Page 1

Product Transition Guide

GPD 515/G5 to G7

PL.G7.02.Transition Guide

Page 2

Product Transition Guide

GPD515/G5 to G7

NOTICE

The information contained within this document is the proprietary property of Yaskawa Electric

America, Inc., and may not be copied, reproduced or transmitted to other parties without the expressed

written authorization of Yaskawa Electric America, Inc. No patent liability is assumed with respect to

the use of the information contained herein. Moreover, because Yaskawa is constantly improving its

high-quality products, the information contained in this document is subject to change without notice.

Every precaution has been taken in the preparation of this document. Nevertheless, Yaskawa assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained in this publication.

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 2 of 38

Yaskawa Electric America, Inc

Page 3

Product Transition Guide

GPD515/G5 to G7

Contents

Feature Overview ....................................................................................................... 5

G7 Benefits vs. G5 ..................................................................................................... 5

Main Specification Differences G5 to G7................................................................... 6

Physical Dimensions .................................................................................................. 9

I/O Terminal Cross Reference G5 to G7.................................................................. 11

Physical I/O Block Terminal Layout.......................................................................... 14

Main Power Terminal Comparison ........................................................................... 14

Available Network Communications ......................................................................... 16

Appendix 1................................................................................................................ 17

Amps, Carriers, Overload, Watt Loss and Dimensions .....................................117

Output Amps, Carrier and Overload Comparison

240V Ratings GPD515/G5 to G7................................................................ 18

Output Amps, Carrier and Overload Comparison

480V Ratings GPD515/G5 to G7................................................................ 19

Mounting Hole Data..................................................................................... 20

Panel Cut-out Data (for external heatsink mounting)................................... 21

Watts Loss Data .......................................................................................... 22

Appendix 2................................................................................................................ 23

........................................................................................23Parameter Differences

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 3 of 38

Yaskawa Electric America, Inc

Page 4

Product Transition Guide

GPD515/G5 to G7

Page Intentionally Left Blank

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 4 of 38

Yaskawa Electric America, Inc

Page 5

Product Transition Guide

GPD515/G5 to G7

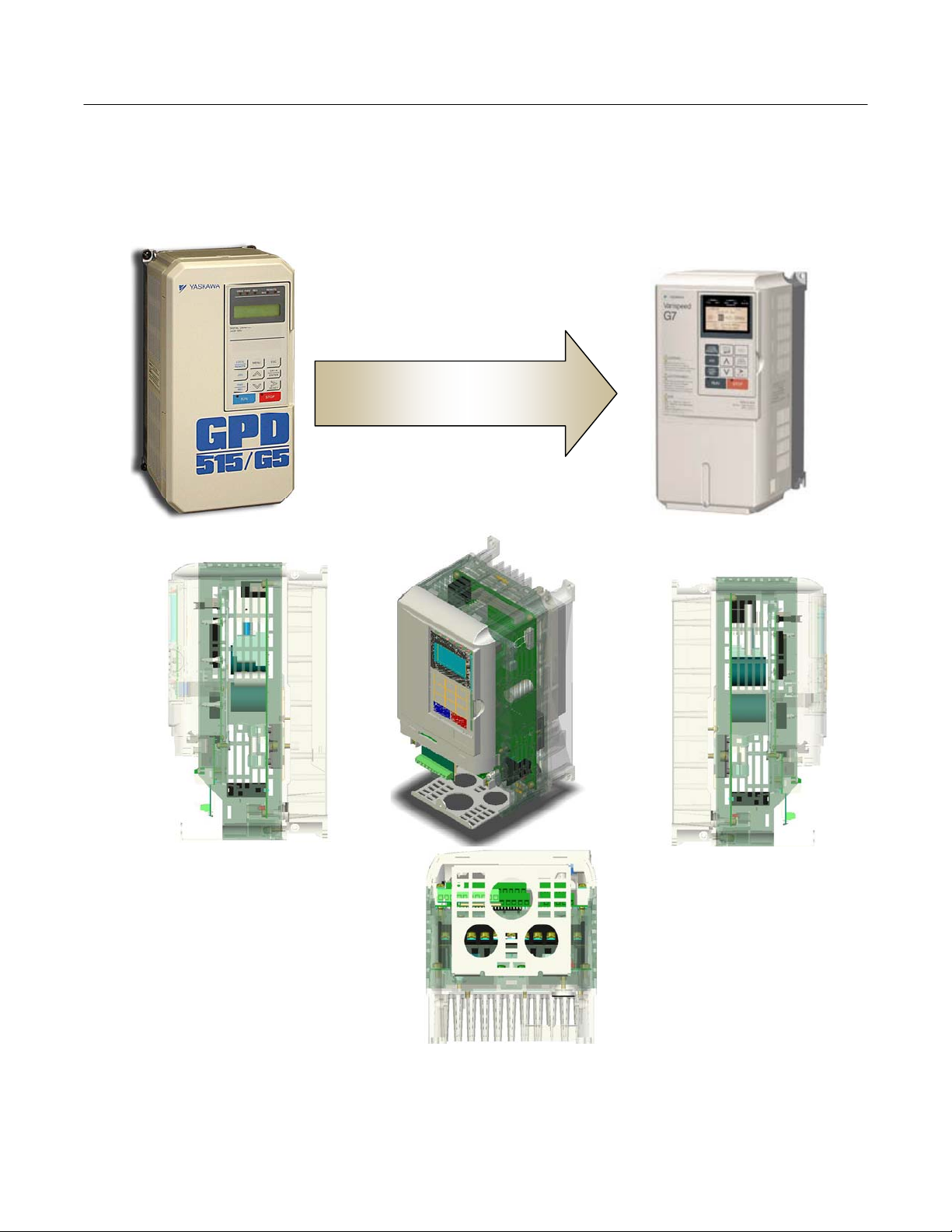

Feature Overview

This document details differences between the GPD515/G5 and G7 product to assist in product transition and new product

introduction.

GPD515/G5 Drive

The GPD 515/G5 drive is a generalpurpose drive, intended for a broad

range of applications in Industrial

Automation. Accordingly, it is

available with many choices of I/O,

communications, and software. It is

available in constant torque ratings,

3/4 to 500 horsepower. The G5

HHP is available to 1500 HP.

G7 Benefits vs. G5

Enhanced G7 Performance

• Auto-tuning 3-Methods (R1/Static/Dynamic)

• World’s first commercial 3-Level Inverter architecture

(480V)

• Static no load auto-tuning offers same torque accuracy

performance as dynamic auto-tuning at base speed &

below

• DC input compatible (all models) simplified connection

to DC power, removal of internal DC bus choke not

required.

• Open-loop torque control

• Improved closed-loop speed response: 60Hz vs. 30Hz

• Improved open-loop speed response: 10Hz vs. 5Hz

• Improved open-loop speed range: 200:1 vs. 100:1

• Higher output frequency resolution: 0.001% vs. 0.01%

• Improved torque response: 300Hz vs. 150Hz

• Improved open loop starting torque: 0.3Hz vs. 0.5Hz

• Improved input voltage specification: 240 vs. 230 and

480 vs. 460.

New Keypad/Digital Operator

• Enhanced digital operator with copy function

• Simplified parameter menu navigation

• New LCD contrast adjustment

• Standard RJ-45 CAT-5 cable connection

New Functions

• New PID sleep function

• More preset speed selections: 17 vs. 9

• New automatic derating based on ambient temperature

setting

• New Bi-directional speed search with speed estimation

mode

applications. The G7 is available in constant torque/heavy dut

ratings 0.5 to 500HP. The G7 is not intended for the simple,

routine AC drive application, it is for the challenges.

(Refer to Yas

Drive” for more details on new G7 Technology.)

ew Functions (continued)

N

• Six additional monitor p

• Improved Energy Savings- manual/

• High Slip Braking

• New cooling fan on

cassette replacement design

• 8.5-300kW

New 12-pulse diode bridge 1

• Built-in DC-link choke 18.5-300kW

Improv

ed Input/Output Functions

• Analog outputs with new 4-20m

resolution.

