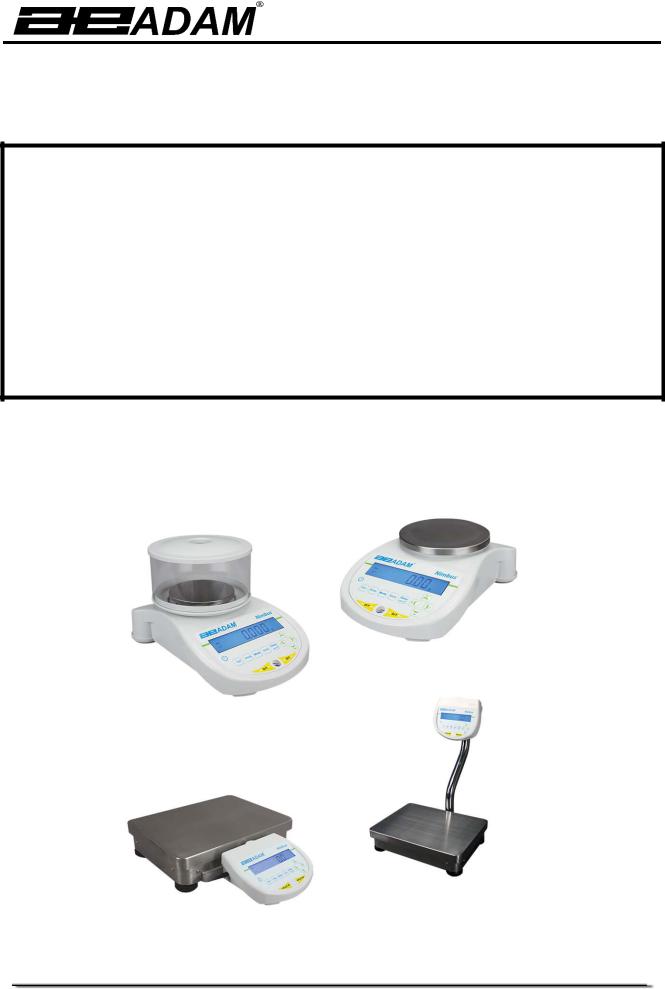

Adam Equipment NBL 22001e, NBL 12001e, NBL 16001e User Manual

Adam Equipment

Nimbus NBL Series

(P.N. 3016612481, Revision 3.00, Effective Aug 2017)

Operating Manual

For internal (‘i’), external (‘e’) calibration (“p”) pillar models

Software rev.: |

V3.1145 |

& above (Force Motor Analytical Models) |

|

V4.1826 |

& above (Precision Load Cell Models) |

© Adam Equipment Company 2017

© Adam Equipment Company 2017

TABLE OF CONTENTS

1 |

KNOW YOUR BALANCE.......................................................................................................... |

3 |

||

2 |

PRODUCT OVERVIEW............................................................................................................ |

4 |

||

3 |

PRODUCT SPECIFICATIONS ................................................................................................. |

5 |

||

4 |

UNPACKING THE BALANCE................................................................................................. |

11 |

||

5 |

LOCATING THE BALANCE.................................................................................................... |

11 |

||

6 SETTING UP THE BALANCE................................................................................................. |

13 |

|||

6.1 |

ASSEMBLING THE BALANCE....................................................................................... |

13 |

||

|

6.1.1 |

Levelling the balance................................................................................................. |

13 |

|

|

6.1.2 |

Warm-Up Time.......................................................................................................... |

13 |

|

|

6.1.3 |

Weighing ................................................................................................................... |

13 |

|

6.2 |

CALIBRATION ................................................................................................................ |

14 |

||

|

6.2.1 |

Manual Calibration .................................................................................................... |

14 |

|

|

6.2.2 Calibration using Internal Calibration mass (if fitted)................................................. |

14 |

||

|

6.2.3 Calibration using External Calibration mass.............................................................. |

14 |

||

|

6.2.4 |

Automatic Calibration ................................................................................................ |

14 |

|

|

6.2.5 |

Calibration Errors ...................................................................................................... |

15 |

|

7 |

DISPLAY................................................................................................................................. |

16 |

||

7.1 |

SYMBOLS AND TEXT .................................................................................................... |

16 |

||

8 |

KEYPAD.................................................................................................................................. |

