A&D MC-10K, MC-30K User Manual

MC-10K

MC-30K

1WMPD4002203A

This Manual and Marks

All safety messages are identified by the following, “WARNING” or “CAUTION”, of ANSI Z535.4 (American National Standard Institute: Product Safety Signs and Labels). The meanings are as follows:

WARNING |

A potentially hazardous situation which, if not avoided, |

could result in death or serious injury. |

|

CAUTION |

A potentially hazardous situation which, if not avoided, |

may result in minor or moderate injury. |

This is a hazard alert mark.

This manual is subject to change without notice at any time to improve the product.

The contents of the product specifications and this manual are subject to change without any obligation on the part of the manufacturer.

Under the copyright laws, the software (program) described in it are copyrighted, with all rights reserved.

The software may be installed into one computer and may not be installed into other computers without the prior written consent of A&D Company. Copying includes translation into another language, reproduction, conversion, photocopy and offer or loan to another person.

Microsoft, Windows, Word and Excel are registered trademarks of the Microsoft Corporation.

2012 |

All rights reserved. |

No part of this publication may be reproduced, transmitted, transcribed, or translated into any language in any form by any means without the written permission of A&D Company, Limited.

Contents

Basic Operation |

|

|

1. |

Introduction ......................................................................................................... |

3 |

1-1. |

About This Manual ......................................................................................................... |

3 |

1-2. |

Features.......................................................................................................................... |

3 |

1-3. |

Compliance..................................................................................................................... |

4 |

1-3-1. Compliance with FCC Rules ..................................................................................... |

4 |

|

1-3-2. Compliance with EMC Directives.............................................................................. |

4 |

|

2. |

Unpacking And Installing The Balance................................................................ |

5 |

2-1. |

Auto-centering Pan (AX-MC10K/30KPAN) Installation Procedure ..................................................... |

6 |

2-2. |

Installing the Balance ..................................................................................................... |

7 |

3. |

Precautions......................................................................................................... |

8 |

3-1. |

Before Use...................................................................................................................... |

8 |

3-2. |

During Use...................................................................................................................... |

9 |

3-3. |

After Use......................................................................................................................... |

9 |

3-4. |

Power Supply .............................................................................................................. |

10 |

4. |

Display Symbols And Key Operation ................................................................ |

11 |

5. |

Weighing Units.................................................................................................. |

12 |

6. |

Weighing ........................................................................................................... |

14 |

6-1. |

Selecting a Weighing Unit (Mode) .............................................................................. |

14 |

6-2. |

Basic Weighing............................................................................................................ |

14 |

6-2-1. For More Stable Weighing....................................................................................... |

14 |

|

6-2-2. When Using as a Mass Comparator....................................................................... |

14 |

|

6-2-3. When Building into a System .................................................................................. |

15 |

|

Adapting to the Environment |

|

|

7. |

Weighing Speed Adjustment / Self Check Function ...................................................... |

16 |

7-1. |

Weighing Speed Adjustment....................................................................................... |

16 |

7-2. |

Self Check Function with Response Adjustment ....................................................... |

17 |

8. |

Calibration......................................................................................................... |

18 |

8-1. |

Calibration Group ........................................................................................................ |

18 |

8-2. |

Automatic Self Calibration........................................................................................... |

19 |

8-3. |

One-Touch Calibration ................................................................................................ |

20 |

8-4. |

Calibration Using an External Weight......................................................................... |

21 |

8-5. |

Calibration Test Using an External Weight ................................................................. |

22 |

8-6. |

Correcting the Internal Mass Value............................................................................. |

23 |

Functions |

|

|

9. |

Function Switch And Initialization...................................................................... |

25 |

9-1. |

Permit or Inhibit............................................................................................................ |

25 |

9-2. |

Initializing the Balance................................................................................................. |

26 |

10. |

Function Table................................................................................................... |

27 |

10-1. |

Structure and Sequence of the Function Table .......................................................... |

27 |

10-2. |

Display and Operation Keys ....................................................................................... |

27 |

10-3. |

Details of the Function Table....................................................................................... |

28 |

10-4. |

Description of the Class "Environment, Display"........................................................ |

32 |

1

10-5. |

Description of the Item "Data Output Mode" .............................................................. |

33 |

|

10-6. |

Description of the Item "Data Format" ........................................................................ |

34 |

|

10-6-1. Description of the Data Format Added to the Weighing Data............................................. |

36 |

||

10-7. |

Data Format Examples ............................................................................................... |

37 |

|

11. |

ID Number And GLP Report.............................................................................. |

38 |

|

11-1. |

Setting the ID Number................................................................................................. |

38 |

|

11-2. |

GLP Report.................................................................................................................. |

39 |

|

RS-232C Serial Interface |

|

||

12. |

Standard Input And Output Interface................................................................. |

42 |

|

12-1. |

RS-232C and External Contact Input ......................................................................... |

42 |

|

12-2. |

Connection to Peripheral Equipment.......................................................................... |

44 |

|

12-2-1. |

Connection to the AD-8121B Printer................................................................... |

44 |

|

12-2-2. |

Connection to a Computer and the Use of WinCT............................................. |

45 |

|

13. |

Commands........................................................................................................ |

46 |

|

13-1. |

Command List ............................................................................................................. |

46 |

|

13-2. |

Acknowledge Code and Error Codes......................................................................... |

47 |

|

13-3. |

Control Using CTS and RTS....................................................................................... |

48 |

|

13-4. |

Settings Related to RS-232C...................................................................................... |

48 |

|

14. |

Extended Function ............................................................................................ |

49 |

|

14-1. |

Description of "Averaging range" and "Averaging time" ...................................................... |

50 |

|

14-1-1. |

Averaging Range ( f1-b ) and Averaging Time ( f1-t )...................................... |

50 |

|

14-1-2. |

Filter Depending on Differences in the Amount to Deliver Powdery and Liquid Material........ |

51 |

|

Maintenance |

|

|

|

15. |

Maintenance ..................................................................................................... |

52 |

|

15-1. |

Treatment of the Balance............................................................................................ |

52 |

|

16. |

Troubleshooting ................................................................................................ |

53 |

|

16-1. |

Checking the Balance Performance and Environment.............................................. |

53 |

|

16-2. |

Error Codes ................................................................................................................. |

54 |

|

16-3. |

Other Display............................................................................................................... |

56 |

|

16-4. |

Asking for Repair ......................................................................................................... |

56 |

|

17. |

Specifications.................................................................................................... |

57 |

|

17-1. |

External Dimensions ................................................................................................... |

58 |

|

17-2. |

Options and Peripheral Instruments ........................................................................... |

59 |

|

18. |

Terms/Index ...................................................................................................... |

61 |

|

18-1. |

Terms ........................................................................................................................... |

61 |

|

18-2. |

Index ............................................................................................................................ |

63 |

|

2

1. Introduction

This manual describes how the MC Series Mass Comparator Balances, MC-10K and MC-30K, work and how to get the most out of them in terms of performance.