• l inputs: 12 vs. 8

More digita

• Inputs now support sinking or

• Inputs now support internal or external power supply

• More digital outputs 6 vs. 4

• More versatile analog output

• New pulse I/O (32kHz)

• New quick disconnect term

• New motor temperature analog input

• New motor overheat alarm outputs

• Additional under-torque and over-to

• Built-in RS485 Modbus RTU communication with self

test mode

G7 Drive

The G7 AC drive is the ultimate

performance solution with increased

speed and torque response to provide

servo-like performance from an i

motor. The 480V G7 drive has the

world’s first commercial 3-Level Inver

architecture for total system protection

This patented 3-Level architecture

eliminate peripheral components

typically required to solve installation

problems. G7 drive performance

the ideal drive for high performance

speed, torque, or position control

kawa document “TR.G7.01 Technology Review G7

arameters

automatic modes

/off control and elapsed time and

A selection and 10 bit

sourcing (PNP/NPN)

s

inal I/O block

rque selection points

nduction

ter

.

can

makes it

y

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 5 of 38

Yaskawa Electric America, Inc

Page 6

Product Transition Guide

GPD515/G5 to G7

Main Specification Differences G5 to G7

Specification G5 Specification G7 Specification

Control mode

V/f, V/f w/ PG,

Open-loop vector,

Closed-loop flux vector

Open-loop vector, Closed-loop flux vector,

V/f, V/f w/ PG,

Open-loop vector 2

460V 0.4kW to 300kW (0.5 to 400HP)

Inverter capacity range

Ratings

Main power circuit

configuration

Rated output current

ASR scan time

CASE scan time

I/O Sequence Scan Time

Microprocessor

Output current limit

protection

Output frequency resolution

Speed control accuracy

Speed control range

Speed response

Starting torque

Motor surge protection

Open loop torque control

Torque reference scan time

Performance Features

(480V)

230V 0.4kW to 110kW (0.5 to 150HP)

575V 1.5kW to 160kW (2 to 200HP)

Modular: 300 to 1800HP (VT)

2-Level 3-Level

Example: 240V class, 3.7kW, 17.5A Example: 240V class, 3.7kW, 18A

2msec 1.25msec (except Open-loop vector 2)

5msec 2.5msec (except Open-loop vector 2)

5msec 2.5msec (except Open-loop vector 2)

First generation Second generation

Hardware Hardware, Software

0.01Hz 0.001Hz

Open-loop vector: ±0.2%,

Closed-loop flux vector: ±0.02%

Open-loop vector: 100:1 Open-loop vector 2: 200:1

Open-loop vector: 5Hz

Closed-loop flux vector: 30Hz

Open-loop vector: 150% at 1Hz Open-loop vector 2: 150% at 0.3Hz

No Yes (3-Level)

No Yes (Open-loop vector 2)

2msec 1.25msec (except Open-loop vector 2)

480V 0.4kW to 300kW (0.5 to 400HP)

240V 0.4kW to 110kW (0.5 to 150HP)

Open-loop vector 2: ±0.1%,

Closed-loop flux vector: ±0.01%

Open-loop vector 2: 10Hz

Closed-loop flux vector: 60Hz

Torque response

150Hz

(Closed-loop flux vector)

(Closed-loop flux vector)

300Hz

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 6 of 38

Yaskawa Electric America, Inc

Page 7

Product Transition Guide

Specification G5 Specification G7 Specification

I/O

Quick disconnect I/O

terminals

No Yes

GPD515/G5 to G7

Analog

Analog

Digital

Digital

Programmable functions

Inputs

Quantity

Type

Outputs

Programmable functions

Quantity

Inputs

Programmable functions

Outputs

Type

Quantity

Type

39 45

0-±10VDC x 2 0-±10VDC/4-20mA x 2

-10-10VDC x 2

(8 bit plus sign)

27 30

8 12

24VDC, NPN

Photo coupler isolation, 8mA

45 51

4 6

• Qty 1: Programmable: Form A,

250VAC, 1A, 30VDC, 1A

• Qty 1: Dedicated Fault, Form C,

250VAC, 1A, 30VDC, 1A

• Qty 2: Programmable, photo-

coupler (open collector output),

48V, 50mA, common emitter

connection

-10-10VDC or 4-20mA x 2

(8 bit plus sign)

24VDC, sinking or sourcing (NPN/PNP)

Photo coupler isolation, 8mA

Internal or external power supply

• Qty 3: Programmable: Form A,

250VAC, 1A, 30VDC, 1A

• Qty 1: Dedicated Fault, Form C,

250VAC, 1A, 30VDC, 1A

• Qty 2: Programmable, photo-coupler

(open collector output), 48V, 50mA,

separate emitter connection

Quantity

0 1

0-32kHz, low level: 0.0-0.8VDC high

Input

Pulse

Pulse

Output

Stopping

Fan

Cooling

Signal level

Programmable functions

Quantity

Signal level

Programmable functions

Braking DB transistor

Flux/High slip braking

Modular replacement

On/Off control

Cumulative fan operation

time

0 standard (1 with option) 1

Built-in to G5M27P5 (10HP)

Built-in to G5M4015 (25HP)

~

level: 3.5-13.2VDC, duty cycle: 30-70%,

3kohm

~ 4

~ 0-32kHz, 9.0VDC, 2.2kohm

~ 6

Built-in to G7U2015 (20HP)

Built-in to G7U4015 (25HP)

No Yes

No Yes

No Yes

No Yes

Rotational

Design

Features

Auto-tuning

Rotational

Stationary

Stationary (primary resistance only)

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 7 of 38

Yaskawa Electric America, Inc

Page 8

Product Transition Guide

GPD515/G5 to G7

Specification G5 Specification G7 Specification

Multi-step speed operation

PID sleep mode

User customized

programming

Design

Features

Speed search

Split front cover

Timer Function

Run permissive

Motor temperature input

9-step speeds 17-step speeds

No Yes

No Yes (DriveWorks EZ)

Current Detection

Uni-Directional

Current Detection or Speed Estimation

Bi-directional for Speed Estimation

No Yes

On/Off delay (0.0-25.5sec) On/Off delay (0.0-300.0sec)

No Yes

No Yes

Harmonics

Keypad/Operator

Network

Communications

Undertorque detection

12-phase rectification input

DC choke built-in

Constant access level

selection

Copy function

Display

Monitoring

Verify function

Viewable monitors

Built-in

Option Card

No Yes

No

230V, G5M2018-G5M2075

460V, G5M4018-G5M4160

3-level selectable

(Quick-Start, Basic, Advanced)

240V, G7U2018-G7U2110

480V, G7U4018-G7U4300

240V, G7U2018-G7U2110

480V, G7U4018-G7U4300

2-level selectable

(Quick-Program, Advanced)

No (optional keypad) Yes

2 Line x 16 Character LCD

5 Line x 16 Character LCD

(Contrast Adjustable)

1 monitor 3 sequential monitors at same time

Yes Modified constants can be displayed.

35 40

Modbus RTU (RS-232, 9.6kbps) Modbus RTU (RS-232/422/485, 19.2kbps)

Modbus RTU (RS-422/485), Ethernet

(Modbus/ TCP/IP), DeviceNet,

Profibus-DP, Modbus Plus

Ethernet (Modbus/ TCP/IP), DeviceNet,

Profibus-DP, Modbus Plus, LonWorks

Input specifications

Vibration/Shock

Service Conditions

Storage

Temp

ºC

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 8 of 38

Yaskawa Electric America, Inc

3-phase, 200-230VAC

3-phase, 380-460VAC,

Tolerance: +10 to -15%

~

240V: 60HP (2037) and Below, 480V: 75HP

240V: 60HP (2045) and Above, 480V: 100HP

3-phase, 200-240VAC

3-phase, 380-480VAC

Tolerance: +10 to -15%

(4045) and Below

1.0G (9.8m/s^2) 10 to 20Hz

0.6G (5.9m/s^2) 20 to 55Hz

(4055) and Above

1.0G (9.8m/s^2) 10 to 20Hz

0.2G (2.0m/s^2) 20 to 55Hz

-10ºC ~ +60ºC -20ºC ~ +60ºC

Page 9

Product Transition Guide

Terminal Comparison

Physical Dimensions

Between 20 - 200 HP, the G7 is 18% smaller volume on average than the equivalent GPD515/G5.

(See appendix 1)

savings over the GPD515/G5.

Based on meeting NEC full load amp requirements, the G7 footprint can offer a space

