Page 1

G7 Drive

Technical Manual

Models: CIMR-G7U Document Number: TM.G7.01

Page 2

Warnings and Cautions

WARNING

WARNING

WARNING

This Section provides warnings and cautions pertinent to this product, that if not

heeded, may result in personal injury, fatality, or equipment damage. Yaskawa is

not responsible for consequences of ignoring these instructions.

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to

incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the

end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

• Read and understand this manual before installing, operating, or servicing this Drive. All warnings, cautions, and

instructions must be followed. All activity must be performed by qualified personnel. The Drive must be installed according

to this manual and local codes.

• Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the power is

on. Do not remove or insert the digital operator while power is on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50Vdc. To prevent electric shock,

wait at least five minutes after all indicators are OFF and measure DC bus voltage level to confirm safe level.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged

by high voltage.

• The Drive is suitable for circuits capable of delivering not more than 100,000 RMS symmetrical Amperes, 240Vac

maximum (200-240V Class) and 480Vac maximum (380-480V Class). Install adequate branch circuit short circuit protection per applicable codes. Failure to do so may result in equipment damage and/or personal injury. Refer to Appendix E for

further details.

• Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices to the

output of the Drive. These devices may generate peak currents that exceed Drive specifications.

i

Page 3

• To avoid unnecessary fault displays caused by contactors or output switches placed between Drive and motor, auxil-

iary contacts must be properly integrated into the control logic circuit.

• YASKAWA is not responsible for any modification of the product made by the user; doing so will void the warranty.

This product must not be modified.

• Verify that the rated voltage of the Drive matches the voltage of the incoming power supply before applying power.

• To meet CE directives, proper line filters and proper installation are required.

• Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These

must be replaced before operation.

• Observe electrostatic discharge procedures when handling circuit boards to prevent ESD damage.

• The equipment may start unexpectedly upon application of power. Clear all personnel from the Drive, motor, and

machine area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the

Drive.

• Please do not connect or operate any equipment with visible damage or missing parts. The operating company is

responsible for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

Intended Use

Drives are intended for installation in electrical systems or machinery.

The Drives are designed and manufactured in accordance with applicable UL and cUL standards, and CE directives.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of the Low Voltage Directive:

EN 50178: 1997-10, Electronic Equipment for Use in Power Installations

EN 60201-1: 1997-12 Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)

EN 61010: 1997-11 Safety Requirements for Information Technology Equipment

(IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

The F7 series Drives comply with the provisions of the Low Voltage Directive 73/23/EEC as amended by 93/68/EEC.

These Drives conform to the following standard: EN 50178: 1997-10.

Your supplier or Yaskawa representative must be contacted when using leakage current circuit breaker in conjunction

with frequency drives.

In certain systems it may be necessary to use additional monitoring and safety devices in compliance with the relevant

safety and accident prevention regulations. The frequency drive hardware must not be modified.

ii

Page 4

Safety Precautions

CAUTION

Installation

• Always hold the case when carrying the Drive.

If the Drive is held by the front cover, the main body of the Drive may fall, possibly resulting in injury.

• Attach the Drive to a metal or other noncombustible material.

Fire can result if the Drive is attached to a combustible material.

• Install a cooling fan or other cooling device when installing more than one Drive in the same enclosure so that the temperature of the air entering the Drives is below 45°C.

Overheating can result in fires or other accidents.

iii

Page 5

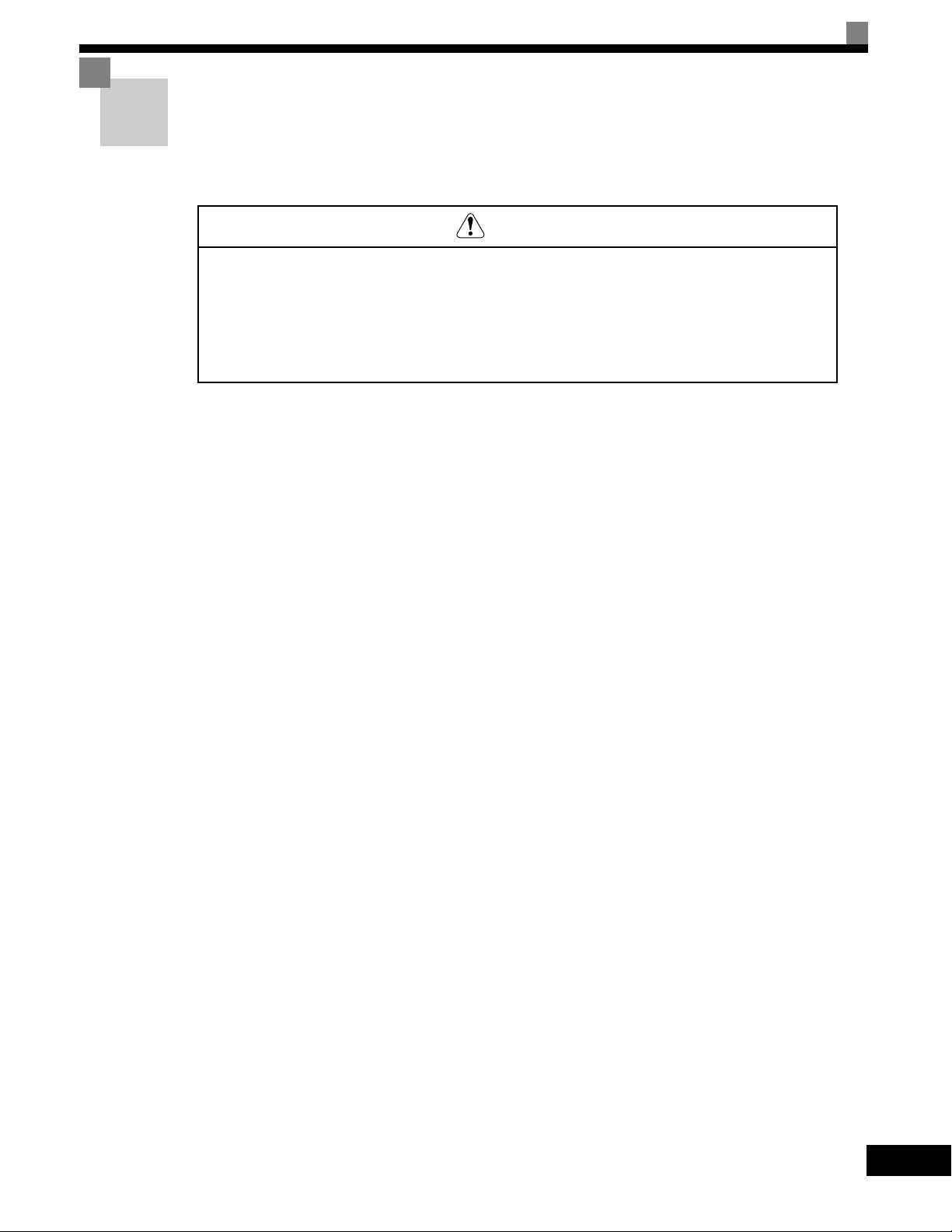

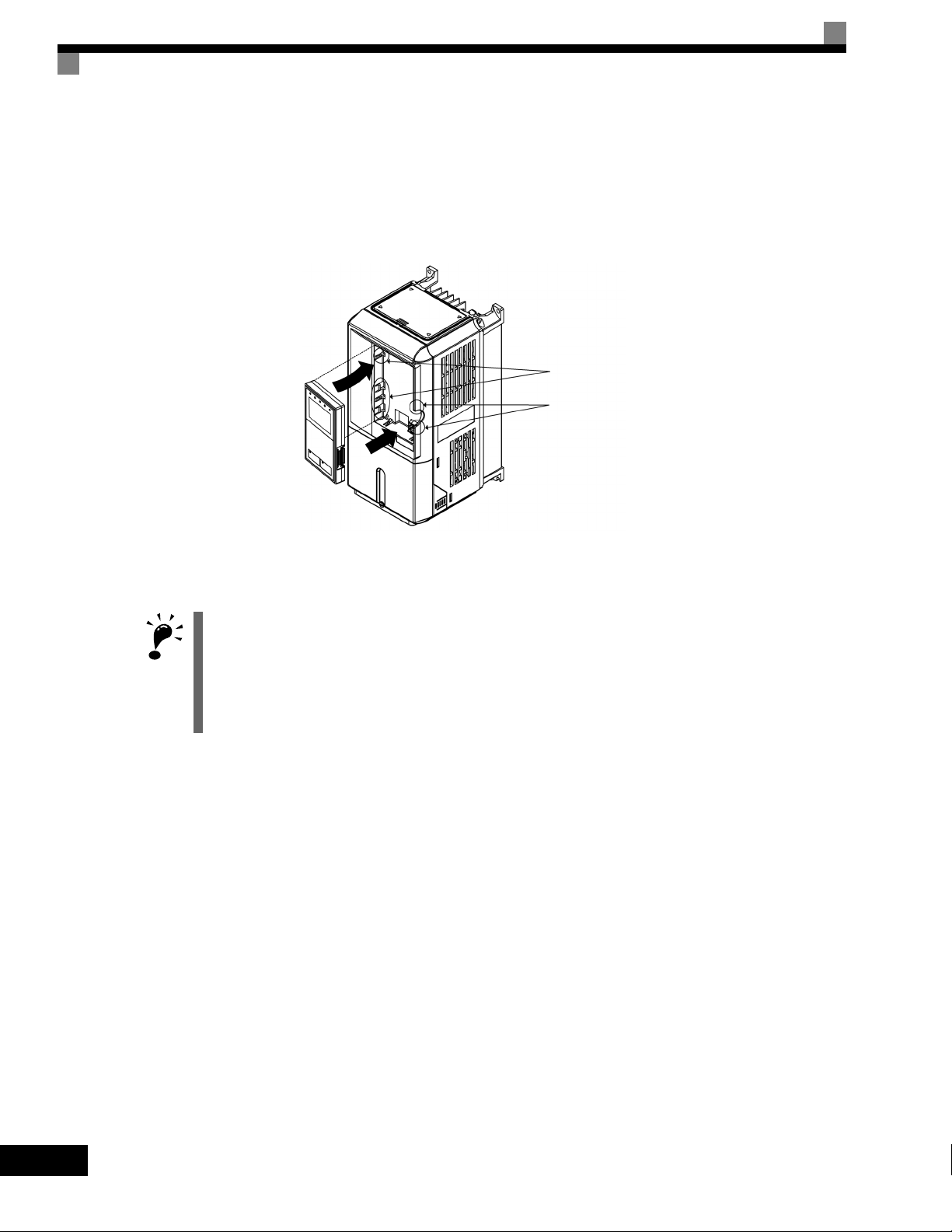

Warning Information and Position

Illustration shows the CIMR-G7U20P4

Warning

information

position

Illustration shows the CIMR-G7U2018

Warning

information

position

There is warning information on the Drive in the position shown in the following illustration.

Always heed the warnings.

Warning Information

iv

Page 6

!"##!$!"

% %

& ' (

( )

(

(

(

(

v

Page 7

Registered Trademarks

The following registered trademarks are used in this manual.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association, Inc.).

• ControlNet is a registered trademark of ControlNet International, Ltd.

• LONworks is a registered trademark of the Echelon.

• MODBUS is a registered trademark of the MODBUS.org.

vi

Page 8

Contents

1 Handling Drives ...................................................................... 1-1

Varispeed G7 Introduction ............................................................................1-2

Varispeed G7 Models .....................................................................................................1-2

Confirmations upon Delivery ........................................................................1-3

Checks............................................................................................................................1-3

Nameplate Information ...................................................................................................1-3

Component Names .........................................................................................................1-5

Exterior and Mounting Dimensions...............................................................1-7

Open Chassis Drives (IP00) ...........................................................................................1-7

NEMA Type 1 Drives (IP 20)...........................................................................................1-8

Checking and Controlling the Installation Site ............................................1-10

Installation Site .............................................................................................................1-10

Controlling the Ambient Temperature ...........................................................................1-10

Protecting the Drive from Foreign Matter...................................................................... 1-10

Installation Orientation and Space ..............................................................1-11

Removing and Attaching the Terminal Cover .............................................1-12

Removing the Terminal Cover ......................................................................................1-12

Attaching the Terminal Cover........................................................................................1-13

Removing/Attaching the Digital Operator and Front Cover ........................1-14

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015 ..............................................1-14

Models CIMR-G7U2018 thru 2110 and 4018 thru 4300 ............................................... 1-17

2 Wiring....................................................................................... 2-1

Connection Diagram.....................................................................................2-2

Terminal Block Configuration ........................................................................2-4

Wiring Main Circuit Terminals .......................................................................2-5

Applicable Wire Sizes and Closed-loop Connectors ......................................................2-5

Main Circuit Terminal Functions ...................................................................................2-13

Main Circuit Configurations...........................................................................................2-14

Standard Connection Diagrams....................................................................................2-15

Wiring the Main Circuits................................................................................................2-16

Wiring Control Circuit Terminals .................................................................2-22

Wire Sizes and Closed-loop Connectors ......................................................................2-22

Control Circuit Terminal Functions ............................................................................... 2-23

Control Circuit Terminal Connections ........................................................................... 2-29

vii

Page 9

Control Circuit Wiring Precautions ............................................................................... 2-30

Control Circuit Wire Sizes ............................................................................................ 2-30

Wire Checks ................................................................................................................. 2-30

Installing and Wiring Option Cards............................................................. 2-31

Option Card Models and Specifications ....................................................................... 2-31

Installation ....................................................................................................................2-32

PG Speed Control Card Terminals and Specifications ................................................. 2-33

Wiring ........................................................................................................................... 2-36

Wiring Terminal Blocks................................................................................................. 2-40

Selecting the Number of PG (Encoder) Pulses ............................................................ 2-41

3 Digital Operator and Modes....................................................3-1

Digital Operator ............................................................................................ 3-2

Digital Operator Display ................................................................................................. 3-2

Digital Operator Keys ..................................................................................................... 3-3

Modes .......................................................................................................... 3-5

Drive Modes ................................................................................................................... 3-5

Switching Modes ............................................................................................................ 3-6

Drive Mode ..................................................................................................................... 3-7

Quick Programming Mode.............................................................................................. 3-9

Advanced Programming Mode ..................................................................................... 3-10

Verify Mode .................................................................................................................. 3-13

Autotuning Mode .......................................................................................................... 3-14

4 Trial Operation .........................................................................4-1

Trial Operation Procedure............................................................................ 4-2

Trial Operation Procedures .......................................................................... 4-3

Setting the Power Supply Voltage Jumper (380-480V Class Drives of 4055 or Higher) 4-3

Power ON ....................................................................................................................... 4-3

Checking the Display Status .......................................................................................... 4-4

Basic Settings................................................................................................................. 4-5

Settings for the Control Methods .................................................................................... 4-7

Autotuning ......................................................................................................................4-9

Application Settings ...................................................................................................... 4-14

No-load Operation ........................................................................................................ 4-14

Loaded Operation......................................................................................................... 4-15

Check and Recording User Parameters....................................................................... 4-16

Adjustment Suggestions ............................................................................ 4-17

viii

Page 10

5 User Parameters ..................................................................... 5-1

User Parameter Descriptions .......................................................................5-2

Description of User Parameter Tables ............................................................................ 5-2

Digital Operation Display Functions and Levels ...........................................5-3

User Parameters Settable in Quick Programming Mode................................................ 5-4

User Parameter Tables...............................................................................5-10

A: Setup Settings.......................................................................................................... 5-10

Application Parameters: b.............................................................................................5-12

Autotuning Parameters: C ............................................................................................ 5-22

Reference Parameters: d..............................................................................................5-28

Motor Setup Parameters: E ..........................................................................................5-34

Option Parameters: F ...................................................................................................5-41

Terminal Function Parameters: H.................................................................................5-50

Protection Function Parameters: L ...............................................................................5-61

N: Special Adjustments.................................................................................................5-74

Digital Operator Parameters: o .....................................................................................5-80

T: Motor Autotuning ......................................................................................................5-84

U: Monitor Parameters..................................................................................................5-86

Factory Settings that Change with the Control Method (A1-02) ...................................5-96

Factory Settings that Change with the Drive Capacity (o2-04)...................................5-102

6 Parameter Settings by Function............................................ 6-1

Frequency Reference ...................................................................................6-2

Selecting the Frequency Reference Source ...................................................................6-2

Using Multi-Step Speed Operation .................................................................................6-5

Run Command .............................................................................................6-7

Selecting the Run Command Source .............................................................................6-7

Stopping Methods.........................................................................................6-9

Selecting the Stopping Method when a Stop Command is Sent..................................... 6-9

Using the DC Injection Brake........................................................................................6-13

Using an Emergency Stop ............................................................................................6-14

Acceleration and Deceleration Characteristics...........................................6-15

Setting Acceleration and Deceleration Times...............................................................6-15

Accelerating and Decelerating Heavy Loads (Dwell Function)..................................... 6-19

Preventing the Motor from Stalling During Acceleration (Stall Prevention During

Acceleration Function)..................................................................................................6-20

Preventing Overvoltage During Deceleration (Stall Prevention During Deceleration

Function).......................................................................................................................6-22

Adjusting Frequency References ...............................................................6-24

Adjusting Analog Frequency References .....................................................................6-24

Operation Avoiding Resonance (Jump Frequency Function) ....................................... 6-27

Adjusting Frequency Reference Using Pulse Train Inputs ...........................................6-29

ix

Page 11

Speed Limit (Frequency Reference Limit Function) ...................................6-30

Limiting Maximum Output Frequency........................................................................... 6-30

Limiting Minimum Frequency ....................................................................................... 6-31

Improved Operating Efficiency ................................................................... 6-32

Reducing Motor Speed Fluctuation (Slip Compensation Function).............................. 6-32

Compensating for Insufficient Torque at Startup and Low-speed Operation

(Torque Compensation) ................................................................................................ 6-35

Hunting-prevention Function ........................................................................................ 6-37

Stabilizing Speed (Speed Feedback Detection Function) ............................................ 6-38

Machine Protection ....................................................................................6-39

Reducing Noise and Leakage Current ......................................................................... 6-39

Limiting Motor Torque (Torque Limit Function) ............................................................ 6-42

Preventing Motor Stalling During Operation ................................................................. 6-44

Changing Stall Prevention Level during Operation Using an Analog Input .................. 6-45

Detecting Motor Torque................................................................................................ 6-45

Changing Overtorque and Undertorque Detection Levels Using an Analog Input ....... 6-50

Motor Overload Protection ........................................................................................... 6-51

Setting Motor Protection Operation Time ..................................................................... 6-53

Motor Overheating Protection Using PTC Thermistor Inputs ....................................... 6-54

Limiting Motor Rotation Direction ................................................................................. 6-56

Continuing Operation ................................................................................. 6-57

Restarting Automatically After Power Is Restored........................................................ 6-57

Speed Search............................................................................................................... 6-59

Continuing Operation at Constant Speed When Frequency Reference Is Lost ........... 6-65

Restarting Operation After Transient Error (Auto Restart Function) ............................ 6-66

Drive Protection.......................................................................................... 6-67

Performing Overheating Protection on Mounted Braking Resistors ............................. 6-67

Reducing Drive Overheating Pre-Alarm Warning Levels ............................................. 6-68

Input Terminal Functions ............................................................................6-69

Temporarily Switching Operation between Digital Operator and Control Circuit

Terminals ...................................................................................................................... 6-69

Blocking Drive Outputs (Baseblock Commands) ......................................................... 6-70

Stopping Acceleration and Deceleration (Acceleration/Deceleration Ramp Hold)....... 6-71

Raising and Lowering Frequency References Using Contact Signals (UP/DOWN) .... 6-72

Accelerating and Decelerating Constant Frequencies in the Analog References

(+/- Speed) ................................................................................................................... 6-75

Hold Analog Frequency Using User-set Timing ........................................................... 6-76

Switching Operations between a Communications Option Card and Control Circuit

Terminals ...................................................................................................................... 6-76

Jog Frequency Operation without Forward and Reverse Commands (FJOG/RJOG) . 6-77

Stopping the Drive by Notifying Programming Device Errors to the Drive

(External Fault Function) .............................................................................................. 6-78

x

Page 12

Monitor Parameterss ..................................................................................6-79

Using the Analog Monitor Parameters..........................................................................6-79

Using Pulse Train Monitor Contents .............................................................................6-82

Individual Functions....................................................................................6-84

Using MODBUS Communications ................................................................................6-84

Using the Timer Function..............................................................................................6-97

Using PID Control .........................................................................................................6-98

Energy-saving ............................................................................................................. 6-107

Setting Motor Parameters...........................................................................................6-108

Setting the V/f Pattern.................................................................................................6-111

Torque Control ............................................................................................................ 6-120

Speed Control (ASR) Structure...................................................................................6-128

Droop Control Function...............................................................................................6-134

Zero-servo Function....................................................................................................6-135

Digital Operator Functions........................................................................6-139

Setting Digital Operator Functions..............................................................................6-139

Copying Parameters ...................................................................................................6-143

Prohibiting Writing Parameters from the Digital Operator........................................... 6-148

Setting a Password .....................................................................................................6-149

Displaying User-set Parameters Only.........................................................................6-149

Options .....................................................................................................6-151

Performing Speed Control with PG.............................................................................6-151

Using Digital Output Cards .........................................................................................6-156

Using an Analog Reference Card ...............................................................................6-159

Using a Digital Reference Card ..................................................................................6-159

7 Troubleshooting ..................................................................... 7-1

Protective and Diagnostic Functions ............................................................7-2

Fault Detection................................................................................................................7-2

Alarm Detection .............................................................................................................. 7-9

Operation Errors ...........................................................................................................7-13

Errors During Autotuning .............................................................................................7-15

Errors when Using the Digital Operator Copy Function................................................7-17

Troubleshooting..........................................................................................7-18

If Parameters Cannot Be Set........................................................................................7-18

If the Motor Does Not Operate......................................................................................7-19

If the Direction of the Motor Rotation is Reversed ........................................................7-21

If the Motor Does Not Put Out Torque or If Acceleration is Slow ..................................7-21

If the Motor Operates Higher Than the Reference .......................................................7-22

If the Slip Compensation Function Has Low Speed Precision......................................7-22

If There is Low Speed Control Accuracy at High-speed Rotation in Open-loop Vector

Control Mode ................................................................................................................7-22

xi

Page 13

If Motor Deceleration is Slow........................................................................................ 7-23

If the Motor Overheats.................................................................................................. 7-24

If There is Noise When the Drive is Started or From an AM Radio.............................. 7-24

If the Ground Fault Interrupter Operates When the Drive is Run ................................. 7-25

If There is Mechanical Oscillation................................................................................. 7-25

If the Motor Rotates Even When Drive Output is Stopped ........................................... 7-26

If 0 V is Detected When the Fan is Started, or Fan Stalls............................................. 7-26

If Output Frequency Does Not Rise to Frequency Reference ...................................... 7-27

8 Maintenance and Inspection ..................................................8-1

Maintenance and Inspection ........................................................................ 8-2

Outline of Maintenance .................................................................................................. 8-2

Daily Inspection .............................................................................................................. 8-2

Periodic Inspection ......................................................................................................... 8-2

Periodic Maintenance of Parts ....................................................................................... 8-3

Cooling Fan Replacement Outline ................................................................................. 8-4

Removing and Mounting the Control Circuit Terminal Card........................................... 8-6

9 Specifications ..........................................................................9-1

Standard Drive Specifications ...................................................................... 9-2

Specifications by Model.................................................................................................. 9-2

Common Specifications.................................................................................................. 9-4

Specifications of Options and Peripheral Devices........................................ 9-5

10 Appendix ................................................................................10-1

Varispeed G7 Control Modes .....................................................................10-2

Control Modes and Features........................................................................................ 10-2

Control Modes and Applications................................................................................... 10-6

Drive Application Precautions .................................................................... 10-7

Selection....................................................................................................................... 10-7

Installation .................................................................................................................... 10-8

Settings ........................................................................................................................ 10-8

Handling .......................................................................................................................10-9

Motor Application Precautions .................................................................10-10

Using the Drive for an Existing Standard Motor ......................................................... 10-10

Using the Drive for Special Motors ............................................................................. 10-11

Power Transmission Mechanism (Speed Reducers, Belts, and Chains) ................... 10-11

xii

Conformance to CE Markings .................................................................. 10-12

CE Markings............................................................................................................... 10-12

Requirements for Conformance to CE Markings ........................................................ 10-12

User Parameters ......................................................................................10-19

Page 14

Handling Drives

This chapter describes the checks required upon receiving or installing an Drive.

Varispeed G7 Introduction ........................................... 1-2

Confirmations upon Delivery........................................1-3

Exterior and Mounting Dimensions..............................1-7

Checking and Controlling the Installation Site ........... 1-10

Installation Orientation and Space ............................. 1-11

Removing and Attaching the Terminal Cover ............1-12

Removing/Attaching the Digital Operator

and Front Cover .........................................................1-14

Page 15

Varispeed G7 Introduction

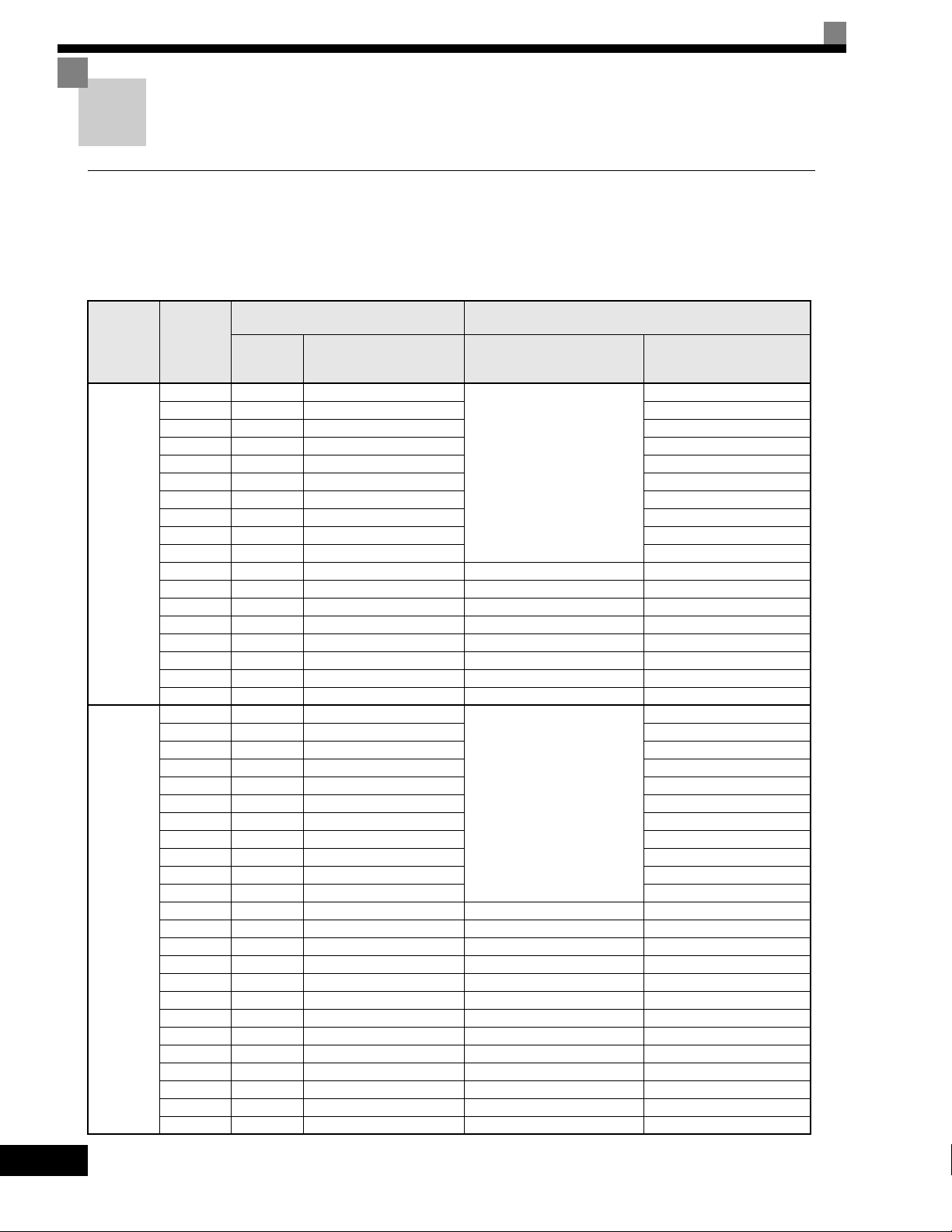

Varispeed G7 Models

The Varispeed-G7 Series of Drives included two Drives in two voltage classes: 200-240V and 380-480V. Maximum motor

capacities vary from 20P4 to 2110 and 40P4 to 4300 (42 models).

Voltage

Class

200-240V

class

380-480V

class

Table 1.1 Varispeed

Maximum

Motor

Capacity

kW

0.4 1.2 CIMR-G7U20P4

0.75 2.3 CIMR-G7U20P7 20P71

1.5 3.0 CIMR-G7U21P5 21P51

2.2 4.6 CIMR-G7U22P2 22P21

3.7 6.9 CIMR-G7U23P7 23P71

5.5 10 CIMR-G7U25P5 25P51

7.5 13 CIMR-G7U27P5 27P51

11 19 CIMR-G7U2011 2011

15 25 CIMR-G7U2015 20151

18.5 30 CIMR-G7U2018 20181

22 37 CIMR-G7U2022 - 20220

30 50 CIMR-G7U2030 20300 -

37 61 CIMR-G7U2037 20370 -

45 70 CIMR-G7U2045 20450 -

55 85 CIMR-G7U2055 20550 -

75 110 CIMR-G7U2075 20750 -

90 140 CIMR-G7U2090 20900 -

110 160 CIMR-G7U2110 21100 -

0.4 1.4 CIMR-G7U40P4

0.75 2.6 CIMR-G7U40P7 40P71

1.5 3.7 CIMR-G7U41P5 41P51

2.2 4.7 CIMR-G7U42P2 42P21

3.7 6.9 CIMR-G7U43P7 43P71

4.0 8.4 CIMR-G7U44P0 44P01

5.5 11 CIMR-G7U45P5 45P51

7.5 16 CIMR-G7U47P5 47P51

11 21 CIMR-G7U4011 40111

15 26 CIMR-G7U4015 40151

18.5 32 CIMR-G7U4018 40181

22 40 CIMR-G7U4022 - 40221

30 50 CIMR-G7U4030 - 40301

37 61 CIMR-G7U4037 - 40371

45 74 CIMR-G7U4045 - 40451

55 98 CIMR-G7U4055 40550 -

75 130 CIMR-G7U4075 40750 -

90 150 CIMR-G7U4090 40900 -

110 180 CIMR-G7U4110 41100 -

132 210 CIMR-G7U4132 41320 -

160 230 CIMR-G7U4160 41600 -

185 280 CIMR-G7U4185 41850 -

220 340 CIMR-G7U4220 42200 -

300 460 CIMR-G7U4300 43000 -

Output

Capacity

kVA

Varispeed G7

Basic Model Number

G7 Models

(Always specify through the protective structure when ordering.)

Open Chassis

(IEC IP00)

CIMR-G7

Remove the top and bottom

covers from the Enclosed

Wall-mounted model.

Remove the top and bottom

covers from the Enclosed

Wall-mount model.

Specifications

Enclosed Wall-mounted

(IEC IP20, NEMA 1)

CIMR-G7

20P41

40P41

1-2

Page 16

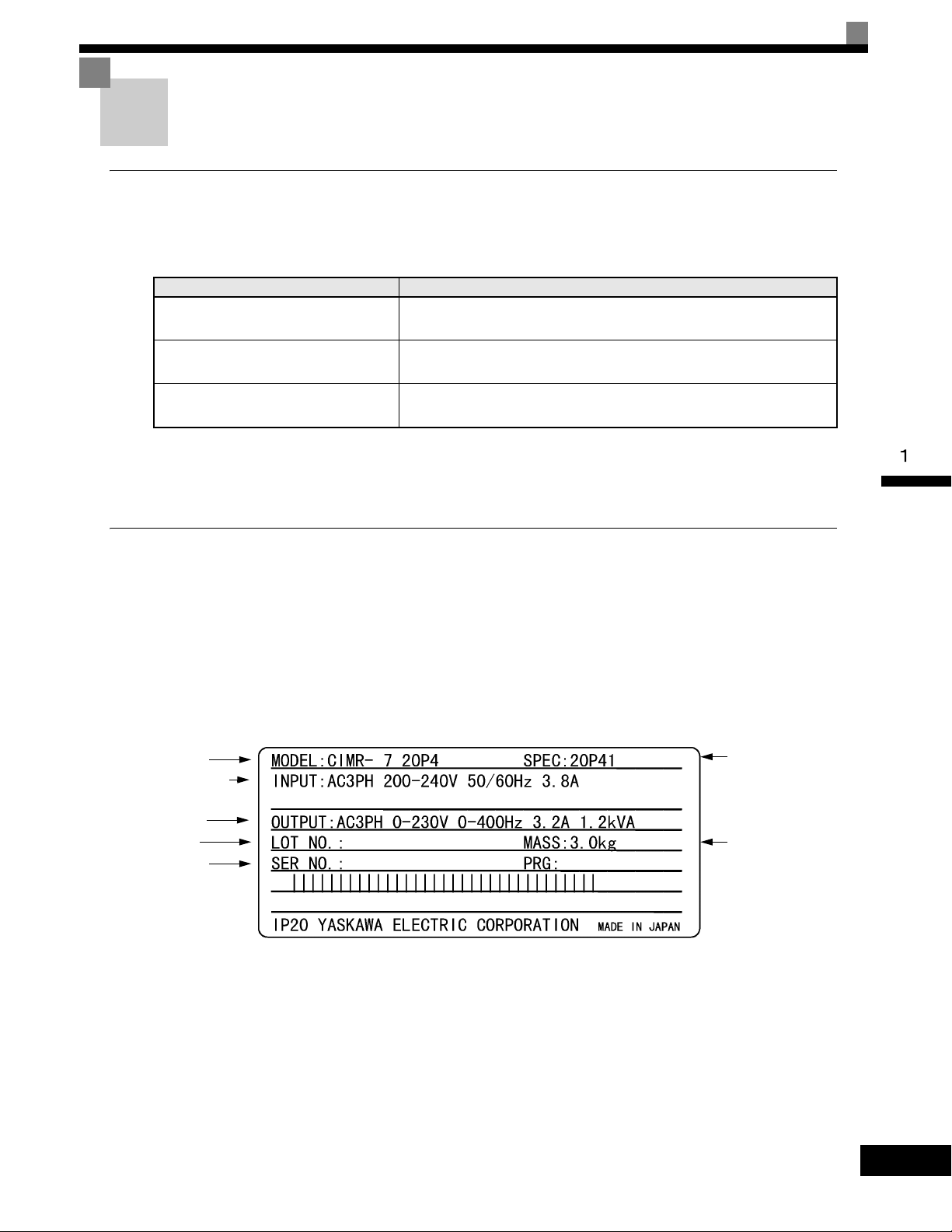

Confirmations upon Delivery

Drive model

Input specifications

Output

specifications

Lot number

Serial number

Input specifications

Drive

specifications

Mass

GU

Checks

Check the following items as soon as the Drive is delivered.

Table 1.2 Checks

Item Method

Has the correct model of Drive been

delivered?

Check the model number on the nameplate on the side of the Drive.

Confirmations upon Delivery

Is the Drive damaged in any way?

Are any screws or other components

loose?

Inspect the entire exterior of the Drive to see if there are any scratches or

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

If you find any irregularities in the above items, contact the agency from which you purchased the Drive or

your Yaskawa representative immediately.

Nameplate Information

There is a nameplate attached to the side of each Drive. The nameplate shows the model number, specifications, lot number, serial number, and other information on the Drive.

Example Nameplate

The following nameplate is an example for a standard Drive: 3-phase, 200-240Vac, 0.4kW, IEC IP20 and

NEMA 1 standards.

Fig 1.1 Nameplate

1-3

Page 17

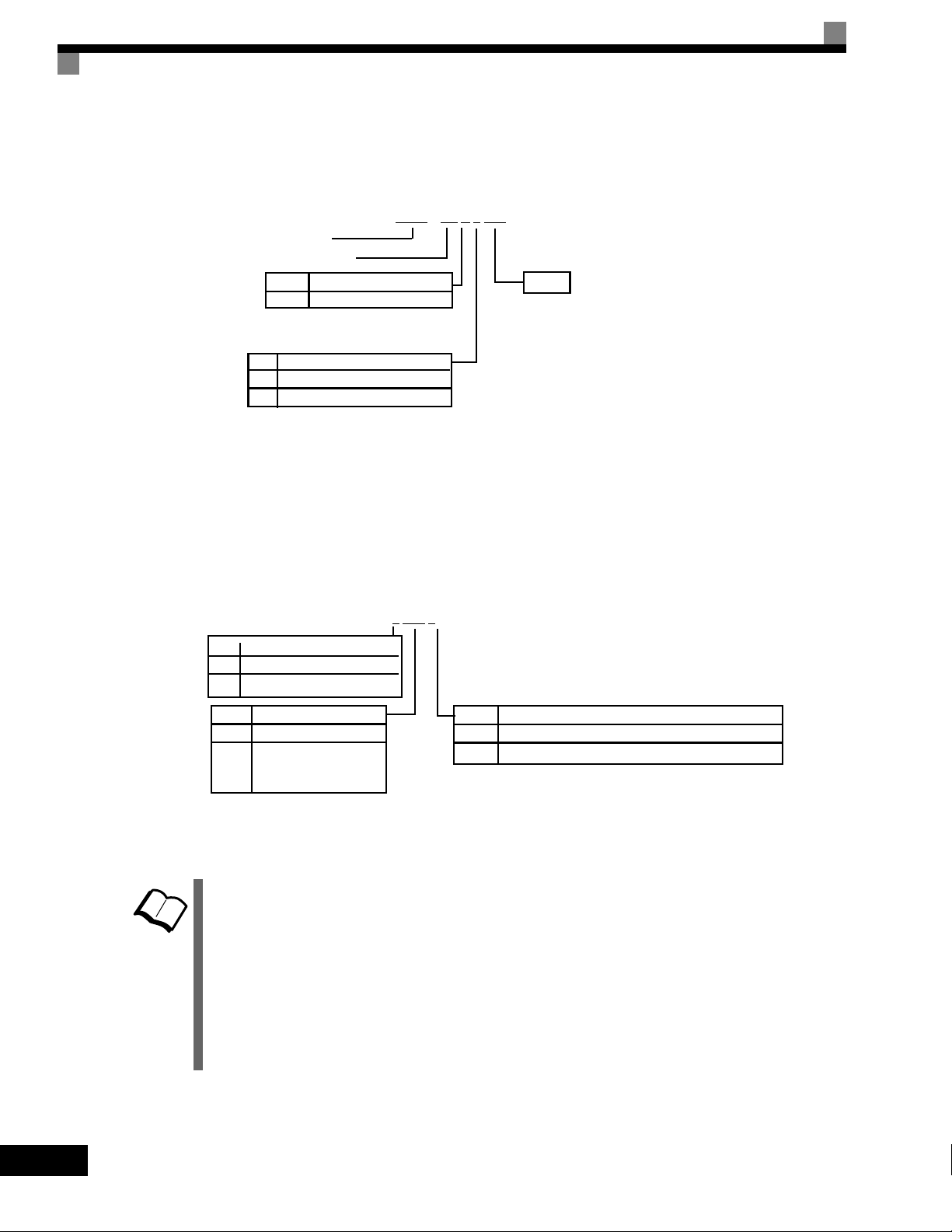

Drive Model Numbers

TERMS

No.

Spec

UL Specification

CIMR – G7 U 2 0P4

AC Drive

U

No.

Voltage

2

4

3-phase, 208-240Vac

3-phase, 480Vac

Rating

G7 Family

2 0P4 1

No.

2

4

Voltage

AC input, 3-phase, 200-240V

AC input, 3-phase, 380-480V

No.

Enclosure Type

0 Open chassis (IEC IP00)

1

NEMA Type 1 (IEC IP20)

No.

0P4 0.4kW

0P7 0.75kW

to

300kW *

to

Max. Motor Capacity

300

“P” indicates the decimal point

The model number of the Drive on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the Drive in alphanumeric codes.

Fig 1.2 Drive Model Numbers

Drive Specifications

The SPEC number on the nameplate indicates the voltage, Drive rating, enclosure type, and the revision code

of the Drive in alphanumeric codes. The SPEC number for Drives that have custom features, i.e. CASE

software, will have a SPEC number that indicates the custom features installed.

1-4

Open Chassis Type (IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when the

Drive is mounted in a control panel.

NEMA Type 1 (IEC IP20)

The Drive is shielded from the exterior, and can thus be mounted to the interior wall of a standard building

(not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA 1

in the USA.

Top protective cover must be installed to conform with IEC IP20 and NEMA 1 Type 1 requirements. Refer to

Fig. 1.4 for details.

Fig 1.3 Drive Specifications

Page 18

Confirmations upon Delivery

Top protective cover

[Required for NEMA Type 1 (IEC IP20)]

Front cover

Digital Operator

Terminal cover

Mounting hole

Nameplate

Bottom protective cover

Diecast case

NPJT31278-1-0NPJT31278-1-0

CAUTIONCAUTION

Charge indicator

Ground terminal

Control circuit terminals

Main circuit terminals

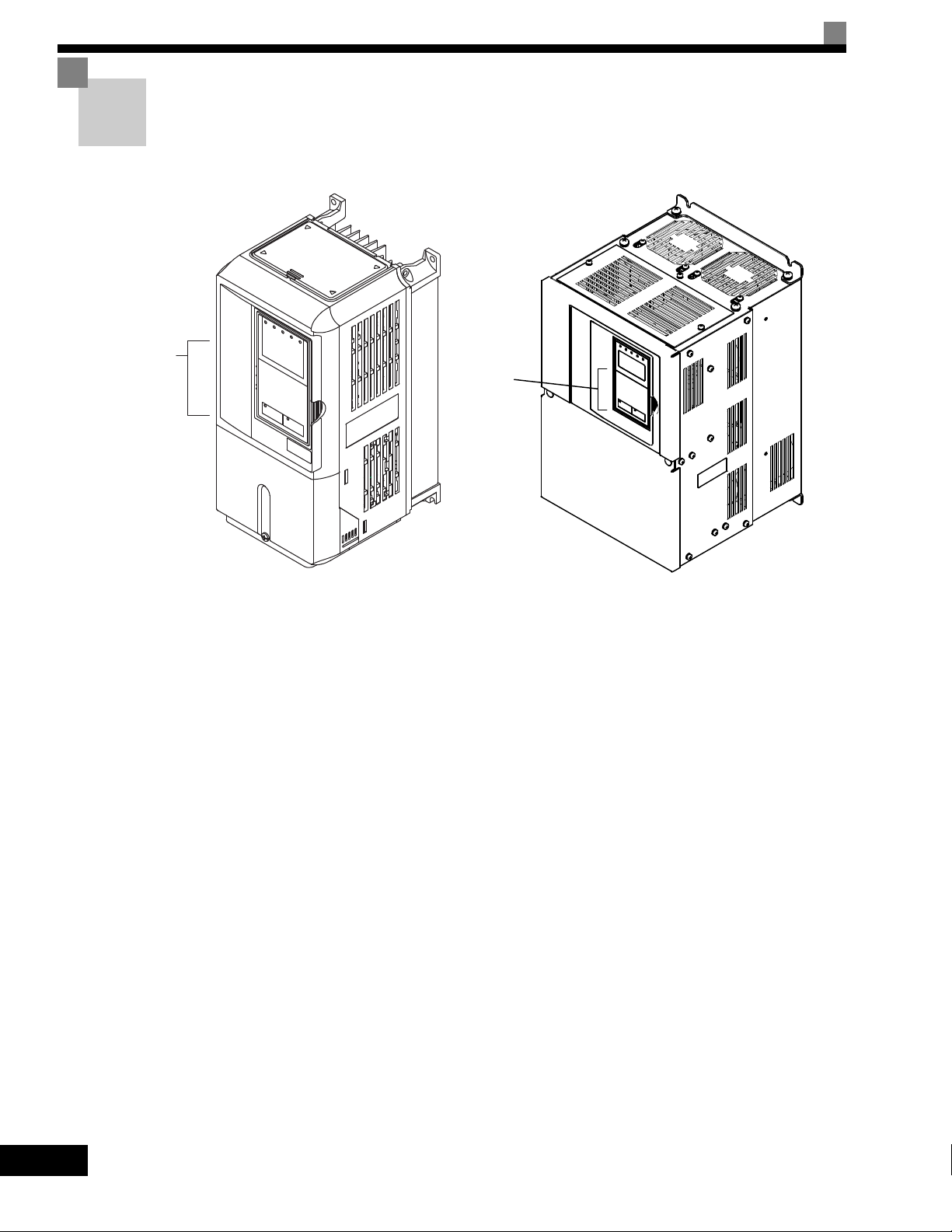

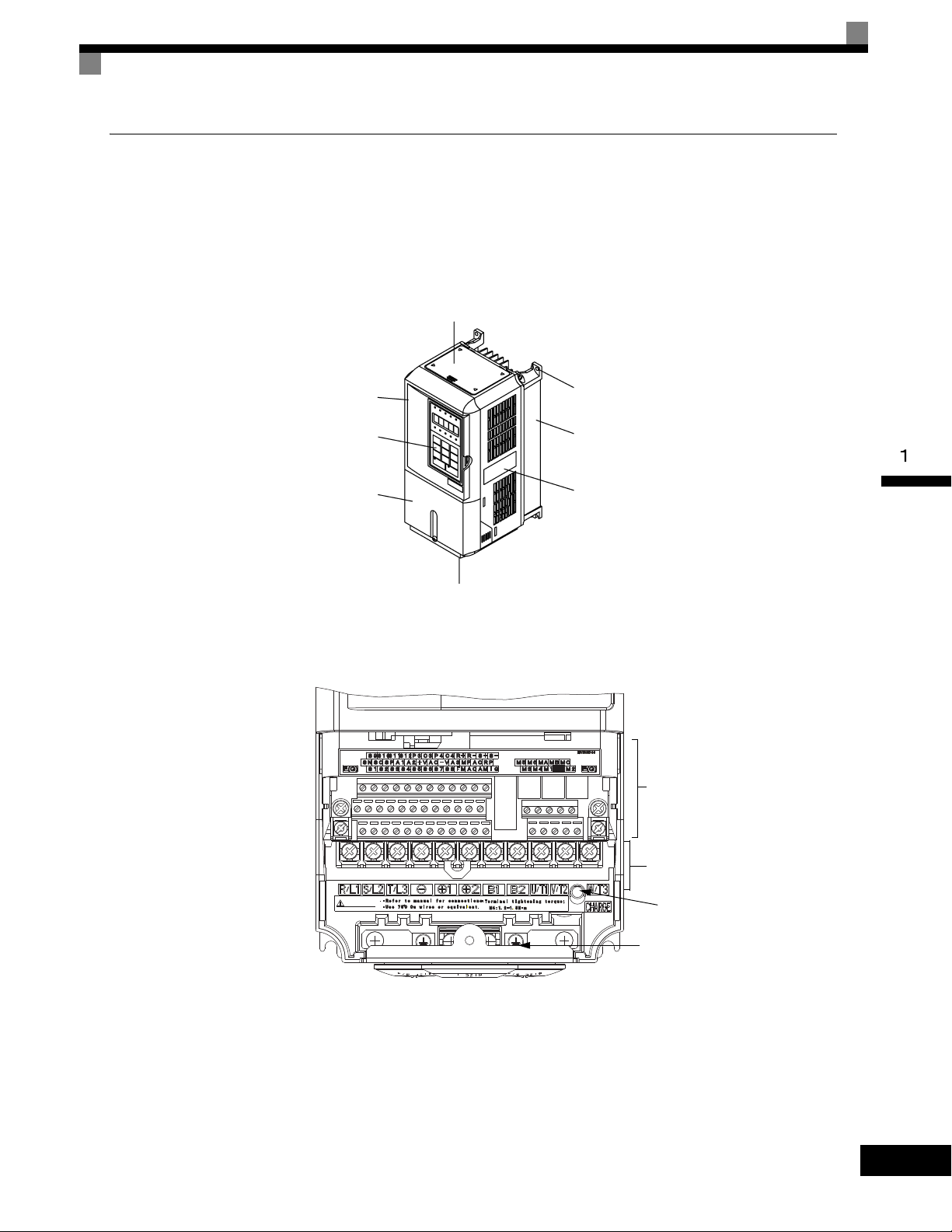

Component Names

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015

The external appearance and component names of the Drive are shown in Fig 1.4. The Drive with the terminal

cover removed is shown in Fig 1.5.

Fig 1.4 Drive Appearance

Fig 1.5 Terminal Arrangement

1-5

Page 19

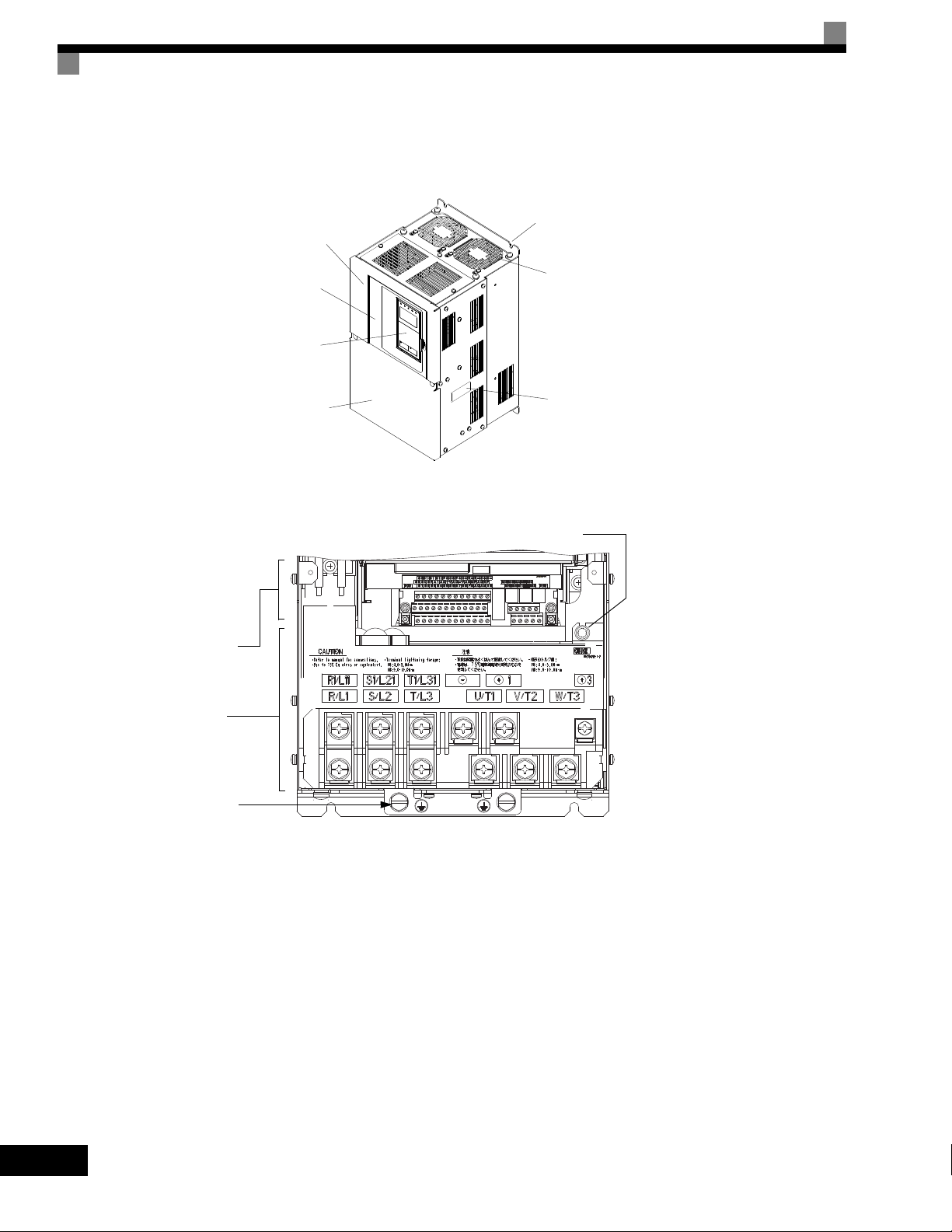

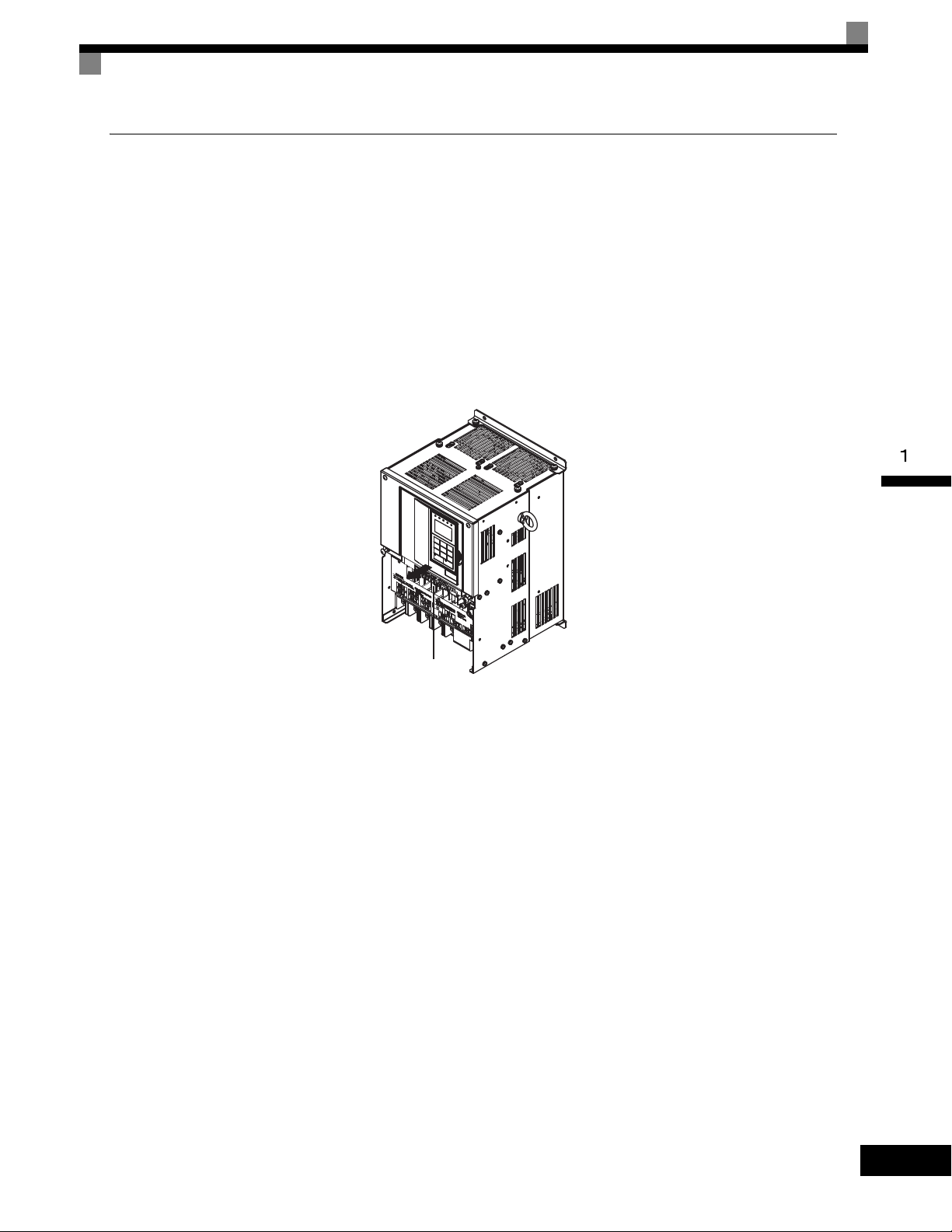

Models CIMR-G7U2018 thru 2110 and 4018 thru 4300

Mounting holes

Cooling fan

Nameplate

Drive cover

Front cover

Digital Operator

Terminal cover

Charge indicator

Control circuit

terminals

Main circuit

terminals

Ground terminal

The external appearance and component names of the Drive are shown in Fig 1.6. The Drive with the terminal

cover removed is shown in Fig 1.7.

Fig 1.6 Drive Appearance

1-6

Fig 1.7 Terminal Arrangement

Page 20

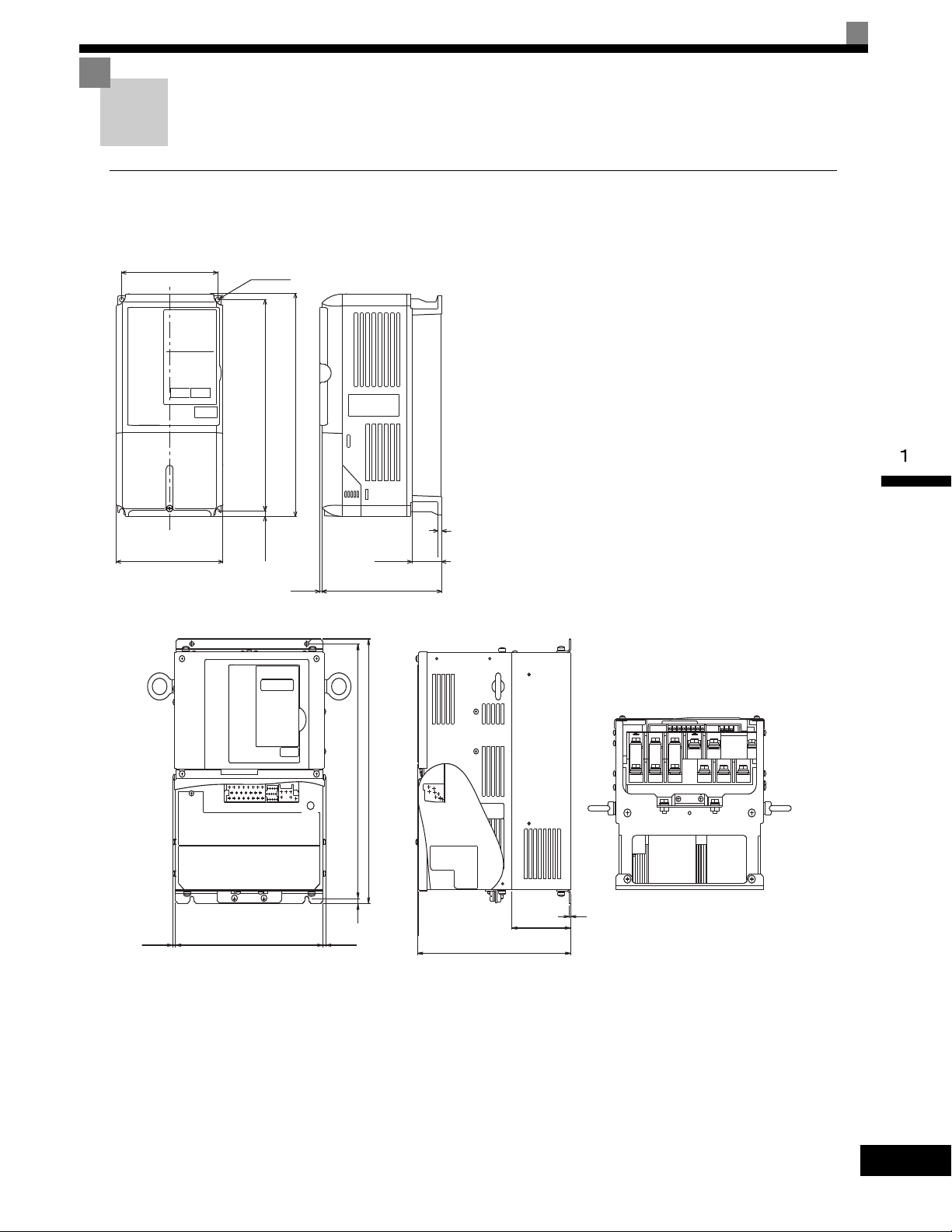

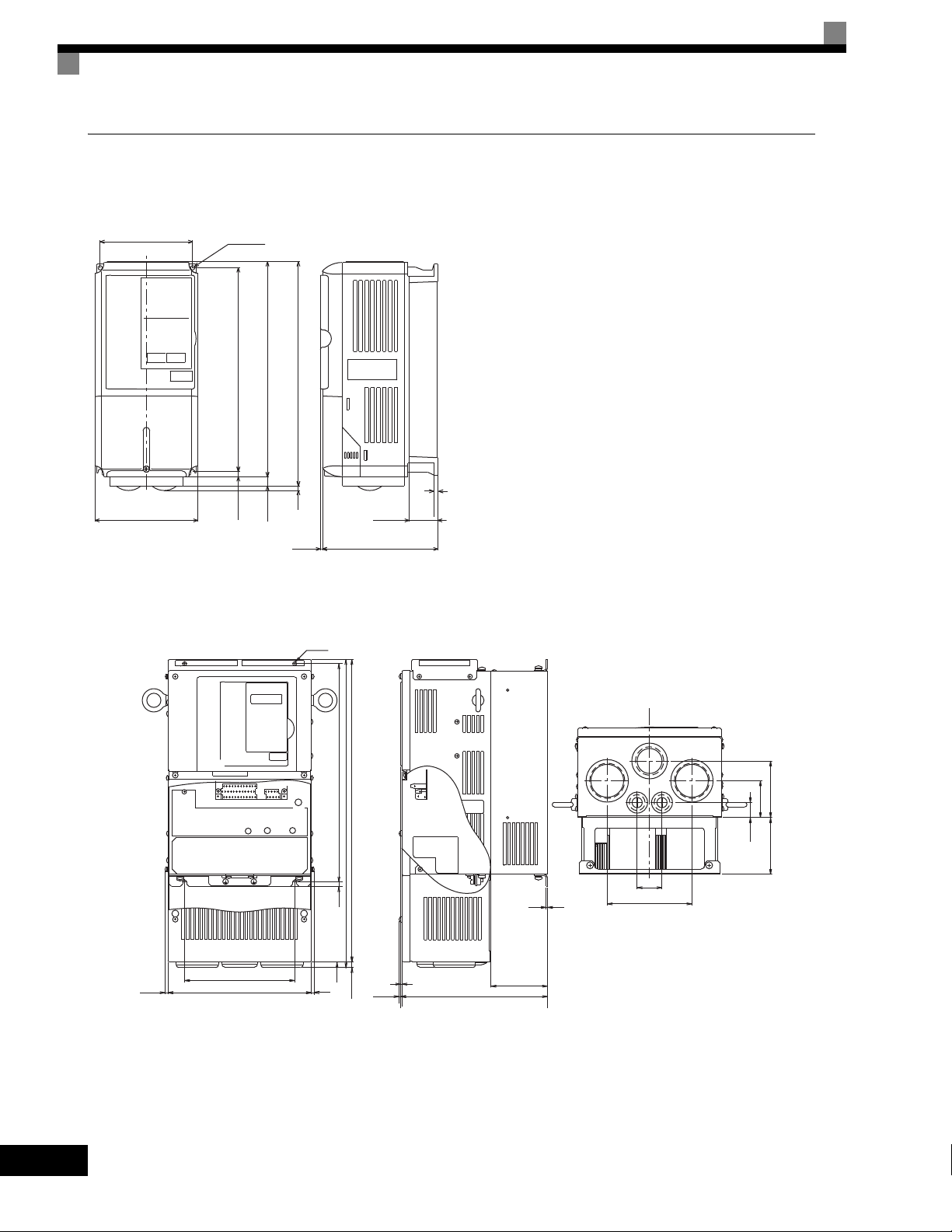

Exterior and Mounting Dimensions

W

W1

3

H1H2DH

D1

4-d

t1

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015

D

D1

H1

H

(5)

∗

(5)

∗

H2

W

CHARGE

t1

Front View Side View Bottom View

Open Chassis Drives (IP00)

Exterior diagrams of the Open Chassis Drives are shown below.

Exterior and Mounting Dimensions

Models CIMR-G7U2018 thru 2110 and 4018 thru 4160

1-7

Page 21

NEMA Type 1 Drives (IP 20)

W

W1

3

H1H2DH0

D1

H3

4 H

4-d

t1

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015

(5)*

(5)

W

D

t1

H

max.10

H0

H3

H2

W1

H1

(5)*

+

-

+

D1

CHARGE

1

3

4-d

Front View Side View Bottom View

Models CIMR-G7U2018 thru 2075 and 4018 thru 4160

Exterior diagrams of the Enclosed Wall-mounted Drives (NEMA1 Type 1) are shown below.

1-8

Page 22

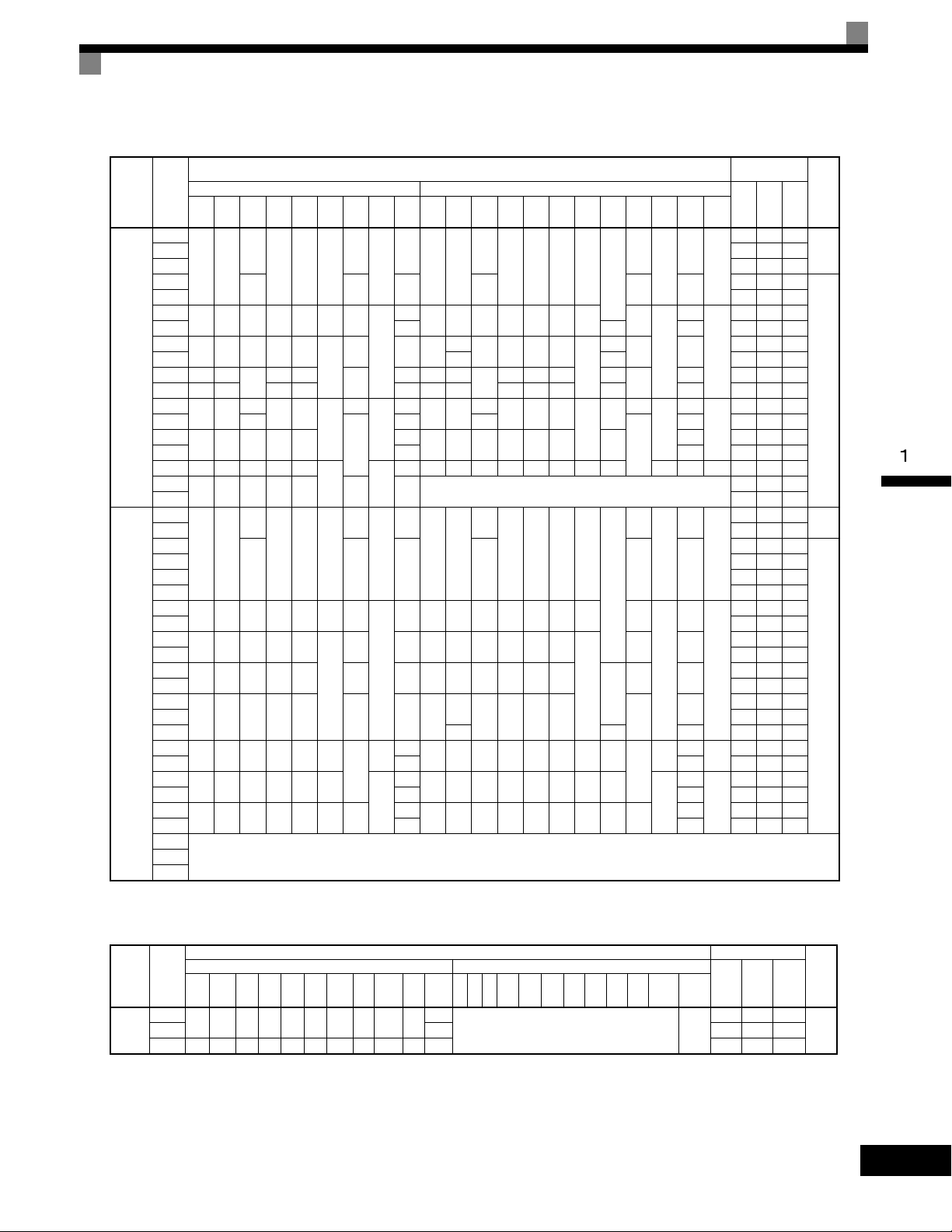

Table 1.3 Drive Dimensions (mm) and Masses (kg)

Model

Voltage

CIMR-

Class

G7U

W H D W1H1H2D1 t1

20P4

140 280

21P5 58 47 105

22P2

23P7 122 64 186

25P5

200 300 197 186 285 8 65.5

27P5 7 0 7 263 112 375

2011

240 350 207 216 335

200-240V

2015 380 30 473 174 647

(3-phase)

2018 250 400

2022 275 450 220 435 24 279 613 220 450 435 165 27 679 257 936

2030

375 600

2037 330

2045

450 725 350 325 700

2055 87 95 1474 607 2081

2075 500 850 360 370 820

2090

575 885 380 445 855 140 150 ---

2110 2389 1194 3583

40P4

40P7 21 44 65

41P5

140 280

42P2 41 49 90

43P7 77 63 140

44P0 100 66 166

45P5

200 300 197 186 285 8 65.5

47P5 197 107 304

4011

240 350 207 216 335

4015 311 135 446

4018

275 450 258 220 435 100 26 279 535 258 220 450 435

380-480V

4022 516 210 726

(3-phase)

4030

325 550 283 260 535 105 37 329

4037 737 285 1022

4045 715 165 40 929 340 1269

4055

450 725 348 325 700 12.5

4075 91 99 1554 597 2151

4090

500 850 358 370 820 15

4110 127 137 2299 928 3227

4132

575 916 378 445 855 45.8 140

4160 175 185 3614 1501 5115

4185

4300

* Same for Open Chassis and Enclosed Wall-mounted Drives

Open Chassis (IP00) Enclosed Wall-mounted (NEMA Type 1)

157

126 266 7

177 59 4 177 59 4

260

300

195 385

250 575

7.5

12.5

15 4.5

157

126 266 7

177 59 4.5 177 59 4.5

7.5

Dimensions (mm)

Approx

W H D W1H0H1H2H3D1 t1

Mass

39

78 11 240

100

100

130

3

5

6

2.3

21 254 535

57

63 328

3.2

86

140 280

126 280 266 7

200 300 197 186 300 285 8 65.5

157

350

207 216 350 335

195 400 385 135

260

380 809

298

250 600 575

453 1027 348 325 725 700 302

108 504 1243 361 370 850 820 15 393 4.5 114 M12 2009 823 2832

39

3.5

5

140 280

157

126 280 266 7

7 200 300 197 186 300 285 8 65.5

78 10 240 350 207 216 350 335

2.3

635

285 260 550 535 105

90

3.2

130

4.5

453 1027 348 325 725 700 12.5 302

109

504 1243 358 370 850 820 15 393

165

579 1324 378 445 916 855 45.8 408 140

See Table 1.44220

Exterior and Mounting Dimensions

Heat Generation

Mount-

External In ternal

ing

Holes*

3

M5

6

M6

24 599 241 840

62

68 1080 434 1514

M10

94 1291 510 1801

1660 871 2531

M5

6

M6

39

98

1239 488 1727

M10

1928 762 2690

M12

7.5

12.5

7.5

0

0

209

0

85

Approx

Mass

39

5

2.3

78 11

100

100

3.2

130

39

5

78 10

2.3

100 29

3.2

130

4.5

3.5

127

175 2612 1105 3717

(W)

Tot a l

Heat

21 36 57

83 53 136

187 87 274

357 136 493

878 362 1240

10 39 49

33 46 79

132 80 212

246 116 362

354 174 528

633 246 879

Cooling

Method

Natural20P7 43 42 85

Fan

Natural

Fan

Voltage

Class

380-

480V

(3-phase)

Table 1.4 480Vac (185 to 300 kW) Drive Dimensions (mm) and Masses (kg)

Model

CIMR-

G7U

W H D W1W2W3 H1 H2 D1 t1

4185

710 1305 413 540 240 270 1270 15 125.5 4.5

Open Chassis (IP00) Enclosed Wall-mounted (NEMA Type1)

4300 916 1475 413 730 365 365 1440 15 125.5 4.5 415 6749 2941 9690

Dimensions (mm) Heat Generation (W)

Mount-

Approx

WHDW1W2W3H1H2D1 t1

Mass

260

Approx

Mass

ing

Holes*

External Internal

4436 1995 6431

--- M12

Tot a l

Heat

Cooling

Method

Fan4220 280 5329 2205 7534

1-9

Page 23

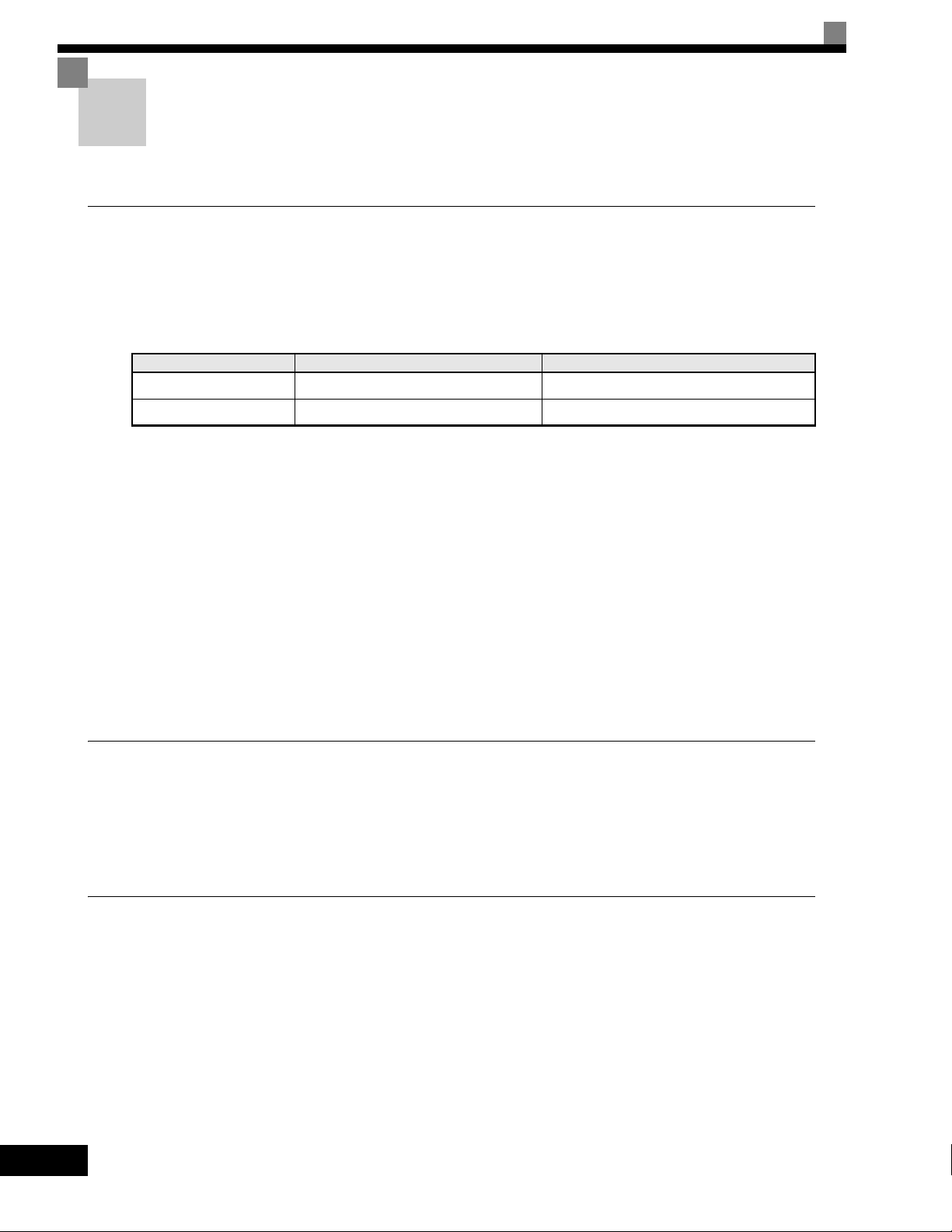

Checking and Controlling the Installation Site

Install the Drive in the installation site described below and maintain optimum conditions.

Installation Site

Install the Drive to a non-combustible surface under the following conditions in UL Pollution Degree 2 environments. This excludes wet locations where pollution may become conductive due to moisture, and locations

containing conductive foreign matter

Table 1.5 Installation Site

Type Ambient Operating Temperature Humidity

NEMA Type 1 14° F-to- 104°F (-10-to- + 40 °C) 95% RH or less (no condensation)

Open chassis 14° F-to- 113°F (-10-to- + 45 °C) 95% RH or less (no condensation)

Protective covers are attached to the top and bottom of the Drive. It is recommended to remove the protective

covers before operating a NEMA Type 1 Drive (Models CIMR-G7U2015/4015 and smaller) in a panel to

obtain the 113° (45°C) ambient operating temperature.

Observe the following precautions when installing the Drive. Make sure to install:

• In a clean location which is free from oil mist and dust.

• In an environment where metal shavings, oil, water, or other foreign materials do not get into the Drive.

• In a location free from radioactive materials and combustible materials (e.g. wood).

• In a location free from harmful gases and liquids.

• In a location free from excessive vibration.

• In a location free from chlorides

• In a location away from direct sunlight.

1-10

Controlling the Ambient Temperature

To enhance the reliability of operation, the Drive should be installed in an environment free from extreme temperature variation. If the Drive is installed in an enclosure, use a cooling fan or air conditioner to maintain the

internal air temperature below 113°

F (45°C).

Protecting the Drive from Foreign Matter

During Drive installation and project construction, it is possible to have foreign matter such as metal shavings

or wire clippings fall inside the Drive. To prevent foreign matter from falling into the Drive, place a temporary

cover over the Drive.

Always remove the temporary cover from the Drive before start-up. Otherwise, ventilation will be reduced,

causing the Drive to overheat.

Page 24

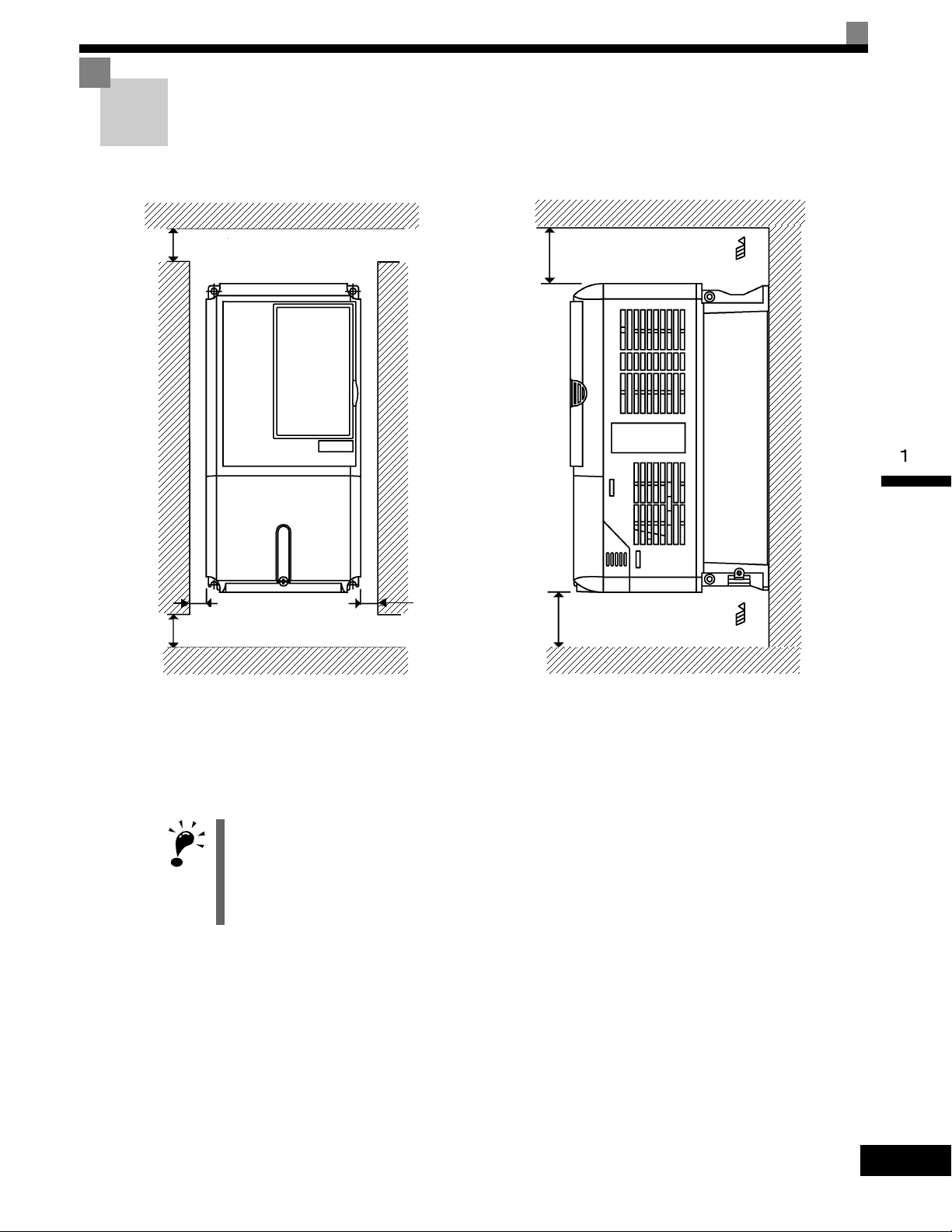

Installation Orientation and Space

IMPORTANT

4.72in (120mm) minimum

4.75in (120mm) minimum

Air

Air

Vertical ClearanceHorizontal Clearance

1.2in

(30.5mm) minimum

1.2in

(30.5mm) minimum

1.97in (50mm) minimum

1.97in * (50mm) minimum

* For Drive model G7U4300, this clearance dimension is 11.81in (300mm) minimum. All other models require 1.97in (50mm) minimum.

Install the Drive vertically so as not to reduce the cooling effect. When installing the Drive, always provide the following installation space to allow normal heat dissipation.

Installation Orientation and Space

Fig 1.8 Drive Installation Orientation and Space

1. The same space is required horizontally and vertically for both Open Chassis (IP00) and Enclosed Wallmounted (IP20, NEMA 1 Type 1) Drives.

2. Always remove the protection covers before installing a 200-240 or 380-480 V Class Drive with an output

of 15 kW or less in a panel.

Always provide enough space for suspension eye bolts and the main circuit lines when installing a 200-240

or 380-480 V Class Drive with an output of 18.5 kW or more in a panel.

1-11

Page 25

Removing and Attaching the Terminal Cover

1

2

1

1

2

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

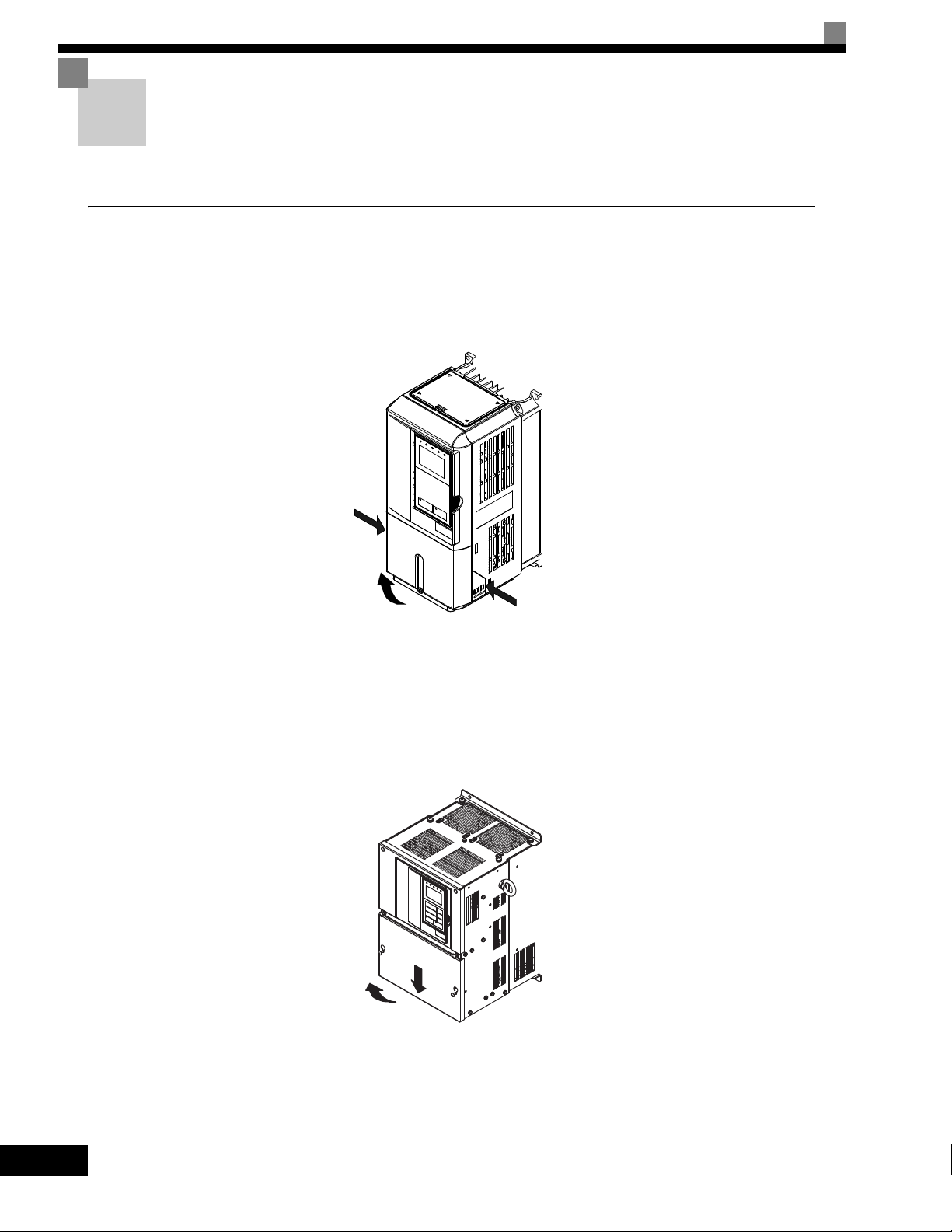

Removing the Terminal Cover

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015

Loosen the screws at the bottom of the terminal cover, press in on the sides of the terminal cover in the

directions of arrows 1, and then lift up on the terminal in the direction of arrow 2.

Fig 1.9 Removing the Terminal Cover (Model CIMR-G7U23P7 Shown Above)

Models CIMR-G7U2018 thru 2110 and 4018 thru 4300

Loosen the screws on the left and right at the top of the terminal cover, pull out the terminal cover in the

direction of arrow 1 and then lift up on the terminal in the direction of arrow 2.

Fig 1.10 Removing the Terminal Cover (Model CIMR-G7U2018 Shown Above)

1-12

Page 26

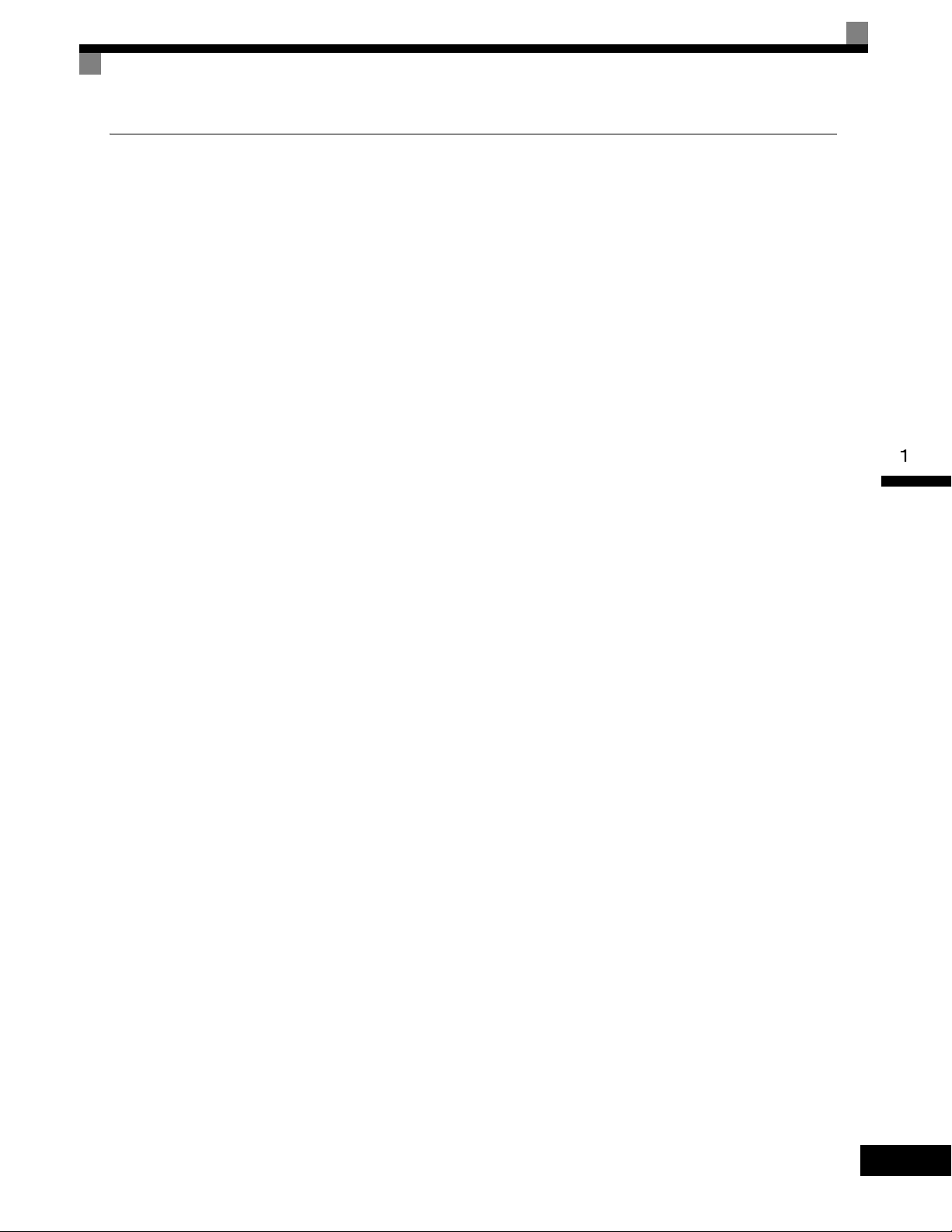

Removing and Attaching the Terminal Cover

Attaching the Terminal Cover

After wiring the terminal block, attach the terminal cover by reversing the removal procedure.

For Models CIMR-G7U2015/4015 and smaller, insert the tab on the top of the terminal cover into the groove on the

Drive, and press in on the bottom of the terminal cover until it clicks into place.

For Drives CIMR-G7U2018/4018 and larger, insert the tab on the top of the terminal cover into the groove on the

Drive, and secure the terminal cover by lifting it up toward the top of the Drive.

1-13

Page 27

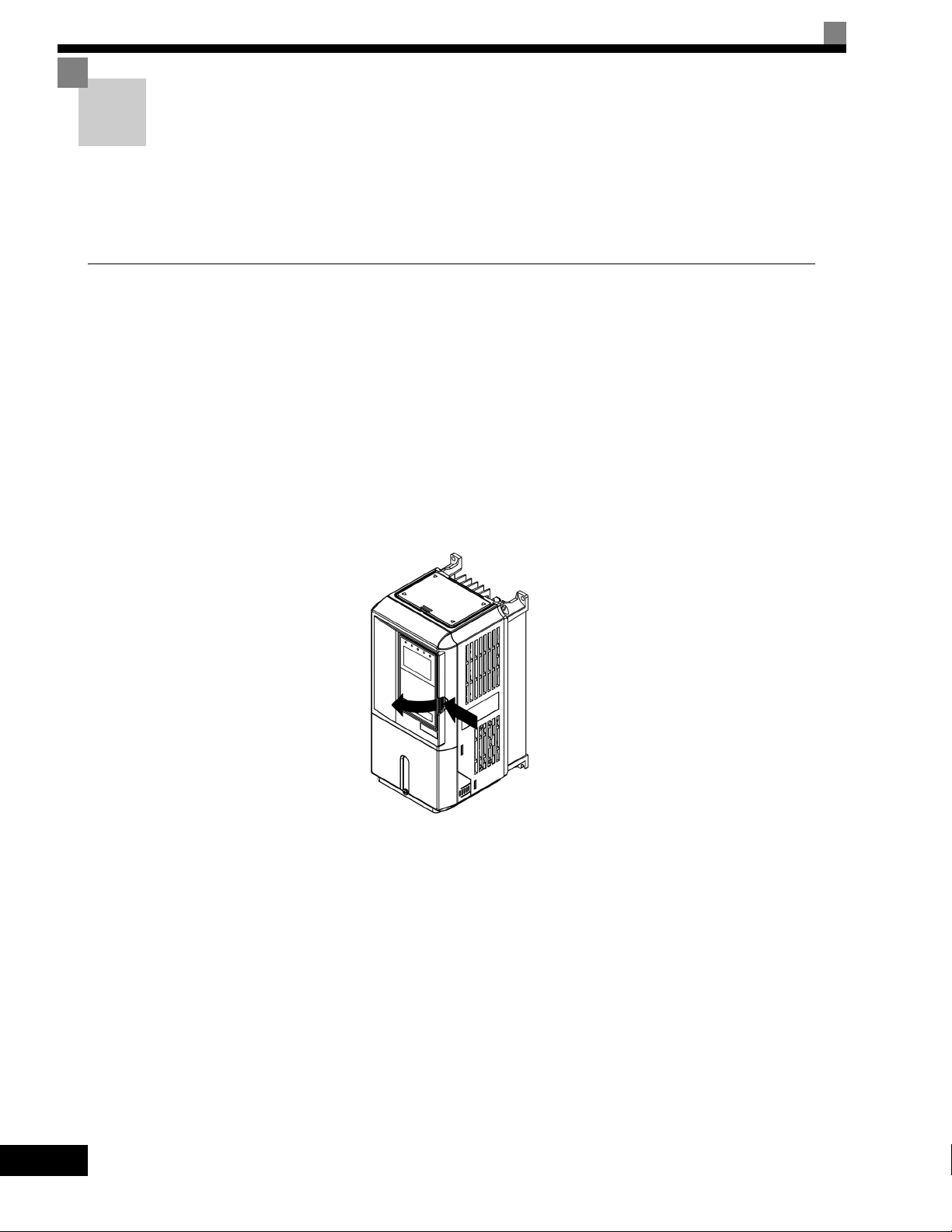

Removing/Attaching the Digital Operator and

1

2

Front Cover

The methods of removing and attaching the Digital Operator and Front Cover are described in this section.

Models CIMR-G7U20P4 thru 2015 and 40P4 thru 4015

To attach optional cards or change the terminal card connector, remove the Digital Operator and front cover in

addition to the terminal cover. Always remove the Digital Operator from the front cover before removing the

terminal cover.

The removal and attachment procedures are given below.

Removing the Digital Operator

Press the lever on the side of the Digital Operator in the direction of arrow 1 to unlock the Digital Operator

and lift the Digital Operator in the direction of arrow 2 to remove the Digital Operator as shown in the following illustration.

1-14

Fig 1.11 Removing the Digital Operator (Model CIMR-G7U43P7 Shown Above)

Page 28

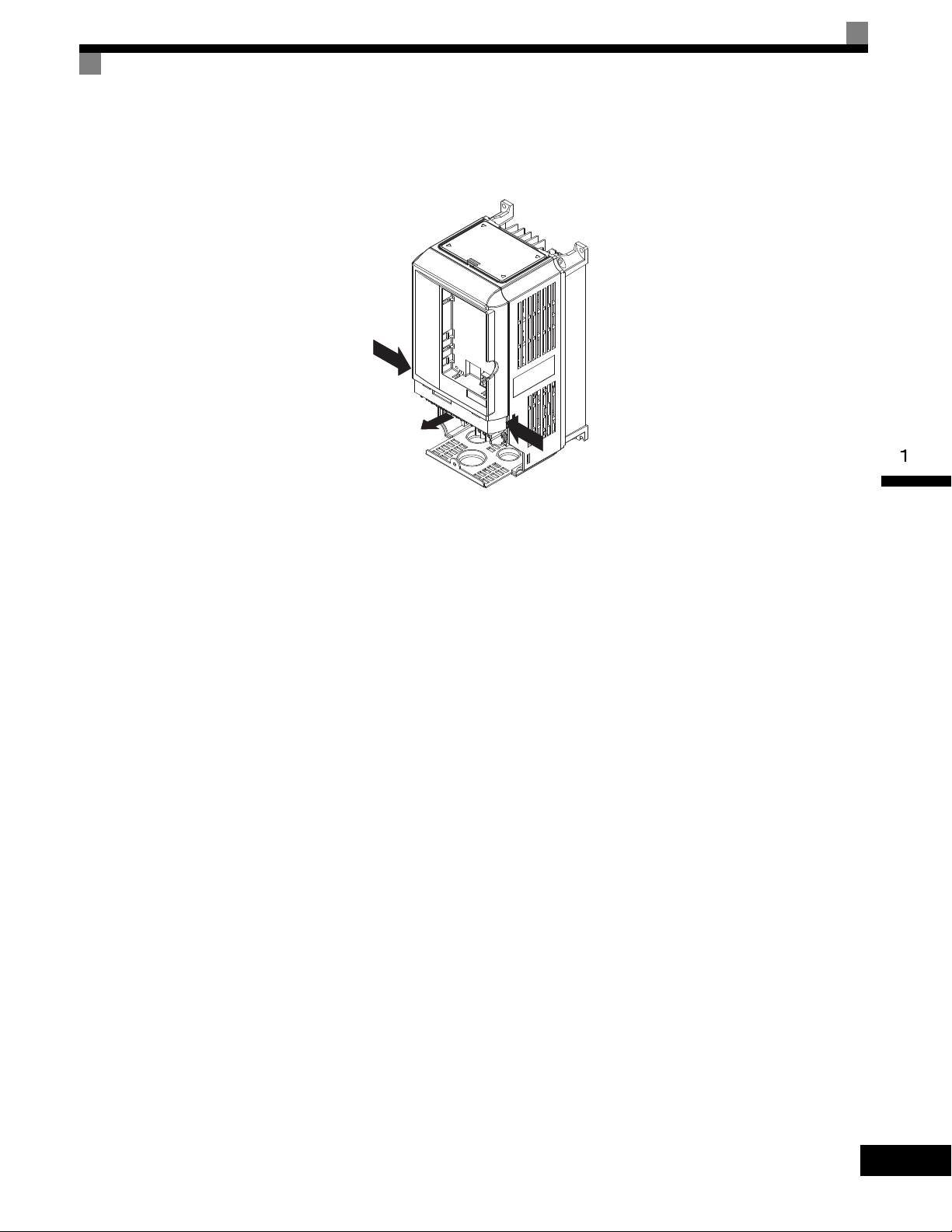

Removing/Attaching the Digital Operator and Front Cover

1

1

2

Removing the Front Cover

Press the left and right sides of the front cover in the directions of arrows 1 and lift the bottom of the cover in

the direction of arrow 2 to remove the front cover as shown in Fig. 1.12.

Fig 1.12 Removing the Front Cover (Model CIMR-G7U43P7 Shown Above)

Mounting the Front Cover

After wiring the terminals, mount the front cover to the Drive by performing in reverse order to the steps to

remove the front cover.

1. Do not mount the front cover with the Digital Operator attached to the front cover; otherwise, Digital

Operator may malfunction due to improper mating with control board connector.

2. Insert the tab of the upper part of the front cover into the groove of the Drive and press the lower part of the

front cover onto the Drive until the front cover snaps into place.

1-15

Page 29

Mounting the Digital Operator

IMPORTANT

A

B

1

2

After attaching the front cover, mount the Digital Operator onto theDrive using the following procedure.

1. Hook the Digital Operator at A (two locations) on the left side of the opening on the front cover in the

direction of arrow 1 as shown in the following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

Fig 1.13 Mounting the Digital Operator

1. Do not remove or attach the Digital Operator or mount or remove the front cover using methods other than

those described above, otherwise the Drive may break or malfunction due to imperfect contact.

2. Never attach the front cover to the Drive with the Digital Operator attached to the front cover. Imperfect

contact can result.

Always attach the front cover to the Drive by itself first, and then attach the Digital Operator to the front

cover.

1-16

Page 30

Removing/Attaching the Digital Operator and Front Cover

1

2

Models CIMR-G7U2018 thru 2110 and 4018 thru 4300

For Drive models CIMR-G7U2018 thru 2110 and 4018 thru 4300, remove the terminal cover and then use the

following procedures to remove the Digital Operator and main cover.

Removing the Digital Operator

Use the same procedure as for Drives with an output of 18.5 kW or less.

Removing the Front Cover

Loosen all screws on the front cover. Lift up at the location labelled 1 at the top of the control circuit terminal

card and move in the direction of arrow 2.

Fig 1.14 Removing the Front Cover (Model CIMR-G7U2018 Shown Above)

Attaching the Front Cover

Attach the front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator is not mounted on the front cover. If the cover is attached while the

Digital Operator is mounted to it, the Digital Operator may malfunction due to improper mating with its

connector.

2. Insert the tab on the top of the front cover into the slot on the Drive and press in on the cover until it clicks

into place on the Drive.

Attaching the Digital Operator

Use the same procedure as for Drives with an output of 18.5 kW or less.

1-17

Page 31

1-18

Page 32

Wiring

This chapter describes wiring terminals, main circuit terminal connections, main circuit termi-

nal wiring specifications, control circuit terminals, and control circuit wiring specifications.

Connection Diagram ....................................................2-2

Terminal Block Configuration .......................................2-4

Wiring Main Circuit Terminals ...................................... 2-5

Wiring Control Circuit Terminals ................................2-22

Installing and Wiring Option Cards ............................ 2-31

Page 33

Connection Diagram

T/L3

S/L2

R/L1

S3 (H1-01)

S2

S1

SC

E(G)

S4 (H1-02)

S5 (H1-03)

S6 (H1-04)

S7 (H1-05)

SN

S+

R-

R+

S-

IG

G7

W/T3

V/T2

U/T1

MC

MB

MA

M2

M1

M4

M3

E(G)

(H4-01) FM

(H4-04) AM

AC

(H2-01)

(H2-02)

Modbus RTU

Communications

RS-485/422

19.2 Kbps

External

Frequency

Reference

MCCB

L3

L2

L1

3-Phase

Power Supply

50/60Hz

Reverse Run/Stop

Foward Run/Stop

Multi-function

Digital Inputs

24VDC, 8mA

M

Motor

Digital Output 1

Fault Contact

250VAC, 30VDC, 1A

Multi-function

Digital Outputs 2-4

250VAC, 30VDC, 1A

+ -

+-

Terminating

Resistor

S8 (H1-06)

M6

M5

(H2-03)

Digital Inputs

24VDC, 8mA

SP +24VDC

+V +15VDC +/-10%, 20mA

AC

2k

Ω

RP 0 to 32kHz, 5 to 12VDC, 3k ***

Multi-function Pulse Input (H6-01)

S1-1

-V -15VDC +/-10%, 20mA

Ω

(H6-06) MP

S9 (H1-07)

S10 (H1-08)

S11 (H1-09)

S12 (H1-10)

C3

P3

(H2-04)

P4

(H2-05)

C4

Multi-function

Digital Outputs 5-6

48VDC, 50mA

+1+2+

3

-

Shorting Bar Standard:

CIMR-G7U20P4 to 2015

CIMR-G7U40P4 to 4015

DC Link Choke

Standard:

CIMR-G7U2018 to 2110

CIMR-G7U4018 to 4300

UX

Remove if adding

external DC link

choke

B1 B2

Jumper CN15

V

CH1

CH2

DIP Switch S1

S1-1

OFF ON

S1-2

T/L31

S/L21

R/L11

Remove jumpers if

using 12 pulse input

2k

Ω

Ω

A3 0 to +/-10VDC, 20k *

Multi-function Analog Input 2 (H3-05)

A1 0 to +/-10VDC, 20 k *

Ω

110

Ω

* +/-11 Bit Resolution, 0.2% Accuracy

** 10 Bit Resolution, 0.2% Accuracy

*** +/-1% Accuracy

See Page 2-25 for details.

A2 4 to 20mA, 250 *

[0 to +/-10VDC, 20k **]

Multi-function Analog Input 1 (H3-09)

Ω

Ω

(S1-2 ON)

(S1-2 OFF)

Output Frequency

T1

T2

T3

Branch circuit

protection supplied

by others.

Fault Reset

External Fault

Multi-Step Reference2

Multi-Step Reference1

Baseblock

Jog Reference

Fast-Stop N.O.

Accel / Decel Time 1

Multi-Step Reference4

Multi-Step Reference3

During Run

Zero Speed

Frequency Agree 1

Inverter Ready

Minor Fault - Alarm

Output Current

Multi-function

Analog Output 1 - 2

0 to +/-10VDC, 2mA

4-20mA, 500

+/-9 Bit Resolution

+/- 8% Accuracy

Ω

Output Frequency

Multi-function

Pulse Output

0 to 32kHz

9VDC @ 3k

+/-1% Accuracy

Ω

+

12 Pulse Input Terminals R1/L11, S1/L21, T1/L31 are standard

on CIMR-G7U2018 - 2110 and CIMR-G7U4018 - 4300.

External Braking Terminal 3 is standard on CIMR-G7U2018

- 2110 and CIMR-G7U4018 - 4300.

Braking Terminals B1, B2 are standard on CIMR-G7U20P4 2015 and CIMR-G7U40P4- 4015.

The connection diagram of the Drive is shown in Fig 2.1.

When using the Digital Operator, the motor can be operated by wiring only the main circuits.

2-2

Fig 2.1 Connection Diagram (Model CIMR-G7U2018 Shown Above)

Page 34

Connection Diagram

IMPORTANT

S12S11

M2

MCMB

M1

MA

M3M5M4

M6

IG

RP

S−

AM

AC

S+

AC

MP

R−

FM

A3

R+

S8

−V

C4

S7

AC

P4

S6

+V

C3

S5

A2

P3

S4

A1

S3

SP

S1

SN

S9

S2

SC

S10

E(G)

E(G)

1. Control circuit terminals are arranged as shown below.

2. The output current capacity of the +V terminal is 20 mA.

3. Disable the stall prevention during deceleration (set parameter L3-04 to 0) when using a Braking Resistor

Unit. If this user parameter is not changed to disable stall prevention, the system may not stop during

deceleration.

4. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single

circles.

5. The wiring for a motor with a cooling fan is not required for self-cooling motors.

6. PG circuit wiring (i.e., wiring to the PG-X2 Card) is not required for open-loop vector control.

7. Sequence input signals S1 to S12 are labeled for sequence connections (0 V common and sinking mode)

for no-voltage contacts or NPN transistors. These are the default settings.

For PNP transistor sequence connections (+24V common and sourcing mode) or to provide a 24-V external power supply, refer toTable 2.13.

8. The master speed frequency reference can set to input either a voltage (terminal A1) or current (terminal

A2) by changing the setting of parameter H3-13. The default setting is for a voltage reference input.

9. The multi-function analog output is a dedicated meter output for an analog frequency meter, ammeter, voltmeter, wattmeter, etc. Do not use this output for feedback control or for any other control purpose.

10.DC reactors to improve the input power factor built into 200-240 V Class Drives for 18.5 to 110 kW and

380-480 V Class Drives for 18.5 to 300 kW. A DC reactor is thus an option only for Drives for 15 kW or less.

11.Set parameter L8-01 to 1 when using a breaking resistor (ERF). When using a Braking Resistor Unit, a

shutoff sequence for the power supply must be made using a thermal relay trip.

2-3

Page 35

Terminal Block Configuration

NPJT31278-1-0NPJT31278-1-0

CAUTIONCAUTION

Charge indicator

Ground terminal

Control circuit terminals

Main circuit terminals

Charge indicator

Control circuit

terminals

Main circuit

terminals

Ground terminal

The terminal arrangement for 200-240 V Class Drives are shown in Fig 2.2 and Fig 2.3.

Fig 2.2 Terminal Arrangement (200-240 V Class Drive for 0.4 kW Shown Above)

2-4

Fig 2.3 Terminal Arrangement (200-240 V Class Drive for 18.5 kW Shown Above)

Page 36

Wiring Main Circuit Terminals

Wiring Main Circuit Terminals

Applicable Wire Sizes and Closed-loop Connectors

Select the appropriate wires and crimp terminals from Table 2.1 to Table 2.3. Refer to instruction manual

TOE-C726-2 for wire sizes for Braking Resistor Units and Braking Units.

2-5

Page 37

Drive Model

CIMR-

G7U20P4

Table 2.1 200-240 V Class Wire Sizes

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

Terminal

Screws

M4

Clamping

To rq u e

lb•in(N•m)

10.6 to 13.2

(1.2 to 1.5)

Terminal

Block

Acceptable

Wire Range

AWG(mm

18 to 10

(0.82 to 5.5)

Recommended

2

)

Wire Size

AWG

2

(mm

14

(2)

Wire Type

)

2-6

G7U20P7

G7U21P5

G7U22P2

G7U23P7

G7U25P5

G7U27P5

G7U2011

G7U2015

G7U2018

G7U2022

G7U2030

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, U/T1,

V/T2, W/T3

B1, B2

R/L1, S/L2, T/L3, , 1, 2, U/T1,

V/T2, W/T3

B1, B2

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

3

r/ 1, / 2

M4

M4

M4

M4

M5

M5

M6

M5

M6

M8

M5

M6

M8

M6

M8

M8

M6

M8

M10

M8

M10

M4

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

20.4 to 22.1

(2.3 to 2.5)

20.4 to 22.1

(2.3 to 2.5)

35.2 to 44

(4.0 to 5.0)

20.4 to 22.1

(2.3 to 2.5)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

20.4 to 22.1

(2.3 to 2.5)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

79.2 to 88

(9.0 to 10.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

155 to 198

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

155 to 198

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

8 to 1

(8 to 50)

12 to 6

(3.5 to 14)

*3 *3

8 to 1

(8 to 50)

12 to 6

(3.5 to 14)

*3 *3

8 to 1/0

(8 to 60)

8 to 22

(8 to 4)

*3 *3

8 to 1/0

(50 to 60)

8 to 22

(8 to 4)

*3 *3

N/A

14

(2)

14

(2)

12

(3.5)

10

(5.5)

8

(8)

6

(14)

4

(22)

Application

Dependent

3

(30)

Application

Dependent

3

(30)

Application

Dependent

1

(50)

Application

Dependent

2/0

(60)

Application

Dependent

2

(30)

16

(1.25)

Power cables,

e.g., 600 V

vinyl power

cables

Page 38

Wiring Main Circuit Terminals

Drive Model

CIMR-

Terminal Symbol

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

G7U2037

3

r/ 1, / 2

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

G7U2045

3

r/ 1, / 2

, 1

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

R1/L11, S1/L21, T1/L31

G7U2055

3

r/ 1, / 2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21,

T1/L31

G7U2075

3

r/ 1, / 2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21,

G7U2090

T1/L31

3

r/ 1, / 2

R/L1, S/L2, T/L3, , 1

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/

G7U2110

L31

3

r/ 1, / 2

* The wire thickness is set for copper wires at 75°C

Terminal

Screws

M10

M8

M10

M4

M10

M8

M10

M4

M12

M10

M8

M12

M4

M12

M12

M8

M12

M4

M12

M12

M8

M12

M4

M12

M12

M8

M12

M4

Clamping

Torque

lb•in(N•m)

155 to 198

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

155 to 198

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

155 to 198

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

155 to 198

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

276 to 345

(31.4 to 39.2)

155 to 198

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

155 to 198

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

276 to 345

(31.4 to 39.2)

276 to 345

(31.4 to 39.2)

78 to 95

(8.8 to 10.8)

276 to 345

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

276 to 345

(31.4 to 39.2)

276 to 345

(31.4 to 39.2)

78 to 95

(8.8 to 10.8)

276 to 345

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

276 to 345

(31.4 to 39.2)

276 to 345

(31.4 to 39.2)

78 to 95

(8.8 to 10.8)

276 to 345

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

Terminal

Block

Acceptable

Wire Range

AWG(mm

N/A

N/A

N/A

N/A

Recommended

2

)

Application

Dependent

Application

Dependent

Application

Dependent

(150 × 2P)

(100 × 2P)

Application

Dependent

350 × 2P, or

(200 × 2P, or

300 × 2P, or

(150 × 2P, or

Application

Dependent

(150 × 2P)

350 × 2P, or

(200 × 2P, or

300 × 2P, or

(150 × 2P, or

Application

Dependent

(150 × 2P)

Wire Size

AWG

2

(mm

3/0

(80)

1

(38)

16

(1.25)

1/0 × 2P

(50 × 2P)

1/0

(50)

16

(1.25)

3/0 × 2P

(80 × 2P)

3/0 × 2P

(80 × 2P)

2/0

(80)

16

(1.25)

250 × 2P

4/0 × 2P

2/0 × 2P

(60 × 2P)

16

(1.25)

1/0 × 4P

50 × 4P)

1/0 × 4P

50 × 4P)

300 × 2P

16

(1.25)

1/0 × 4P

50 × 4P)

1/0 × 4P

50 × 4P)

300 × 2P

16

(1.25)

Wire Type

)

Power cables,

e.g., 600 V

vinyl power

cables

2-7

Page 39

Drive Model

CIMR-

G7U40P4

Table 2.2 380-480 V Class Wire Sizes

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

Terminal

Screws

M4

Tightening

To rq u e

(N•m)

10.6 to 13.2

(1.2 to 1.5)

Possible Wire

Sizes

2

(AWG)

mm

18 to 10

(0.82 to 5.5)

Recommended

Wire Size

2

(AWG)

mm

14

(2)

Wire Type

G7U40P7

G7U41P5

G7U42P2

G7U43P7

G7U44P0

G7U45P5

G7U47P5

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

M4

M4

M4

M4

M4

M4

M5

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

20.4 to 22.1

(2.3 to 2.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

18 to 10

(0.82 to 5.5)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

14

(2)

14

(2)

12

(3.5)

14

(2)

12

(3.5)

12

(3.5)

10

(5.5)

8

(8)

Power cables,

e.g., 600 V

vinyl power

cables

G7U4011

G7U4015

G7U4018

G7U4022

R/L1, S/L2, T/L3, , 1, 2, B1, B2,

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, U/T1,

V/T2, W/T3

B1, B2

R/L1, S/L2, T/L3, , 1, 3, U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, 3, U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

M5

M5

(M6)

M5

M5

M5

(M6)

M6

M8

M6

M8

20.4 to 22.1

(2.3 to 2.5)

20.4 to 22.1

(2.3 to 2.5)

35.2 to 44

(4.0 to 5.0)

35.2 to 44

(4.0 to 5.0)

20.4 to 22.1

(2.3 to 2.5)

35.2 to 44

(4.0 to 5.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

10 to 6

(5.5 to 14)

12 to 3

(3.5 to 30)

*3 *3

12 to 3

(3.5 to 30)

*3 *3

8

(8)

10

(5.5)

8

(8)

8

(8)

8

(8)

6

(14)

4

(22)

2-8

Page 40

Wiring Main Circuit Terminals

Drive Model

CIMR-

G7U4030

G7U4037

G7U4045

G7U4055

G7U4075

G7U4090

G7U4110

G7U4132

Terminal Symbol

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

r/ 1, 200/2200, 400/2400

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

r/ 1, 200/2200, 400/2400

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L33

3

r/ 1, 200/2200, 400/2400

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L33

3

r/ 1, 200/2200, 400/2400

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

r/ 1, 200/2200, 400/2400

Terminal

Screws

M8

M6

M8

M8

M8

M6

M8

M10

M8

M10

M4

M10

M8

M10

M4

M10

M8

M12

M4

M10

M8

M12

M4

M12

M8

M12

M4

Tightening

Torque

(N•m)

79.2 to 88

(9.0 to 10.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

79.2 to 88

(9.0 to 10.0)

79.2 to 88

(9.0 to 10.0)

35.2 to 44

(4.0 to 5.0)

79.2 to 88

(9.0 to 10.0)

154.8 to 197.5

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.5

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.5

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.5

(17.6 to 22.5)

78 to 95

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

276 to 345

(31.4 to 39.2)

78 to 95

(8.8 to 10.8)

276 to 345

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

Possible Wire

Sizes

2

(AWG)

mm

8 to 1/0

(8 to 60)

(8 to 4)

8 to 22

*3 *3

2 to 1/0

(30 to 60)

8 to 1/0

(8 to 60)

8 to 4

(8 to 22)

*3 *3

N/A

Recommended

Wire Size

2

(AWG)

mm

2

(38)

Application

Dependent

2

(38)

1

(50)

Application

Dependent

1/0

(50)

Application

Dependent

2

(38)

16

(1.25)

4/0

(100)

Application

Dependent

1

(50)

16

(1.25)

1/0 × 2P

(50 × 2P)

Application

Dependent

2/0

(60)

16

(1.25)

3/0 × 2P

(80 × 2P)

Application

Dependent

4/0

(100)

16

(1.25)

3/0 × 2P

(80 × 2P)

Application

Dependent

1/0 × 2P

(50 × 2P)

16

(1.25)

Wire Type

Power cables,

e.g., 600 V

vinyl power

cables

2-9

Page 41

Drive Model

3

CIMR-

G7U4160

Terminal Symbol

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

3

r/ 1, 200/2200, 400/2400

Terminal

Screws

M12

M8

M12

M4