Page 1

®

User Manual

Version 1.8.3

Firmware version 1.8.3 www.2n.cz

2N

LiftNet

Lift Communicator

Page 2

The 2N TELEKOMUNIKACE a.s. joint-stock company is a Czech manufacturer and supplier

of telecommunications equipment.

The product family developed by 2N TELEKOMUNIKACE a.s. includes GSM gateways,

private branch exchanges (PBX), and door and lift communicators. 2N TELEKOMUNIKACE

a.s. has been ranked among the Czech top companies for years and represented a

symbol of stability and prosperity on the telecommunications market for almost two

decades. At present, we export our products into over 120 countries worldwide and have

exclusive distributors on all continents.

2N® is a registered trademark of 2N TELEKOMUNIKACE a.s.. Any product and/or other

names mentioned herein are registered trademarks and/or trademarks or brands

protected by law.

2N TELEKOMUNIKACE administers the FAQ database to help you quickly find information

and to answer your questions about 2N products and services. On faq.2n.cz you can find

information regarding products adjustment and instructions for optimum use and

procedures „What to do if...“.

Declaration of Conformity

2N TELEKOMUNIKACE a.s. hereby declares that the 2N® LiftNet product complies with all

basic requirements and other relevant provisions of the 1999/5/EC directive. For the full

wording of the Declaration of Conformity see the CD-ROM enclosed and at www.2n.cz.

2N TELEKOMUNIKACE company is the owner of the ISO 9001:2000 certificate. All

development, production and distribution processes of the company are managed by this

standard and guarantee high quality, technical level and professional aspect of all our

products.

Page 3

2N® LiftNet product is the holder of the Type certificate of the TÜV SÜD Czech company.

Page 4

Table of Contents

1. PRODUCT OVERVIEW.................................................................................... 7

1.1 PRODUCT DESCRIPTION ........................................................................................................................... 8

Basic Features ............................................................................................................................................ 8

Basic Description ........................................................................................................................................ 8

System Block Diagram ............................................................................................................................... 9

1.2 2N

1.3 UPGRADE AND INNOVATIONS ................................................................................................................. 15

1.4 TERMS AND SYMBOLS USED .................................................................................................................. 16

®

LIFTNET COMPONENTS AND ASSOCIATED PRODUCTS ................................................................. 12

System Components ................................................................................................................................ 12

Associated Products ................................................................ ................................................................ . 14

Symbols in Manual ................................................................................................................................... 17

Future functions ........................................................................................................................................ 17

2. DESCRIPTION AND INSTALLATION ................................................................ 19

2.1 PSTN CENTRAL UNIT ............................................................................................................................ 20

Description ................................................................................................................................................. 20

Before You Start........................................................................................................................................ 21

CU Mounting .............................................................................................................................................. 22

CU Connection .......................................................................................................................................... 22

Interruption of Operation, Battery Maintenance ................................................................................... 26

2.2 LIFT CABIN AUDIO UNIT – UNIVERSAL ................................................................................................... 27

Description ................................................................................................................................................. 27

Before You Start........................................................................................................................................ 27

Mounting..................................................................................................................................................... 28

Electric Installation .................................................................................................................................... 30

2.3 LIFT CABIN AUDIO UNIT – COMPACT ..................................................................................................... 36

Description ................................................................................................................................................. 36

Before You Start........................................................................................................................................ 37

Mounting..................................................................................................................................................... 39

Electric Installation (Earlier HW) ............................................................................................................. 40

Electric Installation (Later HW) ............................................................................................................... 40

CANCEL Input Connection (Door Contact, Optional).......................................................................... 44

Mounting Completion ............................................................................................................................... 45

2.4 AUDIO UNIT – MACHINE ROOM .............................................................................................................. 47

Description ................................................................................................................................................. 47

Before You Start........................................................................................................................................ 48

Page 5

Mounting..................................................................................................................................................... 48

Electric Installation .................................................................................................................................... 49

2.5 AUDIO UNIT – LIFT SHAFT / CABIN ROOF .............................................................................................. 51

Description ................................................................................................................................................. 51

Before You Start........................................................................................................................................ 52

Mounting..................................................................................................................................................... 52

Electric Installation .................................................................................................................................... 52

3. CONFIGURATION........................................................................................ 55

3.1 LN PROGRAMMING ................................ ................................ ................................................................ . 56

PSTN Programming ................................................................................................................................. 56

3.2 PARAMETER CHART (FW V. 1.8.0) ........................................................................................................ 59

PC Configuration ....................................................................................................................................... 64

How to Record User Messages and Numbers ..................................................................................... 65

4. FUNCTION AND USE ................................................................................... 67

4.1 USER INSTRUCTIONS .............................................................................................................................. 68

Audio Unit - Lift Cabin .............................................................................................................................. 68

Audio Unit - Lift Shaft / Cabin Roof ........................................................................................................ 68

Audio Unit - Machine Room .................................................................................................................... 69

4.2 DISPATCHING CENTRE INSTRUCTIONS .................................................................................................. 70

ALARM Call ............................................................................................................................................... 70

Dispatching Centre – Lift Call ................................................................................................................. 70

ALARM Call - Intercom ............................................................................................................................ 71

Setting Machine Room Audio Unit Number .......................................................................................... 72

Tone Dialling Control during Call – Complete List of Commands ..................................................... 73

4.3 FIREMAN FUNCTION ................................................................................................................................ 74

Description ................................................................................................................................................. 74

Use .............................................................................................................................................................. 74

Setting......................................................................................................................................................... 74

4.4 FUNCTION DESCRIPTION (FOR ADVANCED USERS) .............................................................................. 75

Purpose of Section ................................................................................................................................... 75

Outgoing Call ............................................................................................................................................. 75

Machine Room Call .................................................................................................................................. 75

Triphony ..................................................................................................................................................... 76

Checking Call ............................................................................................................................................ 76

Incoming Call ............................................................................................................................................. 76

Call Sequencing ........................................................................................................................................ 77

Automatic Dialling of Multiple Numbers with Confirmation ................................................................. 78

Automatic Redialling of Multiple Numbers without Confirmation ....................................................... 79

Automatic Call Receiving ......................................................................................................................... 79

Page 6

Survey of Messages ................................................................................................................................. 80

Call End (Outgoing / Incoming Calls) ..................................................................................................... 80

Use of Switches ........................................................................................................................................ 80

5. MAINTENANCE .......................................................................................... 83

5.1 BATTERY MAINTENANCE ................................................................ ........................................................ 84

Interruption of Operation .......................................................................................................................... 84

List of Battery Endangering Situations .................................................................................................. 84

Battery Pack Replacement ...................................................................................................................... 85

5.2 FIRMWARE UPGRADE ............................................................................................................................. 86

Procedure................................................................................................................................................... 86

6. TECHNICAL PARAMETERS ........................................................................... 87

6.1 TECHNICAL PARAMETERS ...................................................................................................................... 88

Telephone Parameters ............................................................................................................................ 88

Other Parameters ..................................................................................................................................... 89

7. SUPPLEMENTARY INFORMATION .................................................................. 91

7.1 REGULATIONS ......................................................................................................................................... 92

7.2 TROUBLESHOOTING ................................................................................................................................ 93

FAQ ............................................................................................................................................................. 93

7.3 LIST OF FIGURES .................................................................................................................................... 94

7.4 GENERAL INSTRUCTIONS AND CAUTIONS .............................................................................................. 95

Electric Waste and Used Battery Pack Handling ................................................................ ................. 96

Page 7

1

In this section, we introduce the 2N® LiftNet product, outline its application options

and highlight the advantages following from its use.

Here is what you can find in this section:

Product Description

2N

Changes

Terms and Symbols Used

®

LiftNet Components and Associated Products

7

Page 8

Product Description

1.1

1.1 Product Description

Basic Features

Up to 8-lift connectivity

Lift cabin, shaft and machine room audio units

Minimisation of interconnecting wiring

Excellent acoustic features

In-built back-up battery pack

Easy control and programming – voice menu

Checking call function

Lift blocking option during connection failure

Internal communication – triphony

Telephone/PC-based programming

USB port

User message recording option

Local dispatching option (Intercom)

Fireman function

Basic Description

2N® LiftNet (LN) is a communication system similar to the intercom. The audio units

are connected (through a pair of conductors) to a common bus, to which one central

unit (CU) is connected. The CU controls the system operation and provides connection

to the dispatching office. Up to 32 audio units can be connected to the bus.

Each audio unit is uniquely identified: by lift number 1 to 8 and position: shaft bottom,

cabin interior, cabin roof and machine room. The machine room audio unit can be

shared by multiple lifts.

The CU is supplied with 12V DC. It contains an easily replaceable back-up accumulator

battery pack (4 AA Ni-MH cells in a holder). The CU is responsible for battery charging

and status monitoring. It indicates the charging status, telephone line status and

current communication by means of three colour LEDs. It is also equipped with a USB

port to provide comfortable parameter setting, voice message recording and software

upgrade.

