Page 1

H3C WX3000 Series Unified Switches

Installation Manual

Hangzhou H3C Technologies Co., Ltd.

Manual Version: APW105-20090605

Page 2

Copyright © 2008-2009, Hangzhou H3C Te chnologie s Co., Ltd . and it s licen sors

H3C Technologies Co., Ltd., a subsidiary of 3Com Corporation.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form or by any means without prior

written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

Notice

H3C, , Aolynk, , H3Care,

SecPro, SecPoint, SecEngine, SecPath, Comware, Secware, Storware, NQA, VVG, V

, TOP G, , IRF, NetPilot, Neocean, NeoVTL,

2

G, VnG, PSPT,

XGbus, N-Bus, TiGem, InnoVision and HUASAN are trademarks of Hangzhou H3C Technologies Co.,

Ltd.

All other trademarks that may be mentioned in this manual are the property of their respective owners.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Page 3

About This Manual

Organization

H3C WX3000 Series Unified Switches Installation Manual is organized a s follo ws:

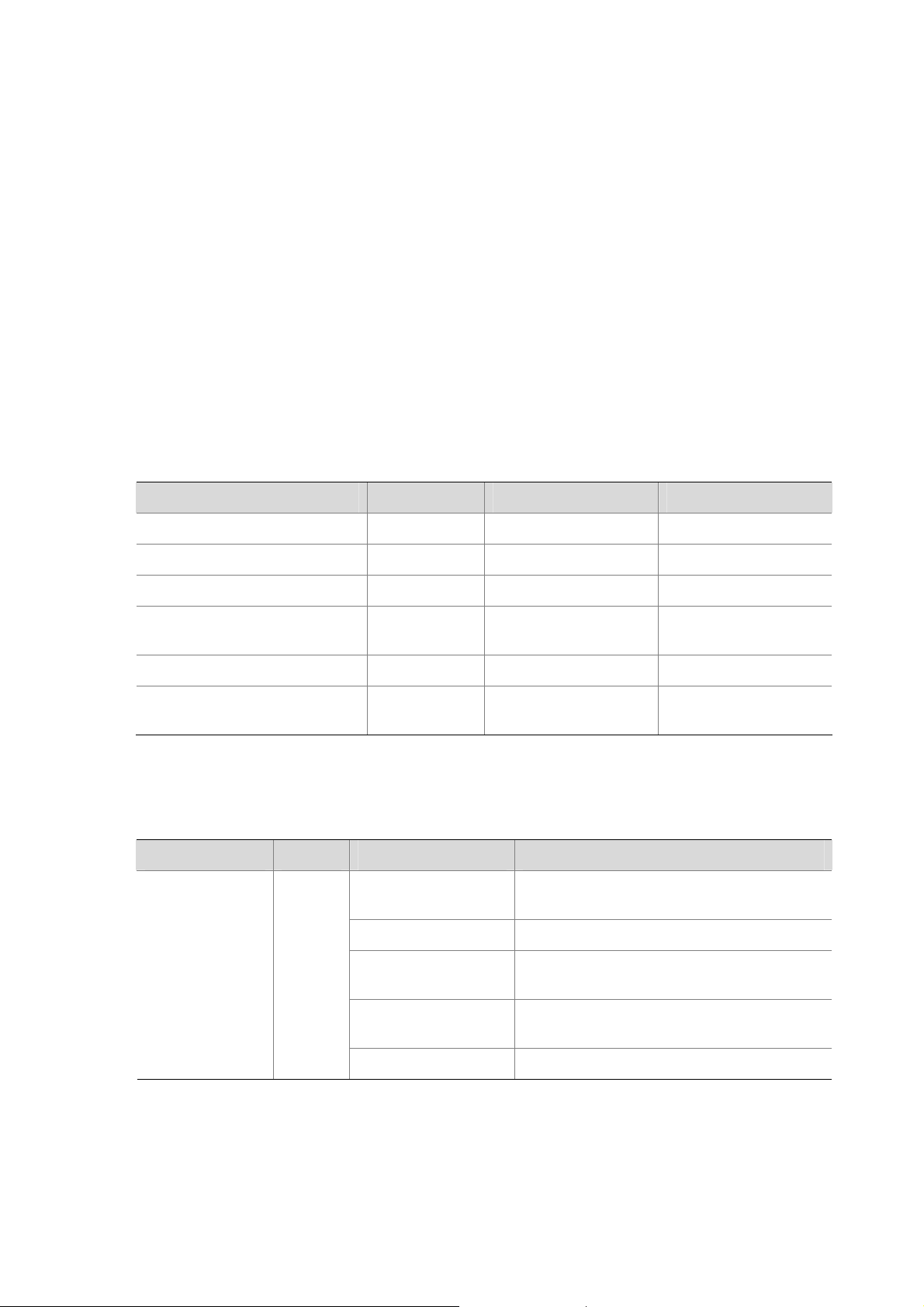

Chapter Contents

Chapter 1 Overview

Chapter 2 Preparing for Installation

Chapter 3 Installing the Device

Chapter 4 Starting and Configuring the

Device

Chapter 5 Maintaining Software

Chapter 6 Troubleshooting

Introduces the characteristics and appearance of the

H3C WX3000 Series Unified Switches.

Specifies the environmental requirements for installing

the H3C WX3000 Series Unified Switches, presents

installation precautions, and introduces the installation

tools needed.

Introduces how to install the H3C WX3000 Series

Unified Switches, how to connect the power supply

units, the console cable, and the Ethernet cable, and

how to verify the installation.

Introduces how to start and configure the H3C WX3000

Series Unified Switches, which involves how to set up

the configuration environment, how to connect the

console cable, how to set the terminal parameters, and

how to power on the switch.

Introduces how to maintain the software of the H3C

WX3000 Series Unified Switches, including BootWare

menu introduction, software updating, and password

recovery process.

Introduces the problems that may occur during the

installation and startup processes of the H3C WX3000

Series Unified Switches and how to troubleshoot these

problems.

Appendix A Specifications of Optional

Interface Modules

Appendix B Installation of Lightning

Arrester for Network Interfaces

Appendix C Installation of Lightning

Arrester for AC Power

Appendix D Obtaining Support for Your

Product

Conventions

The manual uses the following conventions:

GUI conventions

Convention Description

Boldface

>

Introduces interface modules supported on the H3C

WX3000 Series Unified Switches.

Introduces how to install a lightning arrester for network

interfaces.

Introduces how to install a lightning arrester for AC

power.

Introduces how to obtain technical support for your

product.

Window names, button names, field names, and menu items are in

Boldface. For example, the New User window appears; click OK.

Multi-level menus are separated by angle brackets. For example, File >

Create > Folder.

Page 4

Symbols

Convention Description

Means reader be extremely careful. Improper operation may cause

bodily injury.

Means reader be careful. Improper operation may cause data loss or

damage to equipment.

Related Documentation

In addition to this manual, each H3C WX3000 Series Unified Switches documentation set includes the

following:

Manual Description

H3C WX Series Access Controller

Products User Manual

H3C WX3000 Series Unified Switches

Switching Engine Operation Manual

Means a complementary description.

The operation manual provides a guide to the operations

on the access control engines of H3C WX3000 Series

Unified Switches. It includes Login Volume, Access

Volume, IP Services Volume, IP Routing Volume, IP

Multicast Volume, QoS Volume, Security Volume, System

Volume, OAA Volume, WLAN Volume, and Acronyms.

The command manual elaborates on the operation

commands for the access control engines of H3C

WX3000 Series Unified Switches. It includes Command

Index, Login Volume, Access Volume, IP Services

Volume, IP Routing Volume, IP Multicast Volume, QoS

Volume, Security Volume, System Volume, OAA Volume,

and WLAN Volume commands.

Provides a guide to the operations on the switching

engines of H3C WX3000 Series Unified Switches. It

covers the configurations of command line interfaces,

login, VLAN, GVRP, basic port configuration, MAC

address table management, MSTP, 802.1x, AAA, ACL,

QoS, SNMP, RMON, NTP, and SSH.

Elaborates on the operation commands for the switching

engines of H3C WX3000 Series Unified Switches. It

H3C WX3000 Series Unified Switches

Switching Engine Command Manual

H3C WX Series Access Controller

Products WEB-Based Configuration

Manual

covers the configuration commands for command line

interfaces, login, VLAN, GVRP, basic port configuration,

MAC table management, MSTP, 802.1x, AAA, ACL, QoS,

SNMP, RMON, NTP, and SSH.

Describes the Web-based configuration functions of H3C

WX3000 Series Unified Switches.

Obtaining Documentation and Technical Support

To obtain up-to-date documentation and technical support, go to http://www.h3c.com and select your

country or region. Depending on your selection, you will be redirected to either of the following websites:

Page 5

At http://www.h3c.com

Documentation

Go to the following columns for different categories of product documentation:

[Products & Solutions]: Provides information about products and technologies.

[Technical Support & Document > Technical Documents]: Provides several categories of product

documentation, such as installation and configuration.

[Technical Support & Document > Software Download]: Provides the documentation released with the

software version.

Technical Support

customer_service@h3c.com

http://www.h3c.com

At http://www.h3cnetworks.com

Documentation

Select Drivers & Downloads in the Support area.

Select Documentation for Type of File and select Product Category.

Technical Support

Please see the appendix Obtaining Support for Your Product.

Documentation Feedback

You can e-mail your comments about product documentation to info@h3c.com.

We appreciate your comments.

Environmental Protection

This product has been designed to comply with the requirements on environmental protection. For the

proper storage, use and disposal of this product, national laws and regulations must be ob served.

Page 6

Table of Contents

1 Overview·····················································································································································1-1

Introduction ·············································································································································1-1

Appearance·············································································································································1-1

Front Panel ······································································································································1-2

Rear Panel·······································································································································1-3

System Specifications ·····························································································································1-4

Processor and Memory ···················································································································1-4

Dimensions and Weight···················································································································1-4

Fixed Interfaces and Slots···············································································································1-4

Power Input System ························································································································1-5

PoE Power Supply···························································································································1-5

Components············································································································································1-6

LEDs················································································································································1-6

Fixed Interfaces ·······························································································································1-8

Transceiver Modules ·····················································································································1-10

RPS ···············································································································································1-11

DC Power Cables ··························································································································1-11

Fans···············································································································································1-11

Interface Numbering······························································································································1-12

Interface Numbering for the WX3024····························································································1-12

Interface Numbering for the WX3010····························································································1-12

Interface Numbering for the WX3008····························································································1-12

2 Preparing for Installation··························································································································2-1

Safety Precautions ··································································································································2-1

Installation Site Checking························································································································2-1

Temperature and Humidity··············································································································2-1

Cleanliness ······································································································································2-2

ESD Prevention ·······························································································································2-2

EMI Prevention ································································································································2-3

Laser Safety ····································································································································2-4

Installation Tools ·····································································································································2-4

3 Installing the Device··································································································································3-1

Installing the Device in a 19-inch Rack ···································································································3-1

Introduction to Mounting Brackets···································································································3-2

Introduction to Slide Rails················································································································3-3

Installing the Device Using Front Mounting Brackets······································································3-3

Installing the Device Using Front and Rear Mounting Brackets······················································3-4

Installing the Device Using Front Mounting Brackets and a Tray ···················································3-8

Installing the Device Using Front Mounting Brackets and Slide Rails ············································3-9

Installing the Device on a Workbench···································································································3-11

Wall Mounting ·······································································································································3-11

Magnet Mounting ··································································································································3-13

Connecting the Ground Cable ··············································································································3-15

i

Page 7

Connecting the Power Cables ··············································································································3-18

Connecting AC Power Cable·········································································································3-18

Connecting the RPS Cable ···········································································································3-19

Connecting the Interface Cables···········································································································3-20

Connecting the Console Cable······································································································3-20

Connecting the Ethernet Cables ···································································································3-21

Installing and Removing Optional Interface Modules ···········································································3-22

XFP Interface Modules··················································································································3-22

XENPAK Module ···························································································································3-23

Installation Verification ··························································································································3-25

4 Starting and Configuring the Device·······································································································4-1

Setting up a Configuration Environment ·································································································4-1

Connecting the Device to a Configuration Terminal········································································4-1

Setting Terminal Parameters···········································································································4-1

Powering On the Device ·························································································································4-4

Verifying Before Power-On··············································································································4-4

Boot Process ···································································································································4-4

5 Maintaining Software·································································································································5-1

Introduction ·············································································································································5-1

Files Managed by the Device ··········································································································5-1

BootWare Program File···················································································································5-1

Application Files ······························································································································5-2

Configuration Files···························································································································5-2

Web Files·········································································································································5-3

Approaches for Software Maintenance ···························································································5-3

Software Update Flow ·····················································································································5-4

BootWare Menus ····································································································································5-4

BootWare Main Menu······················································································································5-4

BootWare Submenus ······················································································································5-6

Updating Software Through a Serial Connection ···················································································5-7

Introduction to XMODEM·················································································································5-7

Modifying Serial Communication Parameters ·················································································5-8

Updating BootWare Through a Serial Connection ········································································5-10

Updating Applications Through a Serial Connection·····································································5-12

Updating Applications Using TFTP ·······································································································5-13

Updating an Application Using TFTP Through the BootWare Menu ············································5-13

Updating and Backing Up an Application Using TFTP Through the CLI ······································5-15

Updating Applications Using FTP ·········································································································5-17

Updating an Application Using FTP Through the BootWare Menu···············································5-18

Updating and Backing Up an Application Using FTP Through the CLI·········································5-18

Updating Web Files on the Switching Engine·······················································································5-21

Maintaining the Application and Configuration Files·············································································5-22

Displaying All Files ························································································································5-22

Setting the Application File Type···································································································5-22

Deleting a File································································································································5-23

Dealing with Password Loss ·················································································································5-24

BootWare Password Loss ·············································································································5-24

ii

Page 8

User Password Loss······················································································································5-24

Super Password Loss····················································································································5-25

Backing Up and Restoring BootWare ···································································································5-26

Backing Up and Restoring BootWare Through the BootWare Menu············································5-26

Backing Up and Restoring BootWare Through the CLI ································································5-26

6 Troubleshooting ········································································································································6-1

Troubleshooting Software Loading Failure ·····························································································6-1

Troubleshooting the Power System ········································································································6-1

Troubleshooting the Configuration System·····························································································6-1

iii

Page 9

1 Overview

Introduction

The H3C WX3000 Series Unified Switches are networking products wholly developed by Hangzhou

H3C Technologies Co., Ltd. (hereinafter referred to as H3C) that incorporate the functions of WLAN

access controllers and Gigabit Ethernet switches. The WX3000 series unified switches include the

WX3024, WX3010 and WX3008 unified switches (hereinafter referred to as the WX3000 series,

WX3024, WX3010 and WX3008, respectively). The WX3000 series provides Gigabit ports, supports

power over Ethernet plus (PoE+) and 802.11a/b/g/n series access points (APs), with the maximum

output power of 25 W per port. Together with the Fit APs developed by H3C, the WX3000 series can

implement wireless LAN (WLAN) deployments while providing rich data switching features. The

WX3000 series is the ideal solution to the provisioning of integrated wireline and wireless access for

small- and medium-sized enterprises and branches of large-sized enterprises.

