Page 1

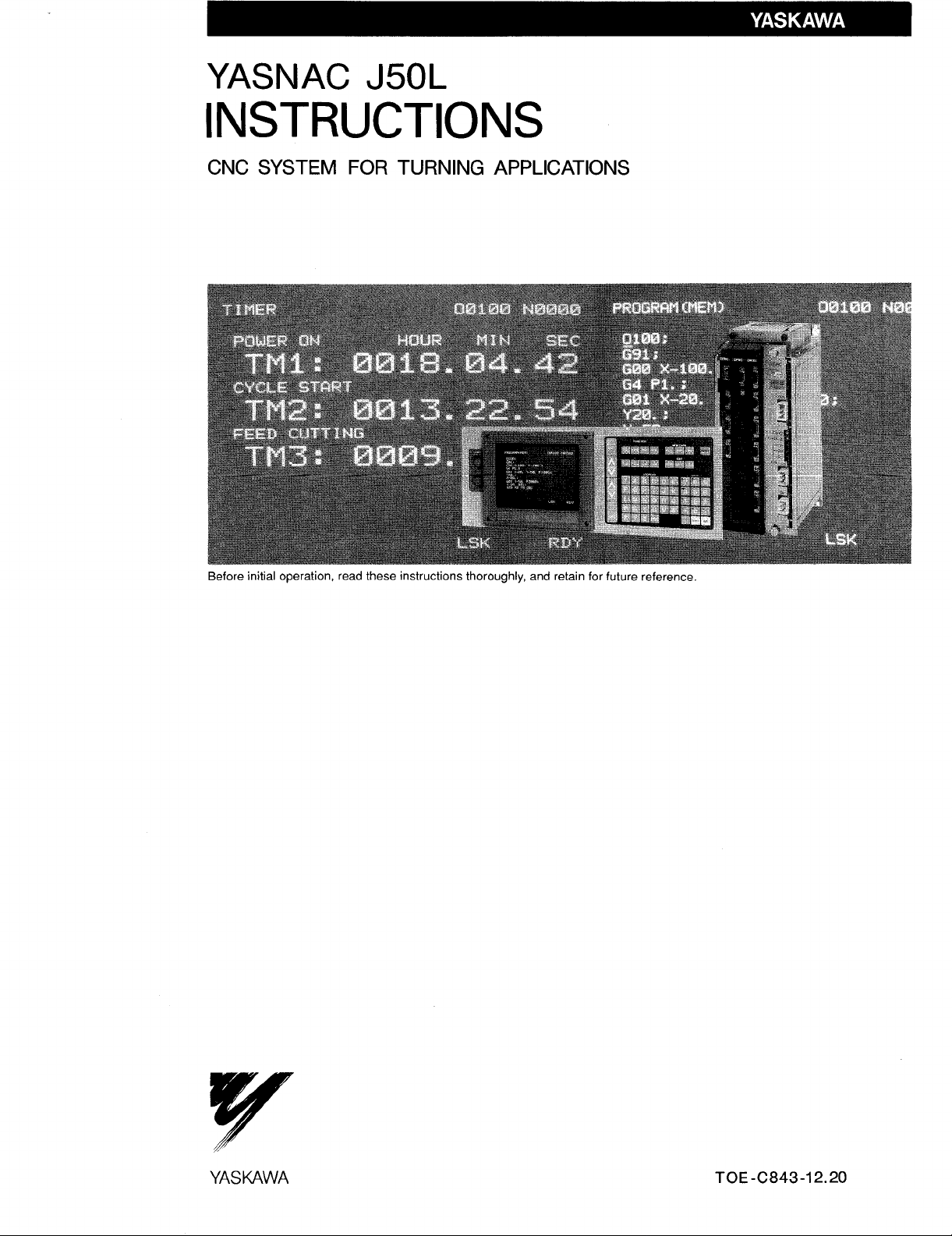

YASNAC J50L

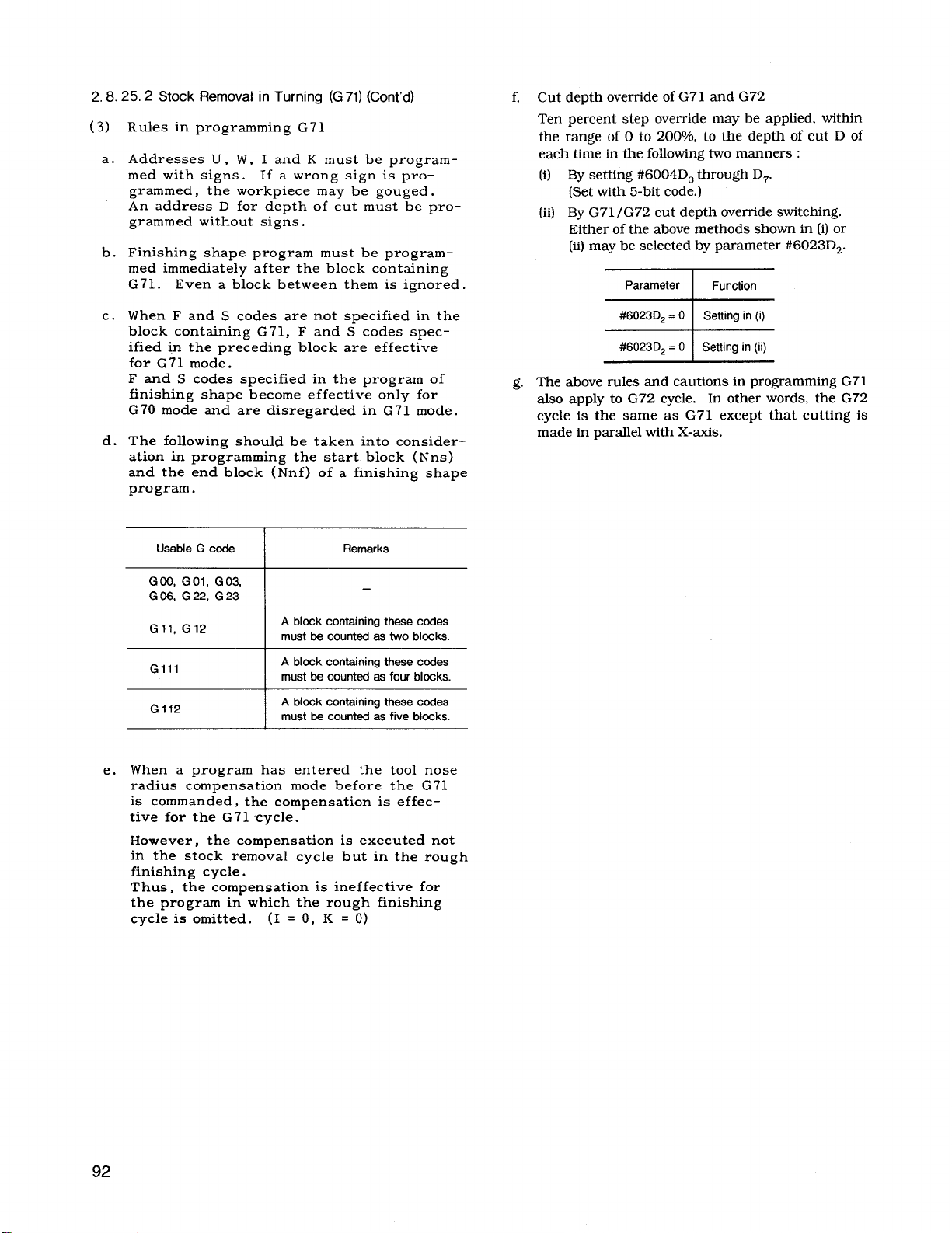

INSTRUCTIONS

CNC SYSTEM FOR TURNING APPLICATIONS

YASUAVVA

TOE-C843-12.20

Page 2

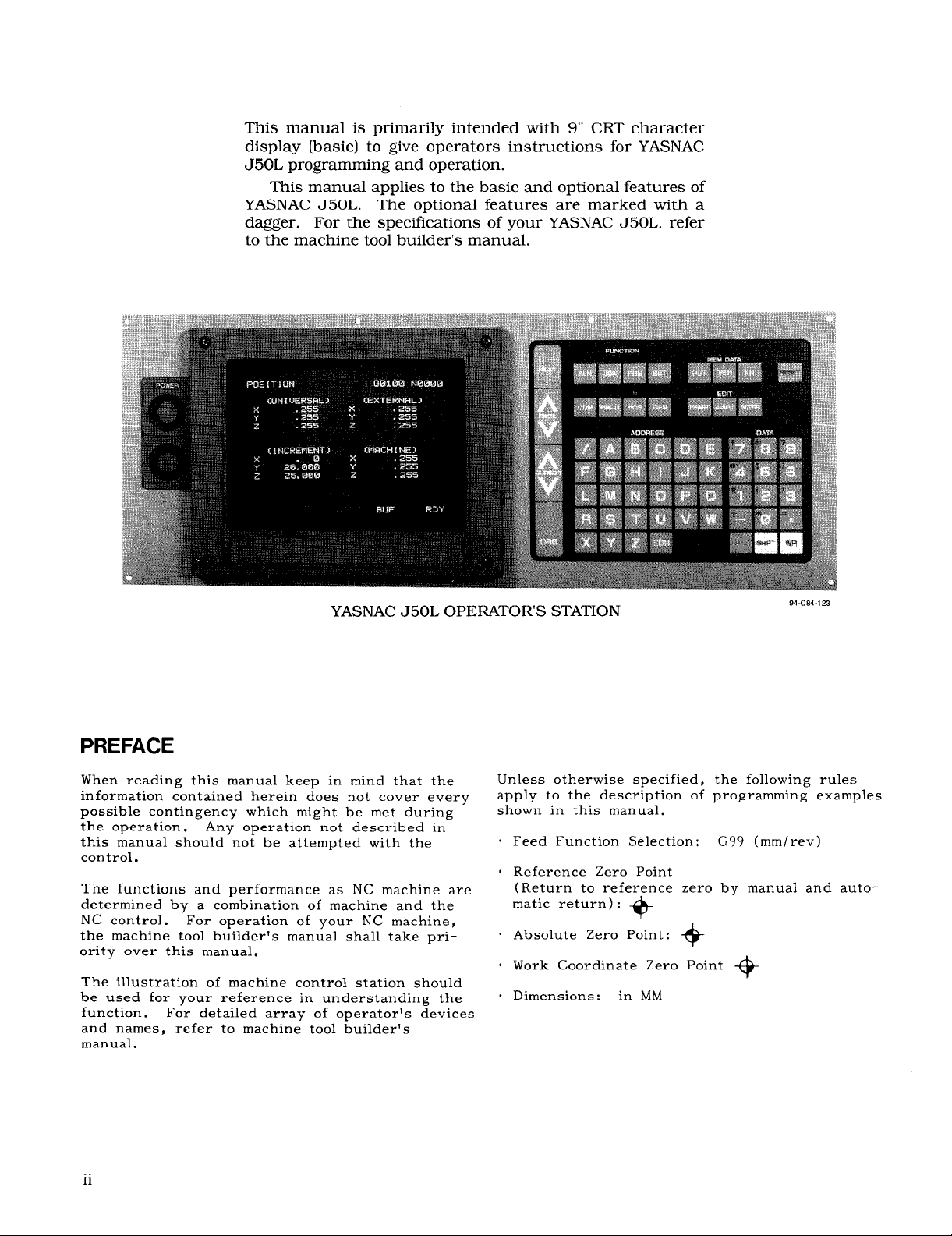

This manual is primarily intended with 9“ CRT character

display (basic)to give operators instructions for YASNAC

J50L programming and operation.

This manual applies to the basic and optionalfeaturesof

YASNAC J50L. The optional features are marked with a

dagger. For the specificationsof your YASNAC J50L, refer

to the machine toolbuilder’smanual.

YASNAC J50L OPERATORS STATION

PREFACE

When reading this manual keep in mind that the

information contained herein does not cover every

possible contingency which might be met during

the operation. Any operation not described in

this manual should not be attempted with the

control.

The functions and performance as NC machine are

determined by a combination of machine and the

NC control.

the machine toolbuilder’smanual shalltake pri-

ority over this manual.

The illustrationof machine control station should

be used for your reference in understanding the

function.

and names,

manual.

For operation of your NC machine,

For detailedarray of operatorls devices

refer to machine toolbuilder’s

23

M-CM-1

Unless otherwise specified,

apply to the descriptionof

the followingrules

programming examples

shown in this manual.

Feed Function Selection:

G99 (mm/rev)

Reference Zero Point

(Return to reference zero by manual and auto-

matic return):

Absolute Zero Point:

Work Coordinate Zero Point

Dimensions:

+

+

+

in MM

ii

Page 3

TABLE OF CONTENTS

1. INTRODUCTION 1

2. PROGRAMMING 1

2.1

TAPE FORMAT 1

PROGRAM NUMBER AND SECNJENCE NUMBER 6

2.2

2.3

COORDINATE WORDS

RAPID TRAVERSE RATE 10

2.4

25

SPINDLE-SPEED FUNCTION (S-FUNCTION) 13

TOOL FUNCTION (T-FUNCTION) 14

2.6

MISCELLANEOUS FUNCTIONS (M-FUNCTION) 17

2.7

PREPARATORY FUNCTIONS (G-FUNCTION) 21

2.8

3. NC TAPE PUNCHING 139

3.1 TAPE CODE 139

3.2 PROGRAMMING 139

3.3 NC TAPE 141

7

3.4 NC TAPE HANDLING 141

4. STANDARD NC OPERATOR’S STATION

WITH CRT CHARACTER DISPLAY 142

PUSHBUTTONS, KEYS, AND LAMPS 142

4.1

POWER ON/OFF OPERATION 146

4.2

4.3

DISPLAY AND WRITING OPERATION 146

4.4

LOADING PART PROGRAMS

AND NC DATA INTO MEMORY (IN) 163

4.5

TAPE VERIFYING 166

4.6

EDIT 168

4.7

PART PROGRAM AND NC DATA OUTPUT

OPERATIONS 170

4.8

SUMMARY OF STORING

AND EDITING OPERATIONS 173

5. MACHINE CONTROL STATION 174

5.1 SWITCHING UNITS ON THE CONTROL

STATION

OPERATION PROCEDURE 181

5.2

6. OPERATION PROCEDURE 195

INSPECTION BEFORE TURNING ON POWER 195

6.1

TURNING ON POWER 195

6.2

MANUAL OPERATION 195

6.3

6.4

PREPARATION FOR STORED LEADSCREW

ERROR COMPENSATION AND

STORED STROKE LIMITt 196

PREPARATIONS FOR AUTOMATIC OPERATION 196

6.5

OPERATION IN TAPE AND MEMORY MODE 197

6.6

MANUAL OPERATION INTERRUPTING

6.7

AUTOMATIC OPERATION 197

AUTOMATIC OPERATION IN MDI MODE 198

6.8

6.9

MDI OPERATION INTERRUPTING AUTOMATIC

OPERATION 198

6.10 PREPARATION FOR TURNING OFF POWER

6.11 TURNING OFF POWER 198

APPENDIX 1

APPENDIX 2

APPENDIX 3

APPENDIX 4

APPENDIX 5

APPENDIX 6

174

LIST OF SETTING NUMBERS A-f

LIST OF PARAMETER NUMBERS

STORED LEADSCREW ERROR

COMPENSATION A-24

LIST OF STANDARD lNPUT/OUTPUT

SIGNALS A-25

LIST OF ALARM CODES A-35

LIST OF DATA A-54

198

A-7

...

111

Page 4

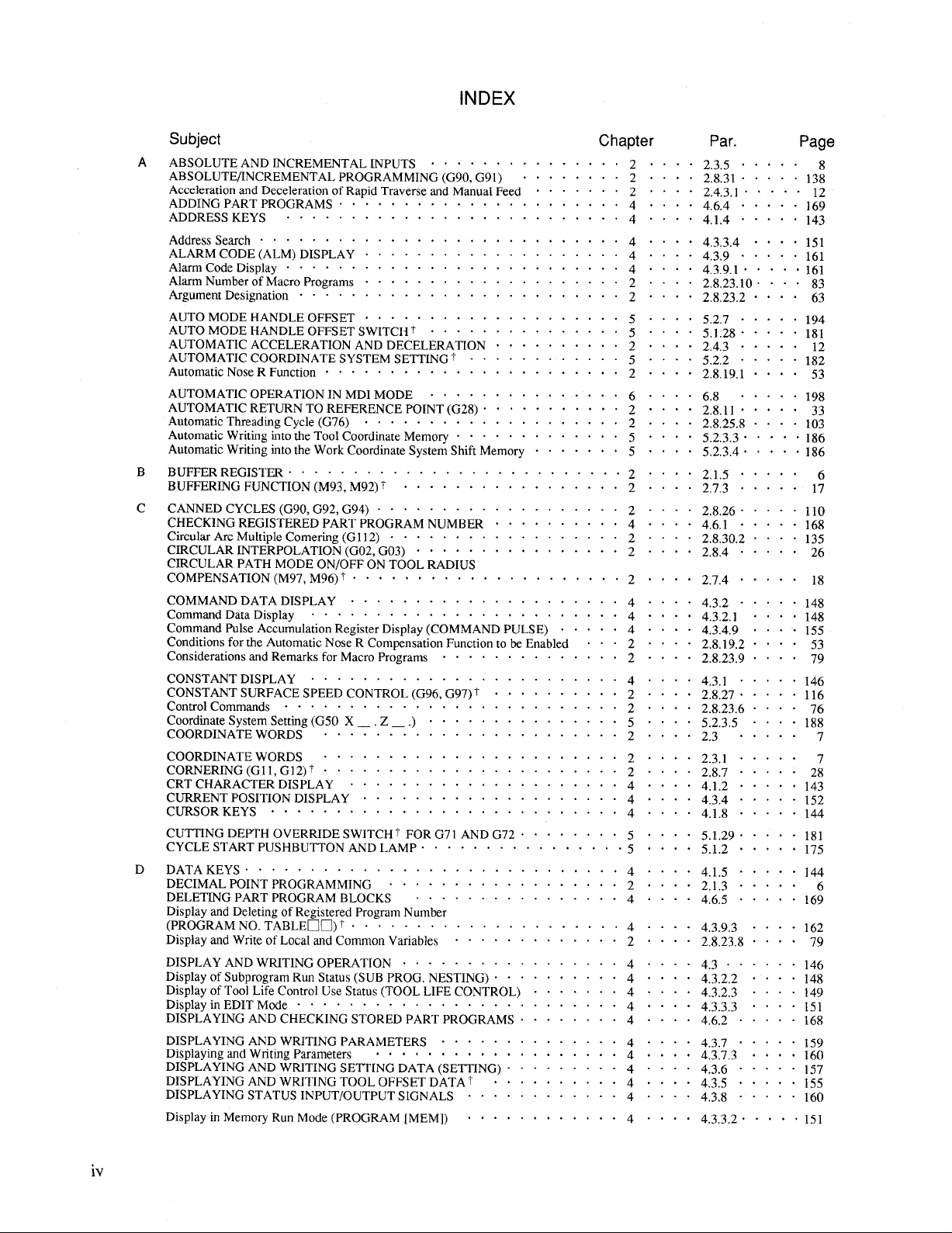

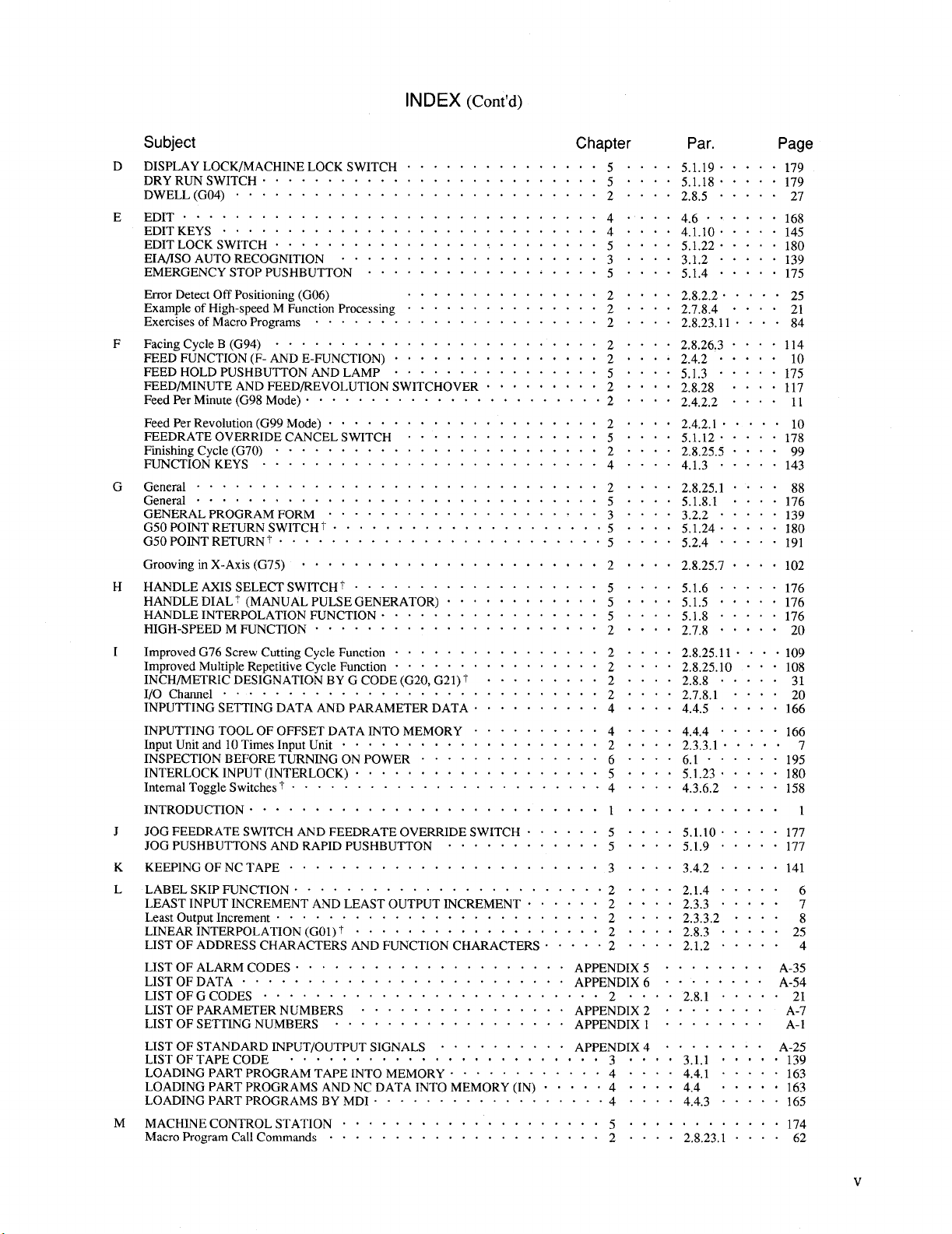

INDEX

Subject Chapter

A ABSOLUTE AND INCREMENTAL LNPUTS . . . . . . . . . . . . . . . 2 . . . . 2.3.5. . . . . 8

ABSOLUTE/lNCREMENTAL PROGRAMMING (G9t3,G91) . . . . . . . . 2 . . . . 2.8.31. . . . . 138

AccelerationandDecelerationofRapidTraverseandManlralFeed . . . . . . . 2 . . - - 2.4.3.]. . . . . 12

ADDING PART PROGRAMS . . . . . ., . . . . . . . . . . . . ...4 . . ..4.6.4 . . . ..]69

ADDRESS KEYS O........ . . . . . . . . . . . . . . ...4 . . ..4. ]4. . . ..I43

AddressSearch. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . 4.3.3.4.... 151

ALARM CODE(ALM) DISPLAY . . . . . . . . . . . . . . . . . ...4 . ...4.3,9.....161

AlarmCodeDisplay. . . . . . . . . . . . . . . . . . . . . . . . ..4 . . ..4.3 .9.I.... .161

AlarmNumberofMicroprograms. . . . . . . . . . . . . . . . . . . . 2 . . . . 2,8,2~,lo.. . . 83

ArgumentDesignation. . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.23.2... .63

AUTO MODE HANDLE OFFSET.. . . . . . . . . . . . . . . . . . . 5....5.2.7.....194

AUTO MODE HANDLE OFFSETSWITClit . . . . . . . . . . . . - . . 5 . . . . 5,],28.. . . . 181

AUTOMATIC ACCELERATION AND DECELERATION . . . . . . . . . . 2 . . . . 2.4.3. . . . . 12

AUTOMATIC COORDINATE SYSTEM SETTING“t. . . . . . . . . . . . 5 . . . . 52,2 . . . . . 182

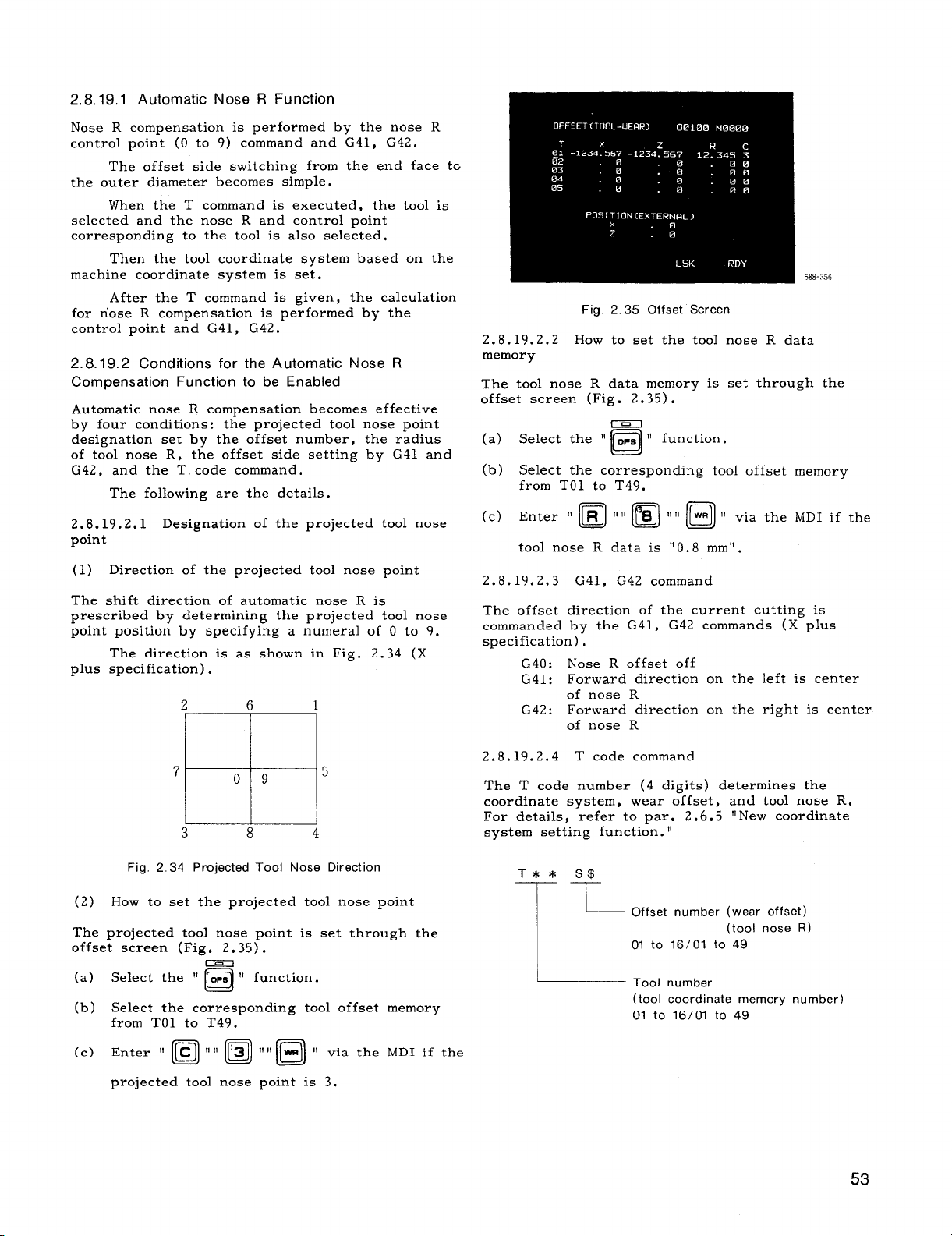

AutomaticNoseR Function. . . . . . . . . . . . . . . . . . . . ...2....2.8.19,1 . ...53

AUTOMATIC OPERATION INMDIMODE . . . . . . . . . . . . . . . 6 . . . . 6.8 . . . . . 198

AUTOMATIC RETURN TO REFERENCE POINT (G28). . . . . . . . . . . 2 . . . . 2.8.11. . , . 0 33

AutomaticThreadingCycle(G76) . . . . . . . . . . . . . . . . . . . . 2 . . . . 2,8,25,8. . . . Io3

AutomaticWritingintotheToolcoordinateMemory . . . . . . . . . . . . . 5 . . . . 5,2,3,3.. . . .186

AutomaticWritingintotheWork CoordinateSystemShiftMemory . . 0 . . . . 5 . . . . 5.2.3.4.. . . .186

B

BUFFER REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.15.....

