Page 1

www.2n.czVersion

Firmware

2N

®

Lift8

Communicator for lifts

User manual

1.6.0

1.6.0

Page 2

The 2N TELEKOMUNIKACE a.s. is a Czech manufacturer and supplier of telecommunications

equipment.

The product family developed by 2N TELEKOMUNIKACE a.s. includes GSM gateways, private

branch exchanges (PBX), and door and lift communicators. 2N TELEKOMUNIKACE a.s. has

been ranked among the Czech top companies for years and represented a symbol of

stability and prosperity on the telecommunications market for almost two decades. At

present, we export our products into over 120 countries worldwide and have exclusive

distributors on all continents.

2N is a registered trademark of 2N TELEKOMUNIKACE a.s. Any product and/or other

®

names mentioned herein are registered trademarks and/or trademarks or brands protected

by law.

2N TELEKOMUNIKACE a.s. administers the FAQ database to help you quickly find

information and to answer your questions about 2N products and services. On

www.faq.2n.cz you can find information regarding products adjustment and instructions for

optimum use and procedures „What to do if...“.

2N TELEKOMUNIKACE a.s. hereby declares that the 2N product complies with all

®

Lift8

basic requirements and other relevant provisions of the 1999/5/EC directive. For the full

wording of the Declaration of Conformity see the CD-ROM (if enclosed) or our website at

www.2n.cz.

The 2N TELEKOMUNIKACE a.s. is the holder of the ISO 9001:2009 certificate. All

development, production and distribution processes of the company are managed by this

standard and guarantee a high quality, technical level and professional aspect of all our

products.

Page 3

Content

1. Product Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1ProductDescription ..............................................6

1.2ComponentsandAssociatedProducts ...............................8

1.3Upgrade .......................................................21

1.4TermsandSymbolsUsed .........................................22

2. Description and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1PSTN/GSM/UMTS/VoIPCentralUnit .................................24

2.2Splitter ........................................................37

2.3AudioUnit–CabinUniversal .......................................43

2.4AudioUnit–MachineRoom ........................................55

2.5AudioUnit–Shaft ................................................60

2.6AudioUnit–Compact .............................................64

2.7PSTNModule ...................................................75

2.8GSM/UMTSModule ..............................................77

2.9VoIPModule ....................................................79

2.10AudioUnit–Fireman ............................................81

2.11I/OModule ....................................................103

3. System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.12N®Lift8Programming ...........................................110

3.2TableofParameters(FW1.6.0) .....................................113

4. Function and Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4.1UserInstructions .................................................127

4.2ControlCentreInstructions .........................................129

4.3FunctionDescription(forAdvancedUsers) ............................131

4.4CallConfirmationTypes ...........................................135

4.5LiftBlockingFunction .............................................138

4.6Four-LiftVersion .................................................139

4.7IntercomFunction ................................................141

5. Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

5.1InstallationandLogin .............................................145

5.2IntroductiontoApplication .........................................148

5.3Use ...........................................................155

Page 4

6. Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

6.1InstallationandLicensing ..........................................167

6.2Use ...........................................................170

7. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

7.1InstallationandLogin .............................................175

7.2IntroductiontoApplication .........................................178

7.3Use ...........................................................183

8. Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

8.1InstallationandLogin .............................................217

8.2IntroductiontoApplication .........................................220

8.3Use ...........................................................224

9. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

9.1OperationInterruptionandBatteryReplacement ........................235

9.2FirmwareUpgrade ...............................................237

10. Technical Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

11. Supplementary Information . . . . . . . . . . . . . . . . . . . . . . . . . 241

11.1Troubleshooting ................................................242

11.2ListofAbbreviations .............................................243

11.3Regulations ....................................................244

11.4GeneralInstructionsandCautions ..................................245

Page 5

1. Product Introduction

In this section, we introduce the product, outline its application options and2N Lift8

®

highlight the advantages following from its use.

Here is what you can find in this section:

1.1 Product Description

1.2 Components and Associated Products

1.3 Upgrade

1.4 Terms and Symbols Used

®

52N TELEKOMUNIKACE a.s., www.2n.cz

Page 6

1.1 Product Description

Basic Features

Up to 8-lift connectivity

Lift cabin, shaft and machine room voice audio units

Optimum acoustic properties

Rechargeable built-in backup battery

Easy control and configuration – voice response system

Check Call function

Lift blocking during connection failure

Internal communication – Triphony

Telephone/PC-based configuration (via USB or Internet)

USB interface

User message recording option

Local control centre (Intercom)

Fireman function

Basic Description

2N Lift8 ®( ) is a communication system with a function similar to an intercom. TheL8

system voice audio units are linked to a common bus (pair of wires), connected to a

splitter. The splitter is always connected to a central unit (CU), which controls the

system operation and provides connection with the control centre. It is possible to

connect up to 40 audio units to the bus. The CU contains an internal splitter.

Each splitter is uniquely identified: by lift number 1 to 8. The audio units are connected

to the splitters and located on the shaft bottom, in the cabin interior, on the cabin roof

and in the machine room. The machine room can be shared by multiple lifts.audio unit

The contains an easily replaceable backup battery pack (lead rechargeable battery). CU

The is responsible for battery charging and status monitoring. It indicates theCU

charging state, signal strength, telephone line state, bus state core state via five colour

LEDs. It is also equipped with a USB interface for comfortable configuration, voice

message recording and software upgrade.

