Page 1

CNC SYSTEM FOR TURNING APPLICATIONS

YASNAC J300L

OPERATING MANUAL

Upon receipt of the product and prior to initial operation, read these

instructions thoroughly, and retain for future reference.

REFERENCE

YASNAC J300L PROGRAMMING MANUAL

TOE-C843-13.21

YASUAVVA

—-—.——— .-.——. —. ——— ——.

———..,.,.-.—— -.. . .

MANUAL NO. TOE-C843-1 3.20

.—.—.——.. .-, ,—..—. —.,—. —-.

Page 2

CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...!

NOTES FOR SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KEY TO WARNING LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1. OUTLINE OF THE PRODUCT

1.1 OUTLINE OF YASNAC SYSTEM . . . . . . . . . . . . . . . . . . . . . . ...1-2

III

1.1.1

1.1.2

1.1.3

1.1.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Machine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.2 PROTECTIVE FIJNCTIONS . . . . . . . . . . . . . . . . . . . . . . . .. . ...1-12

1.2.1

1.2.2 Overtravel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.2.3 Stored Stroke Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1.2.4 Interlock inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

EmergencyStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2. BASIC OPERATION OF YASNAC

2.1 GENERAL FLOW OF OPERATION . . . . . . . . . . . . . . . . . . . . ...2-3

2.2 INSPECTION BEFORE TURNING THE POWER ON . . . . . . . ...2-4

2.2.1

2.2.2

2.2.3

2.3 TURNING THE POWER ON AND

2.3.1

2.3.2 Checking the Motors for Abnormalities . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.3 ProcedureforTurningthe PowerOFF . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.4 inspection ofthe Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-12

inspection ofthe NC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-6

inspection oftheTape Reader.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7’

Preparation before Turningthe Power ON . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

INSPECTION AFTER POWE:R ON...... . . . . . . . . . . . . . . . . ...2-9

ProcedureforTurningthe PowerON . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.4 MANUAL OPERATION (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-15

2.4.1

2.4.2 Jog Feed (JOG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-16

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-16

2.4.4 Handle Feed (HANDLE)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-17

Manual Rapid Traverse (RAPID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-15

1

——.,.— ,—. =. —. —..- ,,.. ! .-~

. ..-.. —-..

—.-. — . . .

Page 3

2.5 MANUAL OPERATION (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-18

2.5.1 Simultaneous 3-axis Handle Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2.5.2 Manual Reference Point Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-19

2.5.3 Manual Reference Point Return tothe Second Reference Point* . . . . 2-22

2.5.4 I-line MDI . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . ...2-23

2.6 AUTOMATIC OPERATION (1) . . . . . . . . . . . . . . . . . . . . . . . . . ...2-24

2.6.1

2.6.2 Memory Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . ...2-26

2.6.3 MDI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-27

2.6.4 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2.6.5

Preparation of Automatic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-29

2.7 AUTOMATIC OPERATION (2) . . . . . . . . . . . . . . . . . . . . . . . . . ...2-31

2.7.1

2.7.2 Optional Block Skip........,., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-31

2,7.3 Dry Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-32

2.7.4 Machine Lock......,,....,.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

2.7.5 Auxiliary Function Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-33

2.7.6 Feed Hold in Thread Cutting*. . . . . . . . . . . . . . . . . . . . . . . . . . . . ., . ...2-34

Optional Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-31

2.8 OPERATION INTERVENTION

DURING AUTOMATIC OPERATION . . . . . . . . . . . . . . . . . . . ...2-35

2.8.1 Manual Operation intervention during Automatic Operation . . . . . . . . . 2-35

2.8.2 MDIOperation intervention during Automatic Operation . . . . . . . . . . . . 2-36

2.8.3 Automatic Handle Mode Offset* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2.8.4 Manual Absolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-38

2.9 AUTOMATIC OPERATIONS AT ENHANCED LEVEL . . . . . ...2-40

2.9.1

2.9.2 Return tothe Operation interrupted Point* . . . . . . . . . . . . . . . . . . . . . . . 2-40

2.9.3 Saving the Present Position Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.9.4 Program Restart* . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., ., .,, .,, , . . ...2-43

Return tothe Setup Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2-40

3. BASICS OF DISPLAY AND WRITING OPERATION

3.1 BASICS OF TERMS REIATED TO OPERATION ,, . .,..,.....3-2

3.1.1

3.1.2 Jobs and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.3 YASNACJ300L Function Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Process Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

ii

Page 4

3.2 NC OPERATION PANEL . . .. . . . . . . . . . . . . . . . . . . . . . . . . . ...3-8

3.2.1

3.2.2 Normal Display onCRTScreen. . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-15

3.2.3

3.2.4

3.2.5

Keys and Display Screen on NC Operation Panel . . . . . . . . . . . . . . . . 3-8

Pop-up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..3-2o

Key Buffer Edit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..3-21

Buzzer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..3-22

4. EDIT PROCESS OPERATION

4.1 PART PROGRAM EDIT JOB . . . . . . . . . ...0................4-3

4.1.1

4.1.2

4.1.3 Saving aPart Program after [:diting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.1.4

Calling aPart F’rogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Editing aPart F’rogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Deleting aPart Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-23

4.2 PART PROGRAM DIRECTORYJOB . . . . . . . . . . . . . . . . . . ...4-26

4.2.1

4.2.2 Calling aPartl%ogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-33

4.2.3

4.2.4

4.2.5 Copying aPart Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4-39

Display ofthe[lirectory ofPart Programs . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Deleting aPart Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4-35

Renaming aPart Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-37

4.3 PART PROGRAM lNPUT/OUTPUTAND VERIFY JOB . . . . ...4-40

4.3.1 inputting aPart Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4-40

4.3.2

4.3.3

4.3.4 Setting the Communication Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.3.5 Other Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4-60

Outputting a Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..4-44

Verifying the Part Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-51

5. SETUP PROCESS OPERATION

5.1 SETUP JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-2

5.1.1

5.1.2 Clearing the Offset Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..5-4

Writing the Tool Offset Data..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 WORKPIECE COORDINATE SYSTEM SHIFT JOB . . . . . . . . ...5-5

5.2.1

5.2.2 Clearing the Workpiece Coordinate System ShiftAmount . . . . . . . . . . . . 5-6

Writing theWorkpiece Coorclinate System ShiftAmount . . . . . . . . . . . . . 5-5

Page 5

5.3 TOOL LIFE CONTROL JOB . . . . . . . . . . . .,. ,.. s. . . . . . . . . . ...5-7

5.3.1 Writing the Tool Life Control Data... . . . . . . . . . . . . . . . . . . . . . . . . . . ...5-7

5.3.2 Displaying the Tool Lite Control Data. . . . . . . . . . . . . . . . . . . . . . . . . . ...5-7

5.3.3 Setting the Tool Life Control Data,,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.3.4 Erasing the Tool Life Control Data... . . . . . . . . . . . . . . . . . . . . . . . . . ...5-10

6. RUN PROCESS

6.1 PROGRAM JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..6-3

6.1.1

6.1.2 Program Number Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.1.3 Address Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.1.4 Editing the Part Program Stored in Memory . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.1.5

6.1.6 Display of Subprogram Nesting information . . . . . . . . . . . . . . . . . . . . . . 6-10

6.2 MDIOPERATION JOB . . . . . . . . . . . . . . . . ., .,, , . ., . . . . . . ...6-11

Program Information [)isplayed on Screen . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Execution ofa Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.2,1

6.2.2

6.2.3

6.2.4

6.2.5

Entry ofan MDI Program ...,..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Editing an MDI Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6 -11

Execution ofan MDI Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...6- 12

Deleting an MDI Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Storing an MDI Program..,,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.3 COMMAND VALUE DISPIAY JOB....,, . . . . . . . . . . . . . . . ...6-14

6.3.1 Collective Display of Command Values . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4 SEITING JOB...............,,.,,.. . . . . . . . . . . . . . . . . ...6-15

6.4.1 internal Switch Function*..,,, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.4.2 Software Switch Function* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .,, ..,6-16

6.4.3 Macro Variable Function, ...,, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4.4 Setting Function.,.......,.. . . . . . . . . . . . . . . . . . . . . . . . . . . . ., .,...6-19

7. COMMON PROCESS OPERATION

7,1 PRESENTPOSITION [)ATACONTROLJOB . . . . . . . . . . . . . ...7-2

7.1.1 Collective Display ofPresentPosition Data . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.2 Display of Present Position Data

7.1.3 Display of Present Position Data

7.1.4 Display of Remaining Distance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-6

7.1.5 Setting the Coordinate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.1.6 Error Pulse Display Function.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ., . ...7-9

in the Workpiece Coordinate System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

in the External Coordinate Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-5

—-...—-...——..-—.—

iv

Page 6

7.2 ALARM DISPLAY JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-10

7.2.1

7.2.2 Servo Alarm Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..7-11

7.2.3

Alarm Functiorl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-10

User’s Message Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..7-12

7.3 TIME CONTROL. JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . ...7-13

7.3.1 Calendar Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..7-14

7.3.2 Operating Time Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7-15

8. MAINTENANCE PROCESS

8.1 PARAMETER JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . ...8-3

8.1.1

8.1.2 Setting Functio n. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.1.3 Sequence ParameterFuncti~n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.1.4 Pitch Error Furlction *....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.2 l/O MONITORING JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-8

8.2.1

8.2.2 DisplayingtheON/OFFStatusofthe Selectedl/OSignals . . . . . . . . . . . 8-9

8.2.3 TurningON/OFFl/OSignalsForcibly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Parameter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

DisplayingtheON/OFFStatusof thel/OSignals . . . . . . . . . . . . . . . . . . . 8-8

8.3 lNPUT/OUTPUT AND VERIF’YJOB . . . . . . . . . . . . . . . . . . . ...8-12

8.3.1

8.3.2

8.3.3

input/outputandVerifyFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-12

Reset Functiorl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..8-14

l/ODeviceSettingFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..8-14

8.4 INTERNAL INFORMATION *JOB . . . . . . . . . . . . . . . . . . . . . . ...8-15

8.4.1

8.4.2

8.4.3

Version Number Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Memory Dump Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Key Memory Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...8-16

9. MAINTENANCE

9.1 MAINTENANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9-2

9.1.1

9.1.2 Checking the lVClnformation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.1.3 Display ofAlarm lnformatiorl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.1.4

9.1.5 Troubleshooting (l) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9:7

9.1.6 Troubleshooting (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...9 -17

9.1.7 Alarms Not indicated byAlarm Numbers . . . . . . . . . . . . . . . . . . . . . . . 9-23

Checking the StatusofTroubles. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 9-2

Cause ofAlarrn and Corrective Action . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

v

Page 7

APPENDIX 1 LIST OF NC lNPUT/OUTPUT SIGNALS

APPENDIXI.I INPUT SIGNALS (PLC--+ NC) . . . . . . . . . . . . . . . . .. A1-2

1.1.1 Operation Mode Control . . . . . . . . . . . ., . . . . . . . . . . . . . . . . . . . . . . . . .. A1-2

1.1.2 CNCPart Program Execution Control . . . . . . . . . . . . . . . . . . . . . . . . . . .. A1-4

1.1.3 ServoAxis Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..A1-5

1.1.4 No. l Spindle Control.....,., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..A1-7

1.1.5

1.1.6 YENET1200Compatible lnverter Control . . . . . . . . . . . . . . . . . . . . . . . . . Al-9

No. 2SpindleControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..A1-8

APPENDIX 1.2 OUTPUT SiGNALS (NC-+ PLCj . . . . . . . . . . . . . . Al -10

1.2.1

1.2.2 NC Part Program Execution Control. . . . . . . . . . . . . . . . . . . . . . . . . . .. A1- 12

1.2.3 Servo Axis Control, . ., . .,, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. Al- 14

1.2.4 No, l Spindle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. Al- 17

1.2.5 No.2Spindle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. A1 -18

1.2.6 YENET1200Compatible lnverter Control . . . . . . . . . . . . . . . . . . . . . . . . A1 -19

1.2.7 Axis Variable Data, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. Al- 20

Operation Mode Control ., .,.,..... . . . . . . . . . . . . . . . . . . . . . . . . . .. A1 -10

APPENDIX 2 PARAMETER TABLE

APPENDIX 2.1 CLASSIFICATION OF THE PARAMETERS . . . . . . . A2 -2

APPENDIX 2.2 PARAMETER TABLE . . . . . . . . . . . . . . . . . . . . . . . . .. A2-3

APPENDIX 3 ALARM TABLE

APPENDIX 3.1 CLASSIFICATION OF ALARMS . . . . . . . . . . . . . . . . . A3 -2

APPENDIX 3.2 ALARM TA13LE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. A3-3

APPENDIX 4 INDEX

vi

Page 8

FOREWORD

This manual describes cautionary items that must be taken into consideraticm when operating

the YASNAC J300L (with basic NC operation panel, 9-inch CRT) as well as the basic configuration and operation procedure of it.

Some information is presented in tables in the Appendix so that readers can easily find the

necessary information. In the specification table, section numbers are given for each specification to allow quick access to a detailecl explanation if necessary.

The YASNAC J300L comes with a programming manual in addition to thi~;operating manual. Use these manuals in conjunction with each other to ensure productive operation.

