GA800 Drive

AC Drive for Industrial Applications

Selection Guide

Catalog Code: GA80Uxxxxxxxx

240V: 1 to 150 HP

480V: 1 to 600 HP

PDF

Copyright © 2019 YASKAWA AMERICA, INC.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of Yaskawa. No patent liability is assumed with respect to the use of the

information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality

products, the information contained in this manual is subject to change without notice. Every precaution has

been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GA800 Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drive Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Drive Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control and Feedback Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

I/O Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Motor Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Network Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Keypads, Accessories, and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Enclosure Adapters and Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DC Bus Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Open Type DC Bus Reactor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enclosed DC Reactor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

AC Input Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Output Reactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AC Open Reactor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

AC Enclosed Reactor Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dynamic Braking Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10% Dynamic Braking Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3% Dynamic Braking Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Dynamic Braking Transistor Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

R1000 Regenerative Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

R1000 External Heatsink Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Single Phase Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Drive Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Single-Phase Derating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Carrier Frequency Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Watt Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Drive Short Circuit Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

GA800 Configured Package Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

1 - 600 HP Type 1, Type 12, & Type 3R GA800 Configured Packages . . . . . . . . . . . . . . . . . . . 60

Type 1 Configured Package Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Type 12 Configured Package Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Type 3R Configured Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Additional Configured Package Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Freestanding Leg Kit, Type 3R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 1

Preface

Intended Audience

This book is intended to help easily locate component information for Yaskawa GA800 Drives and optional accessories.

The intended users for this document are Yaskawa sales personnel, distributors, and partners.

This book may describe trademarked equipment, which is the property of other companies. These trademarks are the property of the regis

tered owner companies and may include the following:

DeviceNet ™ , trademark of ODVA PROFIBUS®, trademark of PROFIBUS International.

Modbus®, trademark of Schneider Automation, Inc. PROFINET®, trademark of PROFIBUS International.

EtherCAT, trademark of Beckhoff Automation GmbH, Germany Ethernet/IP, trademark of ODVA

MECHATROLINK - I, II, III, trademarks of MECHATROLINK Members Association

Unless otherwise noted, throughout this document, the term “Type” (when related to enclosure solutions) refers not only to NEMA Type, but

also represents UL Listing for the specific Type(s).

Other documents and manuals are available to support special use or installation of products. These documents may be provided with the

product or upon request. Contact Yaskawa America, Inc. or visit www.yaskawa.com.

Additional Resources

The Yaskawa.com web site has the most current information for all Yaskawa products. When researching product specifications or features

the Yaskawa web site is the best resource to use. Some useful links for the GA800 drive product are listed here and throughout this document:

Resource Links

GA800 Product Page Product Instructions

Specifications Brochure

Price Book Product Order Page

-

2 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: GA800 Drives \

GA800 Drives

1 - 600 HP

The GA800 drive provides the ultimate combination of power, ease of use, flexibility, and performance. Enjoy effortless setup with a high

®

resolution display or Bluetooth

complex applications connected to networks or discrete / analog signals. Combine all this with modern safety features and a variety of

environmental solutions, and you will have to look no further than GA800 for all your variable speed needs.

• High resolution multi-language display with Startup Wizards and

Data-Logging

• Bluetooth and DriveWizard Mobile for convenient and easy

interaction

• DriveWizard Desktop for comprehensive configuration and

monitoring

• DriveWorks EZ (embedded function blocks) provides extra

flexibility, otherwise accomplished in a separate controller.

• Closed or open loop vector control for outstanding regulation

and torque production

• Fast acting motor control functions provide near tripless

operation

• Popular network connections provide robust control and

monitoring with system controllers

connection to your mobile device while using Yaskawa's free DriveWizard Mobile. Control your simple or

• Embedded Auxiliary Control Power Input (24 V) maximizes

production time and efficiency by maintaining network

communication while main power is removed.

• Embedded Safe Torque Off minimizes downtime for

applications requiring occasional intervention (SIL CL3, PLe,

Category 3).

• Integrated DC Reactor (30 HP and larger) improves power

quality and compatibility

• Integrated 12 Pulse version provides a cost effective solution for

low harmonics.

• Integrated Brake Transistor (up to 125 HP ND) for cost effective

heavy braking

• Standard conformal coating and Type 12 versions help resist

contamination

• Made with RoHS compliant materials for environmental

compliance

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 3

Section: GA800 Drives \ Drive Selection

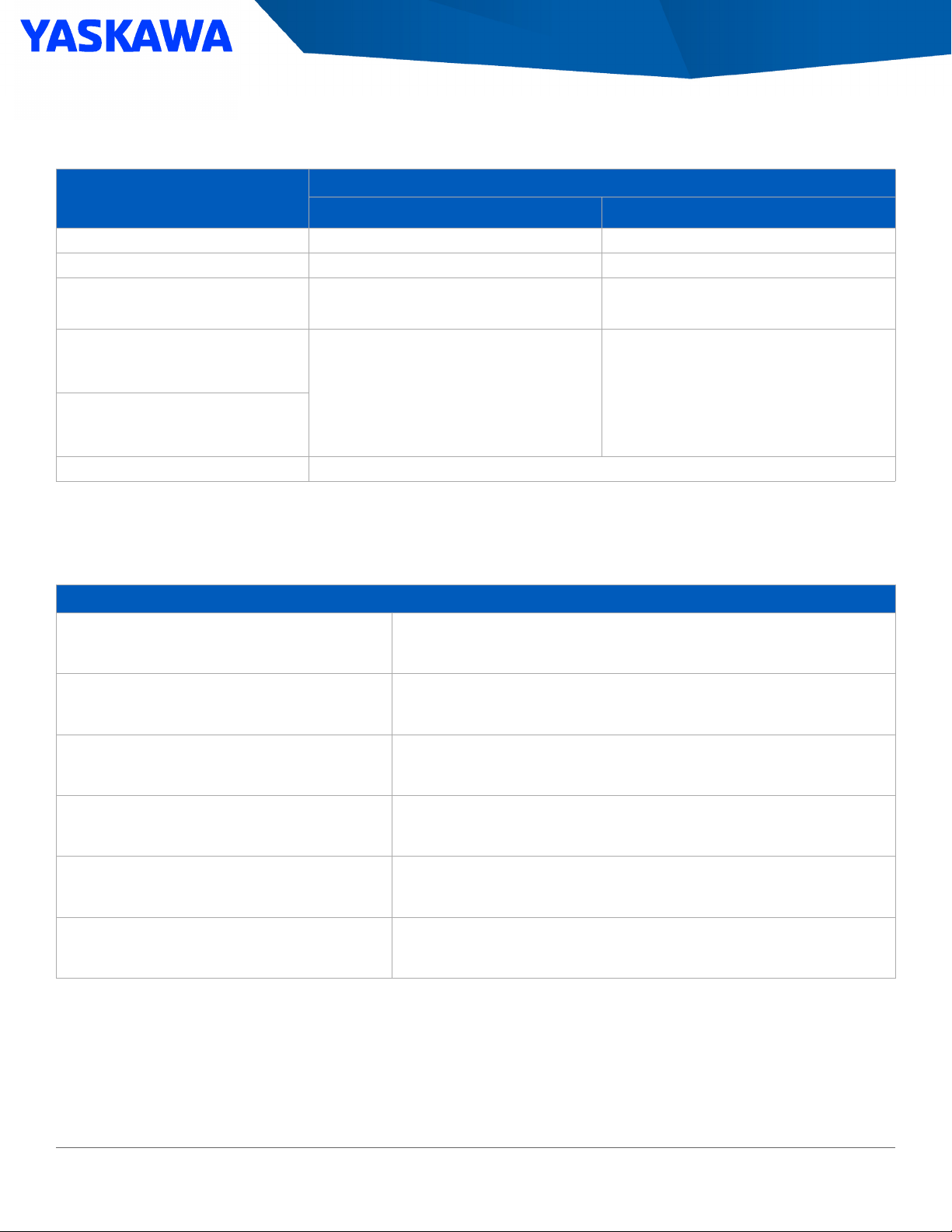

.( < ( ) 4

.O )NPUT0OWER3UPPLY

6OLTAGE

7OHZL=*SHZZ

7OHZL=*SHZZ

.O 2EGION#ODE

< (TLYPJHZ

/UTPUT#URRENT

0UKPJH[LZ[OL5VYTHS+\[`YH[LK

J\YYLU[VM[OLKYP]L

-ODEL3ERIES

.O %-#.OISE&ILTER

( 5V[<ZLK

.O %NVIRONMENTAL

3PECIFICATIONS

4 /\TPKP[`K\Z[

.O %NCOLSURE 4YPE

) 07

>

-SHUNL;`WL)HJRZPKL

Drive Selection

Standard (IP20) drives are intended for clean environments and can be mounted 3 different ways as follows:

1) In a separate enclosure with heatsink internal. Extra mounting

brackets are not required.

2) In a separate enclosure with heatsink external. Refer to Enclo

3) Mounted without an enclosure. Type 1 Adapters must be

used when mounting the drive without an enclosure.

-

sure Adapters and Kits for drives requiring extra mounting

brackets.

The GA800 offers two separate performance ratings; Heavy Duty and Normal Duty. Heavy Duty is capable of creating more powerful torque,

while Normal Duty allows the drive to operate a larger motor.

Figure 1: Catalog Code

4 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Additional Information

GA800 Product Page

Section: GA800 Drives \ Drive Selection

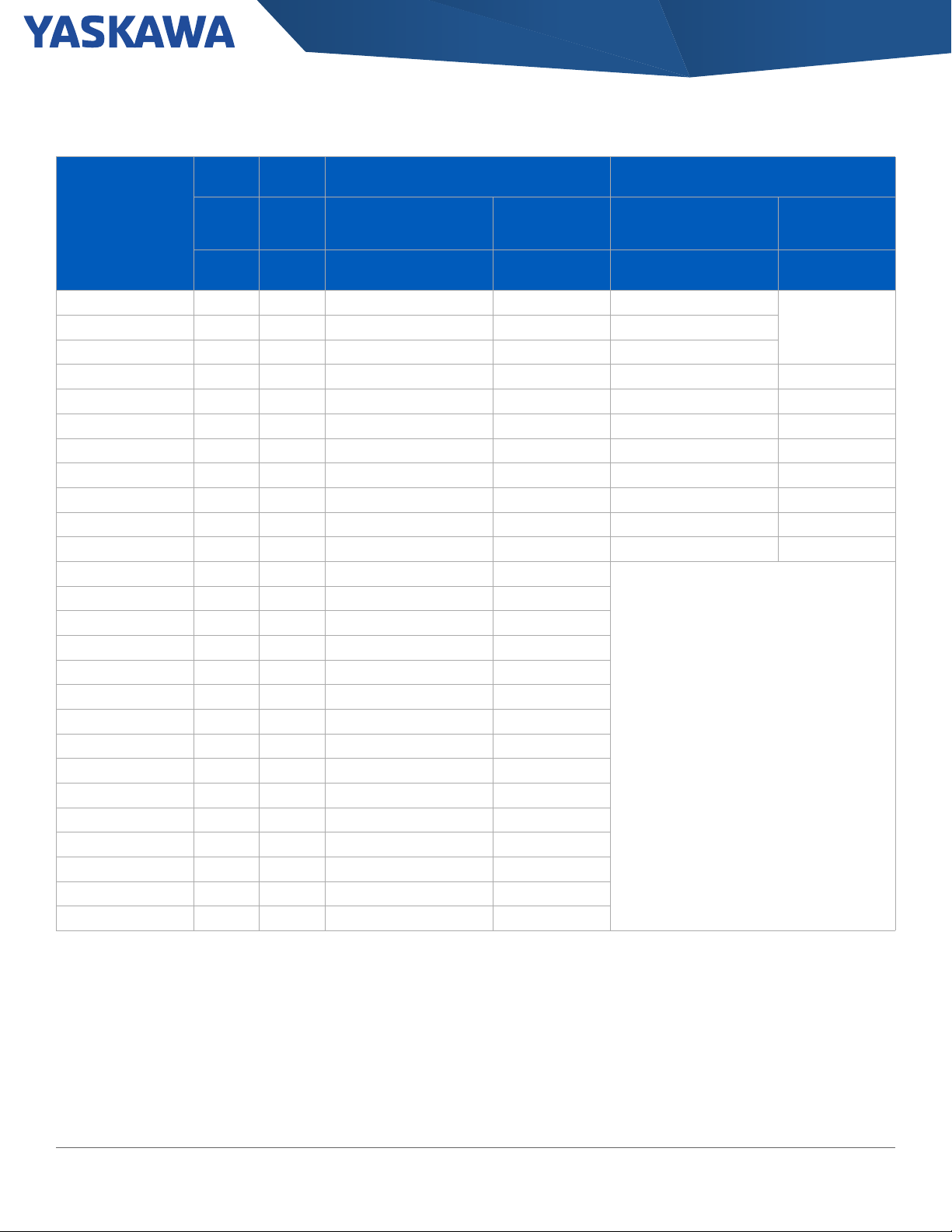

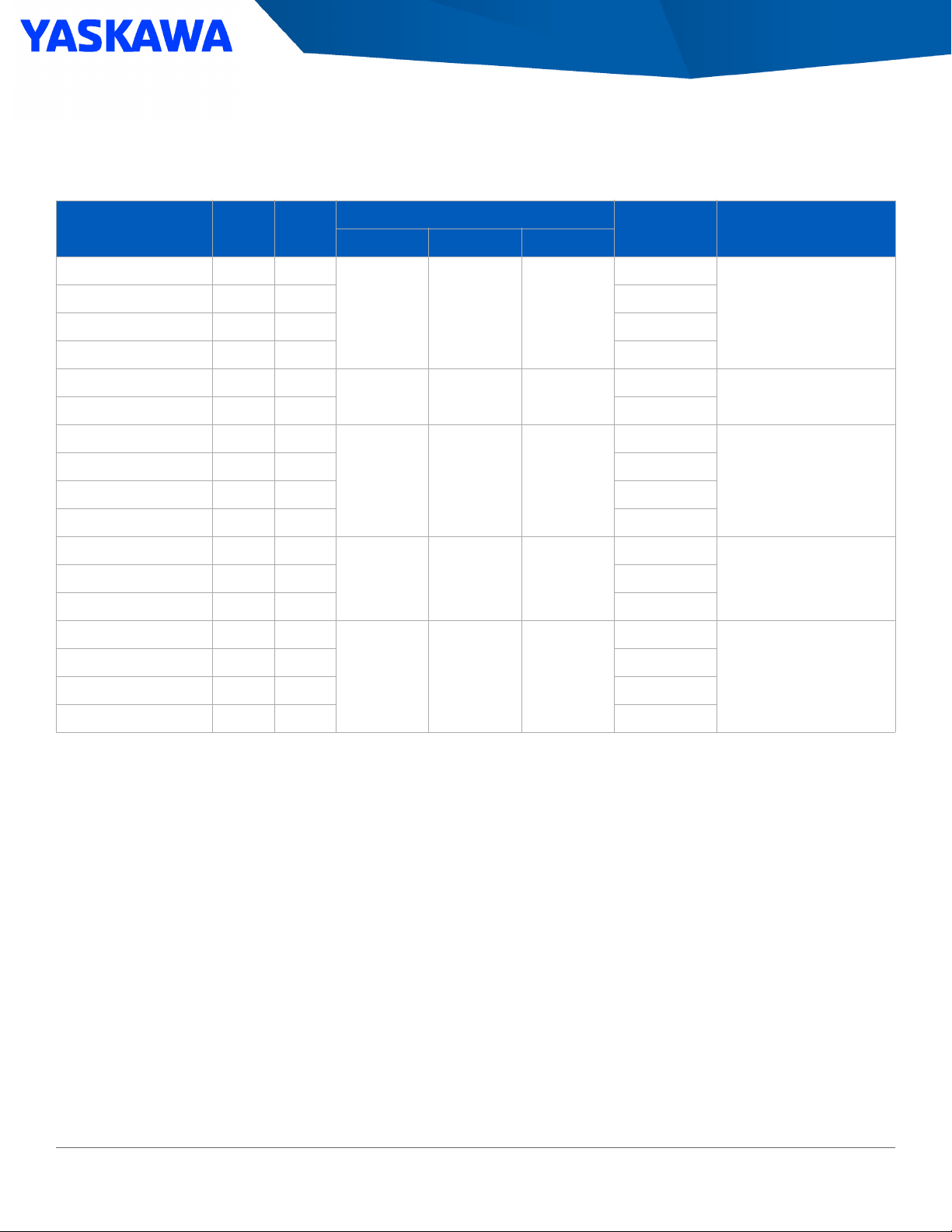

Table 1: Three-Phase, 240 Volt IP20 Drives - 1 to 150 HP

Normal Duty Output

1

Heavy Duty Output

1

Standard IP20 Drives

2

Flange (Type 12 backside)

3

HP Amps HP Amps

1 4.2 0.75 3.5 2004ABM 2004AWM

1.5 6 1 5 2006ABM 2006AWM

2 8 1.5 6.9 2008ABM 2008AWM

3 9.6 2 8 2010ABM 2010AWM

4 12.2 3 11 2012ABM 2012AWM

5 17.5 4 14 2018ABM 2018AWM

7.5 22 5 17.5 2021ABM 2021AWM

10 30 7.5 25 2030ABM 2030AWM

15 42 10 33 2042ABM 2042AWM

20 56 15 47 2056ABM 2056AWM

25 70 20 60 2070ABM 2070AWM

30 82 25 75 2082ABM 2082AWM

40 110 30 88 2110ABM 2110AWM

50 138 40 115 2138ABM 2138AWM

60 169 50 145 2169ABM 2169AWM

75 211 60 180 2211ABM 2211AWM

100 257 75 215 2257ABM 2257AWM

125 313 100 283 2313ABM 2313AWM

150 360 125 346 2360ABM 2360AWM

150 415 150 415 2415ABM 2415AWM

1 Output capacities are for conditions of 3 phase input, DC input, and 12 pulse input. Refer to Drive Derating for

single-phase capabilities.

