Yaskawa GA500 Installation Manual

GA500

Industrial AC Microdrive

Installation & Primary Operation

Catalog Code: GA50Uxxxxxxxx

240 V Single-Phase Input: 1/6 to 5 HP

240 V Three-Phase Input: 1/6 to 30 HP

480 V Three-Phase Input: 1/2 to 40 HP

This Page Intentionally Blank

2 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

Table of Contents

1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Section Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Explanation of Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exclusion of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Moving the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to Read the Catalog Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rated Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6. Overview of Keypad Components and Functions . . . . . . . . . . . . . . . . . . . . . . . 18

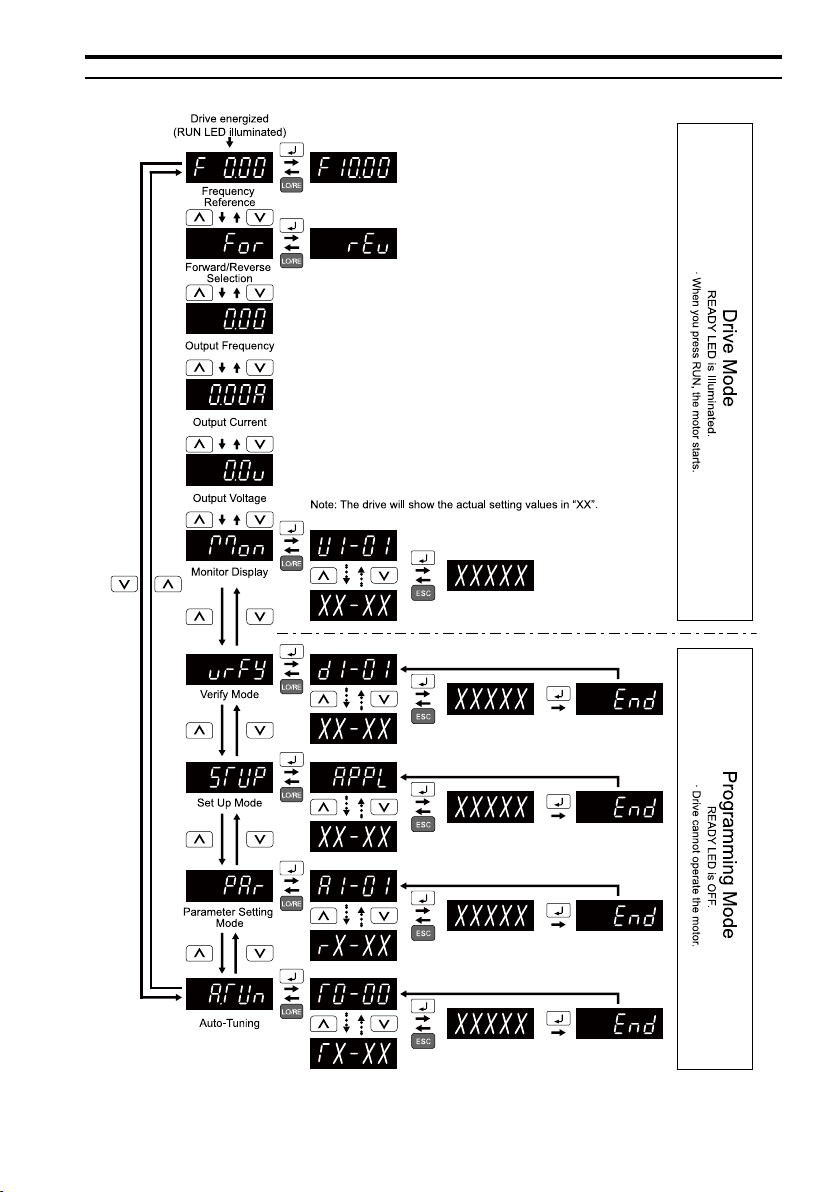

Keypad Mode and Menu Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7. Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

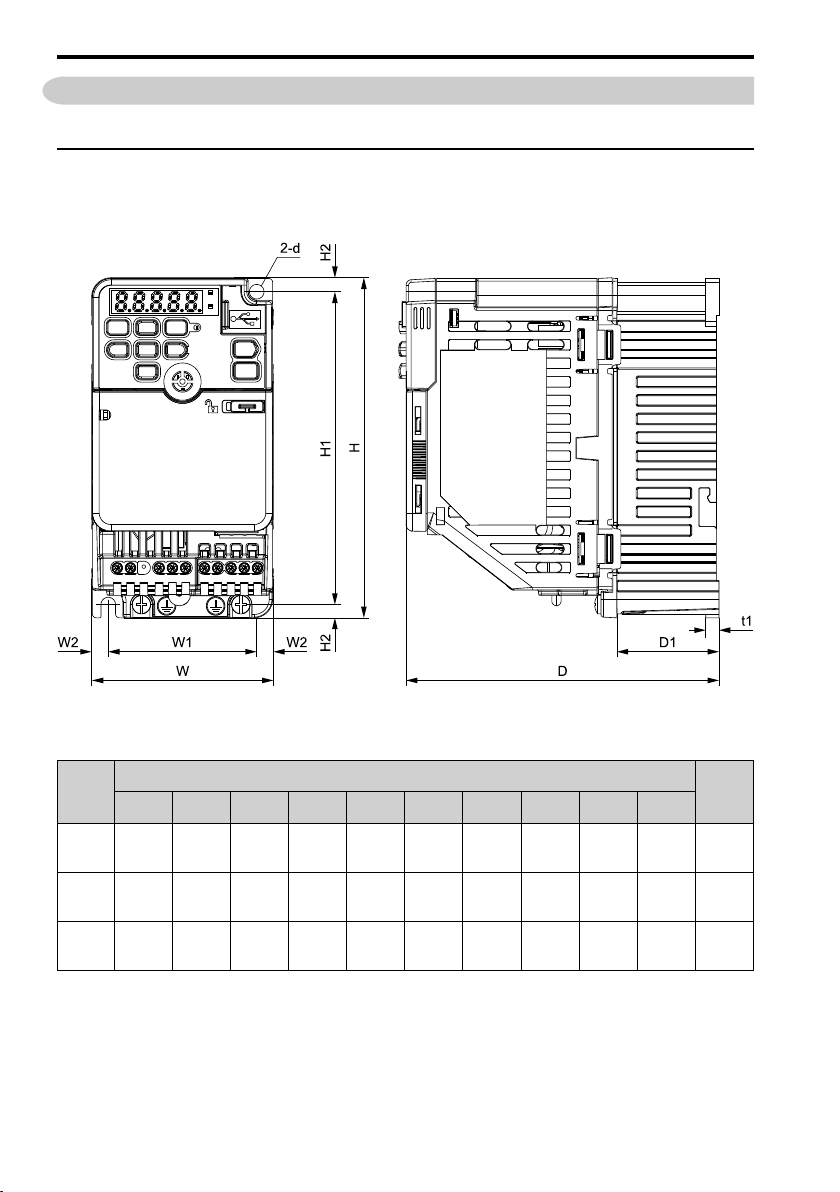

Drive Exterior and Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IP20/UL Open Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation Position and Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Removing/Reattaching Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Remove the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reattach the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8. Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Standard Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Main Circuit Terminal Block Wiring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Wire to the Main Circuit Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Main Circuit Terminal Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Wire Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Single-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Three-Phase 200 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Three-Phase 400 V Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Motor and Main Circuit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 3

Control Circuit Terminal Block Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Output Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

External Power Supply Input Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Serial Communication Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Control Circuit Terminal Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Control Circuit Wire Gauges and Tightening Torques . . . . . . . . . . . . . . . . . . . . . . . . . 57

Wiring the Control Circuit Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Switches and Jumpers on the Terminal Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Control I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Set Sinking Mode/Sourcing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Pulse Train Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Set the Input Signal for the MFAI Terminal A2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Set the Output Signal for the MFAO Terminal AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Switch ON Termination Resistor for MEMOBUS/Modbus Communications . . . . . . . 66

9. Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Auto-Tuning for Induction Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Auto-Tuning for PM Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Auto-Tuning in EZ Open Loop Vector Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

ASR and Inertia Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Precautions before Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Prepare for Basic Auto-Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Precautions before Rotational Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Precautions before Stationary Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Automatically Set E2-02 [Motor Rated Slip] and E2-03 [Motor No-Load

Current] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Precautions before Stationary Auto-Tuning for Line-to-Line Resistance and

Stator Resistance Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Precautions before Using Deceleration Rate Tuning and KEB Tuning. . . . . . . . . . . . 76

10. Drive Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Set up the Drive with General-Purpose Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Set and View Necessary Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Automatic Parameter Settings Optimized for Specific Applications (Application

Presets) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12. Drive Control, Duty Modes, and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Control Method Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Drive Duty Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Auto-Tuning for Induction Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fault Reset Procedure with the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Minor Faults/Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Parameter Setting Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Auto-Tuning Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

Backup Function Operating Mode Display and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

14. European Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

CE Low Voltage Directive Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Area of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Guarding Against Debris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Main Circuit Wire Gauges and Tightening Torques . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Connect a Fuse to the Input Side (Primary Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

CE Standards Compliance for DC Power Supply Input . . . . . . . . . . . . . . . . . . . . . . . 150

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Install a Drive to Conform to the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Installing the External EMC Noise Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

DC Link Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

15. UL Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Area of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Wire the Main Circuit Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Notes on Wiring the Main Circuit Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Main Circuit Wire Gauges and Tightening Torques . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Factory-Recommended Branch Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Low Voltage Wiring for Control Circuit Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Drive Motor Overload and Overheat Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

E2-01: Motor Rated Current (FLA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

E5-03: Motor Rated Current (FLA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

E9-06: Motor Rated Current (FLA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

L1-01: Motor Overload (oL1) Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

L1-02: Motor Overload Protection Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

L1-03: Motor Thermistor oH Alarm Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

L1-04: Motor Thermistor oH Fault Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

16. China RoHS Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Information on Hazardous Substances in This Product . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

17. 对应中国RoHS指令 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

本产品中含有有害物质的信息 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

18. Safe Disable Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Safe Disable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Using the Safe Disable Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Safe Disable Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Connect Safe Disable Input Contacts to Multiple Drives . . . . . . . . . . . . . . . . . . . . . . 190

Enabling and Disabling the Drive Output (“Safe Torque Off”) . . . . . . . . . . . . . . . . . . 193

Safe Disable Monitor Output Function and Keypad Display . . . . . . . . . . . . . . . . . . . 194

Validating the Safe Disable Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

19. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Disposal Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

WEEE Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 5

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

6 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

1 General Information

1 General Information

Do not use this manual as an alternative to the Technical Manual.

The products and specifications given in this manual and the manual contents can change

without notice to make the product and manual better.

Be sure to always use the latest version of this manual. Use this manual to correctly install, wire,

set, and operate this product.

Users can download the Technical Manual from the Yaskawa documentation website printed on

the back cover.

2 Section Safety

Read all safety precautions before you install, wire, or operate the drive.

◆ Explanation of Signal Words

DANGER

prevent it.

WARNING

prevent it.

CAUTION

NOTICE

injury.

This signal word identifies a hazard that will cause serious injury or death if you do not

This signal word identifies a hazard that can cause death or serious injuries if you do not

Identifies a hazardous situation, which, if not avoided, can cause minor or moderate injury.

This signal word identifies a property damage message that is not related to personal

◆ General Safety Instructions

Yaskawa Electric manufactures and supplies electronic components for a variety of industrial

applications. The selection and application of Yaskawa products is the responsibility of the

designer of the equipment or the customer who assembles the final product. Yaskawa is not

responsible for how our products are incorporated into the final system design. In all cases,

Yaskawa products should not be incorporated into a product or design as the exclusive or sole

safety control function. All control functions are designed to dynamically detect failures and

operate safely without exception. All products that are designed to incorporate parts

manufactured by Yaskawa must be provided to the end user and include proper warnings and

instructions regarding their safe use and operation. All warnings from Yaskawa must be

promptly issued to the end user. Yaskawa offers warranties only for the quality of our products,

in compliance with standards and specifications that are described in the manual. Yaskawa does

not offer other warranties, either explicit or implied. Injuries, property damage, and lost business

opportunities caused by improper storage or handling and negligence oversight on the part of

your company or your customers will void Yaskawa's warranty for the product.

Note:

• Read this manual carefully when mounting, operating, and repairing AC drives.

• Obey all warnings, cautions, and notices.

• Approved personnel must perform all work.

• Install the drive according to this manual and local codes.

DANGER

this manual, it will cause serious injury or death. The manufacturer is not responsible for injuries or damage to

equipment.

Do not ignore the safety messages in this manual. If you ignore the safety messages in

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 7

2 Section Safety

DANGER

drive. Before servicing, disconnect all power to the equipment and wait for the time specified on the warning label

at a minimum. The internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF, measure for

dangerous voltages to make sure that the drive is safe. If you do work on the drive when it is energized, it will

cause serious injury or death from electrical shock.

WARNING

the drive and set parameters. If you do not test the system, it can cause damage to equipment or serious injury or

death.

WARNING

virtual input and output function parameters are correct. Virtual input and output functions can have different

default settings and operation than wired input and output functions. Incorrect function settings can cause serious

injury or death.

WARNING

drive, motor, and machine and attach covers, couplings, shaft keys, and machine loads before you energize the

drive. If personnel are too close or if there are missing parts, it can cause serious injury or death.

WARNING

engineer who made the DriveWorksEZ program before you operate the drive. If you do not know how the drive

will operate, it can cause serious injury or death. When you use DriveWorksEZ to make custom programming, the

drive I/O terminal functions change from factory settings and the drive will not operate as written in this manual.

WARNING

drive body and circuitry can cause serious injury or death, will cause damage to the drive, and will void the

warranty. Yaskawa is not responsible for modifications of the product made by the user.