CAUTIONS

This manual describes all the option functions (identified by the “*” symbol) but some of

these may not be available with your YASNAC J300M. To determine the option functions

installed in your NC, refer to the specification document or manuals published by the machine tool builder.

Unless otherwise specifiecl, the following conditions apply in programming explanations

and programming examples.

. Metric system for input and metric system for output/moveme.~t

●

: Zero point in the base coordinate system

+

●

: Reference point

@

Yaskawa has made every effort to describe individual functions and their relationships to other functions as accurately as possible. However, there are many things ttat cannot or must

not be performed and it is not possible to describe all of these. Accordingly, readers are requested to understand that unless it is specifically stated that something can be performed,

it should be assumed that it cannot be performed.

Also bear in mind that the :performance and functions of an NC machine tool are not determined solely by the NC unit. The entire control system consists of the mechanicals ystem,

the machine operation panel and other machine related equipment in addition to the NC.

Therefore, read the manuals published by the machine tool builder for derailed information

relating to the machine.

Page 9

General Precautions

● Some drawings in this manual are shown with the protective cover or shields removed,

in order to describe the detail with more clarity. Make sure all covers and shields are

replaced before operating this product, and operate it in accordance with the directions

in the manual.

● The figures and photographs in this manual show a representative product for reference

purposes and may differ from the product actually delivered to you.

● This manual maybe modified when necessary because of improvement of the product,

modification, or changes in specifications.

Such modification is made as a revision by renewing the manual No.

● To order a copy of this manual, if your copy has been damaged or lost, contact your

Yaskawa representative listed on the last page stating the manual No. on the front

page.

● If any of the nameplates affixed to the product become damaged or illegible, please

send these nameplates to your Yaskawa representative.

● Yaskawa is not responsible for any modification of the product made by the user since

that will void our guarantee.

.——— —

ii

Page 10

NOTES FOR SAFE OPEF{ATION

Read this operating manual thoroughly before installation, operation , maintenance or inspection of the YASNAC J300L. In this manual, the NOTES FOR SAFE OPERATION are

classified as “WARNING” or “CAUTION’.

Indicates a potentially hazardous situation which, if

~ WARNING

~ CAUTION

Even items describedinl ~ CAUTION I may result in a vital accident in some situations.

not avoided, could result in death or serious injury to

personnel.

Indicates a potentially hazardous situi~tion which, if

not avoided, may resuR in minor or moderate injury

to personnel and damage to equipmenk

It may also be used to alert against unsafe practice.

In either case, follow these important items.

Page 11

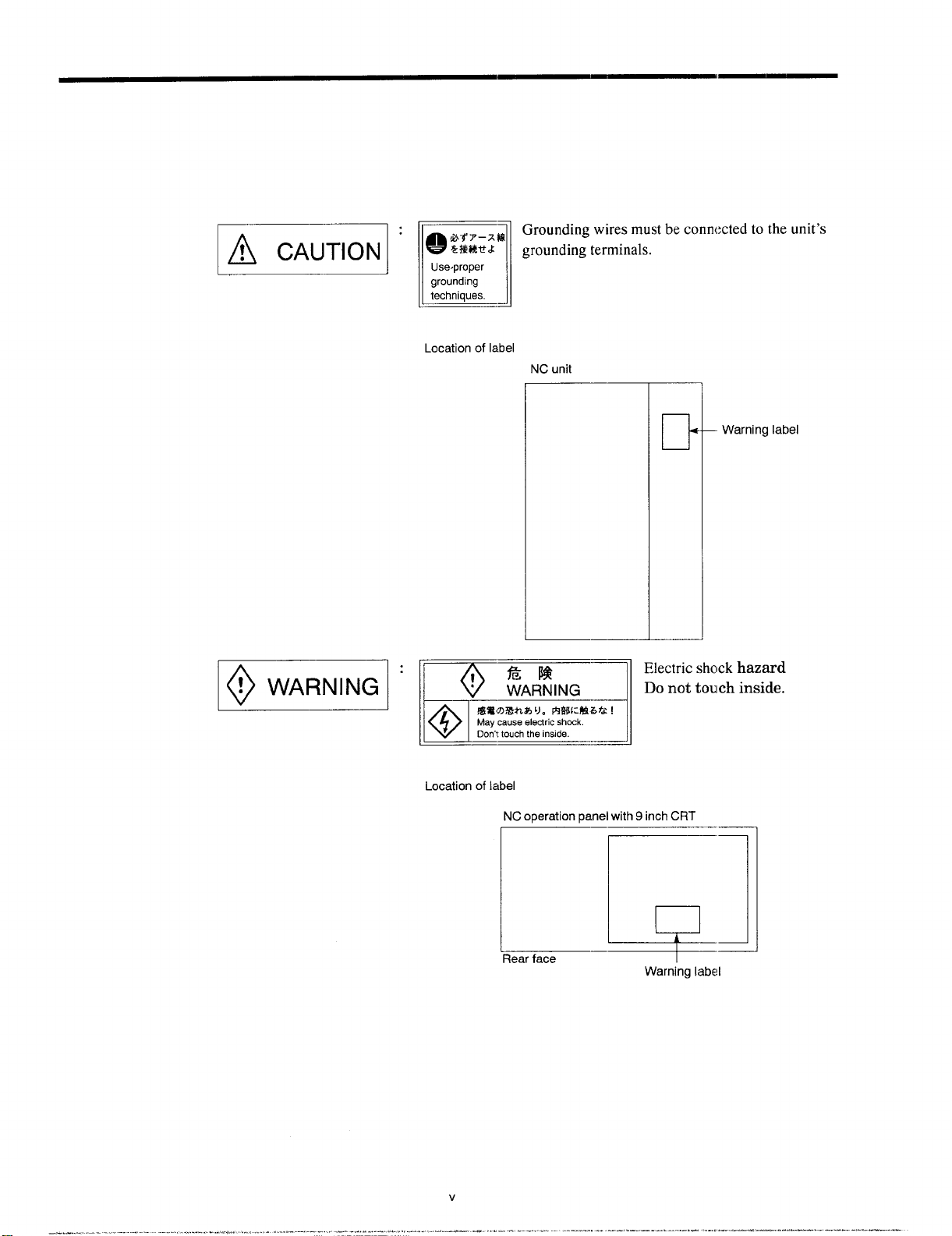

KEY TO WARNING LABELS

The following warning labels are used with the YASNAC J300M.

mq~q ::;::ard

Do not touch the terminals while the power is

on, and for 5 minutes after switching off the

Locationoflabel

NCunit

— Warninglabel

iv

Page 12

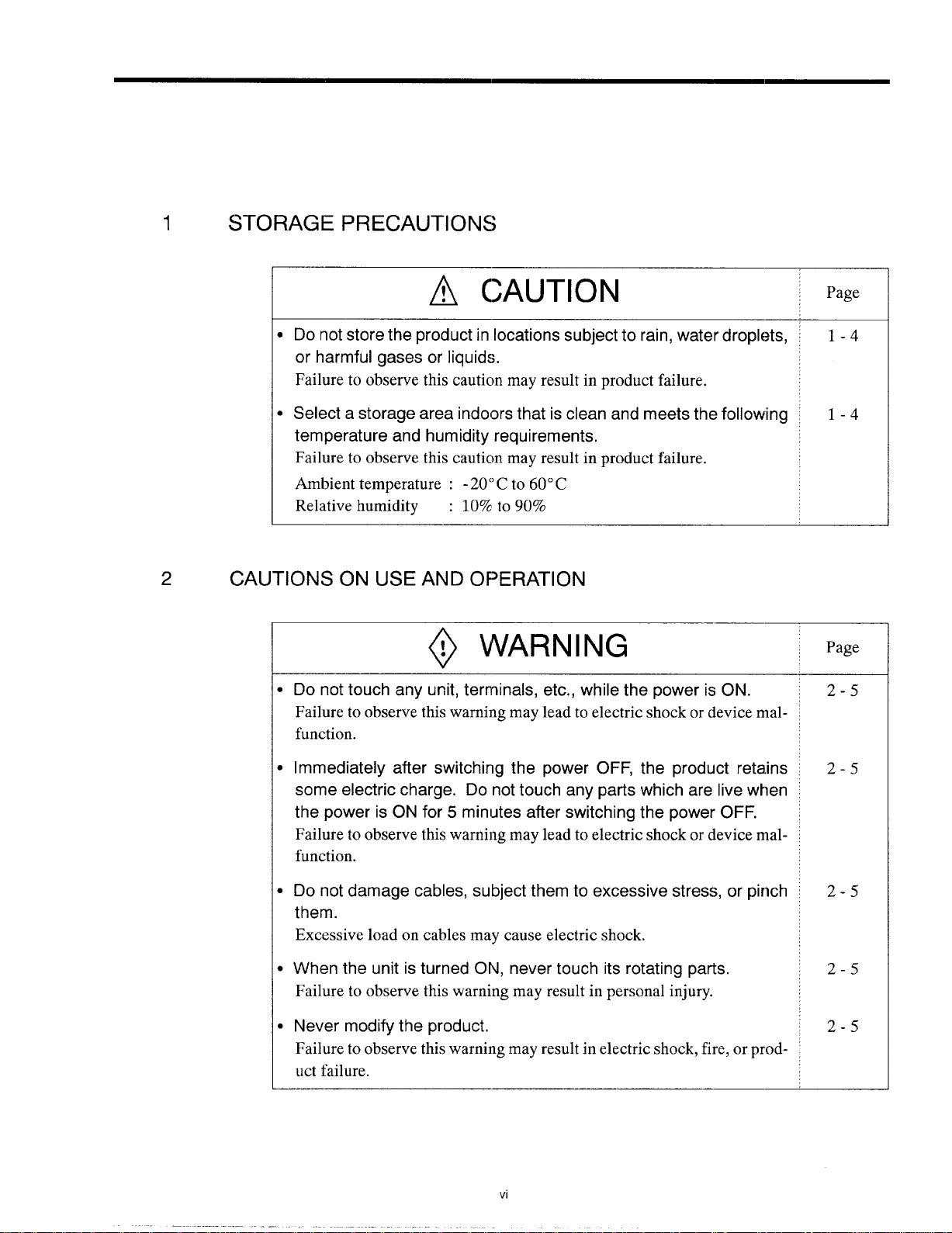

E:

,fi#Y-xkfi

Mi%M&

Q

Use,proper

grounding

techniques.

n

Locationoflabel

Grounding wires must be connected to the unit’s

grounding terminals.

NCunit

—.

Warninglabel

! WARNING

O

IW#UX%n%’JoF%Ji:M3ti !

Maycauseelectric shock.

Il@l

Locationoflabel

Don?touti theinside.

-J

—

NCoperationpanelwith9inchCRT

L]

—–’—

Rearface

Warninglabel

Page 13

1

STORAGE PRECAUTIONS

~ CAUTION

Do not store the product in locations subject to rain, water droplets,

or harmful

gases or liquids.

Page

1-4

Failure to observe this cauticm may result in product failure.

Select a storage area

temperature

and humidity requirements.

indoors that is clean and meets the following

1-4

Failure to observe this caution may result in product failure.

Ambient temperature : - 20’)C to 60° C

Relative humidity : 10%

2

CAUTIONS ON USE

AND OF’ERATION

~ WARNING

B

Do not touch any unit, terminals, etc., while the power is ON.

to 90%

Page

2-5

Failure to observe this warning may lead to electric shock or device malfunction.

●

Immediately after switching the power

some electric

charge. Do not touch any parts which are live when

the power is ON for 5 minutes after switching the power

OFF, the product retains

OFF.

Failure to observe this warning may lead to electric shock or device malfunction.

●

Do not damage cables, subject them to excessive stress, or pinch

them.

Excessive load on cables may cause electric shock.

●

When the unit is turned ON, never touch its rotating parts.

Failure to observe this warning may result in personal injury.

●

Never modify the product,

Failure to observe this warning may result in electric shock, fire, or product failure.

—

2-5

2-5

2-5

2-5

Page 14

~ CAUTION

Use the product in an environment with the following characteris-

tics.

Using it in an environment in which it is subject to high temperatures, high

humidity, dust, corrosive gases, vibration or impacts may cause fire, electric shock or malfunction.

Free from gases or vapors that create a potentially explosive atmosphere.

.

Free from oil, organic solvents,

Relative humidity in the range 10I to 90% RH, with no condensation.

Ambient temperature in the O“C to 45° C with no freezing.

(Installation site must not be exposed to direct sunlight, must be distanced from heat generating devices, and must be indoors.)

Wbration not exceeding 4.9 m/s2 (0.5 G).

etc.

Page

-——

1-4

I

Do not let foreign matter such as electric wire scrap enter the unit.

Failure to observe this caution may :result in fire, product failure or malfunction.

I

Do not restart automatic operation after stopping automatic operation and then performing “tool selection” in manual operation c)r”1

line MDI” operation.

The reason for this is that the “tool selection” operation may cause the

coordinate system to be changed, leading to unexpected operation if a utomatic operation were restarted. This could cause tool damage due to irlterference, and resulting accidents involving injuries to personnel.

Reset the NC after any manual intervention.

