Page 1

YASKAWA

MEMOCON GL120, GL130

HARDWARE USER'S MANUAL

YA S K A WA

MANUAL NO. SIEZ-C825-20.1D

Page 2

Manual Contents

This manual describes the hardware specifications and applications of the MEMOCON GL120, GL130.

Please read this manual carefully and be sure you understand the information provided before attempting to

install and use the MEMOCON GL120, GL130.

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

.

Indicates references for additional information.

NOTICE

The following conventions are used to indicate precautions in this manual. Failure to heed precautions

provided in this manual can result in injury to people or damage to the products.

IMPORTANT

A

EXAMPLE

INFO

'SUMMARY

Note

TERMS

WARNING

!

Indicates important information that should be memorized.

"

Indicates application examples.

Indicates supplemental information.

Indicates a summary of the important points of explanations.

Indicates inputs, operations, and other information required for correct operation

but that will not cause damage to the device.

Indicates definitions of terms used in the manual.

Indicates precautions that, if not heeded, could possibly result in loss of life or

serious injury.

Caution

!

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

Yaskawa, 2001

All rights reserved. Nopart ofthis publicationmay be reproduced, stored in a retrieval system, or transmitted, in any form,or

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is subject to

change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

Page 3

CONTENTS

CHAPTER 1 Introduction and Precautions 1-1............................

1.1 Overview of Manuals 1-2.....................................................

1.2 Precautions 1-7.............................................................

1.2.1 Safety Precautions 1-7................................................

1.2.2 Installation Precautions 1-8............................................

1.2.3 Removal Precautions 1-12..............................................

1.2.4 Wiring Precautions 1-13................................................

1.2.5 Applications Precautions 1-16...........................................

1.2.6 Maintenance 1-18.....................................................

1.3 Using this Manual 1-19........................................................

CHAPTER 2 Overview 2-1.............................................

2.1 Overview of the MEMOCON GL120 and GL130 2-2...............................

CHAPTER 3 System Components 3-1....................................

3.1 Overview of System Components 3-2...........................................

CHAPTER 4 System Components: Functions and Specifications 4-1..........

4.1 General Specifications 4-3....................................................

4.2 Power Supply Modules 4-4....................................................

4.2.1 Appearance of Power Supply Modules 4-4................................

4.2.2 Power Supply Modules: Function and Models 4-9...........................

4.2.3 Specifications of Power Supply Modules 4-10...............................

4.2.4 Selecting Power Supply Modules 4-14.....................................

4.2.5 Using Power Supply Modules 4-18.......................................

4.3 CPU Modules 4-24...........................................................

4.3.1 Appearance of CPU Modules 4-24........................................

4.3.2 CPU Modules: Functions and Models 4-30.................................

4.3.3 Specifications of CPU Modules 4-35......................................

4.3.4 Using CPU Modules 1 (For CPU20, CPU30, and CPU35) 4-65.................

4.3.5 Using CPU Modules 2 (For CPU21) 4-80..................................

4.3.6 Using CPU Modules 3 (For CPU10) 4-88..................................

4.4 Communications Modules 4-100.................................................

4.4.1 Models of Communications Modules 4-100..................................

4.4.2 Remote I/O Driver Module 4-105.........................................

4.4.3 Remote I/O Receiver Module 4-111........................................

4.4.4 2000-Series Remote I/O Driver Module 4-121...............................

4.4.5 MEMOBUS Modules (RS-232) 4-127......................................

4.4.6 MEMOBUS Modules (RS-422) 4-135......................................

4.4.7 PC Link Module 4-147..................................................

4.4.8 Uniwire Interface Module 4-159..........................................

4.4.9 Uniwire H-system Interface Module 4-166..................................

4.4.10 Distributed I/O Driver Module 4-175.......................................

4.4.11 M-NET Module 4-182..................................................

—v—

Page 4

CONTENTS

4.4.12 YENET 1600-D Module 4-188...........................................

4.4.13 Ethernet Interface Module 4-199..........................................

4.4.14 Optical/Electrical Conversion Module 4-209.................................

4.5 I/O Modules 4-218............................................................

4.5.1 Models of I/O Modules 4-218............................................

4.5.2 Appearance of I/O Modules 4-220.........................................

4.5.3 Functions and Specifications of I/O Modules 4-223...........................

4.5.4 Using I/O Modules 4-229................................................

4.6 Special Purpose Modules 4-231..................................................

4.6.1 Models of Special Purpose Modules 4-231..................................

4.6.2 High-speed Counter Module 4-233........................................

4.6.3 Pulse Catch Module 4-239...............................................

4.7 Motion Modules 4-245.........................................................

4.7.1 Models of Motion Modules 4-245.........................................

4.7.2 Four-axis Motion Module 4-246...........................................

4.7.3 One-axis Motion Module 4-257...........................................

4.7.4 Two-axis Motion Module 4-265...........................................

4.8 Other Module 4-277...........................................................

4.8.1 Expander Module 4-277.................................................

4.8.2 Battery Module 4-283...................................................

4.9 Mounting Base 4-296..........................................................

4.10 Rack-to-rack I/O Cables 4-300...................................................

CHAPTER 5 Installation and Wiring 5-1.................................

5.1 Designing the Control Panel 5-2................................................

5.1.1 Structure of Control Panel 5-2..........................................

5.1.2 Cooling the Control Panel 5-2..........................................

5.1.3 Preventing Electrical Noise 5-3.........................................

5.1.4 Approximate Masses of Modules and Mounting Bases 5-5....................

5.1.5 Maximum Heating Value by Modules 5-7.................................

5.1.6 Mounting Base Layout 5-8.............................................

5.1.7 Module Mounting Dimensions 5-12.......................................

5.2 Installing Mounting Bases and Modules 5-16.......................................

5.2.1 Installing Mounting Bases 5-16..........................................

5.2.2 Installing Modules 5-20................................................

5.2.3 Installing the CPU and the Power Supply Module 5-25........................

5.2.4 Installing the Terminal Block for Field Connection Module 5-29................

5.2.5 Connector for Field Connections Module 5-35..............................

5.2.6 Installing the Communications Modules 5-39...............................

5.2.7 Installing the Motion Module 5-44........................................

5.2.8 Installing Rack-to-Rack I/O Cables 5-49...................................

5.3 Panel Wiring 5-51............................................................

5.3.1 Separation of Power Supply Systems 5-51..................................

5.3.2 Wiring the Power Supply Module 5-51....................................

5.3.3 Wiring Digital I/O Modules 5-55.........................................

—vi—

Page 5

CONTENTS

5.3.4 Wiring Other Modules 5-68.............................................

5.3.5 Grounding 5-70.......................................................

5.3.6 Hot Swapping 5-76....................................................

5.4 External Wiring 5-80..........................................................

CHAPTER 6 Low Voltage Directives 6-1.................................

6.1 Power Supply Modules 6-2....................................................

6.1.1 Models of Power Supply Modules 6-2....................................

6.1.2 Appearance of Power Supply Modules 6-3................................

6.1.3 Functions and Specifications of Power Supply Modules 6-5...................

6.1.4 Using Power Supply Modules 6-6.......................................

6.2 I/O Modules 6-11............................................................

6.2.1 Models of I/O Modules 6-11............................................

6.2.2 Appearance of I/O Modules 6-12.........................................

6.2.3 EN Standard for I/O Module 6-14........................................

6.2.4 Specifications of the I/O Module 6-16.....................................

APPENDICES

Examples of Panel Layout and Hole Dimensions A-1.....................................

A.1 Panel Layout A-2.....................................................

A.2 Drilling Plan A-4.....................................................

Dimensions B-1..................................................................

B.1 Power Supply Modules B-2............................................

B.2 CPU Modules B-3....................................................

B.3 Communications Modules B-5..........................................

B.4 I/O Modules B-10.....................................................

B.5 Special Purpose Modules B-13...........................................

B.6 Motion Modules B-14..................................................

B.7 Other Modules B-16...................................................

B.8 Mounting Bases B-19..................................................

B.9 Cables B-22..........................................................

INDEX

— vii —

Page 6

Introduction and Precautions

This chapter introduces this manual and provides precautions for the use of

this manualand the product.

to read the rest of the manual or using the product.

1.1 Overview of Manuals 1-2.....................

1.2 Precautions 1-7.............................

1.2.1 Safety Precautions 1-7.............................

1.2.2 Installation Precautions 1-8..........................

1.2.3 Removal Precautions 1-12...........................

1.2.4 Wiring Precautions 1-13.............................

1.2.5 Applications Precautions 1-16........................

1.2.6 Maintenance 1-18..................................

You must read this chapter before attempting

1

1

1.3 Using this Manual 1-19.......................

— 1-1 —

Page 7

1

Introduction and Precautions

1.1 Overview of Manuals

• This manual provides hardware information on the GL120 and GL130 and contains the following items.

1) System configuration

2) Types of devices used in the system configuration

3) Functions and specifications of the devices used in the system configuration

4) Installation and wiring

5) Examples of panel layout and dimensions for boring

6) Dimensions

• Read this manual carefully in order to properly use the hardware of the MEMOCON GL120

and GL130 Programmable Controllers. Also, keep this manual in a safe place so that it can

be referred to whenever necessary.

• Refer to the following manuals for related peripheral devices, Modules, and software.

