Page 1

HUMPHREY

Eye Care Menu

Operator Manual

Note: Drawings and Schematics are

not available in this revision.

FDT Visual Field Instrument

SERVICE MANUAL

Part Number 112120

Revision B October 1997

Includes CE Model

Copyright 1997

Welch Allyn Inc.

Page 2

Page 3

Part No Rev

Description ECN # Date Approved

112120 A New Release of FDT Service Manual 5-36180 8/22/97 RJS

112120 B

Added CE version Section 9 , Calibration

Limits and Error Messages.

5-36574 10/21/97 RJS

DRAWINGS AND / OR ILLUSTRATIONS AND / OR PART NUMBERS

CONTAINED IN THIS DOCUMENT ARE FOR REFERENCE PURPOSES

ONLY! FOR CURRENT REVISIONS CALL HUMPHREY INSTRUMENTS

CUSTOMER SERVICE

ii HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 4

Page 5

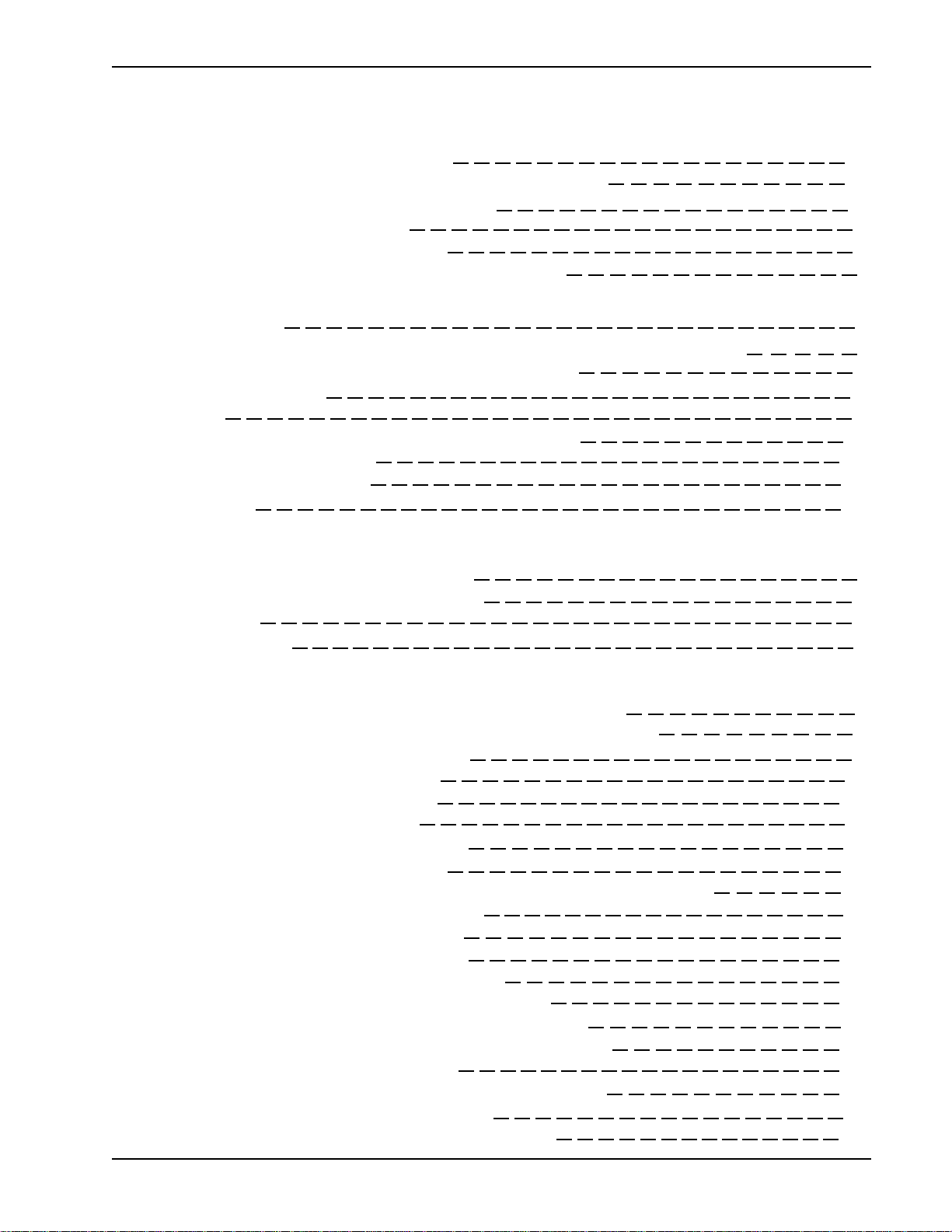

Contents

Section 1: General Information

About The 710 Series and the CE Model 1

Help Information CUSTOMER SERVICE PHONE NUMBER 2

Important Safety Warnings and Service Notes 3

Main Menu Architecture Ver.2.10 5

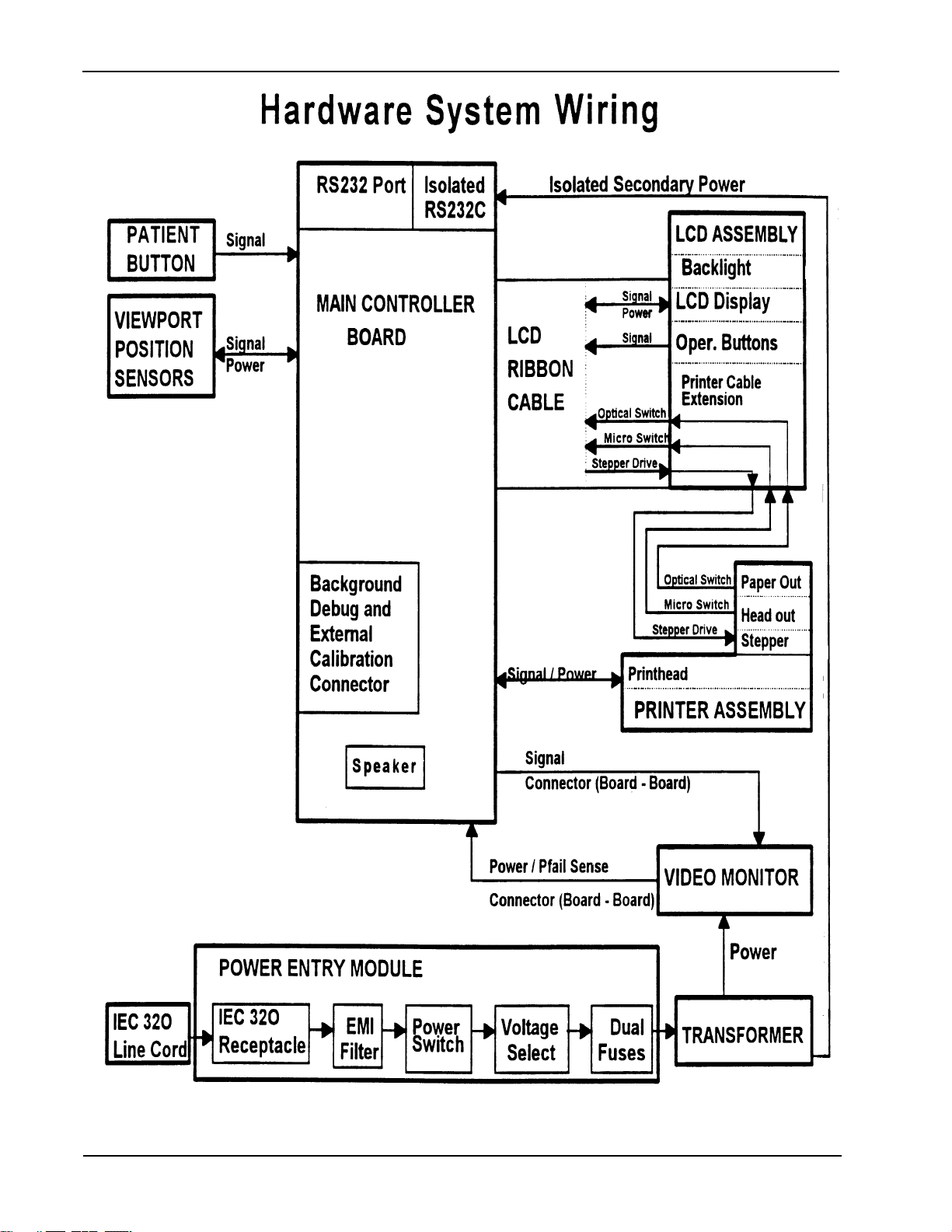

Hardware System Wiring Block Diagram 6

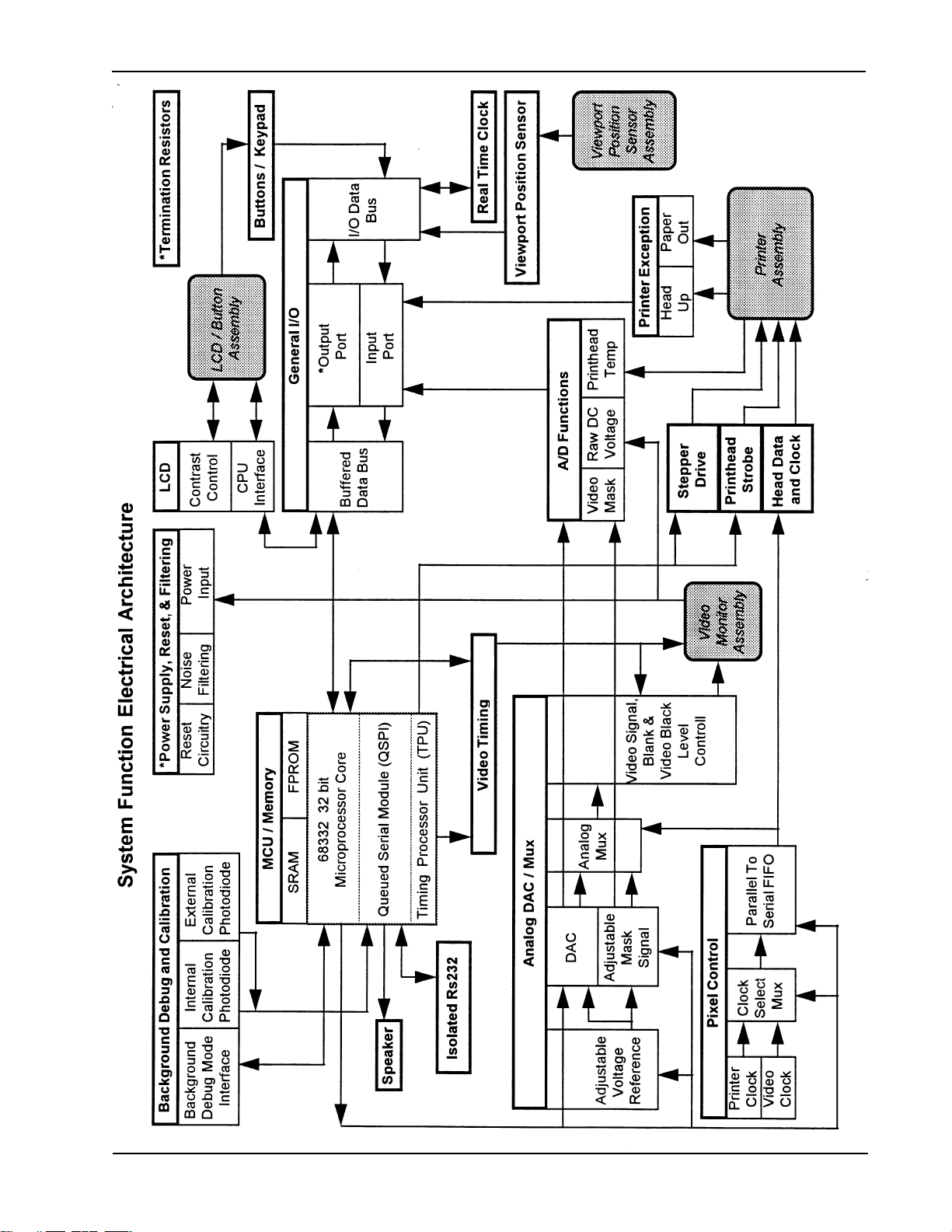

System Function Electrical Architecture Block Diagram 7

Section 2: Service

Incoming Inspection 1

Tools Required for Service and Factory Calibration and Software Uploading 2

Factory Calibration for Software Version 1.20 or Higher 3

Loading Software for FDT 5

Final Testing 6

Hypot Ground Continuity, and Leakage Current Testing 11

Important Shipping Information 12

Calibration Limits Information 13

Product Updates 15

Section 3: Troubleshooting

Chief Complaint, Cause, Corrective Action 1

Power On Self Test (P.O.S.T.) Status Table 3

FDT Terminology 4

FDT Error Messages 5

Section 4: Disassembly and Repair

4.1 Removal of Rear Housing/LCD Assembly 1

4.2 Replacement of Rear Housing/LCD Assembly 3

4.3 Disassembly of Optics 3

4.4 Assembly of Optics 11

4.5 Removal of Printer 15

4.6 Installing Printer 16

4.7 Removal of MCU/ PCB 17

4.8 Installing MCU/PCB 19

4.9 Installing a Replacement Chassis/Monitor Assembly 20

4.10 Removal of Transformer 20

4.11 Installing Transformer 21

4.12 Removal of PRB Jack 21

4.13 Replacement of PRB Jack 21

4.14 Removal of Power Entry Module 21

4.15 Replacement of Power Entry Module 22

4.16 Removal of Visor Position Sensor (VPS) 22

4.17 Replacement of VPS 22

4.18 Removal of Internal Photodetector (IP) 23

4.19 Replacement of IP / PCB 23

4.20 Removal of LCD Module/Keypad 23

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT iii

Page 6

Section 4: Disassembly and Repair Cont’d

4.21 Replacement of LCD Module/Keypad 24

4.22 Removal of Visor Pad 24

4.23 Installing Visor Pad 25

4.24 Removal of Acrylic Lenses and Optics Tube Window 25

4.25 Installing Acrylic Lenses and Optics Tube Window 26

Section 5: Interconnect Diagrams 112119

Section 6: Repair Parts

Key to Repair Parts List 1

Parts List (3 pages) 2

Section 7: FDT Assembly Drawing 112000 Domestic 3 sheets

FDT Assembly Drawing 112200 International (CE) 4 sheets

Section 8: Schematics 112106, 112091 , 112037

Section 9: CE Model Disassembly and Repair

9.1 Removal of Rear Housing/LCD Assembly 1

9.2 Replacement of Rear Housing/LCD Assembly 3

9.3 Disassembly of Optics 3

9.4 Assembly of Optics 10

9.5 Removal of Printer 14

9.6 Installing Printer 15

9.7 Removal of MCU/ PCB 16

9.8 Installing MCU/PCB 19

9.9 Installing a Replacement Chassis/Monitor Assembly 20

9.10 Removal of Transformer 20

9.11 Installing Transformer 21

9.12 Removal of PRB Jack 21

9.13 Replacement of PRB Jack 21

9.14 Removal of Power Entry Module 21

9.15 Replacement of Power Entry Module 22

9.16 Removal of Visor Position Sensor Board (VPS) 22

9.17 Replacement of VPS 22

9.18 Removal of Internal Photodetector (IP) 23

9.19 Replacement of IP 23

9.20 Removal of LCD Module/Keypad 23

9.21 Replacement of LCD Module/Keypad 24

9.22 Removal of Visor Pad 24

9.23 Installing Visor Pad 25

9.24 Removal of Acrylic Lenses and Optics Tube Window 25

9.25 Installing Acrylic Lenses and Optics Tube Window 26

iv HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 7

Section 1 - General Information

The 710 Series FDT Visual Field Instrument

utilizes Frequency Doubling Technology (FDT).

Various preprogrammed patterns of flickering black

and white vertical bars are presented to the patient on a video screen. Each patient is tested on

the degree of contrast between the black and

white bars which enables them to see each pattern.

The Frequency Doubling stimulus taps into a

select subset of retinal ganglion cells that have

been observed to die in early glaucoma patients.