The can be connected via: GSM, UMTS, PSTN or VoIP. CU

®

62N TELEKOMUNIKACE a.s., www.2n.cz

Page 7

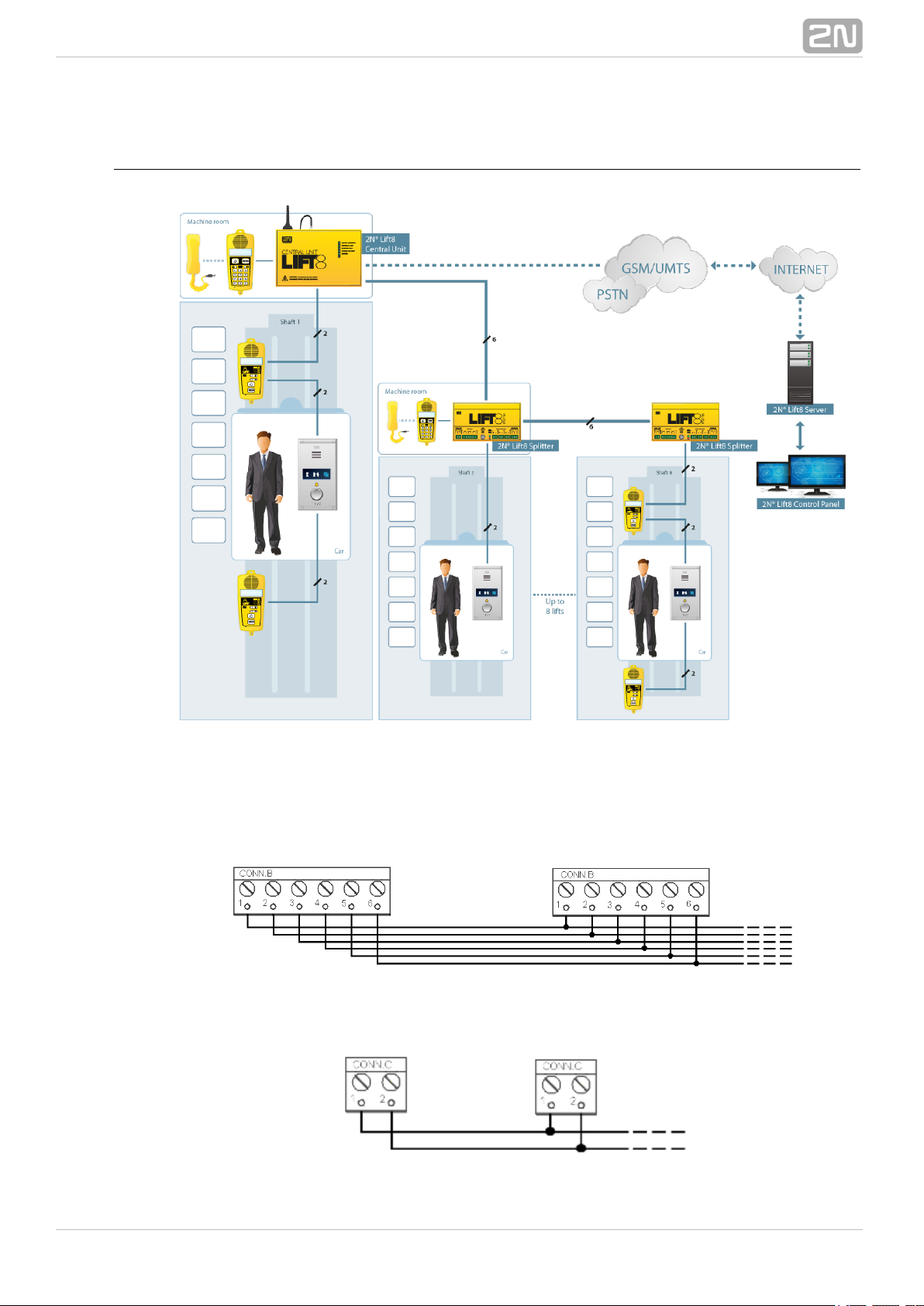

System Diagram

Example of Central Unit, Splitter and audio unit ConnectionFigure: 2N Lift8

®

Main bus

Audio unit bus

®

72N TELEKOMUNIKACE a.s., www.2n.cz

Page 8

1.2 Components and Associated Products

2N Lift8 System Components

®

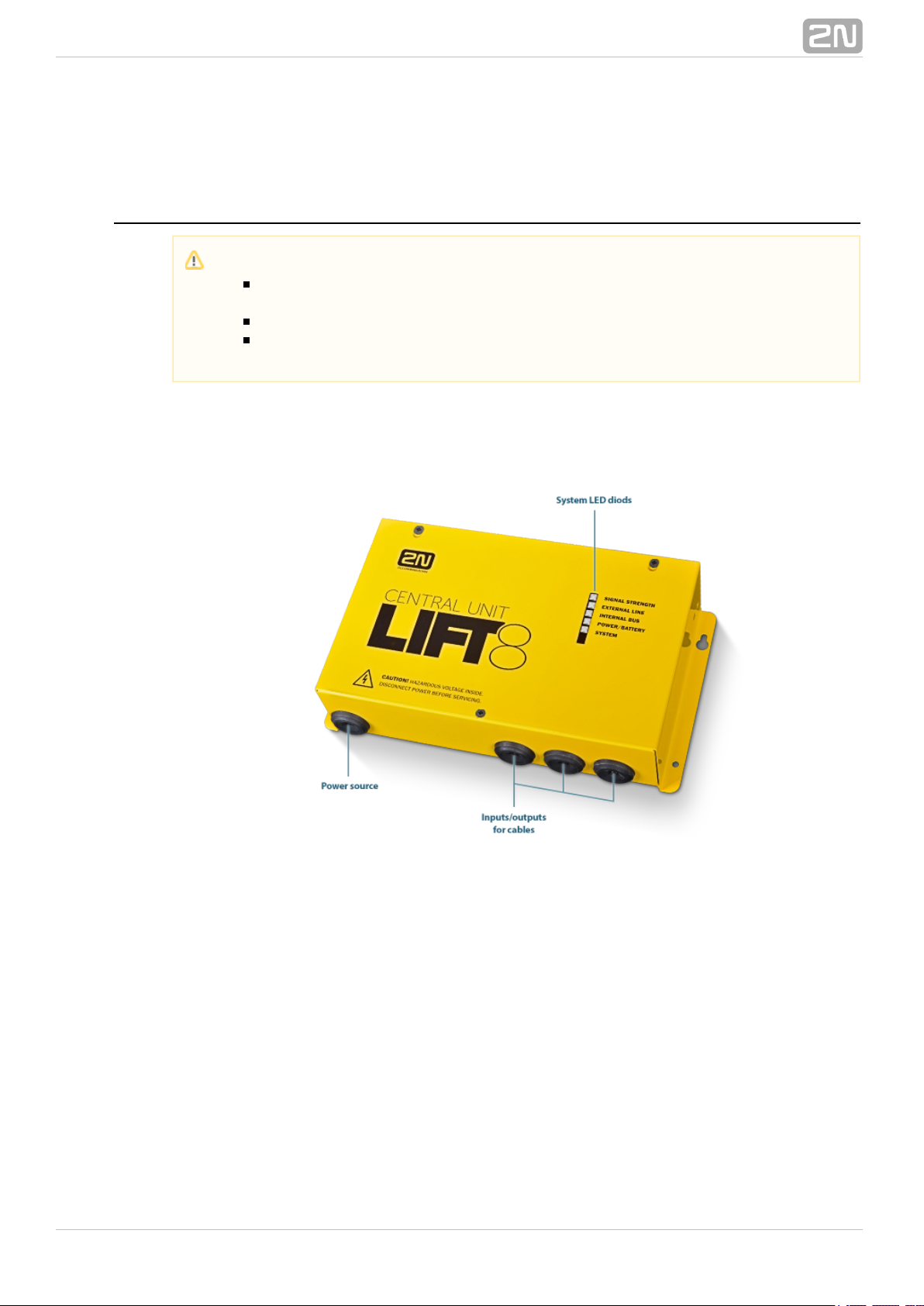

918600 2N Lift8 Central Unit

®

Central UnitFigure: 2N Lift8

®

For connection of up to 8 lifts to a GSM/UMTS/PSTN line. Including a power EURO cable

and rechargeable battery. USB interface for configuration.

Notification

The components of the system cannot be used outside this2N®Lift8

system.

The audio units cannot be connected to a telephone line without the !CU

When shared by multiple shafts, the audio units cannot be connected

without the and splitters.CU

®

82N TELEKOMUNIKACE a.s., www.2n.cz

Page 9

918620E 2N Lift8 Splitter

®

SplitterFigure: 2N Lift8

®

For – lift audio unit interconnection.CU

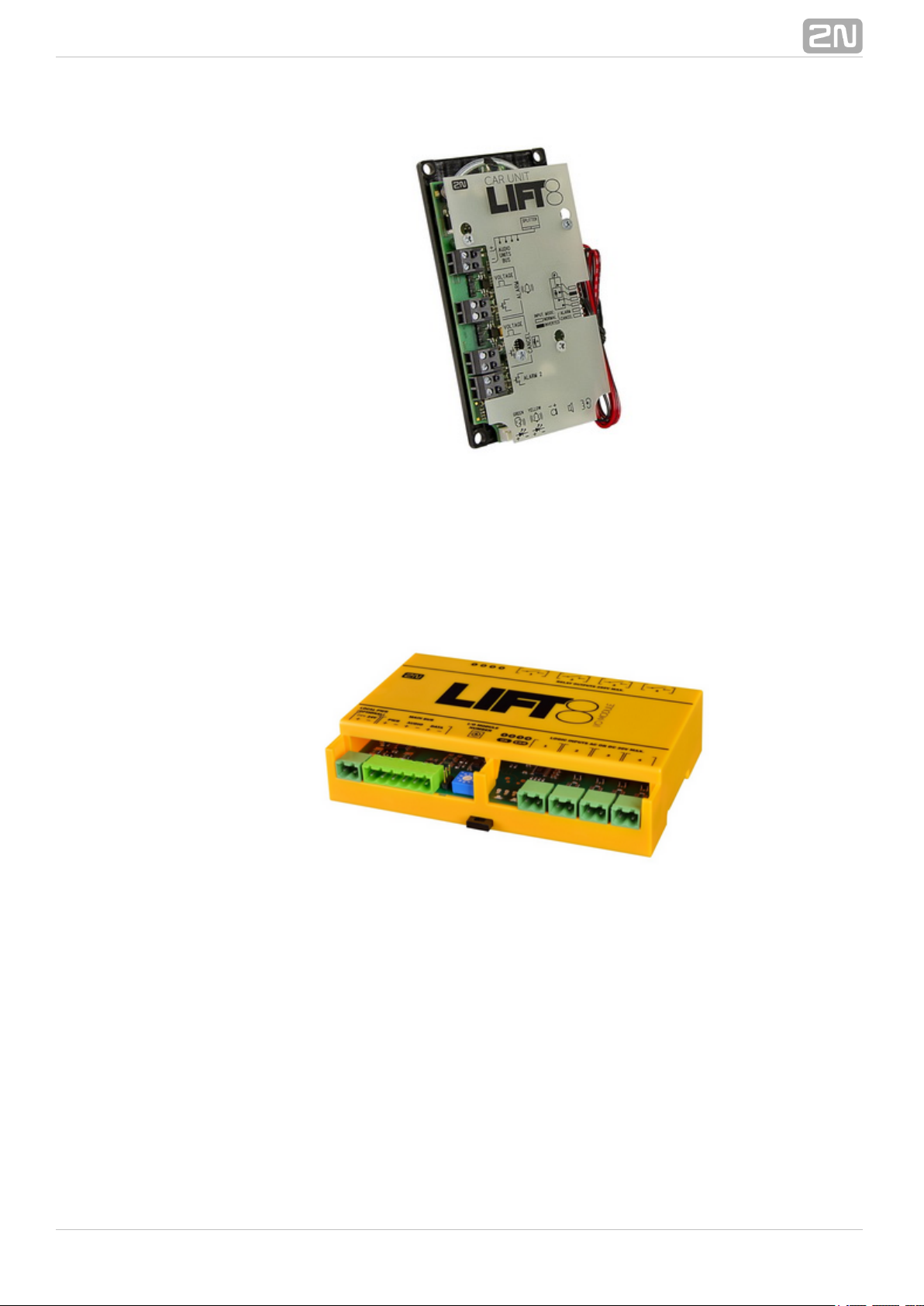

918610E 2N Lift8 Audio Unit – Cabin Universal

®

(Normal version)

Audio Unit – Cabin UniversalFigure: 2N Lift8

®

Audio unit electronics for lift cabin buiiding in. Including speaker and microphone

(HandsFree). Connection terminals for all prescribed elements and door opening signal

input (optional).

®

92N TELEKOMUNIKACE a.s., www.2n.cz

Page 10

918610EX 2N Lift8 Audio Unit – Cabin Universal – Cable Version

®

Contains LED, microphone and speaker connected to cables.

Audio Unit – Cabin Universal – Cable VersionFigure: 2N Lift8

®

918611E 2N Lift8 Audio Unit – Machine Room/Control Centre

®

Audio Unit – Machine Room/Control CentreFigure: 2N Lift8

®

Audio unit for the machine room/control centre. Contains receiver (optional) and

keypad for easy control. Makes it possible to communicate with other system audio

units and configure the without a PC. Equipped with an external siren connector.CU

Can be shared by multiple lifts (shafts). Robust yellow cover.

®

102N TELEKOMUNIKACE a.s., www.2n.cz

Page 11

918612E 2N Lift8 Audio Unit – Shaft

®

Audio Unit – ShaftFigure: 2N Lift8

®

Audio unit for cabin roof and shaft or cabin bottom. Robust yellow cover. HandsFree

mode, ALARM button and Triphony, LED indicators. Not intended for use in the cabin.

918613E 2N Lift8 Audio Unit – Compact

®

Audio Unit – CompactFigure: 2N Lift8

®

Robust, heavy-duty design. Standard-sized ALARM button including signage for the

blind and backlit pictograms (hardened glass). Easy cabin wall mounting. Easy 2-wire

connection.

®

112N TELEKOMUNIKACE a.s., www.2n.cz

Page 12

918615ZK 2N Lift8 Audio Unit – Fireman (1 button)

®

918615E 2N Lift8 Audio Unit – Fireman (knob + 1 push-to-talk

®

button)

Audio Unit – FiremanFigure: 2N Lift8

®

Used for fire fighting operations. Activates top priority calls.

918610FZK 2N Lift8 Audio Unit – Fireman DPS (1 button)

®

918619E 2N Lift8 Audio Unit – Fireman DPS (knob + 1 push-to-talk

®

button)

®

122N TELEKOMUNIKACE a.s., www.2n.cz

Page 13

Audio Unit – Fireman DPSFigure: 2N Lift8

®

Used by fire fighting operations. Activates top priority calls.

918620E 2N Lift8 I/O Module

®

I/O ModuleFigure: 2N Lift8

®

Contains logical inputs and switch relays.

®

132N TELEKOMUNIKACE a.s., www.2n.cz

Page 14

918650E 2N Lift8 GSM Module

®

GSM ModuleFigure: 2N Lift8

®

For central unit connection via a mobile network. Optional data connection for remote

system configuration.

®

142N TELEKOMUNIKACE a.s., www.2n.cz

Page 15

918651E 2N Lift8 UMTS Module

®

UMTS ModuleFigure: 2N Lift8

®

For central unit connection via a mobile network. Optional data connection for remote

system configuration.

®

152N TELEKOMUNIKACE a.s., www.2n.cz

Page 16

918652E 2N Lift8 PSTN Module

®

PSTN ModuleFigure: 2N Lift8

®

For central unit connection via an analogue line.