— 1-2 —

Page 8

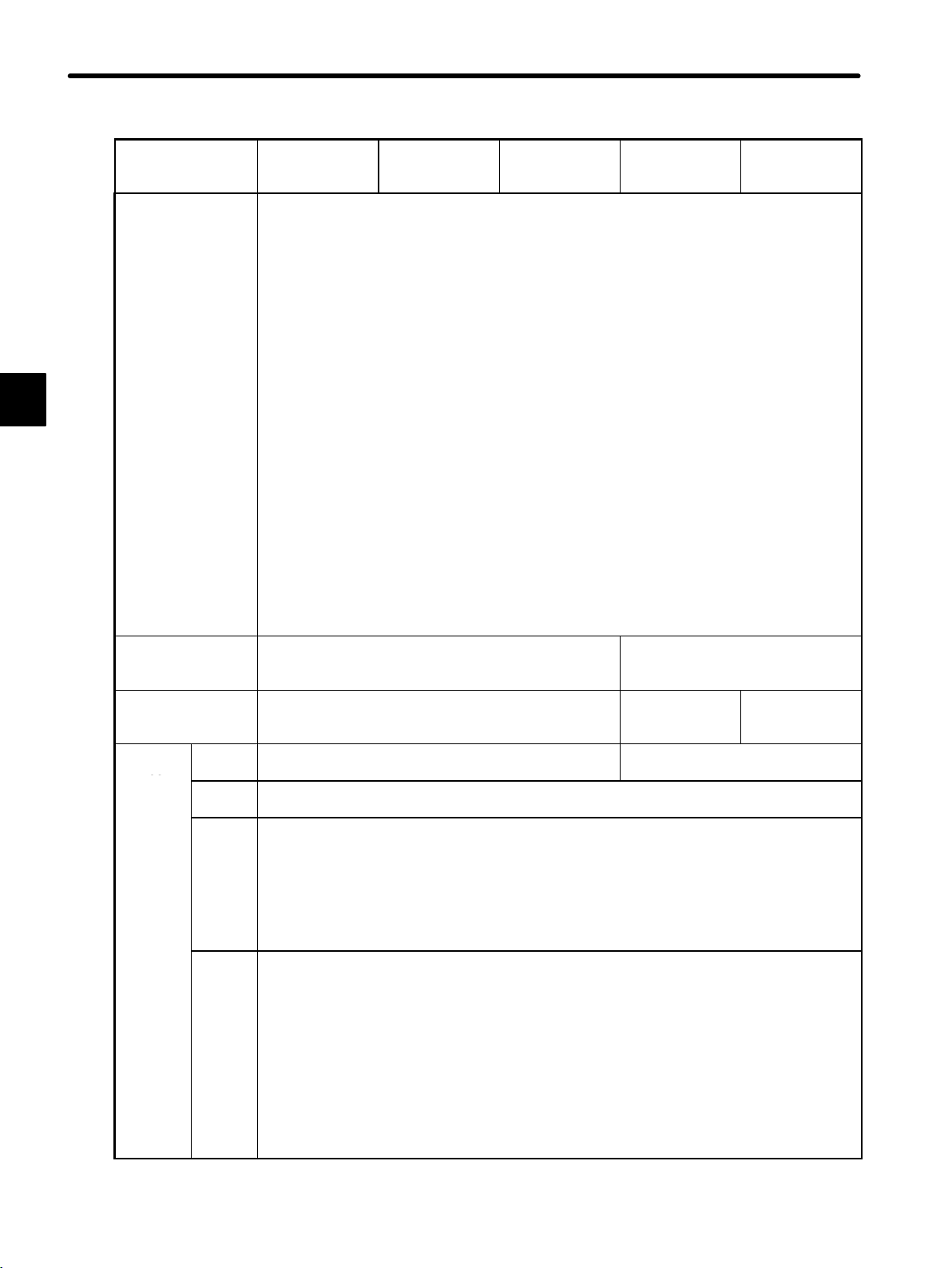

1.1 Overview of Manuals

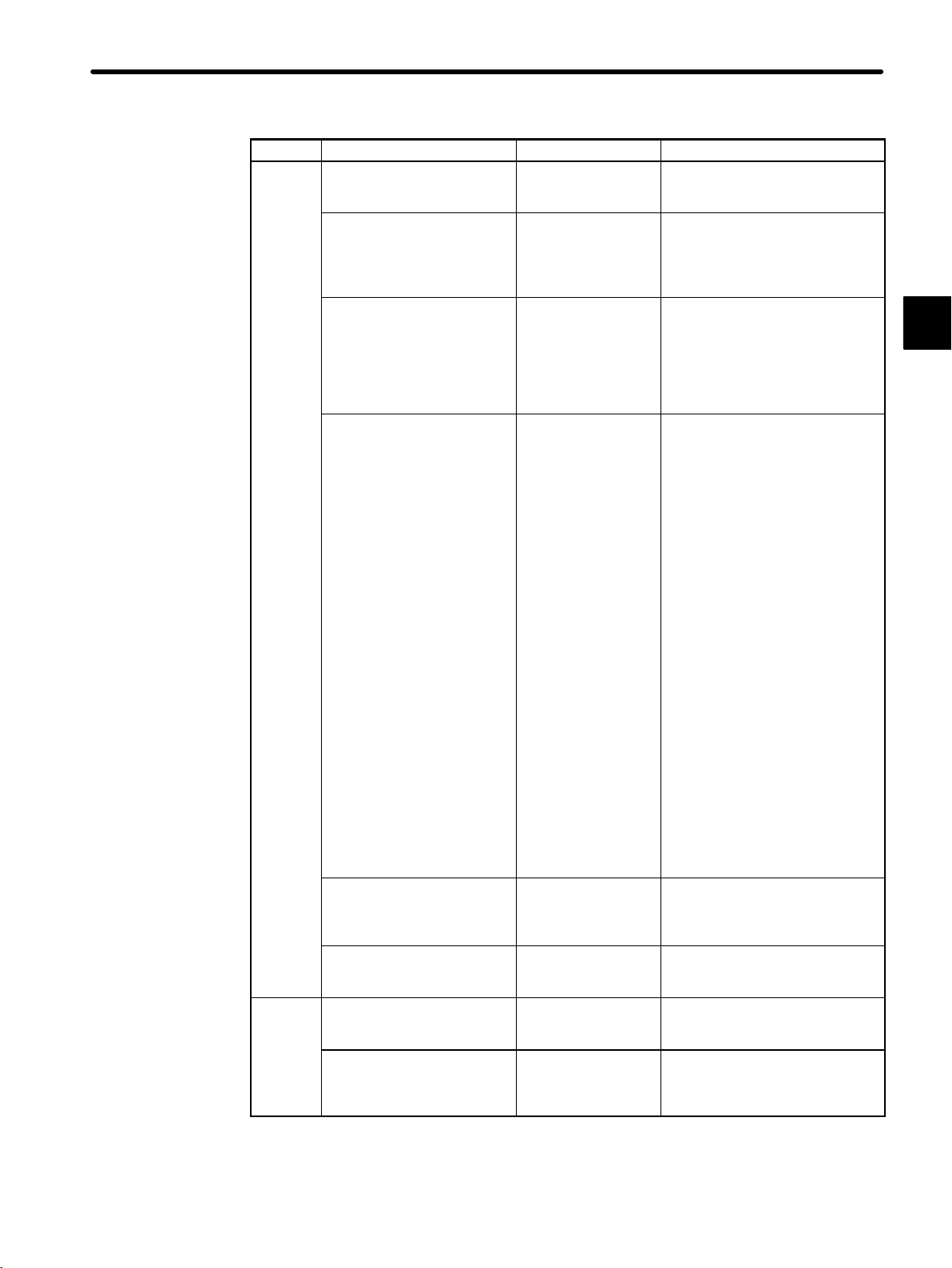

Product Manual Name Manual Number Content

CPU

Module

I/O

Modules

MEMOCON GL120

CPU10 Module

User’s Manual

MEMOCON GL120

CPU21 Module

User’s Manual

MEMOCON GL120, GL130

Software User’s Manual,

Volume 1

MEMOCON GL120, GL130

Software User’s Manual,

Volume 2

MEMOCON GL120, GL130

Software User’s Manual,

Volume 3

MEMOCON GL120, GL130

Software User’s Manual,

Volume 4

MEMOCON GL120, GL130

120-series I/O Modules

User’s Manual

MEMOCON GL120, GL130

Distributed I/O Module

User’s Manual

(MECHATROLINK)

SIEZ-C825-20.1-1 Describes the functions,

specifications, usage, and ROM

operation of the CPU10 Module.

SIEZ-C825-20.1-2 Describes the functions,

specifications, usage, and

expansion memory access

instructions of the CPU21

Module.

SIEZ-C825-20.11 Describes the following for the

GL120 and GL130:

1) Operating principles

2) I/O allocation

3) Overview of instructions

4) Instruction processing times

SIEZ-C825-20.12 Describes the programming

instructions used to create

ladder programs for the GL120

and GL130.

The following instructions are

described in other manuals.

1) Expansion Math Instructions:

Software User’s Manual (Vol.

3)

2) Process Control Instructions:

Software User’s Manual (Vol.

4)

3) CommunIcations Instructions

COM:

COM Instructions User’s

Manual FBUS:

PC Link Module User’s

Manual

MSTR:

MEMOBUS PLUS User’s

Manual

4) Motion Control Instructions

(ladder motion instructions)

Motion Module MC20

Software User’s Manual

5) Motion Language

Motion Module MC20

Software User’s Manual

SIEZ-C825-20.13 Describes expansion math

instructions (floating point math

instructions, etc.) used for the

GL120 and GL130.

SIEZ-C825-20.14 Describes process control

instructions used for the GL120

and GL130.

SIEZ-C825-20.22 Describes the functions,

specifications, and usage of the

120-Series Digital I/O Module.

SIEZ-C825-20.71 Describes the functions,

specifications, and usage of the

Distributed I/O Module for

MECHATROLINK.

1

— 1-3 —

Page 9

1

Introduction and Precautions

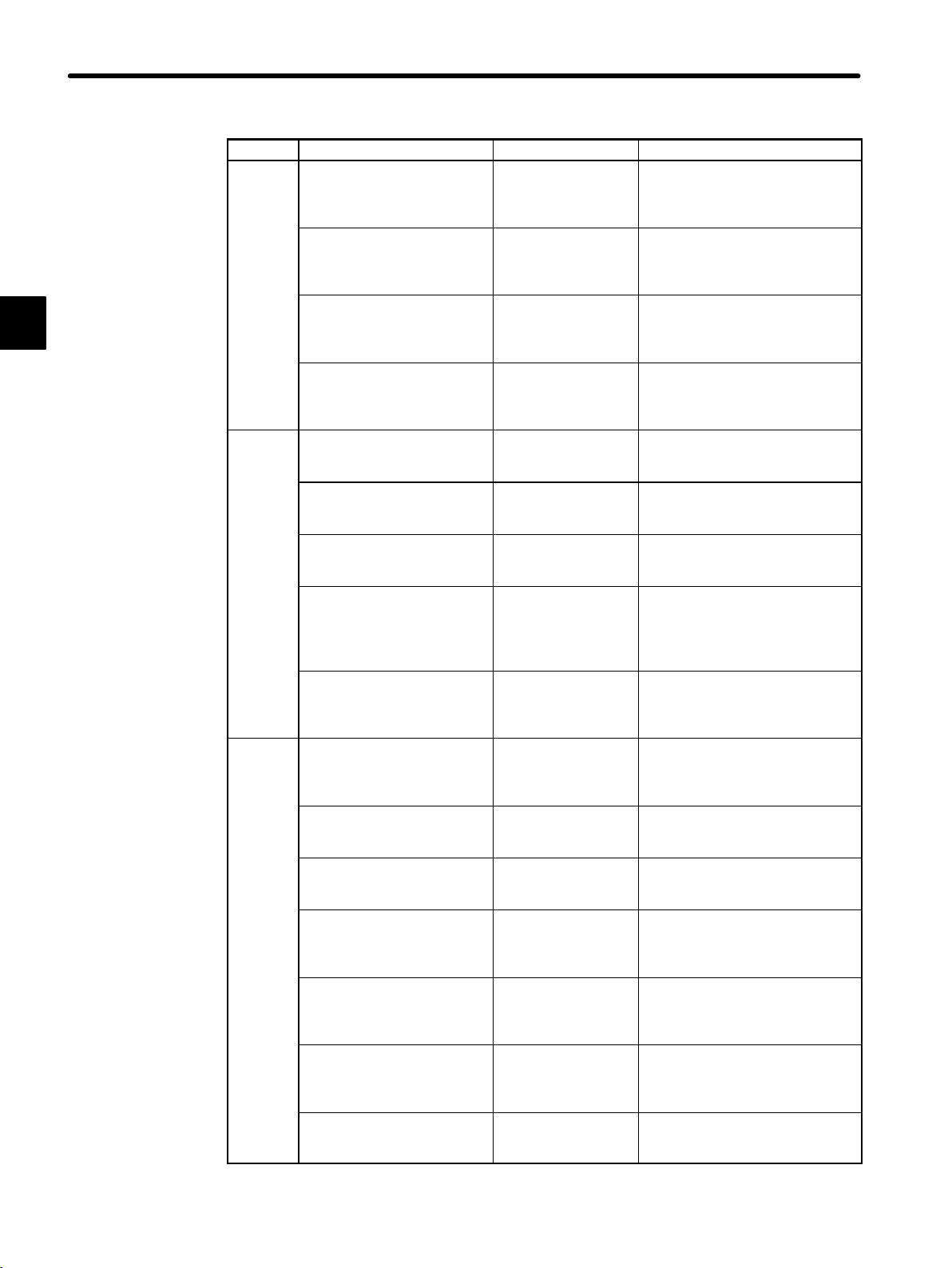

Product ContentManual NumberManual Name

Special

Purpose

Modules

Motion

Modules

HumanMachine

Interface

MEMOCON GL120, GL130

120-series High-speed

Counter Module

User’s Manual

MEMOCON GL120, GL130

Pulse Catch and Counter

Module

User’s Manual

MEMOCON GL120, GL130

Counter Module

User’s Manual

(MECHATROLINK)

MEMOCON GL120, GL130

Pulse Output Module

User’s Manual

(MECHATROLINK)

MEMOCON GL120, GL130

Motion Module MC10

User’s Manual

MEMOCON GL120, GL130

Motion Module MC15

User’s Manual

MEMOCON GL120, GL130

Motion Module MC20

Hardware User’s Manual

MEMOCON GL120, GL130

Motion Module MC20

Software User’s Manual

MEMOCON GL120, GL130

Teach Pendant TB120 for

Motion Module MC20

User’s Manual

MEMOCON GL120, GL130

MEMOSOFT for P120

Programming Panel

User’s Manual

MEMOCON GL120, GL130

MEMOSOFT

User’s Manual

MEMOCON GL120, GL130

MEMOSOFT for Windows

User’s Manual

MEMOCON GL120, GL130

Online Programmer for

P120 Programming Panel

User’s Manual

MEMOCON GL120, GL130

MEMOMAIL for P120

Programming Panel

User’s Manual

MEMOCON GL120, GL130

Online Programmer for

P140 Programming Panel

User’s Manual

FA Monitor for MEMOCON

Series ACGC4200

User’s Manual

SIEZ-C825-20.24 Describes the functions,

specifications, and usage of the

120-series High-speed Counter

Module.

