YAMAHA EDL13000TE SERVICE MANUAL

SERVICE MANUAL

FOREWORD

HOW TO USE THIS MANUAL

This manual was written by the Yamaha

Motor Company primarily for use by Yamaha

dealers and their qualified mechanics. It is

not possible to put an entire mechanic’s

education into one manual, so it is assumed

that persons using this book to perform maintenance and repairs on Yamaha generators

have a basic understanding of the mechanical precepts and procedures inherent to generator repair technology . Without such knowledge, attempted repairs or service to this

model may render it unfit for use and/or unsafe.

Yamaha Motor Company Ltd. is continually

striving to further improve all models manufactured by Yamaha. Modifications and significant changes in specifications or procedures

will be forwarded to all Authorized Yamaha

dealers and will, where applicable, appear in

future editions of this manual.

PARTICULARLY IMPORTANT

INFORMATION

This material is distinguished by the following

notation.

The Safety Alert Symbol means A TTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting

or repairing the machine.

CAUTION:

A CAUTION indicates special precautions that

must be taken to avoid damage to the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

EDL13000TE

SERVICE MANUAL

1999 by Yamaha Motor Co., Ltd.

1st Edition, July 1999

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in JAPAN

MANUAL FORMAT

The procedures in this manual are organized

in a sequential, step-by-step format. The information has been compiled to provide the

mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly , repair , assembly, and

inspection operations.

In this revised format, the condition of a faulty

component will precede an arrow symbol and

the course of action required will follow the

symbol, e.g.,

Bearings

Pitting/damage Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in

identifying the correct disassembly and assembly procedures.

CONTENTS

CHAPTER 1.

GENERAL INFORMATION

ENGINE IDENTIFICATION 1-1. . . . . . . . . . .

IMPORTANT INFORMATION 1-2. . . . . . . . .

SPECIAL TOOLS 1-4. . . . . . . . . . . . . . . . . . .

CHAPTER 2.

SPECIFICATIONS

GENERAL SPECIFICATIONS 2-1. . . . . . . .

DIMENSIONS 2-3. . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE SPECIFICATIONS 2-4. . .

ELECTRICAL SPECIFICATIONS 2-10. . . .

GENERATOR SPECIFICATIONS 2-11. . . .

CHAPTER 3.

PERIODIC INSPECTIONS

AND ADJUSTMENTS

ENGINE BODY 3-1. . . . . . . . . . . . . . . . . . . . .

LUBRICATION SYSTEM 3-4. . . . . . . . . . . . .

COOLING SYSTEM 3-7. . . . . . . . . . . . . . . . .

FUEL SYSTEM 3-9. . . . . . . . . . . . . . . . . . . . .

STARTING SYSTEM 3-15. . . . . . . . . . . . . . .

GLOW SYSTEM 3-18. . . . . . . . . . . . . . . . . . .

KEY SWITCH 3-20. . . . . . . . . . . . . . . . . . . . .

STOP SYSTEM 3-21. . . . . . . . . . . . . . . . . . . .

CHARGING SYSTEM 3-23. . . . . . . . . . . . . .

TIGHTNING TORQUES 3-26. . . . . . . . . . . . .

PERIODIC MAINTENANCE/

LUBRICATION INTERVALS 3-27. . . . .

DAILY CHECK POINTS 3-28. . . . . . . . . . . . .

CHECK POINTS OF EVERY

50 HOURS 3-29. . . . . . . . . . . . . . . . . . . . .

CHECK POINTS OF EVERY

100 HOURS 3-30. . . . . . . . . . . . . . . . . . . .

CHANGING OF EVERY 200 HOURS 3-32. .

CHECK POINTS OF EVERY

500 HOURS 3-33. . . . . . . . . . . . . . . . . . . .

CHECK POINTS OF EVERY

800 HOURS 3-35. . . . . . . . . . . . . . . . . . . .

CHECK POINTS OF 1000 HOURS 3-35. . .

CHAPTER 4.

ENGINE

MEASURING AND ADJUSTING 4-1. . . . . .

ENGINE 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDER HEAD COVER 4-4. . . . . . . . . . .

ROCKER ARM AND PUSH ROD 4-5. . . . .

INTAKE/EXHAUST MANIFOLD 4-7. . . . . .

CYLINDER HEAD AND TAPPETS 4-8. . . .

VALVE AND VALVE SPRING 4-9. . . . . . . . .

EXTERNAL COMPONENTS/

CYLINDER HEAD COVER 4-10. . . . . . .

INJECTION PIPE/NOZZLE/

ROCKER ARM AND PUSH ROD 4-11. .

TAPPETS/CYLINDER HEAD AND

VALVES 4-13. . . . . . . . . . . . . . . . . . . . . . .

SPEED CONTROL PLATE 4-15. . . . . . . . . .

GEAR CASE 4-16. . . . . . . . . . . . . . . . . . . . . .

INJECTION PUMP AND

CAMSHAFT 4-17. . . . . . . . . . . . . . . . . . . .

TIMING GEAR AND CAMSHAFT 4-19. . . .

PISTON AND CONNECTING ROD 4-23. . .

FLYWHEEL AND CRANKSHAFT 4-27. . . .

CHECK THE CYLINDER HEAD AND

VALVES 4-32. . . . . . . . . . . . . . . . . . . . . . .

CHECK THE PISTON AND

CONNECTING ROD 4-37. . . . . . . . . . . .

CHECK THE TIMING GEAR AND

CAMSHAFT 4-39. . . . . . . . . . . . . . . . . . . .

CHECK THE CRANKSHAFT 4-42. . . . . . . .

CHECK THE CYLINDER 4-46. . . . . . . . . . . .

OIL PUMP 4-47. . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5.

