Toshiba B-SA4T User Manual

PRINTED IN JAPAN

TOSHIBA Thermal Printer

B-SA4T SERIES

Document No. EO15-33001A

Original Jul., 2005

(Revised Sep., 2005)

Option Installation Manual

EO15-33001A

(Revision Date: Feb. 14, 2008)

TABLE OF CONTENTS

Page

1. Cutter Module------------------------------------------------------------------------------------------------------1- 1

1.1 B-SA204-QM/ B-SA204-QM-R ----------------------------------------------------------------------------1- 1

1.2 B-SA204P-QM-R----------------------------------------------------------------------------------------------1- 4

2. Strip Module--------------------------------------------------------------------------------------------------------2- 1

2.1 B-SA904-H-QM-R---------------------------------------------------------------------------------------------2- 1

2.2 B-SA904P-H-QM-R-------------------------------------------------------------------------------------------2- 5

3. Wireless LAN Module: B-SA704-WLAN-QM-------------------------------------------------------------3- 1

4. Serial Interface Board: B-SA704-RS-QM-R --------------------------------------------------------------4- 1

5. 300 dpi Print Head Kit: B-SA704-TPH3-QM-R-----------------------------------------------------------5- 1

6. Real Time Clock: B-SA704-RTC-QM-R --------------------------------------------------------------------6- 1

7. Expansion I/O Board: B-SA704-IO-QM-R-----------------------------------------------------------------7- 1

8. RFID Module: B-SA704-RFID-U2-EU-R--------------------------------------------------------------------8- 1

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you

may have in this manual.

Copyright © 2005

by TOSHIBA TEC CORPORATION

A

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 1

INSTALLATION PROCEDURE FOR OPTIONAL

EQUIPMENT

1. Cutter Module

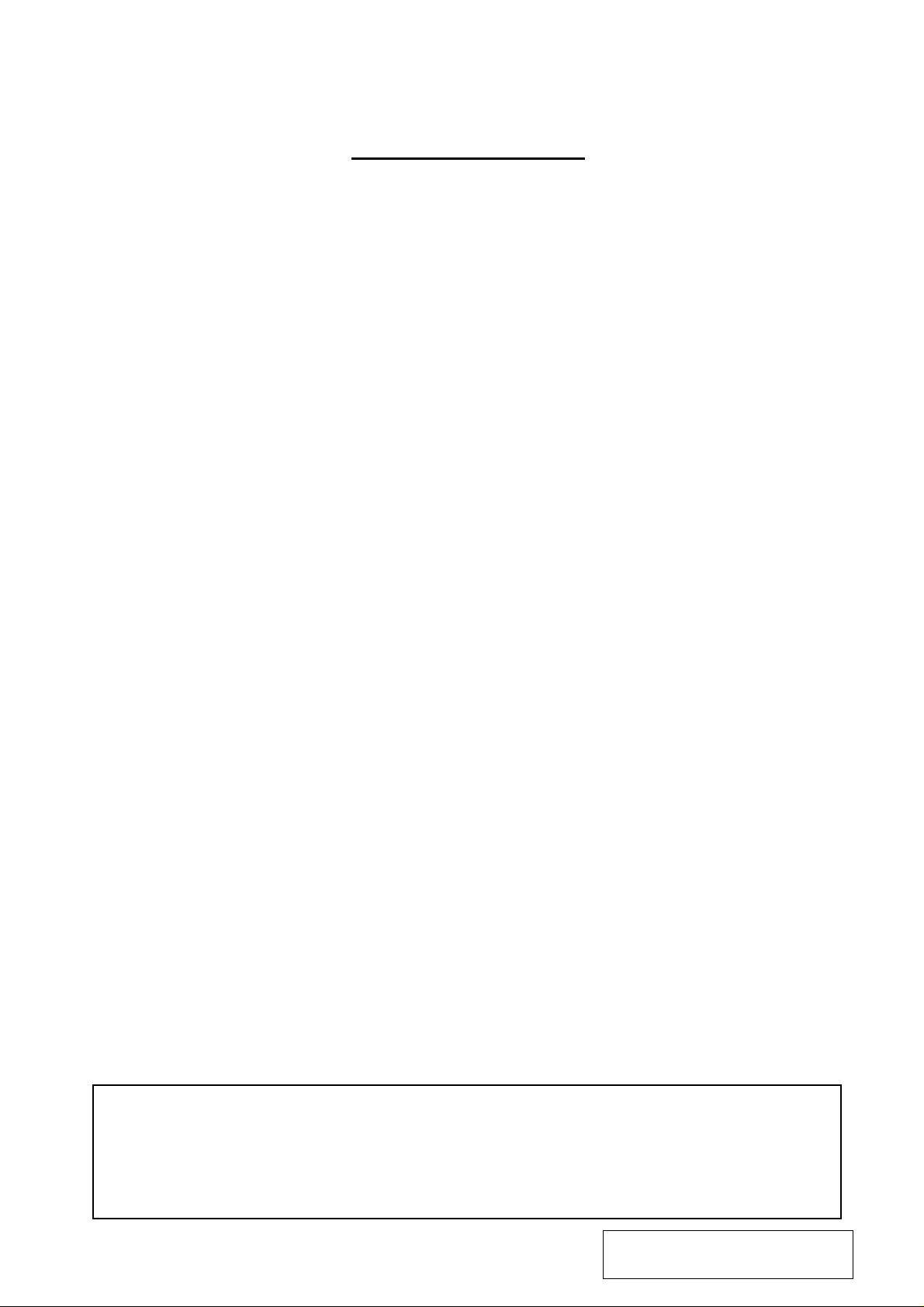

1.1 B-SA204-QM / B-SA204-QM-R

B-SA204-QM/ B-SA204-QM-R is an optional cutter module for the B-SA4TM Series (Metal cover).

•

Packing List

The following parts are supplied with the kit. Make sure you have all items shown below.

Cutter Unit (1 pc.)

Cutter Module Cover (1 pc.)

Installation Manual (1 copy)

• Installation Procedure

1. Open the Front Cover, and remove the B-3x6 screw to detach the Connector Cover.

WARNING!

1. Turn the printer power off and disconnect the power cord before installing an optional

equipment.

2. Be careful not to pinch your fingers or hands with the covers.

3. Be careful not to injure your fingers when installing the cutter module.

CAUTION

!

Do not connect/disconnect the cutter harness to/from the printer within one minute from a power off

to

p

rotect the internal electrical circuit of the

p

rinter.