8

Page 9

Product Description

1.1

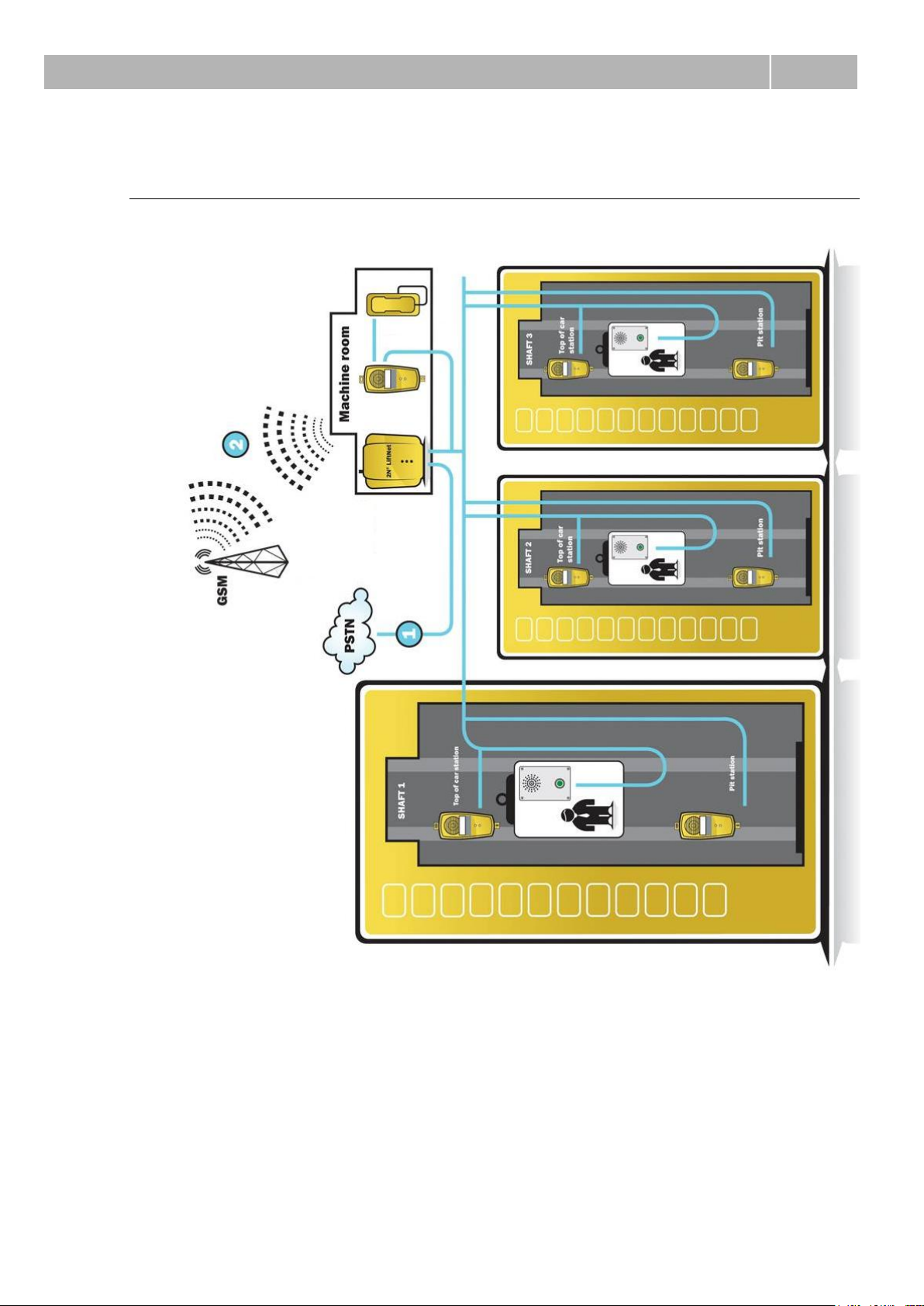

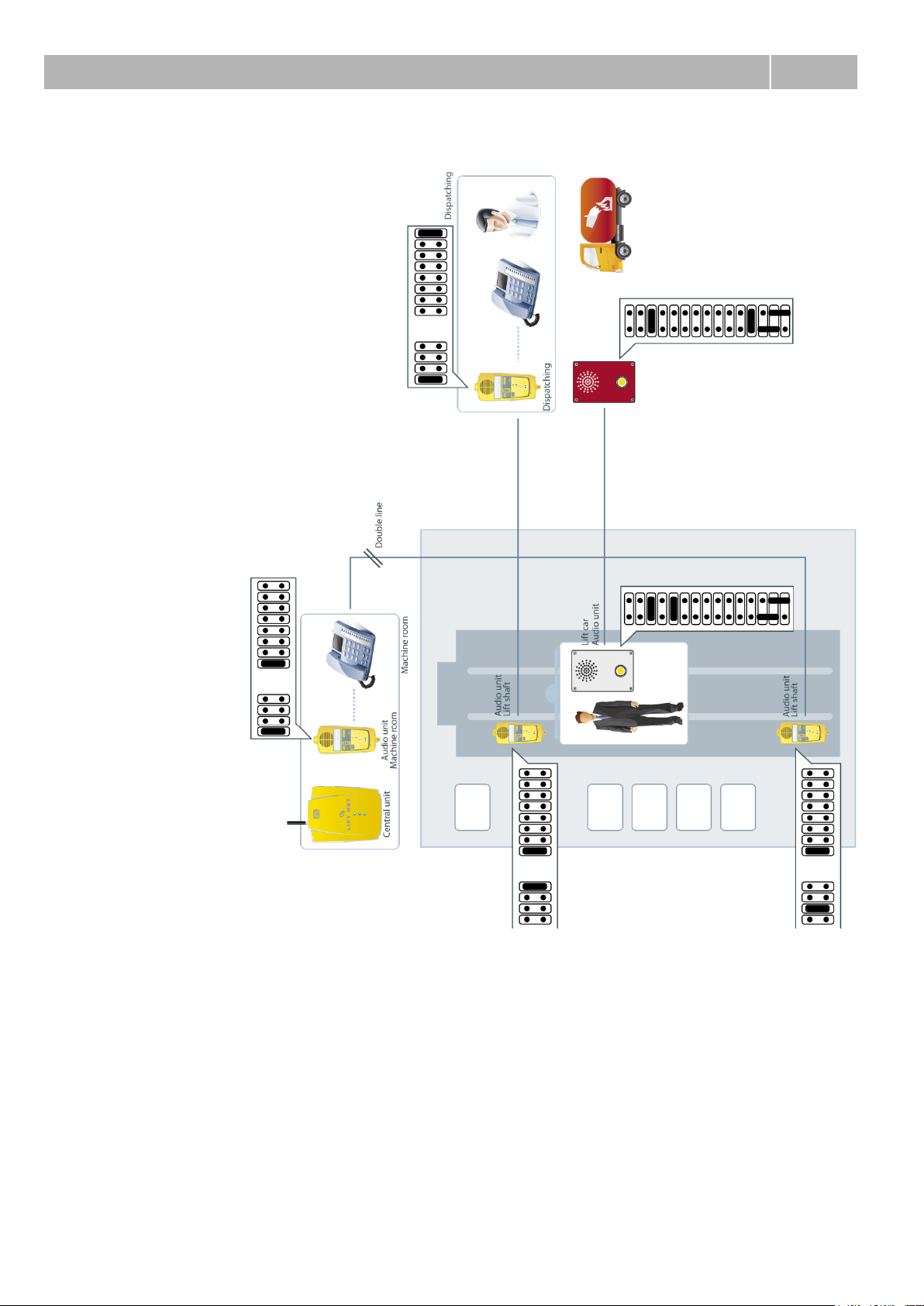

System Block Diagram

Figure 1.1 Example of Connection of PSTN CU and 3 2N® LiftNet Audio Units

9

Page 10

Product Description

1.1

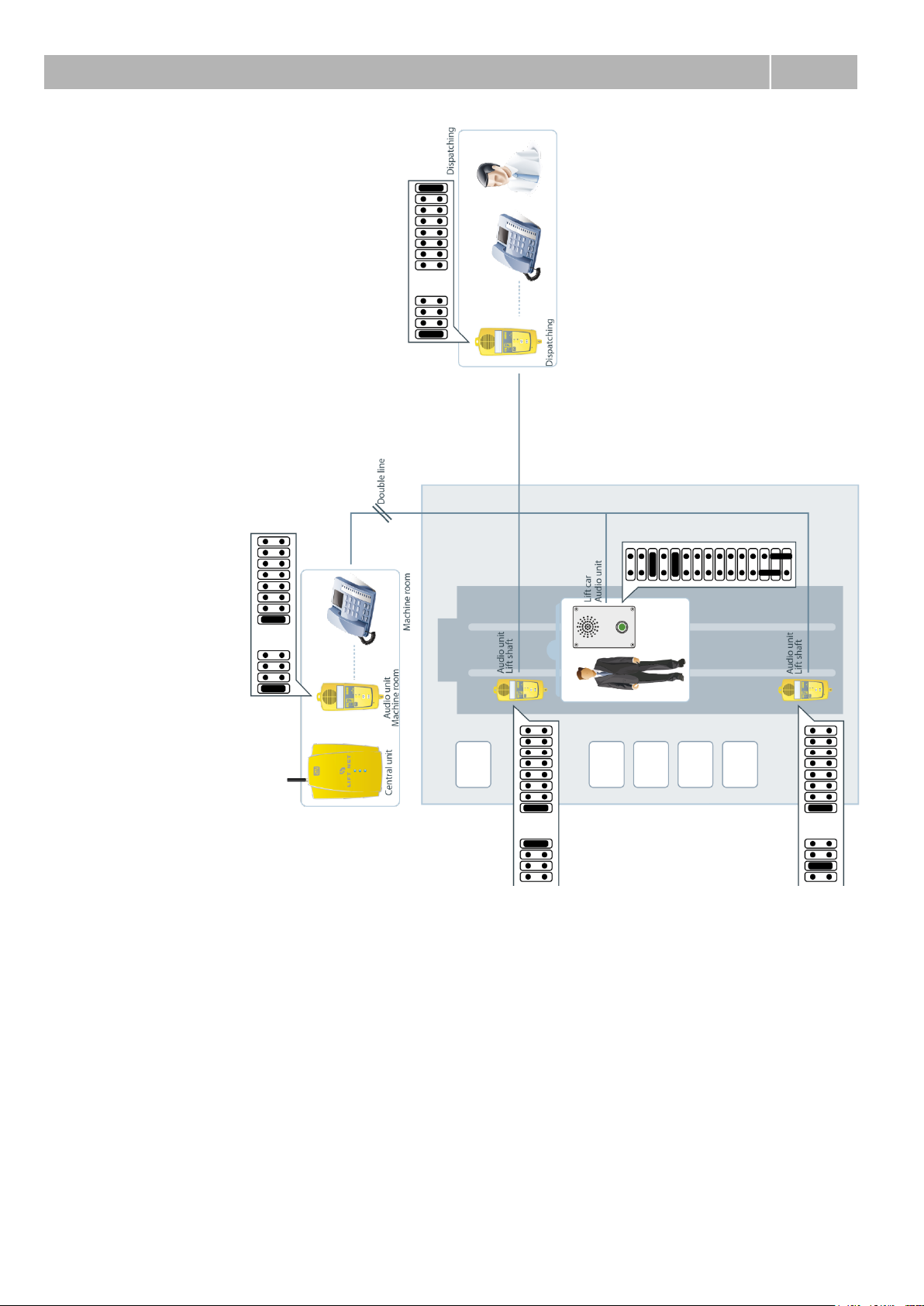

Figure 1.2 Example of CU and 2N® LiftNet Local Dispatching Audio Unit Connection

10

Page 11

Product Description

1.1

Figure 1.3 Example of Fireman Connection in 2N® LiftNet

11

Page 12

2N® LiftNet Components and Associated Products

1.2

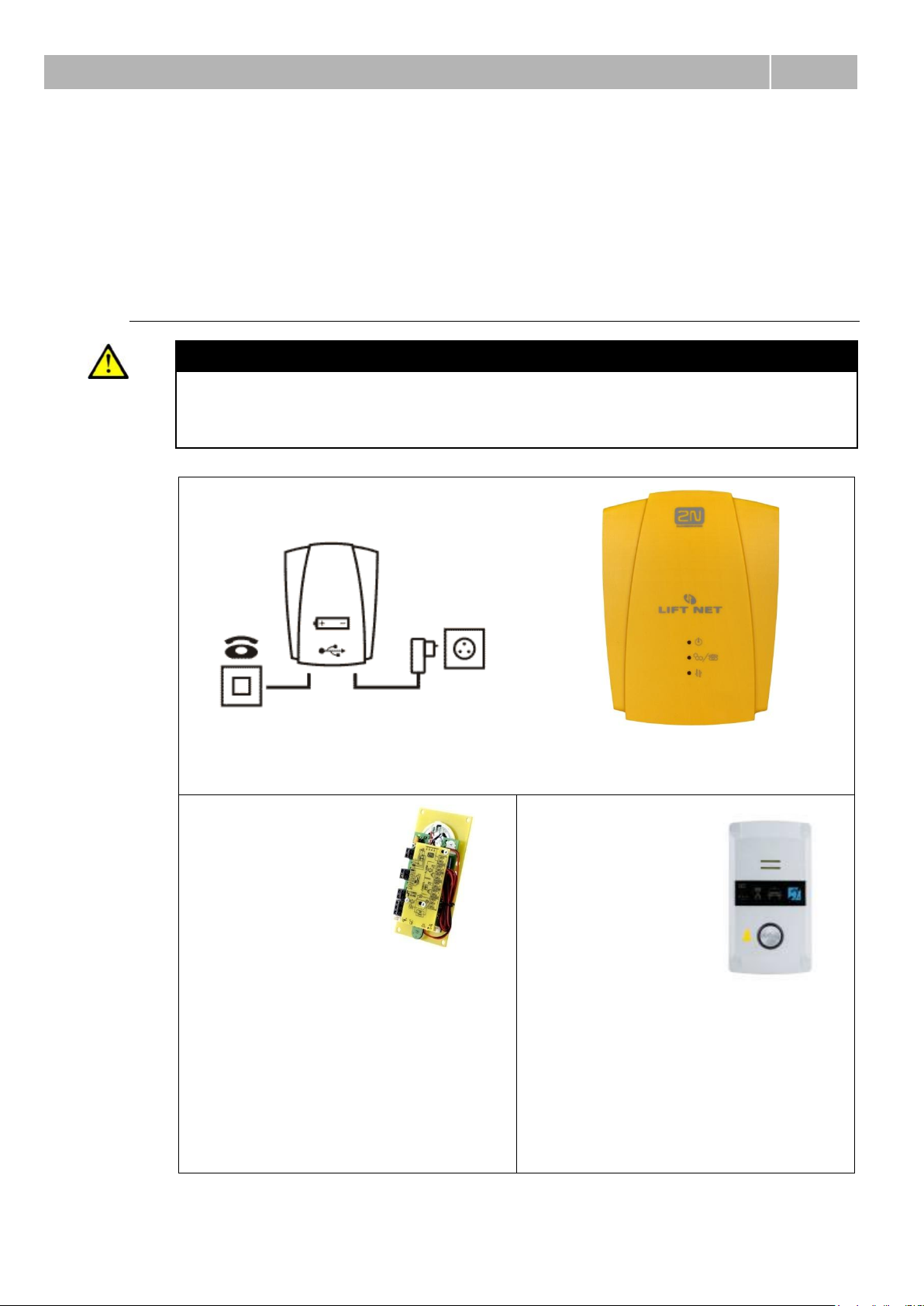

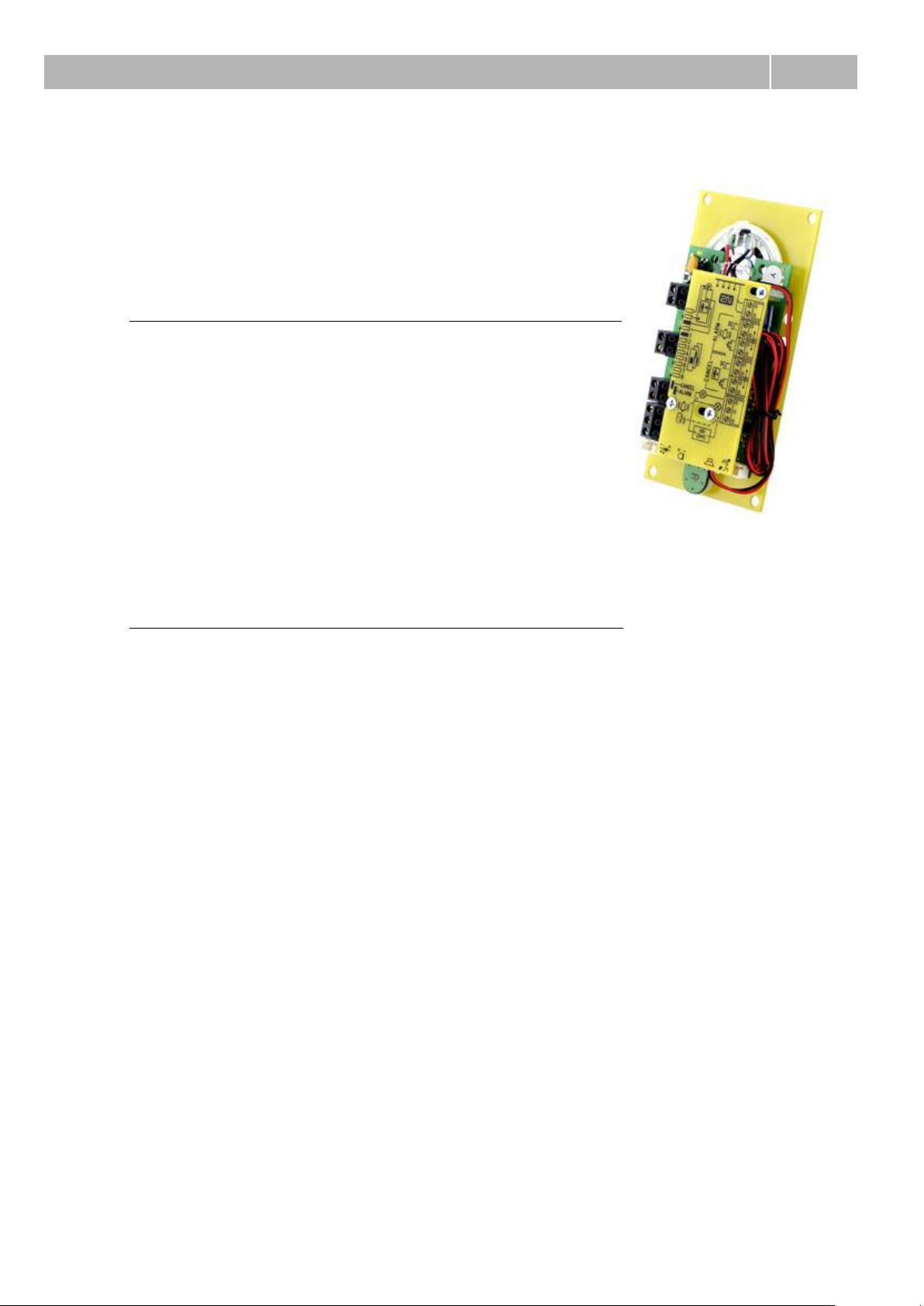

913600E

2N® LiftNet PSTN Central Unit

Enables to connect up to 8 lifts to an analogue PSTN or PBX line. Including a power

supply adapter and accumulator battery pack. A USB port for programming

configuration.

913610E

2N® LiftNet

Lift Cabin Audio

Unit – Universal

913613E

2N® LiftNet

Lift Cabin Audio

Unit – Compact

Audio unit electronics for lift cabins.

Including loudspeaker and microphone

(HandsFree). Necessary terminals and

door opening signal input (not optional).

A robust, metal-encased audio unit,

provided with an ALARM button of the

prescribed size, including indicators for

blind people and backlit pictograms

(hardened glass).

Easy wall surface mounting, 16-mm

thickness only. Easy installation (paired

wire connection).

1.2 2N® LiftNet Components and Associated

Products

System Components

Caution

The 2N

only.

The audio units cannot be connected to a telephone line without the CU!