COOLING SYSTEM

WATER PUMP/THERMOSTAT 5-1. . . . . . .

CHAPTER 6.

FUEL SYSTEM

INJECTION NOZZLE AND INJECTION

PUMP 6-1. . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 7.

ELECTRICAL

DYNAMO AND REGULATOR 7-1. . . . . . . .

STARTER AND GLOW PLUG 7-2. . . . . . . .

STARTER MOTOR 7-3. . . . . . . . . . . . . . . . . .

GENERA TOR 7-9. . . . . . . . . . . . . . . . . . . . . .

POWER SOURCE 7-9. . . . . . . . . . . . . . . . . .

GENERA TOR 7-10. . . . . . . . . . . . . . . . . . . . .

CONTROL FUNCTION 7-11. . . . . . . . . . . . .

CONTROL BOX 7-12. . . . . . . . . . . . . . . . . . .

PANEL WIRING DIAGRAM 7-15. . . . . . . . .

WIRING DIAGRAM (380/220 V) 7-16. . . . .

WIRING DIAGRAM (220/127 V) 7-17. . . . .

WIRING DIAGRAM (D.C. 12 V) 7-18. . . . . .

CHAPTER 8.

TROUBLESHOOTING

ENGINE SYSTEM 8-1. . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION

ENGINE IDENTIFICATION

SERIAL NUMBER

When contacting the manufacturer, always

specify your engine model name and serial

number.

CYLINDER NUMBER

D722 diesel engine are designated as shown

in the figure.

The sequence of cylinder numbers is given

as No.1, No.2, No.3 starting from the gear

case side.

1

PRECAUTION AT OVERHEATING

Take the following actions in the event the

coolant temperature be nearly or more than

the boiling point, what is called “Overheating”.

(1) Stop the machine operation in a safe

place and keep the engine unloaded idling.

(2) Don’t stop the engine suddenly , but stop

it after about 5 minutes of unloaded idling.

(3) Keep yourself well away from the ma-

chine for further 10 minutes or while the

steam spout out.

(4) Checking that there gets no danger such

as burn, get rid of the causes of overheating according to the manual.

And then, start again the engine.

1-1

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

CAUTION ON SERVICE

1. Fire prevention

When servicing the engine, always keep the engine and yourself away from fire.

NOTES ON SERVICE

1. Correct tools

Be sure to use the correct special tool for the job to guard

against damage.

2. Oil, grease and seals

Be sure to use genuine Y amaha oils, grease and sealers, or the

equivalents.

3. Expendable parts

Always replace the gaskets, O-rings, cotterpins and circlips with

new parts when servicing engine.

4. Tightening torque

Be sure to follow torque specifications. When tightening bolts,

nuts or screws, start with the largest-diameter fastener and

work from an inner position to an outer position in a crisscross

pattern.

5. Notes on disassembly and assembly

a. Parts should be cleaned in solvent and blown dry with com-

pressed air after disassembly.

b. Contact surfaces of moving parts should be oiled when reas-

sembled.

c. Make sure that the parts, move smoothly after each section of

the machine is assembled.

1-2

ALL REPLACEMENT PARTS

1. We recommend the use of genuine Yamaha parts for all replacements. Use oil and/or grease, recommended by Yamaha,

for assembly and adjustment.

GASKETS, OIL SEALS AND O-RINGS

1. All gaskets, seals, and O-rings should be replaced when an engine is overhauled. All gaskets surfaces, oil seal lips, and Orings must be cleaned.

2. Properly oil all mating parts and bearings during reassembly.

Apply grease to the oil seal lips.

BEARING AND OIL SEALS

1. Install the bearing(s)

ture’s marks or numbers facing outward. (In other words, the

stamped letters must be on the side exposed to view.) When

installing oil seal(s), apply a light coating of light-weight lithium

base grease to the seal lip(s). Oil the bearings liberally when

installing.

1

and oil seal(s) 2 with their manufac-

CAUTION:

Do not use compressed air to spin the bearings dry. This

causes damage to the bearing surfaces.

1-3

SPECIAL TOOLS

Flywheel puller (For vertical type diesel

engines)

Application: Use exclusively to take off the

flywheel of all vertical type diesel engines safely and easily.

Valve seat cutter set

Application: Use for correcting valve seats.

Special-use puller set

Application: Use for pulling out bearings,

gears and other parts.

Crank sleeve setter

Application: Use to fix the crankshaft

sleeve of the engine models.

