Page 1

A A h

CNC SYSTEM FOR TURNING APPLICATIONS

YASNAC J300L

PROGRAMMING MANUAL

Upon receipt of the product and prior to initial operation, read these

instructions thoroughly, and retain for future reference.

REFERENCE

YASNAC J300L OPERATING MANUAL

TOE-C843-”1 3.20

YASUNNA MANUAL NO. TOE-C843-1 3.21

Page 2

FOREWORD

This manual gives the information necessary for creating a program u;ing the YASNAC

J300L (with basic NC operation panel, 9-inch CRT).

Some information is given in tables in the Appendix so that readers can easily find the necessary information. In the G code table, section numbers are given for each G code to allow

quick access to a detailed explanation if necessary.

The YASNAC J300L comes with an operation manual in addition to this programming

manual. Use these manuals in conjunction with each other to ensure prclductive operation.

CAUTIONS

This manual describes all the option functions (identified by the “*” symbol) but some of

these may not be available with your YASNAC J300L. To determine the option functions

installed in your NC, refer to the specification document or manuals published by the machine tool builder.

Unless otherwise specified, the following conditions apply in programming explanations

and programming examples.

● Metric system for input and metric system for output/movement

●

: Zero point in the base coordinate system

e

●

: Reference point

@

Yaskawa has made every effort to describe individual functions and their relationships to other functions as accurately as possible. However, there are many things t;~at cannot or must

not be performed and it is not possible to describe all of these. Accordingly, readers are requested to understand that unless it is specifically stated that something can be performed,

it should be assumed that it cannot be performed.

Also bear in mind that the performance and functions of an NC machine tool are not determined solely by the NC unit. The entire control system consists of the mechanical system,

the machine operation panel and other machine related equipment in addition to the NC.

Therefore, read the manuals published by the machine tool builder for detailed information

relating to the machine.

Page 3

General Precautions

● Some drawings in this manual are shown with the protective cover or shields removed,

in order to describe the detail with more clarity. Make sure all covers and shields are

replaced before operating this product, and operate it in accordance with the directions

in the manual.

● The figures and photographs in this manua Ishow arepresentative product for reference

purposes and may differ from the product actually delivered to you.

● This manual maybe modified when necessary because of improvement of the product,

modification, or changes in specifications. Such modification is made as arevision by

renewing the manual No.

● To order a copy of this manual, if your copy has been damaged or lost, contact your

Yaskawa representative listed on the last page stating the manual No. on the front

page.

● If any of the nameplates affixed to the product become damaged or illegible, please

send these nameplates to your Yaskawa :representative.

● Yaskawa is not responsible for any modification of the product made by the user since

that will void our guarantee.

Page 4

NOTES FOR SAFE OPERATION

Read this programming manual thoroughly before installation, operatiorl , maintenance or

inspection of the YASNAC J300L.

The functions and performance as NC machine tool are not determined oily by an NC unit

itself. Before the operation, read thoroughly the machine tool builder’s documents relating

to the machine tool concerned.

In this manual, the NOTES FOR SAFE OPERATION are classified as “WARNING”

“CAUTION’.

Indicates a potentially hazardous situa;ion which, if

~ WARNING

m!mi!l

Even items described inl ~

In either case, follow these important items.

Please note that symbol mark used to indicate caution differs between 1S0 and JIS.

not avoided, could result in death or serious injury to

personnel.

Symbol

uct.

Indicates a potentially hazardous situa;ion which, if

not avoided, may result in minor or mo,ierate injury

to perscmnel and damage to equipment.

It may also be used to alert against unsafe practice.

is used in labels attached to the prod-

@

CAUTION I may result in a vital accident insome situations.

or

In this manual, symbol mark stipulated by 1S0 is usecl.

On products, caution symbol marks of 1S0 and JIS are used in labels.

Please follow the same safety instructions concerning caution.

Ill

Page 5

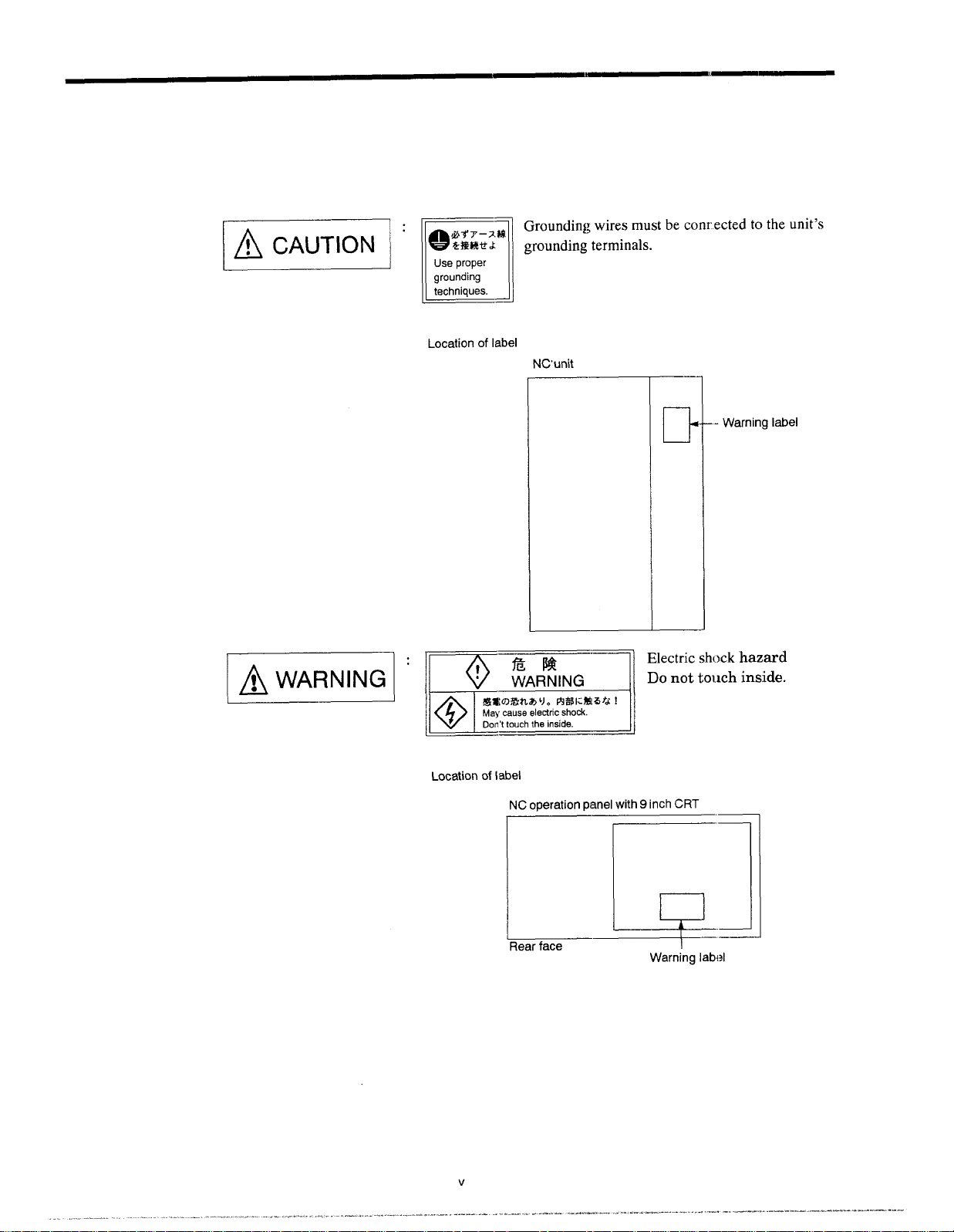

KEY TO WARNING LABELS

The following warning labels are used with the YASNAC J300L.

Electric shock hazard

Do not touch the terminals while the power is

on, and for 5 minutes after switching off the

power supply!

Location of label

NC unit

— Warning label

——

.—.

iv

— .-

Page 6

Grounding wires must be conr ected to the unit’s

grounding terminals.

Use proper

grounding

techniques.

ILJI

Location of label

I ~ WARNING I “

Location of label

NC operation panel with 9 inch CRT

~~——

Rear face

Warning Iab[?l

Page 7

CONTENTS

FOREWORD . . . . .. .. . .. .. . .. .. . . . .. . . . .. . .. . . . .. . . . .. . .. . .

NOTES FOR SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KEY TO WARNING LABELS . . . . . .. . . . .. . . . .. . .. .. . .. . . . .. . .

1. PROGRAMMING BASICS

1.1 FUNDAMENTALS OF PROGRAMMING TERMINOLOGY . ...1-2

1,141

1.1.2 Least lnputlncrement and Least Output Increment . . . . . . . . . . . . . . . . . 1-3

1.1,3 Maximum Programmable Values for Axis Movement........,.. . . . . . 1-5

1.1.4 Tape Format . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.1,5 Program Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.1.6 OptionalBlockSkip(/1),(/2to/9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.1,7 Buffer Register and Multi-active Register . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.2 BASICS OF FEED FUNCTION . ., . . .. . . . .. . . . .. . . . . . . ...1-19

1.2.1

1.2.2 Cutting Feed (FCommand) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.2.3 Switching between Feed per Minute Modeand Feed per

1.2.4 Automatic Acceleratio nandDeceleration . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Numerically Controlled Axesandthe Number of Simultaneously

Controllable Axes . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,. 1-2

Rapid Traverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Revolution Mode (G98/G99) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

iv

I

!,,

Ill

2. COMMANDS CALLING AXIS MOVEMENTS

2.1 INTERPOLATION COMMANDS ..,... . . . . . . .. .. . .. . . . . ...2-3

2.1.1

2.1.2 Linear interpolation (GOl) . . . . . . . . . . . . . . . ., . . . . . . . . . . . . . . . . . . . ...2-5

2.1.3 Circular interpolation (G02, G03, G22, G23) . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.1.4 Chamfering (Gil) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,2-14

2,1.5 Rounding (G12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,2-16

2.1.6 Cylindrical interpolation (G124)G125) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.1.7 Polar Coordinate interpolation (G126, G127)* . . . . . . . . . . . . . . . . . . . . 2-21

2.2 USING THE THREAD CUTTING FUNCTION . . . . . . . . . . . ...2-28

2.2.1 Thread Cutingand Continuous Thread Cutting (G32) . . . . . . . . . . . . . . 2-28

2.2.2

2.2.3 Variable Lead Thread Cutting (G34)* ,, ., . . . . . . . . . . . . . . . . . . . . . ...2-37

2.3 REFERENCE POINT RETURN . . . .. . ., . . . . .. .. . .. . . . . ...2-39

2.3.1

2.3.2 Reference Point Return Check (G27) . . . . . . . . . . . . . . . . . . . . . . . . . ...2-44

2.3.3 Return from Reference Point Return (G29) . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.3.4 Second to Fourth Reference Point Return (G30)* . . . . . . . . . . . . . . . . . 2-49

Positioning (GOO,G06) . . . . . . . . . . . . . . . . . ,,, ,, ...,,,.,.........,.2-3

Multiple-thread Cuttirlg(G32)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2 -34

Automatic Return to Fieference Point (G28) . . . . . . . . . . . . . . . . . . . . . . 2-39

vi

Page 8

3. MOVEMENT CONTROL COMMANDS

3.1 SETTING THE COORDINATESYSTEM . .. .. . .. . . . . . . .. ...3-3

3.1.1 Base”Coordinate System (G!jO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-3

3.1.2 Workpiece Coordinate System (G50T, G51) * . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2 DETERMINING THE COOFIDINATE VALUE

INPUT MODES . . . . .. . . . .. . . . . . .. . . . .. . . . . . . . . .. . . . ...3-16

3.2.1

3.2.2 Diametric and Radial Commands for X-=is . . . . . . . . . . . . . . . . . . . . . . 3-19

3.2.3 Inch/Metric Input Designation (G20, G21) . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Absolute/lncremental Desigrlation . . . . . . . . . . . . . . . . . .1 . . . . . . . . . ...3-16

3.3 TIME-CONTROLLING COMMANDS . . . . . .. . . . .. . . ~~. .. ...3-22

3.3.1

Dwell (G04) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-22

3.4 TOOL OFFSET FUNCTIONS . . .. . . . . . . . . . . . . . .. . . ... ...3-23

3.4.1

3.4.2 Tool Position Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-24

3.4.3 Nose ROffset Function (G4(l, G41/G42) . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Tool Offset Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-23

3.5 SPINDLE FUNCTION (S FIJNCTION) . . . . . . . . . . . . . ... ...3-75

3.5.1

3.5.2 Maximum Spindle Speed Command (G50S) . . . . . . . . . . . . . . . . . . . . . 3-76

3.5.3 Constant Surface Speed Control (G96, G97)* . . . . . . . . . . . . . . . . . . . . 3-77

3.5.4 Rotary Tool Spindle Selection Function . . . . . . . . . . . . . . . . . . . . . . . . . . 3-81

Spindle Command (S5-digit Command) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

3.6 TOOL FUNCTION (T FUNCTION) . . . . . . . . . . . . . . . . . . . ...3-82

3.6.1

3.6.2 T6-digit Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-82

T4-digit Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-82

3.7 MISCELLANEOUS FUNCTION (M FUNCTION) . . . . c. . . ...3-83

3.7.1

3.7.2 internally Processed M Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3- 84

3.7.3 General Purpose M Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3-85

. .—.——-—- ..— ..—.-—-----

MCodes Relating to Stop Operation (MOO, MOl, M02, M30) . . . . . . . . 3-83

vii

——— .- .._—-.—...—..-. -—-.-.... ..—— ..-.. - .—, -—-.. —.-..-,— . .. —.-—.——

Page 9

4. ENHANCED LEVEL (COMMANDS

4.1 PROGRAM SUPPORT FUNCTIONS(l) ,.. .: .,............4-3

4.1.1

4.1.2 Multiple Repetitive Cycles (G70to G76)* . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.1.3 Multiple Chamfering/Rounding on Both Ends of Taper (Gill) * . . . . . . 4-56

4.1.4 Multiple Chamfering/Rounding on Arc Ends (G112) *. , . . . . . . . . . . . . . 4-70

4.1.5

4.2 PROGRAM SUPPORT FUNCTIONS

4.2.1

4.2.2 Programmable Data lnput(GIO) *.... . . . . . . . . . . . . . . . . . . . . . . . ...4-104

4.2.3 Subprogram Call Up Function (M98, M99) . . . . . . . . . . . . . . . . . . . . . . . 4-106

4.2.4 Stored Stroke Limit B(G36to G39) . . . . . . . . . . . . . . . . . . . . . . . . . ...4-108

Canned Cycles (G9Cl. G92. G94) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Hole-machining Canned Cycles

(G80to G89, G831, G841, G861) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-79

(2) , . . . . . . . . . . . . . . ...4-94

Solid Tap Function (G84, G841) *..... . . . . . . . . . . . . . . . . . . . . . . . . ..4-g4

4.3 AUTOMATING SUPPORT FUNCTIONS . . . . .. . . . . . . . . . . .4- 114

4,3.1

4.3.2 Tool Life Control Function (G122, G123) . . . . . . . . . . . . . . . . . . . . . . . . 4-117

4,4 MICROPROGRAMS . . .. .. . . . .. . .. . . . .. . .. .. . .. . . . .. . 4-126

4.4.1

4.4.2

4.4.3 Variables, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4 -138

4.4.4 Operation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-162

4.4.5 Control instructions .,, ,,, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4-164

4,4,6 Registering the Microprogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4 -170

4.4.7 RS-232C Data Output 2( BPRNT, DPRNT) . . . . . . . . . . . . . . . . . . . . . . 4-171

4.4.8 Microprogram Alarm Numbers,,,. , . . . . . . . . . . . . . . . . . . . . . . . . ...4-176

4.4.9 Examples of Microprograms, ,., ,, ., . . . . . . . . . . . . . . . . . . . . . . . ...4-177

Skip Function (G31) *.....,,.,...,.. . . . . . . . . . . . . . . . . . . . . . . ...4-114

Differences from Subprograms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-126

Microprogram Call (G65, G66, G67)*. . . . . . . . . . . . . . . . . . . . . . . ...4-128

APPENDIX 1 G CODE TABLE

APPENDIX l.l GCODE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Al-2

APPENDIX 2 INDEX

..

Vlll

Page 10

PROGRAMMING BASICS

Chapter 1 describes the basic terms used in programming

and

the feed functions.

1.1

FUNDAMEN”rALS OF PROGRAMMING

TERMINOLOGY. . . . . . . . . . . . . . . . . . . . .1-2

1.1,1

Numerically Controlled Axes and the Nulmber

of Simultaneously Controllable Axes . . . . . . . . 1 -2

1.1,2

1.1.3

1,1.4

1,1.5

1.1.6 Optional Block Skip (/1), (/2 to /9) * . . . . . . . . 1-17

1.1.7

1.2

BASICS OF I=EED FUNCTION . . . . . i .. 1-19

1.2.1

1.2.2 Cutting Feed (F Command) . . . . . . . . . . . . . . 1-20

1.2.3

1.2.4

Least Input Increment and Least Output

Increment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ‘1-3

Maximum Programmable Values for Axis

Movemen t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Tape Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Program Format . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Buffer Register and Multi-active Registel’ . . . 1-18

Rapid Traverse . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Switching between Feed per Minute Mode

and Feed per Revolution Mode (G98/G$19) . 1-26

Automatic Acceleration and Deceleration . . . 1-27

Page 11

1.1

FUNDAMENTALS OF PROGRAMMING TERMINOLOGY

This section describes the basic terms used in programming.

