Page 1

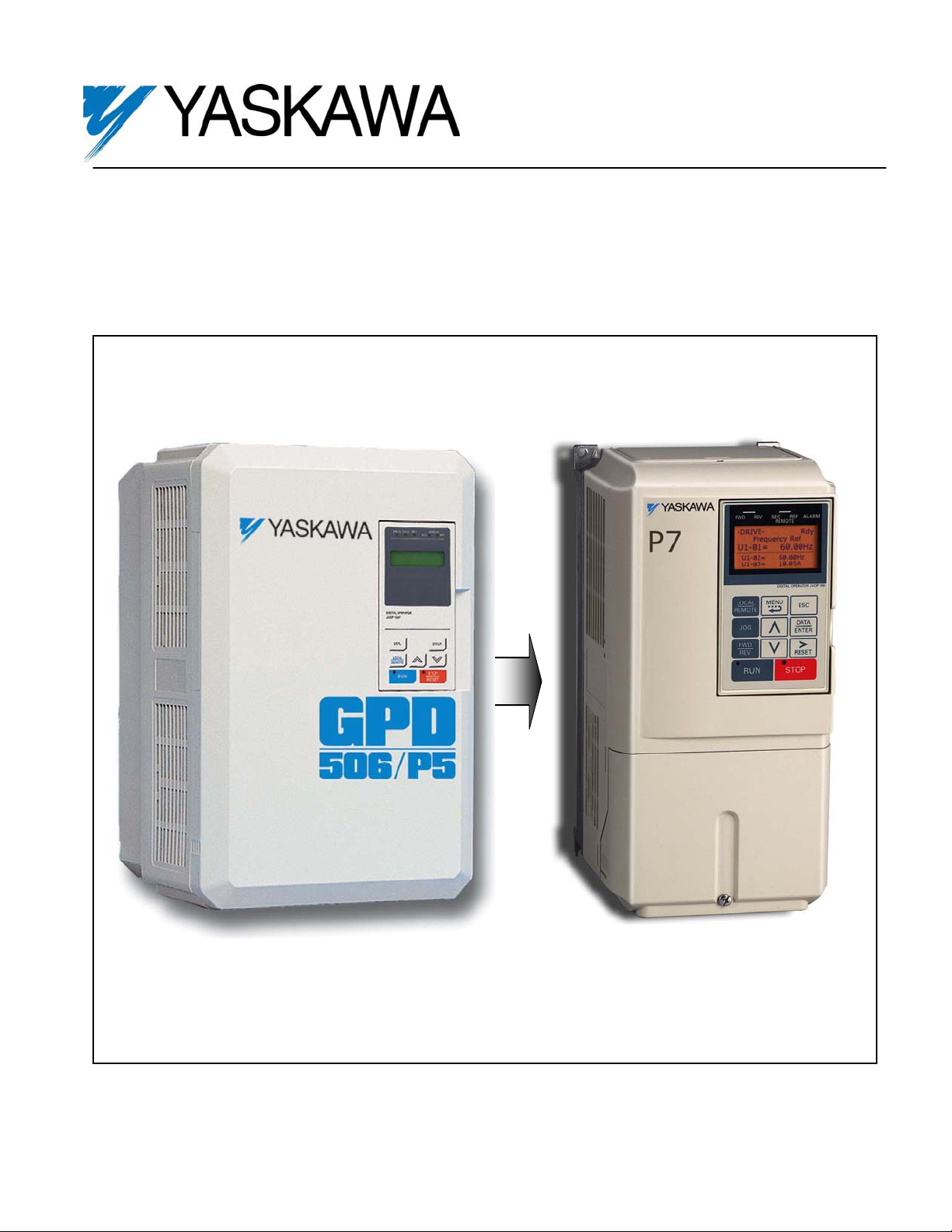

Product Transition Guide

GPD 506/P5 to P7

PL.P7.06.TransitionP5

Page 2

Product Transition Guide

GPD506/P5 to P7

NOTICE

The information contained within this document is the proprietary property of Yaskawa Electric America, Inc., and may not be

copied, reproduced or transmitted to other parties without the expressed written authorization of Yaskawa Electric America,

Inc. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is

constantly improving its high-quality products, the information contained in this document is subject to change without notice.

Every precaution has been taken in the preparation of this document. Nevertheless, Yaskawa assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 2 of 48

Page 3

Contents

Product Transition Guide

GPD506/P5 to P7

FEATURE OVERVIEW ........................................................................................5

BENEFITS OF THE NEW P7 WHEN COMPARED TO GPD506/P5...................5

NEW/ADDITIONAL P7 PARAMETER FUNCTIONS NOT PRESENT IN THE GPD506/P5 ...................... 5

P7 DIGITAL INPUTS (ADDITIONAL FUNCTIONS)............................................................................. 6

P7 DIGITAL INPUTS (ADDITIONAL FUNCTIONS)............................................................................. 6

P7 ANALOG INPUT (ADDITIONAL FUNCTIONS).............................................................................. 6

P7 DIGITAL OUTPUT RELAY (ADDITIONAL FUNCTIONS).................................................................6

NALOG OUTPUTS (ADDITIONAL FUNCTIONS)......................................................................... 6

P7 A

P7 S

ERIAL COMMUNICATIONS .................................................................................................... 7

P7 START-UP, INSTALLATION & MAINTENANCE IMPROVEMENTS.................................................... 7

P7 ADDITIONAL HARDWARE PROTECTION ...................................................................................7

REASONS TO CONTINUE GPD506/P5 ........................................................................................ 7

GPD506/P5 TO P7 SPECIFICATION DIFFERENCES........................................9

DIGITAL OPERATOR COMPARISON .............................................................. 12

GPD506/P5 TO P7 TERMINAL COMPARISON................................................13

NETWORK COMMUNICATIONS ......................................................................17

DETAILS ON NEW P7 FEATURES & FUNCTIONS .........................................18

APPENDIX 1 ......................................................................................................19

RATINGS AND HEAT LOSS COMPARISON ................................................................................... 19

NEC HP RATINGS FOR 240V NORMAL DUTY MODELS .............................................................. 21

NEC HP RATINGS FOR 480V NORMAL DUTY MODELS .............................................................. 22

HEAT LOSS DATA.................................................................................................................... 23

APPENDIX 2 ......................................................................................................25

M

ECHANICAL DIMENSIONS .......................................................................................................25

ANEL CUT-OUT FOR EXTERNAL HEATSINK MOUNTING ..............................................................27

P

MOUNTING HOLE DATA............................................................................................................ 28

APPENDIX 3 – PARAMETER CROSS REFERENCE.......................................29

Page 3 of 48

Page 4

Product Transition Guide

GPD506/P5 to P7

Page Intentionally Left Blank

Page 4 of 48

Page 5

Product Transition Guide

GPD506/P5 to P7

Feature Overview

This document details differences between the GPD506/P5 and P7 product to assist in product transition and new product

introduction.

GPD506/P5 Drive

The GPD 506/P5 inverter is

intended for fan and pump

applications in Building and

Industrial Automation. It is

available in constant and

variable torque ratings, 3/4 to

500 horsepower.

P7 Drive

The P7 drive is an ideal choice for

industrial applications, such as

centrifugal fans and pumps. The

P7 drive is provided in Normal

Duty ratings with 110% overload

capability. V/f control mode,

network communication options,

and an array of input/output

choices are available.

New/Additional P7 Parameter Functions not

Present in the GPD506/P5

Benefits of the New P7 When Compared to GPD506/P5

New Motor preheat function with adjustable current

setting to prevent condensation in motor, (b2-09)

P7 is flash memory upgradeable

Accel/Decel range now adjustable from 0.1 to 6000 sec.

(GPD506/P5 max. range is 3600)

Critical frequency rejection: 3 selectable, adjustable

bands, d3-03—Jump frequency 3 (additional)

(GPD506/P5 only has two)

New Wait To Run Timer function allowing output of

drive to delay start after a Run command (b1-11)

Torque boost with adjustable filter time for better

torque compensation response (C4-02)

Power loss ride-thru time settable to 25 sec.

(GPD506/P5 is 2 sec. Max.)

Auto restart now has maximum restart time after fault if

fault condition doesn’t clear during the first try

New "Up/Down" floating point control capability

Primary resistance auto-tuning

Customizable monitor display

Run permissive input

New PI Snooze function available in conjunction with

Sleep mode (b5-21)

Adjustable Undervoltage Detection level (L2-05) not

available in GPD506/P5

Speed search function with new Speed Estimation

mode and Bi-directional search mode (b3-01)

New Setpoint PI features include:

Two feedback capability, Output Limit, Offset

adjustment, Primary delay, Output gain, Output reverse,

Setpoint accel/decel, Setpoint display scaling,

Selectable sleep input source, Snooze function, Setpoint

boost, Fdbk square root function with output monitor.

(b5-06, b5-07, b5-08, b5-10, b5-11, b5-17 thru 30)

Separately adjustable e-stop times (C1-09)

Accel/decel rate switchover via output frequency (C1-

11)

14 more V/f presets than GPD506/P5 for a total of 15

V/f preset patterns (E1-03)

Mid frequency and voltage V/f points on the custom

V/f pattern (E1-11,12)

Trim speed control function (d4-02)

New/Additional P7 Parameter Functions not

Present in the GPD506/P5

Page 5 of 48

Page 6

Product Transition Guide

GPD506/P5 to P7

Motor thermistor input with

temperature filter and selectable

fault ,alarm settings (L1-02 to L1-

05)

Intelligent stall prevention on

accel/decel with decel time 1 or 2

selections (L3-01,4,5)

Extended 0.5 to 600.0 sec. autorestart time between attempts vs.

10.0 secs for GPD506/P5 (L5-03)

Hunting prevention function (n101,2)

DC Injection braking (b1-03)

Run command can be accepted

while the drive is being programmed (b1-08)

High slip braking function (n3-01,2,3,4)

Selectable power-up monitor (o1-01,2)

Keypad display contrast adjustment (o1-05)

Two independent programmable over and under torque

detection levels

P7 Digital Inputs (Additional Functions)

One more digital input for a total of seven

More versatile PNP/NPN sinking/sourcing 24 VDC

control logic

Transmitter/option power supply

29 more programmable functions for digital inputs than

GPD506/P5. 59 total :

Motor Preheat

MOP increase/decrease function

Forward and reverse jog input

Trim control increase and decrease functions

15 additional external fault action settings such as Fast-

stop, Alarm only, Coast to stop with selectable N.O or

N.C. for each fault action.

PI integral hold and PI cancel functions

Speed search 3

Serial Communication test mode

High slip braking input

Jog 2

P7 Digital Inputs (Additional Functions)

Drive enable, with selectable accept run command or

cycle run command function

P7 Analog Input (Additional Functions)

A convenient PCB switch now changes analog input A2

between current and voltage, cutting PCB jumper for

mA signal is no longer required.

Adjustable analog input signal filter for added stability

Terminal A2 is selectable for :

Frequency bias

Motor thermister

PI differential

Analog input filter

Main and Aux frequency reference is selectable

between terminals A1 and A2

P7 Digital Output Relay (Additional Functions)

27 possible programmable functions for the digital

outputs, seven more than the GPD506/P5.

One additional relay output, M3 and M4 relays

DC bus under voltage output

Reset command active output

Reverse direction output

Drive enable output

OH frequency reduction output

Restart Enabled

P7 Analog Outputs (Additional Functions)

Additional AM analog monitor output with bias and

gain settings.

Analog monitors now selectable between 0-10V and 420ma, GPD506/P5 only 0-10V

18 programmable selections for the analog outputs, 14

more than the GPD506/P5.

Frequency reference monitor

Terminal A1 or A2 monitor

Motor SEC current monitor

SFS output monitor

PI- feedback, input, output and setpoint monitors

PI feedback 2 monitor

Output Voltage

Page 6 of 48

Page 7

P7 Serial Communications

Built-in RS-485/422 modbus serial communications

Optional communication interface: Devicenet, Profibus,

and others

Serial communications loss detection timeout function

Drive Wizard upload/download and monitoring

/graphing software

Product Transition Guide

GPD506/P5 to P7

P7 Start-up, Installation & Maintenance

Improvements

Control terminal board: Quick disconnect

Enhanced digital keypad, 5 Line x 16 Character LCD

(Std)

6 new languages can be displayed on the keypad.

