Page 1

Digital Multimeter

OPERATING

INSTRUCTIONS

Instrucciones en español,

páginas 37-72

Index

Safety Precautions .............................2

Vehicle Service Information ............... 3

Visual Inspection ................................3

Electrical Specifications ................... 35

Warranty ........................................... 72

1. Multimeter Basic Functions

Functions and Display Definitions ............ 4

Setting the Range ..................................... 6

Battery Replacement ................................ 7

Measuring AC Voltage ..............................7

Measuring DC Voltage .............................. 8

Measuring Resistance .............................. 8

Testing for Continuity ................................ 9

Testing Diodes .......................................... 9

Measuring Engine RPM (TACH) ............ 10

Measuring Dwell ...................................... 11

2. Automotive Testing with the CP7676

General Testing .......................................13

- Testing Fuses ....................................... 13

- Testing Switches .................................. 13

- Testing Solenoids and Relays ............. 14

Starting / Charging System Testing............ 15

- No Load Battery Test ........................... 15

- Cranking Voltage/Battery Load Test.... 16

- Voltage Drops ....................................... 17

- Charging System Voltage Test ............ 18

D

2

0

OHMS

®

A

C

OFF

V

C

V

7

5

0

2

0

0

2

0

2

M

2

M

2

0

0

K

2

0

K

2

K

C

P7676

4

RPM

CYL

5

X10

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

2

0

0

CP7676

COM

V

7

5

0

V

A

C

2

0

0

V

D

C

Ignition System Testing ..............................20

- Ignition Coil Testing .............................. 20

- Ignition System Wires ..........................22

- Hall Effect Sensors/Switches ..............23

- Magnetic Pick-Up Coils........................24

- Reluctance Sensors .............................24

- Ignition Coil Switching Action ..............25

Fuel System Testing ................................... 26

- Testing Mixture Control Solenoid

on Feedback Carburetor ......................26

- Measuring Fuel Injector Resistance .... 27

Testing Engine Sensors ..............................28

- Oxygen (O2) Type Sensors ..................28

- Temperature Type Sensors .................. 30

- Position Type Sensors

Throttle and EGR Valve Position,

Vane Air Flow........................................ 31

- Manifold Absolute Pressure (MAP) and

Barometric Pressure (BARO) Sensors ..32

- Mass Air Flow (MAF) Sensors .............34

1

Page 2

SAFETY GUIDELINES

TO PREVENT ACCIDENTS THAT COULD RESULT IN SERIOUS

INJURY AND/OR DAMAGE TO YOUR VEHICLE OR TEST EQUIPMENT,

CAREFULLY FOLLOW THESE SAFETY RULES AND TEST PROCEDURES

Always wear approved eye protection.

Always operate the vehicle in a well ventilated area. Do not inhale exhaust gases they are very

poisonous!

Always keep yourself, tools and test equipment away from all moving or hot engine parts.

Always make sure the vehicle is in park (Automatic transmission) or neutral (manual

transmission) and that the parking brake is firmly set. Block the drive wheels.

Never lay tools on vehicle battery. You may short the terminals together causing harm to yourself,

the tools or the battery.

Never smoke or have open flames near vehicle. Vapors from gasoline and charging battery are

highly flammable and explosive.

Never leave vehicle unattended while running tests.

Always keep a fire extinguisher suitable for gasoline/electrical/chemical fires handy.

Always use extreme caution when working around the ignition coil, distributor cap, ignition wires,

and spark plugs. These components contain High Voltage when the engine is running.

Always turn ignition key OFF when connecting or disconnecting electrical components, unless

otherwise instructed.

Always follow vehicle manufacturers warnings, cautions and service procedures.

CAUTION:

Some vehicles are equipped with safety air bags. You must follow vehicle service manual cautions

when working around the air bag components or wiring. If the cautions are not followed, the air bag

may open up unexpectedly, resulting in personal injury. Note that the air bag can still open up

several minutes after the ignition key is off (or even if the vehicle battery is disconnected) because

of a special energy reserve module.

All information, illustrations and specifications contained in this manual are based on the latest information

available from industry sources at the time of publication. No warranty (expressed or implied) can be made

for its accuracy or completeness, nor is any responsibility assumed by Actron Manufacturing Co. or anyone

connected with it for loss or damages suffered through reliance on any information contained in this manual

or misuse of accompanying product. A

ctron Manufacturing Co. reserves the right to make changes at any time to this manual or accompanying

product without obligation to notify any person or organization of such changes.

2

Page 3

Vehicle Service Manual Sources For Service Information

The following is a list of sources to obtain vehicle service information for your specific vehicle.

Contact your local Automotive Dealership Parts Department.

Contact local retail auto parts stores for aftermarket vehicle service information.

Contact your local library. Libraries often allow you to check-out automotive service manuals.

Do a Thorough Visual Inspection

Do a thorough visual and hands-on underhood inspection before starting any diagnostic

procedure! You can find the cause of many problems by just looking, thereby saving yourself a lot

of time.

Has the vehicle been serviced recently? Sometimes things get reconnected in the wrong place,

or not at all.

Dont take shortcuts. Inspect hoses and wiring which may be difficult to see due to location.

Inspect the air cleaner and ductwork for defects.

Check sensors and actuators for damage.

Inspect ignition wires for:

- Damaged terminals.

- Split or cracked spark plug boots

- Splits, cuts or breaks in the ignition wires and insulation.

Inspect all vacuum hoses for:

- Correct routing. Refer to vehicle service manual, or Vehicle Emission Control

Information(VECI) decal located in the engine compartment.

- Pinches and kinks.

- Splits, cuts or breaks.

Inspect wiring for:

- Contact with sharp edges.

- Contact with hot surfaces, such as exhaust manifolds.

- Pinched, burned or chafed insulation.

- Proper routing and connections.

Check electrical connectors for:

- Corrosion on pins.

- Bent or damaged pins.

- Contacts not properly seated in housing.

- Bad wire crimps to terminals.

3

Page 4

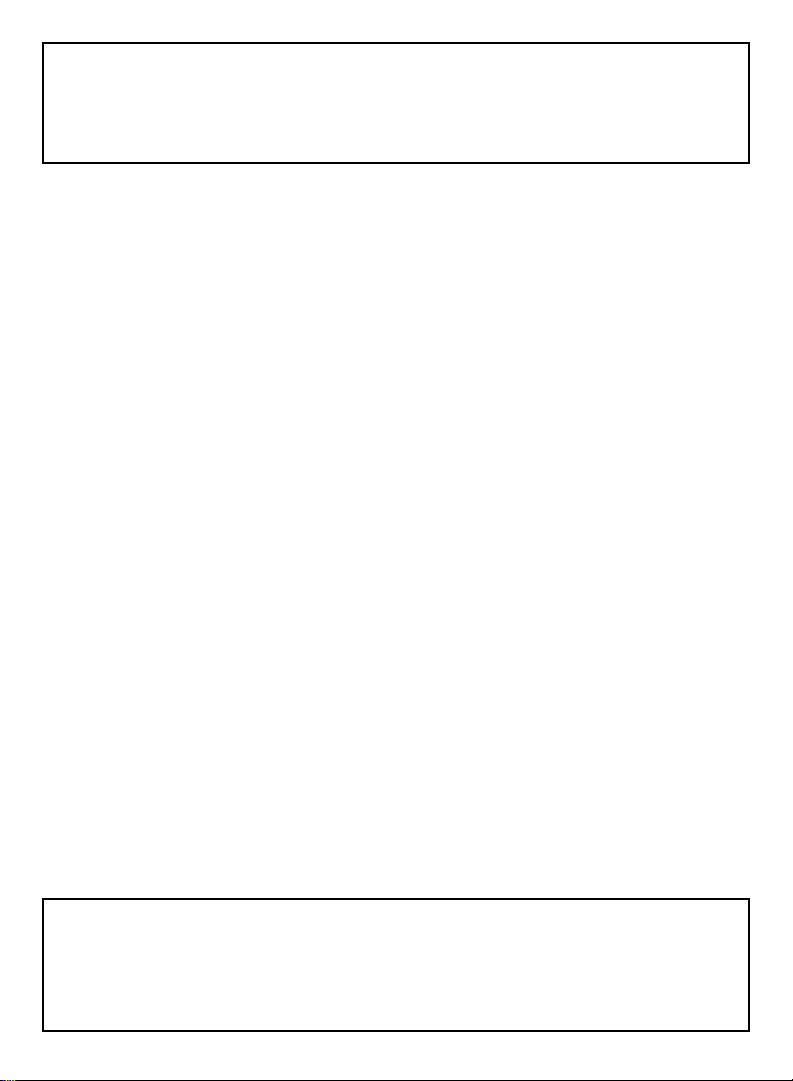

Section 1. Multimeter Basic Functions

Digital multimeters or DMMs have many special features and functions. This section defines these

features and functions, and explains how to use these functions to make various measurements.

9

1

8

®

OFF

V

2

2M

200K

AC

V

750

200

20

20K

2K

200

7

6

DC

20M

OHMS

COM

4

CYL

750V AC

200V DC

CYL

CYL

8

V

5

CP7676

RPM

X10

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

DWELL

Alligator Clip Adapters

Some multimeter tests and measurements are more easily done

using alligator clips instead of test prods. For these tests, push

the crimp end of the alligator clip onto the test prod. If the crimp

on the alligator clip becomes loose, then remove the alligator clip

from the test prod and re-crimp using a pair of pliers.

2

3

4

5

4

Page 5

Functions and Display Definitions

(Refer to Digital Multimeter illustration on facing page)

1. ROTARY SWITCH

Switch is rotated to turn multimeter ON/

OFF and select a function.

2. RPM X 10

This Function is used for measuring

engine speed (RPM).

3. DWELL

This Function is used for measuring

DWELL on distributor ignition systems,

and solenoids.

4. DIODE CHECK

This Function is used to check whether a

diode is good or bad.

5. TEST LEAD JACKS

BLACK Test Lead is always inserted in the

COM test lead jack.

RED Test Lead is always inserted in the

or

Always connect TEST LEADS to the

multimeter before connecting them to

the circuit under test!!

6. OHMS

This Function is used for measuring the

resistance of a component in an electrical

circuit in the range of 0.1Ω to 20MΩ. (Ω is

the electrical symbol for Ohms)

7. DC VOLTS

This Function is used for measuring DC

(Direct Current) Voltages in the range of 0

to 200V.

V

test lead jack.

8. AC VOLTS

This Function is used for measuring AC

(Alternating Current) Voltages in the range

of 0 to 750V.

9. DISPLAY

Used to display all measurements and

multimeter information.