2 Standard (IP20) Drives are intended for clean conditions, and can be mounted three different ways as follows:

A) In a separate enclosure with heatsink internal (no extra mounting brackets required)

B) In a separate enclosure with heatsink external. Refer to Enclosure Adapters and Kits for sizes requiring extra mounting brackets.

C) Without a separate enclosure, all sizes require Type 1 Adapters (refer to Enclosure Adapters and Kits)

3 Flange Drives are intended for mounting inside separate Type 12 enclosures with heatsink external, when the external environment is dirty or dusty (Type 12 backside). No

additional adapters required.

Catalog Code

GA80U . .

Catalog

Code

GA80U . .

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 5

Section: GA800 Drives \ Drive Selection

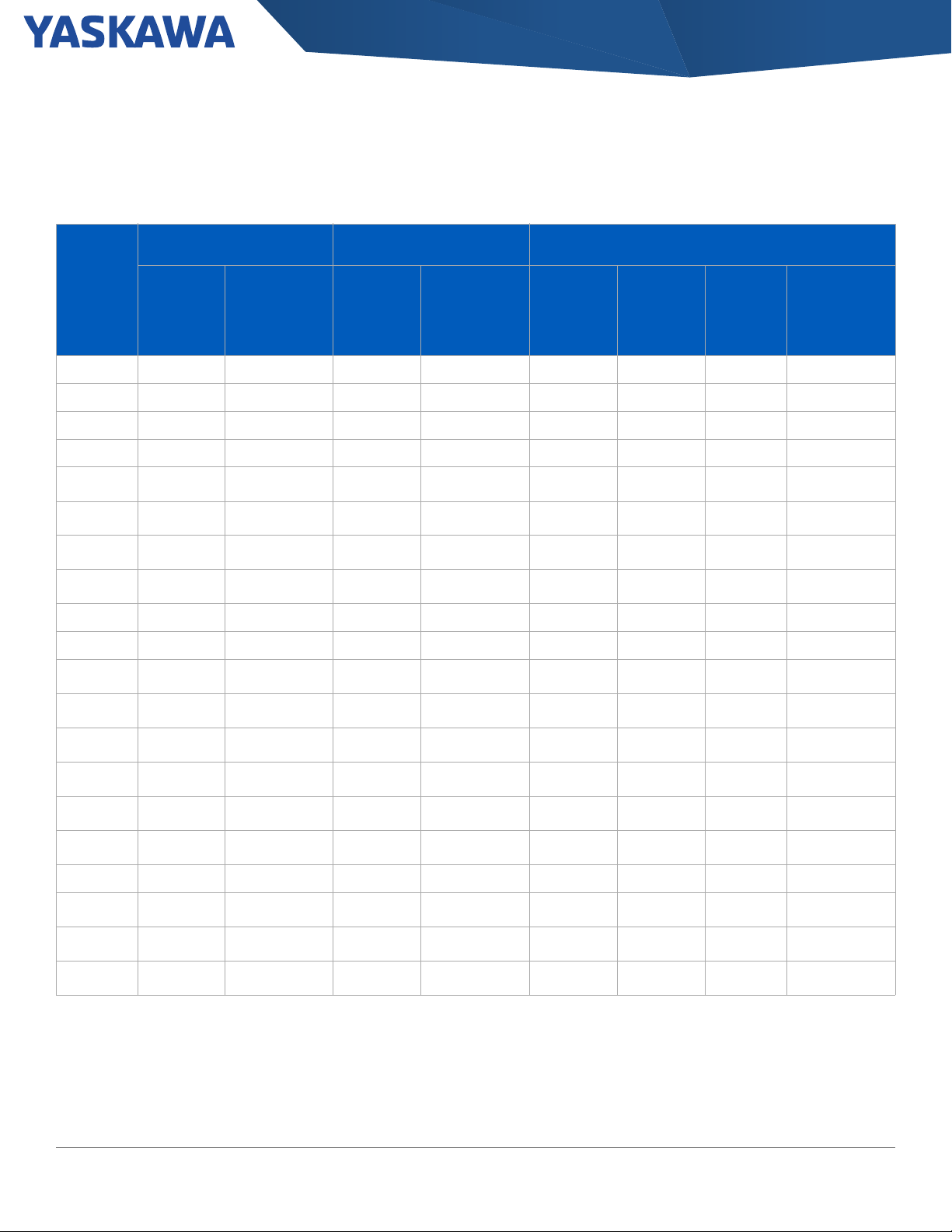

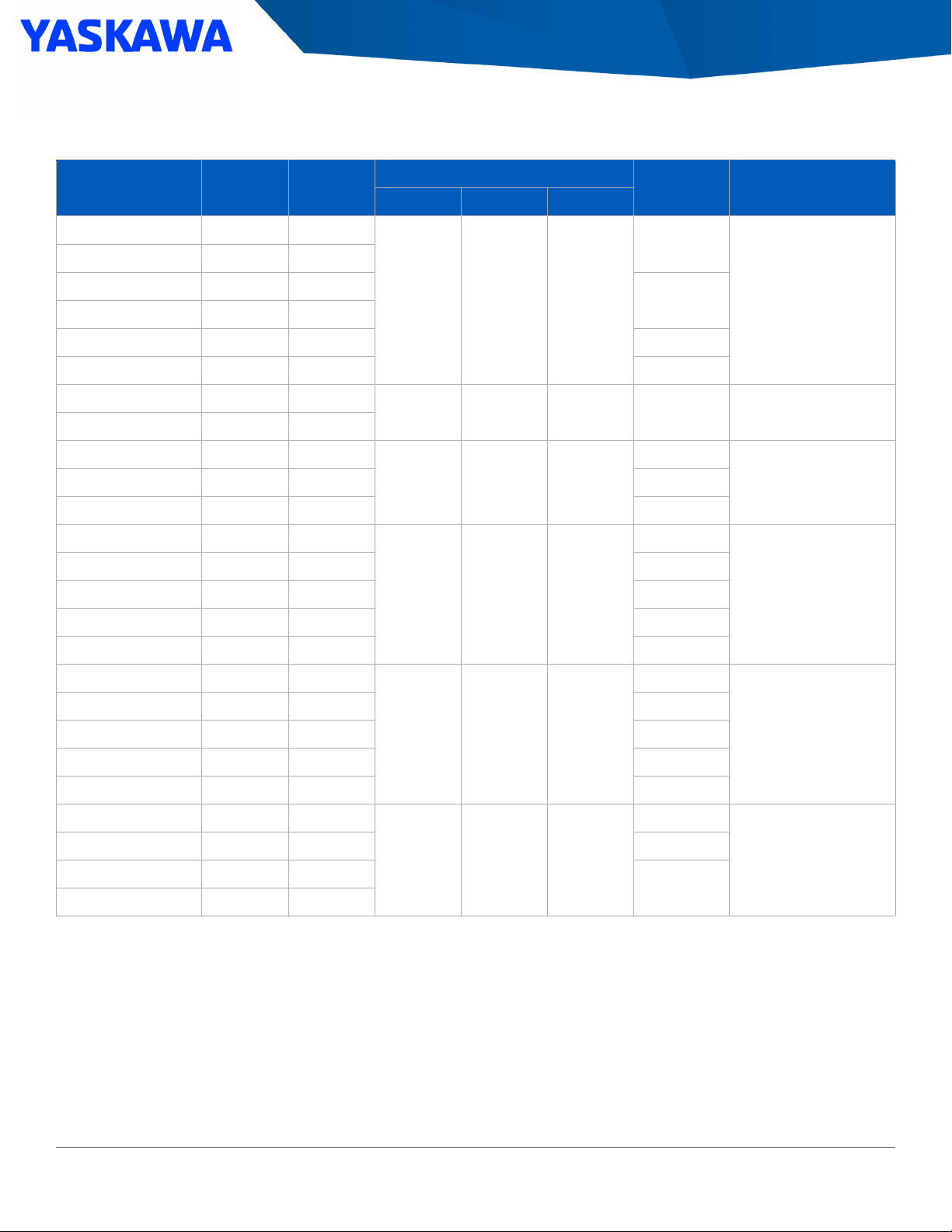

Table 2: Three-Phase, 480 Volt IP20 Drives- 1 to 600 HP

Normal Duty Output

1

Heavy Duty Output

1

Standard IP20 Drives

2

Flange (Type 12 backside)

3

HP Amps HP Amps

1 2.1 0.75 1.8 4002ABM 4002AWM

2 4.1 1.5 3.4 4004ABM 4004AWM

3 5.4 2 4.8 4005ABM 4005AWM

4 7.1 3 5.5 4007ABM 4007AWM

5 8.9 4 7.2 4009ABM 4009AWM

7.5 11.9 5 9.2 4012ABM 4012AWM

10 17.5 7.5 14.8 4018ABM 4018AWM

15 23.4 10 18 4023ABM 4023AWM

20 31 15 24 4031ABM 4031AWM

25 38 20 31 4038ABM 4038AWM

30 44 25 39 4044ABM 4044AWM

40 59.6 30 45 4060ABM 4060AWM

50 74.9 40 60 4075ABM 4075AWM

60 89.2 50 75 4089ABM 4089AWM

75 103 60 91 4103ABM 4103AWM

100 140 75 112 4140ABM 4140AWM

125 168 100 150 4168ABM 4168AWM

150 208 125 180 4208ABM 4208AWM

200 250 150 216 4250ABM 4250AWM

250 302 200 260 4302ABM 4302AWM

300 371 250 304 4371ABM 4371AWM

350 414 300 371 4414ABM 4414AWM

400 477 350 414 4477ABM 4477AWM

450 568 400 477 4568ABM 4568AWM

500 675 450 605 4605ABM 4605AWM

600 720 500 605 4720ABM 4720AWM

1 Output capacities are for conditions of 3 phase input, DC input, and 12 pulse input. Refer to Drive Derating for single-phase

capabilities.

2 Standard (IP20) Drives are intended for clean conditions, and can be mounted three different ways as follows:

A) In a separate enclosure with heatsink internal (no extra mounting brackets required)

B) In a separate enclosure with heatsink external. Refer to Enclosure Adapters and Kits for sizes requiring extra mounting brackets.

C) Without a separate enclosure, all sizes require Type 1 Adapters (refer to Enclosure Adapters and Kits)

3 Flange Drives are intended for mounting inside separate Type 12 enclosures with heatsink external, when the external environment is dirty or dusty (Type 12 backside). No

additional adapters required.

Catalog Code

GA80U . .

Catalog

Code

GA80U . .

6 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: GA800 Drives \ Dimensions

Dimensions

Figure 2: Models 2056, 4031, 4038 Figure 3: Models 2257, 2313, 4208 - 4302

Additional Information

Frame 1 - Models 2004 - 2012 4002 - 4005 Frame 1.5 - Models 2018 - 2042, 4007 - 4023

Frame 2 - Models 2056, 4031 - 4038 Frame 3 - Models 2070 - 2082, 4044

Frame 3.5 - Model 4060 Frame 4 - Models 2110, 4075

Frame 6 - Models 2138, 4084 - 4103 Frame 7 - Models 2169 - 2211, 4140 - 4168

Frame 9 - Models 2257 - 2113, 4208 - 4302 Frame 10 - Models 2360 - 2415, 4371 - 414