GPD506/P5 has only English (A1-00)

User password protection for 32 customizable user

parameters (A1-04)

A2-01 thru A2-32—User access level provides 32 user

selectable parameters.

Parameter copy function to another P7 using standard

digital operator (o3-01)

Improved fault storage, last 10 faults

Quick disconnect I/O blocks for easy wiring

Logged cooling fan hours for scheduled maintenance

Modular cooling fan for easy replacement

Automatic cooling fan run control to extend fan life

P7 Additional Hardware Protection

Adjustable heat-sink overheat pre-alarm level (L8-02)

Selectable ground fault detection (L8-09)

Selectable cooling fan operation with off delay (L8-

10,11)

Automatic ambient temperature compensation to

protect the drive in environments exceeding its rating

(L8-12)

Adjustable OH frequency reference reduction (L8-19)

Adjustable motor overload time constant (L1-02)

Page 7 of 48

Page 8

Product Transition Guide

GPD506/P5 to P7

Page left intentionally blank

Page 8 of 48

Page 9

Product Transition Guide

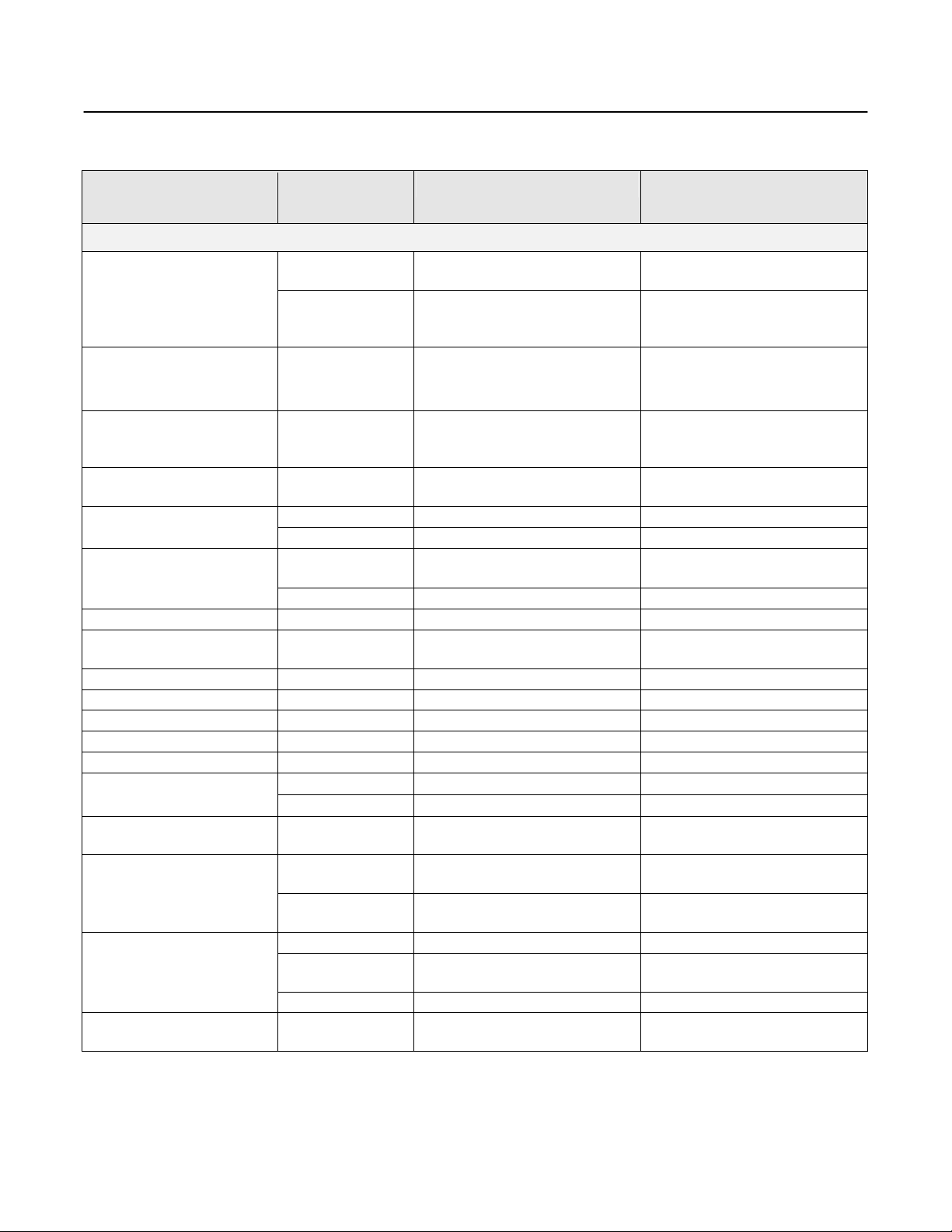

GPD506/P5 to P7 Specification Differences

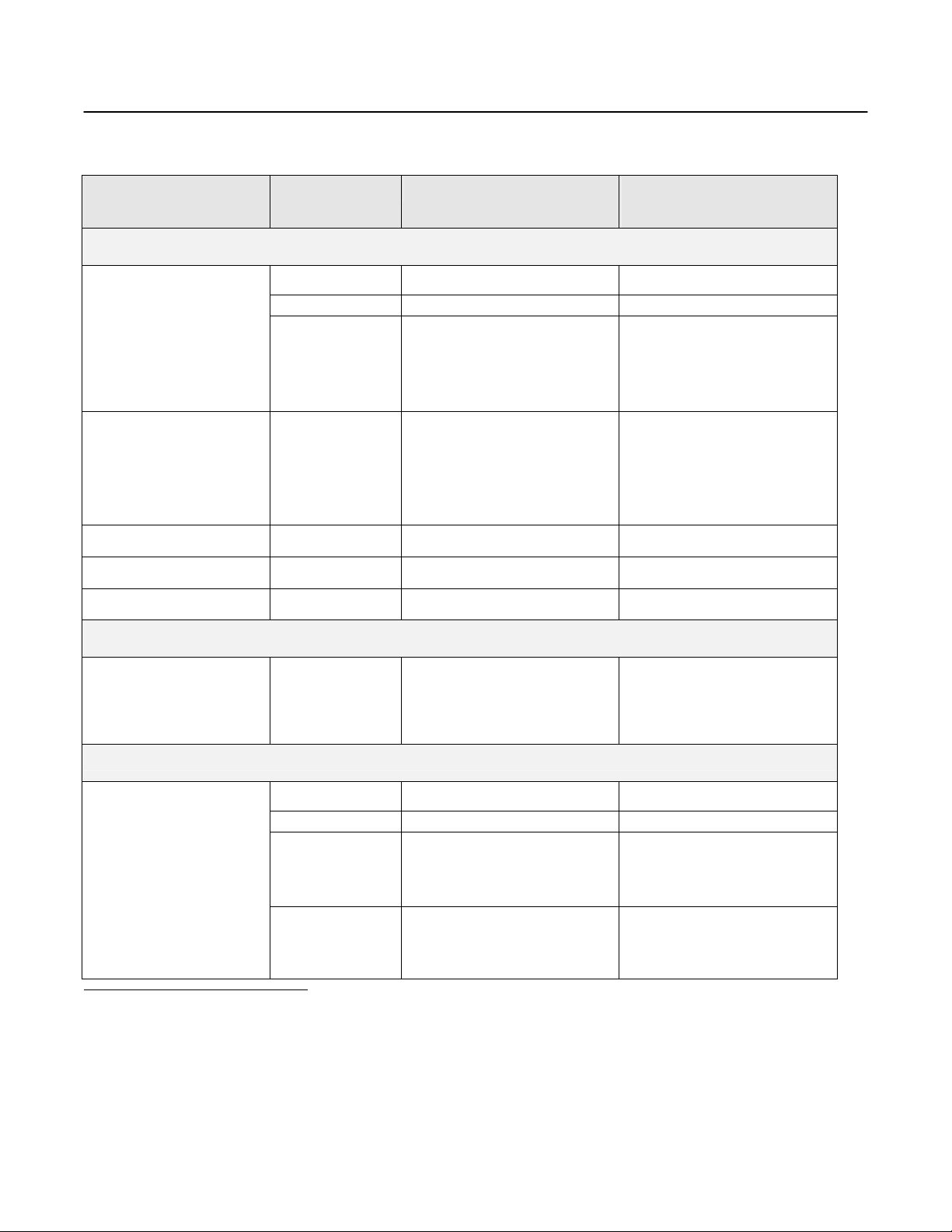

GPD506/P5 to P7

Feature

Item Yaskawa GPD506/P5 Yaskawa P7

or Function

Performance Features

HP Range

Note: The voltage rating in

the “Item” column is

generalized. Refer to the

Service Conditions section

for rated input voltage

requirements.

Overload Rating

% for Minutes

PWM Carrier Frequency

Max. Output Frequency

Speed Range

Protective Features

240V 0.75 to 125HP (VT) 5 to 150HP (ND2)

480V 0.75 to 500HP (VT) 5 to 500HP (ND2)

600V 2 to 200HP (VT)

150% for 1 min (CT)

200% peak

120% for 1 min (VT)

180% peak

Range See Carrier Frequency Table See Carrier Frequency Table

Hz 400Hz 0 To 120Hz

V/f 40:1 40:1

Available w/GPD506/P5

Not Available in P7

110% for 1 min (ND2)

150% peak

Heat Sink Temperature Fault

Fault Action Coast, Ramp, Continue

Design Features

Keypad Design

Qty of keys 7 11

Copy Function No

--Coast, Ramp, Continue or

Continue with reduced speed

--OH Pre-alarm level setting

Language 1 7 (w/LCD)

Yes

Display

LCD display, alpha numeric, 16

char x 2 lines

LCD display, alpha numeric, 16

char x 5 lines, backlit

Page 9 of 48

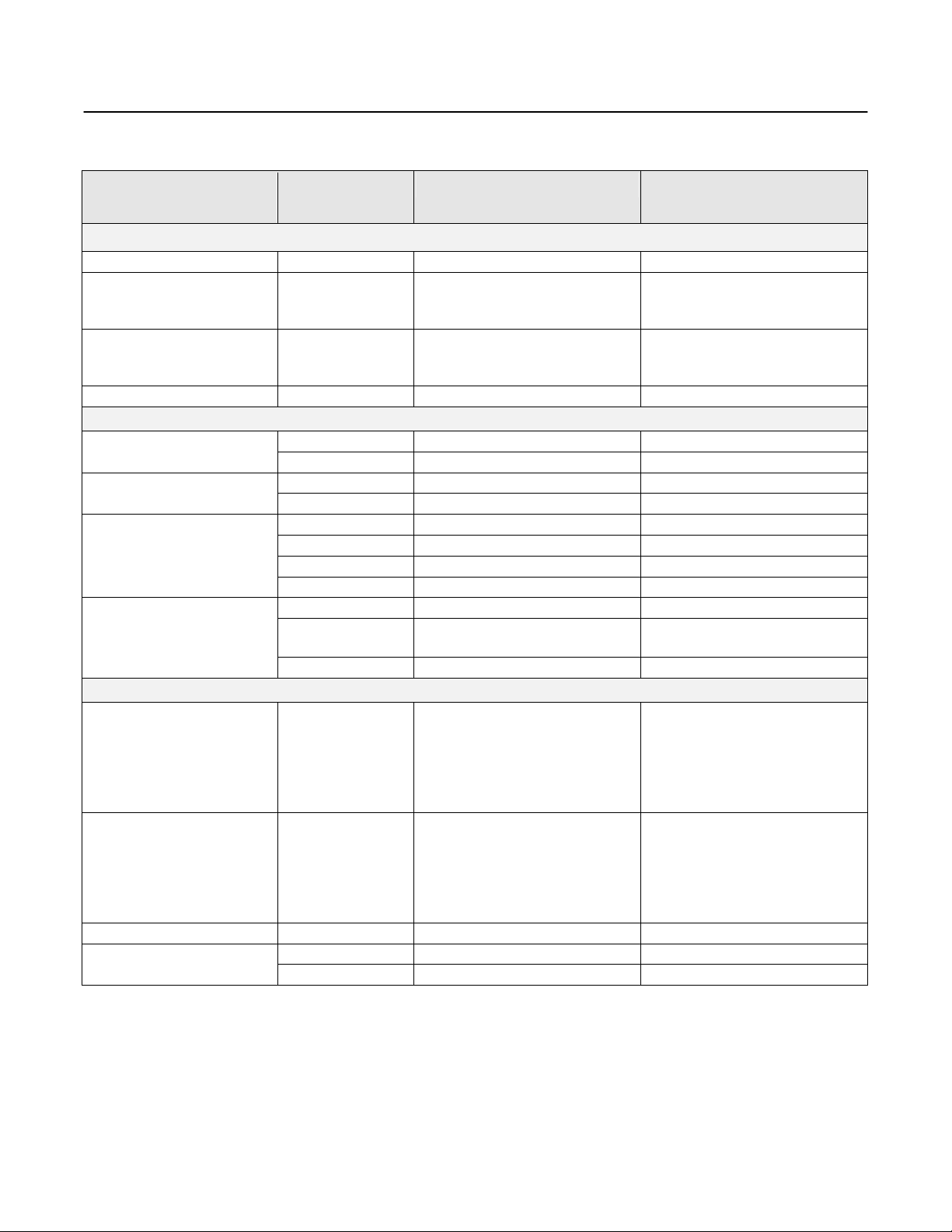

Page 10

Product Transition Guide

GPD506/P5 to P7

GPD506/P5 to P7 Specification Differences (continued)