1-4

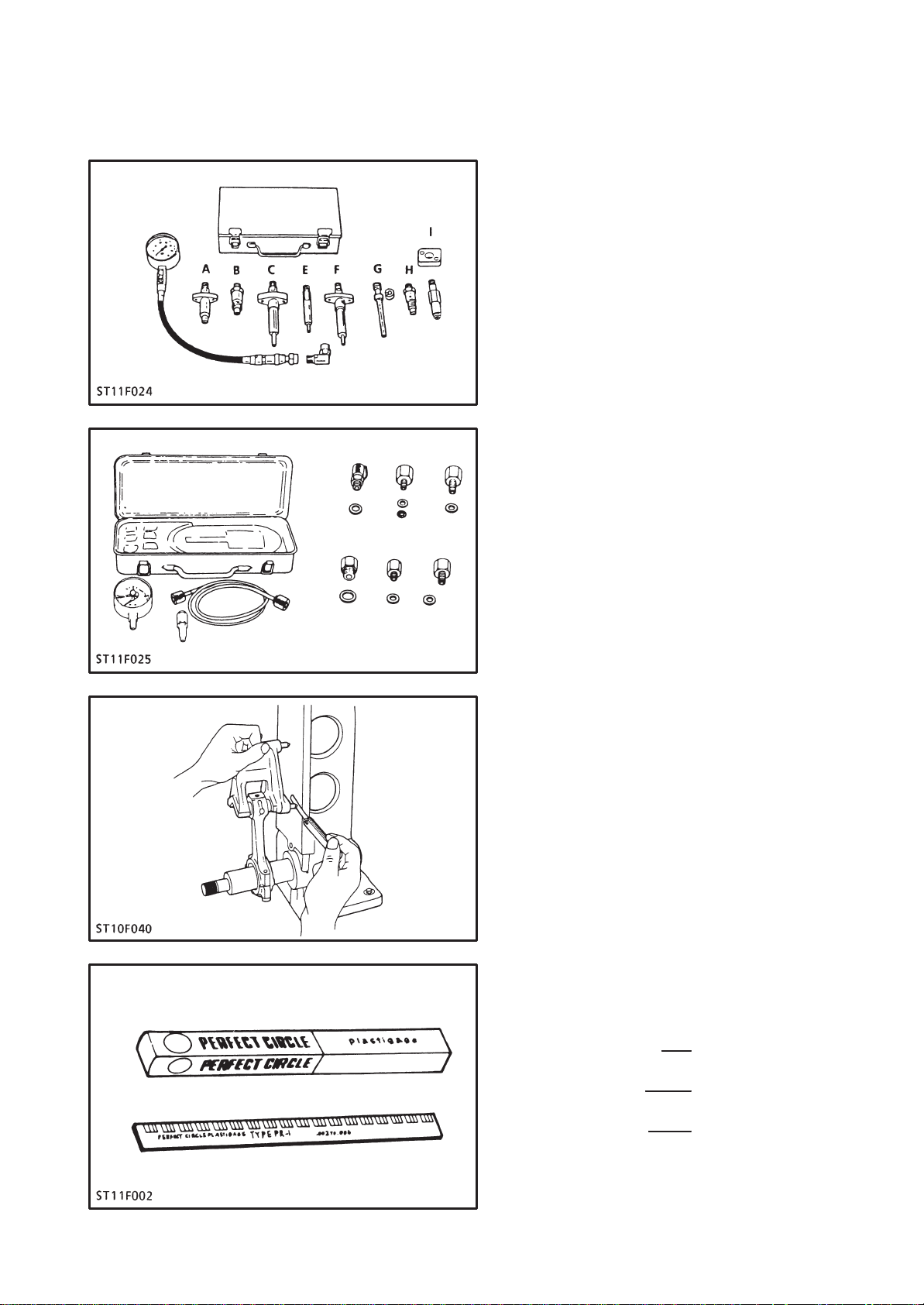

Diesel engine compression tester

Application: Use for measuring diesel en-

gine compression pressure.

Oil pressure tester

Application: Use for measuring lubricating

oil pressure.

Connecting rod alignment tool

Application: Use for checking the connect-

ing rod alignment.

Applicable: Connecting rod big end diarange meter 30 to 75 mm (1.18 to

2.95 in. dia.) Connecting rod

length 65 to 330 mm (2.56 to

12.99 in.)