Front Cove

r

Connector Cover

B-3x6 Screw

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 2

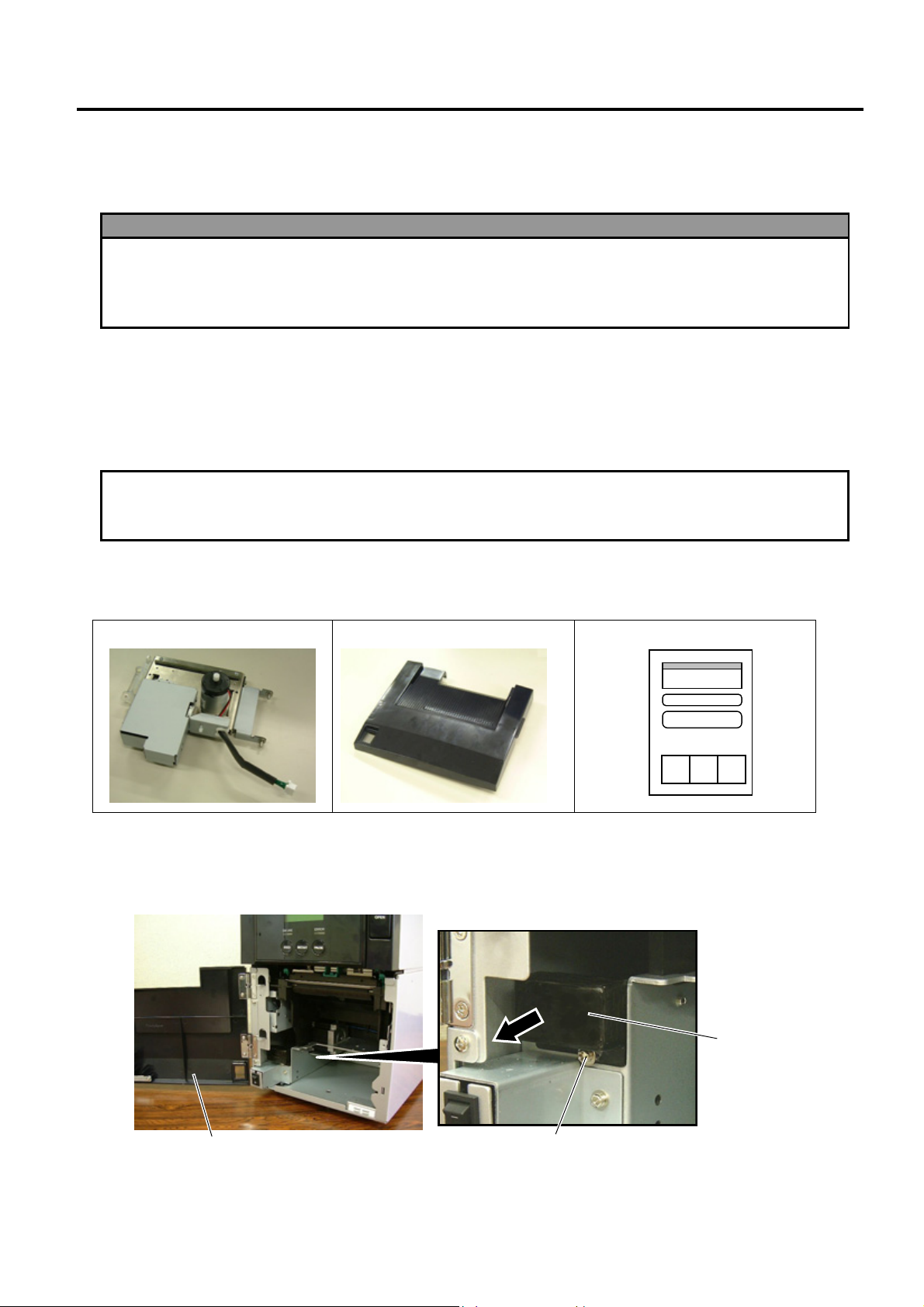

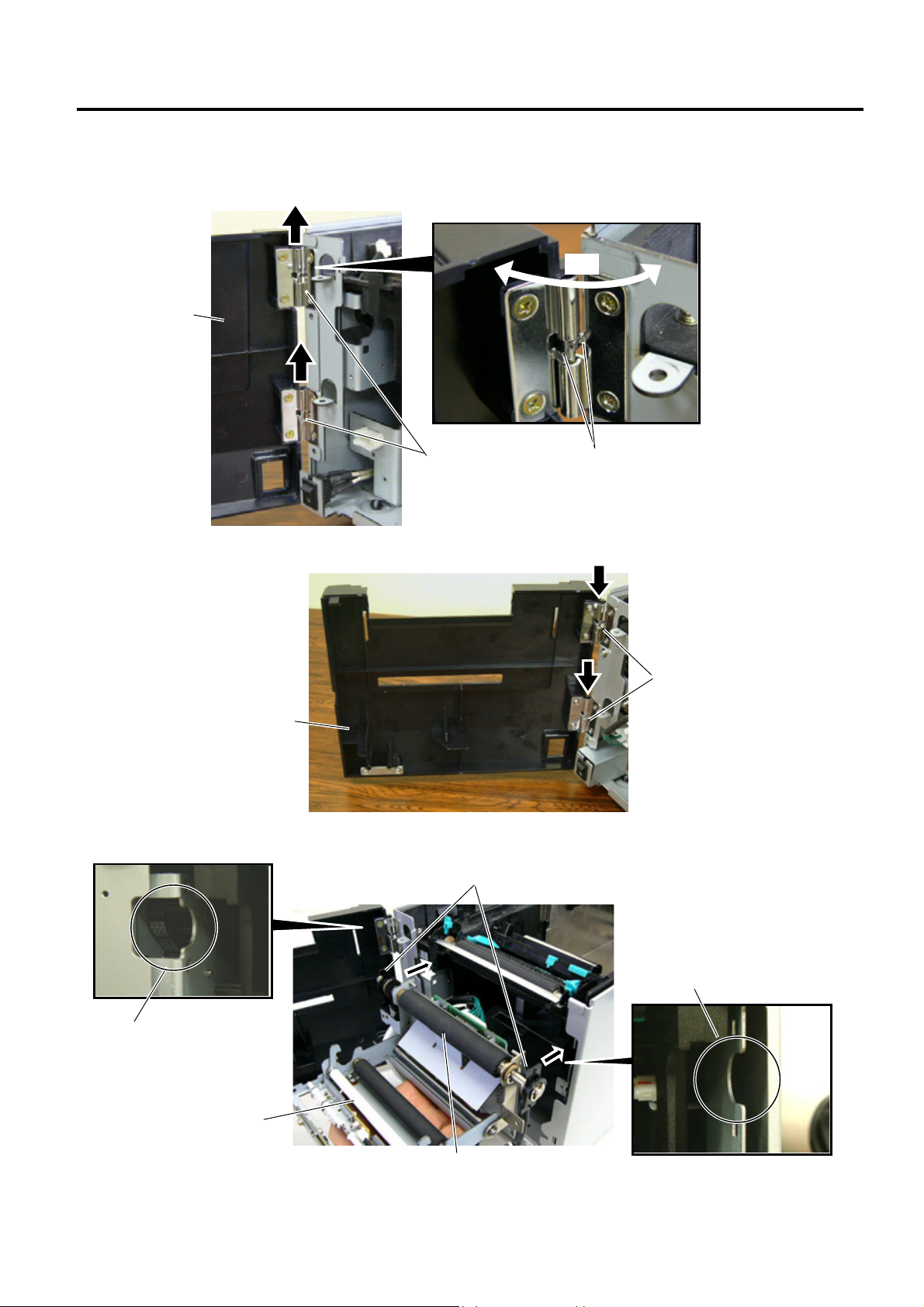

2. Open the Front Cover wider. Remove the Front Cove r by lifting it to disengage the hinge pins from the

hinge. The Front Cover cannot be removed unless it is opened at an angle of over 100 degrees a s the

stoppers of the hinge prevent disengagement.

