Page 1

Catalog CA.G7.01

G7 Drives for Industrial Automation

Date: 6/1/08

Page 2

Table of Contents

G7 Drive (G7)

Description ................................................................... 3

Standard Drives ................................................................... 4

Dynamic Braking Options ................................................................... 6

Ring Kit Options ................................................................... 10

End Cap Kit Options ................................................................... 11

Reactor Options ................................................................... 12

Bus Reactor Options ................................................................... 14

Control Options ................................................................... 15

Communications Options ................................................................... 17

Dimensions and Data ................................................................... 18

Page

G7/Configured Package (G7C)

Description ................................................................... 19

Configured Drives and Options ................................................................... 24

Heatsink Filter Kit Options ................................................................... 26

Dimensions and Data ................................................................... 27

Software, Drawings, Manuals ................................................................... 28

Technical Training ................................................................... 29

Terms and Conditions ................................................................... 30

Options Matrix ................................................................... 32

Page 1

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 3

This price book may describe trademarked equipment, which is the property of other companies. These

trademarks are the property of the registered owner companies and may include the following:

TM

DeviceNet

Profibus

Modbus

LonWorks

, trademark of ODVA.

®

, trademark of PROFIBUS International

®

, trademark of Schneider Automation, Inc.

®

, trademark of Echelon Corporation

Other Documents and Manuals are available to support special use or installation of this product. These

documents may be provided with the product or upon request. Contact Yaskawa Electric America, Inc. or visit

www.yaskawa.com, as required. Documents may include the following:

TM.G7.01... Drive Technical Manual included on CD ROM with product

TM.AFD.12... Profibus-DP... Manual included on CD ROM with product

TM.AFD.13... DeviceNet... Manual included on CD ROM with product

TM.AFD.14... DeviceNet... Manual included on CD ROM with product

TM.AFD.17... Modbus Plus... Manual included on CD ROM with product

TM.AFD.20... LonWorks... Manual included on CD ROM with product

TM.AFD.26... EtherNet/IP... Included on CD ROM with product

DriveWizard... Software and Manual...Included on CD ROM with product

Option Installation Guides... Included on CD ROM with product

REVISIONS

Change Page

Changed revision date all pages

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 2

Page 4

Description

1/2 - 500HP

This amazing AC drive is the ultimate performance solution with increased speed and torque response to

provide servo-like performance from an induction motor. In addition, the G7 has the world’s first 480V 3-level

inverter architecture that eliminates or minimizes the installation problems associated with IGBT switching

and protects the entire motor-drive system.

Several control modes are provided. In open loop vector mode, the latest flux observer algorithms extend

speed range and provide maximum starting torque. In closed loop vector mode, 0.01% speed regulation and

1000:1 control range can be achieved. Zero-servo capability provides position control at zero speed. The G7

power section includes built-in bus choke (most ratings), 12-pulse input capability (most ratings), common

DC bus capability and regeneration options.

This G7 (480V) allows motor operation at very long cable lengths, with peak voltage being 30% less than

conventional drives. Motor bearing current is 50% less than standard drives, providing four times the bearing

life. Audible motor noise is 20% less.

DriveWizard™, DriveWorksEZ™ and Network Communication are available.

G7

Performance Features

• Ratings: 1/2 to 150HP, 208 VAC

1/2 to 150HP, 240 VAC

3/4 to 500HP, 480 VAC

• Overload capacity: heavy duty,

150% for 1 min, 200% Peak

• Starting torque:

150% at 1Hz (V/f), at 0.5 Hz (open loop),

at 0.3 Hz (closed loop)

• Output frequency: 0.01 to 400Hz

• Speed control range:

40:1 (V/f), 200:1 (open loop),

1000:1 (closed loop)

• Speed regulation:

1% (V/f), 0.2% (open loop), 0.01% (closed

loop)

• Speed response: 60Hz

• Torque response: 300Hz

• Speed reference resolution: 0.01% with

digital reference, 0.1% with analog

reference, 0.01 Hz with network input

• Speed/Torque/Position Control

• Zero-servo mode

• Adjustable accel/decel: 0.01 to 6000

seconds

• S-Curve: adjustable 0.00 to 2.50 seconds,

for each corner

• Stall prevention

• Inertia and Power loss ride-thru

• Programmable auto restart after

momentary power loss

Protective Features

• DC bus CHARGE indicator

• Optically-Isolated controls

• Phase-to-phase / phase-to-neutral short

circuit protection

• Ground fault protection

• Electronic motor overload (UL508C)

• Current and torque limit (four quadrant)

• Over-torque / under-torque detection

• Over-current, over-voltage, and overtemperature

• Motor thermistor input

• Input/output phase loss

Design Features

• LCD keypad display: 5 lines x 16 characters, backlit, 7 languages, copy function

• Simplified programming: Quick Start and

modified parameter groups

• Microprocessor logic: 32 bit

• Memory type: Flash memory for easy

upgrades, custom software applications,

and non-volatile program retention

• Control logic: 24VDC (sinking or sourcing)

• Terminal strip: Quick disconnect

• Front cover: Split for easy wiring

• Heat sink fan: Plug-in with on/off control

• Motor auto-tuning: Static and rotational

• Speed search: Bi-directional into rotating

motor

• Process control: PID, reference with PID trim

• Motor parameters: 2 sets

• Stopping methods: Ramp stop, coast stop,

fast stop, or high slip braking

• DC injection braking: Adjustable level, time

• Speed reference presets: 17 available

• Timer function: Programmable on/off delay

• Digital M.O.P.: Up/down/hold/reset reference

• Bias and gain: All analog and pulse train I/O

• Common DC bus capability: All models

• Dynamic braking transistor: 20 HP and below

(240VAC), 25 HP and below (460VAC)

• Bus Reactor: 25 HP and above (240VAC),

30HP and above (460VAC)

• Twelve-pulse capability: 25 HP and above

(240VAC), 30HP and above (460VAC)

Service Conditions

• Enclosure: NEMA 1 or protected chassis

• Ambient service temperatures:

-10 to 40°C (104°F) NEMA1,

-10 to 45°C (113°F) protected chassis

• Input frequency: 50/60Hz ± 5%

• Input voltage: +10% / -15%, 3 phase, 240

or 480VAC, phase insensitive

• Humidity: non-condensing 95% max

• Altitude: to 3300 feet (1000 meters) w/o

derate

• Vibration: 1G or less (10 to 20Hz), 0.6G or

less (20 to 55Hz)

Inputs and Outputs

• Analog inputs: 3 (2 programmable),

±10VDC (20K ohms) or 4 to 20 mA

(250 ohm), 11 bit plus sign

• Analog outputs: 2 programmable,

±10VDC or 4- to 20mA, 9 bit plus sign

• Digital inputs: 12 (10 programmable),

sinking or sourcing

• Digital outputs: 5 programmable, 3 form A

and two open collector

• Pulse train input: 1 programmable, 32 KHz

max

• Pulse train output: 1 programmable,

32 KHz max

• Fault contacts: 1 form C

• RS-232/422/485: Modbus RTU

Standards & Reliability

• UL, cUL & CE

• MBTF: Exceeds 28 years

Options

• DriveWorksEZ™ programming tool

• DriveWizard™ software (upload / download)

• Custom drive software

• Ethernet, DeviceNet, Profibus-DP, and

others

• Remote display/keypad

• High resolution I/O cards

• 120 VAC interface

• NEMA 12 enclosures

• Input breaker, disconnect, fuses

• Input/output reactors

• EMC-compliant filters

• Dynamic braking transistor (if not standard)

• Bus Reactor (if not standard)

• Line regeneration (RC5 or DC5)