Feature

or Function

Item Yaskawa GPD506/P5 Yaskawa P7

Design Features (continued)

Network Communications

Diagnostics

Quick Disconnect I/O

Terminals

Auto-Tuning

Synchronized Start

PI / PID Control

Sleep Function In Open Loop Mode No Yes

Automatic Restart Time Between

V/Hz Patterns Qty. 1 Preset, 1 Custom 15 Preset, 2 Custom

Skip Frequencies Qty. 2 3

Custom Drive Software Embedded No Flash memory

Parameter Upload/Download PC Software InverterWin Drive Wizard Software

Accel/Decel Time Sec. 0.0 - 3600.0 sec 0.1 - 6000.0 sec.

DC Injection Function

Braking Function

Cooling Fan

Timer Function

Standard Modbus RTU via RS232

RS232 to RS485, DeviceNet,

Optional

Fault Storage Last 4 Faults

Type No

Rotating/Stationary No

Bi/Uni-Directional Uni-Directional Bi-Directional Speed Search

Method Current Current/Speed

Analog Input Signal

Filter

Two Feedback No Yes

Attempts

Analog Input Filter No Yes Closed Loop PID Control

Two Feedback No Yes

At Start/At Stop At Start/At Stop

DB Transistor

Special No

On/Off Control Power-up based Run Based

Service Disassembly required

Operating Hours Drive power-up hours logged Logged

On/Off Delay On/Off Delay (0-25.5 sec)

Lonworks, ApogeeFLN,

MetasysN2

No Yes

Not Adjustable 0.0 – 600.0 sec (selectable)

Built-in to 10HP (VT-230V)

Built-in to 25HP (VT-460V)

Modbus RTU via built in

RS485/422

DeviceNet, Profibus-DP,

Lonworks,

Ethernet

Last 10 Faults with Elapsed Time,

Most Recent Fault with all

Operating Conditions

Yes (Phoenix)

With split front cover for easy

wiring

Primary

resistance auto-tuning

At Start/At Stop (adjustable)

+HSB during stop

Built-in to 25HP

High Slip Braking all models

(Faster stopping without options)

Modular/pluggable fan select

models

On Delay at start (0-600 sec)

On/Off Delay Timer ( 0-3000sec)

Page 10 of 48

Page 11

Product Transition Guide

GPD506/P5 to P7

GPD506/P5 to P7 Specification Differences (continued)

Feature

or Function

Item Yaskawa GPD506/P5 Yaskawa P7

Design Features (continued)

Common DC Bus Capable - No Yes

DC Link or AC Choke

Harmonic Counter Measures

Unique Feature/Function - - HSB – High Slip Braking

-

-

230V: 30HP to 125HP (VT)

460V: 30 to 250HP (VT)

12 Pulse: 230V: 30HP and Above

460V: 30HP to 250HP

Inputs and Outputs

Total Qty. 6 7 (optically isolated) Digital Input Terminal

NPN/PNP NPN Switchable NPN/PNP

Total Qty 2 3 Digital Output Terminal

Relay Output 1 x Form C, 1 x Form A, 2 x Form A, 1 x Form C

Analog Input

Analog Output

Qty. 2 2

Level Input 0-10V or 4-20mA 0-10 or 4-20mA

Scan Rate 5 msec 5 msec

Loss Detection Ramp or Continue Ramp, Coast or Continue

Qty. 1 2

Output Level 0-10V

Resolution 9 bit 10 bit plus sign

Service Conditions

Rated Input

-

Ambient Temperature

ºC

Storage Temperature ºC -10ºC ~ +60ºC -20ºC ~ +60ºC

NEMA 4X Optional N/A Enclosure Types

NEMA 3/3R Optional N/A

3-phase, 200-230Vac

3-phase, 380-460Vac

Tolerance +10 to –15%

3-phase,500-600Vac

Tolerance +10 to –10%

Frequency: 50/60 Hz +/- 5%

(IP21/NEMA1)

-10ºC ~ +40ºC

(IP00/Protected Chassis)

-10ºC ~ +45ºC

DC Link (Standard)

240V: 30HP to 150 HP

480V: 40 HP to 500 HP

12 Pulse:

240V: 30HP to 150HP

480V: 40HP to 500HP

0-10V or 4-20ma

With independent level selections

3-phase, 200-240Vac

3-phase, 380-480Vac

Tolerance +10 to –15%

Frequency: 50/60 Hz +/- 5%

Note: P7 Models 2037-2110 rated

for 200-230Vac.

-10ºC ~ +40ºC (IP21/NEMA1)

-10ºC ~ +45ºC

(IP00/Protected Chassis)

(Automatic OL protection curve

based on ambient temperature

setting of L8-12)

Page 11 of 48

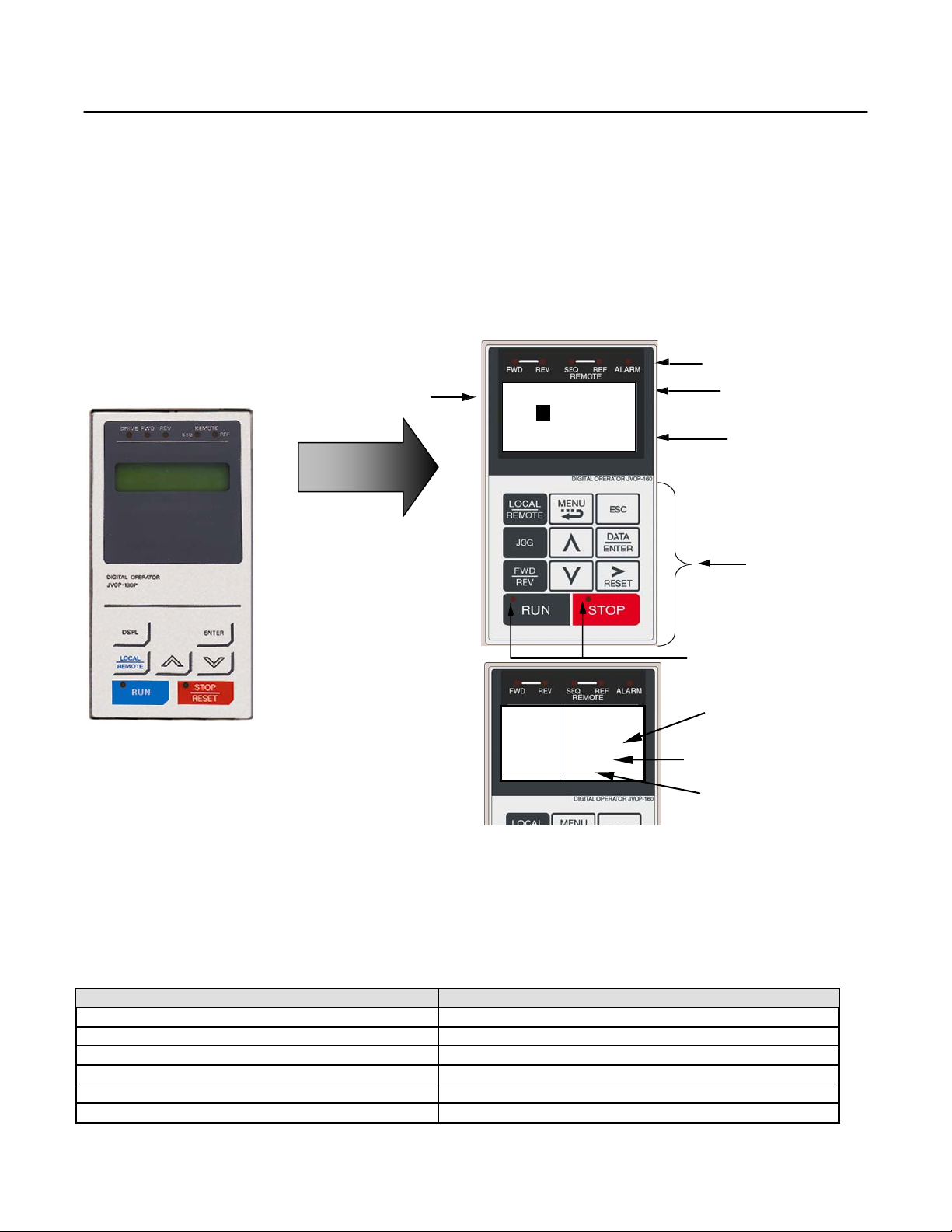

Page 12

Product Transition Guide

A

GPD506/P5 to P7

Digital Operator Comparison

• Enhanced LCD operator with built-in copy function and parameter verify for P7

• Optional LED operator available for P7

• LCD contrast adjustment

• Simplified parameter grouping for easier navigation and set-up

GPD506/P5 Operator New P7 Operator

LCD DISPLAY

Frequency Ref

-

=

Menu Display

-DRIVE- Rdy

Frequency Ref

U1-01= 60.00Hz

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

U1-02= 60.00Hz

U1-03= 10.05A

-QUICK-

Accel Time 1

------------------------------

21.0secs

C1-01=

(0.0~6000.0)

“30.0 sec”

-Rdy-

• P7 copy keypad is capable of uploading all of the parameter settings from the P7 drive memory.

o Upload of GPD506/P5 parameters to P7 not possible at this time

o P7 Drives must have the same software version, model, and control mode to copy parameters.

• A Quick Start menu is added to aid in simple start-ups.

• The Quick Start menu consists of 64 parameters. The Advanced menu is the other menu choice.

