Page 1

GA500

Industrial AC Microdrive

Maintenance & Troubleshooting

Catalog Code: GA50Uxxxxxxxx

240 V Single-Phase Input: 1/6 to 5 HP

240 V Three-Phase Input: 1/6 to 30 HP

480 V Three-Phase Input: 1/2 to 40 HP

Page 2

This Page Intentionally Blank

2 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 3

Table of Contents

1. Periodic Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Recommended Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4 Replace Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Number of Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replace the Cooling Fan (Procedure A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Replace the Cooling Fan (Procedure B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.5 Replace the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

About the Control Circuit Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replace the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.6 Storage Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2 Types of Faults, Minor Faults, Alarms, and Errors. . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3 List of Fault, Minor Fault, Alarm, and Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4 Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.5 Minor Faults/Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.6 Parameter Setting Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.7 Auto-Tuning Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.8 Backup Function Operating Mode Display and Errors . . . . . . . . . . . . . . . . . . . . . 74

2.9 Diagnosing and Resetting Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Fault Occurs Without Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Fault Occurs Without Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Fault Reset Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.10 Troubleshooting Without Fault Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Typical Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

The Parameter Settings Will Not Change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

The Motor Does Not Rotate after You Enter a Run Command . . . . . . . . . . . . . . . . . . . . . 79

The Motor Rotates in the Opposite Direction from the Run Command . . . . . . . . . . . . . . 80

The Motor Rotates in Only One Direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

The Motor Is Too Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

The Correct Auto-Tuning Mode Is Not Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

The Motor Stalls during Acceleration or Accel/Decel Time Is Too Long . . . . . . . . . . . . . . 81

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 3

Page 4

The Drive Frequency Reference Is Different than the Controller Frequency Reference

Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

The Motor Speed Is Not Stable When Using a PM Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

There Is Too Much Motor Oscillation and the Rotation Is Irregular . . . . . . . . . . . . . . . . . . . . . . 82

Deceleration Takes Longer Than Expected When Dynamic Braking Is Enabled . . . . . . . . . . 82

There Is Audible Noise from the Drive or Motor Cables When the Drive Is Energized . . . . . . 83

The Ground Fault Circuit Interrupter (GFCI) Trips During Run . . . . . . . . . . . . . . . . . . . . . . . . . 83

Motor Rotation Causes Unexpected Audible Noise from Connected Machinery . . . . . . . . . . 83

Motor Rotation Causes Oscillation or Hunting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

PID Output Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

The Starting Torque Is Not Sufficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

The Motor Rotates after the Drive Output Is Shut Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

The Output Frequency Is Lower Than the Frequency Reference. . . . . . . . . . . . . . . . . . . . . . . 84

The Motor Will Not Restart after a Loss of Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3. Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.2 How to Read the Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Icons and Terms that Identify Parameters and Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.3 Parameter Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

3.4 A: Initialization Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A1: Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

A2: User Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.5 b: Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

b1: Operation Mode Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

b2: DC Injection Braking and Short Circuit Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

b3: Speed Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

b4: Timer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

b5: PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

b6: Dwell Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

b8: Energy Saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.6 C: Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

C1: Accel & Decel Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

C2: S-Curve Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

C3: Slip Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

C4: Torque Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

C5: Automatic Speed Regulator (ASR: Automatic Speed Regulator) . . . . . . . . . . . . . . . . . . 104

C6: Duty & Carrier Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.7 d: Reference Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

d1: Frequency Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

d2: Reference Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

d3: Jump Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

d4: Frequency Ref Up/Down & Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

d6: Field Weakening /Forcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

d7: Offset Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.8 E: Motor Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

E1: V/f Pattern for Motor 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

E2: Motor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

E3: V/f Pattern for Motor 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

E4: Motor 2 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

E5: PM Motor Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

E9: Motor Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

3.9 F: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 5

F1: Fault Detection in PG Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

F6: Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

F7: Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.10 H: Terminal Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

H1: Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

H2: Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

H3: Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

H4: Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

H5: Modbus Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

H6: Pulse Train Input/Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

H7: Virtual MFIO selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.11 L: Protection Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

L1: Motor Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

L2: Power Loss Ride Through. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

L3: Stall Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

L4: Speed Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

L5: Fault Restart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

L6: Torque Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

L7: Torque Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

L8: Drive Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

3.12 n: Special Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

n1: Hunting Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

n2: Auto Freq Regulator (AFR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

n3: High Slip/Overexcite Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

n5: Feed Forward Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

n6: Online Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

n7: EZ Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

n8: PM Motor Control Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

nA: PM Motor Control Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

3.13 o: Keypad-Related Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

o1: Keypad Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

o2: Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

o3: Copy Keypad Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

o4: Maintenance Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

o5: Log Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

3.14 q: DriveWorksEZ Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

q1-01 to qx-xx: Reserved for DriveWorksEZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3.15 r: DWEZ Connection 1-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

r1-01 to r1-40: DriveWorksEZ Connection Parameters 1 to 20 (Upper / Lower) . . . . . . . . . . 159

3.16 T: Motor Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

T0: Tuning Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

T1: Induction Motor Auto-Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

T2: PM Motor Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

T3: ASR and Inertia Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

T4: EZ Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

3.17 U: Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

U1: Operation Status Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

U2: Fault Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

U3: Fault History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

U4: Maintenance Monitors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

U5: PID Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

U6: Operation Status Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

U8: DriveWorksEZ Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 5

Page 6

3.18 Parameters that Change from the Default Settings with A1-02 [Control Method

Selection]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.19 Parameters that Change from the Default Settings with E3-01 [Motor 2 Control

Mode Selection] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

3.20 Parameters Changed by E1-03 [V/f Pattern Selection] . . . . . . . . . . . . . . . . . . . . . . . 180

3.21 Defaults by Drive Model and Duty Rating ND/HD. . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

3.22 Parameters Changed by PM Motor Code Selection. . . . . . . . . . . . . . . . . . . . . . . . . . 194

Yaskawa SMRA Series SPM Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Yaskawa SMRD Series SPM Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Yaskawa SSR1 Series IPM Motors (Derated Torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4. Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

4.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

4.2 Removing/Reattaching Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Remove the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Reattach the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

4.3 Remove and Reattach the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Remove the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Reattach the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

5. Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

5.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

5.2 Standard Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

5.3 Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Motor and Main Circuit Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Main Circuit Terminal Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

5.4 Control Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Control Circuit Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Control Circuit Terminal Block Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Control Circuit Terminal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Switches and Jumpers on the Terminal Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

5.5 Control I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Pulse Train Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Set Sinking Mode/Sourcing Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Set the Input Signal for the MFAI Terminal A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Set the Output Signal for the MFAO Terminal AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Switch ON Termination Resistor for MEMOBUS/Modbus Communications . . . . . . . . . . . . . 228

5.6 Connect the Drive to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

6. Startup Procedure and Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

6.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

6.2 Overview of Keypad Components and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Indicator flashing statuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Keypad Mode and Menu Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Set up the Drive with General-Purpose Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Change Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Verify and Set the Changed Parameters (Verify Menu). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

6 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 7

How to Switch between LOCAL and REMOTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

6.3 Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Digital character mapping table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Show the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Check Modified Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Set and View Necessary Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Change Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Save a Backup of Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Write Backed-up Parameters to the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Verify Keypad Parameters and Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Delete Parameters Backed Up to the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

6.4 Automatic Parameter Settings Optimized for Specific Applications (Application

Presets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

6.5 Auto-Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Auto-Tuning for Induction Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Auto-Tuning for PM Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Auto-Tuning in EZ Open Loop Vector Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

ASR and Inertia Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Precautions before Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

7. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

7.1 Drive Duty Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

7.2 Model-Specific Specifications (Single-Phase 200 V Class) . . . . . . . . . . . . . . . . . . . . 255

7.3 Model Specifications (Three-Phase 200 V Class) . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

7.4 Model-Specific Specifications (Three-Phase 400 V Class) . . . . . . . . . . . . . . . . . . . . 259

7.5 Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

7.6 Drive Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Carrier Frequency Settings and Rated Current Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Derating Depending on Ambient Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Altitude Derating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

8. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

8.1 Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

8.2 Disposal Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

8.3 WEEE Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

9. Preface and General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

9.1 Receiving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

About Registered Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

9.2 Using the Product Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Explanation of Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 7

Page 8

8 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 9

1

Periodic Inspection and Maintenance

This chapter gives information about how to examine and maintain drives in use, how to replace

cooling fans and other parts, and how to store drives.