Appearance

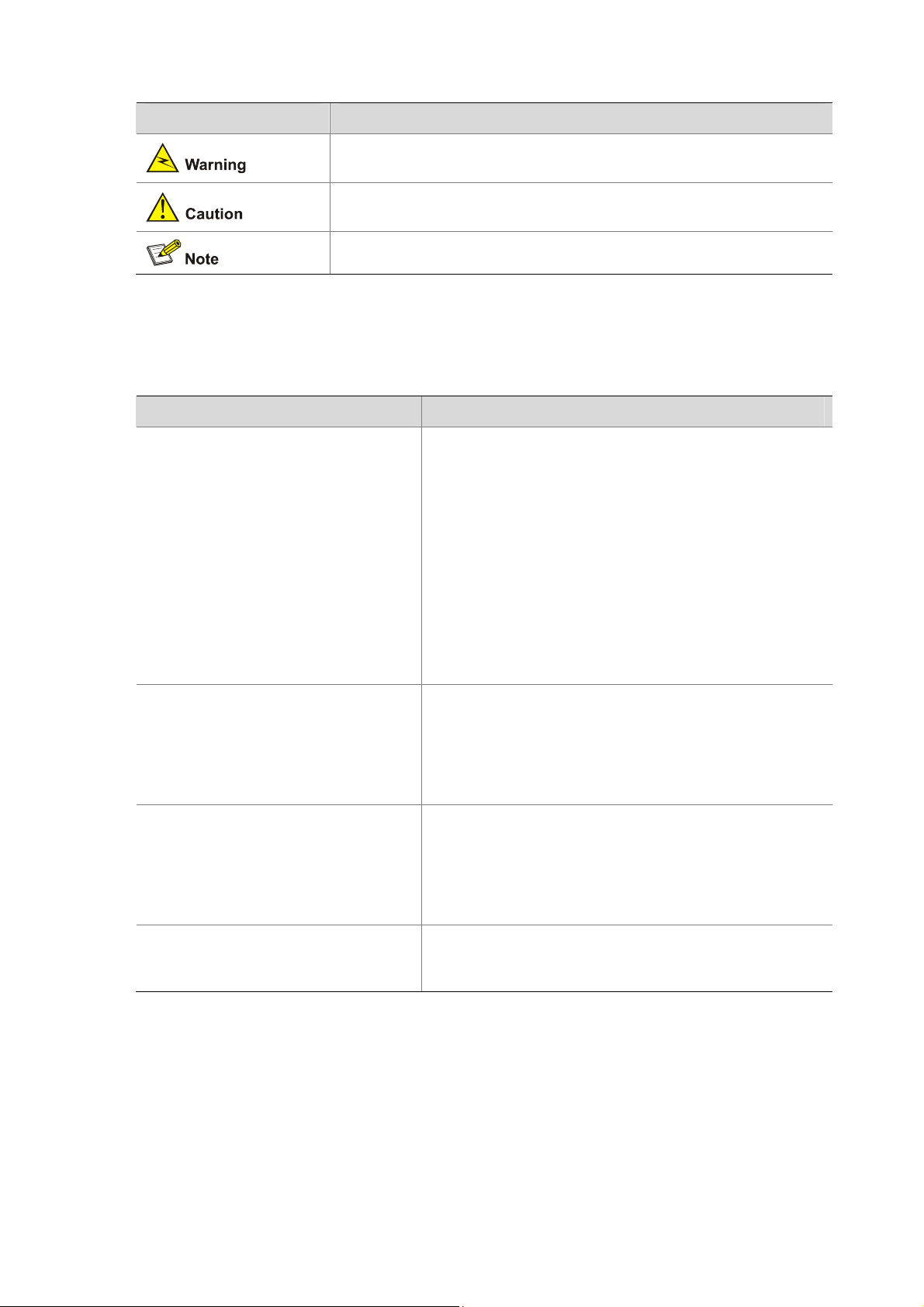

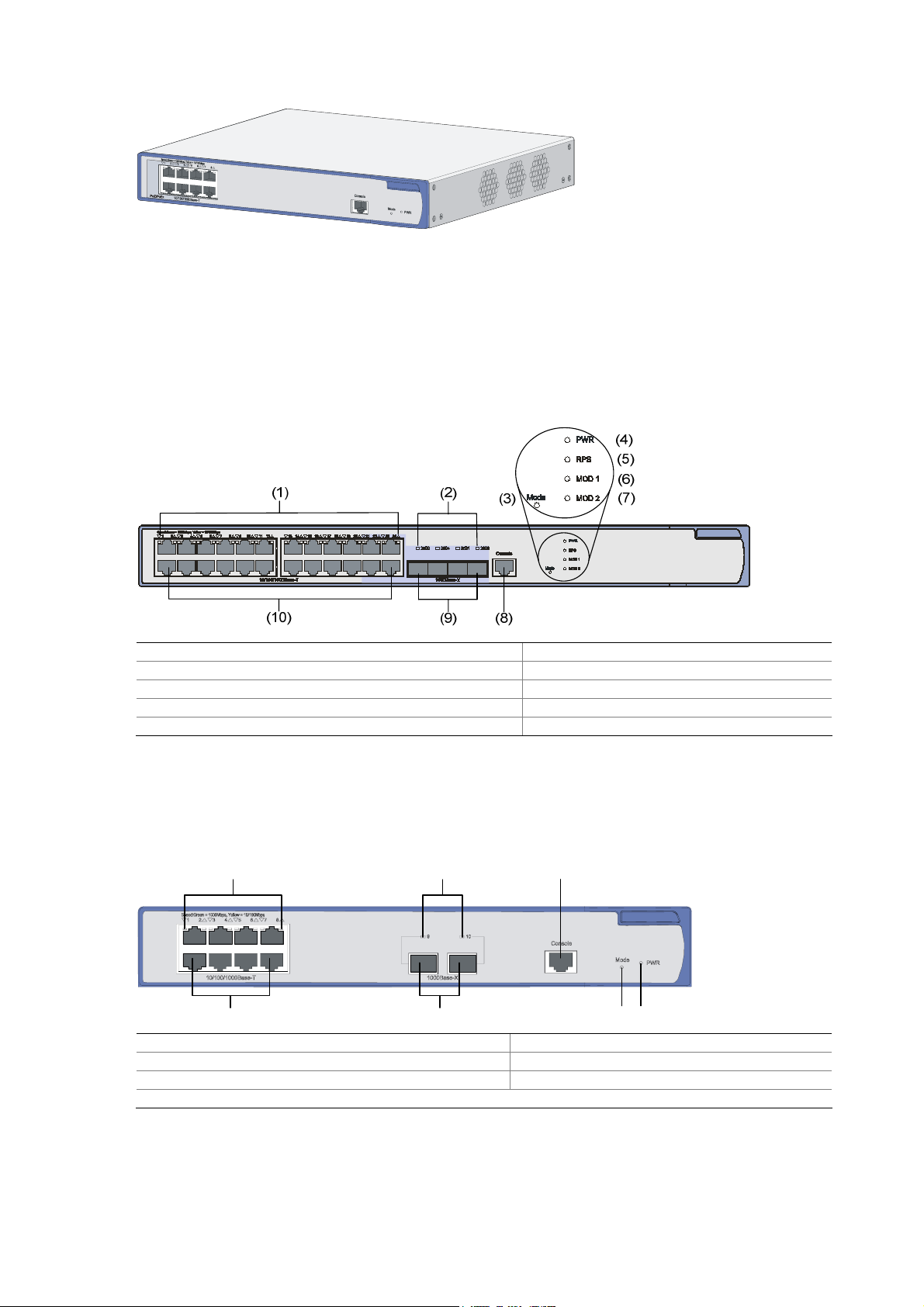

Figure 1-1 shows the appearance of the WX3024.

Figure 1-1 Appearance of the WX3024

Figure 1-2 shows the appearance of the WX3010.

Figure 1-2 Appearance of the WX3010

Figure 1-3 shows the appearance of the WX3008.

1-1

Page 10

Figure 1-3 Appearance of the WX3008

Front Panel

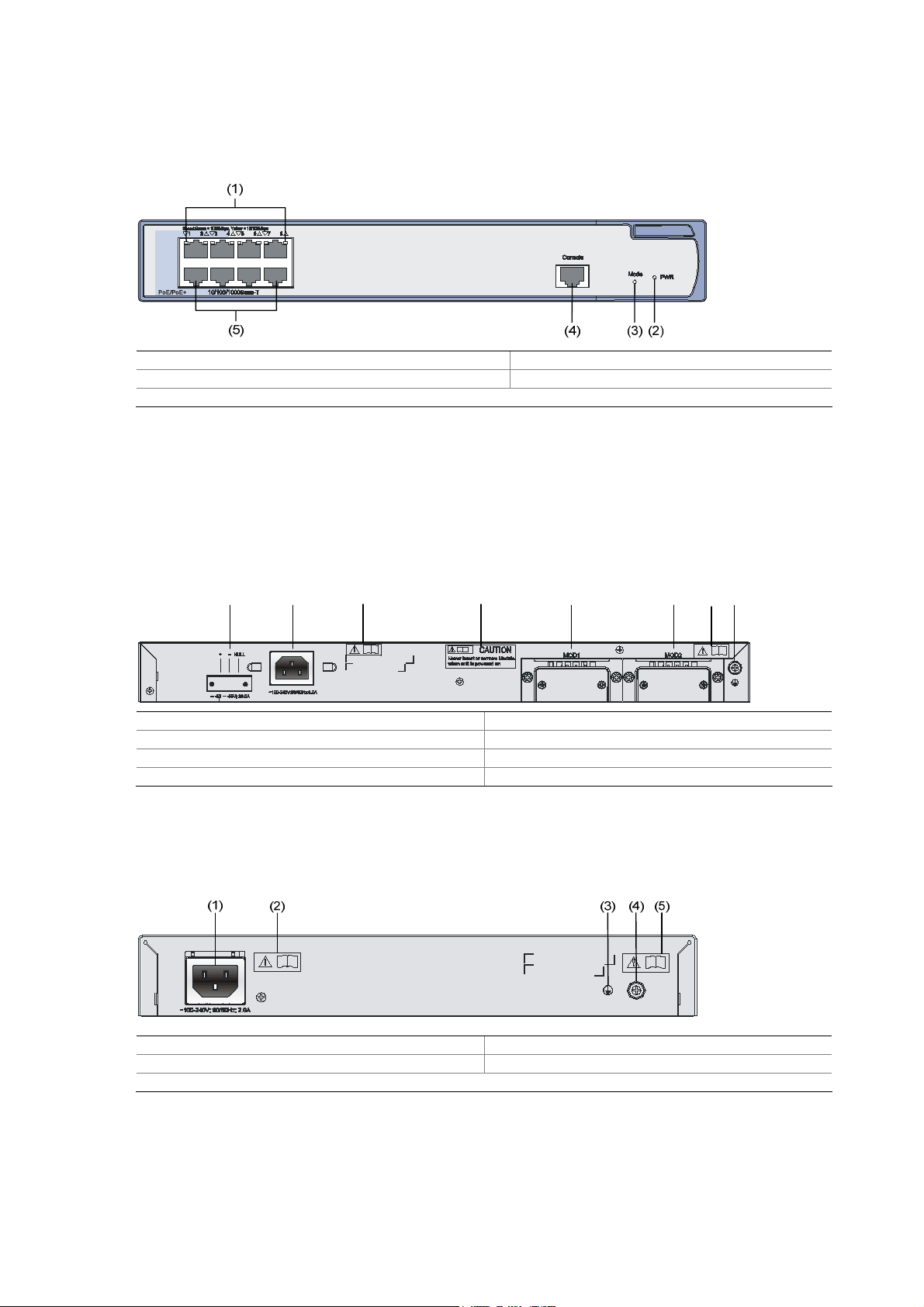

As shown in Figure 1-4, the front panel of the WX3024 provides twenty-four 10/100/1000Base-T

Ethernet ports, four 1000Base-X SFP ports, and one console port.

Figure 1-4 Front panel of the WX3024

(1) LEDs of 10/100/1000 Base-T Ethernet ports (2) LEDs of 1000Base-X SFP ports

(3) PoE/PoE+ LED (Mode) (4) Power status LED (PWR)

(5) RPS LED (RPS) (6) Extension slot LED (MOD1)

(7) Extension slot LED (MOD2) (8) Console port

(9) 1000Base-X SFP ports (10) 10/100/1000 Base-T Ethernet ports

As shown in

Figure 1-5, the front panel of the WX3010 provides eight 10/100/1000Base-T Ethernet

ports, two 1000Base-X SFP ports, and one console port.

Figure 1-5 Front panel of the WX3010

(1) (2)

(3)

(4)(5)(6)(7)

(1) LEDs of 10/100/1000 Base-T Ethernet ports (2) LEDs of 1000Base-X SFP ports

(3) Console port (4) Power status LED (PWR)

(5) PoE/PoE+ LED (Mode) (6) 1000Base-X SFP ports

(7) 10/100/1000 Base-T Ethernet ports

1-2

Page 11

As shown in Figure 1-6, the front panel of the WX3008 provides eight 10/100/1000Base-T Ethernet

ports (among which only GigabitEthernet 1/0/1 through GigabitEthernet 1/0/4 support PoE) and one

console port.

