User ’s

Manual

Model GX10/GX20/GP10/GP20/GM10

Log Scale (/LG)

User’s Manual

IM 04L51B01-06EN

4th Edition

Introduction

Thank you for purchasing the SMARTDAC+ Series GX10/GX20/GP10/GP20/GM10

(hereafter referred to as the recorder, GX, GP, or GM).

This manual explains the Log scale (/LG option) function of the GX, GP, and GM.

Although the display of GX20 is used in this manual, GX10/GP10/GP20 can be

operated similarly. Moreover, for the GM10, the same content can be displayed on a

Web browser.

To ensure correct use, please read this manual thoroughly before beginning operation.

For details on other settings, procedures, and communication features, read also the

following user’s manuals.

• Model GX10/GX20/GP10/GP20 Paperless Recorder User’s Manual (IM 04L51B01-01EN)

• Data Acquisition System GM User’s Manual (IM 04L55B01-01EN)

• Model GX10/GX20/GP10/GP20/GM10 Communication Command User’s Manual (IM

04L51B01-17EN)

The following manuals are provided for the GX/GP.

• Paper Manuals

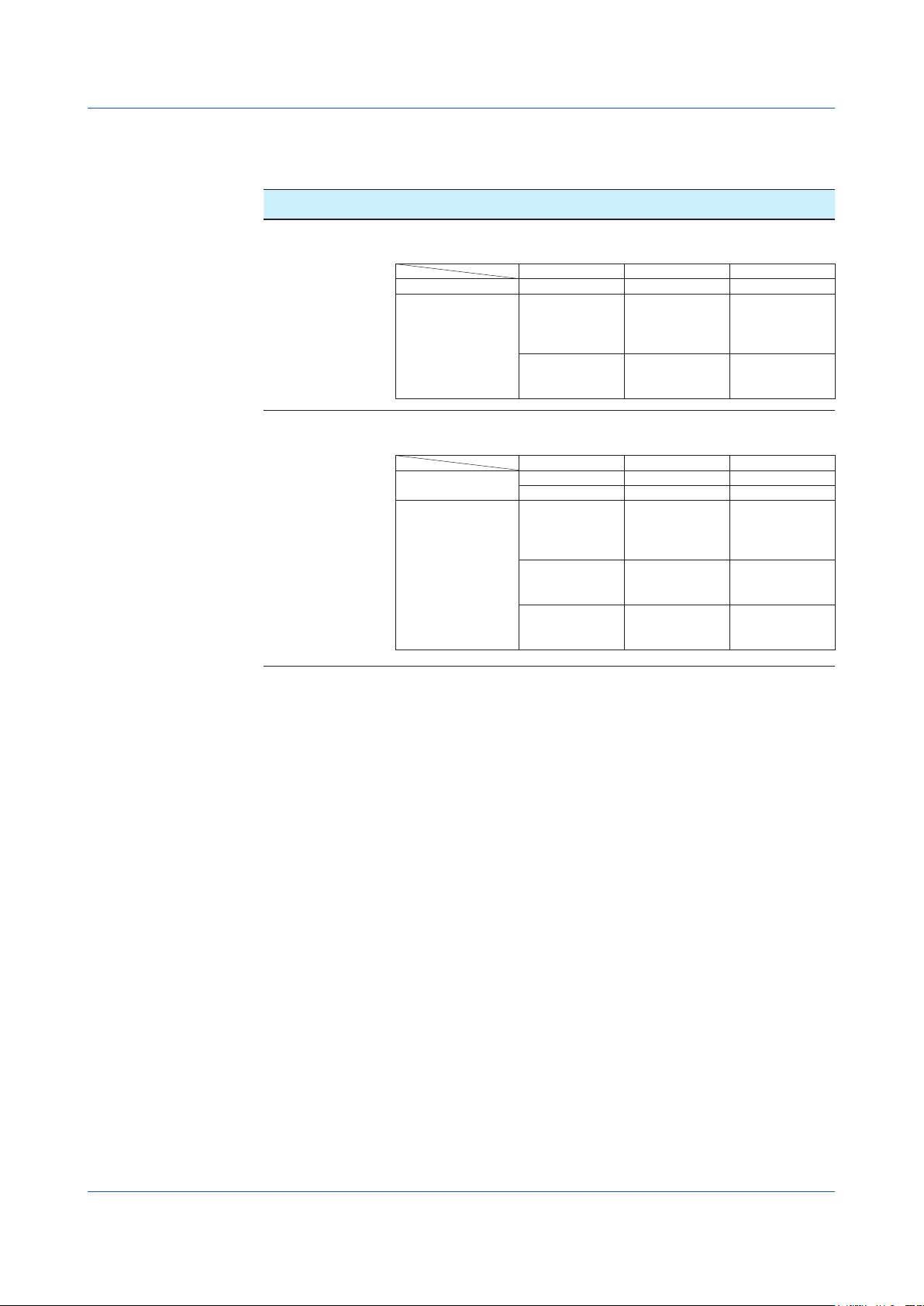

Manual Title Manual No. Description

Model GX10/GX20/GP10/GP20

Paperless Recorder

First Step Guide

IM 04L51B01-02EN Explains the basic operations of the GX/GP.

