Page 1

.....

>

......

:•

-

:

...

%

YASKAWA

ELECTRIC

Ha

This

which

ing

the

ance

manual

ftfi

88

manual

is

an

man-machine

14-inch

Operators

before

describes

option

color

should

using

YASNA

C

LX

/MX

3

ACGC

CONNECTING

the

connection

YASNAC

the

of

function

thoroughly

120.

CRT.

the

interface

become

ACGC

MANUAL

with

LX3/MX3

with

the

the

familiar

series,

3

120

with

120,

featur¬

this

ACGC

high-perform¬

ACGC

1.

1.1

1.2

ENVIRONMENTAL

2.

STRUCTURAL

3.

THERMAL

4.

4.1

4.2

CONNECTION

5.

SETTING

6.

MEMORY

7.

PRESHIPMENT

8.

8.1

8.2

8.3

EXTERNAL

9.

120

OVERVIEW

OVERVIEW

SELECTION

TOTAL

SYSTEM

SWITCHES

PARAMETERS

HEAT

OVERVIEW

THE

OF

OF

THE

CONDITIONS

DESIGN

DESIGN

THE

OF

GENERATION

DIAGRAM

MODULE

THE

SPACE

SETTINGS

GENERATION

DIMENSIONS

TABLE

PRODUCT

CONTROL

OF

THE

THE

OF

HEAT

SHORT-CIRCUIT

(INITIAL

OF

MODULE

CABINET

CABINET

EXCHANGER

OF

EACH

SETTING)

CONTENTS

••••

UNIT

PLUG

SWITCHES

2

2

4

5

5

6

6

7

8

20

22

23

23

24

26

27

BATTERY

10.

SUPPLEMENT

this

manual,

The

In

meaning.

MAINTENANCE

terms

the

“portable"

terms

“(printed

and

circuit)

"stand-alone"

board

are

(card)"

also

used

and

with

“module"

same

the

used

are

meaning.

with

the

31

same

Page 2

1f

ACGC-1

1.

OVERVIEW

1.1

porduct

The

point

ACGC-120

(1)

of

Internal

view.

OVERVIEW

20

OF

is

classified

Internal

controller

fj

type

r

Debug

Portable

type

type

I

THE

unit

PRODUCT

into

the

P

following

Type

Type

be

Can

internal

into

the

Mainly

opment.

Desktop

Mainly

four

I

H

incorporated

type

controller.

in-house

for

type

for

software

types,

The

the

as

(400mm

The

to

allow

printed

560mm

,

II

CPU

CPU

X

but

display

from

rack

series

3

X

X

450mm

rack

mounting

circuit

190mm)

on

cannot

OEM

of

width

width

board.

the

at

the

standard

190mm)

X

of

CPU

be

software

the

hardware

is

the

same

.

expanded

is

optional

the

(400mm

rack

incorporated

devel¬

OEM.

rack

X

of

Type

The

CPU

I

same

into

controller.

However,

tural

The

the

(2)

Type

changes

maximum

application

Internal

H

NC.

CPU

The

the

and

Four

more

circuit

feature.

CNP

CNS

connector

connector

the

is

CPU

the

the

is

the

rack

structure

slots,

boards.

basic

rack

NC.

size

may

capacity

program

type

expanded

width

The

...

...

type,

as

This

of

be

H

the

of

as

shown

structure

Memory

ROM

type

of

Two

The

cannot

where

the

eliminates

the

14"

necessary.

(option

created

type,

somewhat

is

NC

3MB,

I

RS-232C

floppy

be

the

conventional

the

color

ROM

at

where

controller

below,

basically

is

card

for

RAM

used.

is

ports,

disk

mounted

NC

panel

the

larger

can

the

1MB)

drive

need

3

OEM.

the

may

be

floppy

on

is

X3

MB,

OEM

is

the

incorporated

series

change

to

box

is

RAM

ACGC-120

than

the

need

used

the

same

application

The

.

same

disk

special

NC

controller.

used,

is

the

small

too

MB)

1

is

conventional

changing.

to

mount

type

as

memory

drive

to

the

into

the

incorporate

to

structure

and

can

incorporated

additional

except

I

software

card

interface

debug

ACGC-120.

of

the

some

be

struc-

used

into

X

series

3

printed

for

(option;

as

card.

unit,

and

this

that

the

NC

for

the

i

i

,

1

CNT

CNU

connector

connector

...

...

Optional

card

for

expanding

2

functions

(Spare)

I

Page 3

(3)

Debug

r

unit

Used

The

when

open

conditions.

The

same

incorporated

be

mounted

CNP

CNS

CNT

connector

connector

connector

developing

type

CPU

on

the

unit

rack

into

expanded

Memory

...

ROM

of

However,

enable/

Two

...

The

is

development

(PC-9800

The

NC

RAM

...

ware.

ing

space,

by

to

slot

the

to

is

that

as

the

3MB,

type

RS-232C

3.5-inch

used

3.5-inch

controller.

memory

address

the

change

into

application

be

used

of

NC

controller.

4

slots

card

RAM

I

is

used.

special

disable

floppy

upload/

to

environment

series)

floppy

Two-MB

setting

in

rotary

a

MB

1

the

RAM,

in

internal

are

the

for

1MB).

notice

status

ports,

with

card

RAM

unit.

switch

ROM

and

software

location

type

As

as

follows.

OEM

of

floppy

disk

download

the

disk

development

for

is

anywhere

The

on

area

cannot

at

having

It

in

application

The

must

the

disk

drive

the

of

the

debug

drive

mounted

address

the

card.

on

the

is

type

same

be

ROM

can

NEC

cannot

in

the

be

OEM.

favorable

used,

,

II

memory

taken

on

drive

be

software

unit.

of

on

a

the

setting

This

memory

applied

but

the

software

when

this

interface

used.

created

personal

be

mounted

the

single

1

to

card

to

environmental

unit

the

cards

that

(option:

card

setting

card.

as

card.

This

connector

in

computer

on

application

card,

MB

16

simply

is

designed

is

card

the

of

product.

cannot

are

that

the

the

the

soft¬

allow¬

memory

done

the

;

1st

CNU

In

for

(4)

The

side

the

can

tion

•

Two

•

Cabinet

•

•

•

connector

addition

debugging.

Full

CRT

9"

O

1/

Portable

ACGC-120

does

showroom

debugged.

be

machine.

3.5"

...

to

the

keyboard

panel

simulator

type

not

function.

at

The

floppy

specialized

Same

above,

control

the

It

features

disk

card

OEM.

can

drives

for

as

the

This

also

15"

the

following

alone

type

The

be

are

in

color

CNT

expanded

as

the

connector

optional

is

stored

provided

is

application

follows.

standard

CRT

(incorporating

peripheral

in

a

for

software

into

an

configuration

specialized

displaying

automatic

a

of

TV

tools

the

tuner)

are

box.

the

OEM

program

offered

The

system

f

NC

in

alone

crea¬

-3-

Page 4

OVERVIEW

1.2

Module

Name

CG23

CG24

CG25

CG26

*

CG27•OEM

*

CG28

*

CG29

SP23-1

-2

*SP23

*

CG30•Same

•

module,

CPU

•

One

RS-232C

•

keyboard

Full

•

Interface

(Video

signal,

keyboard

•

System

number

is

mounted

•

Graphic

•

Floppy

(the

debug

floppy

the

•

RS232-C

Two

•

•

•

OEM

P-ROM

S-RAM

Battery

backup

mounted

The

to

be

memoty

P-ROM

application

enabled

application

S-RAM

•

S-RAM

The

battery

CG26

the

•

The

mounted

to

be

enabled

•

CPU

bus

•

External

connector

enforcement

•S-RAM

application

•

The

rotary

•

The

unitofthe

module.