G7– 18% less volume

compared to GPD515/G5

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 9 of 38

Yaskawa Electric America, Inc

Page 10

Product Transition Guide

GPD515/G5 to G7

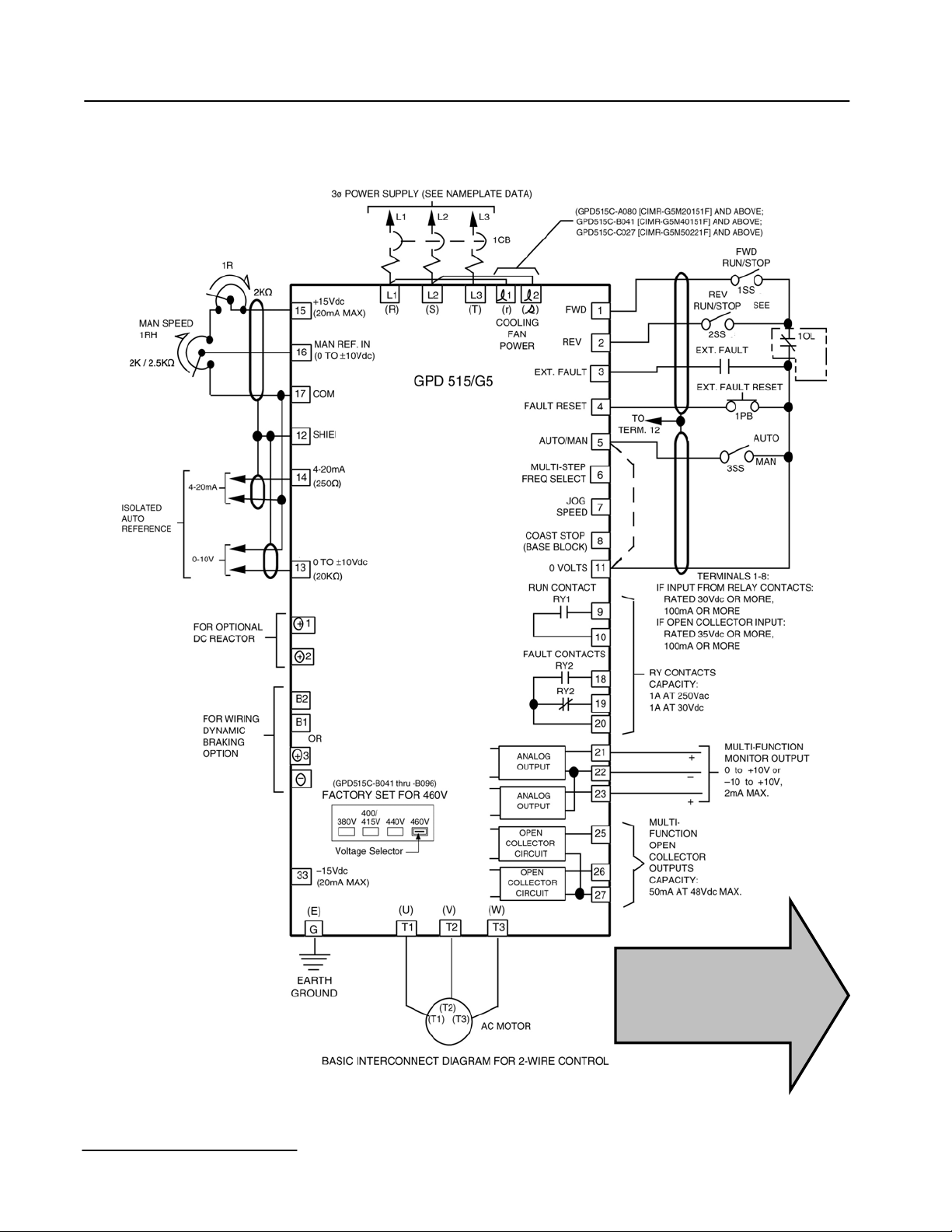

GPD515/G5 Terminal Description

GPD515/G5

PL.G7.02.TransitionGuide 4/21/04

Page 10 of 38

Yaskawa Electric America, Inc

Compare to G7

terminals, see

next page.

Page 11

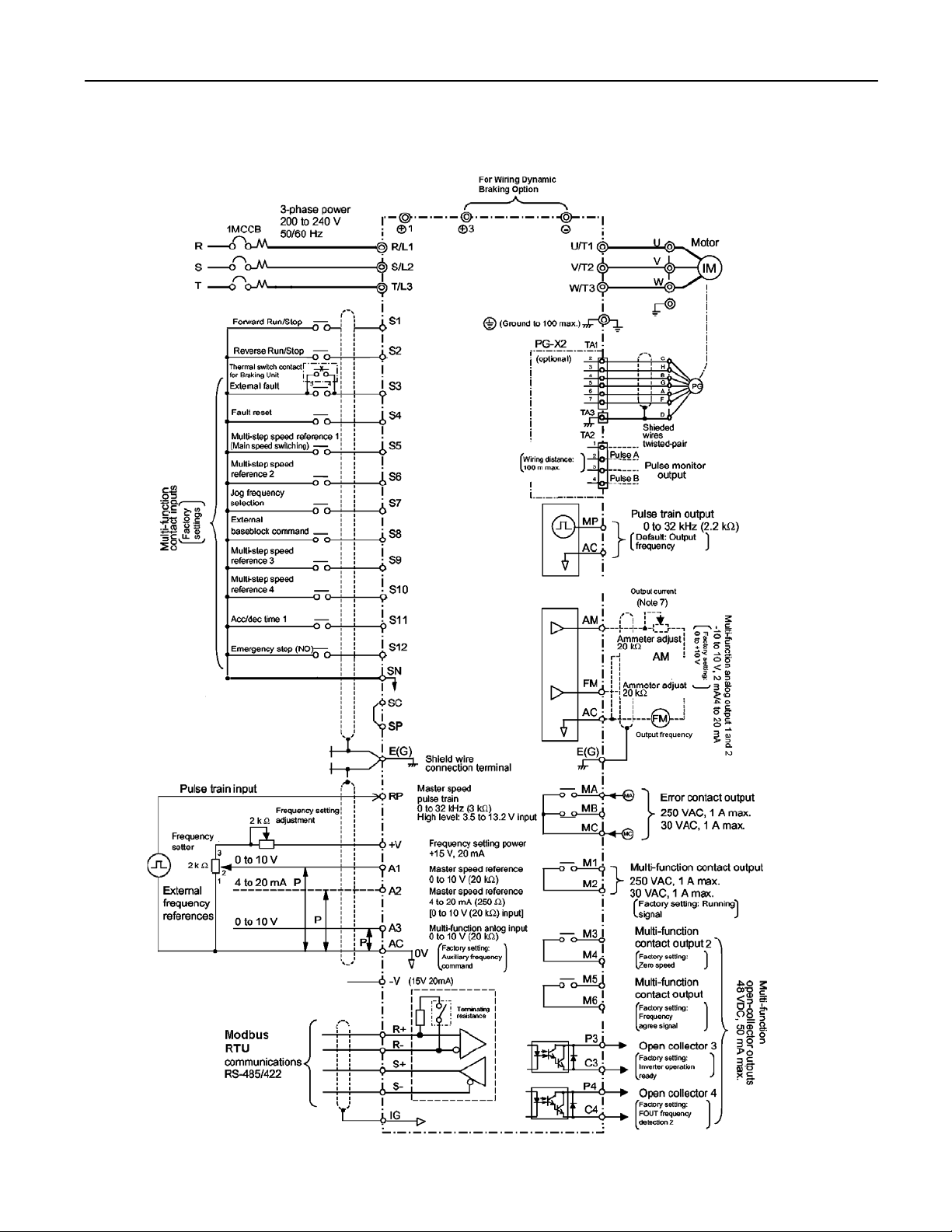

G7 Terminal Description

Product Transition Guide

GPD515/G5 to G7

G7

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 11 of 38

Yaskawa Electric America, Inc

Page 12

Product Transition Guide

GPD515/G5 to G7

I/O Terminal Cross Reference G5 to G7

GPD515/G5 Terminal

GPD515/G5

Type

Terminal

1

2

3

4

5

6

7

8

Digital Input Signals

11

–

–

Forward run/stop

Signal level: (Photo-coupler

insulated input: +24VDC, 8mA)

Reverse run/stop

External fault input

Fault reset input

Master/Aux. change Multi-step speed reference 1

Multi-step speed ref.1

Multi-step speed ref.2

Jog reference

External baseblock

Sequence control input common

Default Function

–

–

–

–

G7

Terminal

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

SN

SC

SP

G7 Terminal

Default Function G7 Description

Forward run/stop command –

Reverse run/stop command –

External fault input

Fault reset

(Master/auxiliary switch)

Multi-step speed reference 2

Jog frequency reference

External baseblock N.O.

Multi-step speed reference 3

Multi-step speed reference 4

Accel/Decel time select

Emergency Stop N.O.

Digital input common

Factory connected to SP

Factory connected to SC

Multi-function digital inputs

Functions set by:

H1-01 to H1-10.

+24VDC, 8mA

Photo coupler isolation

Factory connected for internal

supply, sinking mode.

Refer to G7 User Manual for

other methods.

15

33

13

14

Analog Input Signals

16

17

12

+15VDC Power supply

(20mA ma ximum)

-15VDC Power supply

(20mA ma ximum)

Master frequency ref. (voltage)

-10 to +10VDC (20kohm)

0 to +10VDC (20kohm)

Master frequency ref. (current)

4 to 20mA (250ohm)

Multi-function analog input

-10 to +10VDC (20kohm),

0 to +10VDC (20kohm)

Common for control circuit 0V

Connection to shield sheath of

signal lead

+V

-V

A1

A2

A3

AC

E(G)

+15VDC power supply

-15VDC power supply

Master frequency reference

Add to terminal A1

Auxiliary frequency

reference 1

Analog common –

Shield wire, optional ground

line connection point

+15VDC

(20mA ma ximum)

-15VDC

(20mA ma ximum)

0 to +10VDC=100%

0 to +/-10VDC=100% (H3-01)

(20kohm)

4 to 20mA=100% (250ohm)

0 to +10VDC=100% (20kohm)

Function set by H3-09.

0 to +10Vdc=100%/(20kohm)

0 to +/-10Vdc=100%

Function set by H3-05

–

PL.G7.02.TransitionGuide 4/21/04

Page 12 of 38

Yaskawa Electric America, Inc

Page 13

I/O Terminal Cross Reference G5 to G7

GPD515/G5 Terminal G7 Terminal

GPD515/G5

Type

Terminal

9 M1

10

25

27

26

27

Digital Output Signals

18 MA

19 MB

20

During run (NO contact)

Form A dry contact

250VAC1A

30VDC, 1A

Zero speed detection

Open collector output, 48V, 50mA

Open collector output common

Speed agree detection

Open collector output

48V, 50mA or less

Open collector output common

Dedicated fault contact

Form C dry contact

250VAC, 1A

30VDC, 1A

Default Function

G7

Terminal

M2

P3

C3

P4

C4

MC

Default Function G7 Description

During run

(N.O. contact)

Factory setting:

Drive ready

Open collector output common

Factory setting:

Fout detect 2

Open collector output common

Fault contact output

Product Transition Guide

GPD515/G5 to G7

Multi-function digital output

Form A dry contact

250VAC, 1A

30VDC, 1A

Function set by H2-01

Multi-function open collector

output

48VDC, 50mA

Function set by H2-04

Multi-function open collector

output

48VDC, 50mA

Function set by H2-05

Dedicated fault contact

Form C dry contact:

250VAC, 1A

30VDC, 1A

~

~

Frequency monitor

21

23

Analog Output Signals

10VDC=100% output frequency

(2mA max imum)

Current monitor

5VDC=drive rated current

(2mA max imum)

~

~

M3

M4

M5

M6

FM

AM

Zero speed

(N.O. contact)

Frequency agree

(N.O. contact)

Output frequency

Output current

Multi-function digital output

Form A dry contact

250VAC, 1A

30VDC, 1A

Function set by H2-02.