Read this manual thoroughly before using the balance and keep it at hand for future reference.

For other functions and operations that this manual does not describe, refer to the GX-K series instruction manual.

1-1. About This Manual

This manual consists of the following five parts:

Basic operation ........................ |

Describes precautions, the balance's construction and basic |

|

operation. |

Adapting to the environment .... |

Describes response (and stability) adjustment to adapt to |

|

the environment where there is vibration or drafts, the way to |

|

maintain weighing precision in a variation of ambient |

|

temperature, calibration and calibration test. |

Selecting functions.................... |

Describes functions of the balance. |

Interface and communication ... Describes the RS-232C serial interface and external contact input. The RS-232C serial interface can communicate with a computer that requests weighing data and controls the balance. This RS-232C interface is for use with a computer or printer. The external contact input commands the balance re-zeroing and data output.

Maintenance ............................ |

Describes maintenance, error codes, troubleshooting, |

|

specifications and options. |

1-2. Features

Display resolution, one digit greater than a standard balance. This allows management of OIML class F1 or lower weights.

Capable of weighing small amounts of powdery or liquid material, even with a massive tare.

When used as a mass comparator, the balance can achieve even more precise weighing, by using the optional auto-centering pan (sold separately), which reduces eccentric loading errors.

3

1-3. Compliance

1-3-1. Compliance with FCC Rules

Please note that this equipment generates, uses and can radiate radio frequency energy. This equipment has been tested and has been found to comply with the limits of a Class A computing device pursuant to Subpart J of Part 15 of FCC rules. These rules are designed to provide reasonable protection against interference when equipment is operated in a commercial environment. If this unit is operated in a residential area, it may cause some interference and under these circumstances the user would be required to take, at his own expense, whatever measures are necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

1-3-2. |

Compliance with EMC Directives |

||

|

This device features radio interference suppression and safety regulation in |

||

|

compliance with the following Council Directives |

||

Council directive 89/336/EEC |

EN61326 |

EMC directive |

|

Council directive 73/23/EEC |

EN60950 |

Safety of Information Technology Equipment |

|

The CE mark is an official mandatory European marking.

Please note that any electronic product must comply with local laws and regulations when sold or used anywhere outside Europe.