Figure 1-6 Front panel of the WX3008

(1) LEDs of 10/100/1000 Base-T Ethernet ports (2) Power status LED (PWR)

(3) PoE/PoE+ LED (Mode) (4) Console port

(5) 10/100/1000 Base-T Ethernet ports

Rear Panel

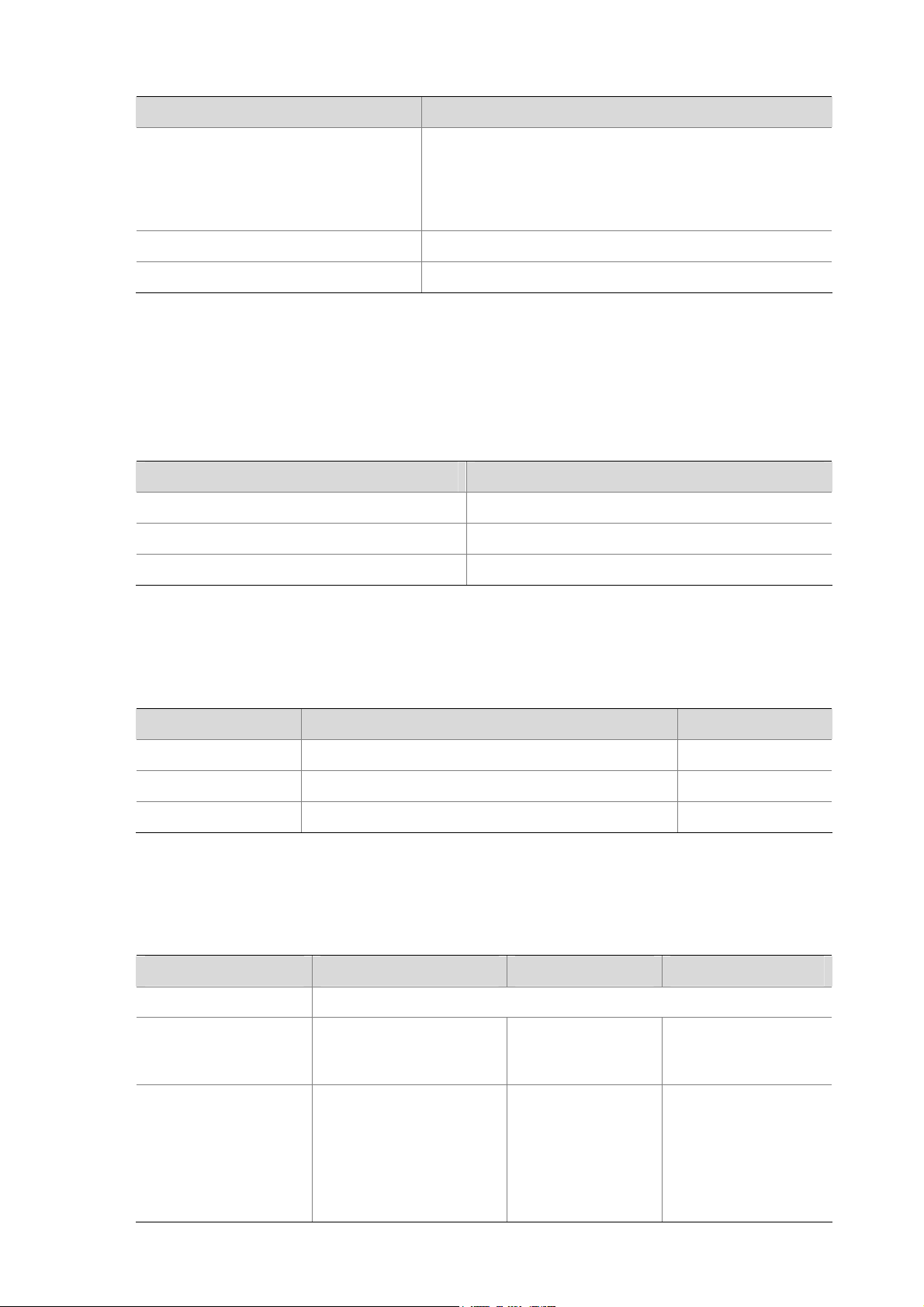

As shown in Figure 1-7, the rear panel of the WX3024 provides an AC power receptacle, a DC power

receptacle, and two extension slots for 10 GE interface modules.

Figure 1-7 Rear panel of the WX3024

(1)

(2) (3)

(4) (6)

(5)

(7) (8)

(1) DC power receptacle (2) AC power receptacle

(3) OPEN BOOK mark (4) CAUTION mark

(5) 10 GE port slot 1 (6) 10 GE port slot 2

(7) OPEN BOOK mark (8) Grounding screw

As shown in

Figure 1-8, the rear panel of the WX3010 and WX3008 provides an AC power receptacle.

Figure 1-8 Rear panel of the WX3010

(1) AC power receptacle (2) OPEN BOOK mark

(3) Grounding sign (4) Grounding screw

(5) OPEN BOOK mark

When seeing the OPEN BOOK and CAUTION marks, refer to relevant sections before performing the

corresponding operations.

1-3

Page 12

Table 1-1 Meanings of the OPEN BOOK mark

Operation Related section

Connect the power cable

Connect the ground cable Connecting the Ground Cable

Install optional interface modules Installing and Removing Optional Interface Modules

System Specifications

Processor and Memory

Table 1-2 Processor and memory specifications

Item Specification

Power Input System

RPS

DC Power Cables

Connecting the Power Cables

Processor XLS208 (750 MHz)

Flash memory 64 MB

Memory module type and size

Dimensions and Weight

Table 1-3 Dimension and weight specifications

Device model Dimensions (H × W × D) Weight

WX3024 43.6 × 440 × 429 mm (1.7 × 17.3 × 16.9 in.) 7.2 kg (15.9 lb.)

WX3010 43.6 × 300 × 269 mm (1.7 × 11.8 × 10.6 in.) 2.9 kg (6.4 lb.)

WX3008 43.6 × 300 × 269 mm (1.7 × 11.8 × 10.6 in.) 2.9 kg (6.4 lb.)

Fixed Interfaces and Slots

Table 1-4 Fixed interface and slot specifications

DDR2 SDRAM (512 MB)

Item WX3024 WX3010 WX3008

Console interface 1 console interface: 9600 bps to 115200 bps, (9600 bps by default)

8 × 10/100/1000

Base-T Ethernet

ports

2 × 1000Base-X

SFP ports

numbered 9 and 10.

8 × 10/100/1000

Base-T Ethernet ports

—

Ethernet ports

SFP ports

24 × 10/100/1000 Base-T

Ethernet ports

4 × 1000Base-X SFP

ports. Each of these ports

and the corresponding

10/100/1000Base-T

Ethernet port numbered in

the range of 21 to 24 form

a Combo interface.

1-4

Page 13

Item WX3024 WX3010 WX3008

Slots

Power Input System

z The WX3024 supports several power input modes: AC input only, DC input only, and concurrently

use of AC and DC inputs. When AC and DC inputs are used concurrently, they serve as backup for

each other.

z The WX3010 and WX3008 support AC input only.

z Only an H3C-recommended redundancy power supply (RPS) unit can be used to provide DC input.

AC power supply

Table 1-5 AC power supply specifications

2 extension slots for 10

GE interface modules

— —

Item WX3024 WX3010 WX3008

Rated voltage range

Maximum voltage range

Maximum system power

consumption (without external

PoE devices)

Minimum power consumption

DC power supply

DC voltage range: –52 V to –55 V

PoE Power Supply

The WX3000 series supports Power over Ethernet (PoE) to provide –48 VDC supply to attached

powered devices, such as IP phones, WLAN APs, security and Bluetooth APs, through twisted pair

cables.

100 to 240 VAC, 50/60 Hz

90 to 264 VAC, 47 to 63 Hz

100 W 50 W 40 W

220 V × 0.282 A = 63 W 220 V × 0.165 A =

36.5 W

220 V × 0.128

A = 28.2 W

Only the H3C-recommended external PoE power supply can be used as the DC input, rather than the

–48 VDC power supply of the equipment room, which may cause device damage.

1-5

Page 14

z As a power sourcing equipment (PSE), the WX3000 series supports the IEEE 802.3af standard

while being compatible with some PoE powered devices that do not comply with the 802.3af

standard.

z The WX3000 series provides power supply through fixed electrical Ethernet ports, with the

maximum power transmission distance of 100 meters (328.08 ft.).

z Each Ethernet port of the WX3000 series provides a maximum of 25 W output power to the

attached PoE powered device. In the case of AC input, the maximum output power with full load of

the WX3024 is 370 W, and that of the WX3010 and WX3008 is 125 W; in the case of RPS input, the

maximum output power of the WX3024 is 25 W × 24 = 600 W (Note that the RPS output power

should be at least 700 W).

Components

LEDs

Table 1-6 lists the support of the WX3000 series for LEDs.

Table 1-6 LEDs supported by the WX3000 series

LED WX3024 WX3010 WX3008

Power status LED (PWR) Supported Supported Supported

PoE/PoE+ status LED (Mode) Supported Supported Supported

RPS status LED (RPS) Supported Not supported Not supported

Gigabit Ethernet port status

LEDs

Supported Supported Supported

Gigabit SFP port status LEDs Supported Supported Not supported

Extension slot status LEDs

(MOD1 and MOD2)

Supported Not supported Not supported

Table 1-7 shows the description of the LEDs status

Table 1-7 Description of the LEDs status

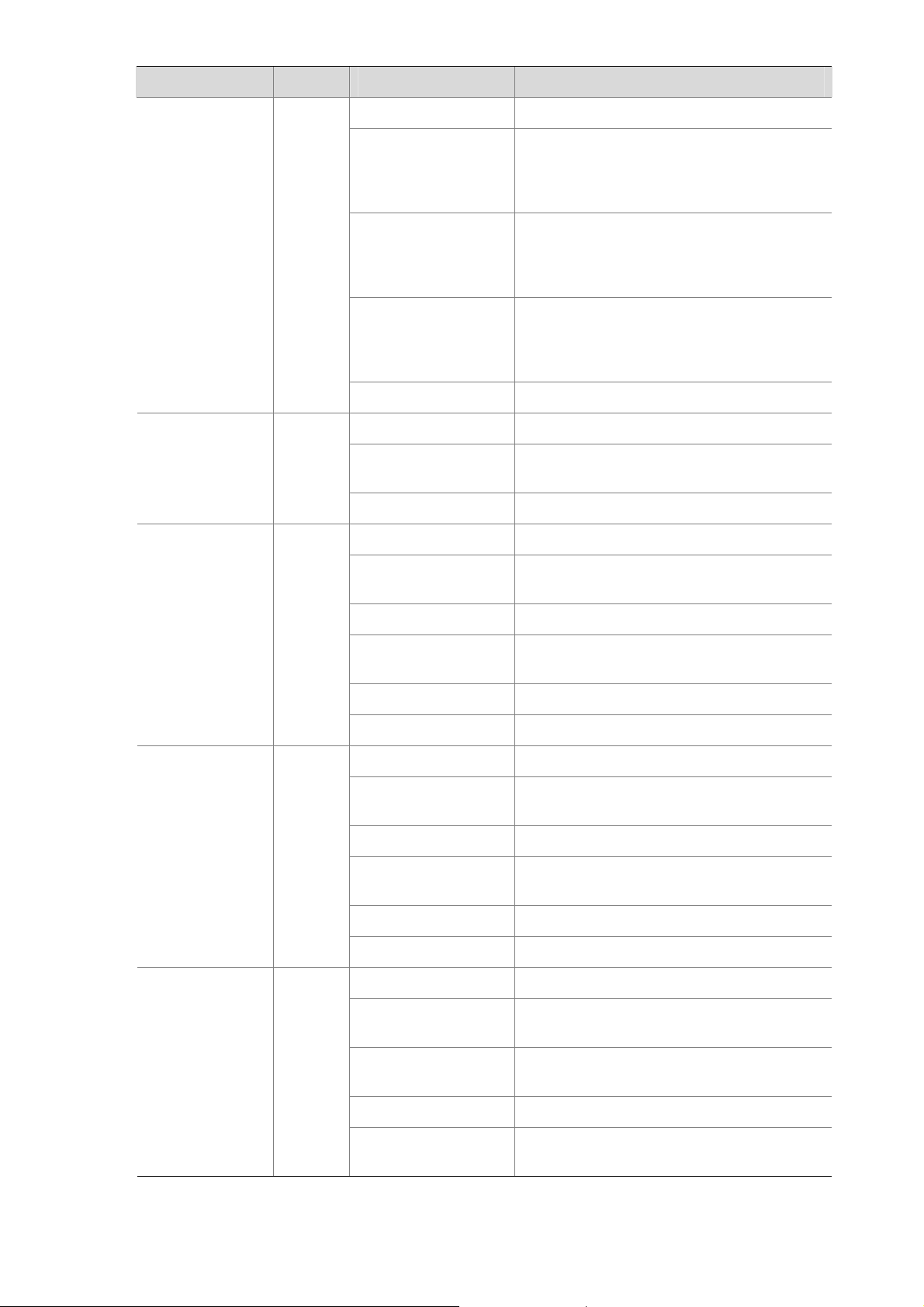

LED Mark Status Description

Solid green

Blinking green (1 Hz) The system is working normally.

The system is going through the power on

self test (POST) or downloading software.

Power status

LED

(green/yellow/red

PWR

Solid red

The system failed to pass the POST or has

detected a serious fault.

)

At least one port has failed the POST or

Solid yellow (1 Hz)

detected a minor fault.

Off

1-6

No AC input is present.

Page 15

LED Mark Status Description

PoE/PoE+ status

LED

(green/yellow)

RPS status LED

(yellow/green)

Mode

RPS

Solid green The PoE/PoE+ is operational.

PoE/PoE+ supply is not available because

Blinking green (3 Hz)

the maximum output power of the port is

exceeded or the remaining power is

insufficient.

The ports cannot provide PoE/PoE+ supply

Solid yellow

due to an over-temperature, over-voltage, or

under-voltage protection shutdown of the

PoE/PoE+ system.

At least one port failed to pass the POST; if

Blinking yellow (3 Hz)

Off No PoE/PoE+ supply.

Solid green Both AC and DC inputs are normal.

Solid yellow

Off No DC input is present.

the PoE sub-board is in position, it may be

caused by a UART communication failure or

some other self test failure.

The AC input is abnormal or no AC input is

present, while the DC input is normal.

Solid green A 1000 Mbps link is present on the port.

10/100/1000

Base-T Ethernet

port status LED

(yellow/green)

Gigabit SFP port

status LED

(yellow/green)

Extension slot

LED

(yellow/green)

—

—

MOD1

(or

MOD2)

Blinking green (33

Hz)

The port is receiving or transmitting data at

1000 Mbps.

Solid yellow A 10/100 Mbps link is present on the port.

Blinking yellow (33

Hz)

Blinking yellow (3 Hz) The port failed to pass the POST.

Off No link is present on the port.

Solid green A 1000 Mbps link is present on the port.

Blinking green (33

Hz)

Solid yellow A 100 Mbps link is present on port.

Blinking yellow (33

Hz)

Blinking yellow (3 Hz) The port failed the POST.

Off No link is present on the port.

The port is receiving or transmitting data at

10/100 Mbps.

The port is receiving or transmitting data at

1000 Mbps.

The port is receiving or transmitting data at

100 Mbps.

Solid green An extension module is present in the slot.

Solid yellow

Blinking green

Blinking yellow The extension module failed the POST.

The slot does not support the extension

module installed in it.

The extension module is receiving or

transmitting data.

Off

No extension module is present in the slot or

the extension module is not connected.

1-7

Page 16

Fixed Interfaces

Console port

The WX3000 series provides an RS-232 asynchronous serial console port, which can be used to

connect a background terminal (a PC, for example) for system debugging, configuration, maintenance,

management, and software loading.