Because the stimulus is selective only to this

subset of cells, the test is accurate and rapid.

About The 710 Series FDT

Visual Field Instrument

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 8

Section 1 - General Information

Help Information:

All service and repairs must be performed by authorized

Humphrey Instruments personnel or agents, using genuine

replacement parts. Failure to do so will invalidate the prod-

uct warranty.

Read and understand all safety warnings and service

notes printed in this Service Manual and the User’s

Guide. If in doubt about any precaution or procedure,

call Humphrey Instruments Customer Service phone

number below.

For Phone Help, call Humphrey Instruments Customer Service at: 800-341-6968

The part and serial numbers are located on the bottom of

the unit.

Troubleshooting assistance is contained in Section 3 of this

manual. Troubleshooting is limited to board level replacement and not board component replacement.

Please read and understand FDT User’s Guide #112098,

a copy of which may be obtained by calling Humphrey Instruments Customer Service Department at the toll free 800

number above.

2 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 9

Section 1 - General Information

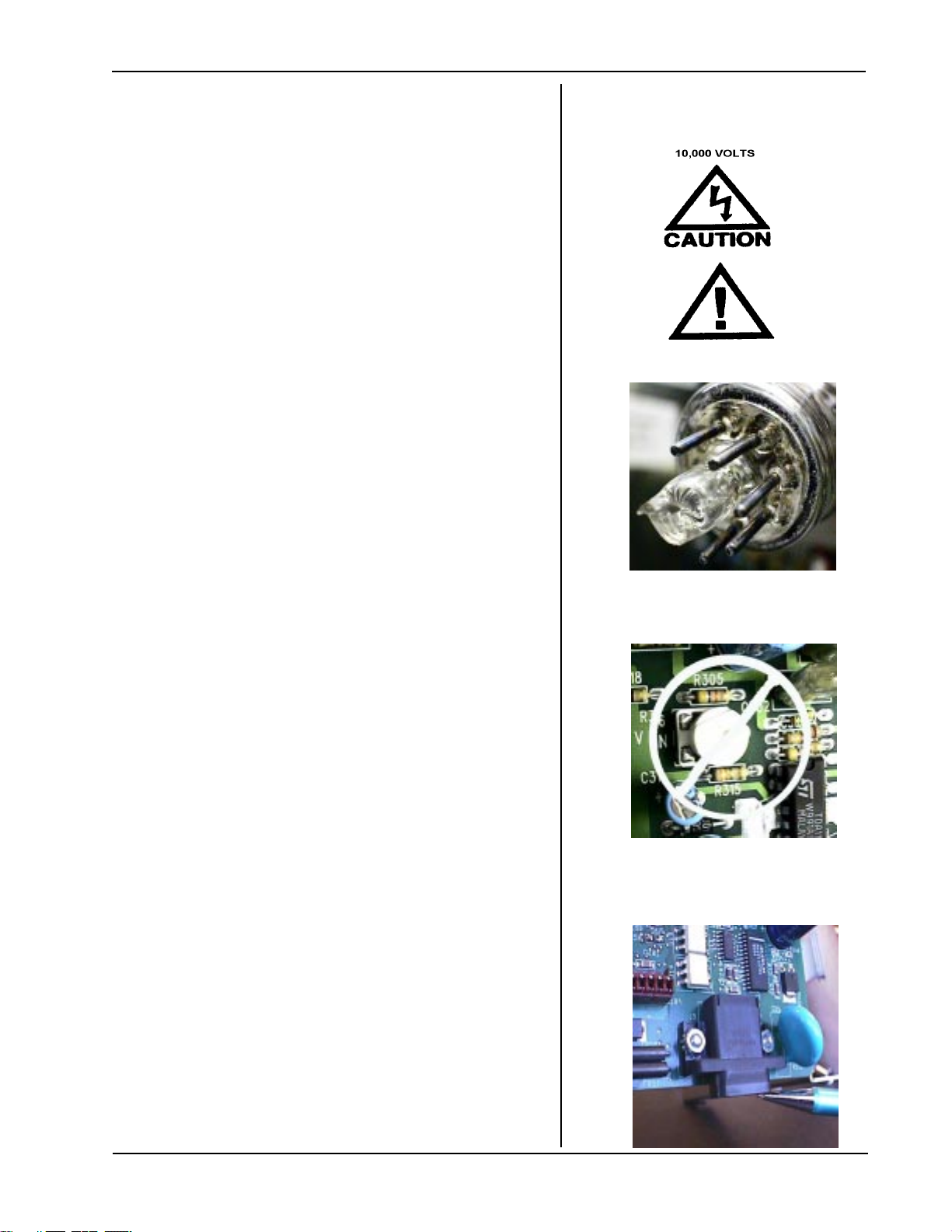

Read Important Safety Information in User’s Guide.

EXERCISE EXTREME CAUTION WHEN

SERVICING THE FDT! THE MONITOR ASSEMBLY

OPERATES ON APPROXIMATELY 10,000 VOLTS!

Do not remove the plug from the end of the CRT

exposing sharp glass process tube. This can

cause cuts! (Photo 1 at right.)

Disconnect FDT from Mains when disassembling.

Clean as recommended in Users Guide.

Follow ESD precautions during service.

Test repaired FDT units at 115v and 230v prior to

returning them to customers.

Support the FDT by holding under the base to protect

the upper optics section from stress.

Important Safety Warnings

and Service Notes

Photo 1

Please DO NOT adjust pots on the monitor board.

The video monitor is a non-standard design and

because of this, there are no field monitor or video

service adjustments. Video adjustments can only be

performed by the monitor manufacturer with special

equipment. Unauthorized adjustments may result

in clinically invalid results without obvious

indications of any malfunction. (Photo 2 at right)

Tighten fasteners carefully. Refer to drawing

#112000 in this manual for recommended fastener

torque specifications.

Put a calibration cap (see bubble number 90 on

drawing 112000) on the optics tube assembly during

servicing to protect optics tube window.

The RS232 connector housing of the MCU PCB

projects below the bottom of the MCU PCB (Photo 3

at right). Do not stand the chassis monitor assembly

on this connector. Put the chassis monitor assembly

on its back between repair steps.

Photo 2

Photo 3

Always install latest revision software when installing

a new MCU/PCB. Call Humphrey Customer Service.

See Section 2 Pg. 4 for details.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 3

Page 10

Section 1 - General Information

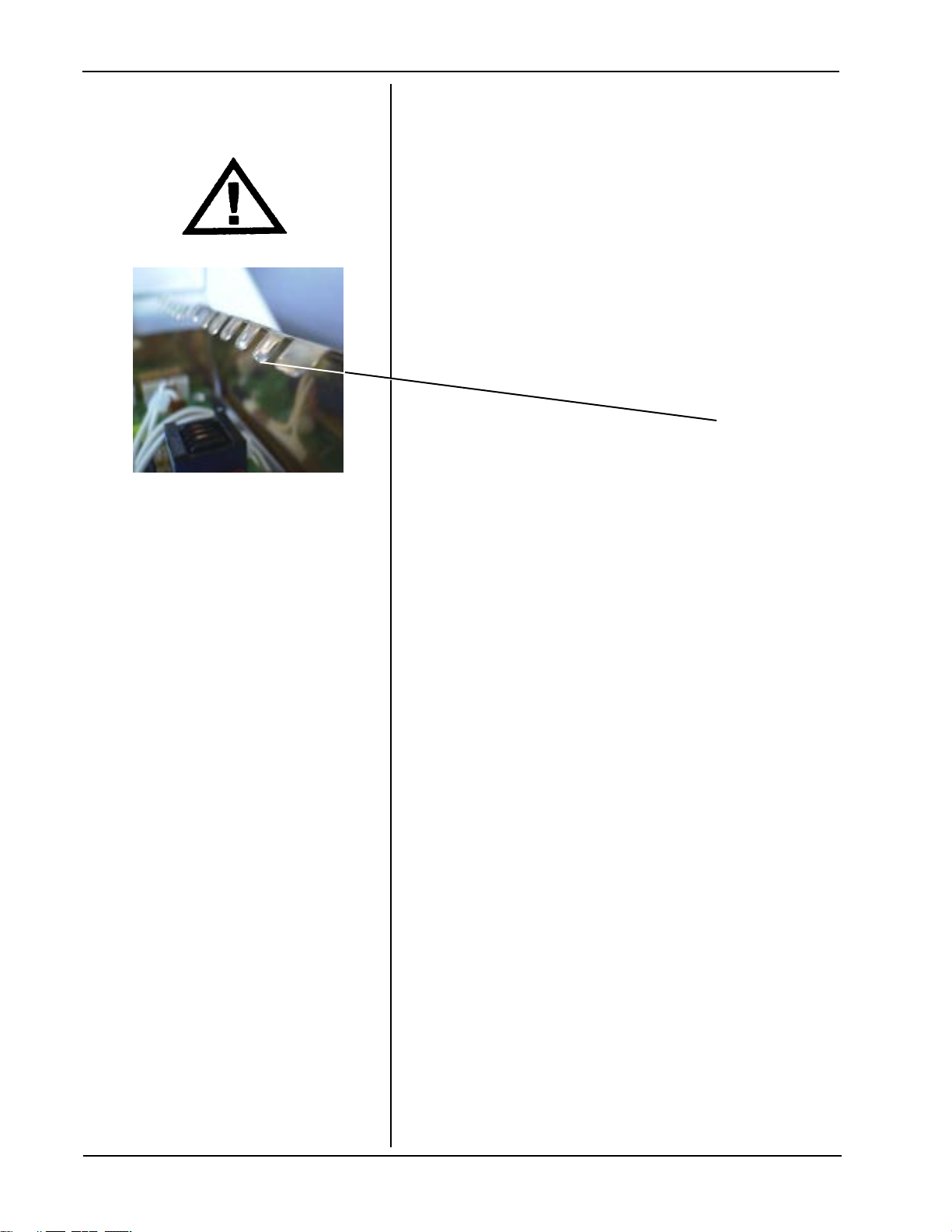

Important Safety Warnings

and Service Notes

Photo 4

Copper ESD shields may have sharp edges.

Exercise caution to avoid cuts!