Frame 11 - Models 4477 - 4720

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 7

Section: GA800 Drives \ Dimensions

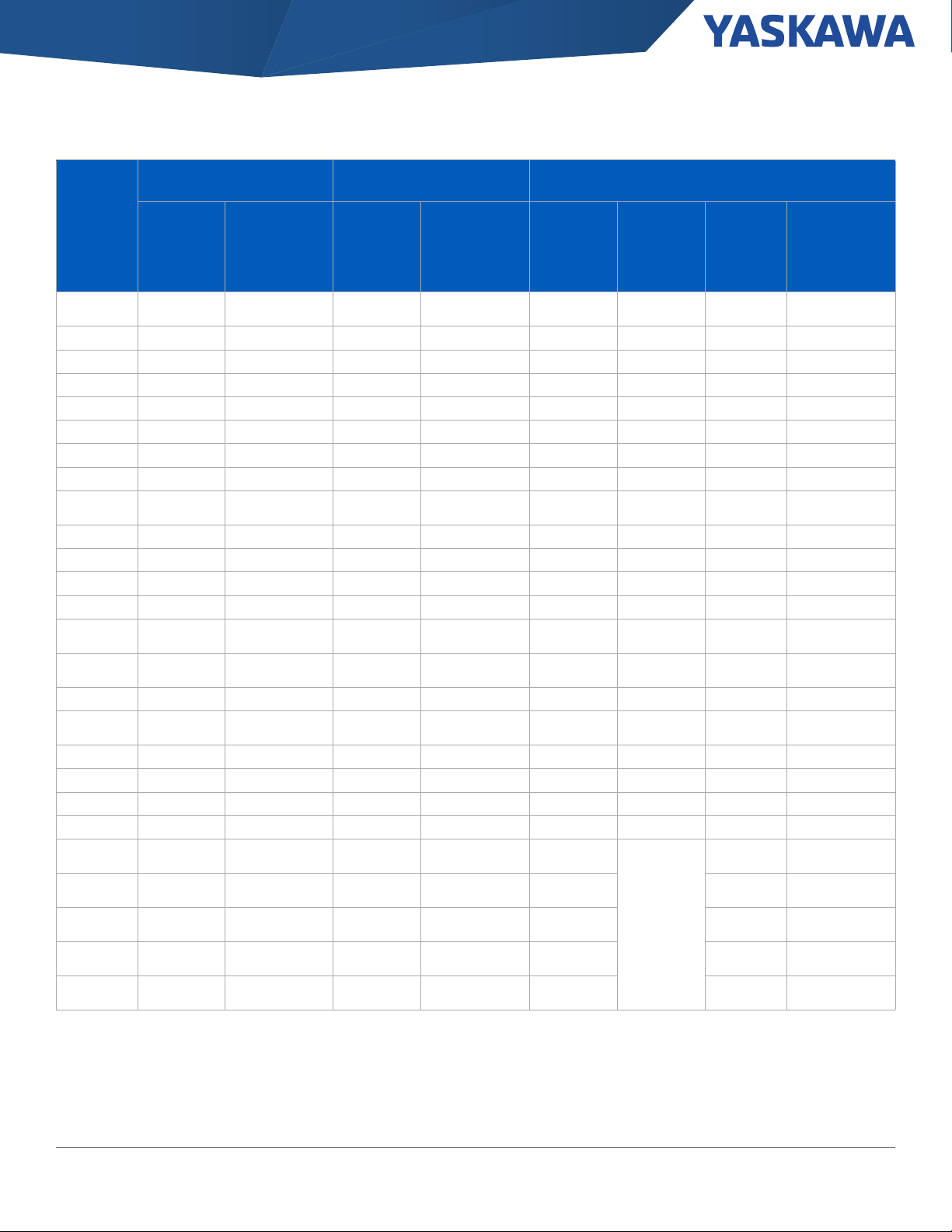

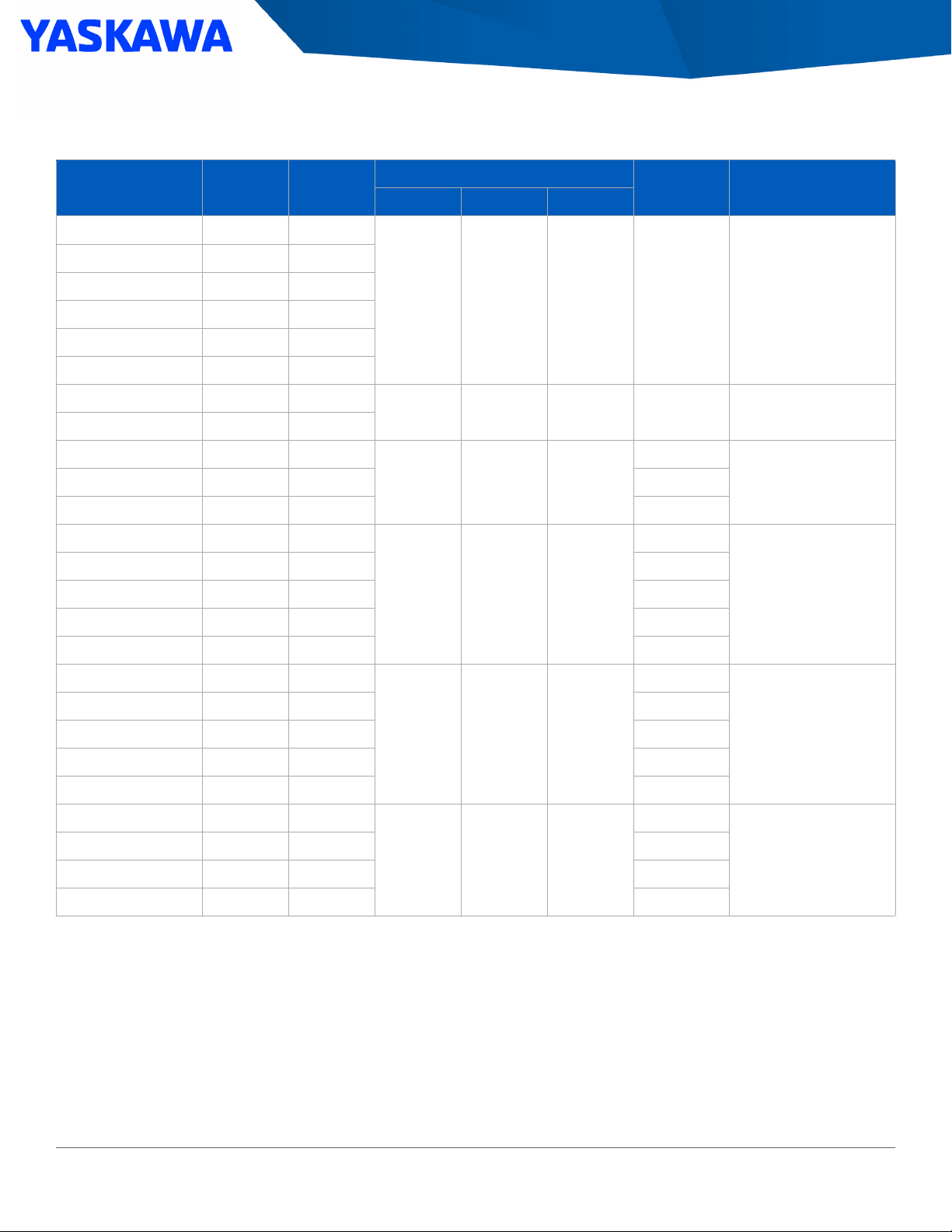

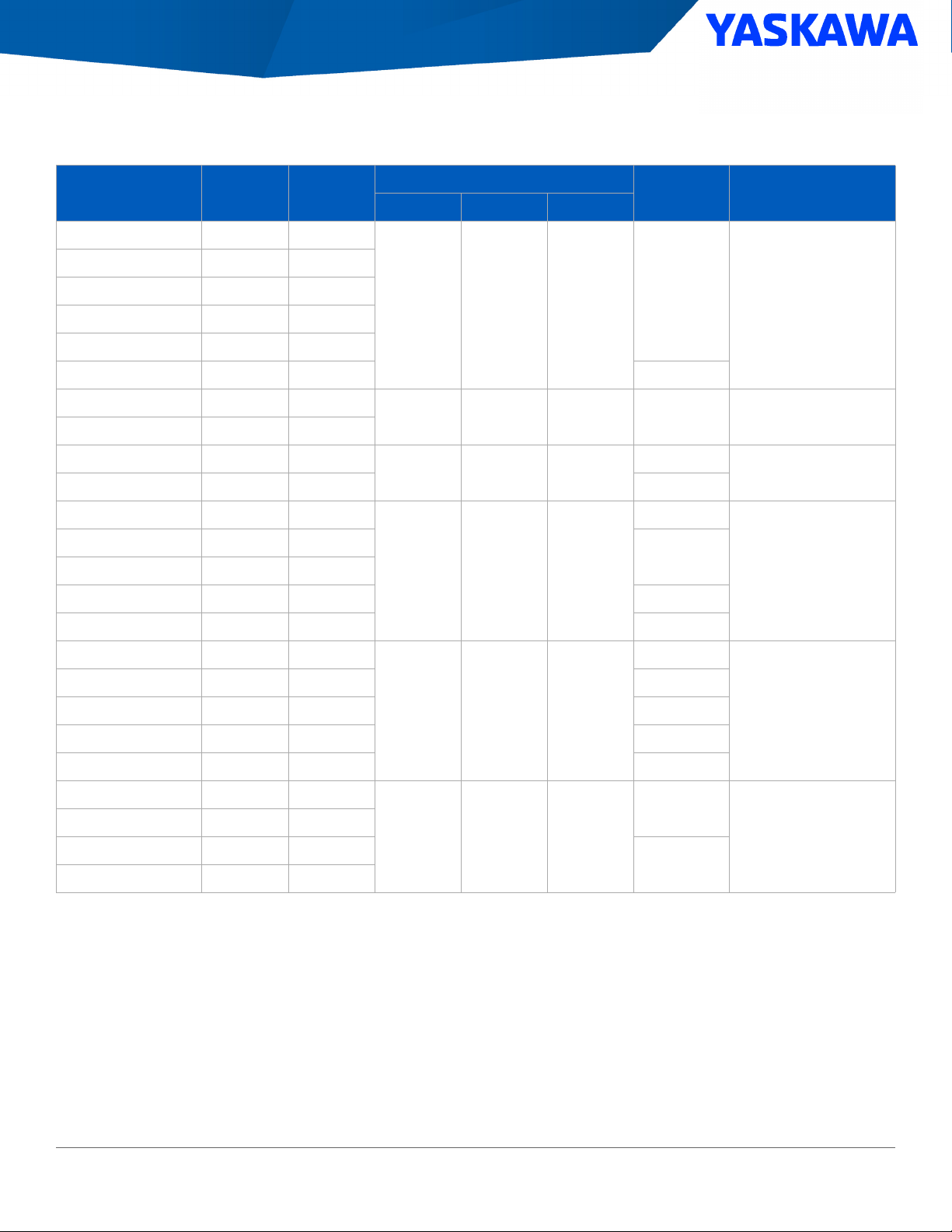

Table 3: Frame Size and Approximate Dimensions

Power Output (HP) 240 V Drives 480 V Drives Approximate Dimensions in (mm)

Normal

Duty

(ND)

1.0 0.75 2004ABM 0.2 3.5 1 4002ABM 2.1 1.8 1 1

1.5 1 2006ABM 6 5 1 - - - -

2 1.5 2008ABM 8 6.9 1 4004ABM 4.1 3.4 1

3 2 2010ABM 9.6 8 1 4005ABM 5.4 4.8 1

4 3 2012ABM 12.2 11 1 4007ABM 7.1 5.5 1.5

5 4 2018ABM 17.5 14 1.5 4009ABM 8.9 7.2 1.5

7.5 5 2021ABM 21 17.5 1.5 4012ABM 11.9 9.2 1.5

10 7.5 2030ABM 30 25 1.5 4018ABM 17.5 14.8 1.5

15 10 2042ABM 42 33 1.5 4023ABM 23.4 18 1.5

20 15 2056ABM 56 47 2 4031ABM 31 24 2

25 20 2070ABM 70 60 3 4038ABM 38 31 2

30 25 2082ABM 82 75 3 4044ABM 44 39 3

40 30 2110ABM 110 88 4 4060ABM 59.6 45 3.5

50 40 2138ABM 138 115 6 4075ABM 74.9 60 4

60 50 2169ABM 169 145 7 4089ABM 89.2 75 6

75 60 2211ABM 211 180 7 4103ABM 103 91 6

100 75 2257ABM 257 215 9 4140ABM 140 112 7

125 100 2313ABM 313 283 9 4168ABM 168 150 7

150 125 2360ABM 360 346 10 4208ABM 208 180 9

150 150 2415ABM 415 415 10 - - - -

200 150

250 200 4302ABM 302 260 9

300 250 4371ABM 371 304 10

350 300 4414ABM 414 371 10

400 350 4477ABM 477 414 11

450 400 4568ABM 568 477 11

500 450 4605ABM 675 605 11

600 500 4720ABM 720 605 11

Heavy

Duty

(HD)

Catalog

Code

GA80U. .

Output Amps

Frame

ND HD ND HD

N/A

Catalog

Code

GA80U . .

4250ABM 250 216 9

Output Amps

Frame Frame Height Width Depth

1.5

3.5

10

11

10.2

(260)

10.2

(260)

11.8

2

(300)

13.8

3

(350)

13.8

(350)

15.7

4

(400)

17.7

6

(450)

21.4

7

(543)

27.6

9

(700)

31.5

(800)

44.72

(1136)

5.51

(140)

5.51

(140)

7.09

(180)

8.66

(220)

8.66

(220)

9.45

(240)

10.0

(255)

10.4

(264)

12.3

(312)

17.3

(440)

20.1

(510)

6.93

(176)

8.31

(211)

7.95

(202)

8.94

(227)

9.69

(246)

11.0

(280)

11.0

(280)

13.2

(335)

16.5

(420)

18.6

(472)

18.9

(480)

8 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: GA800 Drives \ Drive Specifications

Drive Specifications

Item Specification

Overload Capacity 150 % for 60 seconds. (HD), 110 % for 60 seconds. (ND)

Output Frequency 0 to 590 Hz

Control Methods

Motor Types

Protective Design Types

Ambient Operating Temperature

Humidity 95 % Relative Humidity or less in a non-condensing environment

Global Certifications UL, CSA, CE, RCM, RoHS

Functional Safety Safe Torque Off, SIL3 according to IEC 62061, PLe according to ISO 13849-1

Standard I/O

I/O Expansion (optional)

Feedback (optional)

Network Communication

Speed Control Range

Speed Control Accuracy 0.02 %: Closed Loop Vector; 0. 2%: Open Loop Vector

Speed Response

Function Block Diagrams Up to 200 connections, 500 µs program scan time

Open and Closed Loop Vector

Open and Closed Loop V/f

Induction

Surface Permanent Magnet

Interior Permanent Magnet

Synchronous Reluctance

IP20 (Type 1 kit available)

Flange (Type 12 backside)

-10 to +50 °C (IP20 and flange types)

-10 to +40 °C (with Type1 kit)

Up to +60 °C (with derate)

(8) multi-function digital inputs (24 Vdc)

(3) multi-function analog inputs (0 +/- 10 Vdc, 4-20 mA)

(1) multi-function pulse inputs

(2) Safe Torque Off inputs

(1) fault relay output (form C)

(3) multi-function relay outputs (form A)

(2) multi-function analog output (0 +/- 10 Vdc, 4-20 mA)

(1) multi-function pulse output

(3) Analog Inputs -10 to +10 V, 13 bit plus sign, 4 to 20 mA

(16) Digital Inputs

(2) Analog Outputs (-10 to +10 V, 11 bit magnitude)

(8) Digital Outputs (6 transistor, 2 relay)

Incremental

Absolute (Stegmann, Heidenhain, Resolver)

Standard: Modbus RTU, RS-485, 115 kbps

Optional: EtherNet/IP, DeviceNet, Modbus TCP/IP, PROFINET, PROFIBUS-DP

1500:1 Closed Loop Vector (IM and PM Motors)

200:1 Open Loop Vector (IM Motors)

100:1 Open Loop Vector (PM Motors)

50 Hz: Closed Loop Vector (Induction Motors); 250 Hz: Closed Loop Vector (PM Motors)

20 Hz: Open Loop Vector (Induction Motors); 40 Hz: Open Loop Vector (PM Motors)

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 9

Section: Control and Feedback Options \ I/O Adapters

Control and Feedback Options

Control Options - These cards and devices add control functionality to the standard drive. Items are shipped loose, unmounted.

Additional Information

Network Communications I/O Adapters

Feedback Encoders

I/O Adapters

Option Purpose Part Number

Analog Input (provides 3 additional inputs)

Digital Input (provides 16 additional inputs)

120 V Digital Interface (converts existing inputs)

Analog Output (provides 2 additional outputs)

Digital Output (provides 8 additional outputs)

Motor Feedback

Option Purpose Part Number

Open Collector

Line Driver

Provides 3 high resolution (13-bit signed) analog inputs. These inputs are configurable for

0 - 10 Vdc, -10 Vdc to +10 Vdc, or 4 - 20 mA, and can be combined with the drive’s

standard analog inputs.

Provides an additional 16 digital inputs which can be programmed individually

(multi-function) or used as a binary-coded decimal (BCD) speed reference, configurable as

2, 3, or 4 digit BCD.

Mounts directly to the control terminal block on the drive and allows the use of 120 Vac

control logic circuits to produce multi-function control input signals for the drive. Used for

digital inputs S1 to S8.

Provides 2 signals for remote metering of any two of the drive's "U1" monitors. Additive to

the two standard analog outputs. Signal level: 0 to +/- 10 Vdc (20 kOhm).

Provides 8 additional digital outputs for use in monitoring the status outputs of the drive.

Signal levels: 6 channels PHC (48 Vdc, 50 mA maximum) and 2 channels of Form A (250

Vac at 1 A or less, 30 Vdc at 1 A or less). Shared Common.

This option provides velocity and direction feedback from an encoder. This is primarily used

for motor speed feedback in closed loop flux vector control. A 24 DC buffered output (open

collector) is also included. 32 kHz maximum input frequency.

Provides velocity and direction feedback from an encoder. Primarily used for motor speed

feedback in closed loop flux vector control. A 5 Vdc buffered output is also included. Signal

levels: 5 or 12 Vdc differential line driver with compliments, maximum input frequency of 300

kHz, phases A and B (Z required with some custom software).

AI-A3

DI-A3

DI-101

AO-A3

DO-A3

PG-B3

PG-X3

10 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Control and Feedback Options \ Motor Feedback

Option Purpose Part Number

This card reads a maximum input frequency from the encoder of 20 kHz. The card allows

Absolute Encoder

Resolver

the user to connect a rotary encoder, either EnDat2.1/01 or EnDat2.2/01 by HEIDENHAIN

for motor speed feedback to the drive and take advantage of the Closed Loop Vector for PM

Motors control mode.

This card reads a maximum input frequency from the encoder of 20 kHz. The card allows

the user to connect a rotary encoder, either EnDat2.1/01 or EnDat2.2/01 by HEIDENHAIN

for motor speed feedback to the drive and take advantage of the Closed Loop Vector for PM

Motors control mode.

PG-F3

PG-RT3

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 11

Section: Control and Feedback Options \ Network Communication Options

Network Communication Options

These cards, cables, and devices add control functionality to the standard drive. Items are shipped loose and unmounted.

Option Purpose Part Number

EtherNet/IP

EtherNet/IP Dual Port SI-EN3D

PROFINET PI compliant option cards to connect to a PROFINET network. SI-EP3

Modbus TCP Simple and effective solution to connect the drive to a Modbus TCP/IP network. SI-EM3

Modbus TCP Dual Port Simple and effective solution to connect the drive to a Modbus TCP/IP network. SI-EM3D

EtherCAT Option cards to turn the drive into an EtherCAT slave on the network. SI-ES3

DeviceNet ODVA compliant option cards to connect to a DeviceNet network. SI-N3

PROFIBUS-DP PI compliant option cards to connect to a PROFIBUS-DP network. SI-P3

CANopen CANopen is a CAN-based communication system. SI-C3

CC-Link

BACnet MSTP BACnet is a data communications protocol for Building Automation and Control Networks. SI-B3

APOGEE/METASYS

LONWORKS LONWOKRS provides building automation communication capabilities. SI-W3

MECHATROLINK II

MECHATROLINK III

ODVA compliant option cards to connect to Ethernet/IP.

CC-Link is an open industrial network protocol that enables devices from different

manufacturers to communicate.

APOGEE/METASYS is a multi-portocol card that provides communications between

different systems and devices.

Option cards to turn the drive into a M-II node and connect to a high-speed

MECHATROLINK-II network.

Option cards to turn the drive into a M-III node and connect to a high-speed

MECHATROLINK-III network.

SI-EN3

SI-C3

SI-J3

SI-T3

SI-ET3

12 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Keypads, Accessories, and Cables \

Keypads, Accessories, and Cables

Additional Information

Keypads and Cables

Table 4: Keypads

Part Number Description

JVOP-KPLCC04MBB LCD Keypad with Bluetooth

LCD Keypad with Bluetooth

Table 5: Remote Mount Adapters

Part Number Description

900-192-933-001 Type 1 Keypad Panel Mount Kit A (brackets have tapped holes for use with screws)

900-192-933-002 Type 1 Keypad Panel Mount Kit B (brackets have untapped holes for use with panel studs)

900-239-230-001 Type 12/3R Keypad Panel Mount (with embedded studs)

-001 Type 1 Screw Mount -002 Type 1 Stud Mount Type 12/3R Mount (with embedded studs)

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 13

Section: Keypads, Accessories, and Cables \

Table 6: Cables

Part Number Description

UWR0051 Keypad Remote Mount Cable - 1 Meter

UWR0052 Keypad Remote Mount Cable - 3 Meter

UWR01258 USB Cable for PC to Drive Communication - 3 Meter

Table 7: Android Mobile Device Interface Cables (for connecting Android device to USB port on drive)

Part Number Description

UWR01516-B USB Mini-B to USB Micro-B. On-The-Go (OTG) compatible, 2-meter length.

UWR01516-C USB Mini-B to USB Type-C. On-The-Go (OTG) compatible, 2-meter length.