WARNING

replace parts, and repair the drive. If personnel are not approved, it can cause serious injury or death.

WARNING

energized. If you touch the internal components of an energized drive, it can cause serious injury or death.

WARNING

energize the drive or operate peripheral devices. Wait for the time specified on the warning label at a minimum

and make sure that all indicators are OFF. Then check the wiring and peripheral device ratings to find the cause

of the problem. If you do not know the cause of the problem, contact Yaskawa before you energize the drive or

peripheral devices. If you do not fix the problem before you operate the drive or peripheral devices, it can cause

serious injury or death.

WARNING

Operate the drive in the specified range of the input voltage on the drive nameplate. Voltages that are higher than

the permitted nameplate tolerance can cause damage to the drive.

NOTICE

applicable codes and this manual. The drive is suitable for circuits that supply not more than 31,000 RMS

symmetrical amperes, 240 Vac maximum (200 V Class), 480 Vac maximum (400 V Class). Incorrect branch

circuit short circuit protection can cause serious injury or death.

CAUTION

drive. If the drive or covers fall, it can cause moderate injury.

NOTICE

applicable for use with an AC drive. If the motor does not have the correct insulation, it can cause a short circuit or

ground fault from insulation deterioration.

NOTICE

observe correct electrostatic discharge (ESD) procedures. If you do not follow procedures, it can cause ESD

damage to the drive circuitry.

NOTICE

megger insulation tester on the drive. These tests can cause damage to the drive.

NOTICE

can cause damage to the drive and connected equipment.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized

Crush Hazard. Test the system to make sure that the drive operates safely after you wire

Sudden Movement Hazard. Before you do a test run, make sure that the setting values for

Sudden Movement Hazard. Remove all personnel and objects from the area around the

Sudden Movement Hazard. Examine the I/O signals and internal sequence with the

Electrical Shock Hazard. Do not modify the drive body or drive circuitry. Modifications to

Electrical Shock Hazard. Only let approved personnel install, wire, maintain, examine,

Electrical Shock Hazard. Do not remove covers or touch circuit boards while the drive is

Electrical Shock Hazard. After the drive blows a fuse or trips a GFCI, do not immediately

Damage to Equipment. Do not apply incorrect voltage to the main circuit of the drive.

Fire Hazard. Install sufficient branch circuit short circuit protection as specified by

Crush Hazard. Tighten terminal cover screws and hold the case safely when you move the

Use an inverter-duty motor or vector-duty motor with reinforced insulation and windings

Damage to Equipment. When you touch the drive and circuit boards, make sure that you

Damage to Equipment. Do not do a withstand voltage test or use a megohmmeter or

Do not operate a drive or connected equipment that has damaged or missing parts. You

8 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

3 Drive Specifications

NOTICE

alternative methods, for example heat treatment, before you package the components. Gas from wood packaging

fumigated with halogen disinfectants, for example fluorine, chlorine, bromine, iodine or DOP gas (phthalic acid

ester), can cause damage to the drive.

Note:

• Do not use unshielded wire for control wiring. Use shielded, twisted-pair wires and ground the shield to the ground

terminal of the drive. Unshielded wire can cause electrical interference and unsatisfactory system performance.

• Do not put devices that radiate strong electromagnetic waves, for example radio transmitters, near the drive. If you use

these devices near the drive, the drive can operate incorrectly.

Do not use steam or other disinfectants to fumigate wood for packaging the drive. Use

◆ Warranty Information

■ Exclusion of Liability

• This product is not designed and manufactured for use in life-support machines or systems.

• Contact a Yaskawa representative or your Yaskawa sales representative if you are considering

the application of this product for special purposes, such as machines or systems used for

passenger cars, medicine, airplanes and aerospace, nuclear power, electric power, or undersea

relaying.

WARNING

cause the loss of human life, a serious accident, or physical injury, you must install applicable safety devices. If

you do not correctly install safety devices, it can cause serious injury or death.

Injury to Personnel. When you use this product in applications where its failure could

3 Drive Specifications

Note:

• To get the OLV specifications, do Rotational Auto-Tuning.

• To get the longest product life, install the drive in an environment that meets the necessary specifications.

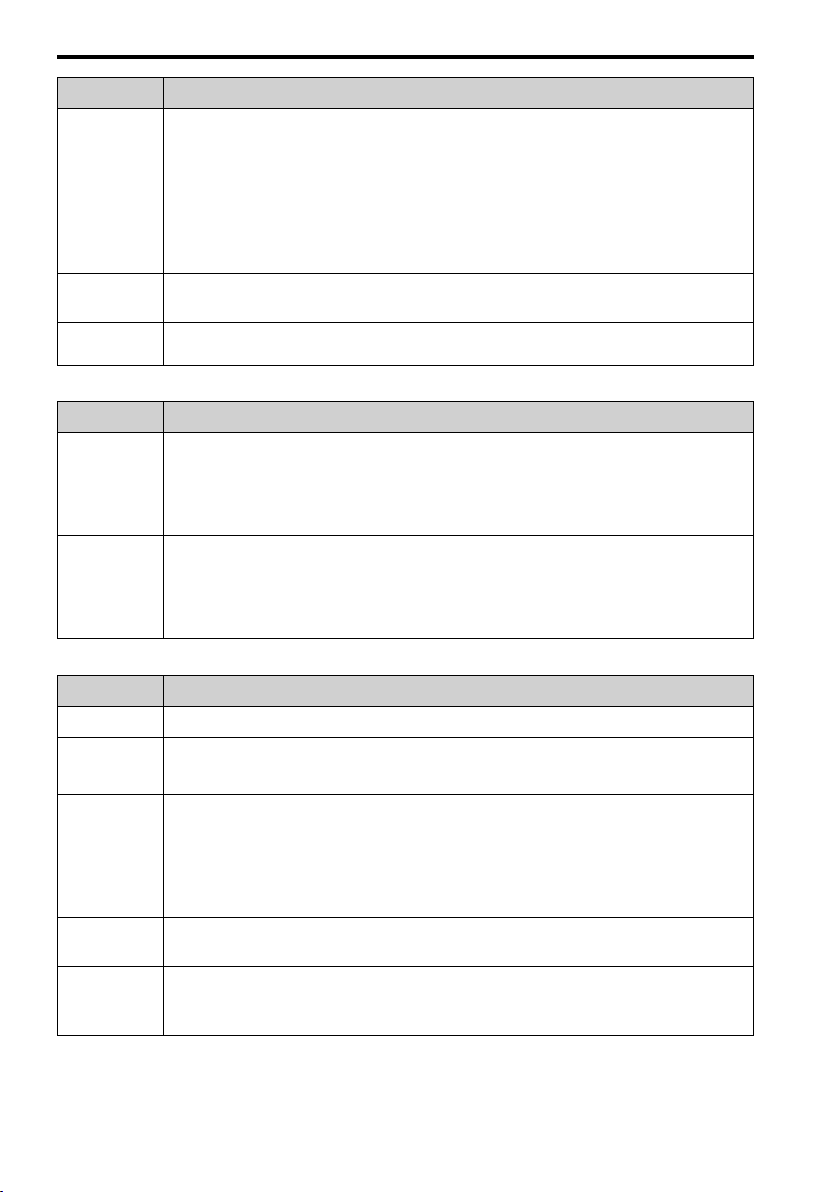

Table 3.1 Environment

Item Specification

Area of Use

Power Supply

Ambient

Temperature

Setting

Humidity

Storage

Temperature

Surrounding

Area

Indoors

Overvoltage Category III

IP20/UL Open Type: -10°C to +50 °C (14 °F to 122 °F)

IP20/UL Type 1: -10 °C to +40 °C (14 °F to 104 °F)

• When you install the drive in an enclosure, use a cooling fan or air conditioner to keep the internal

air temperature in the permitted range.

• Do not let the drive freeze.

95% RH or less

Do not let condensation form on the drive.

-20 °C to +70 °C (-4 °F to +158 °F) (short-term temperature during transportation)

Pollution degree 2 or less

Install the drive in an area without:

• Oil mist, corrosive or flammable gas, or dust

• Metal powder, oil, water, or other unwanted materials

• Radioactive materials or flammable materials, including wood

• Harmful gas or fluids

• Salt

• Direct sunlight

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 9

3 Drive Specifications

Item Specification

1000 m (3281 ft) Maximum

Note:

Derate the output current by 1% for each 100 m (328 ft) to install the drive in altitudes between

Altitude

Vibration

Installation

Orientation

1000 m to 4000 m (3281 ft to 13123 ft).

It is not necessary to derate the rated voltage in these conditions:

• Installing the drive at 2000 m (6562 ft) or lower

• Installing the drive between 2000 m to 4000 m (6562 ft to 13123 ft) and grounding the neutral

point on the power supply.

Contact Yaskawa or your nearest sales representative when not grounding the neutral point.

• 10 Hz to 20 Hz: 1 G (9.8 m/s

• 20 Hz to 55 Hz: 0.6 G (5.9 m/s

2

, 32.15 ft/s2)

2

, 19.36 ft/s2)

Install the drive vertically for sufficient airflow to cool the drive.

Table 3.2 Standard

Item Specification

• UL 61800-5-1

Harmonized

Standard

Protection design

• EN 61800-3

• EN 61800-5-1

• Two Safe Disable inputs and one EDM output according to EN ISO 13849-1 (Cat.3, PL e), EN

61800-5-2 SIL3

IP20/UL Open Type

IP20/UL Type 1

Note:

Install a UL Type 1 kit (optional) on an IP20/UL Open Type drive to change the drive to an IP20/

UL Type 1 enclosure.

Table 3.3 Protection Functions

Item Specification

Motor Protection

Momentary

Overcurrent

Protection

Overload

Protection

Overvoltage

Protection

Undervoltage

Protection

10 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

Electronic thermal overload protection

Drive stops when the output current is more than 200% of the HD output current.

Drive stops when the output current is more than these overload tolerances:

• HD: 150% of the rated output current for 60 seconds.

• ND: 110% of the rated output current for 60 seconds.

Note:

If output frequency < 6 Hz, the drive can trigger the overload protection function when the output

current is in the overload tolerance range.

200 V class: Stops when the DC bus voltage is more than approximately 410 V

400 V class: Stops when the DC bus voltage is more than approximately 820 V

Single-phase 200 V class: Stops when the DC bus voltage decreases to less than approximately 160 V

Three-phase 200 V class: Stops when the DC bus voltage decreases to less than approximately 190 V

Three-phase 400 V class: Stops when the DC bus voltage decreases to less than approximately 380 V

Item Specification

Stops when power loss is longer than 15 ms and continues operation if power loss is shorter than 2 s

(depending on parameter settings).

Momentary

Power Loss

Ride-thru

Heatsink

Overheat

Protection

Braking Resistor

Overheat

Protection

Stall Prevention

Ground Fault

Protection

DC Bus Charge

LED

Note:

• Load size and motor speed can cause the stop time to be shorter.

• Drive capacity will change the continuous operation time. A Momentary Power Loss Recovery

Unit is necessary to continue operation through a 2 s power loss on models 2001 to 2042 and

4001 to 4023.

Thermistor

Overheat detection for braking resistor (optional ERF-type, 3% ED)

Stall prevention is available during acceleration, deceleration, and during run.

Electronic circuit protection

Note:

This protection detects ground faults during run. The drive will not provide protection when:

• There is a low-resistance ground fault for the motor cable or terminal block

• Energizing the drive when there is a ground fault.

Charge LED illuminates when DC bus voltage is more than 50 V.

Table 3.4 Control Characteristics

Item Specification

• V/f Control

Control Methods

Frequency

Control Range

Frequency

Accuracy

(Temperature

Fluctuation)

Frequency

Setting

Resolution

Output

Frequency

Resolution

Frequency

Setting Signal

• Open Loop Vector

• PM Open Loop Vector

• PM Advanced Open Loop Vector

• EZ Vector Control

• V/f, OLV, and OLV/PM: 0.01 Hz to 590 Hz

• AOLV/PM: 0.01 Hz to 270 Hz

• EZOLV: 0.01 Hz to 120 Hz

Digital inputs: ±0.01% of the maximum output frequency (-10 °C to +40 °C (14 °F to 104 °F))

Analog inputs: In ±0.1% of the maximum output frequency (25 °C ±10 °C (77 °F ±18 °F))

Digital inputs: 0.01 Hz

Analog inputs: 1/2048 of the maximum output frequency (11-bit signed)

0.001 Hz

Main speed frequency reference: -10 Vdc to +10 Vdc (minimum 15 kΩ), 0 Vdc to 10 Vdc (minimum

15 kΩ), 4 mA to 20 mA (250 Ω), 0 mA to 20 mA (250 Ω)

Main speed reference: Pulse train input (maximum 32 kHz)