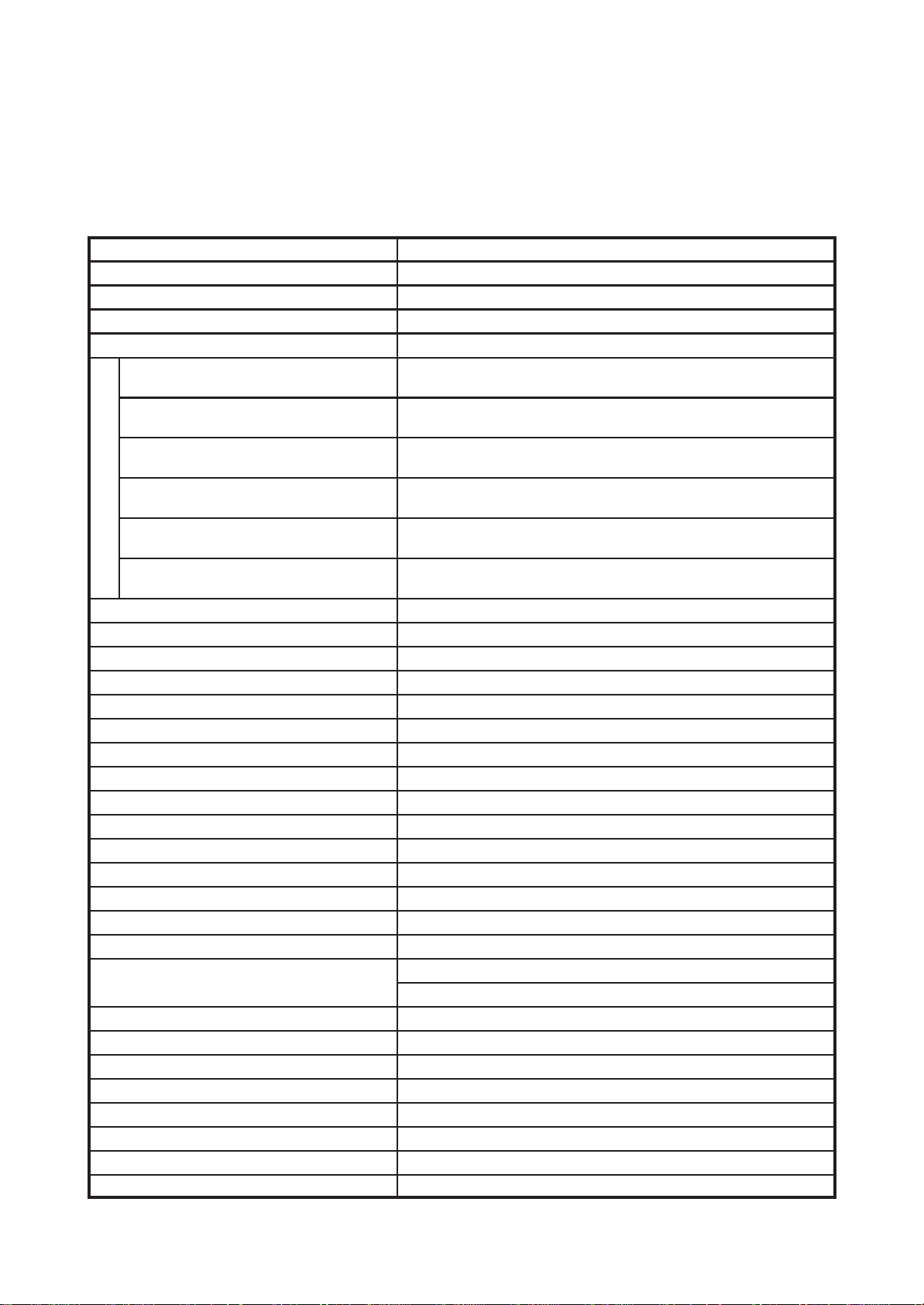

Plastigage

Application: Use for checking the oil clear-

ance between crankshaft and

bearing, etc.

Measuring: Green 0.025 to 0.076 mm

range (0.001 to 0.003 in.)

Red 0.051 to 0.152 mm

(0.002 to 0.006 in.)

Blue 0.102 to 0.229 mm

(0.004 to 0.009 in.)

1-5

Unit: mm (in.)

Red check (Crack check liquid)

Application: Use for checking cracks on cyl-

inder head, cylinder block, etc.

(use the goods on the market)

NOTE:

The following special tools are not pro-

vided, so make them referring to the figures.

Valve guide replacing tool

Application: Use to press out and press fit

the valve guide.

Unit: mm (in.)

Unit: mm (in.)

Crankshaft bearing 1 replacing tool

Application: Use to press out and press fit

the crankshaft bearing 1.

(0.45)

Connecting rod small end bushing tool

Application: Use to press out and press fit

the connecting rod small end

bushing.

1-6

Unit: mm (in.)

idle gear bushing replacing tool

Application: Use to press out and press fit

the idle gear bushing.

Unit: mm (in.)

Injection pump pressure tester

Application: Use to check the fuel tight-

ness.

Pressure gauge, full scale: more than

A

24.9 MPa (300 kgf/cm2, 4267 psi)

Copper gasket

B

Flange (material: steel)

C

Hex. nut, 27 mm (1.06 in.) across the flat

D

(material: steel)

Injection pipe

E

a

Adhesive application

Fillet welding on the enter circumference

b

1-7

SPECIFICATIONS

Starting system

GENERAL SPECIFICATIONS

Model D722-B (YMH)

Type Vertical, liquid cooled, 4-cycle diesel engine

Number of cylinders 3

Bore Stroke mm (in.) 67 68 (2.64 2.68)

Total displacement CC (cu. in.) 719 (43.89)

SAE net

Cont. H.P.

SAE net

Intermittent H.P.

SAE gross

Intermittent H.P.

DIN 6271-NA

Brake horse power

DIN 6271-NB

DIN 70020

Maximum bare speed 3850 r/min

Minimum bare idling speed 3150 3250 r/min

Combustion chamber Spherical type

Fuel Injection pump Bosch MD mini pump

Governor Centrifugal ball mechanical governor

Direction of rotation Counter-clockwise (Viewed from flywheel)

Injection nozzle Bosch throttle type

Injection timing 0.35 to 0.38 rad. (20 to 22) before T.D.C.

Injection order 1-2-3

Injection pressure 13.73 MPa (140 kgf/cm2, 1991 psi)

Compression ratio 23 : 1

Lubricating system Forced lubrication by pump

Oil Pressure indication Electrical type switch

Lubricating filter Full flow paper filter (Cartridge type)

Cooling system Pressurized radiator, forced circulation with water pump

Starting support device by glow plug in combustion chamber

Battery 12 V, 36 AH, equivalent

Generator for charging 12 V, 150 W

Fuel Diesel fuel No.2-D (ASTM D975)

Lubricating oil API service CD or CE

Lubricating oil capacity 3.1 (3.3 U.S.qts., 2.7 Imp.qts)

Weight (Dry) 74.4 kg (164 lbs)

Application Generator

12.2 kW/3600 r/min

16.3 HP/3600 r/min

14.0 kW/3600 r/min

18.8 HP/3600 r/min

15.6 kW/3600 r/min

20.9 HP/3600 r/min

12.1 kW/3600 r/min

16.4 PS/3600 r/min

13.3 kW/3600 r/min

18.1 PS/3600 r/min

14.6 kW/3600 r/min

19.9 PS/3600 r/min

Electric starting with cell starter

12 V, 1.0 kW

2-1

D722-B (YMH)

(SAE) (DIN)

2

1 Brake horsepower

2 Engine speed

3 B.S.F.C.

4 Torque

5 Gross intermittent torque

6 Net intermittent torque

7 Net cont. torque

8 Gross intermittent B.H.P.

9 Net intermittent B.H.P.

10 Net cont. B.H.P.

11 B.S.F.C. (Net intermittent)

2-2

DIMENSIONS

D722-B (YMH)

2-3

MAINTENANCE SPECIFICATIONS

CYLINDER HEAD

Item

Cylinder head surface flatness

Factory Specification Allowable Limit

–

Top clearance 0.50 to 0.70 mm

0.0197 to 0.0276 in.

Cylinder head gasket thickness

(Grommet section)

Free

Tightened

1.15 to 1.30 mm

0.04153 to 0.0512 in.

1.05 to 1.15 mm

0.0413 to 0.0453 in.

