Page 1

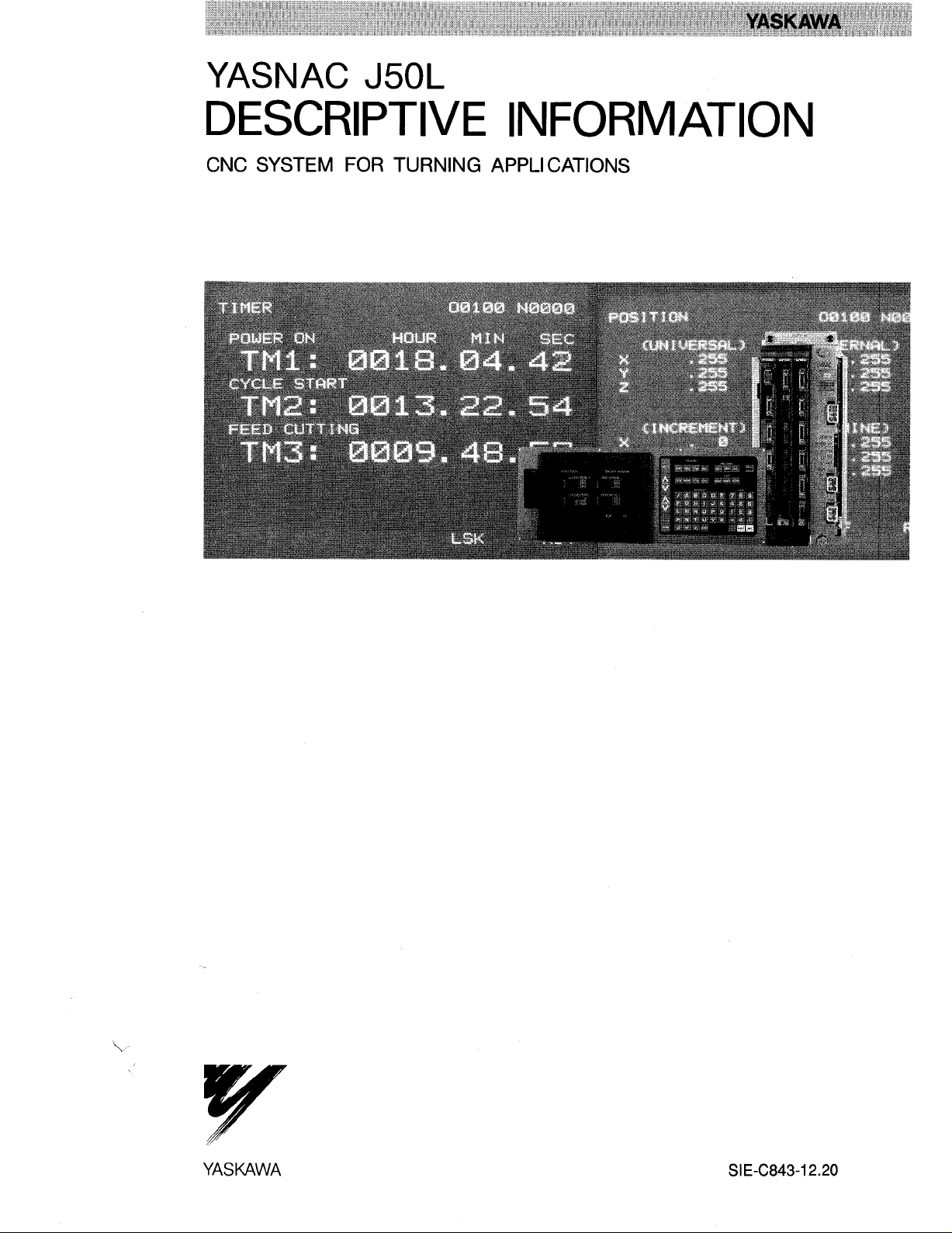

YASNAC J50L

DESCRIPTIVE INFORMATION

CNC SYSTEM FOR TURNING APPLI CATIONS

\

Y

YASUAWA

SIE-C843-12.20

Page 2

1 INTRODUCTION

The YASNAC J50L is a high-performance CNC for the simultaneous control of

2 or 3 axes of a lathe machining tools, with emphasis placed on high-speed

machining, and programming capability.

FEATURES

1.

Ultra-high-speed Performance

“High-speed, computing system” is achieved by installing a 32-bit microprocessor in the YASNAC J50L.

Significant Downsizing (miniaturized)

2.

YASNAC J50L is significantly downsized because it has surface mounted

devices and customized gate arrays.

This manual explains both basic and optional features of

YASNAC J50L as

well as the servo system.

You can determine your own hardware requirements after carefully reading

this manual.

This manual is subject to change without

notification due to product improvements,

model changes, etc.

Page 3

CONTENTS

f INTRODUCTION i

2 BASIC FEATURES

2.1 CONTROLLED AXES 1

2.2 SIMULTANEOUS

CONTROLLABLE AXES 1

2.3 LEAST INPUT INCREMENT 1

2.4 LEAST OUTPUT INCREMENT 1

1

2.5 MAXIMUM PROGRAMMABLE DIMENSIONS 1

2.6 TAPE CODE i

2.7 EIAo 1S0 AUTO-RECOGNITION 1

2.8 TAPE FORMAT 1

2.9 DECIMAL POINT PROGRAMMING 1

2.10 BUFFER REGISTER 1

2.11 RAPID TRAVERSE RATE AND FEEDRATE 2

2.12 FEED FUNCTION (F-, E-FUNCTION) 2

2.13 AUTOMATIC

ACCELERATION/DECELERATION 2

2.14 FEEDRATE OVERRIDE AND

FEEDRATE OVERRIDE CANCEL 2

2.15 PREPARATORY FUNCTION

(G-FUNCTION) 3

2.16 ABSOLUTE/INCREMENTAL

PROGRAMMING (G90/G91) 3

2.17 PROGRAMMING OF

ABSOLUTE ZERO POINT (G50) 3

2.18 POSITIONING (GOO) 3

2.19 POSITIONING IN ERROR

DETECT OFF MODE (G06) 3

2.20 LINEAR INTERPOLATION (GO1) 3

2.21 CIRCULAR INTERPOLATION (G02, G03) 4

2.22 DWELL (G04) 4

2.23 REFERENCE POINT RETURN CHECK (G27) 4

2.24 AUTOMATIC RETURN TO

REFERENCE POINT (G28) 4

2.25 RETURN FROM REFERENCE POINT (G29) 4

2.26 MULTI-START THREADCUTTING (G32) 5

2.27 CANNED CYCLES (G90, G92, G94) 5

2.28 FEED FUNCTION DESIGNATION

(G98, G99) 6

SPECIAL G-CODE I 6

2.29

2.30 MISCELLANEOUS FUNCTION

(M-FUNCTION) 6

2.31 SPINDLE-SPEED FUNCTION

(S-FUNCTION) 7

2.32 TOOL FUNCTION (T-FUNCTION) 7

2.33 TOOL POSITION OFFSET 7

2.34 BACKLASH COMPENSATION 7

2.35 MANUAL FEED 7

2.36 MANUAL RETURN TO REFERENCE POINT 7

2.37 BUILT-IN TYPE NC OPERATOR’S STATION 7

2.38 PART PROGRAM STORAGE AND EDITING 8

2.39 SUBROUTINE PROGRAM (M98, M99) 8

2.40 PARAMETER STORAGE 8

2.41 SETTING FUNCTION 8

2.42 INTERNAL DATA TAPE INPUT 8

2.43 OPERATION TIME DISPLAY 8

2.44 ADDRESS SEARCH 9

2.45 PROGRAM NUMBER 9

2.46 LABEL SKIP 9

2.47 CONTROL IN/OUT 9

2.48 SINGLE BLOCK 9

2.49 OPTIONAL BLOCK SKIP 9

2.50 DRY RUN 9

2.51 MACHINE LOCK AND DISPLAY LOCK 9

2.52 AUXILIARY FUNCTION LOCK 9

2.53 MANUAL ABSOLUTE ON/OFF 9

2.54 EDIT LOCK 10

2.55 INTERLOCK 10

2.56 RAPID PULL OUT OF THREADING 10

2.57 ERROR DETECT 10

2.58 DOOR INTERLOCK 10

2.59 FEED HOLD 10

2.60 EMERGENCY STOP 10

2.61 OVERTRAVEL 10

2.62 REMOTE RESET 10

2.63 REMOTE POWER ON/OFF 10

2.64 MACHINE READY INPUT SIGNAL 10

2.65 CONTROL POWER ON OUTPUT SIGNAL 10

2.66 SERVO POWER ON OUTPUT SIGNAL 10

2.67 TOOL MOVE OUTPUT SIGNAL AND

THREAD CUTTING OUTPUT SIGNAL 10

2.68 NC ALARM OUTPUT SIGNAL 10

2.69 INPUT ERROR OUTPUT SIGNAL 11

2.70 NC RESET OUTPUT SIGNAL 11

2.71 EXTERNAL ERROR INPUT SIGNAL 11

2.72 RS-232C INTERFACE PORT 11

2.73 ON-LINE DIAGNOSTICS 11

2.74 POSITION DETECTOR INTERFACE 11

2.75 INPUT/OUTPUT CONNECTORS 11

2.76 POWER INPUT 11

2.77 AMBIENT CONDITIONS 11

2.78 SPINDLE PULSE GENERATOR 12

Page 4

CONTENTS (Cent’d)

3 BASIC OPTIONS 72

AC SERVO CONTROL UNITS 12

3.1

3.2 AC SERVOMOTORS 12

OPTIONS 13

4

SEPARATE TYPE NC OPERATORS

4.1

STATION 13

4,2 SEPARATE TYPE TAPE READER 13

4.3 TAPE READER WITH REELS 13

4.4 M3-DIGIT BCD OUTPUT 13

4.5 ADDITIONAL TOOL OFFSET MEMORY

4.6 ADDITIONAL PART PROGRAM STORAGE 13

4.7 ADDITIONAL PROGRAM NUMBER

REGISTRATION 13

13

4.8 OPERATION TIME DISPLAY B 14

4.9 STEP-MODE SIMULTANEOUS

ONE-AXIS OPERATION 14

4.10 INTERNAL TOGGLE SWITCHES 14

4.11 G50 POINT RETURN 14

4.12 RESTART AFTER MANUAL

INTERRUPTION 14

4.13 PROGRAM RESTART 15

4.14 EXTERNAL INPUT, COLLATION,

AND OUTPUT 15

4.15 BUFFERING FUNCTION (M92, M93) 15

4.16 INCH/METRIC SETTING 15

4.17 RADIUS PROGRAMMING FOR

CIRCULAR INTERPOLATION (G22, G23) 15

4.18 ANGLE PROGRAMMING FOR LINEAR

INTERPOLATION (GO1) 15

4.19 TOOL OFFSET VALUE SETTING (G 10) 16

4.20 CORNERING (Gil, G12) 16

4.21 MULTIPLE CORNERING

(BEVELING/ROUNDING) (Gl 11, G1 12) 16

4.22 MULTI-START THREADCUTTING (G32) 18

4.23 VARIABLE LEAD THREADCUTTING (G34) 18

4.24 2ND REFERENCE POINT RETURN (G30) 18

4.25 TOOL NOSE RADIUS COMPENSATION

(G40 TO G44) 19

4.26 MULTIPLE REPETITIVE CYCLE

(G70 TO G76) 19

4.27 THREADCUTTING INTERRUPTION 23

4.28 CONSTANT SURFACE SPEED CONTROL

(G96, G97) 23

4.29 SPINDLE-SPEED OVERRIDE 23

4.30 SPECIAL G-CODE 11 23

4.31 OPTIONAL BLOCK SKIP B (/2 TO /9) 23

4.32 X-AXIS MIRROR IMAGE 23

4.33 AUTOMATIC COORDINATE SYSTEM

SETTING 24

4.34 WORK COORDINATE MULTI-SHIFT

(G50T) 24

4.35 MDI OF MEASURED WORK INPUT 24

4.36 WORK COORDINATE SYSTEM SHIFT 25

4.37 EXTERNAL WORK NUMBER SEARCH A 25

4.38 EXTERNAL DATA INPUT 25

4.39 SPINDLE INDEXING 25

4.40 STORED STROKE LIMIT (G36 TO G39) 25

4.41 STORED STROKE LIMIT FOR

EACH TOOL 26

4.42 SKIP FUNCTION (G31) 26

4.43 TOOL LIFE CONTROL (G122, G123) 26

4.44 MACRO PROGRAMS (G65, G66, G67) 27

4.45 STORED LEADSCREW ERROR

COMPENSATION 28

BUILT-IN TYPE PROGRAMMABLE

5

CONTROLLER (PC) 28

APPENDIX 1 LIST OF DATA 29

APPENDIX 2 DIMENSIONS in mm (inch) 36

...