®

162N TELEKOMUNIKACE a.s., www.2n.cz

Page 17

918653E 2N Lift8 VoIP Module

®

VoIP ModuleFigure: 2N Lift8

®

For central unit via a VoIP line.connection

®

172N TELEKOMUNIKACE a.s., www.2n.cz

Page 18

Cooperating 2N Applications

®

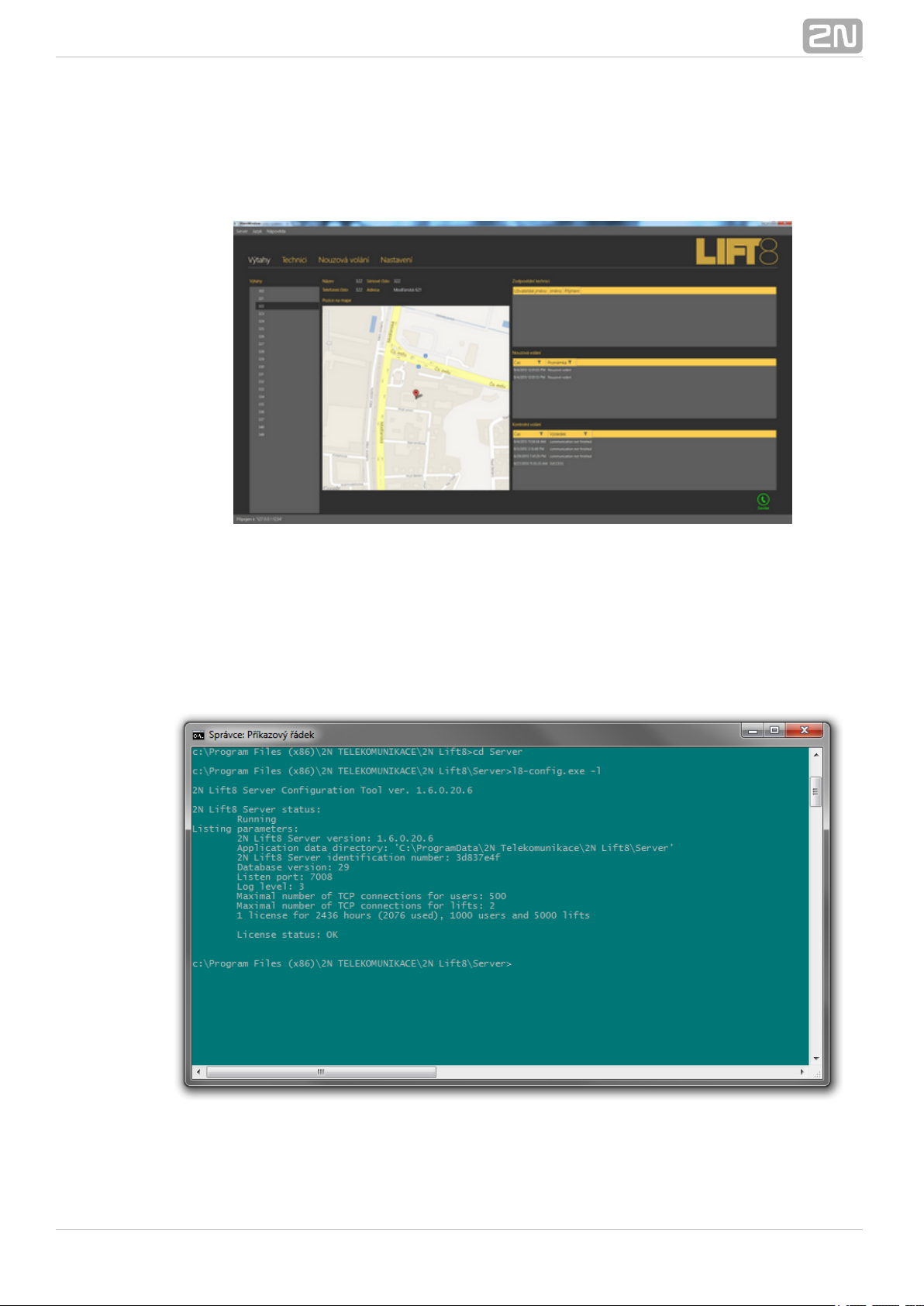

918700E 2N Lift8 Service Tool

®

Figure: 2N Lift8®Service Tool

The is intended for remote supervision and2N Lift8 Service Tool® application

configuration of the communicators.2N Lift8

®

918700E 2N Lift8 Control Panel

®

Figure: 2N Lift8 Control Panel

®

The application is intended for administration of users, lifts2N Lift8 Control Panel

®

®

182N TELEKOMUNIKACE a.s., www.2n.cz

Page 19

and authorisations.

918700E 2N Lift8 Communicator

®

Figure: 2N Lift8 Communicator

®

The is intended for receiving alarm calls by the2N Lift8 Communicator®application

dispatcher.

918700E 2N Lift8 Server

®

Figure: 2N Lift8 Server

®

®

192N TELEKOMUNIKACE a.s., www.2n.cz

Page 20

The processes check calls and mediates communication2N Lift8 Server®application

between the s and PC applications.CU

Associated 2N Products

®

918655E – 2N Lift8 External Pictograms Driver

®

External Pictograms DriverFigure: 2N Lift8

®

Transforms the cabin into universal pilot lamps.2N Lift8

®

LED outputs

®

202N TELEKOMUNIKACE a.s., www.2n.cz

Page 21

1.3 Upgrade

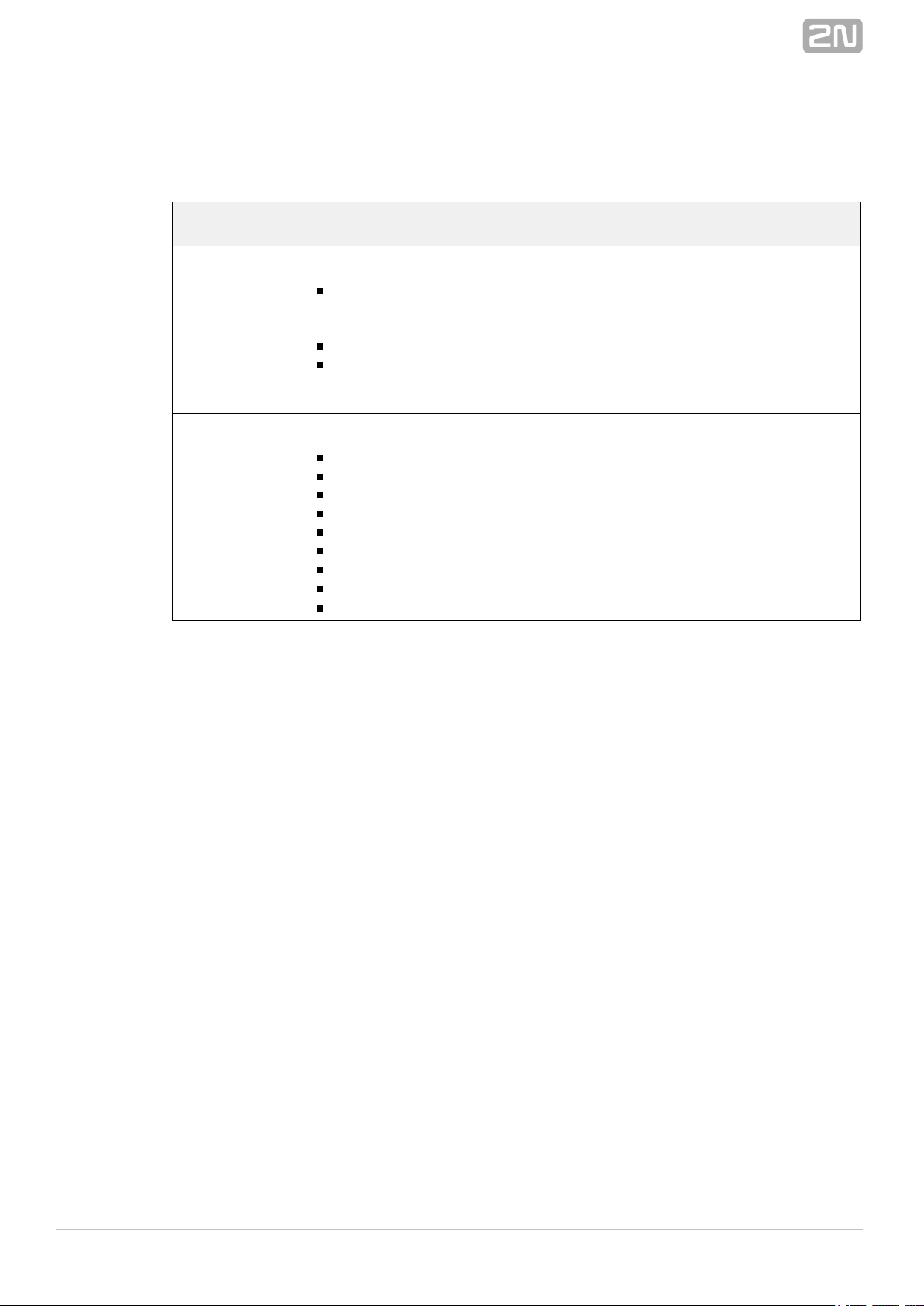

The table below sums up the User Manual upgrade changes made so far.

Manual

version

Description of changes

1.0.0

Firmware 1.0.0

Basic version

1.5.0

Firmware 1.5.0

VoIP parameters added

Internal splitter configuration optionfour-lift

(up to four cabin units can be connected to one internal splitter

with lift 1-4 identification)

1.6.0

Firmware 1.6.0

Fireman

I/O modules (inputs only)

Configurable rechargeable battery capacity

New alarm call protocols added (shaft/announcer identification)

Dial-in option (for PSTN modules with non-standard tones)

CZ, EN, RU language support

Important warnings -Upgrade ServerDatabase from ver. 1.5.x to ver. 1.6.x

PSurveillance mode intheControl anel

Improvements inapplications

®

212N TELEKOMUNIKACE a.s., www.2n.cz

Page 22

1.4 Terms and Symbols Used

Symbols Used

The following symbols and pictograms are used in the manual:

Future Functions, New Features

The grey-marked text in this document designates the functions and features that are

under preparation or development at present.

Safety

abide by this information to prevent persons from injury.Always

Warning

abide by this information to prevent damage to the device.Always

Caution

Important information for system functionality.

Tip

Useful information for quick and efficient functionality.

Note

Routines or advice for efficient use of the device.

®

222N TELEKOMUNIKACE a.s., www.2n.cz

Page 23

2. Description and Installation

The section is divided according to system components into the following subsections:

2.1 PSTN/GSM/UMTS/VoIP Central Unit

2.2 Splitter

2.3 Audio Unit – Cabin Universal

2.4 Audio Unit – Machine Room

2.5 Audio Unit – Shaft

2.6 Audio Unit – Compact

2.7 PSTN Module

2.8 GSM/UMTS Module

2.9 VoIP Module

2.10 Audio Unit – Fireman

2.11 I/O Module

Each subsection includes:

Description of Components

Before You Start

Fitting

Electrical Wiring

®

232N TELEKOMUNIKACE a.s., www.2n.cz

Page 24

2.1 PSTN/GSM/UMTS/VoIP Central Unit

Description

Central UnitFigure:

®

242N TELEKOMUNIKACE a.s., www.2n.cz

Page 25

Figure: Central Unit Indication Elements

®

252N TELEKOMUNIKACE a.s., www.2n.cz

Page 26

Figure: Central Unit Connectors

There are a USB connector and reset button to the right of the (see the figureCU

below).

