Page 1

PLCNpCROGRAMMING

MANUAL

HI

RUNNING

G40

G91

N1

G49

G30

T09

;

G80

YO

M06

RUN

;

ZO

;

M05

;

mil

V

UNIVERSAL

X

T

Y

Z

NO

111.

:T0000

49.

6.

INCREMENT

042

296

638

X

Y

Z

ACT

S:S

0.

0.

0,

000

000

000

0

G/M

GOO

G17

G90

G94

G21

CODE

r

G80

G98

G52

G67

,J

tir

r

—

n

llliH

YASKAWA

SIE-C843-13.1

Page 2

Page 3

FOREWORD

The

Programmable

NC

functions

quence

For

fline

bugging

ting

PLC

using

tions

a

This

for

control

edition

the

mode

board

programs

the

sequence

the

standard

the

to

sequence

manual

writing

programming.

PLC

program

explains

the

development

Logic

the

interface

as

specific

of

PLC

(model:

the

to

be

can

hardware

sequence

without

programs

writing

to

Controller

between

to

the

machine

a

sequence,

The

JANCD-JCP02-3,

NC.

edited

without

which

the

PLC

flash

to

the

program

personal

created

This

feature

online

in

requiring

already

is

using

a

instructions,

ROM,

(hereafter

YASNAC

the

tools

computer

programs

name:

allows

mode.

in

personal

program

so

etc.

flash

to

refereed

NC

simply

and

can

be

JXSD)

efficient

The

online

JXSD

the

operation.

computer.

debugging

that

a

series

PROM

can

to

PLC)

as

and

efficiently

be

can

checked

installed

program

mode

board,

is

It

of

be

performed

for

YASNAC

a

machine

by

used.

This

by

using

the

in

development.

editing

permitting

of

course

methods,

operation

J300

tool

to

execute

software.

feature

the

sequence

NC

after

can

executed

be

simple

possible

the

procedure

from

PLC

smoothly.

series

se¬

allows

of¬

de¬

transmit¬

by

modifica¬

to

develop

used

program

Page 4

CONTENTS

FOREWORD

5?

1

SYSTEM

1

SYSTEM

.1

J300

SEQUENCE

2

SEQUENCE

2.1

PLC

3

3.1

BASIC

PROGRAM

3.2

3.3

INPUT/OUTPUT

SEQUENCE

4

4.1

DIFFERENCES

CONFIGURATION

CONFIGURATION

PLC

SYSTEM

PROGRAM

PROGRAM

PROGRAM

SPECIFICATIONS

SPECIFICATIONS

FUNCTIONS

SPECIFICATIONS

CONTROL

OPERATION

IN

YASNAC

OF

DEVELOPMENT

DEVELOPMENT

METHOD

1-2

PROCEDURE

2-2

3-2

3-3

3-4

4-2

4.2

4.3

4.4

ADDRESS

5

5.1

5.2

PLC

6

6.1

6.2

AND

LEVEL

RELATIONSHIP

COUNT

SEQUENCE

MEMORY

AND

OPERATION

BETWEEN

AND

THE

PROGRAM

CONFIGURATION

NUMBERS

ADDRESS

ADDRESS

MAP

MAP

AND

INSTRUCTIONS

INSTRUCTIONS

PLC

BASICS

TYPES

OF

AND

LIST

OF

SEQUENCE

OF

THE

SEQUENCE

MEMORY

AND

DISPLAY

TASK

ADDRESS

SYMBOLS

INSTRUCTIONS

LADDER

CAPACITY

PROGRAM

STOP

MAP

4-3

4-6

4-7

5-2

5-3

6-2

6-3

Page 5

6.3

RELAY

INSTRUCTIONS

6-8

7

TIMER

6.4

6.5

REGISTER

6.6

CONTROL

MACRO

6.7

JXSD

7.1

OUTLINE

7.1.1

7.1.2

7.1.3

7.1

.4

7.2

SOURCE

7.2.1

COMPILER

7.3

7.3.1

7.3.2

7.3.3

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

OFFLINE

OF

THE

Operating

Execution

Outline

Ladder

Source

7Compiler

Compiler

Compiler

Environment

Files

Execution

the

of

Program

FILE

Format

File

Operation

Error

Check

SYSTEM

JXSD

Development

OFFLINE

Files

.

...

List

Items

SYSTEM

Procedure

6-15

6-17

6-41

6-44

7-2

7-2

7-2

7-2

7-3

7-6

7-6

7-18

7-18

7-19

7-19

LINKER

7.4

7.4.1

7.4.2

7.4.3

7.5

REMOTE

7.5.1

7.5.2

7.5.3

7.5.4

LIST

7.6

MESSAGES

7.6.1

7.6.2

Object

Linker

Linker

Data

Operation

Output

CONTROLLER

Connecting

Starting

Description

Operation

Error

Warning

the

OF

ERROR

Messages

Messages

and

Linker

File

the

JXSD

Remote

of

Screen

of

Remote

MESSAGES

.

.

.

Processing

OPERATION

to

PLC

Controller

Display

Controller

ii

Information

AND

.

.

..

.

WARNING

7-21

,7-21

.7-22

7-23

7-24

7-24

7-25

7-26

7-28

7-33

7-33

7-33

Page 6

8

ONLINE

EDITING

OUTLINE

8.1

8.1.1

.2

8.1

FUNCTION

8.2

8.2.1

8.2.2

LADDER

8.3

8.3.1

8.3.2

8.3.3

8.3.4

NET

8.4

8.4.1

8.4.2

8.4.3

8.4.4

8.4.5

8.4.6

8.4.7

Creating

Creating

Sequence

Function

Ladder

Display

DISPLAY

BT/TOP

DIS

SYM

NET

SEL

GO/STP

EDITING

Selection

Keys

Used

Inputting

Inputting

Inputting

Canceling

Exiting

the

OF

ONLINE

Sequence

a

Sequence

a

Program

TREE

Tree

AND

Screen

FUNCTION

(Bottom/Top)

(Symbol

(Net

(Run/Stop)

Display)

Selection)

FUNCTION

Edit

for

the

Edit

Mode

Editing

and

Instructions

Edit

Net

Function

of

Contacts

Vertical

Register

EDITING

Program

Program

DISPLAY

Functionÿ

Function

Function

Function

the

Ladder

Horizontal

Function

Newly

Modifying

by

SCREENS

Lines

the

Existing

8-2

8-2

8-3

8-4

8-4

.

8-5

8-6

8-6

8-6

8-7

8-8

8-10

8-11

8-15

8-19

8-22

8-23

8-34

8-34

TABLE

8.5

8.5.1

8.5.2

8.5.3

8.6

INPUT/OUTPUT

8.6.1

8.6.2

SEQ

8.7

8.7.1

8.7.2

LIST

8.8

8.8.1

8.8.2

8.8.3

EDIT

Editing

Editing

Editing

Downloading

Uploading

STS

Display

(Initialization)

INITl

OF

of

List

List

of

of

List

FUNCTION

the

the

the

Data

Data

Data

in

in

in

the

the

the

FUNCTION

Sequence

the

Sequence

the

(SEQUENCE

Sequence

of

Function

MESSAGES

Messages

Warning

Alarm

Messages

Messages

Conversion

Message

Symbol

Program

Program

STATUS)

Status

Hi

Table

Table

Table

FUNCTION

8-38

8-39

8-40

8-41

8-43

8-43

8-45

8-47

8-47

8-48

8-51

8-51

8-52

8-52

Page 7

DOWNLOADING

9

AND

UPLOADING

LADDER

PROGRAM

DOWNLOADING

9.1

(PC

CARD

UPLOADING

9.2

(FLASH

ROM

LADDER

FLASH

LADDER

PC

ROM)

CARD)

PROGRAM

9-2

PROGRAM

9-4

Page 8

*»

Page 9

1

r

SYSTEM

Chapter

J300

1

.1

1

describes

PLC

system.

SYSTEM

J300

PLC

CONFIGURATION

SYSTEM

CONFIGURATION

the

system

configuration

YASNAC

OF

of

YASNAC

1

-2

-1

1

Page 10

1.1

SYSTEM

CONFIGURATION

OF

YASNAC

J300

PLC

SYSTEM

f

ooa

Input/output

z

/PLC

i

operation

NC

aoo

NC

boa

1

i

JANCD-

JCP02-L2

unit

signal

i

k

t

P

panel

°am\)

display

Se

rial

To

send

persona)

is

(JXSD)

commu

ladder

the

computer,

necessary.

Personal

(with

nication

a

from

JCP02-3

ft

offline

r

Printer

A

i

f

computer

system

software

package)

-PCMCIA

A

card

YENET

I/O

(JANCD-

FC810)

Fig.

1200

unit

!

1.1

PC

TH6SS1

send

To

a

PC

card

the

card

(Toshiba)

AAA

60051

to

ladder

necessary.

is

l

the

flash

ROM,

1

-2

Page 11

2

SEQUENCE

PROGRAM

Chapter

development

2.1

describes

2

offline

-

SEQUENCE

DEVELOPMENT

DEVELOPMENT

the

and

PROGRAM

PROCEDURE

procedure

online

mode

sequence

of

operation.

program

2-2

r

2-1

Page 12

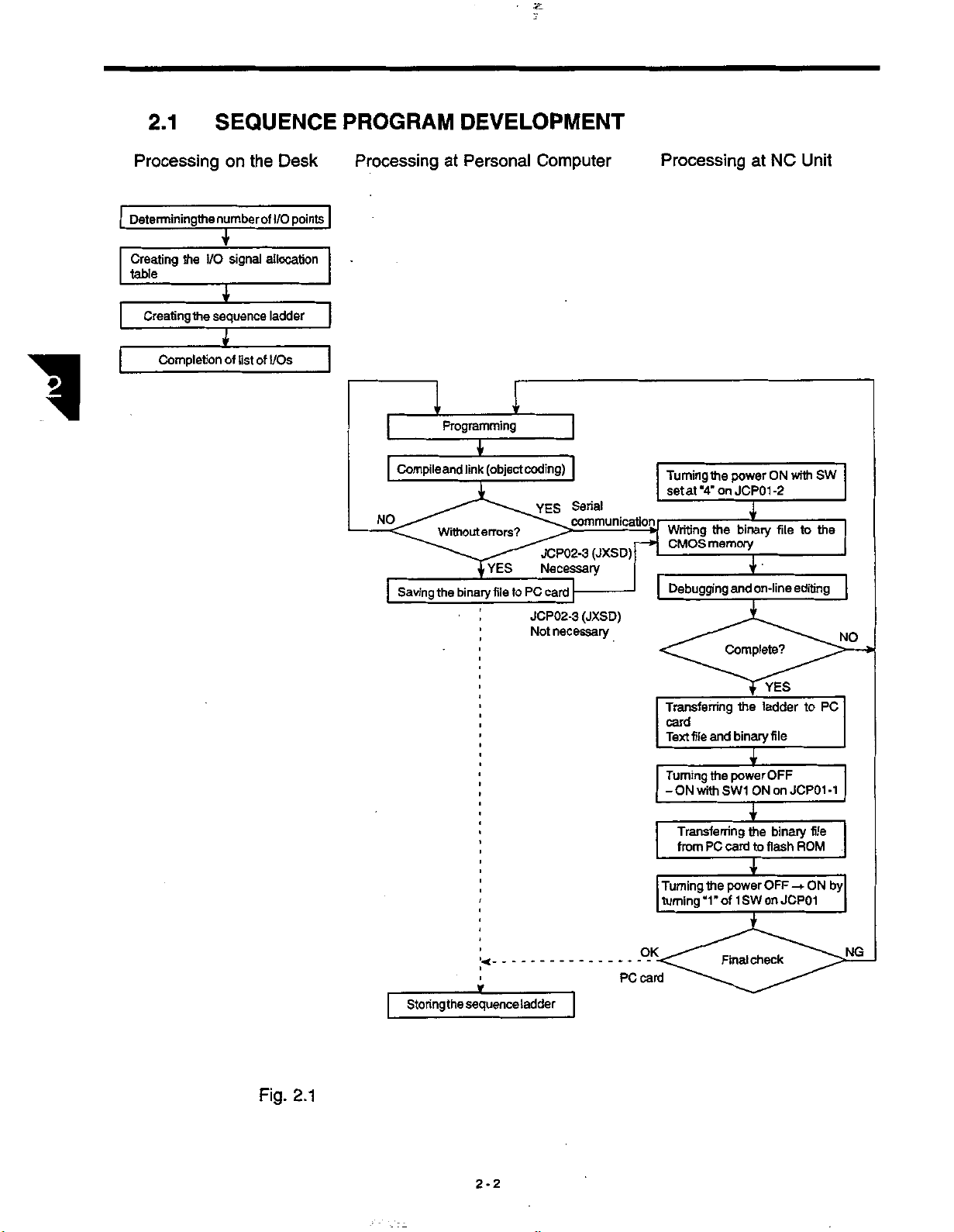

2.1

SEQUENCE

PROGRAM

DEVELOPMENT

1

Processing

Determiningthe

Creating

table

the

Creating

Completion

I/O

the

on

the

numberof

T

signal

I

sequence

I

of

list

Desk

I/O

points

allocation

ladder

of

I/Os

Processing

Compile

NO

Saving

Personal

at

Programming

I

(object

link

and

errors?

Without

YES

binary

file

the

Computer

'f

coding)

YES

JCP02-3

Necessary

card

PC

to

JCP02-3

necessary

Not

Serial

communication

(JXSD)

(JXSD)

Processing

Turning

setat“4’on

Writing

CMOS

Debugging

power

the

JCP01-2

the

memory

and

Complete?

at

T

binary

£

on-line

NC

ON

file

Unit

with

to

editing

SW

the

NO

Fig.

2.1

Storing

jr

sequence

the

ladder

PC

Transferring

card

Text

Turning

-

Turning

turning

OK

card

file

and

power

the

SW1

ON

with

Transferring

from

PC

card

power

the

“1”

of1SW

Final

the

binary

I

ON

I

the

to

T

check

YES

ladder

file

OFF

on

binary

flash

OFF

on

JCP01

to

JCP01

file

ROM

ON

-+

PC

-1

by

NG

2-2

Page 13

3

PLC

PROGRAM

Chapter

3.1

3.2

3.3

describes

3

BASIC

PROGRAM

INPUT/OUTPUT

SPECIFICATIONS

FUNCTIONS

SPECIFICATIONS

programs.

specifications

the

SPECIFICATIONS

of

PLC

....

3-2

3-3

-

3

4

¥

3-1

Page 14

3.1

BASIC

SPECIFICATIONS

1

Control

Processing

method

High-speed

Low-speed

Note:

Program

Instructions

memory

Basic

Program

Table

Note:

Basic

time

Value

symbol

128K

instruction

The

processing

processing

”n”

capacity

bytes

basic

specifications

time

scan

time

scan

determinedbythe

is

are

equivalent

of

to

approximately

programs

PLC

Scanning

0.5

4

ms

ms

4

high-speed

256K

128K

128K

61

fis/step

x

processing

bytes

bytes

bytes

kinds

indicated

are

method

(approximate

n

32K

steps

below.

value)

capacity

of

basic

total

and

instructions.

program

capacity.

Macro

instruction

22

kinds

3-2

Page 15

PROGRAM

3.2

FUNCTIONS

3.2

Internal

Registers

Timers

Sequence

Keep

Battery

relays

8

50

100

1

1

relays

back-up

PROGRAM

to

msec

255

to

to

memory

2.4

to

to

255

12.75

msec

msec

sec

min

parameters

sec

25.5

sec

min

FUNCTIONS

sec

sec

11960

1495

timers

188

timers

40

timers

60

timers

60

timers

20

timers

8

100

sets

7200

2900

points

registers

(5

bits/set)

(8

points

sets

(8

bits/register)

types)

l

&

1

.