Simplified Menu Structure in P7:

GPD506/P5 P7

-- Operation “DRIVE”

Quick Start -- 16 Parameters Quick Setting “QUICK”

Programming (All Parameters) Programming “ADV”

-- Modified Constants “VERIFY”

-- Auto-Tuning “A.TUNE”

--

Drive Mode Indicators

Dr ive ca n o pe rate when a driv e co mman d is inpu t

Displays monitor data, parameter data and settings

Read y Display

Data Display

1 line x 13 characters

3 li nes x 1 6 ch arac ter s

RUN & STOP Indicators

Present Setting

(user adjusts)

llowed Setting Range

Factory Default

Keys

Page 12 of 48

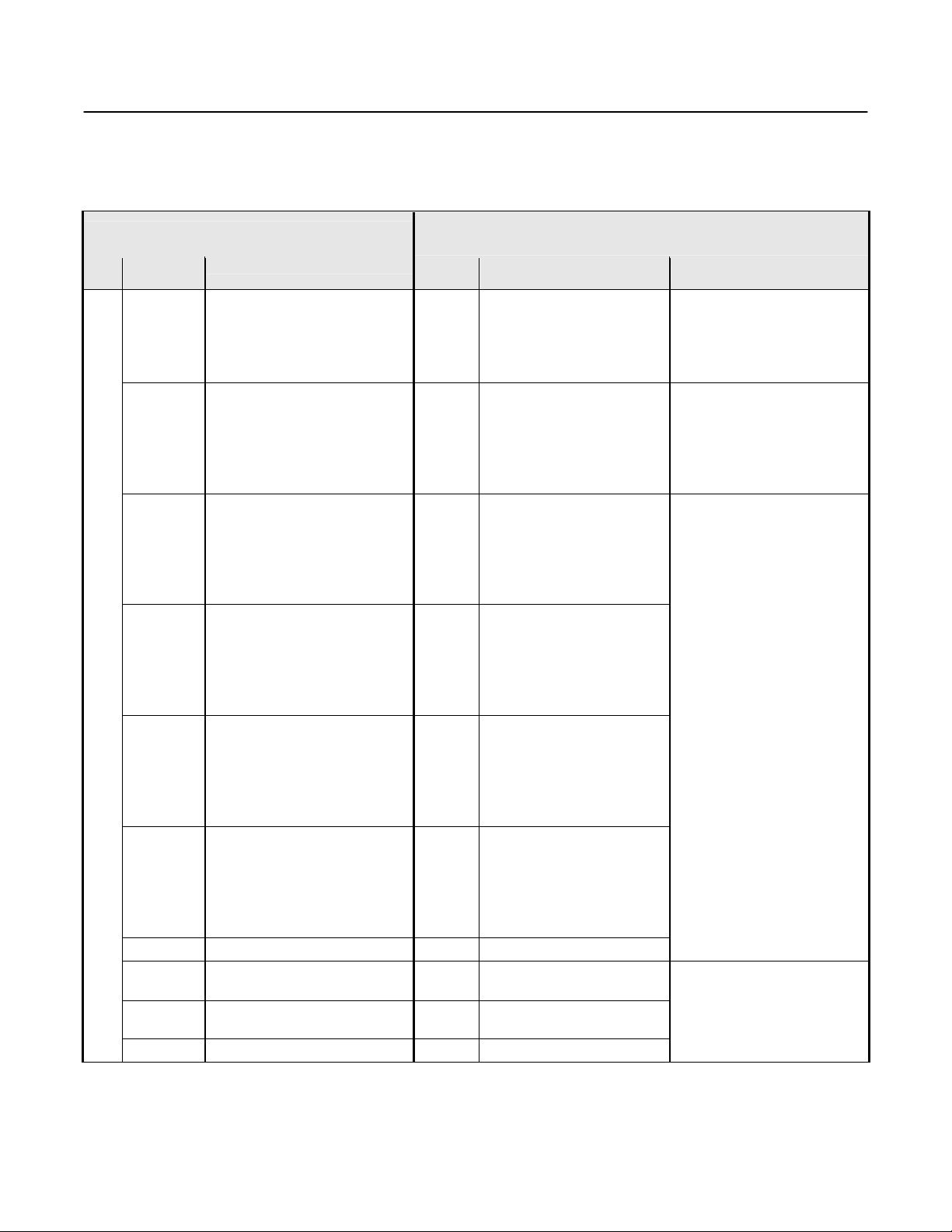

Page 13

GPD506/P5 to P7 Terminal Comparison

The factory default is 2-wire control as shown.

Type

Digital Input Signals

GPD506/P5 Terminal

GPD506/P5

Terminal

S1

S2

S3

S4

S5

S6

SC

Default Function & Description P7

Forward run/stop, Forward run

when closed, and stop when

open.

Photo-coupler insulation

Input: +24VDC 8mA

Reverse run/stop, Reverse run

when closed, Stop when open.

Multi-function contact

input (n036)

Photo-coupler insulation

Input: +24VDC 8mA

External fault input, Fault when

closed, normal state when open.

Multi-function contact input

(n037)

Photo-coupler insulation

Input: +24VDC 8mA

Fault reset input,

Reset when closed.

Multi-function contact input

(n038)

Photo-coupler insulation

Input: +24VDC 8mA

Multi-step speed reference 1,

Enabled when closed.

Multi-function contact input

(n039)

Photo-coupler insulation

Input: +24VDC 8mA

Multi-step speed reference 2,

Enabled when closed.

Multi-function contact input

(n040)

Photo-coupler insulation

Input: +24VDC 8mA

– –

Sequence input common

terminal

–

–

Terminal

S1

S2

S3

S4

S5

S6

S7

SN

SC

SP

(Designations similar to GPD506/P5)

Default Function P7 Description

Forward run/stop command –

Reverse run/stop command –

External fault input

Fault reset

Multi-step speed reference 1

Multi-step speed reference 2

Jog frequency reference

Digital input common

Factory connected to SP

Factory connected to SC

Product Transition Guide

GPD506/P5 to P7

P7 Terminal

Multi-function digital inputs.

Functions set by:

H1-01 to H1-05.

24 VDC, 8mA

Photo coupler isolation

Factory connected for internal

supply sinking mode.

Refer to P7 User Manual for

other methods.

Page 13 of 48

Page 14

Product Transition Guide

g

GPD506/P5 to P7

Type

Analog Input Signals

Digital Output Signals

Analog Output

GPD506/P5 Terminal

GPD506/P5

Terminal

FS

FV

FI

FC

E(G)

M1 M1

M2

MA MA

MB MB

MC

nals

AM

Si

Default Function & Description P7

+15V Power supply output for

analog command

(Allowable current, 20mA max.)

Frequency reference input

(voltage) 0 to +10V/100%,

n043 = “FV=MSTR”:

FV enabled

n043 = “FI=MSTR”:

FI enabled

0 to +10V (20kW)

Frequency reference input

(current) 4 to 20mA/100%

n043 = “FV=MSTR”:

FV enabled

n043 = “FI=MSTR”:

FI enabled

4 to 20mA (250W)

Common terminal 0V

Connection to shield sheath of

signal lead

During running (N.O. contact)

Closed when running.

Multi-function contact output

(n042)

Dry contact capacity:

250VAC 1A or less

30VDC 1A or less

–

–

–

Fault contact output

(N.O./N.C. contact)

Fault when closed between

terminals MA and MC

Fault when open between

terminals MB and MC

Multi-function contact output

(n041)

Dry contact capacity:

250VAC 1A or less

30VDC 1A or less

Frequency meter output

0 to +10V/100% frequency

Multi-function analog monitor 1

(n052)

0 to +10V

2mA or less

–

Terminal

+V

A1

A2

AC

E(G)

M2

M3

M4

MC

FM

Page 14 of 48

(Designations similar to GPD506/P5)

Default Function P7 Description

+15Vdc power output

Analog input or speed

command

Analog input or speed

command

Analog common –

Shield wire, optional ground

line connection point

During run

(N.O. contact)

Remote/Auto Operation

(N.O. contact)

Same function as

GPD506/P5. Nonprogrammable

Output frequency

P7 Terminal

+15Vdc

(Max. current: 20mA)

0 to +10Vdc=100%

(20k ohm)

4 to 20mA=100%/(250 ohms)

0 to +10Vdc=100%/(20k ohm)

Function set by H3-09.

–

Form A Dry contacts capacity:

1 A max. at 250Vac

1 A max. at 30Vdc

Multi-function digital output.

Function set by H2-01.

Form A Dry contacts capacity:

1 A max. at 250Vac

1 A max. at 30Vdc

Multi-function digital output.

Function set by H2-02.

Form C Dry contacts

capacity:

1 A max. at 250Vac

1 A max. at 30Vdc

0 to +10Vdc

10V=100% Output frequency

(Max current 2mA).

Function set by H4-01.

Page 15

Product Transition Guide

Terminal Comparison

Type

GPD506/P5 Terminal

GPD506/P5

Terminal

AC

RS-485/422

Default Function & Description P7

–

Frequency meter output “AM”

Common

–

–

–

–

–

P7 Terminal

(Designations similar to GPD506/P5)

Terminal

–

AM

AC

–

–

–

–

–

R+

RS+

S-

IG

Default Function P7 Description

0 to +10Vdc or

10V=100% Drive output

Output current

Analog common –

Modbus communication

Differential input,

PHC isolation

Modbus communication

Differential output,

PHC isolation

Signal common –

current (Max current 2mA)

Drive's rated output current /

Function set by H4-04.

–

Page 15 of 48

Page 16

Product Transition Guide

Ω

Ω

Ω

A

(

)

(

)

)

(

)

(

) (0V)

(

A

y

A

Terminal Comparison

Multi-Function

Inputs

nalog Inputs

Input FI selectable

4~20mA

or

0~10V

Serial Port

0~ + 10V

4~20mA

L1

L2

GPD506/P5

L3

L11

L21

L31

S1 - Fixed

S2

S3

S4

S5

S6

SC (Com

G

FS

+15V

Ω

FV

20k

Ω

250

RS-232

10-pin

FI

FC

Gate Drive

PWM

8 bit

/D

10 bit

Digital

Operator

0~10VAM

Com) AC

G

MA

MB

MC

M1

M2

Shorting Bar Standard:

Ω

2k

PP

CIMR-P7U23P7 to 2018

CIMR-P7U43P7 to 4018

R/L1

S/L2

T/L3

S1

S2

S3 (H1-01)

S4 (H1-02)

S5 (H1-03)

S6 (H1-04)

S7 (H1-05)

SN

SC

SP

E(G)

+V +15VDC, 20mA

A1 0-10VDC, 20 K

A2 (H3-08)

4-20mA, 250 K

[0 to +10VDC, 20K ]

AC

R+

R-

S+

S-

T1

T2

IM

T3

Foward Run/Stop

Reverse Run/Stop

External Fault

Multi-Function

nalog Outputs

Fault Reset

Multi-step Speed Setting 1

Multi-step Speed Setting 2

Jog Frequency Reference

Multi-Function

Outputs

Rela

Power Supply

L1

L2

L3

PE

2k

Modbus

RS-485/422

3-Phase

50/60Hz

MCCB

Multi-function

Contact Inputs

(Factory Default)

External

Frequency

Reference

4 to 20mA

UX

Terminating

Resistance

110

1+2+

P7

E7

Digital Outputs

250VAC/30VDC, 1A

S1-1

DC Reactor Standard:

CIMR-P7U2022 to 2110

CIMR-P7U4030 to 4300

+

3

-

Multi-function

(H2-01)

(H2-02)

(H4-01) FM

(H4-04) AM

U/T1

V/T2

W/T3

MA

MB

MC

M1

M2

M3

M4

E(G)

AC

Motor

M

Fault Contact

Digital Output

250VAC/30VDC, 1A

Digital Output 1

(Default: During RUN)

Digital Output 2

(Default: Remote/

Auto Operation)

Multi-function

Analog Outputs

0 to +10VDC, 2mA

+

+

-

-

IG

Page 16 of 48

Page 17

Product Transition Guide

GPD506/P5 to P7

Network Communications

GPD506/P5 P7

Not Available DeviceNet

Not Available EtherNet

Not Available Profi-Bus

RS-232 PCB Port (2CN) RS-232 via Digital Operator Port

SI-K2/P RS-485 Modbus Communication Card Standard Built-in RS-485

Lon Works Lon Works2

Johnson Controls MetaSys N2 Not Applicable

Software Upload/Download Tool

2

Available as an option based on market demands

FLN Network for System 600/ Apogee Not Applicable

InverterWin DriveWizard

Network Communications Option Availability

Note: Communication option release schedule is subject to change. Yaskawa Marketing

Communications will provide official notice of product availability.

Ethernet

Ethernet

MODBUS TCP/IP

MODBUS TCP/IP

Present

Present

Ready now, available at P7 launch

Ready now, available at P7 launch

P7 (CM058) available at P7 launch

P7 (CM058) available at P7 launch

Modbus - Plus, testing, available at P7 launch

Modbus - Plus, testing, available at P7 launch

Available at P7 launch

Available at P7 launch

Ready now, available at P7 launch

Ready now, available at P7 launch

Page 17 of 48

Page 18

Product Transition Guide

GPD506/P5 to P7

Details on New P7 Features & Functions

Note: This section details only a few of the new P7 features.

o New Auto Tuning

The P7 comes with a Motor Auto-tuning function to help to optimize the drive performance.

Feature GPD506/P5 P7

R1 Primary Resistance Tuning No Yes

R1 Primary Resistance Auto-tuning method is for motor terminal resistance. This method involves no motor shaft

rotation.

o New High Slip Braking

The P7 incorporates a

new braking function called High

Slip Braking (HSB).

By using a method that utilizes

increased rotor slip, the drive

will gain the capability of

stopping up to 50% faster than

without a braking resistor.

All of this without the need of any

external equipment or resistors!

Greater than 150% brake

torque is possible.