3. Mount the Cutter Module Cover by inserting the hinge pins into the hinges.

4. Fit the Cutter Unit to the front of the printer by inserting the Hinge Pins into the Hinge Pin Holes.

Cutter Module Cove

r

Hinge

Hinge

Front Cove

r

Scre

w

100°

Cutter Unit

Hinge Pin Hole

Hinge Pin

Hinge Pin Hole

Hinge Pin

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 3

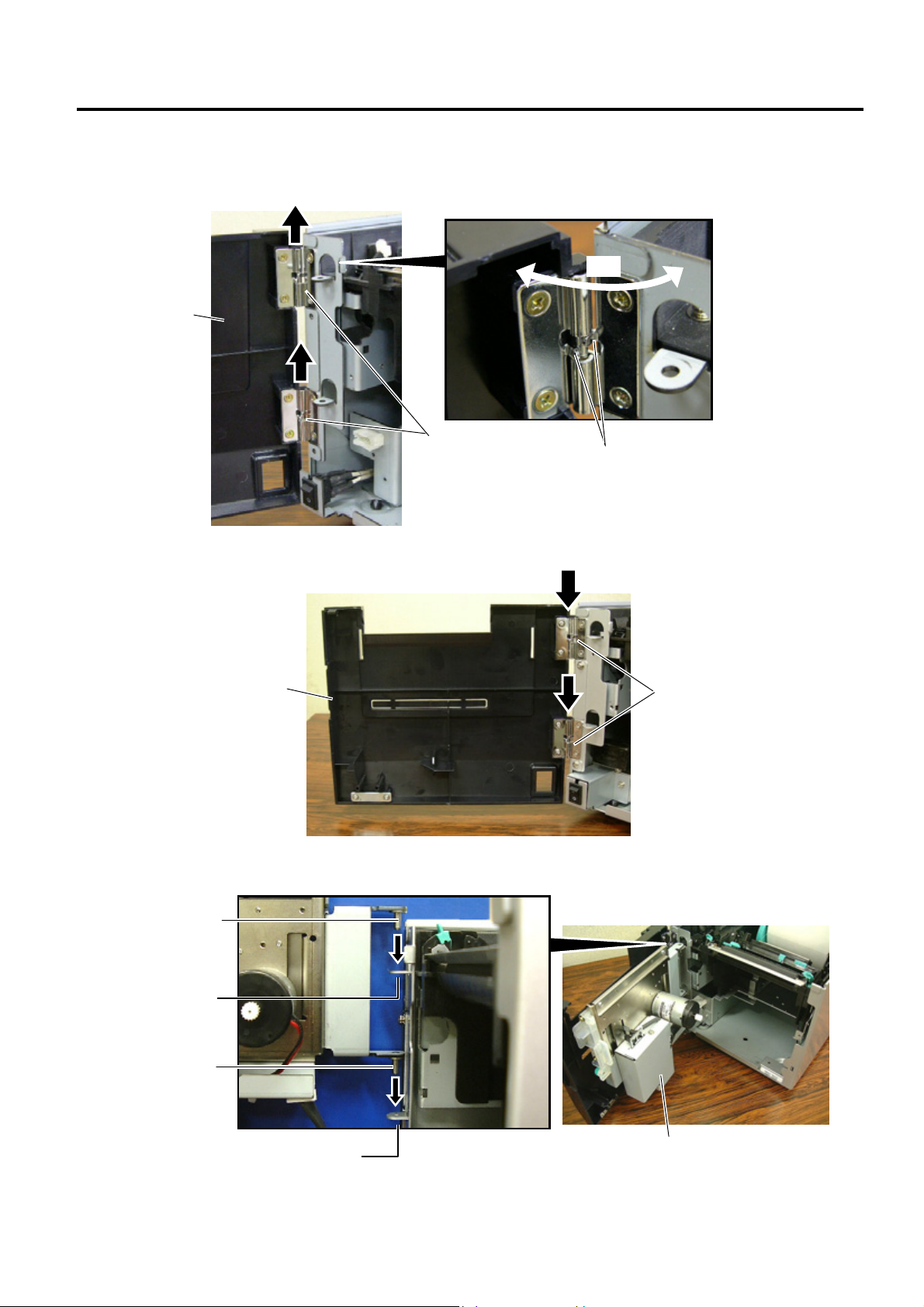

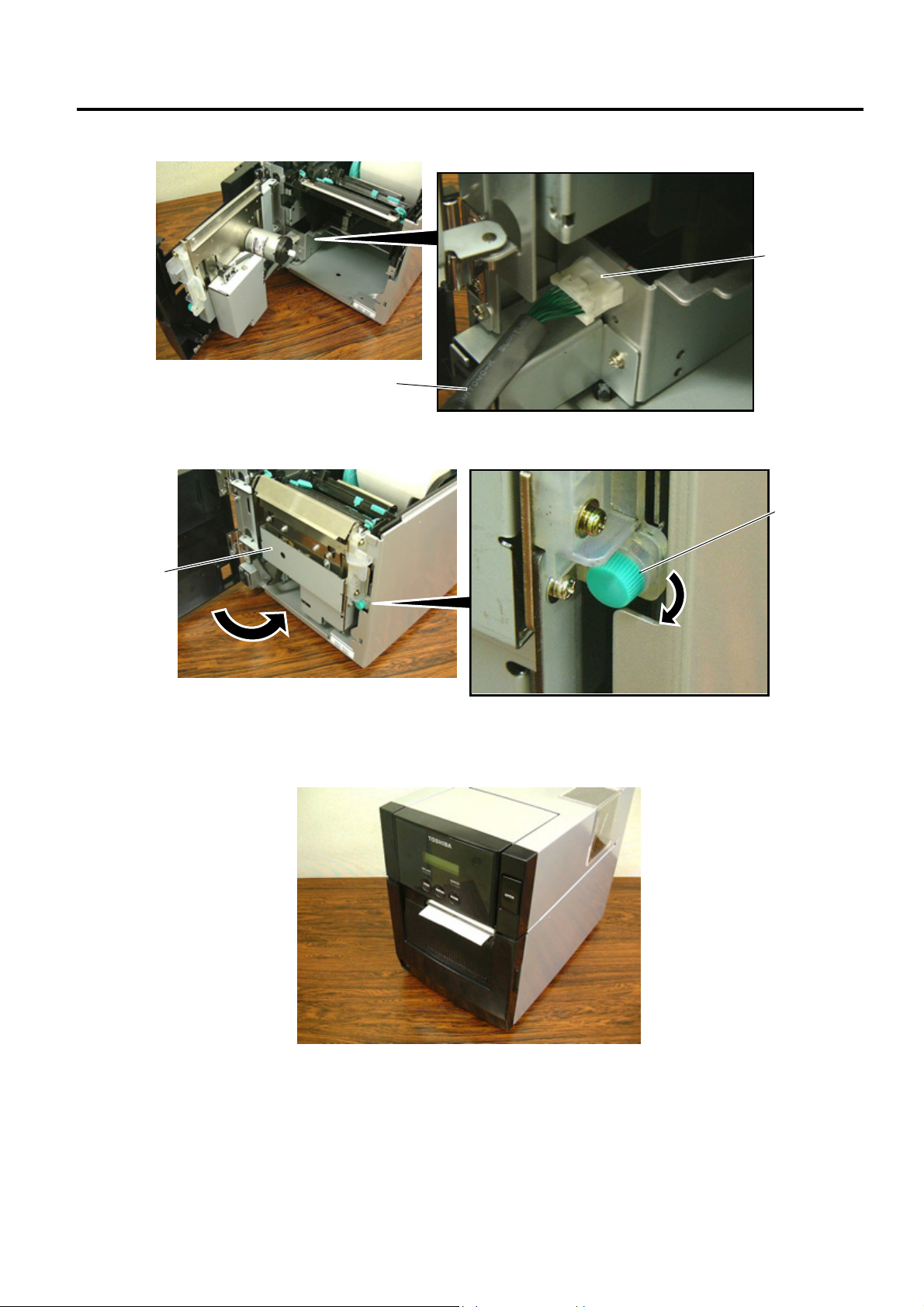

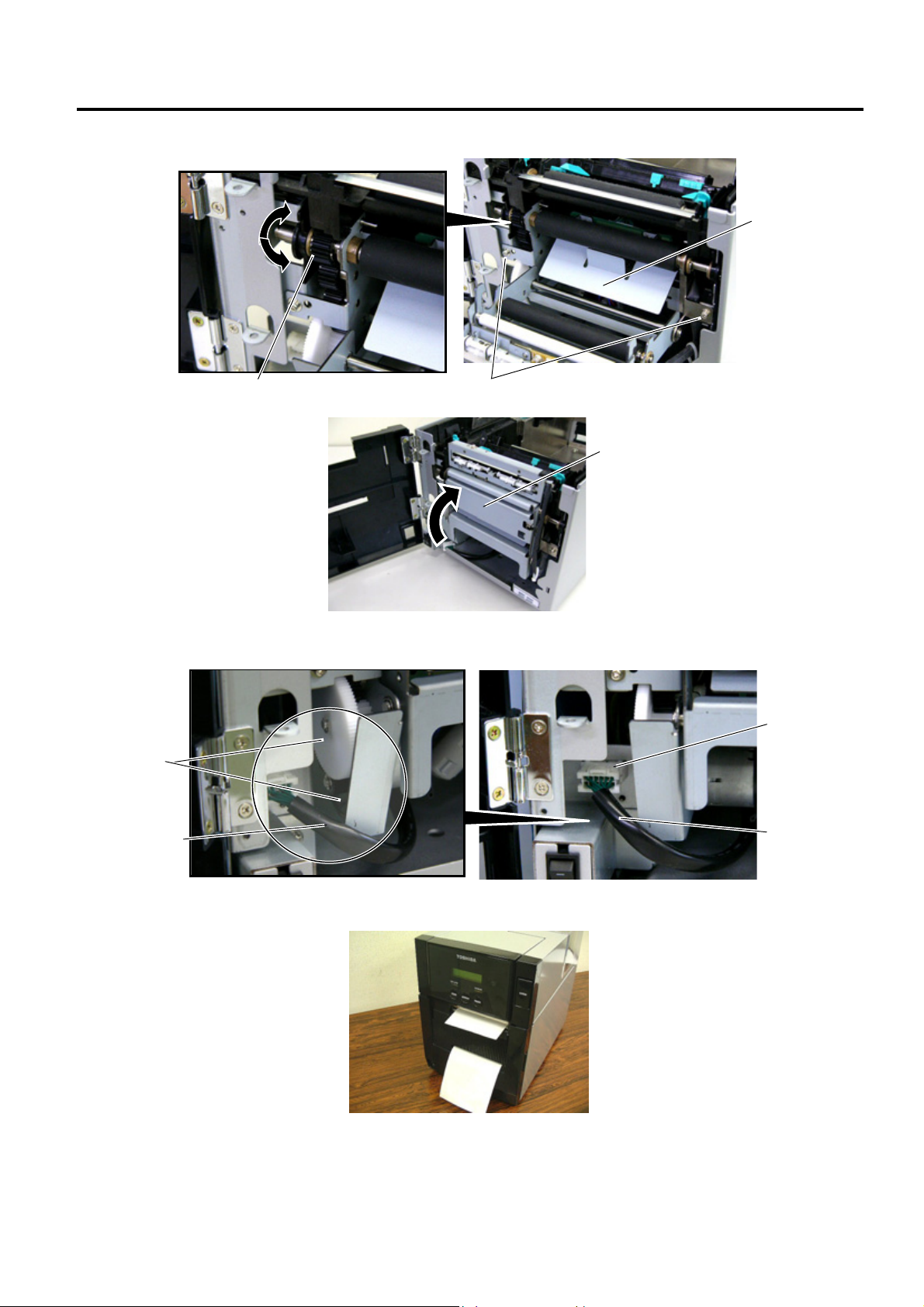

5. Connect the Cutter Harness to the connector at the front of the printer.

6. Close the Cutter Unit and secure it to the printer with the Set Screw.

7. Close the Cutter Module Cover.

• Media loading procedure------------- Owner’s Manual, Section 2.3

• Operation check------------------------ Owner’s Manual, Section 2.9

• System mode setting------------------System Mode Manual

• Cleaning --------------------------------- Owner’s Manual, Section 4.1.3

Cutter Harness

Connector

Cutter Unit

Set Screw

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 4

1.2 B-SA204P-QM-R

B-SA204P-QM-R is an optional cutter module for the B-SA4TP Series (Plastic cover).