Internal

internal

ters

Keep

2.

dresses

the

that

relays

relays

cannot

addresses

the

relays

used

keep

be

and

for

used

registers

and

cannot

used

battery

keep

for

registers

be

used

internal

for

back-up

relays

battery

(#8000

occupy

registers.

for

relays.

memory

cannot

back-up

#9999)

to

the

be

same

used

memoiy

cannot

addresses

Similarly,

occupy

battery

for

cannot

be

the

the

same

back-up

be

used

and

the

addresses

addresses,

memory.

used

for

the

for

addresses

for

used

and

Similarly,

relays.

keep

relays.

keep

used

regis¬

the

Note

for

ad¬

I

3-3

Page 16

3.3

INPUT/OUTPUT

SPECIFICATIONS

General-purpose

FC860,

The

FC861)

number

Module

FC810,

FC861

JSP02

An

input/output

panel.

boards

FC861

input:

and

I/O

of

JANCD-

FC860

Therefore,

(max.

input:

is

added,

points)

560

input/output

the

JSP

board

each

points

port

on

Number

Points

is

incorporated

modules

if

512

addition

is

possible.

112

64

64

points;

of

installed

are

ports

(JSP02)

module

of

Input

Number

the

in

FC810/FC860

max.

output:

maximum

a

the

in

indicated

is

Points

control

are

of

9

on

NC

of

Output

96

56

56

added,

440

boards

the

I/O

operation

below.

(JSP02)

board

addition

points)

(max.

module

panel.

machine

For

in

is

possible,

input:

(JANCD-FC810,

Remark

operation

NC

of

the

a

640

operation

maximum

and

if

points,

panel

4

of

module

max.

3-4

Page 17

4

SEQUENCE

Chapter

Sequence

ware,

which

in

characteristic,

erably

sing.

understood.

4.1

4.2

describes

4

control

which

When

DIFFERENCES

LEVEL

OF

differs

processing

different

developing

SEQUENCE

CONTROL

sequence

PLC

by

from

is

sequence

the

operation

AND

the

is

executed

ordinary

the

executed

control

from

programs,

IN

OPERATION

OPERATION

PROGRAM

control

sequentially

control

simultaneously.

by

ordinary

this

METHOD

method.

by

the

soft¬

by

resultsinconsid¬

PLC

relay

circuit

be

must

circuits

relay

Duetothis

proces¬

completely

4-2

4-3

f

RELATIONSHIP

4.3

THE

LADDER

AND

SEQUENCE

4.4

THE

CAPACITY

CONFIGURATION

4-1

BETWEEN

STOP

SEQUENCE

PROGRAM

AND

COUNT

MEMORY

!'

TASK

MEMORY

4-6

4-7

Page 18

4.1

DIFFERENCES

are

There

sequence.

two

types

OPERATION

IN

operation

of

modes

in

the

sequence

control

-

relay

sequence

and

PLC

1

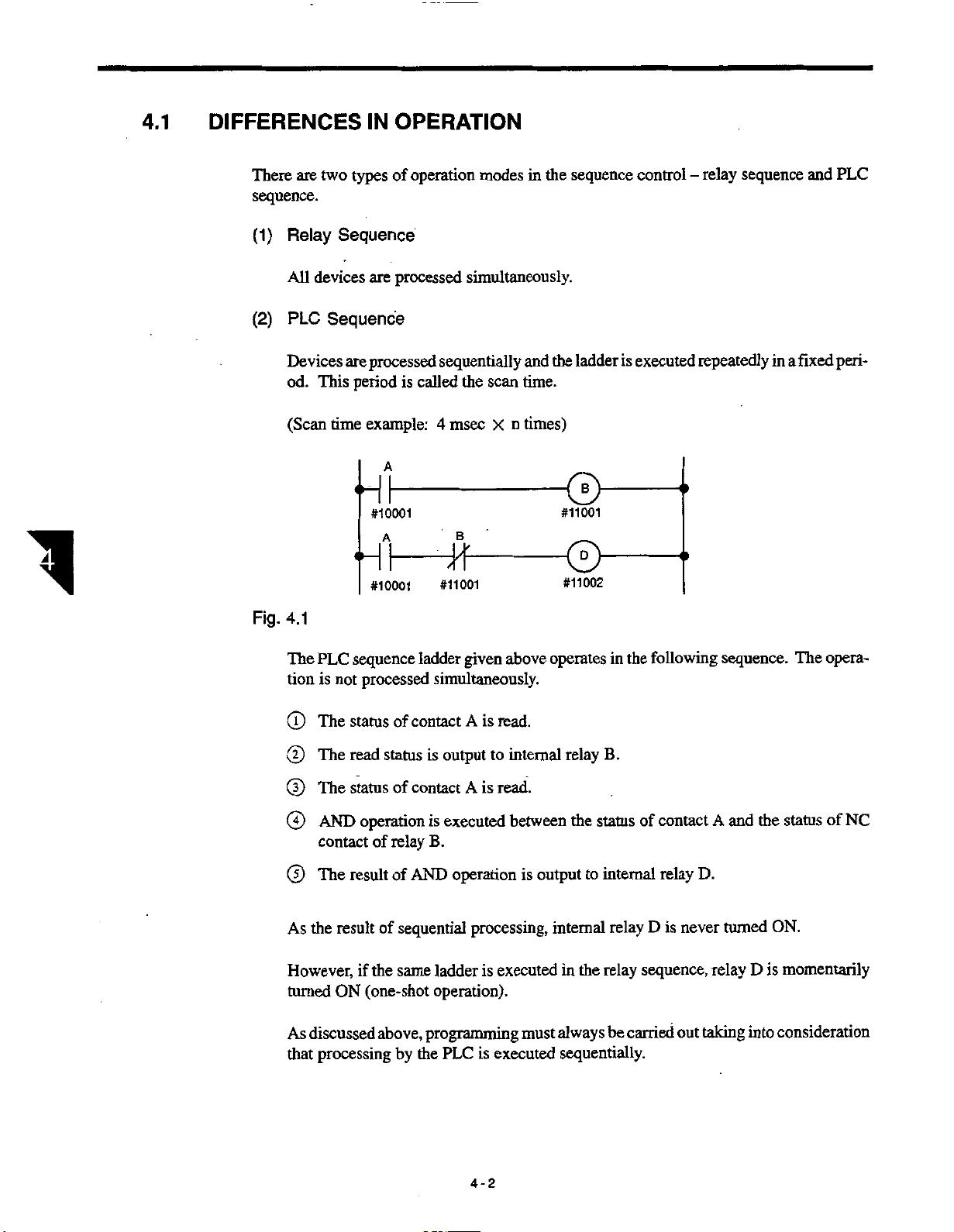

(1)

(2)

Fig.

Relay

All

devices

Sequence

PLC

Devices

od.

This

(Scan

time

4.1

PLC

The

tion

is

Sequence

are

processed

processed

are

period

example:

A

#10001

A

#10001

sequence

processed

not

simultaneously.

sequentially

called

4

msec

the

B

is

-

#11001

ladder

given

simultaneously.

scan

n

X

above

the

and

time.

times)

operates

ladder

©

#11001

®

#11002

is

executed

in

the

repeatedly

following

a

in

sequence.

fixed

The

peri¬

opera¬

The

©

The

©

The

©

AND

©

contact

The

©

the

As

However,

turned

As

that

result

ON

discussed

processing

contact

of

status

read

statusofcontact

operation

of

result

the

if

(one-shot

is

status

is

B.

relay

of

AND

sequential

of

same

above,

programming

the

by

ladder

operation).

PLC

is

A

read.

output

executed

to

is

read.

A

operation

processing,

executed

is

executed

is

internal

between

is

output

internal

always

must

B.

relay

status

internal

relay

relay

carried

be

of

D

sequence,

in

the

to

the

sequentially.

contact

relay

never

is

out

A

D.

turned

relay

taking

and

the

status

ON.

momentarily

is

D

into

consideration

of

NC

4-2

Page 19

4.2

LEVEL

AND

OPERATION

SEQUENCE

OF

PROGRAM

4.2

\

LEVEL

Length

scan

This

speed

be

AND

time

of

time.

High-speed

•

Low-speed

•

means,

processing

written

OPERATION

necessary

The

with

the

in

LD#

:

:

6TH1,

;

sm

scan

this

part

format

for

of

time

processing

processing

the

PLC,

and

low-speed

indicated

High-speed

End

Low-speed

End

SEQUENCE

OF

execution

the

this

model

scan

scan

sequence

processing

below.

processing

instruction

processing

instruction

of

PLC

of

time:

time:

program

high-speed

ot

sequence

of

one

4

msec

msec

4

part.

part

part

is

cycle

of

indicated

X

be

can

processed

Therefore,

processing

program

PROGRAM

a

sequence

below.

n

dividing

by

the

sequence

program

is

called

into

a

it

program

the

high¬

must

Fig.

4.2

indicated

As

tered

be

entered

Operation

(3)

The

4.3

Fig.

first

and

after

operation

NC

I/O

High-speed

Low-speed

Service

Processing

/

User’s

(

I/O

{

Background

V

above,

the

that.

Time

processing

processing

task

message

signal

the

sequence

sequence

Chart

chart

time

ladder

ladder

for:

display

display

processing

program

program

sequence

of

a

\

\

|

J

for

i

4=L

4

ms

that

which

program

i

r-i

-

i

:

requires

low-speed

I

I

—

high-speed

processing

is

indicated

-

I

I

—

n

i=L

i=i

processing

is

acceptable

below.

i

r-i

should

i

1

|

be

en¬

should

¥

4-3

Page 20

(a)

High-speed

The

gram

time

processing

high-speed

the

to

up

chart

RTH

above.

processing

instruction,

sequence

sequence

program,

is

executed

program

from

once

the

every

beginning

msec

or

4

the

of

less

sequence

showninthe

as

pro¬

1

During

changed.

Low-speed

(b)

The

divided

in

executed

As

speed

Since

input

in

Reading

(c)

At

lectively.

(d)

Outputting

processing

the

low-speed

into

each

4-msec

once

above,

seen

processing

the

low-speed

status

(3)

item

the

the

beginning

processing

processing

“n”

sections

interval.

“4

msec

in

value

program

processing

changed

be

will

below

must

input

of

the

the

output

of

“n”

always

state

4-msec

the

status

high-speed

sequence

sequence

one

is,

n”.

be

sequence

during

be

interval,

of

smaller

its

observed.

and

That

X

will

capacity

sequence

program

program

these

sections

the

low-speed

as

smaller.

are

program

execution.

the

status

program,

entered

the

total

is

Therefore,

of

the

input

following

is

executedinthe

processing

program

executed

all

inputs

in

the

is

status

the

RTH

instruction

remaining

sequence

capacity

several

and

sections,

precautions

read

into

the

remains

program

the

high¬

indicated

PLC

un¬

is

time

is

the

col¬

At

ly.

(4)

Precautions

The

response

Therefore,

less

(5)

Precautions

(T)

the

beginning

high-speed

is

required,

this

than

1000

time

Scan

capacity

The

sequence

mately

cessing

3000

sequence

of

the

High-speed

on

processing

such

should

when

steps

Low-speed

on

the

of

low-speed

the

sequence

of

program

steps

4-msec

sequence

counting

as

limited

be

converted

program.

size

contact

in

program

intervals,

the

Processing

program

the

only

to

the

into

the

Processing

processing

It

that

can

be

instructions.

and

low-

speed

previous

Sequence

only

treats

contact

ON/OFF.

requisite

contact

Sequence

sequence

is

calculated

processed

This

processing

output

status

Program

the

portion

program.

instructions.

Program

program

in

size

is

by

“4

4-msec

a

is

the

sequence

msec

total

is

output

where

capacity

The

influenced

n”.

x

interval

of

high-speed

program.

collective¬

high-speed

be

must

total

the

by

is

approxi¬

pro¬

4-4

Page 21

4.2

LEVEL

OPERATION

AND

SEQUENCE

OF

PROGRAM

Fig.

the

Since

©

the

status

fore,

the

quence

program

processing

sequence

shouldbeused

High-speedprocessing

Low-speed

4.4

creating

By

quence

program

low-speed

inputs

of

inputs

that

should

sequence

program,

the

as

processing

the

program

can

processing

will

be

changed

used

are

taken

be

program,

the

contacts

signals.

input

in

executed

be

program

program

this

sequence

sequence

sequence

during

for

the

into

the

for

and

of

the

manner,

under

is

program

the

executedinseveral

executionofthe

executionofthe

internal

the

relays

one

the

relays

executionofthe

where

the

shouldbetaken

relays.

of

cycle

same

the

input

low-speed

the

at

start

low-speed

have

inputs

low-speed

status.

signal

program.

processing

of

the

low-speed

processing

been

.

ieed

into

the

processing

sections,

There¬

se¬

received

ogram

internal

se¬

Fig.

(D

©

the

resultsofthe

If

processing

speed

creation

The

signals

program

ternal

outputs.

of

the

that

is

executed

program.

shouldbeconnectedtothe

processing

sequence

RTH

4.5

high-speed

sequence

should

not

should

Such

signals

program.

•

Write

—

execution

programatthis

processing

program,

be

output

be

not

should

external

outputs

the

one

of

the

until

directly

first

output

that

cycle

part

sequence

consideration

same

cycle

one

to

output

be

input

addressesatthe

should

of

the

output

be

low-speed

program

the

of

the

PLC

the

internal

to

externally

processing

are

output

be

must

given

low-speed

address

used

relays

the

of

end

the

after

sequence

the

low-

to

the

to

processing

ex¬

for

and

they

low-speed

F

4-5

Page 22

4.3

RELATIONSHIP

BETWEEN

THE

LADDER

STOP

COUNT

AND

THE

1

SEQUENCE

The

service

User’s

•

I/O

•

Background

•

Others

•

task

The

cessing

The

stopped)

Recommended

operates

sequence

ladder

should

TASK

task

includes

message

signal

during

program

count

stop

be

value:

the

display

display

processing

the

and

(the

based

set

1

following:

processing

processing

until

the

from

the

of

load

period,

number

on

completion

the

of

start

times

during

the

next

the

low-speed

the

processing

one

of

scan.

processing

scan

of

the

the

of

ladder

service

low-speed

should

task.

pro¬

be

4-6

Page 23

4.4SEQUENCE

PROGRAM

MEMORY

CAPACITY

AND

MEMORY

CONFIGURATION

4.4

SEQUENCE

PROGRAM

CONFIGURATION

The

The

sequence

program

program

memory

128K

bytes

>

bytes

128K

is

of

finally

this

PLC

High-speed

Low-speed

MEMORY

the

written

to

can

Message

divided

be

Controllable

Processing

Processing

Data

Table

Table

CAPACITY

flash

memory

into

the

areas

Program

Program

AND

(ROM).

indicated

MEMORY

below.

Fig.

4.6

Generally,

that

32K

one

steps

ing

to

relay

instructions

instruction

(128K/4

occupy

occupies

K).

32

=

3

an

average

to

bytes

7

of

and

bytes,

4

other

128K

instructions

byte

memory

¥

25

bytes.

to

1

area

Assum¬

equivalent

is

4-7

Page 24

Page 25

5

ADDRESS

NUMBERS

Chapter

5.1

5.2

5

describes

ADDRESS

ADDRESS

SYMBOLS

AND

the

MAP

MAP

ADDRESS

address

AND

numbers

DISPLAY

and

MAP

address

map.

