YAMAHA VK540EF SERVICE MANUAL

SERVICE MANUAL

ESS00002

ESS00004

NOTICE

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible

to put an entire mechanic’s education into one

manual, so it is assumed that persons using this

book to perform maintenance and repairs on

Yamaha snowmobiles have a basic understanding of the mechanical concepts and procedures inherent in snowmobile repair. Without

such knowledge, attempted repairs or service

to this model may render it unfit and/or unsafe

to use.

Yamaha Motor Company, Ltd. is continually

striving to improve all models manufactured by

Y amaha. Modifications and significant changes

in specifications or procedures will be forwarded to all authorized Yamaha dealers and

will, where applicable, appear in future editions

of this manual.

HOW TO USE THIS MANUAL

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION!

BE ALERT! YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions could

result in severe injury or death to the snowmobile operator, a bystander, or a person inspecting or repairing the snowmobile.

CAUTION:

A CAUTION indicates special precautions that

must be taken to avoid damage to the snowmobile.

NOTE:

A NOTE provides key information that can

make procedures easier or clearer.

ESS00003

VK540E

SERVICE MANUAL

2000 by Yamaha Motor

Corporation, U.S.A.

1st Edition, May 2000

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

LIT-12618-02-13

MANUAL FORMAT

All of the procedures in this manual are organized in a sequential, step-by-step format. The

information has been compiled to provide the

mechanic with an easy to read, handy reference

that contains comprehensive explanations of all

inspection, repair, assembly, and disassembly

operations.

In this revised format, the condition of a faulty

component will precede an arrow symbol and

the course of action required to correct the problem will follow the symbol, e.g.,

Bearings

Pitting/damage Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section to facilitate correct disassembly and assembly procedures.

ESS00006

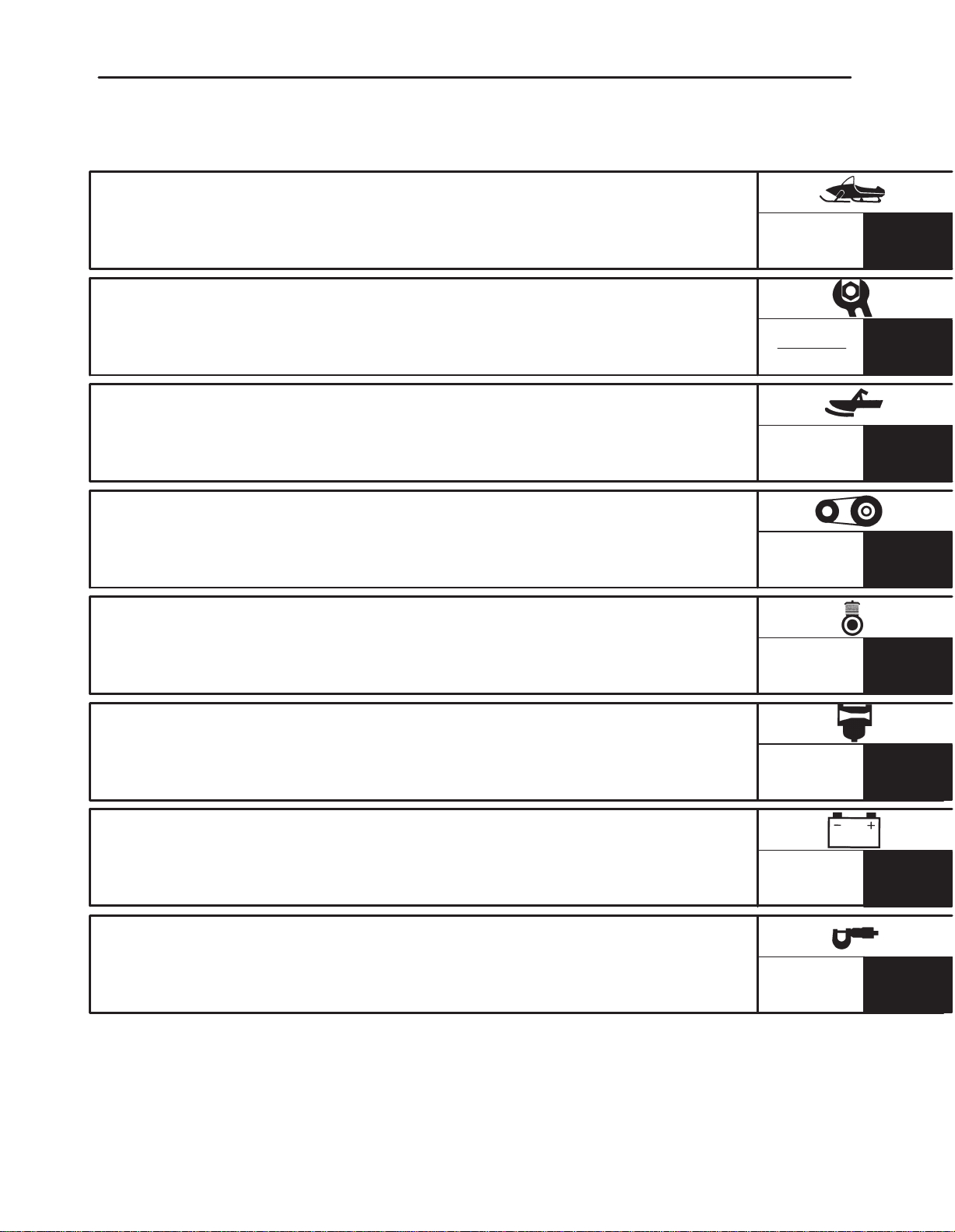

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 8 are designed as

thumb tabs to indicate the chapter’s number

and content.

General information

1

Periodic inspection and adjustment

2

Chassis

3

Power train

4

Engine overhaul

5

Carburetion

6

Electrical

7

Specifications

8

Illustrated symbols 9 to 15 are used to identify

the specifications which appear.

Filling fluid

9

10

Lubricant

11

Tightening

12

Wear limit, clearance

13

Engine speed

14

Special tool

15

Ω, V, A

Illustrated symbols 16 to 24 in the exploded diagram indicate grade of lubricant and location of

lubrication point.

16

Apply locking agent (LOCTITE)

17

Apply Yamabond No.5

18

Apply engine oil

19

Apply gear oil

20

Apply molybdenum disulfide oil

21

Apply wheel bearing grease

22

Apply low-temperature lithium-soap base grease

23

Apply molybdenum disultide grease

24

Use new one

INDEX

GENERAL INFORMATION

PERIODIC INSPECTIONS AND

ADJUSTMENTS

CHASSIS

POWER TRAIN

ENGINE

GEN

INFO

INSP

ADJ

CHAS

POWR

TR

ENG

1

2

3

4

5

CARBURETION

ELECTRICAL

SPECIFICATIONS

CARB

6

ELEC

7

SPEC

8

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION 1-1. . . . . . . . . . .

FRAME SERIAL NUMBER 1-1. . . . . . . . . .

ENGINE SERIAL NUMBER 1-1. . . . . . . . .

THROTTLE OVERRIDE SYSTEM

(T.O.R.S.) CHECK 2-11. . . . . . . . . . . . . . . .

STARTER (CHOKE) CABLE

FREEPLAY ADJUSTMENT 2-12. . . . . . .

EXHAUST SYSTEM

INSPECTION 2-12. . . . . . . . . . . . . . . . . . . .

IMPORTANT INFORMATION 1-2. . . . . . . . . . .

PREPARATION FOR REMOVAL AND

DISASSEMBLY 1-2. . . . . . . . . . . . . . . . . . . .

ALL REPLACEMENT PARTS 1-3. . . . . . . .

GASKETS, OIL SEALS, AND

O-RINGS 1-3. . . . . . . . . . . . . . . . . . . . . . . . .

LOCK WASHERS/PLATES AND

COTTER PINS 1-3. . . . . . . . . . . . . . . . . . . .

BEARINGS AND OIL SEALS 1-3. . . . . . . .

CIRCLIPS 1-4. . . . . . . . . . . . . . . . . . . . . . . . .

LOCTITE

SPECIAL TOOLS 1-5. . . . . . . . . . . . . . . . . . . . .

FOR TUNE UP 1-5. . . . . . . . . . . . . . . . . . . .

FOR ENGINE SERVICE 1-5. . . . . . . . . . . .

FOR POWER TRAIN SERVICE 1-6. . . . . .

FOR CARBURETION SERVICE 1-7. . . . .

FOR ELECTRICAL SERVICE 1-7. . . . . . .

CHAPTER 2.

PERIODIC INSPECTIONS AND

ADJUSTMENTS

INTRODUCTION 2-1. . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE TABLE 2-1. . . . .

POWER TRAIN 2-13. . . . . . . . . . . . . . . . . . . . .

DRIVE V-BELT 2-13. . . . . . . . . . . . . . . . . .

SHEAVE DISTANCE AND OFFSET

ADJUSTMENT 2-16. . . . . . . . . . . . . . . . . .

ENGAGEMENT SPEED CHECK 2-18. . .

ADJUSTING THE BRAKE 2-18. . . . . . . . .

BRAKE PAD INSPECTION 2-19. . . . . . . .

DRIVE CHAIN 2-19. . . . . . . . . . . . . . . . . . .

TRACK TENSION ADJUSTMENT 2-21. .

SLIDE RUNNER INSPECTION 2-22. . . .

1-4. . . . . . . . . . . . . . . . . . . . . . . .

CHASSIS 2-23. . . . . . . . . . . . . . . . . . . . . . . . . .

SKI/SKI RUNNER 2-23. . . . . . . . . . . . . . . .

STEERING SYSTEM 2-23. . . . . . . . . . . . .

LUBRICA TION 2-25. . . . . . . . . . . . . . . . . .

ELECTRICAL 2-27. . . . . . . . . . . . . . . . . . . . . .

HEADLIGHT BEAM

ADJUSTMENT 2-27. . . . . . . . . . . . . . . . . .

BATTERY INSPECTION 2-28. . . . . . . . . .

FUSE INSPECTION 2-30. . . . . . . . . . . . . .

TUNING 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBURETOR TUNING 2-31. . . . . . . . . .

CLUTCH 2-38. . . . . . . . . . . . . . . . . . . . . . . .

GEAR SELECTION 2-39. . . . . . . . . . . . . .

HIGH ALTITUDE TUNING 2-43. . . . . . . .

REAR SUSPENSION 2-44. . . . . . . . . . . . .

ENGINE 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPARK PLUGS 2-3. . . . . . . . . . . . . . . . . . . .

OIL PUMP 2-4. . . . . . . . . . . . . . . . . . . . . . . .

OIL FILTER INSPECTION 2-6. . . . . . . . . .

ENGINE OIL LINE INSPECTION 2-6. . . . .

FUEL LINE INSPECTION 2-7. . . . . . . . . . .

FUEL FILTER INSPECTION 2-7. . . . . . . . .

COOLING FAN BELT TENSION

ADJUSTMENT 2-9. . . . . . . . . . . . . . . . . . . .

ENGINE IDLE SPEED

ADJUSTMENT 2-10. . . . . . . . . . . . . . . . . .

THROTTLE CABLE FREEPLAY

ADJUSTMENT 2-10. . . . . . . . . . . . . . . . . .

CHAPTER 3.

CHASSIS

STEERING 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 3-3. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 3-4. . . . . . . . . . . . . . . . . . . .

SKI 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 3-7. . . . . . . . . . . . . . . . . . . . . .

FRONT SUSPENSION 3-8. . . . . . . . . . . . . . . .

HANDLING NOTES 3-9. . . . . . . . . . . . . . . .

INSPECTION 3-9. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 3-10. . . . . . . . . . . . . . . . . .

CHAPTER 4.

POWER TRAIN

ENGINE ASSEMBLY 5-3. . . . . . . . . . . . . . . . . .

INSPECTION 5-4. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 5-4. . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD AND CYLINDER 5-5. . . . .

REMOV AL 5-6. . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 5-6. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 5-1 1. . . . . . . . . . . . . . . . . . .

PRIMARY SHEAVE AND DRIVE

V-BELT 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOV AL 4-3. . . . . . . . . . . . . . . . . . . . . . . .

DISASSEMBL Y 4-4. . . . . . . . . . . . . . . . . . . .

INSPECTION 4-5. . . . . . . . . . . . . . . . . . . . . .

ASSEMBL Y 4-7. . . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-9. . . . . . . . . . . . . . . . . . . .

SECONDARY SHEAVE 4-10. . . . . . . . . . . . . .

DISASSEMBL Y 4-12. . . . . . . . . . . . . . . . . .