Figure: Reset ButtonUSB Connector and

®

262N TELEKOMUNIKACE a.s., www.2n.cz

Page 27

Reset button function

– press the button quickly.Reset equipment

– press and hold the button until all the LEDs turn red.Restore factory values

Then release the button and wait until the SYSTEM LED flashes yellow. Now press

the button quickly to delete all the user settings.

– press and hold the buttonZero backup rechargeable battery life counter

until all the LEDs turn red. Then release the button and wait until the

POWER/BATTERY LED flashes yellow. Now press the button quickly. Perform this

function after replacing the backup rechargeable batteries with new ones only!

– press and hold the button until all the LEDsCheck system completeness

turn red. Then release the button and wait until the INTERNAL BUS LED flashes

yellow. Now press the button quickly to make the system supervise all the

installed equipment (splitters, Audio Units etc.) for proper connection and

function.

– press and hold the button until allDelete central unit software completely

the LEDs turn red. Then release the button and wait until the SYSTEM LED

flashes red. Now press the button quickly. CAUTION: after performing this

function you can only restore the normal function of the device using a PC!

USB Port Connection

Recommendation

Do not keep your PC connected for a long time unless necessary to reduce the

computer damage due voltage surge from the telephone line during storms, for

example.

Before You Start

CU installation conditions

The (hereinafter referred to as ) is not intended for outdoor use. Central Unit CU

Do not install the onto vibration-producing machines. CU

Install the vertically to allow air flow for cooling purposes (never cover the CU CU

with any cloth or install it in another closed box).

You may install the into the lift switchboard unless the temperature exceedsCU

the acceptable limit. Remember that a higher ambient temperature reduces the

life of backup rechargeable batteries in the .CU

It is recommended that the should be operated in the upright position withCU

the cable openings at the bottom. Such mounting position ensures the lowest

temperatures and thus the longest life of the rechargeable batteries. Horizontal

mounting is also possible. The upright position with the cable openings at the top

(upside down) is forbidden!

After mounting the check that the equipment is firmly fixed in place andCU

cannot come loose and drop down into the shaft.

Warning

during the warranty period.Do not open the CU

Open the only to replace after theCU the rechargeable batteries

warranty period.

®

272N TELEKOMUNIKACE a.s., www.2n.cz

Page 28

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Product Completeness Check

Check whether the product package is complete before installation:

1 central unit

1 main bus terminal

4 bus connection terminals

4 wall plugs

4 wall plug screws

8 cable ties

1 battery connecting cables

1 brief manual

1 warranty sheet

drilling template

CU Mounting

It is recommended to install the in a room that is secured against unauthorisedCU

persons, such as the lift machine room, switching station etc. On an easily accessible

place there is a risk of telephone line misuse or SIM card misappropriation .

The is mounted on a wall with the included wall plugs and screws. CU

CU Electrical Installation

Putting in operation

Keep the disconnected from the mains.CU

Loosen the three screws on the upper cover of the CU.

Move the upper cover of the in such a way that you can remove it.CU

When removing the cover, proceed with caution, be careful about the earth wire

connecting the cover with the bottom part. Do not disconnect the wire unlessCU

there is a reason to do so!

Using the slide-on terminals supplied with the device, connect the Audio Units,

splitters (if there are 2 and more lift shafts) and other components of the system

with the Adhere to polarity!CU.

Install a PSTN, GSM or UMTS module unless installed on the . Abide by theCU

instructions given in the Instructions for Use of the given module (refer to Subs.

2.7 or 2.8).

Connect an analogue telephone line to the PSTN module if used (use a telephone

connector or the terminal board on the module). Do not forget to connect an

antenna to the GSM/UMTS module is used and insert a SIM card!

Connect the rechargeable battery jumper link (see the next subsection –

Rechargeable Battery State Check) to activate the rechargeable battery function.

Replace the upper cover on the and tighten the cover fitting screws. Doing soCU

make sure that the earthing wire is connected to the cover!

Connect the power cable to a 230V socket.CU

Caution

If you connect one lift shaft only, it is not necessary to connect the

splitters. Use the splitters only if you want to connect 2 or more lift shafts.

®

282N TELEKOMUNIKACE a.s., www.2n.cz

Page 29

Power supply

The is powered by 100–240V mains power.CU

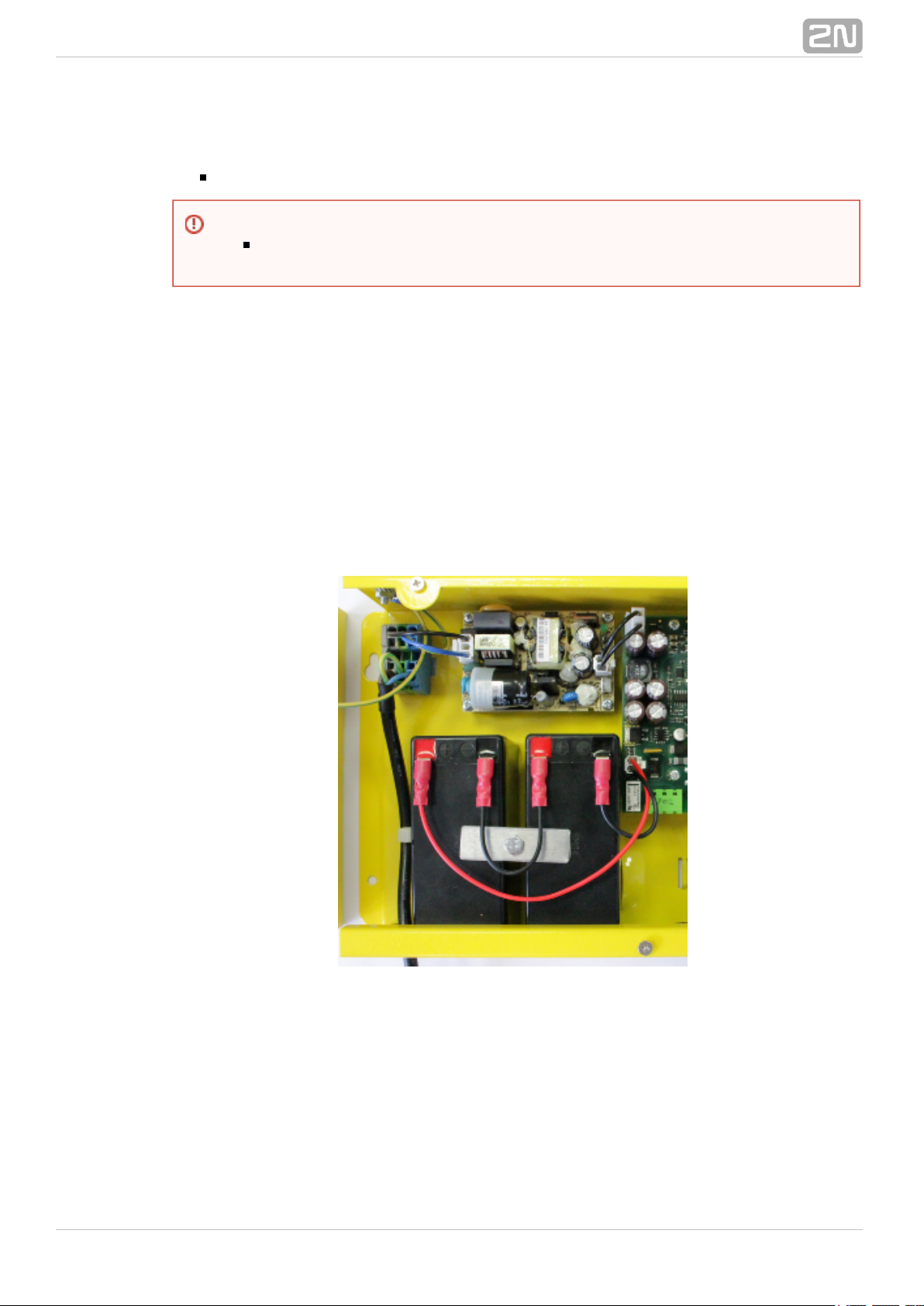

Rechargeable Battery Connection and State Check

Procedure:

1. Keep the disconnected from the mains.CU

2. Loosen the three screws on the upper cover of the CU.

3. Move the upper cover of the in such a way that you can remove it.CU

4. When removing the cover, proceed with caution, be careful about the earth wire

connecting the cover with the bottom part. Do not disconnect the wire unlessCU

there is a reason to do so!

5. Interconnect the rechargeable batteries and connect them with the motherboard

using a FASTON cable (see the figure below). Mind the polarity.

6. Replace the upper cover on the and tighten the cover fitting screws. DoingCU

so make sure that the earthing wire is connected to the cover!

7. Connect the power cable to a 230V socket.CU

After plugging the into the socket the LED (Power/battery) should start to flashCU

(charging). The charges the rechargeable batteries until fully charged. After some CU

time the flashing green LED (charging) should change to a permanently illuminated

green LED (battery charged).

Warning

Never connect an AC source or unstabilised DC source to avoid CU

damage.

®

292N TELEKOMUNIKACE a.s., www.2n.cz

Page 30

Rechargeable Batteries

Splitter – CU Bus Connection

Interconnect the and splitter using a 6-wire main bus (power + - , audio + - , dataCU

+ - ). Mind the polarity.

Warning

Adhere to the polarity of the rechargeable batteries! When the polarity of

the batteries is reversed, there is a danger of fire or explosion or damage

to the electronics.CU

Caution

If backup rechargeable batteries are used for the power supply,2N Lift8

®

the required backup of up to 1 h is guaranteed only if up to 20 audio units

are connected in the system.

The required 1h backup is not guaranteed if more than 20 audio units are

installed.

®

302N TELEKOMUNIKACE a.s., www.2n.cz

Page 31

Main bus

1 … Main bus power +

2 … Main bus power 3 … Main bus audio +

4 … Main bus audio 5 … Main bus data +

6 … Main bus data -

Audio Units – Splitter (CU) Bus Connection

(the is used if one lift shaft is connected)CU

Interconnect the Splitter ( ) and Audio Units using a two-wire bus. Mind the polarity.CU

Audio unit bus

1 … Bus for Audio Units +

2 … Bus for Audio Units -

Caution

6-wire

Use unshielded wires of the cross-section of 0.75 mm .

2

The maximum total cable length is 30 m with the cross-section of

0.75mm .