®

LiftNet system components can be used within the LN system

12

Page 13

2N® LiftNet Components and Associated Products

1.2

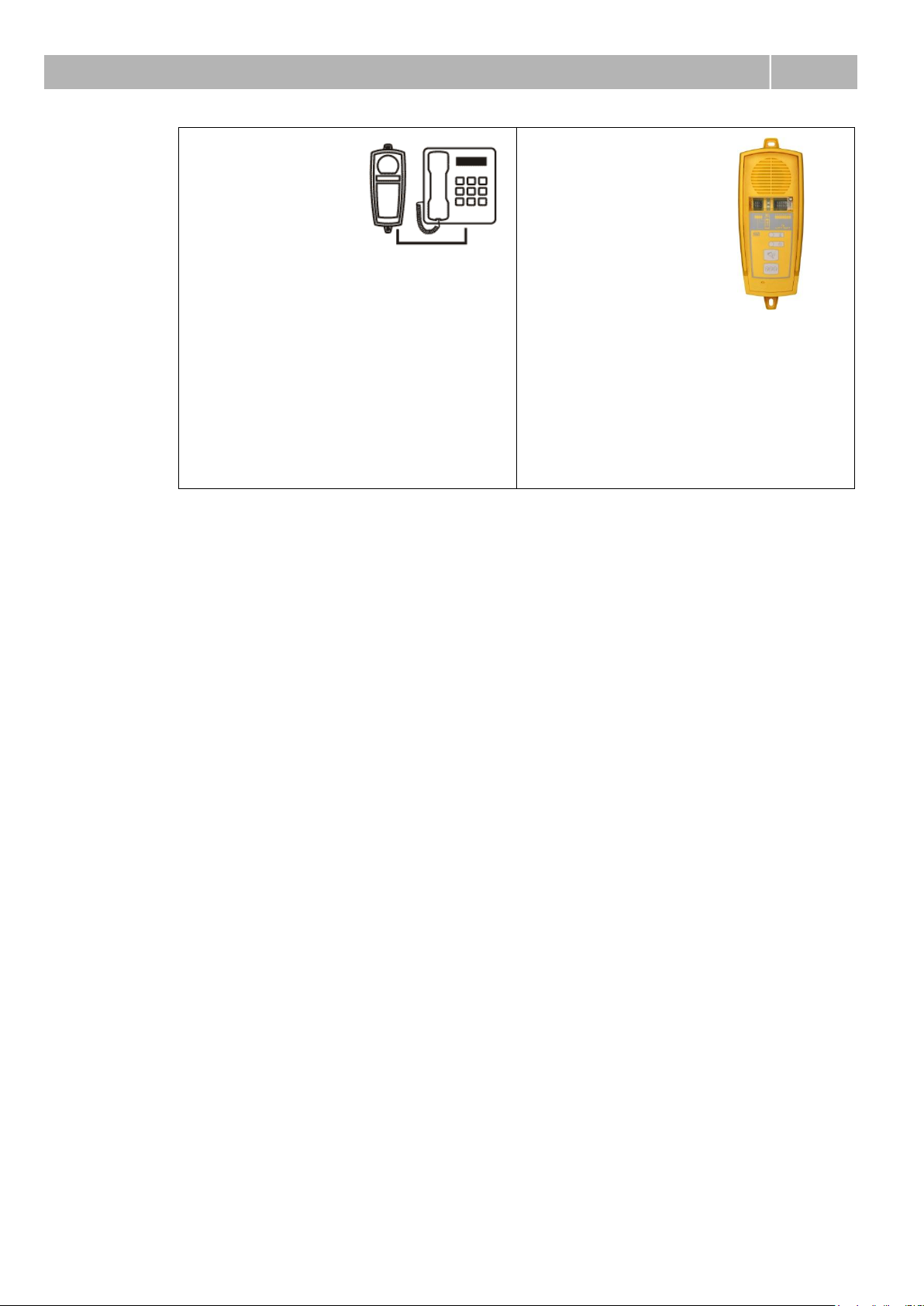

913611ESET

2N® LiftNet

Audio unit –

machine

room/dispatching

913612E

2N® LiftNet

Audio unit –

lift shaft

Audio unit for machine

rooms/dispatching, including siren and

standard telephone set. Helps

communicate with any audio unit in the

system and program the CU without a

PC. Equipped with a lift blocking contact

in case LN fails to call for help. Can be

programmed as a multiple-lift

communicator. A robust yellow cover.

Audio unit to be installed in the lift shaft

or upon the lift cabin roof. A robust

yellow cover. HandsFree mode, ALARM

and TRIPHONY buttons, indication

elements. Not intended for cabin use.

13

Page 14

2N® LiftNet Components and Associated Products

1.2

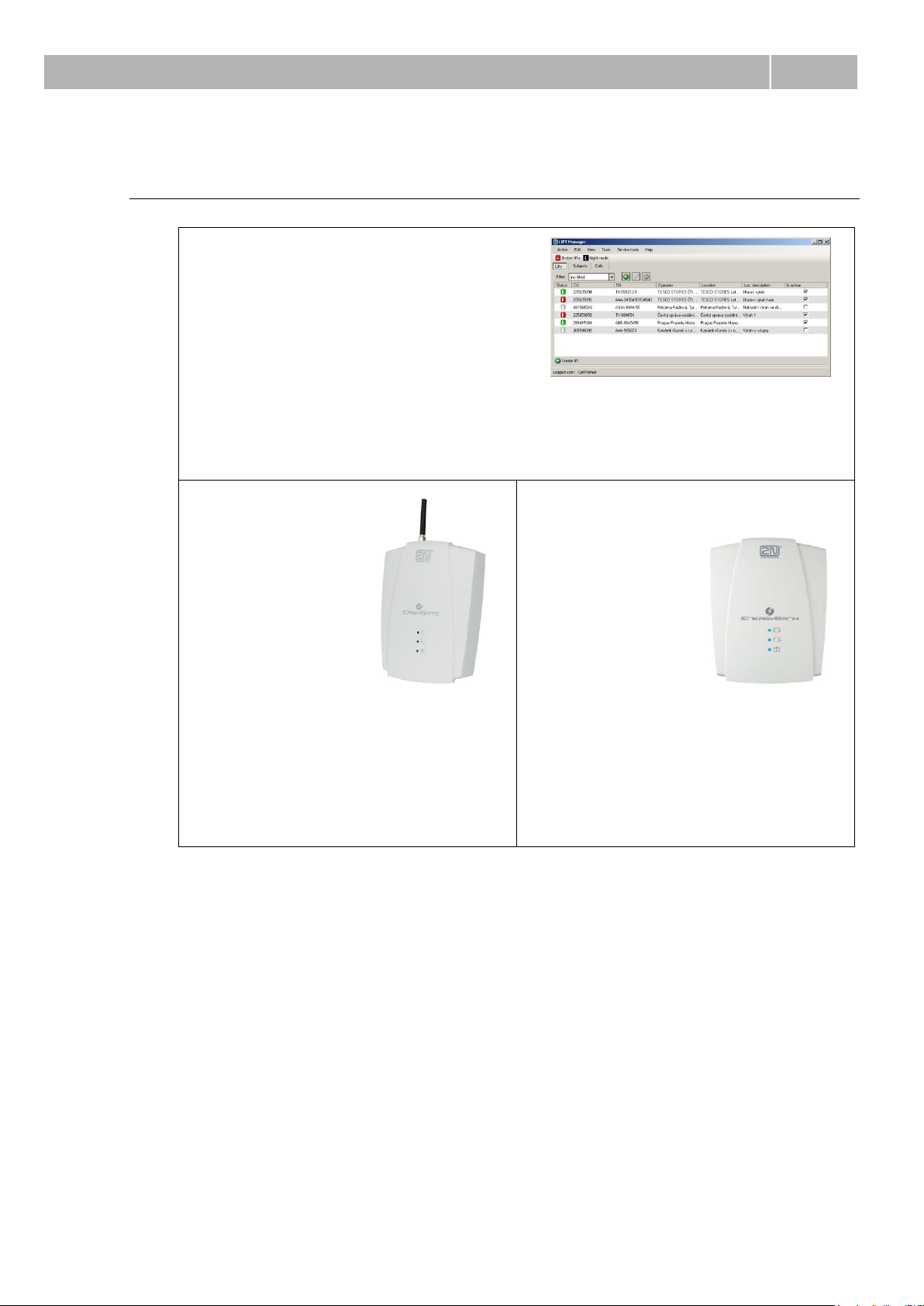

913630E

2N® LiftManager

The 2N® LiftManager system is intended for remote monitoring, control and

communication with 2N® LiftNet, 2N® EasyTalk and 2N® SingleTalk units. Part of the

2N® LiftManager installation is Service Tool application which is aimed to manage

configurations of available devices (2N® LiftNet units). 2N® LiftManager is intended

for use by companies (or individuals) who install or maintain lifts.

501300E

2N® EasyGate

GSM Solution for

2N® LiftNet and

2N® SingleTalk

501399E

2N® EnergyBank

Backup power

supply for GSM

gateway

PSTN line replacement.

Simple installation without programming.

Back-up power source in case of power

supply failure.

Simple installation.

Associated Products

14

Page 15

Upgrade and Innovations

1.3

Manual

version

Upgrade an innovations

1.8.0

In firmware 1.8.0

New Fireman function (fire call setup from the Fire Station to the

cabin in the shaft with the lowest address)

1.7.0

In firmware 1.7.0

New Alarm – intercom function (alarm call setup to the machine

room audio unit)

This new function can also be used for setup of a checking call to

the machine room audio unit

1.6.0

In firmware 1.6.0

Added parameter 932 (cabin audio unit loudspeaker volume

control for alarm and incoming calls)

1.5.8

In firmware 1.5.8

Added Italian voice menu

Support of new audio units - 913613E and 913613WBE

1.5.5

In firmware 1.5.5

Added parameter 990 (System settings)

Automatic restart of audio units for CU – audio unit communication

monitoring (WatchDog)

1.5.2

In the manual

Modified description in Subs. 2.5 Audio Unit - Machine Room

In firmware 1.5.2

New voice menu

Added system messages (page 59)

Shorter timeout for the first “Wait please” message after

emergency call activation

Added parameters 978, 979

New default value for parameter 914 (delayed call set to 0

seconds, CANCEL still active)

1.3 Upgrade and Innovations

15

Page 16

Terms and Symbols Used

1.4

LN

2N® LiftNet

CU

Central unit of the system, typically shared by multiple lifts in a

building

Audio unit

Voice communication unit for lift communication with the

dispatching office or another system unit

System

Central unit interconnected with a group of audio units by a bus

Bus

A pair of conductors interconnecting the CU and all system audio

units

Incoming call

dispatching office-to-CU call

Outgoing call

CU-to-dispatching office call

Checking call

Automatically activated CU-to-dispatching office call

Triphony

Internal communication between audio units, typically all audio units

of one and the same lift, during repairs or rescue work

Dispatching

office

Receives emergency calls, checking calls and, if necessary, lift

failure reports. Separate dispatching offices can be responsible for

different types of calls and mobile telephones can be used too.

LM,

LiftManager

Supervisory software designed for small and medium-size lift

supervising companies. Automatic receiving of checking calls.

Comfortable programming of CU parameters.

DISA

Automatic voice menu, which helps route incoming calls to the

required audio unit or activate additional functions, e.g. remote

programming

ESS

Electronic Security System

PBX

Private branch exchange (equipped with PSTN interface and local

analogue lines)

PSTN

Public switched telephone network. For simplification, it is assumed

that the CU is connected to the PSTN although it works on the PBX

line too in the same way.

1.4 Terms and Symbols Used

16

Page 17

Terms and Symbols Used

1.4

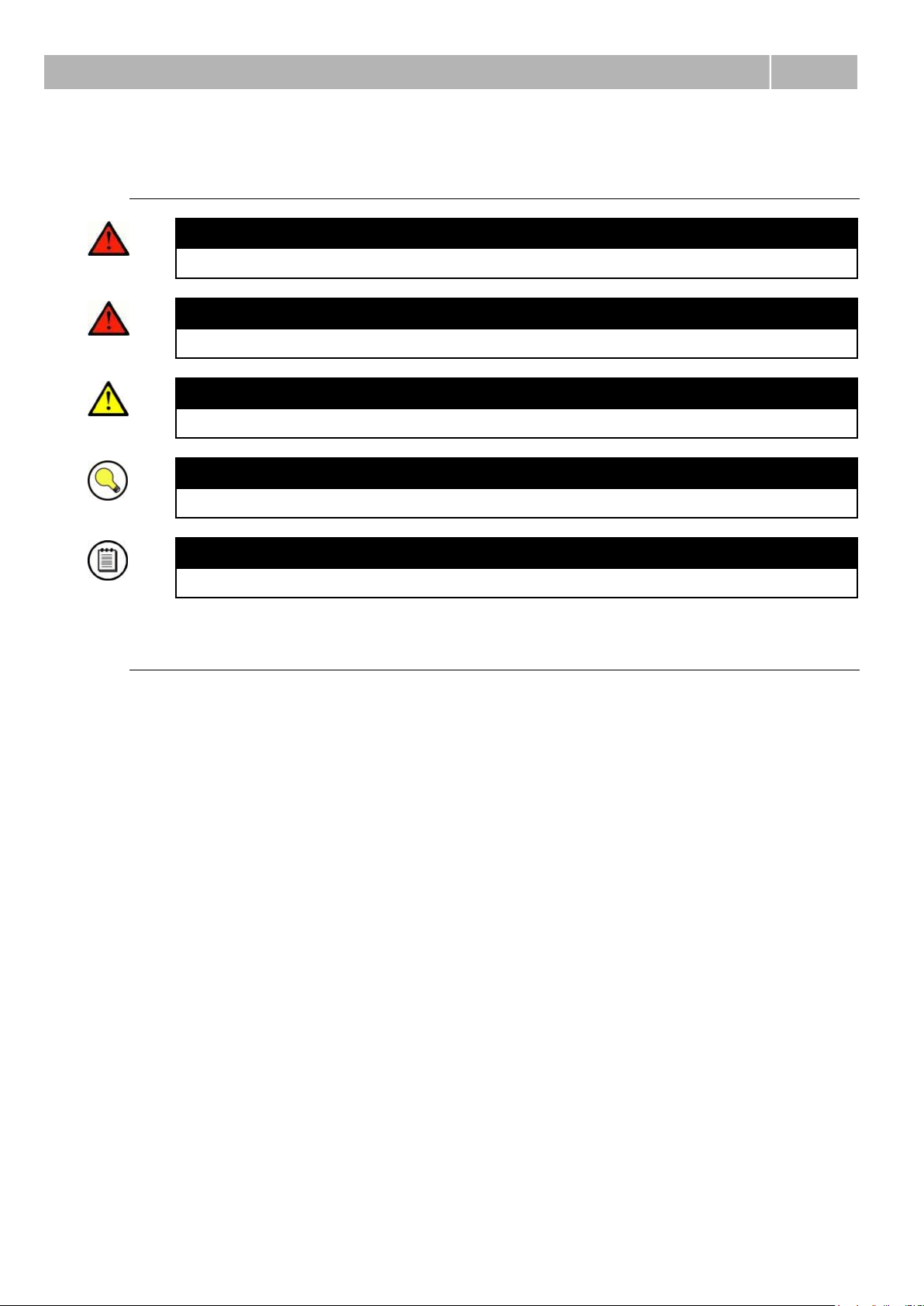

Symbols in Manual

Safety

Always abide by this information to prevent persons from injury.

Warning

Always abide by this information to prevent damage to the device.

Caution

Important information for system functionality.

Tip

Useful information for quick and efficient functionality.

Note

Routines or advice for efficient use of the device.

Future functions

The grey-marked text in this document designates the functions and features that are

under preparation or development at present.