111

Page 5

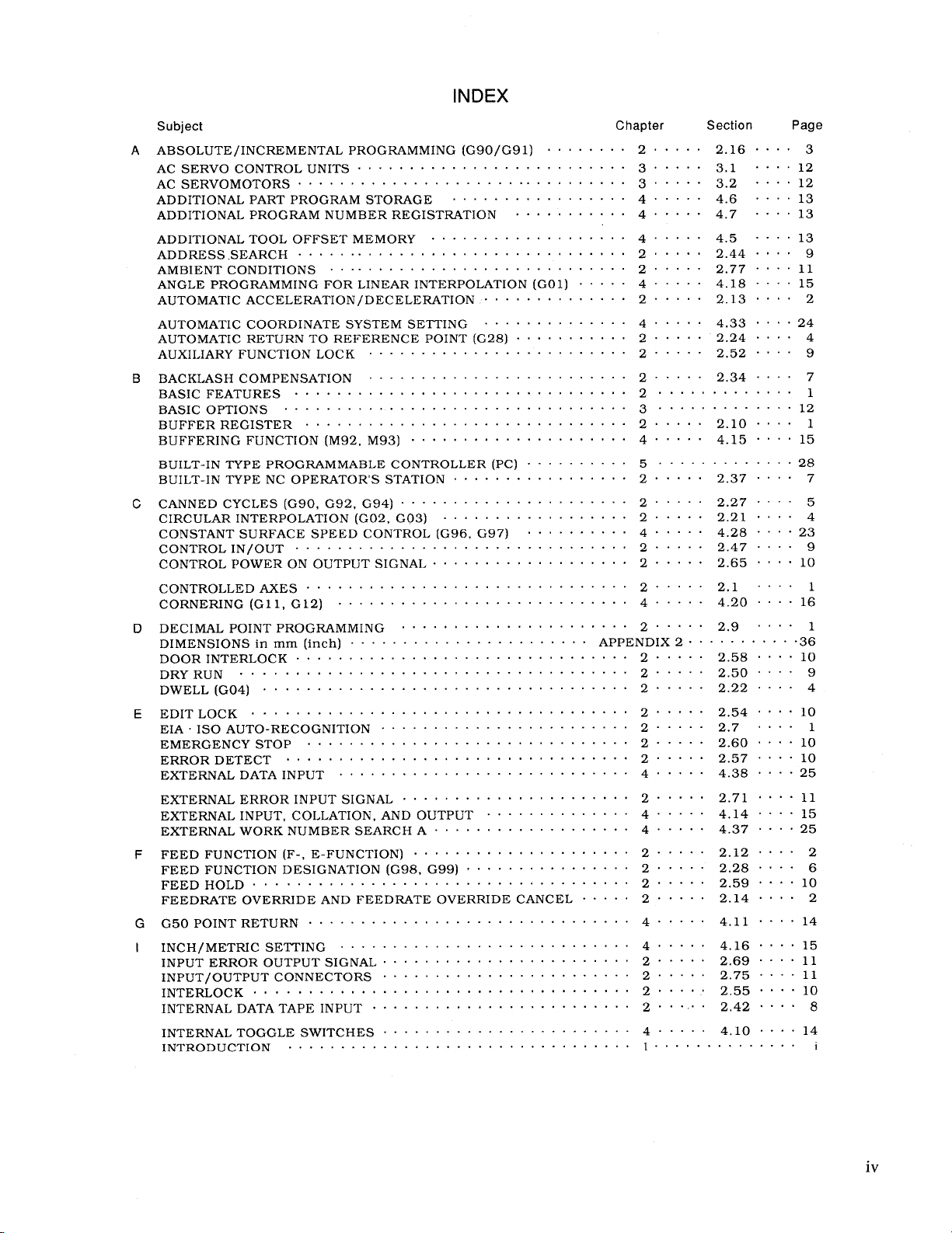

INDEX

Subject

A ABSOLUTE/INCREMENTAL PROGRAMMING (G90/G91) o . . . . . . . 2 . . . . ~ 2.16 “ . “ “ 3

AC SERVO CONTROL UNITS. ..”” $”””””””””””””””” ““”3””””” 3.1 ““””12

AC SERVOMOTORS . . . . . . . . . . . . . . . ...””.””-””. .“””3””” .3.2 ““””12

ADDITIONAL PART PROGRAM STORAGE ........””.”.$””4””” ““4.6 ““””13

ADDITIONAL PROGRAM NUMBER REGISTRATION . . . 0 . . . . . . . 4 $ . “ . “ 4.7 “ “ “ “ 13

ADDITIONAL TOOL OFFSET MEMORY . . . . ...”””””””””””” 4“””””

ADDRESS .SEARCH . . . . . . . . . .,,.,..........’””” ““”2””’”

AMBIENT CONDITIONS . . . . . . . . . ...’......’.’”” ““”””2”””””

ANGLE PROGRAMMING FOR LINEAR INTERPOLATION (GO1) . . . . 4 . . . - .

AUTOMATIC ACCELERATION/DECELERATION . . . . . . 0 . . . . . “ 2 “ “ “ “ “

AUTOMATIC COORDINATE SYSTEM SETTING . . . . . . . . . . . 4 “ “ “ “ “

AUTOMATIC RETURN TO REFERENCE POINT (G28) . 0 - . . . . . . . . 2 . “ “ “ “

AUXILIARY FUNCTION LOCK. . . ...””””””’””””””””” ““”2”””””

B BACKLASH COMPENSATION ............”..””””” ““2”””””

BASIC FEATURES . . . . . . . . . . . . . . . . . . . . ..”. ..” O” “’”24”””’

BASIC OPTIONS . . . . . . . . . . . . . . . . . . . . .“”””””””””” 3”””””

BUFFER REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 ..”””

BUFFERING FUNCTION (M92, M93) .....003.””””.”..-OC”4 ““”.”

BUILT-IN TYPE PROGRAMMABLE CONTROLLER (PC) . . . . . . ~ . . . 5 . . . . .

BUILT-IN TYPE NC OPERATOR’S STATION.”<”.”.””-”O”” “’” 2“””””

C CANNED CYCLES (G90, G92, G94) ““”””””””””””””””””2 ““”

CIRCULAR INTERPOLATION (G02, G03) ..........”.””” 2“”.”.

CONSTANT SURFACE SPEED CONTROL (G96, G97) . . . . . . . . . . 4 ‘ . “ “ “

CONTROL IN/OUT”-””””””” ““.”””””””””””””””””” “2”””””

CONTROL POWER ON OUTPUT SIGNAL . . ..-- ””’” ””. ”””” O” 2“””””

CONTROLLED AXES”””””””” ““”””””””””””””””””””” “2”””””

CORNERING (G1l, G12) ...””” ““”””’””””””””””””””””4 ““”””

D DECIMAL POINT PROGRAMMING “.”” ”””” ”””’ ”””” ”’””””2 ““”””

DIMENSIONS inmm [inch)””” ““””””””””””””””””” Appendix”””

DOOR INTERLOCK . . . . . . . . . . . . . . . . ...””””””””” ““”2”””””

DRY RUN....””””””””” ““”-’”””””’”””””””””” ““”2””””’

DWELL (G04) ””””””””””””” ““””””””””””””””””””””2 ““”””

E EDIT LOCK . . . . . . . . . . . . . ......””’””””oo’o”””” “2””’””

EIA. ISO AUTO-RECOGNITION . ..”””””’””””””””””” ““””2”””””

EMERGENCY STOP . . . ...””””””.”.””” ““”””””””””””2””” ““

ERRORDETECT . . . . . . . . . . . ...”-”””””’”” ““””-””””2”””””

EXTERNAL DATAINPUT” ““”””””””””””””””” ““”””””””4”””””

EXTERNAL ERRORINPUTSIGNAL .“”o..”””--C”””..”” ‘“”2”””””

EXTERNAL INPUT, COLLATION, AND OUTPUT . 0 “ “ “ “ “ “ “ “ o “ “ “ 4 “ “ “ “ “

EXTERNALWORK NUMBER SEARCH””””””””.+” ““””””””4”””””

F FEED FUNCTION (F-, E-FUNCTION) . . . .. ”” ””” O””””””’”” “2””’””

FEED FUNCTION DESIGNATION (G98, G99) “ “ “ “ “ “ “ “ “ “ “ “ “ “ “ 2 “ “ “ “ “

FEED HOLD . . . . . . . . . ..””””””””””””””” ““”””””””2”””””

FEEDRATE OVERRIDE AND FEEDRATE OVERRIDE CANCEL . . . “ “ 2 “ “ “ “ “

G G50 POINTRETURN ”.”””” ““.””””””””.””””.”” .“””” 4”.”””

I INCH/METRICSETTING.. . .<..””.””””’”””””’ ‘“”””””4’””””

INPUT ERROROUTPUTSIGNAL . .””””””’””””””””” ““””””2’””””

INPUT/OUTPUTCONNECTORS . . . . ...””””””””””” ““””””2”””””

INTERLOCK .O. .O..”oo ‘--..””””’””””””””” ““”””””2””’”’

INTERNAL DATATAPEINPUT ““””””””-”o”””””””” ““””””2”””””

INTERNALTOGGLE SWITCHES . . . . . . . . ...””””””” ““””””4”””””

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . .. ”””” ”””” 1”””” ““

Chapter

Section Page

4.5 . ...13

2.44 .,,.9

2.77....11

4.18....15

2.13 ...2

4.33....24

2.24 .,..4

2.52 . ...9

2.34... 7

. . . . . . . .

. . . . . . . .

2.10 . . . . 1

4.15....15

. . . . . . .

2.37 ..,.7

2.27 . . . . 5

2.21 . ...4

4.28....23

2.47 . ...9

2.65....10

2.1 . ..1

4.20....16

2.9 . ...1

. . . . . . . .

2.58....10

2.50 . ...9

2.22 . ...4

2.54.,..10

2.7 . . . . 1

2.60....10

2.57....10

4.38....25

2.71....11

4.14 ..””15

4,37....25

2.12 . . . . 2

2.28 . ...6

2.59....10

2.14 ...2

4.11...14

4.16....15

2.69....11

2.75....11

2.55 ”.”=10

2,42 . ...8

4.10....14

. . . . . . . .

. 28

.36

1

12

i

iv

Page 6

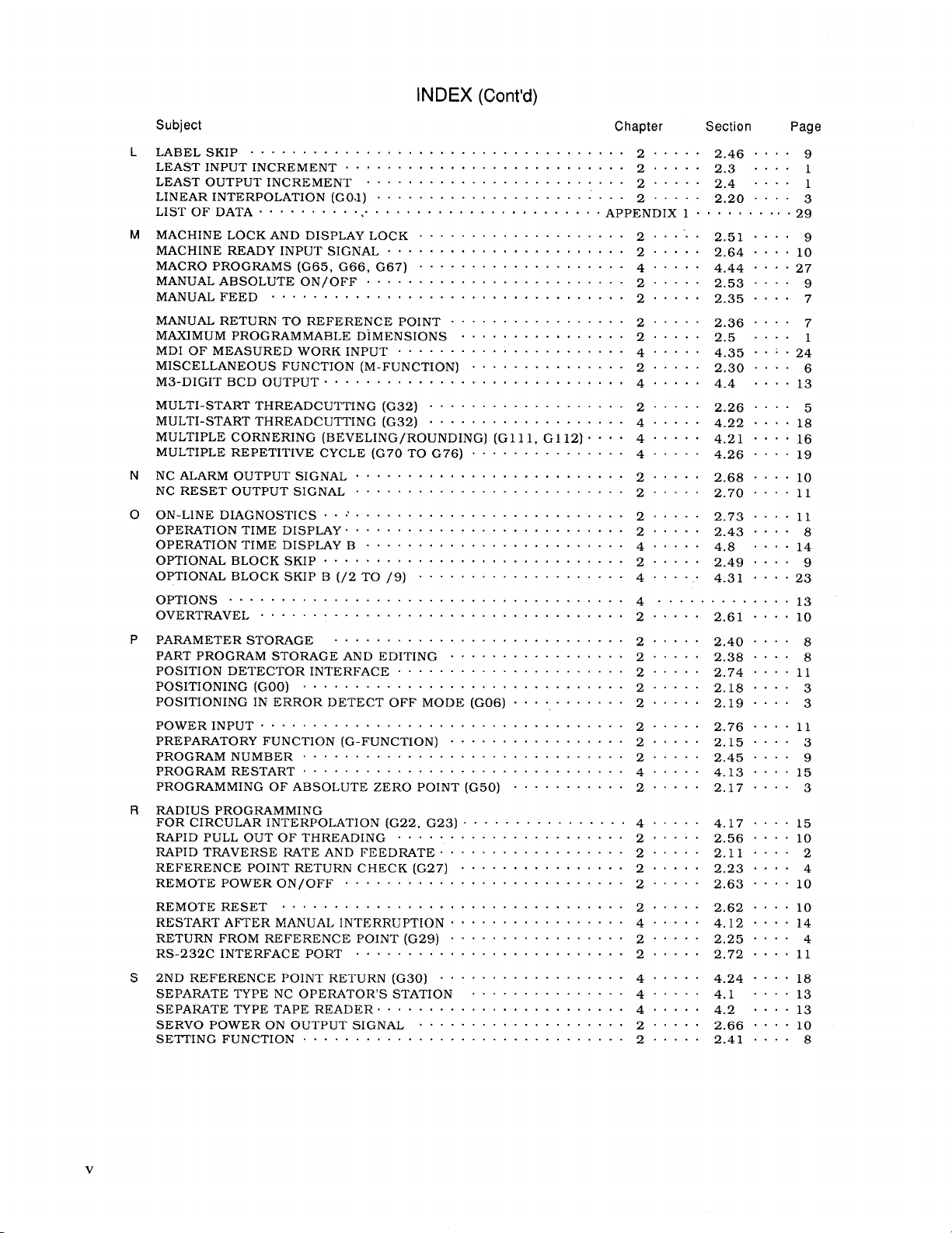

INDEX (Cent’d)

Subject Chapter

L LABEL SKIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . 2.46....9

LEAST INPUTINCREMENT ..c............... . . . . . . ...2.....2.3 . . ..I

LEAST OUTPUTINCREMENT . . . . . . . . . . . . . . . . . . . . . . ...2.....2.4 . ...1

LINEAR INTERPOLATION (GO.l) . . . . . . . . . . . . . . . . . . . . . ...2.....2.20.. ..3

LIST OF DATA . . . . . . . . . .:, . . . . . . . . . . . . . . . . . . . ..APPENDIx I.... . . . ...29

MMACHINE LOCKAND DISPLAY LOCK . . . . . . . . . . . . . . . . . ..2. ..”. .2.51. . ..9

MACHINE READYINPUTSIGNAL . . . . . . . . . . . . . . . . . . . . ...2.....2.64.. ..lo

MACRO PROGRAMS (G65, G66, G67)...........,.. . . ...4..... 4.44....27

MANUALABSOLUTEON/OFF . . . . . . . . . . . . . . . . . . . . . ...2.....2.53. . ..9

MANUALFEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.35 . ...7

MANUAL RETURNTOREFERENCE POINT . . . . . . . . . . . . . . . . . 2 . . . . . 2.36 . . . . 7

MAXIMUM PROGRAMMABLE DIMENSIONS . . . . . . . . . . . . . . . . 2..,.. 2.5 . . . . 1

MDIOFMEASUREDWORK INPUT . . . . . . . . . . . . . . . . . . . . . 4 . . ...4.35 ..:.24

MISCELLANEOUS FUNCTION (M-FUNCTION) . . . . . . . . . . . . . . . 2 . . . . . 2.30 . . . . 6

M3-DIGIT BCD OUTPUT... . . . . . . . . . . . . . . . . . . . . . . . ...4.....4.4 . ...13

MULTI-STARTTHREADCUTTING (G32).............. . . . . 2 . . . ..2.26... .5

MULTI-STARTTHREADCUTTING (G32) . . . . . . . . . . . . . . . . . . . 4 . . . . . 4.22....18

MULTIPLECORNERING(BEVELING/ROUNDING] (Gill, G112)” “ - 0 4 “ . “ - 0 4.21 . 0 . 0 16

MULTIPLE REPETITIVE CYCLE (G70To G76) . . . . . . . . . . . . . . . 4 . . . . . 4.26 . . ..I9

N NC ALARMOUTPUTSIGNAL . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.68. . ..lo

NC RESETOUTPUTSIGNAL . . . . . . . . . . . . . . . . . . . . . . . ...2.....

