Page 1

%

T0E-C843-7

INSTRUCTIONS

206

CNC

YASNAC’mm

OPERATOR'S

SYSTEM

FOR

T1

fe_APÿJCATIONS

-f.,

Btfort

read

thoroughly.

for

future

Inftfol

th«*«

reference.

operation

(n*lrucffon»

retain

ond

This

instructions

ation

features

are

of

builder's

manual

and

This

marked

your

is

primarily

for

maintenance.

manual

of

YASNAC

with

YASNAC

manual.

YASNAC

applies

LXl.

a

dagger.

,

LX1

intended

LX1

to

refer

•

!*>

t&Mz

to

programming,

the

basic

The

optional

the

For

to

the

**?-ÿ,*ÿ*

:<.i

operator's

give

oper¬

and

optional

features

specifications

machine

tool

ff

>uuu

*

&

..

»ÿ

.

.

.

-

.-I***'

000

l

;

.

8915

4820-

000

IS®

QQOOOOBBB

,

i

YASNAC

*1'

LXl

OPERATOR'S

BOOB

STATION

PO

512-22

Page 2

PREFACE

This

manual

tors

instructions

operation

This

manual

tures

marked

of

builder's

Read

mation

of

your

this

contained

possible

The

operations

attended

be

not

The

functions

determined

control.

NC

machine

the

over

ority

is

primarily

and

maintenance.

applies

YASNAC

with

a

dagger

YASNAC

manual.

manual

contingency

and

a

by

For

tool

this

for

YASNAC

to

LX1.

LX1,

keeping

herein

to

not

described

with

the

performance

combination

operation

builder's

manual

intended

the

The

refer

in

does

be

control.

LX1

basic

optional

For

to

mind

not

met

in

of

of

your

manual

to

programming,

and

specifications

the

the

machine

that

cover

operation.

with

this

as

NC

machine

NC

shall

opera¬

give

optional

features

the

every

manual

machine

and

machine,

take

fea¬

tool

infor¬

should

the

pri¬

are

are

Unless

apply

ples

Feed

•

Reference

(Return

matic

Absolute

•

Work

otherwise

to

the

shown

Function

return)

Coordinate

description

in

this

Zero

reference

to

.

Zero

specified,

manual.

Selection’

Point

Point.

Zero

of

zero

...

Point.

the

following

programming

(mm/rev

G99

by

manual

4

rules

exam¬

and

)

auto¬

Page 3

1.

INTRODUCTION

2.

PROGRAMMING

2.1

Tape

2.2

Program

2.3

Coordinate

2.4

Rapid

2,5

Spindle-Speed

2.6

Tool

2.7

Miscellaneous

2.8

Preparatory

NC

3.

3.1

3.2

3.3

3.4

4.

4.1

4,2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5.

5.

5.2

5.3

6.

TAPE

Tape

Programming

NC

Tape

NC

Tape

STANDARD

CRT

Pushbuttons.

Power

Display

Loading

Memory

Tape

Edit

Part

Operations

Summary

Operations

Data

TAPE

1

Tape

Taper

Portable

MACHINE

Format

Number

Words

Traverse

Function

Functions

PUNCHINC

Code

140

140

Handling

ON

and

Part

(in)

NC

/OFF

writing

Programs

CHARACTER

Verifying

J6S

Program

and

1

of

Storing

174

Input

/Output

READER

Reader

Reel

Unit

Tape

CONTROL

TABLE

1

1

1

and

Sequency

7

Rate

10

(C-Function)

140

140

DISPLAY

and

Operation

167

NC

Data

and

Interface

182

unit

STATION

(S-Function)

(M-Function)

Lamps

and

Editing

Function

(T-Function)

Functions

138

OPERATOR'S

Keys,

Operation

163

COMPARTMENT

180

Reader

Number

J5

STATION

141

145

NC

Data

Output

175

182

161

146

156

CONTENTS

OF

6

13

19

22

WITH

J

42

into

Switching

6.1

Operation

6.2

7.

OPERATION

7.1

inspection

7.2

Turning

7.3

Manual

Preparation

7.4

Compensation

7.5

Preparations

7.6

Operation

7.7

Manual

Operation

7.8

Automatic

7.9

MDI

Operation

7.10

Preparation

Turning

7.11

8.

MAINTENANCE

Routine

8.1

8.2

Battery

8.3

Fuse

8.4

Counteracting

Control

8.5

Molded-Case

8.6

Trouble

APPENDIX

APPENDIX

APPENDIX

APPENDIX

APPENDIX

APPENDIX

Units

Procedure

On

Operation

in

Operation

Operation

Operation

Off

Inspection

Replacement

Circuit

and

Unit

Causes

1

LIST

2

LIST

3

STORED

PENSATION

4

LIST

PUT

5

LIST

LIST

6

on

the

PROCEDURE

before

Turning

Power

201

Stored

for

Stored

and

for

Automatic

Tape

and

interrupting

203

Interrupting

204

for

Turning

Power

204

Schedule

Breaker

Alarm

21J

Circuit

and

SETTINC

OF

OF

PARAMETER

LEADSCREW

OF

STANDARO

SIGNALS

OF

ALARM

OF

DATA

Control

192

201

Leadscrew

Stroke

Memory

in

MDI

OFF

204

208

Status

Breaker

Remedies

A-18

A

CODES

A-46

station

201

Power

On

Limit

Operation

Mode

Automatic

Mode

Automatic

Power

206

209

for

Servo

(MCB

212

NO.

A-l

NO.

ERROR

INPUT/OUT¬

-19

Error

203

)

A-28

165

201

202

202

203

204

212

A~6

COM¬

\

Page 4

INDEX

SUBJECT

A

Absoluu

Absolute

Accclci

Act

deration

Manual

ind

ADDRESS

Absolute

ADDRESS

ALARM

ALARM

ALARM

Number

Alarm

Argument

Automatic

Automatic

Automatic

Automatic

Mode

Auto

AUTO

MODE

Automatic

Automatic

APPENDIX

APPENDIX

APPENDIX

COMPENSATION

APPENDIX

SIGNALS

APPENDIX

APPENDIX

Battery

B

Battery

Rate

Baud

Display

Bit

Display

Bit

Buffering

Buffer

Canned

C

Characters

Circuit

Circular

Circular

Circular

(G22

G23)

.

Circular

Compensation

Command

Co

riband

Com

.

a*i».

COMMAND

I

Connecting

Considerations

Constant

Constant

Control

'Incremental

/Incremental

ation

/Deceleration

/Deceleration

Feed

Keys

Zero

SEARCH

CODES

CODE

CODE

Designation

Acceleration

Return

Coordinate

Threading

Handle

HANDLE

Operation

Operation,

1

2

3

4

5

6

Replacement

of

Format,

Format,

Function

Register

Cycles

and

Breaker

Multiple

Arc

Interpolation

Interpolation,

Path

Data

Data

Pulse

PJLSEI

Specifications

Display

Surface

Command

(G50)

Point

REMEDIES

AND

[ALM]

DISPLAY

of

User

to

Reference

Offset+

in

OF

LIST

LIST

OF

STRED

LIST

OF

LIST

OF

OF

LIST

Interfaces

Serial

Parameters

Setting

(M93,

(G90,

Function

for

Servo

Mode

ON

M96)‘l‘

fM97t

Display

Display

Accumulation

Remarks

and

Speed

.....