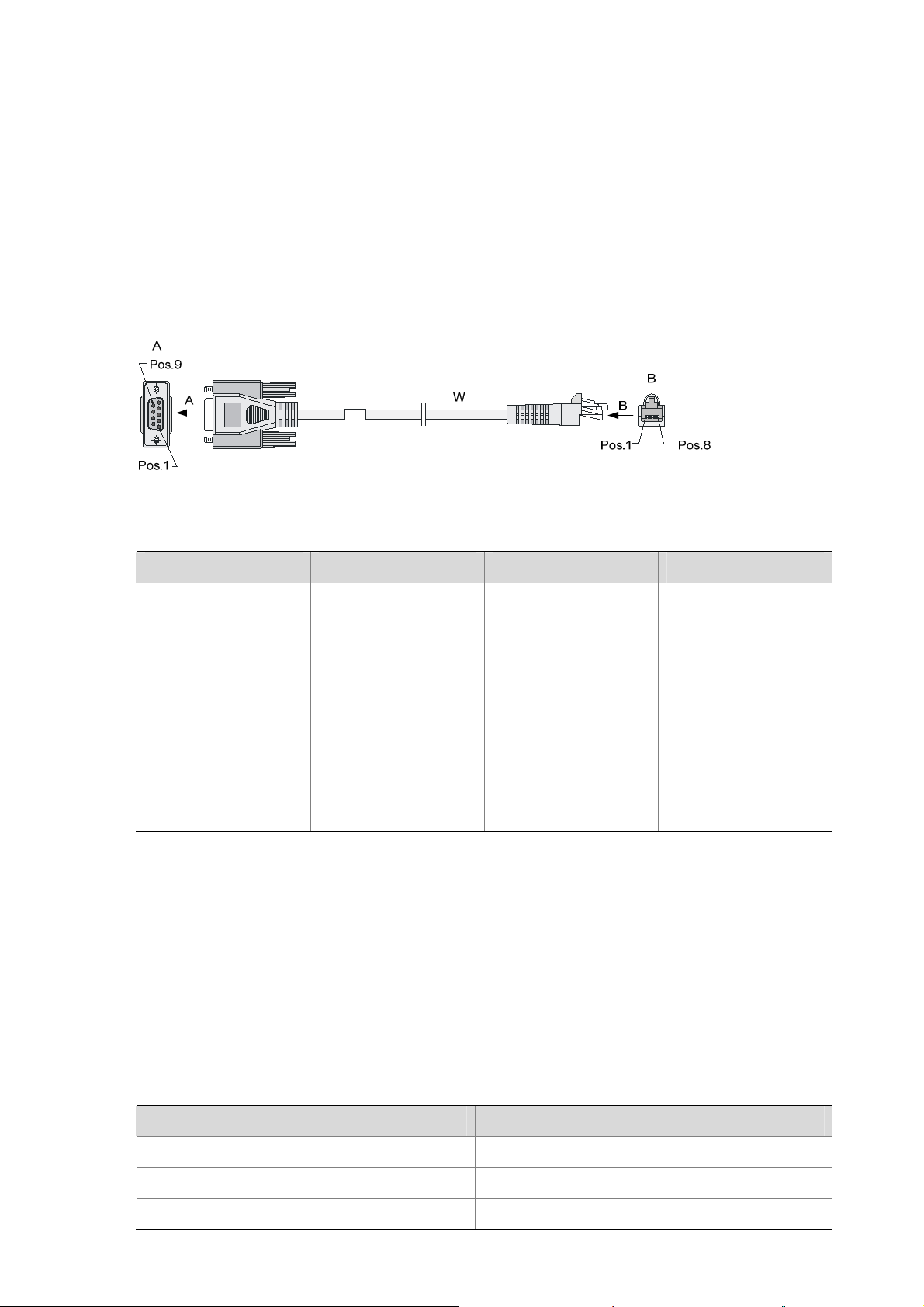

As shown in

Figure 1-9, the console cable is an 8-core cable with an RJ-45 connector at one end for the

console port of the device, and a DB-9 female connector at the other end for the 9-pin serial port of the

configuration terminal.

Figure 1-9 A console cable

Table 1-8 Console cable pinouts

RJ-45 pin Signal Direction DB-9 pin

1 RTS ← 7

2 DTR ← 4

3 TXD ← 3

4 CD → 1

5 GND — 5

6 RXD → 2

7 DSR → 6

8 CTS → 8

Ethernet interfaces

1) Introduction

z The WX3024 provides twenty-four 10/100/1000Base-T Ethernet ports and four 1000Base-X SFP

ports.

Each SFP port and the corresponding 10/100/1000Base-T Ethernet port jointly form a Combo interface.

Only one of the two ports of a Combo interface can be used at a time.

Table 1-9 lists the SFP and

electrical Ethernet ports that form the Combo interfaces.

Table 1-9 SFP and electrical Ethernet ports of the WX3024 that form the Combo interfaces

1000Base-X SFP port 10/100/1000Base-T Ethernet port

25 22

26 24

27 21

1-8

Page 17

1000Base-X SFP port 10/100/1000Base-T Ethernet port

28 23

z The WX3010 provides eight 10/100/1000Base-T Ethernet ports and two 1000Base-X SFP ports.

The electrical Ethernet ports support 10/100/1000 Mbps auto-sensing. The working modes of an

Ethernet port at different speeds are shown in

Table 1-10.

Table 1-10 Ethernet interface speeds and working modes

Interface speed Working mode

10 Mbps (auto-sensing) Half/full duplex auto-negotiation

100 Mbps (auto-sensing)

Half/full duplex auto-negotiation

1000 Mbps (auto-sensing) Full duplex auto-negotiation

z The WX3008 provides eight 10/100/1000Base-T Ethernet ports.

The electrical Ethernet ports support 10/100/1000 Mbps auto-sensing. The working modes of an

Ethernet port at different speeds are shown in

Table 1-10.

The electrical Ethernet port status LEDs are above the RJ-45 sockets. The triangular pointer above

each LED indicates which port the LED is for.

z The optical Ethernet ports of the WX3000 series support 100/1000 Mbps full duplex. The optical

port status LEDs are above the 1000Base-X SFP ports, each indicating the status of the

corresponding optical port.

The support for the speed of optical Ethernet ports depends on the model of the optical transceivers.

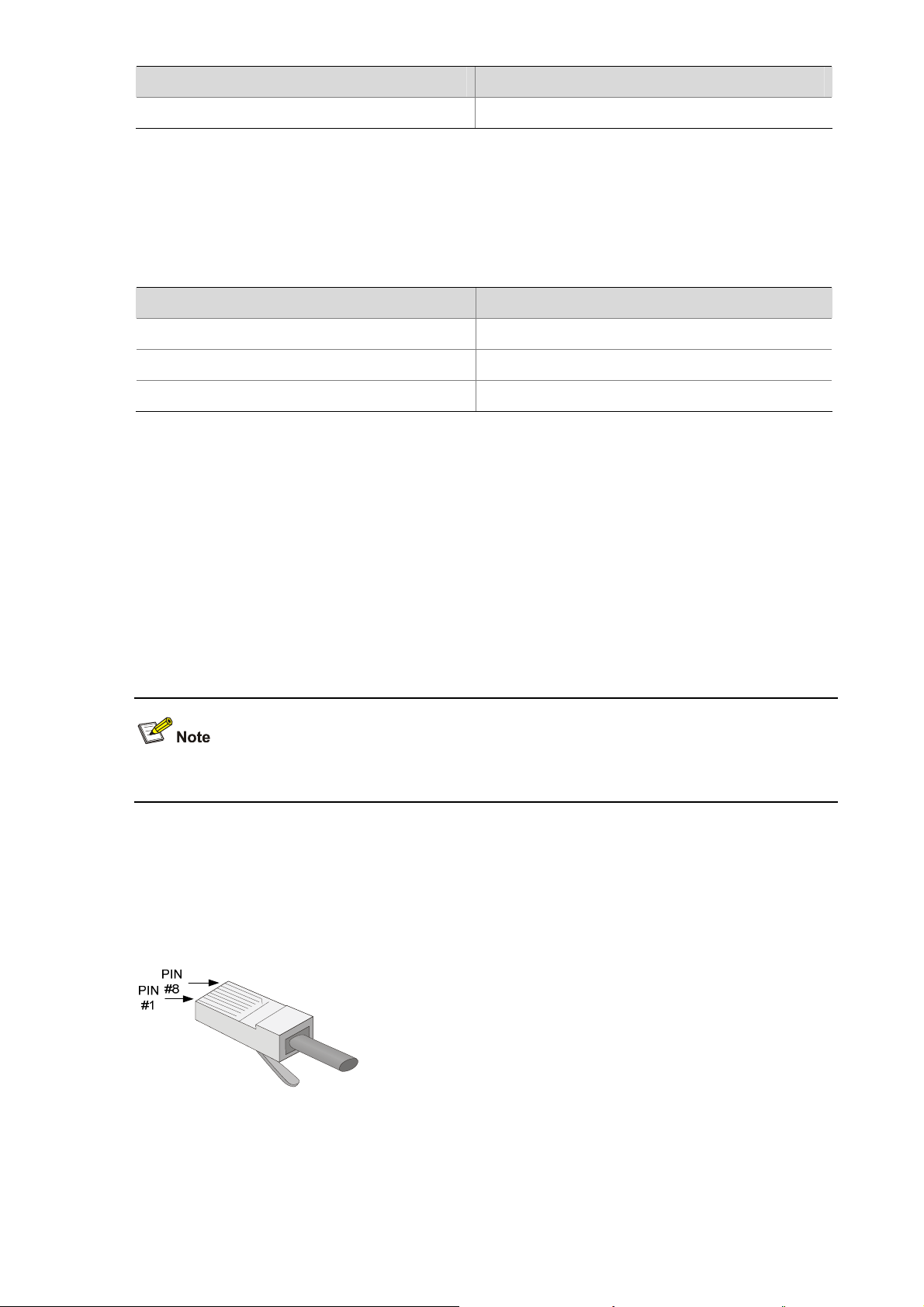

2) RJ-45 connectors

The 10/100/1000M electrical Ethernet ports of the WX3000 series work with Category-5 twisted pair

cables with RJ-45 connectors, as shown in

Figure 1-10.

Figure 1-10 RJ-45 connector

3) LC connectors

As an indispensable passive component in a fiber communication system, a fiber connector is mainly

used for the removable connection between optical tunnels. This facilitates the testing and maintenance

1-9

Page 18

of the optical system and makes optical inter-connections more flexible.

Currently, the WX3000 series supports only LC connectors.

Figure 1-11 LC connector

z When connecting a networking device using optical fibers, first make sure that the fiber connectors

will work with the optical transceivers.

z Before connecting fiber cables, make sure that the optical power of the receiver end does not

exceed the upper threshold of the receiving optical power of the optical transceiver; otherwise, the

optical transceiver may be damaged. For the optical power specifications of the receiver end, refer

to Appendix A.

Transceiver Modules

The WX3000 series supports the following optical transceivers:

Table 1-11 Description of optical transceivers

Item WX3024 WX3010 WX3008

SFP transceivers

XFP transceivers

FE SFP transceivers

Supports SFP-FE-SX-MM1310-A

Supports SFP-FE-LX-SM1310-A

Supports SFP-GE-SX-MM850-A

GE SFP transceivers

Supports SFP-GE-LX-SM1310-A

Not supported

Supports SFP-GE-LX-SM1310-BIDI

GE BIDI transceivers

Supports SFP-GE-LX-SM1490-BIDI

Supports SFP-FE-LX-SM1310-BIDI

FE BIDI transceivers

Supports SFP-FE-LX-SM1550-BIDI

Supports

XFP-SX-MM850

Not supported Not supported

Supports

XFP-LX-SM1310

XENPAK modules

Supports

XENPAK-SX-MM850

Not supported Not supported

Supports

XENPAK-LX-SM1310

1-10

Page 19

RPS

z Optical transceivers are optional components and are not supplied with the WX3000 series. Use

H3C-recommended optical transceivers. For details about the technical specifications of SFP

optical transceiver, refer to Appendix A.

z The WX3024 supports all XFP optical transceivers except those requiring –5.2 V power supply.

z The BIDI optical transceivers must be used in pairs. For example, if an SFP-GE-LX-SM1310-BIDI

is used at one end, an SFP-GE-LX-SM1490-BIDI must be used at the other end. The same is true

for FE BIDI modules.

When the AC power supply fails, an RPS unit can feed power to maintain the normal operation of the

system.

z The WX3010 and WX3008 do not support the RPS unit.

z An RPS unit is an optional accessory to be separately orderly if needed.

z For the RPS unit installation information, refer to section Connecting the RPS Cable on page 3-19.

DC Power Cables

Table 1-12 Description of DC power cables

CAB-48V Pwr-2m-T2.5^2 2 m (6.56 ft.) 14AWG power cable

CAB-RPS Non PoE-2m-JD5 2 m (6.56 ft.) JD5 DC power cable

CAB-RPS Non PoE-2m-JD5-A 2 m (6.56 ft.) JD5-A DC power cable

Item Length Description

Fans

z The WX3010 and WX3008 do not support DC power input.

z DC power cables are optional accessories to be separately order if needed.

z The DC power cables should be shorter than 3 meters (9.84 ft.) to minimize voltage attenuation.

The WX3024 is equipped with five fans: two fans for heat dissipation of the main board and three fans

on the power module for heat dissipation of the power supply system.

1-11

Page 20

The WX3010 is equipped with three fans for heat dissipation of the whole system.

The WX3008 is equipped with three fans for heat dissipation of the whole system.

Interface Numbering

Interface Numbering for the WX3024

The WX3024 provides 29 fixed interfaces numbered GigabitEthernet 1/0/1 through GigabitEthernet

1/0/29, among which:

z GigabitEthernet 1/0/1 through GigabitEthernet 1/0/24: 10/100/1000 Base-T Ethernet ports, with the

last part of the port numbers indicated on the front panel;

z GigabitEthernet 1/0/25 through GigabitEthernet 1/0/28: 1000Base-X SFP optical ports, with the

last part of the port numbers indicated on the front panel;

z GigabitEthernet 1/0/29: a virtual interface for the connection between the access control engine

and the switching engine.

The WX3024 provides two 10 GE interface module slots. The interfaces on the interface modules

installed in these slots are numbered TenGigabitEthernet 1/1/1 and TenGigabitEthernet 1/2/1.

Interface Numbering for the WX3010

The WX3010 provides 11 fixed interfaces numbered GigabitEthernet 1/0/1 through GigabitEthernet

1/0/11, among which:

z GigabitEthernet 1/0/1 through GigabitEthernet 1/0/8: 10/100/1000 Base-T Ethernet ports, with the

last part of the port numbers indicated on the front panel;

z GigabitEthernet 1/0/9 through GigabitEthernet 1/0/10: 1000Base-X SFP optical ports, with the last

part of the port numbers indicated on the front panel;

z GigabitEthernet 1/0/11: a virtual interface for the connection between the access control engine

and the switching engine.

Interface Numbering for the WX3008

The WX3008 provides nine fixed interfaces numbered GigabitEthernet 1/0/1 through GigabitEthernet

1/0/9, among which:

z GigabitEthernet 1/0/1 through GigabitEthernet 1/0/8: 10/100/1000 Base-T Ethernet ports, with the

last part of the port numbers indicated on the front panel;

z GigabitEthernet 1/0/9: a virtual interface for the connection between the access control engine and

the switching engine.