OON-LINE DmGNOsTIcs. . .’ . . . . . . . . . . . . . . . . . . . . - . . . . . 2 . . ...2.73 . ...11

OPERATION TIME DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.43 . ...8

OPERATION TIMEDISPLAYB . . . . . . . . . . . . . . . . . . . . . . ...4.....4.8 . ...14

OPTIONAL BLOCKSKIP . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.49. . ..9

0PTIONALBLOCKSKIPB(/2 TO/9)....O........ 4 . . ...4..... 4.31....23

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . . . . ...13

OVERTRAVEL COO...... . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.61. . ..10

P PARAMETERSTORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.40 . ...8

PART PROGRAM STORAGE AND EDITING . . . . . . . . . . . . . . . . 2 . . ...2.38 . ...8

POSITION DETECTORINTERFACE . . . . . . . . . . . . . . . . . . . . . . 2 . . . ..2.74... .11

POSITIONING (GOD).... . . . . . . . . . . . . . . . . . . . . . ...2.....2.18. . ..3

POSITIONING IN ERROR DETECT 0FFMODE(G06) . . . .. . . . . . . 2 . . . . “ 2.19 “ “ ‘ “ 3

POWER INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.76 . ...11

PREPARATORY FUNCTION (G-FUNCTION) . . . . . . . . . . . . . . . . . 2 . . . . . 2.15 . . . . 3

PROGRAM NUMBER . . . . . . . . . . . . . . . . . . . . . . ., . . . . . . . 2 . . ...2.45 . ...9

PROGRAM RESTART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . ...4.13 . ...15

PROGRAMMING OFABSOLUTE ZERO POINT(G50) . . . . . . . . . . 2 . . . . . 2.17 . . . . 3

R RADIUS PROGRAMMING

FOR CIRCULAR INTERPOLATION (G22, G23). . . . . . . . 0 . . . 0 . . . 4 . . . . . 4.17 . . . . 15

RAPID PULL OUTOFTHREADING . . . . . . . . . . . . . . . . . . ...2.....

RAPID TRAVERSERATEAND FEEDRATE . . . ..c . . . . . . . . . . . 2 . . . . .

REFERENCE POINTRETURN CHECK(G27) . . . . .. s . . . . . . . . . 2...,.

REMOTEPOWERON/OFF. . . . . . . . . . . . . . . . . . . . . . . ...2....

REMOTERESET O..... . . . . . . . . . . . . . . . . . . . . . . ...2.....

RESTARTAFTER MANUAL INTERRUPTION . . . . . . . . . . . . . . . . 4 . . . . .

RETURN FROMREFERENCE POINT(G29) . . . . . . . . . . . . . . . . . 2 . . . . .

RS-232C INTERFACE PORT, .................. . . . ...2.....

S 2ND REFERENCE POINTRETURN (G30) . . . . . . . . . . . . . . . . . . 4 . . . . .

SEPARATE TYPENCOPERATOR’S STATION . . . . . . . . . . . . . . 4 . . . . .

SEPARATE TYPETAPEREADER . . . . . . . . . . . . . . . . . . . . ...4.....

SERVO POWERONOUTPUT SIGNAL . . . . . . . . . . . . . . . . ...2....

SETTING FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

Section

2.70....11

2.56....10

2.11 . ...2

2.23 ..,.4

2.63....10

2.62 .c,.1O

4.12....14

2.25 . ...4

2.72....11

4.24....18

4.1 . ...13

4.2 . ...13

2.66....10

2.41 . . . . 8

Page

Page 7

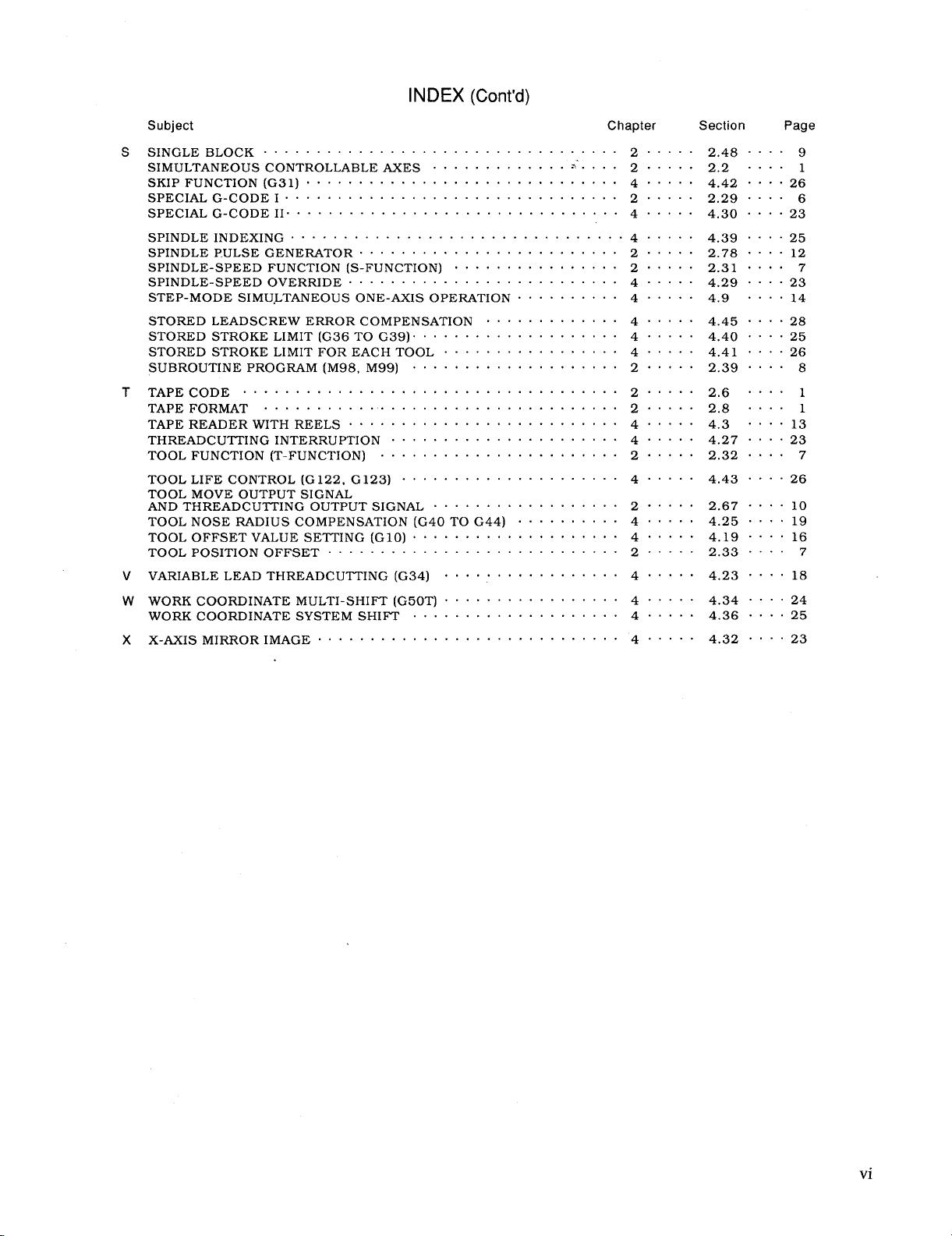

INDEX (Cent’d)

Subject

S SINGLE BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . 2.48....9

SIMULTANEOUS CONTROLLABLE AXES . . . . . . . . . . ...>’.... 2 . . . . . 2.2 . . . . 1

SKIP FUNCTION(G31) . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4.....4.42. . ..26

SPECIAL G-CODEI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.29. . ..6

SPECIAL G-CODEII . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4.....4.30. . ..23

SPINDLE INDEXING .O... . . . . . . . . . . . . . . . . . . . ., . . . ...4.....

SPINDLE P.ULSEGENERATOR . . . . . . . . . . . . . . . . . . . . . ...2.....

SPINDLE-SPEED FUNCTION (S-FUNCTION) . . . . . . . . . 0 , . . . . . 2 0 . . . .

SPINDLE-SPEED OVERRIDE . . . . . . . . . . . . . . . ..- . . . . . ...4.....

STEP-MODE SIMU.LTANEOUS ONE-AXISOPERATION . . . . . . . . . . 4 . . . . .

STORED LEADSCREWERROR COMPENSATION . . . . . . . . . . . . . 4 . . . . .

STORED STROKELIMIT(G36T0 G39)................ . . . 4 . . . . .

STORED STROKELIMITFOR EACH TOOL . . . . . . ..C. . . . . . . . 4 . . . . .

SUBROUTINE PROGRAM(M98, M99) . . ..”. o<do<”o. ”o ..<” 20..-.

T TAPE CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

TAPE FORMAT C.OO. O... . . . . . . . . . . . . . . . . . . . . . . ...2.....

TAPE READERWITHREELS . . . . . . . . . . . . . . . . . . . . . . . ...4.....

THREADCUTTING INTERRUPTION . . . . . . . . . . . . . . . . . . . ...4.....

TOOL FUNCTION (T-FUNCTION) . . . . . . . . . . . . . . . . . . . . . ..2.....

TOOL LIFECONTROL(G122, G123) . . . . . . . . . . ..-. . . . . ...4”””””

TOOLMOVEOUTPUT SIGNAL

AND THREADCUTTING OUTPUT SIGNAL . . . . . . . . . . . . . . . . . . 2 . . . . .

TOOL NOSE RADIUS COMPENSATION (G40TOG44) . . . . . , . . . . 4 ~ . . . 0

TOOL OFFSETVALUE SETTING (GIO)........<.....- ““”””4”””””

TOOL POSITION OFFSET. . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

V VARIABLE LEADTHREADCUTTING (G34) . . . . . . . . . . . . . . . . . 4.””””