Inputs

Programming

of

Cutting

of

Raoid

,

Programming

DISPLAY

Macros

/Deceleration

MDI

Settingÿ

(G76)

switchÿ

Mode

System

Cycle

OFFSET

Preparations

SETTING

PARAMETER

LEADSCREW

STANDARD

ALARM

CODES

DATA

and

of

M92)7

G94)

G92,

Characters,

Control

Cornering

(G02,

G03)

Radius

/OFF

Programming

on

Register

of

Cable

for

Control

(G90,

Feed*

Traverse

•

•

(G28)

Point

*

*

*

•

+

*

•

for

NO.

NO.

ERROR

INPUT/OUTPUT

•

Setting

of

List

(G1I2)

•••

Radius

Tool

Display

Connectors

Macros

User

G97)T

(G96,

C91)

of

•

•

’

*

*

CHAPTER

*

*

‘

*

'

*

*

•

2

2

2

4

2

4

8

4

4

2

2

2

2

6

2

6

6

7

7

SECTION

5

:.3

2

8.32

2.

4.

3.

4.

2.

3.1

4

1.4

2

8.21

4.3.3.

8.6.2

4.3.9

3.

4.

9.1

2.

8.24.10

2.8.24.2

2.4.3

2.8.11

6.2.2

2.8.26.8

6.2.7

1.28

6

7.8

7.5

PACE

$

137

2

13

12

142

56

4

151

212

161

161

81

63

12

34

193

78

200

191

203

202

A-l

6

A-

18

A-

A-19

28

A-

A-46

8

8

*

•

.

of

4

4

4

2

2

2

•

2

8

•

2

2

for

2

2

4

4

4

4

2

4

•

2

2

8.1.5

8.2

4.9.3

3.

7.1

4.

4

3.6.1

2

7.4

2.1.5

2.7.27

2.1.2

8.3.3

2.8.31.2

2.8.4

2.8,9

2.7.6

4.3.2.

4.3.2

4.3.4.

4.9.4

2.8.24.9

4,3.1

2.8.28

2.8.24.6

1

9

208

208

176

160

157

19

6

108

4

210

133

27

32

20

147

147

155

177

79

146

114

76

II

Page 5

INDEX

SUBJECT

C

Control

Panel

COORDINATE

Coordinate

Cornering

COUNTERACTING

SERVO

CRT

CONTROL

Character

CURRENT

CURSOR

Keys

CUTTING

D

CYCLE

DATA

DATA

START

INPUT

INPUT

OPERATION

DECIMAL

DECIMAL

Decimal

DISPLAY

Display

Point

and

D15PLAY

RUN

DRY

(G04)

Dwell

E

Edit

Keys

EDIT

LOCK

EDIT

EDIT

MODE.

EMERGENCY

Error

Detect

Exercises

F

Facing

Feed

Feed

FEED

Feed

Feed

Cycle

Function

Function

HOLD

Per

Per

FEEDRATE

Finishing

FUNCTION

AND

FUSE

FUSE

BLOWING

FUSE

FOR

FOR

CONTROL

FUSES

OF

WORDS

Words

(Gil.

G12)

ALARM

UNIT

Display

POSITION

DEPTH

OVERRIDE

PUSHBUTTON

/OUTPUT

/OUTPUT

WITH

Dat

DISPLAY

DISPLAY

Programming

LOCK

/MACHINE

Write

of

WRITING

AND

SWITCH

*

•

Switch

DISPLAY

STOP

OFF

User

B

(F-

Positioning

Macro

(G94)

,

of

Designation

PUSHBUTTON

Minute

Revolution

Cycle

(G98

OVERRIDE

(G70)+

Keys

CIRCUIT

(ALARM

INTEGRATED

POWER

INPUT

+

STATUS

(G96,

DISPLAY

INTERFACE+

INTERFACE

Keys

FORMAT.

FORMAT.

LOCK

and

Local

OPERATION

IN

Pushbutton

E-Function)

and

Mode)

(G99

(G98.

MODE)

CANCEL

BREAKER

NO.

POWER

FOR

G97)

Switch

AND

for

LAMP

USED.

SETTING

PARAMETERS

Switch

Common

•

•

•

•

•

-

(G06)

G99)

AND

LAMP

•••

•

*

•

Switch

• •

•

332)

331.

SUPPLY

•

•

G71

DATA

•

Variables

•

•

UNIT

and

OF

•

•

OF

•

G72+

•

CHAPTER

8

2

2

2

8

4

4

4

6

6

4

4

4

4

2

6

2

4

6

2

4

4

6

4

6

2

2

2

2

2

6

2

2

6

2

4

8

6

8

8

SECTION

8.1.3

2.3.1

2.8.7

8.4

4.1.2

4.3.4

4.1.8

6.1.29

6.1.2

4.9

4.1.5

3,

6.

4.

7.

3.

4.

2.1.3

6.

1.19

2.8.24.8

4.3

6.1.18

2.8.5

4.6

4.1.10

6.1.22

3.

4.

3.

6.1.4

2.

8.

2.

2.8.24.11

2.8.27.3

2.4.2

2.8.29

6.1.3

2.4.2.

2.4.2.

6.1.12

2.8.26.5

4.

1.3

8.3

8.4.1

8.3.1

8.3.2

PACE

207

7

7

30

211

142

128

143

191

186

175

143

3

2

135

136

6

189

78

146

189

28

168

144

190

3

151

186

2

26

82

88

10

115

2

1

186

12

11

188

99

142

209

211

210

210

C

Codes,

G

(GOO,

(G01)

(G06)

(GQ1)

(G02,

(G

04)

(G10)*

(Gil,

(G20,

by

G

List

G06)

Positioning

Error

+

Linear

G03)

Dwell

Tool

A

12)

G

G21)ÿ

...

Code

of

Positioning

Detect

Interpolation

Circular

Offset

Cornering

Inch/

Positioning

OFF

Interpolation

Value

Metric

Designation

....

2

2

2

2

2

2

2

2

2

2

3.8.

1

2.8.2

2.1

2.

8.

2

2.

8.

2.

2.8.3

2.8.4

2.8.5

2.8.6

2.8.7

•

2.88

*

•

22

23

23

26

26

27

28

29

30

32

Hi

Page 6

INDEX

SUBJECT

(G22.

C

Intel

(G27)

(G28)

G

C

(G30)x

(G31)

(G32)

(G32)

(G34)

(G

(G36

(G40

(G50)

(G50S)

(G50T,

(G65

(G68.

(G70

G70toG76

(G70)J'

{Gil)*

(G72)4'

(G

(G74)

(G75)

G23)~

pol.it

Reference

Automatic

29)

Return

r

Continuous

+

Variable

+

35)

to

to

Programming

*

to

069)"*“

to

*

73)

*

Radius

ion

2Nd

Reference

Skip

Function

Multi-Start

Set

Tool

G39)+

G44)+

Maximum

G51)+Work

G67)+

Program

G76)

+

,

+

Precaution

Finishing

Removal

Stock

Stock

Removal

Pattern

drilling

Peck

Grooving

Point

Return

from

Reference

Thread

Thread

Lead

Error

5tored

Tool

Nose

Spindle-Speed

User

Multiple

Cycle

Repeating

in

Programming

Check

to

Reference

Point

Return

Cutting

Cutting

Thread

Stroke

of

Cutting

Compensation

Radius

Absolute

Coordinate

Macro

Mirror

Repetitive

in

Programming

Turning

in

Facing

in

Z-Axis

in

X-Axis

for

Zero

Limit

Compensation

Zero

Setting

Multi-Shift

Image

Cycles

Circular

Point

....

