Page 1

iTIVi'i

CNC

YASNAC

PROGRAMMING

Upon

instructions

REFERENCE

YASNAC

YASNAC

SYSTEM

J300M/J100M

receipt

J300M/J100M

J300M

of

the

thoroughly,

LARGE-SIZE

FOR

OPERATING

MACHINING

product

and

retain

PROGRAM

prior

and

for

future

MANUAL

OPERATING

CENTERS

MANUAL

to

initial

reference.

MANUAL

operation,

TOE-C844-2.1

TOE-C844-2.1-1

read

these

y

YASKAWA

MANUAL

NO.

TOE-C844-2.2

Page 2

Page 3

Safety

Information

The

following

provided

tions

or

related

ucts

A

Indicates

injury

ous

Symbol

A

Indicates

injury

erate

Even

items

case,

follow

are

conventions

manual

this

in

equipment

usedtoindicate

can

resultinserious

systems.

and

WARNING

potentially

a

personnel.

to

is

used

hazardous

in

labels

CAUTION

potentially

a

personnel

to

described

these

hazardous

in

A

important

damage

and

CAUTION

items.

precautions

situation

attachedtothe

situation

which,

which,

equipment.

to

may

or

possibly

product.

result

if

if

in

not

not

a

in

vital

this

manual.

even

fatal

avoided,

avoided,

accident

Failuretoheed

injury

or

could

resultindeath

may

result

some

in

damage

in

minor

situations.

the

to

the

precau¬

prod¬

or

seri¬

or

mod¬

either

In

Please

note

ISO

A

manual,

In

this

products,

On

instructions

symbol

that

symbol

caution

concerning

markused

mark

symbol

caution.

indicate

to

JIS

<2>

of

by

ISO

stipulated

marks

ISO

and

caution

used.

is

JIS

are

differs

used

between

labels.

in

ISO

Please

and

JIS.

follow

the

same

safety

iii

Page 4

Visual

Aids

POINT

ISUPPLE

IMENT

TERM?

following

The

Indicates

to

plays

Indicates

Indicates

aids

important

damaging

avoid

supplemental

definitions

are

used

to

information

the

devices.

information.

difficult

of

indicate

should

that

terms

certain

or

terms

types

memorized,

be

have

that

of

information

including

been

not

easier

for

precautions

previously

reference.

such

explained

in

as

this

alarm

manual

dis¬

.

©Yaskawa,

rights

All

means,

any

by

No

kawa.

constantly

notice.

out

bility

for

this

publication.

in

1998

reserved.

mechanical,

patent

striving

Every

or

errors

part

No

liability

to

improve

precaution

omissions.

this

of

electronic,

assumed

is

its

has

Neither

publication

photocopying,

respect

with

high-quality

takeninthe

been

any

is

may

to

products,

preparation

liability

be

produced,

recording,

use

the

the

assumed

stored

otherwise,

or

information

of

information

this

of

damages

for

iv

a

in

contained

contained

manual.

resulting

retrieval

system,

without

herein.

in

Nevertheless,

the

this

from

or

prior

Moreover,

manual

Yaskawa

use

the

transmitted,

permission

written

because

subject

is

assumes

of

information

in

change

to

any

form,

of

Yaskawa

no

responsi¬

contained

or

Yas¬

is

with¬

Page 5

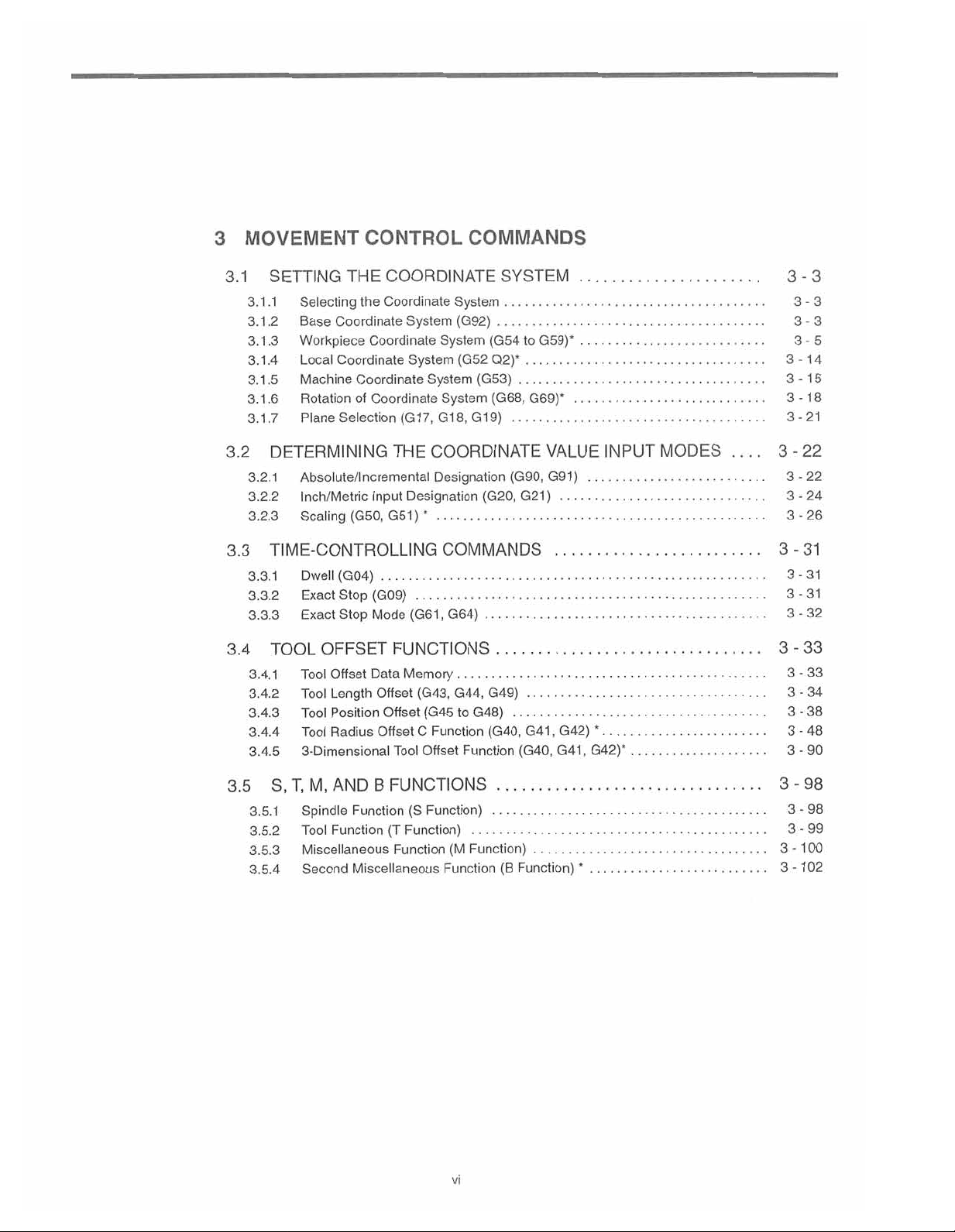

CONTENTS

Safety

Visual

About

Related

NOTES

1

1.1

1.2

Information

Aids

this

Manual

Manuals

SAFE

FOR

PROGRAMMING

FUNDAMENTALS

1.1.1

1.1.2

1.1.3

1.1.4

1.1.5

1.1.6

1.1.7

1.2.1

1.2.2

1.2.3

1.2.4

1

1

BASICS

.2.5

.2.6

Numerically

Controllable

Least

Maximum

Tape

Program

Optional

Buffer

Rapid

Cutting

-Digit

F1

Feed

Solid

Automatic

OPERATION

Controlled

Axes

Input

Increment

Programmable

Format

Format

Block

Register

FEED

OF

Traverse

(F

Feed

Feed

per

Minute

Tap

Mode

Acceleration

BASICS

OF

PROGRAMMING

Axes

and

Skip

(/1),(/2

and

Multi-active

FUNCTION

Command)

*

Function

(G93,

G94)

and

Least

Values

to

(G94)

*

and

Deceleration

the

Output

for

*

/9)

Register

Number

Increment

Movement

Axis

TERMINOLOGY

Simultaneously

of

iii

iv

viii

viii

x

1

-2

1

-2

1

-7

-9

1

10

1

-

1

-13

1

-24

-25

1

1

-26

1

-26

-27

1

-31

1

-32

1

-33

1

1

-34

2

COMMANDS

INTERPOLATION

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.2

2.2.1

2.2.2

2.2.3

2.2.4

Positioning

Linear

Circular

Helical

REFERENCE

Automatic

Reference

Return

Second

CALLING

(GOO,

Interpolation

Interpolation

Interpolation

POINT

Return

Return

Point

from

Reference

to

Fourth

AXIS

COMMANDS

G06,

G60)

....

(G01)

(G02,

G03)

.

(G02,

G03)"

.

RETURN

Check

Point

(G27)

Return

Point

to

Reference

Point

Reference

MOVEMENTS

(G28)

(G29)

....

(G30)

Return

2-2

2-2

2-5

2-7

2

-

2-16

2-16

2-22

2-24

2-28

14

v

Page 6

MOVEMENT

3

CONTROL

COMMANDS

SETTING

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7

3.2

3.2.1

3.2.2

3.2.3

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

Selecting

Base

Workpiece

Local

Machine

Rotation

Plane

DETERMINING

Absolute/Incremental

Scaling

TIME-CONTROLLING

TOOL

Tool

Tool

Tool

Tool

3-Dimensional

THE

Coordinate

Coordinate

Coordinate

of

Selection

Inch/Metric

(G50.G51)*

(G04)

Dwell

Stop

Exact

Stop

Exact

OFFSET

Offset

Length

Position

Radius

COORDINATE

Coordinate

the

System

Coordinate

Coordinate

THE

Input

System

System

System

System

(G17.G18.G19)

COORDINATE

Designation

Designation

COMMANDS

(G09)

,

(G61

Mode

FUNCTIONS

Memory

Data

(G43,

Offset

(G45toG48)

Offset

C

Offset

Tool

Function

Offset

System

(G92)

(G52

G64)

G44,

Function

SYSTEM

(G54

Q2)*

(G53)

(G68,

(G90,

(G20,

G49)

(G40,

G59)*

to

G69)*

G21)

G41

(G40,

.

VALUE

G91)

...

*

,

G42)

G41,

G42)*

INPUT

MODES

—

....

3-3

3-3

3-3

3-5

3-14

3-15

3-18

3-21

3-22

3-22

3-24

3-26

3-31

3-31

3-31

3-32

3-33

3-33

3-34

3-38

3-48

3-90

3.5

3.5.1

3.5.2

3.5.3

3.5.4

T,

M,

S,

Spindle

Tool

Miscellaneous

Second

B

AND

Function

Function

Miscellaneous

FUNCTIONS

(S

Function)

Function)

(T

Function)

Function

(M

Function

vi

Function)

(B

3-98

3-98

3-99

*

3-100

3-102

Page 7

ENHANCED

4

PROGRAM

4.1

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

4.1.6

4.1.7

4.1.8

4.1.9

.

4.

0

1

1

PROGRAM

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

LEVEL

SUPPORT

Canned

Hole

Solid

Deep-hole

Circle

Mirror

Programmable

Subprogram

Polar

Cylindrical

Program

Automatic

Stored

Comment

Break

High-speed

Chamfering

Corner

Cycles

Machining

Tap

Function

Solid

Cutting

Image

Coordinate

Interpolation

SUPPORT

Copy

Corner

Stroke

Output

Point

Feedrate

(G73

Pattern

Tap

(G12,

ON/OFF

Data

Up

Call

Interpolation

(G25)*

Override

Limit

Function

Function

Cutting

Corner

and

Designation

COMMANDS

FUNCTIONS

G89,

to

(G84,

Function

G13)

Input

Function

and

B

*

G181

to

(G70,

Cycles

*

G74)

(G184,

*

*

M95)

(M94,

*

(G10)

(M98,

(G126,

28,

(G

1

29)*

G

1

FUNCTIONS

*

(G106)

(G22,

C

(M191

Rounding

G23)

*

)

Commands*

(G107,

(1)

G189)

G71

G174)*

M99)

G127)*

(2)

*

G108)*

,

G72)

*

...

.

.

4-3

.

..

*

4-3

4-34

4-39

4-50

4-64

4-70

4-76

4-79

4-81

4-91

4-101

4-101

4-104

4-109

4-115

4-116

4-116

4-121

4-126

AUTOMATING

4.3

4.3.1

4.3.2

4.3.3

MACROPROGRAMS

4.4

4.4.1

4.4.2

4.4.3

4.4.4

4.4.5

4.4.6

4.4.7

4.4.8

4.4.9

Appendix

APPENDIX

Appendix

Skip

Function

Life

1

1.1

2

Interrupt

Control

from

Instructions

Instructions

the

Data

of

CODE

G

G

CODE

INDEX

Program

Tool

Differences

Macroprogram

Variables

Operation

Control

Registering

RS-232C

Macroprogram

Examples

SUPPORT

*

(G31)

Function

Function

Subprograms

Call

Macroprogram

Output

Alarm

Macroprograms

(G65,

(BPRNT,

2

Numbers

*

G66,

TABLE

TABLE

FUNCTIONS

(M90,

G67)

..

DPRNT)

*

M91)

.

4-138

4-138

.

4-141

4-144

4-154

4-154

4-156

4-169

4-201

4-203

4-209

4-210

4-214

4-215

-2

A1

vii

Page 8

About

this

Manual

Related

manual

This

J300M/J100M

Some

information

formation.

detailed

a

YASNAC

The

Use

al.

Manuals

Refer

to

Read

this

so

place

gives

(with

the

In

explanation

J300M/J

manuals

these

following

the

manual

can

that

it

Manual

the

basic

given

is

G

code

if

100M

in

manuals

carefully

be

refereed

Name

information

operation

NC

tables

in

table,

section

necessary.

comes

conjunction

as

ensure

to

whenever

to

necessary

panel,

the

in

numbers

with

an

with

required.

proper

the

Manual

9-inch

Appendix

are

operation

each

other

of

use

necessary.

Number

readers

each

for

a

for

so

given

creating

CRT).

that

manualinaddition

to

ensure

productive

J300M/J100M.

program

easily

can

G

codetoallow

this

to

operation.

Also,

keep

Contents

using

the

find

necessary

the

quick

programming

this

manual

YASNAC

in¬

access

to

manu¬

a

in

safe

YASNAC

Operating

YASNAC

PLC

Programming

YASNAC

Connecting

YASNAC

Connecting

YASNAC

Connecting

YASNAC

Signal

I/O

J300M/JI00M

Manual

100

J300/J

Manual

J300

(Type

Manual

J300

(Type

Manual

J

100

Manual

J300M/J100M

Function

Manual

A)

B)

TOE-C844-2.