•

•

•

Video

color

•

Mounted

and

•

•

SP23-1

module

memory

memory

the

switch

SRM

Interfaces

with

the

signal,

Video

signal,

ON,

Power

signal

CRT

keyboard

keyboard

Detach

module

printer

video

as

mountable

OF

Function

mounting

channel

connector

power

signal)

switch

control

disk

drive

unit

disk

1.25MB

0.5MB

unit

is

for

the

P-ROM

module

1.75MB

0.5MB

is

of

unit

module.

P-ROM

expansion

power

is

mounted

for

software

capacity

address

in

is

backed

super

the

CG23

Keyboard

switch

OFF

interface

keyboard

with

selection

interface

functions

interface

CG28

the

modules

THE

interface

with

ON/OFF

(rotary

module

interface

alone

drive)

channels

memory

(max.)

(max.)

mounted

S-RAM

or

disabled.

optional

(max.)

(max.)

backed

super

the

disabled.

or

module

supply

development

at

is

set

is

unit.

1

MB

up

by

C

and

following

module.

Power

signal

interface

connector

interface

switch

are

functions,

have

CONTROL

system

PROM

connector

SP23

module

signal,

switch)

supports

module

as

be

can

by

up

C

be

can

interface

for

OEM

the

MB,

2

and

using

battery

the

CG26

the

signals

ON/OFF

connector

for

14"

connector

connector

plus

the

mounted.

but

been

increased.

and

of

the

set

the

set

the

Internal

Type

I

o o

o

o

o

o

MODULE

Internal

Type

Debug

I

o o

o o

o o

o

o

Two

possible

o

(*

:

Portable

Unit

o

o o

o

o

Two

module

possible

o.

Optional

Type

o

o

o

o

o

module

o

o

modules)

Remark

Mounted

CG23

The

cannot

on

Mounted

CG26

Used

memory

P-ROM

CG26/CG27

the

developing

tion

above

module

floppy

mounted

be

internal

the

above

module

replace

to

space

mountedonthe

S-RAM,

module

when

the

software.

the

disk

type.

the

the

the

of

applica¬

1

drive

by

Tv

-4-

Page 5

ENVIRONMENTAL

2.

CONDITIONS

(1)

Ambient

(2)

Humidity

(3)

Vibration

STRUCTURAL

3.

Consider

rack

(1)

The

However,

be

(a)

(b)

(c)

The

structure.

the

internal

the

and

other

cabinet

of

Set

Do

or

Decide

the

radiation

thermal

ventilated

an

not

oil

cabinet.

recommended

(2)

Design

rise

designing

the

and

temperature

following

units.

must

cabinets

the

filter

air

let

the

mist

and

air

the

of

fin

Placing

loss,

this

for

cabinet

outside

the

the

of

DESIGN

when

always

type,

at

airflow

dust

outlet

feed

the

the

thus

reason.

so

that

air

cabinet.

During

During

to

10

(Non

G

0.5

designing

be

of

feed

when

outside

the

of

may

position

servo

radiation

improving

the

is

operation

storage

%

RH

90

condensing)

less

or

the

closed

servo

following

air

internal

where

unit

and

fin

the

or

THE

OF

of

the

the

adhere

difference

10°C

0°C

20

(relative)

cabinet

structure.

units

inlet.

to

the

dust

spindle

outside

reliability.

between

less.

to

45°C

to

°C

+60°C

CABINET

to

accommodate

spindle

and

conditions

blow

fan

unit

and

and

drive

cabinet,

the

The

the

See

section

are

directly

cause

oil

unit

internal

drive

satisfied.

mist

closed

for

5

units

on

failure.

do

extends

decreases

structure

temperature

the

the

the

not

thermal

CPU

unit,

enter

out

may

of

the

is

(3)

Use

the

necessary

the

flow

(4)

Locate

clearance

(5)

Seal

The

in

The

(a)

(b)

(6)

Distortion

/

The

any

solenoid

the

fan

a

cooling

surface

of

the

the

the

high-voltage

air.

the

following

Seal

no

Seal

the

space.

the

CRT

magnetic

CRT

circulate

to

efficiency

measurements

of

the

blow

fan

parts

from

cable

the

inlet

must

mounting

cable

of

the

display

source

relay,

AC

unit.

the

and

printed

directly

considering

cabinet

and

CRT

be

needs

observed,

surface

inlets

may

display

be

CRT

(e.g.

power

so

door

and

within

air

to

that

an

circuit

on

the

wall

firmly.

special

with

doors

caused

distorted

transformer,

supply

prevent

airflow

board.

the

flow

so

as

consideration,

the

on

packing,

with

by

cable,

the

printed

of

not

CRT

packing.

by

the

closed

local

of

Be

the

to

magnetism:

surrounding

reactor,

etc.)

cabinet

temperature

2

m/s

careful

circuit

air.

obstruct

mounting

and

make

about

or

board.

Secure

the

as

it

fan,

300

so

as

more

to

not

about

air

collects

cabinet.

sure

magnetism.

magnetic

mm

rise.

flows

let

flow.

that

to

away

improve

Take

above

the

100

the

dust

there

Keep

relay,

from

air¬

mm

f

is

-5-

Page 6

THERMAL

4.

DESIGN

OF

THE

CABINET

SELECTION

4.1

cabinets

The

closed

ambient

To

required

Determine

'Z\T

Pv

k

A

qh

.

(1)

Calculate

Pv

(2)

Calculate

A

+

structure,

air

satisfy

inside

Temperature

:

:

Total

:

Heat

Calculate

Effective

:

Required

:

2

X

2

|D

2

OF

that

accommodate

and

temperature.

the

cabinet,

the

the

heating

transmittance

with

radiation

heat

the

total

(Heating

effective

the

|W

(width)

(depth)

THE

the

above

capacity

rise

value

6

exchanger

heating

value

X

H

HEAT

the

internal

conditions

according

of

the

within

(W)

(W

W(m2-°C)

area

value

each

of

radiation

H

(height)

X

(height)

EXCHANGER

CPU

temperature

the

(m2

of

|

module

,

heat

•

°C

when

a

the

to

exchanger

cabinet

]

thermal

circulating

cabinet

effectiveness

Pv

of

the

unit)

area

A.

|

+

and

rise

installed

(degrees

(m2)

electric

|W

s

other

kept

heat

electrical

follows.

as

fan

parts.

(width)

units

within

exchanger

C)

is

X

are

10°C

parts.

provided.

(depth)

D

to

may

of

be

|

of

the

be

(3)

(4)

(5)

Surfaces

surfaces.

Calculate

rise

is

Pv'

heat

No

(Total

(Total

Qh

exchanger

=

Heat

that

When

this

the

2k

T

•

k

exchanger

heating

heating

(Pv

-

do

bottom

a

bottom

allowable

or

less

/AT

A

value)

value)

Pv'

not

surface

with

)

is

50mm

contact

is

considered

than

10°C

-

-6

necessary

is

the

/

/

or

less

above

a

non-effective

heating

10°C.