2

For higher lengths, enlarge the supply pair cross-section: PWR (60m

– 1.5mm , or 100m – 2.5mm ).

2 2

®

312N TELEKOMUNIKACE a.s., www.2n.cz

Page 32

Termination Resistance

Connect the termination resistance connector to the first and last device connected to

the bus: CU, splitter or I/O module.

Caution

2-wire

Use unshielded wires of the cross-section of 0.75 mm .

2

The maximum total length per shaft is 600 m.

With multi-strand cables, always use a pair of wires which match

each other.

With a tow cable, consider the cable length too.

With special cables (to the cabin), use the neighbouring wires and

make sure that the nearest surrounding wires do not radiate

interference (power wire, video signal etc.).

Tip

Do not lead the bus close to power cables, especially in long-distance

sections.

Branch the bus to shorten the total length of sections.

Safety

The bus is electrically isolated from the telephone line circuits according to

the EN60950 standard requirements and its low voltage cannot cause any

electrical accident.

Caution

Find the 2-pin termination resistance connector between the main bus

connector and audio unit connectors (see the figure below).

By default, the termination resistance is connected (jumper mounted).

®

322N TELEKOMUNIKACE a.s., www.2n.cz

Page 33

Examples of connection:

®

332N TELEKOMUNIKACE a.s., www.2n.cz

Page 34

CU Connection to Telephone Network

You can connect the to any of the following telephone networks: CU

PSTN

PBX

GSM

UMTS

VoIP

PSTN

works in a broad band regardless of polarity and line parameters (refer to 2N Lift8

®

Technical Parameters). Connect it using the enclosed cable with an RJ–12 terminal. It

is the most reliable and simplest connection. The disadvantage is the operating cost

(fixed fee).

Caution

Only one may be connected to one telephone line and no other endCU

telephone equipment may be connected to the line including a product

through which the telephone line goes (so-called priority connection –

electronic burglar alarm, e.g.).

No dual or party lines may be used.

No telephone “multiplugs” (adaptors), even the smart ones, may be used.

Never connect to an ISDN line.2N Lift8

®

®

342N TELEKOMUNIKACE a.s., www.2n.cz

Page 35

Telephone line requirements

The line must not be a dual or party one.

The telephone socket and its wiring are usually the network provider's property

and may not be tampered with.

Other recommendations

Notify the telephone network provider of your installation and submit2N Lift8

®

certification upon request.

Your follow-up wiring must comply with the relevant safety regulations.

You are recommended to secure your cabling against pirate connection (with a

telephone lock, e.g.).

Connection via PBX (Private Branch Exchange)

This is the least-cost solution where a PBX and an unused PBX line are available.

PBX line requirements

The PBX to be used must work reliably even in the case of power outage. Large

PBXs are mostly equipped with a back-up power supply, smaller PBXs usually use

PSTN line redirection in the event of power failure. Consult the problem with the

technician responsible for your PBX. An error during power outage may result in

calling an undesired station.2N Lift8

®

Relevant call access rights have to be assigned to the PBX line to be used (use a

standard telephone set to check whether the line can make outgoing calls to all

the required numbers).

While programming, enter the necessary PSTN code (typically a zero), or

(preferably) make the PBX not require a prefix (so-called automatic connection to

the provider's telephone line).

To make the control room – lift calls, you have to know the extension number

and how to get through to it (dial-in, DISA, operator).

The control room – lift connection may not depend on the operator’s presence;

no call forwarding to a fax/answering machine in the night mode is allowed, etc.

Other recommendations

Make an agreement with the PBX owner regarding operating costs (2N Lift8

®

outgoing calls are billed at the owner‘s expense with the exception of free calls

via “green lines”).

GSM

This is used in particular where no PSTN line is available.

Tip

If there is permanent manning in your building (security staff,

receptionist), train the personnel how to rescue people and program 2N

®

to call this service. Lift8

®

352N TELEKOMUNIKACE a.s., www.2n.cz

Page 36

Recommendation

In places with a poor signal quality find an appropriate place or use a special

(directional) antenna.

Protect the SIM card from theft.

If a prepaid SIM card is used, make sure that the credit is monitored and

topped up in time.

UMTS

This is used in particular where no PSTN line is available. If is connected via2N Lift8

®

UMTS, the system can be configured remotely using the appli2N Lift8 ®Service Tool

cation.

Recommendation

In places with a poor signal quality find an appropriate place or use a special

(directional) antenna.

Protect the SIM card from theft.

If a prepaid SIM card is used, make sure that the credit is monitored and

topped up in time.

Operation without SIM card or PSTN line

can be used as an intercom without an inserted SIM card or2N Lift 8

®

connected PSTN line during the lift fitting time. In this case do not enable the

lift blocking function until the telephone line is connected.

VoIP

VoIP is the cheapest solution where a reliable Internet connection is available.

®

362N TELEKOMUNIKACE a.s., www.2n.cz

Page 37

2.2 Splitter

Description

The splitter helps extend installations by interconnecting audio units in multiple lift

. shafts (audio units can be connected directly to the in one-shaft installations)CU It is

connected with the via six wires (power, audio, data). A s are connected toCU udio unit

the splitter using a two-wire bus. The splitter also contains a make/break contact for

the lift blocking function. There can be up to 7 splitters (according to the count of lift

shafts).

Each splitter must be configured for a different address (lift shaft number) for the

system to work. The addresses are 2–8 (lift 2–8). Lift 1 is the .CU

The splitters are connected in series, i.e. one after another (never in parallel), to avoid

system instability. The termination resistance (jumper) is mounted on the last splitter

.or IO module (furthest from the )CU

SplitterFigure: 2N Lift8

®

Caution

Local power supply is not supported yet.

®

372N TELEKOMUNIKACE a.s., www.2n.cz

Page 38

Electrical Installation

Main Bus Connection

Remove the push-in terminal board from the main bus connector and connect six wires

from the maintaining the polarity (power + -, audio + -, data + -). See the printedCU

figure on the splitter cover.

Main bus

1 … Main bus power +

2 … Main bus power 3 … Main bus audio +

4 … Main bus audio 5 … Main bus data +

6 … Main bus data -

Bus Connection between s and SplitterAudio Unit

Interconnect the splitter and a s using a two-wire bus maintaining polarity.udio unit

Audio unit bus

1 … Bus for Audio Units +

2 … Bus for Audio Units -

Warning

Maintain the connection polarity to avoid a error.2N Lift8

®

®

382N TELEKOMUNIKACE a.s., www.2n.cz

Page 39

Address Configuration

Configure the splitter address for the given lift using a 10-position switch 0–9 (see the

figure).

Configure lift 2–8 as 2–8 (set the switch to position 5 for lift 5, e.g.).

Audio Unit Connection

Connect up to 5 s to each splitter. As the splitter has only 3 terminaudio unit audio unit

als, connect 1–2 in parallel. Remove the slide-on terminals from the audio unit audio

connectors and connect the twin-wire. Adhere to polarity to avoid the erunit audio unit

ror. Refer to the schemes printed on the splitter and for connection polarity.audio unit

Requirements

Connect up to 2 s to one terminal.audio unit

With multi-strand cables, always use a pair of wires which match each other. In

standard UTP cables the paired wires are twisted around each other.

With special cables (to the cabin), use the neighbouring wires and make sure

that the nearest surrounding wires do not radiate interference (power wire, video

signal etc.).

Recommendation

Do not run the bus near power wires, especially long sections.

.Branch the bus to shorten the total length of sections

Lift Blocking Function Connection

Lift blocking is enabled by the contact breaking (opening) when there is a telephone

line (PSTN, GSM, UMTS, VoIP) fault or if the rechargeable batteries are2N Lift8

®

almost flat. Connect the contact to the relevant input of the control electronics of the

lift/group of lifts. The control electronics must ensure that, after the contact opening,

the lifts in operation go down to the nearest station and the doors open.

Warning

The bus is electrically isolated from the telephone line circuits according to

the EN60950 standard requirements and its low voltage cannot cause any

electrical accident.

Caution

This function may be mandatory depending on the regulations applicable

and time of installation.for the given country

®

392N TELEKOMUNIKACE a.s., www.2n.cz

Page 40

Termination Resistance

Figure: Termination Resistance Off

Caution

Find the 3-pin termination resistance connecting jumper between the

main bus connector and lift number switch.

Connect the jumper to the first and last device (CU, splitter or I/O

module) on the bus. Refer to the CU describing section for more details on

termination resistance mounting.

By default, the termination resistance jumper is off.

®

402N TELEKOMUNIKACE a.s., www.2n.cz

Page 41

Mounting Types

See below for the mounting types and necessary components. Install the device on

sites not exposed to water leakage or condensation.

Wall Mounting

Use appropriate wall plugs and screws for mounting (not included in the delivery).

Hang the device using the pre-drilled holes on the device bottom.

Figure: Wall Mounting

DIN Rail Mounting

Mount the device on a standard TS 35 DIN rail. The recommended DIN rail length is 14

cm.

Figure: DIN Rail Mounting

®

412N TELEKOMUNIKACE a.s., www.2n.cz

Page 42

Caution

The warranty does not cover any defects or failures of the product arisen

as a result of improper mounting in contradiction to these instructions.

A wrong mounting procedure may lead to damage to the electronics due

to water infiltration. The splitter circuits are constantly under voltage and

water leakage causes electrochemical reaction. No warranty can be

claimed for products damaged in this manner!

®

422N TELEKOMUNIKACE a.s., www.2n.cz

Page 43

2.3 Audio Unit – Cabin Universal

Description

The user does not come into a direct contact with this product. The control and

indication elements depend on the specific installation. The functions of the indication

elements correspond to the applicable standards

Figure: Audio Unit – Cabin Universal

Before You Start

Installation Conditions

The panel has to be installation-ready, including speaker perforation.

The panel has to be equipped with the following obligatory elements:

ALARM button;

illuminated pictogram “Request received”;

illuminated pictogram “Connection made”.

The above mentioned elements have been located as required by the applicable

regulations.

There must be free space of at least 65×130×20 mm behind the panel.

®

432N TELEKOMUNIKACE a.s., www.2n.cz

Page 44

Product Completeness Check

Check the product for completeness before installation.

The cabin package contains (assembled):audio unit

1 electronics board

4 terminals slid onto the board; see the photo

1 jumper slid onto the board; see the cover printing

1 mounting panel

1 speaker connected directly or by cable

1 microphone connected directly or by cable

1 cover with printing

5 tightening straps

Mounting

Electronics Mounting

This is intended for mounting behind the lift control panel. Typically, theaudio unit

panel is ready for installation as shown in the drawing below:

Figure: Mounting Hole Dimensions for Audio Unit – Cabin Universal

To mount the , you need 4 electrically spot welded or screws, aaudio unit M3 M4

sufficiently perforated speaker area and a microphone hole. In emergency, you can fix

®

442N TELEKOMUNIKACE a.s., www.2n.cz

Page 45

the on a perfectly degreased surface with a high-quality double-sided foamaudio unit

self-adhesive tape.