4

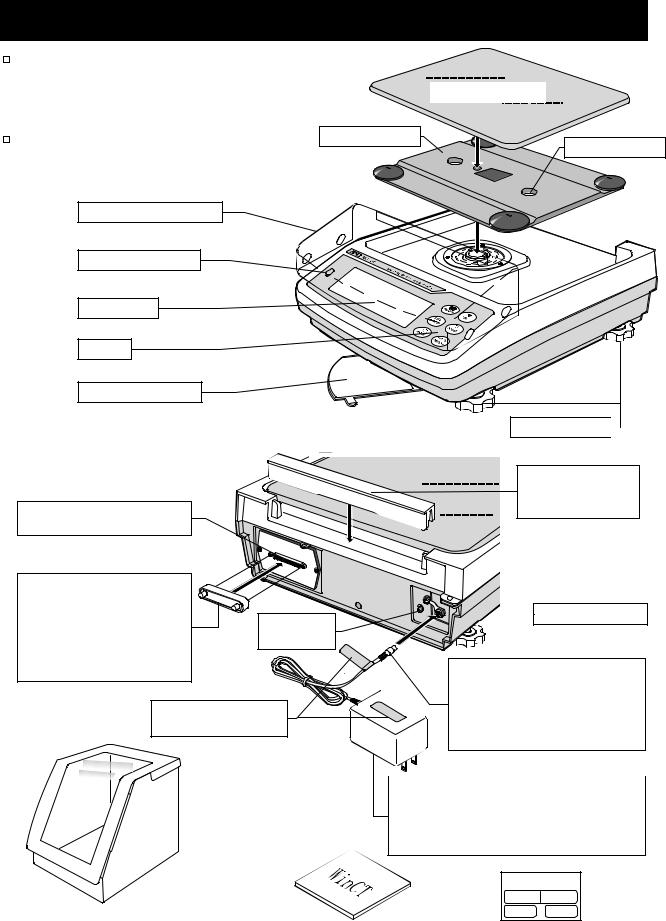

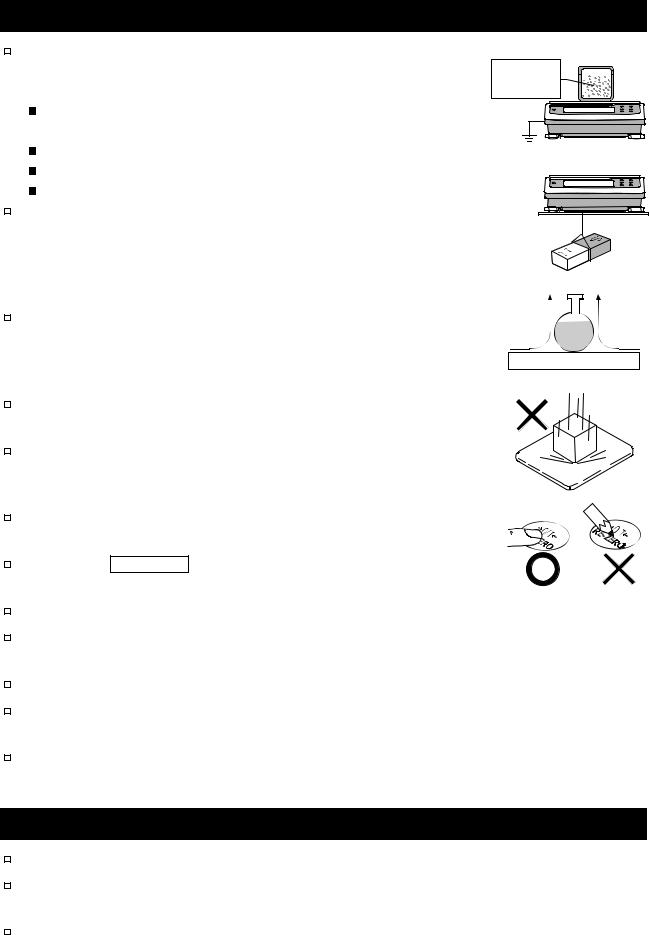

2. Unpacking And Installing The Balance

The balance is a precision instrument. |

|

Unpack the balance carefully. Keep |

|

the packing material to be used for |

|

transporting the balance in the future. |

Pan support |

The packing contents depend on the |

|

balance model. See the illustrations to |

|

confirm that everything is contained. |

|

A clear display cover |

|

Bubble spirit level

Display

Keys

Reference card

RS-232C and external terminals

Note Terminal cover |

|

Cover the terminal or |

Grounding |

connect the waterproof |

|

RS-232C cable (GX-07K) |

terminal |

to keep waterproof and |

|

dustproof. |

|

Position of placing

AC adapter labels

Weighing pan

Handling hole

Leveling foot

Draft gate Remove the gate when cleaning.

AC adapter jack

Note AC adapter plug

Insert the plug into the jack firmly. The connection is tight to keep waterproof and dustproof.

Note |

AC adapter plug |

|

Please confirm that the AC adapter type is correct for your local voltage and receptacle type.

AC Adapter

Breeze break

Windows communication |

AC adapter labels |

tools software

5

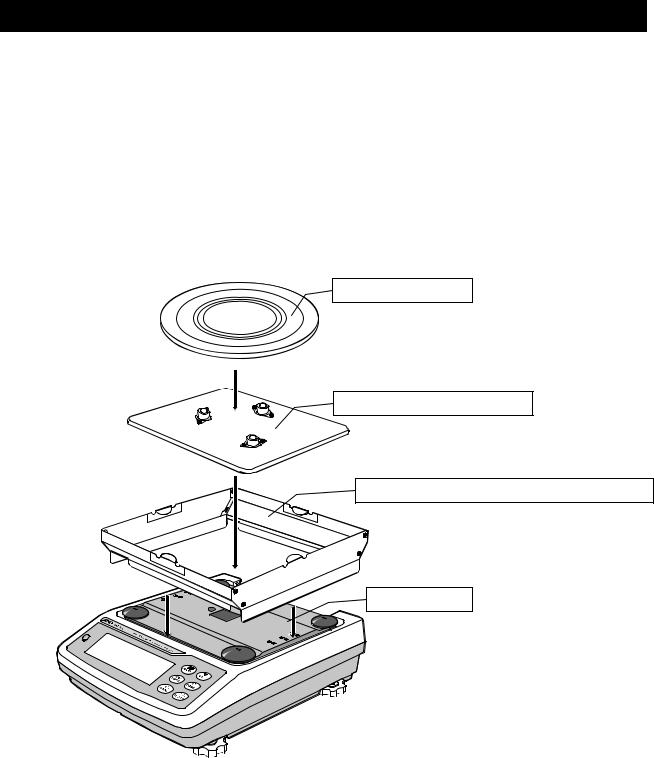

2-1. Auto-centering Pan (AX-MC10K/30KPAN) Installation Procedure

Caution: During installation, do not to apply excessive force to the balance.

When used as a mass comparator, the balance can achieve even more precise weighing, by using the auto-centering pan (sold separately), which reduces eccentric loading errors.

When used as a mass comparator, the balance can achieve even more precise weighing, by using the auto-centering pan (sold separately), which reduces eccentric loading errors.

1.Place the pan support on the balance. Place the breeze break provided with the AX-MC10K/30KPAN option on the balance.

Place the auto-centering pan guide on the pan support, and then place the auto-centering pan on the auto-centering pan guide.

Auto-centering pan

Auto-centering pan guide |

Option AX-MC10K/30KPAN breeze break |

Pan support

Note

When replacing the weighing pan with the auto-centering pan, be sure to calibrate the balance before weighing.

Refer to “8. Calibration”.

6

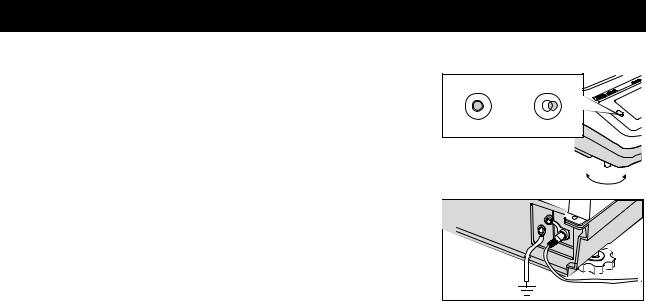

2-2. Installing the Balance

Install the balance as follows:

1Refer to "3. Precautions" for installing the balance.

2Install the pan support, weighing pan and draft gate. Refer to the previous page.

3Adjust the leveling feet to level the balance. Confirm it using the bubble spirit level.

4Confirm that the AC adapter type is correct for the local voltage and power receptacle type.

5Connect the AC adapter to the balance firmly. Earth the balance. Warm up the balance for at least 30 minutes with nothing on the weighing pan.

Bubble spirit level

Good No good

Leveling foot

Grounding |

|

(Earth) |

To AC adapter |

7

3. Precautions

To get the optimum performance from the balance and acquire accurate weighing data, note the following:

3-1. Before Use

The maximum resolution of the precision balance is ten million counts. Therefore, there are tendencies to be influenced by temperature change, air pressure change, static electrisity, vibration and drafts where the balance is placed.

Install the balance in an environment where the temperature and humidity are not excessive. The best operating temperature is about 20°C / 68°F at about 50% relative humidity.

Install the balance where it is not exposed to direct sunlight and it is not affected by heaters or air conditioners.

Install the balance where it is free of dust.

Install the balance away from equipment that produces magnetic fields.

Install the balance in a stable place avoiding vibration and shock. Corners of rooms on the first floor are best, as they are less prone to vibration.

The weighing table should be solid and free from vibration, drafts and as level as possible.

Level the balance by adjusting the leveling feet and confirm it using the bubble spirit level.

If static electricity is a problem at the installation site, use the electrostatic field meter and the static eliminator.

Ensure a stable power source when using the AC adapter.

Connect the AC adapter and warm up the balance for at least 30 minutes. Calibrate the balance periodically for accurate weighing.