5-2

5-3

E

5-1

i

Page 26

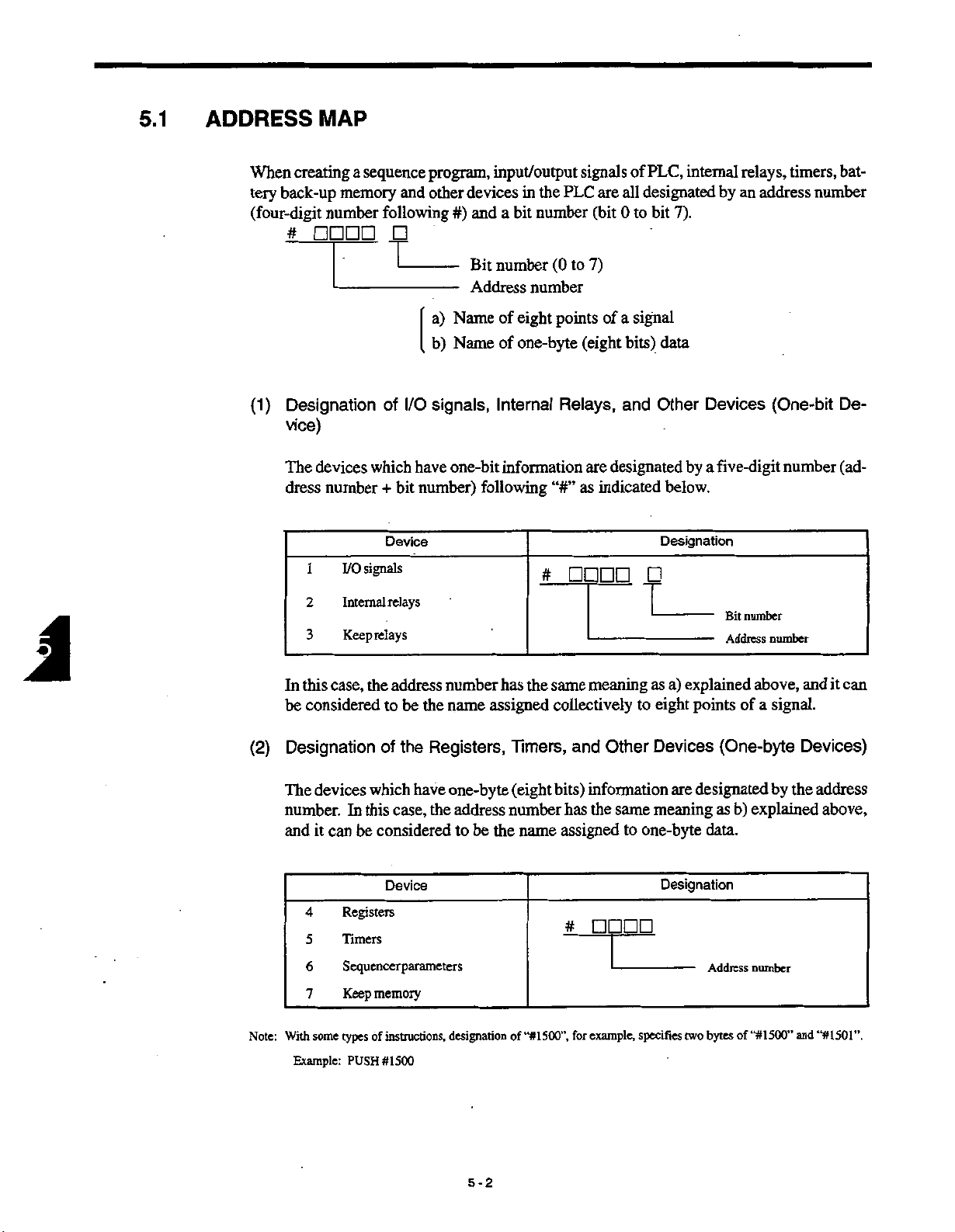

5.1

ADDRESS

MAP

When

creating

back-up

tery

(four-digit

#

Designation

(1)

vice)

The

dress

1

2

3

a

sequence

memory

number

following

of

devices

which

number+bit

I/O

signals

Internal

Keeprelays

and

T

I/O

Device

relays

program,

other

#)

-

-

a)

Name

b)

Name

signals,

one-bit

have

number)

input/output

devices

bit

and

a

number

Bit

Address

of

eight

of

one-byte

Internal

information

following

the

in

number

(0

number

points

“#”

#

signals

PLC

are

(bit

7)

to

of

(eight

Relays,

are

indicated

as

PLC,

of

designated

all

7).

bit

0

to

signal

a

bits)

data

and

Other

designated

below.

Designation

T

internal

by

Devices

by

a

five-digit

Bit

Address

relays,

address

an

(One-bit

number

number

timers,

number

number

bat¬

De¬

(ad¬

In

be

Designation

(2)

The

number.

and

With

Note:

Example:

the

case,

this

considered

address

to

of

devices

it

4

5

6

7

some

which

this

considered

be

Device

memory

instructions,

of

#1500

PUSH

case,

In

can

Registers

Timers

Sequencerparameters

Keep

types

the

be

the

Registers,

have

the

number

assigned

name

one-byte

address

the

be

to

designation

has

the

Timers,

(eight

number

name

“#1500”,

of

same

meaning

as

a)

collectivelytoeight

and

bits)

information

the

has

assigned

#

example,

for

Other

same

to

one-byte

specifies

Devices

are

meaning

Designation

explained

points

of

(One-byte

designated

b)

as

data.

Address

of

bytes

two

a

signal.

and

above,

Devices)

the

by

explained

number

and

“#1500”

can

it

address

above,

“#1501”.

5-2

Page 27

ADDRESS

5.2

MAP

AND

DISPLAY

SYMBOLS

5.2

ADDRESS

The

address

Standard

(1)

Addresses

MAP

map

K>-

te)

AND

and

the

NC

MEM

#7100

#9999

of

Section

beck-up

t

—

—

Input

Main

(Example)

Hi¬

Batteryÿ

memory

pm7000

Jjm7099

DISPLAY

relationship

PLC

Output

Input

-

-

Signals

(4)

outputs!

NC

#3000

die

inputs

NC

#3500

#3699

-

0)

Sequencer

*s

parameters

pm

7000

(11)

(10)

-#7999

sJ

Keep

#7100

|

-#9999

I

memory

from

SYMBOLS

external

with

Section

<1)

in#

Mach

inputs

#1000

•#1063

(21

outputs

Machine

#1100

I

-#1163

I

relays

Internal

registers

end

8'

#1200

•#2994

l

-#1399

#1700

|

-#1799

I

the

Machine

devices

i/O

Section

Input

Output

f

I

(#1000

are

shown

Machine

(Ex.)

-Wh

LS

SOL

to

#1063)

below.

the

those

signals

of

pushbutton

The

For

as

signed.

minedbythe

bit

One

©

Address

©

the

connector

Example:

#1000,

The

©

input

from

input

the

switches

tool

(#

between

builder.

1000s)

number

bit

correspondence

machine

address

of

number

and

numberofthe

54-5

54-21

64-36

Pin

II

signals

(NO

Connector

Enter

of

#1000s

#10000

contact)

No.

the

machine

limit

and

the

corresponds

are

board

I/O

54-35

54-20

10

No.

01

signal

input

are

expressed

operation

switches,

address

to

determined

where

_

2

54-34

name.

by

;

and

panel

addresses

and

the

one

point

depending

the

input

1

54-33

54-19

the

following

m-

(NC

electric

input

of

input

signal

0

#10DOO

contact)

control

#1000

signal

signals.

the

on

is

symbols.

panel,

#1063

to

should

pin

are

deter¬

be

number

connected.

such

as¬

and

5-3

Page 28

(2)

Addresses

For

the

as

respondence

chine

signals

the

signals

tool

Output

of

output

of

lamps

between

builder.

Signals

the

to

and

the

address

the

to

machine

solenoids,

and

Machine

operation

addresses

the

output

#1163)

and

to

electric

(#1100

panel

#1100to#1163are

should

signal

be

determined

control

panel,

assigned.

by

The

the

such

cor¬

ma¬

J

©

©

Example:

(D

(3)

Addresses

For

the

assigned.

bit

One

Address

the

connector

The

output

the

signals

main

NC

address

of

number

(#1

and

number

#1100

/I51-5

signals

Input

input

Signals

from

of

sectiontothe

100s)

bit

of

,

-

7

of

#1100s

#nonn

the

PLC,

corresponds

number

I/O

the

No.

Bit

fi

51-7

51-6

I

Pin

No.

Connector

the

Enter

are

the

from

main

NC

such

to

determined

are

where

board

5

£1-41

151-8

10

No.

08

signal

output

expressed

NC’s

section,

M-BCD

as

one

depending

the

3

lsi

name.

the

by

#•

(NO

Main

other

in

signal,

of

point

output

2

151-26

-27

following

11DDO

contact)

Section

words,

addresses

on

Q

signals.

the

pin

is

connected.

output

signal

151-25

symbols.

#naoo

contact)

(NC

(#3500

signals

the

#3500to#3799

number

#3799)

to

output

and

from

are

The

correspondence

and

©

cannot

One

be

bitofaddress

Example:

between

changed.

#3520

|

MA7

(#3500

7

|

6

MA6

5-4

the

to

Bit

signal

#3799)

No.

3

MA5

[

name

and

corresponds

4

MA3

MA4

|

|

M

First

code

the

3

output

address

to

one

2

MA2

|

is

determined

pointofinput

|

MAO

|

MA1

by

the

NC

signals.

0

|

Page 29

(D

The

input

signals

#3500to#3799

of

5.2

are

expressed

ADDRESS

by

MAP

AND

following

the

DISPLAY

symbols.

SYMBOLS

(4)

Addresses

For

mode

The

and

(T)

Example:

(D

of

Output

the

signals

selection

output

signals,

correspondence

be

of

bit

#3000

output

changed.

address

|

signals

Output

cannot

One

The

#3nnnn

Signals

from

the

to

PLC

addresses

between

(#3000to#3159)

7

EDT|MEM

Edit

Memory

of

to

the

Bit

€

#3000

NC

the

signal

No.

|

Manual

to

(a)

NC

the

to

Main

theNCmain

#3000to#3159

and

name

corresponds

4

5

MDI

#3159

:

-

TP

j

Tape

Q

#3onnn

3

STP

j

Step

are

expressed

—

(b)

-

if

#3nncn

Section

section,

are

the

|

Handle

(#3000

such

assigned.

addressisdetermined

one

to

point

2

1

JOG

H

|

Jog

the

by

following

[

to

as

EDIT

of

0

RT

Rapid

#3159)

output

|

symbols.

and

MEM

the

by

signals.

NC

E

5-5

#3DODD

1

#3nonn

j

Page 30

(5)

Addresses

#1700

#1799)

to

Internal

of

Relays

(#1

200

#2994;

to

excluding

#1

300

to

#1

399

and

For

the

internal

addresses

signed.

One

©

relay.

Example

number

The

©

500

bytes

(3)

The

internal

that

relays

#1200to#2994

bitofaddress

I/O

list:

of

7

#1400

[

usable

of

8

bits

X

relay

Internal

can

(excluding

#1400s,

of

I

internal

4000

=

its

and

relay

be

Bit

6

Enter

contact

:

--

used

for

No.

5

1

an

relays

relays

#140DD

in

PLC

only

the

#1300to#1399

example,

4

corresponds

3

1

interna)

are

name.

relay

indicated

is

expressed

—

to

and

2

below.

by

the

a

create

#1700

one

to

following

sequence

#1799)

to

of

piece

0

]

symbol.

program,

as¬

are

internal

©

There

are

program

The

addresses

limitstothe

no

capacity

used

is

not

for

#14DOO

contact)

(NO

number

exceeded.

registers

5-6

of

contacts

cannot

#140DD

contact)

(NC

be

(NO

used

and

for

contacts)

NC

internal

relays.

as

long

as

the

Page 31

5.2

ADDRESS

MAP

AND

DISPLAY

SYMBOLS

(6)

Addresses

#1700

For

cluding

These

instructions.

®

®

(D

of

Registers

#1799)

to

the

general-purpose

#1300

registers

One

Example

The

#1300

For

to

address

of

#1500

#1501

number

#1399

to

the

registers,

are

I/O

#1399

used

number

list:

[

usable

of

and

the

(#1200

one-byte

and

for

(eight

#1700

register

to

corresponds

Enter

a

register

registers

#1799).

#1700

to

address

number

#2994;

to

bits)

register,

#1799)

are

instructions

a

one-byte

to

name.

the

is

in

range

itself

excluding

addresses

assigned.

and

workpiece

register.

from

is

used

as

#1300

#1200

symbol

the

to

#1200

address

#2994

to

to

in

#1399

#2994

for

(excludes

ladder.

a

and

(ex¬

macro

®

the

See

addresses

The

examples

used

below.

for

internal

t

relays

#isnn

Register

#15DD

Macro

instruction

cannot

}

instruction

(example:

be

used

(example:

for

INR)

PUSH)

registers.

5-7

Page 32

(7)

Addresses

Timers

of

(#1

300

to

#1

399

and

#1

700

to

#1

799)

J

Table

For

©

©

5.1

timers,

the

address

One

Example

#1700

#1701

number

The

#1700

#1300

#1710

#1310

#1730

#1330

addresses

number

list:

I/O

of

of

available

Address

#1760

#1709,

to

to

#1309,

#1360

#1729,

to

to

to

to

#1750

#1350

#1770

#1370to#1373

#1329,

#1749,

#1349,

#1790

#1390

#1780

#1380

#1759

to

#1359

to

to

#1773

#1300

to

#1399

corresponds

timer

Entera

timers

No.

#1769

to

#1369

to

#1799

to

#1399

to

#1789

to

#1389

to

to

and

and

a

timer.

name.

timer

#1700

TtmerType

1

setting

8

1

msec

=

=0.1

1

50

msec

=

sec

1

1

=

1

1

min

=

to

units

sec

#1799

Enter

are

are

assigned.

setting

a

value.

indicated

Number

below.

of

Timers

40

60

60

20

8

An

©

(Example)

example

of

timer

a

-0D-

symbol

-L

Timer

types)

(2

5-8

indicated

is

#170D

instruction

below.

ODH

Do-

Timersettingvalue

(hexadecimal)

Page 33

ADDRESS

5.2

MAP

AND

DISPLAY

SYMBOLS

{8)

Battery

For

the

“battery

tained

even

PLC

the

In

dled.Itis

The

battery

Sequencer

•

Keep

•

Keep

•

Back-up

memory

back-up

when

sequence

possible

not

back-up

relays:

memory:

Standard

Battery

Memory

which

to

addresses

memory”.

the

power

ladder

handle

to

memory

parameters:

Main

NC

back-up

pm

7000

to

7099

pm

#7100

to

#9999

(pm7000

of

#7000s

The

data

is

turned

program,

data

(read

are

OFF.

only

and

pm7000

#7100to#7999

#7100

Section

to

I

memory

to

pm7099,

are

savedtothis

image

the

write)

the

classified

to

#9999

PLC

pm

Keep

#71

Keep

#71

into

pm7099

Section

(Image)

Sequencer

parameters

7000

pm

to

relays

00

#7999

to

memory

#9999

to

00

#7100

assigned,

of

type

dataatthe

source

following

the

7099

#9999)

to

such

memory

memory

PLC

datainthe

are

side

NC

three

called

is

therefore

be

can

main

section.

types.

the

re¬

han¬

E

(a)

Transferring

The

the

If

the

In

attempt

sequencer

following

even

one

entire

sequencer

a

sequence

to

the

parameter

case

item

of

program,

change

sequencer

data

addition

in

sequencer

parameter

is

allowed

it

the

data.

