Page 1

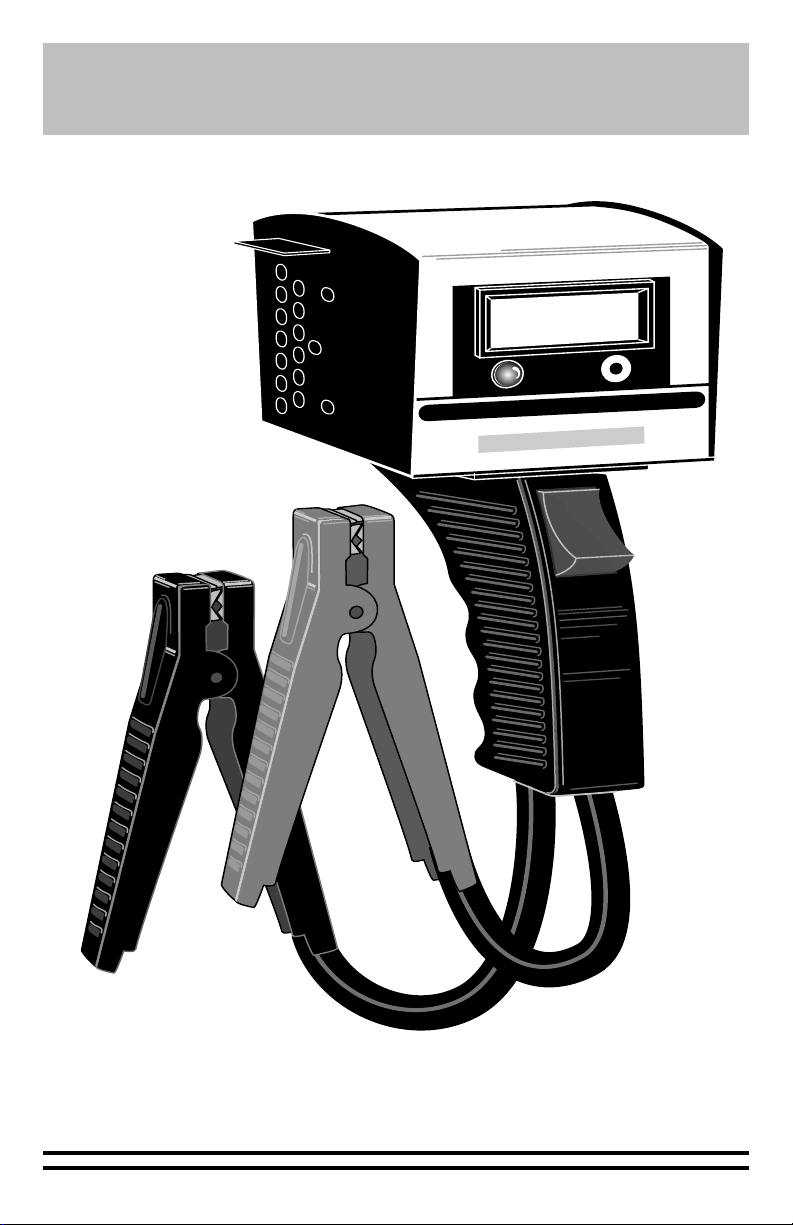

OPERATINGINSTRUCTIONS

12.32

Test Time: 10

Digital 130 Amp Battery Load/Alternator Tester

seconds Max Time: 15 seconds

Load Switch

Battery Load Tester

Page 2

Safety Precautions

When Working on Vehicles

Always wear approved eye protection.

Always operate the vehicle in a well-ventilated area. Do not inhale exhaust

gasesthey are very poisonous!

Never smoke or have open flames near vehicle. Vapors from gasoline and charg-

ing batteries are highly flammable and explosive. Always keep a fire extinguisher

suitable for gasoline/electrical/chemical fires handy.

Always keep yourself, tools, and test equipment away from all moving or hot en-

gine parts.

