that are flammable or explosive should not be tested.

Materials that emit toxic, caustic or noxious fumes should only be tested in suitable fume hoods or with other ventilation.

Materials that will have a film on the surface during drying may cause high internal pressures to be present. These materials should not be tested using this method.

Materials that emit aggressive or corrosive fumes (such as acids) should be tested using small quantities of material in an area with good ventilation.

2

©Adam Equipment 2017

|

|

1.0 CONTENTS |

|

|

|

P.N. 3076610544, Revision D, February 2017 |

|

SAFETY .................................................................................................................................................. |

2 |

||

HOT SURFACES ................................................................................................................................ |

2 |

||

MATERIALS ........................................................................................................................................ |

2 |

||

1.0 |

CONTENTS ..................................................................................................................................... |

3 |

|

2.0 |

OPERATION.................................................................................................................................... |

4 |

|

2.1 |

TURNING ON THE ANALYZER FOR THE FIRST TIME ........................................................... |

4 |

|

2.2 |

SETTING THE TEST PROCEDURE ........................................................................................... |

4 |

|

2.3 |

RUNNING A TEST....................................................................................................................... |

7 |

|

3.0 |

USING THE INTERNAL MEMORY SETTING................................................................................. |

9 |

|

3.1 |

STORING TEST SETTINGS....................................................................................................... |

9 |

|

3.2 |

RECALL TEST SETTINGS ........................................................................................................ |

10 |

|

3.3 |

DELETE TEST SETTINGS ........................................................................................................ |

10 |

|

3.4 |

REVIEW TEST SETTINGS....................................................................................................... |

10 |

|

3.5 |

STORING TEST RESULTS ....................................................................................................... |

10 |

|

3.6 |

RECALLING TEST RESULTS ................................................................................................. |

10 |

|

3.7 |

DELETING TEST RESULTS.................................................................................................... |

11 |

|

4.0 |

COMMUNICATION / INTERFACES.............................................................................................. |

12 |

|

4.1 |

USING THE USB........................................................................................................................ |

12 |

|

4.2 |

STORING AND RECALLING TEST SETTINGS FROM USB MEMORY .................................. |

12 |

|

4.3 |

STORING RESULTS IN USB MEMORY................................................................................... |

13 |

|

4.4 |

STORE AND RECALL CONFIGURATION SETTING FROM USB MEMORY.......................... |

14 |

|

4.5 |

SERIAL INTERFACE ................................................................................................................. |

15 |

|

5.0 |

MENU STRUCTURE ..................................................................................................................... |

16 |

|

6.0 |

CALIBRATION ............................................................................................................................... |

17 |

|

7.0 |

WARRANTY................................................................................................................................... |

17 |

|

8.0 |

SAMPLE PREPARATION.............................................................................................................. |

18 |

|

9.0 |

SPECIFICATIONS......................................................................................................................... |

20 |

|

You use this equipment at your own risk. Adam Equipment, its affiliates and partners will not be liable or responsible for any damage that arises to persons or property when using this moisture analyzer.

3

©Adam Equipment 2017

2.0OPERATION

2.1TURNING ON THE ANALYZER FOR THE FIRST TIME

Set your analyzer in a well ventilate room and away from any flammable substances. Ensure that you are using the correct voltage for the analyzer. The voltage is shown on the back of the unit.

The master on /off switch is located on the back. To turn on the unit press the on / off switch at the rear of the analyzer, the display will show the serial number and software revision before starting its self test sequence. The display will show zero weight accompanied by the 0 symbol. There is a power button on the front that turns the screen off and sets the analyzer into standby mode.

It is a good idea to let the analyzer achieve a stable internal temperature before use – normally 30-60 min warm up time is advisable.

A stable sign ~ is shown when the analyzer is in stable condition. It will turn off if the analyzer is not stable. Exact zero is shown when the “0 “ symbol is on to the left of the display area.

NOTE: If a passcode has been set to limit access to the weighing functions the display will show “PASSCODES”. The display will change to show 7 digits set to zero with the rightmost digit flashing. Use the keypad to enter the secure code. See Supervisors Menu to see how to set the security code.