When the balance is installed for the first time or has been moved, warm up the balance for at least 6 hours to allow the balance to reach equilibrium with the ambient temperature, and then perform calibration before use.

The meaning of IP-65 is "No ingress of dust. Projected against water jets".

If a powerful water jet is used or the balance is immersed in water, it may cause a damage that is due to ingress of water.

Confirm that "the plug is inserted firmly into the jack" and "the terminal is covered using the waterproof cover or the waterproof RS-232C cable (GX-07K)", when using the balance.

Use the waterproof option cable GX-07K, when the RS-232C interface is used with IP-65. AX-KO1710-200, a standard RS-232C cable, is not waterproof or dustproof.

Confirm that the weighing pan does not touch to rim.

Do not install the balance where flammable or corrosive gas is present.

Do not install the balance where flammable or corrosive gas is present.

8

3-2. |

During Use |

|

|

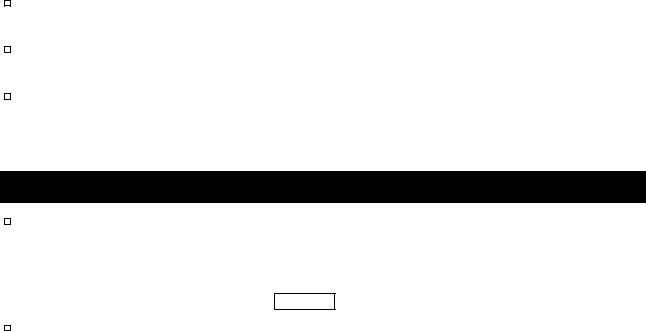

Discharge static electricity from the weighing material. When |

Material case |

||

weighing sample (plastics, insulator, etc.) could have a static |

Charged |

||

charge, the weighing value is influenced. Ground the balance, and |

sample |

||

Eliminate the static electricity by using an optinal static |

|

||

eliminator, AD-1683. |

Grounding |

||

Or try to keep the ambient humidity above 45%RH at the room. |

|||

Or use the metal shield case. |

|

||

Or wipe a charged material (plastic sample etc.) with the wet cloth. |

|

||

This balance uses a strong magnet as part of the balance |

|

||

assembly, so please use caution when weighing magnetic |

Magnetic |

||

materials such as iron. If there is a problem, use the underhook on |

material |

||

the bottom of the balance to suspend the material away from the |

|

||

influence of the magnet. |

Draft |

||

Eliminate any temperature difference between the sample and the |

|||

20°C 40°C |

|||

environment. When a sample is warmer (cooler) than the ambient |

|||

temperature, the sample will be lighter (heavier) than the true |

Weighing Pan |

||

weight. This error is due to a rising (falling) draft around the sample. |

|

||

Make each weighing gently and quickly to avoid errors due to |

Shock |

||

changes in the environmental conditions. |

|

||

Do not drop things upon the weighing pan, or place a sample on the pan that is beyond the balance weighing capacity. Place the sample in the center of the weighing pan.

Do not use a sharp instrument such as a pencil to press the keys.

Use your finger only.

Press the RE-ZERO key before each weighing to prevent possible errors.

Calibrate the balance periodically so as to eliminate possible errors.

Take into consideration the affect of air buoyancy on a sample when more accuracy is required.

It is possible to check the reference card for principle operation.

Prevent foreign matter, such as powder, liquid and metal, from invading the area around the weighing pan.

Use the "breeze break" for a precision weighing.

3-3. After Use

Avoid mechanical shock to the balance.

Do not disassemble the balance. Contact the local A&D dealer if the balance needs service or repair.

Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth that is moistened with warm water and a mild detergent.

9

Do not allow the balance to be immersed in water. Even though the balance complies with IP code, the balance will not withstand being completely immersed in water.

The weighing pan, pan support and draft gate can be removed to clean the balance. Clean by splashing with water.

Use the waterproof option RS-232C cable GX-07K, when RS-232C interface is used with IP-65. AX-KO1710-200, a standard RS-232C cable, is not waterproof or dustproof.

3-4. Power Supply

Do not remove the AC adapter while the internal mass is in motion, for example, right after the AC adapter is connected, or during calibration using the internal mass.

If the AC adapter is removed under the conditions described above, the internal mass will be left unsecured, that may cause mechanical damage when the balance is moved. Before removing the AC adapter, press the ON:OFF key and confirm that zero is displayed.

When the AC adapter is connected, the balance is in the standby mode if the standby indicator is on. This is a normal state and does not harm the balance. For accurate weighing, keep the AC adapter connected to the balance and AC power unless the balance is not to be used for a long period of time.

10

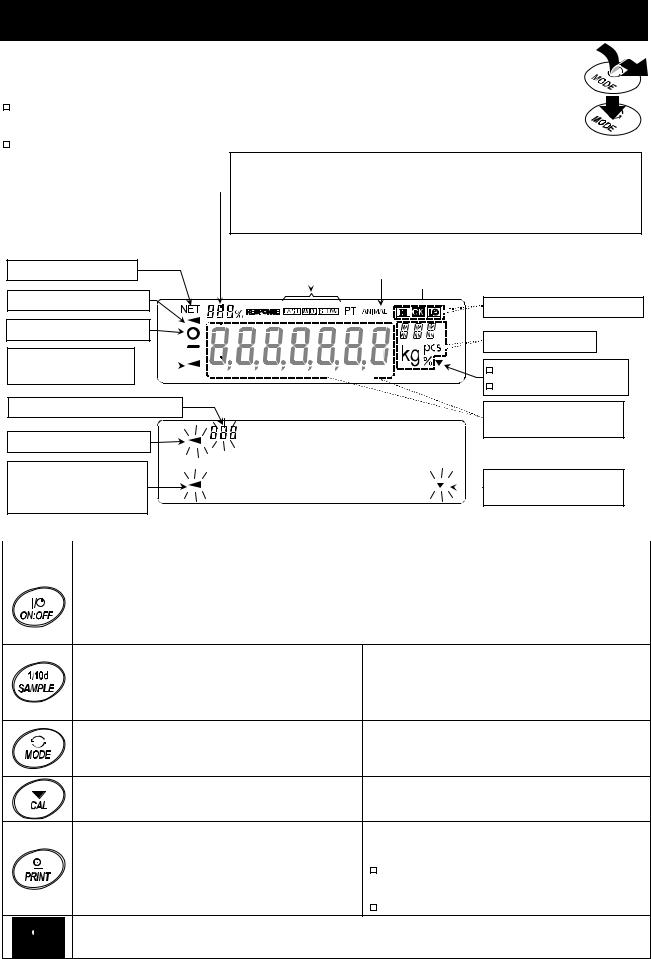

4. Display Symbols And Key Operation

Key Operations

Key operation affects how the balance functions. The basic key operations are:

"Press and release the key immediately" or "Press the key"

= normal key operation during measurement "Press and hold the key".

