Page 1

G5 - HHP Drive

Technical Manual

Compact High-Capacity Inverter Panels

400-V Class: 200-800 kW (320 to 1200 kVA)

575-V Class: 300-1200 kW (400 to 1500 kVA)

Models: CIMR-G5A Document Number: TM.G5HHP.01

Page 2

Preface

Preface

Thank you for purchasing the compact High-capacity VARISPEED-616G5 Inverter Panels with neu-

rovector control.

This manual is designed to ensure correct and suitable application of the High-capacity VA-

RISPEED-616G5 Inverter Panels. Read this manual before attempting to install, operate, maintain,

or inspect an Inverter and keep this manual in a safe, convenient location for future reference. Be sure

you understand all precautions and safety information before attempting application.

i

Page 3

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in

this manual can result in seriousor possibly even fatalinjury or damage to the products or to related equipmentand

systems.

WARNING Indicates precautions that, if not heeded, could possibly result in loss of life or

!

CAUTION Indicates precautions that, if not heeded, could result in relatively serious or minor

!

The warning symbols for ISO and JIS standards are different, as shown below.

The ISO symbol is used in this manual.

Both of these symbols appearon warning labels on Yaskawa products. Please abide by thesewarning labelsregard-

less of which symbol is used.

serious injury.

injury, damage to the product, or faulty operation.

ISO JIS

Yaskawa, 1998

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of Yaskawa. No patent liability is assumed with respect to the use of the information contained

herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information

contained in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained in this publication.

ii

Page 4

Visual Aids

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

AEXAMPLE"

INFO

IMPORTANT

Indicates application examples.

Indicates supplemental information.

Indicates important information that should be memorized.

iii

Page 5

General Precautions

D The diagrams in this manual may be indicated without covers or safety shields to show de-

tails. Be sure to restore covers or shieldsbefore operating the Units and run the Units according to the instructions described in this manual.

D Any illustrations, photographs, or examples used in this manual are provided as examples

only and may not apply to all products to which this manual is applicable.

D The products and specifications described in this manual or the content and presentation of

the manual may be changed without notice to improve the product and/or the manual.

D When ordering a new copy of the manual due to damage or loss, contact your Yaskawarepre-

sentatives or the nearest Yaskawa sales office and provide the manual number shown on the

front cover.

D If nameplates become warn or damaged, order new ones from your Yaskawa representatives

or the nearest Yaskawa sales office.

iv

Page 6

Safety Precautions

J Confirmations upon Delivery

D Never install an Inverter Panel that is damaged or missing components.

Doing so can result in injury.

J Transportation

D Crane operation must be performed only by an authorized person qualified to operate

cranes.

Otherwise, injury or damage caused by dropping lifted objects.

J Wiring

Safety Precautions

CAUTION

Page

2-2

CAUTION

Page

2-4

WARNING

D Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire can occur.

D Wiring must be performed by an authorized person qualified in electrical work.

Otherwise, an electric shock or fire can occur.

D Be sure to ground the ground terminal.

(400-V and 575-V Class Inverters: Ground to 10 Ω or less)

Otherwise, an electric shock or fire can occur.

D Always check the operation of any emergency stop circuits after they are wired.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

D Never touch the output terminals directly with your hands or allow the output lines to

come into contact with the Inverter Panel casing. Never short the output circuits.

Otherwise, electrical shock or grounding can occur.

CAUTION

D Check to be sure that the voltage of the main AC power supply satisfies the rated volt-

age of the Inverter Panel.

Injury or fire can occur if the voltage is not correct.

D Do not perform voltage withstand tests on the Inverter Panel.

Voltage withstand test can damage semiconductor elements and other components.

D Connect Braking Resistor Units and Braking Units as shown in the I/O wiring exam-

ples.

Otherwise, a fire can occur.

D Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

D Do not connect AC power to output terminals U, V, and W.

The internal Inverter Module will be damaged if voltage is applied to the output terminals.

Page

3-2

3-2

3-2

3-2

3-2

Page

3-2

3-2

3-2

3-2

3-2

v

Page 7

CAUTION

D Do not connect phase-advancing capacitors or LC/RC noise filters to the output cir-

cuits.

The Inverter panel can be damaged or internal parts burnt if these devices are connected.

D Do not connect electromagnetic switches or contactors to the output circuits.

If a load is connected while the InverterPanel is operating, surgecurrentwill cause the overcurrent protection circuit to operate.

J Setting User Constants

CAUTION

D Disconnect the load (machine, device) from the motor before autotuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor constants

cannot be correctly set with the motor attached to a load.

J Trial Operation

WARNING

D Check to be sure that the front door is closed before turning ON the power supply. Do

not open the front door during operation.

An electric shock may occur if the front door is open when power is ON.

D Do not come close to the machine when the fault reset function is used. If the alarm is

cleared,the machine may startmoving suddenly.Also, design the machine so that human safety is ensured even when it is restarted.

Injury may occur.

D Provide a separate emergency stop switch; the Digital Operator STOP Key is valid

only when its function is set.

Injury may occur.

D Reset alarms only after confirming that the RUN signal is OFF. If an alarm is reset with

the RUN signal turned ON, the machine may suddenly start.

Injury may occur.

3-2

3-2

Page

4-33

Page

5-2

5-2

5-2

5-2

CAUTION

D Don’t touch the radiation fins (heat sink), braking resistor, or Braking Resistor Unit.

These can become very hot.

Otherwise, a burn injury may occur.

D Be sure that the motor and machine is within the applicable ranges before starting op-

eration.

Otherwise, an injury may occur.

D Provide a separate holding brake if necessary.

Otherwise, an injury may occur.

D Don’t check signals while the Inverter is running.

Otherwise, the equipment may be damaged.

D Be careful when changing Inverter Panel settings. The Inverter Panel is factory set to

suitable settings.

The equipment may be damaged is unsuitable settings are used.

vi

Page

5-2

5-2

5-2

5-2

5-2

Page 8

J Maintenance and Inspection

WARNING

D Do not touch the Inverter Panel terminals. Some of the terminals carry high voltages

and are extremely dangerous.

Touching the terminals can result in electric shock.

D Always have the protectivecover in place when power is being supplied to the Invert-

er. When attaching the cover, always turn OFF power to the Inverter through the

MCCB.

Doing so can result in electric shock.

D After turning OFF the main circuit power supply, wait until the CHARGE indicator light

goes out before performance maintenance or inspections.

The capacitor will remain charged and is dangerous.

D Maintenance, inspection, and replacement of parts must be performed only by autho-

rized personnel.

Remove all metal objects, such as watches and rings, before starting work. Always

use grounded tools.

Failure to heed these warning can result in electric shock.

D Before mounting or dismounting a Module, make sure that the main circuit and control

power supply have been turned OFF.

Not doing so can result in electric shock.

D Do not dismount a Module until the CHARGE lamp on the Module turns OFF after turn-

ing OFF the power supply.

An electric shock may occur is the Module is dismounted while still charged.

D Use special lifts for mounting or dismounting a Module.

Not doing so can result in injury.

D The Modules are heavy, and mounting or dismounting the Modules must be per-

formed by three workers: One to operate the lift and two others for mounting and dismounting the Modules.

Not doing so can result in injury

D Before disposing of a Module, open a hole in the heat sink attached to the Module to

purge gas.

Exposingthe heatsink to a high temperaturewithout opening a hole in the heat sinkcan resultin

explosion and injury.

Safety Precautions

Page

10 - 2

10 - 2

10 - 2

10 - 2

10 - 6

10 - 6

10 - 6

10 - 6

10 - 14

CAUTION

D A CMOS IC is used in the control board. Handle the control board and CMOS IC care-

fully. The CMOS IC can be destroyed by static electricity if touched directly.

The CMOS IC can be destroyed by static electricity if touched directly.

D Do not change the wiring, or remove connectors or the Digital Operator, during opera-

tion.

Performing this word during operation can result in personal injury.

J Others

WARNING

D Do not attempt to modify or alter the Inverter.

Alterations or modifications can result in electrical shock or injury.

vii

Page

10 - 2

10 - 2

Page 9

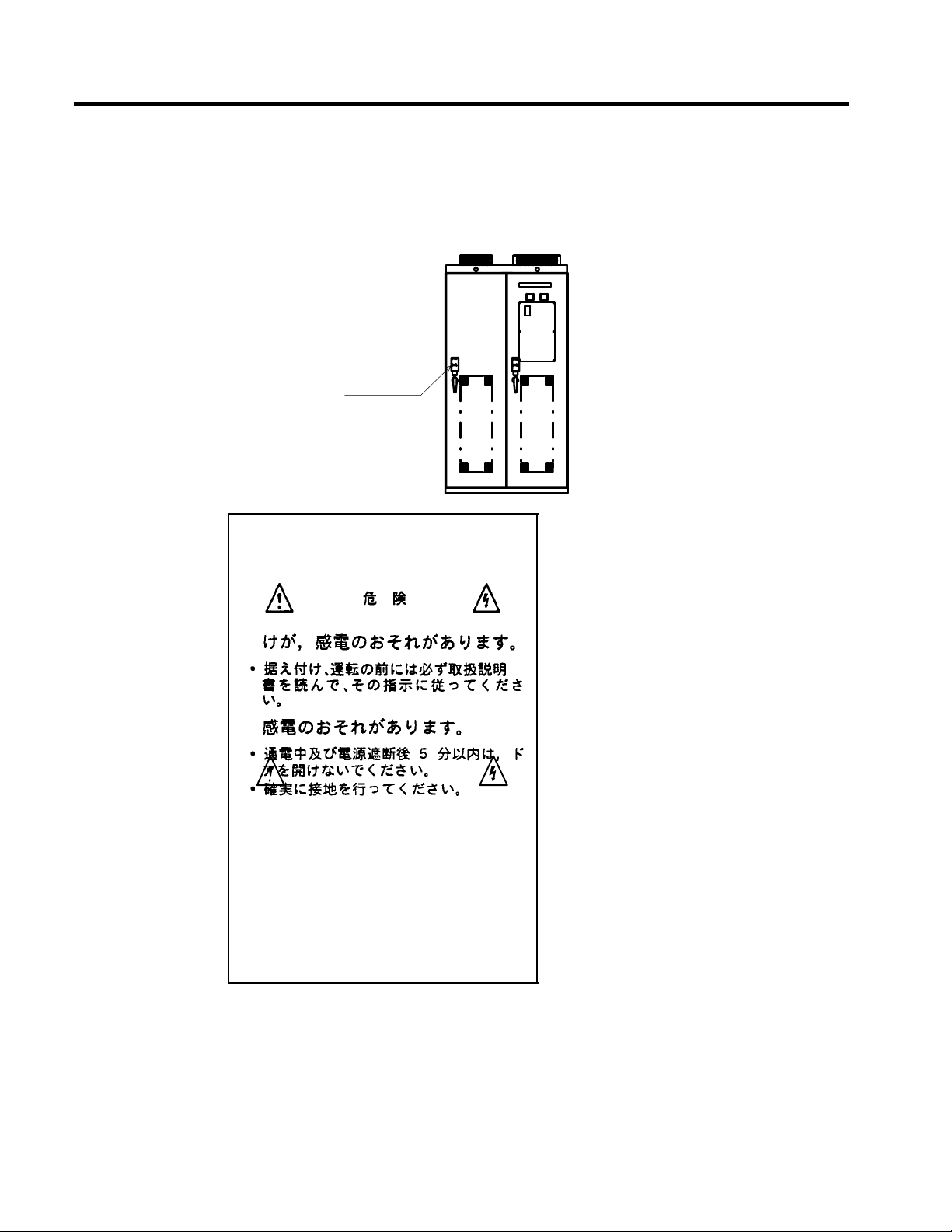

Warning Label Contents and Position

There is a warning label on the Inverter in the position shown in the following illustration. Always heed the warnings

given on this label.

Warning label

position

Warning Label Contents

The illustration shows a 400-V class (200-kW)

and a 575-V class (300-kW) Inverter.

May cause injury or electric

shock.

D Please follow the instructions in

the manual before installation or

operation.

D Disconnect all power before opening

the door of panel. Wait 5 minutes

until DC Bus capacitors discharge.

D Use proper grounding techniques.

Definition of Terms

The following definitions are used in this manual unless otherwise specified.