• Packing List

The following parts are supplied with the kit. Make sure you have all items shown below.

Cutter Unit (1 pc.)

Cutter Module Cover (1 pc.)

Installation Manual (1 copy)

• Installation Procedure

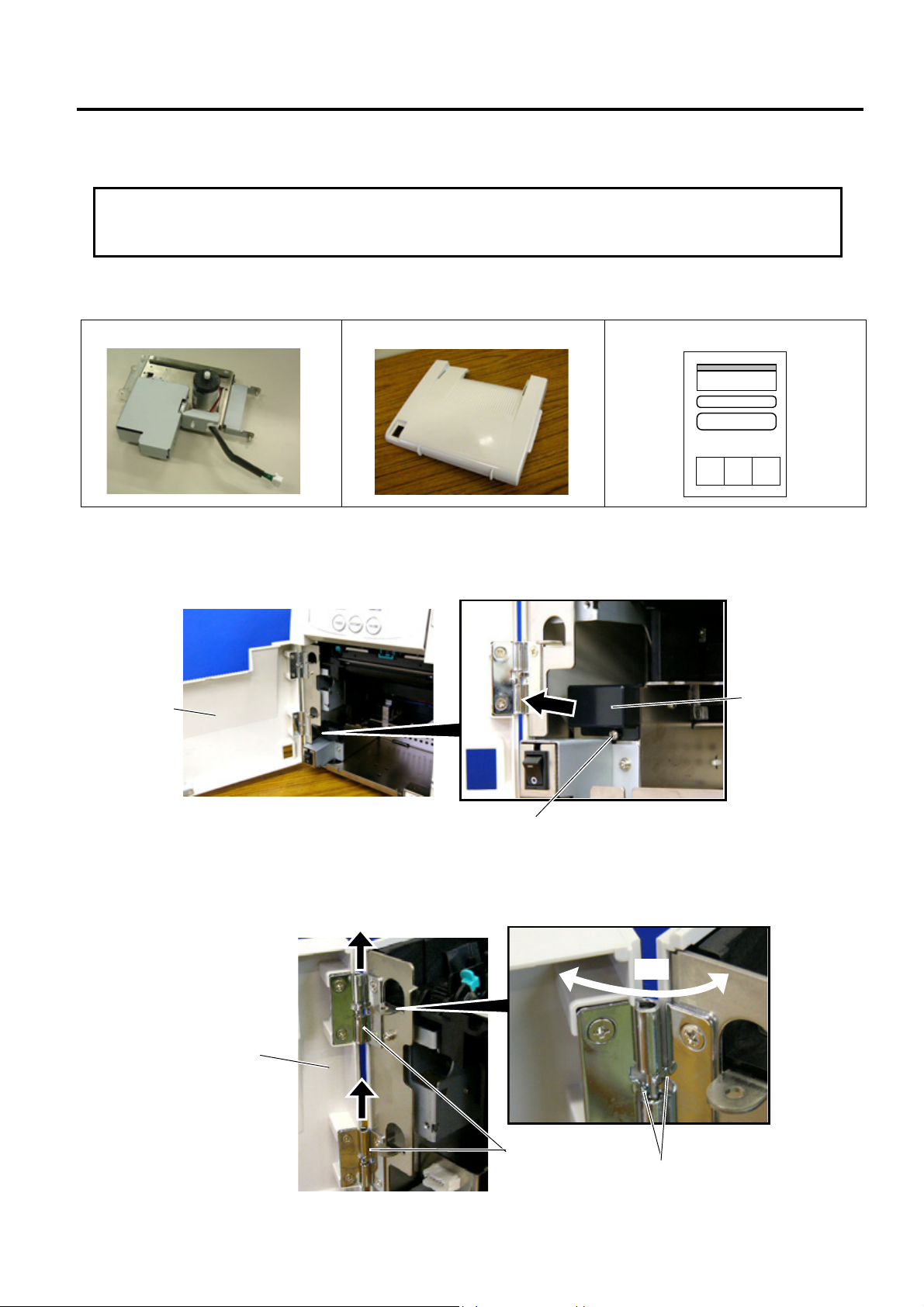

1. Open the Front Cover, and remove the Connector Cover.

2. Open the Front Cover wider. Remove the Front Cove r by lifting it to disengage the hinge pins from the

hinge. The Front Cover cannot be removed unless it is opened at an angle of over 100 degrees a s the

stoppers of the hinge prevent disengagement.

CAUTION

!

Do not connect/disconnect the cutter harness to/from the printer within one minute from a

p

ower of

f

to

p

rotect the internal electrical circuit of the

p

rinter.

Front Cove

r

Connector Cover

B-3x6 Scre

w

Front Cove

r

Hinge

100°

Stopper

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 5

3. Mount the Cutter Module Cover by inserting the hinge pins into the hinges.

4. Fit the Cutter Unit to the front of the printer by inserting the Hinge Pins into the Hinge Pin Holes.

5. Close the Cutter Unit and secure it to the printer with the Set Screw.

Cutter Module Cove

r

Hinge

Cutter Unit

Hinge Pin

Hinge Pin

Hinge Pin Hole

Hinge Pin Hole

Cutter Unit

Set Screw

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

1. Cutter Module

1- 6

6. Secure the ground wire of the cutter unit to the printer with the B-3x6 screw removed in Step 1, as shown

in the picture.

7. Connect the cutter harness to the connector at the front of the printer.

8. Close the Cutter Module Cover. After that, perform an operation check for a proper cut issue.

• Media loading procedure------------- Owner’s Manual, Section 2.3

• Operation check------------------------ Owner’s Manual, Section 2.9

• System mode setting------------------System Mode Manual

• Cleaning --------------------------------- Owner’s Manual, Section 4.1.3

Cutter Harness

Ground Wire

B-3x6 Screw

Ground Wire

Cutter Harness

Connecto

r

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan. 19, 2006)

2. Strip Module

2- 1

2. Strip Module

NOTE: Make sure that the firmware version is V1.1 or greater. Firmware V1.0 does not support the strip module.

2.1 B-SA904-H-QM-R

B-SA904-H-QM-R is an optional strip module for the B-SA4TM Series (Metal cover).

• Packing List

The following parts are supplied with the kit. Make sure you have all items shown below.

Strip Unit (1 pc.)

Strip Module Cover (1 pc.)

SMW-3x6 Screw (4 pc.)

Cutter (1 pc.)

Guide Roller (1 pc.)

Installation Manual (1 copy)

NOTE: When issuing labels in batch mode even though the strip module is fitted, please use the provided cutter

to tear off the issued labels. Do not attach the cutter when labels are stripped one by one.