17

Page 18

Page 19

2

Installation

The section is divided according to system components into the following subsections:

PSTN Central Unit

Lift Cabin Audio Unit – Universal

Lift Cabin Audio Unit – Compact

Audio Unit – Machine Room

Audio Unit – Lift Shaft / Cabin Roof

LN Programming

Each subsection includes:

Component Description

Before You Start

Mounting

Electric Installation

19

Page 20

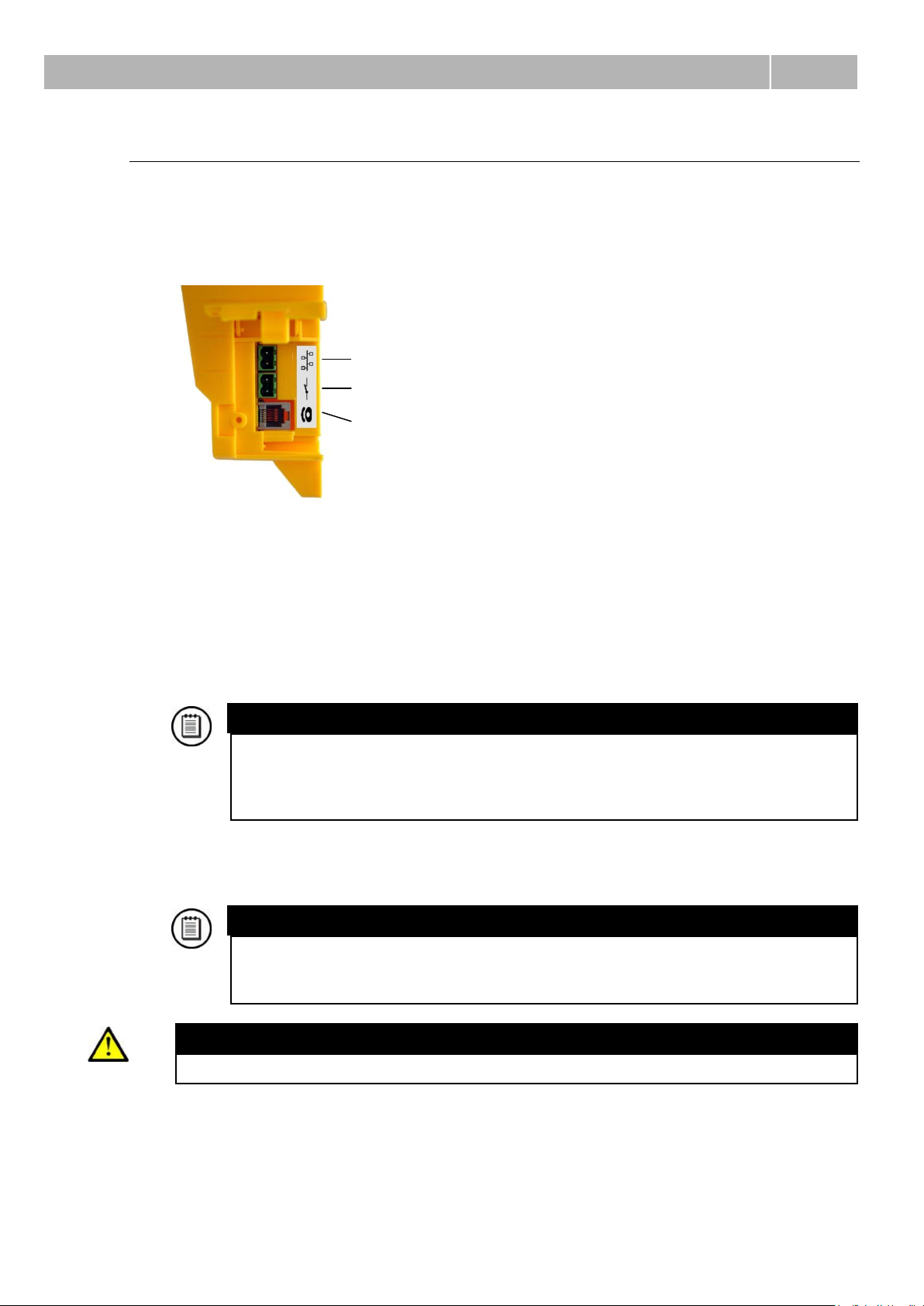

PSTN Central Unit

2.1

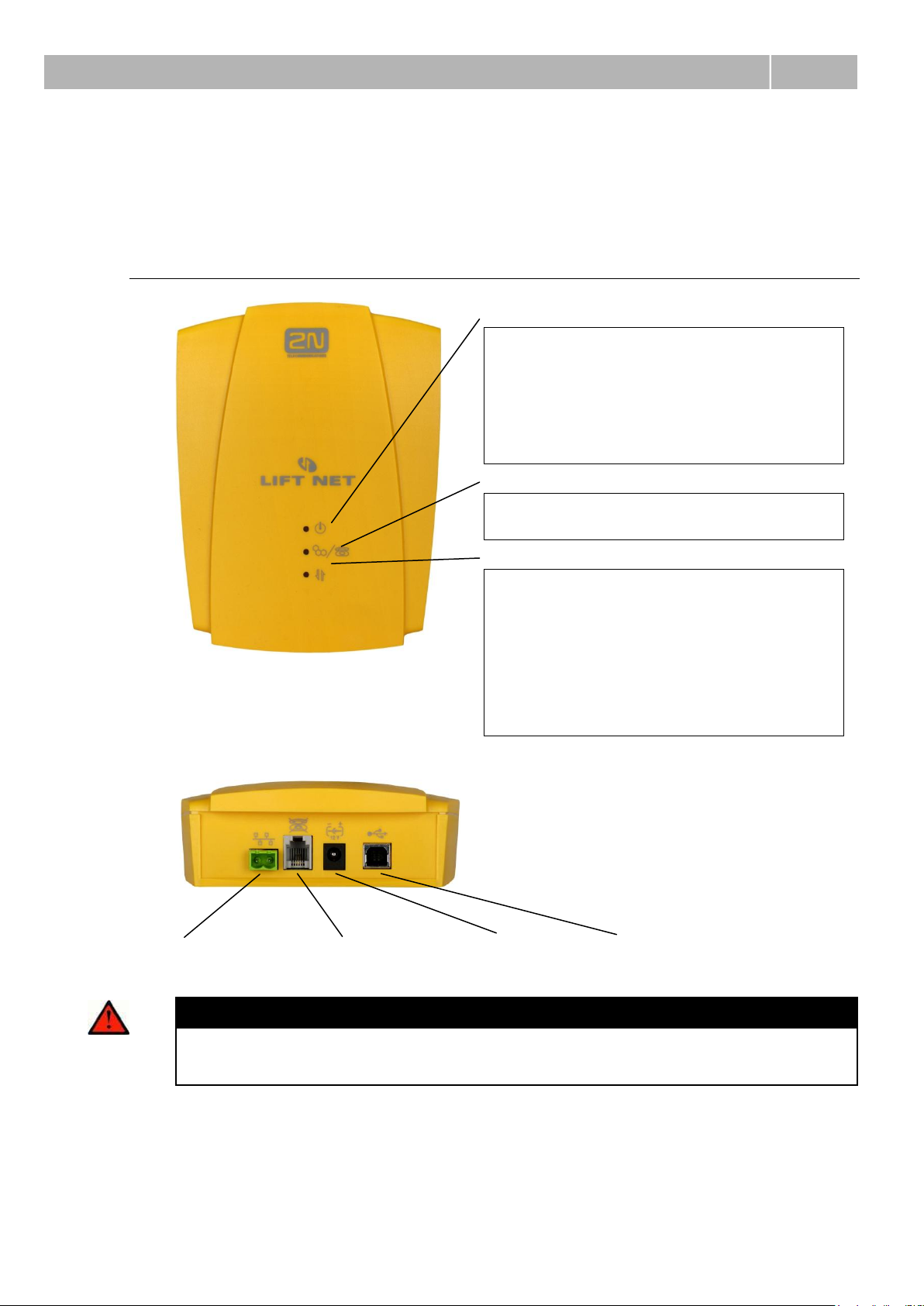

Green

OK (battery full)

Green flashing

Battery charging

Red

Battery failure

Off

Power failure, more than 1 hour of

operating time remains

Red flashing

Power failure, less than 1 hour of

operating time remains

Red flashing after

power up

Audio unit FW upgrade proceeding

Green

Line OK, ready (on-hook)

Green flashing

Line picked up (off=hook, call)

Red

Line failure (no dialtone)

No light

Relax (ALARM reset)

Yellow

ALARM activated (calling)

Green

Call confirmed (ALARM

announced) / Fireman activated

Green flashing

Incoming call

Yellow flashing

Triphony

Fast green flashing

Programming from dispatching office

Fast yellow flashing

Alternate

yellow/green

flashing

Programming from machine room

Bus busy

Bus connector

(to audio units)

Telephone line

connector

Supply

connector

USB connector

(for programming, upgrading etc.)

Figure 2.2

Central Unit

Connectors

Figure 2.1

Central Unit

LED Indicators

2.1 PSTN Central Unit

Description

Power supply

Telephone line

Communication

Warning

Do not open the CU during the warranty period.

Later, open for battery replacement only.

20

Page 21

PSTN Central Unit

2.1

Before You Start

CU installation conditions

The CU is not designed for outdoor applications.

Do not mount the CU onto vibration-producing machines.

Install the CU vertically to allow air flow for cooling purposes (never cover the

CU with any cloth or install it in another closed box).

You may install the CU into the lift switching board unless the temperature

exceeds the acceptable limit.

The CU may be operated in the lying position on a desk at the room

temperature of up to 25 °C.

Product Completeness Check

Check the product for completeness before installation please:

1 central unit

1 terminal – inserted on the bus connector

1 accumulator battery isolation tape is present (sticking out of the cover)

1 power supply adapter conforming 12V DC to the local power network

requirements

1 telephone cable with RJ terminals

2 wall dowels

2 dowel screws

1 manual, either in the printed or CD format

warranty certificate

Checking of Accumulators

Instructions

1. Completely pull out the tape that sticks out of one opening on the back side of

the CU. This tape protects the inserted accumulators against discharging

during storage. With this tape it is possible to store the product (if supplied

including batteries) ½ year since the shipping date, which is indicated on the

packaging. After this period the claims, if any, regarding the battery warranty

cannot be accepted.

2. Do not connect anything to the CU and if any control lamps light up after the

tape has been removed wait a few seconds until they turn off.

3. Now watch the “power” control lamp on the CU carefully for a few seconds (not

in direct sunlight because the flashing is not strong):

21

Page 22

PSTN Central Unit

2.1

a. Weak and short green flashing

The battery is OK and fully charged, you may continue with the

installation. If the product was stored for longer period than ½ year, or

under temperature exceeding 25 °C proceed according to paragraph b.

Caution

The product needs to be put in operation after the tape

has been removed.

It can be stored no longer than one week without charging; after having

been fully charged no more than 1 month.

b. Weak and short red flashing

Some battery cells are discharged. In such case connect the 12V DC

power adapter (do not connect any audio units!) and let the CU charge

for at least 24 hours, even after the indicator has starting showing that

the battery is charged. This is a so-called compensatory cycle, which

balances out the condition of the individual cells after a long period of

storage.

c. No flashing

The battery is fully depleted and may be damaged. Replace the battery

with a new recommended type (SANYO Eneloop 2000).

4. You may now install the CU.

CU Mounting

It is recommended to install the CU in a room that is secured against unauthorised

persons, such as the lift machine room, switching station etc. On an easily accessible

place there is a risk of telephone line misuse or SIM card misappropriation (in the GSM

version).

Mount the CU onto a wall using the attached dowels and screws.

CU Connection

Supply

Use the included adapter or a 12V DC power supply with appropriate parameters

(stabilised).

Warning

Never use an AC or non-stabilised DC power supply to avoid CU

damage.

22

Page 23

PSTN Central Unit

2.1

Bus Connection

Requirements

With multi-wire cables, always use a symmetrical twisted pair of conductors

(i.e. those that match each other). Standard UTP cables contain twisted pairs.

With special cabling (in the cabin), use the adjoining cables and make sure

that the nearest neighbouring conductors do not radiate interference (power

cables, video signals, etc.).

Recommendations

Do not lead the bus close to power cables, especially in long-distance

sections.

Branch the bus to shorten the total length of sections.

Safety

The bus is electrically isolated from the telephone line circuits according to

the EN60950 standard requirements and its low voltage cannot cause any

electrical accident.

CU Connection to Telephone Line

LN works in a wide range regardless of polarity and line parameters (refer to Technical

parameters). Connect it using the attached cable with an RJ-12 terminal.

Caution

One CU may be connected to one telephone line only and no other

telephone terminal equipment may be connected to this line.

2N

No double or group serial lines may be used.

No telephone “multiplugs”, even the “intelligent” ones, may be used.

Never connect LN to an ISDN line.

CU telephone network connection options

There are four connection options:

PSTN line

PBX line

®

LiftNet requires the telephone line exclusively for itself. This means

that NOT even a system through which the telephone line goes (priority

connection, ESS, e.g.) may be connected to this telephone line.

GSM gateway

VoIP adapter

23

Page 24

PSTN Central Unit

2.1

Direct PSTN Connection

This is the simplest and most reliable type of connection. High operational costs (flat

rate costs) are a drawback of this solution.

Telephone line requirements

No double or group serial line.

The telephone socket including cabling is a property of the telecom company

and may not be tampered with.

Other recommendations

Notify the telephone network provider of your LN installation and submit

certification upon request.

Your follow-up cabling has to meet all applicable safety regulations.

You are recommended to secure your cabling physically against piracy (with a

telephone lock, e.g.).

PBX Connection

This is the least-cost solution where a PBX and an unused PBX line are available.

PBX line requirements

The PBX to be used must work reliably even in the case of power outage.

Large PBXs are mostly equipped with a back-up power supply, smaller PBXs

usually use PSTN line redirection in the event of power failure. Consult the

problem with the technician responsible for your PBX. An error during power

outage may result in LN calling an undesired station.

Relevant call access rights have to be assigned to the PBX line to be used (use

a standard telephone set to check whether the line can make calls to all

required „external”/CO line numbers).

While programming, enter all necessary PSTN prefixes (typically a zero), or

(which is a better solution) make the PBX not require a prefix (so-called

automatic CO line seizure).

To make dispatching office–lift calls, you have to know the extension number

and how to get through to it (dial-in, DISA, operator).

The dispatching office–lift connection may not depend on the operator’s

presence, no call redirection to a fax machine in the night mode is allowed,

etc.

Other recommendations

Make an agreement with the PBX owner regarding operating costs (LN outgoing calls

are billed at the owner‘s expense with the exception of free calls on “green lines”).

Tip

Where a non-stop security or porter’s service is available, the personnel

can be trained in rescue operations and LN can be programmed to call this

service.

24

Page 25

PSTN Central Unit

2.1

GSM Gateway Connection (Temporary – Substitutes the GSM CU

Version, Part No. 501303E)

Used wherever no fixed telephone line is available.

Requirements

The GSM gateway has to be functional even in the case of power outage.

The GSM gateway has to recover its function without requiring the PIN.

Other requirements

Find a suitable place or use a special (directional) antenna where the GSM

signal quality is poor.

Secure the GSM gateway SIM card against misappropriation.

With a pre-paid SIM card, monitor the credit use and on-time replenishing.

VoIP Adapter Connection

This is the cheapest solution where a reliable Internet connection is available.

Requirements

The entire system has to be functional even in the case of power outage.

Other recommendations

As the VoIP technology is rather complicated, make sure that the dispatching

office personnel monitor connectivity reliably (evaluate the checking calls).

Tip

Some VoIP adapters have two independent telephone lines. A majority of

subscribers use just one line and the other line is thus available “free of

charge”.

Operation without Telephone Line

LN can be used as an intercom during lift assembly work even without a telephone

line. In that case, make sure that the lift blocking function is not activated until the

telephone line has been connected.

USB Port Connection

Recommendations

Do not leave a PC connected for a long time unless necessary in order to minimise risk

of PC damage due to HV shock from the telephone line during storms, e.g.

25

Page 26

PSTN Central Unit

2.1

Interruption of Operation, Battery Maintenance

Caution

Never leave the batteries discharged for unnecessarily long periods.

If the battery is fully discharged please recharge it as soon as possible.