Compression pressure 2.84 to 3.24 MPa

29 to 33 kgf/cm

412 to 469 psi

VALVES

Valve clearance (Cold)

0.145 to 0.185 mm

0.0057 to 0.0073 in.

Valve seat width 2.12 mm

0.0835 in.

Valve seat angle 0.785 rad

45

0.05 mm

0.0020 in.

–

–

–

2.26 MPa

2

23 kgf/cm

2

327 psi

–

–

–

Valve face angle 0.785 rad

45

Valve recessing –0.10 to 0.10 mm

–0.0039 to 0.0039 in.

Clearance between valve stem and valve

guide

0.030 to 0.057 mm

0.00118 to 0.00224 in.

Valve stem diameter 5.968 to 5.980 mm

0.23496 to 0.23543 in.

Valve guide inside diameter 6.010 to 6.025 mm

0.23661 to 0.23720 in.

VALVE TIMING

Inlet valve

Open 0.35 rad (20) before T.D.C.

Close 0.79 rad (45) after B.D.C.

Exhaust valve

Open 0.87 rad (50) before B.D.C.

Close 0.26 rad (15) after T.D.C.

–

0.30 mm

0.0118 in.

0.10 mm

0.0039 in.

–

–

–

–

–

–

2-4

VALVE SPRING

Item

Factory Specification Allowable Limit

Free length 31.6 mm

1.244 in.

Setting load/Setting length 64.7 N/27 mm

6.6 kgf/27 mm

14.6 lbs/1.063 in.

Tilt

–

ROCKER ARM

Clearance between rocker arm shaft and

shaft hole

0.016 to 0.045 mm

0.00063 to 0.00177 in.

Rocker arm shaft diameter 10.473 to 10.484 mm

0.41232 to 0.41276 in.

Rocker arm shaft hole inside diameter 10.500 to 10.518 mm

0.41339 to 0.41410 in.

TAPPET

Clearance between tappet and guide

0.016 to 0.052 mm

0.00063 to 0.00205 in.

28.4 mm

1.118 in.

54.9 N/27 mm

5.6 kgf/27 mm

12.3 lbs/1.063 in.

1.2 mm

0.047 in.

0.15 mm

0.0059 in.

–

–

0.10 mm

0.0039 in.

Tappet diameter 17.966 to 17.984 mm

0.70732 to 0.70803 in.

Tappet guide inside diameter 18.000 to 18.018 mm

0.70866 to 0.70937 in.

CAMSHAFT

Camshaft side clearance

0.15 to 0.31 mm

0.0059 to 0.01220 in.

Camshaft alignment

–

Cam height (IN., EX.) 26.88 mm

1.0583 in.

Oil clearance of camshaft 0.050 to 0.091 mm

0.0020 to 0.0036 in.

Camshaft journal diameter 32.934 to 32.950 mm

1.2966 to 1.2972 in.

Camshaft bearing inside diameter 33.000 to 33.025 mm

1.2992 to 1.3002 in.

–

–

0.5 mm

0.020 in.

0.01 mm

0.0004 in.

26.83 mm

1.0563 in.

0.15 mm

0.0059 in.

–

–

2-5

TIMING GEAR

Item

Factory Specification Allowable Limit

Timing gear backlash

Crank gear – Oil pump drive gear 0.041 to 0.123 mm

0.00161 to 0.00484 in.

Idle gear – Cam gear 0.047 to 0.123 mm

0.00185 to 0.00484 in.

Idle gear – Injection pump gear 0.046 to 0.124 mm

0.00181 to 0.00488 in.

Idle gear – Crank gear 0.043 to 0.124 mm

0.00169 to 0.00488 in.

Idle gear side clearance 0.20 to 0.51 mm

0.0079 to 0.0201 in.

Clearance between idle gear shaft and idle

gear bushing

0.020 to 0.084 mm

0.00079 to 0.00331 in.

Idle gear shaft diameter 19.967 to 19.980 mm

0.78610 to 0.78661 in.

Idle gear bushing indisde diameter 20.000 to 20.051 mm

0.78740 to 0.78941 in.

CYLINDER LINER

0.15 mm

0.0059 in.

0.15 mm

0.0059 in.

0.15 mm

0.0059 in.

0.15 mm

0.0059 in.

0.60 mm

0.0236 in.

0.10 mm

0.0039 in.

–

–

Cylinder liner inside diameter

67.000 to 67.019 mm

2.63779 to 2.63854 in.

Oversized cylinder liner inside diameter 67.250 to 67.269 mm

2.64764 to 2.64839 in.

CRANKSHAFT

Crankshaft alignment

Oil clearance between crankshaft and

crankshaft bearing 1

0.034 to 0.106 mm

0.00134 to 0.00417 in.

–

Crankshaft diameter 39.934 to 39.950 mm

1.57221 to 1.57284 in.

Crankshaft bearing 1 inside diameter 39.984 to 40.040 mm

1.57418 to 1.57638 in.

Oil clearance between crankshaft and

crankshaft bearing 2

0.034 to 0.092 mm

0.00134 to 0.00362 in.

Crankshaft diameter 43.934 to 43.950 mm

1.72969 to 1.73032 in.

Crankshaft bearing 2 inside diameter 43.984 to 44.026 mm

1.73166 to 1.73331 in.

67.169 mm

2.64444 in.

67.419 mm

2.65429 in.

0.02 mm

0.0031 in.

0.20 mm

0.0079 in.

–

–

0.20 mm

0.0079 in.

–

–

2-6

CRANKSHAFT

Item

Oil clearance between crankshaft and

crankshaft bearing 3

Factory Specification Allowable Limit

0.034 to 0.092 mm

0.00134 to 0.00362 in.