INSPECTION 4-13. . . . . . . . . . . . . . . . . . . .

ASSEMBL Y 4-14. . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-15. . . . . . . . . . . . . . . . . .

DRIVE CHAIN HOUSING 4-16. . . . . . . . . . . .

INSPECTION 4-18. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-22. . . . . . . . . . . . . . . . . .

SECONDARY SHAFT (JACKSHAFT) 4-23.

INSPECTION 4-25. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-25. . . . . . . . . . . . . . . . . .

OIL PUMP, CRANKCASE AND

CRANKSHAFT 5-14. . . . . . . . . . . . . . . . . . . . .

INSPECTION 5-15. . . . . . . . . . . . . . . . . . . .

OIL PUMP STROKE

ADJUSTMENT 5-16. . . . . . . . . . . . . . . . . .

INST ALLA TION 5-18. . . . . . . . . . . . . . . . . .

OIL PUMP 5-19. . . . . . . . . . . . . . . . . . . . . .

CDI MAGNETO 5-20. . . . . . . . . . . . . . . . . . . . .

REMOV AL 5-21. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 5-22. . . . . . . . . . . . . . . . . .

ENGINE COOLING FAN 5-23. . . . . . . . . . . . .

REMOV AL 5-24. . . . . . . . . . . . . . . . . . . . . .

INSPECTION 5-25. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 5-26. . . . . . . . . . . . . . . . . .

RECOIL STARTER 5-27. . . . . . . . . . . . . . . . . .

REMOV AL 5-28. . . . . . . . . . . . . . . . . . . . . .

INSPECTION 5-28. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 5-29. . . . . . . . . . . . . . . . . .

BRAKE 4-26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE PAD REPLACEMENT 4-27. . . . .

BRAKE CALIPER INSPECTION 4-30. . .

INST ALLA TION 4-31. . . . . . . . . . . . . . . . . .

SLIDE RAIL SUSPENSION 4-33. . . . . . . . . .

INSPECTION 4-37. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-37. . . . . . . . . . . . . . . . . .

FRONT AXLE AND TRACK 4-38. . . . . . . . . .

INSPECTION 4-40. . . . . . . . . . . . . . . . . . . .

INST ALLA TION 4-40. . . . . . . . . . . . . . . . . .

CHAPTER 5.

ENGINE

EXHAUST ASSEMBLY 5-1. . . . . . . . . . . . . . . .

INSPECTION 5-2. . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6.

CARBURETION

CARBURETOR 6-1. . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 6-3. . . . . . . . . . . . . . . . . . . . . .

ASSEMBL Y 6-4. . . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 6-5. . . . . . . . . . . . . . . . . . . .

FUEL PUMP 6-6. . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION 6-7. . . . . . . . . . . . . . . . . . . . . .

INST ALLA TION 6-7. . . . . . . . . . . . . . . . . . . .

CHAPTER 7.

STARTER MOTOR 7-21. . . . . . . . . . . . . . .

ELECTRICAL

SWITCH INSPECTION 7-1. . . . . . . . . . . . . . . .

SWITCH INSPECTION 7-1. . . . . . . . . . . . .

INSPECTING A SWITCH SHOWN IN

THE MANUAL 7-1. . . . . . . . . . . . . . . . . . . . .

IGNITION SYSTEM 7-2. . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 7-2. . . . . . . . . . . . . . . .

TROUBLESHOOTING 7-3. . . . . . . . . . . . . .

SPARK PLUG CAP 7-4. . . . . . . . . . . . . . . .

IGNITION COIL 7-4. . . . . . . . . . . . . . . . . . . .

SOURCE COIL/PULSER COIL 7-4. . . . . .

SPARK PLUG 7-5. . . . . . . . . . . . . . . . . . . . .

THROTTLE OVERRIDE SYSTEM

(T.O.R.S.) 7-5. . . . . . . . . . . . . . . . . . . . . . . . .

HANDLEBAR SWITCH (RIGHT) 7-6. . . . .

CARBURETOR SWITCH 7-6. . . . . . . . . . .

MAIN SWITCH 7-7. . . . . . . . . . . . . . . . . . . .

LIGHTING SYSTEM 7-8. . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 7-8. . . . . . . . . . . . . . . .

TROUBLESHOOTING 7-9. . . . . . . . . . . . . .

BULB(S) 7-10. . . . . . . . . . . . . . . . . . . . . . . .

HEADLIGHT BEAM SWITCH 7-10. . . . . .

LIGHTING COIL 7-10. . . . . . . . . . . . . . . . .

CHARGING SYSTEM 7-24. . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 7-24. . . . . . . . . . . . . .

TROUBLESHOOTING 7-25. . . . . . . . . . . .

BA TTERY 7-26. . . . . . . . . . . . . . . . . . . . . . .

CHARGING COIL 7-26. . . . . . . . . . . . . . . .

CHAPTER 8.

SPECIFICATIONS

GENERAL SPECIFICATIONS 8-1. . . . . . . . . .

MAINTENANCE SPECIFICATIONS 8-3. . . . .

ENGINE 8-3. . . . . . . . . . . . . . . . . . . . . . . . . .

POWER TRAIN 8-6. . . . . . . . . . . . . . . . . . . .

CHASSIS 8-9. . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 8-10. . . . . . . . . . . . . . . . . . .

HIGH ALTITUDE SETTINGS 8-12. . . . . .

TIGHTENING TORQUE 8-13. . . . . . . . . .

GENERAL TORQUE

SPECIFICATIONS 8-15. . . . . . . . . . . . . . . . . .

DEFINITION OF UNITS 8-15. . . . . . . . . . . . . .

CABLE ROUTING 8-16. . . . . . . . . . . . . . . . . .

SIGNAL SYSTEM 7-11. . . . . . . . . . . . . . . . . . . .

CIRCUIT DIAGRAM 7-11. . . . . . . . . . . . . . .

TROUBLESHOOTING 7-12. . . . . . . . . . . .

TROUBLESHOOTING 7-13. . . . . . . . . . . .

TAIL/BRAKE LIGHT BULB 7-14. . . . . . . .

BRAKE LIGHT SWITCH 7-14. . . . . . . . . .

GEAR POSITION SWITCH 7-14. . . . . . . .

BACK BUZZER 7-14. . . . . . . . . . . . . . . . . .

GRIP WARMER SYSTEM 7-15. . . . . . . . . . . .

CIRCUIT DIAGRAM 7-15. . . . . . . . . . . . . .

TROUBLESHOOTING 7-16. . . . . . . . . . . .

GRIP AND THUMB WARMER

COIL 7-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

GRIP WARMER SWITCH 7-17. . . . . . . . .

ELECTRICAL STARTING SYSTEM 7-18. . .

CIRCUIT DIAGRAM 7-18. . . . . . . . . . . . . .

TROUBLESHOOTING 7-19. . . . . . . . . . . .

MAIN SWITCH 7-20. . . . . . . . . . . . . . . . . .

RECTIFIER 7-20. . . . . . . . . . . . . . . . . . . . .

MACHINE IDENTIFICATION

ESS00011

GENERAL INFORMATION

ESS00012

MACHINE IDENTIFICATION

ESS00013

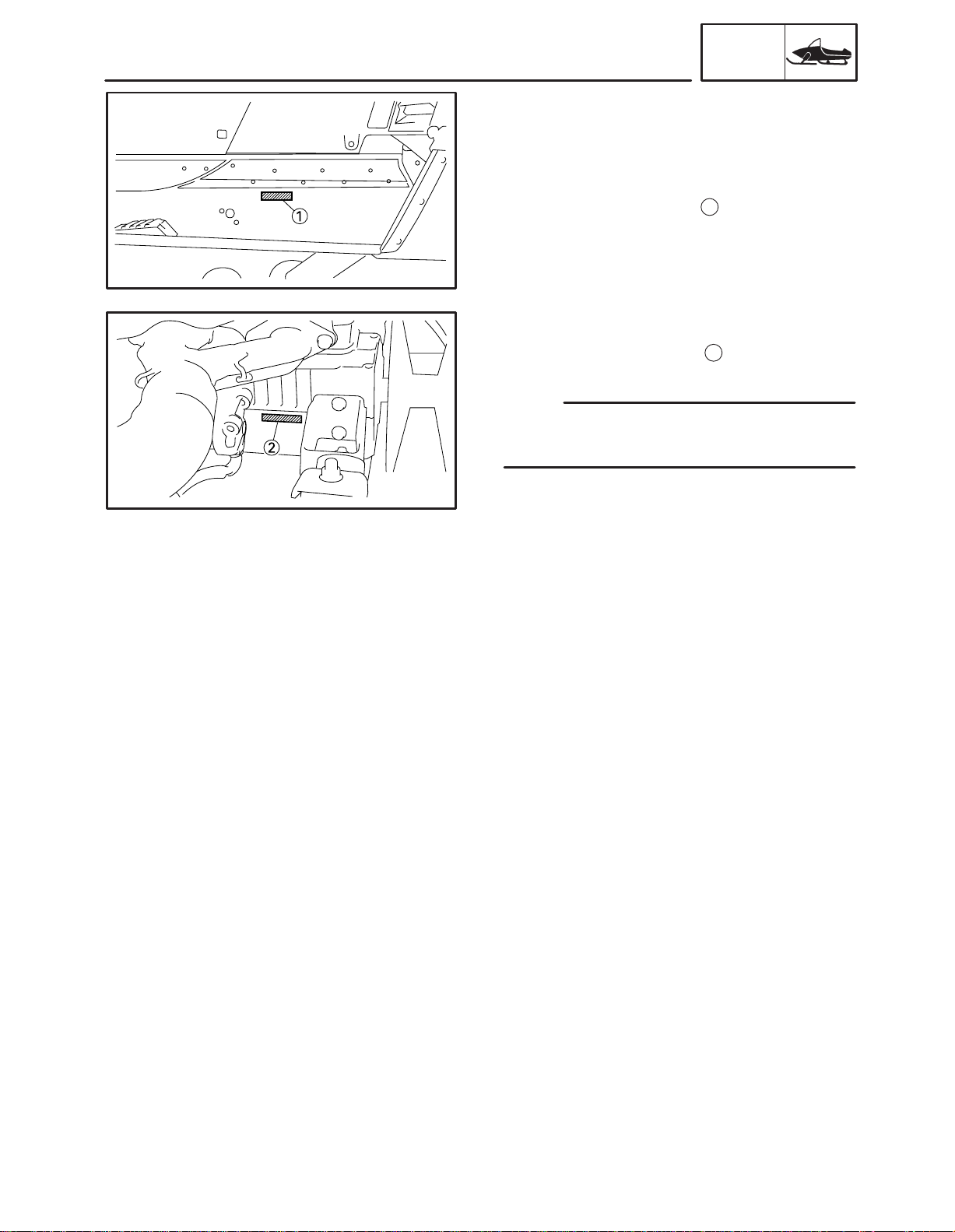

FRAME SERIAL NUMBER

The frame serial number

right hand side of the frame (just below the front

of the seat).

ESS00014

ENGINE SERIAL NUMBER

The engine serial number

left hand side of the crankcase.

NOTE:

Designs and specifications are subject to

change without notice.

GEN

INFO

1

is located on the

2

is located on the

1-1

IMPORTANT INFORMATION

ESS00015

IMPORTANT INFORMATION

ESS00016

PREPARATION FOR REMOVAL AND DISASSEMBLY

1. Remove all dirt, mud, dust, and foreign material before removal and disassembly.

While cleaning, take care to protect the electrical parts, such as relays, switches, motor,

resistors, controllers, etc., from high pressure water splashes.

2. Use proper tools and cleaning equipment.

Refer to “SPECIAL TOOLS”.

GEN

INFO

1

3. When disassembling the machine, keep

mated parts together. This includes gears,

cylinders, pistons, and other parts that have

been “mated” through normal wear. Mated

parts must be reused or replaced as an assembly.

4. During disassembly of the machine, clean all

parts and place them in trays in the order of

disassembly. This will speed up assembly

time and help ensure that all parts are reinstalled correctly.

5. Keep all parts away from any source of fire.

6. Be sure to keep to the tightening torque

specifications. When tightening bolts, nuts,

and screws, start with those that have larger

diameters, and proceed from the inside to

the outside in a crisscross pattern.

1-2

IMPORTANT INFORMATION

ESS00017

ALL REPLACEMENT PARTS

We recommend using genuine Yamaha parts

for all replacements. Use oil and grease recommended by Yamaha for assembly and adjustments.

ESS00018

GASKETS, OIL SEALS, AND O-RINGS

1. All gaskets, seals, and O-rings should be replaced when an engine is overhauled. All

gasket surfaces, oil seal lips, and O-rings

must be cleaned.