Separate Microphone Mounting

If the microphone is supplied separately with a cable on a 25×25 mm large board with

self-adhesive foil, j hole in the panel (one hole must haveust glue it directly behind any

the minimum diameter of 5 mm, a group of smaller holes must have the same total

area). Be sure to degrease and clean the surface carefully before!

Requirements

The minimum distance between the loudspeaker and microphone centres

A lower distance may lead to acoustic feedback. A greater distance is 90 mm.

(within the available 1m cable) does not matter.

The microphone must be stuck on so that it does not pick up (even in part!) the

acoustic pressure from the space behind the control panel. Such sensing might

result in acoustic feedback since the speaker strongly radiates sound into the

cavity.

Separate Speaker Mounting

The speaker is equipped with a cable and can be separated from the electronics (simply

pulled out) within the reach of the cables delivered (1m). This option is useful where

there is not enough space for the whole electronic equipment. Fit the speaker

according to the instructions below:

While gluing the speaker choose such procedures or adhesives that prevent

membrane damage by adhesives and volatile substances or heat.

We recommend you to keep the speaker sealed to eliminate vibrations and

provide electrical insulation.

Frequently Asked Questions about Speaker

Is it possible to use a common speaker for the communicator and floor

?announcer

No, it is not possible.

May I use a speaker of my own?

Yes, but make sure that the impedance is 64 Ω. By doing this you assume

responsibility for sufficient volume and frequency range.

May I place the speaker on the cabin ceiling?

This placement is not recommended.

May I use a longer cable to the speaker?

For the speaker yes, but we do not recommend it for the microphone.

Safety

Leave no gap between the lift control panel and the surface toaudio unit

avoid acoustic speaker fault and acoustic speaker-microphone feedback.

Do not use this type of in a position other than mounted on aaudio unit

sufficiently large board. The acoustic properties of an uninstalled audio

cannot be guaranteed.unit

®

452N TELEKOMUNIKACE a.s., www.2n.cz

Page 46

Electrical Installation

Description of Terminals, Connectors and Jumpers

Figure: Terminals, Connectors and Jumpers on Audio Unit – Cabin Universal

Terminals Connectors

1 Audio unit bus 7 “Connection made” LED

2 ALARM, voltage activation 8 “Request received” LED

3 ALARM, contact activation 9 Microphone connector (optionally)

4 CANCEL, voltage activation 10 Induction loop connector

5 CANCEL, contact activation 11 Speaker connector

6 Alarm 2 (set 2) 13 Servicing connector

Configuration jumpers Two LED signal lamps (other side)

12 positionAudio unit 1. (yellow) Request received

12 ALARM and CANCEL negation 2. (green) Connection confirmed

Note

If external LEDs are connected to connectors 7 and 8, LED indicators 1

and 2 will not be shining.

®

462N TELEKOMUNIKACE a.s., www.2n.cz

Page 47

1.

2.

3.

4.

5.

ocation ConfigurationAudio Unit L

The is configured as a cabin by default and so it is not necessaryaudio unit audio unit

to change the configuration. To use the in a room other than the lift cabin,audio unit

proceed as follows.

Procedure

Reconfigure the jumper on configuration jumper 12.

If there is poor access to the pins, you can remove the electronics cover. Slightly

loosen the four screws and shift the cover downwards. Now you can remove the

cover.

The first 4 pins serve for setting the location (1 – cabin ceiling, 2 –audio unit

cabin, default, 3 – under the cabin, 4 – shaft bottom).

Configure the required changes as printed on the electronics cover.

If you have removed the cover, put it back in the original position and tighten the

screw.

®

472N TELEKOMUNIKACE a.s., www.2n.cz

Page 48

Figure: Address Configuration for Audio Unit – Cabin Universal

Note

Make sure that two s do not have an identical address to avoidaudio unit

system error.

The position-setting jumpers are employed exceptionally, e.g. where a

certain type is used in a position other than normally intended.audio unit

To recover the initial address setting, follow the drawing on the cover.

®

482N TELEKOMUNIKACE a.s., www.2n.cz

Page 49

1.

2.

3.

Bus Connection

Pull the terminal out of connector 1 - Audio units bus, connect the bus audio units

wires and replace the terminal to connector 1. Mind the polarity.

ALARM Button Connection

Requirements

The ALARM button design (colour, symbol, keypad surface, mechanical operation)

and location have to meet the requirements of the particular installation.

Button control

Requirements

The ALARM button has to be equipped with a make or break (NO/NC) contact

that is not connected with any other circuit.

None of the ALARM button terminals may be connected electrically with any other

electrical circuit and no voltage source other than the NO/NC contact may be

connected to them.

If one of the ALARM contacts is connected to another circuit, an appropriate

isolation strength according to the applicable standards has to be ensured

between the contacts.

Procedure

Leave the ALARM terminal in the lower position (3).

If you use a make contact, leave the jumper as it is (5th pin on jumper 12) –

ALARM without jumper fitted (factory setting).

If you use a break contact, fit the jumper (5th pin on jumper 12) – ALARM

inverted – jumper fitted.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the .audio unit

Maintain polarity while connecting the to avoid error.audio unit audio unit

Caution

The is powered via a 2-wire bus. Disconnection of these wiresaudio unit

results in the switch-off.audio unit

Avoid the address duplicity.audio unit

®

492N TELEKOMUNIKACE a.s., www.2n.cz

Page 50

1.

2.

3.

1.

2.

3.

Voltage control

Requirements

DC 12 to 48V voltage

The voltage signal must be active even during a power failure.

Procedure

Move the ALARM terminal two pins up into position (2).

For activation by voltage connection, leave the jumper as it is (5th pin on jumper

12) – ALARM without jumper fitted (factory setting).

For activation by voltage disconnection, fit the jumper (5th pin on jumper 12) –

ALARM inverted – jumper fitted.

CANCEL Input Connection (Door Contact, Optional)

This input helps cancel a rescue request if the lift is fully functional. When the ALARM

button is pressed, the system waits for a pre-programmed period of time, which is a

little longer than the maximum lift running time. If the lift is functional, it arrives in the

required station within this timeout and opens the door. In that case, the rescue

request is cancelled. If the door does not open, the request is accepted.

Find out before installation whether the door opening signal is available in the lift cabin.

Requirements

If the lift has a double door, the signal must be active only if both the door sets

are open, i.e., if it is really possible to leave the cabin.

The door position signal has to work even in the case of power outage.

Contact control

Requirements

None of the contact outlets terminals may be connected electrically with any

other electrical circuit and no voltage source other than the NO/NC contact may

be connected to the CANCEL terminals.

Procedure

Leave the CANCEL terminal in the lower position (5).

f you use a make contact, leave the jumper as it is (6th pin on jumper 12) –

CANCEL without jumper fitted (factory setting).

If you use a break contact, fit the jumper (6th pin on jumper 12) – CANCEL

inverted – jumper fitted.

Warning

Ignoring the instructions above may lead to product damage.

®

502N TELEKOMUNIKACE a.s., www.2n.cz

Page 51

1.

2.

3.

Voltage control

Requirements

DC 12 to 48V voltage

Procedure

Move the CANCEL terminal two pins up into position (4).

For activation by voltage connection, leave the jumper as it is (6th pin on jumper

12) – CANCEL without jumper fitted (factory setting).

For activation by voltage disconnection, fit the jumper (6th pin on jumper 12) –

CANCEL inverted – jumper fitted.

LED Indicator Connection

The current LED technology makes it possible to achieve a relatively good light

intensity with a small current. If the lift indicators are illuminated with a sufficiently

efficient LED requiring a current of approx. 5 mA (with diode loss of about 2 V), no

power supply is needed. See the figure below for the connection.

Figure: Alternative LED Connection for Audio Unit – Cabin Universal

Warning

Ignoring the instructions above may lead to product damage.

The CANCEL function only works when the cabin is set to theaudio unit

cabin position (default).

Caution

Remember to program delayed calling to make the CANCEL connection

work successfully.

Refer to the electronics cover for the ALARM and CANCEL configuration

scheme.

®

512N TELEKOMUNIKACE a.s., www.2n.cz

Page 52

External Pictogram Driver

Description

The device transforms the Car Unit LED outputs into a universal pilot lamp,2N Lift8

®

whose outputs are capable of driving two lamps rated at the maximum of 36 Volts, 0.5

Amps. The outputs are galvanically isolated from the Car Unit. Since the lamp outputs

are polarity independent, both AC and DC power supplies can be used for powering the

lamps. To protect the Car Unit and Pictogram Driver against damage caused by shorts,

always use the included isolating tube when installing the device!

Wiring diagram

Note

The cables required for this configuration are not part of the standard

delivery but are available upon agreement.

In this configuration, the auxiliary indicators on the PCB are not

illuminated.

®

522N TELEKOMUNIKACE a.s., www.2n.cz

Page 53

Volume Configuration

Slightly loosen the four screws and shift the cover downwards. Now you can remove

the cover. Use the trimmer located in the bottom part of the electronics to set the

required volume level (see the figure below).

Induction Loop Connection

The regulations that apply to communicator installations may require a mandatory loop

for persons with defective hearing in the lift cabin. In that case, connect the loop to

connector (10) with any polarity. The loop including a 1m long cable can be part of

your delivery if agreed so.

Requirements

The induction loop has to be placed behind a non-metal, non-magnetic cover in

the control panel as the magnetic field of the induction loop cannot go through a

metal control panel.

The induction loop has to be labelled with an appropriate symbol (ear) placed

according to the applicable standards.

Caution

External pictograms are connected to connectors 7 and 8 on the cabin

audio unit.

The manufacturer, 2N TELEKOMUNIKACE a.s., hereby declares that the

External Pictogram Driver is in compliance with the essential2N Lift8

®

requirements and other relevant provisions of the 1999/5/EC Directive.

The Declaration of Conformity is attached to the basic module of 2N

®

and also available at .Lift8 www.2n.cz

Caution

Use the trimmer to set the best acoustic properties eliminating feedback.

®

532N TELEKOMUNIKACE a.s., www.2n.cz

Page 54

Rescue Process

The rescue (extrication) process is activated after the alarm call end.

The yellow LED keeps shining on the audio unit.

The service technician enters a valid password via the voice menu2N Lift8

®

to terminate the process.

When the rescue password is entered via the voice menu, the yellow LED goes

off on the audio unit and the 'Rescue process was terminated' is played.

Caution

Access the voice menu (during an incoming call to L8 or from the machine

room) to terminate the rescue process. Enter the administration menu (9)

and press (2) to terminate the rescue process. Enter the shaft number

(only if multiple audio units are involved in the rescue process) and enter

the rescue terminating password.