17 |

||

8.1 |

NUMERIC ENTRY METHOD.......................................................................................... |

18 |

||

9 |

INPUT/OUTPUT...................................................................................................................... |

19 |

||

10 |

OPERATIONS...................................................................................................................... |

20 |

||

10.1 |

INITIALISATION.............................................................................................................. |

20 |

||

10.2 |

PASSCODES.................................................................................................................. |

20 |

||

10.3 |

WEIGHING...................................................................................................................... |

21 |

||

10.4 |

FUNCTIONS ................................................................................................................... |

22 |

||

|

10.4.1 |

Parts Counting....................................................................................................... |

23 |

|

|

10.4.2 |

Percentage Weighing ............................................................................................ |

24 |

|

|

10.4.3 |

Dynamic (Animal) Weighing .................................................................................. |

25 |

|

|

10.4.4 |

Density Determination ........................................................................................... |

27 |

|

11 |

RS-232 INTERFACE............................................................................................................ |

29 |

||

11.1 |

HARDWARE ................................................................................................................... |

29 |

||

11.2 |

OUTPUT FORMATS....................................................................................................... |

29 |

||

|

11.2.1 |

SINGLE-LINE OUTPUT FORMAT ........................................................................ |

29 |

|

|

11.2.2 |

STANDARD OUTPUT FORMAT ........................................................................... |

30 |

|

|

11.2.3 |

CUSTOM OUTPUT FORMAT ............................................................................... |

30 |

|

11.3 |

INPUT COMMANDS USING REMOTE KEYS................................................................ |

31 |

||

|

11.3.1 |

Invalid Input Command:......................................................................................... |

31 |

|

12 |

ERROR CHECKING ............................................................................................................ |

33 |

||

13 |

SUPERVISOR MENUS........................................................................................................ |

34 |

||

13.1 |

ENABLE WEIGHING UNITS........................................................................................... |

34 |

||

13.2 |

ENABLE WEIGHING MODES ........................................................................................ |

34 |

||

13.3 |

ENABLE SERIAL INTERFACE PARAMETERS ............................................................. |

34 |

||

13.4 |

FORMAT OF CUSTOM FORMS #1 and #2.................................................................... |

35 |

||

13.5 |

SETUP PARAMETERS................................................................................................... |

36 |

||

13.6 |

CALIBRATION SETUP ................................................................................................... |

37 |

||

13.7 |

PASSCODES.................................................................................................................. |

37 |

||

14 ACCESSORIES & SPARE PARTS...................................................................................... |

39 |

|||

15 |

SAFETY AND MAINTENANCE ........................................................................................... |

41 |

||

16 |

TROUBLE-SHOOTING........................................................................................................ |

42 |

||

16.1 |

TROUBLE-SHOOTING GUIDE....................................................................................... |

43 |

||

17 |

SERVICE INFORMATION ................................................................................................... |

45 |

||

18 |

BALANCE MENU STRUCTURE.......................................................................................... |

46 |

||

19 |

LANGUAGE TABLE............................................................................................................. |

49 |

||

20 |

WARRANTY INFORMATION .............................................................................................. |

50 |

||

© Adam Equipment Company 2017 |

1 |

© Adam Equipment Company 2017 |

2 |

1 KNOW YOUR BALANCE

Thank you for selecting the Nimbus Balance from Adam Equipment.

This Instruction Manual will familiarise you with the installation, use, general maintenance etc. of the balance, and will guide you through the various applications. It also covers accessories, trouble-shooting, after sales service information, and other important information.

These balances are highly accurate precision instruments and contain sensitive mechanisms and components. They should be transported and handled with care. When in operation, be careful to place loads gently on the weighing surface and do not overload or exceed recommended maximum capacity of the instrument or damage may occur.

Please read this Manual thoroughly before starting operation. If you need any clarifications, feel free to contact your supplier or Adam Equipment.

© Adam Equipment Company 2017 |

3 |

2 PRODUCT OVERVIEW

The Nimbus balances are ideal for laboratory and general purpose weighing. They can also be used for some advanced weighing functions.

FEATURES:

External menu-driven calibration allowing user-selectable range of calibration weights.

Internal calibration (option) for outstanding accuracy without the need for manual calibration.

Mains powered, with some models offering rechargeable battery pack option for cordless use.

Solid die-cast aluminium alloy construction with 304 grade stainless steel pan for durability and easy cleaning.