2. Properly oil all mating parts and bearings

during reassembly. Apply grease to the oil

seal lips.

GEN

INFO

ESS00019

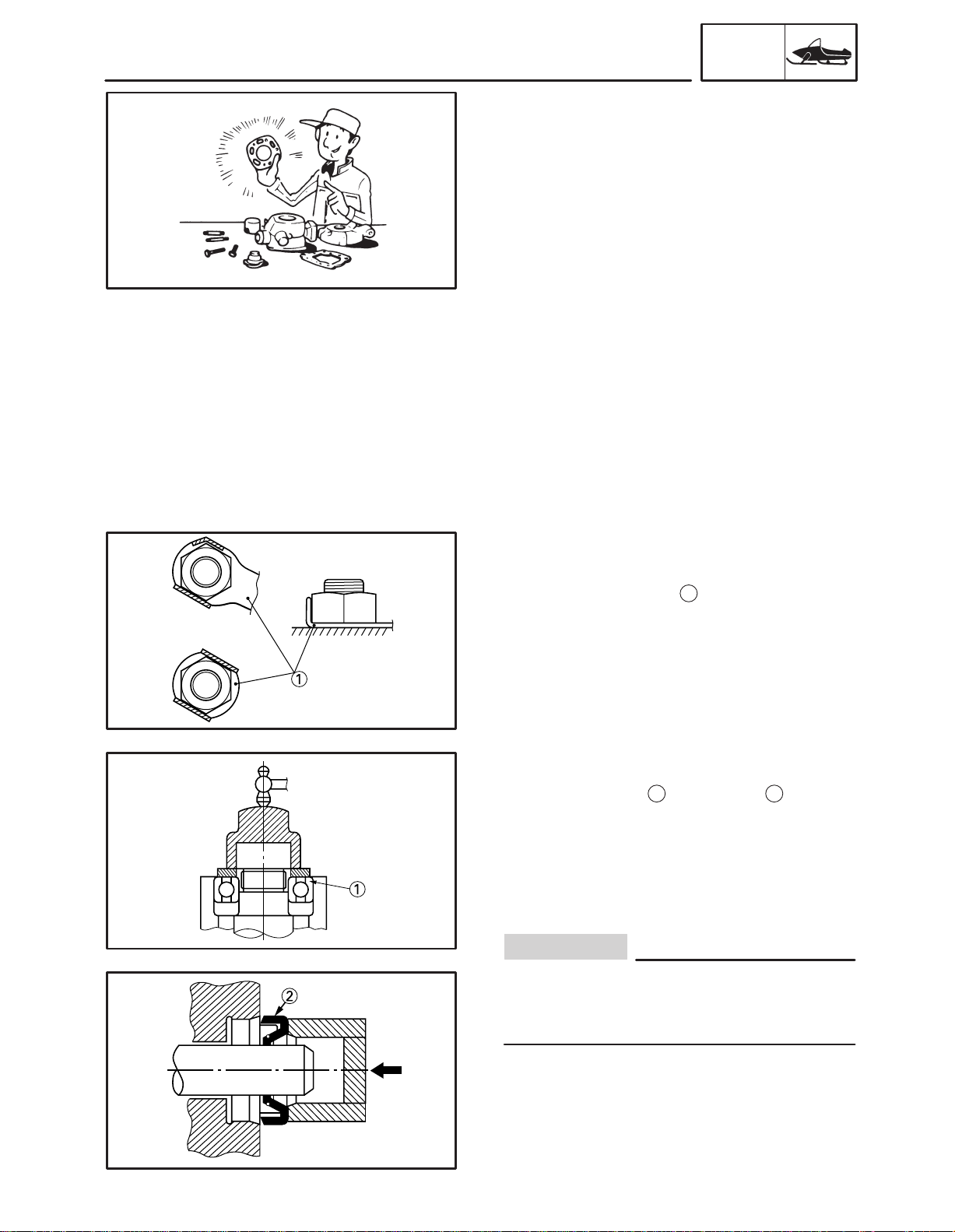

LOCK WASHERS/PLATES AND COTTER

PINS

All lock washers/plates

1

and cotter pins must

be replaced if they are removed. Lock tab(s)

should be bent along the bolt or nut flat(s) after

the bolt or nut has been properly tightened.

ESS00020

BEARINGS AND OIL SEALS

1

Install the bearings

and oil seals 2 with their

manufacturer’s marks or numbers facing outwards. (In other words, the stamped letters

must be on the side exposed to view.) When

installing oil seals, apply a light coating of lightweight lithium base grease to the seal lips. Oil

the bearings liberally when installing.

CAUTION:

Do not use compressed air to spin the bearings dry . This causes damage to the surface

of the bearings.

1-3

IMPORTANT INFORMATION

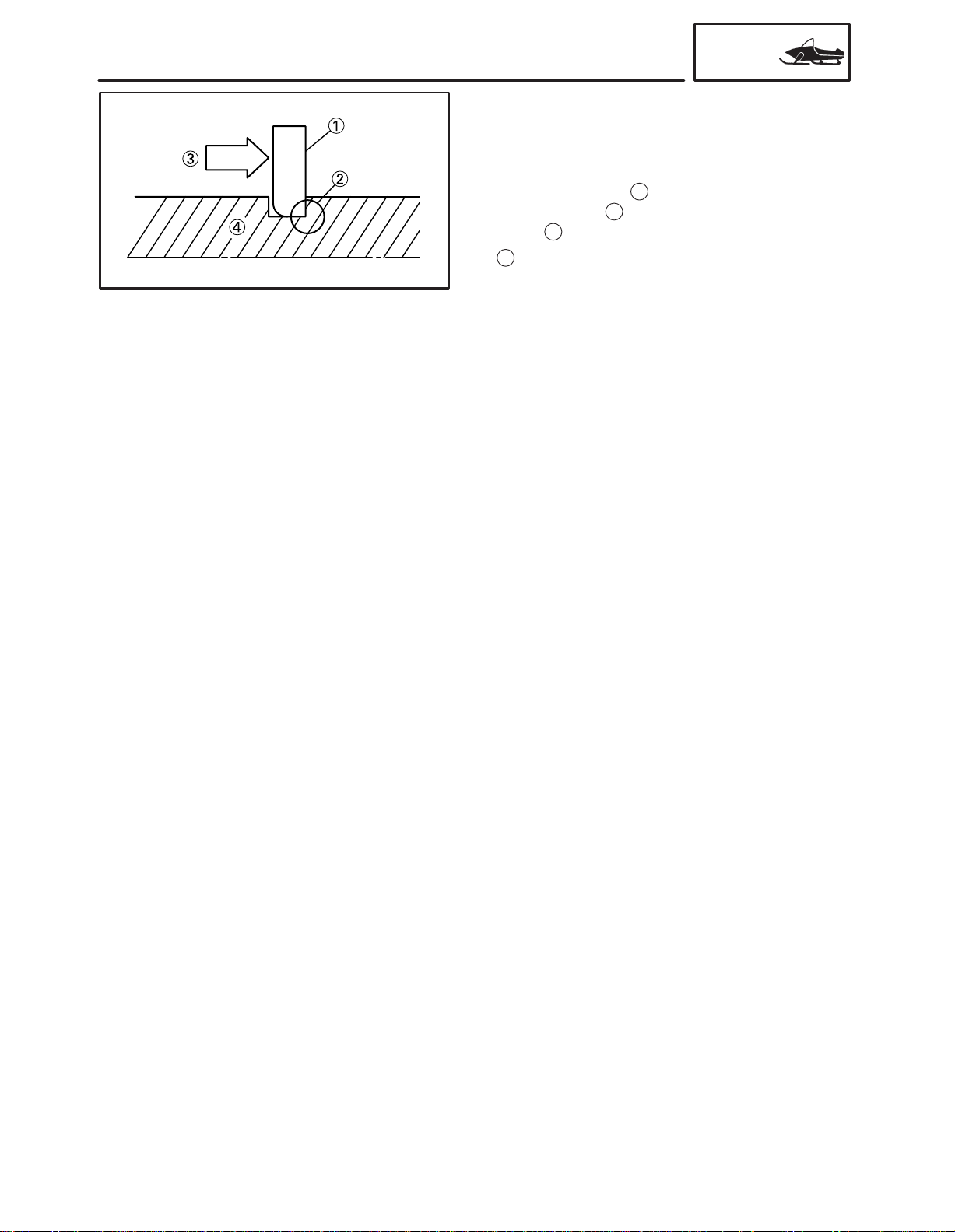

ESS00021

CIRCLIPS

All circlips should be inspected carefully before

reassembly . Always replace piston pin clips after one use. Replace misshapen circlips. When

installing a circlip

edged corner

thrust

4

3

it receives. See the sectional view.

Shaft

1

, make sure that the sharp

2

is positioned opposite to the

GEN

INFO

ESS00022

LOCTITE

After installing fasteners that have LOCTITE

applied, wait 24 hours before using the machine.

This will give the LOCTITE

time to dry proper-

ly .

1-4

GEN

SPECIAL TOOLS

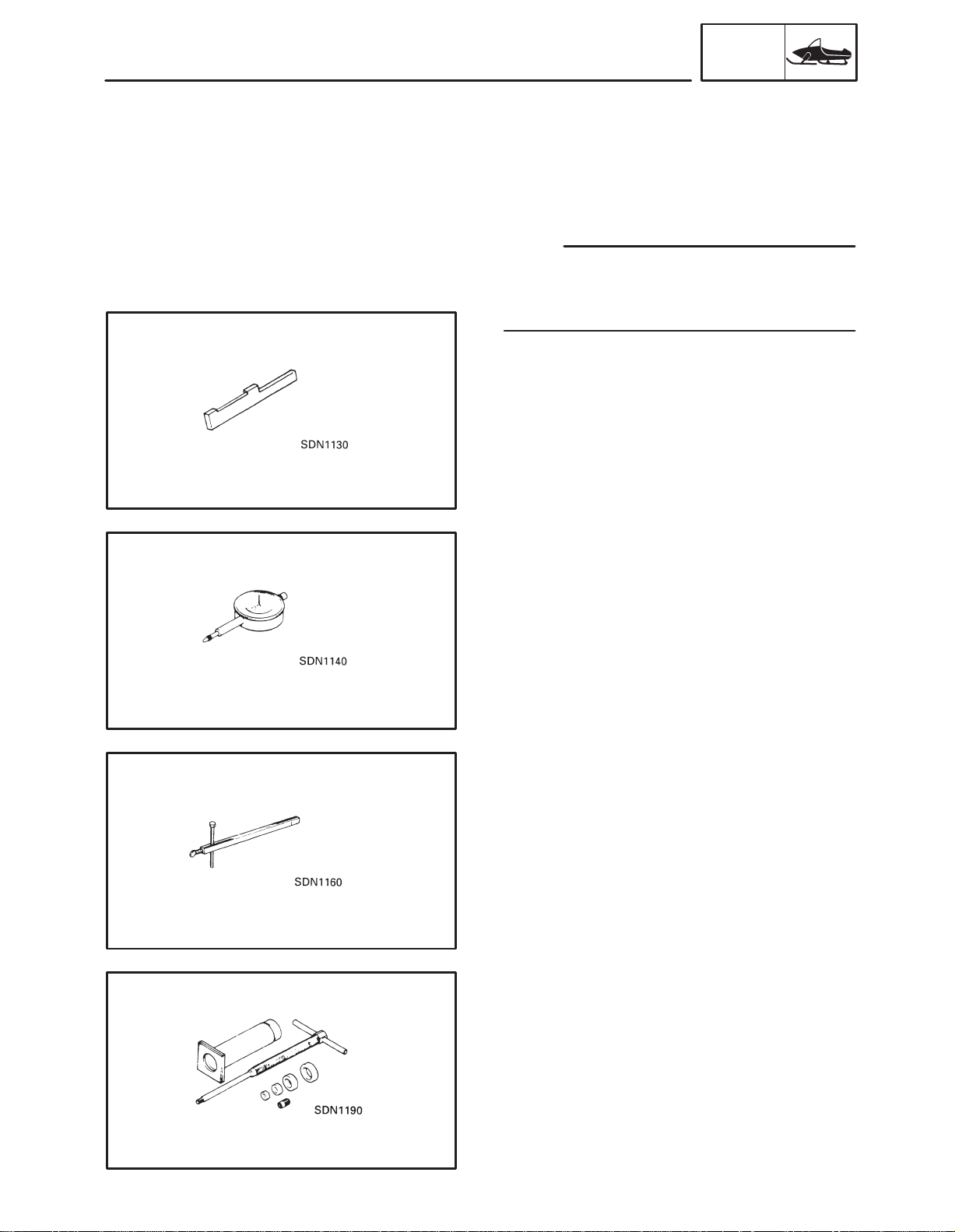

ESS00023

SPECIAL TOOLS

Some special tools are necessary for a completely accurate tune-up and assembly. Using

the correct special tool will help prevent damage that can be caused by the use of improper

tools or improvised techniques.