Inverter: Inverter Panel

Module: Inverter Module or Converter Module

WARNING

viii

Page 10

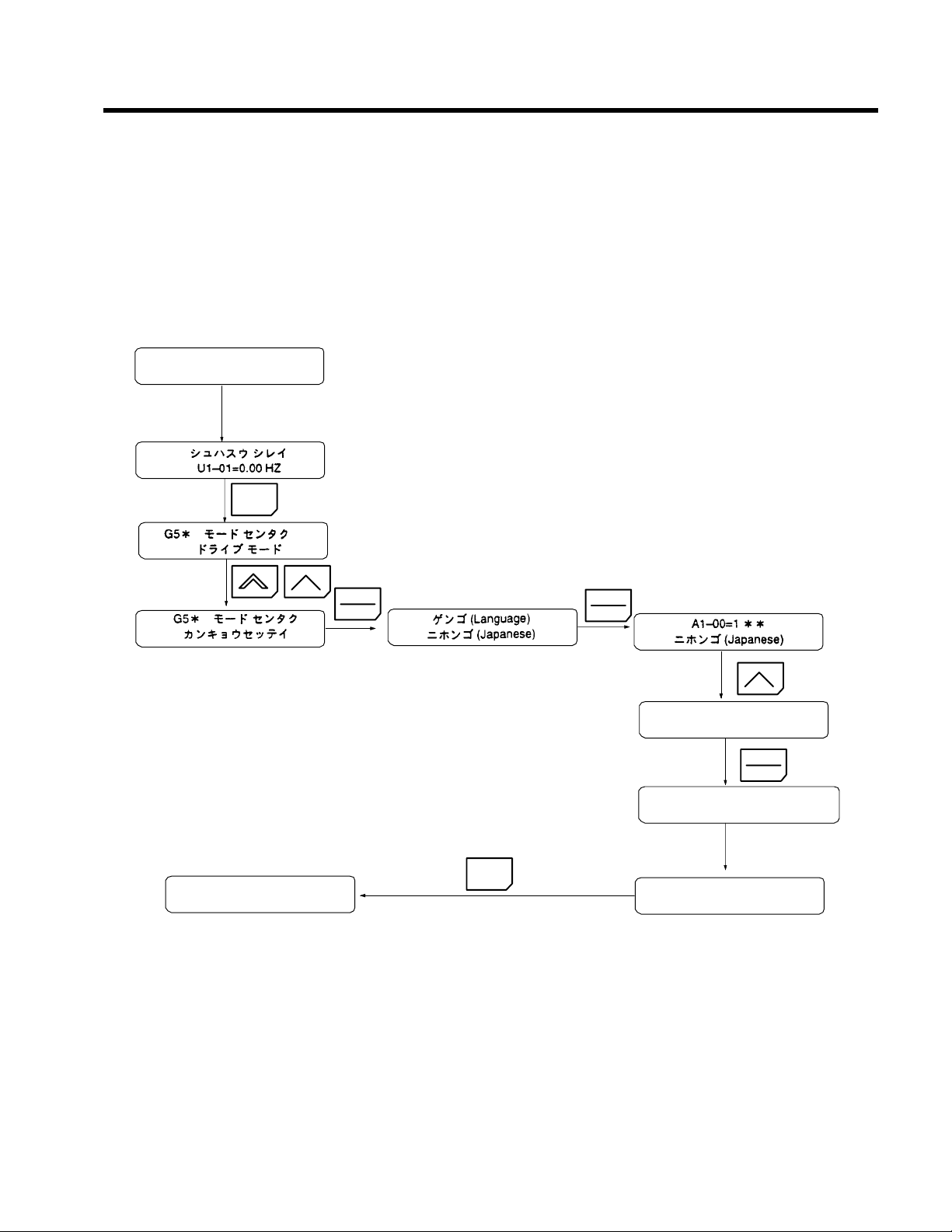

How to Change the Digital Operator Display from Japanese to English

How to Change the Digital Operator Display from Japanese to English

If the Digital Operator displays messages in Japanese, change to the English mode using the following

steps.

(This manual provides descriptions for the English mode.)

Power ON

MENU

* Main Menu *

Operation

DATA

ENTER

MENU

DATA

ENTER

A1--00=0

English

DATA

ENTER

Entry Accepted

Select language

English

ix

Page 11

CONTENTS

11 Introduction

12 Handling Inverters

13 Wiring

14 Setting User Constants

15 Trial Operation

16 Basic Operation

1

2

3

4

5

6

17 Advanced Operation

18 User Constants

19 Troubleshooting

10 Maintenance and Inspection

11 Specifications

12 Appendix

7

8

9

10

11

12

Page 12

Table of Contents

Table of Contents

Preface i.........................................................

Safety Information ii................................................

Visual Aids iii......................................................

General Precautions iv...............................................

Safety Precautions v................................................

Warning Label Contents and Position viii.................................

Definition of Terms viii...............................................

How to Change the Digital Operator Display from Japanese to English ix......