S1E-C844-0.

S1E-C843-I3.2

SIE-C843-13.5

SIE-C844-0.2

S1E-C844-2.3

1

the

basic

1

Describes

tion

procedure

Describes

for

eration

Describes

YASNAC

terface

and

Describes

YASNAC

and

terface

Describes

YASNAC

tween

the

developing

the

J300

the

J

the

configuration

YASNAC

of

PLC

instructions

specifications

machines,

with

external

1

external

equipment.

specifications

machines,

00

with

equipment.

functions

J300M

J300M/J100M.

PLC

the

for

for

I/O

of

PLC.

and

and

and

the

programs.

connecting

machine

connecting

machine

signals

opera¬

op¬

in¬

in¬

be¬

viii

Page 9

CAUTIONS

This

manual

be

available

not

to

otherwise

Metric

:

:

the

Zero

Reference

refer

Unless

gramming

•

•

•

Yaskawa

accurately

as

tions

is

and

it

unless

it

performed.

Also

bear

NC

by

the

and

panel

by

lished

describes

with

specification

examples.

for

system

point

has

made

possible

not

specifically

is

mind

in

unit.

The

other

machine

machine

the

the

all

your

YASNAC

document

specified,

input

the

base

in

point

every

effort

possible.

as

describe

to

stated

the

that

performance

entire

related

tool

option

following

the

and

metric

coordinate

to

However,

that

control

equipment

builder

functions

J300M.

or

manuals

system

describe

these.

of

all

something

and

system

for

detailed

(identified

To

determine

published

conditions

for

output/movement

system

individual

are

there

functions

consistsofthe

many

Accordingly,

can

be

performed,

of

addition

in

information

by

the

the

by

the

apply

in

functions

things

readers

NC

an

mechanical

NC.

the

to

relating

symbol)

“*"

option

functions

machine

programming

and

their

that

cannot

are

requested

should

it

machine

be

tool

system,

Therefore,

the

to

but

some

installed

tool

builder.

explanations

relationships

or

must

not

to

assumed

are

determined

not

the

machine

read

the

machine.

these

of

your

in

and

other

to

be

performed

understand

cannot

that

it

operation

manuals

may

NC,

pro¬

func¬

that

be

solely

pub¬

ix

Page 10

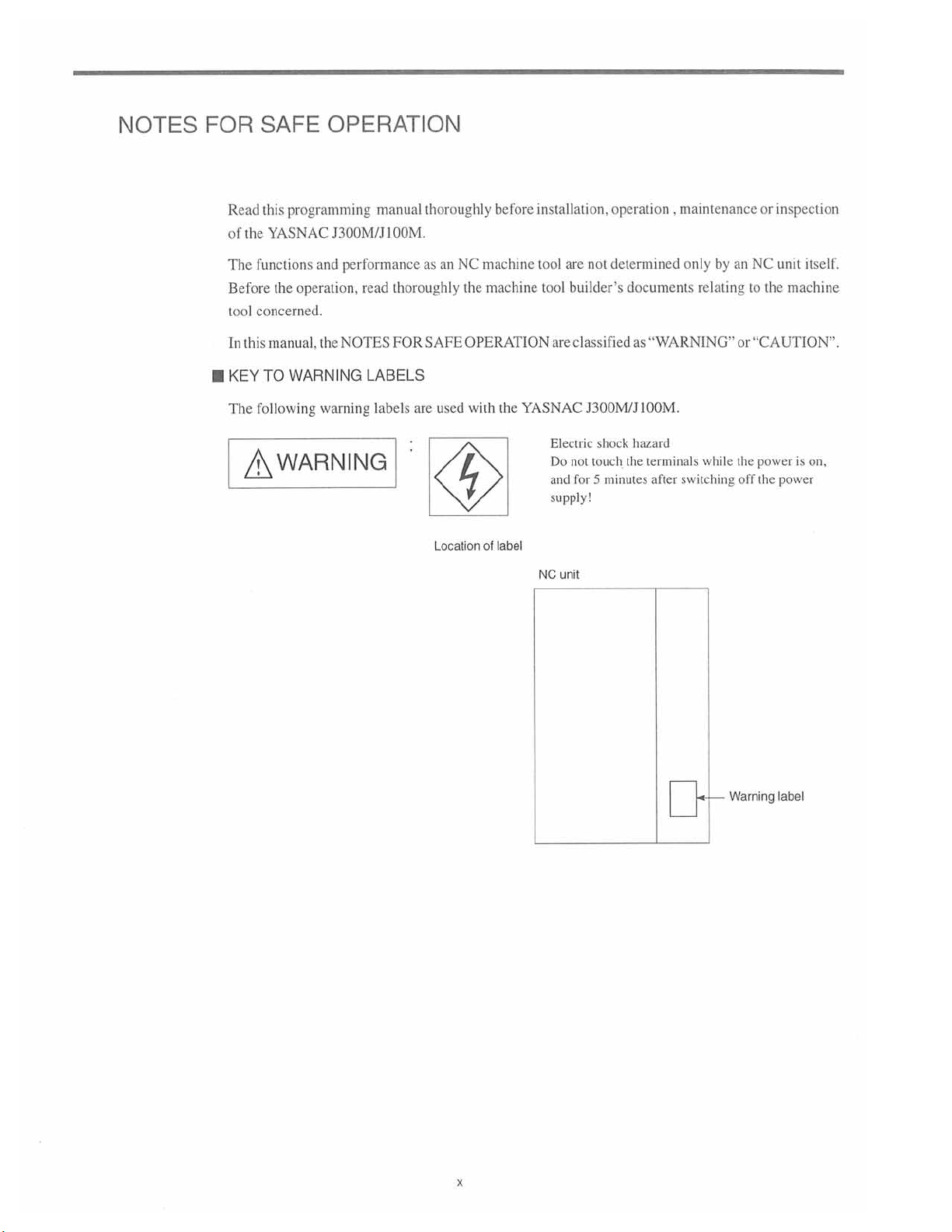

NOTES

FOR

SAFE

OPERATION

Read

the

of

functions

The

Before

tool

concerned.

this

In

KEY

following

The

programming

this

AC

YASN

the

operation,

manual,

WARNING

TO

J300M/J

and

performance

NOTES

the

warning

manual

00M.

1

thoroughly

read

FOR

LABELS

labels

thoroughly

NC

an

as

SAFE

used

are

Location

installation,

before

machine

the

machine

tool

OPERATION

YASNAC

the

with

label

of

NC

tool

are

Electric

Do

and

supply!

unit

are

not

builder’s

classified

J300M/J

shock

touch

not

for

minutes

5

operation

determined

documents

“WARNING”

as

100M.

hazard

the

terminals

after

,

maintenance

by

an

only

relating

while

switching

or

inspection

NC

unit

the

to

machine

or

“CAUTION”.

power

the

off

the

is

power

itself.

on,

Warning

x

label

Page 11

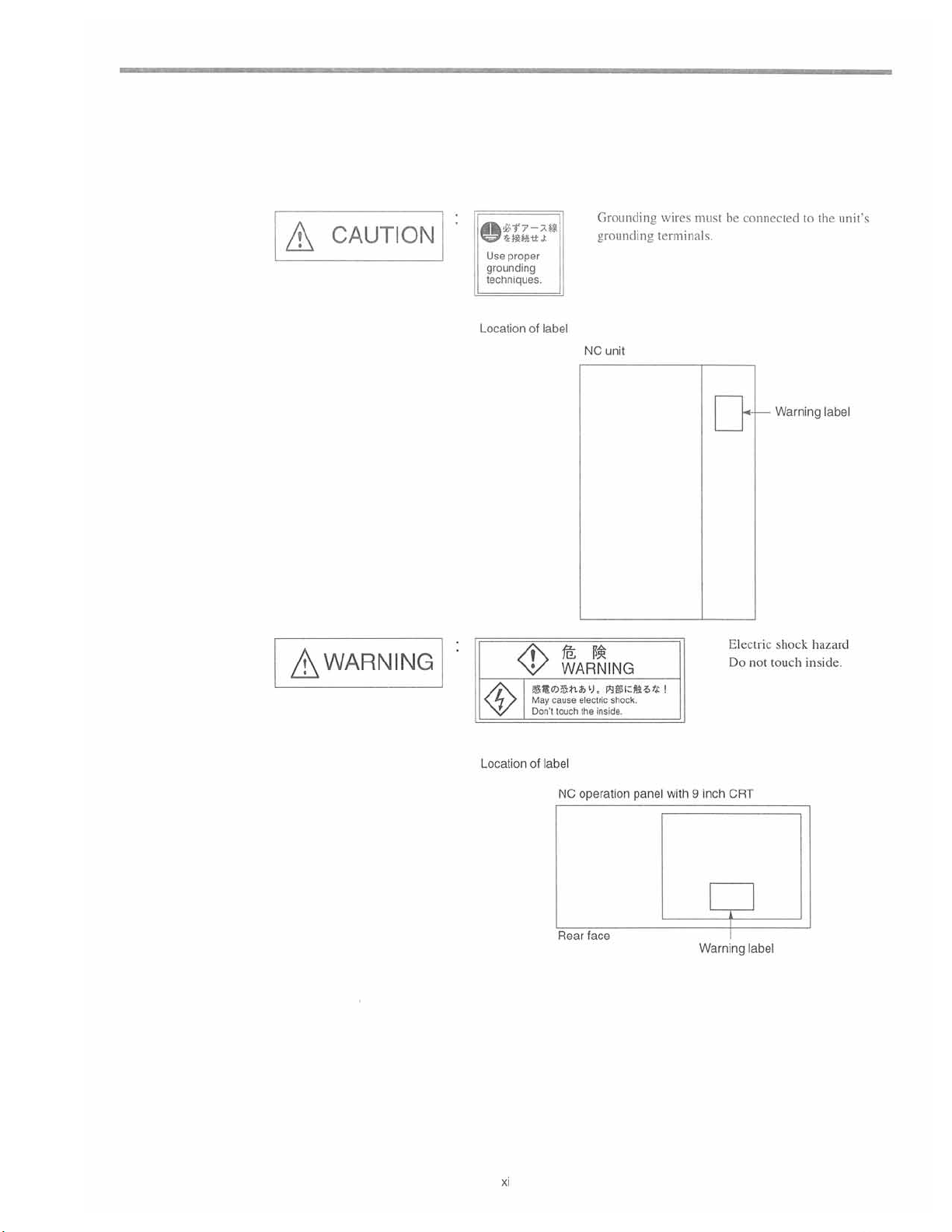

A

CAUTION

&?7-ZH

©

proper

Use

grounding

techniques.

Location

Grounding

grounding

label

of

NC

unit

wires

must

terminals.

be

connectedtothe

unit's

<§>

Location

WARNING

Dsnfcy.

$*<

May

cause

Don't

touch

of

label

NC

1$;

nitcMitti

electric

shock.

the

inside.

operation

panel

with9inch

Electric

Do

not

CRT

Warning

shock

touch

label

hazard

inside.

1

Rear

face

Warning

xi

label

Page 12

General

Precautions

Some

•

describe

ing

this

The

•

and

This

•

tion,

Such

To

order

•

resentative

any

If

•

nameplates

Yaskawa

•

our

drawings

the

detail

product,

figures

and

may

differ

manual

or

may

changes

modification

copy

a

listedonthe

nameplates

of

the

to

not

is

guarantee.

manual

this

in

more

with

operate

and

photographs

the

from

of

your

responsible

product

modified

be

specifications.

in

made

is

manual,

this

Yaskawa

are

clarity.

it

in

this

in

actually

when

as

revision

a

if

your

page

last

to

affixed

representative.

any

for

shown

with

sure

Make

accordance

manual

show

delivered

necessary

renewing

by

copy

has

the

stating

product

the

modification

protective

the

covers

all

with

the

a

representative

to

because

been

manual

become

of

the

cover

shields

and

directionsinthe

you.

improvement

of

the

manual

damaged

No.

product

on

the

damaged

made

or

or

shields

are

product

No.

lost,

contact

front

illegible,

or

by

replaced

manual.

for

of

page.

user

the

removed,

reference

the

product,

your

please

since

in

before

purposes

modifica¬

Yaskawa

send

will

that

order

operat¬

rep¬

these

void

to

xii

Page 13

1

1

PROGRAMMING

Chapter

and

1.1

1

the

describes

feed

functions.

the

basic

FUNDAMENTALS

TERMINOLOGY

1.1.1

.1

.2

1

1.1.3

1.1.4

1.1.5

1.1.6

Numerically

Simultaneously

of

Least

Increment

Maximum

Movement

Tape

Program

Optional

Controlled

Input

Increment

Programmable

Format

Format

Block

terms

OF

PROGRAMMING

Axes

Controllable

and

Least

Values

),

(/1

(/2to/9)

Skip

BASICS

used

and

programming

in

the

Number

Axes

Output

for

Axis

*

1

-2

-2

1

-7

1

-9

1

1

10

-

1

-13

1

-24

.2

1

1.1.7

Buffer

BASICS

1.2.1

1.2.2

1.2.3

.2.4

1

.2.5

1

1.2.6

Rapid

Cutting

F1

Feed

Solid

Automatic

1

OF

-Digit

-1

Register

FEED

Traverse

Feed

Feed*

per

Minute

Tap

Mode

Acceleration

and

Multi-active

FUNCTION

Command)

(F

Function

(G93,

G94)

and

Register

(G94)

*

..

Deceleration

...

..

1

.

