Page 1

GPD 515/G5 Modbus

®

RTU

Technical Manual

Page 2

Technical References

Refer to the following publications for further information about the GPD 515/G5:

• GPD 515/G5 Technical Manual

Publication TM 4515

• GPD 515/G5 RS-232C/485 Interface Card Installation Sheet

Publication 02Y00025-0401

Refer to the following Modicon publication for technical information on Modbus RTU protocol:

• Modicon Modbus Protocol Reference Guide

Publication PI-MBUS-300 Rev. D

Technical Support

Technical Support Center-

Provide telephone assistance related to installation, start-up, programming, and

troubleshooting drives and communication products. For technical phone support

call 1-800-541-0939.

Technical References / Technical Support i

Page 3

CONTENTS

Technical References / Technical Support i

Contents 1

Chapter 1 GPD 515/G5 and Serial Communication 1-1

Introduction to GPD 515 Modbus RTU Communication 1-2

Standard RS-232D Serial Communication 1-2

The RS-232D to RS-485 Converter Board 1-3

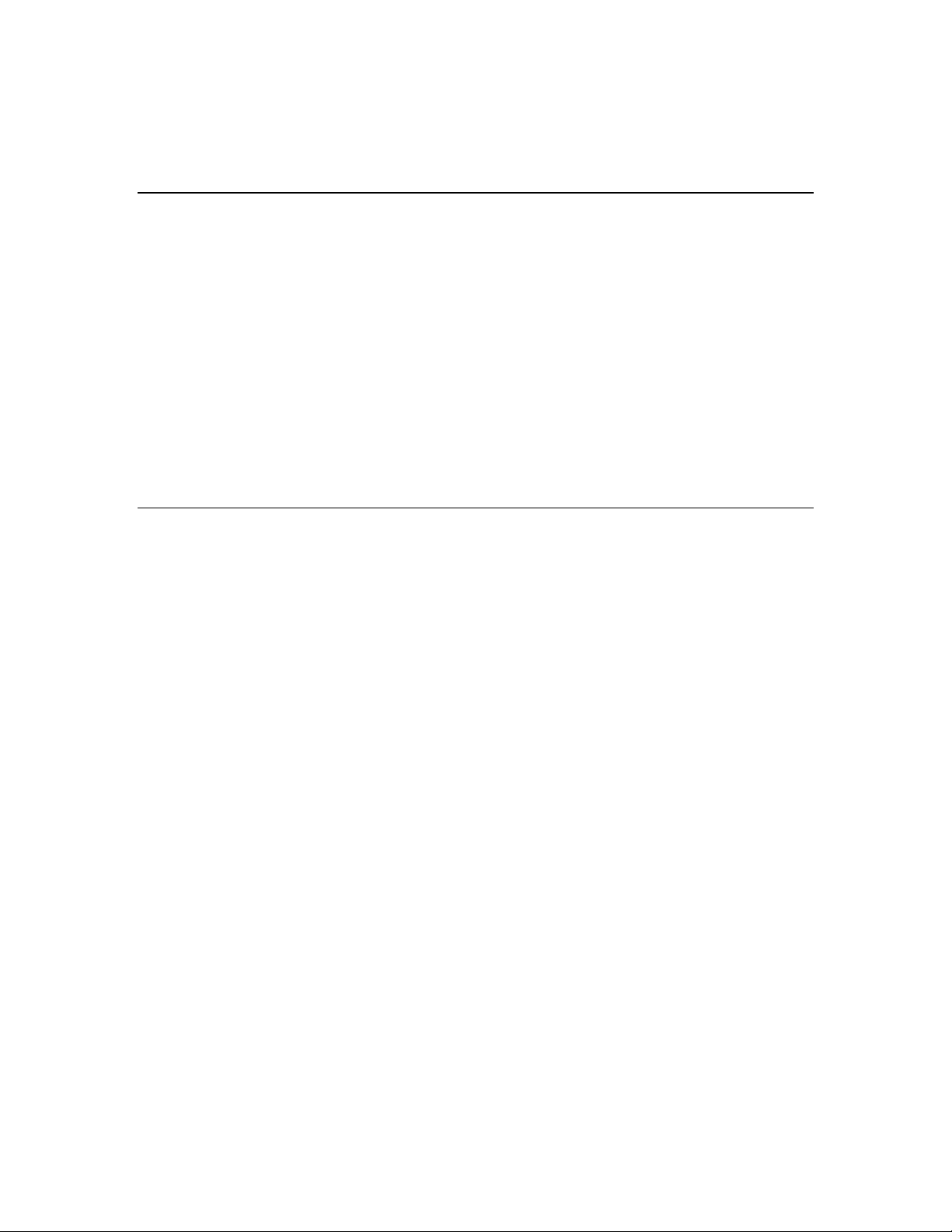

Figure 1-1. The CM085 Board 1-3

Chapter 2 RS-232D Serial Communication 2-1

RS-232D Serial Communication 2-2

Figure 2-1. RS-232D Pin-out at 6CN Connector 2-2

Chapter 3 Installation of CM085 Board 3-1

Installation Procedure 3-2

Figure 3-1. Position of the CM085 Board

on the GPD 515 Drive 3-2

Chapter 4 Wiring of the CM085 Board 4-1

Connection of Multiple Drives 4-2

Figure 4-1. Interconnection Diagram 4-2

Wiring Instructions 4-3

Figure 4-2. Twisted Shielded Wire Termination 4-3

Table 4-1. Functions of Terminal Block TC1 4-3

Table 4-2. Applicable Wire Sizes for Terminal Block TC1 4-3

Terminating Resistors 4-4

Figure 4-3. SW1 Location on the CM085 Board 4-4

Chapter 5 Setting GPD 515 Parameters for Communication 5-1

Run/Stop and Frequency Selection 5-2

Communication Set up Parameters 5-3

“ENTER” Command 5-5

Chapter 6 The Message Format 6-1

Message Functions 6-2

Read Multiple Registers - 03h 6-3

Loop-back Test - 08h 6-6

Write Multiple Registers - 10h 6-8

No Response Message 6-11

CRC-16 6-11

Chapter 7 Registers 7-1

Simultaneous Broadcast Registers 7-2

Command Registers 7-3

Monitor Registers 7-4

Drive Parameter Registers 7-7

Special Registers 7-17

Contents 1

Page 4

Chapter 8 Error Codes and Troubleshooting 8-1

Communication Error (CE) 8-2

Modbus Error Codes 8-2

Figure 8-1. Response Message (Fault) 8-2

GPD Failure Codes 8-3

Chapter 9 Command Priority 9-1

Command Priority 9-2

Table 9-1. Set up for Serial Communication Control 9-3

Table 9-2. Set up for External Terminals Control 9-4

Table 9-3. Set up for Digital Operator Control 9-5

Table 9-4. Set up for Option Board Control 9-6

Appendix A Product Specifications A-1

Appendix B Spare Parts List B-1

Contents 2

Page 5

Chapter 1

GPD 515/G5 and Serial Communication

• Introduction to GPD 515/G5 Modbus RTU Communication

• Standard RS-232D Serial Communication

• Figure 1-1. The CM085 Board

Note: The AC Drive referenced in this manual may be named GPD

515, G5, or GPD 515/G5. These are physically the same drive. This

manual will use the name GPD 515 hereafter.

• The RS-232D to RS-485 Converter Board

GPD 515 and Serial Communication 1-1

Page 6

Introduction to GPD 515 Modbus RTU Communication

This manual describes the set-up and protocol for Modbus Communication. The GPD 515 offers

RS-232D serial communication as a standard, and RS-485 as an option.

The Modbus RTU protocol requires that the controller communicates using a master-slave

technique, in which only one device (the master) can initiate transactions. The other devices (the

slaves) respond by supplying the requested data to the master, or by taking the action requested.

The GPD 515 drive must act in the slave mode.

A complete understanding of drive programming and operation is required before attempting

serial communication operation. A full discussion of programming and operation is covered in the

GPD 515 technical manual TM 4515.

GPD 515 / Modbus RTU Specifications

The data that may be sent or received from the drive consists of:

-Run Command

-Frequency Reference

-Fault Contents

-Drive Status

-Drive Parameter Settings

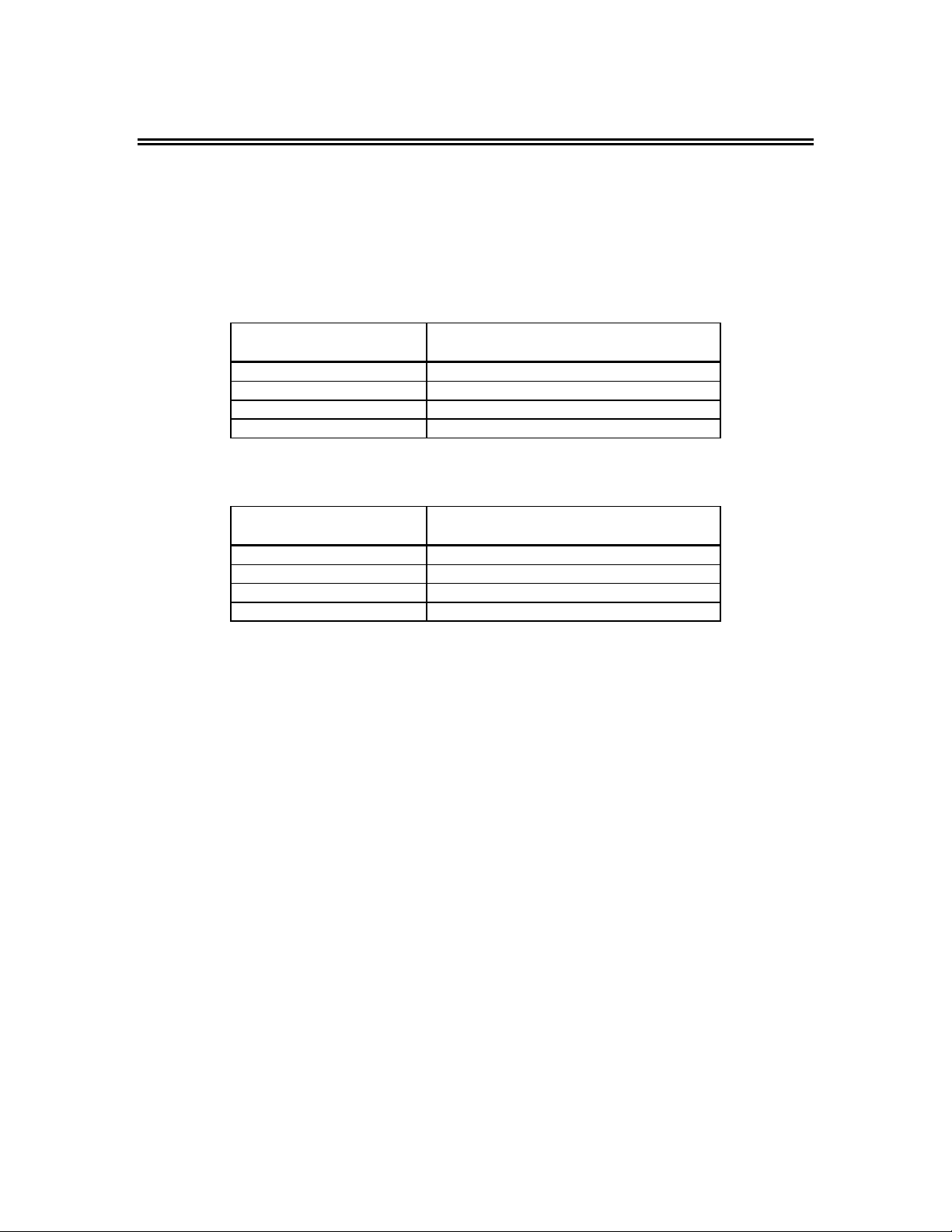

The following table illustrates whether the serial communication specifications are fixed or user

selectable. If the specification is fixed, the fixed value is shown in the last column. If the

specification is selectable, the range of allowed values is shown in the last column.

Communication Specification Fixed or Selectable Range

Baud Rate Selectable 2400, 4800, or 9600 bps

Data Bit Fixed 8

Parity Selectable None, Even, or Odd

Stop Bit Fixed 1

Nodes RS-232D point-to-point only

Nodes Selectable for RS-485 maximum of 31 nodes

Standard RS-232D Serial Communication

The GPD 515 drive offers RS-232D serial communications as a standard feature of the drive.

RS-232D has a maximum transmission distance of 50 feet. RS-232D only allows point-to-point

communications. The specifications for wiring and pin outs for RS-232D are given in Chapter 2.

1-2 GPD 515 and Serial Communication

Page 7

The RS-232D to RS-485 Converter Board

The GPD 515 offers RS-485 serial communications as an option. RS-485 allows a maximum

transmission distance of 4000 feet. RS-485 allows multidrop (multiple devices) communication.

To obtain RS-485 communications an optional converter board must be purchased. This

RS-232D to RS-485 Converter Board is represented by the MagneTek part number CM085.

Read this manual thoroughly before installation, operation, maintenance, and inspection of the

CM085 Option Board.

The CM085 option board employs CMOS technology which may be damaged by static electricity.

Use proper electrostatic discharge (ESD) procedures when handling this board.

The CM085 board is used to convert the drive’s RS-232D standard function to offer RS-485

interface. The following diagram illustrates the CM085 board. (The figure is not actual size.)