• Installation Procedure

1. Open the Top Cover and the Front Cover. Remove the B-3x6 screw to detach the Connector Cover.

Front Cove

r

Top Cover

Connector Cover

B-3x6 Scre

w

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

2. Strip Module

2- 2

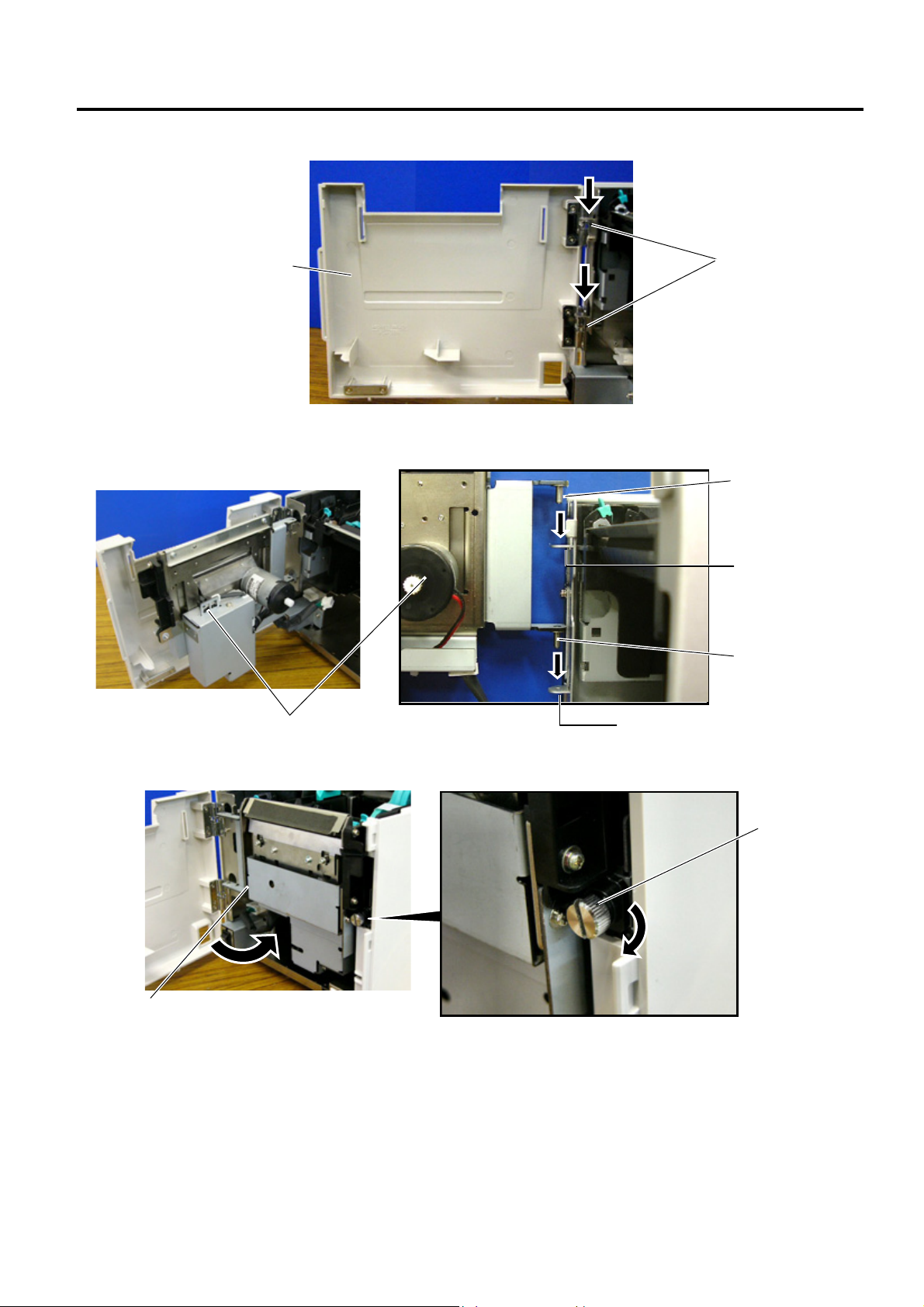

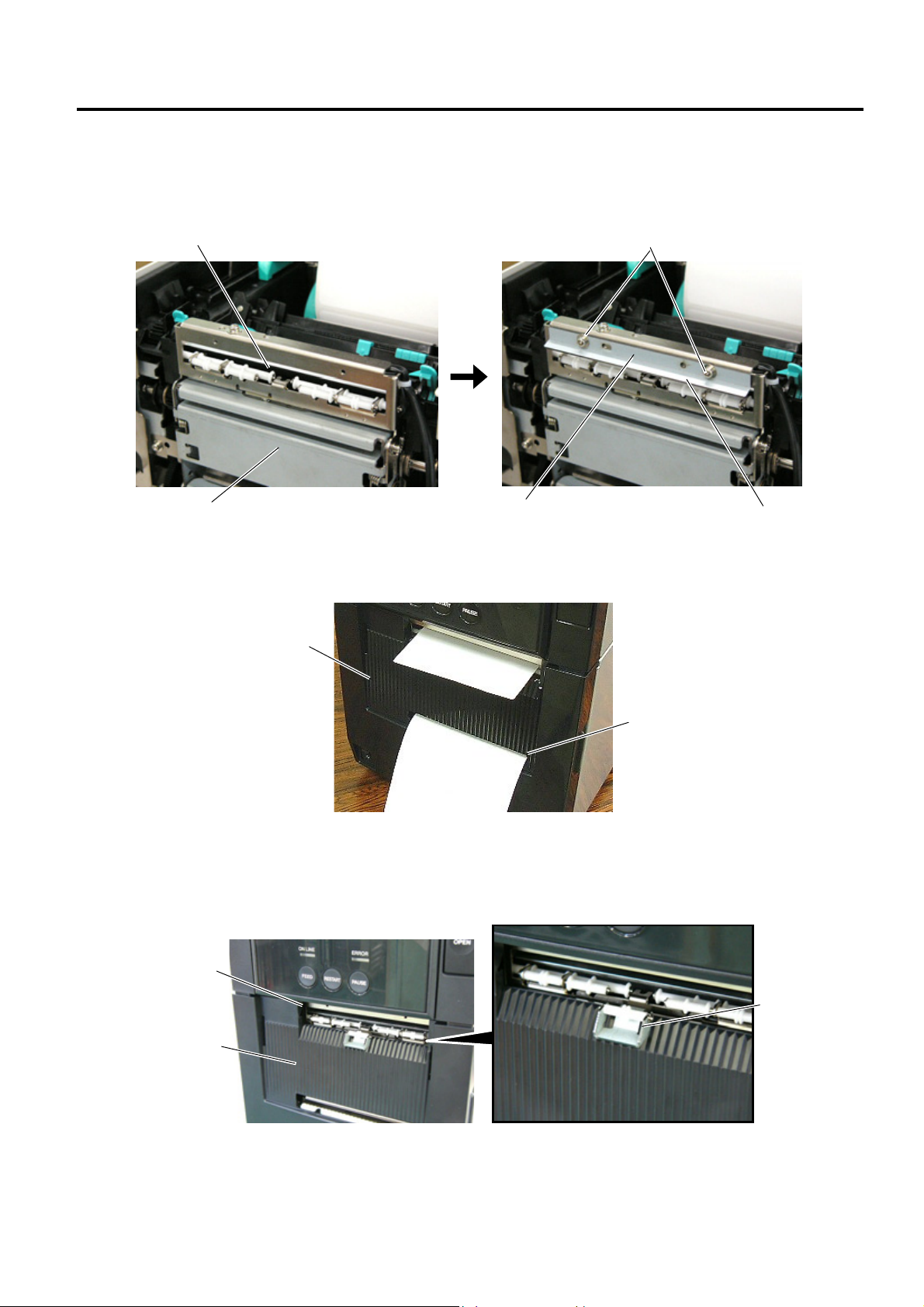

2. Open the Front Cover wider. Remove the Front Cove r by lifting it to disengage the hinge pins from the

hinge. The Front Cover cannot be removed unless it is opened at an angle of over 100 degrees a s the

stoppers of the hinge prevent disengagement.

3. Mount the Strip Module Cover by inserting the hinge pins into the hinges.

4. Fit the Shaft Holders of the Backing Paper Feed Roller into the cuts of the printer.

Hinge

Strip Module Cove

r

Shaft Holder

Strip Unit

Cut

Cut

Backing Paper Feed Roller

Hinge

Front Cove

r

Scre

w

100°

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

2. Strip Module

2- 3

5. Secure the Strip Unit to the printer with the two screws. Make sure that the Feed Roller Gear rotates

smoothly.

6. Close the Strip Unit.

7. Connect the Strip Harness to the connector at the front of the printer. At this time, carefully avoid contact

of the strip harness with the gears.

8. Close the Strip Module Cover.

Perform an operation check for a proper strip issue.