)

After stopping automatic operation and performing a manual irlter-

vention, do not restart automatic operation without resetting first.

If automatic operation is started with the “mirror image” or “manual a’l]solute” function in effect, unexpected operation may be performed. “rhis

could cause tool damage due to interference, and resulting accidents involving injuries to personnel.

Reset the NC after any manual intervention.

—

2-6

2-37

2-37

Page 15

~ CAUTION

Page

Before carrying out cutting operation with a new program, confirm

safety by performing single block operation and dry run operation.

If this check operation is not performed, unexpected operation maybe performed due to mis-setting of the amount of offset, leading to tool damage

due to interference, and resulting accidents involving injuries to perscmnel.

The end user must not change parameters relating to machine ac-

curacy, travel axis control and spindle axis control.

The NC parameters are set to the optimum values for each machine, and

changing them could therefore result in unexpected operation. This could

cause tool damage due to interference, and resulting accidents involving

injuries to personnel.

Reset the NC after any manual intervention.

Strictly observe the cautions in the user’s manual when using pro-

gramming functions.

Ignoring these cautions could lead to accidents involving injuries to personnel and malfunctions.

Use the product with the “System Number Switch” of the CPU set to

6’ ,,

0.

Use while set to another number may lead to malfunction.

2-25

8-3

2-25

2-1o

Wait at least 2 seconds after turning the power OFF before turning it

ON again.

Failure to observe this caution may lead to malfunction.

Vlll

2-1o

Page 16

3

PRECAUTIONS RELATING TO MAINTENANCE AND INSPECTION

@ WARNING ‘-

● Always turn the power OFF (including the primary power supply)

before carrying out daily inspection.

Carrying out the inspection with the power ON may lead to electric shock.

● Wait 5 minutes after turning the power (including the primary power

supply) OFF before removing or replacing any unit or part.

Failure to observe this warning may lead to electric shock and product iailure.

● Be sure to turn the power OFF before replacing the battery.

Failure to observe this warning may lead to electric shock and product ~ailure.

~

I To prevent personnel other than those involved in maintenance ~

inspection work from turning ON the power while maintenance

and

and inspection is in progress, place signs stating “Do not turn the

power on” or words to that effect at the primary power supplies of ~

related control panels and other relevant locations.

Failure to observe this caution may lead to electric shock.

CAUTION

—

Page

2-5

2-5

2-1o

Page

2-6

I Replace fuses and batteries with the designated products.

Failure to observe this caution may result in fire

I Electronic devices such as C MOS ICS are used on the control

boards. If you touch them with your bare fingers the static electrical

charge in your body could destroy them; care must be taken when

handling these devices. Before handling these devices for mair]tenance purposes, first discharge the static electricity in your body by

touching a grounded metal device.

Failure to observe this caution could lead to injurim and product fail.me.

I Do not install or remove boards, wiring, connectors, etc., while the

power is ON.

Failure to observe this caution could leadto electric shock, product fail~re,

and malfunction.

or product failure.

.— .——

2-1o

2-6

2-6

Page 17

~ CAUTION

Page

When an alarm occurs, eliminate its cause and confirm safety be-

fore resetting it.

Failure to observe this cautio:n could result in malfunction.

Be sure to check the following points on completing maintenance

and inspection work.

. Check that all fastening bolts are tightened.

“ Check that no tools or other objects have been left inside the control

panel.

. Check that the control panel door is closed properly.

Failure to carry out these checks may lead to electric shock, injuries, fire,

and malfunction.

For details on trouble relating to the machine-related sequence,

fer to the manual issued by the machine tool builder.

Never attempt to disassemble or modify units or devices inside the

NC unit.

Failure to observe this caution may lead to fire, product failure, or malfunction.

Do not change the set values of the devices, variable resistors, etc.,

in the control panel.

Failure to observe this caution may lead to fire, product failure, and malfunction.

re-

9-2

2-6

9-2

2-6

2-6

Page 18

OUTLINE OF THE: PRODUCT

Chapter 1 describes the outline of the product and the protective functions that should be thoroughly understood for safe

and efficient operaticm of the YASINAC J300L.

1.1

OUTLINE OF YASNAC SYSTEM . . . . ...1-2

1.1.1 Systerrl Configuratiorl . . . . . . . . . . . . . . . . . 1-2

1.1.2 Environmental Requirements . . . . . . . . . . . . 1 -4

1.1.3 Machine Operation Panel . . . . . . . . . . . . . . . . 1-6

1.1.4 General Specificatiorls . . . . . . . . . . . . . . . . . 1-7

1.2

PROTECTIVE FUNCTIONS . . . . . . . ...1-12

1.2.1

1.2.2 Overtrave l . . . . . . .. o. . . . . . . . . . . . . . . . . . 1-12

1.2.3 Stored Stroke Limit . . . . . . . . . . . . . . . . . . . 1-13

1.2.4

Emergenc ySto p. . . . . . . . . . . . . . . . . . . . . . 1-12

Interlock Inputs . . . . . . . . . . . . . . . . . . . . . . . . 11-15

Page 19

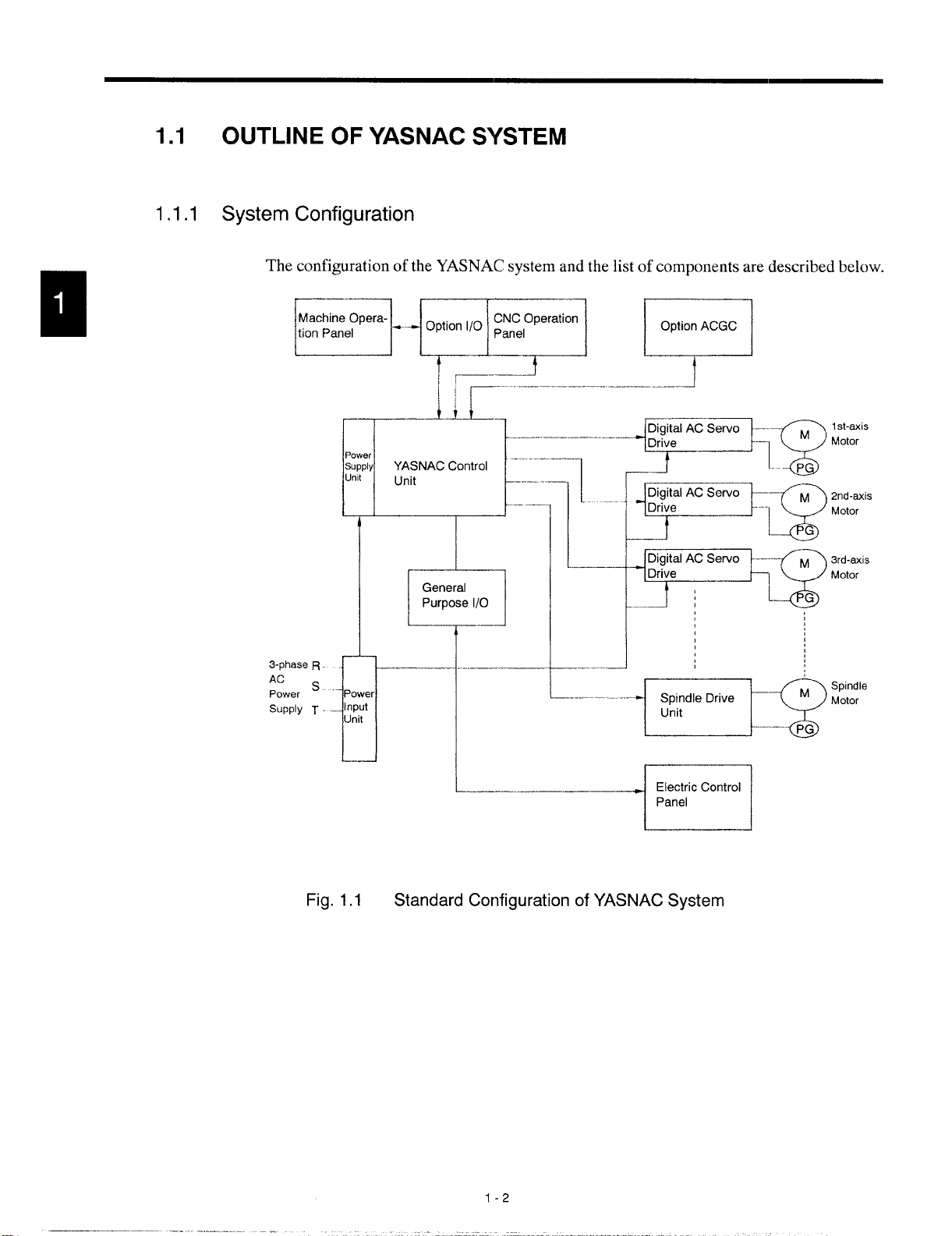

1.1

1.1.1 System Configuration

OUTLINE OF YASNAC SYSTEM

The configuration of the YASNAIC system and the list of components are described below.

m“”EjEI!!Iyl

OptionACGC

Q

3-phase R

AC

Power

SUPPty T

Power

supply

Unit

YASNACControl

Unit

FE:

General

Purpose1/0

~1

-L--–A----J ~ !

r

s

Power

Input

—

Unit

u

Fig. 1.1

t

r

pmfim=--g,,:,s

1

I

‘1

-Fl?’”is

L

ElectricControl

Panel

1

Configuration of YASNAC System

I..+’@

,

Page 20

1.1 OUTLINEO= YASNACSYSTEM

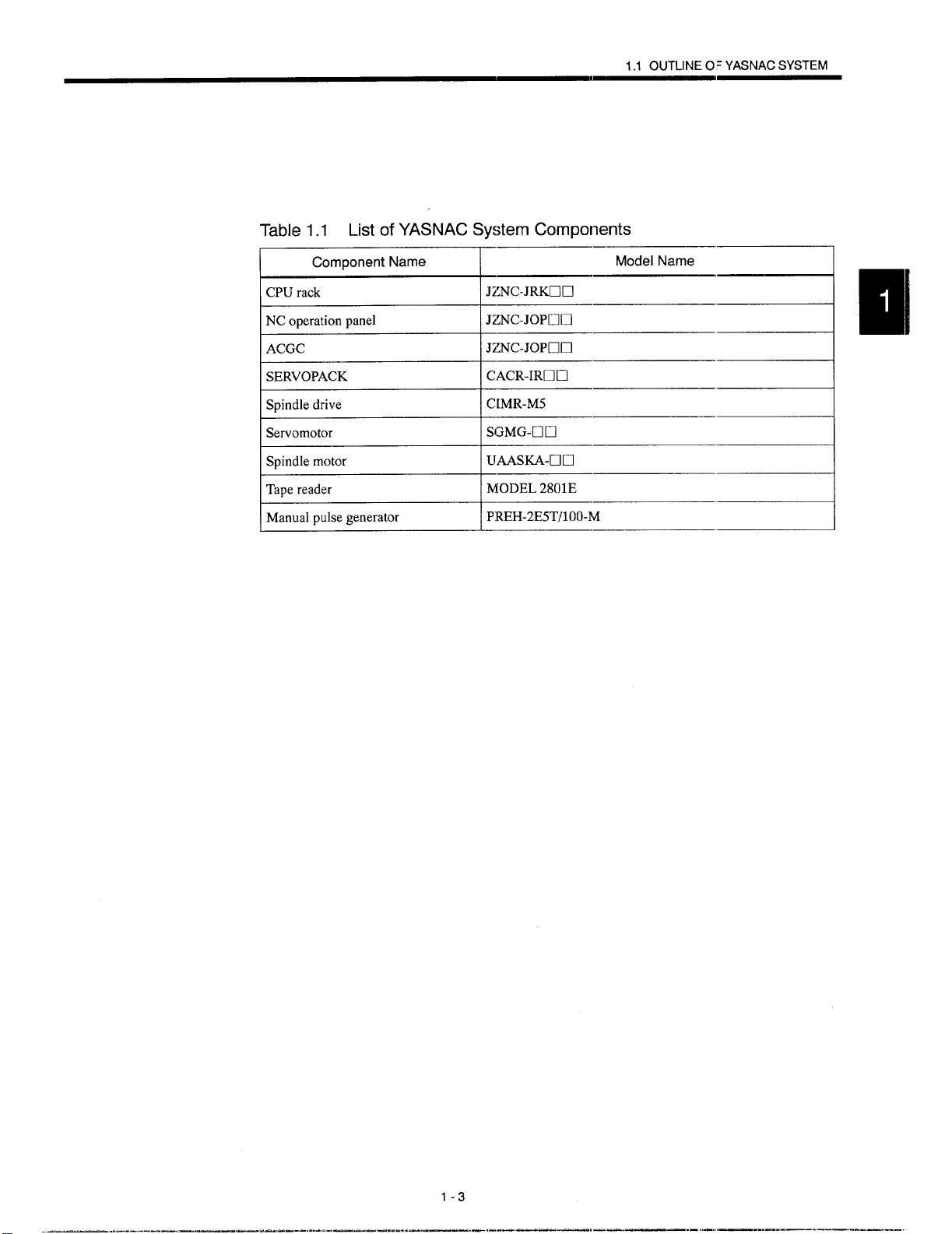

Table 1.1 List of YASNAC System Components

~:..-n...n ““de’”’”’

NCoperationpanel

JZNC-JOPUIJ

ACGC

SERVOPACK

Spindledrive

Servomotor

Manualpulsegenerator

JZNC-JOPCiU

\CACR-IRUU

CIMR-M5

SGMG-CIEl

PREH-2E5T/100-M

1-3

Page 21

1.1.2 Environmental Requirements

Requirements for the installation of an NC unit are indicated below. Install the NC unit only

in a location where these requirements are satisfied to avoid malfunctioning.