CAUTION

Figure 1-1. The CM085 Board

GPD 515 and Serial Communication 1-3

Page 8

Chapter 2

RS-232D Serial Communication

RS-232D Serial Communication

•

•

Figure 2-1. RS-232D Pin-out at 6CN Connector

RS-232D Serial Communication 2-1

Page 9

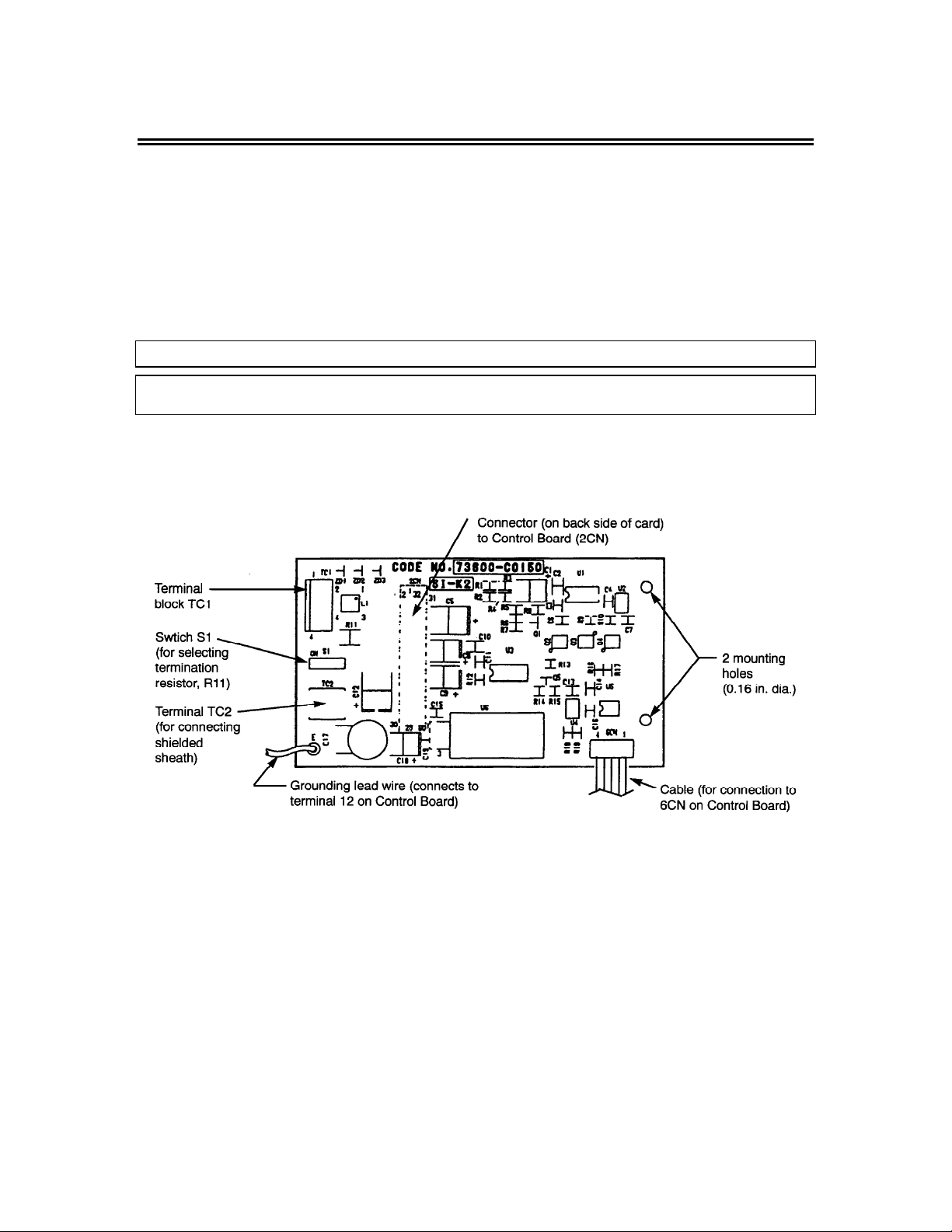

RS-232D Serial Communication

RS-232D Serial Communication is accessed through connector 6CN on the GPD 515ís control

board. Pin 1 on the 6CN connector is for the transmission of data, Pin 2 is for the receipt of data,

and pin 4 is for the ground connection. The RS-232D pin out is shown in the diagram below.

GPD515

2CN

Connector

1CN

Connector

Cable Specifications:

-cable should be a shielded, thin twisted wire 22-28 AWG

-cable pinout is as follows:

Computer - 9 Pin Female

6CN

Connector

Figure 2-1. RS-232D Pin-out at 6CN Connector

GPD 515 Connector for 6CN

D shell

3 - Tx 2 - Rx

2 - Rx 1 - Tx

5 - GND 4 - GND

1

2

3

4

Tx

Rx

GND

-pinout for devices other than a computer (PC), such as a PLC, may vary.

2-2 RS-232D Communication

Page 10

Chapter 3

Installation of the CM085 Board

Installation Procedure

•

• Figure 3-1. Position of the CM085 Board on the

GPD 515 Drive

Installation of the CM086 Board 3-1

Page 11

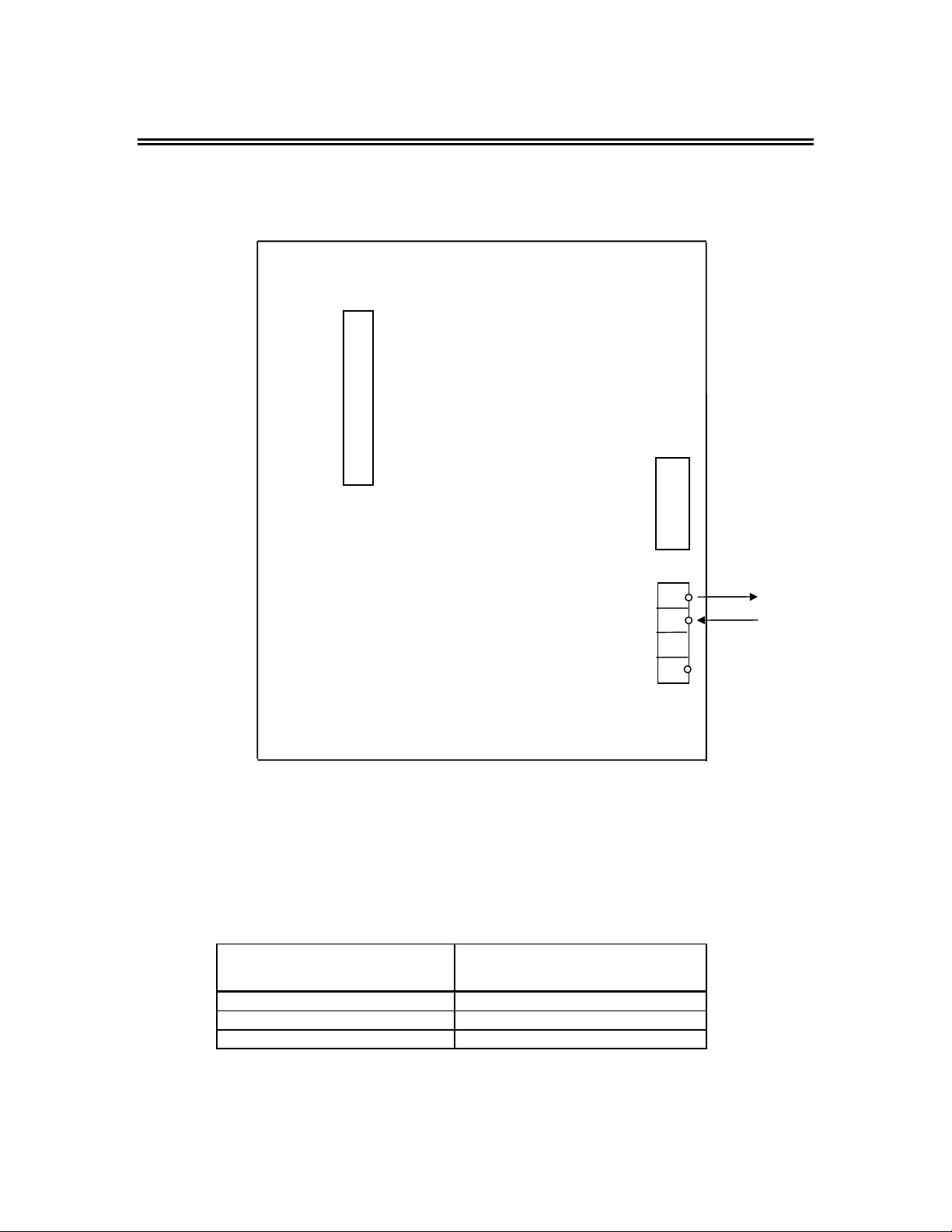

Installation Procedure

These procedures should be followed when installing the CM085 board into the GPD 515 drive.

1. Turn the main power OFF to the drive. Remove the front cover of the drive to verify that the

CHARGE lamp is off.

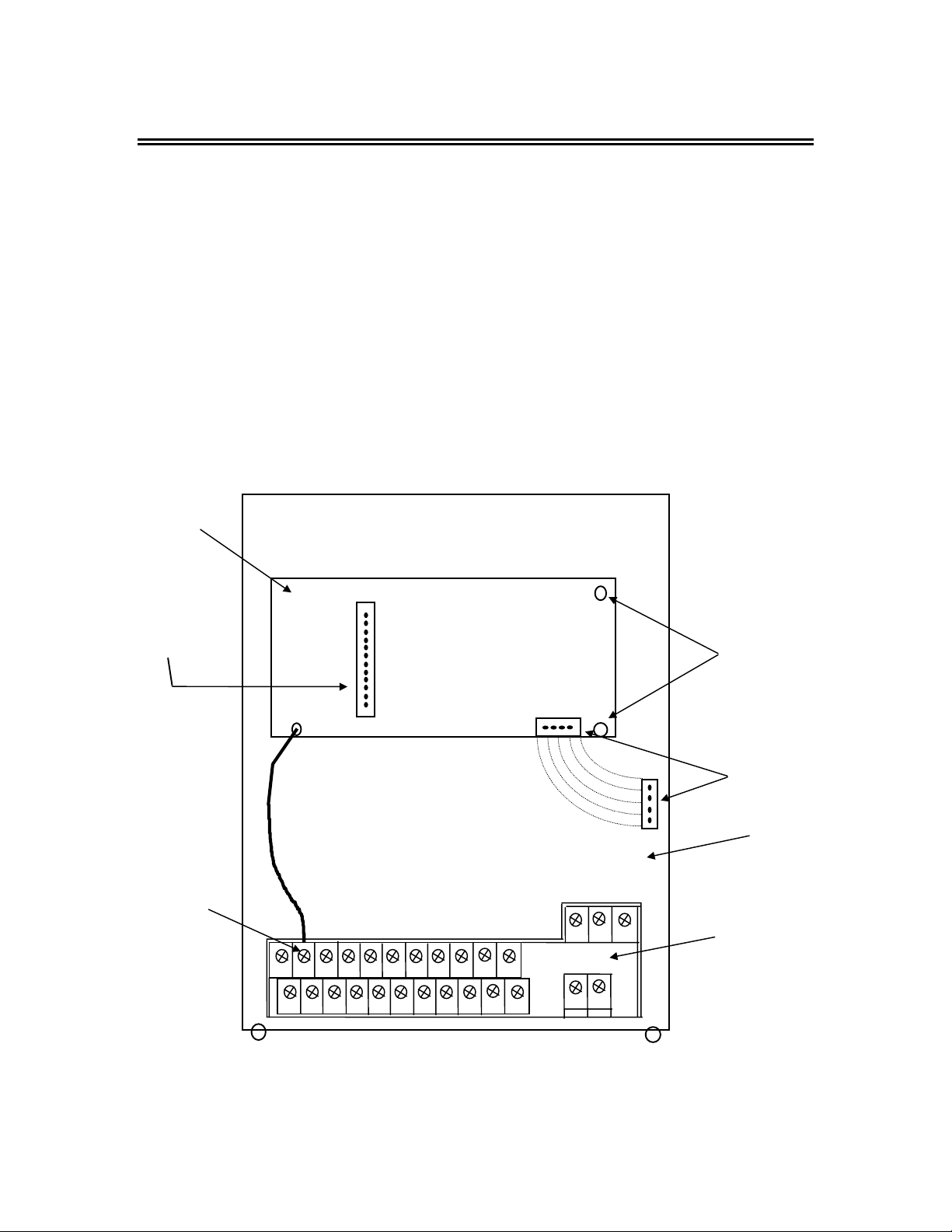

2. Position the CM085 board onto the control board of the drive, lining up the 2CN connector on

the CM085 board with the 2CN connector on the control board of the drive.

3. Position the two spacer holes on the right side of the CM085 board with the plastic stand-offs

on the control board. Snap the CM085 board onto the stand-offs tightly.

4. Plug the 6CN cable from the CM085 board into location 6CN on the control board.

5. Connect the green wire (labeled ëEí) from the CM085 board to terminal 12 on the drive.

6. After installing the CM085 board onto the drive, connect with peripheral devices and replace

the cover of the drive.