....

Point

CHAPTER

2

2

2

2

2

2

2

2

2

2

2

•

•

.

.

.

.

•

•

•

*

*

2

2

2

2

2

•

•

•

•

•

•

*

•

2

2

2

2

2

2

2

2

SECTION

2.8.9

2.8.

10

2.8.11

2.8.12

2.8.13

2.8.14

2.8.15

2.8.16

2.8.17

2.8.18

2.8.19

2.8.20

2.8.21

2.8.22

2.8.23

2.8.24

2.8.25

2.8.26

2.8.26.9

2.8.26.5

2.8.26.2

2.8.26.3

2.8.26.4

2.8.26.6

2.8.26.7

PACE

12

33

34

35

36

36

37

40

41

42

44

46

56

57

58

61

85

87

105

99

88

94

7

100

102

(G

(G90,

<C90,

<G90)+

(G92)ÿ

(G94)~

(G96.

(G98,

(Gl)l.

(GUI)'*'

(G

(G122,

General

General

G50

G50

Grooving

Handle

H

Handle

Handle

up

High-Speed

76)

112)

Point

POINT

to

G92,

Two

Automatic

G91)*

Absolute/

G94)+

Turning

Threading

Facing

G97)+

Constant

G99)J'Feed

G112)*

Taper

Circular

123)

G

"*

Program

Return

RETURN

in

X-Axis

Select

Axis

(Manual

Dial

for

Dials

Axes

Buffer

Threading

Canned

Cycle

Cycle

B

Cycle

Function

Multiple

Multiple

Arc

Tool

Life

Form

Switch

(G75)T

Switch*

Pulse

Simultaneous

Register

Incremental

Cycles

Surface

Designation

Cornering

Cornering

Multiple

Control

Generator)

Cycle

Speed

Cornering

Control

Programming

Control

*

+

of

2

2

2

2

2

2

2

2

2

2

1

•

.

.

2

2

2

3

6

6

2

6

6

6

2

2.8.26.8

2.8.32

2.8.27

2.8.27,1

2.8.27.2

2.8.27.3

28

2.8.

2.8.29

2.8.31

2.8.31.1

2.8.31

2.8.30

2.8.26.1

3.2.2

6.2.4

6.1.24

2.8.26.7

6.1.6

6.

1.5

6.1.8

2.1.6

102

137

108

108

109

112

114

115

125

125

.2

133

116

87

138

172

196

101

186

186

187

8

IV

Page 7

INDEX

SUBJECT

Inch/Metric

Input/Output

Input/

Input

Output

Power

Interfaces

Interlock

Internal

INTRODUCTION

J

JOG

FEEDRATE

OVERRIDE

JOG

Pushbuttons

Skip

Label

L

M

Input

Least

Output

Least

Input

Least

Output

Least

Linear

Interpolation

MAINTENANCE

MACHINE

Maintenance

Maintenance

MANUAL

MANUAL

MANUAL

Manual

Manual

Automatic

Manual

Manual

Manual

Operation

Operation

Pulse

REFERENCE

Return

Maximum

Maximum

(MOO,

M01,

(M90toM109)

(M91,

M90)

M92)+

(M93,

(M94.

M95)*

M96)x

(M97,

on

Tool

(M98)

Subroutine

Operation

MDI

Measured

MEM

DATA

Memory

Message

M-FUNCTION

(Auxiliary

Miscellaneous

MODE

SELECT

Molded-Case

M

3-Digit

Multi-Block

in

MDI

Mode

Multiple

Multiple

Designation

Interface

Signals

Supply,

Functions,

and

(INTERLOCK)

Input

Toggle

Switches

Switch

Switch

and

Function

Increment

Increment

Increment

Increment

CONTROL

Call,

Before

History

ABSOLUTE

INTERRUPTION

INTERRUPTION

Interrupting

Operation

Multiply

POINT

to

Reference

Programmable

Spindle-Speed

M30)

M02,

Codes

M

*

Program

Buffering

Remote

Tool

Circular

Radius

Conpensation

Program

Interrupting

Workpiece

(MEMORY

(PROGRAM

Mode

Run

Display

ALARM]

(

LOCK

Function

Lock)

Functions

Switch

Circuit

Output"*1

Writing

Cornering

Repetitive

and

(Gill,

Cycles

by

to

be

Cautions

Types

*

and

RAPID

•

•

•

and

•

*

•

•

•

*

+

(C01)

STATION

Display

Switch

POINT

POINT

Select

Dimensions

Setting

M

Codes

for

Interruption

Function

Offset

Path

Mode

Value

Direct

DATA)

+

Switch

(M-Function)

Breaker

Operation

G112)+

(G70

Code

used,

on

(G20,

Setting

C

of

•

FFEEDRATE

Pushbutton

(Maintenance)

RETURN+

RETURN

switch*

RETURN

Point

Internal

Automatic

Keys

(G50)*

for

Modification

ON

Input*

MEM),

(MCB)

G76)4’

to

Switch

Stop

Processing

/OFF

G21)ÿ

Operation

Display

*

•

*

Switch

•

•

•

in

•

•

•

*

•

*

•

•

*

•

•

•

•

•

•

•

•

•

•

•

-

•

•

•

•

•

•

*

.

•

SECTION

2.8.8

4.9.2

8.6.3

8.1.1

4.9.

6.1.23

3.

4.

6.1.10

6.1.9

2.1.4

2.3.3

2.

3.

2.

3.

2.8.3

•

8.6.4

*

4.3.9.

•

6.1.21

•

6.2.5

•

6.1.25

7.3

*

•

7.7

•

6.1.7

•

6.1.14

•

6.2.1

•

2.3.4

•

2.8.22

•

2.7.1

2.7.2

•

•

2.7.3

2.7.4

•

2.7.5

•

2.7.6

•

2.7.7

•

7.9

•

6.2.3

4.1.11

‘

•

4.

•

4.

•

6.1.20

•

2.7

•

6.1.1

•

8.5

•

2.7.9

4.

2.8.31

•

•

2.8.26

1

6.

3.1

3.

3.

3.9.

3.

3.

3.1

PACE

32

176

212

206

175

191

2

1S8

1

187

187

6

7

7

2

8

26

204

183

213

5

163

190

197

191

201

203

186

188

192

8

57

19

19

19

19

20

20

21

204

193

144

2

2

150

162

190

19

185

212

22

149

125

87

CHAPTER

2

*

4

8

8

4

6

4

I

6

6

2

2

2

2

2

8

6

8

4

6

•

•

+

6

6

7

7

6

•

•

6

6

2

2

2

•

-

•

*

2

2

2

2

2

2

•

•

•

7

6

4

4

4

6

.

2

6

6

2

4

2

2

Multi-Start

Thread

Cutting

(C32)4,

*

•

•

• •

Z

2.8.16

40

V

Page 8

INDEX

SUBJECT

N

\C

NC

NC

\C

NC

NC

NEXT

ON-Line

O

OPERATION

OPERATION

Opcr

Opi.u“i»i

OPTIONAL

ORG

Other

Overload

Overview

P

PAGE

Paper

Parameters.