• Downloadable Electronic Manuals

You can download the latest manuals from the following website.

www.smartdacplus.com/manual/en/

Model Manual Title Manual No. Description

GX/GP Model GX10/GX20/GP10/GP20

Paperless Recorder

First Step Guide

Model GX10/GX20/GP10/GP20

Paperless Recorder

User’s Manual

Model GX10/GX20/GP10/GP20

Advanced Security Function (/AS)

User’s Manual

GM GM Data Acquisition System

First Step Guide

GM Data Acquisition System

User’s Manual

GM Data Acquisition System

Advanced Security Function (/AS)

User’s Manual

GX/GPGMModel GX10/GX20/GP10/GP20/GM10

Communication Commands

User’s Manual

SMARTDAC+ STANDARD

Universal Viewer

User’s Manual

SMARTDAC+ STANDARD

Hardware Configurator

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Multi-batch Function (/BT)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Log Scale (/LG)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

EtherNet/IP Communication (/E1)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

WT Communication (/E2)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

OPC-UA Server (/E3)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

SLMP Communication (/E4)

User’s Manual

Model GX10/GX20/GP10/GP20/GM10

Loop Control Function, Program Control

Function (/PG Option)

User’s Manual

4th Edition: May 2020 (YK)

All Rights Reserved, Copyright © 2014, Yokogawa Electric Corporation

IM 04L51B01-02EN This is the electronic version of the paper manual.

IM 04L51B01-01EN Describes how to use the GX/GP. The communication

IM 04L51B01-05EN Describes how to use the advanced security function (/

IM 04L55B01-02EN This is the electronic version of the paper manual.

IM 04L55B01-01EN Describes how to use the GM. The communication

IM 04L55B01-05EN Describes how to use the advanced security function (/

IM 04L51B01-17EN Describes how to use command control communication

IM 04L61B01-01EN Describes how to use Universal Viewer, which is a

IM 04L61B01-02EN Describes how to use the PC software for creating setting

IM 04L51B01-03EN Describes how to use the multi-batch function (/BT

IM 04L51B01-06EN Describes how to use the log scale (/LG option).

IM 04L51B01-18EN Describes how to use the communication functions

IM 04L51B01-19EN Describes how to use WT communication (/E2 option).

IM 04L51B01-20EN Describes how to use the OPC-UA server function (/E3

IM 04L51B01-21EN Describes how to use SLMP communication function (/

IM 04L51B01-31EN Describes how to use the Loop Control Function,

control commands and some of the options are excluded.

AS option).

control commands and some of the options are excluded.

AS option).

functions.

software that displays GX/GP/GM measurement data

files.

parameters for various GX/GP/GM functions.

option).

through the EtherNet/IP (/E1 option).

option).

E4 option).

Program Control Function (/PG Option).

Continued on the next page

IM 04L51B01-06EN

i

Notes

QR Code

Trademarks

Model Manual Title Manual No. Description

GX/GP DXA170

DAQStudio

User’s Manual

IM 04L41B01-62EN Describes how to create custom displays (/CG option).

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the

permission of YOKOGAWA is strictly prohibited.

The product has a QR Code pasted for efficient plant maintenance work and asset

information management.

It enables confirming the specifications of purchased products and user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

• SMARTDAC+ is registered trademarks of Yokogawa Electric Corporation.

• Microsoft and Windows are registered trademarks or trademarks of Microsoft Corporation

in the United States and/or other countries.

• Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

Incorporated.

• Company and product names that appear in this manual are registered trademarks or

trademarks of their respective holders.

• The company and product names used in this manual are not accompanied by the

registered trademark or trademark symbols (® and ™).

Using Open Source Software

This product uses open source software.

For details on using open source software, see Regarding the Downloading and Installing

for the Software, Manuals and Labels (IM 04L61B01-11EN).

Revisions

May 2014 1st Edition

December 2014 2nd Edition

June 2017 3rd Edition

May 2020 4th Edition

ii

IM 04L51B01-06EN

Recorder Versions Described in This Manual

The contents of this manual correspond to the GX/GP with release number 4 (see the

STYLE S number) and style number 3 (GX10/GX20/GP10), style number 4 (GP20) (see the

STYLE H number) and the GM10 with release number 4 (see the STYLE S number) and

style number 1 (see the STYLE H number).