For a detailed description of situations that require your attention due to the state of

accumulators during interruption refer to the Maintenance section. Remember that

the state of accumulators is essential for system operation in any case. The

Maintenance section also contains instructions for accumulator maintenance, including

replacement.

26

Page 27

Lift Cabin Audio Unit – Universal

2.2

Figure 2.3 Lift Cabin

Audio Unit – Universal

2.2 Lift Cabin Audio Unit –

Universal

Description

The user is not in a direct contact with this

product.

The controls and indicators depend on the

lift cabin control panel type. The indicators

(e.g. bulbs or LEDs) are working in

accordance with the applicable standards.

Address Setting – see the Installation

section for details.

Before You Start

Requirements

The panel has to be installation-ready, including loudspeaker perforation.

The panel has to be equipped with the following obligatory elements:

o ALARM button;

o Backlit symbol “Request accepted”;

o Backlit symbol “Connection established”.

The above mentioned elements have been located as required by applicable

regulations.

There must be free space of at least 65×130×20 mm behind the panel.

Product Completeness Check

Check the product for completeness before installation please:

1 board with electronics

4 terminals slid on the board pins, see the photo

4 jumpers slid on the board pins, see the cover print

1 mounting panel

1 directly/cable-connected loudspeaker

1 directly/cable-connected microphone

1 printed cover

5 tightening strips

27

Page 28

Lift Cabin Audio Unit – Universal

2.2

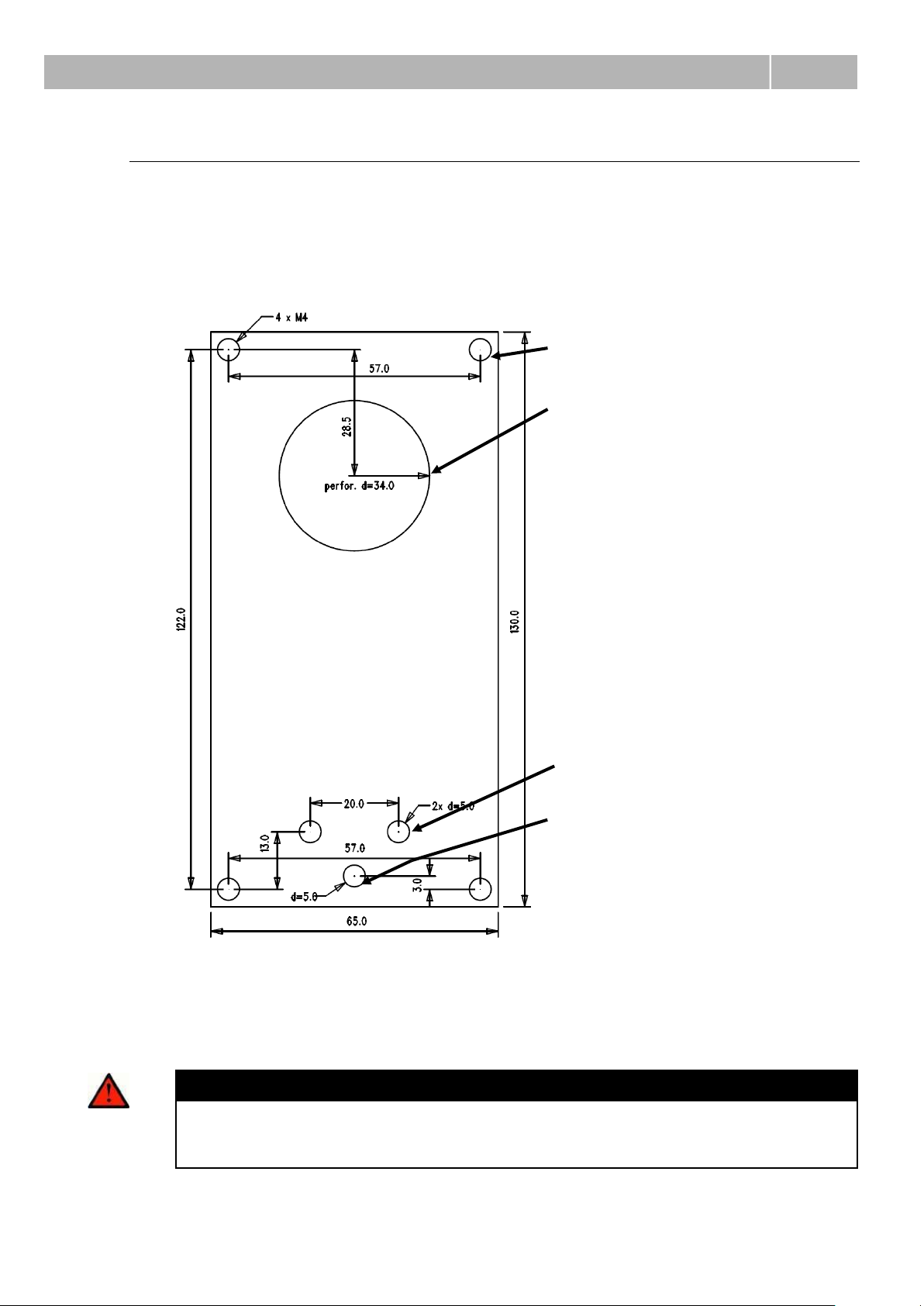

4 spot-welded M4 screws

Perforated loudspeaker area

LED holes (optional)

Microphone hole or perforation

Figure 2.4 Top View of

Mounting Hole Dimensions for

Lift Cabin Audio Unit - Universa

Mounting

Main Board Mounting

This audio unit is mounted behind the lift control panel. Typically, the panel is ready

for installation as shown in the drawing below:

To mount the audio unit, you need 4 electrically spot welded M3 or M4 screws, a

sufficiently large loudspeaker perforation area and a microphone hole on the inner

(back) side of the panel. If needed, you can fix the audio unit on a perfectly degreased

surface with a good-quality two-sided foam self-adhesive tape.

Warning

Leave no gap between the lift control panel and the audio unit surface to

avoid acoustic loudspeaker fault and acoustic loudspeaker-microphone

feedback.

28

Page 29

Lift Cabin Audio Unit – Universal

2.2

Do not use this type of audio unit in a position other than mounted on a

sufficiently large board. The acoustic properties of an uninstalled audio

unit cannot be guaranteed.

Separate Microphone Mounting

If the microphone is separated (connected by cable) it has a 25×25 mm large board

with self-adhesive foil. This helps you mount it easily behind any hole in the panel (the

minimum hole diameter is 5 mm, or a group of smaller holes of the same total area).

Just glue the microphone directly onto the required place from behind (be sure to

degrease and clean the surface carefully before!).

Requirements

The minimum distance between the loudspeaker and microphone

centres is 90 mm. A lower distance may lead to acoustic feedback. A greater

distance (within the available 1m cable) does not matter.

Make sure that the glued-on microphone does not pick up (even

partially!) the acoustic pressure from the space behind the panel.

Such sensing might result in acoustic feedback since the loudspeaker strongly

radiates sound into the cavity.

Separate Loudspeaker Mounting

The loudspeaker is equipped with a cable and can be separated from the electronics

by simply sliding it out within the reach of the cables delivered (1m). This option is

useful where there is not enough space for the whole electronic equipment. Fit the

loudspeaker according to the instructions below:

While gluing choose such procedures or adhesives that prevent membrane

damage by adhesives and volatile substances, or heat.

We recommend you to keep the loudspeaker sealed to eliminate vibrations.

Frequently Asked Questions Concerning Loudspeaker

Is it possible to use a common loudspeaker for the communicator and floor

announcing machine?

No, it is not.

May I use a loudspeaker of my own?

Yes, but make sure that the impedance is 64 Ω. By doing this you assume

responsibility for sufficient volume and frequency range.

May I place the loudspeaker on the cabin ceiling?

This placement is not recommended.

May I use a longer cable with the loudspeaker?

Yes, but not with the microphone.

29

Page 30

Lift Cabin Audio Unit – Universal

2.2

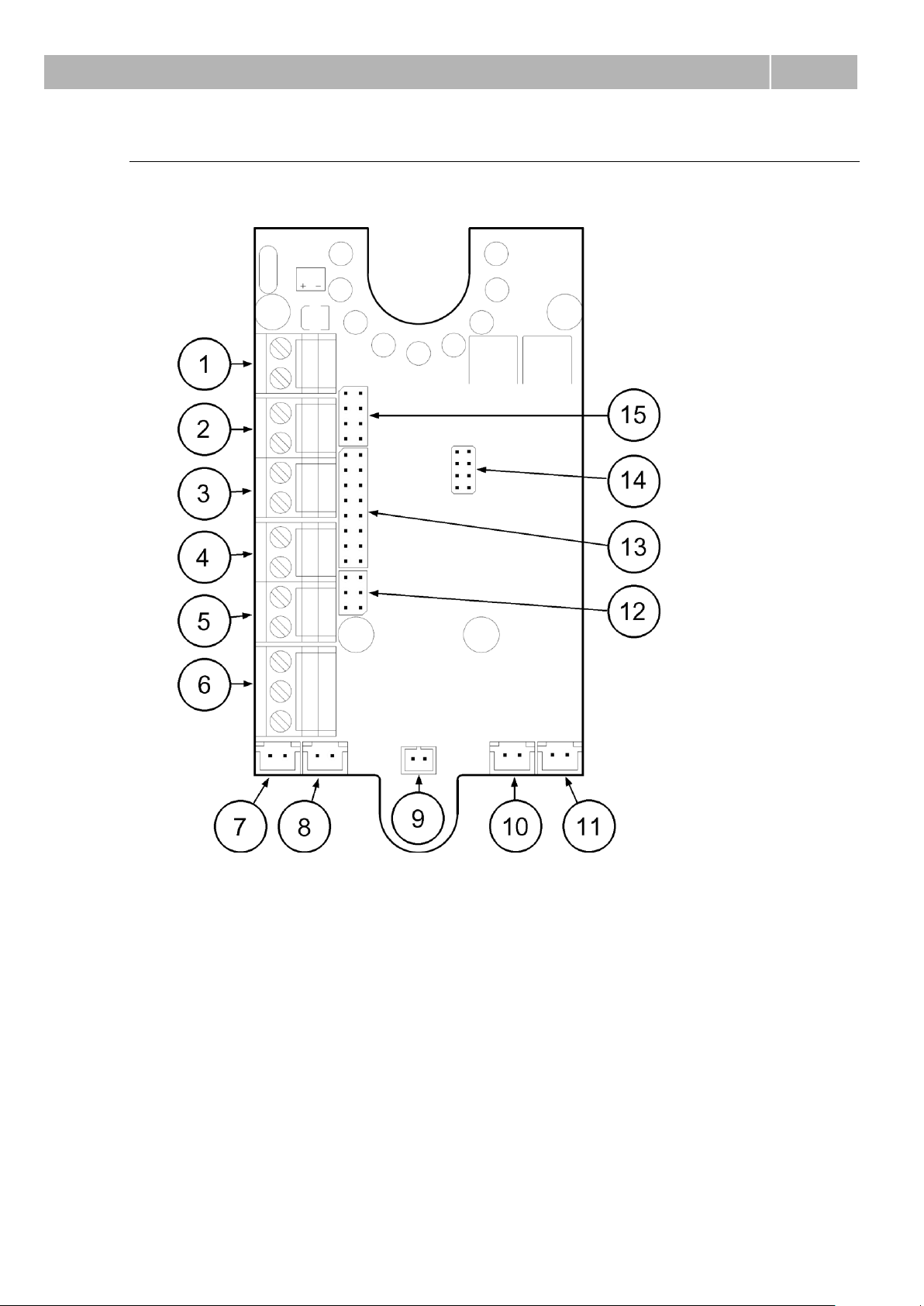

Terminals

Connectors

1

Bus 7 “Request accepted” LED

2

ALARM, voltage activation

8

“Connection established” LED

3

ALARM, contact activation

9

Microphone connector

4

CANCEL, voltage activation

10

Loudspeaker connector

5

CANCEL, contact activation

11

Induction loop connector

6

indicator switches

14

Service connector

Configuration jumpers

LED indicators (rear side):

12

ALARM / CANCEL inversion

1. (yellow)

Request accepted

13

Lift number

2. (green)

Connection confirmed

15

Audio unit position

3. (yellow)

Triphony

4. (red)

Upgrade or error

Figure 2.5 Description of

Terminals, Connectors

and Jumpers for

Lift Cabin Audio Unit –

Universal

Electric Installation

Description of Terminals, Connectors and Jumpers

30

Page 31

Lift Cabin Audio Unit – Universal

2.2

Figure 2.6 Address Setting for Lift Cabin

Audio Unit – Universal

Note

If external LEDs are connected to connectors 7 and 8, on-board LEDs 1

and 2 will not be shining.

Address Setting

The audio unit address means setting of two jumpers,

namely the lift number (1 to 8) and audio unit position

(refer to the cover drawing). If you install the audio unit

in the cabin of lift 1, you need not change the jumper

configuration. In other cases, follow the instructions

below:

Instructions

1. Release slightly the three screws on the

electronics cover.

2. Slide the cover to the right to expose the

jumpers.

3. Set the required changes as shown on the

electronics cover.

4. Replace the cover and tighten the screws.

Notes

Make sure that two audio units do not have an identical address to avoid

system error.

The position-setting jumpers are employed exceptionally, e.g. where a

certain audio unit type is used in a position other than normal.

To recover the initial address setting, follow the drawing on the cover.

Bus Connection

The connection polarity is arbitrary.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Caution

The unit is powered via a 2-wire bus from the central unit. Unplugging of

the bus from the CU causes switching off of the unit.

Avoid the audio unit address duplicity.

31

Page 32

Lift Cabin Audio Unit – Universal

2.2

ALARM Button Connection

Requirements

The ALARM button design (colour, symbol, button surface, mechanical run) and

location have to meet the requirements of the particular installation.

Button control

Requirements

The ALARM button has to be equipped with a normally open (NO) or normally

closed (NC) contact that is not connected with any other circuit.

None of the ALARM button terminals may be connected electrically with any

other electrical circuit and a voltage source other than the NO/NC contact.

If one of the ALARM contacts is connected to another circuit, appropriate

isolation strength according to applicable standards has to be ensured

between the contacts.

Instructions

1. Leave the ALARM terminal in the LOW position (3).

2. With a normally closed contact, leave jumper (12) – right in the default

position.

3. With a normally open contact, switch jumper (12) – right into the HIGH

position.

Voltage control

Requirements

DC 12 to 48V voltage

The voltage signal has to be active even in the case of power failure.

Instructions

1. Switch the ALARM terminal by two pins up into position (2).

2. For activation by voltage connection, leave jumper (12) – right in the default

position.

3. For activation by voltage disconnection, switch jumper (12) – right into the

HIGH position.

Caution

Jumper setting, as printed on the unit cover of pre-production samples, is

only valid for CANCEL and wrong for ALARM.

See above for the proper setting.

Warning

Ignoring the instructions above may lead to product damage.

32

Page 33

Lift Cabin Audio Unit – Universal

2.2

CANCEL Input Connection (Door Contact, Optional)

This input helps cancel a rescue request if the lift is fully functional. When the ALARM

button is pressed, the system waits for a pre-programmed period of time, which is a

little longer than the maximum lift running time. If the lift is functional, it arrives in

the required station within this timeout and opens the door. In that case, the rescue

request is cancelled. If the door fails to open, the request is accepted.

Find out before installation whether the door opening signal is available in the lift

cabin.