Displays the highest-order digit when placing a load of 10 kg

Displays the highest-order digit when placing a load of 10 kg

or more on the MC-10K Display

Displays memory data information

Displays memory data information

Displays the weighing data relative to the weighing capacity in percentage, in weighing mode. (Capacity indicator)

Displays the weighing data relative to the weighing capacity in percentage, in weighing mode. (Capacity indicator)

NET indicator |

|

Weighing speed indicator (Response indicator) |

|||

|

|||||

|

|

|

|

|

|

|

|

|

Animal mode indicator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Processing indicator |

|

Comparator indicators |

Stabilization indicator |

|

Units |

Standby indicator |

|

|

|

Interval memory |

|

of power supply |

|

|

|

|

Standby indicator |

The current data number |

|

Weighing data or |

Processing indicator |

|

stored data |

|

|

|

Prior notice indicator |

Blinking indicators |

Interval memory, |

of automatic self |

|

|

|

active indicator |

|

calibration |

|

|

|

|

Each key, when pressed or when pressed and held, functions as follows:

Key |

When pressed and released |

When pressed and held |

Turns the display ON and OFF. The standby indicator is displayed when the display is turned off. The weighing mode is enabled when the display is turned on. This key is available anytime. Pressing the key during operation will interrupt the operation and turn the display OFF.

In the weighing mode, turns the minimum weighing value ON and OFF.

In the counting or percent mode, enters the sampling mode.

No function at the factory setting.

Switches the weighing units when units other than “g” are stored in the function setting.

Performs calibration using the internal mass.

Stores the weighing data in memory or outputs to a printer or personal computer depending on the function table settings.

(Factory setting = output)

Sets the display to zero.

11

5. Weighing Units

With the balance, only the unit “g” (gram) was set at the factory.

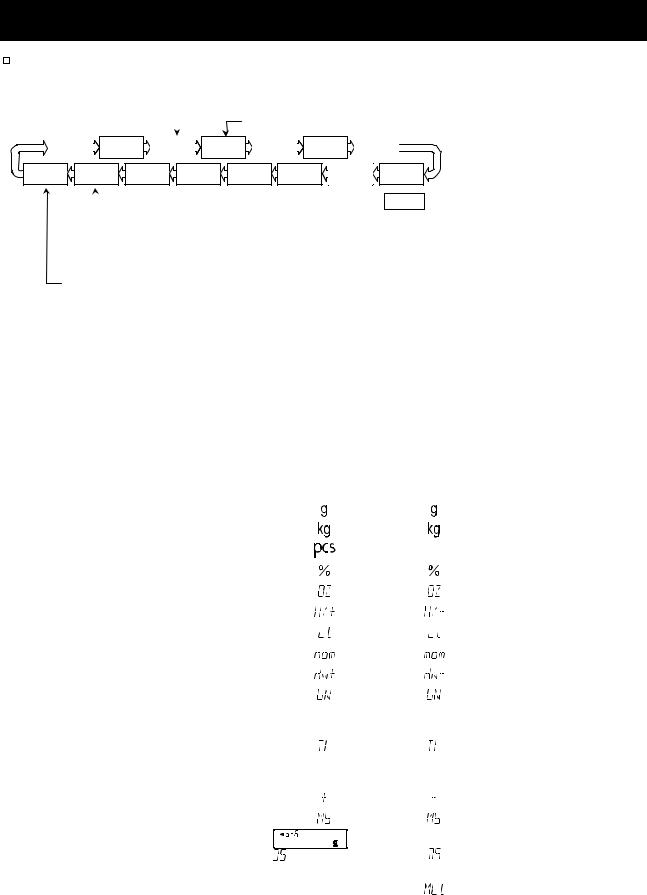

The following weighing units and weighing modes are available for selection:

Counting mode |

|

Percent mode |

|

g |

kg |

pcs |

% |

OZ |

|

OZt |

ct |

DS |

|

MS |

t |

TL |

GN |

dwt |

mom |

Density mode (To select this mode, press the MODE key until the processing indictor blinks with the unit "g" displayed. "

Density mode (To select this mode, press the MODE key until the processing indictor blinks with the unit "g" displayed. "

" appears only when the density value is displayed. For details about this mode, refer to the GX-K instruction manual "15. Density Measurement".)

" appears only when the density value is displayed. For details about this mode, refer to the GX-K instruction manual "15. Density Measurement".)

Programmable-unit. (No unit displayed. For details, refer to the GX-K instruction manual "14. Programmable Units".)

A unit or mode can be selected and stored in the function table as described in the GX-K series instruction manual "5-2. Changing the Units".

If a weighing mode (or unit of weight) has been turned off, that mode or unit will be missing in the sequence. Tael has four varieties, one of which can be selected and installed at the factory.

For details about the units and modes, see the table below:

Name (unit, mode) |

Abbre- |

Display |

Function table |

Conversion factor |

|

viation |

(Storing mode) |

1 g = |

|||

|

|

||||

Gram |

g |

|

|

1 g |

|

Kilogram |

kg |

|

|

1000 g |

|

Counting mode |

pcs |

|

pcs |

- |

|

Percent mode |

% |

|

|

- |

|

Ounce (Avoir) |

OZ |

|

|

28.349523125 g |

|

Troy Ounce |

OZt |

|

|

31.1034768 g |

|

Metric Carat |

ct |

|

|

0.2 g |

|

Momme |

mom |

|

|

3.75 g |

|

Pennyweight |

dwt |

|

|

1.55517384 g |

|

Grain (UK) |

GN |

|

|

0.06479891 g |

|

Tael (HKgeneral,Singapore) |

|

|

|

37.7994 g |

|

Tael (HK jewelry) |

TL |

|

|

37.429 g |

|

Tael (Taiwan) |

|

|

37.5 g |

||

|

|

|

|||

Tael (China) |

|

|

|

31.25 g |

|

Tola (India) |

t |

|

|

11.6638038 g |

|

Messghal |

MS |

|

|

4.6875 g |

|

Density mode |

DS |

is used to |

|

- |

|

|

|

||||

|

|

show the density |

|

|

|

Programmable-unit (Multi-unit) |

Mlt |

- |

|

- |

12

The tables below indicate the weighing capacity and the minimum display for each unit, depending on the balance model.