5-9

parameter

transferred

are

time

the

to

parameter

are

data

only

to

data

from

the

when

changed

is

data

transferred

the

read

to

fi

PLC

the

theNCmain

is

power

turned

by

parameter

collectively.

sequencer

section

ON.

write

parameter

the

PLC

to

operation,

Do

data.

in

not

Page 34

Transferring

(b)

the

data

in

the

keep

relay

and

keep

memory

data

to

the

NC

A

Image

ously

fore,

memory

matic

While

the

(9)

Addresses

For

for

tion.

When

methods

Using

(a)

Example

data

since

it

necessary

is

the

in

data

transfer.

the

power

PLC

to

the

sequencer

sequencer

using

are

To

use

•

To

use

•

as

one-bit

of

in

saved

the

data

main

NC

is

the

NC.

of

Sequencer

parameters,

parameters

data

the

available.

one-bit

as

one-byte

as

data

list:

I/O

the

keep

read

are

transfer

to

section

ON,

these

of

data

data

relays

written

and

the

as

the

data

in

Parameters

addresses

changed

be

can

parameters

and

latest

the

source

#7100

keep

the

the

as

sequence

data

image

data.

to

#9999

(pm7000

pm7000

using

by

a

sequence

in

memory

the

in

data

This

are

to

pm7099

to

the

normal

in

PLC

the

to

is

the

program

PLC

transfer

collectively

pm7099)

assigned.

are

parameter

parameter,

change

executed.

battery

called

is

transferred

The

write

the

following

continu¬

There¬

back-up

auto¬

the

from

data

set

opera¬

two

The

symbol

pm7000

used

in

No.

Sit

i

4

5

6

7

[

the

1.1

ladder

is

I

Entarsignal

indicated

I

name.

below.

2

3

I I

0

I

if

pm

pm70DDD

T

Data

Data

“0”

Closed

=

Open

=

“1*

Data

Data

“0*=Closed

70000

Open

=

5-10

Page 35

Usingasone-byte

(b)

data

ADDRESS

5.2

MAP

AND

DISPLAY

SYMBOLS

Example

In

See

(10)

For

0

of

this

case,

the

example

Addresses

the

keep

bit

One

list:

I/O

pm7000

pm7001

1

)

t

the

address

below

[HI-TT

Keep

of

relays

corresponds

Relays

that

number

where

Variable

instruction

can

to

parameter

Enter

is

itself

a

parameter

#1770,

timer

used

is

pm

7

pD-O-l

parameter

a

(#7100to#7999)

usedinthe

be

one

pieceofkeep

PLC,

data

setting

name.

the

as

used

address

relay.

symbol.

timer

a

with

by

#7100to#7999

]

]

instruction.

are

assigned.

k

©

©

Example

The

900

Keep

of

I/O

#7101

numberofusable

bytes

x

relays

[

8

and

Keep

list:

f

7

-

bits

=

contacts

relay

Bit

6

Enter

keep

7200

are

:

No.

5

keep

relays

relays

expressed

#71DOO

#71DDO

(a)

4

f

relay

name.

indicated

is

by

''

#71DDD

(b)

3

below.

the

following

2

0

symbol.

5-11

Page 36

(11)

Addresses

For

es

the

Therefore,

ry

one-byte

the

#7100

saved

of

data

of

to

#9999

data,

the

keep

macro

Memory

Keep

memory

keep

assigned.

are

it

can

used

be

memory

instructions.

where

in

can

(#7100

the

With

the

same

usedasthe

be

#9999)

to

data

the

exception

maimer

retained

can

be

the

that

with

the

as

objectofregister

after

power

memory

keep

registers.

instructions

OFF,

can

or

address¬

retain

auxilia¬

When

be

used.

0

0

0

writing

For

one-byte

Example

#7105

#7106

The

number

2900

in

For

the

keep

See

the

example

a

sequence

bits)

(8

I/O

list:

of

tr

usable

of

the

range

memory,

below.

HH

Contents

MOV:

to

program

keep

keep

from

the

MOV

memory

keep

memory,

Enter

#7100

address

#1500,

1

register

of

random

for

keep

memory

memory

#9999

to

number

#7100

500

#1

#71

type

address

name.

is:

itself

H

are

transferred

ATC

memory,

number

is

used

#7100

]

as

a

or

the

keep

memory

is

above

symbol.

must

assigned.

5-12

Page 37

ADDRESS

5.2

MAP

AND

DISPLAY

SYMBOLS

For

the

0

ber

devices

is

assigned.

Although

two-byte

as

the

case

In

dress;the

data.

byte

Byte

#7200 #7200

#7201

#7202

#7203

that

the

data

or

four-byte

of

two-

address

Word

start

Double-word

Setting

pm3430<pm3431

have

are

four-byte

or

of

the

number

start

range:

one-byte

basically

data

by

significant

least

Word

#7202

setting

number

to

8000

or

larger

one-byte

of

the

setting

data,

the

parameter

setting

parameter:

9999

information,

construction,

the

for

address

used

is

byte

parameter.

is

specified

the

as

pm3430

pm3431

four-digit

a

data

the

as

address

address

can

one-byte

a

for

two-

handled

be

unit

or

num¬

ad¬

four-

(12)

Writing

When

the

set

the

Set

Set

©

Press

©

Move

©

Use

after

Byte

#8200

#8201

#8203

the

keep

initial

initial

the

the

keying

Initial

relays

values

system

the

the

page

Values

and

for

following

values

number

[MAINT]

cursor

keys

in

the

keep

these

process

the

to

and

keep

Word

#8200

#8202#8202

Keep

for

memory

devices

the

switch

key

required

the

cursor

memory

Relays

used

are

before

procedure

NC

the

in

the

and

memory

keep

up/down

number.

Double-word

#8200

Keep

and

a

in

sequence

to

the

below.

“1”

running

indicted

unit

[SEQPRM]

number.

keys,

or

press

Memory

program,

program.

turn

and

function

the

cursor

necessary

it

is

the

power

soft-key.

up/down

E

to

ON.

keys

5-13

Page 38

0

Press

the

[INSRT]

key

or

the

cursor

right

key.

Cursor

Move

®

[WRITE]

Each

changed.

Data

mal

Example:

[INSRT]

the

time

entry

number

Key

[WRITE]

[0]

[WRITE]

[8]

[5]

[2]

key:

right

cursor

key.

[5]

The

key:

[WRITE]

the

by

numeric

column.

Writing

Operation

[WRITE]

PARAMETER

cursor

The

the

to

decimal

a

#7100

|

I

moves

cursor

for

bit

key

is

keys

7

6

0

0

0

0

1

1

0

0

0

0

00000000

0 0

0

0

00000000

00000000

:OFF

0

PARM~|

PARM

ISETTINGI

I

to

moves

which

is

pressed,

possible

number

Bit

00000000

00001000

11111111

MNT

4

5

0

0

0

0

1

1

i

0

0

0

0

0

0

DIAGN.

ISEOPRÿ

the

to

7

6

3:

0

0

1 1

0

0

0

0

TIME

decimal

the

data

the

ON/OFF

only

bit

for

3

5

4

O*****

2

0

0 0

0

0

0

0

0

1

:

I

P»ERRI

bit

when

data

2

1

0

1 1

0

0

0

0

ON

number

data

should

0

1

0

0

0

0

0

0 0

0

STP

I I

column.

be

status

cursor

the

N00000

0

8

255

0

0

0

0

0

LSK

T

(71

column.

changed

the

of

moved

is

Decimal

and

press

specified

to

the

Number

0

8

255

the

is

bit

deci¬

0

@

Repeat

Return

steps

the

@

and

system

to

©

number

5-14

write

switch

the

initial

to

“0”.

values

for

the

necessary

addresses.

Page 39

ea

6

Chapter

types

61

tions.

bols.

6.1

6.2

6.3

6.4

describes

6

basic

of

Explanation

The

list

BASICS

TYPES

INSTRUCTIONS

RELAY

TIMER

PLC

instructions

coded

of

OF

AND

INSTRUCTIONS

PLC

instructions.

and

for

the

instructions

INSTRUCTIONS

OF

is

PLC

the

given

LIST

....

INSTRUCTIONS

INSTRUCTIONS

11

types

functions

is

also

The

macro

of

and

given.

can

PLC

display

use

instruc¬

sym¬

6-2

6-3

6-8

6-15

REGISTER

6.5

CONTROL

6.6

MACRO

6.7

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

i

\

6-1

6-17

6-41

6-44

Page 40

6.1

BASICS

OF

PLC

INSTRUCTIONS

(13)

(14)

Registers

PLC

The

program

Contact

Result

This

Setting

the

It

is

the

using

are

status

Register

one-bit

is

a

the

contents

also

possible

contents

the

Saving

has

saved.

the

registers

Configuration

Intermediate

where

The

result

_

I

|~RR][STO|ST1

status

of

of

STR

—

/U

L

STR.STR-NOT

(RR)

register

(0or1)

to

RR

to

shift

the

stack

or

AND-STR

\J

KJ

AND-STR,

where

of

relay

the

the

register

intermediate

the

of

operation

of

register

Stack

[

ST3

ST2

1

V_>

KJ

KJ

OR-STR

instruction,

result

the

contact

to

address

contents

RR

to

instruction.

Results

these

presently

ST4|sT5|

1

KJ

instruction,

etc.

RR

by

of

RR

by

results

registers

bits)

(1

6

KJ

of

presently

using

by

using

the

to

bit

one

during

516ÿ1

etc.

of

is

executed

Logical

logical

“1

is

operation

bit

+

saved

Operation

16

bits”.

).

or

(0

1

in

a

_

STISISTHIST-ISI

V_>

W

executed

the

LD

instruction

the

stack

after

OUT

register

the

instruction

completion

“O'

operation

and

are

by

bit

one

of

operation

is

outputting

possible.

or

sequence

set.

to

shift

by

(15)

Stack

When

the

to

The

STR

data

The

STO

bit.

STR

tions

error

an

and

the

register

executing

register

stack

and

STR-NOT

in

stack

the

AND-STR

RR,

and

After

and

must

set

the

execution

STR-NOT

the

be

occurs.

number

to

(STO

a

logical

long

by

up

registers

and

OR-STR

result

the

instructions,

same

during

other

In

data

fetching

of

ST15)

operation,

bits.

16

to

instructions

right

the

to

instructions

and

to

RR

instructions,

these

of

and

execution

the

words,

the

times

it

the

move

one

by

execute

the

shift

number

the

of

number

from

possible

is

data

bit.

data

“0”

is

of

series

a

data

of

stack

the

save

to

RR

to

in

the

operation

in

stack

for

set

ST15.

AND-STR

logical

of

saving

register

the

intermediate

and,

STO

between

register

Both

and

operations

times

to

must

sequentially,

the

the

to

left

number

the

OR-STR

the

the

be

instruc¬

Otherwise,

.

stack

register

same.

result

data

by

one

the

in

of

6-2

Page 41

6.2

TYPES

AND

UST

INSTRUCTIONS

OF

6.2

TYPES

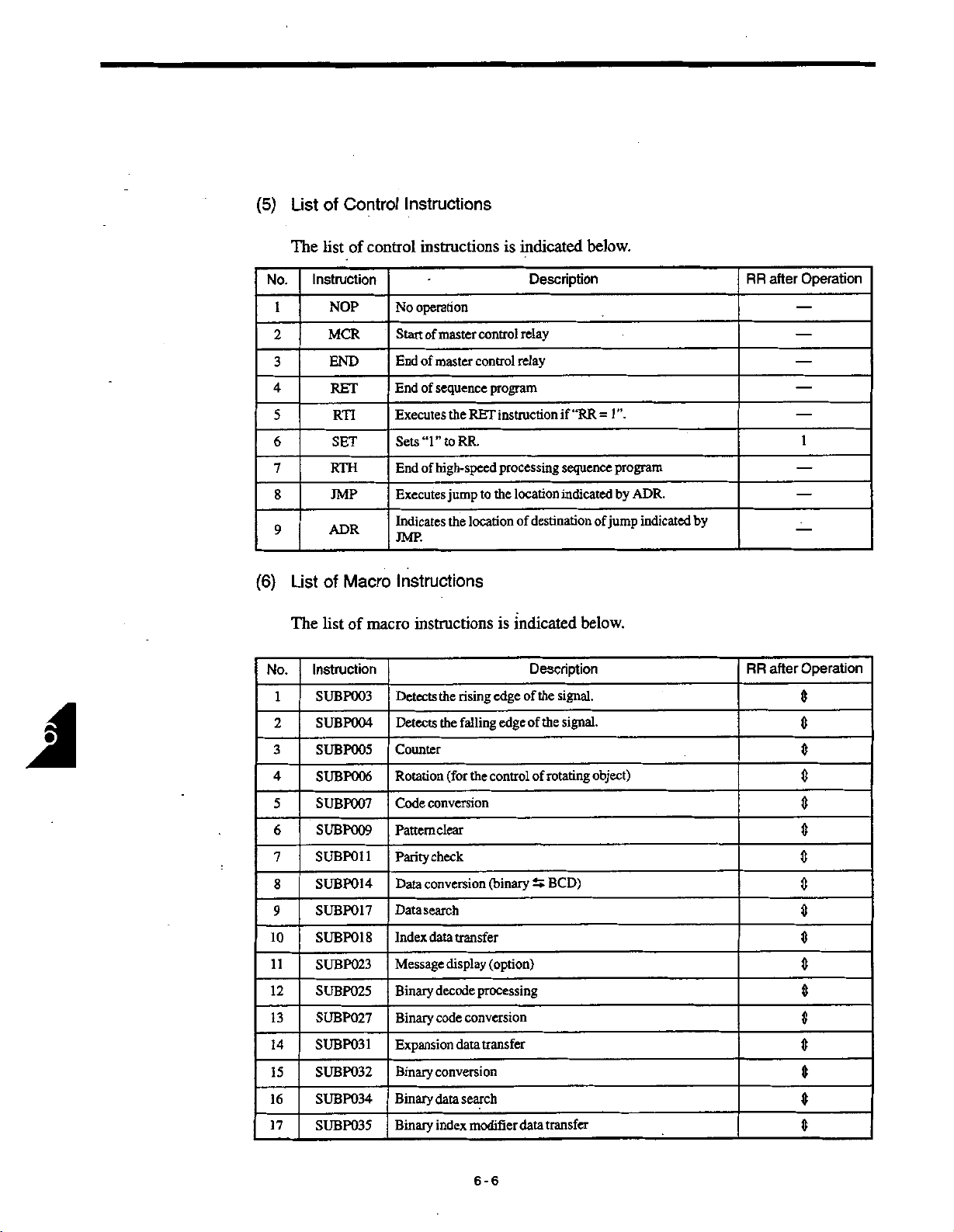

(1)

(a)

(b)

(2)

No.