W WORK COORDINATE MULTI-SHIFT (G50T).....$”””.”””.”. “ 4“”””” 4.34 .”””24

WORK COORDINATESYSTEM SHIFT . . . . . . . . . . . . . . . . . ...4..... 4.36 . ..”25

X X-AXIS MIRRORIMAGE . . . . . . . . . . . . . . ...”-.””-” “.” ””4”. ”” 4.32”” “23

Chapter

Section Page

4.39....25

2.78....12

2.31 .c.07

4.29...-23

4.9....14

4.45....28

4.40....25

4.41..,.26

2.39 ...8

2.6 . . . . 1

2.8 . . . . 1

4.3 . ..13

4.27....23

2.32 . ...7

4.43...-26

2.67....10

4.25....19

4.19....16

2.33 . ...7

4.23....18

vi

Page 8

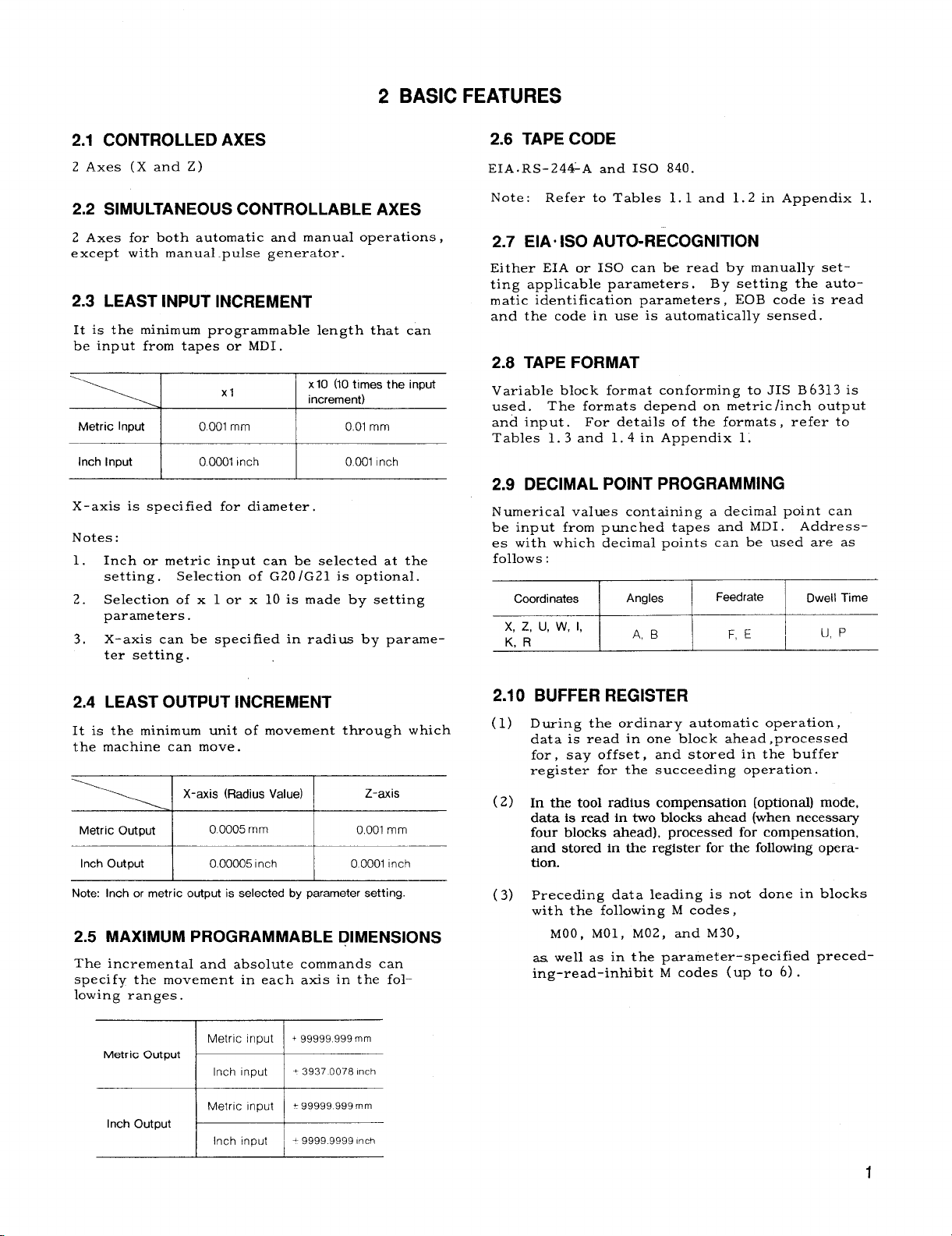

2 BASIC FEATURES

2.1 CONTROLLED AXES

2 Axes (X and Z)

2.2 SIMULTANEOUS CONTROLLABLE AXES

Axes for both automatic and manual operations ,

Z

except with manual pulse generator.

2.3 LEAST INPUT INCREMENT

It is the minimum programmable length that can

be input from tapes or MDI.

x1O (10 times the input

“-’-’J “ 1

Metric Input 0.001 mm 001 mm

Inch Input

X-axis is specified for diameter .

Notes:

Inch or metric input can be selected at the

1.

setting.

Selection of x 1 or x 10 is made by setting

2.

parameters.

X-axis can be specified in radius by parame-

3.

ter setting.

0.0001 Inch 0.001 Inch

Selection of G20/G21 is optional.

increment)

2.6 TAPE CODE

EIA. Rs-24&A and ISO 840.

Note: Refer to Tables 1.1 and 1..2 in Appendix 1.

2.7 EIAoISO AUTO-RECOGNITION

Either EIA or 1S0 can be read by manually setting applicable parameters, By setting the automatic identification parameters, EOB code is read

and the code in use is automatically sensed.

2.8 TAPE FORMAT

Variable block format conforming to JIS B 6313 is

used.

and input.

Tables 1.3 and 1.4 in Appendix 1.

The formats depend on metric /inch output

For details of the formats , refer to

2.9 DECIMAL POINT PROGRAMMING

Numerical values containing a decimal point can

be input from punched tapes and MDI. Addresses with which decimal points can be used are as

follows :

Coordinates

x, z, u, w, 1,

KR

Angles Dwell Ttme

B

A,

I

F, E

1

~ U,p

2.4

LEAST OUTPUT INCREMENT

It is the minimum unit of movement through which

the machine can move.

X-axis (Radius Value)

Metric Output

Inch Output

Note: Inch or metric output is selected by parameter setting.

I 0.0005rnrn I 0,001 mm

0.00005 Inch O0001 Inch

Z-axis

2.5 MAXIMUM PROGRAMMABLE DIMENSIONS

The incremental and absolute commands can

specify the movement in each axis in the fol–

lowing ranges .

Metric Output

s

Inch Output

=

2.10 BUFFER REGISTER

During the ordinary automatic operation,

(1)

data is read in one block ahead, processed

for, say offset,

register for the succeeding operation.

(2)

In the tool radius compensation (optional) mode,

data is read in two blocks ahead (when necessary

four blocks ahead), processed for compensation,

and stored in the register for the following operation.

preceding data leading is not done in blocks

(3)

with the following M codes,

MOO, MO1, M(i2, and M30,

aa well as in the parameter-specified preced–

ing-read–inhibit M codes (up to 6) .

and stored in the buffer

1

Page 9

2.11 RAPID TRAVERSE RATE AND FEEDRATE

The rapid traverse feed, manual feed, and rapid

feed override F~ can be set to the upper limit

s hewn below.

Metric Input

Inch Input

Notes:

Depending on the motor and machine systems,

1.

the upper limit is further restricted.

The upper limit for X-axis speed is half the

2.

above.

30,000 mrn/min

\ 1181.1 inches/rein

“’=-_ I Format I Range of Feed per Minute

Metric

Metric

output

Inch Input

output

Note:

Depending on the conditions of the motor or machine system,

1.

the upper limit of mm/min and inch/rein is further restricted.

2.

Thf upper limit for X–component of speed is the half of the

above values.

Input

Inch

input

Metric

Inch

Input

F50

F 32 FO.01 –F944,88 inches/min

F50 F 1. –F60960, mm/m.in

F 42 FC.01 –F24000.00 inches/mln

F1 - F24000, mmlmin

2.12 FEED FUNCTION (F-, E-FUNCTION)

Feed per revolution (G 99 mode)

(1)

F (normal feed) and E ( accurate. feed) commands can specify the tool feed rate per

rotation of spindle (mm /rev or inch/rev) .

% I‘or”a’‘

Metric

output

Inch

output

‘ ‘~’cl=+====

‘::t ~

Metric

Input

Inch

Input

The feedrates are limited by spindle-speed

S as follows :

I Range of Feed Per Revolution

E0.000004–E 19.685000 inches/rev

F 32 FO.01–F 127000 rnmirev

E34 E0.0003– E 1270.0000 mm/rev

F24

E26 I FO.OOOO1O–E50000000 inches/rev

FO.001–F50.0000 inches/rev

2.13 AUTOMATIC ACCELERATION/

DECELERATION

The following acceleration /deceleration is done

automatically.

(1) In positioning and manual feed

Linear automatic acceleration /deceleration

is done, independently for each axis.

(2) In machining feed

Exponential automatic acceleration /deceler–

ation is

cutting and normal feed, this can be set in–

dependently for each axis.

common to each axis.

v

In thread

b 1,

Metric Output

Inch Output

(The upper limit of X-component of speed

is half of the above. )

(2) Feed per minute ( G 98) mode

F command specifies the tool feedrate per

minute as follows :

] F(E) x SS24,000mrn/min

\ F(E)XS<

=2,400 inches/mln

2

2.14 FEEDRATE OVERRIDE AND

FEEDRATE OVERRIDE CANCEL

(1) Rapid traverse feed override

Rapid traverse rate can be modified to F(I

and 25, 50, and 100% of the original traverse rate.

by parameter .

(2) Feed override

The F-commanded feedrate can be modified

in the range of O to

The FO is a constant speed set

200% in 10% increments.

Page 10

(3) Override cancel

Turning this switch on cancels any override

effect , causing the tool to move at the origi–

nally specified speed.

2.15 PREPARATORY FUNCTION (G-FUNCTION)

The address G and the following numerals up to

3 digits specify a block and its meaning. For

details of G-codes, refer to Table 1.6 in Appendix 1,

(1) Ordinary G-codes

a. G codes in 01 to 11 groups are modal.

Once specified, the y are effective until

other G-codes in the same group are

specified.

b. G codes in *-marked groups are” non-

modal, and effective only in the specified

block .

(2) Special G codes

a. Special G code I can be used in the basic

mode (by parameter switching) .

b. Special code ~ is optional.

2.16 ABSOLUTE/lNCREMENTAL

PROGRAMMING (G90/G91)

Absolute programming (X, Z, G90)

(1)

Addresses X and G are used to specify an

absolute value.

II, X and Z commands in G90 mode specify

an absolute value.

address U and W remain as incremental com–

mands.

(2)

Incremental programming (U, W, G91)

Addresses U and W are used to specify an

incremental value . In the use of special

code I or II , X and Z commands in G91 mode

specify an incremental value .

Combined command

(3)

In the same block,

X.. .;or U; Z; U.. .Z;

can be ‘used as a combined command.

In the use of G90 or G 91, however, both

cannot be specified in the same block.

Addresses 1,

(4)

lation are invariably incremental values.

In use of special code I or

However, in G90 mode,

K , and R for circular interpo-

2.17

PROGRAMMING OF ABSOLUTE ZERO

POINT (G50)

G50 X.. , Z.. . ;

(1)

This command establishes the absolute coordinate system ( = coordinate system) such

that the current tool position becomes the

specified coordinate value.

G50 U.. . W.. .

(2)

This command establishes a new coordinate

system in which the coordinate system already established with G50 has been shifted

by incremental value U. W.

2.18

POSITIONING (GOO)

GOO

x(u) . . . z(w) . . . ;

This

command moves the tool to the specified

position at rapid traverse rate and independently

for each axis.

ar.

The GOO is a modal G-code. In GOO positioning, pulse distribution is started after ERROR

DETECT ON , and after distribution, when ERROR

DETECT ON is again detected, operation goes to

the next block.

The travel is not necessarily line-

; (incremental setting)

2.19 POSITIONING IN ERROR DETECT OFF

MODE (G06)

G06 x(u) . . . z(w) . . . :

Positioning by this command differs from GOO

following ‘points:

the

a.

G06, being non-modal, is effective only ir

the specified block.

b.

G06 starts pulse distribution without ERROR

DETECT ch-eck, and after distribution is com-

pleted, immediately goes to the next block.

In G06 positioning , the corners of workpiece

are slightly rounded.

Note: ERROR DETECT ON means the state where

the servo-lag pulses are reduced to a permissible

number .

and the actual tool position nearly coincide.

At this time the command pulse position

n

2.20 LINEAR INTERPOLATION (GO1)

GO1 X( U)... Z(w) . . . F(E) . . . ;

This command moves the tool to the specified target position along a straight line at the specified

feed rate.

3

/

Page 11

2.21

CIRCULAR INTERPOLATION (G02, G03)

(1)

:~&GO 3 )

. . .

Z(W) . . . 1.. . K.. . F(E) . . . ;

2.24 AUTOMATIC RETURN TO REFERENGE

POINT (G28)

G28 X( U).,. Z(W) . . . ;

(1)

This command moves the tool to the specified

end position along the specified circular path.

G02: Circular interpolation in’ @ockwise (CW)

G03: Circular interpolation in counterclock-

(2)

Circular interpolation is possible across

multiple quadrants or along the full circle.

Notes: Optionally,

fied by r~dius R.

2.22

(1)

This command causes the tool to remain motionless for the time specified by U or P

before the program goes to the next block.

(2)

wise (CCW)

X(U) , Z(W) : End position

I, K:

F(E) :

X- and Z-components of the center

of the circular path with respect to

the starting point.

Feedrate in the tangential direction

of the arc.

a circular path can be speci–

DWELL (G04)

G04 U(P) . . .

The dwell can be increased to a maximum of

8388.607 seconds in increment of 0.001 sec-

ond.

A numerical value containing decimal

point can be specified.

G04 U3.5 ;

;

--- A3. 5-seconds dwell

This command automatically returns the tool

to the reference point . The tool is positioned at the specified intermediate position both

axes at the same time , then undergoes

!lRe feren~e point Return Operation 11both

axes at the same time.

Reference-point-return operation is as shown

(2)

below.