Multi-function digital output

Form A dry contact

250VAC, 1A

30VDC, 1A

Function set by H2-03

0 to +10VDC or 0 to ±10VDC

(Max current 2mA) (500ohm)

10VDC or 20mA=100% output

frequency

Function set by H4-01

0 to +10VDC or 0 to ±10VDC

(2mA maximum) (500ohm)

5VDC or 12mA=100% drive

rated current

Function set by H4-04

22

Common (Current Monitor)

Analog common –

AC

__________________________

PL.G7.02.TransitionGuide 4/21/04

Yaskawa Electric America, Inc

Page 13 of 38

Page 14

Product Transition Guide

GPD515/G5 to G7

I/O Terminal Cross Reference G5 to G7

GPD515/G5 Terminal

GPD515/G5

Terminal

Type

Pulse I/O

–

–

RS-485/422

–

Default Function

–

–

–

–

G7

Terminal

RP

MP

R+

R-

S+

S-

IG

Pulse input

Pulse output

Modbus RTU protocol

Differential input

PHC isolation

Modbus RTU protocol

Differential output

PHC isolation

Signal common –

G7 Terminal

Default Function G7 Description

Physical I/O Block Terminal Layout

G5 Terminal Block

11 12 (G) 13 14 15 16 17 26 27 3325 18 19 20

1 234567821 22 23 910

0-32kHz (3kohm) ±5%

High level: 3.5-13.2VDC

Low level: 0.0-0.8VDC

Duty Cycle: 30%-70%

Function set by H6-01

0-32kHz

Output: +5VDC

Load: 1.5kohm

Function set by H6-06

–

PL.G7.02.TransitionGuide 4/21/04

Page 14 of 38

Yaskawa Electric America, Inc

Page 15

Product Transition Guide

GPD515/G5 to G7

Main Power Terminal Comparison

G5 terminal G7 terminal Function

R L1 R/L1

S L2 S/L2

T L3 T/L3

R1/L11

S1/L21

T1/L31

U T1 U/T1

V T2 V/T2

W T3 W/T3

B1 B1

B2 B2

DC power supply input (Connection 1 to )

1 1 DC power supply connection (Connection 1 to )

2 2 DC reactor connection (Connection 1 to 2)

3 3 Braking unit connection (Connection 3 to )

r r

s200

s400

Feature availability is model dependant. Refer to the table below.

Terminal

Function

s

Product Series

Voltage Class

0.4kW (0.5HP)

0.75kW (1HP)

1.5kW (2HP)

2.2kW (3HP)

3.7kW (5HP)

Main circuit power supply input

Main circuit power supply input (12-pulse units)

Drive output

Braking resistor unit connection

DC reactor connection (Connection 1 to 2)

Cooling fan and control power supply

Cooling fan power supply

Control power supply

Cooling fan power supply

5.5kW (7.5HP)

7.5kW (10HP)

18.5kW (25HP)

15kW (20HP)

22kW (30HP)

30kW (40HP)

11kw (15HP)

37kW (50HP)

75kW (100HP)

45kW (60HP)

90kw (125HP)

55kW (75HP)

132kW (200HP)

160kW (250HP)

110kw (150HP)

185kW (300HP)

220kW (350HP)

300kW (500HP)

12-pulse diode

bridge

Braking

resistor

connection

DC power

supply input

DC reactor

connection

Braking

chopper unit

connection

NEMA1

Enclosure

Open Type

Enclosure

R1,

S1,

T1

B1,

B2

1

1

2

(B1)

3

G5

G7

G5

G7

G5

G7

G5

G7

G5

G7

G5

G7

G5

G7

230V

460V

240V

480V

230V

460V

240V

480V

230V

460V

240V

480V

230V

460V

240V

480V

230V

460V

240V

480V

230V

460V

240V

480V

230V

460V

240V

480V

Not Available No Product

Not Available

Not Available Available No Product

Not Available Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Standard

Standard

Standard

Standard

Remove Upper/Lower Covers

Remove Upper/Lower Covers Standard

Remove Upper/Lower Covers Standard No Product

Remove Upper/Lower Covers Standard

Not Available No Product

Not Available

Not Available No Product

Not Available

Not Available No Product

No Product

N.A. (Reactor Built-in) Special No Product

N.A. (Reactor Built-in)

N.A. (Reactor Built-in) No Product

N.A. (Reactor Built-in)

No Product

No Product

No Product

N.A.

Optional N.A. No Product

Optional N.A.

No Product

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 15 of 38

Yaskawa Electric America, Inc

Page 16

Product Transition Guide

GPD515/G5 to G7

Available Network Communications

Yaskawa Network Communication Options

Market Protocol G5 G5 HHP G7

Industrial

Modbus TCP/IP

Modbus Plus

Modbus RTU

General

Purpose

Ethernet

CM061 CM061 CM061

CM053

CM059

CM090 n/a CM090

CM071 CM071 CM071

Built-in RS-232

[CM085 for RS-485]

n/a

Built-in RS-232

[CM085 for RS-485]

CM057

CM059

Built-in

Commercial

PL.G7.02.TransitionGuide 4/21/04

Page 16 of 38

Yaskawa Electric America, Inc

CM048 n/a CM048

Page 17

Product Transition Guide

Appendix 1

Amps, Carriers, Overload, Heat loss and Dimension Comparison

GPD515/G5 to G7

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 17 of 38

Yaskawa Electric America, Inc

Page 18

Product Transition Guide

GPD515/G5 to G7

Output Amps, Carrier and Overload Comparison

240V Ratings GPD515/G5 to G7

240V

GPD515/G5 G7

GPD515

NEC Motor

HP 240V

0.5 2.2

0.75 3.2

1.5 6

7.5 22 25P51

10 28 27P51

15 42 20111

20 54 20151

25 68

30 80

40 104

50 130

60 154

75 192 20551

100 248 20751

125 312 150 360 -

NEC Motor

Amps

1 4.2

2 6.8 21P51

3 9.6 22P21

5 15.2 23P71

G5

Model

CIMR-G5M

20P41

20P71

20181

20221

20301

20371

20450

Output

Amps

3.2 15 150

6 15 150

8 15 150

11 15 150

17.5 15 150

25 15 150

33 15 150

49 15 150

64 15 150

80 15 150

96 10 150

130 10 150

160 10 150

183 10 150

224 10 150

300 10 150

- - -

- - -

Fc kHz OL %

G7

Model

CIMR-G7U

20P41

20P71

21P51

22P21

23P71

25P51

27P51

20111

20151

20181

20221

20300

20370

20450

20550

20750

20900

21100

Output

Amps

3.2 15 150

6 15 150

8 15 150

12 15 150

18 15 150

27 15 150

34 15 150

49 15 150

66 15 150

80 15 150

96 10 150

130 10 150

160 10 150

183 10 150

224 10 150

300 10 150

358 2 150

415 2 150

Fc

KHz

Overload %

PL.G7.02.TransitionGuide 4/21/04

Page 18 of 38

Yaskawa Electric America, Inc

Page 19

Product Transition Guide GPD515/G5 to G7

Appendix 1 –Amps, Carrier , Overload, Dimensions, Heat Loss

Output Amps, Carrier and Overload Comparison

480V Ratings GPD515/G5 to G7

480V

GPD515/G5 G7

GPD515/

NEC Motor

HP 480V

0.5 1.1

0.75 1.6

1.5 3

7.5 11 44P01

10 14 45P51

15 21 47P51

20 27 40111

25 34 40151

30 40 40181

40 52 40221

50 65 40301

60 77 40371

75 96 40451

100 124 40551

125 156 40751

150 180

200 240 -

250 302

300 361 41850

350 414

400 477

500 590

NEC Motor

Amps

1 2.1

2 3.4

3 4.8 41P51

5 7.6 43P71

G5

Model CIMR-

G5M

40P41

40P71

-

41101

41601

41850

42200

43000

Output

Amps

1.8 15 150

3.4 15 150

4.8 15 150

8 15 150

11.7 15 150

14 15 150

21 12.5 150

27 12.5 150

34 10 150

41 10 150

52 8 150

65 8 150

80 6 150

96 6 150

128 6 150

165 6 150

- - -

224 5 150

- - -

302 5 150

340 2 150

450 2 150

605 2 150

Fc kHz OL%

G7

Model

CIMR-G7U

40P41

40P71

41P51

42P21

43P71

44P01

45P51

47P51

40111

40151

40181

40221

40301

40371

40451

40550

40750

40900

41100

41320

41600

42200

43000

Fc

Output

Amps

1.8 8 150

3.4 8 150

4.8 8 150

6.2 8 150

9 8 150

11 8 150

15 8 150

21 8 150

27 8 150

34 8 150

42 8 150

52 8 150

65 8 150

80 8 150

97 8 150

128 5 150

165 5 150

195 3 150

240 3 150

270 2 150

302 2 150

370 2 150

450 2 150

605 2 150

kHz

(3-Level

Control)

Overload %

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 19 of 38

Yaskawa Electric America, Inc

Page 20

Product Transition Guide

GPD515/G5 to G7

Mounting Hole Data

GPD515/G5

Mounting Hole Data

GPD515/G5 GPD515/G5

Model (Millimeters) (Inches)