Edition Product Explanation

1 GX/GP: Version 2.01 and later —

2 GX/GP: Version 2.01 and later Describes the GM.

GM: Version 2.02 and later

3 GX/GP: Version 4.01 and later Support for Release number 4.

GM: Version 4.01 and later

4 GX/GP: Version 4.08 and later Support for style up (H: 3 (GX10/GX20/GP10), H: 4

GM: Version 4.07 and later —

(GP20)).

IM 04L51B01-06EN

iii

Conventions Used in This Manual

Unit

K Denotes 1024. Example: 768K (file size)

k Denotes 1000.

Markings

WARNING Calls attention to actions or conditions that could cause serious or fatal

CAUTION Calls attention to actions or conditions that could cause light injury

Note Calls attention to information that is important for the proper operation

Reference Item

Improper handling or use can lead to injury to the user or damage to

the instrument. This symbol appears on the instrument to indicate that

the user must refer to the user’s manual for special instructions. The

same symbol appears in the corresponding place in the user’s manual

to identify those instructions. In the manual, the symbol is used in

conjunction with the word “WARNING” or “CAUTION.”

injury to the user, and precautions that can be taken to prevent such

occurrences.

to the user or cause damage to the instrument or user’s data, and

precautions that can be taken to prevent such occurrences.

of the instrument.

Reference to related operation or explanation is indicated after this

mark.

Example: section 4.1

Module Notation

Conventions Used in the Procedural Explanations

Bold characters Denotes key or character strings that appear on the screen.

Example: Volt

A

a# 1

Indicates the character types that can be used.

A

uppercase alphabet,

numbers

1

a

lowercase alphabet,

#

symbol,

Procedure Carry out the procedure according to the step numbers. All procedures

are written with inexperienced users in mind; depending on the

Explanation

operation, not all steps need to be taken.

Explanation gives information such as limitations related the procedure.

Path Indicates the setup screen and explains the settings.

Description

When necessary, the following notations are used to distinguish the GX90XA analog input

modules by type.

Type Suffix Code Notation

-U2 Universal

-C1 Current (mA)

-L1 Low withstand voltage relay

-T1 Electromagnetic relay

-H0 High-speed universal or High speed AI

-R1 4-wire RTD/resistance

iv

IM 04L51B01-06EN

Contents

Using the Log scale Function ............................................................................................................. 1

Setting the Log scale ........................................................................................................................... 3

Introduction ................................................................................................................................................ i

Recorder Versions Described in This Manual ..........................................................................................iii

Conventions Used in This Manual ........................................................................................................... iv

Log Scale Display Function ...................................................................................................................... 1

Restrictions ............................................................................................................................................... 2

AI channel settings ................................................................................................................................... 3

Setup Examples ..................................................................................................................................... 13

IM 04L51B01-06EN

v

Blank

Using the Log scale Function

Log Scale Display Function

You can apply a logarithmic voltage that has been converted from a physical value to the

recorder, and then use the log scale (logarithmic scale) to display and record the physical

value. The recorder supports three types of input signals.

• Logarithmic Input

This is referred to as “Log input”. Log input is input in which the voltage corresponds to

logarithmic values of physical values.

• Pseudo Log Input

This is referred to as “Pseud-log input.” This input supports pseudo logs.

A pseudo log signal is a voltage obtained by summing the one’s digit of the voltage

representing the exponent of the logarithmic data and the decimal digits of the voltage

representing the mantissa.

• Input That Is Linear on a Logarithmic Scale

This is referred to as “Linear-Log input.” Linear log input is input in which the voltage

values correspond to the logarithmic values of physical values at each decade division

(for example, 1 × 102) and in which, within each decade, the voltage values correspond

linearly to physical values.

On the trend display, the recorder displays waveforms with the log scale. Digital values are

displayed as exponents (for example, 1.2E+03).

Display example on the GX/GP main unit

Log scale

Digital value

Trend display example on a Web application (GM)

Log scale

IM 04L51B01-06EN

1

Using the Log scale Function

Restrictions

Partial

You cannot set the partial display on a channel that is set to log scale.

Differential Computation between Channels

If you set the reference channel of a differential computation between channels to a channel

that is set to log scale, an error will be returned as the measured result of the differential

computation between channels.

Computation Channels (/MT option)

Do not include channels that are set to log scale in a computation channel expression.

If you include these channels, an error will be returned as the measured result.