Motor speed

Motor voltag e

DC-Bus voltage

Motor speed

Motor voltage

DC-Bus voltage

Page 18 of 48

Page 19

Product Transition Guide

Appendix 1

Ratings and Heat Loss Comparison

Page 19 of 48

Page 20

Product Transition Guide

GPD506/P5 to P7

Page Intentionally Left Blank

Page 20 of 48

Page 21

Product Transition Guide

Appendix 1 –Ratings and Heat Loss Comparison

NEC HP Ratings for 240V Normal Duty Models

GPD506/P5 230V Models P7 240V Models

Variable Torque (n116=1) Normal Duty (C6-01=2)

NEC

HP

230V

Amps

NEC

GPD506/P5

Model

CIMR-P5U

Output

Amps

Fc

kHz

Overload%

VT

1 minute

P7

Model

CIMR-P7U

Output

Amps

Fc

kHz

Overload %

ND

1 minute

5 15.2

7.5 22

10 28

15 42

20 54

25 68

30 80

40 104

50 130

60 154

75 192

100 248

125 312

150 360

150 360

*Note: Optional NEMA1 kit required for NEMA1 rating. Input voltage rating is 230V on these

models.

23P71 17.5 15 120

25P51 27 10 120

27P51 36 10 120

20111 54 10 120

20151 68 10 120

20181 80 15 120

20221 104 15 120

20301 130 10 120

20371* 160 10 120

20451* 192 10 120

20551* 248 8 120

20751* 312 8 120

- - - -

- - - -

23P71 16.8 10 107

25P51 23 15 120

27P51 31 15 102

20111 46.2 8 117

20151 59.4 10 117

20181 74.8 10 114

20221 88 10 116

20301 115 10 120

20371* 162 5 107

20451* 192 5 113

20551* 215 8 120

20751* 312 2 109

20901* 360 2 115

21100* 415 2 120

Page 21 of 48

Page 22

Product Transition Guide

Appendix 1 –Ratings and Heat Loss Comparison

NEC HP Ratings for 480V Normal Duty Models

GPD506/P5 460V Models P7 480V Models

Variable Torque (n116=1) Normal Duty (C6-02=2)

NEC

HP

Amps

460V

5.0 7.6

7.5 11

10 14

15 21

20 27

25 34

30 40

40 52

50 65

60 77

75 96

100 124

125 156

150 180

200 240

250 302

300 361

350 414

400 477

450 506

500 590

550 660

*Note: Optional NEMA1 kit required on these models for NEMA1 rating.

NEC

GPD506/P5

Model

CIMR-P5U

43P71 8.5 10 120 43P71 7.6 15 120

44P01 11.7 10 120 45P51 12.5 15 120

45P51 14.8 10 120 47P51 17 15 120

47P51 21 10 120

40111 28.6 10 120

40151 34 10 120 40151 34 10 109

40181 41 10 120 40181 40 10 117

40221 52 8 120

40301 65 5 120

40371 80 5 120 40371 77 8 117

40451 96 5 120 40451 96 8 114

40551 128 5 120 40551 125 5 108

40751* 180 5 120 40751* 156 5 115

41101* 240 5 120 41101* 240 5 108

41601* 302 5 120 41601* 304 5 120

41850 380 2.5 120

42200 506 2.5 120

43000 675 2.5 120

Output

Amps

Fc kHz

OL %

VT

1 minute

P7

Model

CIMR-P7U

44P01 8.7 15 120

40111 27 8 107

40301 67.2 8 107

40901* 180 8 120

41321* 260 5 120

41850 414 2 107

42200 506 2 118

43000 675 2 120

Output

Amps

Fc

kHz

Overload %

ND

1 minute

Page 22 of 48

Page 23

Product Transition Guide

Appendix 1 –Ratings and Heat Loss Comparison

Heat Loss Data

Note: Ampacity ratings vary between GPD506/P5 and P7 models.

Refer to NEC Ratings tables in Appendix 1 for the appropriate GPD506/P5 to P7 cross-reference.

GPD506/

P5 Model

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

40P4

40P7

43P7

44P0

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

GPD506/P5 (W)

Internal Heatsink Total

80 135 215

90 210 300

110 235 345

160 425 585

200 525 725

230 655 885

280 830 1110

500 1050 1550

700 1250 1950

750 1550 2300

1000 1950 2950

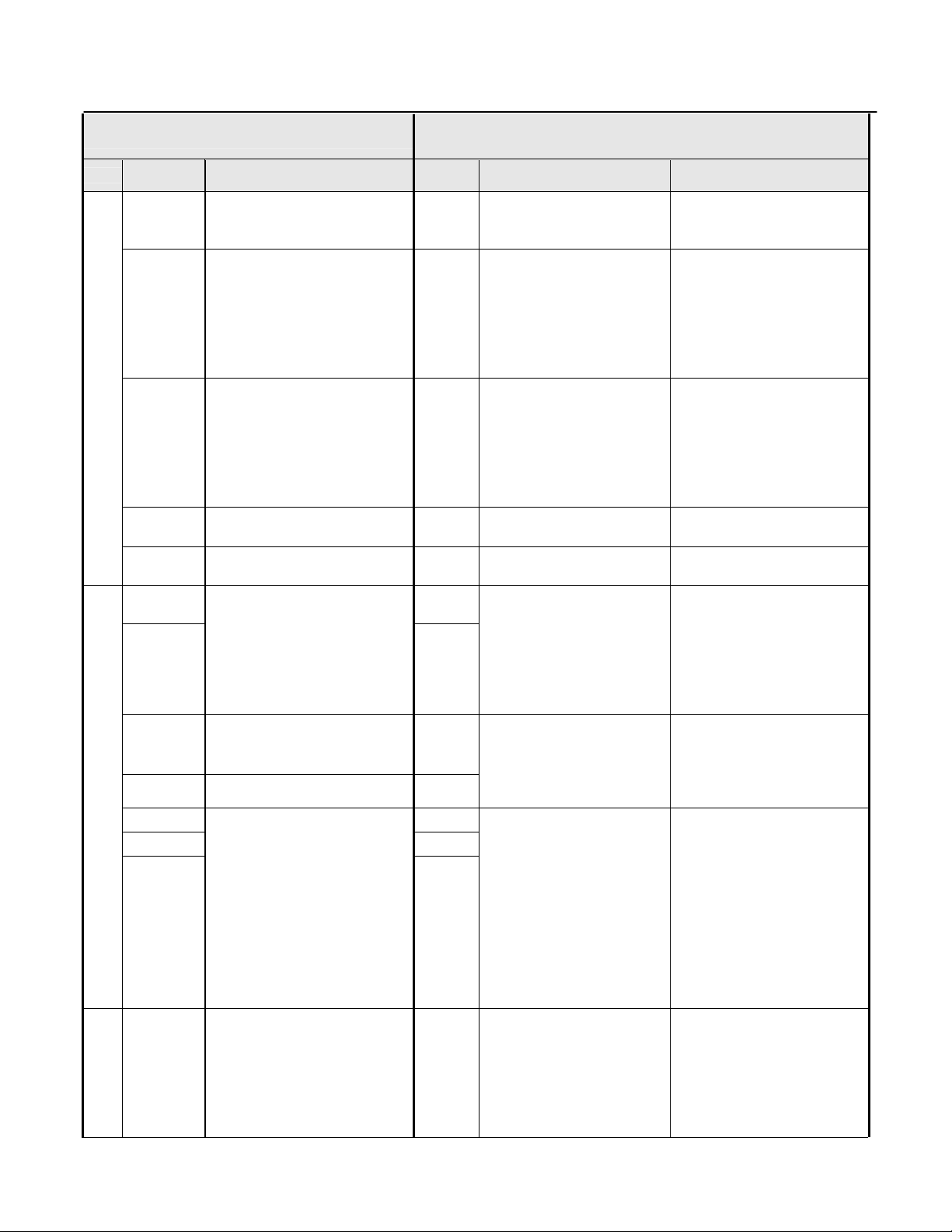

1300 2300 3600

-

-

50 10 60

65 20 85

65 80 145

80 120 200

85 135 220

120 240 360

150 305 455

180 390 570

195 465 660

260 620 880

315 705 1020

370 875 1245

415 970 1385

710 1110 1820

890 1430 2320

-

1160 1870 3030

-

1520 2670 4190

1510 3400 4910

2110 4740 6850

2910 6820 9730

P7

Model

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

40P4

40P7

43P7

44P0

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

P7 (W)

Internal Heatsink Total

74 110 184

84 164 248

113 219 332

168 357 525

182 416 598

208 472 680

252 583 835

333 883 1216

421 1010 1431

499 1228 1727

619 1588 2207

844 1956 2800

964 2194 3158

1234 2733 3967

39 14 53

41 17 58

68 80 148

70 90 160

81 127 208

114 193 307

158 232 390

169 296 465

201 389 590

233 420 653

297 691 988

332 801 1133

386 901 1287

478 1204 1682

562 1285 1847

673 1614 2287

847 1889 2736

1005 2388 3393

1144 2791 3935

1328 2636 3964

1712 3797 5509

2482 5838 8320

Page 23 of 48

Page 24

Product Transition Guide

Appendix 1 – Ratings and Heat Loss Comparison

Page Intentionally Left Blank

Page 24 of 48

Page 25

Product Transition Guide

Appendix 1 – Ratings and Heat Loss Comparison

Appendix 2

Mechanical Dimensions

Page 25 of 48

Page 26

Product Transition Guide

GPD506/P5 to P7

Page Intentionally Left Blank

Page 26 of 48

Page 27

Product Transition Guide

Appendix 2 – Mechanical Dimensions

Panel Cut-out for External Heatsink Mounting

Note: Ampacity ratings vary between GPD506/P5 and P7 models.

Refer to NEC Ratings tables in Appendix 1 for the appropriate GPD506/P5 to P7 cross-reference.

GPD506/P5 Panel Cutout for

External Heatsink

Model GPD506/P5

(mm)

W H W H W H W H

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

43P7

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

138 271 5.43 10.67

180 298 7.09 11.73

180 298 7.09 11.73

200 377 7.87 14.84

200 377 7.87 14.84

308 404 12.13 15.91

308 404 12.13 15.91

403 627 15.87 24.69

403 627 15.87 24.69

445 756 17.52 29.76

445 756 17.52 29.76

555 894 21.85 35.20

-

138 271 5.43 10.67

180 298 7.09 11.73

180 298 7.09 11.73

200 377 7.87 14.84

200 377 7.87 14.84

308 404 12.13 15.91

308 404 12.13 15.91

309 571 12.17 22.48

309 571 12.17 22.48

309 571 12.17 22.48

440 761 17.32 29.96

440 761 17.32 29.96

555 894 21.85 35.20

-

555 894 21.85 35.20

875 1324 34.45 52.13

875 1324 34.45 52.13

873 1475 34.37 58.07

GPD506/P5 (in) Model P7 (mm) P7 (in)

-

-

P7 Panel Cutout for

External Heatsink

23P7

25P5

27P5

2011

2015

2018

2022

2030

2037

2045

2055

2075

2090

2110

43P7

45P5

47P5

4011

4015

4018

4022

4030

4037

4045

4055

4075

4090

4110

4132

4160

4185

4220

4300

138 271 5.43 10.67

138 271 5.43 10.67

197 298 7.76 11.73

197 298 7.76 11.73

233 353 9.17 13.90

233 353 9.17 13.90

244 369 9.61 14.53

269 419 10.59 16.50

359 545 14.13 21.46

359 545 14.13 21.46

434 673 17.09 26.50

434 673 17.09 26.50

484 782 19.06 30.79

555 817 21.85 32.17

138 271 5.43 10.67

138 271 5.43 10.67

197 298 7.76 11.73

197 298 7.76 11.73

233 353 9.17 13.90

233 353 9.17 13.90

269 419 10.59 16.50

269 419 10.59 16.50

309 519 12.17 20.43

309 519 12.17 20.43

309 519 12.17 20.43

434 673 17.09 26.50

434 673 17.09 26.50

484 782 19.06 30.79

484 782 19.06 30.79

555 817 21.85 32.17

-

Page 27 of 48

Page 28

Product Transition Guide

Appendix 2 – Mechanical Dimensions

Mounting Hole Data

Note: Ampacity ratings vary between GPD506/P5 and P7 models.

Refer to NEC Ratings tables in Appendix 1 for the appropriate GPD506/P5 to P7 cross-reference.