Parameters.

Part

Part

Part

Part

Part

Pari

Part

Put

Part

Part

Part

Pattern

Peek

Position

Position

Position

I

•P1

]

I

a|H

1

\\n

TAPL

Tape

Key

ttion

(ORG1N)

Codes

Levs

1

ape

Program

Programs.

Programs,

Programs

Programs

Program.

Program

Program

Program

Program

o_

Pi

Drilling

checking

1

Indlmg

.

keeping

PUNCHING

Punch

.

-

Dugnotics

PROCEDURE

PROCEDURE

Display

Time

Block

SKIP

BLOCK

Keys

(Alarm

User

of

.....

Displaying

Displaying

and

Adding

Displaying

and

by

Making

to

Blocks.

Blocks.

Tape.

Tape

ran»

Repeating

in

ABSOLUTE]

l

(EXTERNAL!

*

•

of

SKIP

NO.

Macro

NC

NC

MD1,

Paper

into

(G73)"

Z-Axas

-

(/I

-

Switch

,

351

Body

and

and

Data

Data

Loading

Addition

TApe,

Deleting

Modifying

Verifying

Memory,

(G74)“

*

• •

•

-

-

. .

/9)-

352)

...

Writing

Writing

Output

and

into

•

•

Operations

Checking

Memory

to

Outputting

....

•

Loading

CHAPTER

3

3

3

3

3

3

4

8

6

7

4

2

6

4

2

8

2

,

.

.

.

4

3

4

4

4

Stored

(IN),

*

Loading

*

*

4

4

4

4

4

4

4

*

4

4

4

2

2

4

4

4

SECTION

3

3

3

4

3

3.4.2

PACE

140

140

140

141

140

3.3.2

4.1.6

8.6.1

6.2

140

143

212

192

201

7.

4

4.

3.

2.2.3

6

1.17

4.1.9

2.7.8

8.4.2

2.8.24.3

7

4

1

3.3.

1

4

3.7

7.

4.

3

3.

4.7

4

•

6.4

4.6.2

4.4

4.4.3

4.4.2

4.7.1

4.6.5

4.6.3

4

5.1

4.)

4

8.26.4

2

2.8.26.6

4

4.3.4

3.4.2

4.

4.3

4.1

162

7

189

144

22

211

64

143

140

160

160

171

170

169

163

166

165

171

169

169

167

163

97

100

129

153

153

3.4.3

Position

Position

Positioning

Positioning

Power

Power

Precautions

Preparatory

Process

Program

Program

Program

PROGRAM

Program

PROGRAM

og

Pi

INCREMENT!

1

Store

ON

/OFF

ON

/OFF

Sheet

lnteri

Mirror

Number

NUMBER

Restart*

RESTART

»*

Return

in

(C00,

fGOl)

in

Functions

PROGRAMMING

Prog

r

rmminjj

Pushbuttons,

G70toG76”.

Pushbutton*

G06)

Operation

Pushbuttons

Programming

•

ON

uption

Image

*

AND

...

Switch*

......

keys,

and

•

*

*

•

G

(G-Function)

/OFF

069)"”

(G68,

5EQUENCY

Precaution

Lamps

70

(M91,

through

M90)

•

.

.

.

G76

•

•

•

•

*

*ÿ

NUMBER

...

.

.

in

•

•

4

6

2

2

4

4

2

2

3

2

2

2

2

6

6

4

2

2

4

4

6.1.30

2.8.2

2.8.2.

4.2

4.1.1

2.8.26.9

2.8

3.2.1

2.7.3

2.8.25

2.2.

2.2

6.2.6

6.

4.

2.8.26.9

.

4.

1.26

3.

I

153

192

23

1

23

145

141

105

22

138

19

85

1

6

6

197

191

4.

5

154

1

105

*

141

vi

Page 9

INDEX

SUBJECT

R

Rapid

Traverse

Rapid

Traverse

Rapid

Traverse

RAPID

Rapid

TRAVERSE

Traverse

Reference

Reference

Reference

Registration

Registered

Registered

Display

Remote

Remote

RESET

Return

\

\

S

Routine

Sequence

Servo

of

Power

Tool

Key

from

Inspection

Lag

Servomotor

Setting

Setting

Setting

Setting

Setting

Setting

S

S

Data

Data

Data

Data

/Parameter

and

4-Digit

4-Digit

Simultaneous

SINGLE

Skip

Spindle

BLOCK

Function

Counter

Rate

Rate

Rate

RATE

Rate,

Range

Point

Point

Point

of

Part

Program

ON

Offset

Reference

Check

Lamps

Return

User

Program

(C27)

Macros

Number

.

(OFF

Pushbuttons

Modification

Zero

Schedule

Number

Pulses

Display

and

DC

[SETTING],

and

Parameter

of

Bit

of

Decimal

Spindle

Display

Data

Parameter

Tapes.

PROGRAMMING

Programming

Controllable

Switch

B*

(G31)*

OVERRIDE

of

(C30)*,

Number,

(Program

(C29)

(ERROR

Motor

Displaying

Data,

Format

Display

Paper

to

Verifying

Aÿ

Axes

2Nd

Checking

(M94,

PULSE].

Inputting

Format

Tape,

Switch

NO.

M95)

and

Outputting

T-ibte),

+

NO.

Wriling

•

•

•

•••

•

•

•

•

-

•

•

of

•

CHAPTER

2

2

2

6

2

2

6

2

2

4

4

4

2

4

2

8

2

4

8

4

4

4

4

4

4

2

2

2

6

2

4

SECTION

2.4

2,4.1

2.4.1.

6.1.11

2.4.1.2

2.8.10

6.1.15

2.8.13

2.8.24.7

4.6.1

4.

3.

9.

4.2.3

2.7.5

4.

1.12

2.8.12

8.

1

2.2.2

4.

4.

3.

8.1.4

4.3.6

4.4.5

4.

3.6.1

6.

3.

4.

4.7.3

4.5.3

2.5.2

2.5.3

2.3.2

6.1.16

14

8.

2

4.

3.

4.

PACE

10

10

1

10

188

10

33

189

36

78

168

3

162

146

20

144

35

206

7

8

155

207

157

167

157

3

159

172

168

13

14

7

189

7

36

155

Spindle-Speed

SPINDLE

Splicing

STANDARD

CHARACTER

Status

Stock

Stock

Stored

Stored

Stored

Stored

Summary

S

2-Digit

Subprogram

Display

Subroutine

Switching

System

T

Tape

Tape

Tape

TAPE

Tape

SPEED

NC

NC

Input/Output

Removal

Removal

Leadscrew

Stroke

Stroke

Stroke

of

Storing

Programming

of

Program

Units

NO.

and

Memory

Code

Code,

FEED

Format

Function

OVERRIDE

Tapes

OPERATOR’S

DISPLAY

Facing

in

Turning

m

Error

Limit.

Limit

Limit"1

Status

Run

on

The

Tape

and

Mode,

of

List

AND

SYSTEM

(S-Function)

Signals,

(G72)'1'

Compensation

Preparation

(G86

to

and

Editing

(SUB

(M98)

Control

Feed

Operation

Switchÿ

STATION

Displaying

(G71)"*"

G89)+

PROG.

Station

Switches

NO.

Swtiches

and

for

Operations

NESTING),

in

WITH

2

6

3

2.5

6.1.