10

11

12

13

AND

Types

With

Basic

Relay

Register

Timer

Control

Macro

Macro

Auxiliary

List

The

1

2

3

4

5

6

7

8

9

LIST

Instructions

of

PLC,

the

instructions

instruction:

instruction:

instruction:

instruction:

instructions

instruction:

instruction:

Relay

of

list

relay

of

Instruction

LD

LD-NOT

AND

AND-NOT

OR

OR-NOT

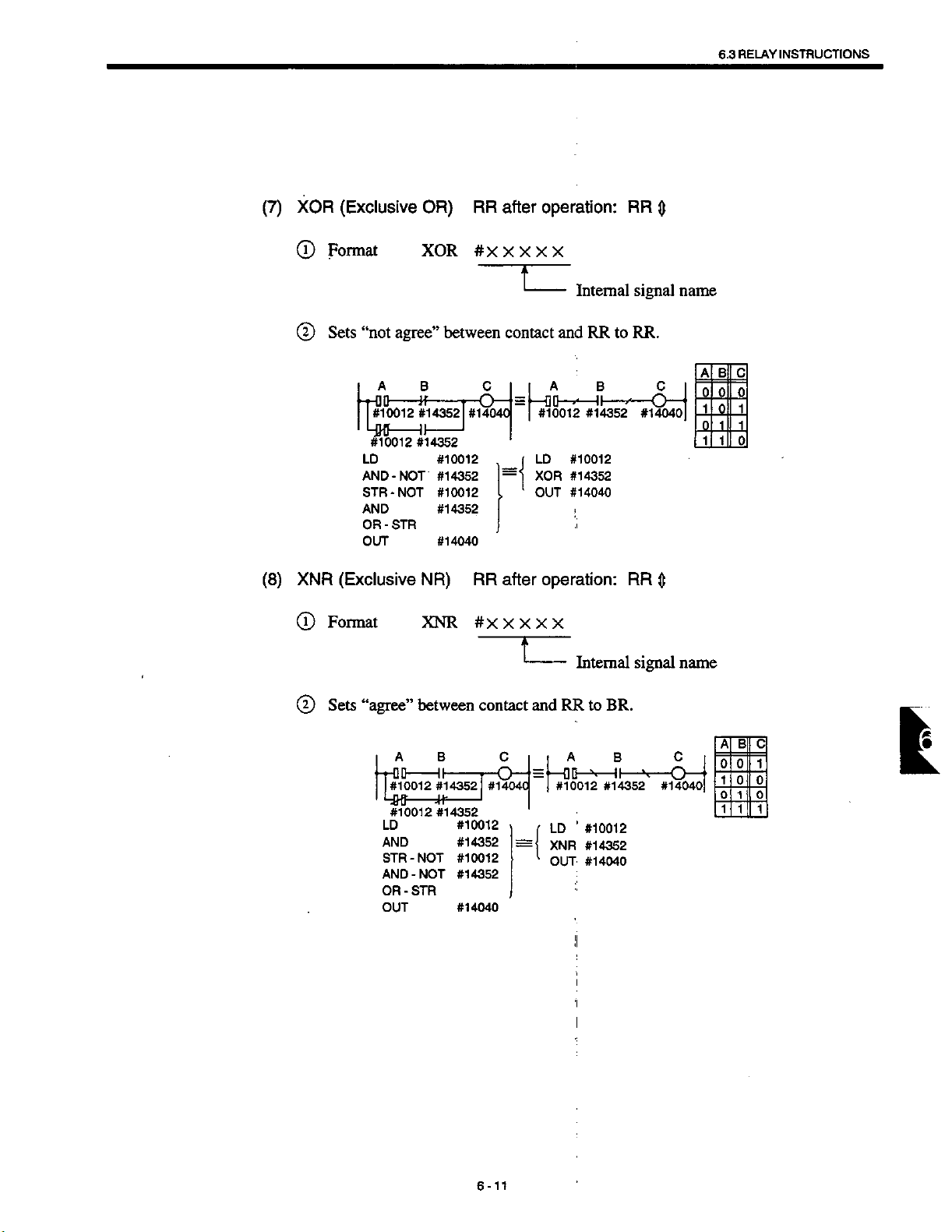

XOR

XNR

STR

STR-NOT

AND-STR

OR-STR

OUT

INSTRUCTIONS

OF

following

the

13

37

2

9

22

5

types

types

types

types

types

types

types

Instructions

is

instructions

Reads

Reads

Executes

result

Executes

RR,

Executes

toRR.

Executes

and

Sets

Sets

Enters

the

Enters

the

Executes

the

Executes

result

Writes

signal

the

the

inversion

AND

to

RR.

AND

and

sets

OR

(Logical

OR

the

sets

“not-coincide”

“coincide”

content

the

LD

instruction.

the

content

LD-NOT

AND

result

to

OR

RR.

to

result

the

indicated

(0,

status

signal

of

between

(Logical

the

between

between

result

instruction.

RR.

betweenRRand

product)

between

result

to

the

sum)

the

RR.

to

between

between

of

RR

of

RR

between

operation

of

of

instructions

Total

below.

Description

1)

and

sets

status

the

contact

the

inversion

(Reverse

RR.

and

contact

inversion

(Reverse

the

to

to

RR

the

signal

the

the

and

(RR)

signal

stack

stack

the

the

logical

and

stack

to

61

to

it

(0,

1)

RR,

and

signal

of

logical

RR,

of

signal

and

RRtoRR.

register

register

stack

register

the

are

types

RR.

and

sets

and

status

product)

and

sets

status

sum)

RRtoRR.

and

and

register

(address).

relay

provided.

RR.

to

it

the

sets

and

the

result

RR,

and

executes

executes

and

sets

sets

the

and

RR

after

Operation

0

*

0

0

0

t

0

0

0

0

0

$

*

Note:

Symbol

The

0

The

—

the

in

content

content

column

of

RR

of

“RR

of

changes

RR

does

after

before

not

Operation”

and

after

change

before

6-3

operation

the

or

after

of

the

instruction.

an

operation

an

of

instruction.

Page 42

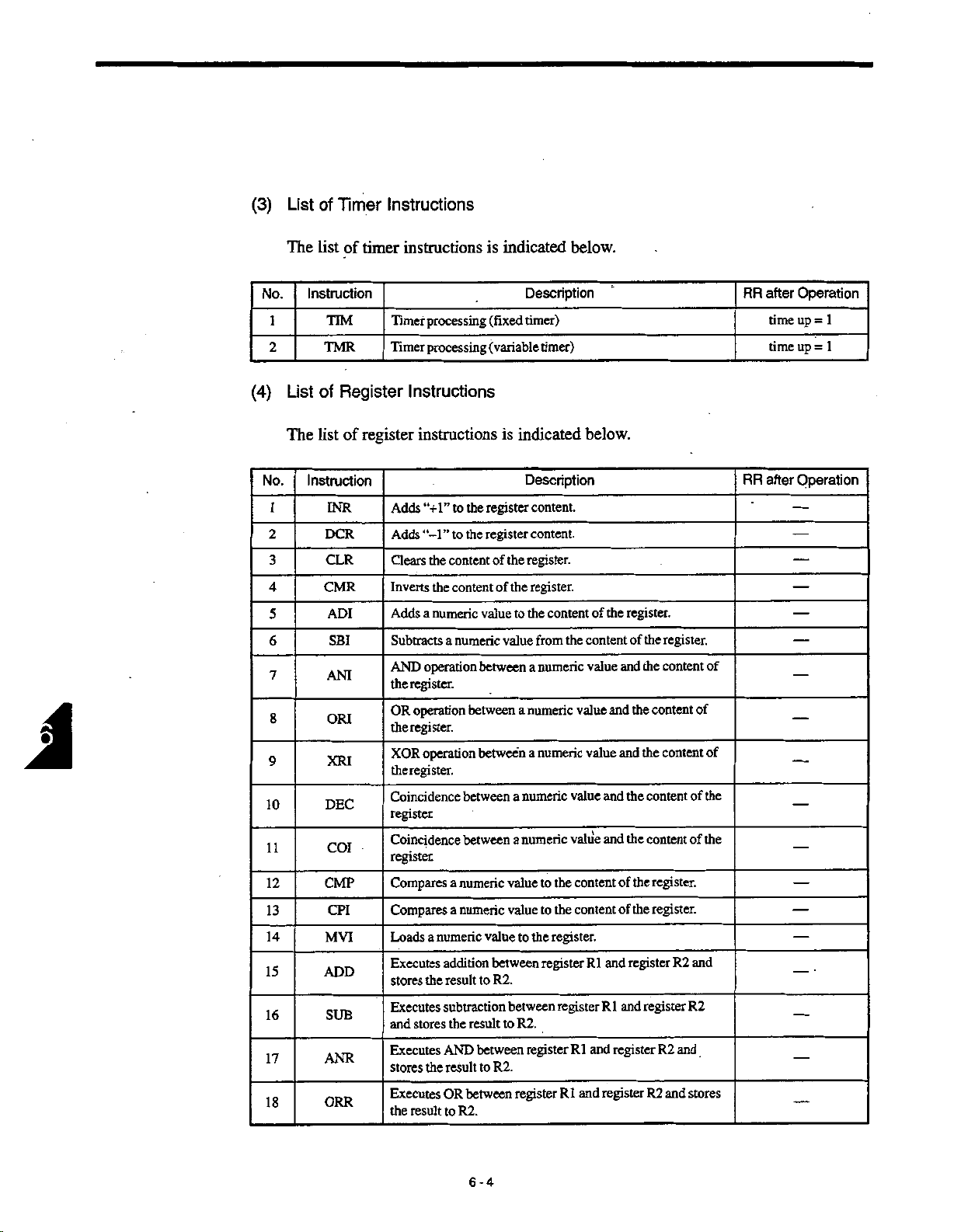

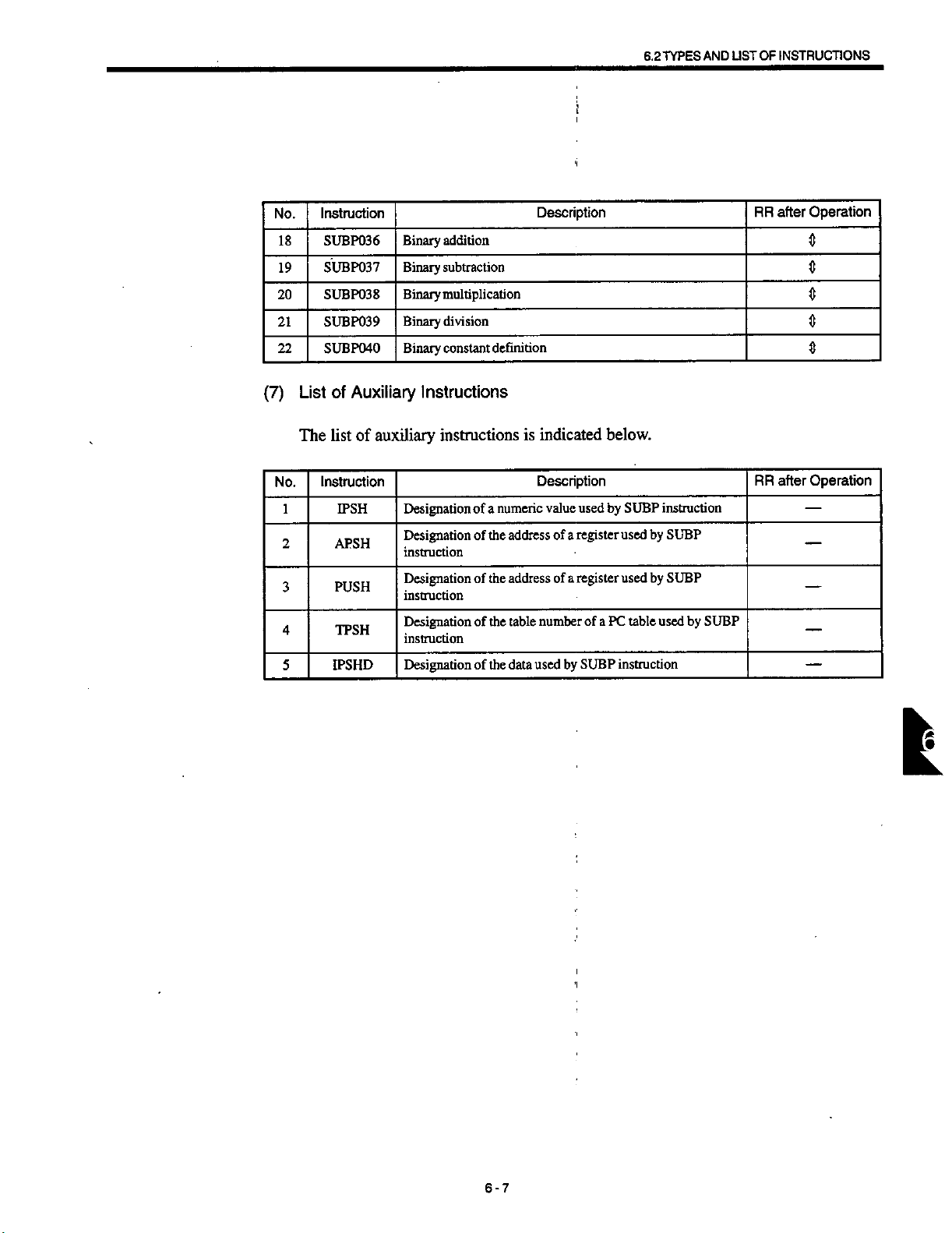

(3)

List

of

Timer

Instructions

(4)

No.