Large easy to read LCD display with backlight.

Standard applications include weighing, percentage weighing, parts counting, dynamic (animal) weighing (not ‘j’ models), and solid and liquid density determination.

Bi-directional RS-232 interface and USB interface as standard.

External display option

Can be configured to print a GLP Compliant report after each calibration to include the time, date, balance number and a verification of the calibration.

Force-restoration mechanism for supreme accuracy, or alloy load cell technology for stable yet accurate weighing.

Automatic temperature compensation.

Multiple weighing units.

Easy to use, wipe-clean sealed membrane keypad.

Below balance weighing facility (accessory hook required).

Display in a choice of 4 languages – English, German, French & Spanish.

Password protection.

Security locking point.

© Adam Equipment Company 2017 |

4 |

3 PRODUCT SPECIFICATIONS

Nimbus NBL Models

(Suffix e for external calibration models, Suffix i for internal calibration models)

Model # |

NBL 84 e/i |

|

NBL 124 e/i |

|

NBL 164 e/i |

|

NBL 214 e/i |

|

NBL 254 e/i |

|

NBL 214j e/i |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum |

80 g |

|

|

120 g |

|

160 g |

|

210 g |

|

250 g |

|

210 g |

Capacity |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Readability (d) |

|

|

|

|

|

0.0001 g |

|

|

|

|

0.0002 g |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of |

800000 |

|

|

1200000 |

|

1600000 |

|

2100000 |

|

2500000 |

|

2100000 |

intervals n= |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. weight |

|

|

|

|

|

0.01 g |

|

|

|

|

0.02 g |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Repeatability |

0.00015 g |

|

|

|

0.0002 g |

|

|

0.0004 g |

||||

(Std. Dev) |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Linearity + |

|

|

|

|

|

0.0002 g |

|

|

|

|

0.0004 g |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

grams, milligrams, carats, grains, Newtons, ounces, troy ounces, |

|

grams, |

|||||||||

Units of Measure |

|

milligrams, |

||||||||||

|

|

|

pennyweight, custom |

|

|

|||||||

|

|

|

|

|

|

carats, |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Stabilization |

|

|

|

|

|

Typically 3 seconds |

|

|

|

|||

Time |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating Temp |

|

|

|

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

|

|||||||

|

|

|

|

External mains power adapter - supplied as standard |

|

|||||||

Power Supply |

|

|

|

|

||||||||

|

|

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

|

||||||||

|

|

|

|

|

||||||||

Input Voltage |

|

|

|

|

|

18 VDC - 830 mA |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Weighing |

|

|

|

|

Force Restoration Balance Motor |

|

|

|

||||

mechanism |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Calibration |

|

Suffix i = internal calibration mechanism, e = external calibration only |

||||||||||

|

|

|

|

Recommended OIML class: E2, ASTM / ANSI class: 1 |

|

|||||||

External |

|

|

|

|

||||||||

Calibration Mass |

50 g |

|

|

100 g |

|

|

|

100 g |

|

|||

|

|

|

|

|

|

|

||||||

Display |

|

|

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Draft Shield |

|

|

|

Sliding door Draft Shield |

(165 x 145 x 240 mm) |

|

||||||

(w x d x h) |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Pan Size |

|

|

|

|

|

Round, 90mm diameter |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Overall |

|

|

|

|

|

220 x 310 x 323 mm |

|

|

|

|||

Dimensions |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

8.7 x 12.2 x 12.7 in |

|

|

|

||||

(w x d x h) |

|

|

|

|

|

|

|

|

||||

|

|

|

5.2 kg / 11 lb 9 oz (external calibration model) |

|

||||||||

Net Weight |

|

|

|

|

||||||||

|

|

|

5.9 kg / 13 lb 0 oz (internal calibration model) |

|

||||||||

|

|

|

|

|

||||||||

© Adam Equipment Company 2017 |

5 |

Model # |

|

NBL 223 e / i |

|

NBL 423 e / i |

|

|

|

|

|

Maximum Capacity |

|

220 g |

|

420 g |

|

|

|

|

|

Readability (d) |

|

|

0.001 g |

|

|

|

|

|

|

Number of intervals |

220000 |

|

420000 |

|

n= |

|

|||

|

|

|

|

|

Min. |

|

0.02 g |

|

0.02 g |

|

|

|

|

|

Repeatability |

|

|

0.002 g |

|

(Std. Dev) |

|

|

||

|

|

|

|

|

Linearity + |

|

|

0.002 g |

|

|

|

grams, milligrams, carats, grains, Newtons, ounces, troy ounces, pennyweight, custom |