1-25

-26

-26

1

-27

1

-31

1

-32

1

-33

1

1-34

Page 14

OF

.1

1

FUNDAMENTALS

PROGRAMMING

TERMINOLOGY

1

basic

section

This

.1

1

Numerically

.1

describes

Controlled

the

Axes

and

terms

the

used

in

Number

programming.

of

Simultaneously

Controllable

Axes

Names

Axes

Numerically

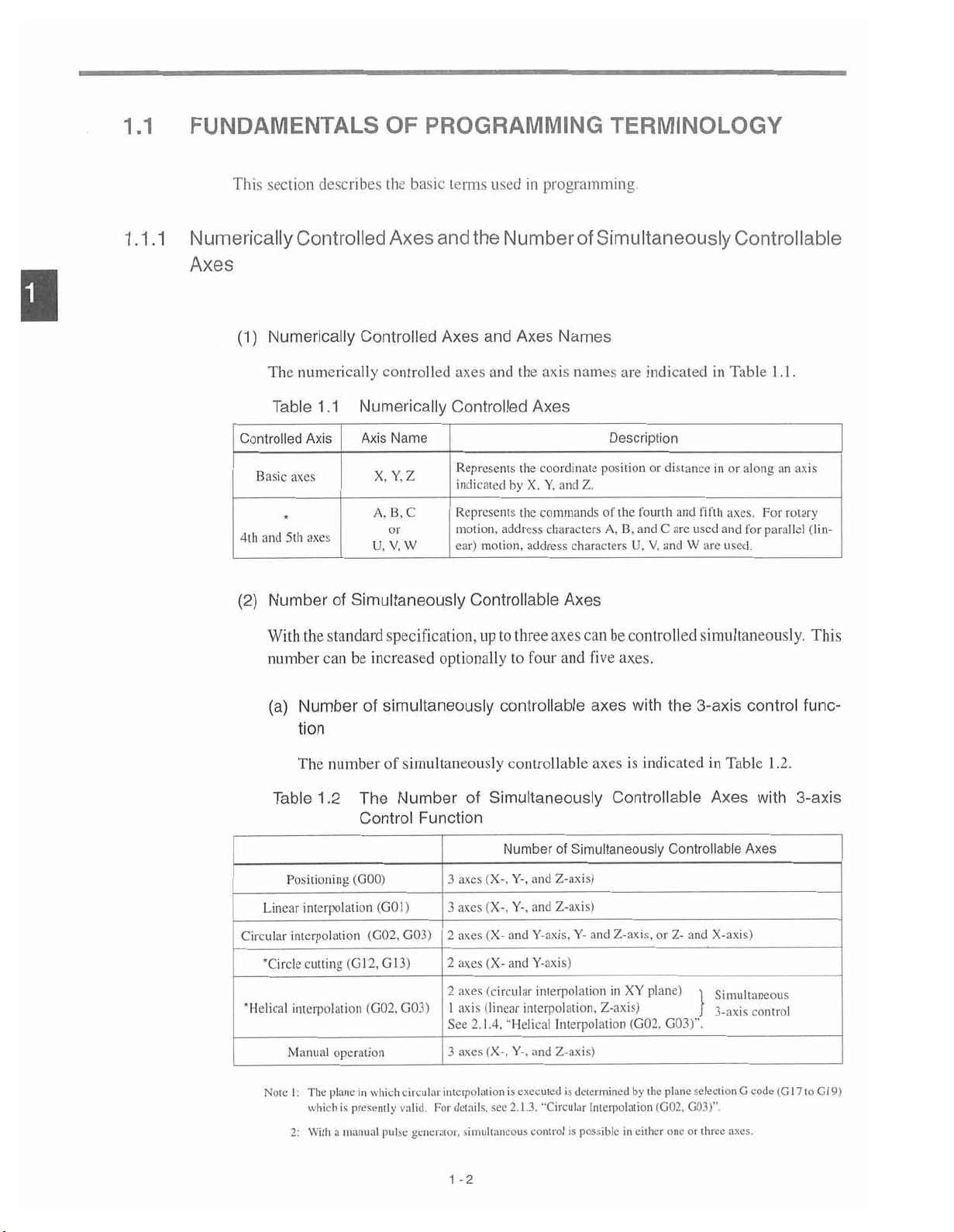

(1)

The

Table

Controlled

Basic

and

5th

4th

(2)

Number

numerically

1.1

Axis Axis

axes

axes

Simultaneously

of

Controlled

controlled

Numerically

Name

Y.Z

X.

A.

B.C

or

W

V.

U.

and

Axes

axes

and

Controlled

Represents

indicated

Represents

motion,

ear)

motion,

Controllable

the

Axes

the

by

X.

the

address

address

names

axis

coordinate

Y,

Z.

and

commands

characters

characters

Axes

are

indicated

Description

position

or

fourth

of

the

and

B.

A.

V.

U.

distance

and

C

are

used

W

and

in

fifth

are

in

and

Table

along

or

axes.

for

used.

1.1.

an

For

rotary

parallel

axis

(lin¬

With

number

(a)

Table

Linear

Circular

'Circle

'Helical

the

standard

can

Number

tion

The

number

1.2

Positioning

interpolation

interpolation

cutting

interpolation

operation

Manual

specification,

increased

be

simultaneously

of

simultaneously

of

Number

The

Control

(GOO)

(G01

G03)

(G02,

GI3)

(G12,

G03)

(G02,

optionally

Function

)

to

up

controllable

Simultaneously

of

(X-.

axes

3

(X-.

axes

3

(X-

axes

2

(X-

axes

2

(circular

axes

2

(linear

axis

1

2.1.4,

See

(X-.

3

axes

axes

three

four

and

to

controllable

Number

and

and

"Helical

of

Z-axis)

and

Y-.

Z-axis)

and

Y-.

Y-axis.

Y-axis)

interpolation

interpolation,

Interpolation

Z-axis)

and

Y-.

can

controlled

be

axes.

five

axes

with

is

axes

indicated

Controllable

Simultaneously

Z-axis,

and

Y-

plane)

in

XY

Z-axis)

(G02,

simultaneously.

3-axis

the

Controllable

or

and

Z-

1

G03)’\

control

Table

in

Axes

X-axis)

Simultaneous

3-axis

1

with

Axes

control

This

func¬

.2.

3-axis

Note

I

2:

:

The

which

With

plane

is

manual

a

which

in

presently

pulse

circular

valid.

generator,

interpolation

details,

For

simultaneous

1

-2

executedisdetermined

is

2.1.3.

"Circular

control

is

see

Interpolation

in

possible

by

the

either

plane

(G02,

one

selection

G03)"

or

three

G

axes.

code

(Ci

9)

G

7

to

1

1

Page 15

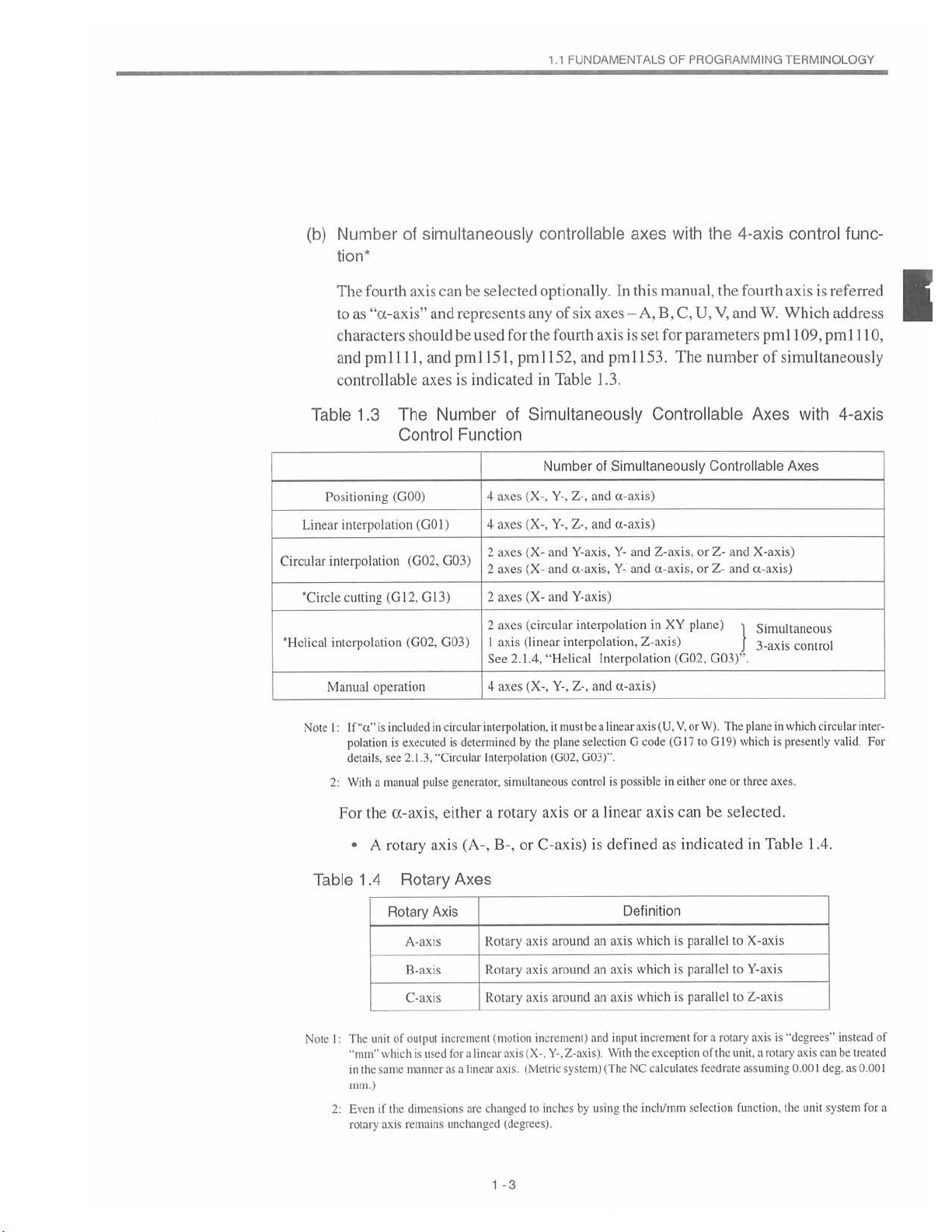

(b)

Number

tion*

simultaneously

of

FUNDAMENTALS

1.1

controllable

axes

OF

PROGRAMMING

with

the

4-axis

TERMINOLOGY

control

func¬

Table

Linear

Circular

"Circle

"Helical

Note

The

fourth

toas“ct-axis”

characters

1

pml

and

controllable

.3

1

(G12,

operation

includedincircular

“a"

is

If

is

polation

details,

see

manual

a

With

(GOO)

Positioning

interpolation

interpolation

cutting

interpolation

Manual

:

I

2:

can

axis

and

should

1,

and

1

axes

The

Number

Control

(G01)

(G02,

G03)

G13)

G03)

(G02,

executed

2.1.3,

"Circular

pulse

be

selected

represents

be used

15

pml

is

indicated

Function

4

4

2

2

2

2

1

See

4

interpolation,

determined

is

Interpolation

generator,

optionally.

any

of

fourth

for

the

1,

152,

pml

Table

in

Simultaneously

of

Number

(X-,

axes

axes

axes

axes

axes

axes

axis

axes

simultaneous

(X-,

(X-

(X-

(X-

(circular

(linear

2.1.4.

(X-,

by

Y-.

Y-.

and

and

and

“Helical

Y-,

it

the

plane

(G02,

must

In

-A,

axes

six

is

axis

pml

and

1.3.

Simultaneously

of

a-axis)

and

Z-.

a-axis)

and

Z-.

Y-axis,

Y-

a-axis,

Y-

Y-axis)

interpolation

interpolation,

Interpolation

Z-,

a-axis)

and

linear

be

a

selectionGcode

G03)’\

control

possible

is

manual,

this

B.C,

for

set

parameters

The

153.

Controllable

and

Z-axis.

a-axis,

and

in

XY

Z-axis)

(G02,

V,

(U,

axis

(GI7

cither

in

the

U,

V,

number

Controllable

or

and

Z-

or

and

Z-

plane)

G03)“.

W).

The

or

G19)

to

one

or

fourth

W.

and

pm

of

Axes

X-axis)

a-axis)

Simultaneous

i

3-axis

plane

in

is

which

axes.

three

referred

axis

is

Which

1

address

09,

1

pml

11

0,

simultaneously

with

4-axis

Axes

control

circular

valid.

inter¬

For

which

presently

I

Table

Note

l

2:

For

:

The

"mm"

in

Even

rotary

•

mm.)

the

rotary

A

1.4

Rotary

unit

whichisused

same

the

the

if

axis

a-axis,

Rotary

A-axis

B-axis

C-axis

output

of

manner

dimensions

remains

either

axis

Axes

Axis

increment

for

as

unchanged

(A-,

a

linear

a

are

linear

rotary

a

B-,

or

Rotary

axis

Rotary

axis

axis

Rotary

(motion

(X-.

axis

axis.(Metric

changed

to

(degrees).

-3

1

or

axis

C-axis)

around

around

aroundanaxis

increment)

Z-axis).

Y-.

system)

by

inches

linear

a

is

defined

axis

an

axis

an

and

input

With

(The

using

axis

as

Definition

which

which

which

increment

exception

the

calculates

NC

the

inch/mm

can

be

selected.

indicatedinTable

is

parallel

is

parallel

parallel

is

for

selection

feedrate

X-axis

to

Y-axis

to

Z-axis

to

axis

unit,

a

assuming

function,

is

rotary

a

rotary

of

the

.4.

1

"degrees"

can

axis

1

0.00

the

unit

instead

be

deg.

system

treated

as

0.001

for

of

a

Page 16

•

A

linear

axis

(U-,

V-,or

W-axis)

defined

is

as

indicatedinTable

1

.5.

1

Table

Note

I:

2:

1.5

The

axes

linear

When

inches

.

unit

(X-.

Linear

of

axes.

the

as

Linear

U-axis

V-axis

W-axis

output

Y-,

and

system

inch

with

other

Axes

Axis

increment

Z-axis).

is

axes

C

linear

A

linear

A

linear

A

(motion

The

linear

selected

(X-.

Y-.

B

Of

Y

axis

axis

axis

increment)

axes

by

using

Z-axis).

and

parallel

parallel

parallel

indicated

inch/mm

V

A

and

If

this

T

k

Definition

to

X-axis

Y-axis

to

Z-axis

to

input

above

selection

linear

this

axis

increment

can

be

treated

function,

axis

regarded

is

U

linear

a

of

in

dimensions

designated

is

as

axisisthe

exactly

the

a-axis.

as

the

must

same

the

same

be

fourth

as

other

manner

inpul

axis.

linear

other

as

of

units

in

Fig.