SIEZ-C825-20.28 Describes the functions,

specifications, and usage of the

120-series Pulse Catch and

Counter Module.

SIEZ-C825-20.79 Describes the functions,

specifications, and usage of the

Counter Module for

MECHATROLINK.

SIEZ-C825-20.80 Describes the functions,

specifications, and usage of the

Pulse Output Module for

MECHATROLINK.

SIEZ-C825-20.41 Describes the functions,

specifications, and usage of the

One-axis Motion Module MC10.

SIEZ-C825-20.43 Describes the functions,

specifications, and usage of the

Two-axis Motion Module MC15.

SIEZ-C825-20.51 Describes the functions,

specifications, and usage of the

Four-axis Motion Module MC20.

SIEZ-C825-20.52 Describes motion control

instructions (ladder motion

instructions) and motion program

language used for the Four-axis

Motion Module MC20.

SIEZ-C825-60.3 Describes the functions,

specifications, and usage of the

Teach Pendant TB120.

SIEZ-C825-60.7 Describes the functions,

specifications, and usage of the

Programming Panel P120 (with

built-in MEMOSOFT).

SIEZ-C825-60.10 Describes the functions and

usage of the MEMOSOFT for

DOS.

SIEZ-C825-60.25 Describes the functions and

usage of the MEMOSOFT for

Windows.

SIEZ-C825-60.19 Describes the functions,

specifications, and usage of the

Online Programmer for the

GL120 and GL130.

SIEZ-C825-60.19-2 Describes the functions,

specifications, and usage of the

Online Programmer MEMOMAIL

for the GL120 and GL130.

SIEZ-C825-60.22 Describes the functions,

specifications, and usage of the

Online Programmer for the

GL120 and GL130.

SIE-C825-60.57 Describes the functions,

specifications and usage of the

FA Monitors ACGC4250/4260.

— 1-4 —

Page 10

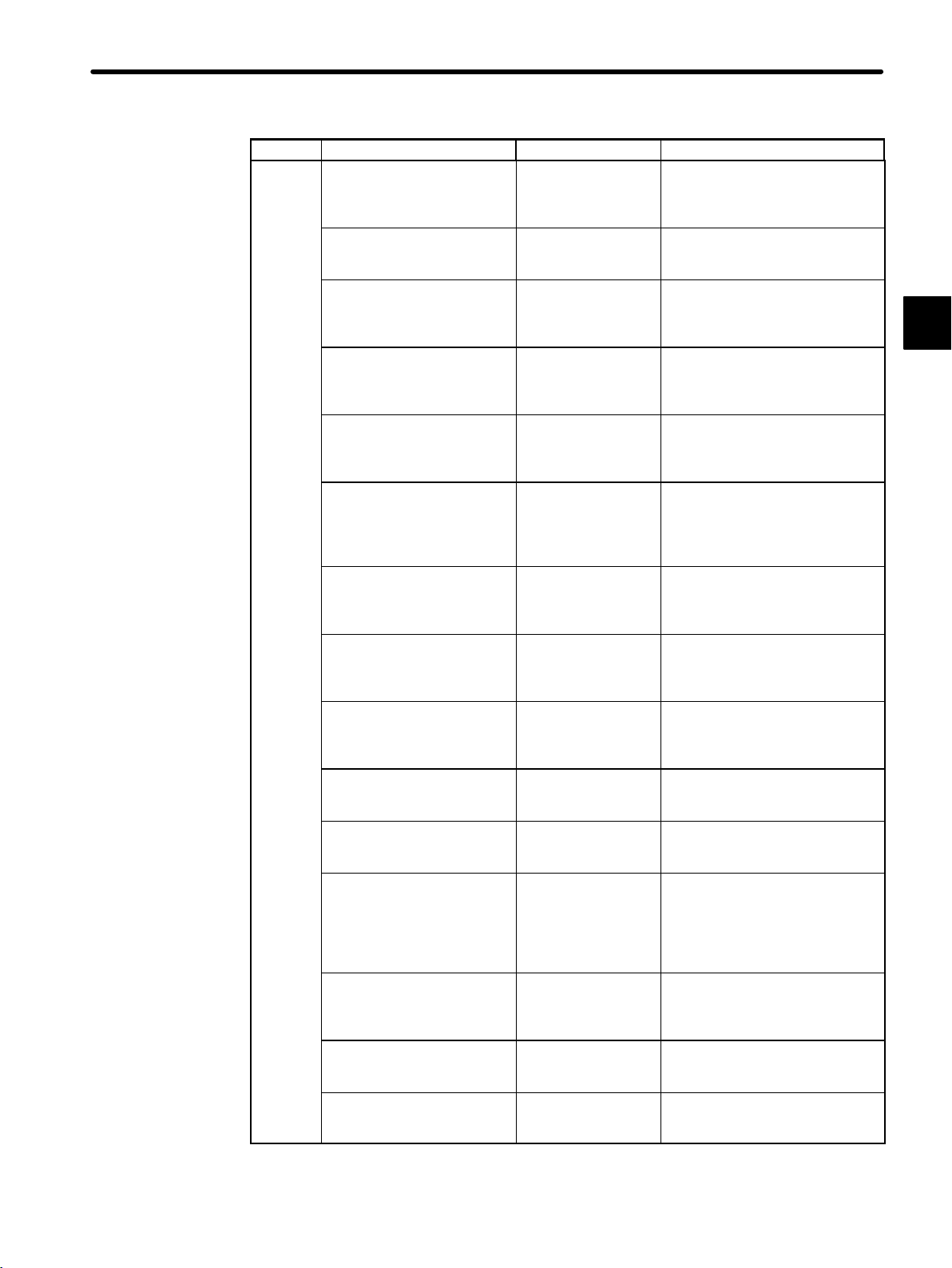

Product ContentManual NumberManual Name

Communication

Modules

MEMOCON GL120, GL130

PC Link Module

User’s Manual

MEMOCON GL120, GL130

MEMOBUS PLUS

User’s Manual

MEMOCON GL120, GL130

MEMOBUS PLUS

SA85 Network Adapter

User’s Manual

MEMOCON GL120, GL130

MEMOBUS PLUS

BM85 Bridge/Multiplexer

User’s Manual

MEMOCON GL120, GL130

Coaxial Remote I/O System

User’s Manual

1000/2000-Series Coaxial

Remote I/O System

User’s Manual

MEMOCON GL120, GL130

Uniwire Interface Module

User’s Manual

MEMOCON GL120, GL130

Uniwire H-system Interface

Module

User’s Manual

MEMOCON GL120, GL130

Distributed I/O Driver

Module

User’s Manual

MEMOCON GL120, GL130

M-NET Module

User’s Manual

MEMOCON GL120, GL130

MEMOBUS

User’s Manual

MEMOCON GL120, GL130

COM Instructions

User’s Manual

MEMOCON GL120, GL130

Optical/Electrical

Conversion Module

User’s Manual

MEMOCON GL120, GL130

YENET 1600-D Module

User’s Manual

MEMOCON GL120, GL130

Ethernet Interface Module

User’s Manual

1.1 Overview of Manuals

SIEZ-C825-70.4 Describes the functions,

specifications, and usage of the

PC Link Module for the GL120

and GL130.

SIEZ-C825-70.5 Describes the functions,

specifications, and usage of the

MEMOBUS PLUS.

SIEZ-C825-70.6 Describes the SA85 Network

Adapter for the MEMOBUS

PLUS.

SIEZ-C825-70.7 Describes the BM85

Bridge/Multiplexer for the

MEMOBUS PLUS.

SIEZ-C825-70.8 Describes the functions,

specifications, and usage of the

Coaxial Remote I/O System for

the GL120 and GL130.

SIEZ-C825-70.9 Describes the functions,

specifications, and usage of the

Coaxial Remote I/O System for

the GL120 and GL130 using

1000 I/O and 2000 I/O

SIEZ-C825-20.26 Describes the functions,

specifications, and usage of the

120-series Uniwire Interface

Module.

SIEZC82052100 Describes the functions,

specifications, and usage of the

120-series Uniwire Interface

Module.

SIEZ-C825-20.29 Describes the functions,

specifications, and usage of the

120-series Distributed I/O Driver

Module for MECHATROLINK.

SIEZ-C825-70.12 Describes the functions,

specifications, and usage of the

M-NET Module.

SIEZ-C825-70.13 Describes the functions,

specifications, and usage of the

MEMOBUS.

SIEZ-C825-70.14 Describes the functions,

specifications, and usage of the

COM instructions. It also

describes the specifications and

usage of the MEMOBUS

Module.

SIEZ-C825-70.18 Describes the functions,

specifications, and usage of the

Optical/Electrical Conversion

Module.

SIEZ-C825-70.20 Describes the functions,

specifications, and usage of the

YENET 1600-D Module.

SIEZ-C825-70.21 Describes the functions,

specifications, and usage of the

Ethernet Interface Module.

1

— 1-5 —

Page 11

1

Introduction and Precautions

Product ContentManual NumberManual Name

Communication

Modules

Other

Products

• Thoroughly check the specifications and conditions or restrictions of the product before

use.

MEMOCON GL120, GL130

FIX Ethernet MEMOBUS

Driver (YME)

User’s Manual

MEMOCON GL120, GL130

Traceback

User’s Manual

SIEZ-C825-70.22 Describes the functions,

specifications, and usage of the

FIX Ethernet MEMOBUS Driver.

SIEZ-C825-60.10-4 Describes the functions,

specifications, and usage of the

Traceback.

— 1-6 —

Page 12

1.2 Precautions

This section outlines general precautions that apply to using this manual and the

product. You must read this section first before reading the remainder of the

manual.

1.2 Precautions

1.2.1 Safety Precautions 1-7...............................................

1.2.2 Installation Precautions 1-8...........................................

1.2.3 Removal Precautions 1-12............................................

1.2.4 Wiring Precautions 1-13...............................................

1.2.5 Applications Precautions 1-16..........................................

1.2.6 Maintenance 1-18....................................................

1.2.1 Safety Precautions

• The GL120 and GL130 were not designed or manufactured for use in devices or systems

directly related to human life. Users who intend to use the product described in this manual

for special purposes such as devices or systems relating to transportation, medical, space

aviation, atomic power control, or underwater use must contact Yaskawa Electric Corporation beforehand.

• This product has been manufactured under strict quality control guidelines. However, if this

product is to be installed in any location in which a failure of GL120 and GL130 involves a life

and death situation or in a facility where failure may cause a serious accident, safety devices MUST be installed to minimize the likelihood of any accident.

1

• Any illustrations, photographs, or examples used in this manual are provided as examples

only and may not apply to all product to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of

the manual may be changed without notice to improve the product and/or the manual. A

new version of the manual will be released under a revised manual number when any

changes are made.

• Contact your Yaskawa representative or a Yaskawa office listed on the back of this manual

to order a new manual whenever this manual is damaged or lost. Please provide the manual

number listed on the front cover of this manual when ordering.

• Contact your Yaskawa representative or a Yaskawa office listed on the back of this manual

to order new nameplates whenever a nameplate becomes worn or damaged.

• Yaskawa cannot guarantee the quality of any products which have been modified. Yaskawa

assumes no responsibility for any injury or damage caused by a modified product.

— 1-7 —

Page 13

Introduction and Precautions

1.2.2 Installation Precautions

1.2.2 Installation Precautions

Abide by the following precautions when installing GL120 and GL130 systems.