3 Drive Specifications

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 11

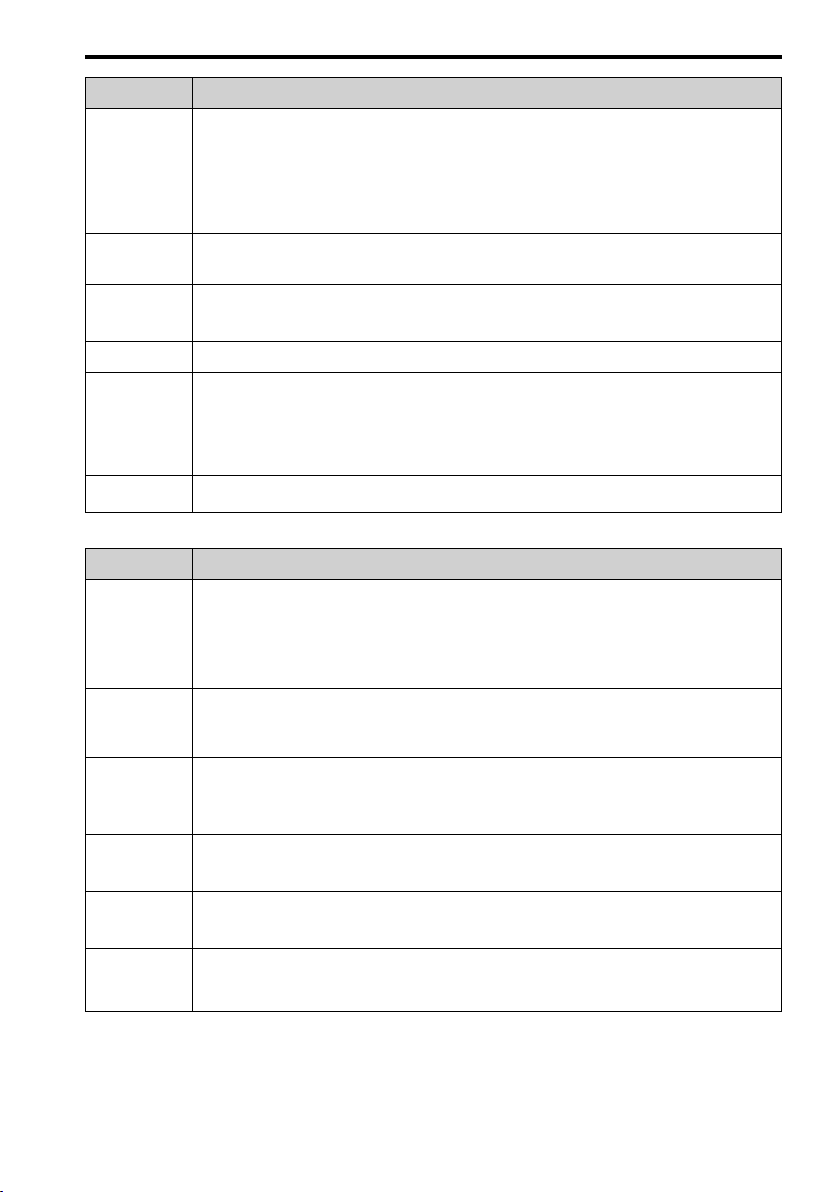

3 Drive Specifications

Item Specification

• V/f: 150%/3 Hz

• OLV: 150%/1 Hz

Starting Torque

Speed Control

Range

Zero Speed

Control

Torque Limits

Acceleration and

Deceleration

Times

Braking Torque

V/f

Characteristics

Main Control

Functions

• OLV/PM: 100%/5% speed

• AOLV/PM: 100%/0 min

• EZOLV: 100%/10% speed

Note:

Correctly select the drive and motor capacity for this starting torque in these control methods:

• OLV

• AOLV/PM

• V/f: 1:40

• OLV: 1:100

• OLV/PM: 1:10

• AOLV/PM: 1:100 (when high frequency injection is enabled)

• EZOLV: 1:10

Possible in AOLV/PM control methods.

You can use parameter settings for different limits in four quadrants in these control methods:

• OLV

• AOLV/PM

• EZOLV

0.0 s to 6000.0 s

The drive can set four pairs of different acceleration and deceleration times.

Approximately 20% without a resistor

Approximately 125% with a dynamic braking option

WARNING

operate the drive with:

• a regenerative converter

• regenerative unit

• braking resistor

• braking resistor unit.

If you set the parameter incorrectly, the drive can decelerate for too long and cause serious

injury or death.

Note:

• Short-time average deceleration torque refers to the torque needed to decelerate the motor

(uncoupled from the load) from the rated speed to zero. Motor characteristics can change the

actual specifications.

• Motor characteristics change the continuous regenerative torque and short-time average

deceleration torque for motors 2.2 kW and larger.

Select from 15 pre-defined V/f patterns, or a user-set V/f pattern.

Feed Forward Control, Restart After Momentary Power Loss, Speed Search, Overtorque Detection,

Torque Limit, 17 Step Speed (max.), Accel/Decel Switch, S-curve Acceleration/Deceleration, 3-wire

Sequence, Auto-Tuning (Rotational and Stationary), Dwell Function, Cooling Fan ON/OFF Switch,

Slip Compensation, Torque Compensation, Frequency Jump, Upper/Lower Limits for Frequency

Reference, DC Injection Braking at Start and Stop, Overexcitation Braking, High Slip Braking, PID

Control (with Sleep Function), Energy Saving Control, MEMOBUS/Modbus Communications (RS485 max, 115.2 kbps), Auto Restart, Application Presets, DriveWorksEZ (customized functions),

Parameter Backup Function, Online Tuning, KEB, Overexcitation Deceleration, Overvoltage

Suppression, High Frequency Injection, etc.

-1

(when high frequency injection is enabled)

Set L3-04 = 0 [Stall Prevention during Decel = Disabled] when you

12 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

4 Moving the Drive

4 Moving the Drive

Obey local laws and regulations when moving and installing this product.

CAUTION

correctly when you move the drive. If the drive or covers fall, it can cause moderate injury.

Crush Hazard. Do not hold the drive by the keypad or front cover. Tighten the screws

5 Receiving

The product packaging contains the product, instruction manual, and drilling template.

1. Examine the drive for damage or missing parts. Immediately contact the shipping company

if the drive is damaged. The Yaskawa warranty does not cover damage from shipping.

2. Examine the catalog code to make sure that you received the correct model. Examine the

catalog code in the “C/C” section of the drive nameplate to make sure that you received the

correct model.

3. Contact your supplier or Yaskawa sales office if you received an incorrect drive model or if

the drive does not operate correctly.

4. When you operate more than one drive, check all drives and motors separately.

NOTICE

can cause damage to the drive and connected equipment.

Do not operate a drive or connected equipment that has damaged or missing parts. You

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 13

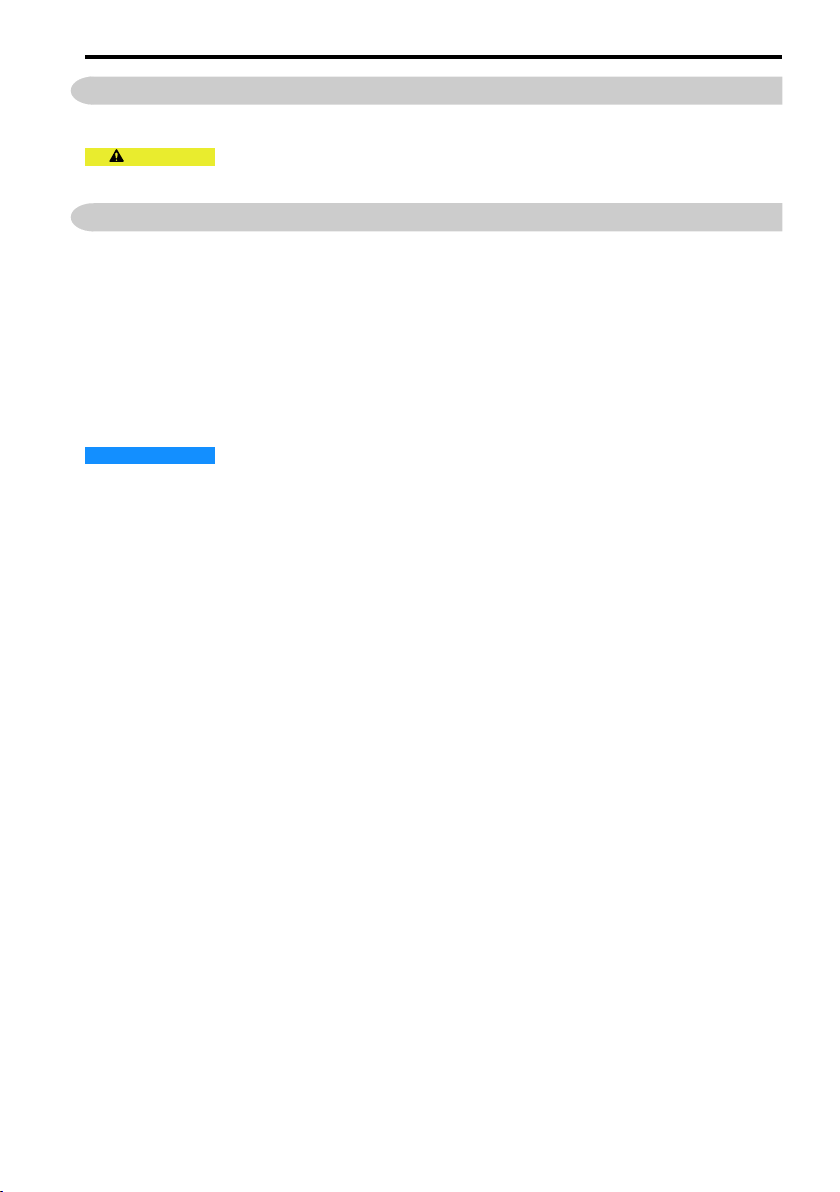

5 Receiving

A - Weight

B - Drive software version

C - The address of the head

office of Yaskawa Electric

Corporation

D - Accreditation standards

E - Ambient temperature

specification

F - Enclosure protection design

G - Product number

H - Serial number

I - Output specifications

J - Input specifications

K - Catalog code

Figure 5.1 Nameplate Information Example

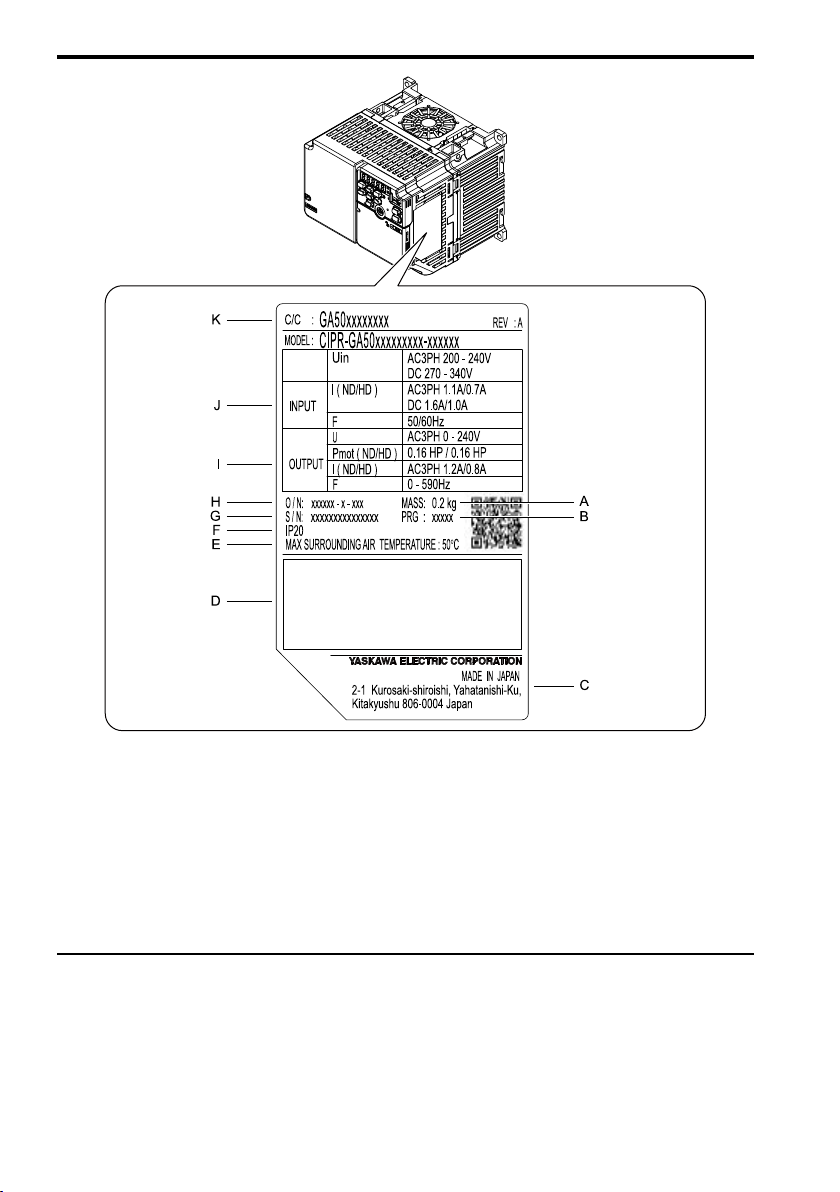

◆ How to Read the Catalog Code

Use the information in Figure 5.2 and Table 5.1 to read the drive catalog code.

14 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

Figure 5.2 Drive Catalog Code

Table 5.1 Catalog Code Details

No. Description

1 Product series

2 Region code

• A: Japan

• B: China

• C: Europe

• T: Asia (Singapore, Taiwan, India, and Korea)

• U: Americas

3 Input power supply voltage

• B: Single-Phase AC 200 V Class

• 2: Three-Phase AC 200 V Class

• 4: Three-Phase AC 400 V Class

4 Rated output current

Note:

Refer to Table 5.2, Table 5.3, and Table 5.4 for the rated output current by model.