1

2

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

The

List

Instruction

TMR

of

List

The

list

Instruction

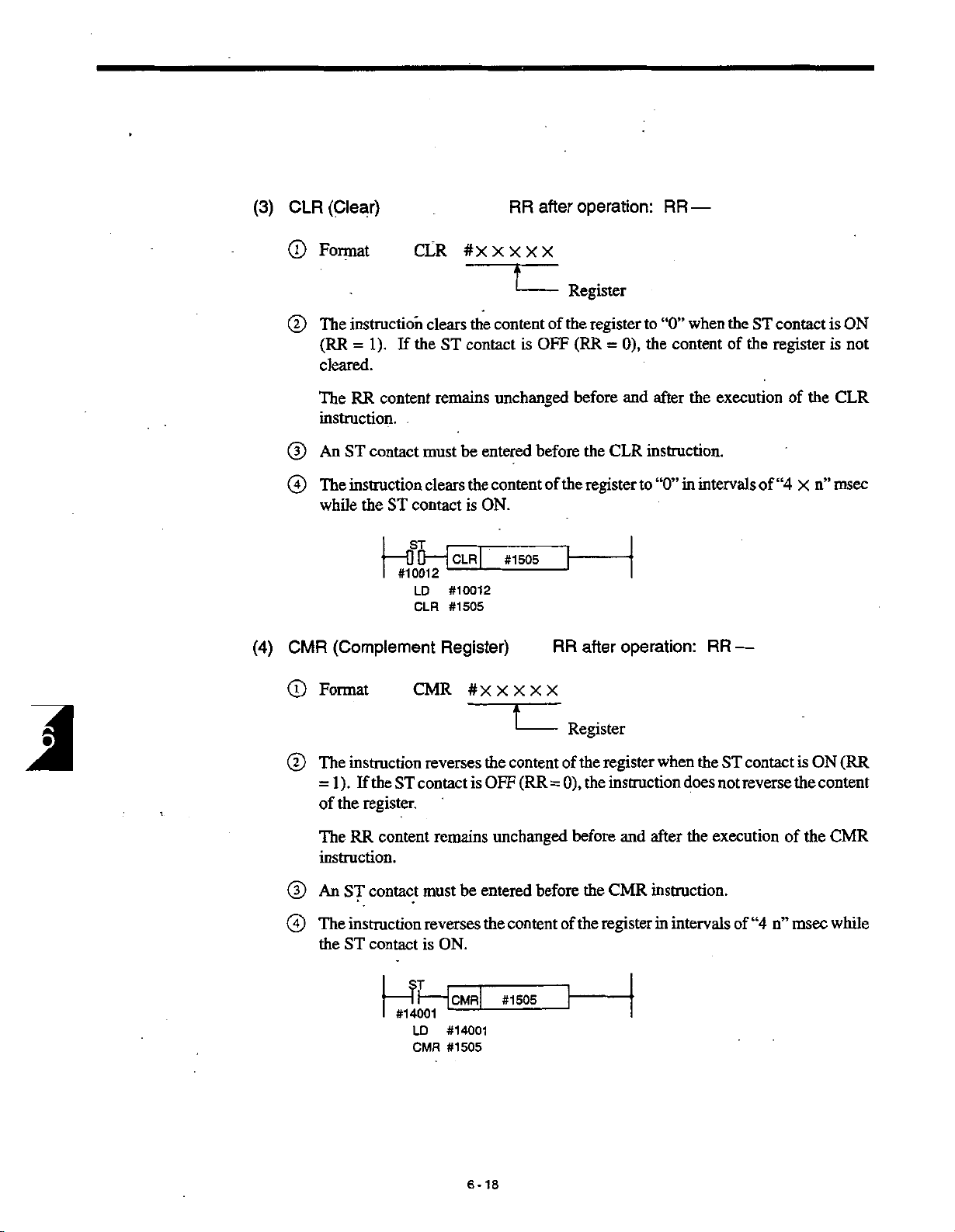

CMR

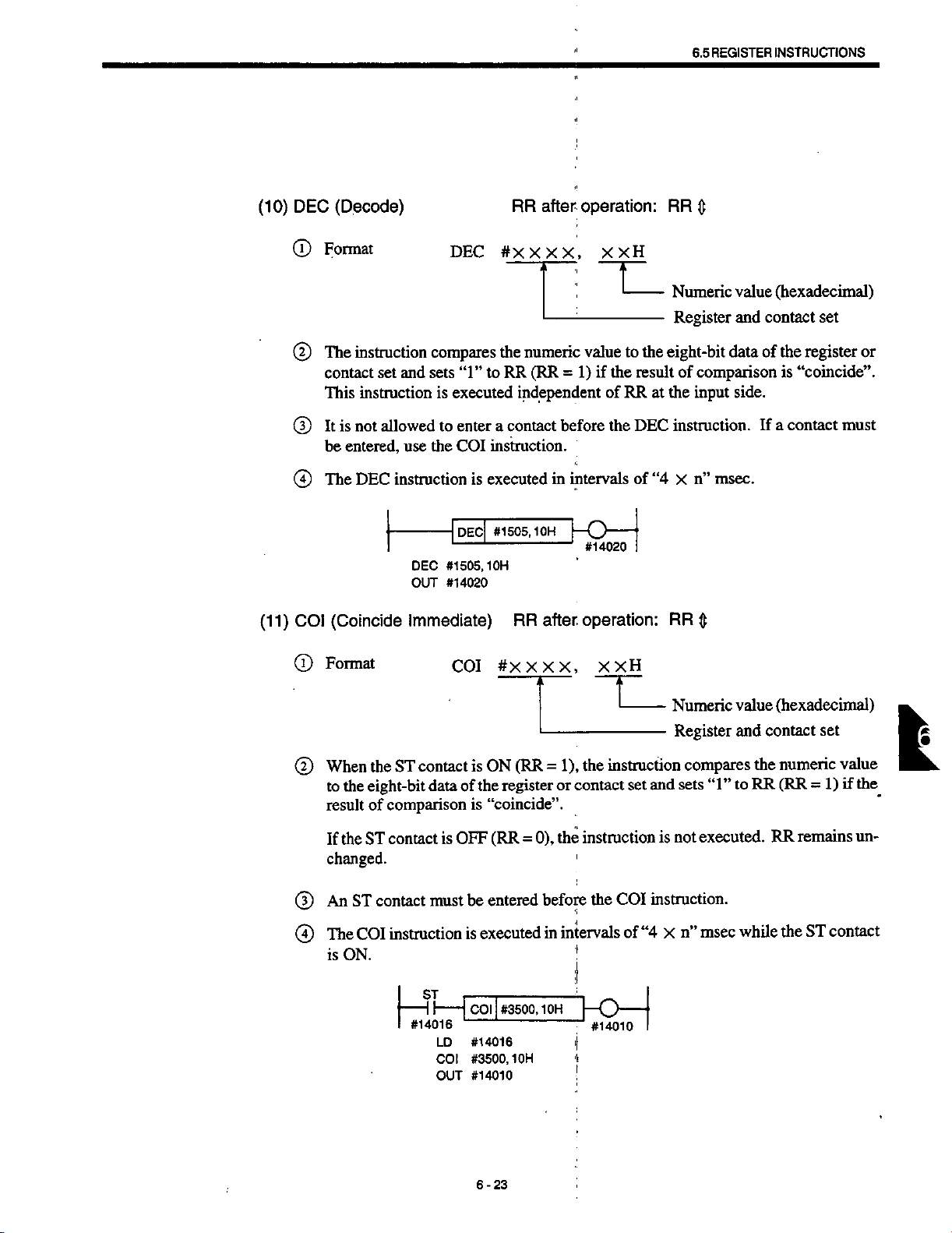

DEC

CMP

MVI

ADD

ORR

of

timer

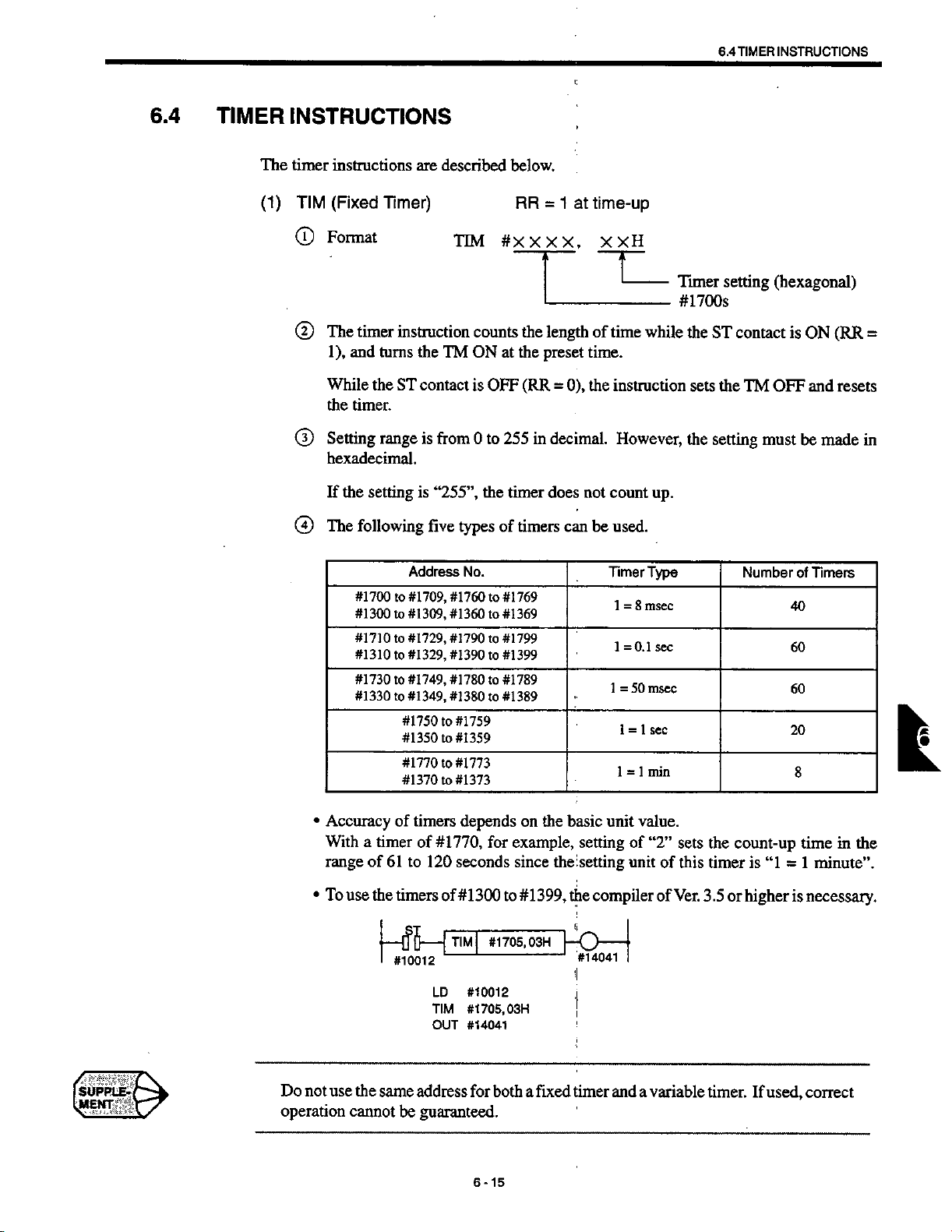

TIM

Register

of

register

INR

OCR

CLR

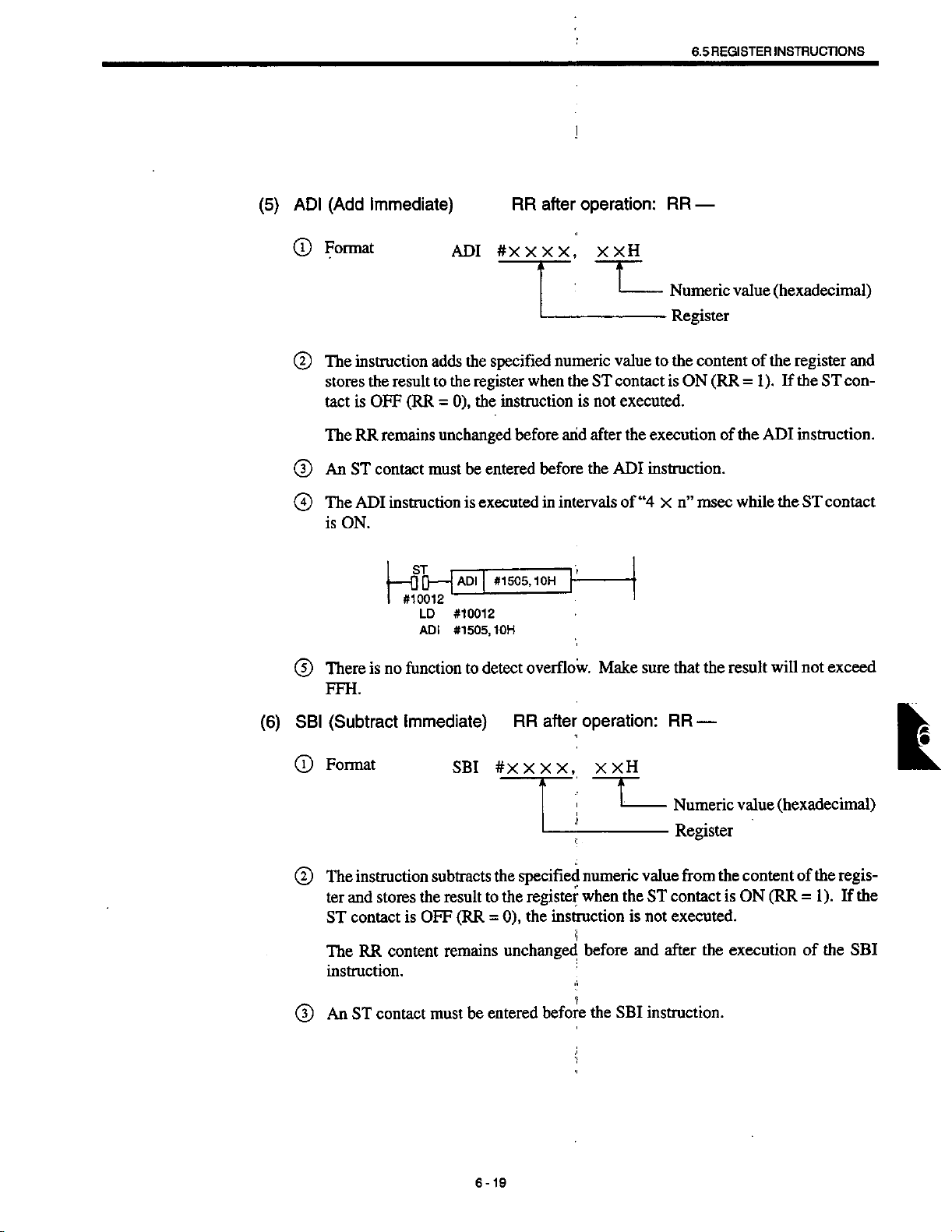

ADI

SBI

ANI

ORI

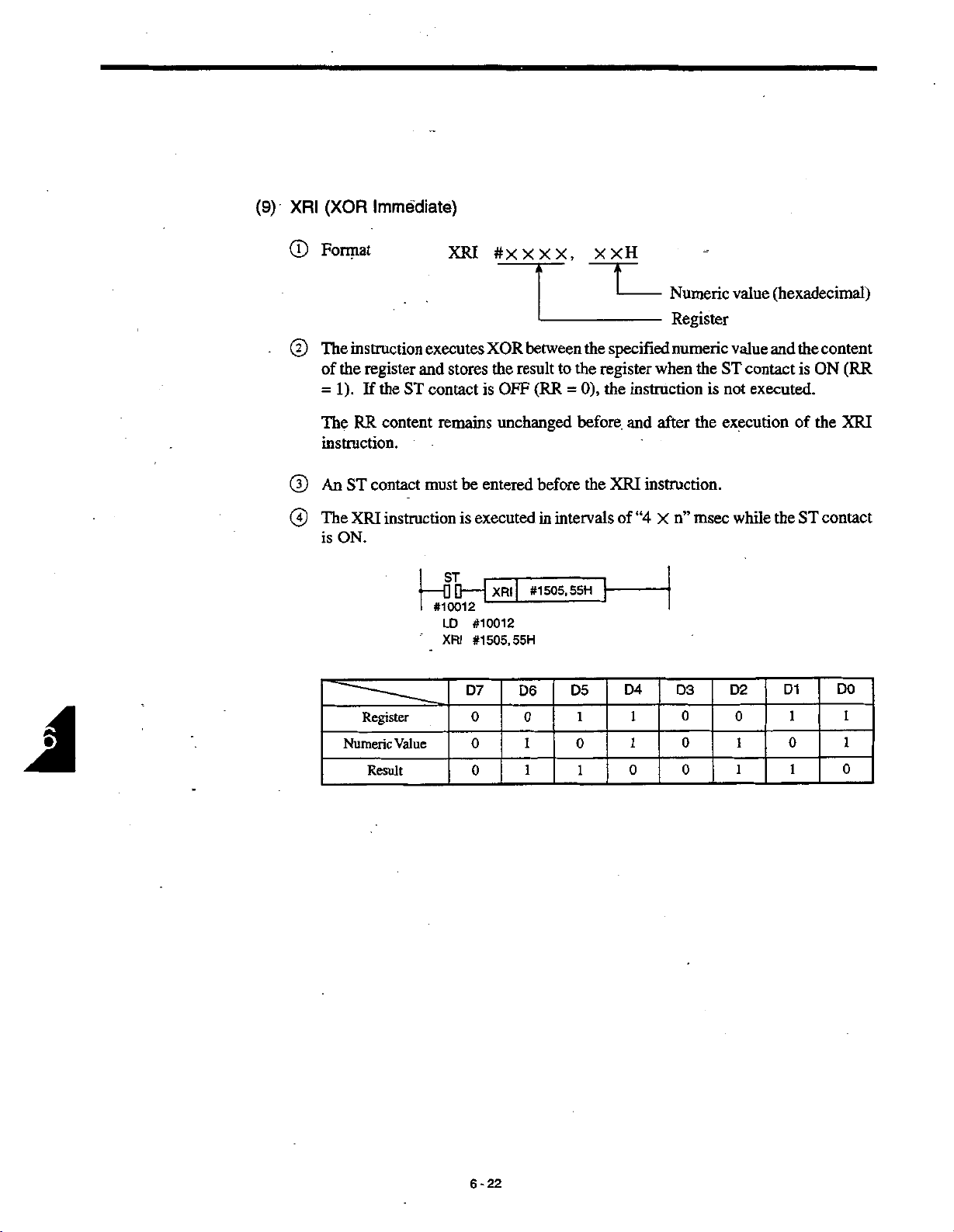

XRI

COI

CPI

SUB

ANR

instructions

processing

Timer

Timer

processing

Instructions

instructions

the

to

“+1”

Adds

the

to

“-1

Adds

Clears

Inverts

Addsanumeric

Subtracts

AND

the

OR

the

XOR

theregister.