Warning

Remember to set the rescue password (parameter 992) to activate the

rescue function.

The rescue process can only be activated on a cabin audio unit configured

as the cabin (default audio unit setting).

®

542N TELEKOMUNIKACE a.s., www.2n.cz

Page 55

2.4 Audio Unit – Machine Room

Description

The machine room audio unit is intended for installation in the machine room or as an

intercom solution located in the reception. It has some compared with thedistinctive

other types:

The is equipped with a keypad.audio unit

The keypad helps you select various functions and program the system.

You can connect a handset to the for better acoustic properties inaudio unit

noisy environments.

You can connect an external siren to the for incoming call signalling.audio unit

You can configure the machine room to be shared by multiple lifts.audio unit

®

552N TELEKOMUNIKACE a.s., www.2n.cz

Page 56

1.

2.

3.

4.

5.

Operation

This type of is operated by qualified people (lift maintenance staff,audio unit

e.g.).

Push the TRIPHONY button to activate voice communication with the other audio

of the same lift. Push and hold the button for over 2 seconds to activateunits

communication with another lift (to display a voice menu and select the required

lift number).

Push the ALARM button to call the control centre, for example. The audio unit

calls the numbers configured in the ALARM memory – set 2 (021–026). The

ALARM button illumination (not required by default) helps you find and activate

the easily in the dark.audio unit

When you press the ALARM or TRIPHONY button, the function is called up

immediately. Speak HandsFree or use a handset for better acoustic properties.

Press for more than 2 s to display the voice menu.

Before You Start

Requirements

Connect a handset supplied by the manufacturer to the to avoidaudio unit

handset operation error.

Product Completeness Check

Check the product for completeness before installation.

1 audio unit

1 handset

2 wall plugs

2 wall plug screws

7–8 jumpers for common machine room configuration

Mounting

The is typically mounted on a wall using the wall plugs and screws includedaudio unit

in the delivery.

Caution

If no number is specified in the ALARM memory – set 2 (021–026), the

dials the numbers defined in the ALARM memory – set 1audio unit

(011–016).

Push the ALARM button to call the control room or machine room audio

configured as an intercom.unit

The ALARM and TRIPHONY buttons shine even at relax.

®

562N TELEKOMUNIKACE a.s., www.2n.cz

Page 57

Electrical Installation

Description of Connectors

There are 3 connectors to the right under the cover:

Figure: Machine Room Audio Unit Connectors

Address Configuration

There is a group of jumpers u . Do not use any of themnder the transparent front cover

if the machine room is only intended for the given lift. The identifies itself asaudio unit

the machine room for the given lift.

If the machine room is to be shared by multiple lifts, configure the corresponding pins

1–8 for the lifts to share the machine room (numbered 1–8 from left to right 1–8).

Group of 8 jumpers for address configuration: If the machine room is shared by

multiple lifts, use one and configure several addresses using theaudio unit

included jumpers. The other types do not have this possibility!audio unit

Note

This audio unit is always configured as the machine room and cannot have

a different location.

Note

Having set more addresses for the , press the TRIPHONY buttonaudio unit

to activate communication of the lift with the lowest of theaudio units

configured addresses.

Caution

.Avoid the address duplicityaudio unit

®

572N TELEKOMUNIKACE a.s., www.2n.cz

Page 58

Bus Connection

Loosen the screws to the right and open the connector cover. There is just one

connector under the cover: a bus connector. Pull out the terminal from the connector,

connect the wires and replace the terminal. Make sure that the polarity is maintained.

Handset Connection

Order an additional handset for your . The handset is delivered including aaudio unit

cable with telephone end pieces.

Testing

Connect a handset and push and hold for over 2 s to display the voice menu for

the function test. If the handset does not work, the voice menu will be played from the

speaker.audio unit

Volume Configuration

Open the protective door on the and adjust the volume .audio unit using the trimmer

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Maintain polarity while connecting the to avoid erroraudio unit audio unit .

Caution

The is powered via a 2-wire bus. Disconnection of these wiresaudio unit

results in the switch-offaudio unit .

Caution

If the handset is not connected, the works in the HandsFreeaudio unit

mode.

A handset of a type other than that supplied by the manufacturer may not

work.

®

582N TELEKOMUNIKACE a.s., www.2n.cz

Page 59

Caution

Use the trimmer to set the best acoustic properties eliminating feedback.

Volume configuration only works in the HandsFree mode.

®

592N TELEKOMUNIKACE a.s., www.2n.cz

Page 60

2.5 Audio Unit – Shaft

Description

This audio unit is designed for installation on the lift shaft bottom or lift cabin roof, or

wherever it is necessary to communicate (during lift maintenance, e.g.). The audio unit

is enclosed in a robust yellow cover. It is not intended for outdoor use but perfectly

tolerates the conditions in lift shafts: is resistant against fall of small objects, dripping

oil, etc. The ALARM button activates the control centre connection, the TRIPHONY

bottom enables conference connection with the other a s of one and the sameudio unit

lift. The contains a built-in microphone and a speaker. A handset can beaudio unit

connected for better acoustic properties. Thanks to its size and robustness, the audio

has a very good, strong sound. unit

®

602N TELEKOMUNIKACE a.s., www.2n.cz

Page 61

1.

2.

3.

4.

5.

Operation

This type of is operated by qualified people (lift maintenance staff,audio unit

e.g.).

Push the TRIPHONY button to activate voice communication with the other audio

of the same liftunits .

Push the ALARM button, for example, when someone falls down the shaft.

The calls the numbers configured in the ALARM memory – set 2audio unit

(021–026).

The ALARM button illumination (not required by default) helps you find and

activate the easily in the darkaudio unit .

Before You Start

Product Completeness Check

Check the product for completeness before installation.

1 audio unit

2 wall plugs

2 wall plug screws

Requirements

This type of has no specific requirements.audio unit

Mounting

The is typically mounted on a wall using the supplied wall plugs and screws.audio unit

There is a drilling template in the product package.

Caution

If no number is specified in the ALARM memory – set 2 (021–026), the

dials the numbers defined in the ALARM memory – set 1audio unit

(011–016).

Push the ALARM button to call the control room or machine room audio

configured as an intercom.unit

The ALARM and TRIPHONY buttons shine even at relax.

Caution

The is not intended for outdoor installations.audio unit

®

612N TELEKOMUNIKACE a.s., www.2n.cz

Page 62

1.

2.

3.

Electrical Installation

Connectors

The has one connector for bus connection. The second RJ–11 connector isaudio unit

used for handset connection. Both the connectors are under the side doors.

Audio Unit Location Configuration

Audio unit location means configuration of jumpers (see the cover print). You do not

have to change the jumper configuration if you are installing the at the shaftaudio unit

bottom. Otherwise, proceed as follows:

Procedure

Loosen the screws on the jumper-protecting door and open the door.

Configure the required change according to the printed figure below the door

(this be configured as common for multiple).audio unit cannot

Close the door and tighten the screw.

Bus Connection

Loosen the screws to the right and open the connector cover. There is just one

connector under the cover: a bus connector. Pull out the terminal from the connector,

connect the wires and replace the terminal. Make sure that the polarity is maintained.

Caution

Avoid the address duplicityaudio unit .

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

Maintain polarity while connecting the to avoid erroraudio unit audio unit .

®

622N TELEKOMUNIKACE a.s., www.2n.cz

Page 63

Handset Connection

Use the handset supplied with the and the included cable with telephoneaudio unit

terminals.

Volume Configuration

Open the protective door on the and adjust the volume audio unit using the trimmer.

Caution

The is powered via a 2-wire bus. Disconnection of these wiresaudio unit

results in the switch-offaudio unit .

Caution

If the handset is not connected, the works in the HandsFreeaudio unit

mode.

A handset other than that supplied by the manufacturer may not work.

Caution

Use the trimmer to set the best acoustic properties eliminating feedback.

Volume configuration only works in the HandsFree mode.

®

632N TELEKOMUNIKACE a.s., www.2n.cz

Page 64

2.6 Audio Unit – Compact

Description

Robust, heavy-duty design. Standard-sized ALARM button including signage for the

blind and backlit pictograms (hardened glass). Designed for cabin wall mounting. No

drilling is required as the device is to be wall-mounted.

Figure: Description of Audio Unit – Cabin Compact

Operation

Push the ALARM button to activate the audio unit. The 'Establishing connection'

symbol goes on. The 'Connection established' symbol goes on when

communication is set up.

®

642N TELEKOMUNIKACE a.s., www.2n.cz

Page 65

Before You Start

Requirements

Make sure that the lift wall is even.

Make sure that the installation meets the standard requirements (ALARM button

height and distance from the other lift buttons, e.g.).

Product Completeness Check

Check the product for completeness before installation.

1 Compact audio unit including: one long, 2 mm ballpoint hexagon key wrench4

M4×8 screws

symbol window

3 terminals slid on the backside connector

4 M4×30 worm screws

4 M4 nuts

4 fan washers

Mounting

Just drill holes into the cabin wall as shown in the figure below (also see the 1:1 figure

on the product box). The larger hole is intended for cabling. Round the hole edges to

avoid cable damage!

®

652N TELEKOMUNIKACE a.s., www.2n.cz

Page 66

Figure: Mounting Hole Dimensions for Audio Unit – Cabin Compact

Note: Two 2.5 mm holes in the symbol window are intended for installations without

access to the back side of the installation panel. The 2.5 diameter is suitable for

plywood wall mounting (chipboard, laminated plastic, etc.) with the screws included in

the delivery. Drill M4-threaded holes for metal panel mounting from the front side.

Do not complete the mounting procedure until connecting the device electrically (see

below).

Electrical Installation

Caution

Connect the wires before mounting the audio unit on the lift cabin wall.

The connectors are separable – remove them, connect the wires, tighten

the screws and replace the connectors.

®

662N TELEKOMUNIKACE a.s., www.2n.cz

Page 67

Description of Terminals

Terminals Description

AUDIO UNIT BUS

Audio unit bus (2-wire) connection, polarity

must be maintained.

terALARM

minals

= voltageVoltage

control (on/off)

6 – 24V DC, any

polarity *)

Alarm call activation

= contactContact

control (on/off)

NO/NC contact *)

terCANCEL

minals

= voltageVoltage

control (on/off)

6 – 24V DC, any

polarity **)

Alarm call deactivation by

door opening

= contactContact

control (on/off)

NO/NC contact

**)

ALARM 2

terminal

= contactContact

control (closing)

NO contact

Alarm call activation from

Alarm set 2

*) By default, ALARM is activated by voltage connection or contact closing. Use a rotary

switch to apply voltage disconnection and contact opening.

**) By default, ALARM is deactivated by voltage connection or contact closing. Use a

rotary switch to apply voltage disconnection and contact opening.