• Media loading procedure------------- Owner’s Manual, Section 2.3

• Operation check------------------------ Owner’s Manual, Section 2.9

• System mode setting------------------System Mode Manual

• Cleaning --------------------------------- Owner’s Manual, Section 4.1.4

SMW-3x6 Screw

Feed Roller Gear

Strip Unit

Strip Unit

Connector

Strip Harness

Strip Harness

Gea

r

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan. 19, 2006)

2. Strip Module

2- 4

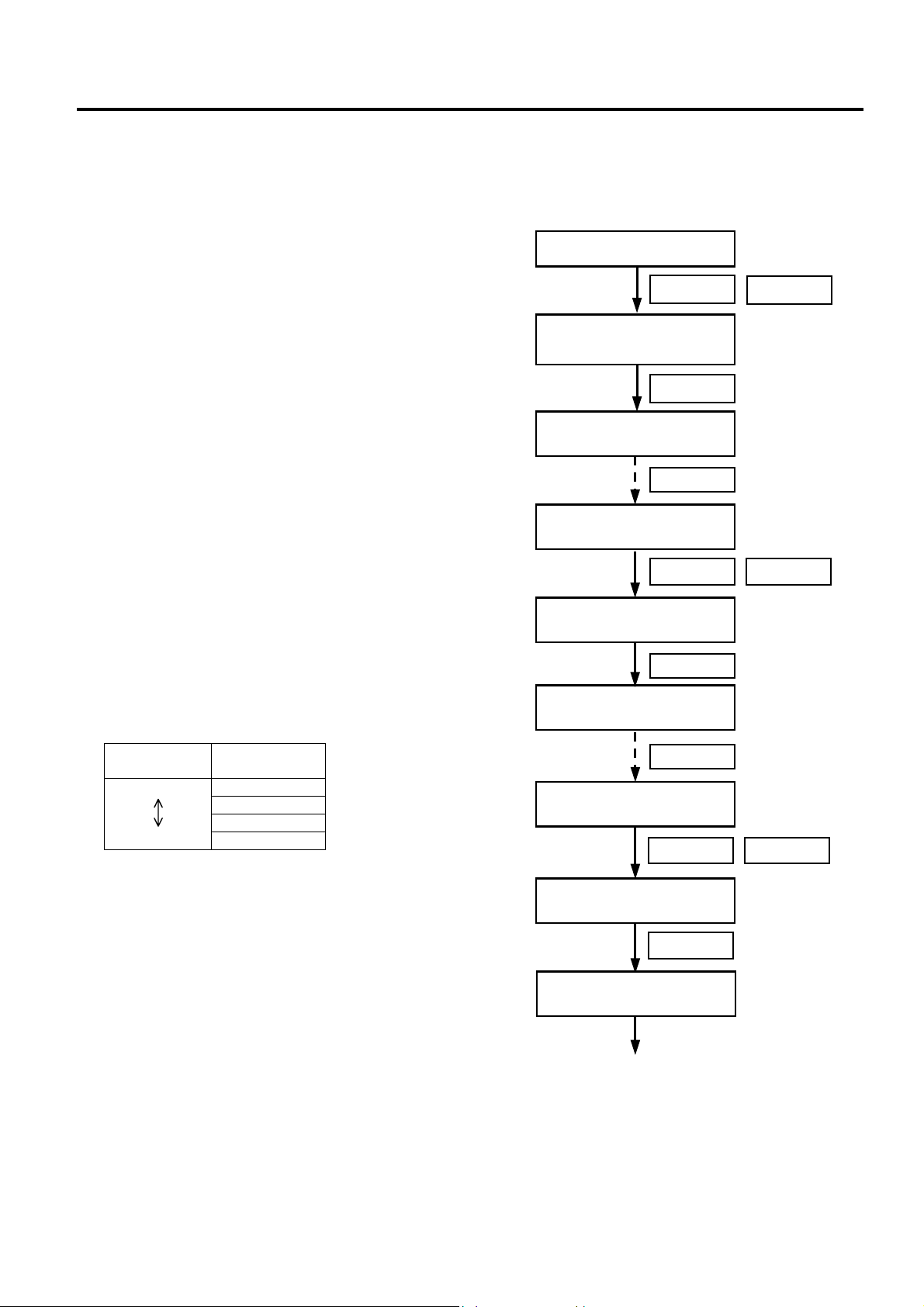

• Attaching the Cutter

The enclosed cutter is used to tear off the batch-issued labels. Attach the cutter with the two SMW-3x6

screws as shown in the picture below. Insert the leading edge of the labels into the opening under the

cutter.

NOTE: Depending on the backing paper types, tearing off the backing paper against the slot of the strip module

cover may cause it to wind onto the inner rollers. It is advisable to tear off or cut the backing paper

outside the strip module cover.

• How to use the Guide Roller

When issuing the label with the length of 50 mm or more, fit the guide roller to the center of the strip module

cover to prevent the stripped label from sticking to the cover.

Strip Unit

SMW-3x6 Screw

Cutte

r

Opening

Edge

Slot

Strip Module Cove

r

Strip Module Cove

r

Guide Roller

Opening

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan. 19, 2006)

2. Strip Module

2- 5

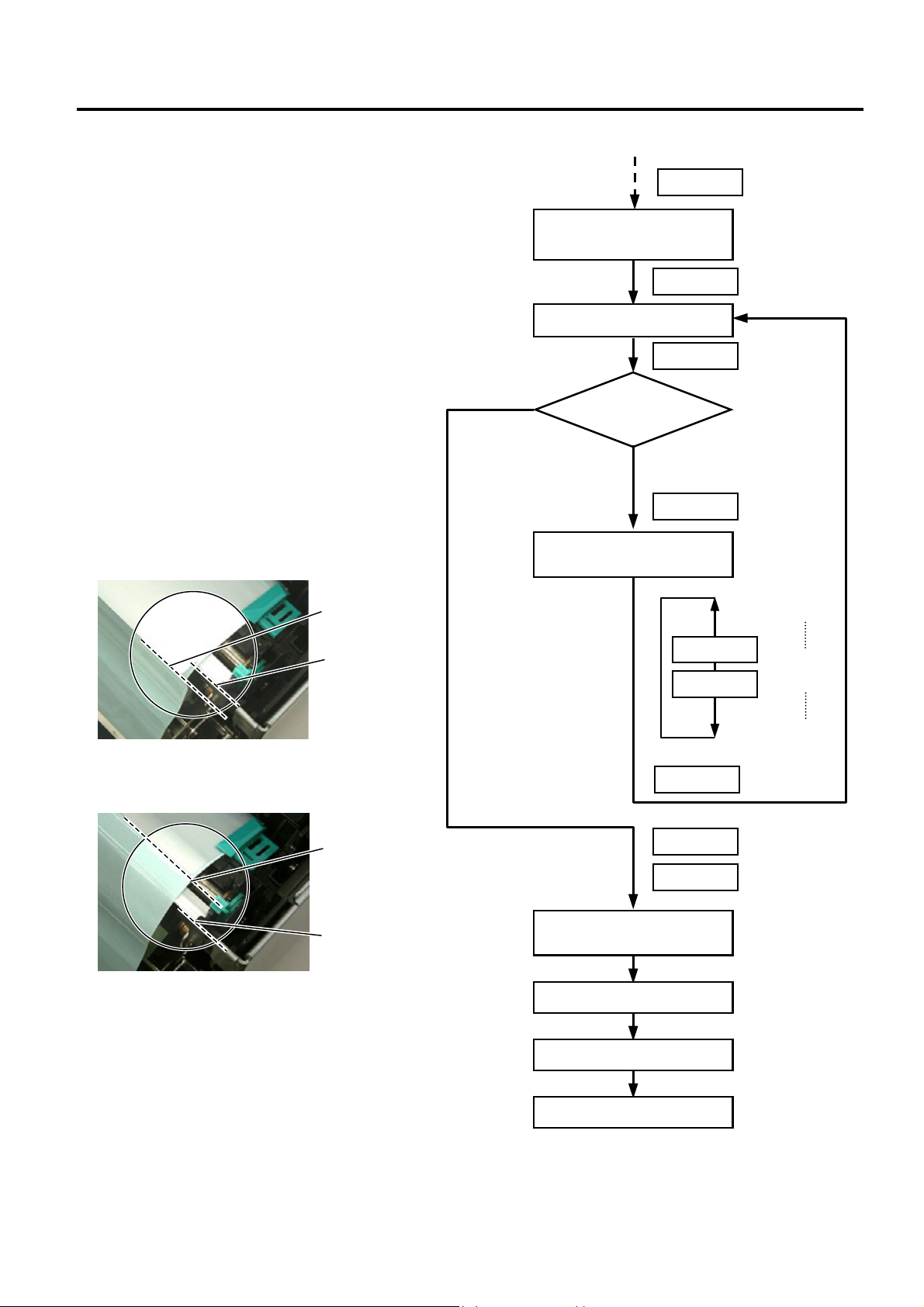

• System Mode Settings for Stripping PET Labels

When using PET labels on the strip module, please set the following system mode parameters in advance.

1. Connect the printer to a PC.

2. Load a PET label stock on the printer.

3. Turn ON the printer while holding down the

[FEED] key and [PAUSE] key.

4. When “<1>DIAG. “ is displayed on the LCD,

press the [FEED] key to choose

<2>PARAMETER SET” menu.

5. Press the [PAUSE] key repeatedly until

“PRE PEEL OFF” appears on the LCD.

6. As the default is OFF, choose “PRE PEEL

OFF ON” with the [FEED] or [RESTART]

key. Then, press the [PAUSE] key.

7. “P.P. FEED +0.0mm” is displayed on the

LCD.

Press the [PAUSE] key repeatedly until

“PEEL OFF TRQ” appears on the LCD.

8. This menu is to set the strip motor torque.

As the default is R0, choose R3 with the

[FEED] or [RESTART] key. Then, press

the [PAUSE] key.