1 Introduction 1 - 1.........................................

1.1 Outline and Functions 1 - 2..........................................

1.1.1 Outline of Control Methods 1 - 2...............................................

1.1.2 Functions 1 - 2.............................................................

1.2 Nomenclature 1 - 7................................................

1.2.1 VS-616G5 Components 1 - 7..................................................

1.2.2 Digital Operator Components 1 - 8..............................................

2 Handling Inverters 2 - 1...................................

2.1 Confirmations upon Delivery 2 - 2....................................

2.1.1 Nameplate Information 2 - 2..................................................

2.2 Temporary Storage 2 - 3............................................

2.2.1 Storage Location 2 - 3.......................................................

2.2.2 Storage Method 2 - 3........................................................

2.3 Transportation 2 - 4................................................

2.3.1 Precautions During Transportation 2 - 4.........................................

2.3.2 Lifting with Wires 2 - 4......................................................

2.3.3 Transporting on Rollers 2 - 5..................................................

2.4 External Dimensions and Mounting Dimensions 2 - 6.....................

2.5 Checking and Controlling the Installation Site 2 - 10.......................

2.5.1 Installation Site 2 - 10........................................................

2.5.2 Controlling the Ambient Temperature 2 - 10.......................................

2.5.3 Protecting the Inverter Panel from Foreign Matter 2 - 10..............................

2.5.4 Floor Level 2 - 10...........................................................

2.5.5 Inverter Panel Connections (Side-by-side Connection) 2 - 10..........................

2.5.6 Tightening Anchor Bolts 2 - 11.................................................

2.6 Installation Orientation and Space 2 - 13................................

2.7 Removing/Attaching the Digital Operator 2 - 14..........................

3 Wiring 3 - 1..............................................

3.1 Connection Diagram 3 - 3...........................................

3.2 Terminal Positions 3 - 5............................................

3.3 Cable Sizes 3 - 7..................................................

3.4 Wiring Main Circuit Terminals 3 - 9...................................

3.4.1 Main Circuit Terminal Functions 3 - 9...........................................

xiii

Page 13

3.4.2 Main Circuit Configurations 3 - 10..............................................

3.4.3 Precautions for Wiring Main Circuit Power Input 3 - 10..............................

3.5 Wiring Control Circuit Terminals 3 - 12.................................

3.5.1 Control Circuit Terminal Functions 3 - 12.........................................

3.6 Wiring Check 3 - 13..................................................

3.7 Installing and Wiring PG Speed Control Cards 3 - 14......................

3.7.1 Installing a PG Speed Control Card 3 - 14.........................................

3.7.2 PG Speed Control Card Terminal Blocks 3 - 15....................................

3.7.3 Wiring a PG Speed Control Card 3 - 17...........................................

3.7.4 Wiring PG Speed Control Card Terminal Blocks 3 - 22...............................

3.7.5 Selecting the Number of PG (Encoder) Pulses 3 - 25.................................

3.8 Grounding 3 - 27...................................................

3.8.1 Connection of Ground Bus Bar 3 - 27............................................

3.8.2 Connection of Ground Cable for Control Signals 3 - 27..............................

4 Setting User Constants 4 - 1................................

4.1 Using the Digital Operator 4 - 2......................................

4.2 Modes 4 - 4......................................................

4.2.1 Inverter Modes 4 - 4........................................................

4.2.2 Switching Modes 4 - 5.......................................................

4.2.3 User Constant Access Levels 4 - 6..............................................

4.2.4 Operation Mode 4 - 12.......................................................

4.2.5 Initialize Mode 4 - 21........................................................

4.2.6 Programming Mode 4 - 29....................................................

4.2.7 Autotuning Mode 4 - 33......................................................

4.2.8 Modified Constants Mode 4 - 35................................................

5 Trial Operation 5 - 1......................................

5.1 Procedure 5 - 3...................................................

5.2 Trial Operation Procedures 5 - 4......................................

5.2.1 Power ON 5 - 4............................................................

5.2.2 Checking the Display Status 5 - 4..............................................

5.2.3 Initializing Constants 5 - 4....................................................

5.2.4 Setting Input Voltage 5 - 5....................................................

5.2.5 Autotuning 5 - 10...........................................................

5.2.6 No-load Operation 5 - 12......................................................

5.2.7 Loaded Operation 5 - 12......................................................

6 Basic Operation 6 - 1......................................

6.1 Common Settings 6 - 2.............................................

6.1.1 Setting the Access Level and Control Method: A1-01, A1-02 6 - 2.....................

6.1.2 Frequency Reference Settings: b1-01, H3-01, H3-08, H3-09 6 - 4.....................

6.1.3 Frequency Reference from Digital Operator: b1-01, o1-03, d1-01 to d1-09 6 - 7..........

6.1.4 Run Source and Sequence Input Responsiveness: b1-02, b1-06, b1-07 6 - 9..............

6.1.5 Acceleration/Deceleration Times: C1-01 through C1-08, C1-09, C1-10, C1-11 6 - 10.......

6.1.6 Prohibiting Reverse Operation: b1-04 6 - 11.......................................

6.1.7 Selecting the Stopping Method: b1-03 6 - 12......................................

6.1.8 Multi-function Input Settings: H1-01 through H1-06 6 - 13...........................

6.2 Open-loop Vector Control 6 - 18.......................................

6.2.1 Autotuning 6 - 18...........................................................

6.2.2 Autotuning Faults 6 - 19......................................................

xiv

Page 14

Table of Contents

6.3 V/f Control 6 - 21..................................................

6.3.1 Setting the Motor Constants: E1-01, E1-02, E2-01 6 - 21.............................

6.3.2 V/f Pattern Selection: E1-03 6 - 22..............................................

6.4 Flux Vector Control 6 - 26...........................................

6.4.1 PG Speed Control Card Settings 6 - 26...........................................

6.4.2 Setting the Zero-speed Operation Constants 6 - 29..................................

6.4.3 Autotuning 6 - 31...........................................................

6.4.4 Speed Control (ASR) Structure 6 - 33............................................

6.4.5 Speed Control (ASR) Gain 6 - 36...............................................

6.5 V/f Control with PG 6 - 39...........................................

6.5.1 Motor Constants: E1-01, E1-02, E2-01, E2-04 6 - 39................................

6.5.2 V/f Pattern Selection: E1-03 6 - 40..............................................

6.5.3 PG Speed Control Card Settings 6 - 41...........................................

6.5.4 Speed Control (ASR) Structure 6 - 43............................................

6.5.5 Adjusting Speed Control (ASR) Gain 6 - 44.......................................

7 Advanced Operation 7 - 1..................................

7.1 Open-loop Vector Control 7 - 2.......................................

7.1.1 Torque Limit Function 7 - 4...................................................

7.1.2 Adjusting Speed Feedback 7 - 5...............................................

7.1.3 Setting/Adjusting Motor Constants 7 - 6.........................................

7.2 Normal V/f Control 7 - 10............................................

7.2.1 Energy-saving Control Function 7 - 12...........................................

7.2.2 Hunting-prevention Function 7 - 12.............................................

7.2.3 Setting Motor Constants 7 - 13.................................................

7.3 Flux Vector Control 7 - 15...........................................

7.3.1 Droop Control Function 7 - 17.................................................

7.3.2 Zero-servo Function 7 - 18....................................................

7.3.3 Torque Control 7 - 19........................................................

7.3.4 Speed/Torque Control Switching Function 7 - 26...................................

7.3.5 Torque Limit Function 7 - 27...................................................

7.3.6 Setting/Adjusting Motor Constants 7 - 29.........................................

7.4 V/f Control with PG Feedback 7 - 33...................................

7.4.1 Energy-saving Control Function 7 - 35...........................................

7.4.2 Hunting-prevention Function 7 - 35..............................................

7.4.3 Setting Motor Constants 7 - 36..................................................

7.5 Common Functions 7 - 38............................................

7.5.1 Application Constants: b 7 - 41.................................................

7.5.2 Tuning Constants: C 7 - 50....................................................

7.5.3 Reference Constants: d 7 - 54..................................................

7.5.4 Option Constants: F 7 - 56.....................................................

7.5.5 External Terminal Functions: H 7 - 62............................................

7.5.6 Protective Functions: L 7 - 84..................................................

7.5.7 Operator Constants: o 7 - 99...................................................

8 User Constants 8 - 1.......................................

8.1 Initialize Mode Constants 8 - 3.......................................

8.2 Programming Mode Constants 8 - 4...................................

8.2.1 Application Constants: b 8 - 4.................................................

8.2.2 Autotuning Constants: C 8 - 10.................................................

8.2.3 Reference Constants: d 8 - 16..................................................

8.2.4 Motor Constant Constants: E 8 - 19..............................................

8.2.5 Options Constants: F 8 - 23....................................................

xv

Page 15

8.2.6 Terminal Constants: H 8 - 26...................................................

8.2.7 Protection Constants: L 8 - 33..................................................

8.2.8 Operator Constants: o 8 - 39...................................................

8.2.9 Factory Settings that Change with the Control Method (A1-02) 8 - 41...................

8.2.10 Factory Settings that Change with the Inverter Capacity (o2-04) 8 - 42..................

9 Troubleshooting 9 - 1......................................

9.1 Protective and Diagnostic Functions 9 - 2..............................

9.1.1 Fault Detection 9 - 2........................................................

9.1.2 Minor Fault Detection 9 - 6...................................................

9.1.3 Operation Errors 9 - 8.......................................................

9.2 Troubleshooting 9 - 9..............................................

9.2.1 If Constant Constants Cannot Be Set 9 - 9........................................

9.2.2 If the Motor Does Not Operate 9 - 9............................................

9.2.3 If the Direction of the Motor Rotation is Reversed 9 - 11.............................

9.2.4 If the Motor Does Not Put Out Torque or If Acceleration is Slow 9 - 11..................

9.2.5 If the Motor Does Not Operate According to Reference 9 - 11.........................

9.2.6 If the Slip Compensation Function Has Low Speed Precision 9 - 11.....................

9.2.7 If There is Low Speed Control Accuracy at High-speed Rotation in Open-loop

9.2.8 If Motor Deceleration is Slow 9 - 12.............................................

9.2.9 If the Motor Overheats 9 - 12...................................................

9.2.10 If There is Noise When the Inverter is Started or From an AM Radio 9 - 13..............

9.2.11 If the Ground Fault Interrupter Operates When the Inverter is Run 9 - 13................

9.2.12 If There is Mechanical Oscillation 9 - 13.........................................

9.2.13 If the Motor Rotates Even When Inverter Output is Stopped 9 - 14.....................

9.2.14 If 0 V is Detected When the Fan is Started, or Fan Stalls 9 - 14........................

9.2.15 If Output Frequency Does Not Rise to Frequency Reference 9 - 14.....................

Vector Control Mode 9 - 12.................................................

10 Maintenance and Inspection 10 - 1............................

10.1 Maintenance and Inspection 10 - 3....................................

10.1.1 Daily Inspection 10 - 3......................................................

10.1.2 Periodic Inspection 10 - 3....................................................

10.1.3 Periodic Maintenance of Parts 10 - 3............................................

10.1.4 Replacement of In-panel Ventilation Fan Unit 10 - 4................................

10.1.5 Dismounting and Mounting the Module 10 - 6....................................

11 Specifications 11 - 1........................................

11.1 Standard Inverter Specifications 11 - 2.................................

11.2 Specifications of Options and Peripheral Devices 11 - 4...................

11.2.1 Selection of MCCB and Ground Fault Interrupter 11 - 4.............................

11.2.2 Module Draw-out Lift 11 - 4..................................................

11.2.3 Option Cards 11 - 6.........................................................

12 Appendix 12 - 1...........................................

12.1 Inverter Application Precautions 12 - 2................................

12.1.1 Selection 12 - 2...........................................................

12.1.2 Settings 12 - 2...........................................................

12.1.3 Handling 12 - 2..........................................................

12.2 Motor Application Precautions 12 - 3.................................

12.2.1 Using the Inverter for an Existing Standard Motor 12 - 3...........................

12.2.2 Power Transmission Mechanism (Speed Reducers, Belts, and Chains) 12 - 3............

12.3 Peripheral Device Application Precautions 12 - 4........................

xvi

Page 16

Table of Contents

12.4 Wiring Examples 12 - 5.............................................

12.4.1 Using Two Braking Units in Parallel 12 - 5.......................................

12.4.2 Using a JVOP-95-j, -96-j VS Operator 12 - 6...................................

12.4.3 Using an Open-collector Transistor for Operation Signals 12 - 7.......................

12.4.4 Using Open-collector, Contact Outputs 12 - 7.....................................

12.5 Function Block Diagram 12 - 8.......................................

12.6 Spare Parts Lists 12 - 10.............................................

12.7 User Constants 12 - 12..............................................

xvii

Page 17

1

Introduction

This chapter provides an overview of the VS-616G5 Inverter and describes

its functions and components.

1.1 Outline and Functions 1 - 2....................

1.1.1 Outline of Control Methods 1 - 2.....................

1.1.2 Functions 1 - 2....................................

1.2 Nomenclature 1 - 7..........................

1.2.1 VS-616G5 Components 1 - 7........................

1.2.2 Digital Operator Components 1 - 8....................

1

1-1

Page 18

1

Introduction

1.1.2 Functions

1.1 Outline and Functions

The VS-616G5 Inverters provides full-current vector control based on advanced control logic. An autotuning

function is included for easy vector control.

The Digital Operator provides a liquid crystal display that is 2 lines by 16 charactersin size. User constant settings

and monitor items are easily read in interactive operations in either Japanese or English. (The display language

can be changed by setting a user constant.)

1.1.1 Outline of Control Methods

The VS-616G5 uses four control methods.

D Open-loop vector control (factory setting)

D Flux vector control

D V/f control without PG

D V/f control with PG feedback

PG stands for pulse generator (encoder).

Vector control is a method for removing interference with magnetic flux and torque, and controlling torque

according to references.

Current vector control independently controls magnetic flux current and torque current by simultaneously

controlling the motor primary current and phases. This ensures smooth rotation, high torque, and accurate

speed/torque control at low speeds.

Vector control can be replaced by the conventional V/f control system. If the motor constants required for

vector control are not known, the motor constants can be automatically set with autotuning.

The control methods are effective for the following applications:

D Open-loop vector control: General variable-speed drive.

D Flux vector control: Simple servodrive, high-precision speed control/torque control.

D V/f control without PG: Conventional Inverter control mode. Used for multi-drive operation

(connecting multiple motors to one Inverter).

D V/f control with PG feedback:Simple speed feedback control. (For applications with the PG

connected to the machine shaft rather than the motor shaft.)

The control characteristics for each mode are shown in Table 1.1.

1.1.2 Functions

J Autotuning

Autotuning is effective for vector control. It solves problems in applicable motor restrictions and difficult

constant settings. The motor constants are automatically set by entering a value from the motor’s rating

nameplate.

Autotuning allows flux vector control to operate accurately with virtually any normal AC induction motor,

regardless of the supplier.

Always perform autotuning for motor unit separately before vector control operation.

J Torque Control

Torque control is effective for flux vector control with PG. Torque is controlled by taking multi-function

analog input signals as torque references. Torque control accuracy is ±5%. Switching is possible between

torque control and speed control.

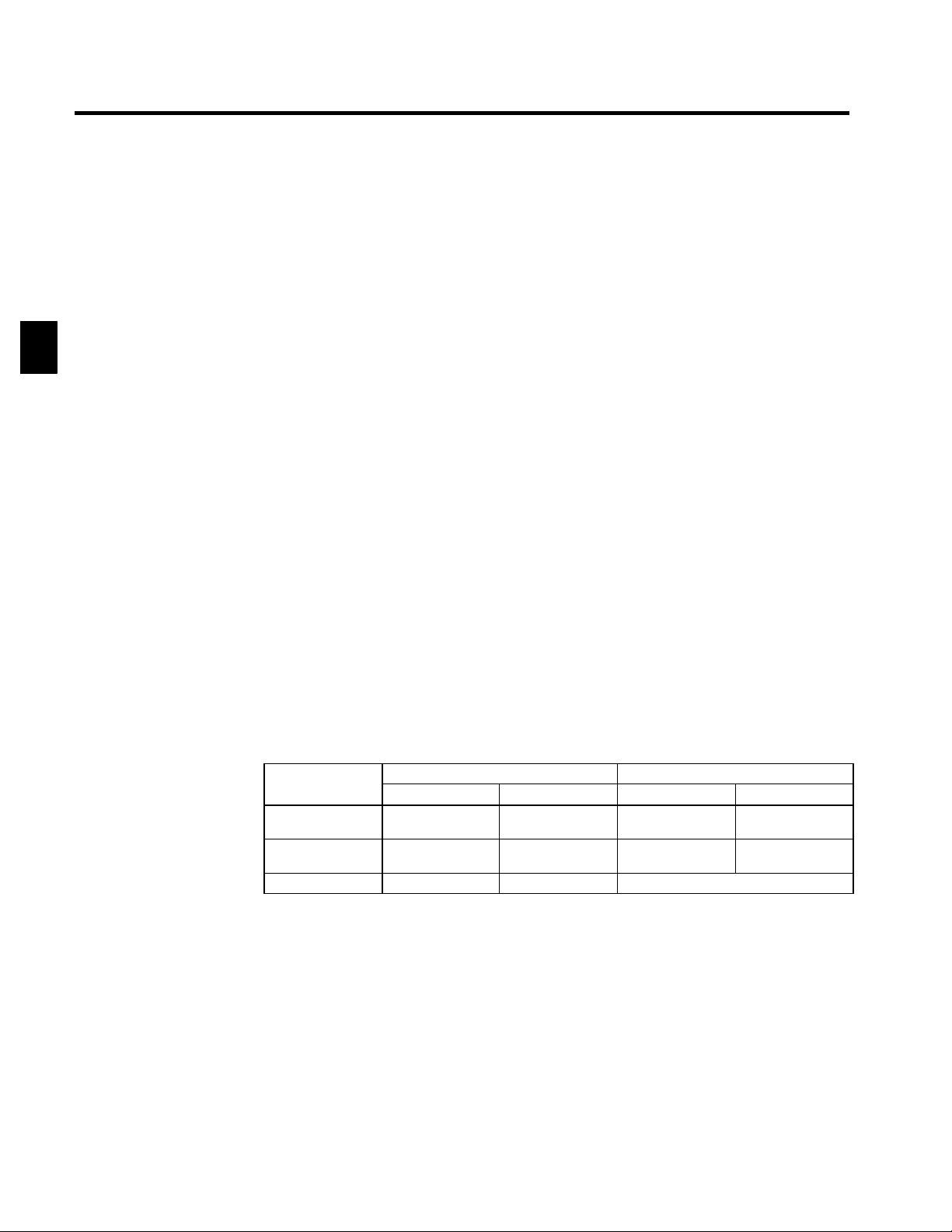

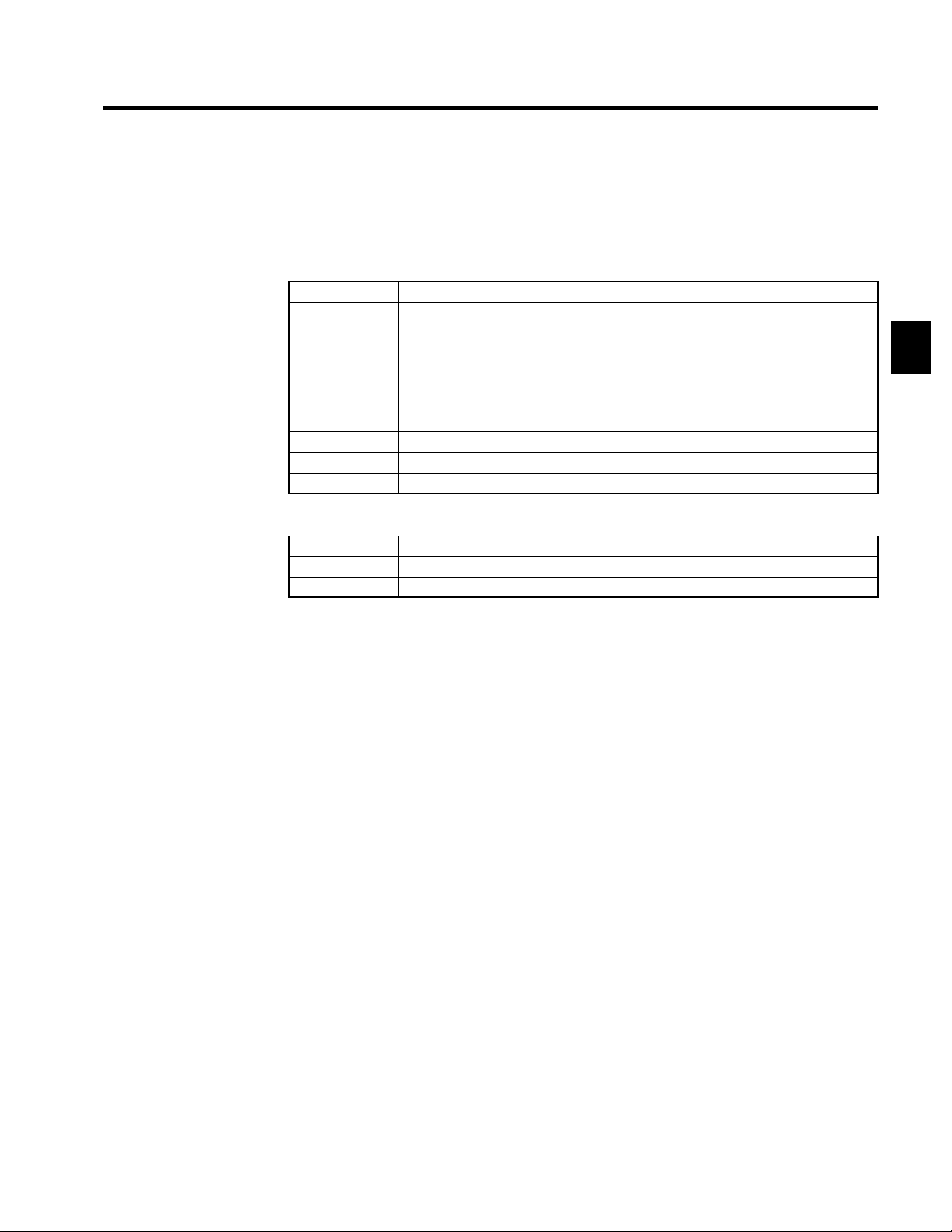

Table 1 . 1 Control Method Characteristics

Characteristic

Open-loop Flux Vector Without PG With PG feedback

Speed Control

Range

Speed Control

Precision

Initial Drive 150% at 1 Hz 150% at 0 r/min 150% at 3 Hz

Vector Control V/f Control

1:100 1:1000 1:40 1:40

±0.2 % ±0.02 % ±2to3% ±0.03 %

1-2

Page 19

J V/f Pattern Settings

V/f pattern settings are effective for V/f control. Select a V/f pattern according to the application from among

the 15 preset V/f patterns. Custom V/f patterns can also be set.