B

Use the product in an environment with the following characteristics.

Using it in an environment in which it is subject to high temperatures, high humidity,

dust, corrosive gases, vibration or impacts may cause fire, electric shock or malfunction.

Free from gases or vapors that create a potentially explosive atmosphere.

Free from oil, organic solvents, etc.

Relative humidity in the range 10 to 90% RH, with no condensation.

Ambient temperature in the 0° C to 45° C with no freezing.

(Installation site must not be exposed to direct sunlight, must be distanced from heat

generating devices, and must be indoors.)

Vibration not exceeding 4.9 m/s2 (0.5 G).

●

Do not store the product in locations subject to rain, water droplets, or harmful

gases or liquids.

Failure to observe this caution may result in product failure.

~, CAUTION

●

Select a storage area indocrs that is clean and meets the following temperature

and humidity requirements.

Failure to observe this caution may result in product failure.

Ambient temperature : –20° C to 60° C

Relative humidity

(1)

Ambient Temperature

For operation

For storage and transportation

: 10% to 90%

0°cto450c

–20°C to +60° C

Install the NC unit in locations not subject to direct sunlight, distant from heat sources,

and indoors.

(2)

Humidity

Relative humidity must be in the range of 10 to 90%RH (non-condensing).

“l-4

Page 22

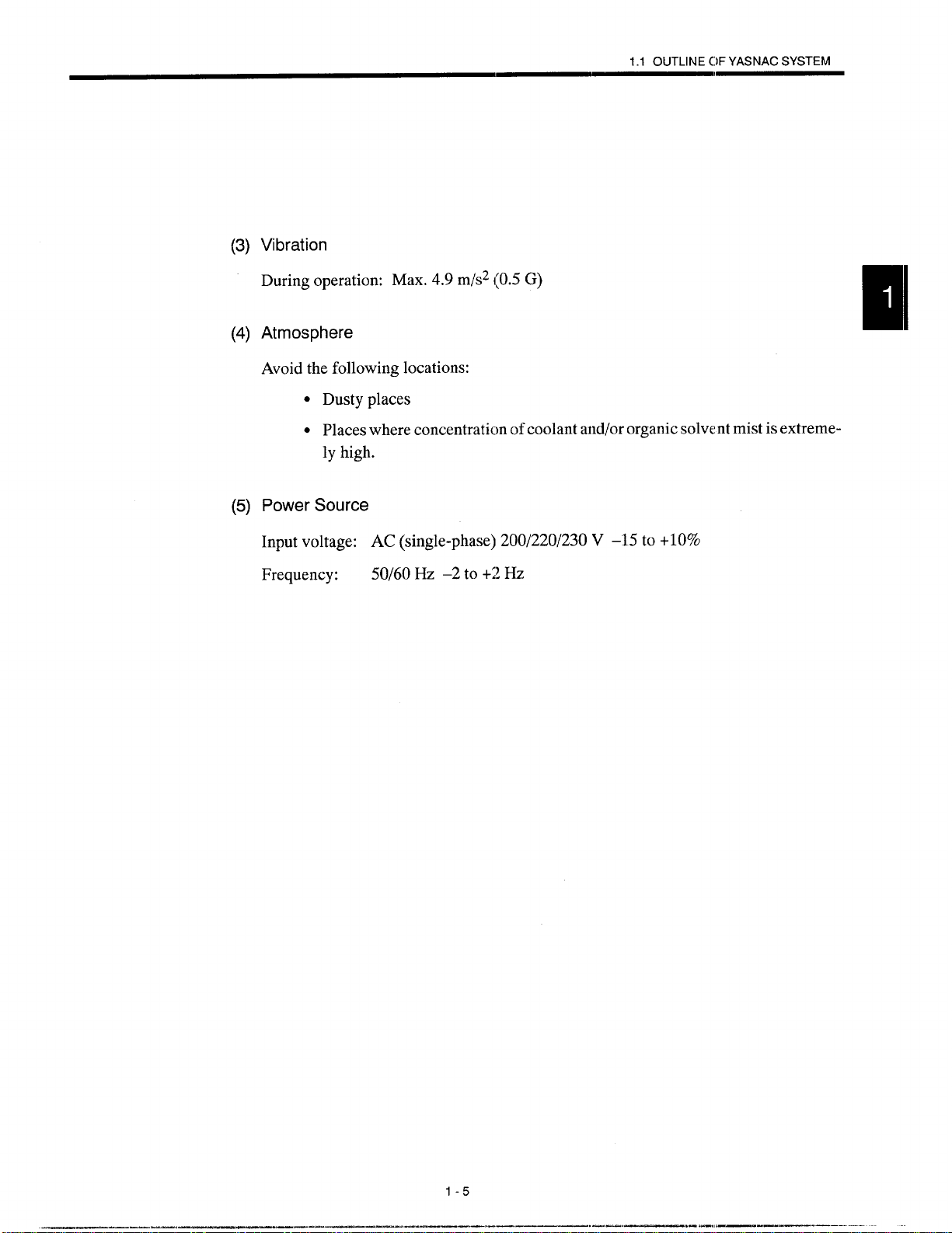

(3) Vibration

During operation: Max.4.9m/s2(0.5G)

(4) Atmosphere

Avoid the following locations:

. Dusty places

1.1 OUTLINEC)FYASNACSYSTEM

Q Places where concentraticm of coolant and/or

ly high.

(5) Power Source

Input voltage: AC (single-phase) 200/220/230 V –15 to

Frequency:

50/60 Hz –2 to +2 Hz

Organic sok nt mist is extreme-

+10%

1-5

.— -

.. —.—.. #-,,—.—.— ..———..

Page 23

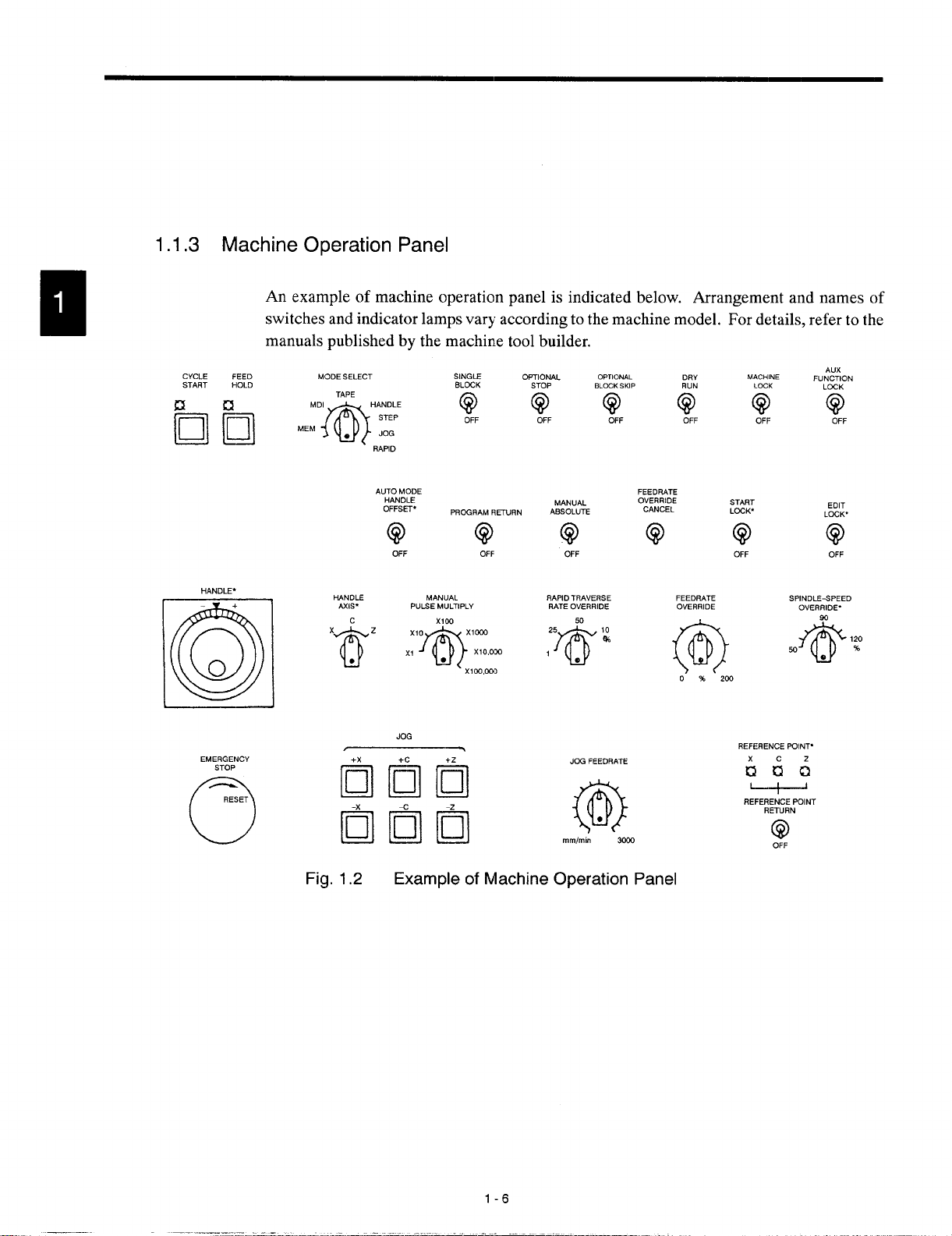

1.1,3

Machine Operation Panel

An

example of machine operation panel is indicated below. Arrangement and names of

switches and indicator lamps vary according to the machine model. For details, refer to the

manuals published by the machine tool builder.

E

la

CYCLE

START

FEED MODE SELECT

HOLD

~ ‘E:~!? z ~F $?F Q @

HANDLE,

+

0

o

O

EMERGENCY

STOP

RESET

o

SINGIE

TAPE

RAPID

AUTOMODE

HANDLE

OFFSET,

(?(?

OFF OFF

mNDLE MANUAL

AXIS*

’62 ~If$~””

JOG

Imm

mm “.

BLOCK

PRCGFIAMFIETURN

PULSEMULTIPLY

X1OO,IXX1

0P70NAL

STOP BLOCKSIUP RUN

MANUAL

ABSOLUTE

Q

OFF

RAPIDTRAVERSE

RATEOVERRIDE

25 10

7@

1

nmlmn

0PTION4L

50

w

e

JOG FEEDRATE

@

FEEDF!ATE

OVERRIOE

CANCEL

DRY

OFF

FEEDRATE

OVERRIDE

MACHINE

LCCK

OFF

START

LCCK*

REFERENCEFUINT.

;;;

1

1

REFERENCEPCINT

REIURN

@

OFF

Au’

FUNCTION

LOCK

Q

OFF

EOIT

LOCK.

6)

OFF

SPINDLE-SPEED

OVERRIDE.