Crankshaft diameter 39.934 to 39.950 mm

1.57221 to 1.57284 in.

Crankshaft bearing 3 inside diameter 39.984 to 40.026 mm

1.57418 to 1.57583 in.

Oil clearance between crank pin and crank

pin bearing

0.019 to 0.081 mm

0.00075 to 0.00319 in.

Crankshaft diameter 33.959 to 33.975 mm

1.33697 to 1.33759 in.

Crank pin bearing inside diameter 33.994 to 34.040 mm

1.33835 to 1.34016 in.

Crankshaft side clearance 0.15 to 0.31 mm

0.0059 to 0.0122 in.

CONNECTING ROD

Connecting rod alignment

Clearance between piston pin and small end

bushing

0.014 to 0.038 mm

0.00055 to 0.00150 in.

–

0.20 mm

0.0079 in.

–

–

0.15 mm

0.0059 in.

–

–

0.5 mm

0.0197 in.

0.05 mm

0.0020 in.

0.10 mm

0.0039 in.

Piston pin diameter 20.002 to 20.011 mm

0.78748 to 0.78783 in.

Small end bushing inside diameter 20.025 to 20.040 mm

0.78839 to 0.78897 in.

PISTON/PISTON RING

Piston pin hole inside diameter

20.000 to 20.013 mm

0.78740 to 0.78791 in.

Piston ring clearance

Ring gap

Second compression

ring 2

Oil ring

Top compression

ring and oil ring

Second compression

ring

0.085 to 0.115 mm

0.0033 to 0.0045 in.

0.02 to 0.06 mm

0.0008 to 0.0024 in.

0.15 to 0.30 mm

0.0059 to 0.0118 in.

0.30 to 0.45 mm

0.0118 to 0.0177 in.

Oversize of piston rings +0.25 mm

+0.0098 in.

–

–

20.05 mm

0.7894 in.

0.15 mm

0.0059 in.

0.15 mm

0.0059 in.

1.2 mm

0.0472 in.

1.2 mm

0.0472 in.

–

2-7

OIL PUMP

Engine oil pressure

Item

At idle

speed

At rated

speed

Factory Specification Allowable Limit

98 kPa

2

1.0 kgf/cm

, 14 psi

196 to 441 kPa

2.0 to 4.5 kgf/cm

28 to 64 psi

Clearance between inner rotor and outer

rotor

Clearance between outer rotor and pump

body

0.03 to 0.14 mm

0.012 to 0.0055 in.

0.07 to 0.15 mm

0.0028 to 0.0059 in.

End clearance between inner rotor and cover 0.075 to 0.135 mm

0.0029 to 0.0053 in.

THERMOSTAT

Thermostat’s valve opening temperature

69.5 to 72.5C

157.1 to 162.5F

Temperature at which thermostat completely

opens

85C

185F

RADIATOR

–

98 kPa

2

1.0 kgf/cm

2

14 psi

–

–

–

–

–

Radiator water tightness

Water tightness at

specified pressure

157 kPa

1.6 kgf/cm

2

, 23 psi

Radiator cap air leakage 10 seconds or more

88 59 kPa

0.9 0.6 kgf/cm

13 9 psi

Fan belt tension Approx. 10 mm/10 kgf

0.39 in./10 kgf (22.1 lbs.)

INJECTION PUMP

Injection timing

0.35 to 0.38 rad before

T.D.C. (20 to 22)

Fuel tightness of pumpe element

–

Fuel tightness of delivery valve

–

–

2

–

–

–

14.71 MPa

2

150 kgf/cm

,

2133 psi

5 seconds

14.7 13.7 MPa

150 140 kgf/cm

2

2133 1990 psi

2-8

INJECTION NOZZLE

Item

Factory Specification Allowable Limit

Fuel Injection pressure 13.73 to 14.71 MPa

140 to 150 kgf/cm

2

1991 to 2133 psi

Fuel tightness of nozzle valve seat When the pressure is

12.75 MPa (130 kgf/cm

1849 psi), the valve seat

must be fuel tightness

–

2

,

–

2-9

ELECTRICAL SPECIFICATIONS

STARTER

Commutator diameter

Mica undercut 0.5 to 0.8 mm

Brush length 16.0 mm

DYNAMO

No-load voltage

GLOW PLUG

Glow plug resistance

28.0 mm

1.102 in.

0.020 to 0.031 in.

0.630 in.

AC20 V or more

at 5200 rpm

Approx. 0.9 Ω –

27.0 mm

1.063 in.

0.2 mm

0.008 in.

10.5 mm

0.413 in.

–

2-10

GENERATOR SPECIFICATIONS

Out ut

Max. out ut

GENERATOR

SET MODEL

Generator model PX209YK

p

p

Phases 3 Phases 4 wires

Power factor % 80

Voltage V 380/220 220/127

Current A 15.2 31.5

Frequency Hz 50 60

Insulation class F (Stator, Rotor)

Excitation Brushless

Poles 2

Engine revolution r.p.m. 3000 3600

Ambient temperature C –15 +40

Boundary dimensions (mm)

Length Width Height

kVA 10 12

kW 8 9.6

kVA 11 13

kW 8.8 10.4

1020 640 770 (Without wheels)

1020 640 928 (With wheels)

EDL13000TE

Weight kg 260

Engine model D722-B (YMH)

Engine model Vertical type water-cooled 4 cycle diesel

Number of cylinders – Bore Stroke 3 – 67 68

Rating output PS 13.8 16.3

Type 2-pole revolving-field type brushless alternator

Voltage regulating type A.V.R.

Power factor 0.8

Drive type Direct drive by engine

AC overcurrent protective device NFB

Alternating current switch capacity (A) 16 32

Output take off type Terminals

Voltage regulations (%) Less than ± 2.5

Frequency regulations (%) Less than 5

2-11

A.V.R.