1.1 Outline and Functions

1

1-3

Page 20

1

Introduction

1.1.2 Functions

J Frequency References

The following five types of frequency references can be used to control the output frequency of the Inverter.

D Numeric input from the Digital Operator

D Voltage input within a range from 0 to 10 V

D Voltageinput within a range from 0 to ±10 V (with negative voltages, rotation is in the opposite direction

from the run command.)

D Current input within a range from 4 to 20 mA

D Input from Option Card

Any of the above frequency references can be used by setting a constant.

A maximum of nine frequency references can be registered with the Inverter. With remote multi-step speed

referenceinputs, the Inverter can operate in multi-step speed operation with a maximum of nine speed steps.

J PID Control

The Inverter has a PID control function for easy follow-up control. Follow-up control is a control method

in which the Inverter varies the output frequency to match the feedback value from the sensor for a set target

value.

Follow-up control can be applied to a variety of control operations, such as those listed below, depending

on the contents detected by the sensor.

D Speed Control: With a speed sensor, such as a tachogenerator, the Inverter regulates the rotat-

ing speed of the motor regardless of the load of the motor or synchronizes the

rotating speed of the motor with that of another motor.

D Pressure Control: With a pressure sensor, the Inverter performs constant pressure control.

D Flow-rate Control: By sensing the flow rate of a fluid, the Inverter performs precise flow-rate con-

trol.

D Temperature Control: With a temperature sensor, the Inverter performs temperature control by fan

speed.

J Zero-servo Control

Zero-servo control is effective with flux vector control. Even at a motor speed of zero (r/min), a torque of

150% of the motor’s rated torque can be generated and the average servomotor holding power (stopping

power) can be obtained.

J Speed Control By Feedback

Speed control using feedback is effective with a PG. An optional PG Speed Control Card be used to enable

feedback control for speeds, thereby improving speed control accuracy.

J Dwell Function

By holding the output frequency for a constant time during acceleration and deceleration, acceleration and

deceleration can be performed without stepping out even when driving a motor with a large startup load.

J Low Noise

The output transistor of the Inverter is an IGBT (insulated gate bipolar transistor). Using sine-wave PWM

with a high-frequency carrier, the motor does not generate metallic noise.

J Monitor Function

The following items can be monitored with the Digital Operator: Frequency reference, output frequency,

output current, motor speed, output voltage reference, main-circuit DC voltage, output power, torque reference, status of input terminals, status of output terminals, operating status, total operating time, software

number, speed deviation value, PID feedback value, fault status, fault history, etc.

All types of data can be monitored even with multi-function analog output.

J Bilingual Digital Operator

The Digital Operator can display either English or Japanese. The Digital Operator’s liquid crystal display

provides a 16-character x 2-line display area.

Easy-to-readdisplays allow the advanced functions of the Inverter to be set in interactive operations to input

constants, monitoring items, etc. Change the constant setting to select the English display.

J Harmonic Countermeasures

All VS-616G5 Inverters incorporate a DC reactor in the Inverter Panel to easily handle high-frequency control guidelines.

1-4

Page 21

J User Constant Structure and Three Access Levels

The VS-616G5 has a number of user constants for setting various functions. These user constants are classified into a hierarchy to make them easier to use.

The levels are as follows from top to bottom: Modes, Groups, Functions, and Constants. The access levels

for the user constants are shown in Table 1.2.

Table 1 . 2 Access Levels for User Constants

Level Contents

Mode Classified according to operation

Operation: For operating the Inverter. (All kinds of monitoring are possible.)

Initialize: For selecting the language displayed at the Digital Operator, setting

Programming: For setting user constants for operation.

Autotuning: For automatic calculation or setting motor constants. (Only under

Modified constants: For referencing or changing user constants after shipping.

Groups Classified by application.

Functions Classified by function. (See user constants.)

Constants Individual user constant settings.

The VS-616G5 allows the following three access levels to be set in order to further simplify setting user

constants. (An access level is a range of user constants that can be referenced or set.)

Quick-Start Reads/sets user constants required for trial operation. [Factory setting]

Basic Reads/sets user constants that are commonly used.

Advanced Reads/sets all the user constants that can be used.

access levels, initialization, and the control modes.

the vector control mode.)

1.1 Outline and Functions

1

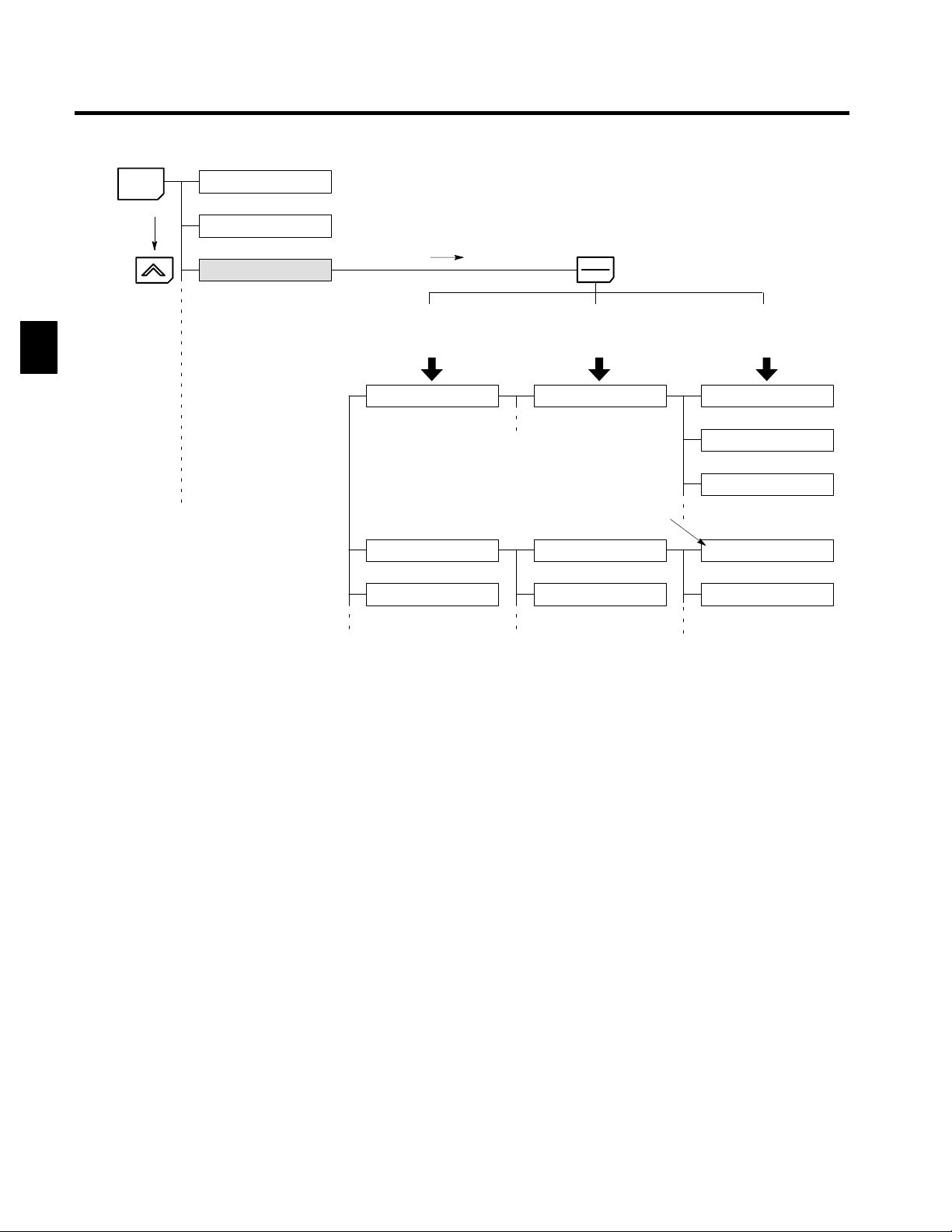

In general, press the DATA/ENTER Key to move from an upper to a lower level. This varies somewhat,

however, according to the access level, as shown in Fig. 1.1. For the Quick-Start access level, which has

few user constants that can be set, pressing the DATA/ENTER Key jumps directly to the user constant level;

whereas for the Advanced access level, which has many user constants, pressing the DATA/ENTER Key

first leads to the Group level.

1-5

Page 22

Introduction

1.1.2 Functions

1

MENU

Operation mode

Initialize mode

Programming mode

DATA

ENTER

(Advanced) (Basic) (Quick-Start)

Displays group level.

Application

Tuning

Reference

Displays function level.

b1 Sequence

Constant to be changed

C1 Accel/Decel

C2 S-curve Acc/Dec

Displays constant level.

b1-01 Reference source

b1-02 Run source

b1-03 Stopping method

C1-01 Accel Time 1

C1-02 Decel Time 1

(Mode)

(Groups)

Fig 1.1 Access Level Structure

(Functions)

(Constants)

1-6

Page 23

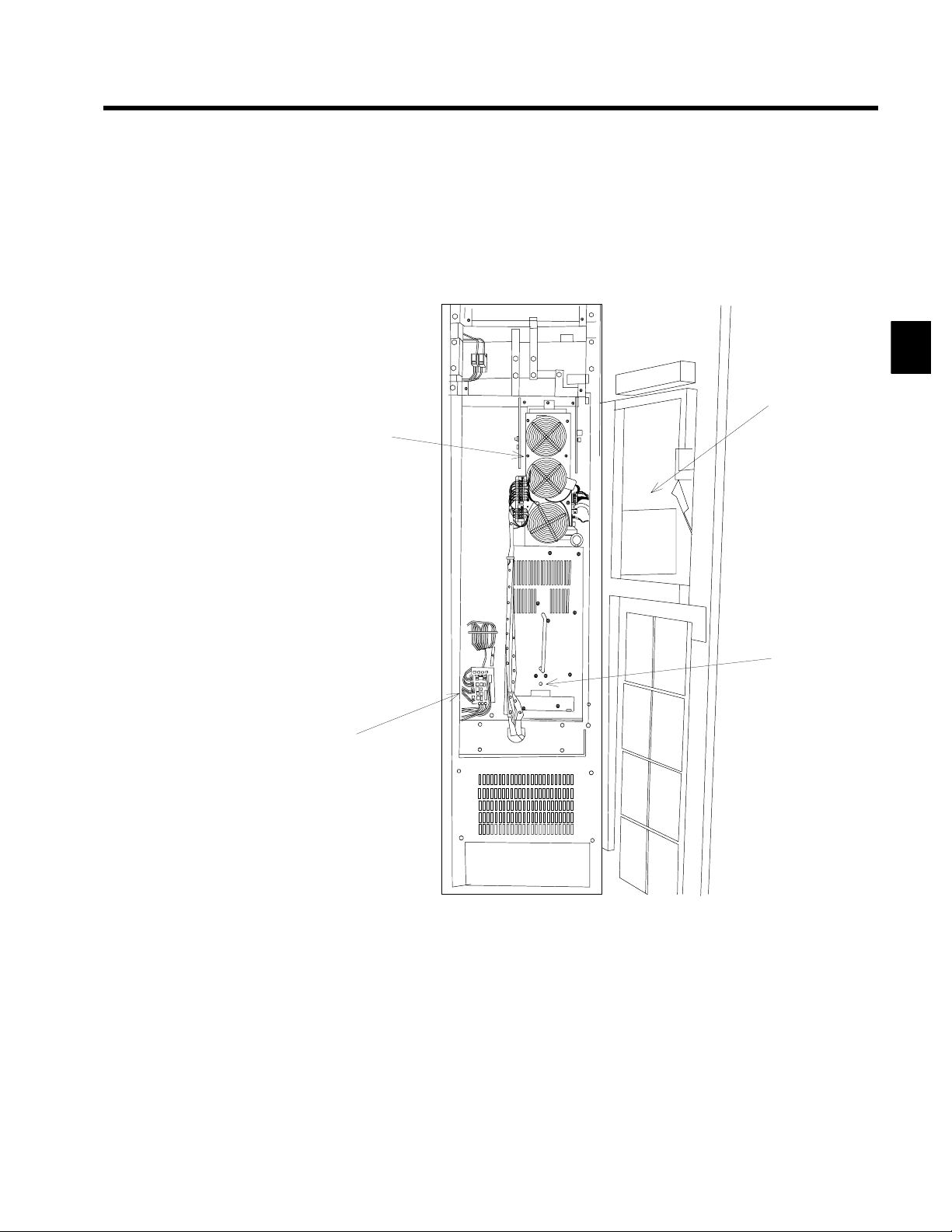

1.2 Nomenclature

This section provides the names of VS-616G5 components, and the components and functions of the Digital Operator.