(W)

W/(m2.°C)

(Allowable

following

(Allowable

>

Z\T

the

the

outside

CTIVE

surface,

floor

surface.

amount

it

if

effectiveness

(W/°C)

air

Pv2

is:

heating

heating

are

,

as

value

value

considered

internal

the

)

Pv'

q

h

required

is

)

Pv'

non-effective

temperature

if

it

is:

u

10°C

-6-

Page 7

4.2

(1)

TOTAL

NC

unit

HEAT

GENERATION

OF

EACH

UNIT

(2)

ACGC-1

Control

CPU

NC

control

Tape

I/O

unit

20

Module/Unit

JANCD-CG23

JANCD-CG24

JANCD-CG25

JANCD-CG26

JANCD-CG27

JANCD-CD28

JANCD-CG29

JANCD-SP23

JANCD-CG30

14"

color

Unit

module

reader

module

CRT

panel

Heating

MAX.

Amount

5

6

2.5

5

1.5

0.1

0.5

2.5

0.1

100

TYP.70

Heating

(W)

Value

70

20

25

Optional

Optional

Optional

Module

Module

5

(W)

Remark

module

module

module

for

for

debug

portable

!

unit

type

1

/

:

-7-

Page 8

1

CONNECTION

5.

YASNAC

5.1

CNF

CNB

CN

CN6

CNZ

CND

CNC

20)

CN

CN2

CN

CN4

CNH

CN

(TU)

CNA

D

]

7

][

8

]

][*

JL

1

3

][

5

X

module

MEMORY

*

L-1

CNR

CNA

CG23

[

CNC

TZT

PC

MEMORY

MEMORY

10

POWER

CPS

(Internal

CONTROL

nr

PC

I/O

1

DIAGRAM

Optional

:

*

MAIN

BOARD

MB21

OR

MB20E

(OPT./SD)

CN

(HDLC)

(PC)

Note

2

SW5

(RS232C)

(OPT./SD)

(MM21)

(MM

(IO/SR)

(CPS)

LX3

]

BOARD

CG27

MEMORY

CG26

CNB

izr

£

£

CN49

CN48

CN47][]

GRAPHIC

24

CG

BOARD

CN21

20

CN22

BOARD

MM

BOARD

20

MM

BOARD

CN51

CN52

20

CN53

CN54

CN55

SUPPLY

CN

CN12][]

0N

CN13][]

(ACGC

ACGC

BOARD

D

BOARD

C

Note

1

ADDITIONAL

1

-

p[}

BOARD

][}

J

RS232C

B

21

A

MODULE

11

D

U

-

-

-

DIAGRAM

120)

120

CARD

MODULE

READER

Model

2801

I/O

2

B

-

I)

control

MODULE

type

CPU

RS232C

I/O

TAPE

GENERAL

unit

CONTROL

PANEL

r~

CN2

CN

MODULE

I/O

CNB

CN2

r-ac

CN3

I-OC

[CN1

{][

CN

X

_

_o

CNB

SP23

1

-

1

I

CNA

SP20B

SERVO

1st

SERVO

2nd

1

SPINDLE

UNIT

ESP

-oTo-i

CNC

CNA

CNE

CND

CN

CN

CN4

CN

UNIT

AXIS

CN

UNIT

AXIS

CN2]Q

DRIVE

o

Q

i

—

INTERCONNECTION

]ÿ

[JÿEVBOARD|]

—

LF

Note

MACHINE

SVM

NCM

2

o-

o-l

6

1

5

2

30

EXT.

POWER

ON

OFF

r

o

d

—

CONTROL'PANEL

IN

POINT

48

POINT,

16

IN

VOLTAGE

HIGH

DIRECT

IN

POINT

IN

40

POINT,

8

IN

POINT,

IN

24

POINT

IN

40

POINT

IN

40

i

FKEY

I

POWER

ON

OFF

MANUAL

GENERATOR

OUT

32

AC

MOTOR

AXIS

1st

AC

MOTOR

AXIS

2nd

SPNDLE

PG

PANEL

4

POINT

POINT

OUT

8

OUT

16

200/220VAC

50/60

PLUSE

Note

!

i

POINT

POINT

Hz

±2

2

Hz

+

10%

15%

f

I.

V

:

i

1

)

i

-8-

Page 9

!

YASNAC

:

DIAGRAM

Optional

:

*

CONTROL

BOARD

*

CG

28

1

CN

CN2

'EXTERNAL'

POWER

,

.SUPPLY

BOARD

MAIN

MB21

MB20E

(OPT./SD)

(HDLC)

Note

2

SW

(RS232C)

(OPT./SD)

(MM

(MM

(IO/SR)

(CPS)

MAIN

CNU

CNT]

CNS

CN

CNP

OR

CNF

CN

CNB

(PC)

CN8

5

CN6

CNE

CND

CNC

CN

CN

CN3

CN4

CNH

CN5

(TU)

CNA

ADDITIONAL

L

21

20)