Coincidence

register

Coincidence

register

Compares

Compares

Loadsanumeric

Executes

stores

Executes

and

Executes

stores

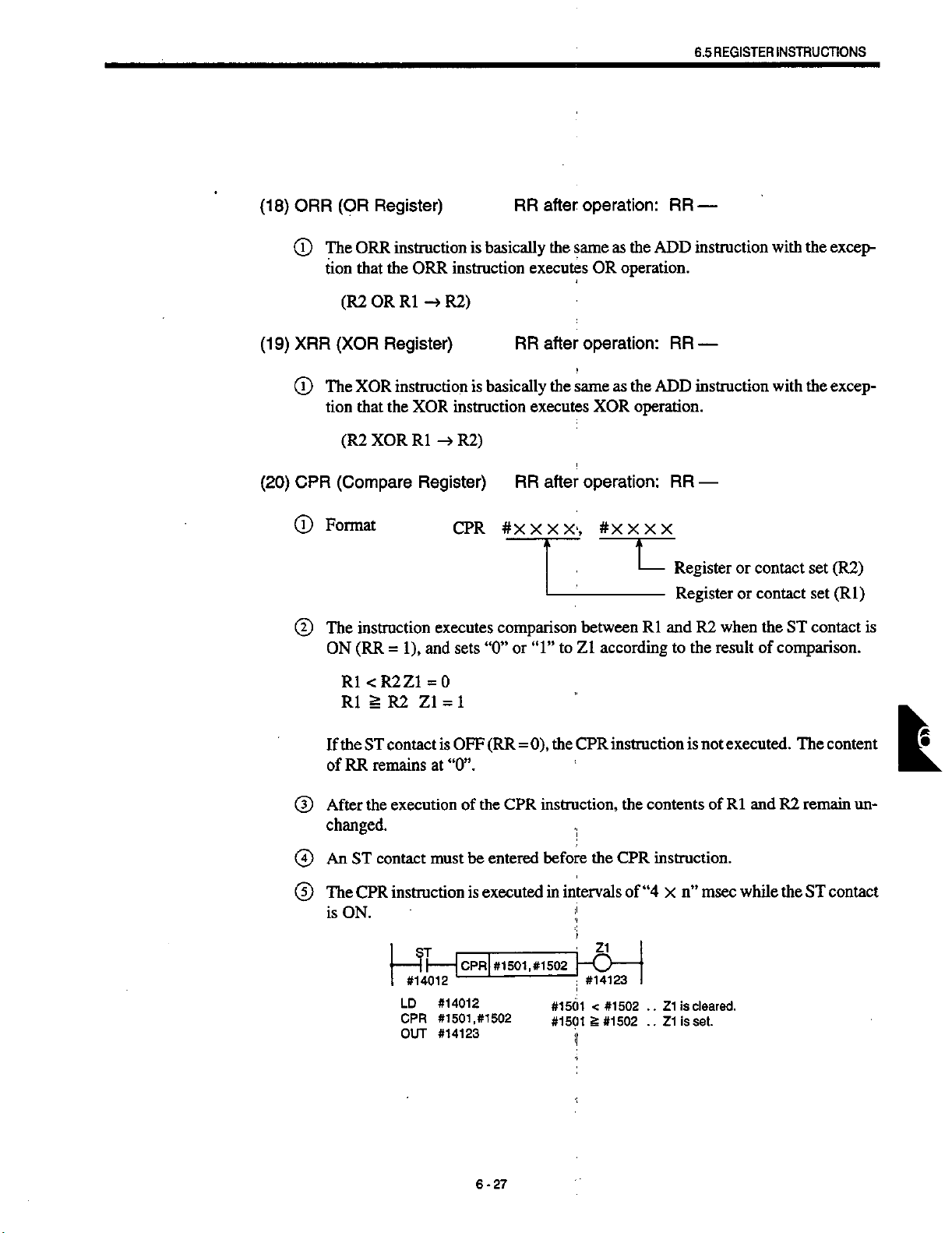

Executes

the

”

the

content

the

a

operation

register.

operation

register.

operation

a

a

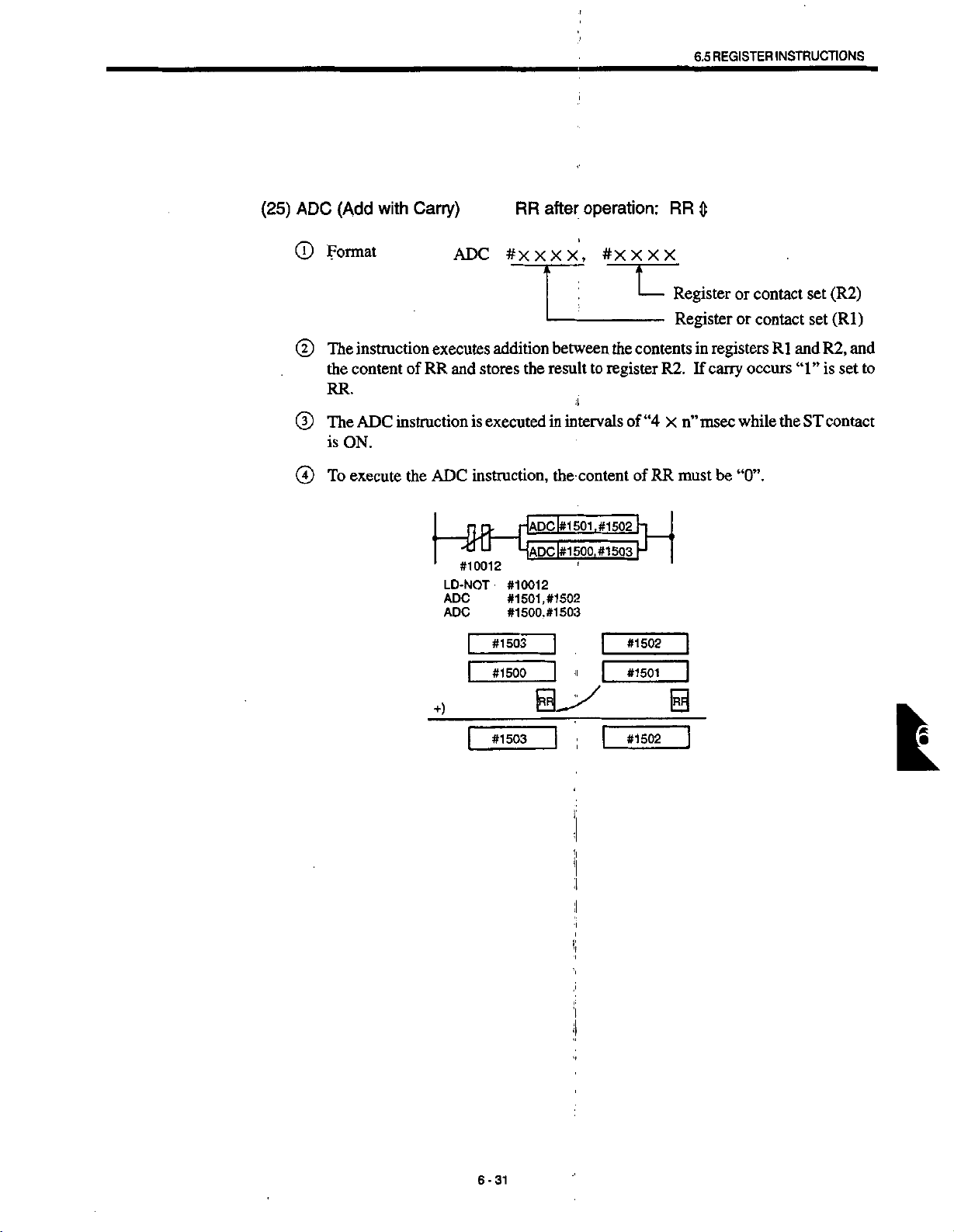

addition

result

the

subtraction

the

stores

AND

the

result

OR

result

to

content

numeric

between

between

between

numeric

numeric

result

between

R2.

is

indicated

(fixed

(variable

indicated

is

register

register

the

of

the

of

value

to

value

between

a

between

a

a

value

value

valuetothe

between

R2.

to

between

to

R2.

between

to

R2.

register

below.

Description

timer)

timer)

Description

content.