CM085

Board

2CN

Connector

Ground

Terminal

Spacer Holes

inserted onto

stand-offs

E

6CN

Connection

Drive Control

Board

Main Control

Terminals

Terminal Block

Figure 3-1. Position of the CM085 Board on t he GPD 515 Drive

3-2 Installation of CM086 Board

Page 12

Chapter 4

Wiring of the CM085 Board

Connection of Multiple Drives

•

• Figure 4-1. CM085 Connection Diagram

Wiring Instructions

•

• Figure 4-2. Shielded Wire Termination

• Table 4-1. Functions of Terminal Block TC1

• Table 4-2. Applicable Wire Sizes for Terminal

Block TC1

Terminating Resisto r

•

• Figure 4-3. SW1 Location on the CM085 Board

Wiring of the CM085 Board 4-1

Page 13

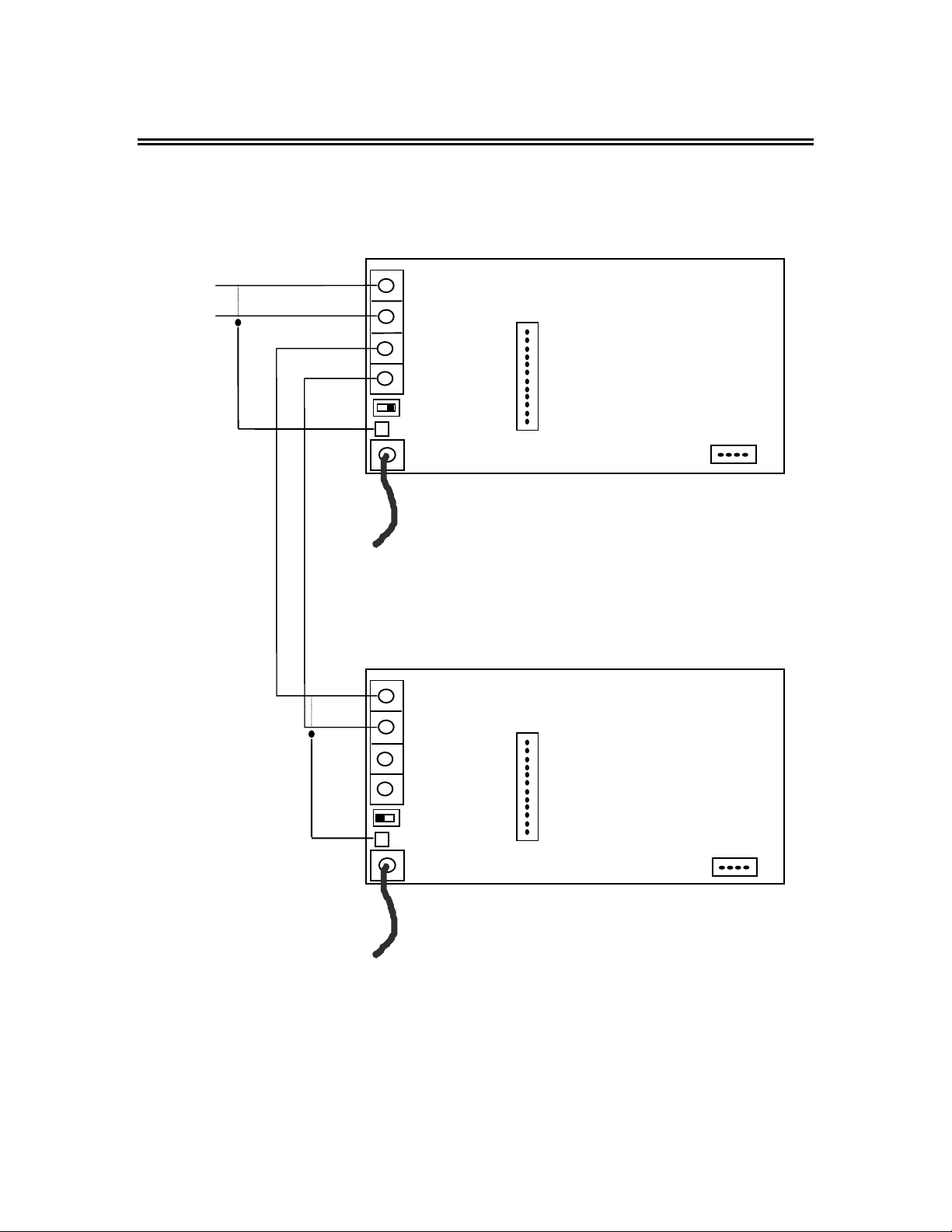

Connection of Multiple Drives

With the RS-485/RS-422 Conversion Board (CM085) multiple drives may be connected together

for a multiple drive communication system. The following diagram illustrates the connection

between multiple CM085 boards.

(+)

RS-485

(-)

Shielded Sheath

Connection

S/R (+)

S/R (-)

S/R (+)

S/R (-)

S/R (+)

S/R (-)

TC1

1

2

3

4

SW1

TC2

Ground

Connection

TC1

1

2

2CN

CM085

BOARD

6CN

2CN

Shielded Sheath

Connection

Figure 4-1. Interconnection Diagram

4-2 Wiring of the CM085 Board

3

4

SW1

TC2

Ground

Connection

CM085

BOARD

6CN

Page 14

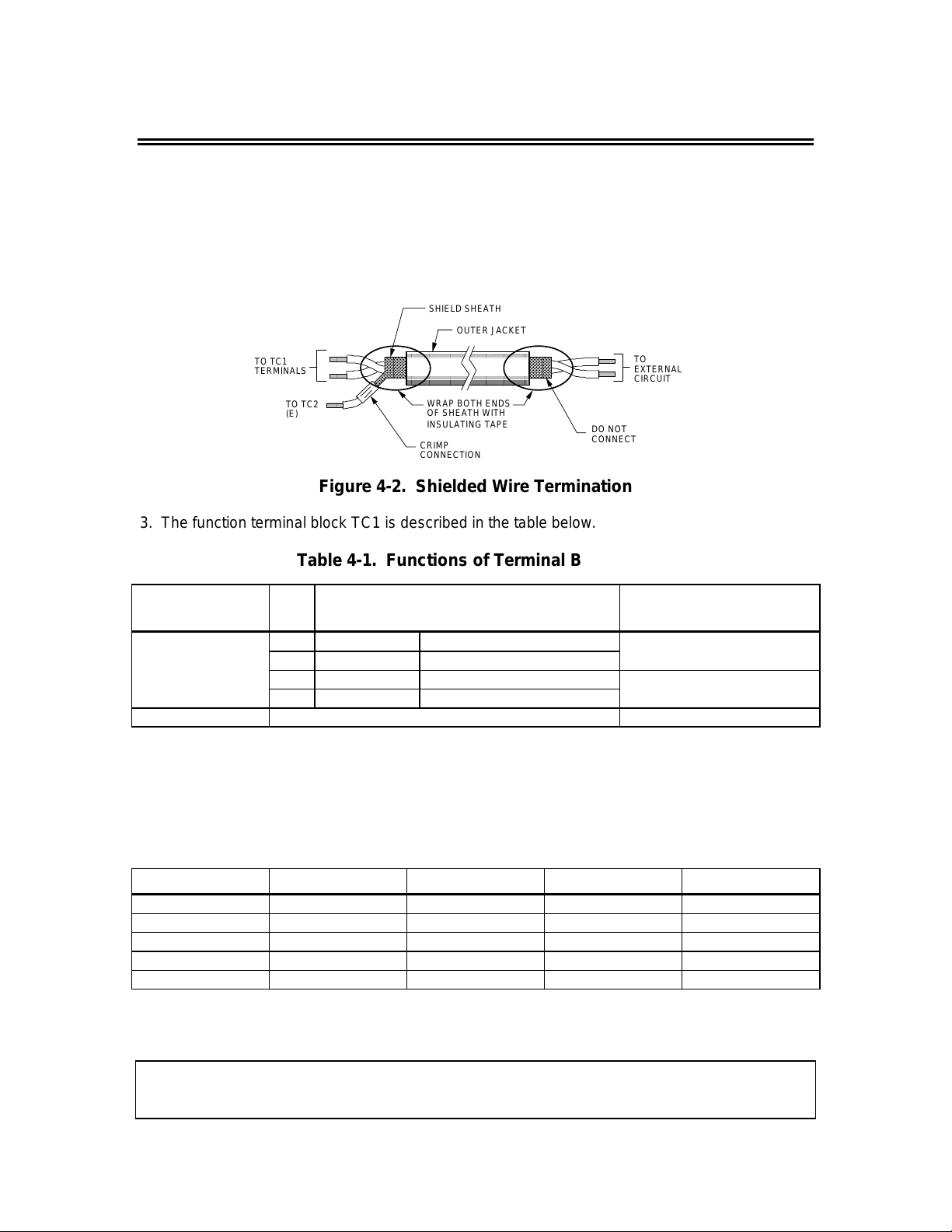

Wiring Instructions

1. Locate terminal block at TC1 on the CM085 board. (See Figure 1-1 in this manual.)

TC1 should have 4 terminal locations (1, 2, 3 and 4) on it.

2. A twisted shielded wire should be used for connection to TC1. The shielded wire should

be separated and connected per the drawing below to eliminate interference due to

noise.

SHIELD SHEATH

OUTER JACKET

DO NOT

CONNECT

TO

EXTERNAL

CIRCUIT

TO TC1

TERMINALS

TO TC2

(E)

WRAP BOTH ENDS

OF SHEATH WITH

INSULATING TAPE

CRIMP

CONNECTION

Figure 4-2. Shielded Wire Termination

3. The function terminal block TC1 is described in the table below.

Table 4-1. Functions of Terminal Block TC1

Terminal Block

Symbol

TC1 2 S/R (-) RS-485 input/output (-) parallel connection

TC2 Shield connection terminal -

4. It is important that an appropriate wire size is selected. When the wire gauge is too thick,

it may apply pressure to the CM085 board and cause failure. When the wire gauge is too

thin, it may lead to imperfect contact or a break in the wire. The table below indicates

the suggested wire size to be used at TC1.

Pin

Functions Remarks

No.

1 S/R (+) RS-485 input/output (+) Use as input at

3 S/R (+) RS-485 input/output (+) Use as output at

4 S/R (-) RS-485 input/output (-) parallel connection

Table 4-2. Applicable Wire Sizes for Terminal Block TC1

[mm2] AWG I [A] VAC [V]

Twisted wire 1.0 16 12 125

Single wire 1.5 16 12 125

UL - 22-16 10 300

CSA - 28-16 10 300

CSA - 28-16 10 150

5. When stripping the wire end to be connected at TC1, approximately 5.5 mm of wire

should be exposed to make a good connection.

Note: Avoid sources of electric interference capable of inducing noise into the cable.

Communication and signal wiring should be kept separate from power wiring. If communication

or signal wiring must cross power wiring, it must cross at a right angle.

Wiring of the CM085 Board 4-3

Page 15

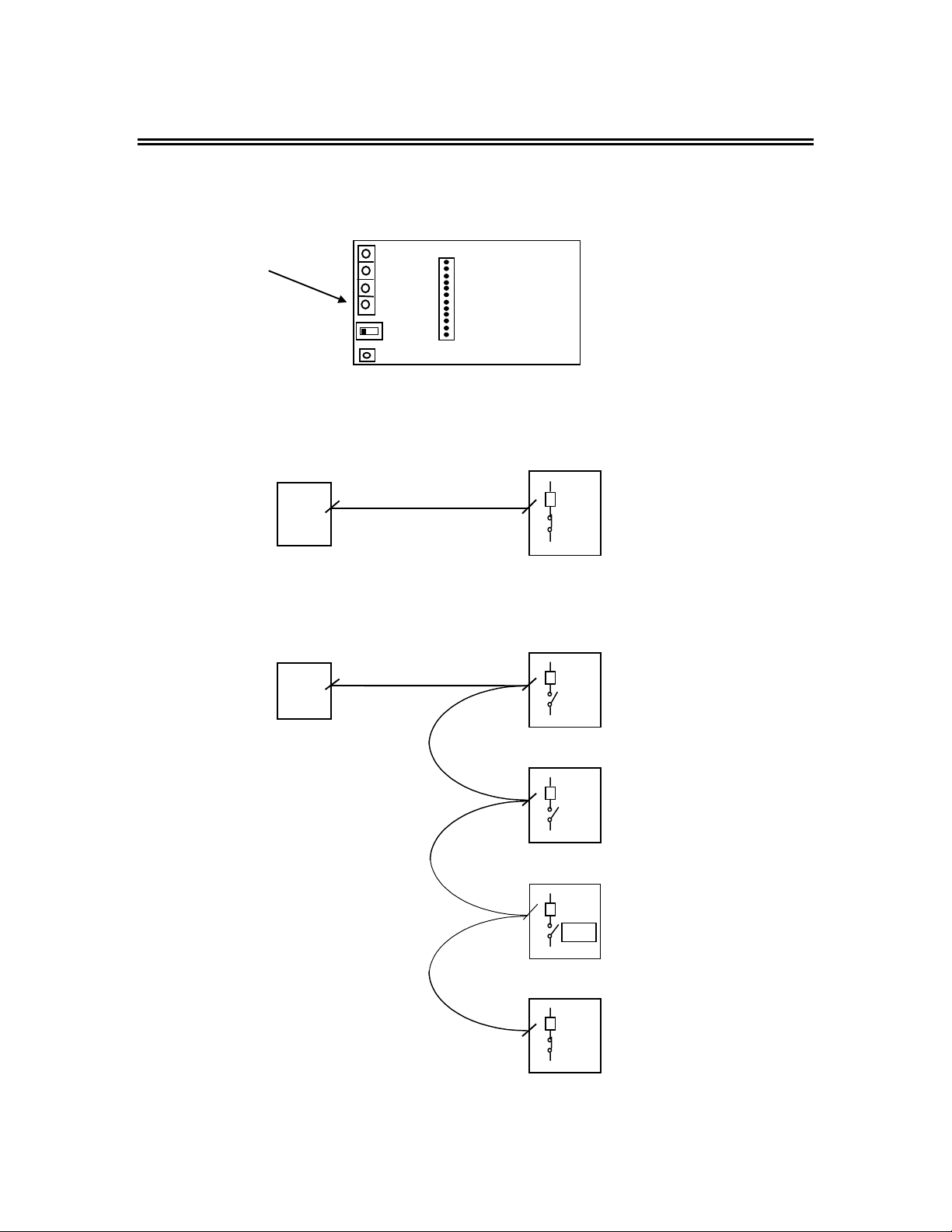

Terminating Resistor

Dip Switch SW1 is located on the lower right hand corner of the CM085 board. (See Figure 4-3

below) When SW1 is on, a termination resistor (100 Ohms) is connected between S/R (+) and

S/R (-).

TC1

1

2

3

4

on

SW1

TC2

Figure 4-3. SW1 Location on the CM085 Board

For one-to-one connections of the CM085 card and a master device set SW1 to ON as shown

below.

RS-485

2CN

CM085

BOARD

ON

Master Device

CM085 Board

If multiple CM085 cards are connected to a master device, set SW1 on the last CM085 board to

ON as shown below.