1.2.1 VS-616G5 Components

The appearance of Inverter and the names of its components are shown in Figure 1.2.

Inverter Module

1.2 Nomenclature

1

Control Unit

Power Supply

Unit

Fig 1.2 Appearance of VS-616G5, Model CIMR-G5A (400 V, 200 kW)

Charge lamp

1-7

Page 24

Introduction

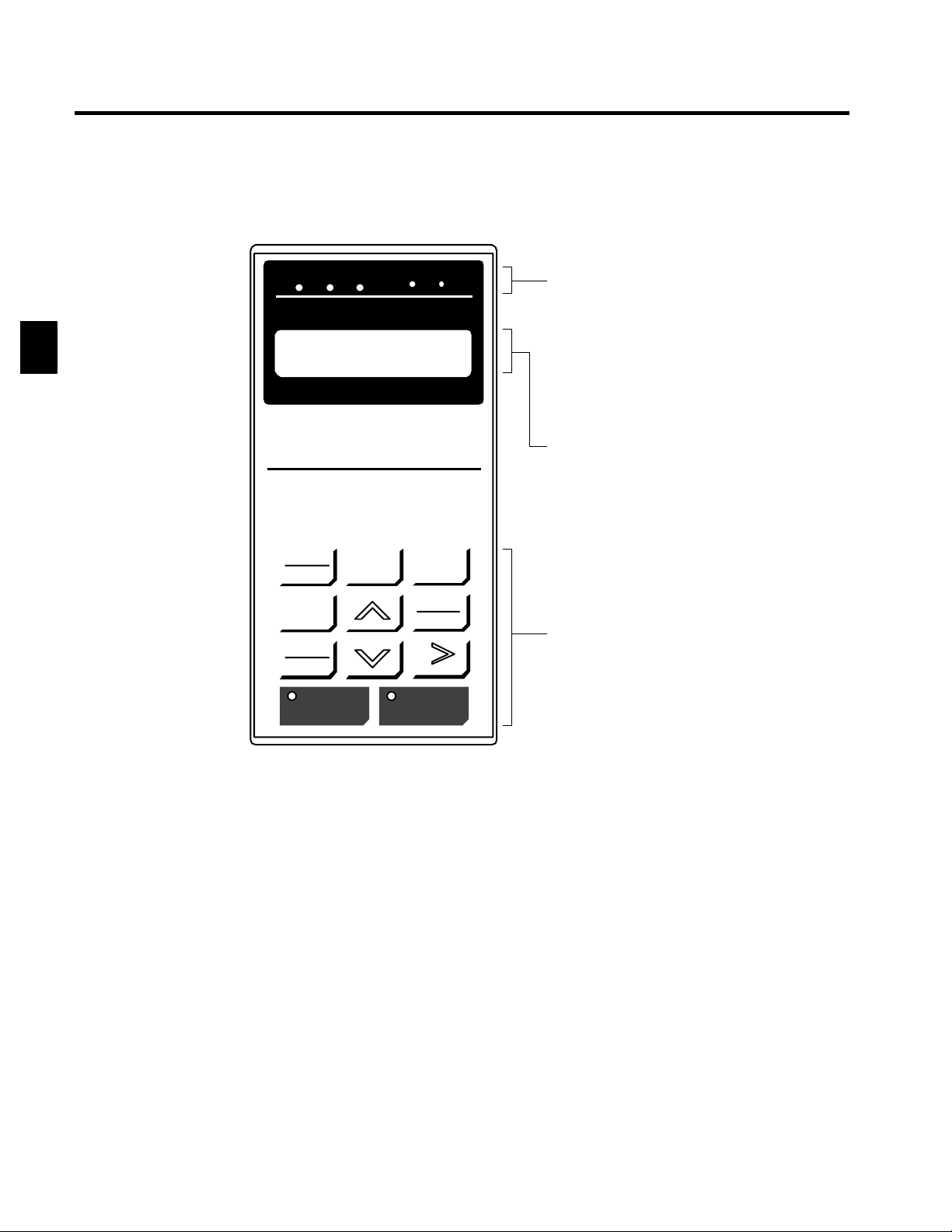

1.2.2 Digital Operator Components

1.2.2 Digital Operator Components

This section describes the component names and functions of the Digital Operator. The component names

and functions are shown in Figure 1.3 and key functions are described in Table 1.3.

1

DRIVE FWD REV REMOTE

Frequency Ref

U1--01 = 00.00 HZ

DIGITAL OPERATOR

JVOP-130

LOCAL

REMOTE

JOG

FWD

REV

RUN STOP

SEQ REF

MENU

ESC

DATA

ENTER

RESET

Operation Mode Indicators

DRIVE: Lit when in operation mode.

FWD: Lit when there is a forward reference input.

REV: Lit when there is a reverse reference input.

SEQ: Lit when an operation reference from the

REF: Lit when the frequency reference from con-

control circuit terminal is enabled.

trol circuit terminals 13 and 14 is enabled.

Data Dis play

Two-line LCD that displays data for monitoring,

user constants, and set values with 16 characters

per line.

Keys

Execute operations such as setting user constants,

monitoring, jogging, and autotuning.

Fig 1.3 Digital Operator Component Names and Functions

1-8

Page 25

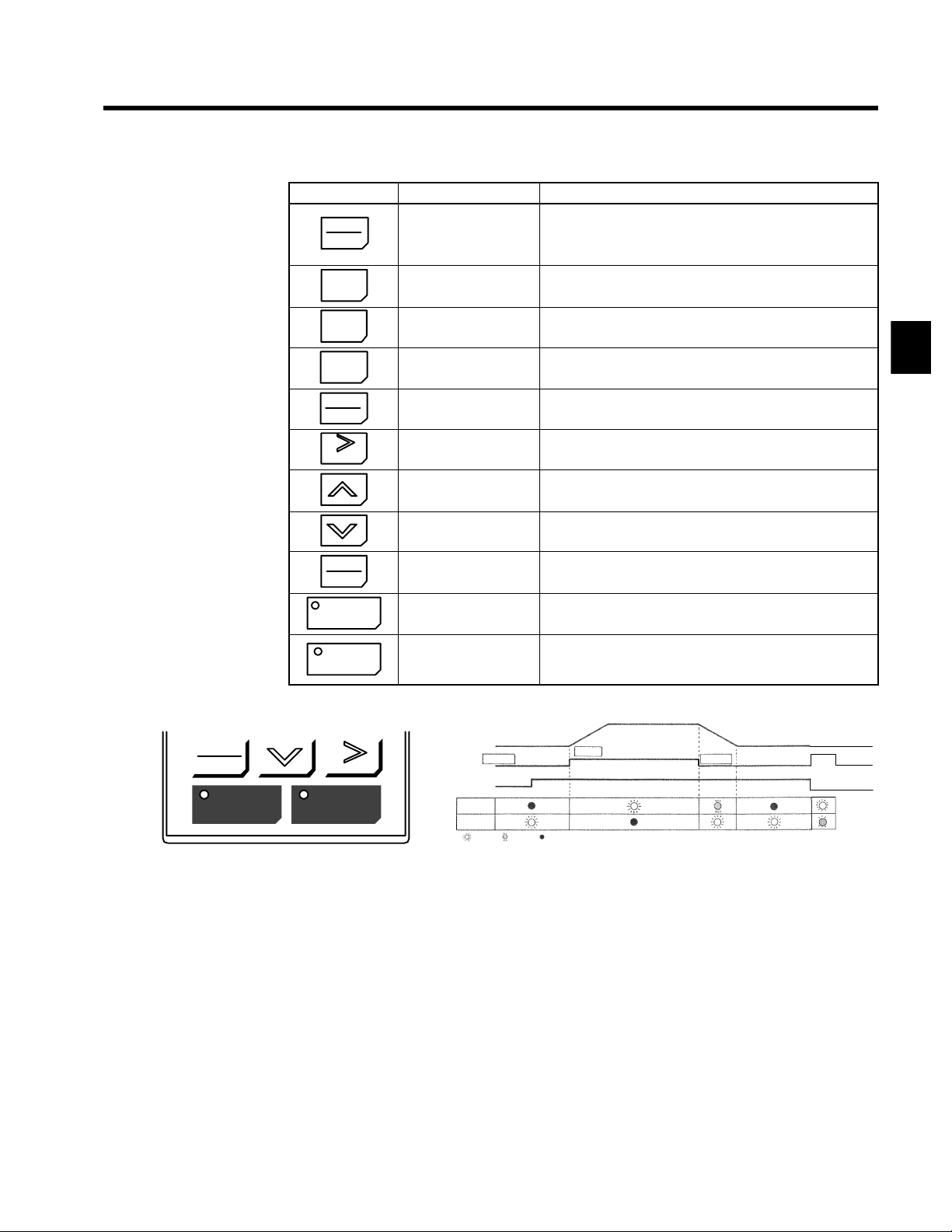

Table 1 . 3 Key Functions

Key Name Function

Switches between (LOCAL) operation via the Digital Operator

LOCAL

REMOTE

LOCAL/REMOTE Key

and control circuit terminal (REMOTE) operation.

This key can be enabled or disabled by setting a user constant

(o2-01).

1.2 Nomenclature

MENU

ESC

JOG

FWD

REV

RESET

DATA

ENTER

RUN

MENU Key Displays menus.

ESC Key Returns to the status before the DATA/ENTER Key was pressed.

JOG Key

FWD/REV Key

RESET Key

Increment Key

Decrement Key

DATA/ENTER Key

RUN Key

Enables jog operation when the VS-616G5 is being operated

from the Digital Operator.

Selects the rotation direction of the motor when the VS-616G5 is

being operated from the Digital Operator.

Sets the number of digits for user constant settings.

Also acts as the reset key when a fault has occurred.

Selects menu items, groups, functions, and user constant names,

and increments set values.

Selects menu items, groups, functions, and user constant names,

and decrements set values.

Enters menu items, functions, constants, and set values after they

are set.

Starts the VS-616G5 operation when the VS-616G5 is in operation with the Digital Operator.

Stops VS-616G5 operation.

STOP

STOP Key

This key can be enabled or disabled by setting a user constant

(o2-02) when operating from the control circuit terminal.

Note Except in diagrams, keys are referred to using the key names listed in the above table.

1

FWD

REV

RUN STOP

RESET

Inverter output frequency

STOP

Frequency setting

RUN

OP

ST

Lit Blinking Not lit

RUN

STOP

The RUN and STOP indicators light and blink to indicate operating status.

Fig 1.4 RUN and STOP Indicators

1-9

Page 26

1

Introduction

1.2.2 Digital Operator Components

1-10

Page 27

2

Handling Inverters

This chapter describes the checks required upon receiving a VS-616G5 Inverter and describes installation methods.

2.1 Confirmations upon Delivery 2 - 2..............

2.1.1 Nameplate Information 2 - 2.........................

2.2 Temporary Storage 2 - 3......................

2.2.1 Storage Location 2 - 3..............................

2.2.2 Storage Method 2 - 3...............................

2.3 Transportation 2 - 4..........................

2.3.1 Precautions During Transportation 2 - 4................

2.3.2 Lifting with Wires 2 - 4.............................

2.3.3 Transporting on Rollers 2 - 5.........................

2.4 External Dimensions and Mounting

Dimensions 2 - 6...........................

2.5 Checking and Controlling the Installation

Site 2 - 10.................................

2.5.1 Installation Site 2 - 10...............................

2.5.2 Controlling the Ambient Temperature 2 - 10..............

2.5.3 Protecting the Inverter Panel from Foreign Matter 2 - 10....

2.5.4 Floor Level 2 - 10..................................

2.5.5 Inverter Panel Connections

(Side-by-side Connection) 2 - 10....................