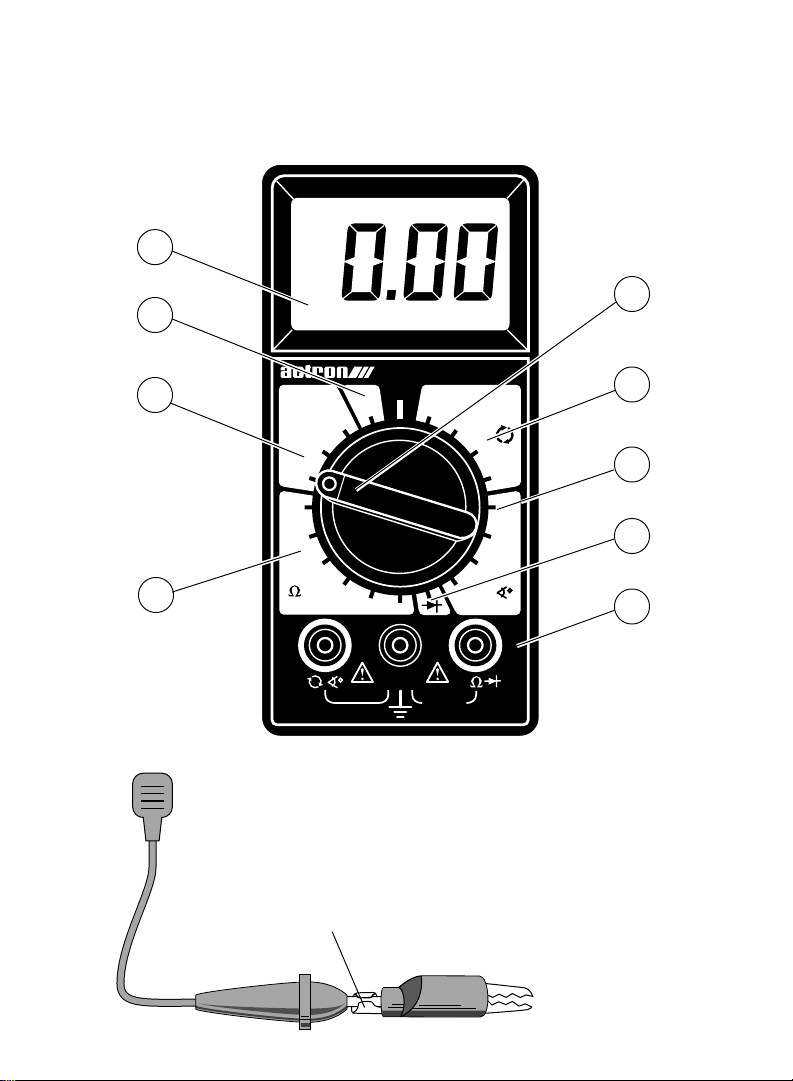

Low Battery If LO BAT appears in the

upper left corner of the display, then

replace the internal 9V

battery. (see Battery

Replacement on page 7.)

Overrange Indication If 1

or -1 appears on the left

side of the display, then the

multimeter is set to a range

that is too small for the

present measurement being

taken. Increase the range

until this disappears. If it

does not disappear after all the ranges for

a particular function have been tried, then

the value being measured is too large for

the multimeter to measure. (see Setting

the Range on page 6.)

Zero Adjustment

The multimeter will automatically zero on the

Volts, Amps, and RPM functions.

Automatic Polarity Sensing

The multimeter display will show a minus (-)

sign on the DC Volts and DC Amps functions

when test lead hook-up is reversed.

5

Page 6

Setting the Range

Two of the most commonly asked questions

about digital multimeters are What does

Range mean? and How do I know what

Range the multimeter should be set to?

What Does Range mean?

Range refers to the largest value the

multimeter can measure with the rotary

switch in that position. If the multimeter is

set to the 20V DC range, then the highest

voltage the multimeter can measure is 20V

in that range.

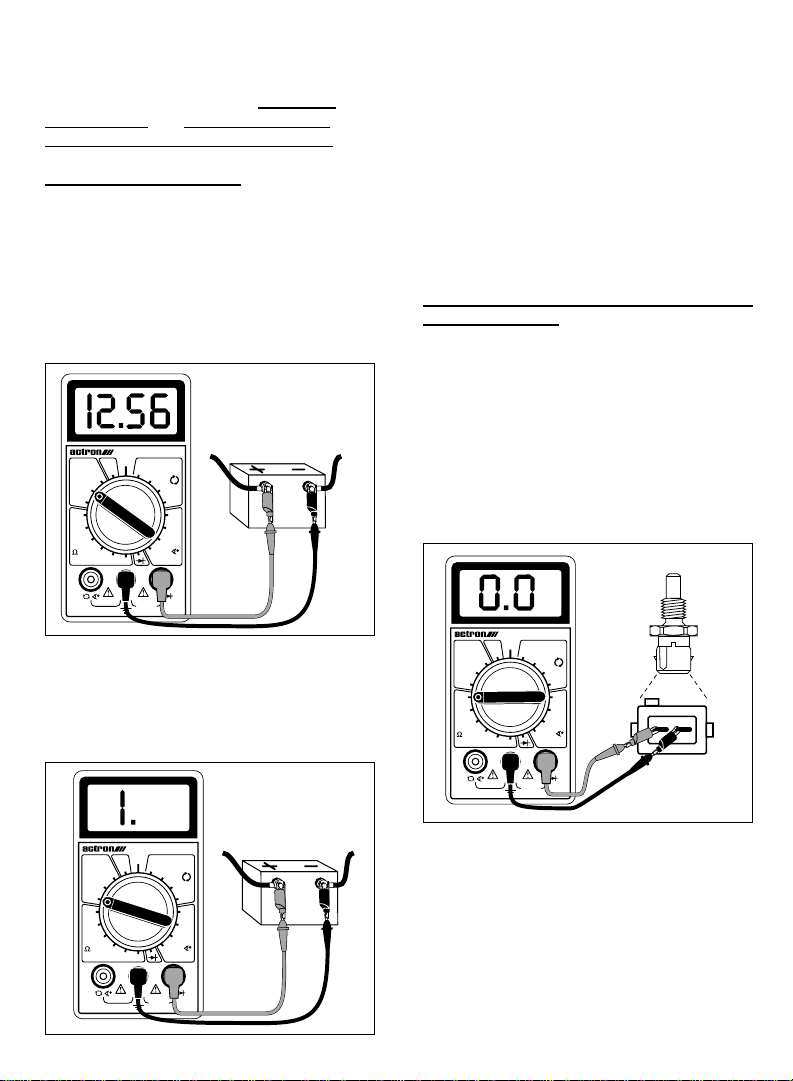

EXAMPLE: Measuring Vehicle Battery

Voltage (See Fig. 1)

Fig. 1

®

CP7676

OFF

V

C

A

V

DC

750

200

20

2

20M

2M

200K

20K

OHMS

2K

Lets assume the multimeter is connected to

the battery and set to the 20V range.

The display reads 12.56. This means there is

12.56V across the battery terminals.

COM

M

P

R

4

CYL

10

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

LL

E

W

D

200

V

750V AC

200V DC

Red

Black

Fig. 2

Now assume we set the multimeter to the 2V

range. (See Fig. 2)

The multimeter display now shows a 1 and

nothing else. This means the multimeter is

being overranged or in other words the

value being measured is larger than the

current range. The range should be

increased until a value is shown on the

display. If you are in the highest range and

the multimeter is still showing that it is

overranging, then the value being measured

is too large for the multimeter to measure.

How do I know what Range the multimeter

should be set to?

The multimeter should be set in the lowest

possible range without overranging.

EXAMPLE: Measuring an unknown

resistance

Lets assume the multimeter is connected to

an engine coolant sensor with unknown

resistance. (See Fig. 3)

Start by setting the multimeter to the largest

OHM range. The display reads 0.0Ω or a

short circuit.

Fig. 3

®

CP7676

OFF

V

C

DC

20M

2M

200K

OHMS

A

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

Red

ELL

W

D

200

750V AC

200V DC

V

Black

DC

20M

2M

200K

OHMS

®

CP7676

OFF

V

C

A

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

ELL

W

D

200

V

750V AC

200V DC

Red

Black

This sensor cant be shorted so reduce the

range setting until you get a value of

resistance.

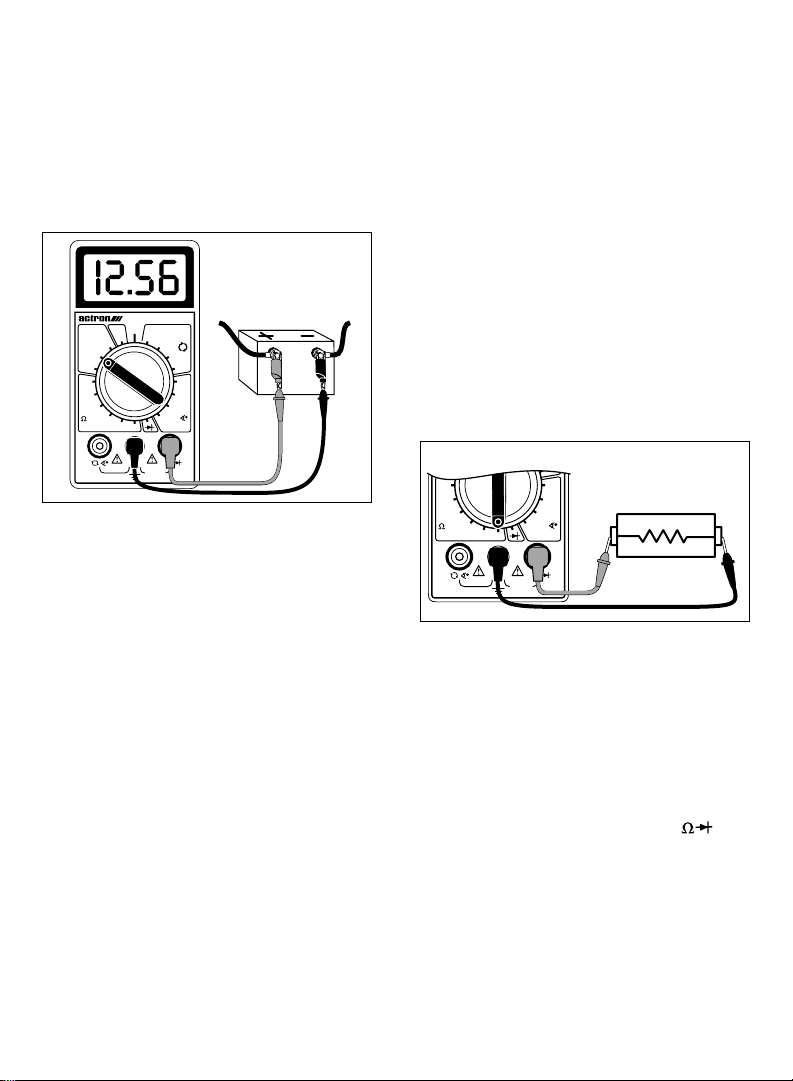

At the 200KΩ range the multimeter

measured a value of 4.0. This means there

is 4KΩ of resistance across the engine

coolant sensor terminals. (See Fig. 4)

If we change the multimeter to the 20KΩ

range (See Fig. 5) the display shows a value

of 3.87KΩ. The actual value of resistance is

6

Page 7

DC

20M

OHMS

2M

200K

Fig. 4

Battery Replacement

Important: A 9 Volt battery must be installed

before using the digital multimeter. (See

®

CP7676

OFF

V

C

A

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

Red

LL

E

W

D

200

750V AC

200V DC

V

Black

procedure below for installation.)

Battery Replacement

1. Turn multimeter rotary switch to OFF

position.

2. Remove test leads from multimeter.

3. Remove three screws from back of

multimeter.

4. Remove back cover.

5. Install a new 9 Volt battery.

6. Re-assemble multimeter.

3.87KΩ and not

4KΩ that was

Fig. 5

measured in the

200KΩ range. This

is very important

because if the

manufacturer

specifications say

that the sensor

should read 3.8-

3.9KΩ at 70°F then

on the 200KΩ range

the sensor would be

defective, but at the

20KΩ range it would

DC

20M

2M

200K

OHMS

®

CP7676

OFF

V

C

A

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

ELL

W

D

200

V

750V AC

200V DC

test good.

Now set the

multimeter to the 2KΩ range. (See Fig. 6) The

display will indicate an overrange condition

because 3.87KΩ is larger than 2KΩ.

This example shows that by decreasing the

range you increase

the accuracy of

Fig. 6

your measurement.

When you change

the range, you

change the location

of the decimal

point. This changes

the accuracy of the

measurement by

either increasing or

decreasing the

number of digits

after the decimal

point.