4 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

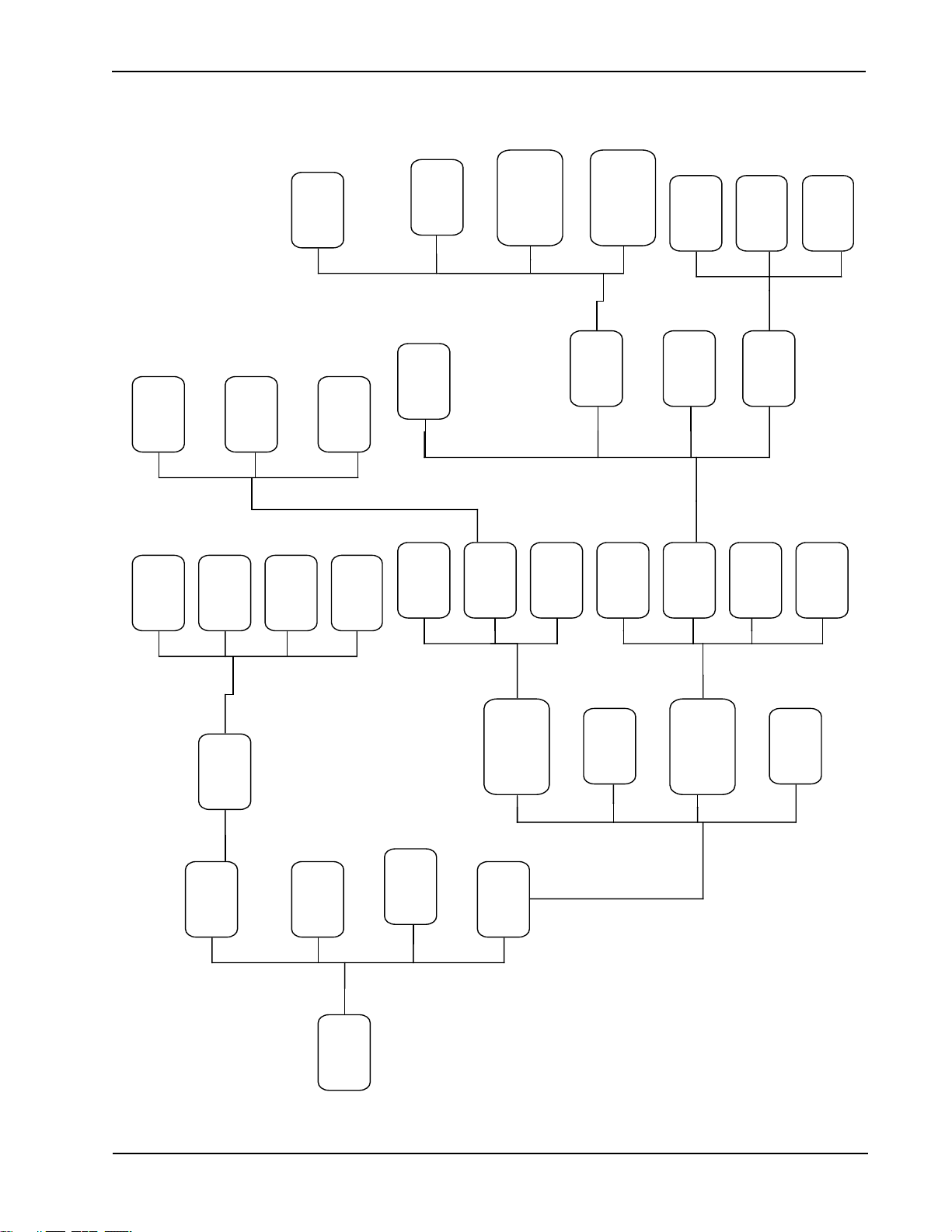

Page 11

Section 1 - General Information

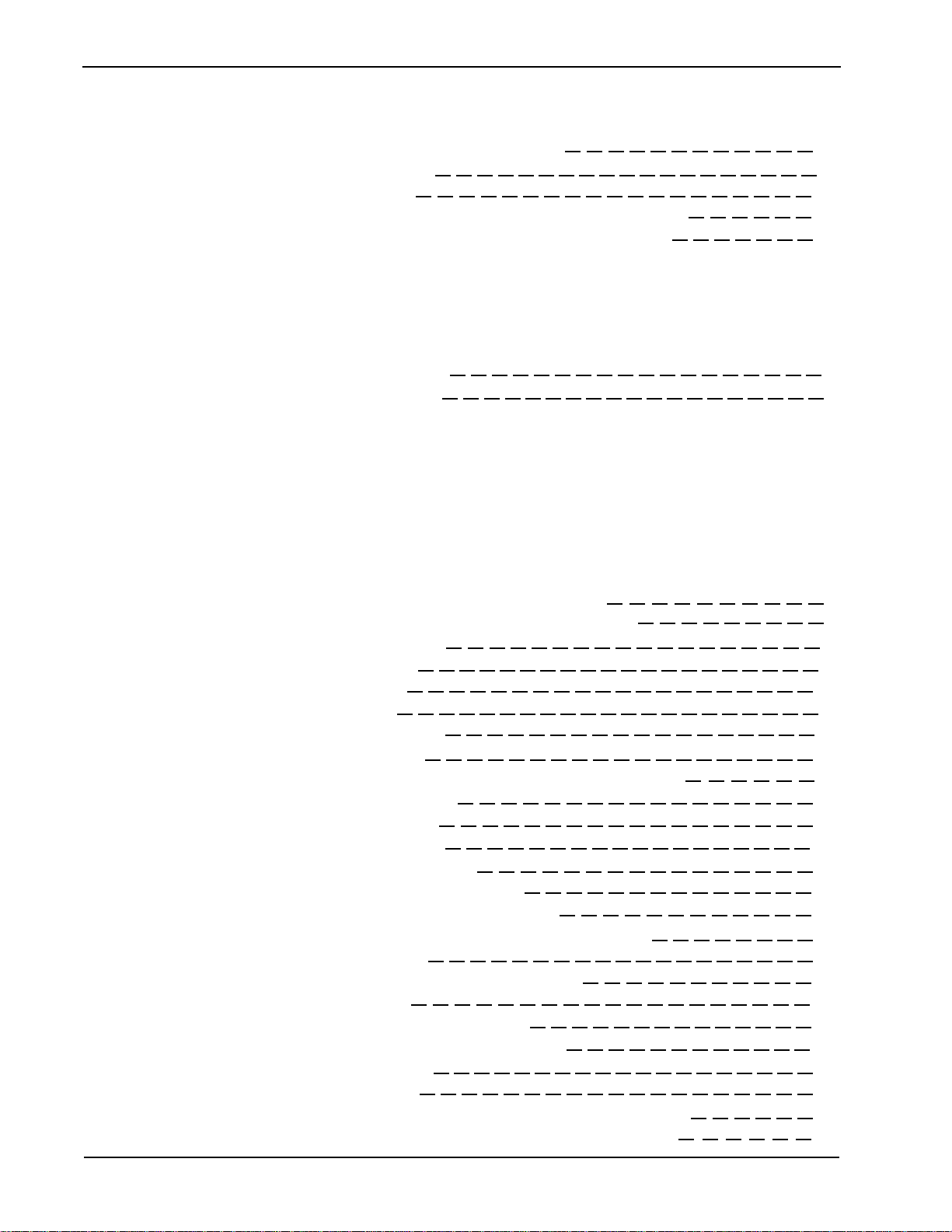

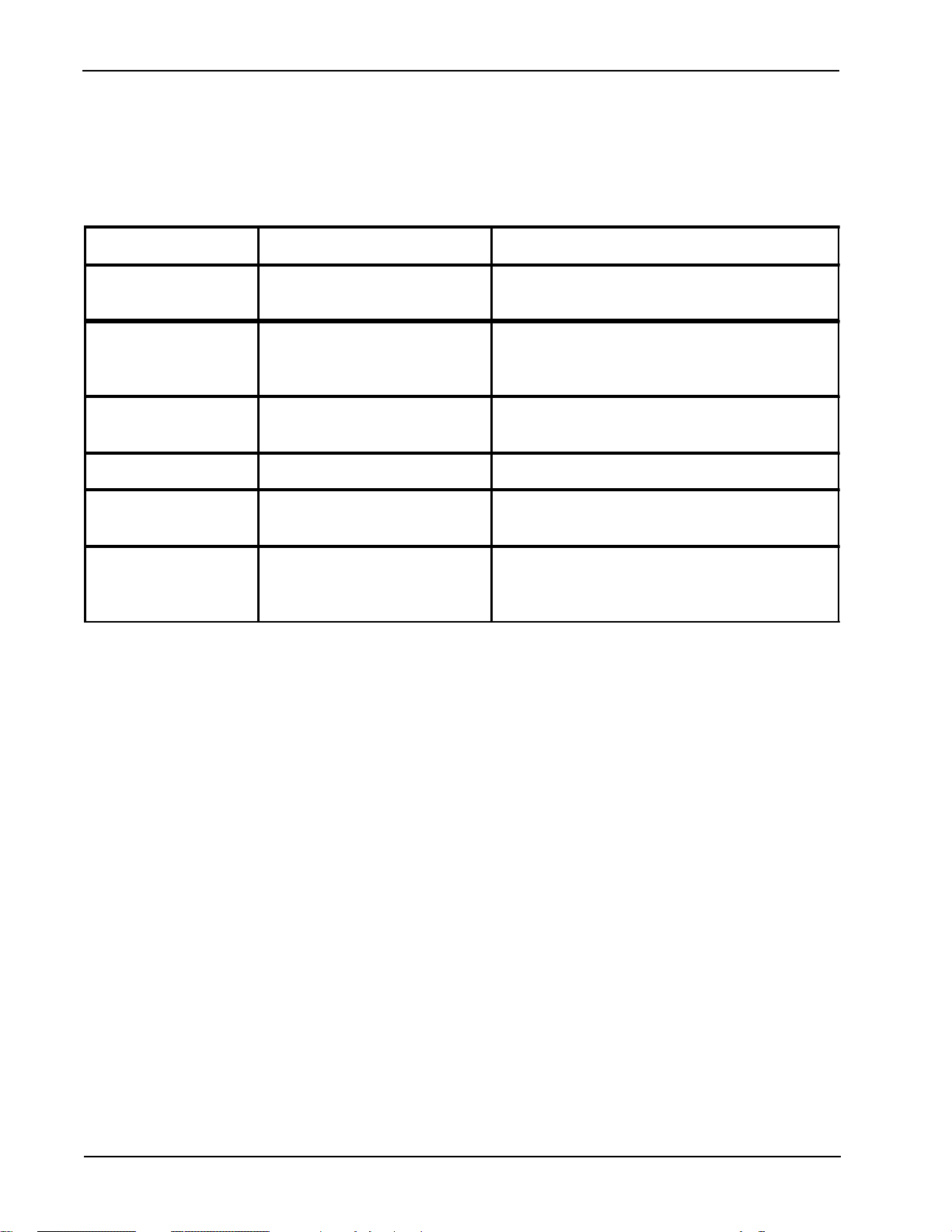

FDT MAIN

ENTER

PATIENT

AGE

UTILITIES

MENU

**ADVANCE

PAPER

RUN DEMO.

RUN

PATIENT

TESTS

SET-UP

INSTRUMENT

MENU

RUN SELF

CAL.

INSTRUMENT

TESTS MENU

ABOUT FDT

RUN

SCREENING

C-20 TEST

RUN FULL

THRESHOLD

C-20 TEST

RUN FULL

THRESHOLD

N-30 TEST

SKIP EYE

SET CLOCK

MENU

SET-UP

OPTIONS

MENU

PRINT

SET-UP

REPORT

TEST

INPUTS

TEST

OUTPUTS

TEST

SERIAL

PORT

SELECT

LANGUAGE

OPTIONS

RESET TO

DEFAULTS

TEST LCD

TEST VIDEO

MENU

TEST

SPEAKER

TEST

PRINTER

MENU

AMBIENT

LIGHT

CHECK

CALIBRATION

CHECK

FACTORY

CALIBRATION

RUN

PRINTOUT

TEST

ADVANCE

PAPER

TEST VIDEO

SYSTEM

TEST A/D

CIRCUITRY

+10 years

-10 years

+ 1 year

ACCEPT SETTING

BUTTONS

PRB

VIEWPORT

POS

CHECKERBOARD

BLANK SCREEN

FULL SCREEN

** AFTER TEST PERFORMED, WILL READ

LAST PATIENT RESULTS

DIXIE PATTERN

LCD MEMORY

BACKLIGHT (ON/OFF)

Printer

Status

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 5

Page 12

Section 1 - General Information

6 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 13

Section 1 - General Information

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 7

Page 14

Page 15

Section 2 - Service

When an FDT unit is returned, check:

1) Physical condition of packaging.

2) Physical condition of unit.

3) List any accessories with unit, for example:

power cord

Patient Response Button (PRB)

calibration cap

dust cover

computer interface cable

Incoming Inspection

4) Perform “PRINT SET-UP REPORT” if

possible, and keep for reference.

5) Perform Cleaning/Disinfection per instuctions

in User’s Guide, Section 4, Maintenance.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 16

Section 2 - Service

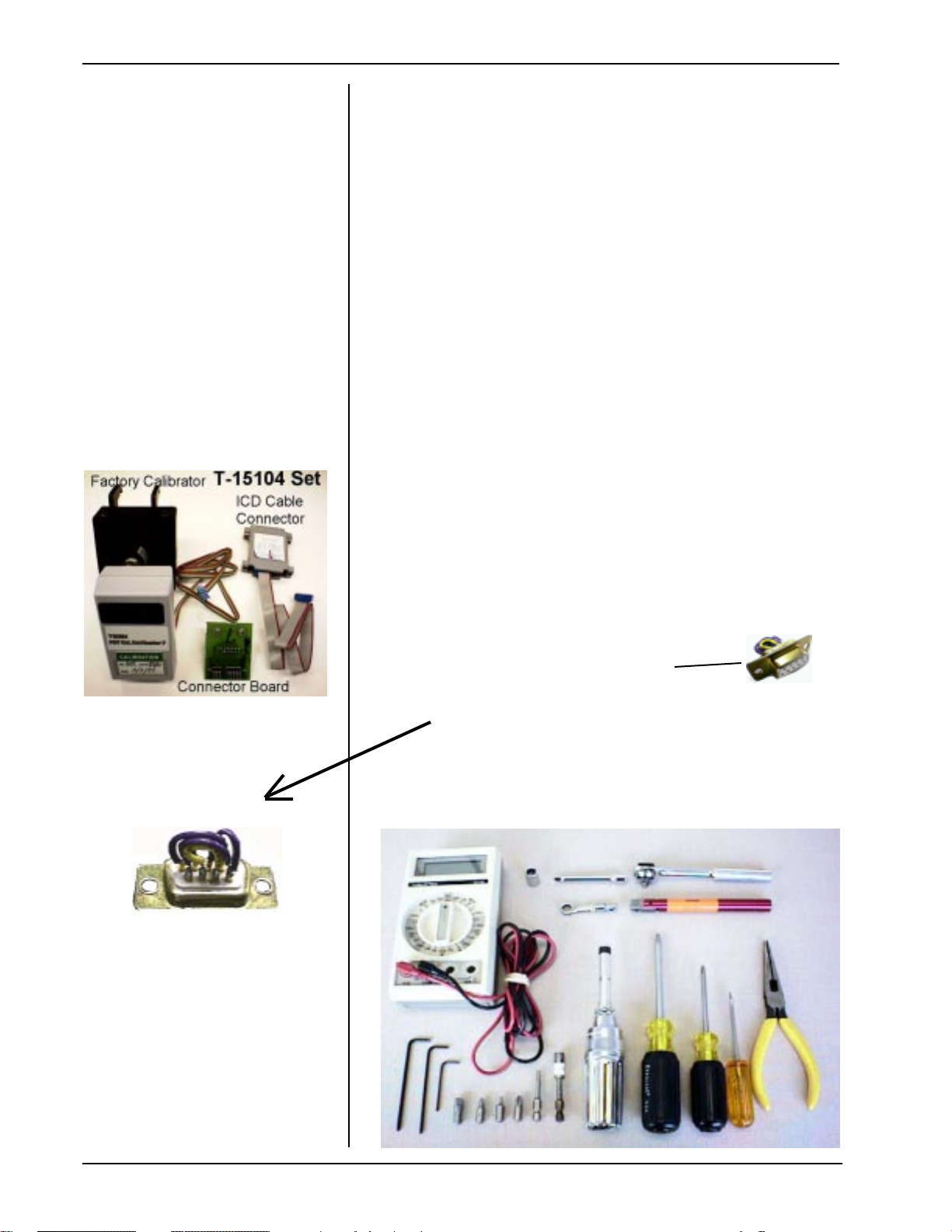

Tools Required for Service

Factory Calibration

and Software

Uploading

Photo 1

#1 Flathead screwdriver - 2” length

#1 Phillips screwdriver - 4” length

#2 Philips screwdriver - 4” length

1/4” drive ratchet with 1/4” extender

11/32” socket

3/32” hex key

7/64” hex key

Adjustable torque driver - 2 - 14 in/lbs range

Bits for Torque Driver:

#1 Phillips

#2 Phillips

3/32” hex

7/64” hex

1/4” square to hex adapter

Torque Wrench - Adjustable 2 - 14 in/lbs range

Torque Handle: Mountz 06-8002 TB1H 12-21

in/lb or equivalent.

Torque Handle Box Wrench accessory:

Mountz 068127 Box Head - 11/32”

Photo 1b

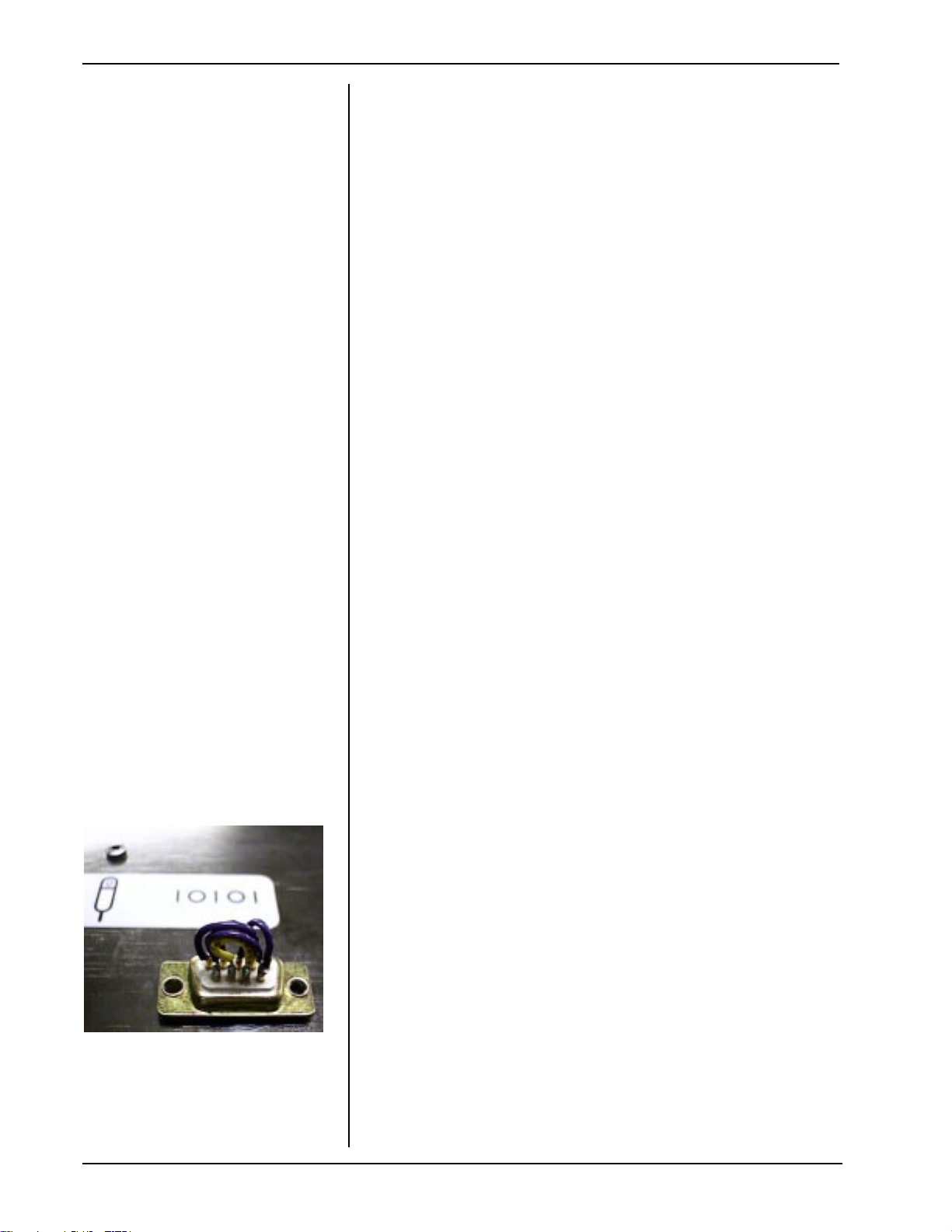

T15145 - for PRB connector

T15104 - Calibrator and Software Floppy Disc

(see Photo 1 at left)

T15810- Serial Port Tester

(can be made with a standard DB 9 female with

these connections: Pins 1,4,6,9 common

Pins 2,3 common

Pins 6,8 common

Digital volt meter ( three plus range)

