Page 1

<

D

c)

in

0

Z

z

D

z

0

m

D

l-

-l

<

-0

m

v,

?

D

Page 2

Safety lnfor

The following conventions are used to indicate precautions in this manual. Failure to heed the precautions provided in this manual can result in serious or possibly even fatal injury or damage to the products or related equipment and systems.

/A WARNING /

Indicates a potentially hazardous situation which, if not avoided, could result in death or seri-

ous injury to personnel.

-mati In

Symbol

is used in labels attached to the product.

IA CAUTION 1

Indicates a potentially hazardous situation which, if not avoided, may result in minor or mod-

erate injury to personnel and damage to equipment.

Even items described in

case, follow these important items.

A CAUTION

may result in a vital accident in some situations. In either

iii

Page 3

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

Indicates important information that should be memorized, including precautions such as alarm displays to avoid damaging the devices.

Indicates supplemental information.

Indicates definitions of difficult terms or terms that have not been previously explained in this manual.

0 Yaskawa, 1998

All rights reserved. No part of this publication may be produced, stored in a retrieval system, or transmitted, in any form, or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed with respect to the use of information contained herein. Moreover, because Yaskawa is

constantly strivin,o to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of information contained

in this publication.

Page 4

CONTENTS

Safety Information

...............................................

VisualAids .....................................................

About this Manual

Related Manuals

Notes for Safe Operation

...............................................

................................................

.........................................

1 GENERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 CONFIGURATION

1.1.1 System Configuration

1.1.2

1.1.3 ConnectorLayout

ConnectionbetweenDevices.. .......................................

1.2 GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 DESIGNOFBOX

1.3.1 ThermalDesign ....................................................

1.3.2 Dustproof Design

1.3.3 Countermeasures against Magnetic Fields

1.4 CABLE CLAMP AND SHIELDING

1.5 PACKAGING ..............................................

1.5.1 GeneralNotes

1.5.2

1.53 Installation of Servo Unit

Installation of CNC Unit

.........................................

................................................

...................................................

..........................................

................................................... 1 - 11

.............................

............................

......................................................

..............................................

.................. :.

.........................

iii

iv

ix

ix

X

l-l

l-2

l-2

l-3

l-4

1 - 5

l-6

l-6

l-13

1 - 14

l-15

l-15

l-16

l-17

2 CONNECTION OF POWER SUPPLY . . . . . . . . . . . . . . . . . .

2.1 CONNECTION BETWEEN DEVICES

2.1.1 Power Supply to CNC Unit

2.1.2 Power Supply to Converter Unit

2.2 DETAILED CONNECTION

2.2.1 PowerSupplytoCNCUnit

2.2.2 Power Supply to Converter Unit

........................................... 2-2

....................................... 2-2

...................

........................................... 2-3

.......................................

.........................

:

..............

3 CONNECTION OF CNC OPERATION PANEL . . . . . . . . . .

3.1 CONNECTION BETWEEN DEVICES

3.1.1 Connection with g-inch CRT Operation Panel ...........................

3.2 DETAILED CONNECTION OF CNC OPERATION PANEL

3.2.1

3.2.2 General Notes on the Connenction of CRT Operation Panel

Connection with g-inch CRT Operation Panel .......................

.........................

....... 3 - 3

:.

..............

..

2 - 1

2 - 2

2-3

2 . 3

3 - 1

3 - 2

3 - 2

3-3

3-4

Page 5

4 CONNECTION OF MANUAL PULSE GENERATOR . . . . . . 4 - 1

4.1 CONNECTION BETWEEN DEVICES

4.1.1 Connection with g-inch CRT Operation Panel

......................... 4 - 2

........................... 4 - 2

4.2 DETAILED CONNECTION OF MANUAL PULSE GENERATOR . .

4.2.1 Non-parallelI/F..................................................... 4-3

4.2.2

ParallelI/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 CONNECTION OF POWER ON/OFF

EXCLUSIVE SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CONNECTION BETWEEN DEVICES . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1

5.2 DETAILED CONNECTION OF POWER ON/OFF

5.2.1 Connection to CNC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 DETAILS OF SIGNAL ......................................

5.3.1

5.3.2 Emergency Stop (‘ESP) Input ........................................

5.3.3

Connection to CNC Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

EXCLUSIVE SIGNAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servo Power ON (SVMX), Brake Release (BKX) Output

External Power ON/OFF (EON, EOF, ECOM) Input

.................. 5 - 4

...................... 5-5

4 - 3

4-4

5-l

5 - 2

5 - 3

5-3

5 - 4

5 - 5

6 CONNECTION OF FEED SERVO UNIT . . . . . . . . . . . . . . . .

6.1 CONNECTION BETWEEN DEVICES

6.1.1 Connection with l-axis Servo Unit ....................................

6.1.2 Connection with 3-axis Servo Unit ....................................

6.2 DETAILED CONNECTION WITH FEED SERVO UNIT . . . . . . . . . .

6.2.1 No.1 Axis .................

6.2.2 No.2 Axis .................

6.2.3

6.2.4 No.4 Axis .................

6.2.5

6.2.6

No.3 Axis .................

No.5 Axis .................

IR Type Servo Unit .........

. .

6.3 DETAILED CONNECTION OF SERVO UNIT MAIN CIRCUIT . . . .

6.3.1

6.3.2 Connection with 3-axis Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection with l-axis Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 USEOFSERVOUNIT.. ....................................

6.4.1

6.4.2 Protection of Power Line .............................................

Noise Suppression ..................................................

vi

......................... 6 - 2

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . . . . . . . .

6 - 1

6-2

6 . 4

6-6

6-6

6-6

6-7

6-7

6-8

6-8

6 - 10

6-10

6- 11

6-12

6-12

6-16

Page 6

7 CONNECTION OF SPINDLE DRIVE UNIT

.............

7-l

7.1 CONNECTION BETWEEN DEVICES .........................

7.1.1 Pulse Generator with Built-in Motor

7.1.2

7.1.3 Main Circuit, Converter, and

Separate Spindle Pulse Generator

lnverter

...................................

....................................

...................................

7.2 DETAILED CONNECTION WITH SPINDLE DRIVE UNIT .......

7.2.1

7.2.2 Separate Spindle Pulse Generator

7.2.3 Main Circuit, Converter, and

8 CONNECTION OF TAPE READER

Pulse Generator with Built-in Motor

lnverter

...................................

....................................

..........................

....................

8.1 CONNECTION BETWEEN DEVICES .........................

8.1.1 Connection with CNC Unit

...........................................

8.2 DETAILED CONNECTION OF TAPE READER ................

8.2.1

MODEL2801E

9 CONNECTION OF RS-232C

.....................................................

.........................

9.1 CONNECTION BETWEEN DEVICES .........................

9.1.1 Connection with CNC Operation Panel

.................................

.........

7-2

7-2

7-2

7-3

7-4

7-4

7-5

7-6

8-1

8-2

8-2

8-3

8-3

9-l

9-2

9-2

9.2 DETAILED CONNECTION OF RS-232C ......................

9.2.1 Connection with CNC Operation Panel

9.3 RS-232C INTERFACE

9.3.1

9.3.2

9.3.3

9.3.4 Cable Length

9.3.5 Connection between Devices

9.3.6

TransmissionMethod

CodestobeUsed

Communication Baud Rate

.......................................................

Signal Communication Timing

.....................................

................................................

...................................................

...........................................

.........................................

........................................

10 CONNECTION OF DIRECT-IN

10.1 CONNECTION BETWEEN DEVICES

10.1.1 Connection to CNC Unit

10.2 DETAILED CONNECTION OF DIRECT-IN

10.2.1 Connection to CNC Unit

.............................................

.............................................

vii

.................................

.......................

.........................

....................

9-3

9-3

9-4

9-4

9-4

9-5

9-5

9-5

9-7

10 - 1

.

10 2

10-2

.

10 3

10-3

Page 7

10.3 DESCRIPTION OF SIGNAL

10.3.1 Input Circuit on CNC Side

............................................

.................................

10 - 4

10-4

11 CONNECTION OF I/O MODULE . . . . . . . . . . . . . . . . . . . . . . 11 - 1

11.1 CONNECTION BETWEEN DEVICES.. . . . . . . . . . . . . . . . . . . . . . . .

11 .l .l Connection between Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 DETAILED CONNECTION OF I/O MODULE . . . . . . . . . . . . . . . . . .

11.2.1 Connection between Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 -3

11 - 2

11 -2

11 - 3

11.3 CONNECTION BETWEEN DEVICES OF

ADDITIONAL I/O MODULE

11.3.1 Connection between Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 DETAILED CONNECTION OF ADDITIONAL I/O MODULE . . . . . .

11.4.1 Connection between Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 -5

11 - 4

11 -4

11 - 5

12 CONNECTION OF GENERAL-PURPOSE l/O . . . . . . . . . . 12 - 1

12.1 CONNECTION BETWEEN DEVICES

12.1 .l Connection of Signal Line with I/O Module

.........................

.............................. 12-2

12.2 DETAILED CONNECTION OF GENERAL-PURPOSE I/O

12.2.1 FC81O/FC860 Module

12.2.2 FC861 Module

12.2.3 JSP02 Module

......................................................

...............................................

.....................................................

.......

12 - 2

12 - 4

12-4

12 - 20

12 - 29

12.3 DESCRIPTION OF GENERAL-PURPOSE I/O SIGNAL

12.3.1 I/OPort ............................................................

12.3.2 I/O Circuit of I/O Port

12.3.3 Power Supply for I/O Signal

................................................

..........................................

.........

12 - 38

12-38

12 - 42

12 - 50

Page 8

About this Manua

This manual describes the specifications for connecting YASNAC J300 with machines, machine interfaces and external equipment.

Necessary connections to be provided by the machine tool builder differ depending on the type of the

CNC cabinet supplied by Yaskawa. Make additions or deletions of connections in accordance with

the combination for standard cabinets and integrated units.

The programmable controller system (hereafter called PLC) is installed in the YASNAC J300 CNC

cabinet. For details of the PLC, refer to YASNAC J300/3100 PLC Progamming Manual (SlEC844-0.1).

.I

Related Manuals

Refer to the following manuals as required.

Read this manual carefully to ensure the proper use of J300. Also, keep this manual in a safe place

so that it can be refereed to whenever necessary.

Manual Name

YASNAC J3OOM/J IOOM

Operating Manual

YASNAC J3OOM/J IOOM

Programming Manual

YASNAC J3OOL

Operating Manual

YASNAC J3OOL

Programming Manual

YASNAC J3OO/J 100

PLC Programming Manual

YASNAC J300M/J 1 OOM

110 Signai Function Manual

YASNAC J3OOL

l/O Signal Function Manual

Manual Number

TOE-C844-2. I

TOE-C844-2.2

TOE-C843-13.20

TOE-C843-13.21

SIE-C844-0.1 Describes the PLC instructions and the op-

SIE-C844-2.3

SIE-C843-13.4

Describes the basic configuration and operation procedure of YASNAC J3OOM/JlOOM.

Describes the information necessary for

creating a program using the YASNAC

J3OOM/JlOOM.

Describes the basic configuration and operation procedure of YASNAC J3OOL.

Describes the information necessary for

creating a program using the YASNAC

J3OOL

eration for developing the PLC programs.

Describes the functions of UO signals be-

tween YASNAC J3OOM/J 1 OOM and PLC.

Describes the functions of l/O signals be-

tween YASNAC J3OOL and PLC.

Contents

YASNAC J300

Connecting Manual(Type B)

SIE-C843-13.5

ix

Describes the specifications for connectin-

gYASNAC

interface and external equipment.

5300 with machiones, machine

Page 9

Notes for Safe Operation

Read this programming manual thoroughly before installation, operation , maintenance or inspection

of the YASNAC 5300.

The functions and performance as an NC machine tool are not determined only by an CNC unit itself.

Before the operation, read thoroughly the machine tool builder’s documents relating to the machine

tool concerned.

In this manual, the Notes for Safe Operation are classified as “WARNING” or “CAUTION”.

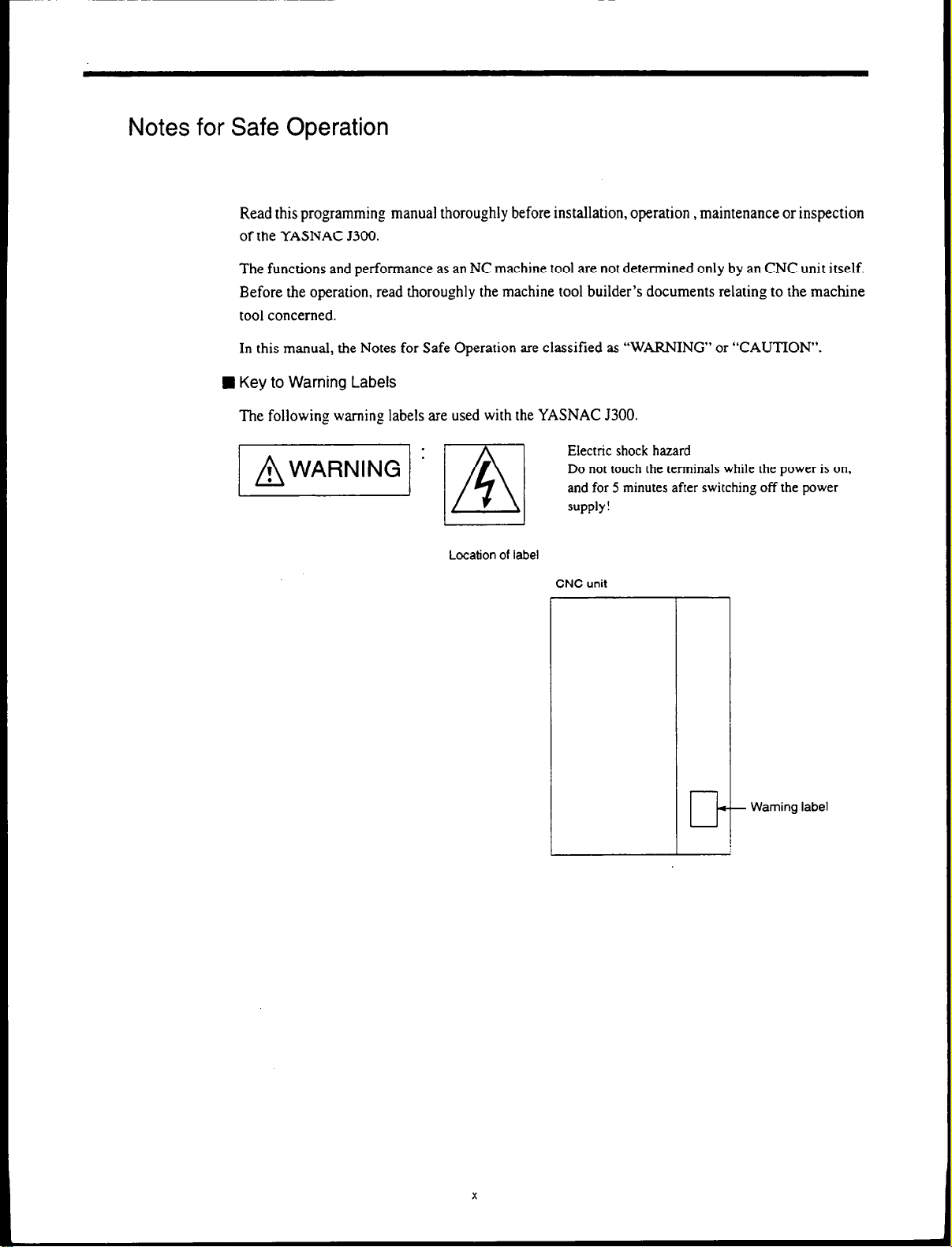

W Key to Warning Labels

The following warning labels are used with the YASNAC 5300.