Bus Connection

Pull the connector out of the terminal board. Connect the audio unitAUDIO UNIT BUS

bus (keep polarity as shown on the audio unit cover) and replace the connector.

Warning

Connection to different, e.g. higher-voltage, cables leads to damage or

destruction of the audio unit.

®

672N TELEKOMUNIKACE a.s., www.2n.cz

Page 68

Connectors

Figure: Connectors on Audio Unit – Cabin Compact (New Type)

Rotary Switch

There is a glass-covered rotary switch on the audio unit front side. Use the switch to

set ALARM/CANCEL (normal/inverted input) and audio unit type (cabin, cabin roof,

cabin bottom, shaft bottom).

Safety

Make sure that the minimum button isolation distance is 1.5 mm and

breakdown voltage is 1,500 V. The button contacts may not be connected

to any other circuits. If you cannot meet these conditions, use voltage

control.

You can use the switch on the audio unit front side or closing/opening

button connected to the ALARM CONTACT connector or both of them if

necessary.

Note

The ALARM button on the cover keeps functional even if an external

button is connected.

®

682N TELEKOMUNIKACE a.s., www.2n.cz

Page 69

Procedure

Rotary switch

position

Figure

1. Insert the hexagonal

spanner (included) in the

hole

on the product bottom edge

(window lock screw) and

turn left (about 10 times)

until you feel resistance.

Position 1 – ALARM

normal, CANCEL

normal, cabin

2. The window slides down

by itself or with a slight aid,

revealing its upper brim.

Position 2 – ALARM

inverted, CANCEL

normal, cabin

3. Tilt the window forward

and remove it.

Position 3 – ALARM

normal, CANCEL

inverted, cabin

4. Set the required address.

Position 4 – ALARM

inverted, CANCEL

inverted, cabin

5. Replace the window. Position 5 – cabin roof

6. Insert the hexagonal

spanner (included) in the

hole on

the product bottom edge

(window lock screw) and

turn right

(about 10 times) until the

window slides under the

panel edge.

Tighten slightly.

Position 6 – cabin

bottom

Position 7 – shaft

bottom

Positions 8, 9, 0 / not

used (red bus LED

flashing)

ALARM and CANCEL Setting (Rotary Switch)

Contact closing/voltage connection control of ALARM and CANCEL

Set the rotary switch (under the front glass) to position 1 to make

ALARM/CANCEL be controlled by contact closing or voltage connection.

Contact opening/voltage disconnection control of ALARM, contact

closing/voltage connection control of CANCEL

Set the rotary switch (under the front glass) to position 2 to make ALARM be

controlled by contact opening or voltage disconnection and CANCEL be controlled

by contact closing or voltage connection.

®

692N TELEKOMUNIKACE a.s., www.2n.cz

Page 70

Contact closing/voltage connection control of ALARM, contact

opening/voltage disconnection control of CANCEL

Set the rotary switch (under the front glass) to position 3 to make ALARM be

controlled by contact closing or voltage connection and CANCEL be controlled by

contact opening or voltage disconnection.

Contact opening/voltage disconnection control of ALARM and

CANCEL

Set the rotary switch (under the front glass) to position 4 to make ALARM and

CANCEL be controlled by contact opening or voltage disconnection.

CANCEL input connection (door contact, optional)

This input helps you cancel the rescue request if the lift is fully functional. Press ALARM

to make the system wait for a defined period of time, which slightly longer than the

maximum lift ride. If functional, the lift reaches the required station and opens the

door within the timeout, thus cancelling the rescue request. If the lift door does not

open, the rescue request is accepted.

Make sure before installation that the door opening signal is available in the lift cabin.

Requirements

If the lift is equipped with a double door, the signal must be active only if both

the door parts are open and the people can leave the cabin safely.

The door opening signal must be active even during power outage.

Caution

Use 6 to 24 V DC of any polarity. However, make sure that the power

supply is backed up against power outage.

Combine the control with buttons if you need to activate ALARM and

CANCEL from more sites.

Note

Make sure that delayed calling is configured to make the CANCEL input

connection effective.

®

702N TELEKOMUNIKACE a.s., www.2n.cz

Page 71

1.

2.

3.

4.

5.

6.

Volume Setting

Insert the hexagon key wrench (included in the delivery) in the hole on the

product bottom edge (window lock screw) and turn (about 10 times) untilleft

you feel resistance.

The window slides down by itself or with a slight aid, revealing its upper brim.

Tilt the window forward and remove it.

Set the required volume level using a trimmer.

Replace the window.

Insert the hexagon key wrench (included) in the hole on the product

bottom edge (window lock screw) and turn (about 10 times)right

until the window slides under the panel edge. Tighten slightly.

Mounting Completion

Having connected the wires, complete the cabin wall mounting. If you can access the

lift wall from the outside, the Installation is easier and the audio unit cannot be stolen

as its screws are not accessible from the cabin. If you can access the cabin wall from

the back side, follow the instructions in item a) or b). If not, obey the steps in item c).

Caution

Use the trimmer to set the best acoustic properties eliminating

feedback.

®

712N TELEKOMUNIKACE a.s., www.2n.cz

Page 72

a.

b.

c.

Figure: Mounting of Audio Unit – Cabin Compact

If the cabin wall is thin (stainless steel sheet), use the four M4 screws of

the length of 8 mm and fan washers included in the delivery.

If the cabin wall is thick (up to 20 mm – laminated chipboard, e.g.), use

the four M4 headless screws of the length of 30 mm. Screw the screws into

the audio unit backside holes with the enclosed spanner and tighten them.

Then push the set through the pre-drilled holes and insert the fan washers

and nuts from the back.

If you cannot access the cabin wall from the rear, follow the instructions on

®

722N TELEKOMUNIKACE a.s., www.2n.cz

Page 73

c.

the next page. TIP: If you have drilled the corner holes too, use the four

M4 headless screws of the length of 30 mm included in the delivery. Screw

the screws into the audio unit backside holes and tighten them as

instructed in item b) above. Although not equipped with nuts, the screws

will prevent the product from shifting or turning.

Mounting Completion – Without Rear Access

®

732N TELEKOMUNIKACE a.s., www.2n.cz

Page 74

1.

2.

3.

4.

5.

6.

Insert the hexagon key wrench (included in the delivery) in the hole on the

product bottom edge and turn (about 10 times) until you feel resistance.left

The window slides down by itself or with a slight aid, revealing its upper brim.

Tilt the window forward and remove it.

Now you have access to the two corner holes. Put the audio unit (including the

wires) on the cabin wall with the pre-drilled holes. Screw and tighten the audio

unit using the screws (for plywood, chipboard, laminated plastic walls) or short

M4 screws with fan washers (for sheet walls with M4-threaded holes) included in

the delivery to the cabin wall.

Replace the window.

Insert the hexagon key wrench (included) in the hole on the product bottom

edge (window lock screw) and turn (about 10 times) until the windowright

slides under the panel edge. Tighten slightly.

Connection of induction loop for hearing-impaired

The induction loop for people with impaired hearing is part of the Compact cabin audio

unit. No more accessories are required for the given case.

®

742N TELEKOMUNIKACE a.s., www.2n.cz

Page 75

2.7 PSTN Module

Description of Connection

The module should be part of the Central Unit (hereinafter referred to as ). If the CU

does not contain the PSTN module, proceed as follows:CU

1. Keep the CU disconnected from the mains.

.2. Loosen the three screws on the upper cover of the CU

3. Move the upper cover of the in such a way that you can remove it.CU

4. When removing the cover, proceed with caution, be careful about the earth

wire connecting the cover with the CU bottom part. Do not disconnect the wire

!unless there is a reason to do so

5. Connect the module to the connector on the motherboard (see the figure

below).

6. Be careful while putting the module on the pins. Make sure that you have

connected all the pins to the module connector.

7. Having fitted the pins into the connector correctly, you can fix the module using

2 bolts and 1 screw.

®

752N TELEKOMUNIKACE a.s., www.2n.cz

Page 76

8. Now connect the PSTN line. There are 2 options:

using the RJ 11 connector;

using a slide-on terminal board.

Warning

While fitting the module, make sure that all the pins are fitted correctly

into the connector to avoid module damage.

®

762N TELEKOMUNIKACE a.s., www.2n.cz

Page 77

2.8 GSM/UMTS Module

Description of Connection

The module should be part of the Central Unit (hereinafter referred to as CU). If the

CU does not contain the PSTN module, proceed as follows:

1. Keep the CU disconnected from the mains.

2. Loosen the three screws on the upper cover of the .CU

3. Move the upper cover of the in such a way that you can remove it.CU

4. When removing the cover, proceed with caution, be careful about the earth

wire connecting the cover with the CU bottom part. Do not disconnect the wire

!unless there is a reason to do so

5. Connect the module to the connector on the motherboard (see the figure

below).

6. Be careful while putting the module on the pins. Make sure that you have

connected all the pins to the module connector.

7. While fitting the module mind the antenna connector. Make sure that it is

pushed through the cover hole.CU

8. Having fitted the pins into the connector correctly, you can fix the module

.using 2 bolts and 1 screw

®

772N TELEKOMUNIKACE a.s., www.2n.cz

Page 78

9. Now insert the SIM card and connect the antenna.

Warning

While fitting the module, make sure that all the pins are fitted correctly

into the connector to avoid module damage.

Caution

In places with a poor signal quality find an appropriate place or use a

special (directional) antenna.

Should you have DTMF transmission problems, set parameter 710 to 1

(for GSM modules only).

®

782N TELEKOMUNIKACE a.s., www.2n.cz

Page 79

2.9 VoIP Module

Description of Connection

The module should be part of the Central Unit (hereinafter referred to as CU). If the

CU does not contain the PSTN module, proceed as follows:

1. Keep the CU disconnected from the mains.

.2. Loosen the three screws on the upper cover of the CU

3. Move the upper cover of the in such a way that you can remove it.CU

4. When removing the cover, proceed with caution, be careful about the earth

wire connecting the cover with the CU bottom part. Do not disconnect the wire

!unless there is a reason to do so

5. Connect the module to the connector on the motherboard (see the figure

below).

6. Be careful while putting the module on the pins. Make sure that you have

connected all the pins to the module connector.

7. Having fitted the pins into the connector correctly, you can fix the module

.using 2 bolts and 1 screw

®

792N TELEKOMUNIKACE a.s., www.2n.cz

Page 80

8. Now connect the VoIP line via the RJ–45 connector.

Warning

While fitting the module, make sure that all the pins are fitted correctly

into the connector to avoid module damage.

®

802N TELEKOMUNIKACE a.s., www.2n.cz

Page 81

2.10 Audio Unit – Fireman

The Fireman audio unit is available in two versions.

2.10.1 Fireman PCB

2.10.2 Fireman

2.10.3 Fireman – Mechanical Mounting