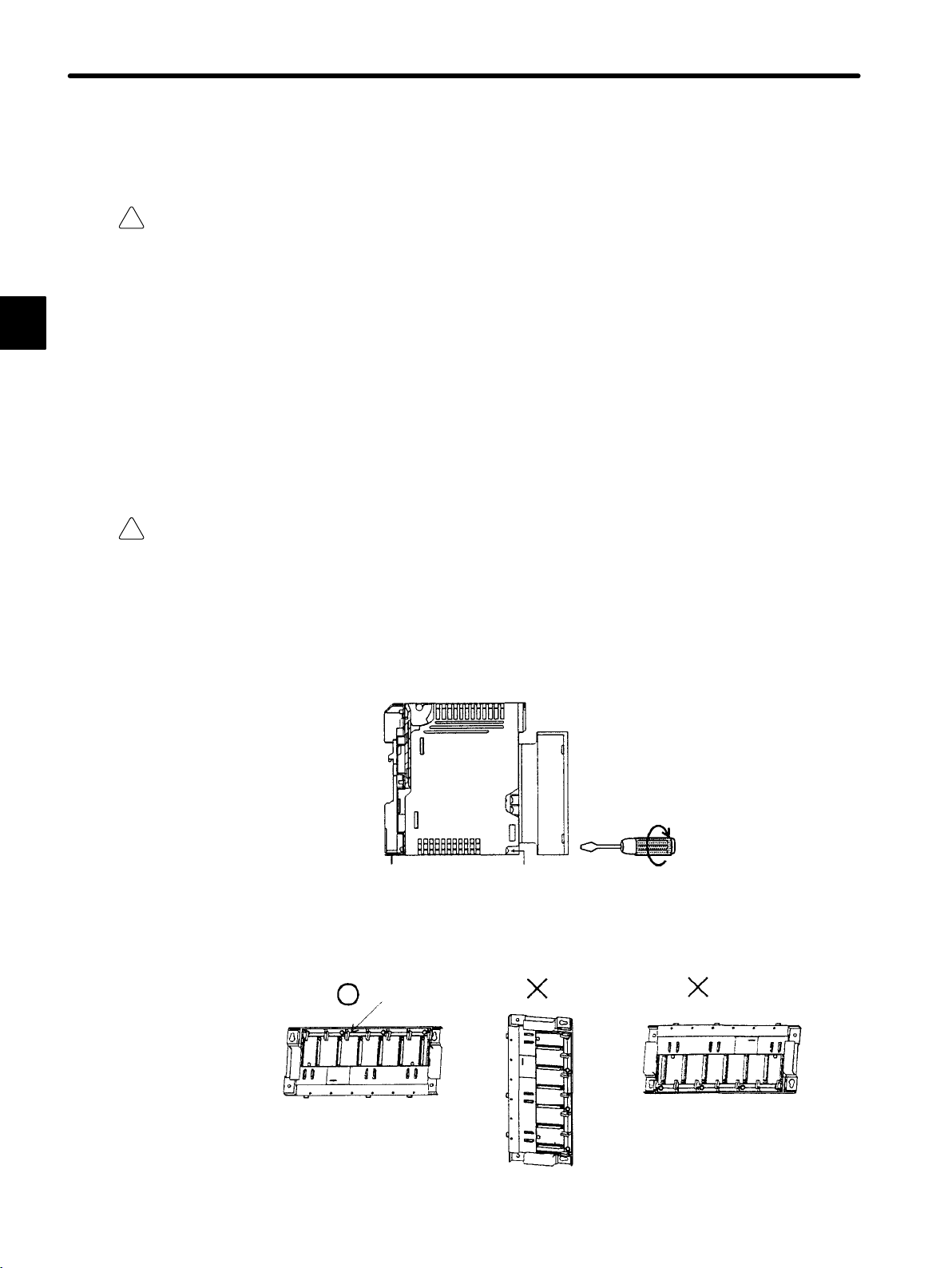

!

Caution The installation environment must meet the environmental conditions given in product cata-

logs and manuals. Using the GL120 and GL130 in environments subject to high temperatures, high humidity, excessive dust, corrosive gases, vibration, or shock can lead to electrical shock, fire, or faulty operation. Do notuse the GL120 and GL130 in the following locations.

1

• Locations subject to direct sunlight or ambient temperatures not between 0 and 60 _C.

• Locations subject to relative humidity in excess of 95%, or condensation because of

rapid changes in humidity.

• Locations subject to corrosive or flammable gas.

• Locations that would subject the GL120 and GL130 to direct vibration or shock.

• Locations subject to contact with water, oil, chemicals, etc.

!

Caution Install the GL120 and GL130 as described in this product manual. Improper installation can

cause product failure, malfunctions, or Modules or other components to fall off.

1) Make sure that all mounting screws are securely tightened.

Make sure that all installation screws for Modules or terminal block for field connection

are securely tightened so that they do not become loose. Loose screws will cause failures in the GL120 and GL130.

Power

Supply

Module

Module mounting screw

2) Install Mounting Bases in the correct direction. Faulty or inappropriate installation may

result in detachment, failure, or malfunction.

Module hooks

Install Mounting Base perpendicularly so

that the Module hooks face upwards.

— 1-8 —

Page 14

1.2 Precautions

!

Caution

!

Caution Connector covers are attached to the Module connectors on the Mounting Base. Leave the

!

Caution When installing the Power Supply Module, turn OFF the power supply to the field wiringtermi-

Never install a Mounting Base on the DIN track when transporting over long distances or

when the control panel which houses the GL120 or GL130 will be used in an environment

subject to excessive vibration. In such cases, install the Mounting Base directly onto a steel

installation plate.

If the Mounting Base is installed on DIN track, it may fall off if subject to strong shock or

vibration.

Module connectors attached to the connector covers when mounting the Mounting Base so

that foreign matter does not enter the Module connectors during mounting operations.

The GL120 and GL130 may malfunction if any foreign matter enters a Module connector.

nals.

1

Installing the Power Supply Module while the power is being supplied may damage the

Module or cause malfunction of the GL120 and GL130.

!

Caution When installing the CPU or the Expander Module, turn OFF the power supply to all Power

Supply Modules.

Installing the CPU or the Expander Module while the power is being supplied to Power

Supply Modules may damage the Module or cause malfunction of the GL120 and GL130.

!

Caution When installing the terminal block for the AC I/O Modules, turn OFF the AC power supply to

the AC I/O Modules for input signal or driving loads.

Installing a terminal block with AC power to the external power supply terminal of the AC

I/O Modules may cause an electric shock at touching the power supply terminals.

!

Caution Make sure that all mounting screws for the terminal block are securely tightened.

Make sure that all mounting screws for the terminal block are securely tightened so that

they do not become loose. Loose screws may cause malfunctioning of the GL120,

GL130.

!

Caution Male sure that all cable connectors for the Module are securely inserted and tightened.

Insufficient insertion and/or looseness may cause malfunction of the GL120 and GL130.

— 1-9 —

Page 15

1

Introduction and Precautions

1.2.2 Installation Precautions cont.

!

Caution

!

Caution Mount the Modules mentioned in the table below on local channel racks.

Mount the Modules mentioned in the table below on CPU racks (racks with CPU Modules).

Mounting these Modules on any other racks may damage the Modules or cause a malfunction of the GL120 and GL130.

Modules to be Mounted on CPU Rack Model No.

Remote I/O Driver Module JAMSC-120CDR13100

2000-series Remote I/O Driver Module JAMSC-120CDR13110

PC Link Module JAMSC-120NFB23100

Ethernet Interface Module JAMSC-120NET12100

Mounting these Modules on remote channel racks may damage the Modules or cause a

malfunction of the GL120 and GL130.

Modules to be Mounted on Local Channel Rack Model No.

MEMOBUS Module (RS-232) JAMSC-120NOM13100

MEMOBUS Module(RS-422) JAMSC-120NOM13110

!

Caution When installing the Modules that do not support hot swapping, turn OFF the power supply to

Power Supply Modules.

Installing the Modules that do not support hot swapping while the power is being supplied

to Power Supply Modules may damage the Module or cause malfunction of the GL120

and GL130.

Modules that Do Not Support Hot Swapping Model No.

Remote I/O Driver Module JAMSC-120CDR13100

2000-series Remote I/O Driver Module JAMSC-120CDR13110

!

Caution

When connecting the cables connected to the Ethernet Interface Modules, turn OFF the power supply to the Power Supply Modules on the racks where the Ethernet Interface Modules

are mounted.

Connecting the cables while power is being supplied to the Power Supply Modules may

damage the Ethernet Interface Module or cause a malfunction of the GL120 and GL130.

!

Caution Mount the MC20 Module on a CPU Rack(a rack with CPU Module).

Installing the MC20 Module on any other rack may damage the Module or cause the malfunction of the GL120 and GL130.

!

Caution When using the absolute position detecting function with the MC15 Module, it must be

mounted on the CPU Rack (a rack with CPU Module).

Installing the MC15 Module on any other rack may damage the Module or cause the malfunction of the GL120 and GL130.

— 1-10 —

Page 16

1.2 Precautions

!

Caution

!

Caution When connecting the cables to the Motion Module, turn OFF the power supply to the Power

When installing the Motion Module, turn OFF the power supply to the Power Supply Module

on the rack with the Motion Module mounted.

Installing the Motion Module while the power is being supplied to the Power Supply Module may damage the Module or cause malfunction of the GL120 and GL130.

Supply Module on the rack with the Motion Module mounted.

Connecting cables to a Motion Module while the power is being supplied may damage

the Module or cause malfunction of the GL120 and GL130.

!

Caution When connecting the Rack-to-rack I/O cables to the Motion Module, turn OFF the power Sup-

ply to all Power Supply Modules.

Connecting the cables while the power while the power is being supplied may damage

the Module or cause a malfunction of the GL120 and GL130.

!

Caution The total length of the rack-to rack I/O cable for each station is always 6.0 m or less.

If the total length of the cables exceeds 6.0 m, operational errors may occur at the station.

!

Caution Make sure that all cable connectors for the Module are securely inserted and tightened.

Insufficient insertion and/or looseness may cause malfunction of the GL120 and GL130.

!

Caution Do not remove the connector covers from the Module connectors on the Mounting Base slots

where no Modules are installed.

1

The GL120 and GL130 may malfunction if any foreign matter enters a Modules connector.

!

Caution Make sure that all mounting screws for the Module are securely tightened.

Make sure that all mounting screws for the Modules are securely tightened so that they

do not become loose. Loose screws may cause malfunction of the GL120 and GL130.

!

Caution Do not mount more than one Power Supply Modules on a single Mounting Base.

Mounting more than one Power Supply Modules on a single Mounting Base may damage

the Power Supply Module and cause malfunction of the GL120 and GL130.

!

Caution

Do not mount more than CPU Modules and Expander Module on a single Mounting Base.

Mounting more than CPU Modules and Expander Module on a single Mounting Base

may damage the CPU Modules and Expander Module or cause malfunction of the

GL120 and GL130.

— 1-11 —

Page 17

Introduction and Precautions

1.2.3 Removal Precautions

1.2.3 Removal Precautions

!

Caution Always turn OFF the power to field wiring terminals before removing the Power Supply Mod-

ule.

Removing the Power Supply Module while power is supplied to field wiring terminals may

damage the Power Supply Module or cause malfunction of the GL120 and GL130.

1

!

Caution Always turn OFF the power to the Power Supply Module before removing the CPU Modules

or Expander Module.

Removing the CPU Modules and Expander Module while power is supplied to Power

Supply Module may damage the CPU Modules and Expander Module or cause malfunction of the GL120 and GL130.

!

Caution

!

Caution When inserting or removing an AC I/O Module while the AC power supply is turned ON, install

!

Caution Always turn OFF the power to the Power Supply Module before removing the Modules that do

Always turn OFF the AC power supply to the AC I/O Modules for inputting signal or for driving

loads before removing the terminal block from the AC I/O Modules.

Removing a terminal block with AC power supply to the external power supply terminal of

the AC I/O Modules may cause an electric shock at touching the power supply terminals.

a safety switch for each Module and always turn this safety switch OFF to turn OFF the AC

power supply to the Module.