Never lay tools on vehicle battery. You may short the terminals together, causing

harm to yourself, the tools, or the battery.

Always turn ignition key OFF when connecting or disconnecting electrical compo-

nents, unless otherwise instructed.

Keep away from engine cooling fan. On some vehicles, the fan may start up unex-

pectedly.

Never leave vehicle unattended while running tests.

Always make sure the vehicle is in Park (automatic transmission) or Neutral

(manual transmission) and that the parking brake is firmly set. Block the drive

wheels.

Always follow vehicle manufacturers warnings, cautions, and service procedures.

Additional Precautions When Testing

Discharged batteries will freeze. Store batteries above 32°F (0°C) or maintain

batteries in a charged condition.

The Battery Load Tester becomes hot during test. Allow it to cool between tests.

The display begins dimming when the tester is not allowed to cool. Repeated use

in the overheated condition can damage the testers electronics.

Lead-acid batteries contain sulfuric-acid as the electrolyte. The electrolyte is ex-

tremely corrosive and evolves oxygen and hydrogen during charging, which can

ignite and cause an explosion. Have ventilation and keep flames and sparks away

from charging battery. Follow the manufacturers charging procedures.

If electrolyte contacts skin, immediately rinse with water. If electrolyte contacts

eyes, flush eyes with water and contact physician. When handling batteries, wear

eye protection, chemical resistant gloves and protective clothing.

DISCLAIMER!

Due to inherent dangers associated with automotive maintenance

procedures, the manufacturer and all parties involved with the distribution

and/or sale of this equipment will not be held liable or responsible, either

wholly or in part, for any injury, damage or claims resulting in its

performance or the use of the instructions contained in this manual.

2

Page 3

Battery Load Tester

The Battery Load Tester is a hand-held, diagnostic tool used to test 12V (volt) and

6V lead-acid type automotive batteries. A 10-second test determines the condition of the battery: Good, Weak or Bad. Further testing will identify possible problems in the charging and starting systems. Tests can be performed on fully or

partially charged batteries by inspecting the electrolyte or open-circuit voltage

and adjusting the values for temperatures other than 70°F (21.1°C).

If the electrolyte is accessible, measure its specific gravity with a hydrometer.

The specific gravity reading should be 1.225 or higher at 70°F (21.1°C). For

every 10°F (5.6°C) above/below 70°F (21.1°C), add/subtract 0.004 to/from the

reading.

The open-circuit voltage should be at least 12.45V at 70°F (21.1°C).

The Battery Load Tester contains a four-character LCD (liquid crystal display) to

display battery voltage, a switch to apply the test load and a red LED that is used

to indicate the condition of the alternator. The tester is powered by the battery

under test.

CAUTION!

Test procedures and information provided in this manual are intended

as general guidelines for engine tune-up and adjustments only. Con-

sult the applicable vehicle service manuals for all specific tests.

Before testing, read and follow all safety precautions.

Do not activate and hold the load switch for more than 15 seconds. This

will overload the tester resulting in damage and void the warranty.