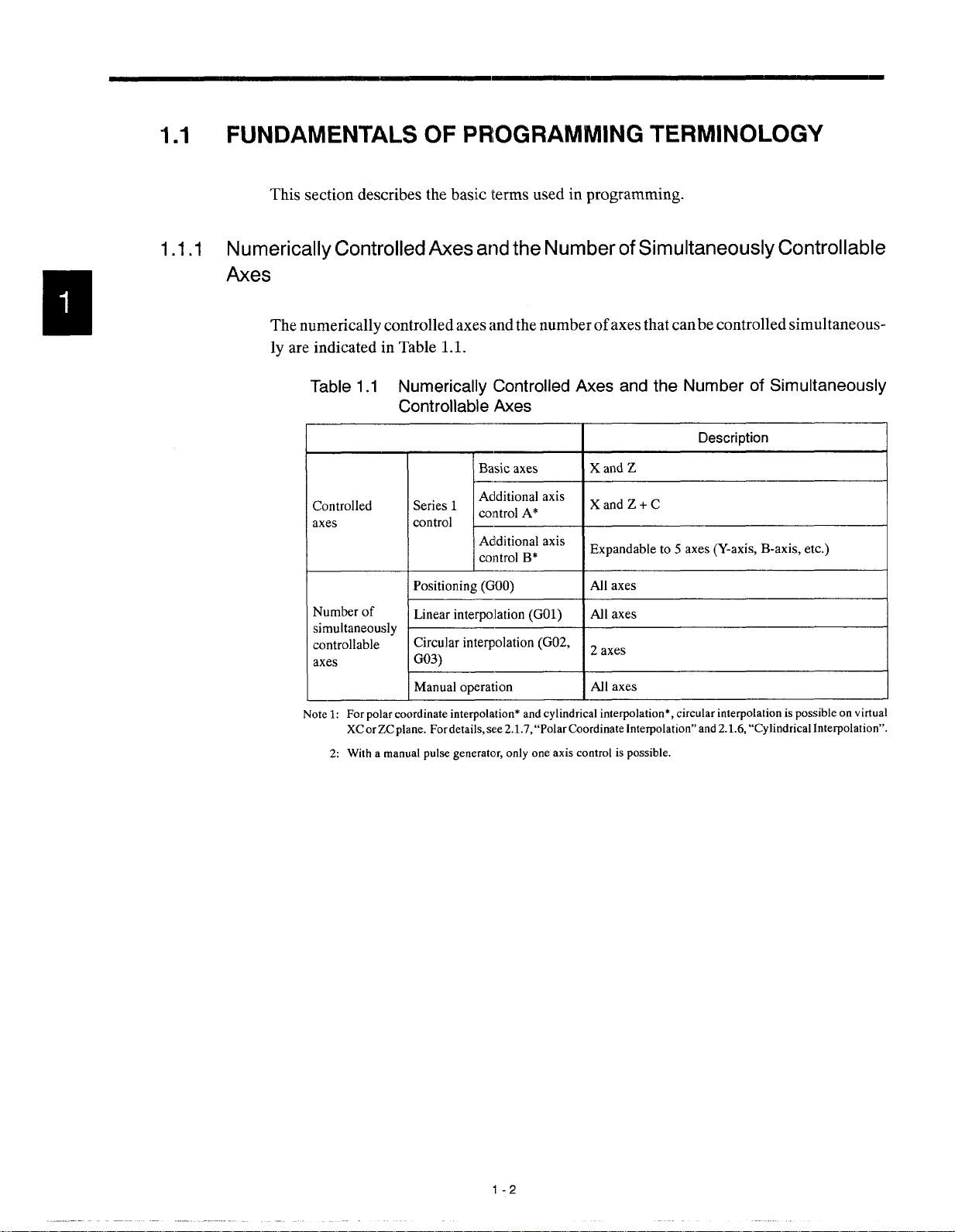

1.1.1

Numerically Controlled Axes and the Number of Simultaneously Controllable

Axes

The numerically controlled axes and the number of axes that can be controlled simultaneously are indicated in Table 1.1.

—.. . . . . .,-. .. . . ... . ,, , -. ,.

[able 1.1 Numerically Uontroilea Axes ana tne NumDer oT Slmul[aneously

Controllable Axes

I

Description

IBasic axes lXand Z

Controlled

axes

Number of

simttltaneousl y

controllable

axes

Note 1: For polar coordinate interpolation* and cylindrical interpolation

XCor ZCplane. For details, see 2.1.7,’’Polar Coordinate Interpolation” and 2.1.6, “Cylindrical Interpolation”.

2: With a manual pulse generator, only one axis control is possible.

Series 1

control

Positioning (GOO) All axes

Linear interpolation ((301)

Circular interpolation (G02,

G03)

Manual operation

Aclditional axis

control A*

Additional axis

control B*

}

Xand Z+C

Expandable to 5 axes (Y-axis, B-axis, etc.)

AUaxes

2 axes

All axes

*, circular interpolation is possible on virtual

,

I

I

—

1-2

..—.- —

Page 12

1.1 FUNDAMENTALS OF PROGRAMMING TERMINOLOGY

1.1.2 Least Input Increment and Least Output Increment

The least input and output increments vary depending cmthe type of controlled axis whether

it is a rotary axis or a linear axis.

(1)

LeastInput Incrementand10-tilmeInputIncrement

The least input increment to express axis movement distance that is input by using

punched tape or manual data input switches is indicated in Table 1,2.

Table 1.2 Least Input Increment (pml 000 DO=O)

@

!

i

2

i

?

q

O

Metric Input

Inch Input

By setting “l” for parameter pm1000 DO (pm1000 DO = 1), the “lO-time input increment” specifications indicated in Table 1.3 is selected.

Table 1.3 10-time Input Increment (pml 000 DO= 1)

Metric Input

Inch Input

Note: Selection of “mm-input” and “inch-input” is made by the setting parameter pmOO07[IOorbythespecification

ofG20/G21

Disregarding of the least input increment mode which has been select ed, tool.offset data

are always written in units of 0.001 mm (or 0.0001 inch, or 0.001 deg.). Offset movement is possible in the specified

the following operations and the commands for them must be given in units c}f0.01 mm.

●

Data writing in the MDI mode

‘X-’:zzz:::: :3

‘X-’::z ~:G:-”-3

vake. If the offset data are set in units of 0.01 mm,

●

Programming for the memory mode operation

●

Program editing

Page 13

1. If an NC program written in units of 0.001 mm is executed while the 0.01 mm

setting increment is selected, dimension commands are.all executed 10 times the

specified value.

2. If the program stored in memory is executed in the memory mode after changing

the setting for pm1000 DO (input increment setting parameter), dimension commands in the stored program are executed in either 1/10 or 10 times the specified

value.

3. When a program stored in memory is output to a tape, the stored program is output as it is and not influenced by the setting for pm1000 DO (input increment setting parameter).

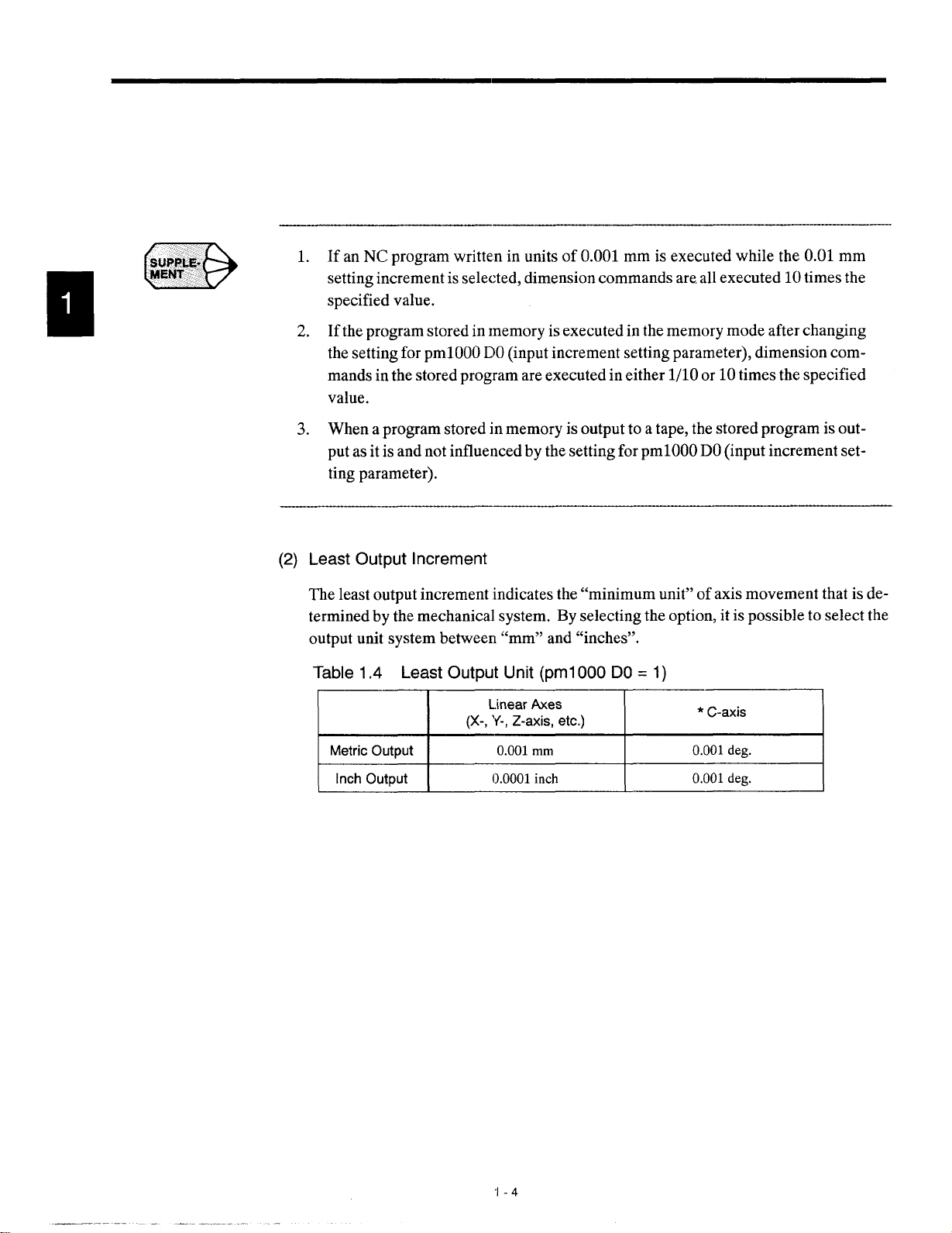

Least Output Increment

(2)

The least output increment indicates the “minimum unit” of axis movement that is determined by the mechanical system. By selecting the option, it is possible to select the

output unit system between “mm” and “inches”.

Table 1.4 Least Output Unit (pml 000 DO = 1)

Linear Axes

(X-, ‘f-, Z-axis, etc.)

Metric Output 0.001 mm 0.001 deg.

Inch Output

E

0.0001inch

* C-axis

0.001 deg.

..—.— ———

“l-4

Page 14

1.1 FUNDAMEN”rALS OF PROGRAMMING TERMINOLOGY

1.1.3 Maximum Programmable Values for Axis Movement

The maximum programmable values that can be designated for a move command are indicated in Table 1.5. The maximum programmable values indicated in these tables are applica-

ble to addresses I, J, K, R, A, and B which are used for designating “distance” in addition

to the move command addresses X, Y, Z, C, U, W, V, and H.

u

Table 1.5 Maximum Programmable Values for Axis Movement

Linear Axes

(X-, Y-, Z-axis, etc.)

Metric Output

Metric Input

Inch Input

Metric Input

Inch Output

Inch Input

+ 999999.999mm + 999999.999 deg.

+ 39370.0787inch t 999999.999 deg.

A999999.999 mm

+ 99999.9999 inch

—,

* C-axis

,—

—.

k

!199999.999deg.

k S199999.999deg.

=

In incremental programming, the values 10be designated must not exceed he maximum programmable values indicated above. In absolute programming, the mmw distance of each

axis must not exceed the maximum programmable values indicated abclve. In addition to

the notes indicated above, it must also be taken into consideration that the cumulative values

of move command must not exceed the values indicted in Table 1.6.

Table 1.6 Maximum Cumulative Values

\ Metric Input ] + 999999.999mm

I Inch Input I + 999999.9999inch

Note: The values indicated above do not depend on the “least output increment”.

I A 999999.999 deg. I

*

I

999999.999deg.

I

1-5

Page 15

1.1.4 Tape Format

The following describes the important items concerning the tape format.

(1) Label and Label Skip

By entering “label” at the beginning of a punched tape, classification and handling of

tape can be facilitated.

The label skip function disregards the data appearing before the first EOB code. With

this feature, label can contain address characters and function codes which are not supported by the NC. A code that does not match the selected parity scheme can also be

used. The label skip function becomes enabled when the power is turned ON or when

the NC is reset. While the li~belskip function is enabled, “LX” message is displayed

on the screen.

Tape Start and Tape End

(2)

At the start and end of a tape, the same code (see Table 1.7) should be punched.

Table 1.7 Tape Start and Tape End

Description

F’:

● The ER code (rewind stop code) entered following the tape start label indicates

the rewind stop when the tape is rewound by the tape rewind command.

● The ER code, expressing the tape end, indicates the stop point when several

part programs are stored in NC memory.

Tape startflape end

.—

1-6

Page 16

1.1 FUNDAMENTALS OF PROGRAMMING TERMINOLOGY

l——

- Label

~=~

ER CR

‘— Program part

T T

/

Tape start

(Called as ‘(%” or “Rewind Stop” code)

Note:

As theendof program code, M02

are

used as the p;ogram end Mcode is determined according to the setting forparamt.terpm3005 D3.

Fig.1.1

Program start

(Called as “EOW or “End of Block’’. code)

SingleMainProgramPunchedonTape(EIACocle)

‘~—

(

Comment y ,–

part

+i

orM99canbeusedinsteadof’M30.Whetherornotthe Wcodesindicatedabove

~—

1~1

Tape end

LF/NL

0/0

—=— Program part

=I=Q=

- “beITrlTI T

Tape start

Program part _

Fig. 1,2

Program start

M3O&-

Program —

end

r

-p

Program part

Multiple Programs F’unched on Tape (EIA Code)

Tape end —-

r

\

Tape end

1-7

Page 17

(3) Program Start and Program End

(a) Program start

When punching a program on a tape, the following code should be punched to declare the beginning of a program. This code cancels the label skip function.

Table 1.8 Program St:irt

Description

E=.

(b)

Program end

Program start

Any of the following codes indicated in Table 1.9 should be punched at the end of

a program to declare the program end.

Table 1.9 Program End

EIA 1s0 Description

M02CR

M30CR

M99CR M99LFJNL Subprogram end

B

Note 1:

When “M02CR” or “M30LF,’NL” is executed, the equipment may or may not be reset or rewound depending

on equipment specifications.

Refer to the manual published by the machine tool builder.

2:

When multiple part programs are started in the NC memory, control may move to the next part program after

reading the program end code shown above.

Thisoccurs when part programs are entered by total input.

3:

If ER or LF/NLcode is executed for a program in which neither M02 nor M30 is entered at the end of the program; the NC is reset.

Mo2LF/NL

M30LFINL Program end and rewind

Program end

. — —-

“I-8

Page 18

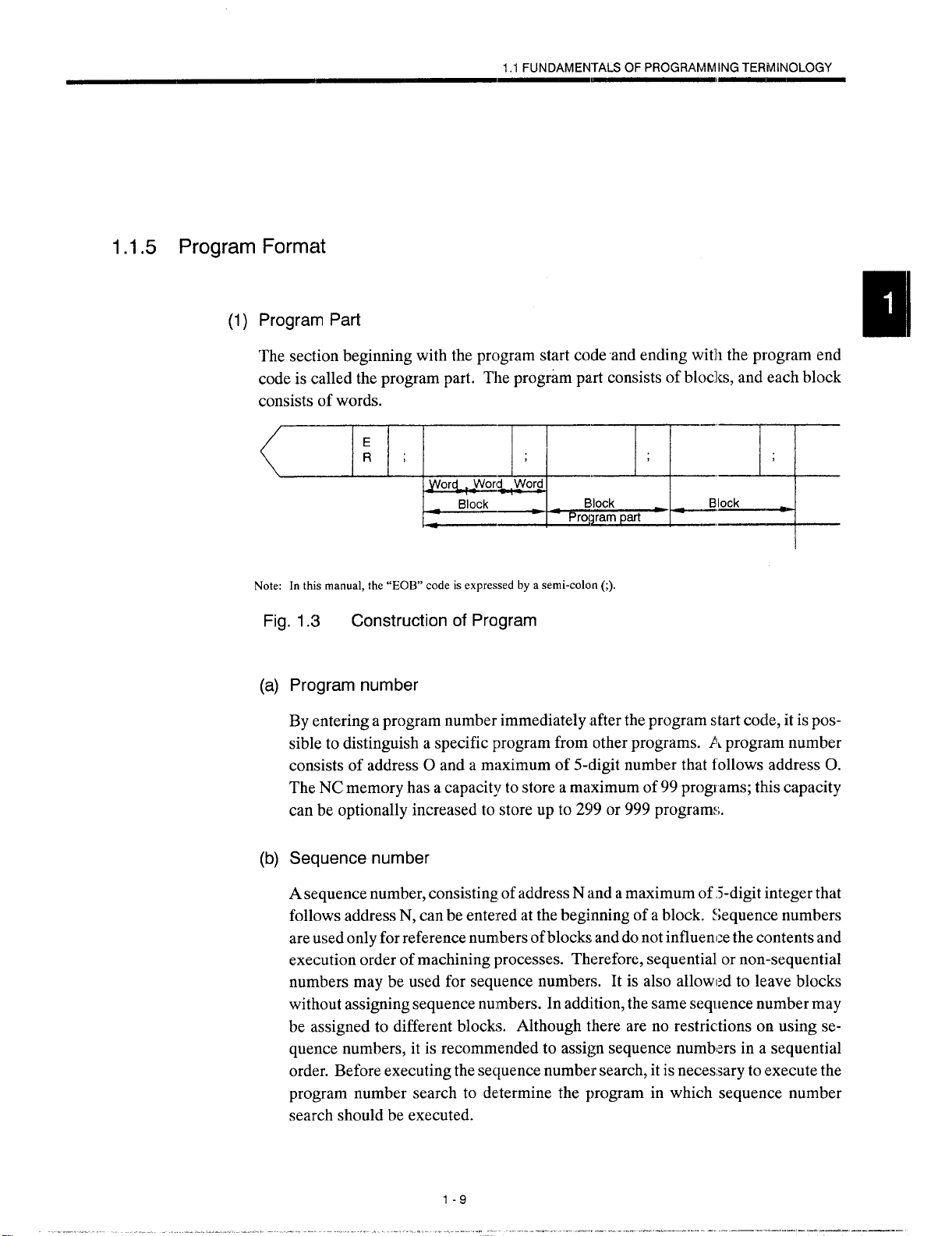

1.1.5 Program Format

(1) Program Part

The section beginning with the prc)gram start code-and ending with the program end

code is called the program part. The program part consists of blocks, and each block

consists of words.

E

R ;

1.1 FUNDAMENTALS OF PROGRAMMING TERMINOLOGY

l——

I

Block

Note: In this manual, the “EOB” code is expressed by a semi-colon C).

- -

Block Block

Program part

- = z

,—

Fig. 1.3 Construction of Program

Program number

(a)

By entering a program number immediately after the program start cocle, it is possible to distinguish a specific program from other programs. A program number

consists of address O and a mi~ximum of 5-digit number that follows address O.

The NC memory has a capacity to store a maximum of 99 prog]ams; this capacit y

can be optionally increased to store up to 299 or 999 programx.

(b)

Sequence number

A sequence number, consisting, of address N and a maximum of 5-digit integer that

follows address N, can be ente:red at the beginning of a block. Sequence numbers

are used only for reference numbers of blocks and do not influence the contents and

execution order of machining processes. Therefore, sequential or non-sequential

numbers may be used for sequence numbers,

It is also allowed to leave blocks

without assigning sequence nu:mbers. In addition, the same sequence number may

be assigned to different blocks. Although there are no restrictions on using se-

quence numbers, it is recommended to assign sequence numblars in a sequential

order. Before executing the sequence number search, it is necessary to execute the

program number search to determine the program in which sequence number

search should be executed.