1-12

Page 21

2 Preparing for Installation

Safety Precautions

To avoid any device impairment and bodily injury caused by improper use, observe these rules:

z Pull the power plug(s) out of the device before cleaning the device. Do not clean the device using

wet cloth or liquid.

z Keep the device away from water or dampness. Prevent water or moisture from entering the device

chassis.

z Do not place the device on an unstable case or desk. The device might be damaged severely in

case of a fall.

z Ensure proper ventilation in the equipment room and keep the vents of the device free of

obstruction.

z Make sure that the operating voltage is within the range as labeled on the device.

z To avoid electrical shocks, do not open the chassis when the device is operating or when electrical

hazards are present.

z When replacing interface modules, always wear an ESD-preventive wrist strap.

Installation Site Checking

The device is designed for indoor use. You can mount the device either in a rack or on a workbench, but

make sure that:

z Adequate space is reserved at the air inlet and exhaust vents for heat dissipation.

z The rack or workbench has a good ventilation system.

z The rack is sturdy enough to support the device and its accessories.

z The rack or workbench is well grounded.

To ensure normal operation and a long service life of your device, install it in an environment that meets

the following requirements.

Temperature and Humidity

The temperature and humidity in the equipment room must be kept within a proper range.

z Lasting high humidity may lead to bad insulation, electricity creepage, mechanical property

changes, and corrosion.

z If the relative humidity is too low, captive screws may become loose as a result of contraction of

insulation washers, and static electricity may be produced in a dry environment to interfere the

circuits on the device.

z Lasting high temperatures accelerate the aging of insulation materials and thus significantly lower

the reliability and service life of the device.

The temperature and humidity requirements for the WX3000 series are listed in

2-1

Table 2-1.

Page 22

Table 2-1 Working environment

Temperature 0°C to 45°C (32°F to 113°F)

Relative humidity 10% to 95% (noncondensing)

Cleanliness

Dust is hazardous to the operating safety of the device. Dust buildup on the chassis may result in static

adsorption, causing poor contact of metal connectors or metal contact points. When the relative indoor

humidity is low, especially, electrostatic adsorption is more likely to happen. This not only shortens the

service life of your device but also causes communication failures. The following table lists the dust

concentration limit in the equipment room.

Table 2-2 Dust concentration limit in the equipment room

Physical active substance Limit (particles/m3)

Item Specification

Dust particles

Note: The dust particle diameter is ≥ 5 μm

In addition, the equipment room should also meet the rigorous limits on salts, acids, and sulfides to

eliminate corrosion and premature aging of some parts.

equipment room.

Table 2-3 Limit on harmful gases in the equipment room

SO2 0.2

H2S 0.006

NH3 0.05

Cl2 0.01

ESD Prevention

≤ 3 × 104 (No visible dust on the tabletop over three days)

Table 2-3 lists the limits on harmful gases in the

Gas Limit (mg/m3)

Static electricity generation and harms

The electrostatic induction that adversely affects the operation of the device mainly comes from:

z Outdoor electric fields caused by high-voltage power lines or lightning strikes.

z Internal systems, such as the indoor environment, floor materials, and the structure of the

integrated equipment.

Although a great deal of electrostatic discharge (ESD) prevention considerations have been taken in

the design of the WX3000 series, excessive static electricity is still remarkably harmful to the whole

device.

ESD prevention methods

To prevent ESD damage, do the following:

2-2

Page 23

z Make sure that the device and the floor are well grounded.

z Keep the equipment room clean.

z Keep proper temperature and humidity conditions.

z When touching a circuit board, always wear ESD-preventive gloves or an ESD-preventive wrist

strap, and wear antistatic work clothes.

z When mounting, removing, observing, or moving an interface module, always take the printed

circuit board (PCB) by the edges without touching the components on the PCB.

z After removing an interface module, place the PCB on an antistatic workbench with the

component-side facing upward or place it in an antistatic bag.

ESD-preventive wrist strap

The ESD-preventive wrist strap is not provided with the device.

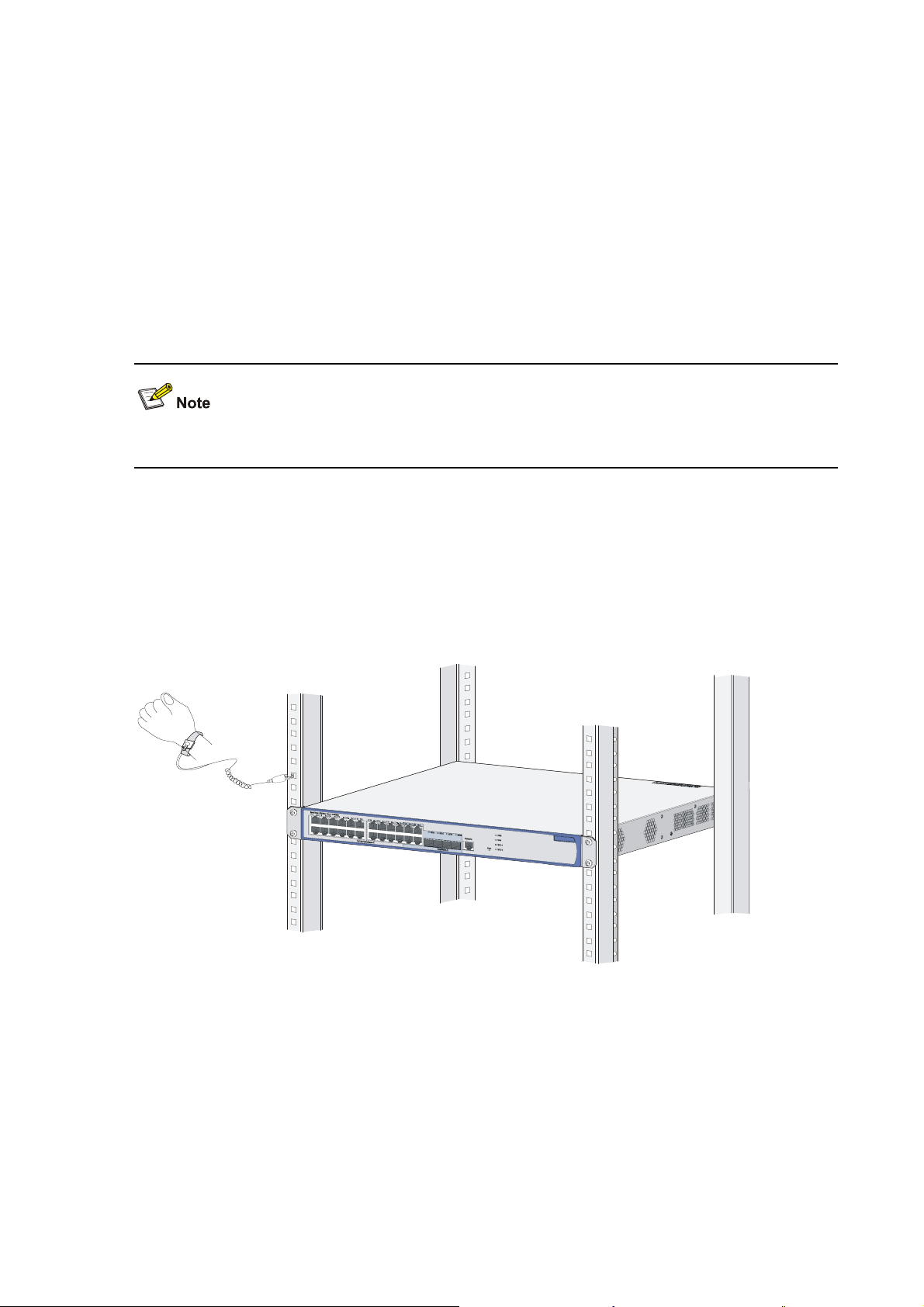

Follow these steps to use an ESD-preventive wrist strap:

Step1 Put on and fasten the wrist strap and make sure the wrist strap has good skin contact.

Step2 Attach grounding wire to the wrist strap and the alligator clip to the rack.

Step3 Verify that the rack is well grounded.

Figure 2-1 Wear an ESD-preventive wrist strap

EMI Prevention

All interference sources, from the outside or inside of the device and application system, adversely

affect the device in the conduction patterns of capacitance coupling, inductance coupling,

electromagnetic wave radiation, and common impedance (including grounding system) coupling, and

cable conduction (including power cables, signal cables and output cables). To prevent interference, do

the following:

2-3

Page 24

z Use a TN system for the system earthing of the AC power supply, and use a single-phase

three-wire AC socket with a protection earth (PE) to effectively filter interference from the power

grid.

z Keep the device away from high-power radio transmitters, radars, and high-frequency

heavy-current devices.

z Take electromagnetic shielding measures when necessary. For example, use shielded interface

cables.

z Route the interface cables only indoors to protect signal interfaces against over-voltage or

over-current conditions cause by lightning strikes.

Laser Safety

The WX3000 series is the Class 1 laser product.

Do not look directly at any working optical transceivers on the WX3000 series because the high-energy

laser beam emitted from the optical fiber may hurt your eyes.

Staring into the laser beam emitted from an optical fiber may hurt your eyes.

Installation Tools

Flat-blade screwdrivers

Philips screwdrivers: P2-150 mm

EDS-preventive wrist straps

The installation tools are not provided with the device.

2-4

Page 25

3 Installing the Device

When you ask your sales agent to maintain your device, make sure that the dismantlement-preventive

seal of H3C on a mounting screw of the device chassis is intact. If you want to open the chassis, you

should contact the agent for permission. Otherwise, you will bear any consequence resulting from your

actions.

Installing the Device in a 19-inch Rack

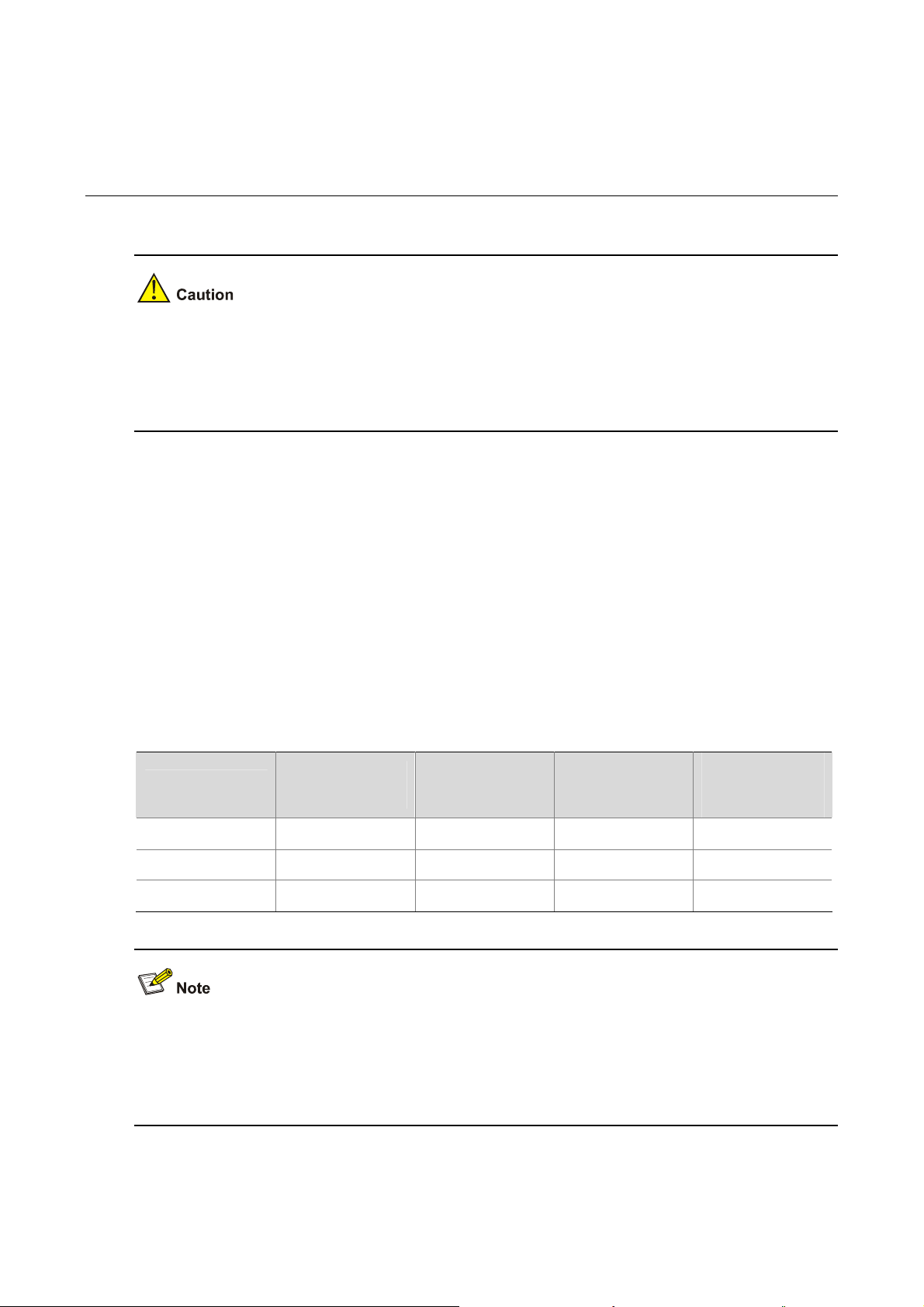

The WX3000 series can be installed in a standard 19-inch rack, and the installation falls into the

following four scenarios:

z Installing the device with front mounting brackets.

z Installing the device with front and rear mounting brackets.

z Installing the device with front mounting brackets and a tray.

z Installing the device with front mounting brackets and slide rails.

Refer to

Table 3-1 Installation scenarios supported by the WX3024 and WX3010

WX3024 Not supported Supported Supported Supported

WX3010 Supported Not supported Supported Not supported

WX3008 Supported Not supported Supported Not supported

Table 3-1 for the installation scenarios supported by the device models.

Device Model

Front mounting

brackets

Front and rear

mounting

brackets

Front mounting

brackets and a

tray

Front mounting

brackets and

slide rails

z If the width of the device is more than 300 mm (11.8 in.), the front mounting brackets can be used

only for fixing the device, rather than weight-bearing.

z The slide rails provided by H3C are suitable only for H3C standard racks with the depth of 1000 mm

(39.37 in.). You need to seek other supporting means if your rack has a different depth.