5

EMC noise filter

A: No internal EMC filter

E: Built-in EMC Filter

6 Enclosure protection design

B: IP20/UL Open Type

7 Environmental specification

A: Standard

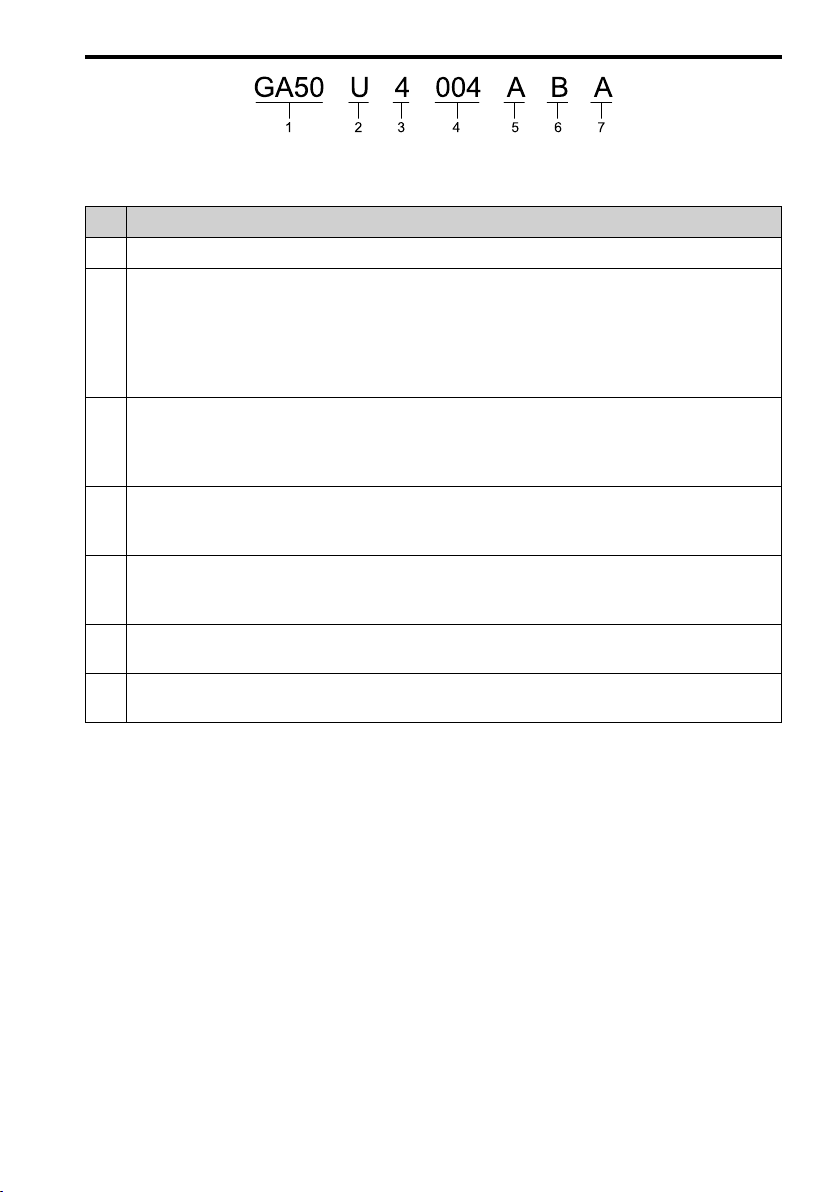

■ Rated Output Current

Table 5.2, Table 5.3, and Table 5.4 give the rated output current values.

Note:

• Rated output current values are applicable for drives that operate at standard specifications.

• Derate the output current in applications that:

–Increase the carrier frequency

–Have high ambient temperature

–Install drives side-by-side

• Use C6-01 [Normal / Heavy Duty Selection] to select Normal Duty rating (ND) or Heavy Duty rating (HD).

5 Receiving

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 15

5 Receiving

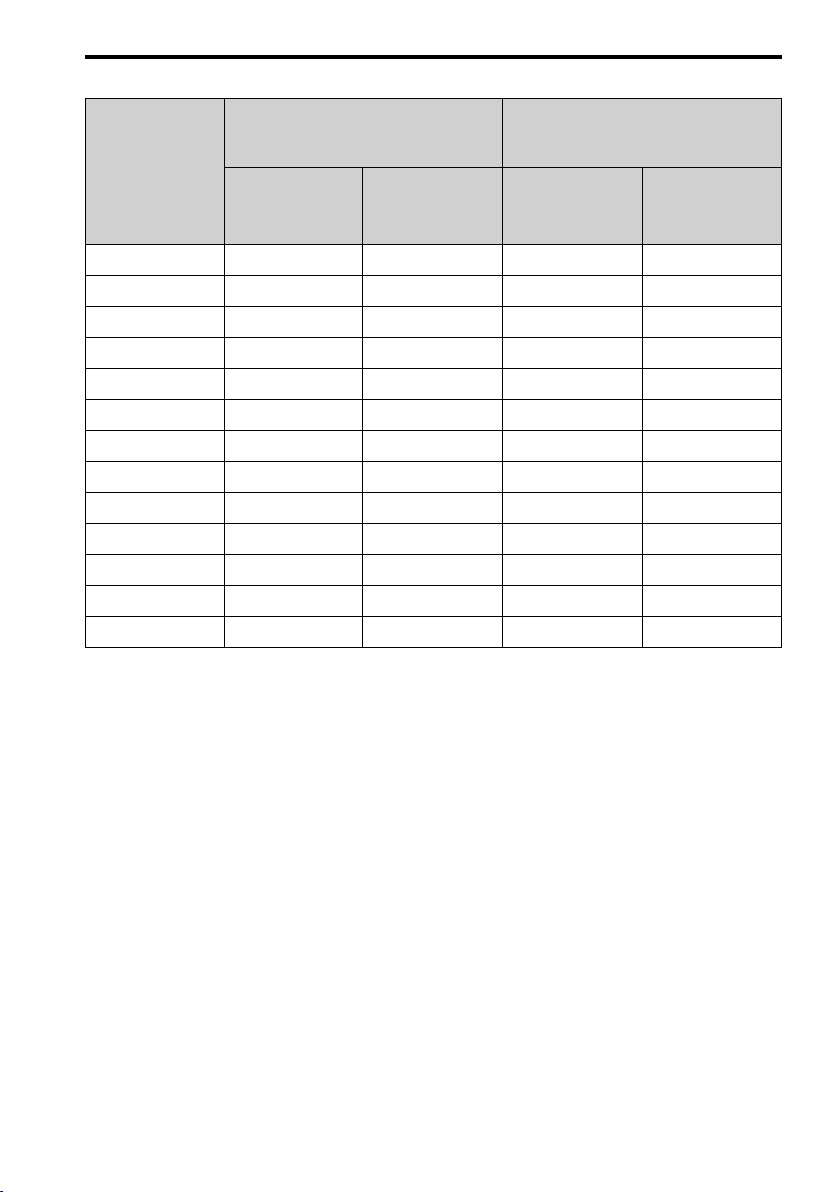

Table 5.2 Single-Phase AC 200 V Class

Heavy Duty Rating (HD)

[C6-01 = 0]

Model

B001 0.1 (1/6) 0.8 0.2 (1/6) 1.2

B002 0.2 (1/4) 1.6 0.4 (1/4) 1.9

B004 0.4 (1/2) 3.0 0.75 (3/4) 3.5

B006 0.75 (1) 5.0 1.1 (1.5) 6.0

B010 1.5 (2) 8.0 2.2 (3) 9.6

B012 2.2 (3) 11.0 3.0 (3) 12.2

B018 3.7 (5) 17.6 - -

Maximum

Applicable Motor

Output

kW (HP)

Rated Output

Current

A

Normal Duty Rating (ND)

Maximum

Applicable Motor

Output

kW (HP)

Table 5.3 Three-Phase AC 200 V Class

Heavy Duty Rating (HD)

[C6-01 = 0]

Model

2001 0.1 (1/6) 0.8 0.2 (1/6) 1.2

2002 0.2 (1/4) 1.6 0.4 (1/4) 1.9

2004 0.4 (1/2) 3.0 0.75 (3/4) 3.5

2006 0.75 (1) 5.0 1.1 (1.5) 6.0

2010 1.5 (2) 8.0 2.2 (3) 9.6

2012 2.2 (3) 11.0 3.0 (4) 12.2

2021 3.7 (5) 17.6 5.5 (5) 21.0

2030 5.5 (7.5) 25.0 7.5 (10) 30.0

2042 7.5 (10) 33.0 11.0 (15) 42.0

2056 11.0 (15) 47.0 15.0 (20) 56.0

2070 15.0 (20) 60.0 18.5 (25) 70.0

2082 18.5 (25) 75.0 22.0 (30) 82.0

Maximum

Applicable Motor

Output

kW (HP)

Rated Output

Current

A

Normal Duty Rating (ND)

Maximum

Applicable Motor

Output

kW (HP)

[C6-01 = 1]

(Default)

[C6-01 = 1]

(Default)

Rated Output

Current

A

Rated Output

Current

A

16 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

5 Receiving

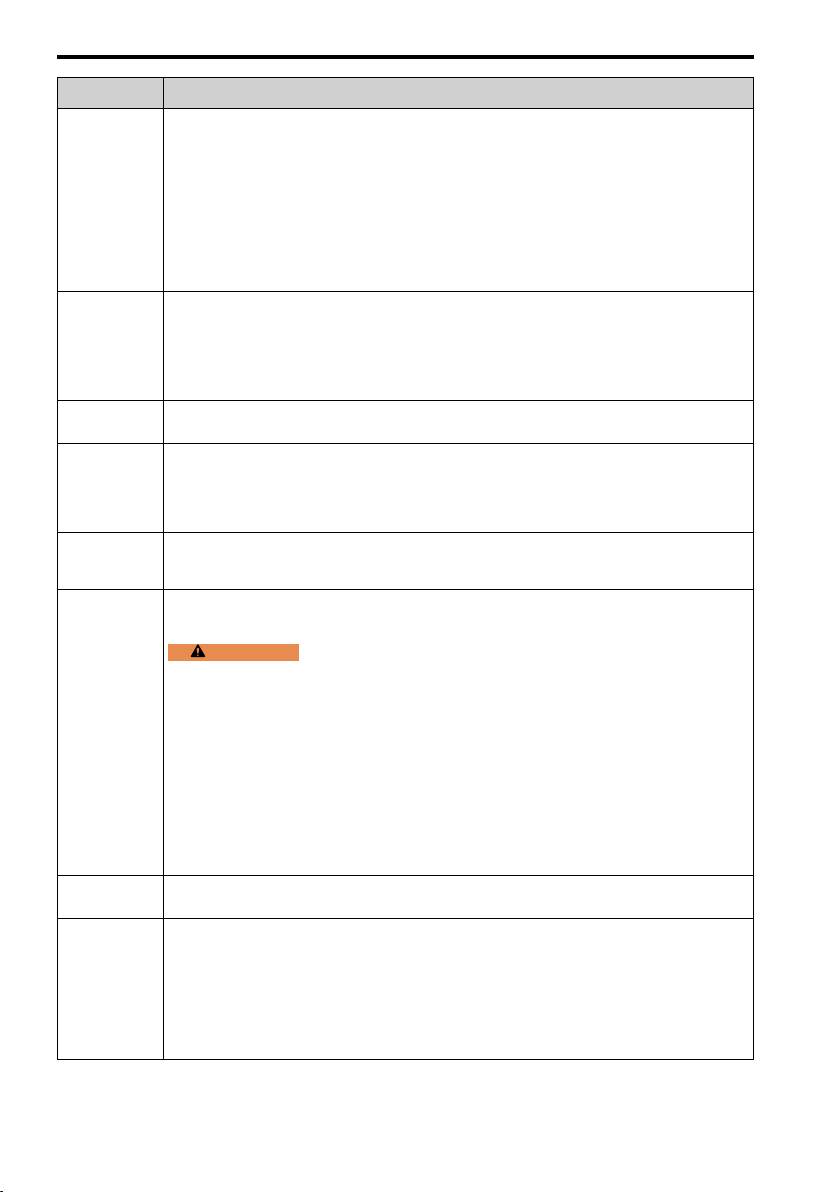

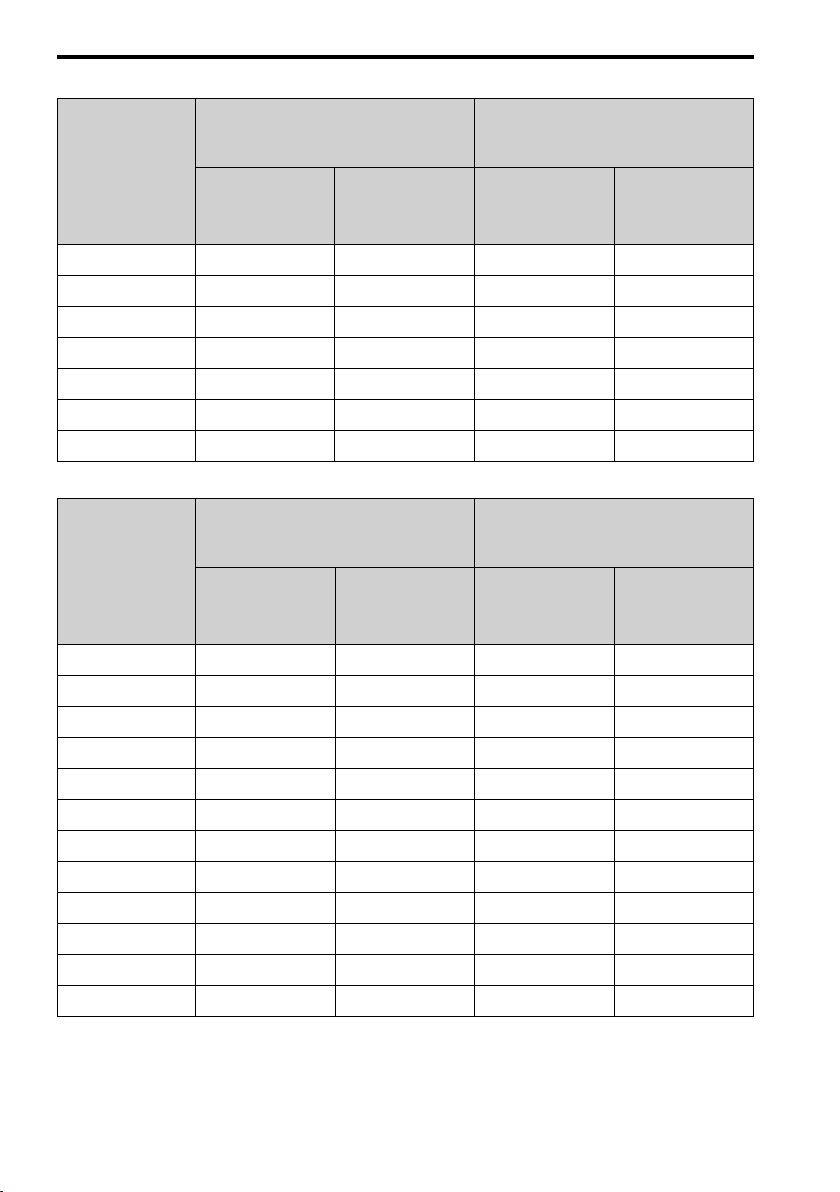

Table 5.4 Three-Phase AC 400 V Class

Heavy Duty Rating (HD)