2.5.6 Tightening Anchor Bolts 2 - 11........................

2.6 Installation Orientation and Space 2 - 13..........

2

2.7 Removing/Attaching the Digital Operator 2 - 14....

2-1

Page 28

2

Handling Inverters

2.1.1 Nameplate Information

2.1 Confirmations upon Delivery

D Never install an Inverter Panel that is damaged or missing components.

Doingsocanresult in injury.

Check the following items as soon as the Inverter is delivered.

Table 2 . 1 Checks

Item Method

Has the correct model of Inverter been

delivered?

Is the Inverter damaged in any way? Inspect the entire exterior of the Inverter to see if there are any scratches or

Are any screws or other components

loose?

If you find any irregularities in the above items, contact the agency from which you purchased the Inverter or

your Yaskawa representative immediately.

2.1.1 Nameplate Information

CAUTION

Check the model number on the nameplate on the back of the front panel of

the Inverter Panel (See 2.1.1).

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

J Example Nameplate

Standard domestic (Japan) Inverter: 3-phase, 400 VAC, 200 kW standards

TRANSISTOR INVERTER

Model number

Input specifications

Output specifications

Output capacity

Lot number

Serial number

MODEL CIMR--G5A4200 SPEC 42008A

RATINGS

INPUT 380 -- 460 V 385 A

OUTPUT 3PH 0 -- 460 VAC 0 -- 414 A

CODE No. 71616--G5A42008A.

SER No. MASS 800Kg DATA

YASKAWA ELECTRIC CORPORATION

J Inverter Panel Model Numbers

CIMR -G5A 4 2008 A

Inverter Panel

VS-616G5

No. Specification

A Standard domestic model

No. Voltage Class

4 AC input, 3-phase, 400 V

5 AC input, 3-phase, 575 V

KVA

JAPAN

Revision code (Specification code is entered for special specifications.)

No. Protective structure

8 Enclosed self-standing structure

No. Max. Motor Capacity

200

400

to

800

200 kW

400 kW

to

800 kW

Inverter specifications

Mass

2-2

Page 29

2.2 Temporary Storage

Observe the following precautions when storing the Inverter Panel for a period of time before installation.

2.2.1 Storage Location

Store the Inverter Panel under the following conditions.

D Indoors

D In a level and flat location

D In a well-ventilated location at a low temperature and low humidity

D In a locations not subject to vibration

D In a locations not subject to dust, harmful gases, or salt

2.2.2 Storage Method

2.2 Temporary Storage

Store the Inverter Panel in the following manner.

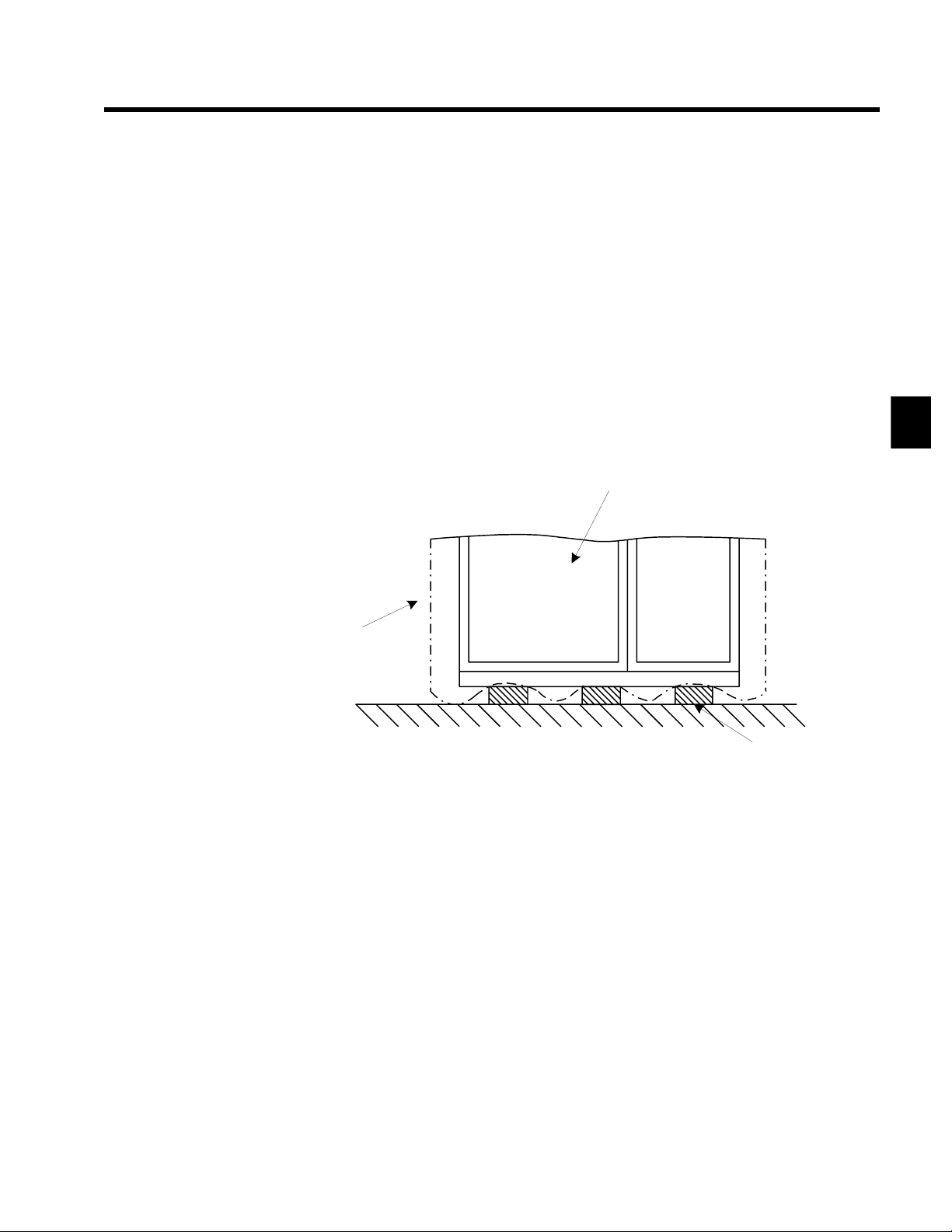

D Place the Inverter Panel on sleepers as shown below. (Do not place it directly on the floor.)

D Cover the Inverter Panel with the polyethylene cover that is attached at the time of shipment.

Inverter Panel

Cover

Floor

Sleeper

Fig 2.1 Storage Method

2

2-3

Page 30

2

Handling Inverters

2.3.1 Precautions During Transportation

2.3 Transportation

D Crane operation must be performed only by an authorized person qualified to operate cranes.

Otherwise, injury or damage caused by dropping lifted objects.

The Inverter Panel should be transported using either the lifting wires or rollers. Before transporting the Inverter

Panel, make sure that the door and internal components are secured.

2.3.1 Precautions During Transportation

D Do not push or drag the Inverter Panel on concrete floors or floors other than ones which have embedded

channel base or steel plates.

D Do not turn over or roll the Inverter Panel.

D Do not subject the Inverter Panel to vibration or shock exceeding 4.9 m/s

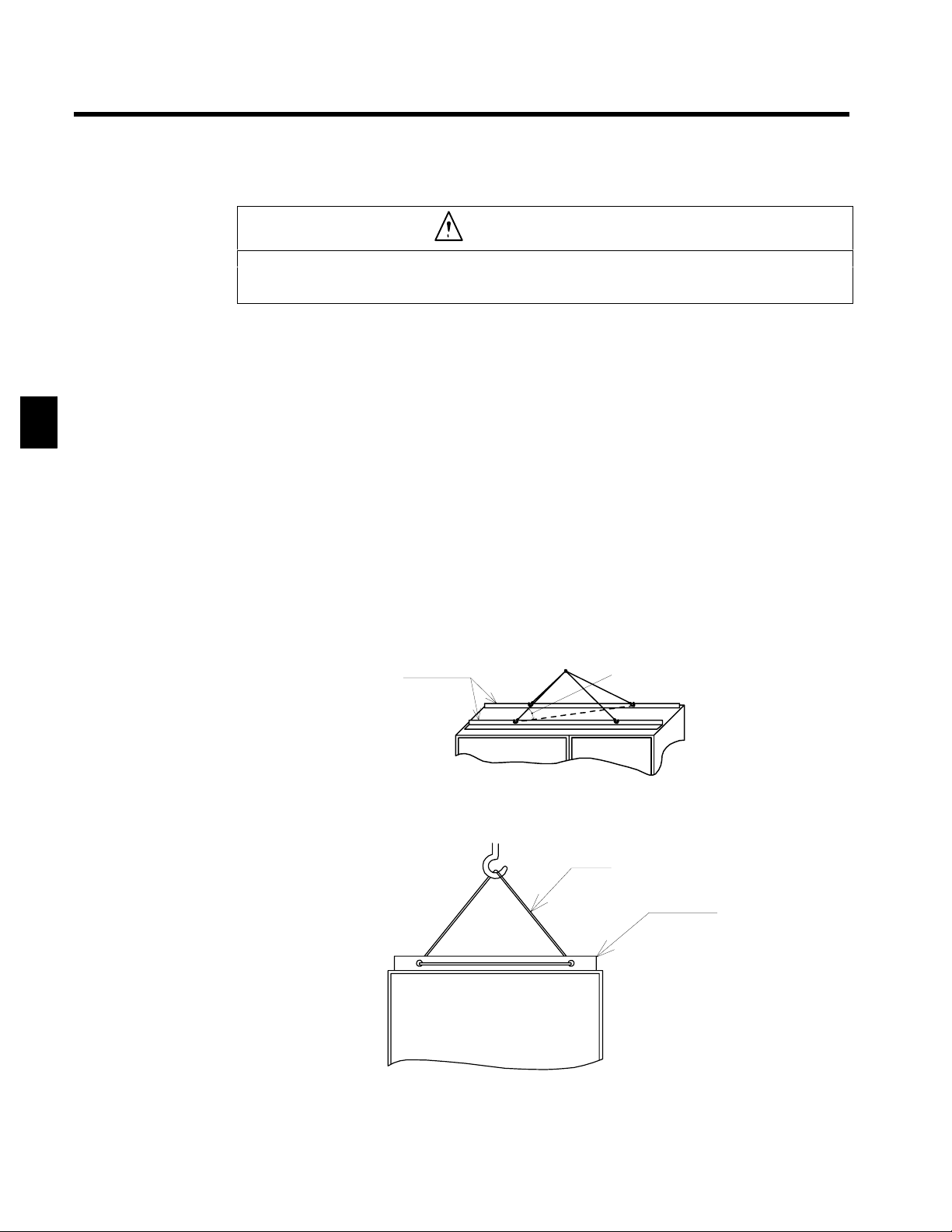

2.3.2 Lifting with Wires

D When lifting the Inverter Panel, use wires with sufficient strength that withstand the mass.

D When using wires to lift the Inverter Panel, route wires so as to provide a lifting angle of 60° min., as

shown in Figuure 2.2 below. If the lifting angle is less than this, allowable lifting loads will not be assured.

D Place each wire through the lifting hole provided in the lifting angle.

D Do not lift the Inverter Panel as shown in Figure 2.3.

D When lifting the Inverter Panel using a crane, first gradually lift the wires until they become taught. Lift

the Inverter Panel only after making sure that the wires are taught. Lift the Inverter Panel up or down

slowly. When placing the Inverter Panel on the floor, stop lowering it just before it reaches the floor and

then slowly lower it on the floor to avoid any shock to the Inverter Panel.

Lifting angle

CAUTION

60° min.

2

(0.5 G) during transportation.

Fig 2.2 Wire Lifting

Fig 2.3 Bad Lifting Example

2-4

Wire

Lifting angle

Page 31

2.3.3 Transporting on Rollers

When transporting the Inverter Panel using rollers, carefully push the Inverter Panel so as not to distort the frame

or damage the Inverter Panel surface.

D Use rollers equivalent to gas pipes with an approx. diameter of 30 to 50 mm. The length should be such

that the rollers extend beyond the Inverter Panel on both sides by approx. 100 mm.

D When the Inverter Panel has been moved to a desired location, carefully lift the Inverter Panel with a

lifting bar and remove the rollers. Insert the lifting bar at the four corners of the box as shown in Figure 2.4.

When inserting a lifting bar under the door, be careful not to damage the door with the lifting bar.

2.3 Transportation

2

Fig 2.4 Lifting Bar Insertion Locations

2-5

Page 32

Handling Inverters

2.4 External Dimensions and Mounting Dimensions

J 400-V Class (200 kW) and 575-V Class (300 kW) Inverter Panels

2

175

2100

50

600

1200

YASK AWA

VARISPEED

600

With door

open:

570 max.