Location of label

CNC unit

-

cl-

Warning label

Page 10

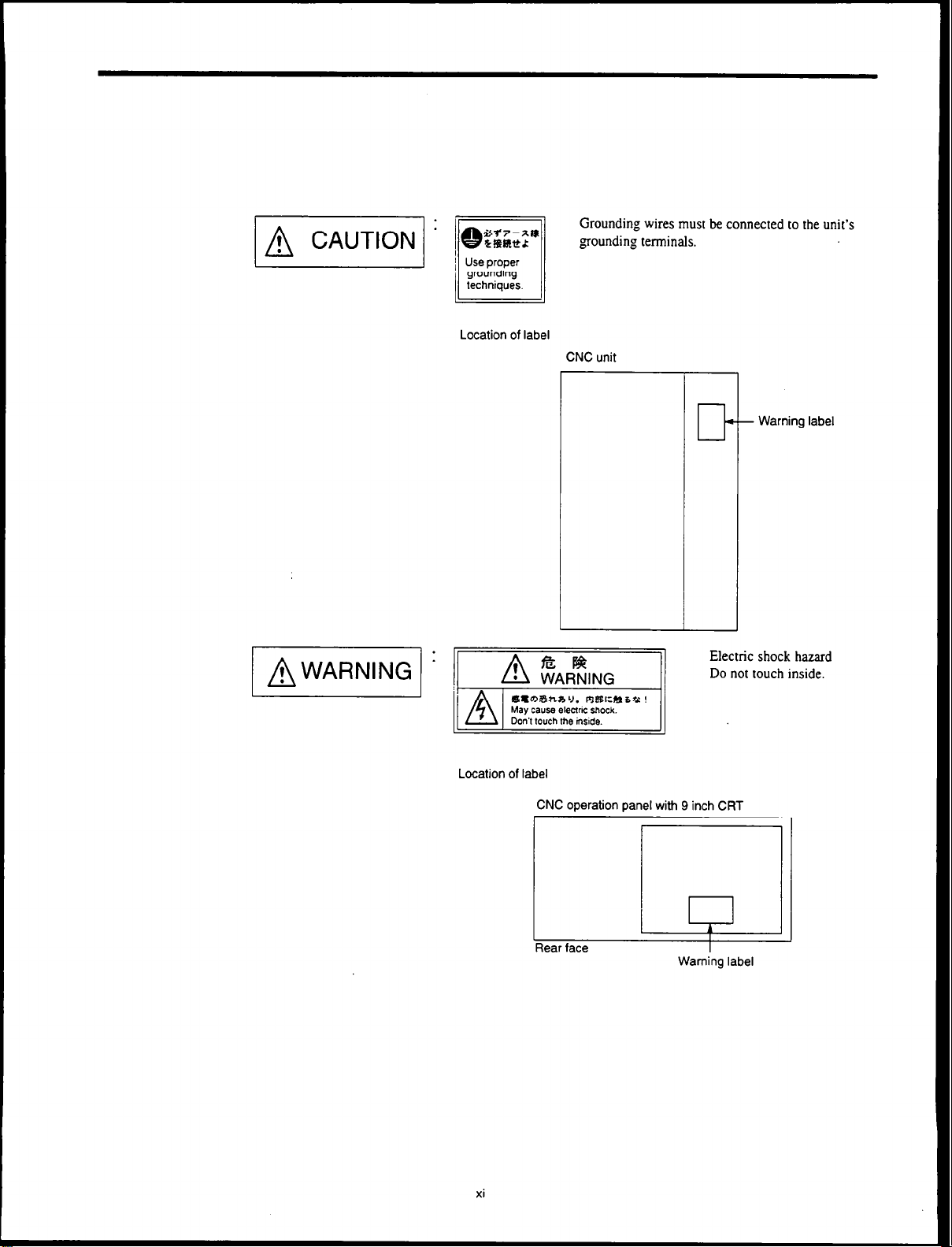

VI ’ ml

Location of label

1

AWARNING 1

Grounding wires must be connected to the unit’s

goundin,o tet-tea

CNC

unit

-

+ Warning label

II-

Electric shock hazard

Do not touch inside.

Location of label

CNC operation panel with 9 inch CRT

I

,

Rear face

xi

I

I

Warning label

Page 11

H Transport Precautions

A CAUTION

l

Do not lift the cable when moving the product.

Failure to observe this caution may lead to personal injury or product failure.

l

Cover the eyebolt mounting holes with bolts of the corresponding size after having removed the

eyebolts with the product installed on the machine.

Failure to observe this caution may lead to product failure.

l

Do not move the product in a place subject to rain, water drops, harmful gases or liquids.

Failure to observe this caution may result in personnel accident or product failure.

W Storage

A CAUTION

l

Do not store the product in a place subject to rain, water drops, harmful gases or liquids.

Failure to observe this caution may result in product

l

Select a storage area indoors that is clean and meets the following temperature and humidity

conditions.

Failure to observe this caution may result in product failure.

-20

l

Ambient temperature :

l

Relative humidity :

l

Altitude

“C to 60 “C (-4

10% to 90%

1000 m and less

failure.

“F to 140 “F)

n

Installation

I I

A CAUTION

l

When installing the product, avoid shutting the intake port or the exhaust port. Also avoid foreign

matter from entering the device.

Failure to observe this caution may lead to fire or product failure.

l

Avoid strong impact during installation.

Failure to observe this caution may result in product failure.

l

Set the power line capacity higher than the power consumption of the device.

Failure to observe this caution may result in product malfunction.

xii

Page 12

A CAUTION

l

The current capacity of 24 VDC external power unit for input/output contacts is determined by the

numberof contact points to be used. When the current capacity is low, install an additional external

power unit.

l

Rust preventive has been applied to the shaft end and the flange surface of the motor, so remove it

by wiping with a clean cloth before installing the device.

l

When connecting the motor shaft to a driven machine, make sure that they are centered accurate-

ly to prevent vibration.

Failure to observe this caution may lead to vibration causing product failure or personal injury

l

Design and install the box in accordance with the following.

Failure in box such as electric control panel may result in product failure or malfunction.

I. Use an ainight enclosure.

2. Limit the average temperature increase of internal air within the enclosure to under 10 “C (50 “F)

compared to the ambient temperature.

3. Use a fan to circulate air in order to improve the cooling efficiency of a closed enclosure and to prevent

abnormal temperature rise.

4. Seal the cable inlet, door. etc. completely.

5. CRT display attracts airborne particles

therefore, provide a structure to prevent the entry of such particles.

6. In the CNC unit, various

units

malfunction, therefore, make structures to prevent the entry of dust.

7. Install packing on the cable inlet,

8. Ambient magnetic field may cause screen fluctuations of the CRT display, therefore,

prevent this by layout and magnetism shield.

because

of its high voltage and may result in malfunction,

and printed circuit boards, dust in the air may result in

doors,

back covers, etc. to eliminate gaps or openings.

A CAUTION

l

Install various units in accordance with the following.

Failure 10 observe this caution may result in product failure or malfunction.

I. Mount the servo unit vertically with screws or bolts.

2. The servo unit will generate heat, therefore, install it with adequate clearance around it.

3 In order to reduce the internal loss causing heat generation, arrange the cooling tin of the servo unit

outside the enclosure so that the fin

is exposed lo the external

4. When circulating air inside the enclosure, do not blow air directly onto the servo unit (in order lo pre

vent dust contamination).

5. Regenerating resistor will generate heat. therefore, install it away from devices that may

heat.

6. Arrange units so that maintenance. inspection or change of parts may be made easily.

XIII

atmosphere.

be affected by

Page 13

n

Wiring

A CAUTION

l

Correct and precise wiring should be performed by qualified, authorized personnel only.

Failure to observe this caution may result in electric shock, fire, or malfunction.

l

Never connect a 3-phase power supply to motor output terminals “U, V, and W” of the drive unit.

Otherwise, the device may be damaged.

l

Select the type of wire and its size according to your requirement and current capacity.

When the ambient temperature exceeds 30 “C (86 “F), the allowable current goes down.

Select the cable size in conformance with local electrical codes orthe cable manufacturer’s techni-

cal data.

Failure to observe this caution may result in fire.

l

Use twisted wire or multi-core twisted pair shielded wire for general signal wires and feedback

signal wires for the encoder.

This helps

the prevention of malfunction.

A CAUTION

l

Connect wires in the shortest possible length.

This helps the prevention of malfunction.

l

Connect the power supply +24 VDC to the CNC unit.

I. The power supply should be provided at the customer side.

(The power supply unit (JZNC-JAUO7) is available as option.)

2. Suuply the power in the range of +24 VDC 2 10% to the power terminals of the CNC unit.

l

Do not run the I/O signal wires with power wires or in the same duct with power wires.

Sufficient separation of signal wires from power wires will reduce the noise influence

l

In the event of noise from a power wire, use a noise suppressor to prevent it.

As for the specifications and capacity of noise filter, refer to this connection manual.

Correct

use

of noise filter will reduce the noise influence.

l

Be sure to complete the end terminal processing to the last module of the remote I/O module.

Set the “TERMINATION” shorting pin to “ON.”

slight.

Failure to observe this caution may lead to malfunction.

Page 14

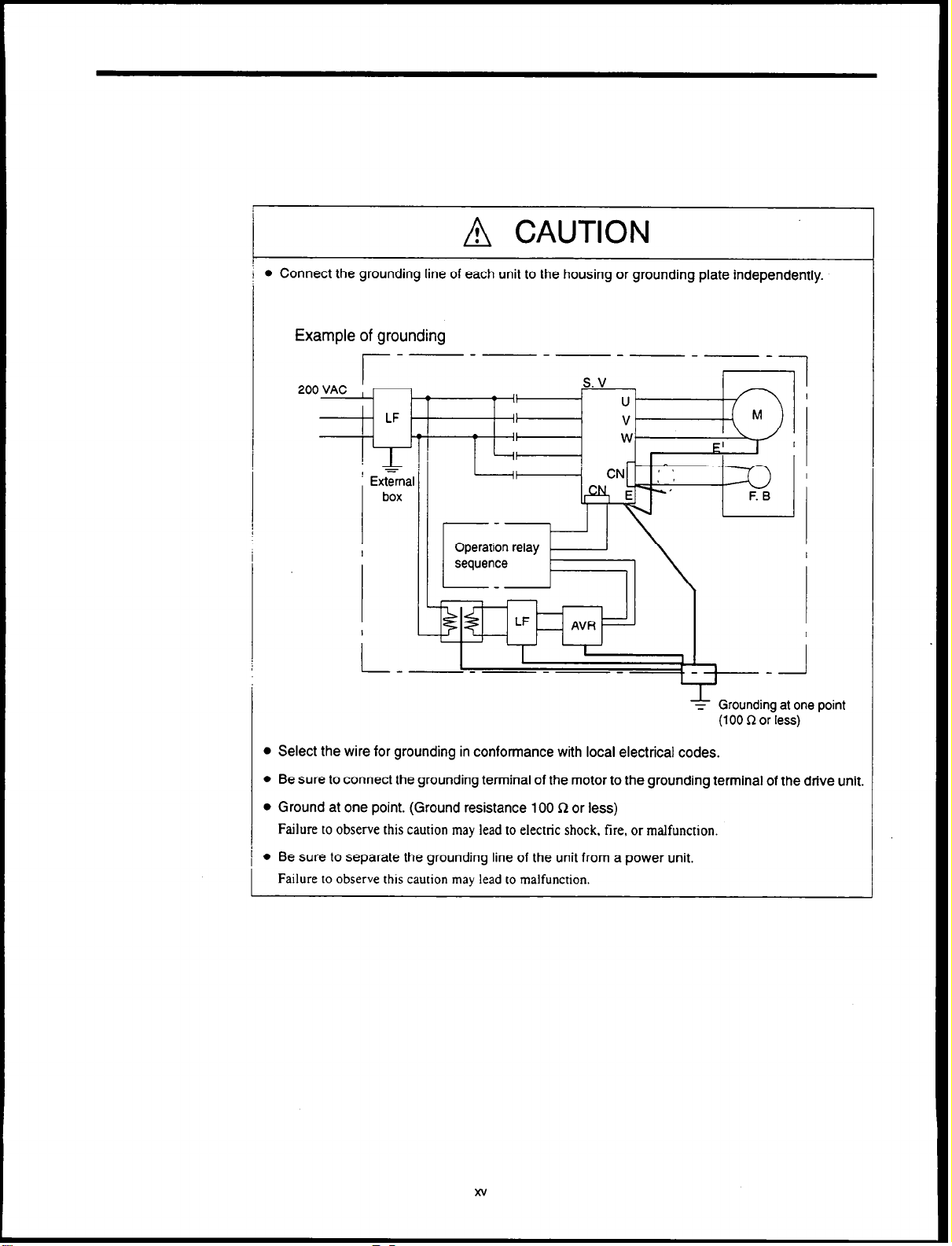

A CAUTION

0 Connect the grounding line of each unit to the housing or grounding plate independently.

Example of grounding

Grounding at one point

z

(100 R or less)

l

Select the wire for grounding in conformance with local electrical codes.

0 Be sure to connect the grounding terminal of the motor to the grounding terminal of the drive unit.

l

Ground at one point. (Ground resistance 100 R or less)

Failure to observe this caution may lead to electric shock. tire, or malfunction.

l

Be sure to separate the grounding line of the unit from a power unit.

Failure to observe this caution may

lead to malfunction.

xv

Page 15

n

Application Safety Precautions

A WARNING

l

During operation, be sure to observe the following.

Failure to observe this warning may lead to electric shock or device malfunction.

1. Do not touch the unit or terminal while the unit is turned ON.

2. JustaftertheunitistumedOFF,itisstillinchargingstatus. Donottouchtherunningpattsfor5minutes

after the unit is turned OFF.

l

Do not damage, pinch, or give excessive stress to cables.

Excessive load on cable may

l

While the unit is turned ON, never touch its rotating parts.

cause electric shock.

Failure to observe this warning may lead to personal injury.

l

Never modify the product.

Failure to observe this warning may result in electric shock, fire, or product failure.

A CAUTION

l

Use the product under the following conditions.

Use in an environment with high temperature, high humidity, dust, corrosive gases, vibration, or impact

may cause fire, electric shock, or malfunction.