90

@

w

0

I

120

%

Fig. 1.2 Example of Machine Operation Panel

1-6

Page 24

1.1 OUTLINEOFYASNACSYSTEM

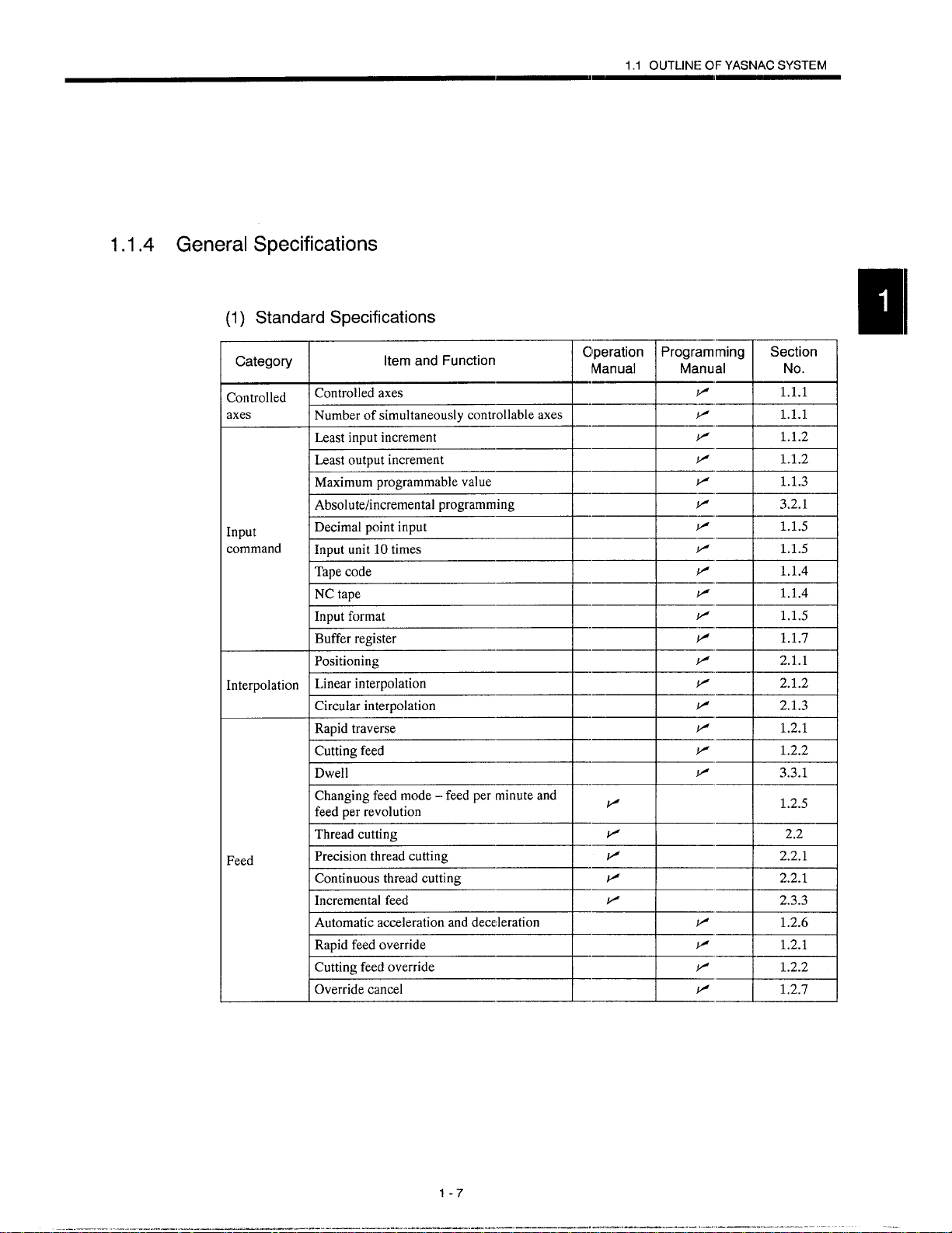

1.1.4

General

(1)

Controlled

axes

Interpolation Linearinterpolation

Specifications

Standard Specifications

Category

Controlledaxes

Numberof simultaneouslycontrollableaxes

E%%E=-----+----H*

Absolutehncrementalprogramming

~--t---t-+--w--

~--t--+--+-t+i

Positioning

Circularinterpolation

Rapidtraverse

“emand’unc’i0n7.-um

--m

=lSa

Feed

Changingfeed

feedperrevolution

mode – feedperminuteand

v

I

I

E=%=i----+-+---+-*

Icontinuous threadcutting

Automaticaccelerationanddeceleration

~--t-+-Y=t+w

Overridecancel

1-7

_----L-

IJ=I

..——.———-. .. .——

1.2.5

I

\

2.2.1 I

V

1,2.7

... ...-.—. .

I

Page 25

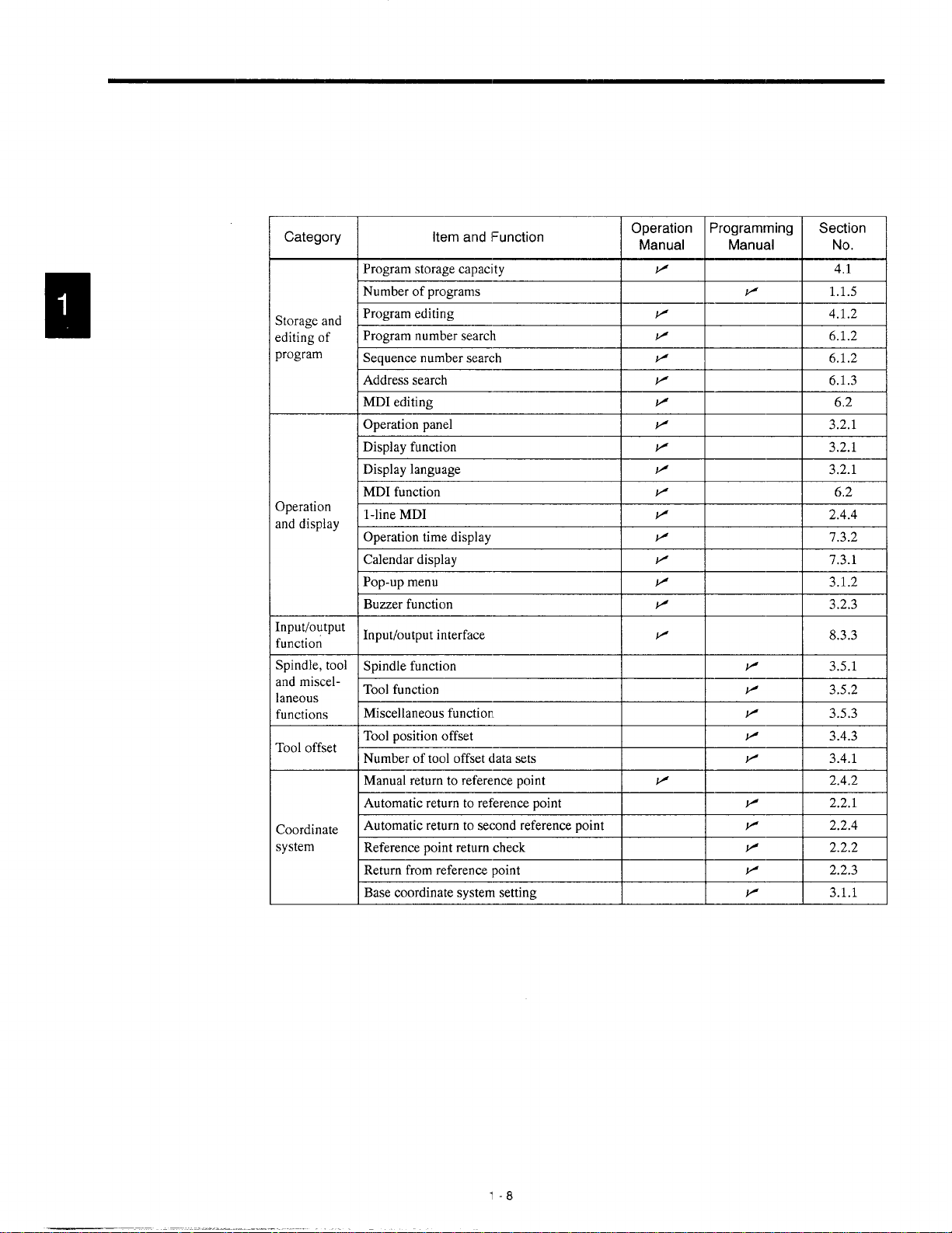

Category

Storageand

editingof

program

Operation

anddisplay

input/output

function

Spindle,tool

andmiscellaneous

functions

Tooloffset

Coordinate

system

Item and I=unction

Program storage capacity

Numberof programs

Programediting

Programnumbersearch

Sequencenumbersearch

Addresssearch

MDIediting

Operationpanel

Displayfunction

Displaylanguage

MDIfunction

l-line MDI

Operationtimedisplay

Calendardisplay

Pop-upmenu

Buzzerfunction

Input/outputinterface

Spindlefunction

Toolfunction

Miscellaneousfunction

Toolpositionoffset

Numberof tool offsetclatasets

Manualreturnto referencepoint

Automaticreturntoreferencepoint

Automaticreturntosecondreferencepoint

Referencepointreturncheck

Returnfromreferencepoint

Basecoordinatesystemsetting

Operation Programming

Manual Manual

v

v

P

v

1=

v

v

P

v

P 3.2.1

v

P

P

v 7.3.1

K

Y

P 8.3.3

P

v

v

P

P

P

v

v

P

v

v

Section

No.

4.1

1.1.5

4.1.2

6.1.2

6.1.2

6.1.3

6.2

3.2.1

3.2.1

6.2

2.4.4

7.3.2

3.1.2

3.2.3

3.5.1

3.5.2

3.5.3

3.4.3

3.4.1

2.4.2

2.2.1

2.2.4

2.2.2

2.2.3

3.1.1

1-8

Page 26

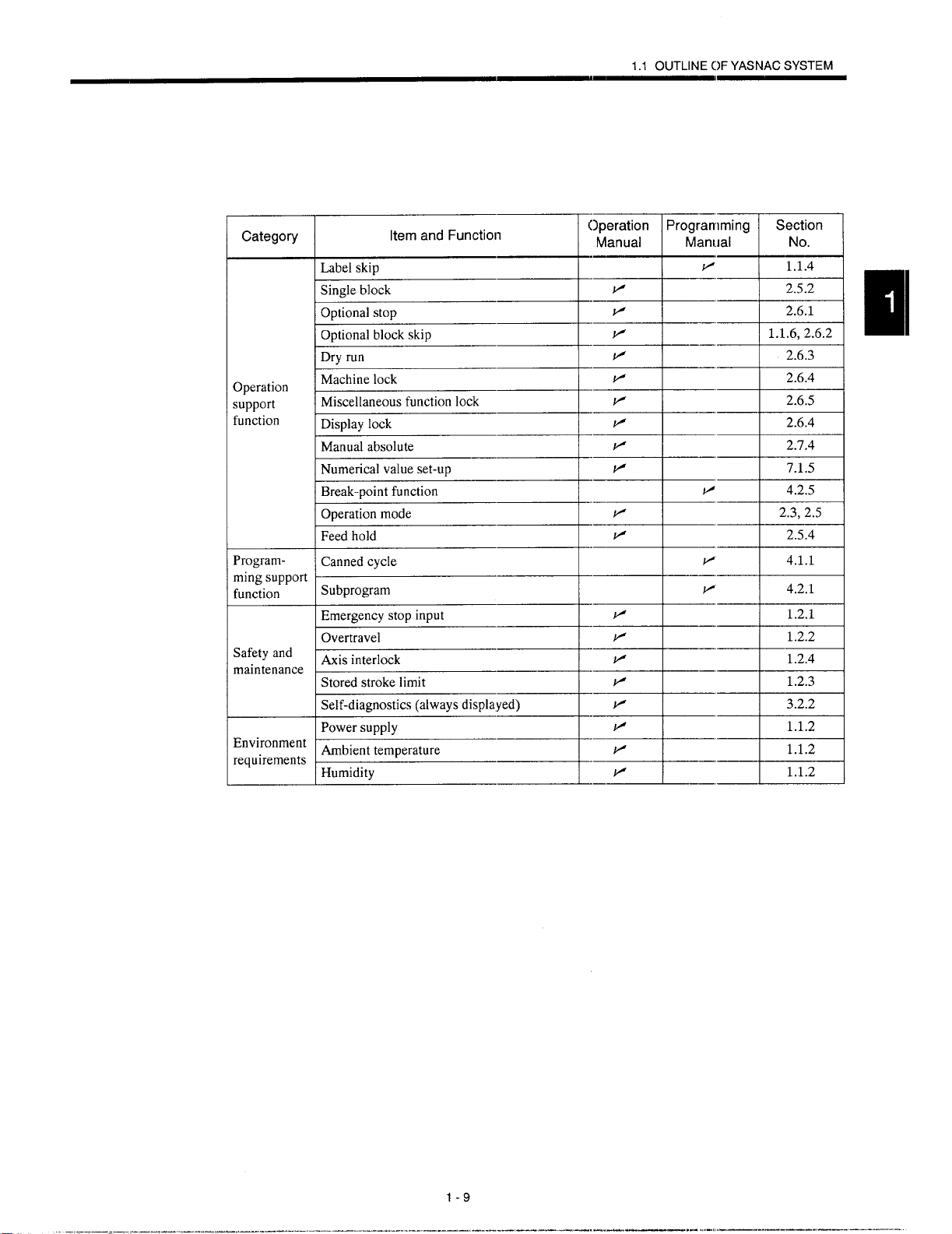

1.1 OUTLINE OF YASNAC SYSTEM

Category

3peration

;upport

function

Programmingsupport

function

Safetyand

maintenance

Environment

requirements

Item and Function

Label skip

Singleblock

Optionalstop

Optionalblockskip

Dryrun

Machinelock

Miscellaneousfunctionlock

Displaylock

Manualabsolute

Numericalvalueset-up

Break-pointfunction

Operationmode

Feedhold

Cannedcycle

Subprogram

Emergencystopinput

Overtravel

Axisinterlock

Storedstrokelimit

Self-diagnostics(alwaysdisplayed)

Powersupply

Ambienttemperature

Humidity

Operation Programming

Manual

Manual

v’

P 2.5.2

v 2.6.1

P 1.1.6,2.6.2

P 2.6.3

v 2.6.4

v

v

v 2.7.4

v 7.1.5

—

w

v

P 2.5.4

P

~

v 1.2.1

.—

P 1.2.2

v 1.2.4

v 1.2.3

v

v

v

F 1.1.2

—

Section

No.

1.1.4

2.6.5

2.6.4

4.2.5

2.3,2.5

4.1.1

4.2.1

3.2.2

1.1.2

1.1.2

1-9

— .——. .- .,-!, ,—.—.—-..—. ——-.