NOTE:

Be sure to use the correct part number when ordering the tool, since the part number may differ

according to country.

ESS00024

FOR TUNE UP

Sheave gauge

P/N: YS-39506-5 (16 mm offset)

This gauge is used to measure the sheave distance and for offset adjustment.

INFO

Dial gauge

P/N: YU-03097 (for U.S.A./Canada)

90890-03097 (for Europe)

This gauge is used for run out measurement.

Distance gauge

P/N: YS-91047-3 (for U.S.A./Canada)

90890-01702 (for Europe)

This gauge is used to measure the distance between the center of the primary sheave and the

center of the secondary sheave.

ESS00025

FOR ENGINE SERVICE

Piston pin puller

P/N: YU-01304 (for U.S.A./Canada)

90890-01304 (for Europe)

This tool is used to remove the piston pin.

1-5

GEN

SPECIAL TOOLS

Rotor holding puller

P/N: YU-33270 (for U.S.A./Canada)

90890-01362 (for Europe)

This tool is used to remove the magneto rotor.

Rotor holding tool

P/N: YU-01235 (for U.S.A./Canada)

90890-01235 (for Europe)

This tool is used to remove the starter pulley.

INFO

ESS00026

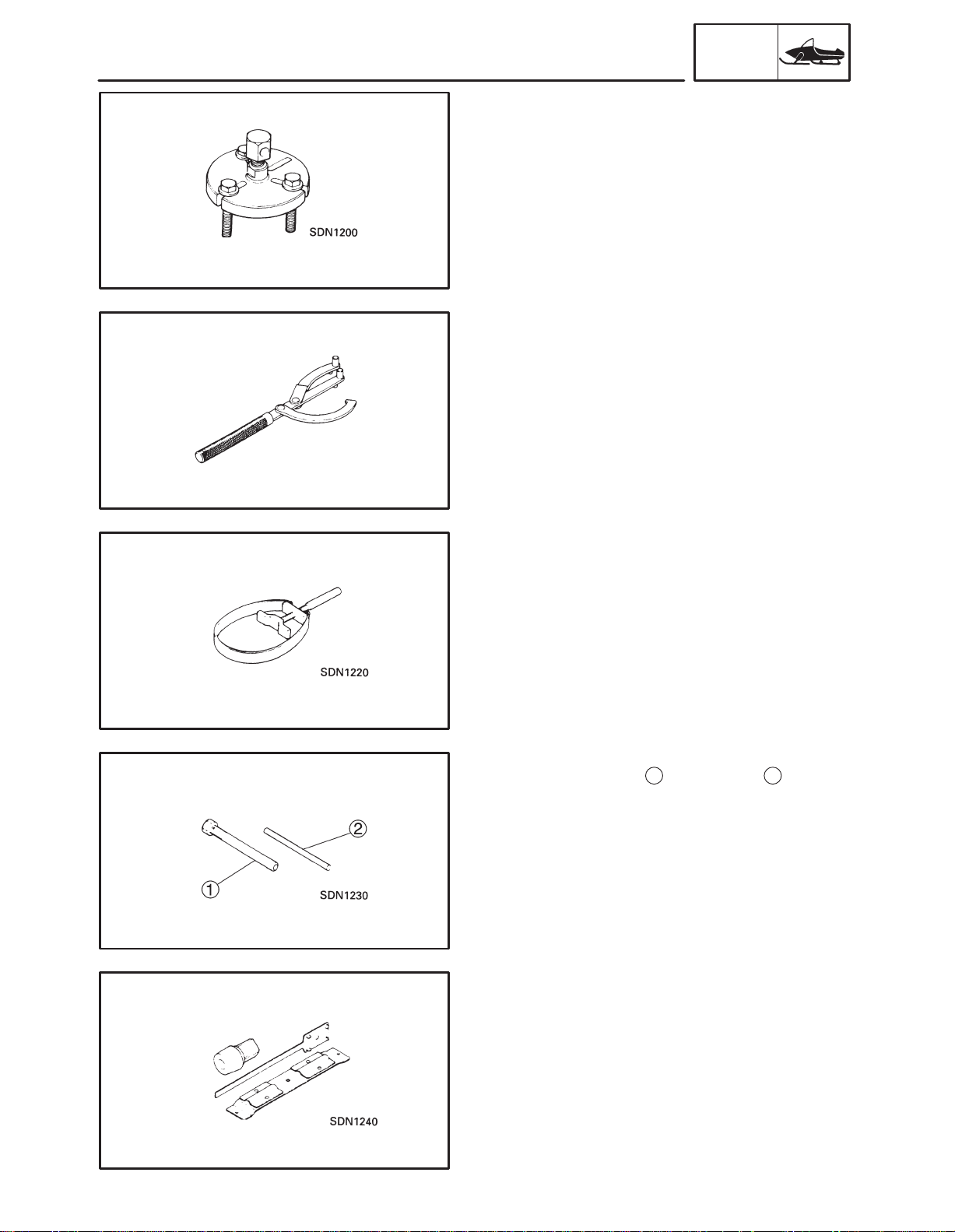

FOR POWER TRAIN SERVICE

Primary sheave holder

P/N: YS-01880 (for U.S.A./Canada)

90890-01701 (for Europe)

This tool is used to hold the primary sheave.

Primary sheave puller

P/N: YS-01881-1 1, YS-01882-1 2 (18 mm)

This tool is used for removing the primary

sheave.

Clutch spider separator

P/N: YS-28890-B (for U.S.A./Canada)

90890-01711 (for Europe)

This tool is used when disassembling and assembling the primary sheave.

1-6

GEN

SPECIAL TOOLS

Clutch separator adapter

P/N: YS-34480 (for U.S.A./Canada)

90890-01740 (for Europe)

This tool is used when disassembling and assembling the primary sheave.

YXR clutch bushing jig kit

P/N: YS-39752

This tool is used for removal and installation of

primary clutch weight and roller bushings.

INFO

Track clip installer

P/N: YS-91045-A (for U.S.A./Canada)

90890-01721 (for Europe)

This tool is used for installing the track clip.

ESS00027

FOR CARBURETION SERVICE

Mity vac

P/N: YB-35956 (for U.S.A./Canada)

90890-06756 (for Europe)

This tool is used to check the fuel pump.

ESS00028

FOR ELECTRICAL SERVICE

Pocket tester

P/N: YU-03112 (for U.S.A./Canada)

90890-03112 (for Europe)

This instrument is necessary for checking the

electrical components.

1-7

GEN

SPECIAL TOOLS

Electro tester

P/N: YU-33260-A (for U.S.A./Canada)

90890-03021 (for Europe)

This instrument is invaluable for checking the

electrical system.

INFO

1-8

INSP

Engine oil

Carburetor

INTRODUCTION/PERIODIC MAINTENANCE TABLE

ESS00029

ESS00030

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments.

These preventive maintenance procedures, if followed, will ensure more reliable machine operation

and a longer service life. In addition, the need for costly overhaul work will be greatly reduced. This

information applies to machines already in service as well as new machines that are being prepared for

sale.

All service technicians should be familiar with this entire chapter.

ESS00031

PERIODIC MAINTENANCE TABLE

ADJ

Pre-

Item Remarks

Spark plug

Oil filter

Fuel Check fuel level.

Fuel filter

Fuel line

Oil line

Fan belt

Manual starter

Engine stop switch

Throttle override

system

Throttle lever

Exhaust system

Decarbonization More frequently if necessary.

Drive V-belt guard

Drive V-belt

Check condition adjust the gap and clean.

Replace if necessary.

Check oil level.

Air bleed the oil pump if necessary .

Check condition.

Replace if necessary.

Check condition.

Replace if necessary.

Check fuel hose for cracks or damage.

Replace if necessary.

Check oil hose for cracks or damage.

Replace if necessary.

Check throttle lever

operation.

Adjust the jets.

Check wear and damage.

Replace if necessary.

Adjust fan belt if necessary .

Check operation and rope damage.

Replace if necessary.

Check operation.

Repair if necessary.

Check operation.

Repair if necessary.

Check operation.

Repair if necessary.

Check for leakage.

Retighten or replace gasket if necessary.

Check cracks, bends or damage.

Replace if necessary.

Check wear and damage.

Replace if necessary.

operation

check

(Daily)

Whenever operating condition

(elevation/temperature) is changed.

Initial

1 month

or

800 km

(500 mi)

(40 hr)

Every

Seasonally

3,200 km

(2,000 mi)

(160 hr)

2-1

or

INTRODUCTION/PERIODIC MAINTENANCE TABLE

Slide runners

Brake/

Drive chain oil

Steering system

Secondary sheave

INSP

ADJ

Initial

Pre-

Item Remarks

Drive track/Idler

wheels

Parking brake

Drive chain

Ski/

Ski runner

Lights

Battery

Primary sheave

Steering column bearing Lubricate with specified grease.

Ski and front suspension Lubricate with specified grease.

Suspension component Lubricate with specified grease.

Brake cable end and

lever end/Throttle cable

end

Shroud latches

Fittings/Fasteners

Service tools/Spare

parts

Check deflection, wear and damage.

Adjust/replace if necessary.

Check wear and damage.

Replace if necessary.

Check operation.

Adjust free play and/or replace pads if

necessary.

Check oil level.

Replace. **

Check deflection.

Adjust if necessary.

Check wear and damage.

Replace if necessary.

Check operation.

Adjust toe-out if necessary.

Check operation.

Replace bulbs if necessary.

Check fluid level.

Check specific gravity and breather pipe

operation.

Charge/Correct if necessary.

Check engagement and shift speed.

Adjust if necessary. Whenever operating elevation is changed.

Check wear and damage.

Replace if necessary.

Lubricate with specified grease.

Lubricate with specified grease.

Adjust if necessary. Whenever operating elevation is changed.

Lubricate with specified grease.

Check cable damage.

Replace if necessary.

Make sure the shroud

Iatches are hooked.

Check tightness.

Repair if necessary.

Check proper placement.

operation

check

(Daily)

Initial at 480 km (300 Mi) and

every 800 km (500 Mi) thereafter.

1 month

or

800 km

(500 mi)

(40 hr)

Every

Seasonally

3,200 km

(2,000 mi)

(160 hr)