1. Free from explosive gases or steam

2. Free from oil, organic solvent, corrosive liquids, etc.

3. Relative humidity 20 to 90% RH

4. Ambient temperature 0 “C to 45 “C (32 “F to 113 “F) and without freezing

(Free from direct sunlight, heat generating devices, and outside atmosphere)

5. Vibration under 4.9m/s2 (0.5G)

and

non-condensation

l

Do not let foreign matter such as electric wire scrap enter the unit.

Failure to observe this caution may result in fire, product failure or malfunction.

l

For the programming functions, follow the procedures in the user’s manual.

Failure to observe this caution may lead to personnel accident or malfunction.

l

Use the unit with “System Number Switch” of CNC unit set to “0.”

Failure to observe this caution may lead to malfunction.

xvi

Page 16

A CAUTION

l

Before turning the unit ON again, wait for 2 seconds or more after turning it OFF.

Failure to observe this caution may lead to malfunction.

l

Never disassemble or modify the components of the unit.

Failure

to observe this caution may result in tire, product failure or malfunction.

l

Never change the set values of the components and variable resistors used in the control panel.

Failure to observe this caution may result in tire, product failure or malfunction.

xvii

Page 17

GENERALS

Chapter 1 describes the requirments for designing the controller..

CONFIGURATION

1 .l

1.1.1 System Configuration .....................

1.1.2

1.1.3

Connection between Devices

Connector Layout ........................

1.2 GENERAL SPECIFICATIONS

DESIGNOFBOX

1.3

1.3.1 Thermal Design

1.3.2 Dustproof Design .......................

1.3.3 Countermeasures against Magnetic Fields . 1 - 13

1.4 CABLE CLAMP AND SHIELDING

PACKAGING

1.5

1.51

1.5.2 Installation of CNC Unit

1.5.3 Installation of Servo Unit .................

General Notes

...................

..............

.........

...................

..........................

....

......................

..........................

..................

1 - 2

1 - 2

1 - 3

1 - 4

1 - 5

1-6

1 - 6

1 - 11

1 - 14

1 - 15

1 - 15

1 - 16

1 - 17

l-l

Page 18

1.1

CONFIGURATION

This section describes the configuration of the controller.

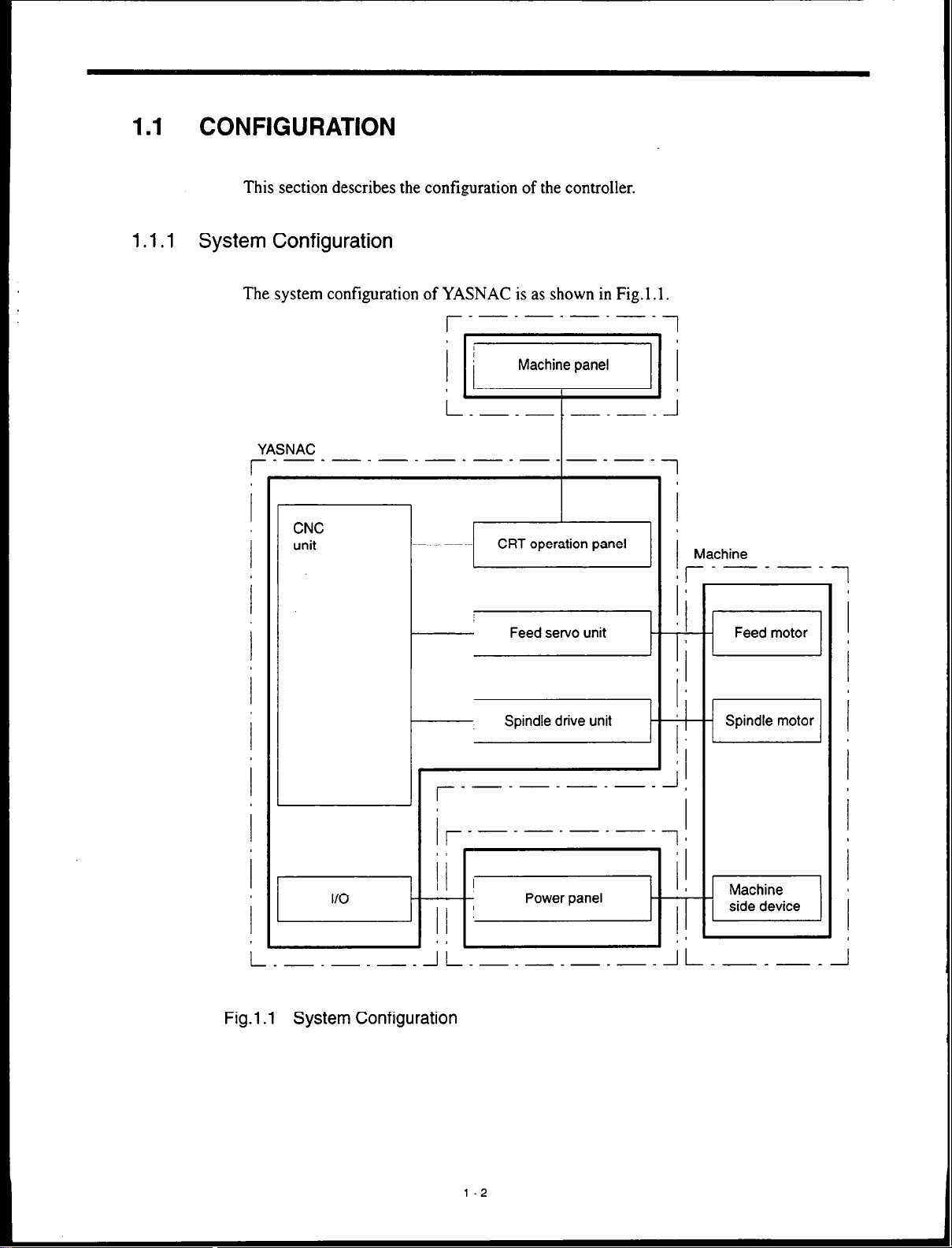

1.1.1

System Configuration

The system configuration of YASNAC is as shown in Fig. 1.1.

-_-_-_-_

r-

YASNAC

r--------‘--------

CNC

unit

1

1

l-

Machine

r-----

0 I

Ia

1

r-

L

I

Fig.1 .l System Configuration

I

---------,

J

--l

I

I

Spindle motor

I

Machine

J

1 side device

l-2

Page 19

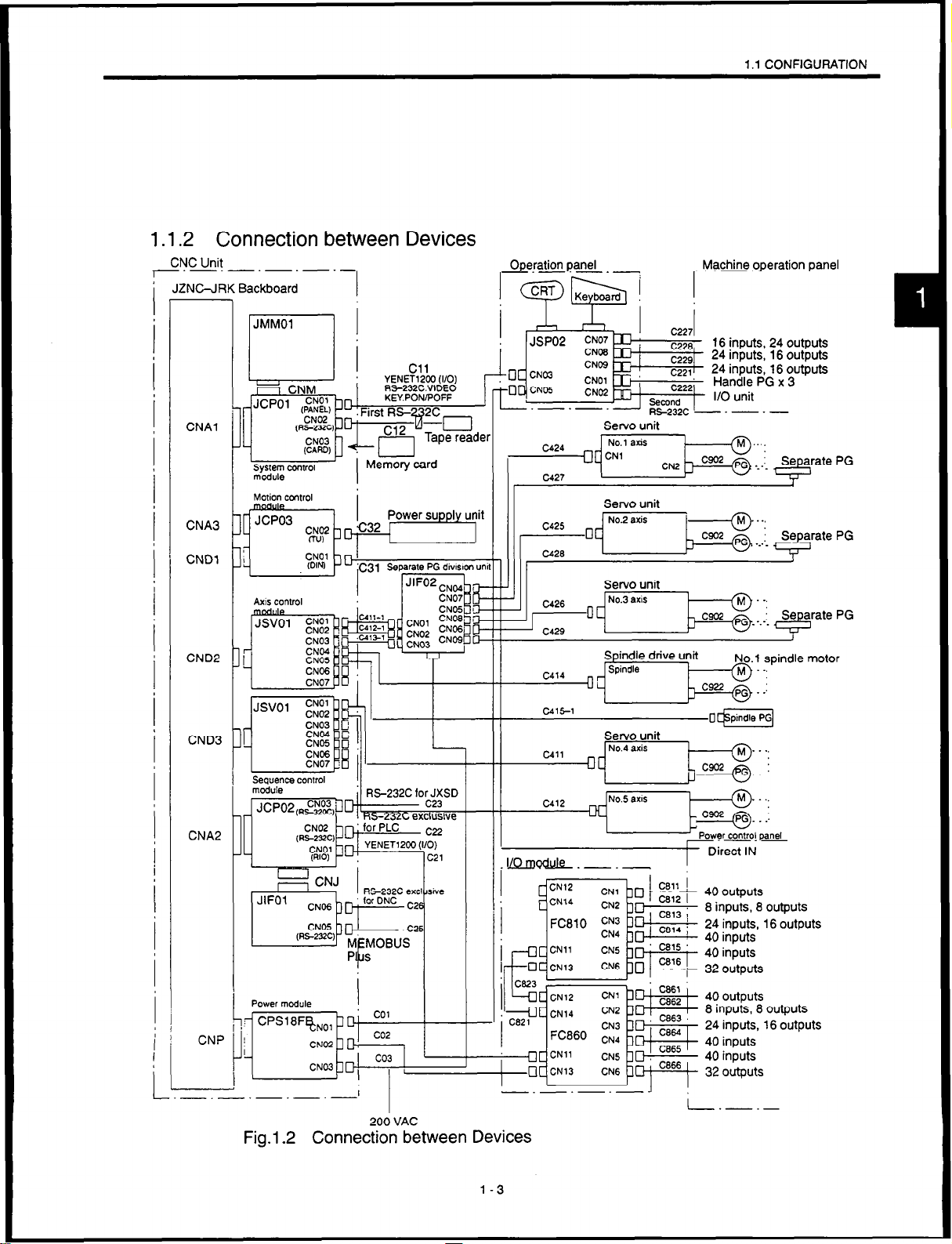

1.1.2 Connection between Devices

+JC&i!

1 f-jBy;@; , 1

-.-.-.-

I I I I I I

RS-232C.VldEd

KEYPONiPOFF

‘CNOZ'

CNAl

CNA3

I Ii I

(Rs-mc

L-&J 1 I I II

. -..-. --rr., -....

C425

-I No2 axis I

Servo unit

. - .~

1 .l CONFIGURATION

M ..,

CNDl

CND2

CND3

CNAP

CNP

Axis conlrol

-1 II

I

-.-.-.-

200 VAC

Fig.l.2 Connection between Devices

I

c4,, _ No.4 axis

CN14

Servo unit

-1 I

c?

40

outputs

8 inputs, 8 outputs

24 inputs, 16 outputs

40 inputs

40 inputs

32 outputs

40 outputs

8 inputs, 8 outputs

24 inputs, 16 outputs

40 inputs

40 inputs

32 outputs

L.-_-

1-3

Page 20

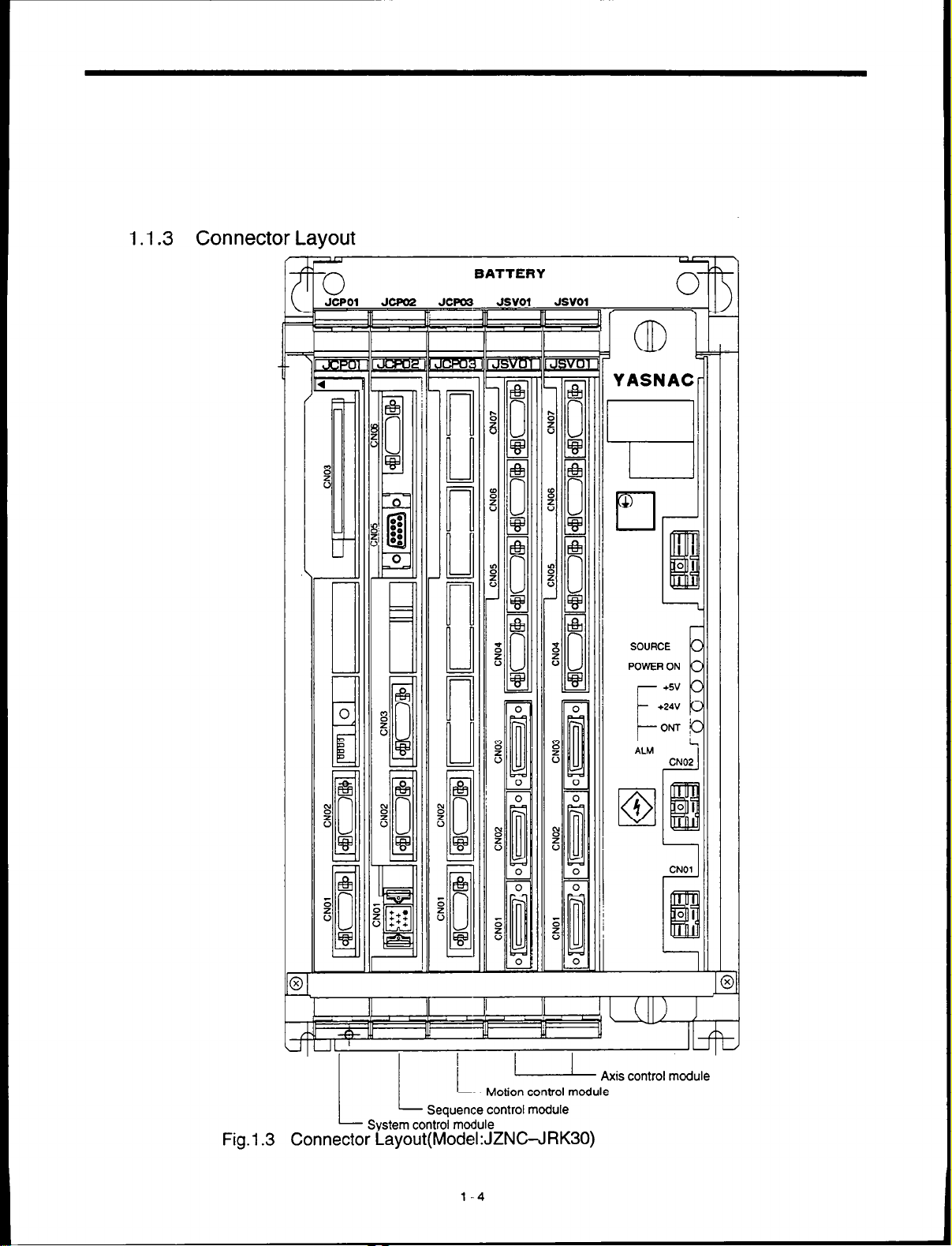

1.1.3 Connector Layout

BATTERY

Fig.1

UIUL ’

- Axis control mod: ’ u

Motion control module

LL

System control module

Connector Layout(ModekJZNGJRK30)

.3

Sequence control module

l-4

I

Page 21

1.2 GENERAL SPECIFICATIONS

Design the controller to meet the following conditions completely.

Table 1.1 Specifications

Item Specifications

1.2 GENERAL SPECIFICATIONS

Ambient Conditions

Avoid installation of the control panel in B location subject to direct sunlight. near heat generating devices, or out-

Note:

doors even if the ambient temperature is lower than 45 c.