Page 19

——..

——-

———

1. If a sequence number consisting of 6 of more digits is designated, 5 digits from

the least insignificant digit are regarded as a sequence number.

2. If address search is executed for a sequence number which is assigned to more

than one block, the block searched first is read and search processing is completed

at that block.

3. For blocks for which a sequence number is not assigned, search is possible by

the address search operation if address data in the block to be searched are designated as the object of address search operation.

4. When designating a sequence number following G25 or M99, designate a 4-digit

number.

(c) Word

A word consists of an address character included in the function characters and a

numeral of several digits that follow the address character. For example, word

“G02” consists of address character “G’ and numeral “2”.

The function character means a character that can be used in the significant data

area. For details of address character and function character codes, refer to Tables

1.10 and 1.11.

1-1o

Page 20

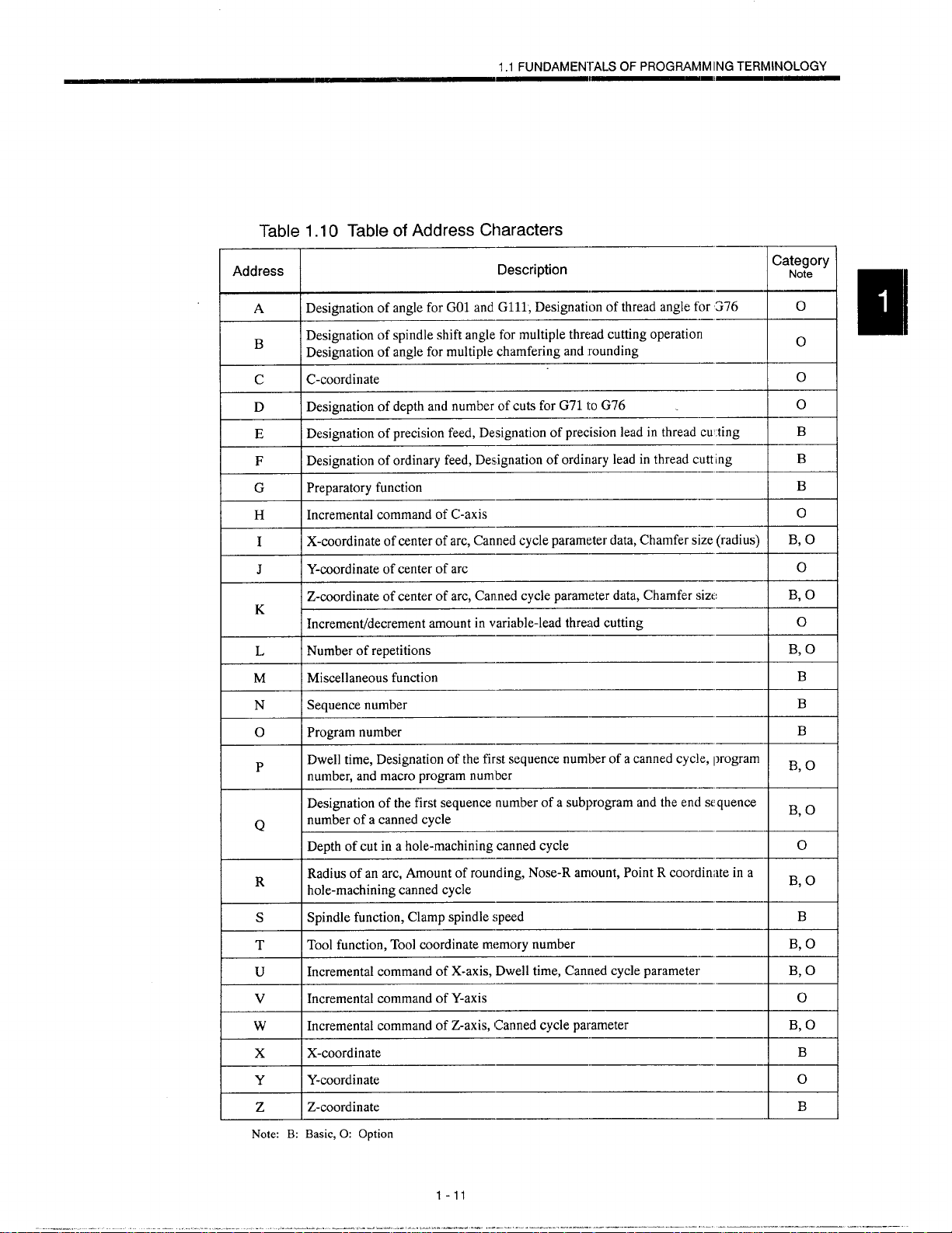

1.1 FUNDAMENTALS OF PROGRAMM ING TERMINOLOGY

Table 1.10 Table of Address Characters

1——

Address

I

A

B

c

D

E

F

G

H

I

J

‘t----- ‘–

L

M IMiscellaneous function

Designation of angle for GO1 and Gill, Designation of thread angle for S76

Designation of spindle shift angle for multiple thread cutting operation

Designation of angle for multiple chamfering and rounding

IC-coordinate

Designation of depth and number of cuts for G71 to G76 .

Designation of precision feed, Designation of precision lead in thread cu.ting

Designation of ordinary feed, Designation of ordinary lead in thread cutting

Preparatory function

Incremental command of C-axis

X-coordinate of center of arc, Canned cycle parameter data, Chamfer size (radius) B, O

Y-coordinate of center of arc

Z-coordinate of center of arc, Canned cycle parameter data, Chamfer sizti

Increment/decrement amount in variable-lead thread cutting

INumber of repetitions

Description

——

—.

%

o

o

H

Iol

o

B

B

B

o

o

B, O

o

t----i

I B,O I

IBI

Dwell time, Designation of the first sequence number of a canned cycle, Iprogram ~ o

-

Q

R

s

T

u

v

w

X IX-coordinate IBI

Y

z

Note: B: Basic. O: O~tion

number, and macro program number

Designation of tbe first sequence number of a subprogram and the end sequence B o

number of a canned cycle

Depth of cut in a hole-machining canned cycle

Radius of an arc, Amount of rounding, Nose-R amount, Point R coordinate in a B o

hole-machining canned cycle

Spindle function, Clamp spindle speed

Tool function, Tool coordinate memory number

Incremental command of X-axis, Dwell time, Canned cycle parameter B, O

Incremental command of Y-axis o

Incremental command of Z-axis, lCannedcycle parameter

IY-coordinate

IZ-coordinate

1-11

—,

—

—.

‘H

o

u

1-.-d

B

B, O

.+

I B,O I

IBI

.-...—.—

Page 21

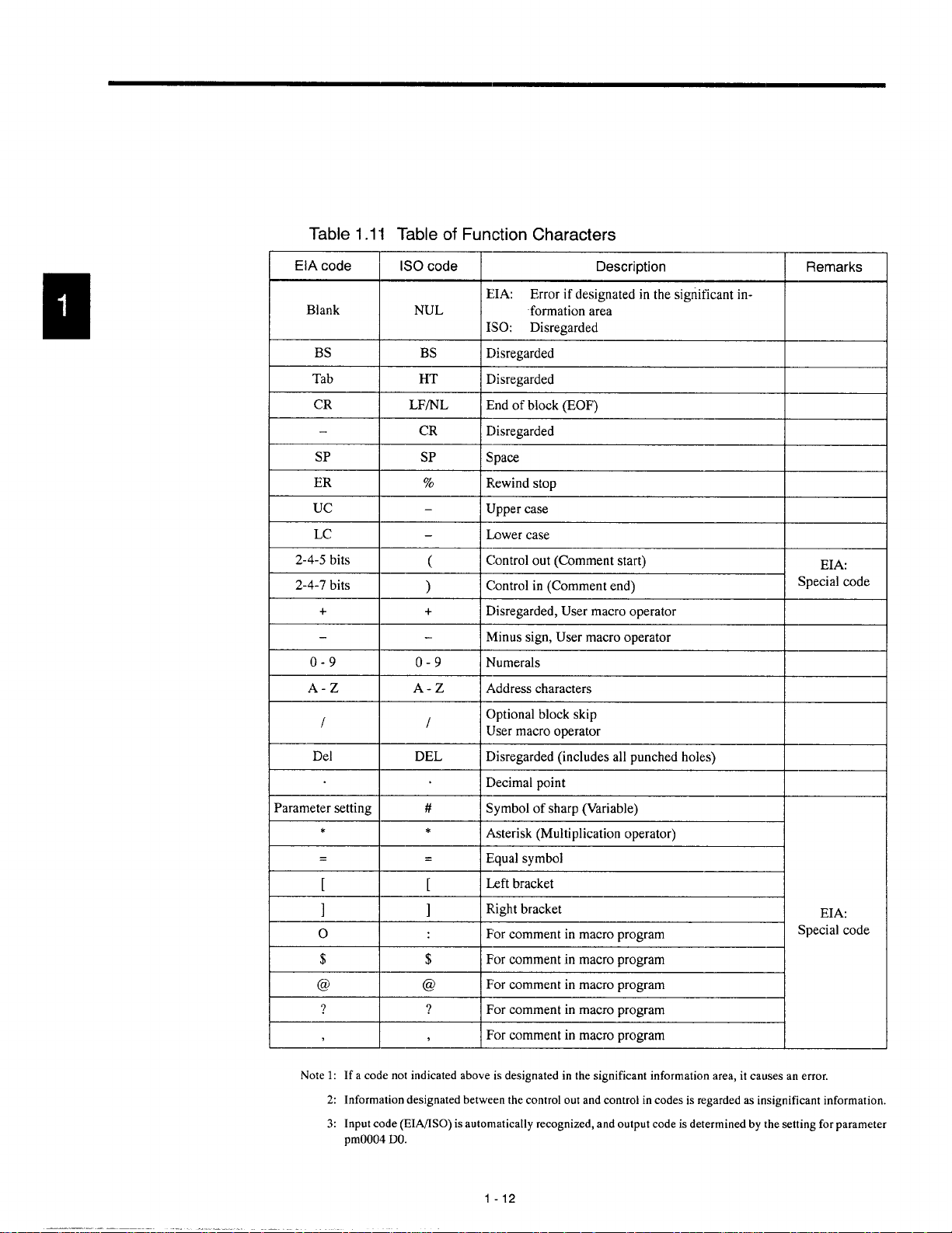

Table 1.11 Table of Function Characters

EIA code ISO code Description

EIA: Error if designated in the significant in-

Blank NUL

formation area

ISO: Disregarded

BS BS Disregarded

Tab

HT

Disregarded

CR LF/NL End of block (EOF)

CR Disregarded

SP SP Space

ER

Uc

LC

2-4-5 bits

2-4-7 bits

+

—

%

—

—

(

)

+

Rewind stop

tJpper case

Lower case

Control out (Comment start)

Qrrrtrol in (Comment end)

Disregarded, User macro operator

Minus sign, User macro operator

o-9 0-9 Numerals

A-Z

I

Del

A-Z

/

Address characters

C)ptionalblock skip

tJser macro operator

DEL Disregarded (includes all punched holes)

Decimal point

Parameter setting # Symbol of sharp (Variable)

*

.

[

1

o

$ $

@ @

? ‘/

*

=

[

1

Asterisk (Multiplication operator)

Equal symbol

L,eftbracket

Right bracket

For comment in macro program

For comment in macro program

For comment in macro program

For comment in macro program

,

For comment in macro program

Remarks

EIA:

Special code

EIA:

Special code

Note

1: If a codenot indicatedaboveis designatedinthesignificantinformationarea,it causesanerror.

2: Informationdesignatedbetweenthecontroloutandcontrolincodesis regardedasinsignificantinformation.

3: Input code (EIA/fSO) is automatically recognized, and output code is determined by the setting for parameter

pmOO04

DO.

1-12

Page 22

1.1 FUNDAMENTALS OF PROGRAMMI NG TERMINOLOGY

(d) Block

● A block consists of words to define a single step of operatio]l. One block ends

with the EOB (end of block) code. The EOB code is expressed by “CR’ in

the EIA code system and “;LF/NL” in the 1S0 code system.

In this manual, it is expressed by a semicolon “;”

ple.

● Characters not indicated in Tables 1.10 “Table of Addrew Characters” and

1.11 “Table of Function Characters” must not be used.

● One block can contain up to 128 characters. Note that inval id chamcters such

as “Del” are not counted.

to make the explanation sim-

.—

~=,,e,) +--A

(a) Adding a character for TV check (an error occurs if an even number of characters is coI Itained in a block.)

; NO058G03X .-. Z . . .

3 E“””” F’”; ,___!

L—____— ‘essth”’129 –

Fig. 1,4 Block

(2) Comment Part

A comment can be displayed by using the contrcd out and control in

(a) Entering a comment in a program

It is possible to display a required comment on the screen by enclosing it with the

control out and control in codes in a part program. The information enclosed by

these codes is regarded as insignificant information.

characters in a block

(b) Number of valid characters atlowed in a block

A

codes.

Page 23

(b) Entering the control out and control in codes

The control out and control in codes can be entered in.the same manner as entering

ordinary characters.

● “(’’:Press the [U] key after pressing the [SHIFT] key.

● “)’’:Press the [V] key after pressing the [SHIFT] key.

(Operation panel with 9-inch CRT)

,GQ

o

o—

0

I

Note 1: The characters that can be entered between the control out and control in codes are those that are entered by

2: It is not allowed to use tbe control out and control in codes in the area which are already enclosed by the control

Fig. 1.5 Characters that can be Entered between Control Out and Control

+&

using the keys enclosed by dark line in Fig. 1.5.

out and control in codes.

In Codes (Keys Enclosed by Dark Line)

-“

Charactersthat

“(” (control out) and “)” (control in) codes

can be entered between

I

1-14

Page 24

1.1 FUNDAMEN1-ALS OF PROGRAMMIIQG TERMINOLOGY

1—

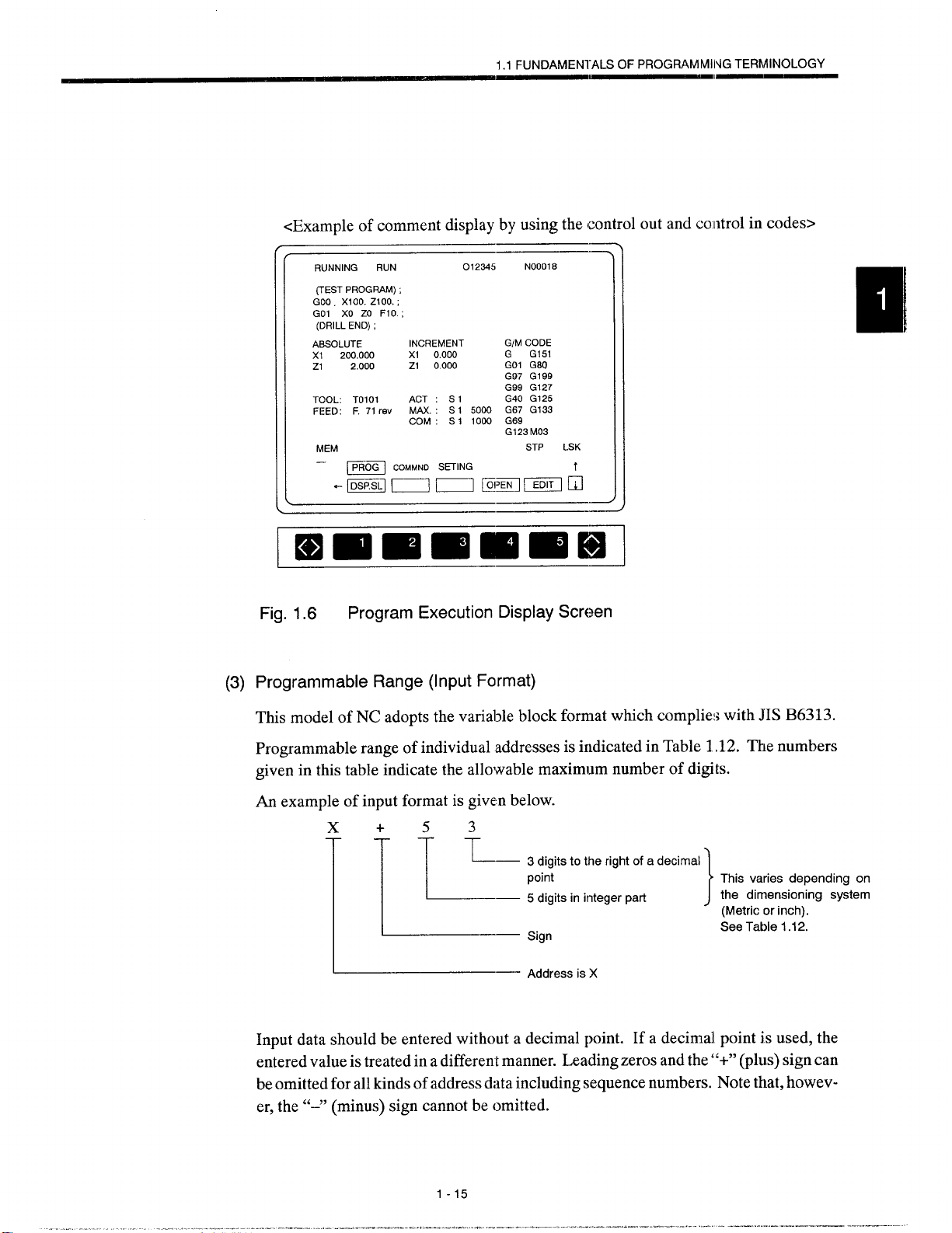

<Example of comment display by using the control out and co lntrol in codes>

RUNNING RUN

(TESTPROGRAM);

GOO X1OO.Z1OO.;

Go1 XO ZO F1O.;

(DRILLEND);

ABSOLUTE

xl 200.000

Z1 2.000

TOOL: TOIO1 ACT : S1

FEED: F. 71rev

MEM

INCREMENT

xl 0.000

Z1 0000

MAX : S1 5000 G67 G133

COM: S1 10MI G69

- p] co. . . . SETING

“EEJmn@zElL2iA

.