Requirements

In double-door lifts, the signal has to be active only if both the doors open successfully

and let the people out.

The door position signal has to work even in the case of power outage.

Contact control

Requirements

None of the CANCEL terminals may be connected electrically with any other

electrical circuit and a voltage source other than the contact.

Instructions

1. Keep the CANCEL terminal in the LOW position (5).

2. With a normally open contact, leave jumper (12) – left in the default position.

3. With a normally closed contact, switch jumper (12) – left into the LOW

position.

Voltage control

Requirements

DC 12 to 48V voltage

Instructions

1. Switch the CANCEL terminal by two pins up into position (4).

2. For activation by voltage connection, leave jumper (12) – left in the default

position.

3. For activation by voltage disconnection, switch jumper (12) – left into the LOW

position.

Warning

Ignoring the instructions above may lead to product damage.

Note

Remember to program delayed calling to make the CANCEL connection

work successfully.

33

Page 34

Lift Cabin Audio Unit – Universal

2.2

Figure 2.7 Basic

Indicator Connection for

Lift Cabin Audio Unit –

Universal

Figure 2.8 Alternative

Indicator Connection for Lift

Cabin Audio Unit – Universal

Indicator Connection

The basic configuration providing (using an external source) a sufficient illumination

intensity of indication elements is shown in the figure:

Requirements

The DC power supply has to be backed-up.

Notes

LN continues working except for the indicators during power outage.

The indication elements (bulbs, e.g.) may have the maximum current of

200 mA each.

Mind polarity in this case.

Alternative indicator connection (LED)

Today’s LED producing technologies help achieve a relatively good illumination

intensity at a low current supply. If a 5 mA LED (with diode loss of approx. 2V) is able

to provide efficient illumination in the lift, no power supply is needed. For this

configuration see the figure below:

Notes

The cables required for this configuration are not part of the standard

In this configuration, the auxiliary indicators on the PCB are not shining.

delivery but are available upon agreement.

34

Page 35

Lift Cabin Audio Unit – Universal

2.2

Induction Loop Connection

The regulations that apply to communicator installations may require a mandatory

loop for persons with defective hearing in the lift cabin. In that case, connect the loop

to connector (10) with any polarity. The loop including a 1m long cable can be part of

your delivery if agreed.

Requirements

The induction loop has to be placed behind a non-metal, non-magnetic cover

in the control panel because the magnetic field of the induction loop cannot go

through the metal control panel.

The induction loop has to be labelled with an appropriate symbol (ear) placed

according to applicable standards.

35

Page 36

Lift Cabin Audio Unit – Compact

2.3

Loudspeaker

Symbol window (also access to address switches)

Symbol indicating location of induction loop for

people with defective hearing

“Connection established” symbol – green

“Establishing connection” symbol – yellow

TRIPHONY symbol – yellow if activated

ALARM button

Window bezel hole

Microphone hole

Figure 2.9

Description of Lift bin

Audio Unit – Compact

2.3 Lift Cabin Audio Unit – Compact

Description

This audio unit is designed for lift wall mounting. No opening has to be cut for

installation since the audio unit is surface mounted.

Operating instructions

1. Activate by pressing the ALARM button. The “Wait” symbol lights up and, once

communication has been established, the “Connection established” symbol

comes on.

2. To activate the TRIPHONY mode press the button on the shaft or machine

room audio unit for which the same address has been set.

36

Page 37

Lift Cabin Audio Unit – Compact

2.3

Audio unit position setting 0–3 with a

possibility of inverting CANCEL (4–7)

Lift number setting 1–8

Before You Start

Requirements

The lift wall surface must be perfectly flat.

The mounting place must comply with applicable regulations (e.g. standard

ALARM button elevation and relative distance from other lift buttons).

Product Completeness Check

Check the product for completeness before installation please:

1 Compact audio unit

o 1 window with printing

o 2 terminals inserted in the back side connector

1 long hexagonal 2mm round-head wrench

4 M4×8 screws

4 headless M4×30 screws

4 M4 nuts

4 fan washers

Address Setting

The audio unit is set as lift cabin 1 by default. If you want to change the address, you

are recommended to do so before mounting.

37

Page 38

Lift Cabin Audio Unit – Compact

2.3

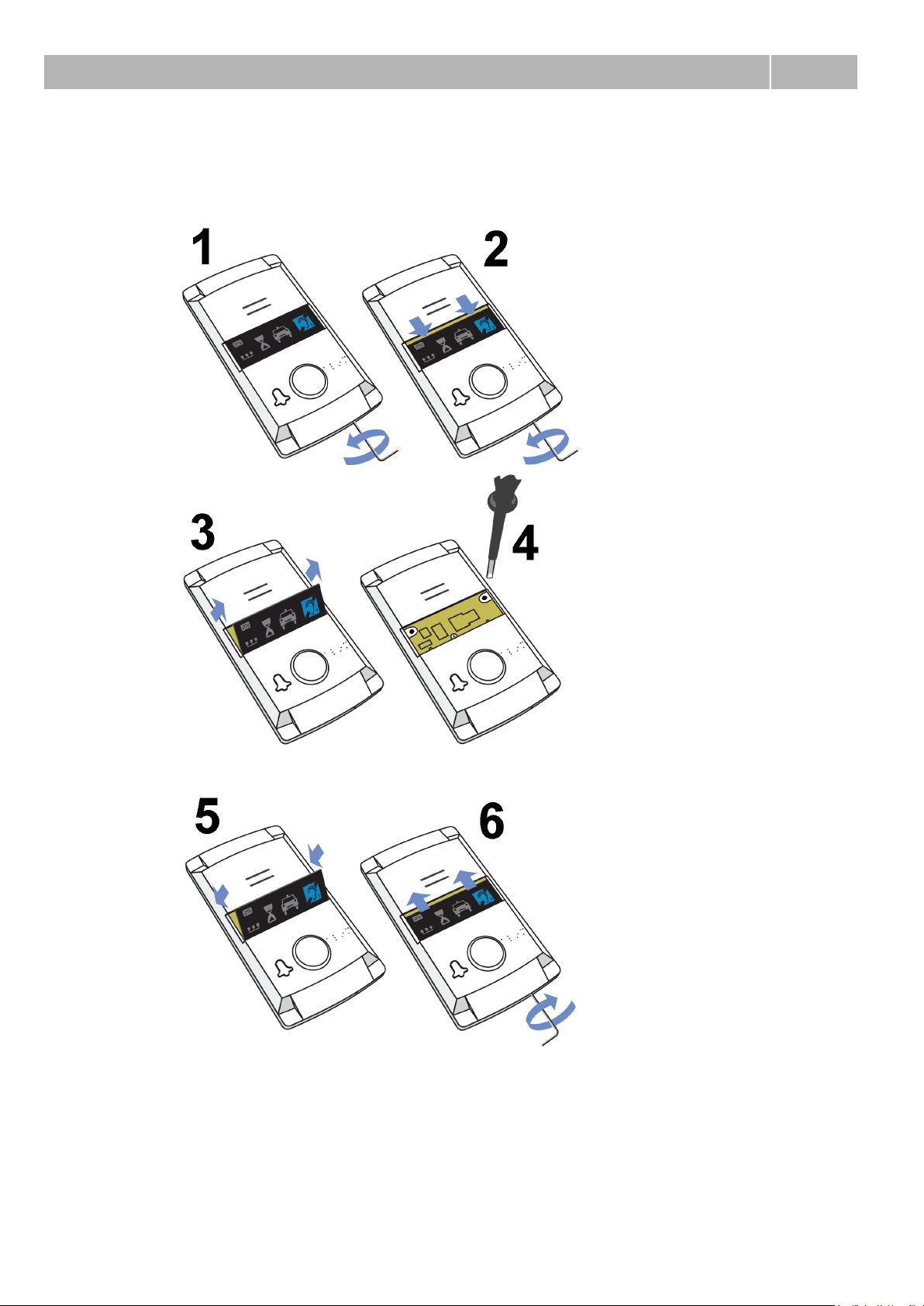

1. Insert the hex wrench (included in the delivery) in

the bottom unit edge hole; turn left about 10 times

until it puts up resistance.

2. The window slides down by itself or with little

assistance, showing its upper brim.

3. Tilt the window forwards and remove.

4. Set the audio unit address using a screw driver:

left rotary switch:

0 or 4 … machine room

1 or 5 … shaft bottom

2 or 6 … lift cabin

3 or 7 … lift cabin

ceiling

right rotary switch:

1–8 = lift number

Caution

Right rotary switch: 1 to 8 print, i.e.

set 1 for lift number 2 etc.

Note

Left rotary switch: If you use the

CANCEL input and the contact is open

with the door closed, set the left switch

into one of positions 0 to 3; if the

contact is closed with the door closed,

set the left switch into one of positions

4 to 7.

5. Replace the window.

6. Insert the hex wrench (included in the delivery) in

the bottom unit edge hole, turn right about 10 times

until the window slides under the panel edge and

tighten applying light force.

Figure 2.10 Address Setting for

Lift Cabin Audio Unit – Compact

Instructions

38

Page 39

Lift Cabin Audio Unit – Compact

2.3

Figure 2.11 Mounting

Hole Dimensions for Lift

Cabin Audio Unit Top -

Compact

Mounting

Just drill holes into the lift cabin wall as indicated in the drawing below or as printed

1:1 on the audio unit package. The larger hole is intended for cable passage. Round

the hole edges to avoid cable damage!

Note: The two 2.5 mm large holes in the window area are used where the mounting

panel rear is inaccessible. The 2.5 mm diameter is suitable for all wall mounting

options using plywood, chipboard, laminated plastic etc. with the aid of the screws

included. For front metal panel wall mounting drill M4 threaded holes.

Further steps can only be made after connection and are thus included in the next

section.

39

Page 40

Lift Cabin Audio Unit – Compact

2.3

Telephone line / LN bus

Refer to ST or LN User Manual

ALARM

terminals

DC = voltage

control *)

5 – 24Vdc, any polarity

Emergency call

activation

N.O. = N/O contact

Normally open contact

N.C. = N/C contact

Normally closed contact

WARNING! If unused, the

contact should not be opened!

CANCEL

terminal

voltage control *)

5 – 24Vdc, any polarity **)

Emergency call

deactivation upon

door opening

contact control

any contact **)

Figure 2.12

Connectors of

Lift Cabin

Audio Unit –

Compact

Electric Installation (Earlier HW)

Caution

Be sure to connect the wires before wall mounting. The connectors are

separable – remove them, connect the wires, tighten the screws and

replace the connectors.

Connectors

Bus connector

CANCEL connector (optional)

in contact-control position

in voltage-control position

Electric Installation (Later HW)

Terminals

*) For safety reasons, these terminals are electrically isolated from the telephone line.

**) You need not do anything to activate ALARM if you keep the factory settings. For

deactivation, voltage application or contact closing is necessary. To change the

settings use parameter 916 for ST and the rotary switch for LN.

40

Page 41

Lift Cabin Audio Unit – Compact

2.3

Figure 2.14 ALARM

Button Connection with

N/O Contact

Figure 2.13 Connectors of

Lift Cabin Audio Unit –

Compact (Later HW)

Connectors

Warning

Make sure that the button is safe, i.e. that the minimum isolation distance

is 1.5 mm and the minimum breakdown voltage value is 1,500 V. The

button contacts may not be connected to any other circuits. If any of the

above conditions cannot be met, use voltage control.

You can use an N/O or N/C button or both.

Refer to the rear cover for internally connected terminals – see Fig. 2.13.

ALARM Button Connection with N/O Contact

41

Page 42

Lift Cabin Audio Unit – Compact

2.3

Figure 2.15 ALARM

Button Connection with

N/C Contact

Figure 2.16 Voltage Activation

ALARM Button Connection with N/C Contact

Note

The ALARM button mounted on the cover is still functional when an

external button is connected.

Voltage Activation

Caution

5 - 24 dc voltage of any polarity can be used. Make sure that the power

Where activation from multiple places is necessary, voltage control can be

A buzzer or horn can be connected in parallel, see the figure to the right.

supply is backed up properly.

combined with buttons.

42

Page 43

Lift Cabin Audio Unit – Compact

2.3

Figure 2.17 Inversion Voltage Control

Inversion Voltage Control

The figure to the right shows a configuration where voltage is present and activation is

caused by non-presence of voltage.

Bus Connection

The connection polarity is arbitrary.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Caution

Avoid the audio unit address duplicity.

43

Page 44

Lift Cabin Audio Unit – Compact

2.3

CANCEL Input Connection (Door Contact, Optional)

This input helps cancel a rescue request if the lift is fully functional. When the ALARM

button is pressed, the system waits for a pre-programmed period of time, which is a

little longer than the maximum lift running time. If the lift is functional, it arrives in

the required station within this timeout and opens the door. In that case, the rescue

request is cancelled. If the door fails to open, the request is accepted.

Make sure before installation that the “door open” signal is available in the lift cabin.

Requirements

In double-door lifts, the signal has to be active only if both the doors open

successfully and let the people out.

The door position signal has to work even in the case of power outage.

Contact control

Requirements

None of the CANCEL terminals may be connected electrically with any other

electrical circuit and a voltage source other than the contact.

Instructions

1. Connect the CANCEL terminal into upper position.

2. Make sure that the switch position matches the door contact configuration

(open or closed when the door is closed) – see Address setting.

Voltage control

Requirements

DC 12 to 48V voltage

Instructions

1. Connect the CANCEL terminal into lower position.

2. Make sure that the switch matches voltage presence or absence when the door

is closed – see Address Setting. Voltage presence corresponds to a closed

contact; voltage absence means an open contact.

Warning

Ignoring the instructions above may lead to product damage.

Note

Remember to program delayed calling to make the CANCEL connection

work successfully.

44

Page 45

Lift Cabin Audio Unit – Compact

2.3

Figure 2.18 Lift

Cabin Audio Unit –

Compact Mounting

Mounting Completion

Connect the wires before wall mounting. The connectors are separable – remove

them, connect the wires, tighten the screws and replace the connectors.

Mounting the audio unit from the outer lift cabin

wall is easier. In that case, no screws are

accessible from the lift cabin and the audio unit

cannot be stolen. If the cabin wall is accessible

from the outside, follow the instructions in item

a) or b). If not, follow item c).

a) If the lift cabin wall is thin (stainless steel

sheet), seek four 8 mm long M4 screws and fanshaped washers in the accessories.

b) If the lift cabin wall is thick (up to 20 mm

– laminated chipboard), seek four headless, 30

mm long M4 screws. Screw them into the unit

backside using the wrench included in the

delivery and tighten properly. Then push the

assembly through the pre-drilled holes, insert

the fan-shaped washers from the back and screw

in the nuts.

c) If the lift cabin wall is inaccessible from

the rear, follow instructions on the next page.

TIP: If you have pre-drilled corner holes, find

four headless M4 screws of the length of 30 mm

in the package. Drive the screws into the holes

on the rear side of the audio unit and tighten as

mentioned in item b) above. Though unequipped

with nuts, the screws fix the product reliably,

preventing it from sliding or turning.

Induction loop connection

The induction loop for people with defective hearing is included in the product, no

other loop is needed.

45

Page 46

Lift Cabin Audio Unit – Compact

2.3

Mounting Completion – without Rear Access

1. Insert the hex wrench

(included in the delivery) in the

bottom unit edge hole; turn left

about 10 times until it puts up

resistance.