Temperature

Input Power Source

Input Voltage

Frequency

Momentary Power Loss

0 “C to 45 “C

at operation. (nore)

-20 “C to +6O’C at storage and transportation.

10% to 90% RH (non-condensing)

Free from much dust, coolant or organic solvent.

CPU unit 200/220/230 VAC-15% to +lO%

50160

Hz f 2 Hz

Power loss is detected at power storage over 1 cycle.

l-5

Page 22

1.3 DESIGN OF BOX

1.3.1 Thermal Design

Design should be made on the condition that the average temperature increase of internal air

of the box to contain the CNC unit and other units should be below 10”Cof the external air.

(1) Enclosure Internal Temperature Increase (Average temperature increase)

The internal temperature increase of enclosure made of sheet metal is generally as

shown below:

where,

AT:I.ntemaI temperature increase (‘C)

P :Heat generation in enclosure (W)

qe : Enclosure heat percolation ratio (WPC)

k : Heat transit ratio of sheet metal (W/m2

: 6W/m* “C : With internal circulating fan

4W/m* “C : Without internal circulating fan

A : Efficient heat diffusion area of enclosure (m*)

Area capable of diffusing heat in surface area of the enclosure

(Excluding area contacting other devices)

-

“C)

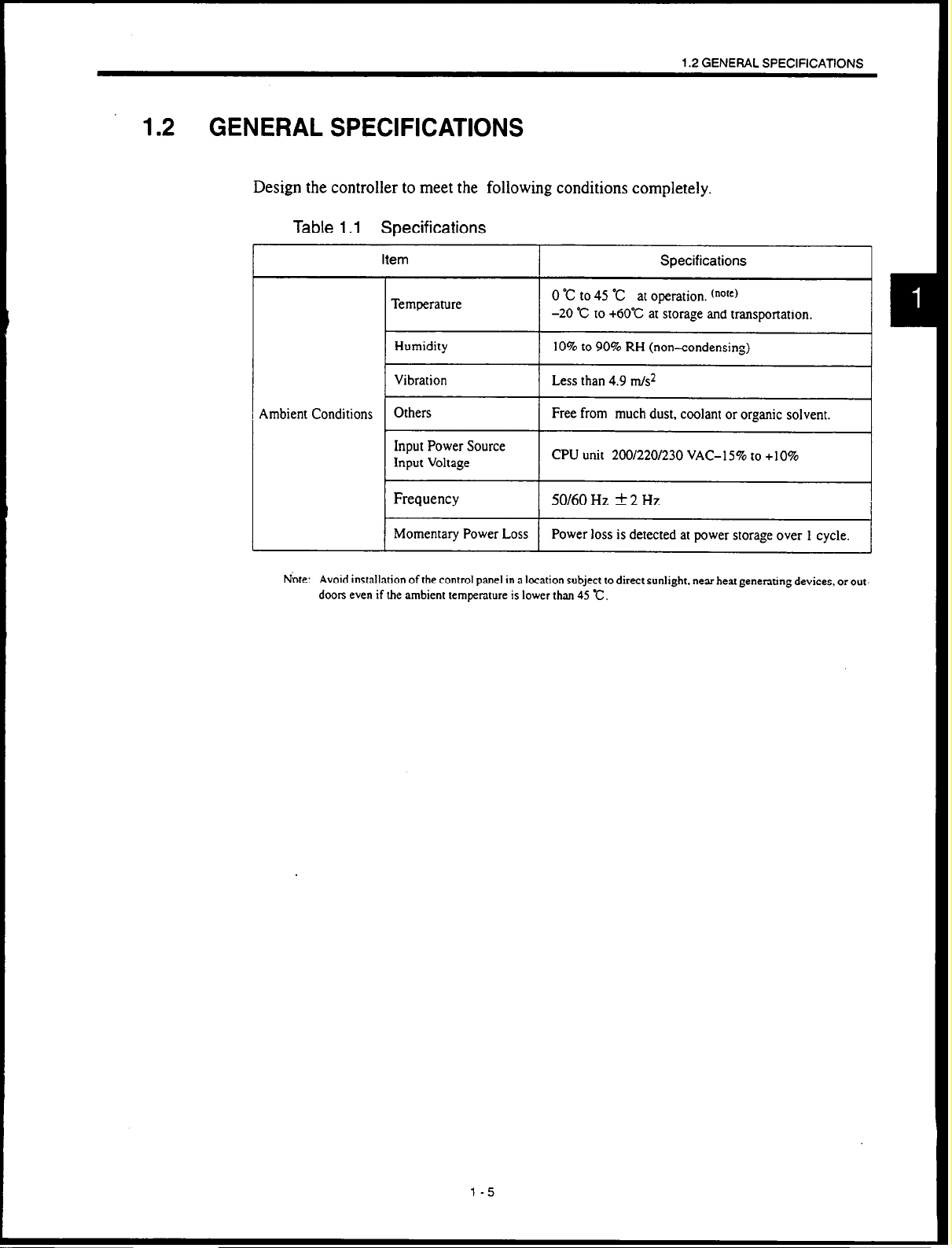

(Example) Allowable heat generation in the enclosure with internal circulating fan

8

8

.a*

1200

I;:

I

0

800

70

Efficient heat diffusion area is independently located, so bottom area is excluded.

A= 4.16m’

If the heat generation in the enclosure is supposed to be 246 W (113 W in CNC portion,

104 W in servo portion, and 29 W in I/O portion),

AT=F=m

P P

246

= 6 x 4.16 = “’

(C)

I

l-6

Page 23

1.3 DESIGN OF BOX

Therefore, it is all right to clear the temperature increase value below 10°C.

Where 10°C is exceeded, it is necessary to arrange separate cooling countermeasures.

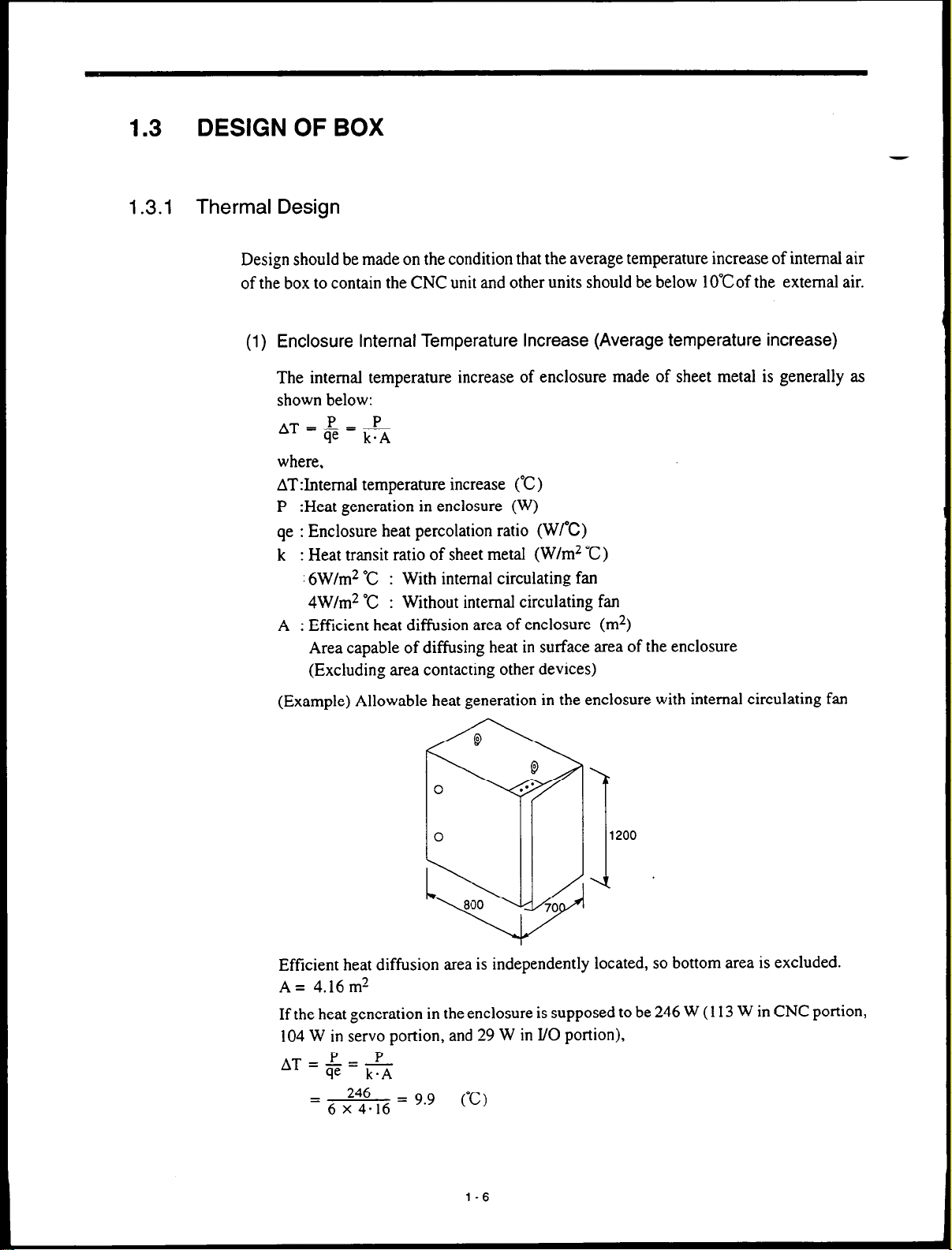

(2) Cooling Capacity of Heat Exchanger

Where cooling capacity is insufficient by mounting the circulating fan in the enclosure,

the following heat exchangers are supplied by Yaskawa:

Table 1.2 Heat Exchangers

I

I

I

I

Heat Exchanger

REX1 550

HEATEX02

I

I

I

Cooling Capacity External Dimensions (mm)

1 oow/ 1 O’C

25OW/lO”c

295(W) x890(H) X 50(D)

I

440(W) x924(H) X 50(D)

I

I

The heat generation in the cooling capacity column is the allowable heat generation

amount where the internal temperature increase within the enclosure is limited to below

10°C.

(Example) Allowable heat generation amount in the enclosure with heat exchanger

The internal heat generation amount to make the internal temperature increase below

10°C when the enclosure equipped with HEATEXO:! is expressed by the following

equation:

P = k.A.AT + 25OWllO”C

=6x4.16x10+250

= 499WI 10°C

therefore, it is necessary to be below 499W.

1-7

Page 24

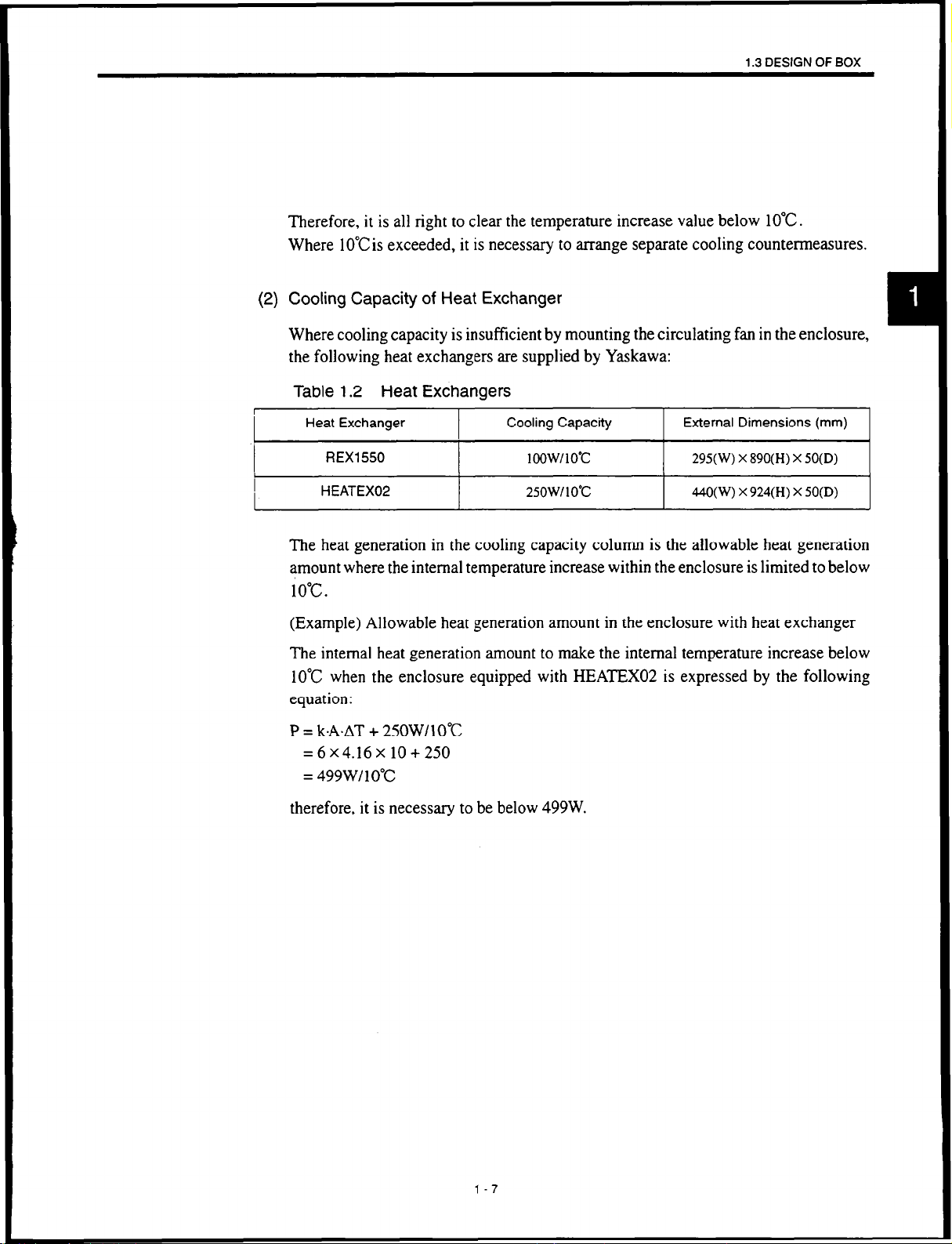

(3) Mounting of Heat Exchanger

Heat exchanger should be mounted on the enclosure manufactured by the machine tool

builder.

Fig. 1.4 shows an example. Mount it so that internal air is taken in from the upper portion and discharged from the lower portion, while external air is taken in from the lower

portion and discharged from the upper portion.