Emilmmniiiiiil

Fig. 1.6

Programmable Range (Input Format)

(3)

Program Execution Display Screen

012345

NooO18

G/MCODE

G151

G

Go1 G80

G97 G199

G99 G127

G40 G125

G123M03

STP

LSK

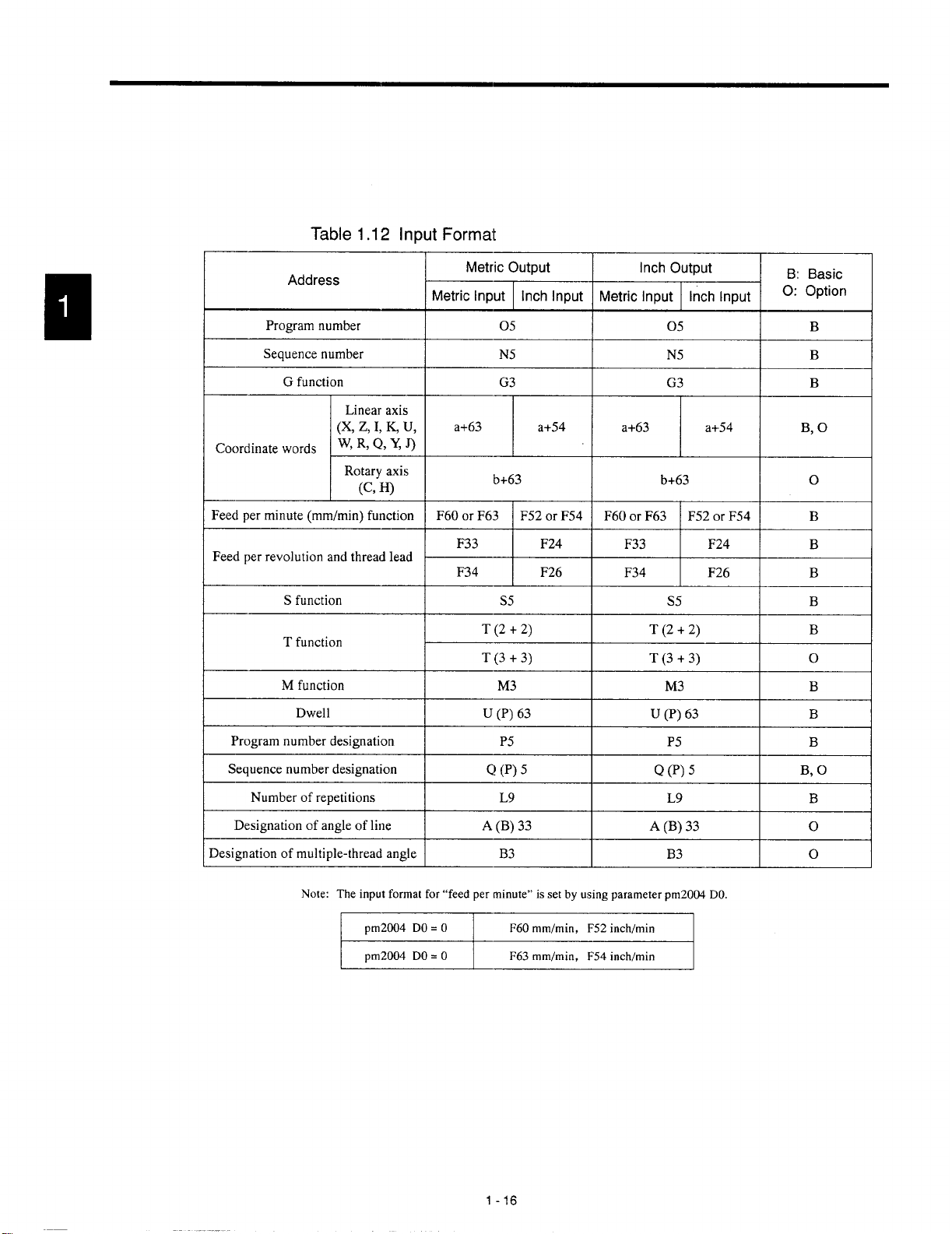

This model of NC adopts the variable block format which complies with .lIS B6313.

Programmable range of individual addresses is indicated in Table 1.12. The numbers

given in this table indicate the allowable maximum number of digits.

An example of input format is given below.

x+53

3 digits to the right of a decimal

point

5 digits in integer part

Sign

Address is X

This varies depending on

the dimensioning system

1

(Metric or inch).

See Table 1.12.

Input data should be entered without a decimal point. If a decimall point is used, the

entered value is treated in a different manner. Leading zeros and the’ ‘+” (plus) sign can

be omitted for all kinds of address data including sequence numbers. Note that, howev-

er, the “-” (minus) sign cannot be omitted.

Page 25

Table 1.12 Input Formal

Address

Program number

Sequence number

G function

Linear axis

(x z, L K u,

Coordinate words

Feed per minute (mm/min) function

Feed per revolution and thread lead

S function

T function

M function

W, R, Q,~J)

Rotary axis

(c, H)

Dwell

Metric Output Inch Output

MetricInput Inch Input MetricInput Inch Input

05 05

N5

G3 G3

a+63

F60 or F63

F33

F34

T(2+2) T(2+2)

T(3+3) T(3+3)

U (P) 63 U (P) 63

a+54 a+63 a+54 B, O

b+63 b+63 o

F52 or F54 F60 or F63 F52 or F54

F24 F33 F24

F26 F34 F26

S5 S5

M3 M3

N5 B

B: Basic

O: Option

B

B

B

B

B

B

B

o

B

B

Program number designation

Sequence number designation

Number of repetitions

Designation of angle of line

Designation of multiple-thread angle

Note: The input format for “feed per minute” is set by using parameter pm2004 DO,

P5 P5

c! (P) 5

L9 L9

A (B) 33 A (B) 33

B3 B3

Q(P)5

B

B, O

B

0

o

1-16

Page 26

1.1,6 Optional Blclck Skip (/1), (/2 to /9) *

If a block containing the slash code “/n (n=l to 9)” is executed with the external optional

block skip switch corresponding to the designated number set ON, the commands in the

block following the slash code to the end of block code are disregarded. The slash code “/n”

can be designated at any position in a block.

Example:

/ 2 N 1234 GOOX1OO / 3 Z200;

If the “/2” switch is ON, the entire block is disregarded, and

if “/3” switch is ON, this block indicates the following.

1.1 FUNDAMENTALS OF PROGRAMMING TERMINOLOGY

SUPPLE-

MENT

(3

N 1234

“l” can be omitted for “/1”.

1.

2. The optional block skip function is processed when a part program is read to the

buffer register from either the tape or memory. If the switch is set ON after the

block containing the optional block skip code is read, the block is not skipped.

3. ~le optional block skip function is disregarded for program reacling (input) and

punch out (output) operation.

GOOX1OO;

. .-. .—.....-. .—

1-17

— ....-. -—.--.. --.. —”---------

~—... ,-. —

_.-. —- ——. — ——. —

Page 27

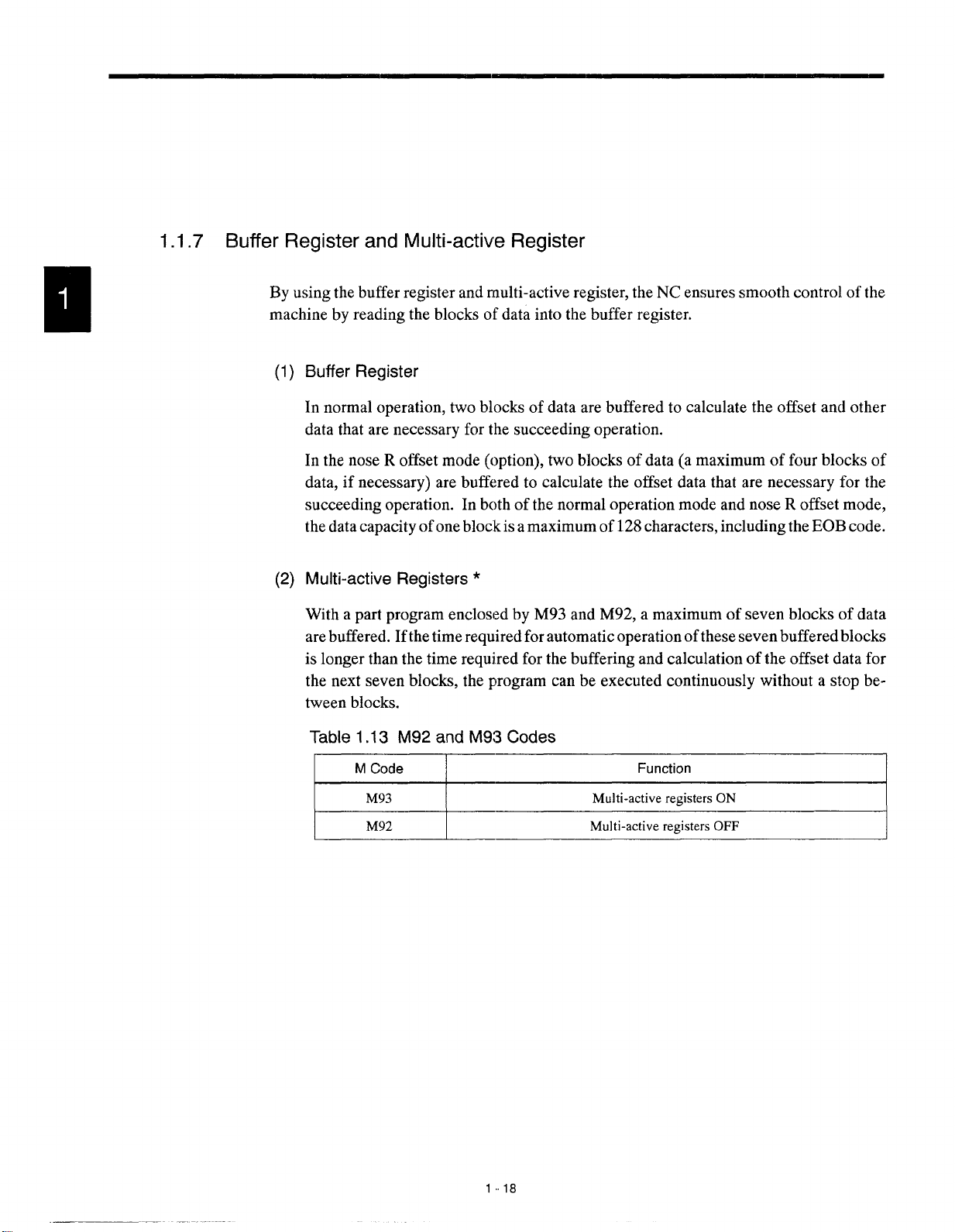

1.1.7 Buffer Register and Multi-active Register

By using the buffer register and multi-active register, the NC ensures smooth control of the

machine by reading the blocks of data into the buffer register.

(1)

Buffer Register

In normal operation, two blocks of data are buffered to calculate the offset and other

data that are necessary for the succeeding operation.

In the nose R offset mode (option), two blocks of data (a maximum of four blocks of

data, if necessary) are buffered to calculate the offset data that are necessary for the

succeeding operation. In both of the normal operation mode and nose R offset mode,

the data capacity of one block is amaximum of 128 characters, including the EOB code.

(2)

Multi-active Registers *

With a part program enclosed by M93 and M92, a maximum of seven blocks of data

are buffered. If the time required for automatic operation of these seven buffered blocks

is longer than the time required for the buffering and calculation of the offset data for

the next seven blocks, the program can be executed continuously without a stop between blocks.

Table 1,13 M92 and M9:3 Codes

m

M92 Multi-active registers OFF

Function

Multi-activeregistersON

A

Page 28

1.2 BASICS OF FEED FUNCTION

This section describes the feed function that specifies feedrate (distance per minute, distance

per revolution) of a cutting tool.

1.2.1 Rapid Traverse

1.2 BASICS CIF FEED FUNCTION

SUPPLEMENT

(ID

Rapid traverse is used for positioning (GOO)and manual rapid traverse (RAPID) operation.

In the rapid traverse mode, each axis moves at the rapid traverse rate set for the individual

axes; the rapid traverse rate is determined. by the machine tool builder and :Setfor the individual axes by using parameters. Since the. axes move independently of each other, the axes

reach the target point at different time. Therefore, the resultant tool paths are not a straight

line generally.

The rapic, traverse override function can adjust the set rapid traverse rate to Fo, 25%, 50%,

and 100%~where F. indicates a fixed feedrate set for parameter pm244’7.

1. Rapid traverse rate is set in the following units for the individual axes.

Setting units of rapid traverse rate

2. The upper limit of the rapid traverse rate is 240,000 mm/min. Since the most appropriate value is set conforming to the machine capability, refer to the manuals

published by the machine tool builder for the rapid traverse rate of your machine.

0.001 mm/min

or

1 deg.lmin

m

Page 29

1.2.2 Cutting Feed (F Command)

The feedrate at which a cutting tc)olshould be moved in the linear interpolation (GO1) mode

or circular interpolation (G02, G03) mode is designated using address characters F and E.

The axis feed mode to be used is selected by designating the feed function G code (G98 or

G99) as indicated in Table 1.14. Select the required feed mode by designating the feed func-

tion G code before specifying an F and E code.

Table 1,14 Cutting Feecl Mode G Codes

m~

G98

\ G99 IDesignation of feed per revolution (mm/rev) mode \ 10 I

Designation of feed per minute (mm/min) mode

! 1

Function

Group

10

See 1.2.3 “Switching between Feed per Minute Mode and Feed per Revolution Mode” for

details of these G codes. F and IEcodes are modal and once designated they remain valid

until another For E code is designated. If feed mode designation G codes are switched between G98 and G99, however, it is necessary to designate the F and E code again. If no new

F and E codes are designated, alarm “0370” occurs. Note that it is not allowed to designate

an E code in the G98 (feed per minute) mode. If an E code is designated in the G98 mode,

alarm “0371” occurs.

————

.- ..— —. .— -—

1-20

Page 30

1.2 BASICS OF FEED FUNCTION

(1) Feed per Revolution Mode (G99)

A feedrate of a cutting tool per revolution of the spindle (mm/rev, inch/rev) can be designated by a numeral specified following address character F or E.

Table 1.15 Programmable Range of F and E Commands

(Feed

perRevolutionMode)

Format

F33

mm input

mm output

inch input

mm input

inch output

inch input

I -

Note:!: Theallowablemaximumvalueforthe X-axisis1/2ofthe value indicatedin theta ble.

;!: The upper ]jmjt of feedrates could be re~tr-jcted

programmable feedrate range, refer to the manuals published by the machine tool builder.

The feedrate per revolution is further restricted as indicated in Table 1.16 due to spindle

speed S.

Table 1.16 Restrictions on F and E Commands by Spindle Speed

E34

F24

E26

F33

E34

F24

E26

FO.001.to F500.000 mm/rev

EO.0001 to E500.0000 mm/rtv

FO.0001 to F19.6850 inch/re’~

EO.000001 to E19.685000 inch/rev

FO.001 to F1270.000 mm/re~

EO.0001 to E1270.0000 mm/rev

FO.0001 to F50.0000 inch/re+~

EO.000001 to E50.00000 inch/rev

bytheservosystemand[hemechanical system. For the actual

Programmable

Range

Page 31

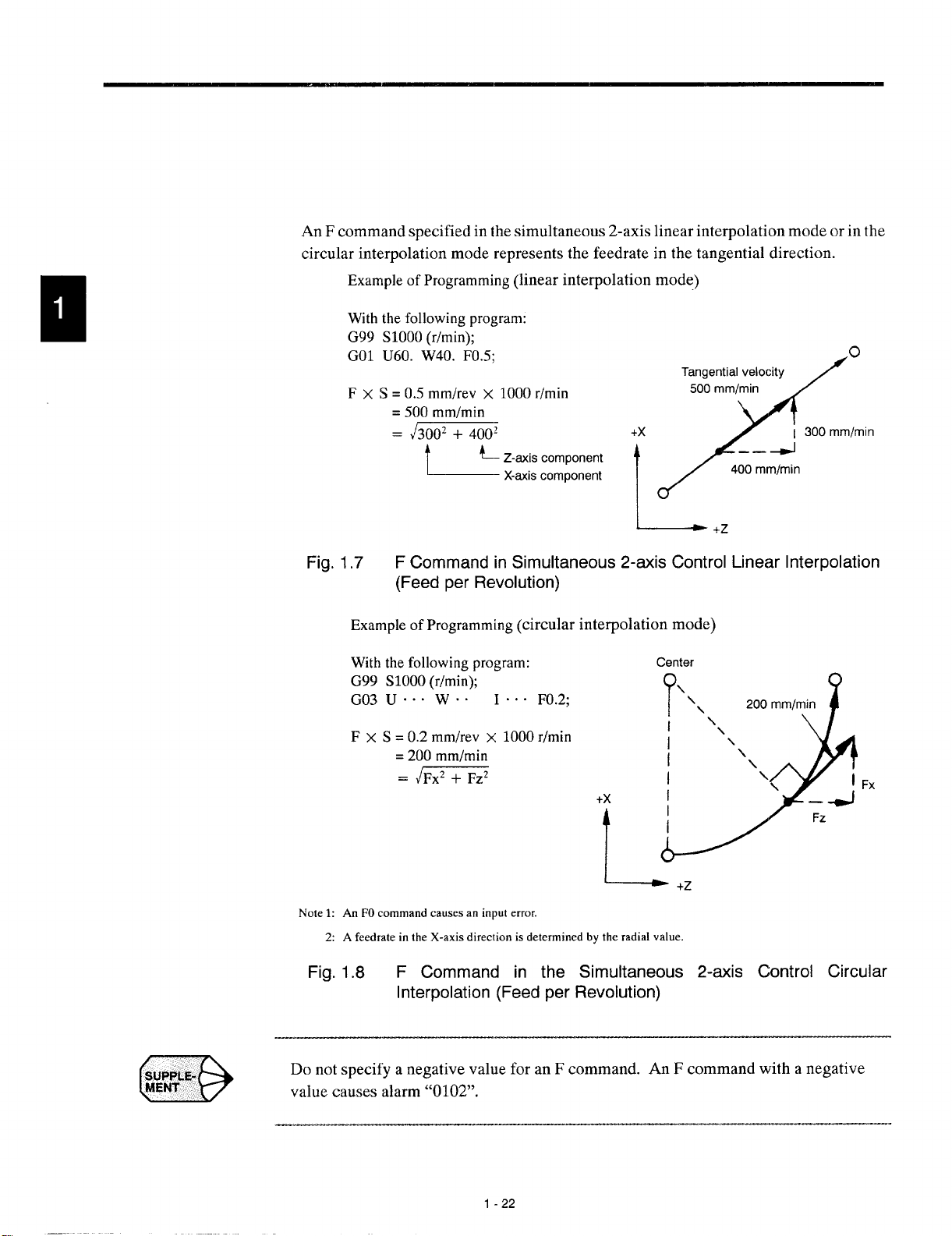

An F command specified in the simultaneous 2-axis linear interpolation mode or in the

circular interpolation mode represents the feedrate in the tangential direction.

Example of Programming (linear interpolation mode)

Whh the following program:

G99 S1OOO(r/rein);

GO1 U60. W40. FO.5;

F x S = 0.5 mm/rev x 1000 r/rein

= 500

mm/min

= ~~

~-

Z-axis component

- X-axis component

Tangential velocity

mm/min

500

+x I 300

——

4

400 mm/min

o

mm/min

L~

+Z

Fig. 1.7 F Command in Simultaneous 2-axis Control Linear Interpolation

(Feed per Revolution)

Example of Programming (circular interpolation mode)

With the following program:

G99 S1OOO(r/rein);

G03U. ”” W”.

