Delta AFE2000, C2000 User Manual

Product Application

Industrial Automation BU, Delta Electronics, Inc.

Case |

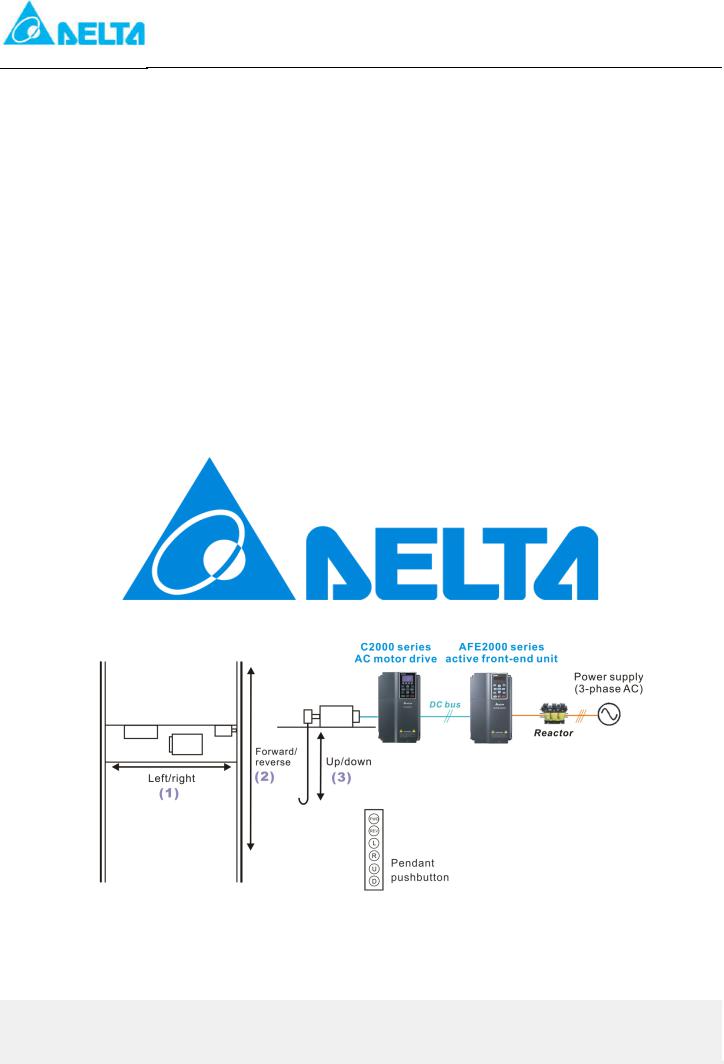

Application: Delta C2000 Series AC Motor Drive and AFE2000 Active Front-End Unit for Bridge |

|||||

Crane (Overhead Travelling Crane) |

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

|

|

Issued by |

Solution Center |

Date |

November, 2010 |

|

Pages |

5 |

|

|

|

|

|

|

|

Applicable to |

C2000 series AC motor drive, AFE2000 series active front-end unit |

|

|

|||

|

|

|

|

|

|

|

|

crane, hoist, Delta AC motor drive, high-level field oriented control, built-in PLC, torque control, |

|||||

Key words |

reliability, AFE2000 active front-end, power quality, power improvement, power factor, harmonics, |

|||||

|

fast braking, brake resistor, current control PWM converter, switch rectifier, energy-saving |

|||||

|

|

|

|

|

|

|

Introduction |

|

|

|

|

|

|

A bridge crane (also known as an overhead travelling crane) finds wide application in warehouses, factories, docks, open storage yards, and more. A three-phase induction motor offers many benefits including simple structure, durability, low cost, and easy maintenance. If we employ a Delta AC motor drive to drive the induction motor rather than using a traditional drive, the crane’s malfunction rate decreases substantially. Moreover, if Delta’s AFE2000 series active front-end unit is employed, it saves the cost of purchasing a brake resistor and excessive energy is transformed into reusable energy through IGBT switch, which is fed back to the mains for other electronic devices. Delta’s AC motor drive and AFE2000 is an outstanding combination for bridge cranes.

Application |

|

|

The bridge crane |

starting load is large, |

|

it is common to |

bridge cranes with |

|

more than four |

each wheel. The |

|

motion is done by |

|

|

1. |

Trolley: |

. |

2. |

Endtruck: |

REV). |

3.Hoist: To lift and lower the item (up/down).

[Figure 1]

The bridge crane hoist, unlike the trolley and the runway girder, has lower requirements for precision control, and it benefits a lot from the AC motor drive. Different from traditional drives, an AC motor drive offers more thorough

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 1 -

Product Application

Industrial Automation BU, Delta Electronics, Inc.

safety protection and additional features such as large load inertia and 4-quadrant operation. The suggested AC motor drive and the active front-end unit model for the bridge crane are:

VFD VFD110C23A

AFE AFE075A23A + CHOKE: 2.1mH

Application Case

System Solution |

|

|

|

For bridge cranes, |

long-term system |

stability issues as |

|

|

1. |

Full vector |

in steady motion. |

2. |

Optional braking |

|

3. |

Constant torque |

|

4. |

With AFE2000, |

and fed back to |

|

the mains. |

|

System Features

SVC control

The Delta C2000 provides sensorless vector control (SVC) to perform a nearly close-loop control function which saves from purchasing an encoder and lowers maintenance cost. In addition, it overcomes activation difficulties, and is capable of initiating a start-up under full load and short-term over-load conditions.

Braking process control

Prevention of sudden drops and jerky movements is an important factor in overall bridge crane system design. The coordination between the AC motor drive and the mechanical control should be rigid to prevent sudden drops and jerking, especially when lifting or lowering a heavy load and when stopping a heavy load in mid-air. The Delta C2000 series offers a special set of parameters and multiple output commands to promptly solve the problem.

Overload capacity

Normal load: rated output current 120%/min; Heavy load: rated output current 150%/min. This offers sufficient start-up torque and maintains the DC Bus voltage at 730VDC when torque decreases and it will not trigger OU alarm. The test report reveals the system allows the bridge crane to operate long-term

Soft-start, soft-stop, wide speed range and precise positioning.

With solid experience and advanced technology, Delta’s IABU offers efficient and reliable solutions and service — we are your most trustworthy partner.

COPYRIGHT © 2008 DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED.

- 2 -

Loading...

Loading...