DC

20M

2M

200K

OHMS

®

CP7676

OFF

V

C

A

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

LL

E

W

D

200

V

750V AC

200V DC

Measuring AC Voltage

This multimeter can be used to measure AC

voltages in the range of 0 to 750V. You can

use this multimeter for trouble-shooting

household electrical wiring and appliances.

To measure AC Voltages:

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

lead jack.

3. Connect RED test lead to either side of

AC voltage source.

4. Connect BLACK test lead to remaining

side of AC voltage source.

NOTE: Since AC voltages alternate

between a positive and negative value,

test lead hook-up polarity is not important.

5. Turn multimeter rotary switch to 750

AC V voltage range.

6. View reading on display.

test

V

7

Page 8

Measuring DC Voltage

This multimeter can be used to measure DC

voltages in the range from 0 to 200V. You

can use this multimeter to do any DC voltage

measurement called out in the vehicle

service manual. The most common

applications are measuring voltage drops,

and checking if the correct voltage arrived at

a sensor or a particular circuit.

Fig. 7

®

CP7676

V

C

A

OFF

M

P

R

4

V

DC

750

CYL

10

X

200

20

2

20M

2M

200K

OHMS

To measure DC Voltages (see Fig. 7):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test lead

jack.

3. Connect RED test lead to positive (+)

side of voltage source.

4. Connect BLACK test lead to negative

(-) side of voltage source.

NOTE: If you dont know which side is

positive (+) and which side is negative (-),

then arbitrarily connect the RED test lead

to one side and the BLACK to the other.

The multimeter automatically senses

polarity and will display a minus (-) sign

when negative polarity is measured. If you

switch the RED and BLACK test leads,

positive polarity will now be indicated on

the display. Measuring negative voltages

causes no harm to the multimeter.

5. Turn multimeter rotary switch to

desired voltage range.

If the approximate voltage is unknown, start

at the largest voltage range and decrease

to the appropriate range as required. (See

Setting the Range on page 6)

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

20K

CYL

2K

COM

ELL

W

D

200

V

750V AC

200V DC

Red Black

6. View reading on display - Note range

setting for correct units.

NOTE: 200mV = 0.2V

Measuring Resistance

Resistance is measured in electrical units

called ohms (Ω). The digital multimeter can

measure resistance from 0.1Ω to 20MΩ or

(20,000,000 ohms). Infinite resistance is

shown with a 1 on the left side of display

(See Setting the Range on page 6). You can

use this multimeter to do any resistance

measurement called out in the vehicle

service manual. Testing ignition coils, spark

plug wires, and some engine sensors are

common uses for the OHMS (Ω) function.

To measure Resistance (see Fig. 8):

Fig. 8

200

COM

750V AC

200V DC

CYL

8

V

6

CYL

DWELL

4

CYL

5

CYL

Unknown

Resistance

Red

V

20M

2M

200K

20K

OHMS

2K

1. Turn circuit power OFF.

To get an accurate resistance

measurement and avoid possible damage

to the digital multimeter and electrical

circuit under test, turn off all electrical

power in the circuit where the resistance

measurement is being taken.

2. Insert BLACK test lead into the COM

test lead jack.

3. Insert RED test lead into the

lead jack.

4. Turn multimeter rotary switch to 200Ω

range.

Touch RED and BLACK multimeter leads

together and view reading on display.

Display should read typically 0.2Ω to 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are

found, replace test leads.

8

Black

test

Page 9

5. Connect RED and BLACK test leads

across component where you want to

measure resistance.

When making resistance measurements,

polarity is not important. The test leads

just have to be connected across the

component.

6. Turn multimeter rotary switch to

desired OHM range.

If the approximate resistance is unknown,

start at the largest OHM range and

decrease to the appropriate range as

required. (See Setting the Range on page 6)

7. View reading on display - Note range

setting for correct units.

NOTE: 2KΩ = 2,000Ω; 2MΩ = 2,000,000Ω

If you want to make precise resistance

measurements, then subtract the test

lead resistance found in Step 4 above

from the display reading in Step 7. It is a

good idea to do this for resistance

measurements less than 10Ω.

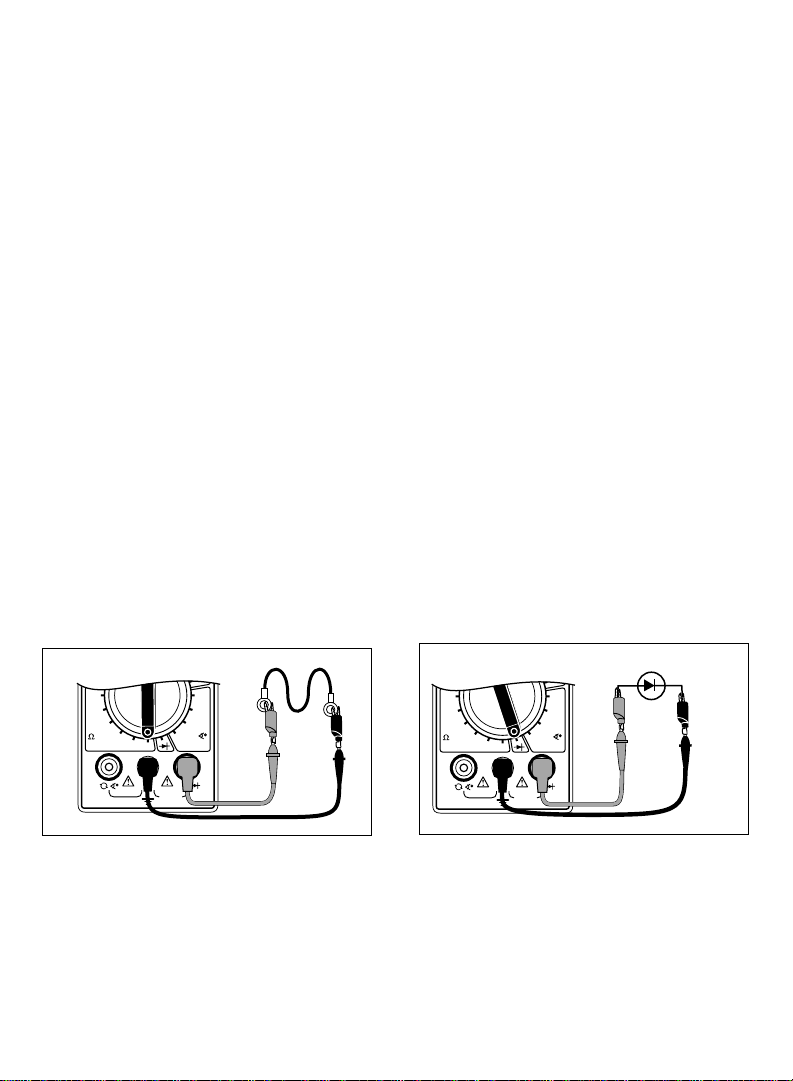

Testing for Continuity

Continuity is a specific type of resistance test

to determine if a circuit is open or closed. The

multimeter will display circuit resistance.

Resistance smaller than 10Ω usually

indicates continuity. Continuity checks are

usually done when checking for blown fuses,

switch operation, and open or shorted wires.

4. Touch RED and BLACK test leads

together and view reading on display.

Display should read typically 0.2Ω to 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are found,

replace test leads.

5. Connect RED and BLACK test leads

across component where you want to

check for continuity.

View reading on display:

Continuity - Display reading is less than

10Ω.

No Continuity - Display reading is greater

than 10Ω.

Testing Diodes

A diode is an electrical component that allows

current to only flow in one direction. When a

positive voltage, generally greater than 0.7V,

is applied to the anode of a diode, the diode

will turn on and allow current to flow. If this

same voltage is applied to the cathode, the

diode would remain off and no current would

flow. Therefore, in order to test a diode, you

must check it in both directions (i.e. anode-tocathode, and cathode-to-anode). Diodes are

typically found in alternators on automobiles.

Performing Diode Test (see Fig. 10):

Fig. 9

20M

2M

200K

20K

OHMS

2K

COM

To measure Continuity (see Fig. 9):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test lead

jack.

3. Turn multimeter rotary switch to 200Ω

range.

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

200

Black

750V AC

200V DC

V

Red

9

Fig. 10

20M

2M

200K

20K

OHMS

Anode

4

CYL

5

CYL

6

CYL

8

CYL

2K

DWELL

200

COM

750V AC

200V DC

Red

V

Cathode

Black

Page 10

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

test

V

lead jack.

3. Turn multimeter rotary switch to

function.

4. Touch RED and BLACK test leads

together to test continuity.

Display reading should be approximately

zero volts.

If display reads greater than 0.5V, then

check both test leads for bad connections.

If bad connections are found, replace test

leads.

5. Disconnect one end of diode from

circuit.

Diode must be totally isolated from circuit

in order to test its functionality.

6. Connect RED and BLACK test leads

across diode and view display.

Display will show one of three things:

A typical voltage drop of around 0.7V.

A voltage drop of 0 volts.

A 1 will appear indicating the

multimeter is overranged.

7. Switch RED and BLACK test leads and

repeat Step 6.

8. Test Results

If the display showed:

A voltage drop of 0 volts in both

directions, then the diode is shorted and

needs to be replaced.

A 1 appears in both directions, then the

diode is an open circuit and needs to be

replaced.

The diode is good if the display reads

around 0.7V in one direction and a 1

appears in the other direction indicating

the multimeter is overranged.

Measuring Engine RPM (TACH)

The CP7676 has a RPM X 10 function for

measuring engine speed or RPM. When

using the RPM X 10 function, you must

multiply the display reading by 10 to get

actual RPM. If display reads 200, then the

actual engine RPM is 10 times 200 or 2000

RPM.

OFF

V

AC

OFF

4

V

DC

750

CYL

5

YL

C

8

CYL

2K

200

COM

V

750V AC

200V DC

20M

2M

200K

OHMS

200

20

2

20K

To Measure Engine RPM (TACH) (see Fig. 11):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test

lead jack.

3. Connect RED test lead to RPM (TACH)

signal wire.

If vehicle is DIS (Distributorless Ignition

System), then connect RED test lead to

the RPM (TACH) signal wire going from

the DIS module to the vehicle engine

computer. (refer to vehicle service

manual for location of this wire)

For all vehicles with distributors, connect

RED test lead to negative side of primary

ignition coil. (refer to vehicle service

manual for location of ignition coil)

4. Connect BLACK test lead to a good

vehicle ground.

5. Turn multimeter rotary switch to correct

RPM X 10 CYLINDER selection.

6. Measure engine RPM while engine is

cranking or running.

7. View reading on display.

R

X

6

CYL

6

CYL

DWELL

Fig. 11

M

P

0

1

8

CYL

4

CYL

5

CYL

Red

Black

Ground

Typical

Ignition

Coil

10

Page 11

Measuring Dwell

Dwell measuring was extremely important on

breaker point ignition systems of the past. It

referred to the length of time, in degrees, that

the breaker points remained closed, while the

camshaft was rotating. Todays vehicles use

electronic ignition and dwell is no longer

adjustable. Another application for dwell

is in testing the mixture control solenoid on

GM feedback carburetors.

To Measure Dwell (see Fig. 12):

20M

2M

200K

OHMS

Fig. 12

4

CYL

5

CYL

6

CYL

8

20K

CYL

2K

DWELL

200

COM

V

750V AC

200V DC

Red

Black

Ground

Typical

Ignition

Coil

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test lead

jack.

3. Connect RED test lead to DWELL signal

wire.

If measuring DWELL on breaker point

ignition systems, connect RED test lead

to negative side of primary ignition coil.