or

2

** Apply “initial 1 month or 400 km (250 mi, 20 hr)”

2-2

INSP

SPARK PLUGS

ESS00032

ENGINE

ESS00033

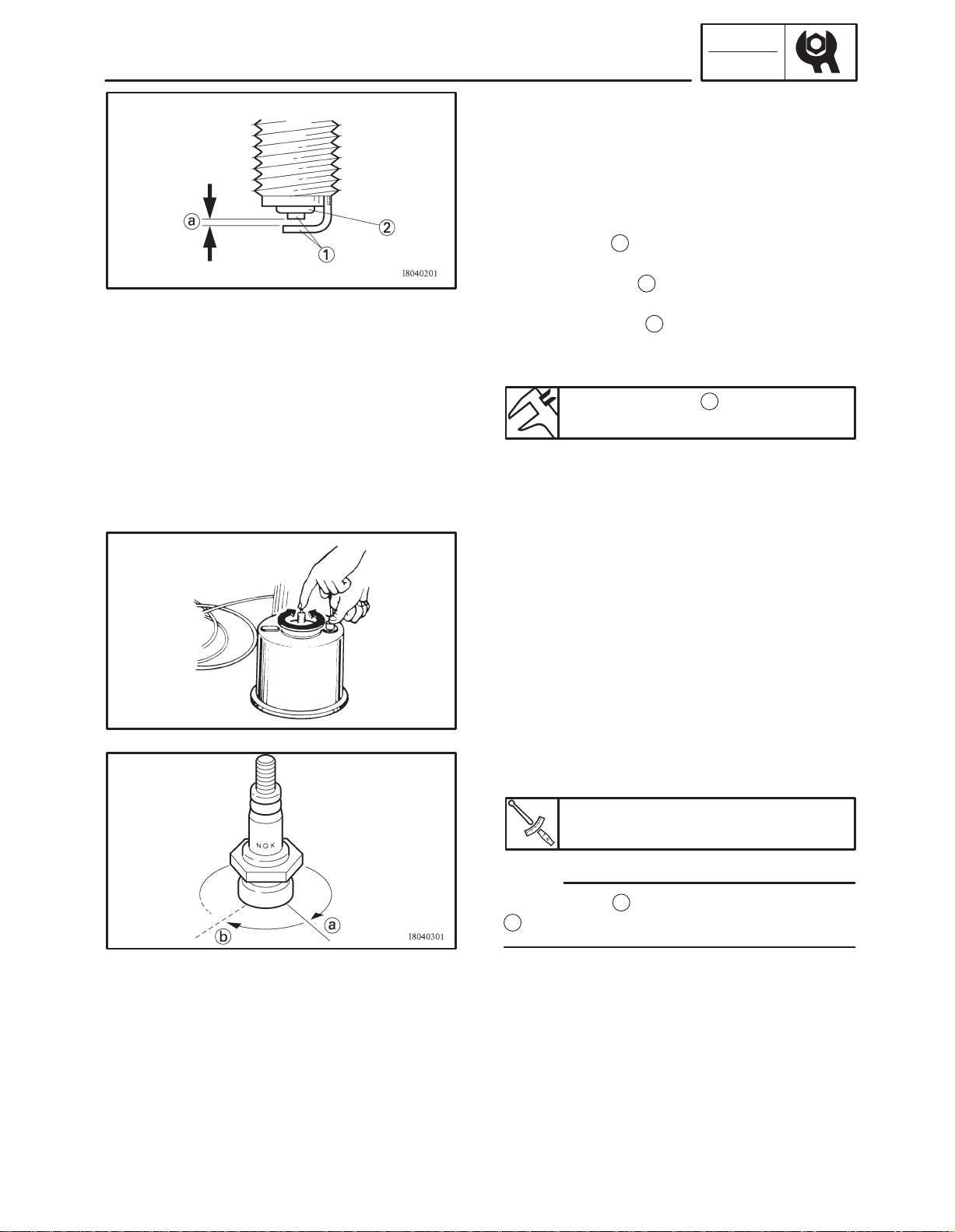

SPARK PLUGS

1. Remove:

S Spark plug caps

S Spark plugs

2. Inspect:

S Electrodes

Damage/wear Replace the spark plug.

S Insulator color

3. Measure:

S Spark plug gap

Out of specification Regap.

Use a wire thickness gauge.

1

2

a

Spark plug gap a:

0.7 0.8 mm (0.028 0.032 in)

ADJ

If necessary , clean the spark plugs with a spark

plug cleaner.

Standard spark plug:

BR9ES (NGK)

Before installing a spark plug, clean the gasket

surface and spark plug surface.

4. Install:

S Spark plugs

Spark plug:

20 Nm (2.0 mSkg, 14 ftSlb)

NOTE:

Finger-tighten

b

it to specification.

a

the spark plug before torquing

2-3

INSP

OIL PUMP

ESS00034

OIL PUMP

ESS00035

Air bleeding

CAUTION:

The oil pump and oil delivery line must be

bled in the following cases:

S Any portion of the oil system has been dis-

connected.

S The machine has been turned on its side.

S The oil tank has been run empty.

S As part of the pre-delivery service.

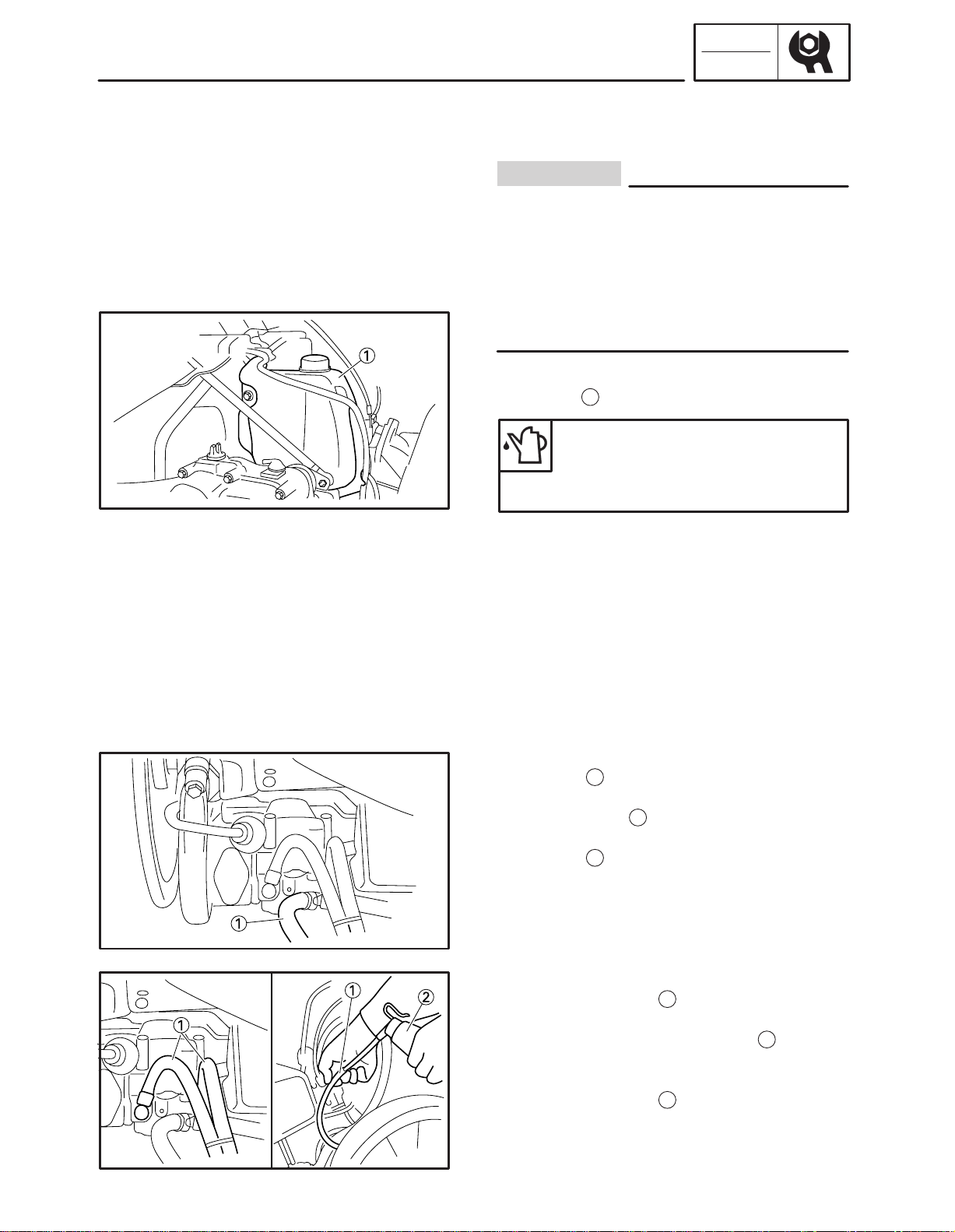

1. Fill:

S Oil tank

1

Recommended oil:

YAMALUBE 2-cycle oil

Oil tank capacity:

2.5 L (2.2 Imp qt, 2.6 US qt)

ADJ

2. Remove:

S Drive V-belt guard

S Carburetors

Refer to “CARBURETORS” in CHAPTER 6.

3. Place a rag under the oil pump assembly to

soak up any spilled oil.

4. Disconnect:

S Oil hose

1

5. Drain the oil until no more air bubbles appear

1

in the oil hose

.

6. Connect:

S Oil hose

1

7. Disconnect:

S Oil delivery hoses

1

8. Feed the “Y AMALUBE 2-cycle oil” into the oil

delivery hose using an oil can

2

for com-

plete air bleeding.

9. Connect:

S Oil delivery hoses

1

2-4

INSP

OIL PUMP

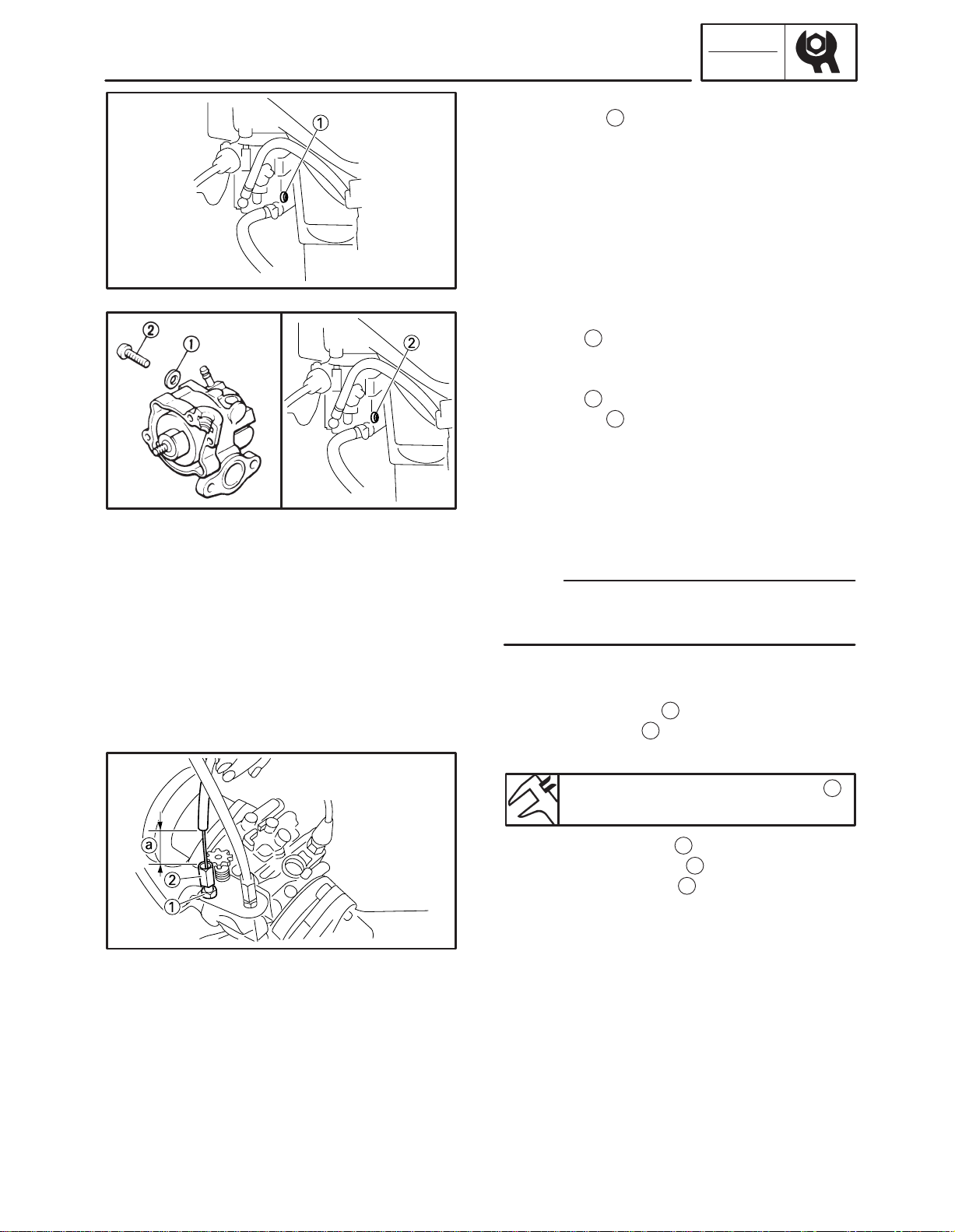

10. Remove:

S Bleed bolt

S Gasket (bleed bolt)

11. Drain the oil until no more air bubbles appear from the bleed hole.

12. Inspect:

S Gasket 1 (bleed bolt)

Damage/wear Replace.

13. Install:

S Gasket

S Bleed bolt

14. Install:

S Carburetors

Refer to “CARBURETORS” in CHAPTER 6.

1

1

(bleed bolt)

2

ADJ

ESS00036

Cable adjustment

NOTE:

Before adjusting the oil pump cable, the throttle

cable distance should be adjusted.

Adjustment steps:

S Pull back the adjuster cover.

S Loosen the locknut

S Turn the adjuster

distance is obtained.

Oil pump cable adjusting length

24 26 mm (0.9 1.0 in)

Turning in Length

Turning out Length

S Tighten the locknut

juster cover.

1

.

2

in or out until the specified

a

is increased.

a

is decreased.