BUFFERING FUNCTION (M93,M92)t . . . . . . . . . . . . . . ...2 . . . . 2.7.3. . ...1.

c

CANNED CYCLES (G90,G92,G94) . . . . . . . . . . . . . . . . ...2 . ...2.8.26.....110

CHECKING REGISTEREDPART PROGRAM NUMBER . . . . 0 . . . . . 4 . . . . 4.6.1. . . . . 168

CircularArcMultipleComering(Gl12). . . . . . . . . . . . . . . . . . 2 . . . . 2.8.30,2. . . . 135

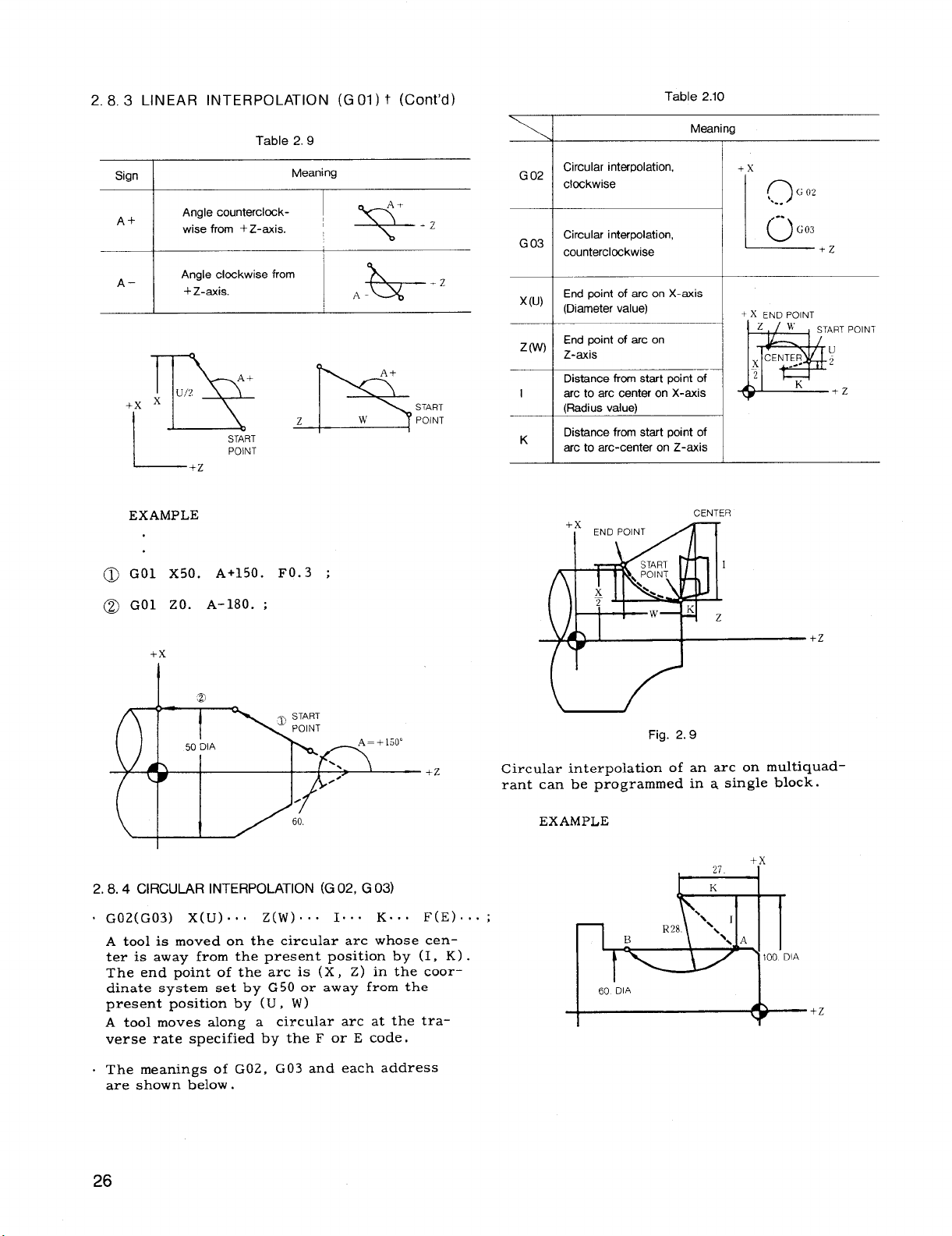

CIRCULAR INTERPOLATION(G02,G03) . . . . . . . . . . . . . . . . 2 . . . 0 2.8.4. . . . . 26

CIRCULAR PATH MODE ON/OFFON TOOL RADIUS

COMPENSATION (M97,M96)t . . . . . . . . . . . . . . . . . . ...2.. . . 2,7,4. . ...18

COMMAND DATA DISPLAY . . . . . . . . . . . . . . . . . . ...4 . ...4.3,2.....148

Command DataDisplay. . . . . . . O + . . . . . . . . . . . . . . .4 . . ..4.3 .2148 . ..I48

Command pukeAccumulationRegisterDisplay(COMMAND PULSE) . . . . . 4 . . . . 4.3.4.9. . . . 155

ConditionsfortheAutomaticNoseR CompensationFunctiontobeEnabled . . . 2 . . . . 2.8.19.2. . . , 53

ConsiderationsandRemarksforMacroPrograms. . . . . . . . . . . . . . 2 . . . . 2.8.23.9. . . . 79

CONSTANT DISPLAY . . . . . . . . . . . . . . . . . . . . . ...4 . . ..4.3 .] . . ...146

CONSTANT SURFACE SPEED CONTROL (G96,G97)t c . . . . . . . . . 2 . . . 0 2.8.27.. . . . 116

ControlCommands . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.23.6.... 76

CoordinateSystemSetting(G50X_. Z_.) . . . . . . . . . . . . . . . 5 . . . . 5.2.3.5. . . . 188

COORDINATE WORDS . . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.3.....7

COORDINATE WORDS . . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.3.1. . . . .

CORNERING (Gil,G12)t . . . . . . - . - . . . . . . . . . . . ...2 . . . - 2.8,7-....22

CRT CHARACTER DISPLAY . ..C . . . . . . . . . . . . . . ...4 . ...4.1,2.....143

CURRENT POSITIONDISPLAY . . . . . . . . . . . . . . . . . ...4 . ...4.3,4.....152

CURSOR KEYS . . . .. O.. CC . . . . . . . . . . . . . . ...4 . . ..4.1 .8 . . . ..I44

CUTTING DEPTH OVERRIDE SWITCH’iFORG71 ANDG72 . . . . . . . . 5 . . . . 5.1.29.. . . . 181

CYCLE START PUSHBUTTON AND LAMP . . . . . . . . . . . . . . . .5 . . . . 5.1.2. . . . . 175

D

DATA KEYS . . . . . . . . . . . . . . . . . . . . . . . . . . ...4 . ...415.....144

DECIMAL POINTPROGRAMMING. . . . . . . . . . . . . . . ...2 . . . . 2.1.3. . . . .

DELETING PART PROGRAM BLOCKS . . . . . . . . . . . . . . . . 4 . . . . 4.6,5. . . . . 16j

DisplayandDeletingofRegisteredProgramNumber

(PROGRAM NO.TABLEnn)t . . . . . . . . . . . . . . . . . ...4.... 4.3.9.3....162

DisplayandWriteofLocalandCommon Varfab]es. . . . . . . . . . . . . 2 . . . . 2.8.23.8. . . . 79

DISPLAY AND WRITING OPERATION . . . . . . . . . . . . . . ...4 . ...4.3......146

DisplayofSubprogramRunStatus(SUBPROG.NESTING). . . . . . . . . . 4 . . . . 4.3.2.2, . . . 148

DisplayofToolLifeControlUseStatus(TOOLLIFECONTROL) . . . . . . . 4 . . . . 4.3.2.3. . . . 149

DisplayinEDITMode . . . . . . . . . . . . . . . . . . . . . . . . .4 . . ..4.3 .3151 . ..I51

DISPLAYINGAND CHECKING STORED PART PROGRAMS . . . . . . . . 4 . . . . 4.6,2. . . . . 168

DISPLAYINGAND WRITING PARAMETERS . . . . . . . . . . . - . . 4 . . . . 4.3.7. . . . . 159

DisplayingandWritingParameters, , . , , , . . . . . . . . . . . . . 4 . . . . 4.3.7,3. . . . 160

DISPLAYINGAND WRITING SETTINGDATA (SETTING). . . . . . . . . 4 . . . . 4,3,6. . . . . 157

DISPLAYINGAND WRITING TOOL OFFSET DATAt . . . . . . . . . . 4 . . . . 4.3.5. . . . . 155

DISPLAYINGSTATUS INPUT/OUTPUTSIGNALS . . . . . . . . . . . . 4 . . . . 4,3.8. . . . . 160

DisplayinMemoryRttnMode(PROGRAM [MEM]) . . . . . . . . . . . . 4 . . . . 4.3.3.2.. . . .151

Par. Page

iv

Page 5

INDEX (Cent’d)

Subject

D

DISPLAYLOCK/MACHINE LOCK SWITCH . . . . . . . . . . . . . . . 5 . . . . 5.1.19.. . . . 179

DRY RUN SWITCH . . . . . ..O. . . . . . . . . . . . . . . ...5 . ...5.1.18.....179

DWELL (G04)----------- . . . . . . . . . -.......2 . . . . 2.8.5. . ...27

E

EDIT....,.00...o..o . . . . . . . . . . . . . . ...4 . ...4.6......168

EDITKEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 . . ..4.1 .145. . ..I45

EDITLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . 5....5.1.22.....180

EIA/ISOAUTO Recognition . . . . . . . . . . . . . . . . . ...3 . ...3.1.2.....139

EMERGENCY STOP PUSHBUTTON. . . . . . . . . . . . . . . ...5 . ...5.1.4.....175

ErrorDetectOffPositioning(G06)

ExampleofHigh-speedM FunctionProcessing. . . . . . . . . . . . . . . 2 . . . . 2.7.8.4. . . . 21

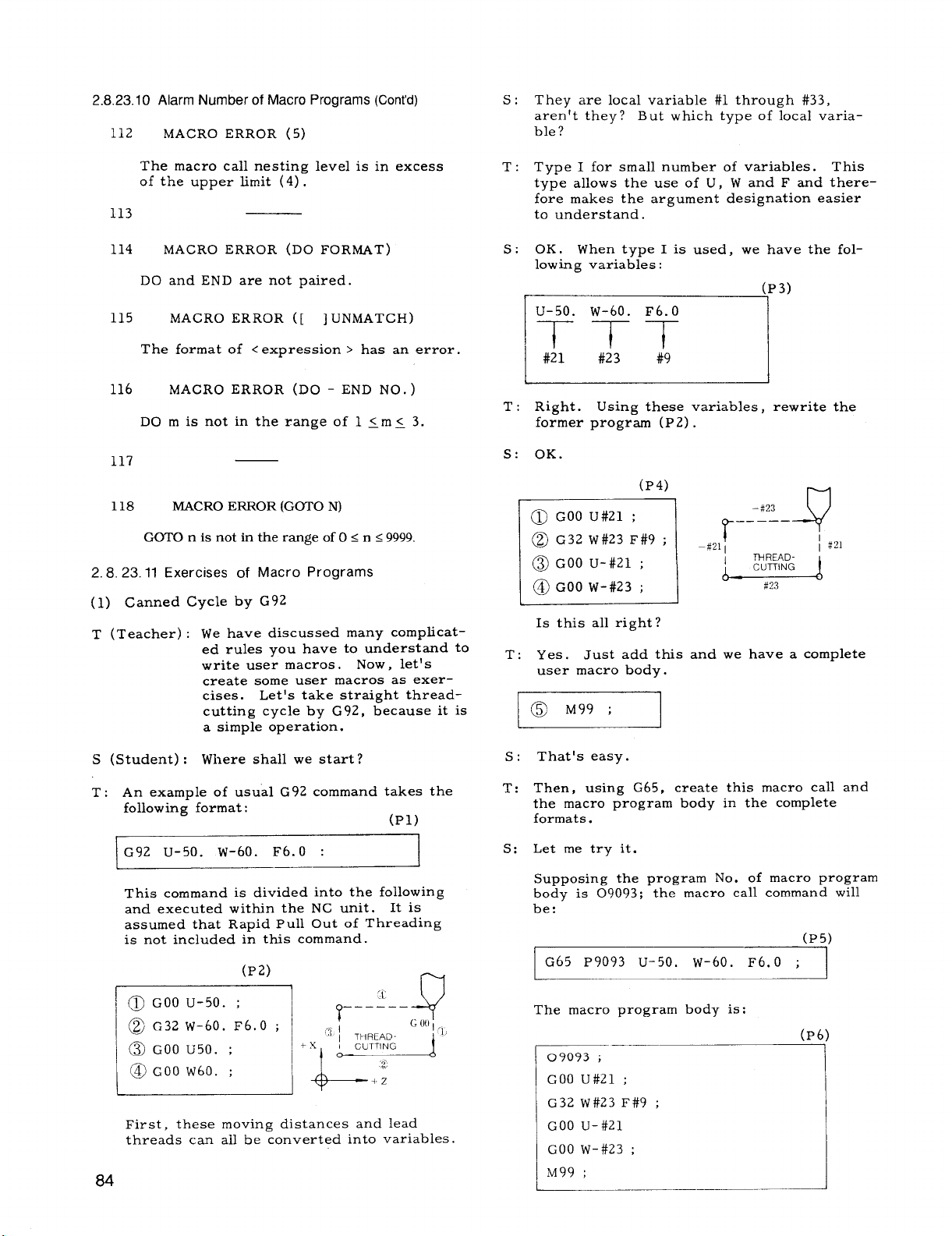

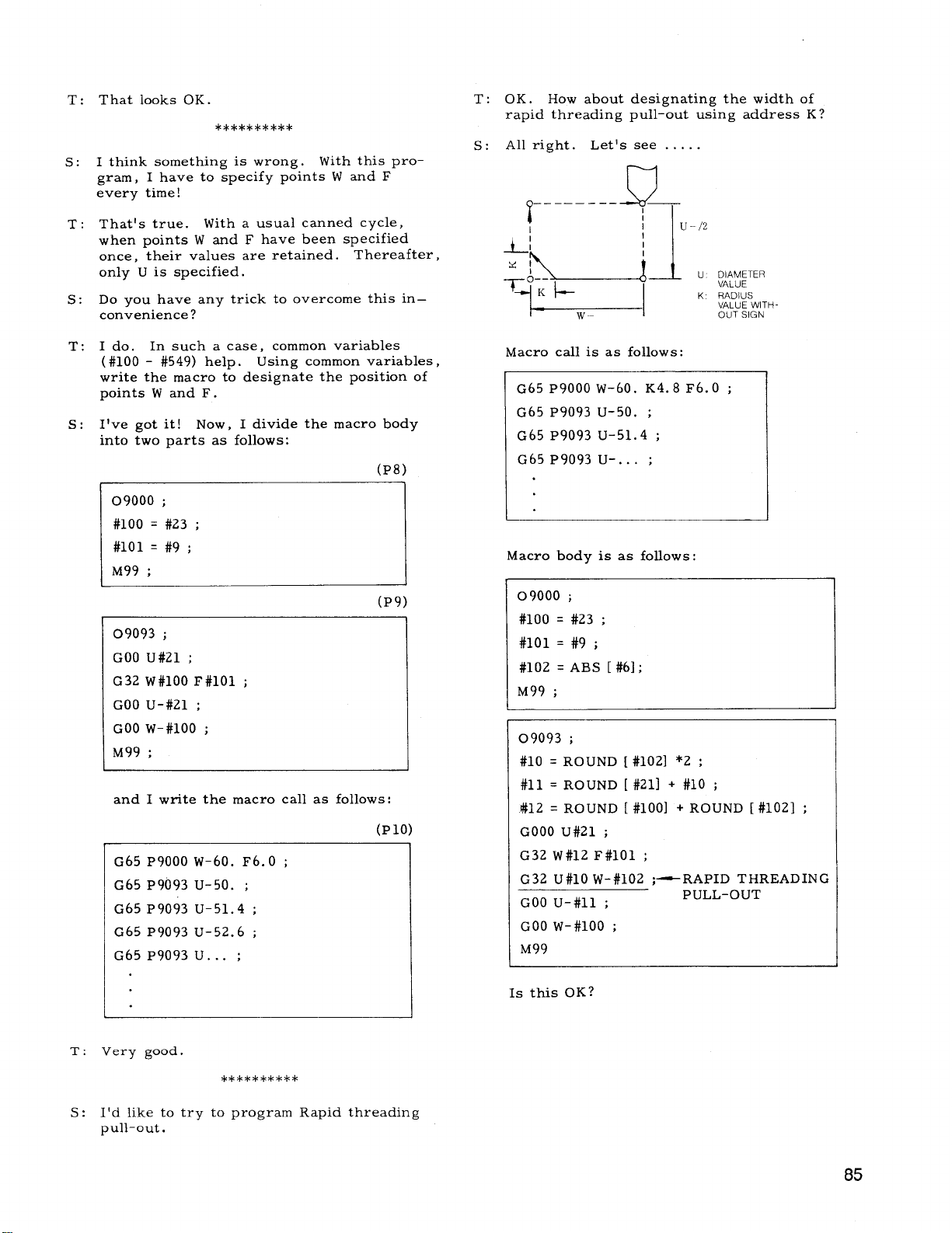

ExercisesofMicroprograms................ , . . . . . 2 . . . . 2.8.23.11. ...84

F

FacingCycleB(G94) . . . . . . . . . . . . . . . . . . . . . . ...2 . ...2.8.26.3....114

FEED FUNCTION (F-AND E-FUNCTION) . . . . . 0 0 0 0 0 , . . 0 0 0 2 , 0 0 . 2.4.2. . . , . 10

FEED HOLD PUSHBUTTON AND LAMP . . . . . . . . . . . . . . . . 5 . . . . 5.].3. . . . .

FEED/MINUTE AND FEED/REVOLUTIONSWITCHOVER . , , . 0 , , . 0 2 . 0 , , 2,8,28 . . . . 117

FeedPerMinute(G98Mode). . . . . . . . . . . . . . . . . . . . . . . 2.. o.2.4,2.2 . . ..1 I

FeedPerRevohrtion(G99Mode). . . ................. . 2 .,, ,2.4.2.1.....10

FEEDRATE OVERRIDE CANCEL SWITCH . . . . . . . . . . . . . . . 5 . . . . 5.1.12.. . . . 178

FinishingCycle(G70) . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.8.25.5....99

FUNCTION KEYS . . .. O.... . .,...,........4.4 . ...4.1.3.....143

G

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.25.1....88

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 . . . . 5.1.8.1.... 176

GENERAL PROGRAM FORM..- . . . . . . . . . . . . . . . . . -3....3.2.2.....139

G50P01NT RETURN SWITCH ~”... . . . . . . . . . . . . . . . . . .5....5,1.24.....180

G50POINTRETURNt . . . . . . . . . . . . . . . 4 . . . . . . ...5 . ...5.2.4.....19]

GroovinginX-Axis(G75) . . . . . . .,, ,,, . . . . . . . . ...2 . ...2.8.25.7....102

HANDLE AXISSELECT SWITCH t.. . . . . . . . . . -.......5 . ...5.1.6.....176

H

HANDLE DIALt (MANUAL PULSEGENERATOR) . . . . . . 0 0 0 . . . 5 0 0 , . 5.1.5. , , . 0 176

HANDLE INTERPOLATIONFUNCTION . . . . . . . . . . . . . . . . . 5 . . . . 5.1.8. . . . . 176

HIGH-SPEEDMFUNCTJON . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.7.8. . ...20

ImprovedG76ScrewCuttingCycleFunction. . . . . . . . . . . . . . . . 2 . . . . 2.8.25.11. . . .109

I

ImprovedMultipleRepetitiveCycleFunction. . . . . . . . . . . . . . . . 2 . . . . 2.8.25.10. . . 108

INCH/METRICDESIGNATION BY G CODE (G20,G21)t . . . . . . 0 . . 2 . . . . 2.8.8. . . . . 31

I/OChannel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.7.8.1....20

INPUTTINGSETTINGDATA AND PARAMETER DATA . . . . . . . . . . 4 . . . . 4.4.5. . . . . 166

INPUTTINGTOOL OF OFFSETDATA INTO MEMORY . . . . . . . . . 0 4 . . . . 4.4.4. . . . . 166

InputUnitand10TimesInputUnit, . . . c c c o . . . 0 . . . . . . . . 2 . . . 0 2.3,3.1.. . . . 7

INSPECTIONBEFORE TURNINGON POWER . . . . . . . . . . . . . . 6 . . . . 6.1. . . . . . 195

INTERLOCK INPUT (INTERLOCK). . . . . . 0 . . . . . . . . . . c . 5 . 0 . . 5.1.23.. . . . 180

InternalToggleSwitchest..... . . . . . . . . . . . . . . . . . . . 4 . . . . 4.3.6.2.... 158

INTRODUC~ON . . . . . . . . . . . . . . . . . . . . . . . . ...1 . . . . . . . . . ...1

JOG FEEDRATE SWITCH AND FEEDRATE OVERRIDE SWITCH . . . . . . 5 . . . . 5.1.10.. . . . 177

J

JOG PUSHBUTTONS AND RAPID PUSHBUTTON . . . . . . . . . . 0 . 5 . . . . 5.1.9. . , . . 177

KEEPINGOF NC TAPE . . . . . . . . . . . . . . . . . . . . . . . . 3....3.4.2.....141

K

L

LABEL SKIPFUNCTION . . . . . . . . . . . . . . . . . . . . . . . .2 . . . . 2.1.4. . ...6

LEAST INPUTINCREMENT AND LEAST OUTPUT INCREMENT . . . . . . 2 . . . . 2.3.3. . , . . 7

LeastOutputIncrement. . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.3.3.2.... 8

LINEARINTERPOLATION(GOl)t. . . . . . . . . . . . . . . . ...2 . . . . 2.8.3. . ...25

LISTOF ADDRESS CHARACTERS AND FUNCTION CHARACTERS . . . . . 2 . . . . 2.1.2. . . . . 4

LISTOF ALARM CODES O..,., .,..,.,,4.000..APPENDIX5 ...,.... A-35

LISTOF DATA . . . . . . . . . . . . . . . . . . . . . . . .. APPENDIx6 . . . . . . .. A-54

LISTOF GCODESOO. ., CO.. . . . . . . . . . . . . . . ...2 ,0,,2.8.1.,,0,21

LISTOF PARAMETER NUMBERS . . . . . . . . . . . . . . . . APPENDIX2 . . . . . . . .

LISTOF SETTINGNUMBERS,,, ,.OO,O. ., . . . . .. APPENDIX 1 . . . . . . . . A-1

LISTOF STANDARD INPUT/OUTPUTSIGNALS . . . . . . . . . . APPENDIX 4 . . , . . . . . A-25

LISTOF TAPE CODE .C .,.., ,,,.,.so,o.,,,$.13 ... ,3.1.1 ooo, .139

LOADING PART PROGRAM TAPE INTOMEMORY - - . . . . - . - . . . 4 . - . . 4.4,1. - . . . 163

LOADING PART PROGRAMS AND NC DATA INTO MEMORY (IN). 0 0 0 . 4 . . . . 4.4 0 . . 0 “ 163

LOADING PART PROGRAMS BYMDI . . . . . . . . . . . . . . . . . .4 . ...4.4.3 . . ...165

M

MACHINE CONTROL STATION . . . ., . . . . . . . . . . . . ...5 . . . . . . . . . ...174

MacroPromamCallCommands. . . . . . . . . . . . . . . . . . ...2....2.8.23.1 . ...62

. . . . . . . . . . . . . . . . .