(refer to vehicle service manual for

location of ignition coil)

If measuring DWELL on GM mixture

control solenoids, connect RED test lead

to ground side or computer driven side

of solenoid. (refer to vehicle service

manual for solenoid location)

If measuring DWELL on any arbitrary

ON/OFF device, connect RED test lead

to side of device that is being switched

ON/OFF.

4. Connect BLACK test lead to a good

vehicle ground.

5. Turn multimeter rotary switch to correct

DWELL CYLINDER position.

6. View reading on display.

11

Page 12

Page 13

Section 2. Automotive Testing

The digital multimeter is a very useful tool for

trouble-shooting automotive electrical

systems. This section describes how to use

the digital multimeter to test the starting and

charging system, ignition system, fuel system,

and engine sensors. The digital multimeter

can also be used for general testing of fuses,

switches, solenoids, and relays.

General Testing

The digital multimeter can be used to test

fuses, switches, solenoids, and relays.

Testing Fuses

This test checks to see if a fuse is blown.

To test Fuses (see Fig. 13):

Fig. 13

Red

Fuse

V

Black

test

200

COM

750V AC

200V DC

8

CYL

V

6

CYL

DWELL

4

CYL

5

CYL

20M

2M

200K

OHMS

20K

2K

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

lead jack.

3. Turn multimeter rotary switch to 200Ω

range.

4. Touch RED and BLACK test leads

together and view reading on display.

Display should read typically 0.2Ω to 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are found,

replace test leads.

5. Connect RED and BLACK test leads to

opposite ends of fuse.

View reading on display:

Fuse is good if display reading is less

than 10Ω.

Fuse is blown if display reading indicates

an overrange condition. (see Setting the

Range on page 6)

NOTE: Always replace blown fuses with

same type and rating.

Testing Switches

This test checks to see if a switch Opens

and Closes properly.

To test Switches (see Fig. 14):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test lead

jack.

Fig. 14

C

A

V

DC

750

200

20

2

20M

2M

200K

20K

OHMS

2K

3. Turn multimeter rotary switch to 200Ω

range.

4. Touch RED and BLACK test leads

together and view reading on display.

Display should read typically 0.2Ω to 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are found,

replace test leads.

5. Connect BLACK test lead to one side of

switch.

6. Connect RED test lead to other side of

switch.

13

V

OFF

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

200

V

750V AC

200V DC

Red

Typical

"Push"

Button

Switch

Black

Page 14

View reading on display:

Switch is closed if display reading is less

than 10Ω.

Switch is open if display reading

indicates an overrange condition. (see

Setting the Range on page 6)

7. Operate switch.

View reading on display:

Switch is closed if display reading is less

than 10Ω.

Switch is open if display reading indicates

an overrange condition. (see Setting the

Range on page 6)

8. Repeat Step 7 to verify switch

operation.

Good Switch: Display reading alternates

from a 10Ω or less value to an overrange

condition as you operate switch.

Bad Switch: Display reading remains

unchanged as you operate switch.

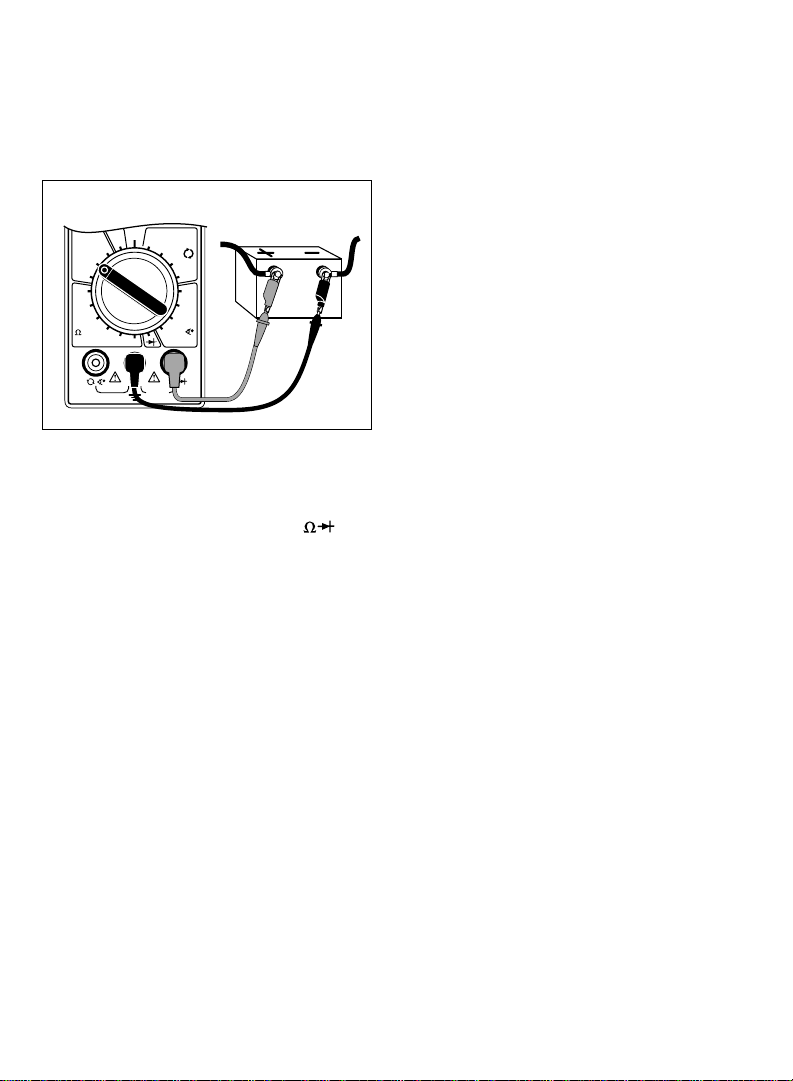

Testing Solenoids and Relays

This test checks to see if a solenoid or relay

have a broken coil. If the coil tests good, it is

still possible that the relay or solenoid are

defective. The relay can have contacts that

are welded or worn down, and the solenoid

may stick when the coil is energized. This test

does not check for those potential problems.

To test Solenoids and Relays (see Fig. 15):

Fig. 15

Relay or Solenoid

200

COM

750V AC

200V DC

8

CYL

V

6

CYL

DWELL

4

CYL

5

CYL

Red

Black

20M

2M

200K

OHMS

20K

2K

3. Turn multimeter rotary switch to 200Ω

range.

Most solenoids and relay coil resistances

are less than 200Ω. If meter overranges,

turn multimeter rotary switch to next

higher range. (see Setting the Range on

page 6)

4. Touch RED and BLACK test leads

together and view display.

Display should read typically 0.2Ω to 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are

found, replace test leads.

5. Connect BLACK test lead to one side

of coil.

6. Connect RED test lead to other side of

coil.

7. View reading on display.

Typical solenoid / relay coil resistances

are 200Ω or less.

Refer to vehicle service manual for your

vehicles resistance range.

8. Test Results

Good Solenoid / Relay Coil: Display in

Step 7 is within manufacturers

specification.

Bad Solenoid / Relay Coil:

Display in Step 7 is not within

manufacturers specifications.

Display reads overrange on every ohms

range indicating an open circuit.

NOTE: Some relays and solenoids have

a diode placed across the coil. To test this

diode see Testing Diodes on page 9.

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

V

lead jack.

test

14

Page 15

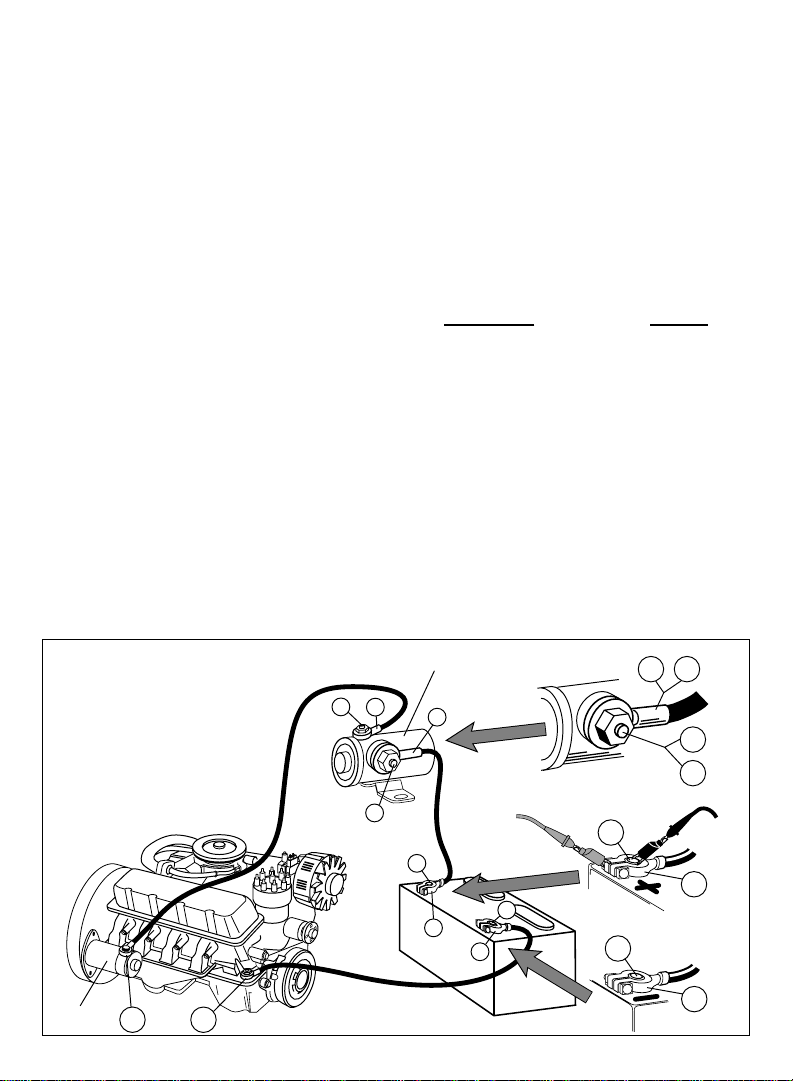

Starting/Charging System Testing

The starting system turns over the engine. It consists of the battery, starter motor, starter solenoid

and/or relay, and associated wiring and connections. The charging system keeps the battery

charged when the engine is running. This system consists of the alternator, voltage regulator,

battery, and associated wiring and connections. The digital multimeter is a useful tool for checking

the operation of these systems.

No Load Battery Test

Before you do any starting/charging system

checks, you must first test the battery to

make sure it is fully charged.

Fig. 16

V

AC

OFF

V

DC

750

200

20

2

20M

2M

200K

20K

OHMS

2K

200

COM

Test Procedure (see Fig. 16):

1. Turn Ignition Key OFF.

2. Turn ON headlights for 10 seconds to

dissipate battery surface charge.

3. Insert BLACK test lead into the COM

test lead jack.

4

CYL

750V AC

200V DC

M

P

R

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

Red

V

Black

4. Insert RED test lead into the

lead jack.

5. Disconnect positive (+) battery cable.

6. Connect RED test lead to positive (+)

terminal of battery.

7. Connect BLACK test lead to negative

(-) terminal of battery.

8. Turn multimeter rotary switch to 20V DC

range.

9. View reading on display.

10.Test Results.

Compare display reading in Step 9 with

chart below.

Voltage Percent Battery is Charged

12.60V

or greater 100%

12.45V 75%

12.30V 50%

12.15V 25%

If battery is not 100% charged, then charge

it before doing any more starting/charging

system tests.

test

V

15

Page 16

Cranking Voltage - Battery Load Test

This test checks the battery to see if it is

delivering enough voltage to the starter

motor under cranking conditions.

Fig. 17

V

AC

OFF

V

DC

750

200

20

2

20M

2M

200K

20K

OHMS

2K

200

COM

Test Procedure (see Fig. 17):

1. Disable ignition system so vehicle

wont start.