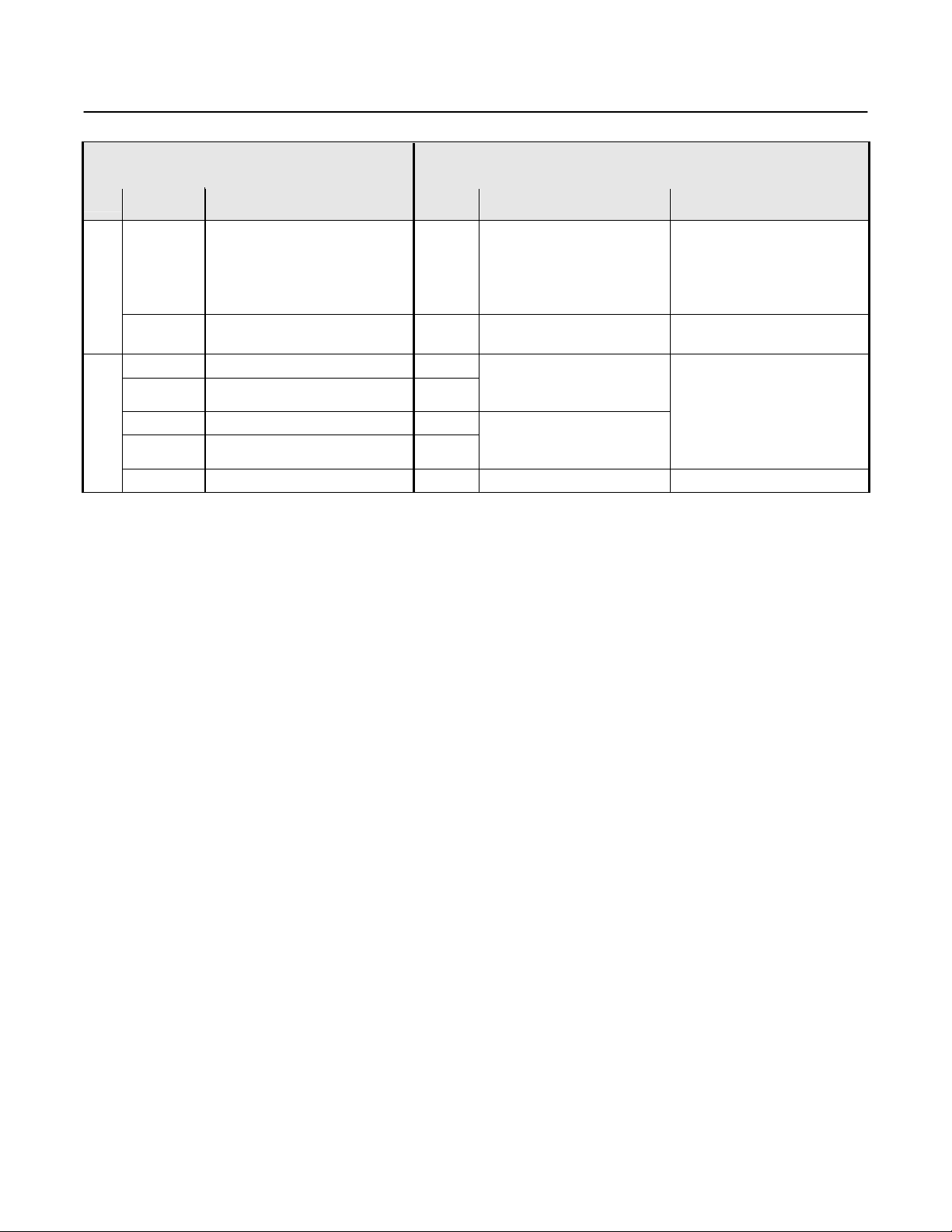

GPD506/P5 P7

Model Enclosure

23P71

25P51

27P51

20111

20151

20181

20221

20301

20371

20451

20551

20751

20900

21100

43P71

45P51

47P51

40111

40151

40181

40221

40301

40371

40451

40551

40751

40901

41101

41321

41601

41850

42200

43000

NEMA1 10.47 4.96 266 126

NEMA1 11.22 7.32 285 186

NEMA1 11.22 7.32 285 186

NEMA1 14.37 9.29 365 236

NEMA1 14.37 9.29 365 236

NEMA1 17.13 10.83 435 275

NEMA1 17.13 10.83 435 275

NEMA1 25.59 12.6 650 320

NEMA1 25.59 12.6 650 320

NEMA1 30.51 14.57 775 370

NEMA1 30.51 14.57 775 370

NEMA1 35.24 17.52 895 445

Open (IP00) -

Open (IP00) -

NEMA1 10.47 4.96 266 126

NEMA1 10.22 7.32 260 186

NEMA1 10.22 7.32 260 186

NEMA1 14.37 9.29 365 236

NEMA1 14.37 9.29 365 236

NEMA1 17.13 10.83 435 275

NEMA1 17.13 10.83 435 275

NEMA1 24.02 10.83 610 275

NEMA1 24.02 10.83 610 275

NEMA1 24.02 10.83 610 275

NEMA1 31.3 13.78 795 350

NEMA1 31.3 13.78 795 350

NEMA1 -

NEMA1 35.24 17.52 895 445

NEMA1 35.24 17.52 895 445

NEMA1 35.24 17.52 895 445

Open (IP00) 55.12 29.53 1400 750

Open (IP00) 55.12 29.53 1400 750

Open (IP00) 61.02 29.53 1550 750

(in) (mm) (in) (mm)

H1 W1 H1 W1

Model Enclosure

23P71

25P51

27P51

20111

20151

20181

20221

20301

20371

20451

20551

20751

20901

21100

43P71

45P51

47P51

40111

40151

40181

40221

40301

40371

40451

40551

40751

40901

41101

41321

41601

41850 (1)

42200 (1)

43000 (1)

Note (1): 3 mounting holes top and 3 mounting holes bottom.

Dimension is between each mounting hole.

NEMA1 10.47 4.96 266 126

NEMA1 10.47 4.96 266 126

NEMA1 11.22 7.32 285 186

NEMA1 11.22 7.32 285 186

NEMA1 13.19 8.5 335 216

NEMA1 13.19 8.5 335 216

NEMA1 15.16 7.68 385 195

NEMA1 17.13 8.66 435 220

NEMA1 22.64 9.84 575 250

NEMA1 22.64 9.84 575 250

NEMA1 27.56 12.8 700 325

NEMA1 27.56 12.8 700 325

NEMA1 32.28 14.57 820 370

Open (IP00) 33.56 17.52 852 445

NEMA1 10.47 4.96 266 126

NEMA1 10.47 4.96 266 126

NEMA1 11.22 7.32 285 186

NEMA1 11.22 7.32 285 186

NEMA1 13.19 8.5 335 216

NEMA1 13.19 8.5 335 216

NEMA1 17.13 8.66 435 220

NEMA1 17.13 8.66 435 220

NEMA1 21.06 10.24 535 260

NEMA1 21.06 10.24 535 260

NEMA1 21.06 10.24 535 260

NEMA1 27.56 12.8 700 325

NEMA1 27.56 12.8 700 325

NEMA1 32.28 14.57 820 370

NEMA1 32.28 14.57 820 370

NEMA1 33.66 17.52 855 445

Open (IP00) 50 10.63 1270 270

Open (IP00) 50 10.63 1270 270

Open (IP00) 56.7 14.37 1440 365

H1 W1 H1 W1

Page 28 of 48

Page 29

Product Transition Guide

Appendix 3 – Parameter Cross Reference

The following parameter list shows each GPD506/P5 parameter and

the P7 equivalent. P7 parameters without a GPD506/P5 equivalent

are omitted for brevity. For details on P7 parameters please refer to

the P7 manual. Parameters are listed numerically by GPD506/P5.

Page 29 of 48

Page 30

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

001

002

003

004

005

006

007

008

009

Parameter

Description or Selection

Name

Password

Run Signal Selection

Input voltage Set unit:0.1V and set ranges:150.0-733.1V

Stop method selection 0: Deceleration stop

Motor Rotation

Reverse inhibit 0: Reverse enabled

Remote/Local key 0: The function of the Remote/Local key is

Function selection of STOP

key

Frequency Reference

selection

0: Parameter n001 read/write and parameter

n002 ~ n116 read only. (Operator's FREF and

F/R is read/write. Others are read only,

1: The 1st function (n001 ~ n036)are

read/write, others read only

2: The 2nd function (n001 ~ n053) are

read/write, others read only

3: The 1st, 2nd, and 3rd functions

(n001 ~ n116) are read/write

6: 2-wire initialization (Japanese spec.)

8: Initialization (2wire sequence)

9: Initialization (3wire sequence)

Value--Run Command-------Freq Reference

0: Operator---------------------Operator

1: Terminal block ------------Operator

2: Operator-------------------- Terminal block

3: Terminal block -------------Terminal block

4: Operator --------------------Communication

5: Terminal block -------------Communication

6: Communication-------------Transmission

7: Communication-------------Operator

8: Communication------------ Terminal block

1: Coast to stop

2: Coast to stop 1 with timer

3: Coast to stop 2 with timer

0: Rotation CCW from load side.

1: Rotation CW from load side

1: Reverse disabled

disabled.

1: The function of the Remote/Local key is

enabled.

0: The STOP key is effective when run

command is from the operator.

1: The STOP key is always enabled.

0: Frequency reference setting by the operator,

the 'Enter' input is not required.

1: Frequency reference setting by the operator,

the 'Enter' input is required.

Description or Selection

0: Operation Only

1: User Level (only available if A2

parameters have been set)

2: Advanced Level

0: No Initialize

1110: User Initialize (The user must first

set their own parameter values and then

store them using parameter o2-03.)

2220: 2-Wire Initialization

3330: 3-Wire Initialization

0: Operator - Digital preset speed U1-01 or

d1-01 to d1-17.

1: Terminals - Analog input terminal A1

(or terminal A2 based on parameter

H3 13).

2: Serial Com - Modbus RS-422/485

terminals R+, R-, S+, and S-.

3: Option PCB - Option board connected

on 2CN.

0: Operator - RUN and STOP keys on

Digital Operator.

1:Terminals - Contact closure on terminals

S1 or S2.

2: Serial Com - Modbus RS-422/485

terminals R+, R-, S+, and S-.

3: Option PCB - Option board connected

on 2CN.

Set to the nominal voltage of the incoming

line. Sets the maximum and base voltage

used by preset V/F patterns, adjusts the

levels of drive protective features (i.e.

overvoltage, braking resistor turn-on, stall

prevention, etc.).

0: Ramp to Stop

1: Coast to Stop

2: DC Injection to Stop

3: Coast with Timer

(A new run command is ignored if received

before the timer expires).

Determines the forward rotation of the

motor, and if reverse operation

is disabled.

0: Reverse Enabled

1: Reverse Disabled

2: Exchange Phase - Change direction of

forward motor rotation.

3: ExchgPhs, Rev Dsbl - Change direction

of forward motor

rotation and disable reverse operation.

0: Disabled

1: Enabled

0: Disabled

1: Enabled

0: Disabled - Data/Enter key must be

pressed to enter a frequency reference.

1: Enabled - Data/Enter key is not required.

The frequency reference is adjusted by

the up and down arrow keys on the

Digital Operator without having to press

the data/enter key.

Parameter

Name

Access Level Selection

Initialize Parameters

Frequency Reference

Selection

Run Command Selection

Input Voltage Setting

Stopping Method Selection

Reverse Operation Selection

Local/Remote Key Function

Selection

STOP Key Function

Selection

Frequency Reference Setting

Method Selection

Param.

No.