1.1 Section Safety ........................................................................................................... 10

1.2 Inspection................................................................................................................... 12

1.3 Maintenance .............................................................................................................. 15

1.4 Replace Cooling Fans ............................................................................................. 17

1.5 Replace the Drive ..................................................................................................... 23

1.6 Storage Guidelines .................................................................................................. 27

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 9

Page 10

1.1 Section Safety

1.1 Section Safety

DANGER

Electrical Shock Hazard

Do not examine, connect, or disconnect wiring on an energized drive. Before servicing, disconnect

all power to the equipment and wait for the time specified on the warning label at a minimum. The

internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF,

measure for dangerous voltages to make sure that the drive is safe.

If you do work on the drive when it is energized, it will cause serious injury or death from electrical shock.

Disconnect all power to the drive and wait for the time specified on the warning label before you

remove covers. Check the drive for dangerous voltages before servicing or repair work.

If you do work on the drive when it is energized and there is no cover over the electronic circuits, it will cause

serious injury or death from electrical shock. The drive has internal capacitors that stay charged after you deenergize the drive.

WARNING

Electrical Shock Hazard

The motor will run after you de-energize the drive. PM motors can generate induced voltage to the

terminal of the motor after you de-energize the drive.

If you touch a motor that is moving or energized, it can cause serious injury or death.

Do not operate the drive when covers are missing. Replace covers and shields before you operate

the drive. Use the drive only as specified by the instructions.

Some figures in this section include drives without covers or safety shields to more clearly show the inside of the

drive. If covers or safety shields are missing from the drive, it can cause serious injury or death.

Always ground the motor-side grounding terminal.

If you do not ground the equipment correctly, it can cause serious injury or death if you touch the motor case.

Only let approved personnel install, wire, maintain, examine, replace parts, and repair the drive.

If personnel are not approved, it can cause serious injury or death.

Do not wear loose clothing or jewelry when you do work on the drive. Tighten loose clothing and

remove all metal objects, for example watches or rings.

Loose clothing can catch on the drive and jewelry can conduct electricity and cause serious injury or death.

Fire Hazard

Tighten all terminal screws to the correct tightening torque.

Connections that are too loose or too tight can cause incorrect operation and damage to the drive. Incorrect

connections can also cause death or serious injury from fire.

Damage to Equipment

Do not apply incorrect voltage to the main circuit of the drive. Operate the drive in the specified

range of the input voltage on the drive nameplate.

Voltages that are higher than the permitted nameplate tolerance can cause damage to the drive.

Fire Hazard

Do not put flammable or combustible materials on top of the drive and do not install the drive near

flammable or combustible materials. Attach the drive to metal or other noncombustible material.

Flammable and combustible materials can start a fire and cause serious injury or death.

10 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 11

1.1 Section Safety

WARNING

Electrical Shock Hazard

Do not modify the drive body or drive circuitry.

Modifications to drive body and circuitry can cause serious injury or death, will cause damage to the drive, and will

void the warranty. Yaskawa is not responsible for modifications of the product made by the user.

Sudden Movement Hazard

Make sure that you align the phase order for the drive and motor when you connect the motor to

drive output terminals U/T1, V/T2, and W/T3.

If the phase order is incorrect, it can cause the motor to run in reverse. If the motor accidentally runs in reverse, it

can cause serious injury or death.

CAUTION

Burn Hazard

Do not touch a hot drive heatsink. De-energize the drive, wait for a minimum of 15 minutes, then

make sure that the heatsink is cool before you replace the cooling fans.

If you touch a hot drive heatsink, it can burn you.

NOTICE

Damage to Equipment

When you touch the drive and circuit boards, make sure that you observe correct electrostatic

discharge (ESD) procedures.

If you do not follow procedures, it can cause ESD damage to the drive circuitry.

Use the instructions in this manual to replace the cooling fans. When you do maintenance on the

fans, replace all the fans to increase product life.

If you install the fans incorrectly, it can cause damage to the drive.

Make sure that all connections are correct after you install the drive and connect peripheral

devices.

Incorrect connections can cause damage to the drive.

Do not energize and de-energize the drive more frequently than one time each 30 minutes.

If you frequently energize and de-energize the drive, it can cause drive failure.

Do not operate a drive or connected equipment that has damaged or missing parts.

You can cause damage to the drive and connected equipment.

Note:

Do not use unshielded cable for control wiring. Use shielded, twisted-pair wires and ground the shield to the ground terminal of the drive.

Unshielded wire can cause electrical interference and unsatisfactory system performance.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 11

Page 12

1.2 Inspection

1.2 Inspection

Power electronics have limited life and can show changes in performance and deterioration of performance after years

of use in usual conditions. To help prevent these problems, it is important to do preventive maintenance and regular

inspection, and replace parts on the drive.

Drives contain different types of power electronics, for example power transistors, semiconductors, capacitors,

resistors, fans, and relays. The electronics in the drive are necessary for correct motor control.

Follow the inspection lists in this chapter as a part of a regular maintenance program.

Note:

Examine the drive one time each year at a minimum.

The operating conditions, environmental conditions, and use conditions will have an effect on the examination frequency for connected

equipment.

Examine the drive more frequently if you use the drive in bad conditions or in these conditions:

• High ambient temperatures

• Frequent starting and stopping

• Changes in the AC power supply or load

• Too much vibration or shock loading

• Dust, metal dust, salt, sulfuric acid, or chlorine atmospheres

• Unsatisfactory storage conditions.

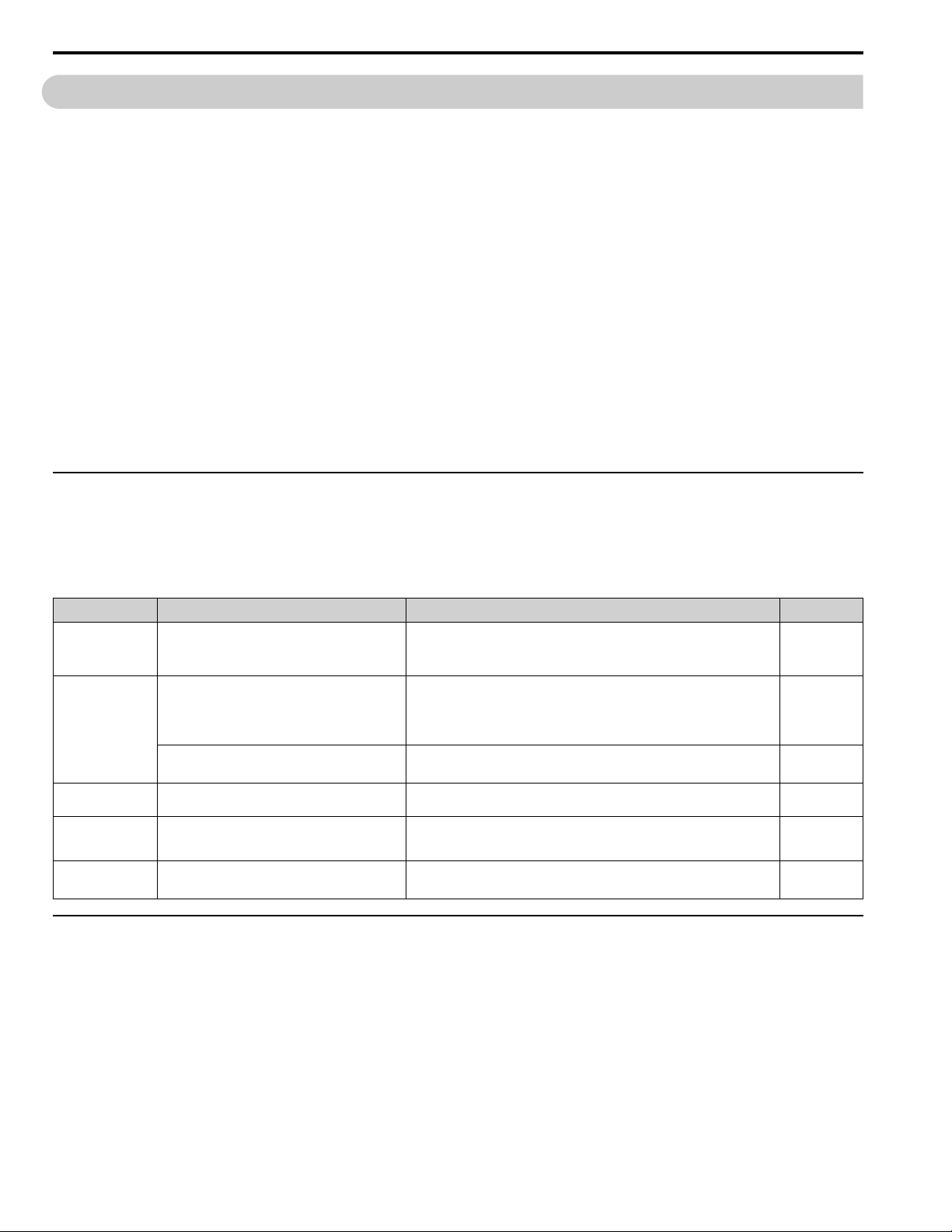

◆ Recommended Daily Inspection

Table 1.1 gives information about the recommended daily inspection for Yaskawa drives. Examine the items in Table