Disconnect the primary of the ignition coil

or the distributor pick-up coil or the cam/

crank sensor to disable the ignition

system. Refer to vehicle service manual

for disabling procedure.

2. Insert BLACK test lead into the COM

test lead jack.

3. Insert RED test lead into the test lead

jack.

4

CYL

750V AC

200V DC

M

P

R

0

1

X

5

YL

C

6

YL

C

8

YL

C

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

Red

V

Black

4. Connect RED test lead to positive (+)

terminal of battery.

5. Connect BLACK test lead to negative

(-) terminal of battery.

6. Turn multimeter rotary switch to 20V

DC range.

7. Crank engine for 15 seconds

continuously while observing display.

8. Test Results.

Compare display reading in Step 7 with

chart below.

Voltage Temperature

9.6V or greater 70 °F and Above

9.5V 60 °F

9.4V 50 °F

9.3V 40 °F

9.1V 30 °F

8.9V 20 °F

8.7V 10 °F

8.5V 0 °F

If voltage on display corresponds to above

voltage vs. temperature chart, then cranking

system is normal.

If voltage on display does not correspond to

chart, then it is possible that the battery,

battery cables, starting system cables,

starter solenoid, or starter motor are

defective.

16

Page 17

Voltage Drops

This test measures the voltage drop across

wires, switches, cables, solenoids, and

connections. With this test you can find

excessive resistance in the starter system.

This resistance restricts the amount of

current that reaches the starter motor

resulting in low battery load voltage and a

slow cranking engine at starting.

Test Procedure (see Fig. 18):

1. Disable ignition system so vehicle

wont start.

Disconnect the primary of the ignition coil

or the distributor pick-up coil or the cam/

crank sensor to disable the ignition

system. Refer to vehicle service manual

for disabling procedure.

2. Insert BLACK test lead into the COM

test lead jack.

3. Insert RED test lead into the test lead

jack.

4. Connect test leads.

Refer to Typical Cranking Voltage Loss

Circuit (Fig. 18).

Connect RED and BLACK test leads

alternately between 1 & 2, 2 & 3, 4 & 5,

5 & 6, 6 & 7, 7 & 8, 8 & 9, and 8 & 10.

5. Turn multimeter rotary switch to

200mV DC range.

If multimeter overranges, turn multimeter

rotary switch to the 2V DC range. (See

Setting the Range on page 6)

6. Crank engine until steady reading is on

display.

Record results at each point as

displayed on multimeter.

Repeat Step 4 & 5 until all points are

checked.

7. Test Results

Estimated Voltage Drop of Starter

Circuit Components

Component Voltage

Switches 300mV

Wire or Cable 200mV

Ground 100mV

Battery Cable Connectors 50mV

Connections 0.0 V

Compare voltage readings in Step 6

with above chart.

If any voltages read high, inspect

component and connection for defects.

If defects are found, service as

necessary.

Fig. 18 Typical Cranking

Voltage Loss Circuit

This is a representative sample of

one type of cranking circuit. Your

vehicle may use a different circuit with

different components or locations.

Consult your vehicle service manual.

Starter

10

1

Solenoid

9

8

6

6 8

7

9

7

5

Red

5

Black

4

4

3

2

3

2

17

Page 18

Charging System Voltage Test

This test checks the charging system to see

if it charges the battery and provides power

to the rest of the vehicles electrical systems

(lights, fan, radio etc).

Fig. 19

V

AC

OFF

V

DC

750

200

20

2

20M

2M

200K

20K

OHMS

2K

200

COM

Test Procedure (see Fig. 19):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

lead jack.

3. Connect RED test lead to positive (+)

terminal of battery.

4. Connect BLACK test lead to negative

(-) terminal of battery.

5. Turn multimeter rotary switch to 20V

DC range.

6. Start engine - Let idle.

4

CYL

750V AC

200V DC

M

P

R

0

1

X

5

YL

C

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

Red

V

Black

test

V

7. Turn off all accessories and view

reading on display.

Charging system is normal if display

reads 13.2 to 15.2 volts.

If display voltage is not between 13.2 to

15.2 volts, then proceed to Step 13.

8. Open throttle and Hold engine speed

(RPM) between 1800 and 2800 RPMs.

Hold this speed through Step 11 - Have

an assistance help hold speed.

9. View reading on display.

Voltage reading should not change from

Step 7 by more than 0.5V.

10.Load the electrical system by turning

on the lights, windshield wipers, and

setting the blower fan on high.

11.View reading on display.

Voltage should not drop down below

about 13.0V.

12.Shut off all accessories, return engine

to curb idle and shut off.

13.Test Results.

If voltage readings in Steps 7, 9, and 11

were as expected, then charging system

is normal.

If any voltage readings in Steps 7, 9, and

11 were different then shown here or in

vehicle service manual, then check for a

loose alternator belt, defective regulator

or alternator, poor connections, or open

alternator field current.

Refer to vehicle service manual for

further diagnosis.

18

Page 19

Page 20

Ignition System Testing

The ignition system is responsible for providing the spark that ignites the fuel in the cylinder.

Ignition system components that the digital multimeter can test are the primary and secondary

ignition coil resistance, spark plug wire resistance, hall effect switches/sensors, reluctance pickup coil sensors, and the switching action of the primary ignition coil.

Ignition Coil Testing

This test measures the resistance of the

primary and secondary of an ignition coil. This

test can be used for distributorless ignition

systems (DIS) provided the primary and

secondary ignition coil terminals are easily

accessible.

Test Procedure:

1. If engine is HOT let it COOL down

before proceeding.

2. Disconnect ignition coil from ignition

system.

3. Insert BLACK test lead into the COM

test lead jack. (See Fig. 20.)

Fig. 20

20

2

20M

2M

200K

OHMS

750

200

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

200

V

750V AC

200V DC

Secondary

Coil

Red

Typical Cylindrical

Ignition Coil

Black

6. Connect test leads.

Connect RED test lead to primary

ignition coil positive (+) terminal.

Connect BLACK test lead to primary

ignition coil negative (-) terminal.

Refer to vehicle service manual for

location of primary ignition coil terminals.

7. View reading on display.

Subtract test lead resistance found in Step

5 from above reading.

8. If vehicle is DIS, repeat Steps 6 and 7

for remaining ignition coils.

9. Test Results - Primary Coil

Typical resistance range of

primary ignition coils is 0.3 -

2.0Ω.

Refer to vehicle service manual

for your vehicle's resistance

range.

10.Turn multimeter rotary switch

to 200KΩ range (see Fig. 21).

Primary

Coil

4. Insert RED test lead into the

test lead jack.

V

5. Turn multimeter rotary switch

to 200Ω range.

Touch RED and BLACK test

leads together and view reading

on display.

Display should read typically

0.2Ω to 1.5Ω.

If display reading was greater

than 1.5Ω, check both ends of

test leads for bad connections.

If bad connections are found,

replace test leads.

Fig. 21

20

2

20M

2M

200K

OHMS

200

20

M

P

R

4

750

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

20K

CYL

2K

DWELL

200

COM

V

750V AC

200V DC

Secondary

Coil

Red

Typical Cylindrical

Ignition Coil

Black

Primary

Coil

Page 21

11.Move RED test lead to secondary

ignition coil terminal.

Refer to vehicle service manual for

location of secondary ignition coil

terminal.

Verify BLACK test lead is connected to

primary ignition coil negative (-) terminal.

12.View reading on display.

13.If vehicle is DIS, repeat Steps 11 and 12

for remaining ignition coils.

14.Test Results - Secondary Coil

Typical resistance range of secondary

ignition coils is 6.0 - 30.0KΩ.

Refer to vehicle service manual for your

vehicles resistance range.

15.Repeat test procedure for a HOT

ignition coil.

NOTE: It is a good idea to test ignition

coils when they are both hot and cold,

because the resistance of the coil could

change with temperature. This will also

help in diagnosing intermittent ignition

system problems.

16.Test Results - Overall

Good Ignition Coil: Resistance readings in

Steps 9, 14 and 15 were within

manufacturers specification.

Bad Ignition Coil: Resistance readings in

Steps 9, 14 and 15 are not within

manufacturers specification.

21

Page 22

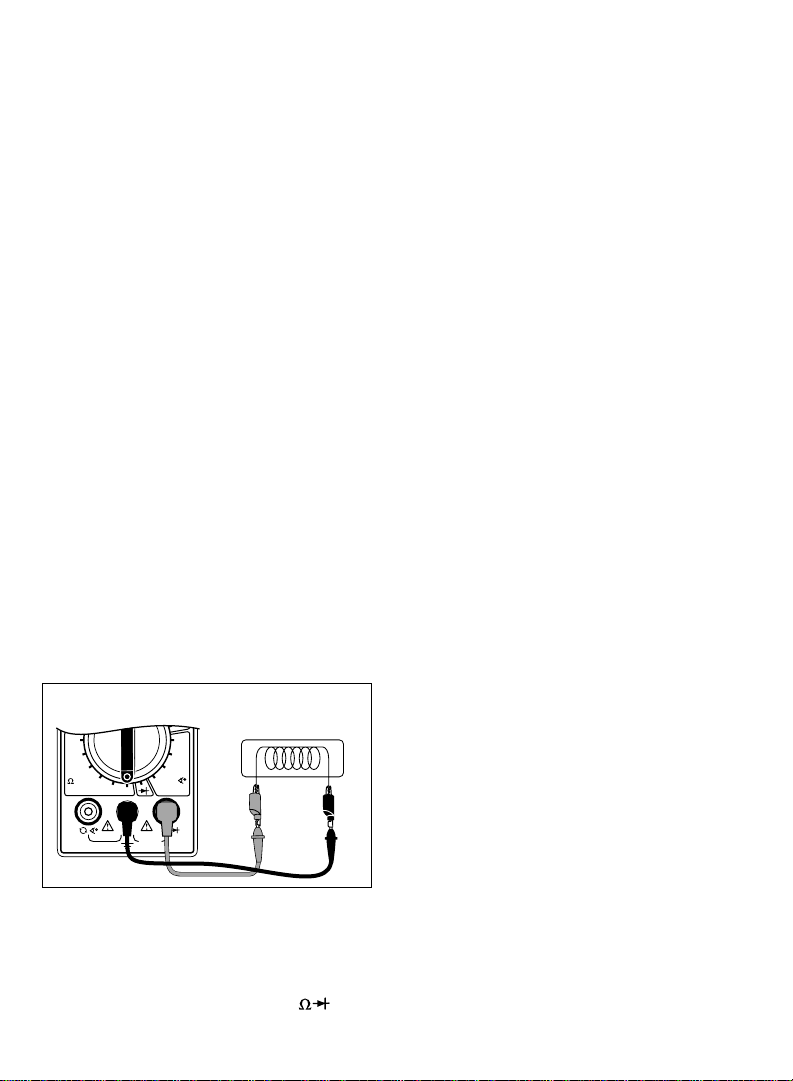

Ignition System Wires

This test measures the resistance of

spark plug and coil tower wires while they are

being flexed. This test can be used for

distributorless ignition systems (DIS) provided

the system does not mount the ignition coil

directly on the spark plug.

Test Procedure:

1. Remove ignition system wires one at a

time from engine.

Always grasp ignition system wires on

the boot when removing.

Twist the boots about a half turn while

pulling gently to remove them.

Refer to vehicle service manual for

ignition wire removal procedure.

Inspect ignition wires for cracks, chaffed

insulation, and corroded ends.

NOTE: Some Chrysler products use a

positive-locking terminal electrode spark

plug wire. These wires can only be

removed from inside the distributor cap.

Damage may result if other means of

removal are attempted. Refer to vehicle

service manual for procedure.