Inserting or removing an AC I/O Module while the AC power supply is being supplied may

result in an electric shock at touching the power supply terminals.

not support hot swapping.

Removing the Modules that do not support hot swapping while the power is being supplied to the Power Supply Module may damage the Modules or cause a malfunction of

the GL120 and GL130.

Modules that Do Not Support Hot Swapping Model No.

Remote I/O Driver Module JAMSC-120CDR13100

2000-series Remote I/O Driver Module JAMSC-120CDR13110

!

Caution Always turn OFF the power to Power Supply Modules on the rack having the Ethernet I/F

Module Mounted, before removing the cables connected to the Ethernet I/F Module.

Removing cables connected to the Ethernet I/F Module while power is being supplied to

Power Supply Module may damage the Modules or cause malfunction of the GL120 and

GL130.

— 1-12 —

Page 18

1.2 Precautions

!

Caution

!

Caution Always turn OFF the power to Power Supply Module on the rack, having the Motion Module

!

Caution Always turn OFF the power to Power Supply Module before removing the Rack−to rack I/O

Always turn OFF the power to Power Supply Module on the Rack, having the Motion Module

mounted, control power of Servo Amp, and power supply for the external I/O devices, before

removing cables to the Motion Module.

Removing cables connected to the Motion Module while power is being supplied to these

devices may damage the Motion Module or cause malfunction of the GL120 and GL130.

mounted, control power of Servo Amp, and power supply for the external I/O devices before

removing the Motion Module.

Removing the Motion Module while the power is being supplied to these devices may

damage the Motion Module or cause malfunction of the GL120 and GL130.

cables connected to the Expander Module.

1

Removing cables connected to the Expander Module while power is being supplied to

Power Supply Module may damage the Expander Module or cause malfunction of the

GL120 and GL130.

1.2.4 Wiring Precautions

!

Caution Connect the correct power supply for the required ratings.

Connecting unsuitable power supplies may result in fires.

!

Caution Wiring must be performed by qualified personnel.

Wrong or inappropriate wiring may result in fire, product failure, or electric shock.

!

Caution Wire power supply wires to the DC Power Supply Module with the correct polarity.

Wiring with incorrect polarity may result in damage to the DC Power Supply Module.

!

Caution

Connect power supplies of the same phases to the common 1 and common 2 of the AC I/O

Module.

If power supplies of different phases are connect, overheating or fire may occur.

— 1-13 —

Page 19

1

Introduction and Precautions

1.2.4 Wiring Precautions cont.

!

Caution

!

Caution When using one of the following Output Modules, connect an external fuse corresponding to

When inserting or removing an AC I/O Modules while the AC power supply is turned ON,

install a safety switch for each Module and always turn this safety switch OFF to turn OFF the

AC power supply to the Module.

the specifications of the load and in series with the load.

Inserting or removing an AC I/O Modules while the AC power supply is being supplied

may result in an electric shock at touching power supply terminals.

a) 100/200-VAC 8-point Output Module (Model No.: JAMSC-120DAO83000)

(Model No.: JAMSC-120DAO83009)

b) 100/200-VAC 16-point Output Module (Model No.: JAMSC-120DAO84300)

(Model No.: JAMSC-120DAO84309)

c) 12/24-VDC 16-point Output Module (sinking) (Model No.: JAMSC-120DDO34310)

d) 12/24-VDC 16-point Output Module (sourcing) (Model No.: JAMSC-120DDO34320)

e) 12/24-VDC 32-point Output Module (sinking) (Model No.: JAMSC-120DDO35410)

f) 12/24-VDC 64-point Output Module (sinking) (Model No.: JAMSC-120DDO36410)

g) Relay Contact 16-point Output Module (Model No.: JAMSC-120DRA84300)

(Model No.: JAMSC-120DRA84309)

Not connecting an external fuse may result in fire, damage to the device, or damage to

output circuit due to an overload or a short-circuit at the load.

!

Caution Ground the protective ground terminal to a resistance of 100 Ω max.

Not grounding the protective ground terminal may result in electric shock or malfunction.

Insert the Interface Cables Properly

• Insert the connectors of the various interface cables that are to be connected to GL120

and GL130 into the communication ports and secure them properly.

Improper insertion of interface cables may cause operational errors in the GL120 and

GL130.

— 1-14 —

Page 20

1.2 Precautions

Power Supply Noise Reduction

• Prevent noise from penetrating into the product by installing an isolation transformer or

a noise filter for the external power supply.

Noise from power supply may result in the malfunctioning of GL120 and GL130.

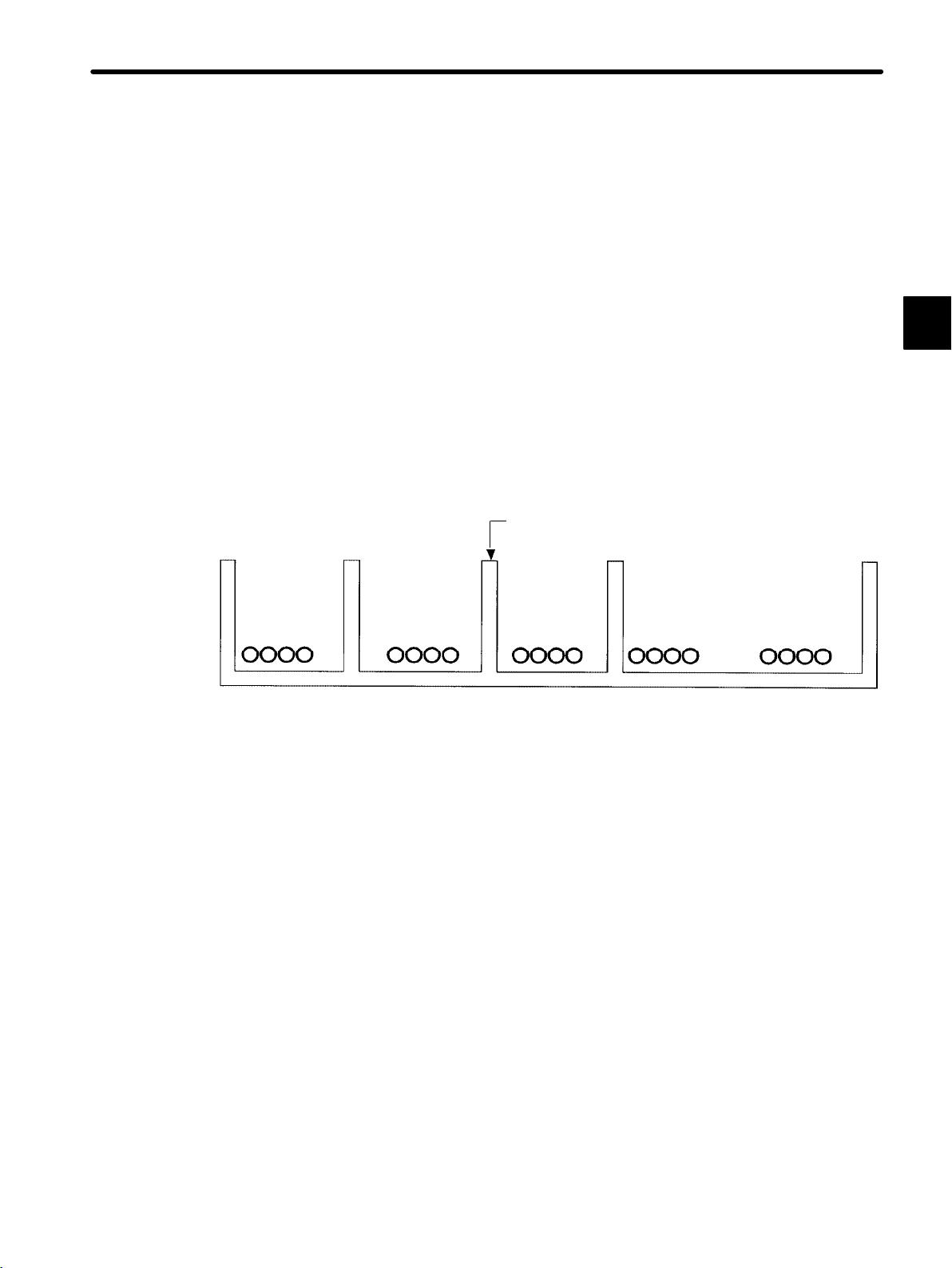

Select, Separate, and Lay External Wiring Correctly

• I/O lines connecting external devices to the 120-series I/O Modules must be selected

based on the following considerations: mechanical strength, resistance to noise, wiring

distance, signal voltage, etc.

• I/O lines must be separated from power lines both inside and outside the control panel

to minimize theaffects of noise. Faulty operation may result if I/O lines are not sufficiently separated from power lines.

1

Example of external wiring separation

Power lines General control

circuit cables

Control panel separator

Digital I/O

signal cables

Analog I/O

signal cables

Pulse input

signal cables

— 1-15 —

Page 21

1

Introduction and Precautions

1.2.5 Applications Precautions

1.2.5 Applications Precautions

!

WARNING

!

WARNING

Do not touch terminals while the power is ON.

Construct an emergency stop circuit and an interlock circuit outside of the GL120 and GL130.

Install an Emergency Stop Circuit Outside the GL120 and GL130.

Touching live terminals may cause electric shock.

The absence of emergency stop and interlock circuits may result in machine damage or

accidents should the GL120 or GL130 fail.

An emergency stop circuit for the control system should not be constructed using the ladder programming in the GL120 and GL130. Always construct the emergency stop circuit

externally using a relay circuit, as shown in the figure below.

Use an N.C. contact (mechanical contact) in the emergency stop switch. The main power

supply to the servo must be cut off by pressing the switch.

Failure to provide an emergency stop circuit as described above, may result in failure of

the emergency stop when input circuits fail or cables break, and may cause machine

damage or injury.