Needle nose pliers

Photo 2

2 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 17

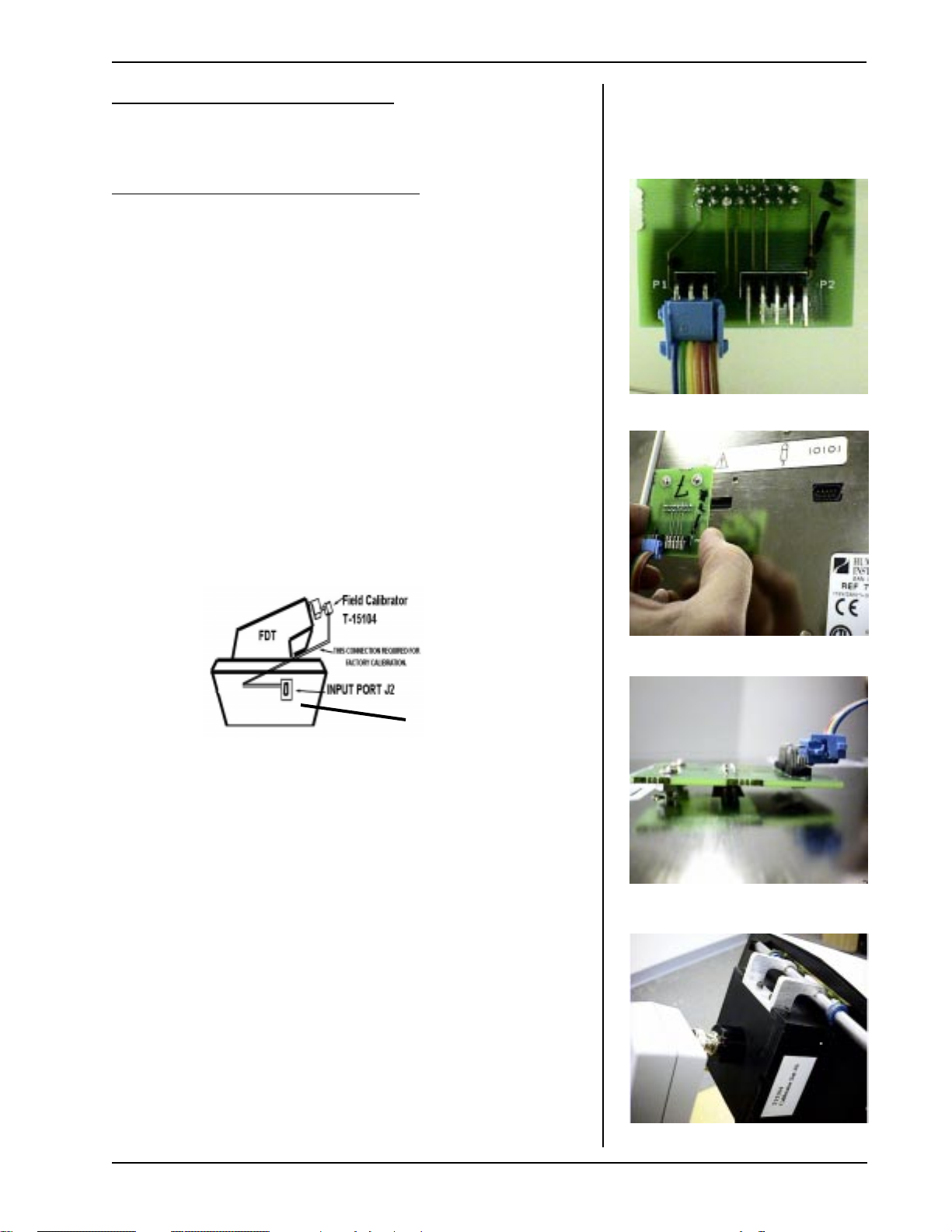

Section 2 - Service

Upgrade recommendation: Upgrade all re-

turned FDT’s with Software Version 2.10. Perform

Factory Calibration Process.

Start Factory Calibration Process:

1 Turn FDT unit OFF.

2 Connect the wire from the T-15102 Factory

Calibrator to connector board as shown in Photo 3.

Wires must exit from top of connector as shown.

3 Remove Visor/Browrest (Sect 4 or 9 for CE FDT)

Factory Calibration

for Software Version.

1.20 or higher

4 Tilt FDT on its side to remove label over Calibration/

Software loading port J2.

5 Align threaded studs of connector board with the two

holes near port J2 as shown in Photo 4.

6 Insert T 15102 into port J2 as shown in Photo 5.

Hookup should be as shown in Figure 1 below.

Fig. 1

connector board

T 15102

7 Position the FDT in upright position and place

calibrator onto the slide bracket . See Photo 6

Note: Place calibrator on viewport tightly to prevent

light from entering the calibrator housing.

Photo 3

Photo 4

8 Turn the FDT ON and view the menu on the LCD:

a) Press button next to UTILITIES MENU

b) Press button next to INSTRUMENT TEST MENU

c) Press button next to TEST OUTPUTS

d) Press button next to TEST VIDEO MENU

e) Press button next to FACTORY CALIBRATION

NOTE: Unit can be calibrated with PC utility Calibrat

through the FDT computer interface. Refer to the Calibrate utility for more information.

9 Press any button to indicate that you have placed

the factory calibrator on the view port.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 3

Photo 5

Photo 6

Page 18

Section 2 - Service

Factory Calibration

for Software Version.

1.20 or higher

(continued)

10 Press any button to start the Factory Calibration

calibration process. Duration : less than 1minute.

NOTE: Self-Calibrate is automatically performed

during Factory Calibration in Version 2.10

11 Turn the FDT OFF and remove calibrator from

slide bracket.

12 Remove T-15102 connector board from Port J2 on

bottom of FDT. Install a new label part # 112066

over J2 port.

13 Turn FDT ON and view the menu on the FDT LCD:

a) Press the green button until the UTILITIES

Menu is reached.

b) Put the black calibration cap on the viewport.

c) Press the button next to RUN SELF

CALIBRATION. (Process time: 2 - 3 min.)

Note: A progress indicator will display on the LCD. It

will indicate what percentage of the calibration is

complete. The unit will indicate when calibration is

complete and return to UTILITIES MENU.

14 Now perform a Calibration check:

a) Press button next to INSTRUMENT TEST

MENU.

b) Press button next to TEST OUTPUTS

c) Press button next to TEST VIDEO MENU

d) Press button next to CALIBRATION CHECK

Note: The meter will indicate that the FDT is fully

calibrated.

15 Press any button to continue.

16 Press the green button 4 times or until FDT MAIN

MENU is reached.

17 Install the visor/browrest with the 4 black hex socket

head cap screws as shown in Section 4.

Note: See Calibration Limits/Parameters Tables

4 HUMPHREY FDT VISUAL FIELD INSTRUMENT

in this section.

(End of Factory Calibration Process)

SERVICE MANUAL 112120 REV. B

Page 19

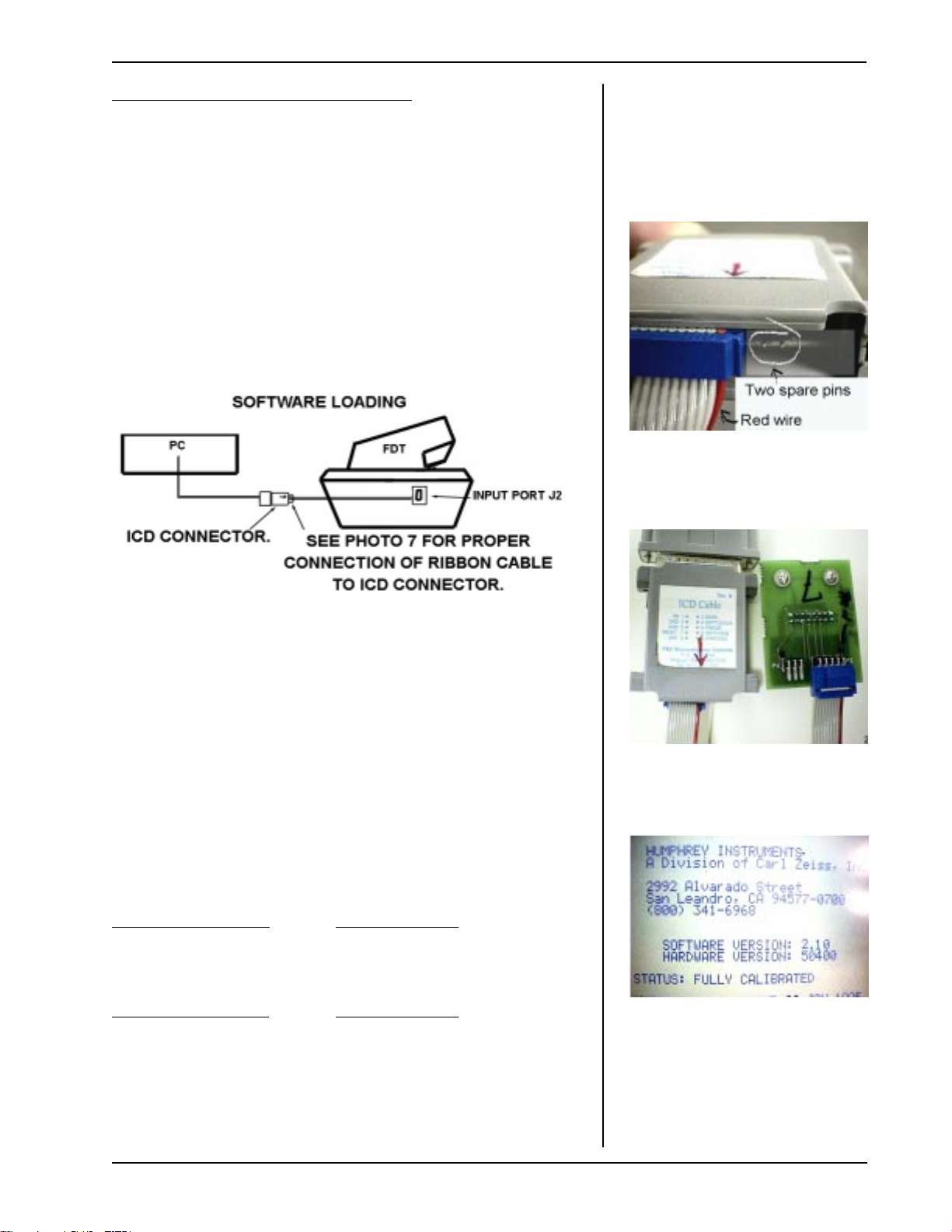

Section 2 - Service

Start Software Loading Process:

1 Connect the ribbon cable to the ICD Cable

connector as shown in Photo 7 at right.

Note: a) 2 Pins at right are not used

b) Align the red wire of the ribbon cable

with the red arrow on ICD connector.

2 Connect the ribbon cable to the connector board as

shown in Photo 8.

3 Connect ICD connector to the PC Parallel Port .

See Figure 2 below.

Loading Software for FDT

Note: FDT software is not

Mac compatible.

Photo 7

Figure 2

4 Insert T 15102 into port J2 as shown in Photo 5

and follow software loading instructions displayed

on the PC when running FDT Software Installation

Program.

Note: Whenever installing a new MCU/PCB and

loading highest revision software, verify proper

hardware (marked on MCU/PCB) version using

“ABOUT FDT”. LCD Screen will display

software/hardware data. See Photo 9

Software Version: Release Date:

Ver. 1.20 July 1997

Ver. 2.10 October 1997

Hardware Version: Release Date:

MCU/PCB Rev 503 August 1997

MCU/PCB Rev 504 September 1997

Photo 8

Photo 9 FDT LCD Screen

Note: See Product Updates in this section.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 5

Page 20

Section 2 - Service

Final Testing

(page 1 of 6)

Note: Follow this final testing process to verify

correct operation after the FDT has been serviced.

1. Calibration

Follow instructions in the calibration section of

manual.

2. 230 Volt testing

Remove fuse block. Replace the 115v fuses

(.315A) with those recommended for

230v.(.160A)

Place fuse block back into unit so the 230v

shows. Plug unit into a 230v line and turn unit

on. After approximately 10-15 seconds the unit

should go through a series of beeps and the

FDT Main menu should appear. After this test is

done, turn off unit, remove power and replace

the fuses with the 115V (.315A) ones. Be sure

that the115V shows in the fuse drawer.

3. Operational testing

3.1 Plug in PRB.

3.2 Turn unit on. After approximately 10-15

seconds the unit will complete self

diagnostics and emit two double beeps.

The FDT main menu will appear.

3.3 Press the button next to UTILITIES

MENU.

3.3.1 Check the intensity adjustment.

a) Press the button pointing

b) Press the button pointing

c) Use both buttons as needed

downward. The LCD

contrast will decrease.

upward. The LCD contrast

will increase.

to return to usable LCD

contrast.

6 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 21

Section 2 - Service

3.3.2 Press the button next to ABOUT

3.3.3 Press the green button on the

3.4 Press the button to the left of

INSTRUMENT TESTS MENU.

3.4.1 Press the button next to

FDT. The screen will indicate that

the unit is fully calibrated and show

the software revision. Make

sure that it has the latest revision

software.

bottom left. This should bring you

back to the UTILITIES MENU.

TEST INPUTS.

a) Press each of the 4 upper

left buttons. When each

buttons is pressed, the

word PRESS to the right of

the button will change to a

PRESSED highlighted.

Release the button. PRESS

will reappear unhighlighted.

b) Move the visor to the three

different positions - left,

middle and right (patients

side). The Eye test posi-

tion on the right hand side

of the display will change

state to indicate the current

eye test position.

c) The Patient button will

indicate NOT PRESSED.

Press the PRB and it

will report a highlighted

PRESSED.

d) Unplug the PRB plug from

the PRB jack. The Patient

Button status will indicate:

Not connected. Plug the

PRB plug into the PRB jack.

Final Testing

(page 2 of 6)

3.4.2 Press the green button on the

bottom left to return to

INSTRUMENT TESTS MENU.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 7

Page 22

Section 2 - Service

Final Testing

(page 3 of 6)

3.5 Press the button next to TEST OUTPUTS.

3.5.1 Press the button next to TEST

LCD.

a) Observe highlighted test

option on screen.

b) Press button next to RUN

TEST. The LCD will reflect

state of the highlighted test

option.

c) Press any button to exit

present LCD test.

d) Press button next to NEXT

CHOICE to change test

option.

e) Perform the above steps for

the CHECKERBOARD,

BLANK SCREEN, FULL

SCREEN, AND DIXIE

PATTERN options.

f) Press button next to NEXT

CHOICE to highlight LCD

MEMORY TEST.

g) Press button next to RUN

TEST. The display will be;

Testing LCD memory and

change to LCD memory

passed. Press any button

to exit test.

h) Press button next to NEXT

CHOICE to highlight the

BACKLIGHT option.

i) Press button next to RUN

TEST a number of times

and observe the LCD

screen. The backlight

should toggle on and off.

Make sure the Backlight is

on before exiting this test.

j) Press the green button to

return to OUTPUT TESTS.

8 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 23

Section 2 - Service

3.5.2 Press the button next to TEST

3.5.3 Press the button next to AMBIENT

VIDEO MENU.

a) Press the button next to

TEST VIDEO SYSTEM.

b) Look into the patient viewing

area. A large flashing circle

exhibiting the Model 710

Seriesgrating pattern in the

center of the viewing area

will be visible.

c) Press the Green button to

return to TEST VIDEO

MENU.

LIGHT CHECK.

a) There may be a short time

for monitor warm up.

b) With the calibration cap on,

the pointer will be in the

dark range.

c) Remove the calibration cap.

The pointer will rise to

the light or bright range,

depending upon the intensity of the room lighting.

d) Put the calibration cap back

on and press the green

button to return to TEST

VIDEO MENU.

Final Testing

(page 4 of 6)

3.5.4 Put Calibration cap on. Press

button next to CALIBRATION

CHECK.

NOTE:Calibration will be denied if cap is off and room

light level is too high.

a) The pointer should be in the

fully calibrated range.

b) Do not press the factory

calibration option. If this

option is accidentally

chosen, the unit will detect that a calibrator is not

attached and warn user.

c) Press the green button twice

to return to OUTPUT

TESTS MENU.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 9

Page 24

Section 2 - Service

Final Testing

(page 5 of 6)

Final Testing

3.6 Press the button next to TEST SPEAKER.

3.6.1 There will be increasing tones.

3.7 Press the button next to TEST PRINTER

MENU.

3.7.1 The TEST PRINTER MENU will be

displayed. Press the button next to

RUN PRINTOUT TEST. The FDT

will print out a series of patterns

and instrument data.