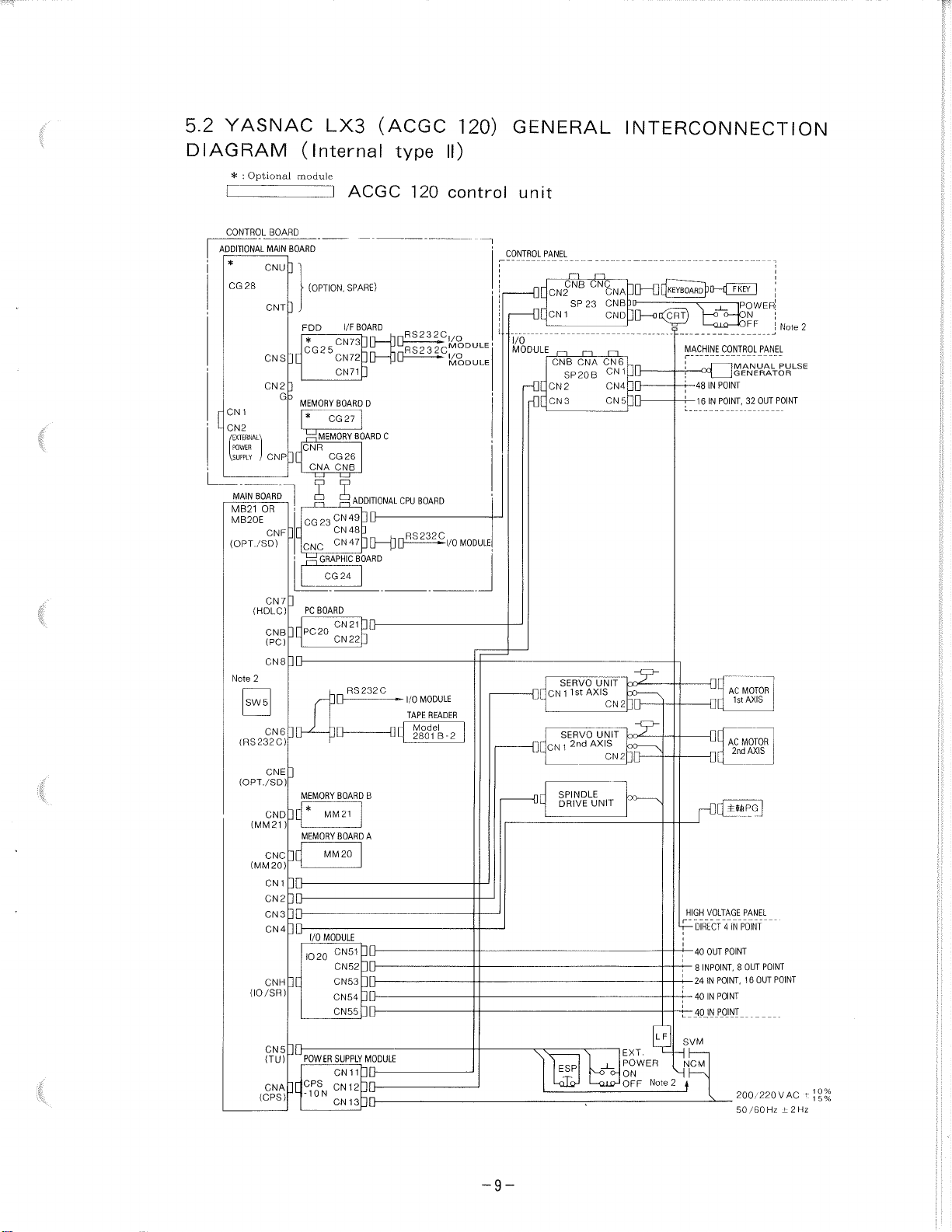

5.2

(Internal

module

BOARD

'

]

•

(OPTION.

.

FDD

*

CG2

x

]

2

3

G

MEMORY

*

1

CNR

X

CNA

i

1

“i

CG

pn

CNC

]

7

PC

][

PC20

][K

]

MEMORY

1C*

)

MEMORY

X

1

2

I/O

IO

ii:

POWER

CPS

X

-10N

LX3

5

CG

'MEMORY

CG26

£

)

i

—

23

GRAPHIC

CG

BOARD

MM

MM

MODULE

20

(ACGC

ACGC

SPARE)

BOARD

l/F

cN73h[}—

][]

CN72

-

]

CN71

BOARD

D

27

C

BOARD

CNB

£

ADDITIONAL

i

i

—

-

CN49

JU

]

CN48

47

CN

(J

]

BOARD

24

HQ-

CN

21

]

CN22

RS232C

BOARD

B

21

A

BOARD

20

CN51

CN52

CN53

CN54

CN55

SUPPLY

MODULE

1

1

CN

CN

1

2

CN

1

3

type

ho

p0

CPU

p

Q

120

RS232C

RS232C

BOARD

RS

232

MODULE

I/O

TAPE

Model

2801

120)

II)

control

I/O

MODULE

I/O

MODULE

C

I/O

READER

B-2

MODULE

GENERAL

unit

CONTROL

PANEL

CNB

CN2

CN1

l

I/O

MODULE

CNB

SP20B

CN2

HX

CN3

HX

SERVO

Q[CN

1

SERVO

1

OCCN

SPINDLE

DRIVE

\\

ESP

-OLQ-1

SP

1st

2nd

23

i—i

CNA

CNC

AXIS

L-

INTERCONNECTION

30-OkEY

KEYBOARD

DD—OC

CNA

CNB

CND

CN

CN

CN4

CN

UNIT

CN2]Q

UNIT

AXIS

CN2]Q

UNIT

YOON

CLUHOFF

6

5

3D

]ÿ<CRT)

1

LF

T

EXT.

POWER

Note

_

_

_

POWER

\

_j

tÿJoN

MACHINE

CONTROL

r

HIGH

I—

—

X

4—24

—

X_4pJN_P0JNT

SVM

NCM

NK

2

A

POINT

IN

48

POINT,

IN

16

AC

1st

AC

2nd

VOLTAGE

•

VI

DIRYCT

POINT

OUT

40

INPOINT,

8

POINT,

IN

POINT

40

IN

MANUAL

GENERATOR

MOTOR

MOTOR

POINT"

N

8

200/220

50/60

32

AXIS

PANEL

OUT

16

l

FF

OUT

AXIS

OUT

!

PANEL

POINT

~

POINT

POINT

VAC

Hz

Note

PULSE

±2

2

'

.

i.

10%

t

5%

1

Hz

-9-

Page 10

•r

wrw&ijsggssw—

V

YASNAC

5.3

DIAGRAM

Optional

:

*

BOARD

MAIN

MB21

OR

MB20E

CNF

(OPT./SD)

CN

(HDLC)

CNB

tPC)

CN

2

Note

CN6

(RS232C)

CNE

(OPT./SD)

CND

(MM

21

CNC

20)

(MM

CN

CN

CN3

CN4

CNH

/SR)

(10

CN5

(TU)

CNA

(CPS)

module

CONTROL

MEMORY

*

CNR

CG23

X

CNC

7

PC

][

PC

8

]

MEMORY

][*

)

MEMORY

X

1

2

]ÿ

ADDITIONAL

][

POWER

CPS

J[

-

MX3

(Internal

ACGC

BOARD

BOARD

CG

27

MEMORY

BOARD

CG

26

CNA

CNB

LYI

£ £

SP21

0

1

CN49

CN48

CN47

GRAPHIC

CG24

BOARD

CN

20

CN

RS232C

BOARD

MM

21

BOARD

20

MM

CN

CN62

CN63

CN64

CN65

CN66

SUPPLY

CN

CN

N

CN

Note

ADDITIONAL

BOARD

21

22

AXIS

61

1

1

2

1

3

1

(ACGC

D

C

1

J

]Q—

DD

I/O

B

A

BOARD

MODULE

type

CPU

RS232C

MODULE

TAPE

Model

2801

120

BOARD

READER

B-2

120)

I)

control

MODULE

I/O

GENERAL

unit

CONTROL

PANEL

i.

I/O

MODULE

r-QC

r0[

[CNllst

[|[CN

{][

~Q[CN1

-[][

CNB

CN2

SP23

1

ON

CNB

SP20B

CN2

CN3

[

H][

rOC

XC

DU

—

DC

SERVO

SERVO

2nd

1

SERVO

1

CN

SPINDLE

DRIVE

*

SERVO

4th

SERVO

*

5th

1

CN

ESP

UiJ

CNC

CNA

MODULE

I/O

CN1

1

CN

1021

CN

13

CN1

MODULE

I/O

CN12

CN1

1021

CN1

CN11CN6

UNIT

AXIS

AXIS

AXIS

3rd

UNIT

AXIS

AXIS

s-°

—

INTERCONNECTION

48

IN

“16

IN

40

IN

8

24

40

40

4

OUT

40

8

IN

24

40

40

4

OUT

DIRECT

I

—

NCM

I

F

0

d

—

o

CONTROL

POINT

P0I0T,

OUT

POINT

POINT,

POINT,

IN

IN

POINT

POINT

IN

POINT

OUT

POINT

POINT,

POINT,

IN

IN

POINT

POINT

IN

POINT

4

AC

AC

AC

SPINDLE

DMPG

Of

AC

Of

AC

1

Q[

CNA

CNE

CND

CN

6

CN

1

CN4

5

CN

1

CN

2

4

2

CN

CN3

CN4

CN5

1

6

CN

1

CN

4

CN2

CN3

CN4

5

3

CN

CN

2

UNIT

CN2]Q

UNIT

CN

2

UNIT

CN2]Q

UNIT

CN2]0

EXT.

