User's

Manual

ROTA

Coriolis Mass Flow and Density Meter

MASS

Total Insight

Safety Manual

IM 01U10D00-00EN-R

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Table of contents

Table of contents

1 Scope and purpose of the document ...................................................................................................... 3

2 Using Rotamass Total Insight for a SIS application .............................................................................. 4

2.1 Safety function .................................................................................................................................. 4

2.2 Safety accuracy ................................................................................................................................ 5

2.3 Diagnostic response time ................................................................................................................. 5

2.4 Setup ................................................................................................................................................ 5

2.5 Proof testing...................................................................................................................................... 5

2.6 Repair and replacement ................................................................................................................... 6

2.7 Startup time ...................................................................................................................................... 6

2.8 Firmware update............................................................................................................................... 6

2.9 Reliability data .................................................................................................................................. 6

2.10 Lifetime limits .................................................................................................................................... 7

2.11 Required parameter settings ............................................................................................................ 7

2.12 Environmental limits.......................................................................................................................... 7

2.13 Application limits ............................................................................................................................... 7

3 Definitions and abbreviations .................................................................................................................. 8

3.1 Definitions ......................................................................................................................................... 8

3.2 Abbreviations .................................................................................................................................... 9

2 / 10

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Scope and purpose of the document

1 Scope and purpose of the document

When using the Rotamass Total Insight Coriolis flow meter for the Safety Instrumented

Systems (SIS) application, the instructions and procedures in this section must be strictly

followed in order to preserve the transmitter for that safety level.

This document provides an overview of the user responsibilities for installation and operation of the Rotamass Total Insight Coriolis flow meter in order to maintain the designed

safety level.

Items that will be addressed are proof testing, repair and replacement of the flow meter,

reliability data, lifetime, environmental and application limits, and parameter settings.

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

3 / 10

Using Rotamass Total Insight for a SIS application

Safety PLC/DCS

Actuators

4-20 mA output1

4-20 mA output2

Mass flow rate

Density

Temperature

2 Using Rotamass Total Insight for a SIS application

For more detail information, refer to FMEDA report.

(YEC 20-02-160 R002 V1R2 FMEDA ROTAMASS TI)

The documents can be downloaded from the website of Yokogawa or purchased from the

Yokogawa representatives.