Resistance (20C)

U – V

V – W

2.0 Ω 0.5 Ω

W – U

UnitEx.

3 – 4 0.51 Ω ———

J – K 8.25 Ω

U – V

V – W

0.713 Ω

W – U

F+ – F– 24.9 Ω

380 V 220 V

When the alternator is revolved at 3000

(3600) r/min. with DC12 V loaded on the EX

stator coil (F+, F–).

Generated voltage (V)

JK

U – V

V – W

W – U

O – U

O – V

O – W

About 480 V

(About 290 V)

About 277 V

(About 170 V)

NOTE:

Numerical values in ( ) are for 60 Hz, 220

V class.

CAUTION:

To perform this test, remove AVR.

When the alternator is revolved at 3000

(3600) r/min. with A VR and other lead wires

disconnected.

Generated voltage (V)

U – V

V – W

W – U

About 90 V

(About 50 V)

2-12

O – U

O – V

O – W

About 52 V

(About 29 V)

PERIODIC INSPECTIONS AND ADJUSTMENTS

ENGINE BODY

CYLINDER BLOCK

The engine has a high durability tunnel-type

cylinder block in which the crank bearing

component is a constructed body. Furthermore, liner less type, allow effective cooling,

less distortion, and greater wear-resistance.

The noise level is reduced to a minimum because each cylinder has its own chamber.

CYLINDER HEAD

The cross-flow type intake/exhaust ports in

this engine have their openings at both sides

of the cylinder head. Because overlaps of intake/exhaust ports are smaller than in ports

of other types which have openings on one

side, the suction air can be protected from

being heated and expanded by heated exhaust air. The cool, high density suction air

has high volume efficiency and raises the

power of the engine. Furthermore, distortion

of the cylinder head by heated exhaust gas

is reduced because intake ports are arranged alternately. The combustion chamber is exclusive New TVCS combustion

chamber type. Suction air is whirled to be

mixed effectively with fuel, prompting combustion and reducing fuel consumption.

In the combustion chamber are installed

throttle type injection nozzle and rapid heating sheathed type glow plug. This glow plug

assures easier than ever engine starts even

at – 15C (5°F).

Combustion chamber

1

Intake port

2

Exhaust port

3

Nozzle assembly

4

Glow plug

5

Cylinder head

6

Fan-shaped concave

7

Stream

8

Air inlet

9

3-1

Combustion system

These engine use the “NTVCS” (New Three

Vortex Combustion System) to achieve perfect combustion for maximum power. The

NTVCS combustion system provides unique

9

shape of throat in the air inlet

tion chamber, to produce three streams

1

air in the chamber

when compressing, giv-

for combus-

8

of

ing an ideal mixture of air and fuel.

7

In addition, a fan-shaped concave

is provided on top of the piston to allow a smooth

ejection of the exhaust gas, offering highly

efficient combustion.

CRANKSHAFT

The crankshaft with the connecting rod converts the reciprocating motion of the piston

into the rotating motion.

The crankshaft is made of tough special alloy

steel, and the journals, pins and oil seal sliding

portions are induction hardened to increase

the hardness for higher wear resistance.

The front journal is supported by a solid type

bearing, the intermediate journal by a split

type, and the rear journal by a split type with

thrust bearings.

The crankshaft is provided with an oil gallery ,

through which engine oil is fed to the crank

pin portion, and lubricate it.

PISTON AND PISTON RINGS

The piston is made of aluminum alloy.

Two recesses for the valves are provided on

top of the piston. A fan-shaped depression is

also given stop the piston in order to allow

combustion gas to jet smoothly. The piston

pin is slightly out of the center of the piston.

In this design, the run-out of the piston at the

top and bottom dead points can be reduced,

thereby resulting in lower operating noise.

The piston has a slightly oval shape when

cold (in consideration of thermal expansion)

and a concave head.

Three rings are installed in grooves in the

piston.

1

The top ring

stand against heavy loads, and the barrel face

on the ring fits well to the cylinder wall.

The second ring

effectively prevents the oil from being carried

up.

The oil ring

and an expander ring, which increase the pressure of the oil ring against the cylinder wall.

Several grooves are cut on the topland to

help heat dissipate and to prevent scuffing.

Fan-shaped concave

4

Valve recess

5

is a keystone type, which can

2

is an undercut type, which

3

has chamfered contact faces

3

3-2

CONNECTING ROD

2

Connecting rod

piston with the crankshaft. The big end of the

connecting rod has a crank pin bearing

(split type) and the small end has a small end

1

bushing

(solid type).

is used to connect the

3

CAMSHAFT

3

The camshaft

is made of special cast iron

and the journal and cam sections are chilled to

resist wear. The journal sections are force-lu-

5

bricated. The fuel camshaft

controls the reciprocating movement of the injection pump.

The fuel camshaft is made of carbon steel and

the cam sections are quenched and tempered

to provide greater wear resistance.

1 Cam gear

2 Camshaft stopper

3 Camshaft

4 Injection pump gear

5 Fuel camshaft

FLYWHEEL

The flywheel stores the rotating force in the

combustion stroke as inertial energy , reduces

crankshaft rotating speed fluctuation and

maintains the smooth rotating conditions.

The flywheel periphery is inscribed with the

marks showing top dead center mark TC.

The flywheel periphery is inscribed with the

fuel injection period mark FI.

The flywheel has gear teeth around its outer

rim, which mesh with the drive pinion of the

starter.

1 Crankshaft

2 Flywheel

3 Flywheel screw

ROCKER ARM

The rocker arm assembly includes the rock-

1

er arms

er arm shaft

, rocker arm brackets 4 and rock-

5

and converts the reciprocating movement of the push rods to an

open/ close movement of the inlet and exhaust valves.