3.4

13

1

13

188

140

CRT

•

•

•

•

•

•

•

4

4

2

2

7

2

4

4

2

4

2

6

5

7

3

3

4

2

4.3.8

2.8.26.3

2.8.26.2

7.4

2.8.19

4.

3.4.

4.8

2.5.

1

4.

2.

3.

2.7.7

6

1

5.

1.

1

7.6

3.

1

3.1.

1

4.1

13

2.1

6

2

141

161

94

88

202

44

154

174

13

46

1

21

185

180

203

138

138

145

1

vii

Page 10

INDEX

SUBJECT

T

Tape

Tape

Tape

Tape

Tape

Tape

Taper

Tape

Tape

T

TC

Thread

Threading

Tool

Tool

CONTROL).

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Trouble

T

Tumble

Turning

Turning

Turning

Turning

Turning

Turning

Fur

Reader

Reader

Reader

Reader

Reader

Reel

Verifying

4-Digit

Error

Function

Life

Nose

Offsets

Offset

Offset

Offset

Offset

Offset

Life

Position

Set

Wear

3-Digit

mat

Compartment

Unit-*-.

Unit

Unit*,

Multiple

Cornering

Unit*

Programming"!"

(ALARM

Cutting

Cycle

(T“Function)

Control

DISPLAY

Radius

to

Paper

Data,

Data

Memory

Value

Value

Control

Offsets

Compensation

Error

Compensation

Causes

Programming

Box

cle

A

C>

Oil

Power

Off

Power

Power,

Oil

On

Power

On

Power

•

»

•

•

Portable

391,

NO.

(G32)

,

Continuous

(G92)*

Use

Status

OF

Compensation

Tape,

Displaying

Memory,

into

"!"

<G10)+

Tape,

(G122,

....

and

Remedies

(C90)

Preparation

...

•

•

(Glll)

392)-

(TOOL

Outputting

and

Inputting

Verifying

GJ23)T

(G35)4'

(T90AA)a

. .

.

+

(G40

Writing

.

for

•

*

.

*

•

• •

LIFE

to

-

•

•

G44)

•

CHAPTER

2

5

5

5

8

5

2

5

4

2

6

2

2

2

4

•

2

4

4

4

2

2

4

2

•

•

2

2

2

8

2

5

2

4

7

7

4

7

SECTION

2.1.1

5.1

1.2

5

8.1.2

5.3

2.8.31.1

5.2

4.5

2.6.2

8.4.3

2.8.15

2.8.27.2

2.6

4.3.2.

2.8.20

4.7.2

4.3.5

4.4.4

2.6.3

2.8.6

4.5.2

2.8

30

2.6.4

2.8.18

2.6.6

8.6

2.6.1

5.1.3

2.8.27.1

4.2.2

7.11

7.10

4.2;

7.2

PACE

1

180

180

180

206

182

125

181

167

14

212

37

109

14

3

149

46

172

156

167

15

29

168

116

15

42

18

212

14

181

108

145

204

204

145

201

viii

U

V

W

X

Turning

TV

Check

User

User

Variable

V

iridbles

Work

W'ork

Writing

\-Aÿis

X

-

AXIS

On

(Tape

(G65

Macro

Call

Macro

Lead

Coordinate

Coordinate

Blocks

in

Diameter

MIRROR

Power,

Thread

-

Inspection

Vertical

067)"!“

to

Command

Cutting4-

Multi-Shift

System

Displaying

and

/Rrtdius

IMAGE

Parity

(C50T,

5hiftT

Switching

Switch-

before

Check)

Contents

*

G51)4*

by

7.

7

3

2

2

2

2

•

•

•

2

2

MDI

4

2

6

1

3.2.3

2.8.24

2.8.24

2.8.

2.8.24.4

2.8.23

2.6.5

4.3.3

2.3.6

6.1.27

17

201

140

61

1

61

41

64

58

17

149

10

191

Page 11

1.

INTRODUCTION

YASNAC

a

is

microprocessors

ing

provide

to

The

•

duces

speed

creased

tion

•

Enhanced

of

command,

continuous

cutting

•

To

tion,

error

and

LX1,

combination

modern

our

the

dual

the

cutting.

by

and

buffering

meters

24

,

and

meet

FMS

tool

correction

other

"Ultraspeed

of

two

running

system

highest

processor

data

processing

Block-to-block

the

use

function.

cutting

/min

capability

feed

500-millimeter

thread

life

functions

variable

trends,

control,

,

stored

cutting,

dual

processor

high-performance

in

parallel.

technique,

lathe

performance.

CNC

system

time

of

high-speed

includes

command,

lead

thread

multiple

pitch

thread

program

user

can

be

interrupt

macro,

stroke

installed.

Incorporat¬

is

it

drastically

meet

to

time

stop

buffer

precise

cutting,

thread

cutting

tool

limit

CNC"

16-bit

designed

high¬

de¬

func¬

a

maximum

feed

.

func¬

set

per

tool

re¬

•

•

•

E

,

program

Part

maximum

interface

addition,

in

of

is

high-speed

Programming

tool

radius

coordinate

ar

interpolation,

function.

ing

servo

The

ized

control

motor

standard

the

low-noise,

and

unit

.

The

position

inductosyn-

system.

memory

320

available

RS422

long

is

compensation

system

function

and

pulse

generator

applied

can

be

with

facilitated

combined

uses

newly

Its

FACIT,

interface

transmission.

function,

a

meters.

serial

distance

further

setting,

and

high-performance

a

feedback

(PG)

complete

extended

data

input

RS232C

capable

by

G

50-work

angle-specified

beveling

drastically

transistorized

available

is

system

closed

a

to

/output

improved

/round¬

miniatur¬

PWM

DC

servo

with

and,

loop

and,

of

line¬

the

2.1

TAPE

2.1.1

A

variable

6313

is

Table

following

indicate

EXAMPLE

a

TAPE

used

2.1

T

FORMAT

FORMAT

block

for

shows

the

address

the

programmable

I

T

format

YASNAC

the

tape

characters

Down

decimal

Four

integer

Sign

Coordinate

(X,

conforming

LX1.

format.

number

to

third

places

digits

K)

Z,

I,

m

of

address

2.

to

JIS#

Numerals

Table

of

digits.

in

mm

or

in.

PROGRAMMING

B

2.1

Note:

actual

including

Decimal

The

leading

dress

med,

In

is

programming,

code)

(;).

codes.

but

manual,

the

represented

should

programming.

all

The

Point

decimal

decimal

Programming.

zeros

Plus

minus

EOB

by

CR

be

used

point

points,

can

be

signs

signs

code

semicolon

a

(EIA

instead

may

For

refer

suppressed

need

must

in

a

code)

be

making

not

be

program

(;)

or

LF/NL

of

the

.

omitted

a

program

2.

1.3

to

for

all

be

program¬

programmed.

example

actual

In

(ISO

semicolon

in

ad¬

#

Japanese

Industrial

Standard

1

Page 12

2.1.1

TAPE

FORMAT

(CONT'D)

Table

2.1

Tape

Format

No.

1

2

3

4

5

6

7

8

9

Program

Sequence

G-

Function

coordinate

Z,

X,

a.

/min

Feed

rev

/

Feed

Thread

S-Function

-Function

T

M-Function

Address

No.

No.