1.1

Z

Fourth

W

Axis

(a-axis)

-4

1

in

the

II

rotary

this

this

axis

regarded

is

Right-hand

designated

is

axis

Coordinate

as

the

as

a-axis.

fourth

the

System

axis,

Page 17

.1

FUNDAMENTALS

1

OF

PROGRAMMING

TERMINOLOGY

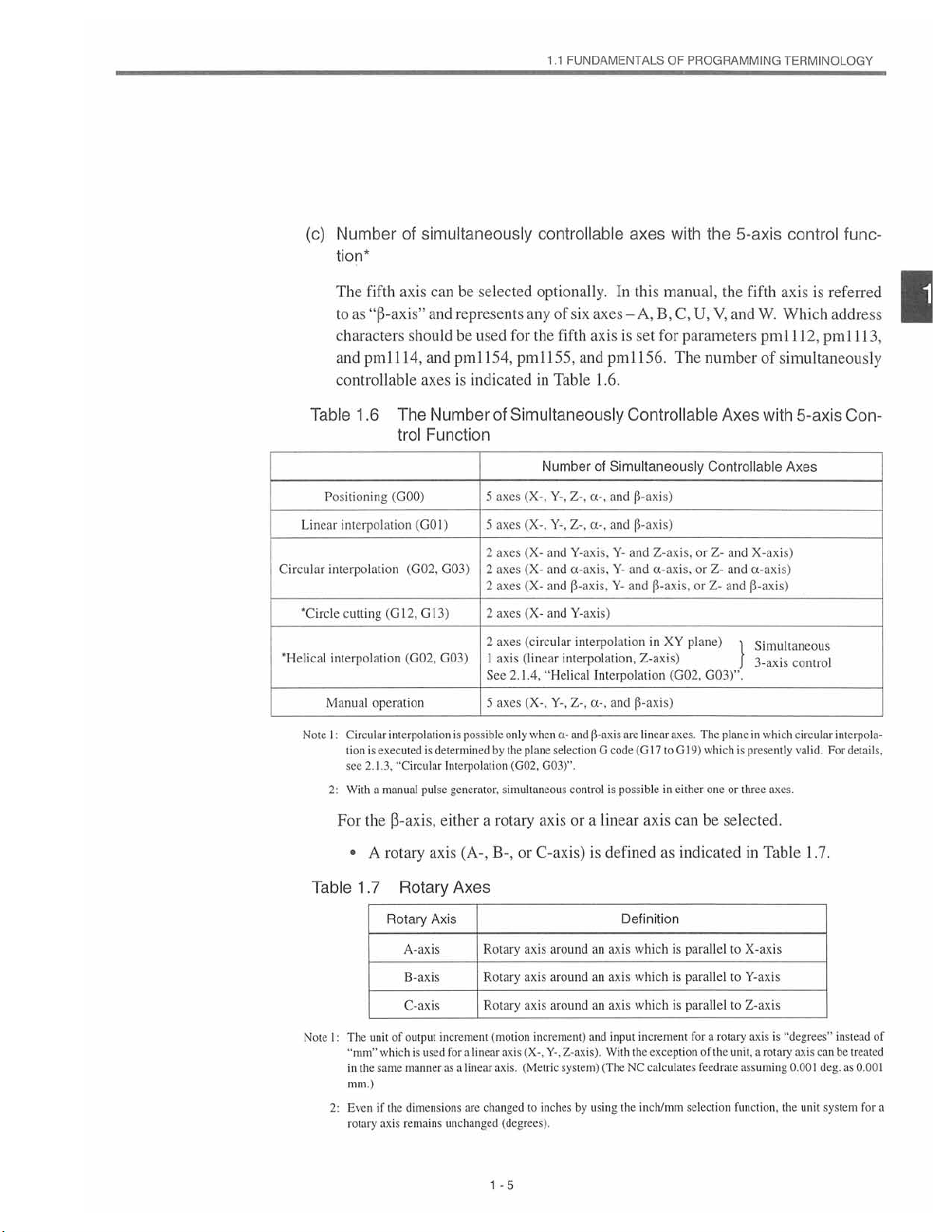

(c)

Table

Linear

Circular

'Circle

'Helical

Number

tion*

The

fifth

“(3-axis”

as

to

characters

and

pml

controllable

.6

1

Positioning

interpolation

interpolation

(G

culling

interpolation

Manual

operation

simultaneously

of

can

axis

and

be

represents

shouldbeused

14,

and

1

The

trol

(GOO)

(G02,

2,

1

(G02,

pml

axes

is

Number

Function

(GOI)

G03)

3)

G

1

G03)

selected

any

for

154,

pml

indicated

of

Simultaneously

(X-,

axes

5

(X-.

axes

5

(X-

2

axes

(X-

axes

2

(X-

axes

2

(X-

axes

2

(circular

axes

2

(linear

1

axis

2.1.4,

Sec

(X-.

axes

5

controllable

optionally.

of

axes

six

the

in

axis

fifth

155,

and

Table

Number

a-,

Z-,

Y-.

a-,

Z-,

Y-.

Y-axis,

and

a-axis,

and

(3-axis.

and

Y-axis)

and

interpolation

interpolation,

"Helical

a-,

Z-,

Y-,

1

of

Interpolation

axes

with

manual,

this

In

C,

B,

A,

-

for

is

set

pml

156.

The

.6.

Controllable

Simultaneously

(5-axis)

and

and

(3-axis)

Z-axis,

and

Y-

ct-axis,

Y-

and

(3-axis,

Y-

and

XY

in

Z-axis)

(G02.

(3-axis)

and

the

5-axis

the

U,

V,

and

parameters

number

Axes

Controllable

or

Z-

and

or

Z-

and

or

Z-

and

plane)

!

G03)”.

control

axis

fifth

W.

Which

pm

111

of

simultaneously

with

5-axis

Axes

X-axis)

a-axis)

(3-axis)

Simultaneous

3-axis

control

is

referred

2,

pml

func¬

address

3,

1

1

Con¬

1

Note

Table

Note

:

I

2:

1

2:

For

:

interpolationispossible

Circular

is

executed

tion

see

With

•

2.1.3.

the

.7

1

manual

a

(3-axis,

rotary

A

“Circular

Rotary

Rotary

A-axis

B-axis

C-axis

of

unit

the

which

same

(he

if

axis

output

manner

dimensions

remains

The

"mm”

in

mm.)

Even

rotary

is

determined

pulse

axis

Axis

is

used

Interpolation

generator,

a

either

(A-,

Axes

Rotary

Rotary

Rotary

increment

for

linear

a

linear

as

a

changed

are

unchanged

only

whena-and

by

the

plane

(G02,

simultaneous

rotary

B-,

or

axis

axis

axis

(motion

increment)

(X-.

axis

(Metric

axis.

to

(degrees).

1

-5

(3-axis

selectionGcode

G03)".

control

axis

or

a

C-axis)

inches

is

around

aroundanaxis

around

and

Z-axis).

Y-.

system)

by

using

axes.

The

are

possible

is

linear

linear

(G17

axis

toGI9)

either

in

can

plane

which

one

or

be

selected.

in

presently

is

three

which

definedasindicatedinTable

Definition

which

an

an

axis

axis

input

With

(The

which

which

increment

the

NC

inch/mm

the

is

is

is

parallel

exception

calculates

parallel

parallel

for

feedrate

selection

X-axis

to

Y-axis

to

Z-axis

to

rotary

axis

a

unit,

of

the

a

assuming

function,

axes.

is

rotary

circular

valid

1.7.

"degrees"

axis

0.001

the

unit

interpola¬

For

instead

can

be

deg.

system

details.

treated

as

0.001

for

of

a

Page 18

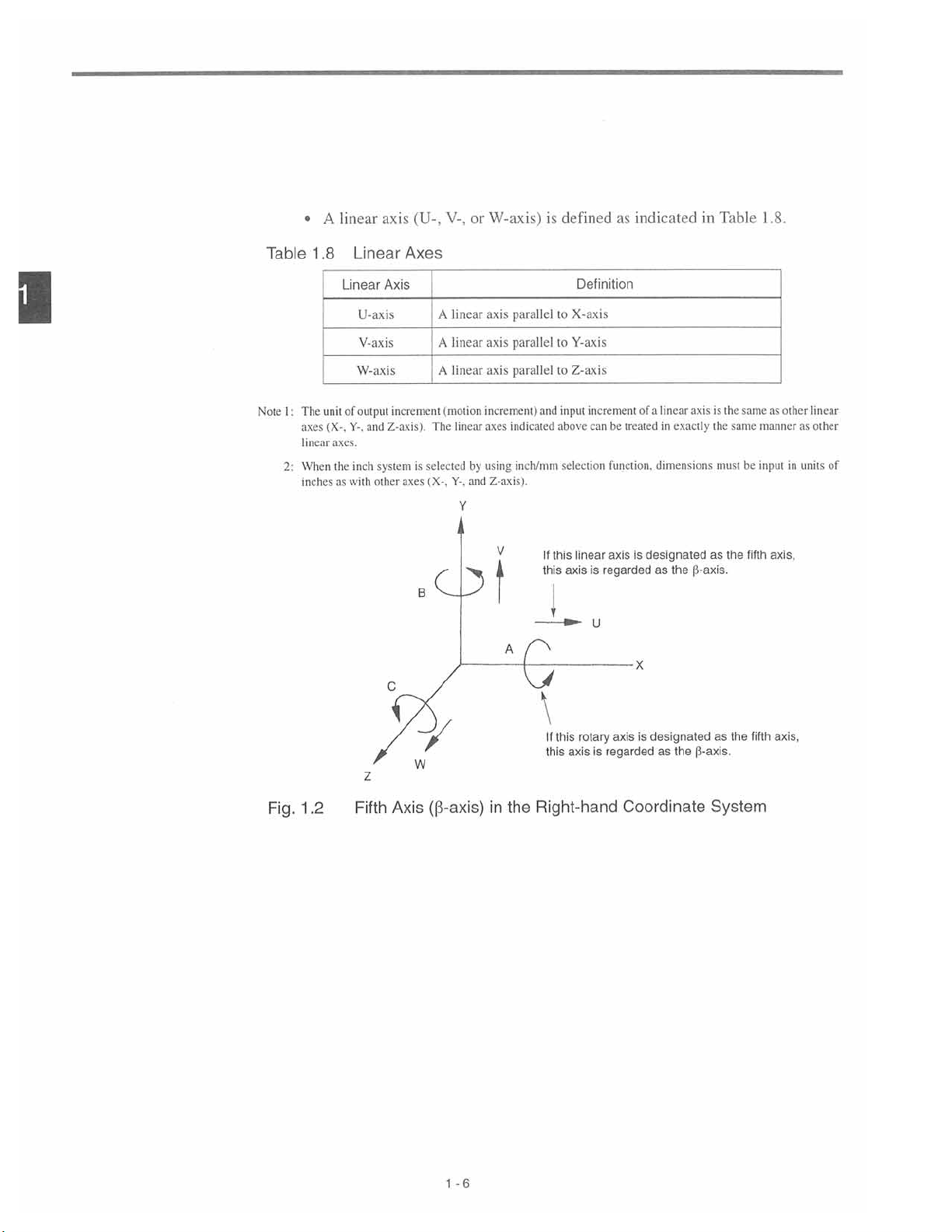

•

A

linear

axis

(U-,

V-,

W-axis)

or

is

definedasindicated

in

Table

1.8.

1

Table

Note

I

2:

:

.8

1

The

axes

linear

When

inches

unit

(X-.

axes.

Linear

of

Y-.

the

as

with

Linear

Axis

U-axis

V-axis

W-axis

output

and

system

inch

other

Axes

increment

Z-axis).

is

axes

B

C

linear

A

linear

A

linear

A

(motion

linear

The

selected

(X-,

Y-.

Of

axis

axis

axis

increment)

axes

by

using

and

indicated

Z-axis).

V

A

parallel

parallel

parallel

and

inch/mm

If

this

Definition

X-axis

to

to

Y-axis

Z-axis

to

input

above

selection

this

linear

axis

increment

be

treated

can

function,

axis

regarded

is

U

of

a

linear

in

dimensions

designated

is

as

axisisthe

exactly

|5-axis.

the

as

the

must

same

the

same

be

fifth

as

other

manner

input

axis.

linear

as

other

of

units

in

Fig.

\

the

as

p-axis.

System

rotary

this

If

this

Right-hand

the

Axis

W

((3-axis)

in

Z

Fifth

.2

1

axis

is

designated

axis

is

regarded

as

Coordinate

the

fifth

axis,

-6

1

Page 19

.1

1

FUNDAMENTALS

OF

PROGRAMMING

TERMINOLOGY

.2

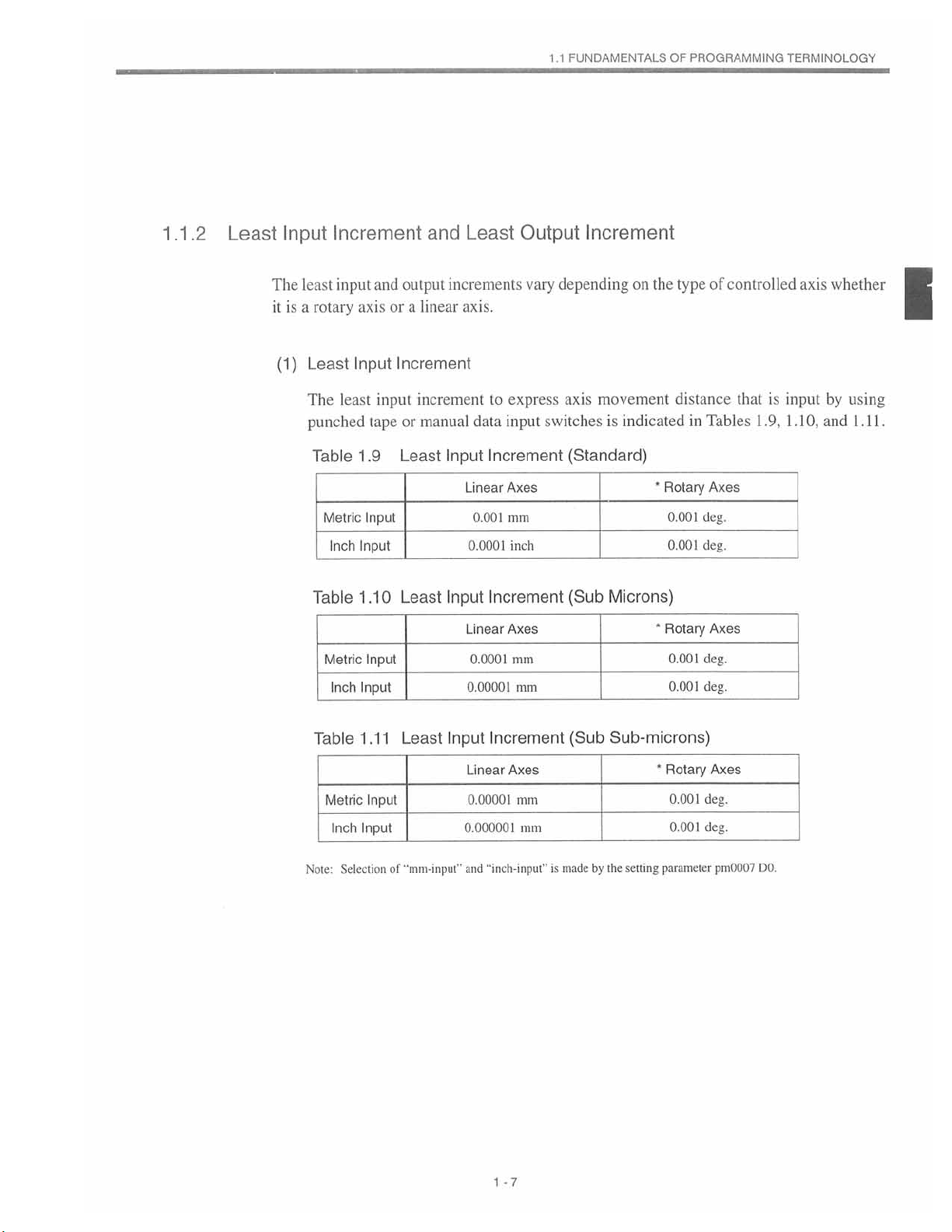

Least

.1

1

Input

The

is

it

(1)

Increment

least

input

a

rotary

Least

least

The

punched

Table

Metric

Inch

Table

Metric

and

axis

Input

input

tape

1.9

Input

Input

1.10

Input

output

or

a

Increment

increment

or

Least

Least

and

increments

linear

manual

Input

Input

Least

axis.

data

Linear

0.001

0.0001

Linear

0.0001

Output

vary

express

to

input

Increment

Axes

mm

inch

Increment

Axes

mm

Increment

on

depending

axis

movement

switchesisindicated

(Standard)

(Sub

the

•

Microns)

*

Rotary

0.001

0.001

Rotary

0.001

of

type

distance

Tables

in

Axes

deg.

deg.