A1-01

A1-03

b1-01

b1-02

E1-01

b1-03

b1-04

o2-01

o2-02

o2-05

Page 30 of 48

Page 31

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

010

011

012

013

014

015

016

017

018

019

020

021

022

Parameter

Description or Selection

Name

V/f pattern selection 1: Fixed V/f pattern

Max. output frequency Set unit: 0.1Hz and set range: 50.0-400.0Hz

Maximum voltage Set unit: 0.1V and set ranges: 0.1-733.1V

Base Frequency Set unit: 0.1Hz and set range: 0.2-400.0Hz

Mid Freq output Set unit: 0.1Hz and set range: 0.1-399.9Hz

Mid Freq. voltage Set unit: 0.1V and set ranges: 0.1-733.1V

Min output frequency Set unit: 0.1Hz and set range: 0.1-10.0Hz

Min output voltage Set unit: 0.1V and set ranges: 0.1-143.7V

Acceleration time 1 Set unit: 0.1sec (1sec in 1000sec or more)

Deceleration time 1 Set unit: 0.1sec (1sec in 1000sec or more)

Acceleration time 2 Set unit: 1sec and set range: 0-255sec

Deceleration time 2 Set unit: 1sec and set range: 0-255sec

S curve selection 0: No S curve

0: Adjustible V/f pattern

(Constant n011-n017 can be set)

Set range: 0 to 3600sec

Set range: 0.to 3600sec

1 : 0.2sec

2 : 0.5sec

3 : 1.0sec

Description or Selection

There are 15 different preset V/F patterns

to select from (E1-03 = 0 to E) with

varying voltage profiles, base levels (base

level = frequency at which maximum

voltage is reached), and maximum

frequencies. There are also settings for

Custom V/F patterns that will use the

settings of parameters E1-04 through E1-

13. E1-03 = F selects a custom V/F pattern

with an upper voltage limit and E1-03 = FF

selects a custom V/F pattern without an

upper voltage limit.

0: 50 Hz

1: 60 Hz

2: 60Hz (50 Hz Base)

3: 72 Hz (60 Hz Base)

4: 50 Hz VT1

5: 50 Hz VT2

6: 60 Hz VT1

7: 60 Hz VT2

8: 50 Hz HST1

9: 50 Hz HST2

A: 60 Hz HST1

B: 60 Hz HST2

C: 90 Hz (60Hz Base)

D: 120 Hz (60Hz Base)

E: 180 Hz (60Hz Base)

F: Custom V/F

FF: Custom w/o limit

0.0 to 120.0

0 to 255.0 (240V), 0 to 510.0(480V) Maximum Output Voltage

Parameter

V/F Pattern Selection

Maximum Output Frequency

0.0 to 200.0

0.0 to 200.0

0 to 255.0 (240V, ) 0 to 510.0 (480V) Mid Output Voltage A

Base Frequency

Mid Output Frequency A

0.0 to 200.0

0 to 255.0 (240V), 0 to 510.0 (480V) Minimum Output Voltage

Minimum Output Frequency

Acceleration Time 1

0.0 to 6000.0

Deceleration Time 1

Acceleration Time 2

Deceleration Time 2

0.00 to 2.50

S-Curve Characteristic at

Accel Start

S-Curve Characteristic at

Accel End

Name

Param.

No.

E1-03

E1-04

E1-05

E1-06

E1-07

E1-08

E1-09

E1-10

C1-01

C1-02

C1-03

C1-04

C2-01

C2-02

Page 31 of 48

Page 32

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

023

024

025

026

027

030

031

032

033

034

Parameter

Description or Selection

Name

Digital operator

display mode

Freq Ref 1 Set unit: Set range by constant n023 setting:

Freq Ref 2 Set unit: Set range by constant n023 setting:

Freq Ref 3 Set unit: Set range by constant n023 setting:

Freq Ref 4 Set unit: Set range by constant n023 setting:

Jog Ref Set unit: Set range by constant n023 setting:

Output freq upper

limit

Output freq lower

limit

Rated motor current

Motor protection selection

(OL1)

Set range: 0-4999

0: Hz with 0.1Hz

1: % speed with 0.1%

2-39: RPM. RPM =120 * freq ref(Hz) /n023

(N023 is a motor pole)

40-4999:

n23 fourth digit = decimal point

n23 1,2,3 digits = 100% freq set value

(100% frequency = xxx*10 in case of 4xxx)

0-9999

0-9999

0-9999

0-9999

0-9999

Set unit: 1% and set range:0-109%

Set unit: 1% and set range:0-100%

Set unit: 0.1A (In 1000A or more, every 1A)

Set range:10-200% of drive rated current

0: Disabled.

1: Standard motor (eight minutes)

2: Standard motor (five minutes)

3: Inverter rated motor (eight minutes)

4: Inverter rated motor (five minutes)

Description or Selection

Sets the units of the Freque ncy Refe rences (d 1- 01 to

d1-17), the F requency Reference M o nitors (U1-01,

U1-02 , U1 -05 ), and the Modbus communication

frequency reference.

0: H z

1: % (100% = E1-04)

2 to 39: R PM (E nter the nu mb e r of mot o rpole s ).

40 to 39999: User display.

Example 1: o1-03 = 12 000, will result in fre qu ency

refere nce fr om 0.0 to 20 0.0 ( 200.0 = Fmax ).

Example 2: o1-03 = 21 234, will result in fre qu ency

refere nce from 0. 00 to 12.34 (1 2.34 = Fmax) .

Setting units are affected by o1-03

Frequency reference when multi-function

input “Multi-step speed reference 1” is ON.

Setting units are affected by o1-03.

Frequency reference when multi-function

input “Multi-step speed reference 2” is ON.

Setting units are affected by o1-03.

Frequency reference when multi-function

input “Multi-step speed reference 1,2” is

ON. Setting units are affected by o1-03.

Frequency reference when:

“Jog frequency reference” is selected via

multi-function input

terminals. “Jog frequency reference” has

priority over “multi-step speed reference 1

to 4”. d1-17 is also the reference for the

JOG key on the Digital Operator, and the

multi-function inputs “forward jog” and

“reverse jog”. Setting units are affected by

o1-03.

Determines maximum frequency reference,

set as a percentage of maximum output

frequency (E1-04). If the frequency

reference is above this value, actual Drive

speed will be limited to this value. This

parameter applies to all frequency

reference sources.

Determines minimum frequency reference,

set as a percentage of maximum output

frequency (E1-04). If frequency reference

is below this value, actual Drive speed will

be set to this value. This parameter applies

to all frequency reference sources.

Set to the motor nameplate full load current

in amperes (A). This value is automatically

set during Auto-Tuning.

Sets the motor thermal overload protection

(OL1) based on the cooling capacity of the

motor.

0: Disabled

1: Standard Fan Cooled

Set the number desired at maximum

output frequ enc y.

4 digit number

Number of digits from the right of the

decimal po int

0.00 to E1-04 Value

0.00 to E1-04 Value

0.00 to E1-04 Value

0.00 to E1-04 Value

0.00 to E1-04 Value

0.0 to 110.0

0.0 to 110.0

Parameter

Name

Digital Operator Display

Selection

Frequency Reference 1

Frequency Reference 2

Frequency Reference 3

Frequency Reference 4

Jog Frequency Reference

Frequency Reference Upper

Limit

Frequency Reference Lower

Limit

Motor Rated Current

Motor Overload Protection

Selection

Param.

No.

o1-03

d1-01

d1-02

d1-03

d1-04

d1-17

d2-01

d2-02

E2-01

L1-01

Page 32 of 48

Page 33

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

035

036

037

Parameter

Name

Cooling fin overheat

Stop method

selection

Multi-function

contact input 1

(terminal S2)

Multi-function

contact input 2

(terminal S3)

Description or Selection

0: Deceleration stop

(Decelerate by deceleration time 1)

1: Coast to stop

2: Deceleration stop

(Decelerate by deceleration time 2)

3: Operation continues

(The alarm is displayed, and drive runs at

80% of the freq ref)

0: REV command (2wire sequence selection)

1: FWD/REV Command

(3wire sequence selection)

2: External fault. (N.O contact input)

3: External fault. (N.C contact input)

4: Fault reset

5: LOCAL/REMOTE switch

(run and freq ref)

6: Communication/Control circuit terminal

switch (run and freq ref)

7: Emergency stop (N.O. contact input)

8: Emergency stop (N.C contact input)

9: FV/FI terminal switch

10: Multistep speed set 1

11: Multistep speed set 2

12: Multistep speed set 3

13: Jog frequency select

14: Accel/decel time switch

15: External base block instruction

(N.O.contact input)

16: External base block instruction

(N.C contact input)

17: Speed search command from Max

frequency

18: Speed search command from set

frequency

19: Parameter set enable/disable

20: PID integral value reset

21: PID control disable

22: Timer start command

23: Inverter overheat

(blinking display of OH3)

24: Sample/holding of analog reference

25: KEB instruction (N.O. contact)

26: KEB instruction (N.C. contact)

27: Decel/accel prohibit

28: PID input characteristic switchover

Set range: 2-28

(It is the same as constant n036)

Description or Selection

Drive Operation upon OH Pre Alarm

Detection.

0: Ramp to Stop (Decel Time C1-02).

1: Coast to Stop

2: Fast-Stop (Decel Time = C1-09).

3: Alarm Only

*0 to 2 is recognized as fault detection, and

3 is

recognized as alarm. (For the fault

detection, the fault

contact operates.)

4: OH Alarm & Reduce (Continue

operation and reduce

output frequency by L8-19)

0 to 70

Selects the function of terminal S3.

0: 3-wire control

FWD/REV selection for 3-wire sequence

1: Local/Remote Sel

Hand/Auto Selection - Closed = Hand,

Open = Auto

2: Option/Inv Sel

Selects source of speed command and

sequence

Closed = Option Card, Open = b1-01 & b102

3: Multi-Step Ref 1

Closed = speed command from d1-02 or

Terminal A2,

Open = speed command determined by b101

4: Multi-Step Ref 2

Closed = speed command from d1-03 or

d1-04

Open speed command determined by b1-01

Parameter

Name

Overheat Pre-Alarm

Operation Selection

Param.

No.

L8-03

Terminal S2 is not

programmable in P7 :

P7 default setting for terminal

S2:

Reverse run when closed,

stopped when open.

Initialization parameter

A1-03 programs terminals

S1 and S2 for 2-Wire or

3-Wire run control.

Multi-Function Digital Input

Terminal S3 Function

Selection

-

H1-01

Page 33 of 48

Page 34

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

(con’t)

037

Parameter

Name

Multi-function

contact input 2

(terminal S3)

Description or Selection

Set range: 2-28

Description or Selection

6: Jog Freq Ref

Closed = speed command from d1-17

Open = speed command determined by b101

7: Multi-Acc/Dec 1

Closed = Accel & Decel Ramps

determined by C1-03 & C1-04,

Open = Accel & Decel Ramps determined

by C1-01 & C1-02

8: Ext BaseBlk N.O.

Closed = Output transistors forced off,

Open = Normal operation

9: Ext BaseBlk N.C.

Closed = Normal Operation, Open =

Output transistors forced

off

A: Acc/Dec RampHold

Closed = Acceleration suspended and

speed held, Open =

Normal Operation

C: Term A2 Enable

Closed = Terminal A2 is active, Open =

Terminal A2 is disabled

F: Term Not Used

Terminal has no effect

10: MOP Increase

Closed = Speed Command Increases, Open

= Speed Command

Held.

Must be set in conjunction with MOP

Decrease and b1-02 must

be set to 1.

11: MOP Decrease

Closed = Speed Command Decreases,

Open = Speed Command

Held.

Must be set in conjunction with MOP

Increase and b1-02 must

be set to 1.

12: Forward Jog

Closed = drive runs forward at speed

command entered into

parameter d1-17.

13: Reverse Jog

Closed = drive runs in reverse at speed

command entered into

parameter d1-17.

14: Fault Reset

Closed = Resets the drive after the fault

and the run

command have been removed.

15: Fast-Stop N.O.

Closed = Drive decelerates using C1-09,

regardless of run

command status.

17: Fast-Stop N.C.

Closed = Normal operation

Open = Drive decelerates using C1-09,

regardless of run

command status.

Closed = Normal operation

Open = Drive decelerates using C1-09,

regardless of run command status.

18: Timer Function

Input for independent timer, controlled by

b4-01 and b4-02.

Used in conjunction with a multi-function

digital output.

19: PI Disable

Turns off the PI controller, and PI setpoint

becomes speed command.

1B: Program Lockout

Closed =All parameter settings can be

changed.

Parameter

Name

Multi-Function Digital Input

Terminal S3 Function

Selection

Param.

No.

H1-01

Page 34 of 48

Page 35

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Parameter

Nxxx

Multi-function contact input 2

(con’t)

(terminal S3)

037

Name

Description or Selection

Set range: 2-28

(It is the same as constant n036)

Description or Selection

Open = Only speed command at U1-01 can

be changed.

1C: TrimCtl Increase

Closed = Increase motor speed by value in

d4-02.