NOTE: Some spark plug wires have sheet

metal jackets with the following

symbol: . This type of plug wire

contains an air gap resistor and can only

be checked with an oscilloscope.

2. Insert BLACK test lead into the COM

test lead jack. (See Fig. 22.)

Fig. 22

750

200

20

2

20M

2M

200K

20K

OHMS

2K

COM

3. Insert RED test lead into the

M

P

R

4

YL

C

0

1

X

5

CYL

6

YL

C

8

CYL

4

CYL

5

YL

C

6

CYL

8

CYL

DWELL

200

V

750V AC

200V DC

Spark Plug Wire

Red

Black

V

test

lead jack.

4. Connect RED test lead to one end of

ignition wire and BLACK test lead to

other end.

5. Turn multimeter rotary switch to 200KΩ

range.

6. View reading on display while flexing

ignition wire and boot in several places.

Typical resistance range is 3KΩ to 50KΩ

or approximately 10KΩ per foot of wire.

Refer to vehicle service manual for your

vehicles resistance range.

As you flex ignition wire, the display

should remain steady.

7. Test Results

Good Ignition Wire: Display reading is

within manufacturers specification and

remains steady while wire is flexed.

Bad Ignition Wire: Display reading

erratically changes as ignition wire is

flexed or display reading is not within

manufacturers specification.

22

Page 23

Hall Effect Sensors/Switches

Hall Effect sensors are used whenever the

vehicle computer needs to know speed and

position of a rotating object. Hall Effect

sensors are commonly used in ignition

systems to determine camshaft and

crankshaft position so the vehicle computer

knows the optimum time to fire the ignition

coil(s) and turn on the fuel injectors. This test

checks for proper operation of the Hall Effect

sensor / switch.

Test Procedure (see Fig. 23):

1. Remove Hall Effect Sensor from

vehicle.

Refer to vehicle service manual for

procedure.

2. Connect 9V battery to sensor POWER

and GROUND pins.

Connect positive(+) terminal of 9V

battery to sensor POWER pin.

Connect negative(-) terminal of 9V

battery to sensor GROUND pin.

Refer to illustrations for POWER and

GROUND pin locations.

For sensors not illustrated refer to

vehicle service manual for pin locations.

3. Insert BLACK test lead into the COM

test lead jack.

4. Insert RED test lead into the

test

V

lead jack.

5. Connect RED test lead to sensor

SIGNAL pin.

6. Connect BLACK test lead to 9V battery

negative (-) pin.

7. Turn multimeter rotary switch to 200Ω

range.

Multimeter display should read a small

ohm value.

8. Slide a flat blade of iron or magnetic

steel between sensor and magnet. (Use

a scrap of sheet metal, knife blade, steel

ruler, etc.)

Multimeter display should indicate an

overrange condition.

Remove steel blade and multimeter

should again display a small ohm value.

It is O.K. if display changes erratically

after steel blade is removed.

Repeat several times to verify results.

9. Test Results.

Good Sensor: Display reading toggles

from a small ohmic value to an overrange

condition as steel blade is inserted and

removed.

Bad Sensor: Display reading remains

unchanged as steel blade is inserted and

removed.

Fig. 23

200

20

2

20M

2M

200K

20K

OHMS

Chrysler Distributor

Black

M

P

R

4

750

CYL

0

1

X

5

CYL

6

YL

C

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

2K

DWELL

COM

200

V

750V AC

200V DC

Red

GROUND

SIGNAL

9V

POWER

Jumper

Wires

Steel Blade

Sensor

Typical Hall

Effect Sensor

Iron or

Magnet

POWER

Hall Effect

GROUND SIGNAL

Ford Distributor

Hall Effect

POWER

GROUND

SIGNAL

23

Page 24

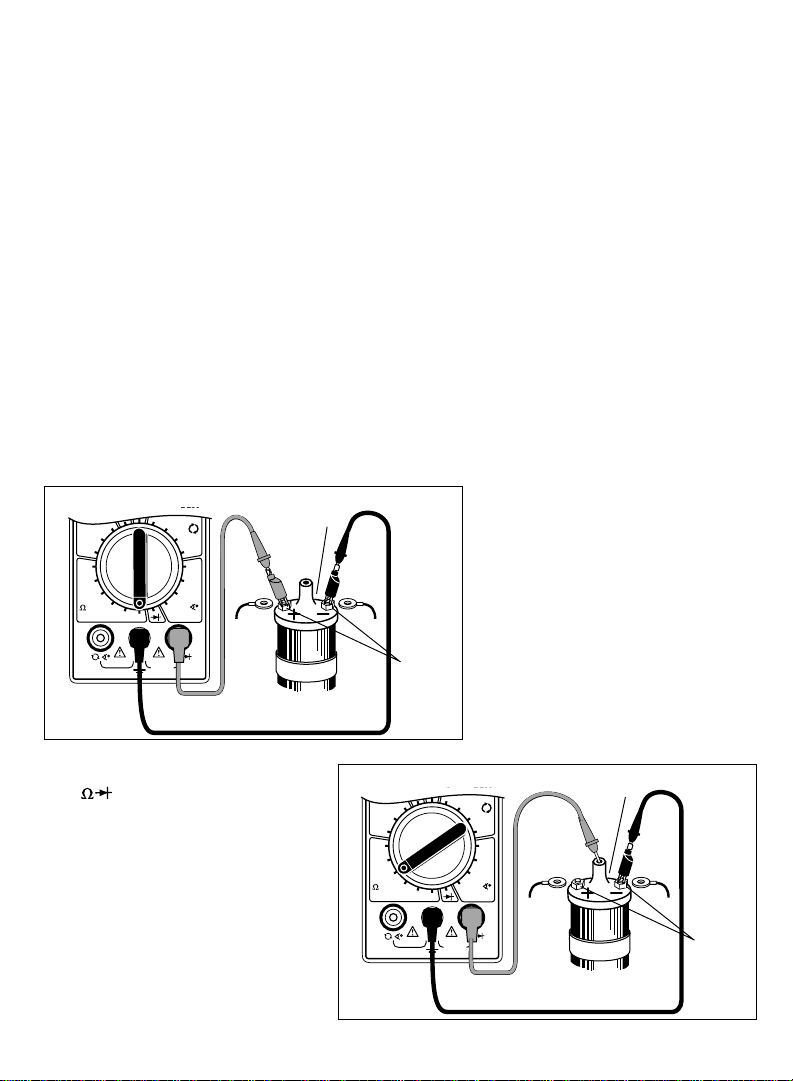

Magnetic Pick-Up Coils Reluctance Sensors

Reluctance sensors are used whenever the

vehicle computer needs to know speed and

position of a rotating object. Reluctance

sensors are commonly used in ignition

systems to determine camshaft and

crankshaft position so the vehicle computer

knows the optimum time to fire the ignition

coil(s) and turn on the fuel injectors. This test

checks the reluctance sensor for an open or

shorted coil. This test does not check the air

gap or voltage output of the sensor.

Fig. 24

200

20

2

20M

2M

200K

20K

OHMS

M

P

R

4

750

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

2K

DWELL

200

COM

V

750V AC

200V DC

Red

Reluctance

Sensor

Black

Test Procedure (see Fig. 24):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

lead jack.

3. Connect RED test lead to either sensor

pin.

4. Connect BLACK test lead to remaining

sensor pin.

5. Turn multimeter rotary switch to 2KΩ

range.

6. View reading on display while

flexing sensor wires in several

places.

Reluctor

Ring

Typical resistance range is 150 -

1000Ω.

Refer to vehicle service manual

Magnet

for your vehicles resistance range.

As you flex sensor wires, the

display should remain steady.

7. Test Results

Good Sensor: Display reading is

within manufacturers specification

and remains steady while sensor

wires are flexed.

Bad Sensor: Display reading

erratically changes as sensor wires

are flexed or display reading is not

within manufacturers specification.