NOTE: Setting the motor torque higher

makes the strip issue easier.

Strip motor

torque

Value

R0

R1

R2

Low

High

R3

RESTARTFEED

<2>PARAMETER SET

PRE PEEL OFF ON

<2>PARAMETER SET

P.P.FEED +0.0mm

<1>DIAG.

V1.1

Turn the power ON.

FEED

PAUSE

FEED

PAUSE

<2>PARAMETER SET

<2>PARAMETER SET

PRE PEEL OFF OFF

PAUSE

<2>PARAMETER SET

PEEL OFF TRQ R0

RESTARTFEED

<2>PARAMETER SET

PEEL OFF TRQ R3

PAUSE

<2>PARAMETER SET

PAUSE

(Continued.)

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan. 19, 2006)

2. Strip Module

2- 6

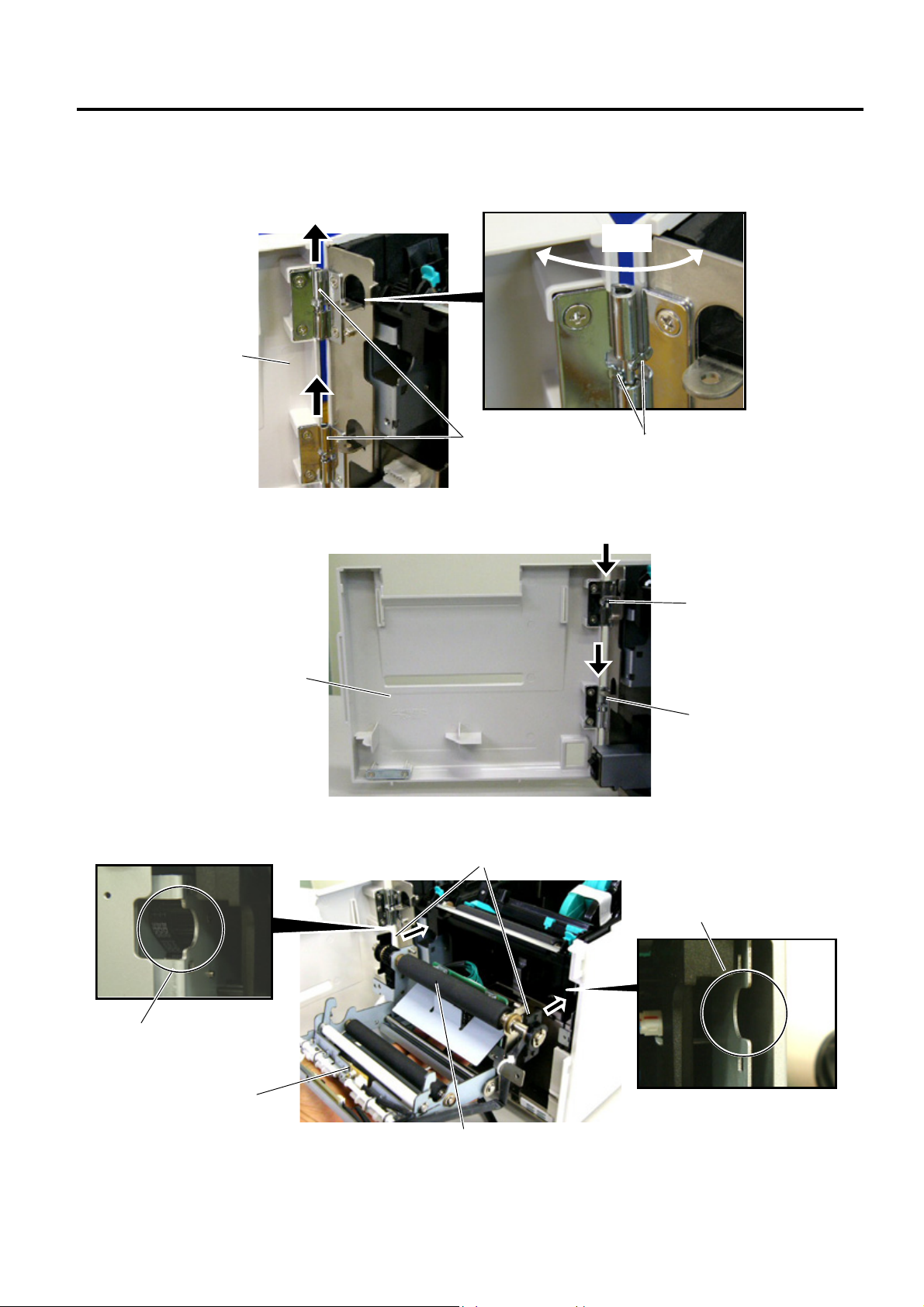

9. Turn off the printer, and then back to on.

Send an issue command to the printer for

strip issue.

10. If necessary, fine adjust the print start

position and strip position in the system

mode.

NOTES:

1. It is recommended that the print start

position and strip position are adjusted on

the actual print condition.

2. When short-pitch labels are used, the print

start position may misalign on the first few

labels. In that case, feed the labels

between the media sensor and the strip

shaft, and discard them.

11. Repeat Steps 9 and 10 for position fine

adjustment.

12. After the print position and strip position

are properly adjusted, access

“<2>PARAMETER SET” menu in the

system mode again.

Turn the power OFF.

Issue labels.

(Continued.)

<3>ADJUST SET

FEED ADJ. +0.0mm

<3>ADJUST SET

CUT ADJ. +0.0mm

Print position fine adjustment

Strip position fine adjustment

Power OFF

Power ON

FEED RESTART

<1>DIAG.

V1.1

Turn the power ON.

Print position

Adjustment

is re

q

uired.

Good

Turn the power OFF.

Turn the power ON.

FEED RESTART

<1>DIAG.

V1.1

FEED

<2>PARAMETER SET

Continued.

Strip Shaft

Media Senso

r

Discard labels between the

media sensor and the strip shaft.

Label

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan. 19, 2006)

2. Strip Module

2- 7

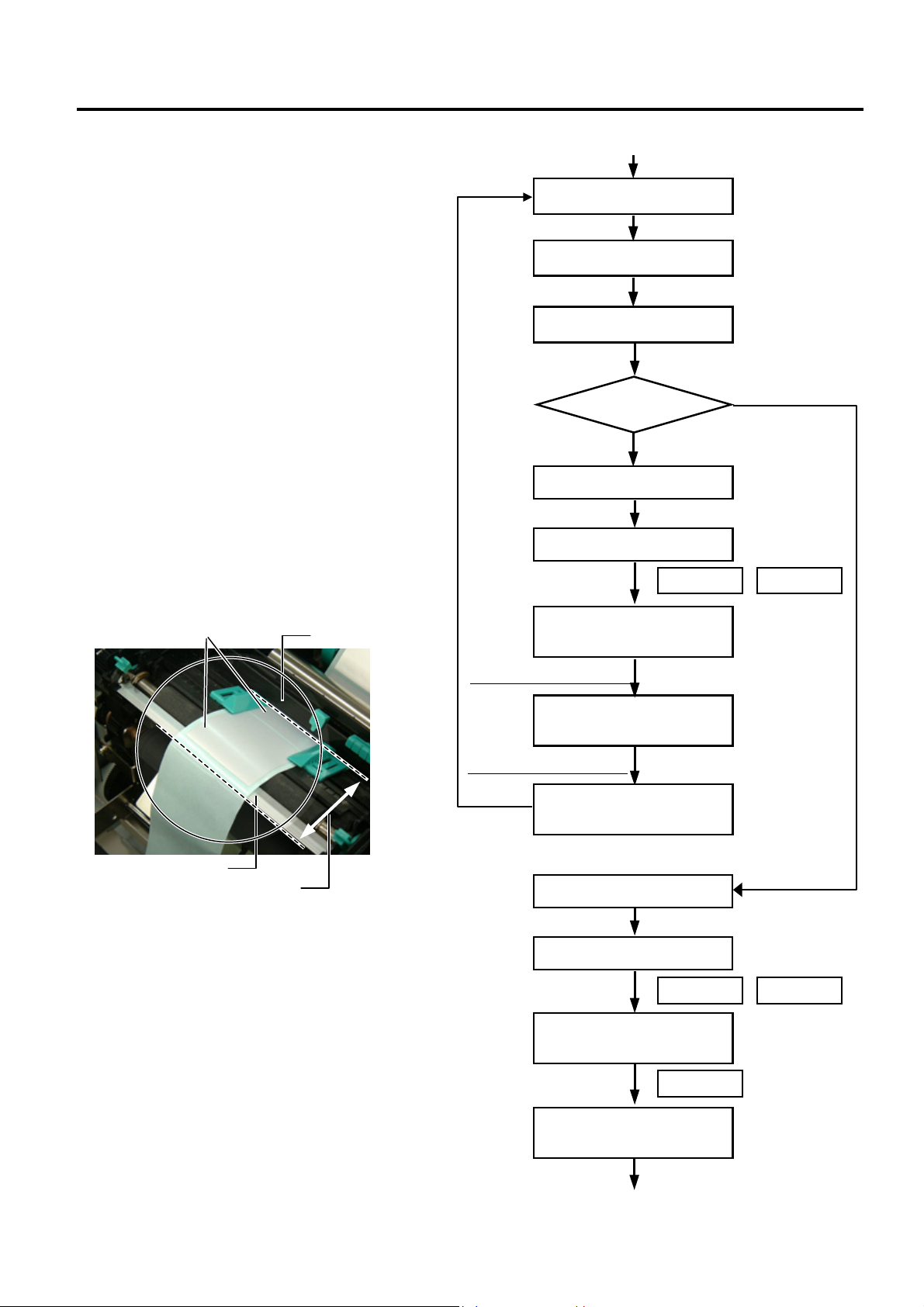

13. Press the [PAUSE] key repeatedly until

“P.P.FEED” appears on the LCD.