1.1 each day to make sure that the components do not wear out or fail. Make a copy of this checklist and put a check

mark in the “Checked” column after each inspection.

Table 1.1 Daily Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Motor

Cooling System

Surrounding

Environment

Load

Power Supply Voltage Examine main power supply and control voltages.

Examine for unusual oscillation or noise coming from

the motor.

Examine for unusual heat from the drive or motor and

visible discoloration.

Examine the cooling fans.

Make sure that the installation environment is

applicable.

Make sure that the drive output current is not more

than the motor or drive rating for an extended period of

time.

• Check the load coupling.

• Measure motor vibration.

• Tighten all loose components.

• Check for a load that is too heavy.

• Tighten loose screws.

• Check for a dirty heatsink or motor.

• Measure the ambient temperature.

• Check for a clogged or dirty fan.

• Use the performance life monitor to check for correct fan operation.

Remove the source of contamination or correct unsatisfactory environment.

• Check for a load that is too heavy.

• Check the correct motor parameter settings.

• Correct the voltage or power supply to agree with nameplate specifications.

• Verify all main circuit phases.

◆ Recommended Periodic Inspection

Table 1.2 to Table 1.6 give information about the recommended periodic inspections for Yaskawa drives. Examine the

drive one time each year at a minimum. The operating conditions, environmental conditions, and use conditions will

have an effect on the examination frequency for connected equipment. You must use your experience with the

application to select the correct inspection frequency for each drive installation. Periodic inspections will help to

prevent performance deterioration and product failure. Make a copy of this checklist and put a check mark in the

“Checked” column after each inspection.

12 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 13

1.2 Inspection

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below 50

Vdc. When all indicators are OFF, measure for dangerous voltages to make sure that the drive is safe. If you do work on the drive

when it is energized, it will cause serious injury or death from electrical shock.

Table 1.2 Main Circuit Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

General

Conductors and

Wiring

Terminal Block

Electromagnetic

Contactors and

Relays

Dynamic Braking

Option

Electrolytic Capacitor

Diodes, IGBT (Power

Transistor)

• Examine equipment for discoloration from too

much heat or deterioration.

• Examine for damaged parts.

Examine for dirt, unwanted particles, or dust on

components.

• Examine wiring and connections for discoloration

or damage. Examine wiring and connections for

discoloration from too much heat.

• Examine wire insulation and shielding for

discoloration and wear.

Examine terminals for stripped, damaged, or loose

connections.

• Examine contactors and relays for too much noise

during operation.

• Examine coils for signs of too much heat, such as

melted or broken insulation.

Examine the insulation for discoloration from too

much heat.

• Examine for leaks, discoloration, or cracks.

• Examine if the cap has come off, if there is

swelling, or if there are leaks from broken sides.

Examine for dust or other unwanted material collected

on the surface.

• Replace damaged components as necessary.

• The drive does not have many serviceable parts and it could be necessary to

replace the drive.

• Examine enclosure door seal.

• Use a vacuum cleaner to remove unwanted particles and dust without touching

the components.

• If you cannot remove unwanted particles and dust with a vacuum cleaner,

replace the components.

Repair or replace damaged wiring.

• Tighten loose screws.

• Replace damaged screws.

• Check coil voltage for overvoltage or undervoltage conditions.

• Replace broken relays, contactors, or circuit boards that you can remove.

If there is discoloration in the option, check to make sure that there is not damage to

the wiring. A small quantity of discoloration is not a problem.

The drive does not have many serviceable parts and it could be necessary to replace

the drive.

Use a vacuum cleaner to remove unwanted particles and dust without touching the

components.

Table 1.3 Motor Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Operation Check Check for increased vibration or unusual noise. Stop the motor and contact approved maintenance personnel as necessary.

Table 1.4 Control Circuit Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

• Tighten loose screws.

• Replace damaged screws or terminals.

• If terminals are integral to a circuit board, it could be necessary to replace the

control board or the drive.

• Tighten loose connections.

• Use a vacuum cleaner to remove unwanted particles and dust without touching

the components.

• If you cannot remove unwanted particles and dust with a vacuum cleaner,

replace the components.

• Do not use solvents to clean the board.

• The drive does not have many serviceable parts and it could be necessary to

replace the drive.

General

Circuit Boards

• Examine terminals for stripped, damaged, or loose

connections.

• Make sure that all terminals have been correctly

tightened.

• Check for odor, discoloration, or rust.

• Make sure that all connections are correctly

fastened.

• Make sure that the surface of the circuit board does

not have dust or oil mist.

Table 1.5 Cooling System Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Cooling Fan

Heatsink

Air Duct

• Check for unusual oscillation or unusual noise.

• Check for damaged or missing fan blades.

• Examine for dust or other unwanted material

collected on the surface.

• Examine for dirt.

Examine air intake, exhaust openings and make sure

that there are no unwanted materials on the surface.

Clean or replace the fans as necessary.

Use a vacuum cleaner to remove unwanted particles and dust without touching the

components.

Clear blockages and clean air duct as necessary.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 13

Page 14

1.2 Inspection

Table 1.6 Keypad Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

General

• Make sure that the keypad shows the data correctly.

• Examine for dust or other unwanted material that

collected on components in the area.

• If you have problems with the display or the keys, contact Yaskawa or your

nearest sales representative.

• Clean the keypad.

14 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 15

1.3 Maintenance

1.3 Maintenance

The drive Maintenance Monitors keep track of component wear and tell the user when the end of the estimated

performance life is approaching. The Maintenance Monitors prevent the need to shut down the full system for

unexpected problems. Users can set alarm notifications for the maintenance periods for these drive components:

• Cooling fan

• Electrolytic capacitor

• Soft charge bypass relay

• IGBT

Contact Yaskawa or your nearest sales representative for more information about part replacement.

◆ Replaceable Parts

You can replace these parts of the drive:

• Cooling fan

If there is a failure in the main circuit, replace the drive.

If the drive is in the warranty period, contact Yaskawa or your nearest sales representative before you replace parts.

Yaskawa reserves the right to replace or repair the drive as specified by the Yaskawa warranty policy.

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below 50

Vdc. When all indicators are OFF, measure for dangerous voltages to make sure that the drive is safe. If you do work on the drive

when it is energized, it will cause serious injury or death from electrical shock.

◆ Part Replacement Guidelines

Table 1.7 shows the standard replacement period for replacement parts. When you replace these parts, make sure that

you use Yaskawa replacement parts for the applicable model and design revision number of your drive.

Table 1.7 Standard Replacement Period

Parts Standard Replacement Period

Cooling fan 10 years

Electrolytic capacitor

*1 If there is damage to parts that you cannot repair or replace, replace the drive.