P# UWR01516-B - USB Mini-B to USB Micro-B P# UWR01516-C - USB Mini-B to USB Type-C

14 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Enclosure Adapters and Kits \

Enclosure Adapters and Kits

These adapters are for mounting the standard IP20 drives directly to a wall, a machine in a clean environment (Type 1), or inside a Type 1

enclosure with external heatsink. The Type 1 Adapters convert an Open Chassis Drive (IP20) to an enclosed wall-mounted drive (Type 1). The

A1000 to GA800 adapters allow a GA800 to mount where an A1000 was previously mounted.

Type 1 Adapter External Heatsink Adapter A1000 to GA800 Adapters

Additional Information

Type 1 Adapter Manual

Table 8: 240 Volt Drive Mounting Adapters

Catalog Code

GA80U . .

2004ABM

2006ABM

2008ABM

2010ABM

2012ABM

2018ABM

2021ABM

2030ABM

2042ABM

2056ABM 900-192-121-002 900-193-209-002 900-195-081-002

2070ABM 900-192-121-003

2082ABM 900-192-121-004

2110ABM 900-192-121-005

2138ABM 900-192-121-006

2169ABM 900-192-121-007

2211ABM 900-192-121-008

2257ABM

2313ABM

2360ABM

2415ABM

Type 1 Adapters

Part Number Part Number Part Number Part Number

900-192-121-001

900-192-121-009

900-192-121-010

Internal Fuses (Bussman FWH Series)

for Type 1 Adapters

Not Available

External Heatsink Adapter

900-193-209-001 900-195-081-001

900-193-209-003

Included as standard

(see instructions)

Drive Adapters

(A1000 to GA800)

Not Available

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 15

Section: Enclosure Adapters and Kits \

Table 9: 480 Volt Drive Mounting Adapters

Catalog Code

GA80U . .

4002ABM

4004ABM

4005ABM

4007ABM

4009ABM

4012ABM

4018ABM

4023ABM

4031ABM

4038ABM

4044ABM

4060ABM

4075ABM 900-192-121-005

4089ABM

4103ABM

4140ABM

4168ABM

4208ABM

4302ABM

4371ABM

4414ABM UFU000048

4477ABM

4568ABM

4605ABM

4720ABM

Type 1 Adapters

Part Number Part Number Part Number Part Number

900-192-121-001

900-192-121-002 900-193-209-002 900-195-081-002

900-192-121-003 900-193-209-003

900-192-121-006

900-192-121-007

900-192-121-0094250ABM

UUX001700

UUX001701

Internal Fuses (Bussman FWH Series)

for Type 1 Adapters

Not

Available

UFU000047

UFU000049

UFU000050

1 2

External Heatsink

Adapter

900-193-209-001 900-195-081-001

Included as standard

(see instructions)

Drive Adapters

(A1000 to GA800)

Not Available

1. Type 1 Adapters for 4371 and larger are input fuse ready. UL requires Bussman FWH series semiconductor fuses to be installed within the Type 1 Adapter

on these models.

2. Fuses sold individually. A quantity of three are required per drive.

16 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \

Power Options

Power options are add on devices that can be used to help increase power factor, improve harmonics, and dissipate regenerative energy.

Name Purpose

• Improves the drive input power factor.

• Prevents damage to the drive when the power supply capacity is large. Only use this option when the

DC Bus Reactor

AC Reactor

power supply capacity is more than 600 kVA.

• Decreases harmonic current

• Improves the power supply total power factor.

• Improves the drive input power factor.

• Prevents damage to the drive when the power supply capacity is large. Only use this option when the

power supply capacity is more than 600 kVA.

• Decreases harmonic current

• Improves the power supply total power factor.

3% Braking Resistor

10% Braking Resistor Unit

Braking Unit Use with a braking resistor unit to decrease motor deceleration times.

R1000

Single Phase Converter

Decreases the regenerative energy of the motor and decrease the deceleration time (Duty cycle of 3%

ED). An installation attachment is required.

Decreases the regenerative energy of the motor and decrease the deceleration time (Duty cycle of 10%

ED). The unit contains a thermal overload relay.

The R1000 regenerative module is used to divert energy generated by the motor back onto the line for

use by other loads. The energy is directed back onto the line by taking DC voltage from the drive running

the motor and converting it into a three-phase AC voltage waveform.

The Single Phase Converter is used in single-phase to three-phase conversion applications to eliminate

drive derating. The Single Phase Converter significantly reduces stresses on the power grid with near

unity power factor and less than 10% iTHD.

Additional Information

GA800 Power Options

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 17

Section: Power Options \ DC Bus Reactors

DC Bus Reactors

Use a DC Bus Reactor on the DC bus terminals of a drive to reduce the effect of line-side transients and input current total harmonic

distortion (THD). Large HP drives include a 3% bus impedance as standard. The DC bus reactor is available loose in a separate Type 1

enclosure.

Table 10: 240 Volt DC Bus Reactors

HP

Catalog Code GA80U

Normal

Duty

. .

Heavy

Duty

Open Type

Part Number

3% DC Bus Reactor 5% DC Bus Reactor

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

Open Type

Part Number

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

0.5 2004 . . . 2004 . . . URX000036 URX000207 2 10 URX000037 URX000217 2 15

0.75 2004 . . . 2004 . . . 05P00608-3007 URX000208 4 5 URX000041 URX000207 4 12

1 2006 . . . 2006 . . . 05P00608-3007 URX000208 4 5 URX000041 URX000207 4 12

1.5 2006 . . . 2008 . . . 05P00620-0110 URX000257 9 3.22 05P00620-0111 URX000208 9 7.5

2 2008 . . . 2010 . . . 05P00620-0110 URX000257 9 3.22 05P00620-0111 URX000208 9 7.5

3 2010 . . . 2012 . . . URX000371 URX000258 12 2.1 05P00652-0213 URX000209 12 4

4 2012 . . . 2018 . . . 05P00620-0115 URX000259 18 1.375 URX000048 URX000210 18 2.75

5 2018 . . . 2021 . . . 05P00620-0115 URX000259 18 1.375 URX000048 URX000210 18 2.75

7.5 2021 . . . 2030 . . . URX000051 URX000212 25 1 URX000052 URX000211 25 1.75

10 2030 . . . 2042 . . . 05P00620-0120 URX000261 32 0.85 URX000055 URX000223 32 1.62

15 2042 . . . 2056 . . . URX000059 URX000262 50 0.625 URX000060 URX000222 50 0.97

20 2056 . . . 2070 . . . URX000063 URX000264 62 0.35 URX000064 URX000213 62 0.61

25 2070 . . . 2082 . . . 05P00620-0129 URX000214 80 0.31 URX000069 URX000265 80 0.5

30 2082 . . . - URX000072 URX000266 92 0.2 URX000073 URX000265 92 0.6

40 to 150 Drive models 2110 through 2415 have built-in DC reactors.

18 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ DC Bus Reactors

Table 11: 480 Volt DC Bus Reactors

Catalog Code GA80U

HP

0.5 4002 . . . 4002 . . . URX000033 URX000215 1 35 URX000034 URX000215 1 60

0.75 4002 . . . 4002 . . . URX000038 URX000216 2 20 URX000039 URX000215 2 50

1 4002 . . . 4004 . . . URX000038 URX000216 2 20 URX000039 URX000215 2 50

1.5 4004 . . . 4004 . . . 05P00620-0109 URX000217 4 15 URX000042 URX000216 4 25

2 4004 . . . 4005 . . . URX000041 URX000207 4 12 URX000042 URX000216 4 25

3 4005 . . . 4007 . . . URX000044 URX000218 9 11.5 URX000044 URX000218 9 11.5

4 4007 . . . 4009 . . . URX000044 URX000218 9 11.5 URX000044 URX000218 9 11.5

5 4009 . . . 4012 . . . 05P00620-0111 URX000208 9 7.5 URX000044 URX000218 9 11.5

7.5 4012 . . . 4018 . . . 05P00652-0213 URX000209 12 4 URX000046 URX000219 12 6

10 4018 . . . 4023 . . . 05P00652-0216 URX000220 18 3.75 URX000049 URX000260 18 6

15 4023 . . . 4031 . . . URX000052 URX000211 25 1.75 URX000054 URX000224 25 4

20 4031 . . . 4038 . . . URX000055 URX000223 32 1.62 URX000056 URX000221 32 2.68

25 4038 . . . 4044 . . . URX000057 URX000184 40 1 URX000058 URX000225 40 2.5

30 4044 . . . - URX000061 URX000222 50 1.35 URX000062 URX000263 50 2

50 to 600 Drive models 4060 through 4720 have built-in DC reactors.

Normal

Duty

. .

Heavy

Duty

Open Type

Part Number

3% DC Bus Reactor 5% DC Bus Reactor

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

Open Type

Part Number

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 19

Section: Power Options \ DC Bus Reactors

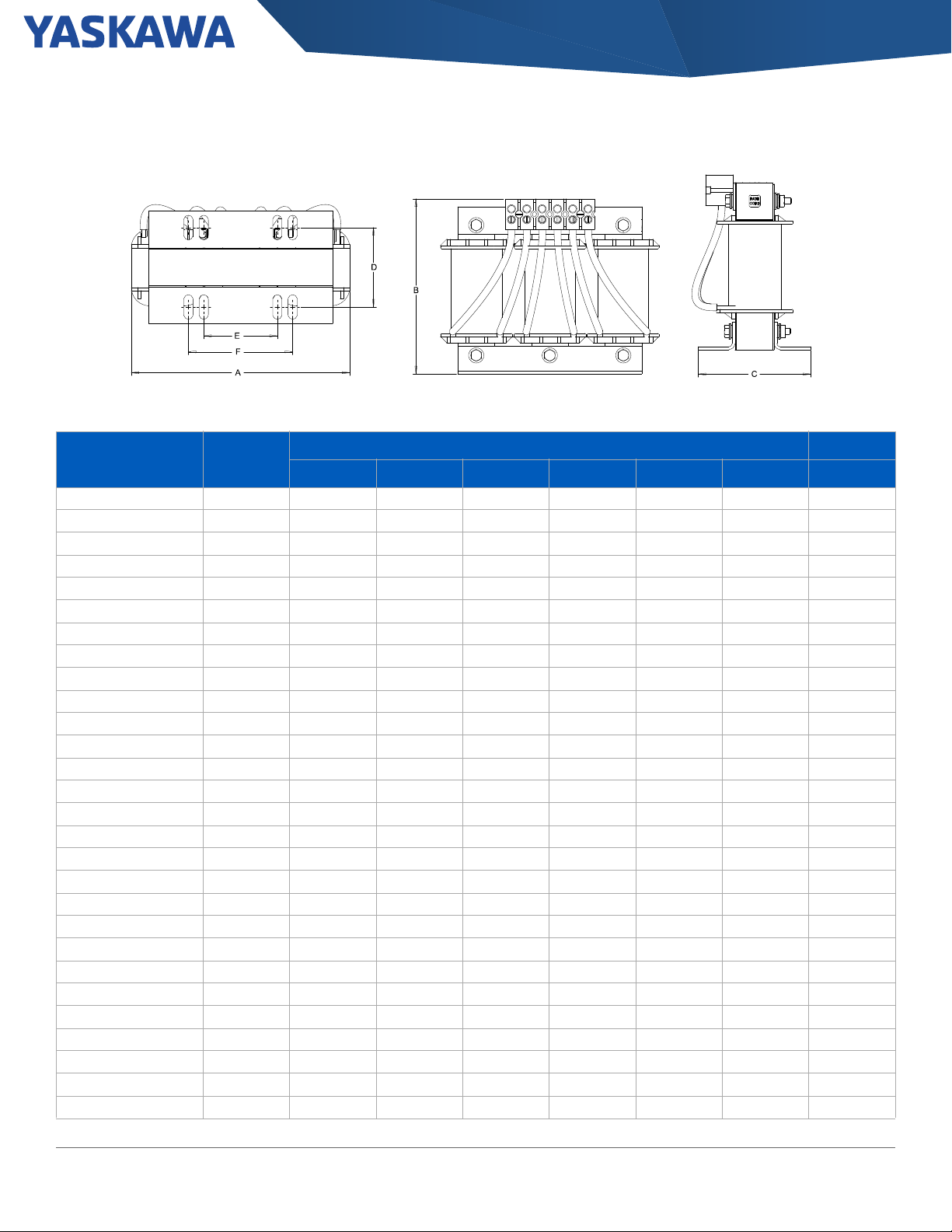

Open Type DC Bus Reactor Dimensions

Figure 4: Figure 5:

Figure 6:

Table 12: Open Type Reactor Dimensions

DC Bus Reactor Figure DC Bus Reactor Figure

05P00608-3007 4 URX000048 5

05P00620-0109 4 URX000049 5

05P00620-0110 4 URX000051 5

05P00620-0111 5 URX000052 5

05P00620-0115 5 URX000054 5

05P00620-0120 5 URX000055 5

05P00620-0129 6 URX000056 5

05P00652-0213 5 URX000057 5

05P00652-0216 5 URX000058 5

URX000033 4 URX000059 5

URX000034 4 URX000060 5

URX000036 4 URX000061 5

URX000037 4 URX000062 6

URX000038 4 URX000063 6

URX000039 4 URX000064 6

URX000041 5 URX000069 6

URX000042 5 URX000072 6

URX000044 5 URX000073 6

URX000046 5 URX000371 5

20 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ DC Bus Reactors

«%#$

#55'/$.;*1.'5

5.)43).#(%3

5.)43).#(%3

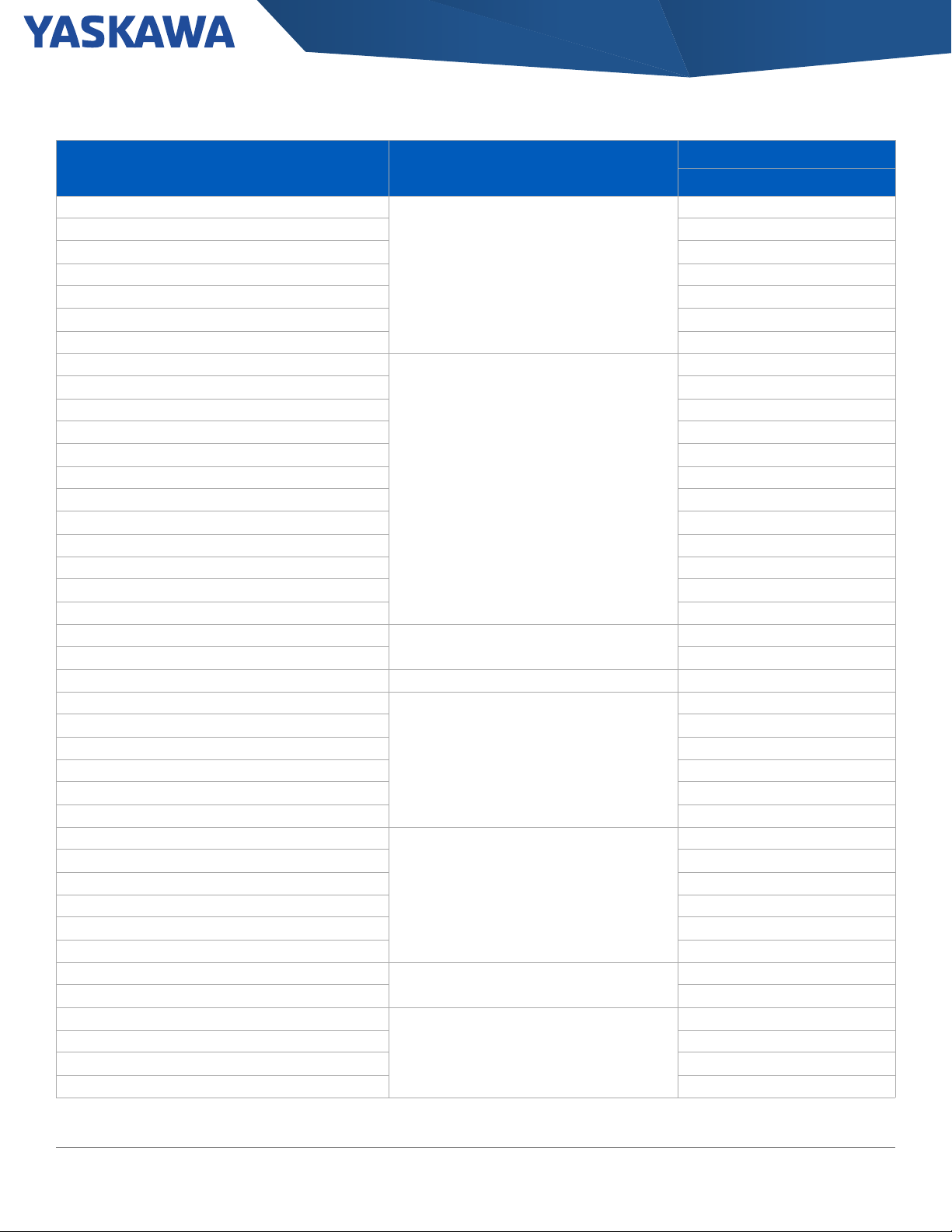

Enclosed DC Reactor Dimensions

Figure 7: CAB-8 Figure 8: CAB-13V

Table 13: Enclosed Type Reactor Dimensions

DC Bus Reactor Figure

URX000207

URX000208

URX000209

URX000210

URX000211

URX000213

URX000215

URX000216

URX000217

URX000218

URX000219

URX000221

URX000222

URX000223

URX000224

URX000225

URX000260

URX000263

URX000265

7

8

7

8

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 21

Section: Power Options \ AC Input Reactors

AC Input Reactors

3% and 5% impedance reactors may be used on either the input or output to reduce the effects of line or load side transients on the drive.