Report Function (/MT option)

You cannot create reports for channels that are set to log scale. An error will be returned as

the result of report computations on channels that are set to log scale.

Manual Sampled Data

For channels that are set to log scale, the data is stored using the “mantissa + exponent”

format, the same format as that of digital values on the recorder.

Number of Channels Set to Log Scale

Keep the number of channels set to log scale no greater than 300.

When there are many channels set to log scale, log scale processing may not finish within

the scan interval and may cause computation data dropouts.

2

IM 04L51B01-06EN

Setting the Log scale

AI channel settings

Log input computation cannot be specified on current (mA), 4-wire RTD/resistance modules.

Range settings

Path

GX/GP: MENU key > Browse tab > Setting > Setting menu AI channel settings > Range

Web application: Config. tab > AI channel settings > Channel range (display example:

0001-0010) > Range

Hardware configurator: AI channel settings > Channel range (display example: 0001-

Description

Setup Item Selectable Range or Options Default Value

First-CH AI channel —

Last-CH AI channel —

First-CH, Last-CH

Set the target channels. The channels that you can specify appear depending on the module

configuration.

Range

Setup Item Selectable Range or Options Default Value

Type Skip, Volt, GS (general signal), TC

Range See “Range Details.” See “Range Details.”

Span Lower Numeric value (depends on the range) –2.0000

Span Upper Numeric value (depends on the range) 2.0000

Calculation Off, Delta, Linear scaling, Square root,

1 Cannot be specified for the electromagnetic relay type analog input module and low withstand

voltage relay type.

0010) > Range

(thermocouple), RTD (resistance

temperature detector)

voltage level)

Log input, Pseudo-Log input, Linear-Log

input

1

, DI (contact,

Volt

Off

IM 04L51B01-06EN

Type

Set the type to Volt. You cannot use the log scale display for any other type.

Note

For the channels in which you are not using an electromagnetic relay type module, set the range

type to Skip.

3

Setting the Log scale

Range

Set the input type range.

Range Details

Type Range Selectable Range Default Value

Volt 20mV –20.000 mV to 20.000 mV 2V

60mV –60.00 mV to 60.00 mV

200mV –200.00 mV to 200.00 mV

1V –1.0000 V to 1.0000 V

2V –2.0000 V to 2.0000 V

6V –6.000 V to 6.000 V

20V –20.000 V to 20.000 V

50V –50.00 V to 50.00 V

1

100V

1 For high-speed universal type.

–100.00 V to 100.00 V

Span Lower, Span Upper

Set the input range. The selectable range varies depending on the range setting.

For the selectable ranges, see “Range Details.”

Note

You cannot set the same value to Span Lower and Span Upper.

Calculation

Set the log scale type to Log input, Pseudo-log input, or Linear-log input.

Scale

1

Setup Item Selectable Range or Options Default Value

Decimal place 1, 2 2

Scale Lower Log input: 1.00E‒15 to 1.00E+14

Scale Upper Log input: 1.00E‒14 to 1.00E+15

Unit

1 Appears when the range calculation is set to Log input, Pseudo-log input, or Linear-log

input.

Linear-Log, Pseudo-Log: 1.00E–15 to

1.00E+15

Linear-Log, Pseudo-Log; 1.00E–15 to

1.00E+15

Character string (up to 6 characters,

A

1.00E+00

1.00E+15

—

a

1

#

)

Decimal Place

Set the decimal place for scale lower and scale upper.

This value is also applied to the lower and upper limits of the displayed point of color scale

band as well as alarm values.

Scale Lower, Scale Upper

Set the Scale Lower and Scale Upper.

4

IM 04L51B01-06EN

Setting the Log scale

• When Calculation is Log input

Set the settings so that Scale Lower is less than Scale Upper.

The mantissas of scale lower and scale upper can be set to different values.

Mantissa of Scale

Lower

1.00 1.00E‒15 to 1.00E+15. However, the difference between the exponents must

Setting Range

be at least 1.

The scale width must be 15 decades or less.

Example 1.00E+01 1.00E+02

Examples of invalid

settings

Scale Lower Scale Upper Notes

1.00E+01 2.00E+01 The difference

1.00E‒01 1.00E+15 The scale width

between the

exponents is less

than 1.

is greater than 15

decades.

A value other than 1.00 1.01E‒15 to 1.00E+15. However, the difference between the exponents must

be at least 2.

The scale width must be 15 decades or less.

Example 2.00E+01 1.00E+03

Examples of invalid

settings

Scale Lower Scale Upper Notes

2.00E+00 5.00E+14

2.00E+01 7.00E+02 The difference

2.00E‒01 1.00E+15 The scale width

2.00E+03 2.00E+15 The upper limit

between the

exponents is less

than 2.

is greater than 15

decades.

is greater than

1.00E+15.