||

Units of Measure |

||||

|

|

|

|

|

Stabilization Time |

|

|

Typically 3 seconds |

|

|

|

|

||

Operating Temp |

|

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

||

|

|

External mains power adapter - supplied as standard |

||

|

||||

Power Supply |

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

||

|

|

Factory-fit NiMH battery pack option. |

||

Input Voltage |

|

|

18 VDC - 830 mA |

|

|

|

|

|

|

Weighing |

|

|

Precision Load Cell |

|

mechanism |

|

|

||

|

|

|

|

|

Calibration |

|

Suffix i = internal calibration mechanism, e = external calibration only, |

||

|

|

Recommended OIML class: E2, ASTM / ANSI class: 2 |

||

External Calibration |

|

|||

Mass |

|

100 g |

|

200 g |

|

|

|

|

|

Display |

|

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

||

|

|

|

|

|

Draft Shield |

|

Glass Ring Draft Shield With Alloy Lid (180 mm diam. x 90 mm) |

||

(w x d x h) |

|

|||

|

|

|

|

|

Pan Size |

|

|

Round, 120 mm diameter |

|

|

|

220 x 310 x 90 mm without breeze ring |

||

Overall Dimensions |

|

|||

(w x d x h) |

|

|

8.7 x 12.2 x 3.5 in |

|

Net Weight |

|

3.1 kg / |

6 lb 12 oz (external calibration model) |

|

|

3.7 kg / 8 lb 8 oz (internal calibration model) |

|||

|

|

|||

© Adam Equipment Company 2017 |

6 |

Model # |

|

NBL 623 e / i |

|

NBL 823 e / i |

|

|

|

|

|

|

|

Maximum Capacity |

|

620 g |

|

820 g |

|

|

|

|

|

|

|

Readability (d) |

|

|

0.001 g |

||

|

|

|

|

|

|

Number of intervals |

620000 |

|

820000 |

||

n= |

|

||||

|

|

|

|

||

Min. weight |

|

0.02 g |

|

0.02 g |

|

|

|

|

|

|

|

Repeatability |

|

|

0.002 g |

||

(Std. Dev) |

|

|

|||

|

|

|

|

||

Linearity + |

|

|

0.002 g |

||

|

|

grams, milligrams, carats, grains, Newtons, ounces, troy ounces, pennyweight, custom |