Chapter

2

Par. Page

. . 2.8.2.2.. . . . 25

175

A-7

Page 6

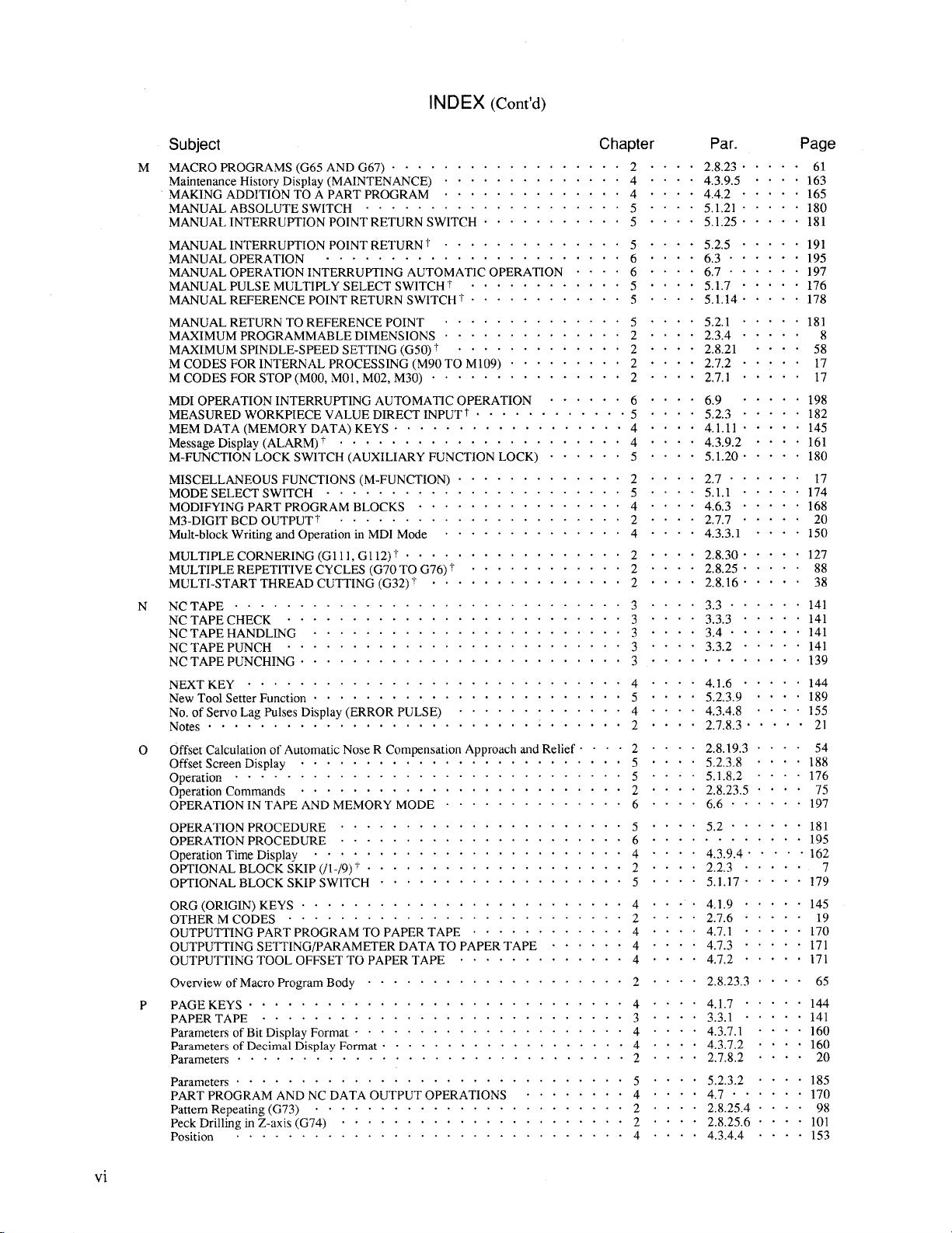

INDEX (Cent’d)

Subject

M MACRO PROGRAMS (G65ANDG67) . . . . . . . . . . . . . . . . . . 2 . ..” 2.8.23.”””” 61

MaintenanceHistoryDisplay(MAINTENANCE) . . . . . . “ “ “ o “ “ $ - 4 ‘ - - “ 4.3.9.50 “ “ “ 163

MAKING ADDITIONTO A PART PROGRAM . . . . . . . . + . . “ “ - 4 “ “ - “ 4.4.2“ . 4 ‘ “ 165

MANUAL ABSOLUTE SWITCH... . . . . . ..”. ”””” +---5 ““”” 5.1.21.””” ”180

MANUAL INTERRUPTIONPOINTRETURN SWITCH . . . . . . . . . ‘ “ 5 “ “ “ “ 5.1.25.“ “ “ “ 181

MANUAL INTERRUPTIONPOINTRETURN7 . “ + $ . . “ “ - . “ . “ “ 5 “ “ “ “ 5.2.5- - “ “ - 191

MANUAL OPERATION . . . . . . . . . . . . . . . . . ..”<””6 ““”” 6.3” ”””” ”195

MANUAL OPERATION INTERRUPTINGAUTOMATIC OPERATION . . - “ 6 “ “ “ “ 6.7- “ “ - “ “ 197

MANUAL PULSE MULTIPLY SELECT SWITCH”t . . . . . . . . . - “ “ 5 0 0 “ o 5.1.7‘ o “ “ o 176

MANUAL REFERENCE POINT RETURN SWITCH”I’. . . . . . . . . . . . 5 “ “ “ “ 5.1.14“ “ - “ “ 178

MANUAL RETURN TO REFERENCE POINT o . . . . . “ . “ $ “ “ o “ 5 “ “ “ “ 5.2.1“ “ “ “ “ 181

MAXIMUM PROGRAMMABLE DIMENSIONS . . . . . . . . . . . . . . 2 . . . . 2.3.4. . . - “ 8

MAXIMUM SPINDLE-SPEEDSETTING(G50)“t “ o . . . “ “ “ “ “ “ o “ 2 “ “ “ - 2.8.21“ “ “ “ 58

M CODES FOR INTERNAL PROCESSING(M90T0 M109) . . . . . . + . “ 2 “ - “ “ 2.7.2“ “ “ - - 17

MCODESFOR STOP(MOO,MO1,M02,M30) . . . . . 0 “ o c c “ “ c . 0 2 “ + “ o 2.7.10 0 0 “ . 17

MDI OPERATION INTERRUPTINGAUTOMATIC OPERATION . . . “ - 0 6 0 0 “ . 6.9 - “ “ “ “ 198

MEASURED WORKPIECE VALUE DIRECTINPUTt - “ “ “ - “ . “ “ - “ “ 5 e “ “ “ 5.2.3“ - - - “ 182

MEMDATA (MEMORY DATA)KEYS. . . . . . . . . . . . ..+ 4..4 ‘+0” 4.1.11$+”” ”145

MessageDisplay(ALARM)t”.... “..”.””.+.”+.”””*4 ““. .4.3.9.2. ”. <161

M-FUNCTION LOCK SWITCH (AUXILIARYFUNCTION LOCK) . . . . . . 5 . . . . 5.1.20.. “ “ . 180

MISCELLANEOUS FUNCTIONS (M-FUNCTION). “ “ “ “ “ . . - “ “ “ “ 2 “ “ “ “ 2.7“ “ “ “ “ “ 17

MODE SELECT SWITCH . . . . . . . . . . . . . . . . . ..-”-”5 ‘“”” 5.1.1””” ”-174

MODIFYING PART PROGRAM BLOCKS “ . “ “ “ “ “ - “ - “ “ - - “ “ 4 “ “ “ “ 4.6.3“ “ “ “ “ 168

M3-DIGITBCDOUTPUTt. ..O. . . . ..”” .”. ”.. ”.””2 .“. ”2.7.7 ”--”-20

Mult-blockWritingandOperationinMDI Mode . . . - . - “ - . “ “ “ “ “ 4 “ “ “ “ 4.3.3.1“ “ “ “ 150

MULTIPLE CORNERING (Gill,Gl12)”t. “ “ “ . - - “ o 0 0 . . - “ “ “ 2 “ “ “ “ 2.8.30.“ “ “ “ 127

MULTIPLE REPETITIVECYCLES (G70TO G76)“t o 0 0 “ “ “ “ - “ “ “ “ 2 “ “ “ “ 2.8.25“ “ “ “ “ 88

MULTI-START THREAD CUTTING (G32)+ ‘ . “ o 0 0 “ . “ “ “ . . “ “

N NC TAPE . . . . . . . . . . . . . . . . . ..”” ””” ”-”---3 ““”” 3.3- ””-” ”141

NC TAPE CHECK . . . . . . . . . ““. ”””” .””. ”’””””3 ‘“”” 3.3.3””” ”-141

NC TAPE HANDLING . . . . . . . . . . ..++ ””-” ”<. .’”3 ““”” 3.4” ”””” ”141

NC TAPE PUNCH””””””””” “.. .””” ”””” ””””””3 ..”” 3.3.2””+” ”141

NC TAPE PUNCHING . . . . . . . . “.. ”.”” -””. +”. ”””3 ““””””””””””139

NEXT KEY . . . . . . . . . . . -“.”””””””””””””” “4”” .”4.1.6””” ..144

New ToolSetterFunction. . . . . ....””...”””.””” 0“”5”. +” 5.2.3.9--o ’189

No.ofServoLagPulsesDisplay(ERROR PULSE) . “ “ “ “ . “ “ “ “ “ . “ 4 “ “ “ “ 4.3.4.8“ “ - “ 155

Notes..........++. “o..””.”.”.”.... .“.2. .” . 2.7.8.3..”- ’21

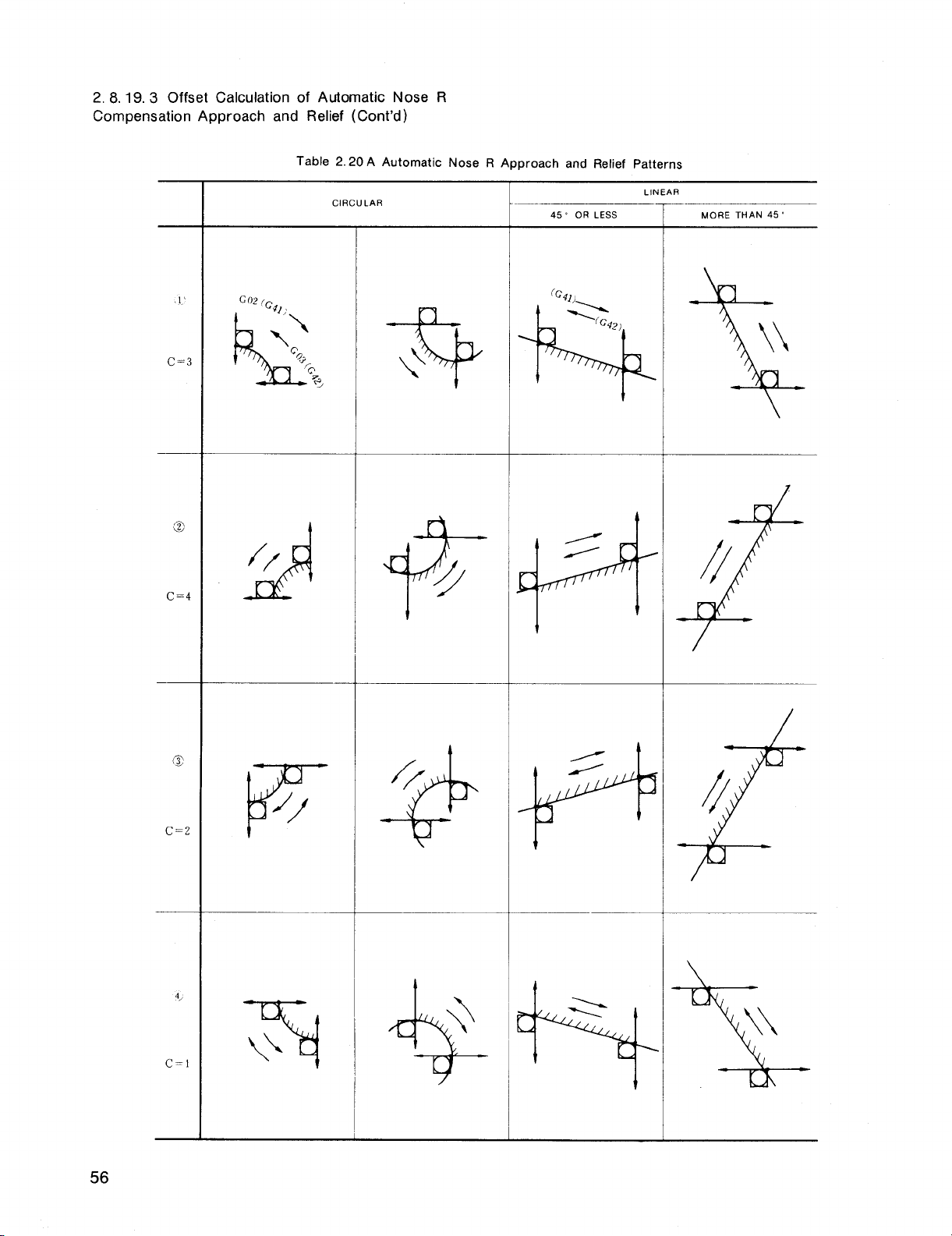

0 OffsetCalculationofAutomaticNoseR CompensationApproachandRelief. “ “ “ 2 . “ “ “ 2.8.19.3“ “ “ - 54

OffsetScreenDisplay..”.”. ..”.”.””...”.”.. ..”5”+” .5.2.3.8-+.. 1~~

Operation”””--””””””” ““”-”””.””””””””” “5”” ””5.1.8.2”””” 176

OperationCommands ”””... ““.”..”.”..”++-” ““”2+”” ” 2.8.23.5-++. 75

OPERATION INTAPE AND MEMORY MODE . “ “ “ “ “ “ “ “ “ “ “ “ . 6 - - - “ 6.6“ “ “ “ “ “ 197

OPERATION PROCEDURE””””” “.. ”””” -””-- .-”””5 “.-” 5.2” .”” ”-181

OPERATION PROCEDURE . . . . . . . . . ..”” ””. ””””””6 ““-””””’””””195

OpemtionTimeDisplay”--”.. “..””-”””.-.””..” “4-.””4.3.9.4.”.””16~

oPTIoNALBLocK sKIP(/1-/9)*...” ““””””””””””””””2” ““”2.’2.3 ”””””

OPTIONAL BLOCK SKIPSWITCH.’ ‘“”” ”””. ””-” -<”””5 ““”” 5.1.17--”” ”179

ORG(ORIGIN)KEYS..””.””” ““. ”””” ”””- ””””””4 ‘“”” 4.1.9”””” ”145

OTHER MCODES ””-””.””” ..”+ ””-” --”” ”.. ””2 ““””2.7.6-”-”-19

OUTPUTTING PART PROGRAM TO PAPER TAPE “ “ . . . . . . . . . “ 4 “ “ “ “ 4.7.1“ “ - “ “ 170

OUTPUTTING SETTING/PARAMETER DATA TO PAPER TAPE “ - “ . “ “ 4 “ “ “ - 4.7.3“ “ “ “ “ 171

OUTPUTTING TOOL OFFSET TO PAPER TAPE ~ “ . . . . “ “ “ . “ “ . 4 - “ - + 4.7.2“ “ “ - 0 171

OverviewofMacroProgrtamBody “ - ‘ - . . “ “ “ “ “ “ . . - “ “ “ “ “ 2 “ . “ “ 2.8.23.3“ “ “ - 65

PAGEKEYS,,,O..,.... . ..”””.----.-”””” ‘4”” ””4.1.7””””” 144

P

PAPER TAPE . . . . . . . . . . . . . . . . . . . . . . . . . . . “3-- ””3.3.1””””” 141

ParametersofBitDisplayFormat,. . - “ . “ “ “ - “ “ . “ “ “ “ < “ “ “ 4 “ “ “ “ 4.3.7.1“ “ “ “ 160

ParametersofDecimalDisplayFormat- . . . . . . . . . . . . . . . . . . 4 . . . . 4.3.7.2. 0 “ - 160

parameters. . . . . . . . . . . ““”””””..”..”””. ““”2. ””” 2.7.8.2””. “20

parameters. . . . . . . . . . . ......””””.”.””” .“”5. ””” 5.2.3.2”.” “185

PART PROGRAM AND NC DATA OUTPUT OPERATIONS - “ “ . “ “ “ “ 4 “ “ “ “ 4.7“ “ “ “ “ “ 170

PatternRepeating(G73) . . . . . . . . . . . . . . . . . . . . . ...2 .“””2.8.25.4. .””98

PeckDrillinginZ-axis(G74) ..”.” ““””””.”””.””””””2 ‘“”- 2.8.25.6”-”-101

Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4” ””” 4.3.4.4”‘“”153

Chapter

2 “ . “ . 2.8.16.0 “ - “ 38

Par.

Page

Page 7

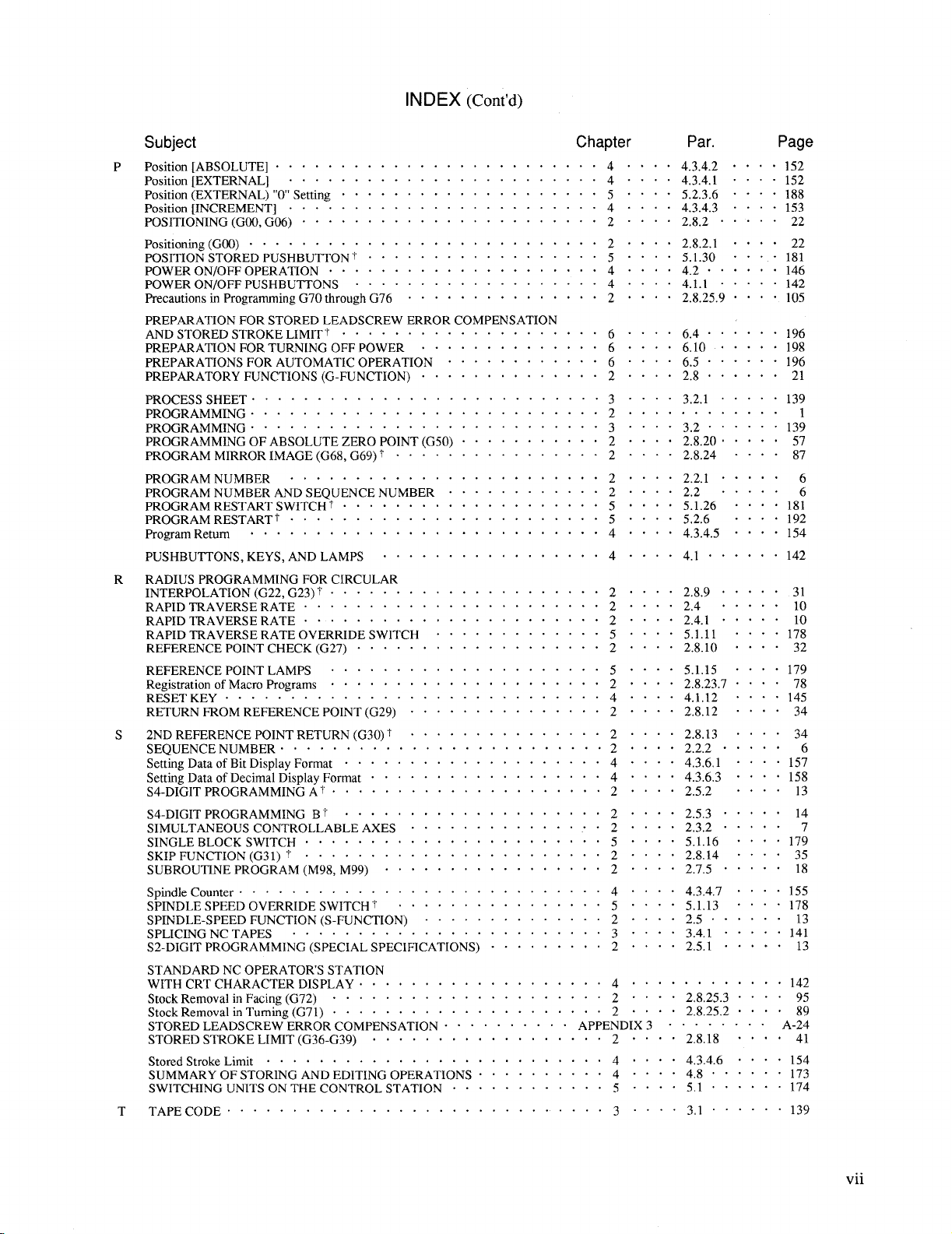

INDEX (Cent’d)

Subject Chapter

Position[ABSOLUTE] . . . . . . . . . . 4 . . . . . . . . . . . ...4 ..”” 4.3.4.2. ””” 152

P

Position[EXTERNAL] . . . . . . . . . . . . . . . . . . . . . ...4 “.”. 4.3.4.1..”” 152

Position(EXTERNAL)“O’’Setting. . . . . . . . . . . . . . . . . . . “ 5 “ “ “ ‘ 5.2.3.6- - “ “ 188

Position[INCREMENT] . . . . . . . . . . . . . . . . . . . . . . . .4 . . ..4.3 .4.3. . ..1S3

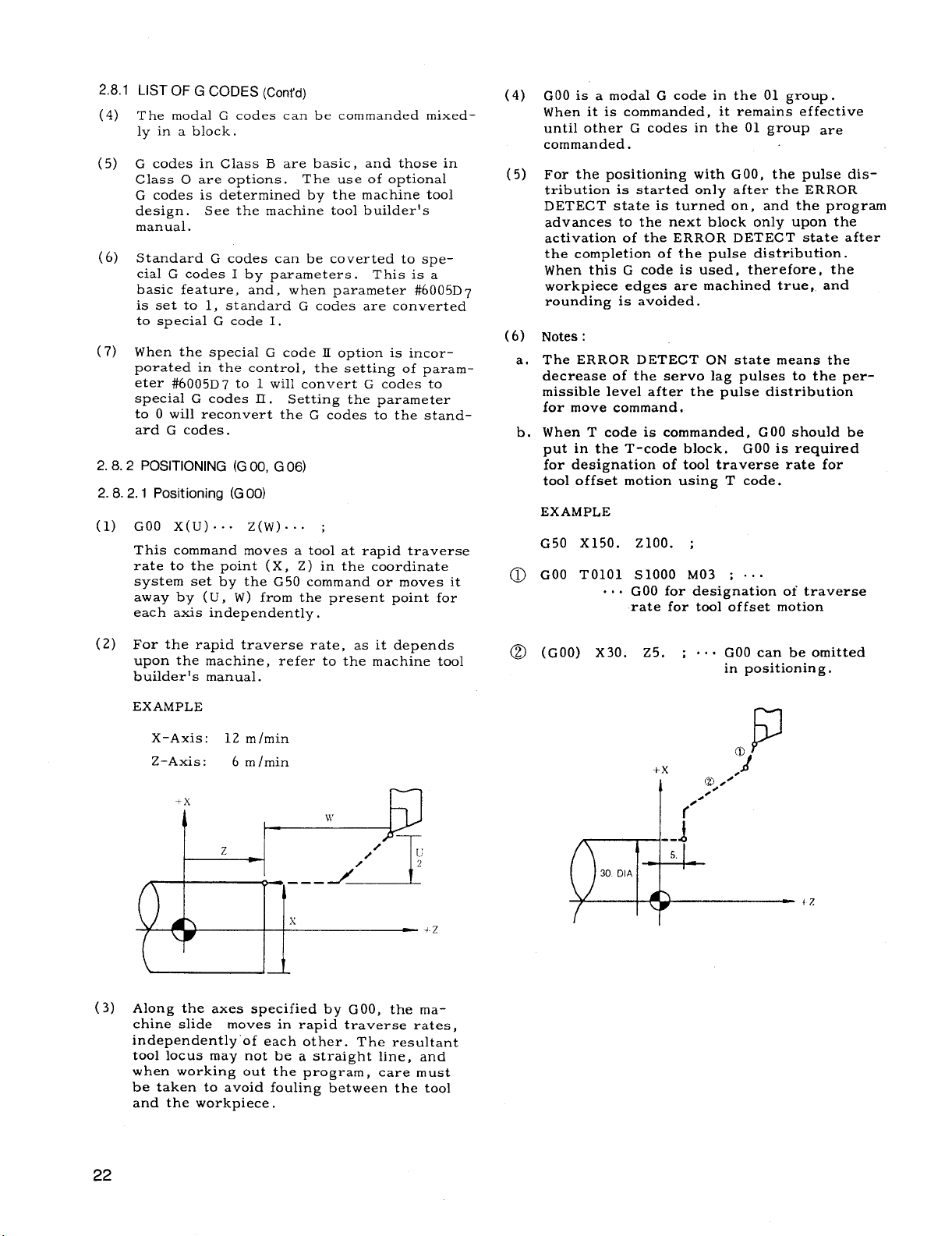

POSITIONING(GOO,G06) . . . . . . . . . . . . . . . . . . . . ..”2 .“””2.8.2”””””22

Positioning(GOD). . . ...!... . . . . . . . . . . . . . . ..”2 ““”.2.8.2.1....22

POSITIONSTORED PUSHBUTTON~ . . . . . . . . . . . . . - . . . “ 5 “ “ “ “ 5.1.30 “ - “ “ 181

POWER ON/OFF OPERATION . . . . . . . . . . . . . . . . . . . . .4. ””.4.2””””” .146

POWER ON/OFFPUSHBUTTONS. . . . . . . . . . . . . . . . . . .4. ..”4.1.1”. ””” 142

PrecautionsinProgrammingG70throughG76 . . “ . “ “ . “ . . 0 . “ . “ 2 + - “ . 2.8.25.90 0 “ “ 105

PREPARATION FOR STORED LEADSCREW ERROR COMPENSATION

AND STORED STROKE LIMIT”t. . . . . . . . . . ...”””””” .6”” ””6.4””$-”” 196

PREPARATION FOR TURNING OFF POWER . . . . . . . . . . . . . . 6 . . . 0 6.10 0 “ “ “ + 198

PREPARATIONS FOR AUTOMATIC OPERATION “ “ “ “ “ “ . “ “ “ . “ 6 . + . “ 6.5“ - “ - “ “ 196

PREPARATORY FUNCTIONS (G-FUNCTION). . . . . . . . . 0 . . . . 2 . . . - 2.84 “ . “ “ < 21

PROCESS SHEET . . . . . . . . . . . . . . . . . . . ..”” ”””.3 ““”” 3.2.1”””” ”139

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . ...2 “c.”.”””””.*1

PROGRAMMING . ..”.....” . . . . ..+-- ”-”” .”””3 .“. ”3.2”””””” 139

PROGRAMMING OF ABSOLUTE ZERO POINT(G50). . . . . . . . . . 0 2 . . . 0 2.8.20+ “ o “ . 57

PROGRAM MIRROR IMAGE (G68,G69)t . . . . . . . . . . . . . . . . 2 - . “ - 2.8.24 - “ “ “ 87

PROGRAM NUMBER . . .. O.. . . . . . . . ..”- ””. .-”2 ““”” 2.2.1.”. .”6

PROGRAM NUMBER AND SEQUENCE NUMBER . . . . . . . . “ “ “ “ 2 “ “ - “ 2.2 “ “ ‘ “ “ 6

PROGRAM RESTART SWITCH t.. . . . . . . . . . . . . ...++ “5. ..”5.1.26. +”” 181

PROGRAM RESTART t...., . . . . . . . . . . . . . . . . ..”5””””5.2.6”””4 192

ProgramRetur n........ . . . . . . ..-+ +.. O.O “--4 ”””” 4.3.4.5”””- 154

PUSHBUTTONS, KEYS,AND LAMPS . . . . . . ..++ ”.”- ”.”4 ““”” 4.1” ””. .” 142

R RADIUS PROGRAMMING FOR CIRCULAR

INTERPOLATION(G22,G23)~. . . . . . . . . . . . . . ...”.” .2. ”””2.8.9””. .”31

RAPIDTRAVERSE RATE -+”..+ ‘“”--”--””””-””””2 ““”” 2.4” -”. ”10

RAPIDTRAVERSE RATE..... . . . . . . . ...+-”””-” “2”. ..2.4.1 ”””””10

RAPIDTRAVERSE RATE OVERRIDE SWITCH “ “ “ “ “ “ “ “ “ “ “ - “ 5 “ “ “ “ 5.1.11“ “ “ “ 178

REFERENCE POINT CHECK (G27). . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.10“ “ “ “ 32

REFERENCE POINT LAMPS.... . . ..”” -””” ””----”5 ‘“”- 5.1.15--”” 179

RegistrationofMicroprograms. . . . . . . . 0 # . . , , . . . . . . . 2 0 “ ‘ “ 2.8.23.7“ . “ + 78

RESET KEY . . . . . . . . . . . . . . ...--”.””””””” “4”” ”-4.1 .12. ””” 145

RETURN FROM REFERENCE POINT(G29) , , . . . . 0 0 0 “ “ “ o “ o 2 . . “ . 2.8.12 - 0 0 0 34

2ND REFERENCE POINTRETURN (G30)t . . . . . . . . . , . . . . . 2 . . . . 2.8.13 “ “ “ “ 34

s

SEQUENCE NUMBER ”O” OO. .O 0“o+”o$o.000--”-”2 ‘+$ ’2.2.2 <”-””6

SettiogDataofBitDisplayFormat“ . “ “ “ “ . “ “ “ “ . “ . “ “ “ “ “ “ 4 “ o “ - 4.3.6.1- “ “ “ 157

SettingDataofDecimalDisplayFormato “ “ “ . 0 “ “ . “ “ “ “ o “ o “ c 4 $ 0 $ 0 4.3.6.3- - 0 0 158

S4-DIGITPROGRAMMING At.... . . . . . . . . ..”. ”””””2 .“””2.5.2”. ”.13

S4-DIGITPROGRAMMING B”t ”.. “.. ..”” ”.-. .”-O ”-2 ..-” 2.5.3.. +0.14

SIMULTANEOUS CONTROLLABLE AXES . . . . . “ “ “ “ “ . “ . “ “ 2 “ “ “ “ 2.3.2“ - “ “ “ 7

SINGLE BLOCK SWITCH O....” “4.””””..00”.”””05 ““”. 5.1.16 ””+ +179

SKIPFUNCTION (G31)”t. . . . . . . . . . . . . . . . . . ..”””2 ““. .2.8.14 ””””35

SUBROUTINE PROGRAM (M98,M99) . . . “ “ “ . c “ “ “ . “ . . 0 . 2 . . “ “ 2.7.5“ “ “ “ “ 18

SpindleCounter. . . . . . . . . . . . . . . . ..”....”” ““”4. ””” 4.3.4.7””” ’155

SPINDLESPEED OVERRIDE SWITCHt + “ “ + “ - - “ “ “ - “ “ “ “ “ 5 “ “ “ “ 5.1.13“ “ “ “ 178

SPINDLE-SPEEDFUNCTION (S-FUNCTION) . . . . . . “ . . “ “ “ “ “ 2 - - - - 2.5“ “ o 0 “ “ 13

SPLICINGNC TAPES . . . . . . . . . . . . . . . . . . ...”. “3”” ””3.4.1”””-” 141

S2-DIGITPROGRAMMING (SPECIALSPECIFICATIONS). . “ “ “ “ . “ “ 2 “ . “ “ 2.5.1“ “ “ - “ 13

STANDARD NC OPERATORS STATION

WITH CRT CHARACTER DISPLAY.. .....””””..”.”””+4 .“””. .”. ..”” 142

StockRemovalinFacing(G72) “ “ “ “ “ “ . “ “ . “ “ . “ . “ “ “ “ “ “ 2 “ + “ “ 2.8.25.3“ “ “ “ 95

StockRemovalinTuming(G71). . . . .........”..””.”.2 “.. .2.8.25.2. ”.”89

STORED LEADSCREW ERROR COMPENSATION . - . “ “ “ - “ “ . APPENDIX3 “ “ “ - “ - “ “

STORED STROKE LIMIT(G36-G39). . . . 0 . . “ . . “ . . “ . “ . “ 2 “ - 0 0 2.8.18“ “ “ “ 41

StoredStrokeLimit. . . . . . . ...........”+”.+ “.”4. ”-” 4.3.4.6+”- “154

SUMMARY OF STORING AND EDITINGOPERATIONS . . . . . . . . “ “ 4 - “ “ “ 4.8“ “ “ “ “ “ 173

SWITCHING UNITSON THE CONTROL STATION . . . . . . . - . . . . 5 . “ “ “ 5.1“ “ “ “ “ “ 174

T TAPE CODE . . . . . . . . . . . . . . . . . . . . . . . . . ..+”3 ““”” 3.1” ”””” ”139

Par.