test

V

24

Page 25

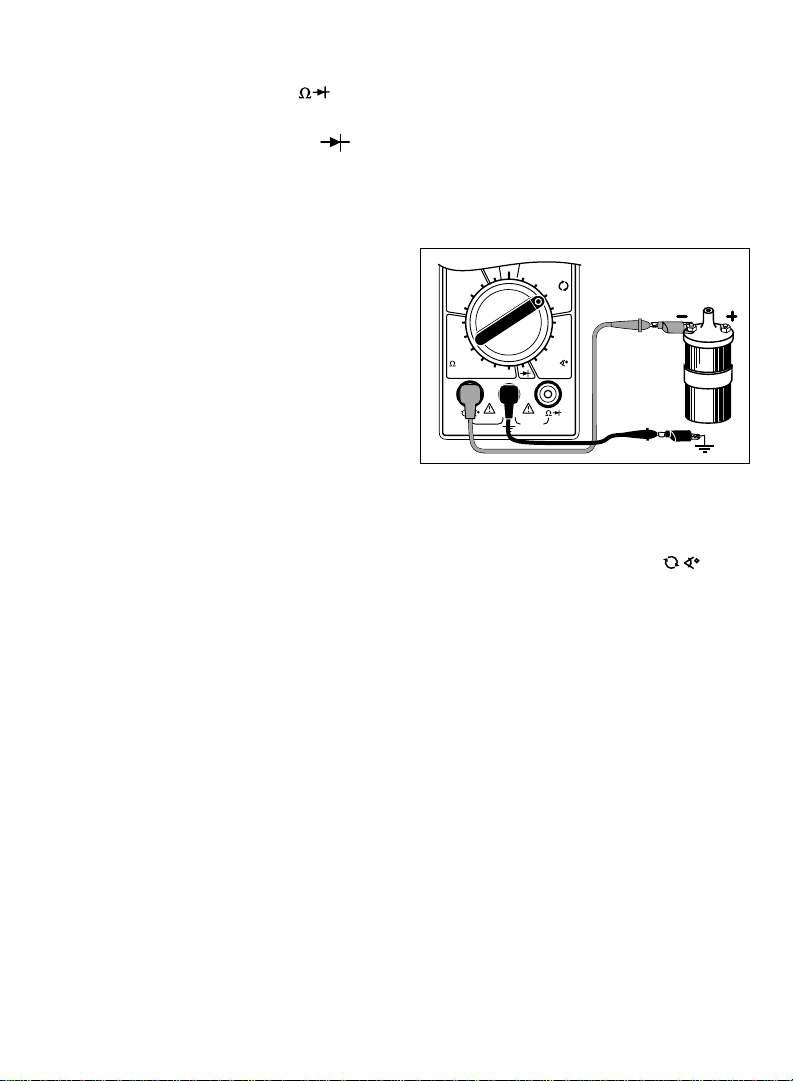

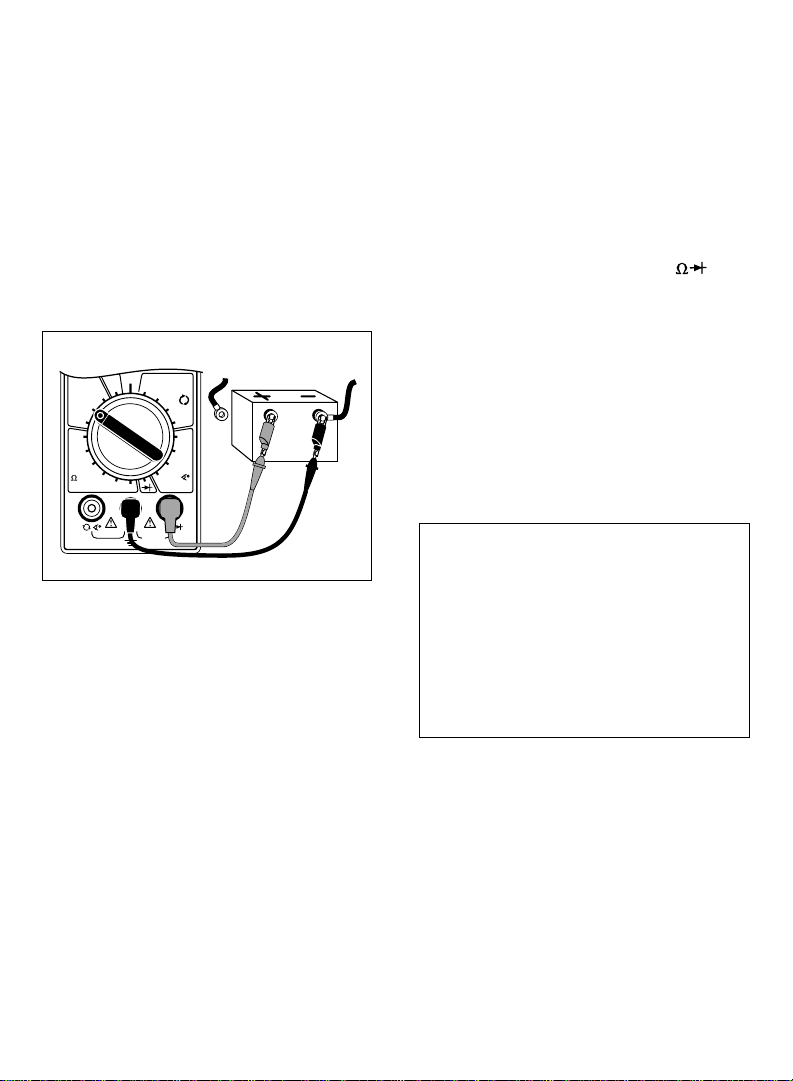

Ignition Coil Switching Action

This test checks to see if the negative

terminal of the primary ignition coil is getting

switched ON and OFF via the ignition module

and camshaft / crankshaft position sensors.

This switching action is where the RPM or

tach signal originates. This test is primarily

used for a no start condition.

V

AC

DC

20M

2M

200K

OHMS

OFF

V

750

200

20

2

20K

2K

COM

M

P

R

4

CYL

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

DWELL

200

V

750V AC

200V DC

Red

Black

Ground

Fig. 25

Typical

Ignition

Coil

Test Procedure (see Fig. 25):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the test

lead jack.

3. Connect RED test lead to TACH signal

wire.

If vehicle is DIS (Distributorless Ignition

System), then connect RED test lead to

the TACH signal wire going from the DIS

module to the vehicle engine computer.

(refer to vehicle service manual for

location of this wire)

For all vehicles with distributors, connect

RED test lead to negative side of primary

ignition coil. (refer to vehicle service

manual for location of ignition coil)

4. Connect BLACK test lead to a good

vehicle ground.

5. Turn multimeter rotary switch to correct

RPM X 10 CYLINDER selection.

6. View reading on display while engine is

cranking.

Typical cranking RPM range is 50-275

RPM depending on temperature, size of

engine, and battery condition.

Refer to vehicle service manual for

specific vehicle cranking RPM range.

7. Test Results.

Good Coil Switching Action: Display

reading indicated a value consistent with

manufacturers specifications.

Bad Coil Switching Action:

Display read zero RPM, meaning the

ignition coil is not being switched ON

and OFF.

Check ignition system for wiring defects,

and test the camshaft and crankshaft

sensors.

25

Page 26

Fuel System Testing

The requirements for lower vehicle emissions has

increased the need for more precise engine fuel control.

Auto manufacturers began using electronically controlled

carburetors in 1980 to meet emission requirements.

Todays modern vehicles use electronic fuel injection to

precisely control fuel and further lower emissions. The

digital multimeter can be used to test the fuel mixture

control solenoid on General Motors vehicles and

to measure fuel injector resistance.

Testing GM C-3 Mixture Control Solenoid Dwell

Typical Mixture Control

Solenoid Connection

Mixture Control

Solenoid

This solenoid is located in the carburetor. Its

purpose is to maintain an air/fuel ratio of 14.7

to 1 in order to reduce emissions. This test

checks to see if the solenoid dwell is varying.

Test Description:

This test is rather long and detailed. Refer to

vehicle service manual for the complete test

procedure. Some important test procedure

highlights you need to pay close attention to

are listed below.

1. Make sure engine is at operating

temperature and running during test.

2. Refer to vehicle service manual for

multimeter hook-up instructions.

3. Turn multimeter rotary switch to 6

Cylinder Dwell position for all GM

vehicles.

4. Run engine at 3000 RPM.

5. Make engine run both RICH and LEAN.

6. Watch multimeter display.

7. Multimeter display should vary from 10°

to 50° as vehicle changes from lean to

rich.

26

Page 27

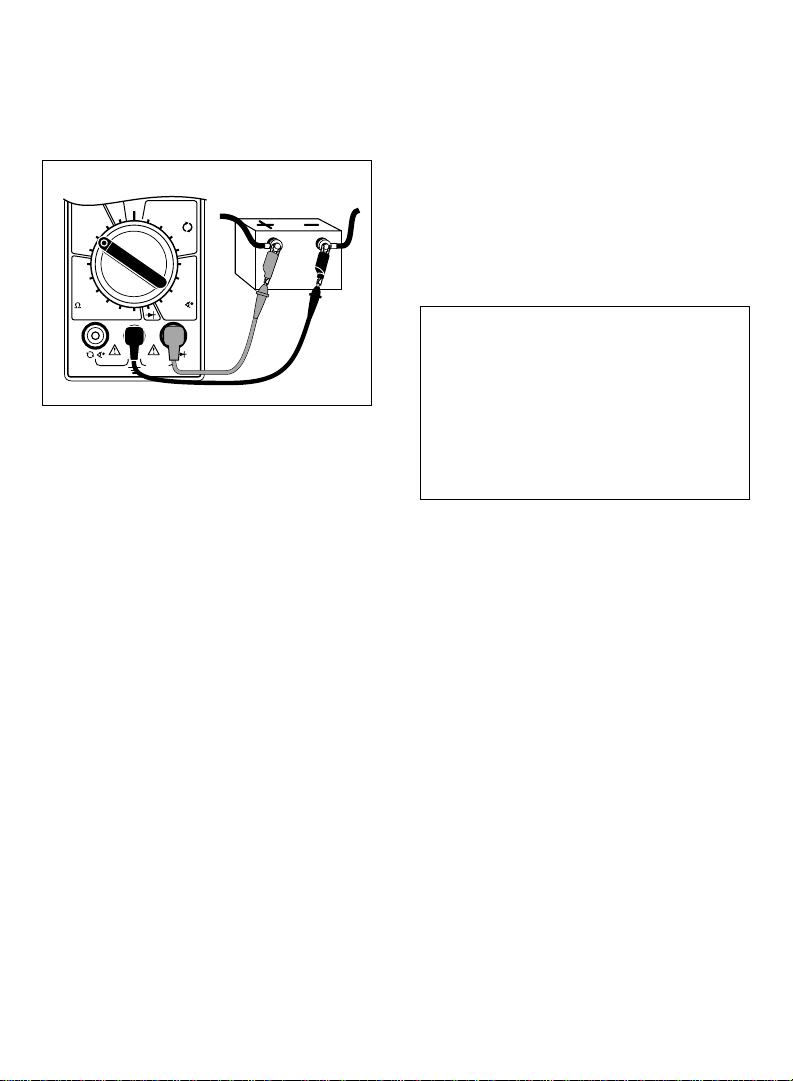

Measuring Fuel Injector Resistance

Fuel injectors are similar to solenoids. They

contain a coil that is switched ON and OFF by

the vehicle computer. This test measures the

resistance of this coil to make sure it is not an

open circuit. Shorted coils can also be

detected if the specific manufacturer

resistance of the fuel injector is known.

Fig. 26

200

20

2

20M

2M

200K

20K

OHMS

M

P

R

4

750

YL

C

0

1

X

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

2K

DWELL

200

COM

V

750V AC

200V DC

Typical Fuel

Black

Injector

Red

Test Procedure (see Fig. 26):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

test

V

lead jack.

3. Turn multimeter rotary switch to 200Ω

range.

Touch RED and BLACK multimeter leads

together and view reading on display.

Display should read typically 0.2 - 1.5Ω.

If display reading was greater than 1.5Ω,

check both ends of test leads for bad

connections. If bad connections are found,

replace test leads.

4. Disconnect wiring harness from fuel

injector - Refer to vehicle service

manual for procedure.

5. Connect RED and BLACK test leads

across fuel injector pins.

Make sure you connect test leads across

fuel injector and not the wiring harness.

6. Turn multimeter rotary switch to desired

OHM range.

If the approximate resistance is unknown,

start at the largest OHM range and

decrease to the appropriate range as

required. (see Setting the Range on page

6)

7. View reading on display - Note range

setting for correct units.

If display reading is 10Ω or less, subtract

test lead resistance found in Step 3 from

above reading.

Compare reading to manufacturers

specifications for fuel injector coil

resistance.

This information is found in vehicle

service manual.

8. Test Results

Good Fuel Injector resistance: Resistance

of fuel injector coil is within manufacturers

specifications.

Bad Fuel Injector resistance: Resistance

of fuel injector coil is not within

manufacturers specifications.

NOTE: If resistance of fuel injector coil is

within manufacturers specifications, the

fuel injector could still be defective. It is

possible that the fuel injector is clogged or

dirty and that is causing your driveability

problem.

27

Page 28

Testing Engine Sensors

In the early 1980s, computer controls were installed in vehicles to meet Federal Government

regulations for lower emissions and better fuel economy. To do its job, a computer-controlled

engine uses electronic sensors to find out what is happening in the engine. The job of the sensor

is to take something the computer needs to know, such as engine temperature, and convert it to

an electrical signal which the computer can understand. The digital multimeter is a useful tool for

checking sensor operation.

Titania-Type

Oxygen Sensor

Oxygen (O2) Type Sensors

The Oxygen Sensor produces a voltage or

resistance based on the amount of oxygen in

the exhaust stream. A low voltage (high

resistance) indicates a lean exhaust (too

much oxygen), while a high voltage (low

resistance) indicates a rich exhaust (not

enough oxygen). The computer uses this

voltage to adjust the air/fuel ratio. The two

types of O2 Sensors commonly in use are

Zirconia and Titania. Refer to illustration for

appearance differences of the two sensor

types.

Test Procedure (see Fig. 27):

1. If engine is HOT, let it COOL down

before proceeding.

2. Remove Oxygen Sensor from vehicle.

3. Insert BLACK test lead into the COM

test lead jack.

4. Insert RED test lead into the test lead

jack.

Zirconia-Type

Oxygen Sensor

5. Test heater circuit.

If sensor contains 3 or more wires, then

your vehicle uses a heated O2 sensor.

Refer to vehicle service manual for

location of heater pins.

Connect RED test lead to either heater

pin.

Connect BLACK test lead to remaining

heater pin.

Exposed

flat element

Flutes

Fig. 27

200

20

2

20M

2M

200K

S

OHM

20K

RPM

4

750

L

Y

C

X10

5

L

Y

C

6

L

Y

C

8

L

Y

C

4

L

Y

C

5

L

Y

C

6

L

Y

C

8

L

Y

C

2K

200

COM

750V AC

200V DC

DWELL

V

Rich

Red

Black

Lean

1-wire or 3-wire: Ground is sensor housing

Ground

2-wire or 4-wire: Ground is in sensor wiring harness

28

Page 29

Turn multimeter rotary switch to 200Ω

range.

View reading on display.

Compare reading to manufacturer's

specification in vehicle service manual.

Remove both test leads from sensor.

6. Connect BLACK test lead to sensor

GROUND pin.