IM 04L51B01-06EN

5

Setting the Log scale

• Pseudo-Log, Linear-Log

You can set the settings so that Scale Lower is less than Scale Upper or so that Scale Lower

is greater than Scale Upper.

The mantissa that you set for Scale Lower is automatically set as the mantissa of Scale

Upper.

The scale is referred to as the positive scale or reverse scale depending on the scale value

settings.

Scale Span value (Input voltage) Scale value

Positive scale [Span Lower] < [Span Upper] [Scale Lower] < [Scale Upper]

Reverse scale [Scale Lower] > [Scale Upper]

Mantissa of Scale

Lower

1.00 1.00E–15 to 1.00E+15. However, the difference between the exponents must

A value other than 1.00 1.00E–15 to 9.99E+14. However, the difference between the exponents must

Setting Range

be at least 1.

The scale width must be 15 decades or less.

Example 1.00E+01 1.00E+02

Examples of invalid

settings

be at least 1.

The scale width must be 14 decades or less

Example 1.33E+01 1.33E+02

Examples of invalid

settings

The scale displayed on the recorder is zoomed in until the value that is less

than the lower scale limit and whose mantissa is 1.00 and the value that is

greater than the upper scale limit and whose mantissa is 1.00 are displayed.

See Example 4 under Scale Examples.

Scale Lower Scale Upper Notes

1.00E+15 1.00E+00

1.00E‒01 1.00E+15 The scale width

is greater than

15 decades.

Scale Lower Scale Upper Notes

1.33E+00 1.33E+13

1.33E+13 1.33E+00

1.33E–15 1.33E+00 The scale width

is greater than

14 decades.

1.33E+03 1.33E+15 The upper limit

is greater than

9.99E+14.

6

Unit

Set the unit.

Moving average

Setup Item Selectable Range or Options Default Value

On/Off Off, On Off

1

Count

1 Appears when On/Off is set to On.

On/Off

Set this to On to perform moving average.

Count

Set the number of data points to take the moving average of.

Scan interval

Sampling count

2 to 100

2 to 500 (High-speed AI)

Average

Average

2

IM 04L51B01-06EN

Actual input When the time constant

When the time constant

Setting the Log scale

First-order lag filter (high-speed AI module only)

Setup Item Selectable Range or Options Default Value

On/Off Off, On Off

Filter coefficient

1 Appears when On/Off is set to On.

On/Off

Set this to On to use the first-order lag filter.

Filter coefficient

Filter time constant = scan interval × filter coefficient N

The following table shows the relationship between filter coefficient N of the first-order lag

filter, scan interval, and time constant for filter coefficient N = 3, 10, 30, 100, and 300.

Scan interval Time constant (s)

1ms 0.003 0.01 0.03 0.1 0.3

2ms 0.006 0.02 0.06 0.2 0.6

5ms 0.015 0.05 0.15 0.5 1.5

10ms 0.03 0.1 0.3 1 3

20ms 0.06 0.2 0.6 2 6

50ms 0.15 0.5 1.5 5 15

100ms 0.3 1 3 10 30

200ms 0.6 2 6 20 60

500ms 1.5 5 15 50 150

1s 3 10 30 100 300

2s 6 20 60 200 600

5s 15 50 150 500 1500

1

N = 3 N = 10 N = 30 N = 100 N = 300

3 to 300 3

Description

When there is noise riding on the input signal, inserting a first-order lag filter has the effect of

rejecting noise. The larger the filter coefficient (time constant), the higher the noise rejection

effect. However, setting the filter coefficient too large will distort the waveform.

is small

Example when a

Input

time constant 2-s

filter is inserted

is large

Example when a time constant

10-s filter is inserted

IM 04L51B01-06EN

7

4

Setting the Log scale

Bias

Setup Item Selectable Range or Options Default Value

Value Numeric value (–999999 to 999999) 0

Value

Set the bias to add to input values or linear scaling values (input calculation).

Channel on which bias is added

Input value

+

Bias (a constant value)

Measured value

Scale Examples

Below are scale examples in which the trend direction is set to vertical on the GX/GP main

unit. With the GM, the measurement data is displayed on a Web application, so the following

items are different.

• The trend is displayed with the time plotted on the horizontal axis. Therefore, the scale is

displayed vertically.

• For example, a scale value of 1×10

3

is displayed as “1E3.”

• Scale marks other than decades (e.g., 1E3) are displayed only when there is space.

Log input

Example 1

In this example, the mantissa of the scale lower limit and the mantissa of the scale upper

limit are both 1.