RS-485

OFF

Master Device

CM085 Board

OFF

CM085 Board

OFF

CM085 Board

4-4 Wiring of the CM085 Board

ON

CM085 Board

Page 16

Chapter 5

Setting GPD 515 Parameters for

Communication

Run/Stop and Frequency Selection

•

Communication Set up Parameters

•

ìENTERî C ommand

•

Setting GPD 515 Parameters for Communication 5-1

Page 17

Run/Stop and Frequency Selection

The run/stop commands and frequency reference command can originate from serial

communication, the Digital Operator, the external terminals, or an option board. The origin of the

run/stop command does not have to be the same as the origin for the frequency reference

command. Parameter b1-01 (Reference Selection) allows you to set up the origin of the

frequency reference, and parameter b1-02 (Operatoin Mode Selection) sets the origin of the

run/stop commands. Parameter b1-01 is Modbus register number 180h, and b1-02 is Modbus

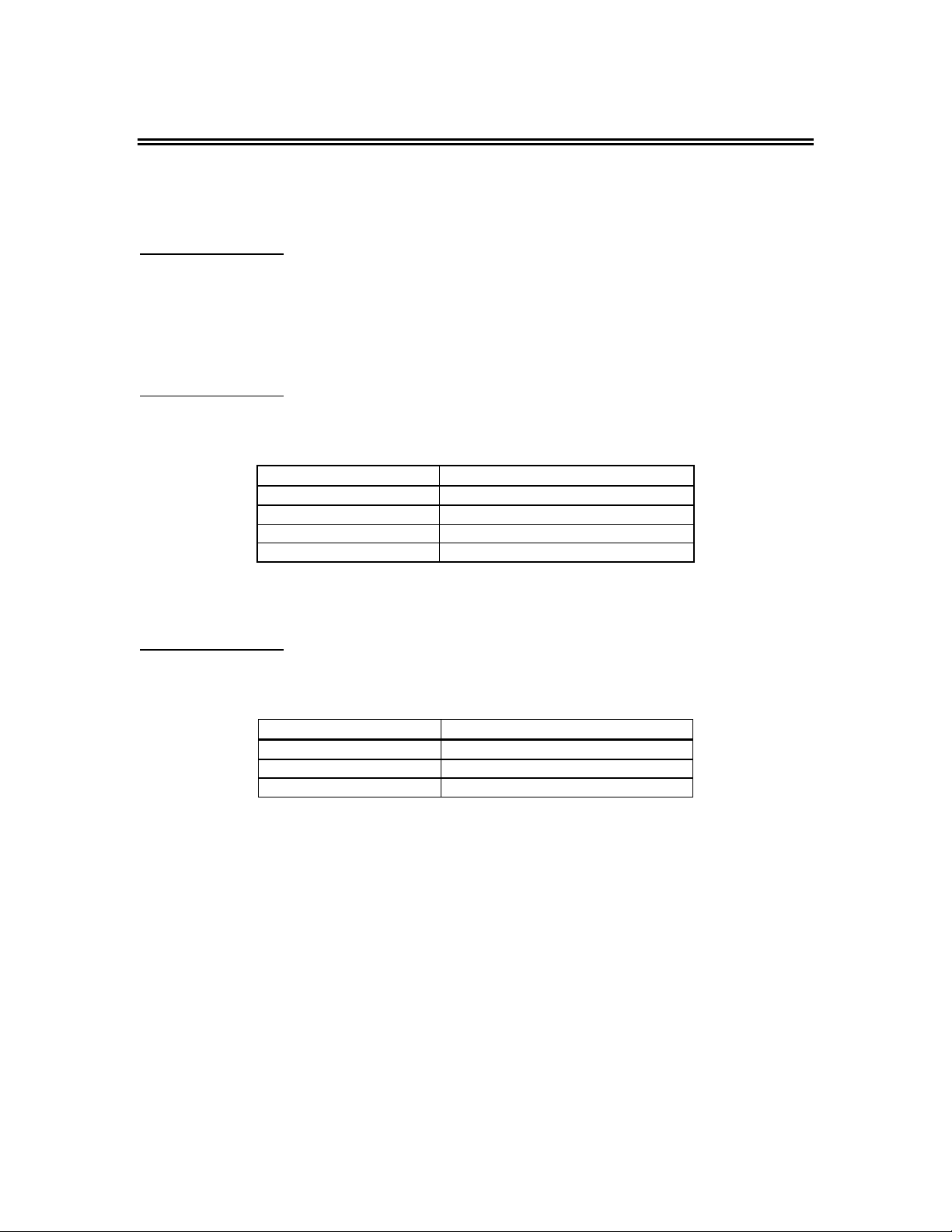

register 181h. The charts shown below illustrate the possible frequency reference and run/stop

selections.

Parameter b1-01 (180h)

Setting

0 Digital Operator

1 External Terminals

2 Serial Communication

3 Option board

The default setting of parameter b1-01 is ë1í.

Parameter b1-02 (181h)

Setting

0 Digital Operator

1 External Terminals

2 Serial Communication

3 Option board

The default setting of parameter b1-02 is ë1í.

Frequency Reference Selection

Operation Method Selection

(Run/Stop)

5-2 Setting GPD 515 Parameters for Communication

Page 18

Serial Communication Set up Parameters

The GPD 515 has parameters used for the set up of serial communication. These

communication set up parameters are H5-01 through H5-05 and o2-09.

Parameter H5-01 - Serial Communication Station Address

Parameter H5-01 (or Modbus Register 41Ch) is used to set the Modbus slave address of the GPD

515 drive. The slave address can be any number from 1 to 1F in hexadecimal (or 1 to 31

decimal). Two nodes may not have the same address. The default setting for parameter H5-01

is ë1Fíh.

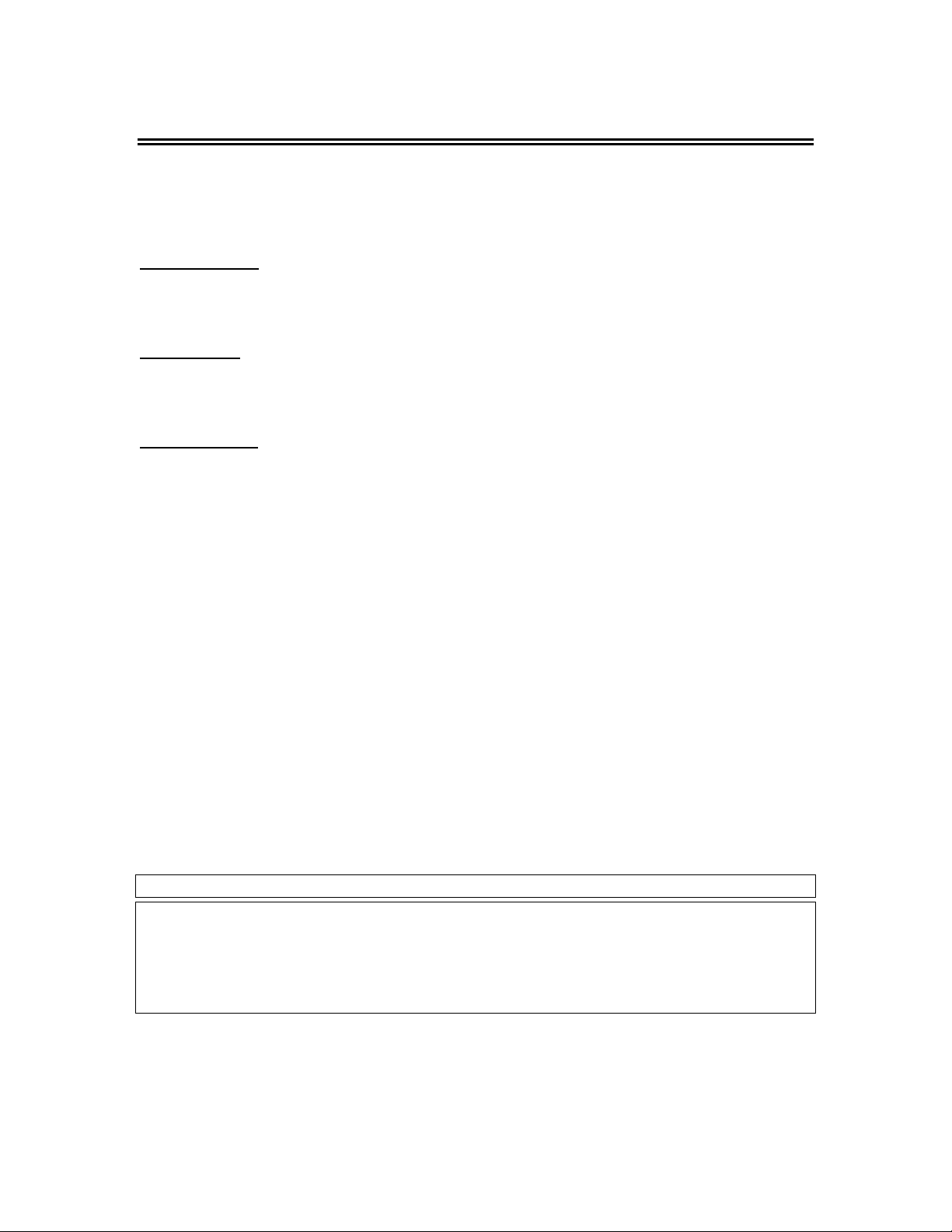

Parameter H5-02 - Serial Communication Baud Rate Selection

Parameter H5-02 (or Modbus Register 41Dh) is used to select the baud rate. The table below

indicates the baud rates that may be selected.

Setting Value (in hex) Baud Rate Selection

0 1200 bps

1 2400 bps

2 4800 bps

3 9600 bps

The default setting of parameter H5-02 is ë3í.

Parameter H5-03 - Serial Communication Parity Selection

Parameter H5-03 (or Modbus Register 41Eh) is used to select the parity . The table below

indicates the parity that may be selected.

Setting Value (in hex) Parity Selection

0 No parity

1 Even parity

2 Odd parity

The default setting of parameter H5-03 is ë0í.

Communication Error (CE)

A communication error can occur only after communication has been established between the

master and the drive. The drive waits for the master to initiate communication.

The message data is always checked for CRC, parity, overrun, framing, and overflow. If the data

has discrepancies in any of these areas a communication error will occur. If the drive does not

receive a message (addressed to its appropriate slave address set up in H5-01) within a period of

2 seconds, a time-out occurs. A time-out can also cause a communication error if it is enabled

(see parameter H5-05).

Parameters H5-04 and H5-05 are the set up parameters that determine how the drive will respond

to a communication error.

Setting GPD 515 Parameters for Communication 5-3

Page 19

Parameter H5-04 - Stopping Method after Serial Communication Error

Parameter H5-04 (or Modbus Register 41Fh) is used to determine the method of stopping the

motor if there is a communication error. The table below indicates the stopping methods that can

be used when a communication error occurs.

Setting Value (in hex) Stopping Method

0 Decelerate to stop

1 Coast to stop

2 Fast Stop

3 Alarm Only / Continue Operation

The default setting of parameter H5-04 is ë3í.

Parameter H5-05 - Serial Fault Detection Selection

Parameter H5-05 (or Modbus Register 420h) is used to enable or disable the Time-out detection.

The table below indicates how to enable or disable the communication error.

Setting Value (in hex) Time-out Detection Selection

0 disabled

1 enabled

The default setting of parameter H5-05 is ‘1’.

Parameter o2-09 - Initial Mode Select

Parameter o2-09 (or Modbus Register 50Dh) determines the Modbus Register Address of the

operational signals register and frequency reference register. Set this parameter to ë1í so that the

Modbus Register Addresses of the Operation Signal register is 001h and the Frequency

Reference register is 002h. The Modbus Register Address for Operation Signals is 00h and the

Frequency Reference register is 01h for flach software versions previous to ‘1024’ and CPU

version ‘20’.

The default setting for parameter o2-09 is ‘0’.

Note: Power must be cycled to the drive,

to make the serial communication set up parameters effective.

5-4 Setting GPD 515 Parameters for Communication

Page 20

ìENTERî Command

The GPD 515 has two types of memory: ëVolatileí and ëNon-Volatileí. Data held in the Volatile

memory will be lost when power is removed from the drive. Data held in Non-Volatile memory will

be retained when power is removed from the drive. Different types of registers are stored in

different areas of memory.

Command Data:

The command registers (000h to 00Fh) are stored in Volatile memory. When writing to a

command register the new data becomes active immediately. In the case of a power loss all data

stored in these registers will not be retained.

Monitor Data:

The monitor registers (010h to 01Fh) are stored in Volatile memory. These registers can not be

written to (read only registers). Any data read from the monitor registers will not be retained

during a power loss situation.

Parameter Data:

The parameter registers (100h to 50Dh) are stored in Non-Volatile memory. When writing new

data to parameter registers, an ëENTERí command must be given for the new data to become

active.

There are two different types of ëENTER’ commands, ‘ACCEPT’ and ‘ENTER’. For an ‘ACCEPT’,

write the value ‘0’ to Modbus register FFDDh. This causes data to become “active”. If a power

loss occurs, the data will not be retained. For an ‘ENTER’, write the value ‘0’ to Modbus register

FFFDh. This causes data to become “active” and saves the date to Non-Volatile memory. If a

power loss occurs, the data will be retained.

Some Parameter Data registers may be written to while the drive is running. These parameters

are called run operative parameters. For a list of these paremeters, refer to Appendix A, Table

A1-11 of the GPD 515 technical manual (TM 4515).

All other Parameter Data registers may only be written to when the drive is stopped. These are

called non-run operative parameters.

If new data is written to any parameter serially, and is not followed by an ‘ENTER’ command, a

“Busy Write Protected” message will flash on the Digital Operator display if an attempt is then

made to change a parameter using the Digital Operator.

The same message will be displayed if an attempt is made to change a parameter via the Digital

Operator while the contents of the ‘ENTER’ command register is any value other than ‘0’.

NOTE

Use the ‘ENTER’ (FFFDh) command only when necessary!

The life of the EEPROM (Non-Volatile memory) on the GPD 515 will support a finite number of

operations. This means that the ‘ENTER’ command, value ‘0’ written to

register FFFDh, can only be used a maximum of a 100,000 times to store data in the EEPROM.

After the specified number of operations, the EEPROM may fault

control board to be replaced.