F x S = 0.2 mm/rev x 1000 r/rein

= 200 mm/min

=~

Note 1: An FOcommand causes an input error.

2: A feedrate in the X-axis direc(ion is determined by the radial value.

Fig. 1.8

F Command in the Simultaneous

1.. ”FO.2;

+x

Center

\

\

T

I ‘\

/

I

I

\

mm/min

200

\

\

\

\

\

2-axis Control Circular

Interpolation (Feed per Revolution)

y&LE-

CD

Do not specify a negative value for an F command. An F command with a negative

value causes alarm “0102”.

1-22

Page 32

1.2 BASICS 01: FEED FUNCTION

(2) Feed per Minute Mode (G98)

A feedrate of a cutting tool per minute (mm/min, inch/rein) can be designated by a numeral specified following address character F. It is possible to set ttle F60 format and

F63 format (mm input) by the setting for parameter pm2004 DO. T!he programmable

range is indicated in Table 1.17.

~=

pm2004

DO=O

I

pm2004

DO=l

BE

‘“C’””’PU’=R

I

WE

inch output

Table 1.17 f

1

inch input

,

“r

F54

Note1: The allowablemaximumvalue

2: The upper limit of feedrates could be restricted by the servo system and the mechanical system. For the actual

programmable feedrate range, refer to the manuals published by the machine tool builder.

‘ogrammable Range of F Commands (Feed per Minute Mode)

Programmable Range (Linear Axis)

F1to F240000mm/min

FO.01to F94488.18 inch/rein

F1 to F609600 mm/min

FO.01to F24000.00 inch/rein

FO.001 to F240000.000 min/min

FO.0001 to F94488.1890 inch/rein

FO.001 to F609600.000 mm/min

FO.0001 to F24000.0000 inch/rein

~i~a

for the X-axis is 1/2 of the value indicated in the table.

Programmable Range (Rotary Axis)

I F0.01toF240000.00 deg/min I

F1 to F240000 deg/min

FO.01 to F240CIO0.00deg/min

FO.001 to F240000.000 deg/min

FO.001 to F240000.0000 degjmin

FO.001 to F240000.000 deg/min

FO.0001 to F240100.0000deg/min

.—

(3) Simultaneous 2-axis Control

An F command specified in the simultaneous 2-axis linear interpolar ion mode or in the

circular interpolation mode represents the feedrate in the tangential direction.

Example of Programming (linear interpolation mode)

With the following program:

G98;

GO1 U60. W40. F500.;

F = 500 = ~3002 + 4002

(mm/min)

Fig, 1.9 F Command in Simultaneous 2-axis Control Linear Interpolation

(Feed per Minute)

..--—.-.___________________...__. _______ .. . .

. . .......... .

o

Tangential velocity

500 mm/mi I

t

~ z..mis component .X

X.axis component

\/’

1-23

\,~

——

400 mm/min

—..—...-. ———, —,.-,.

/’”

I 300 mm/min

4

— ___________

Page 33

Example of Programming (circular

interpolation mode)

y+#E.

(II)

Whh the following program:

G98;

G03X. .” Z”” l.”o F200.;

F = 200 = V’FX2+- FZ2

(mm/min)

+x

t

Note 1: An FO command causes an input error.

2: A feedrate in the X-axis direetion is determined by the radial value.

Fig. 1.10

Do not specify a negative value for an F command. An F command with a negative

value causes alarm “O102”.

F Command

Interpolation (Feed per Minute)

in the Simultaneous

Center

\

\

\

T

: ‘i,

I

I

;

2-axis Control Circular

200 mm/min

\

\

Fx

1-24

Page 34

1.2 BASICS CIF FEED FUNCTION

Rotary Axis and Linear Axis

(4)

An F command specified in the interpolation mode between a rotar,y axis and a linear

axis represents the feedrate in the tangential direction.

Example of Programming

G98;

GOI.

W1O. H60. F1OO.;

● mm input (F60)

01

Distance = ~100002 + 600002

~T

60827.625 = 0.6082

‘ime = 1000000

● inch input (F52)

Distance

Time =

Fig. 1,-11

Independent Rotary Axis Command

(5)

If a rotary axis command is specified independently, feedrate is det{,xmined according

to the selected input increment systsm. In the case of inch input syst~m, the unit of fee-

drale is determined by the setting for parameter,

=

~1000002 + 600002 = 1166190.0379

LET:::!:::::;:::

11~o~o~~~79 = 0.1166 (rein) = 6.9 (s)

FCommand in Interpolation between Rotary Axis and Linear Axis

(Feed per Minute)

= 60827.625

C-axiscomponent

Z-l~is component

(rein) = 36.5 (s)

+-z ./=!’omm

1-

+C

Tangential velocity

100 mm/min

-- —... —

--, —-.

6[)deg

Ta131e1.18

1-25

,——-.———.—..—..——

—.—..—..——-- — _____________

Page 35

1,2.3 Switching between Feed per Minute Mode and Feed per Revolution Mode

(G98/G99)

Before specifying a feedrate command (E, F), a G code that determines whether the specified

feedrate command is interpreted as feed per minute value or feed per revolution value should

be specified. These G codes (G9!3, G99) are modal and once they are specified they remain

valid until the other G code is specified. When the feed mode designation G code is specified,

the presently valid E and F codes are canceled. Therefore, an E and F code must be specified

newly after switching the feed mc)de by designating G98 or G99 command. The initial status

that is established when the power is turned on is set by parameter pm4000.

Table 1.19 Parameter pm4000 and Initial Status

l-%=%-f-

1 pmqooo D2 = I I

(1) Feed per Minute Mode ((398)

G99

I

By specifying “G98;”,

minute mode.

Table 1.20 Meaning of (>98 Command

mm input

’98

the F codes specified thereafter are all executed in the feed per

-+%+

L..___H!

(2) Feed per Revolution Mocle (G99)

By specifying “G99;”,

revolution mode.

Table 1.21 Meaning of G99 Command

==

the F codes specified thereafter are all executed in the feed per

inch/rein

1-26

Page 36

1.2.4 Automatic Acceleration and Deceleration

Automatic acceleration/deceleration control is provided for rapid traver:;e and cutting feed

operation, respectively.

(1) Acceleration and Deceleration for Rapid Traverse and Manui4 Axis Feed Op-

eration

For positioning (GOO),manual rapid traverse (RAPID), manual cent inuous feed (JOG),

and manual handle feed (HANDLE), linear pattern automatic acceleration/deceleration

is applied. Rapid traverse rate and acceleration/deceleration time co:mtant for rapid traverse are set for following parameters.

1.2 BASICS OF FEED FUNCTION

ml

Table 1.22 Parameters Used for Setting Rapid Traverse Rate and Accelera-

tion/Deceleration Time Constant

Rapid traverse rate

Acceleration/deceleration time constant

v

,----,Pi,

Feedrate

GOO

:***

K

Time ~

Fig. 1.12 Automatic Accelera,tion/Deceleration in Linear Pi~ttern

-t

Page 37

Acceleration and Deceleration for Cutting Feed

(2)

For cutting feed (GO1 to G03 mode), feedrate is controlled by the automatic acceleration/deceleration in the exponential pattern.

v

f

F1

—---

t

Feed rate

L“=‘.

Fig. 1.13 Acceleration/Deceleration in Exponential Pattern

Time constant for cutting feed and feedrate bias are set for parameters. For tapping,

time constant and feedrate bias can be set independently.

Table 1.23 Parameters for Tapping

X-axis Z-axis

Feedrate time constant pm2501

Feedrate bias pm2821

Tapping time constant pm2511

Tapping feedrate bias pm2831

For the parameters indicated above, the most optimum values are set for respective

machines. Do not attempt to change the setting unless necessary.

pm2502 pm2503

pm2822

pm2512 pm2513

pm2832 pm2833

3rd-axis

pm2823

4th-axis

pm2504

pm2824 pm2825

pm2514 pm2515

pm2834 pm2835

t

5th-axis

pm2505

1-28

Page 38

2

COMMANDS CALLING A)(IS

MOVEMENTS

Chapter 2 describes the interpolation commands, thread cut-

ting function, and reference point return function.

2.1 INTERPOLATION COMMANDS . . . . . ...2-3

2.1,1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.2 USING THE THREAD CUTTING

FUNCTION,, . . . . . . . . . . . . . . . . . . . . . . 2-28

2.2.1 Thread Cutting and Continuous Thread

2.2.2

2.2.3 Variable Lead Threacl Cutting (G34) * ., , . . . 2-37

Positiorling (GOO,G06) . . . . . . . . . . . . . .. . .. 2-3

Linear interpolation (Gil) . . . . . . . . . . . . . . . . 2-5

Circular Interpolation

(G02, G03, G22, G23) . . . . . . . . . . . . . . . . . . . 2-9

Chamfering (Gil) . . . . . . . . . . . . . . . . . . . . ..2-f14

Rounding (G12) . . . . . . . . . . . . . . . . . . . . . ..2-t6

Cylindrical Interpolation (G124, G1 25)* . . . . 2-18

Polar Coordinate Interpolation

(G126, G127) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Cutting (G32) . . . . . . . . . . . . . . . . . . . . . . . . .:!-28

Multiple-thread Cutting (G32) * . . . . . . . . . . 2-34

2-1

—.— ..—.—

Page 39

2.3 REFERENCE POINT RETURN . . . . ...2-39

2.3.1

2.3.2

2.3.3

2.3.4

Automatic Return to Reference Point

(G28)” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-39

Fteference Point Return Check (G27) . . . . . . 2-44

Fleturn from Reference Point Return (G29) . 2-45

Second to Fourth Reference Point Return

(GO)* .,.......,.........”..........,,, 2-49

2-2

Page 40

2.1 INTERPOLATION COMMANDS

2.1

2.1.1

INTERPOLATION COMMANDS

This section describes the positioning commands and the interpolation cclmmands that control the tool path’ along the specified functions such as straight line and wc.

Positioning (GOO,G06)

In the absolute programming mode, the axes are moved to the specified pcint in a workpiece

coordinate system, and in the incremental programming mode, the axes move by the specified distance from the present position at a rapid traverse rate,

For calling the positioning, the following G codes can be used.

Table 2,1 G Codes for Positioning

Positioning in the errcr detect ON mode

=+2!!+

(1) Positioning

Positioning in the errcr detect OFF mode

in the Error Detect CIN Mode (GOO)

?

m

When “GOOX(U) o“ . Z(W) 0. “ (*C(H) o “ . *Y(V) 0.. );” is designated, positioning is executed in the “error detect ON” mode, in which the program advances to the

next block only when the number cf lag pulses due to servo lag are checked after the

completion of pulse distribution has reduced to the permissible val~e.

In the GOOmode, positioning is made at a rapid traverse rate in the simultaneous 2-axis

(*5-axis) control mode. The axes not designated in the GOOblockdo not move. In positioning operation, the individual axes move independently of each other at a rapid traverse rate that is set for each axis. The rapid traverse rates set for t]le individual axes

differ depending on the machine. For the rapid traverse rates of you] machine, refer to

the manuals published by the machine tool builder.

+x

Fig. 2.1

Positioning in Simultaneous 2-axis

Control Mode

2-3

——.—-—---

.——-— ..-,—..——--—-————-.

Page 41

-D

—

GOOdetermines the speed

for offset movement.

Designation of GOOcan be omitted

@

since it is a modal command.

—

1. In the GOOpositioning mode, since the axes move at a rapid traverse rate set for

the individual axes independently, the tool paths are not always a straight line.

Therefore, positioning must be programmed carefully-so that a cutting tool will

not interfere with a workpiece or fixture during positioning.

2. The block where a T comlmand is specified must contain the GOOcommand. Designation of the GOO command is necessary to determine the speed for offset

movement which is called by the T command,

Example of Programming

G50 X150. Z1OO. ;

GOO TO1O1 S1OOO M03 ;

(GOO) X30. Z5. ; -

—

+x

1

/

?,/”

/

If

---

t

5.

@30. —

+Z

F‘i‘

Fig. 2.2

Positioning in the Error Detect OFF Mode (G06)

(2)

When “G06 X(U) .0 “ Z(W) “ “ o (* C(H). “ “ Y(V) c “ .);” is specified, positioning

is executecl in the “error detect OFF” mode.

In the G06 mode, positioning is executed in the simultaneous 2 axis (*up to 5 axis) con-

trol mode. Note that the G06 command is not modal and valid only in the designated

block. In this mode, program advances to the next block immediately after the comple-

tion of pulse distribution.

Page 42

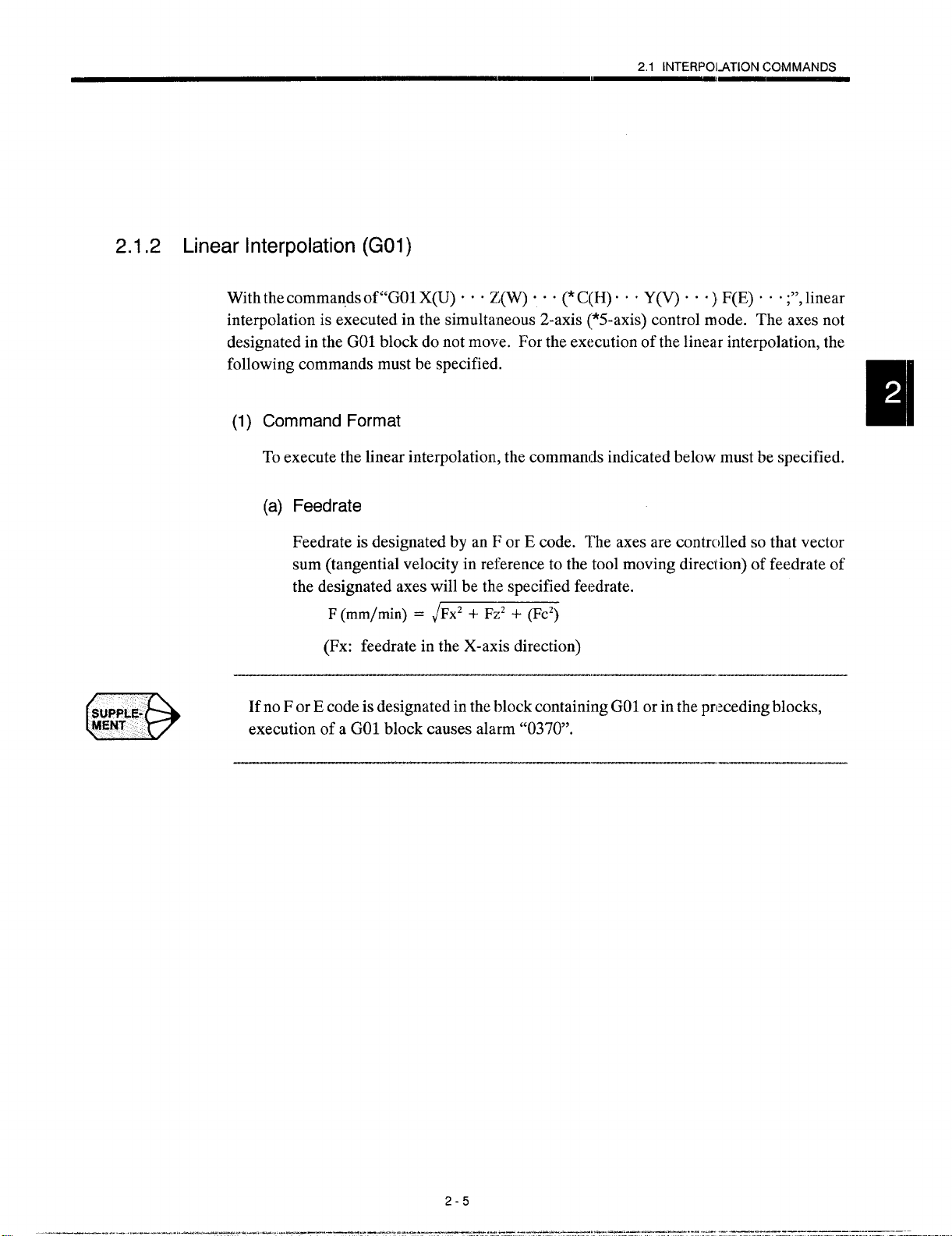

2.1,2 Linear Interpolation (GOI )

With thecommaqds of ’’GOl X(U) “ “ . Z(W) “ “ “ (*C(H)” “ “Y(V) . ““)1F(E) ‘ “ “;“,linear

interpolation is executed in the simultaneous 2-axis (*5-axis) control mode. The axes not

designated in the GO1 block do not move. For the execution of the linear interpolation, the

following commands must be specified.

(1) Command Format

To execute the linear interpolation, the commands indicated below must be specified.

(a) Feedrate

2.1 INTERPOLATION COMMANDS

SUPPLEMENT

(3)

Feedrate is designated by an For E code. The axes are controlled so that vector

sum (tangential velocity in reference to the tool moving direcltion) of feedrate of

the designated axes will be the specified feedrate.

F (mm/min) = ~Fx2 + FZ2+ (Fc2)

(Fx: feedrate in the X-axis direction)

If no F or E code is designated in the block containing GO1 or in the preceding blocks,

execution of a GO1 block causes alarm “0370”.

Page 43

● With an F code, axis feedrate is specified in either feed per spindle revolution

(mm/rev or inch/rev) or feed per minute (mm/min or inch/rein).

● If the optional C-axis is selected, the feedrate of X- and Z-axis and that of C-

axis differ from each other. Feedrates of these axes obtained by the same F

code are indicated in Table 2.2 below.

Table 2.2 Feedrates of X-/Z-axis and C-axis (F Command)

\\ I/,

POINT

n

‘Q’

Minimum F Command Unit

1 mm/min 1 deg/min

0.1 inch/rein

1 mm/min

0.0001 inch/rein

0.001 mm/min 0.0003937 degjmin

0.0001 inch/rein

2.54 deg/min

0.3937 deg/min

0.1 deglmin

0.001 deg/min

0.00254 deg/min

0.0001 deg/min

pm2004

DO=O

pm2004

DO=l

F Function

(Feed

mm output

inch output

mm output

—

inch output

per Minute)

mm input F60

inch input F51

mm input F60

inch input F51 0.1 inch/rein

mm input F63 0.001 mm/min

inch input F54

mm input

inch input F54

F63

Feedrate of X-/Z-axis Feedrate of C-axis

For the C-axis, a feedrate cannot be specified in the feed per minute mode.

2-6

Page 44

2.1 INTERPOLATION COMMANDS

(b) End Point

The endpoint can be specified in either incremental or absolute values corresponding to the designation of an address character or G90/G91. For details, see 3.2.1,

“Absolute/Incremental Programming”.