Axes

deg.

controlled

input

is

that

1.9,

1.10,

axis

whether

by

using

and

1.11.

l

Table

Metric

Note:

Input

Inch

1

Input

Inch

Selection

.11

Input

Least

"mm-input"

of

0.00001

Input

Linear

0.00001

0.000001

and

mm

Increment

Axes

mm

mm

“inch-input”

is

(Sub

made

Sub-microns)

*

by

setting

the

0.001

Rotary

0.001

0.001

parameter

deg.

Axes

deg.

deg.

pm0007

DO.

-7

1

Page 20

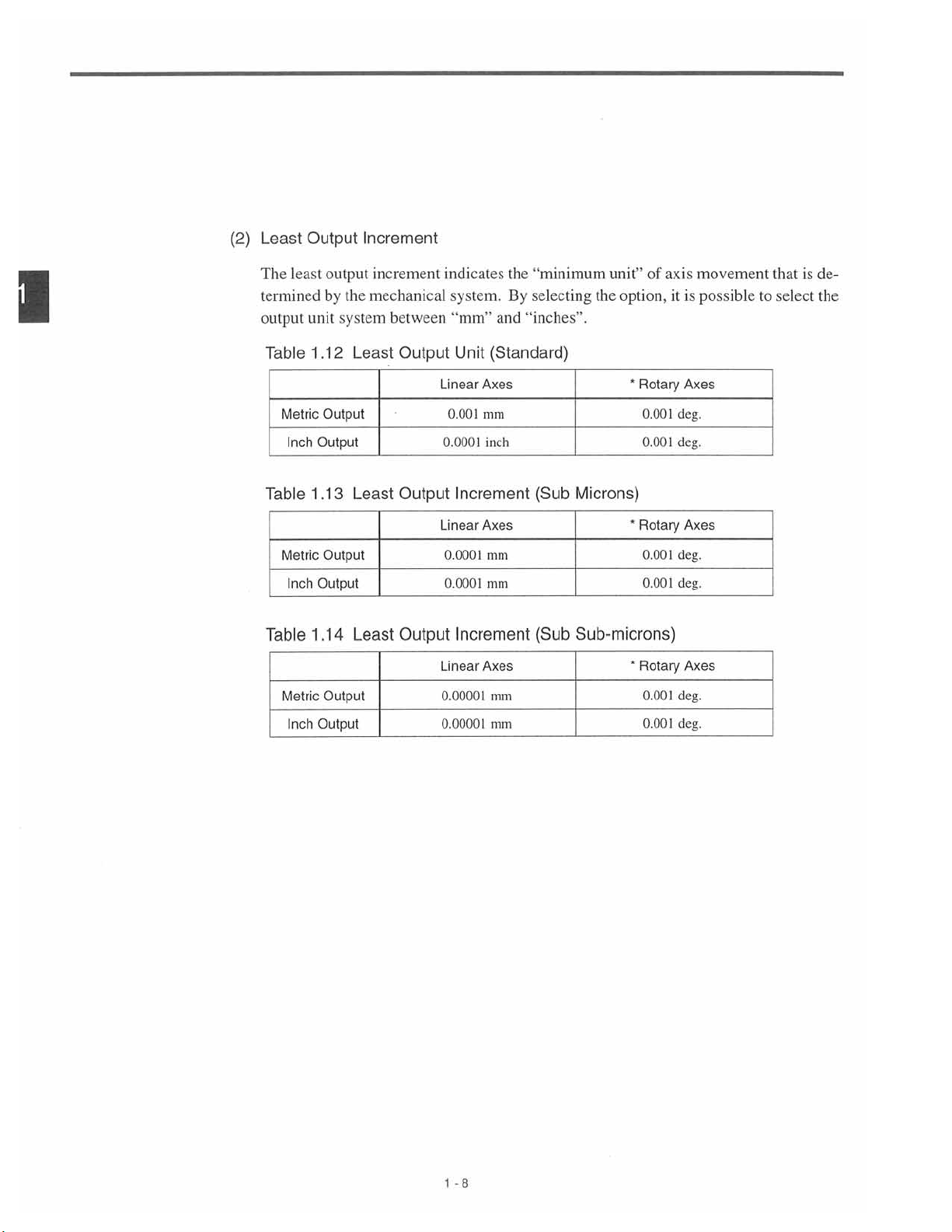

(2)

Least

Output

Increment

1

The

least

termined

output

unit

Table

Metric

Inch

Table

Metric

Inch

Table

Metric

Inch

output

by

1.12

Output

Output

1.13

Output

Output

1.14

Output

Output

increment

the

mechanical

system

Least

Least

Least

between

Output

Output

Output

indicates

system.

“mm”

Unit

Axes

Linear

0.001

mm

0.0001

inch

Increment

Axes

Linear

0.0001

mm

mm

0.0001

Increment

Axes

Linear

0.00001

0.00001

the

“minimum

By

selecting

“inches”.

and

(Standard)

(Sub

(Sub

mm

mm

of

unit”

option,

the

'

Rotary

0.001

0.001

Microns)

*

Rotary

0.001

0.001

Sub-microns)

*

Rotary

0.001

0.001

axis

it

deg.

deg.

deg.

deg.

deg.

deg.

is

Axes

Axes

Axes

movement

possible

to

that

select

is

de¬

the

1

-8

Page 21

.1

1

FUNDAMENTALS

OF

PROGRAMMING

TERMINOLOGY

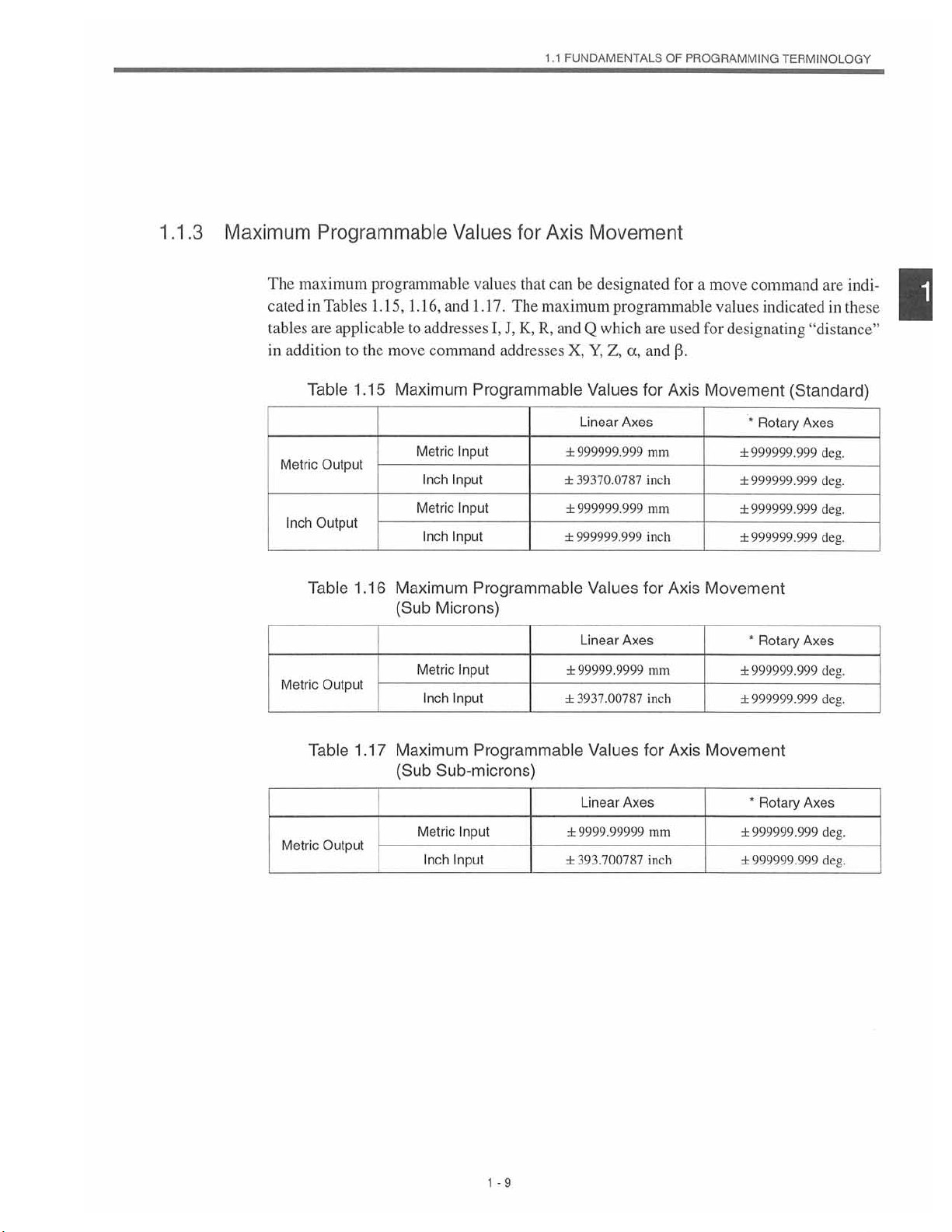

1.1.3

Maximum

The

maximum

cated

tables

addition

in

Metric

Inch

Metric

Programmable

programmable

Tables

in

are

Table

Output

Output

Table

Output

1.15,

applicable

the

move

to

Maximum

1.15

Maximum

1.16

(Sub

1.16,

and

addresses

to

command

Metric

Inch

Metric

Inch

Microns)

Metric

Inch

Values

values

1.17.

I,

The

J,

for

that

K,

addresses

Programmable

Input

Input

Input

Input

Programmable

Input

Input

Axis

Movement

can

be

designated

maximum

R,

Q

and

X,Y,Z,

Values

Linear

±999999.999

39370.0787

±

±999999

±999999.999

Values

Linear

±99999.9999

±3937.00787

for

programmable

are

which

Axes

999

Axes

used

a,

and

Axis

for

mm

inch

mm

inch

for

Axis

mm

inch

a

move

for

(3.

Movement

Movement

command

values

indicated

designating

*

Rotary

±999999.999

±999999.999

±999999.999

999999.999

±

*

Rotary

±999999.999

999999.999

±

are

indi¬

in

these

“distance”

(Standard)

Axes

deg.

deg.

deg.

deg.

Axes

deg.

deg.

1

Table

Metric

1.17

Output

Maximum

Sub-microns)

(Sub

Metric

Input

Inch

Programmable

Input

-9

1

Values

Axes

Linear

±9999.99999

393.700787

±

for

mm

inch

Axis

Movement

*

Rotary

Axes

±999999.999

±999999.999

deg.

deg.

Page 22

1

incremental

In

grammable

axis

must

notes

move

indicated

command

the

of

programming,

values

exceed

not

indicated

the

maximum

above,

must

it

not

be

the

values

to

designated

above.Inabsolute

programmable

alsobetaken

must

the

exceed

values

not

must

programming,

values

consideration

into

indicated

indictedinTables

exceed

the

move

the

maximum

distance

above.Inaddition

the

that

1.18,

cumulative

1.19,

and

1

.20.

of

pro¬

each

to

values

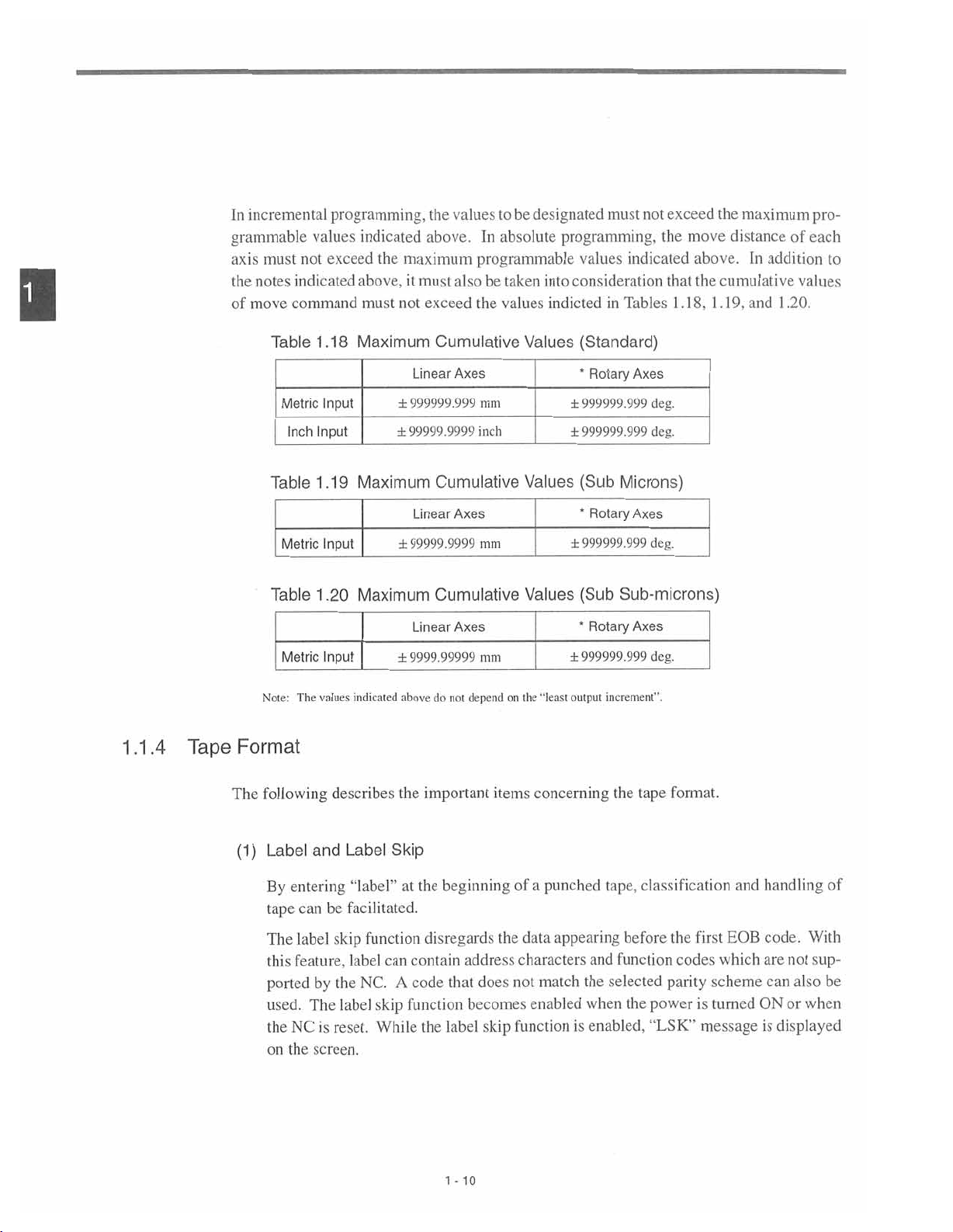

1.1.4

Tape

Table

Metric

Inch

Table

Metric

Table

Metric

Note:

Format

The

1.18

Input

Input

1.19

Input

.20

1

Input

values

Maximum

Linear

±999999.999

±99999.9999

Maximum

Linear

±99999.9999

Maximum

Linear

±9999.99999

indicaled

above

Cumulative

Axes

mm

inch

Cumulative

Axes

mm

Cumulative

Axes

mm

on

depend

do

not

Values

Values

Values

the

"least

(Standard)

*

Rotary

Axes

±999999.999

±999999.999

Microns)

(Sub

*

Rotary

Axes

±999999.999

(Sub

Sub-microns)

*

Rotary

Axes

±999999.999

increment".

output

deg.

deg.

deg.

deg.

The

(1)

following

Label

and

entering

By

can

tape

label

The

feature,

this

by

ported

The

used.

NC

the

screen.

on

the

describes

Label

“label”

facilitated.

be

skip

label

NC.

the

label

is

reset.

the

Skip

at

function

can

A

function

skip

While

important

beginning

the

disregards

contain

that

code

label

the

1

address

does

becomes

skip

10

-

items

of

the

data

characters

not

function

concerning

a

punched

appearing

match

the

enabled

when

enabled,

is

the

tape,

and

selected

format.

tape

classification

before

the

function

parity

power

the

“LSK”

first

codes

is

message

and

EOB

which

scheme

turned

handling

code.

are

not

can

also

ON

or

displayed

is

of

With

sup¬

be

when

Page 23

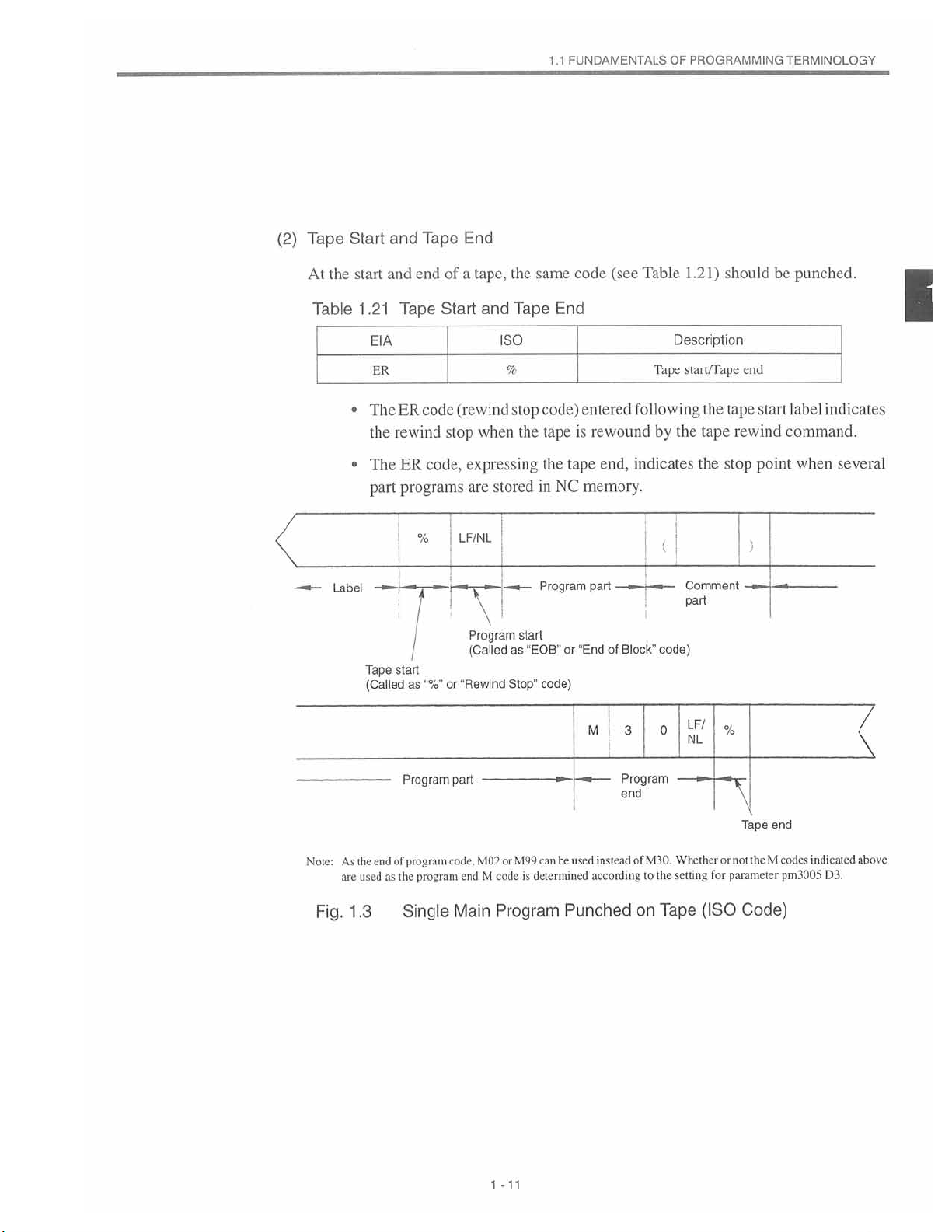

(2)

Tape

Start

and

Tape

End

FUNDAMENTALS

1.1

OF

PROGRAMMING

TERMINOLOGY

the

At

Table

•

•

Label

start

.21

1

The

The

part

Tape

(Called

EIA

ER

the

and

rewind

start

of

end

Tape

Start

code

ER

stop

code,

ER

programs

%

I

as

or

a

tape,

and

iso

%

(rewind

when

expressing

are

stored

LF/NL

"

!

Program

(Called

"Rewind

Stop"

the

Tape

stop

the

start

“EOB"

as

same

End

code)

tape

the

NC

in

Program

or

code)

(see

code

entered

is

rewound

end,

tape

memory.

part

"EndofBlock”

Table

1

Description

Tape

start/Tape

following

the

by

indicates

(

Comment

part

code)

.2

the

1)

the

tape

should

end

tape

rewind

stop

)

be

start

command.

point

punched.

label

indicates

when

I

several

Note:

Fig.

As

are

the

1.3

used

end

of

as

the

Program

program

program

Single

part

code.

end

Main

can

M99

or

M02

codeisdetermined

M

Program

M

used

instead

be

according

Punched

3

I

Program

end

of

to

on

0

M30.

the

Tape

LF/

NL

Whether

setting

(ISO

%

or

for

Tape

theMcodes

not

parameter

Code)

end

pm3005

indicated

D3.

above

1

-11

Page 24

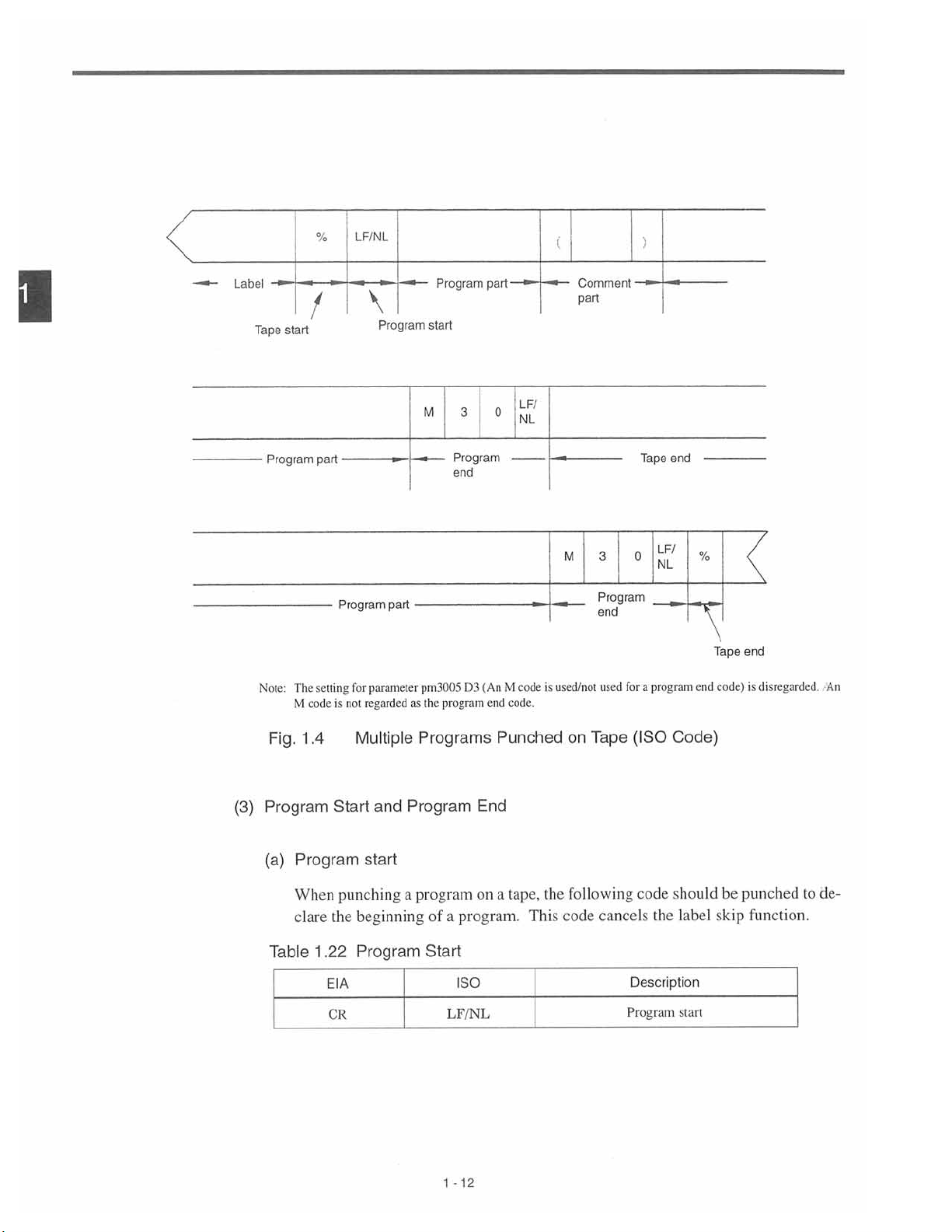

LF/NL

%

(

)

1

Label

Tape

Program

Note:

start

The

M

/

part

setting

code

Program

for

is

not

\

Program

part

parameter

regarded

start

M

pm3005

the

as

Program

3

Program

end

D3

program

part

(

An

end

0

M

code.

ILF/

NL

is

code

Comment

part

M

used/not

3

Program

end

for

used

Tape

0

a

end

LF/

NL

program

%

end

Tape

code)

end

disregarded

is

An

(3)

1

Fig.

.4

Program

Program

(a)

When

clare

1

Table

Multiple

Start

punching

beginning

the

Program

.22

EIA

CR

and

start

Programs

Program

a

program

of

a

Start

LF/NL

1

Punched

End

on

a

program.