3.7.2 Press the button next to ADVANCE

PAPER. The paper will

advance about 1-2 inches beyond

the slot in the paper door.

3.7.3 Press the button next to PRINTER

STATUS. “PRINTER OK”

message will appear.

Photo 10

3.7.4 Press the green button 3 times to

return to INSTRUMENT TESTS

MENU.

3.8 Press the button next to TEST SERIAL

PORT.

3.8.1 Press any of top four buttons to

execute test.

3.8.2 Both the data transfer and hand

shaking test should fail.

3.8.3 Press the green button to return to

INSTRUMENT TESTS MENU.

3.8.4 Place T-15810 into the serial port

on bottom of unit. See Photo 10.

3.8.5 Press the button next to TEST

SERIAL PORT.

a) Press any of top four but-

tons to execute tests.

b) LCD will display:

DATA TRANFER PASSED

HANDSHAKING PASSED

10 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 25

Section 2 - Service

3.8.6 Press the green button twice to

3.8.7 Remove T-15810.

3.9 Press the button next to A/D CIRCUITRY.

3.9.1 A reading will come up for

3.10 Perform a screening test to check unit

operation.

3.11 Turn unit off.

4. Agency testing

4.1 Hypot

Testing at 1500VAC for one second.

Apply the voltage between primary wiring

(supply terminals connected together)

and accessible dead metal parts without

breakdown indication.

4.2 Ground continuity

Total resistance of the product shall not

exceed 0.2 ohms (2.0VDC). The test will

be conducted using a 10 amp DC current

source with a no load voltage no greater

than 6.0VDC for five seconds. Measure

ment will be taken from the grounding pin

of the power supply cord to the accessible

metal part of the product.

4.3 Leakage current

The leakage current measured from any

exposed grounded metal parts to the

grounding pin of the power supply cord

shall not exceed 100 microamps, AC

RMS (95.5MVAC RMS) with input voltage

set to 120VAC, 60HZ or 240VAC, 50HZ.

return to INSTRUMENT TESTS

MENU.

Mean gray and printhead tem perature. If the unit fails this test

a malfunction error will appear.

Final Testing

(Page 6 jof 6)

Hypot, Ground Continuity,

and Leakage Current

Testing

(For In-House use only.)

If a FTD fails any test in this section, set it aside for

troubleshooting and repair. When the FDT is repaired and passes all the tests, place a label over

the calibration port.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 11

Page 26

Section 2 - Service

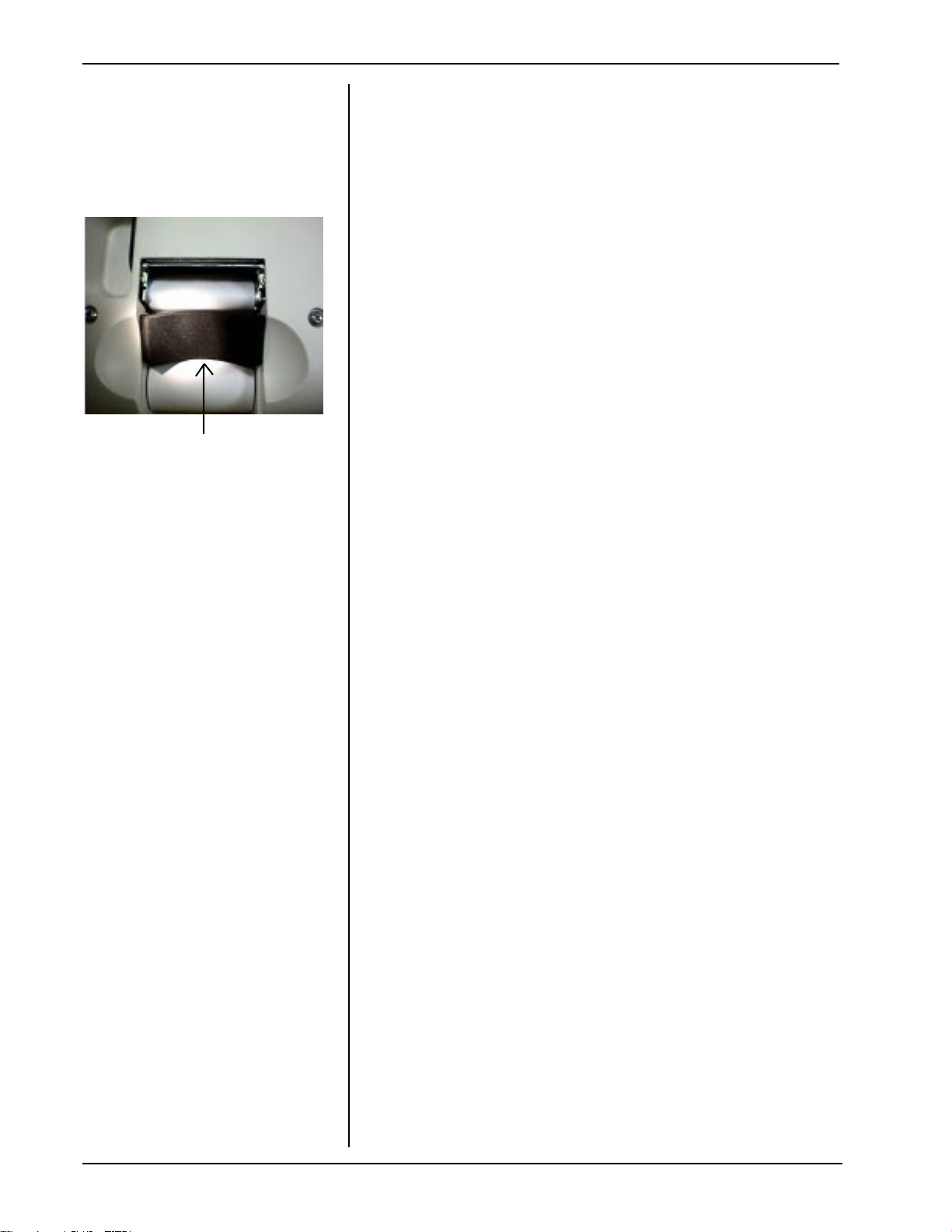

Important Shipping

Information

Paper roll foam prevents

un-winding during ship-

ping

Note: Install a new roll of paper.

Install the paper roll foam before

packing the unit for shipping. See

photo at left. This foam strip (called

foam shipping wedge in User’s Guide)

prevents the paper roll from unwinding

during shipping.

Return all of the customer’s

accessories.

12 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 27

Section 2 - Service

Calibration Limits Information

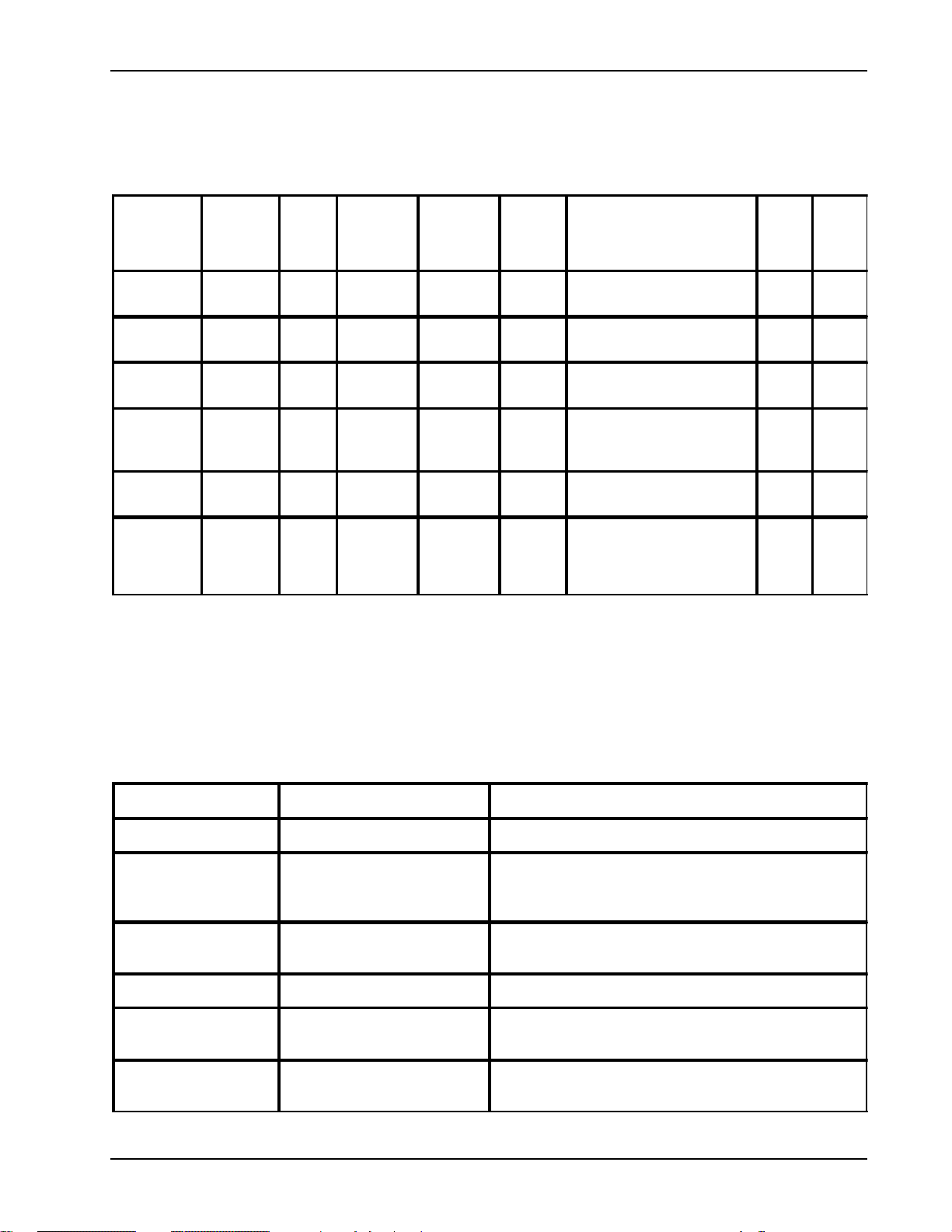

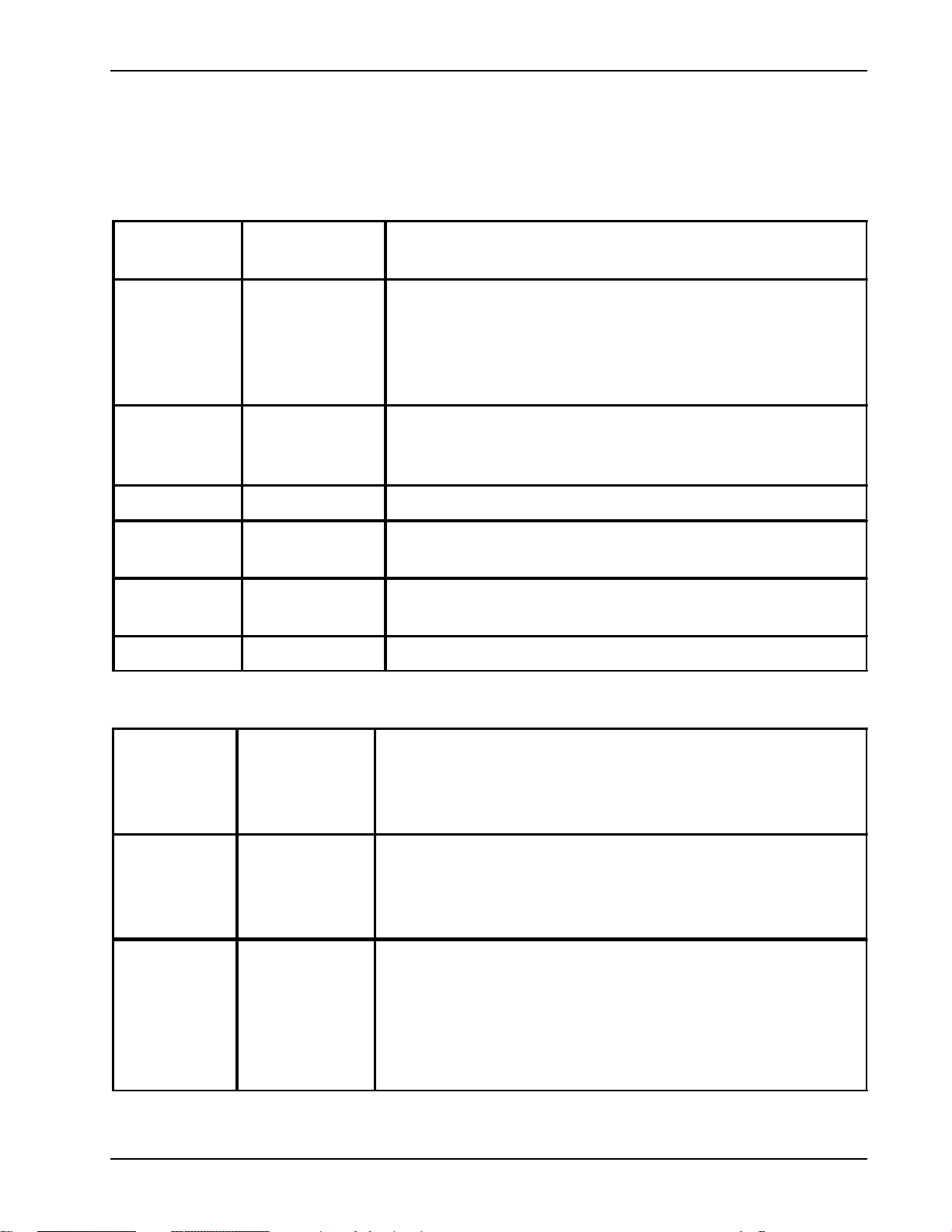

Table A:Calibration Parameters Printed on the System Status Report

Parameter Nominal SW

Limit

Expected

Min

Min

SCAN LINE

(internal)

GAMMA *2.35 1.0 *2.2 *2.5 <3.0

REFERENCE

POT

INTERNAL

TARGET

DC OFFSET 30 0 *10 *50 1023

INTERNAL

PEAK

*90 6 *60 *110 235

NA 0

*2250 0 *1500 *3000 4095

Internal

Target 0

*15

(new CRT)

Internal

Target - 40

Expected

Max

*60

(new CRT)

Internal

Target + 40

SW

Limit

Max

255

4095

Comments/Description F.C.** S.F.***

Reflects mechanical alignment of

photodetector to CRT.

CRT response correction

exponent.

Adjusts for CRT aging.

( *150 expected max on old CRT)

Absolute value read from Internal

photodetector ADC when CRT is

200 c/m^2.

DC offset on internal

photodetector signal.

Absolute value read from Internal

photodetector ADC when CRT is

as close to 200 c/m^2 as the

reference pot can adjust.

X

X

X

* These numbers are approximate and have not been verified by statistical tracking.

** Adjusted during Factory Calibration

***Adjusted during Self Calibration

X

X

Table B:Calibration Parameters to LCD and Serial Port: Factory Calibration

Message Expected Limits Comment

INTERNAL PEAK NA This is a transeint message that reports DAC settings.

External

Photo Sensor Stop

Line

External Photosensor 3000+/- 20

DC OFFSET Same as in table (A) above. Same as in table (A) above.

Internal Photosensor

Stop Line

Internal Photosensor

* These numbers are approximate and have not been verified by statistical tracking.

SERVICE MANUAL 112120 REV. B

*40 min, *70 nom, *100 max Two passes: Second pass should be within 16 of first.

External target 3000 = 200c/m^2. This is how close the

reference pot gets to 200 c/m^2.

Same as SCAN LINE in table

(A) above.

Same as INTERNAL TARGET

in table (A) above.

Same as in table (A) above.

Same as in table (A) above.

HUMPHREY FDT VISUAL FIELD INSTRUMENT 13

Page 28

Section 2 - Service

Calibration Limits Information

Table C:Calibration Parameters to LCD and Serial Port: Self Calibration

Message Expected Limits Comment

Internal Photosensor

Ambient Light

REFERENCE POT

Dynamic Range 82 min allowed by SW (50:1) Full screen brightness to zero screen brightness ratio.