Word

I,

and

Lead

K,

U,

W,

Metric

Metric

Input

+

a

43

(

a

R

+

53

F50

F32

E34

output

Inch

input

Inch

Metric

Input

04

N

4

G3

+

a

(

a

F50

F42

E44

)$

+

a

34

+

(

44

a

H

F32

F24

E26

S2

S4

T(

T

1)

2

«ÿ

2)

(

2

M3 M3

53

53

T(2

T(

04

)+

2

output

Inch

N

4

G3

(

S2

S4

+

:

B

Basic

:

O

input

Option

B

B

B

+

34

a

a

+

F42

F24

E26

44

In¬

B

B

B

B

B

O

1)

2)

B

O

B

10

11

12

13

14

15

1.

Dwell

Program

Sequence

Designation

No.

Angle

for

Straight

Angle

for

Multiple

.

Notes

Data

2.

Inch/Metric

3.

Inch

4.

F

No.

of

Repetitions

Designation

Designation

with

/Metric

codes

Designation

No.

Line

Thread

|

indicates

output

input

feedrate

for

is

set

is

/mm

maximum

by

set

setting

by

or

U(P)53

Q(P)

A(B)33

cumulative

setting

feedrate

P4

4

L8

3

B

parameter

(#600lDo).

/rev

value.

can

#6007D3-

switched

be

U(P)

P4

Q(P)

L8

A(B)33

3

B

by

53

4

G98,

G99.

B,

B

B

0

B

O

0

2

Page 13

i

Program

Sequence

function

G

Coordinate

Z,

X,

Feed

Feed

Thread

S-fyjiction

T-function

I,

/min

/rev

Address

No.

No.

K,

and

Lead

O

N

G

Address1

W,

U.

input

2601

944.88

-

in

in

in

/

min

/rev

/rev

Commands

in.

in.)

(*99999-999

Inch

-

input

60960

mm

1270.00

-

mm

1

/min

/rev

1

0

mro

mm)

-

-

-

Metric

*21307.061

1

0.01

°-m:oooo

mm

/rev

0-99

0

-

0-99

0

-

output

Inch

9999

9999

199

*838.8607

1(

*9999

0.

01

0.0001

9999

9999

input

9999

2400.00

-

in

-

in

m

in.

mm)

/

min

50.0000

/rev

rev

/

2.

24000

mm

500.00

-

mm/rev

mm

2

Metric

input

mm

/

min

/rev

List

1

1

0

mm)

0-99

0

0-99

0

Table

Metric

F

F

E

S2

S4

T3

T4

*8388.607

(*99999.999

1

-

0.01

Mÿ.OOOO

R

Program

of

output

Inch

9999

-

9999

-

199

-

*330.

(*9999.9999

0.01

0.0001-19.6850

-

9999

9999

-

M-function

No.

of

Angle

for

Straight

Multiple

i

Parenthesized

2

For

U

Repetitions

Designation

Designation

Dwell

Program

Sequence

Angle

for

,

P

No.

angle

Designation

No.

Designation

Line2

Thread

designation

data

indicates

of

maximum

included

0.001

angle

0

999

-

99999.

-

1

-

9999

1

9999

-

0

99999999

-

*360.000°

0

-

0

360°

-

cumulative

G76,

for

999

sec

value.

see

2.8.26.8

0.001

Automatic

0

999

-

99999.

-

9999

1

-

1

9999

-

99999999

0

-

*360.000°

0

-

0

360°

-

Threading

999

sec

Cycle

(G76).

3

Page 14

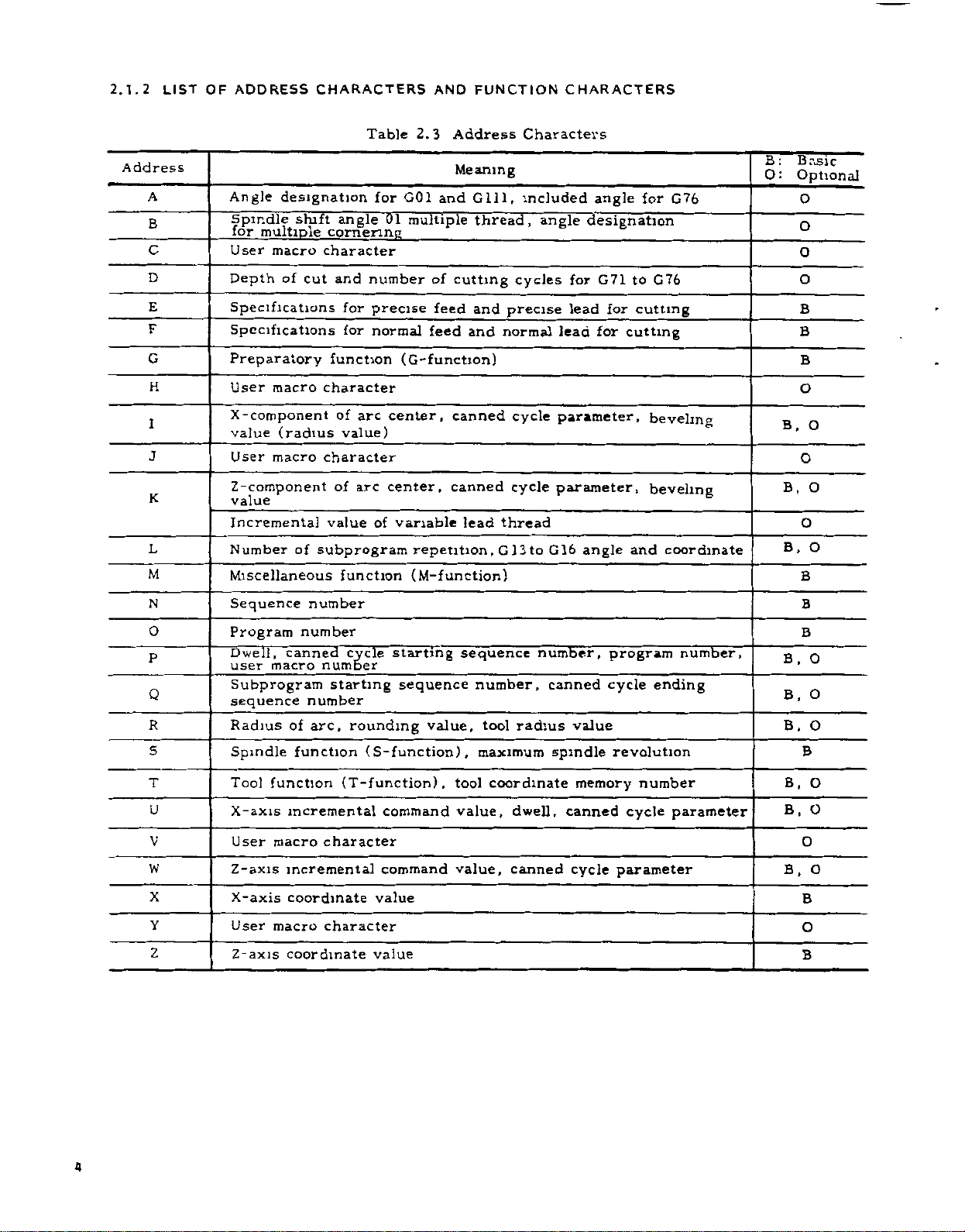

2.1.2

LIST

OF

ADDRESS

CHARACTERS

AND

FUNCTION

CHARACTERS

Address

A

B

c

D

E

F

G

H

1

J

K

L

M

Angle

Spindle

for

User

Depth

Specifications

Specifications

designation

shift

multiple

macro

of

cut

Preparatory

User

macro

X-component

(radius

value

User

macro

Z-component

value

Incremental

Number

of

Miscellaneous

Table

angle

cornering

character

and

number

for

precise

for

normal

function

character

arc

of

value)

character

arc

of

of

value

subprogram

function

tor

G01

01

multiple

___

(G-function)

center,

center,

variable

2.3

Address

Meaning

and

of

cutting

feed

feed

and

canned

canned

lead

repetition

(M-function)

Gill,

thread,

and

,

Characters

included

cycles

precise

normal

cycle

cycle

thread

G

13

to

angle

G

angle

designation

G71

for

for

lead

for

lead

parameter,

parameter,

16

angle

for

to

cutting

cutting

beveling

beveling

and

G76

G76

coordinate

B:

O:

Basic

Optional

O

O

O

O

B

B

B

O

B.