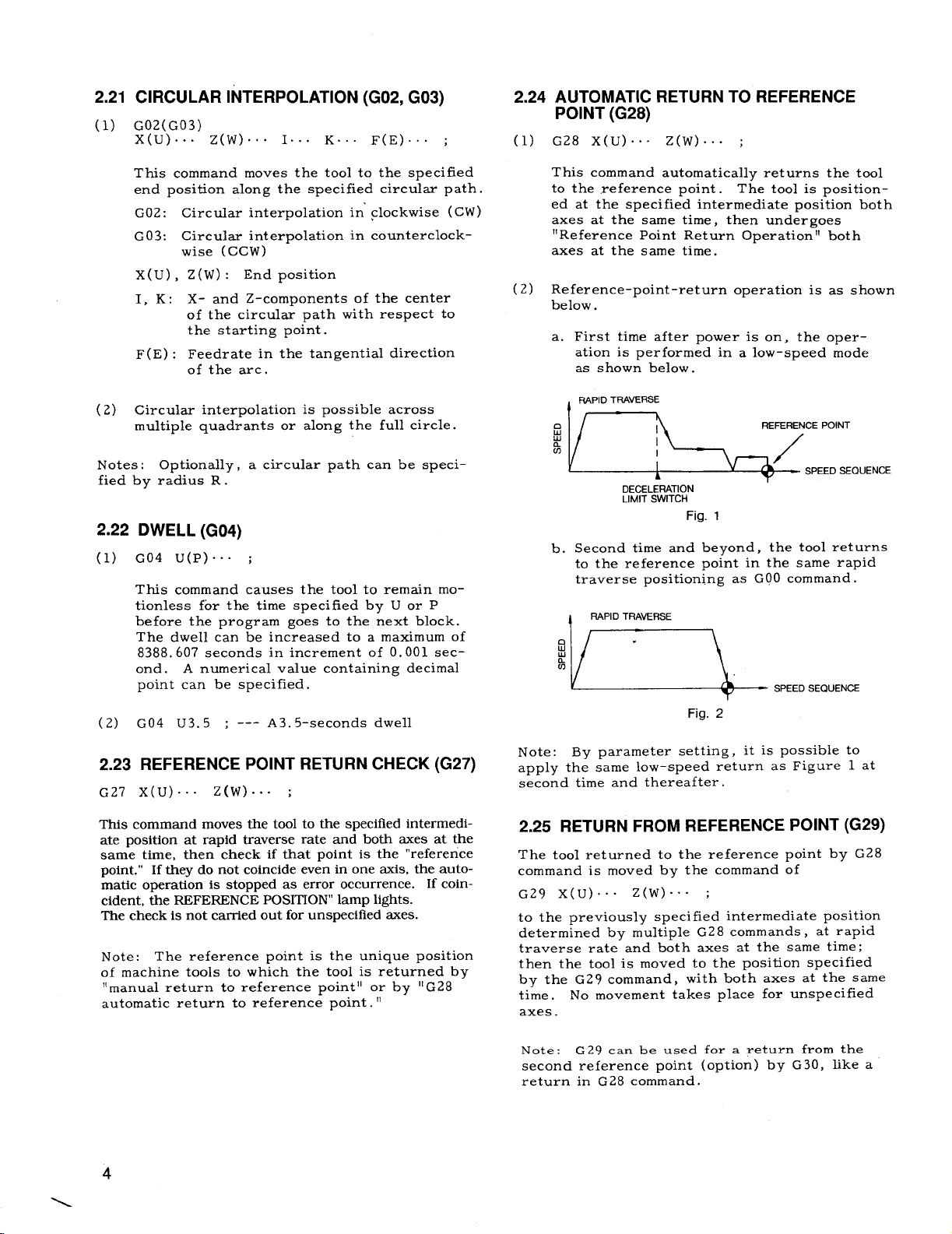

a. First time after power is on, the oper-

ation is performed in a low–speed mode

as shown below.

‘=Z:QUE

b. Second time and beyond, the tool returns

\.

DECELERATION

LIMIT SWITCH

Fig. 1

to the reference point in the same rapid

traverse positioning as GOO command.

RAPID TRAVERSE

<

‘u.-,.-

Fig. 2

2.23 REFERENCE POINT RETURN CHECK (G27)

G27 X( U)... z(w) . . . ;

l%is command moves the tool to the specified intermedi-

ate position at rapid traverse rate and both axes at the

same time, then check if that point is the “reference

point.”

matic operation is stopped as error occurrence. If coincident, the REFERENCE POSITION” lamp lights.

The check is not carried out for unspecified axes.

Note: The reference point is the unique position

of machine tools to which the tool is returned by

“manual return to reference point” or by 11G28

automatic return to reference point. ”

4

If they do not coincide even in one axis, the auto-

Note: By parameter setting, it is possible to

apply the same low-speed return as Figure 1 at

second time and thereafter.

2.25 RETURN FROM REFERENCE POINT (G29)

The tool returned to the reference point by G28

command is moved by the command of

G29 X( U)... ‘2(W)””” ;

to the previously specified intermediate position

determined by multiple G.28 commands , at rapid

traverse rate and both axes at the same time;

then the tool is moved to the position specified

by the G29 command, with both axes at the same

time.

axes.

Note : G 29 can be used for a return from the

second reference point (option) by G30, like a

return in G28 command.

No movement takes place for unspecified

Page 12

2.26

MULTI-START THREADCUTTING (G32)

G32 X( U)... Z(W) . . . F(E) . . . ;

(1)

This command allows straight thread, taper

thread, and scroll thread to be cut.

Type of Thread

Commands

*––––––––––––J

s

G32

r-

G32

-z

Straight Thread

Taper Thread

Scroll Thread

F specifies ordinary thread lead; E precise

thread lead.

sPeclficatlon is the same as the command

range of feed per revolution (mm /rev or

inch/rev) in 2.14 Feed Function.

(2)

Continuous thread cutting

G32 X( U)... Z(W)” OO F(E) . . . ;

x(u) . . .

x(u) . . . z(w) . . . ;

With this type of continuously programmed

block command for threading,

ting is allowed to continue to the next thread

cutting operation, reducing the stop time to

110.!1

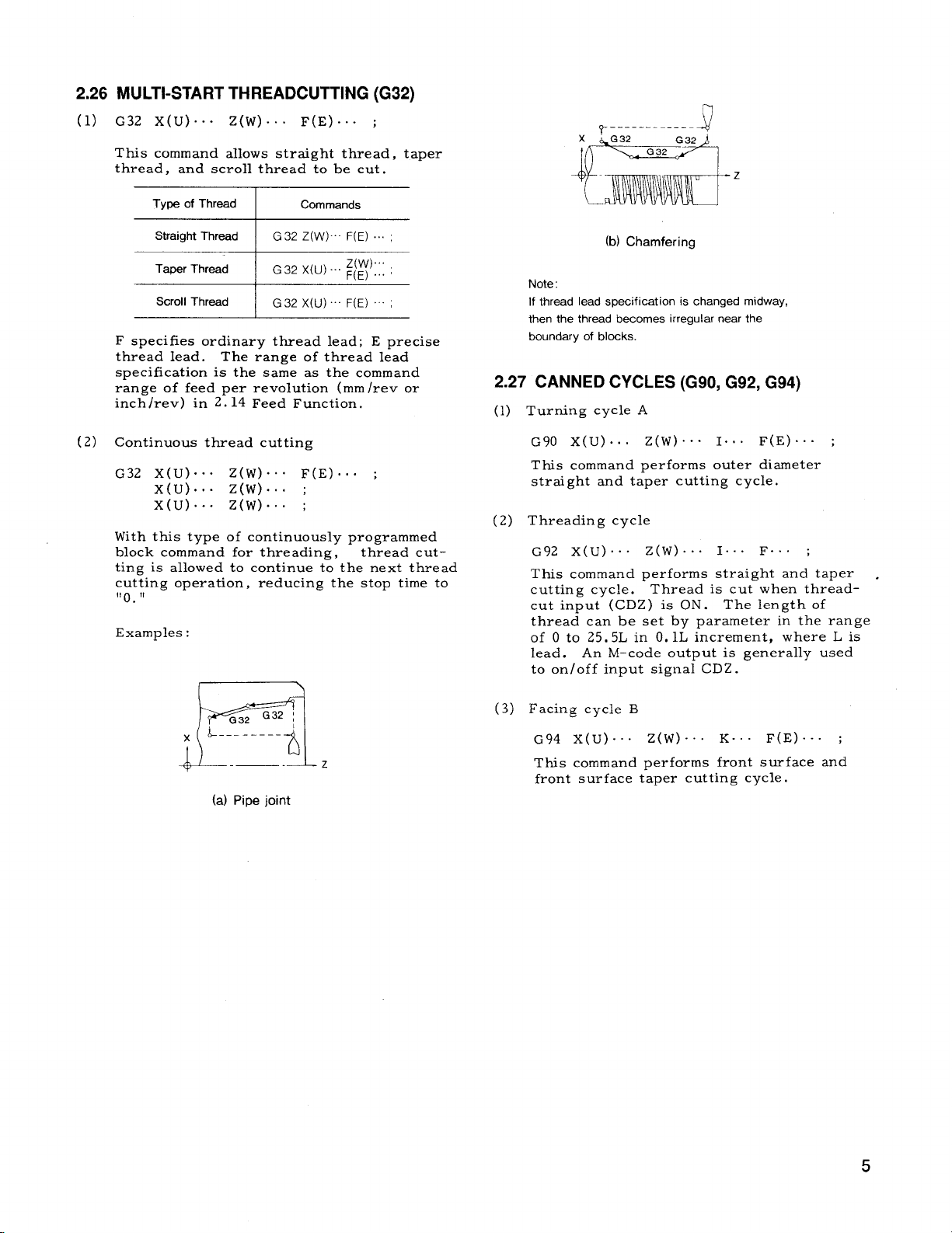

Examples :

I G32 Z(W) F(E) ~~~~

G32 X(U) ~(~) ... .

I

G32 X(U). F(E) ~~~;

The range of thread lead

z(w) ... ;

z(w).

thread cut-

(b) Chamfering

Note:

If thread lead specif icat ion is changed midway,

then the thread becomes irregular near the

boundary of blocks.

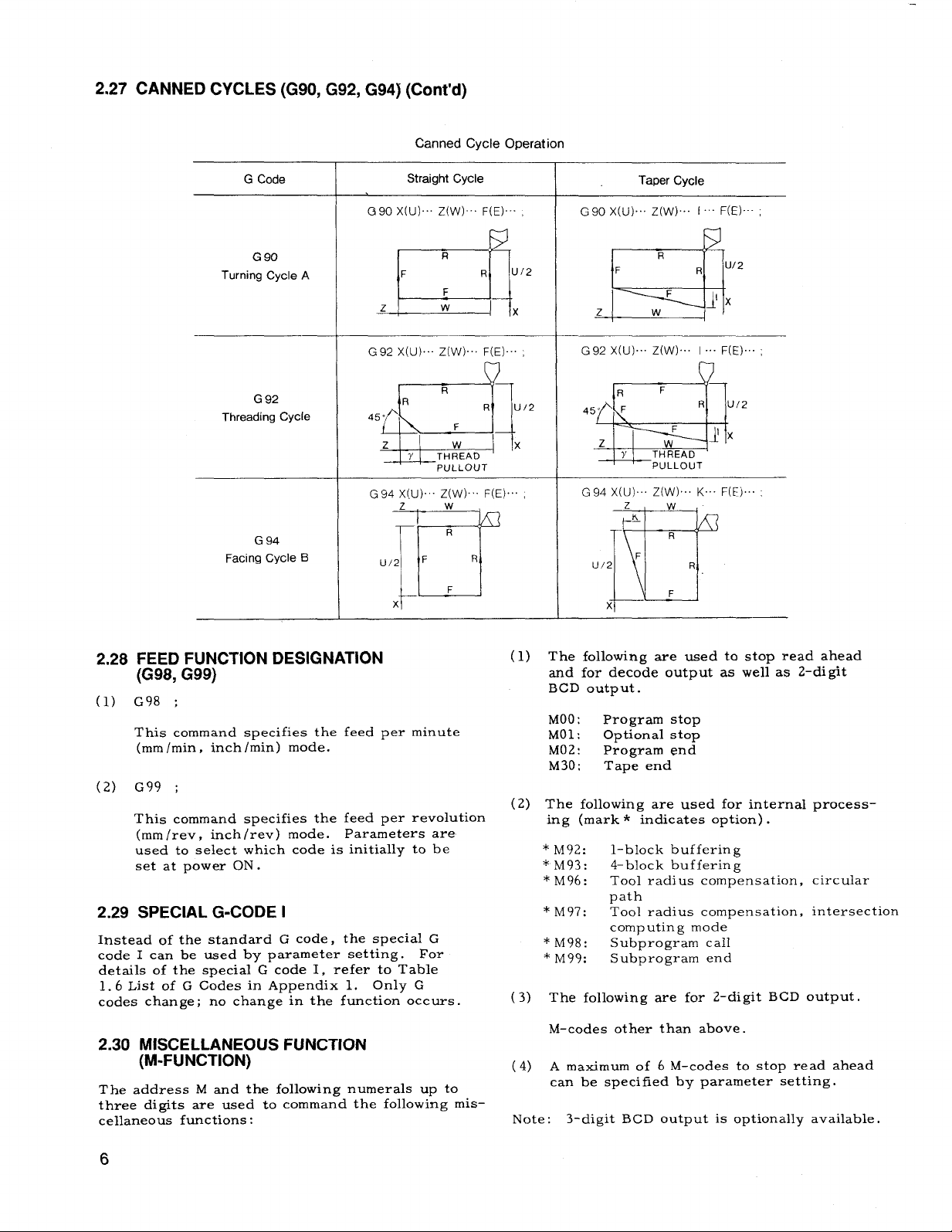

2.27 CANNED CYCLES (G90, G92, G94)

(1) Turning cycle A

G90 X( U)... Z(W)””” 1.. . F(E). . . ;

This command performs outer diameter

straight and taper cutting cycle.

(2) Threading cycle

G92 X( U)... Z(w) . . . 1.. . F“. ” ;

This command performs straight and taper .

cutting cycle.

cut input (CDZ) is ON. The length of

thread can be set by parameter in the range

of O to 25, 5L in O. lL increment, where L is

lead.

to on/off input signal CDZ.

An M-code output is generally used

Thread is cut when thread-

~32 G32 :

~ L-------- ‘

II

E=l

(a) Pipe joint

z

(3) Facing cycle B

G94 X( U)... Z(W)””. K.. . F(E)””” ;

Ttis command performs front surface and

front surface taper cutting cycle.