Website address: http://www.yokogawa.com/fld/

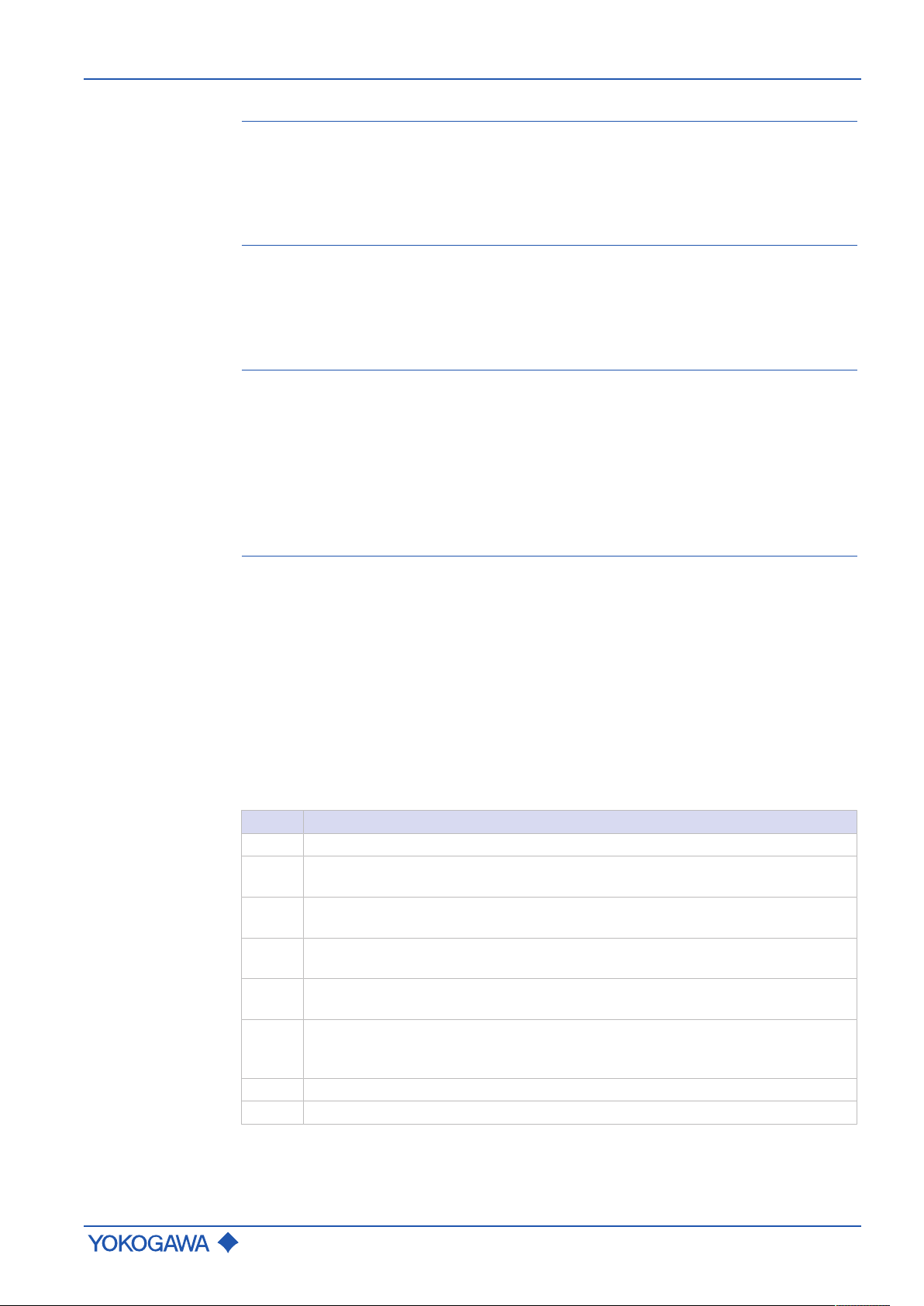

2.1 Safety function

The Rotamass Total Insight Coriolis flow meter for HART communication is intended for

use as a mass flow, fluid density and fluid temperature measurement component in a

Safety Instrumented System. It has one or two 4 – 20 mA analog outputs and other I/Os.

The flow meter must be used with one of the two or both 4 – 20 mA outputs to feed signals to a logic solver that is part of the safety instrumented function (SIF) as shown in the

following figure. The fault annunciation mechanism is an out of-range analog current. In

order to take advantage of the automatic diagnostics in the flow meter, this annunciation

mechanism must be connected.

Safety function

4 / 10

Fig.1: Example Safety Instrumented Function

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Safety accuracy

Using Rotamass Total Insight for a SIS application

2.2 Safety accuracy

The Rotamass Total Insight Coriolis flow meter has a specified safety accuracy of 2 %.

This means that internal component failures are listed in the device failure rate if they will

cause an error of 2 % or greater.

2.3 Diagnostic response time

The Rotamass Total Insight Coriolis flow meter will report an internal failure within 3

minutes of fault occurrence for amplitude errors and within 7 seconds of fault occurrence

for all other errors (e. g. frequency error, signal fault).

2.4 Setup

During installation the flow meter must be set up with engineering unit parameters. This is

typically done with a field communicator. These parameters must be verified during the

installation to insure that the correct parameters are in the flow meter. Engineering range

parameters can be verified by reading these parameters from the optional local display or

by checking actual calibration of the flow meter.

Proof-Testing of the flow meter must be done after parameter setting.