POWER

°-

ON

QJ_Q-*0FF

-

HO

]Q

—

]Q

]Q

oo

-

fir

00(CRT

Note

KEYBOARD)]

MACHINE

HIGHVOLTAGE

I

\

SVM

2

KEY

POWER

ON

OFF

PANEL

MANUAL

GENERATER

OUT

32

PANEL

POINT

OUT

8

OUT

16

(READ

OUT

POINT

8

OUT

16

(READ

POINT

IN

MOTOR

AXIS

1st

MOTOR

AXIS

2nd

MOTOR

AXIS

3rd

MOTOR

AXIS

4th

MOTOR

AXIS

5th

200/220

Hz

50/60

i

Note

PULSE

POINT

POINT

RELAY)

POINT

RELAY)

VAC

±2Hz

I

I

2

/

1

i

ft]

I

I

;

10%

+

-

5%

1

-10-

Page 11

1

%

ACGC

SPARE)

(ACGC

type

120

YASNAC

£

5.4

DIAGRAM

Optional

:

*

CONTROL

BOARD

ADDITIONAL

CG

MAIN

BOARD

]

CNU

28

MX3

(Internal

module

]

'

(OPTION.

CNT]

FDD

*

CG2

][

CN

S

]

CN

2

3

G

,

CNP

BOARD

OR

CNF

SD)

CN7

(HDLC)

CNB

(PC)

CN

2

CN

CNE

CND

CNC

20)

MM

CN

CN

CN

CN4]Q

CNH

/SR)

CN5

(TU)

CNA

(CPS)

MEMORY

*

CNR

X

CNA

CG

on

CNC

[ÿGRAPHIC

]

PC

][

PC20

8

6

]

MEMORY

][*

MEMORY

X

1

2

][}

3

ADDITIONAL

SP21

JL

POWER

CPS

J[

-

1

CN

1

D

CN2

'EXTERNAL'

POWER

.SUPPLY

MAIN

MB21

MB20E

(OPT.

Note

SW5

(RS232C)

,KV

(OPT./SD)

(MM21)

(

(10

l/F

CN73hD

5

CN72

CN7

BOARD

CG

27

MEMORY

CG26

CNB

£

£

CN49

23

CN48

CN47

CG24

BOARD

CN

CN

RS232C

BOARD

MM

21

BOARD

MM

20

CN61

CN62

CN63

CN

64

CN

CN66

SUPPLY

CN

CN

0

N

CN

BOARD

hQ

-

-

PQ

3D

]

1

D

C

BOARD

1

Note

ADDITIONAL

]

OQ

ID—

BOARD

}

21

}

22

B

A

BOARD

AXIS

65

MODULE

11

2

1

3

1

RS232C

RS232C

CPU

RS232C

MODULE

I/O

TAPE

Model

2801

BOARD

II)

control

I/O

I/O

I/O

READER

B-2

120)

MODULE

MODULE

MODULE

GENERAL

unit

PANEL

CONTROL

2

CN

1

CN

i

—

CNB

SP20B

CN2

rOC

CN

3

rOC

DC

oc

I—

rOC

4J[

L-0[

r-OC

SERVO

Q[CN1

SERVO

Q[CN1

SERVO

1

CN

SPINDLE

DC

0[CN1

—

[

—

CN

*

*

DRIVE

SERVO

SERVO

1

ESP

oi-T

—

—

CNB

SP23

i

1st

2nd

3rd

4th

5th

CNC

CNA

MODULE

I/O

CN

1

2

1

CN

1021

CN

1

1

CN

MODULE

I/O

CN12

CN14

1021

CN13

CN1

UNIT

AXIS

AXIS

UNIT

AXIS

UNIT

AXIS

AXIS

Y)

—

INTERCONNECTION

CNA

CNE

CND

CN

CN

CN4

CN

CN

4

CN

CN3

CN

CN5

3

1

CN

CN

CN2

CN3

CN4

CN

1

CN6

CN2

UNIT

CN2]Q

CN2]Q

UNIT

CN2]D

UNIT

CN

QI.Q~ÿ

6

1

5

1

2

4

6

1

5

2

o-ON

OFF

]0

[[KEYBOARD)]

—

4.

L

:

f-

f-

f-

+

]Q

][}

LF

Note

SVM

NK

2

|

EXT

POWER

D-RT

CONTROL

MACHINE

POINT

48

IN

POINT,

IN

16

HIGH

VOITAGE

40

OUT

POINT,

8

IN

POINT,

IN

24

40

IN

POINT

IN

POINT

40

4

OUT

OUT

40

POINT,

IN

8

POINT,

IN

24

POINT

40

IN

POINT

IN

40

OUT

POINT

4

DIRECT

Dq

I

—

or

{][

on*

NCM

F

MANUAL

GENERATOR

POINT

POINT

POINT

4

IN

AC

1st

AC

2nd

AC

3rd

SPINDLEI

PG

AC

4th

AC

KEY~1

POWER

ON

OFF

PANEL

OUT

32

PANEL

OUT

8

OUT

16

(READ

POINT

OUT

8

OUT

16

(READ

POINT

MOTOR

AXIS

MOTOR

AXIS

MOTOR

AXIS

MOTOR

AXIS

MOTOR

AXIS

5th

200/220

50/60

Note

PULSE

POIOT

POINT

RELAY)

POINT

RELAY)

VAC

Hz

±2Hz

2

+

—

I

!

:

!

E

:

:•

:

I

I!

I

K

1

1

:

f

t

:

I

:

0%

1

5%

1

i

l

-11

:

-

Page 12

::r

w.-wasw"’"

S82S33®®«ffl

5.5

JANCD-CG

SYSTEM

SWITCH

i

Note

CN49

MRP-20F01

MR-20L

;

CN47

7

SD

6

RD

RS

5

4

CS

3

DTR

2

DSR

SG(OV)

1

ACGC

23(DTN5580)

NUMBER

SW1

i)

8

£oi

CONNECTOR

VSYNC

VSYNCHSYNC-15

HSYNC

POFF

PCOM-3

*

*

7777

CN

48

1

KSD

2

15V

3

V

5

I

4

OV

5

0V

6

0V

CONNECTOR

13I

19

12

18

11

17

10

16

(RST)

9

15

(0V)

14

120

CN

VDRVDR

VDG-11

VDG-

VDB-9

VDB-8

PON-

KRD-4

KRD-5

KSD-6

KSD-7

OV-1

V

0

FG

CN

CN

TABLE

FG

49

-

),

7

1

16)

4

4

-

1

4

4

13

4

-

1

2)

4

4

10

4

j

4

4

18

4

-

9

1

4

4

4

4

4

4

*

-

2

J

)

-

20

Note

FULL

48

(SUPPORTING

USER

1

CONNECTOR

47

MRP-20F01

J

MR-20L

(MANUFACTURED

CABLE

CABLE

LENGTH

TP

IE

IE

IE

IE

IE

IE

Note

3

77/7"

4

KEYBOARD

ONLY

CPS-

1

OR

10

21

RS-232C

CONNECTION

Max.