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

-

40P4

40P7

41P5

42P2

43P7

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

-

4110

-

4160

4185

4220

4300

PL.G7.02.TransitionGuide 4/21/04

Page 20 of 38

Yaskawa Electric America, Inc

W1 H1 W1 H1

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

186 285 7.32 11.22

186 285 7.32 11.22

236 365 9.29 14.37

236 365 9.29 14.37

275 435 10.83 17.13

275 435 10.83 17.13

320 650 12.60 25.59

320 650 12.60 25.59

370 775 14.57 30.51

370 775 14.57 30.51

445 895 17.52 35.24

- - - -

- - - 126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

186 285 7.32 11.22

186 285 7.32 11.22

236 365 9.29 14.37

236 365 9.29 14.37

275 435 10.83 17.13

275 435 10.83 17.13

275 610 10.83 24.02

275 610 10.83 24.02

275 610 10.83 24.02

350 795 13.78 31.30

350 795 13.78 31.30

- - - 445 895 17.52 35.24

- - - 445 895 17.52 35.24

750 1400

750 1400

750 1550

29.53 55.12

29.53 55.12

29.53 61.02

G7

Mounting Hole Data

G7 G7

Model (Millimeters) (Inches)

W1 H1 W1 H1

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

40P4

40P7

41P5

42P2

43P7

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

186 285 7.32 11.22

186 285 7.32 11.22

216 335 8.50 13.19

216 335 8.50 13.19

195 385 7.68 15.16

220 435 8.66 17.13

250 575 9.84 22.64

250 575 9.84 22.64

325 700 12.80 27.56

325 700 12.80 27.56

370 820 14.57 32.28

445 855 17.52 33.66

445 855 17.52 33.66

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

126 266 4.96 10.47

186 285 7.32 11.22

186 285 7.32 11.22

216 335 8.50 13.19

216 335 8.50 13.19

220 435 8.66 17.13

220 435 8.66 17.13

260 535 10.24 21.06

260 535 10.24 21.06

260 535 10.24 21.06

325 700 12.80 27.56

325 700 12.80 27.56

370 820 14.57 32.28

370 820 14.57 32.28

445 895 17.52 35.24

445 895 17.52 35.24

1270 540

1270 540

1440 730

21.26 50.00

21.26 50.00

28.74 56.69

Page 21

Product Transition Guide GPD515/G5 to G7

Appendix 1 –Amps, Carrier , Overload, Dimensions, Heat Loss

Panel Cut-out Data (for external heatsink mounting)

Refer to NEC Ratings tables in Appendix 1 for the appropriate GPD515/G5 to G7 cross-reference.

Note: Ampacity ratings vary between GPD515/G5 to G7 models

GPD515/G5

PANEL CUT OUT OPENING

EXTERNAL HEATSINK MOUNTING

Millimeters Inches

Model W H W H

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

40P4

40P7

41P5

42P2

43P7

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4110

4160

4185

4220

4300

(mm) (mm) (Inches) (Inches)

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

180 298 7.09 11.73

180 298 7.09 11.73

200 377 7.87 14.84

200 377 7.87 14.84

300 404 11.81 15.91

300 404 11.81 15.91

380 627 14.96 24.68

380 627 14.96 24.68

451 756 17.76 29.76

451 756 17.76 29.76

555 894 21.85 35.20

-

-

-

-

- - - -

- - - 138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

180 298 7.09 11.73

180 298 7.09 11.73

200 377 7.87 14.84

200 377 7.87 14.84

300 404 11.81 15.91

300 404 11.81 15.91

309 571 12.17 22.48

309 571 12.17 22.48

309 571 12.17 22.48

440 761 17.32 29.96

440 761 17.32 29.96

- - - 555 894 21.85 35.20

- - - 555 894 21.85 35.20

875 1324 34.45 52.13

875 1324 34.45 52.13

873 1475 34.37 58.07

G7

PANEL CUT OUT OPENING

EXTERNAL HEATSINK MOUNTING

Millimeters

Model W H W H

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

40P4

40P7

41P5

42P2

43P7

44P0

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

(mm) (mm) (Inches) (Inches)

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

197 298 7.76 11.73

197 298 7.76 11.73

233 353 9.17 13.90

233 353 9.17 13.90

244 369 9.61 14.53

269 419 10.59 16.50

359 545 14.13 21.46

359 545 14.13 21.46

434 673 17.09 26.50

434 673 17.09 26.50

484 782 19.06 30.79

555 817 21.85 32.17

555 817 21.85 32.17

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

138 271 5.43 10.67

197 298 7.76 11.73

197 298 7.76 11.73

233 353 9.17 13.90

233 353 9.17 13.90

269 419 10.59 16.50

269 419 10.59 16.50

309 519 12.17 20.43

309 519 12.17 20.43

309 519 12.17 20.43

434 673 17.09 26.50

434 673 17.09 26.50

484 782 19.06 30.79

484 782 19.06 30.79

555 817 21.85 32.17

555 817 21.85 32.17

693 1227 27.28 48.31

693 1227 27.28 48.31

875 1397 34.45 55.00

Inches

__________________________

PL.G7.02.TransitionGuide 4/21/04

Page 21 of 38

Yaskawa Electric America, Inc

Page 22

Product Transition Guide

GPD515/G5 to G7

Watts Loss Data

G5

Model

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

-

40P4

40P7

41P5

42P2

43P7

44P0

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4110

4160

4185

4220

4300

GPD515/G5 (W)

Internal Heatsink Total

50 15 65

65 25 90

80 40 120

60 80 140

80 135 215

90 210 300

110 235 725

160 425 585

200 525 725

230 655 885

280 830 1110

440 930 1370

620 1110 1730

660 1380 2040

890 1740 2630

1160 2050 3210

- - -

- - 50 10 60

65 20 85

80 30 110

60 65 125

65 80 145

80 120 200

85 135 220

120 240 360

150 305 455

180 390 570

195 465 660

260 620 880

315 705 1020

370 875 1245

415 970 1385

710 1110 1820

890 1430 2320

- - -

1160 1870 3030

- - -

1520 2670 4190

1510 3400 4910

2110 4740 6850

2910 6820 9730

Model

20P4

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

40P4

40P7

41P5

42P2

43P7

44P0

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

Internal Heatsink Total

36 21 57

42 43 85

47 58 105

53 83 136

64 122 186

87 187 274

112 263 375

136 357 493

174 473 647

241 599 840

257 679 936

362 878 1240

434 1080 1514

510 1291 1801

607 1474 2081

823 2009 2832

871 1660 2531

1194 2389 3583

39 10 49

44 21 65

46 33 79

49 41 90

63 77 140

66 100 166

80 132 212

107 197 304

116 246 362

135 311 446

174 354 528

210 516 726

246 633 879

285 737 1022

340 929 1269

488 1239 1727

597 1554 2151

762 1928 2690

928 2299 3227

1105 2612 3717

1501 3614 5115

1995 4436 6431

2205 5329 7534

2941 6749 9690

G7

G7 (W)

PL.G7.02.TransitionGuide 4/21/04

Page 22 of 38

Yaskawa Electric America, Inc

Page 23

y

Appendix 2

Parameter Differences

The following parameter list shows the differences

between GPD515/G5 and G7 parameters. Parameters not

listed are identical between GPD515/G5 and G7. Refer to

the G7 instruction manual for details on specific

parameter functions. Parameters are listed alphabetically

b

GPD515/G5.

Product Transition Guide

Appendix 2- Parameter Differences

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 23 of 38

Yaskawa Electric America, Inc

Page 24

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

A1-01

(Digital Operator Display)

Access Level 0: Operation Only

Name

Setting or Selection

1: User Level

2: Quick-Start [Q]

3: Basic Level [B]

4: Advanced Level [A]

Parameter

No.

A1-01

(Digital Operator Display)

Name

Access Level Selection

Remarks on

Setting or Selection

Removed:

3: Basic Level [B]

Modified selection:

2: Advanced Level

Control Method Selection

A1-02

Reference Selection 0: Operator

B1-01

Operation Method

B1-02

Selection

Speed Search Selection at

B3-01

Start

— — —

— — —

— — —

— — —

Energy -saving Mode

B8-03

Selection

0: V/F control without PG

1: V/F control with PG

2: Open Loop Vector

3: Flux Vector

1: Terminals

2: Communication Serial Com

3: Option PCB

4: EWS Reference from CP-717

0: Operator

1: Terminals

2: Communication Serial Com

3: Option PCB

4: EWSRun from CP-717

0: Disabled

1: Enabled

0:Disabled

1:Enabled

A1-02

b1-01

b1-02

b3-01

b3-05

b5-15

b5-16

b5-17

b8-01

Control Method Selection

Reference Selection

Run Command Selection

Speed Search Selection

Speed Search Delay Time

Sleep Function Start Level

Sleep Delay Time

PID Accel/Decel Time

Energy Saving Control

Selection

Additional function:

4: Open Loop Vector control 2

Changed to:

4: Pulse Input

Removed selection 4:

4: EWSRun from CP-717

Modified selections:

0: Speed Estimation Speed Search Disable

1: Speed Estimation Speed Search Enable

2: Current Detection Speed Search Disable

3: Current Detection Speed Search Enable

New Parameter

New Parameter

New Parameter

New Parameter

Changed Parameter No.