Page

A-24

vii

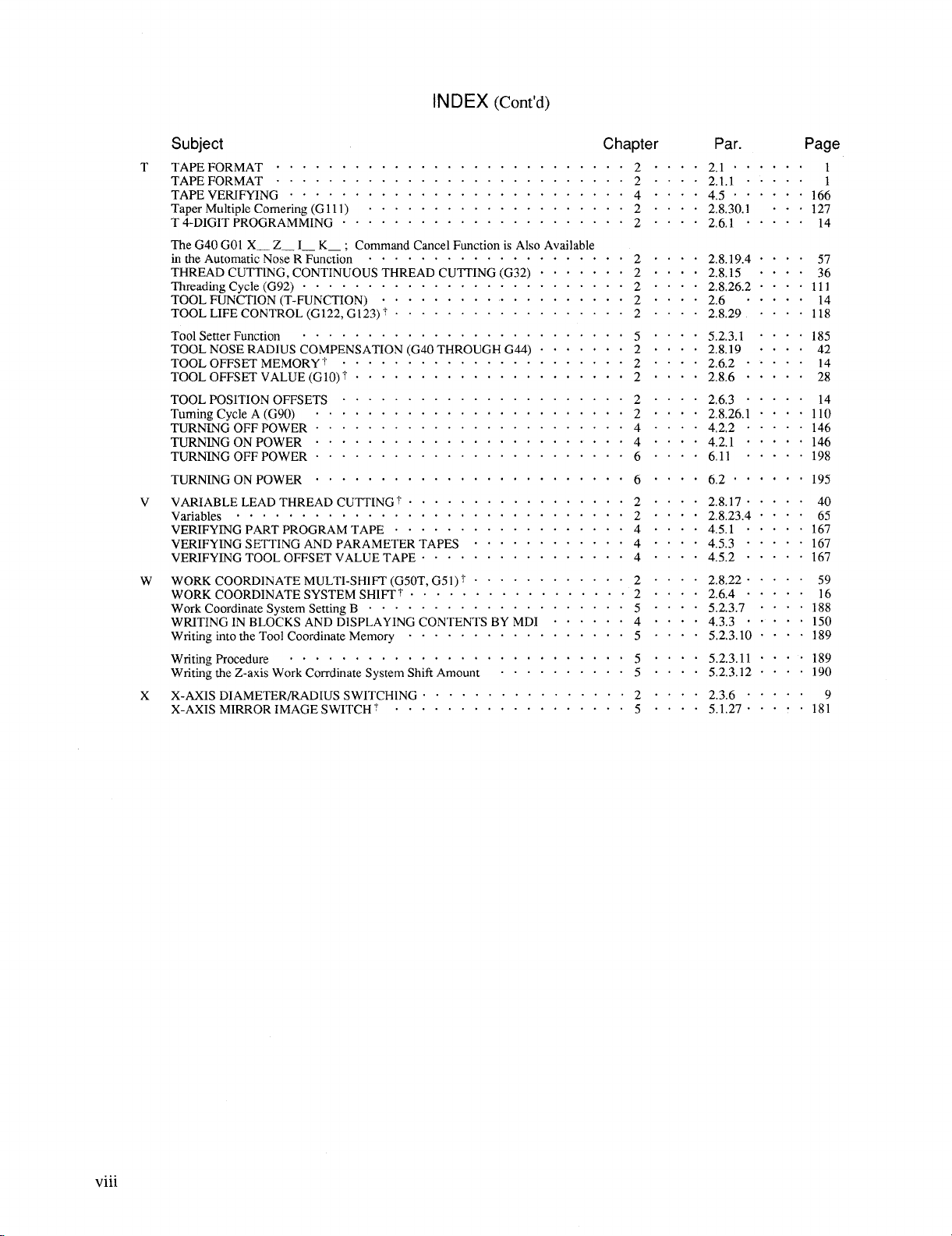

Page 8

INDEX (Cent’d)

Subject Chapter

T TAPE FORMAT . . . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.1. . . ...1

TAPE FORMAT . . . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . 2.1.1. . ...1

TAPEVERIFYING . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . 4.5. . . . . .166

TaperMultipleCornering(Glll). . . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.30.1. . . 127

T4-DIGITPROGRAMMING . . . . . . . . . . . . - . . . . . . ...2 . . . . 2.6.1. . ...14

TheG40GO1X_ Z_ I_ K_ ;CommarrdCancelFunctionisAlsoAvailable

intheAutomaticNoseRFunction. . . . . . . . . . . . . . . . . . . . 2 . . . . 2.8.19.4. . . . 57

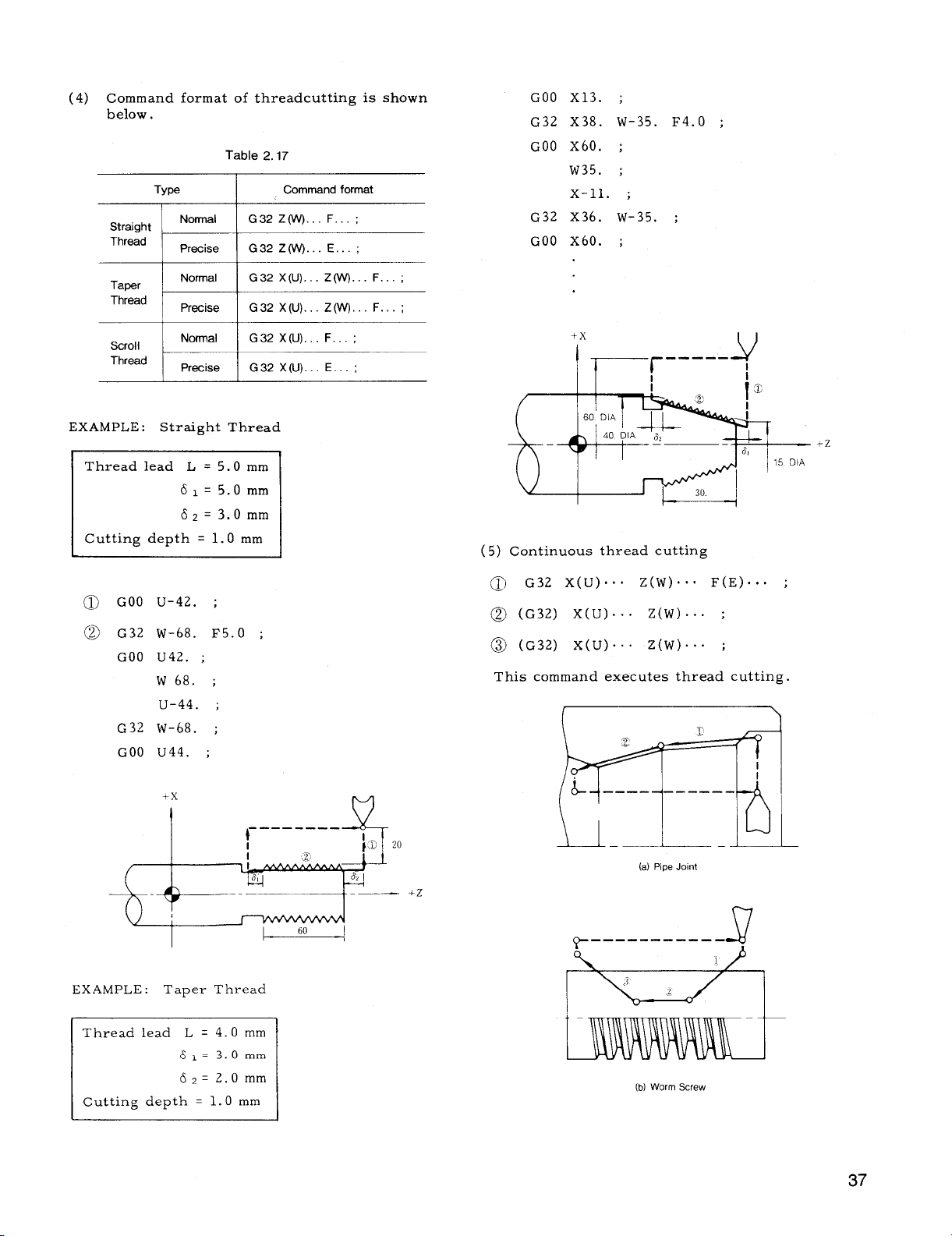

THREAD CUTTING,CONTINUOUS THREAD CUllTNG (G32). . 0 . . . 0 2 0 . 0 0 2.8.15. . . . 36

ThreadingCycle(G92). . . . . . . . . . . . . . . . . . . . . . . . . 2....2.8,26.2....111

TOOL FUNCTION (T-FUNCTION).. . . . . . . . . . . . . . . ...2 . . . . 2.6 . . ...14

TOOL LIFECONTROL (G122,G123)~. . . . . . . . . . . . . . . . . . 2 . . . . 2.8.29 . . . . 118

ToolSetterFunction . . . . . . . . . . . . . . . . . . . . . . . . . 5 . . . . 5.2.3.1... .185

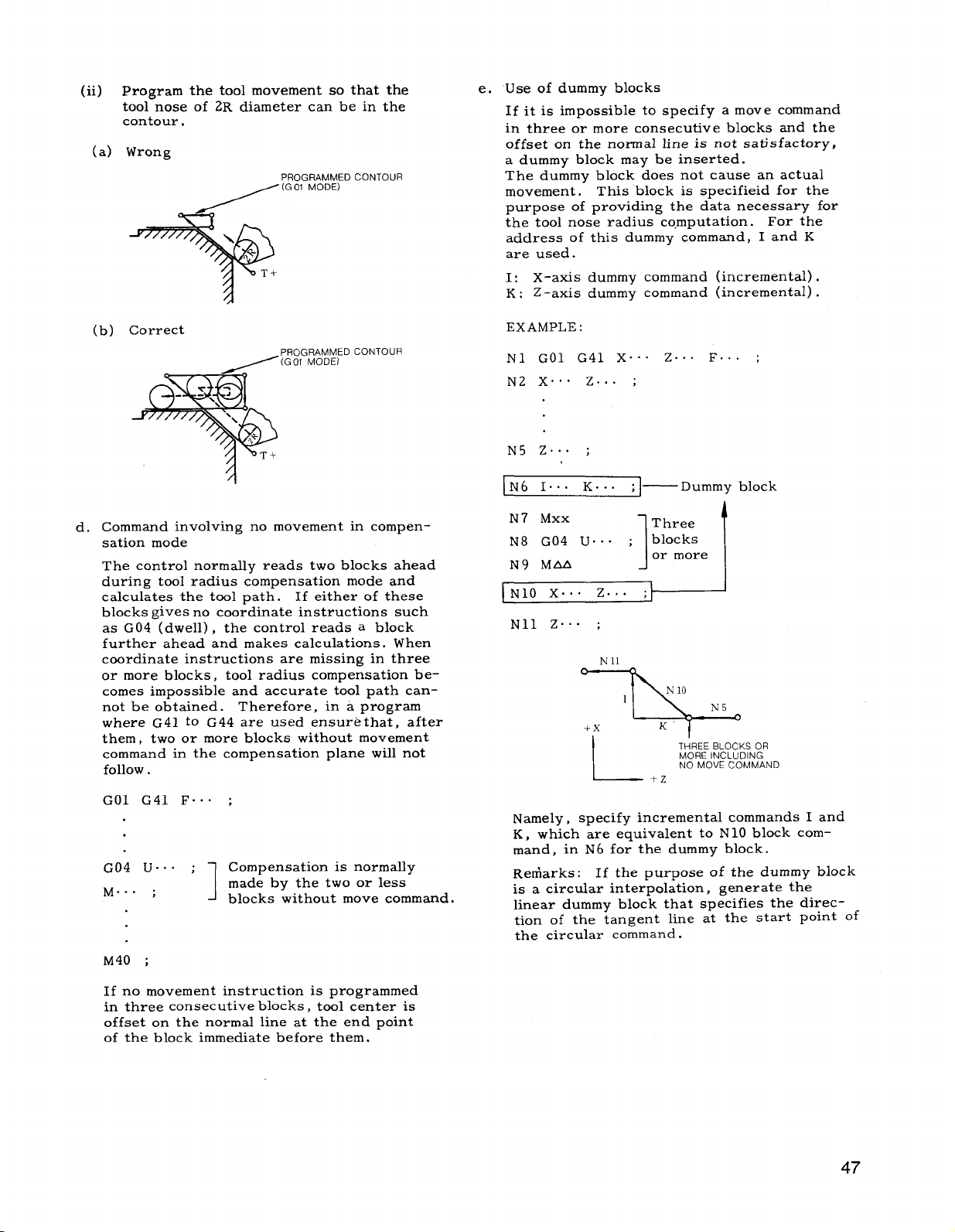

TOOL NOSE RADIUS COMPENSATION (G40THROUGH G44). . . . . . . 2 . 0 . . 2.8.19. . . . 42

TOOL OFFSETMEMORY ”~. . . . . . . . . . . . . . . . . . . . . . 2 . . . . 2.6.2. . ...14

TOOL OFFSET VALUE (GIO)T. . ..O . . . . . . . . . . . . . ...2. , . . 2.8.6. . ...28

TOOL POSITIONOFFSETS . . . . . . . . . . . . . . . . . . . ...2 . . ..2.6 .3”” ”””14

TurningCycleA(G90) ..,.... . . . . . . . . . . . . . . ...2 . . ..2.8 .26.1.”” .110

TURNLNG OFF POWER . . . . . . . . . . . . . . . . . . . . . ...4 . ...4.2.2.....146

TURNING ON POWER . . . . . . . . . . . . . . . . . . . . . ...4 .“””4.2.1”” ...146

TURNLNG OFF POWER . . . . . . . . . . . . . . . . . . . . ...6 ..”” 6.11 .””” ”198

TURNING ON POWER .O. ..O. ...c””.”t”””””””.6 .“. .6.2 ”””” ”” 195

v VARIABLE LEAD THREAD CUTTING”t. . . . . . . . . . . . . . . . . 2 . . . . 2.8.17.. “ . “ 40

Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . ““.2 ””” . 2.8.23.4..” “65

VERIFYINGPART PROGRAM TAPE. . . . . . . . . . . . . . . ...4 . . ..4.5 .1. .” ..167

VERIFYINGSETTINGAND PARAMETER TAPES - “ “ “ . “ “ “ “ “ - 0 4 “ o “ “ 4.5.3- “ “ “ - 167

VERIFYINGTOOL OFFSETVALUE TAPE . . . . . . . . . . . . . . “ “ 4 “ “ - “ 4.5.2“ “ “ “ “ 167

W WORK COORDINATE MULTI-SHIFT(G50T,G51)“~. . . . . “ o “ . “ o . 2 “ “ “ “ 2.8.220“ “ “ “ 59

WORK COORDINATE SYSTEM SHl~t . . . . . . . . . . . . . . . . . 2 “ $ + $ 2.6.4- - “ “ “ 16

WorkCoordinateSystemSettingB . . . “ - - “ “ “ “ . . “ “ “ . . . . . 5 - - - - 5.2.3.7“ “ . “ 188

WRITING INBLOCKS AND DISPLAYINGCONTENTS BY MDI . . . . . + 4 0 “ “ o 4.3.3“ . “ “ o 150

WritingintotheToolCoordinateMemory “ “ “ “ “ “ “ “ “ “ “ “ “ “ “ “ “ 5 “ . “ “ 5.2.3.10“ “ - “ 189

WritingProcedure. . . . . . . ....”.......””.” .“”5” ...5.2.3.11””.+ 189

WritingtheZ-axisWorkCoordinateSystemShiftAmount . . “ “ “ “ “ “ “ “ 5 “ “ “ “ 5.2.3.12+ “ “ “ 190

x X-AXISDIAMETER/RADIUSSWITCHING . . . c . c . + + # . 0 . - 0 - 2 0 0 0 “ 2.3.6“ “ “ o 0 9

X-AXISMIRROR IMAGE SWITCH~ . . . . . . . . . . . . . . . . . .5 . . ..5.1 .27.”””” 181

Par. Page

Page 9

1. INTRODUCTION

YASNAC J50L,“UltraspeeddualprocessorCNC” isa combinationoftwo high-performance16-bitmicroprocessors

runningin parallel.Incorporatingour modern system

technique,itisdesignedtoprovidethehighestlatheperformance.

The dual processor CNC system drasticallyreduces the data processing time to meet highspeed cutting.

creased by the use of high–speed buffer func–

tionand buffering function.

Enhanced cutting capabilityincludes a maximum

of 24 meters/reinfeed command, precise feed E

command, 500-milimet-erlead thread cutting,

continuous thread cutting, multiplethread

cutting, and variable pitch thread cutting.

To meet FMS trends, program interruptfunction,toollifecontrol,user macro, toolset

error correction, stored stroke limitper tool,

and other functionscan be installed.

Block-to-blockstop time de-

2. PROGRAMMING

Part program memory can be extended to a

maximum of 320 meters. Its data input/output

interfaceis availablewith FACIT, RS232C and,

in addition,RS422 serialinterfacecapable of

high-speed long distancetransmission.

Programming is further facilitatedby improved

toolradius compensation function,G 50–work

coordinatesystem setting,angle-specifiedlinear interpolation,and combined beveling/round–

ing function.

The servo functionuses a drasticallyminiaturized and low–noise, newly transistorizedPWM

controlunit and a high–performance DC servo

motor.

The positionfeedback is availablewith the

standard pulse generator (PG ) system and,

the inductosyn-appliedcomplete closed lcQp

system.

2.1 TAPE FORMAT

2.1.1TAPE FORMAT

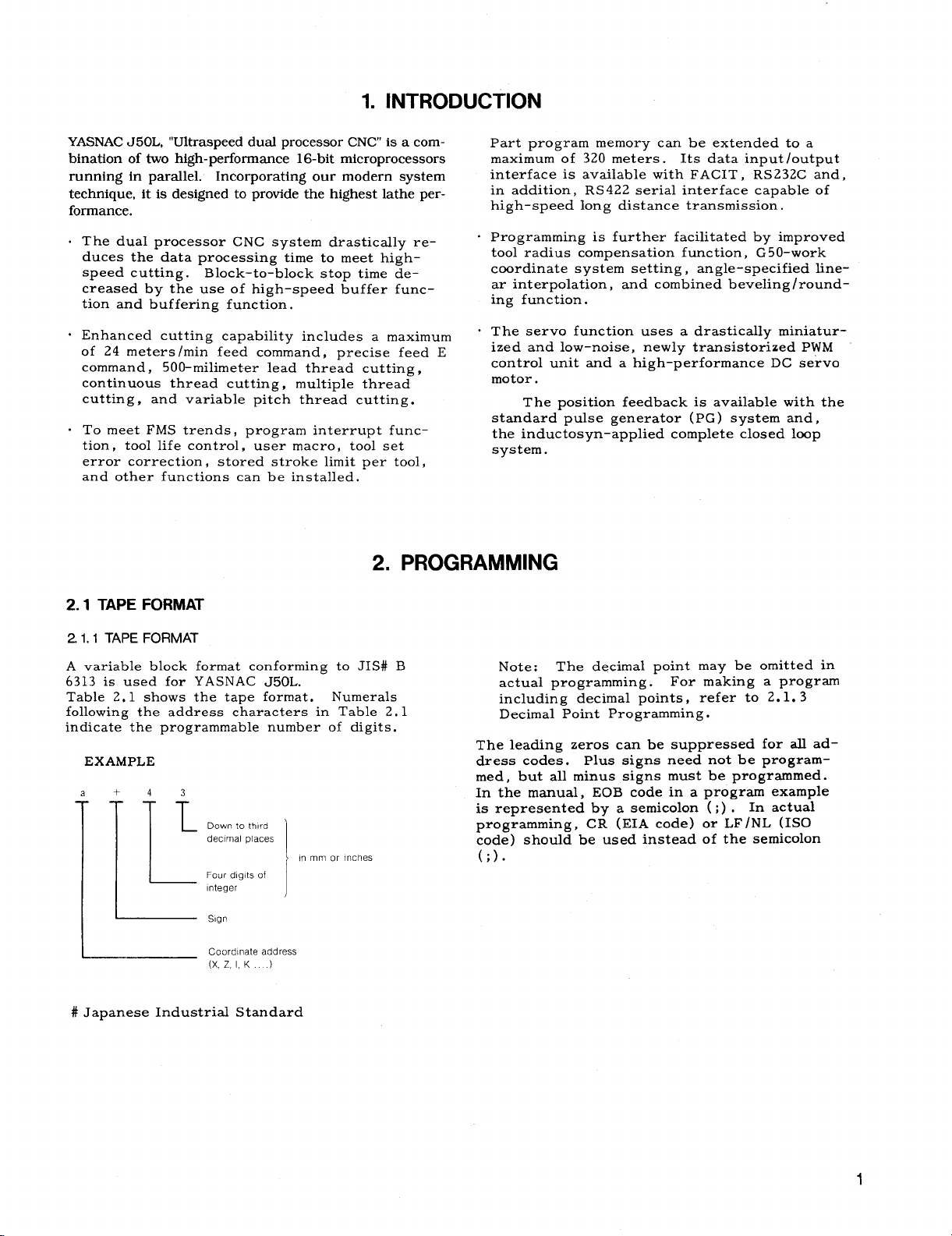

A variableblock format conforming to JIS# B

6313 is used for YASNAC J50L.

Table 2,1 shows the tape format.

followingthe address charactersin Table 2.1

indicate-the programmable number of digits.

EXAMPLE

+

4

a

[[L

# Japanese IndustrialStandard

3

L

Down to th,rd

decimal places

Four dlgils of

Integer

1

I

Numerals

!n mm or Inches

Note: The decimal point may be omitted in

actualprogramming.

including decimal points, refer to 2.1.3

Decimal Point Programming.

The leading zeros can be suppressed for alladdress codes.

med, but allminus signs must be programmed.

In the manual, EOB code in a program example

is represented by a semicolon (;). In actual

programming, CR (EIA code) or LF /NL (1S0

code ) should be used instead of the semicolon

(;).