|||

Units of Measure |

|||||

|

|

|

|

||

Stabilization Time |

|

|

Typically 3 seconds |

||

|

|

|

|||

Operating Temp |

|

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

|||

|

|

External mains power adapter - supplied as standard |

|||

Power Supply |

|||||

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

||||

|

|

||||

Input Voltage |

|

|

18 VDC - 830 mA |

||

|

|

|

|

|

|

Weighing |

|

Force Restoration Balance Motor |

|||

mechanism |

|

||||

|

|

|

|

||

Calibration |

|

Suffix i = internal calibration mechanism, e = external calibration only |

|||

|

|

Recommended OIML class: E2, ASTM / ANSI class: 2 |

|||

External Calibration |

|

||||

Mass |

|

|

500 g |

||

|

|

|

|||

Display |

|

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

|||

|

|

|

|

|

|

Draft Shield |

|

Glass Ring Draft Shield With Alloy Lid (180 mm diam. x 90 mm) |

|||

(w x d x h) |

|

||||

|

|

|

|

||

Pan Size |

|

|

Round, 160 mm diameter |

||

|

|

220 x 310 x 90 mm without breeze ring |

|||

Overall Dimensions |

|

||||

(w x d x h) |

|

|

8.7 x 12.2 x 3.5 in |

||

Net Weight |

|

4.0 kg / |

8 lb 13 oz (external calibration model) |

||

|

4.8 kg / 10 lb 9 oz (internal calibration model) |

||||

|

|

||||

|

|

|

|

|

|

© Adam Equipment Company 2017 |

7 |

Model # |

NBL 1602 e / i |

|

NBL 2602 e / i |

|

NBL 3602 e / i |

|

NBL 4602 e / i |

|

|

|

|

|

|

|

|

Maximum Capacity |

1600 g |

|

2600 g |

|

3600 g |

|

4600 g |

|

|

|

|

|

|

|

|

Readability (d) |

0.01 g |

|

0.01 g |

|

0.01 g |

|

0.01 g |

|

|

|

|

|

|

|

|

Number of |

160000 |

|

260000 |

|

360000 |

|

460000 |

intervals n= |

|

|

|

||||

|

|

|

|

|

|

|

|

Min. weight |

0.2 g |

|

0.2 g |

|

0.2 g |

|

0.2 g |

|

|

|

|

|

|

|

|

Repeatability |

|

|

|

0.02 g |

|

||

(Std. Dev) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

Linearity + |

|

|

|

0.02 g |

|

||

|

|

grams, carats, grains, Newtons, ounces, troy ounces, |

|

||||

Units of Measure |

|

|

|||||

|

|

pennyweight, pounds, kilograms, custom |

|

||||

|

|

|

|

||||

Stabilization Time |

|

|

Typically 3 seconds |

|

|||

|

|

|

|

||||

Operating Temp |

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

||||||

|

|

External mains power adapter - supplied as standard |

|

||||

|

|

|

|||||

Power Supply |

|

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

|

|||

|

|

|

Factory-fit NiMH battery pack option. |

|

|||

Input Voltage |

|

|

18 VDC - 830 mA |

|

|||

|

|

|

|

|

|

|

|

Weighing |

|

|

Precision Load Cell |

|

|||

mechanism |

|

|

|

||||

|

|

|

|

|

|

|

|

Calibration |