I

h-

External air

t-+YFw

Fig.l.4 Mounting of Heat Exchanger

3

7

Internal air flow

I

Heat exchanger

(Upper

Enclosure

J

Page 25

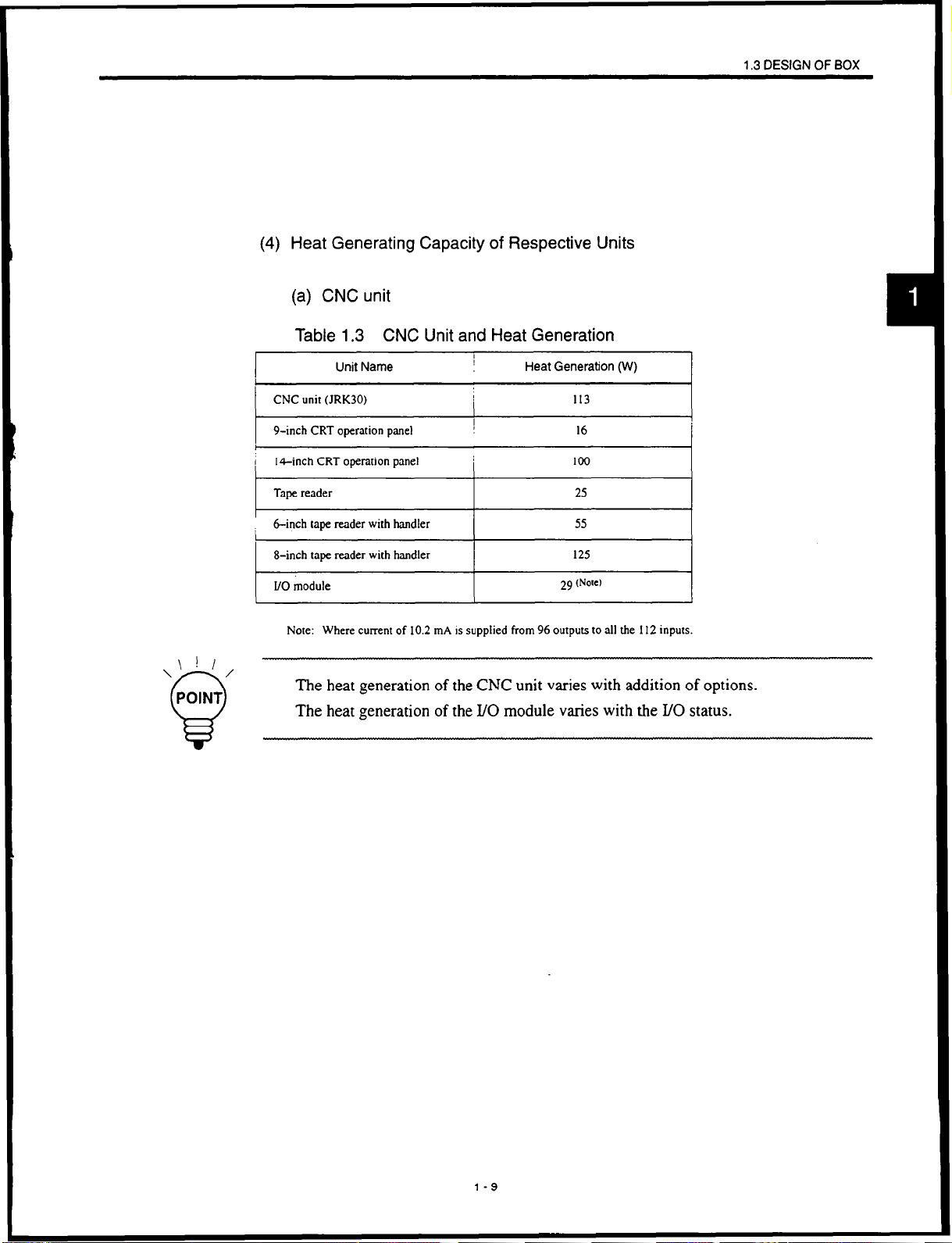

(4) Heat Generating Capacity of Respective Units

(a) CNC unit

Table 1.3 CNC Unit and Heat Generation

Unit Name

I

Heat Generation (W)

1.3 DESIGN OF BOX

\ ! I

\I.‘/

POINT

0

CNC unit (JRK30)

9-inch CRT operation panel

,

( 14-inch CRT operation panel

Tape reader

binch tape reader with handler 55

I

8-inch tape reader with handler 125

I/O module

Note: Where current of 10.2 mA is supplied from 96 outputs to all the I12 inputs.

I

1

I

I

I

29

113

16

loo

25

(Note)

The heat generation of the CNC unit varies with addition of options.

The heat generation of the I/O module varies with the I/O status.

I

I

l-9

Page 26

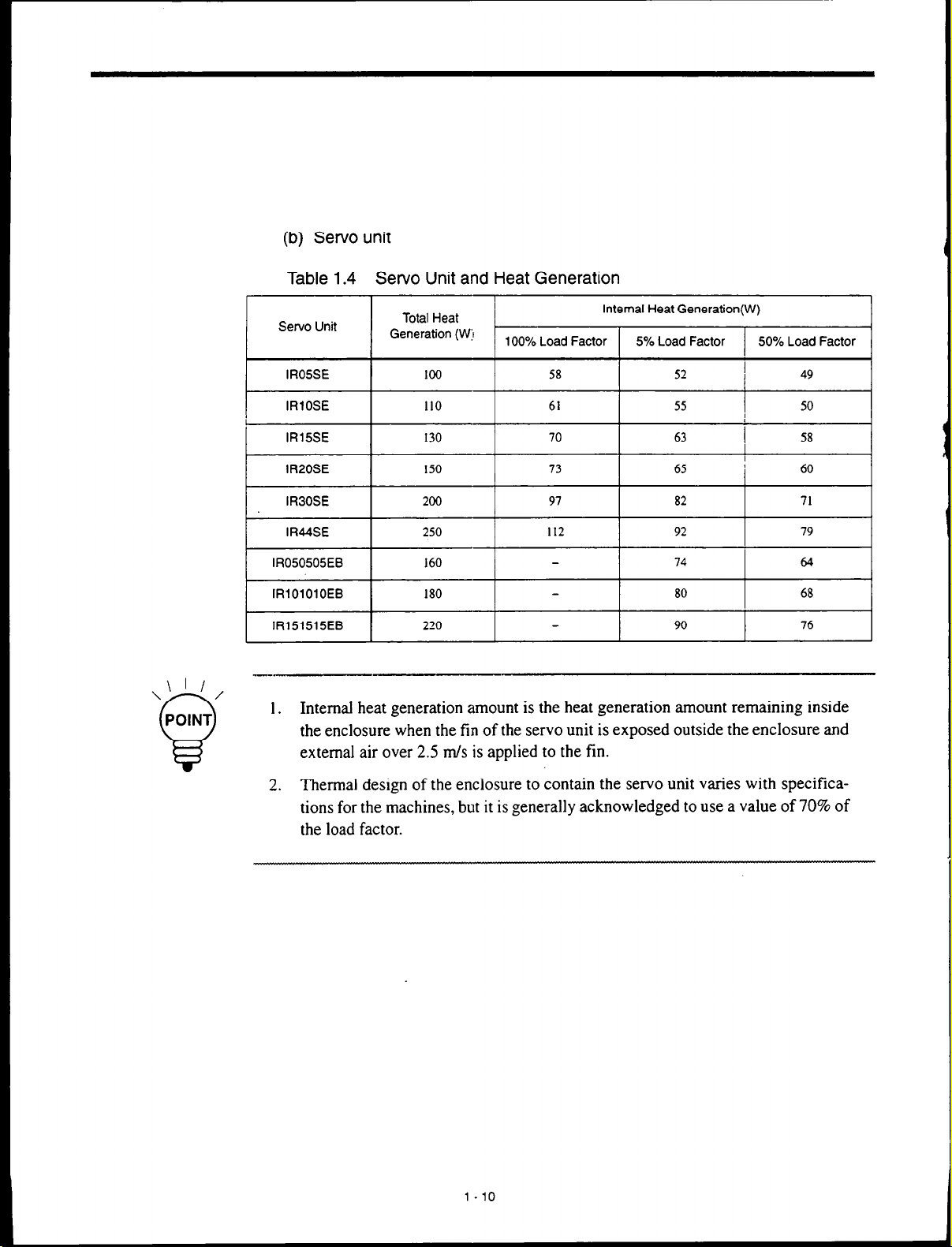

(b) Servo unit

Table 1.4 Servo Unit and Heat Generation

I

\’ ’ 5

POINT

Q

Servo Unit

IRlOSE

IR15SE 130 70 63 I 58

IR20SE 150 73 65 I

IRBOSE 200 97 82 71

IR44SE 250 112 92 79

IR050505EB 160 74 I 64

IRlOlOlOEB 180 80 68

IR151515EB 220 90 76

Internal heat generation amount is the heat generation amount remaining inside

1.

Total Heat

Generation (Wj

100 58

I

110

100% Load Factor 5% Load Factor 50% Load Factor

I

61

Internal Heat Generation(W)

I

I

52

55

I

I 5o I

I

I

49

60

the enclosure when the fin of the servo unit is exposed outside the enclosure and

external air over 2.5 m/s is applied to the fin.

2. Thermal design of the enclosure to contain the servo unit varies with specifications for the machines, but it is generally acknowledged to use a value of 70% of

the load factor.

I

Page 27

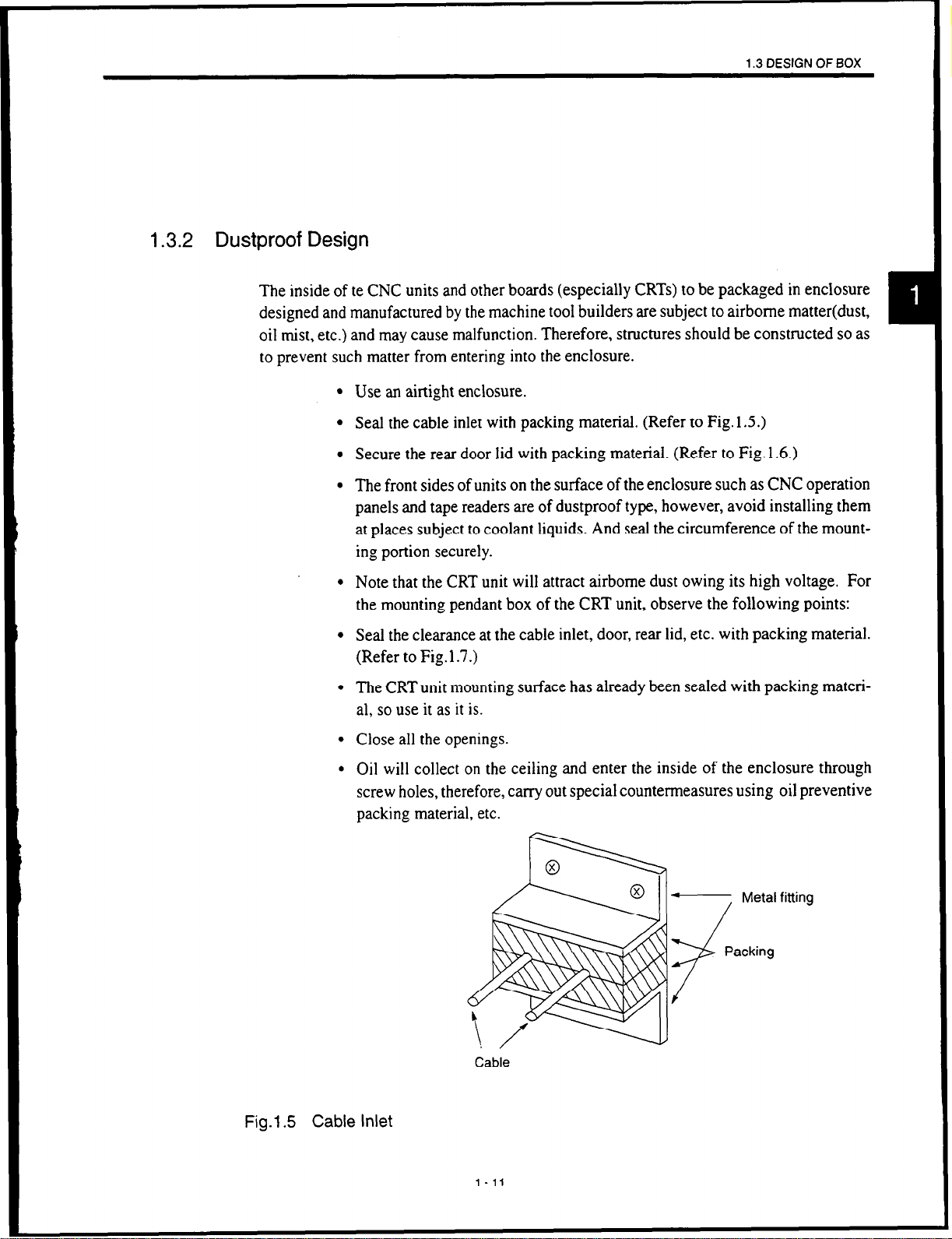

1.3.2 Dustproof Design

The inside of te CNC units and other boards (especially CRTs) to be packaged in enclosure

designed and manufactured by the machine tool builders are subject to airborne matter(dust,

oil mist, etc.) and may cause malfunction. Therefore, structures should be constructed so as

to prevent such matter from entering into the enclosure.

l

Use an airtight enclosure.

l

Seal the cable inlet with packing material. (Refer to Fig. 1 S.)

l

Secure the rear door lid with packing material. (Refer to Fig. 1.6.)

l

The front sides of units on the surface of the enclosure such as CNC operation

panels and tape readers are of dustproof type, however, avoid installing them

at places subject to coolant liquids. And seal the circumference of the mounting portion securely.

1.3 DESIGN OF BOX

l

Note that the CRT unit will attract airborne dust owing its high voltage. For

the mounting pendant box of the CRT unit, observe the following points:

l

Seal the clearance at the cable inlet, door, rear lid, etc. with packing material.

(Refer to Fig. 1.7.)

l

The CRT unit mounting surface has already been sealed with packing materi-

al, so use it as it is.

l

Close all the openings.

l

Oil will collect on the ceiling and enter the inside of the enclosure through

screw holes, therefore, carry out special countermeasures using oil preventive

packing material, etc.