Plus signs need not be program-

For making a program

Page 10

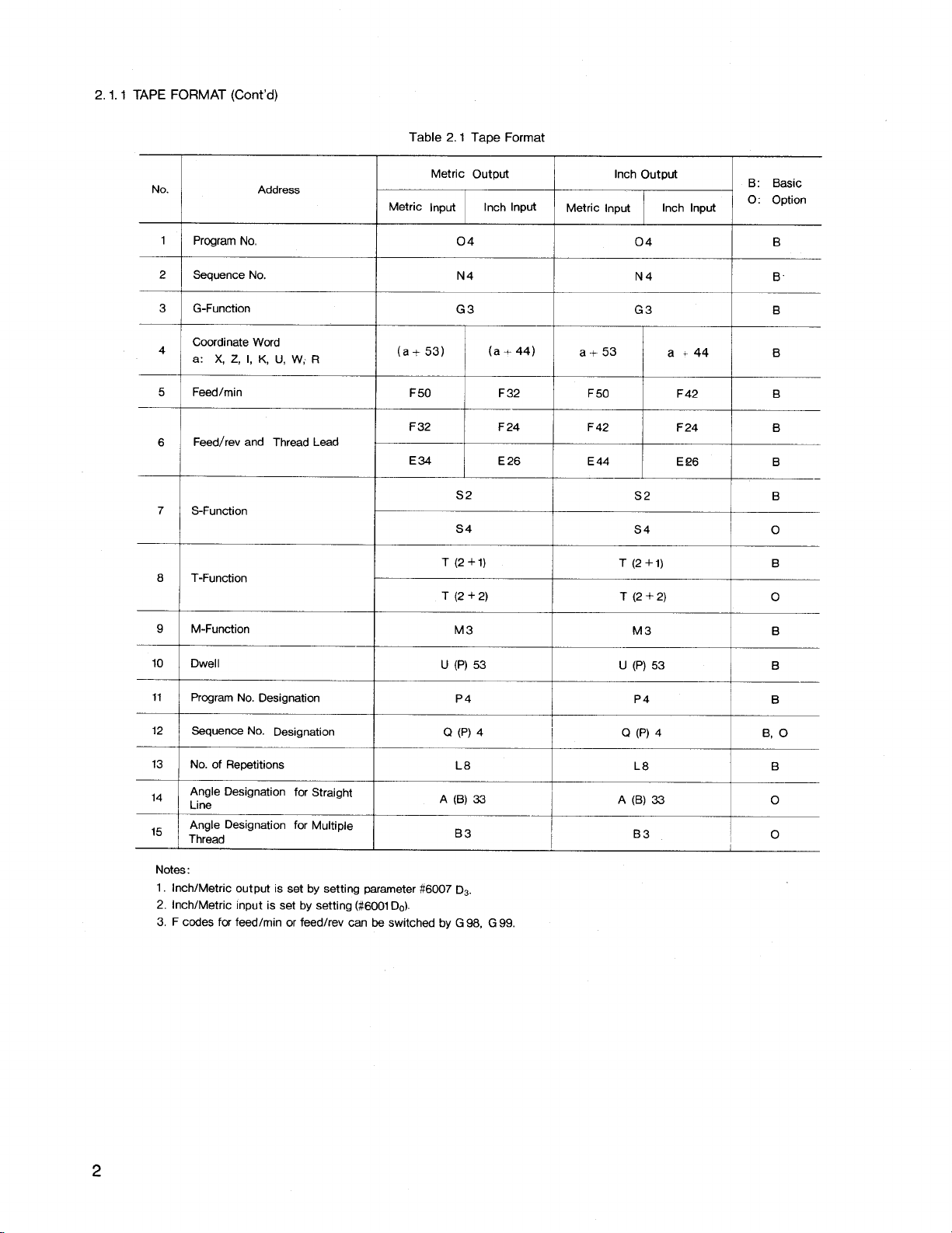

2.1.1TAPE FORMAT (Cent’d)

2.1Tape Format

Table

No.

1

Program No,

Sequence No.

2

G-Function

3

Coordinate Word

4

a: X, Z, 1,K, U, W; R

5

Feed/rein

Feed/rev and Thread Lead

6

7

S-Function

8 T-Function

Address

Metric Output

Metric Input Inch Input

04 04 B

N4 N4

G3 G3 B

(a+ 53)

F 50 F32

F32 F 24

E34 E26 E44

(a+44)

S2 S2 B

S4

T (2+1)

T(2+2) T(2+2)

Inch Output

Metric Input

a+53

F 50

F42

T(2+I)

B: Basic

Inch Input

O: Option

a+44

F 42 B

F24 B

E!26 B

S4 o

B

B

—

B

o

9

M-Function

10

DwelI

ProgramNo. Designation

11

12

Sequence No. Designation

13

No. of Repetitions

Angle Designation for Straight

14

Line

Angle Designation for Multiple

15

Thread

Notes:

1. Inch/Metric output is set by setting parameter #6007 DS

2. Inch/Metric input is set by setting (#6001 Do).

3. F codes for feed/rein or feed/rev can be switched by G 98, G 99,

M3

u (P)53

P4 P4

Q (P) 4

L8 La B

A (B) 33 A (B) 33

B3 B3

M3 B

u (P)53 B

B

Q (P) 4 B, O

0

o

2

Page 11

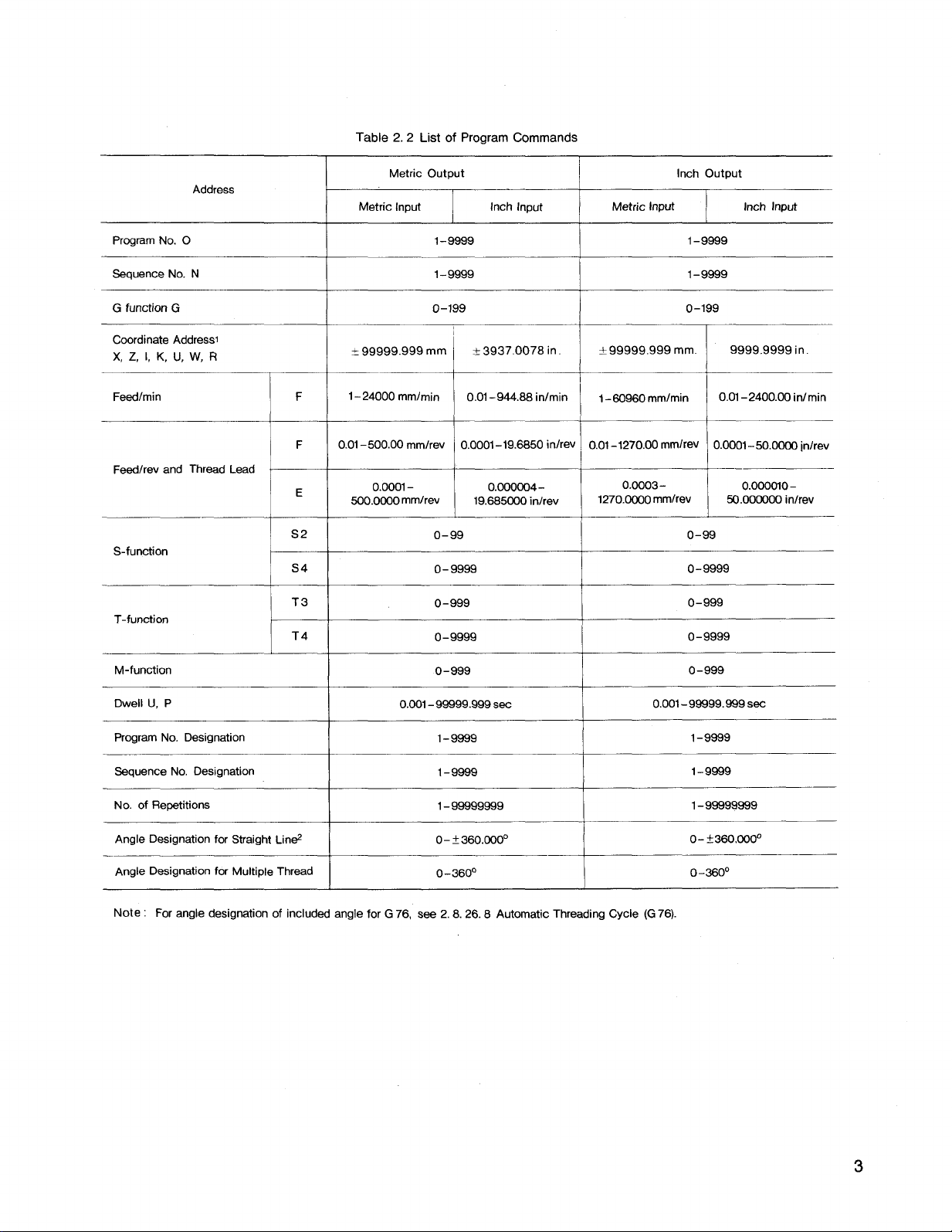

Table 2.2 List of ProgramCommands

Address

Program No. O

Sequence No. N

G function G

Coordinate Address

X, Z, 1, K, U, W, R

Feed/rein

Feed/rev and Thread Lead

S-function

T-function

S2

S4

T3

T4

F

F

E

1–24000 mmlmin

0.01–500.00 rnmlrev

Metric Output

Metric Input

+99999.999rnrn I *3937.0078 in. j *99999.999 mm. I 9999.9999 in.

I Inch Input

1–9999

1-9999

0-199 0-199

0.01–944.88 in/rein

1

I I I

0.0001 –19.6850 inlrev I 0.01–1270.00 mmlrev 0.0001-50.0000 ~n/rev

I

I Metric Input I inch Input

1–80960 mmlmin

I

Inch Output

1–9999

1–9889

0.01–2400.00 inlmin

I

—

0.0001- 0.ooooo4-

500.OCOOmmlrev 19.685030 in/rev

o-99 0-99

0-9999

0-999

0-9999

0.ooo3-

1270.0000 mmlrev

1

0-9999

0-999

0-9999

0.000cno-

50.000000 inlrev

M-function

Dwell U, P

Program No. Designation

Sequence No. Designation

No. of Repetitions

Angle Designation for Straight Lin&

Angle Designation for Multiple Thread

Note : For angle designation of included angle for G 76, S= 2.8.26.8 Automatic Threading Cycle (G76).

0-999

0.001–99999.999 Sec

1-9899

1-9689

1–99999999

0-?360.000°

0–360°

0.001-99999.999 Sec

0-999

1-9899

1–9999

1-99999989

0– ~36&r3@3°

o–3800

3

Page 12

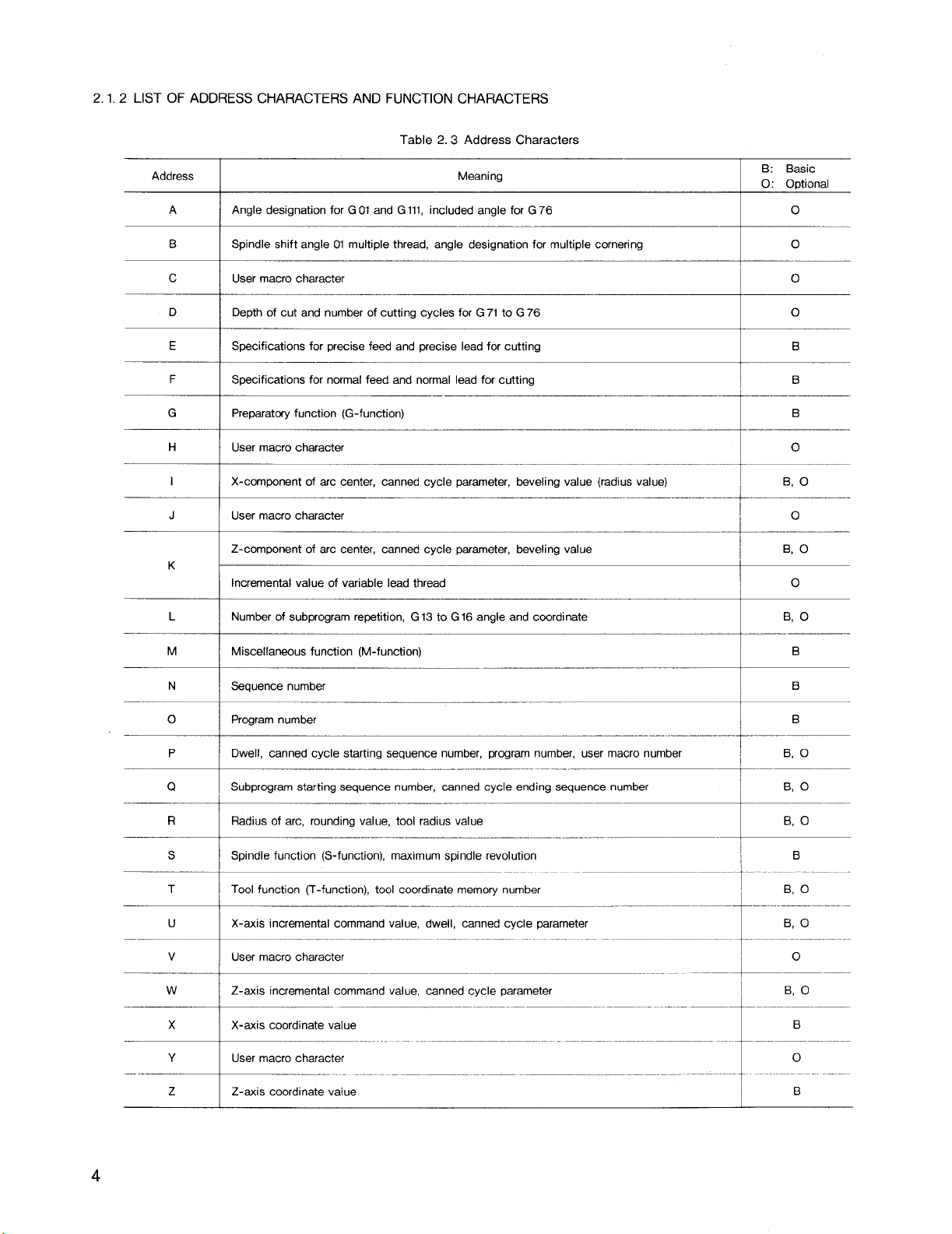

2.1.2 LIST OF ADDRESS CHARACTERS AND FUNCTION CHARACTERS

Table 2.3 Address Characters

Address

A

Angle designation for GOland Gill, included angle for G76

Spindle shift angle Ol multiple thread, angle designationfor multiple corneringB

Meaning

c User macro character

D Depth of cut and number of cutting cycles for G 71 to G 76

E Specifications for precise feed and precise lead for cutting

F Specifications for normal feed and normal lead for cutting

G

H

I

J

K

L

Preparatoryfunction (G-function)

User macro character

X-component of arc center, canned cycle parameter, beveling value (radius value)

User macro character

Z-component of arc center, mnned cycle parameter, beveling value

Incremental value of variable lead thread

Number of subprogram repetition, G 13 to G 16 angle and coordinate

B: Basic

O: Optional

o

0

o

0

B

B

B

.-

0

B, O

o

B, O

o

B, O

M

N

o

P

Q

R

s

T

u

v

w

x

Y

z

Miscellaneous function (M-function)

Sequence number

Programnumber

Dwell, canned cycle starting sequence number, program number, user macro number

Subprogramstarting sequence number, canned cycle ending sequence number

Radius of arc, rounding value, tool radius value

Spindle function (S-function), maximum spindle revolution

Tool function (T-function), tool coordinate memory number

X-axis incremental command value, dwell, canned cycle parameter

User macro character

Z-axis incremental command value, canned cycle parameter

X-axis coordinate value

User macro character

Z-axis coordinate value

-.

B

B

B

B, O

Page 13

Table 2,4 Function Characters

EIA Code

Blank I NuL

ISO Code Function

Error in significant data area in EIA Disregarded in ISO

I

I

Remarks

+--”=--- i ‘--

CR

SP SP Space

ER

‘~+sp”ia’cde

—

oto9 oto9

LF/NL ~ End of Block (EOB)

~

Disregarded

I

O/. I

—

Rewind stop

Disregarded, User macro operator

Minus sign, User macro operator

Numerals

t

T

I

~---

.

atoz

I / Optional block skip

Del DEL Disregarded (Including All Mark)

Parameter

starting

*

— —

—

[ [

1

$ $

@

?

Notes:

1. Characters other than the above cause error in significant data area.

2. Informationbetween Control Out and Control In is ignored as insignificant data.

3. Tape code (EIA or ISO) is automatically recognized.

Ato Z

I

# Sharp (Variable designation)

I* I

—

1

I

I 1

@

I

1? I

1

Address characters

I

Decimal point

Asterisk (Multiplication operator)

Equal mark

~ Left bracket

I

Right bracket

User macro operator

User macro operator

1

User macro operator

I

‘- +

4-”

I

I

I

Special code

EIA:

I

~

I

Page 14

2.1.3DECIMAL POINT PROGRAMMING

Numerals containinga decimalpoint may be used

as the dimensionaldata of addresses relatedto

coordinates(distance), angle, time and speed.

They can be input from punched tape or MDI .

Decimal pointscan be used in the followingaddress words.

Coodinate words;

X, Z, U, W, I, K, R

Angle words: A, B

Feedrate word: F, E

Time words: U, P

EXAMPLE

[mm]

X15. X15.000 mm

Z20.5— Z20.500 mm

(G99)F.2t —FO.20 mm/rev

(forF32)

(G98)F25.6 F25 mm/min

(for F50)

G04Pl.—

When data without a decimal point is input, the

control regards 1!11!as 0,001 ~m (or 0.0001”inch).

LABEL SKIP FUNCTION

2.1.4

Dwell 1.000 sec

[inch]

or X15.0000 in.

Z20. 5000 in.

or

or FO.2000 idrev

(forF24)

or F25.60 mm/min

(for F32)

Notes:

1. This function is effectivefor G 22 and G 23

where the control is provided with Radius

Programming for CircularInterpolationoption.

2.

Block-to-block stop time due to the time

required to compute toolradius compensa–

tionis not eliminatedor remains.

To reduce

this stopping time, use 2.7.3 Buffering

Function (h193,M92) (optional). When operation of consecutiveblocks up to 5 in M93

mode, inter–blockstoppage time is reduced

to zero.

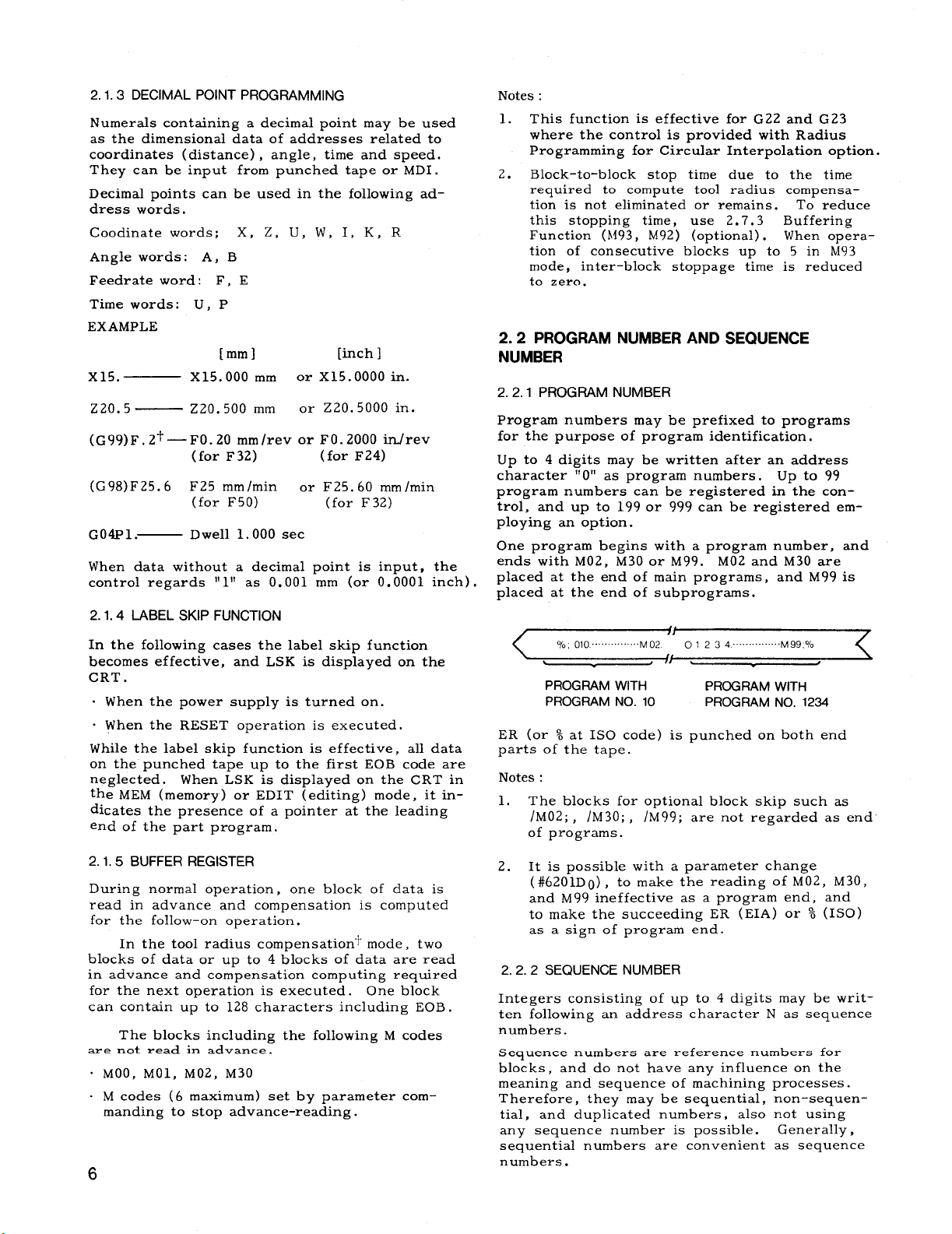

2.2

PROGRAM NUMBER AND SEQUENCE

NUMBER

2.2.1PROGRAM NUMBER

Program numbers may be prefixed to programs

for the purpose of program identification.

Up to 4 digitsmay be written afteran address

character “O“ as program numbers.

program numbers can be registeredin the control,and up to 199 or 999 can be registered employing an option.

One program begins with a program number, and

ends with M02, M30 or M99. M02 and M30 are

placed at the end of main programs, and M99 is

placed at the end of subprograms.

up to 99

In the followingcases the labelskip function

becomes effective,and LSK is displayed on the

CRT .

. When the power supply is turned on.

. When the RESET operationis executed.

While the labelskip functionis effective,alldata

on the punched tape up to the firstEOB code are

neglected.

When LSK is displayed on the CRT in

the MEM (memory) or EDIT (editing)mode, itindicatesthe presence of a pointer at the leading

end of the part program.

BUFFER REGISTER

2.1.5

During normal operation, one block of data is

read in advance and compensation is computed

for the follow-on operation.

In the toolradius compensation”tmode, two

blocks of data or up to 4 blocks of data are read

in advance and compensation computing required

for the next operationis executed. One block

can contain up to 128 characters including EOB .

The blocks including the followingM codes

are not read in advance .

. MOO, MO1, M02, M30

. M codes (6 maximum) set by parameter com-

manding to stop advance-reading.

6

PROGRAM WITH

PROGRAM NO. 10 PROGRAM NO.

PROGRAM WITH

1234

ER (or % at 1S0 code) is punched on both end

parts of the tape.

Notes:

1. The blocks for optionalblock skip such as

/M02;, /M30;, /M99; are not regarded as end

of programs.

2. It is possiblewith a parameter change

(#6201Do), to make the reading of M02, M30,

and M99 ineffectiveas a program end, and

to make the succeeding ER (EIA) or % (ISO)

as a sign of program end.

SEQUENCE NUMBER

2.2.2

Integers consistingof up to 4 digitsmay be written followingan address character N as sequence

numbers.

Sequence numbers are reference numbers for

blocks, and do not have any influenceon the

meaning and sequence of machining processes.

Therefore, they may be sequential,non-sequen-

tial,and duplicated numbers , also not using

any sequence number is possible.

Generally,

sequentialnumbers are convenient as sequence

numbers.

Page 15

When searching for sequence numbers, be sure

to search or specifyprogram numbers beforehand.

Notes:

1. Five or more digitsmust not be written as a

sequence number.

2.

When two or more blocks have the same se–

quence number, only one is retrievedand

read, and no more searching is performed.

3. Blocks without sequence numbers can also

be searched for with respect to the address

data contained in the blocks.

2.2.3.

OPTIONAL BLOCK SKIP (/1-/9j+)

Those blocks in which “/n” (n = (1 - 9) is included are neglected between In and the end of

that block, when the externaloptionalblock skip

switch for that number “n” is on.

EXAMPLE

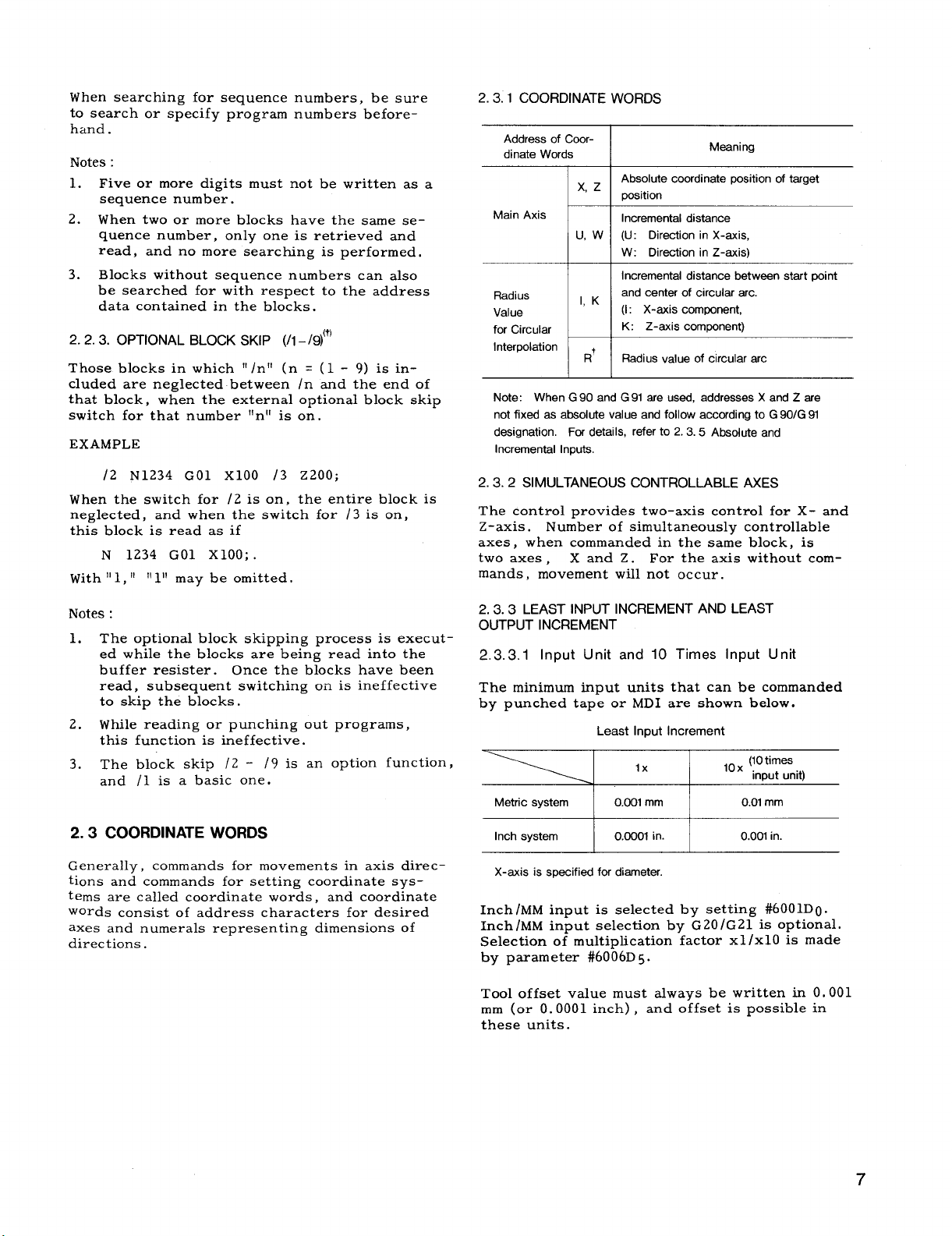

2.3.1

COORDINATE WORDS

Address of Coordinate Words

Absolute coordinate position of target

x, z

I I

Main Axis

Radius

Value

for Circular

Interpolation

Note: When G 90 and G 91 are used, addresses X and Z are

not fixed as absolute value and follow according to G 90/G 91

designation. For details, refer to 2.3.5 Absolute and

Incremental Inputs,

position

Incremental distance

(U: Direction in X-axis,

u. w

W: Direction in Z-axis)

Incremental distance between start point

and center of circular arc.

1, K

(1: X-axis component,

K: Z-axis component)

R+

Rsdius value of circular arc

Meaning

/2 N1234 GO1 X1OO /3 z200;

When the switch for /2 is on, the entireblock is

neglected,

and when the switch for /3 is on,

thisblock is read as if

N 1234 GO1 XIOO; .