[C6-01 = 0]

Model

4001 0.2 (1/2) 1.2 0.4 (1/2) 1.2

4002 0.4 (3/4) 1.8 0.75 (1) 2.1

4004 0.75 (2) 3.4 1.5 (2) 4.1

4005 1.5 (3) 4.8 2.2 (3) 5.4

4007 2.2 (3) 5.6 3.0 (4) 7.1

4009 3.0 (4) 7.3 3.7 (5) 8.9

4012 3.7 (5) 9.2 5.5 (7.5) 11.9

4018 5.5 (10) 14.8 7.5 (10) 17.5

4023 7.5 (10) 18.0 11.0 (15) 23.4

4031 11.0 (15) 24.0 15.0 (20) 31.0

4038 15.0 (20) 31.0 18.5 (25) 38.0

4044 18.5 (25) 39.0 22.0 (30) 44.0

4060 22.0 (30) 45.0 30.0 (40) 60.0

Maximum

Applicable Motor

Output

kW (HP)

Rated Output

Current

A

Normal Duty Rating (ND)

[C6-01 = 1]

(Default)

Maximum

Applicable Motor

Output

kW (HP)

Rated Output

Current

A

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 17

6 Overview of Keypad Components and Functions

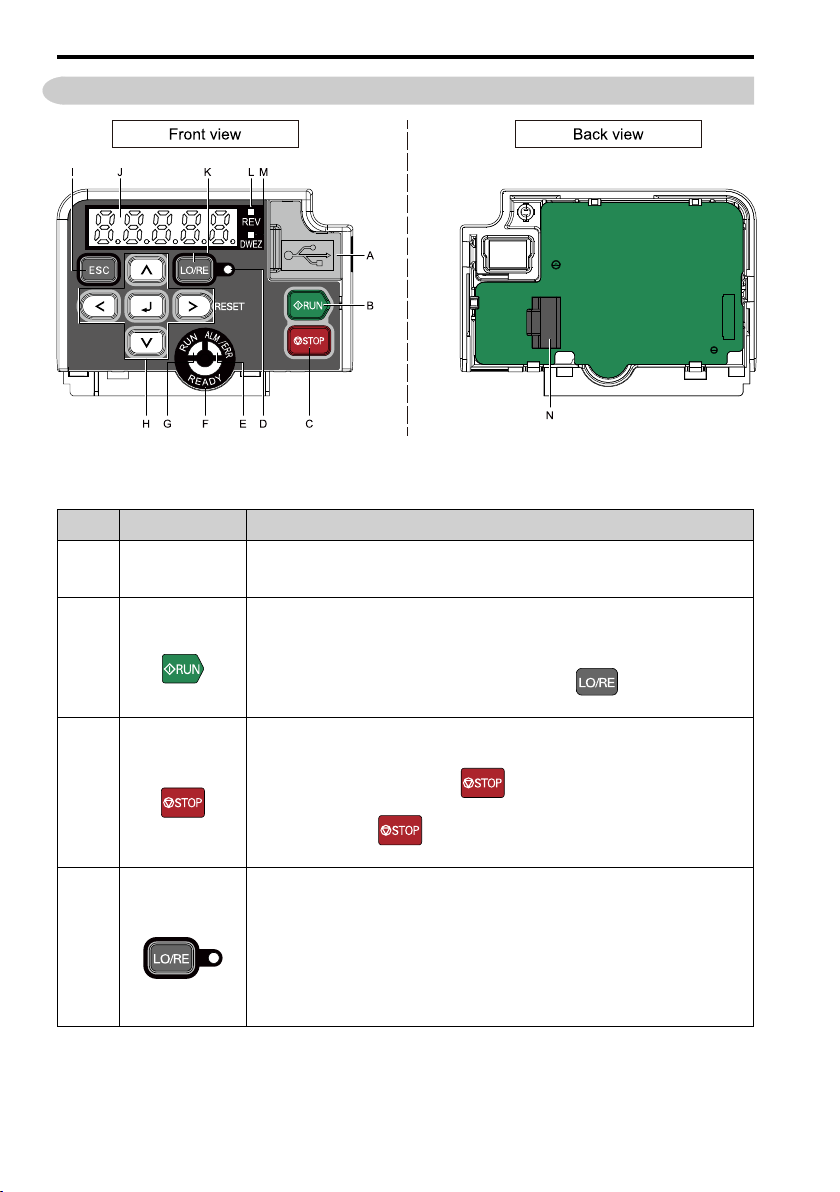

6 Overview of Keypad Components and Functions

Figure 6.1 Keypad

Table 6.1 Keypad Components and Functions

Symbol Name Function

USB Terminal Pass-

A

B

C

D

through

RUN Key

STOP Key

LO/RE LED

Pass-through point to connect a USB cable to the drive to support the DriveWizard PC

tool and the DriveWizard Mobile App. Uses a USB cable (USB standard 2.0, type A mini-B) to connect the drive to a PC, Android smartphone, or tablet.

Starts the drive in LOCAL Mode.

Starts the operation in Auto-Tuning Mode.

Note:

Before you use the keypad to operate the motor, push on the keypad to set

the drive to LOCAL Mode.

Stops drive operation.

Note:

Uses a stop-priority circuit. Push to stop the motor. This will also apply

when a Run command (REMOTE Mode) is active at an external Run command

source. To disable priority, set o2-02 = 0 [STOP Key Function Selection =

Disabled].

Illuminated: The keypad controls the Run command (LOCAL Mode).

OFF: The control circuit terminal or serial transmission device controls the Run

command (REMOTE Mode).

Note:

• LOCAL: Use the keypad to operate the drive. Use the keypad to enter Run/Stop

commands and the frequency reference command.

• REMOTE: Use the control circuit terminal or serial transmission to operate the

drive. Use the frequency reference source entered in b1-01 and the Run command

source selected in b1-02.

18 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

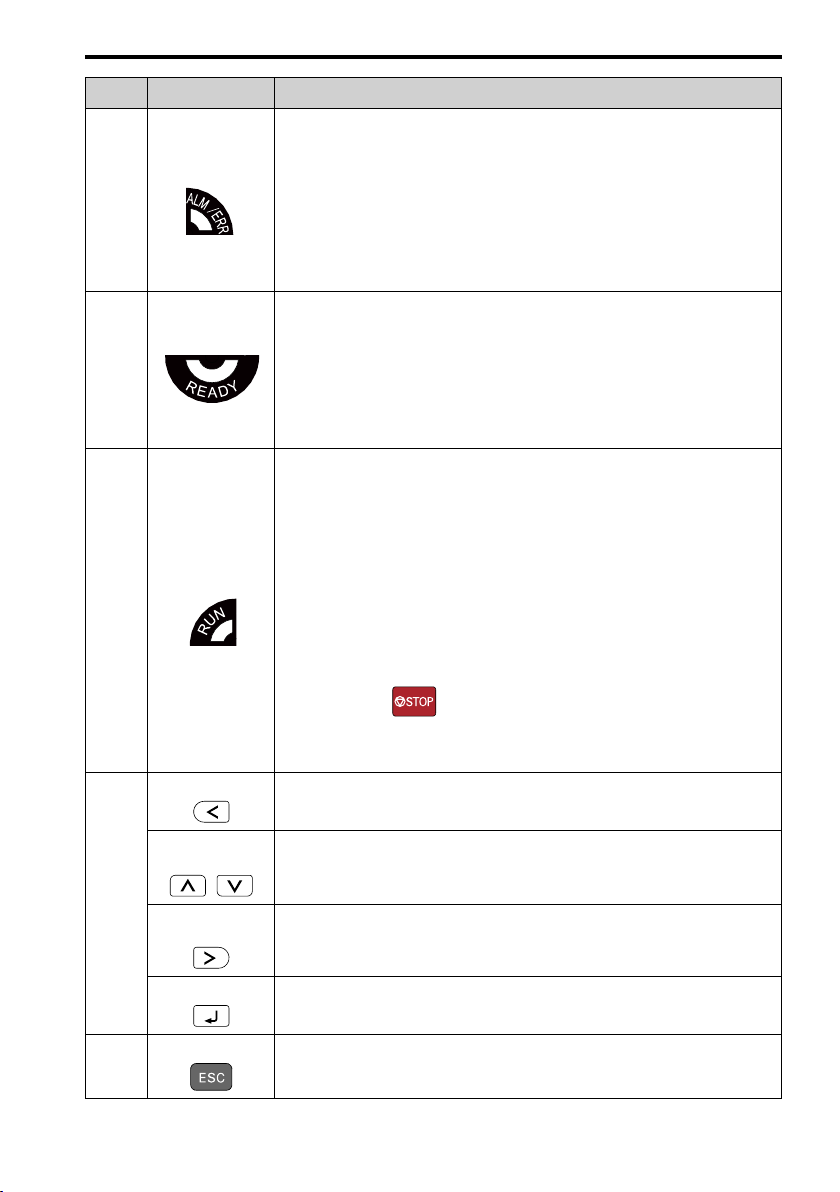

6 Overview of Keypad Components and Functions

Symbol Name Function

Illuminated: The drive detects a fault.

OFF: There are no drive faults or alarms.

ALM/ERR LED

E

READY LED

F

RUN LED

G

Flashing:

• An alarm

• Operation Errors

• An Auto-Tuning error

Note:

The LED will illuminate to identify a fault if the drive detects a fault and an alarm at

the same time.

Illuminated: The drive is operating or is ready for operation.

OFF:

• The drive detects a fault.

• There is no fault and the drive received a Run command, but the drive cannot run.

For example, in Programming Mode.

Flashing: The drive is in STo [Safe Torque OFF] condition.

Flashing quickly: The voltage of the main circuit power supply is not in drive nameplate

specifications, and the external 24 V power supply provides the only power to the drive.

Illuminated: The drive is in normal operation.

OFF: The drive is stopped.

Flashing:

• The drive is decelerating to stop.

• The drive received a Run command, but the frequency reference is 0 Hz.

Flashing quickly:

• When the drive is in LOCAL Mode, the drive received a Run command from the

MFDI terminals and is switched to REMOTE Mode.

• The drive received a Run command from the MFDI terminals when the drive is not

in Drive Mode.

• The drive received a Fast Stop command.

• The safety function shut off the drive output.

• The user pushed on the keypad while the drive is operating in REMOTE

Mode.

• The drive is energized with an active Run command and b1-17 = 0 [Run Command

at Power Up = Disregard Existing RUN Command].

Left Arrow Key Moves the cursor to the left.

Up Arrow Key/

Down Arrow Key

H

I

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 19

/

Right Arrow Key

(RESET)

ENTER Key • Enters parameter values and settings.

ESC Key • Goes back to the previous screen.

• Moves to a different screen.

• Selects parameter numbers and increments or decrements setting values.

• Moves the cursor to the right.

• Resets the drive to clear a fault.

• Selects each mode, parameter, and set value.

• Push and hold to go back to the frequency reference screen (the initial screen).