When a measurement unit other than gram is used, it is not possible to weight up to capacity of the balance because the display does not have sufficient digits.

Use the MC series balance within the values shown in the tables below.

|

|

|

MC-10K |

|

|

Unit |

|

|

|

||

Capacity |

Gram |

Minimum |

|||

|

|

|

|

|

display |

|

|

|

|

|

|

Gram |

10100 g |

10100 |

g |

0.001 |

|

Kilogram |

10.1 kg |

10100 |

g |

0.000001 |

|

Ounce (Avoir) |

197 |

OZ |

5600 |

g |

0.00005 |

Troy Ounce |

199 |

OZt |

6200 |

g |

0.00005 |

Metric Carat |

19500 ct |

3900 |

g |

0.005 |

|

Momme |

1973 mom |

7400 |

g |

0.0005 |

|

Pennyweight |

6494 dwt |

10100 |

g |

0.001 |

|

Grain (UK) |

155866 |

GN |

10100 |

g |

0.02 |

Tael (HKgeneral,Singapore) |

198 |

TL |

7500 |

g |

0.00005 |

Tael (HK jewelry) |

195 |

TL |

7300 |

g |

0.00005 |

Tael (Taiwan) |

194 |

TL |

7300 |

g |

0.00005 |

Tael (China) |

198 |

TL |

6200 |

g |

0.00005 |

Tola (India) |

865 t |

10100 |

g |

0.0001 |

|

Messghal |

1984 |

MS |

9300 |

g |

0.0005 |

|

|

|

|

|

|

|

|

|

MC-30K |

|

|

Unit |

|

|

|

||

Capacity |

Gram |

Minimum |

|||

|

|

|

|

|

display |

|

|

|

|

|

|

Gram |

31000 g |

31000 |

g |

0.01 |

|

Kilogram |

31.0 kg |

31000 |

g |

0.00001 |

|

Ounce (Avoir) |

1093 |

OZ |

31000 |

g |

0.0005 |

Troy Ounce |

966 |

OZt |

31000 |

g |

0.0005 |

Metric Carat |

155000 ct |

31000 |

g |

0.05 |

|

Momme |

8266 mom |

31000 |

g |

0.005 |

|

Pennyweight |

1933 dwt |

31000 |

g |

0.01 |

|

Grain (UK) |

478403 |

GN |

31000 |

g |

0.2 |

Tael (HKgeneral,Singapore) |

820 |

TL |

31000 |

g |

0.0005 |

Tael (HK jewelry) |

828 |

TL |

31000 |

g |

0.0005 |

Tael (Taiwan) |

826 |

TL |

31000 |

g |

0.0005 |

Tael (China) |

992 |

TL |

31000 |

g |

0.0005 |

Tola (India) |

2657 t |

31000 |

g |

0.001 |

|

Messghal |

6613 |

MS |

31000 |

g |

0.005 |

|

|

13 |

|

|

|

6. Weighing

6-1. Selecting a Weighing Unit (Mode)

Press the MODE key to select a unit or mode for weighing.

The unit “g” (gram) was set at the factory.

To use other units, select and store units and displaying order in the function setting of “ Unit ”. For details on weighing unit storing procedure, refer to the GX-K series instruction manual, “5-2. Chaning the Units”.

6-2. Basic Weighing

6-2-1. For More Stable Weighing

zTo reduce the influence of drafts and vibration, set the following function settings as below.

“Condition ( Cond )” of “Environment, Display ( ba5fnc )” to “Slow ( 2 )” “Filter ( f1l )” of “Environment, Display ( ba5fnc )” to “Used (1 )”

Function Settings

Refer to “10. Function Table” on page 27 to check or change the function settings.

Class |

Item and Parameter |

Description |

|

|||

ba5fnc |

Cond |

Condition |

2 |

Slow response rate, stable value |

|

|

SLOW |

|

|||||

Environment |

|

|

|

|

|

|

f1l |

Filter |

1 |

Used |

|

||

Display |

|

|||||

6-2-2. When Using as a Mass Comparator

zTo avoid eccentric loading errors, place the sample in the center of the weighing pan. As an option, AX-MC10K/30KPAN auto-centering pan is available.

Using an AD-8922A remote controller, which is sold separately, the balance can be controlled remotely by the AD-8922A key operations in the same way as when the

CAL or RE-ZERO key of the balance is pressed. For the connection procedure between the balance and the AD-8922A, refer to the AD-8922A instruction manual.

zTake measures against causes of weighing error at the installation site, such as changes in temperature, atmospheric pressure, drafts, vibration and static electricity. Perform weighing operations in an stable environment.

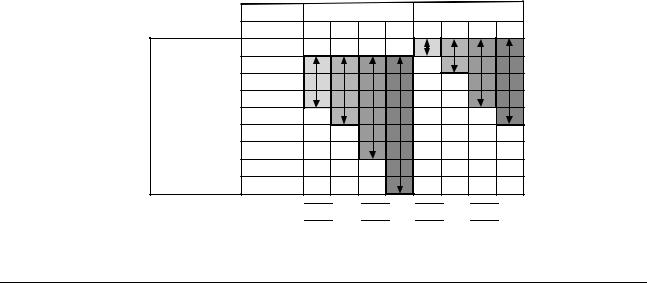

zThe table below lists the weight class and recommended measuring range for each model of the MC series. The measuring range is determined so that the balance repeatability is to be less than one third of the maximum permissible error for each weight class.

14

Weight class and recommended measuring range

|

Model |

M C - 1 0 K |

M C - 3 0 K |

|

Class |

F 1 F 2 M 1 M 2 F 1 F 2 M 1 M 2 |

|

|

20 kg |

|

|

|

10 kg |

|

|

|

5 kg |

|

|

Weight |

2 kg |

|

|

1 kg |

|

|

|

(Displayed value) |

|

|

|

500 g |

|

|

|

|

200 g |

|

|

|

100 g |

|

|

|

50 g |

|

|

F 1

F 1

F 2

F 2

M 1

M 1

M 2

M 2

6-2-3. When Building into a System

zWhen a special weighing pan is to be designed, the weight of the pan and the material to be weighed should not exceed the weighing capacity of the balance.