5

Page 13

2.27

CANNED CYCLES (G90, G92, G94) (Cent’d)

Canned Cycle Operation

G Code

G 90

Turning Cycle A

G 92

Threading Cycle

G 94

Facing Cycle B

Straight Cycle

G90 x(u).. Z(W) F(E). ,

R

u/2

F

z

R

450

d

z w

q+__J

Y THREAD

G94 X(U) Z(W) F(E) ,

z

u/2 F

p

x

R

F

w

R

R U12

F

PULLOUT

w

R

R

F

Taper Cycle

G90 X(U)... Z(W).. I “’” F(E)’””,

w

2

R

F

x

x

=$!

L

G92 X(U).. Z(W)... I . F(E). ;

F

R

45” F

z

Q

G94 X(U) Z(W).. K F(E)..

u/2

TH!EAD

Y

PULLOUT

z

K

F

~H

x

Jx

I-Y

R u/2

F

]X

w

R

R

F

2,28

FEED FUNCTION DESIGNATION

(G98, G99)

G98 ;

(1)

This command specifies the

(mm /rein, inch /rein) mode.

G99 ;

(2)

This command specifies the

(mm /rev, inch /rev) mode.

used to select which code is initially to be

set at power ON .

2.29

SPECIAL G-CODE I

Instead of the standard G code, the special G

code I can be used by parameter setting.

details of the special G code 1, refer to Table

1.6 List of G Codes in Appendix 1. Only G

codes change; no change in the function occurs.

feed per minute

feed per revolution

Parameters are

For

2.30 MISCELLANEOUS FUNCTION

(M-FUNCTION)

The address M and the following numerals up to

three digits are used to command the following mis–

cellaneous functions:

The following are used to stop read ahead

(1)

and for decode output as well as 2–di git

BCD output.

MOO: Program stop

MOl: Optional stop

M02: Program end

M30:

(2)

The following are used for internal process-

ing (mark * indicates option) .

* M92: l-block buffering

* M93:

* M96:

*M97:

* M98:

* M99: Subprogram end

The following are for 2-digit

(3)

M-codes other than above.

A maximum of 6 M-codes to stop read ahead

(4)

can be specified by parameter setting.

Note:

Tape end

4-block buffering

Tool radius compensation, circular

path

Tool radius compensation, intersection

computing mode

Subprogram caIl

BCD output.

3-digit BCD output is optionally available.

6

Page 14

2.31 SPINDLE-SPEED FUNCTION (S-FUNCTION)

Spindle speed function called S 4-digit

programming A is executed.

The spindle rpm can be designated by com-

(1)

mand consisting of address S followed by

4 digits, instead of the basic S 2-digit corn, -

mand. As the output to the machine

(spindle) , an analog voltage (t10 V max. )

is output from the DA converter.

The control makes necessary computation to

(2)

meet the programmed rpm, outputs the signals (up to 4 signals) to shift the spindle

gear ratio, and outputs an analog voltage

or 12-bit binary signal suited to the shifted

gear ratio. The speed ranges and other required data are set by parameters.

The maximum spindle rpm can be designated

(3)

by G50S command.

TOOL FUNCTION (T-FUNCTION)

2.32

The address T and the following 4-digit numerals

are used to specify tool selection and tool offset

number.

This is T 4-digit programming.

2.34 BACKLASH COMPENSATION

The lost motion of a machine can be compensated

in the range of -8192 to 8192P with each axis

indepenently, where P is the least output increment, The value of compensation is initially set

in parameter.

2.35 MANUAL FEED

Manual feed is possible in the following three

modes,

(1)

(2)

(3)

with both axes at the same time.

Manual rapid traverse (RAPID)

The tool moves at the rapid traverse rate,

independently in each axis,

Manual jog feed (JOG)

The tool moves at the speed specified by

JOG FEEDRATE selection switch, independently in each axis.

specified in the specifications.

Manual step feed (STEP)

The tool moves step by step in the increment

value specified by the MANUAL PULSE MUL–

TIPLY switch.

Any speed curve can be

~Tool offset number (O to 16)

I

~ Tool selection

(T 2-digit BCD output)

Selecting this option automatically provides

16 sets of offset memories corresponding to the

offset number.

2.33 TOOL POSITION OFFSET

(1) When T function specifies the tool offset

number, the content of the tool offset memory corresponding to the specified offset

number is algebraically added to the pro-

gram-specified coordinate value in both Xand Y-axes, and the tool is moved to this

corrected position.

(2) In the basic mode

specified up to 16 sets, 1 to 16.

O cancels the tool position offset.

(3) Using MD1, initially write the range of tool

off sets in the offset memory. Absolute values

can be written by the use of X and Z address keys.

, offset memory can be

Specifying

Multiplication

Metric Input

Inch Input

xl

x 10 Xloo x 1000 x 10000 x100000

1

0001 I 001 01 1

0.0001 0.001 0.01 01 1 10. In /step

10,

100. mm/step

2.36 MANUAL RETURN TO REFERENCE POINT

After the REFERENCE POINT switch is turned on,

the tool can be returned to the reference point

by manual operation.

turn to Reference Point (G28) , “ the return to the

reference point can be made in the low-speed mode

by parameter setting.

Like” 2.24 Automatic Re–

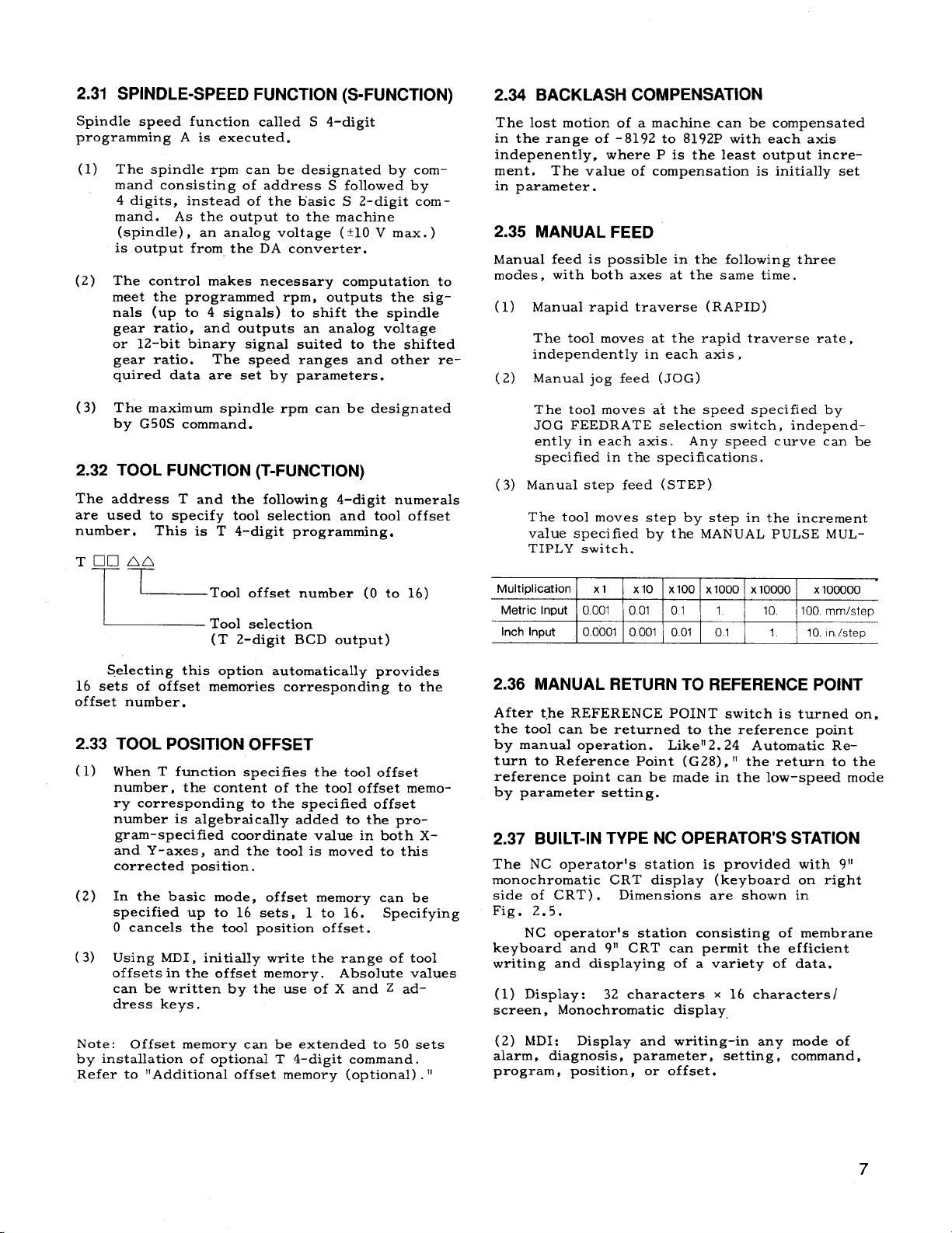

2.37 BUILT-IN TYPE NC OPERATOR’S STATION

The NC operator!s station is provided with 911

monochromatic CRT display (keyboard on right

side of CRT) .

Fig. 2.5.

NC operator’s station consisting of membrane

keyboard and 911 CRT can permit the efficient

writing and displaying of a variety of data.

(1) Display: 32 characters x

screen, Monochromatic display

Dimensions are shown in

16 characters

Note:

by installation of optional T 4-digit command.

Refer to “Additional offset memory (optional) . “

Offset memory can be extended to 50 sets

(2) MDI:

alarm, diagnosis, parameter, setting, command,

program, position, or offset.

Display and writing-in any mode of

7

Page 15

2.38 PART PROGRAM STORAGE AND “EDITING

Part programs can be loaded into memory for tape–

less operation and for editing.

Storage capacity is equivalent to 40 meters

(1)

of tape. (Note 1. )

M99 P.. . ;

If this command is added to the end of the

program, control returns to the P-specified

sequence number in the main program.

(3)

Multiple call

(2)

Part program, added with a program number

of 4–digit numerals,

(from paper tape or MD1) . In the basic

mode, Up to 99 program numbers can be

stored in memory. (Note 2.)

(3)

The stored part program can be- edited by

ERASE, INSERT , and ALTER keys. Editing is done in one to several words at a time.

(4)

The OUT, VER, and IN keys are used to

output the stored part programs to external

equipment, to collate them with

punched cards, and store them from tape

readers (Note 3. ) (option) .

(5)

Address search function permits the speci-

fied program number to b-e searched for the

purpose of an automatic operation (MEM mode)

Notes :

1. Optionally, the part program storage may be extended

to 320 meters.

2. Optionally, the number of stored programs may be

extended to 999.

3. To output the part program to an external equipment,

the optional “RS232C interface” is required.

can be stored in memory

2.39 SUBROUTINE PROGRAM (M98, M99)

A subprogram can call nested subpro-

grams up to 4 times successively.

2.40

PARAMETER STORAGE

Parameters for machine constants such as backlash compensation values and rapid traverse rate

can be set to determine or change the specifica–

tions. Set parameters while the SYSTEM switch

No. 1 is set at No. 1 and the control in idle

condition.

2.41 SETTING FUNCTION

Any of the functions can be selected to on or off.

This is possible if the SYSTEM No. switch is set

to normal “O. “

2.42 INTERNAL DATA TAPE INPUT

Normally, tool offset values, parameter data, and setting

data are input from the MD1. These data may be stored,

via RS232C interface, in respective memories.

Note:

ternal equipment by installing optionaI RS232C

interface. (Example output: tape punch out,

type out)

These stored data may be output to an ex-

Subprogram Call (M98)

(1)

M98 P.. . Q.. . L.. . ;

With this command, the subprogram starting

with sequence number Q is called from the

part programs having the program number

specified by P and the subprogram is executed L times.

If P is omitted, the subprogram starting

with sequence number Q is called from the

main program.

If Q is omitted, the starting subprogram

having P-specified program number is called.

If L is omitted, the execution is only once.

Subprogram end (M99)

(2)

M99 ;

This command is added to the end of the

subprogram to end it.

the subprogram,

block immediately following the main pro-

gram that has called the subprogram.

control returns to the

After completion of

8

2.43 OPERATION TIME DISPLAY

The cumulative time of the following operations

can be displayed:

(1) Total time after switching power supply on:

POWER ON

(2) Total time of automatic operation: CYCLE

START

(3) Total cutting time ( during interpolation

moving) : FEED

TIMER

HOUR MIN SEC

TMI :

0012. 34. 56

TM2: 0001. 02. 59

TM3: 0000. 36. 38

The above time display is stored after power is

turned off.

operation from the panel.

The display can be reset to O by

Page 16

2.44 ADDRESS SEARCH

Through MDI operation,

for: on NC tape (TAPE mode) or on part program (MEM, EDT mode) . Either single address

data or arbitrary data up to 32 characters can

be searched.

numbers can also be searched for.

Example

=

Data consisting of any type and arrangement of

characters can be searched.

Program numbers and sequence

all data can be searched

2.45 PROGRAM NUMBER

A program number can be a maximum of 4-numeri-

cal digits following the address O. It can be written

at the head of the program.

2.46 LABEL SKIP

The label skip function is effective and message

“LSK” is displayed on the lower part of CRT

while:

(1) The power supply is being turned on, and

2.51

MACHINE LOCK AND DISPLAY LOCK

OFF

DISPLAYLo.K/’’’--lMAcHlN, ,0..

0

Off Condition

(1)

Normal automatic and manual operations are

carried out in off condition.

(2)

Machine lock condition

In machine lock condition, NC commands are

executed while the machine is standing still.

M, S, and T functions operate normally,

and the current position is continuously up–

dated and displayed. The same applies to

manual operation.

(2) Control is being reset.

When the label skip function is effective , all the

tape information before the first FOB code is

ignored. In the MEM or EDIT mode, “LSK” display means that a pointer is at the head of the

selected part program.

2,47 CONTROL lN/OUT

Data between a control out “(” and a control in

“ ) “ is ignored as insignificant.