Page 27

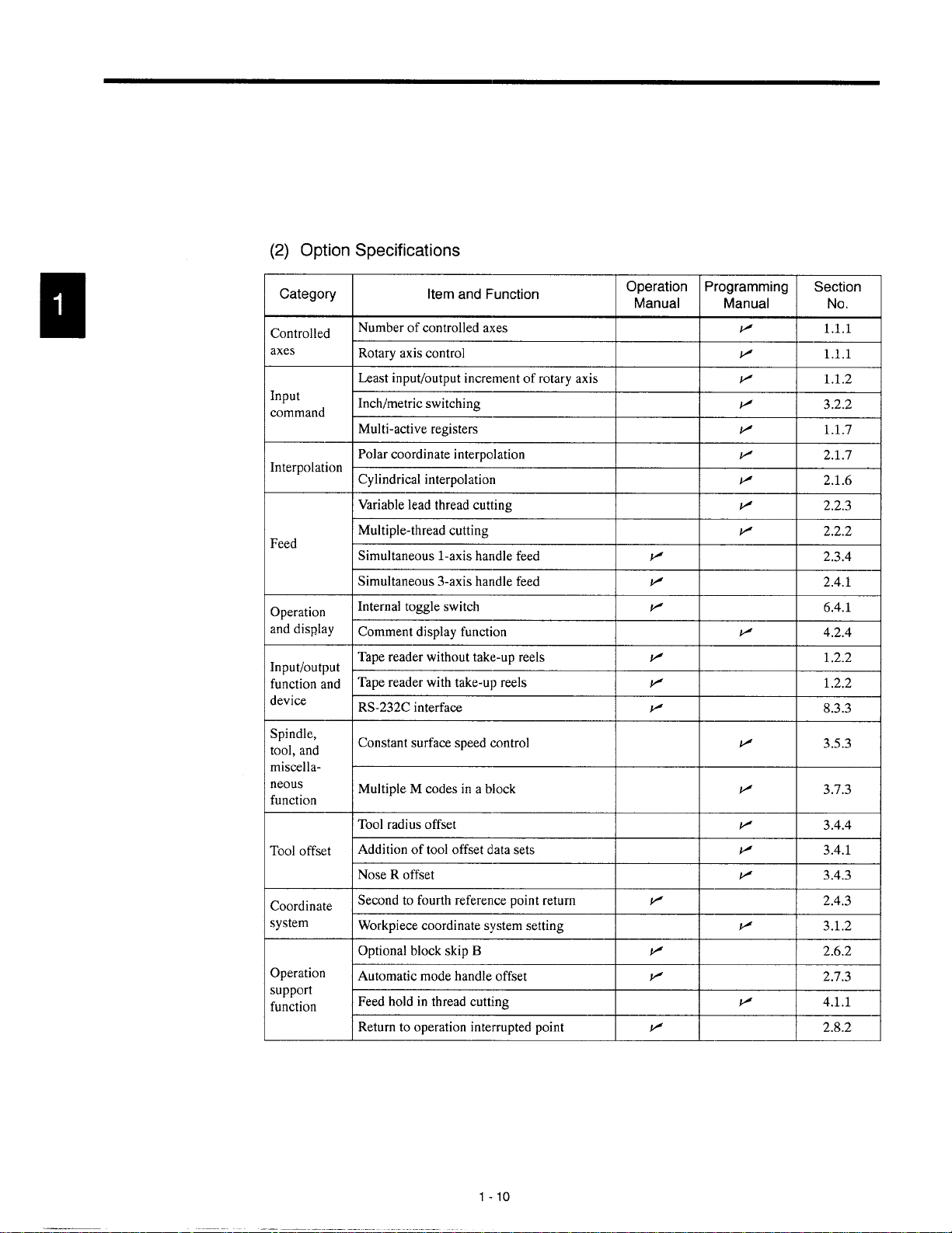

(2) Option Specifications

Category

Controlled

axes

Input

command

Interpolation

Feed

Operation

anddisplay

Input/output

functionand

device

Spindle,

tool,and

miscellaneous

function

Tooloffset

Coordinate

system

Operation

support

function

Item and Function

Number of controlled axes

Rotaryaxiscontrol I 1.1.1 I

Least input/output increment ofrotary axis \

Inch/metricswitching

Multi-activeregisters

Polarcoordinateinterpolation

Cylindrical interpolation

Variableleadthreadcutting

Simultaneousl-axis handlefeed

‘“’tip’e-threadc”tting~

Simultaneous3-axishandlefeed

Internaltoggleswitch

Commentdisplayfunction

Tapereaderwithouttake-upreels

Tapereaderwithtake-upreels IF

RS-232Cinterface v

Constantsurfacespeedcontrol

MultipleM codesinablock

Toolradiusoffset

Additionof tool offsetdatasets

Nose R offset

Secondto fourthreferencepointreturn

Workpiececoordinatesystemsetting

OptionalblockskipB

Automaticmodehandleoffset

Feedholdin threadcutting

Returnto operationinterruptedpoint

-----H-

Operation

Manual

I

I

I

I

I

-+---+%

-++-=+

I

I

+-+-=-l

-R+---l

I

1.2.2

8.3.3

I

I

I

v

+

+--t-=l

I

I

1P I 2.4.3 I

I

1P

I

P

-+--+=+

v

3.5.3

I 3.1.2 I

1 2.6.2 I

I 2.7.3 I

1-1o

Page 28

1.1 OUTLINE OF YASNACSYSTEM

Category

CircularinterpolationbyR command

CornerroundingbyRcommand

Program-

ming

support

function

Automation

support

function

Safetyand

maintenance StoredstrokelimitC

Multiple-repetitivecycle

Hole-machiningcannedcycle

Microprogram

I.Skipfunction

Toollifecontrolfunction

~1--+++--=-

‘t=’un’t’””-:ii:m

__l_~~

v’

v’ 2.1.4

P’

v’

v’ 4.4.1

a

I

1P

/

2.2.3

4.1.2

4.1.5

4.3.1 1

1-11

Page 29

1.2

PROTECTIVE

FUNCTIONS

1.2.1

1.2.2

Emergency Stop

Press the emergency stop button immediately if a problem occurs with the NC or system. The execution of all commands stops instantaneously when the emergency stop

button is pressed. Servo power supply of the NC is shut OFF and dynamic broke is applied

to stop all mechanical movement. In the emergency stop state, the NC is in the alarm state

“3002”. In the state the emergency stop signal input (CN02-19 pin on JANCD-JCP03 board)

is “opened”, the NC stops the entire operation, and turns OFF SVMX (CN2-17 pin on

JANCD-JCP03 board) and BKX (CN-18 pin on JANCD-JCP03 board).

overtravel

The overtravel function stops axis feed operation when an axis reaches the travel limit; for

the detection of travel limit, a limit switch and a dog are used and if an axis reaches the travel

limit, the limit switch outputs a signal and the function stops axis feed operation in response

to this input. The axis reached and stopped at the travel limit can be moved manually

into the axis movable range.

When the overtravel input is “opened”, axis move is stopped in the manner as indicated in

Table 1.1. In response to this input, the alarm output (ALM) is “closed” and the correspond-

ing alarm message is displayed on the screen.

Table 1.2 Axis Stop Direction with Clvertravel Input “Opened”

I I

Manual Operation Mode

Automatic Operation Mode

I

Movementof all axesis stoppedin

I

H&alldirectiOn

* Normally closedcontact

If the overtravel input is “opened”, select the manual mode (jog, pulse handle) and move the

axis in the direction opposite to the direction for which the overtravel input is “opened” to

“close” the input. After that press the [RESET] key on the NC operation panel, and the

alarm output and display are canceled.

1-12

Page 30

—1

1.2 PROTI:CTIVE FUNCTIONS

1. After the occurrence of an alarm due to the “open” of the overtraval input, the M,

S, and T code read output signals (MF, SF, and TF) are not turmd OFF.

2. If it is necessary to interrupt the operation called by M, S, and/or T code, set the

interlock by an external sequence.

3. The alarm numbers at the occurrence of overtravel are 2001 to 2035. If the over-

travel alarm occurs, axis move is stopped. Note that the servo is Ilot turned OFF.

M

—.

1.2.3 Stored Stroke Limit

To ensure improved safety in operation, the function prevents axes from l>ntering the preset

entry prohibited areas both in manual and automatic operation.

(1) Stored Stroke Limit A

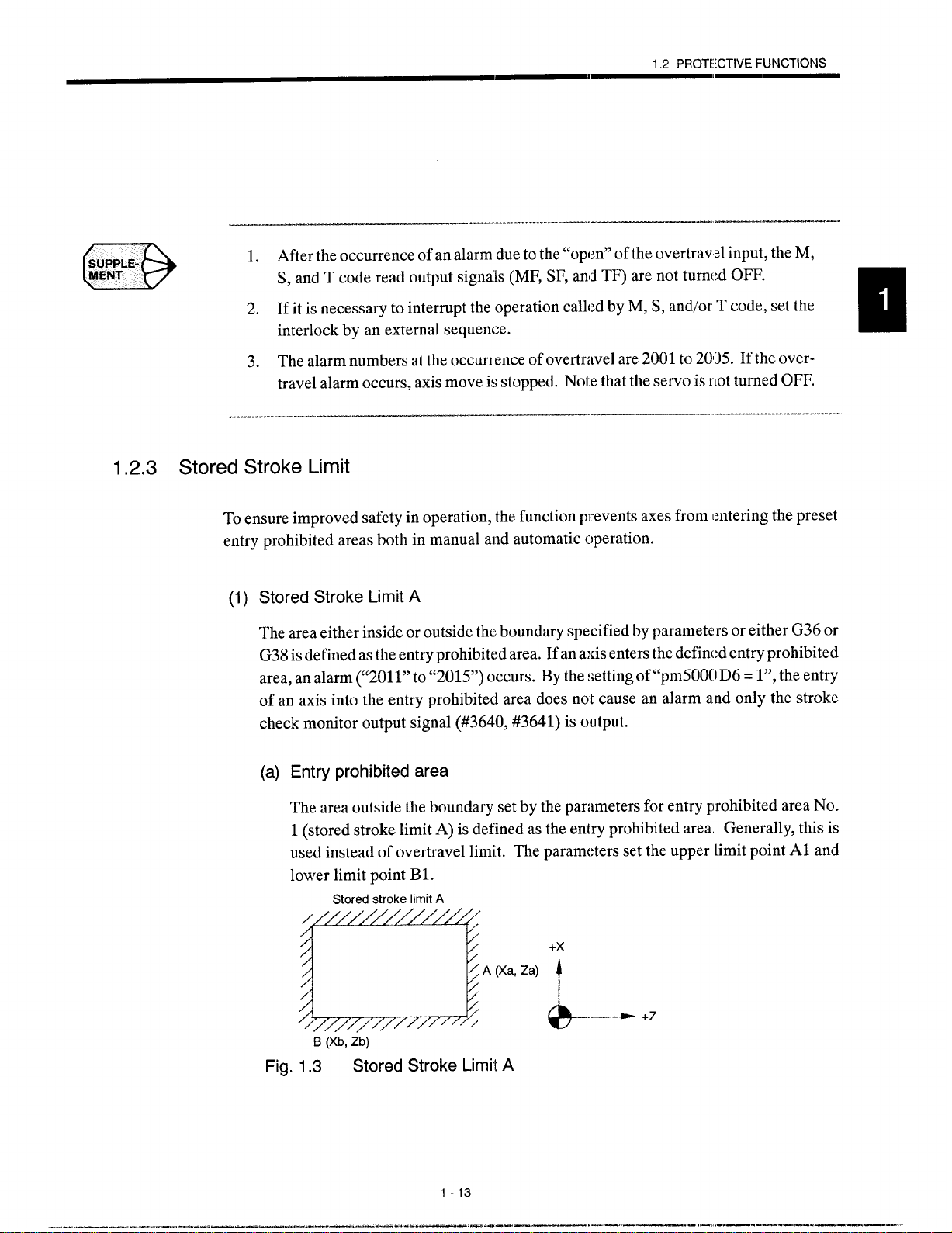

The area either inside or outside the boundary specified by parameters or either G36 or

G38 is defined as the entry prohibited area. If an axis enters the defined entry prohibited

area, an alarm (“2011” to “2015”) occurs. By the setting of “pm500(j D6 = l“, the entry

of an axis into the entry prohibited area does not cause an alarm and only the stroke

check monitor output signal (#3640, #3641) is output.

Entry prohibited area

The area outside the boundary set by the parameters for entry prohibited area No.

1 (stored stroke limit A) is defined as the entry prohibited area. Generally, this is

used instead of overtravel limit. The parameters set the upper limit point Al and

lower limit point B1.

Stored stroke limit A

_-——

[z~AVaz@~ ~+z

B (Xb, Zb)

Fig. 1.3 Stored Stroke Limit A

1-13

—... .....—

.—=. ——— m——... — ‘. !-,!.—. .—. —..,

———. -

Page 31

(b) Setting the stored stroke limit A check

Whether or not the stored stroke limit A is made valid is set for the individual axes

using the following parameters.