Control power

supply OFF

Emergency stop

Noise filter

Control power supply ON

ESP-TBOX

Noise filter

Servo OFF

Servo ON

Surge absorber

— 1-16 —

Control signal to MC Module

Encoder

Servo motor

Page 22

1.2 Precautions

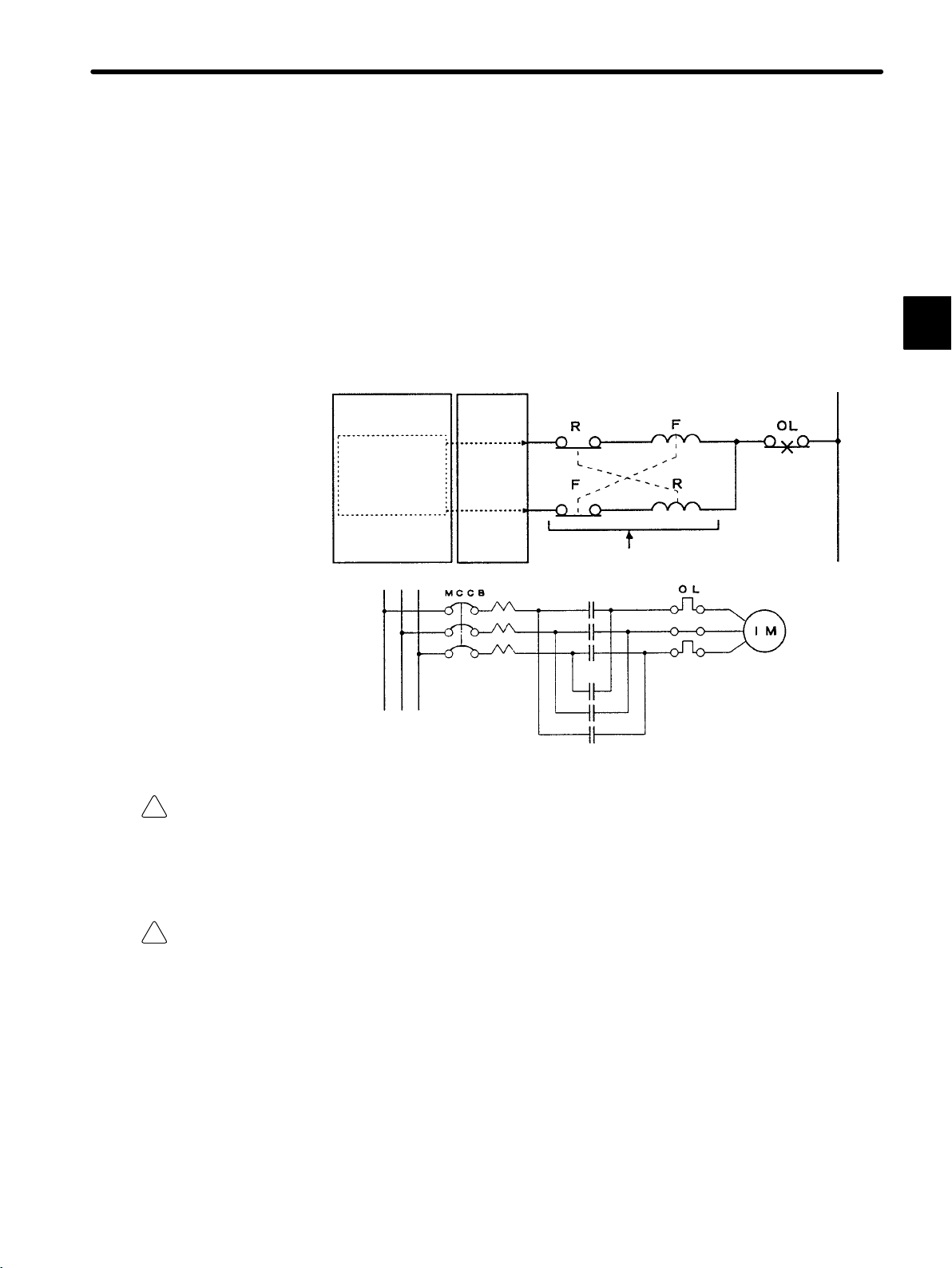

External Interlocks for the GL120 and GL130

Externally connect an interlock to the GL120 and GL130 if there is any chance that

GL120 and GL130 failure could result in bodily harm or equipment damage.

Always use an external interlock system as shown in the following example when reciprocal operations (e.g., forward and reverse directions) are being performed with a motor.

An interlock is generally programmed in the GL120/GL130 ladder program to ensure that

forward and reverse signals are not simultaneously output. An external interlock circuit

must also be provided using the auxiliary contacts of electromagnetic contactors.

CPU Module Output Module

Ladder logic program

1

!

Caution

Output program with an

interlock which prohibit

simultaneous forward

and reverse runs

Electric interlock using the auxiliary contacts

of electromagnetic contactors

F (Forward run)

R (Reverse run)

Contact of overcurrent protection

device.

Induction motor

Always make sure that power supply to the external power supply terminals (AC1, AC2) is

OFF when operating the input voltage selector switch of Power Supply Module.

Operating the input voltage selector switch of Power Supply Module while power is being

supplied to the external power supply terminals may damage the Module.

!

Caution Set the Rack numbers according to the following rules.

If the Rack No. is not set according to the following rules, the PLC system will not run

normally. In other words, it may result in failure of the CPU Module to run, communication

errors, I/O process errors, etc.

• Set each Rack No. between 1 and 4 (rotary switch No: between 0 and 3).

• Always set the Rack No. where CPU Module or Remote I/O Receiver Module is

installed to 1 (rotary switch: 0).

• Do not use the same Rack No. more than once at the same station.

— 1-17 —

Page 23

1

Introduction and Precautions

1.2.6 Maintenance

1.2.6 Maintenance

!

WARNING

!

Caution

!

Caution Do not replace any of the built-in fuses.

Do not reverse the positive and negative terminals, charge, dismantle, heat, throw into fire or

short-circuit batteries.

Do not disassemble or modify Modules and Mounting Bases.

Monitor the Life of Battery

These may cause explosion and/or ignition.

Doing so can cause fires, product failure, or malfunction.

Replacing built-in fuse by users may result in failure or malfunction of the Power Supply

Modules. Built-in fuse must be replaced by a Yaskawa service department.

• Monitor the life of the built-in battery in the CPU Module. If the “BAT ALM” indicator lights,

replace the battery with a new one (replacement battery: BR-2/3A-1) within 2 weeks.

Delay in replacing the battery may result in the memory content loss of the ladder program and the motion program in the CPU Module and any Motion Modules.

• When the BAT Module’s “ALARM1” indicator lights, be sure to replace the battery with an

ER6VC3N replacement battery within one week. Delay in replacing the battery may result

in the memory content loss of the rotation data in the absolute encoder.

Regularly Overhaul Power Supply Modules

• Overhaul the Power Supply Module once every 5 years.

Deterioration of parts such as smoothing capacitors may result in malfunctioning of power supply sections. When a Power Supply Module is used in one of the following environment, overhaul more frequently.

• When used in places subject to high temperature or humidity, or subject to high variations in these.

• When variations in the power supply (voltage, frequency, wave-form distortion, etc.) or

load are high.

• When subject to bad storage environments before use, including long-term storage or

stoppage.

— 1-18 —

Page 24

1.3 Using this Manual

This Manual is compiled for the following readers:

1) Those estimating purchase prices of GL120 or GL130 systems.

1.3 Using this Manual

2) Those considering application of the GL120 or GL130.

3) Those designing control panels for the installation of the GL120 or GL130.

4) Those creating control panels to include the GL120 or GL130.

5) Those inspecting control panels on which GL120 or GL130 has been installed.

6) Those testing or adjusting control panels on which GL120 or GL130 has been installed.

7) Those maintaining control panels on which the GL120 or GL130 has been installed.

• Meaning of Basic Terms

In this manual, the following terms are defined as follows, unless otherwise specified:

• PLC=Programmable (Logic) Controller

• PP=Programming Panel

1

• GL120, GL130=MEMOCON GL120 and/or MEMOCON GL130 Program-

mable Controller

— 1-19 —

Page 25

Overview

2

This chapter provides an outline of the MEMOCON GL120 and GL130, including system configuration examples, main modules, etc.

2.1 Overview of the MEMOCON GL120 and

GL130 2-2.................................

2

— 2-1 —

Page 26

2

Overview

2.1 Overview of the MEMOCON GL120 and GL130

This section outlines the MEMOCON GL120 and GL130.

1) The MEMOCON GL120 (abbreviated GL120) and MEMOCON GL130 (abbreviated

GL130) are programmable controllers (PLCs) developed to succeed the MEMOCONSC GL60 Series. The MEMOCON-SC GL60 Series has been well received and is very

popular for key controllers in FA systems. The GL120 and GL130 are mid- to large-capacity programmable controllers. They provide greater compactness, higher quality, and

higher performance while retaining the functions of the GL60 Series. The GL120 and

GL130 have program memory capacity of 8K words, 16K words, 32K words, and 40K

words, making the GL120 a mid-capacity controller and the GL130 a large-capacity controller.

2) The GL120 and GL130 can be used as high-speed machine controllers or as key controllers for various automatic devices, and can be applied to the following control:

D Sequence control D Motion control D Process control D Computational control

3) The difference between the GL120 and GL130 lies in the CPU Module that is used. A

PLC using the CPU20 CPU Module is a GL120, while a PLC using a CPU30 CPU Module

is a GL130. All devices other than the CPU Module can be used in both PLCs.

Example 1

Example of system configuration for MEMOCON GL120

— 2-2 —

Page 27

2.1 Overview of the MEMOCON GL120 and GL130

Example 2

Example of system configuration for MEMOCON GL130

2

PS10: Power Supply Module

(7 A)

CPU20: CPU Module (16 KW) DO: Digital Output Module MB12: 12-slot Mounting Base

CPU30: CPU Module (32 KW) MC20: Four-axis Motion Module

DI: Digital Input Module EXP: Expander Module

4) The following table shows the main Modules and other devices used in the GL120 and

GL130. Any itemslisted as “Optional” in the Use column may be used as required according to the system control specifications of the GL120 or GL130.

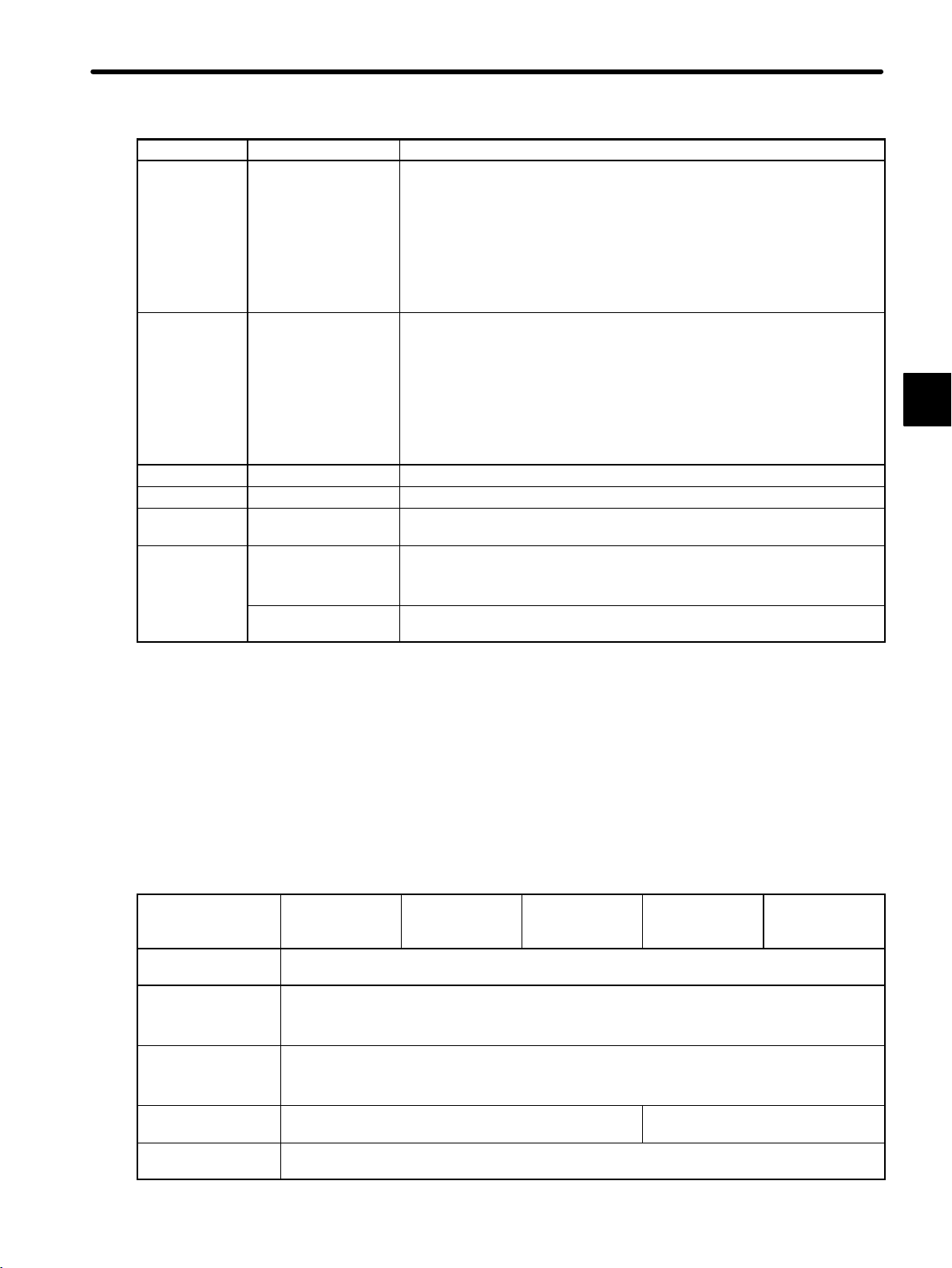

Table 2.1 Main GL120 and GL130 Modules and other Products

Use Name Features

Required Power Supply

Module

Required CPU Module 1) Stores the user program, solves the program based on the information

Supplies DC power to various Modules to operate them.

from the input section, and outputs the results to the output section.