The reactors listed are available loose or in a separate Type 1 enclosure.

Table 14: 240 Volt AC Input Reactors

Catalog Code

HP

0.5 2004 . . . 2004 . . . URX000287 URX000583 1.6 6.9 URX000292 URX000502 2.1 11

0.75 2004 . . . 2004 . . . URX000295 URX000409 3.4 3.2 URX000296 URX000584 3.4 6.8

1 2006 . . . 2006 . . . URX000295 URX000409 3.4 3.2 URX000300 URX000503 4.8 4.8

1.5 2006 . . . 2008 . . . URX000299 URX000410 4.8 2.3 URX000300 URX000503 4.8 4.8

2 2008 . . . 2010 . . . URX000303 URX000411 7.6 1.5 URX000304 URX000504 7.6 3

3 2010 . . . 2012 . . . URX000307 URX000413 11 1 URX000308 URX000414 11 2.1

4 2012 . . . 2018 . . . URX000307 URX000413 11 1 URX000312 URX000416 14 1.6

5 2018 . . . 2021 . . . URX000311 URX000415 14 0.79 URX000316 URX000419 21 1.1

7.5 2021 . . . 2030 . . . URX000315 URX000418 21 0.53 URX000320 URX000421 28 .82

10 2030 . . . 2042 . . . URX000319 URX000420 28 .39 URX000324 URX000423 35 .71

15 2042 . . . 2056 . . . URX000326 URX000424 46 0.3 URX000330 URX000553 55 0.48

20 2056 . . . 2070 . . . URX000332 URX000426 65 0.19 URX000333 URX000554 65 0.36

25 2070 . . . 2082 . . . URX000335 URX000427 83 0.17 URX000336 URX000555 83 0.29

30 2082 . . . - URX000338 URX000428 104 0.12 URX000339 URX000556 104 0.23

30 - 2110 . . . URX000338 URX000428 104 0.12

40 2110 . . . 2138 . . . URX000338 URX000428 104 0.12

50 2138 . . . 2169 . . . URX000341 URX000429 130 0.095

60 2169 . . . 2211 . . . URX000344 URX000430 160 0.08

75 2211 . . . 2257 . . . URX000347 URX000431 200 0.06

100 2257 . . . 2313 . . . URX000350 URX000432 250 0.05

125 2313 . . . 2360 . . . URX000356 URX000434 414 0.033

150 2360 . . . 2415 . . . URX000356 URX000434 414 0.033

GA80U . .

Normal

Duty

Heavy

Duty

Open Type

Part Number

3% Input Reactor 5% Input Reactor

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

Open Type

Part Number

5% input reactor not recommended for these drive sizes

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

22 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Input Reactors

Table 15: 480 Volt AC Input Reactors

Catalog Code

HP

0.5 4002 . . . 4002 . . . URX000284 URX000585 1.1 21 URX000286 URX000569 1.1 42

0.75 4002 . . . 4002 . . . URX000288 URX000551 1.6 14 URX000285 URX000570 1.1 33

1 4002 . . . 4004 . . . URX000292 URX000502 2.1 11 URX000289 URX000571 1.6 23

1.5 4004 . . . 4004 . . . URX000301 URX000552 4.8 7.7 URX000293 URX000572 2.1 18

2 4004 . . . 4005 . . . URX000296 URX000584 3.4 6.8 URX000297 URX000573 3.4 11

3 4005 . . . 4007 . . . URX000300 URX000503 4.8 4.8 URX000301 URX000552 4.8 7.7

4 4007 . . . 4009 . . . URX000304 URX000504 7.6 3 URX000306 URX000412 7.6 6

5 4009 . . . 4012 . . . URX000304 URX000504 7.6 3 URX000305 URX000574 7.6 4.8

7.5 4012 . . . 4018 . . . URX000308 URX000414 11 2.1 URX000309 URX000505 11 3.3

10 4018 . . . 4023 . . . URX000312 URX000416 14 1.6 URX000313 URX000417 14 2.6

15 4023 . . . 4031 . . . URX000316 URX000419 21 1.1 URX000317 URX000568 21 1.8

20 4031 . . . 4038 . . . URX000320 URX000421 28 .82 URX000321 URX000575 28 1.3

25 4038 . . . 4044 . . . URX000324 URX000423 35 .71 URX000325 URX000576 35 1.2

30 4044 . . . - URX000327 URX000425 46 0.55 URX000328 URX000577 46 0.98

30 - 4060 . . . URX000327 URX000425 46 0.55

40 4060 . . . 4075 . . . URX000330 URX000553 55 0.48

50 4075 . . . 4089 . . . URX000333 URX000554 65 0.36

60 4089 . . . 4103 . . . URX000336 URX000555 83 0.29

75 4103 . . . 4140 . . . URX000339 URX000556 104 0.23

100 4140 . . . 4168 . . . URX000342 URX000557 130 0.18

125 4168 . . . 4208 . . . URX000345 URX000558 160 0.155

150 4208 . . . 4250 . . . URX000348 URX000559 200 0.115

200 4250 . . . 4302 . . . URX000351 URX000560 250 0.095

250 4302 . . . 4371 . . . URX000354 URX000561 322 0.07

300 4371 . . . 4414 . . . URX000357 URX000562 414 0.066

350 4414 . . . 4477 . . . URX000360 URX000563 515 0.05

400 4477 . . . 4568 . . . URX000360 URX000563 515 0.05

450 4568 . . . 4605 . . . URX000363 URX000564 600 0.04

500 4605 . . . 4720 . . . URX000363 URX000564 600 0.04

600 4720 . . . - URX000366 URX000565 750 0.035

GA80U . .

Normal

Duty

Heavy

Duty

Open Type

PartNumber

3% Input Reactor 5% Input Reactor

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

Open Type

Part Number

5% input reactor not recommended for these drive sizes

Enclosed Type 1

Part Number

Amps Inductance

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 23

Section: Power Options \ AC Output Reactors

AC Output Reactors

Table 16: 240 Volt AC Output Reactors

Catalog Code GA80U . . 3% Output Reactor

HP

Normal Duty Heavy Duty

0.5 2004 . . . 2004 . . . 05P00620-0132 05P00620-0021 4 6.5

0.75 2004 . . . 2004 . . . 05P00620-0017 05P00620-0020 4 3.0

1 2006 . . . 2006 . . . 05P00620-0133 05P00620-0028 8 3.0

1.5 2006 . . . 2008 . . . 05P00620-0133 05P00620-0028 8 3.0

2 2008 . . . 2010 . . . 05P00620-0024 05P00620-0027 8 1.5

3 2010 . . . 2012 . . . 05P00620-0134 05P00620-0032 12 1.25

4 2012 . . . 2018 . . . 05P00620-0134 05P00620-0032 12 1.25

5 2018 . . . 2021 . . . 05P00620-0136 05P00620-0036 18 0.8

7.5 2021 . . . 2030 . . . URX000083 05P00620-0041 25 0.5

10 2030 . . . 2042 . . . 05P00620-0044 05P00620-0046 35 0.4

15 2042 . . . 2056 . . . 05P00620-0140 05P00620-0050 45 0.3

20 2056 . . . 2070 . . . 05P00620-0143 05P00620-0058 80 0.20

25 2070 . . . 2082 . . . 05P00620-0143 05P00620-0058 80 0.20

30 2082 . . . 2110 . . . 05P00620-0143 05P00620-0058 80 0.20

40 2110 . . . 2138 . . . URX000085 URX000204 100 0.15

50 2138 . . . 2169 . . . 05P00620-0064 05P00620-0066 130 0.10

60 2169 . . . 2211 . . . 05P00620-0069 URX000206 160 0.075

75 2211 . . . 2257 . . . 05P00620-0075 05P00620-0077 200 0.055

100 2257 . . . 2313 . . . URX000175 URX000248 250 0.045

125 2313 . . . 2360 . . . 05P00620-0085 URX000249 320 0.040

150 2360 . . . 2415 . . . URX000181 URX000250 400 0.030

150 2415 . . . - URX000181 URX000250 400 0.030

Open Type

Part Number

Enclosed Type 1

Part Number

Amps

Inductance

(mH)