3-1

Page 26

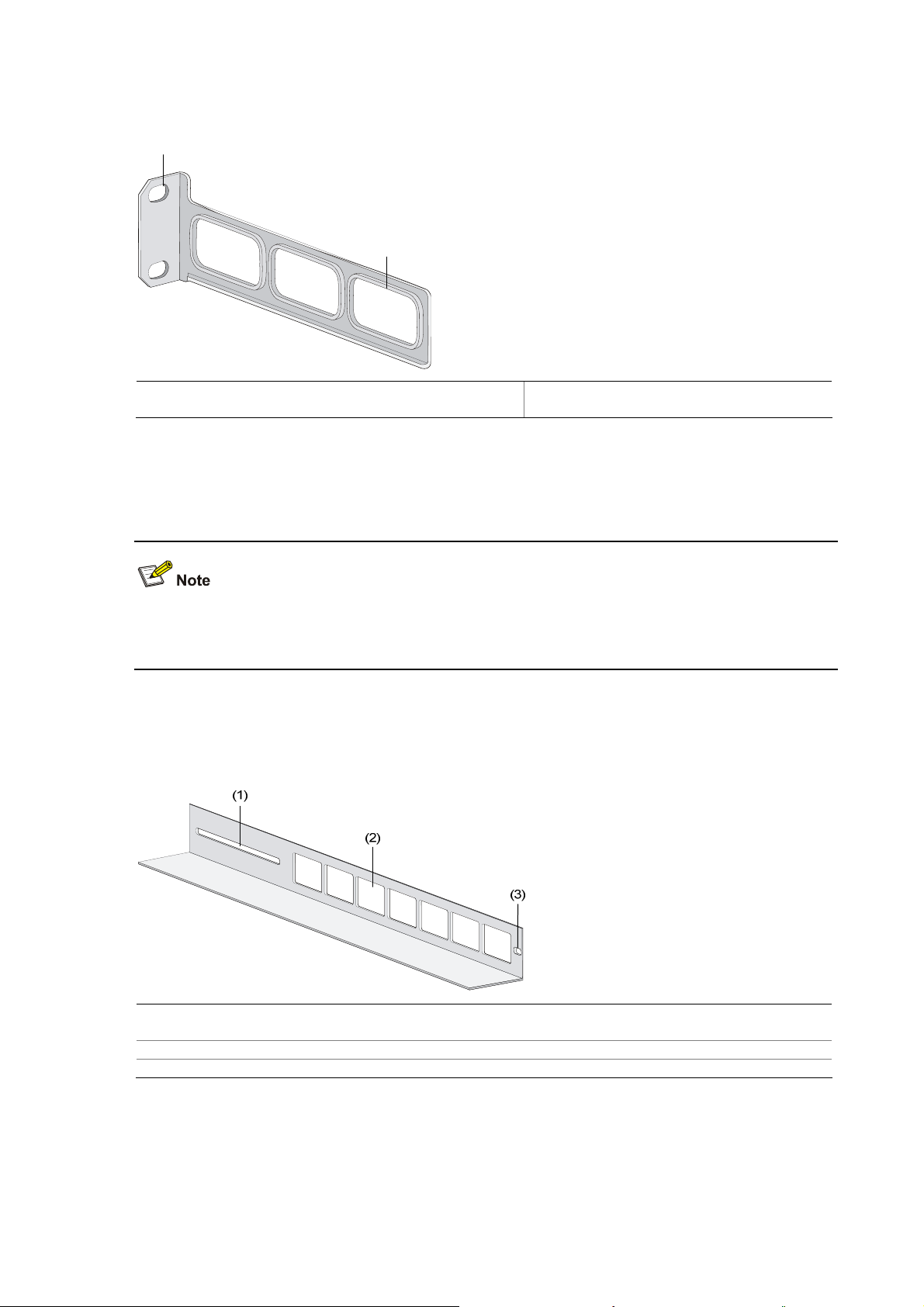

Introduction to Mounting Brackets

Appearance of a front mounting bracket

Figure 3-1 Front mounting bracket of the WX3024

(1) Screw holes for fixing the front mounting bracket

onto the rack (using M6 screws)

Figure 3-2 Front mounting bracket of the WX3010 and WX3008

(1) Screw holes for fixing the front mounting bracket

onto the rack (using M6 screws)

The front mounting bracket of the WX3010 and WX3008 is an optional component that needs to be

separately ordered if needed for the installation scenario selected in

(2) Screw hole for fixing the front mounting

bracket to the device chassis

(2) Screw hole for fixing the front mounting

bracket to the device chassis

Table 3-1.

3-2

Page 27

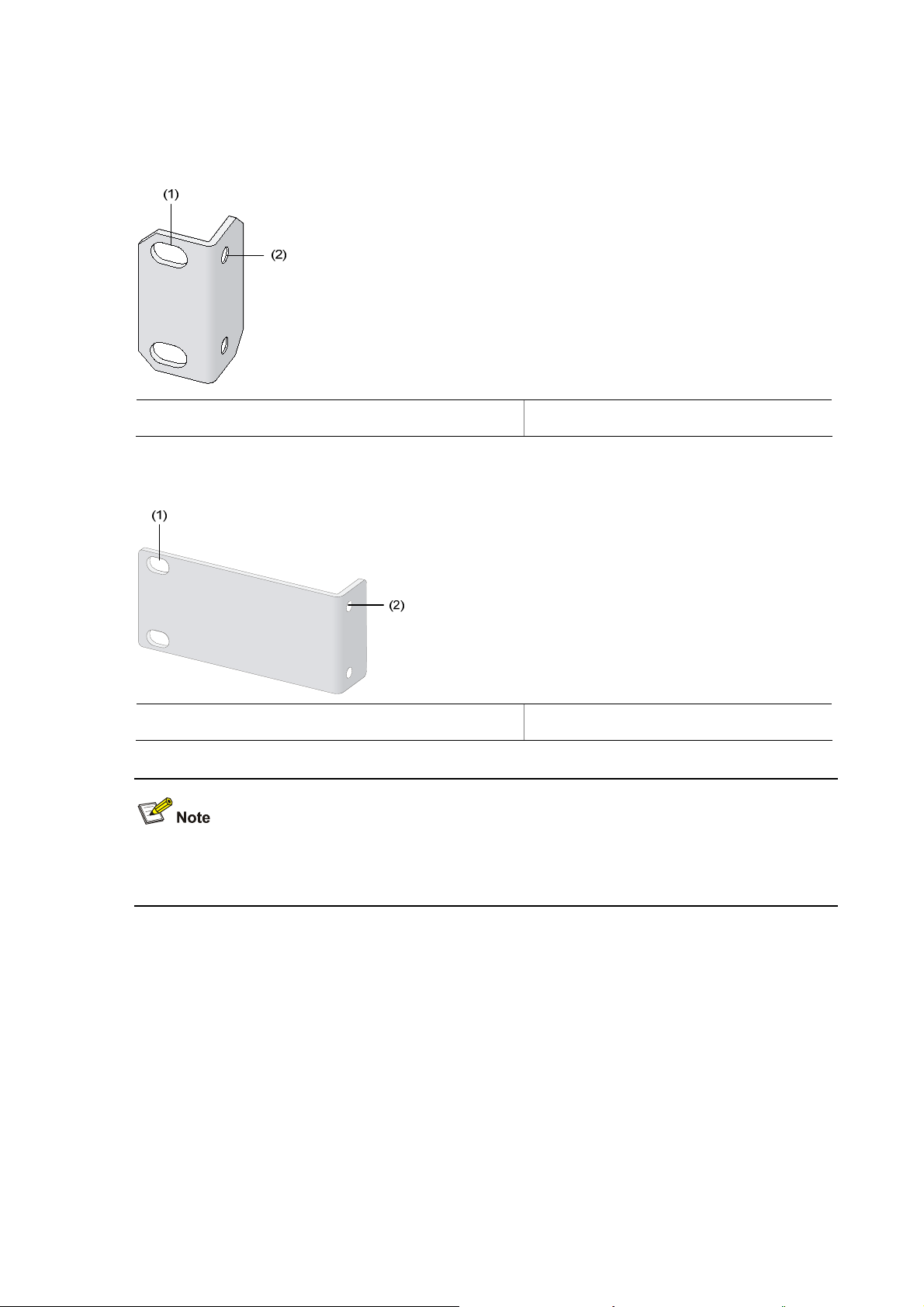

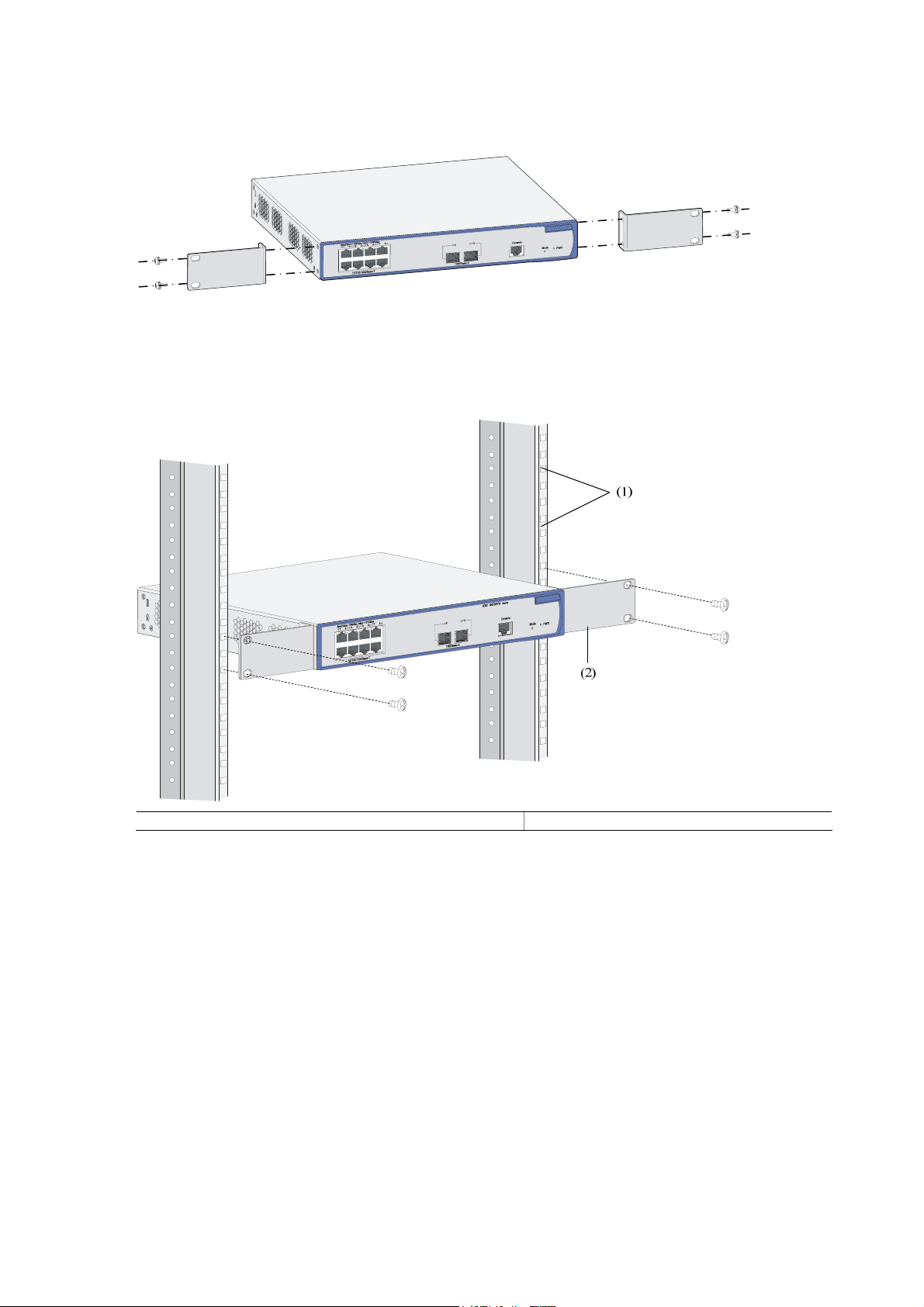

Appearance of a rear mounting bracket

Figure 3-3 Rear mounting bracket of the WX3024

(1)

(1) Screw holes for fixing the rear mounting bracket

onto the rack (using M6 screws)

Introduction to Slide Rails

(2)

(2) Heat dissipation holes

The slide rails are optional components that need to be separately ordered if needed for the installation

scenario selected in

Table 3-1.

Appearance of a slide rail

Figure 3-4 A slide rail

(1) Slot hole for fixing the slide rail onto the rear bracket of the rack. It allows adjustment of the device

mounting screw position according to the device position.

(2) Heat dissipation holes. Holes for heat dissipation between the device and the rack.

(3) Slot hole for fixing the slide rail onto the front bracket of the rack.

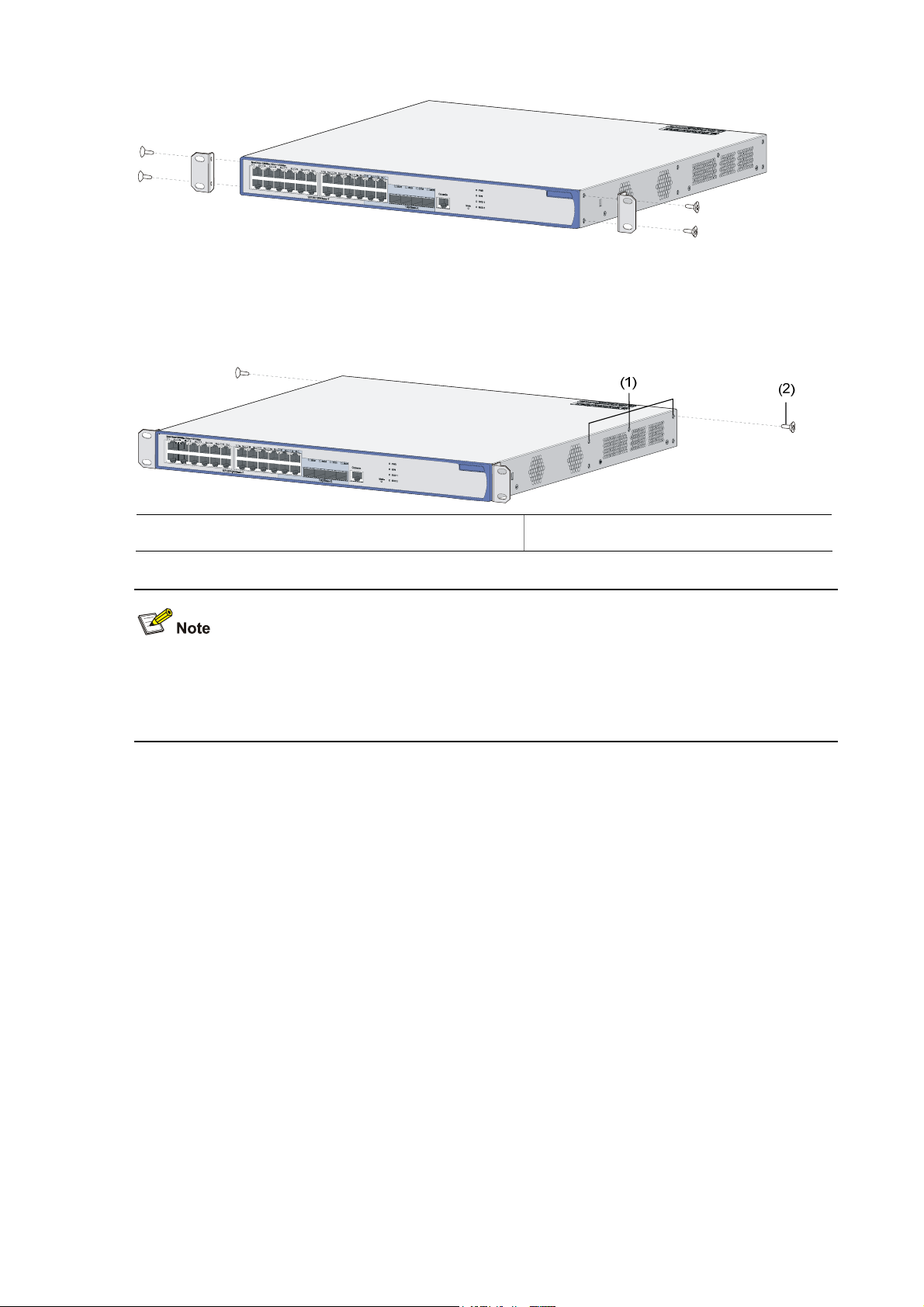

Installing the Device Using Front Mounting Brackets

Follow these steps to install the device (take the WX3010 for example) using front mounting brackets:

Step1 Put on an ESD-preventive wrist strap and verify that the rack is sturdy and properly grounded.