Energy-saving Control

B8-04

Gain

Energy-saving Control

B8-05

Time Constant

— — —

— — —

— — —

Output Voltage Limit 0:Disabled

C3-06

Operation Selection 1:Enabled

PL.G7.02.TransitionGuide 4/21/04

Page 24 of 38

Yaskawa Electric America, Inc

—

—

Energy Saving Gain

b8-02

Energy Saving Control

b8-03

Filter Time Constant

Energy Saving Coefficient

b8-04

Value

Power Detection Filter

b8-05

Time

Search Operation Voltage

b8-06

Limit

Output Voltage Limit

C3-05

Opera tion Selection

Changed Parameter No.

Changed Parameter No.

New Parameter

—

—

Changed Parameter No.

Page 25

GPD515/G5 Parameters G7 Parameters

Parameter

No.

— — —

Name

(Digital Operator Display)

Setting or Selection

Parameter

No.

C6-02

Name

(Digital Operator Display)

Carrier Frequency

Selection

Product Transition Guide

Appendix 2- Parameter Differences

Remarks on

Setting or Selection

New parameter function different than old

C6-02 in GPD515/G5

0: Low noise

1: Fc = 2.0 kHz

2: Fc = 5.0 kHz

3: Fc = 8.0 kHz

4: Fc = 10.0 kHz

5: Fc = 12.5 kHz

6: Fc = 15.0 kHz

F: Program Determined by the settings of C603 thru C6-05

Carrier Frequency Upper

C6-01

Limit

Carrier Frequency Lower

C6-02

Limit

Carrier Frequency

C6-03

Proportional Gain

— — —

Hunting Prevention

C7-01

Selection

Hunting Prevention Gain —

C7-02

AFR Gain —

C8-08

AFR Time Constant —

C8-09

— — —

— — —

— — —

— — —

— — —

— — —

— — —

— — —

— — —

Jog Frequency Reference

D1-09

— — —

0:Disabled

1:Enabled

—

—

—

C6-03

C6-04

C6-05

C6-11

n1-01

n1-02

n2-01

n2-02

n2-03

d1-09

d1-10

d1-11

d1-12

d1-13

d1-14

d1-15

d1-16

d1-17

d2-03

Carrier Frequency

Upper Limit

Carrier Frequency

Lower Limit

Carrier Frequency

Proportional Gain

Carrier Frequency

Selection Open Loop

Vector Control 2

Hunting Prevention

Selection

Hunting Prevention Gain

Setting

Speed Feedback Detection

Control AFR Gain

AFR Time

Speed Feedback Detection

Control

AFR Time Constant 2

Frequency Reference 9

Frequency Reference 10

Frequency Reference 11

Frequency Reference 12

Frequency Reference 13

Frequency Reference 14

Frequency Reference 15

Frequency Reference 16

Jog Frequency Reference

Master Speed Reference

Lower Limit

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

New Parameter

Select the carrier frequency when open loop

vector control 2 is used.

1: 2 kHz

2: 4 kHz

3: 6 kHz

4: 8 kHz

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

New parameter

Sets the time constant to control the amount

of change in the speed at low speed.

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

Changed Parameter No.

New Parameter

— — —

— — —

d6-01

d6-02

Magnetic Field Weakening

Level

Magnetic Field Frequency

New Parameter

New Parameter

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 25 of 38

Yaskawa Electric America, Inc

Page 26

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

(Digital Operator Display)

— — —

E1-02

Motor Selection

Motor 2 Control Method

E3-01

Selection

Motor 2 Max. Output

E4-01

Frequency

Motor 2 Max.Voltage —

E4-02

Motor 2 Max.

E4-03

Voltage Frequency

Base Frequency

Motor 2 Mid.

E4-04

Output Frequency 1

Mid Frequency

Motor 2 Mid.

E4-05

Output Frequency

Voltage 1

Mid Voltage

Motor 2 Min.

E4-06

Output Frequency

Min Frequency

Motor 2 Min.

E4-07

Output Frequency

Voltage

Min Voltage

Motor 2 Rated Current —

E5-01

Motor 2 Rated Slip —

E5-02

Motor 2

E5-03

No-load Current

Motor 2

E5-04

Number of poles

Motor 2 Line-to-line

E5-05

Resistance

Motor 2 Leak Inductance —

E5-06

— — —

— — —

— — —

Name

Setting or Selection

0:Std Fan-Cooled

1:Std Blower-Cooled

2:Vector Motor

—

0: V/F control

1: V/F with PG Feedback

2: Open Loop Vector

3: Flux Vector

—

—

—

—

—

—

—

—

—

Parameter

(Digital Operator Display)

No.

Magnetic Field Forcing

d6-03

Function Selection

Motor Overload Protection

Selection

L1-01

Motor Rated Output

E2-11

Motor 2 Control Method

E3-01

Selection

Motor 2 Maximum Output

E3-02

Frequency

Motor 2 Maximum Output

E3-03

Voltage

Motor 2 Base Frequency

E3-04

Base Frequency

Motor 2 Mid Output

E3-05

Frequency

Mid Frequency

Motor 2 Mid Output

E3-06

Voltage VA

Mid Voltage

Motor 2 Minimum Output

E3-07

Frequency

Min Frequency

Motor 2 Minimum Output

E3-08

Voltage

Min Voltage

Motor 2 Rated Current

E4-01

Motor 2 Rated Slip

E4-02

Motor 2 No-Load Current

E4-03

Motor 2 Number of Poles

E4-04

Motor 2 Line-to-Line

E4-05

Resistance

Motor 2 Leakage

E4-06

Inductance

Motor 2 Rated Output

E4-07

AO-12 Channel 1 Signal

F4-07

Level

AO-12 Channel 2 Signal

F4-08

Level

Name

Remarks on

Setting or Selection

New Parameter

0:Disabled

1:Enabled

Changed Parameter No.

Additional selection

0: Disabled

1: Standard Fan Cooled

2: Standard Blower Cooled

3: Vector Motor

New Parameter

This value is automatically set during auto

tuning.

Additional selection

4: Open Loop Vector Control 2

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

New Parameter

This value is automatically set during autotuning.

New Parameter

Sets the range of the voltage output.

0: 0 to 10 Vdc

1: -10 to +10 Vdc

New Parameter

Sets the range of the voltage output.

0: 0 to 10 Vdc

1: -10 to +10 Vdc

PL.G7.02.TransitionGuide 4/21/04

Page 26 of 38

Yaskawa Electric America, Inc

Page 27

GPD515/G5 Parameters G7 Parameters

Parameter

No.

— — —

Name

(DigitalOperator Display)

Setting or Selection

Parameter

(Digital Operator Display)

No.

DO-08 Channel 3 Output

F5-03

Selection

Product Transition Guide

Appendix 2- Parameter Differences

Name

New Parameter

Remarks on

Setting or Selection

— — —

— — —

— — —

— — —

— — —

— — —

Option External Fault

F9-02

Detection Selection

Option External Fault

F9-03

Detection Operation

Selection

0:Always Detected

1:Only During Run

0: Ramp to Stop

1: Coast to Stop

2: Fast - Stop

3: Alarm Only

F5-04

F5-05

F5-06

F5-07

F5-08

F5-09

F6-02

F6-03

DO-08 Channel 4 Output

Selection

DO-08 Channel 5 Output

Selection

DO-08 Channel 6 Output

Selection

DO-08 Channel 7 Output

Selection

DO-08 Channel 8 Output

Selection

DO-08 Output Mode

Selection

Option External Fault

Detection Selection

Option External Fault

Detection Operation

Selection

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

New Parameter

0:8-channel individual outputs.

1:Binary code output.

2:Output according to

F5-01 to F5-08 settings.

Changed Parameter No.

Changed Parameter No.

Trace Sampling Time —

F9-04

TorqueReference/

F9-05

Torque Limit Selection

through DP-RAM

communication

DP-RAM Communication

F9-06

Error Detection Operation

Selection

0: Disabled

1: Enabled

0:Ramp to Stop

1:Coast to Stop

2:Fast - Stop

3:Alarm Only

Trace Sampling from

F6-04

Communications Option

Board

Torque Reference/Torque

F6-06

Limit Selection through

DP- RAM communication

DP-RAM Communication

F6-01

Error Detection Operation

Selection

Changed Parameter No.

Changed Parameter No.

Changed Parameter No.

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 27 of 38

Yaskawa Electric America, Inc

Page 28

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

H1-01

Name

(DigitalOperator Display)

Terminal 3 Selection

Setting or Selection

Multi-function input terminal 3

0: 3-Wire Control

1: Local/Remote Selection

2: Option/Inverter Selection

3: Multi-Step Reference 1

4: Multi-Step Reference 2

5: Multi-Step Reference 3

6: Jog Frequency Reference

7: Multi-Accel/Decel 1

8: External Baseblock N.O.

9: External Baseblock N.C.

A: Accel/Decel Ramp Hold

B: OH2 Alarm Signal

C: Terminal 16 Enable

D: V/F Mode Select

E: ASR Integral Reset

F: Terminal Not Used

10: MOP Increase

11: MOP Decrease

12: Forward Jog

13: Reverse Jog

14: Fault Reset

15: Fast-Stop N.O.

16: Motor 2 Select

17: Fast Stop N.C. input

18: Timer Function

19: PID Disable

1A: Multi-Accel/Decel 2

1B: Program Lockout

1C: Trim Control Increase

1D: Trim Control Decrease

1E: Ref Sample Hold

1F: Terminal 13/14 Switch

24: External Fault

30: PID Integral Reset

31: PID Control Integral Hold

60: DC Injection Activate

61: Speed Search 1

62: Speed Search 2

63: Energy Save Mode

64: Speed Search 3

65: KEB Ridethrough N.C.