(ERR)

requiring the GPD 515

Setting GPD 515 Parameters for Communication 5-5

Page 21

Chapter 6

The Message Format

Message Functions

•

Read Multiple Registers

•

Loop Back Test

•

Write Multiple Registers

•

No Response Message

•

CRC-16

•

The Message Format 6-1

Page 22

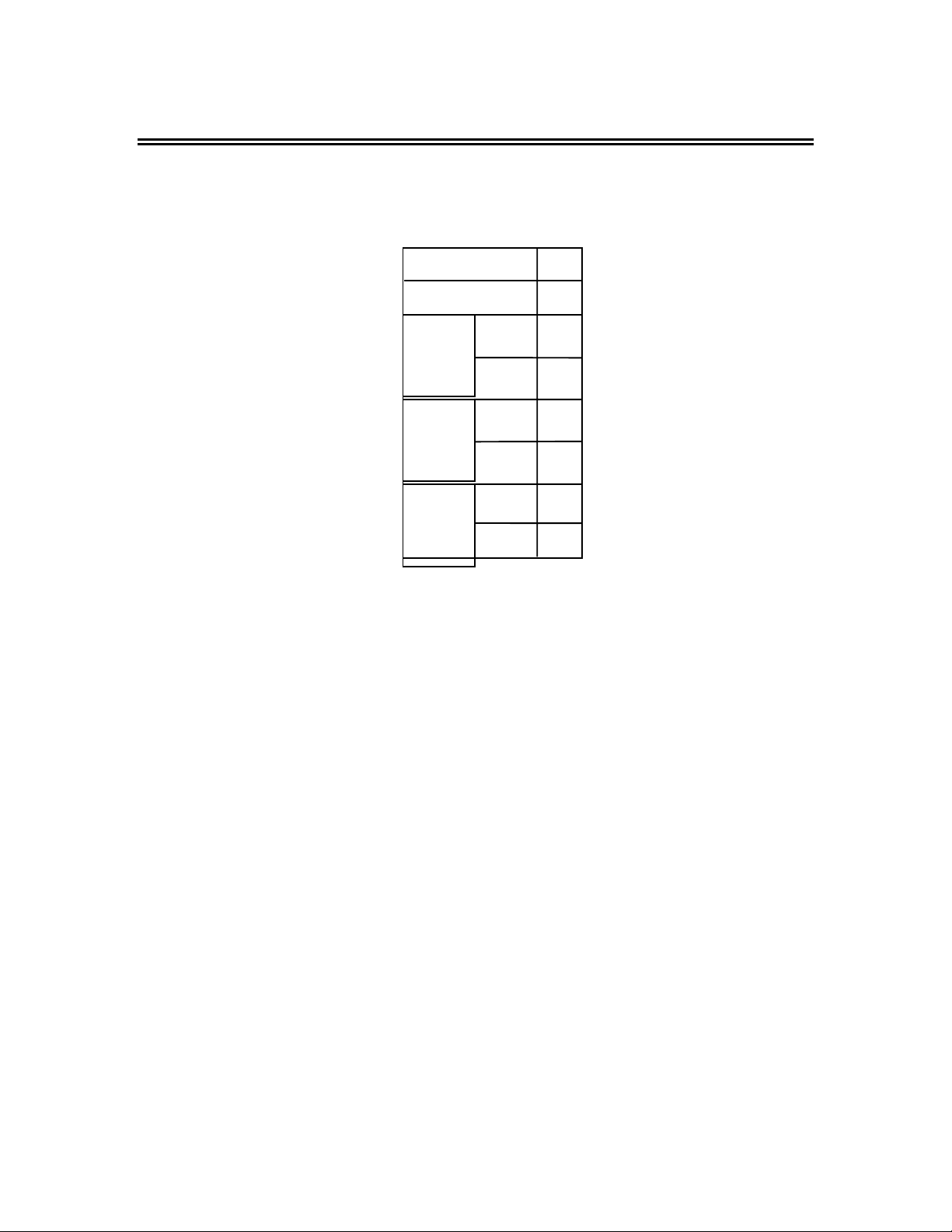

Message Functions

In communicating to the GPD 515 drive via Modbus RTU, there are three message functions

available. The master specifies the function to be executed by the slave according to the function

code. The following table shows the types of function codes available, and the length (quantity)

and contents of the message according to the function.

Function

Code (hex)

3 Read Multiple Registers 8 8 7 37

8 Loop-back test 8888

10 Write Multiple Registers 11 41 8 8

The message format varies depending upon the function of the message. For each function,

there is a command message from the master and a response message initiated from the slave.

The following sections review the format of the command message and the response message

for each function.

Function

Command

Message

min.

(bytes)

max.

(bytes)

Response

Message (Normal)

min.

(bytes)

max.

(bytes)

6-2 The Message Format

Page 23

Read Multiple Registers - 03h

N

The multiple register read function (03h) allows the master to request information from the slave.

The command message of a multiple register read is structured as shown below.

Command Message

SLAVE ADDRESS

FUNCTION CODE

STARTING

REGISTER

O.

UPPER

LOWER

UPPER

03h

00h

20h

00h

QTY.

LOWER

LOWER

04h

45h

CRC-16

UPPER

F0h

Each GPD 515ís slave address is set in advance by the drive parameter H5-01. Valid slave

addresses must be in the range of 1 to 31 decimal (1 to 1F hex). No two slaves may have the

same address. The master addresses the slave by placing the slave address in the address field

of the message. In the command message above, the slave is addressed at 2.

The function code of this message is 03h (read multiple registers).

The starting number is the first register to be read. In the command message above the starting

register is 20h, indicating that the first register is the Frequency Reference. A listing of the GPD

515ís registers is shown in Chapter 7, Registers.

The quantity indicates how many consecutive registers are to be read. The quantity may range

from 1 to 16 registers. If the quantity is greater than 16, an error code of ë3í is returned in the

fault response message. In this command message there is four consecutive registers to be

read: 20h-Frequency Reference, 21h-Output Frequency, 22h-Output Current, and 23h-Control

Method.

A CRC-16 value is generated from a calculation using the values of the address, function code,

and data sections of the message. The procedure for calculating a CRC-16 is described at the

end of this chapter. When the slave receives the command message it calculates a CRC-16

value and compares it to the one in CRC-16 field of the command message. If these two CRC-16

values are the same the slave has received the proper command message. If the two CRC-16

values are not the same the slave will not respond.

If the command message has a valid slave address, function code, starting register, and quantity

value, the slave will respond with a normal response message. If the command message has an

invalid slave address, function code, starting register, and/or quantity the slave will respond with a

fault response message.

The Message Format 6-3

Page 24

6-4 The Message Format

Page 25

Normal Response Message

SLAVE ADDRESS

FUNCTION CODE

NO. OF DATA BYTES

STARTING

REGISTER

CONTENTS

UPPER

LOWER

03h

08h

17h

70h

The starting register, 20h

(Frequency Reference),

has a value of 1770h or

6000 dec. (60.00 Hz)

The next register, 21h

(Output Freque ncy), has

a value of 1770h or 6000

dec. (60.00 Hz).

The next register, 22h

(Output Current), has a

value of 109h or 265 dec.

NEXT

REGISTER

CONTENTS

NEXT

REGISTER

CONTENTS

UPPER

LOWER

UPPER

LOWER

17h

70h

01h

09h

(drive rating / 8192).

NEXT

REGISTER

CONTENTS

UPPER

LOWER

00h

00h

The next register, 23h

(Control Method), has a

value of 00h or 0 dec.

CRC-16

LOWER

UPPER

38h

AC

h

(V/f Control).

The normal response message contains the same slave address and function code as the

command message, indicating to the master which slave is responding and to what type of

function it is responding.

The number of data bytes is the number of data bytes returned in the response message. The

number of data bytes is actually the quantity (in the command message) times 2, since there are

two bytes of data in each register.

The data section of the response message contains 8 upper and 8 lower bits of data for each

register that has been read from the drive.

A CRC-16 value is generated from a calculation using the values of the address, function code,

number of data bytes, and register data sections of the message. The procedure for calculating a

CRC-16 value is described at the end of this chapter. How the response message is handled by

the master depends on what master is used. When the master receives the response message it

should calculate a CRC-16 value and compare it to the one in the CRC-16 field of the response

message. If these two CRC-16 values are the same the master has received the proper

response message.

The Message Format 6-5

Page 26

Fault Response Message

SLAVE ADDRESS

80h + FUNC. CODE

ERROR CODE

LOWER

CRC-16

UPPER

83h

02h

30h

F1h

The fault response message contains the same slave address as the command message,

indicating to the master which slave is responding.

The function code of a fault response message is actually a value of 80h plus the original function

code of 03h. This indicates to the master that the message is a fault response message, instead

of a normal response message.

The error code indicates where the error occurred in the command message. The value of 2h in

the error code field of this fault response message, indicates that the command message

requested data be read from an invalid register. A complete listing of the error codes is shown in

Chapter 8, Troubleshooting and Error Codes.

A CRC-16 value is generated from a calculation using the values of the address, function code,

and error code sections of the message. The procedure for calculating a CRC-16 value is

described at the end of this chapter. How the response message is handled by the master

depends on what master is used. When the master receives the fault response message it

should calculate a CRC-16 value and compare it to the one in the CRC-16 field of the fault

response message. If these two CRC-16 values are the same the master has received the

proper fault response message.

6-6 The Message Format

Page 27

Loop-back Test - 08h

The loop-back test function (08h) is used for checking signal transmission between master and

slaves. The command message format is shown below.

Command Message

SLAVE ADDRESS

FUNCTION CODE

TEST

UPPER

08h

00h

CODE

LOWER

UPPER

00h

A5h

DATA

LOWER

LOWER

37h

DAh

CRC-16

UPPER

8Dh

Each GPD 515ís slave address is set in advance by the drive parameter H5-01. Valid slave

addresses must be in the range of 1 to 31 decimal (1 to 1F hex). No two slaves may have the

same address. The master addresses the slave by placing the slave address in the address field

of the message. In the command message above, the slave is addressed at 1.

The function code of this message is 08h (loop-back test).

The test code must be set to ë0000í. This function specifies that the data passed in the

command message is to be returned (looped back) in the response message.

The data section contains arbitrary data values. These data values are used to verify that the

slave receives the correct data.

A CRC-16 value is generated from a calculation using the values of the address, function code,

test code, and data sections of the message. The procedure for calculating a CRC-16 is

described at the end of this chapter. When the slave receives the command message it

calculates a CRC-16 value and compares it to the one in CRC-16 field of the command message.

If these two CRC-16 values are the same the slave has received the proper command message.

If these two CRC-16 values are not the same the slave does not respond.

If the command message has a valid slave address, function code, test code, and data value, the

slave will respond with a normal response message. If the command message has an invalid

slave address, function code, test code, and/or data value the slave will respond with a fault

response message.

The Message Format 6-7

Page 28

Normal Response Message

SLAVE ADDRESS

FUNCTION CODE

TEST

UPPER

08h

00h

CODE

LOWER

UPPER

00h

A5h

DATA

LOWER

LOWER

37h

DAh

CRC-16

UPPER

8Dh

A normal response message for the loop-back test should be identical to the command message.

Fault Response Message

SLAVE ADDRESS

80h + FUNC. CODE

ERROR CODE

88h

01h

CRC-16

LOWER

UPPER

87h

C0h

The fault response message contains the same slave address as the command message,

indicating to the master which slave is responding.

The function code of a fault response message is actually a value of 80h plus the original function

code of 08h. This indicates to the master that the message is a fault response message, instead

of a normal response message.

The error code indicates where the error occurred in the command message. A complete listing of

the error codes is shown in Chapter 8, Troubleshooting and Error Codes.

A CRC-16 value is generated from a calculation using the values of the address, function code,

and data sections of the message. The procedure for calculating a CRC-16 value is described at

the end of this chapter. How the response message is handled by the master depends on what

master is used. When the master receives the fault response message it should calculate a

CRC-16 value and compare it to the one in the CRC-16 field of the fault response message. If

these two CRC-16 values are the same the master has received the proper fault response

message.

6-8 The Message Format

Page 29

Write Multiple Registers - 10h

N

The multiple register write function (10h) allows the master to write data to the driveís registers.

The multiple register write message format is shown below.

Command Message

SLAVE ADDRESS

FUNCTION CODE

STARTING

REGISTER

O.

UPPER

LOWER

UPPER

QTY.

LOWER

NO. OF DATA BYTES

UPPER

DATA TO

FIRST

REGISTER

DATA TO

NEXT

REGISTER

LOWER

UPPER

LOWER

LOWER

CRC-16

10h

00h

01h

00h

02h

04h

00h

01h

17h

70h

6Dh

The first register, 01h

(Operation Command) has

a value of 01h or 1 dec.

(forward run command)

The next register, 02h

(Frequency Reference) has

a value of 1770h or 6000

dec. (60.00 Hz)

UPPER

B7h

Each GPD 515ís slave address is set in advance by the drive parameter H5-01. Valid slave

addresses must be in the range of 1 to 31 decimal (1 to 1F hex). No two slaves may have the

same address. The master addresses the slave by placing the slave address in the address field

of the message. In the command message above, the slave is addressed at 1.

By setting the slave address to zero (0) in the address section of the message, the master can

send operation signals (register 1h) and frequency reference (register 2h) to all slaves on the

network. The master can send a single transmission to all the slaves simultaneously. This is

called simultaneous broadcasting. In a simultaneous broadcast message all of the slaves on the

network act upon one message. Simultaneous Broadcast registers are shown in Chapter 7,

Registers (page 7-2).

The function code of this message is 10h (write multiple registers).

The starting register number is the first register to be written to. In the command message above

the starting number is 01h, indicating that the first register is the frequency reference. A listing of

the GPD 515ís registers is shown in Chapter 7, Registers.

The Message Format 6-9

Page 30

6-10 The Message Format

Page 31

The quantity indicates how many consecutive registers are to be written to. The quantity may

range from 1 to 16 registers. If the quantity is greater than 16, an error code of ë3í is returned in

the fault response message. In this command message there is two consecutive registers to be

written to: 01h-Operation Command and 02h- Frequency Reference.