With II1,IIIIIllmay be omitted.

Notes:

1. The optionalblock skipping process is executed while the blocks are being read intothe

buffer resister.

Once the blocks have been

read, subsequent switching on is ineffective

to skip the blocks.

2.

While reading or punching out programs,

thisfunctionis ineffective.

3. The block skip /2 - /9 is an option function,

and /1 is a basic one.

COORDINATE WORDS

2.3

Generally,

commands for movements in axis direc–

tions and commands for settingcoordinatesystems are calledcoordinatewords, and coordinate

words consistof address characters for desired

axes and numerals representing dimensions of

directions.

2.3.2 SIMULTANEOUS CONTROLLABLE AXES

The controlprovides two-axis controlfor X- and

Z-axis.

Number of simultaneouslycontrollable

axes, when commanded in the same block, is

two axes ,

Xand Z. For the axis without com-

mands, movement willnot occur.

LEAST INPUT INCREMENT AND LEAST

2.3.3

OUTPUT INCREMENT

2.3.3.1

Input Unit and 10 Times input Unit

The minimum input units that can be commanded

by punched tape or MD I are shown below.

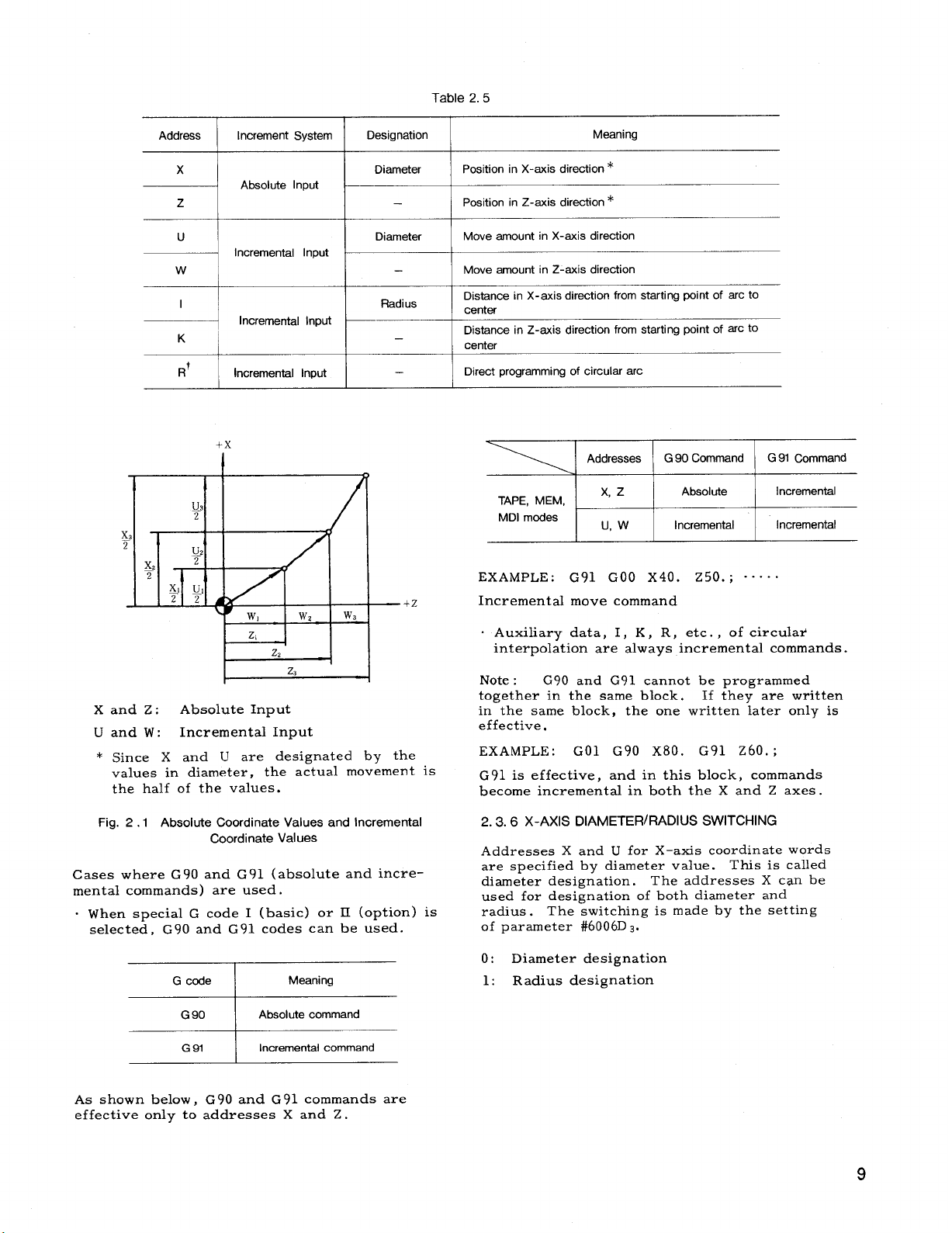

Least Input Increment

lx

Metric system 0.00f mm O.Of

Inch system I 0.0001 in. I

X-axis is specified for diameter.

,0x (?Otimes

Input unit)

mm

0.001 in.

Inch /MM input is selectedby setting#6001D0.

Inch/MM input selectionby G20/G21 is optional.

Selectionof multiplicationfactorxl/x10 is made

by parameter #6006D

5.

Tool offsetvalue must always be written in 0.001

mm (or O.0001 inch), and offsetis possiblein

these units.

7

Page 16

2.3,3,1 Input Unit and 10 Times Input Unit

(Cent’d)

In 0.01 mm increment system, the followingoperationmust be made in the unit of O.01 mm.

. Programming for operationin TAPE mode.

o Write operationin MDI mode.

. Programming for operationin MEMORY mode.

o Program editingoperationin EDT mode .

Notes:

If NC tape programmed by O.001 mm is fed

1.

intoor stored in an equipment set by O.01

mm increment, the machine willmove ten

times the intended dimensions.

If the increment system is switched when the

2.

contents of NC tape are stored in memory,

the machine willmove by ten times or one

tenth of the commanded dimensions.

When the stored program is punched out on

3.

the tape+, the stored figures are punched

out 1!as stored!lregardlessof switching of

the increment system.

Multiplicationfactor 10X (10 times the input

4.

unit)is effectivefor distancecommand only.

Itdoes not functionon the designationof

time, angle, etc. When multiplicationfactor

10X is set as effective(#6006D5 = 1), the

same address word is multipliedby 10 or not

depending on type of G command.

EXAMPLE

G04 U...

GOO U... ;—

2.3.3.2 Least

output increment is the minimum unit of

Least

;—Not multipliedby 10 (Time)

Multipliedby 10 (Distance)

Output Increment

toolmotion. Selectionof metric system or inch

system is made by parameter (#6007D3).

Least Output Increment

I

I

I

Z-axis

0.001 mm

0.0001 in.

Metric output

Inch output

I

I

I

X-axis

(Radius value)

0.0005 mm

0.00005 in.

Maximum Programmable Values

Metric input

Metric Output

Inch input ~ + 3937.0078 in.

-...t -––-–.—–. -----

Metric input * 99999.999 mm.

Inch Outout

Inch input

+.9999.999 mm.

I

– + –- ——–—-—-

I

?c99999.999 in

In incrementalprogramming, specifiedvalues must

not exceed the maximum programmable values. In

absolute programming, move amount of each axis

must not exceed the maximum programmable value.

THE MACHINE MAY NOT FUNCTION PROPERLY

IF MOVE COMMAND OVER THE MAXIMUM PRO-

GRAMMABLE VALUES IS GIVEN.

The above maximum programmable values also

apply to distancecommand addresses 1, K, R

in additionto move command addresses X, U, W.

ABSOLUTE AND INCREMENTAL INPUTS

2.3.5

Both absolute

input and incrementalinput can

be used for the control.

Absolute input is specifiedby the addresses

Xand Z.

EXAMPLE: X.. . Z.. . ;

Incrementalinput is specifiedby the addresses U andw.

EXAMPLE: U,. . W.. , ;

Absolute input and incrementalinput can be

used in one block mixedly.

EXAMPLE: X.. . W.. . ;

u.. . z... ;

Note :

When addresses X and U or addresses Z

and W are used inone block, the latteris effective.

The addresses 1 and K for designationof arccenter must be specifiedby the incremental

dimension.

MAXIMUM PROGRAMMABLE DIMENSIONS

2.3.4

Maximum programmable values of move command

are shown below.

8

Page 17

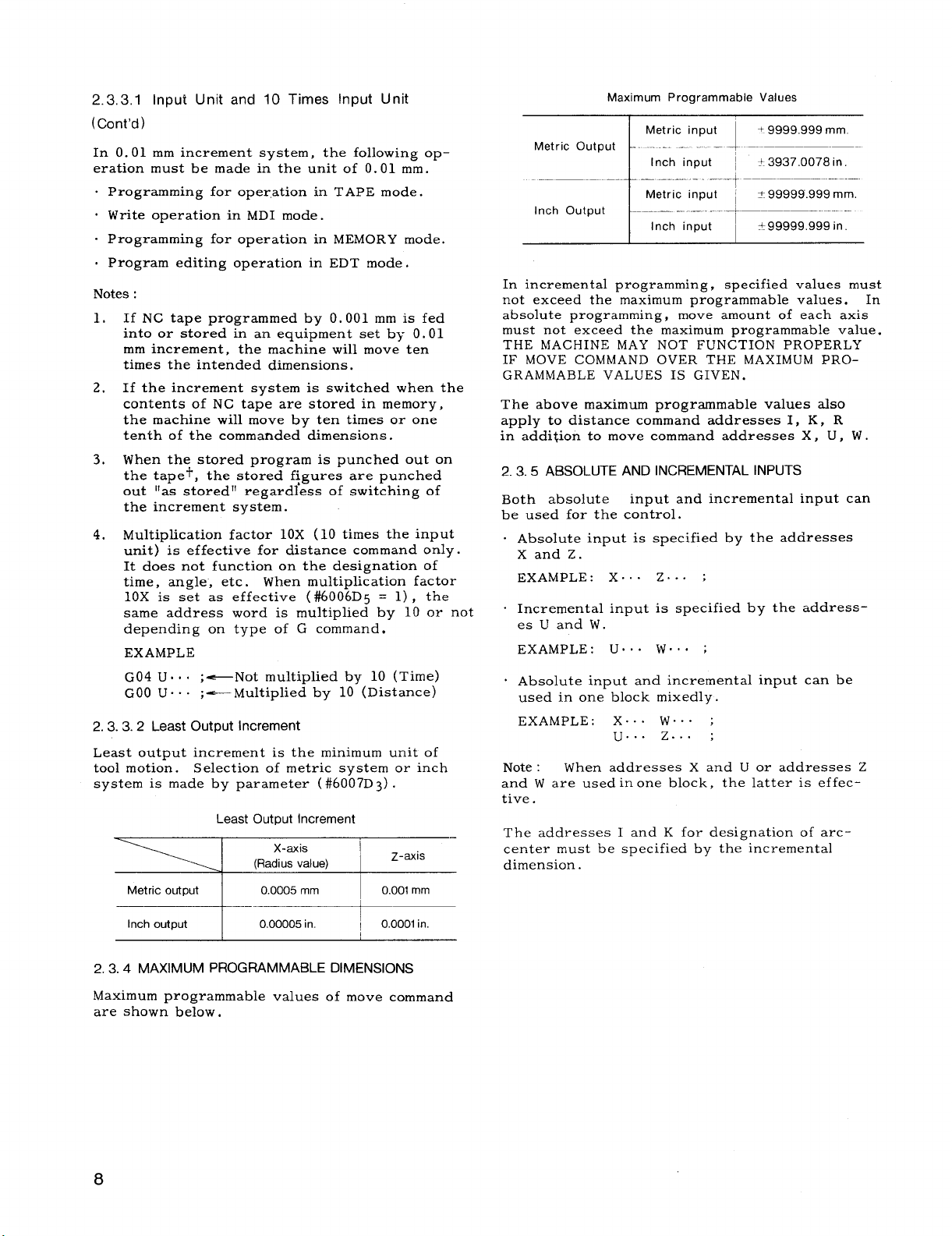

Table 2.5

Address

i

Increment System Designation

x

Absolute Input

z

u

Incremental Input

I

Incremental Input

K

R’

Incremental Input

Diameter Position in X-axis direction*

—

Diameter

—

Radius

—

—

~

Position in Z-axis direction *

Move amount in X-axis direction

Move amount in Z-axis direction

Distance in X-axis direction from starting point of arc to

center

Distance in Z-axis direction from starting point of arc to

center

Direct programmingof circular arc

TAPE, MEM,

MDI modes

EXAMPLE :

—+Z

Incrementalmove command

Meaning

Addresses G 90 Command G 91 Command

x, z Absolute Incremental

u, w Incremental

Incremental

G91 GOO X40. z50. ; ““”..

w

Xand Z: Absolute Input

Uand W:

* Since X and U are designated by the

values in diameter,the actual movement is

the half of the values.

Fig. 2.1 Absolute Coordinate Values and Incremental

Cases where G 90

mental commands ) are used.

When specialG code I (basic) or II (option)is

selected,G90 and G91 codes can be used.

Incremental Input

Coordinate Values

and G 91 (absoluteand incre-

G code

90

G

91 Incremental command

G

Meaning

Absolute command

. Auxiliarydata, I, K, R, etc., of circular

interpolationare always incrementalcommands.

Note:

together in the same block.

G90 and G91 cannot be programmed

If they are written

in the same block, the one writtenlater only is

effective,

EXAMPLE :

GO1 G90 x80. G91 z60.;

G 91 is effective,and in thisblock, commands

become incrementalin both the X and Z axes.

X-AXIS DIAMETER/RADIUS SWITCHING

2.3.6

Addresses X and U for X-axis coordinatewords

are specifiedby diameter value. This iscalled

diameter designation.

The addresses X can be

used for designationof both diameterand

radius.

of parameter #6006D

The switchingis made by the setting

3.

0: Diameter designation

1: Radius designation

As shown below, G90 and G91 commands are

effectiveonly to addresses X and Z .

9

Page 18

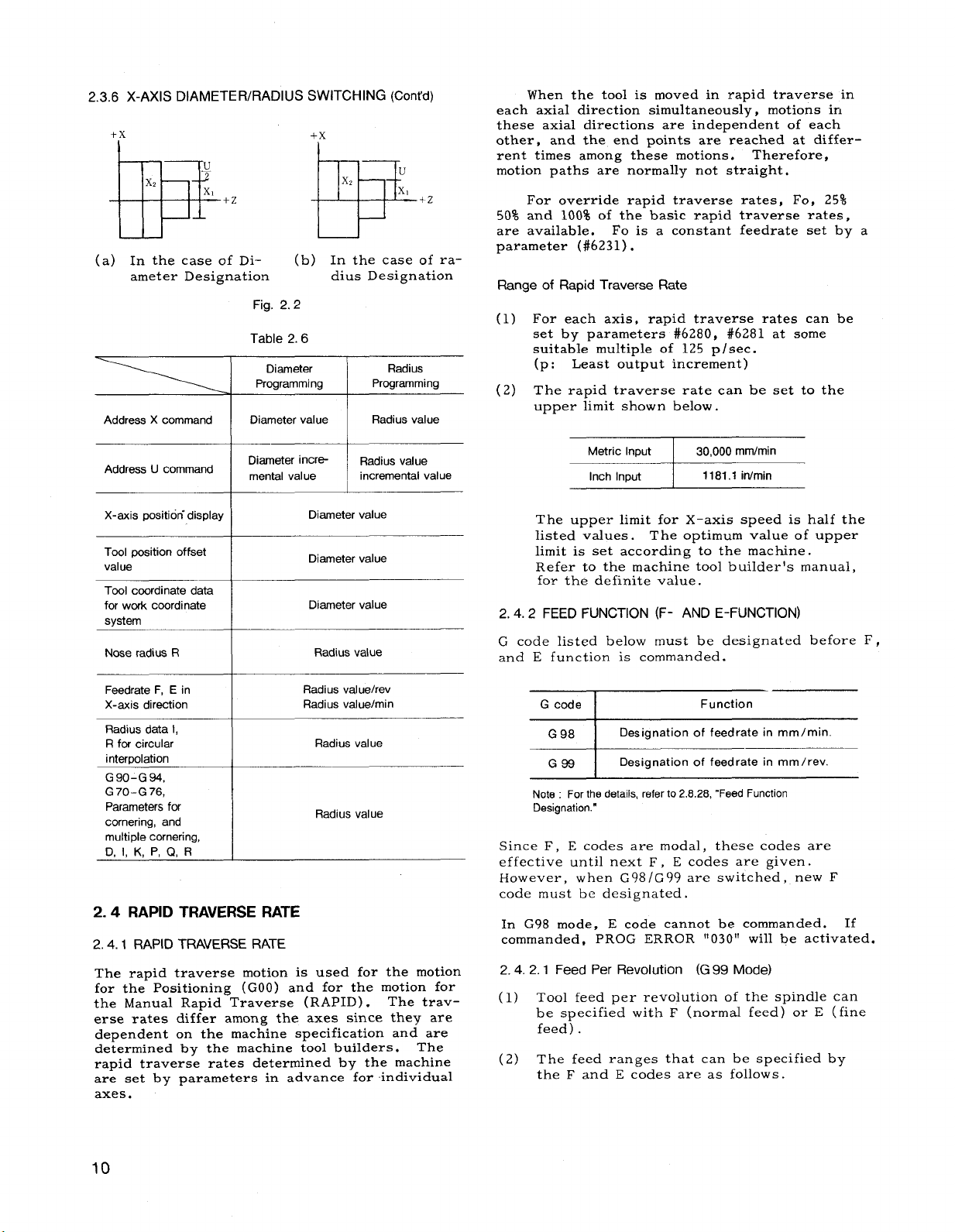

2.3.6 X-AXIS DIAMETER/RADIUS SWITCHING (Cent’d)

each axialdirectionsimultaneously,motions in

+x

+x

I

these axial directionsare independent of each

other. and the end Doints are reached at differ-

rent times among these motions.

motion paths are normally not straight.

50% and 100% of the basic rapid traveree ratee,

BEl=$+zEF+z

(a) In the case of Di-

ameter Designation dius Designation

Address X command

(b) In the case of ra-

-.-f,

r-lg. z. z

Table 2.6

Diameter

Programming

Radius

Programming

are available.

parameter (#6231).

Range of Rapid Traverse Rate

(1)

(2) The rapid traverse rate can be set to the

When the toolis moved in rapid traversein

“.

.

Therefore,

For override rapid traverse rates, Fo, 25%

Fo is a constant feedrateset by

For each axis, rapid traverse rates can be

set by parameters #6280, #6281 at some

suitablemultipleof 125 p/see.

Least output increment)

(p:

uPPer limitshown below.

a

Address U command

X-axis position-display

Tool position offset

value

Tool coordinate data

for work coordinate

system

Nose radius R

Feedrate F, E in

X-axis direction

Radius data 1,

R for circular

interpolation

G90-G 94,

G70-G76,

Parameters for

cornering, and

multiple cornering,

D, 1, K, P, Q, R

Diameter value

Diameter value

Diameter value

Radius value

Radius value/rev

Radius value/rein

Radius value

Radius value

2.4 RAPID TRAVERSERATE

2.4.1RAPID TRAVERSE RATE

The rapid traverse motion is used for the motion

for the Positioning(GOO ) and for the motion for

the Manual Rapid Traverse (RAPID). The traverse rates differamong the axes since they are

dependent on the machine specificationand are

determined by the machine toolbuilders.

The

rapid traverse rates determined by the machine

are set by parameters in advance for-individual

axes.

~

The upper limitfor X-axis speed is halfthe

listedvalues. The optimum value of upper

limitis set according to the machine.

Refer to the machine toolbuilder’smanual,

for the definitevalue.

FEED FUNCTION (F- AND E-FUNCTION)

2.4.2

code listedbelow must be designated before F,

G

and E functionis commanded.

Designation of feedrate in mm/min.

~

Note: Forthsdetails,referto2.8.28, “FeedFunction

Designation.”

Designation of feedrate in mm/rev.

Since F, E codes are modal, these codes are

effectiveuntilnext F , E codes are given.

However, when G98/G99 are switched, new F

code must be designated.

In G98 mode, E code cannot be commanded. If

commanded, PROG ERROR “030” willbe activated.

2.4.2.1

(1)

Feed Per Revolution (G99 Mode)

Tool feed per revolutionof the spindlecan

be specifiedwith F (normal feed) or E (fine

feed).

(2) The feed ranges that can be specifiedby

the F and E codes are as follows.

10

Page 19

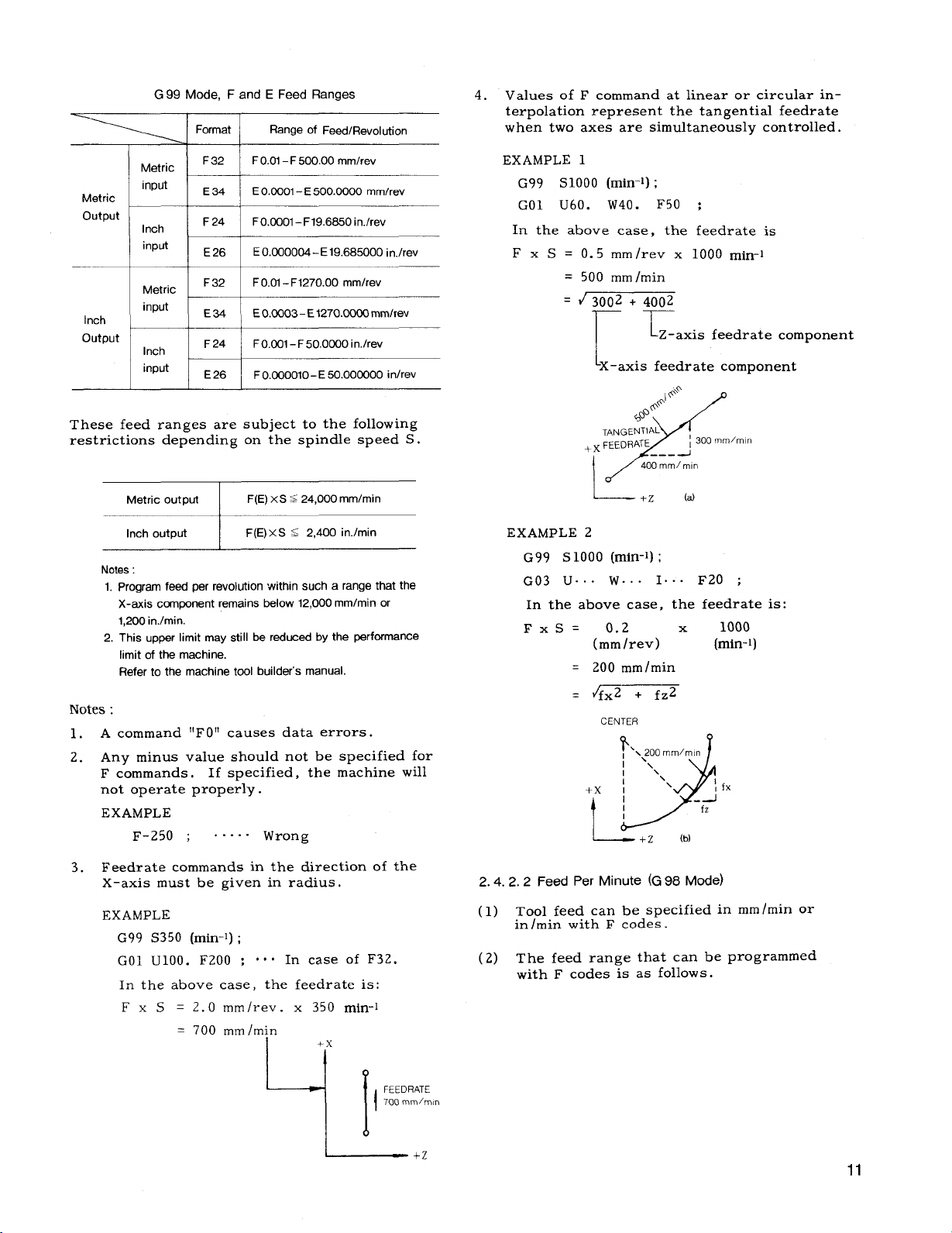

G99 Mode, Fand E Feed Ranges

‘~ I Format I Range of Feecf/Revel.tion

4.

Values of F command at linearor circularinterpolationrepresent the tangentialfeedrate

when two axes are simultaneouslycontrolled.

Metric

1

Metric

output

Inch

output

These feed ranges are subjectto the following

restrictionsdepending on the spindlespeed S.

lVotes :

1.

2.

input

Inch

i

input

I

Metric

‘nPut1+=~

Inch

input

Metric output

Inch output

Notes:

1. Program feed per revolution within such a range that the

X-axis ccwnponentremains below 12,000 mm/min or

1,200 in./min.

2.

This upper limit may still be reduced by the performance

limit of the machine.

Refer to the machine tool builder’s manual.

A command “F O“ causes data errors.

Any minus value should not be specifiedfor

F commands.

not operate properly.

EXAMPLE

F-250 ; s““”” Wrong

F 32

E34

F 24

E 26

I

F24 FO.001–F 50.0000 in./rev

E26

F0.01– F 500.00 mmlrev

I

E0.0001 – E 500.0000 mmfrev

FO.CQOI–F19.6850 in./rev

E0.C00004 – E 19.685000

~

F O.OQOO1O–E 50.000000 in/rev

F(E)XS S 24,000 mmlmin

F(E)XS S 2,400 in./min

If specified,the machine will

—.

in.lrev

EXAMPLE 1

G99 S1OOO (rein-l);

GO1 U60. W40. F50 ;

In the above case, the feedrate is

F x S = 0.5 mm/rev x 1000 rein-l

= 500 mm/min

~ 3002 + 4002

——

1

!

Z-axis feedratecomponent

[~_axisfeedrate component

I$’$’

@+

@

TANGENTIAL

+x FEEDRATE

X

I

J

L-

EXAMPLE 2

G99 S 1000 (rein-l);

G03 U.. . W.. . 1.

In the above case,

FxS= 0.2

(mm/rev)

= 200 mm/min

Jfx2 + fz2

=

CENTER

}

,‘1.200

I

I x,

+x I

t ! 7-’:

~ +Z

400 mm/mln

+Z

‘\

~ 300 mm/mln

---

(a)

.. F20 ;

the feedrateis:

1000

x

(rein-l)

mm/mtn

\\.

f!fx

‘d”

(b)

Feedrate commands in the directionof the

3.

X-axis must be given in radius.

EXAMPLE

G99 S350 (rein-l);

GO1 U1OO. F200 ;

In the above case, the feedrateis:

F x S = 2.0 mm/rev. x 350 rein-l

= 700 mm /rein

000 In case of F3Z.

+x

9[

L___ +,

FEEDRATE

700 mmlmm

I

2.4.2.2

(1) Tool feed can be specifiedin

(2) The feed range that can be programmed

Feed Per Minute (G98 Mode)

mm /reinor

in/reinwith F codes.

with F codes is as follows.