- Metal fitting

Fig.l.5 Cable Inlet

Cable

l-11

Page 28

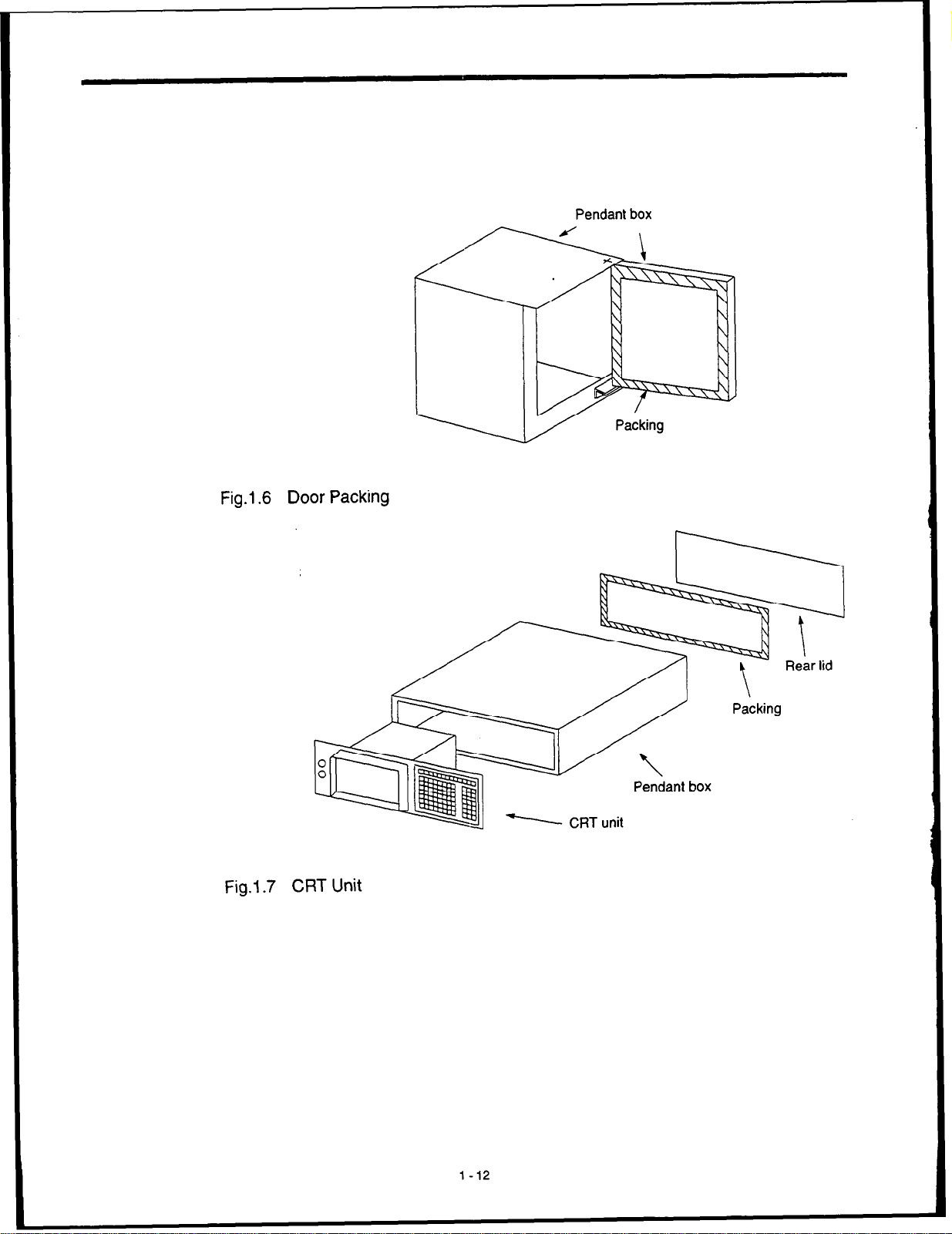

Fig.l.6 Door Packing

Pendant box

Fig.l.7 CRT Unit

Pendant box

N CRT unit

Page 29

1.3.3

Countermeasures against Magnetic Fields

The screen of CRT display may fluctuate owing to ambient magnetic fields.

Keep magnetism generating materials (for example, transformers, reactors, fans, electromagnetic switches, solenoid relays, exchange power supply cables, etc.) 300 mm from the

CRT display. This value of 300 mm is a general standard and may vary with different situa-

tions, therefore, pay sufficient attention to determining the layout of magnetism generating

sources, and finally check them with the machine.

1-13

Page 30

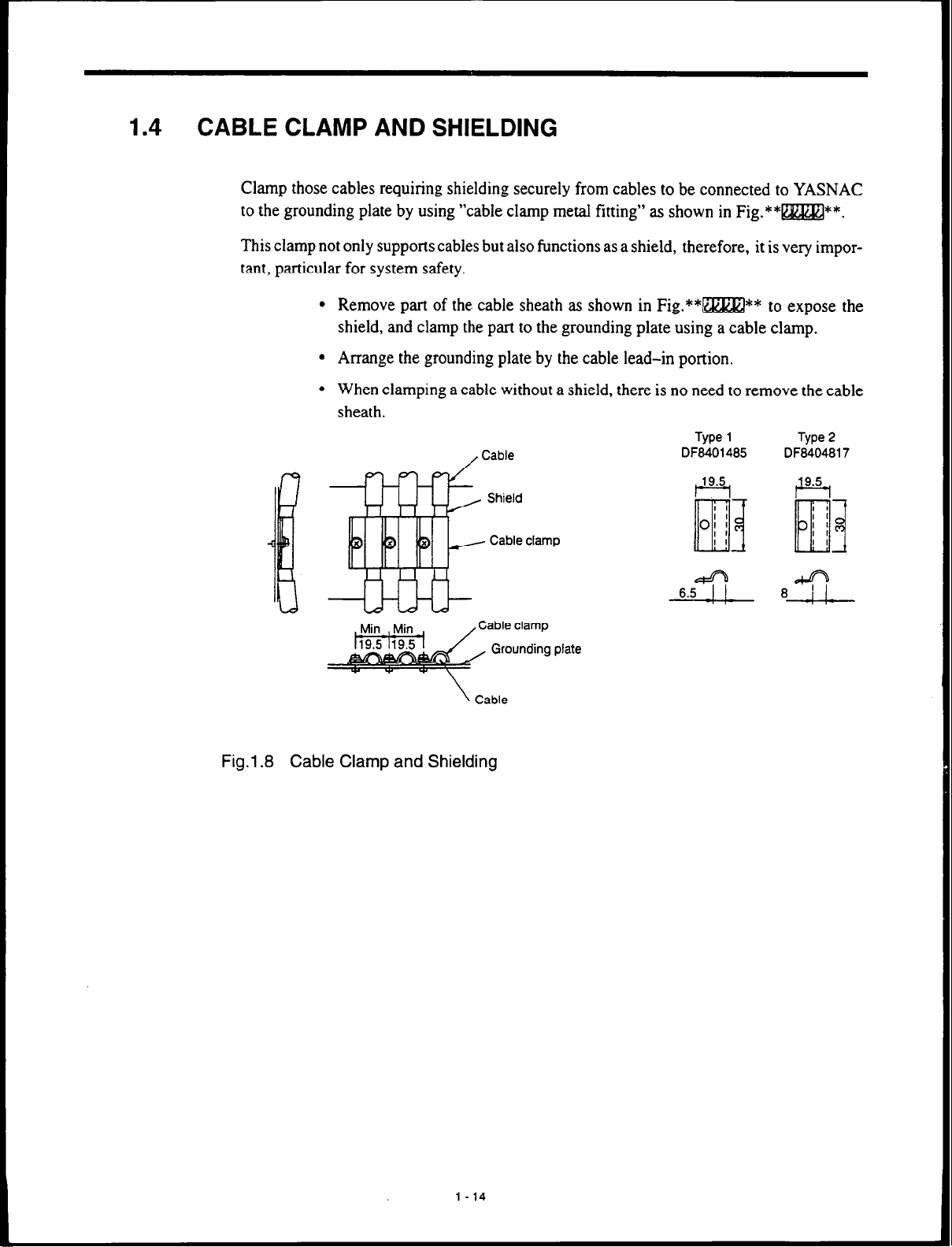

1.4

CABLE CLAMP AND SHIELDING

Clamp those cables requiring shielding securely from cables to be connected to YASNAC

to the grounding plate by using “cable clamp metal fitting” as shown in Fig.**m**.

This clamp not only supports cables but also functions as a shield, therefore, it is very impor-

tant, particular for system safety.

l

Remove part of the. cable sheath as shown in Fig.**=** to expose the

shield, and clamp the part to the grounding plate using a cable clamp.

l

Arrange the grounding plate by the cable lead-in portion.

l

When clamping a cable without a shield, there is no need to remove the cable

sheath.

Type 1

DF8401485 DF8404817

& f/j

We

2

\ Cable

Fig.l.8 Cable Clamp and Shielding

8 $ 8.ST

l-14

Page 31

1.5 PACKAGING

When designing the box to contain CNC unit and other units, take the following into consideration.

1.5.1 General Notes

l

l

l

l

l

1.5 PACKAGING

Use an air-tight enclosure.

Arrange packaging of units so that maintenance, inspection, removal, mount-

ing should be performed easily.

Secure clearance of 100 mm between parts and enclosure wall in order not to

restrict air flow.

When the operation panel is built-in the machine door or the like, it is subject

to vibration of the machine, therefore, be sure to reinforce it against vibration.

Limit the average temperature increase of internal air of enclosure to below

10 “C of the external air.

l

Use a fan to circulate air in order to improve the cooling efficiency of a closed

enclosure and to prevent local temperature increase. (As a standard, arrange

so that air over In-r/s flows over the surface of printed circuit boards within

various units.)

l

Do not blow the fan air directly onto printed circuit boards.

l

In order to prevent malfunctions owing to noise, keep various units 10 mm

away from cables or parts over 90 VDC, cables such as AC power supply or

parts.

l

When wiring, observe the following points:

Separate AC lines from DC lines.

Separate the primary side and the secondary side of transformer, line filter, etc.

1-15

Page 32

1.52 installation of CNC Unit

When installing the CNC unit, observe the following notes:

l

Mount the CNC unit in the direction as shown in Fig.l.9.

Fig.l.9 Mounting of CNC Unit

(Upper)

Power

SUPPlY

l

This CNC unit has a built-in fan so that air flows at lm/s over the upper side

of the unit.

l

Arrange clearance over 50 mm above the CNC unit and over 100 mm below

it for ventilation and ease of maintenance.

1-16

Page 33

1.5.3

Installation of Servo Unit

l

Since the servo unit is a wall-mounted type, mount it vertically with screws

or bolts.

l

Arrange it so that maintenance, inspection and parts replacement can be made

easily.

l

Since the servo unit will generate heat to some extent, arrange other

units or devices with sufficient space above and below it.

l

In order to reduce the internal loss from the viewpoint of heat generation, arrange the cooling fin of the servo unit outside of the enclosure, and blow external air on the cooling fin. (2 m/s)

l

When circulating the internal air in the enclosure, do not blow air directly to

the servo unit (in order to prevent dust contamination).

l

For the installation of the feed servo unit and the spindle drive unit, refer to

the respective operation manuals.

l

In order to reduce the internal loss from the viewpoint of heat generation, it

is recommended to arrange the cooling fin of the servo unit outside of the enclosure. This helps make the enclosure closed structure and make the capacity

of the heat exchange unit small.

Fig.1 .lO

1

Cooling fin

-i

External air

Cooling Fin Installed Outside of Enclosure

c

1

1-17

-

Feed servo unit and

.

4 spindle drive unit

-

Page 34

2

CONNECTION OF POWER SUPPLY

Chapter 2 describes the power supply connection.

2.1 CONNECTION BETWEEN DEVICES . . 2 - 2

2.1 .l

Power Supply to CNC Unit ................

2 - 2

2.1.2

2.2 DETAILED CONNECTION

2.2.1

2.2.2 Power Supply to Converter Unit

Power Supply to Converter Unit

Power Supply to CNC Unit ................

............ 2 - 2

............

............

2 - 3

2 - 3

2 - 3

2-1

Page 35

2.1

CONNECTION BETWEEN DEVICES

This section describes the connection between devices.

2.1.1

2.1.2

Power Supply to CNC Unit

CNC unit

Fig. 2.1

Power Supply to CNC Unit

Power Supply to Converter Unit

Converter unit

Fig. 2.2

Power Supply to Converter Unit

2-2

Page 36

2.2 DETAILED CONNECTION

This section describes the detailed connection of power supply.

2.2 DETAILED CONNECTION

2.2.1

2.2.2

Power Supply to CNC Unit

Fig. 2.3 Detailed Connection of Power Supply

Power Supply to Converter Unit

:onverter unit

:IMR-MR5

R/L1 (

L

Single-phase

200/220/230 VAC - 15 to 10%

50160 Hz f 2 Hz

560vA

1MC 1 MCCB

- R 2OOQ20/230 VAC

- 15 to 10%

- s 50160 Hz -c 2 Hz

Fig. 2.4

A2

Detailed Connection of Power Supply

2-3

t

Page 37

CONNECTION OF

CNC OPERATION PANEL

Chapter 3 describes the connection between the CNC unit

and the CNC operation panel.

3.1 CONNECTION BETWEEN DEVICES . . 3 - 2

3.1 .l

3.2 DETAILED CONNECTION OF

CNC OPERATION PANEL . . . . . . . . . . . . 3 - 3

Connection with 9-inch CRT Operation Panel 3 - 2

3.2.1

3.2.2

Connection with 9-inch CRT Operation Panel 3 - 3

General Notes on the Connenction of

CRT

Operation Panel . . . . . . . . . . . . . . . . . . . . . 3 - 4

3-1

Page 38

3.1

CONNECTION BETWEEN DEVICES

This section describes the connection between CNC unit (including the power supply unit)

and CNC operation panel and the type of connector as well as the cable specifications.

3.1 .l

Connection with 9-inch CRT Operation Panel

CNC unit

~---

JANCD-JCPOl

CNOl

10220-52A2JL

CPS-18FB

I

g-inch CRT operation panel

-- -12

J

CNOl

17204&l

Fig. 3.1 Connection between Devices

I-

3-2

Page 39

3.2 DETAILED CONNECTION OF CNC OPERATION PANEL

3.2

3.2.1

DETAILED CONNECTION OF CNC OPERATION PANEL

This section describes the detailed connection between CNC unit (including the power unit)

and CNC operation panel and the type of connector as well as the cable specifications.

Connection with 9-inch CRT Operation Panel

CNC unit

CNOl-12,,

CNOl-1 )/

CNOl-2 ).

CN01-8).

CNOl-9 ),

CNOl-181,

CNOl-191,

CNOl-162,

.G.

.

.

.

POFF : ’

PCOM : ’

VIDEO : 1

‘VIDEO

VCLK :

*VCLK

HSYNC 0 :

’ *HSYNC : p ’

VSYNC : ’

‘VSYNC

FG I._,’

OjP: ’

’ {P:

: tP0

O-inch CRT operation panel

----

/

,,CN03-12

.&NOW

&NO%2

. CN03-8

.(CN03-9

.(CN03-18

.cCN03-19

.(CN03-16

,(CN03-17

/,

11 Hoodcase

Fig. 3.2

Connection with g-inch CRT Operation Panel

3-3

Page 40

3.2.2

General Notes on the Connenction of CRT Operation Panel

(1) Wiring of the Power ON/OFF Switch

For a standard horizontal g-inch CRT operation panel, the wiring of the power ON/OFF

switch has been made by Yaskawa. For a vertical type, use the wiring in the figure below or external ON/OFF switch.

Operation panel

“Power ON” pushbutton

Page 41

3.2 DETAILED CONNECTION OF CNC OPERATION PANEL

(2) Switches for External Power Supply

External power supply ON/OFF is selected by the following switches:

Switches (SWl, 2) are arranged on JANCD-JCP03.

JANCD-JCPOB

100

SW1

l

For setting external power ON/OFF effective, and operation panel power ON/

SW2

CN02

I I

CNOl

OFF effective

l

For setting external power ON/OFF invalid, and operation panel power ON/

OFF effective

l

For setting external power ON/OFF effective, and operation panel power ON/

OFF invalid

-

l

Do not set. Setting shown below disables the power ON/OFF.