480V Three-Level Inverter Benefits

• Lead length; Meets NEMA MG1 Part 31

• Motor bearing life: 4 times increase

• Quiet operation: 5-10dB of noise reduction

• Common mode current: 50% reduction

Page 3

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 5

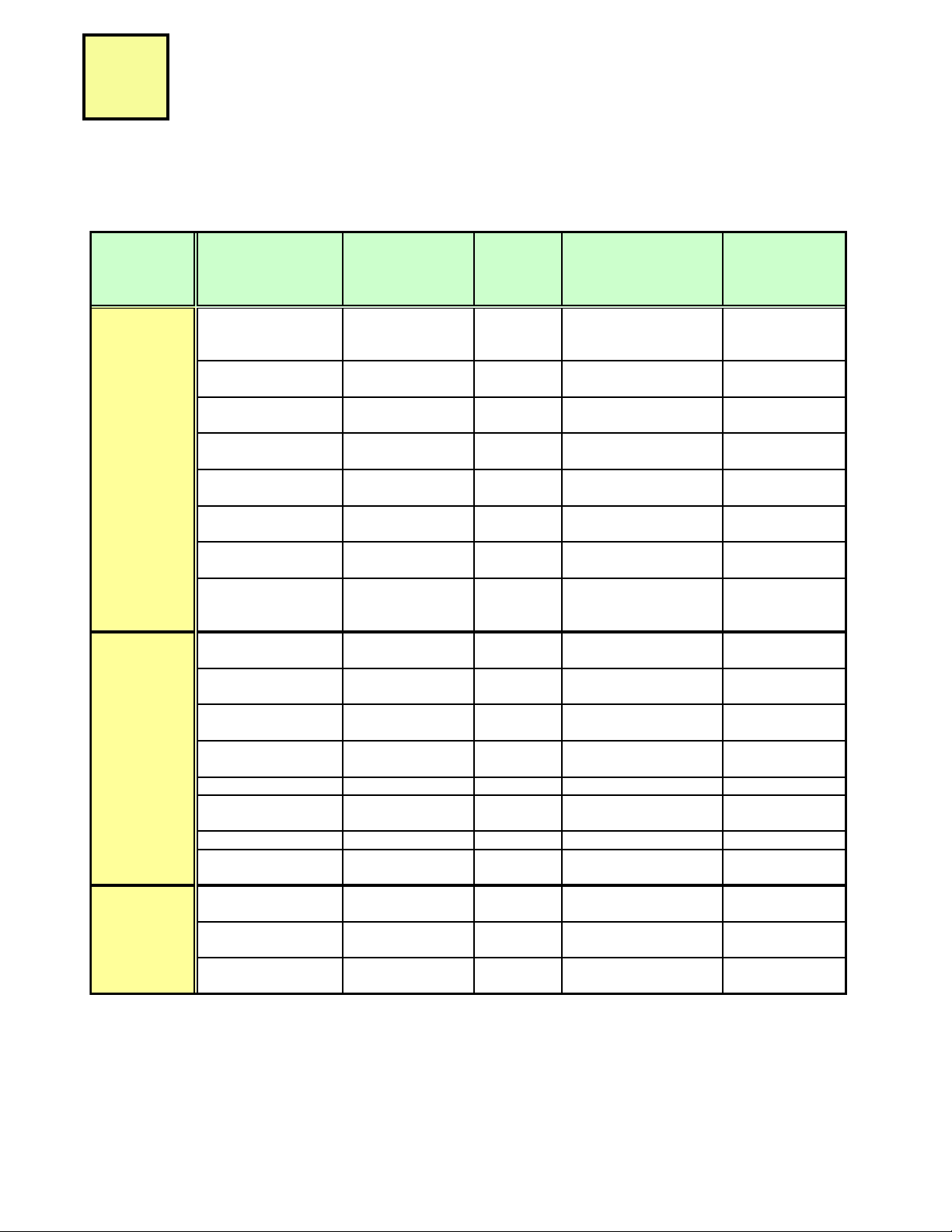

G7

Rated Input

Voltage

Drive Model Number

CIMR-G7U

Rated Output

Current (Amps)

Nominal HP

(2)

Standard Enclosure

Drive List

Price $

20P41 3.2 1/2

20P71 61

21P51 82

22P21 12 3

23P71 18 5

25P51 27 7.5

27P51 34 10

20111 49 15

20151 66 20

20181 80 25

20221 96 30

20300 130 40

20370 160 50

20450 183 60

20550 224 75

20750 300 100

20900 358 125

21100 415 150

20P41 3.2 3/4

20P71 61

21P51 82

22P21 12 3

23P71 18 5

25P51 27 7.5

27P51 34 10

20111 49 15

20151 66 20 NEMA 1

25

30

20221 96

(3)

NEMA 1

40

50

20370 160 60

20450 183

(3)

20550 224 75

20750 300 100

20900 358 125

21100 415 150

Protected Chassis

NEMA 1

Protected Chassis

Protected Chassis

Protected Chassis

NEMA 1

NEMA 1

NEMA 1

NEMA 1

80

130

NEMA 1

NEMA 1

NEMA 1

NEMA 1

NEMA 1

Protected Chassis

Protected Chassis

Protected Chassis

208V

240V

230V

20181

20300

Standard Drives

(1)

input, NEMA 1 or protected chassis enclosure

30

60

Page 4

G7 Drives - 1/2-500HP, 208-230/240 and 480V, 3-phase

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(3) Check motor FLA for proper drive sizing

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 6

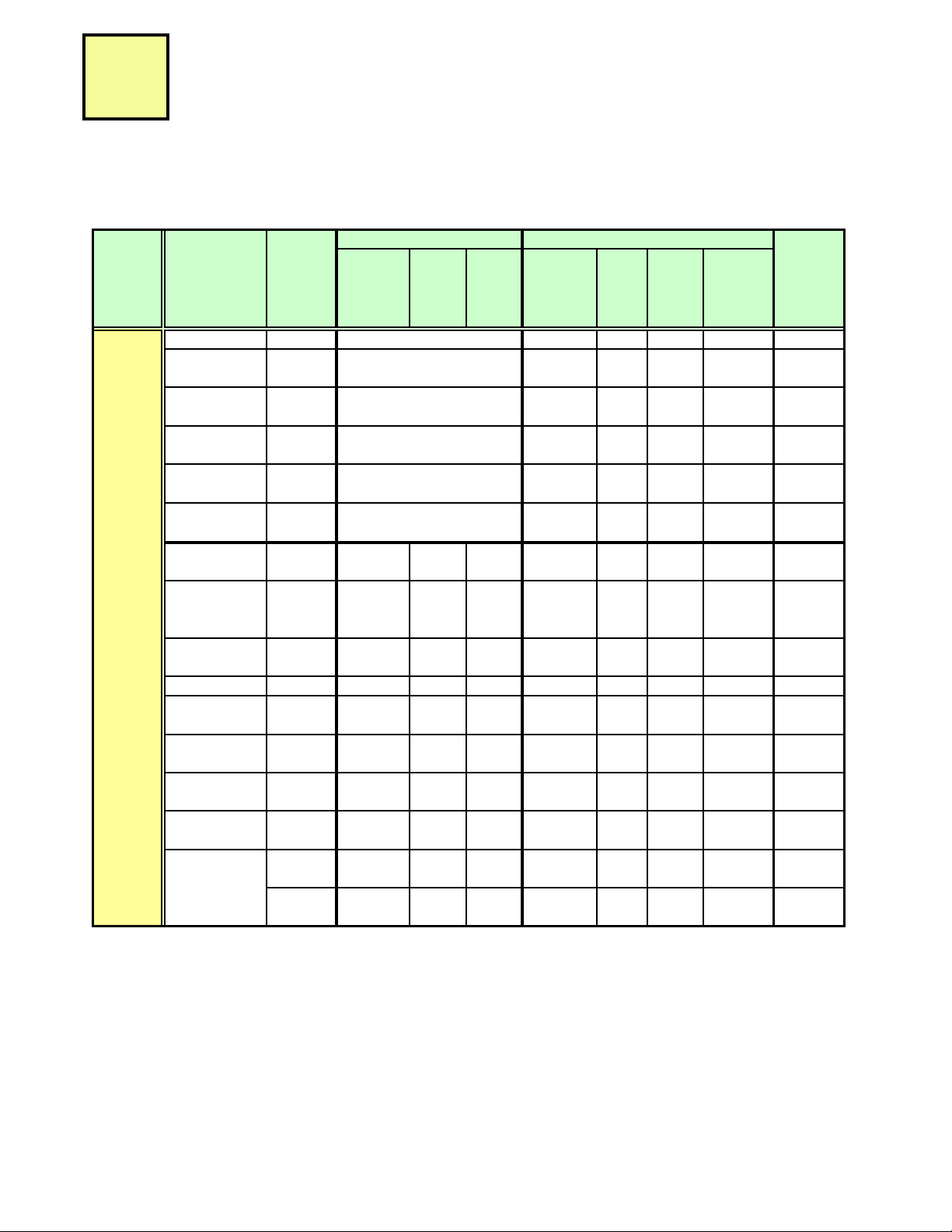

G7 Drives (Continued)

Rated Input

Voltage

Drive Model Number

CIMR-G7U

Rated Output

Current (Amps)

Nominal HP

(2)

Standard Enclosure

Drive List

Price $

40P41 1.8

3/4

NEMA 1

1

2

41P51 4.8 3

42P21 6.2

3

43P71 9 5

44P01 11 7.5

45P51 15

10

47P51 21 15

40111 27

20

40151 34

25

40181 42

30

40221 52 40

40301 65

50

40371 80 60

40451 97 75

40550 128 100

40750 165 125

40900 195 150

41100 240 200

41320 270

200

41600 302 250

41850 370 300

42200 450

350

400

500

NEMA 1

NEMA 1

NEMA 1

NEMA 1

NEMA 1

Protected Chassis

Protected Chassis

Protected Chassis

Protected Chassis

Protected Chassis

480V

40P71

43000

3.4

605

NEMA 1

NEMA 1

Standard Drives

G7

(3)

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

(3) Check motor FLA for proper drive sizing

Three-Phase Alternating Current Motors

Page 5

(3)

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 7

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Config-

uration

(2)

20P41 1/2 034 1

Single

(3)

3/4

1

21P51 2 023 1

Single

(3)

22P21 3 024 1

Single

(3)

23P71 5 025 1

Single

(3)

25P51 7.5 026 1

Single

(3)

27P51 10 027 1

Single

(3)

20111 15 140 1

Single

(4)

20151 20 136 1

Single

(4)

20181 25 135 1 Dual

20221 30 135 1 Dual

20300 40 129 1 Dual

20370 50

20450 60

20550 75 2110B 1 096 1 Single

Single

Single

1 Single

2 Dual

21100 150 2110B 2 097 1 Dual

1 each

Single

1 each

100

096 & 128

096 & 127

1

2110B

1

2110B &

2022B

1 each

2110B &

2022B

2022B 2

Included

Included

Included

Included

Rated

Input

Voltage

Drive Model

Number

CIMR-G7U

Nominal

HP

(1)

208V

20P71

20750

20900

100

125

Single

(3)

Resistor(s)

Total

List

Price $

(5)

1

Transistor Module(s)

Included

Included

022

G7

Dynamic Braking, 10% Duty Cycle - Used to assist the drive to periodically decelerate a load without overvoltage

trips. Ten percent dynamic braking is not typically used for "hold-back" type applications, such as unwinders, elevators, hoists,

or downhill conveyors. Dynamic braking consists of at least one transistor and at least one resistor, and are sized for rated

motor horsepower. The braking transistor may be included in the standard drive; this is indicated in the tables below. The

resistors are sized for a 10% duty cycle (10 seconds maximum on-time of every 100 seconds), and will provide approximately

150% braking torque. Refer to the dynamic braking instruction sheet for more details; consult Yaskawa for information on

higher duty cycles.

10% Duty

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Single = 1 resistor per package

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 6

Page 8

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Config-

uration

(2)

1/2 034 1

Single

(3)

3/4 022 1

Single

(3)

20P71 1 022 1

Single

(3)

21P51 2 023 1

Single

(3)

22P21 3 024 1

Single

(3)

23P71 5 025 1

Single

(3)

25P51 7.5 026 1

Single

(3)

27P51 10 027 1

Single

(3)

20111 15 140 1

Single

(4)

20151 20 136 1

Single

(4)

25

30

20221 30 2022B 2 135 2 Dual

20300 50

20370 60

20450 60 100 1 Single

20550 75 096 1 Single

Single

Single

1 Single

2 Dual

21100 150 2110B 2 097 1 Dual

Resistor(s)

Total

List

Price $

(5)

Transistor Module(s)

Rated

Input

Voltage

Drive Model

Number

CIMR-G7U

Nominal

HP

(1)

Included

Included

20900

100

125

Included

Included

Included

2110B

230/

240V

2022B

2

20P41

20181

20750

2110B &

2022B

2110B &

2022B

1

1

1 each

2110B

135

100

096 & 128

096 & 127

2

1

1 each

1 each

Dual

Single

Dynamic Braking, 10% Duty Cycle (continued for 230/240V)

10% Duty

G7

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Single = 1 resistor per package

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

Page 7

Data subject to change without notice

Yaskawa Electric America

CA.G7.01, 6/1/08

Page 9

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Configuration

(2)

40P41 3/4 32 1

Single

(3)

1

2

41P51 3

42P21 3

43P71 5 35 1

Single

(3)

44P01 7.5 36 1

Single

(3)

45P51 10 37 1

Single

(3)

47P51 15 38 1

Single

(3)

40111 20

40151 25

40181 30 150 1 Single

40221 40 142 1 Single

40301 50 151 1 Dual

40371 60 151 1 Dual

40451 75 143 1 Dual

40550 100

40750 125

40900 150 4220B 1 165 1 Single

Single

Single

Single

Single

1 Single

2 Dual

41850 300

42200 350

Dual

Single

450

500

1

Resistor(s)

Total

List

Price $

(5)

Transistor Module(s)

Included

Included

33

Rated

Input

Voltage

Drive Model

Number

CIMR-G7U

Nominal

HP

(1)

40P71

480V

41100 200

41320 200

41600

Included

Included

Included

Included

4045B 2

1

4220B &

4045B

1

4045B

1

400

4220B

4220B &

4045B

4220B &

4045B

4220B

43000

1

250

4220B

4220B

2

3

3

120 & 165

167

34

40

165 & 142

119

165 & 142

165 & 143

166

1

1

1

1

1

1

1 each

1 each

1 each

Single

(3)

Single

(3)

Single

(3)

Single

Dual

Triple

G7

Dynamic Braking, 10% Duty Cycle (continued for 480V)

10% Duty

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Single = 1 resistor per package

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 8

Page 10

Dynamic Braking Options

Part Number Qty List Price $ Braking Torque %

20P41 1/2 R7505 220

20P71 1 R7505

125

21P51 2 R7504

125

22P21 3 R7503

120

23P71 5 R7510

1 100

20P41 1/2 R7505 220

20P41 3/4 R7505 220

20P71 1 R7505

125

21P51 2 R7504

125

22P21 3 R7503

120

23P71 5 R7510

100

40P41

3/4

R7508 1 230

40P71

1

R7508 130

40P71

2

R7508 130

41P51 3 R7507

125

42P21 3 R7506

115

43P71 5 R7505

1 110

1

1

1

1

Resistor

208V

240V

480V

Rated Input

Voltage

Drive Model Number

CIMR-G7U

Nominal HP

(1)

1

1

1

3% Duty

Dynamic Braking, 3% Duty Cycle - Used to assist the drive to periodically decelerate a load without overvoltage

trips. Three percent dynamic braking is not applicable for "hold-back" type applications, such as unwinders, elevators, hoists,

or downhill conveyors. Dynamic braking consists of at least one transistor and at least one resistor, and are sized for rated

motor horsepower. The braking transistor is included in the standard drive for these resistors. The resistors are sized for a 3%

duty cycle (3 seconds maximum on-time of every 100 seconds), and will provide at least 100% braking torque. Refer to the

dynamic braking instruction sheet for more details; consult Yaskawa for information on higher duty cycles. These resistors

can be mounted directly to the heatsink on the back of the drive.

G7

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

Page 9

Data subject to change without notice

Yaskawa Electric America

CA.G7.01, 6/1/08

Page 11

Ring Kit Options

Rated Input Voltage

Drive Model Number

CIMR-G7U

Kit Model No.

UDA00417-

Kit List Price $

20P41 thru 23P71 D

25P51

27P51

20111

20151

20181 F

20221 E

20300 thru 21100

40P41 thru 44P01 D

45P51

47P51

40111

40151

40181

40221

40301 thru 40451 A

40550 thru 43000

208-230/240V

Not Available

480V

Not Available

C

B

C

B

E

G7

Ring Kit - These kits allow installation of the drive into a customer's enclosure with the heatsink mounted out the back to

reduce overall enclosure size. Each kit includes all of the necessary components, including hardware, gaskets and

instructions.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 10

Page 12

End Cap Kit Options

Height (in.) Width (in.) Depth (in.)

20P41 thru 20221

20300

20370

20450

20550

20750 F 48.94 19.84 No Change

20900

21100

40P41 thru 40451

40550

40750

40900

41100

41320

41600

41850

42200

43000

48.94

52.13

17.83

19.84

22.80

40.43

Kit List

Price $

480V

Not Required

Not Available

Not Required

Not Available

No Change

No Change

No Change

No Change

Overall Drive Dimensions

Rated Input

Voltage

Drive Model

Number

CIMR-G7U

Kit Model No.

UDA00365-

208-230/240V

No Change

31.85

40.43

14.96

17.83

C

E

E

F

P

G7

End Cap Kit, NEMA 1 - This option consists of a top and bottom cover to convert a protected chassis drive to a NEMA

1 enclosed unit. This option DOES NOT provide additional space for mounting auxilliary components (i.e. circuit breaker, input

fuses, reactor, etc.).

Page 11

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 13

HLW HLW

20P41 3.2 0020 0021

20P71 6

0027

0028

21P51 8

0032

0033

22P21 12

0036

0032

23P71 18

0041

0036

8.0 8.0 6.0

25P51 27

0046 0047 13.0 13.0 13.0

27P51 34 0050 0048

20111 49

0054

0055

20151 66

0058

0059

20181 80

0172

0062

20221 96

0066

0067

20300 130

0066

0067

20370 160

0072

0073

20450 183

0077

0078

20550 224

0082 13.0 13.0 13.0

0083

20750 300

0087

24.0 17.0 17.0 0088

20900 358

0173 0092

21100 415

0174 0096

20P41 3.2 0020 0021

20P71 6

0027

0028

21P51 8

0027

0028

22P21 12

0036

0037

23P71 18

0036 8.0 8.0 6.0

0037

8.0 8.0 6.0

25P51 27

0046 13.0 13.0 13.0

0047

13.0 13.0 13.0

27P51 34

0050

0051

20111 49

0054

0055

20151 66

0058

0059

20181 80 0172 0062

20221 96

0172 0062

20300 130 0066 0067

20370 160 0072 0073

20450 183 0077 0078

20550 224

0082 13.0 13.0 13.0 0083

20750 300 0087 24.0 17.0 17.0

0088

20900

358 0173 0092

21100 415 0174 0096

24.0 17.0 17.0

24.0 17.0 17.0

13.0

13.0 13.0 13.0

13.0

13.0

13.0 13.0 13.0

6.0

8.0 8.0 6.0

8.0

13.0

24.0 17.0 17.0

13.0

13.0 13.0 13.0

6.0

8.0 8.0 6.0

24.0 17.0 17.0

8.0

13.0

13.0

13.0

8.0

13.0

13.013.0 13.0 13.0

13.0 13.0 13.0

13.0 13.0

13.0 13.0 13.0

13.0

13.0 13.0

17.0 17.0

13.0

13.0 13.0

13.0 13.0 13.0

8.0 6.0

8.0 8.0 6.0

8.0

Dimensions (in)

208V

230/

240V

8.0 8.0 6.0

8.0 8.0 6.0

13.0

24.0 17.0

8.0

13.0

13.0

13.013.0

13.0

13.0

17.0

13.0

24.0

13.0 13.0

13.0 13.0

Rated

Input

Voltage

Drive Model

Number

CIMR-G7U

Rated

Output

Current

(Amps)

5% Enclosed Reactor3% Enclosed Reactor

Part

Number

05P00620-

List

Price $

Part

Number

05P00620-

List

Price $

Dimensions (in)

Reactor Options

G7

Reactor, 3% and 5% Impedance - May be used on either the input or output of a drive to reduce the effect of load or

line side transients on the drive. The three-phase reactors are provided in a separate NEMA 1 enclosure.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 12

Page 14

Reactor, 3% and 5% Impedance (continued for 480V)

HLW HLW

40P41 1.8 0015 0016

40P71 3.4 0021 0022

41P51 4.8 0029 0030

42P21 6.2 0028 0030

43P71 9 0028 0029

44P01 11 0033 0034

45P51 15 0037 8.0 8.0 6.0

0038

47P51 21 0042 13.0 13.0 13.0 0043

40111 27 0047 0048

40151 34 0051

0048

40181 42 0055

0056

40221 52 0055

0056

40301 65 0059

0060

40371 80 0062 0063

40451 97 0062 0063

40550 128 0067

0068

40750 165 0073

0074

40900 195 0078

0079

41100 240 0083 0084

41320 270 0088 0089

41600 302

0088 0089

41850 370 0092

0093

42200 450 0096

0097

43000 605 0100

0101

17.0 17.024.0 17.0 17.0 24.0

13.0

13.0

480V

13.0 13.0 13.0

8.0 8.0 6.0

24.0

Rated

Input

Voltage

Drive Model

Number

CIMR-G7U

Rated

Output

Current

(Amps)

5% Enclosed Reactor3% Enclosed Reactor

Part

Number

05P00620-

List

Price $

Part

Number

05P00620-

List

Price $

Dimensions (in)

13.0

13.0

8.0

13.0

13.0 13.0

8.0

13.0

13.0

13.

0

13.0

13.0

8.0 8.0

Dimensions (in)

8.0 8.0 6.0 8.0 6.0

8.0 8.0 6.0

17.0

8.0 6.0

13.0 13.0

13.0 13.0

24.0 17.0 17.0

17.0

13.0

13.0 13.0

13.0 13.0

6.0

13.0

13.0 13.0 13.0

13.0

13.0

13.0 13.0 13.0

17.0 17.0

24.0 17.0 17.0

24.0

Reactor Options

G7

Page 13

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 15

Bus Reactor Options

HLW HLW

20P41 3.2 URX000040 2.50 2.88 1.50 URX000041 3.25 3.75 2.00

20P71 6 TBD 3.25 3.75 2.00 05P00620-0111 4.50 3.81 2.82

21P51 8 URX000045 4.50 3.81 2.82 05P00652-0213 4.50 3.81 2.82

22P21 12 TBD 4.50 3.81 2.82 URX000048 4.50 3.81 3.75

23P71 18 URX000051 4.50 3.81 2.82 URX000053 4.50 3.81 3.00

25P51 27 05P00620-0120 4.31 3.81 3.32 URX000055 5.25 4.63 4.25

27P51 34 05P00620-0123 4.50 3.81 3.13 URX000057 5.25 4.63 4.00

20111 49 URX000063 4.00 4.63 5.00 URX000065 5.50 6.50 6.25

20151 66 05P00620-0129 4.00 4.63 6.00 URX000069 4.00 4.63 7.00

20181 thru

21100

80 thru 415

20P41 3.2 05P00620-0111 4.50 3.81 2.82 URX000044 5.25 4.63 4.00

20P71 6 TBD 3.25 3.75 2.00 05P00620-0111 4.50 3.81 2.82

21P51 8 TBD 3.25 3.75 2.00 URX000046 5.25 4.63 3.50

22P21 12 TBD 4.50 3.81 2.82 URX000048 4.50 3.81 3.75

23P71 18 URX000052 4.50 3.81 3.75 URX000053 4.50 3.81 3.00

25P51 27 05P00620-0120 4.31 3.81 3.32 URX000055 5.25 4.63 4.25

27P51 34 05P00620-0124 4.50 3.81 3.75 URX000057 5.25 4.63 4.00

20111 49 URX000063 4.00 4.63 5.00 URX000065 5.50 6.50 6.25

20151 66 05P00620-0129 4.00 4.63 6.00 URX000069 4.00 4.63 7.00

20181 thru

21100

80 thru 415

40P41 1.8 URX000042 4.50 3.81 2.82 URX000039

3.25 3.75 2.00

40P

71 3.4 URX000041 3.25 3.75 2.00 URX000042 4.50 3.81 2.82

41P51 4.8

42P21 6.2

43P71 9 URX000046 5.25 4.63 3.50 URX000044 5.25 4.63 4.00

44P01 11 05P00652-0216 5.25 4.63 4.00 URX000049 5.25 4.63 5.25

45P51 15 URX000048 4.50 3.81 3.75 URX000049 5.25 4.63 5.25

47P51 21 URX000053 4.50 3.81 3.00 URX000054 5.25 4.63 5.25

40111 27 URX000055 5.25 4.63 4.25 URX000056 5.25 4.63 5.25

40151 34 URX000057 5.25 4.63 4.00 URX000058 6.55 6.50 6.00

40181 thru

43000

42 thru 605

Built-in;

additional DC bus reactor not required

05P00620-0111

4.50 3.81 2.82

URX000044

5.25 4.63

208V

230/

240V

480V

Built-in;

additional DC bus reactor not required

Built-in;

additional DC bus reactor not required

Built-in;

additional DC bus reactor not required

Built-in;

additional DC bus reactor not required

4.00

Dimensions (in)

Built-in;

additional DC bus reactor not required

Rated

Input

Voltage

Number

CIMR-G7U

Rated

Output

Current

(Amps)

5% DC Bus Reactor3% DC Bus Reactor

Part Number

List

Price $

Part Number

List

Price $

Dimensions (in)

G7

DC Bus Reactor - May be used on the DC bus of a drive to reduce the effect of line side transients on the drive. The DC

bus reactors are available loose in an open configuration, and must be mounted in a NEMA 1 enclosure.

Drive Model

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 14

Page 16

Control Options

G7

Control Options - These cards, cables and devices add control functionality to the standard drive. Items are

shipped loose, unmounted. See Configured Section for factory mounted and wired control.

Analog Input Options

Analog Input (14 Bit). This option provides for the

interface of 2 high resolution analog inputs to

the drive.

Signal levels (fixed):

1 channel, 0 to 10VDC (20kOhm)

1 channel, 4 to 20mADC (250Ohm)

Mounts at option connector 2CN

Model No. AI-14U........................................ List $

Analog Input (13 Bit + Sign). This option provides for the interface

of 3 high resolution analog inputs to the drive.

Signal levels (individually selectable):

0 to ±10VDC (20kOhm),

4 to 20mADC (250Ohm)

Mounts at option connector 2CN

Model No. AI-14B........................................ List $

Analog Input, Isolated (13 Bit + Sign or 14 Bit). This option

provides for the interface of 3 isolated, high resolution analog inputs

to the drive.

Signal levels (individually selectable):

0 to ±10VDC (20kOhm), 13 Bit + Sign,

0/4 to 20mADC (250Ohm), 14 Bit

Mounts at option connector 2CN

Model No. AI-040.........................................List $

Analog Output Options

Analog Output (8 Bit). This option provides 2 signals for remote

metering of any two of the drive’s “U1” monitors. These are in

addition to the two standard analog outputs.

Signal levels (fixed):

0 to 10VDC (20kOhm)

Mounts at option connector 3CN

Model No. AO-08......................................... List $

Analog Output (11 Bit + Sign). This option provides 2 signals for

remote metering of any two of the drive’s “U1” monitors. These are

in addition to the two standard analog outputs.

Signal levels (individually selectable):

0 to ±10VDC (20kOhm)

Mounts at option connector 3CN

Model No. AO-12......................................... List $

Analog Output, Isolated (11 Bit + Sign). This option provides 2

isolated signals for remote metering of any two of the drive’s “U1”

parameters. These are in addition to the two standard analog

outputs.

Signal levels (individually selectable):

0 to ±10VDC (20kOhm),

0 to 20mADC (500Ohm max),

4 to 20mADC (500Ohm max)

Mounts at option connector 3CN

Model No. AO-001 (formerly AO-12B2) List $

Trim Potentiometer. This option provides a 5kOhm potentiometer

for use as a dropping resistor for maximum or minimum analog

input trim.

Mounts to control terminal strip

Model No. AI-001.........................................List $

3-15PSI Transducer. This option provides for the interface of a 3 to

15PSI pneumatic signal, and provides a 4 to 20mA output signal

proportional to the input signal to the drive.

Mounts to control terminal strip

Model No. AI-010.........................................List $

Digital Input Options

Digital Input (8 Bit). This option provides for the interface of an 8

bit digital input (binary or BCD) to the drive.

Mounts at option connector 2CN

Model No. DI-08............................................ List $

Digital Input (12 or 16 Bit). This option provides for the interface of

a 12 or 16 bit digital input (binary or BCD) to the drive.

Mounts at option connector 2CN

Model No. DI-16H2 .................................... List $

120VAC Logic Interface (8-Input). This option provides for the

interface of 120VAC control logic circuits to the drive. This option is

used for digital inputs S1 to S8.

Mounts to control terminal strip

Model No. DI-001.........................................List $

120VAC Logic Interface (4-Input). This option provides for the

interface of 120VAC control logic circuits to the drive. This option is

used for digital inputs S9 to S12.

Mounts to control terminal strip

Model No. DI-003........................................ List $

Page 15

Data subject to change without notice

Yaskawa Electric America

CA.G7.01, 6/1/08

Page 17

Control Options

G7

Control Options (continued)

Digital Output Options

Digital Output (2 Channel). This option provides 2 additional

digital outputs for use in monitoring the status outputs of the drive.

Signal levels:

2 channels, Form C, 250VAC, 30VDC, 1A

Mounts at option connector 3CN

Model No. DO-02C.................................... List $

Digital Output (8 Channel). This option provides 8 additional

digital outputs for use in monitoring the status outputs of the drive.

Signal levels:

2 channels, Form A, 250VAC, 30VDC, 1A

6 channels, PHC, 48VDC, 50mA, Shared Common

Mounts at option connector 3CN

Model No. DO-08 ......................................... List $

Encoder Feedback Options

Single Encoder (PG) Feedback - Line Driver. This option

provides velocity and direction feedback from an encoder. This is

primarily used for motor speed feedback in closed loop flux vector

control. A 5VDC buffered output is also included.

Signal levels:

5 or 12VDC differential line driver with compliments

Maximum input frequency: 300kHz

Phases A and B (Z required with some custom software)

Mounts at option connector 4CN

Model No. PG-X2 ........................................ List $

Single Encoder (PG) Feedback - Open Collector. This option

provides velocity and direction feedback from an encoder. This is

primarily used for motor speed feedback in closed loop flux vector

control. A 24DC buffered output (open collector) is also included.

Signal levels:

12VDC differential open collector with compliments

Maximum input frequency: 32kHz

Phases A and B (No marker pulse capability)

Mounts at option connector 4CN

Model No. PG-B2 ........................................ List $

Digital Operator Options

Digital Operator (LCD). This option is the standard digital operator

found on the drive. This option is only needed if the original keypad

is lost or damaged.

Features include:

LCD keypad display, 5 lines x 16 characters, backlit

7 languages

Copy function

Mounts to keypad port

Model No. 300-016-999 ..........................List $

UL Rated Remote Operator Kits. This option is used to extend

the existing Digital Operator to the wall of a separately priced,

oversized UL Type 1, 3R, 4, 4X, or 12 enclosure (IPX6

environment). Price includes a faceplate bezel with digital operator

carrier and membrane to cover the operator cutout in the enclosure

door, a 3-foot cable, a 10-foot cable, and a 1:1 template for cutting

the necessary cutouts in the enclosure. Keypad can be removed

after kit installation.

Mounts to keypad port and enclosure wall.

Model No. UUX000458 (Blank Membrane) .........................List $

Model No. UUX000459 (Yaskawa Logo Membrane) .......... List $

Remote Operator Kit. This option is used to extend the existing

Digital Operator to the wall of a separately priced, oversized NEMA

1 enclosure (No UL rating). Price includes a faceplate membrane to

cover the operator cutout in the enclosure door, a 3-foot cable, a 10foot cable, a remote digital operator carrier, and a 1:1 template for

cutting the necessary cutouts in the enclosure.

Note: Keypad cannot be removed after initial installation.

Mounts to keypad port and enclosure wall.

Model No. UUX000444 (Yaskawa Logo Membrane) .......... List $

Dual Encoder (PG) Feedback - Line Driver. This option provides

velocity and direction feedback from 2 encoders. This card is used

for 2-motor operation with standard software and for some custom

software titles. A 5VDC buffered output is also included.

Signal levels:

5 or 12VDC differential line driver with compliments

Maximum input frequency: 300kHz

Phases A and B (Z required with some custom software)

Mounts at option connector 4CN

Model No. PG-W2 ...................................... List $

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 16

Page 18

Communications Options

G7

Communications Options - These communications options are provided loose, unmounted. Network

communications are available for most popular protocols.

DeviceNet™ With ADR. Each DeviceNet network supports up to

63 drives. Controllers are available from many PLC and/or PC

suppliers. The DeviceNet network communications option board is

designed to comply with all pertinent aspects of the ODVA (Open

DeviceNet Vendor Association) specification and AC drive profile.

All parameters, diagnostics, and operational commands are

accessible via DeviceNet. Automatic Device Replacement (ADR) is

supported in this DeviceNet option, including the functions of Auto

Baud Rate sensing and Faulted Node Recovery (using Group 4

messaging). The DeviceNet satellite board mounts integrally in the

drive and provides a DeviceNet standard open tap connector.

Electronic Data Sheets may be downloaded from

www.yaskawa.com to assist with network configuration and drive

setup.

Mounts at option connector 2CN.

Model No. CM012 ............................................List $

Other DeviceNet Options. For DeviceNet option kits CM056 and

CM059, please follow the guidelines listed below. Please download

the application note AN.AFD.14 from www.yaskawa.com, which

details the exact differences between all the DeviceNet option kits.

New Installations

New installations without any requirements of backwards

compatibility should use CM012 kit. The CM012 incorporates all the

functionality of the CM056 and CM059 as well as ADR and many

other new features.

Existing Installations

When replacing a failed card in the field or adding an additional

drive to an existing network, it is generally recommended to use the

existing kit (CM056 or CM059) found in the installation. This will

ease in the support of the network.

Note: Each DeviceNet kit has unique EDS (electronic data sheets)

files for each model of every drive series. These can be found on

www.yaskawa.com. If you choose to replace an existing kit with a

different kit, you must use the new EDS file as well.

Profibus DP. This option complies with the Profibus DP protocol

specification. All parameters, diagnostics and operational

commands are accessible via Profibus. The option board provides

convenient Phoenix-type teminations for landing the shielded,

twisted-pair wiring. Each Profibus network supports up to 99 drives.

This option supports all of the Profibus data rates from 9.6 Kbps to

12 Mbps. Up to 32 bytes of input data and 32 bytes of output data

are provided per message transaction. GSD files may be

downloaded from www.yaskawa.com to assist with network

configuration and drive setup.

Mounts at option connector 2CN.

Model No. CM061 ..................................List $

LonWorks. This option is compatible with the Lon Mark

Interoperability Association and complies with the Functional Profile

for a Variable Frequency Motor Drive. The option board features the

FFT-10A Free Topology Twisted-Pair Transceiver. Network

connectivity is facilitated by either a Phoenix-style screw termination

or RJ-45 connector. The kit includes a 12-inch pigtail (UWR00567-

1) for interface wiring of the phoenix terminal block. Optional longer

pigtail assemblies are available for use when drive is mounted

within another enclosure. The 20-inch cable is for wall mount

enclosures. The 78-inch cable may be used with any enclosure and

may be cut to any length required.

Mounts at option connector 2CN. Covers 3CN. Blocks 4CN.

Model No. CM048................................................................. List $

Model No. UWR00567-2 (20-inch cable)............................. List $

Model No. UWR00567-3 (78-inch cable)............................. List $

Modbus Plus. This option complies with Modicon's ModConnect

Partners program and provides a seamless interface to Quantum,

984 and Compact PLCs. All parameters, diagnostics and

operational commands are accessible via Modbus Plus. The option

board provides a 9-pin D-shell connector for easy wiring and

communicates via a 1 Mbps, twisted-pair, Local Area Network.

Each Modbus Plus network supports up to 63 drives.

Mounts at option connector 2CN. Covers 3CN.

Model No. CM071...................................... List $

Modbus TCP/IP. This option complies with the Modbus TCP/IP

protocol specification. This allows for communication over 10/100

Mbps Ethernet networks. This option has the ability to configure the

IP Address from a user specified IP address, from a DHCP host or

from a BootP host. All parameters, diagnostics and operational

commands are accessible via Modbus TCP/IP. Auto-tuning the

motor is also possible through this option using the DriveWizard PC

program. This option supports up to 10 simultaneous PLC/PC

connections.

Mounts at option connector 2CN.

Model No. CM090...................................... List $

EtherNet/IP. This option complies with the EtherNet/IP protocol

specification. This allows for communication over 10/100 Mbps

Ethernet networks. This option has the ability to configure the IP

Address from a user specified IP address, from a DHCP host or

from a BootP host. All parameters, diagnostics and operational

commands are accessible via EtherNet/IP. Auto-tuning the motor is

also possible through this option using the DriveWizard PC

program.

Mounts at option connector 2CN.

Model No. CM092...................................... List $

Page 17

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 19

G7

H W D Heatsink Internal Total

20P41 3.2 3/4 21 36 57

20P71 6 1 43 42 85

21P51 8 2 58 47 105

22P21 12 3 83 53 136

23P71 18 5 122 64 186

25P51 27 7.5 13.2 187 87 274

27P51 34 10 15.4 263 112 375

20111 49 15 13.78 DD.G7.FR4A.N1.01 357 136 493

20151 66 20 14.96 DD.G7.FR4C.N1.01 473 174 647

20181 80 25 & 30 21.06 10.00 10.24 52.8 DD.G7.FR5.N1.01 599 241 840

20221 96 30 24.21 10.98 10.24 59 DD.G7.FR6A.N1.01 679 257 936

20300 130 40 & 50 11.81 125 DD.G7.FR7.IP00.01 878 362 1240

20370 160 60 12.99 139 DD.G7.FR8.IP00.01 1080 434 1514

20450 183 60 189 1291 510 1801

20550 224 75 191 1474 607 2081

2075 300 100 33.46 19.69 14.17 238 DD.G7.FR11.IP00.01 2009 823 2832

20900 358 125 1660 871 2531

21100 415 150 2389 1194 3583

40P41 1.8 3/4 10 39 49

40P71 3.4 1 & 2 21 44 65

41P51 4.8 3 33 46 79

42P21 6.2 3 41 49 90

43P71 9 5 77 63 140

44P01 11 7.5 100 66 166

45P51 15 10 132 80 212

47P51 21 15 197 107 304

40111 27 20 246 116 362

40151 34 25 311 135 446

40181 42 30 354 174 528

40221 52 40 516 210 726

40301 65 50 633 246 879

40371 80 60 737 285 1022

40451 97 75 28.15 12.95 11.22 88 DD.G7.FR9B.N1.01 929 340 1269

40550 128 100 198 1239 488 1727

40750 165 125 200 1554 597 2151

40900 195 150 240 1928 762 2690

41100 240 200 279 2299 928 3227

41320 270 200 363 2612 1105 3717

41600 302 250 385 3614 1501 5115

41850 370 300 579 4436 1995 6431

42200 450 350 616 5329 2205 7534

43000 605 400 & 500 58.07 36.06 16.34 906 DD.G7.FR15.IP00.01 6749 2941 9690

DD.G7.FR10.IP00.01

DD.G7.FR11.IP00.01

DD.G7.FR13.IP00.01

DD.G7.FR14.IP00.01

DD.G7.FR3A.N1.01

DD.G7.FR4B.N1.01

DD.G7.FR6B.N1.01

DD.G7.FR9A.N1.01

DD.G7.FR12.IP00.01

DD.G7.FR1.N1.01

DD.G7.FR2.N1.01

DD.G7.FR2.N1.01

DD.G7.FR1.N1.01

DD.G7.FR2.N1.01

DD.G7.FR3A.N1.01

DD.G7.FR10.IP00.01

NEMA 1

Protected

Chassis

NEMA 1

NEMA 1

Protected

Chassis

NEMA 1

36.06 22.64 14.96

51.38 27.95 16.34

28.54 17.72 13.78

33.46 19.69 14.17

25.00 12.95 11.22 86

21.06 10.98 10.24 64

13.78 9.45 8.27 22

11.81 7.87 7.87 15.4

Standard

Enclosure

Dimension

Drawing

Number

(3)

Heat Loss (watts)

(4)

208V/

240V/

230V

11.02 5.51

6.30

7.09

11.81 7.87

Weight

(lbs.)

(2)

7.87

6.6

8.8

Rated

Input

Voltage

Drive

Model

Number

CIMR-G7U

Rated

Output

Current

(Amps)

9.45

Nominal

HP

(1)

Physical

Dimensions (in.)

8.27 24.2

23.62 14.76

480V

28.54 17.72 13.78

34.84 22.64 14.96

11.02 5.51

6.30

330

7.09

7.7

9.9

Dimensions and Data

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

(2) This data represents the drive weight only, not shipping weight.

(3) Please refer to Yaskawa’s website at www.yaskawa.com for dimension drawings.

(4) Total Heat Loss is the amount of heat dissipated by the drive at full load. This data is separated into "Heatsink" and "Internal" values.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Three-Phase Alternating Current Motors

The value in the "Heatsink" column is the amount of heat dissipated by the heatsink, and would not need to be considered when

calculating the enclosure size for applications that may require mounting the heatsink out the back of the enclosure using the Ring Kit

option.

Page 18

Page 20

Description

3/4-500HP

G7/Configured

The G7/Configured package provides a G7 drive in a NEMA 12, UL Type 1, IP22 or 54 enclosure, with space

for several commonly used options, such as reactors, RFI filters, circuit breakers, etc. The G7/Configured

has been designed for flexibility in providing the features and options commonly demanded by industrial

control designers.

The G7 drive is the ultimate performance solution with increased speed and torque response to provide

servo-like performance from an induction motor in speed, torque, or position control applications. In addition,

the G7 has the world’s first 480V 3-level inverter architecture that eliminates or minimizes the installation

problems associated with IGBT switching and protects the entire motor-drive system. This patented design

can eliminate peripheral components typically required to solve installation problems. This G7 allows motor

operation at very long cable lengths, meeting NEMA MG1 Part 31, with peak voltage being 30% less than

conventional drives. With motor bearing current being typically 50% less than standard drives, the G7

provides four times the motor bearing life. Audible motor noise on the 480V G7 drive is 5-10dB (20%) less

than the prior generation drive, even when operating at half the carrier frequency. Common mode current is

half that of conventional drives.

G7C

Performance Features

• Ratings: 1/2 to 150HP, 208 VAC

1/2 to 150HP, 240 VAC

3/4 to 500HP, 480 VAC

• Overload capacity: heavy duty,

150% for 1 min, 200% Peak

• Starting torque:

150% at 1Hz (V/f), at 0.5 Hz (open loop),

at 0.3 Hz (closed loop)

• Output frequency: 0.01 to 400Hz

• Speed control range:

40:1 (V/f), 200:1 (open loop),

1000:1 (closed loop)

• Speed regulation:

1% (V/f), 0.2% (open loop), 0.01% (closed

loop)

• Speed response: 60Hz

• Torque response: 300Hz

• Speed reference resolution: 0.01% with

digital reference, 0.1% with analog

reference, 0.01 Hz with network input

• Speed/Torque/Position Control

• Zero-servo mode

• Adjustable accel/decel: 0.01 to 6000

seconds

• S-Curve: adjustable 0.00 to 2.50 seconds,

for each corner

• Stall prevention

• Inertia and Power loss ride-thru

• Programmable auto restart after

momentary power loss

Protective Features

• DC bus CHARGE indicator

• Optically-Isolated controls

• Phase-to-phase / phase-to-neutral short

circuit protection

• Ground fault protection

• Electronic motor overload (UL508C)

• Current and torque limit (four quadrant)

• Over-torque / under-torque detection

• Over-current, over-voltage, and overtemperature

• Motor thermistor input

• Input/output phase loss

Design Features

• LCD keypad display: 5 lines x 16 characters, backlit, 7 languages, copy function

• Simplified programming: Quick Start and

modified parameter groups

• Microprocessor logic: 32 bit

• Memory type: Flash memory for easy

upgrades, custom software applications,

and non-volatile program retention

• Control logic: 24VDC (sinking or sourcing)

• Terminal strip: Quick disconnect

• Front cover: Split for easy wiring

• Heat sink fan: Plug-in with on/off control

• Motor auto-tuning: Static and rotational

• Speed search: Bi-directional into rotating

motor

• Process control: PID, reference with PID trim

• Motor parameters: 2 sets

• Stopping methods: Ramp stop, coast stop,

fast stop, or high slip braking

• DC injection braking: Adjustable level, time

• Speed reference presets: 17 available

• Timer function: Programmable on/off delay

• Digital M.O.P.: Up/down/hold/reset reference

• Bias and gain: All analog and pulse train I/O

• Common DC bus capability: All models

• Dynamic braking transistor: 20 HP and below

(240VAC), 25 HP and below (460VAC)

• Bus Reactor: 25 HP and above (240VAC),

30HP and above (460VAC)

• Twelve-pulse capability: 25 HP and above

(240VAC), 30HP and above (460VAC)

Service Conditions

• Enclosure: NEMA 1 or protected chassis

• Ambient service temperatures:

-10 to 40°C (104°F) NEMA1,

-10 to 45°C (113°F) protected chassis

• Input frequency: 50/60Hz ± 5%

• Input voltage: +10% / -15%, 3 phase, 240

or 480VAC, phase insensitive

• Humidity: non-condensing 95% max

• Altitude: to 3300 feet (1000 meters) w/o

derate

• Vibration: 1G or less (10 to 20Hz), 0.6G or

less (20 to 55Hz)

Inputs and Outputs

• Analog inputs: 3 (2 programmable),

±10VDC (20K ohms) or 4 to 20 mA

(250 ohm), 11 bit plus sign

• Analog outputs: 2 programmable,

±10VDC or 4- to 20mA, 9 bit plus sign

• Digital inputs: 12 (10 programmable),

sinking or sourcing

• Digital outputs: 5 programmable, 3 form A

and two open collector

• Pulse train input: 1 programmable, 32 KHz

max

• Pulse train output: 1 programmable,

32 KHz max

• Fault contacts: 1 form C

• RS-232/422/485: Modbus RTU

Standards & Reliability

• UL 508C (Power Conversion)

• CSA 22.2 No. 14-95 (Industrial Control

Equipment)

• UL, cUL listed; CE marked

• UL 1995 (Plenum)

• EN 50178 (LVD)

• EN 61800-3 (w/ External Filter)

• IEC 529, 146

• FCC CFR 47 Part 15 Subpart B

(w/ External Filter)

Configured Options

• Encoder feedback cards

• Input/Output expansion cards

• DriveWizard™ software (upload / download)

• Network cards such as Ethernet,

DeviceNet, Profibus-DP, and others

• Custom drive software

• Input breaker

• Input disconnect

• Input fuses

• 120 VAC logic interface

• Analog input trim pot

• Input reactor

• Input filter

• Bus Reactor (25HP and below)

• Dynamic braking

Page 19

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 21

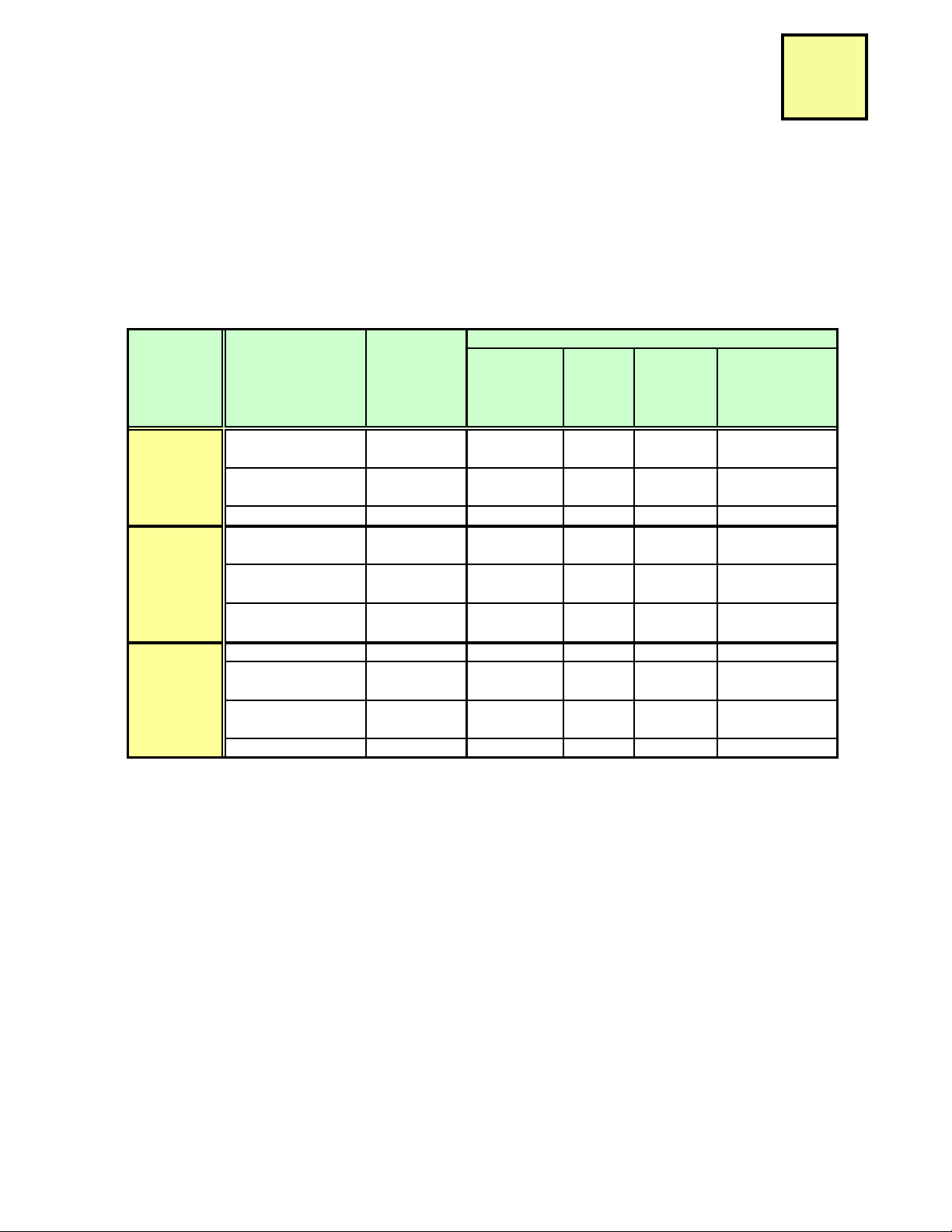

Description

PT S

1

H

2

B 3

4

A

B

G

H

J

L

Q

N

U

V

W

X

Y

C

D

F

R

X

N

B

J

(Ex.: "040" = 40A)

P Options (Power)

NEMA 12 (IP54)

(5)

NEMA 12 FVFF (IP22)

(6)

BASE NUMBER

Enclosure

TBD

Choose None

or One

Rated Amps Code

T Options (Control and Communications)

DeviceNet

Profibus-DP

OPTIONS

POWER

CONTROL SOFTWARE

Current

Vol t ag e

230/240V

480V

G 7 C

Choose None

or One

Choose None

or One

Choose None or One

Circuit Breaker/MCP

Disconnect

Input Fuses

Modbus Plus

(2)

LonWorks

(2), (3)

Ether

D

Ethernet (EtherNet/IP)

net (Modbus TCP/IP)

Choose None or One

Choose None or One

Analog Output

Digital Output, Dual

120VAC Interface

Analog Input Trim Pot

3% Bus Reactor

(1)

Cap Filter Choose None or One

3% Input Reactor

Choose None

or One

Choose None

or One

DB w/ OH Shutdown

(4), (7)

PG-X2 Feedback Card

PG-W2 Feedback Card

S Option (Software)

TBD

TBD

TBD

Choose None or One

Choose None or One

Dynamic Braking

G7CBB040PCXTH

(7)

(2)

G7C

Model Number Configuration & Pricing:

Step 1. Step 1. First complete the Base Number for the required enclosure type, voltage and current rating.

Step 2. Step 2. Add the Option code letter for each required option. Any Power option must be preceded by (P); any

Step 3. Step 3. Find the list price for the Base Number selected from the following pages. Add the list price of each

Example: G7 Configured package (G7CB) with a 30HP, 480V, (B040), with Circuit Breaker and 3% Bus reactor

3/4-500HP

G7/Configured

Control Option by (T), and Software Option by (S). No more than seven options may be selected. The letters P, T or

S must be deleted if no options of that type are selected.

selected option to this base price.

P followed by CX), Profibus-DP network communication capability (T followed by H) and no software option

(

(delete the

S). Model number is:

(1) 3% Bus Reactors are only available as an option on base numbers up to and including G7C_A068 and B034; larger drives have a Bus

Reactor as standard

(2) When this option is selected, port 3CN "Control Output" options N and U cannot be used

(3) When this option is selected, port 4CN "Feedback" options X and Y cannot be used

(4) When this option is selected, Power options C and D are not available

(5) Enclosure type "H" is available 20HP (230V), 25HP (480V) and smaller.

(6) Enclosure type "B" is available 25HP (230V), 30HP (480V) and larger.

(7) Resistors for Dynamic Braking are NOT included, NOT factory-mounted. Price from DB section.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 20

Page 22

Description

3/4-500HP

G7/Configured

Configured Option Descriptions:

Enclosure Options

(H) NEMA 12: The drive and configured controls are provided in a NEMA 12 (IP54, UL Type 1) enclosure, large enough to accommodate

any or all of the Configured package options.

(B) NEMA 12 FVFF: The drive and configured controls are provided in a NEMA 12 (IP22, UL Type 1) force-ventilated fan-filtered enclosure,

large enough to accommodate any or all of the configured package options.

P Options (Power)

(C) Circuit Breaker: The standard configuration provides no branch short circuit protection or input disconnecting means. This option

provides a thermal-magnetic circuit breaker that meets NEC branch circuit protection requirements, with a flange-mounted operating

handle.

(D) Disconnect: The standard configuration provides no input disconnecting means. This option provides a non-fused disconnect with a

flange-mounted operating handle.

G7C

(F) Input Fuses: The standard configuration does not include Drive Input Fuses. This option provides high-speed semi-conductor drive

input fuses, rated for 200,000 amp RMS symmetrical interrupting capacity, that provides both drive input I2T protection and NEC

approved branch circuit and short circuit protection.

(R) Input Reactor: No form of input impedance is normally required for the Configured Drive. A 3% line reactor is available if additional

impedance is desired (usually to reduce the effects of line-side transients and input THD).

(X) DC Bus Reactor: No form of bus impedance is normally required for the Configured Drive. A 3% bus reactor is available if additional

impedance is desired (usually to reduce the effects of line-side transients and input THD).

(N) Input Filter: The standard configuration does not include a filter. The cap filter is a delta-wye capacitive network.

(B) Dynamic Braking: This option is used to enhance the drive's ability to brake/stop the motor. The braking transistor module is included

in the Configured package, and is sized for standard duty (10-15%). This option does NOT include DB resistors or any other DB resistor

overtemp protection. See Dynamic Braking Section to select DB resistor.

(J) Dynamic Braking with Overtemp Shutdown: This option is used to enhance the drive's ability to brake/stop the motor. The braking

transistor module is included in the Configured package along with a shunt trip MCP and power circuitry to disconnect the input power

from the drive, should the DB resistor overtemperature switch activate. The braking transistor is sized for standard duty (10-15%). This

option does NOT include DB resistors, and cannot be ordered with Power Options (C) or (D). See Dynamic Braking Section to select

DB resistor.

T Options (Control and Communications)

(G)

DeviceNet:

diagnostics, and operational commands are accessible via DeviceNet. The option board provides a DeviceNet standard open tap

connector. Each DeviceNet network supports up to 63 drives. Controllers are available from many PLC and/or PC suppliers. Electronic

Data Sheets may be downloaded from www.yaskawa.com to assist with network configuration and drive setup. (CM057)

(H) Profibus-DP: This option complies with the Profibus DP protocol specification. All parameters, diagnostics and operational commands

are accessible via Profibus. The option board provides convenient Phoenix-type teminations for landing the shielded, twisted-pair

wiring. Each Profibus network supports up to 99 drives. This option supports all of the Profibus data rates from 9.6 Kbps to 12 Mbps. Up

to 32 bytes of input data and 32 bytes of output data are provided per message transaction. GSD files may be downloaded from

www.yaskawa.com to assist with network configuration and drive setup.(CM061)

This option complies with the ODVA (Open DeviceNet Vendor Association) specifiation and AC drive profile. All parameter,

Page 21

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 23

This page intentionally left blank

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 22

Page 24

Description

3/4-500HP

G7/Configured

Configured Option Descriptions (continued):

T Options (Control and Communications) (continued)

(J) Modbus Plus: This option complies with Modicon's ModConnect Partners program and provides a seamless interface to Quantum, 984

and Compact PLCs. All parameters, diagnostics and operational commands are accessible via Modbus Plus. The option board

provides a 9-pin D-shell connector for easy wiring and communicates via a 1 Mbps, twisted-pair, Local Area Network. Each Modbus

Plus network supports up to 63 drives. (CM071)

(L) LonWorks: This option is compatible with the Lon Mark Interoperability Association and complies with the Functional Profile for a

Variable Frequency Motor Drive. The option board features the FFT-10A Free Topology Twisted-Pair Transceiver. Network connectivity

is facilitated by either a Phoenix-style screw termination or RJ-45 connector. (CM048)

(Q) Modbus TCP/IP: This option complies with the Modbus TCP/IP protocol specification. This allows for communication over 10/100 Mbps

Ethernet networks. This option has the ability to configure the IP Address from a user specified IP address, from a DHCP host, or from

a BootP host. All parameters, diagnostics and operational commands are accessible via Modbus TCP/IP. Auto-tuning the motor is also

possible through this option using the DriveWizard PC program. This option supports up to 10 simultaneous PLC/PC connections.

(CM090)

(D) EtherNet/IP: This option complies with the EtherNet/IP protocol specification. This allows for communication over 10/100 Mbps

Ethernet networks. This option has the ability to configure the IP Address from a user specified IP address, from a DHCP host, or from

a BootP host. All parameters, diagnostics and operational commands are accessible via EtherNet/IP. Auto-tuning the motor is also

possible through this option using the DriveWizard PC program. (CM092)

G7C

(N) Analog Output, Bi-polar, 12 Bit: This option provides 2 signals for remote metering of any two of the drive’s “U1” monitors. These are

in addition to the two standard analog outputs.