There are 5 types of CPU Modules, namely the CPU10, CPU20,

CPU21, CPU30, and CPU35.

2) Equipped with 1 MEMOBUS port (slave, RS-232C).

(CPU20, CPU21, CPU30, CPU35)

3) Equipped with 1 MEMOBUS PLUS port

(CPU20, CPU21, CPU30, CPU35)

4) Execute the ROM operation.

(CPU10, CPU21)

— 2-3 —

Page 28

Overview

Use FeaturesName

Optional Communications

Module

1) Remote I/O Driver Module:

Used as the master station of a Remote I/O system.

2) Remote I/O Receiver Module:

Used as the slave station of a Remote I/O system.

3) 2000-Series Remote I/O Driver Module:

Used as the master station of a Remote I/O system for 2000 I/O.

4) MEMOBUS Module (RS-232):

Used to increase the number of RS-232C MEMOBUS ports.

2

5) MEMOBUS Module (RS-422):

Used to increase the number of RS-422 MEMOBUS ports.

6) PC Link Module:

Used for high-speed communications between PLCs.

7) Uniwire Interface Module:

Used as the master station of a Uniwire system.

8) Uniwire H-system Interface Module:

Used as the master station of a Uniwire H-system.

9) Distributed I/O Driver Module:

Used as the master station of the VINUS I/O system.

10) M-NET Module:

Used for high-speed communications between PLCs.

11) YENET 1600-D Module:

Used for high-speed communications between PLCs.

12) Ethernet Interface Module:

Used for communications between PLCs.

13) Optical/Electrical Conversion Module:

Used for an Optical PC Link system or an Optical Remote I/O system.

Optional I/O Module 1) Digital Input Module:

Used to input digital signals.

2) Analog Input Module:

Used to input analog signals.

3) Digital Output Module:

Used to output digital signals.

4) Analog Output Module:

Used to output analog signals.

— 2-4 —

Page 29

Use FeaturesName

Optional Special Purpose

Optional Motion Module 1) Four-axis Motion Module:

Optional Expander Module Used to expand the number of racks.

Required Mounting Base Used to install Modules.

Optional Rack-to-rack I/O

Required (one

or the other)

Module

Cable

Programming Panel

P120

MEMOSOFT A general-purpose personal computer software application for online or

1) High-speed Counter Module (1 channel):

Used to count high-speed pulses.

2) Pulse Catch Module (16 channels):

Used to read input signals that are ON for less than one scan time.

3) Register I/O Module:

Used to input/output the signal of the numerical value.

Used for 4-axis motion control.

2) One-axis Motion Module:

Used for 1-axis motion control.

3) Two-axis Motion Module:

Used for 2-axis motion control.

Used to connect between Expander Modules of adjacent racks.

1) A dedicated programming panel for MEMOCON PLCs.

2) Used for online or offline programming of the GL120 and GL130.

offline programming of the GL120 and GL130. (Software package)

2.1 Overview of the MEMOCON GL120 and GL130

2

5) The difference of the GL120 and GL130 lies in the difference in specifications of the CPU

Modules. The following table shows the specifications of the CPU10, CPU20, CPU21,

CPU30, and CPU35 Modules. The main differences in specifications of the CPU Modules lies in their program memory capacities, the numbers of digital I/O points and scan

times.

Table 2.2 CPU Module Summary Specifications

Item CPU10

Execution control

method

I/O connection

method

I/O control method 1) Synchronous refresh

CPU General-purpose 16-bit microprocessor General-purpose 32-bit

Programming

language

(DDSCR-

120CPU14200)

Cyclic scan method

1) Direct I/O

2) Remote I/O

2) Direct (direct I/O)

Ladder diagram

CPU20

(DDSCR-

120CPU34100)

CPU21

(DDSCR-

120CPU34110)

CPU30

(DDSCR-

130CPU54100)

microprocessor

130CPU54110)

CPU35

(DDSCR-

— 2-5 —

Page 30

Overview

be

2

Item CPU35

Types and number

of instructions

CPU20: 166

CPU30: 166

CPU35: 166

CPU21: 169

CPU10: 165

CPU10

(DDSCR-

120CPU14200)

1) Basic instructions: 16

2) Math operations: 25

3) Data manipulation instructions: 48

4) System status monitoring instruction: 1

5) Sequence control instructions: 3

6) Program control instructions: 7

7) I/O control instructions: 2

8) Communications instructions: 9 (CPU10: 8)

9) Motion control instructions: 22

10) Expansion math instructions: 32

11) Process control instruction: 1

CPU20

(DDSCR-

120CPU34100)

CPU21

(DDSCR-

120CPU34110)

CPU30

(DDSCR-

130CPU54100)

(DDSCR-

130CPU54110)

12) Expansion memory access instructions: 2 (CPU21)

Scan time Ladder logic program:

Program memory

capacity

Maximum

number

of input

and

output

points

Digital

I/O

Register

I/O

Local

I/O

Remote

I/O

Approx. 1 ms for 1K-word program

16K words

(1 word = 24 bits)

1,024 points (1 point = 1 bit) *1 4,096 points (1 point = 1 bit) *1

512 registers (1 register= 16 bits) * 2

1) Number of channels: 1

2) Number of racks: 4 racks (including CPU rack)

3) Number of mountable I/O Modules: 54

The total number of points, including remote I/O points, must not exceed the limits

indicated at * 1 and * 2, above.

1) Number of channels: 2

2) Number of stations per channel: 15

3) Number of racks per station: 4

4) Number of I/O points per station:

(Digital input points ÷ 8) + (register input points × 2) ± 512 bytes

(Digital output points ÷ 8) + (register output points × 2) ± 512 bytes

The total number of points, including local I/O points and remote I/O points of other

remote stations, must not exceed the limits indicated at * 1 and * 2, above.

Ladder logic program:

Approx. 0.6 ms for 1K-word

program

32K words

(1 word = 24

bits)

40K words

(1 word = 24

bits)

— 2-6 —

Page 31

2.1 Overview of the MEMOCON GL120 and GL130

Item CPU35

Maximum number

of coils, relays, etc.

Maximum capacity

of data register

CPU10

(DDSCR-

120CPU14200)

1) When the number of data registers is the initial value, the following condition must be

met:

(Number of coils) + (Number of relays) ≤ 65,520.

2) The maximum value for each reference can be freely set within the above limit from the

Programming Panel (Unit: point (1 point = 1 bit)).

Item

Coils 16 to 65,472

Link coils 0 to 4,096

MC coils 0 to 512

MC control coils 0 to 320

Input relays 16 to 65,472

MC relays 0 to 512

MC control relays 0 to 512

M code relays 0 to 192

1) When the number of coils and relays is the initial value, the number of words of holding

registers plus the number of words of constant registers plus the number of words of link

registers must not exceed 25,998.

2) The maximum value for each reference can be freely set within the above limit from the

Programming Panel (Unit: word (1 word = 16 bits)).

Holding register 1 to 25,995

Constant register 1 to 4,096

Link register 0 to 4,096

CPU20

(DDSCR-

120CPU34100)

Setting range

Setting range

CPU21

(DDSCR-

120CPU34110)

CPU30

(DDSCR-

130CPU54100)

Setting

unit

1,024

Setting

unit

1,024

Defaults Example

16

8,192 57,328 65,472

2,048 2,048 0

256

160

16

1,024 4,096 16

256

256

96

Defaults

1

9,999 19,854 25,995

1

4,096 4,096 1

2,048 2,048 0

(DDSCR-

130CPU54110)

1

512 512 0

320 320 0

512 512 0

512 512 0

192 192 0

Example1Example

Example

2

2

2

— 2-7 —

Page 32

Overview

Previous node

6) Figure 2.2 shows GL120 and GL130 system configurations.

MEMOBUS PLUS Cable

HUB

Next node

2

GL130

Programing Panel P120C

Remote I/O Systems

D Two systems per PLC

D Coaxial cable

D 4 Mbps max.

D 1 km max.*

D 15 stations max.

A

MB10

W0203-02

05

MB10

Remote I/O Cable

A

A

MB10

A

T

C

M

PC Link Cable

Station 1

W0100-02

A

EXPI/OI/OCPU30PS10 LNC

EXPI/OI/OI/OI/OI/OI/OI/OI/OPS

EXPI/OI/OI/OI/OI/OI/OI/OPS05RRC

EXPI/OI/OI/OI/OI/OI/OI/OPS05RRC

Next station

Local

channel

Rack 1

(CPU Rack)

MEMOBUS

PLUS Networks

D One network per PLC

D Twisted-pair cable

D 1 Mbps (fixed)

Local

channel

D Without Repeater

450 m max.

Rack 2

Rack 1

Rack 1

32 nodes max.

D With Repeater

1,800 m max.

64 nodes max.

PC Link system

D Two systems per PLC

D Coaxial cable

D 4 Mbps max.

D 1 km max.

D 32 stations max.

R

T

C

M

MEM

RDC

422

MP

M

Can be extended up to Rack 4.

T

C

M

R

T

C

Station 1 of remote channel 1

Can be extended up to Rack 4.

Station 15 of remote channel 1

MB10

M

Can be extended up to Rack 4.

Figure 2.1 Outline of GL120/GL130 System Configuration

* The transmission distance varies according to the baud rate and specifications of the coax-

ial cable. For example, if the baud rate is 4 Mbps and the 12C-5AF Coaxial Cable is used, it

is possible to transmit up to 1 km max.

— 2-8 —

Page 33

2.1 Overview of the MEMOCON GL120 and GL130

co ca

Previous node

Previous station

(DOS computer running

MEMOSOFT)

GL120

A

MB12

W0202-02

MB12

05

HUB

MEMOBUS PLUS Cable

Station 2

T

C

M

MEM

LNC

232

MP

M

M

PC Link Cable

MC20MC20

Next node

A

W0100-02

Can be extended up to Rack 4.

I/OI/O

Next station

Local channel

Rack 1

EXPI/OCPU20PS10

(CPU Rack)

Local channel

Rack 2

EXPI/OI/OI/OI/OI/OI/OI/OI/OPS

2

1) Legend

PS10: Power Supply Module

(7 A)

PS05: Power Supply Module

(3 A)

CPU20: CPU Module (16 KW) EXP: Expander

CPU30: CPU Module (32 KW) MB10:

RDC: Remote I/O Driver

Module

RRC: Remote I/O Receiver

Module

LNC: PC Link Module W0202-02: MEMOBUS

MEM232: MEMOBUS Module

(RS-232)

MEM422: MEMOBUS Module

(RS-422)

MC20: 4-axis Motion

Module

I/O: Input/Output

Module

Module

10-slot Mounting

Base

MB12:

W0100-02:

12-slot Mounting

Base

Rack-to-rack I/O

Cable

Cable

W0203-02: MEMOBUS

Cable

MEMOSOFT: Programming

device

HUB: Hub Module

T: T-adapter

R:

Terminator

A: Conversion

Adapter

P: MEMOBUS

PLUS port

M: MEMOBUS

port

C: Coaxial cable

communications port

2) The following five types of Mounting Base are available. Up to four Mounting Bases can

be used for each station.

D MB06: 6-slot Mounting Base D MB12: 12-slot Mounting Base

D MB08: 8-slot Mounting Base D MB16: 16-slot Mounting Base

D MB10: 10-slot Mounting Base

— 2-9 —

Page 34

Overview

3) Up to two of each of the following Modules can be used for each GL120 or GL130 PLC.

D Remote I/O Driver Module: Mount to CPU Rack

D PC Link Module: Mount to CPU Rack

D MEMOBUS Module (RS-232/RS-422): Mount to any Rack of the local channel

D 4-axis Motion Module: Mount to CPU Rack

4) I/O Modules can be used within themaximum number of I/O points shown in the following

table.