+x

1.

z

x

Programmed point

w

;

Present tool position

— +Z

e ~:~

Fig.2,3

Example of Programming

G50 X1OO. Z60.;

GOO T0202 S600 M03;

GO1 ZO F1.;

LinearInterpolation

x35. Z5.;

X60. FO.2;

Axes are

}

+x

I

mc

moved in the GO1 linear interpolation mcde,

D

)’

/

/

/

/

/

/

_________ ,. _. ._. ... .. . ._

Fig.2.4 Exampleof Programming

—.-— -—-—.. .—.-’..—--.. —.-

2-7

. . .--—-.——~

,—,.-... -——. .- .— .——.. —-——, —. —.-—-— -

Page 45

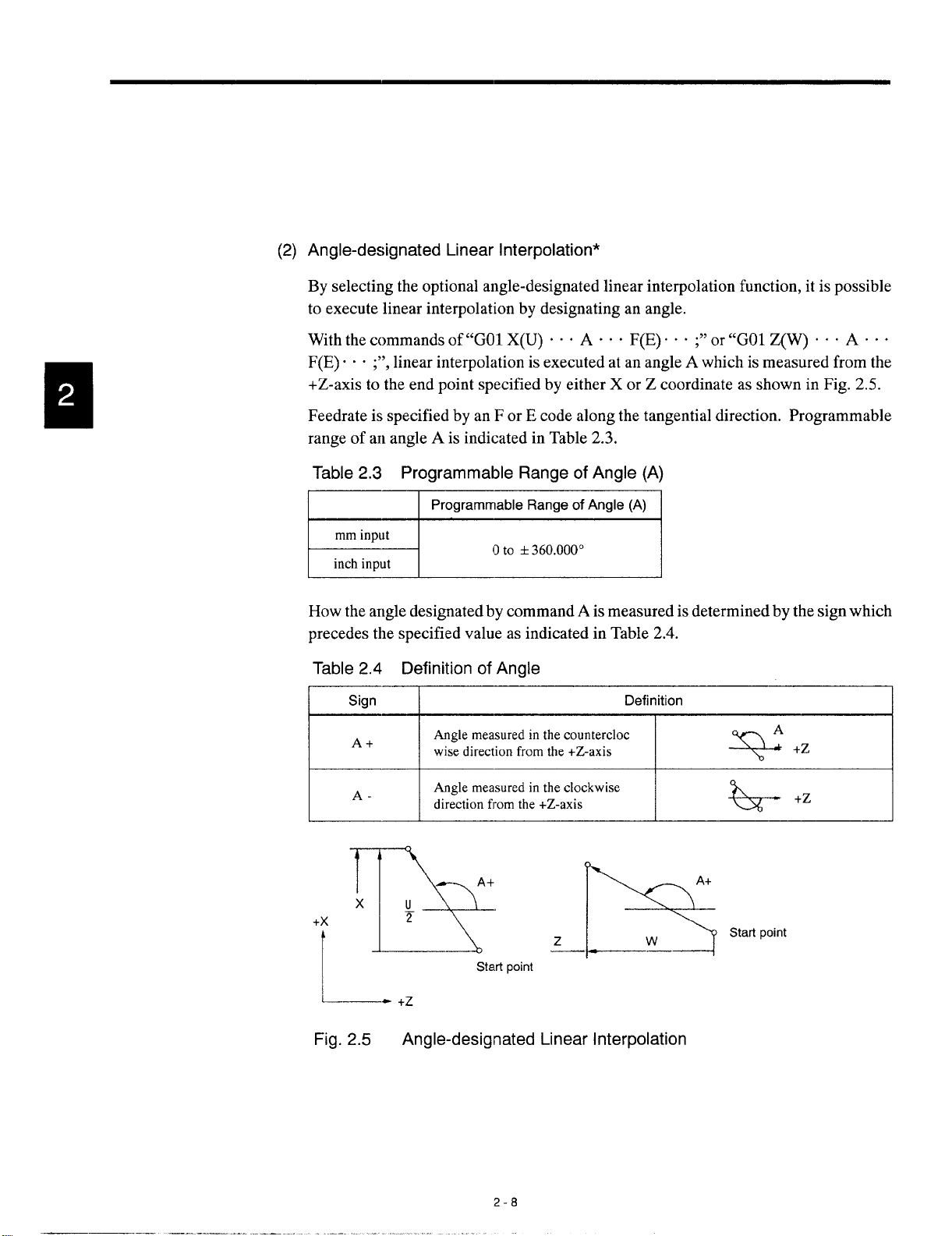

(2) Angle-designated Linear Interpolation*

By selecting the optional angle-designated linear interpolation function, it is possible

to execute linear interpolation by designating an angle.

With the commands of “GO1 X(U) “ 00 A “ “ “ F(E)” 0. ;“ or “GO1 Z(W) “ .0 A “ “ o

F(E) “ . “ ;“, linear interpolation is executed at an angle A which is measured from the

+Z-axis to the end point specified by either X or Z coordinate as shown in Fig. 2.5.

Feedrate is specified by an F or E code along the tangential direction. Programmable

range of an angle A is indicated in Table 2.3.

Table 2.3 Programmable Range of Angle (A)

Programmable Range of Angle (A)

E=

How the angle designated by command A is measured is determined by the sign which

precedes the specified value as indicated in Table 2.4.

Table 2.4 Definition of Angle

Definition

Angle

measured in the countercloc

l=-t-- *+Z

A-

x

+x

wise direction from the +.-axis

Angle measured in the clockwise

direction from the +.-axis

A+

$

b

Starl point

+Z

B

1

I

L-------

Fig. 2.5 Angle-designated

+Z

Start point

Linear Interpolation

2-8

Page 46

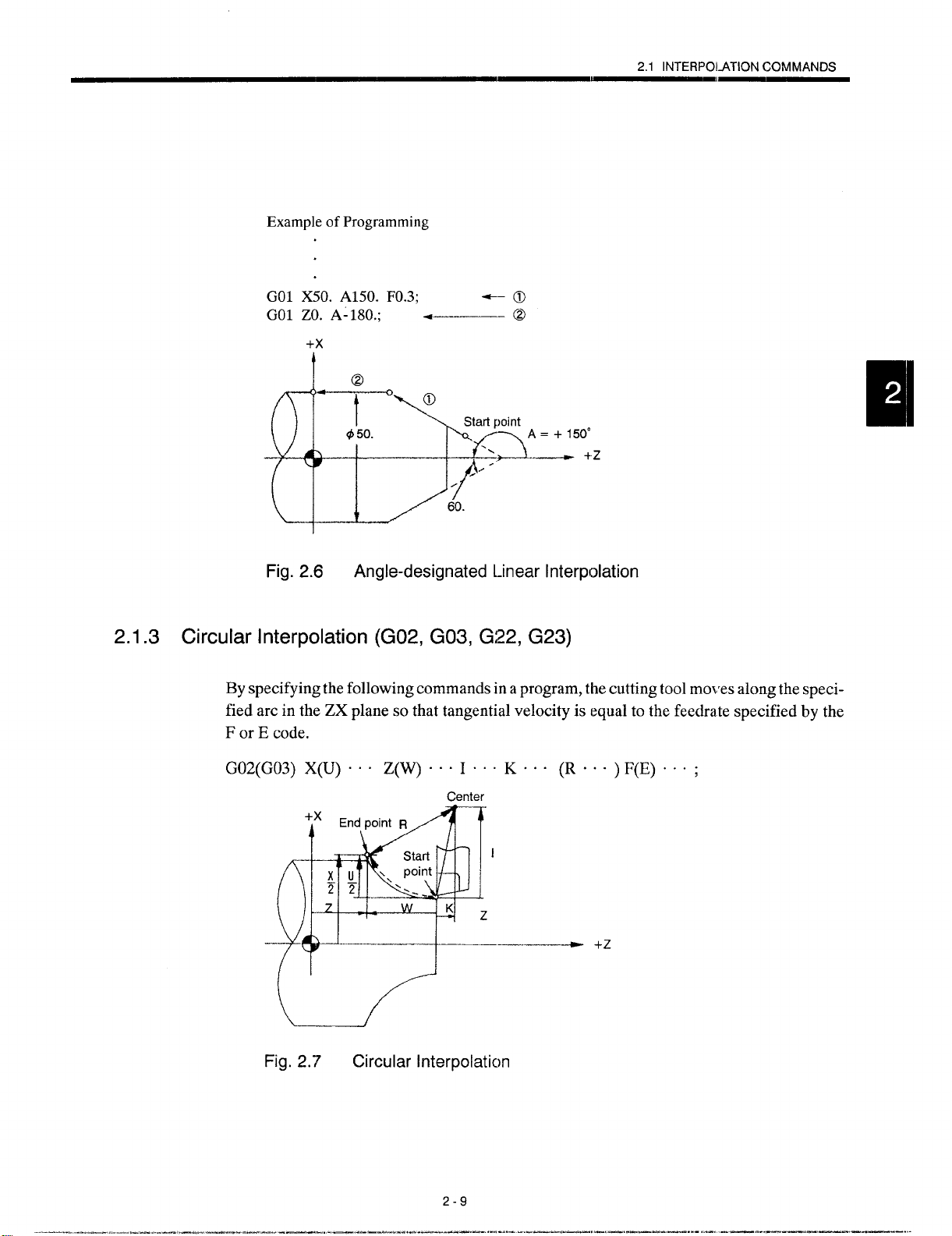

Example of Programming

2.1 INTERPOLATION COMMANDS

GO1 X50. A150. FO.3;

GO1 ZO. A-180.; .-

+— @)

@

+x

t

@

Fig. 2.6 Angle-designated Linear Interpolation

2.1.3 Circular Interpolation (G02, G03, G22, G23)

By specifying the following commands in a program, the cutting tool mo~’es along the specified arc in the ZX plane so that tangential velocity is equal to the feedrate specified by the

For E code.

G02(G03) X(U) .O” Z(W) ”C” I” C. K.””(R ““”) F(E).””;

Center

-—— +Z

Fig. 2.7 Circular Interpolaticm

2-9

——.——. ———=—.. —.——-. .—. -—-. —..—-—-. ——.. --... ———. —,—. .-—... ..—.-— ...—. ——.——... ..

Page 47

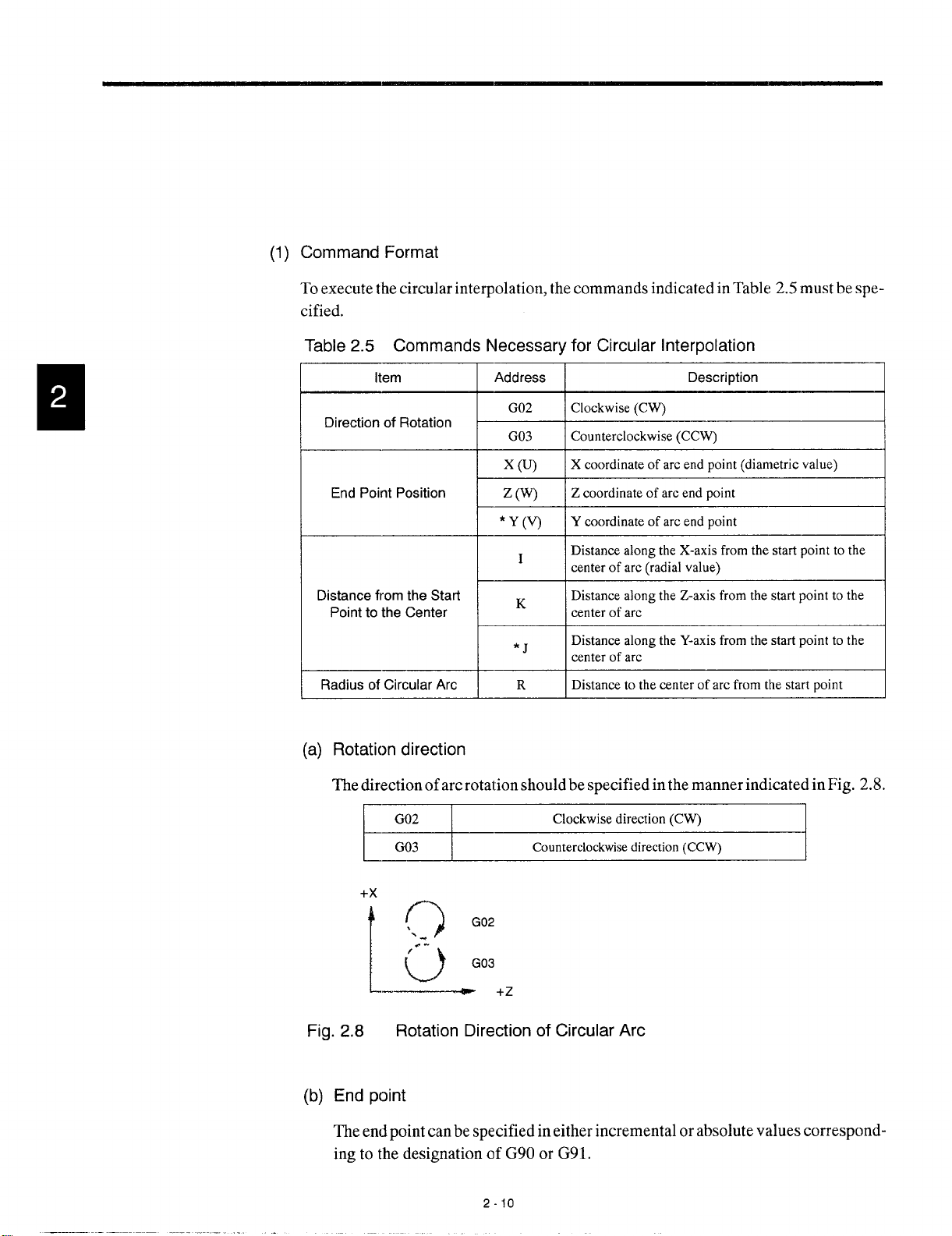

(1) Command Format

To execute the circular interpolation, the commands indicated in Table 2.5 must be specified.

Table 2.5 Commands Necessary for Circular Interpolation

Item

Direction of Rotation

End Point Position z (w)

Distance fromthe Start

Point to the Center centerof arc

Radius of Circular

(a) Rotation direction

The direction of arc rotation should be specified in the manner indicated in Fig. 2.8.

Arc R

G02

Address Description

G02

G03

x (u) X coordinate of arc end point (diametric value)

*Y(V)

I

K

*J

Clockwise (CW)

Counterclockwise (CCW)

Z

coordinate of arc end point

Y coordinate of arc end point

Distance along the X-axis from the start point to the

center of arc (radial value)

DistancealongtheZ-axisfromthe startpointto the

DistancealongtheY-axisfromthe startpointto the

centerofarc

Distance to the center of arc from the start point

Clockwise direction (CW)

Counterclockwisedirection (CCW)

+x

\

o

‘-

.-

/

0

[

—~

Fig. 2.8

(b) End point

The end point can be specified in either incremental or absolute values correspond-

ing to the designation of G90 or G91.

Rotation Direction of Circular Arc

G02

G03

+2

2-1o

I

Page 48

2.1 INTERPOLATION COMMANDS

If the specified end point is not on the specified arc, the arc radius i:; gradually

changed from the start point to the endpoint to generate a spiral so that the endpoint

lies on the specified arc.

Example of Programming

GO1 Z1OO. XO F1O.;

G03 Z-50. K-1OO.;

/

f

(

-

!50. O

100.

‘\

—---l-

\

100. z

Example of Programming

GO1 Z50. XO;

G03 Z- 100. K-50.;

Fig. 2.9

Interpolation with End Point off the Specified

-100

(a) End point positioned inside the circumference

1

I

i

(b) End point lying outside the circumference

Arc

Page 49

(c) Center of arc

The center of arccanbe specified in two methods - designation of the distance from

the start point to the center of the arc and designation of the radius of the arc.

I

End point

w

!;tart point

/

+x

z

—---

R

k

I

+2

‘qk[

;

.l-.–_._—

+P-

Center

.0”

K

--L

Fig. 2.10

c Specifying the distance from the start point to the center

Independent of the designated dimensioning mode (G90 or G91), the center

of an arc must be specified in incremental values referenced from the start

point.

● Specifying the radius

When defining an arc, it is possible to specify the radius by using address R

instead of specifying the center of the arc by addresses I or K. This is called

“circular interpolation with R desigmtion” mode.

o For the circular arc with the central angle of 180 deg. or smaller, use an R

value of “R > O“.

. For the circular arc with the central angle of 180 deg. or larger, use an R

value of “R < O“.

Example of Programming

.—— ———. —

Fig, 2.11

G02X(U) ””” Z(W) ””” R*”” ”F(E)”’ “;

or smaller

Start point

Circular interpolation with Radius R Designation

2-12

Page 50

2.1 INTERPCILATION COMMANDS

SJJPJLE-

C3

If an R command is used to specify the radius of an arc, G22 and (;23 can be used

instead of G02 and G03. When G22 or G23 is used, the programming format is the

same as used when G02 or G03 is specified with an exception of a G code. l[fG22 or

G23 is used, however, it is not allowed to define the center of the arc by I and K com-

mands. If these commands are used with G22 or G23, alarm “0162” occurs.

—

(2) Supplements to Circular Interpolation

A circular arc extending to multiple quadrants can be defined by the commands in a

single block.

Example of Programming

GOIZ””” F. O”;

G02 X60. Z-46.6 120. K-19.596 F . “. ;

\

\ AA

+x

@ 100.

27.

K

\

R28. “\

B

H

I ~

b 60.

I

—.——

Fig. 2.12 Circular Interpolation over Multiple Quadrants

Table 2.6

F==t=-&’;’m1

‘?

I

*

+Z

–428::–202 = –fi = –Ig.sgfj “m

Page 51

2.1.4 Chamfering (G11)

With thecommandsof’’Gll X(U) .00 K “ ‘ “ {orZ(W) .00 I “ c J}F(E) ~“ . ;“,chamfering

at corners is specified. In the designation of chamfering, single axis command of either Xaxis or Z-axis should be used.

Gll is a modal G code of 01 group. Once designated, it remains valid until other G code in

the 01 group is specified next.

(1) X-axis Chamfering

G1l X(U) O”. K+ ..” F(E)””;

——

L

Chamfer size

—

— Designation of chamfering direction

With the commands indicated above, X-axis chamfering is executed.

K- K+

End

point \

+x

t

L.-

+Z

Fig. 2.13 X-axis

\~ ‘

T

450

B

Start

point

Q

X (diametric value)

2

Chamfering

(2) Z-axis Chamfering

G1l Z(W) ”O” I+

““. F(E)”””;

—.

— Chamfer size (radial value)

t---!--

— Designation of chamfering direction

With the commands indicated above, Z-axis chamfering is executed.

End point

+1

-1

z

0’

b

450

1’

‘/

w

Start point

Fig. 2,14 Z-axis Chamfering

2-14

Page 52

Example of Programming

GOOX30. ZO;

Gll Z-20. 18. F30 ; — @

(Gil) X80. ,K-7. ;

7.