Suffix i = internal calibration mechanism, e = external calibration only |

||||||

|

|

Recommended OIML class: F1, ASTM / ANSI class: 3 |

|

||||

External |

|

|

|||||

Calibration Mass |

1 kg |

|

2 kg |

|

2 kg |

|

2 kg |

|

|

|

|

|

|||

Display |

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

||||||

|

|

|

|

|

|

|

|

Draft Shield |

|

|

|

None |

|

||

(w x d x h) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

Pan Size |

|

|

Round, 160 mm diameter |

|

|||

|

|

|

220 x 310 x 90 mm |

|

|||

Overall |

|

|

|

||||

Dimensions |

|

|

8.7 x 12.2 x 3.5 in |

|

|||

(w x d x h) |

|

|

3.1 kg / 6 lb 14 oz (external calibration model) |

|

|||

Net Weight |

|

|

|

||||

|

|

3.9 kg / 8 lb 10 oz (internal calibration model) |

|

||||

|

|

|

|

||||

© Adam Equipment Company 2017 |

8 |

Model # |

NBL 4201e |

|

NBL 6201e |

|

NBL 8201e |

|

|

|

|

|

|

Maximum Capacity |

4200g |

|

6200g |

|

8200g |

|

|

|

|

|

|

Readability (d) |

0.1g |

|

0.1g |

|

0.1g |

|

|

|

|

|

|

Number of |

42000 |

|

62000 |

|

82000 |

intervals n= |

|

|

|||

|

|

|

|

|

|

Min. weight |

2 g |

|

2 g |

|

2 g |

|

|

|

|

|

|

Repeatability |

|

|

0.1g |

|

|

(Std. Dev) |

|

|

|

||

|

|

|

|

|

|

Linearity + |

|

|

0.1g |

|

|

|

|

grams, carats, grains, Newtons, ounces, troy ounces, |

|

||

Units of Measure |

|

|

|||

|

pennyweight, pounds, kilograms, custom |

|

|||

|

|

|

|||

Stabilization Time |

|

|

Typically 3 seconds |

|

|

|

|

|

|||

Operating Temp |

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

||||

|

|

External mains power adapter - supplied as standard |

|

||

|

|

|

|||

Power Supply |

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

|

||

|

|

Factory-fit NiMH battery pack option. |

|

||

Input Voltage |

|

|

18 VDC - 830 mA |

|

|

|

|

|

|

|

|

Weighing |

|

|

Precision Load Cell |

|

|

mechanism |

|

|

|

||

|

|

|

|

|

|

Calibration |

|

|

External calibration only |

|

|

|

Recommended OIML class: F2, ASTM / ANSI class: 4 |

||||

External |

|||||

Calibration Mass |

2 kg |

|

2 kg |

|

|

|

|

|

|||

Display |

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

||||

|

|

|

|

|

|

Draft Shield |

|

|

None |

|

|

(w x d x h) |

|

|

|

||

|

|

|

|

|

|

Pan Size |

|

|

Round, 160 mm diameter |

|

|

|

|

|

220 x 310 x 90 mm |

|

|

Overall |

|

|

|

||

Dimensions |

|

|

8.7 x 12.2 x 3.5 in |

|

|

(w x d x h) |

|

|

|

|

|

Net Weight |

|

|

3.1 kg / 6 lb 14 oz |

|

|

|

|

|

|

|

|

© Adam Equipment Company 2017 |

9 |

(Suffix e for external calibration models, Suffix p for internal calibration models)