ISO

12

-

tape,

the

This

Tape

on

following

cancels

code

Code)

(ISO

.should

code

the

label

Description

Program

start

be

skip

punched

function.

de¬

to

Page 25

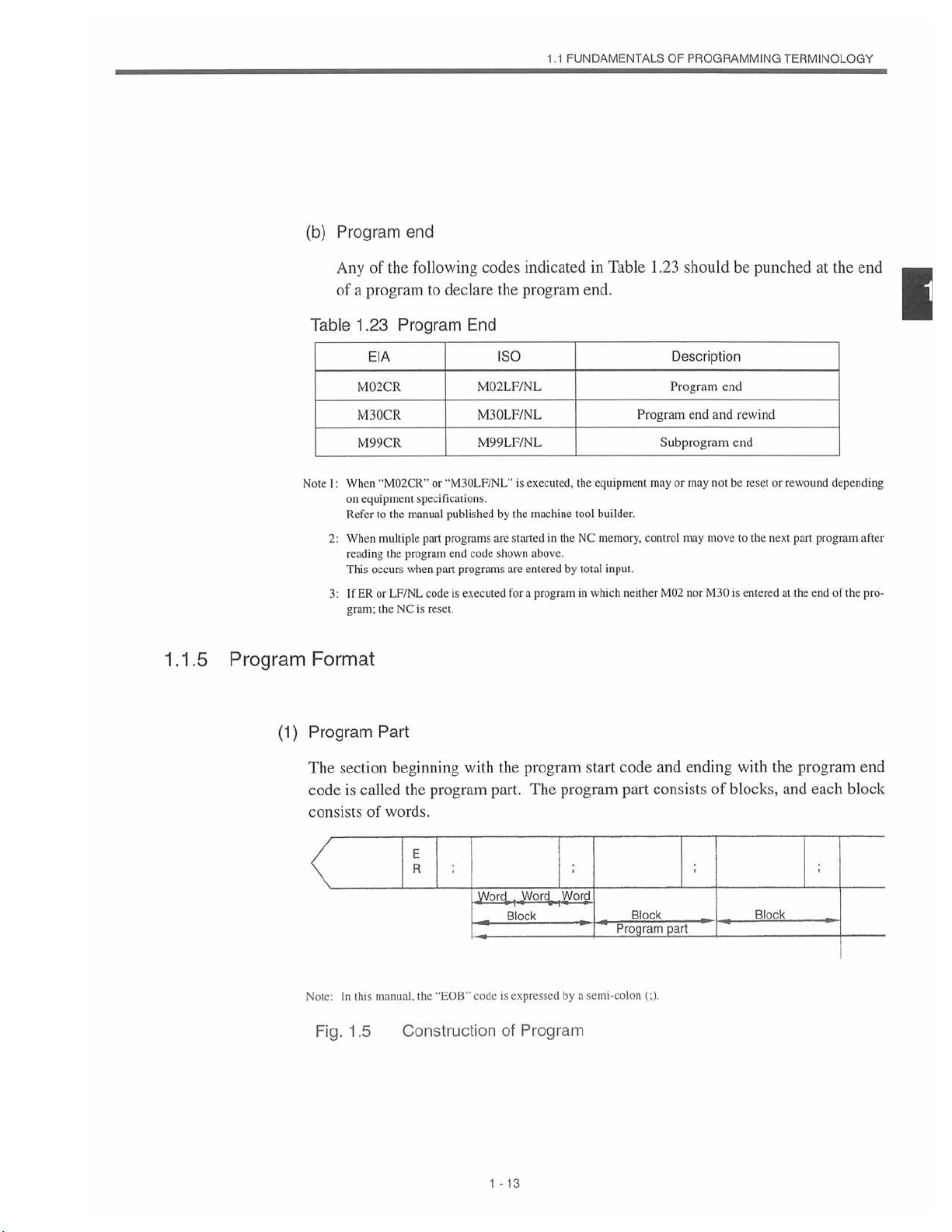

1

FUNDAMENTALS

.1

OF

PROGRAMMING

TERMINOLOGY

1.1.5

Program

Program

(b)

Any

of

Table

:

I

Note

2:

3:

Format

of

a

program

1.23

ElA

M02CR

M30CR

M99CR

When

on

equipment

Refer

When

reading

occurs

This

ER

If

gram;

end

the

Program

"M02CR”

manual

the

to

multiple

program

the

when

or

LF/NL

NC

the

following

declare

to

End

or

"M30LF/NL"

specifications.

published

programs

part

code

end

programs

part

is

executed

code

is

reset.

indicatedinTable

codes

program

the

iso

M02LF/NL

M30LF/NL

M99LF/NL

executed,

is

by

the

machine

are

started

shown

above.

are

enteredbytotal

a

program

for

1.23

should

end.

Description

Program

Program

Subprogram

input.

control

neither

mayormay

may

nor

M02

the

equipment

tool

builder.

memory,

NC

the

in

which

in

end

move

M30

be

punched

end

and

rewind

end

notbereset

the

to

is

enteredatthe

or

next

at

rewound

program

part

end

the

end

depending

after

pro¬

of

the

1

(1)

Program

section

The

is

code

consists

Note;

In

1.5

Fig.

called

of

manual,

this

Part

beginning

the

program

words.

E

R

"EOB”

the

Construction

with

Word

code

the

part.

is

of

1

-

13

program

The

Wortÿ

]

_

Block

expressed

Program

start

program

Word

by

semi-colon

a

code

part

Block

Program

(;).

and

ending

consists

part

of

with

blocks,

Block

the

and

program

each

end

block

Page 26

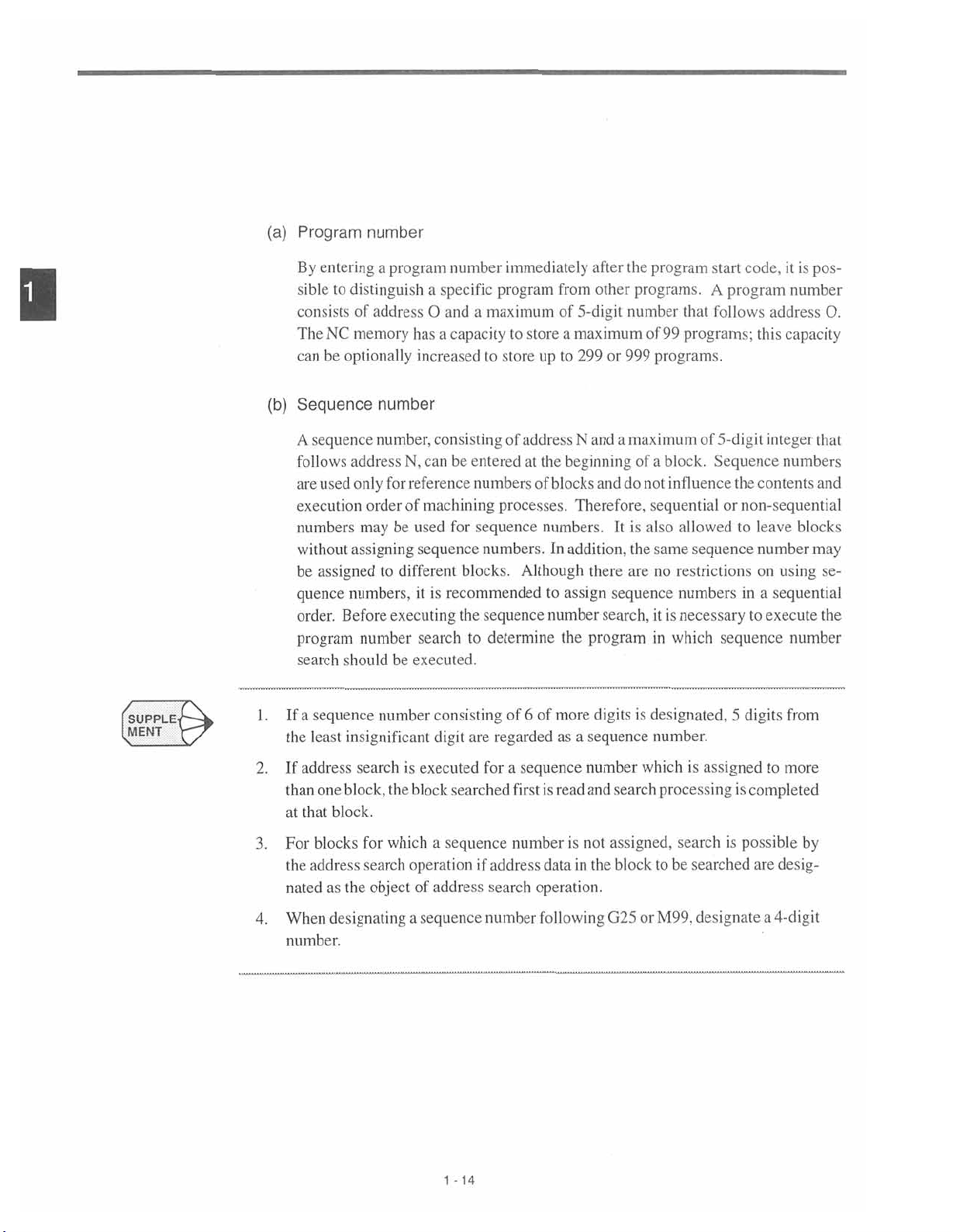

(a)

Program

number

1

(SUPPLE/-ÿ

IMENT

(b)

.

1

entering

By

sible

consists

NC

The

can

be

Sequence

sequence

A

follows

are

used

execution

numbers

without

assigned

be

quence

order.

program

search

sequence

If

a

the

least

a

program

distinguish

to

of

addressOandamaximum

memory

optionally

number

a

specific

has

capacity

a

increased

number

number,

address

for

only

order

may

assigning

to

numbers,

Before

number

shouldbeexecuted.

number

insignificant

consisting

N,

can

reference

machining

of

be

used

sequence

different

is

it

executing

search

consisting

digit

be

for

blocks.

recommended

the

immediately

program

to

to

storeupto

of

enteredatthe

numbersofblocks

from

of

store

a

addressNand

beginning

processes.

sequence

numbers.

sequence

determine

to

regarded

are

numbers.

Although

of6of

addition,

In

to

assign

number

the

more

as

after

the

program

other

programs.Aprogram

5-digit

maximum

299or999

Therefore,

and

there

number

of

programs.

maximum

a

of

a

do

not

sequential

is

also

It

same

the

are

no

99

block.

sequence

search,

program

digitsisdesignated,5digits

a

sequence

it

in

number.

start

that

follows

programs;

5-digit

of

Sequence

influence

allowed

sequence

restrictions

numbers

is

necessary

which

sequence

or

code,

is

pos¬

it

number

address

this

capacity

integer

that

numbers

the

contents

and

non-sequential

leave

to

in

to

blocks

number

using

on

a

sequential

execute

may

number

from

O.

se¬

the

2.

3.

4.

address

If

one

than

that

at

For

blocks

the

address

as

nated

designating

When

number.

search

block,

block.

for

search

the

the

which

object

is

executed

block

searched

a

sequence

operation

of

address

sequence

a

1

-

14

for

address

if

search

number

sequence

a

is

first

number

datainthe

operation.

following

read

is

number

and

search

assigned,

not

blocktobe

G25

which

processing

search

M99,

or

assigned

is

is

is

searched

designate

more

to

completed

possible

desig¬

are

4-digit

a

by

Page 27

(c)

Word

1.1

FUNDAMENTALS

OF

PROGRAMMING

TERMINOLOGY

word

A

numeral

“G02”

The

function

For

area.

and

1.24

consists

of

several

consists

details

1.25.

of

an

digits

of

address

character

of

address

address

that

character

means

character

character

follow

“G”

character

a

and

includedinthe

the

address

and

numeral

that

can

function

function

character.

“2”.

be

used

character

For

in

the

codes,

characters

example,

significant

refer

to

and

word

data

Tables

a

1

15

1

-

Page 28

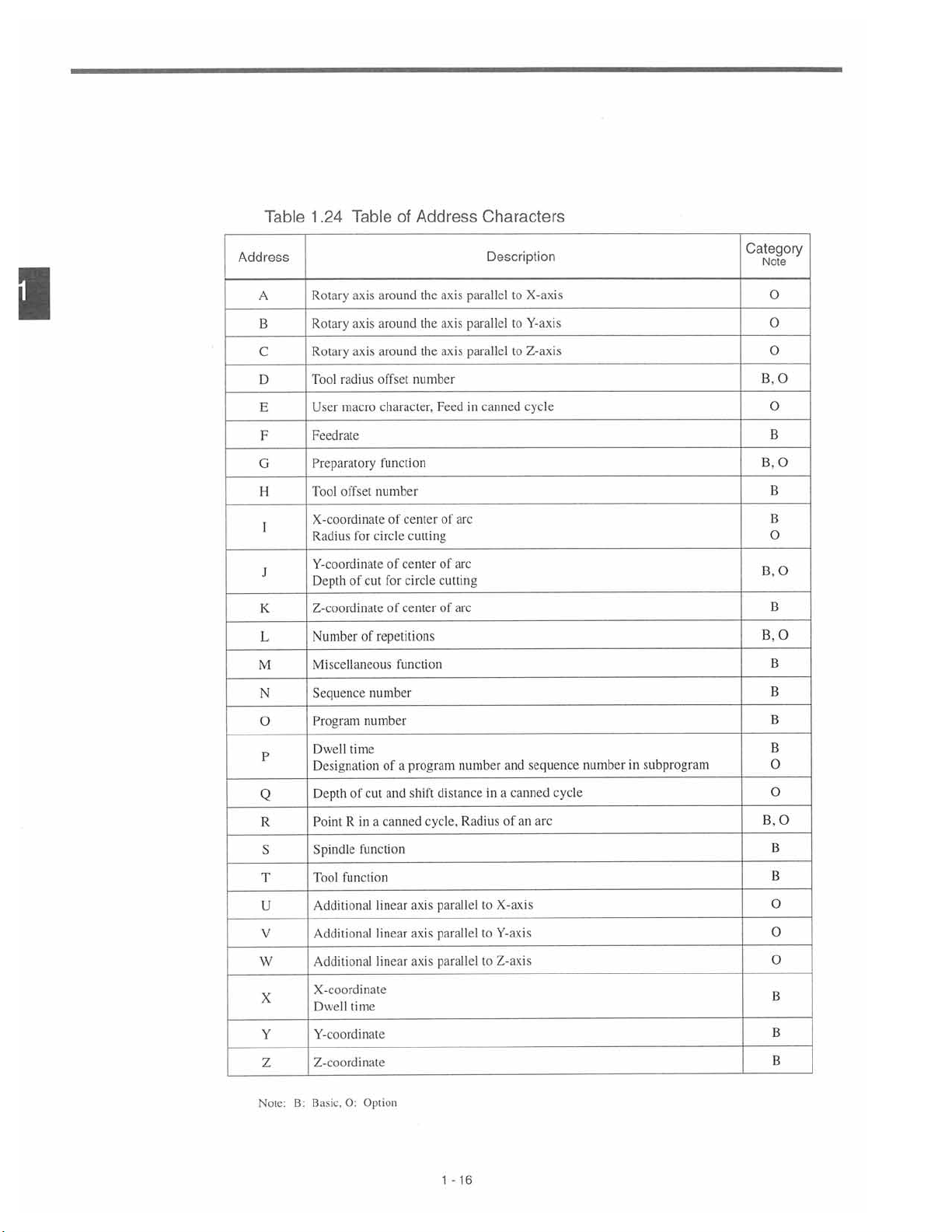

Table

TableofAddress

.24

1

Characters

1

Address

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

Rotary

Rotary

Rotary

Tool

User

Feedrate

Preparatory

Tool

X-coordinate

Radius

axis

axis

axis

radius

macro

offset

for

around

around

around

offset

character.

function

number

circle

Y-coordinate

of

Depth

Z-coordinate

Number

cut

of

repetitions

Miscellaneous

Sequence

Program

number

number

of

center

cutting

of

center

for

circle

of

center

function

axis

the

the

axis

the

axis

number

Feedincanned

arc

of

of

arc

cutting

arc

of

Description

parallel

parallel

parallel

to

to

to

X-axis

Y-axis

Z-axis

cycle

Category

Note

O

O

O

O

B.

O

B

O

B.