Note:

Performance life estimate is based on these use conditions. These conditions are provided for the purpose of replacing parts to maintain

performance. Some parts may require more frequent replacement due to poor environments or rigorous use. Operating conditions for

performance life estimate: Ambient temperature: Yearly average of 40 °C (IP20/UL Open Type), Load factor: 80%, Operating rate: 24 hours

a day

*1

10 years

◆ Monitors that Display the Lifespan of Drive Components

The drive keypad shows percentage values for the replacement parts to help you know when you must replace those

components. Use the monitors in Table 1.8 to check replacement periods. When the monitor value is 100%, the

component is at the end of its useful life and there is an increased risk of drive malfunction. Yaskawa recommends

that you check the maintenance period regularly to make sure that you get the maximum performance life.

Table 1.8 Performance Life Monitors

Monitor No. Parts Description

U4-03

U4-04

U4-05 Electrolytic Capacitor

Cooling fan

Shows the total operation time of fans as 0 to 99999 hours. After this value is 99999, the drive automatically resets it

to 0.

Shows the total fan operation time as a percentage of the specified maintenance period.

Shows the total capacitor usage time as a percentage of the specified maintenance period.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 15

Page 16

1.3 Maintenance

Monitor No. Parts Description

U4-06 Soft charge bypass relay

U4-07 IGBT

Shows the number of times the drive is energized as a percentage of the performance life of the inrush circuit.

Shows the percentage of the maintenance period for the IGBTs.

◆ Alarm Outputs for Maintenance Monitors

You can use H2-xx [MFDO Function Selection] to send a message that tells you when a specified component is near

the end of its performance life estimate. Set the applicable value to H2-xx as shown in Table 1.9 for your component.

When the specified component is near the end of its performance life estimate, the MFDO terminals set for H2-xx =

2F [Maintenance Notification] will activate, and the keypad will show an alarm that identifies the component to

replace.

Table 1.9 Maintenance Period Alarms

Display Alarm Name Cause Possible Solutions

LT-1

LT-2

LT-3

LT-4

TrPC

Cooling Fan

Maintenance Time

Capacitor Maintenance

Time

SoftChargeBypassRe

lay MainteTime

IGBT Maintenance

Time (50%)

IGBT Maintenance

Time (90%)

The cooling fan is at 90% of its expected

performance life.

The capacitors for the main circuit and control

circuit are at 90% of expected performance life.

The soft charge bypass relay is at 90% of its

performance life estimate.

The IGBT is at 50% of its expected performance

life.

The IGBT is at 90% of its expected performance

life.

Replace the cooling fan, then set o4-03 = 0 [Fan Operation

Time Setting = 0 h] to reset the cooling fan operation time.

Replace the board or the drive.

Contact Yaskawa or your nearest sales representative to

replace the board.

Replace the board or the drive.

Contact Yaskawa or your nearest sales representative to

replace the board.

Check the load, carrier frequency, and output frequency.

Replace the IGBT or the drive.

Digital Outputs

(Setting Value in

H2-xx)

2F

10

◆ Related Parameters

Replace the component, then set o4-03, o4-05, o4-07, and o4-09 [Maintenance Setting] = 0 to reset the Maintenance

Monitor. If these parameters are not reset after the corresponding parts have been replaced, the Maintenance Monitor

function will continue to count down the performance life from the value that was reached with the old part. If the

Maintenance Monitor is not reset, the drive will not have the correct value of the performance life for the new

component.

Note:

The maintenance period changes for different operating environments.

Table 1.10 Maintenance Setting Parameters

No. Name Function

o4-03 Fan Operation Time Setting Sets the value from which to start the cumulative drive cooling fan operation time in 10-hour units.

Note:

When o4-03 = 30 has been set, the drive will count the operation time for the cooling fan from 300 hours and

U4-03 [Cooling Fan Ope Time] will show 300 h.

o4-05

o4-07 Softcharge Relay Maintenance Set Sets as a percentage the value from which to start the count for the soft charge bypass relay maintenance time.

o4-09 IGBT Maintenance Setting Sets the value from which to start the count for the IGBT maintenance period as a percentage.

Capacitor Maintenance Setting Sets the value from which to start the count for the main circuit capacitor maintenance period as a percentage.

16 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 17

1.4 Replace Cooling Fans

1.4 Replace Cooling Fans

NOTICE: Use the instructions in this manual to replace the cooling fans. When you do maintenance on the fans, replace all the fans

to increase product life. If you install the fans incorrectly, it can cause damage to the drive.

To replace a cooling fan, contact Yaskawa or your nearest sales representative.

◆ Number of Cooling Fans

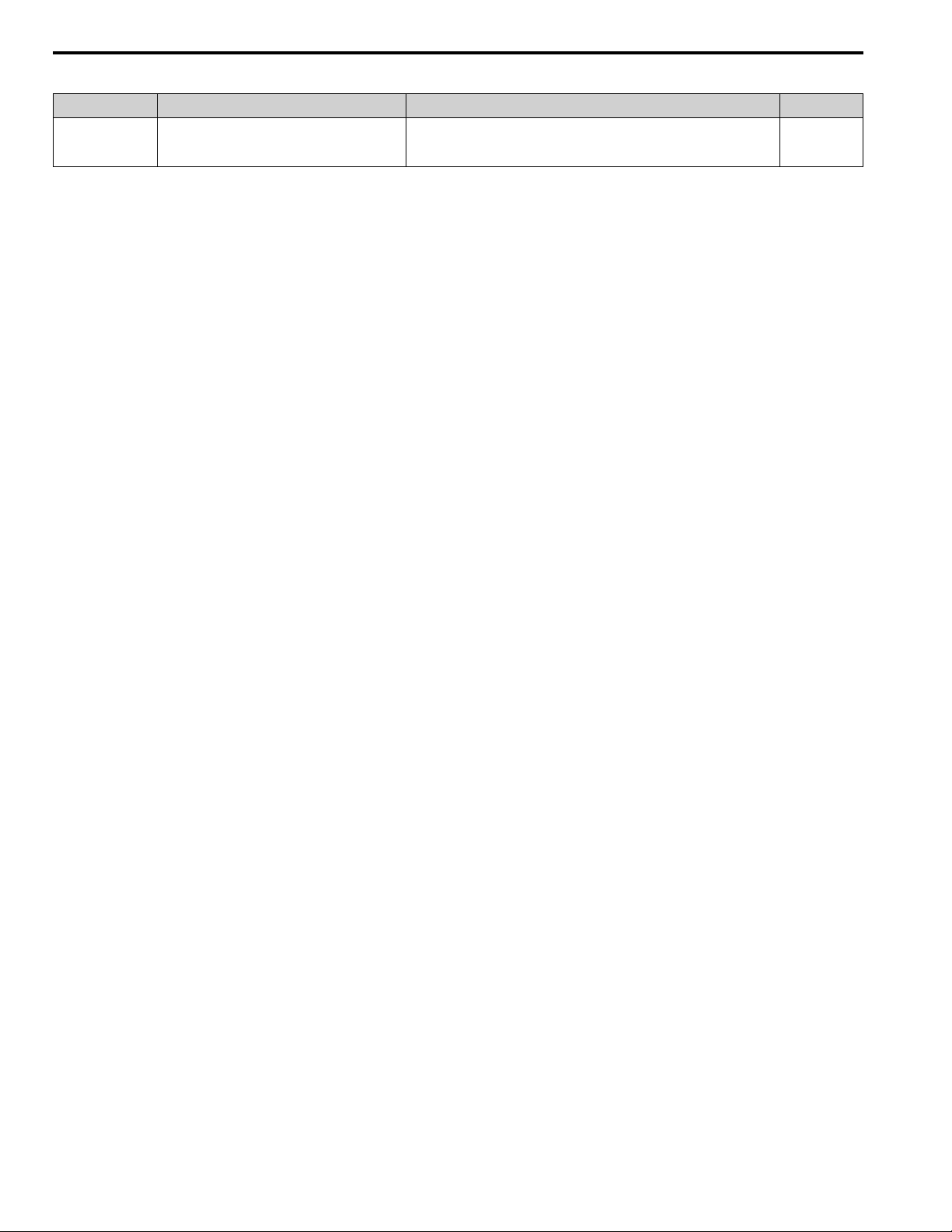

Table 1.11 Single-Phase 200 V Class

Model Cooling Fans Replacement Procedure Ref.

B001 - B006 -

B010, B012 1

B018 2 B

Table 1.12 Three-Phase 200 V Class

Model Cooling Fans Replacement Procedure Ref.