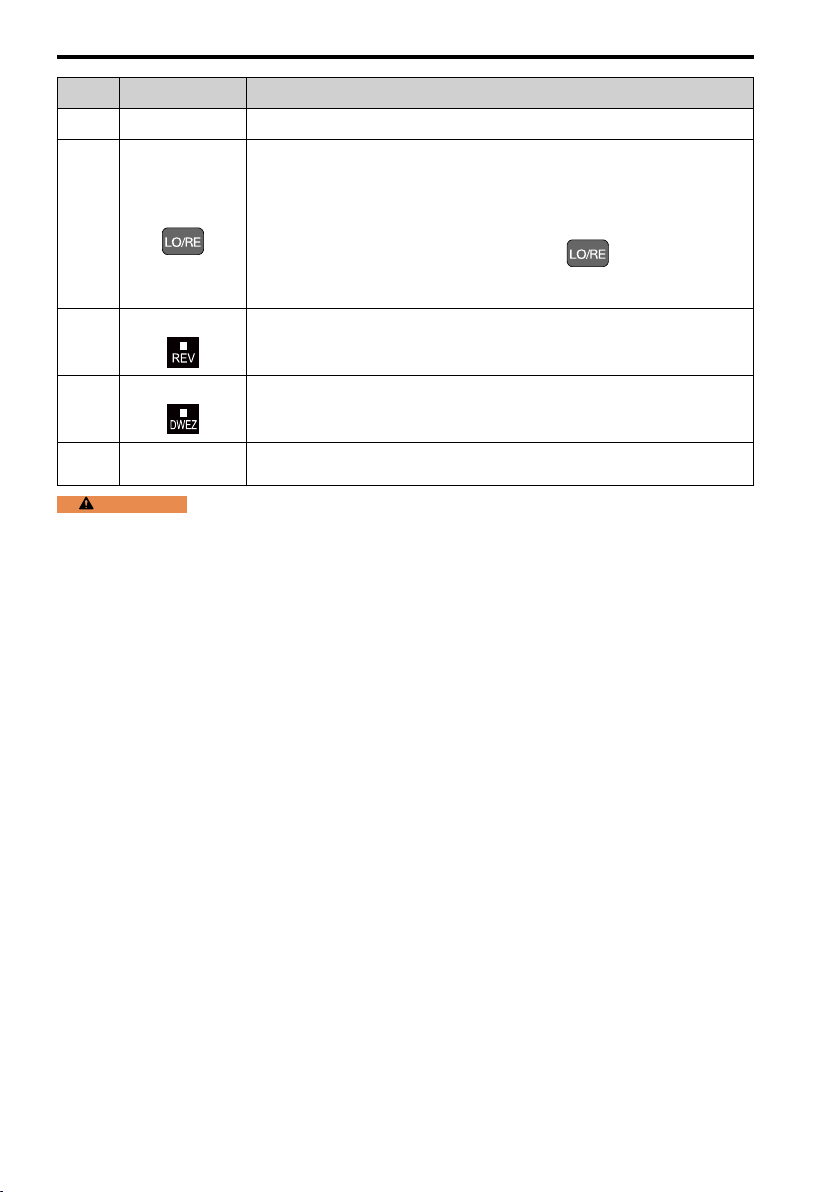

6 Overview of Keypad Components and Functions

Symbol Name Function

J LED Display

LO/RE Selection

K

L

Key

REV LED Illuminated: The drive received a Reverse run command.

Shows parameters, errors, and other data.

Switches drive control for the Run command and frequency reference between the

keypad (LOCAL) and an external source (REMOTE).

Note:

• The LOCAL/REMOTE Selection Key continuously stays enabled after the drive

stops in Drive Mode. If the application must not switch from REMOTE to LOCAL

because it will have a negative effect on system performance, set o2-01 = 0 [LO/

RE Key Function Selection = Disabled] to disable .

• The drive will not switch between LOCAL and REMOTE when it is receiving a

Run command from an external source.

M

N RJ-45 Connector

REMOTE Run Selection = Accept Existing RUN Command], the drive can start suddenly. Before you change the

control source, remove all personnel from the area around the drive, motor, and load. Sudden starts can cause

serious injury or death.

DWEZ LED Illuminated: The drive is In DriveWorksEZ operation.

Connects to the drive. Use an RJ-45 8-pin straight through UTP CAT5e extension cable

to install the keypad in a different location than the drive.

WARNING

Sudden Movement Hazard. If you change the control source when b1-07 = 1 [LOCAL/

20 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

◆ Keypad Mode and Menu Displays

6 Overview of Keypad Components and Functions

Figure 6.2 Keypad Functions and Display Levels

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 21

7 Mechanical Installation

7 Mechanical Installation

This chapter gives information about the correct environment and clearances to install the drive.

◆ Drive Exterior and Mounting Dimensions

■ IP20/UL Open Type

B001 to B004, 2001 to 2006

Figure 7.1 Exterior and Mounting Dimensions

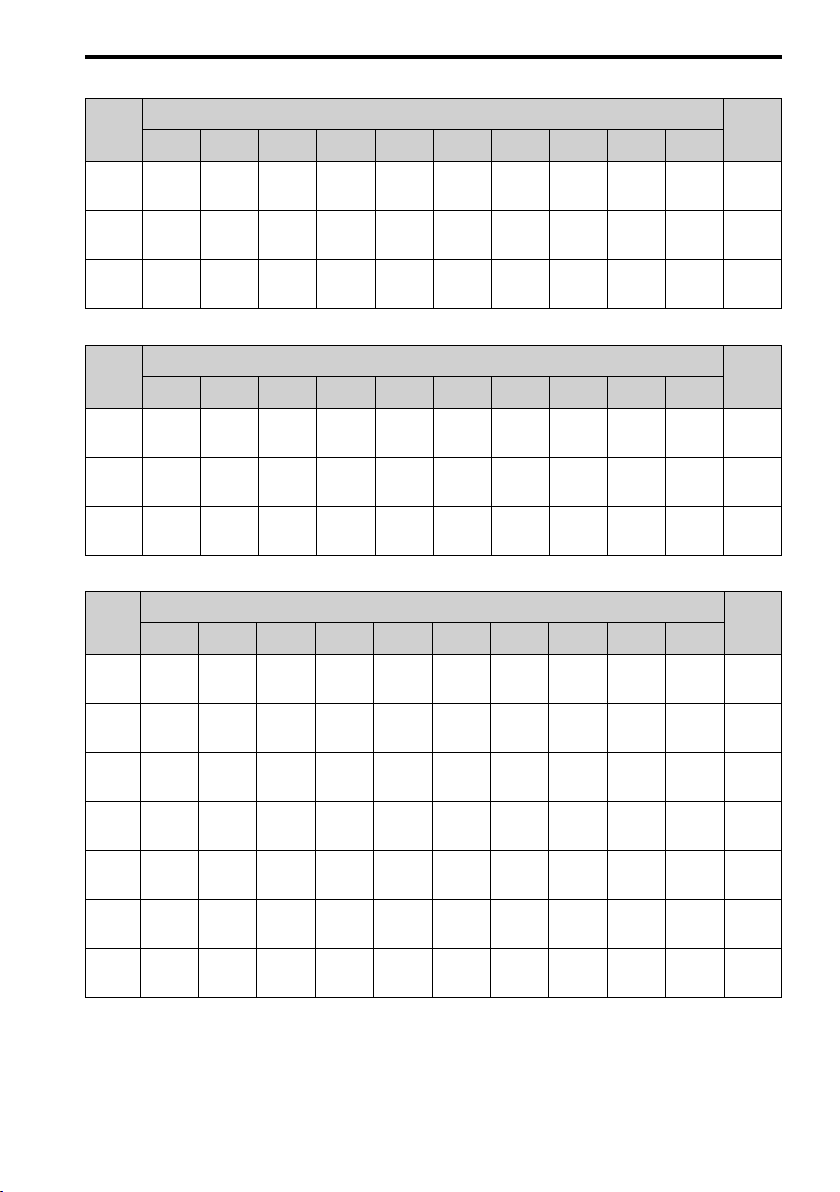

Table 7.1 Single-Phase 200 V Class (IP20/UL Open Type, without Built-in EMC Filter)

M5

M5

M5

Est.

Weight

d

kg (lb)

0.5

(1.1)

0.5

(1.1)

0.8

(1.8)

Model

B001A

B002A

B004A

22 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

W H D W1 W2 H1 H2 D1 t1

68

128

(2.68)

(5.04)76(2.99)56(2.20)6(0.24)

68

128

(2.68)

(5.04)76(2.99)56(2.20)6(0.24)

68

128

(2.68)

(5.04)

118

(4.65)56(2.20)6(0.24)

Dimensions mm (in)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

6.5

(0.26)3(0.12)

6.5

(0.26)3(0.12)

38.5

(1.52)5(0.20)

7 Mechanical Installation

Table 7.2 Single-Phase 200 V Class (IP20/UL Open Type, with Built-in EMC Filter)

Model

B001E

B002E

B004E

W H D W1 W2 H1 H2 D1 t1

68

128

(2.68)

68

(2.68)

68

(2.68)

(5.04)

(5.04)

(5.04)

116

(4.57)56(2.20)6(0.24)

128

116

(4.57)56(2.20)6(0.24)

128

158

(6.22)56(2.20)6(0.24)

Dimensions mm (in)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

6.5

(0.26)3(0.12)

6.5

(0.26)3(0.12)

38.5

(1.52)5(0.20)

Table 7.3 Three-Phase 200 V Class (IP20/UL Open Type, without Built-in EMC Filter)

Model

2001A

2002A

2004A

2006A

W H D W1 W2 H1 H2 D1 t1

68

(2.68)

(2.68)

(2.68)

(2.68)

128

(5.04)76(2.99)56(2.20)6(0.24)

68

128

(5.04)76(2.99)56(2.20)6(0.24)

68

128

(5.04)

68

(5.04)

108

(4.25)56(2.20)6(0.24)

128

128

(5.04)56(2.20)6(0.24)

Dimensions mm (in)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

6.5

(0.26)3(0.12)

6.5

(0.26)3(0.12)

38.5

(1.52)5(0.20)

58.5

(2.30)5(0.20)

M5

M5

M5

M5

M5

M5

M5

Est.

Weight

d

kg (lb)

0.7

(1.6)

0.7

(1.6)

1.0

(2.2)

Est.

Weight

d

kg (lb)

0.5

(1.1)

0.5

(1.1)

0.8

(1.8)

0.9

(2.0)

Table 7.4 Three-Phase 200 V Class (IP20/UL Open Type, with Built-in EMC Filter)

M5

M5

M5

M5

Est.

Weight

d

kg (lb)

0.6

(1.3)

0.6

(1.3)

0.9

(2.0)

1.1

(2.4)

Model

2001E

2002E

2004E

2006E

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 23

W H D W1 W2 H1 H2 D1 t1

68

128

(2.68)

68

(2.68)

68

(2.68)

68

(2.68)

(5.04)

(5.04)

(5.04)

(5.04)

116

(4.57)56(2.20)6(0.24)

128

116

(4.57)56(2.20)6(0.24)

128

148

(5.83)56(2.20)6(0.24)

128

168

(6.61)56(2.20)6(0.24)

Dimensions mm (in)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

6.5

(0.26)3(0.12)

6.5

(0.26)3(0.12)

38.5

(1.52)5(0.20)

58.5

(2.30)5(0.20)