11

Page 20

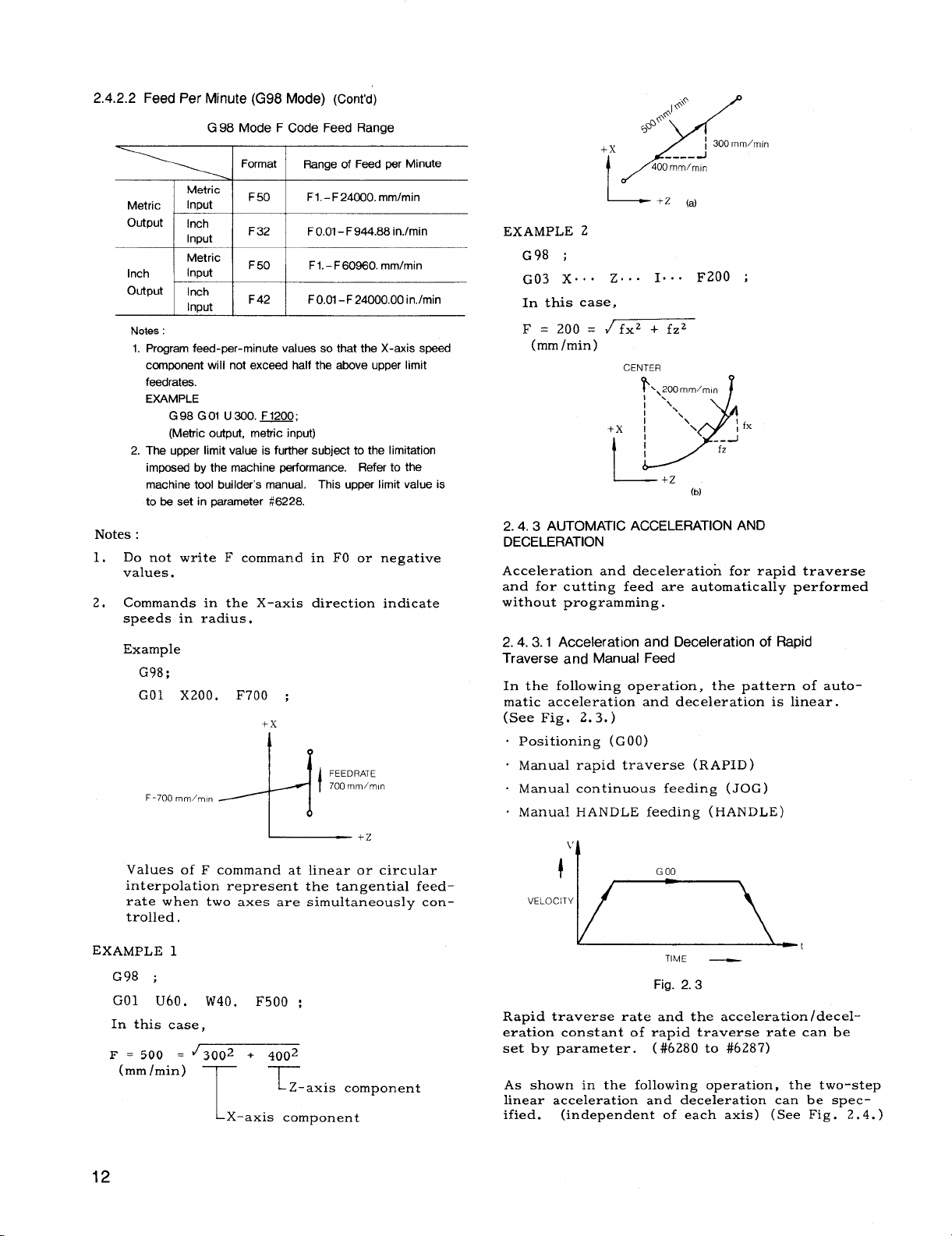

2.4.2.2 Feed Per Minute (G98 Mode) (Cent’d)

‘ELO’:ln

G98 Mode FCode

% lFormatl Range of Feedpar Min.te

Metric

Intwt

I

Metric

output

Inch

output

Notes:

1. Program feed-per-minute values so that the X-axis speed

2. The upper limit value is further subject to the limitation

Notes:

Do not write F command in FO or negative

1.

values.

2. Commands in the X–axis directionindicate

speeds in radius.

Example

G98;

GO1 X200. F700 :

Inch

I

Irmut

Metric

Input

i

Inch

hlDut

~

ccmponent wiIi not exceed half the above upper limit

faedrates.

EXAMPLE

G98 GOI U300. F1200

(Metric output, metric input)

imposed by the machine performance. Refer to the

machine tool buiIder’s manual, This upper limit value is

to be set in Daremeter #8228.

F=700mm/m, n

F50

I

F32

I

F 50

I

F 42

I

—!

+x

’13-

FeedRange

F1.– F 24000. mm/min

~

F0.01–F944.88 in.lmin

1

F1.– F60860. mmlmin

1

FO.01–F 24000.00 in,lmin

I

FEEDRATE

700 mm/mln

1

+Z

*I @o

~@

&

+x

400mm/mln

/

L

EXAMPLE 2

G98 ;

G03 X.. . Z... 1“”” F200 ;

In this case,

F= 200= {fx2 +fz2

(mm/min)

+x I

2.4.3

AUTOMATIC ACCELERATION AND

DECELERATION

Accelerationand decelerationfor rapid traverse

and for cutting feed are automaticallyperformed

without programming.

2.4.3.1 Acceleration and Deceleration of Rapid

Traverse and Manual Feed

In the followingoperation,the pattern of auto-

matic accelerationand decelerationis linear.

(See Fig, 2.3,)

. Positioning(GOO)

“ Manual rapid traverse (RAPID)

. Manual continuous feeding (JOG)

. Manual HANDLE feeding (HANDLE)

CENTER

?’.\,oomm/m(”

1,

9

I

-

+ z (a)

/ 300mm/m[n

-----J

‘\\

+-Z

J

\

;fx

\

J

-c

(b)

Values of F command at linearor circular

interpolationrepresent the tangentialfeed–

rate when two axes are simultaneouslycontrolled.

EXAMPLE 1

G98 ;

GO1 u60, W40. F500 ;

In thiscase,

500 . ~3002 . 4002

F =

(mm/min)

T

T

Z-axis component

X-axis component

TIME _

Fig. 2.3

Rapid traverse rate and the acceleration/decel-

erationconstant of rapid traverse rate can be

set by parameter. (

As shown in the followingoperation,the two-step

linearaccelerationand decelerationcan be specified. (independent of each axis) (See Fig. 2.4.)

#6280 to #6287)

Page 21

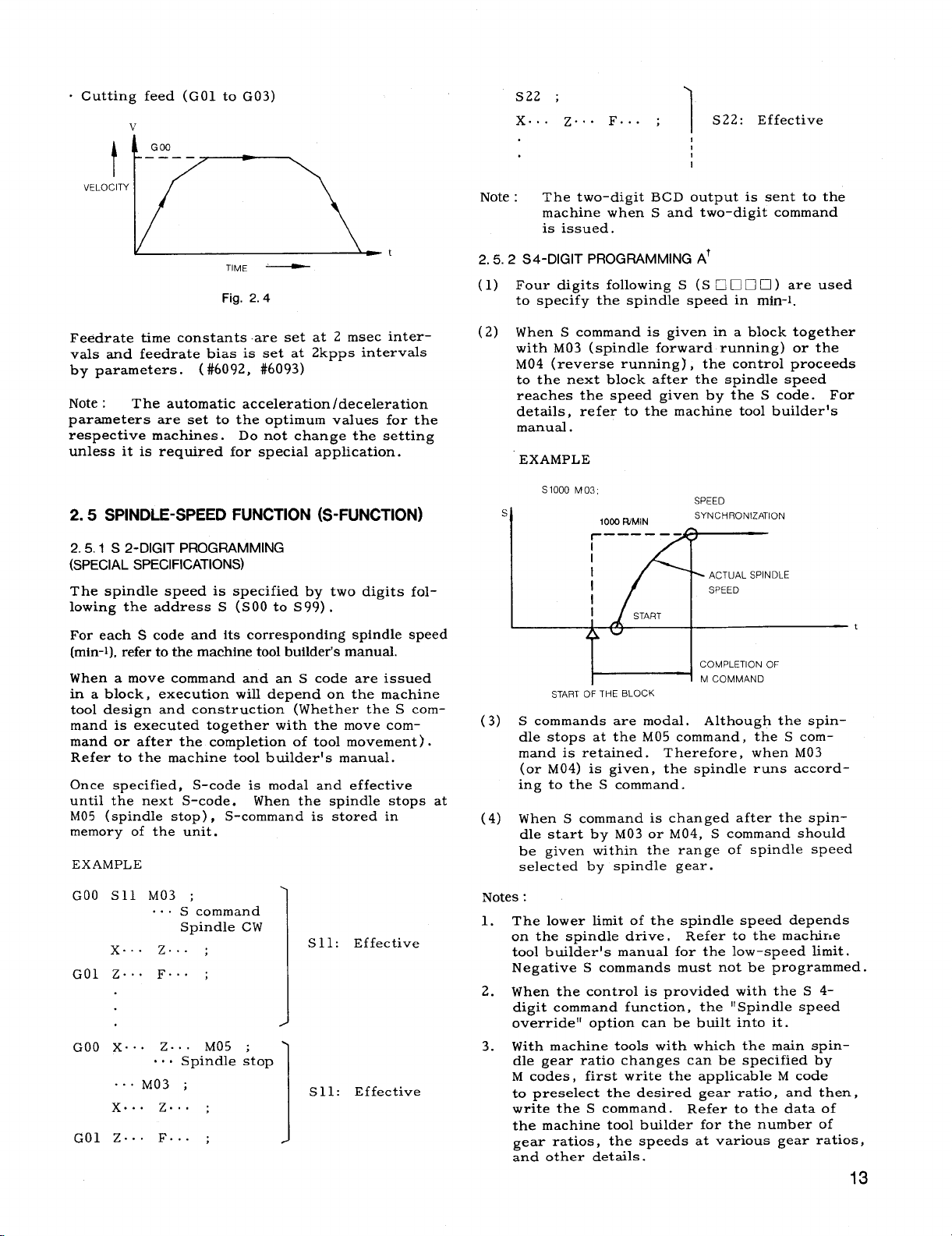

. Cutting feed (GO1 to G03)

v

G00

.———

L

t

VELOCITY

TIME —

Fig. 2.4

S22 ;

X.. .

z.. F.. . ;

S22: Effective

1

Note : The two-digitBCD output is sent to the

machine when S and two–digitcommand

is issued.

t

2.5.2 S4-DIGIT

PROGRAMMING AT

(1) Four digitsfollowingS (S El❑ ❑ •l) are used

to specify the spindle speed in rein-l.

Feedrate time constants-areset at 2 msec intervals and feedrate bias is set at 2kpps intervals

by parameters. (

#6092, #6093)

Note: The automaticacceleration/deceleration

parameters are set to the optimum values for the

respective machines.

Do not change the setting

unless itis required for specialapplication.

SPINDLE-SPEED FUNCTION (S-FUNCTION)

2.5

2.5.1 S 2-DIGIT PROGRAMMING

(SPECIAL

SPECIFICATIONS)

The spindlespeed is specifiedby two digitsfol-

lowing the address S (S00 to S

99) .

For each S code and itscorrespondingspindlespeed

(rein-l),refertothemachinetoolbuilder’smanual.

When a move command and an S code are issued

in a block, execution willdepend on the machine

tooldesign and construction (Whether the S command is executed together with the move com-

mand or afterthe completionof toolmovement) .

Refer to the machine toolbuilder’smanual.

Once specified,S-code is modal and effective

untilthe next S-code.

When the spindlestops at

M05 (spindlestop), S-command is stored in

memory of the unit.

EXAMPLE

(2) When S command is given in a block together

with M03 (spindle forward running) or the

M04 (reverse running) , the controlproceeds

to the next block afterthe spindle speed

reaches the speed given by the S code. For

details,refer to the machine toolbuilder’s

manual.

EXAMPLE

S1OOO M03,

s

I

START OF THE BLOCK

S commands are modal. Although the spin-

(3)

1003 R/MIN

———— —-

11

I

I

I

‘fl

I

u

%

START

SPEED

SYNCHRO)

ACTUAL

SPEED

dlZATION

SPINDLE

~::::fi”’

dle stops at the M05 command, the S command is retained.

Therefore, when M03

(or M04) is given, the spindleruns accord-

ing to the S command.

(4)

When S command is changed afterthe spin-

dle startby M03 or M04, S command should

be given within the range of spindle speed

selectedby spindle gear.

t

GOO S11 M03 ;

... S command

Spindle CW

x.. . z... ;

GO1 Z.. . F.. . ;

GOO X.. . z... M05 ;

.,. Spindle stop

...M03 ;

x.. . z.. . ;

... ...

F

z

GO

;

Sll: Effective

S 11: Effective

Notes:

The lower limitof the spindle speed depends

1.

on the spindle drive.

Refer to the machir,e

toolbuilder’smanual for the low-speed limit.

Negative S commands must not be programmed.

2.

When the control is provided with the S 4digitcommand function,the “Spindle speed

override” option can be builtintoit.

3.

With machine toolswith which the main spin-

dle gear ratiochanges can be specifiedby

M codes, firstwrite the applicableM code

to preselectthe desired gear ratio,and then,

write the S command. Refer to the data of

the machine toolbuilder for the number of

gear ratios,the speeds at various gear ratios,

and other details.

13

Page 22

2.5.2 S 4-DIGIT PROGRAMMING At (Cent’d)

When the controlis provided with this func-

4.

tion,the spindlemaximum speed commanding

functionwith the instruction“G50 S. .. ;”

can be used.

2.5.3S 4-DIGIT

PROGRAMMING Bf

(1) This functionis to modify the S4-digitcom-

mand A output freelythrough the program–

mable machine interface.

(2) Basically,thisfunctionisusedin thesame way as

theS 4-digitcommand A function,but itisnormallyused tosetthemanuallycontrolledspindle

speeds controlledby the rotaryswitchon the

machine controlstationcorrespondingto S command speeds.

For the detailsofS command

speeds,refertothemachinetoolbuilder’smanual.

TOOL FUNCTION (T-FUNcTiON)

2.6

2,6.1 T 4-DIGIT PROGRAMMING

(1) Four digitsfollowingthe address T specifies

the toolnumber.

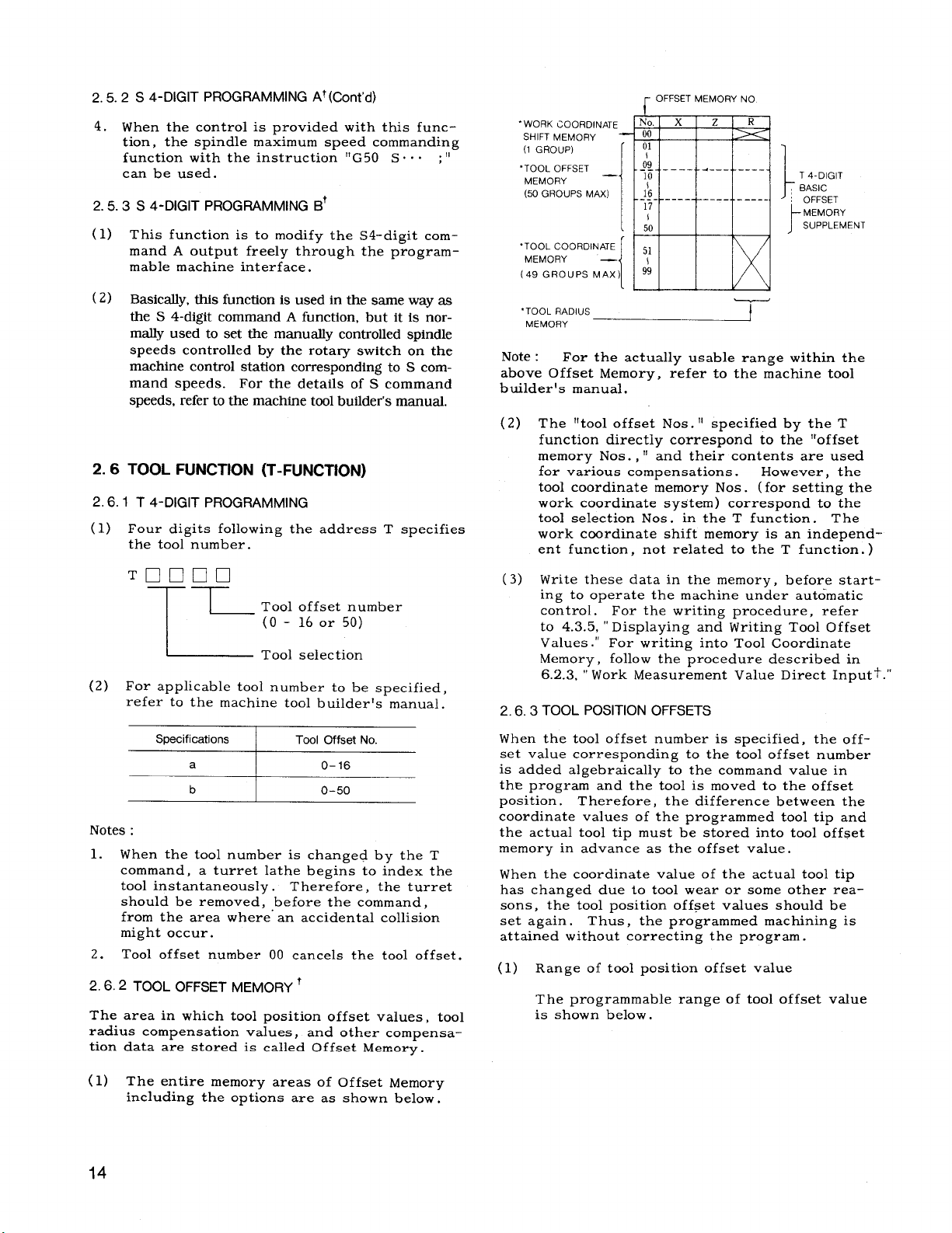

OFFSET MEMORY NO

x

‘ WORK COORDINATE

SHIFT MEMORY

(1 GROUP)

‘TOOL OFFSET

MEMORY —

(50 GROUPS MAX)

‘TOOL COORDINATE

MEMORY —

(49 GROUPS MAX)

Note :

For the actuallyusable range within the

No.

00

01

;9

--- ------ -4- —-.

y

J.

______

I ‘

50

51

99

[ ‘

_____

z R

-----

-----

-‘

T 4-DIGIT

; BASIC

: OFFSET

MEMORY

SUPPLEMENT

F

above OffsetMemory, refer to the machine tool

builder’smanual.

(2) The “tooloffsetNos. “ specifiedby the T

functiondirectlycorrespond to the “offset

memory Nos. ,“ and theircontents are used

for various compensations.

However, the

toolcoordinatememory Nos. (for settingthe

work coordinatesystem) correspond to the

toolselectionNos. in the T function. The

work coordinateshiftmemory is an independent function,not relatedto the T function.)

Tnmmn

TC(o_160r50)

Tool offsetnumber

Tool selection

(2) For applicabletoolnumber to be specified,

refer to the machine toolbuilder’smanual.

Notes:

1.

When the toolnumber is changed by the T

command, a turret lathe begins to index the

toolinstantaneously.

Therefore, the turret

should be removed, before the command,

from the area where”an accidentalcollision

might occur.

Tool offsetnumber 00 cancelsthe tooloffset.

2.

TOOL OFFSET MEMORY t

2,6.2

The area in which toolpositionoffsetvalues, tool

radius compensation values, and other comPensa–

tiondata are stored is calledOffset Memory.

(3) Write these data in the memory, before start-

ing to operate the machine under automatic

control. For the writing procedure, refer

to 4.3.5,“Displaying and WritingTool Offset

Values.“

For writingintoTool Coordinate

Memory, followthe procedure described in

6.2.3,“Work Measurement Value DirectInputt.“

TOOL POSITION OFFSETS

2.6.3

When the tooloffsetnumber is specified,the off-

set value corresponding to the tooloffsetnumber

is added algebraicallyto the command value in

the program and the toolis moved to the offset

position. Therefore, the differencebetween the

coordinatevalues of the programmed tooltipand

the actualtooltip must be stored intotooloffset

memory in advance as the offsetvalue.

When the coordinatevalue of the actualtooltip

has changed due to toolwear or some other rea-

sons, the toolpositionoffsetvalues should be

set again.

Thus, the programmed machining is

attainedwithout correctingthe program.

(1) Range of tool positionoffsetvalue

The programmable range of tooloffsetvalue

is shown below.

(1) The entirememory areas of Offset Memory

including the options are as shown below.

14

Page 23

output I

Metric

output

Inch

output

(2)

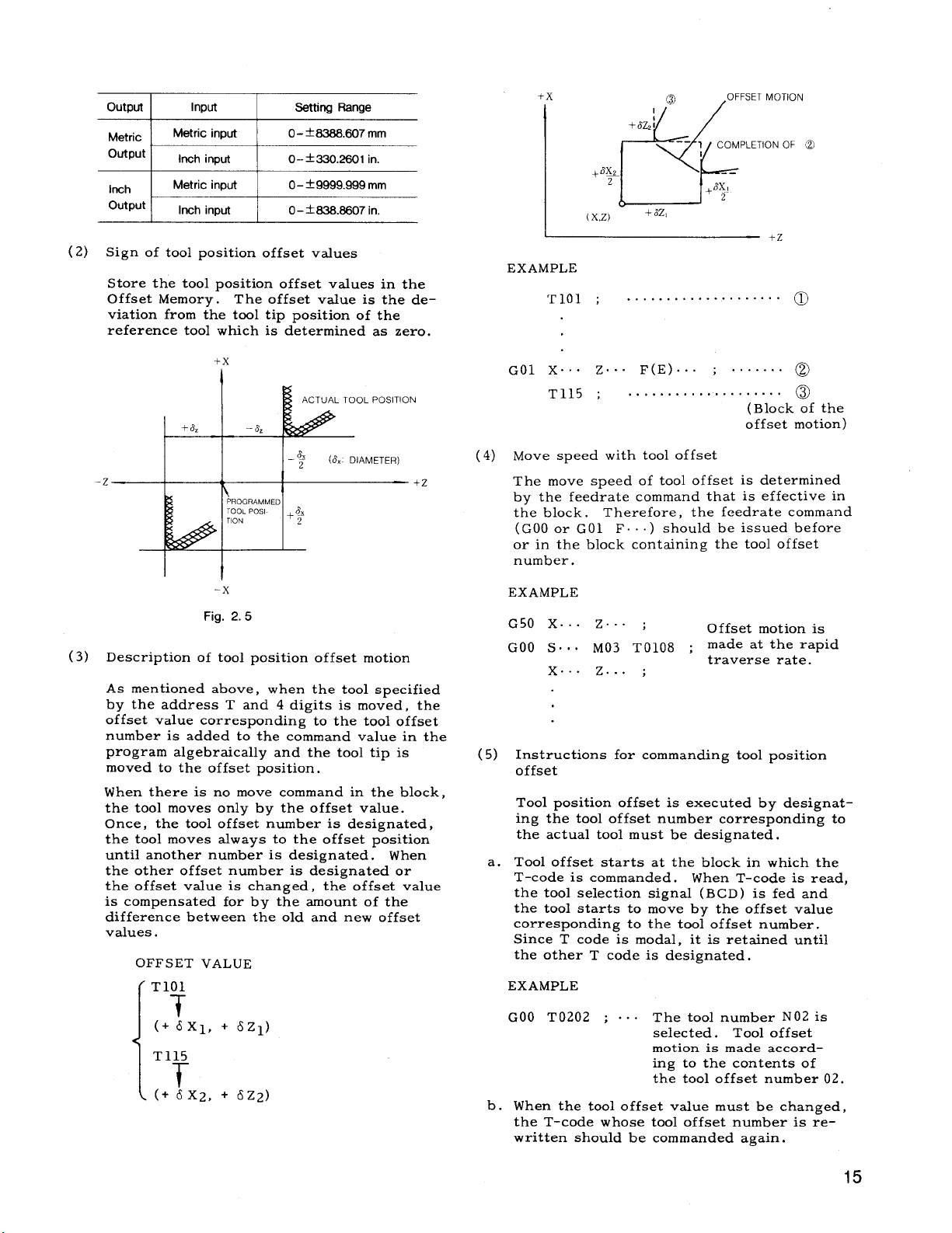

Sign of toolpositionoffsetvalues

Store the toolpositionoffsetvalues in the

OffsetMemory.

viationfrom the tooltippositionof the

reference toolwhich is determined as zero.

Input

Metric input O- k6366.607

Inch input O–+330.260t in.

Metric input O– ~9999.999 mm

Inch input O- t636.t?607 in.

The offsetvalue is the de-

I

setting Range

mm

+x

,’+

8X3

+

2

X,z)

(

EXAMPLE

TIOI ; ....................

CIZ2:

+

+Sz,

(2

‘- 1 COMPLETION

,OFFSET MOTION

--

ax!

+

2

o

+x

tiOLpOs’T’ON

-z

I

Descriptionof toolpositionoffsetmotion

(3)

As mentioned above,

by the address T and 4 digitsis moved, the

offsetvalue corresponding to the tooloffset

number is added to the command value in the

program algebraicallyand the tooltipis

moved to the offsetposition.

When there is no move command in the block,

the toolmoves only by the offsetvalue.

Once, the tooloffsetnumber is designated,

the toolmoves always to the offsetposition

untilanother number is designated. When

the other offsetnumber is designated or

the offsetvalue is changed, the offsetvalue

is compensated for by the amount of the

differencebetween the old and new offset

values.

OFFSET VALUE

T101

T

(+ 6X1, + 6Z1)

[

T115

T

(+ 6X2, + 6Z2)

[

I I

PROGRAMMED

–x

Fig. 2.5

8

.2

(& DIAMETER)

2

when the toolspecified

+-z

GO1 X.. . Z...

T115 ; ....................

(4) Move speed with tooloffset

The move speed of tooloffsetis determined

by the feedratecommand that is effectivein

the block. Therefore, the feedratecommand

(GOO or GO1 F.

or in the block containingthe tooloffset

number.

EXAMPLE

G50 X.. . Z.. . ;

GOO S.. . M03 TO1O8 ;

x.. . z... ;

(5)

Instructionsfor commanding toolposition

offset

Tool positionoffsetis executed by designating the tooloffsetnumber corresponding to

the actual toolmust be designated.

a.

Tool offsetstartsat the block in which the

T-code is commanded. When T-code is read,

the tool selectionsignal (BCD ) is fed and

the toolstartsto move by the offsetvalue

corresponding to the tooloffsetnumber.

Since T code is modal, itis retaineduntil

the other T code is designated.

EXAMPLE

GOO T0202 ; ...

b.

When the tooloffsetvalue must be changed,

the T-code whose tooloffsetnumber is rewritten should be commanded again.

F(E) ... ; .......

(Block of the

offsetmotion)

..) should be issued before

Offset

made at the rapid

traverse rate.