Model # |

NBL 12001e / p |

|

NBL 16001e / p |

|

NBL 22001e / p |

||

|

|

|

|

|

|

|

|

Maximum Capacity |

12000g |

|

16000g |

|

22000g |

||

|

|

|

|

|

|

|

|

Readability (d) |

0.1g |

|

0.1g |

|

0.1g |

||

|

|

|

|

|

|

|

|

Number of |

120000 |

|

160000 |

|

|

220000 |

|

intervals n= |

|

|

|

||||

|

|

|

|

|

|

||

Min. weight |

2 g |

|

2 g |

|

2 g |

||

|

|

|

|

|

|

|

|

Repeatability |

|

|

0.1g |

|

|||

(Std. Dev) |

|

|

|

||||

|

|

|

|

|

|

||

Linearity + |

|

|

0.1g |

|

|||

|

grams, carats, grains, Newtons, ounces, troy ounces, |

||||||

Units of Measure |

|||||||

|

pennyweight, pounds, kilograms, custom |

|

|||||

|

|

|

|||||

Stabilization Time |

|

|

Typically 3 seconds |

|

|||

|

|

|

|

||||

Operating Temp |

15ºC to 35ºC recommended, 40 – 60 % RH (non-condensing) |

||||||

|

External mains power adapter - supplied as standard |

||||||

|

|||||||

Power Supply |

|

(Input Voltage 100–240 VAC, 50/60 Hz) |

|

||||

|

|

Factory-fit NiMH battery pack option. |

|

||||

Input Voltage |

|

|

18 VDC - 830 mA |

|

|||

|

|

|

|

|

|

|

|

Weighing |

|

|

Precision Load Cell |

|

|||

mechanism |

|

|

|

||||

|

|

|

|

|

|

||

Calibration |

|

|

External calibration only |

|

|||

|

Recommended OIML class: F2, ASTM / ANSI class: 4 |

||||||

External |

|||||||

Calibration Mass |

5 kg |

|

10 kg |

|

|

10 kg |

|

|

|

|

|

|

|||

Display |

LCD with blue backlight, 7 characters, 20 mm high, and symbols |

||||||

|

|

|

|

|

|

|

|

Draft Shield |

|

|

None |

|

|||

(w x d x h) |

|

|

|

||||

|

|

|

|

|

|

||

Pan Size |

|

|

400 x 300 mm |

|

|||

|

400 x 480 x 100 mm (590 mm tall with pole accessory) |

||||||

Overall |

|||||||

Dimensions |

|

|

15.7 x 12.2 x 3.5 in |

|

|||

(w x d x h) |

|

|

|

|

|

|

|

Net Weight |

|

|

7.6 kg / 16 lb 12 oz |

|

|||

|

|

|

|

|

|

|

|

© Adam Equipment Company 2017 |

10 |

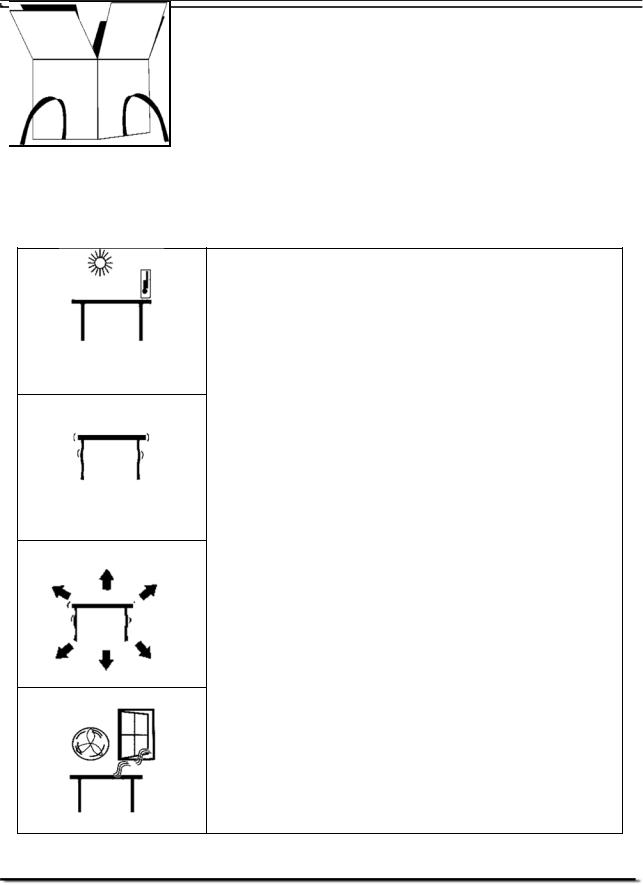

4 UNPACKING THE BALANCE

Remove the balance from the packing by carefully lifting it out of the box. Inside the box you will find everything needed to start using the balance-

AC mains power adapter & cord

Stainless Steel Top Pan

Alloy sub-pan

Draught shield (for mg models only)

User documentation

Carefully follow the quick setup guide included to assemble the balance.

5 LOCATING THE BALANCE

The balance should not be placed in a location that will reduce the accuracy.

Avoid extremes of temperature. Do not place in direct sunlight or near air conditioning vents.

Avoid unsuitable tables. The table or floor must be rigid and not vibrate.

Avoid unstable power sources. Do not use near large users of electricity such as welding equipment or large motors.

Do not place near vibrating machinery.

Avoid high humidity that might cause condensation.

Avoid direct contact with water. Do not spray or immerse the balances in water.

Avoid air movement such as from fans or opening doors. Do not place near open windows or air-conditioning vents.

Keep the balance clean. Do not stack material on the balances when they are not in use.

Avoid sources of static electricity. This can affect measurement accuracy and may damage sensitive electronics.

© Adam Equipment Company 2017 |

11 |

© Adam Equipment Company 2017 |

12 |

6 SETTING UP THE BALANCE

6.1 ASSEMBLING THE BALANCE

Carefully follow the included quick setup guide to assemble the balance. Ensure that you locate the balance on a solid level surface, free from vibration.

6.1.1 Levelling the balance

After placing the balance in a suitable location, level it by using the spirit level on the front of the balance. To level the balance turn the two adjustable feet at the rear of the balance until the bubble in the spirit level is centred.

6.1.2 Warm-Up Time

Before you start weighing, you should allow the balance to achieve a stable internal temperature. For accurate weighing to the manufacturer’s specification it is important to power on the balance and allow to warm up for at least 6 hours for load cell mechanisms, and 12 hours for force motor mechanisms.