2.2 SETTING THE TEST PROCEDURE

The analyzer can be set up via the keypad, recalled from memory (internal or USB), or via a PC using the RS232 or USB. For information on using the computer interface for communicating with the analyzer please consult the full manual. Information on using the USB can be found under the section USING THE USB.

The PMB can perform 4 types of moisture tests:

% moisture =100 x ((initial mass - dry mass)/initial mass)

% solid =100 x (dry mass/initial mass)

% moisture vs. dry weight =100 x ((initial mass - dry mass)/dry mass) Also called ATRO Moisture

% solid vs. dry weight = 100 x (initial mass/dry mass) Also called ATRO Solid

ATRO Moisture or Solid tests are special applications specific to some industries. %Moisture and %Solid are the more common calculations.

4

©Adam Equipment 2017

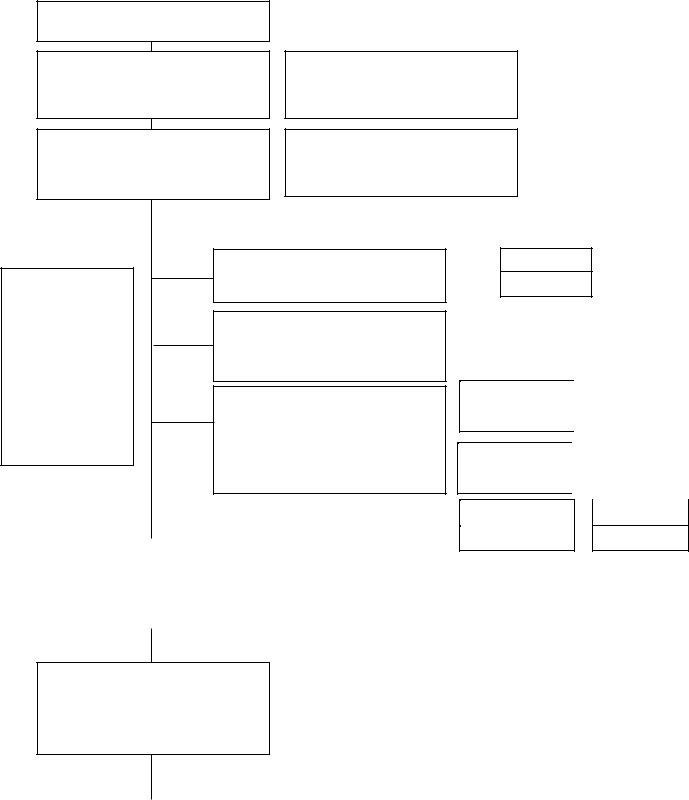

To set a test press the [Test] key

Display shows rESULt

Options are: Moisture, Solid, ATRO Moist, ATRO Solid

Display, shows HEAt

Options are: Single, Ramp, Step

Use arrow keys, [Dspl] and [Test], to change and press [Setup/Enter] to continue.

Use arrow keys, [Dspl] and [Test], to change and press [Setup/Enter] to select.

Use arrow keys,

[Dspl] and [Test], to change up and down. The [Print] and [PST] key to move to the right or left. Press

[Setup/Enter] to continue.

Option SINGLE

A single temp setting to heat to

Option RAMP

Will ramp up to a temperature with a user defined time

Option STEP

Heats to one temperature for a set time then to another temperature for another period of time. There are a maximum of 3 settings.