2. The window slides down by

itself or with little assistance,

showing its upper brim.

3. Tilt the window forwards

and remove.

4. Now you have access to two

holes in the window corners.

Put unit (including the

connected wires) on the predrilled lift cabin wall. Drive and

tighten the included screws for

plywood, chipboard, laminated

plastic etc. wall mounting or

short M4 screws with fanshaped washers (intended for

metal plate mounting with predrilled M4 threaded holes).

5. Replace the window.

6. Insert the hex wrench

(included in the delivery) in the

bottom unit edge hole, turn

right about 10 times until the

window slides under the panel

edge and tighten applying light

force.

46

Page 47

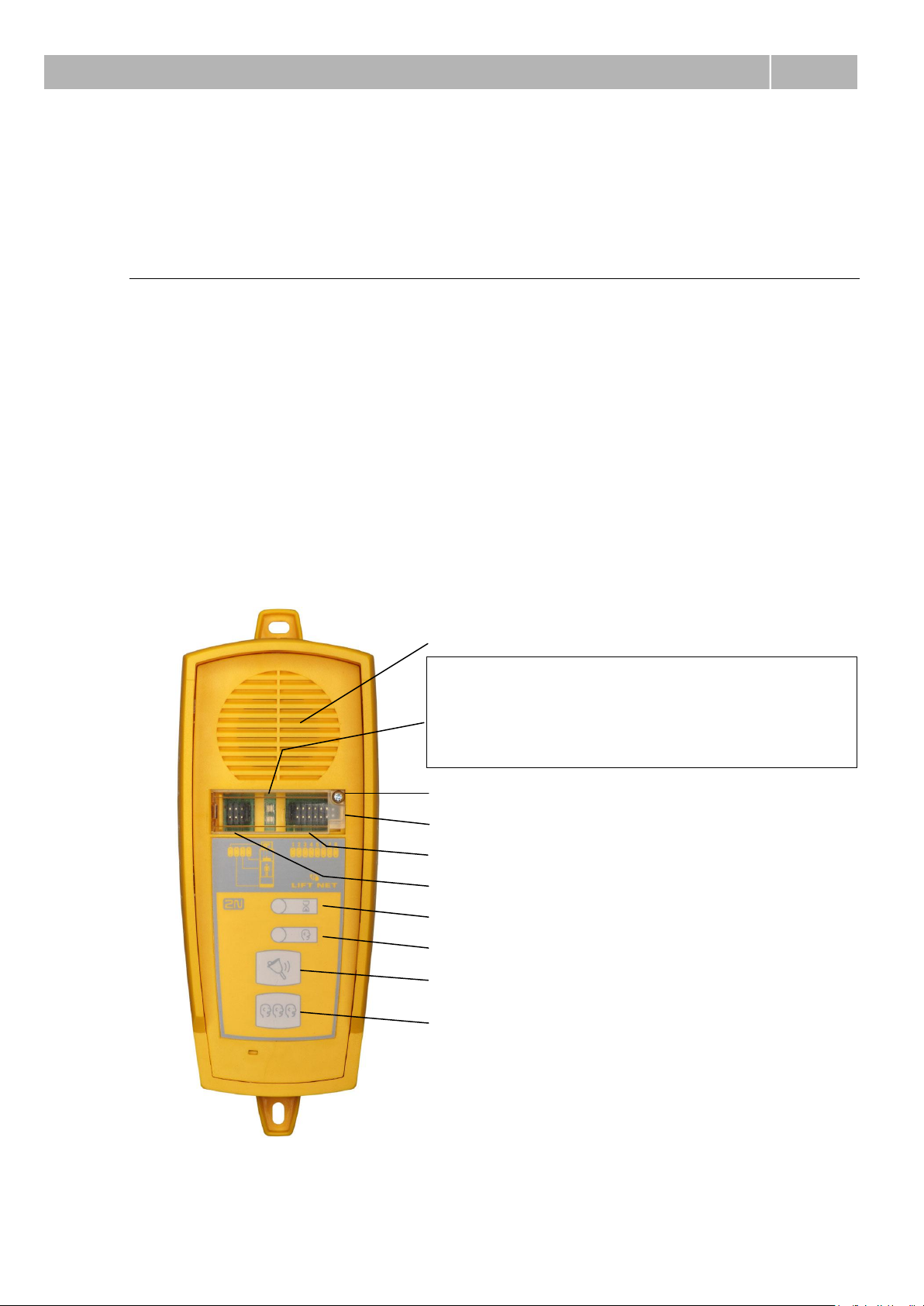

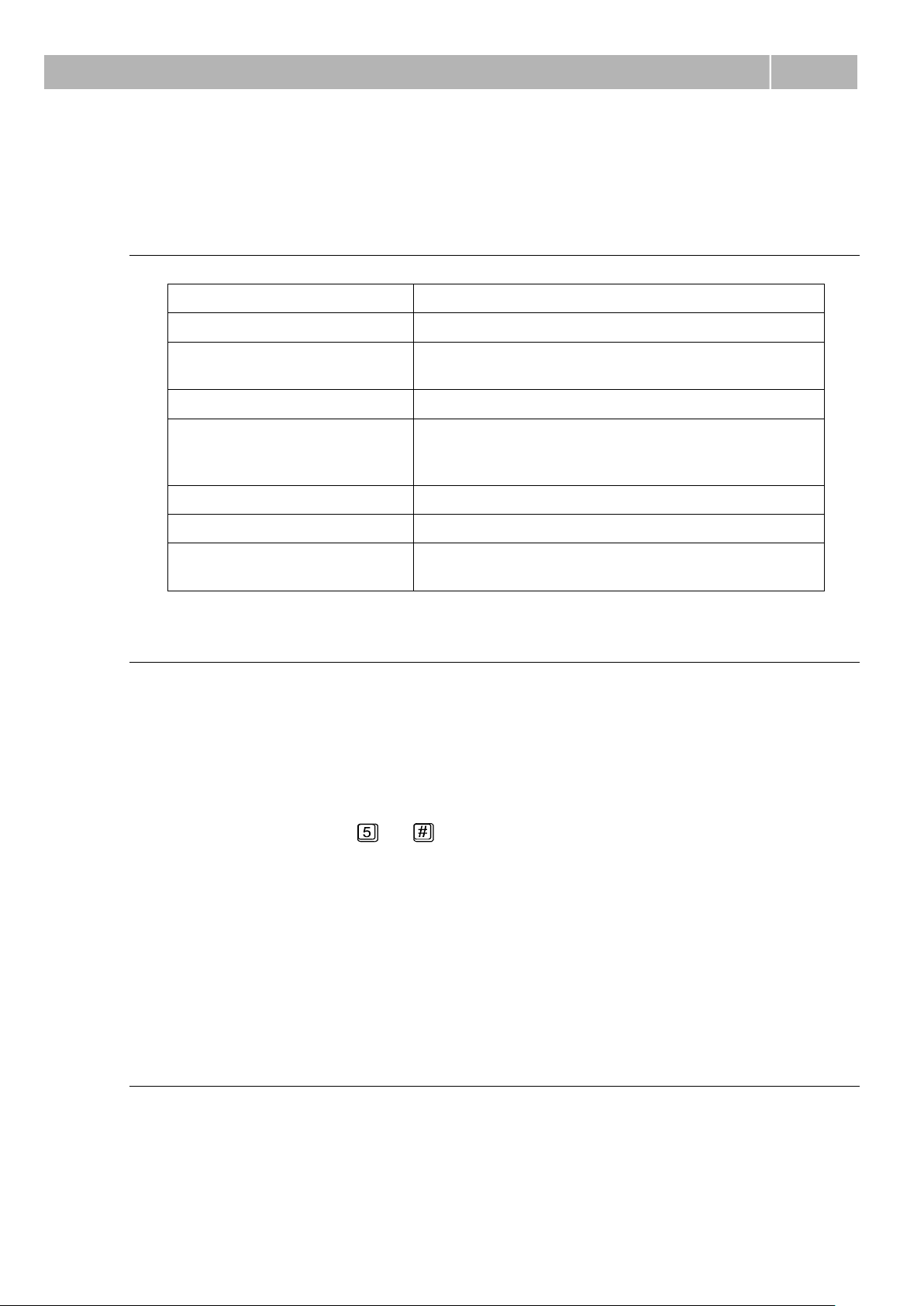

Audio Unit – Machine Room

2.4

siren – beeps to alert incoming call or triphony beginning

LED indicator (red)

shining – initialisation (10s)

constantly shining – initialisation error

brightly shining – light bell (together with the siren beep)

Door locking screw

Address adjustment doors

Lift number (1–8) adjustment

Audio unit position adjustment

“Call in progress” indicator – yellow

“Call established” indicator – green

“Fireman connection” – green flashing

ALARM button – white-backlit at relax

TRIPHONY button – yellow-backlit when the triphony mode is

active

Figure 2.19 Audio Unit

– Machine Room

Description

2.4 Audio Unit – Machine Room

Description

This audio unit is designed for machine room installation. Compared with the other

types, it has some unique features:

The audio unit contains a telephone set with the HandsFree/receiver modes

for good function in a noisy environment.

The attached telephone is equipped with a keypad for function selection and

system programming.

The attached telephone does not ring. The audio unit is equipped with a

siren that is loud enough for a noisy environment.

o The machine room audio unit can be shared by multiple lifts.

The audio unit is equipped with a lift blocking contact in case LN fails to call

for help.

47

Page 48

Audio Unit – Machine Room

2.4

Operating instructions

This unit may only be used by authorised persons such as the lift maintenance staff.

The TRIPHONY button activates voice communication between all units with the same

lift number.

The ALARM button can be used for calls to the dispatching centre. The ALARM button

backlight (not required by standards) allows you to find the unit in a dark

environment.

In both cases, it is necessary to pick up the attached phone.

If the attached phone is picked up and neither ALARM nor TRIPHONY is pressed, you

can make use of other functions; refer to the machine room voice menu.

Before You Start

Requirements

Be sure to connect the telephone set included in the audio unit delivery. No

other telephone type may be used except with the consent of the

manufacturer.

The lift control circuit must be equipped with a function blocking input in case

the LN is unable to provide connection with the dispatching centre.

Product completeness check

Check the product for completeness before installation please:

1 audio unit

1 telephone set (a separate unit including accessories and the manual)

2 wall dowels

2 dowel screws

7 address setting jumpers

Mounting

Typically, the audio unit including a telephone set is mounted onto a wall using

available dowels and screws. The recommended machine-telephone distance is

approximately 10 cm. The maximum distance is determined by the interconnecting

cable delivered together with the telephone.

48

Page 49

Audio Unit – Machine Room

2.4

Connectors (under the side door)

Bus connector

Lift blocking connector

Phone connector

Figure 2.20

Audio Unit –

Machine

Room

Connectors

Electric Installation

Description of connectors

Release the screw on the right-hand side and open the connector cover. There are

three connectors:

Address Setting

There two groups of jumpers under the transparent front cover. For their meanings

see the printing located directly under them.

Left-hand group of 4 jumpers: leave them in the “machine room” position.

Note

You can set another position too – if, for example, you want to

have a classic telephone and thus program the CU on the shaft

bottom, you can use this audio unit and set the jumper into the

appropriate position.

Right-hand group of 8 jumpers: address setting. If the machine room is

shared by multiple lifts, you can use one audio unit and set more addresses

with the available jumpers. This is impossible with other types of audio units!

Note

If more addresses have been set in the audio unit, press the

TRIPHONY button to activate communication with the lift with the

lowest address.

Caution

Avoid the audio unit address duplicity.

49

Page 50

Audio Unit – Machine Room

2.4

Bus Connection

Remove the terminal board from the connector, connect the wires and replace the

terminal board. The connection polarity is arbitrary.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Caution

The unit is powered via a 2-wire bus from the central unit. Unplugging of

the bus from the CU causes switching off of the unit.

Telephone Connection

Use the telephone set including the cable with telephone terminals that are part of the

audio unit delivery.

Caution

The audio unit is not functional without a telephone set connected.

Connecting a telephone set of different type may result in difficulties, such

as system failure.

Testing

To test the function, pick up the handset. If no other call is currently being made, you

can hear the machine room voice menu.

Lift Blocking Function Connection

Caution

This function may be mandatory if the local applicable regulations require

so at the time of installation.

Blocking procedure: the contact opens whenever a telephone line fault is detected or

the LN batteries are low. Connect the contact to the appropriate controller input of the

lift or a group of lifts. The control electronics shall ensure that, upon contact opening,

the lifts that are in operation arrive in the nearest station and open the door. If the

audio unit is shared by multiple lifts, all lifts must stop the function identically.

50

Page 51

Audio Unit – Lift Shaft / Cabin Roof

2.5

Loudspeaker

LED indicator (red) – unit initialisation error

Door locking screw

Address setting door

Lift number (1–8) setting

Audio unit position setting

“Call in progress” indicator – yellow

“Call established” indicator – green

ALARM button – white-backlit at relax

TRIPHONY button – yellow-backlit when the triphony mode is active

Figure 2.21

Audio Unit – Lift

Shaft / Cabin

Roof Description

2.5 Audio Unit – Lift Shaft / Cabin Roof

Description

This audio unit is designed for installation on the lift shaft bottom or lift cabin roof, or

similar places where communication is needed during lift maintenance, for example.

The audio unit is enclosed in a robust yellow cover. It is not intended for outdoor use

but perfectly fits in lift shafts – is resistant against fall of small objects, dripping oil,

etc. The ALARM button activates the dispatching centre connection, the TRIPHONY

bottom enables conference connection with the other audio units of one and the same

lift. The audio unit contains a built-in microphone and a loudspeaker. Thanks to its

size and robustness, the audio unit features a very good sound.

Operating instructions

This unit may only be used by authorised persons such as the lift maintenance staff.

The TRIPHONY button activates voice communication between all units with the same

lift number.

51

Page 52

Audio Unit – Lift Shaft / Cabin Roof

2.5

The ALARM button can be used, for example, when somebody falls into the shaft. The

ALARM button backlight (not required by standards) allows you to find the unit in a

dark environment.

Before You Start

Product completeness check

Check the product for completeness before installation please:

1 audio unit

2 wall dowels

2 dowel screws

Requirements

There are no special requirements for this unit type.

Caution

This audio unit is not designed for lift cabins.

Mounting

Typically, the audio unit is mounted onto a wall using the dowels and screws included

in the delivery. Find the drilling pattern on the product package.

Caution

The audio unit is not designed for outdoor applications.

Electric Installation

Connectors

This unit has only one connector (bus) under the side door.

Address setting

The audio unit address means setting of two jumpers, namely the lift number (1 to 8)

and audio unit position (refer to the cover drawing). If you install the audio unit on the

shaft bottom of lift 1, you need not change the jumper configuration. Otherwise,

follow the instructions below:

Instructions

1. Release the screw on the jumper window cover and open the window.

2. Configure the required changes as printed below the window (this audio unit

cannot be shared by multiple lifts).

3. Close the window and tighten the screw.

52

Page 53

Audio Unit – Lift Shaft / Cabin Roof

2.5

Warning

Avoid the audio unit address duplicity.

Connection

Release the screw on the right-hand side and open the connector cover. There is just

one connector – for bus connection. Remove the terminal board from the connector,

connect the wires and replace the terminal board. The connection polarity is arbitrary.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Caution

The unit is powered via a 2-wire bus from the central unit. Unplugging of

the bus from the CU causes switching off of the unit.