Gamma Factor

Linearity

Same as INTERNAL TARGET

in table (A) above.

82 max allowed by SW

(2% of full brightness)

Same as REFERENCE POT in

table (A) above.

Same as in GAMMA

CORRECTION in table (A) above.

Second Column is limited to 120

(3% deviation from straight line)

Same as in table (A) above.

Keep unit as dark as possible. If this fails in dark, unit

is broken, or DC offset is bad - Factory calibration

needed.

Same as in table (A) above.

Same as in table (A) above.

First column is linear ramp target value written to

DAC. Second column is photodetector reading

deviation from the linear ramp. Scale is 127 - 4095.

* These numbers are approximate and have not been verified by statistical tracking.

14 HUMPHREY FDT VISUAL FIELD INSTRUMENT SERVICE MANUAL 112120 REV. B

Page 29

Section 2 - Service

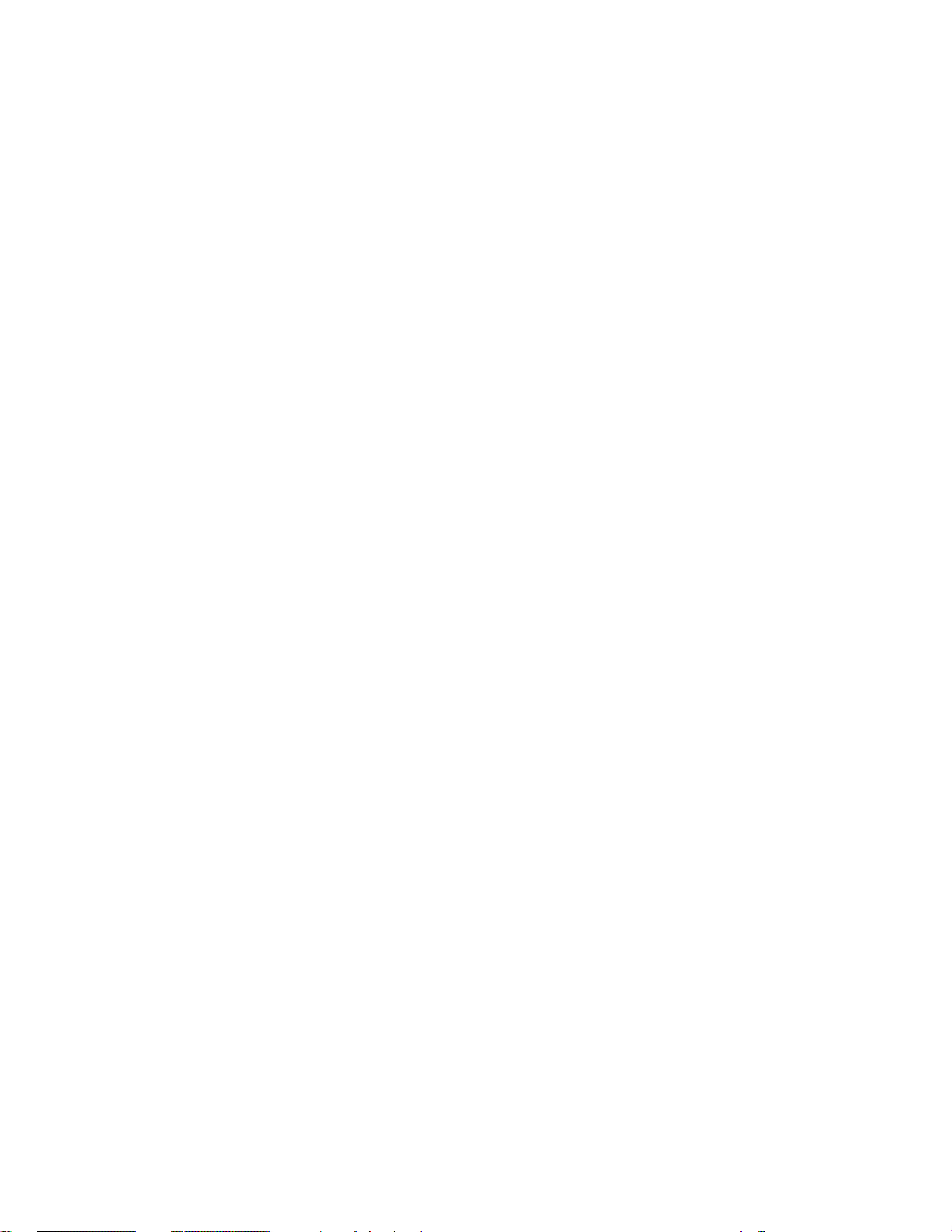

Product Updates

Effectivity S/N Cut-In

7/97 S#9700200

8/97 S#9701000

8/29/97 ~S#9701145 Color changes of housings:cream to gray.

9/11/97 S#9701199

9/15/97 ~S#9701210

10/3/97 S#9701294 SW Version 2.10 (Language translations)

DOMESTIC FDT UNITS :

Description of Changes for 00710-11

Sales Demo Units (all S#>9700199 and

9701000) . Monitor needs rework at some time

to extend calibration life.

SW Version 8.30.

HW Version 50300 (MCU PCB 112037-503)

Initial Production units for end users (all

S#>9701000). SW Version 1.20.

HW Version 50300 (MCU PCB 112037-503)

HW version 50400 (MCU PCB 112037-504 for

CE)

Calibration Caps (pn112078-1) Started shipping

with instruments.

Effectivity S/N Cut-In

9/97 S#9731000

S#9731025

(also

10/3/97

S#9731019

and

S#9731023

are Ver. 2.10

SERVICE MANUAL 112120 REV. B

CE INTERNATIONAL FDT UNITS :

Description of Changes for 00710-X1 (X=2-9)

Note:Domestic S#'s have a 0 in the 3rd digit,

International S#'s have a 3)

Initial International Production units (all

S#'s>9731000)

SW Version 1.20.

HW version 50400 (MCU PCB 112037-504 for CE)

SW Version 2.10 (language translations)

HUMPHREY FDT VISUAL FIELD INSTRUMENT 15

Page 30

Page 31

3 Troubleshooting

Note: Install Latest Revision Software with New MCU/PCB

Chief Complaint Cause Corrective Action

Does not power up.

No LCD backlight or text

(with high or low contrast)

LCD has backlight but no

text

LCD has text but no

backlight

a) Improper fuse drawer

setting.

b) Blown fuse(s) Replace fuses. No

c) Improperly wired power

entry module.

d) Defective transformer Replace transformer No

a) Loose connections,

damaged cables.

b) Failed LCD module Replace LCD No

c) MCU PCB defective Replace MCU PCB Yes

a) Failed LCD contrast

keypad

a) Loose connections Restore connections No

b) Defective LCD module Replace LCD module No

Correct fuse drawer No

Restore correct connections No

Check connection. No

Clean or replace keypad No

Factory Calibration

Required

PRB not working

(patient response button)

Unit not sure of visor

position

Unit will not calibrate using

the calbrator

c) Defective MCU PCB Replace MCU PCB Yes

a) Improper/Defective

connection with unit

b) Defective PRB Replace PRB No

c) Defective PRB

connector

d) Defective MCU PCB Replace MCU PCB Yes

a) Defective VPS PCB Replace VPS PCB No

b) Reflective labels

missing

c) Defective MCU PCB Replace MCU PCB Yes

a) Defective calibrator

b) Defective internal light

meter.

Check connections of PRB

connector and MCU PCB

Replace PRB connector No

Replace labels No

Check calibrator on another

unit. (If calibrator is defective,

send in for calibration.)

Replace internal light meter

(PCB)

FDT does not require cal.,

but calibrator does need

to be calibrated at factory.

No

Yes

c) Defective Monitor

Assembly.

d) Defective MCU PCB Replace MCU PCB Yes

Replace Monitor Assemlby Yes

See next page for important note when installing a new MCU/PCB.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 32

3 Troubleshooting

Note: Install Latest Revision Software with New MCU/PCB

Chief Complaint Cause Corrective Action

No printing on paper a) Incorrectly installed paper.

b) Defective paper Replace paper No

c) Incorrect paper Replace paper No

d) Defective printer Replace printer No

e) Wiring problems

f) Defective MCU PCB Replace MCU PCB Yes

RS 232 Port Malfunctions

Does not advance paper

a) No output (8.5Vac) from

purple transformer wires.

b) Defective MCU PCB.

Broken RS232 connector.

(Bent pins, bad solder joint.)

a) Loose connectors,

damaged cables.

b) Defective printer motor. Replace printer No

Install paper correctly referen cing Users' Guide.

Correct wiring or replace

printer.

Replace transformer No

Replace MCU PCB Yes

Restore connection or replace

cables .

Factory Calibration

Required

No

No

No

Optics tube window

damaged

Spots on optics a) Debris on lens Clean optics

Install new optics tube window. Yes

(If optics are

disassembled, Factory

Calibration is required due

to possible change in

allignment of Internal

Photodetector.)

Important Note when installing a new MCU/PCB:

For new MCU/PCB’s, use the PC utility SETNVRAM to initialize NVRAM and to load

the following:

PATIENT TESTS

CRT ACTIVE TIME

UNIT ON TIME

Calibration Count

S/N (Serial Number)

HW VER (Hardware Version)

MODEL NUMBER

ODOMETER SEG

Yes

REFER TO THE PC UTILITY SETNVRAM FOR MORE INFORMATION.

2 HUMPHREY FDT VISUAL FIELD INSTRUMENT SERVICE MANUAL 112120 REV. B

Page 33

3 Troubleshooting

A “P.O.S.T.” test is automatically programmed to occur

each time the FDT unit is switched to ON. Two double

“beeps” will be made by the unit near the end of the test.

Four conditions can occur when the unit Powers UP:

Fully Calibrated, Needs Calibration/Return Unit to Factory,

Needs Self Calibration, and Hardware Failure.

These are shown in the POST table below:

Printout

STATUS and

Message

ABOUT FDT:

Status Code

found in SET

NVRAM utility

RUN STATUS "

"

Display on

LCD

Cause(s) of Message(s) Next Step

Power On Self Test

(P.O.S.T.) Status

Table

FULLY

CALIBRATED

NEEDS

CALIBRATION

RETURN UNIT

TO FACTORY

NEEDS SELF

CALIBRATION

HARDWARE

FAILURE,

RETURN UNIT

TO FACTORY

"0" Main Menu

"1" Utilities Menu

CALIBRATION"

"2"

"3" Utilities Menu

*NOTE:

FOR VER

2.10

SELF

CALIBRATION

AUTOMATIC ALLY

FACTORY

FOLL OW

CALIBRATION

(NOTE: Depress

green button 2 times

to go to UTILITY

MENU to print out a

.

WILL

"SYSTEM

FAILURE

NEEDS

report.)

1.Unit passed internal

calibration.

1.Cancelled or failed factory

calibration.

2.Start factory calibration.

3.Fails loading of default values

to nvram.

1.Fails gamma checksum test.

2.Fails cal check.

3.Fails mean calc

4.Fails gamma table check.

5.Odom seg filled

6.Passed factory calibration.

7.Fail or cancel self calibration.

8.Fails nvram checksum.

1.Fails mean pot test.

2.Fails head temp circuit.

Unit is O.K.

Calibration

Calibration

Calibration

Perform

Factory

Perform

Self

Perform

Factory

Bit: Test:

0 RAM

1 ROM

2 RTC INITIALIZED

3 RTC WORKING

4 NVRAM

5 MEAN CALCULATED

6 MEAN_POT

7 REF_POT

8 HEAD_TEMP

9 LCD MEMORY

A GAMMA TABLE

SERVICE MANUAL 112120 REV. B

All passed = F

All passed = F

All passed = 7

HUMPHREY FDT VISUAL FIELD INSTRUMENT 3

POST Test Key

7FF = GOOD

NOTE:

Test results will appear on Set Up

Report printout. If FDT will not

print or will not complete calibration successfully, refer to Calibrat

Utility for more information.

Page 34

3 Troubleshooting

FDT Terminology

RAM

ROM

RTC INITIALIZED

RTC WORKING

NVRAM

MCU board memory test. Patterns written and read from RAM. If failure

occurs, look for bad solder connections or bad traces associated with the RAM.

MCU ROM checksum test. If failure occurs, first try a new software upload. If

no success, look for bad solder connections or bad traces associated with the

FPROM.

If failure is indicated, the software has determined that the RTC was never told

to start keeping time. Use WAM GT or a PC utility to initialize the clock and set

the time.

If failure is indicated, the software has determined that the RTC can not be

programmed to start keeping time for some reason. Check for problems on the

MCU board in the areas of the RTC and the General IO sections.

If failure is indicated, the RTC memory checksum has failed. Use WAM GT or a

PC utility to initialize the clock, set the time, and re-initialize the RTC. If this

does not fix the problem, check for problems on the MCU board in the areas of

the RTC and the General IO sections.

MEAN CALCULATED

MEAN_POT

REF_POT

HEAD_TEMP

The software attempts to match the shade and mask signals on the MCU

board. If failure occurs, make sure that the system is calibrated. If failure still

occurs, check for problems on the MCU board in the areas of the DAC,

reference pot, mask pot, mask/shade comparator and the General IO sections.

This should be called "MASK POT". The software tests the mask pot by

setting the mask pot to two different values, and verifies that the shade and

mask match at two different values. If failure occurs, make sure that the system

is calibrated. If failure still occurs, check for problems on the MCU board in the

areas of the DAC, reference pot, mask pot, mask/shade comparator and the

General IO sections.

The software tests the reference pot by setting the reference pot to two different

values, and verifies that the value reported from the pseudo DAC when

measuring a constant voltage (the head temperature signal) reports two

different values. (Normally, the reference pot is set to its highest value,

guaranteeing an accurate reference voltage to the DAC, to measure the head

temperature). If failure occurs, check for problems on the MCU board in the

areas of the DAC, reference pot, head temperature comparator, and the

General IO sections.

The software tests the head temperature by setting the reference pot to its

highest value, (guaranteeing an accurate reference voltage to the DAC) and

then incrementing the DAC until the head temperature comparator toggles. If

failure occurs, check for problems on the MCU board in the areas of the DAC,

reference pot, head temperature comparator, and the General IO sections.

The software does a RAM type memory test to the LCD. If failure occurs, look

LCD MEMORY

GAMMA TABLE

for problems in the LCD module, and the LCD ribbon cable. On the MCU

board, it could be a problem with the MSB bus transceiver or the LCD section.

This normally gets deleted whenever a software upload is done. It is fixed by

self calibration.

4 HUMPHREY FDT VISUAL FIELD INSTRUMENT SERVICE MANUAL 112120 REV. B

Page 35

3 Troubleshooting

Error Messages

"Printer Overheated"

Normal Printing Operations

(Printer Tests)

"Too Much Ambient

Light"

Normal Operation or

During Self Cal.

"Data Transfer Failed"

Loopback Test Only

"Handshaking Failed"

Loopback Test Only

"Stop Not Found"

Factory Cal. Only

This message is invoked when the video monitor shuts down the +24V when the controller

board asks for it. The video monitor +24V supply is linear, and designed to shut down if

the pass transistor temperature gets too hot. It is very unlikely that this will ever happen,

as it has been shown that a complete roll of paper worth of consecutive tests can be

printed at high line without this happening. Consecutive printer tests can do this, though,

because of the higher density printout in this test. If this message appears when there

has not been an extreme amount of printing, suspect the +24V enable, and the +24V

supply itself.

Either there is too much ambient light, or the video monitor won't dim, or the ADC on the

video controller board is malfunctioning, or the Factory Cal (specifically the DC Offset or

Internal Target or Internal Peak parameters) is bad.

During the RS232 testing, the data signals TXD and RXD are tested. Failure can occur

with no loop back cable, bad loop back cable. If not, follow the signal paths from the

MCU through the cable.

During the RD232 testing, the hardware handshaking signals, CTS, RTS, DTR, DCD, and

RI are tested. Failure can occur with no loop back cable, bad loop back cable. If not,

follow signal paths from the MCU through the cable.