To reduce influences of static electricity and magnetism, use materials other than resin and magnetic material such as iron.

zWhen a special weighing pan is to be designed, the weight of the pan and the material to be weighed should not exceed the weighing capacity of the balance.

To reduce influences of static electricity and magnetism, use materials other than resin and magnetic material such as iron.

zThere is a function available to maintain the previous weight value in non-volatile memory, even if the AC adapter is removed.

When “Zero upon power-on ( p-tr )” of “Environment, Display ( ba5fnc )” is set to “ 1 ”, the previous weight value is displayed upon power-on.

For details, refer to “Zero upon power-on” on page 32.

zThere is a function available to perform span calibration only, when performing calibration with a tare on the weighing pan.

When “Span calibration ( 5pn )” of “Environment, Display ( ba5fnc )” is set to “ 1 ”, span calibration using the internal mass is performed, with a tare on the weighing pan. For details, refer to “Span calibration” on page 32.

zTo set a higher response rate (weighing speed) or to batch-weigh small amounts of material, such as a powdery material, refer to “14. Extended Function”.

15

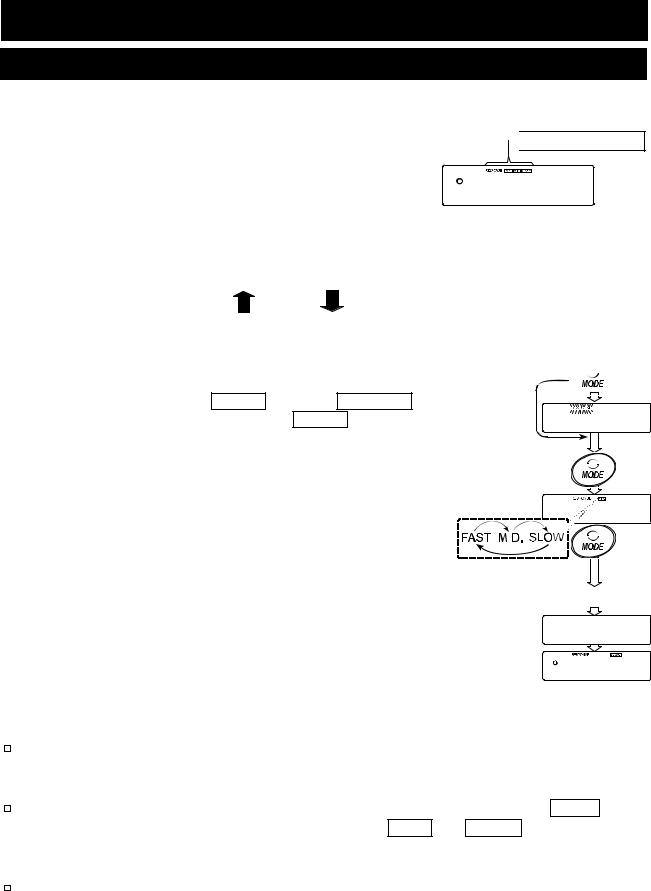

7. Weighing Speed Adjustment / Self Check Function

7-1. Weighing Speed Adjustment

This function detects the influence on weighing that is caused by drafts and/or vibration at the place where the balance is installed and sets the following three weighing speeds (response characteristics) automatically.

The function has three rates as follows:

Changing the weighing speed changes the display refresh rate.

Weighing speeds

Weighing speeds

0.000 g

Indicator |

Parameter |

Weighing Speed |

Stability |

Display refresh rate |

FAST |

Cond 0 |

Fast response, Sensitive value |

If the weighing speed is changed as follows: |

|

MID. |

Cond 1 |

|

|

MID. or SLOW FAST =10 times/second |

SLOW |

Cond 2 |

Slow response, |

Stable value |

FAST MID. or SLOW = 5 times/second |

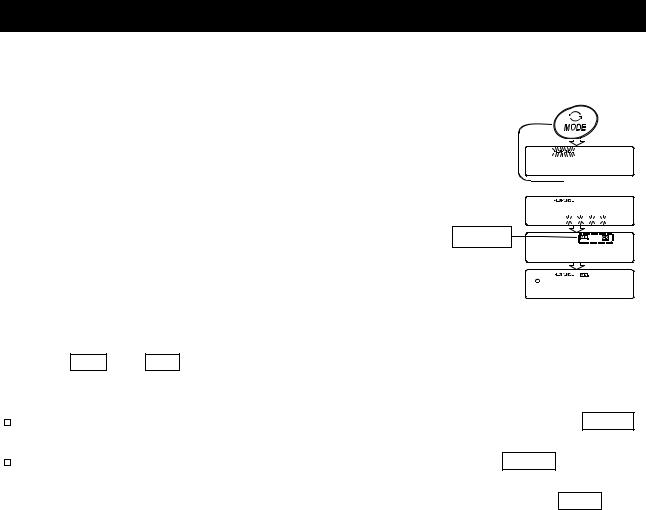

Step 1 Press and hold the MODE key until RESPONSE is displayed. And then, press the MODE key again quickly.

Press and hold

Release

Press again

Step |

2 |

Press the |

MODE |

key to select a weighing speed. |

|

|

|

|

|

|

|

|

|

|||||||

|

|

Either |

|

, |

|

or |

|

can be selected. |

|

|

|

|

|

|

|

|

|

|||

|

|

FAST |

MID. |

SLOW |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

Select a parameter |

||||||||||

|

|

|

|

|

|

|

|

|

|

with pressing it. |

||||||||||

Step |

3 |

After a few seconds of inactivity the balance displays |

|

|

. |

|

|

|

Release and wait |

|||||||||||

|

end |

|

|

|

|

|

|

|

||||||||||||

|

|

Then, it returns to the weighing mode and displays the |

|

|

|

|

|

|

|

|

|

end |

||||||||

|

|

updated response indicator. The response indicator |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

remains displayed for a while. |

|

|

|

|

|

|

|

|

0.000 g |

|||||||||

Note

The weighing speed adjustment can be changed at "Condition (Cond)" of "Environment, Display (ba5fnc)" in the function table. Refer to "10. Function

Table" for details.

To set a refresh rate of 5 times/second when the response rate is FAST or 10 times/second when the response rate is MID. or SLOW , change the "Display refresh rate (5pd)" parameter of "Environment, Display (ba5fnc)" in the function table.