Open = Return to normal speed command.

Not effective when using d1-01 thru d1-04

as a speed command.

Must be used in conjunction with Trim Ctrl

Decrease.

1D: Trim Ctl Decrease

Closed = Decrease motor speed by value in

d4-02

Open = Return to normal speed command.

Not effective when using d1-01 thru d1-04

as speed command.

Must be used in conjunction with Trim Ctrl

Increase.

1E: Ref Sample Hold

Analog speed command is sampled then

held at time of input

closure.

20: External fault, Normally Open, Always

Detected, Ramp To

Stop

21: External fault, Normally Closed,

Always Detected, Ramp To

Stop

22: External fault, Normally Open, During

Run, Ramp To Stop

23: External fault, Normally Closed,

During Run, Ramp To Stop

24: External fault, Normally Open, Always

Detected, Coast To

Stop

25: External fault, Normally Closed,

Always Detected, Coast To

Stop

26: External fault, Normally Open, During

Run, Coast To Stop

27: External fault, Normally Closed,

During Run, Coast To Stop

28: External fault, Normally Open, Always

Detected, Fast-Stop

29: External fault, Normally Open, Always

Detected, Fast-Stop

2A: External fault, Normally Open, During

Run, Fast-Stop

2B: External fault, Normally Closed,

During Run, Fast-Stop

2C: External fault, Normally Open, Always

Detected, Alarm Only

2D: External fault, Normally Closed,

Always Detected, Alarm

Only

2E: External fault, Normally Open, During

Run, Alarm Only

2F: External fault, Normally Closed,

During Run, Alarm Only

30: PI Integral Reset

Resets the PI Integral component to zero

when closed

31: PI Integral Hold

Holds the PI integral value when closed

34: PI SFS Cancel (SFS= SoftStart, also

called Accel/Decel,

See Parameter b5-17)

35: PI Input Level Sel

Inverts the PI error signal when closed

36: Option/Inv Sel 2 Selects source of

speed command and

sequence

Closed = b1-01 & b1-02, Open = Option

Card

Parameter

Name

Multi-Function Digital Input

Terminal S3 Function

Selection

Param.

No.

H1-01

Page 35 of 48

Page 36

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Parameter

Nxxx

Multi-function

(con’t)

contact input 2

037

(terminal S3)

Multi-function contact input 3

038

(terminal S4)

Multi-function contact input 4

039

(terminal S5)

Multi-function contact input 5

040

(terminal S6)

Name

Description or Selection

Set range: 2-28

(It is the same as constant n036)

Set range: 2-28

(It is the same as constant n036)

Set range: 2-28

(It is the same as constant n036)

Set range: 2-29

Description or Selection

60: Motor Preheat

Applies current to create heat to avoid

condensation

Closed = Apply amount of current as set in

parameter b2-09

61: Speed Search 1

When closed as a run command is given,

drive does a speed

search starting at maximum frequency (E1-

04).

62: Speed Search 2

When closed as a run command is given,

drive does a speed

search starting at speed command.

64: Speed Search 3

When opened, the Drive performs a

baseblock (motor coasts).

When closed, the Drive performs Speed

Search from set

frequency.

67: Com Test Mode - Used to test RS485/422 interface.

68: High Slip Braking - Closed = Drive

stops using High Slip

Braking regardless of run command status.

69: Jog2 - Closed = Drive runs at speed

command entered into

parameter d1-17. Direction determined by

fwd/rev input.

3-wire control Only.

6A: Drive Enable - Closed = Drive will

accept run command.

Open = Drive will not run.

If running, drive will stop per b1-03.

Run Command must be cycled

6B: Com/Inv Sel - Selects source of Speed

Command and

Sequence.

Closed = Serial Communication (R+,R,S+,S-), Open = b1-01

& b1-02

6C: Com/Inv Sel 2 - Selects source of

Speed Command and

Sequence.

Closed = b1-01 & b1-02, Open = Serial

Communication

(R+,R-,S+,S-)

6D: Auto Mode Sel - Hand/Auto Selection

- Closed = Auto, Open

= Hand

6E: Hand Mode Sel - Hand/Auto Selection

- Closed = Hand,

Open = Auto

70: Drv Enbl. Same as 6A except a run

command is accepted

Same selections as H1-01

Same selections as H1-01

Same selections as H1-01

0-70

0-70

0-70

Parameter

Name

Multi-Function Digital Input

Terminal S3 Function

Selection

Multi-Function Digital Input

Terminal S4 Function

Selection

Multi-Function Digital Input

Terminal S5 Function

Selection

Multi-Function Digital Input

Terminal S6 Function

Selection

Param.

No.

H1-01

H1-02

H1-03

H1-04

Page 36 of 48

Page 37

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

Multi-function

041

contact output 1

(terminal MA-MB-MC)

Parameter

Name

Description or Selection

0: Fault

1: During run.

2: Frequency agree

3: At set frequency agree

4: Freq detect

(output freq = set freq detection level)

5: Freq detect

(output frequency = set freq detect level)

6: Overtorque detect. (N.O contact)

7: Overtorque detect. (N.C contact)

8: The base block.

9: Operation mode

10: Inverter drive ready

11: Timer function

12: Auto restart. (Fault retry)

13: OL pre-alarm (OL1,OL2)

14: Frequency reference loss

15: Closed from serial communication.

16: PID feedback loss

17: OH1 alarm

Description or Selection

Selects the function of terminals M1 to M4.

0: During RUN 1 = Closed when a run

command is input or

the drive is outputting voltage.

1: Zero Speed = Closed when drive output

frequency is less

than Fmin (E1-09)

2: Fref/Fout Agree 1 = Closed when drive

output speed

equals the speed command within the

bandwidth of L4-02.

3: Fref/Set Agree 1 = Closed when the

drive output speed

and the speed command are equal to

the value in L4-01 within the bandwidth of

L4-02.

4: Freq Detect 1 = Closed when the drive

output speed is

less than or equal to the value in L4-01,

with hysteresis determined by L4-02.

5: Freq Detect 2 = Closed when the drive

output speed is

greater than or equal to the value in

L4-01, with hysteresis determined by L4-

02.

6: Inverter Ready = Closed when the drive

is not in a fault

state, and not in program mode.

7: DC Bus Undervolt = Closed when the

DC bus voltage

falls below the UV trip level (L2-05)

8: Base Blk 1 = Closed when the drive is

not outputting

voltage.

9: Operator Reference = Closed when the

speed command

is coming from the digital operator.

A: Remote/Auto Oper = Closed when the

run command is

coming from the digital operator.

B: Trq Det 1 N.O. - Closes when the output

current exceeds

the value set in parameter

L6-02 for more time than is set in

parameter L6-03.

C: Loss of Ref - Closes when the drive has

detected a loss

of analog speed command.

Speed command is considered lost when it

drops 90% in

0.4 seconds.

Parameter L4-05 determines drive reaction

to a loss of

speed command.

E: Fault - Closes when the drive

experiences a major fault.

F: Not Used

10: Minor Fault - Closes when drive

experiences a minor

fault or alarm.

11: Reset Cmd Active - Closes when the

drive receives a

reset command from terminals or serial

comms.

12: Timer Output - Output for independent

timer, controlled

by b4-01 and b4-02.

Used in conjunction with a multi-function

digital input.

17: Trq. Det 1 N.C. - Opens when the

output current

exceeds the value set in parameter

L6-02 for more time than is set in

parameter L6-03.

Parameter

Name

Terminal M3-M4 Function

Selection

Param.

No.

H2-01

Page 37 of 48

Page 38

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

Multi-function

(con’t)

contact output 1

041

(terminal MA-MB-MC)

Parameter

Name

Description or Selection

Description or Selection

1A: Reverse Dir - Closes when the drive is

running in the

reverse direction.

1E: Restart Enabled - Closes when the

drive is performing

an automatic restart.

Automatic restart is configured by

parameter L5-01.

1F: Overload (OL1) - Closes before a

motor overload

occurs. (90% of OL1 time)

20: OH Prealarm - Closes when the Drive’s

heatsink

temperature exceeds the setting

of parameter L8-02.

38: Drive Enable - Closes when the drive

enable input is

active.

39: Waiting to Run - Closes during the time

after a run

command is issued, but the Drive is not

running due to

the time set in parameter b1-10.

3A: OH Freq Reduce

3B: Run Src Com/Opt

Parameter

Name

Param.

No.

H2-01

Page 38 of 48

Page 39

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

042

044

045

046

047

048

049

050

051

052

Parameter

Description or Selection

Name

Multi-function

contact output 2

(terminal M1-M2)

Terminal FI signal Level

Selection

Frequency Reference

Retention

Frequency Ref

Loss selection

Frequency Ref

when frequency reference is

lost

Terminal FV gain Set unit: 1% and set range: 0 to 200%

Terminal FV bias Set unit: 1% and set range = -100 to +100%

Terminal FI gain Set unit: 1% and set range: 0 to 200%

Terminal FI bias Set unit: 1% and set range -100 to +100%

Analog output

Select

(terminal AM-AC)

It is the same as constant n041.

0: The FI terminal inputs 0-10V.

(Jumper J1 is cut)

1: The FI terminal inputs 4-20mA.

1: The holding frequency reference is not

memorized.

0: The holding frequency reference is

memorized and stored in n024

0: No detection

1: Continue running at n047 setting

Set unit: 1% and set range: 0-100%

0: Output frequency

(10V = Max frequency n011)

1: Output current

(10V = rated current of inverter)

2: Output power (10V = inverter rated power)

3: DC bus voltage (10V = 1150VDC)

Description or Selection

Same selections as H2-01

Selects the signal level of terminal A2.

0: 0 to 10Vdc (switch S1-2 must be in the

OFF position).

2: 4 to 20mA (switch S1-2 must be in the

ON position)

This parameter is used to retain the held

frequency reference in U1-01 (d1-01) when

power is removed. This function is

available when the multi-function inputs

“accel/decel ramp hold” or “up/down”

commands are selected

(H1-XX = A or 10 and 11).

0: Disabled

1: Enabled

The frequency reference is considered lost

when reference drops 90% or more of its

current value in less than 400ms.

0: Normal Operation - Drive will run at the

frequency reference.

1: Run at L4-06 PrevRef - Drive will run at

the percentage set in L4-06 of the

frequency reference level at the time

frequency reference was lost.

0 to 100.0

If the frequency reference loss function is

enabled (L4-05=1) and frequency reference

is lost, the Drive will run at a reduced

frequency reference determined by the

following formula:

Fref=Fref at time of loss * L4-06.

0.0 to1000.0

Sets the output level when 10V is input, as

a percentage of the maximum output

frequency (E1-04).

–100.0 to +100.0

Sets the output level when 0V is input, as a

percentage of the maximum output

frequency (E1-04).

0.0 to 1000.0

Sets the output level when 10V is input.

–100.0 to+100.0

Sets the output level when 0V is input.

Selects which monitor will be output on

terminals FM

and FC.

1: Frequency Ref (100% = max. output

frequency)

2: Output Freq (100% = max. output

frequency)

3: Output Current (100% = drive rated

current)

6: Output Voltage (100% = 230V or 100%

= 460V)

7: DC Bus Voltage (100% = 400V or 100%

= 800V)

8: Output kWatts (100% = drive rated

power)

15: Term A1 Level

16: Term A2 Level

18: Mot SEC Current (100% = Motor rated

secondary

current)

20: SFS Output (100% = max. output

frequency)

24: PI Feedback

Parameter

Name

Terminal M3-M4 Function

Selection

Terminal A2 Signal Level

Selection

MOP Ref Memory

Frequency Reference Loss

Detection Selection

Frequency Reference Level at

Loss Frequency

Terminal A1 Gain Setting

Terminal A1 Bias Setting

Terminal A2 Gain Setting

Terminal A2 Bias Setting

Terminal FM Monitor

Selection

Param.

No.

H2-02

H3-08

d4-01

L4-05

L4-06

H3-02

H3-03

H3-10

H3-11

H4-01

Page 39 of 48

Page 40

Appendix 3- Parameter Cross Reference

GPD506/P5 Parameter P7 Parameter

Param

No.

Nxxx

(cont)

052

053

054

Parameter

Description or Selection

Name

Analog output

Select

(terminal AM-AC)

Analog output gain Set unit: 0.01 and set range: 0.01-2.00