During calibration, the software finds the peak of the CRT electron beam light output as it

appears on the photodetector waveform. Then, during subsequent measurements, it

stops sampling the light waveform at the scan line that it found the peak. This process

provides for extremely precise and repeatable the light measurements. This process is

used for both the internal and external light meters. It corrects for the slight differences in

mechanical alignment. This failure will occur if the offending light meter is mechanically

misaligned, dirty, or nonfunctional. ADC problems could also indirectly cause this

message. A defective CRT could also indirectly cause this failure.

"Photosensor Not

Attached"

Factory Cal. Only

"Runtime Error"

Normal

The software tests for this is by setting the CRT first bright, then dim, then bright, and

looking for the corresponding photodetector changes. If this failure occurs, either the

photosensor is not attached, not working, occluded, or the ADC is not functional. A

defective CRT could also indirectly cause this failure.

This is strictly a software issue, possibly caused by ESD, induced EMI, or bad software.

If it occurs, reboot the system. If it still occurs, re-load the software.

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 5

Page 36

Page 37

.

Section 4 - Disassembly and Repair

EXERCISE EXTREME

CAUTION WHEN SERVICING THE FDT!

THE MONITOR ASSEMBLY OPERATES

ON APPROXIMATELY 10,000 VOLTS!

4.1 REMOVAL OF REAR HOUSING/

LCD

4.1.1 Lower paper door. See photo.

4.1.2 Remove paper:

a) pull lever down

b) pull paper out

Caution: It is essential that you

use proper ElectroStatic Discharge (ESD) precautions when

disassembling or handling the

instrument circuitry or printed

circuit boards (PCB’s). Many

components in the instrument

such as the MCU/PCB, are

highly susceptible to static

discharge damage. Keep all

boards in their protective ESD

packaging.

4.1.3 Remove 4 screws from rear

housing.

4.1.4 Lower rear housing/LCD assembly .

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 38

Section 4 - Disassembly and Repair

4.1.5 Disconnect LCD ESD shield strap

from upper printer shelf. Use 11/32”

socket to remove nut.

4.1.6 Disconnect wiring from LCD/PCB:

a) Pull Printer Ribbon Cable

connector J1 from LCD/PCB .

4.1.6 Disconnect wiring from LCD/PCB:

b)Disconnect 3 connectors

(shown in photo from left to right)

Stepper Motor Connector - P3

Paper Out Connector - P2

Head Up Connector - P1

4.1.7 Place rear housing/LCD sub assem

bly into a clean anit-static bag for

later use.

4.1.8 Pull paper door up from base

housing.

2 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 39

Section 4 - Disassembly and Repair

4.2 REPLACEMENT OF REAR

HOUSING/LCD ASSEMBLY

4.2.1 Reassemble in reverse order with follow

ing notes:

a) Push Keyed ribbon cable into

connector J1 of the LCD module.

b) Run wire assemblies OVER the

ribbon cable.

c) Restore P1, P1, and P3 connections

to the LCD/PCB.

d) Ensure that the LCD ESD ground

shield stays on the inside of the rear

housing as rear housing/LCD sub

assembly is closed. See photo.

4.2.2 Plug unit in and turn on

4.2.3 Replace paper roll per instructions in

user’s manual.

4.2.4 Close paper door.

4.3 DISASSEMBLY OF OPTICS

4.3.1 Remove rear housing/LCD sub

assembly. (Refer to 4.1)

4.3.2 Remove front housing:

a) Remove screw from front housing

b) Pull front housing out

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 3

Page 40

Section 4 - Disassembly and Repair

4.3.3 Remove left and right rear housings:

a) Pull clip from top of housings.

b) Remove screw from top inside of

unit to disconnect side housings

from front housings. (Use magnetic

tip screwdriver to keep the screw

from falling into the unit.)

4.3.3 Remove left and right rear housings:

c) Remove 2 screws that connect

each housing to chassis.

4.3.3 Remove left and right rear housings:

d)Pull housing up and out of base

assembly

4 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 41

Section 4 - Disassembly and Repair

4.3.4 Remove visor/browrest assembly:

a) Unscrew 4 set screws (7/64” key)

b) Pull visor/browrest assembly off.

4.3.5 Remove screw and lockwasher from

right side of ground cable.

4.3.6 Remove slide/bracket/ rod assembly:

a)Remove screw and lock washer at

each end of the slide bracked/rod

assembly.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 5

Page 42

Section 4 - Disassembly and Repair

4.3.6 Remove slide/bracket/ rod assembly:

b)Remove visor backplate from visor

guide by lifting out from top, then

up.

Caution: Do not break the visor guide

(indicated by arrow in photo

graph) in this step! Do not pull

the visor backplate out too far

as this will break the visor

guide!

4.3.6 Remove slide/bracket/ rod assembly:

c)Remove rod from slide-bracket.

Note: Place finger on visor wear pad to

prevent it from falling.

4.3.6 Remove slide/bracket/ rod assembly:

d)Remove visor wear-pad and visor

spring bracket.

6 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 43

Section 4 - Disassembly and Repair

4.3.6 Remove slide/bracket/ rod assembly:

e)Remove 2 screws.

f)Remove bracket.

4.3.7 Remove front left and front right

housings:

a)Remove two black screws from

front of housings.

4.3.7 Remove front left and front right

housings:

b)Remove the rear EMI shield by

removing the nut on each side

(shown in Photo Inset) Use 11/32”

wrench or socket.

c)Remove 3 screws from each

housing.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 7

Page 44

Section 4 - Disassembly and Repair

4.3.7 Remove front left and front right

housings:

d)Spread and lift housings from base.

4.3.8 Disconnect wiring:

a) Pull the VPS wires from J107 of

the MCU PCB.

4.3.8 Disconnect wiring:

b) Remove the screw and lock

washer which attaches the ground

wire ring terminal to the front ESD

shield.

8 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 45

Section 4 - Disassembly and Repair

4.3.8 Disconnect wiring:

c)Lift front housing backplate from

optics tube assembly.

4.3.9 Remove front ESD shield:

a)Remove screws from both ends of

shield.

4.3.9 Remove front ESD shield:

b) Gently pull front ESD shield from

chassis without contacting compo

nents on the PCB.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 9

Page 46

Section 4 - Disassembly and Repair

4.3.9 Remove front ESD shield:

c)Disconnect IP (Internal

Photodetector) connector from J110

of MCU/ PCB.

4.3.10 Remove optics tube assembly:

a)Remove 4 screws while supporting

optics tube assembly.

4.3.10 Remove optics tube assembly:

b)Remove optics tube assembly.

c)Put optics tube assembly into dust

free container or bag.

10 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 47

Section 4 - Disassembly and Repair

4.4 ASSEMBLY OF OPTICS

4.4.1 Replace the optics tube assembly:

a)Place foam gasket into position.

Note: Notches on left and right sides of foam

gasket must fit over the tabs.

4.4.1 Replace the optics tube assembly:

b)Hold the optics tube assembly with

the IP PCB on the right side and fit it

onto the monitor.

4.4.1 Replace the optics tube assembly:

c)Position the optics tube assembly

all the way on to the Monitor/Chas

sis assembly. Make sure the optics

tube assembly is not caught on the

CRT band on top. Check slotted

holes. Photo at right depicts right

side of optics tube assembly

positioned all the way onto the

chassis.

d)Install and tighten 4 screws.

4.4.2 Place front housing backplate on to

front of optics tube assembly.(See

step 4.3.8)

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 11

Page 48

Section 4 - Disassembly and Repair

4.4.3 Replace front ESD shield and

restore connector to J110 of MCU

PCB :(See 4.3.10 a,b,c)

4.4.4 Restore wiring connections:

a)Ground Wire (See 4.3.9 b)

External Tooth lockwasher must

be used for ground connection.

b)VPS wire connector to J107 of

MCU PCB (See 4.3.9 a)

4.4.5 Replace front left and right housings:

a)Place wires while installing front

right housing.

Note:Proper alignment of front right and left

housings is critical to proper sliding of visor.

See photo for notch/tab relationship.

4.4.5 Replace front left and right housings:

b)Put housings onto threaded studs

at corners (this photo.)

c)Install slide/bracket rod assembly

(See 4.3.6)

d)Install 2 black screws into front

housings (See 4.3.8)

e)Fasten left and right housings with

3 screws each. Use the longer

where shown.

4.4.6 Install Rear EMI shield:

a)Shield must contact but not move

BLUE CAP of CRT. Put shield over

screws. Tighten nuts. See Tools.

4.4.7 Install Rod into slide bracket:

a)Put visor spring and visor wear pad

into position.

12 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 49

Section 4 - Disassembly and Repair

4.4.7 Install Rod into slide bracket:

b)Hold wear pad in place and slide

the rod (as shown in photo) in

from the left side of bracket.

c)Test this assembly by sliding the

rod left and right. The rod must

engage the detent at each end of

the stroke to pass the test.

d)Put rod in center position.

4.4.8 Install visor backplate:

a)Put visor backplate into notch in

visor guide as shown in photo.

b)Put visor backplate over the slide

bracket/rod assembly. (See 4.3.6)

c)Attach visor backplate to rod with

screws and lockwashers. (See

4.3.6)

d)Restore ground cable connection

with screw and External tooth

lockwasher. (See 4.3.5)

4.4.9 Install visor/browrest sub assembly:

a)Slide the visor backplate to right.

b)Put visor/browrest onto visor

backplate with ground cable in

position shown in photo.

c)Secure with 4 set screws.

d)Test this assembly by sliding left

and right. The Visor must:

1)move smoothly

2)click (detent) at end of

stroke.

3)not rub the ground cable.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 13

Page 50

Section 4 - Disassembly and Repair

4.4.10 Install left and right rear housings:

a)Put side housing bottom tabs into

slots in base.

b)Secure each cover with 2 screws

(See 4.3.3 c)

c)Fasten covers inside upper section

with one screw(See 4.3.3 b)

4.4.10 Install left and right rear housings:

d)Put clip on covers.

4.4.11 Install front housing:

a)Align tabs and secure with one

central screw. (See 4.3.2 a)

4.4.12 Install rear housing/LCD assembly:

a)Follow instructions in Section 4.2

NOTE: If a new Internal

Photodetector board was

installed, perform a Factory

Calibration.

14 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 51

Section 4 - Disassembly and Repair

4.5 REMOVAL OF PRINTER

Note: Printers on early model FDT’s have

upper and lower printer shelves. Later

FDT units use printer enclosures which

are described in Section 9.5.

4.5.1 Remove rear housing/LCD

assembly (See 4.1)

4.5.2 Remove left and right rear housings

(See 4.3.3)

4.5.3 Remove upper printer shelf (see

photo):

a)Remove 2 screws with washers.

4.5.3 Remove upper printer shelf (see

photo):

b)Lift shelf out .

4.5.4 Remove ribbon cable from printer.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 15

Page 52

Section 4 - Disassembly and Repair

4.5.5 Remove printer plate:

a)Remove 2 screws with washers.

b)Pull printer plate from chassis

4.6 INSTALLING PRINTER

4.6.1 Attach edge protectors as follows:

(see assembly drawing for exact

locations of edge protectors)

a)1 for each side of chassis

b)1 on the back of both printer

plates (shelfs).

c)1 circular protector on upper

printer plate (shown in photo).

4.6.2 Install printer/printer plate assembly

on chassis:

a)Secure with 2 screws.

b)Connect ribbon cable (keyed)

4.6.3 Replace upper printer shelf.See 4.5.3

a)Secure with 2 screws.

4.6.4 Install left and right rear housings.

(See 4.4.10)

4.6.5 Install front housing.(See 4.4.11)

4.6.6 Install rear housing/LCD assembly.

(See 4.4.12)

16 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 53

Section 4 - Disassembly and Repair

4.7 REMOVAL OF MCU PCB

4.7.1 Remove rear housing/LCD assembly.

(See 4.1)

4.7.2 Remove Optics up to, but not in

cluding the optics tube assembly.

(See 4.3.1 through 4.3.10)

4.7.3 Disconnect wiring:

a)Unplug J7 and J102 of MCU PCB.

b)Unplug J1 (Shown in Photo)

4.7.3 Disconnect wiring:

c)Unplug PRB wire from J105 of

MCU PRB.

4.7.3 Disconnect wiring:

d)Unplug P5 from Monitor Board.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 17

Page 54

Section 4 - Disassembly and Repair

4.7.4 Remove Chassis/Monitor/MCU assy:

a)Use 11/32” socket and extension

to remove 4 nuts at base of chas

sis.

4.7.4 Remove Chassis/Monitor/MCU assy:

b)Tilt chassis/Monitor/MCU assy.

forward as you lift up.

CAUTION: Do not allow the MCU board to

contact front edge of opening in

base (SEE arrow in photo.)

c)Lift assembly straight up from base.

CAUTION:See caution note and Photo #3 on

page 3 of Section 1 regarding not

standing the chassis monitor

asembly on the (RS232)

connec of the MCU/PCB.

4.7.5 Remove MCU/PCB from Chassis:

a)Remove 4 screws with split

lockwashers from MCU/PCB

four corners.

b)Gently remove MCU/PCB .

CAUTION: There are Board to Board pin

connectors (J108 and J109 )at

the top and bottom of the

MCU/ PCB. Separate the

boards carefully.

c)Remove PCB TO PCB connectors

from board and store board in

antistatic bag

18 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 55

Section 4 - Disassembly and Repair

4.8 INSTALLING MCU/PCB

NOTE: Use PC utility to initialize/set

NVRAM when installing new

MCU/PCB. Factory calibration is also required.

4.8.1 Install MCU/PCB

a)Insert Connector,PCB to PCB (pn

112086) into top and bottom

sockets of new MCU/PCB.

b)Align the pins with the sockets of

Monitor Board in chassis and

gently press boards together.

c)Secure with 4 screws.

4.8.2 Install Chassis/Monitor/MCU assy.

a)Important:Move all wires from

footprint area of the chassis to

avoid pinching of wires.

4.8.2 Install Chassis/Monitor/MCU assy.

b)Tilt the chassis assembly forward.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 19

Page 56

Section 4 - Disassembly and Repair

4.8.2 Install Chassis/Monitor/MCU assy.

c)Position chassis onto base plate

threaded studs.

d)Secure the chassis with 4 nuts.

4.8.3 Complete the installation of the MCU/

PCB by following steps 4.7.1 - 4.7.3

in reverse order.

NOTE: Use PC utility to initialize/set

NVRAM when installing new

MCU/PCB. Factory calibration is also required. See

Section 3 pg. 2 for additional

information on PC utility.

4.9 INSTALLING A REPLACEMENT

CHASSIS/MONITOR ASSEMBLY

4.9.1 Secure ribbon cable clamps to

chassis over ribbon cables.

4.9.2 Install MCU/PCB to new chassis.

4.9.3 Reassemble unit. Follow steps 4.7.1

through 4.7.3 in reverse order.

NOTE:

matched set. If either the CRT or the Monitor PCB

fails, a new matched chassis/monitor assembly

must be installed or the FDT will not function

properly. DO NOT ADJUST POTS!

The chassis/monitor assembly is a

4.9.4 Perform a Factory Calibration only if

you installed a new Chassis/Monitor.

4.10 REMOVAL OF TRANSFORMER

4.10.1 Remove rear housing/LCD assy.

(Sect. 4.1.1 - 4.1.8)

4.10.2 Remove front housing. (Sect. 4.3.2)

4.10.3 Remove left and right rear housings.

(Sect 4.3.3)

4.10.4 Disconnect J1 and J105 from MCU.

4.10.5 Partially lift Chassis/Monitor assembly

from base and disconnect P5 from

Monitor Board.

4.10.6 Remove Chassis/Monitor assembly.

(Sect. 4.7.4)

4.10.7 Remove Transformer from base.

a)Remove 4 nuts with 11/32” socket.

20 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 57

Section 4 - Disassembly and Repair

4.10.7 Remove Transformer:

b)Disconnect transformer wires from

power entry module.

c)Lift transformer from base.

4.11 INSTALLING TRANSFORMER

4.11.1 Install transformer in reverse order of

removal.