2.5 Proof testing

The objective of proof testing is to detect failures within the flow meter that are not detected by the diagnostics of the flow meter. Of main concern are undetected failures that

prevent the safety instrumented function from performing its intended function. The frequency of the proof tests (or the proof test interval) is to be determined in the reliability

calculations for the safety instrumented functions for which the flow meter is applied. The

actual proof tests must be performed more frequently, or as frequently as specified in the

calculation in order to maintain the required safety integrity of the safety instrumented

function.

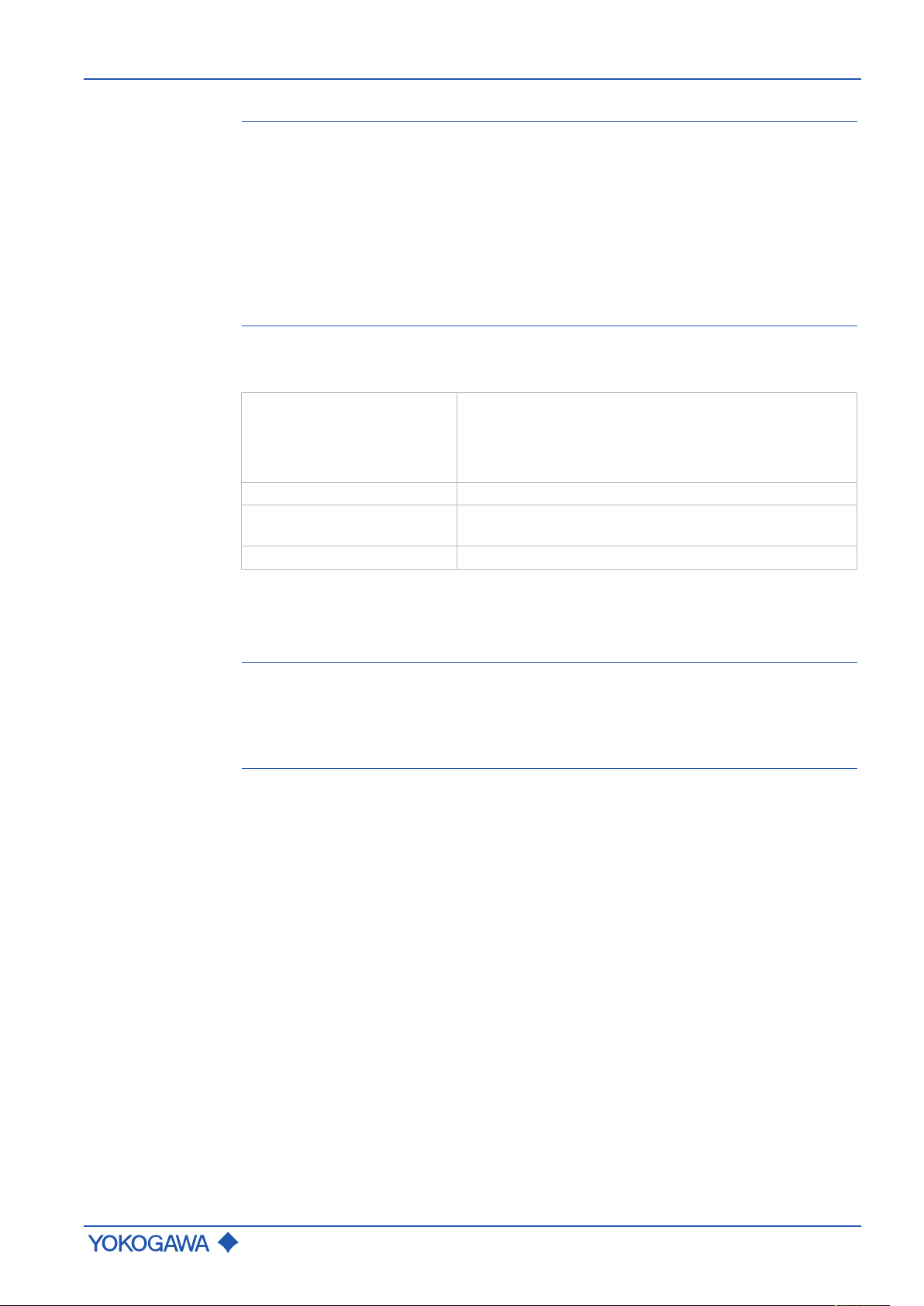

The following tests need to be specifically executed when a proof test is performed. The