66: KEB Ridethrough N.O

71: Speed/Torque Control Change

72: Zero Servo Command

77: ASR Gain Switch

Parameter

No.

H1-01

Name

(Digital Operator Display)

Multi-Function Digital

Input Terminal S3

Function Selection

Remarks on

Setting or Selection

Modified selection:

C: Multi-function Analog Input Selection

Additional selections:

32: Multi-Step Reference 4

34: PID Soft Starter Cancel

35: PID Input Error Polarity Change

67: Communications Test Mode

68: High Slip Braking

78: Polarity Reversing Command for

External Torque Control

PL.G7.02.TransitionGuide 4/21/04

Page 28 of 38

Yaskawa Electric America, Inc

Page 29

Parameter

No.

Appendix 2- Parameter Differences

GPD515/G5 Parameters G7 Parameters

Name

(DigitalOperator Display)

Setting or Selection

Parameter

No.

Name

(Digital Operator Display)

Product Transition Guide

Remarks on

Setting or Selection

H1-02

Terminal 4

Selection

—

H1-02

H1-03

H1-04

H1-05

H1-06

— — —

— — —

— — —

Terminal 5 Selection —

Terminal 6 Selection —

Terminal 7 Selection —

Terminal 8 Selection —

H1-03

H1-04

H1-05

H1-06

H1-07

H1-08

H1-09

Multi-Function Digital

Input Terminal S4

Function Selection

Multi-Function Digital

Input Terminal S5

Function Selection

Multi-Function Digital

Input Terminal S6

Function Selection

Multi-Function Digital

Input Terminal S7

Function Selection

Multi-Function Digital

Input Terminal S8

Function Selection

Multi-Function Digital

Input Terminal S9

Function Selection

Multi-Function Digital

Input Terminal S10

Function Selection

Multi-Function Digital

Input Terminal S11

Function Selection

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

New Parameter

New Parameter

New Parameter

— — —

H1-10

Multi-Function Digital

Input Terminal S12

Function Selection

New Parameter

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 29 of 38

Yaskawa Electric America, Inc

Page 30

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

Multi-function Output

H2-01

Terminal 9-10

Multi-function Output

H2-02

Terminal 25/27

Open Collector

Multi-function Output

H2-03

Terminal 26/27

Open Collector

— — —

— — —

Signal Level Selection

H3-01

Terminal 13

Terminal 13 Gain Frequency reference gain of AI-

H3-02

Terminal 13 Bias

H3-03

Terminal 16 Signal Level

H3-04

Selection

Terminal 16

H3-05

Multifunction Analog

Input

Name

(DigitalOperator Display)

Setting or Selection

—

—

—

—

14U, AI-14B 3ch addition input,

DI-08, and DI-16 is common.

0:0 - 10 VDC

1:10 +10 VDC

Multi-function analog input

selection terminal 16

0: Auxiliary Reference

1: Frequency Gain

2: Frequency Bias

4: Voltage Bias

5: Accel/Decel Change

6: DC Brake Current

7: Overtorque Level

8: Stall Prevention Level

9: Reference Lower Limit

A: Jump Frequency

B: PID Feedback

C: PID Setpoint

D: Frequency Bias 2

10: Forward Torque Limit

11: Reverse Torque Limit

12: Regenerative Torque Limit

13: Torque reference

14: Torque Compensation

15: Forward/Reverse Torque Limit

1F: Not Used

Parameter

(Digital Operator Display)

No.

Terminal M1-M2 Function

H2-01

Selection

Terminal M3-M4 Function

H2-02

Selection

Terminal M5-M6

H2-03

Function Selection

Terminal P3 Function

H2-04

Selection

Open Collector

Terminal P4 Function

H2-05

Selection

Open Collector

Terminal A1 Signal Level

H3-01

Selection

Terminal A1 Gain Setting

H3-02

Terminal A1 Bias Setting

H3-03

Terminal A3 Signal Level

H3-04

Selection

Name

Remarks on

Setting or Selection

Additional selections:

32: During Speed Limit

38: Drive Enable

Terminal number renamed

Terminal number renamed

New Parameter

New Parameter

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Modified selection:

2:Aux Frequency Reference1

Used in conjunction with multi-function

inputs “multi-step frequency reference 1-4”.

Additional

3:Aux Frequency Reference 2

Used in conjunction with multi-function

inputs “multi-step frequency reference 1-4”.

E: Motor Temperature

See parameters L1-03 & L1-04.

Terminal 16 Gain —

H3-06

Terminal 16 Bias —

H3-07

Signal Level

H3-08

Selection Terminal 14

Multi-function Analog

H3-09

Input Terminal 14

Terminal 14 Gain

H3-10

H3-11

H3-12

Terminal 14 Bias

Filter Avg Time

PL.G7.02.TransitionGuide 4/21/04

Page 30 of 38

Yaskawa Electric America, Inc

—

—

Terminal A3 Gain Setting

H3-06

Terminal A3 Bias Setting

H3-07

Terminal A2 Signal Level

H3-08

Selection

Terminal A2 Function

H3-09

Selection

Terminal A2 Gain Setting

H3-10

Terminal A2 Bias Setting

H3-11

Filter Avg Time

H3-12

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Input is from the A2 terminal for the G7.

Page 31

Parameter

No.

H4-01

H4-02

H4-03

H4-04

H4-05

H4-06

H4-07

—

H5-04

—

—

Appendix 2- Parameter Differences

GPD515/G5 Parameters G7 Parameters

Name

(DigitalOperator Display)

Monitor Selection

Terminal 21

Terminal 21

Output Gain

Terminal 21Output Bias —

Terminal 23 Monitor —

Terminal 23

Output Gain

Terminal 23

Output Bias

Analog Output

Signal Selection

— —

Stopping Method After

Communication Error

— —

— —

Setting or Selection

Analog output selection terminal

21 same as F4-01

1: Frequency reference

2: Output frequency

3: Inverter output current

5: Motor speed

6: Output voltage

7: DC bus voltage

8: Output power

9: Torque reference internal

15: External terminal 13 input

voltage

16: External terminal 14 input

voltage

17: External terminal 16 input

voltage

18: Motor secondary current Iq

19: Motor excitation current Id

20: Primary frequency after SFS

21: Speed controller ASR input

22: Speed controller ASR output

23: Speed deviation

24: PID feedback

26: Voltage reference Vq output

27: Voltage reference Vd output

31: Not Used

32: ACR q Output

33: ACR d Output

36: PID Input

37: PID Output

38: PID Reference

—

—

—

0: 0 - +10 VDC

1: 10V +10 VDC

0: Ramp to Stop

1: Coast to Stop

2: Fast - Stop

3: Alarm Only

Parameter

H4-01

H4-02

H4-03

H4-04

H4-05

H4-06

H4-07

H4-08

H5-06

H5-07

(Digital Operator Display)

No.

H4-01Terminal FM

Monitor Selection

Terminal FM Gain Setting

Terminal FM Bias Setting

Terminal AM Monitor

Selection

Terminal AM Gain

Setting

Terminal AM Bias Setting

Terminal FM Signal

Level

Selection

Terminal AM Signal

Level Selection

Drive Transmit Wait

Time

RTS Control Selection

Name

Product Transition Guide

Remarks on

Setting or Selection

Terminal number renamed

15: Terminal A1 Input Level

100% = 10Vdc

16: Terminal A2 Input Level

100% = 10Vdc or 20mA

17: Terminal A3 Input Level

100% = 10Vdc

Removed:

23: Speed deviation

Additional:

42: Motor flux calculation value

43: Motor flux current compensation

44: ASR Output without filter

45: Feedforward Control Output

48: Stabalizing speed during regen

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

Terminal number renamed

0: 0 - 10 Vdc

1: -10 to +10V

2: 4-20 mA*

* Set the analog output jumper CN15 in the

proper position.

New Parameter

0: 0 - 10 Vdc

1: -10 to +10V

2: 4-20 mA*

* Set the analog output jumper CN15 in the

proper position.

Additional selection:

4: Run at D1-04

New parameter

New parameter

0: Disabled RTS is always on

1: Enabled RTS turns on only when

sending

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 31 of 38

Yaskawa Electric America, Inc

Page 32

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

—

—

—

—

—

—

—

L1-01

—

—

—

—

—

L3-07

L3-08

— — —

— — —

L4-05

—

Name

(DigitalOperator Display)

— —

—

—

—

—

—

—

— —

— —

— —

Motor Protection

Selection

MOL Fault Select

— —

— —

— —

— —

— —

Stall Prevention

Function P Gain

Stall Prevention

Function Integral Time

Frequency Loss

Detection Selection

— —

Setting or Selection

0:Disabled

1:Coast to Stop

See: GPD515/G5 E1-02

0: Stop

1: Run@ 80% PrevRef

—

—

Parameter

No.