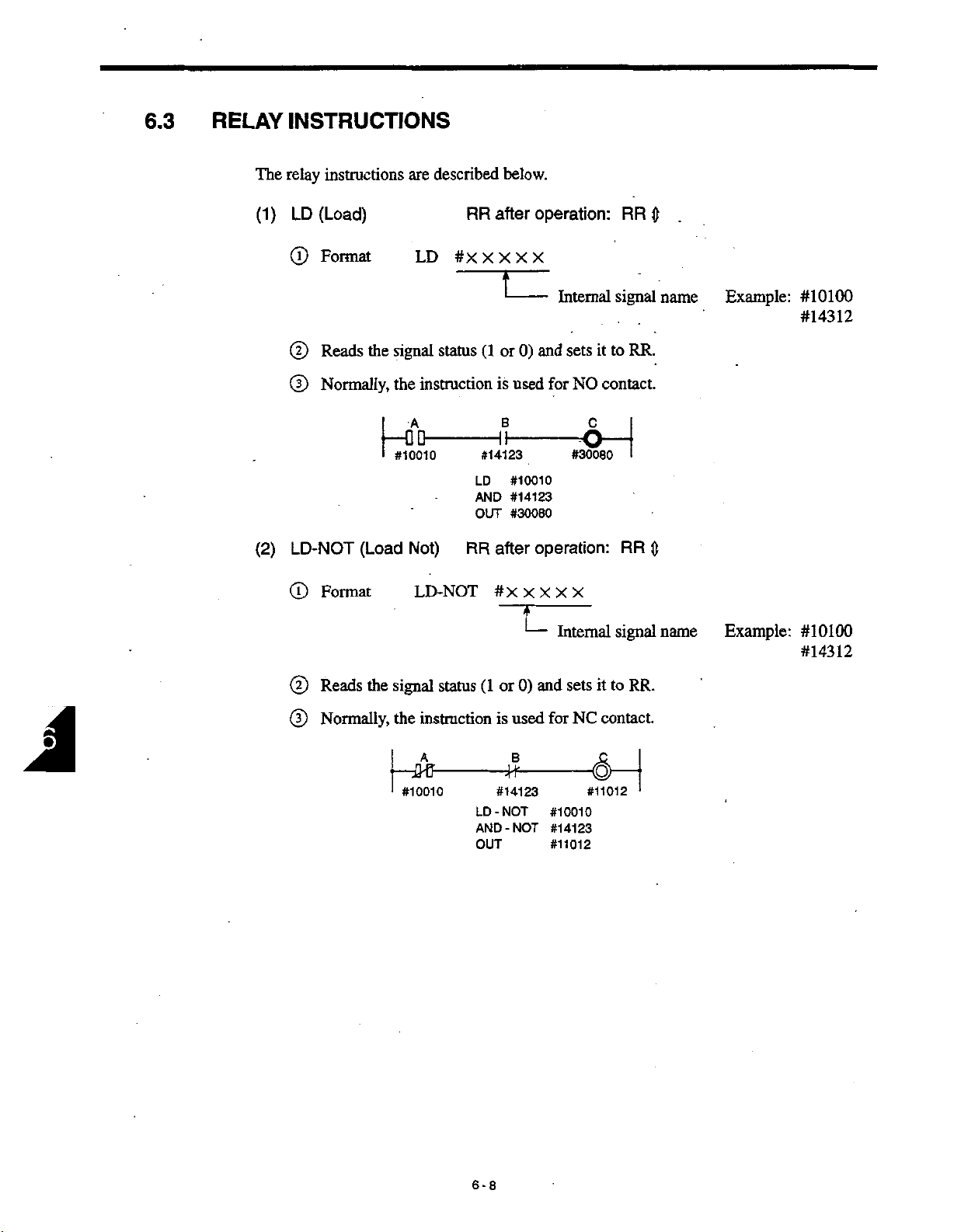

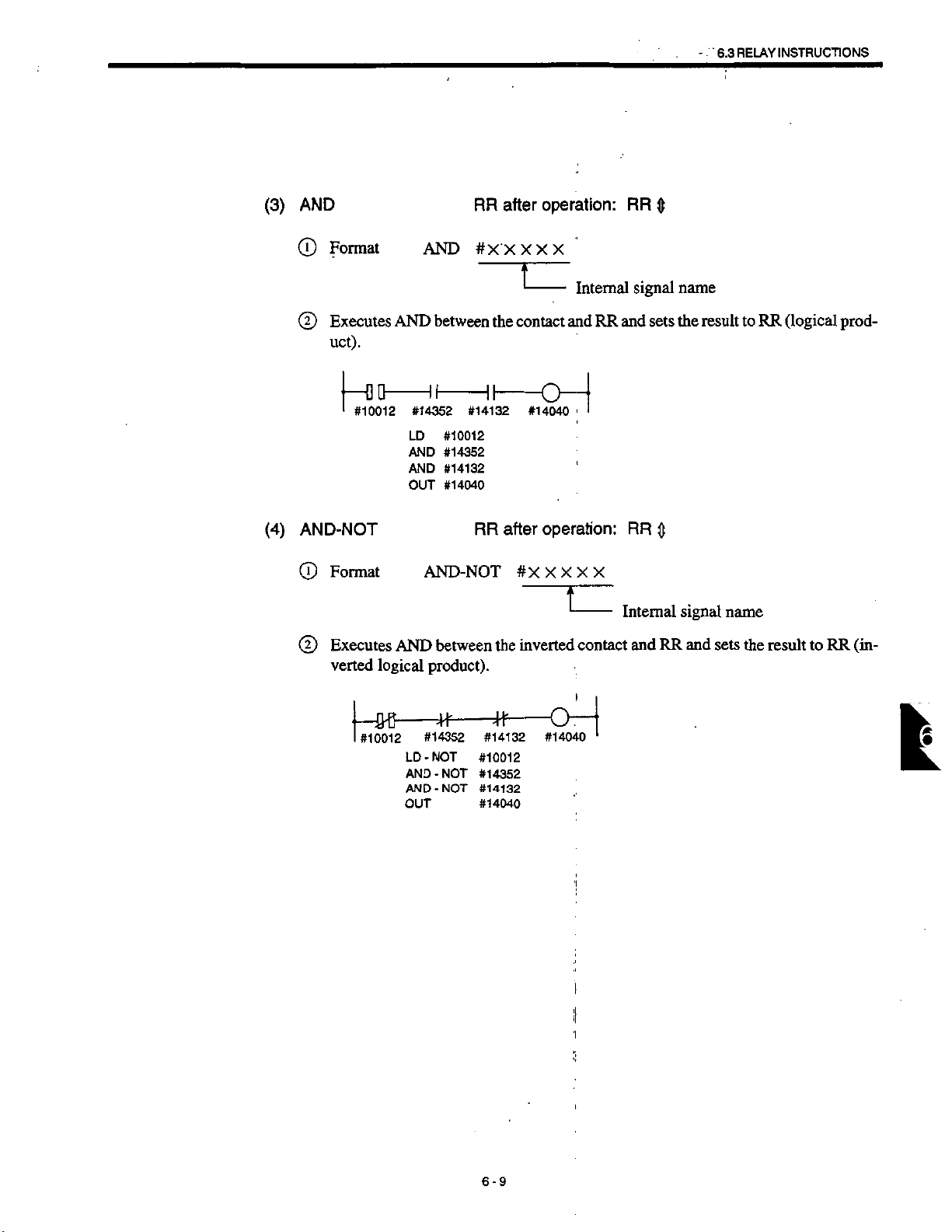

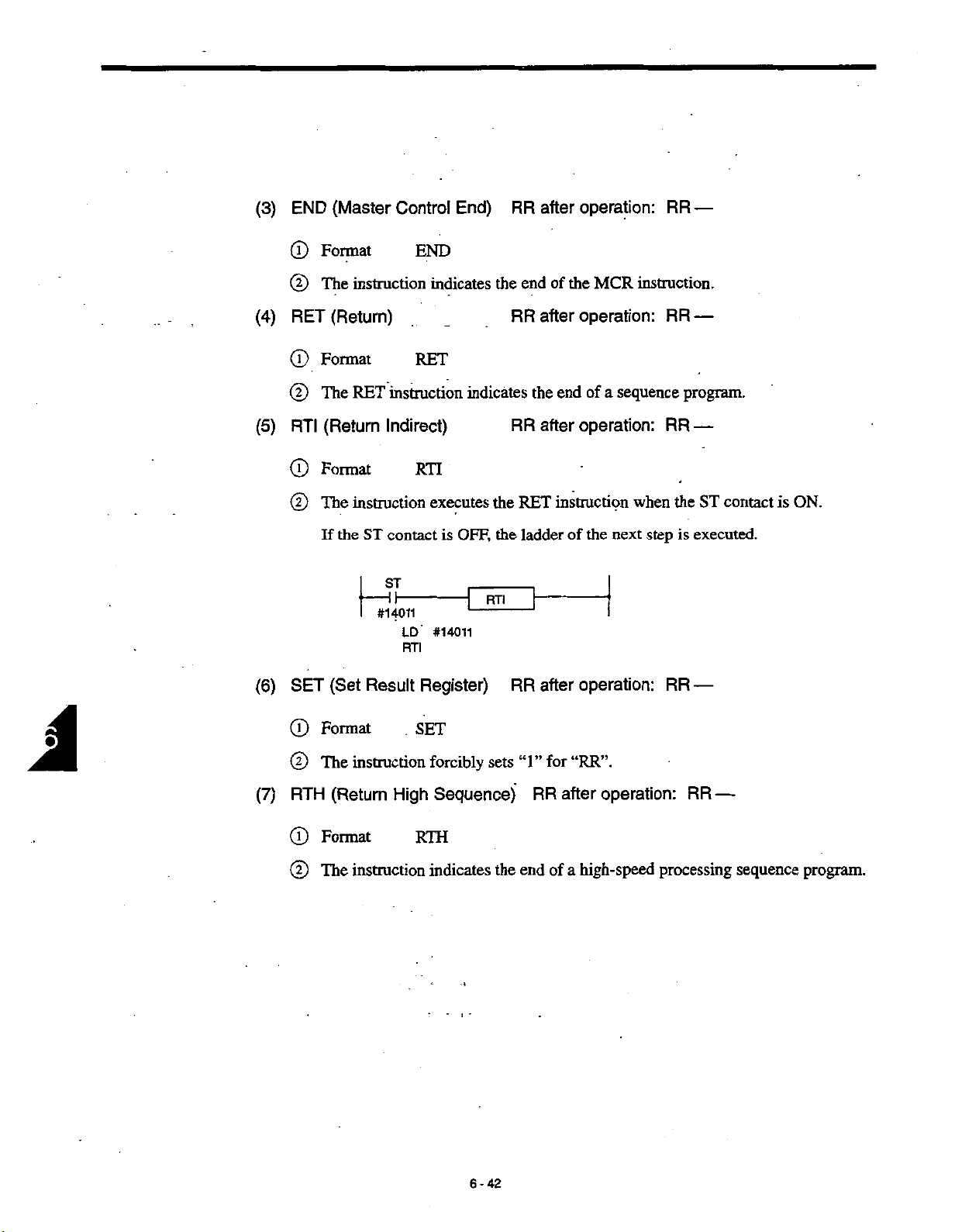

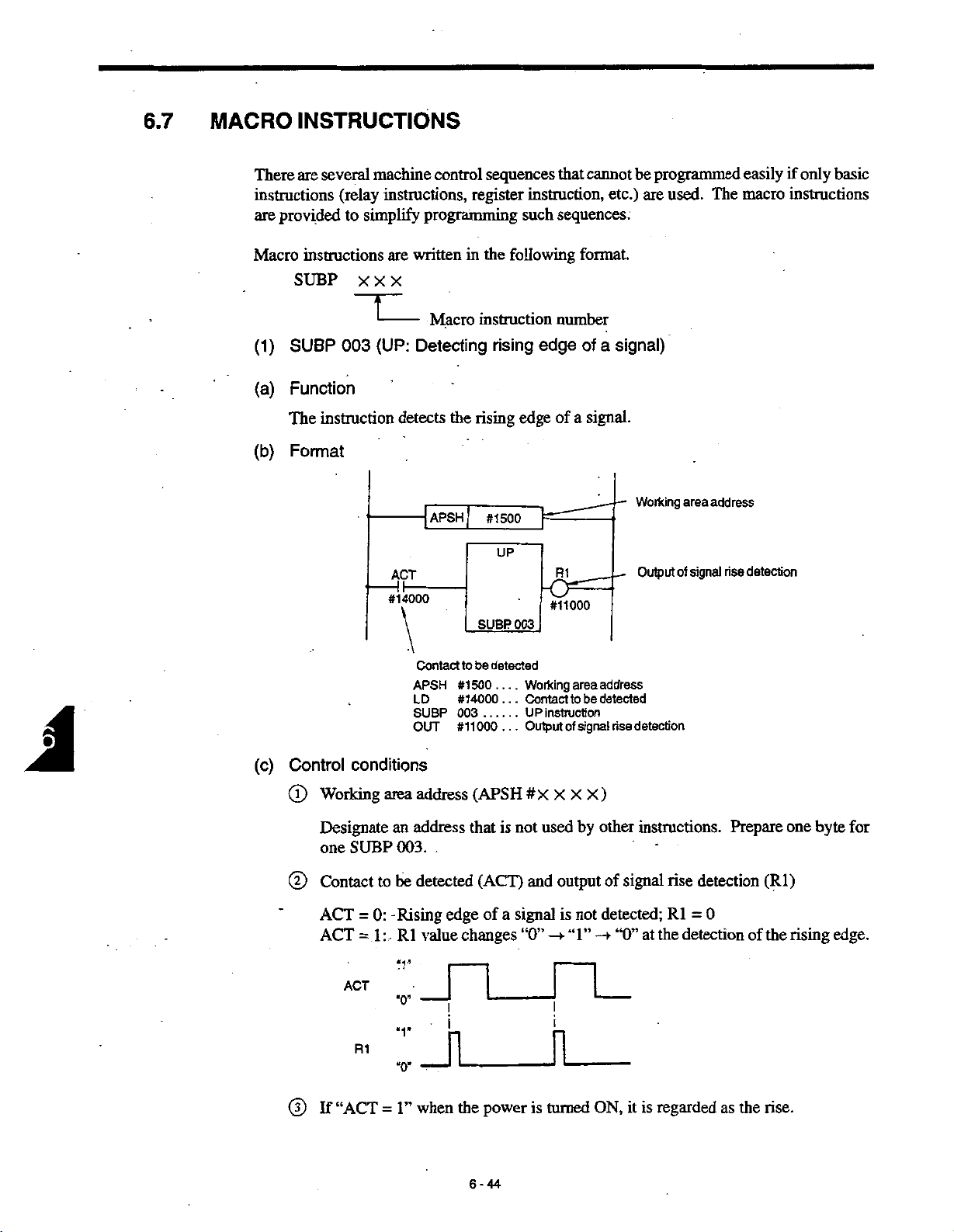

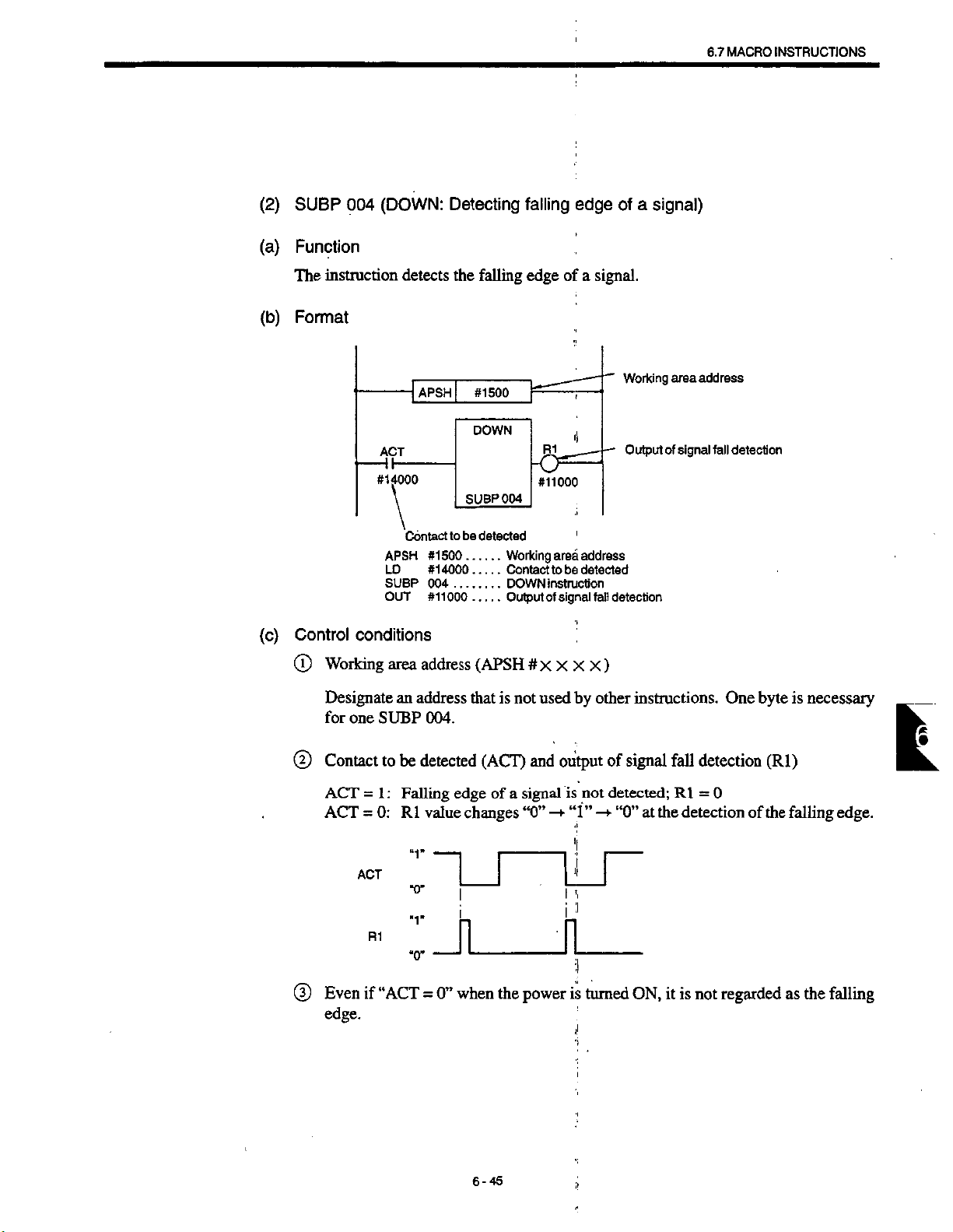

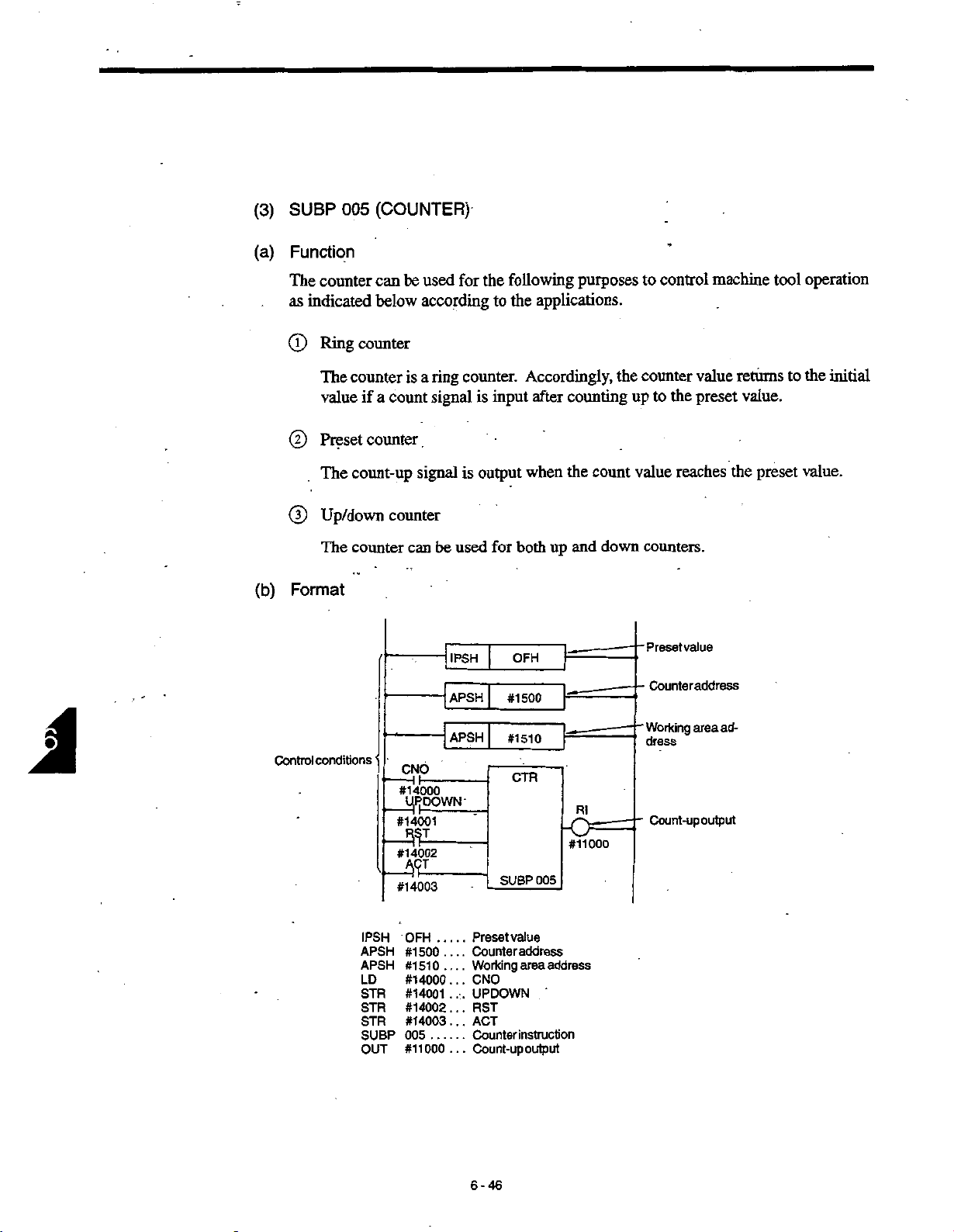

content.