results of the proof test need to be documented and this documentation should be part of

a plant safety management system. Failures that are detected should be reported to

Yokogawa.

Step Action

1. ▶ Bypass the safety function and take appropriate action to avoid a false trip.

2.

3.

4.

5.

6.

7. ▶ Cycle power to transmitter so RAM soft errors are cleared.

8. ▶ Remove the bypass and otherwise restore normal operation.

1)

This tests for possible quiescent current, low loop voltage and high loop impedance re-

lated failures.

▶ Verify plausibility of current with flow tube filled and zero flow rate within

stated accuracy.

▶ Verify plausibility of current with flow tube filled at two different flow rates

able to be independently estimated to approximately 10 % accuracy.

▶ Use digital communications to retrieve process fluid temperature measure-

ment and verify against independent measurement.

▶ Use digital communications to retrieve any diagnostics and take appropriate

action.

▶ Send a digital command to the transmitter to go to the high and low alarm

level output state current and verify that the analog current reaches these

values.

1)

For details, refer to FMEDA No. YEC 20-02-160 R002 V1R2.

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

5 / 10

Using Rotamass Total Insight for a SIS application

In case of non-IS 4 – 20 mA output, the proof test will detect 93.3 % of possible DU failures.

In case of IS 4 – 20 mA output, the proof test will detect 93.3 % of possible DU failures.

The following tools need to be available to perform proof testing:

▪ Flow meter display or alternatively for digital communication: HART field communica-

tor, PRM or FieldMate.

▪ Measurement instrument to verify output current.

▪ Reference temperature measurement as close as possible to the flow meter under

test.

The person(s) performing the proof test of the Rotamass Total Insight Coriolis flow meter

should be trained in SIS operations including bypass procedures, flow meter maintenance and company management of change procedures.

2.6 Repair and replacement

If repair is to be performed with the process online the Rotamass Total Insight Coriolis

flow meter will need to be bypassed during the repair. The user should set up appropriate

bypass procedures for that. Contact the Yokogawa sales office if this instrument requires

repair. The person(s) performing the repair and / or replacement of the Rotamass Total

Insight Coriolis flow meter should have a sufficient skill level.

Repair and replacement

2.7 Startup time

The Rotamass Total Insight Coriolis flow meter will generate a valid signal within 20

seconds of power-on startup.

2.8 Firmware update

In case firmware updates are required, they will be performed at factory. The replacement

responsibilities are then in place. The user will not be required to perform any firmware

updates.

2.9 Reliability data

A detailed Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is available

from Yokogawa with all failure rates and failure modes. The Rotamass Total Insight

Coriolis flow meter is intended for use in a Low Demand Mode. Low Demand Mode

means the average interval between dangerous conditions occurs infrequently.

The Rotamass Total Insight Coriolis flow meter is certified up to SIL2 for use in a simplex

(1oo1) configuration, depending on the PFDavg calculation of the entire Safety Instrumented Function. The development process of the Rotamass Total Insight Coriolis flow

meter is certified up to SIL3, allowing redundant use, with hardware fault tolerance of 1,

of the flow meter up to this Safety Integrity Level, depending the PFDavg calculation of

the entire Safety Instrumented Function.

6 / 10

When using the Rotamass Total Insight Coriolis flow meter in a redundant configuration,

the use of a common cause factor (β-factor) of 2 % is suggested.

For details, refer to FMEDA No. YEC 20-02-160 R002 V1R2.