Test Preparation

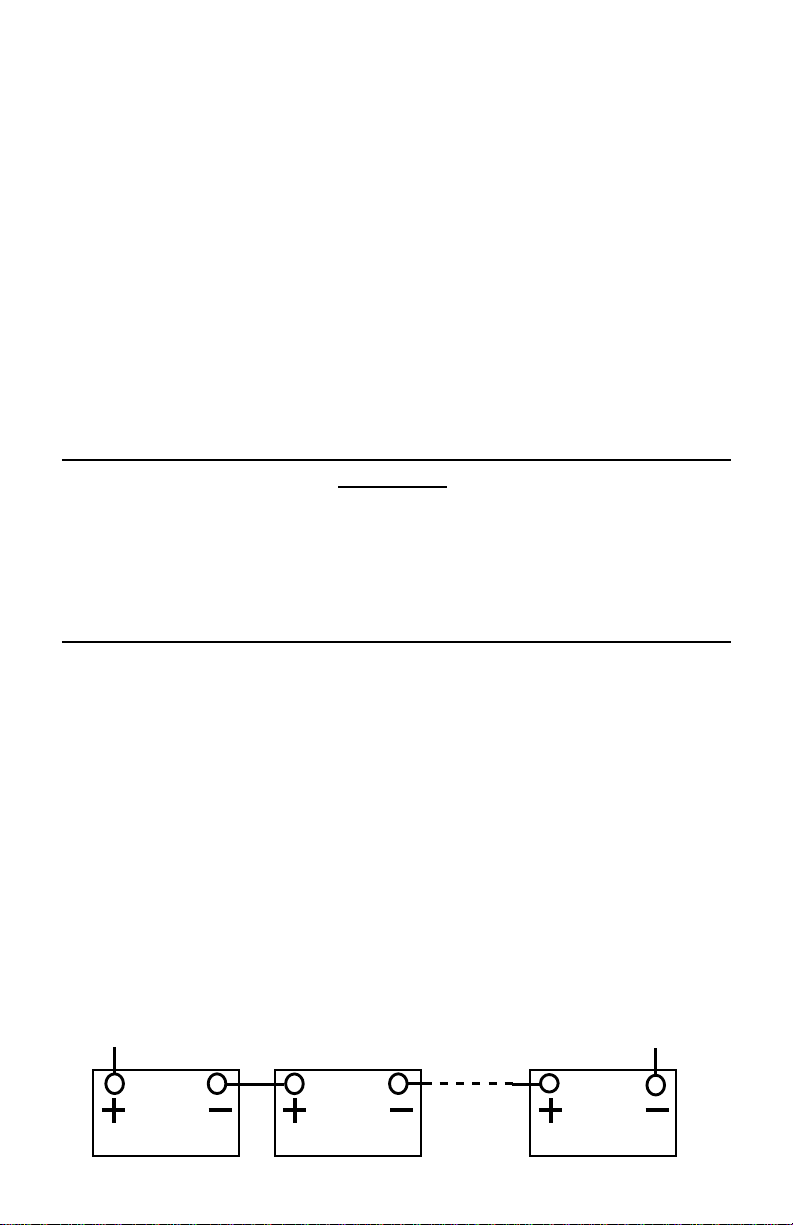

Multi-Battery Systems

In all multiple battery systems, all batteries must be tested separately. Batteries

may be connected in series, parallel or a combination of both. Only batteries

connected in series may remain connected during test. See Figure 1.

For series connections, all batteries are connected from the negative (-) terminal

of one battery, to the positive (+) terminal of the other. Only the negative terminal

of the first battery and the positive terminal of the last battery are to be connected

to the vehicle. Any number of batteries may be connected in a series. However,

each battery must be tested separately.

For all other connections (parallel or a combination of parallel and series), the

batteries must be disconnected and electrically isolated from each other.

Figure 1 Multi-Battery Test Configuration

TO VEHICLE POWER

POS

NEG

POS

NEG

3

TO VEHICLE GROUND

POS

NEG

Page 4

Vehicle Battery

1. Turn ignition key OFF; not in the ACCESSORIES

position (Figure 2). Engine needs to be OFF and

all electrical loads must be removed from the

battery for proper testing. If loads still exist, refer to the vehicles operator and service manual.

2. If battery is being charged, then stop, turn

charger OFF and disconnect clamps or leads.

The battery cannot be tested while being

charged.

3. The connections must be clean and must make good contact to achieve correct test results.

4. On side-post type batteries, install terminal stud adapters. These are not included, but are available at most automotive parts stores.

Figure 2 Engine OFF

Battery Temperature

The most accurate test results will be obtained when battery temperature is at

approximately 70°F (21.1°C). If testing battery between 70°F (21.1°C) and

40°F(4.4°C), add 0.1 volt for every 10°F (5.6°C) below 70°F. If testing a battery

between 70°F (21.1°C) and 100°F (37.8°C), subtract 0.1V for every 10°F (5.6°C)

above 70°F (21.1°C).