24 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Output Reactors

Table 17: 480 Volt AC Output Reactors

Catalog Code GA80U . . 3% Output Reactor

HP

Normal Duty Heavy Duty

0.5 4002 . . . 4002 . . . 05P00620-0014 05P00620-0016 2 20.0

0.75 4002 . . . 4002 . . . 05P00620-0131 05P00620-0015 2 12.0

1 4002 . . . 4004 . . . 05P00620-0131 05P00620-0015 2 12.0

1.5 4004 . . . 4004 . . . 05P00620-0018 05P00620-0022 4 9.0

2 4004 . . . 4005 . . . 05P00620-0132 05P00620-0021 4 6.5

3 4005 . . . 4007 . . . 05P00620-0025 05P00620-0029 8 5.0

4 4007 . . . 4009 . . . 05P00620-0025 05P00620-0029 8 5.0

5 4009 . . . 4012 . . . 05P00620-0133 05P00620-0028 8 3.0

7.5 4012 . . . 4018 . . . 05P00620-0135 05P00620-0033 12 2.5

10 4018 . . . 4023 . . . 05P00620-0137 05P00620-0037 18 1.5

15 4023 . . . 4031 . . . 05P00620-0138 05P00620-0042 25 1.2

20 4031 . . . 4038 . . . 05P00620-0139 05P00620-0047 35 0.8

25 4038 . . . 4044 . . . 05P00620-0139 05P00620-0047 35 0.8

30 4044 . . . 4060 . . . 05P00620-0049 05P00620-0051 45 0.7

40 4060 . . . 4075 . . . 05P00620-0142 05P00620-0055 55 0.50

50 4075 . . . 4089 . . . 05P00620-0144 05P00620-0059 80 0.40

60 4089 . . . 4103 . . . 05P00620-0144 05P00620-0059 80 0.40

75 4103 . . . 4140 . . . 05P00620-0145 05P00620-0062 100 0.30

100 4140 . . . 4168 . . . 05P00620-0013 05P00620-0067 130 0.20

125 4168 . . . 4208 . . . 05P00620-0070 05P00620-0073 160 0.150

150 4208 . . . 4250 . . . URX000586 05P00620-0078 200 0.110

200 4250 . . . 4302 . . . URX000176 05P00620-0083 250 0.090

250 4302 . . . 4371 . . . URX000179 05P00620-0088 320 0.075

300 4371 . . . 4414 . . . URX000182 05P00620-0092 400 0.060

350 4414 . . . 4477 . . . 05P00620-0094 05P00620-0096 500 0.050

400 4477 . . . 4568 . . . 05P00620-0094 05P00620-0096 500 0.050

450 4568 . . . 4605 . . . 05P00620-0098 05P00620-0100 600 0.040

500 4605 . . . 4720 . . . 05P00620-0098 05P00620-0100 600 0.040

600 4720 . . . - 05P00620-0102 05P00620-0104 750 0.029

Open Type

Part Number

Enclosed Type 1

Part Number

Amps Inductance

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 25

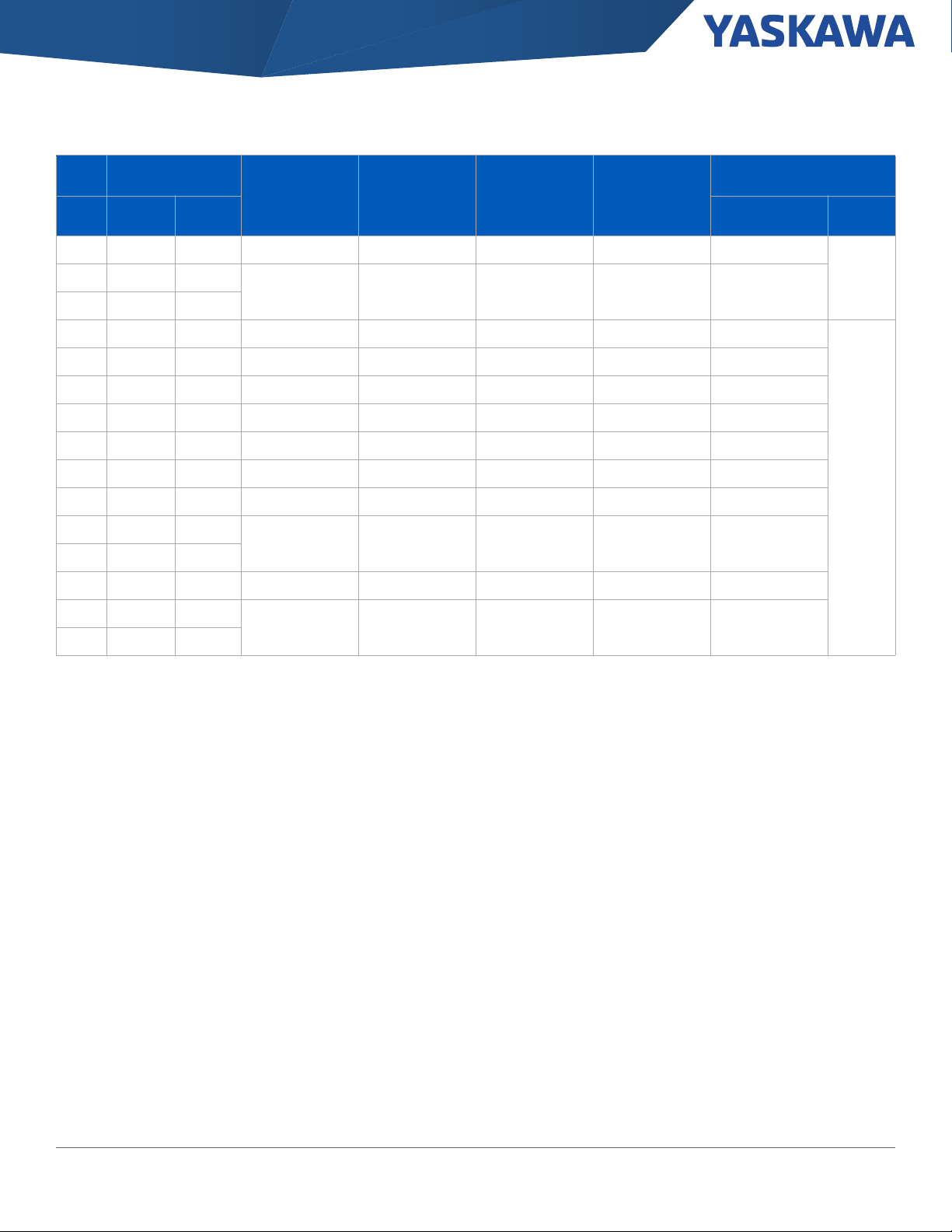

Section: Power Options \ AC Open Reactor Dimensions

AC Open Reactor Dimensions

Table 18: AC Open Reactor Dimensions

Open Type Reactor

Part number

05P00620-0013 180 229/9 183/7.2 172/6.8 93/3.66 92/3.63 - 28/62

05P00620-0014 11.3 112/4.4 104/4.1 71/2.8 50/1.98 37/1.44 - 1.8/4

05P00620-0017 14.5 112/4.4 104/4.1 71/2.8 50/1.98 37/1.44 - 1.8/4

05P00620-0018 20 112/4.4 104/4.1 86/3.4 60/2.35 37/1.44 - 2.3/5

05P00620-0024 19.5 152/6.0 122/4.8 76/3.0 53/2.10 51/2.00 - 3.2/7

05P00620-0025 25.3 152/6.0 122/4.8 86/3.4 67/2.62 51/2.00 - 5.0/11

05P00620-0044 49 183/7.2 147/5.8 102/4.0 66/2.60 76/3.00 - 6.4/14

05P00620-0049 62 229/9.0 188/7.4 119/4.7 80/3.16 76/3.00 - 13/28

05P00620-0064 108 229/9.0 179/7.1 118/4.7 80/3.16 76/3.00 - 13/29

05P00620-0069 116 229/9 183/7.2 172/6.8 80/3.16 92/3.63 - 19/42

05P00620-0070 149 274/10.8 277/8.3 152/6 88/3.47 92/3.63 - 23/51

05P00620-0075 124 229/9 191/7.5 185/7.3 106/4.16 92/3.63 - 22/49

05P00620-0080 154 229/9 191/7.5 229/9 106/4.16 92/3.63 - 31/68

05P00620-0085 224 274.3/10.8 213.4/8.4 200.7/7.9 131/5.2 117/4.6 - 36.3/80

05P00620-0088 224 275/11 214/8.5 201/8 131/5.2 117/4.6 - 36/80

05P00620-0090 333 381/15 286/11.3 292/11.5 172/6.76 117/4.60 - 71/155

05P00620-0094 340 366/14.4 292/11.5 292/11.5 172/6.76 117/4.60 - 82/180

05P00620-0098 414 366/14.4 286/11.3 305/12 203/8.00 117/4.60 - 114/250

05P00620-0102 630 366/14.4 292/11.5 318/12.5 204/8.01 183/7.20 - 141/310

05P00620-0131 7.5 112/4.4 104/4.1 71/2.8 50/1.98 37/1.44 - 1.8/4

05P00620-0132 20 112/4.4 104/4.1 71/2.8 50/1.98 37/1.44 - 1.8/4

05P00620-0133 29 152/6.0 122/4.8 76/3.0 53/2.10 51/2.00 - 3.6/8

05P00620-0134 26 152/6.0 127/5.0 84/3.3 53/2.10 51/2.00 - 4.1/9

05P00620-0135 31 152/6.0 127/5.0 84/3.3 53/2.10 51/2.00 - 4.5/10

05P00620-0136 36 152/6.0 135/5.3 81/3.2 54/2.10 51/2.00 - 4.1/9

05P00620-0137 43 152/6.0 135/5.3 89/3.5 63/2.48 51/2.00 - 5.5/12

05P00620-0138 52 183/7.2 147/5.8 89/3.5 60/2.35 76/3.00 - 6.4/14

05P00620-0139 54 183/7.2 147/5.8 102/4.0 70/2.75 76/3.00 - 7.3/16

Watt Loss

A B C D E F kg/lb

Dimensions (mm/in) Weight

26 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Open Reactor Dimensions

Open Type Reactor

Part number

05P00620-0140 54 229/9.0 188/7.4 119/4.7 80/3.16 76/3.00 - 10/23

05P00620-0142 67 229/9.0 178/7.0 135/5.3 80/3.16 76/3.00 - 12/27

05P00620-0143 82 229/9 183/7.2 160/6.3 88/3.47 92/3.63 - 20/43

05P00620-0144 86 229/9 183/7.2 165/6.5 88/3.47 92/3.63 - 23/51

05P00620-0145 84 229/9 185/7.3 173/6.8 93/3.66 92/3.63 - 23/51

05P00620-0147 231 274/10.8 216/8.5 229/9 131/5.16 117/4.60 - 48/106

05P00620-0148 264 274/10.8 229/9 254/10 149/5.88 117/4.60 - 57/125

URX000083 48 183/7.2 147/5.8 89/3.5 60/2.35 76/3.00 - 5.0/11

URX000085 94 229/9 185/7.3 165/6.5 88/3.46 92/3.62 - 21/47

URX000175 154 243.8/9.6 177.8/7 205.7/8.1 106/4.2 92/3.63 - 21.3/47

URX000176 231 274.3/10.8 215.9/8.5 193/7.6 131/5.2 117/4.6 - 36.3/80

URX000179 264 274.3/10.8 213.4/8.4 226.1/8.9 149/5.9 117/4.6 - 46.3/102

URX000181 213 280/11 214/8.5 219/8.6 131/5.2 117/4.6 - 38/84

URX000182 571 363.2/14.3 281.9/11.1 238.8/9.4 172/6.8 117/4.6 - 53.5/118

URX000284 7.8 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000285 10.1 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000286 11.9 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.8/1.7

URX000287 6.9 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.5

URX000288 10.9 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000289 15 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000292 14.3 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000293 19.6 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.8/1.7

URX000295 12.3 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000296 19.6 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.7/1.6

URX000297 26.5 112/4.4 127/5 71/2.8 51/2 36/1.4 - 1.2/2.7

URX000299 13.8 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.8/1.7

URX000300 23 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.8/1.8

URX000301 37.5 112/4.4 127/5 71/2.8 51/2 36/1.4 - 1.3/2.8

URX000303 19.2 114/4.5 94/3.7 38/1.5 0/0 102/4 - 0.8/1.8

URX000304 37.2 112/4.4 127/5 71/2.8 51/2 36/1.4 - 1.3/2.8

URX000305 47.8 112/4.4 127/5 79/3.1 53/2.1 36/1.4 - 1.9/4.1

URX000306 53.8 112/4.4 127/5 79/3.1 53/2.1 36/1.4 - 1.9/4.2

URX000307 26.8 112/4.4 127/5 71/2.8 51/2 36/1.4 - 1.2/2.7

URX000308 40.9 112/4.4 127/5 79/3.1 53/2.1 36/1.4 - 1.9/4.2

URX000309 54.4 112/4.4 127/5 89/3.5 66/2.6 36/1.4 - 2.4/5.3

URX000311 32.7 112/4.4 135/5.3 71/2.8 51/2 36/1.4 - 1.3/2.8

URX000312 48.2 112/4.4 127/5 79/3.1 53/2.1 36/1.4 - 2/4.3

URX000313 60.6 152/6 147/5.8 74/2.9 53/2.1 51/2 - 3.2/7.1

URX000315 38.3 112/4.4 135/5.3 84/3.3 61/2.4 36/1.4 - 1.9/4.2

URX000316 57.4 152/6 155/6.1 74/2.9 0/0 102/4 - 3.3/7.2

Watt Loss

A B C D E F kg/lb

Dimensions (mm/in) Weight

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 27

Section: Power Options \ AC Open Reactor Dimensions

Open Type Reactor

Part number

URX000317 73.5 152/6 155/6.1 84/3.3 0/0 102/4 - 4.5/10

URX000319 48.2 112/4.4 135/5.3 89/3.5 0/0 102/4 - 2.3/5.1

URX000320 66.8 152/6 155/6.1 84/3.3 0/0 102/4 - 4.3/9.5

URX000321 93.8 152/6 155/6.1 84/3.3 0/0 102/4 - 4.7/10.4

URX000324 102 183/7.2 152/6 95/3.8 0/0 102/4 - 5.9/13

URX000325 121 183/7.2 152/6 109/4.3 0/0 102/4 - 8.2/18

URX000326 77 183/7.2 152/6 95/3.75 0/0 102/4 - 5.9/13

URX000327 99 183/7.2 152/6 109/4.3 0/0 102/4 - 7.7/17

URX000328 179 229/9 211/8.3 122/4.8 0/0 102/4 108/4.26 10.9/24

URX000330 109 229/9 211/8.3 130/5.1 0/0 102/4 - 9.1/20

URX000332 87 183/7.2 152/6 102/4 0/0 102/4 - 8.2/18

URX000333 105 183/7.2 152/6 109/4.3 0/0 102/4 - 43395

URX000335 119 183/7.2 152/6 109/4.3 0/0 102/4 - 8.6/19

URX000336 155 229/9 178/7 165/6.5 0/0 102/4 108/4.26 11.8/26

URX000338 94 183/7.2 152/6 165/6.5 70/2.75 76/3 108/4.26 43395

URX000339 200 229/9 178/7 178/7 82/3.24 76/3 108/4.26 12.7/28

URX000341 132 235/9.25 191/7.5 171/6.75 83/3.25 76/3 108/4.26 11.8/26

URX000342 152 235/9.25 191/7.5 171/6.75 95/3.75 76/3 108/4.26 16.8/37

URX000344 110 235/9.25 191/7.5 171/6.75 95/3.75 76/3 108/4.26 15.4/34

URX000345 195 235/9.25 191/7.5 210/8.25 121/4.75 76/3 108/4.26 22.2/49

URX000347 159 235/9.25 191/7.5 178/7 10/0.375 76/3 108/4.26 15.4/34

URX000348 224 235/9.25 191/7.5 210/8.25 121/4.75 76/3 108/4.26 22.2/49

URX000350 275 235/9.25 191/7.5 191/7.5 95/3.75 76/3 108/4.26 15.9/35

URX000351 284 235/9.25 191/7.5 216/8.5 121/4.75 76/3 108/4.26 24.9/55

URX000354 383 274/10.8 222/8.75 216/8.5 136/5.37 92/3.63 142/5.58 34.5/76

URX000356 333 229/9 222/8.75 241/9.5 136/5.37 92/3.63 142/5.58 35.4/78

URX000357 531 229/9 222/8.75 292/11.5 174/6.87 92/3.63 142/5.58 44.4/98

URX000360 496 229/9 222/8.75 305/12 162/6.37 92/3.63 142/5.58 53.5/118

URX000363 747 366/14.4 292/11.5 318/12.5 206/8.12 117/4.6 150/5.9 65.3/144

URX000366 838 366/14.4 292/11.5 318/12.5 194/7.62 117/4.6 183/7.2 81.2/179

URX000586 168 229/9 191/7.5 211/8.3 112/4.41 92/3.63 - 31/67

URX000587 224 274/10.8 229/9 277/8.3 131/5.16 117/4.60 - 50/110

URX000588 231 274/10.8 254/10 254/10.0 131/5.16 117/4.60 - 46/100

Watt Loss

A B C D E F kg/lb

Dimensions (mm/in) Weight

28 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Enclosed Reactor Dimensions

«%#$

#55'/$.;*1.'5

5.)43).#(%3

5.)43).#(%3

8'06'&2#0'.

(4106$#%-

5.)43).#(%3

5.)43).#(%3

AC Enclosed Reactor Dimensions

Figure 9: CAB-8 Figure 10: CAB-13V

Figure 11: CAB-17V Figure 12: CAB-26C

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 29

Section: Power Options \ AC Enclosed Reactor Dimensions

5.)43).#(%3

Figure 13: CAB-30B

30 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Enclosed Reactor Dimensions

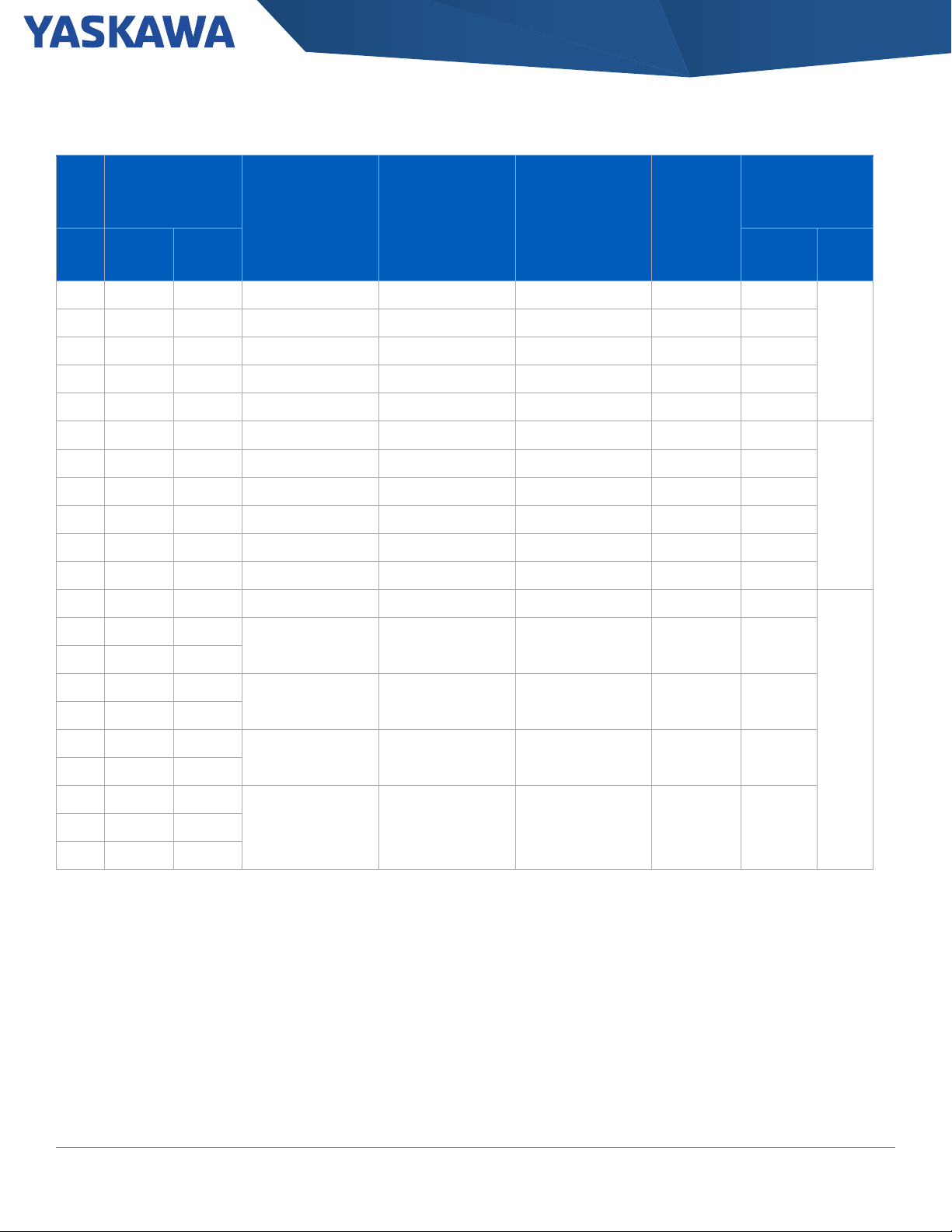

Table 19: AC Input/Output Enclosed Reactor Specifications

Enclosed Type 1 Reactor

Part number

05P00620-0015

05P00620-0016 5/11

05P00620-0020 5/11

05P00620-0021 5/11

05P00620-0022 5/12

05P00620-0027 6/14

05P00620-0028 7/15

05P00620-0029 8/18

05P00620-0032 7/16

05P00620-0033 8/17

05P00620-0036 7/16

05P00620-0037 9/19

05P00620-0041

05P00620-0042 15/32

05P00620-0046 15/32

05P00620-0047 16/34

05P00620-0050 19/41

05P00620-0051 21/46

05P00620-0055 20/45

05P00620-0058 20/43

05P00620-0059 23/51

05P00620-0062 32/51

05P00620-0066 21/47

05P00620-0067 28/61

05P00620-0073 31/68

05P00620-0077 25/56

05P00620-0078 33/72

05P00620-0083

05P00620-0088 59/129

05P00620-0092 66/145

05P00620-0096

05P00620-0100 145/319

05P00620-0104 13 158/349

URX000204

URX000206 27/59

URX000248 30/65

URX000249

URX000250 50/111

URX000409

URX000410 3.9/8.7

Cabinet Reference (Figure)

9

10

11

12

10

11

9

Weight

kg/lb

5/11

13/23

49/107

119/262

21/47

49/107

3.9/8.6

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 31

Section: Power Options \ AC Enclosed Reactor Dimensions

Enclosed Type 1 Reactor

Part number

URX000411

URX000412 5.1/11.2

URX000413 4.4/9.7

URX000414 5.1/11.2

URX000415 4.4/9.8

URX000416 5.1/11.3

URX000417 6.4/14.1

URX000418

URX000419 11/25.2

URX000420 10/23.1

URX000421 12/27.5

URX000423 14/31

URX000424 14/31

URX000425 16/35

URX000426 16/36

URX000427 17/37

URX000428 14/40

URX000429 20/44

URX000430 24/52

URX000431

URX000432 28/62

URX000434 12 101/222

URX000502

URX000503 4.0/8.8

URX000504 4.4/9.8

URX000505 5.6/12.3

URX000551 3.9/8.6

URX000552 4.4/9.8

URX000553

URX000554 18/40

URX000555 20/44

URX000556 21/46

URX000557 25/55

URX000558 30/67

URX000559

URX000560 37/82

URX000561

URX000562 110/242

URX000563 119/262

URX000564 131/288

Cabinet Reference (Figure)

9

10

11

9

10

11

12

Weight

kg/lb

4.0/8.8

10/22.2

28/61

3.9/8.6

17/38

34/76

100/220

32 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ AC Enclosed Reactor Dimensions

Enclosed Type 1 Reactor

Part number

URX000565 12 147/323

URX000568 10 13/28

URX000569

URX000570 3.9/8.6

URX000571 3.9/8.6

URX000572 3.9/8.7

URX000573 4.4/9.7

URX000574 5/11.1

URX000575

URX000576 16/36

URX000577 19/42

URX000583

URX000584 3.9/8.6

URX000585 3.9/8.6

Cabinet Reference (Figure)

9

10

9

Weight

kg/lb

3.9/8.7

13/28.4

3.9/8.5

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 33

Section: Power Options \ Dynamic Braking Options

Dynamic Braking Options

Additional Information

Braking Resistor Specifications Braking Resistor Drawings

Braking Connection Diagrams

10% Dynamic Braking Options

Dynamic Braking Resistor, 10% Duty Cycle - are rated for 10% duty cycle over a 100 second interval. The resistors will achieve a minimum

150% peak braking torque for heavy duty horsepower ratings and a minimum of 100% peak braking power for normal duty horsepower

ratings. These resistors are designed for separate panel mounting.

Table 20: 240 Volt 10% Dynamic Braking Options

10% Dynamic Braking Option (maximum 10 second on-time)

Catalog

Normal Duty HP Heavy Duty HP

0.75 0.75 2004. . .

1.5 1 2006. . . URS000276 1 125 101 GCE1

2 1.5 2008. . . URS000277 1 85 151 GCE1

3 2 2010. . . URS000278 1 63 201 GCE1

4 3 2012. . . URS000279 1 42 302 GCE1

5 4 2018. . . URS000368 1 34 373 GCE1

7.5 5 2021. . . URS000280 1 25 504 GCE2

10 7.5 2030. . . URS000269 1 19 671 GCE2

15 10 2042. . . URS000282 1 12.6 1007 GCE3

20 15 2056. . . URS000369 1 9.2 1492 GCE4

25 20 2070. . . URS000370 1 6.9 1865 GCE6

30 25

40 30 2110. . . URS000372 1 4.6 2984 GCE6

50 40

Code

GA80U . .