.— Q)

+x

20.

H+

2.1 lNTERPOLATION COMMANDS

SUPPLE.

MENT

(3

+Z

2.15 Example of Programming

Fig.

1. The following restrictions apply to the chamfer size K and I.

\KICIU/2],l 11<1 Wl

The K and I values must be smaller than the total move distance 1n the direction

of the designated axis. A formad error occurs if a value exceeding this limit is

specified.

2. Alarm “0445” occurs if both addresses X and Z are specified in the same block,

a block not including I or K is specified in the Gll mode, or I or K value is “O”.

3. The nose R offset offset function* is valid for the block where G 11 is specified.

4. It is possible to specify the Gll block in the commands of blocks that define fin-

ishing shape for a multiple repetitive cycle (G70 to G73).

5. It is possible to specify chamfering by specifying GO1 instead clf Gil.

GOIX(U) .”” K””” {or Z(W) ””” I.”} F(E) o“”;

.— _______ ____. — ._ -—... ..

2-15

— . . . .. —. —.. ,— .-,. =-—.. ,-< ..—. .—. ———-— —-—

Page 53

2.1.5 Rounding (G12)

With the commands of “G12 X(U) “ “ . K “ c “ {or Z(W) “ . “ I . “ “} F(E) o “ . ;“, corner

rounding is executed. In the designation, single axis command of either X-axis or Z-axis

should be used. Rounding is executed in a quarter circle.

G12 is a modal G code of 01 group. Once designated, it remains valid until other G code in

the 01 group is specified next.

(1) X-axis Rounding

G12X(U). ”.K* -“” F(E)..;

——

v-

I

————

— Designation of rounding direction

Rounding size

With the commands indicated above, X-axis rounding is executed.

K- K+

End

point

‘\

+x

t

L._

-

Fig. 2,16 X-axis Rounding

T

+Z

Start point

u

T

2

)( (diametric

value)

(2) Z-axis Rounding

G12Z(W)””” I* ““. F(E) ”.o;

~ –L—

~—

Rounding size (radial value)

Designating of rounding direction

—-. ..

With the commands indicated above, Z-axis rounding is executed.

End point

+1

—.. - —

-1

/

/

---1--w

Start point

a

I

Fig. 2.17 Z-axis Rounc!ing

2-16

Page 54

Example of Programming

GOO X20. ZO ;

G12 Z-25. 19. F30 ;

(G12) X70. K-6. F20 ;

6.

$70.

9.

— (b

+ @

25.

@

——

o

2.1 INTERPOLATION COMMANDS

+x

$20.

G’:

J

Fig. 2.18 Example of Programming

1. The following restrictions apply to the rounding size K and 1.

lKl<lU/21,111<lWl

The K and I values must be sma”ller than the total move distance in the direction

of the designated axis. A format error occurs if a value

specified.

2. Alarm “0445” occurs if both addresses X and Z are specified in Ihe same block,

a block not including I or K is specified in the G12 mode, or I or K value is “O”.

exceeding this limit is

3. The nose R offset offset function* is valid for the block where G12 is specified.

4. It is possible to specify the G12 block in the commands of blocks that define finishing shape for a multiple repetitive cycle (G70 to G73).

5. It is possible to specify chamfering by specifying GO1 instead clf G12.

GOIX(U) ””” R.. ”{or Z(W) ””” R”””} F@)”””;

.

2-17

.—— — .—— —.-. .-— .. —-. .—- —

—.—

,=..—.. .— ..

——

—..—.————. .

Page 55

2.1.6 Cylindrical Interpolation (GI 24, G125) *

The cylindrical interpolation function allows programming of machining on a cylindrical

workpiece (grooving on a cylindrical workpiece) in the manner like writing a program in a

plane using the cylinder developed coordinate system. This functions allows programming

both in absolute commands (C, Z) and incremental commands (H, W).

(1) Programming Format

(a) Features of GI 24, G 125

The following G codes are used for cylindrical interpolation.

Table 2,7 G Codes Used for Cylindrical Interpolation

Cylindrical interpolation mode ON

Group

e ‘“”’’ion :

Cylindrical interpolation mode OFF

These G codes are buffering prohibiting G codes.

Specify G124 and G125 in a block without other commands. If other G code is

specified with G124 or G125 in the same block, alarm “0161” (UNMATCH G

CODE) occurs,

G124 and G125 are modal G codes of 20 group. Once G124 is specified, the cylin-

drical interpolation mode ON state remains until G125 is specified. When the power is turned ON or the NC is reset, the G125 (cylindrical interpolation mode OFF)

state is set.

(b) Programming format

Cylindrical interpolation mode ON

G124CO”. ;

+

-=--Machining program in the cylindrical interpolation mode

G125 ;

+ Cylindrical interpolation mode OFF

where, C = Radius of cylindrical workpiece

(1 = 0.001 mm or 0.0001 inch)

‘Theradius of a cylindrical workpiece must always be specified. If a C command

is not specified, alarm “0162” (LACK OF ADDRESS) occurs.

2-18

Page 56

Feedrate

(c)

In the cylindrical interpolation mode, interpolation is executecl in the virtual C-Z

plane. Therefore, after the entry to the cylindrical interpolation. mode, it is necessary to specify feedrates in the C-Z plane.

value represents feedrates (mrn/min, inchhnin) in the C-Z plane.

● For cylindrical interpolation, use the G98 (feed per minute) mode. Cylindrical

interpolation is not possible in the GOOmode. To execute ~Jositiorling, cancel

the cylindrical interpolation mode. Note that GOOmode nlay be specified in

a plane other than the C-Z plane.

(2) Example of Programming

2.1 INTERPOLATION COMMANDS

lJse address F to specify feedrates. F

Cu”ng’oo’u----z

Example of programming

0100 ;

G98 ;

TO1O1;

GOOX44.O CO; .—

G124 C45.O ; c—

GO1 G42 Z47.5 F1OO;

C60.O;

Z32.5 C120.O ;

C240.O;

G03Z40.OC249.549R7.5;

G02Z47.5C259.099R7.5;

GO1C360.O;

G40Z44.O;

G125;

M30; —

c

Positioning at the start point c,f cutting

Cylindrical interpolation mode ON

Machining program

1

Cylindrical interpolation mode OFF

Fig. 2.19 Coordinate System for Cylindrical Interpolation

———— ,.———=—..=— ... .... .. ... ..— ,,.—.—-.” .-. .

2-19

—.. -

——., —. —. —. —.. .-~ -=—— -.”-. ——. +—.. --—

Page 57

Relationships between Cylindrical Interpolation and Operations

(3)

In the cylindrical interpolation mode, the following G codes maybe specified: (GOO),

GO1, G02, G03, G04, G1O, G22, G23, G40, G41, G42, G65, G66, G67, (G90, G91),

G98, and G134. Alarm “0161” (UNMATCH G CODE) occurs if a G code other than

those indicated above is specified in the cylindrical interpolation mode.

1. In the GOOmode, only X.-axis can be specified.

2. G90 and G91 are valid only when special G code specification is selected.

3, In the G134 mode, only M commands maybe specified.

●

In the cylindrical interpolation mode, the tool radius offset function can be

used. Turning ON/OFF of the tool radius offset function must be made in the

cylindrical interpolation mode. The tool radius offset function is valid only

in the cylindrical interpolation mode and the polar coordinate interpolation

mode.

●

In the cylindrical interpolation mode, cutting in the linear interpolation (GO1)

mode and circular interpolation (G02/G03) mode is available. Circular interpolation is permitted only in the C-Z plane. If circular interpolation commands are specified in other plane, an alarm occurs. For the definition of an

arc, use either addresses I and K to specify the center of arc or address R to

directly specify the radius of the arc. Note that designation of address R is optional.

●

The nose R offset function must be canceled before specifying G124.