(3) Factory Setting

-

Before shippment, the operation panel power ON/OFF is set to “Effective,” and the external power ON/OFF is set to “Invalid.”

3-5

Page 42

4

CONNECTION OF

MANUAL PULSE GENERATOR

Chapter 4 describes the connection between the CNC operation panel and the manual pulse generator and type of the

connector as well as the cable specifications.

4.1 CONNECTION BETWEEN DEVICES . . 4 - 2

4.1.1 Connection with 9-inch

CRT Operation Panel . . . . . . . . . . . . . . . . . . . . . 4 - 2

4.2 DETAILED CONNECTION OF

MANUAL PULSE GENERATOR . . . . . . . 4 - 3

4.2.1

4.2.2 Parallel I/F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Non-parallel I/F.. . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

4-1

Page 43

4.1

CONNECTION BETWEEN DEVICES

This section describes the connection between the CNC operation panel and devices of the

manual pulse generator, and the type of connector, and the cable specifications.

4.1 .l Connection with 9-inch CRT Operation Panel

CNC operation panel

-1

JANCD-JSP02

---

Fig. 4.1

CNOl

10220-6202JL

Connection between Devices

Manual pulse generator No

Manual pulse generator No.2

.l

4-2

Page 44

4.2 DETAILED CONNECTION OF MANUAL PULSE GENERATOR

4.2

DETAILED CONNECTION OF MANUAL PULSE GENERATOR

This section describes the detailed connection between the CNC operation panel and the

manual pulse generator.

4.2.1 Non-parallel I/F

CNC operation panel

JANCDJSP02-1.2

LNUl-1 I /,UV

’ I

Manual pulse generator No.1

I \

Manual pulse generator No.2

Fig. 4.2 Detailed Connection of Manual Pulse Generator

(Model:PREH-2E5T/lOO-M)

Use the cable within 5 m for non-parallel type I/F.

Connect FG and the cable to the case using cable clamp metal fitting.

4-3

Page 45

4.2.2 Parallel I/F

CNC operation panel

JANCD-JSPOPa

CNOl-16

CNOl-17 _

CN01-6 ,PAHB ; - ‘,

PAHl ’ - ’

Manual pulse generator No.1

Manual

Manual pulse generator No.3

,3

a *PAH3 ,4

pulse generator No.2

\ I I

\’ ‘/

POINT

0

H

Fig. 4.3

Detailed Connection of Manual Pulse Generator (Parallel I/F)

Use the cable within 15 m in the case of parallel I/F.

Parallel type manual pulse generator is not provided by Yaskawa.

Connect FG and the cable to the case using cable clamp metal fitting.

Page 46

CONNECTION OF POWER ON/OFF

EXCLUSIVE SIGNAL

Chapter 5 describes the connection of the power ON/OFF

exclusive signal.

5.1 CONNECTION BETWEEN DEVICES . . 5 - 2

51.1

5.2 DETAILED CONNECTION OF

POWER ON/OFF EXCLUSIVE SIGNAL 5 - 3

52.1

5.3 DETAILS OF SIGNAL . . . . . . . . . . . . . . . . 5 - 4

5.3.1 Servo Power ON (SVMX), Brake Release

Connection to CNC Unit . . . . . . . . . . . . . . . . . . 5 - 2

Connection to CNC Unit . . . . . . . . . . . . . . . . . . 5 - 3

(BKX)

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -

4

5.3.2

5.3.3

Emergency Stop (*ESP) Input . . . . . . . . . . . . . 5 - 5

External Power ON/OFF (EON, EOF, ECOM)

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Page 47

5.1

CONNECTION BETWEEN DEVICES CONNECTION BETWEEN DEVICES

This section describes the connection between devices related to the power ON/OFF exclu- This section describes the connection between devices related to the power ON/OFF exclu-

sive signal, the type of connector. and the cable specifications. sive signal, the type of connector. and the cable specifications.

5.1.1

Connection to CNC Unit

CNC unit

JANCD-JCP03

10220-52A2JL

Fig.

5.1 Connection between Devices

CN02

C32 UL20276 AWG28 x 10 pairs

101204000VE

(1032~52AO-008)

Power supply interface

5-2

Page 48

5.2 DETAILED CONNECTION OF POWER ON/OFF EXCLUSIVE SIGNAL

5.2 DETAILED CONNECTION OF POWER ON/OFF EXCLUSIVE

SIGNAL

This section describes the detailed connection of the power ON/OFF exclusive signal.

5.2.1 Connection to CNC Unit

CNC unit

-----JANCD-JCPOB

Machine end

Machine end release

External power ON

External power OFF

Fig. 5.2

Detailed Connection of Power ON/OFF Exclusive Signal

For the relay of SVMX, BKX, use miniature relay 24 VDC.

(Recommended part: MY-4Z by OMRON)

-___--.--

.-..-.--.-I

5-3

Page 49

5.3

DETAILS OF SIGNAL

This section describes the signals to be used in the power supply sequence.

5.3.1

Servo Power ON (SVMX), Brake Release (BKX) Output

(1) Signal

SVMX : This is the output that turns ON when the power is supplied to the servo unit.

BKX : This is the output to release the holding brake of the feed axis (vertical axis).

(2) Power Supply Sequence

Power supply sequence is executed as shown below:

@ Supply power to the controller.

@ : Perform the power supply operation (Press [POWER ON] pushbutton on the CNC

@ Perform the power supply operation again. SVMX output is closed, and the servo

Names and Descriptions

When a servo unit is externally installed, supply power to the servo unit by

this output.

operation panel, or close the circuit between the external EON and ECOM.), and

the logic circuit power is turned ON.

power is turned ON.

When a servo unit is externally installed, carry out servo power ON sequence by

SVMX output.

@ After completion of servo ready (servo clamp status), BKX output is closed

after the time set by parameter. Release the brake unit by this signal.

@ After SVMX output is closed and the controller is ready, if external preparation

has been completed, close the MRD (machine ready completed) input of the general-purpose output module. “RDY” is displayed on the CRT screen, and operation is possible .

5-4

Page 50

POWER ON PB or

EON input

POWER OFF PB or

EOF input

*ESP input

;

SVMX output

Servo ready completed

(internal status)

BKX output

MRD input

1

Alarm code “3000 TIDY” 3302” “3000

4

>---a

“2190

Fig. 5.3 Power Supply Sequence

[RESET] key ON

4

5.3.2

5.3.3

Emergency Stop (*ESP) input

When the emergency stop input circuit is opened, the controller stops all the actions and turns

SVMX and BKX OFF. During emergency stop of the general-purpose I/O module, it makes

output (*ESPS) “open.”

In response to the emergency stop input, the servo should DB stop and spindle stop with

brake using the delay circuit.(The spindle coasts after the main connector 1MC is “opened”

by the delay timer.)

External Power ON/OFF (EON, EOF, ECOM) Input

The controller may be turned ON/OFF by external input in the same manner as by the POWER ON/OFF pushbutton on the CNC operation panel.

Setting the portion between EON and ECOM “closed” in the state the EOF and ECOM is

“closed” turns ON the logic circuit of the controller or the servo power.

Setting the portion between EON and ECOM “open” turns OFF the logic circuit of the controller and the servo power.

5-5

Page 51

6

CONNECTION OF

FEED SERVO UNIT

Chapter 6 describes the connection between the CNC unit,

the feed servo unit, and the servo motor.

6.1 CONNECTION BETWEEN DEVICES . . 6 - 2

6.1.1 Connection with l-axis Servo Unit ......... 6 - 2

6.1.2 Connection with 3-axis Servo Unit ......... 6 - 4

6.2 DETAILED CONNECTION WITH

FEED SERVO UNIT ................. 6 -6

6.2.1 No.1 Axis ............................... 6 - 6

6.2.2

6.2.3 No.3 Axis ............................... 6 - 7

6.2.4 No.4Axis ............................... 6-7

6.2.5 No.5 Axis ............................... 6 - 8

6.2.6

6.3 DETAILED CONNECTION OF SERVO UNIT

MAINCIRCUIT ..................... 6-10

6.3.1

6.3.2

6.4 USE OF SERVO UNIT .............. 6 - 12

6.4.1

6.4.2

No.2 Axis ............................... 6 - 6

IRTypeServoUnit ....................... 6-8

Connection with l-axis Servo Unit ........ 6 - 10

Connection with 3-axis Servo Unit ........ 6 - 11

Noise Suppression ...................... 6 - 12

Protection of Power Line ................. 6 - 16

6-1

Page 52

CONNECTION BETWEEN DEVICES

This section describes the connection between the CNC unit, the feed servo unit, and the servo motor, as well as the type of connector and the cable specifications.

6.1 .l

Connection with l-axis Servo Unit

CNC unit

JANCD-JSVOl

No.1

- -, 5w80 Hr. 3-#lase

PCR-E28Lh4DTSO

PCFM28LMOTSO

PCR-ER28LMOTSD

CNOl

CNOZ

CN03

ZCOt22W23OVAC

I I

Feed servo unit Feed motor

__-..-

@3

MR-2ofOl (MFmL)

KOW-sBtype DE&UX)os3

3

Da

Is31OaB2a-295

1sc57-1

PG

0

CACR-!RClOSEB

Fig. 6.1

Connection of Cable (No.1 axis to No.3 axis)

6-2

Page 53

6.1 CONNECTION BETWEEN DEVICES

CNC unit

IANCD-JSVOI

40.1

--

PCR428LMDTSD

PCR-E28LMDTSD

PCR428LMDTSD

CNOl

CNM

CNC!3

PCR-EZBFC

Feed servo unit

CACR-IROOSEB

CACR-lROOSEB

1CN

PCR-E28LMD

‘I

No.4 axis

XN

MR-ZORMA

No.5 axis

2CN

MR-ZORMA

Feed motor

@3

@3

I

Fig. 6.2

Connection of Cable (No.4 axis and No.5 axis)

6-3

Page 54

6.1.2 Connection with 3-axis Servo Unit

200/220/230 VAC

CNC unit

IANCD-JSVOI

W.1

50160 Hi

!, .

3-phase

B

Servo unit (for 3 axes)

CN2

l-1782934

CNl;

MR-2OFtMP

KOW-SB type

DE8400093

CNOl

PCR-E28LMD

CNOZ

PCR-E28LMD

CN03

PCR-E28LMD

227,

ICI-

‘CR-E28FC

‘CS-E28LB)

s271

ICI-

‘CR-E28FC

“CS-E28LB)

227,

IC-

‘CR-E28FC

PCS-E28LB)

CNll

PCR-EZBLMD

CN31

PCR-E28LMO

CN3

1-178138-2

CN3;

MR-20RMi

KQW-SB type

DE8400093

KOW-SB type

DE8400093

-

PG 1 No.2 axis

Fig. 6.3

Connection of Main Circuit

6-4

Page 55

200/220/230 VAC

50160 Hz, %phase

6.1 CONNECTION BETWEEN DEVICES

I

m

Fig. 6.4

CN12

MRGORMA

MR

Connection of Main Circuit

I

I

KOW-SB twe

MS3108B2&29S

KQW-SB twe

6-5

Page 56

6.2 DETAILED CONNECTION WITH FEED SERVO UNIT

This section describes the detailed connection between the CNC unit, the feed servo unit,

and the servo motor.

6.2.1 No.1 Axis

CNC unit

6.2.2 No.2 Axis

r-1

L--l 1

Fig. 6.5 No.1 Axis

CNC unit

No.1

P 1

JANCD-JSVOl

CACRdROOSEE

Feed servo unit (No.2 axis)

c

2s

c

zc

;> ICN-15

L---.--l

zc

CACR-IROOSEB

‘2’

Fig. 6.6 No.2 Axis

6-6

Page 57

6.2.3 No.3 Axis

6.2 DETAILED CONNECTION WITH FEED SERVO UNIT

6.2.4 No.4 Axis

CNC unit

p”

L---l I

JANCD-JSVOl

Fig. 6.7 No.3 Axis

Feed servo unit (No.3 axis)

r--i

L-I

CACR-IROOSEB

&

CNC unit

I

Fig. 6.8

No.4 Axis

FeyEunit (No.4 ajis)

l----I t

CACR-IROCISEB

6-7

Page 58

6.2.5 No.5 Axis

CNC unit

Fig. 6.9 No.5 Axis

6.2.6 IR Type Servo Unit

For IR type servo unit, the setting of connector number to be connected to CNC unit is made

by SW2.

(1) IRCICISEB Type (for 1 axis) Servo Unit

SW1 : This is for test, so do not change the default setting; SWl-0 to 3: open

SW2 : Axis setting (to determine the connector to be connected)

SW2

0

1 JSVOI CN02

2

3

to

F

CNC Side Connection Connector

JSVOl CNOl

JSVOI CN03

Invalid

I

6-8

Page 59

6.2 DETAILED CONNECTION WITH FEED SERVO UNIT

(2) IROOEB Type (for 3 axes) Servo Unit

SW1 : This is for test, so do not change the default setting; SWl-0, 1:

short-circuited, SWI-2, 3: open

SW2 :

Axis setting (to determine the connector to be connected)

SW2 CNll Connection Destination CN21 Connection Destination CN31 Connection Destination

0 JSVOI CNOl JSVOI CN02

1 JSVOI CN02 JSVOl CNOl

2

3 JSVOI CNOl JSVOl CN03

4

5 JSVOl CN03

’ 6 JSVOI CNOl

7

8 JSVOI CN03

9 Invalid

JSVOl CN02 JSVOl CN03

JSVOI CN03

JSVOl CN02

Invalid

Invalid

invalid

Invalid

Invalid

JSVOl CNOl

JSVOI CN02

Invalid

Invalid

Invalid

JSVOl CNOl

JSVOl CN02

JSVOl CN03

Invalid

Invalid

Invalid

JSVOl CN03

JSVOl CN03

JSVOl CNOl

JSVOl CN02

J&O1 CNq

JSVOl 0401

Invalid

Invalid

Invalid

Invalid

Invalid

Invalid

JSVOI CNOl

JSVOI CN02

JSVOI CN03

JSVOl CNOI

JSVOl CN02

Invalid

The rotation direction of AC servo motor is described for normal connection.

It is counterclockwise (CCW) rotation when viewed from the motor load side

(flange side), when a positive (+) move command is given.

6-9

Page 60

6.3 6.3 DETAILED CONNECTION OF SERVO UNIT MAIN CIRCUIT DETAILED CONNECTION OF SERVO UNIT MAIN CIRCUIT

This section describes the connection between the CNC unit, the feed servo unit, and the ser- This section describes the connection between the CNC unit, the feed servo unit, and the servo motor, as well as the type of connector, and the cable specifications. vo motor, as well as the type of connector, and the cable specifications.

6.3.1 6.3.1

Connection with l-axis Servo Unit

Connection with l-axis Servo Unit

*

-

c-

L-

L

: -, -rm1ZI9- ; :

6

c

Q,y

No.5 axis

Fig. 6.10 Connection with l-axis Servo Unit

6-10

Page 61

6.3 DETAILED CONNECTION OF SERVO UNlT MAIN CIRCUIT

6.3.2

Connection with 3-axis Servo Unit

200/2207230 VAC_

50160 Hz

-

+

t

I

Servo unit (for 3 axes)

R ()

Necessary only for the hold

brake.