1

and push in the ad-

a

:

2-5

OIL FILTER INSPECTION/ENGINE OIL LINE INSPECTION

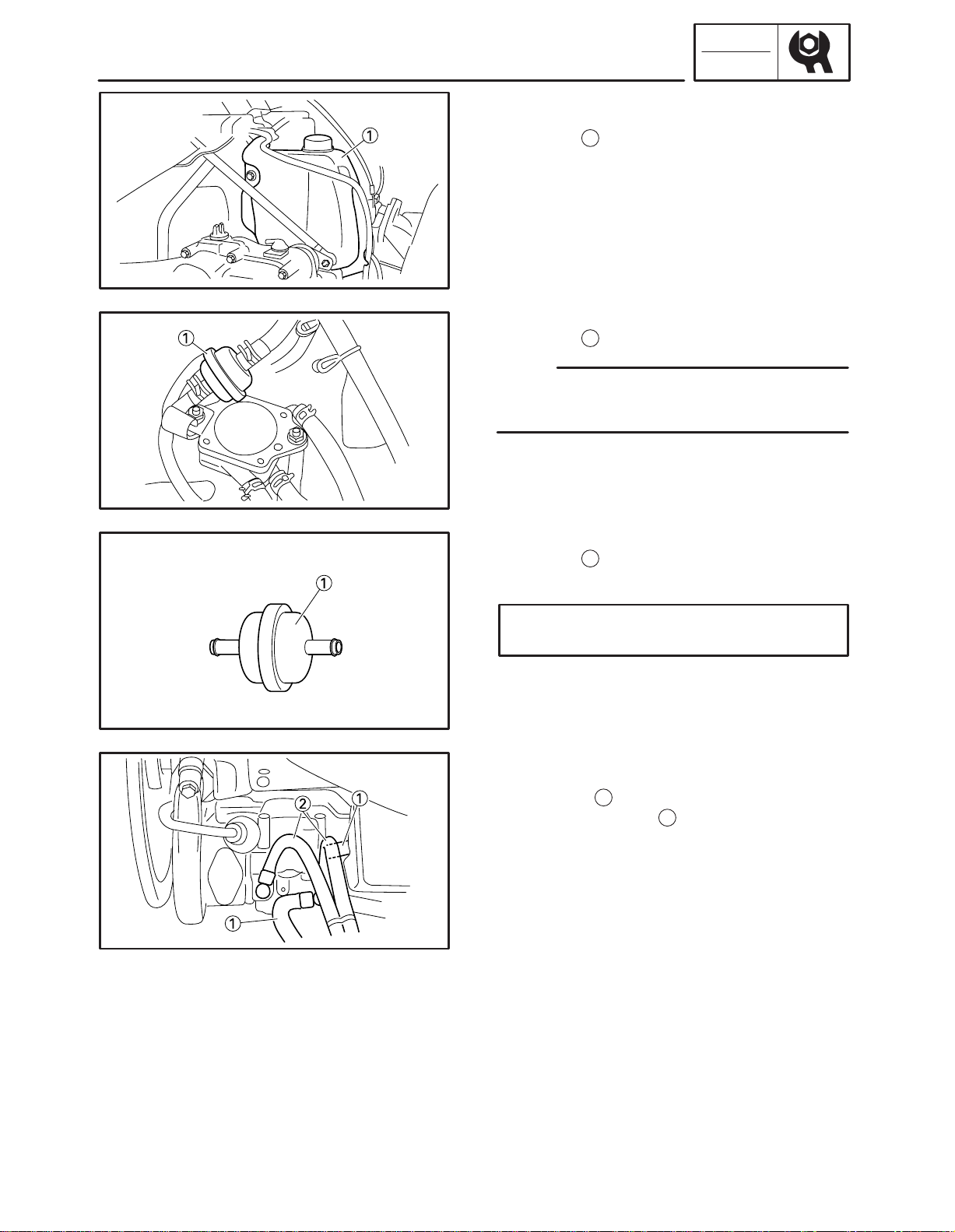

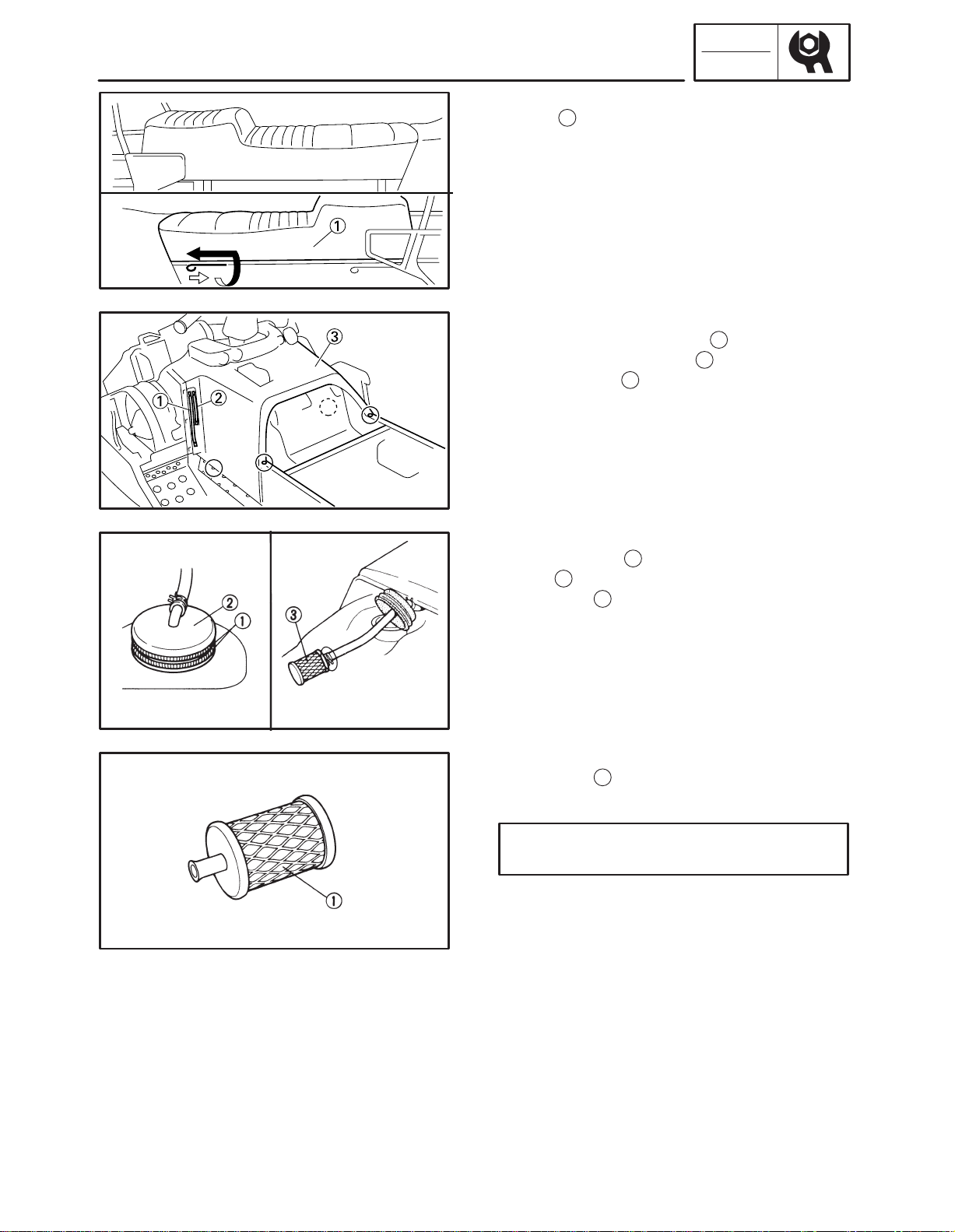

OIL FILTER INSPECTION

1. Remove:

S Oil tank

2. Remove:

S Oil filter

NOTE:

Plug the oil hoses so that the oil will not run out

of the oil tank and oil pump.

1

1

INSP

ADJ

3. Inspect:

S Oil filter

Contamination Replace.

Recommended replacement interval:

ENGINE OIL LINE INSPECTION

1. Inspect:

S Oil hoses

S Oil delivery hoses

Cracks/Damage Replace.

1

Every season

1

2

2-6

FUEL LINE INSPECTION/FUEL FILTER INSPECTION

ESS00037

FUEL LINE INSPECTION

1. Inspect:

S Fuel hose

S Fuel delivery hoses

S Vacuum hose

Cracks/damage Replace.

FUEL FILTER INSPECTION

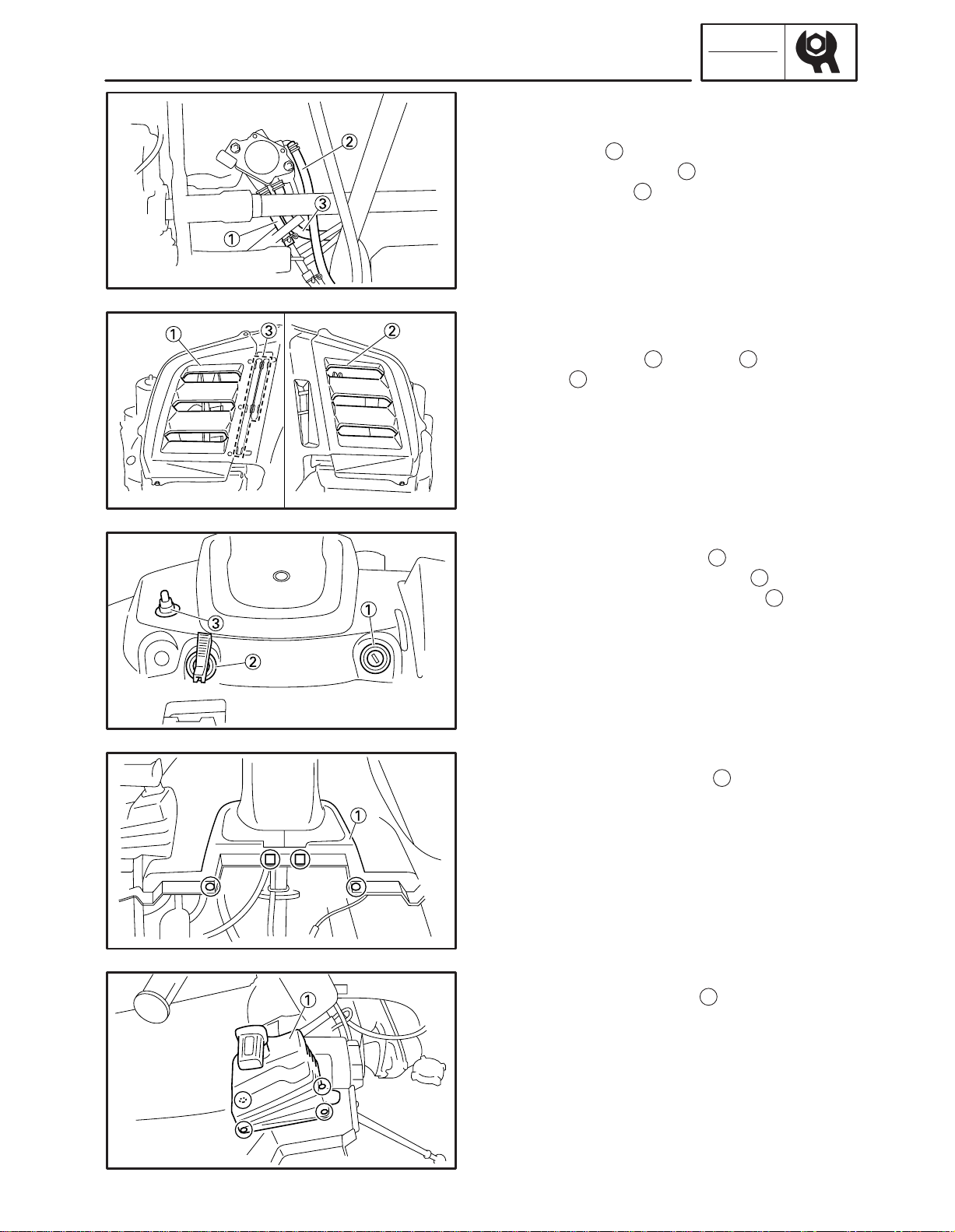

1. Remove:

S Side cover (left

S Plate

1

3

1

and right 2)

3

INSP

ADJ

2

2. Remove:

S Main switch holding nut

S “STARTER” lever holding nut

S Grip warmer switch holding nut

3. Remove:

S Handlebar cover (lower)

4. Remove:

S Drive select lever boot

1

1

1

2

3

2-7

FUEL FILTER INSPECTION

5. Remove:

S Seat

6. Remove:

S Fuel lever indicator hose

S Oil level indicator hose

S Center cover

1

3

INSP

ADJ

1

2

7. Remove:

S Spring bands

S Cap

S Fuel filter

8. Inspect:

S Fuel filter

2

Contamination Replace.