3-3

Page 28

Step2 As shown in Figure 3-5, use the screws packed with the front mounting brackets to fix the front mounting

brackets on the device.

Figure 3-5 Attach the front mounting brackets to the device

Step3 As shown in

nuts to fix the front mounting brackets on the front square-holed brackets of the rack.

Figure 3-6 Attach the front mounting brackets to the rack

Figure 3-6, determine the device installation position in the rack and use screws and cage

(1) Front square-holed bracket (2) Front mounting bracket

Installing the Device Using Front and Rear Mounting Brackets

Follow these steps to install the device using front and rear mounting brackets:

Step1 Put on an ESD-preventive wrist strap and verify that the rack is sturdy and properly grounded.

Step2 As shown in

brackets on both sides of the device.

Figure 3-7, use the screws packed with the front mounting brackets to fix the front mounting

3-4

Page 29

Figure 3-7 Attach the front mounting brackets to both sides of the device

Step3 As shown in

sides of the device.

Figure 3-8 Install the weight-bearing screws

(1) Three holes for mounting the weight-bearing screw

(select one as needed)

There are three holes on each side of the device for the weight-bearing screws. You can select a proper

location as needed. The rear mounting brackets will support the weight of the device through firm

contact with the weight-bearing screws.

Figure 3-8, fix the weight-bearing screws packed with the rear mounting brackets on both

(2) Weight-bearing screw

Step4 As shown in

nuts to fix the rear mounting brackets on the rear square-holed brackets of the rack.

Figure 3-9, determine the device installation position in the rack and use screws and cage

3-5

Page 30

Figure 3-9 Install rear mounting brackets

(1) Rear square-holed brackets (2) Rear mounting bracket

Step5 Hold the bottom of the device with one hand and the front part with the other hand, and gently push the

device into the rack, as shown in

Figure 3-10.

Figure 3-10 Install the device using front and rear mounting brackets (1)

(1) Front mounting bracket (2) Front square-holed bracket

(3) Weight-bearing screw

(4) Screw for fixing the rear mounting bracket onto the

rear square-holed bracket

(5) Rear mounting bracket (6) Rear square-holed bracket

3-6

Page 31

After pushing the device into the rack, make sure that the upper edges of the rear mounting brackets

fixed on the rack have close contact with the weight-bearing screws on the device, as shown in

Figure

3-11.

Figure 3-11 Install the device using front and rear mounting brackets (2)

(1) Rear square-holed bracket (2) Weight-bearing screw

(3) Rear mounting bracket

Step6 Fix the front mounting brackets on the front square-holed brackets of the rack with screws and cage

nuts. Make sure that the device is firmly fixed on the rack through the front and rear mounting brackets,

as shown in

Figure 3-12.

3-7

Page 32

Figure 3-12 Install the device using front and rear mounting brackets (3)

(1)

(2)

(1) Front square-holed bracket (2) Front mounting bracket

Installing the Device Using Front Mounting Brackets and a Tray

The tray is an optional component that needs to be separately ordered if needed.

Follow these steps to install the device (take the WX3024 as example) in a rack using front mounting

brackets and a tray:

Step1 Put on an ESD-preventive wrist strap and check that the rack is sturdy and properly grounded.

Step2 As shown in

brackets on both sides of the device.

Step3 Fix the tray on the rack as shown in

actual installation on your rack).

Figure 3-7, use the screws packed with the front mounting brackets to fix the front mounting

Figure 3-13 (this figure is for reference only and may differ from the

3-8

Page 33

Figure 3-13 Install a tray

Step4 Place the device horizontally on the tray, push it into the rack along the tray, and fix the front mounting

brackets onto the front square-holed brackets of the rack using the screws and cage nuts, as shown in

Figure 3-14.

Figure 3-14 Install the device using front mounting brackets and a tray

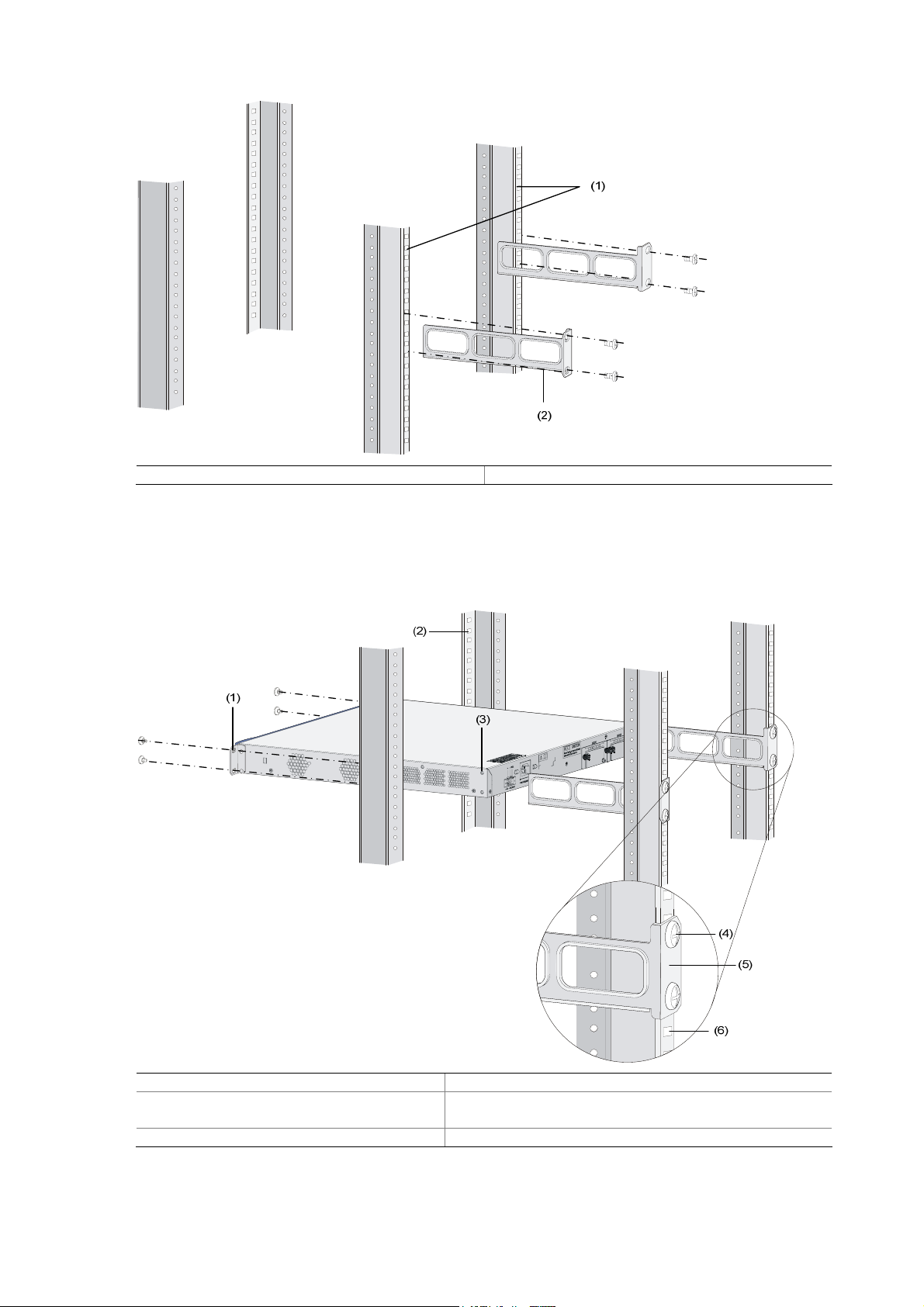

Installing the Device Using Front Mounting Brackets and Slide Rails

Installing a device with front mounting brackets and slide rails

Follow these steps to install the device with front mounting brackets and slide rails:

Step1 Put on an ESD-preventive wrist strap and verify that the rack is sturdy and properly grounded.

Step2 As shown in

brackets on both sides of the device.

Step3 Fix the slide rails on both sides of the rack with M5 self-tapping screws as shown in

figure is for reference only and may differ from the actual installation on your rack).

Figure 3-7, use the screws packed with the front mounting brackets to fix the front mounting

Figure 3-15 (this

3-9

Page 34

Figure 3-15 Install slide rails

Step4 Hold the device by both sides of it and gently push it into the rack along the slide rails, as shown in

Figure 3-16. Verify that the bottom of the device is in firm contact with the slide rails.

Figure 3-16 Install the device using front mounting brackets and slide rails (1)

Step5 Fix the front mounting brackets on the front square-holed brackets of the rack using the M6 screws and

cage nuts. Make sure that the device is firmly fixed on the rack through the front mounting brackets and

slide rails, as shown in

Figure 3-17.

3-10

Page 35

Figure 3-17 Install the device using front mounting brackets and slide rails (2)

You are recommended to keep a distance of 1 U (44.45 mm/1.75 in.) between two devices to ensure

good heat dissipation.

Installing the Device on a Workbench

Without a standard 19-in rack, you can install the device on a clean workbench. During the installation,

make sure that:

z The workbench is sturdy and well grounded.

z The workbench is a well-ventilated environment. Keep at least 10 cm (3.94 in.) clearance around

the device for heat dissipation.

z No heavy object is placed on the device.

z At least 15 mm (0.59 in.) distance is provided between two devices when they are stacked one

above the other.

Wall Mounting

You can mount the WX3010 and WX3008 on concrete walls or wood walls.

Introduction to screw and wall anchor

Figure 3-18 and Figure 3-19 show the recommended sizes (in millimeters) of screws and wall anchor

used for mounting.

3-11

Page 36

Figure 3-18 Screw

Figure 3-19 Wall anchor

(1)(1)

(1) Outside edge of wall anchor

Installation procedure

Follow these steps to mount the device on the wall:

Step1 As shown in

Figure 3-20, drill two holes with a diameter of 5 mm (0.2 in.) across in the wall on the same

horizontal line, with a distance of 170 mm (6.69 in.).

Drill two holes according to the sizes of wall anchors and screws so that wall anchors could go into the

holes, only the edges could remain outside the wall, and the screws could be fixed on the wall tightly.

Step2 Insert wall anchors into the holes and keep only the edges outside the wall.

Step3 Drive screws into the wall anchors, keeping the inside of screw head at least 1.5 mm (0.06 in) away

from the edge of the wall anchor so that the device could hang on the screws securely.

3-12

Page 37

Figure 3-20 Mount the device on the wall

Step4 Align the two installation holes at the bottom of the device with these two screws to hang the device.

When mounting the device, keep the Ethernet ports of the device facing downwards and the two sides

with ventilation holes vertical to the ground.

Magnet Mounting

The WX3010 and WX3008 can be installed using magnet mounting.

Introduction to magnetic accessories

Magnetic accessories consists of four permanent magnets and four M3*6 countersunk head screws, as

shown in

Figure 3-21 Magnets and countersunk head screws

Figure 3-21.

(1) M3*6 countersunk head screw (2) Permanent magnet

3-13

Page 38

Installation procedure

Follow these steps to complete magnet mounting:

Step1 As shown in

Figure 3-22, use a Phillips screwdriver to pass the countersunk head screw through the

round hole at the center of the permanent magnet, fasten it to a blind nut in the dent of the device

bottom, and ensure that the permanent magnet and the device are fastened reliably.

Remove the cushion, if any, from the dent before installation.

Step2 Attach the magnet-mounted device to the specified location. Do not to get your fingers stuck between

because the magnetism is very huge.

Figure 3-22 Magnet mounting

(1) (2)

(3)

(1) M3*6 countersunk head screw (2) Permanent magnet

(3) Blind nut in the dent of the device bottom

3-14

Page 39

z Select the installation location carefully. In the case of poor surface, magnet mounting may not be

reliable.

z Put the device at a stable place free from vibrations or shocks. Otherwise, personal injuries or

equipment damage may occur.

z Avoid installing the device at a high place because personal injuries or equipment damage may

occur in case of a falloff.

z Avoid frequently moving the desk-mounted device because such movements may damage the

surface coating.

z Keep the front panel of the device facing downwards and the two sides with ventilation holes

vertical to the ground, if you want to install the device vertically.

z Pay attention that the weight of external cables should not bring about a falloff, which may result in

personal injuries or equipment damage.

z Keep floppy disks and magnetic cards away from magnets to avoid erasure of any information.

z Keep computers and monitors that are easily influenced by magnetic fields away from magnets.

Otherwise, faults may occur to these electronic devices.

z The power cords may vary with different standards of different countries, so you may need to select

a bail latch as needed.

Connecting the Ground Cable

The correct connection of the protection ground cable of the device is an essential safeguard against

lightning strokes and interference. You must correctly connect the ground cable before using your

device.

The power input end of the device has a noise filter, whose central ground is directly connected with the

chassis, forming the protection ground (PGND) of the chassis. This chassis ground must be securely

earthed so that the induction and creepage currents can be safely discharged to the earth to enhance

the anti-EMI capability of the device. The following describes how to connect the PGND cable in

different situations.

If a grounding strip is available

Attach one end of the yellow-green PGND cable of the device to the grounding screw on the chassis

and the other end to the grounding terminal on the grounding strip and fasten the nut.

3-15

Page 40

Figure 3-23 Connect the PGND cable when a grounding strip is available

(1) AC power receptacle (2) Grounding screw

(3) PGND cable (4) Grounding strip in the equipment room

The fire main and the lightning rod of the building are not good grounding options. The PGND cable of

the device should be connected to the earthing system of the equipment room.

Without a grounding strip

1) If an area with exposed earth is available nearby where a grounding conductor can be buried

Hammer a 0.5 m (1.64 ft.) or longer angle iron or steel tube longer into the earth. Weld the yellow-green

grounding cable to the angle iron or steel tube, and treat the joint for corrosion protection.