Table 1.3 Valid/invalid of Stored Stroke Limit A Check

E==3=s

pm6002 DO pm6002 D1 pm6002 D2 pm6002 D3

BitSetting

t--

(c) Parameters for specifying the boundary of stored stroke limit A

Table 1,4 Parameters for Specifying the Boundary of Stored Stroke Limit A

Name 1st Axis

Axis

Boundary(+):PointA pm6901

Boundary(–):Point B pm6911 pm 6912 pm 6913 pm 6914

(2) Stored Stroke Limit B (G36 to G39) *

The area either outside or inside the boundary set by parameters or by the commands

in a program is established as the entry prohibited area. The boundary is set with the

coordinate values in the machine coordinate system. Whether the entry prohibited area

is established outside or inside the boundary can be determined by the setting for a parameter. The function is made valid upon completion of the reference point return after

turning ON the power.

2“’%’s

0: Executesstoredstrokelimitcheck.

1: Doesnotexecutestoredstrokelimitcheck.

2nd Axis 3rd Axis

pm6902

‘“w’

pm6903 pm6904

‘thMs5thh

AXi’

4th

pm6002 D4

5th AXi’

pm6905

pm6915

Table 1.5 G Code Used to Turn ON/OFF the Stored Stroke Limit B Function

G Code Function Group

G36 TurningONthestoredstrokelimitB, C (entryprohibitedareasNo, 07

2 to No.5)

G37

G38

G39 TurningOFFthestoredstrokelimitC (entryprohibitedareaNo. 3) 08

.

TurningOFFthestoredstrokelimitB,C(entryprohibitedareasNo.

2 to No.5)

TurningONthestoredstrokelimitC (entryprohibitedareaNo.3)

1-14

07

08

Page 32

1.2 PROTECTIVE FUNCTIONS

●

In addition to the stored stroke limit A, stored stroke limits B and C can be added.

●

With the stored stroke limits B and C, set the boundary of the area and inside

or outside the boundary by parameters.

1.2.4

●

According to the setting fc)rthe parameter, either of stored stroke limits B and

C can be made valid.

●

For details of the stored stroke limit B, refer to 4.2.3 “Sul~program Call Up

Function (M98, M99)” in the PROGRAMMING MANUAL.

Interlock inputs

The interlock input is the signal used to disable axis movement, and is pro!:ided for each axis.

● When an axis is interlocked during movement, it is stopped after deceleration.

● When the interlock is released, the axis continues moving to complete the re-

maining commands. Upon completion of the command:,, the program advances to the next block.

● For simultaneous three axis interpolation commands, interpolation operation

is disabled if one of these two or three axes is interlocked.

YASNAC

—-—.

1

cl---l+’

ml

*C

d

Fig. 1.4 Interlock Inputs

1-15

Axis interlock

z

——.——. —.— ..—..—

Page 33

BASIC OPERATION OF YASNAC

Chapter 2 describes various kinds of operations including

power ON procedure: manual operation, and automatic operation,

2.1 GENERAL FLOW OF OPERATION . ~. ..2-3

2.2 INSPECTION BEFORE TURNING

THE POWERON . . . . . . . . . . . . . . . . . ...2-4

2.2.1 inspection of the NC IJnit . . . . . . . . . . . . . . ...2-6

2.2.2

2.2.3

Inspection of the Tape Reader . . . . . . . . . . . . . 2-7

Preparation before Turning the Power

CIN . . . 2-8

2.3 TURNING TI+E POWER ON AND

INSPECTION A17ER POWER ON . . ...2-9

2.3.1 Procedure for Turning the Power ON . . . . . . . 2-9

2.3.2 Checking the Motors ‘for Abnormalities . . . . . 2-10

2.3.3

2.3.4

2.4 MANUAL OF)ERATION (l) . . . . . . . . ...2-15

2.4.1 Manual Rapid Traverse (RAPID) . . . . . . . . . . 2-15

2.4.2 Jog Fef?d (JOG) . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . .2-16

2.4.4 Handle Feed (HANDLE) . . . . . . . . . . . . . ...2-17

Procedure for Turning the Power OFF . . . . . 2-11

inspection of the Battery . . . . . . . . . . . . . . . 2-12

—-— —.. .—. ———. —.. ——. — .—. -.. .’...—

2-1

. .. ..—. . ..—

—.. .—.,.—-. —.-——..—

Page 34

2.?5 MANUAL OPERATION(2) . . . . . . . . ...2-18

2.5.1 Simultaneous 3-axis Handle Feed * . . . . . . . 2- 18

2.5.2 Manual Reference Point Return . . . . . . . . . 2-19

2.5.3 Manual Reference Point Return

to the Second Reference Point* . . . . . . . . .

2-22

2.5.4

l-line MDl . . . . . . . . . . . . . . . . . . . . . . . . ... ..2-23

2.6 AUTOMATIC OPERATION (1) . . . . . ...2-24

2.6.1 Preparation of Automatic Operation . . . . . . . 2-24

2.6.2 Memory Operation . . . . . . . . . . . . . . . . . . . ...2-26

2.6.3 MDI Operation . . . . . . . . . . . . . . . . . . . . . . ...2-27

2.6.4 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-28

2.6.5 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-29

2.7 AUTOMATIC OPERATION (2) . . . . . . . .2-31

2.7.1 Optional Stop . . . . . . . . . . . . . . . . . . . . . . . ...2-31

2.7.2 Optional Block Skip . . . . . . . . . . . . . . . . . . ...2-31

2.7.3 Dry Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-32

2.7.4 Machine Lock . . . . . . . . . . . . . . . . . . . . . . . ...2-33

2.7.5 Auxiliary Function Lock . . . . . . . . . . . . . . . . . . 2-33

2.7.6 Feed Hold in Thread Cutting*.. . . . . . . . . . . 2-34

2.8 OPERATION INTERVENTION

DURING AUTOMATIC OPERATION ., .2-35

2.8.1 Manual Operation Intervention

during Automatic Operation . . . . . . . . . . . . . . 2-35

_--- ...—.

2.8.2 MDI Operation Intervention

during Automatic Operation . . . . . . . . . . . . . . 2-36

2.8.3 Automatic Handle Mode Offset* . . . . . . . . . . 2-37

2.8.4

Manual Absolute . . . . . . . . . . . . . . . . . . . . . ...2-38

2.9 AUTOMATIC OPERATIONS

AT EN14ANCED LEVEL ., . . . 2. . . . . ...2

2.9.1 Fleturn to Setup Point . . . . . . . . . . . . . . . . ...2-40

2.9.2 Return to the Operation Interrupted Point* . 2-40

2.9.3 Saving the Present Position Data . . . . . . . . . 2-42

2.9.4 Program Restart . . . . . . . . . . . . . . . . . . . . ...2-43

2-2

-40

Page 35

2.1 GENERAL FLOW OF OPERATION

2.1

GENERAL FLOW OF OPERATION

The operation procedure usually followed for daily operation is indicated in Fig. 2.1. This

Chapter gives explanation on these operation items.

MODE SELECT

wchecking’heNc”ni’

&-

ConfirmingREADY signal ON

Setting the switches

on the operation panel

~ CYCLE START ON

$-

-

- SINGLE-BLOCK

‘tc,

RESET ON

FEED HOLD or

SINGLE-EILOCK ON

Manual operation

intervention

k

-__!ic= ---------”:

Zero point

return operation

I

--vF _...._:

Manual or by G28 ,

I

Pitch error compensa- ~

tion,

Stored stroke limit ON/

L

Preparation for

automatic operation

Positioning

at the start point

$-

$-

K

CYCLE START ON

SINGLE-BLOCK ON

MDI operation

intervention

CYCLE S-I”ART ON

Setting NC tape

J

1

LoadingNCprogramfromtape,

letit.g:toredN;programand

executingprogramnumbersearch

1

I

(!!!!

Preparation for

turning

*rrence

Checking tool

offset amounts

I

I

Fig. 2.1 Operation Procedure

I

I

r

.4-

OFF the power

End of mtichining

- CYCLE START OFF

- Checking for alarm

2-3

——. ——- . . ..- .——. -.- ——, - —.

—... ..—.-.—--— .———..—

.-. ——-—

Page 36

2.2 INSPECTION BEFORE TURNING THE POWER ON

Before turning the power ON for YASNAC J300, it is necessary to carry out inspection to

ensure safety. If the power is turned ON while the system has troubles, it could cause malfunctioning of the system itself as well as hazards to the operators. Make sure to carry out

daily inspection before turning the power ON.

@ WARNING

Always turn the power OFF (including the primary power supply) before carrying

~

out daily inspection.

Carrying out the inspection with the power ON may lead to electric shock.

D Wait 5 minutes after turning the power (including the primary power supply) OFF

before removing or replacing any unit or part.

Failure to observe this warning may lead to electric shock and product failure.

o Do not

Failure to observe this warning may lead to electric shock or device malfunction.

D Immediately after switching the power OFF, the product retains some electric

charge. Do not touch any parts which are live when the power is ON for 5 min-

utes after switching the power OFF.

Failure to observe this warning may lead to electric shock or device malfunction.

● Do not damage cables, subject them to excessive stress, or pinch them.

Excessive load on cables may cause electric shock.

o When the unit is turned ON, never touch its rotating parts,

Failure to observe this warning may result in personal injury.

c Never modify the product.

Failure to observe this warning may result in electric shock, fire, or product failure.

touch any unit, terminals, etc., while the power is ON.

Page 37

2.2 INSPECTION BEFORE TURNING THE POWER ON

~ CAUTION

To prevent personnel other than those involved in maintenance and inspection

I

work from turning ON the power while maintenance and inspection is in progress, place signs stating “Do not turn the power on” or words to ‘lhat effect at the

primary power supplies of related control panels and other relevant locations.

Failure to observe this caution may lead to electric shock.

J Electronic devices such as C MOS ICS are used on the control boards. If you

touch them with your bare fingers the static electrical charge in your body could

destroy them; care must be taken when handling these devices, Before han-

dling these devices for maintenance purposes, first discharge the static electric-

ity in your body by touching a grounded metal device.

Failure to observe this caution could lead to injuries and product failure.

D Do not install or remove boards, wiring, connectors, etc., while the power is ON.

Failure to observe this caution could lead to electric shock, product failure, and malfunction.

o Do not let foreign matter such as electric wire scrap enter the unit.

Failure to observe this caution may result in fire, product failure or malfunction.

I Be sure to check the following points on completing maintenance and inspection

work.

● Check that all fastening bolts are tightened.

● Check that no tools or other objects have been left inside the conl.rol panel.

● Check that the control panel door is closed properly.

Failure to carry out these checks may lead to electric shock, injuries, fire, and malfunction.

~ Never attempt to disassemble or modify units or devices insidls the NC unit.

Failure to observe this caution may lead to fire, product failure, or malfunction.

o Do not change the set values of the devices, variable resistors, etc., in the con-

trol panel.

Failure to observe this caution may lead to fire, product failure, and malfunction.

——— ——-. — .—.. ---- -

2-5

.———, . —. —.. .-,, ,—.— —-. —.—. -.

Page 38

2.2.1 Inspection of the NC Unit

In this subsection, the items to be inspected before turning ON the power are indicated for

the standard NC box supplied by Yaskawa. For the control box specific to the machine tool,

refer to the manuals published by the machine tool builder.

(1) inspecting the Doors

Make sure that the doors are securely closed before turning the power ON.

The NC box is completely shielded to keep outside air out to protect the precision de-

vices in the NC box from oil mist or other airborne foreign matter. The doors of the NC

box must always be kept closed.

(2) Inspecting the Shielding Parts

Inspect the shielding parts in the NC box every month for gaps and/or damages.

@ Open the doors and check the packings which are installed around the door for

damage.

@ Inspect the inside of the NC box for abnormal contamination. If the inside is

abnormally dirty, clean it immediately after locating the cause of contamination.

@ Lock the doors securely and inspect the doors to make sure that there are no

gaps.

By carrying out the inspection indicated above at regular intervals, performance of

YASNAC J300 can be maintained for a long period.

2-6

Page 39

2.2 INSPECTION BEFORE TURNING THE POWER ON

——

2.2.2

Inspection of the Tape Reader

If the tape reader is dirty or does not operate smoothly, it could cause mal:~unctioning of the

NC. Inspect and clean the tape reader from time to time.

Tape hol

Reading head

Fig. 2.2 Tape Reader

Clean the glass in the reading head by removing tape chips and dust with a soft

brush. If oily stain is found, wipe it off with clean gauze 01soft cloth soaked

with absolute alcohol. Clean both the tape guide face and tape holder at the

same time.

Fig. 2.3

If dust is found on the LED face in the upper light source, clean it with soft

brush.

For the tape reader equipped with 6-inch cm8-inch tape take-up reels, if tension

arm movement seems to be heavy, apply a small amount of machine oil to the

shaft base portion.

C)*

Supply oil here

o

\

/

\

\

8-inch Take-up Reel

Tension arm

2-7

----- .. —

,—.—.

.. .—..—.. —.—— ..—

——-—.

Page 40

.——_, ._.. __. __. _.-- . .. ._______ ——

suPP&E-

klENT

D

If a problem occurs with tape winding or tape feed operation with the tape reader

equipped with 8-inch tape reels, open the front door, and clean the area around the photocoupler located near the reel drive motor.