Display, shows INTERVAL |

|

|

|

INTERVAL |

|||

Set the time interval at which the |

|

||

|

|

||

results are computed, displayed |

|

SEC 10 |

|

and printed. Range is 1 to 99 sec. |

|

|

|

|

|||

|

|

|

SINGLE ºC

123

RAMP ºC |

|

RAMP TIME |

|

|

|||

|

|

|

|

|

|

|

|

123 |

|

|

06:00 |

|

|

||

|

|

|

|

|

|||

STEP 1 TEMP ºC |

|

|

STEP |

1 TIME |

|||

100 |

|

|

|

|

|

||

|

|

|

|

03:00 |

|||

|

|

|

|

||||

STEP 2 TEMP ºC |

|

|

STEP 2 TIME |

||||

120 |

|

|

|

|

|

||

|

|

|

|

03:00 |

|||

|

|

|

|

|

|||

STEP 3 TEMP ºC |

|

|

STEP |

3 TIME |

|||

140 03:00

Display, shows RAPID (not enabled with RAMP heating)

Options: On, Off or manual (manual asks each time the user runs a test)

Note: RAPID heat will cause the target temp to be 145% or 160°C (whichever is less) of the value set for single or the first ramp step for a time of 3 minutes.

Rapid – off means the function is disabled, on means it will always work for every test and manual will ask the user each time the test is run.

5

©Adam Equipment 2017

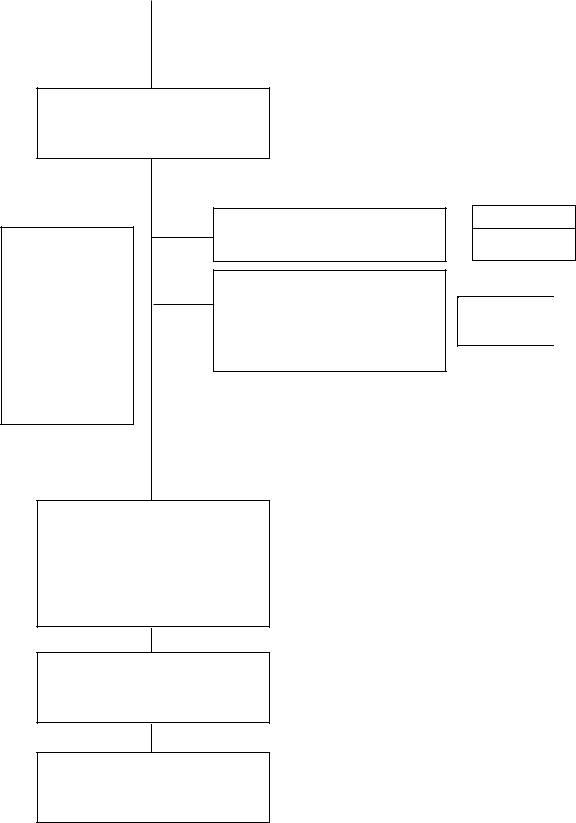

Display, shows StOP

Options are: Time, Stab or Time / Stab

Use arrow keys,

[Dspl] and [Test], to change up and down. The [Print] and [PST] key to move to the right or left. Press

[Setup/Enter] to continue.

Option TIME

Will stop at a set time

Option STAB

Stops automatically when a stable reading is recorded for a set time. User can define the time and stability range.

STOP TIME

Min 30

STAB RANGE |

|

stAB time |

02 |

|

|

|

sec15 |

|

Option TIME / STAB |

|

|

|

|

|

|

|

|

stop time |

|

stop RANGE |

|

stop time |

|

|

A combination of the other two |

|

|

|

|

|

|

|

min 30 |

|

02 |

|

sec15 |

||

|

|

|

|

||||

|

settings, a max time and |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

stability setting. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display, shows Start Options are: Manual (when the start button is pressed), or

automatically (once the cover is lowered after a 5 second delay the test will start).

Display, shows PRINT TEST Options are: on, off

Display, shows FORMAT

Options are: comp, summ

Note: PRINT TEST allows for the printing / saving the results during the test. If set to on the PMB will also store the results to memory using the file name given by the user. See section on USING THE INTERNAL MEMORY SETTING.

The FORMAT option lets the user select the type of printing output. Comp shows all the results and Summ shows just the final results. See the complete manual for information on the different output settings.

The user can print the current configuration by pressing the [Print] key during the process providing the second function for that key is not needed.

6

©Adam Equipment 2017

Loading...

Loading...