If sensor is 1-wire or 3-wire, then

GROUND is sensor housing.

If sensor is 2-wire or 4-wire, then

GROUND is in sensor wiring harness.

Refer to vehicle service manual for

Oxygen Sensor wiring diagram.

7. Connect RED test lead to sensor

SIGNAL pin.

8. Test Oxygen Sensor.

Turn multimeter rotary switch to...

2V range for Zirconia Type Sensors.

200Ký range for Titania Type Sensors.

Light propane torch.

Firmly grasp sensor with a pair of

locking pliers.

Thoroughly heat sensor tip as hot as

possible, but not glowing. Sensor tip

must be at 660°F to operate.

Completely surround sensor tip with

flame to deplete sensor of oxygen (Rich

Condition).

Multimeter display should read...

0.6V or greater for Zirconia Type

Sensors.

an Ohmic(Resistance) value for Titania

Type Sensors. Reading will vary with

flame temperature.

While still applying heat to sensor, move

flame such that oxygen can reach

sensor tip (Lean Condition).

Multimeter display should read...

0.4V or less for Zirconia Type Sensors.

an overrange condition for Titania Type

Sensors. (See Setting the Range on

page 6.)

9. Repeat Step 8 a few times to verify

results.

10.Extinguish Flame, let sensor cool, and

remove test leads.

11.Test Results.

Good Sensor:

Heater Circuit resistance is within

manufacturer's specification.

Oxygen Sensor output signal changed

when exposed to a rich and lean

condition.

Bad Sensor:

Heater Circuit resistance is not within

manufacturer's specification.

Oxygen Sensor output signal did not

change when exposed to a rich and lean

condition.

Oxygen sensor output voltage takes

longer than 3 seconds to switch from a

rich to a lean condition.

29

Page 30

Temperature Type Sensors

A temperature sensor is a thermistor or a

resistor whose resistance changes with

temperature. The hotter the sensor gets, the

lower the resistance becomes. Typical

thermistor applications are engine coolant

sensors, intake air temperature sensors,

transmission fluid temperature sensors, and

oil temperature sensors.

Fig. 28

Hair Dryer

M

P

R

4

750

CYL

0

1

X

200

20

2

20M

2M

200K

20K

OHMS

Test Procedure (see Fig. 28):

1. If engine is HOT let it COOL down

before proceeding.

Make sure all engine and transmission

fluids are at outside air temperature

before proceeding with this test!

2. Insert BLACK test lead into the COM

test lead jack.

3. Insert RED test lead into the

lead jack.

4. Disconnect wiring harness from

sensor.

5. If testing Intake Air Temperature

Sensor - Remove it from vehicle.

All other temperature sensors can remain

on vehicle for testing.

6. Connect RED test lead to either sensor

pin.

7. Connect BLACK test lead to remaining

sensor pin.

5

CYL

6

CYL

8

CYL

4

CYL

5

CYL

6

CYL

8

CYL

2K

DWELL

200

COM

750V AC

200V DC

V

Red

Typical

Intake Air

Temperature

Sensor

Black

test

V

8. Turn multimeter rotary switch to

desired OHM range.

If the approximate resistance is unknown,

start at the largest OHM range and

decrease to the appropriate range as

required. (See Setting the Range on page

6)

9. View and record reading on display.

10.Disconnect multimeter test leads from

sensor and reconnect sensor wiring.

This step does not apply to intake air

temperature sensors. For intake air

temperature sensors, leave multimeter

test leads still connected to sensor.

11.Heat up sensor.

If testing Intake Air Temperature Sensor:

To heat up sensor dip sensor tip into

boiling water, or...

Heat tip with a lighter if sensor tip is

metal or a hair dryer if sensor tip is

plastic.

View and record smallest reading on

display as sensor is heated.

You may need to decrease the range to

get a more accurate reading.

For all other temperature sensors:

Start engine and let idle until upper

radiator hose is warm.

Turn ignition key OFF.

Disconnect sensor wiring harness and

reconnect multimeter test leads.

View and record reading on display.

12.Test Results.

Good Sensor:

Temperature sensors HOT resistance is

at least 300ý less than its COLD

resistance.

The key point is that the COLD

resistance decreases with increasing

temperature.

Bad Sensor:

There is no change between the

temperature sensors HOT resistance

from the COLD resistance.

The temperature sensor is an open or a

short circuit.

30

Page 31

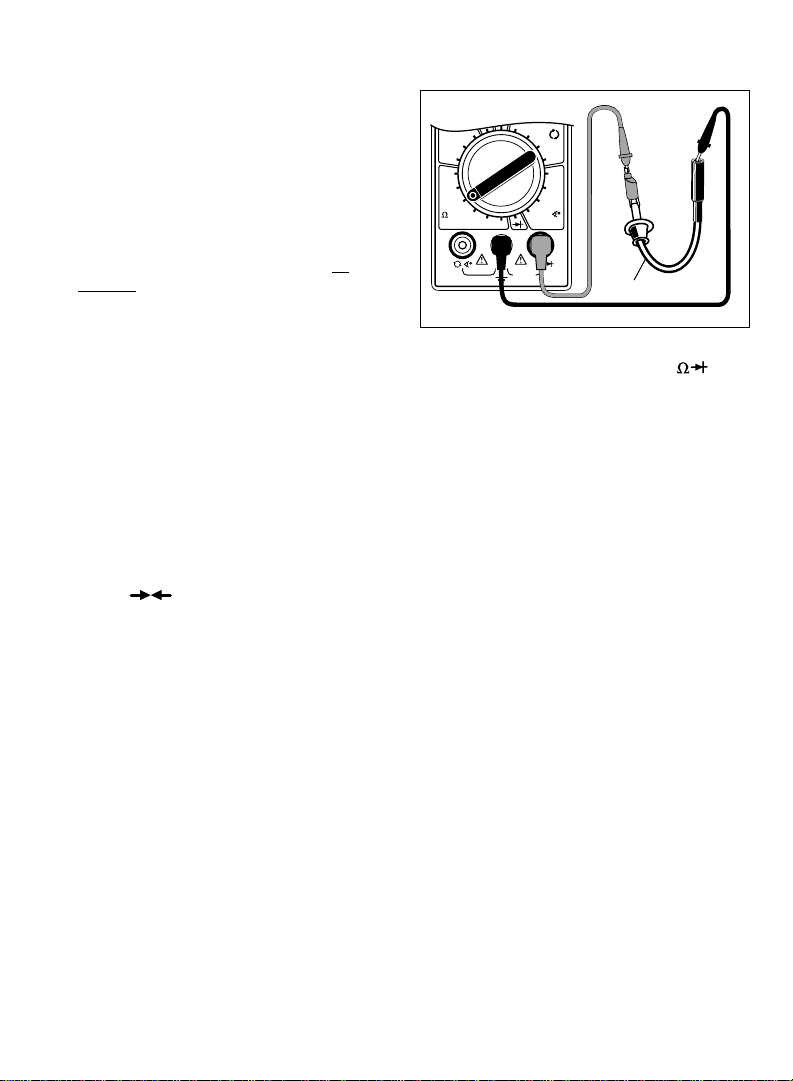

Position Type Sensors

Position sensors are potentiometers or a type of

variable resistor. They are used by the computer to

determine position and direction of movement of a

mechanical device. Typical position sensor

applications are throttle position sensors, EGR

valve position sensors, and vane air flow sensors.

Fig. 29

20

2

20M

2M

200K

OHMS

4

750

CYL

200

20K

5

YL

C

6

C

8

CYL

2K

DWELL

200

COM

V

750V AC

200V DC

Typical Toyota Throttle

M

P

R

0

1

X

YL

8

CYL

4

CYL

5

CYL

6

CYL

Red

POWER

Position Sensor

Black

GROUND

SIGNAL IDLE SWITCH

Test Procedure (see Fig. 29):

1. Insert BLACK test lead into the COM

test lead jack.

2. Insert RED test lead into the

test

V

lead jack.

3. Disconnect wiring harness from

sensor.

4. Connect Test Leads.

Connect RED test lead to sensor

POWER pin.

Connect BLACK test lead to sensor

GROUND pin.

Refer to vehicle service manual for

location of sensor POWER and

GROUND pins.

5. Turn multimeter rotary switch to 20KΩ

range.

6. View and record reading on display.

Display should read some resistance

value.

If multimeter is overranging, adjust the

range accordingly. (See Setting the

Range on page 6.)

If multimeter overranges on largest

range, then sensor is an open circuit

and is defective.

7. Move RED test lead to sensor

SIGNAL pin.

Refer to vehicle service manual for

location of sensor SIGNAL pin.

8. Operate Sensor.

Throttle Position Sensor:

Slowly move throttle linkage from

closed to wide open position.

Depending on hook-up, the display

reading will either increase or

decrease in resistance.

The display reading should either

start at or end at the approximate

resistance value measured in Step 6.

Some throttle position sensors have

an Idle or Wide Open Throttle (WOT)

switch in addition to a potentiometer.

To test these switches, follow the

Testing Switches test procedure on

page 13.

When you are told to operate switch,

then move throttle linkage.

Vane Air Flow Sensor:

Slowly open vane door from closed to

open by pushing on it with a pencil or

similar object. This will not harm sensor.

Depending on hook-up, the display

reading will either increase or decrease

in resistance.

The display reading should either start

at or end at the approximate resistance

value measured in Step 6.

Some vane air flow sensors have an

idle switch and an intake air

temperature sensor in addition to a

potentiometer.

To test idle switch see Testing Switches

on page 13.

When you are told to operate switch,

then open vane door.

To test intake air temperature sensor

see Temperature Type Sensors on page

30.

31

Page 32

EGR Valve Position

Remove vacuum hose from EGR valve.

Connect hand vacuum pump to EGR

valve.

Gradually apply vacuum to slowly open

valve. (Typically, 5 to 10 in. of vacuum

fully opens valve.)

Depending on hook-up, the display

reading will either increase or decrease

in resistance.

The display reading should either start

at or end at the approximate resistance

value measured in Step 6.

9. Test Results.

Good Sensor: Display reading gradually

increases or decreases in resistance as

sensor is opened and closed.

Bad Sensor: There is no change in

resistance as sensor is opened or closed.

Manifold Absolute Pressure

(MAP) and Barometric

Pressure (BARO) Sensors

This sensor sends a signal to the

computer indicating atmospheric pressure

and/or engine vacuum. Depending on the

type of MAP sensor, the signal may be a dc

voltage or a frequency. GM, Chrysler, Honda

and Toyota use a dc voltage MAP sensor,

while Ford uses a frequency type. For other

manufacturers refer to vehicle service manual

for type of MAP sensor used.

Fig. 30

V

AC

Frequency

Only

V

DC

200

20

2

20M

2M

200K

20K

OHMS

Red

Red

Typical GM

MAP Sensor

OFF

750

2K

200

COM

4

C

750V AC

200V DC

M

P

R

L

Y

10

X

5

L

Y

C

6

L

Y

C

8

L

Y

C

DC

Only

4

L

Y

C

5

L

Y

C

6

L

Y

C

8

L

Y

C

DWELL

V

Black

15

20

5

2

0

3

VACUUM PUMP

Ground

10

5

0

A

B

C

To

Computer

Test Procedure (see Fig. 30):

1. Insert BLACK test lead into the COM

test lead jack.

2. For DC Volts type MAP sensor, insert

RED test lead into the

V

jack.

For Frequency type MAP sensor, insert

RED test lead into the test lead

jack.

32

test lead

Page 33

3. Disconnect wiring harness and vacuum

line from MAP sensor.

4. Connect jumper wire between Pin A on

wiring harness and sensor.

5. Connect another jumper wire between

Pin C on wiring harness and sensor.