Figure 3-24 Connect the PGND cable to a buried grounding conductor

(1) AC power receptacle (2) Grounding screw

(3) PGND cable (4) Earth ground

(5) Angle iron

2) If it is not allowed to bury a ground conductor

z If the device is AC powered, you can ground it through the PE wire of the AC power supply. Make

sure that the PE wire is well grounded in the power distribution room or on the AC transformer side.

3-16

Page 41

Figure 3-25 Ground the device through the AC PE wire

(1)

(2)

(4)

(5)

(3)

(1) Power transformer (2) AC power receptacle

(3) Grounding screw (4) Three-core AC power cable

(5) PE wire

z If the device is –48 VDC powered, you can ground it through the return wire (RTN) of the DC power

supply. Make sure that the RTN wire is well grounded at the DC output of the DC power cabinet.

Figure 3-26 Ground the device through the PGND of a power cabinet

(1) AC/DC power cabinet (2) –48 V busbar

(3) -48 V (4) RTN busbar

(5) RTN (6) PGND busbar

(7) Earth ground (8) PGND cable

(9) Grounding screw (10) DC power receptacle

The WX3010 and WX3008 do not support DC power input.

3-17

Page 42

Connecting the Power Cables

Connecting AC Power Cable

The power cords may vary with different standards of different countries, so you may need to select a

bail latch as needed.

Follow these steps to connect the AC power cable:

Step1 Verify that the chassis PGND is correctly connected to the earth ground.

Step2 Install the bail latch onto the device and pivot the bail latch up.

Step3 Plug one end of the power cable to the AC power receptacle on the rear panel of the chassis and plug

the other end to the AC power source.

Step4 Place the bail latch over the AC power cable to secure the plug in place.

Figure 3-27 Connect the AC power cable

(1) Rear panel (2) Bail latch holder

(3) Bail latch (4) AC power cable

Step5 Check the RPS LED on the front panel of the device. Solid green indicates that the AC power input is

normal.

z Since the WX3010 and WX3008 do not have the RPS LED, blinking green of the PWR LED

indicates that the AC power input is normal. For details about LED status, refer to

LEDs on page

1-6.

z The bail latch prevents the power cable from accidentally falling off.

3-18

Page 43

Connecting the RPS Cable

The WX3010 and WX3008 do not support RPS.

Follow these steps to connect the RPS cable:

Step1 Check that the device is powered off and the RPS unit is switched off.

Step2 Use a Philips screwdriver to remove the screws on the cover on the DC power receptacle and take off

the cover.

Step3 Connect the RPS cable to the DC power receptacle on the chassis.

Step4 Turn the strain release screws on the RPS cable clockwise so that the RPS cable plug is firmly seated in

the DC power receptacle, and then fasten the strain release screws.

Step5 Connect the other end of the RPS cable to an output interface of the RPS unit.

Figure 3-28 Connect the RPS cable

(5)

(1) (2)

(3)

(7)

(6)

(4)

(1) DC power receptacle (2) RPS cable plug for the DC power receptacle

(3) RPS cable (4) RPS cable plug for the RPS output

(5) RPS unit (6) Output interfaces of the RPS unit

(7) AC power input interfaces of the RPS unit

Step6 Check the RPS LED on the front panel of the device. LED ON means the RPS unit is correctly

connected.

z The RPS unit is an optional accessory. The WX3024 supports the RPS1000.

z Check that the ground cable is properly connected before powering on the device.

3-19

Page 44

Connecting the Interface Cables

Connecting the Console Cable

1) Prepare a configuration terminal

The configuration terminal can be an ASCII terminal with an RS232 serial port or a PC. The description

in this section assumes that you use a PC as the configuration terminal.

2) Connect the console cable

Power off the device, plug the DB-9 female connector of the console cable to the serial port of the PC

that will be used to configure your device, and connect the RJ-45 connector of the console cable to the

console port of the device.

Pay attention to the mark on the console port and be sure to plug the connector into the right port.

Figure 3-29 Connect the console cable

(2)

(1)

(5)

(3)

(4)

(1) RJ-45 connector (2) Console port

(3) DB-9 female connector (4) Serial port on the configuration terminal

(5) Console cable

If the device has been powered on:

z When connecting the console cable, first connect the DB-9 connector to the PC before connecting

the RJ-45 connector to the device.

z When removing the console cable connection, first unplug the RJ-45 connector from the device

and then unplug the DB-9 connector from the PC.

3-20

Page 45

Connecting the Ethernet Cables

Connecting an electrical Ethernet port

Follow these steps to connect an electrical Ethernet port:

Step1 Connect one end of the Ethernet cable to the electrical Ethernet port on the device and the other end to

an Ethernet interface of the peer device.

Step2 After powering on the device, check the LEDs of the fixed electrical Ethernet port. For details about the

LED description, refer to

Connecting an optical Ethernet interface

Follow these steps to connect a 100/1000 Mbps optical interface:

Step1 Point the end of the optical transceiver without a release lever toward the SFP transceiver socket, verify

that the optical transceiver is not positioned upside down, and gently insert it into the socket.

Figure 3-30 Insert an optical transceiver

Table 1-7.

Step2 Identify the Rx and Tx ports on the optical transceiver and plug the two LC connectors at one end of the

fibers into the Rx and Tx ports and the LC connectors at the other end of the fiber into respectively the

Tx and Rx ports of an optical interface on the peer device.

Figure 3-31 Connect fiber connectors

3-21

Page 46

Step3 After powering on the device, check the LEDs of the SFP interfaces. For details about the SFP LEDs,

refer to

Table 1-7.

Installing and Removing Optional Interface Modules

z The WX3010 and WX3008 do not support installing interface modules.

z The interface modules and inner optical modules of the WX3024 are not hot swappable.

XFP Interface Modules

Introduction

10-Gigabit small form-factor pluggable (XFP) modules are used for electrical-to-optical and

optical-to-electrical conversion in optical signal transmission. An XFP transceiver requires fiber cables

with LC connectors.

Front panel of an XFP interface module

Figure 3-32 Front panel of an XFP interface module

Installing an XFP interface module

Step1 Put on an ESD-preventive wrist strap and verify that the wrist strap is properly grounded. Then, take the

XFP interface module out of the package.

Step2 Loosen the captive screws on blank panel covering an extension slot on the rear panel of the device

and remove the blank panel.

Step3 Take the XFP interface module by the captive screws on the front panel, and push the XFP interface

module steadily into the slot along the slide rails until it is firmly seated in the device.

Figure 3-33 Install an XFP interface module

3-22

Page 47

Step4 Fasten the captive screws on the XFP module to secure it in place.

z Keep the removed blank panel properly for future use.

z Do not over-tighten the captive screws on the front panel of the interface module.

Removing an XFP interface module

Step1 Put on an ESD-preventive wrist strap and check that the wrist strap is properly grounded.

Step2 Use a Philips screwdriver to loosen the captive screws on the front panel of the XFP interface module.

Step3 Pull the XFP interface module toward you until it is completely out of the device chassis.

When installing or removing an optional interface module, pay attention to the following points:

z Do not use excessive force in the operation and do not touch the surface-mounted components

directly with your hands.

z After removing an optional module, if the slot is to remain empty, install a blank panel to prevent

dust and ensure normal ventilation in the device.

XENPAK Module

Introduction

The 10-Gigabit Ethernet transceiver package (XENPAK) module provides the optical-to-electrical and

electrical-to-optical conversion function and multiple signal processing functions.

Front panel of an XENPAK module

Figure 3-34 Front view of an XENPAK module

Installing an XENPAK module

Step1 Put on an ESD-preventive wrist strap and verify that the wrist strap is properly grounded. Then, take the

XENPAK module out of the package.

3-23

Page 48

Step2 Loosen the screws on the cover plate in the middle of the blank panel covering an extension slot on the

rear panel of the device with a screwdriver and remove the cover plate.

When installing an XENPAK module, you only need to remove the small cover plate in the middle of the

blank panel instead of removing the entire blank panel.

Step3 Take the XENPAK module by the screws on the front panel and steadily push the module into the slot

along the slide rails until it is firmly seated in the device.

Figure 3-35 Install an XENPAK module

Step4 Fasten the screws on the XENPAK module to secure it in place.

z Keep the removed cover plate properly for future use.

z Do not over-tighten the screws on the XENPAK module.

z XENPAK modules are hot-pluggable on the device.

Removing an XENPAK module

Step1 Put on an ESD-preventive wrist strap and verify that the wrist strap is properly grounded.

Step2 Loosen the captive screws on the XENPAK module with a flat-blade screwdriver.

Step3 Pull the XENPAK module toward you until it is completely out of the device chassis.

3-24

Page 49

When installing or removing an optional module, pay attention to the following points:

z Do not use excessive force during the operation and do not touch the surface-mounted

components directly with your hands.

z After removing a module, if the slot is to remain empty, install a blank panel to prevent dust and

ensure normal ventilation in the device.

Installation Verification

During the installation of the device, always verify the installation before powering on the device:

z The power supply system meets the device requirements.

z The ground cable is correctly connected.

z Both the console cable and power cables are correctly connected.

z All interface cables are routed indoors. If outdoor routing of cables cannot be avoided, check that

network port lightning arrestors and an AC power supply lightning arresters have been correctly

installed. For details, refer to Appendix B and Appendix C.

3-25

Page 50

4 Starting and Configuring the Device

Setting up a Configuration Environment

Connecting the Device to a Configuration Terminal

For details of connecting a device to a configuration terminal, refer to section Connecting the Console

Cable on page

Setting Terminal Parameters

Before configuring your device through a console terminal, a PC running Microsoft Windows XP for

example, you need to set some parameters for the console terminal to communicate with the device.

Follow these steps to set the terminal parameters:

3-20.

Step1 Start the PC and select Start > Programs > Accessories > Communications > HyperTerminal. The

Connection Description dialog box appears, as shown below. Type the name for the new connection

and click OK.

Figure 4-1 Connection description interface

Step2 In the Connect To dialog box, select the serial port to be used for local configuration from the Connect

using drop-down list, as shown below. Make sure the serial port is the one actually connected with the

console port of the device. Then, click OK.

4-1

Page 51

Figure 4-2 Select the serial port for local configuration

Step3 Set the serial port parameters as shown below.

Set the properties of the serial port in the COM1 Properties dialog box, as shown in

Table 4-1 Set serial port parameters

Item Value

Bits per second

Data bits

Parity

Stop bits

Flow control

9600 bps (default)

8

None

1

None

Table 4-1.

4-2

Page 52

Figure 4-3 Set serial port parameters

To restore the default settings, click Restore Defaults.

Step4 After setting the serial port parameters, click OK to enter the HyperTerminal window.

Figure 4-4 HyperTerminal window

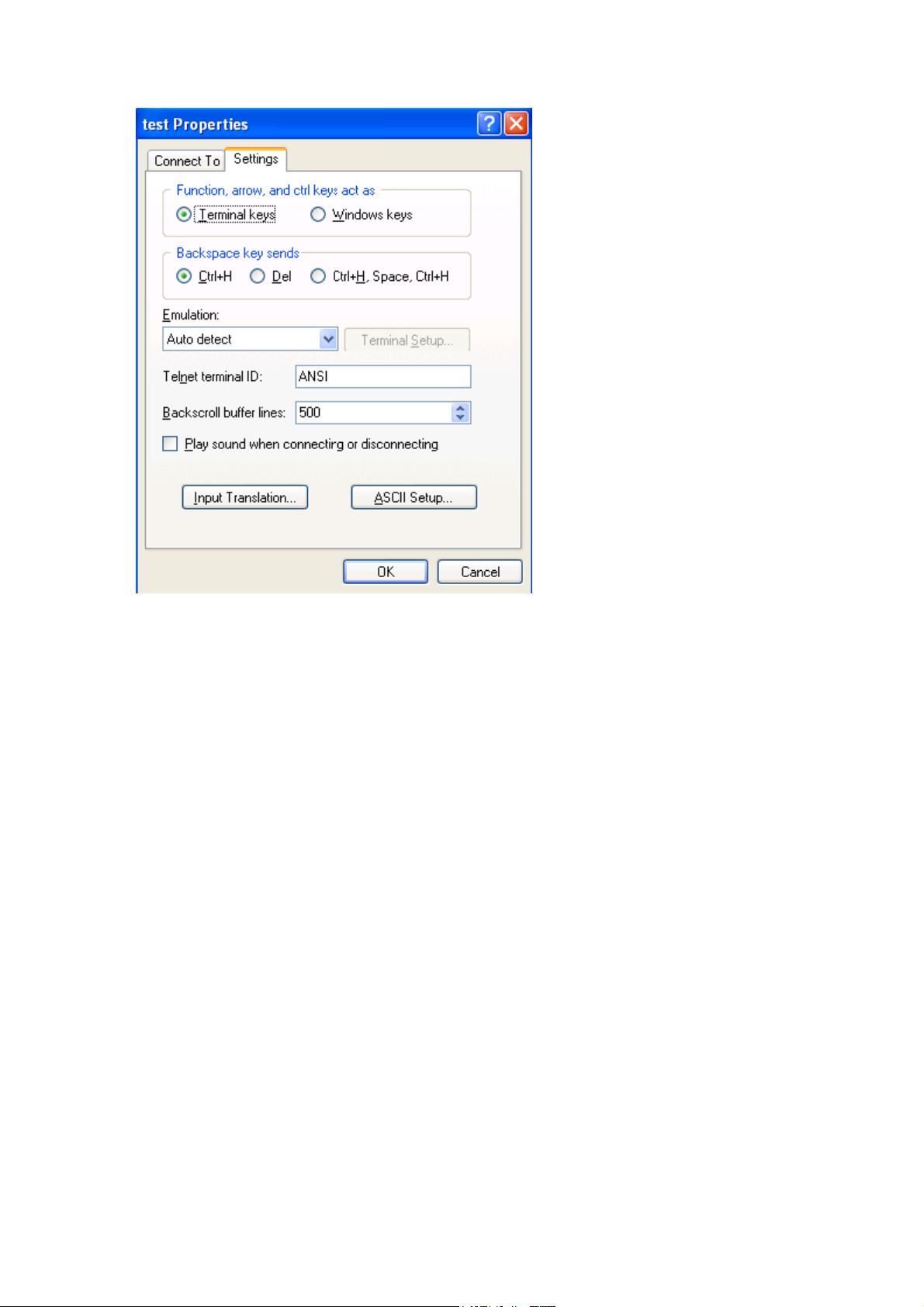

Step5 Configure the properties of the HyperTerminal. Select File > Properties, and click the Settings tab.

Select VT100 or Auto detect from the Emulation drop-down list box and click OK.

4-3

Page 53

Figure 4-5 Set the terminal emulation

Powering On the Device

Verifying Before Power-On

Before powering on the device verify that:

z The power cable and ground cable are properly connected.

z The power supply voltage is within the range labeled on the device.

z The console cable is properly connected, the configuration terminal to be used for configuration is

running, and the terminal parameters have been set.

Boot Process