H6-01

H6-02

H6-03

H6-04

H6-05

H6-06

H6-07

L1-01

L1-03

L1-04

L1-05

L2-07

L2-08

—

—

L3-11

L3-12

L4-05

L4-06

(Digital Operator Display)

Name

Pulse Train Input

Function Selection

Pulse Train Input Scaling

Pulse Train Input Gain

Pulse Train Input Bias

Pulse Train Input Filter

Time

Pulse Train Monitor

Selection

Pulse Train Monitor

Scaling

Motor Overload

Protection Selection

Motor Overheat Alarm

Operation Selection

Motor Overheat Fault

Oper ation Selection

Motor Temperature Input

Filter Time

Momentary Recovery

Time

Frequency Reduction

Gain at KEB Start

—

—

OV Supression function

selection

OV suppression function

level

Frequency Reference Loss

Detection Selection

Frequency Reference

Level at Loss Frequency

Remarks on

Setting or Selection

New parameter

0: Frequency reference

1: PID feedback value

2: PID setpoint value

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

Modified function

0: Disabled

1: Fan Cooled <10:1 motor

2:Blower Cooled 10:1 motor

3: Vector Motor 1000:1 motor

New parameter

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

New parameter

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

New parameter

New parameter

New parameter

Deleted in G7

Deleted in G7

New parameter

New parameter

Modified function

0: Normal Operation - Drive will run at the

frequency reference.

1: Run at L4-06 PrevRef

Drive will run at the

percentage set in L4-06

New parameter

PL.G7.02.TransitionGuide 4/21/04

Page 32 of 38

Yaskawa Electric America, Inc

Page 33

Parameter

No.

L6-01

L6-04

L8-07

L8-10

—

—

—

Appendix 2- Parameter Differences

GPD515/G5 Parameters G7 Parameters

Name

(DigitalOperator Display)

Overtorque

Detection Selection 1

Overtorque

Detection Selection 2

Output phase loss

protection

Short-circuit

Protection Selection

— —

— —

— —

Setting or Selection

0: Disabled

1: @SpdAgree - Alm

2: At RUN - Alarm

3: @SpdAgree - Flt

4:At RUN - Fault

0: Disabled

1: @SpdAgree - Alm

Detected during speed agree

only.

2: At RUN - Alarm

Overtorque detection during

running.

3: @SpdAgree - Flt

Detected during the speed

agree only.

4: At RUN - Fault

Detected during running, and

the inverter trips on OL4.

0: Disabled

1: Enabled

0:Disabled

1: Enabled

Parameter

No.

L6-01

L6-04

L8-07

L8-09

L8-10

L8-11

L8-12

(Digital Operator Display)

Torque Detection

Selection 1

Torque Detection

Selection 2

Output phase loss

protection

Output Ground Fault

Detection Selection

Heatsink Cooling Fan

Operation Selection

Heatsink Cooling Fan

Operation Delay Time

Ambient Temperature

Setting

Name

Product Transition Guide

Remarks on

Setting or Selection

Additional selections:

5: UL3 at SpeedAgree - Alarm Undertorque

Detec tion is only active during Speed Agree

and operation continues after detection.

6: UL3 at RUN - Alarm Undertorque

Detection is always active and operation

continues after detection.

7: UL3 at Speed Agree - Fault Undertorque

Detection only active during Speed Agree

and drive output will shut down on an OL3

fault.

8: UL3 at RUN - Fault Undertorque

Detection is always active and drive output

will shut down on an OL3 fault.

Additional selections:

5: UL4 at SpeedAgree - Alarm Undertorque

Detec tion is only active during Speed Agree

and opera tion continues after detection.

6: UL4 at RUN - Alarm Undertorque

Detection is always active and operation

continues after detection.

7: UL4 at Speed Agree - Fault Undertorque

Detection only active during Speed Agree

and drive out put will shut down on an OL4

fault.

8: UL4 at RUN - Fault Undertorque

Detection is always active and drive output

will shut down on an OL4 fault.

Additional selections

2: 2/3 phase loss protection

Changed parameter number

New parameter

0: Fan On-Run Mode

1: Fan Always On

New parameter

New parameter

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 33 of 38

Yaskawa Electric America, Inc

Page 34

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

L8-17

L8-19

—

—

—

—

—

—

—

—

(DigitalOperator Display)

Name

IGBT Protection

Selection at Low

Frequency

OL2 Characteristic

Selection at Low Speed

— —

— —

— —

— —

— —

— —

—

—

— —

Setting or Selection

0: Conventional

1: Lower fc

Carrier frequency is decreased

when fout 10Hz and the

load is > 100% iac.

2: Short term OL2

OL occurs after 2 seconds

during low speed

[fout 6Hz] current limit.

3: I-Limit=150%

Current limit is set to 150% of

the inverter rated current.

0: Disabled-Low frequency OL

disabled

1: Enabled-Low frequency OL

enabled

Parameter

No.

L8-15

L8-18

n3-01

n3-01

n3-02

n3-03

n3-04

n4-07

n4-08

n4-10

n4-11

n4-15

n4-17

n4-18

n4-28

n4-29

n4-30

n4-32

n4-33

n4-34

n5-01

n5-02

n5-03

(Digital Operator Display)

Name

OL2 Characteristic

Selection at Low Speeds

Soft CLA Selection

High Slip Braking

Deceleration Frequency

Width

High slip braking decel

frequency width

High Slip Braking Current

Limit

High Slip Braking Dwell

Time at Stop

High Slip Braking

Overload Time

Observer Integral Time

Observer Proportional

Gain

Proportional Gain on HiSpeed Side of Observer

Observer Switching

Frequency

Lo-Speed + Regen

Stability Coefficient 1

Torque Adjustment Gain

Gain for Feeder

Resistance Adjustment

Observer Switching

Frequency 2

Torque Adjustment Gain

2

Low Speed + Regen

Stability Coefficient 2

Observer Gain

Modulation Frequency

Observer Gain

Modulation Frequency 2

Observer Gain

Modulation Rate

Feed Forward Control

Selection

Motor Accel Time

Feed Forward

Proportional Gain

Remarks on

Setting or Selection

Deleted in G7

Changed parameter number

New parameter

0: Disabled

1: Enabled.

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

New parameter

0:Disabled

1:Enabled

New parameter

New parameter

PL.G7.02.TransitionGuide 4/21/04

Page 34 of 38

Yaskawa Electric America, Inc

Page 35

Parameter

No.

O1-01

Appendix 2- Parameter Differences

GPD515/G5 Parameters G7 Parameters

(DigitalOperator Display)

Name

Monitor Selection

User Monitor Sel

Setting or Selection

Monitor selection

4: Control method

5: Motor speed

6: Output voltage

7: DC bus voltage

8: Output power

9: Torque reference internal

10: Input terminal status

11: Output terminal status

12: Internal Control Status 1

13: Elapsed time

14: Flash software ID number

15: External terminal 13 input

voltage

16: External terminal 14 input

voltage

17: External terminal 16 input

voltage

18: Motor secondary current Iq

19: Motor excitation current Id

20: Primary frequency after SFS

21: Speed controller ASR input

22: Speed controller ASR output

23: Speed deviation

24: PID feedback

25: DI-16 reference

26: Voltage reference Vq output

27: Voltage reference Vd output

28: CPU ID number

32: ACR output of q axis

33: ACR output of d axis

34: First Parameter Causing an

OPE

35: Zero Servo Pulse Count

36: PID Input

37: PID Output

38: PID Setpoint

Parameter

No.

(Digital Operator Display)

Name

Product Transition Guide

Remarks on

Setting or Selection

Modified name:

15:Terminal A1 Input Voltage

16:Terminal A2 InputVoltage

17:Terminal A3 Input Voltage

Deleted in G7

23: Speed deviation

Added selections:

29: kWh Lo 4 Digits

30: MWh kWh Hi 5 Digits

39: Memobus Communication Error Code

Transmit Err

40:Heatsink Cooling Fan Operation Time

41: Heatsink Temperature

42: Motor flux calculation value

43: Motor flux current compensation

44: ASR output without filter

45: Feed forward control output

48: Stabalizing speed during regen

____________________________

PL.G7.02.TransitionGuide 4/21/04

Page 35 of 38

Yaskawa Electric America, Inc

Page 36

Product Transition Guide

GPD515/G5 to G7

GPD515/G5 Parameters G7 Parameters

Parameter

No.

O1-05

—

—

—

—

—

Name

(DigitalOperator

Display)

Parameter No.

Display Selection

Address Display

— —

— —

— —

— —

— —

Setting or Selection

0:Parameter Number

1:Memobus Address

Parameter

No.

o1-05

o2-10

o2-12

o2-14

o3-01

o3-02

(Digital Operator Display)

Name

LCD Brightness

Adjustment

Cumulative CoolingFan

Operation Time Setting

Fault Trace/Fault

History Clear Function

kWh User Monitor

Initialization

Copy Function

Selection

Copy Allowed

Selection

Read Allowable

Remarks on

Setting or Selection

Modified function:

Sets the contrast of the digital

operator LCD. A set ting of

“1” is the lightest contrast and

a setting of “5” is the darkest

contrast.

New parameter

New parameter

0: Disabled no effect.

1: Enabled - resets U2 and U3

monitors, and returns o2-12 to

zero.

New parameter

0: Disabled no change.

1: Enabled - Resets U1-29 to

zero and returns o2-14 to zero.

New parameter

0: COPY SELECT no

function

1: INV -> OP READ - All

parameters are copied from

the Drive to the digital

operator.

2: OP -> INV WRITE - All

parameters are copied from

the digital operator to the

Drive.

3: OP<-->INV VERIFY Parameter settings in the Drive

are compared to those in the

digital operator.

NOTE: When using the copy

function, the Drive model

number o2-04, software

number U1-14, and control

method A1-02 must match or

an error will occur.

New parameter