Recommended replacement interval:

Every season

1

3

1

2-8

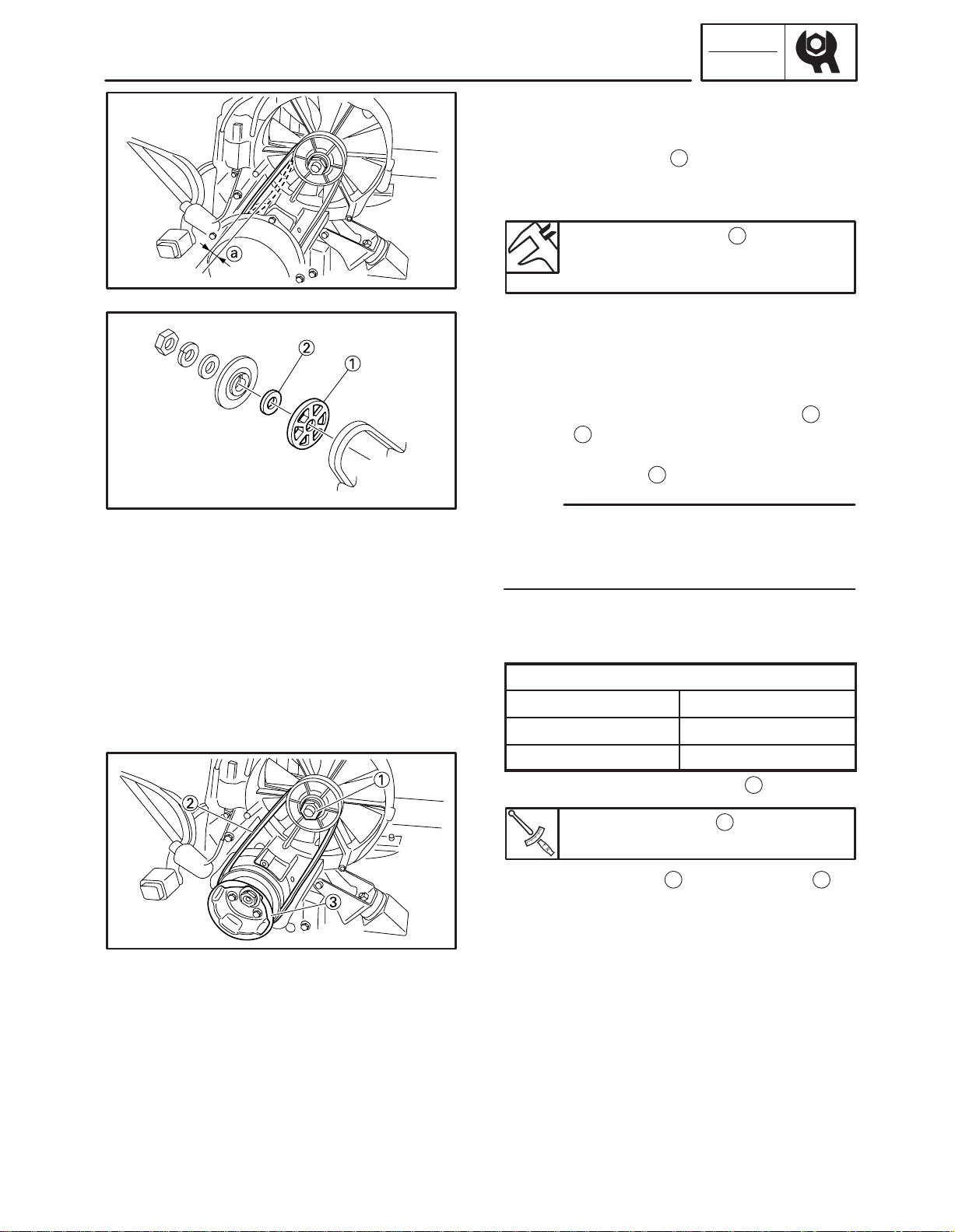

COOLING FAN BELT TENSION ADJUSTMENT

COOLING FAN BELT TENSION ADJUSTMENT

1. Adjust:

S Fan belt deflection

Pushed at belt center by hand.

Out of specification Adjust.

INSP

ADJ

a

Fan belt deflection

8 mm (0.31 in)/

4 6 kg (8.8 13.2 lb)

2. Adjust:

S Fan belt deflection.

Adjustment steps:

S Remove the recoil starter assembly, drive

pulley and fan belt.

S Remove the driven pulley (outer half)

2

shim(s)

S Adjust the drive belt tension by adding or re-

moving a shim(s)

NOTE:

Install the removed shim(s) on the outside of the

driven pulley. Do not dispose of the removed

shim(s).

Adding shim Belt tension decreases.

Removing shim Belt tension increases.

.

2

.

Shim size

a

:

1

and

Part number Thickness

90214-17017 0.5 mm (0.02 in)

90214-17018 1.0 mm (0.04 in)

S Tighten the driven pulley nut 1.

Driven pulley nut

43 Nm (4.3 mSkg, 31 ftSlb)

S Install the fan belt

2

1

:

and drive pulley 3.

2-9

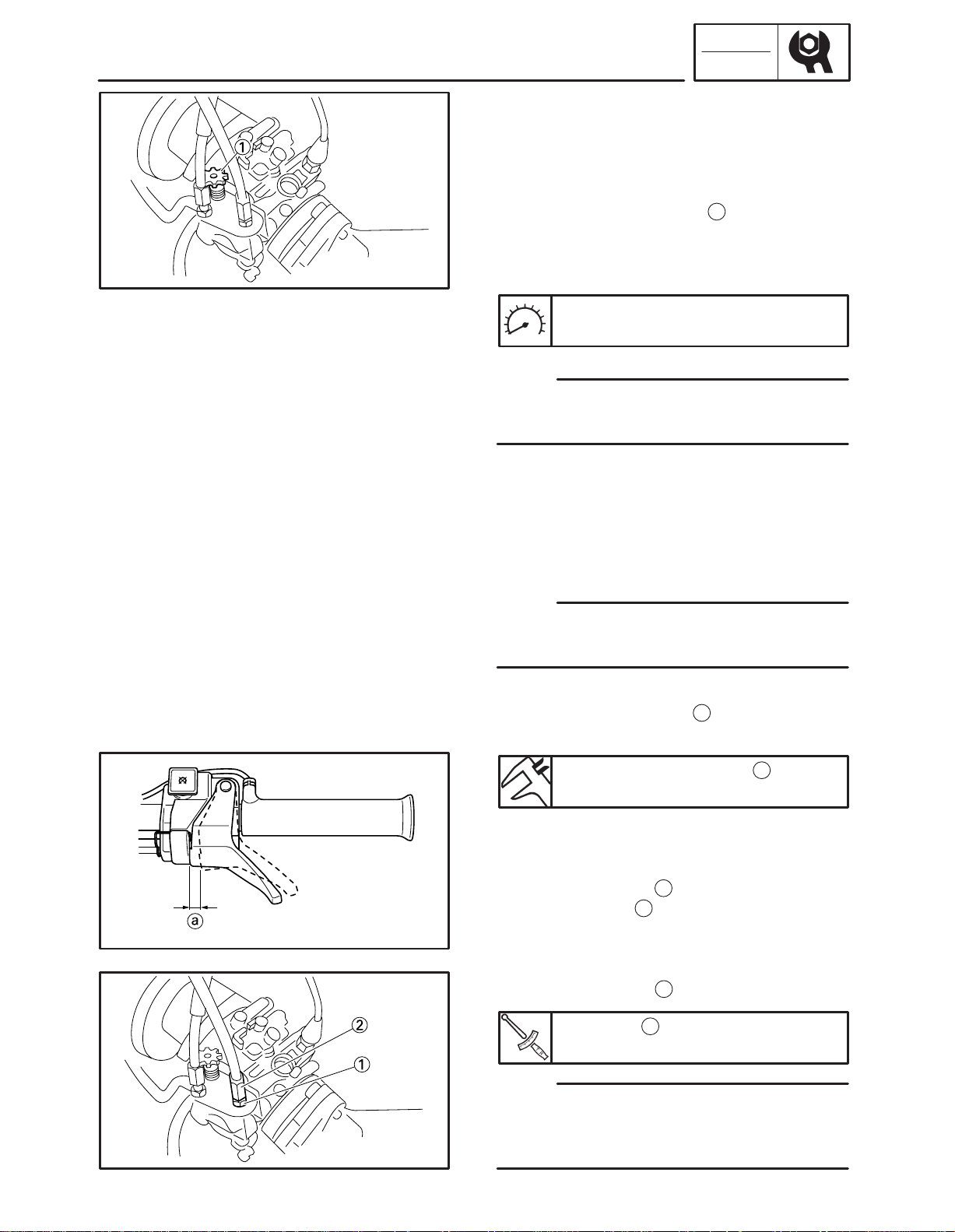

ENGINE IDLE SPEED ADJUSTMENT/

THROTTLE CABLE FREEPLAY ADJUSTMENT

ESS00044

ENGINE IDLE SPEED ADJUSTMENT

1. Adjust:

S Engine idle speed

Adjustment steps:

S Start the engine and let it warm up.

S Turn the throttle stop screw

specified engine idle speed is obtained.

Turning in Idle speed is increased.

Turning out Idle speed is decreased.

Engine idle speed:

1,200 ± 100 r/min

NOTE:

After adjusting the engine idle speed, the

throttle cable freeplay should be adjusted.

INSP

ADJ

1

in or out until the

ESS00046

THROTTLE CABLE FREEPLAY ADJUSTMENT

NOTE:

Before adjusting the throttle cable freeplay , the

engine idle speed should be adjusted.

1. Measure:

S Throttle cable freeplay

a

Out of specification Adjust.

Throttle cable freeplay

a

:

1.0 2.0 mm (0.04 0.08 in)

2. Adjust:

S Throttle cable freeplay

Adjustment steps:

S Loosen the locknut

S Turn the adjuster

1

.

2

in or out until the specified

freeplay is obtained.

Turning in Freeplay is increased.

Turning out Freeplay is decreased.

S Tighten the locknut

1

.

Lock nut

1

:

0.8 Nm (0.08 mSkg, 0.58 ftSlb)

NOTE:

After adjusting the freeplay, turn the handlebar

to right and left, and make sure that the engine

idling does not run faster.