2001-2004 -

2006 - 2021 1 A

2030 1 B

2042 - 2082 2 A 17

- -

A

- -

17

17

20

Table 1.13 Three-Phase 400 V Class

Model Cooling Fans Replacement Procedure Ref.

4001 - 4004 -

4005 - 4012 1

4018, 4023 1 B

4031 - 4060 2 A 17

- -

A 17

20

◆ Replace the Cooling Fan (Procedure A)

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below 50

Vdc. When all indicators are OFF, measure for dangerous voltages to make sure that the drive is safe. If you do work on the drive

when it is energized, it will cause serious injury or death from electrical shock.

CAUTION! Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait for a minimum of 15 minutes, then make

sure that the heatsink is cool before you replace the cooling fans. If you touch a hot drive heatsink, it can burn you.

NOTICE: Use the instructions in this manual to replace the cooling fans. When you do maintenance on the fans, replace all the fans

to increase product life. If you install the fans incorrectly, it can cause damage to the drive.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 17

Page 18

1.4 Replace Cooling Fans

■ Remove a Fan

1. To remove the fan finger guard from the drive, push the hooks on the left and right sides of it and pull up.

A - Fan finger guard

Figure 1.1 Remove the Fan Finger Guard

2. Pull the cooling fan straight up from the drive. Disconnect the power supply connector and remove the fan

from the drive.

A - Cooling fan

Figure 1.2 Remove the Cooling Fan

■ Install a Fan

Reverse the removal procedure to install a cooling fan.

1. Connect the power supply connector between the drive and cooling fan.

Figure 1.3 Connect the Power Supply Connector

18 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 19

1.4 Replace Cooling Fans

2. Align the notches on the fan with the pins on the drive and install the cooling fans in the drive.

A - Alignment pins on drive

B - Front of drive

Figure 1.4 Install the Cooling Fan

Note:

When you install the cooling fan, make sure that you do not pinch cables between the cooling fan and the drive.

C - Notch on fan

3. Put the cable and connector in the recess of the drive.

A - Front of drive

Figure 1.5 Put the Cable and Connector in the Drive Recess

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 19

Page 20

1.4 Replace Cooling Fans

Note:

The connector installation position is different for different models.

Figure 1.6 Put the Connector in the Recess

Figure 1.7 Put the Connector in Between the Fans

Figure 1.8 Put the Connector in Between the Drive and Fan

4. Insert the fan cover straight until the hook clicks into place.

Figure 1.9 Reattach the Fan Finger Guard

5. Energize the drive and set o4-03 = 0 [Fan Operation Time Setting = 0 h] to reset the cooling fan operation

time.

◆ Replace the Cooling Fan (Procedure B)

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below 50

Vdc. When all indicators are OFF, measure for dangerous voltages to make sure that the drive is safe. If you do work on the drive

when it is energized, it will cause serious injury or death from electrical shock.

CAUTION! Burn Hazard. Do not touch a hot drive heatsink. De-energize the drive, wait for a minimum of 15 minutes, then make

sure that the heatsink is cool before you replace the cooling fans. If you touch a hot drive heatsink, it can burn you.

NOTICE: Use the instructions in this manual to replace the cooling fans. When you do maintenance on the fans, replace all the fans

to increase product life. If you install the fans incorrectly, it can cause damage to the drive.

20 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 21

1.4 Replace Cooling Fans

■ Remove a Fan

1. Push the tabs toward the back of the drive and pull up to remove the fan finger guard from the drive.

A - Fan finger guard

Figure 1.10 Remove the Fan Finger Guard

2. Pull the cooling fan straight up from the drive. Disconnect the power supply connector and remove the fan

from the drive.

A - Cooling fan

Figure 1.11 Remove the Cooling Fan

■ Install the Cooling Fans

Reverse the removal procedure to install a cooling fan.

1. Connect the power supply connector between the drive and cooling fan.

Figure 1.12 Connecting the power supply connector

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 21

Page 22

1.4 Replace Cooling Fans

2. Install the cooling fans so that they align with the pins on the drive.

A - Alignment pins on drive

B - Front of drive

Figure 1.13 Installing the cooling fans

Note:

When you install the cooling fan, make sure that you do not pinch cables between the cooling fan and the drive.

C - Notches

3. Put the cable and connector in the recess of the drive.

A - Front of drive

Figure 1.14 Putting the cable and connector in the recess

4. Insert the tabs of the fan cover into the holes in the drive and press in the fan cover until the hook clicks into

place.

Figure 1.15 Reattach the Fan Finger Guard

5. Energize the drive and set o4-03 = 0 [Fan Operation Time Setting = 0 h] to reset the cooling fan operation

time.

22 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 23

1.5 Replace the Drive

1.5 Replace the Drive

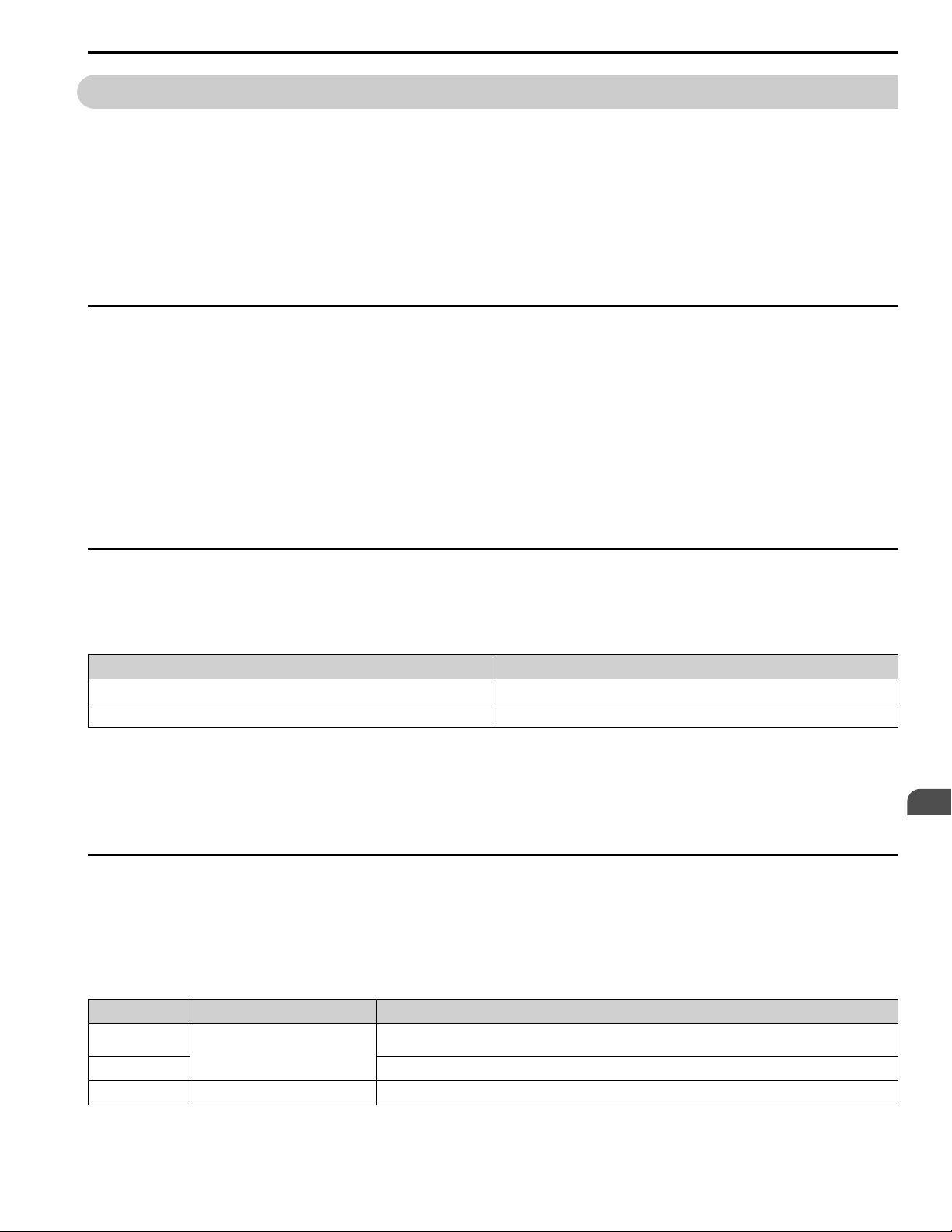

◆ About the Control Circuit Board

You can remove the control circuit board of the drive and install a new board. If there is a failure in the drive, you can

use this feature to easily replace the control circuit board.