2082. . .

2138. . .

1

1

Transistor Module Resistor Resistor Specifications

Part Number Quantity Part Number Quantity Resistance Watts Enclosure

URS000275 1 170 76 GCE1

Built-in

URS000371 1 6.6 2238 GCE6

URS000373 1 4.2 3730 GCE9

34 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ 10% Dynamic Braking Options

10% Dynamic Braking Option (maximum 10 second on-time)

Catalog

Normal Duty HP Heavy Duty HP

60 50 2169. . . CDBR-21100D 1 URS000100 1 2.1 5250 GCE9

75 60 2211. . . CDBR-21100D 1 URS000100 1 2.1 5250 GCE9

100 75 2257. . . CDBR-21100D 1 URS000096 1 1.6 6553 GCE12

125 100 2313. . .

150 125 2360. . .

150 150 2415. . . CDBR-21100D 2 URS000097 1 2 x 1.6 2 x 6553 GCE24

1. The resistor used for models 2082 & 2138 achieve a minimum of 125% peak braking torque for heavy duty horsepower ratings and a minimum of 100%

peak braking power for normal duty horsepower ratings.

Code

GA80U . .

Transistor Module Resistor Resistor Specifications

Part Number Quantity Part Number Quantity Resistance Watts Enclosure

CDBR-21100D 1 URS000096 1 1.6 6554 GCE12

CDBR-20220D 1 URS000128 1 6.8 1740 GCE6

CDBR-21100D 1 URS000096 1 1.6 6554 GCE12

CDBR-20220D 2 URS000129 1 2 x 6.8 2 x 1740 GCE2

Table 21: 480 Volt 10% Dynamic Braking Options

10% Dynamic Braking Option (maximum 10 second on-time)

Normal Duty HP Heavy Duty HP

1 0.75 4002. . .

2 1.5 4004. . . URS000241 1 375 134 GCE1

3 2 4005. . . URS000253 1 250 201 GCE1

4 3 4007. . . URS000254 1 170 302 GCE1

5 4 4009. . . URS000375 1 138 373 GCE1

7.5 5 4012. . . URS000255 1 100 504 GCE2

10 7.5 4018. . . URS000256 1 67 755 GCE3

15 10 4023. . . URS000257 1 50 1007 GCE3

20 15 4031. . . URS000258 1 34 1511 GCE4

25 20 4038. . . URS000259 1 25 1865 GCE6

30 25 4044. . . URS000376 1 22.2 2238 GCE6

40 30 4060. . . URS000377 1 18.5 2984 GCE8

50 40 4075. . . URS000378 1 13.9 3730 GCE6

60 50 4089. . . URS000379 1 11.1 4476 GCE9

75 60 4103. . . URS000380 1 9.2 5595 GCE12

100 75 4140. . . URS000381 1 7.4 7460 GCE15

125 100 4168. . . URS000382 1 5.6 9325 GCE18

150 125 4208. . . CDBR-42200D 1 URS000119 1 4.2 10500 GCE18

200 150 4250. . . CDBR-42200D 1 URS000165 1 3.2 13107 GCE24

Catalog

Code

GA80U . .

Transistor Module Resistor Resistor Specifications

Part Number Quantity Part Number Quantity Resistance Watts Enclosure

URS000374 1 740 76 GCE1

Built-in

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 35

Normal Duty HP Heavy Duty HP

Catalog

Code

GA80U . .

Section: Power Options \ 10% Dynamic Braking Options

10% Dynamic Braking Option (maximum 10 second on-time)

Transistor Module Resistor Resistor Specifications

Part Number Quantity Part Number Quantity Resistance Watts Enclosure

250 200 4302. . .

300 250 4371. . .

350 300 4414. . . CDBR-42200D 2 URS000166 1 2 x 3.2 2 x 13107 ED3

400 350 4477. . . CDBR-42200D 2 URS000166 1 2 x 3.2 2 x 13107 ED3

450 400 4568. . .

500 450 4605. . . CDBR-42200D 3 URS000167 1 3 x 3.2 3 x 13107 ED4

600 500 4720. . . CDBR-42200D 3 URS000167 1 3 x 3.2 3 x 13107 ED4

CDBR-42200D 1 URS000165 1 3.2 13107 GCE24

CDBR-40450D 1 URS000142 1 13.6 3481 GCE6

CDBR-42200D 1 URS000165 1 3.2 13107 GCE24

CDBR-40450D 2 URS000143 1 2 x 13.6 2 x 3481 GCE18

CDBR-42200D 2 URS000120 1 2 x 4.2 2 x 10500 ED2

CDBR-42200D 1 URS000165 1 3.2 13107 GCE24

36 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ 3% Dynamic Braking Options

3% Dynamic Braking Options

3% Duty cycle resistors are rated for a 3% duty cycle at 100 second intervals.

Table 22: 240 Volt 3% Dynamic Braking Options

Normal Duty HP Heavy Duty HP

1 0.75 2004. . . R7506 1 300 150

1.5 1 2006. . . R7505 1 200 150

2 1.5 2008. . . R7504 1 100 150

3 2 2010. . . R7504 1 100 150

4 3 2012. . . R7510 1 62 150

5 4 2018. . . R7510 1 62 150

7.5 5 2021. . . R7510 2 62 150

These resistors offer approximately 100% peak braking power.

Catalog Code

GA80U . .

Table 23: 480 Volt 3% Dynamic Braking Options

Normal Duty HP Heavy Duty HP

1 0.75 4002. . . R7508 1 750 150

2 1.5 4004. . . R7507 1 400 150

3 2 4005. . . R7505 1 200 150

4 3 4007. . . R7505 1 200 150

5 4 4009. . . R7505 1 200 150

7.5 5 4012. . . R7504 1 100 150

These resistors offer approximately 100% peak braking power.

Catalog Code

GA80U . .

Resistor

Part Number Quantity Ohms (each) Watts (each)

Resistor

Part Number Quantity Ohms (each) Watts (each)

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 37

Table 24: Resistor Mounting Adapter

Part Number Description

900-192-126-001

s

DD.GCE.01 DD.ED.01

Section: Power Options \ 3% Dynamic Braking Options

For use with Drive Models 2004ABM - 2042ABM and 4002ABM - 4023ABM

Mounting bracket for 3% Dynamic Braking Resistors

Resistor Mounting Adapter

Dimension Drawings

Figure 14: ED Type Enclosure

38 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ 3% Dynamic Braking Options

FRONT VIEW

TOP VIEW

RESISTOR COMPARTMENT

CONDUIT KNOCKOUT

Figure 15: GCE Type Enclosure

Table 25: ED Type Enclosure Dimensions (Figure. 14)

Model

ED1 10

ED2 16

ED3 24

ED4 32

ED5 40

ED6 48

ED7 56

ED8 84

ED9 72

Dimensions (in)

Height

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 39

Section: Power Options \ 3% Dynamic Braking Options

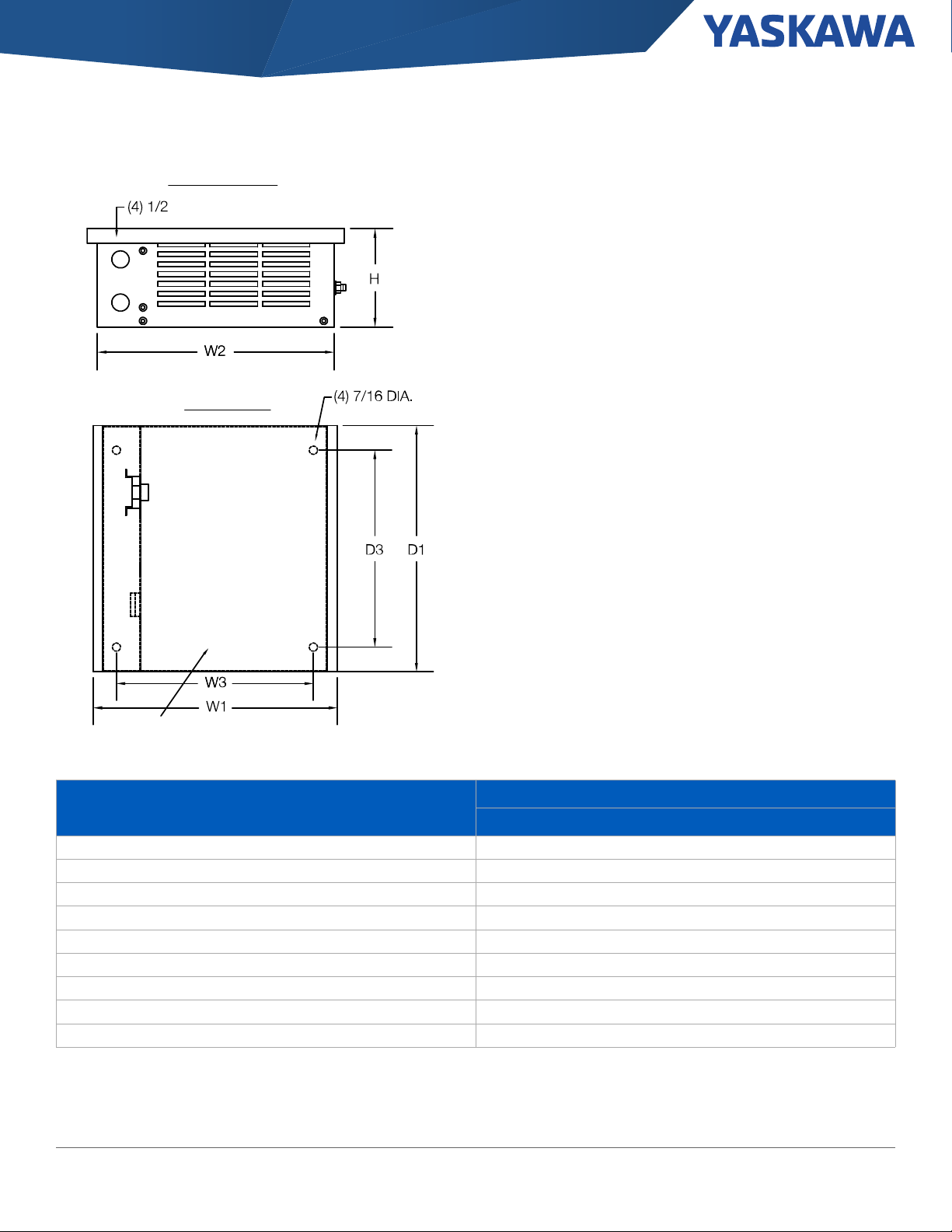

Table 26: GCE Type Enclosure Dimensions (Figure. 15)

Model

W1 W2 W3 D1 D2 D3 H

GCE1 12.5 12 10.5 5.13 5 - 5

GCE2 12.5 12 10.5 7.13 7 4.5 5

GCE3 12.5 12 10.5 10.13 10 7.5 5

GCE4 12.5 12 10.5 13.13 13 10.5 5

GCE5 12.5 12 10.5 16.13 16 13.5 5

GCE6 19.5 19 17.5 10.13 10 7.5 5

GCE8 19.5 19 17.5 13.13 13 10.5 5

GCE9 27 26.5 25 10.13 10 7.5 5

GCE10 19.5 19 17.5 16.13 16 13.5 5

GCE12 27 26.5 25 13.13 13 10.5 5

GCE15 27 26.5 25 10.13 16 13.5 5

GCE18 28.5 28 26.5 10.13 10 7.5 10

GCE24 28.5 28 26.5 13.13 13 10.5 10

GCE30 28.5 28 26.5 16.13 16 13.5 10

Dimensions (in)

40 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ Dynamic Braking Transistor Modules

Dynamic Braking Transistor Modules

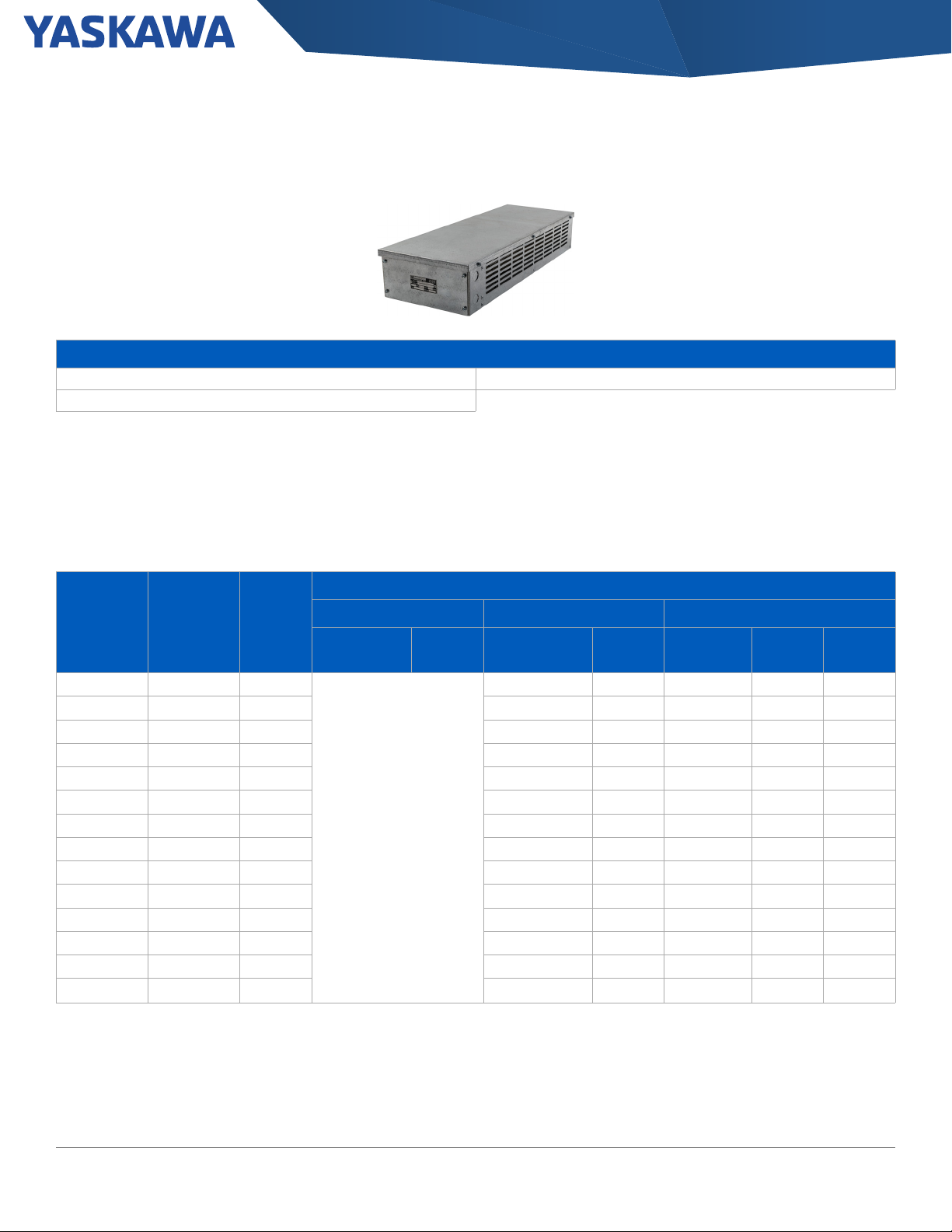

The Dynamic Brake Module is an economical solution for braking applications that do not result in large amounts of annual energy cost. Ratings

are available from 22 kW to 220 kW.