770 5

30

Generated

loss (W)

CIMR--G5Aj

Converter Module 1030 1030

Inverter Module 3430 4410

Control Unit 50 50

Discharge Resistor 60 100

Control Power Transformer 80 80

DC Reactor 150 150

Coupling Reactor -- --

Tot a l 4800 5820

2-6

4200 5300

Page 33

2.4 External Dimensions and Mounting Dimensions

J 400-V Class (400 kW) and 575-V Class (600 kW) Inverter Panels

75

VARISPEEDYASK AWA

100

0

Generated

loss (W)

570

With door

600

1400

CIMR--G5Aj

Converter Module 2060 2060

Inverter Module 6860 8820

Control Unit 50 50

Discharge Resistor 120 200

Control Power Transformer 80 80

DC Reactor 370 370

Coupling Reactor 1480 1480

Tot a l 11020 13060

800

4400 5600

125

open:

770 max.

30

615

770

2

5

2-7

Page 34

Handling Inverters

J 400-V Class (600 kW) and 575-V Class (900 kW) Inverter Panels

2

175

2100

50

800

200 800

1000

1800

VARISPEEDYASK AWA

627

570

125

With door

open:

770 max.

770 5

30

Generated

loss (W)

CIMR--G5AV

Converter Module 3090 3090

Inverter Module 10290 13230

Control Unit 50 50

Discharge Resistor 180 300

Control Power Transformer 80 80

DC Reactor 700 700

Coupling Reactor 2220 2220

Tot a l 16610 19670

4600 5900

2-8

Page 35

2.4 External Dimensions and Mounting Dimensions

J 400-V Class (800 kW) and 575-V Class (1200 kW) Inverter Panels

175

2100

50

700 700

800 1400

2200

YASKAWA

VA-

RISPEED

570

125

With door

open:

770 max.

627

770 5

30

2

Generated

loss (W)

CIMR--G5Aj

4800 512C

Converter Module 4120 4120

Inverter Module 13720 17640

Control Unit 50 50

Discharge Resistor 240 400

Control Power Transformer 80 80

DC Reactor 740 740

Coupling Reactor 2960 2960

Tot a l 21910 25990

2-9

Page 36

2

Handling Inverters

2.5.1 Installation Site

2.5 Checking and Controlling the Installation Site

Install the VS-616G5 in the installation site described below and maintain optimum conditions.

2.5.1 Installation Site

Install the Inverter Panel under the following conditions.

D Install the Inverter Panel at an altitude of 1,000 m or less.

D Install the Inverter Panel in a location with an ambient temperature ranging from --5 to 40 °C.

• Do not expose the Inverter Panel to hot air currents.

• Install the Inverter Panel in a well-ventilated location. If the Inverter Panel is located in a poorly

ventilated location, ambient temperature will rise due to the Inverter panel or other heat sources.

D Install the Inverter Panel in a location free from harmful gasses or sea wind that may cause rust or corro-

sion.

D Install the Inverter Panel in a location free from dripping water or condensation.

Observe the following precautions when installing the Inverter Panel indoors.

• Thebuilding roof made of metal or glass may cause water condensation to drip on the Inverter Panel.

• Water leakage from water pipes may drip on the Inverter Panel.

• When installing the Inverter Panel in a concrete room, particularly in building underground, where

concrete tends to keep moisture, the Inverter Panel may be affected by moisture. In such case, provide a space heater inside the Inverter Panel to constantly keep the in-panel temperature higher than

the ambient temperature.

D Install the Inverter Panel in a clean location free from dust. Otherwise, contacts may malfunction or in-

sulation destruction may occur.

D Install the Inverter Panel in a location free from excessive vibration or shock.

D Install the Inverter Panel in a location free from explosive or combustible gases.

D Installthe Inverter Panel in a location where openings are provided for cleaning,inspection, and mainte-

nance. (The Fire Protection Law specifies minimum openings in the front and back sides of the Inverter

Panel.)

2.5.2 Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter Panel should be installed in an environment free from

extreme temperature increases. If the Inverter Panel is installed in an enclosed environment, such as a box,

use a cooling fan or air conditioner to maintain the internal air temperature below 40°C.

2.5.3 Protecting the Inverter Panel from Foreign Matter

Place a cover over the Inverter Panel during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter Panel after completing installation. Otherwise, ventilation will

be reduced, causing the Inverter Panel to overheat.

2.5.4 Floor Level

The floor where the Inverter Panel is installed must be level to within ±3 mm per square meter.

2.5.5 Inverter Panel Connections (Side-by-side Connection)

When connecting more than one Inverter Panel in a series, use connection bolts.

Tighten the four bolts along both the front side and back side. Tighten them carefully so that the front surfaces of each Inverter Panels are aligned with each other and so that all the connected Inverter Panels remain

stable.

2-10

Page 37

2.5 Checking and Controlling the Installation Site

Connection holes for Inverter Panels

(Six 14-dia holes)

Connection holes for other panels

(Eight 14-dia holes)

2

Fig 2.5 Inverter Panel Side-by-side Connection

The method for connecting Inverter Panels Side-by-side is different from the method for connecting an Inverter Panel with other panels.

M10×90 bolt

Hardwood washer

Mounting frame

Side plate

Fig 2.6 Side-by-side Connection Joint

2.5.6 Tightening Anchor Bolts

When the installation work described in 2.5.5, above, has been completed, secure the Inverter Panel with

four anchor bolts. Perform the foundation work according to the external dimensions drawings provided

by Yaskawa.

M10×60 bolt

Hardwood washer

M10 nut, S washer,

hardwood washer

Mounting frame

Side plate

Inverter Panel Inverter PanelInverter Panel Other panel

(b) Connection with an ordinary panel(a) Connection with Inverter Panel

M10 nut, S washer, hardwood washer

2-11

Page 38

Handling Inverters

2.5.6 Tightening Anchor Bolts

Main circuit lead-in port (for 400-V class (200 kW)

W4

W3

30

H3

H

H1

Control circuit lead-in port

and 575-V class (300 kW) Inverters only)

Anchor bolt hole

(Four 17-dia. holes)

80225

125

2

Main circuit lead-in port

Fig 2.7 Tightening Anchor Bolts

Maximum mo-

tor capacity

400 V, 200 kW

575 V, 300 kW

400 V, 400 kW

575 V, 600 kW

400 V, 600 kW

575 V, 900 kW

400 V, 800 kW

575 V, 1200 kW

H2

30

W W1 W2 W3 W4 H H1 H2 H3

1200 960 300 125 145

1400 1160 500 125 125

1800 1560 700 125 165

2400 1960 1100 115 160 95 580

125

60

W

125

770 710

50

90

W2

120120 W1

240 435

240

Anchor bolt

Fig 2.8 Details of Anchor Bolts

2-12

710

Page 39

2.6 Installation Orientation and Space

Install the Inverter Panel so as not to reduce cooling effects. When installing the Inverter Panel, always provide

the following installation space to allow normal heat dissipation.

J 400-V Class (200 kW, 400 kW, 600 kW, and 800 kW) and 575-V Class (300 kW, 600

kW, 900 kW, and 1200 kW) Inverters

The following example shows examples for the 400-V class (400 kW) and 575-V class (600 kW) Inverters.

Air

VARISPEEDYASK AWA

100 mm min.

2.6 Installation Orientation and Space

10 mm min.

2

Air

Fig 2.9 Installation Orientation and Space for VS-616G5 Inverters

2-13

Page 40

2

Handling Inverters

2.7 Removing/Attaching the Digital Operator

Remove or attach the Digital Operator using the following procedure.

J Removing the Digital Operator

Press the lever on the side of the Digital Operator in the direction of arrow 1 to unlock the Digital Operator,

and lift the Digital Operator in the direction of arrow 2 to remove the Digital Operator as shown in the following illustration.

Digital Operator

Control Unit Panel

1

2

Fig 2.10 Removing the Digital Operator

J Mounting the Digital Operator

IMPORTANT

1. Hook the Digital Operator at A (two locations) in the direction of arrow 1 as shown in the following

illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

Hook A

Digital Operator

1

Hook B

Control Unit Panel

2

Fig 2.11 Mounting the Digital Operator

Do not remove or attach the Digital Operator using methods other than those described above, otherwise the

Inverter Panel may break or malfunction due to imperfect contact.

2-14

Page 41

3

Wiring

This chapter describes wiring terminals, main circuit terminal connections,

main circuit terminal wiring specifications, control circuit terminals, and

control circuit wiring specifications.

3.1 Connection Diagram 3 - 3.....................

3.2 Terminal Positions 3 - 5.......................

3.3 Cable Sizes 3 - 7............................

3.4 Wiring Main Circuit Terminals 3 - 9.............

3.4.1 Main Circuit Terminal Functions 3 - 9.................

3.4.2 Main Circuit Configurations 3 - 10.....................

3.4.3 Precautions for Wiring Main Circuit Power Input 3 - 10.....

3.5 Wiring Control Circuit Terminals 3 - 12...........

3.5.1 Control Circuit Terminal Functions 3 - 12................

3.6 Wiring Check 3 - 13...........................

3

3.7 Installing and Wiring PG Speed Control

Cards 3 - 14................................

3.7.1 Installing a PG Speed Control Card 3 - 14...............

3.7.2 PG Speed Control Card Terminal Blocks 3 - 15...........

3.7.3 Wiring a PG Speed Control Card 3 - 17.................

3.7.4 Wiring PG Speed Control Card Terminal Blocks 3 - 22.....

3.7.5 Selecting the Number of PG (Encoder) Pulses 3 - 25.......

3.8 Grounding 3 - 27.............................

3.8.1 Connection of Ground Bus Bar 3 - 27...................

3.8.2 Connection of Ground Cable for Control Signals 3 - 27.....

3-1

Page 42

Wiring

WARNING

D Always turn OFF the input power supply before wiring terminals.

Otherwise, an electric shock or fire can occur.

D Wiring must be performed by an authorized person qualified in electrical work.

Otherwise, an electric shock or fire can occur.

D Be sure to ground the ground terminal.

(400 V Class and 575 V Class Inverters: Ground to 10 Ω or less)

Otherwise, an electric shock or fire can occur.

D Always check the operation of any emergency stop circuits after they are wired.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

D Never touch the output terminals directly with your hands or allow the output lines to come into

contact with the Inverter Panel case. Never short the output circuits.

Otherwise, electrical shock or grounding can occur.

CAUTION

3

D Check to be sure that the voltage of the main AC power supply s atisfies the rated voltage of the

Inverter Panel.

Injury or fire can occur if the voltage is not correct.

D Do not perform voltage withstand tests on the Inverter Panel.

Voltage withstand test can damage semiconductor elements and other components.

D Connect Braking Resistor Units and Braking Units as shown in the I/O wiring examples.

Otherwise, a fire can occur.

D Tighten all terminal screws to the specified tightening torque.

Otherwise, a fire may occur.

D Do not connect AC power to output terminals U, V, and W.

The interior parts of the Inverter Module will be damaged if voltage is applied to the output terminals.

D Do not connect phase -advancing capacitors or LC/RC noise filters to the output circuits.

The internal Inverter Panel will be damaged if voltage is applied to the output terminals.

D Do not connect electromagnetic switches or contactors to the output circuits.

If a load is connected while the Inverter Panel is operating, surge current will cause the overcurrent protection circuit to operate.