15m

JCN2-17

J

<

J-14

j-13

<*

«T9

(

<*

<*

J

;)

:•

<4-4

«

<<

4

V

5

TSUSHIN)

CONNECTOR

DEVICE)

«

<f4-+

<<

«

CONNECTOR

DEBUG

THE

+

0N

0

12V

+

BY

HONDA

AC

200/220

50/60

W

1

60

JANCD-SP23-1

1

R

2

G

3

4

5

B

6

7

E1W

8

9

10

11

12

13

14

15

H-

SYNC

16

V.

17

SYNC

18

19

2Q|FG

-

1

6

15

:

'

-

1

1

-

0

1

-8

-18

19

-

-3

-5

6

ov

1

-2

2

20

3

FG

4

CNA

TABLE

i

1

CN

-

1

5V

+

4

0

sv

V

2

1

I

CONNECTOR

CNB

13

6

121W

5

11

4

10

3

9

mi

2

8

3ETTJ

1

1

+-

V

-15%

Hz

±1%

Max.

(DTN5910)

OV

OV

OV

OV

OV

OV

OV

LEVEL

CON-

VERIER

MPU

o

o

o

Keyboard

o

o

o

Select

o

o

o

SW

ABC

BZR0

2

3

CETSO

4

5

LED2

6

8

LED4

FG

10

it

0V

12

13

14

0V

16

0V

16

17

DK0

18

'9

20

DK2

21

22

DK4

23

24

OK6

25

26

SELO

27

SEL2

28

29

SLL4

30

30

32

SEL6

33

34

SEL8

35

36

SEL10

37

SEL1238SEL13

39

SEL14

40

TABLE

20

m

19

18

17

16

“SETS

15

14

0

'

DIAGRAM

AC

CONNECTOR

1-48700-0

(AMP)

R

%

S

FLAT

CND

CNC

-10

m

•8

-9

-

1

2

1

-17

-18

ov

CNE-21

PON

1

-

>

-3(;PCOM

ROM

fesl

27256

BZR1

LED1

LED3

LED5

FG

+6V

5V

+

5V

+

DK1

OK3

DK5

DK7

SEL1

SEL3

SEL5

SEL7

SEL9

SEL11

SEU5

FG

DZR1

DZR0

DR7‘

TO”

EE3T

W

CNB

CNA

i

FLAT

(40-CORE)

Note

DETACHED

KEYBOARD

(1/2)

POWER

SUPPLY

«

<<

1

CABLE

(20-CORE)

VIOEO

PRINTER

(SUPPORTING

CNE

CONNECTOR

VHR-3N

(MANUFACTURED

POWER

QXJT-GREEN(SW784)

o

-

1

QXJT-RED(SW785)

1

-ole

-

FLAT

(10-CORE)

UL

CABLE

CNA

5

TX1424AD(CRT

INPUT

AC

FUSE(4A,

-1

-2

-3

IN

CONNECTOR

SIG.

7

Note

BRIGHTNESS

VR.

¥

IN

SIG.

ONLY)

l/F(SP23-2

ONLY

BY

JANCD-SP24(DTW5930)

CABLE

CNE

GNJR||

UNIT)

DEBUG

THE

ACCHAKU-TANSHI

NIPPON

ON/OFF

SOFT

CONNECTOR

1

£iK0

[2|~5ET8

3

4

DKT

T5KT

5

6

7

DK3

8

WJ

1C

9

|

1

BZRO

2IBZR1

4

LEDO

3

5

6

7

8

9

1

121

r.i

1

141

1

19

;

1

1

2i

2;

2

DRT

i]

23

DK6

24

2‘

21

2;

2‘

2

3i

3;

311

33*5‘EL8

34JSEL9

1

3

31

4

13)

250V)

1

R

2

4

G

3

B

5

6

7

HTYN7:.

8

73YNCI0

9

12

14

13

16

15

17

18

19

20

SW.

<EY

UNIT

TABLE

T£iT

~WT

DK6

DK5ÿ

-ÿ

BUZZER

EFB-RC24201

o

+5V

+5V

+5V

DK7

CRT

TABLE

0V

0V

0V

ov

OV

FG

)

#-

i

I

f:

I

%

%

*

%

£

I

i

-12-

S'

s

8

I

1

1

.

Page 13

1

*

!

ACGC

5.5

JANCD-CG28

CNS

<

CABLE

120

JANCD-CG25(DTN5600)

BOARD

OPTION

i

CNS

CN

72,

7

6

5

4

3

2

1

CONNECTION

CN

73,

CONNECTOR

SD

13

RD

RS

CS

DTR

DSR

SG(OV)

20

12

19

1

18

1

17

10

9

16

8

15

14

TABLE

FG

DIAGRAM

USER

CN

72

73

MRP-20F01

MR-20L

HONDA

USER

1

MRP-20F01

MR-20L

HONDA

J

CN

(2/2)

RS-232C

CONNECTOR

(MANUFACTURED

TSUSHIN)

RS-232C

CONNECTOR

(MANUFACTURED

TSUSHIN)

BY

BY

!

f

CN

71

i

i

FDD

(SUPPOTING

CONNECTOR

l/F

ONLY

THE

DEBUG

DEVICE)

:

l

.

:

I

!

i

CN

7

1

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

CONNECTOR

Signal

Pin

ov

0V

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

OV

Number

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

TABLE

Name

Signal

/LSP

/HOLD

/DRIVES

/INDEX

DRIVEO

DRIVE1

DRIVE2

MOTOR

ON

/DIR

/STEP

/WDATA

/WGATE

,/TRACKO

WRPROT

,/RDDATA

/SIDESEL

READY

13~

;

!

!

I

i

:

I

i

:

i

M

I

;

Page 14

[CONNECTORS]

•

List

of

CPU

Module

JANCD-CG23

•

List

of

CRT

Panel

JANCD-SP23

CRT

CPU

Name

Panel

Name

unit

Module

Connector

No.

CNA

CNB

CN47

CN48

CN49

Connectors

Connector

No.

CNA

CNB

CNC

CND

CNE

CN1

CN2

Power

supply

Signal

Connectors

Connector

FRC2-C50L12-OL

FRC2-C50L12-OL

MR-20RMA

TM5RA-66

MR-20RMA

Connector

FRC2-C40L12-OL

MR-20RFA

MR-20RFA

FRC2-C20L12-OL

B3PS-VH

172040-1

MR-20RMA

1-480701-0

FRC2-C20L12-OL

Board

Board

Side

Name

Side

Name

Cable

Connector

Connected

Connected

MRP-20F01

Free

MRP-20F01

Cable

Connector

Connected

Free

Free

Connected

Connected

172026-1

MRP-20F01

1-480700-0

Connected

Side

Name

Side

Name

I

5

[RS-232C

JANCD-CG23

Interface]

MODULE

CPU

CN47-7

4f

3

1

I

V

3

RO

-i

SD

RD

RS

CS

DR

ER

T

SG

FG

-4"

3

T4

4-

4

I

2

5

7

1

-14-

RS-232C

FOR

ACGC

INTERFACE

I

fy

Page 15

I

c

(

5.6

Note

Note

NOTES

1

O

4

o

7

lo

10

o

(Preset

1

Connect

as

2

The

OFF

selection

circuit

(basic)

SW

5

o

ol

at

the

ON

follows.

power

(POF)

3

6

o

9

o

12—

factory

between

CG23

can

plug

or

14"

-

-“For

EOF

—

prior

THE

MODULE

be

can

or

the

be

SW

CRT

14"

CRT/9"

system

the

(disable/

(disable/enable)

shipment)

to

CONNECTION

CG23

FLAT

supplied

done

5.