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Lifetime limits

Using Rotamass Total Insight for a SIS application

2.10 Lifetime limits

The expected lifetime of the Rotamass Total Insight Coriolis flow meter is 10 years. The

reliability data listed in chapter Reliability data [}6] is only valid for this period. The failure

rates of the Rotamass Total Insight Coriolis flow meter may increase sometime after this

period. Reliability calculations based on the data listed in chapter Reliability data [}6] for

Rotamass Total Insight Coriolis flow meter lifetimes beyond 10 years may yield results

that are too optimistic, i.e. the calculated Safety Integrity Level will not be achieved.

For details, refer to FMEDA No. YEC 20-02-160 R002 V1R2.

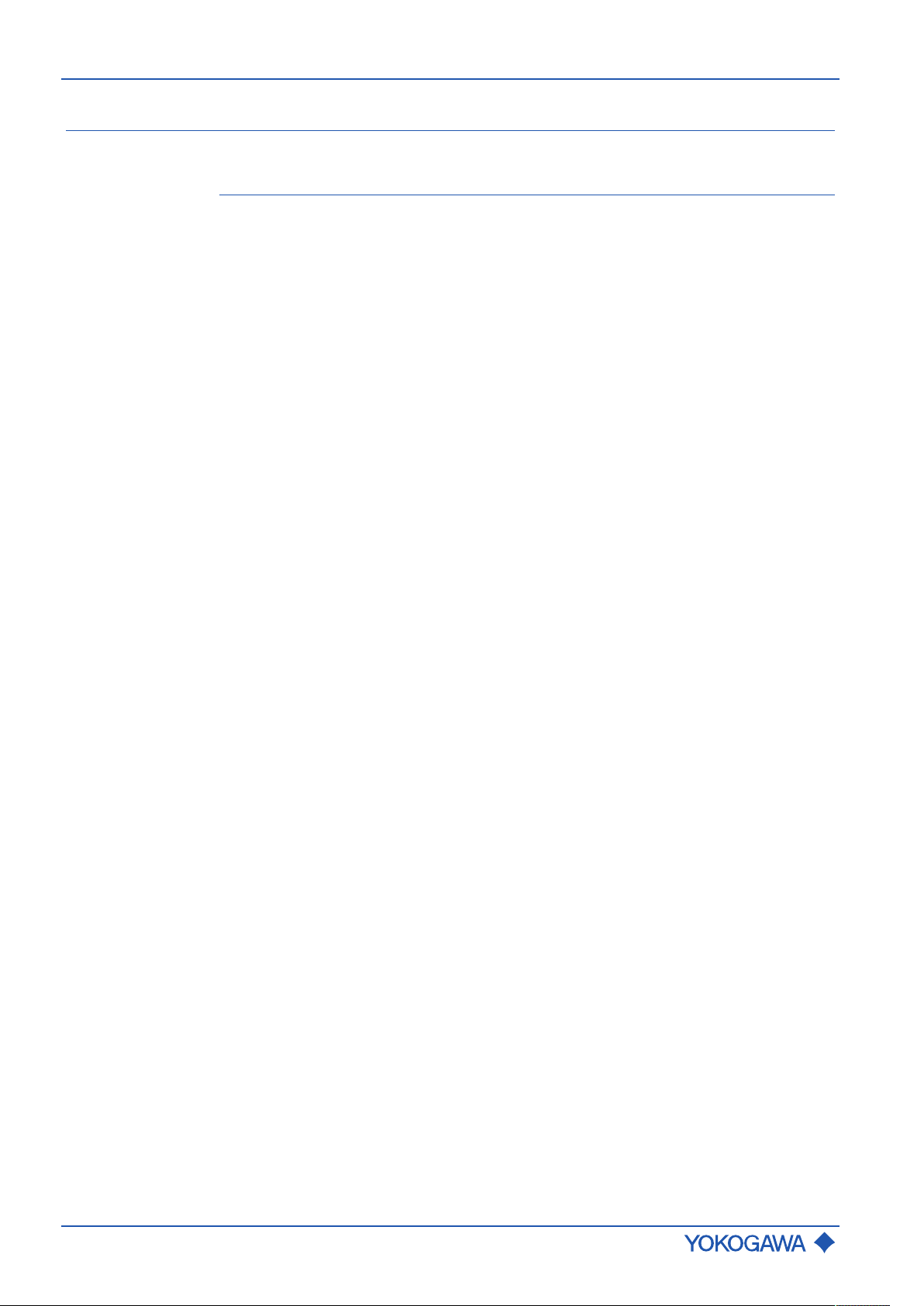

2.11 Required parameter settings

The following parameters need to be set in order to maintain the designed safety integrity.

4 – 20 mA output setting One of the following values should be set:

▪ Mass flow

▪ Density

▪ Temperature

Write lock setting The parameter “write lock” should be set to “All locked”.

High-Low (Burnout) switch To specify if the output should go high (> 21.6 mA) or low

(< 2.4 mA) upon detection of an internal failure.

Write Protect (Security) The write function should be disabled.

The detail is described in the user’s manual and the software instruction manual of

Rotamass Total Insight.

2.12 Environmental limits

The environmental limits of the Rotamass Total Insight Coriolis flow meter are specified in

the applicable General Specifications (GS) of Rotamass Total Insight.

2.13 Application limits

The application limits of the Rotamass Total Insight Coriolis flow meter are specified in

the applicable General Specifications (GS) of Rotamass Total Insight.

If the flow meter is used outside of the application limits the reliability data listed in chapter Reliability data [}6] becomes invalid.

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

7 / 10

Definitions and abbreviations

3 Definitions and abbreviations

3.1 Definitions

Safety

Freedom from unacceptable risk of harm.

Functional safety

The ability of a system to carry out the actions necessary to maintain a defined safe state

for the equipment / machinery / plant / apparatus under control of the system.