2.48 SINGLE BLOCK

When the SINGLE BLOCK switch is turned on,

automatic operation with tape or memory is performed block by block.

2.49 OPTIONAL BLOCK SKIP

With the OPTIONAL BLOCK SKIP switch on, data

is ignored from command “ /“ of “ /1” to EOB on

a block.

2.50 DRY RUN

With the DRY RUN switch on, the feedrates for

automatic operation (rapid traverse and F(E)

specified feedrates) are ignored and the follow-

ing feedrates are available. This dry run func–

tion is used to test programs .

Display lock condition

(3)

In display lock condition, the machine moves

normally, but no change occurs in the dis–

plays of the current value ,external and the

current value (optional) . These displays

do not change if feed is done manually.

2.52 AUXILIARY FUNCTION LOCK

While this switch is on,

for M, S, and T functions. However, the oper-

ation is normal for decoding MOO, MO1, M02, and

M30, and for internal handling of M codes (M90

to M109) .

Note: The miscellaneous function lock does not affect S-4

digit command (option)

2.53

MANUAL ABSOLUTE ON/OFF

While ON

(1)

Manual movement distances are added to the

absolute register, and the coordinate system

remains unchanged.

While OFF

(2)

Manual movement distances are not added,

and the coordinate system is shifted in parallel to the movement.

no BCD code is output

9

Page 17

2.54 EDIT LOCK

With this switch on,

ations are inhibited.

a. ERASE, INSERT,

b. NC tape storing operation.

the following editing oper-

and ALTER key operations.

2.55 INTERLOCK

When an interlock signal is on during automatic

operation, the tool stops after deceleration in

both X and Z axes; when the signal is cleared,

the tool resumes the motion.

2.61 OVERTRAVEL

This function is to stop the tool motion by receiving a stroke–end signal from the machine.

the machine is stopped by this function, the

machine member must be moved backward by

manual feed.

When

2.62 REMOTE RESET

This function is to reset the NC with an external

signal.

tive, and tool motion is stopped.

When reset ,

all commands become ineffec-

2.63 REMOTE POWER ON/OFF

2.56 RAPID PULL OUT OF THREADING

When this signal is input, thread is cut during

thread cutting cycle of G92 and G76X. When the

signal is off, thread is not cut. In normal usage,

any M codes are output if this signal (CDZ) is

turned on and off.

2.57 ERROR DETECT

While this signal is turned on, operation goes to

the next block after pulses are distributed for

feed and ERROR DETECT is on (square corner) .

If the signal is off, the operation goes to the

next block immediately after pulses are distributed.

In normal usage, if any M codes are output, then

this signal (SMZ) is turned on and off.

Note: This function is effective only for feed.

The error detect for positioning is controlled only

by GOO and

G06.

2.58 DOOR INTERLOCK

When the door is open, the power supply is turn-

ed off.

2.59 FEED HOLD

Depressing this pushbutton temporarily interrupts

the tool feed during automatic operations. It does

not function, however , to stop thread cutting.

The operation is resumed by depressing CYCLE

START pushbutton.

2.60 EMERGENCY STOP

Depressing the EMERGENCY pushbutton makes

all commands ineffective.

ply is turned off, and all moving members are

stopped by dynamic brake.

The servo power sup-

In addition to the POWER ON /OFF pushbutton on

the NC operator’s station, the power can be turned on and off by inputting an external contact

signal.

2.64 MACHINE READY INPUT SIGNAL

This signal indicates on the control that the machine is ready for operation.

possible when the signal is received in the con-

dition of “Servo Power ON . “ When the signal is

off during operation, all functions are stopped,

with “Machine Unready. “

The operation is

2.65 CONTROL POWER ON OUTPUT SIGNAL

An output signal to indicate that the power is

input to the control section.

2.66 SERVO POWER ON OUTPUT SIGNAL

An output signal to indicate that the servo power

is normally input in the condition of NC power-on.

2.67 TOOL MOVE OUTPUT SIGNAL AND

THREADCUTTING OUTPUT SIGNAL

Moving Signal

(1)

An output signal to indicate the tool is moving

in automatic operation mode.

(2)

Threading Signal

A signal to be output specifically during

thread cutting..

2.68 NC ALARM OUTPUT SIGNAL

A signal to be output during any one of alarms

except for inpur error. The signal is off

immediately after the cause is removed and the

reset procedure is followed.

10

Page 18

2.69 INPUT ERROR OUTPUT SIGNAL

A signal to be made on by an error relating to

program input, such as one in part program

parity, format, or numerals. The signal is turn

ed off by reset operation.

output for a

“Simple Error” displayed on CRT.

The signal is not

2.70 NC RESET OUTPUT SIGNAL

A signal to be turned on by pushing the reset

key on the NC operator’s station or by input

of external reset signal.

(3) Input /Output Signal Diagnosis

2.74 POSITION DETECTOR INTERFACE

Position and speed is detectec by feedback signal

from the rotary-type pulse generator. (Note 2. )

The motion per rotation of the pulse generator is

varied by the number of pulses from the pulse

generator as shown in the table below.

Pulse Generator

Motion per Rotation of

Pulse Generator

EXTERNAL ERROR INPUT SIGNAL

2.71

External Error Detect Input O

(1)

When this signal is input, the operation

stops after the end of the current block,

and alarm is displayed.

External error detect input 1

(2)

When this signal is input, the current mo-

tion is immediately stopped, and alarm is

displayed.

2.72

RS-232C INTERFACE PORT

RS-232C interface is provided to connect tape

puncher, separate type tape reader unit and

other external equipment.

Interface Type

Transmission speed 110 to 9600 baud

Connector

Max Cable Length

Output from Memory

Storage in Memory

Tape Mode Operation

Note : Data which are output from memory

or stored in memory are as follows :

. Part program

. Offset data, tool coordinate data

and tool wear data

. Setttng and parameter data

Serial voltage interface

—

DB-25S

15 m

Possible

Possible

Possible

Metric

output

E=..

The “motion per rotation of pulse generator” in

X-axis is the half of the above values.

Note: The multiplication of pulses can be set

from servo unit and the NC.

2.75 lNPUT/OUTPUT CONNECTORS

The connection of the machine and the NC control is made

via “Half pitch connectors” directly to the CPU rack.

2.76 POWER INPUT

The standard input power is as follows:

200/220/230 VAC, +10%, -15%, 50/60 HZ fl Hz,

3-phase

2.77 AMBlENT CONDITIONS

(1) Ambient Temperature

(2) Relative Humidity: 10% to 90% RH

For operation: 0° C to +450 C

For storage:

-20° C to +65°C

2.73 ON-LINE DIAGNOSTICS

During operation, the following self-diagnoses

are made online:

(1) 3-digit Alarm Code and Alarm Message Dis-

play.

(2) System Diagnosis

a. System memory total check.

b. RAM check (when power is input) .

c. Watchdog timer.

(3) Vibration:

Note: When the ambient conditions do not con-

form to the above requirements, or organic solvent or other fumes are present in high concentration,

we offer special measures.

4.9 mis’max.

11

Page 19

2.78 SPINDLE PULSE GENERATOR

This provides the spindle position detector connected to the lathe spindle with 1 : 1 ratio.

number of pulses are :

The

a. 4000 rpm max.

b. 6000 rpm max.

(provided with oil seal)

(not provided with oil seal)

3 BASIC

3.1 AC SERVO CONTROL UNITS

Transistorized PWM servo control units are further miniaturized to be available for use in either

of the folIowing systems:

(1) NC board built-in system:

Built in the free-standing type cabinets.

(Z) External install system:

Supplied in unbundled type to the freestanding type cabinets.

to be less than 10 meters (30 feet) .

Servo capacity is as follows :

No.

--+

1

2

3

4

Continuous Max

Torque of F Series

AC Servomotor

30kg cm

60 kg cm SR1OBB

I

90 kg cm

120kgcm

Cable connection

Type

CACR -

SR05BB

I

SR15BB

SR20BB

OPTIONS

3.2 AC SERVOMOTORS

The following AC servo motors that incorporate

the position-detecting pulse generator (PG) and

speed–detecting pulse generator (PG) are avail–

able.

rpm.

The rated speed of AC servomotor is 1500

No.

2

4

6

* II; indicates depending on detector type(P/rev)

as follows:

Continuous Max Torque

of F Series AC Servomotor

1 30 kg. cm

60 kg-cm

3

5

A: 6000 P/rev

B: 5000 P/rev

90 kg-cm

120 kg-cm

230 kg.cm

380 kg-cm

Type

USAFED-

05F[:; *

09F[;

13F::;

20F[:;

30F[.;

44F[:;

5 230 kg cm

6

I

12

380kg cm

I

SR30BB

SR44BB

Page 20

4.1 SEPARATE TYPE NC OPERATOR’S

STATION

The separate stations are available in two configurations :

“ Keyboard on right side of CRT

(The power on~off push button not provided)

See Fig.” 2.2.

Keyboard below CRT

-

See Fig. 2.3.

4.2 SEPARATE TYPE TAPE READER

The separate type tape reader can be

to the NC contr~l th~ough RS- 232C interface

port 1.

- Read speed: 200 char. /see

● Reading system:

LED-photoelectric

connected MEMORY \30 SETS MAX. ) _

4.3 TAPE READER WITH REELS

*

WORK COORDINATE

SYSTEM SHIFT MEMORY ~ CO

* TOOL COORDINATE

(0NE SET)

TOOL OFFSET

MEMORY -

(50 SETS MAX )

f-

k

---

1

* TOOL RADIUS —

MEMORY

TOOL OFFSET NUMBER

No.

01

09

10

16

—-

17

50

51

@o

81

99

_——

--- ____.__..

STANDARO T 4- DIGIT

‘ COMMAND

(BASIC)

J

ADDITIONAL OFFSET

MEMORY *

J

Attached type 1 can be provided with

reader with reels.

(1) 6-inch reel

Reel diameter: 150 mm (6 inches)

Tape length:

Tape thickness: O. 108 mm

The tape reader speed determines

and rewind speed.

80 m (262 ft. )

the following tape

tape read

4.4 M3-DIGIT BCD OUTPUT

A digit is added to the basic M 2-digit BCD output to provide a total of M 3-digit BCD output.

M codes being output are MOO to M89 and M11O to

M999.

4.5 ADDITIONAL TOOL OFFSET MEMORY

To meet T 4-digit command, 50 sets of offset memories are available to replace 16 sets.

The map of offset memory including other options

are shown as reference.

4.6 ADDITIONAL PART PROGaRAM STORAGE

Any of the following storage capacities can be

selected to replace the memory equivalent to the

basic tape len-gth of 40 meters.” “

31

320 m (1049 ft.)

4.7 ADDITIONAL PROGRAM NUMBER

REGISTRATION

Either of the following number of registrable programs can be selected to replace the basic number

of 99.

Total Number of Registrable Programs

+t=-

13

Page 21

4.7 ADDITIONAL PROGRAM NUMBER

REGISTRATION (Cent’d)

Note that if the optional

ber registration” is adopted, the storage capacity

for the part program is reduced by the following

amount.

Additional Number

of Registered Programs

“additional program num-

Reduced

Storage Capacity

4.10 INTERNAL TOGGLE SWITCHES

Input to the following 8 switches (all basic)

can be turned on and off by setting operation on

the NC control panel (Setting #6000) .

0 Single block

1: Machine lock

2: DIsP@ lock

3: Optional block skip

(Block delete)

4: Dry run

5: Manual absolute

6: Miscellaneous functim lock

7: Edit lock

199

999

\ 2m (66ft)

18m (59 ft.)

I

4.8 OPERATION TIME DISPLAY B

The CRT displays the cumulative time while the

external signal (EXTC) is being input.

HOUR MIN

TM4: 9999. 59.

SEC

59 max.

4.9 STEP-MODE SIMULTANEOUS ONE-AXIS

OPERATION

The step-mode of operation is enabled one–axisat–a-time using the axis selection switch.

axis moves by the amount of turning of the

manual pulse generator. The manual pulse gen–

erator is graduated in 100 scales per rotation.

The motion per rotation can be specified by the

manual step multiple selection switch as follows:

Multiplication

Switch

Metric Input [ 0001mm I O.Olmm I Olrnrr

xl Xlo x100 or greater

The

582-217

Example of Internal Toggle Switches CRT Display

4.11 G50 POINT RETURN

This function manually returns the tool to the po-

sition specified by G50 coordinate system setting

command.

(SRN input) and perform manual jog or manual

rapid traverse operation, then the tool automati–

tally stops at the setup position.

Turn on the Setup Point Return Switch

-+ ‘etu””’ntre’urnswitch

Inch Input 0.0001 Inch 0.001

The motion by the manual pulse generator is possible when “Automatic mode handle offset switch

(HOFS input)” is on during the automatic operation mode. This motion, however, is impossible

during execution of positioning command ( GOO,

G06) .

ative thread cutting, etc.

Notes :

1.

2. Installation of the manual pulse generator (one axis at

This function is convenient for regener-

The automatic operation mode means TAPE,

MDI (manual data input) , and MEM (memory)

operation modes .

a time) eliminates the function of manual step feed.

Inch

0.01 Inch

14

4.12 RESTART AFTER MANUAL

INTERRUPTION

This function manually returns the tool to the position where the operation has been changed from

the automatic mode to the manual to carry out a

manual operation.

Return Switch (CRRN input) , and manually feed

the tool with jog or rapid traverse in the direc-

tion at which the mode has been changed from

automatic to manual, then the tool automatically

stops at the mode-changed position.

~++ ret.rnswitch

Turn on the Interrupted-Point

Interrupted–machining point

Page 22

4.13 PROGRAM RESTART

This function resumes the program at any sequence

number. Turn on the program resume switch

(PRST input) , search for the sequence number,

and then turn off the switch.

output required M, S , and T codes, and depress

the Cycle Start button to resume the program.