CRT

(operation

enable)

CABLE

external

The

(optional)

and

on

hold)

the

SW

CG26

CG

or

5

DIAGRAMS

modules

CONNECTOR

w

mm

MODULE

26

disconnected

power

.

main

also

SW

ON

allows

5

card

1

4

7

10

with

/OFF

Use

To

Panel

ooo

ooo

o

lo

two

by

the

(EOF).

(MB

21

selection

Setting

Only

(POF)

3

6

9

o

10

12

ol

50-core

panel

or

of

To

External

1

o

4

o

i

o

lo

of

Use

SW5

o

o

o]

The

MB

the

Only

(EOF)

o

o

o

flat

power

2

OE

3

1

6

4

9

7

10

12

cables,

ON/

following

)

short

"

CRT

9

Use

To

Both

o

o

o

ooo

[c/ol

o

o

fcTol

12

;

:

'

\

3

6

9

Note

3

Always

SW5

Make

open.

sure

set

Nos.

that

4

and

the

6

of

shield

line

of

the

signal

cable

is

treated

as

fol¬

lows.

(l)

When

the

connection

In

of

the

cable

the

grounding

prevents

to

This

connect

NDING

GROU

PLATE

control

this

the

fO

c

diagram

case,

and

external

outer

/CABLE

OUTER

COVER

CABLE

/

CLAMP

panel

shows

always

clamp

plate.

shielding

CABLE

HIELDING

S

and

the

noise

the

this

use

cable

cover

NC

separated

the

so

from

to

OUTER

SHIELDING

COVER

control

shielded

that

flowing

CN2-20

the

CABLE

unit

case)

the

cable.

shielding

into

pin

4-

are

the

CABLE

separated

Strip

cover

control

of

the

GROUNDING

CLAMP

the

SP23

PLATE

(the

outer

grounded

is

unit.

module.

cable

cover

Also

\

(

-15-

Page 16

5.6

(2)

NOTES

When

ture

the

ON

control

THE

CONNECTION

panel

and

the

DIAGRAMS

NC

control

unit

(Cont'd)

are

of

integrated

struc¬

(a)

When

Generally,

in

but

the

(the

wiring

this

Also,

cable

end

Though

connection

noise

test.

JANCD-CG23

CN-49

VSYNC

VSYNC

1

ov

ov

FG

rb

path

-17J,

-16),

-1

-%

To!

using

follow

case,

clamp

at

to

I

j

T

use

the

the

or

improve

the

cable

method

always

shielded

as

CPU

above

configuration

the

in

module

the

(l).

perform

cable

(l).

wherever

Connect

side)

single-end

noise

JANCD-SP23

|CN2

-17

L

Tie

r

4bL

FG

>20

L

The

a

noise

with

connection

of

resistance.

A

following

test.

possible.

one

the

the

control

simple

end

of

pin

FG

is

Evaluate

Simple

In

an

cabinet

external

that

the

feed

drive

within

I/O

cable

cable

NC

the

But

the

on

be

to

unit

method

integrated

acts

noise.

affect

servo

unit

the

cable

,

and

that

unit.

way

there

outer

the

basically

may

the

as

the

,

magnetic

NC

,

are

can

also

is

no

shielding

connector.

require

connection

structure

shield

a

The

signal

drive

unit,

unit

servo

AC

/

power

connected

be

need

applied,

a

noise

cable

relay

,

spindle

used,

to

cover

two-end

with

,

against

sources

spindle

and

supply

outside

use

the

a

the

are

unit

the

PG

When

be

power

Also,

(b)

using

careful

cable

always

When

Connection

distance

the

cable

cannot

*

Use

•

Keep

become

uate

•

Treat

•

Always

of

using

with

single

the

the

cables

the

that

perform

single

between

be

1/

the

noise

the

twisted

perform

without

binding.

can

single

used,

lines

O

source

become

evaluation

lines

lines

CG2

the

use

0.3mm2

of

cable,

of

by

performing

pair

noise

shielding,

Keep

the

generally

is

3

single

a

PG

cable

noise

lines

test

the

source

with

and

line,

or

above.

separated

noise

with

to

evaluate

no

I/O

a

SP23

of

care.

special

cable,

of

noise

not

taking

the

test.

ing

method,

prevent

to

noise

test.

allowed.

modules

care

servo,

from

the

noise.

wiring

The

etc.

this

connection

PG

cable

separated

However,

is

short

of

the

AC

power

each

other.

path,

can

noise

required,

is

of

the

from

and

following.

cable

Always

line

bind¬

arranged

be

interference.

servo,

each

only

shielded

a

other.

when

that

eval¬

but

AC

can

f.

-16-

Page 17

Note

4

The

not

Do

full

keyboard

use

full

provided

is

keyboards

other

only

than

for

specified

the

debug

unit.

by

YASKAWA.

Note

Full

5

The

and

operating

board

within

the

Example

DETACHED

keyboard

detached

detached

box,

The

3

standard

4

1

D

KEYBOARD

the

function

m

from

1

"CRT

BOX

model

keyboard

to

keyboard

permit

to

vertical

*7

B5GS-C098-406

from

the

key

is

SP23

the

keyboard,

CABLE(20-C0RE)

Max.

3

m

used

function

control

for

some

operation

as

module.

(manufactured

allows

panel.

time,

while

follows.

The

is

offered

Example

the

This

to

establish

sitting.

The

detached

as

4"CRT

1

keyboard

function

cable

keyboard

option.

an

2

OMRON)

by

to

is

a

detached

length

THE

CRT

PANEL

MADE

COMPACT.

CABLE(20-CORE)

Max.

3m

be

used

box,

attached

is

CA

N

BE

when

key¬

to

using

be

Note

6

Select

corresponding

the

the

standard

representative

In

this

refer

JANCD-SP23

_

I

ll

to

_

the

case,

keyboard

Par.

I

L

If

vertical

when

our

9.2

for

select

keyboard.

and

specialized

a

system

details

SW1

switch

The

horizontal

software

on

SW1

following

keyboards.

keyboard

development

the

OEMs.

short-circuit

is

the

produced

is

will

(Four

SW1

l

olo

2

lo

olo

|o

3

olo

4

0

00

ABC

1

lo

olo

o[o~o1

2

3

lo

olo

4

0

0 0

ABC

Contact

A,

ol

Set

standard

(The

sideofthe

Set

standard

(The

sideofthe

plug,

method

required.

be

B,

and

keyboard

the

keyboard

keyboard

the

keyboard

according

for

your

by

the

Cs

are

vertical

CRT)

horizontal

CRT)

setting

Yaskawa

OEM.

not

of

the

CRT

is

the

at

the

of

CRT

isatthe

to

Also

used)

unit.

lower

unit.

right

-17-

Page 18

5.6

Note

NOTES

7

A

The

follows.

AC

setting

fore

the

and

100V

ON

left

power

supplying

switch

lower

side

THE

rear

side

100V/220V

always

up,

set

set

normally

is

CONNECTION

of

the

14"

selection

the

the

at

screws

check

power.

10

can

not

that

0V

used.

DIAGRAMS

color

switch

the

If

200

side,

be

loosened

CRT.

switch

VAC

the

for

is

or

CRT

to

(Cont'd)

Sections

the

14"

set

higher

will

change

at

A

color

the

is

connected

fail.

the

to

CRT.