Basic safety

The equipment must be designed and manufactured such that it protects against risk of

damage to persons by electrical shock and other hazards and against resulting fire and

explosion. The protection must be effective under all conditions of the nominal operation

and under single fault condition.

Verification

The demonstration for each phase of the life-cycle that the (output) deliverables of the

phase meet the objectives and requirements specified by the inputs to the phase. The

verification is usually executed by analysis and / or testing.

Definitions

Validation

The demonstration that the safety-related system(s) or the combination of safety related

system(s) and external risk reduction facilities meet, in all respects, the Safety Requirements Specification. The validation is usually executed by testing.

Safety assessment

The investigation to arrive at a judgment – based on evidence – of the safety achieved by

safety-related systems.

Safety Freedom from unacceptable risk of harm.

The ability of a system to carry out the actions necessary to

Functional safety

maintain a defined safe state for the equipment / machinery /

plant / apparatus under control of the system.

The equipment must be designed and manufactured such

that it protects against risk of damage to persons by electrical

Basic safety

shock and other hazards and against resulting fire and explosion. The protection must be effective under all conditions of

the nominal operation and under single fault condition.

The demonstration for each phase of the life-cycle that the

Verification

(output) deliverables of the phase meet the objectives and requirements specified by the inputs to the phase. The verification is usually executed by analysis and / or testing.

The demonstration that the safety-related system(s) or the

combination of safety related system(s) and external risk re-

Validation

duction facilities meet, in all respects, the Safety Requirements Specification. The validation is usually executed by

testing.

Safety assessment

The investigation to arrive at a judgment – based on evidence

– of the safety achieved by safety-related systems.

8 / 10

Further definitions of terms used for safety techniques and measures and the description

of safety-related systems are given in IEC 61508-4.