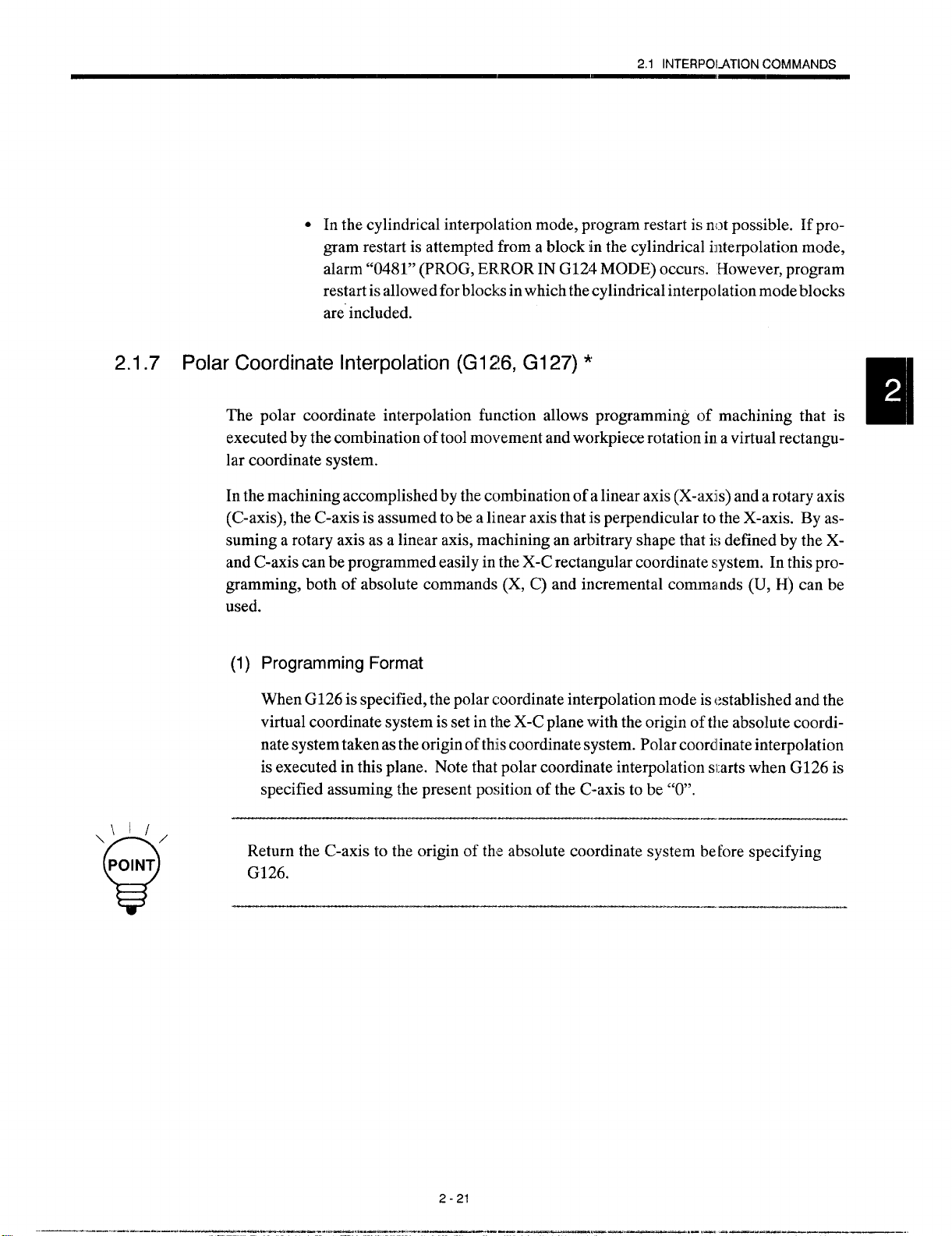

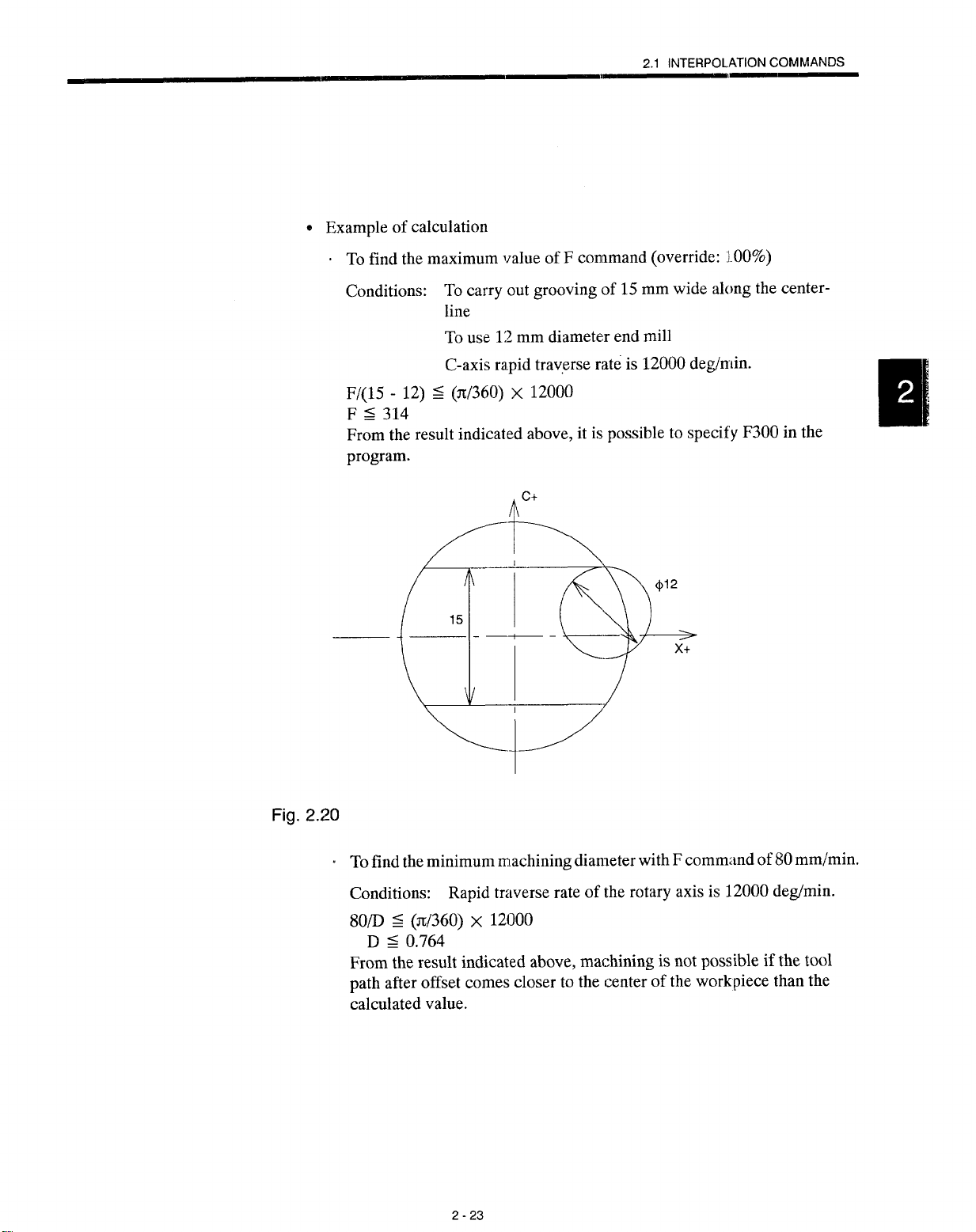

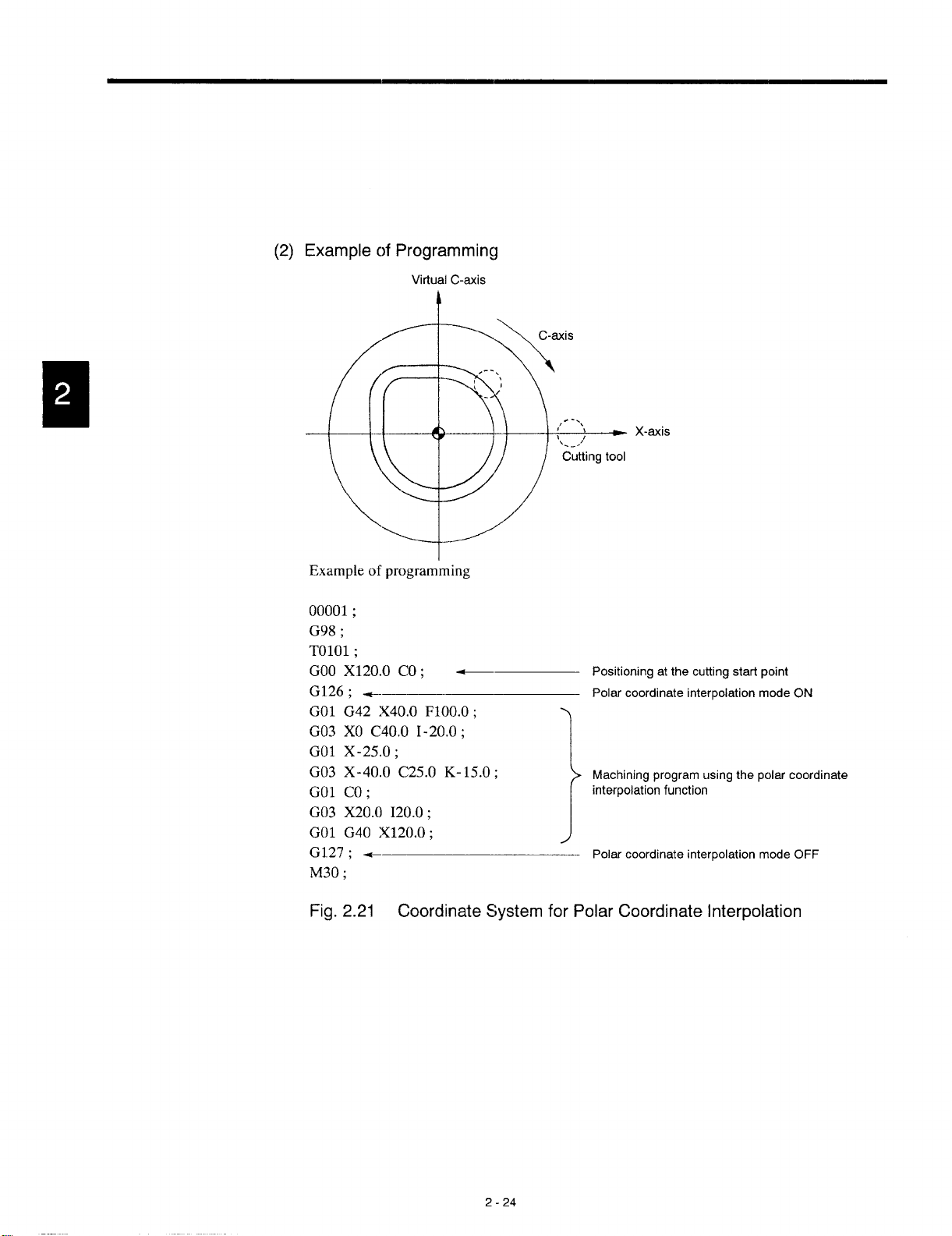

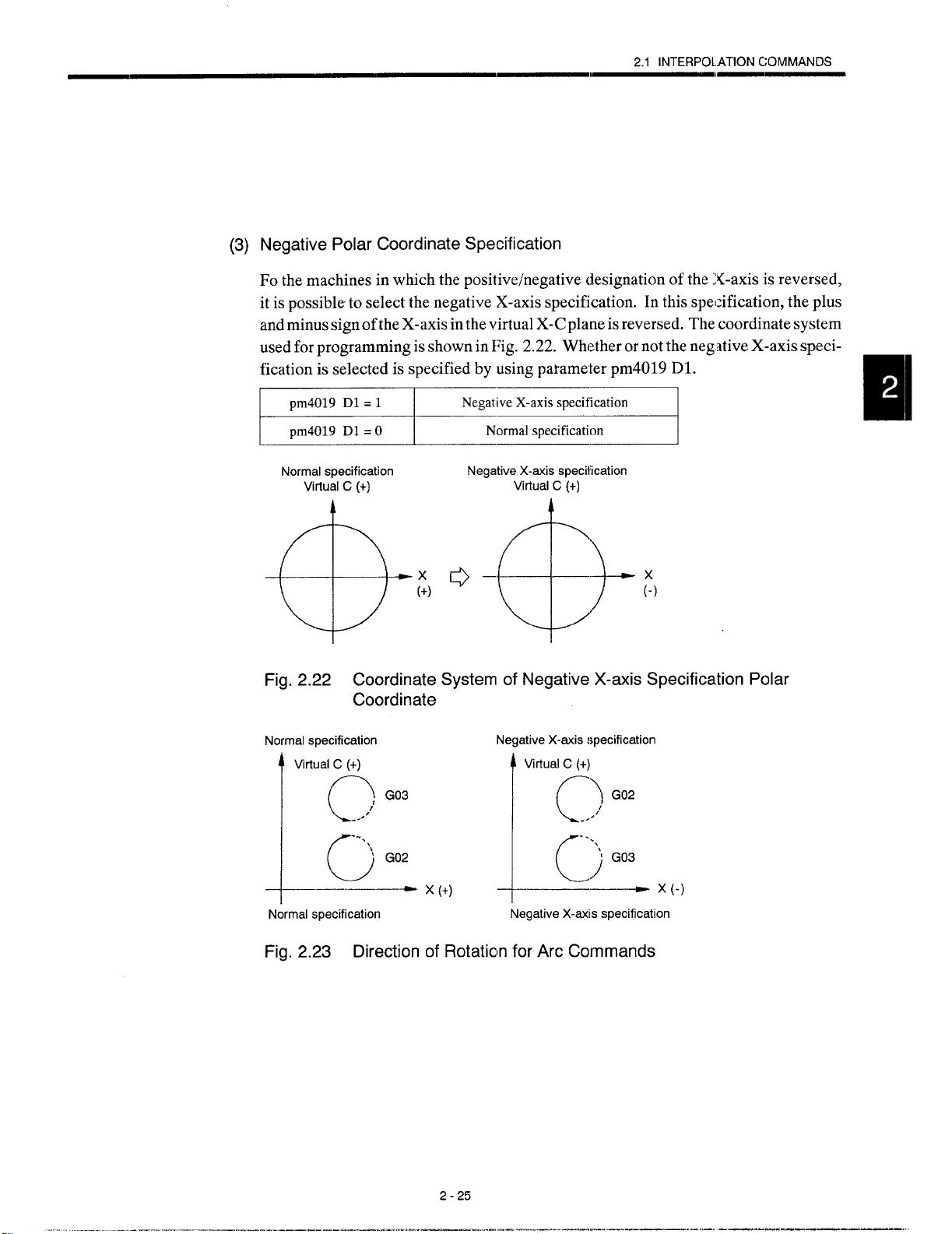

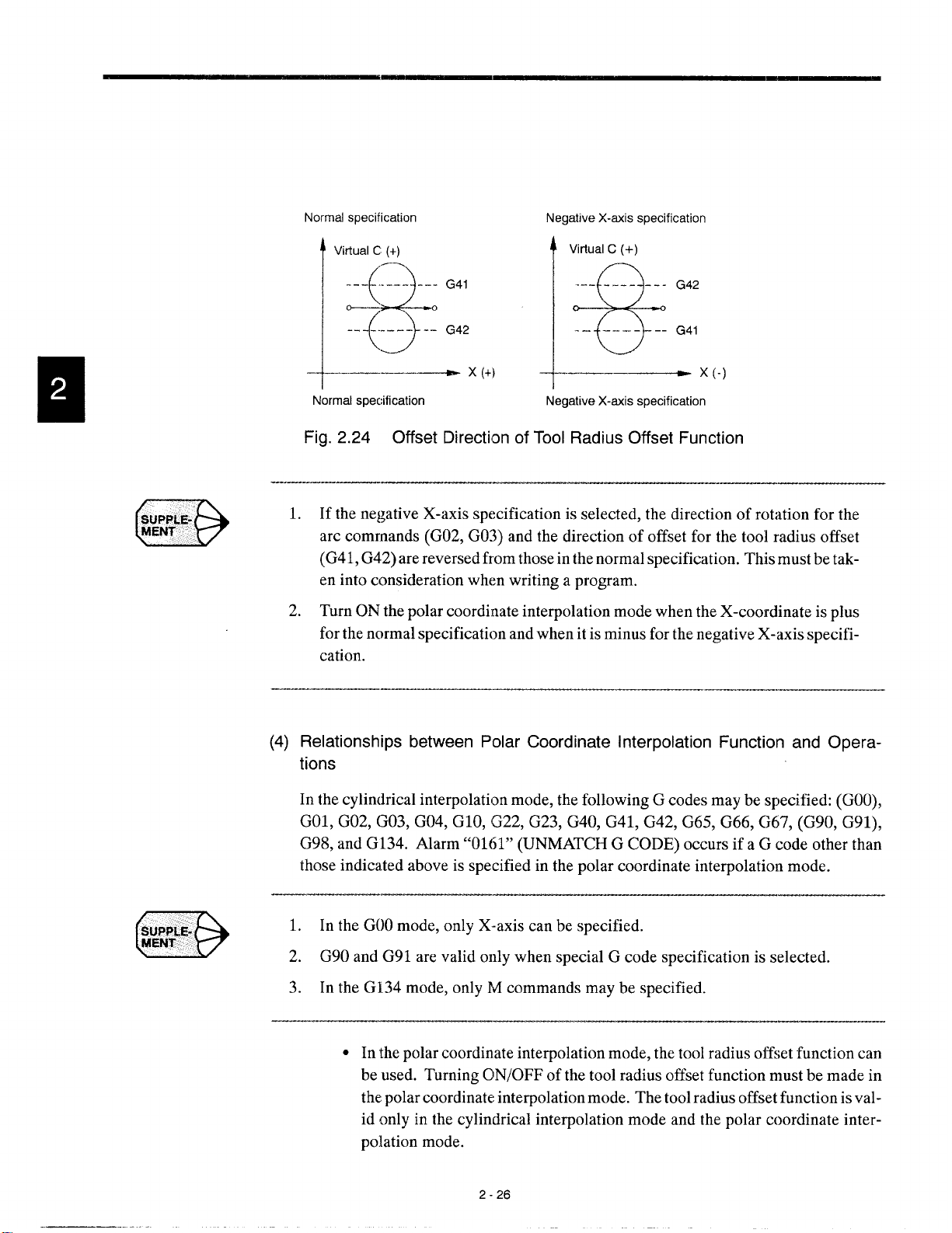

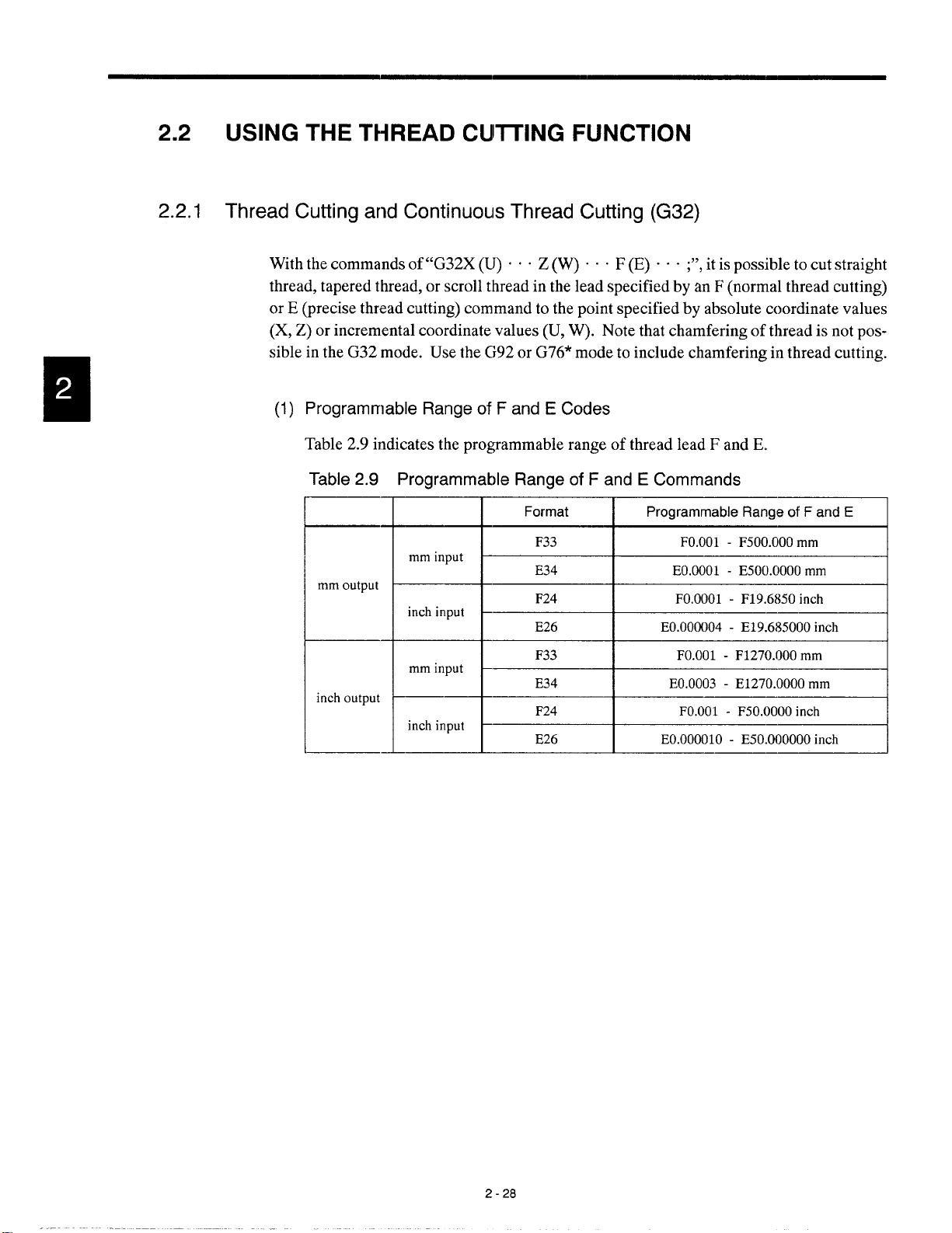

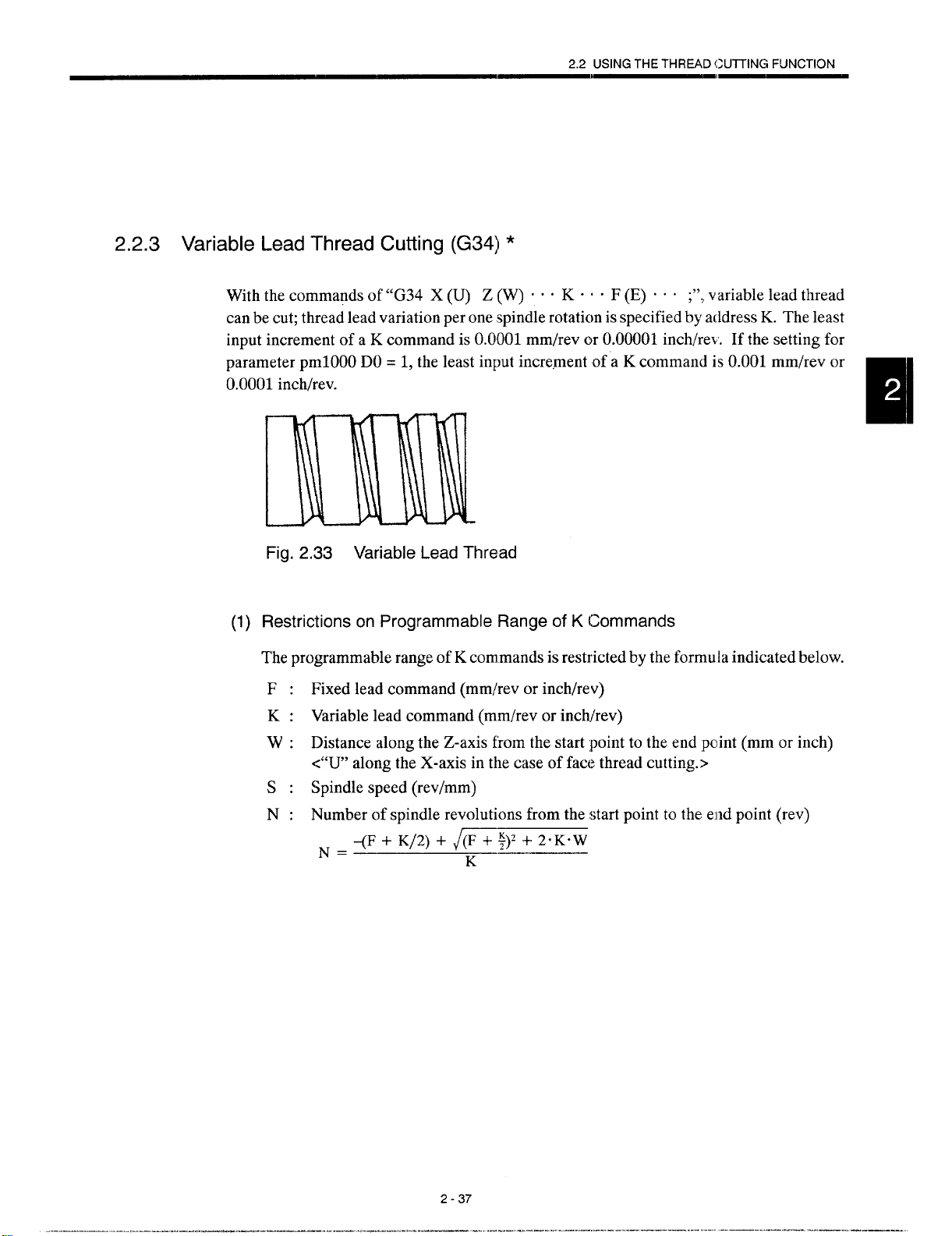

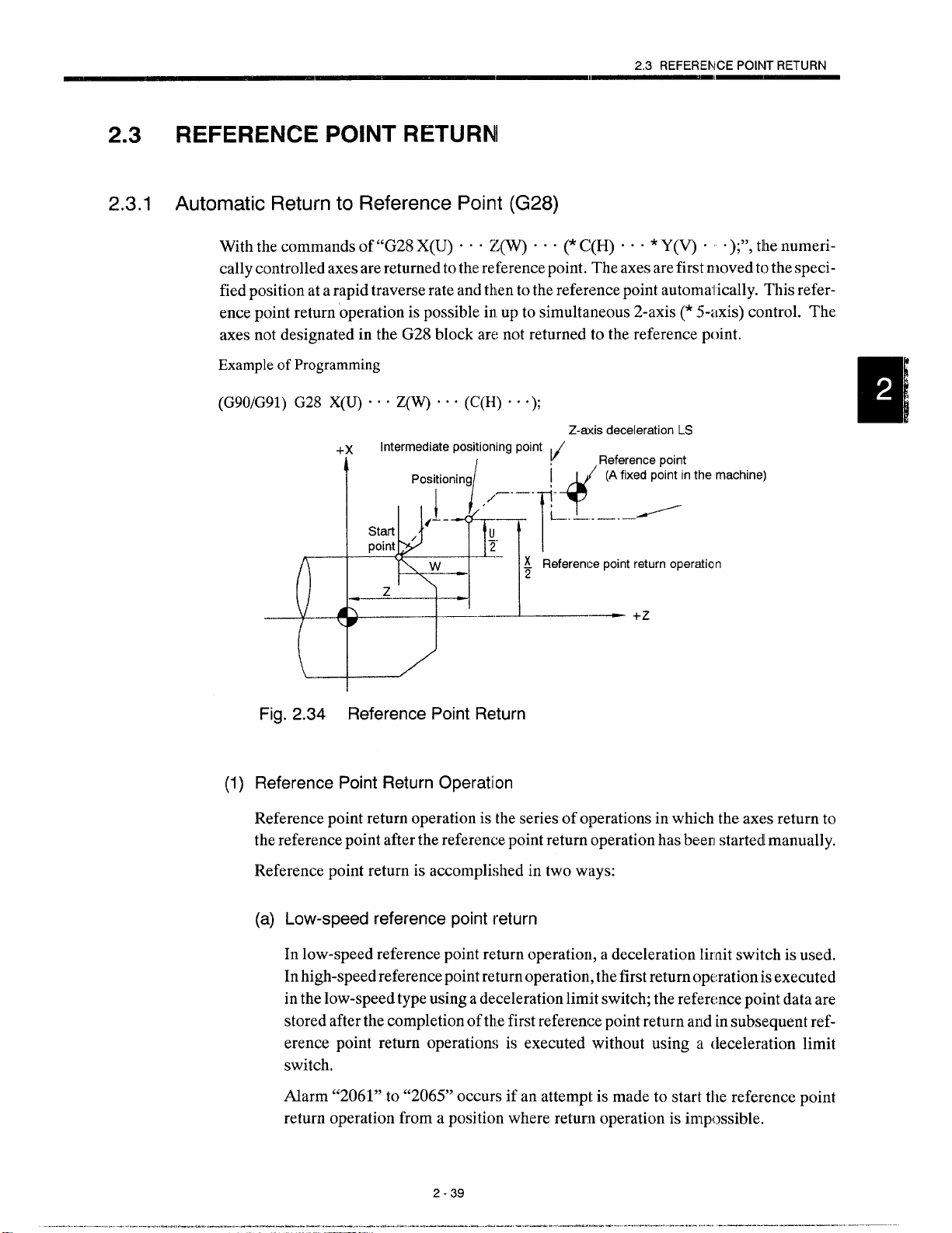

●