Additional Information

Brake Module Product Page Brake Module Drawings

Manual Brochure

Table 27: Brake Modules

Voltage Rating Model Number

CDBR-20220D 20 60

240 Vac

460 Vac

CDBR-20370D 24 80 5 38 150x120x157 IP20

CDBR-20550D 40 120 3.8 64 235x160x186 IP00

CDBR-21100D 80 250 1.6 152 294x175x200 IP00

CDBR-40300D 15 40

CDBR-40450D 18 60 13.4 36 150x120x157 IP20

CDBR-40900D 30 100 8 51 235x160x186 IP00

CDBR-42200D 80 250 3.2 152 294x175x200 IP00

1. Based on 10% duty, maximum 10 seconds.

Current Rating

(Amps)

Table 28: Type 1 Adapters

Voltage Rating Model Number Part Number

230 Vac

460 Vac

Current

Rating (Amps

1

Peak)

Power Supply

Vdc

240 to 400 Vdc

Peak

460 to 800 Vdc

Peak

CDBR-20220D

CDBR-20370D

CDBR-20550D EZZ022490B

CDBR-21100D EZZ022490C

CDBR-40300D

CDBR-40450D

CDBR-40900D EZZ022490B

CDBR-42200D EZZ022490C

Minimum

Connectible

Resistance

(Ohms)

6.7 27 150x120x157 IP20

20 24 150x120x157 IP20

Heat Loss (W)

Dimensions

H x W x D mm

EZZ022490A

EZZ022490A

Enclosure

Ratings

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 41

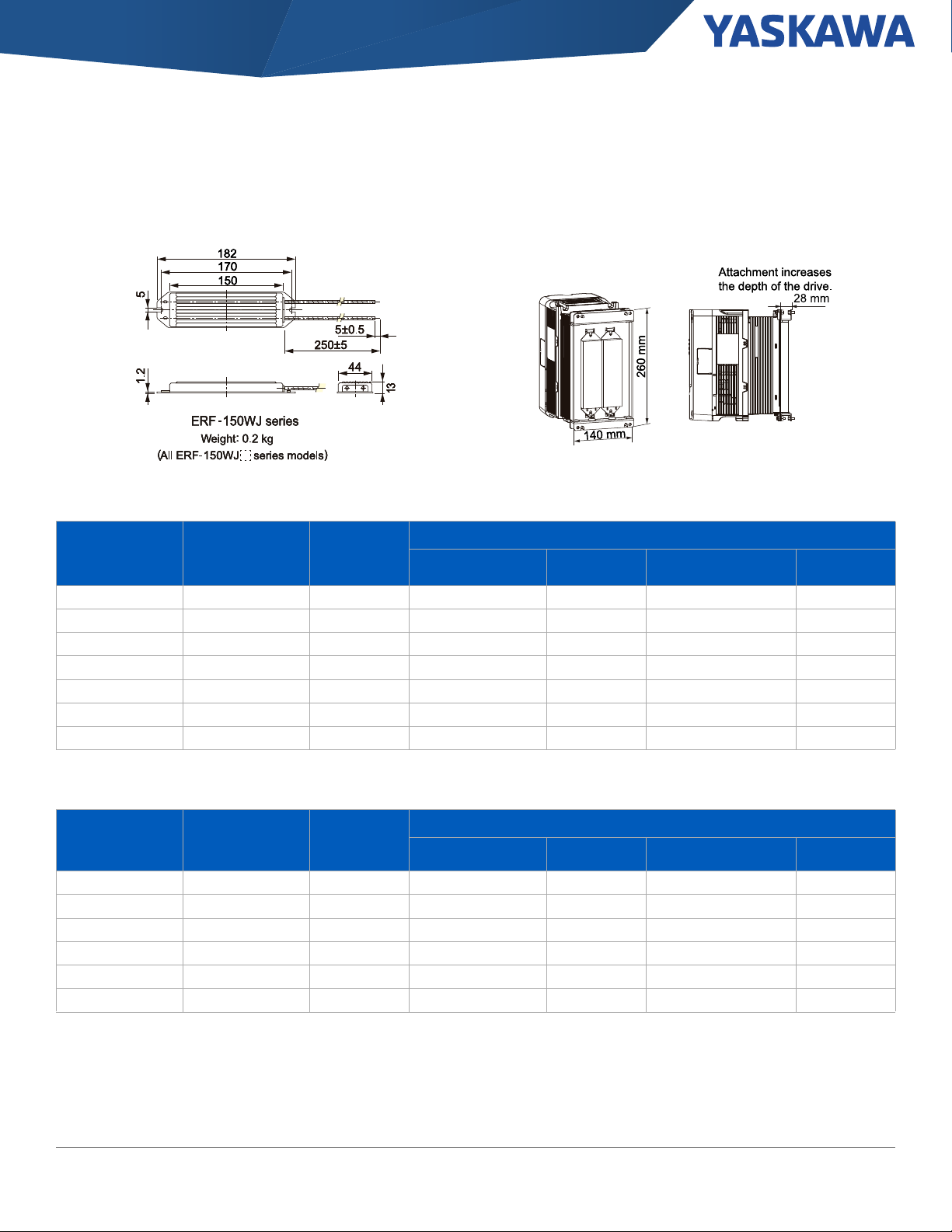

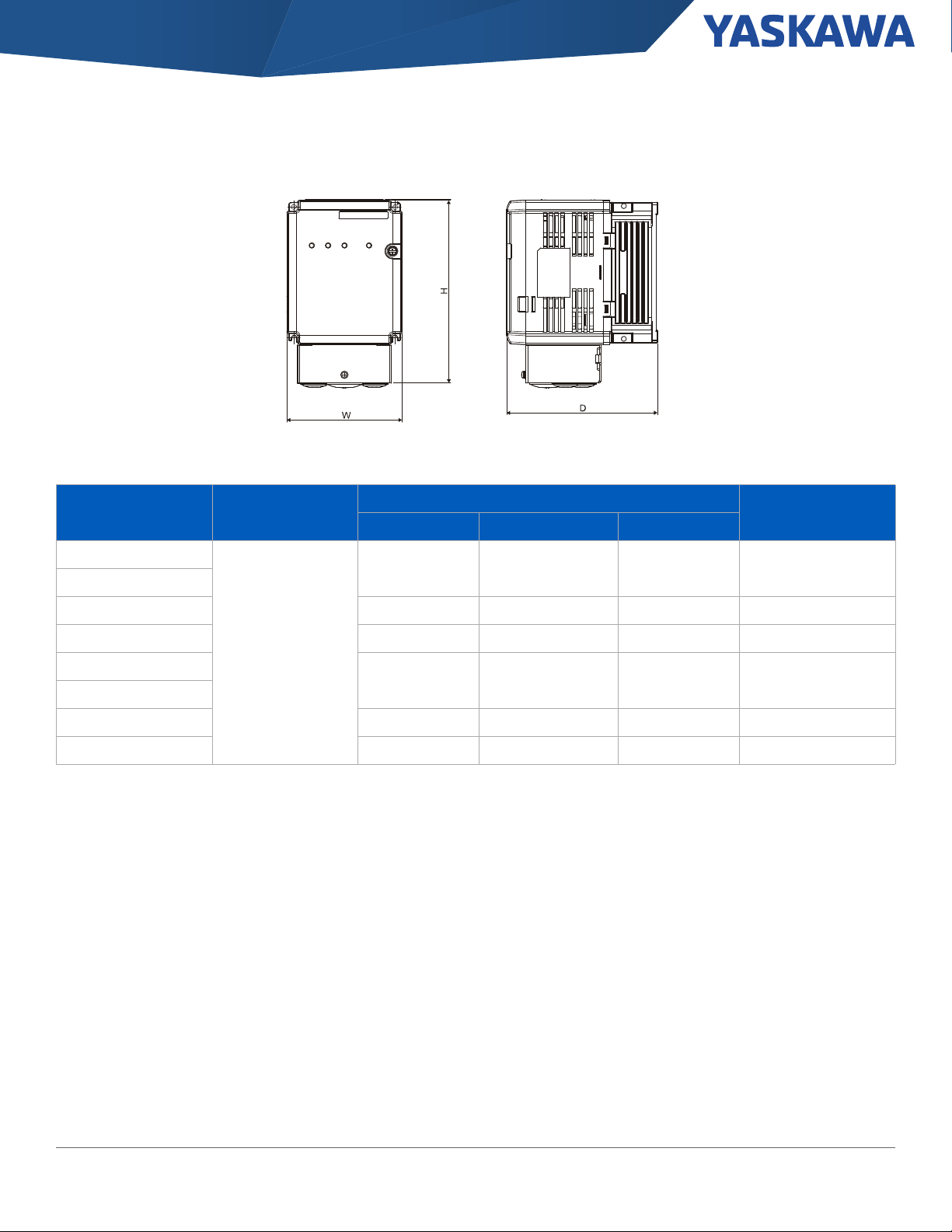

Table 29: Brake Unit (IP20) Dimensions

Model

CDBR-

Figure

Section: Power Options \ Dynamic Braking Transistor Modules

Figure 16: Open Type Chassis Dimensions

Dimensions (mm/in)

W H D

Weight

kg/lb

2022D

2037D

4030D

4045D

16 120 /4.72 150/5.91 157/6.18 2/4.4

Table 30: Brake Unit (IP00) Dimensions

Model

CDBR-

2055D

2110D 175/6.89 294/11.57 200/7.87 7.5/16.53

4090D 160/6.30 235/9.25 185.9/7.32 5.5/12.13

4220D 175/6.89 294/11.57 200/7.87 7.5/16.53

Figure

16

Dimensions (mm/in)

W H D

160/6.30 235/9.25 185.9/7.32 5.5/12.13

Weight

kg/lb

42 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ Dynamic Braking Transistor Modules

Figure 17: Type 1 Dimensions

Table 31: Brake Unit (Type 1) Dimensions

Model

CDBR-

Figure

W H D

Dimensions (mm/in)

Weight

kg/lb

2022D

2037D

2055D 165/6.50 250/9.84 185.9/7.32 5.9/13.01

2110D 180/7.09 367/14.45 200/7.87 8.3/18.30

17

4030D

4045D

4090D 165/6.50 250/9.84 185.9/7.32 5.9/13.01

4220D 180/7.09 367/14.45 200/7.87 8.3/18.30

120/4.72 190/7.48 157/6.18 2.3/5.07

120/4.72 190/7.48 157/6.18 2.3/5.07

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 43

Section: Power Options \ R1000 Regenerative Systems

R1000 Regenerative Systems

Additional Information

R1000 Online Resources

• Compatible with all conventional drives having full power access

Flyer Manual

• 0.9 Power Factor at full load

to DC bus

• Overload capability of 150% for 30 seconds

• Rated for 100% power, 25% duty cycle (60 seconds maximum

on time), or 80% continuous

• Overcurrent and Overheat Protection

Each R1000 regenerative unit requires the following:

• R1000: The R1000 regenerative module is used to divert energy

generated by the motor back onto the line for use by other

loads. The energy is directed back onto the line by taking DC

voltage from the drive running the motor and converting it into a

three phase AC voltage waveform.

• Power Coordination Reactor: The power coordination

reactor provides impedance to limit peak current. The power

coordination reactor represents minimum impedance required

to limit current to levels acceptable to the R1000.

• Fuses and Fuse Holder: Recommended fusing and their

corresponding holder(s) is provided for device protection and

UL certification.

• Current Suppression Reactor: The current suppression

reactor provides impedance to protect the connected drive's

input section from peak current that may result from the R1000

IGBT switching section. The current suppression reactor

provides isolation from the dv/dt of the R1000 switching

section.

Typical Applications

Stopping Cyclic Loading Continuous Regeneration

Elevators and Lifts Presses Winders

Centrifuges Dryers Downhill Conveyors

Saws Vibratory Equipment Dynamometers

Large Fans

Machine Tool Spindles

44 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ R1000 Regenerative Systems

Table 32: 240 Volt R1000 Regenerative Systems

Motor

Power

HP

5 2012. . . 2018. . .

Catalog Code

GA80U . .

Normal

Duty

Heavy

Duty

R1000 Part Number

CIMR-RU__

2A03P5FAA

1 2

1

Current Suppression

Reactor

Part Number

05P00620-0134 05P00620-0136 FU-002031 FU-002055

Power Coordination

Reactor

Part Number

Fuses

( Quantity: 3)

Part Number

Fuse Holder

Part Number Quantity

2A0005FAA

1

URX000083 05P00620-0138 FU-002031 FU-002055

7.5 2021. . . 2030. . .

10 2030. . . 2042. . .

15 2042. . . 2056. . .

20 2056. . . 2070. . .

25 2070. . . 2082. . .

30 2082. . . 2100. . .

40 2110. . . 2138. . .

50 2138. . . 2169. . .

60 2169. . . 2211. . .

2A0007FAA

2A0010FAA

2A0014FAA

2A0017FAA

2A0020FAA

2A 0028FAA

2A0035AAA

2A0053AAA

1

1

1

1

1

1

2

2

URX000083 05P00620-0044 FU-002032 FU-002055

05P00620-0044 05P00620-0140 UFU000153 FU-002082

05P00620-0141 05P00620-0141 UFU000479 FU-002082

05P00620-0143 05P00620-0143 UFU000154 FU-002083

URX000085 05P00620-0143 UFU000155 FU-002083

URX000085 05P00620-0013 UFU000156 FU-002083

05P00620-0064 05P00620-0070 UFU000156 FU-002083

URX000086 05P00620-0146 UFU000494 FU-002083

75 2211. . . 2257. . .

100 2257. . . 2313. . .

125 2313. . . 2360. . .

2A0073AAA

2A0105AAA

2

2

URX000175 URX000175 UFU000375 UFU000378

URX000178 URX000181 UFU000376 UFU000122

150 2360. . . 2415. . .

1. Type 1 / IP20 enclosure is standard for CIMR-RU2A03P5FAA through CIMR-RU2A0028FAA

2. Open-Type / IP00 enclosure is standard for CIMR-RU2A0035AAA through CIMR-RU2A0105AAA

16 2018. . . 2021. . .

3

GA800 Selection Guide SL.GA800.01, Yaskawa America, Inc. 45

Section: Power Options \ R1000 Regenerative Systems

Table 33: 480 Volt R1000 Regenerative Systems

Motor

Power

HP

Catalog Code

GA80U . .

Normal

Duty

Heavy Duty

5 4009. . . 4012. . .

7.5 4012. . . 4018. . .

10 4018. . . 4023. . .

15 4023. . . 4031. . .

20 4031. . . 4038. . .

25 4038. . . 4044. . .

30 4044. . . 4060. . .

40 4060. . . 4075. . .

50 4075. . . 4089. . .

60 4089. . . 4103. . .

75 4103. . . 4140. . .

100 4140. . . 4168. . .

125 4168. . . 4208. . .

150 4208. . . 4250. . .

R1000 Part Number

CIMR-RU__

4A03P5FAA

4A0005FAA

4A0007FAA

4A0010FAA

4A0014FAA

4A0017FAA

4A0020FAA

4A0028FAA

4A0035AAA

4A0043AAA

4A0053AAA

4A0073AAA

4A0105AAA

1 2

1

1

1

1

1

1

1

1

2

2

2

2

2

Current Suppression

Reactor

Part Number

Power Coordination

Reactor

Part Number

Fuses

(Quantity: 3)

Part Number

Part

Number

05P00620-0025 05P00620-0133 FU-002030 FU-002055

05P00620-0133 05P00620-0135 FU-002030 FU-002055

05P00620-0135 05P00620-0137 FU-002030 FU-002055

05P00620-0137 05P00620-0138 FU-002032 FU-002055

URX000083 05P00620-0139 FU-002032 FU-002082

05P00620-0044 05P00620-0139 FU-000783 FU-002082

05P00620-0049 05P00620-0049 FU-000783 FU-002082

05P00620-0142 05P00620-0142 UFU000480 FU-002082

05P00620-0144 05P00620-0144 FU-000806 FU-002084

05P00620-0143 05P00620-0144 FU-000807 FU-002084

URX000085 05P00620-0145 FU-000809 FU-002084

05P00620-0064 05P00620-0070 FU-000809 FU-002084

05P00620-0075 05P00620-0146 UFU000374 UFU000378

Fuse Holder

Quantity

1

3

200 4250. . . 4302. . .

4A0150AAA

2

URX000175 URX000176 UFU000375 UFU000378

250 4302. . . 4371. . .

300 4371. . . 4414. . .

4A0210AAA

2

URX000181 URX000182 UFU000376 UFU000122

350 4414. . . 4477. . .

400 4477. . . 4568. . .

4A0300AAA

2

URX000088 05P00620-0094 UFU000377 UFU000122450 4568. . . 4605. . .

500 4605. . . 4720. . .

1. Type 1/ IP20 enclosure is standard for CIMR-RU4A03P5FAA through CIMR-RU4A0028FAA

2. Open-Type / IP00 enclosure is standard for CIMR-RU4A0035AAA through CIMR-RU4A0300AAA

3

46 Yaskawa America, Inc., GA800 Selection Guide SL.GA800.01

Section: Power Options \ R1000 Regenerative Systems

Table 34: R1000 Reactor Dimensions (Open Type)

Dimensions

Reactor

Part Number

05P00620-0013 130 0.20 180 229/9 183/7.2 172/6.8 93/3.66 92/3.63 28/62

05P00620-0025 8 5.0 25.3 152/6.0 122/4.8 86/3.4 67/2.62 51/2.00 5.0/11

05P00620-0044 35 0.4 49 183/7.2 147/5.8 102/4.0 66/2.60 76/3.00 6.4/14

05P00620-0049 45 0.7 62 229/9.0 188/7.4 119/4.7 80/3.16 76/3.00 13/28

05P00620-0064 130 0.10 108 229/9.0 179/7.1 118/4.7 80/3.16 76/3.00 13/29

05P00620-0070 160 0.150 149 274/10.8 277/8.3 152/6 88/3.47 92/3.63 23/51

05P00620-0075 200 0.055 124 229/9 191/7.5 185/7.3 106/4.16 92/3.63 22/49

05P00620-0094 500 0.050 340 366/14.4 292/11.5 292/11.5 172/6.76 117/4.60 82/180

05P00620-0133 8 3.0 29 152/6.0 122/4.8 76/3.0 53/2.10 51/2.00 3.6/8

05P00620-0134 12 1.25 26 152/6.0 127/5.0 84/3.3 53/2.10 51/2.00 4.1/9

05P00620-0135 12 2.5 31 152/6.0 127/5.0 84/3.3 53/2.10 51/2.00 4.5/10

05P00620-0136 18 0.8 36 152/6.0 135/5.3 81/3.2 54/2.10 51/2.00 4.1/9

05P00620-0137 18 1.5 43 152/6.0 135/5.3 89/3.5 63/2.48 51/2.00 5.5/12