B

B

O

B.O

B

B,

O

B

B

B

P

Q

R

S

T

U

V

W

X

Y

Z

Note:

Dwell

Designation

Depth

Point

Spindle

Tool

Additional

Additional

Additional

X-coordinate

Dwell

Y-coordinate

Z-eoordinale

B:

Basic.

time

cut

of

a

in

R

function

function

linear

linear

time

0:

Option

of

and

canned

linear

program

a

shift

cycle,

axis

axis

axis

number

distance

Radius

parallel

parallel

parallel

16

1

-

in

to

to

to

and

canned

a

of

an

X-axis

Y-axis

Z-axis

sequence

cycle

arc

number

subprogram

in

B

O

O

B.O

B

B

O

O

O

B

B

B

Page 29

1.1

FUNDAMENTALS

OF

PROGRAMMING

TERMINOLOGY

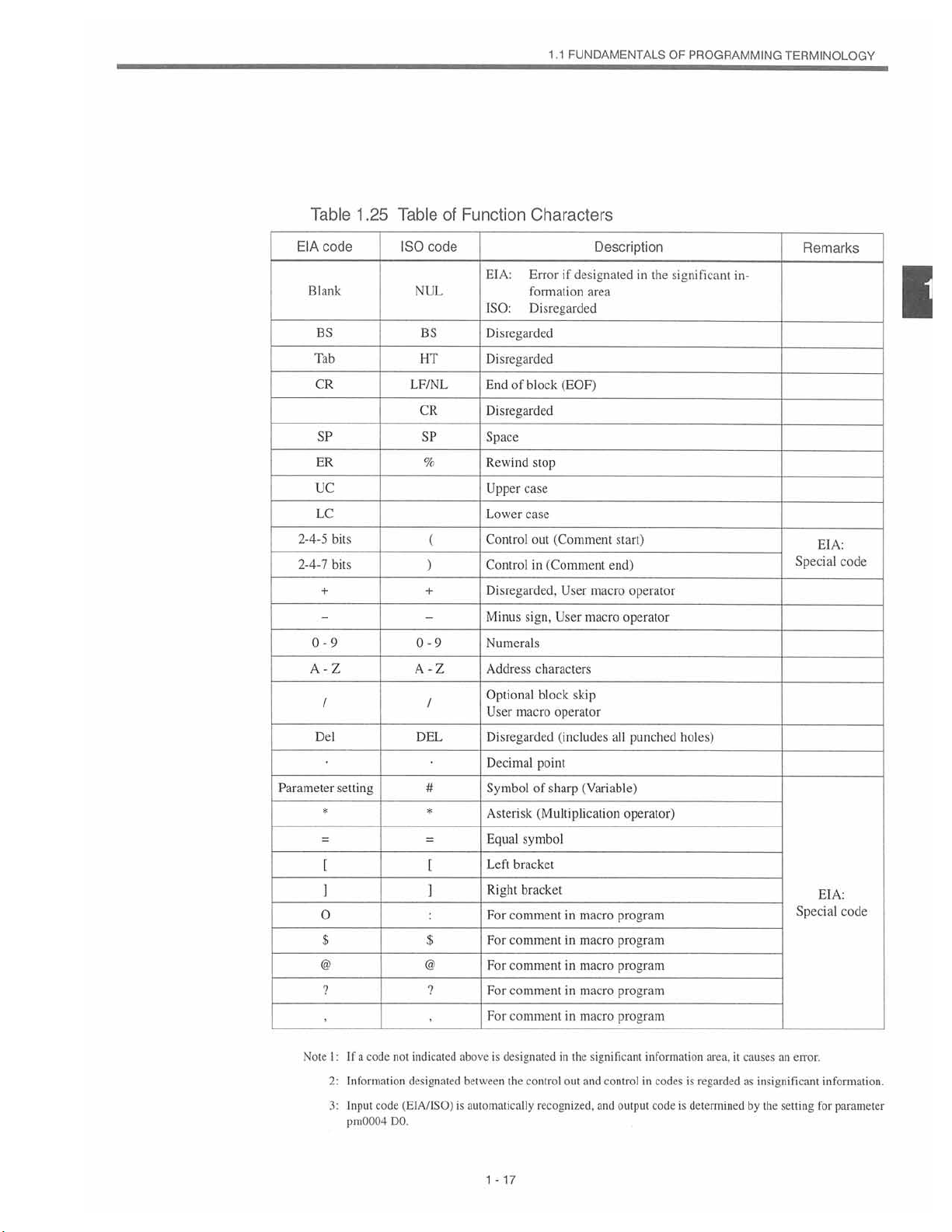

Table

code

EIA

Blank

BS

Tab

CR

SP

ER

UC

LC

bits

2-4-5

2-4-7

bits

+

0-9

A-Z

/

Del

Parameter

setting

*

[

I

O

$

@ @

?

Table

ISO

NUL

BS

HT

LF/NL

CR

SP

%

+

0-9

A-Z

DEL

#

*

zr

$

code

(

)

/

[

?

of

Function

Characters

EIA:

Error

formation

ISO:

Disregarded

Disregarded

Disregarded

of

End

block

Disregarded

Space

Rewind

Control

Control

Optional

Symbol

stop

Upper

case

case

Lower

out

in

Disregarded.

sign.

Minus

Numerals

Address

characters

block

User

macro

Disregarded

Decimal

point

of

Asterisk

Equal

Left

Right

For

For

For

For

For

(Multiplication

symbol

bracket

bracket

comment

comment

comment

comment

comment

designated

if

area

(EOF)

(Comment

(Comment

User

User

macro

skip

operator

(includes

(Variable)

sharp

in

macro

macro

in

macro

in

in

macro

macro

in

Description

in

start)

end)

macro

operator

operator

all

punched

operator)

program

program

program

program

program

the

significant

holes)

in¬

Remarks

EIA:

Special

EIA:

Special

1

code

code

1

.25

Note

:

a

If

I

Information

2:

Input

3:

pm0004

code

code

indicated

not

designated

(El

DO.

A/ISO)

designated

above

is

between

automatically

is

1

17

-

the

in

control

recognized,

the

out

significant

and

information

controlincodes

and

output

code

area,

regarded

is

is

determined

it

causes

insignificant

as

by

the

error.

an

setting

information.

for

parameter

Page 30

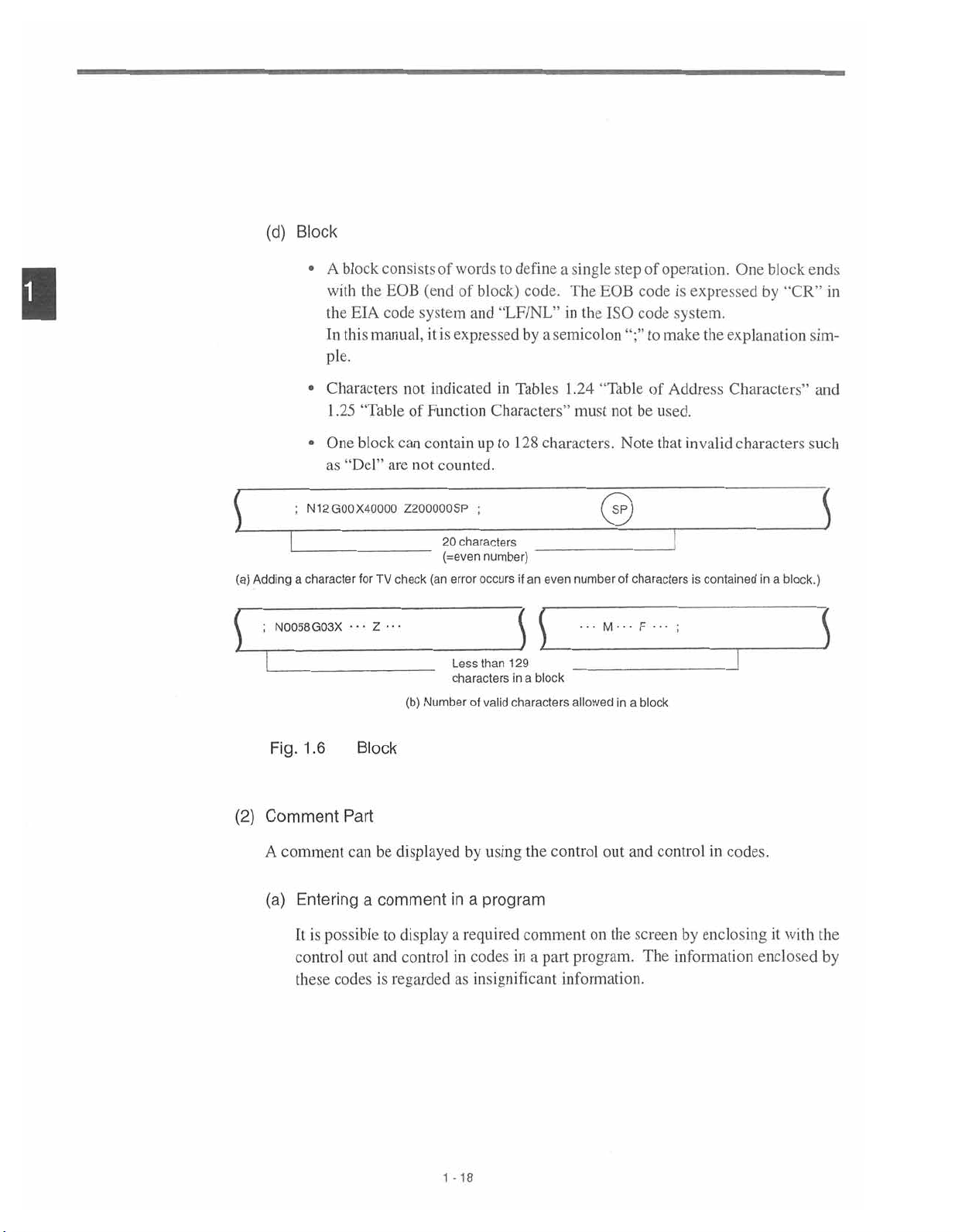

I

(d)

Block

•

A

with

the

In

pie.

block

consistsofwordstodefine

EOB

code

(end

system

is

it

of

expressed

EIA

this

the

manual,

block)

and

code.

“LF/NL”

by

a

single

a

EOB

The

the

in

ISO

semicolon

step

operation.

of

code

code

make

to

is

expressed

system.

the

One

block

by

“CR”

explanation

ends

in

sim-

[

(a)

1

(2)

Adding

•

•

N12G00X40Q00

;

character

a

;

N0058G03X

Fig.

1.6

Comment

Characters

.25

1

One

“Del”

as

••

not

“TableofFunction

can

block

are

Z200000SP

TV

check

for

•

•

•

•

Z

(b)

Block

Part

indicatedinTables

Characters”

contain

counted.

not

20

(=even

(an

error

Numberofvalid

up

;

characters

number)

occurs

Less

than

characters

to

129

in

characters

128

characters.

_

even

an

if

31

a

block

.24

1

must

number

...

allowed

“Table

not

Note

0

of

characters

•••

M

in

a

of

be

•••

F

block

Address

used.

that

invalid

is

;

Characters’’

characters

contained

in

block.)

a

and

such

3

3

comment

A

Entering

(a)

It

control

these

is

possible

codes

can

out

a

and

be

displayed

comment

display

to

controlincodes

regarded

is

1

by

using

program

a

in

a

required

as

insignificant

18

-

the

comment

a

in

part

control

out

on

the

program.

information.

and

screen

The

control

in

by

enclosing

information

codes.

enclosed

it

with

the

by

Page 31

(b)

Entering

The

control

ordinary

the

control

and

out

characters.

out

control

and

in

.

FUNDAMENTALS

1

1

control

can

codes

in

codes

be

enteredinthe

OF

PROGRAMMING

same

TERMINOLOGY

manner

as

entering

(Operation

I

ft

panel

©

©

with

9-inch

Fig.

1

•

•

CRT)

.7

“(”:Press

“)”:Press

±_

\msms]

V

Characters

In

the

the

“IT

Codes

[U]

[V]

(Keys

key

key

that

after

pressing

pressing

after

©

©

can

be

Enclosed

[SHIFT]

the

[SHIFT]

the

Characters

“("

(control

±_

HUN

KT

PWOOt

I

j

j

HHEEimrgp

[Q.LRJEII

0000B

00E00

~3~

by

between

Dark

Line)

Entered

key.

key.

that

out)

Control

can

and

MUM]

be

“)"

vj

Out

entered

(control

/

0

0

3

H

0

and

between

in)

codes

Control

I

Note

:

The

characters

1

using

It

2:

out

is

not

and

keys

the

allowed

control

can

that

enclosed

use

to

codes.

in

the

be

entered

by

control

dark

1

-

line

out

19

between

Fig.

in

and

the

1.7.

control

control

codesinthe

in

out

and

control

area

in

which

codes

are

are

already

(hose

enclosed

that

are

by

entered

the

control

by

Page 32

<Example

of

comment

displaybyusing

the

control

out

and

control

codes>

in

1

Fig.

Programmable

(3)

This

RUNNING

0123

G91G30Z0

G30X0

T01

UNIVERSAL

X

Y

2

T.NO

FEED

MEM

S3

.8

1

model

YO;

M06;

0.000

0.000

0.000

:

:

DSP.SL

-

Program

of

TOOO

FO

NC

M91:

RUN

H

Range

adopts

INCREMENT

0.000

X

Y

0.000

Z

0.000

ACT:SO

ORDER:

SO

Execution

(Input

variable

the

O'

G/M

GOO

G17

G90

G23

G94

G21

G40

G49

OPEN

Display

Format)

block

NOOOOO

CODE

G80

G98

G52

G67

LSK

STP

cmm

|

EDIT

Screen

format

S

which

complies

with

JIS

B63

3.

1

Programmable

table

given

An

this

in

example

of

X

shouldbeentered

data

Input

entered

be

er,

value

omitted

the

for

(minus)

range

input

is

treated

all

of

indicate

format

5

kinds

sign

individual

allowable

the

given

is

3

T

without

different

a

in

address

of

cannot

-20

1

addresses

3

digits

point

digits

5

Sign

Address

manner.

data

omitted.

be

maximum

below.

to

the

integer

in

X

is

decimal

a

including

is

indicatedinTable

number

right

Leading

decimal

of

a

part

point.

If

zeros

sequence

a

numbers.

1

digits.

of

This

dimensioning

the

(Metricorinch).

See

Table

decimal

and

the

.26.

varies

point

“+”

Note

The

depending

1.18.

is

(plus)

that,

numbers

on

system

used,

the

can

sign

howev¬

Page 33

FUNDAMENTALS

1.1

OF

PROGRAMMING

TERMINOLOGY

Sequence

Coordinate

per

Feed

Feed

Tool

Address

Program

G

function

words

minute

per

minute

1/10

S

function

function

T

function

M

offset

B

function

Table

number

number

(mm/min)

(mm/min)

function

number

1.26

Linear

Rotary

function

axis

axis

Input

Format

Metric