Span value (Input voltage) 1V 5V

Scale value 1.00E+01 1.00E+04

Display example on the GX/GP main unit Display example on a Web application (GM)

1V

Lower Upper

5V

5V

1E4

5E3

2E3

1E3

5E2

Displayed only when

there is enough space.

8

2E2

1E2

5E1

2E1

1V

1E1

Example 2

In this example, the mantissa of the scale lower limit and the mantissa of the scale upper

limit are both a value other than 1.

Span value (Input voltage) 1V 5V

Scale value 5×1.00E+00 2×1.00E+04

10

5

1V

2

10

Lower Upper

3

10

10

2

5V

The end points of the scale are displayed using single digits if there is space to display them.

IM 04L51B01-06EN

Setting the Log scale

Pseudo-Log input, Linear-Log input

Example 3

Positive scale in which the mantissa of the scale lower limit and the mantissa of the scale

upper limits are 1

This is the same as when the mantissa of the scale lower limit and the mantissa of the scale

upper limit are both 1 in log input example 1.

Example 4

Positive scale in which the mantissa of the scale lower limit and the mantissa of the scale

upper limits are not 1

The scale displayed on the recorder is zoomed in until the value that is less than the lower

scale limit and whose mantissa is 1.00 and the value that is greater than the upper scale

limit and whose mantissa is 1.00 are displayed. Only the scale is zoomed in.

Span Lower equals Scale Lower, and Span Upper equals Scale Upper.

Span value (Input voltage) 1V 5V

Scale value 1.33E+01 1.33E+04

Scale displayed on the GX/GP 1.00E+01 1.00E+05

2

10

10

10

Lower Upper

3

4

10

5

10

Scale

1V (1.33E+01)

5V (1.33E+04)

Example 5

Reverse scale in which the mantissa of the scale lower limit and the mantissa of the scale

upper limits are 1

On the reverse scale of a vertical waveform display, the left side is always the minimum

scale value and the right side the maximum.

Span value (Input voltage) 1V 5V

Scale value 1.00E+04 1.00E+01

10

2

10

5V

Lower Upper

3

10

4

10

Scale

1V

The scale image shows 10-1 as 0.1, 100 as 1, and 101 as 10.

Note

Regarding Log Scale Over-range

A value less than –5% of the voltage span is a negative over-range, and a value greater than 105%

of the scale is a positive over-range. They are displayed as –Over and +Over. The “Value on overrange” setting (see section 1.11.2, “Setting the Over-range Detection Method” in the user’s manual

(IM 04L51B01-01EN) or section 2.12.2, “Setting the Over-range Detection Method” in the user’s

manual (IM04L55B01-01EN)) is not applied to channels that are set to log scale.

Example: If the span lower limit is set to 0 V and the span upper limit is set to 10 V, a value less

than –0.5 V will result in “–Over” being displayed. A value greater than 10.5 V will result in “+Over”

being displayed.

IM 04L51B01-06EN

9

Setting the Log scale

Path

Description

Alarm settings

GX/GP: MENU key > Browse tab > Setting > Setting menu AI channel settings > Alarm

Web application: Config. tab > AI channel settings > Channel range (display example:

0001-0010) > Alarm

Hardware configurator: AI channel settings > Channel range (display example: 0001-0010)

> Alarm

Setup Item Selectable Range or Options Default Value

First-CH AI channel —

Last-CH AI channel —

First-CH, Last-CH

Set the target channels. The channels that you can specify appear depending on the module

configuration.

Level 1, Level 2, Level 3, Level 4

Setup Item Selectable Range or Options Default Value

On/Off Off, On Off

1

Type

1

Value

1

Logging

Output type

Output No.

1

2

1 Appears when Level (1 to 4) is set to On.

2 Appears when Output type is not set to Off.

3 Appears when the range type of any of the DO channels is set to Alarm.

4 Appears when any of the internal switch type is set to Alarm.

H: High limit, L: Low limit, T: Delay high limit, t: Delay

low limit

Log scale range that corresponds to –5% to 105% of

the span width

Off, On On

Off, Relay3, Internal switch

DO channel or internal switch —

4

H: High limit

1.00E+00

Off

On/Off

To use an alarm level (1 to 4), set this to On.

Type

Set the alarm type.

Options Description

H: High limit An alarm is activated when the measured value is greater than or equal to the

L: Low limit An alarm is activated when the measured value is less than or equal to the

T: Delay high limit An alarm is activated if measured values remain greater than or equal to the

t: Delay low limit An alarm is activated if measured values remain less than or equal to the alarm

alarm value.

alarm value.

alarm value for a specified time period (delay period).

value for a specified time period (delay period).