Lubricating oil is pressurized through the

bracket to the rocker arm shaft, which serves

as a fulcrum so that the rocker arm and the

entire system are lubricated sufficiently.

1 Rocker arm

2 Lock nut

3 Adjusting screw

4 Rocker arm bracket

5 Rocker arm shaft

VALVE TIMING

The timing for opening and closing the valve

is extremely important to achieve effective

air intake and sufficient gas exhaust.

The appropriate timing can be obtained by

aligning the marks on the crank gear and the

cam gear when assembling.

Inlet valve open 0.35 rad. (20) before T.D.C.

Inlet valve close 0.79 rad. (45) after B.D.C.

Exhaust valve open 0.87 rad. (50) before B.D.C.

Exhaust valve close 0.26 rad. (15) after T.D.C.

1

2

3

4

T.D.C. TOP DEAD CENTER. .

B.D.C. BOTTOM DEAD CENTER. .

3-3

LUBRICATING SYSTEM

GENERAL, LUBRICATING SYSTEM

This engine’s lubricating system consists of oil strainer, oil pump, relief

valve, oil filter cartridge and oil

switch. The oil pump sucks lubricating oil from the oil pan through the oil

strainer and the oil flows down to the

filter cartridge, where it is further filtered. Then the oil is forced to crankshaft, connecting rods, idle gear,

camshaft and rocker arm shaft to lubricate each part.

Some part of oil, splashed by the

crankshaft or leaking and dropping

from gaps of each part, lubricates

these parts: pistons, cylinders, small

ends of connecting rods, tappets,

pushrods, inlet and exhaust valves

and timing gears.

3-4

Engine oil flow

1 Oil pan

2 Oil strainer

3 Oil pump

4 Relief valve

5 Oil filter cartridge

6 Idle gear

7 Main oil gallery

8 Main bearing

9 Big end

10 Timing gear

11 Splash

12 Bore

13 Small end

14 Piston

15 Fuel camshaft

16 Tappets

17 Camshaft bearing

18 Camshaft

19 Drain

20 Rocker arm

21 Oil switch

22 Rocker arm shaft

[A]Oil pump

[B]Oil strainer

[C]Rocker arm and rocker

arm shaft

[D]Piston

[E]Camshaft

[F] Oil filter cartridge and

relief valve

OIL PUMP

The oil pump is a trochoid pump, whose rotors have trochoid lobes. The inner rotor

3

has 4 lobes and the outer rotor 4 has 5

lobes, and they are eccentrically engaged

with each other. The inner rotor, which is

driven by the crankshaft through the gears,

rotates the outer rotor in the same direction,

varying the space between the lobes.

While the rotors rotate from

A

to B, the

space leading to the inlet port increases,

which causes the vacuum to suck in the oil

from the inlet port

When the rotors rotate to

1

.

C

, the space between both rotors switches from the inlet port

to the outlet port.

D

At

, the space decreases and the sucked

2

oil is discharged from the outlet port

.

RELIEF VALVE

The relief valve prevents the damage to the

lubricating system due to the high pressure

of the oil.

The relief valve is ball direct acting type, and

is best suited for low pressures.

When the pressure of the oil, forced by the

pump, exceeds the specified value, the oil

pushes back the ball

2

and escapes to the

oil pan.

1 Spring

2 Ball

3 Valve seat

3-5

OIL FILTER CARTRIDGE

After lubricating, the lubricating oil brings back

various particles of grit and dirt to the oil pan.

Those particles and the impurities in the lubricating oil can cause wear or seizure of the engine parts. It may also impair the physical and

chemical properties of the oil itself.

The lubricating oil which is force-fed by the

pump, is filtered by the filter cartridge with

the filter element

2

. When the filter element

accumulates on excessive amount of dirt

and the oil pressure in the inlet line builds up

by 98 kPa (1.0 kgf / cm

the outlet line, the bypass valve

2

, 14 psi) more than

1

opens to

allow the oil to flow from the inlet into the outlet line, bypassing the filter element.

OIL PRESSURE SWITCH

The oil pressure switch is mounted on the

cylinder block and is led to the lubricating oil

passage.

When the oil pressure falls below the specified value, the oil pressure warning lamp

lights.

[A]At the proper oil

pressure

1 Terminal

2 Insulator

3 Spring

4 Rubber gasket

[B]At lower oil pressure,

49 kPa (0.5 kgf/cm2,

7 psi) or less

5 Contact rivet

6 Contact

7 Oil switch body

3-6

COOLING SYSTEM

GENERAL, COOLING SYSTEM

1 Radiator

2 Suction fan

3 Water pump

4 Thermostat

5 Cylinder head

6 Cylinder block

The cooling system consists of a radiator , centrifugal water pump , suction fan and thermostat .

4

3

1

2

The water is cooled through the radiator core, and

the fan set behind the radiator pushs cooling air

through the core to improve cooling.

The water pump sucks the cooled water, forces it

into the cylinder block and draws out the hot water.

Then the cooling is repeated. Furthermore, to

control temperature of water, a thermostat is provided in the system. When the thermostat opens,

the water moves directly to radiator, but when it

closes, the water moves toward the water pump

through the bypass between thermostat and water pump. The opening temperature of thermostat

is approx. 71C (160F).

WATER PUMP

The water pump is driven by the crankshaft

via a V-belt. Water cooled in the radiator is

sucked into the water pump from its lower

portion and is sent from the center of the wa-

4

ter pump impeller

radially outward into

the water jacket in the crankcase.

The special mechanical seal is installed as a

seal between bearing and pump chamber,

which is effective to water and heat.

1 Bearing unit

2 Water pump body

3 Mechanical seal

4 Water pump impeller

3-7

Loading...

Loading...