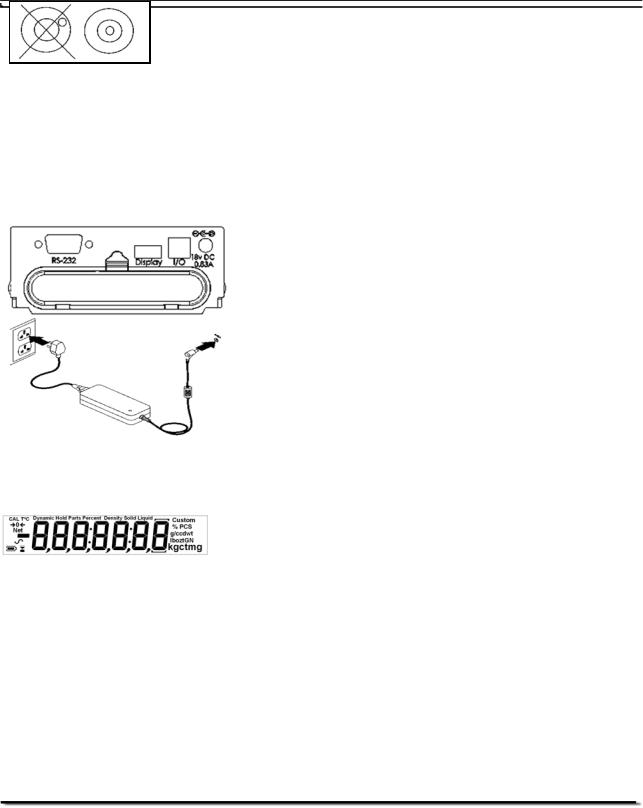

Insert the power supply cable DC connector to the connector on the rear of the balance. Plug the power supply module into the mains and press the power switch on the keypad to turn on the balance. The display will indicate the balance serial number followed by the software revision number, followed by the maximum capacity of the balance. Next the balance will run a selftest by displaying all segments followed by a busy symbol and a line of 7 dashes indicating the balance is in busy mode. Once ready, the display will show a zero weight reading, accompanied by the 0 symbol.

6.1.3 Weighing

Once a suitable warm-up period is complete and you are ready to start weighing, place an item to be weighed on the balance. A stable symbol  is shown when the balance is in stable condition. It will turn off if the balance is not stable.

is shown when the balance is in stable condition. It will turn off if the balance is not stable.

Exact zero is shown when the “0“ symbol is visible on the top left of the display area.

© Adam Equipment Company 2017 |

13 |

6.2CALIBRATION

Units with an ‘i’ suffix can be calibrated using either internal calibration mechanism or by using an external mass. Units with an ‘e’ suffix can only be calibrated with an external mass. Internal calibration option must be enabled in the setup menu options or else external calibration mode will be used when the [Cal] key is pressed.

6.2.1 Manual Calibration

Pressing the [Cal] key will start calibration. Calibration can also be initiated by a change in internal temperature or a set time period as determined by the user.

Pressing [0/T] will abort the calibration at any time.

Calibration should be performed carefully and in conditions of no vibration, air movement or other disturbance. Make sure the pan is empty, clean, and correctly fitted.

6.2.2 Calibration using Internal Calibration mass (if fitted)

Note: Internal calibration (if fitted) will only initiate if it is enabled as the default calibration method in the Supervisor level calibration setup menu.

On pressing the [Cal] key the display will show the busy symbol and a line of 7 dashes and then after a few seconds will display ‘ ’. Then the busy symbol and a line of 7 dashes will reappear, followed by ‘ ’. Then ‘ ’ will appear again, followed by

the busy symbol and a line of dashes. Finally ‘ ’ will be displayed, followed by a beep and the busy symbol and a line of dashes. A final beep will sound the end of

calibration and the display should return to ‘ . g’ or similar. Internal calibration is now complete and normal operations may proceed.

6.2.3 Calibration using External Calibration mass

Note: Calibration mass used should be a known accurate item, ideally with an OIML or ASTM/ANSI classification appropriate to the accuracy of the balance.

On pressing the [Cal] key the display will show the balance setting a new Zero condition by showing “ ”. Make sure the pan is empty then press the [Setup] key to continue

The display will show the busy symbol and a line of dashes and then after a few seconds will display the required calibration mass. For example, for a 213e model the display will

be “ g” where 100 g is the required calibration mass.

Place the selected mass on the balance. The balance will automatically continue. The display will show the busy symbol and a line of dashes and after calibration is complete it

will sound a beep and display “ ”. Remove the weight. Another beep will be heard confirming the unloading action. The balance will display the busy symbol and a line of dashes for a few seconds and then sound a beep and return to normal weighing.

6.2.4 Automatic Calibration

The balance will indicate the need for calibration when the balance has automatic calibration enabled and the set pre-conditions for automatic calibration have been met.

Conditions that will trigger an automatic calibration are:

© Adam Equipment Company 2017 |

14 |

Internal temperature change greater than a pre-set amount (typically 2ºC for Precision balances).

Time since last calibration exceeds a pre-set time (typically 4 hours, or 15 minutes after power is applied).

The balance will indicate the need for calibration to be carried out by flashing the “CAL” symbol on the display. As soon as the balance is calibrated the symbol will be turned off.

The Auto calibration feature can be enabled, disabled or changed within the user options to meet the requirements of the users.

6.2.5 Calibration Errors

Occasionally during calibration an error will be detected. These errors can be caused by:

Unstable readings

Improper calibration weights being used

Large shifts of zero from the factory settings

When an error is found a displayed message will be shown and the calibration must be done again. If the balance has error messages more than once it is possible the mechanics have been damaged.

© Adam Equipment Company 2017 |

15 |

Loading...

Loading...