The number of data bytes is the number of bytes of data to be written to the drive. The number of

data bytes is actually the quantity times 2, since there are two bytes of data in each register.

The data section of the response message contains 8 upper and 8 lower bits of data for each

register that is being written to.

A CRC-16 value is generated from a calculation using the values of the address, function code,

starting register number, quantity, number of data bytes, and data sections of the message. The

procedure for calculating a CRC-16 is described at the end of this chapter. When the slave

receives the command message it calculates a CRC-16 value and compares it to the one in CRC16 field of the command message. If these two CRC-16 values are the same the slave has

received the proper command message. If these two CRC-16 values are not the same the slave

does not respond.

If the command message has a valid slave address, function code, starting register number,

quantity, number of data bytes, and data values, the slave will respond with a normal response

message. If the command message has an invalid slave address, function code, starting register

number, quantity, number of data bytes, and/or data values the slave will respond with a fault

response message.

Normal Response Message

SLAVE ADDRESS

FUNCTION CODE

STARTING

REGISTER

NUMBER

UPPER

LOWER

UPPER

10h

00h

01h

00h

QTY.

LOWER

LOWER

02h

10h

CRC-16

UPPER

08h

The normal response message contains the same slave address and function code as the

command message, indicating to the master which slave is responding and to what type of

function it is responding.

The starting number is the first register that was written to. In the response message above the

starting number is 01h, indicating that the first register is the operation command.

The quantity indicates how many consecutive registers were written to.

The Message Format 6-11

Page 32

A CRC-16 value is generated from a calculation using the values of the address, function code,

starting register number, and quantity value of the message. The procedure for calculating a

CRC-16 value is described at the end of this chapter. How the response message is handled by

the master depends on what master is used. When the master receives the response message it

should calculate a CRC-16 value and compare it to the one in the CRC-16 field of the response

message. If these two CRC-16 values are the same the master has received the proper

response message.

Fault Response Message

SLAVE ADDRESS

80h + FUNC. CODE

ERROR CODE

LOWER

90h

02h

CDh

CRC-16

UPPER

C1h

The fault response message contains the same slave address as the command message,

indicating to the master which slave is responding.

The function code of a fault response message is actually a value of 80h plus the original function

code of 10h. This indicates to the master that the message is a fault response message, instead

of a normal response message.

The error code indicates where the error occurred in the command message. The value of 2h in

the error code field of this fault response message, indicates that the command message

requested data to be written to an invalid register. A complete listing of the error codes is shown

in Chapter 8, Troubleshooting and Error Codes.

A CRC-16 value is generated from a calculation using the values of the address, function code,

and error code sections of the message. The procedure for calculating a CRC-16 value is

described at the end of this chapter. How the response message is handled by the master

depends on what master is used. When the master receives the fault response message it

should calculate a CRC-16 value and compare it to the one in the CRC-16 field of the response

message. If these two CRC-16 values are the same the master has received the proper

response message.

6-12 The Message Format

Page 33

No Response Message

The slave disregards the command message and does not return the respond message in the

following cases:

1.

In simultaneous broadcasting of data (slave address field is 0), all slaves execute but

do not respond.

2.

When a communication error (overrun, framing, parity, or CRC-16) is detected in the

command message.

3.

When the slave address in the command message does not coincide with the address

set in the slave.

4.

When the command message data length is not proper.

CRC-16

At the end of the message, the data for CRC error checking is sent in order to detect errors in

signal transmission. In Modbus RTU, the error check is conducted in the form of a CRC-16

(Cyclical Redundancy Check). The CRC field checks the contents of the entire message. It is

applied regardless of any parity check method used for the individual characters of the message.

The CRC field is two bytes, containing 16-bit binary value. The CRC value is calculated by the

transmitting device, which appends the CRC to the message. The receiving device recalculates a

CRC during receipt of the message, and compares the calculated value to the actual value it

received in the CRC field. If the two values are not equal, an error results.

The CRC is started by first preloading a 16-bit register to all 1ís. Then a process begins of

applying successive 8-bit bytes of the message to the current contents of the register. Only the

eight bits of data in each character are used for generating the CRC. Start and stop bits, and the

parity bit (if one is used) do not apply to the CRC.

During generation of the CRC, each 8-bit character is exclusive ëORíed with the register contents.

Then the result is shifted in the direction of the least significant bit (LSB), with a zero filled into the

most significant bit (MSB) position. The LSB is extracted and examined. If the LSB is a 1, the

register is then exclusive ëORíed with a preset, fixed value (A001h). If the LSB is a 0, no

exclusive OR takes place.

This process is repeated until eight shifts have been performed. After the last (eighth) shift, the

next 8-bit byte is exclusive ëORíed with the registerís current value, and the process repeats for

eight more shifts as described above. The final contents of the register, after all the bytes of the

message have been applied, is the CRC value.

For applications using a host computer, a detailed example of a CRC generation using Quick

Basic is shown on the following page.

The Message Format 6-13

Page 34

Typical CRC-16 Calculation Program in Quick Basic:

crcsum# = &HFFFF&

crcshift# = &H0&

crcconst# = &HA001&

CLS

PRINT "***************************************************"

PRINT

PRINT " CRC-16 calculator"

PRINT

PRINT "***************************************************"

PRINT "If entering data in hex, preceed the data with '&H'"

PRINT " Example: 32decimal = 20hex = &H20"

PRINT "***************************************************"

PRINT

INPUT "Enter the number of bytes in the message: ", maxbyte

FOR bytenum = 1 TO maxbyte STEP 1

PRINT "Enter byte "; bytenum; ":":

INPUT byte&

byte& = byte& AND &HFF&

crcsum# = (crcsum# XOR byte&) AND &HFFFF&

FOR shift = 1 TO 8 STEP 1

crcshift# = (INT(crcsum# / 2)) AND &H7FFF&

IF crcsum# AND &H1& THEN

crcsum# = crcshift# XOR crcconst#

ELSE

crcsum# = crcshift#

END IF

NEXT shift

NEXT bytenum

lower& = crcsum# AND &HFF&

upper& = (INT(crcsum# / 256)) AND &HFF&

PRINT "Lower byte (1st) = ", HEX$(lower&)

PRINT "Upper byte (2nd) = ", HEX$(upper&)

6-14 The Message Format

Page 35

CRC-16 Calculation Example:

A two byte message for a read-out of a

specified coil status is as follows.

0000 0010

0000 0111

Slave Address = 2

Function Code = 7

The actual CRC calculation would look like

this:

CRCTMP FLAG

1111 1111 1111 1111 Initial Value

0000 0010 Slave Address

1111 1111 1111 1101 Result of EX

OR

0111 1111 1111 1110 1 Shift #1

1010 0000 0000 0001 CRC-16

constant A001h

1101 1111 1111 1111 Result of EX

OR

0110 1111 1111 1111 1 Shift #2

1010 0000 0000 0001 CRC-16

constant A001h

1100 1111 1111 1110 Result of EX

OR

0110 0111 1111 1111 0 Shift #3

0011 0011 1111 1111 1 Shift #4

1010 0000 0000 0001 CRC-16

constant A001h

1001 0011 1111 1110 Result of EX

OR

0100 1001 1111 1111 0 Shift #5

0010 0100 1111 1111 1 Shift #6

1010 0000 0000 0001 CRC-16

constant A001h

1000 0100 1111 1110 Result of EX

OR

0100 0100 0111 1111 0 Shift #7

0010 0001 0011 1111 1 Shift #8

1010 0000 0000 0001 CRC-16 constant A001h

1000 0001 0011 1110 Result of EX

OR

0000 0111 Function Code

1000 0001 0011 1001 Result of EX

OR

0100 0000 1001 1100 1 Shift #1

1010 0000 0000 0001 CRC-16

constant A001h

1110 0000 1001 1101 Result of EX

OR

0111 0000 0100 1110 1 Shift #2

1010 0000 0000 0001 CRC-16

constant A001h

1101 0000 0100 1111 Result of EX

OR

0110 1000 0010 0111 1 Shift #3

1010 0000 0000 0001 CRC-16

constant A001h

1100 1000 0010 0110 Result of EX

OR

0110 0100 0001 0011 0 Shift #4

0011 0010 0000 1001 1 Shift #5

1010 0000 0000 0001 CRC-16

constant A001h

1001 0010 0000 1000 Result of EX

OR

0100 1001 0000 0100 0 Shift#6

0010 0100 1000 0010 0 Shift #7

0001 0010|0100 0001 0 Shift #8

1 2 4 1

CRC-16

(Upper 8)

CRC-16

(Lower 8)

The Message Format 6-15

Page 36

After calculating the CRC-16 upper and

lower values they are inserted into the

message format as shown below.

0000 0010

0000 0111

0100 0001

0001 0010

Slave Address = 2

Function Code = 7

CRC-16 Lower = 41h

CRC-16 Upper = 12h

6-16 The Message Format

Page 37

Chapter 7

Registers

Simultaneous Broadcast Registers

•

Command Registers

•

Monitor Registers

•

Drive Parameter Re gisters

•

Special Registers

•

Registers 7-1

Page 38

Simultaneous Broadcast Registers (Write only)

p

REGISTER FUNCTION BIT DATA DESCRIPTION

(in hex) NO. SET

001* Operational Signals 0 0 Sto

1 Run

1 0 Forward Run

1 Reverse Run

2 not used

3 not used

4 1 External Fault

5 1 Fault Reset

6 not used

7 not used

002* Frequency Reference

Notes:

1. Scaling depends on the setting of o1-03.

* Set parameter o2-09 to ‘1’ so that the Modbus Register Address of the Operation Signals register is 01h and the Frequency Reference register is 02h. The

Modbus Register Address for Operation Signals register is 00h and the Frequency Reference is 01h for flash software versions previous to ‘1024’

and CPU version ‘20’.

Frequency Reference (6000 = 100%)

(1)

7-2 Registers

Page 39

Command Registers (Read / Write)

g

(5)

g

(6)

(3)

(4)

)

REGISTER FUNCTION BIT DESCRIPTION

(in hex) NO.

001* Operational Signals 0 Forward operation

1 Reverse Operation

2 Closed External Terminal 3

3 Closed External Terminal 4

4 Closed External Terminal 5

5 Closed External Terminal 6

6 Closed External Terminal 7

7 Closed External Terminal 8

002* Frequency Reference / Output Frequency

003

004

005 Not Supported will return zeros

006 Not Supported will return zeros

007 Analog Output 1 Settin

008 Analog Ouptut 2 Settin

009 Contact Output Setting 0

1

2

3 not used

4 not used

5 not used

6 Fault Contact code

7 Fault Contact state (effective only when bit 6 = ‘1’

00A-00Fh Reserved return all zeros

–10V / –660 to +10V / +660 analog output on terminals 21 & 22

–10V / –660 to +10V / +660 analog output on terminals 22 & 23

Multi-function Contact Output (terminals 9 & 10): “closed”

Multi-function Contact Output (terminals 25 & 27): “closed”

Multi-function Contact Output (terminals 26 & 27): “closed”

1 Hz / 100

(1)

(2)

Notes:

1. Desired frequency of 35.75 Hz requires a value of 3575 in register data code 002h. Scaling depends on the setting of o1-03.

2. Effective when H2-01 = 0Fh.

3. Effective when H2-02 = 0Fh.

4. Effective when H2-03 = 0Fh.

5. Effective when H4-01 = 1Fh.

6. Effective when H4-04 = 1Fh.

* Set parameter o2-09 to ‘1’ so that the Modbus Register Address of the Operation Signals register is 01h and the Frequency Reference register is 02h. The

Modbus Register Address for Operation Signals register is 00h and the Frequency Reference is 01h for flash software versions previous to ‘1024’

and CPU version ‘20’.

7-3 Registers

Page 40

Monitor Registers (Read only)

y

(

)

)

)

)

)

)

ge (oV)

)

)

)

)

)

)

)

)

REGISTER FUNCTION BIT DESCRIPTION

(in hex) NO.

010h Status Signal 0 Run Command

1 At zero speed

2 Reverse Operation

3 Reset Signal Input

4 Speed Agreed

5 Drive Read

6 Minor Fault

7 Major Fault

8-15 will return zeros

011h Drive Fault Contents 0 oPE Error

1 not used

2 Program Mode

3 1CN Status:

4

5-15 not used

012h oPE No. oPE Error Code (oPE01=1, oPE02=2, oPE03=3, oPE06=6, oPE10=10, oPE11=11)

013h not used will return zeros

014h Fault Content 1 0 Fuse Blown (FU)

1 DC Bus Undervoltage (UV1

2 Control Power Supply Undervoltage (UV2

3 Main Circuit Answerback (UV3

4 Short Circuit (SC

5 Ground Fault (GF

6 Overcurrent (oC

7Overvolta

8 Heatsink Overtemperature (oH

9 Drive Overheat (oH1

10 Motor Overload (oL1

11 Drive Overload (oL2

12 Overtorque 1 (oL3

13 Overtorque 2 (oL4

14 Dynamic Braking Transistor (RR

15 Dynamic Braking Resistor (RH

01

=JVOP132 / 00=JVOP130

std. operator) / 11=Personal Computer / 10=JVOP100

7-4 Registers

Page 41

Monitor Registers (continued)

)

)

)

)

)

p

)

p

)

p

)

)

)

)

)

)

)

)

REGISTER FUNCTION BIT DESCRIPTION

(in hex) NO.

015h Fault Content 2 0 External Fault 3 (EF3)

1 External Fault 4 (EF4

2 External Fault 5 (EF5

3 External Fault 6 (EF6

4 External Fault 7 (EF7

5 External Fault 8 (EF8

6 not used

7Overs

8 S

9PG O

10 Input Phase Loss (PF

11 Output Phase Loss (LF

12 DCCT Fault (CF

13 Operator Disconnected (OPR

14 EEPROM Write-in Fault (ERR

15 not used

016h Fault Content 3 0 Modbus Communication Error (CE)

1 not used

2 not used

3 not used

4 Control Fault (CF

5 Zero Servo Fault (SVE

6-15 not used

017h CPF Content 1 0 not used

1 not used

2 CPF02 Fault

3 CPF03 Fault

4 CPF04 Fault

5 CPF05 Fault

6 CPF06 Fault

7-15 not used

eed Deviation (DEV

eed (oS

en (PGo

7-5 Registers

Page 42

Monitor Registers (continued)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

REGISTER FUNCTION BIT DESCRIPTION

(in hex) NO.