A - Control circuit board

Figure 1.16 Control Circuit Terminal Block

◆ Replace the Drive

DANGER! Electrical Shock Hazard. Disconnect all power to the drive and wait for the time specified on the warning label before you

remove covers. Check the drive for dangerous voltages before servicing or repair work. If you do work on the drive when it is

energized and there is no cover over the electronic circuits, it will cause serious injury or death from electrical shock. The drive has

internal capacitors that stay charged after you de-energize the drive.

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases below 50

Vdc. When all indicators are OFF, measure for dangerous voltages to make sure that the drive is safe. If you do work on the drive

when it is energized, it will cause serious injury or death from electrical shock.

WARNING! Electrical Shock Hazard. Only let approved personnel install, wire, maintain, examine, replace parts, and repair the

drive. If personnel are not approved, it can cause serious injury or death.

NOTICE: Damage to Equipment. When you touch the drive and circuit boards, make sure that you observe correct electrostatic

discharge (ESD) procedures. If you do not follow procedures, it can cause ESD damage to the drive circuitry.

■ Notes on Wiring the Main Circuit Terminal Block

Read these notes before you wire the main circuit terminal block.

• Use UL-Listed, vinyl-coated insulated copper wires for operation with a continuous maximum permitted

temperature of 75 °C at 600 V.

• Remove all unwanted objects that are near the terminal block connections.

• Remove the insulation from the connection wires to the wire stripping lengths shown in the manual.

• Do not use bent or crushed wires. Remove the damaged end of the wire before you use it. Incorrect connections can

cause death or serious injury from fire.

• Do not solder stranded wire. Soldered wire connections can become loose over time and cause unsatisfactory drive

performance.

• If you use stranded wire, make sure that all of the wire strands are in the connection. Also, do not twist the stranded

wire too much. Incorrect connections can cause death or serious injury from fire.

• Put the wire all the way into the terminal block. Remove the insulation from the wire to the recommended wire

stripping length to fit the wire with insulation in the plastic housing.

• Use a torque driver, torque ratchet, or torque wrench for the screws. A slotted driver or a hex tool will be necessary

to wire the screw clamp terminal. Use applicable tools as specified by the recommended conditions in the product

manual.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 23

Page 24

1.5 Replace the Drive

• If you use power tools to tighten the terminal screws, use a low speed setting (300 to 400 r/min). Failure to obey can

cause damage to the terminal screws.

• Users can purchase wiring tools from Yaskawa. Contact Yaskawa or your nearest sales representative for more

information.

• Wire gauges on existing drive models to be replaced may not match wire gauge ranges on new drives. Contact

Yaskawa or your nearest sales representative for more information about the connection procedures.

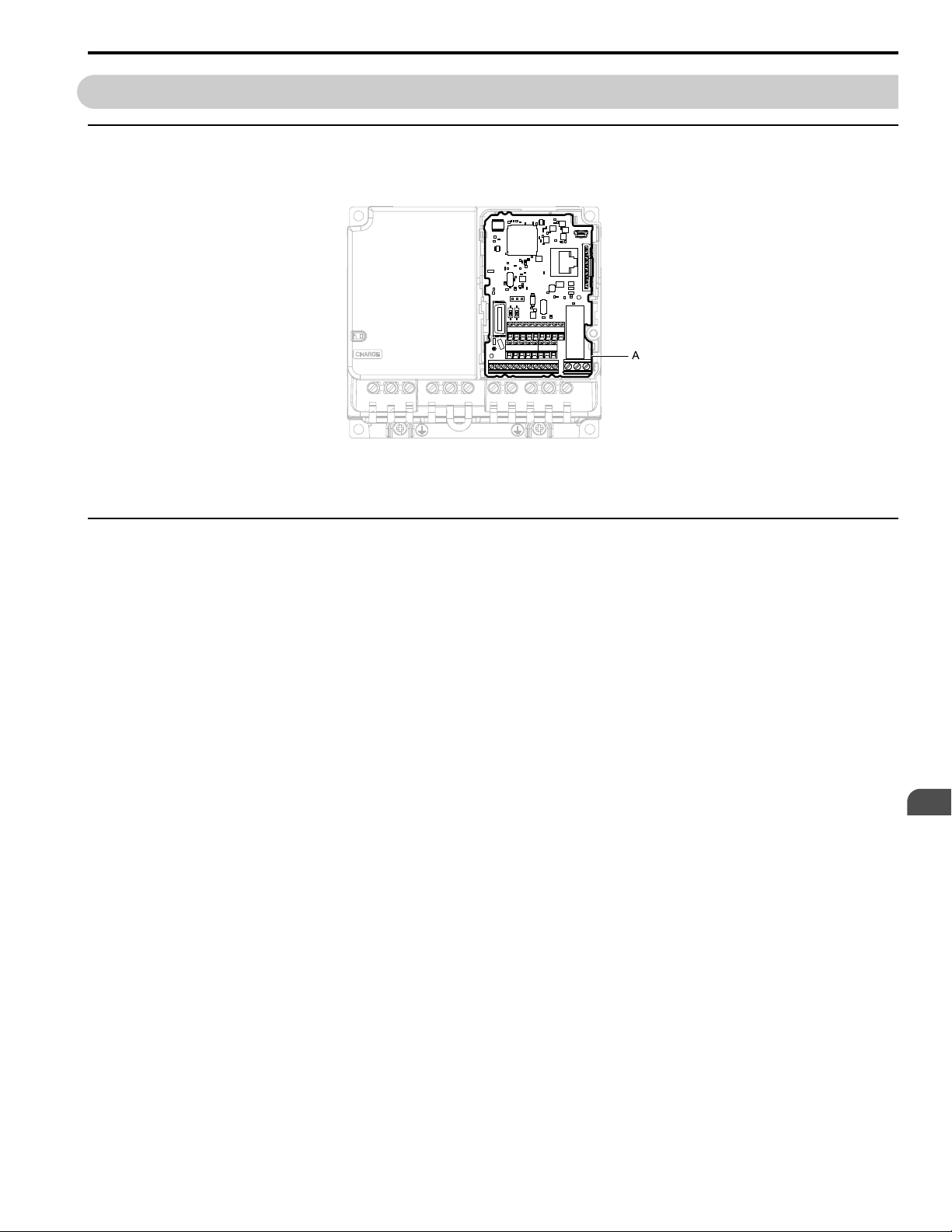

• Do not tighten the terminal screws at an angle of 5 degrees or more. Failure to obey can cause damage to the

terminal screws.

If you damage a terminal screw, contact Yaskawa or your nearest sales representative.

Figure 1.17 Permitted Angle

• Put the bit all the way into the hex socket to tighten the hex socket cap screw.

• When you tighten slotted screws, hold the straight-edge screwdriver perpendicularly to the screw. Make sure that

you align the end of the straight-edge screwdriver with the screw groove.