Load Test

1. Connect the testers Black clamp

to the negative (-) battery

terminal and the Red clamp to

the positive (+) battery terminal

(Figure3). Make sure both jaws

make good contact. If required,

rock clamps back and forth to

improve connection.

Figure 3 Battery Connections

2. The LCD display will turn on and display the battery voltage. The battery must

be at least 75% charged before conducting the Load Test. At 70°F (21.1°C),

the voltage should be at least 12.45V (or 6.23V for a 6V battery). Remember to

adjust voltage for temperatures other than 70°F (21.1°C).

CAUTION!

The Battery Load Tester becomes hot when applying the load. Allow

tester to cool between discharges; about 2 minutes. In warm temperatures, allow more time to cool. If overheating occurs, the LCD

might temporarily become dim. After cooling down, the testers LCD

will return to normal.

Do not activate and hold the load switch for more than 15 seconds. This

will overload the tester resulting in damage and void the warranty.

4

Page 5

3. Press and hold the LOAD SWITCH for

10 seconds. Refer to Figure 4.

4. Observe the voltage on the LCD and

note the value. Release the LOAD

SWITCH immediately after reading the

display.

5. Disconnect the Red clamp from the battery and then the Black clamp.

6. Figure 5 shows the range for a 500CCA

(Cold-Cranking Amperage) battery

tested at 70°F (21.1°C). For batteries

rated at other CCA values, subtract 0.1V

for every 100 CCA below 500 CCA from

the values shown in Figure 5. Add 0.1V

for every 100 CCA above 500CCA.

If the voltage is in the WEAK region, then

the battery is probably discharged and

needs to be charged before testing.

Disconnect tester and charge battery;

follow battery charger manufacturers

instructions for charging procedures.

Load Switch

Figure 4 Load Switch and Display

12.85

ax Tim

e: 10 seconds

Test Tim

Digital 130 Amp Battery Load/Alternator Tester

M

Load Switch

WARNING!

Charging a battery with a bad cell may cause severe personal injury and damage to vehicle and/or equipment.

e: 15 se

conds

Disconnect charger, reconnect tester and retest. If the voltage remains low,

then the battery is not accepting a charge and should be replaced.

Test Results

GOOD - means the battery is in

good condition and should start

the vehicle in any environment.

WEAK - Indicates the battery is

discharged and requires charging. Charge battery and then retest.

If battery tests WEAK a sec-

ond time, this could indicate

one or more cells are bad

and battery must be replaced.

If battery reads GOOD, the

battery was not sufficiently

charged during the first test.

BAD - Indicates the battery is deeply discharged and requires a complete charge

or the battery is bad and requires replacement. Check the following (on page 6)

and retest.

12V Battery 6V Battery

GOOD

10.00V

5.00V

WEAK

6.10V

3.05V

BAD

Figure 5 500 CCA Test Results at 70°F (21.1°C)

5

Page 6

Battery clamps are securely fastened to the terminals.

Terminals are clean and free of debris for a good electrical continuity.

If a side-post type battery is being tested, verify the terminal stud adapters are

screwed in tightly.

If no fault is detected, then charge battery and retest before replacing the battery.

If tester still indicates a bad battery, then replacement is required.

NOTE: A WEAK or BAD indication may be due to excessive resistance

caused by a bad connection or corrosion between battery cables and the

battery posts. Remove battery cables from battery, connect the tester directly

to the posts and retest.

Starting Test

This test evaluates the vehicles starting system by measuring the battery voltage

while cranking the engine.

1. While observing polarity, connect the tester across the vehicles battery posts:

Red to positive (+), Black to negative (-). Refer to Figure 6.

2. Disable the ignition system to prevent the vehicle from starting. Refer to a

vehicle service manual if necessary.