7 Mechanical Installation

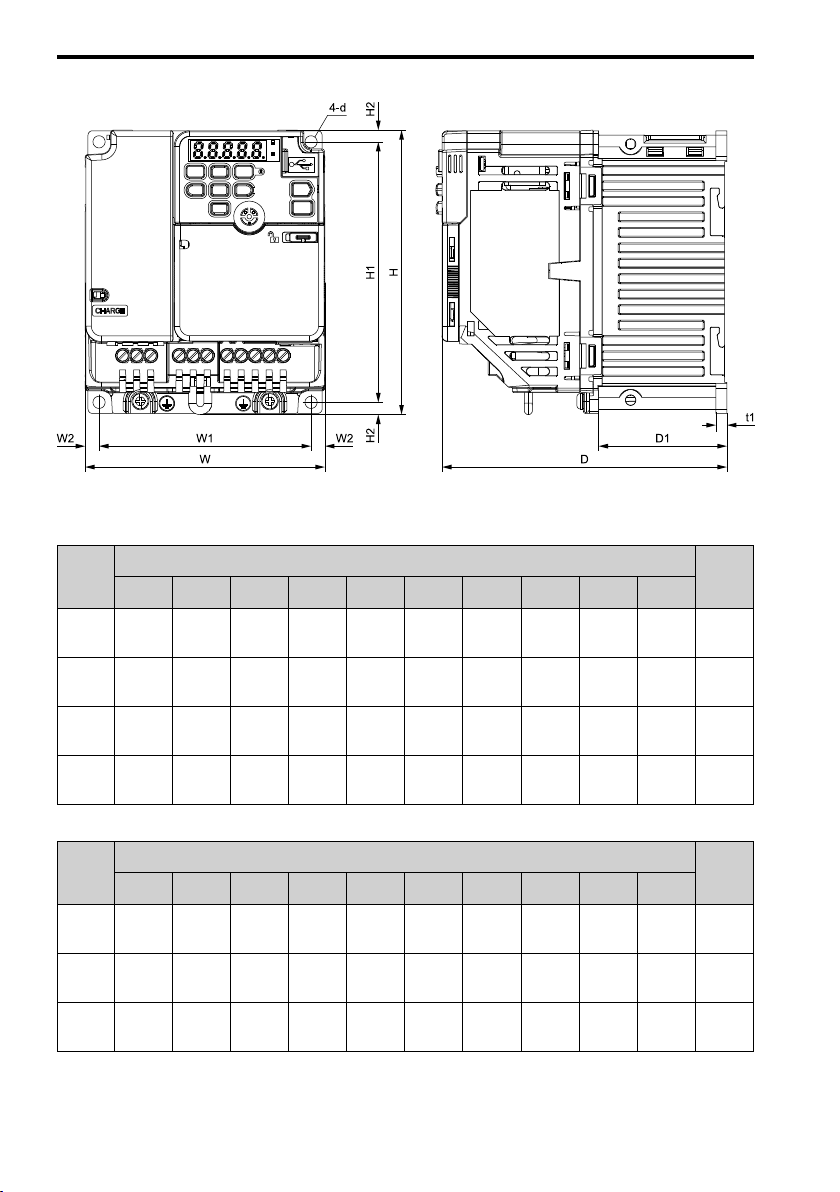

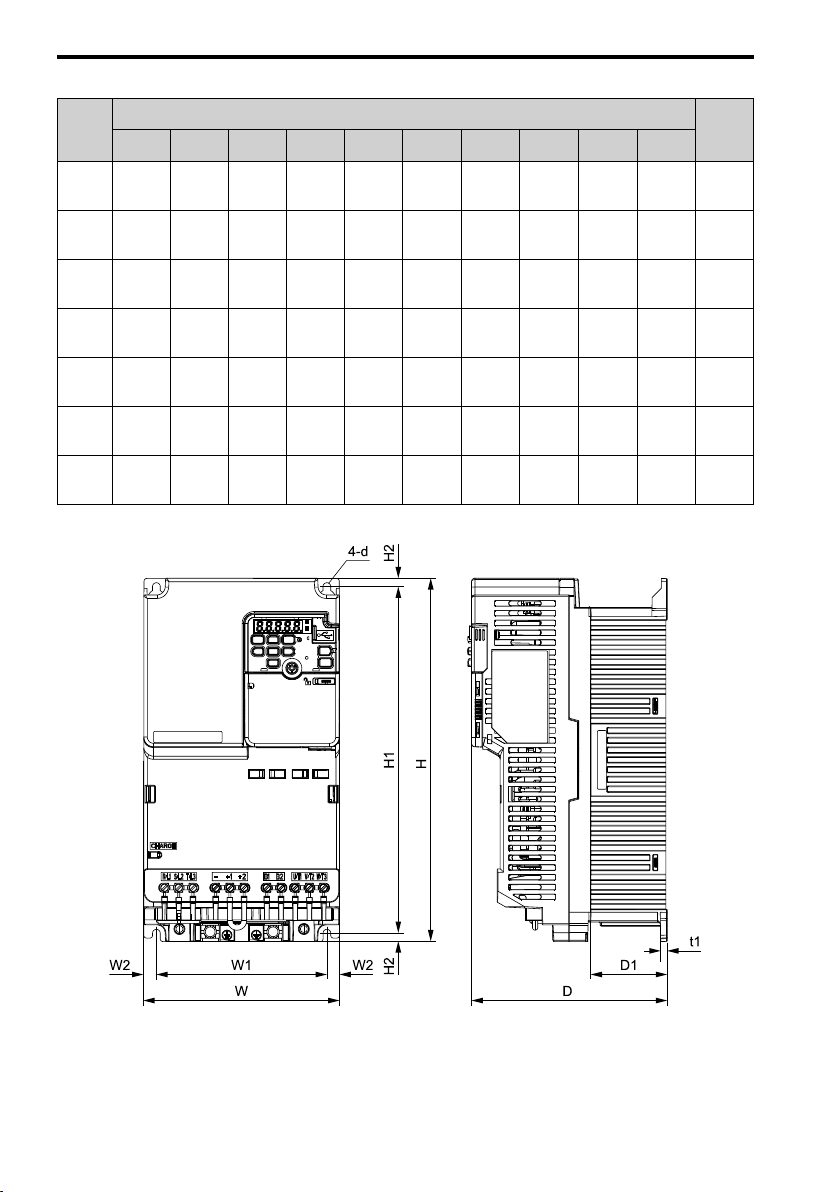

B006 to B018, 2010 to 2021, 4001 to 4012

Figure 7.2 Exterior and Mounting Dimensions

Table 7.5 Single-Phase 200 V Class (IP20/UL Open Type, without Built-in EMC Filter)

Model

B006A

B010A

B012A

B018A

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

108

(4.25)

140

(5.51)

170

(6.69)

137.5

(5.04)

(5.41)96(3.78)6(0.24)

128

(5.04)

(5.04)

(5.04)

154

(6.06)96(3.78)6(0.24)

128

163

(6.42)

128

180

(7.09)

Dimensions mm (in)

128

(5.04)6(0.24)

158

(6.22)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

M5

M5

M5

M5

Est.

Weight

kg (lb)

1.5

(3.3)

1.5

(3.3)

2.1

(4.6)

2.9

(6.4)

Table 7.6 Single-Phase 200 V Class (IP20/UL Open Type, with Built-in EMC Filter)

M5

M5

M5

Est.

Weight

kg (lb)

1.8

(4.0)

1.8

(4.0)

2.7

(6.0)

Model

B006E

B010E

B012E

24 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

108

(4.25)

140

(5.51)

182.5

(5.04)

(7.19)96(3.78)6(0.24)

128

(5.04)

(5.04)

199

(7.83)96(3.78)6(0.24)

128

203

(7.99)

Dimensions mm (in)

128

(5.04)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

7 Mechanical Installation

Table 7.7 Three-Phase 200 V Class (IP20/UL Open Type, without Built-in EMC Filter)

Model

2010A

2012A

2021A

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

108

(4.25)

140

(5.51)

(5.04)

(5.04)

(5.04)

129

(5.08)96(3.78)6(0.24)

128

137.5

(5.41)96(3.78)6(0.24)

128

143

(5.63)

Dimensions mm (in)

128

(5.04)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

Table 7.8 Three-Phase 200 V Class (IP20/UL Open Type, with Built-in EMC Filter)

Model

2010E

2012E

2021E

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

108

(4.25)

140

(5.51)

(5.04)

(5.04)

(5.04)

174

(6.85)96(3.78)6(0.24)

128

182.5

(7.19)96(3.78)6(0.24)

128

193

(7.60)

Dimensions mm (in)

128

(5.04)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

Table 7.9 Three-Phase 400 V Class (IP20/UL Open Type, without Built-in EMC Filter)

Model

4001A

4002A

4004A

4005A

4007A

4009A

4012A

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

(5.04)81(3.19)96(3.78)6(0.24)

108

(4.25)

(4.25)

(4.25)

(4.25)

(4.25)

(5.51)

128

(5.04)99(3.90)96(3.78)6(0.24)

108

128

137.5

(5.04)

(5.41)96(3.78)6(0.24)

108

128

(5.04)

108

(5.04)

108

(5.04)

140

(5.04)

154

(6.06)96(3.78)6(0.24)

128

154

(6.06)96(3.78)6(0.24)

128

154

(6.06)96(3.78)6(0.24)

128

143

(5.63)

Dimensions mm (in)

128

(5.04)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

8.5

(0.33)5(0.20)

26.5

(1.04)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

M5

M5

M5

M5

M5

M5

M5

M5

M5

M5

M5

M5

M5

Est.

Weight

kg (lb)

1.5

(3.3)

1.5

(3.3)

2.0

(4.4)

Est.

Weight

kg (lb)

1.6

(3.5)

1.6

(3.5)

2.4

(5.3)

Est.

Weight

kg (lb)

0.8

(1.8)

0.9

(2.0)

1.5

(3.3)

1.5

(3.3)

1.5

(3.3)

1.5

(3.3)

2.0

(4.4)

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 25

7 Mechanical Installation

Table 7.10 Three-Phase 400 V Class (IP20/UL Open Type, with Built-in EMC Filter)

Model

4001E

4002E

4004E

4005E

4007E

4009E

4012E

W H D W1 W2 H1 H2 D1 t1 d

108

128

(4.25)

108

(4.25)

108

(4.25)

108

(4.25)

108

(4.25)

108

(4.25)

140

(5.51)

(5.04)

(5.04)

(5.04)

(5.04)

(5.04)

(5.04)

(5.04)

126

(4.96)96(3.78)6(0.24)

128

144

(5.67)96(3.78)6(0.24)

128

182.5

(7.19)96(3.78)6(0.24)

128

199

(7.83)96(3.78)6(0.24)

128

199

(7.83)96(3.78)6(0.24)

128

199

(7.83)96(3.78)6(0.24)

128

193

(7.60)

Dimensions mm (in)

128

(5.04)6(0.24)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)

118

(4.65)5(0.20)65(2.56)5(0.20)

8.5

(0.33)5(0.20)

26.5

(1.04)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

56.5

(2.22)5(0.20)

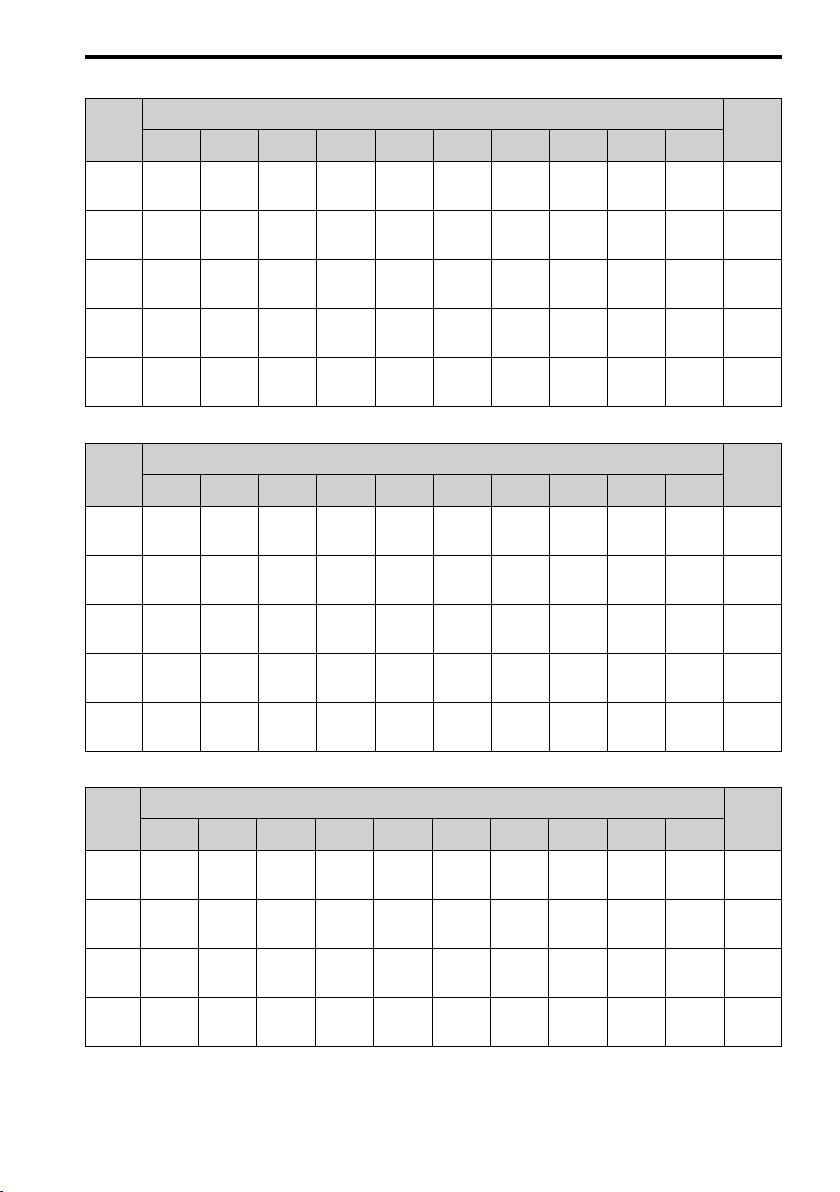

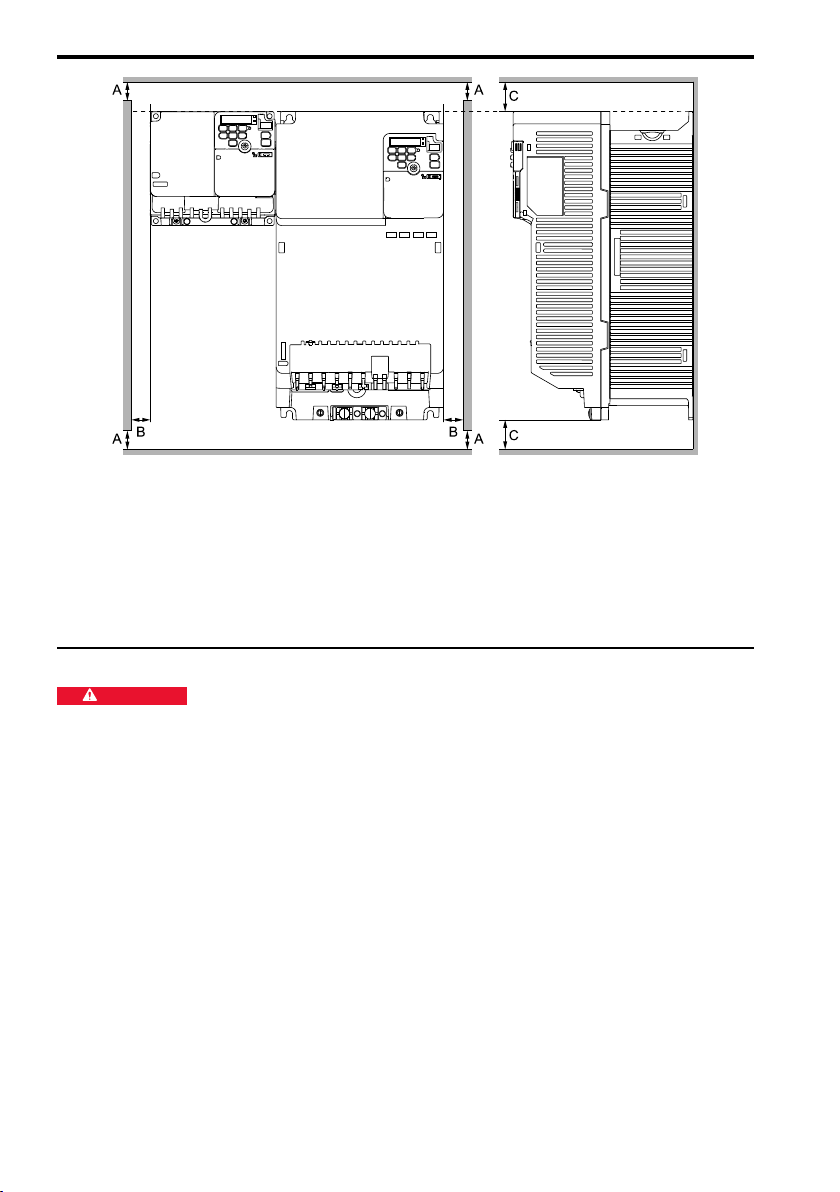

2030 to 2082, 4018 to 4060

M5

M5

M5

M5

M5

M5

M5

Est.