018h CPF Content 2 0 CPF20 Fault

1 CPF21 Fault

2 CPF22 Fault

3 CPF23 Fault

4-15 not used

019h Minor Fault Content 1 0 Undervoltage Detection (UV)

1 Overvoltage Detection (oV

2 Heatsink Overtemperature (oH

3 Drive Overheat Alarm (oH1

4 Overtorque 1 Detection (oL3

5 Overtorque 2 Detection (oL4

6 2-wire Sequence Input Fault (EF

7 During External Baseblock (BB

8 External Fault 3 (EF3

9 External Fault 4 (EF4

10 External Fault 5 (EF5

11 External Fault 6 (EF6

12 External Fault 7 (EF7

13 External Fault 8 (EF8

14 Cooling Fan Fault (FAN

15 Overspeed (oS

01Ah Minor Fault Content 2 0 Speed Deviation (DEV)

1 PG Open (PGo

2 Operator Disconnected (OPR

3 Modbus Communication Error (CE

4 not used

5 not used

6 Motor Overload (oL1

7 Drive Overload (oL2

8-15 not used

7-6 Registers

Page 43

Drive Parameter Registers (U1-XX / Monitor Only)

REGISTER PARAMETER PARAMETER PARAMETER BIT LIMITS / DESCRIPTION

(in hex) FUNCTION SETTING NO.

020h U1-01 Frequency Reference

021h U1-02 Output Frequency

022h U1-03 Output Current Drive rating / 8192

023h U1-04 Control Method

024h U1-05 Motor Speed Motor Speed (in 0.1 Hz)

025h U1-06 Output Voltage Output Voltage (in 0.1 V)

026h U1-07 DC Bus Voltage DC Bus Voltage (in 1 V)

027h U1-08 Output Power Output Power (in 0.1 kW)

028h U1-09 Torque Reference Torque Reference (in 0.1%)

029h U1-10 Input Terminal Status 0 Input Terminal 1 closed

02Ah U1-11 Output Terminal Status 0 Control Circuit terminals 9 & 10: ìClosedî

Frequency Reference of drive (0.1 Hz)

Output Frequency of drive (0.1 Hz)

0

1 V/f with PG Feedback

2 Open Loop Vector

3 Flux Vector

1 Input Terminal 2 closed

2 Input Terminal 3 closed

3 Input Terminal 4 closed

4 Input Terminal 5 closed

5 Input Terminal 6 closed

6 Input Terminal 7 closed

7 Input Terminal 8 closed

1 Control Circuit terminals 25 & 27: ìClosedî

2 Control Circuit terminals 26 & 27: ìClosedî

3-6 not used

7 Control Circuit terminals 18 & 20: ìClosedî

V/f Control

(1)

(1)

Notes (for this page only):

1. Scaling depends on setting of o1-03.

7-7 Registers

Page 44

Drive Parameter Registers (U1-XX / Monitor Only) (continued)

REGISTER PARAMETER PARAMETER PARAMETER BIT LIMITS / DESCRIPTION

(in hex) FUNCTION SETTING NO.

02Bh U1-12 Operation Status 0 Run

02Ch U1-13 Elapsed Time hours

02Dh U1-14 Software No. (CPU ID No.) software version number

02Eh U1-15 Control Circuit Term 13 Input Voltage

02Fh U1-16 Control Circuit Term 14 Input Voltage

030h U1-17 Control Circuit Term 16 Input Voltage

031h U1-18 Motor Secondary Current (Iq) Motor Secondary Current-Iq (0.1%)

032h U1-19 Motor Exciting Current (Id) Motor Rated Primary Current-Id (0.1%)

033h U1-20 Output Frequency after Soft-start Max. Output Frequency (0.01 Hz)

034h U1-21 Automatic Speed Regulator (ASR)

Input

035h U1-22 Automatic Speed Regulator (ASR)

Output

036h U1-23 Speed Deviation Regulator Input Speed Deviation Regulator Input (0.01%)

037h U1-24 PID Feedback Amount PID Feedback Amount (0.01%)

038h U1-25 DI - 16 H Input Status displays an input value according to the setting of F3-01

039h U1-26 Output Voltage Reference Vq Output Voltage-Vq (0.1V)

03Ah U1-27 Output Voltage Reference Vd Output Voltage-Vd (0.1V)

03Bh U1-28 Software No. CPU processor version number

03Dh U1-32 ACR Output q Axis ASR Output q Axis (0.1%)

03Eh U1-33 ACR Output d Axis ASR Output d Axis (0.1%)

03Fh U1-34 OPE Detected parameter setting error

1 Zero-Speed

2 Reverse Run

3 Reset Signal Input

4 Speed Agree

5 Drive Operation Ready

6 Minor Fault

7 Major Fault

Input voltage signal at terminal 13 (+10V / +100.0% ∼ -10V / -100.0%)

Input voltage or mAmp signal at terminal 14 (+10V / +100.0% ∼ -10V / -

100.0%) or (4mA / 0.0% ∼ 20mA / 100.0%)

Input voltage signal at terminal 16 (+10V / +100.0% ∼ -10V / -100.0%)

ASR Input (0.01%)

ASR Output (0.01%)

7-8 Registers

Page 45

Drive Parameter Registers (U2-XX / Fault Trace and U3-XX / Fault History)

REGISTER PARAMETER PARAMETER PARAMETER BIT LIMITS / DESCRIPTION

(in hex) FUNCTION SETTING NO.

080h U2-01 Current Fault

081h U2-02 Last Fault

082h U2-03 Frequency Ref. at Fault Frequency Reference at the time of the current fault (0.0 to 400.0 Hz)

083h U2-04 Output Frequency at Fault Output Frequency at the time of current fault (0.0 to 400.0 Hz)

084h U2-05 Output Current at Fault Output Current at the time of current fault (drive rating /8192)

085h U2-06 Motor Speed at Fault Motor Speed at the time of current fault (in 0.1 Hz)

086h U2-07 Output Voltage at Fault Output Voltage at the time of current fault (in 0.1 V)

087h U2-08 DC Bus Voltage at Fault Output Voltage at the time of current fault (in 1 V)

088h U2-09 Output kWatts at Fault Output Power at the time of current fault (in 0.1 kW)

089h U2-10 Torque Reference at Fault Torque Reference at the time of current fault (in 0.1%)

08Ah U2-11 Input Terminal Status at Fault 0 Input Terminal 1 closed at time of fault

08Bh U2-12 Output Terminal Status at Fault 0 Control Circuit terminals 9 & 10: ìClosedî

Code of current fault

Code of second to current fault

1 Input Terminal 2 closed at time of fault

2 Input Terminal 3 closed at time of fault

3 Input Terminal 4 closed at time of fault

4 Input Terminal 5 closed at time of fault

5 Input Terminal 6 closed at time of fault

6 Input Terminal 7 closed at time of fault

7 Input Terminal 8 closed at time of fault

1 Control Circuit terminals 25 & 27: ìClosedî

2 Control Circuit terminals 26 & 27: ìClosedî

3-6 not used

7 Control Circuit terminals 18 & 20: ìClosedî

(1)

(1)

Notes (for this page only):

1. List of Drive Error Codes can be found in Chapter 8, Error Codes and Troubleshooting.

7-9 Registers

Page 46

Drive Parameter Registers (U2-XX / Fault Trace and U3-XX / Fault History) (continued)

REGISTER PARAMETER PARAMETER PARAMETER BIT LIMITS / DESCRIPTION

(in hex) FUNCTION SETTING NO.

08Ch U2-13 Drive Status at Fault 0 Running at the time of fault

1 Zero-Speed at the time of fault

2 Reverse Running at the time of fault

3 Reset Signal Input at the time of fault

4 Speed Agree at the time of fault

5 Drive Operation Ready at the time of fault

6 Minor Fault

7 Major Fault

08Dh U2-14 Elapsed Time at Fault Elapsed Time at the time of fault (in hrs.)

090h U3-01 Last Fault

091h U3-02 Fault Message 2

092h U3-03 Fault Message 3

093h U3-04 Fault Message 4

094h U3-05 Elapsed Time 1 Elapsed Time at the most recent fault occurrence

095h U3-06 Elapsed Time 2 Elapsed Time at the second to most recent fault occurrence

096h U3-07 Elapsed Time 3 Elapsed Time at the third to most recent fault occurrence

097h U3-08 Elapsed Time 4 Elapsed Time at the fourth to most recent fault occurrence

Notes (for this page only):

1. List of Drive Error Codes can be found in Chapter 8, Error Codes and Troubleshooting.

Code of the most recent fault

Code of the second to most recent fault

Code of the third to most recent fault

Code of the fourth to most recent fault

(1)

(1)

(1)

(1)

7-10 Registers

Page 47

Drive Parameter Registers (Read/Write)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

100h A1-00 Language Selection

101h A1-01 Parameter Access Level 0 Monitor Only

102h A1-02 Control Method Selection

103h A1-03 Initialize Parameters 0000 No Initialize

104h A1-04 Enter Password 0000 to 9999 0000

0

1

1 User Program

2 Quick-start 2

3Basic

4 Advanced

0

1

V/f with PG Feedback 2

2

3

1110 User Initialize 0000

2220 2-wire Initialize

3330 3-wire Initialize

English 0

Japanese

V/f Control

Open Loop Vector

Flux Vector

7-11 Registers

Page 48

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

180h b1-01 Reference Selection

181h b1-02 Operation Method Selection 0 Digital Operator

182h b1-03 Stopping Method Selection 0 Ramp to Stop

183h b1-04 Reverse Operation Prohibit 0 Enable Reverse Operation 0

184h b1-05 Zero Speed Operation 0 Run at Frequency Reference

(level determined by E1-09) 1 Stop 0

185h b1-06 Logic Input Scan Rate 0 2ms - 2 scans 1

186h b1-07 Local / Remote RUN Selection 0 Cycle External Run 0

187h b2-01 DC Injection Braking Start

Frequency

188h b2-02 DC Injection Braking Current 0 - 100% 50

189h b2-03 DC Injection Braking Time at Start 0.00 - 10.00 seconds 0.00

18Ah b2-04 DC Injection Braking Time at Stop 0.00 - 10.00 seconds 0.00

18Bh-18Dh

Reserved

0

1

2

3

1 Terminal 1

2 Serial Communication

3 Option PCB

1 Coast to Stop 0

2 DC Injection to Stop

3 Coast with Timer

1 Disable Reverse Operation

2 Run at Min. Frequency (E1-09)

3 Run at Zero Speed

1 5ms - 2 scans

1 Accept External Run

0.0 to 10.0 Hz 0.5

Digital Operator

Terminal 1

Serial Communication

Option PCB

7-12 Registers

Page 49

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

18Eh b3-01 Speed Search Selection 0 Disabled 0

18Fh b3-02 Speed Search Current 0 to 200% 150

190h b3-03 Speed Search Decel Time 0.0 to 10.0 seconds 2.0

191h

192h b4-01 Timer Function ON-Delay Time 0.0 to 300.0 seconds 0.0

193h b4-02 Timer Function OFF-Delay Time 0.0 to 300.0 seconds 0.0

194h b5-01 PID Control Mode Selection 0 Disabled

195h b5-02 PID Proportional Gain 0.00 to 10.00 1.00

196h b5-03 PID Integral Time 0.0 to 360.0 seconds 1.0

197h b5-04 PID Integral Limit 0.0 to 100.0% 100.0

198h b5-05 PID Differential Time 0.00 to 10.00 seconds 0.00

199h b5-06 PID Output Limit 0.0 to 100.0% 100.0

19Ah b5-07 PID Offset Adjustment -100.0 to +100.0% 0.0

19Bh b5-08 PID Primary Delay 0.00 to 10.00 seconds 0.00

19Ch b6-01 Dwell Frequency at Start 0.0 to 400.0 Hz 0.0

19Dh b6-02 Dwell Time at Start 0.0 to 10.0 seconds 0.0

19Eh b6-03 Dwell Frequency at Stop 0.0 to 400.0 Hz 0.0

19Fh b6-04 Dwell Time at Stop 0.0 to 10.0 seconds 0.0

1A0h b7-01 Droop Control Gain 0.0 to 100.0 0.0

1A1h b7-02 Droop Control Delay Time 0.03 to 2.00 seconds 0.05

1A2h b8-01 Energy Saving Gain 0 to 100% 80

1A3h b8-02 Energy Saving Frequency 0.0 to 400.0 Hz 0.0

1A4h b9-01 Zero-Servo Gain 0 to 100 5

1A5h b9-02 Zero-Servo Completion Width 0 to 16383 10

Reserved

1 Enabled

1 Enabled (D=Feedback) 0

2 Enabled (D=Feed Forward)

7-13 Registers

Page 50

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

200h C1-01 Acceleration Time 1

201h C1-02 Deceleration Time 1

202h C1-03 Acceleration Time 2

203h C1-04 Deceleration Time 2

204h C1-05 Acceleration Time 3

205h C1-06 Deceleration Time 3

206h C1-07 Acceleration Time 4

207h C1-08 Deceleration Time 4

208h C1-09 Fast Stop Deceleration Time

209h C1-10 Accel / Decel Time Setting Unit 0 0.01 seconds 1

20Ah C1-11 Accel / Decel Time Switching Freq. 0.0 to 400.0 Hz 0.00

20Bh C2-01 S-curve Characteristic at Accel Start 0.0 to 2.50 seconds 0.20

20Ch C2-02 S-curve Characteristic at Accel End 0.0 to 2.50 seconds 0.20

20Dh C2-03 S-curve Characteristic at Decel Start 0.0 to 2.50 seconds 0.20

20Eh C2-04 S-curve Characteristic at Decel End 0.0 to 2.50 seconds 0.20

20Fh C3-01 Slip Compensation Gain 0.0 to 2.5

210h C3-02 Slip Compensation Primary Delay

Time

211h C3-03 Slip Compensation Limit 0 to 250% 200

212h C3-04 Slip Compensation Selection 0 Disabled 0

during Regeneration 1 Enabled

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

0.00 to 600.00 or 0.0 to 6000.0 seconds

1 0.1 seconds

0 to 10000 msec.