220V

The

setting.

D

are

side

f

as

When

be¬

with

upjjer

The

SP

the

adjustment

unnecessarily

at

not

CRT

OFF

stand-by

the

connector

to

70W)

connector

module

3

2

Video

variable

value

under

viewing

key

on

mode

CRT.

select

200/220V

type

at

Press

100V

the

no

brightness

CRT.

depress

the

the

power

for

max.

where

connected.

are

adjustment

standard

further

When

the

CRT

the

in

life

of

input

method

specifications

(typ.

input

B

Connector

(20-core)

C

CRT

sted

needs

the

of

plied,

to

prolong

the

D

The

above

AC

brightness

at

CRT

the

set

CRT.

AC

power

100W

power

AC

CND

signal

input

resistor.

factory

the

normal

high

CRT

the

keyboard

the

(the

CRT

the

for

the

or

+10%

1-480700-0

connector

value

key

1

220V

while

turns

4

-15%,

and

connector.

The

resistor

before

circumstances.

will

shorten

power

the

(standard

black)

color

power.

more

CRT.

once

"

AC

50/60Hz

(AMP

Co.)

flat

delivery

keyboard)

which

to

3-pin

cable

adju¬

is

and

Setting

the

sup-

is

can

activate

See

±1%,

lock

A

life

A

connector.

A

SP

MODULE

23

,

AC

(

t

c:

LSIG,

.r.

M

SELECT

V

100

V

220

4-

B

IN

4>

I

BRIGHT

*

j-r-,

4

1

D

I

I

-18

Page 19

8

Note

(l)

The

Keep

the

no

other

the

machine

setting

than

function

(2)

The

Keep

the

developing

must

tion

system

the

Also

check

system

(3)

System

mode.

The

end

or

the

The

switch

to

0

number

the

end

system

is

does

machine

system

be

to

the

user

system

operation

are

can

E

switch)

following

user

number

tool

necessary

may

0

not

application

the

made

number

that

end

number

or

will

as

follows.

set

be

at

when

switch

manufacturer

by

cause

work

tool

the

during

manufacturer

number

with

the

switch

system

the

users.

switch

machine

fail.

modes

with

the

setting.

the

system

switch

software.

system

0

to

number

settings

tool

for

rotary

the

upper

fixed

with

user.

right

at

the

Starting

to

operation.

fixed

However,

number

after

setting

switch

5

to

manufacturer

setting

the

0.

fail.

at

E

switch

corner

The

system

0,

are

on

SW

the

Also

as

parameter

switch

and

is

set

for

should

the

1

or

switch

number

machine

note

with

set

changing

at

Yaskawa's

never

ACGC

(hereafter

CG23

the

will

be

switch

with

the

that

the

end

setting

1.

at

before

0

use

120

delivered

the

self

users,

Always

the

system

these

system

called

system

module.

set

at

setting

diagnosis

and

altera¬

return

parameters.

shipping

diagnosis

settings

number

from

0

if

Note

,

so

at

not

the

Setting,

System

Specifications

CD

The

(

immediately

(2)

The

display

The

(3)

The

execute

(4)

This

index

tion

the

is

It

program

Note

utility

Multiple

Number

Application

Mode

When

When

the

system

the

system

the

development

When

the

system

the

When

specifications.

the

mode

"1"

program

necessary

not

replacement

that

and

is

is

the

dividing

files

Internal

All

GMISC

Execution

system

starts

up,

execute

system

starts

application

up,

mode

system

starts

application

system

basically

immediately

not

be

can

file

name

cannot

0

type

commands

can

number

synchronizing

the

number

synchronizing

program

screen

number

up

in

program

number

equivalent

replaced

input

to

under

file,

the

exist

on

1

Debug

unit

and

be

used.

Development

switch

application

switch

is

switch

ACGC

switch

executed

the

these

created

cannot

on

a

System

the

Portable

Commands

GMISC

be

used.

Execution

is

with

program

is

with

development

equivalent

is

unit,

(index

is

to

the

by

the

alphabet

specifications.

when

be

single

Number

2

type

related

set

at

at

set

at

set

power

as

"1"

set

at

system

as

power

floppy

merging

changed.

diskette.

3

NCREQ,

to

Execution

0

NC,

the

(index

1

NC,

the

mode

to

the

2

).

3

disk

key

Switch

FREQ

the

existing

is

number

supplied,

is

drive.

on

is

executed

4

and

NC

cannot

Development

power

as

).

"1"

power

as

screen.

supplied,

switch

the

screen

Program

the

createdbythe

sational

be

Yaskawa's

is

is

screen.

to

and

The

by

-

5

Do

not

and

prog:

destroyed.

system

supplied,

supplied,

immediately

mode,

2

the

following

application

of

EXE.MRG

the

E

touch

data

conver-

ram

diagnosis

but

applica¬

are-

will

to

to

-19-

Page 20

*'!

'

SETTING

6.

SWITCHES

OEM

The

(1)

JANCD-CG26/CG27

Switch

(Also

see

SW2

Section

SW1

should

Name

8.)

THE

refer

MODULE

Par.

to

module

Enables/disables

to

or

the

the

setting

the

VPP

factory

the

SW2

module

replace

when

stand-alone

short-circuit

on

by

CG26/CG27

set

this

side

supplied

is

on

the

setting

necessary

Used

module,

unit

Set

on

The

necessary

Sets

Always

The

power

If

mounted

The

normally

is

9.2.

the

the

application

(ROM

delivery

the

machine

switch

8)

(5

to

module

SHORT-CIRCUIT

Descriptions

ROM

ROM

PROHIBIT

modules

is

with

on

type

plug

is

at

used

the

will

delivery

by

the

mounted

memory

software

at

at

at

the

manufacturer

tool

at

the

NORMAL

for

setting

be

machine

on

space

is

OEM.

the

the

status)

side.

EN

online

factory

at

destroyed.

is

the

at

the

to

developed

side,

DIS

.

No

mode

side

maintenance

the

NORMAL

manufacturer

tool

PLUG

CG26/CG27

on

using

disable

end

offline

side,

the

is

user.

mode)

(offline

side.

RAM

to

change

or

or

(offline

VPP

Enable:

Disable:

modules.

CG29

the

normally

mode.

the

No

or

debug

the

1

mode).

ROM

end

EN

DIS

ROM

to

change

user.

%

4.

V

The

CNP

t

0 0

0

Arty

5

CD

SIS

SW2s

JANCG-CG26

CNA

l

CO

0.

0

r-

o

Z>

CD

a

in

CO

<

CM

g

Z

in

CNR

the

[

CNB

]

CM

5f°lb

above

o

]

O'*

Q

SW

SW

figures

JANCD-CG27

2

1

3

CD

are

ts3

o

u

i-Lfl.

0

a

CO

r-.

CD

in

co

CM

both

CNR

Q.

Z>

<

o

]

D

0

D

ENVOIS

INHIBIT

ROM

set

at

NOT

the

SW

SW

1

2

USED

EN

(enable)

A

side.

-20-

0

Page 21

(2)

JANCD-CG29

module

Switch

(Rotary

(Also

SW2,

see

Name

3

switch)

Section

8.)

o

2

MB

can

set

This

the

of

cation

SW2