14. Press the [FEED] key to feed a label for

checking the next label’s stop position. If

the next label stops with its top edge

aligning with the strip shaft edge, an

adjustment is not required. Go to Step 15.

If not, press the [RESTART] key to return

to “P.P.FEED +0.0mm” display, and

adjust the pre-strip amount. Set the value

in a range from +9.9 to −2.5 with the

[FEED] or [RESTART] key.

When the top edge of the label stops past

the strip shaft edge, set a negative (−)

value.

When the top edge of the label stops short

of the strip shaft edge, set a positive (+)

value.

15. When the adjustment is completed, press

the [PAUSE] key twice to finish the setting.

16. Send an issue command to the printer

and check for proper strip issue.

Top edge of

the label

Strip Shaft Edge

Top edge of

the label

Strip Shaft Edge

Continued.

PAUSE

<2>PARAMETER SET

P.P.FEED +0.0mm

PAUSE

A label is fed.

+9.9mm

+9.8mm

:

:

+0.1mm

+0.0mm

-0.1mm

:

:

-2.4mm

-2.5mm

RESTART

FEED

PAUSE

<2>PARAMETER SET

P.P.FEED +0.0mm

Check the next

label’s stop

p

osition

The next label stops with its

top edge aligning with the

strip shaft edge.

The next label stops with its

top edge misaligning with the

strip shaft edge.

RESTART

PAUSE

PAUSE

<2>PARAMETER SET

BACK SPEED STD

Turn the powe

r

OFF.

Turn the power ON.

Label issue

FEED

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

(Revision Date: Jan: 19, 2006)

2. Strip Module

2- 8

2.2 B-SA904P-H-QM-R

B-SA904P-H-QM-R is an optional strip module for the B-SA4TP Series (Plastic cover).

• Packing List

Strip Unit (1 pc.)

Strip Module Cover (1 pc.)

SMW-3x6 Screw (4 pcs.)

Cutter (1 pc.)

Guide Roller (1 pc.)

Installation Manual (1 copy)

NOTE: When issuing labels in batch mode even though the strip module is fitted, please use the provided

cutter to tear off the issued labels. Do not attach the cutter when labels are stripped one by one.

• Installation Procedure

1. Open the Top Cover and the Front Cover. Remove the Connector Cover.

Front Cove

r

Connector Cover

Top Cove

r

B-3x6 Scre

w

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

2. Strip Module

2- 9

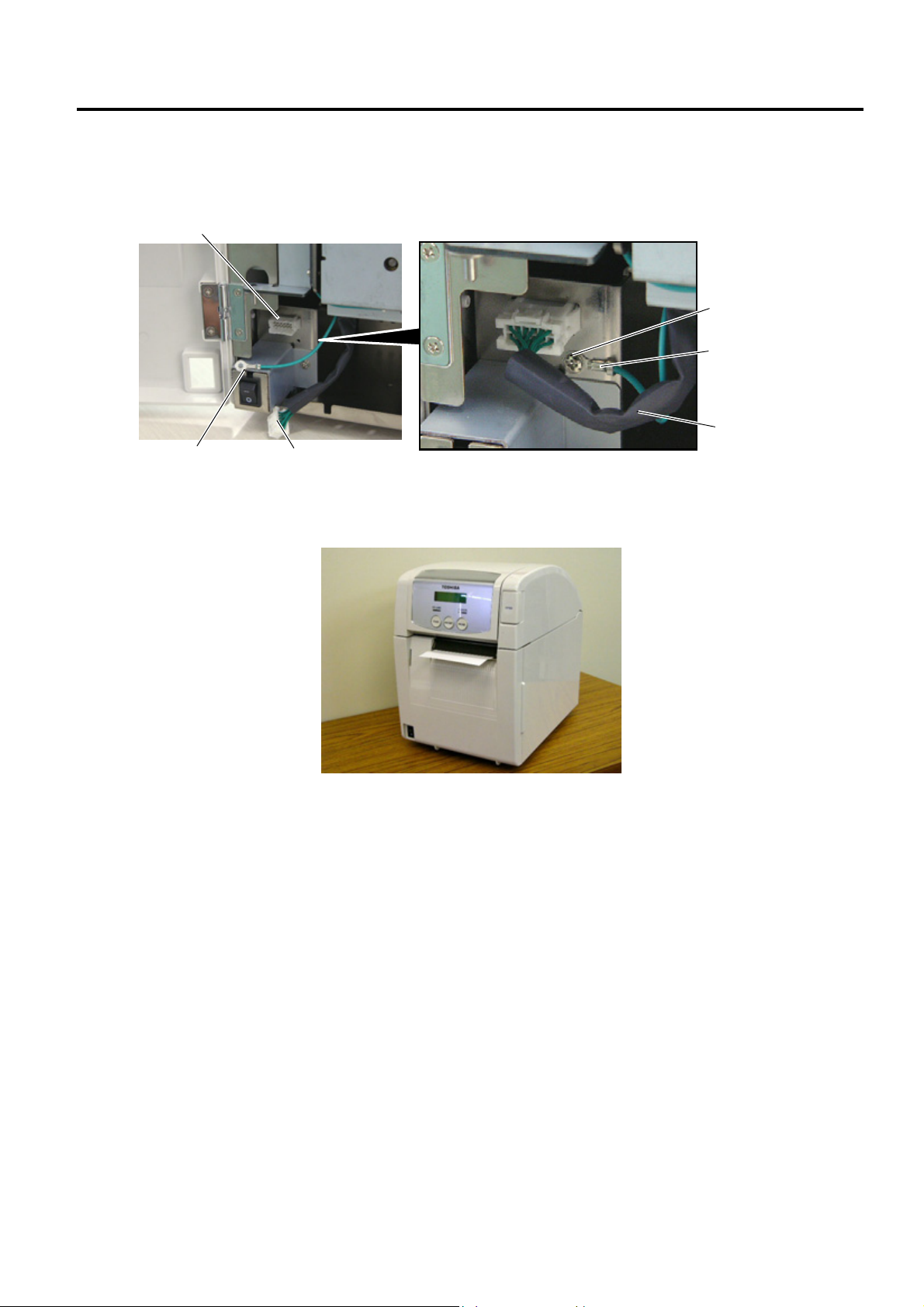

2. Open the Front Cover wider. Remove the Front Cover by lifting it to disengage the hi nge pins from the

hinge. The Front Cover cannot be removed unless it is opened at an angle of over 100 deg rees as the

stoppers of the hinge prevent disengagement.

3. Mount the strip Module Cover by inserting the hinge pins into the hinges.

4. Fit the Shaft Holders of the Backing Paper Feed Roller into the cuts of the printer.

Front Cove

r

Hinge

100°

Stopper

Hinge

Hinge

Strip Module Cove

r

Shaft Holder

Strip Uni

t

Cut

Cut

Backing Paper Feed Roller

INSTALLATION PROCEDURE FOR OPTIONAL EQUIPMENT EO15-33001A

2. Strip Module

2- 10

5. Secure the Strip Unit to the printer with the two screws. Make sure that the Feed Roller Gear rotates

smoothly.

6. Close the Strip Unit.

7. Close the Strip Module Cover. Perform an operation check for a proper strip issue.

• Media loading procedure------------- Owner’s Manual, Section 2.3

• Operation check------------------------ Owner’s Manual, Section 2.9

• System mode setting------------------System Mode Manual

• Cleaning --------------------------------- Owner’s Manual, Section 4.1.4

Strip Unit

SMW-3x6 Screw

Strip Unit

Feed Roller Gear

Loading...

Loading...