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

10.0

10.0

10.0

10.0

10.0

10.0

10.0

10.0

10.0

(2)

(2)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Notes (for this page only):

1. Values are dependent upon C1-10 setting.

2. Initial setting differs depending on the Control Method (A1-02).

7-14 Registers

Page 51

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

213h C4-01 Torque Compensation Gain 0.00 to 2.50 1.00

214h C4-02 Torque Compensation Time

Constant

215h C5-01 ASR Proportional Gain 1 0.00 to 300.00

216h C5-02 ASR Integral Time 1 0.0000 to 10.000 seconds

217h C5-03 ASR Proprotional Gain 2 0.00 to 300.00

218h C5-04 ASR Integral Time 2 0.0000 to 10.000 seconds

219h C5-05 Automatic Speed Regulator (ASR)

Output Limit

21Ah C5-06 ASR Primary Delay Time 0.000 to 0.500 seconds 0.004

21Bh C5-07 ASR Switching Frequency 0.0 to 400.0 Hz 0.0

21Ch C6-01 Carrier Frequency Upper Limit

21Dh C6-02 Carrier Frequency Lower Limit

21Eh C6-03 Carrier Frequency Proportional Gain

21Fh C7-01 Hunting Prevention Selection 0, 1 1

220h C7-02 Hunting Prevention Gain 0.00 to 2.50 1.00

221h

222-229h

22Ah C8-08 AFR Gain 0.00 to 10.00 1.00

22B-23Fh

240h C8-30 Carrier in Tune 0 Fc = 2kHz 0

Reserved

Reserved

Reserved

0 to 10000

0.0 to 20.0% 5.0

(2)

(2)

(2)

15.0

15.0

00

0.4 to 15.0 kHz

0.4 to 15.0 kHz

00 to 99

1Fc = C6-01

(1)

(1)

(1)

(1)

1)

(2)

(2)

(2)

Notes (for this page only):

1. Initial value differs depending on the Control Method (A1-02).

2. Setting range and initial value differ depending on the drive capacity and Control Method.

7-15 Registers

Page 52

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

280h d1-01 Frequency Reference 1

281h d1-02 Frequency Reference 2

282h d1-03 Frequency Reference 3

283h d1-04 Frequency Reference 4

284h d1-05 Frequency Reference 5

285h d1-06 Frequency Reference 6

286h d1-07 Frequency Reference 7

287h d1-08 Frequency Reference 8

288h d1-09 Jog Frequency Reference

289h d2-01 Frequency Reference Upper Limit 0.0 to 110.0% 100.0

28Ah d2-02 Frequency Reference Lower Limit 0.0 to 100.0 % 0.0

28Bh d3-01 Critical Frequency Rejection 1 0.0 to 400.0 Hz 0.0

28Ch d3-02 Critical Frequency Rejection 2 0.0 to 400.0 Hz 0.0

28Dh d3-03 Critical Frequency Rejection 3 0.0 to 400.0 Hz 0.0

28Eh d3-04 Critical Frequency Rejection Width 0.0 to 20.0 Hz 1.0

28Fh d4-01 Frequency Reference Hold 0 Disabled 0

Function Selection 1 Enabled

280h d4-02 Speed Limits 0 to 100% 25

291h d5-01 Torque Control Selection 0 Speed Control 0

292h d5-02 Torque Reference Delay Time 0 to 1000 msec. 0

293h d5-03 Speed Limit Selection 1 Analog Input (term. 13 & 14) 1

294h d5-04 Speed Limit –120 to +120% 0

295h d5-05 Speed Limit Bias 0 to 120% 10

296h d5-06 Speed/Torque Control Switching

Timer

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

0.00 to 400.00 Hz

1 Torque Control

2 d5-04 setting

0 to 1000 msec. 0

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

6.00

Notes (for this page only):

1. Scaling depends on the setting of o1-03.

7-16 Registers

Page 53

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

300h E1-01 Input Voltage Setting 155 to 255V (230V unit)

301h E1-02 Motor Selection 0 General Purpose Motor (TEFC) 0

302h E1-03 V/f Pattern Selection 0 to Eh 15 preset V/f patterns

303h E1-04 Maximum Ooutput Frequency 50.0 to 400.0 Hz 60.0

304h E1-05 Maximum Voltage 0.0 to 255.0V (230V unit)

305h E1-06 Maximum Voltage Frquency 0.0 to 400.0 Hz 60.0

306h E1-07 Mid. Output Frequency 0.0 to 400.0 Hz

307h E1-08 Mid. Output Frqeuency Voltage 155 to 250V (230V unit)

308h E1-09 Min. Output Frequency 0.0 to 400.0 Hz

309h E1-10 Min. Output Frequency Voltage 155.0 to 255.0V (230V unit)

30Ah E1-11 Mid. Frequency B 0.0 to 400.0 Hz 0.0

30Bh E1-12 Mid. Voltage B 0.0 to 255.0 VAC 0.0

30Ch E1-13 Base Voltage 0.0 to 255.0 VAC 0.0

30Dh

30Eh E2-01 Motor Rated Current 0.00 to 99.99 or 100.0 to 1500.0 Amps

30Fh E2-02 Motor Rated Slip 0.00 to 20.00 Hz

310h E2-03 Motor no-Load Current 0.00 to 99.99 or 100.0 to 1500.0 Amps

311h E2-04 Number of Motor Poles 2 to 48 poles 4

312h E2-05 Motor Line-to-Lline Resistance 0.000 to 65.000 Ohms

Reserved

310 to 510V (460V unit)

1 Blower Cooled Motor (TENV or

TEBC)

Fh Custom Pattern (using E1-04 to

E1-10)

0.0 to 510.0V (460V unit)

310 to 510V (460V unit)

310.0 to 510.0V (460V unit)

230

460

Fh

230.0

460.0

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

Notes (for this page only):

1. Initial value differs depending on the Control Method (A1-02).

2. Initial value differs depending on drive capacity.

7-17 Registers

Page 54

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

313h E2-06 Motor Leakage Inductance 0.0 to 30.0%

314h E2-07 Motor Iron-core Saturation Coefficient 1 0.00 to 0.50 0.50

315h E2-08 Motor Iron-core Saturation Coefficient 2 0.00 to 0.75 0.75

316h E2-09 Motor Mechanical Loss 0.0 to 10.0% 0.0

317h E3-01 Motor 2 Control Method Selection 0 V/f Control

318h E4-01 Motor 2 Max. Output Frequency 50.0 to 400.0 Hz 7

319h E4-02 Motor 2 Maximum Voltage 0.0 to 255.0V (230V unit)

31Ah E4-03 Motor 2 Max. Voltage Frequency 0.0 to 400.0 Hz 60.0

31Bh E4-04 Motor 2 Mid. Output Frequency 0.0 to 400.0 Hz

31Ch E4-05 Motor 2 Mid. Output Freq. Voltage 0.0 to 255.0V (230V unit)

31Dh E4-06 Motor 2 Min. Output Frequency 0.0 to 400.0 Hz

31Eh E4-07 Motor 2 Min. Output Freq. Voltage 0.0 to 255.0V (230V unit)

31Fh E5-01 Motor 2 Rated Current 0.00 to 99.99 or 100.0 to 1500.0 Amps

320h E5-02 Motor 2 Rated Slip 0.00 to 20.00 Hz

321h E5-03 Motor 2 No-Load Current 0.00 to 99.99 or 100.0 to 1500.0 Amps

322h E5-04 Motor 2 Number of Poles 2 to 48 poles 4

323h E5-05 Motor w Line-to-Line Resistance 0.000 to 65.000 Ohms

324h E5-06 Motor 2 Leakage Inductance 0.0 to 30.0%

(2)

1 V/f with PG Feedback 2

2 Open Loop Vector

3 Flux Vector

230.0

0.0 to 510.0V (460V unint)

0.0 to 510.0V (460V unint)

0.0 to 510.0V (460V unint)

460.0

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(2)

Notes (for this page only):

1. Initial value differs depending on the Control Method (A1-02).

2. Initial value differs depending on drive capacity (o2-04).

7-18 Registers

Page 55

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

380h F1-01 Encoder (PG) Constant 0 to 60000 ppr 600

381h F1-02 Operation Selection at PG Open 0 Ramp to Stop

Circuit 1 Coast to Stop 1

382h F1-03 Operation Selection at Overspeed 0 Ramp to Stop

383h F1-04 Operation Selection at Speed 0 Ramp to Stop

Deviation 1 Coast to Stop 3

384h F1-05 PG Rotation 0 Counter-clockwise 0

385h F1-06 PG Division Rate (PG Pulse Monitor) 1 to 132 (effective only with PG-B2 control board) 1

386h F1-07 Integral Value during Accel/Decel 0 Disabled 0

Selection 1 Enabled

387h F1-08 Overspeed Detection Level 0 to 120% 115

388h F1-09 Overspeed Detection Delay Time 0.0 to 2.0 seconds

389h F1-10 Excessive Speed Deviation

Detection Level

38Ah F1-11 Excessive Speed Deviation

Detection Delay Time

38Bh F1-12 Number of PG Gear Teeth 1 0 to 1000 0

38Ch F1-13 Number of PG Gear Teeth 2 0 to 1000 0

397h F1-14 PG Open Detection Time 0 to 10.0 seconds 2.0

2 Fast-Stop

3 Alarm Only

1 Coast to Stop 1

2 Fast-Stop

3 Alarm Only

2 Fast-Stop

3 Alarm Only

1 Clockwise

(1)

0 to 50% 10

0.0 to 10.0 seconds 0.5

Notes (for this page only):

1. Initial value differs depending on the control method (A1-02).

7-19 Registers

Page 56

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

38Dh F2-01 AI-14 Bi-polar or Uni-polar Input 0 3-channel Individual 0

Selection 1 3-channel Addition

38Eh F3-01 DI-16 Digital Input Option 0 BCD 1%

38Fh F4-01

390h F4-02 AO-08/AO-12 Channel 1 Gain 0.00 to 2.50 1.00

391h F4-03

392h F4-04 AO-08/AO-12 Channel 2 Gain 0.00 to 2.50 0.50

393h F5-01 DO-02 Channel 1 Output Selection 0 to Fh 0

394h F5-02 DO-02 Channel 2 Output Selection 0 to Fh 1

395h F6-01 DO-08 Output Mode Selection 0 8-channel Individual 0

396h F7-01 PO-36F Frequency Multiple

AO-08/AO-12 Channel 1 Monitor Select.

AO-08/AO-12 Channel 2 Monitor Select.

Selection

1 BCD 0.1%

2 BCD 0.01%

3 BCD 1 Hz 0

4 BCD 0.1 Hz

5 BCD 0.01 Hz

6 BCD (5DG) 0.01 Hz

7 Binary

1 to 33h

1 to 33h

(1)

(1)

1 Binary Output

0 1 x Output Frequency

1 6 x Output Frequency

2 10 x Output Frequency 1

3 12 x Output Frequency

4 36 x Output Frequency

2

3

Notes:

1. Range shown is for flash software version ‘1030’ and CPU version ‘30’. Range differs for previous versions.

7-20 Registers

Page 57

Drive Parameter Registers (Read/Write) (continued)

REGISTER PARAMETER PARAMETER PARAMETER LIMITS / DESCRIPTION INITIAL

(in hex) FUNCTION SETTING VALUE

400h H1-01 Multi-function Input (terminal 3) 0 to 77h 24h

401h H1-02 Multi-function Input (terminal 4) 0 to 77h 14h

402h H1-03 Multi-function Input (terminal 5) 0 to 77h

403h H1-04 Multi-function Input (terminal 6) 0 to 77h

404h H1-05 Multi-function Input (terminal 7) 0 to 77h

405h H1-06 Multi-function Input (terminal 8) 0 to 77h

406h H2-01 Multi-function Output (term. 9 & 10) 0 to 37h 0

407h H2-02 Multi-function Output (term. 25-27) 0 to 37h 1

408h H2-03 Multi-function Output (term. 26-27) 0 to 37h 2

409h H3-01 Auto Speed Reference Signal 0 0 to 10 V DC 0

Level Selection (term. 13) 1 -10 to +10 V DC

40Ah H3-02

40Bh H3-03 Auto Speed Reference Signal Bias -100.0 to +100.0% 0.0

40Ch H3-04

40Dh H3-05 Multi-function Analog Input 1 Select. 0 to 1Fh 0

40Eh H3-06 Multi-function Analog Input 1 Gain 0.0 to 1000.0% 100.0

40Fh H3-07 Multi-function Analog Input 1 Bias -100.0 to +100.0% 0.0

410h H3-08 Multi-function Analog Input 2 Signal 0 0 to 10 V DC

411h H3-09 Multi-function Analog Input 2 Select. 0 to 1Fh 1Fh

412h H3-10 Multi-function Analog Input 2 Gain 0.0 to 1000.0% 100.0

413h H3-11 Multi-function Analog Input 2 Bias -100.0 to +100.0% 0.0

414h H3-12 Analog Input Filter Time Constant 0.00 to 2.00 seconds 0.00

Auto Speed Reference Signal Gain

Multi-function Analog Input 1 Signal

Level Selection (term. 16) 1 -10 to +10 V DC

Level Selection (term. 14) 1 -10 to +10 V DC 2

3 (or 0)

4 (or 3)

6 (or 4)

8 (or 6)

0.0 to 1000.0% 100.0

0 0 to 10 V DC 0

2 4 to 20 mA

(1)

(1)

(1)

(1)

Notes: