Page 1

Modbus Communication Manual

G7 Drive

Drive Model: CIMR-G7U* Document Number: TM.G7.11

Page 2

Page intentionally blank

2

Page 3

W arnings and Ca utio ns

This section provides Warnings and Cautions pertinent to this product that if not heeded, may

result in personal injury, fatality, or equipment damage. Yaskawa is not responsible for

consequences of ignoring these instructions.

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of i ndustrial applications. The selection and application of

YASKAWA products remains the responsib ility of the equipment designer or end user. YASKAWA accepts no responsi b ility for the way its

products are incorpor ated into the final system design. Under no circumstances should any YASKAWA product be incor porated int o any

product or design as the e xclusive or sole safety control. Without exc eption, all controls should be designed to detect faults dyna m ically and to

fail safely under al l circumstances. All products designe d to incorporat e a component part manufactured by YASKAWA must be supplied to the

end user with appropriate warnings and i nstructions as to that part’s sa fe use and operation. Any warnings provided by YASKAWA must be

promptly provided to t he end user. YASKAWA offers an express warranty only as to the quality of it s products in conforming to standards and

specifications publi shed in the YASKAWA manual. NO OTHER WARRANTY , EXPRESS OR IMPLIED, IS OFFERED. YASKAWA

assumes no liabilit y for any personal injury, prope rty damage, losses, or claims arising from misapplication of its products.

WARNING

Read and unde rstand this ma nual before installing, ope rating, or servicing this G 7 drive. All war nings, cauti ons, and instructions must

be followed. All activity must be perf orm ed by qualified personnel. The G7 drive must be instal led accordi ng to this manual a nd local

code.

Do not connec t or disconnec t wiring while the pow er is on. Do not remove covers or touch circuit boards while the power is on. Do

not remove or insert the digital opera tor while power is on.

Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply is turned

off. Stat us indicator LEDs and D igital Operator display will be extinguished when the DC bus voltage is below 50 VDC. To prevent

electric shock, wai t at least 5 minutes after all indicators are O FF and m easure DC bus voltage and veri fy that it is at a saf e level.

Do not perf orm a withstand vol tage test on any pa rt of the unit. This equipment uses sensitive devices and may be damaged by high

voltage.

The G7 drive is not suitable for circuits capable of delivering more than the specified RMS symmetrical amperes. Install adequate

branc h short circuit protecti on per applicable codes. Refer to the specification. Fa ilure to do so may result in equipment damage a nd/or

personal injury.

Do not connec t unapproved LC or RC interference suppression fi lters, capacitors, or over voltage protection devices to the output of

the G7 drive. Capacitors may generate peak currents that exceed G7 drive specifications.

To avoid unne cessary fa ult displays, caused by contactors or output s witches placed between G7 drive and motor, auxiliary contacts

must be pr operly integra ted into the c ontrol logic circuit.

YASKAWA is not responsible for any modification of the product made by the user; doing so will voi d the warranty. This product

must not be modified.

Verif y that the rated voltage of the G7 dri ve matches the voltage of the incoming power supply before applying power.

To meet CE directives, proper line filters and pr ope r installation are requi red.

Some drawings in this ma nual may be shown wit h protective c overs or shields re moved, to describe details. These must be replaced

before operation.

Observe Electrostatic Discharge Procedures w hen handling the G7 dri ve and G7 drive com ponents to preve nt ESD damage.

The attached equipment may start unexpe ctedly upon application of power to the G7 drive. Clear all personnel fr om the G7 drive,

motor, and ma chine area pri or to applyi ng power. Secure covers, couplings, shaft keys, machine beds and all safety equipment before

ener gizing the G7 drive.

Do not attem p t to disassem ble this unit. There are no user se rviceable parts. Disassembling this unit will void any and all warranties.

3

Page 4

Introduction

This manual is intended as an overvie w of pa rameter access for the Yaskawa model G7 drive and describes how to connect the G7 dr ive to RS232, RS-422 or RS-485. Refer to the G7 Driv e Technica l Manua l ( T M .G 7 .0 1 ) for detaile d pa rameter information.

This docume n t pertains to the G7 drive. In t his document, the word “inver ter”, “ac drive” and “drive” may be used inter changeably.

For details on installation and oper ation of the G7 drive, refer to the G7 Drive Technical Manual (TM.G7.01). All manuals and support files are

available on the CD that came with the G7 drive and ar e also available for downloa d at www.yaskawa.com.

®

Modbus

All trademarks are the property of their respe ctive owners.

is a regist er ed trademark of Schneider Automation , Inc.

4

Page 5

Table of Contents

Chapter 1 - Connections....................................................................7

Connection Check Sheet................................................................................................ 8

Verify Operation.............................................................................................................. 9

G7 Drive Connections....................................................................................................10

Network Connections.....................................................................................................11

Communic at ions Par am eters.........................................................................................13

Run/Stop and Frequency Reference Source..................................................................15

Verify Communication....................................................................................................16

Chapter 2 - Message Formats.........................................................18

Protocol.........................................................................................................................20

Read Multiple Registers – Functi on Code 03H ..............................................................21

Write Single Register – Function Code 06H...................................................................23

Loop-Back Test – Function Code 08H...........................................................................25

Write Multiple Registers – Function Code 10H...............................................................27

No Response .................................................................................................................29

Error Codes...................................................................................................................29

CRC-16 Calculations.....................................................................................................30

Chapter 3 - Troubleshooting...........................................................31

General Information.......................................................................................................33

RS-232 Co mmunic at ion.................................................................................................35

RS-422/ RS- 485 Co mmunic at ion....................................................................................37

RS-422/ RS- 485 Self-Test ..............................................................................................40

Chapter 4 - G7 Drive Parameters....................................................41

Command Registers (Read/Writ e) f or Modbus RTU ......................................................42

Broadcas t R egis t ers (Write Only)...................................................................................43

Monitor Regis ters (R ead Only ).......................................................................................44

Parameter Registers (Read/Write).................................................................................52

CM090 Modbus TCP/IP Option Kit Specific Registers...................................................75

ENTER/ACCEPT Command (Write Only) ......................................................................78

Modbus Fault Decoding Table for Monitors....................................................................79

Chapter 5 - User Notes ....................................................................81

Notes.............................................................................................................................82

User Parameter Settings................................................................................................83

Hex/Dec Conversion Table............................................................................................91

5

Page 6

Notes:

6

Page 7

Chapter 1 - Connections

This chapter describes how to connect the G7 drive to a RS-232, RS-422 or RS-485 network.

Connection Check Sheet.............................................................. 8

Verify Operation............................................................................ 9

G7 Drive Connections.................................................................10

Serial Network Connections...................................................... 11

Communications Parameters.................................................... 13

Run/Stop and Frequency Reference Source............................ 15

Verify Communications.............................................................. 16

7

Page 8

Connection Check Sheet

The following is a quick reference guide to connect and configure the G7 drive for serial communications. Make a copy of this page and checkoff each item as it is completed. For detailed information please refer to the detailed sections that follow.

1: Unpack the G7 drive and verify that all com ponents are pres ent and undamaged.

2: Connect powe r to the G7 drive a nd verify that the G7 drive functi ons correctly. This includes running the G7 dri ve from the operator

keypad. Re fer to the G7 Technical Manual for information on connecti ng and operating t he G 7 drive.

3: Remove power from the G7 drive and wait for the charge lamp to be compl etely extinguished. Wait at least five additional minutes for

the G7 drive to be completely discharged. Measure the DC bus voltage and verify that it is at a safe level.

4: Connect the G7 drive to an RS-232 network. Note: It is not possible to use the drive’s key pad and an RS-232 connection at the same

time.

4.1: Remove the G7 drive’s operator keypad.

4.2: Connect the RJ-45 port on the front of the G 7 drive to the controller serial port. Refe r to Figure 1.1 - G7 D iagram for the

location of drive connectors. Use a DB9 to RJ-45 adapter with a standard Ethernet CAT-5 patch cable or use Yaskawa cable

UWR00468-2. Do NOT connect this cabl e to an Ethernet port on the controller, as damage to the controller and/or G7

drive may re su l t. R efer to Figure 1.2 – RS-232 Connections for a description of the interface cable.

4.3: V erify that the cont roller communications parameters match the G7 drive’s communications parameters. Re fer to Table 1.1

– RS-232 (RJ-45 port) Communications Parameters for a list of default G7 drive communications parameters.

4.4: Reapply power to the G7 drive.

5: Connect the G7 drive to an RS-422/RS-485 network.

5.1: Remove th e G7 drive’s te rminal cover.

5.2: Connect the controller to the S+/S- and R+/R- terminals on the G7 drive’s terminal block as shown in Figure 1.3 – RS-

422/RS-485 Connections.

5.3: If this device is either the first or last device on the network, set the network termination, S1, to the ON position.

5.4: Reapply power to the G7 drive.

5.5: Set the G7 drive communication para me ters to match t hose of the controller. Refer to Table 1.2 –Baud Rate, Table 1.3 –

Parity and Table 1.4 - RTS.

5.6: Set the node address of the G7 drive.

6: Verif y that the G7 drive a nd controller are communicating and that the exchanged data is valid.

8

Page 9

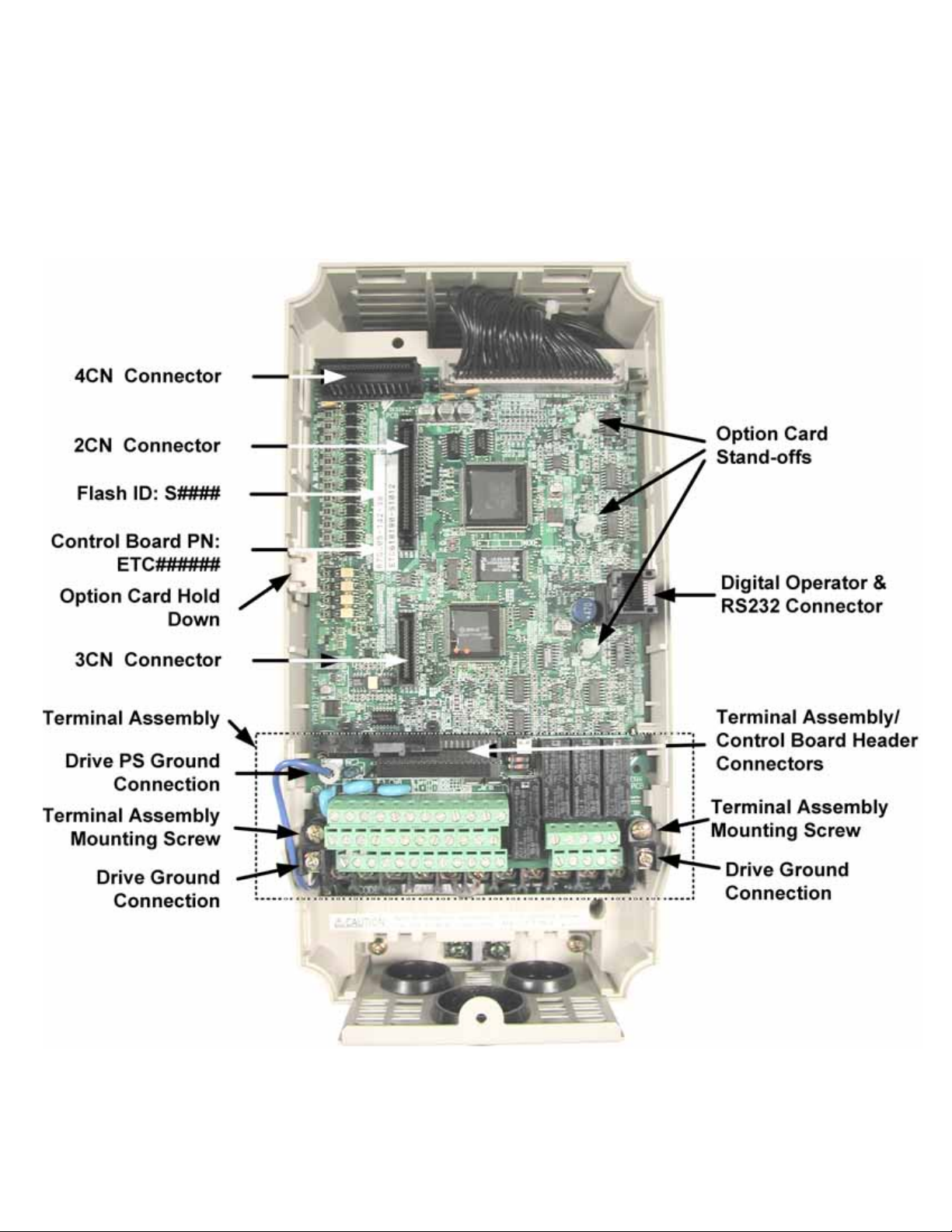

Verify Operation

Connect powe r to the G7 drive a nd verify that the G7 drive functions properly. This includes running the G7 drive from the operat or keypad.

Refer to the G7 drive Technical Manual for infor ma tion on connecting and operating the G7 drive.

Remove power from the G7 drive and wait for the charge lamp to be completely extinguished. Wait at least five additional minutes for the G7

drive to be completely discharged. Measure the DC bus voltage and verify that it is at a safe level.

Remove the ope rator keypad and terminal cover.

Figure 1.1 G7 Connection Diagram

9

Page 10

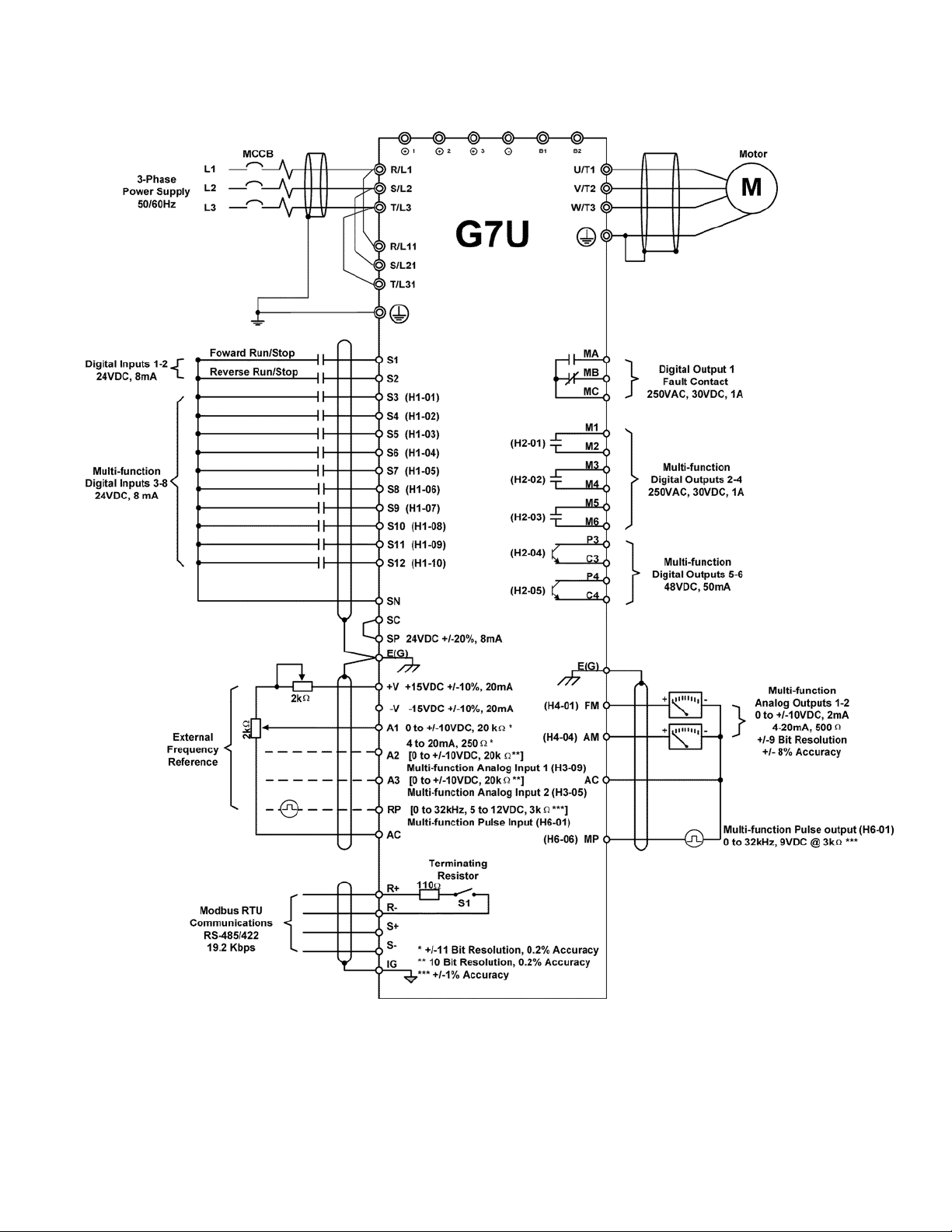

G7 Drive Connections

Figure 1.2 G7 Drive Connecti ons

10

Page 11

Network Connections

The following describes how to connect the G7 drive to an RS-232, RS-422 or RS-485 network. For detailed information please refer to the

appropriate sections of this manual or the G7 drive Technical Manual.

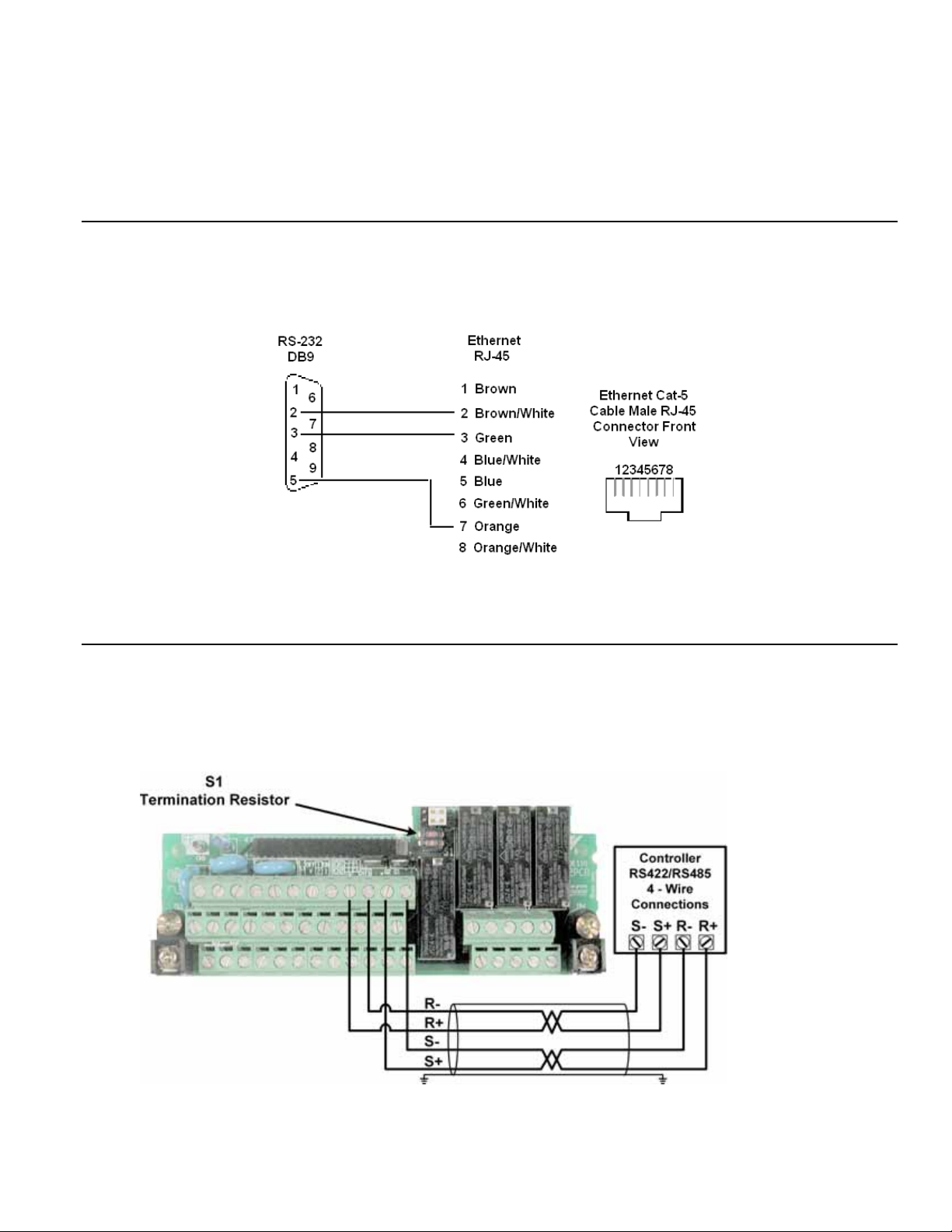

RS-232 Network

The RS-232 network is a single ended network wit h limited data trans mission rates and cable lengt hs. The G7 drive RS- 232 data transmission is

fixed at 9600bps, no parity, 8 data bits and 1 st op bit. The maximum cable length is 50 ft ( 16 m). It is recommende d that Yaskawa cable

UWR00468-2 be used. Note: It is not possible to use the drive’s keypad and an RS-232 connection at the same time.

Figure 1.3 RS-232 Network Connection

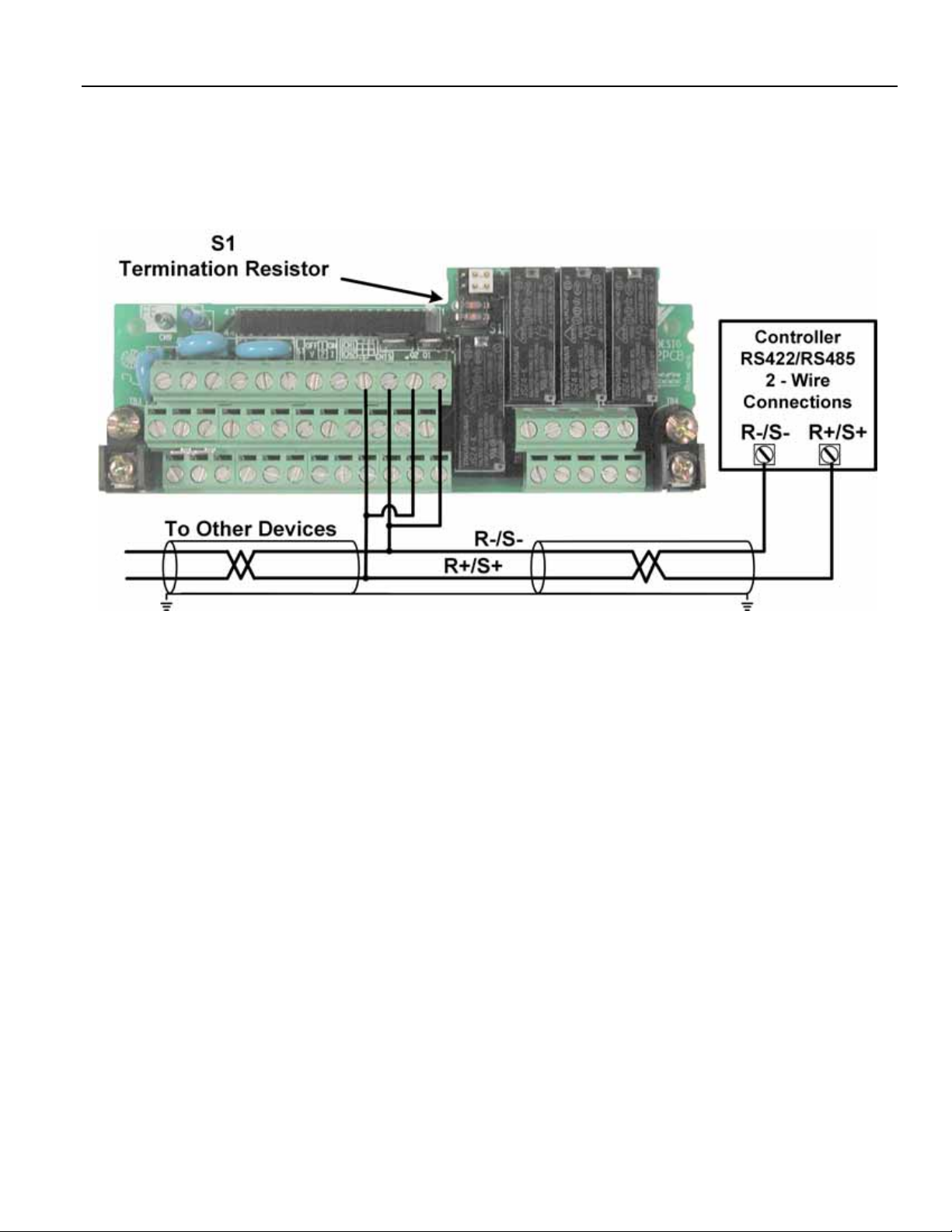

RS-422/RS-485 4-Wire Network

RS-422/RS-485 4-wire net w orks allow for longer cable lengths, maximum 4000 ft (1200 m ), and are more im m une to noise than RS-232

networ ks because of thei r balanced li ne drivers. RS-422/RS-485 4-wire communicati on does not requir e RTS (request to send) control. See

parameter H5-07. Set the Termination Resistor S1 sw itch to ON (slide the switch to the right) fo r each RS-422 device and the last RS-485

device on the network.

Figure 1.4 RS-422/RS-485 4-Wire Network Connection

11

Page 12

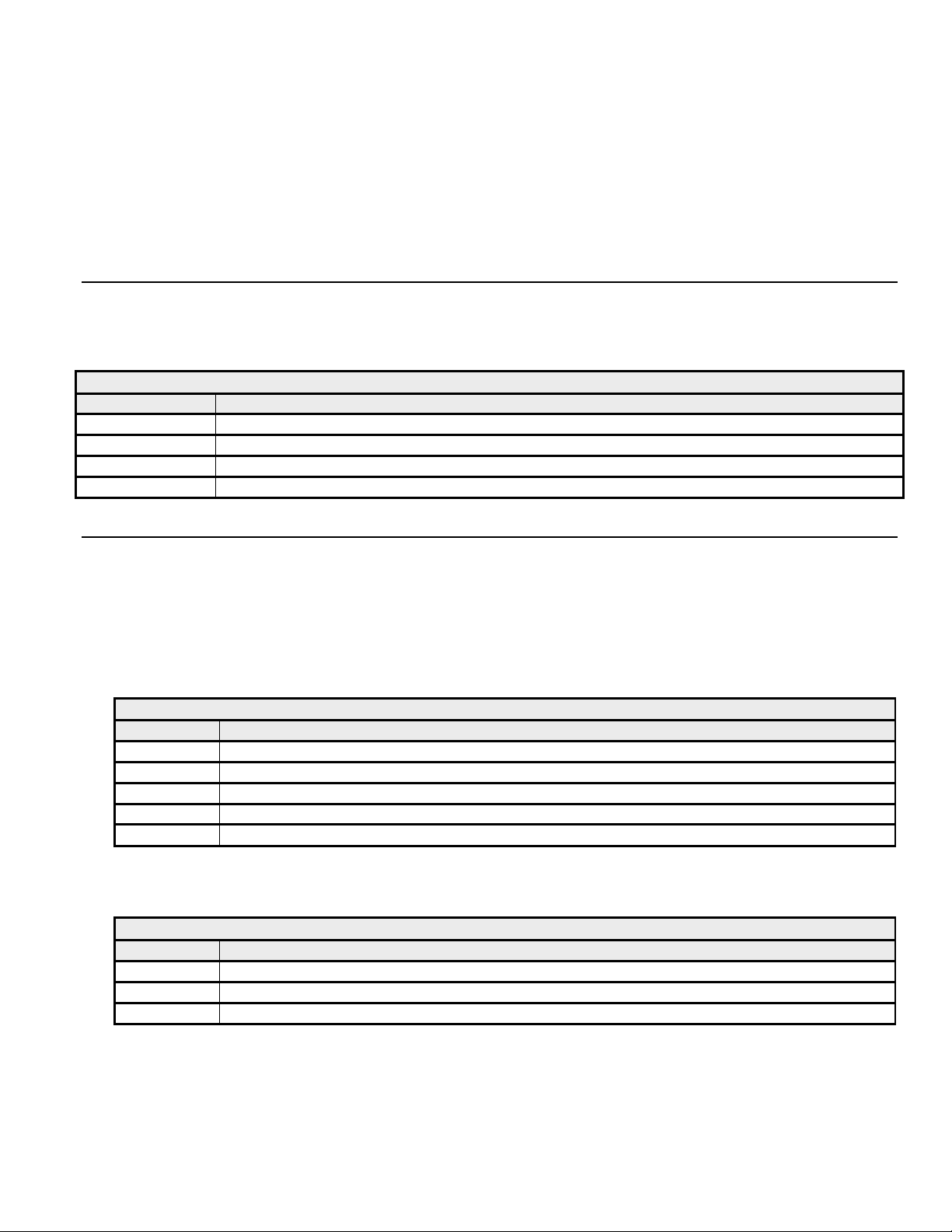

RS-485 2-Wire Network

RS-485 2-wire networks can be either single or multi-drop networks, with each slave de vice on the networ k assigned a unique nod e address. A

maximum of 31 devices may reside on any network segment bef ore a repeater is required. The ma ximum segment le ngth is 4000 ft (1200 m).

Set the T erm ination Resi stor S1 switch t o O N (s lide the switch to the right) on the last device on the network. RS- 485 2-wire communication

requires RTS (request to send) control. See parameter H5-07.

Figure 1.5 RS-485 2-Wire Network Connection

12

Page 13

Communication Parameters

The following communicati ons parameters affect communication over RS-232, RS-422 and RS-485 networks. The RS- 232 communication

paramet ers are fixe d. In addition, the node address is ignored when comm unicating via RS-232.

H5 group communication parameters can onl y be changed via the drive keypad.

Note: Drive power must be cycled for changes to H5 Group parameter s to be recognize d.

RS-232 Communication

The RS-232 co m m unications param eters are fixed at the values show n below. Although the node address is ignore d, the master when

communicating to the G7 drive in this method typically uses a node address of 1.

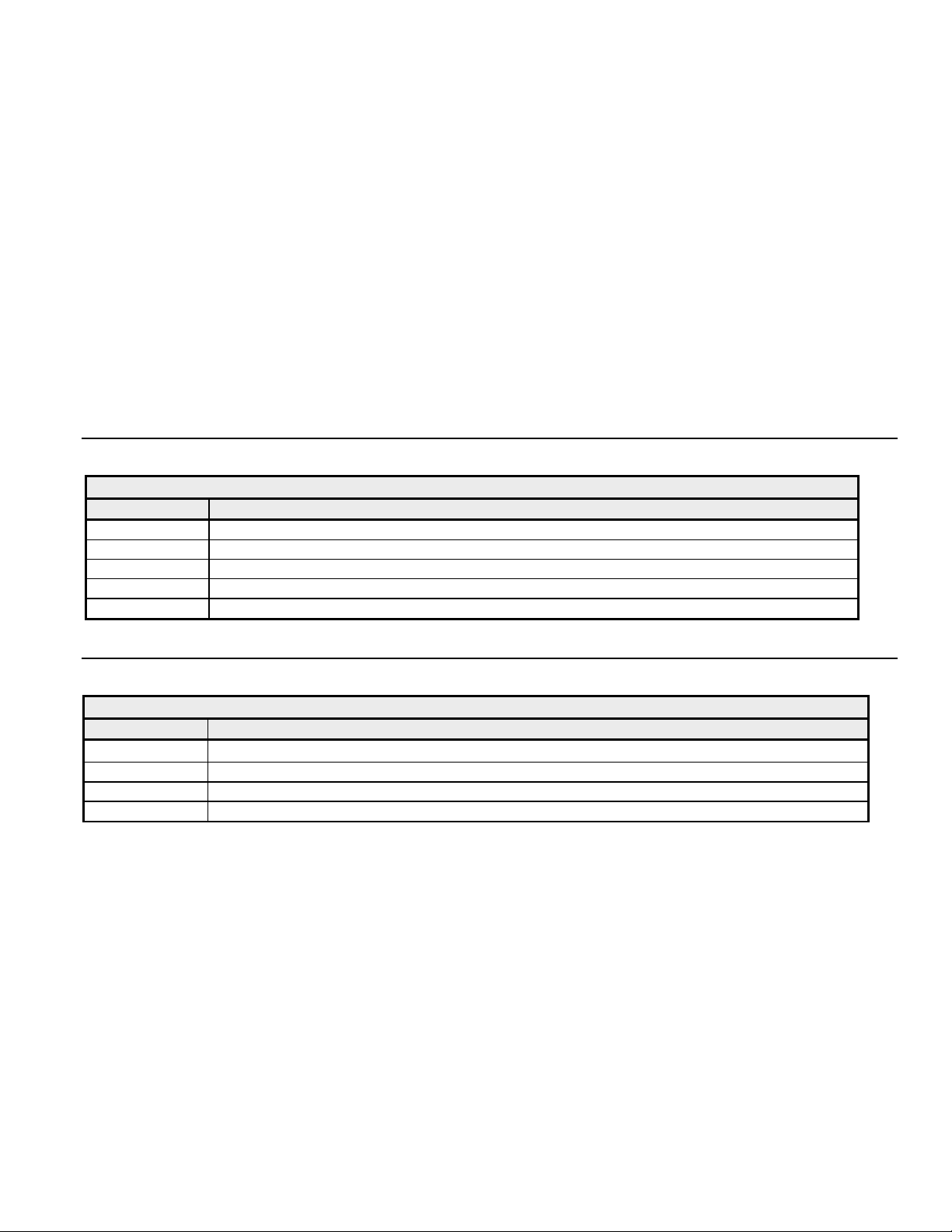

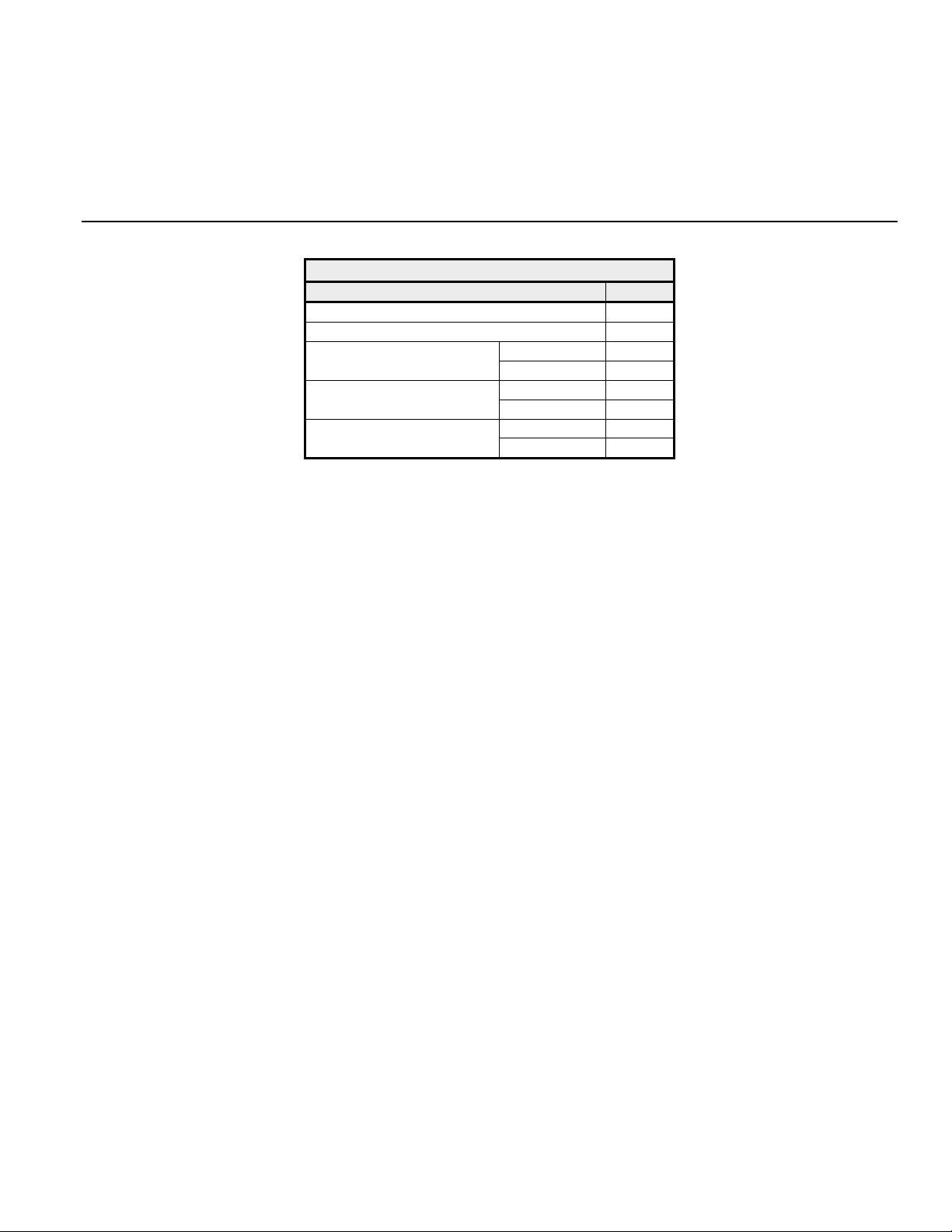

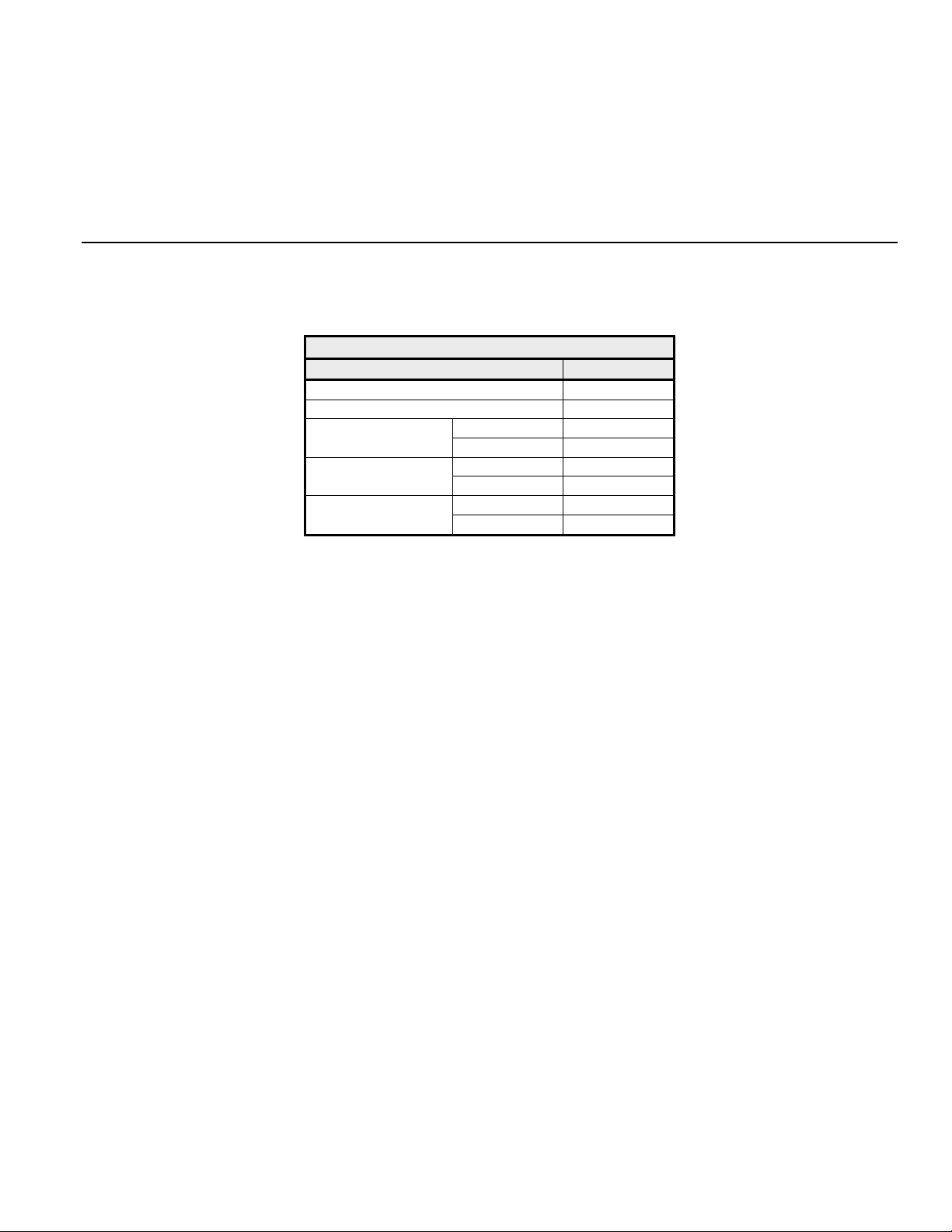

Table 1.1 RS-232 (RJ-45 port) Communi cati on Parameters

Value Description

Baud rate 9600

Parity None

Stop Bits 1

Node Address N/A

RS-422/RS-485 Communication

Node Address – H5-01. The node address is set thr ough G 7 drive paramete r H5-01. When communi cating via RS- 422 or RS-485, a

unique node address between 0 and 20h (32 decima l), inclusive, must be entered. The defa ult G7 drive addres s is 1Fh (31 decimal).

The addres s is always ente red as a hexadecimal number (ref er to the conversion chart in Chapter 4). A ddress 0 is typica lly reserved for

global me ssages.

Baud Rate – H5-02. Select the baud rate that matches the controller’s communica tion configur ation.

Table 1.2 Baud Rate – Parameter H5-02

Value Description

0 1200bps

1 2400bps

2 4800bps

3 9600bps (Default Setting)

4 19,200bps

Parity – H5-03. Select t he parity that matc hes the controller’s communi cation conf iguration.

Table 1.3 Parit y – Param eter H5-03

Value Description

0 None (Default Setting)

1 Even

2 Odd

13

Page 14

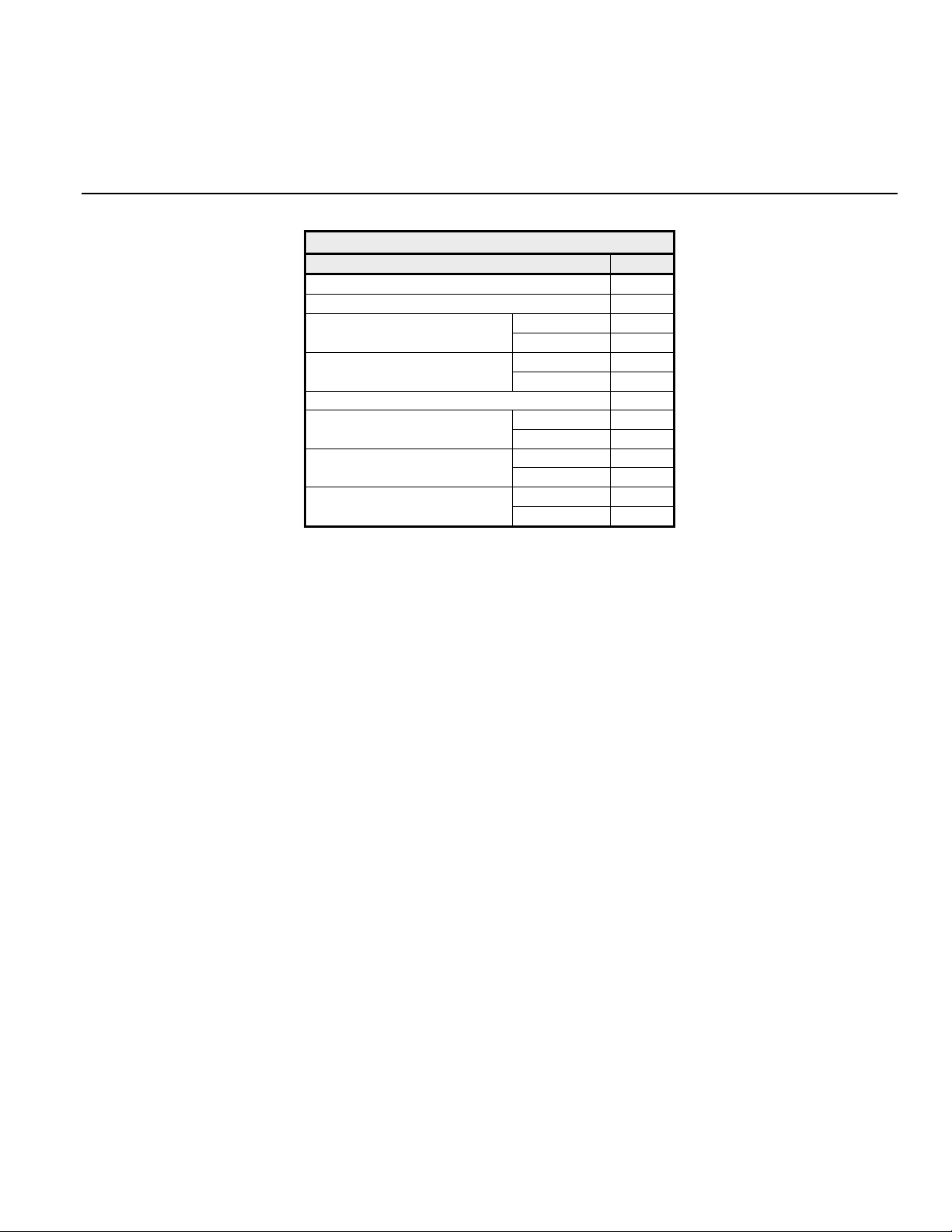

Communication Fault (CE) Response Selection – H5-04. Select the drive operation method when a communic ation fault (CE)

occurs . See parameter H5-05 also.

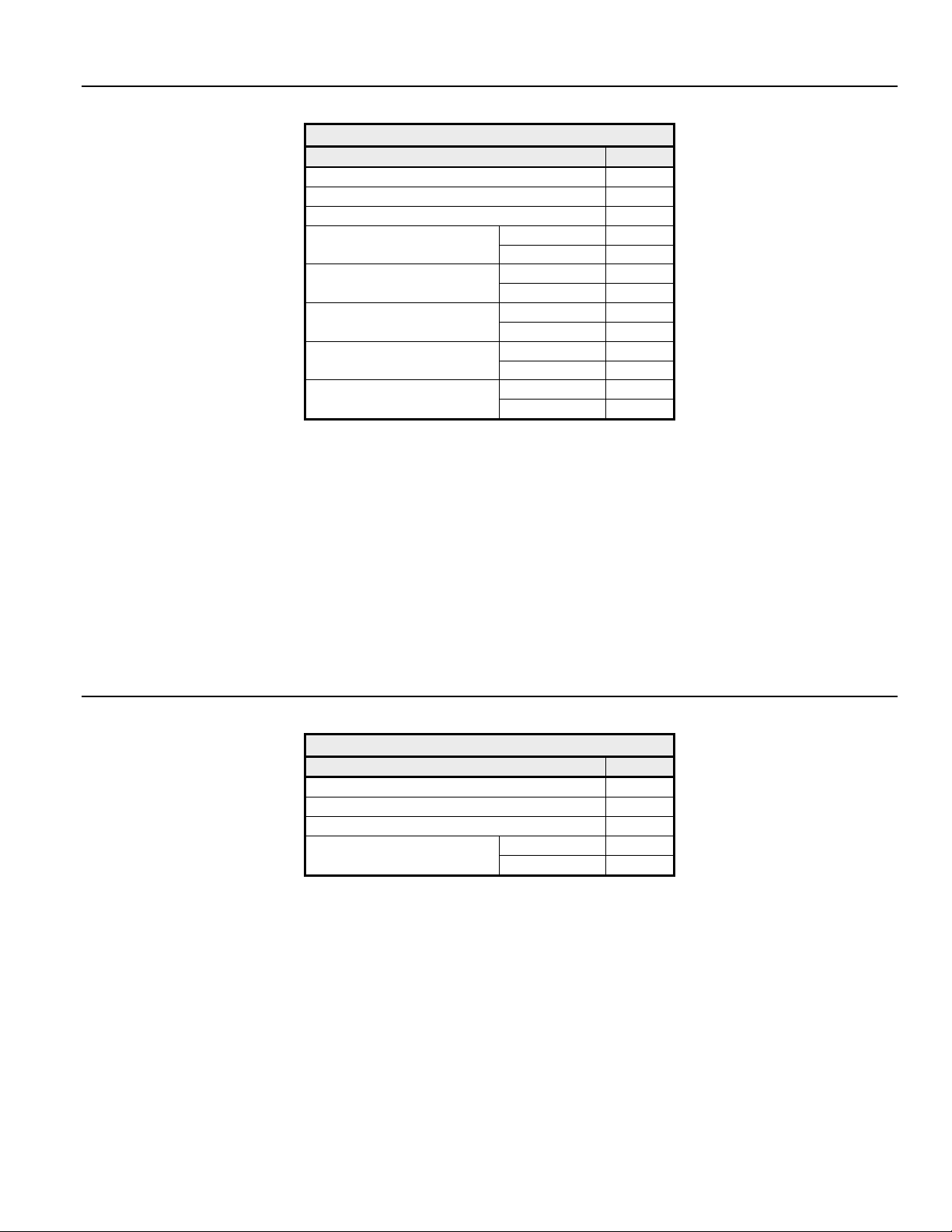

Table 1.4 Communicati on Fault Response Sel ection – Parameter H5-04

Value Description

0 Ramp to Stop (Fault)

1 Coast to Stop (Fault)

2 Fast Stop (Fault)

3 Alarm Only (Alarm) (Default Setting)

4 Run at D1-04 frequency

Communication Fault (CE) Detection Selection – H5-05. Selects whether the communication fa ult (CE) is monitor ed. Please note

that either B1-01 or B1-02 must also be set to a 2 (Serial Communication) for fault monitoring to occur. If the CE fault is enabled, the

G7 will flash CALL on the keypad after power up until a message is rec eived. The dri ve w ill trip and respond according to H5-04 if

communication is lost (a message is not received) for more than 2 seconds after s uccessful communication has been initiat ed.

Table 1.5 Communicati on Fault Det ecti on Selection – Parameter H5-05

Value Description

0 Disabled (Default Setting)

1 Enabled

Serial Com munication Send Delay – H5-06. A delay can be inserted bef ore the G7 drive responds to a command message. This

allows for slower communication devices to switch their transceiver state in order to get ready to receive a message. A value of 5 ~ 65

ms can be inserted, with 5 ms being the default.

RTS Control – H5-07. This paramete r determines whether RTS is cont inually asserted (disabled) or asserted only duri ng send

(enabled). RTS must be enabl ed for use with RS- 485 2-wire communication.

Table 1.6 RTS Control – Parameter H5-07

Value Description

0 Disable (always ON) (Default Setting)

1 Enable (ON only during send) (Use this s e tting for RS-485 2-wire systems)

14

Page 15

Run/Stop and Frequency Refere nce

The Run/Stop and Frequency Reference commands can originate from:

Serial communication (Built-in Modbus: Keypad or R+/-, S+/- T erm inals)

Keypad (Digital Operator)

Terminal Strip

Option Card

Paramet er B1-01 (Run/Stop Method Selection) allows the selection of t he origin of the Run/Stop command. Parameter B1-02 (Re ference

Selection) allows the selection of the origin of the Frequency Reference com m and. The Run/Stop and Frequency Reference commands may

have different origi ns.

For exampl e, the Run/Stop co m ma nd m ay be set to Termina ls (B1-01=1) while the Freque ncy Reference command may be set to Serial

Communicat ion (B1-02=2).

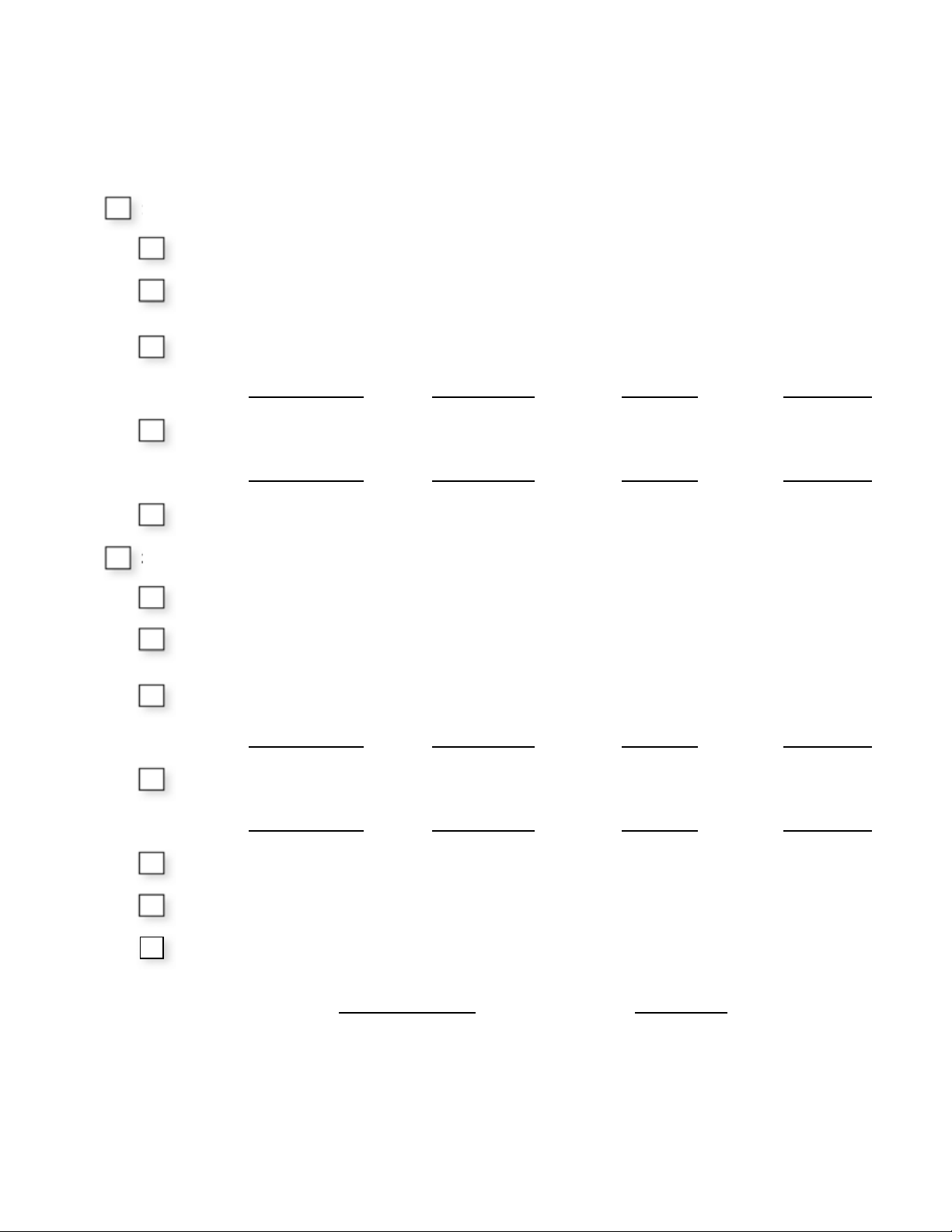

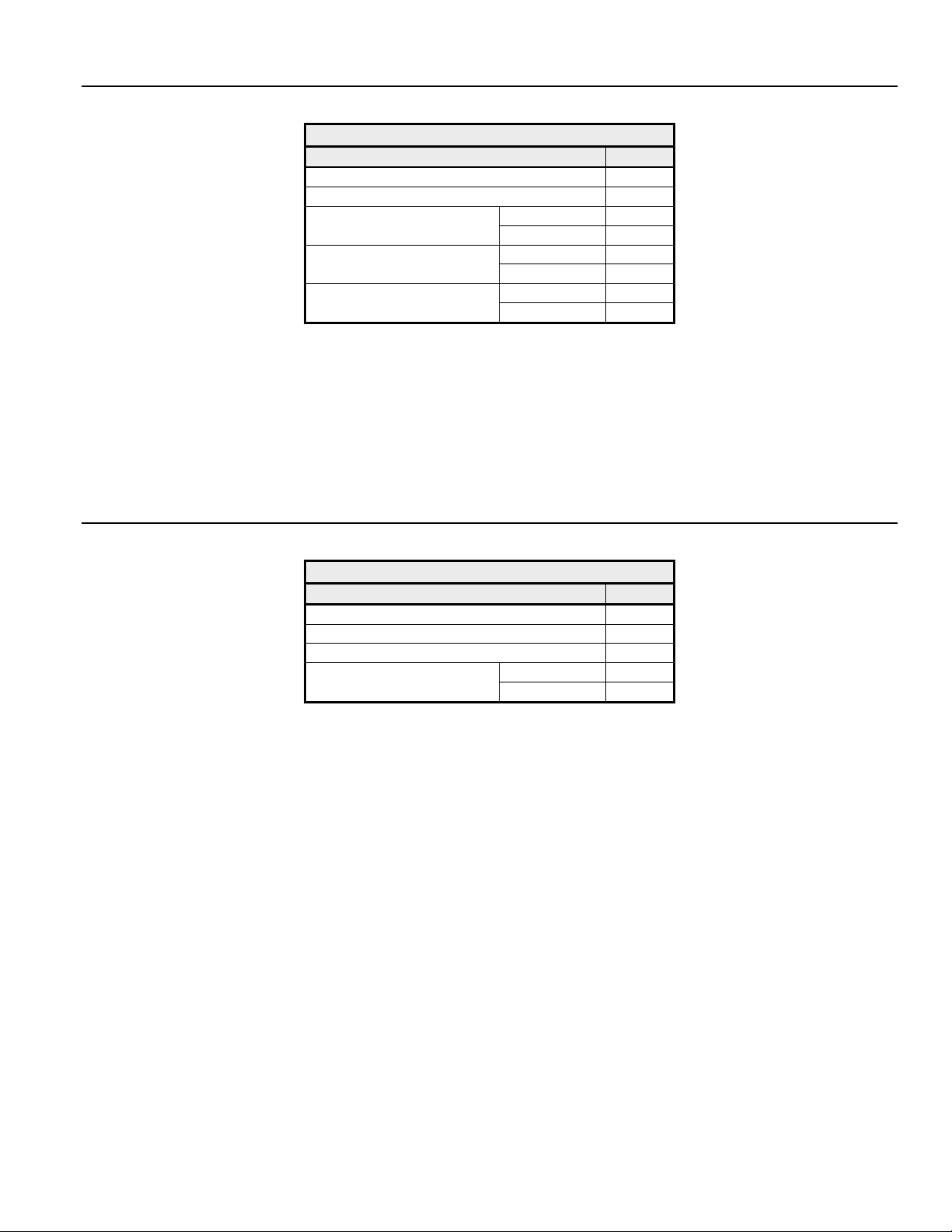

Run/Stop Source

Table 1.7 Run/Stop Method Selecti on

B1-01 Operation Method Selection (Run/Stop)

0 Keypad

1 Terminal Strip (Default Setting)

2 Serial Communication (Built-in Modbus: Keypad or R+/-, S+/- Terminals)

3 Option Card (EtherNet/IP, Modbus TCP/IP, DeviceNet, Profibus DP, LonWorks, etc.)

4 Pulse Input (RP Terminal)

Frequency Reference Source

Table 1.8 Frequency Ref erence Source Selection

B1-02 Frequency Reference Selection

0 Keypad

1 Terminal Strip (Default Setting)

2 Serial Communication (Built-in Modbus: Keypad or R+/-, S+/- Terminals)

3 Option Card ( EtherNet/ IP, Modbus TCP/IP, DeviceNet, Profibus D P, LonWorks, etc. )

15

Page 16

Verify Communication

The following is a quick ref erence guide for serial communications to the G7 drive. Make a copy of this page and check-off eac h item as it is

completed. For detailed information please refer to the detailed sections that follow.

1: RS-232 Communication.

1.1: Verify that the correct cable is used to connect the controller to the G7 drive.

1.2: V erify that the controller is set f or RS-232 communica tion and that the communication cable is connected to the c orrect

communication port.

1.3: Record the control ler communication parameters.

Baud Rate

1.4: Record the G7 drive comm unication para m eters (H5-02, H5-03, H5-07) .

Baud Rate

1.5: Verify that the communication parameters match.

2: RS-422/RS-485 Communication.

2.1: V erify that the G7 drive is connected correctly.

2.2: V erify that the controller is set f or RS-422/RS-485 c om munications and that the communications cable is connected to

the correct communica tions port.

2.3: Record the control ler communications parameters.

Baud Rate

2.4: Record the G7 drive comm unication para m eters (H5-01, H 5-02, H5-03, H5-07).

Baud Rate

Parity Data Bits Stop Bits 1

Parity Data Bits Stop Bits 1

Parity Data Bits Stop Bits 1

Parity Data Bits Stop Bits 1

2.5: Verify that the communication parameters match.

2.6: Verify that parameter H5-07 (RTS) is set to enable.

2.7: V erify that paramet er H5-01 (Node A ddress) is set to the correct, unique, hexadecimal value and that it matches the

node address required by the controller.

Controller Node Address

G7 Drive Node Address

16

Page 17

3: Send a command message to the G7 drive fr om t he controller and verify the data of the comma nd and response messages.

3.1: Verify the conten ts of th e com mand message.

Notes:

[

[

[

[

3.2: Verify the contents of the response message.

[

[

[

[

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

17

Page 18

Notes:

18

Page 19

Chapter 2 - Message Formats

This chapter provides information on the message (telegram) contents and configuration.

Protocol....................................................................................... 20

Read Multiple Registers – Function Code 03H......................... 21

Write Single Register – Function Code 06H............................. 23

Loop-Back Test – Function Code 08H...................................... 25

Write Multiple Registers – Function Code 10H........................ 27

No Response............................................................................... 29

Error Codes................................................................................. 29

CRC-16 Calculation .................................................................... 30

19

Page 20

Protocol

The parame ter access met hod supported by the G 7 drive is a subset of the Modbus♦ communication protocol, which Yaskawa refers to as

MEMOBUS. The G7 drive supports Modbus functions 3, 6, 8 and 10h. The message format varies depending upon the f unction code of the

message. For each function code, there is a command message from the master and a response me ssage from the slave. The following sections

review the format of the command and response messages for each funct ion.

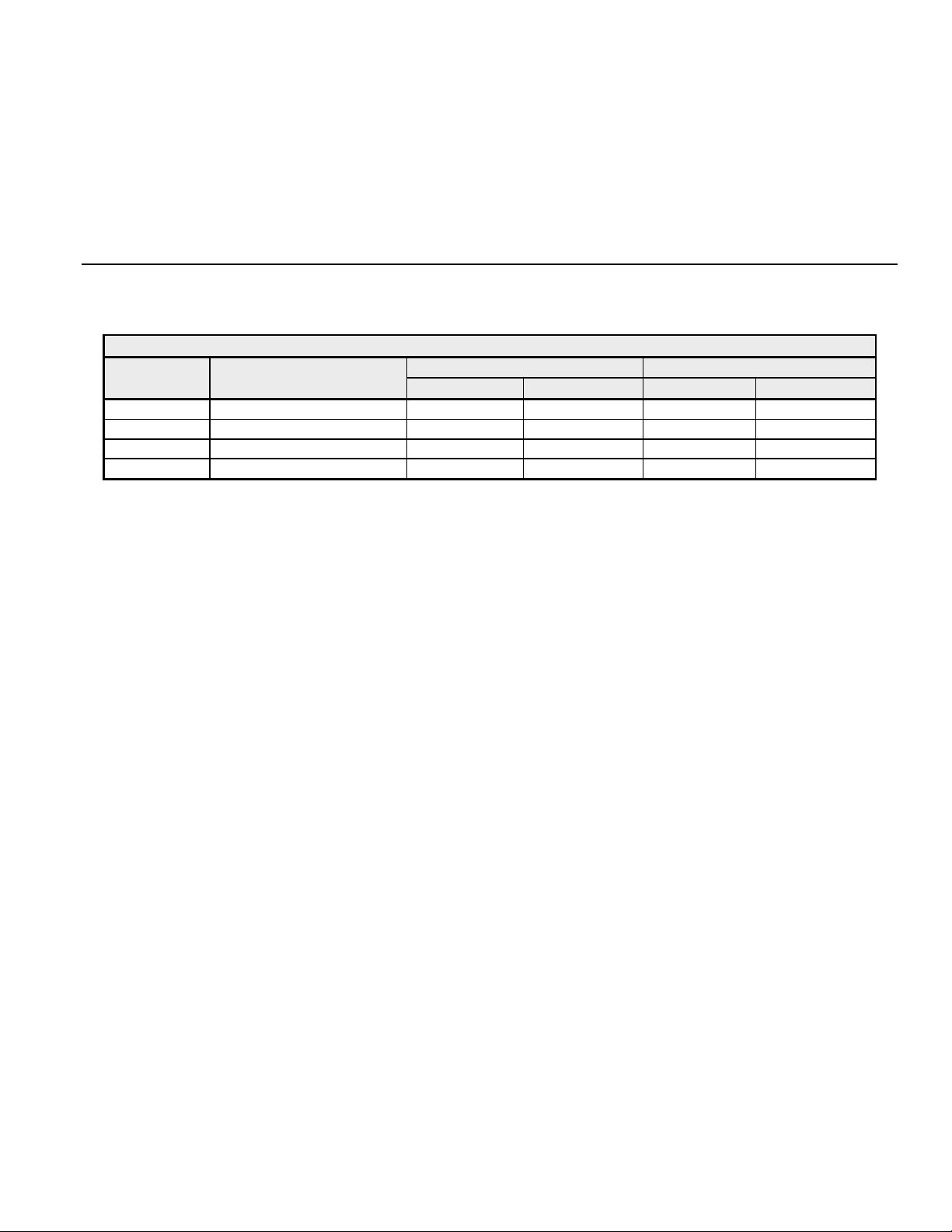

Message Functions Supported

The following table lists the Modbus functi on codes availa ble and their mi nimum and m aximum byte lengths.

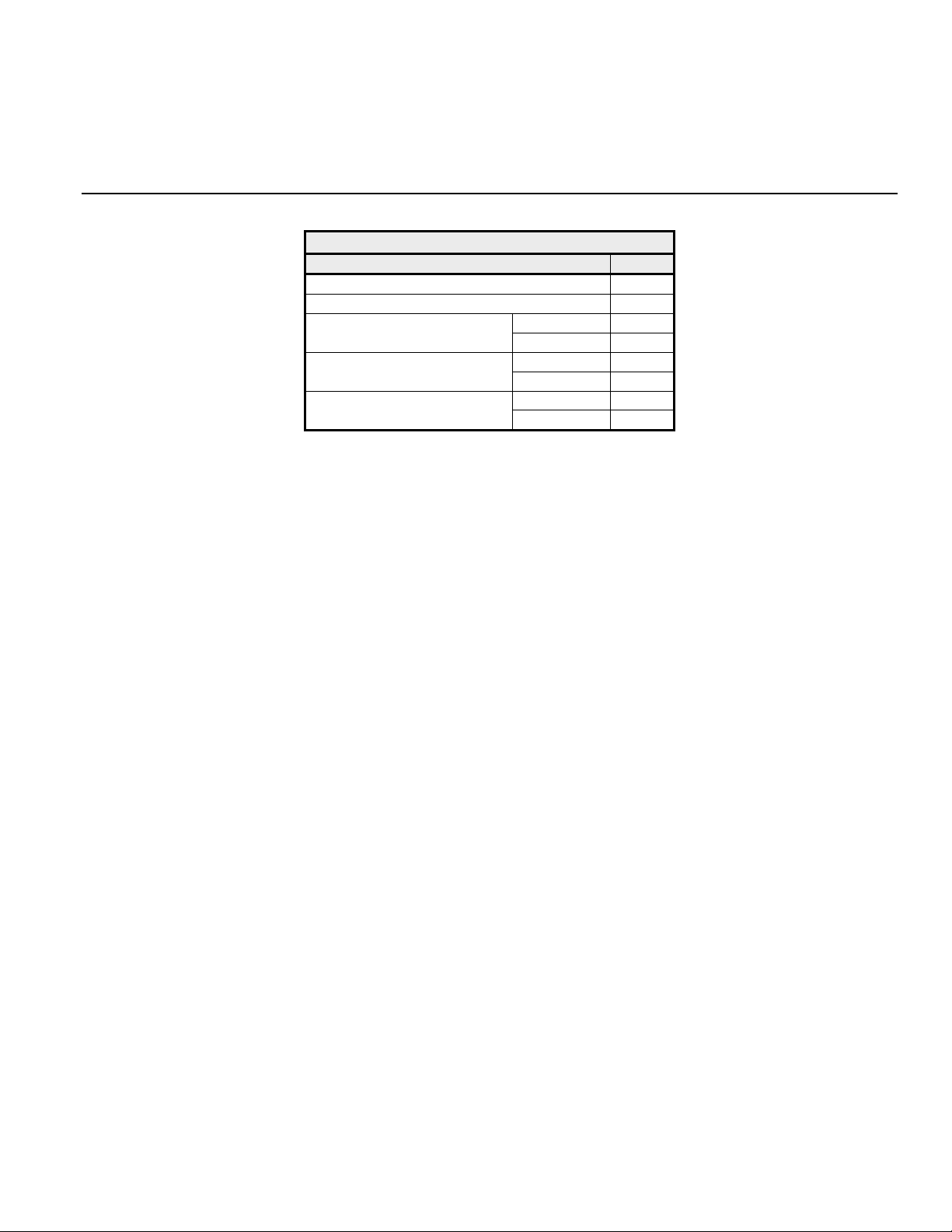

Table 2.1 Supported Function Codes

Function Code Function

3h (3 dec) Read Multiple Registers 8 8 7 21

6h (6 dec) Write Single Register 8 8 8 8

8h (8 dec) Loop-Back Tes t 8 8 8 8

10h (16 dec)

Write Multiple Re g iste rs 11 25 8 8

Minimum (bytes) Maximum (bytes) Minimum (bytes) Maximum (byt es )

Command Message Response Message ( N ormal)

20

Page 21

Read Multiple Registers – Function Code 03H

The Read Multiple Register function is used to read the contents of from 1 to 8 consecutive registers. The formats of the read command and

response m essages are shown below.

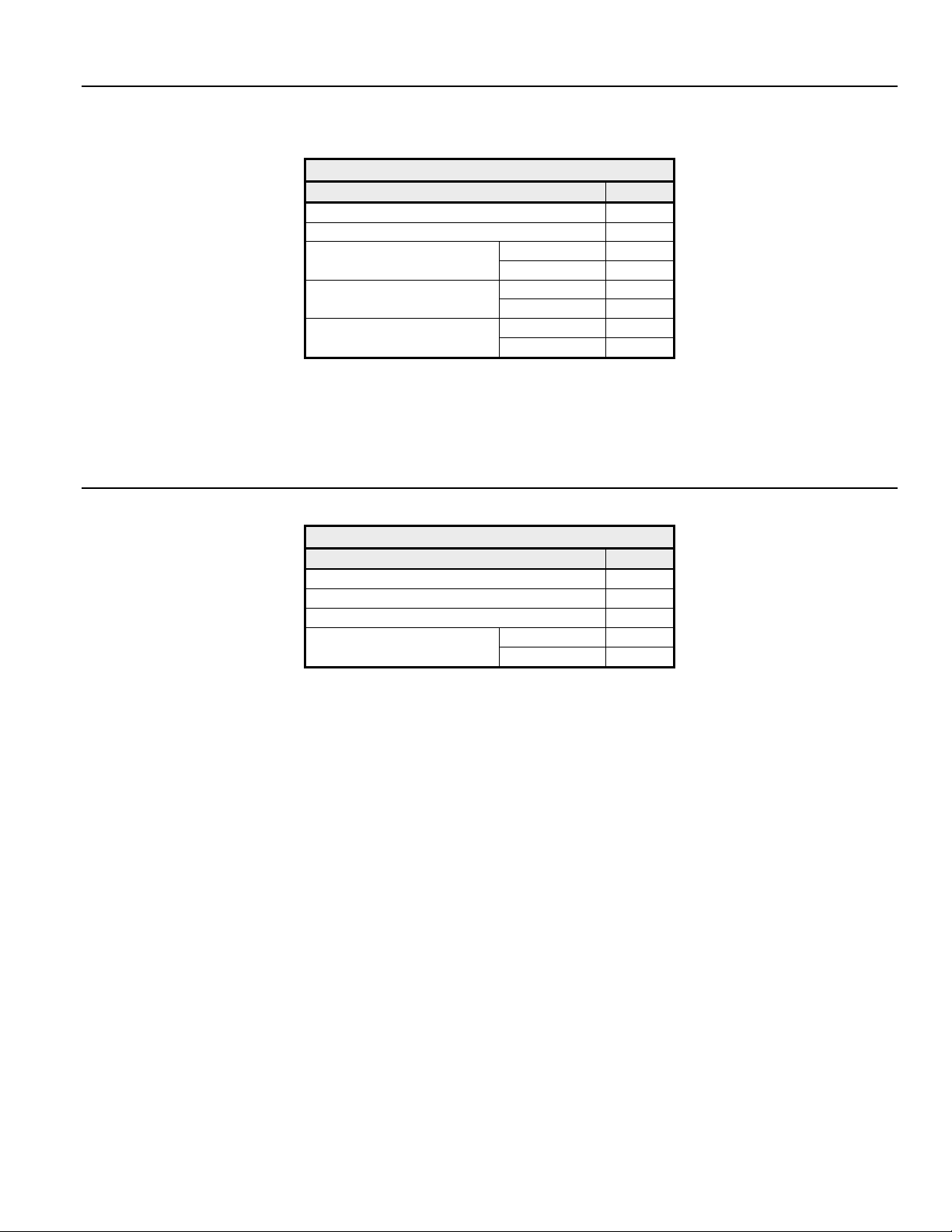

Read Multiple Registers Command Message

Table 2.2 Read Command Message

Description Data

Starti ng Register

Each G7 dri ve slave address is set via parameter H5-01. Vali d slave address es must be in the ra nge of 1 ~ 20 hex (1 ~ 32 dec) and entered as a

hexadec imal number. No two slaves may have the same address . The master addresses the slave by placing the slave address in the Slave

Address field of the message. In the command message above, t he slave is addr essed at 02h. Broadcast address 0 is not valid for register re ad

commands.

Slave Address 02h

Function Code 03h

Upper 00h

Lower 20h

Quantity

CRC-16

Upper 00h

Lower 04h

Upper 45h

Lower F0h

The function code of this mes sage is 03h (read multiple registers) .

The starting regist er is the addres s of the first register to be read. In the command message a bove the starting register a ddress is 20h (0020h).

The quantity indicates how many consecu tive registers are to be read. The quantit y ma y range from 1 to 8 registers. If an invalid quantity is

entere d, error code 03h is returned i n a fault response message. I n this example, four consecutive register s are to be read: 20h, 21h, 22h and 23h.

A CRC-16 value is generated from a calculation including the message sla ve address, function code, sta rting register and quanti ty. The

procedure for calculating a CRC-16 is described at the end of this chapter. When the slave receives the command message it calculates a CRC16 value and compa res it to the CRC-16 of the command message. If the two CRC-16 values are identical and the Slave Addr ess is correct, the

slave process es the command message. If the two CRC- 16 values are not identica l, the slave will discard the command message and not

respond.

If the com ma nd me ssage has a valid slave address, function code, starting register, and quantity , the slave wil l respond with a normal response

message. If the command message has an invalid function code, starting register, and/or quantity, the slave will respond with a fault response

message. If the command message has an i nvalid slave addr ess or CRC-16, no response will be returned.

21

Page 22

Read Multiple Registers Normal Response Message

Table 2.3 Read Normal Response Message

Description Data

Starti ng Register

Next Register

Next Register

Last Register

The normal response message contains the same slave address and funct ion code as the command message, indicating to the master which

specific slave is responding and to what type of function it is responding.

Slave Address 02h

Function Code 03h

Number of Data Bytes 08h

Upper 17h

Lower 70h

Upper 17h

Lower 70h

Upper 01h

Lower 09h

Upper 00h

Lower 00h

CRC-16

Upper 38h

Lower ACh

The number of data bytes is t he num ber of data bytes returned in t he response message. The number of da ta bytes is actually the number of

regist er s read time s 2, since th er e ar e tw o by te s of data in each register.

The starting register is the address of the first register read.

The data section of the response message contains the data for the registers' requested re ad, in this case registers 20h, 21h, 22h and 23h. Their

data is 20h = 1770h, 21h = 1770h, 22h = 0109h and 23h = 0h.

Read Multiple Registers Fault Response Message

Table 2.4 Read Fault Response Message

Description Data

The fault response message contai ns the same slave address as the command message, indicating to the master, which slave is responding.

The function code of a fault response message is the logical OR of 80h and the original function code of 03h. This indicates to the master that

the message is a fault response message, instead of a normal response message.

Slave Address 02h

Function Code 83h

Error Code 02h

CRC-16

Upper 30h

Lower

F1h

The error code indicates w h ere the err or occurred in the com mand message. The value of 02h in the error code field of this fault response

message indicates that the command me ssage requested data be read from an invalid register. Refer to section Error Codes, Table 2- 14, for

more info rmation on retu rned erro r co d es.

22

Page 23

Write Single Register – Function Code 06H

The Write Single Register function allows the writing of data to one regi ster only.

Write Single Register Command Message

Table 2.5 Write Command Message

Description Data

Register Address

Each G7 dri ve slave address is set via parameter H5-01. Vali d slave address es must be in the ra nge of 1 ~ 20 hex (1 ~ 32 dec) and entered as a

hexadec imal number. No two slaves may have the same address . The master addresses the slave by placing the slave address in the Slave

Address field of the message. In the command me ssage above, t he slave is addr essed at 01h. Broadcast address 0 is valid for register write

commands.

Slave Address 01h

Function Code 06h

Upper 00h

Lower 01h

Data

CRC-16

Upper 00h

Lower 03h

Upper 98h

Lower H0B

By setting the slave address to zero (0) in the command message, the master can send a message to all the slaves on the network simultaneously.

This is called simultaneous broadcasting. In a simultaneous broadcast message there is no response message.

The function code of this mes sage is 06h (writ e single regi ster).

In the command message above the register address is 01h (0001h).

The data section contains the data to be written.

A CRC-16 value is generated from a calculation including the message slave address, function code, starting register, quantity, Number of Data

Bytes, and all register data. The procedure for calculating a CRC-16 is described at the end of this chapter. When the slave receives the

command message it calculates a CRC-16 value and compares it to the CRC-16 of the command messa ge. If t he two CRC-16 values are

identical and the slave address is correct, the slave processes the command messa ge. If the two CRC-16 values are not identical, the slave will

discard the command messa ge and not respond.

If the com ma nd me ssage has a valid slave address, function code, regis ter address and data, the sla v e w ill respond wi th a normal response

message. If the command message has an invalid function code, regi ster addres s and/or data, the slave will respond with a fault response

message. If the command message has an i nvalid slave addr ess or CRC-16, no response will be returned.

23

Page 24

Write Single Register Normal Response Message

Table 2.6 Write Register Normal Response Message

Description Data

Register Address

The normal response message contains the same slave address, funct ion code, re gister address and data as the command message, indicating to

the master which slave is responding and t o w hat type of function it is responding.

In the response message above the register address is 01h (0001h).

Slave Address 01h

Function Code 06h

Upper 00h

Lower 01h

Data

CRC-16

Upper 00h

Lower 03h

Upper 98h

Lower 0Bh

Write Single Register Fault Response Message

Table 2.7 Write Register Faul t Response Message

Description Data

The faul t response message contai ns the same slave address as the command message, indicating to the master which slave is responding.

The function code of a fault response message is the logical OR of 80h and the original function code of 06h. This indicates to the master that

the message is a fault response message, instead of a normal response message.

The error code indicates w h ere the err or occurred in the com mand message. The value of 21h in the error code field of this fault response

message indicates that the command me ssage data to be written was invalid for that register . Refer to the sec tion Error Codes, Table 2-14, for

more info rmation on retu rned erro r co d es.

Slave Address 01h

Function Code 86h

Error Code 21h

CRC-16

Upper 82h

Lower 78h

24

Page 25

Loop-Back Test – Function Code 08H

The Loop-Bac k Test is used to ver ify that the com m unications pa rameters for the G7 drive have been set correctly and that the connection i s

correct. The message should be constructed exactly as shown below. If everything is set and connected correctly, the received response will

match the response shown below.

Loop-Back Test - 08h

The Loop-Back test function (08h) is used for checking signal transmiss ion between maste r and slaves. The com ma nd m essage format is shown

below.

Table 2.8 Loop-Back Command Message

Description Data

Slave Address 01h

Function Code 08h

Test Code

Data

CRC-16

Upper 00h

Lower 00h

Upper A5h

Lower 37h

Upper DAh

Lower 8Dh

Each G7 dri ve slave address is set via parameter H5-01. Vali d slave address es must be in the ra nge of 1 ~ 20 hex (1 ~ 32 dec) and entered as a

hexadec imal number. No two slaves may have the same address . The master addresses the slave by placing the slave address in the slave

address field of the message. In the co m ma nd m essage above, the slave is addressed at 01h. Broadcast address 0 is not valid for Loop-Back test

commands.

The function code of this message is 08h (Loop- Back test).

The test code must be set to 0000h. This function specifies that the data passed in the command message is to be returned (looped back) in the

response message.

The Data sec tion contains arbitrary values.

A CRC-16 value is generated from a calculation including the message slave a ddress, funct ion code, test code, and data. The pr ocedure for

calculating a CRC-16 is described at the end of this chapter. When the slave receives the command me ssage it calculates a CRC- 1 6 value and

compares it to the CRC- 16 of t he comma nd messa ge. If the two CRC-16 values are identical and the Slave Address is correct, the slave

processes the command mes sage. If the two CRC-16 values are not identical, the slave will disc ard the command mes sage and not respond.

If the comma nd me ssage has a vali d slave address, function code, test code, data and CRC-16, t he slave will respond with the normal response

message. If the command message has an invalid function code, tes t code, and/or data, the slav e w ill respond wit h a fault response me ss ag e. If

the command message has an invalid slave address or CRC-16, no response will be returned.

25

Page 26

Loop-Back Normal Response

The normal Loop-Back Test response is identical to the command message.

Table 2.9 Loop-Back Normal Response Message

Description Data

Slave Address 01h

Function Code 08h

Test Code

Data

CRC-16

Upper 00h

Lower 00h

Upper A5h

Lower 37h

Upper DAh

Lower 8Dh

Loop-Back Fault Response

Table 2.10 Loop-Back Fault Response Message

Description Data

Slave Address 01h

Function Code 88h

Error Code 01h

CRC-16

Upper 87h

Lower C0h

The faul t response message contai ns the same slave address as the command message, indicating to the master which slave is responding. The

function code of a fault res ponse message is the logical OR of 80h and the origin al function code of 08h. This indicates to the master that the

message is a fault response message, instead of a normal response message.

The error code indicates where the error occurred in the command message. Refer to the section Error Codes, Table 2-14, for more inf o rm at io n

on return ed error cod e s.

26

Page 27

Write Multiple Registers – Function Code 10H

The Write Mul tiple Register function allows the writi ng of data to from 1 t o 16 consecutive re gisters.

Write Multiple Registers Command Message

Table 2.11 Write Command Message

Description Data

Starti ng Register

First Register Data

Next Register Data

Slave Address 01h

Function Code 10h

Upper 00h

Lower 01h

Quantity

Number of Data Bytes 04h

CRC-16

Upper 00h

Lower 02h

Upper 00h

Lower 01h

Upper 02h

Lower 58h

Upper 63h

Lower 39h

Each G7 dri ve slave address is set via parameter H5-01. Vali d slave address es must be in the ra nge of 1 ~ 20 hex (1 ~ 32 dec) and entered as a

hexadec imal number. No two slaves may have the same address . The master addresses the slave by placing the slave address in the Slave

Address field of the message. In the command me ssage above, t he slave is addr essed at 01h. Broadcast address 0 is valid for register write

commands.

By setting the slave address to zero (0) in the command message, the master can send a message to all the slaves on the network simultaneously.

This is called simultaneous broadcasting. In a simultaneous broadcast message there is no response message.

The function code of this mes sage is 10h (writ e m ultiple registers).

The starting register is the address of the first register to be written. In the command message above the starting register address is 01h (0001h).

The quantity indicates how m any consecuti ve registers are to be written. The quantity may range fr om 1 to 16 registers. If an invalid quantity is

entere d, error code of 03h is returne d in a fault respons e m essage. In this command messa ge there are t w o consecutive registers to be written:

0001h (Oper ation Command) and 0002h ( F requency Ref erence).

The number of data bytes is t he num ber of bytes of dat a to be written. The number of data byt es is actual ly the quantity multiplie d by 2, since

there are two bytes of data in each register.

The Data section contains the data for each register to be written in the order in which they are to be written.

A CRC-16 value is generated from a calculation including the message slave address, function code, starting register, quantity, Number of Data

Bytes, and all register data. The procedure for calculating a CRC-16 is described at the end of this chapter. When the slave receives the

command message it calculates a CRC-16 value and compares it to the CRC-16 of the command messa ge. If t he two CRC-16 values are

identical and the slave address is correct, the slave processes the command messa ge. If the two CRC-16 values are not identical, the slave will

discard the command messa ge and not respond.

If the com ma nd me ssage has a vali d slave address, function code, starting register, quantity, number of data byte s and data, and the slave will

respond with a normal response message. If the command message has an invalid function code, starting register, quantity, Number of Data

Bytes a nd/or data, the slave will respond with a fault response message. If the command message has an invali d slave address or CRC-16, no

response w ill be returned.

27

Page 28

Write Multiple Registers Normal Response Message

Table 2.12 Write Registers Normal Response Message

Description Data

Starti ng Register

The normal response message contains the same slave address, function code, starting register and quantity as the command message, indicating

to the mast er which slave is responding and to what type of f unction it is responding.

The starting register is the address of the first register written. In the response message above the starting register address is 01h (0001h).

The quantity indicates how m any consecuti ve registers were written. In this case the quantity is 2.

Slave Address 01h

Function Code 10h

Upper 00h

Lower 01h

Quantity

CRC-16

Upper 00h

Lower 02h

Upper 10h

Lower 08h

Write Multiple Registers Fault Response Message

Table 2.13 Write Registers Fault Response Message

Description Data

The faul t response message contai ns the same slave address as the command message, indicating to the master which slave is responding.

The function code of a fault response message is the logical OR of 80h and the original function code of 10h. This indicates to the master that

the message is a fault response message, instead of a normal response message.

The error code indicates w h ere the err or occurred in the com mand message. The value of 02h in the error code field of this fault response

message indicates that the command me ssage requested data to be written to an invalid register . Refer to the section Error Codes, Table 2-14,

for more information on returned error codes.

Slave Address 01h

Function Code 90h

Error Code 02h

CRC-16

Upper CDh

Lower C1h

28

Page 29

No Response

The slave disregards t he command message and does not return a response message in the follow ing cases:

1. In broadcasting of data (slave addres s is 0), all slaves execute, but do not respond.

2. When a communicati on error (overrun, fr aming, parity, or CRC-16) is detected in the command message.

3. When the slave address in the command message does not coincide with the address set in the slave.

4. When it ta kes longer than 2 seconds to send a mes sage.

5. When the time interval between characters exceeds 3.5 ms.

6. When the command message data length is not proper.

Error Codes

Table 2.14 Fault Codes

Code Fault Description

1 F unction Error Invalid or unsupported function code in command message

2 Invalid Regis ter Invalid regis ter address

3 Invalid Number of Registers Invalid command message quantity

21 Data Limits Exceeded The write command message data is out of range for the requested r e gister

22 Write Fai lure The register to be written is write protected

29

Page 30

CRC-16 Calculation

The last two bytes of a message contain the CRC-16 ( C yclical Redunda ncy Check). The CRC-16 is one method for verifying the validity of the

message contents and is part of the protocol. The CRC-16 field checks the contents of the entire message, regardless of any parity check method

used for the individua l characters of the message.

The CRC-16 fiel d is a 16- bit binary value consisting of two 8-bit bytes. The CRC-16 value is calculated by t he transmitting device, which

appends the CRC-16 to the messa ge. The receiving device recal culates a CRC-16 dur ing receipt of the message, and compares this calculated

value to the value received in the transmitted CRC-16 field. If the two values are not equal, the entire message is invalid.

Detailed examples of a CRC-16 generati on using Quick Basic and C are shown below.

CRC-16 Calculation Example in Basic

crcsum# = &HFFFF&

crcshift# = &H0&

crcconst# = &HA001&

CLS

PRINT “*********** ****************************************”

PRINT

PRINT “ CRC-16 calculator”

PRINT

PRINT “*********** ****************************************”

PRINT “If e ntering data in hex, preceed the data with ‘&H’”

PRINT “ Example: 32decimal = 20hex = &H20”

PRINT “*********** ****************************************”

PRINT

INPUT “Enter the number of bytes in the message: “, maxbyte

FOR bytenum = 1 TO maxbyte STEP 1

PRINT “Enter byte “; bytenum; “:”:

INPUT byte&

byte& = byte& AND &HFF&

crcsum# = (crcsum# XOR byte&) AND &HFFFF&

FOR shift = 1 TO 8 STEP 1

crcshift# = (INT(crcsum# / 2)) AND &H7FFF&

IF crcsum # A ND &H1& TH EN

crcsum# = crcshift# X O R cr cco nst#

ELSE

crcsum# = crcshift#

END IF

NEXT shift

NEXT bytenum

lower& = crcsum# AND &HFF&

upper& = (INT(crcsum# / 256)) AND &HFF&

PRINT “Lower byte (1

PRINT “Upper byte (2

st

) = “, HEX$(lower&)

nd

) = “, HEX$(upper&)

30

Page 31

CRC-16 Calculation Example in C

void getMBCRC(char *, int, char *) // function prototype

void getMBCRC(char *buf, int bufLen, char *cr c) { // Function name and par am eter list returning a void

// *buf pointer to character array used to calcula te CRC

// bufLen number of characters to calculate CRC for

// *crc pointer to the array that contains the calculated CRC

unsigned long crc_0 = 0xffff; // Declare and initialize variables

unsigned long crc_1 = 0x0000; // Declare and initialize variables

int i,j; // Declare and initialize variables

for (i=0; i<bufLen; i++) { // Loop through characters of input array

crc_0 ^= (( unsigned long) buf[i] & 0x00ff); // XOR current character w ith 0x00ff

for (j=0;j<8;j++) { // Loop through characters bits

crc_1 = (crc_0 >> 1) & 0x7fff; // shift result right one place and store

if (crc_0 & 0x0001) // if pre-shifted value bit 0 is set

crc_0 = (crc_1 ^ 0xa001); // XOR the shift ed value with 0xa 001

else // if pre-shifted value bit 0 is not set

crc_0 = crc_1; // set the pre-shifted value equal to the shifted value

} // End for loop - Loop through characters bits

} // End for loop - Loop through c haracters of input array

crc[0] = (unsigned char)((crc_0/256) & 0x00ff); // Hi byte

crc[1] = (unsigned char)(crc_0 & 0x00ff); // Lo byte

return; // Return to calling function

} // End of CRC calculation function

31

Page 32

Notes:

32

Page 33

Chapter 3 - Troubleshooting

This chapter describes basic troubleshooting methods for serial communication.

General Information ................................................................... 34

RS-232 Communication.............................................................. 35

RS-422/RS-485 Communication ................................................ 37

RS-422/RS-485 Self-Test ........................................................... 40

33

Page 34

General Information

Please fill in the infor ma tion on this and the following pa ges prior to contacting cust ome r support. If customer suppor t is necessary, please have

the information below available.

1: G7 Drive Model CIMR-_____

2: Input__

3: Serial Number_______________

VAC____Hz 5: Software ID (U1-14) __________________

4: Control Board ETC-_____

6: Initialization Type (2 or 3 wire control) _____________

Please provide a sketc h of the network in t he space below.

34

Page 35

RS-232 Communication

The following is a quick reference guide for troubleshooting RS-232 communication to the G7 drive. Make a copy of the following pages and

check-off each item as it is completed. For detailed information on the RS-232 standard please refer to EIA RS-232-C or later revision. For

information on the G7 dri ve RS-232 interface, refer to previous sections of this manual.

1: For RS-232 communicati on.

1.1: Verify that the correct cable is used to connect the controller to the G7 drive.

1.2: V erify that the controller is set f or RS-232 communica tion and that the communication cable is connected to the c orrect

communication port.

1.3: Record the control ler communications parameters.

Baud Rate

1.4: Record the G7 drive’s communication parameters (H5-02, H5-03, H5-07).

Baud Rate

1.5: Verify that the communication parameters match.

2: Check the controller RS-232 wiring requirement s.

2.1: CTS (Clear to Send)/RTS (Rea dy to Send) jumper required on the controller end?

2.2: DTR (Data Terminal Ready)/DSR (Data Set Ready)/RLSD (Receive Line Signal Detector) jumper required on the

controller end?

2.3: TXD (Transmit Data) /RXD (Receive Data) connecti ons are made correctly?

3: Send a message from t he controller to the G7 drive.

3.1: Connect an oscilloscope between the G 7 drive RXD and GND.

3.1.1: Verify that the me ssage pulse train exists and contains the correct number of pulses. Re fer to the chapter

Message Formats for information on the message contents.

Parity Data Bits Stop Bits 1

Parity Data Bits Stop Bits 1

3.1.2: Verify that the signal levels adhere to the RS-232 standar d.

3.2: Insert a data analyzer in the RS-232 ci rcuit and capt ure the message sent by the controller in a he xadecimal format.

Record the command message below.

[

[

[

[

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

35

Page 36

3.3: V erify that the contents of the messa ge adhere to the pr otocol format as described previously.

3.3.1: Verify that the node address is valid.

3.3.2: Verify that the function code is valid.

3.3.3: Verify that the register address is valid.

3.3.4: Verify that the num ber of data bytes is valid.

3.3.5: Verify that the CRC is correctly calculated.

3.3.6: Verify that t he me ssage requires a response.

4: Verify the contents of the response message.

4.1: Connect an oscilloscope between the contr oller RXD and GND.

4.1.1: Verify that the me ssage pulse train exists and contains the correct number of pulses. Re fer to the chapter

Message Formats for information on the message contents.

4.1.2: Verify that the signal levels adhere to the RS-232 standar d.

4.2: Capture the response me ssage sent by the controller in a hexadecimal format and recor d it below.

[

[

[

[

4.3: V erify that the contents of the messa ge adhere to the pr otocol format as described previously.

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

4.3.1: Verify that the node address is valid.

4.3.2: Verify that the function code is valid.

4.3.3: Verify that the num ber of data bytes is valid.

4.3.4: Verify that the register address is valid.

4.3.5: Verify that the CRC is correctly calculated.

36

Page 37

RS-422/RS-485 Communication

The following is a quick reference guide for troubleshooting RS-422/RS-485 communicati on to the G7 drive. Ma ke a copy of the following

pages a nd check-off eac h item as it is completed. For detailed information on the RS-422/RS-485 standard ple ase refer to EIA RS-422-A or later

revision. For information on the G7 dri ve RS-422/RS-485 interface, refer to previous sections of this ma nual.

1: For RS-422/RS-485 communic ations.

1.1: Verify that the correct cable is used to connect the controller to the G7 drive.

1.2: V erify that the controller is set for RS-422 or RS-485 comm unications and that the communications cable is connected

to the correct communications port.

1.3: Record the control ler communication parameters.

1.4: Verify that the polarity of the signal wires is correct (+ to + and - to -).

Baud Rate

1.5: Record the G7 drive comm unication para m eters (H5-01, H 5-02, H5-03, H5-07).

Baud Rate

1.6: Verify that the communication parameters match.

1.7: For RS-485 2-wire networks only, verify that G7 drive param eter H5-07 (RTS) is set to 1 (Enable ).

1.8: V erify that G7 drive parameter H5-01 (Node Address) is set to the correct, unique, hexadecimal value and that it

matches the node address required by the controller.

2: Check the controller RS-422/RS-485 wiring requirements.

2.1: The controller transmit termi nals are connected to the G7 drive receive term inals and the receive terminals connected to

the G7 dr ive trans mit terminals.

2.2: The transmit and rece ive connection polarities are correct.

2.3: The controller either assert s R T S w hen transmitting or utilizes send detect circuitry.

2.4: The network is terminated only at the beginning and end of each network segment.

Parity Data Bits Stop Bits 1

Parity Data Bits Stop Bits 1

2.5: There are no m o re than 31 device s on any network segment, incl uding the contro ller and repeater.

3: Verify that the G7 drive passes the self-test as described in the following section.

37

Page 38

4: Send a message from t he controller to the G7 drive.

4.1: Connect an oscilloscope between the G 7 drive’s R+ and R- termi nals for RS-422/RS-485 4-wire netw orks or between

terminals R+/S+ and R-/S- for RS-485 2-wire netw orks.

4.1.1: Verify that the message pulse train exists a nd contains the c orrect number of pulses. Refer to the chapter

4.1.2: Verify that the signal levels adhere to the RS-422/RS-485 standar d.

4.2: Insert a data analyzer in the RS-422/RS-485 circui t and capture the me ssage sent by the controller in a hexadecimal

format. Record the command message below.

[

[

[

[

4.3: V erify that the contents of the message adhere to the M odbus format as describe d previously.

4.3.1: Verify that the node address is valid.

4.3.2: Verify that the function code is valid.

4.3.3: Verify that the register address is valid.

Message Formats for information on the message contents.

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

4.3.4: Verify that the number of data bytes is valid.

4.3.5: Verify that t he CRC is correctly calculated.

4.3.6: Ve rify that the message requires a response.

38

Page 39

5: Verify the contents of the response message.

5.1: Connect an oscilloscope between the controller R+ and R- terminals for RS-422 and RS-485 4-Wire networks or

between ter m inals R+/S+ and R-/S- for RS-485 2-wire net w orks.

5.1.1: Verify that the message pulse train exists a nd contains the c orrect number of pulses. Refer to the chapter

5.1.2: Verify that the signal levels adhere to the RS-422/RS-485 standar d.

5.2: Capture the response me ssage in hexadec imal format and record it below.

[

[

[

[

5.3: V erify that the contents of the message adhere to the M odbus format as describe d previously.

5.3.1: Verify that the node address is valid.

5.3.2: Verify that the function code is valid.

5.3.3: Verify that the register address is valid.

Message Formats for information on the message contents.

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ] [ ]

5.3.4: Verify that the number of data bytes is valid.

5.3.5: Verify that t he CRC is correctly calculated.

39

Page 40

RS-422/RS-485 Self-Test

The G7 drive can perform a self-test of the communications interface. To perform the self-test:

Apply power to the G7 drive.

Set parame ter H1-05 to 67 (communication self-test ). Terminal S7 is just an example. Any terminal can be used.

Remove power from the G7 drive and wait for the charge lamp to be completely extinguished. Wait at least five additional minutes for

the G7 drive to be completely discharged. Measure the DC bus voltage and verify that it is at a safe level.

Connect jumper wires to the following G7 drive control terminals (see picture below):

- Connect S+ to R+

- Connect S- to R-

- Connect S7 to SC

Reapply power to the G7 drive.

Successful Self-Test

- The fre quency reference is displayed on the digital operator i f the communications interface is functioning normally.

Unsuccessful Self-Test

- If “CE” is displayed on the keypad, the communications i nterface is not functioning properly. Cont act the fact ory for assist ance.

Figure 3.1 RS-422/RS-485 Self-Test Example using Terminal S7

40

Page 41

Chapter 4 - G7 Drive Parameters

This chapter describes the G7 drive’s communication registers.

Command Registers (Read/Write) for Modbus RTU.................42

Broadcast Registers (Write Only)...............................................43

Monitor Registers (Read Only)...................................................44

Parameter Registers (Read/Write)..............................................52

“A” Parameters............................................................................53

“B” Parameters............................................................................54

“C” Parameters............................................................................56

“D” Parameters............................................................................57

“E” Parameters............................................................................58

“F” Parameters ............................................................................59

“H” Parameters............................................................................63

“L” Parameters ............................................................................68

“N” Parameters............................................................................71

“O” Parameters............................................................................72

“P” Parameters............................................................................74

CM090 Modbus TCP/IP Option Kit Specific Registers..............75

ENTER/ACCEPT Command (Write Only)...................................78

Modbus Fault Decoding Table for Monitors..............................79

41

Page 42

Command Registers (Read/Write) for Modbus RTU

Command registers are those used to cont rol the operation of the G7 drive either through a network inte rface (opti on card) or via serial

communication (defined as Modbus built into the drive’s keypad port or terminal strip). These registers are available during an active Run

command. It should be noted that multi-function di gital inputs that are commanded ove r a communication network are l ogically OR’d with their

physical digital input terminal counterpart.

The “Address” column contains the re gister addre ss in hexadecimal format. G7 drive registers are always referred to in hexadecima l for mat. The

“Functio n” colum n con t ains the register n am e . The “B it ” an d “Descrip tio n” colum n s co ntain th e li st of avail ab le bit s fo r that register and a short

description of each. If the “Bit” colum n is empty, the re gister contains word data and i ndividual bits have no meaning.

Please note that these Command Re gisters are diffe rent from those used in theCM090 Modbus TCP/ IP Ethernet Option card. Refer to the

section t oward the end of this chapter for more information on Modbus TCP/IP.

Table 4.1 Command Registers ( Read/Write)

Addr. Function Bit Description

0h Run Command (0 = Stop, 1 = Run)

1h Direction Command (0 = Forward, 1 = Reverse)

2h External Fault

3h Fault Reset

4h Frequency Reference Source (0 = b1-01 Setting, 1 = Modbus communication)

5h Run Command Source (0 = b1-02 Setting, 1 = Modbus communication)

6h Multi-Function Digital Input Terminal S3. Function set by setting of H1-01

0001h

0002h

0006h PID Setpoint - PID Setpoint

0007h

0008h

0009h

000Fh Command Selection

Note: * Overrides the standard functionality of the Fault Contacts. Use caution.

** These bits must be set to “1” in order to use the Simultaneous Broadcast Register multi-function inputs S3, S4, S5 and S6 (bits 0Ch, 0Dh, 0Eh and

Digital Input

Command

Frequency Reference

Setpoint

Analog Output FM

Setpoint

Analog Output AM

Setpoint

Digital Output

Command

0Fh respectively). Refer to Table 4.2 Br oadcas t Registers .

7h Multi-Function Digital Input Terminal S4. Function set by setting of H1-02

8h Multi-Function Digital Input Terminal S5. Function set by setting of H1-03

9h Multi-Function Digital Input Terminal S6. Function set by setting of H1-04

Ah Multi-Function Digital Input Terminal S7. Function set by setting of H1-05

Bh Multi-Function Digital Input Terminal S8. Function set by setting of H1-06

Ch Multi-Function Digital Input Terminal S9. Function set by setting of H1-07

Dh Multi-Function Digital Input Terminal S10. Function set by setting of H1-08

Eh Multi-Function Digital Input Terminal S11. Function set by setting of H1-09

Fh Multi-Function Digital Input Terminal S12. Function set by setting of H1-10

- Scaling Dependent Upon o1- 03 Setting

- Sets the value of analog output terminal FM. (-1540 / -11VDC ~ 1540 / +11VDC)

- S ets the value of analog output of terminal AM (-1540 / -11VDC ~ 1540 / +11V D C)

0h Multi-Function Digital Output 1 (M1-M2)

1h Multi-Function Digital Output 2 (M3-M4)

2h Multi-Function Digital Output 3 (M5-M6)

3h Multi-Function Digital Output 4 (P3-C3)

4h Multi-Function Digital Output 5 (P4-C4)

5h Reserved

6h Fault Contact Output Enable (1 = Enable bit 7)*

7h Fault Contact Digital Output (MA, MB, MC)

8h-Fh Reserved

0h Reserved

1h PID Setpoint Enable (when set to “1”, use Regi s ter 0006h for the P ID Setpoint)

2h–Bh

Ch Broadcast Data Terminal S5 E nable**

Dh Broadcast Data Terminal S6 Enable**

Eh Broadcast Data Term inal S7 Enable**

Fh Broadcast Data Terminal S8 Enable**

Reserved

42

Page 43

Broadcast Registers (Write Only)

Broadcast Registers are those registers used to control the simul taneous opera tion of multi ple devices either through a netw ork interfa ce (op tio n

card) or via Modbus RTU communication. These registers are available during drive Run.

The “Add r e ss” column co ntains th e reg is ter addr es s in hex adecimal format. Drive reg i sters are always ref e renced in hexadecimal format. The

“Functio n” colum n con t ains the register n am e . The “B it ” an d “Descrip tio n” colum n s co ntain th e li st of avail ab le bit s fo r that register and a short

description of each. If the “Bit” colum n is empty, the re gister contains word data and i ndividual bits have no value.

Table 4.2 Broadcast Regi sters (Write Only)

Addr. Function Bit Description

0000h

0001h

0002h

Note: * These bits mus t be enabled using register 0Fh, bits 0Ch, 0Dh, 0Eh and 0Fh. Refer to Tabl e 4.1 Command Registers (Read/Write).

** This value must be s e nt to the drive as a hexadeci mal value. E xample: 4096 = 1000h.

Reserved - Reserved

0h 0 = Stop, 1 = Run

1h 0 = Forward, 1 = R e verse

2h Reserved

3h Reserved

4h Reserved

5h Multi-Function Digital Input Terminal S3. Function set by setting of H1-01

6h Multi-Function Digital Input Terminal S4. Function set by setting of H1-02

Digital Input

Command

Frequency

Reference

The scaling is fixed at 30000 / 100% and is not affected by parameter o1-03. It is affected by the maximum output frequency (E1-04) of the drive

receiving the command. Simpl y it is ((decimal f requency reference) / 30000) x ( E1-04).

Example: Send 1000h to dr ive. 1000h = 409 6 decimal. (4096 x 100%) / 30000 = 13.65%. If drive’s maximum fr equency is 60Hz, then the

frequency reference comman d to the drive is 60H z x 13.65% or 8.19Hz.

7h Reserved

8h Reserved

9h Reserved

Ah Reserved

Bh Reserved

Ch Multi-Function Digital Input Terminal S5. Function set by setting of H1-03*

Dh Multi-Function Digital Input Terminal S6. Function set by setting of H1-04*

Eh Multi-Function Digital Input Terminal S7. Function set by setting of H1-05*

Fh Multi-Function Digital Input Terminal S8. Function set by setting of H1-06*

- 30000 / 100% **

43

Page 44

Monitor Registers (Read Only)

The follow ing table lists monitor para meters for the G7 drive. These parameters are used to monitor G7 drive inf ormation and cannot be written.

The “U-##” column contai ns the reference, if it exists, to the “U” moni tor, parameter dis played via the oper ator keypad.

The “Address” column contains the register addresses for that parameter in hexadecimal format. G7 drive registers are always referred

to in hexadecimal format.

The “Funct ion” column contains the register name.

The “Bit” column contains the list of available bits for that register. If the “Bit” column is empty, the register contains word data and

the individual bits are mea ningless.

The “Description” column contains a short description of each register or register bit.

Reserved registers and data are meaningless and should be ignored.

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

0010h Inverter Status

0011h Operator Status

0012 h OPE – Keypad Setting Error

Function Bit Description

0h Run

1h Reserved

2h Reserved

3h Fault Reset Signal

4h Speed Agree

5h Inverter Ready

6h Minor Fault (Alarm)

7h Major Fault

8h Reserved

9h Reserved

Ah Reserved

Bh Reserved

Ch Reserved

Dh Reserved

Eh Frequency Reference Source (0 = b1-01 Setting, 1 = Modbus Com munication)

Fh Run Command Source ( 0 = b1-02 Setting, 1 = Modbus Communication)

0h OPE - Keypad Setting Error

1h ERR - EEPROM Write Failure

2h PRG - Keypad Pr ogramming Mode

3h 0: Digital Operator Present, 1: PC C onnected

4h-Fh Reserved

0h Reserved

1h OPE01 - drive kVA Setti ng Error (O2-04)

2h OPE02 - Parameter Setting Out of Range

3h OPE03 - Multi-Function Digital Input Setting Error

4h Reserved

5h OPE05 - Run Command Selection Error - Option Card Missing

6h OPE06 - Control Method Selection Error - PG Option Card Missing

7h OPE07 - Multi-Function Analog Input Selection Error

8h OPE08 - Function Selection Error for Current Control Mode

9h OPE09 - PID Control Setup Error

Ah OPE10 - V/F Parameter/Pattern Setting Error

Bh OPE11 - Carrier Frequency Setting Error

Ch Reserved

Dh Reserved

Eh Reserved

Fh

Reserved

44

Page 45

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

0013h Inverter Product Code -

0014 h Fault Cont ents 1

0015 h Fault Cont ents 2

0016 h Fault Cont ents 3

Function Bit Description

0000: G5

1000: V7

2010: G7

2020: F7C (Y EG)

2030: F7A (YEC)

2040: F7U (YEA)

2050: G7C (YE G)

2060: G7A (YE C)

2070: G7U (YEA)

0h PUF - DC Bus Fuse Failure

1h UV1 - Main Circuit Undervoltage

2h UV2 - Control Circuit Undervoltage

3h UV3 - Pre-char ge C ontactor Answerback Failure

4h Reserved

5h GF - Ground Fault

6h OC - Over Current

7h OV - Overvoltage

8h OH - Inverter Overheat

9h OH1 - Inverter O ver heat Warning

Ah OL1 - Motor Overload

Bh OL2 - Inverter Overload

Ch OL3 - Overtorque Detection 1

Dh OL4 - Overtorque Detection 2

Eh RR - Braking Resistor Failure

Fh RH - Braking Resistor Overheat

0h EF3 - External Fault 3

1h EF4 - External Fault 4

2h EF5 - External Fault 5

3h EF6 - External Fault 6

4h EF7 - External Fault 7

5h EF8 - External Fault 8

6h Reserved

7h OS - Overspeed

8h DEV - Speed Deviation

9h PGO - Encoder (PG) Feedback L os s

Ah PF - Input Phase Loss

Bh LF- Output Phase Loss

Ch OH3 - Overheat

Dh OPR - Operator Disconnected

Eh ERR - EEPROM Write Failure

Fh OH4 - Motor Overheat

0h CE - Communication Loss

1h BUS - Communication Option Ca rd Fault

2h E-15 - SI-F/G Fault

3h E-10 - SI-F/G Fault

4h CF - Loss of Motor Control

5h SVE - Zero Servo Fault

6h EF0 - Communications Option External Fault

7h FBL - PID Feedback Loss

8h UL3 - Undertorque Detection 1

9h UL4 - Undertorque Detection 2

Ah OL7 - High Slip Br a king Overload

Bh EF9 - External Fault 9

Ch EF10 - External Fault 10

Dh EF11 - External Fault 11

Eh EF12 - External Fault 12

Fh Reserved

45

Page 46

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

0017 h CPF Contents 1

0018 h CPF Contents 2

0019h Minor Fault Contents 1

001Ah Minor Fault Contents 2

Function Bit Description

0h Reserved

1h Reserved

2h CPF02

3h CPF03

4h CPF04

5h CPF05

6h CPF06

7h CPF07

8h CPF08

9h CPF09

Ah CPF10

Bh-Fh Reserved

0h CPF20

1h CPF21

2h CPF22

3h CPF23

4h-Fh Reserved

0h UV - Undervoltage

1h OV - Overvoltage

2h OH - Inverter Overheat

3h OH2 - Inverter O ver heat Warning

4h OL3 – Overtorque Detection 1

5h OL4 – Overtorque Detecti on 2

6h EF - 2-wire Sequence Input Fault

7h BB - Baseblock

8h EF3 - External Fault 3

9h EF4 - External Fault 4

Ah EF5 - External Fault 5

Bh EF6 - External Fault 6

Ch EF7 - External Fault 7

Dh Reserved

Eh Reserved

Fh OS - Overspeed

0h DEV - Speed Deviation

1h PGO - Encoder (PG) Feedback L os s

2h OPR - Operator Disconnected

3h CE - Communication Loss

4h BUS - Communication Option Ca rd Fault

5h CALL - Waiting for Communications

6h OL1 - Motor Overload

7h OL2 - Inverter Overload

8h E-15 - SI-F/G Communication Fault

9h E-10 - SI-F/G Fault

Ah

Bh FBL - PID Feedback Loss

Ch CALL - Waiting for Initial Communication after Power Up

Dh UL3 - Undertorque Detection 1

Eh UL4 - Undertorque Detection 2

Fh

“Motor Runni ng” is flashed on the keypad. S ee Motor 2 Selection, H1-XX = 16)

“SE” is flashed on the keypad. See C ommunication Self -test, H1-X X = 67)

(Attempting to switch Motor 1/2 during Run.

(Attempting to perform communication self-test during run.

Motor Switch

Communication Test Fault

46

Page 47

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

001Bh

0020h

0021h

0022h

U1-01 0023h

U1-02 0024h

U1-06 0025h

U1-03 0026h

U1-08 0027h

U1-09 0028h

Output Voltage Reference Monitor - Scaling Dependent Upon H5-10 S etting

Function Bit Description

0h OH3 - Motor Overheat Alarm

1h

Minor F ault Contents 3

2h-Fh Reserved

0h Run

1h Reverse Direction

2h Inverter Ready

3h Fault

4h Data Setting Error

Inverter Status

Fault Contents

Data Link Status

Frequency Reference Monitor - Scaling Dependent Upon o1-03 Setting

Output Frequency Monitor - Scaling Dependent Upon o1-03 Setting

Output Current Monitor - Units 0.01A

Output Power Monitor - Units 0.1kW

Torque Reference Monitor -

5h Multi-Function Digital Output 1 (M1-M2)

6h Multi-Function Digital Output 2 (M3-M4)

7h Multi-Function Digital Output 3 (M5-M6)

8h Multi-Function Digital Output 4 (P3-C3)

9h Multi-Function Digital Output 5 (P4-C4)

Ah-Fh

0h OC or GF - Overcurrent/Ground Fault

1h OV - Overvoltage

2h OL2 - Inverter Overload

3h OH1 or OH2 - Overheat Fault

4h RR or RH - Braking Resistor Fault

5h PUF - DC Bus Fuse Failure

6h FBL - PID Feedback Loss

7h EFx or EFO - External Faul t

8h CPF - Control Board Hardware Fault

9h OL1, or OL3, or OL4 - Motor Overload/Overtorque 1 or 2

Ah PGO, OS, or DEV - Speed Feedback

Bh UV - Undervoltage

Ch UV1, UV2, or UV3 - Undervoltage

Dh SPI or SPO - Input/O utput Phase Los s

Eh CE - Communication Loss

Fh OPR - Operator Disconnected

0 Writing Data

1 Reserved

2 Reserved

3 Upper or Lower Data Limit Error

4 Data Integrity Error

5h-Fh Reserved

(Attempting to run when drive Enable input is not closed.

Drive Not Enabled

See drive Enable , H1-XX = 6A)

Reserved

Units 0.1%

47

Page 48

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

002Bh

002Ch

002Dh

U1-07 0031h

U1-18 0032h

U1-08 0033h

U1-24 0038h

U1-36 0039h

U1-37 003Ah

U1-28 003Bh

U1-14 003Ch

003Dh

o2-04 003Eh

U1-04 003Fh

U1-01 0040h

U1-02 0041h

U1-03 0042h

U1-04 0043h

U1-05 0044h

Function Bit Description

0h Terminal S1 Closed

1h Terminal S2 Closed

2h Terminal S3 Closed

3h Terminal S4 Closed

4h Terminal S5 Closed

Digital Input Status

Inverter Status

Digital Output Status

Main Circuit DC Bus Voltage - Units 1.0VDC

Motor Secondary Current - Units 0.1%

Output Power - Units 0.1kW

PID Feedback Level - 10 / 1% with sign, 100% = E1- 04

PID Input Level - 10 / 1% with sign, ±100% / ±E1-04

PID Output Level - 10 / 1% with sign, ±100% / ±E1-04

Drive CPU Number - Last 5 Digits CPU Software Number

Drive Software Number - Last 5 Digits of Software Number

Communication Error

kVA Setting - Same Data as Parameter o2-04

Control M ode - Range = 0 ~ 4. See A1-02

Frequency Reference - Scaling Dependent Upon o1-03 Setting

Output Frequency - Scaling Dependent Upon o1-03 Setting

Output Current - Units 0.1A

Control M ode - Range = 0 ~ 4. See A1-02

Motor Speed - Scaling Dependent Upon o1-03 Setting

5h Terminal S6 Closed

6h Terminal S7 Closed

7h Terminal S8 Closed

8h Terminal S9 Closed

9h Terminal S10 Closed

Ah Terminal S11 Closed

Bh Terminal S12 Closed

Ch-Fh

0h During R un 1 (H2-0X = 0)

1h Zero Speed (H2-0X = 1)

2h Speed Agree 1 (H2-0X = 2)

3h Fref/Set Speed Agree 1 (H2-0X = 3)

4h Frequency Detection 1 (H2-0X = 4)

5h Frequency Detection 2 (H2-0X = 5)

6h Inverter Ready (H2-0X = 6)

7h Undervoltage (H2-0X = 7)

8h Bas e block (H2-0X = 8)

9h Frequency Reference from Digital Operator (H2-0X = 9)

Ah Run Command from Digital Operator (H2-0X = A)

Bh Overtorque Detection 1 (H 2-0X = B)

Ch Loss of Frequency Reference (H2- 0X = C)

Dh During Fault Retry

Eh Fault

Fh Communication Timeout (CE Fault)

0h Multi-Function Digital Output 1 (M1-M2)

1h Multi-Function Digital Output 2 (M3-M4)

2h Multi-Function Digital Output 3 (M5-M6)

3h Multi-Function Digital Output 4 (P3-C3)

4h Multi-Function Digital Output 5 (P4-C4)

5h-Fh Reserved

0h CRC Error

1h Invalid Data Length Error

2h Reserved

3h Parity Error

4h Overrun Error

5h Framing Error

6h Timeout

7h-Fh Reserved

Reserved

48

Page 49

Table 4.3 G7 Monitor Register s (Read only)

U-## Addr.

U1-06 0045h

U1-07 0046h

U1-08 0047h

U1-09 0048h

U1-10 0049h

U1-11 004Ah

U1-12 004Bh

U1-13 004Ch

U1-14 004Dh

Digital Output Terminal Status

Function Bit Description

Output Volt a ge R e ference - Units 0.1VAC

DC Bus Voltage - Units 1.0VDC

Output Power - Units 0.1kW

Torque Reference - Units 0.1%

0h Terminal S1

1h Terminal S2

2h Terminal S3

3h Terminal S4

4h Terminal S5

5h Terminal S6

6h Terminal S7

Digital Input Terminal Status

drive Operation Status

Elapsed Time - Units 1.0hr

Drive Software Number - Last 5 Digits of Drive Software Number

7h Terminal S8

8h Reserved

9h Reserved

Ah Reserved

Bh Reserved

Ch Reserved

Dh Reserved

Eh Reserved

Fh Reserved

Multi-function Digital

0h

1h

2h

3h

4h

5h Reserved

6h Reserved

7h Fault Output

8h Reserved

9h Reserved

Ah Reserved

Bh Reserved

Ch Reserved

Dh Reserved

Eh Reserved

Fh Reserved

0h Run