3-2

Page 43

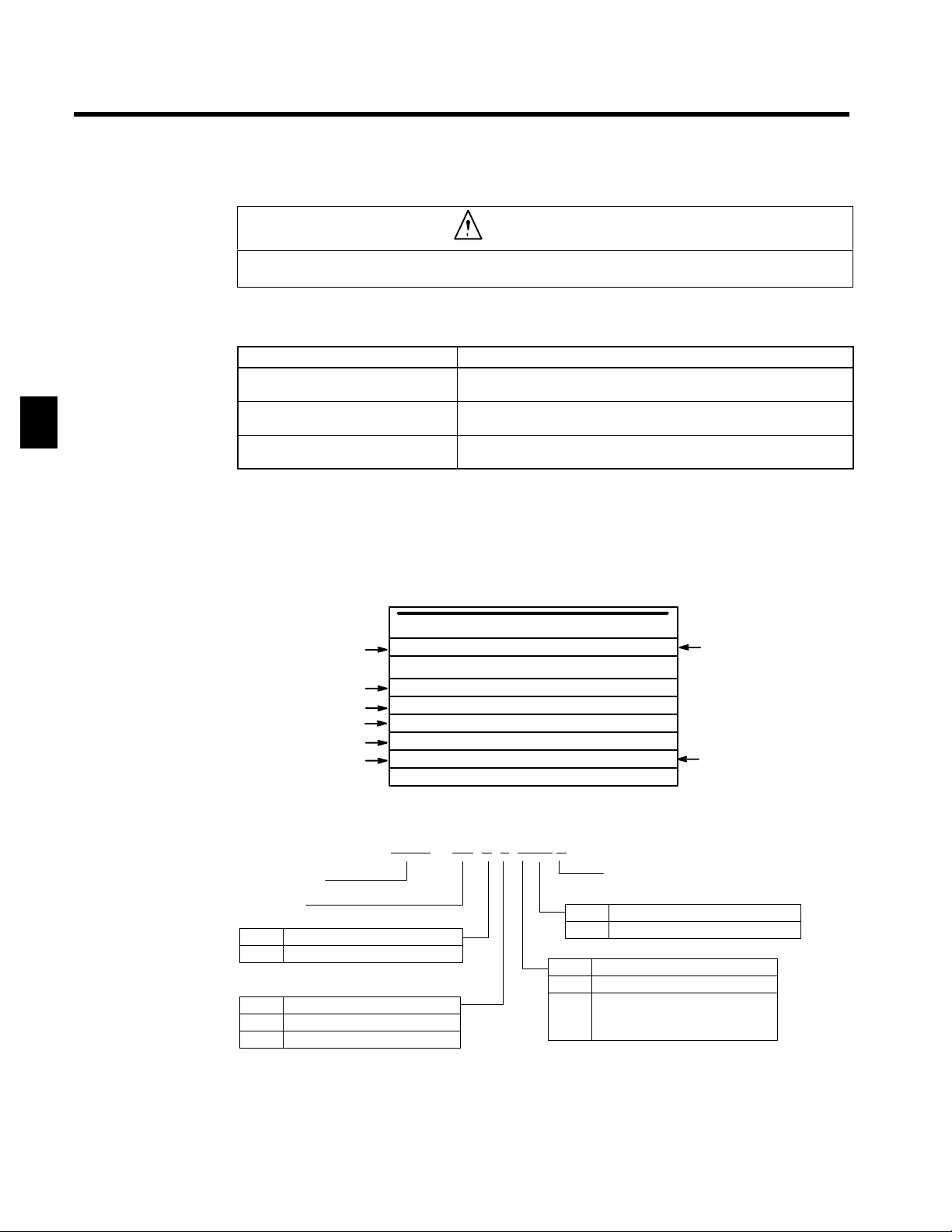

3.1 Connection Diagram

The connection diagram of the VS-616G5 is shown in Figure 3.1.

When using the Digital Operator, the motor can be operated by wiring only the main circuits.

3.1 Connection Diagram

3

3-3

Page 44

Wiring

Braking Resistor Unit (Optional)

Braking Unit

(Optional)

3

Forward Run/Stop

Reverse Run/Stop

Multi-function contact

input 1

Multi-function contact

input 2

Multi-function contact

input 3

Multi-function contact

input 4

Multi-function contact

input 5

Multi-function contact

input 6

Speed setting

resistor (2 kΩ)

Frequency reference

Frequency reference

Multi-function

analog input

*Power transformer for

12-phase rectification

MCCB

Control power input

terminals

200-VAC input terminals for

ventilation fan

Speed setting adjust ment resistor (2 kΩ)

R/L1

S/L2

When using the 12-phase

rectification input, remove the input

T/L3

terminal short-circuit bus bar.

R1/L11

S1/L21

T1/L31

r/

(Not for 575 V)

575 V:

r200

1TB

9

10

11

12

13

14

15

16

17

38

44

34

36

39

42

35

VS--616G5

1

2

200/

200

2

400

400/

575/ 575

2

200

Forward run command

(forward when closed)

Reverse run command

(reverse when closed)

(External fault)

(Fault reset)

(Master/auxiliary speed)

(Multi-step speed 2)

(Jog reference)

(External baseblock

reference)

Sequence common

(Insulated from 0V

terminal)

Shield terminal

--15 V power for analog refer-

ence

+15 V power for analog

reference

Master speed frequency reference

(--10 to +10V/0 to 10V)

Master speed frequency

reference (4 to 20 mA)

Multi-function analog input

(--10to+10V/0to10V)

Speed reference

common

0V

+

1

4CN

2CN

3CN

Frequency meter

Output ammeter

0V

--

PG

(Optional)

Reference

(Optional)

Monitor

(Optional)

FM

AM

U/T1

V/T2

W/T3

2TB

2TB

1TB

+

+

F1

Ventilation fan fault detection

F2

45

48

Analog output

monitor

46

25

Fault contact output

52

250 VAC, 1A max.

30 VDC, 1Amax.

23

53

Operation output

250 VAC, 1A max.

57

30 VDC, 1Amax.

19

Open collector 1

20

Open collector 2

50

Multi-function output common

Motor

IM

PG

Multi-function

open-collector output

48 VDC, 50 mA max.

Note (1) Double circles indicate main circuit terminals and single circles indicate control circuit terminals.

(2) When using the 12-phase rectification, the user must prepare the transformer.

Fig 3.1 Connection Diagram (Model CIMR-G5A4200 Shown Above)

3-4

Page 45

3.2 Terminal Positions

J 400-V Class (200 kW) and 575-V Class (300 kW) Inverters

+1 --

3.2 Terminal Positions

--

Converter Module

Input terminals

(Connector)

R1/L11R/L1S1/L21S/L2T/L3T1/L31

Work cable input

side (Main circuit)

Connection cable: 325 mm2max.)

(600-V CV cable, etc.)

Note The main circuit terminals on the output side are provided as bus bar terminals on the side

surface. Connections are normally made to the output terminal block on the right side.

2

Work cable

(Control circuit)

1

U/T1V/T2W/T3

Work cable output

side (Control circuit)

Connection cable: 325 mm

(600 V CV cable, etc.)

DC bus

Inverter

Module

Output

terminals

1 1TB (Control circuit terminal block)

2 2TB (General terminal block)

2

max.)

3

3-5

Page 46

Wiring

J 400-V Class (400 kW, 600 kW, 800 kW) and 575-V Class (600 kW, 900 kW,

1200 kW) Inverters

The following illustration is for 400-V class (400 kW) and 575-V class (600 kW) Inverters.

+1 --

--

3

Converter Module

Input terminals

(Connector)

S/L2S1/L21T1/L31 R1/L11T/L3 R/L1

Work cable input

side (Main circuit)

Connection cable: 325 mm2max.

(600-V CV cable, etc.)

Note The main circuit terminals on the output side are provided as bus bar terminals on the side

surface. Connections are normally made to the output terminal block on the right side.

2

1

Work cable

(Control circuit)

DC bus

Inverter Module

U/T1

V/T2

W/T3

Output

terminals

1 1TB (Control circuit terminal block)

2 2TB (General terminal block)

3-6

Page 47

3.3 Cable Sizes

J Connection Cables

1TB (Control Circuit Terminal Block)

CN1

20P

CN2

50P

Top Bottom

1

30

2

31

32

3

33

4

PS5D-INV-LA

Connection Cable Specifications

Applicable cable: 2 mm

Charge current: 0.5 mA

End treatment: 7 mm

2

max.

3.3 Cable Sizes

3

10P

2TB (General

Terminal Block)

CN3

56

27

28

57

29

58

(M2.3)

UK--15 (M3.5)

Connection cable: 2 mm

UKT--81(M5)

Connection cable: 14 mm

2

2

max.

Fig 3.2 Connection Cables

7mm

max.

3-7

Page 48

3

Wiring

J Transmission Cables

When the Inverter Panels is designed to be applicable to transmission connection, the Inverter Panel is provided with transmission junction terminals.

Connect the transmission cables directly to the transmission junction terminals on the input side and output

side.

Treat the transmission cables as low-current cables and separate them from high-power lines.

Terminal Block Arrangement

JC--215--01

4X3XSX2X1

XX

Transmission Cable

IPEV--S, 1Px1.25 mm

E

M3.5--8L

2

Fig 3.3 Transmission Cable

3-8

Page 49

3.4 Wiring Main Circuit Terminals

MainC

i

itPowerI

(

A

(Atthetimeofshipmen

t,short-circuitbusbarsareconnectedbetweenR/L1andR1/L1

1

//,//

w

)

InverterOutputs

k

i

Control

PowerI

(

ForModulef

)

ControlPowerInput

s

i

lationf

3.4.1 Main Circuit Terminal Functions

Main circuit terminal functions are summarized according to terminal symbols in Table 3.1 . Wire the terminals correctly for the desired purposes.

3.4 Wiring Main Circuit Terminals

Voltage Class 400-V Class 575-V Class

Table 3 . 1 Main Circuit Terminal Functions

CIMR-G5Aj

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

U/T1

V/T2

W/T3

¨1

©

200/ℓ2200

400/ℓ2400

r/ℓ

1

575/ℓ2575 --

r200

200

t the time ofshipment, short-circuit bus bars are connected between R/L1 and R1/L11,

S/L2 and S1/L21, and between T/L3 and T1/L31. Remove these short-circuit bus bars

4200 to 4800 5300 to 512C

rcu

hen applying 12-phase rectification.

Inverter Outputs

For connecting theBra

nputs

an powerinput

Powerinput to the Inverter Panelvent

Ground

nputs

ng Unit

--

--

Control Power Inputs

(For Module fan power input)

an

,

3

3-9

Page 50

Wiring

3.4.3 Precautions for Wiring Main Circuit Power Input

3.4.2 Main Circuit Configurations

The main circuit configuration of the CIMR-G5A4800 is shown below.

3

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

r/

2

200/

200

2

400/ 400

1CONV

200 VAC

2CONV

200 VAC

1

To fan and MC

200 VAC

Power supply

to control circuit/Gate drive

To Gate Drive

MC

1INV

Gate Drive

2INV

3INV

4INV

Operator

Control

circuit

I/O

200 VAC

Power supply

200 VAC

Power supply

200 VAC

Power supply

200 VAC

Power supply

U/T1

V/T2

W/T3

r200

200

F1

F2

M

Fig 3.4 Main Circuit Configuration (CIMR-G5A4800)

3.4.3 Precautions for Wiring Main Circuit Power Input

At the time of shipment, short-circuit bus bars are provided between R/L1 and R1/L11, S/L2 and S1/L21,

and between T/L3 and T1/L31 on the main circuit power input terminal. Remove these short-circuit bus bars

when applying 12-phase rectification.

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

Fig 3.5 Short-circuit Bus Bar Connections

U/T1

V/T2

W/T3

Atthetimeofshipment, short-circuit

bus bars are connected between

these terminals.

3-10

Page 51

3.4 Wiring Main Circuit Terminals

R/L1

S/L2

T/L3

R1/L11

S1/L21

T1/L31

Remove the short-circuit bus bars when

applying 12-phase

rectification.

Fig 3.6 Wiring when Applying 12-phase Rectification

U/T1

V/T2

W/T3

3

3-11

Page 52

,

Photocouplerisolation

p

(

d

b

ttingH

1-0

1

outpu

t

p

input

f

A

VAC

t)T

2

3and25

b

dwh

l

i

1Amax.at250VA

C

gg(

p

g

q

50mAmax.at48V

A

g

Analo

g

2mAmax.

g

p

Shieldstrip

3

Wiring

3.5.1 Control Circuit Terminal Functions

3.5 Wiring Control Circuit Terminals

3.5.1 Control Circuit Terminal Functions

The functions of the control circuit terminals are shown in Table 3.2. Use the appropriate terminals for the

correct purposes.

Table 3 . 2 Control Circuit Terminals

External

Terminal

Code

1TB

Control PCB

Terminal

Code

9CN

9

10 18 Reverse run/stop command Reverse run when CLOSED; stopped when OPEN.

11 19 External fault input Fault when CLOSED; normal

12 20 Fault reset Reset when CLOSED

13 21

14 22

15 23 Jog frequency reference Jog run when CLOSED.

16 24 External baseblock Inverter output stopped when

17 25 Sequence input common --

34 1 15 V power output 15 V power supply for analog references 15 V

44 10 --15 V power output --15 V power supply for analog references --15 V

36 4

39 6

42 8 Multi-function analog input --10 to 10 V/--100% to 100%

35 3 Analog input common --

TB2

52

25 3

23 1

53 4 Running signal (1NO con57 5 Sequence

10CN

19

20 12 Speed agree detection Within ±2 Hz of set frequency when

50 18 Open-collector output com-

45 2

48 4

46 3

29 -- -- For shield connection

38 -- -41 -- -47 -- -51 -- -58 -- --

Typ e Signal Name Function Signal Level

17 Forward run/stop command Forward run when CLOSED; stopped when OPEN.

Multi-function contact inputs

Command signals can be

selecte

to H1-06.)

--

1 (H4-01, H4-02)

2 (H4-04,H4-05)

-- --

yse

Auxiliary analog input

(H3-05)

en outputsigna

outputs

10

2

Sequence

output

signals

Analog

ut

in

signals

output

signals

nalo

output

signals

Shield stri

connection

when OPEN.

Main/auxiliary switch Auxiliary frequency reference

Multi-step speed reference2Multi-step setting 2 when

Master speed frequency

reference

Fault output signal

(Single-pole, double-throw

contac

tact)

Zero speed detection Zero level (b2-01) or below when

mon