53

Page 54

Page 55

3

This section describes programming of 2N® LiftNet. It is possible to program 2N®

LiftNet in three ways.

PSTN Line Programming

Machine Room Telephone Programming

PC Programming

55

Page 56

LN Programming

3.1

1. Remote (PSTN) telephone

programming

The access is password-protected. The voice menu is

in the national language.

2. Machine room telephone

programming

3. PC USB programming

Use 2N® LiftManager including the Service Tools.

Also, you can use the firmware upgrade, download of

language mutations and user-recorded message.

3.1 LN Programming

The advantage is that it is only the CU that has to be programmed. Thus, it is

unnecessary to re-program the parameters after audio unit replacement. With a

multiple-lift system, you just program one CU. The memory is independent of the CU

power supply.

To program the CU choose one of the following three ways:

PSTN Programming

Before You Start

Make sure that your telephone enables tone dialling (troubles may occur with

the so-called system/key telephones in some PBX systems).

Prepare a list of all parameters to be programmed in advance.

Make sure that, if LN is not entirely new, the service password is correct and,

if you are not quite sure of your LN configuration, execute full initialisation.

Caution

Remember to initialise the service password too!

Entering Programming Mode

You can enter the programming mode only during an incoming call (PSTN call to LN)

or upon line seizure by the machine room telephone.

To enable the programming mode press to enter services and after that enter the

service password in the format service password .

Note

Remember to enter an asterisk before and after the password!

If the password is correct, LN reports “You have entered the programming menu” and

displays a context-dependent help. The default password is 12345 and you have a 5second timeout by default (or a user-defined limit of 1 to 9 seconds) to enter every

character of your password. If you fail to keep the timeout, LN hangs-up.

56

Page 57

LN Programming

3.1

Note

You are recommended to change it to secure your equipment against

unauthorised access.

If you forget your password, contact the manufacturer to recover your

data.

Programming Procedure

Having entered the programming mode, you can change any programmable value(s)

in any order. Proceed as follows: enter the function number and then the value. Use

an asterisk as a separator or Enter. In general, the function has the following format:

function number value

The function number has three digits (see the table). After you enter the function

number and an asterisk, LN reports the number or name, current value and potential

range of the parameter to be programmed. After you enter the value and another

asterisk, LN reports “Value stored”, or “Invalid value” if the value is beyond the

allowed range.

Warning

A drawback of some telephone sets is that, after you press a button, i.e.

send a DTMF signal, they go “deaf” for a fraction of a second. In that case,

you cannot hear the whole text and are recommended to use another

telephone.

Programming Error

If you make a mistake during entering (the function number or value) and have not

entered an asterisk yet, you can cancel the whole number by pressing and re-enter

the digits.

If LN rejects a parameter number or value you have entered, go on programming but

re-enter the function number even if it was the value not the number that was wrong.

If you have programmed and stored a value other than you intended to, you can reenter the value of course.

Programming End

Having stored all values to be changed, terminate programming by pressing . LN

sends a hang-up signal and hangs up. If you do not use the character, LN hangs up

later without affecting the stored values (the values are stored immediately after

being entered).

If you are not quite sure of LN’s programming behaviour, save the filled-in form for

later check.

Troubleshooting

LN fails to respond correctly to DTMF commands, e.g. the programming mode cannot

be entered.

57

Page 58

LN Programming

3.1

Today, voice transmission is prevailingly digital, using variable compression

algorithms. Therefore, the DTMF signal to be transmitted is often distorted. Moreover,

it may, in some cases, be transmitted through the so-called command channel, whose

delay may differ from that of the speech channel.

Caution

Experience shows that, especially recently, it is practically impossible to

recover the DTMF signal in GSM networks

In such cases, try some other equipment (a digital PBX, e.g.) or the machine room

telephone set. If the machine room or PSTN programming attempts fail too, you have

probably entered an invalid password.

58

Page 59

Parameter Chart (FW v. 1.8.0)

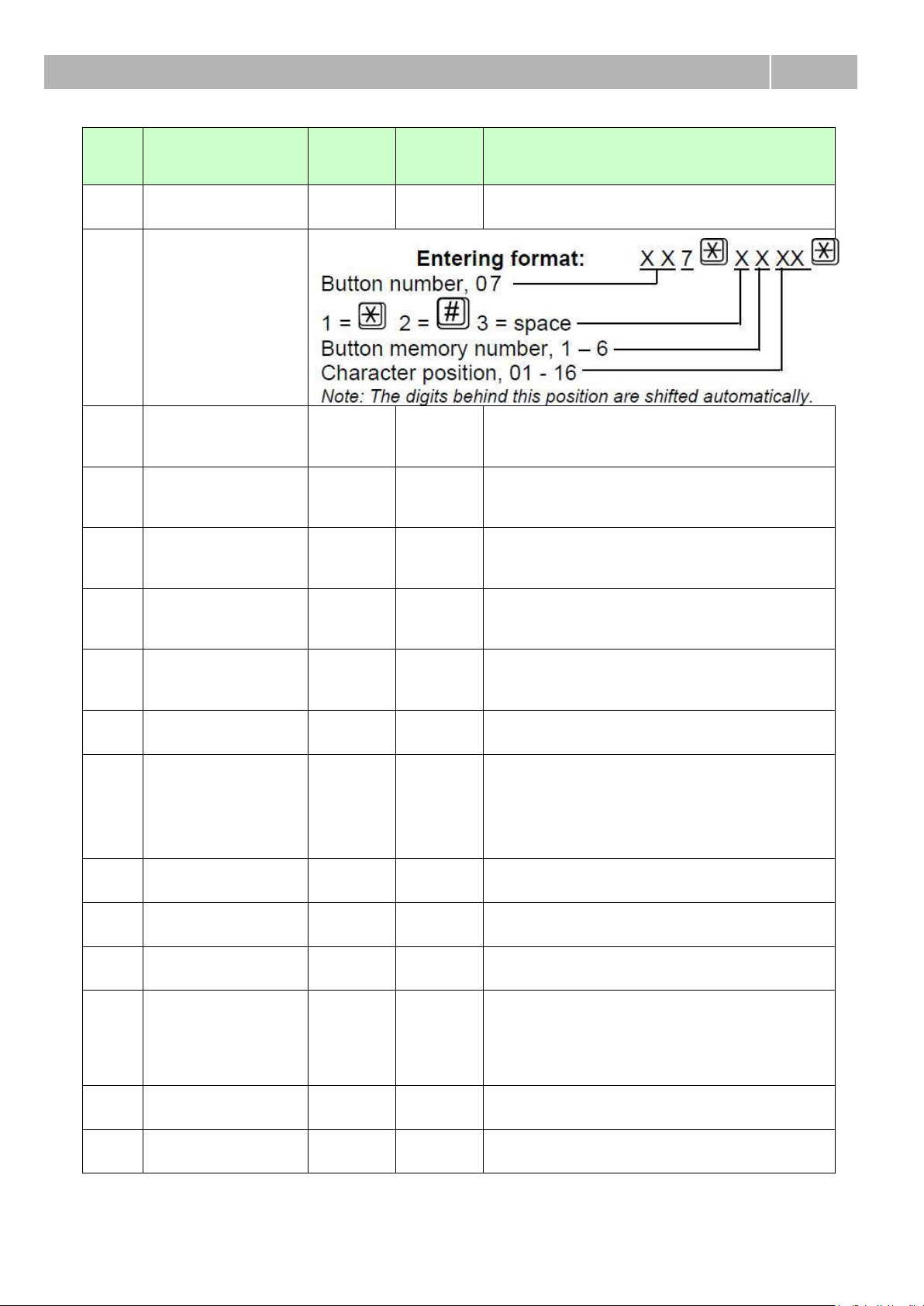

3.2

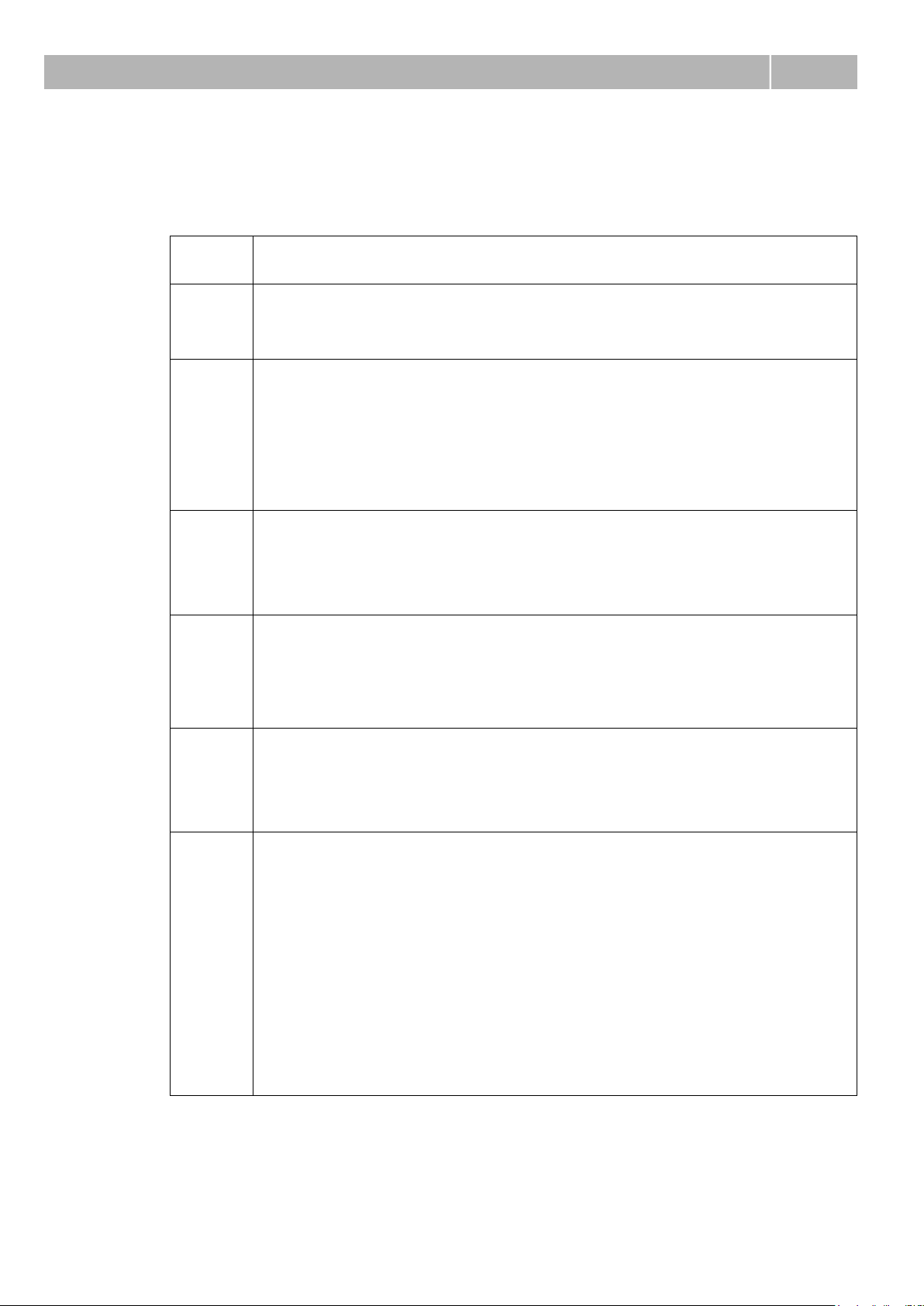

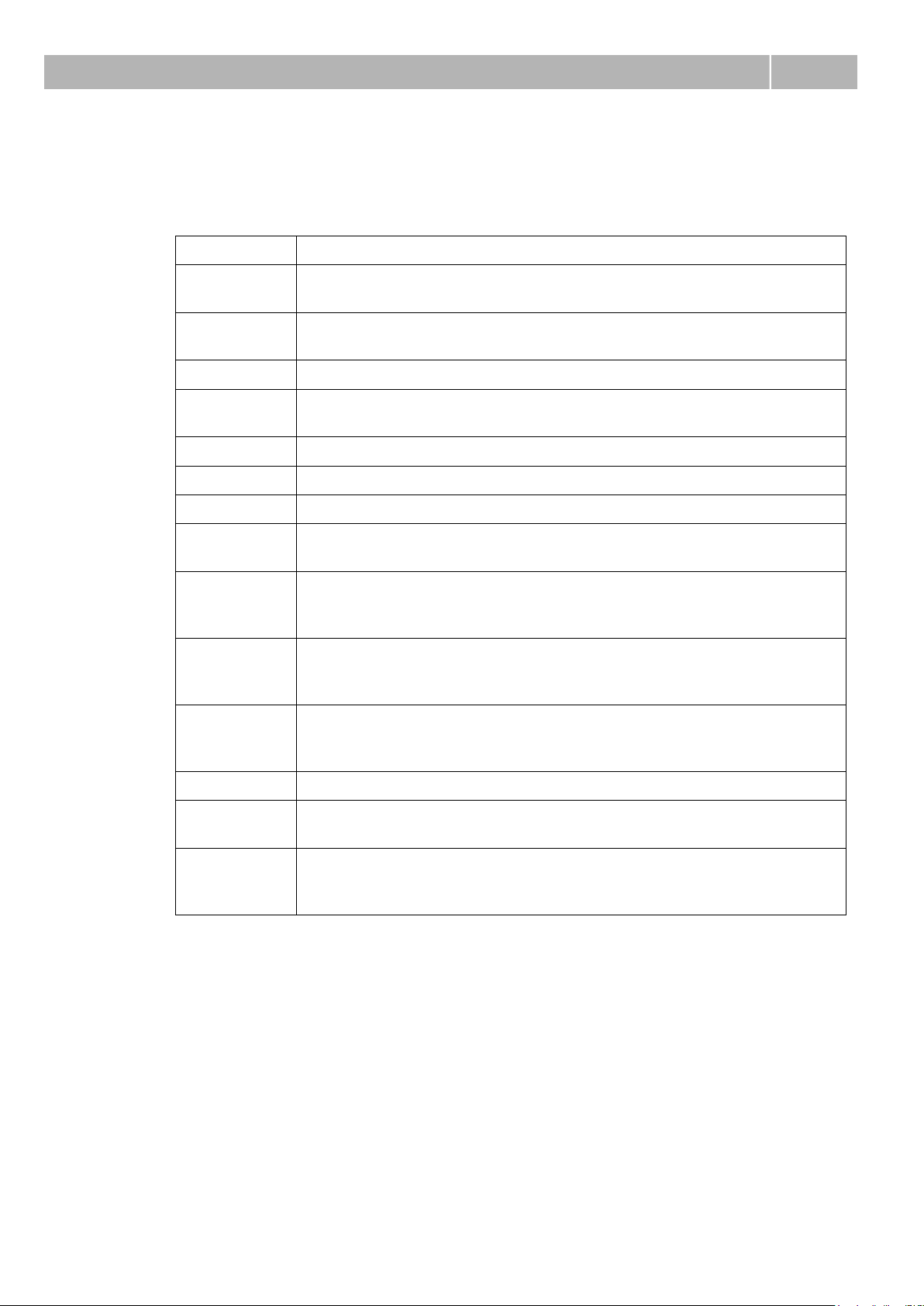

Par.

No.

Parameter Name

Range

Default

Note

011

ALARM button

memory 1