2

Item GL120 (CPU20, CPU21, CPU10) GL130 (CPU30 and CPU35)

Number of

digital I/O

points

Number of I/O

registers

Number of

remote I/O

points

1,024 points max. (1 point = 1 bit) 4,096 points max. (1 point = 1 bit)

512 registers max. (1 register = 16 bits)

The number of I/O points and registers at each station must meet the following

conditions:

1) (No. of digital input points ÷ 8) + (No. of input registers x 2) ≤ 512 (bytes)

2) (No. of digital output points ÷ 8) + (No. of output registers x 2) ≤ 512 (bytes)

Figure 2.2 Outline of GL120,GL130 System Configuration (Continued)

— 2-10 —

Page 35

System Components

3

3.1 Overview of System Components 3-2...........

3

— 3-1 —

Page 36

System Components

g

g

3.1 Overview of System Components

This section describes the GL120/GL130 system components and provides an overview

of each component.

Table 3.1 shows the GL120/GL130 system components and provides an overview of each

component.

Table 3.1 Overview of System Components: Modules and Mounting Bases

3

Product Name Model Name Model

Power

Supply

Module

AC Power

Supply Module

(7 A)

AC Power

Supply Module

(3 A)

DC Power

Supply Module

(7 A)

DC Power

Supply Module

(3 A)

PS10 JRMSP-

PS05 JRMSP-

PS11 JRMSP-

PS06 JRMSP-

Number

120CPS11300

120CPS11100

120CPS21300

120CPS21100

Features Number

1) Supplies DC power to operate Modules.

2) One AC Power Supply Module is required

for each Mounting Base.

3) PS10: 100/200 VAC (switchable), 7 A

4) PS05: 100/200 VAC (switchable), 3 A

1) Supplies DC power to operate Modules.

2) One DC Power Supply Module is required

for each Mounting Base.

3) PS11: 24 VDC, 7 A

4) PS06: 24 VDC, 3 A

of Slots

Required

2

1

2

1

— 3-2 —

Page 37

3.1 Overview of System Components

Approx

scan

time:1ms/KW

g

Number

of

digital

I/O

points:

1,024

max

)

6)

CPU35

quipp

Equipped

with

one

MEMOBUS

Port

2

quipp

Product Number

CPU

Module

CPU Module

(8 KW)

CPU Module

(16 KW)

CPU Module

(16 KW)

Model NameName

Number

CPU10 DDSCR-

120CPU14200

CPU20 DDSCR-

120CPU34100

CPU21 DDSCR-

120CPU34110

1) Stores user program, executes programs

according to information from the input

section, and outputs processing results to

the output section.

2) CPU10

Program memory capacity: 8K words

Number of digital I/O points: 1,024 max.

Number of I/O registers: 512 max.

Approx. scan time: 1 ms/KW

.

3) CPU20

Program memory capacity: 16K words

Number of digital I/O points: 1,024 max.

Number of I/O registers: 512 max.

Approx. scan time: 1 ms/KW

4) CPU21

Program memory capacity: 16K words

Number of di

Number of I/O registers: 512 max.

Approx. scan time: 1 ms/KW

FeaturesModel

ital I/Opoints: 1,024 max.

of Slots

Required

1

2

.

2

3

CPU Module

(32 KW)

CPU Module

(40 KW)

CPU30 DDSCR-

130CPU54100

CPU35 DDSCR-

130CPU54110

5) CPU30

Program memory capacity: 32K words

Number of digital I/O points: 4,096 max.

Number of I/O registers: 512 max.

Approx. scan time: 0.6 ms/KW

6

CPU35

Program memory capacity: 40K words

Number of digital I/O points: 4,096 max.

Number of I/O registers: 512 max.

Approx. scan time: 0.6 ms/KW

7) MEMOBUS Ports

CPU10:

Equipped with one MEMOBUS Port 1

(slave, RS-232C).

E

ed with one MEMOBUS Port 2

(shared by master and slave, RS-232C).

CPU20, CPU21, CPU30, CPU35:

Equipped with one MEMOBUS Port (slave,

RS-232C).

8) MEMOBUS PLUS Ports

CPU10: None

CPU20, CPU21, CPU30, CPU35:

E

ed with one MEMOBUS PLUSport.

2

2

— 3-3 —

Page 38

System Components

3

Product Number

Communications

Modules

Remote I/O

Driver Module

Remote I/O

Receiver

Module

Model NameName

Number

RIOD-COAX JAMSC-

120CRD13100

RIOR-COAX JAMSC-

120CRR13100

1) Used to install input and output sections at a

remote site.

2) Serves as a master station for the Remote

I/O System.

3) Up to two Remote I/O Driver Modules can

be used.

4) Uses coaxial cables as transmission cables.

5) Mounted to CPU Rack.

1) Used to install input and output sections at a

remote site.

2) Serves as a slave station for the Remote I/O

System.

3) Up to 15 Remote I/O Receiver Modules can

be connected to each Remote I/O Driver

Module.

FeaturesModel

of Slots

Required

1

1

2000-Series

Remote I/O

Driver Module

MEMOBUS

Module

(RS-232)

RIOD-2000 JAMSC-

MEMOBUSRS232

120CRD13110

JAMSC120NOM26100

4) Uses coaxial cables as transmission cables.

5) Equipped with one MEMOBUS port with the

following specifications:

Usable for both master and slave ports

RS-232C

1) Used to install 1000 I/O and 2000 I/O at

remote sites.

2) Serves as a master station for the Remote

I/O System.

3) Up to two Remote I/O Driver Modules can

be used.

4) Uses coaxial cables as transmission cables.

5) Mounted to CPU Rack.

1) Used to add MEMOBUS ports.

2) Equipped with two MEMOBUS ports that

have the following specifications:

Usable for both master and slave ports

RS-232C

1

1

3) Up to two RS-232/RS-422 MEMOBUS

Modules can be used.

4) Can be mounted to any Rack of the local

channel.

— 3-4 —

Page 39

3.1 Overview of System Components

Product Number

Communications

Modules,

continued

MEMOBUS

Module

(RS-422)

PC Link

Module

Model NameName

MEMOBUSRS422

PCLINK−

COAX

Number

JAMSC120NOM27100

JAMSC120NFB23100

1) Used to add MEMOBUS ports.

2) Equipped with two MEMOBUS ports that

have the following specifications:

Usable for both master and slave ports

RS-422

3) Up to two RS-232/RS-422 MEMOBUS

Modules can be used.

4) Can be mounted to any Rack of the local

channel.

1) Used for high-speed data communications

between PLCs.

2) Serves as a station of PC Link System.

3) Up to two PC Link Modules can be used.

4) Uses coaxial cables as transmission cables.

5) Equipped with one MEMOBUS port that has

the following specifications:

Usable for both master and slave ports

RS-232C

FeaturesModel

of Slots

Required

1

1

3

Uniwire

Interface

Module

UNIWIRE I/F JAMSC-

120CRD21110

6) Mounted to CPU Rack.

1) Used for Uniwire system to reduce wiring.

2) Serves as the master station of a Uniwire

system.

3) Number of transmission points:

256 points max.

(One register is 16 points.)

4) Up to 20 slave stations (Uniwire system

devices) can be connected to each Uniwire

Interface Module.

5) Uses two-core cable for transmission

cables.

1

— 3-5 —

Page 40

System Components

3

Product Number

Communications

Modules,

continued

Uniwire

H-system

Interface

Module

Model NameName

UNIWIRE (H)

I/F

Number

JAMSC120CRD21120

1) Used for a Uniwire H-system to reduce

wiring.

2) Serves as the master station of a Uniwire

H-system.

3) Number of transmission points:

256 points max.

(One register is 16 points.)

4) Up to 50 slave stations (Uniwire H-system

devices) can be connected to each Uniwire

Interface Module.

5) Can detect the error of I/O Terminal Unit.

6) Indicates the broken line detection of the

transmission cable.

7) Branch the transmission line and detecting

breaks in branch lines.

FeaturesModel

of Slots

Required

1

Distributed I/O

Driver Module

VIOD JAMSC-

120CRD21100

8) Uses two-core cable for transmission

cables.

1) Used for a VINUS I/O System to reduce

wiring.

2) Serves as a master station of VINUS I/O

Systems.

3) Number of transmission points:

480 inputs, 512 outputs

(One register is 16 points.)

4) Up to 30 slave stations (distributed I/O slave

devices) can be connected to each

Distributed I/O Driver Module.

5) Uses special VINUS I/O cables for

transmission cables.

1

— 3-6 —

Page 41

3.1 Overview of System Components

Product Number

Communications

Modules,

continued

M-NET

Module

YENET

1600-D

Module

Model NameName

M-NET JAMSC-

YENET

1600-D

Number

120NMN31000

JAMSC120NDN31110

1) Used for high-speed data communications

between PLCs.

2) Serves as a station of the M-NET System.

3) Up to 15 M-NET Modules (slaves) can be

connected to each M-NET Module (master).

4) Can be connected to GL60S and U84

M-NET Modules.

5) Uses special M-NET cables as transmission

cables.

6) Can be mounted to any Rack.

1) Used for high-speed data communications

between PLCs.

2) Serves as a station of the YENET 1600-D

System.

3) Up to 63 YENET 1600-D Modules (slaves)

can be connected to each YENET 1600-D

Module (master).

FeaturesModel

of Slots

Required

1

1

3

Ethernet

Interface

Module

EIF JAMSC-

120NET12100

4) Can be connected to masters and slaves

conforming to the DeviceNet protocol.

5) Uses special YENET 1600-D cables as

transmission cables.

6) Can be mounted to any Rack.

1) Used for data communications between

PLCs.

2) Serves as an interface for connections in

Ethernet network systems.

3) Communications supported for up to 19

connections for each Ethernet Interface

Module.

4) Provides a 10Base5 port and a 10Base-T

port.

5) Mounted to CPU Rack.

1

— 3-7 —

Page 42

System Components

3

Product Number

Communications

Modules,

continued

Digital

Input

Modules

Analog

Input

Modules

Optical/

Electrical

Conversion

Module

100-VAC

16-point Input

Module

200-VAC

16-point Input

Module

12/24-VDC

16-point Input

Module

12/24-VDC

32-point Input

Module

12/24-VDC

64-point Input

Module

Analog Input

Module

±10 V,

(

4 channels)

Analog Input

Module

(0 to 10 V,

4 channels)

Analog Input

Module

(4 to 20 mA,

4 channels)

Model NameName

O/E

CONVERT

AC100IN-16P JAMSC-

AC200IN-16P JAMSC-

DC24IN-16P JAMSC-

DC24IN-32P JAMSC-

DC24IN-64P JAMSC-

A/D-VOL4CH

A/D 0-10V

4CH

A/D-CUR4CH

Number

JAMSC120NAH93500

(4 models)

120DAI54300

120DAI74300

120DDI34300

120DDI35400

120DDI36400

JAMSC120AVI02000

JAMSC120AVI02100

JAMSC120ACI02000

1) Used in combination with PC Link Module or

Remote I/O Module to configure an Optical

PC Link System or Optical Remote I/O

System.

2) Equipped with an electric port for connecting

a PC Link Module or Remote I/O Module,

and two optical ports for connecting pairs of

O/E Conversion Modules.

3) Enables duplex optical communications

paths.

4) The following optical fiber cables are used

as transmission cables:

5) Can be mounted to any Rack.

1) Used to input digital signals.

2) 100 VAC, 16 points, 7 mA (50 Hz)

1) Used to input digital signals.

2) 200 VAC, 16 points, 7 mA (50 Hz)

1) Used to input digital signals.

2) 12/24 VDC, 16 points, 4 mA (12 VDC),

8 mA (24 VDC)

1) Used to input digital signals.

2) 12/24 VDC, 32 points, 2 mA (12 VDC),

4 mA (24 VDC)

1) Used to input digital signals.

2) 12/24 VDC, 64 points, 2 mA (12 VDC),

4 mA (24 VDC)

1) Used to input analog signals.

2) −10 to10 V, 4 channels

1) Used to input analog signals.

2) 0 to10 V, 4 channels

1) Used to input analog signals.

2) 4 to 20 mA/1 to 5 V, 4 channels

FeaturesModel

of Slots

Required

1

H-PCF cables

Quartz crystal fiber cable

1

1

1

1

1

1

1

1

— 3-8 —

Page 43

3.1 Overview of System Components

Product Number

Digital

Output

Modules

Analog

Output

Modules

100/200-VAC