Value

Set the alarm value for the specified alarm type.

The selectable range is the Log scale range that corresponds to –5% to 105% of the span

width. The mantissa range is 1.00 to 9.99 or 1.0 to 9.9 (depending on the decimal place

setting).

If the alarm value is set outside the selectable scale range of the range setting, the alarm

mark will be displayed at the lower or upper limit position of the scale setting.

Options Value Examples of Alarm Value Range

H, L Log scale range that corresponds to –5%

to 105% of the span width

T, t Same as H and L Same as H and L

For 6 V range (span lower: 1.000 V, span

upper: 6.000V), LOG input (decimal place:

2, scale lower: 1.00E+01, scale upper:

1.00E+04), 7.08E+00 to 1.41E+04

10

IM 04L51B01-06EN

Setting the Log scale

Logging

Set this On to display an alarm (notify you) when an alarm occurs. If set to Off, when an

alarm occurs, the recorder outputs signals to alarm output DO channels or internal switches

but does not display the alarm. Alarms are also not recorded in the alarm summary.

Output type

Set the alarm output destination.

Alarm status can be output to the relay (DO channel) or internal switches (100 software

switches). Internal switch values are shown below. Like the DO output relay, you can specify

AND/OR operation.

Alarm occurrence

Alarm

Internal switch

0

Alarm release

1

Internal switches can be used as events of the event action function (See section 1.19,

“Configuring the Event Action Function” in the GX/GP user’s manual or section 2.20,

“Configuring the Event Action Function” in the GM user’s manual (IM 04L55B01-01EN)). In

addition, they can also be written in calculation expressions of math channels (/MT option).

Output No.

Set the number of the relay (DO channel) or internal switch to output alarms to.

Note

• The decimal place of the alarm setting is the same as the decimal place of the scale. You

cannot specify a value using more than the number of significant digits.

• The alarm hysteresis on channels that are set to log scale is fixed to 0%.

• The “lower and upper limits of available range” shown on the alarm setting screen are

guidelines.

IM 04L51B01-06EN

11

Setting the Log scale

Path

Description

Color scale band settings (Display settings)

GX/GP: MENU key > Browse tab > Setting > Setting menu AI channel settings > Display

settings

Web application: Config. tab > AI channel settings > Channel range (display example:

0001-0010) > Display settings

Hardware configurator: AI channel settings > Channel range (display example: 0001-0010)

> Display settings

Color scale band

Setup Item Selectable Range or Options Default Value

Band area Off, In, Out Off

Color 24 colors (red, green, blue, blue violet, brown, orange,

yellow-green, light blue, violet, gray, lime, cyan, dark

blue, yellow, light gray, purple, black, pink, light brown,

light green, dark gray, olive, dark cyan, and spring

green) and a user-defined color (1 color)

Display position Lower Scale lower limit to scale upper limit 1.00E+00

Display position Upper Scale lower limit to scale upper limit 1.00E+15

Band area

Displays a specified section of the measurement range using a color band on the scale. This

setting is shared with the bar graph display.

Options Description

Off Disables the function.

In Displays the area inside using the color band.

Out Displays the area outside using the color band.

—

Color

Set the display color.

For instructions on how to set the user-defined color, see section 1.2.3, “Setting the

Display” in the GX/GP user’s manual (IM 04L51B01-01EN) or section 2.3.3, “Setting the

Display” in the GM user’s manual (IM 04L55B01-01EN).

Display position Lower and Display position Upper

Set a value within the selectable scale range. (The selectable range is 1.00E‒15 to

1.00E+15. Set the mantissa to a value in the range of 1.00 to 9.99.

12

IM 04L51B01-06EN

Setup Examples

Setting the Log scale

pseudo-Log input and Log input (nonlinear log) setup examples are shown below.

Setting the Pseudo-Log Range

This setting is for logging the pseudo log output (see the table below) of a vacuum gauge.

Pressure Reading [Pa] Output Voltage [V] Pressure Reading [Pa] Output Voltage [V]

-7

1.30x10

5.00x10

1.00x10

5.00x10

1.00x10

5.00x10

1.00x10

-7

-6

-6

-5

-5

-4

0.13 5.00x10

0.50 1.00x10

1.10 5.00x10

1.50 1.00x10

2.10 5.00x10

2.50 1.00x10

3.10 9.90x10

GX/GP main unit: Press MENU key, Tap the Brows tab > Setting > AI channel settings >

Range.

Web application: Click the Setting tab > AI channel settings > Channel range (0001-0010)

> Range

Hardware configurator: Click AI channel settings > Channel range (0001-0010) > Range

Set the channel 0001 range as shown below.