If the weight value is not stabilized due to drafts or vibration when “Cond 0 ” is selected by the automatic response adjustment, change the parameter of “Cond ” manually in the function table.

16

7-2. Self Check Function with Response Adjustment

This function automatically updates the response adjustment by analyzing the influence of the environment on the weighing data and also self-checks the balance performance using

the internal mass.

Step |

1 |

Press and hold the |

MODE |

key until |

RESPONSE |

is |

|

|

displayed, and then |

release |

the key. |

|

|

Step |

2 |

The balance automatically starts to check the balance |

||||

|

|

performance and sets the response characteristic. |

||||

Caution |

Do not allow vibration or drafts to affect the |

|||||

|

|

balance during adjustment. |

||||

Press and hold

Release

CH . . . .

Result

CH

Step 3 After automatic adjustment, the balance displays the updated |

0.000 g |

|

response indicator and returns to the weighing mode. |

||

|

||

The response indicator remains displayed for a while. |

|

Example of display

MID. and OK : The example above indicates that the result of the self check is good and MID. is selected as the response rate..

Note

If improper performance is found in the self check, the balance displays CH no .

Contact the local A&D dealer for repair.

If the automatic response adjustment fails, the balance displays CH ng . Check the ambient conditions such as breeze and vibration, also check the weighing pan. Then, perform the adjustment again. To return to the weighing mode, press the CAL key.

17

8. Calibration

8-1. Calibration Group

The balance has the following modes as a calibration group.

Calibration

Automatic self calibration (Calibration due to changes in temperature) Calibration using the internal mass (One-touch calibration) Calibration using an external weight

Calibration Test

Calibration test using an external weight (Calibration test does not perform calibration)

Correction of the internal mass value

Terms

The following terms are defined as follows:

Internal mass |

= Built-in calibration weight |

External weight |

= A weight that you have. Referred to as a calibration weight when |

|

used for calibration. |

Calibration weight |

= A weight used for calibration |

Target weight |

= An external weight used for calibration test |

Caution

Calibration adjusts the balance for accurate weighing.

Besides periodic calibration and before each use, perform calibration when:

The balance is installed for the first time.

The balance has been moved.

The ambient environment has changed.

Do not allow vibration or drafts to affect the balance during calibration.

To output the data for GLP using the RS-232C interface, set "GLP output (info)" of "Data output (dout)". Refer to "10. Function Table". Time and date can be added to the GLP report. If the time or date is not correct, adjust them. Refer to the GX-K series instruction manual "10-7. Clock and Calendar Function".

Calibration test is available only when "GLP output (info)" of "Data output ( dout )" is set to "1" or "2",

The calibration and calibration test data can be stored in memory. To store them, set "Data memory (data)" to "3". Refer to the GX-K series instruction manual "12. Data Memory" for details.

The value of the internal mass may change due to aging, corrosion or other damage caused by the operating environment. Check the internal mass periodically. Correct the internal mass value as necessary.

18

Caution on using an external weight

The accuracy of an external weight can influence the accuracy of weighing. Select an appropriate weight as listed below:

Select a mass for calibration and calibration test from the following table.

Model |

Usable calibration weight |

Adjustable range |

MC-10K |

2 kg, 3 kg, 4 kg, 5 kg, 6 kg, 7 kg, 8 kg, 9 kg, 10 kg |

-0.150 g ~ +0.159 g |

|

|

|

MC-30K |

20 kg, 30 kg |

-1.50 g ~ +1.59 g |

|

|

|

The calibration weight in bold type: factory setting

The calibration weight value can be adjusted within the range above.

Display

This indicator means "In process of measuring calibration data".

Do not allow vibration or drafts to affect the balance while the indicator is displayed.

8-2. Automatic Self Calibration

Automatic self calibration due to changes in temperature

This function automatically calibrates the balance when the balance detects an ambient temperature change. If GLP output is selected in the function table, the balance outputs the calibration report or stores the data in memory. Automatic self calibration functions even if the display is turned off (standby state). Refer to "9-1. Permit Or Inhibit" for the operation.

Caution

If something is on the weighing pan, the balance judges that it is in use and does not perform automatic self calibration. To maintain the calibrated state, keep the weighing pan clear while not in use.

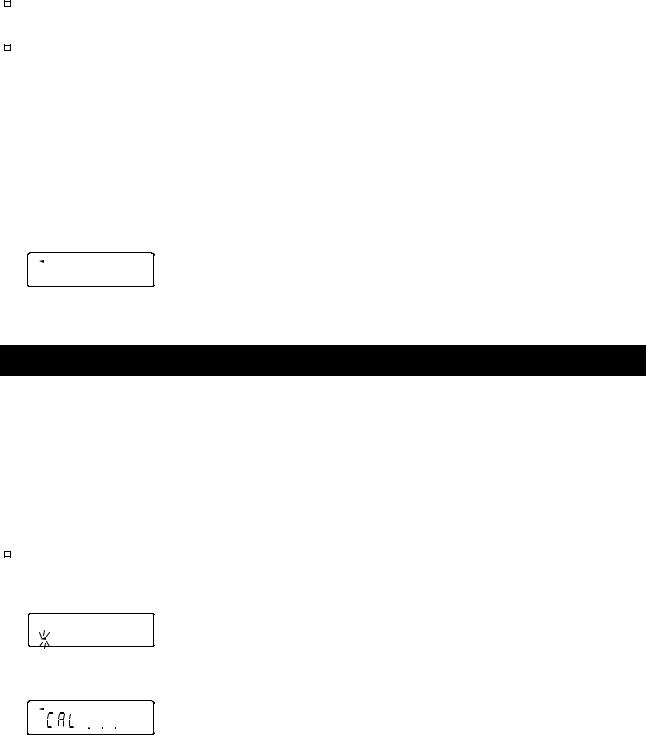

Indicates that the balance detects a change in ambient temperature and automatic self calibration will start. If the balance is not used for a few minutes with this indicator blinking, the balance performs automatic self

calibration. The blinking duration depends on the environment.

Indicates that the balance is measuring calibration data. Do not allow vibration or drafts to affect the balance while this indicator is displayed.

After calibration, the balance returns to indicate the previous display.

Note The balance can be used while the indicator blinks. But, it is recommended that to maintain the accuracy, stop using the balance and confirm that there is nothing on the pan and allow the balance to perform self calibration.

19

Loading...

Loading...