Figure 1.18 Tightening Slotted Screws

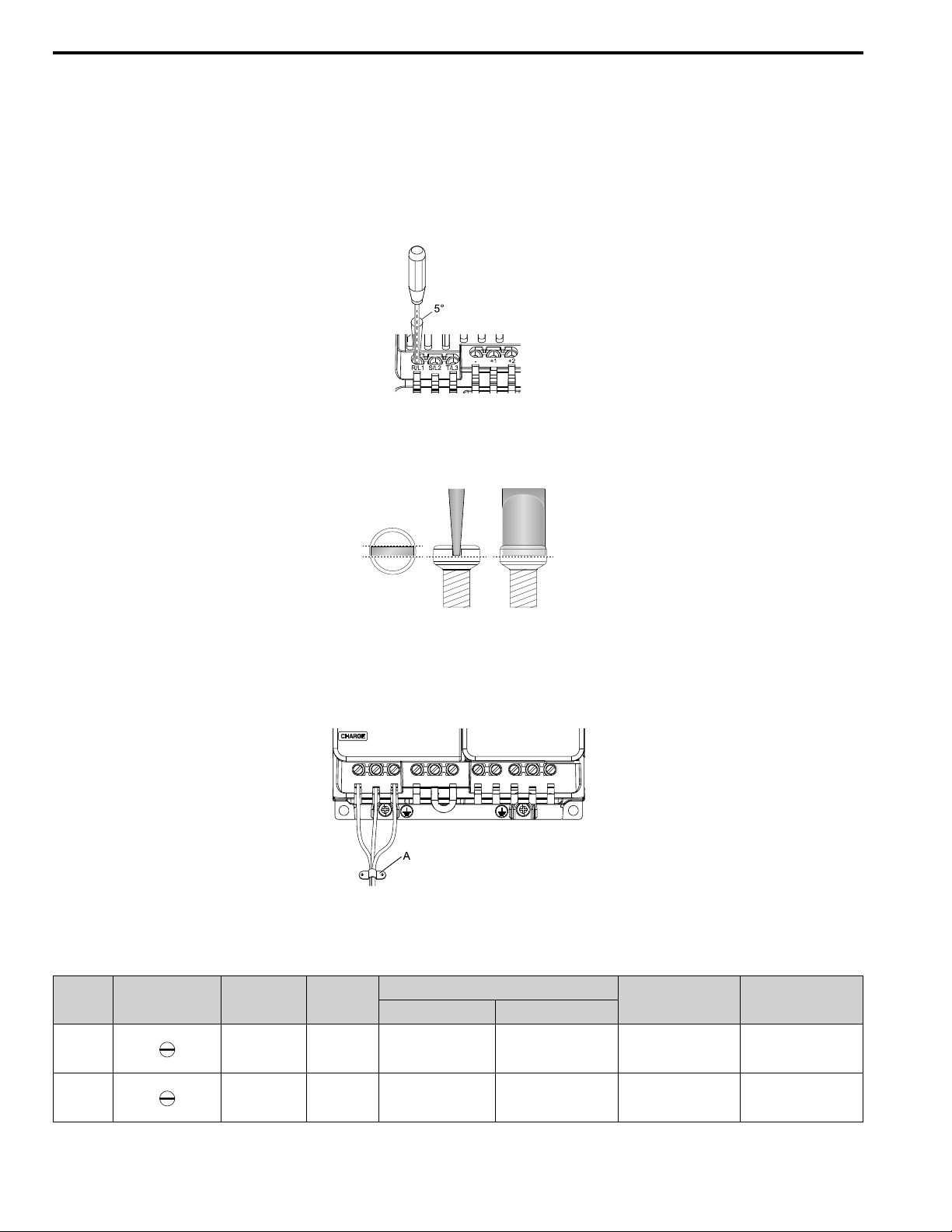

• After you connect the wires to the terminal block, lightly pull on the wires to make sure that they do not come out

of the terminals.

• Do not let strain on the wiring cause damage. Use a strain relief near the wiring to release the tension. Refer to

Figure 1.19 for an example.

A - Cable clamp

Figure 1.19 Strain Relief Example

Table 1.14 Recommended Wiring Tools

Screw

Size

M3 - Bit SF-BIT-SL 0,5X3,0-70 PHOENIX CONTACT

M4 - Bit SF-BIT-SL 1,0X4,0-70 PHOENIX CONTACT

Screw Shape Wire Gauge Adapter

Model Manufacturer

Bit

Torque Driver Model

(Tightening Torque)

TSD-M 1,2NM

(0.3 - 1.2 N∙m

(2.7 - 10.6 in∙lb))

TSD-M 3NM

(1.2 - 3.0 N∙m

(10.6 - 26.6 in∙lb))

Torque Wrench

(Tightening Torque)

-

-

24 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 25

1.5 Replace the Drive

Screw

Size

M5

M6

Screw Shape Wire Gauge Adapter

2

≤ 25 mm

*1

(WAF: 5 mm)

(AWG 10)

2

≥ 30 mm

(AWG 8)

- Bit SF-BIT-HEX 5-50 PHOENIX CONTACT -

Bit SF-BIT-SL 1,2X6,5-70 PHOENIX CONTACT

Model Manufacturer

Bit

Torque Driver Model

(Tightening Torque)

TSD-M 3NM

(1.2 - 3.0 N∙m

(10.6 - 26.6 in∙lb))

-

*1 When you wire drive models 2042, 2056, 4031, 4038, 4044, and 4060, select the correct tools for the wire gauge.

*2 Use 6.35 mm (0.25 in) bit socket holder.

*3 Use a torque wrench that can apply this torque measurement range.

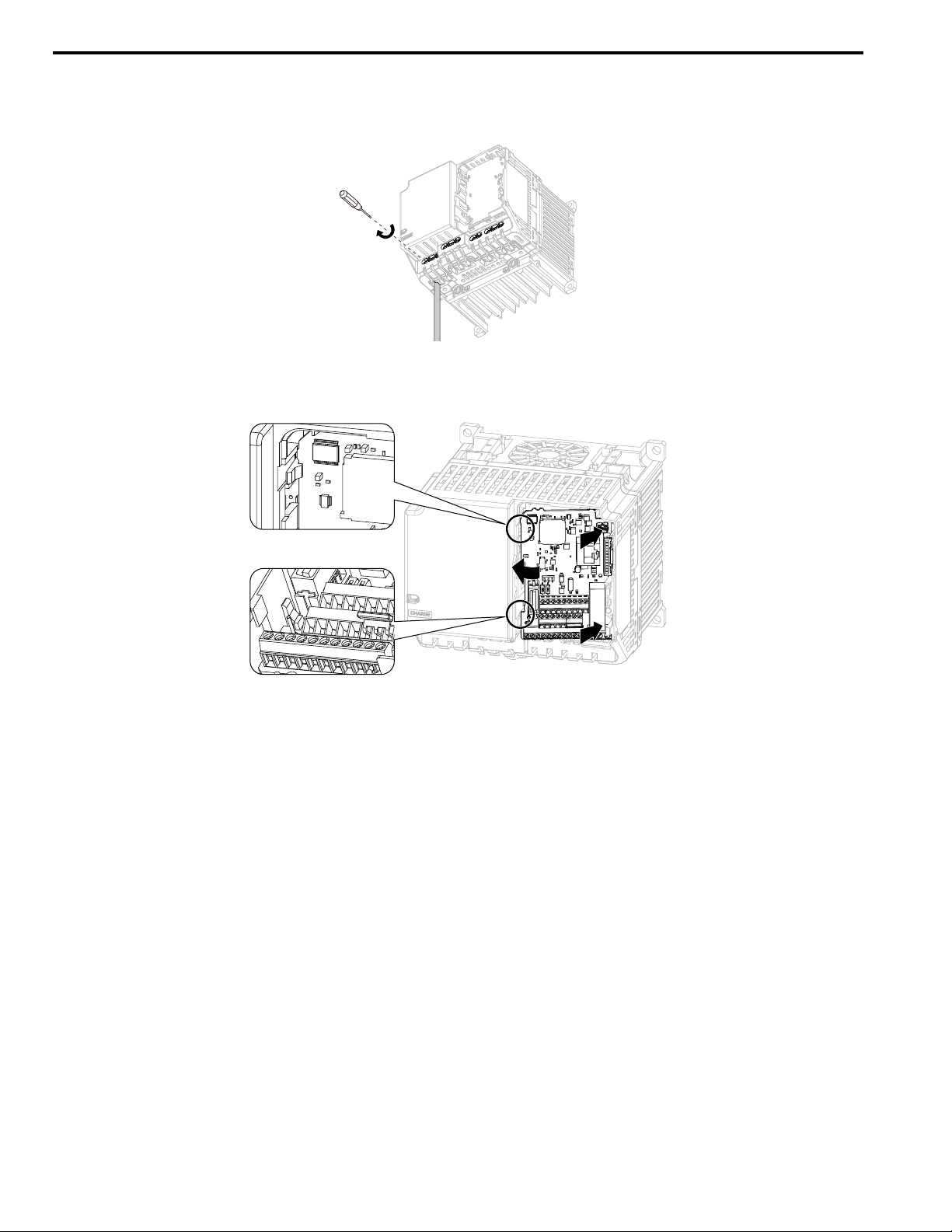

■ Remove the Control Circuit Board

Remove the front cover and keypad from the drive.