——— —.———-——.—,——-.———

2.2.3 Preparation before Turning the Power ON

Before turning the power ON, confirm the following items.

● Make sure that both the front and rear sides of the NC unit are closed. If the

door is open or if there is a gap between the door and the box panels, securely

close the door using the door lock.

● Carry out the inspection for the machine and machine related controllers ac-

cording to the instructions given in the manuals published by the machine tool

builder.

—.-—-.., --. -.—-..-.——---------

—.. ..-. ..-—. — - —

:2.8

Page 41

2.3 TURNING THE POWER ON AND INSPECTION AFTER POWER ON

2.3 TURNING THE POWER ON AND INSPECTION AFTER

POWER ON

In this section, the procedure to be used for turning the power ON is explained. Inspection

that must be conducted after turning the power ON is also described.

@ WARNING

2.3.1

. Be sure to turn the power OFF before replacing the battery.

Failure to observe this warning may lead to electric shock and product failure

~

●

Replace fuses and batteries with the designated products.

Failure to observe this caution may result in fire or product failure.

●

Use the product with the “System Number Switch” of the CPU set to ‘(O”.

Use while set to another number may lead to malfunction.

●

Wait at least 2 seconds after turning the power OFF before turning it ON again.

Failure to observe this caution may lead to malfunction.

CAUTION

I

Procedure for Turning the Power ON

Turn the power ON in the following procedure.

@) Make sure that the power is supplied to the NC unit from an external power

source.

“7

___l__l

ml

Press the POWER ON button on the NC operation panel. Control power is

turned ON and the cooling fan starts rotating.

Make sure that air is flowing out at the upper part on the side of the NC unit.

In approximately 20 seconds, the control is ready for turning ON the servo

power (alarm code 3000).

Press the POWER ON button once again.

The servo power is turned ON. When the machine is read y for operation, the

NC enters the ready state.

When the power is correctly turned ON to the NC unit, the NRD (NC ready)

signal is output.

2-9

.——-— . ..... ——=. —

,— —,.. —.. ,.., ,—.—. —.. ——— —..

Page 42

When the power is turned ON at the machine side in response to the NRD signal, the MRD (machine ready) signal will be returned to the NC. The READY

lamp goes on when the MRD signal is returned. Note that the READY lamp

is not used with some types of machines.

When the NC unit enters the ready state, the alarm message displayed on the

screen will go off.

If the NC unit fails to enter the ready state, locate the cause by referring to Section 7.2, “ALARM DISPLAY JOB”, and take appropriate measures. For turning the power ON, there are items that must be inspected at the machine side

in addition to the NC unit related items. For such items, refer to the manuals

published by the machine tool builder. ‘

POWER ON POWER ON

44

–JAPP,OX, :

;- ;

—

—

.~.

—

—

\

Control power supply

Control ready

Servo power supply

NRD (NC ready)

Machine power supply

MRD (machine ready)

Alarm code: “3000 “21 90;’ “Blank”

Fig. 2,4 Power ON Sequence

2.3.2 Checking the Motors for Abnormalities

Check the motors for their operation. If abnormal vibration or noise is found, turn OFF the

power and contact the maintenance personnel.

::

,,

2-1o

Page 43

2.3 TURNING THE POWER ON AND INSPECTION AFTER POWER ON

2.3.3 Procedure for Turning the Power OF:F

Turn the power OFF in the following procedure.

Make sure that the CYCLE START lamp on the machine operation panel is

OFF with the machine stopped.

Make sure that there is no alarm message displayed on the CRT screen. If an

alarm message is displayed, locate the cause by referring to Section 7.2,

“ALARM DISPLAY JOB” and take appropriate measures to clear it.

Carry out inspection necessary for turning the power OFF at the machine side.

For details, refer to the mimuals published by the machine tool builder.

Press the EMERGENCY STOP button on the machine operation panel to turn

OFF the servo power.

Press the POWER OFF button on the NC operation panel to shut off the power

to the control panel.

Turn the power supply to the NC OFF by turning OFF such as a circuit breaker.

Control power supply

Control ready

NRD (NC ready)

Machine

M.D(.achinerea(~Q-.–.

READY lamp

2.5 Power OFF Sequence

Fig.

~—{

+-—.—

power

----1 / —.

Alarm: “ENank”

EMERGENCY STOP POWER OFF

; ---——l___

IIL ! -

,-

“3002 i

2-11

..-, -—..——. — .—..——. -—. ———.—

——-—

Page 44

2.3.4 Inspection of the Battery

After turning the power ON, check the CRT screen if “BAT’ message is blinking at the lower

right area. If it is displayed, it indicates that the battery is weakening. The battery must be

replaced within one month. If the display of “BAT’ message is given, make sure to leave

the NC unit power ON at least

Standard batteries cannot be used. For a spare battery, contact your Yaskawa representative.

Battery type: ER6VC3, Parts code: BA507

olme hour every three days.

rmsmr

BAT

Eg:

Battery alarm indication

Connector

The location of battery and related indicator (LED) is shown in Fig. 2.5.

(1) Checking the Battery Which Needs Replacing

Follow the procedure indicated below to check whether or not battery must be replaced.

Press the POWER OFF button.

If a door interlock switch is installed, place the door interlock key in the OFF

position. This makes power ON possible with the door opened.

Open the door so that the front part of the NC unit is visible.

Press the POWER ON button once again.

Check the red LED on the JCPO1 board. If it is lit, the battery must be replaced.

2-12

Page 45

2.3 TURNING THE POWER ON AND INSPECTION AFTER POWER ON

—1

Red LED—

[

w

JCPO1 JOPO2

Battely

JCP04

Battery cover

—

L,

E

Fig. 2.6

!

1

1

1

1

Arrangement of Battery and Indicator Lamp (LED)

2-13

Page 46

(2) Replacing the Battery

the battery quickly in the following procedure.

Turn the power OFF.

Remove the battery cover by prying it up with a screwdriver. Then, remove

the battery from the holder.

Fit the new battery in the holder and insert the connector. Although the connector may be inserted in either direction, it must be securely inserted. Other-

wise, the power will not be supplied by the battery. (See Fig. 2,7.)

\\ I//

POINT

Q

(Correct) (Correct)

Fig. 2.7

1. If the red LED remains lit after replacing the battery, the connector might be inserted incorrectly or the battery might be faulty.

2. Power OFF operation is allowed a few seconds after turning the power ON.

3. After turning the power OFF, replace the battery quickly. If the NCunit is left with

the battery removed, the clata stored in the memory could be lost.

4. If the NC unit has two battery packs, replace both of battery packs at the same

time. Note that the date of manufacture of the battery packs to be installed newly

should be as close to each other as possible. If the battery packs manufactured

in different years are used, the service lives of them will be shortened and in the

worst case, the life will be that of a single pack.

Connecting the Battery Connector

Turn the power ON.

Make sure that “BAT” is not blinking on the CRT screen and that the red LED

in the board is OFF,

(Incorrect)

——— ——

2-14

Page 47

2.4 MANUAL OPERATION (1)

This section describes general explanation on manual operation. To move an axis manually,

select the operation mode of wID, JC)G, STEP or HANDLE with the MODE SELECT

switch on the machine operation panel.

2.4.1 Manual Rapid Traverse (RAPID)

An

axis can be moved at a rapid traverse rate. Follow the procedure indicated below.

Select the rapid mode by placing the MODE SELECT switch on the machine

operation panel in the RAPID position.

MEM

Mc)l

2.4 MANUAL OPERATION (1)

TAPE

HANDLE

STEP

JOG

e

m

RAPID

Select the feedrate to be used for axis feed operation by the RAPID TRAVERSE RATE OVERRIDE switch on the machine operat ion panel.

Override setting is possible in four steps of 100%, 50%, 25’%,and Fo. The feedrate corresponding to the ~settingat 100%, 50%, and 25% isset for parameters

pm2801 to pm2805. For the setting at F(),feedrate set for parameter pm2447

is used.

Optionally, F1 and Fz positions are selectable. Feedrate to be selected accord-

ing to the switch setting at F1 and F2 is set

On the machine operation panel, press the JOG button that corresponds to the

axis and the direction in which the axis should move. The ax is moves at a rapid

traverse rate while the button is held pressed.

JOG

+x

+C +Z

“

Ifor parameters pm2448 and pm2449.

❑ IEIIID

mm

2-15

Page 48

2.4.2 Jog Feed (JOG)

It is possible to move an axis in the jog feed mode. Follow the procedure indicated below.

@) Select the jog mode by placing the MODE SELECT switch on the machine

operation panel in the JOG position.

@ Select the feedrate with the JOG FEEDRATEswitch on the machine operation

panel.

● Feedrate can be selected from 32 steps, with actual feedrates of individual set-

ting positions set for parameters pm2400 to pm2431. The actual number of

steps and feedrates selectable by the JOG FEEDRATE switch vary depending

on the machine model. For details, refer to the manuals published by the machine tool builder.

@ Press the JOG switch corresponding to the axis to be moved and the required

axis move direction.

@ The axis moves at the selected feedrate while the JOG switch is held pressed.

2.4.3 Step Feed (STEP)

Manual step feed operation is pcs.sible. Follow the procedure indicated below.

Select the step mode by placing the MODE SELECT switch on the machine

operation panel in the STEP position.

Select the feed distance per step with the MANUAL PULSE MULTIPLY

switch on the machine operation panel.

Metric system :

Inch system

0.001,0.01,0.1, 1.0,10.0, 100.0 mm (per step)

: 0.0001,0.001,0.01,0.1, 1.0, 10.0 inch (per step)

Press the JOG switch corresponding to the axis to be moved and the required

axis move direction.

Each time the JO(3 switch is pressed, the selected axis moves in the selected

direction by the set feed distance per step.

2-16

Page 49

2.4.4 Handle Feed (HANDLE) *

When the NC is equipped with a manual pulse generator, pulse handle fetid opemtion is possible. Follow the procedure indicated below.

Select the handle mode by placing the MODE SELECT sw;tch on the machine

operation panel in the HANDLE position.

Select the axis to be movedby the HANDLEAXIS selection switch on the machine operation panel.

With the MANUAL PULSE MULTIPLY switch on the machine operation

panel, select the axis feed distance per pulse (one division of the pulse handle).

2.4 MANUAL OPERATION (1)

Clockwise rotation:

Counterclockwise direction:

Metric system

: 0.001,0 .01,0.1 mm (per division)

In the positive direction

In the negative direction

Inch system : 0.0001,0.001,0.01. inch (per division)

Turn the pulse handle. The axis moves in the positive or negative direction

according to the direction in which the pulse handle is turned.

2-17

Page 50

2.5 MANUAL OPERATION (2)

This section describes manual operations carried out in daily production using the manual

operation functions explained in 2.4 “MANUAL OPERATION (l)”.

2.5.1 Simultaneous 3-axLs Handle

By installing the pulse handle for the individual axes, it is possible to move three axes among

the X-, Z-, and C-axis simultaneously. Follow the procedure indicated below.

1st HANDLE AXIS

c

Xj-w

o

1st HANDLE AXIS

—

0

D

Fig. 2.8

z

Q

i-

0

Simultaneous 3-axis Pulse Handle Feed

Feed *

2nd HANDLE AXIS

c

XA z

e

o

2nd HANDLE AXIS

+

0

o

01

MANUAL PULSE MULTIPLY

xl 00

xl o

xl *

@

xl 000

Xlo,ooo

Xloo,ooo

3rd HANDLE AXIS

3rd HANDLE AXIS

—

i-

0

0

D

@ Select the handle mode by placing the MODE SELECT switch on the machine

operation panel in the HANDLE position.

@ Select the axis feed distance per graduation of the pulse handle with the

MANUAL PULSE MULTIPLY switch on the machine operation panel. This

switch is used in common for the three pulse handles.

@ Turn the pulse handle. The selected axis is movedin the positive or negative

direction according to the handle turning direction.

2-18

Page 51

2.5.2 Manual Reference Point Return

Axes can be returned to the reference point in manual operation. Follow the procedure indi-

cated below.

Select the rapid orjogmode by placing the MODE SELECT switch on the ma-

@

chine operation panel in the RAPID or JOG position.

Move an axis manually (manual rapid traverse or jog feed) lo a position away

@

from the reference point (within the reference point return enabled area).

When an axis is located in range A in Fig. 2.9, reference point return ca be

executed correctly.

Turn ON the REFERENCE POINT RETURN switch.

@

2.5 MANUAL OPERATION (2)

TERM?

D

Keep the JOG switch pressed corresponding to the axis to be returned to the

@

reference point and in the return direction. When the JOG switch is held

pressed, the corresponding axis starts moving in the same manner as ordinary

manual axis feed operation. When the axis reaches the deceleration point, feedrate is decelerated to a low feedrate and the axis stops automatically at the

reference point.

Upon completion of the reference point return, the REFERENCE POINT

@

lamp of that axis lights.

Rapid traverse rate

~<F@S2ce

I

Dog width ~ ~

la

J

I

-,

----

MnJL.l@L

Area A

Fig. 2.9 Manual Reference fsoint Return

+ Reference Point

e-