Brake is built in motor.

A

-

-

I

Fig. 6.11

+ MPON and /MPON

MPON and IMPON are the con&w points 10 shut OFF the power supply to the main circuit by turning ON/OFF

the built-in connector. The conracr point capacity is 200/220/230 VAC. 12 mA.

Connection with 3-axis Servo Unit

6-11

CN23-1 ), U

1 R &CACR-IROEICIOOOEB

Page 62

6.4

USE OF SERVO UNIT

This section describes the use of the servo unit.

6.4.1 Noise Suppression

Servopack uses power transistors in its main circuit.

The influence (switching noise) by di/dt when switching these power transistors may be

caused by wiring or grounding arrangement.

Servopack has a built-in CPU. For that reason, it is necessary to arrange wiring and processing so as to prevent external noise as much as possible.

To prevent noise interference, arrange the wiring and grounding as shown in Fig.Fig. 6.12.

(1) Grounding

L___L&oGG&G!ne point

- (100 R or less)

Fig. 6.12 Grounding

1. Use a heavy wire over 3.5 mm2 (flat copper wire) as an external connection wire

for grounding.

2. For the use of a noise suppressor, observe “(2) Installation of Noise suppressor”.

3. Use twisted wire in connection of portion P as much as possible.

6-12

Page 63

6.4 USE OF SERVO UNIT

(a) Motor frame grounding

When the motor is grounded via the frame at the machine side, Cf (moter floating

capacity) dv/dt current flows out from PWM power portion via motor floating capacity. Be sure to connect the terminal E (motor frame) of the motor to prevent

the influence by this current to the terminal of Servopack.

(Be sure to ground the terminal of Servopack directly to the ground.)

(b) Servopack SG OV

If noise is on the input signal line, ground SG OV; if motor wiring is contained in

metallic conduit, be sure to ground the conduit and box.

The above grounding processings are all to be one-point grounding.

(2) I+allation of Noise Suppressor

When using a noise suppressor to prevent noise from the power line, it is necessary to

use a prevention type.

Applicable noise suppressors are shown in Table 6.1.

Insert noise suppressor into power supply of peripheral devices in the same manner.

When using a noise suppressor, using it the wrong way will reduce its effect by half.

During assembling, follow the notes shown in Fig. 6.13 through Fig. 6.16.

Table 6.1

Servopack Type CACR-

IR05 0 Cl

IRIO 00

IRIS Cl0

IR20 0 0

Applicable Noise Filter

Kind of Applicable Noise

Suppressor (Reference Figure)

I

Recommended Noise Suppressor

VW

LF-3 10 3-phase 200 VAC, 10A

LF-3 I5 3-phase 200 VAC, 15A

LF-320 3-phase 200 VAC. 20A

Specifications

l

IR30 0 0

IR44 00

Note: * : Made by Tohkin Co.. Ltd.

3-phase 200 VAC. 30A

3-phase 200 VAC. 40A

6-13

Page 64

(a) General notes on wiring

Separate I/O lines. Do not bundle them or run them in a single duct.

l

Poor

Good

Fig. 6.13

Do not bundle the grounding line with the suppressor output lines or other sig-

l

nal lines, or run it together with them in a single duct.

SlJppreSSOt

!%

iix

Poor

I

0

Suppressor

=

‘-

BOX

Separate lines.

Good

I

Fig. 6.14

6- 14

0

input line is acceptable.

Page 65

l

Arrange the grounding line singly to the enclosure or grounding plate.

Fig. 6.15

l

Poor

Thick and short

Good

E

-E

Box

When there is a suppressor within the unit, connect the suppressor grounding

line and the grounding line of the devices in the unit to the base of the unit.

-

Box

Fig. 6.16

6-15

Page 66

6.4.2

Protection of Power Line

Servopack is of a line operating type using a commercial power source (200V system).

Therefore, it is necessary to use a circuit breaker (MCCB) or fuse according to the number

of Servopacks to be used in order to protect the power line from grounding or contact with

other wires. (Table 6.2)

Table 6.2 Power Capacity

Note: *:&he at rated load.

6- 16

Page 67

CONNECTION OF

SPINDLE DRIVE UNIT

Chapter 7 describes the connection of the spindle drive unit.

7.1 Connection between Devices

7.1.1 Pulse

7.1.2 Separate Spindle Pulse Generator

7.1.3 Main Circuit, Converter, and lnverter

Generator

with Built-in Motor

.........

7.2 DETAILED CONNECTION WITH

SPINDLE DRIVE UNIT

7.2.1

7.2.2 Separate Spindle Pulse Generator

7.2.3 Main Circuit, Converter, and lnvetter

Pulse Generator with Built-in Motor

...............

7 - 2

........ 7 - 2

......... 7 - 2

....... 7 - 3

7 - 4

........ 7 - 4

......... 7 - 5

....... 7 - 6

7-1

Page 68

7.1

CONNECTION BETWEEN DEVICES

This section describes the connection between devices of the spindle drive unit.

7.1.1 Pulse Generator with Built-in Motor

CNC unit

JANCD-JSVOl-2.4 -

1

1025~52A2JL

102X1-52QJL

10220-52A2JL

Fig. 7.1

Pulse Generator with Built-in Motor

7.1.2 Separate Spindle Pulse Generator

CNC unit

10120-3OOOVE

c912

”

1

Fig. 7.2

Separate Spindle Pulse Generator

7-2

Page 69

7.1 CONNECTION BETWEEN DEVICES

7.1.3

Main Circuit, Converter, and Inverter

200/220/230 VAC

50160 Hz

L

.

Fig. 7.3 Main Circuit, Converter, and lnverter

Converter

CIMR-RM5

5CN

CIMR-MS

I

lnverter

I

I- - - - - _ _ _

7-3

Page 70

7.2

DETAILED CONNECTION WITH SPINDLE DRIVE UNIT

This section describes the detailed connection of the spindle drive unit.

7.2.1

Pulse Generator with Built-in Motor

CNC unit

Spindle drive unit

Fig. 7.4

Pulse Generator with Built-in Motor

7-4

Page 71

7.2 DETAILED CONNECTION WITH SPINDLE DRIVE UNIT

7.2.2

Separate Spindle Pulse Generator

CNC unit

---

JANCD-JSVOl-2.4

--

1 1

CN05-18

CN05-19

CN05-14

CN05-15

<

Spindle pulse generator (No.1 spindle)

I

Fig. 7.5 Separate Spindle Pulse Generator

7-5

Page 72

7.2.3

Main Circuit, Converter, and lnverter

200/220/230 VAC

50160Hz

R S T

- I I

1 MCCB

Spindle motor

1MC

0

L

,,U

.J

.,V

\/

,.W

.J

---

Fig. 7.6

Main Circuit, Converter, and lnverter

7-6

Page 73

8

CONNECTION OF TAPE READER

Chapter 8 describes the connection between the CNC unit

and the tape reader unit.

8.1 CONNECTION BETWEEN DEVICES . . 8 -

8.1.1

8.2 DETAILED CONNECTION OF

TAPE READER . . . . . . . . . . . . . . . . . . . . . 8-3

8.2.1

Connection with CNC Unit

MODEL2801E . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

. . . . . . . . . . . . . . . . 8 - 2

2

8-l

Page 74

8.1

CONNECTION BETWEEN DEVICES

This section describes the connection between the CNC unit and the tape reader unit, the type

of connector, and the cable specifications.

8.1.1

Connection with CNC Unit

CNC unit

JANCD-JCPOI

10220-52A2JL

Fig. 8.1

Connection between Devices

CN02

Tape reader

unit

UL20276 AWUG28 x 10 pairs

10120-3000VE

C

2

2OOl220 VAC

50160 Hz

8-2

Page 75

8.2 DETAILED CONNECTION OF TAPE READER

8.2

8.2.1

DETAILED CONNECTION OF TAPE READER

This section describes the detailed connection between the CNC unit and the tape reader unit.

MODEL 2801 E

CNC unit

JANCD-JCPOI

CN02-7 ,SD

CN02-6 , RD

CN02-2 , DR

CN02-1 /. SG

Hood case 11

.

.

.,

FG

From the

main circuit

I ’

I t

\ ,

Pkver supply

200/l 00 VAC

50160 Hz

’

’

T

Transfo%er

20011 oov

1 OOVA

Tape reader unit

L

Tape reader

, 3 type MODEL 2801E

,‘l3 412 8

m

UWY Y

” ”

()L

ON

00

Power supply for

tape reader

EYG 300155

’ Tape handier

2 Type MODEL 1402

MODEL 1500

+E

r\

”

,-,

7

Fig. 8.2 Detailed Connection of Tape Reader

The length of wire from the tape reader to the CNC unit shall be within 3 m.

If the length exceeds 3 m, contact your Yaskawa representative.

8-3

Page 76

- -- ..-.-~.-...-

CONNECTION OF RS-232C

Chapter 9 describes the connection between the CNC unit

and the devices having RS-232C interface.

9.1 CONNECTION BETWEEN DEVICES . . 9 - 2

9.1.1

9.2 DETAILED CONNECTION OF RS-232C 9 - 3

9.2.1 Connection with CNC Operation Panel ...... 9 - 3

9.3 RS-232C INTERFACE ............... 9 - 4

9.3.1

Connection with CNC Operation Panel ...... 9 - 2

Transmission Method ..................... 9 - 4

9.3.2

9.3.3

9.3.4

9.3.5

9.3.6

CodestobeUsed ........................ 9-4

Communication Baud Rate ................ 9 - 5

Cable Length ............................ 9 - 5

Connection between Devices .............. 9 - 5

Signal Communication Timing ............. 9 - 7

9-l

Page 77

9.1

9.1 .I Connection with CNC Operation Panel

CONNECTION BETWEEN DEVICES

This section describes the connection between the CNC operation panel and devices having

RS-232C interface, the type of connector, and the cable specifications.

For the port of RS-232C, No. 1 port is CN02 of JCPOI, while No.2 port is CN02 of JSP02.

CNC operation panel

------

JANCD-JSP02

1022042A2JL

CN02

I

1

~_-_--

Ficj. 9.1

Connection between Devices

A

DB-25s

9-2

Page 78

9.2 DETAILED CONNECTION OF RS-232C

9.2

9.2.1

DETAILED CONNECTION OF RS-232C

This section describes the detailed connection between the CNC operation panel and devices

having RS-232C interface.

Connection with CNC Operation Panel

Besides No.1 and No.2 ports, there are PLC exclusive ports (CN02, CN03 of JCP02) and

DNC exclusive port (CN06 of JIFOl).

The pin number to each signal on the CNC side is the same as that for No. 1 and No.2 ports.

CNC operation panel

---JANCD4SPOP

----

-7

10120-3000VE

Interface connector

DE-25s DB-25P

0

---

----I

Fig. 9.2 Detailed Connection of RS-232C

9-3

Page 79

9.3 RS-232C INTERFACE

This section describes the specifications for RS-232C interface, including important related

data.

9.3.1 Transmission Method

Start-stop transmission, where the start signal goes ahead of information bits, and the stop

signal follows the information bits.

Km _ _ - - - - - - - - - - - _ - - - - - - _ _ - - - - _ - - _ - _ _ _ _ _ _ _ _ _ _ _ _ _ ->I

OFF _ _ _ _ _

1 character in start-stop transmission

DO Dl D2 D3 D4 D5 D6 D7

ON

Table 9.1

9.3.2 Codes to be Used

There are the following 2 kinds of codes to be used, and they may be switched by parameters.

l

EIA code or IS0 code

l

EIA code or IS0 code + control code (DC1 to DC4)

When using the control code, it is necessary for the objective device to be able to discriminate

codes from DC1 to DC4.

v

Start bit Information biis

RS-232C Voltage Level

/\

Stop bit

(1 or 2 bits)

/

v

Pattern of the codes and characters of DC1 to DC4 are as shown in Table Table 9.2.

Table 9.2

Codes and Characters of DC1 to DC4

9-4

.

Page 80

9.3 RS-232C INTERFACE

9.3.3

9.3.4

9.3.5

Communication Baud Rate

Communication baud rate may be designated by parameters.

Cable Length

The maximum cable length varies with devices, so follow the operation manual for each device. (Standard maximum cable length : 15 m)

Connection between Devices

(1) Connection Cable for RS232C interface

Connection is shown in Table 9.3.

Table 9.3 Connection Cable for RS-232C Interface for End Connection (A)

ER

Data end

ready

IO BUSY

CNC can start and stop the objective device by sending out control codes DC 1 to DC4.

However, the objective device cannot control CNC by sending out control codes.

But, if the processing of the objective device is not in time, the data sending from CNC

can be stopped temporarily by controlling CS signal at CNC side.

When the CS signal is not used at CNC side, short CS and RS as shown in Table 9.4.

9-5

Page 81

Table 9.4 Connection Cable for RS-232C Interface for End Connection (B)

(2) Description of Signals

FG : Frame

grounding

SD : Send data (output)

RD : Receive data (input)

RS : Send request (output) -

This is the output signal that turns ON upon send start

of data from CNC and turns OFF upon completion of send.

CS : Send possible (input) -When this input signal is ON, data may be sent out from

CNC.

Therefore, when the processing of the objective device is not in time, turning OFF

this signal causes send data from CNC to stop within 2 characters.

When this signal is not used, connect as shown in Table 9.4.

SG : Signal ground

ER : Data end ready -

This is used as a tape rewind signal when using RS-232C

interface for a tape reader.

When this signal is ON, tape reader rewind is possible.

DR : Data set ready

ER : Data end ready

If “1” is set to pm0012 D2, pm0014 D2, pm0017 D2 or pm0019 D2, interlock of

DR is added.

Normally, signals DR and ER of RS-232C interface are not used on CNC side

I

9-6

Page 82

9.3.6 Signal Communication Timing

) When CNC Receives Data

(1

Receiving is accomplished in the following order and timing.

CNC sends out DC1 code.

@

Upon receiving DC 1 code, the objective device starts sending data to CNC.

@

When the processing of CNC side is not in time, CNC sends out DC3 code.

@

Upon receiving DC3 code, the objective device stops sending data within 10 char-

@

acters.

9.3 RS-232C INTERFACE

After completion of processing, CNC sends out DC1 code again.

@

Upon receiving DC 1 code, the objective device sends out the remainder of the pre-

@

vious data.

Upon completion of data reading, CNC sends out DC3 code.

@

The objective device stops sending data.

@

RS output

SD output

RD input

CS input

DC1 DC3

c!J 14

‘-l---v

DC1

10 or fewer characters

- q

m L

DC3

1’

9-7

Page 83

(2) When CNC Sends out Data

Sending is made in the following order and timing.

@ CNC

sends out DC2 code and

data.

@ When the processing of the objective device is not in time, IO BUSY signal turns

CS OFF at CNC side. CNC stops sending data within 2 characters.

@ After completion of the processing of the objective device, CS at CNC side is

turned ON. CNC sends out the remainder of the previous data.