Figure 6 Starting Test and Charging Test Setup

6

Page 7

3. Have an assistant turn the ignition switch to the Start Position and crank engine

for 15 seconds. If working alone, use a remote starter switch. Do not press the

Load Switch. Observe the battery voltage indicated on the display.

4. A healthy starting system, with a good, fully charged battery, should read above

9.0V during this test.

5. Readings below 9.0V may indicate a problem in the starting system. Recharge

battery and repeat this test. If voltage readings still remain below 9.0V, then

probably either the battery is bad (perform the Load Test), the starter is defective or the cables are loose or corroded.

Charging Test

This test measures the battery voltage while the engine is running to determine if

the charging system is operating properly.

1. Start the vehicle and allow it to warm-up. This may take 10 to 15 minutes.

2. Turn engine OFF.

3. When performing the Charging Test, the battery should be partially discharged.

Turn the ignition switch to the ACCESSORIES position and turn headlights ON

and fan to HIGH for 1 minute.

4. When done, turn headlights and fan OFF and then turn ignition switch to the

OFF position.

5. While observing polarity, connect the tester across the battery posts: Red to

positive (+), Black to negative (-). Refer to Figure 6.

6. Start engine and run at fast-idle (1200-1500 RPM). A healthy 12V charging

system should maintain readings between 13.5V and 15.5V.

Proper Charging System Operation

Within several minutes, the voltage will gradually increase to the regulated

voltage range of 13.5V to 15.5V. In a 6V system, the voltage should gradually

rise to the regulated voltage range of 6.7V to 7.4V.

Incorrect Charging System Operation

Low Regulated Voltage: If after several minutes, the voltage is below 13.5V

for a 12V system (6.7V for a 6V system), than a problem exists with either the

charging system or battery. Perform the Load Test on the battery and then

repeat the Charging Test.

High Regulated Voltage: If the voltage is above the regulated voltage limit

(15.5V for a 12V system, 7.4V for a 6V system), then a problem exists in the

charging system. Damage to the vehicle electrical system may result from the

excessively high voltage.

A decision to REPLACE the alternator or other electrical system components

should not be based solely on these test results. Refer to the applicable vehicle

service manual for additional test and troubleshooting procedures.

7

Page 8

Alternator Test

This test identifies problems associated with the alternator.

1. As shown in Figure 7, connect the testers clamps to the vehicles battery

posts: Red to positive (+), Black to negative (-). Connect the test lead to the

tester and positive terminal on alternator. On GM alternators, attach the test

lead to terminal Nº 1 without disconnecting the plug.

2. Start engine and allow it to idle.

3. If a GM alternator is being tested, observe the testers Red LED and do not

press the LOAD SWITCH. Otherwise, continue with Step 4.

If the LED flashes On and goes OFF, or never comes ON, then the Diode

Trio is functioning properly.

If the LED stays ON, then the Diode Trio might be defective. The alternator

needs repair or replacement.

4. Rev the engine to a fast idle (1200-1500 RPM).

CAUTION!

The Battery Load Tester becomes hot when applying the load. Allow

tester to cool between discharges; about 2 minutes. In warm temperatures, allow more time to cool. If overheating occurs, the LCD

might temporarily become dim. After cooling down, the testers LCD

will return to normal.

Do not activate and hold the load switch for more than 15 seconds. This

will overload the tester resulting in damage and void the warranty.

5. Press and hold LOAD SWITCH on tester for 5 seconds and observe the testers

Red LED. When done, turn engine OFF and disconnect the test leads.

If the LED flashes ON and then goes OFF, or never comes ON, then the

diodes (rectifiers) are functioning properly.

If the LED stays ON or flashes continuously, then one or more diodes (rec-

tifiers) are defective. Repair or replace the alternator and/or voltage regulator.

Figure 7 Alternator Test Setup

8

Printed in China

©2002

0002-000-2407

Loading...

Loading...