4.11.2 Restore wiring connections.

a)Refer to Sheet 2 of Drawing

#112000 for correct placement of

transformer wires to power entry

module.

4.12 REMOVAL OF PRB JACK

4.12.1 Remove rear housing/LCD assy.

(Sect. 4.1.1 - 4.1.8)

4.12.2 Remove front housing. (Sect. 4.3.2)

4.12.3 Remove left and right rear housings.

(Sect 4.3.3)

4.12.4 Remove Upper printer shelf.

(Sect 4.5.3)

4.12.5 Disconnect J1 and J105 from MCU.

4.12.6 Disconnect P5 from Monitor Board.

4.12.7 Remove Chassis/Monitor assembly.

(Sect. 4.7.4)

4.12.8 Unscrew Ring Nut of PRB Jack with

T-15145 (See Photo)

4.13 REPLACEMENT OF PRB JACK

4.13.1 Install new PRB Wire Assembly (jack

and wire harness) in reverse order of

disassembly.

4.14 REMOVAL OF POWER ENTRY

MODULE

4.14.1 Remove Chassis/Monitor assembly

per above steps 4.12.1-4.12.7.

4.14.2 Separate Housing and Base Plate:

a)Remove 4 screws from rubber feet.

b)Lift housing from base.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 21

Page 58

Section 4 - Disassembly and Repair

4.14.3 Remove wires from module.

4.14.4Slide power entry module up and out

of base plate.

4.15 REPLACEMENT OF POWER

ENTRY MODULE

4.15.1Install power entry module.

a)Press power entry module into

base plate assembly.

4.15.2 Restore wiring connections.

a)Refer to Sheet 2 of Drawing

#112000 for correct placement of

wires to power entry module.

4.15.2 Replace the housing in reverse order.

(See 4.14.1- 4.14.2)

4.16 REMOVAL OF VISOR POSITION

SENSOR (VPS) PRINTED CIRCUIT

BOARD (PCB)

4.16.1 Disassemble optics to VPS/PCB

(See 4.3)

4.16.2 Remove VPS/PCB

a)Cut cable tie.

b)Remove screw as shown in photo.

c)Disconnect VPS/PCB from front

housing backplate.

P1 Phillips

4.17 REPLACEMENT OF VPS/PCB

4.17.1 Install VPS/PCB in reverse order.

22 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 59

Section 4 - Disassembly and Repair

4.18 REMOVAL OF INTERNAL PHOTO

DETECTOR (IP) PCB.

4.18.1 Disassemble optics to optics tube

assembly. (See 4.3)

4.18.2 Remove 2 screws from IP/PCB .

4.19 REPLACEMENT OF IP/PCB.

4.19.1 Install IP/PCB in reverse order of

removal. Make sure sensor is clean.

NOTE:If you replaced the IP with a new IP,

factory calibration is required.

4.20 REMOVAL OF LCD MODULE/

KEYPAD

4.20.1 Remove Rear housing/LCD

subassembly. Follow instructions in

Sect. 4.1.1 through 4.1.6.

4.20.2 Remove LCD module.

a)Unscrew 4 screws from module.

Note: Do not lose the insulating plastic

washer from screw shown in photo.

4.20.2 Remove LCD module.

b)Carefully lift module from housing.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 23

Page 60

Section 4 - Disassembly and Repair

4.20.3 Remove keypad

a)Lift keypad from housing.

4.21 REPLACEMENT OF LCD MODULE/

KEYPAD

4.21.1 Perform LCD module/keypad removal

in reverse order.

NOTE: Install plastic insulating washer

in position as shown in photo.

This screw prevents shorting of

adjacent component and is

found in both CE and non CE

units.

4.22 REMOVAL OF VISOR PAD

4.22.1 Remove visor/browrest sub assembly

(Sect. 4.3.4)

4.22.2 Remove visor pad

a)Pull and press simultaneously in

directions of arrows as shown in

photo.

b)Repeat with other end of visor pad.

24 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 61

Section 4 - Disassembly and Repair

4.23 INSTALLING VISOR PAD

4.32.1 Install visor pad.

a)Place visor into visor as shown.

b)Press loops over posts on inside of

visor.

4.23.2 Replace visor/browrest sub assembly

(Sect. 4.4.9)

4.24 REMOVAL OF ACRYLIC LENSES

and OPTICS TUBE WINDOW

4.24.1 Remove optics tube assembly

(Sect. 4.3)

4.24.2 Remove optics tube housing:

a)Remove screws that hold housings

together.

b)Carefully pull one housing off.

4.24.3 Remove acrylic lenses and or optics

tube window by holding edges and

gently sliding them from the optics

tube.

4.24.4 If lenses or optics tube window are

dirty, clean with a swab and alcohol

and air dry.

If a lens cannot be cleaned, install a

clean replacement lens.

SERVICE MANUAL 112120 REV B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 25

Page 62

Section 4 - Disassembly and Repair

4.25 INSTALLING ACRYLIC LENSES

and OPTICS TUBE WINDOW.

NOTE:Since replacement lenses and window

may have slightly different light transmittance characteristics , it is important to

perform Factory Calibration.

4.25.1 Assure that all lenses have foam tape

on edges. See Drawing#112000.

4.25.2 Clean housings with air.

NOTE:SEE PHOTO AT RIGHT. Be careful to

leave one space between the lenses when

inserting them into the housings. If put into

two adjacent grooves, they will scratch

eachother when inserting the second one.

4.25.3 Put lenses and optics tube window

into one optics tube.

4.25.4 Assemble housings together.

a)Slide other optics tube over lenses.

b)Replace screws.

4.25.5 Reassemble optics (Sect. 4.4)

4.25.6 If any combination of new lenses

and/or optics tube window have been

installed, perform factory calibration.

26 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV B

Page 63

Section 5 - Interconnect Diagrams

Interconnect Diagram

112119 Rev B

(2 sheets)

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 64

Page 65

6 Repair Parts

This column shows the quantities

to order to get started per 100

FDT Instruments in your market.

A shaded box indicates low

probability that the part will be

needed. THIS IS ONLY AN

ESTIMATE TO GET STARTED.

These columns indicate voltage

of country of use. The check

mark indicates the part is found

in the unit of that voltage.

This column displays a number

which appears on the assembly

drawing. The number points out

the specific part. “NA” indicates

that the part is not referenced on

the assembly drawing.

Key to Repair Parts List

Description of part.

Note: All fastener parts are

listed at the end of the

spreadsheet.

Manufacturer repair part number.

Part No. Description Bubble Number 115 V 230 V Recommended

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 66

6 Repair Parts

x

x

Part No. Description Bubble Number 115V 230V

M11526 ANTISTATIC POLY BAG(30X36)PINK N/A

112050-502 PRB ASSEMBLY (BLACK) N/A

112065-2 LABEL, PRB MODEL N/A

112098 FDT - USER'S GUIDE, ENGLISH N/A

112098C OPERATING INSTRUCTIONS, N/A

112098FR FDT USER'S GUIDE, FRENCH N/A

112098GR FDT USER'S GUIDE, GERMAN N/A

112098IT FDT USER'S GUIDE, ITALIAN N/A

112098SP FDT USER'S GUIDE, SPANISH N/A

112113-504 BOX ASSEMBLY N/A

112131 DESICCANT BAG N/A

112132 FDT, REGISTRATION CARD,ENGLISH N/A

112136 FDT - QUICK REFERENCE,ENGLISH N/A

761076-0 POWER CORD, DETACH.(DOM/JAPAN) N/A

761076-2 POWER CORD, DETACH. (EUROPEAN) N/A

761076-4 POWER CORD, DETACH. (UK) N/A

761076-6 POWER CORD, DETACH. (AUSTRALIA) N/A

112120 REPAIR MANUAL N/A

112002-1 BASE PLATE ASSY 0001

112002-2 BASE PLATE ASSY 0001

112101-1 PRB, WIRE ASSY 0002

112143-2 PRB, WIRE ASSY 0002

112075 WIRECLIP 0003

112006-1 TRANSFORMER (120V/230V ISOLAT) 0004

112006-2 TRANSFORMER 0004

112005 POWER ENTRY MODULE 0006

112085-1 WIRE ASSY, 4.25 0007

488383 GROUND LABEL 0008

112064-2 LABEL, FUSE/READ MANUAL 0009

112003-2 HOUSING,BASE 0010

112004-2 FOOT, RUBBER (BLACK) 0011

112057-4 LABEL,MODEL DOMESTIC 0013

112057-3 LABEL,MODEL INTL 0013

M11478 PARTS LABEL 0014

112067-1 LABEL, CONNECTOR ID 0015

112007-1 VISOR 0016

236174-1 BATTERY COVER PAD 0017

112010-1 BROWREST 0018

112008-1 OPTICS TUBE 0019

112076-501 PCB ASSY, LIGHT METER 0020

112141-502 PCB ASSY, LIGHT METER 0020

112013 LENS, ACRYLIC 0022

112110-2 FOAM TAPE, LENS 0023

112011-1 WINDOW, OPTICS TUBE 0024

112110-1 FOAM TAPE OPTICS TUBE WINDOW 0025

112056 MONITOR GASKET 0027

112025-505 HOUSING,REAR, PRINTED 0029

112025-505R HOUSING,REAR, PRINTED 0029

112043-1 LCD ESD SHIELD 0030

112145 LCD ESD SHIELD 0030

112042-1 WINDOW,LCD 0031

112092-1 LCD BUTTONS 0032 1

2 HUMPHREY FDT VISUAL FIELD INSTRUMENT

xx

xx

xx

xx

x

x

x

x

x

xx

xx

xx

xx

x

x

x

x

xx

x

x

x

x

xx

x

x

xx

xx

xx

xx

xx

xx

x

x

xx

xx

xx

xx

xx

xx

x

x

xx

xx

xx

xx

xx

x

x

x

x

xx

SERVICE MANUAL 112120 REV. B

10

2

2

2

2

2

2

1

20

2

2

2

2

1

1

1

2

2

2

1

1

4

2

2

1

2

1

1

10

2

2

2

4

2

4

10

1

1

1

1

5

Page 67

6 Repair Parts

Part No. Description Bubble Number115V230VRecommended

112091-1T LCD MODULE 0033

112091-2 LCD MODULE 0033

106103-43 MYLAR WASHER 0034

112041-502 MONITOR ASSY 0035

112041-503 MONITOR ASSY 0035

112037-504 PCB ASSY,MCU 0036

112086 CONNECTOR, PCB TO PCB 0037

112105-2 FRONT ESD SHIELD 0040

112026 PRINTER SHELF W/ PEMS 0042

112124-1 EDGE PROTECTOR 0043

112017 THERMAL PRINTER, 2 0044

112044-1 RIBBON CABLE ASSY, PRN (26PSN) 0046

112074 LABEL, OPTICS TUBE 0047

112072-2 FRONT HSG BACKPLATE W/ PEMS 0048

112085-2 WIRE ASSY,10.5 0049

112033-1 GUIDE, VISOR 0052

112079-501 PCB ASSY, VPS 0053

112142-501 PCB ASSY, VPS 0053

112049-3 HOUSING, FRONT LEFT 0055

112048-3 HOUSING, FRONT RIGHT 0057

106144-5 NYLINER BEARING 0059

112031-1 SLIDE BRACKET 0060

112018 SPRING VISOR 0062

112081 VISOR WEAR PAD 0063

112082-2 ROD, FINISHED 0064

112061-1 LABEL, VPS REFLECTIVE 0065

112039-1 VISOR BACKPLATE ASSY 0066

112094 FLEX CABLE W/ RINGS 0068

112124-3 EDGE PROTECTOR 0070

112077 RIBBON CABLE CLAMP 0071

112077-2 CABLE CLAMP 0071

112080-4 EDGE PROTECTOR,U CHANNEL 3.14 0072

112063 UPPER SHELF W/ PEMS 0073

112046-2 HOUSING, REAR RIGHT 0074

112044-2 LCD CABLE ASSY (40PSN) 0075

112124-2 EDGE PROTECTOR, 4 0076

112047-2 HOUSING, REAR LEFT 0077

112068-2 LABEL, PAPER LOADING INSTR 0079

112027-4 HSG, PAPER DOOR,PRINTED 0080

112019 THERMAL PAPER ROLL, 2 0081

112024-4 HSG,FRONT COVER,PRINTED 0083

112129-1 LABEL, FRONT COVER LOGO G 0085

106138-6 SCREW, BUTTON HS SOCKET G 0086

112066 LABEL, BACKGRND DEBUG CONN 0088

112078-1 CALIBRATION CAP 0090

106127-1 STANDOFF-SCREW MOUNT 0095

112121 CLIP 0096

112122 EMI SHIELD, REAR 0098

112155 EMI SHELD, CRT 0098

112130 FOAM, PAPER ROLL 0099

236706-3109 FUSE, 160 MA 0100

236706-3112 FUSE- 315 MA 0100

x

x

xx

x

x

xx

xx

xx

x

xx

xx

xx

xx

xx

xx

xx

x

x

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

x

x

x

xx

x

xx

x

x

xx

xx

xx

xx

xx

xx

xx

xx

x

xx

xx

xx

x

xx

x

x

1

1

6

1

1

1

4

2

1

2

1

2

5

1

1

1

1

2

1

5

5

1

1

1

1

1

1

2

1

1

2

1

1

60

1

1

10

10

20

4

20

1

1

60

20

20

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 3

Page 68

6 Repair Parts

x

Part No. Description Bubble Number 115V 230V Recommended

112140-1 JUMPER ASSY RS232 0103

112133-1 FRONT EMI SHIELD 0104

112135 PRINTER ENCLOSURE 0108

112147 PRINTER GASKET 0109

112151 COPPER TAPE 0110

112149 FOAM, BLOCK 0111

112137 BASE SHIELD 0112

112146 TOP EMI SHIELD 0113

112150 FOAM, STRIP 0114

112148 PRINTER ENCLOSURE GASKET 0115

112138-501 SHIELDED RIBBON CABLE ASSY 0116

761077-1 TIE WRAP 0117

106137-2 NUT,8-32 EXTLOCK 0005

106100-51 PHPS 8-32 X .750 0012

106124-4 #4 X.250 LG PPHS SELF TPG 0021

106124-30 SCREW #6 X .375 0026

106105-3 #4 LOCKWASHER,HEL 0038

106100-42 4-40 X.25 SCREW 0039

106100-12 PHPS 8-32 X.281 0041

711776 SCREW,M3 PHPS METRIC 0045

745147 #6 LOCKWASHER-EXTERNAL TOOTH 0050

106100-50 6-32 X .125 PHILLIPS,STL 0051

106124-31 #4 X.250 LG PPHS SELF TPG 0054

106102-27 FHPHPS 6X32X.250 LG 0056

483017 PHPS 6-32 X 5/16 0061

106140-5 6-32 W/EXT WASHER 0067

106140-9 8-32 W/EXT WASHER 0069

106124-36 SCREW .500 AB PAN PHILLIPS 0078

106119-34 .344 HEX SOCKET ST BLACK ANODI 0089

106137-7 NUT 6-32 EXTLOCK 0094

106100-52 PHPS 8-32 X .500 0097

106103-6 WASHER, FLAT 0106

x

x

x

x

x

x

x

x

x

x

x

x

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

1

1

1

1

2

1

1

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

12

4 HUMPHREY FDT VISUAL FIELD INSTRUMENT

SERVICE MANUAL 112120 REV. B

Page 69

Section 7 - FDT Assembly Drawings

FDT Assemby Drawings:

112000 Domestic

sh1 Rev D

sh2 Rev D

sh3 Rev D

112200 International

sh1 Rev B

sh2 Rev A

sh3 Rev B

sh4 Rev B

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 70

Page 71

Section 8 - Schematics

Schematics

112106

Schematic, Controller PCB, Patt C

sh1 Rev D

sh2 Rev D

112091

Schematic, LCD Module Custom

Circuitry

sh3 Rev C

112037

PCB Assembly, MCU

Rev D

SERVICE MANUAL 112120 REV. B

HUMPHREY FDT VISUAL FIELD INSTRUMENT 1

Page 72

Page 73