2-10

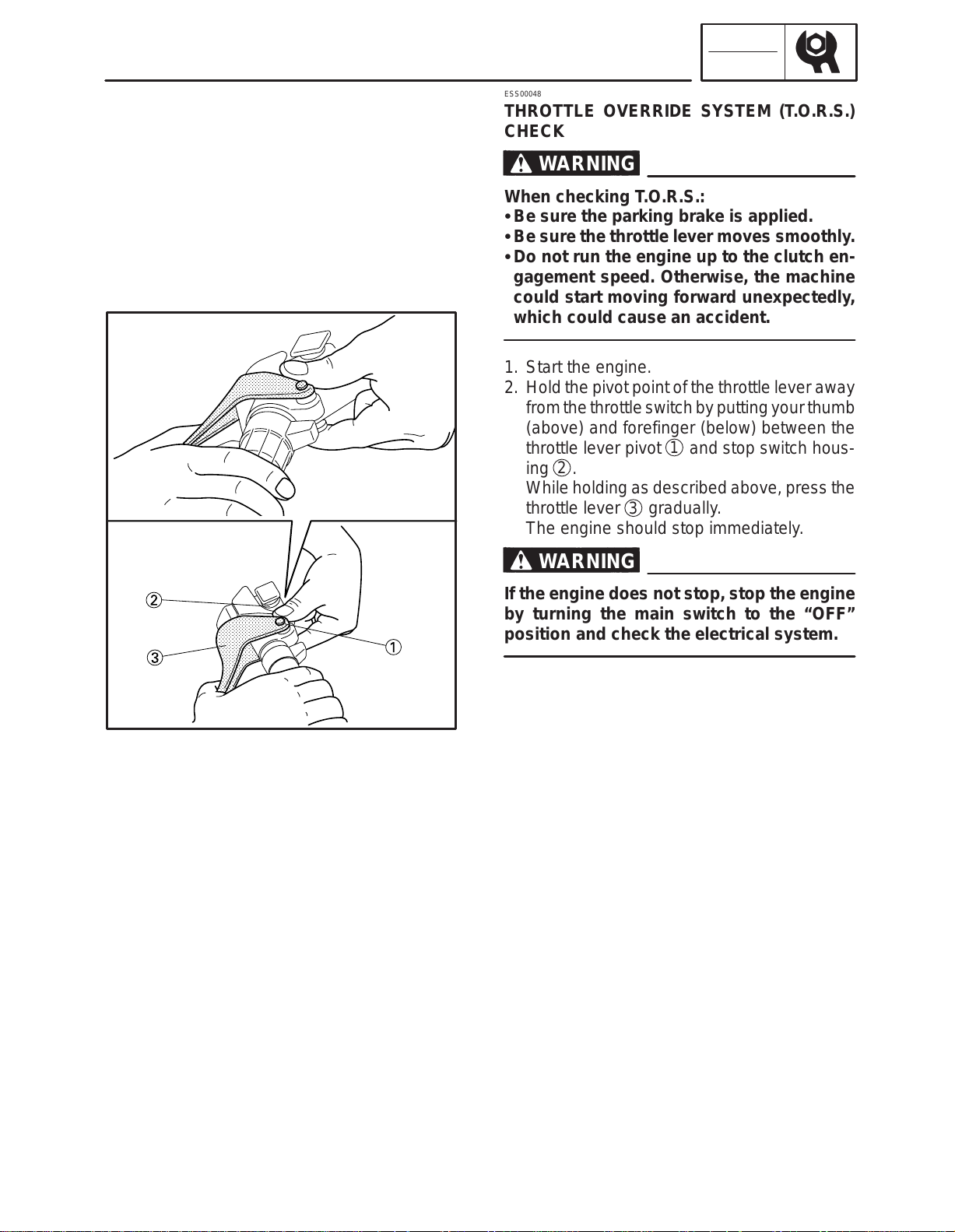

THROTTLE OVERRIDE SYSTEM (T.O.R.S.) CHECK

,,,,

,,,,

,,,,

ESS00048

THROTTLE OVERRIDE SYSTEM (T.O.R.S.)

CHECK

WARNING

When checking T.O.R.S.:

S Be sure the parking brake is applied.

S Be sure the throttle lever moves smoothly.

S Do not run the engine up to the clutch en-

gagement speed. Otherwise, the machine

could start moving forward unexpectedly,

which could cause an accident.

1. Start the engine.

2. Hold the pivot point of the throttle lever away

from the throttle switch by putting your thumb

(above) and forefinger (below) between the

throttle lever pivot

2

ing

.

While holding as described above, press the

throttle lever

The engine should stop immediately.

3

gradually.

INSP

ADJ

1

and stop switch hous-

WARNING

If the engine does not stop, stop the engine

by turning the main switch to the “OFF”

position and check the electrical system.

2-11

STARTER (CHOKE) CABLE FREEPLA Y ADJUSTMENT/

EXHAUST SYSTEM INSPECTION

ESS00050

STARTER (CHOKE) CABLE FREEPLAY ADJUSTMENT

1. Pull back the starter cable outer tube

2. Measure:

S Starter cable freeplay

Out of specification Adjust.

INSP

ADJ

a

1

.

Starter cable freeplay

a

:

0.5 1.5 mm (0.02 0.06 in)

3. Adjust:

S Starter cable freeplay

Adjustment steps:

S Pull back the adjuster cover

2

S Loosen the locknut

S Turn the adjuster

.

3

in or out until the specified

1

.

freeplay is obtained.

Turning in Freeplay is increased.

Turning out Freeplay is decreased.

S Tighten the locknut and push in the adjuster

cover.

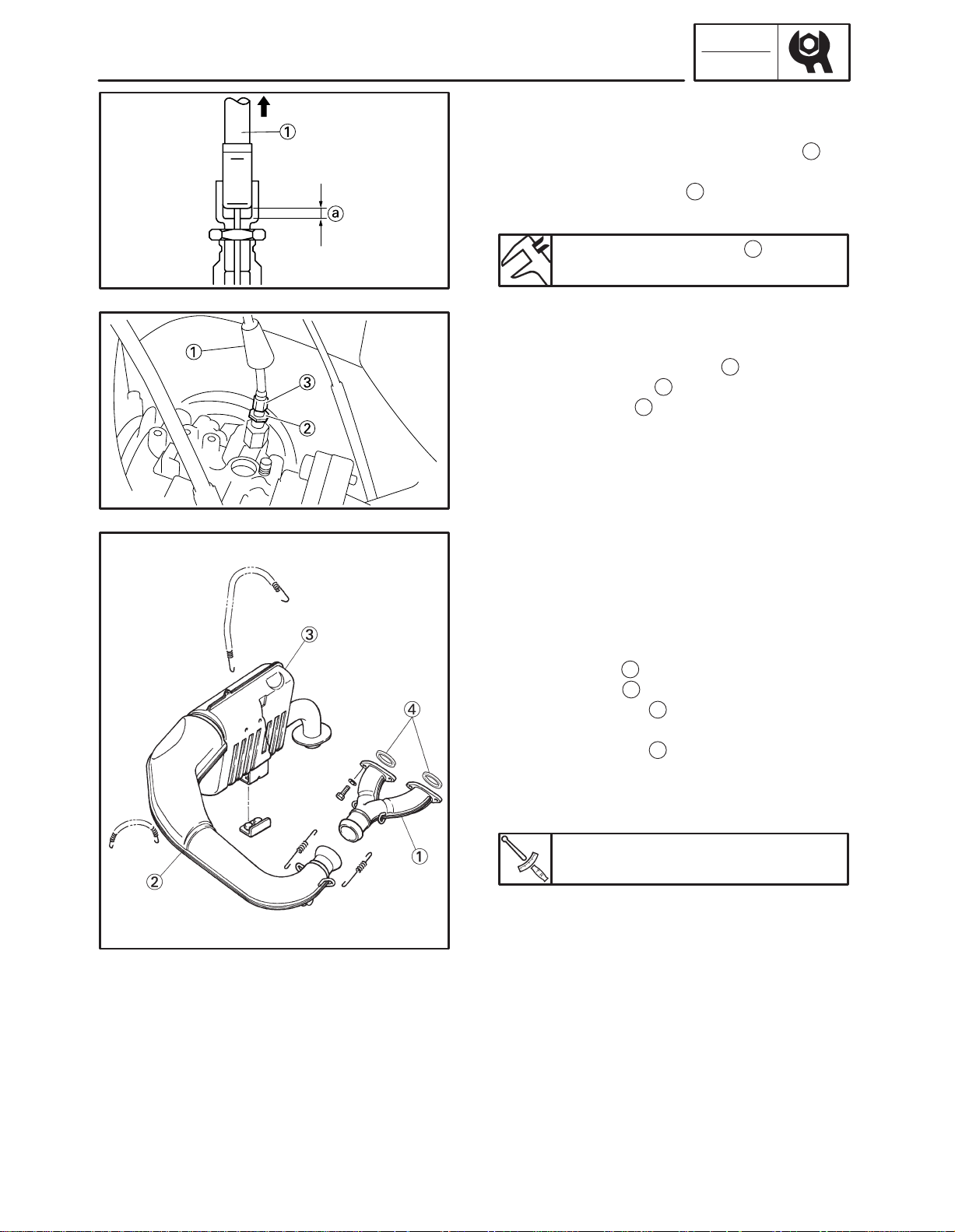

ESS00053

EXHAUST SYSTEM INSPECTION

1. Remove:

S Springs

Refer to “EXHAUST ASSEMBLY” in CHAPTER 5.

2. Inspect:

S Exhaust joint

S Exhaust pipe

S Exhaust silencer

1

2

3

Cracks/damgae Replace.

S Exhaust gaskets

4

Exhaust gas leaks Replace.

3. Check:

S Tightening torque

2-12

Bolt (exhaust pipe joint):

30 Nm (3.0 mSkg, 22 ftSlb)

4. Install:

S Springs

Refer to “EXHAUST ASSEMBLY” in CHAPTER 5.

,,,

,,,

,

INSP

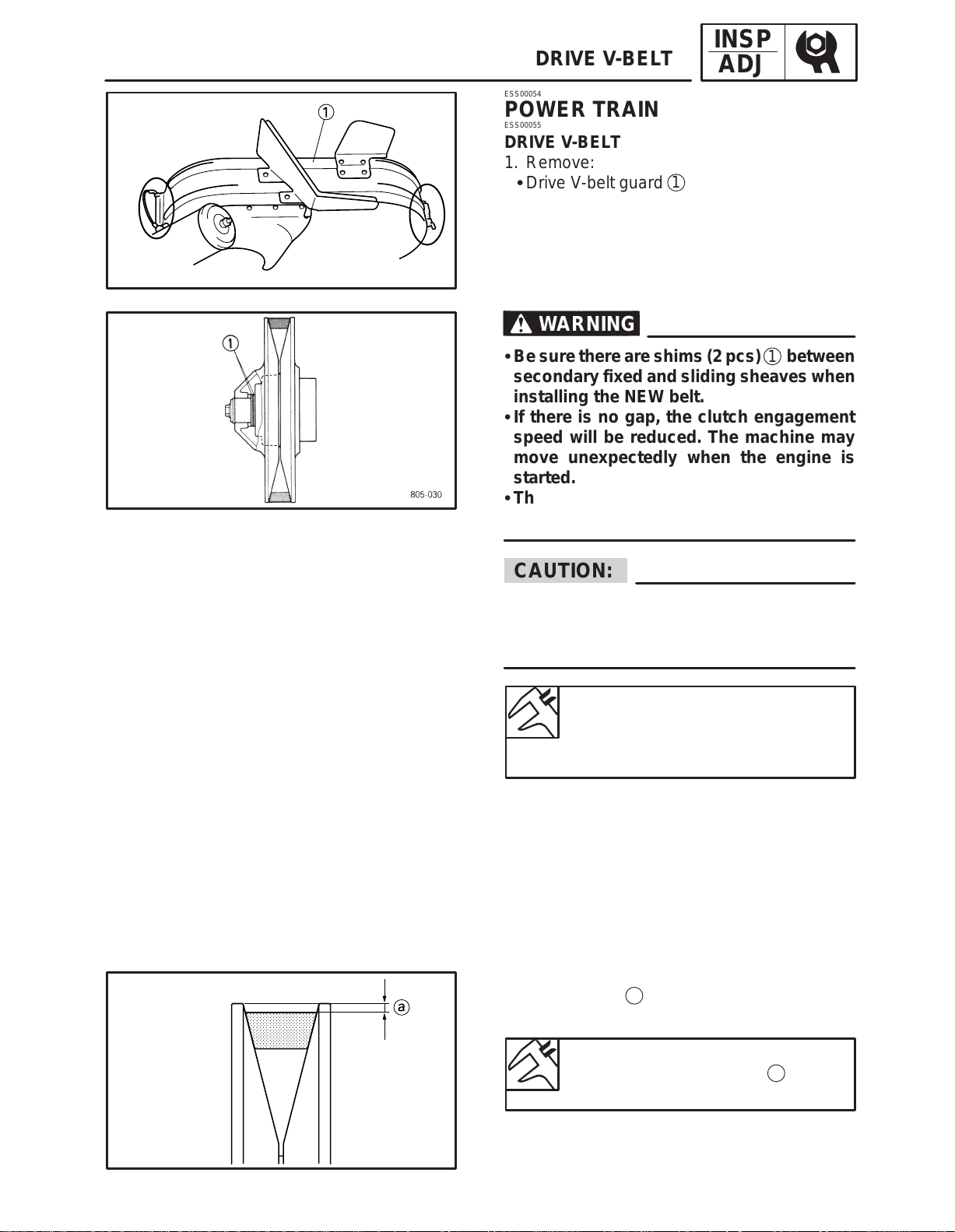

DRIVE V-BELT

ESS00054

POWER TRAIN

ESS00055

DRIVE V-BELT

1. Remove:

S Drive V-belt guard

1

WARNING

S Be sure there are shims (2 pcs) 1 between

secondary fixed and sliding sheaves when

installing the NEW belt.

S If there is no gap, the clutch engagement

speed will be reduced. The machine may

move unexpectedly when the engine is

started.

S The spacer of the secondary sheave

should be adjusted.

ADJ

CAUTION:

To ensure proper clutch performance, the

spacers in the secondary clutch must be repositioned as the V-belt wears.

New belt width:

35.0 mm (1.38 in)

Belt wear limit width:

32.0 mm (1.26 in)

2. Measure:

S V-belt height

Out of specification Adjust.

a

2-13

Standard V-belt height

(Below sheave surface)

0 2 mm (0 0.08 in)

a

:

Loading...

Loading...