RRST

I

“+

Then , use MD I to

Program restart switch

4.14 EXTERNAL INPUT, COLLATION, AND

OUTPUT

Deletion, input, collation, and output of part

program can be commanded to the part program

stored in the control by external contact input.

To execute this function, RS232C. interface is

used as the transmission line of part program

data. Data input and output interface should be

provided.

4.15 BUFFERING FUNCTION (M92, M93)

(1) 4-block Buffering (M93)

In general, these G codes are specified in a

single block at the head of program.

Notes:

Inch /metric input can be selected by setting

1.

operation (basic) .

2.

G20 /G21 command rewrites the above setting

data.

ther G20 or G21 at the time of power on.

Thus , the setting data determines ei-

4.17 RADIUS PROGRAMMING FOR

CIRCULAR INTERPOLATION (G22, G23)

G22(G23) X( U) O.. Z(W) .”. R,. . F(E) . . . ;

This command specifies the radius of an arc by

address R instead of specifying the center of arc

by I and K. Note that:

Where R > CI:

R< I):

Note:

by GOZ and G03 instead of GZ2 and G23 respectively.

The radius-designated arc can be specified

an arc less than 1800,

an arc greater than 1800

The “M93 ;”

read-ahead mode until “M92” command is

issued.

ing 4 blocks is stored in the buffer for the

succeeding operations.

ahead in 4 blocks contains a program whose

operation time is longer than the time needed to read and compute the data in the 4

blocks following the above 4, then stop time

between blocks is eliminated. Thus, this is

effective in avoiding bright streaks on works

that might be caused by stop time between

blocks .

(2) l-block Buffering (M92)

The “M92 ; “

read–ahead mode and the operation returns

to the normal l--block read-ahead mode.

Note: During tool radius compensation in M93

mode, a maximum of 6-block read– ahead mode

might occur,

block without move command.

command specifies a 4-block

The data read ahead in the follow-

If the data read

command cansels the 4–block

because 2 blocks are allowed as the

4.16 lNCH/METRIC SETTING

The following G codes specify the input increment

either as metric input or inch input.

4.18 ANGLE PROGRAMMING FOR LINEAR

INTERPOLATION (GO1)

GO1 X( U)... A.. . F(E) . . . ;

or

GOl Z(W), . . A.. . F(E)oc. :

Either command specifies an an~le-desi~nated

linear interpolati&.

—

x

Tx

b

I

Plus ( +) sign of angle A

wise angle from +Z axis.

indicates a counterclock-

o

@

w

@

A+

STARTING

POINT

G Code

G 20

G21

\

Input Increment

I

I

Inch Input

Metric Input

15

Page 23

4.19 TOOL OFFSET VALUE SEITING(GIO)

GICI P.. .

This command sets or corrects a tool offset on

the part program,

where P:

* R:

x(u) . . . Z(w) . . . R.’. :

Tool offset number

x:

w:

Tool offset value in absblute

setting

z:

}

u:

Tool offset value in incremental

setting ( = additive write)

}

Tool radius value in absolute setting

Fl%

Note:

ing GO1–code format instead of G12.

Rounding can be specified with the follow-

There is no change in compensation values for

the omitted addresses.

be prepared using G1O format and stored in the

tool offset memory all at once.

An offset value tape may

4.20 CORNERING (Gil, G12)

(1) Beveling (Gil)

Gll X( U)... K.. . F(E) ”””$ ;

Gll Z(W) . . . 1.. s F(E) .0” ;

This command performs beveling of K or 1

at the end of blocks. The operation is limited

to a single axis command for X or Z axis.

t=%%

@

@ or

@

GO1 X( U)... R.. . F(E) ”.” ; or

GO1 Z(W) . . . R.. . F(E) . . . ;

Address R replaces K and 1.

4.21 MULTIPLE CORNERING

(BEVELING/ROUNDING) (Gill , G112)

Programming a beveling /rounding operation on a

work having a given taper or arc portion requires

a complicated computation. The combined bev-

eling /rounding codes provide an autoprogramrning

function to carry out such a complicated computation automatically within the CNC.

The following two functions are available:

G Cede

~

Group

Taper comb[ned bevellng/rounding

Arc combined beveling/round!ng

Function

lNote: A chamfer can be commanded by GO1 code

instead of G 11 as shown below :

GOl X( U)... K.. . F(E) . . . ; or

GOl Z(W) . .. IO.. F(E) . . . ;

(Z) Rounding (G12)

G12 x( IJ) ..” K.. . F(E) . . . ; 1 or

G12 Z(W) . . . I“”” F(E) o”. ; 2

The command performs a rounding with radius K or I at the end of blocks. The oper-

ation is limited to a single axis command for

X or Z axis.

16

(1) Taper Combined Beveling /Rounding (Gill)

The following taper contour can be specified:

Page 24

END ~

POINT

#>2N~m”NDlNGQOR BEVELlNG D

IMAGINARYCROSSPOINT

—

2NDSTRAIGHTLINE

1ST ROUNDING P OR

BEVELING C

z—

w

[x(u)... ~(!/.J)...,... ~...

1A... ~(w)... ~... ~

(2) Arc Combined Beveling /Rounding (G112)

The following contour of

line can be specified.

an arc and straight

P

g

\

----1

P(C). Q(D) ;

‘

1ST STRAIGHT

LINE

K

A

START POINT

—

u12

I

x

END POINT

—.

+’

Q

ROUNDINGOR

2ND

BEVELING

ARC

i) G112 X(U)... 1... K... R... P(C),.. Q(D).. ;

I

A

\

STRAIGHT

r

1ST ROUNDINGOR

BEVELING

I

P

I

1

U12

A

STARTPOINTX, Z

A

I

x

17

Page 25

4.21

MULTIPLE CORNERING

BEVELING/ROUNDING) (Gil 1, G112)

Cent’d)

1

z

START

POINTx, z

T

K

t

w

i

STRAIGH

7

/

ROUNDINGOR

1ST

SEVELING

ARC

ii) G112 Z(W)... 1... K R,. P(C).. Q(D)... ;

P

i

END POINT

4.22 MULTI-START THREADCUlllNG (G32)

This function allows multiple threadcutting to

provide multiple grooves in a lead. The function

permits grooves to be cut without shifting the

start point of thread

G32 X( U)... Z(W) . . . B.. . F(E) . . . ;

The above command starts cutting at the

spindle position shifted by angle B from the posi–

tion where the spindle start point synchronous

pulses are generated.

spindle for multiple thread and specified in the

range of O to 360°.

Note:

tiple thread.

Continuous threading cannot include mul-

grooves.

B is a shift angle of the

Two-Start Threads

4.23 VARIABLE LEAD THREADCUTTING (G34)

G34 X( U)... Z(W) . . . K.. . F(E) . . . ;

This command allows a variable lead thread to be

cut where a lead increment per rotation of thread

is specified by address K,

follows :

Metric Input

Inch Input fO.000001 -–fl.000000 Inch

Other specifications are the same as G 32.

Notes :

1. G34 cannot be used for continuous threading

and multiple threading,

2.

G 34 cannot use the function of “temporary

interrupt during threading. “

increasing–Lead Threads

The range of K is as

Range of K

*O 0001 – f100.0000 mm

4.24 2ND REFERENCE POINT RETURN (G30)

G30 X( U)... Z(W) . . . ;

This command moves the tool to the specified

intermediate position , then to the second reference point.

the position of the 2nd reference point by its

distance from the 1st reference point.

Parameters are used to determine

18

Note: If G29 is specified immediately after G 30

command, then the tool motion is the same as G28:

return to the 1st reference point.

Page 26

4.25 TOOL NOSE RADIUS COMPENSATION

(G40 TO G44)

This function compensates for cutting errors

caused by the roundness of the tool.

(1) G Codes in Compensation Mode (G41 to G44)

Four directions of G41 to G44 are used to

specify the imaginary tool directions with

respect to the tool centers and to specify

to enter the compensation mode,

(a)

,--. \

,.

CENTERI

(b)

G 42

d. Lb ‘;

>

G 41

IMAGINARY TOOL

DIRECTIONS

4-

TOOL CENTER

G Code to Cancel Compensation ( G 40)

The command “G40 ; “ cancels the tool radius compensation.

(3) Specifying compensation direction .

+:

The compensation of tool

center is to the right of

advancement.

—.

The compensation of tool

center is to the left of

advancement.

Offset Memory for Setting Tool Radius

(4)

The number of memories to store tool radius

depends on the usable tool offset number.

(6) Motion during Compensation Mode

a. For inner corner (less than 180° tangent

angle)

+Z

(7) The compensation is normally done even in

--- Cross point is computed, and the tool

passes through the cross point.

b. For outer corner ( more than 180° tangent

angle)

M Code

M 96

M 97

continuance of two blocks not having move

command, during compensation mode. In

the case of three blocks or more, a temporary cancel condition occurs.

block can be used.

TOOI nose radius compensation-arc

mode

round

TOOI nose radius compensation- crosspoint

commutation mode.

Functions

A dummy

4.26 MULTIPLE REPETITIVE CYCLE

(G70 TO G76)

By specifying a finish contour with this command,

the tool path is automatically computed for rough

cutting and rough finishing, and the cutting is

carried out. Because of the capability to handle

a finish contour having depression, the programming time is drastically reduced.

Where T 3-digit specified:

Where T 4-digit specified:

Motion at Start of Compensation and at

(5)

Cancel

a.b.At the start of compensation, the tool cen-

ter comes on the normal line of the start

point of the block immediately following

G41, G42, G43, or G44 command.

At the cancel of compensation, the tool

center comes on the normal line of the end

point of the block immediately before G40

command.

9 (basic)

16 or 50

(1) Stock Removal in Turning (G71)

The specified format is shown in the list.

By specifying 1, K, and tool radius compens ation, the tool radius compensation is carried out during the rough finish along the

broken line.

a finish contour having depression with a

maximum of three interrupted points.

A maximum of 45-block programming can be

used to specify a finish contour .

of cut D may have cut–override in the range

of 10 to 200% in steps of 10%.

The R1 command can specify

The depth

19

Page 27

4.26 MULTIPLE REPETITIVE CYCLE

(G70 TO G76) (Cent’d)

(2) Stock Removal in Facing (G72)

The same as G71 except that the operation

is parallei to X-axis. Example of cutting

path when RI is specified in G71.

—.- —————.___

____ ___

(5) Peck Drilling in Z-axis (G74)

The tool nose radius compensation is not

effective. If R 1 is specified, the allowance

per cutting is made available only up to the

start point of cutting.

(6) Grooving in X-axis (G75)

The same as G74 except that the operation

is parallel to X–axis.

(7) Automatic Threading Cycle (G76)

The cutting near the point B is as follows:

+x

FINISH

L-

I

(3)

(4)

+Z

Pattern Repeating (G73)

This cycle carries out cutting by dividing

the operation in D–times and ends it, leaving an allowance for finishing .

compensation, if specified, is carried out

throughout the cycle . Finish contour can

be programmed up to 45 blocks.

Finishing Cycle (G70)

After the end of rough cutting specified by

G71, G72, or G73, finish cutting is carried

out according to the finish contour specified

by G70 command.

if specified, is done throughout the cycle.

The memory search function for finish contcur program allows such a sequence as :

rough cutting cycle (A) + rough cutting

cycle ( B ) + finish cycle (A) + finish

cycle (B) .

For this purpose, the internal memory to

store the finish contour program is installed

separately from the part program memory of

45 blocks.

CONTOIJR

— ROUGH CUTTING CYCLE

- – ‘-- ROUGH FINISH CYCLE

Tool radius compensation,

FINISH

ALLOWANCE

Tool radius

D-ANGLE

;ATION

(%=’’”

\\\\~ I

m.

O,

A;

D

The tool nose radius compensation is not

effective. When the threadcutting input

is on, threadcutting is carried out.

29°, 30°, 55°, 60°, 80°

.=&D

20

Page 28

Code

Cutting Cycle

Command

G 71

Stock

Removal

in

Turning

G 72

Stock

Removal

in

Facing

—

Elr

TAPE COMMAND

[N(ns) - N (nf)l

TAPE COMMAND

--———- -

c

(ns)

N

A

WK

t-%

; ,(n~,)

inish contour program

, c---

1,w--

~ ....

II

LJ

L

I@’

-- J

B

WK

T

K+W

} I

u

)

.. .... .. .. ............ ... .

M . ;

.. .......... .................. .

A+ A’-+B

Sequence No. to start

and end cycle

Fresh allowance !n X and

Z dbrectfions

(U. Speclfled d[ameter)

For G71, G72:

flnlsh allowance

Rough

In X and Z dlrect!ons

For G 73

Cutting allowance in

X and Z directions

For G71, G72:

Depth of cut in

rough cutting

For G 73:

Number of cutting

operations

lSD~127

(Specify unsigned D)

G 73

Pattern

Repeating

G 70

N(ns) to N(nf) finish cutting carried out

5peclfy

U, W, 1, and K wl?h signs)

21

Page 29

4.26 MULTIPLE REPETITIVE CYCLE (G70 TO G76) (Cent’d)

Code

G 74

Peck

Drilling

in

Z–axis

G 75

Grooving

in

X–axis

Cutting Cycle

‘:; X(u).. z(w)

}

I.. K. D. F(E).. (RI)

For G74

X(U) -- X-component of point B

I

I

z

F

,

--- _

—---

+R R

F,

F

I

1- ‘ fPR

w

I

J

F,

x

8: SETTING

A

I

c?

u

2

Z(w) -- Z–component of point C

I

- Motlorl In X direction

K

-- Cutting value in Z direction