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Abbreviations

Definitions and abbreviations

3.2 Abbreviations

Value Name / Description

DU Dangerous Undetected

FMEDA Failure Mode, Effects and Diagnostic Analysis

IS Intrinsically safe explosion-proof

non-IS Non-intrinsically safe explosion-proof

PFDavg Average Probabilty of Failure on Demand

PLC/DCS Programmable Logic Controller / Distributed Control System

PRM Plant Resource Manager

SIF Safety Instrumented Function

SIL Safety Integrity Level

SIS Safety Instrumented System

SLC Safety Lifecycle

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

9 / 10

TRADEMARKS

YOKOGAWA ELECTRIC CORPORATION

YOKOGAWA CORPORATION OF AMERICA

YOKOGAWA AMERICA DO SUL LTDA.

YOKOGAWA EUROPE B. V.

Euroweg 2, 3825 HD Amersfoort,

THE NETHERLANDS

Phone : 31-88-4641000

Fax : 31-88-4641111

YOKOGAWA INDIA LTD.

Plot No.96, Electronic City Complex,

Hosur Road, Bangalore - 560 100,

INDIA

Phone : 91-80-4158-6000

Fax : 91-80-2852-1442

YOKOGAWA AUSTRALIA PTY. LTD.

Tower A, 112-118 Talavera Road,

Macquarie Park NSW 2113,

AUSTRALIA

Phone : 61-2-8870-1100

Fax : 61-2-8870-1111

YOKOGAWA MIDDLE EAST & AFRICA B.S.C.(C)

P.O. Box 10070, Manama, Building 577,

Road 2516, Busaiteen 225, Muharraq,

Kingdom of BAHRAIN

Phone : 973-17358100

Fax : 973-17336100

Headquarters

2-9-32, Nakacho, Musashino-shi,

Tokyo, 180-8750 JAPAN

Phone : 81-422-52-5555

Branch Sales Offices

Osaka, Nagoya, Hiroshima,

Kurashiki, Fukuoka, Kitakyusyu

Head Office

12530 West Airport Blvd, Sugar Land,

Texas 77478, USA

Phone : 1-281-340-3800

Fax : 1-281-340-3838

Georgia Office

2 Dart Road, Newnan, Georgia 30265, USA

Phone : 1-800-888-6400/ 1-770-253-7000

Fax : 1-770-254-0928

Praca Acapulco, 31 - Santo Amaro, Sáo Paulo/SP,

BRAZIL, CEP-04675-190

Phone : 55-11-5681-2400

Fax : 55-11-5681-4434

YOKOGAWA ELECTRIC CIS LTD.

Grokholskiy per 13 Building 2, 4th Floor 129090,

Moscow, RUSSIA

Phone : 7-495-737-7868

Fax : 7-495-737-7869

YOKOGAWA CHINA CO., LTD.

3F Tower D, No.568 West Tianshan RD.

Shanghai CHINA, 200335

Phone : 86-21-62396262

Fax : 86-21-62387866

YOKOGAWA ELECTRIC KOREA CO., LTD.

(Yokogawa B/D, Yangpyeong-dong 4-Ga),

21, Seonyu-ro 45-gil, Yeongdeungpo-gu,

Seoul, 150-866, KOREA

Phone : 82-2-2628-6000

Fax : 82-2-2628-6400

YOKOGAWA ENGINEERING ASIA PTE. LTD.

5 Bedok South Road, Singapore 469270,

SINGAPORE

Phone : 65-6241-9933

Fax : 65-6241-2606

ISO 9001

HART: registered trademark of FieldComm Group, Inc., US

ROTAMASS: registered trademark of Rota Yokogawa GmbH & Co. KG, DE

FieldMate: registered trademark of YOKOGAWA ELECTRIC CORPORATION

All other company and product names mentioned in this document are trade names, trademarks or

registered trademarks of their respective companies. In this document, trademarks or registered trademarks are not marked with ™ or ®.

All rights reserved. Copyright © 2020-05-13

IM 01U10D00-00EN-R, 4

th

edition, 2020-05-13

Loading...

Loading...