O

B,

O

B,

B

O

O

O

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Sequence

Program

Dwell,

user

Subprogram

sequence

Radius

Spindle

Tool

X-axis

User

Z-axis

X-axis

User

Z-axis

number

number

canned

macro

number

arc,

of

function

function

incremental

macro

incremental

coordinate

macro

coordinate

cycle

number

starting

rounding

(T-function)

character

character

starting

sequence

(

S-function)

command

command

value

value

value,

,

sequence

number,

tool

,

maximum

tool

coordinate

value,

value,

number,

radius

dwell,

canned

canned

value

spindle

memory

canned

cycle

program

cycle

revolution

number

cycle

parameter

number,

ending

parameter

B.

B,

B,

B,

B.

B,

B

B

O

O

O

B

O

O

O

O

B

O

B

4

Page 15

E1A

Code

ISO

Code

Table

2,4

Function

Characters

Function

Remarks

Blank

BS

Tab

CR

SP

ER

UC

LC

2-4-5

0

a

bits

2-4-7

bits

+ +

to

9

z

to

/

Del

NuL

BS

HT

LF/NL

CR

SP

%

(

)

to

0

to

A

/

DEL

Error

Disregarded

in

significant

in

ISO

data

area

in

EIA

Disregarded

Disregarded

stop

(comment

out

(comment

in

User

characters

block

(Including

(EOB)

User

skip

end)

macro

macro

start)

operator

operator

All

Mark)

EIA:

Special

code

of

End

Disregarded

Space

Block

Rewind

Upper

Lower

shift

shift

Control

Control

Disregarded,

Minus

9

Z

Numerals

Address

sign,

Optional

Disregarded

Parameter

starting

*

r

(

3

$

?

Notes:

1,

Characters

2.

Information

3.

Tape

code

#

*

t

3

$

?

other

between

(EIA

or

than

ISO)

Decimal

Sharp

Asterisk

Equal

Left

bracket

Right

User

User

User

the

Control

is

point

(Variable

(Multiplication

mark

bracket

macro

macro

macro

operator

operator

operator

above

cause

Out

and

automatically

designation)

operator)

error

Control

in

In

recognized.

significant

is

ignored

EIA:

area.

data

as

insignificant

Special

code

data.

5

Page 16

2.1.3

Numerals

as

the

coordinates

can

They

Decimal

dress

Coordinate

Angle

words.

words

Feedrate

Time

words:

EXAMPLE

5.

-

XI

20.

5

Y

IG99)F.

(G98)F25.6—

G04P1.-

Normally,

inputted,

(or

0.0001

ter

setting

as

1"

"

to

parameter

2.1.4

the

In

becomes

CRT.

•

When

•

When

the

While

on

the

neglected.

the

MEM

dicates

of

end

2.1.5

During

read

lor

blocks

in

for

can

BUFFER

in

the

the

In

of

advance

the

contain

DECIMAL

containing

dimensional

(distance),

inputted

be

points

words.

•

word:

U,

X15.000

Y20.500

FO.

2*

—

(for

F25

(for

Dwell

-

when

the

control

inch

,

the

(or

mm

1

#6019D6.

LABEL

following

the

the

punched

the

the

normal

advance

follow-on

next

SKIP

effective,

power

RESET

label

When

(memory)

presence

part

tool

or

data

and

operation

up

POINT

a

data

can

be

X,

,

B

A

F,

E

P

[

mm

mm/rev

20

32

F

mm/rev

50)

F

.

1

data

without

or

control

inch

1

FUNCTION

cases

and

supply

operation

function

skip

up

tape

LSK

or

of

program.

RECISTER

operation,

and

compensation

operation.

radius

up

to

compensation

to

128

characters

PROGRAMMING

decimal

of

angle,

from

used

Z,

]

mm

mm

)

000

regards

1

deg.),

may

or

the

LSK

to

is

EDIT

a

point

addresses

time

punched

in

the

K,

I,

or

X15.0000

or

Y20.5000

or

F0.2000

(for

F25.

or

(forF32)

sec

decimal

a

"1"

but

be

0.001

label

displayed

is

is

turned

is

effective,

is

the

first

displayed

(editing)

pointer

one

block

R

(inch

as

made

deg.).

skip

executed.

at

is

compensationÿ

4

blocks

is

executed.

of

computing

including

may

related

and

speed.

tape

following

1

in.

in.

in./rev

F24)

60

in

point

0.001

with

to

interpret

function

on.

EOB

on

the

mode,

the

leading

of

data

computed

mode,

are

data

required

One

be

or

/min

mm

a

parame-

Refer

on

the

all

code

CRT

is

two

read

block

EOB.

used

to

MDI.

ad¬

is

data

it

in¬

are

The

are

not

•

MOO.

•

codes

M

mandnijs

2.1.6

A

high-speed

standard

consecutive

cutting

time

stop

this

function

ous

thread

ed

stop

NOTES:

This

1.

where

Programming

2.

Block-to-block

quired

not

is

this

Function

ation

mode,

blocks

read

M01

HICH-SPEED

in

\U)2.

.

maximum)

(6

to

stop

including

advance.

buffer

serve

to

group

(G32)

or

between

(Note

cutting

time

between

function

the

control

to

compute

eliminated

stopping

(M93,

of

consecutive

inter-block

M30

ad\

for

of

linear

blocks

a

is

for

stop

time,

set

aiu

BUFFER

register

high-speed

blocks

interpolation

2).

This

smooth

blocks.

effective

is

provided

Circular

time

tool

or

use

M92)

blocks

stoppage

the

following

by

parameter

e-readmg

RECISTER

is

is

specified

reduced

is

permits

cutting

for

Interpolation

due

radius

remains.

2.7.4

(optional).

up

.

installed

cutting.

(G01),

to

in

with

G22

and

with

to

the

compensation

To

Buffering

When

to

5

time

is

M

codes

com

as

in

thread

zero

continu¬

shorten¬

G23

Radius

time

reduce

in

M93

reduced

the

If

a

the

by

option

re¬

oper¬

zero.

PROGRAM

2.2

NUMBER

AND

SEQUENCE

NUMBER

2.2.1

Program

for

Up

character

program

trol,

ploying

One

ends

in

placed

placed

ER

parts

NOTES:

1.

the

to

and

program

with

*0

<

PROGRAM

PROGRAM

(or

The

/M02;

of

PROCRAM

numbers

purpose

4

digits

"0"

numbers

up

an

option.