The toolnumber N02 is

selected.

motion is made accord–

ing to the contents of

the tooloffsetnumber 02.

motion is

Tool offset

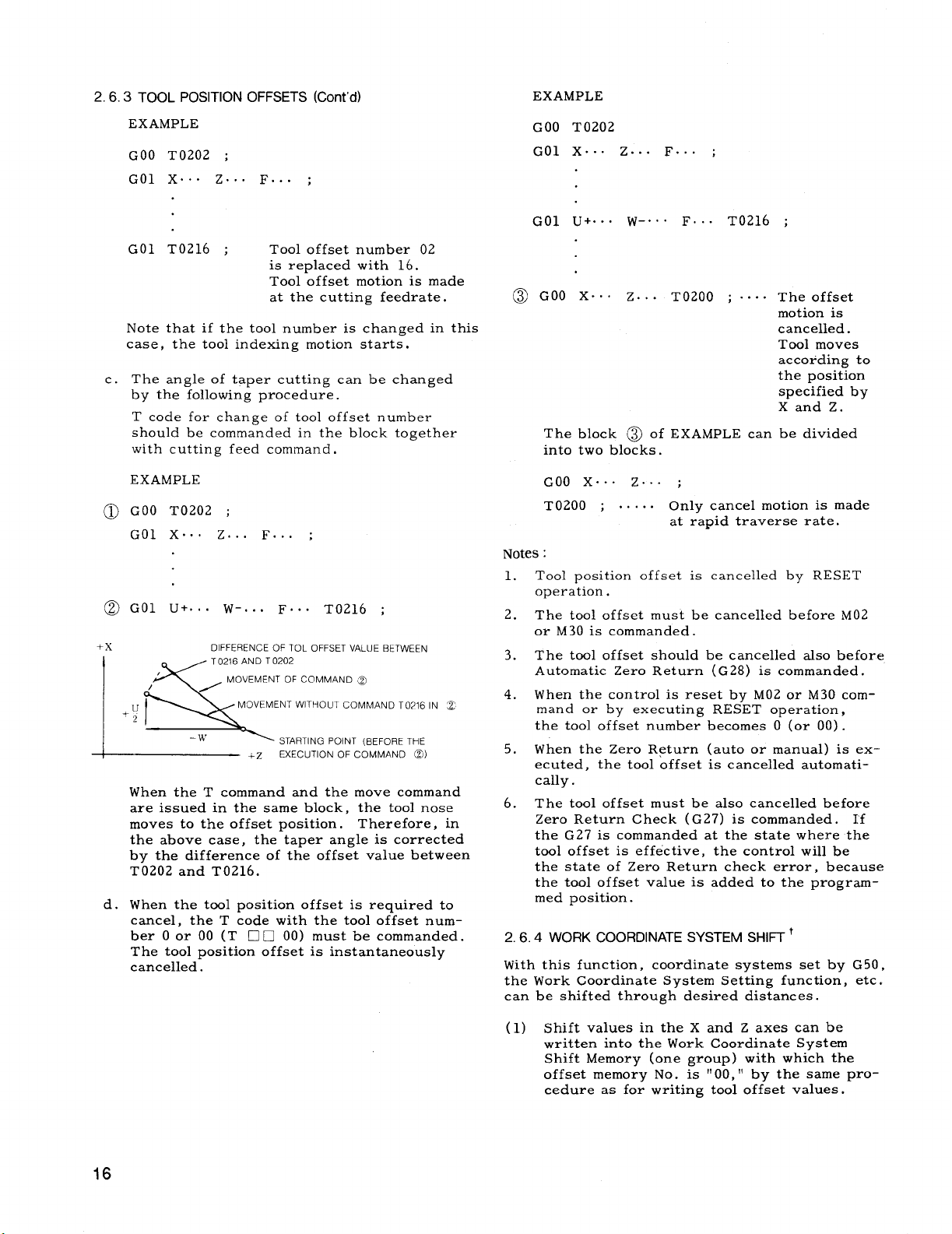

@

@

15

Page 24

2.6.3 TOOL POSITION OFFSETS (Cent’d)

EXAMPLE

EXAMPLE

GOO T0202 ;

GO1 X.. . ZOO. F.. . ;

GO1 T0216 ;

Tool offset

isreplaced

Tool offset

at the cutting feedrate.

number 02

with 16.

motion is made

Note that ifthe toolnumber is changed in this

case, the toolindexing motion starts,

c. The angle of taper cutting can be changed

by the followingprocedure.

T code for change of tooloffsetnumber

should be commanded in the block together

with cuttingfeed command .

EXAMPLE

@ GOO T0202 ;

GO1 X.. . Z... F... ;

@GOl U+... W-... F... TI)216 ;

+x

,

/

.U

2

la

DIFFERENCE OF TOL OFFSET VALUE BETWEEN

T0216 AND T 0202

MOVEMENT OF COMMAND ~~

MOVEMENT WITHOUT COMMAND T0216 IN c

–w

STARTING POINT (BEFORE THE

EXECUTION OF COMMAND @)

~z

When the T command and the move command

are issued in the same block, the toolnose

moves to the offsetposition. Therefore, in

the above case, the taper angle is corrected

by the differenceof the offsetvalue between

T0202 and T0216.

d.

When the toolpositionoffsetisrequired to

cancel,the T code with the tooloffsetnum–

ber O or 00 (T ❑ 0 00) must be commanded.

The toolpositionoffsetisinstantaneously

cancelled.

GOO T0202

...

GO1 X.. . Z...

Gol

u+. . . w-.

@GOO X... Z..

F

. F.. .

;

T0216

T0200 ;. ...

,

The offset

motion is

cancelled.

Tool moves

according to

the position

specifiedby

Xand Z.

The block @ of EXAMPLE can be divided

intotwo blocks.

GOO X.. . Z.. . ;

. .

T0200 ; ..

only cancel motion is made

at rapid traverse rate.

Notes:

Tool position

1.

offsetis cancelledby RESET

operation.

2.

The tooloffsetmust be cancelledbefore Mf)2

or M30 is commanded.

The tooloffsetshould be cancelled alsobefore

3.

Automatic Zero Return (G28) is commanded.

When the controlis reset by M02 or M30 com-

4.

mand or by executing RESET operation,

the tooloffsetnumber becomes O (or 00).

When the Zero Return (autoor manual) is ex-

5.

ecuted, the tooloffsetis cancelledautomatically.

The tooloffsetmust be alsocancelledbefore

6.

Zero Return Check (G27) is commanded. I’f

the G27 is commanded at the statewhere the

tooloffsetis effective,the controlwillbe

the stateof Zero Return check error, because

the tooloffsetvalue is added to the programmed position.

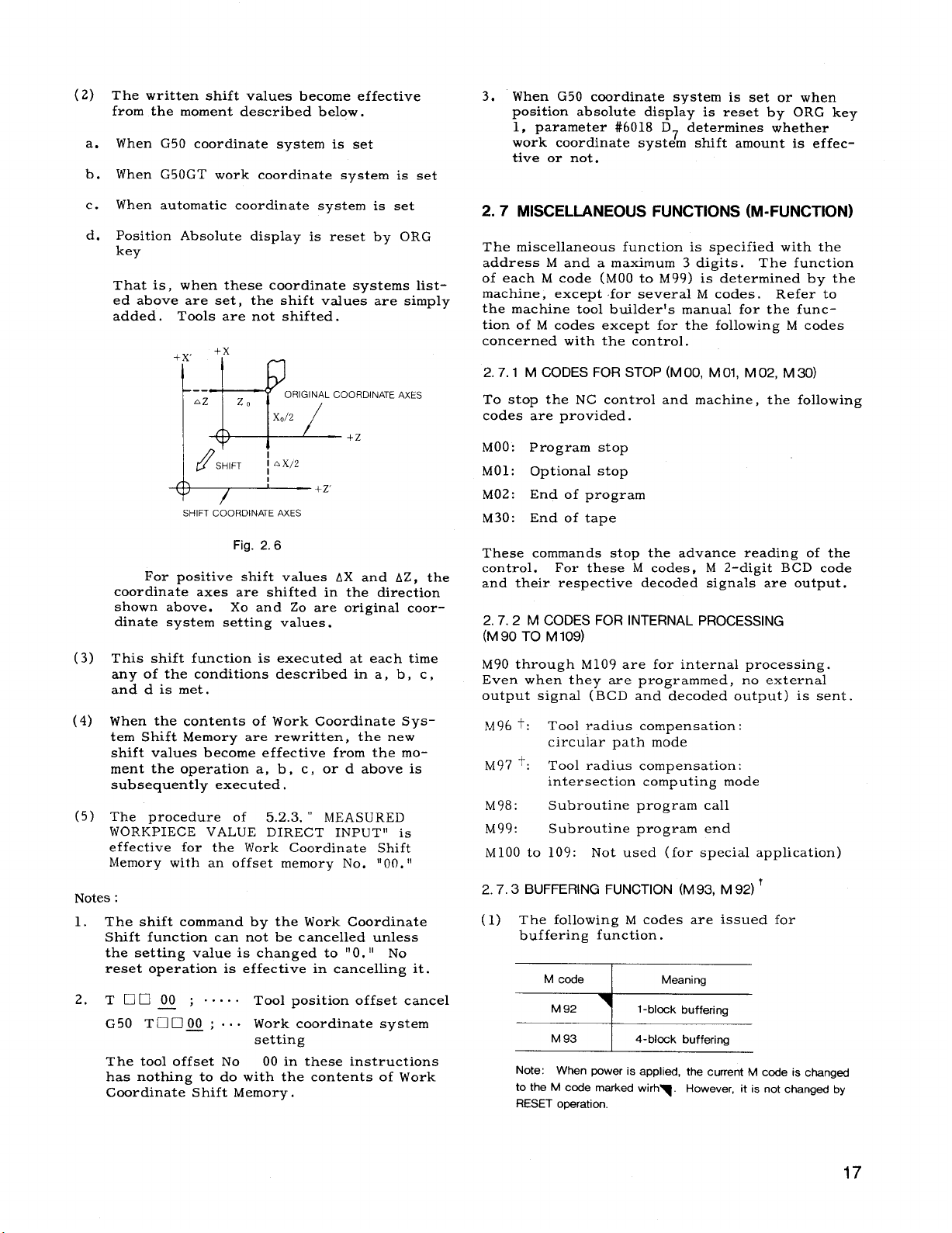

WORK COORDINATE SYSTEM SHIFT+

2.6.4

With thisfunction,coordinatesystems set by G 50,

the Work Coordinate System Setting function, etc.

can be shiftedthrough desired distances.

(1) Shiftvalues in the X and Z axes can be

written intothe Work Coordinate System

ShiftMemory (one group ) with which the

offsetmemory No. is ,

!!00 !!by the same pro-

cedure as for writingtooloffsetvalues.

Page 25

(2)

The written shiftvalues become effective

from the moment described below.

When G50 coordinatesystem is set

a.

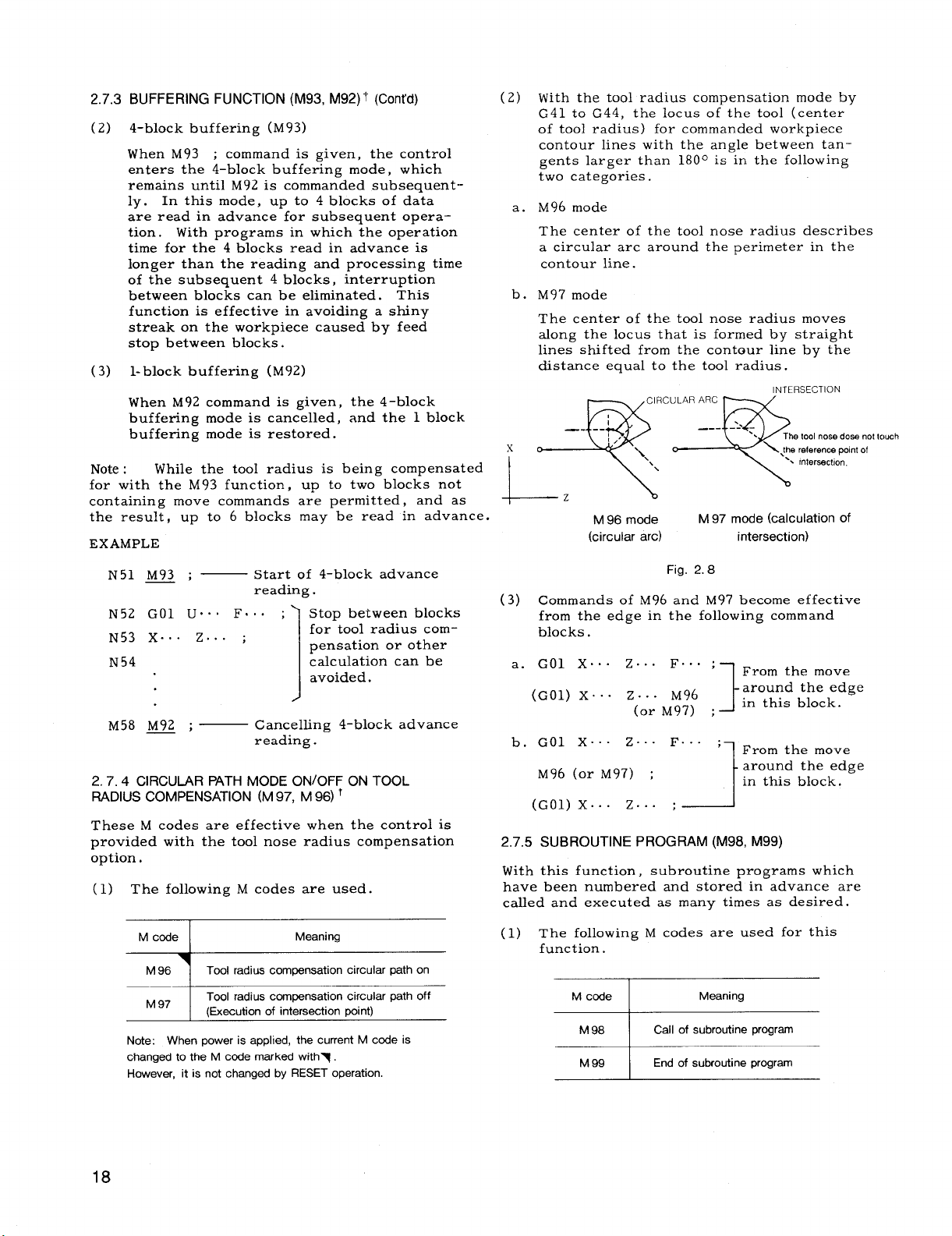

When G50GT work coordinatesystem is set

b.

When automaticcoordinatesystem is set

c.

PositionAbsolute displayis reset by ORG

d.

key

That is, when these coordinate systems listed above are set, the shiftvalues are simply

added.

Tools are not shifted.

‘N+

z,

II

ORIGINAL COORDINATE AXES

I

/

x,/2 /

3. When G50 coordinate system is set or when

positionabsolutedisplayis reset by ORG key

1, parameter #6o18 D7 determines whether

work coordinatesystem shiftamount is effectiveor not.

2.7

MISCELLANEOUS FUNCTIONS (M-FUNCTION)

The miscellaneousfunctionis specifiedwith the

address M and a maximum 3 digits. The function

of each M code (MOO to M99) is determined by the

machine, except for severalM codes.

the machine toolbuilderfsmanual for the func–

tionof M codes except for the followingM codes

concerned with the control.

M CODES FOR STOP (M 00, M 01, M 02, M 30)

2.7.1

To stop the NC controland machine, the following

codes are provided.

Refer to

+-#----+z

SHIFT COORDINATE AXES

Fig. 2.6

For positiveshiftvalues AX and AZ, the

coordinateaxes are shiftedin the direction

shown above. Xo and Zo are originalcoordinate system settingvalues.

This shiftfunctionis executed at each time

(3)

any of the conditionsdescribed in a, b, c,

and d is met.

When the contents of Work Goordinate Sys-

(4)

tem ShiftMemory are rewritten, the new

shiftvaluesbecome effectivefrom the moment the operation a, b, c, or d above is

subsequently executed.

(5)

The ~rocedure of 5.2.3.“ MEASURED

WOR.K’PIECE VALUE DIRECT INPUTi’ is

effectivefor the Work Coordinate Shift

Memory with an offsetmemory No. “00.“

Notes:

1. The shiftcommand by the Work Coordinate

Shift function can not be cancelledunless

the setting value is changed to “O.“ No

resetoperationis effectivein canceling it.

Moo:

MOl: Optionalstop

M02:

M30:

These commands stop the advance reading of the

control.

and their respectivedecoded signalsare output.

(M 90 TO M 109)

M90

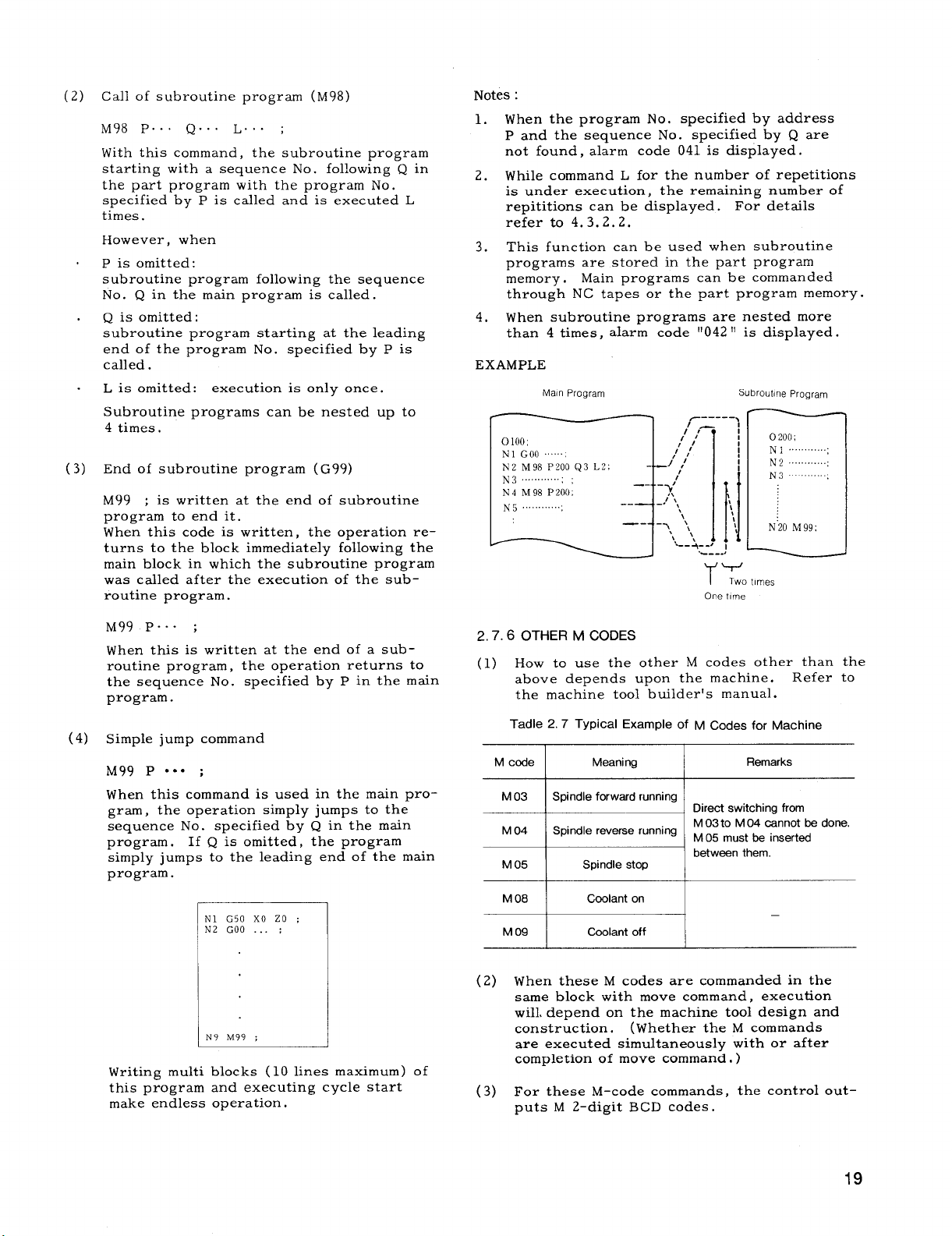

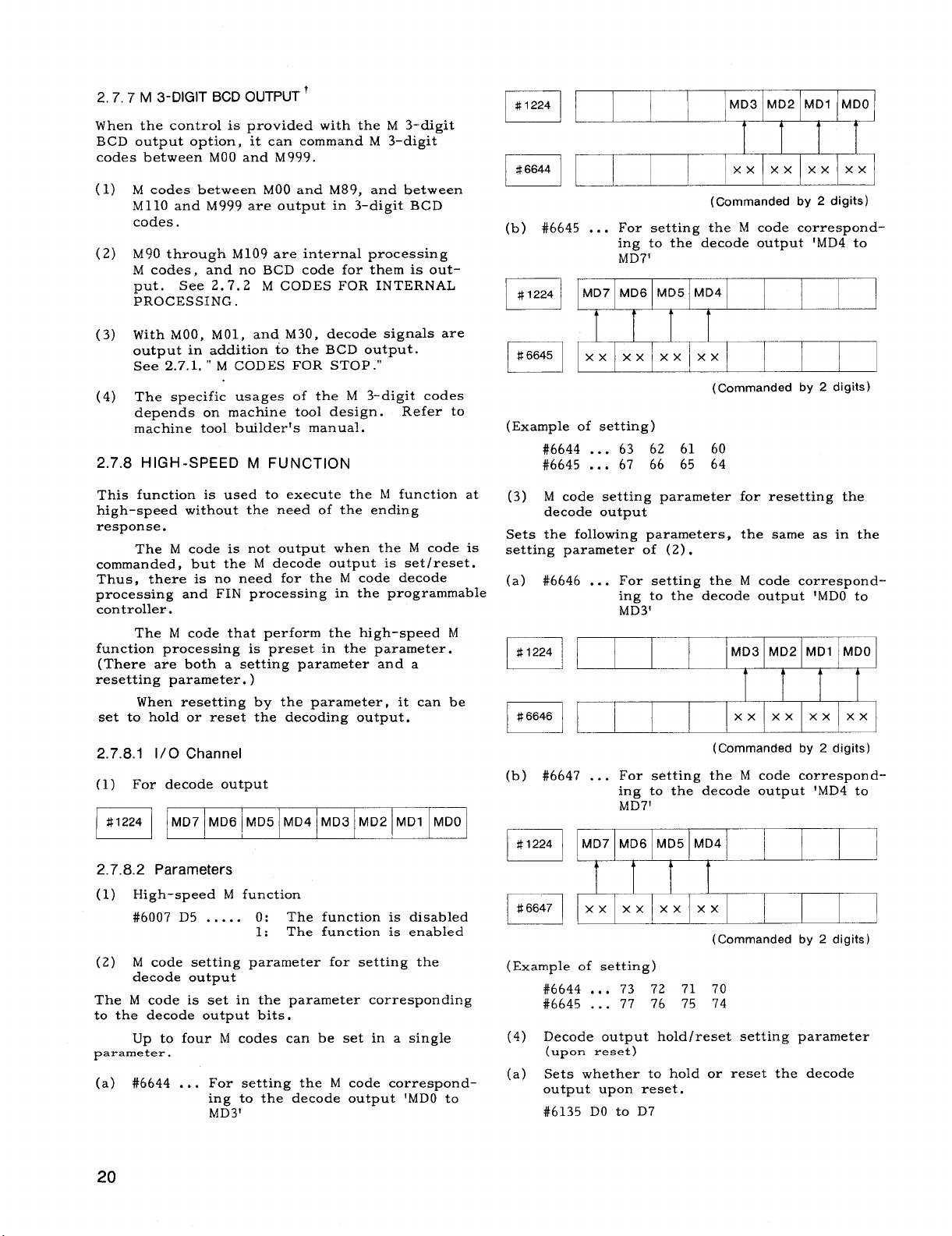

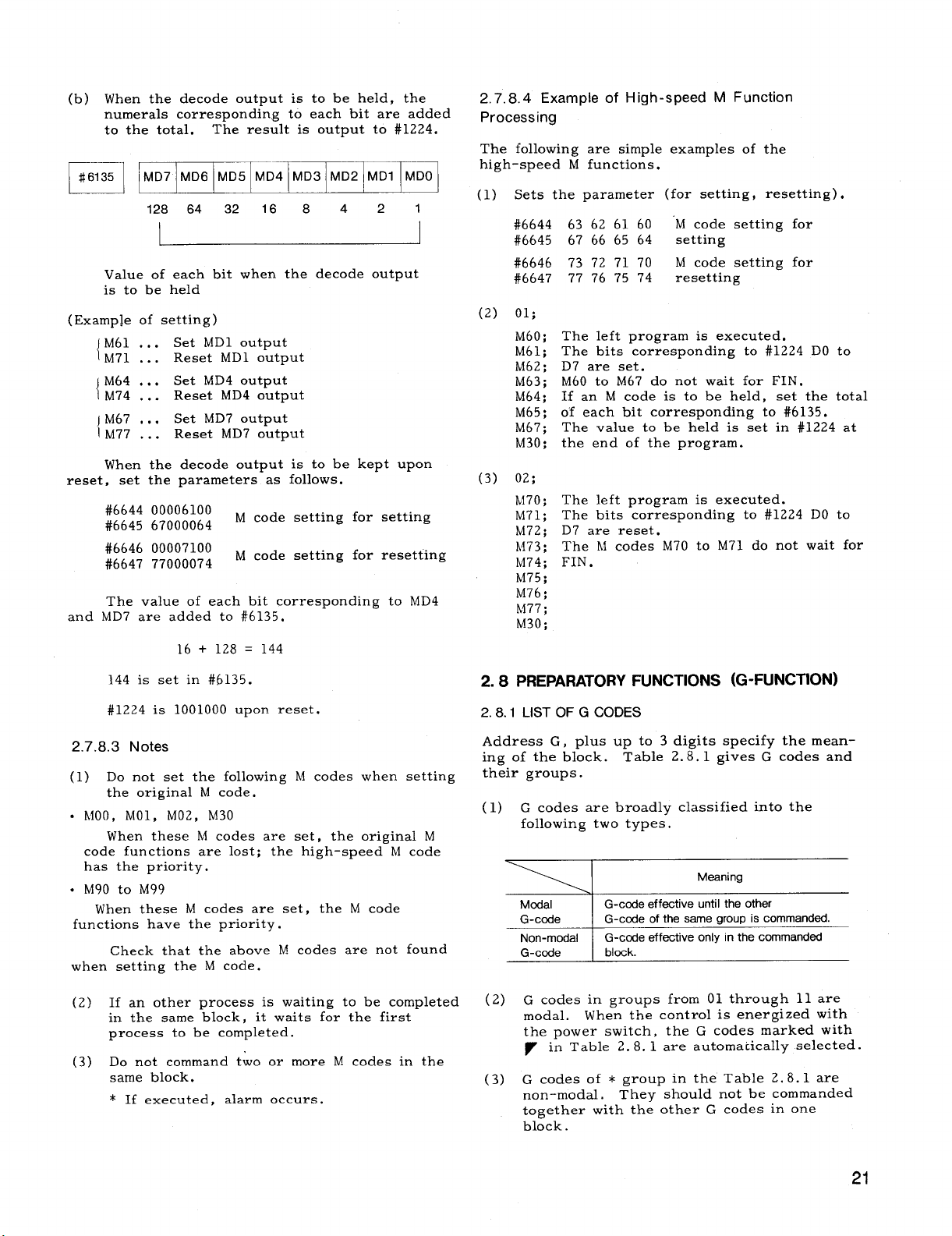

Even when they are programmed, no external