Weight

kg (lb)

1.4

(3.1)

1.5

(3.3)

1.9

(4.2)

1.9

(4.2)

1.9

(4.2)

1.9

(4.2)

2.6

(5.7)

Figure 7.3 Exterior and Mounting Dimensions

26 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

7 Mechanical Installation

Table 7.11 Three-Phase 200 V Class (IP20/UL Open Type, without Built-in EMC Filter)

Model

2030A

2042A

2056A

2070A

2082A

W H D W1 W2 H1 H2 D1 t1 d

140

260

260

300

350

350

140

(5.51)

140

(5.51)

143

(5.63)

187

(7.36)

187

(7.36)

(5.51)

140

(5.51)

180

(7.09)

220

(8.66)

220

(8.66)

(10.24)

(10.24)

(11.81)

(13.78)

(13.78)

Dimensions mm (in)

122

(4.80)9(0.35)

122

(4.80)9(0.35)

160

(6.30)10(0.39)

192

(7.56)14(0.55)

192

(7.56)14(0.55)

248

(9.76)6(0.24)55(2.17)5(0.20)

248

(9.76)6(0.24)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

336

(13.23)7(0.28)78(3.07)5(0.20)

336

(13.23)7(0.28)78(3.07)5(0.20)

M5

M5

M5

M6

M6

Table 7.12 Three-Phase 200 V Class (IP20/UL Open Type, with Built-in EMC Filter)

Model

2030E

2042E

2056E

2070E

2082E

W H D W1 W2 H1 H2 D1 t1 d

140

260

260

300

350

350

196

(7.72)

196

(7.72)

196

(7.72)

216

(8.50)

216

(8.50)

(5.51)

140

(5.51)

180

(7.09)

220

(8.66)

220

(8.66)

(10.24)

(10.24)

(11.81)

(13.78)

(13.78)

Dimensions mm (in)

122

(4.80)9(0.35)

122

(4.80)9(0.35)

160

(6.30)10(0.39)

192

(7.56)14(0.55)

192

(7.56)14(0.55)

248

(9.76)6(0.24)55(2.17)5(0.20)

248

(9.76)6(0.24)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

336

(13.23)7(0.28)78(3.07)5(0.20)

336

(13.23)7(0.28)78(3.07)5(0.20)

M5

M5

M5

M6

M6

Est.

Weight

kg (lb)

3.4

(7.5)

3.6

(7.9)

5.5

(12.1)

7.5

(16.5)

8.0

(17.6)

Est.

Weight

kg (lb)

3.9

(8.6)

4.1

(9.0)

6.0

(13.2)

8.5

(18.7)

9.0

(19.9)

Table 7.13 Three-Phase 400 V Class (IP20/UL Open Type, without Built-in EMC Filter)

M5

M5

M5

M5

Est.

Weight

kg (lb)

3.0

(6.6)

3.2

(7.1)

4.6

(10.2)

4.8

(10.6)

Model

4018A

4023A

4031A

4038A

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 27

W H D W1 W2 H1 H2 D1 t1 d

140

260

260

300

300

140

(5.51)

140

(5.51)

143

(5.63)

143

(5.63)

(5.51)

140

(5.51)

180

(7.09)

180

(7.09)

(10.24)

(10.24)

(11.81)

(11.81)

Dimensions mm (in)

122

(4.80)9(0.35)

122

(4.80)9(0.35)

160

(6.30)10(0.39)

160

(6.30)10(0.39)

248

(9.76)6(0.24)55(2.17)5(0.20)

248

(9.76)6(0.24)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

7 Mechanical Installation

Model

4044A

4060A

W H D W1 W2 H1 H2 D1 t1 d

190

350

204

(7.48)

190

(7.48)

(13.78)

(13.78)

350

(8.03)

204

(8.03)

Dimensions mm (in)

160

(6.30)15(0.59)

160

(6.30)15(0.59)

336

(13.23)7(0.28)94(3.70)5(0.20)

336

(13.23)7(0.28)94(3.70)5(0.20)

Table 7.14 Three-Phase 400 V Class (IP20/UL Open Type, with Built-in EMC Filter)

Model

4018E

4023E

4031E

4038E

4044E

4060E

W H D W1 W2 H1 H2 D1 t1 d

140

260

260

300

300

350

350

196

(7.72)

196

(7.72)

196

(7.72)

196

(7.72)

251

(9.88)

251

(9.88)

(5.51)

140

(5.51)

180

(7.09)

180

(7.09)

190

(7.48)

190

(7.48)

(10.24)

(10.24)

(11.81)

(11.81)

(13.78)

(13.78)

Dimensions mm (in)

122

(4.80)9(0.35)

122

(4.80)9(0.35)

160

(6.30)10(0.39)

160

(6.30)10(0.39)

160

(6.30)15(0.59)

160

(6.30)15(0.59)

248

(9.76)6(0.24)55(2.17)5(0.20)

248

(9.76)6(0.24)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

284

(11.18)8(0.31)55(2.17)5(0.20)

336

(13.23)7(0.28)94(3.70)5(0.20)

336

(13.23)7(0.28)94(3.70)5(0.20)

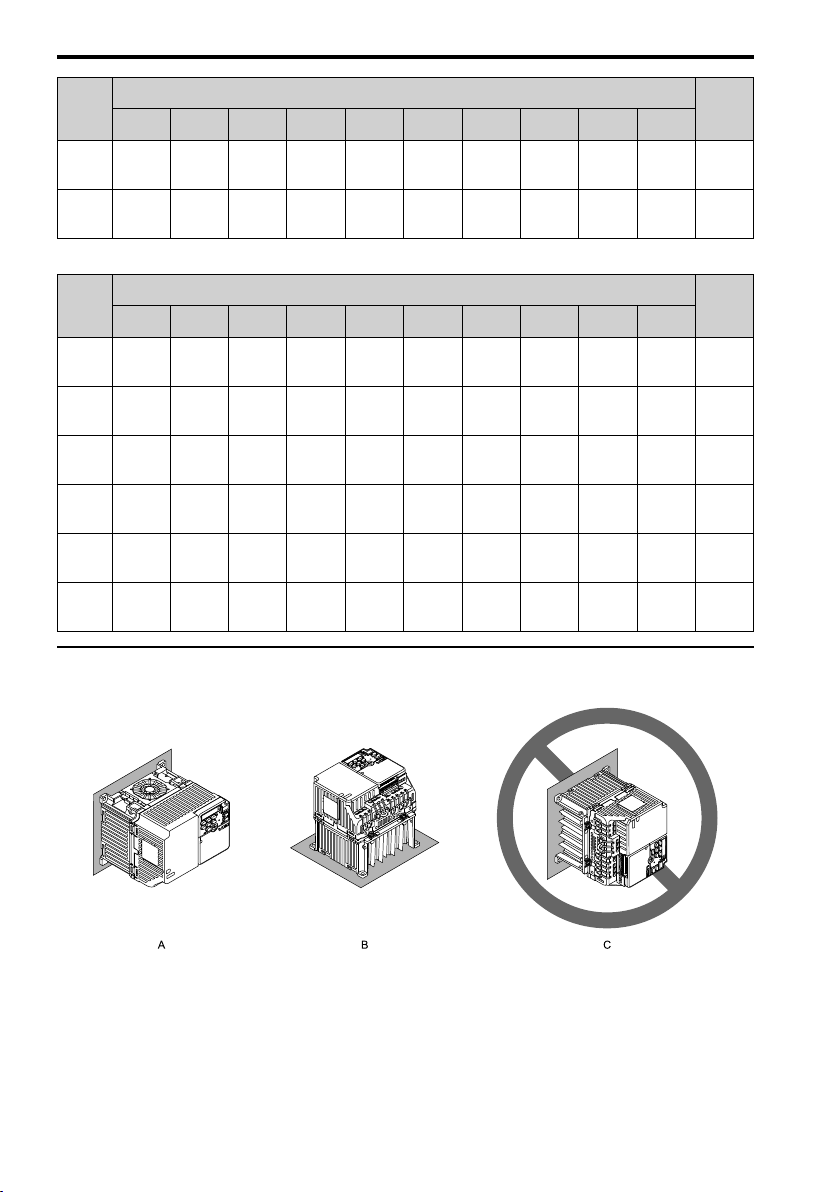

◆ Installation Position and Clearances

Install the drive as shown in Figure 7.4 for sufficient airflow to cool the drive.

M6

M6

M5

M5

M5

M5

M6

M6

Est.

Weight

kg (lb)

6.5

(14.3)

6.5

(14.3)

Est.

Weight

kg (lb)

3.9

(8.6)

3.9

(8.6)

5.5

(12.1)

5.5

(12.1)

8.0

(17.6)

8.5

(18.7)

A - Vertical installation

B - Horizontal installation

C - Rotated installation

*1

Figure 7.4 Installation Orientation

*1 Refer to the drive Technical Reference (SIEP C710617 52) for more information about horizontal installation.

28 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

7 Mechanical Installation

■ Single Drive Installation Clearances

Use the clearances specified in Figure 7.5 to install the drive. Make sure that there is sufficient

space for wiring and airflow.

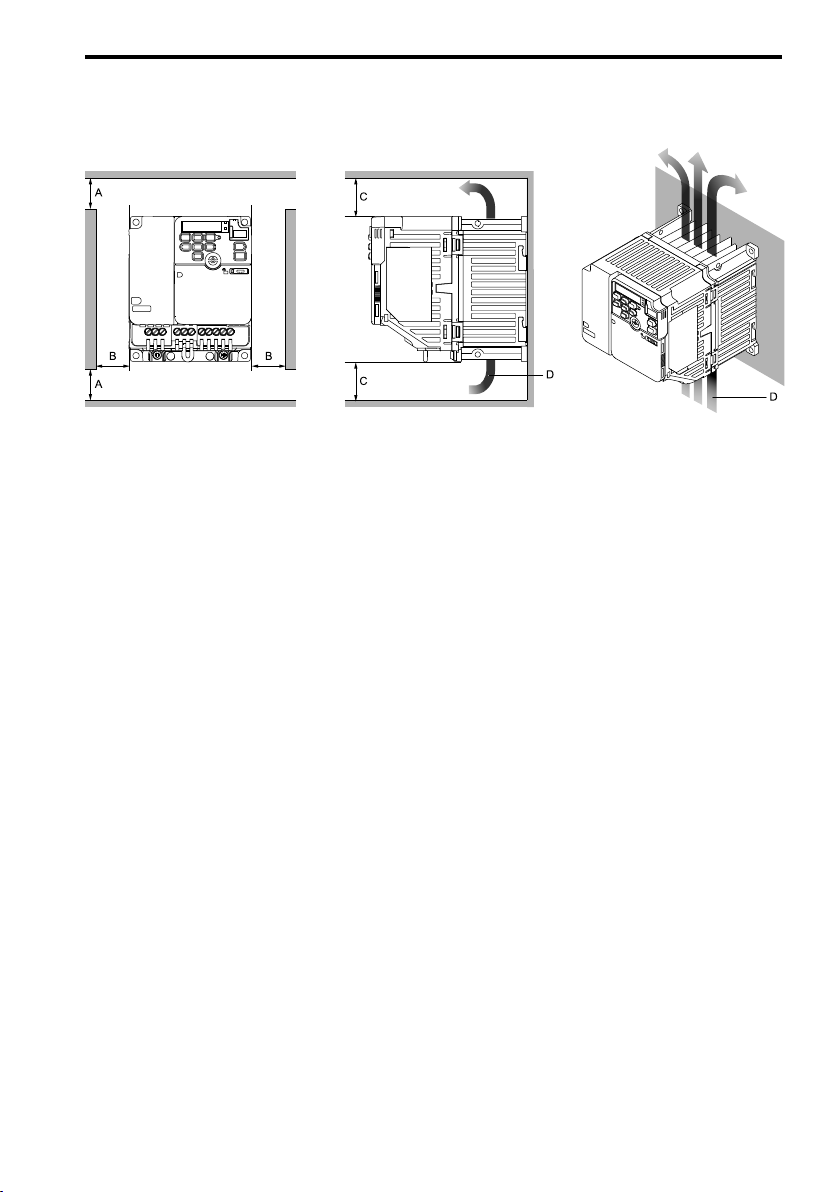

A - 50 mm (2 in) minimum

between upper and lower

openings

B - 30 mm (1.18 in) minimum on

each side

C - 100 mm (3.94 in) minimum

above and below

D - Airflow direction

Figure 7.5 Installation Clearances for One Drive

■ Install Drives Side-by-Side

When you install drives side-by-side, set to L8-35 = 1 [Installation Method Selection = Side-bySide Mounting].

Refer to the Technical Reference and derate the drives for the ambient temperature.

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 29

7 Mechanical Installation

A - 50 mm (1.97 in) minimum

between upper and lower

openings

B - 30 mm (1.18 in) minimum on

each side

C - 100 mm (3.94 in) minimum

above and below

Figure 7.6 Installation Spacing for More than One Drive (Side-by-Side)

Note:

Align the tops of drives that have different dimensions to help when you replace cooling fans.

◆ Removing/Reattaching Covers

DANGER

drive. Before servicing, disconnect all power to the equipment and wait for the time specified on the warning label

at a minimum. The internal capacitor stays charged after the drive is de-energized. The charge indicator LED

extinguishes when the DC bus voltage decreases below 50 Vdc. When all indicators are OFF, measure for

dangerous voltages to make sure that the drive is safe. If you do work on the drive when it is energized, it will

cause serious injury or death from electrical shock.

Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized

■ Remove the Front Cover

1. Use a slotted screwdriver to unlock the front cover of the drive.

Use a slotted screwdriver with a tip width of 2.5 mm (0.1 in) or less and a thickness of

0.4 mm (0.02 in) or less.

30 YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation

Loading...

Loading...