1. Push the tabs to the left that hold the control board to the drive.

Torque Wrench

(Tightening Torque)

-

4.1 - 4.5 N∙m

(36.3 - 39.8 in∙lb)

5 - 9 N∙m

(44.3 - 79.7 in∙lb)

*2 *3

*2 *3

Figure 1.20 Unhook the Tabs

2. Pull the left side of the control circuit board out first.

Figure 1.21 Remove the Control Circuit Board

■ Put the Control Circuit Board in a New Drive

Remove the keypad, front cover, and control circuit board of the new drive.

Wire the main circuit terminals of the new drive, then attach the wired control circuit board.

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 25

Page 26

1.5 Replace the Drive

1. Wire the main circuit terminals.

Note:

To wire terminals +1 and +2, remove the jumper between terminals +1 and +2.

Figure 1.22 Wire the Main Circuit Terminals

2. Attach the wired control circuit board to the drive.

Push the control circuit board until the hooks click into place on the drive.

Figure 1.23 Attach the Control Circuit Board

3. Attach the keypad and front cover to the new drive.

4. Energize the drive and set these parameters:

• o2-04 [Drive Model (KVA) Selection]: Set this parameter to the model number of the new drive.

• o4-01 to o4-13 [Maintenance Period]: Reset the performance life monitors for the components.

26 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 27

1.6 Storage Guidelines

1.6 Storage Guidelines

The chemicals in the electrolytic capacitors and other electronic parts of the drive change over time. When you store

the drive for long periods of time, use the information in this section to help keep the performance life estimates.

◆ Storage Location

• Temperature and Humidity

When you store the drive for approximately one month, for example during shipping, you can put the drive in a

location where the temperature is -20 °C to +70 °C (-4 °F to +158 °F). Correctly package and store the drive during

shipping to prevent vibration and impact damage.

Do not put the drive in direct sunlight or where there will be condensation or ice. Put the drive in a location where

the relative humidity is 95% or less.

• Dust and Oil Mist

Do not keep the drive locations with dust or oil mist. For example, cement factories and cotton mills.

• Corrosive Gas

Do not keep the drive in locations with corrosive gas. For example, chemical plants, refineries, and sewage plants.

• Salt Damage

Do not keep the drive in salty locations. For example, locations near the ocean, and salt damage-designated

locations.

Do not keep the drive in unsatisfactory locations. Keep all drives in storage rooms that are safe from unsatisfactory

elements.

◆ Regular Application of Power

To prevent deterioration of the capacitors, Yaskawa recommends that you apply power to the drive a minimum of one

time each year for a minimum of 30 minutes.

If you store the drive for longer than two years and do not apply power, Yaskawa recommends that you use a variable

power source and gradually increase the power from 0 V to the rated drive voltage over a period of 2 to 3 minutes.

Apply power for a minimum of 1 hour with no load to reform the main circuit electrolytic capacitor. When you

operate the drive after you apply power, wire the drive correctly and check for drive faults, overcurrents, motor

vibration, motor speed differences, and other defects during operation.

A - AC power supply

B - Variable power source

Figure 1.24 Power Distribution Method

C - Drive

Periodic Inspection and Maintenance

1

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 27

Page 28

1.6 Storage Guidelines

28 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 29

2

Troubleshooting

2.1 Section Safety ........................................................................................................... 30

2.2 Types of Faults, Minor Faults, Alarms, and Errors ..........................................32

2.3 List of Fault, Minor Fault, Alarm, and Error Codes..........................................33

2.4 Fault .............................................................................................................................38

2.5 Minor Faults/Alarms ................................................................................................55

2.6 Parameter Setting Errors........................................................................................ 65

2.7 Auto-Tuning Errors .................................................................................................. 70

2.8 Backup Function Operating Mode Display and Errors................................... 74

2.9 Diagnosing and Resetting Faults.........................................................................76

2.10 Troubleshooting Without Fault Display..............................................................78

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 29

Page 30

2.1 Section Safety

2.1 Section Safety

DANGER

Electrical Shock Hazard

Do not examine, connect, or disconnect wiring on an energized drive. Before servicing, disconnect

all power to the equipment and wait for the time specified on the warning label at a minimum. The

internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF,

measure for dangerous voltages to make sure that the drive is safe.

If you do work on the drive when it is energized, it will cause serious injury or death from electrical shock.

WARNING

Electrical Shock Hazard

Do not operate the drive when covers are missing. Replace covers and shields before you operate

the drive. Use the drive only as specified by the instructions.

Some figures in this section include drives without covers or safety shields to more clearly show the inside of the

drive. If covers or safety shields are missing from the drive, it can cause serious injury or death.

Always ground the motor-side grounding terminal.

If you do not ground the equipment correctly, it can cause serious injury or death if you touch the motor case.

After the drive blows a fuse or trips a GFCI, do not immediately energize the drive or operate

peripheral devices. Wait for the time specified on the warning label at a minimum and make sure

that all indicators are OFF. Then check the wiring and peripheral device ratings to find the cause of

the problem. If you do not know the cause of the problem, contact Yaskawa before you energize the

drive or peripheral devices.

If you do not fix the problem before you operate the drive or peripheral devices, it can cause serious injury or death.

Only let approved personnel install, wire, maintain, examine, replace parts, and repair the drive.

If personnel are not approved, it can cause serious injury or death.

Do not wear loose clothing or jewelry when you do work on the drive. Tighten loose clothing and

remove all metal objects, for example watches or rings.

Loose clothing can catch on the drive and jewelry can conduct electricity and cause serious injury or death.

Do not remove covers or touch circuit boards while the drive is energized.

If you touch the internal components of an energized drive, it can cause serious injury or death.

Do not modify the drive body or drive circuitry.

Modifications to drive body and circuitry can cause serious injury or death, will cause damage to the drive, and will

void the warranty. Yaskawa is not responsible for modifications of the product made by the user.

Fire Hazard

Tighten all terminal screws to the correct tightening torque.

Connections that are too loose or too tight can cause incorrect operation and damage to the drive. Incorrect

connections can also cause death or serious injury from fire.

Tighten screws at an angle in the specified range shown in this manual.

If you tighten the screws at an angle not in the specified range, you can have loose connections that can cause

damage to the terminal block or start a fire and cause serious injury or death.

Damage to Equipment

Do not apply incorrect voltage to the main circuit of the drive. Operate the drive in the specified

range of the input voltage on the drive nameplate.

Voltages that are higher than the permitted nameplate tolerance can cause damage to the drive.

30 YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting

Page 31

2.1 Section Safety

WARNING

Fire Hazard

Do not put flammable or combustible materials on top of the drive and do not install the drive near

flammable or combustible materials. Attach the drive to metal or other noncombustible material.

Flammable and combustible materials can start a fire and cause serious injury or death.

Crush Hazard

Wear eye protection when you do work on the drive.

If you do not use correct safety equipment, it can cause serious injury or death.

Use a crane or hoist to move large drives when necessary.

If you try to move a large drive without a crane or hoist, it can cause serious injury or death.

NOTICE

Damage to Equipment

When you touch the drive and circuit boards, make sure that you observe correct electrostatic

discharge (ESD) procedures.

If you do not follow procedures, it can cause ESD damage to the drive circuitry.

Do not break the electrical connection between the drive and the motor when the drive is

outputting voltage.

Incorrect equipment sequencing can cause damage to the drive.

Make sure that all connections are correct after you install the drive and connect peripheral

devices.

Incorrect connections can cause damage to the drive.

Note:

Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the ground terminal of the drive.

Unshielded wire can cause electrical interference and unsatisfactory system performance.

Troubleshooting

2

YASKAWA TOEPYAIGA5001A GA500 Maintenance & Troubleshooting 31

Page 32

2.2 Types of Faults, Minor Faults, Alarms, and Errors