M02,

the

at

at

the

0.

1

%

ISO

at

of

the

tape.

blocks

,

/M30;

programs.

may

as

to

199

begins

M30

end

end

WITH

NO.

for

NUMBER

may

of

program

be

program

can

or

with

or

of

main

of

subprograms.

it-

MO

2.

if-

10

code)

optional

,

/M99;

be

written

be

registered

999

M99.

0

1

is

punched

are

prefixed

numbers.

a

programs,

to

programs

identification.

after

an

address

to

Up

in

can

be

registered

program

M02

number,

and

and

4.

3

2

-------

-----

PROGRAM

PROGRAM

block

not

WITH

NO.

on

both

skip

regarded

the

M30

M

1234

such

are

M99

9

9

99

con¬

,

%

end

as

em¬

and

is

as

enc

6

Page 17

2.

It

(#6201Do).

and

to

as

2.2.2

Integers

ten

following

numbers.

Sequence

blocks,

meaning

Therefore,

tial,

and

any

sequence

sequential

numbers.

When

searching

to

search

.

hand

NOTES:

1.

Five

sequence

is

possible

ineffective

M99

make

the

a

sign

SEQUENCE

consisting

an

numbers

and

do

sequence

and

they

duplicated

numbers

or

specify

more

or

with

to

make

succeeding

of

program

NUMBER

address

not

may

number

for

digits

number.

a

the

as

of

up

are

reference

have

of

sequential,

be

numbers,

is

are

convenient

sequence

program

must

parameter

reading

a

program

ER

end.

to

4

digits

character

any

influence

machining

also

possible.

numbers,

numbers

not

change

(EIA)

N

numbers

as

be

M02,

of

end,

and

(ISO)

or

%

may

be

sequence

as

for

on

the

processes.

non-sequen-

using

not

Generally,

sequence

sure

be

before¬

written

M30,

writ¬

as

2.3

COORDINATE

Generally,

tions

are

tems

words

axes

and

directions

2.3.1

Address

dinate

Axis

Main

Radius

Value

for

Circular

a

Interpola¬

tion

commands

commands

and

called

consist

coordinate

of

numerals

.

COORDINATE

of

Coor¬

Words

X,

Z

U,

W

I,

K

R+

WORDS

for

setting

for

address

representing

WORDS

Absolute

target

Incremental

(U:

Direction

W:

Direction

Incremental

point

start

circular

(I:

X-axis

K:

Z-axis

Radius

movements

words,

characters

Meaning

coordinate

position

distance

distance

and

arc.

component

component)

value

of

in

coordinate

and

coordinate

for

dimensions

position

X-axis,

in

Z-axis)

in

center

circular

axis

direc¬

sys¬

desired

of

between

of

,

arc

of

2.

When

quence

read,

3.

Blocks

be

searched

data

2.2.3

Those

cluded

that

switch

OPTIONAL

blocks

are

block,

for

EXAMPLE

12

When

the

neglected,

this

block

1234

N

"l,"

With

NOTES:

The

1.

ed

while

buffer

read,

to

skip

While

2.

this

The

3.

and

two

number,

and

without

contained

in

neglected

when

that

N1234

switch

and

is

read

G01

"1"

optional

the

resister.

subsequent

the

reading

function

block

1

/

i$

or

no

which

number

G01

when

may

blocks

skip

basic

a

more

only

more

sequence

for

with

in

BLOCK

the

X100

for

12

as

X100,.

be

block

blocks

or

ineffective.

is

12

blocks

one

searching

respect

the

blocks.

SKIP

"In"

between

external

"n"

/3

on,

is

switch

the

if

omitted.

skipping

are

Once

switching

.

punching

9

/

-

one.

have

is

numbers

(n

In

optional

on.

is

the

being

the

an

is

retrieved

is

to

(/l

(1-9)

=

and

Z200;

for

process

blocks

on

out

option

the

same

performed.

can

address

the

19)ÿ

-

the

block

entire

3

is

/

into

read

have

ineffective

is

programs,

function,

and

also

is

in¬

end

block

on,

is

se¬

of

skip

is

execut¬

the

been

Note:

and

X

follow

For

cremental

2.3.2

The

control

Z-axis.

axes,

two

axes

mands,

2.3.3

OUTPUT

2.

3.

3.1

The

minimum

punched

by

Metric

Inch

X-axis

When

Z

are

G90

not

according

details,

refer

Inputs.

SIMULTANEOUS

provides

Number

when

,

movement

LEAST

INCREMENT

Least

of

commanded

and

X

will

INPUT

Input

input

or

tape

Least

system

system

is

specified

0.

0.0001

G91

and

as

fixed

to

to

simultaneously

.

Z

absolute

G90/G91

2.3.5

CONTROLLABLE

two-axis

the

in

the

For

not

occur

INCREMENT

Increment

units

that

are

MDI

Input

1

001

Increment

x

mm

in.

diameter.

for

used,

are

designation.

Absolute

control

same

axis

can

shown

s

10

0.01

0.001

addresses

value

and

AXES

for

controllable

block,

without

LEAST

AND

commanded

be

below.

(

times

10

input

mm

in

and

X-

is

unit)

In¬

and

com¬

7

Page 18

2.3.3.

Inch

1

/MM

Inch/MM

Selection

parameter

by

loo!

ol

(or

mm

these

In

eration

NOTES

1.

units.

0.01

•

Programming

•

Write

•

Programming

•

Program

If

NC

into

mm

times

the

ll

contents

the

tenth

3.

When

the

out

the

Multiplication

A.

unit)

It

does

time,

10X

same

depending

EXAMPLE

G04

GOO

Least

input

input

of

value

I

set

0.0001

mm

increment

must

operation

editing

:

tape

or

stored

increment,

the

increment

machine

of

the

tape4-,

stored"

"as

increment

is

not

angle,

set

is

address

U--.

•

•

L

is

Increment

selected

Input

selection

multiplication

#6006D5-

must

inch)

,

and

made

be

for

for

programmed

intended

of

the

stored

the

effective

function

as

on

,«

in

operation

in

MDI

operation

operation

an

in

the

system

NC

tape

move

will

commanded

program

stored

regardless

system.

factor

for

etc

effective

word

type

Not

—

Multiplied

by

by

G20/G21

factor

always

offset

system,

the

unit

mode.

by

equipment

machine

dimensions.

is

are

stored

by

dimensions.

figures

10X

distance

on

the

When

multiplication

(#6006D5

multiplied

is

command.

of

G

multiplied

(Cont'd)

setting

xl/xlO

be

is

the

in

TAPE

in

MEMORY

m

EDT

0.001

will

switched

ten

punched

is

of

(10

designation

10

by

#6OO1D0.

is

written

possible

following

of

0.01

mode.

mode.

mm

set

move

in

memory,

times

punched

are

switching

times

command

1),

=

by

10

by

(Distance)

optional.

is

made

in

mm.

mode.

is

by

0.01

ten

when

one

or

out

the

input

factor

the

or

10

(Time)

0.001

in

op¬

fed

the

on

of

only.

of

not

2.3.4

Maximum

are

MAXIMUM

programmable

shown

Maximum

Metric

Output

Inch

Output

In