Range

Type: Volt

Range: 20V

Span: Span Lower 0.000, Span Upper 7.000

Calculation: Pseudo-Log input

Scale:

Decimal place: 2

Scale: Scale Lower 1.00E‒07, Scale Upper 1.00E+00

Unit: Pa

-4

-3

-3

-2

-2

-1

-1

3.50

4.10

4.50

5.10

5.50

6.10

6.99

Display Example

Below is a screen example in which the trend direction is set to vertical on the GX/GP main

unit.

Log scale

Digital value

Note

• Set the mantissa to 1.00.

• The output voltage for pressure reading whose mantissa is 1.00 has a certain deviation.

For example, if the pressure reading is 1.00E–07, the output voltage is 0.00 to 0.10 V. In this

situation, set the range (Span Lower) to the minimum value (0.00 V).

IM 04L51B01-06EN

13

Output to recorder (V)

( ‒ (minimum of ))

((‒2) ‒ (‒5))

=

Setting the Log scale

Setting the Log input (Nonlinear Log)

In this example, pressure is measured by applying calibration correction to linearly

approximate the nonlinear output of a vacuum gauge.

Calculating linearizer Input and linearizer output

The following figure is an example of a nonlinear output of a vacuum gauge. The 10 red dots

in the figure are the set points for the linearizer approximation. Their values are shown under

and in the table below. Keep the number of set points to no more than 12.

10

8

6

4

2

0

10

-5

-4

10

Pressure indication of the vacuum gauge (Torr)

10

-3

10-2

No.

Pressure

indication [Torr]

Output to

recorder [V]

1 1.00E-05 0.2

2 5.00E-05 0.55

3 1.00E-04 1.25

4 2.00E-04 2.7

5 3.00E-04 3.95

6 5.00E-04 5.7

7 7.00E-04 6.75

8 1.00E-03 7.5

9 5.00E-03 8.8

10 1.00E-02 9.1

Calculate the output (, linearizer output) that correspond to the recorder input (, linearizer

input) in the following manner.

• : Take a log of the pressure indication values ().

• : Linearly scale the value of each row of using the span. The calculation formula is

shown below.

=

(maximum of

(

‒ (‒5))

‒ minimum of )

×(9.1 ‒ 0.2)+ 0.2

× (maximum of ‒ minimum of ) + minimum of

+5

×8.9+ 0.2=

3

14

IM 04L51B01-06EN

Setting the Log scale

The combination of and is the set point.

log() Linearly scale using .

——→

Set

point

Linearizer

input [V]

Linearizer

output [V]

-5 0.2 1 0.200 0.200

-4.301029996 2.273611013 2 0.550 2.274

-4 3.166666667 3 1.250 3.167

-3.698970004 4.05972232 4 2.700 4.060

-3.522878745 4.582126389 5 3.950 4.582

-3.301029996 5.24027768 6 5.700 5.240

-3.15490196 5.673790852 7 6.750 5.674

-3 6.133333333 8 7.500 6.133

-2.301029996 8.206944346 9 8.800 8.207

-2 9.1 10 9.100 9.100

Setting the Channels to Use

Set the channels that you want to use as follows.

Setting the Range

GX/GP main unit: Press the MENU key, tap the Browse tab > Setting > AI channel

settings > Range

Web application: Click the Setting tab > AI channel settings > Channel range (0001-0010)

> Range

Hardware configurator: Click AI channel settings > Channel range (0001-0010) > Range

Item Description Explanation

Mode

Log input

It is an input in which voltages correspond to

logarithmic values of physical values.

Range 20V

Span 0.200 to 9.100

Range that can cover the output to recorder ()

Minimum to the maximum of the output to recorder ()

Scale 1.00E-5 to 1.00E-2 Minimum to the maximum of the pressure indication

() of the vacuum gauge

Decimal

2 Decimal place of mantissa

place

Unit Torr

Unit of the pressure indication () of the vacuum

gauge

IM 04L51B01-06EN

Configuring calibration correction

GX/GP main unit: Press the MENU key, tap the Browse tab > Setting > AI channel

settings > Calibration correction

Web application: Click the Setting tab > AI channel settings > Channel range (0001-0010)

> Calibration correction

Hardware configurator: Click AI channel settings > Channel range (0001-0010) >

Calibration correction

Item Description Explanation

Mode Linearizer

Correction type

approximation

Number of

set points

10

The number of rows of and . If the number exceeds 12,

decimate to no more than 12 while maintaining appropriate

approximation.

Linearizer

(Value)

Value of

input

Linearizer

(Value)

Value of

output

15

Blank

Loading...

Loading...