Signal levels (individually selectable): ±10VDC (20kOhm), 11 bit + sign (AO-12)

(R) Analog Output, Isolated, Bi-polar, 12 Bit: This option provides 2 isolated signals for remote metering of any two of the drive’s “U1”

parameters. These are in addition to the two standard analog outputs.

Signal levels (individually selectable): 0 to ±10VDC (20kOhm), 0/4 to 20mADC (500Ohm max), 11 bit + sign (AO-001)

(U) Digital Output, Dual Relay: This option provides 2 additional digital outputs for use in monitoring the status outputs of the drive. These

are in addition to the 5 standard digital outputs.

Signal levels: 2 channels, Form C, 250VAC, 30VDC, 1A (DO-02C)

(V) 120VAC Input: This option provides for the interface of 120VAC control logic circuits to the drive. This option is used for digital inputs S1

to S12 and is comprised of 2 option cards. (DI-001 & DI-003)

(W) Analog Input Trim Pot: This option provides a 5kOhm potentiometer for use as a dropping resistor for maximum or minimum analog

input trim. This voltage in turn can be used to supply a remote speed pot. (AI-001)

(X) Single Encoder Feedback: This option provides velocity and direction feedback from an encoder. This is primarily used for motor

speed feedback in closed loop flux vector control. A 5VDC buffered output is also included. Signal levels: 5 or 12VDC differential line

driver with compliments, maximum input frequency of 300kHz, phases A and B (Z required with some custom software).

(PG-X2)

(Y) Dual Encoder Feedback: This option provides velocity and direction feedback from 2 encoders. This card is used for 2-motor

operation with standard software and for some custom software titles. A 5VDC buffered output is also included. Signal levels: 5 or

12VDC differential line driver with compliments, maximum input frequency of 300kHz, phases A and B (Z required with some custom

software). (PG-W2)

S Options (Software)

None at this time.

Page 23

Data subject to change without notice

CA.G7.01, 6/1/08

Yaskawa Electric America

Page 25

Input

Fuses

Input

Filter

C=MCP

D=

Disconnect

F=Fuses

Filter

G7CV

Base

List $

G7CB

Base

List $C List $

D

List $

F

List $R List $X List $N List $B List $J List $

3.2 3/4 A003 ---

4.2 1 A004 ---

6.8 2 A006 ---

9.6 3 A009 ---

15.2 5 A015 --22 7.5 A022 --28 10 A028 --42 15 A042 --54 20 A054 --68 25 --- A068

80 30 --- A080

104 40 --- A104

130 50 --- A130

154 60 --- A154

192 75 --- A192

248 100 --- A248

312 125 --- A312

360 150 --- A360

1.6 3/4 B001 ---

2.1 1 B002 ---

3.4 2 B003 ---

4.8 3 B004 ---

7.6 5 B007 --11 7.5 B011 --14 10 B014 --21 15 B021 --27 20 B027 --34 25 B034 --40 30 --- B040

52 40 --- B052

65 50 --- B065

77 60 --- B077

96 75 --- B096

124 100 --- B124

156 125 --- B156

180 150 --- B180

240 200 --- B240

302 250 --- B302

361 300 --- B361

414 350 --- B414

477 400 --- B477

515 450 --- B515

590 500 --- B590

230V

240V

Rated

Input

Voltage

Rated

Output

Current

(Amps)

(4)

Base Number P Options (Power)

Circuit Breaker Line Impedance

Nominal

HP

(1)

Configured Enclosure

Dynamic Braking

(5)

B=Standard Duty

J=Standard Duty

w/ Overtemp

Shutdown

480V

R=3% Input Reactor

X=3% Bus Reactor

V=NEMA 12, IP54

B=NEMA 12 FVFF, IP22

3% DC Bus

Reactor is

included as

standard

3% DC Bus

Reactor is

included as

standard

N/AN/A

Configured Drives and Options

G7C

G7 Configured Drives - 3/4-500HP, 208-230/240 or 480V, 3-phase input, NEMA 12 enclosure, with factory-installed

and wired options

N=Cap

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This is the maximum rated output for the configured drive package, not the drive's output current rating.

(3) Resistors for Dynamic Braking are NOT included, NOT factory-mounted. Price from DB section.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 24

Page 26

G7 Configured (Continued)

1

Term. 2

V=120

VAC

Inter-

face

W=Tri m

Pot

G

List $H List $J List $L List $Q List $D List $N List $R List $U List $V List $W List $X List $Y List $

List $ List $

3.2 3/4 20P41

4.2 1 20P71

6.8 2 21P51

9.6 3 22P21

15.2 5 23P71

22 7.5 25P51

28 10 27P51

42 15 20111

54 20 20151

68 25 20181

80 30 20181

104 40 20300

130 50 20300

154 60 20370

192 75 20550

248 100 20750

312 125 20900

360 150 21100

1.6 3/4 40P41

2.1 1 40P71

3.4 2 40P71

4.8 3 41P51

7.6 5 43P71

11 7.5 44P01

14 10 45P51

21 15 47P51

27 20 40111

34 25 40151

40 30 40181

52 40 40221

65 50 40301

77 60 40371

96 75 40451

124 100 40550

156 125 40750

180 150 40900

240 200 41100

302 250 41600

361 300 41850

414 350 42200

477 400 43000

515 450 43000

590 500 43000

S Options

Uses

Drive

Model

CIMR-

G7U

Control Outputs

Encoder

Feedback

Software

N=Analog Output

R=Analog Output,

Isolated

U=Digital Output

X=PG-X2

Y=PG-W2

None

available at

this time

480V

230V

240V

Rated

Input

Voltage

Rated

Output

Current

(Amps)

(4)

HP

(1)

T Options (Control and Communication)

Network Communication

G=DeviceNet

H=Profibus-DP

J=Modbus Plus (2)

L=LonWorks (2) (3)

Q=Modbus TCP/IP

D=EtherNet/IP

Configured Drives and Options

G7C

Term.

Nominal

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) When this option is selected, port 3CN "Control Output" options (N, U) cannot be used

(3) When this option is selected, port 4CN "Encoder Feedback" options (X, Y) cannot be used

(4) This is the maximum rated output for the configured drive package, not the drive's output current rating.

Page 25

Number

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 27

Heatsink Filter Kit Options

Model

Number

List Price $

Model

Number

List Price $

A003 thru A015 UFL00003-1 UFL00002-1

A022, A028 UFL00003-2 UFL00002-2

A042, A054 UFL00003-3 UFL00002-3

B001 thru B011 UFL00003-1 UFL00002-1

B014, B021 UFL00003-2 UFL0002-2

B027, B034 UFL00003-3 UFL00002-3

Heatsink Filter Kit Replacement Filter

208-230V/240V

480V

Rated Input

Voltage

Configured Package

Model Number G7CH

G7C

Heatsink Filter Kit Option (only for Configured product) - The filter kit is mounted to the back of the enclosure,

providing additional protection to the exposed drive heatsink and fan assemblies. It has been designed for extremely dirty or

dusty environments in which cooling fans and heatsink fins could easily become clogged. The kit contains a duct and a pair

of filters, which can be removed and cleaned, increasing fan life and cooling efficiency.

CA.G7.01, 6/1/08

Data subject to change without notice

Yaskawa Electric America

Page 26

Page 28

Dimensions and Data

HWD

A003 3.2 3/4 87

A004 4.2 1 87

A006 6.8 2 90

A009 9.6 3 92

A015 15.2 5 102

A022 22 7.5 128

A028 28 10 138

A042 42 15 192

A054 54 20 225

A068 68 25 301

A080 80 30 346

A104 104 40 84.00 38.00 27.00 804 DD.AFD.095.01

A130 130 50 804

A154 154 60 820

A192 192 75 880

248 100 880

A312 312 125 1340

360 150 1450

3.4 2 88

4.8 3 96

B007 7.6 5 93

B011 11 7.5 101

B014 14 10 134

B021 21 15 138

B027 27 20 178

B034 34 25 196

B040 40 30 295

B052 52 40 295

B065 65 50 366

B077 77 60 370

B096 96 75 387

B124 124 100 890

B156 156 125 890

B180 180 150 890

B240 240 200 925

B302 302 250 1075

B361 361 300 1740

B414 414 350 1800

B477 477 400 1800

B515 515 450 2125

B590 590 500 2125

DD.AFD.132.0119.7529.0052.00

Configured

G7CH

or

G7CB

NEMA 12

NEMA 12

NEMA 12 FVFF

15.50 NEMA 12

28.50 17.50

39.50 25.00

480V

DD.AFD.130.01

DD.AFD.131.01

27.00 DD.AFD.095.01

DD.AFD.096.01

11.75 DD.AFD.129.01

DD.AFD.130.01

NEMA 12 FVFF

84.00 37.75 27.00

84.00 73.25 27.00

NEMA 12 FVFF

17.50

34.50 20.00

230V

84.00 37.75

84.00 73.25

Weight

(lbs.)

(3)

15.00

11.75

Dimension

Drawing

Number

(4)

DD.AFD.129.01

Configured

Enclosure

NEMA 12

Rated

Input

Voltage

Rated

Output

Current

(Amps)

(2)

25.00

240V

Nominal

HP

(1)

Dimensions (in.)

28.50

15.5039.50

27.00

52.00 29.00 19.75

34.50 20.00 15.00 NEMA 12

NEMA 12

NEMA 12 FVFF

NEMA 12 FVFF

NEMA 12 FVFF

DD.AFD.131.01

DD.AFD.132.01

DD.AFD.095.01

DD.AFD.096.01

Physical

G7C